Patents

Literature

120results about How to "Increase feed water temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

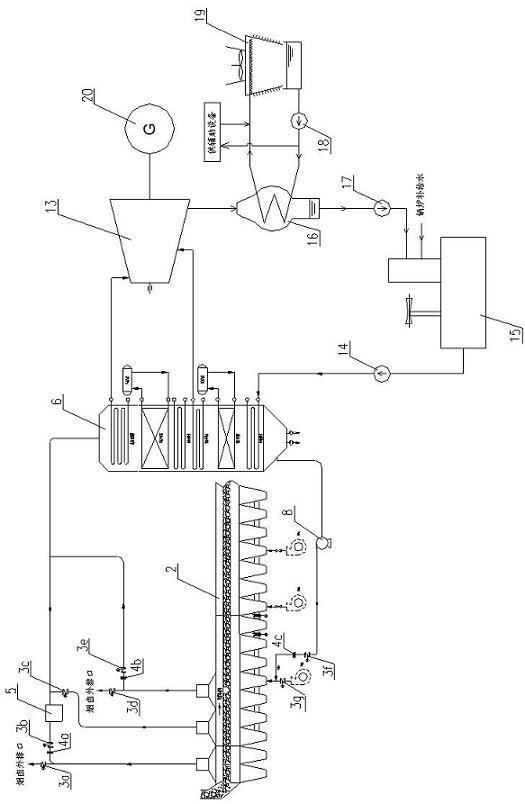

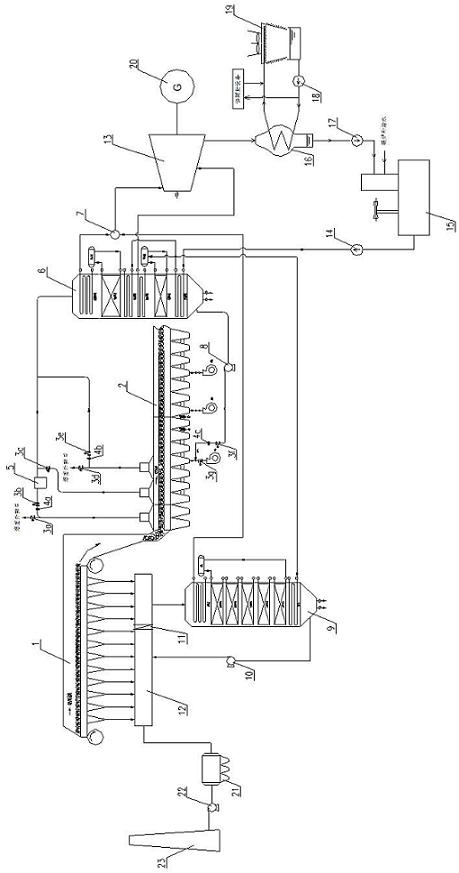

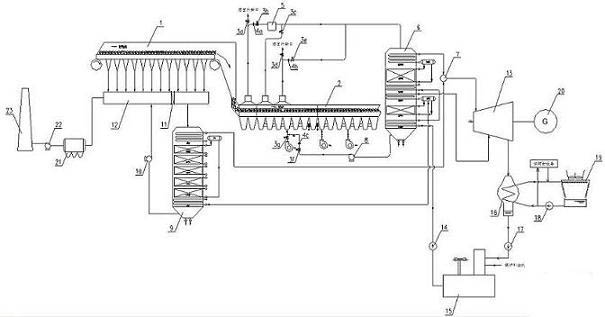

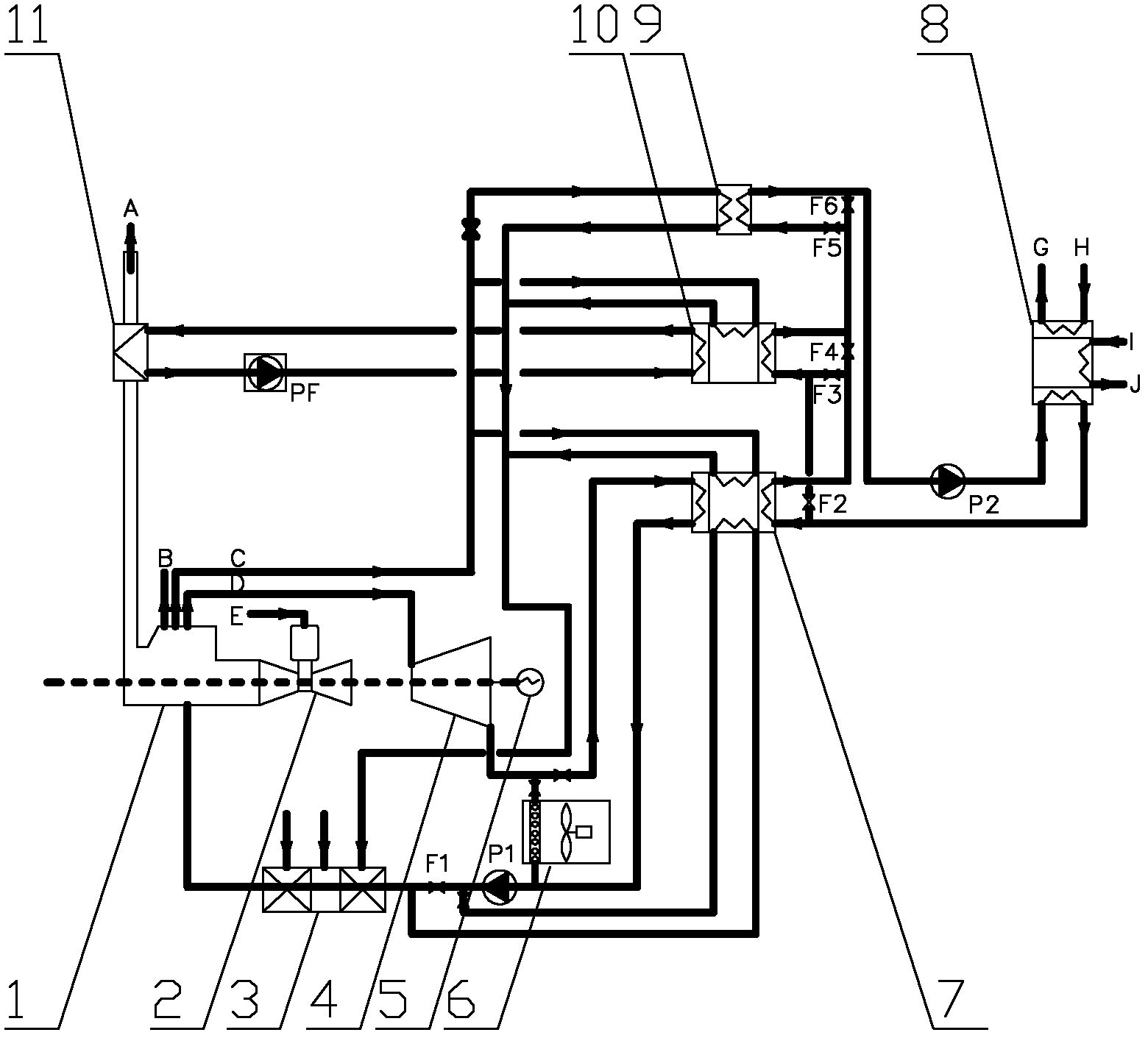

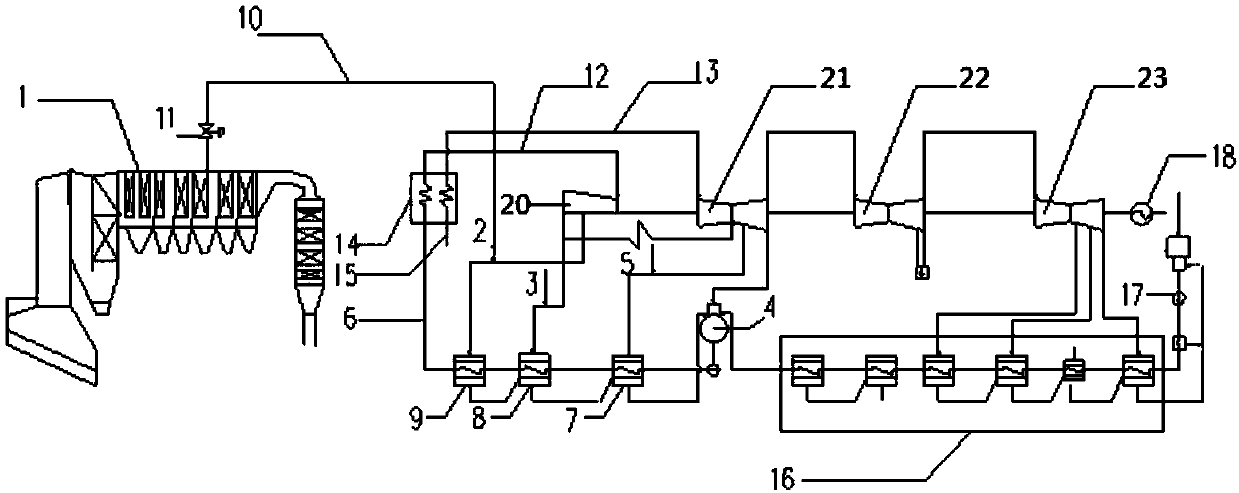

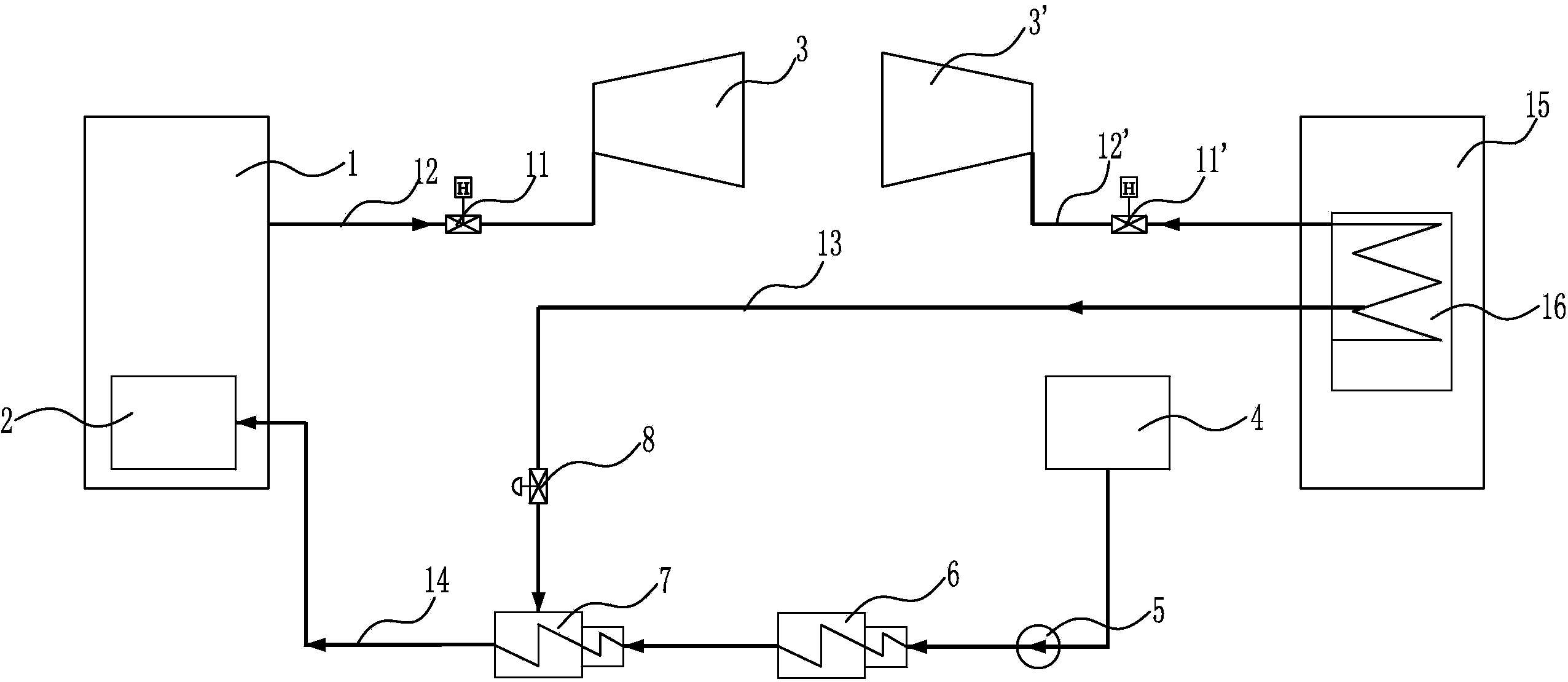

System and method for power generating by jointly recovering waste heat of flue gas of sintering machine and exhaust gas of cooling machine

ActiveCN102012167AImprove the efficiency of waste heat recovery and utilizationIncrease feed water temperatureEnergy industryIncreasing energy efficiencyWaste heat recovery unitIron plant

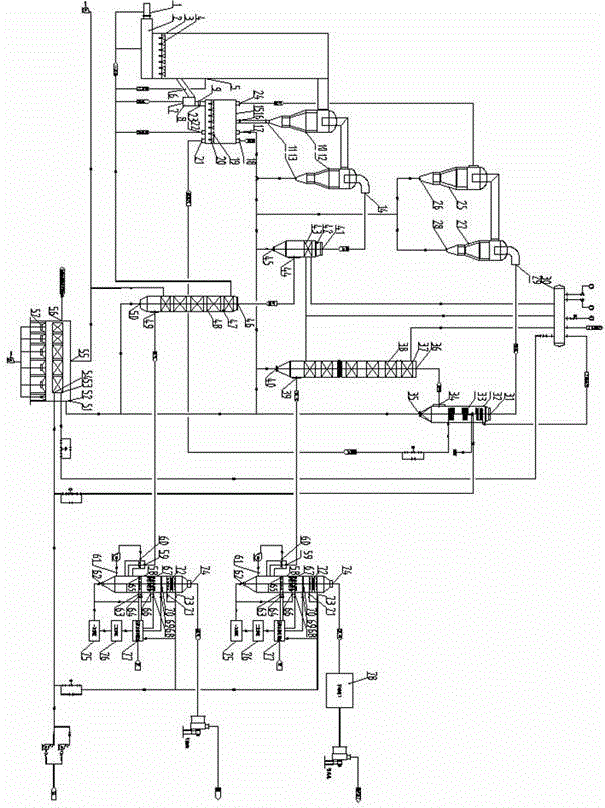

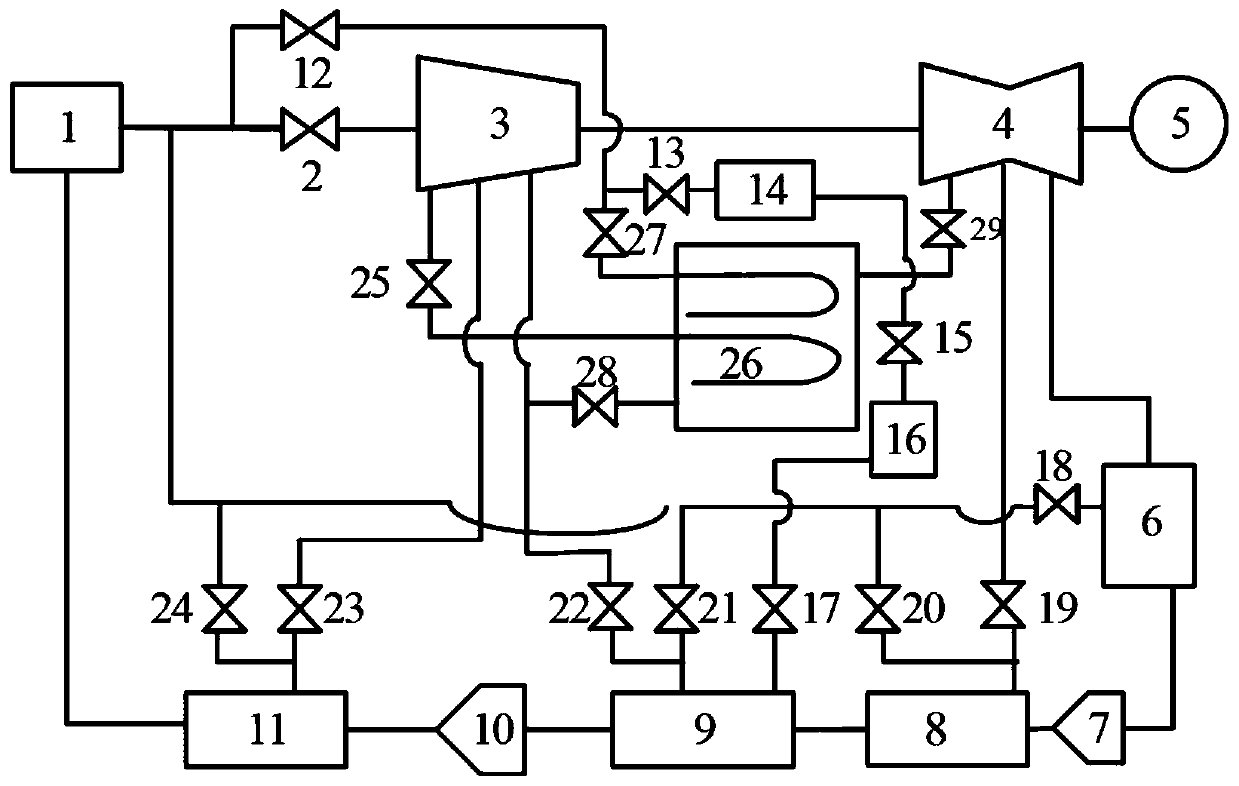

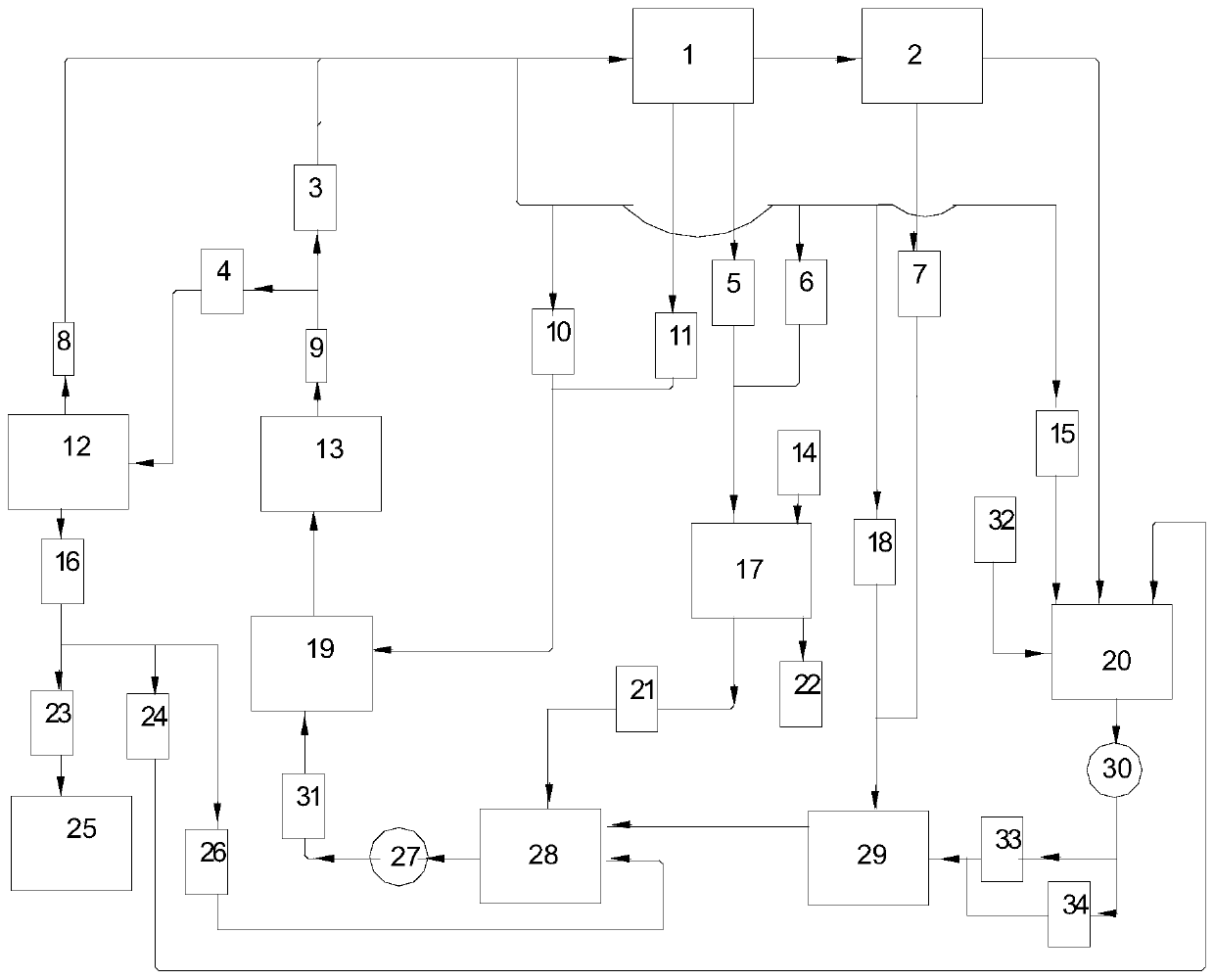

The invention discloses a system and method for power generating by jointly recovering the waste heat of a flue gas of a sintering machine and an exhaust gas of a cooling machine, belonging to the technical field of power generation by using waste sintering heat of a steel and iron plant. The power generating system comprises a sintering machine flue gas waste heat utilizing system, a cooling machine exhaust gas waste heat utilizing system, a turbine generating system and a relevant auxiliary system, wherein a main waste heat discharging boiler is utilized to recover the waste heat of the flue gas of a high-temperature segment of the tail part of the sintering machine; a cooling machine waste heat boiler is utilized to recover the waste heat of the high-temperature exhaust gas of the cooling machine; and a high-temperature electric butterfly valve is arranged between the high-temperature segment and a low-temperature segment of a large flue positioned on the tail part of the sintering machine to prevent the wind pickup temperature of the flue gas from being reduced because a low-temperature flue gas and a high-temperature flue gas are directly mixed so as to ensure the high-temperature flue gas to enter the main waste heat discharging boiler for waste heat recovery. The system and method effectively utilizes the waste heat resources of the high-temperature flue gas of the machine tail of the sintering machine and a hot gas of the high-temperature segment of the cooling machine, enhances the waste heat recovery and utilization efficiency of a sintering process and increases the power generation capacity of the waste heat power generating system.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

