Patents

Literature

134results about How to "Raise the inlet temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

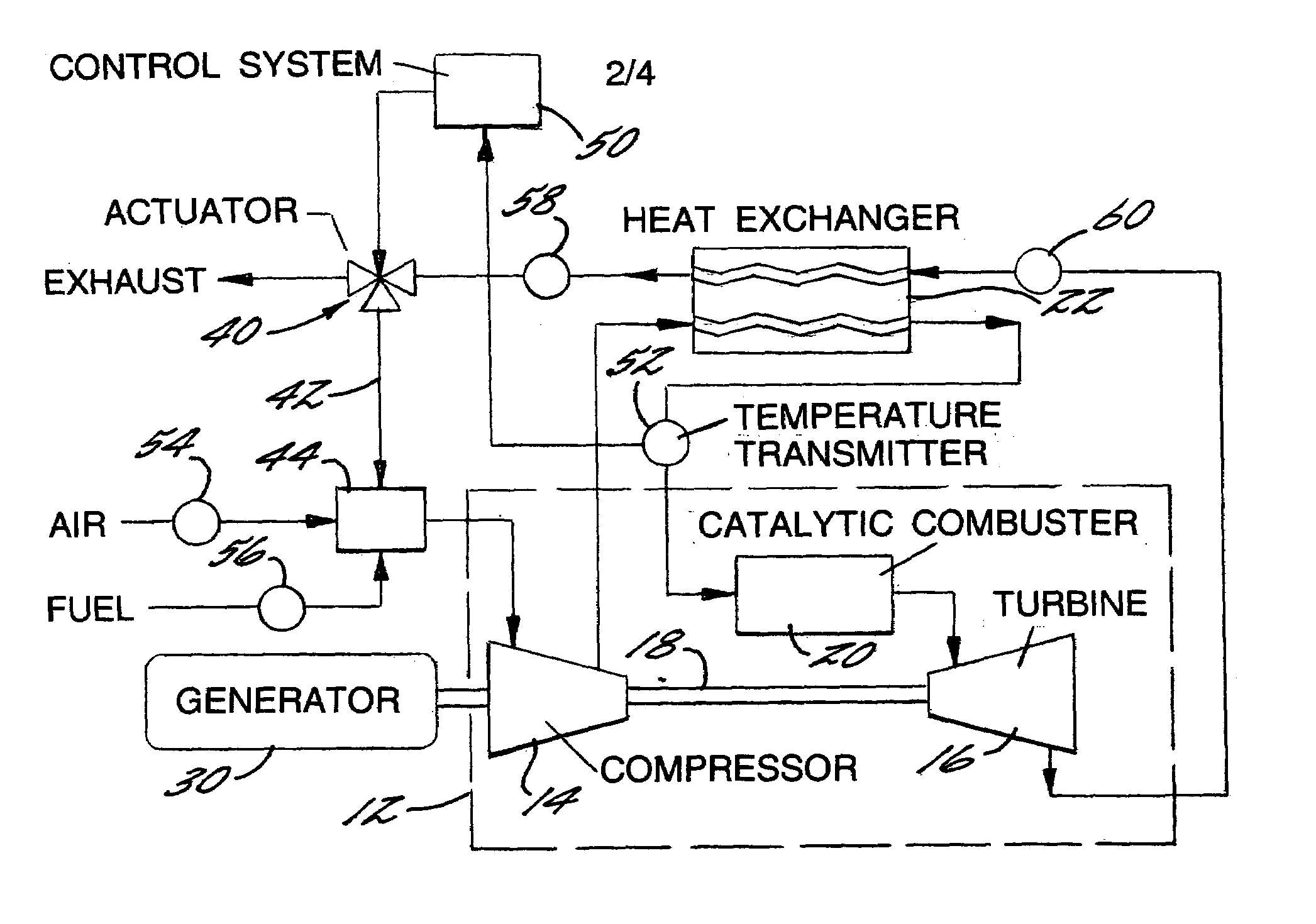

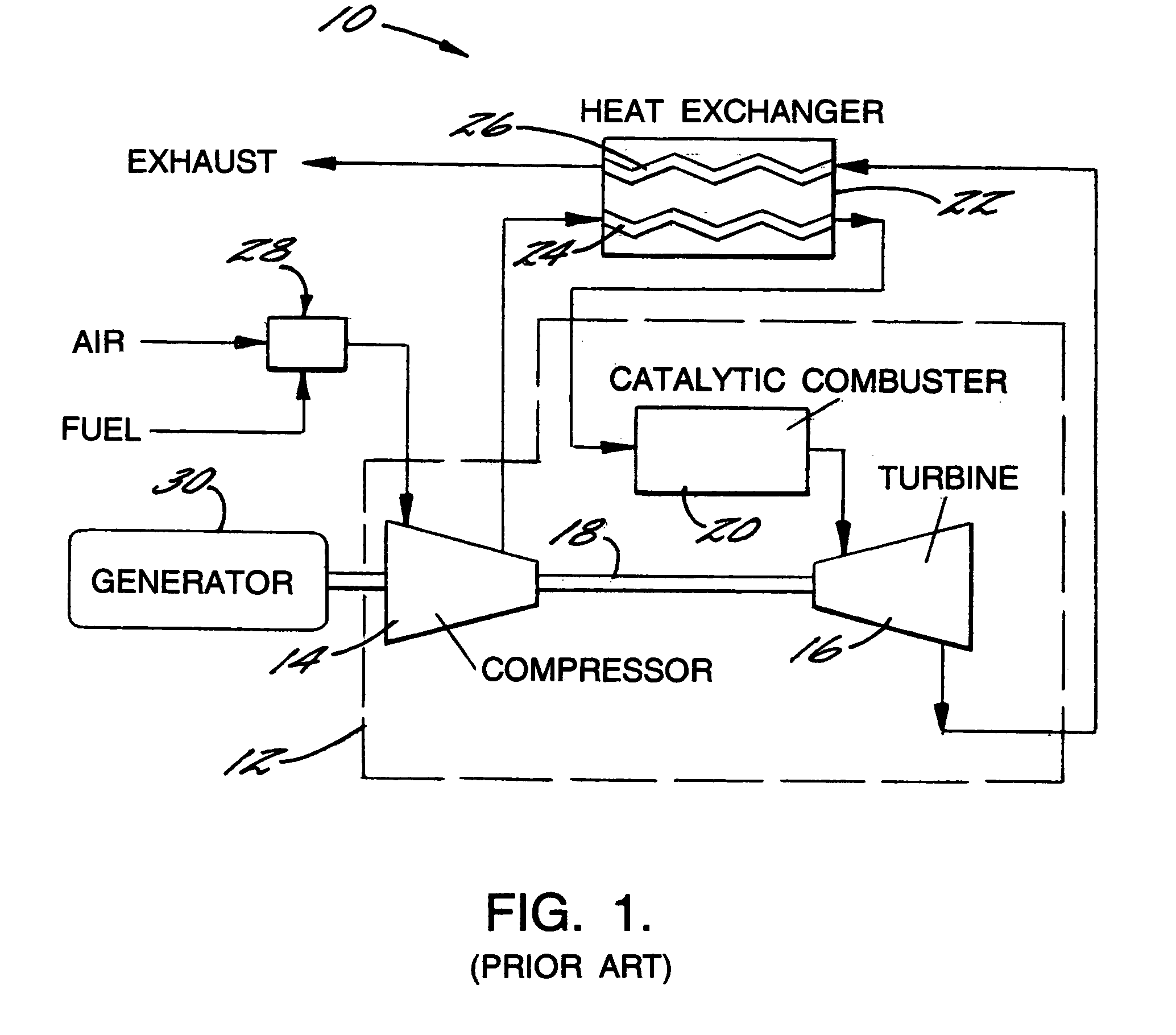