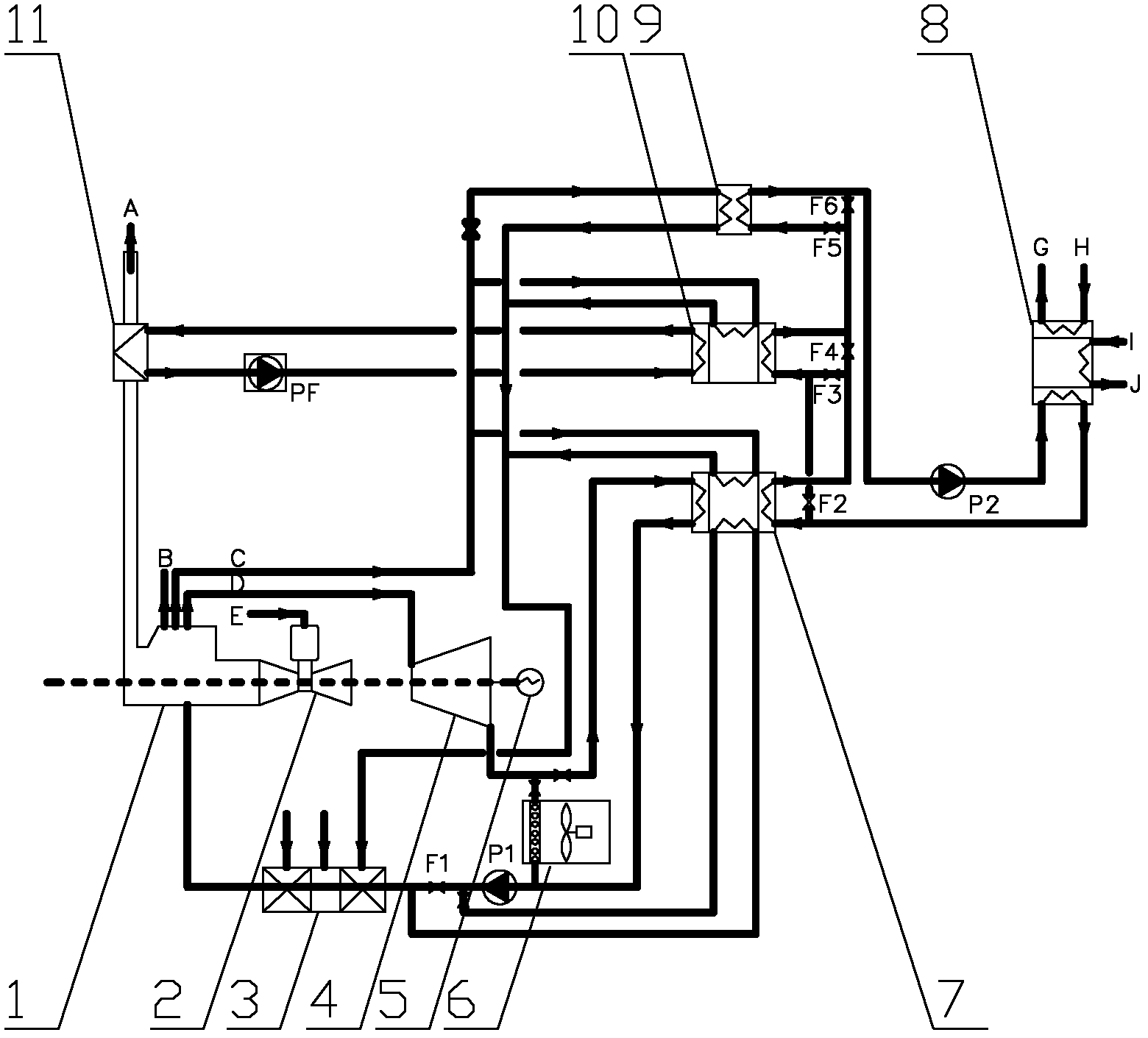

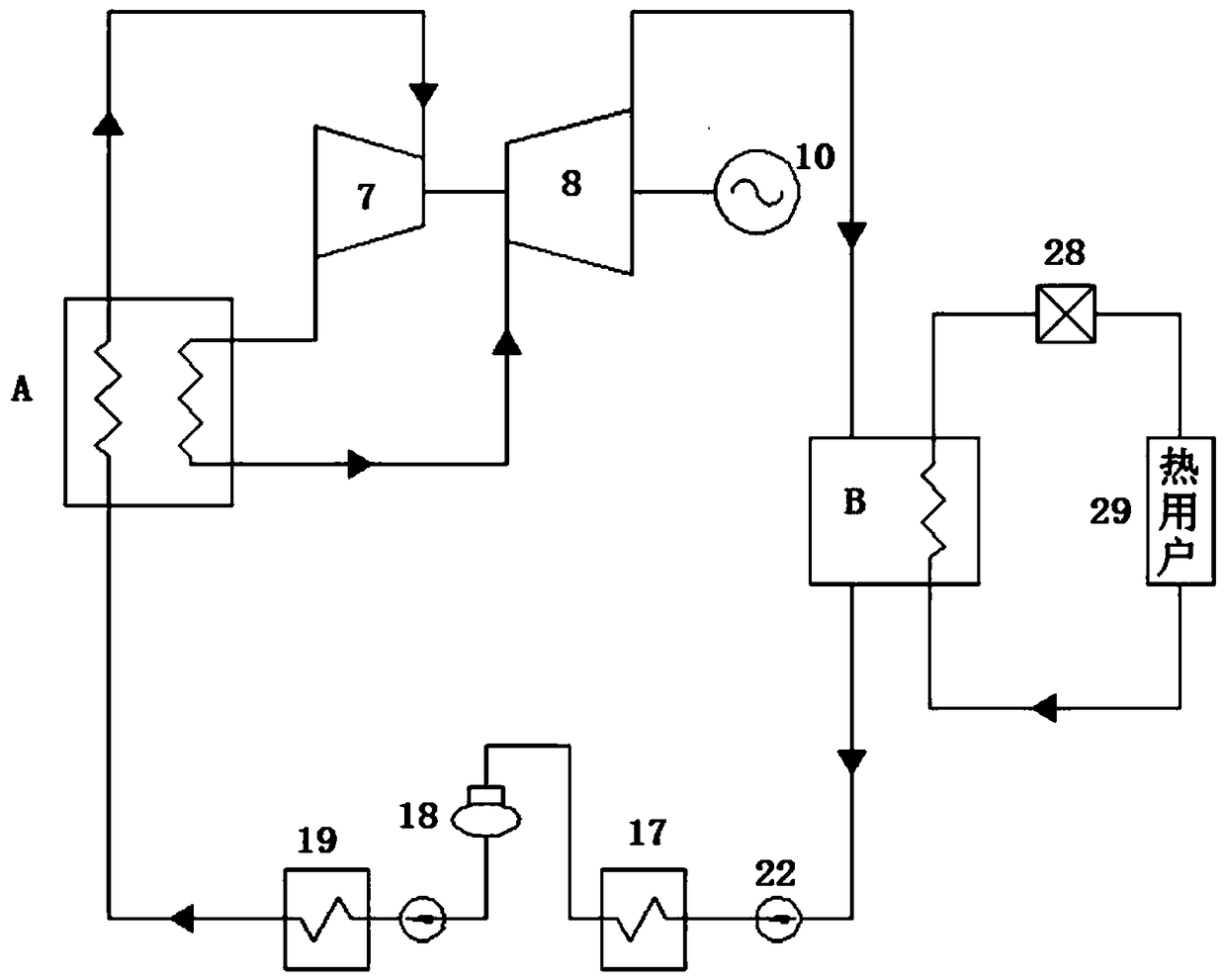

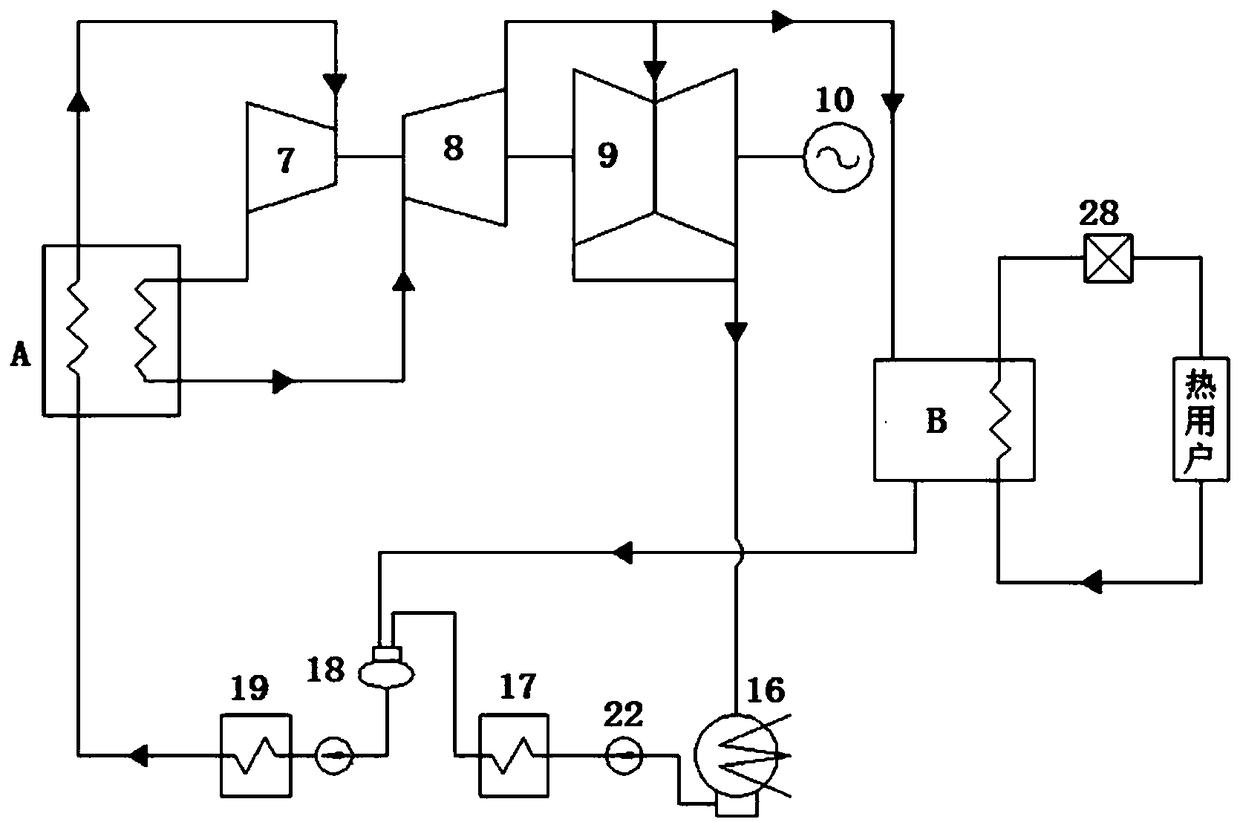

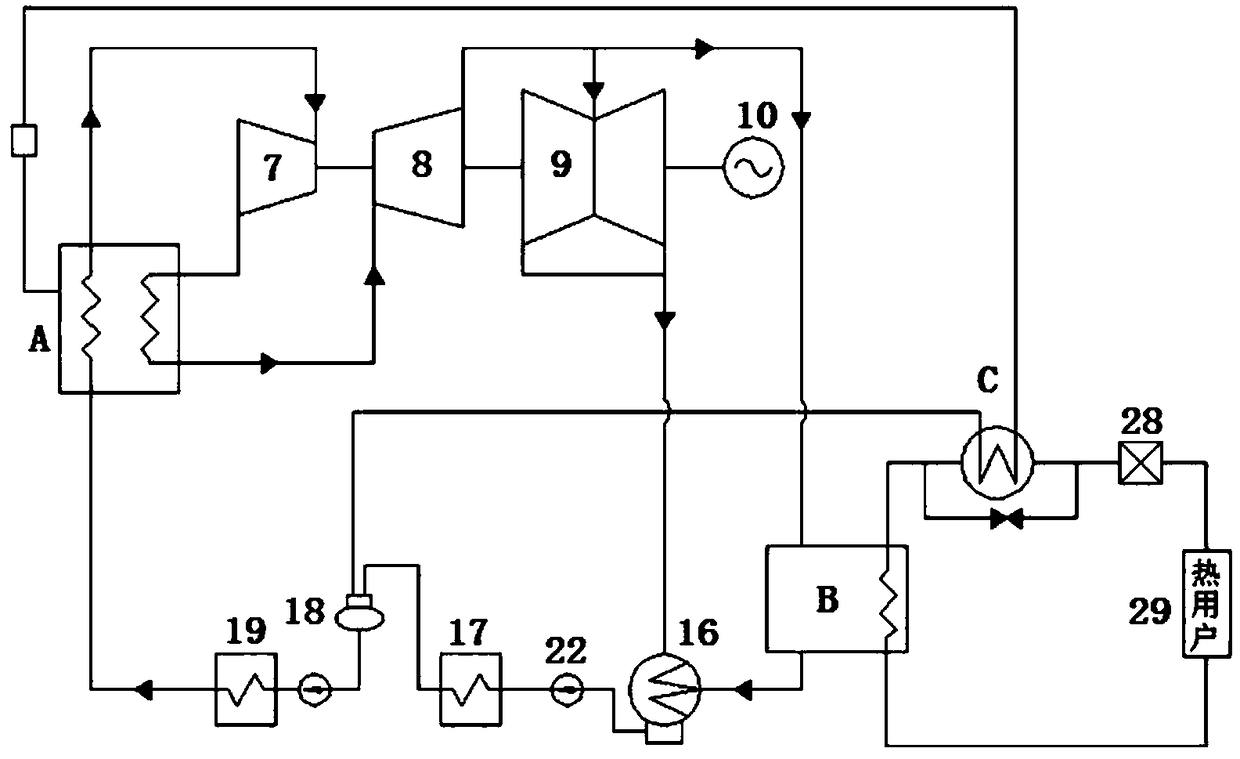

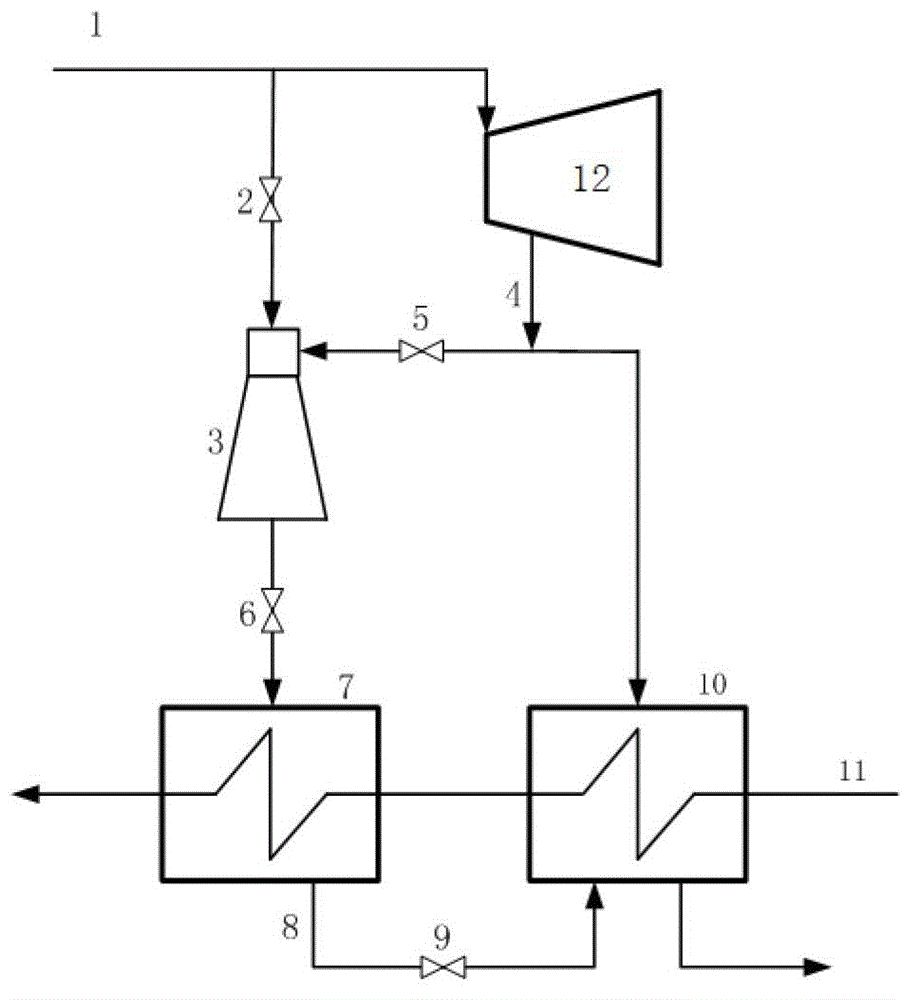

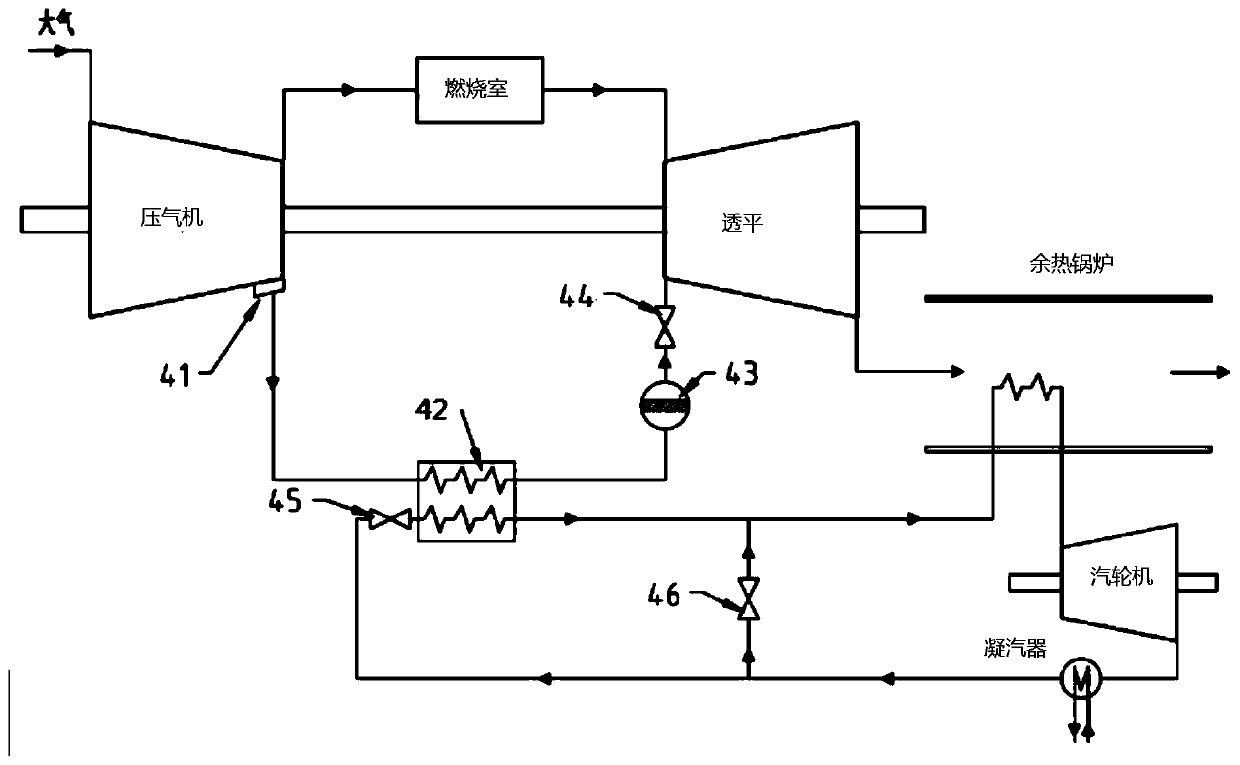

Gas-steam circulation heating-electricity-cooling combined supply system and method for thermal power plant with zero energy loss rate

InactiveCN102359739AIncrease the temperature difference between supply and return waterIncrease feed water temperatureHeat recovery systemsGas turbine plantsEffective energyFlue gas

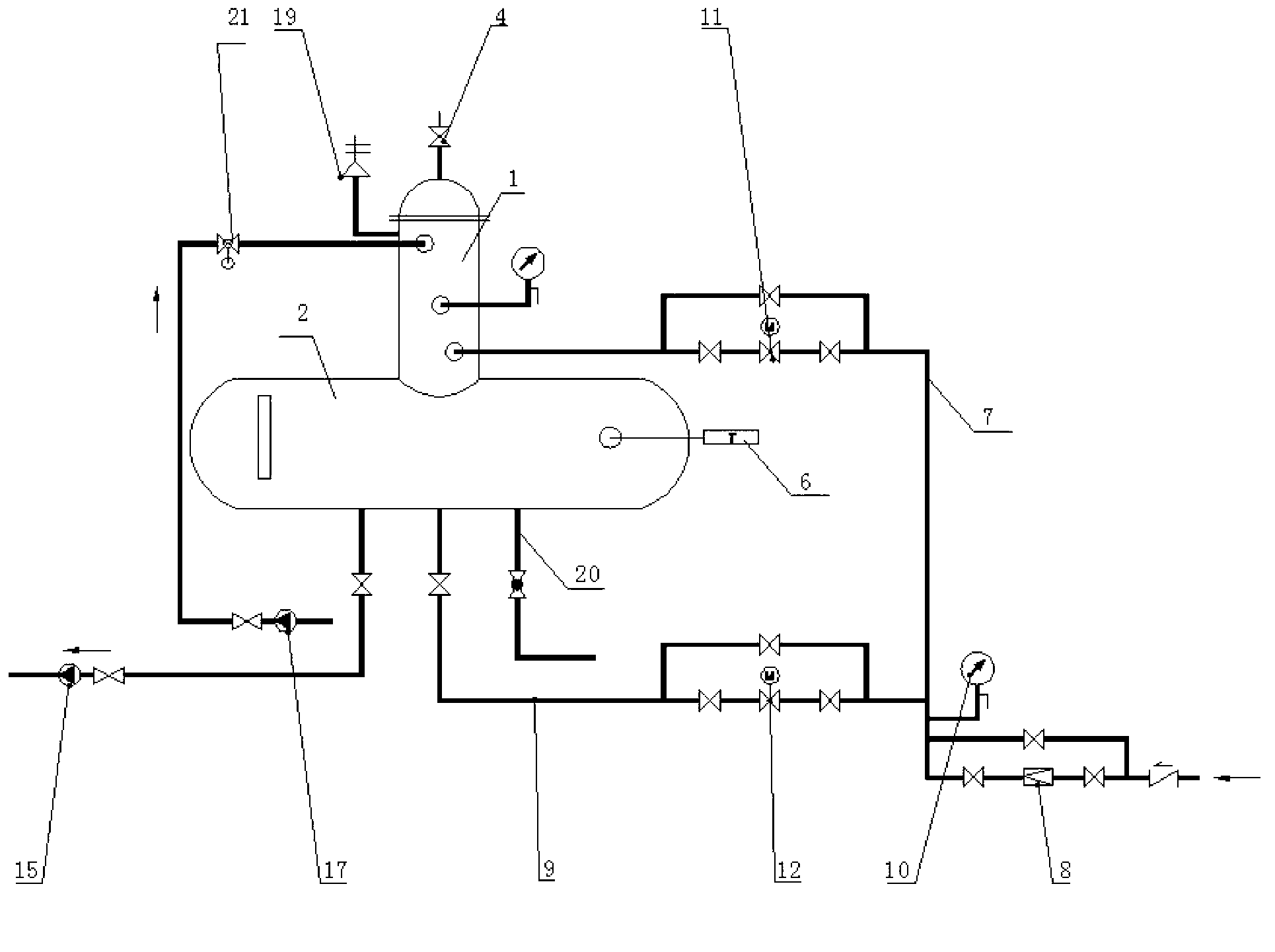

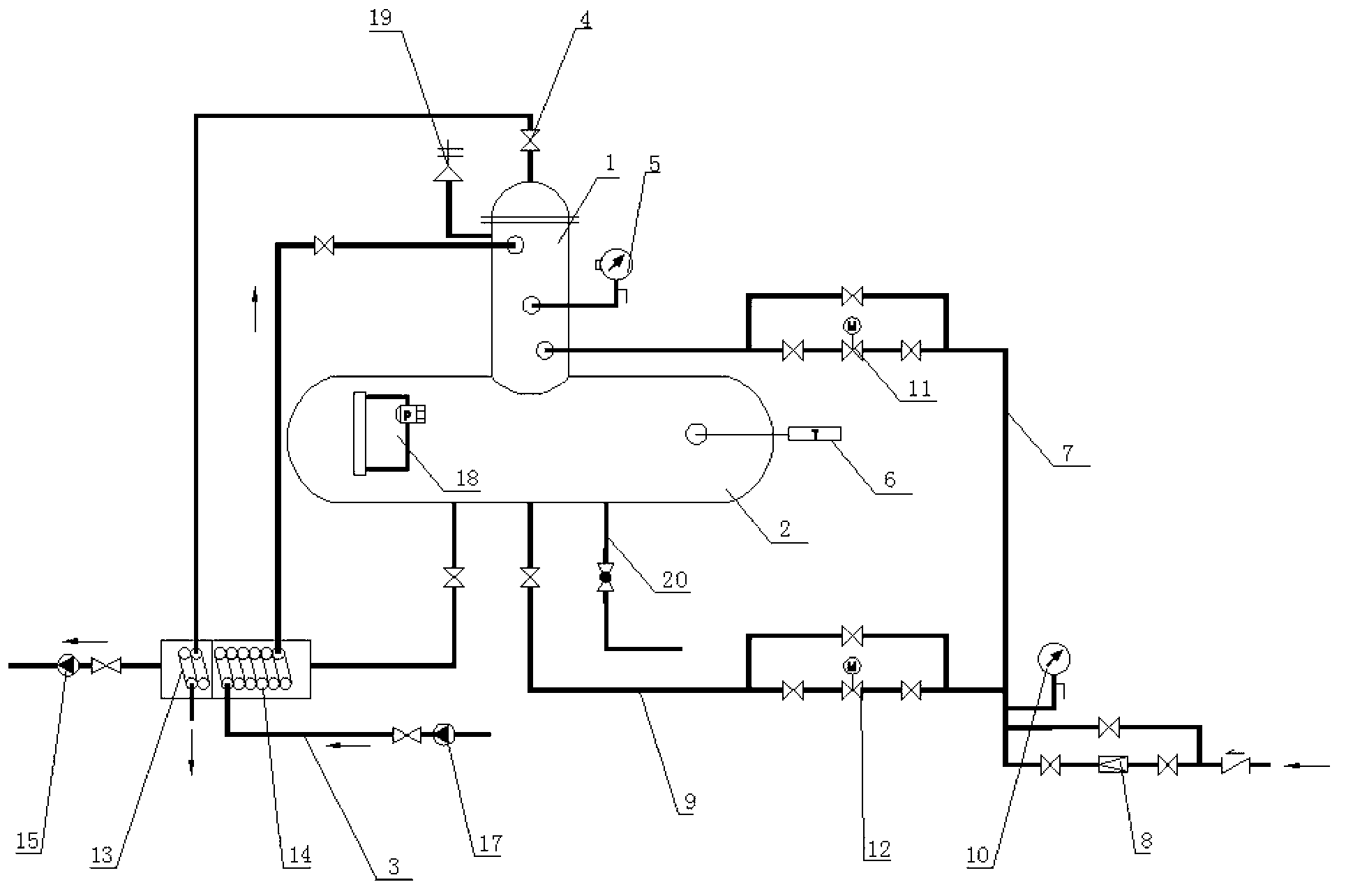

The invention relates to a gas-steam circulation heating-electricity-cooling combined supply system and a gas-steam circulation heating-electricity-cooling combined supply method for a thermal power plant with zero energy loss rate and belongs to the technical field of gas-steam combined circulation heating-electricity-cooling combined supply. The gas-steam circulation heating-electricity-coolingcombined supply system comprises a heat-electricity combined circulation part, a large temperature difference adsorption waste steam recovery heat pump, a large temperature difference adsorption fluegas recovery heat pump, a flue gas condensation recovery acquisition device, an initial station steam-water heat exchanger, an adsorption heat pump / refrigeration all-in-one machine and the like, wherein the heat-electricity combined circulation part consists of a burning machine, a waste heat boiler, a steam turbine, a generator and the like. An operation regulating method for carrying out combination energy optimization on an integral thermal system, which is based on an adsorption heat-exchange waste heat recovery and large temperature difference heat supply technology and combines a climate compensation technology, is adopted, so that aiming at the characteristics of a gas-steam combined circulation system, the effect that the energy utilization efficiency for once of the thermal powerplant is close to, even exceeds 100 percent is realized. In the invention, energy resources at each energy grade are utilized to drive generating equipment, heating equipment and air-conditioning cold supply equipment, so that the energy-saving effect that compared with a flue gas low heating value, the effective energy output has no energy loss is achieved.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

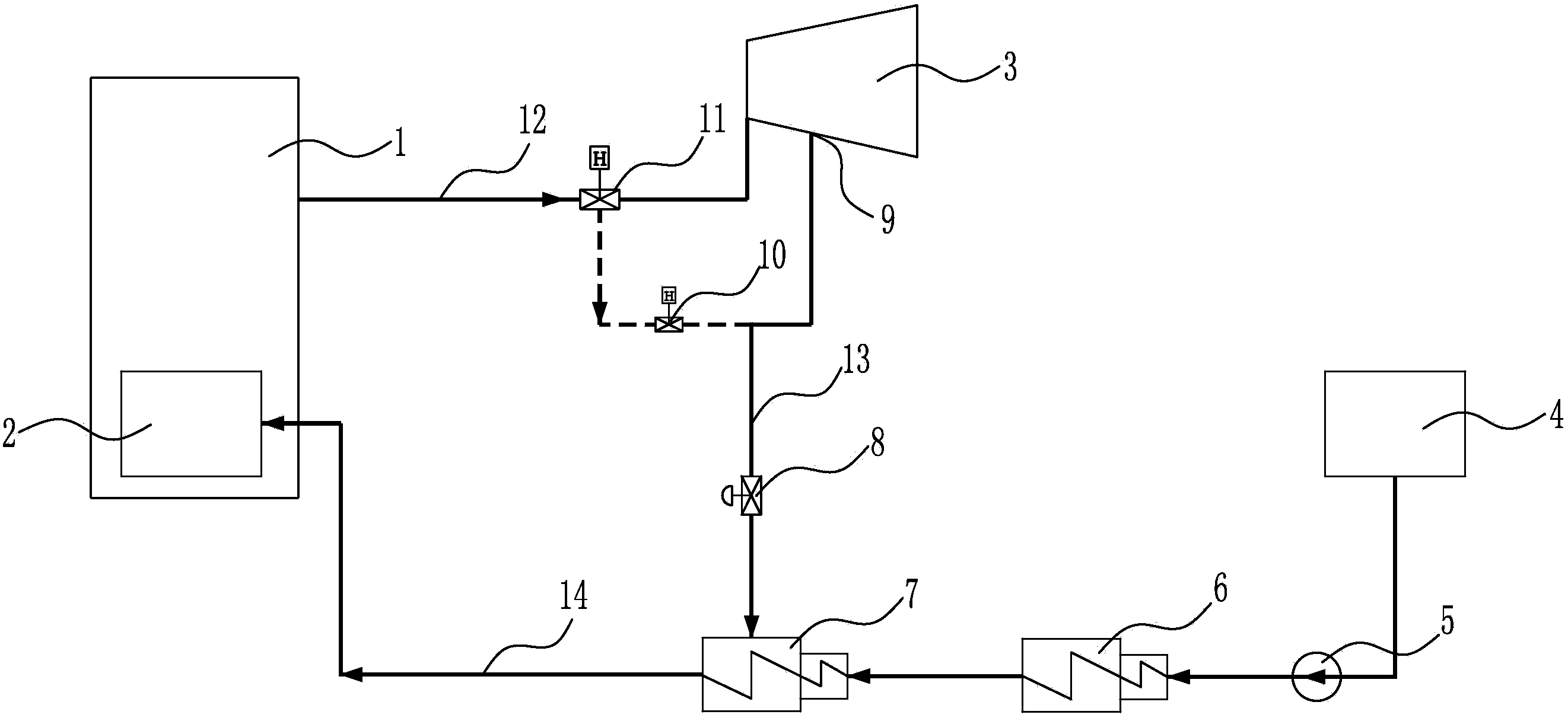

Thermodynamic system for improving heat supply unit electric output adjusting capacity

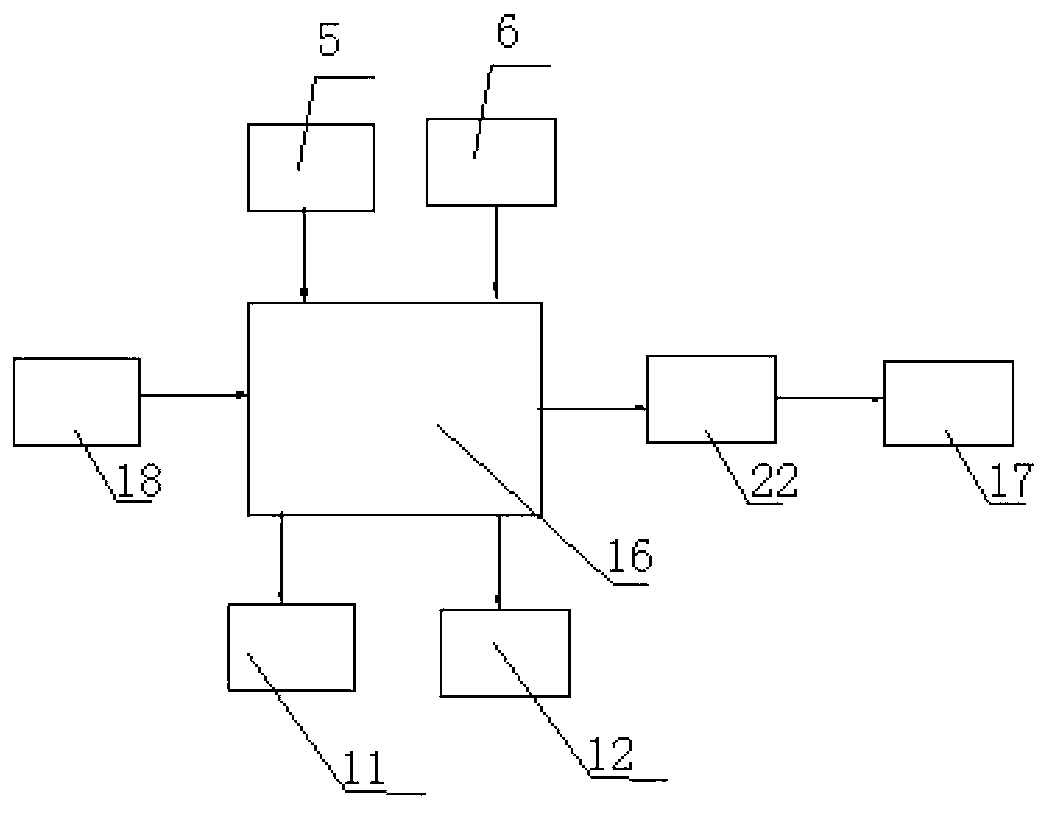

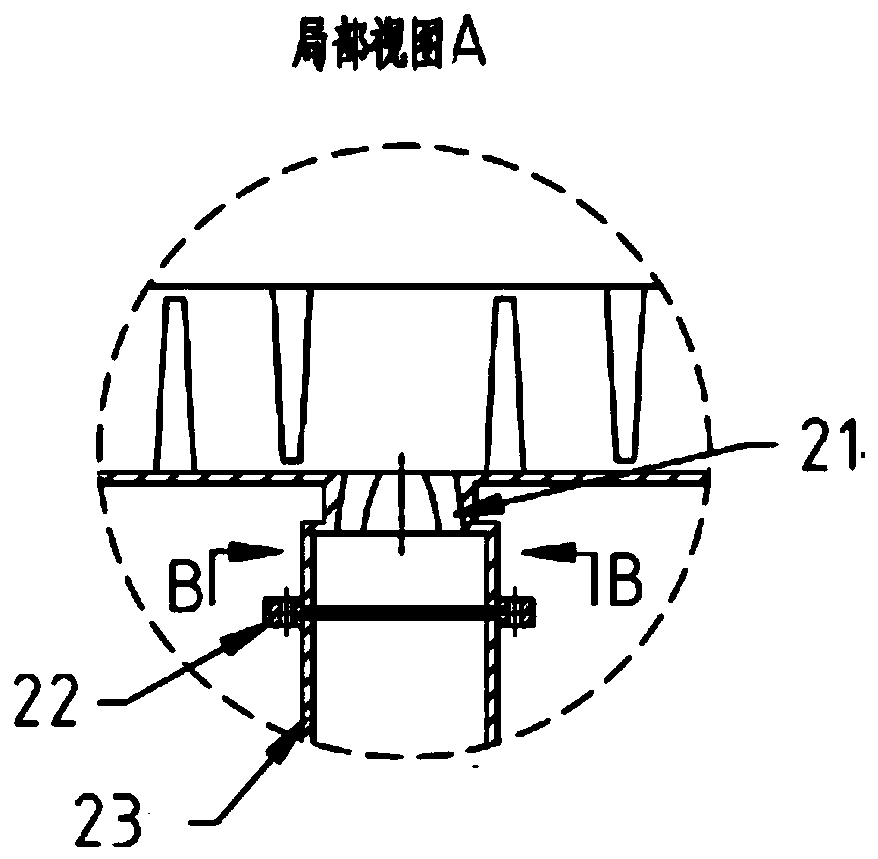

The invention relates to a thermodynamic system for improving heat supply unit electric output adjusting capacity. The thermodynamic system is characterized in that main steam or reheating section steam is subject to temperature and pressure reduction to directly serve as heat source steam for industrial heat users; an absorption heat pump 23 of a first-stage heat exchange device serves as a heatsource of a first-stage heat exchange station 25 in the heating period to supply heat to heat users 29 and supplies cold to the users in the non-heat supply period; a high-pressure electric boiler 24of a second-stage heat exchange device improves the boiler water feeding temperature, reduces heat absorbed by boiler fed water in an economizer 4, accordingly improves the boiler tail smoke discharging temperature, and guarantees normal running of an SCR denitration device 5; and according to a three-stage heat exchange device, exhaust steam of a turbine intermediate pressure cylinder 8 serves asheat source steam of a third-stage heat exchange station 27, the unit heat load is guaranteed, and the heat using requirement of the heat users 29 is met. The electric output adjusting capacity of the heat supply unit can be improved, it is guaranteed that the unit heat supply capacity is not decreased under the low load running working conditions, pyroelectric decoupling is achieved, and the electric output adjusting capacity of the heat supply unit is improved.

Owner:NORTHEAST DIANLI UNIVERSITY +2

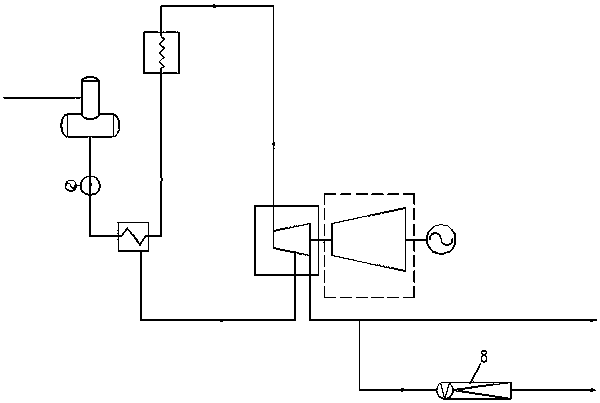

Low-load feed-water heating system of thermal power generating unit

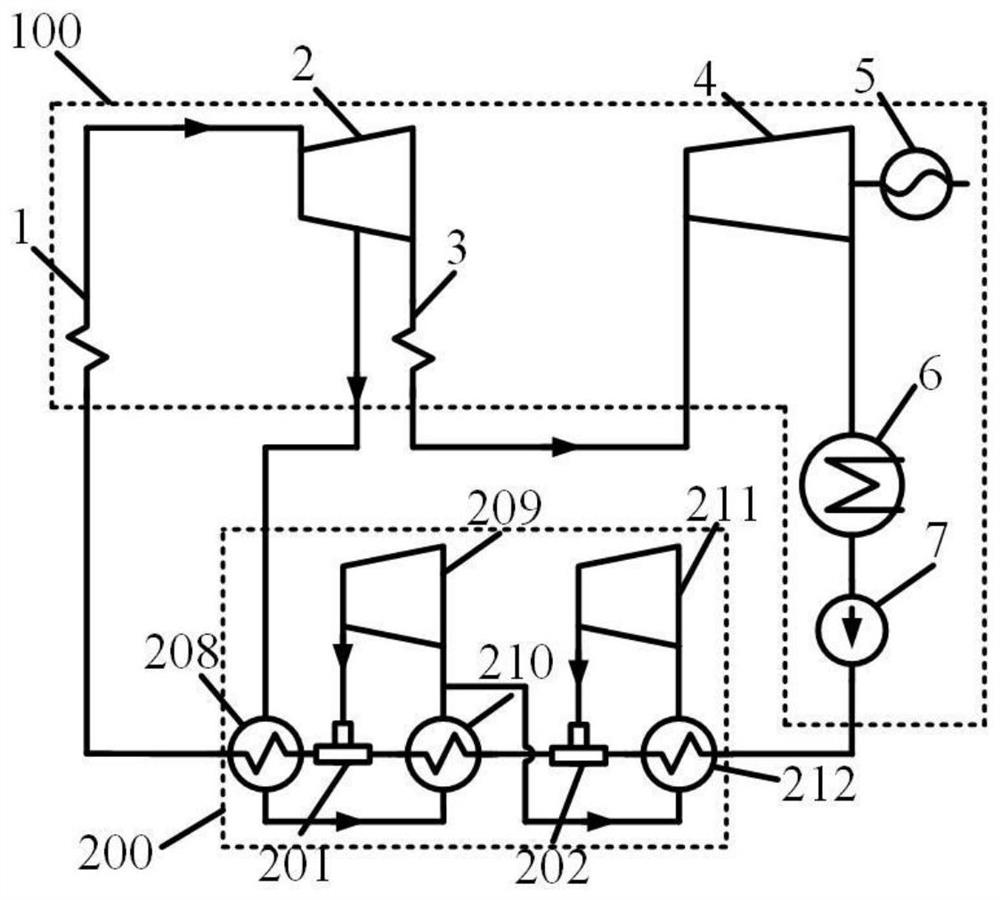

ActiveCN103335301AIncrease feed water temperatureImprove efficiencyFeed-water heatersEngineeringGenerating unit

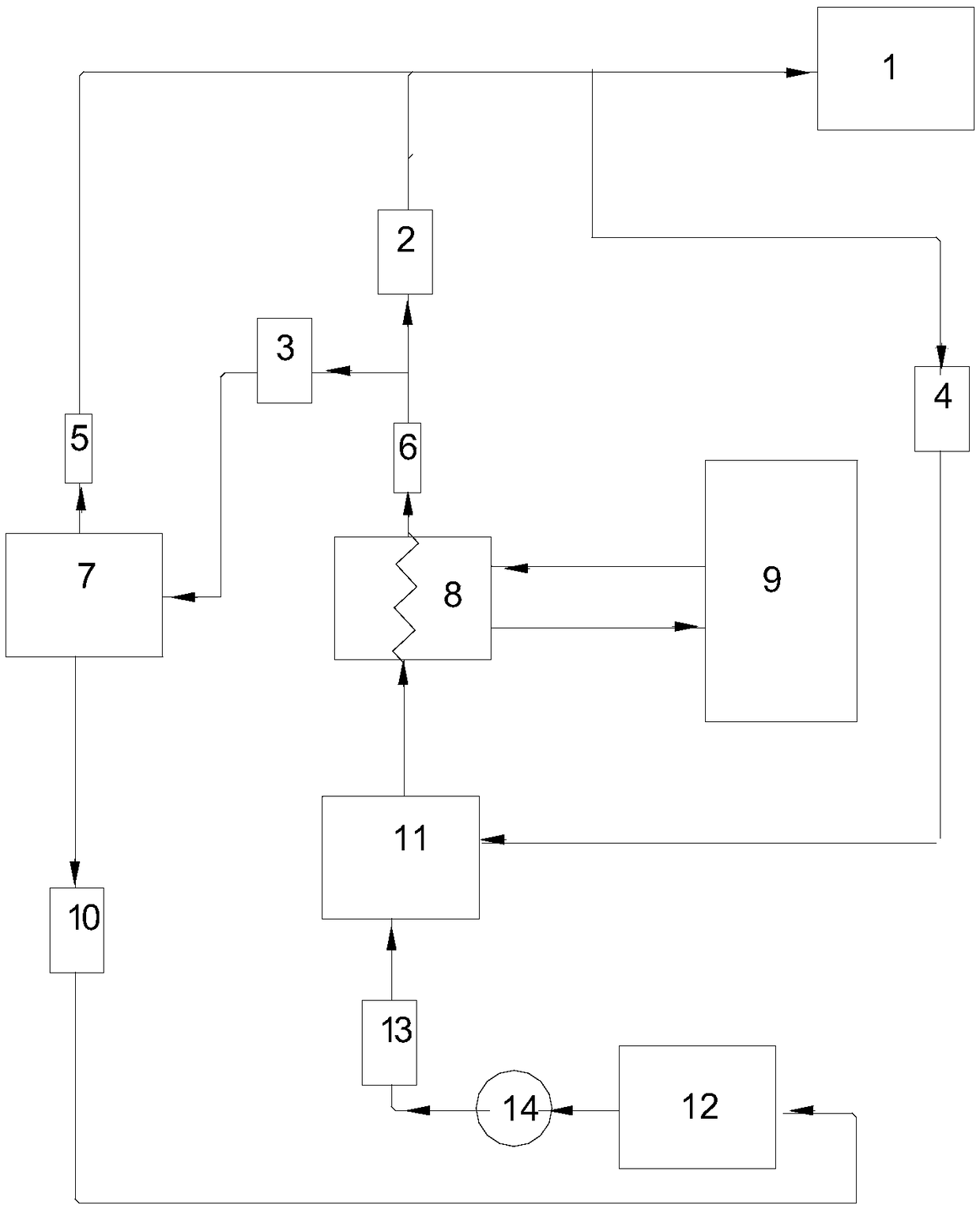

A low-load feed-water heating system of a thermal power generating unit comprises a jet heat pump and a steam turbine which are communicated with a main steam pipeline, wherein a steam valve is mounted on a pipeline between the main steam pipeline and the jet heat pump; regenerative extraction steam of the steam turbine is led out by a regenerative extraction steam pipe; one path is communicated with a high pressure heater; the other path is communicated with the jet heat pump after passing through an ejected steam valve; an outlet of the jet heat pump is communicated with a steam side of a low-load feed-water heater; a heating water inlet side of the low-load feed-water heater is communicated with a feed-water side of the high pressure heater; and a feed-water pipeline is communicated with a boiler after sequentially penetrating through the high pressure heater and the low-load feed-water heater. The system takes main steam as ejection steam; one-section regenerative extraction steam with highest ejection regenerative extraction steam pressure is ejected, so that mixed steam with the pressure higher than the one-section regenerative extraction steam pressure is obtained; and the mixed steam at the outlet of the jet heat pump heats feed water of the boiler to raise the temperature of the feed water.

Owner:XI AN JIAOTONG UNIV

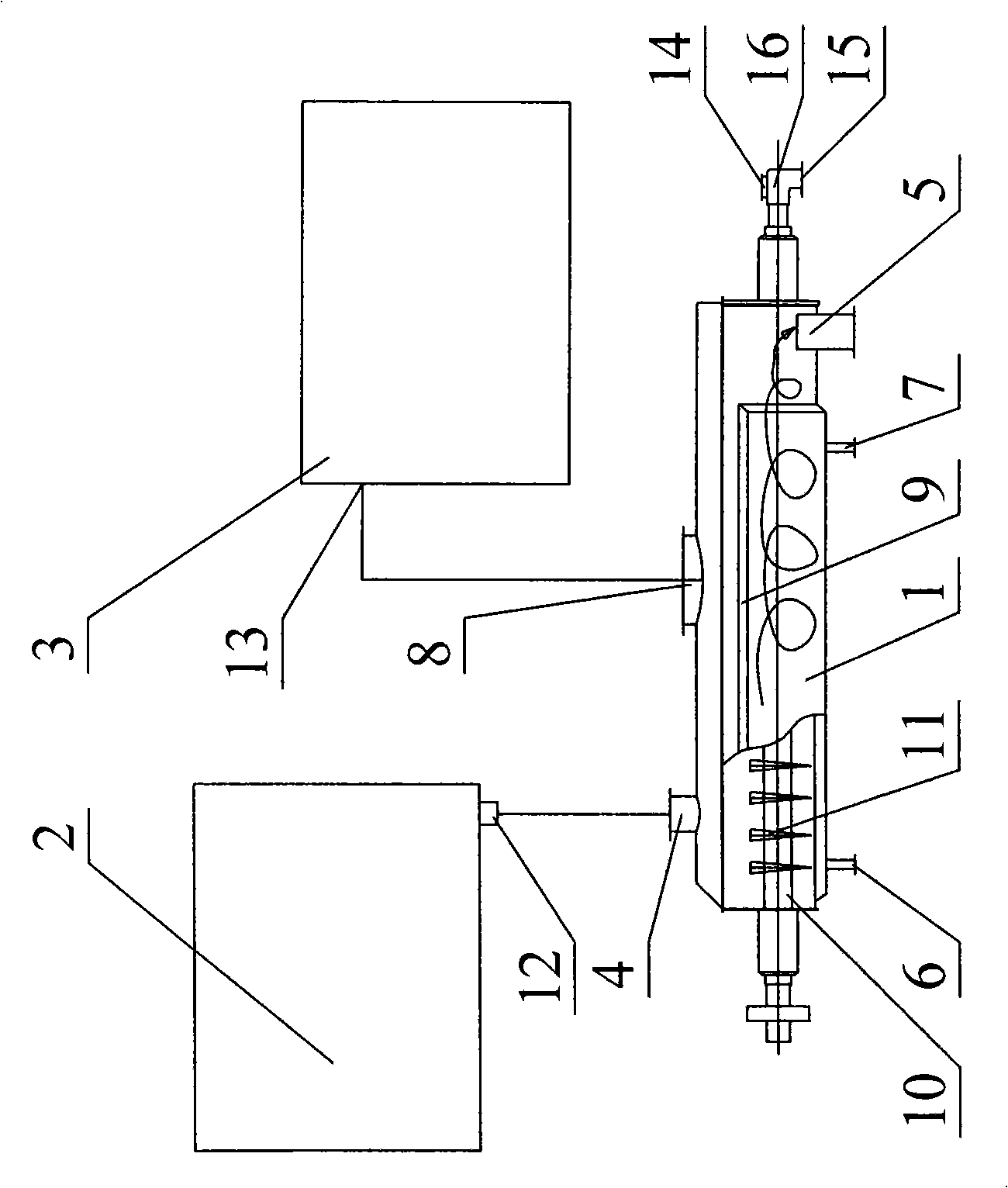

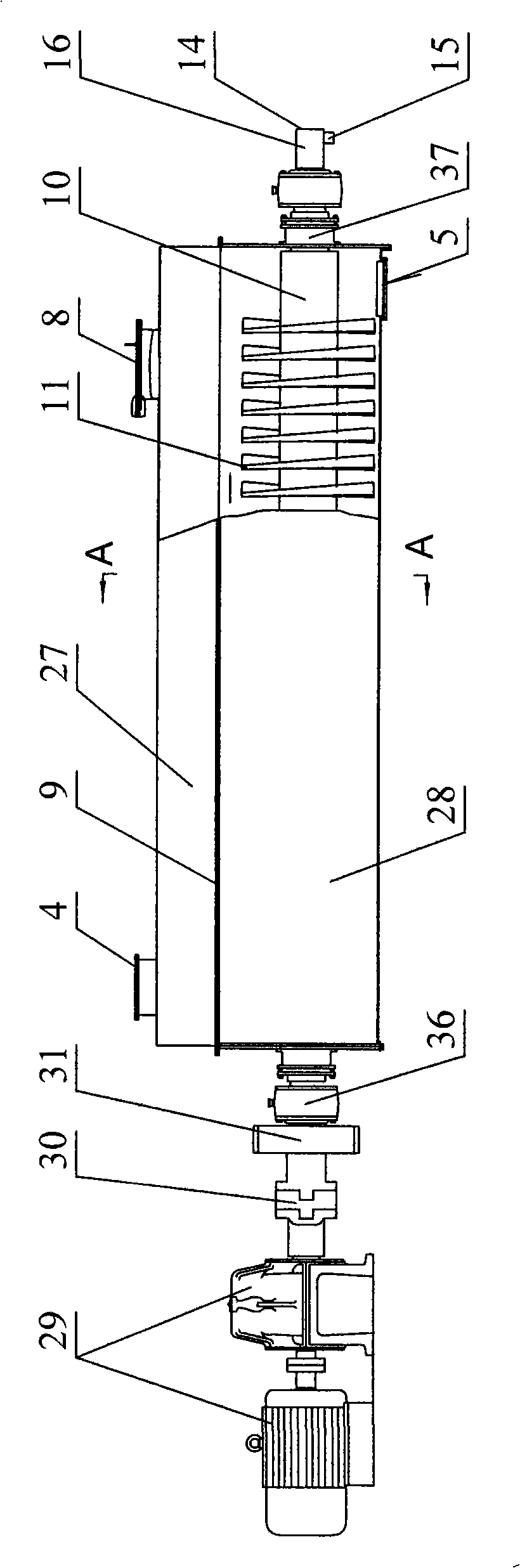

Set treatment device of sludge drying

InactiveCN101549945AIncrease flow rateLow costSludge treatment by de-watering/drying/thickeningSludgeExhaust gas