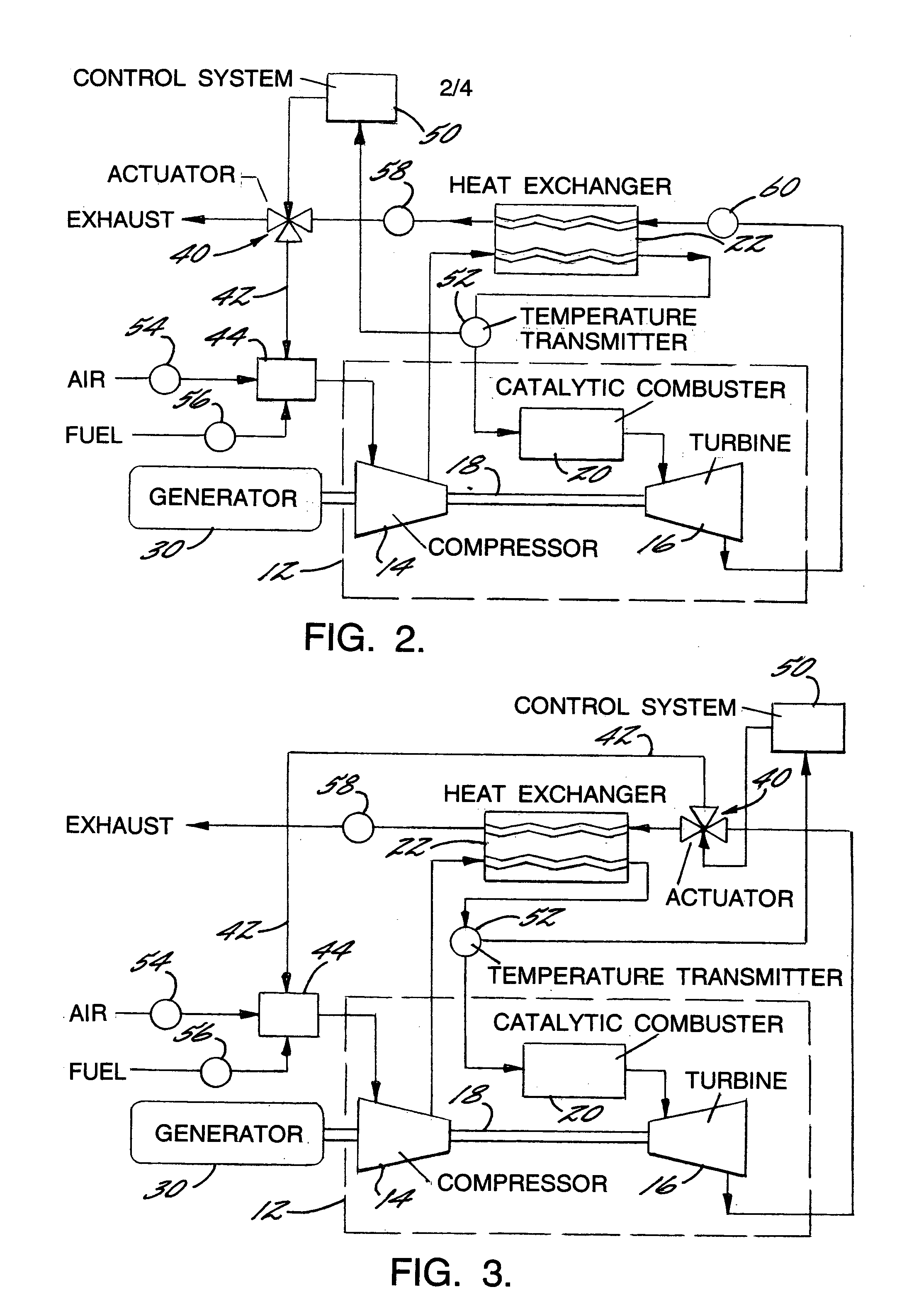