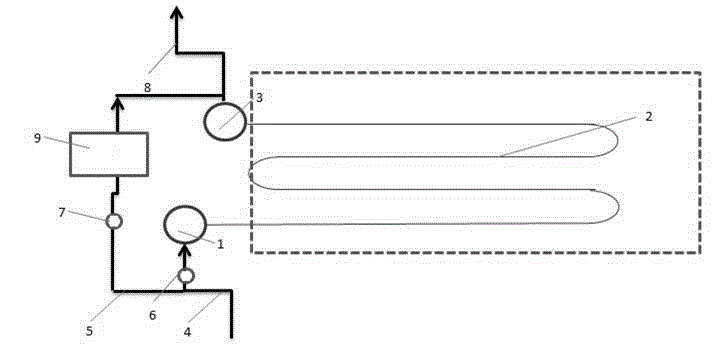

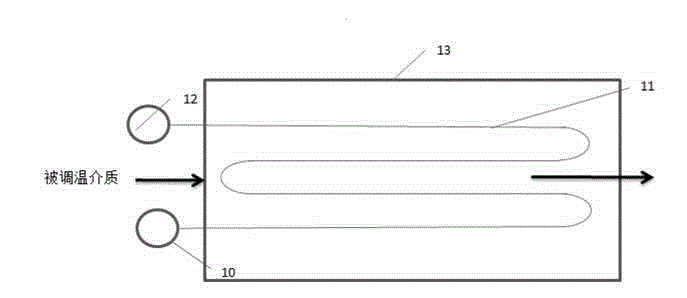

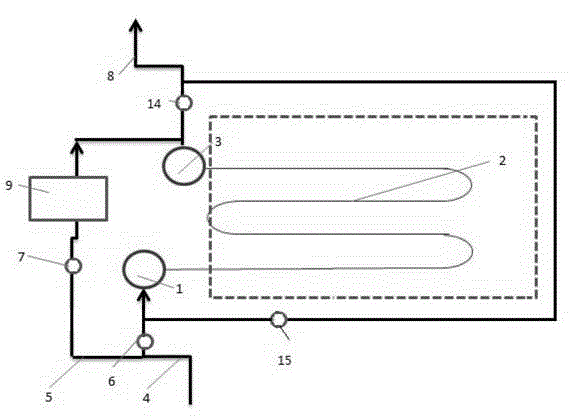

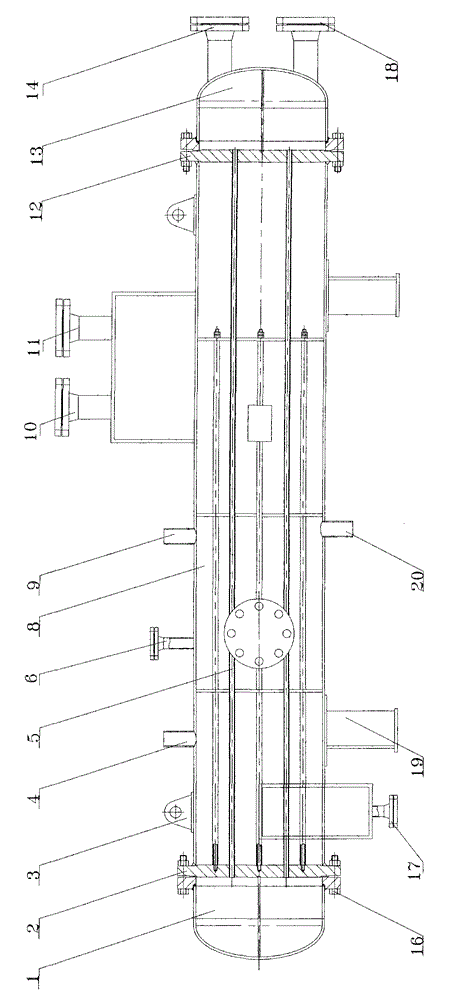

The invention relates to a treatment device of sludge drying in the field of environmental protection, in particular to a set treatment device of sludge drying, comprising a paddle sludge drier (1) with a feeding inlet (4), a discharging hole (5), a steam inlet pipe (6), a water outlet pipe (7), a tail gas outlet (8), a cylinder (9), a hollow shaft (10) and hollow paddles (11); the hollow paddles (11) are arranged on the hollow shaft (10); the set treatment device of sludge drying also comprises a storing and feeding device (2) and a tail gas purifying processing device (3); the discharging hole (12) of the storing and feeding device (2) and the feeding inlet (4) of the paddle sludge drier (1) are connected; and the tail gas outlet (8) of the paddle sludge drier (1) and the gas inlet (13) of the tail gas purifying processing device (3) are connected. The treatment device has the advantages of simple structure, good drying effect, low cost, environmental protection, high cost performance, continuous drying and realization of sludge integrated treatment.

Owner:史少军

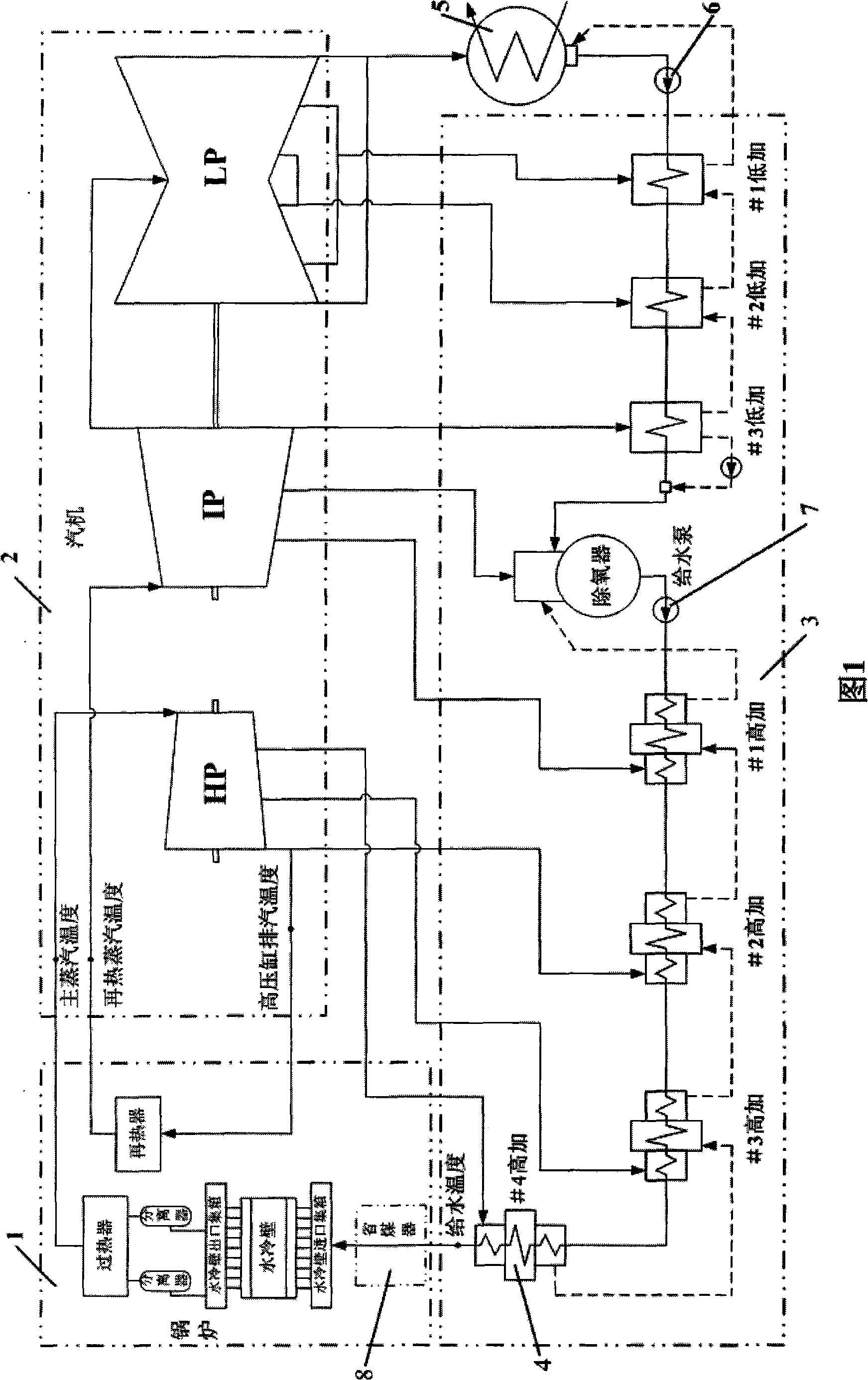

Super or super supercritical coal fired power generation heat system improvement method

InactiveCN101261002AIncrease feed water temperatureRaise the average endothermic temperatureSteam generation heating methodsIndirect carbon-dioxide mitigationAir preheaterSteam pressure

The invention discloses a measure for improving a supercritical or ultra supercritical coal-burning power generation thermal system belonging to the thermal power generation technical field, relating to the supercritical or ultra supercritical coal-burning power generation thermal system without an economizer and a parameter configuration. The invention concretely comprises following steps of removing the economizer which is requisite for a conventional boiler to simplify the flow of a boiler and reduce the flow resistance of a system and the station service power consumption rate; increasing a primary high-voltage bleeder heater to increase the feed temperature; possibly reducing the exhaust steam pressure and the temperature of a high pressure cylinder to enable the exhaust steam temperature of the high pressure cylinder to be equal or similar to the feed temperature; possibly increasing the temperature of reheat steam on the premise of guarantee of safety; and increasing or providing an air preheater and increasing the temperature of secondary wind to improve the average temperature of heat release of flue gas of the boiler to the cycle fluid of power generation and improve the second-law efficiency of the boiler and the combustion stability of unit coal species changing.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

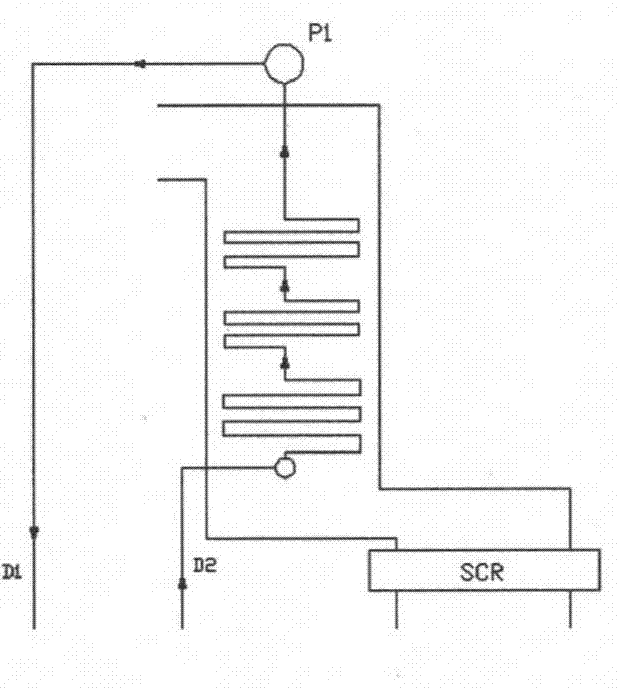

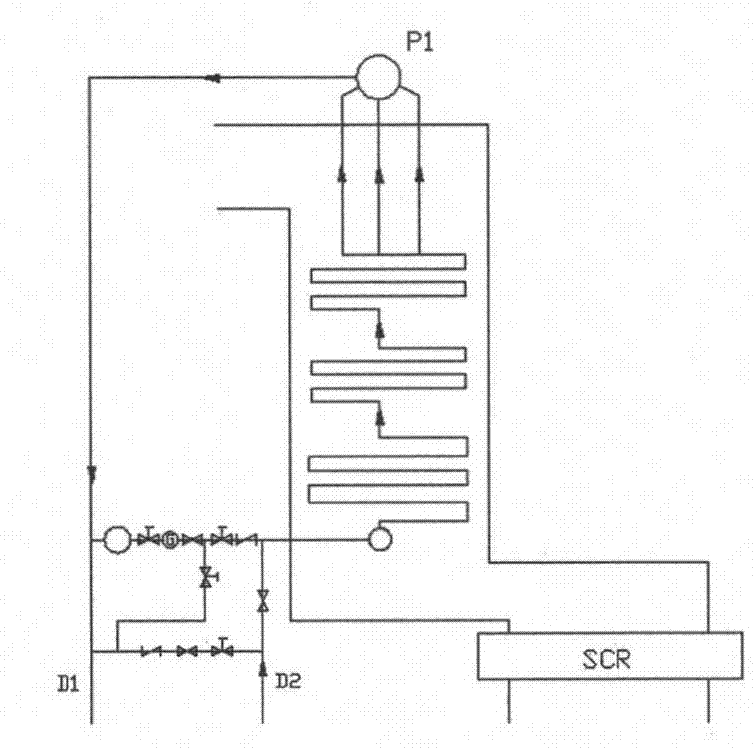

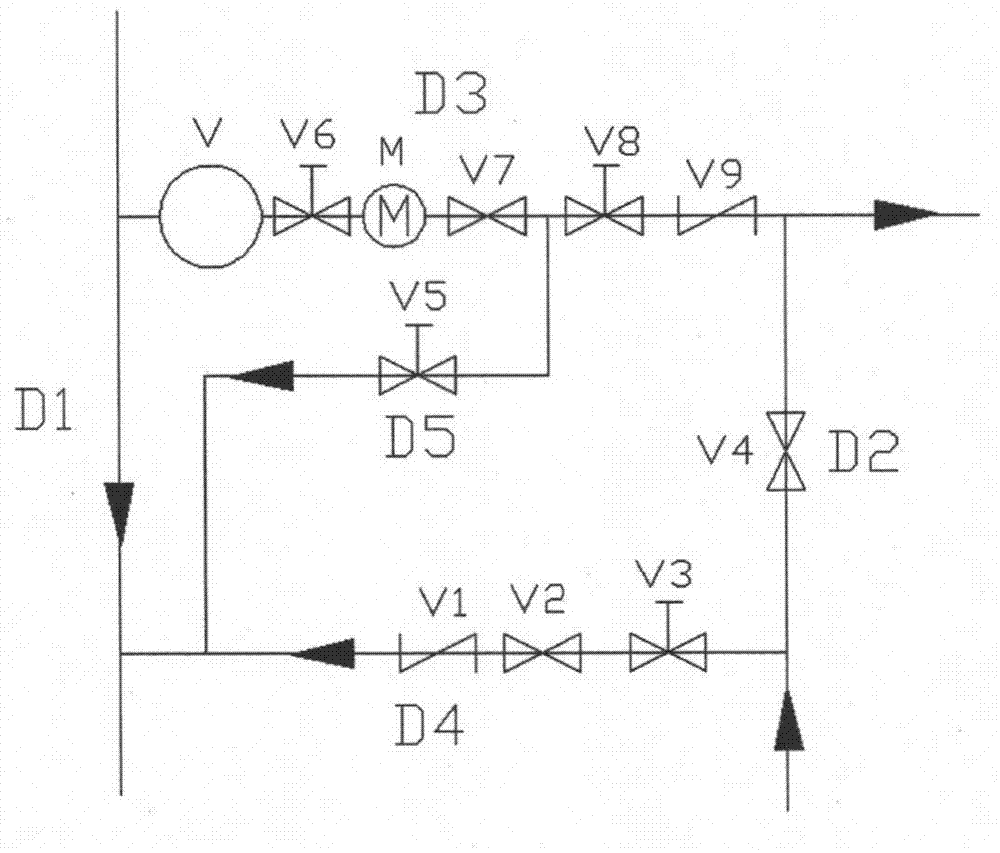

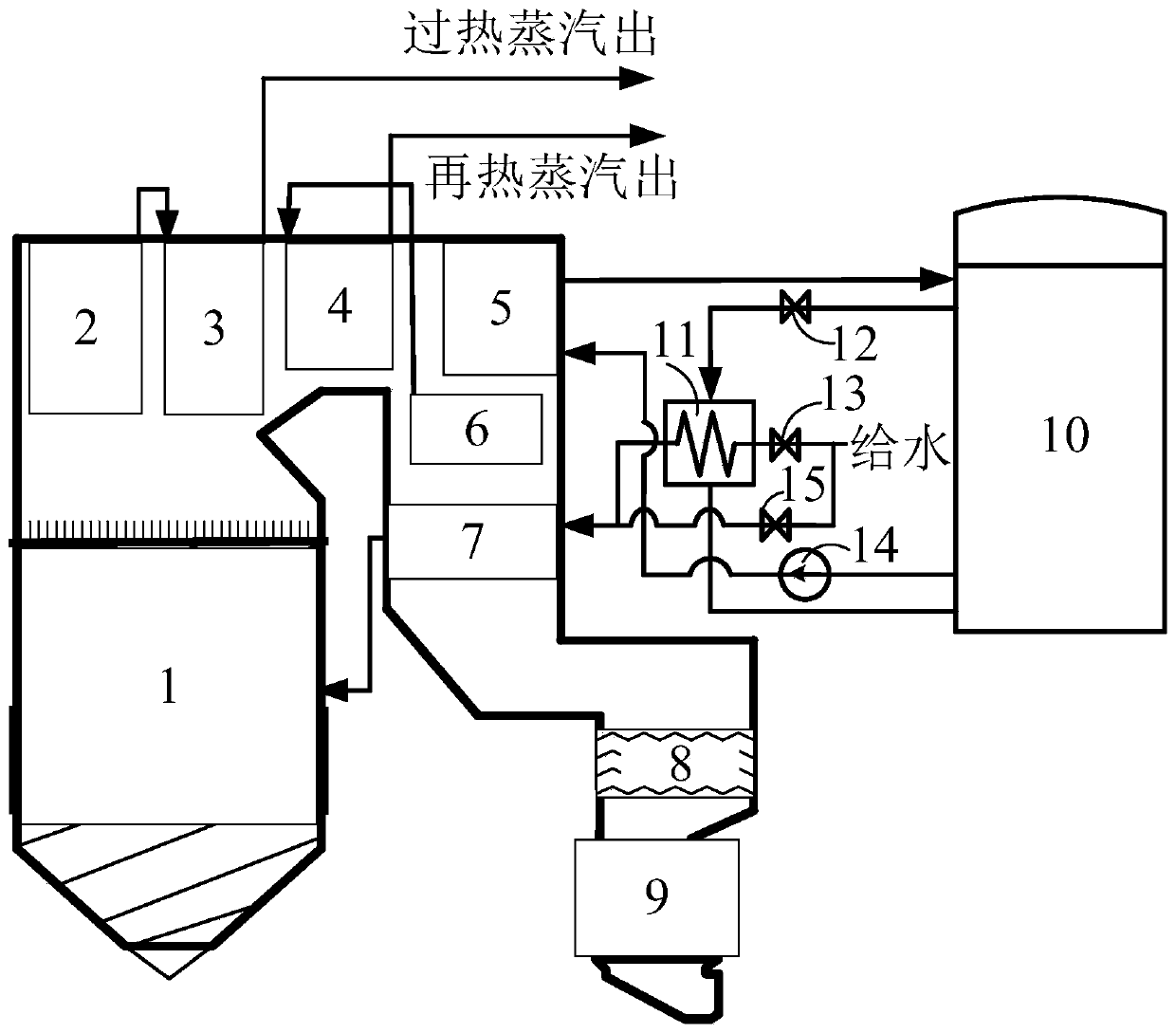

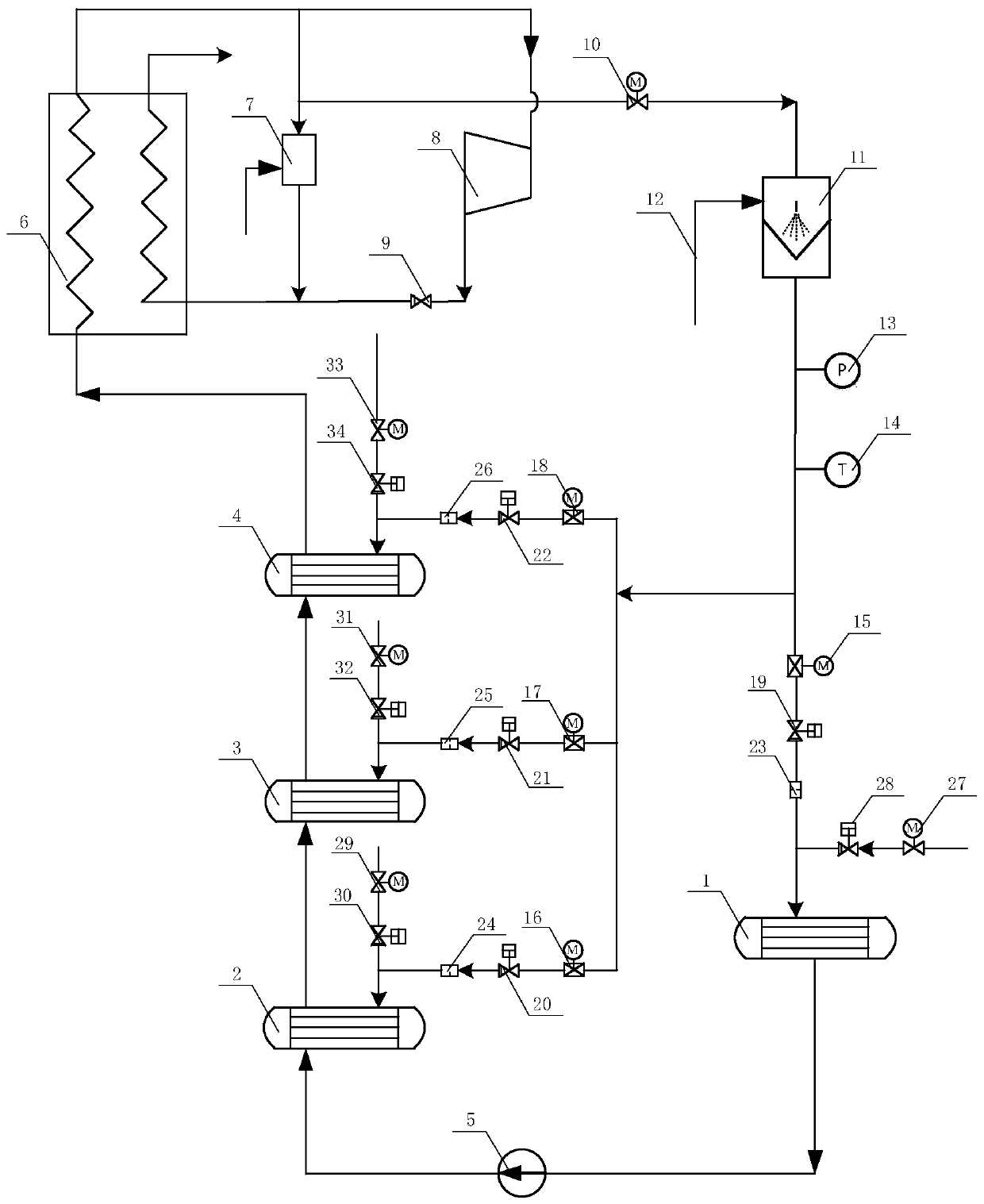

Feedwater replacement type economizer system for whole commissioning of denitration device

The invention provides a feedwater replacement type economizer system for whole commissioning of a denitration device. The feedwater replacement type economizer system is characterized in that the feedwater replacement type economizer system comprises a first bypass, a second bypass and a third bypass, the first bypass and the second bypass are arranged between a downcomer and a feedwater pipeline, the first bypass is provided with a vessel pot, a stop valve, a circulating pump, a flow control valve, a stop valve and a check valve in sequence from the downcomer to the feedwater pipeline, the second bypass is provided with a stop valve, a flow control valve and a check valve in sequence from the feedwater pipeline to the downcomer, one end of the third bypass is in the position between the flow control valve and the stop valve of the first bypass, the other end of the third bypass is connected with the downcomer, the third bypass is provided with a stop valve, and a flow control valve is arranged between the first bypass and the second bypass in the feedwater pipeline. By means of the feedwater replacement type economizer system, economy of a boiler is not sacrificed under heavy load, the smoke temperature of an inlet of the denitration device can be increased under low load, and the feedwater replacement type economizer system is suitable for boilers with the smoke temperature of the denitration device inlet under low load reaching 40 DEG C.

Owner:SHANGHAI POWER EQUIP RES INST +1

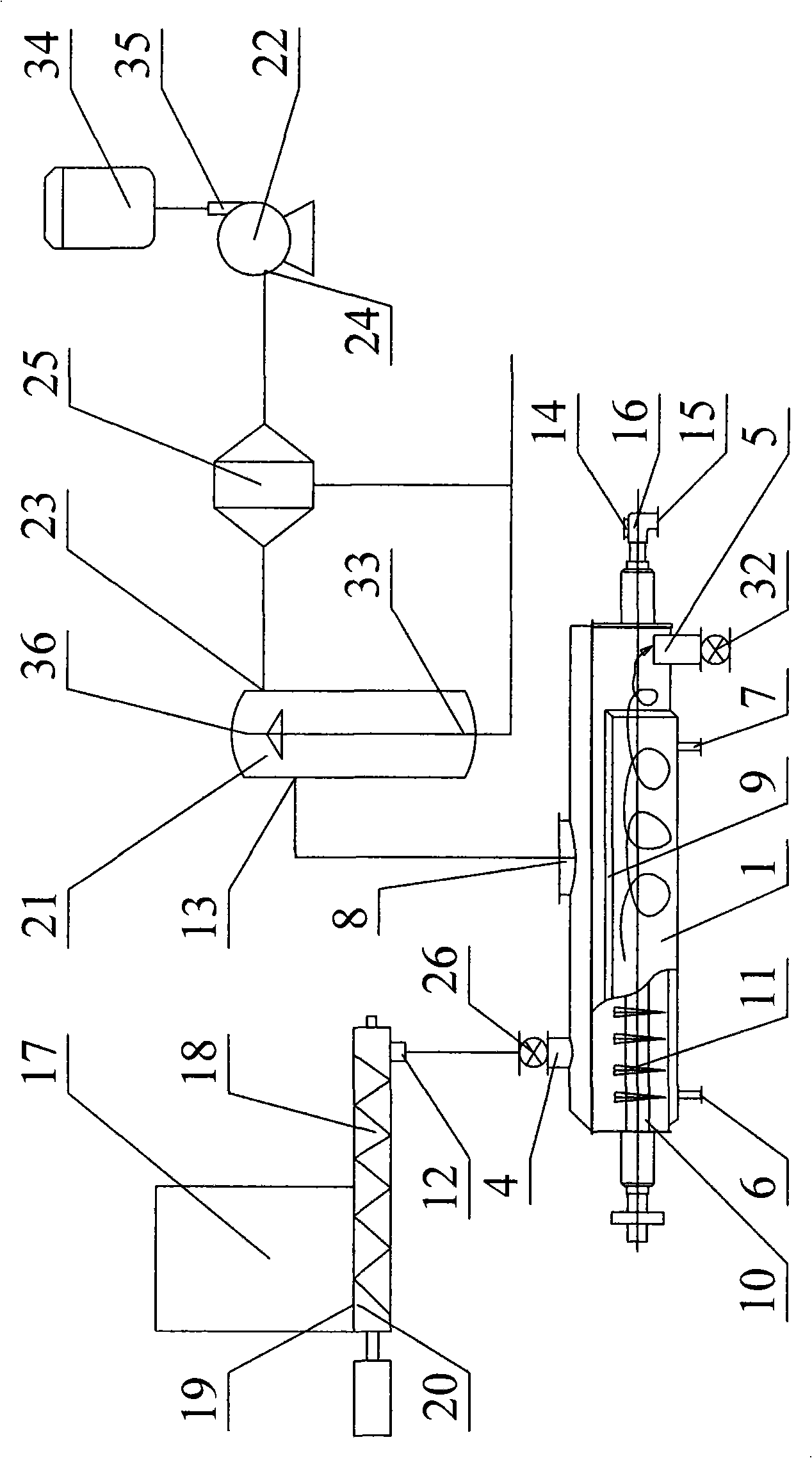

Gasification process system for fine particle biomass or solid fossil fuel

ActiveCN104449872AWell mixedReduce dust accumulationEnergy inputGasification processes detailsCyclonic separationSeparation technology

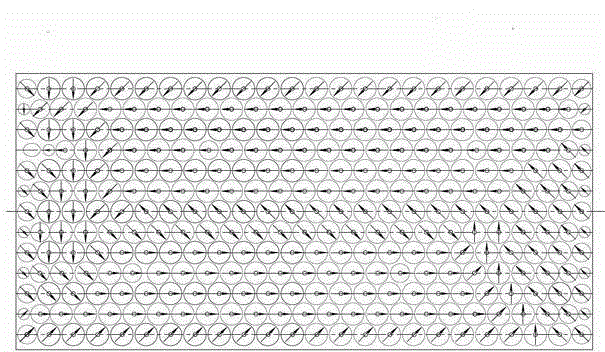

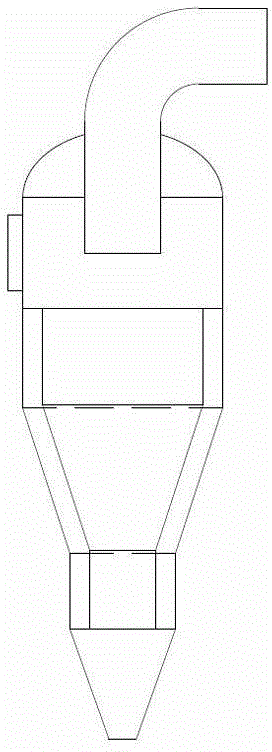

The invention discloses a gasification process system for fine particle biomass or solid fossil fuel. A combustion system adopts a circulating fluidized bed combustion technology and an efficient cyclone separation technology of the fine particle biomass or solid fossil fuel. The fine-particle circulating fluidized bed combustion technology adopts a flat-plate directional wind cap, so that refining combustion of coal particles is achieved; a fluidized bed gasification reactor system of the fine particle biomass or solid fossil fuel adopts a fine-particle gasification technology, and the fine-particle gasification technology adopts the flat-plate directional wind cap, so that the problems of low gas production rate and low gas production heat value in an existing coal gasification process system are solved; by virtue of an afterheat utilization system, the heat carried in the gasification process is transformed into steam, and is supplied to the fluidized bed gasification reaction system of the fine particle biomass or solid fossil fuel, so that the cost is reduced by using self-energy sources; and the gasification process system also comprises an ash treatment system and a gasification process gas purification system, so that the problem of waste of the heat carried in ash, and the problem that sulfide and dust carried in the gasification process are not thoroughly treated are solved.

Owner:大连科林能源工程技术开发有限公司

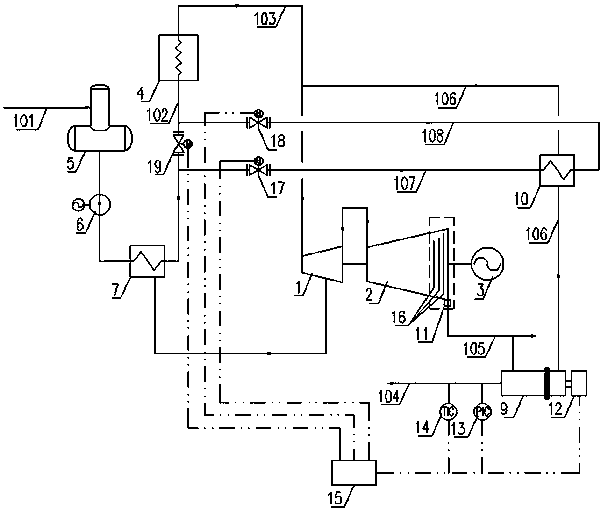

System and method for extreme hot start of high temperature gas cooled reactor nuclear power unit

ActiveCN108665991AImprove usabilityReduce coolingLiquid degasificationPlant parameters regulationNuclear engineeringNuclear power

The invention discloses a system and method for extreme hot start of a high temperature gas cooled reactor nuclear power unit. The system comprises a steam turbine, an evaporator, a primary loop system, a steam-water separator, a high-pressure heater, a deaerator, a water supply pump and seven valve groups. The method comprises the following main steps that factors for triggering reactor protection are analyzed, the protection factors that helium circulation of the primary loop system and feed-water circulation of the secondary loop evaporator do not need to be terminated after reactor protection actions are identified, and circulation of the primary loop system and the secondary loop system is maintained after the reactor protection actions; in the re-start process of the reactor unit, steam and water are recycled, and the water is conveyed through the steam-water separator into the deaerator so as to increase the feed-water temperature; before impulse starting of the steam turbine, the steam generated by the evaporator is introduced into the high-pressure heater so as to further increase the feed-water temperature. According to the method, the time from shutdown to re-start of the high temperature gas cooled reactor nuclear power unit is reduced to 3 hours or below from 170 hours or above, and the availability of the high temperature gas cooled reactor nuclear power unit is greatly improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

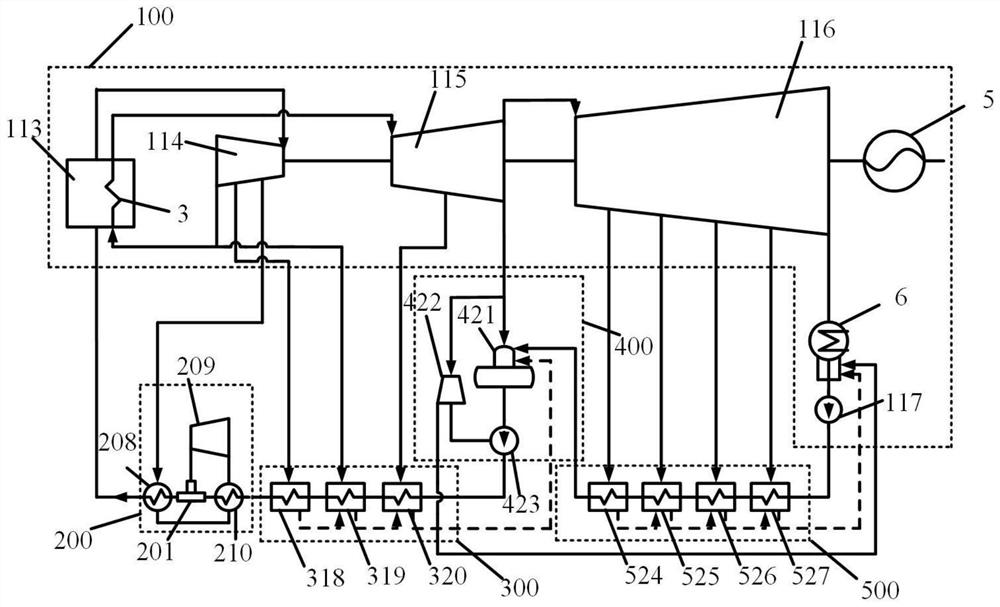

Pressurized water reactor nuclear power unit secondary circuit thermodynamic system self-adaptive steam supply system and method

PendingCN110259532AReduce startup timeSafe and stable operationNuclear energy generationSteam generator primary sideStart stopPressurized water reactor

The invention discloses a pressurized water reactor nuclear power unit secondary circuit thermodynamic system self-adaptive steam supply system and method. By means of the system and the method, a main steam bypass can be self-adaptively put into use or cut out to supply a heating steam source to a low-pressure heater, a deaerator and a high-pressure heater according to secondary circuit thermodynamic parameters in the unit start-stop and normal running process, the defect of long-time hot stand-by duty of an auxiliary boiler is avoided, energy cascade recycling is achieved, meanwhile the reliability, stability and safety are high, and the power consumption is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

Heat filler type deaerator with stable deaerating function and atomizing function

InactiveCN103292311AConstant and reliable water levelEnsure water qualityLiquid degasificationBlowoff valveDifferential pressure

The invention discloses a heat filler type deaerator with a stable deaerating function and an atomizing function. The heat filler type deaerator is characterized in that a heat-side inlet of an exhaust heat exchanger is communicated with a blowoff valve through a pipeline, a cold-side inlet of the exhaust heat exchanger is communicated with a deaerator water supply pipe, a cold-side water outlet of the exhaust heat exchanger is communicated with a deaerator water supply inlet through a pipeline, a heat-side inlet of a water outlet heat exchanger is communicated with a deaerator water outlet, a boiler water supply pump is connected to a heat-side outlet pipeline, a cold-side water inlet of the water outlet heat exchanger is communicated with the deaerator water supply pipe, a water supply pump is arranged on the deaerator water supply pipe, a differential pressure transmitter is arranged in a deaerator water tank, detected water level signals in the deaerator water tank are transmitted to a controller through the differential pressure transmitter, the controller transmits signals to a frequency converter, the frequency converter controls rotation speed of the water pump to adjust water supply, a pressure control gauge transmits pressure signals to the controller which controls opening of preheating pipeline electromagnetic valves, a temperature sensor transmits temperature signals to the controller, and then the controller controls opening of reheating steam electromagnetic valves.

Owner:JIHUA 3539 SHOE MAKING

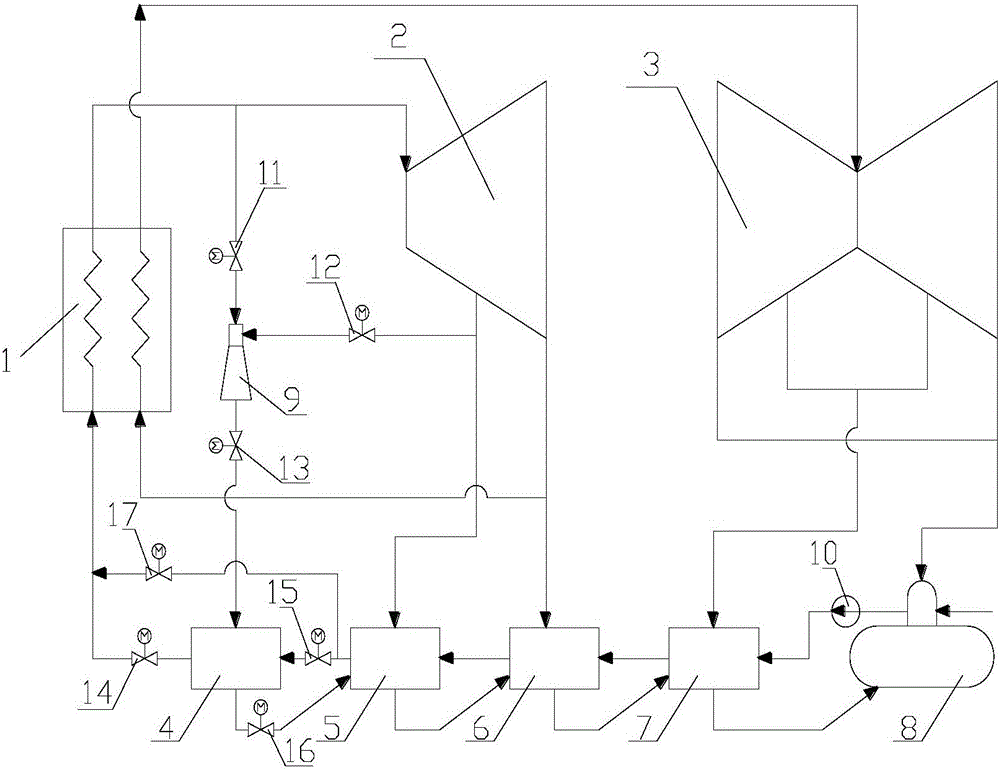

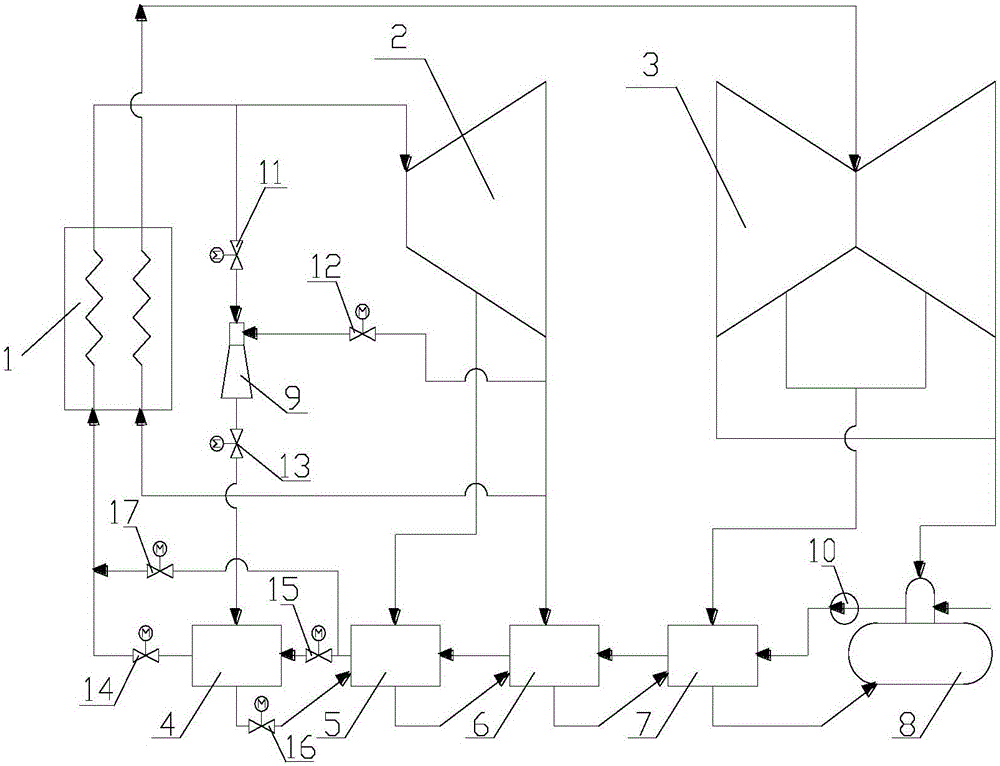

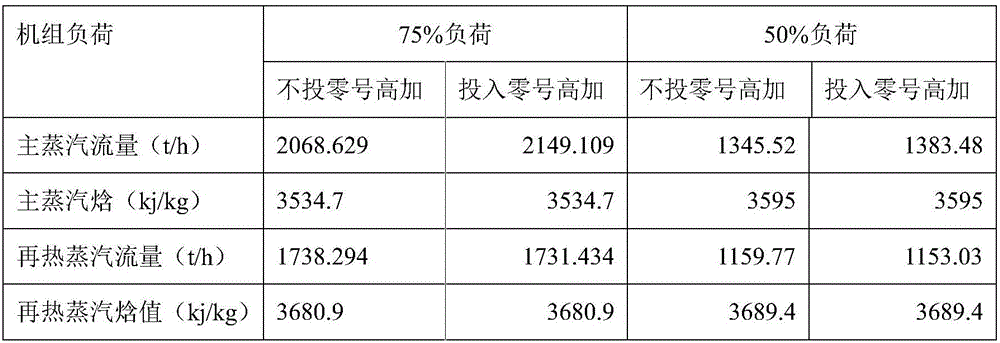

Hot-pressing type ultra supercritical unit number-zero high-pressure heater and switching system thereof

ActiveCN105953213AIncrease feed water temperatureImprove economyLiquid degasificationFeed-water heatersPipe fittingProcess engineering

The invention provides a hot-pressing type ultra supercritical unit number-zero high-pressure heater, a switching system thereof and a novel technological process for improving the low-load running economical efficiency of thermal power generating units. A hot press, the number-0 high-pressure heater and related valves and pipe fittings connected with the hot press and the number-0 high-pressure heater are used as core parts of the technological process, and all other devices are devices of existing units. The technological process has a main effect of adding a level of regenerative heating to an existing steam extraction heat recovery system, the thermal economical efficiency of the units under low loads is improved, the smoke temperature of an outlet of an economizer can be effectively improved, and the removal efficiency of a denitration system under the low-load work condition is ensured. In addition, due to input of the set of technological process, the air temperature can be effectively increased, and impact generated on the unit thermal economical efficiency and the boiler safety under the high-pressure cut-off work condition can be relieved.

Owner:张曙光

Full-working-condition auxiliary denitration system and running method

ActiveCN109945223AEmission reductionGuaranteed denitrification efficiencyGas treatmentBoiler water tubesAir preheaterWater flow

The invention discloses a full-working-condition auxiliary denitration system and a running method. The system comprises a water cooling wall, a platen superheater, a tail stage superheater, a tail stage reheater, a heat storage medium heater, a low-temperature reheater, an economizer, an SCR denitration device an air preheater and further comprises a heat storage medium tank and a heat storage medium and feed water heat exchanger; through a heat storage medium pump communicating with a cold heat storage medium outlet of the heat storage medium tank, the cold heat storage medium flow enteringthe heat storage medium heater is subjected to adjusting, the heat storage medium heat absorbing amount and boiler loads are matched, meanwhile, through a feed water adjusting valve and a heat heat-storage medium outlet adjusting valve communicating with the heat heat-storage heat medium outlet of the heat storage medium tank, the heat heat-storage medium flow and the feed water flow entering theheat storage medium and feed water heat exchanger are adjusted, through a bypass feed water adjusting valve, the main feed water flow is subjected to auxiliary adjusting, the smoke temperature entering the SCR denitration device is kept within the optimal running temperature range of the denitration system under the different boiler loads, and the denitration efficiency is ensured.

Owner:XI AN JIAOTONG UNIV

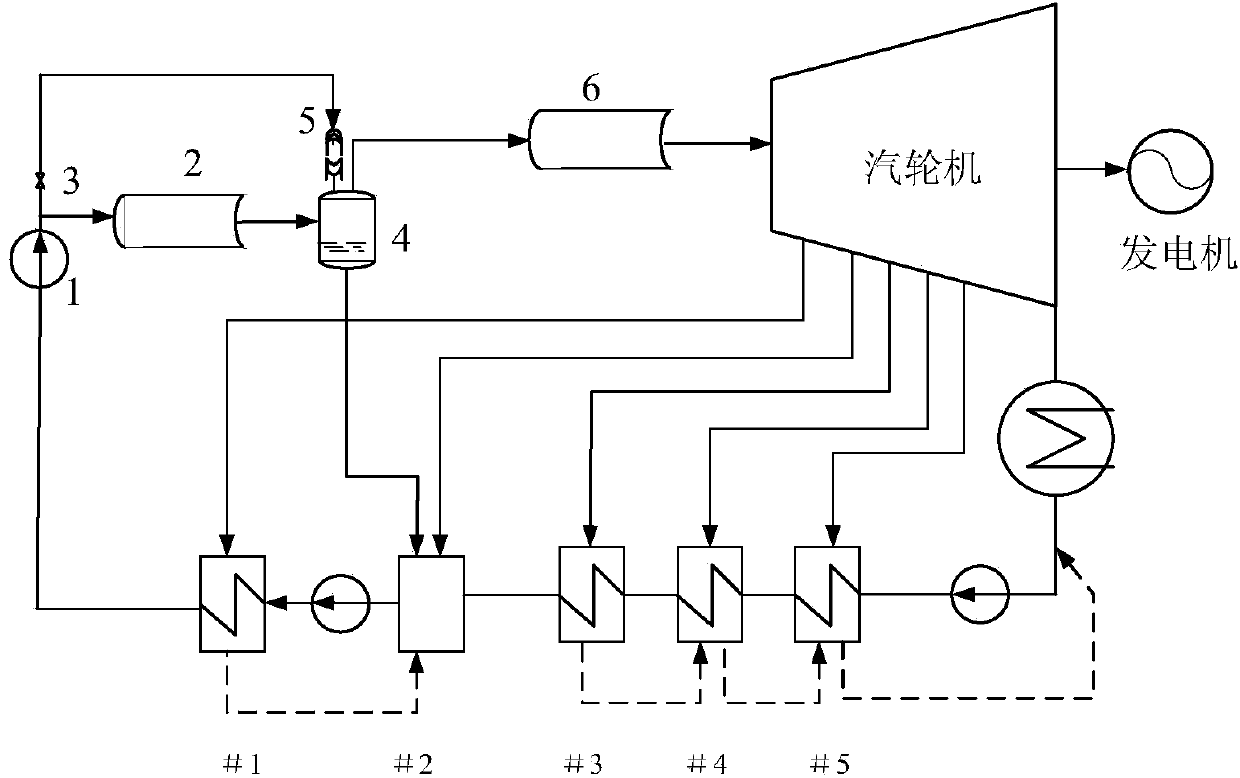

Regenerative system of turbogenerator unit and operation method thereof

ActiveCN103644005ASolve environmental problems that cannot be put into operationIncrease feed water temperatureSteam useFeed-water heatersEngineeringHigh pressure

The invention discloses a regenerative system of a turbogenerator unit and an operation method thereof. The system comprises a high-pressure cylinder and a high-pressure heater, wherein an steam exhaust port and a plurality of high-pressure steam extraction ports whose steam extraction pressure is increased sequentially are formed in the high-pressure cylinder, the high-pressure steam extraction ports are connected with the same high-pressure heater through high-pressure steam extraction pipelines, and an extraction check valve and an isolated valve are arranged on each high-pressure steam extraction pipeline. When the turbogenerator unit operates at a rated load, a first high-pressure steam extraction port with the lowest steam extraction pressure supplies steam for the high-pressure heater, and the steam extraction pressure at the time is set to be P0; when the turbogenerator unit operates in a state lower than the rated load, a high-pressure steam extraction port with steam extraction pressure less than or equal to P0 or closer to P0 is selected to supply steam for the high-pressure heater, and the isolated valves on other high-pressure steam extraction pipelines are switched off. According to the regenerative system of the turbogenerator unit and the operation method thereof, a denitration system can operate normally when the unit operates at a low load, the boiler feeding temperature is increased, and the thermodynamic cycle efficiency of the unit is improved accordingly.

Owner:王振宇

Boiler thermal system and control method thereof

PendingCN110056853AIncrease feed water temperatureAccelerate cold start rateLiquid degasificationSteam generation plantsFlue gasEngineering

The invention relates to a boiler thermal system and a control method thereof, and belongs to the technical field of thermal power generation. Part of superheated steam generated by a boiler superheater selectively enters a deaerator, a third high-pressure heater, a second high-pressure heater and a third high-pressure heater respectively after being subjected to temperature reduction and pressurereduction effect of a temperature reduction and pressure reduction device, the boiler heat is recycled by increasing the feed water temperature of a boiler, the inlet flue gas temperature of an SCR denitration device is increased, and the cold start speed of the boiler can be accelerated.

Owner:SPIC POWER PLANT OPERATION TECH (BEIJING) CO LTD

Thermal coupling power generation system of garbage incinerator medium pressure steam and coal-fired unit

ActiveCN107559058AIncrease temperatureIncrease feed water temperatureLiquid degasificationSteam engine plantsEngineeringDeaerator

The invention discloses a thermal coupling power generation system of a garbage incinerator medium pressure steam and coal-fired unit. The thermal coupling power generation system is technically characterized in that a garbage incinerator body and a coal-fired unit are included; a high-pressure heater comprises a first-stage high-pressure heater body and a second-stage high-pressure heater body which communicate with each other; an ultrahigh-pressure cylinder is connected with a high-pressure cylinder; a water feed pump is connected with a low-pressure heater through a pipeline and is connected with a deaerator through a pipeline; the deaerator is connected with the high-pressure heater through a pipeline; the high-pressure heater is connected with the coal-fired unit through a water feedpipeline; the coal-fired unit is connected with a main steam pipeline; the main steam pipeline is connected with the ultrahigh-pressure cylinder; the ultrahigh-pressure cylinder is connected with a third-stage high-pressure heater body through a first-stage steam extraction pipeline; the ultrahigh-pressure cylinder is connected with the second-stage high-pressure heater body through a second-stagesteam extraction pipeline; the coal-fired unit is connected with the high-pressure cylinder through a reheater pipeline; and the high-pressure cylinder is connected with a condenser. According to thethermal coupling power generation system, by means of steam generated by a waste heat boiler for incinerating garbage, the steam is guided into a coal-fired unit thermal system, the efficiency of garbage incineration power generation is improved, and thermal consumption and power generation consumption are reduced.

Owner:HARBIN BOILER

Secondary reheating steam turbine generator unit system provided with overheating steam feed water heater

InactiveCN102678194AHigh thermal efficiencyImprove efficiencySteam engine plantsUnit systemEngineering

The invention provides a secondary reheating steam turbine generator unit system provided with an overheating steam feed water heater. The secondary reheating steam turbine generator unit system comprises a boiler, a steam turbine, a generator, a first reheater, a second reheater, a feed water heater group, and an overheating steam feed water heater, wherein the steam turbine comprises a high pressure cylinder, a first intermediate pressure cylinder, a second intermediate pressure cylinder and a low pressure cylinder, wherein the high pressure cylinder is connected with the outlet of the boiler; the first reheater is arranged in the boiler and connected between the high pressure cylinder and the first intermediate pressure cylinder; the second reheater is arranged in the boiler and connected between the first intermediate pressure cylinder and the second intermediate pressure cylinder; the feed water heater group is connected with the steam turbine; and the overheating steam feed water heater is connected between the feed water heater group and the inlet of the boiler. According to the invention, through the overheating steam feed water heater on a feed water system, the feed water temperature is improved by overheating degree of extracted stream, so that the heat efficiency of a secondary reheating steam turbine generator unit can be improved.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Coal economizer for power station boiler

InactiveCN102913896AReduce the temperatureOptimize system designFeed-water heatersSystems designPower station

The invention discloses a coal economizer for a power station boiler. The coal economizer comprises a water supply pipeline (4), an inlet header (1), a heat transfer face (2), an outlet header (3) and an outlet pipeline (8), wherein flue gas flows outside the heat transfer face to heat up water, a first bypass duct (5) which is used for connecting the water supply pipeline (4) and the outlet pipeline (8) is arranged between the water supply pipeline (4) and the outlet pipeline (8), and a bypass temperature adjusting device (9) is arranged on the first bypass duct (5). According to a system of the coal economizer, the traditional system design is improved, and the coal economizer has a function of temperature adjustment at the same time when the coal economizer can reduce the temperature of the flue gas at an outlet of the boiler and increase the water supply temperature.

Owner:SHANGHAI BOILER WORKS

Vessel atmospheric condenser, manufacturing method thereof and vessel closed cycle system

ActiveCN103604305AImprove corrosion resistanceExtended service lifeFeed water supplySteam/vapor condensersCavitationIsoetes triquetra

The invention discloses a vessel atmospheric condenser, manufacturing method thereof and a vessel closed cycle system. The vessel atmosphere condenser comprises a cylinder body, the front end and the rear end of the cylinder body are provided with a front tube sheet and a rear tube sheet, the front tube sheet is connected with a front tube box, the rear tube sheet is connected with a rear tube box, the rear tube box is provided with a water inlet and a water outlet, a plurality of heat exchange tubes are arranged inside the cylinder body, a steam inlet, a steam outlet, a condensate water outlet extend out of the surface of the cylinder body, and the inner sides of the front tube box and the rear tube box are respectively provided with a lining plastic layer which is a hot-melt combined layer of polytetrafluoroethylene and stainless steel substrates. The vessel atmospheric condenser has the advantages of cavitation resistance, corrosion resistance, high degree of automation, structural design optimization and energy conservation and environment protection.

Owner:RIZHAO HAICHEN ENVIRONMENTAL PROTECTION TECH

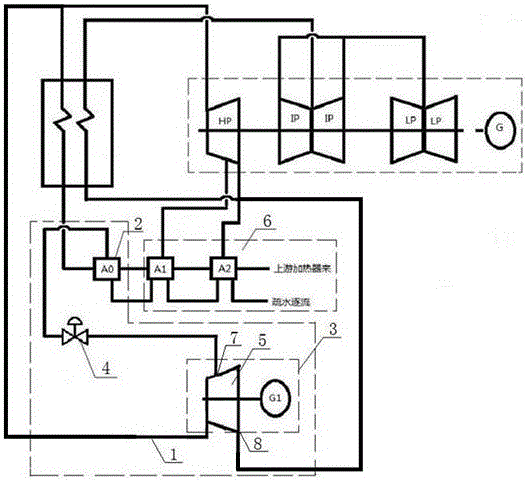

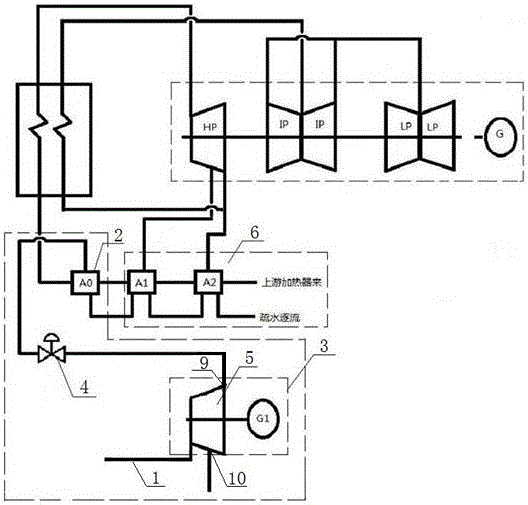

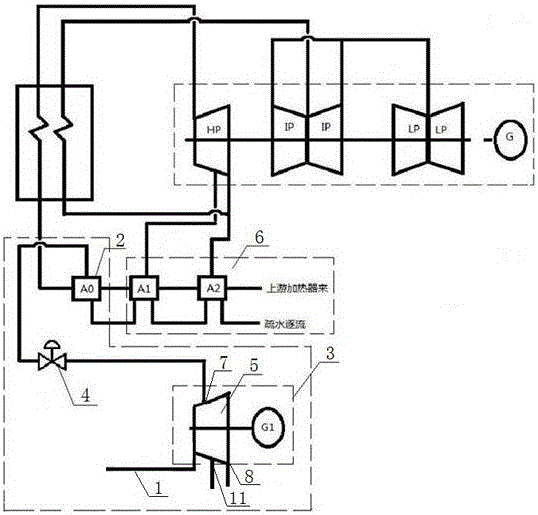

Device and method for increasing boiler feedwater temperature

PendingCN106224935AUnlimited capacityIncrease feed water temperatureSteam engine plantsFeed-water heatersEngineeringDeaerator

The invention discloses a device for increasing the boiler feedwater temperature. The device comprises a steam pipeline, a newly added final-stage high-pressure heater, a back pressure type steam turbine generator and a back pressure type steam turbine extraction control valve, wherein steam of the steam pipeline is from a boiler, and the steam flows through a high-pressure cylinder of the back pressure type steam turbine generator, the back pressure type steam turbine extraction control valve and the newly added final-stage high-pressure heater in sequence. The steam which enters the newly added final-stage high-pressure heater is cooled to be hydrophobic, then flows automatically step by step through a high-pressure heater of an original feedwater system and enters a deaerator at last; the other part of the steam continues to do work at the last stages of the back pressure type steam turbine generator, a part of the steam can be extracted from a plurality of subsequent stages so as to be supplied to other users, and the final exhaust steam can also be used for other applications.

Owner:上海量朝能源科技有限公司

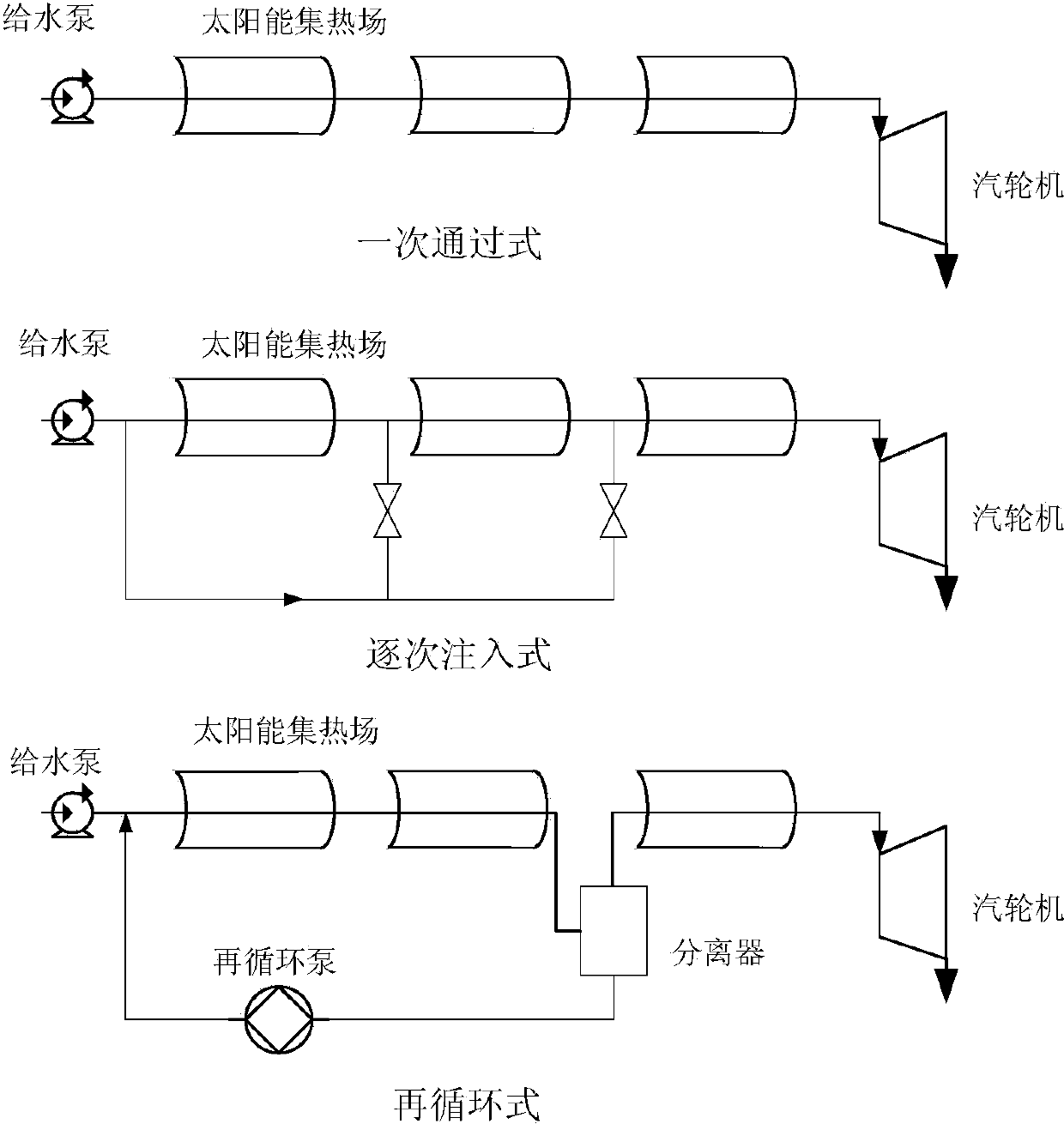

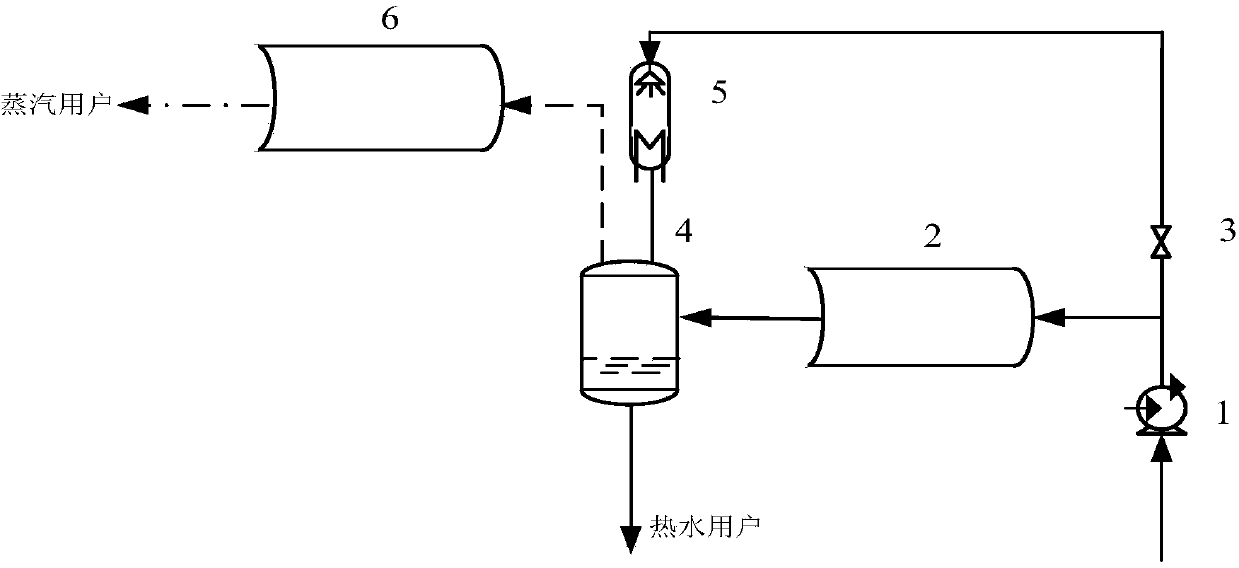

Novel trench-type solar recirculating heat collection system

InactiveCN103438591AMeet actual needsIncrease feed water temperatureSolar heat devicesSolar thermal energy generationCollection systemSolar water

The invention provides a novel trench-type solar recirculating heat collection system, belonging to the technical field of solar heat utilization. A flash evaporator of the system is provided with a passive pressure stabilizer to ensure that the trench-type solar water heating section is single-phase flow, flashing is performed in the flash evaporator, and generated vapor is introduced into a solar superheat section to be heated. Saturated water condensed in the flash evaporator is introduced into a deaerator. The invention also provides a novel trench-type solar heat power generation system which contains the novel trench-type solar recirculating heat collection system. The novel trench-type solar recirculating heat collection system and the trench-type solar heat power generation system can enable solar energy to directly generate vapor, and no two-phase-flow conversion process exists in the solar heat collector, thereby avoiding the problems of gas-liquid nonuniform distribution and the like in the solar water heating field; and thus, stable vapor is generated, thereby being beneficial to controlling the temperature and flow of the superheated vapor, and enhancing the system stability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for treating water in process of thermal power generation

InactiveCN101955277ACirculating water quality improvedWater quality index qualifiedMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processSocial benefitsChemical treatment

The invention relates to a method for treating water in the process of thermal power generation. The process comprises the treatment processes of surface water and circulating cooling water. The method is characterized in that in the process, part of water in a circulating water return pipe of a steam engine is introduced to a pretreatment system of the surface water, so that the water is taken as water inflow in the chemical pretreatment process directly for chemical treatment; and simultaneously, fresh water of which the water volume is more than that of water led out of the circulating water return pipe of the steam engine is replenished additionally in a circulating water inlet pipe of the steam engine. The method of the invention has the advantages of improving the water quality of circulating water substantially, improving condenser vacuum degree and the generating efficiency of machine sets, utilizing heat effectively and saving energy, along with simple process, wide source of medicaments, low cost and simple and convenient system operation, and has the obvious economic and social benefits.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

0# high-pressure heater system with back heating crossing units

ActiveCN104061564AImprove heat recovery efficiencyAvoid negative effectsFeed-water heatersSuperheaterEngineering

The invention discloses a 0# high-pressure heater system with back heating crossing units. The 0# high-pressure heater system heats supplied water of a supercritical (ultra supercritical) unit through high-temperature steam of a subcritical unit. The supercritical (ultra supercritical) unit comprises a supercritical (ultra supercritical) boiler, a supercritical (ultra supercritical) turbine high-pressure cylinder, a 0# high-pressure heater, a boiler economizer and a water supply pump, wherein the water supply pump supplies water to the boiler economizer. The subcritical unit comprises a subcritical boiler, a boiler overheater and a subcritical turbine high-pressure cylinder. Main steam in the subcritical unit or middle steam in the boiler overheater is sucked into the 0# high-pressure heater through a steam pipeline and is used for heating supplied water of the supercritical (ultra supercritical) unit. The 0# high-pressure heater system with back heating crossing the units is suitable for various units and is not confined to units with turbines provided with a steam supplement valve connector. The 0# high-pressure heater system with back heating crossing the units has the advantages of being low in power consumption and high in back heating efficiency and can effectively improve the temperature of supplied water entering the economizer and reduce the drop-out rate of an underload denitration system of the units.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

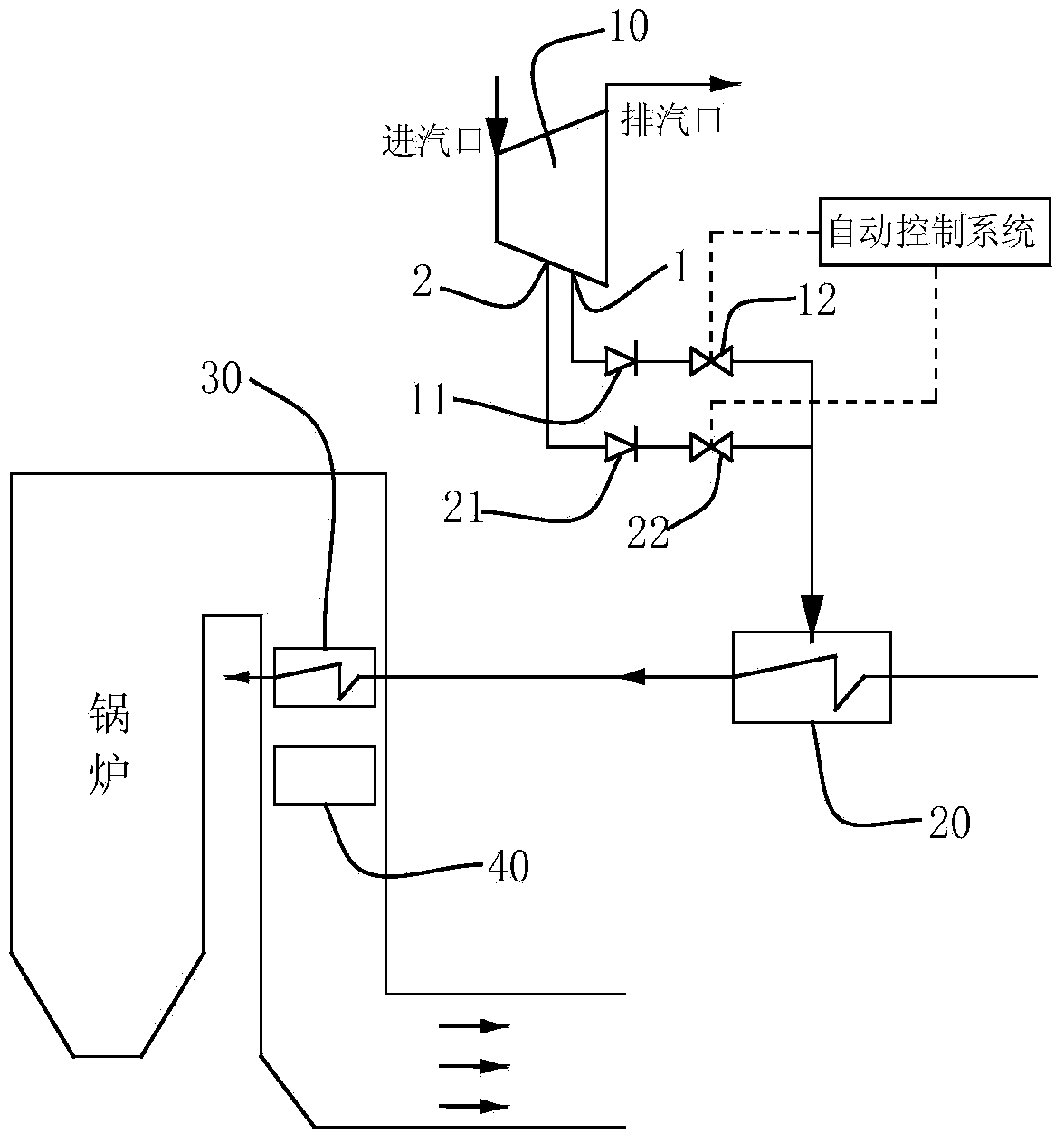

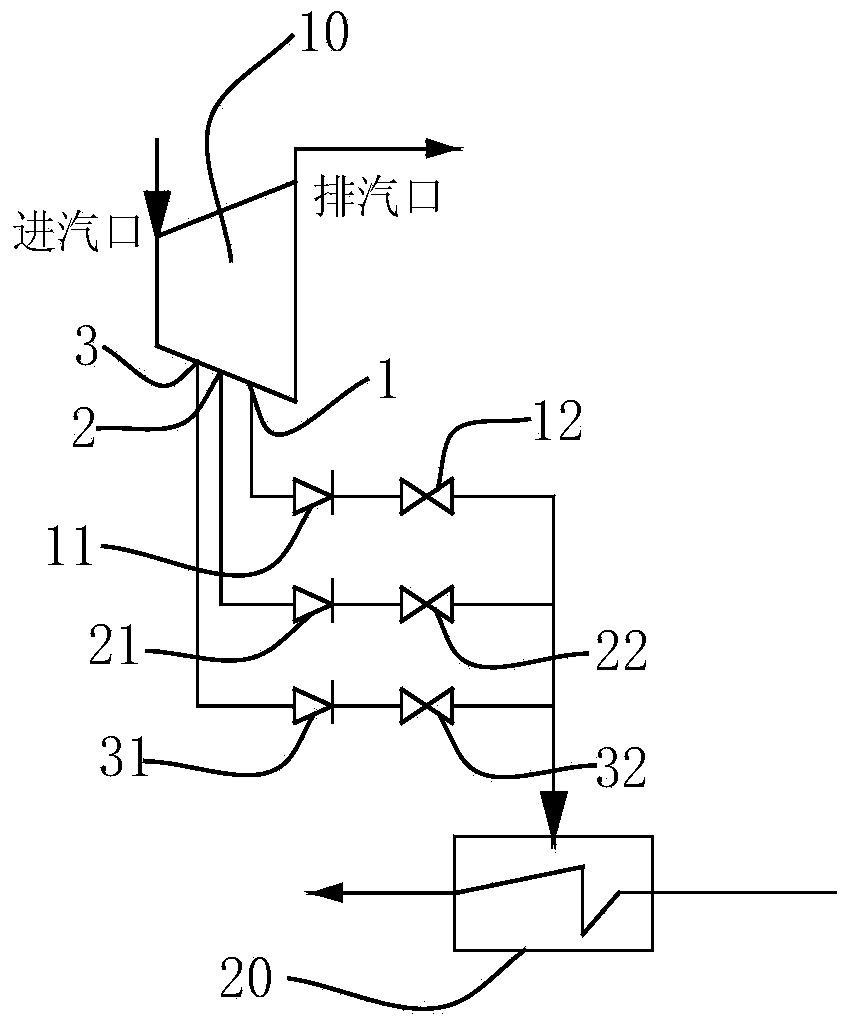

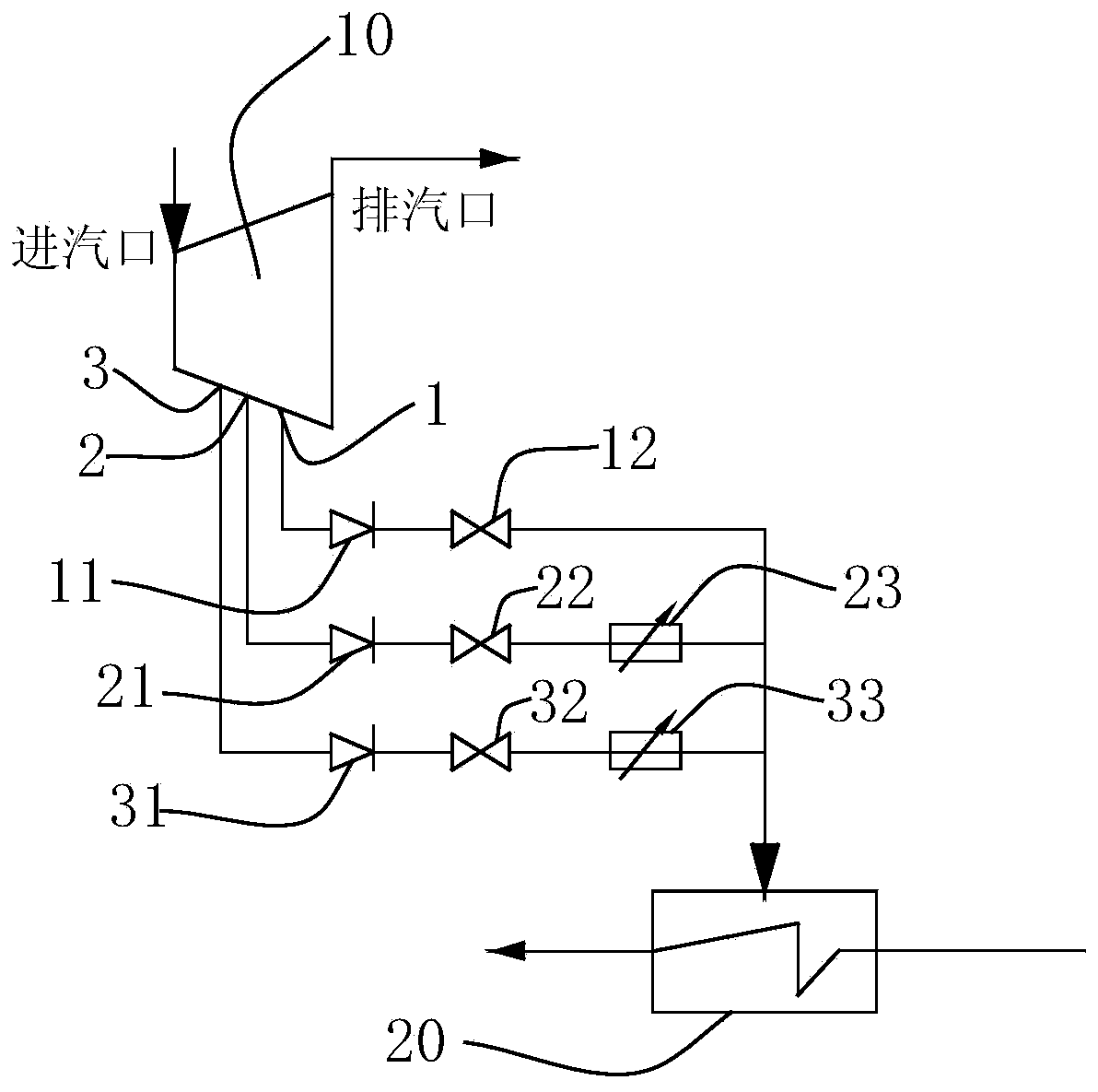

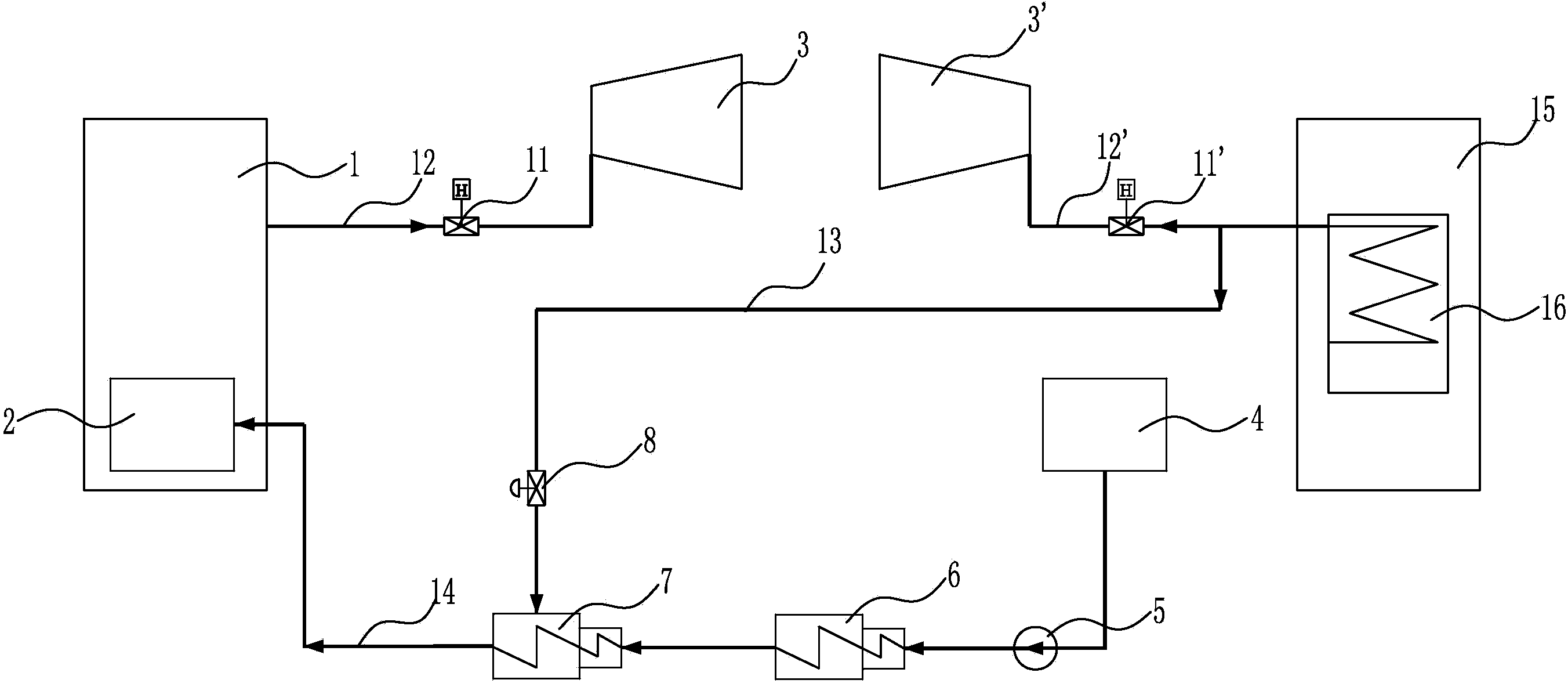

System with extraction condensing unit changed into back pressure unit on basis of spraying heat pump and operation method of system

PendingCN108468575AReduce investment feesLow retrofit costSteam engine plantsControl systemEngineering

The invention provides a system with an extraction condensing unit changed into a back pressure unit on the basis of a spraying heat pump and an operation method of the system. The system is reasonable in structural design and efficient, and saves energy. The system comprises a high-pressure cylinder, a low-pressure cylinder, a boiler, an oxygen removing device, a water feeding pump, a high-pressure heater, a boiler water feeding pipeline, a main steam input pipeline, the spraying heat pump, a water supplementing heater, a cooling device, a control system, a first valve, a second valve, a third valve, a high-pressure heat supply steam pipeline, a low-pressure heat supply steam pipeline, a high-pressure drive steam pipeline, a water supplementing heater water input pipeline and a water supplementing heater water output pipeline. For heat users requiring high-pressure steam parameters, the spraying heat pump injects low-pressure heat supply steam with high-pressure drive steam, and the high-pressure heat supply steam pipeline supplies the high-pressure heat supply steam. When the requirement for temperature of the high-pressure heat supply steam needed by the heat users is not high,the water supplementing heater is additionally arranged in the high-pressure drive steam pipeline, and the boiler supplies water to cool and drive the high-pressure drive steam of the spraying heat pump.

Owner:CHINA UNITED ENG

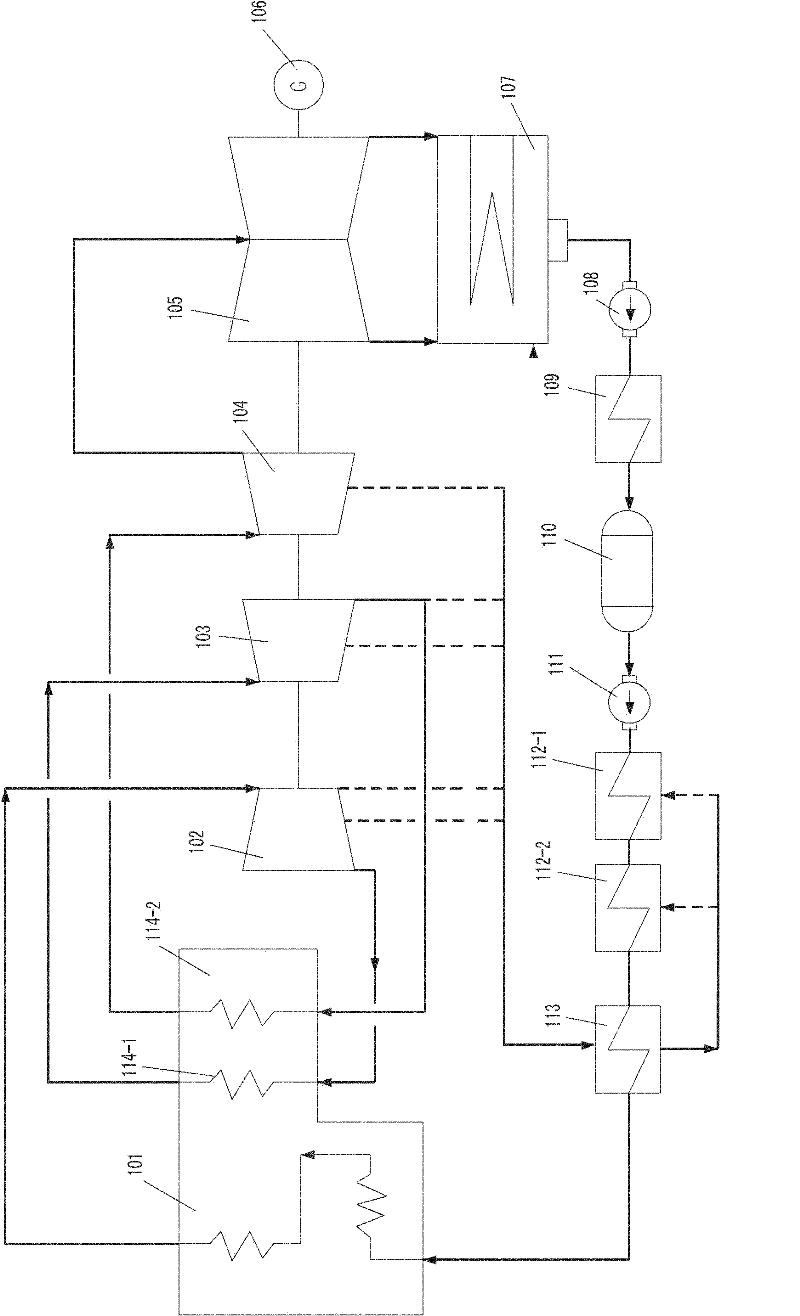

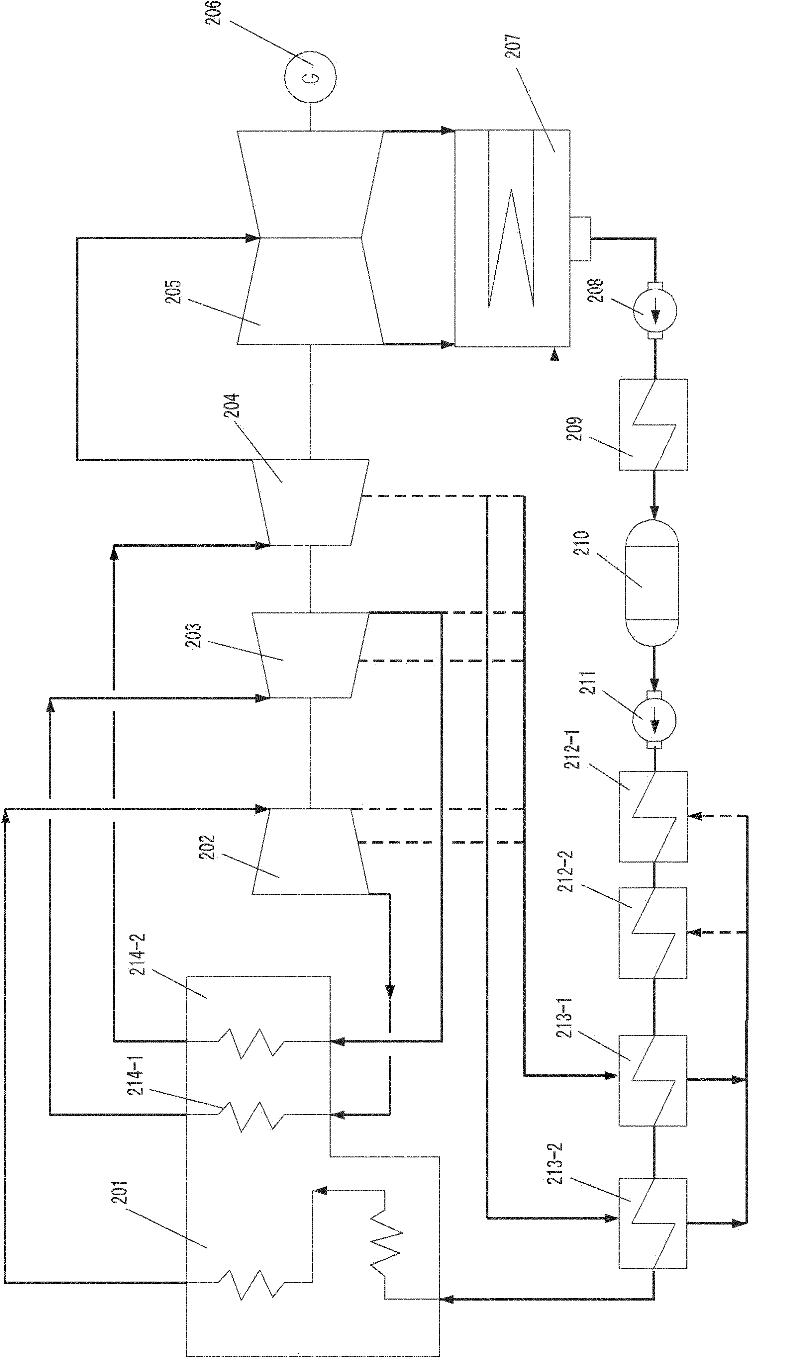

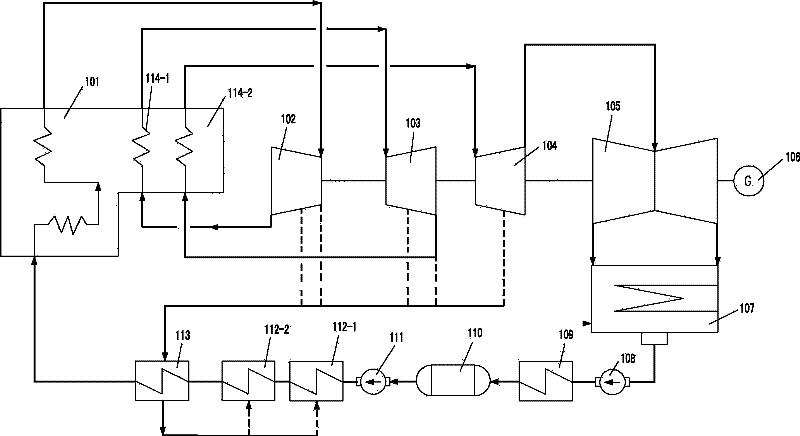

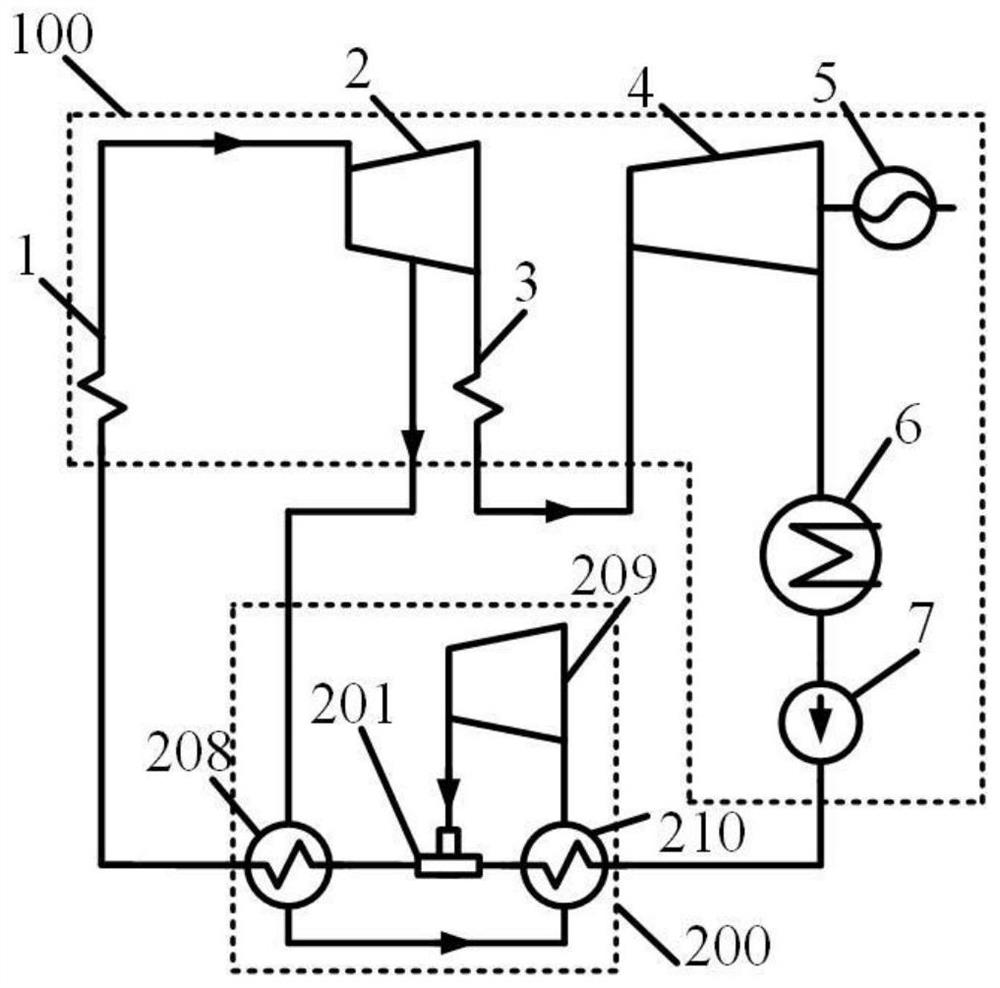

Water vapor cycle based on supercritical and subcritical heat regeneration

ActiveCN112780373AEfficient use ofHigh quality feed water flowSteam engine plantsWater vaporThermal efficiency

The invention discloses a water vapor cycle based on supercritical and subcritical heat regeneration, and belongs to the field of steam engine devices. A low-temperature vapor outlet of a compression supercritical heat regeneration system is connected with a low-temperature vapor inlet of a Rankine cycle system, and a high-temperature vapor inlet of the compression supercritical heat regeneration system is connected with a high-temperature vapor outlet of the Rankine cycle system, a low-temperature water inlet of the compression supercritical heat regeneration system is connected with a low-temperature water outlet of the Rankine cycle system; a low-temperature water inlet of a second high-temperature heat regenerator, a main tee joint and a low-temperature vapor inlet of a first high-temperature heat regenerator are sequentially connected; and low-temperature vapor flowing out of a first compressor and low-temperature vapor flowing out of the second high-temperature heat regenerator are converged into the first high-temperature heat regenerator for heat exchange. A working medium in the cycle is in a supercritical state, the cycle mass flow rate is high, feed water can be generally heated to 400 DEG C or above, due to the characteristics, the average heat absorption temperature is increased, and the cycle heat efficiency is further improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

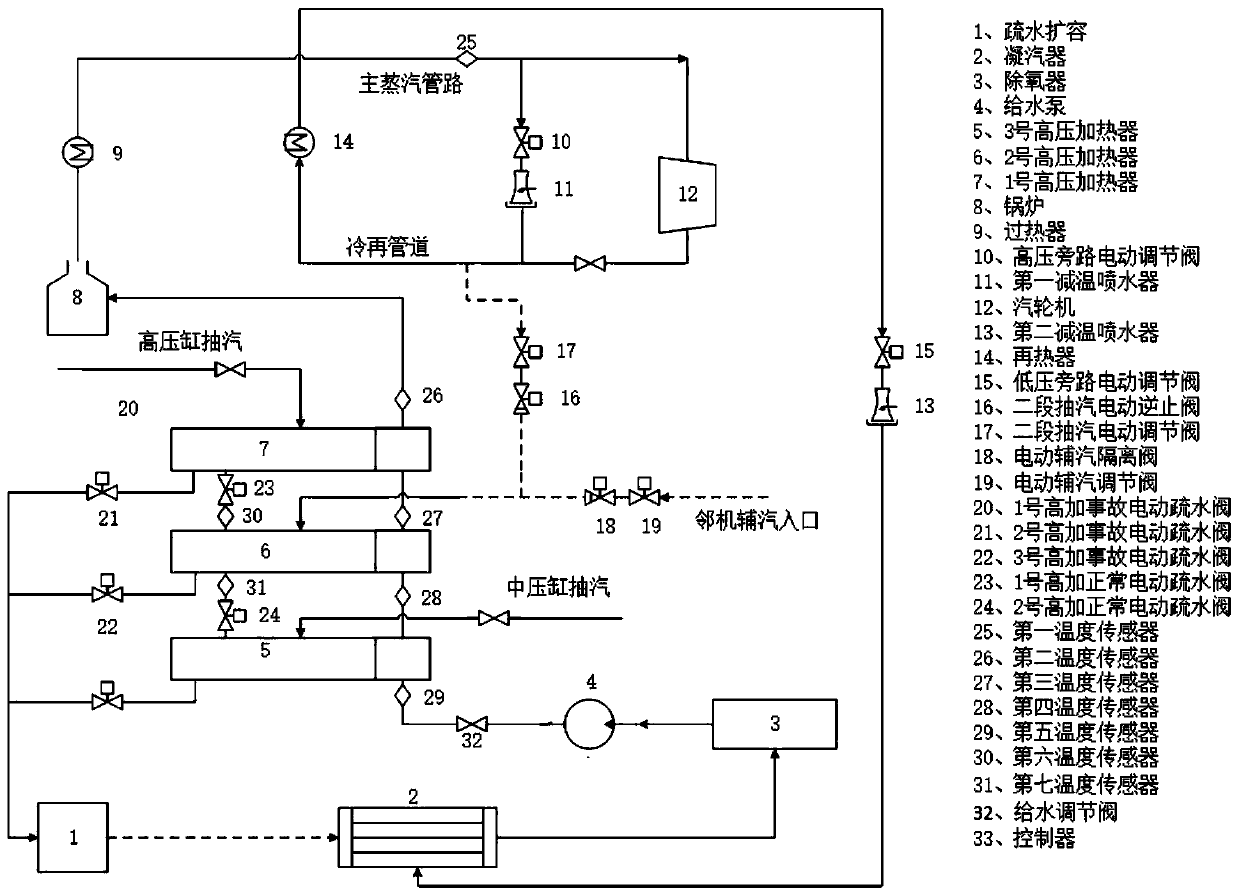

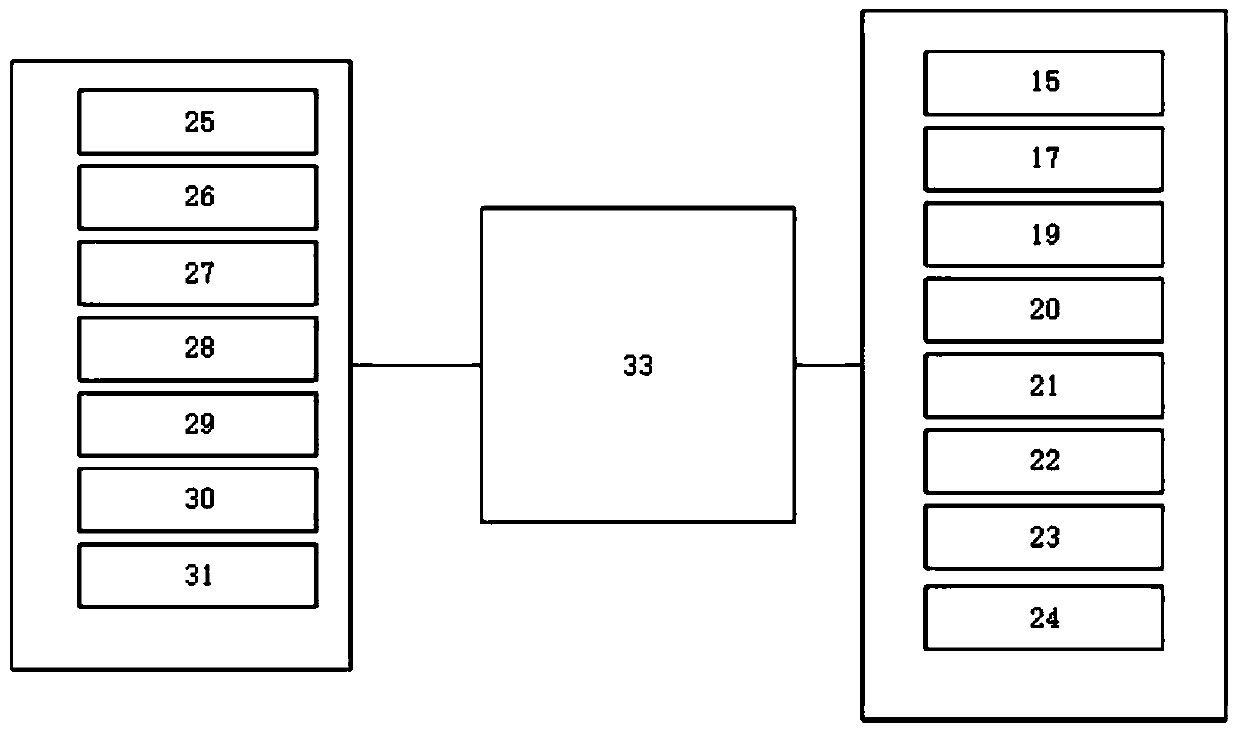

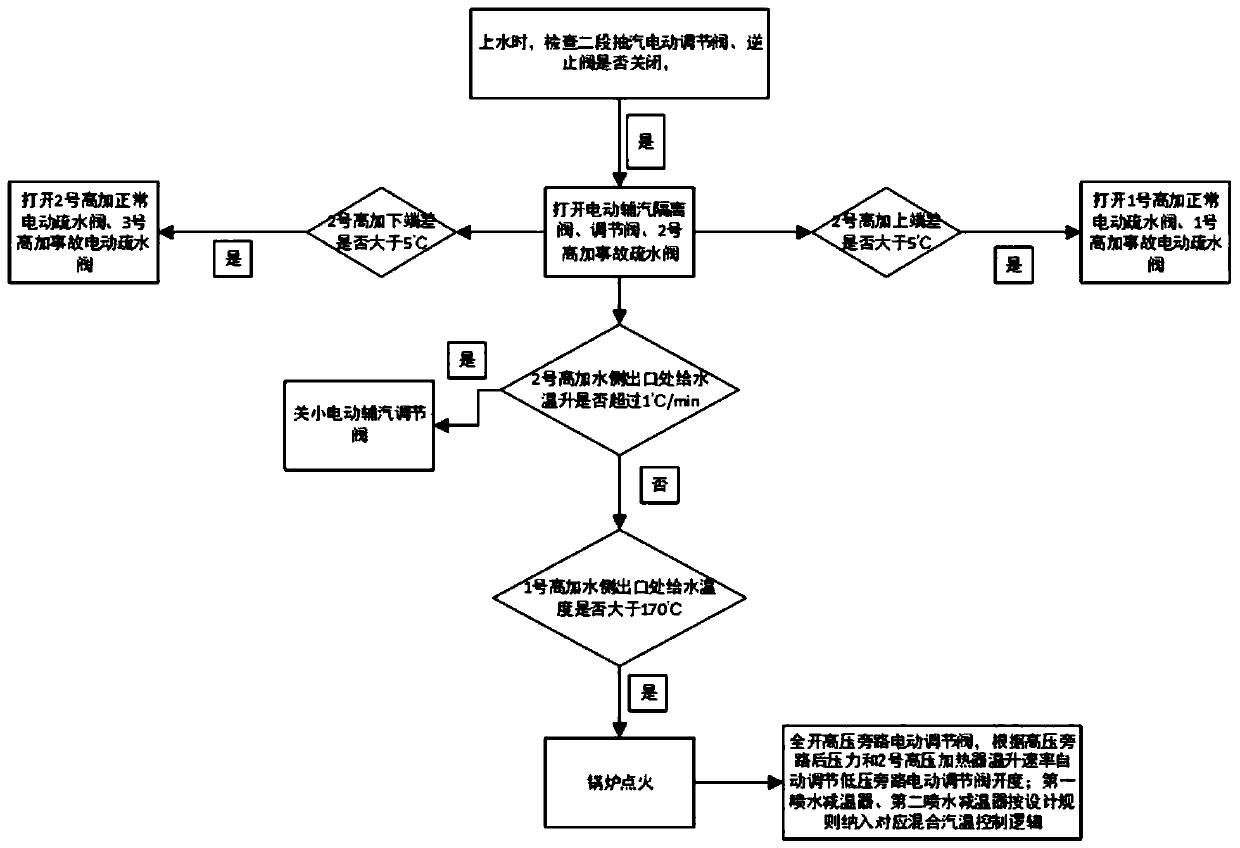

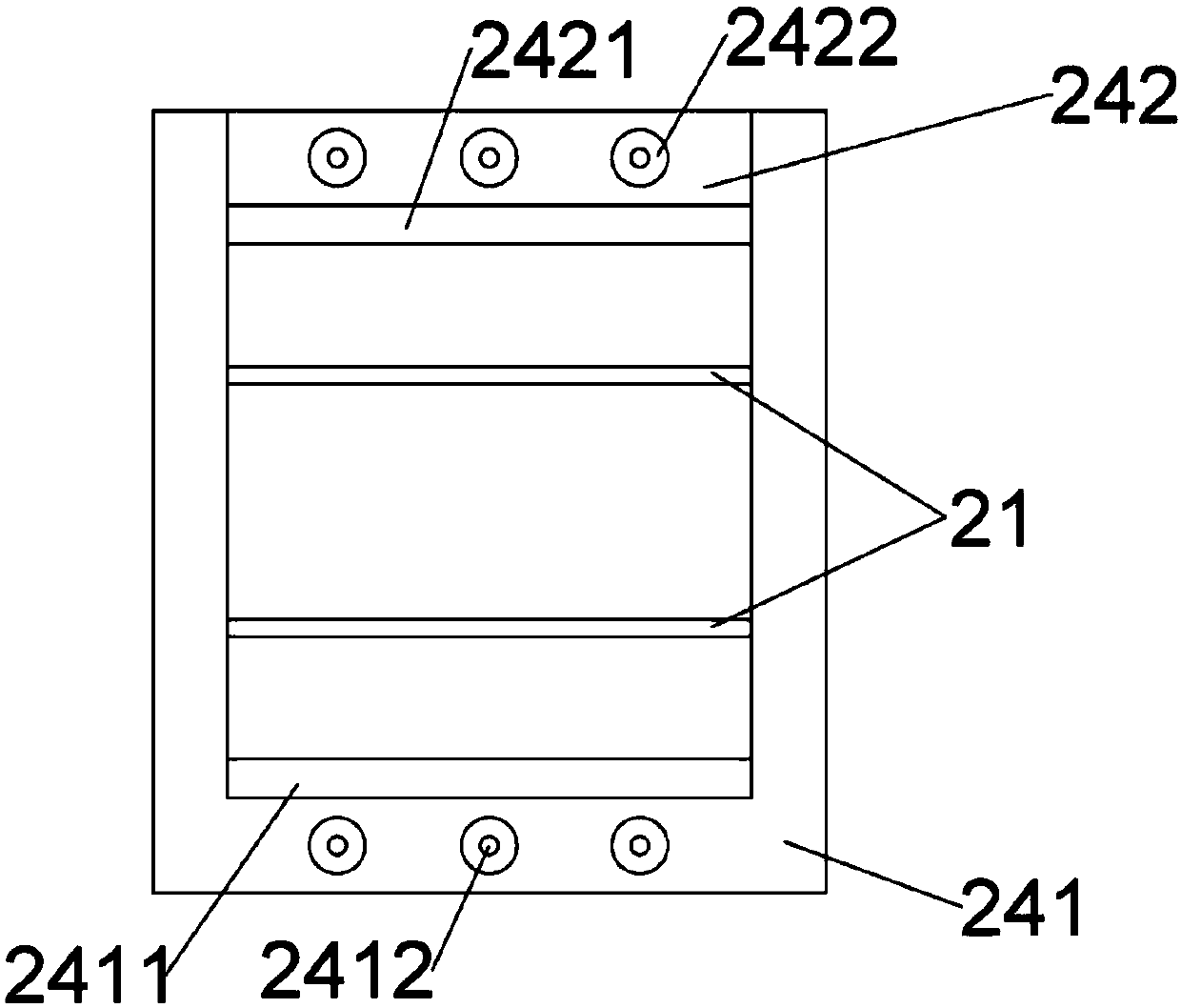

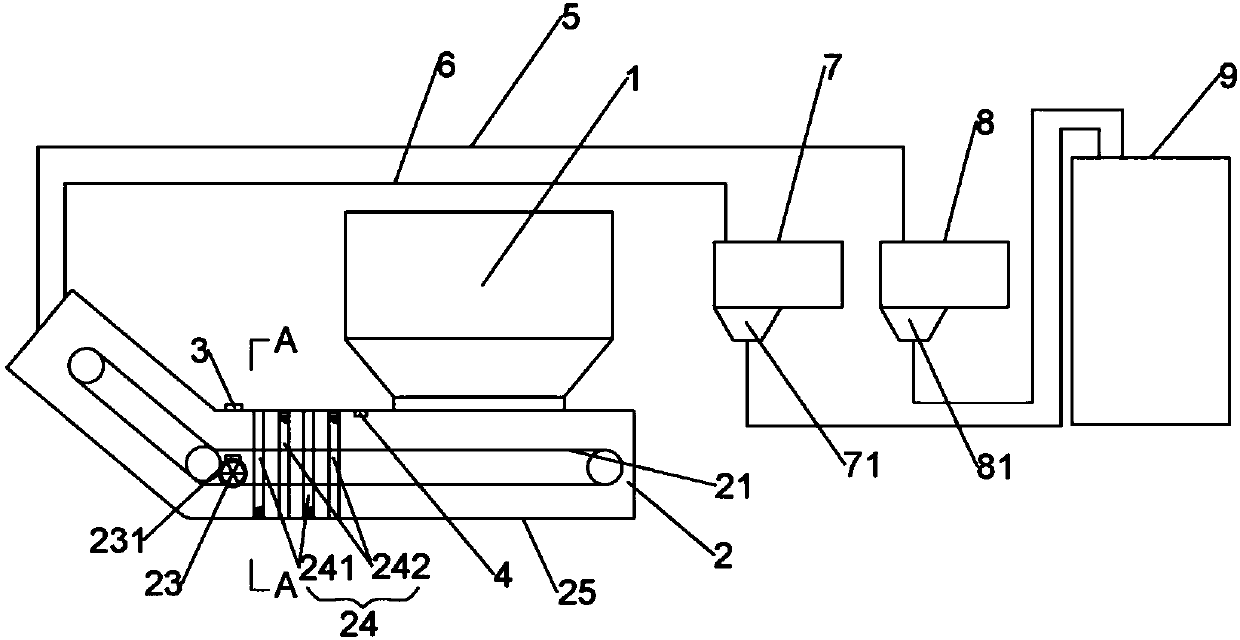

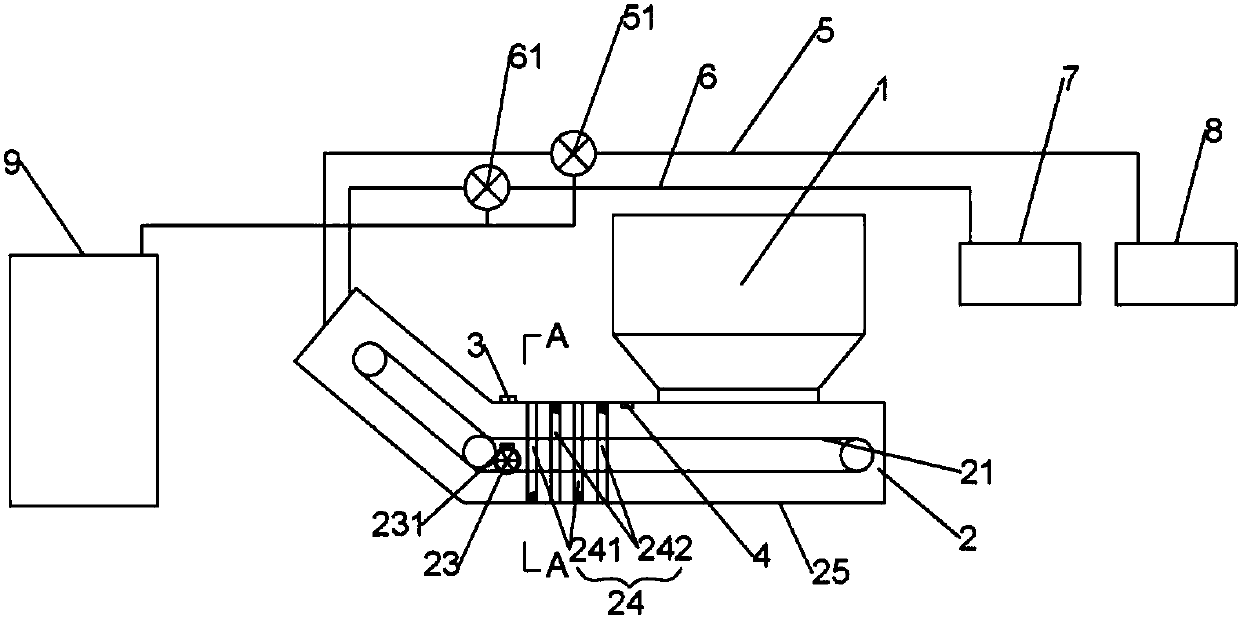

Control system and control method for starting high-pressure heater in advance

ActiveCN111322607AIncrease profitReduce startup timeWater feed controlFeed-water heatersControl systemProcess engineering

The invention relates to a control system and a control method for starting a high-pressure heater in advance. The control system can make full use of steam heat, and accurately controls the steam supply mode of the high-pressure heater through the cooperation between a temperature sensor and a controller. Before a boiler is ignited, steam supply heating is performed on the high-pressure heater No. 2 by an auxiliary steam system of an adjacent machine to increase the water feeding temperature of the boiler, and the wall surface of a heating surface of the boiler is increased by water change toprevent scale falling off due to too high increase speed of the wall temperature when steam flows through a superheater and a reheater after water plugs in a superheater and a reheater are removed when the steam temperature is about 100 DEG C after the boiler is ignited; and after the boiler is ignited and before a steam turbine starts to turn, the high-pressure heater No.2 is used to absorb heatof steam on a high-pressure by-pass to further increase the water feeding temperature and effectively recover the heat of the boiler before grid connection, so that on the one hand, the heating speedof the boiler is increased, and the start-up time is shortened, and on the other hand, the amount of steam discharged to a cold end is reduced, and the loss of a cold source during the start-up process is reduced.

Owner:大唐宝鸡第二发电有限责任公司

Slag sensible heat recycling system for air-cooling dry slag machine

ActiveCN107741021AAvoid influenceImprove efficiencyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a slag sensible heat recycling system for an air-cooling dry slag machine. A horizontal segment, close to one side of a lifting segment, of the dry slag machine is provided with a shutter rotation opening-closing mechanism air inlet; the side, away from the lifting segment, of the air inlet is provided with an isolating device; the position, on the inner side of the top ofan outer shell, close to a joint of the dry slag machine and a boiler is provided with a temperature sensor; and the outer wall of the outer shell is provided with a controller, and the top of the dry-slag-machine lifting segment in the air-cooling dry slag machine is connected with a second air preheater and a first air preheater correspondingly through air pipes. The slag sensible heat recycling system for the air-cooling dry slag machine is reasonable in design, the influence of cold air on the operation of the boiler can be effectively avoided, the slag cooling efficiency is improved, meanwhile the slag sensible heat is used sufficiently, the low temperature corrosion environment of the air preheaters is improved, the tail gas temperature of the boiler is raised, at the same time theheat can be recycled by a low temperature economizer to raise the feed-water temperature, the total air volume entering the boiler is controlled, the low nitrogen combustion and low oxygen combustionare achieved, the discharging of NOX from boiler combustion is lowered, the amount of ammonia spraying in SCR area is reduced, and the efficiency of the boiler is improved.

Owner:史震伟

High temperature gas cooled reactor nuclear power unit secondary circuit starting and stopping system and method

ActiveCN110131003AWith energy saving effectGuaranteed uptimeNuclear energy generationFeed water supplyNuclear powerDeaerator

The invention discloses a high temperature gas cooled reactor nuclear power unit secondary circuit starting and stopping system and method. The system comprises a high-pressure cylinder, a low-pressure cylinder, sixteen valve groups, a steam-water separator, an evaporator, an external steam source, a bypass regulating valve, an auxiliary steam header, a high-pressure heater, a condenser, an auxiliary steam user, a unit drainage channel, a water feeding pump, a deaerator, a low-pressure heater, a condensation water pump, a condensation water supplementing system and a fine treatment system. Themethod comprises the following main steps that 1) steam is supplied by the external steam source to the auxiliary steam header in an initial stage of starting of a unit; 2) water in the steam-water separator is recovered to the deaerator; 3) bypass steam is recovered to the low-pressure heater, the auxiliary steam header and the high-pressure heater; 4) when steam extraction pressure of a steam turbine is sufficient, the steam turbine is used for extracting and supply the steam to the low-pressure heater, the auxiliary steam header and the high-pressure heater; and 5) in a secondary circuit stopping process, along with the decrease of a unit load, when the steam extraction pressure of the steam turbine is insufficient, steam in front of the bypass regulating valve is supplied to the low-pressure heater, the auxiliary steam header and the high-pressure heater.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Beryllium oxide generation preventing method for boilers of power plant

InactiveCN106642062APrevention of dry burningOptimizationLiquid degasificationBoiler water tubesEngineeringDeaerator

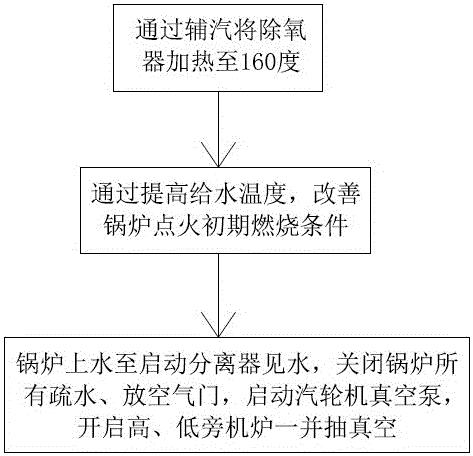

The invention discloses a beryllium oxide generation preventing method for boilers of a power plane, and the method can effectively avoid dry burning of heated surfaces. The method includes the following steps that firstly, a deaerator is heated, specifically, auxiliary steam is used for heating the deaerator, the heat source can increase the water temperature of the deaerator to 160 DEG C, and the temperature of a start-up separator outlet (or a steam pocket) of the corresponding boiler reaches 75 DEG C or above; secondly, feed water is heated, specifically, feed water heaters for starting of a unit are added through technical transformation or unit high-pressure heaters are directly selected, a steam source is taken from an adjacent unit and connected into the heaters, the feed water temperature is increased to a larger extent, the steam production amount is increased, the temperatures of the heated surfaces are greatly increased, the hearth temperature is increased, and the combustion condition in the ignition preliminary stage of the boilers is greatly improved; and thirdly, water is fed to the boilers till start-up separators encounter water, all drainage and vent valves of the boilers are closed, a steam turbine vacuum pump is started, and high-pressure bypass boilers and low-pressure bypass boilers are started and vacuumized.

Owner:CHANGSHA POWER STATION CO LTD OF HUNAN CHD

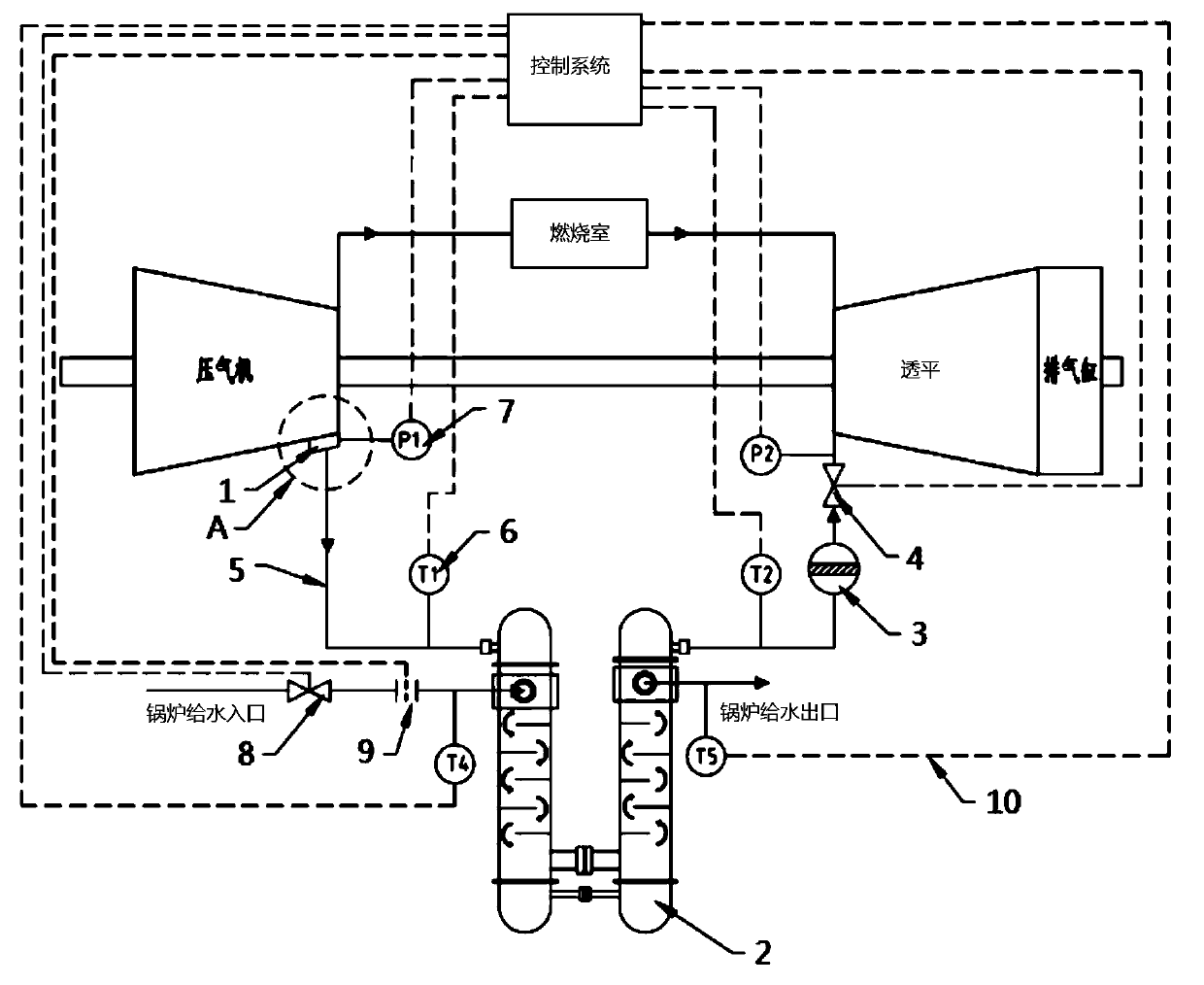

Cooling method of turbine rotor of combustion gas turbine and cooling gas system

ActiveCN109812299AImprove performanceImprove cooling effectDispersed particle filtrationBlade accessoriesGas turbinesTurbine blade

The invention discloses a cooling method of a turbine rotor of a combustion gas turbine and a cooling gas system. A gas pumping pipeline is connected between a gas compressor and a turbine, wherein agas pumping adjusting valve is arranged on the gas pumping pipeline; a temperature measuring device and a pressure measuring device are arranged at different points on the combustion gas turbine and are connected to a control system through signal circuits; the temperature measuring device and the pressure measuring device are used for transmitting detecting signals to the control system through the signal circuits; the control system is used for controlling the gas pumping adjusting valve and a water supplying adjusting valve to adjust to reach the temperature and flow rate required by gas tocool a turbine blade of the combustion gas turbine and a wheel disc; a water cooling temperature conditioning device for cooling gas is arranged between the gas compressor and the gas pumping adjusting valve on a gas pumping pipeline; the temperature T2 of cooling gas exhausted through the temperature conditioning device and fed into the turbine can be determined based on the gas temperature forcooling the turbine blade of the combustion gas turbine and the wheel disc; and the water inlet flow rate m1 of the temperature conditioning device is adjusted to control the temperature T2 of the cooling gas exhausted by the temperature conditioning device. The method and the system reach the best cooling effect with the least cooling gas volume.

Owner:HANGZHOU TURBINE POWER GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com