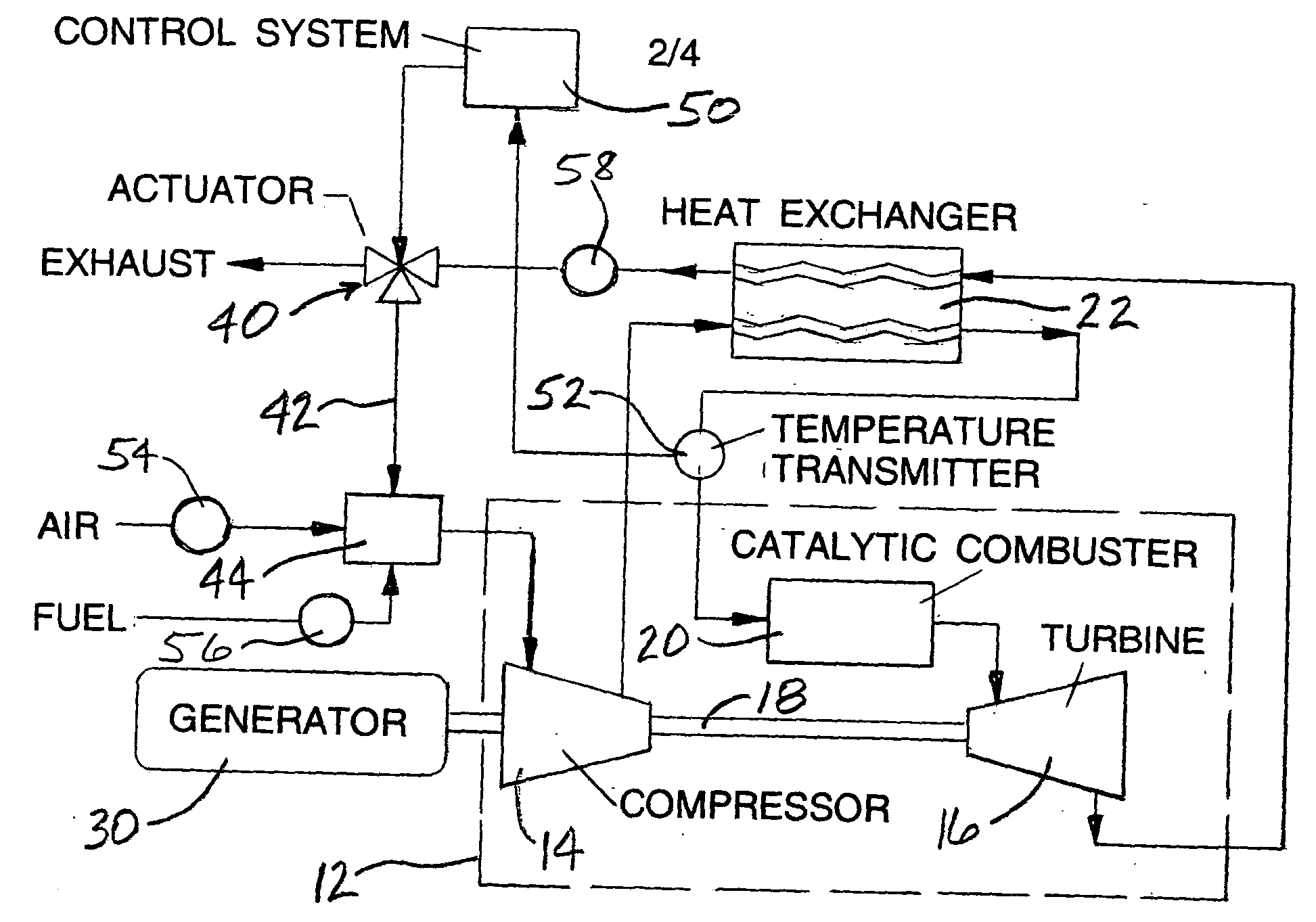

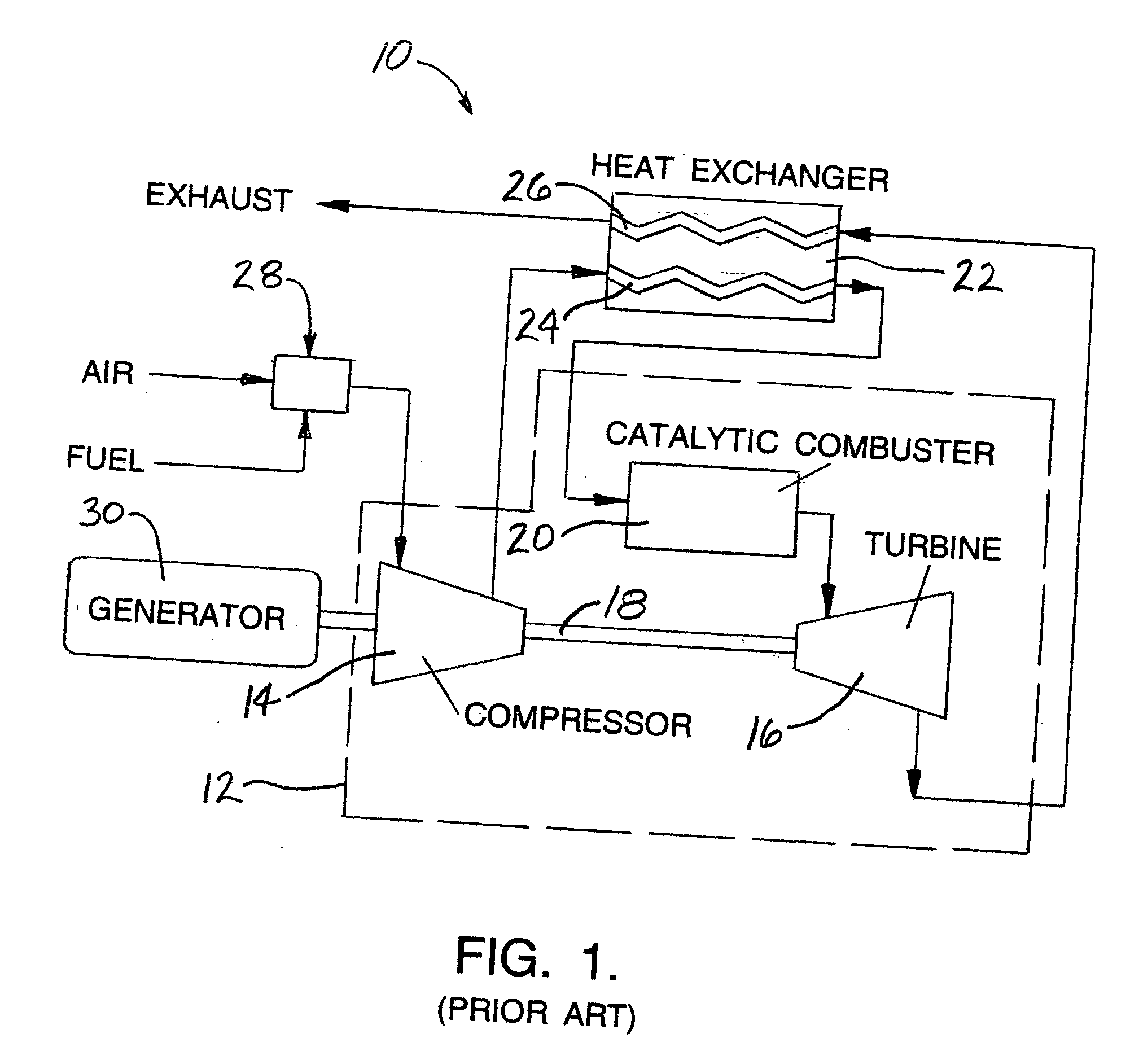

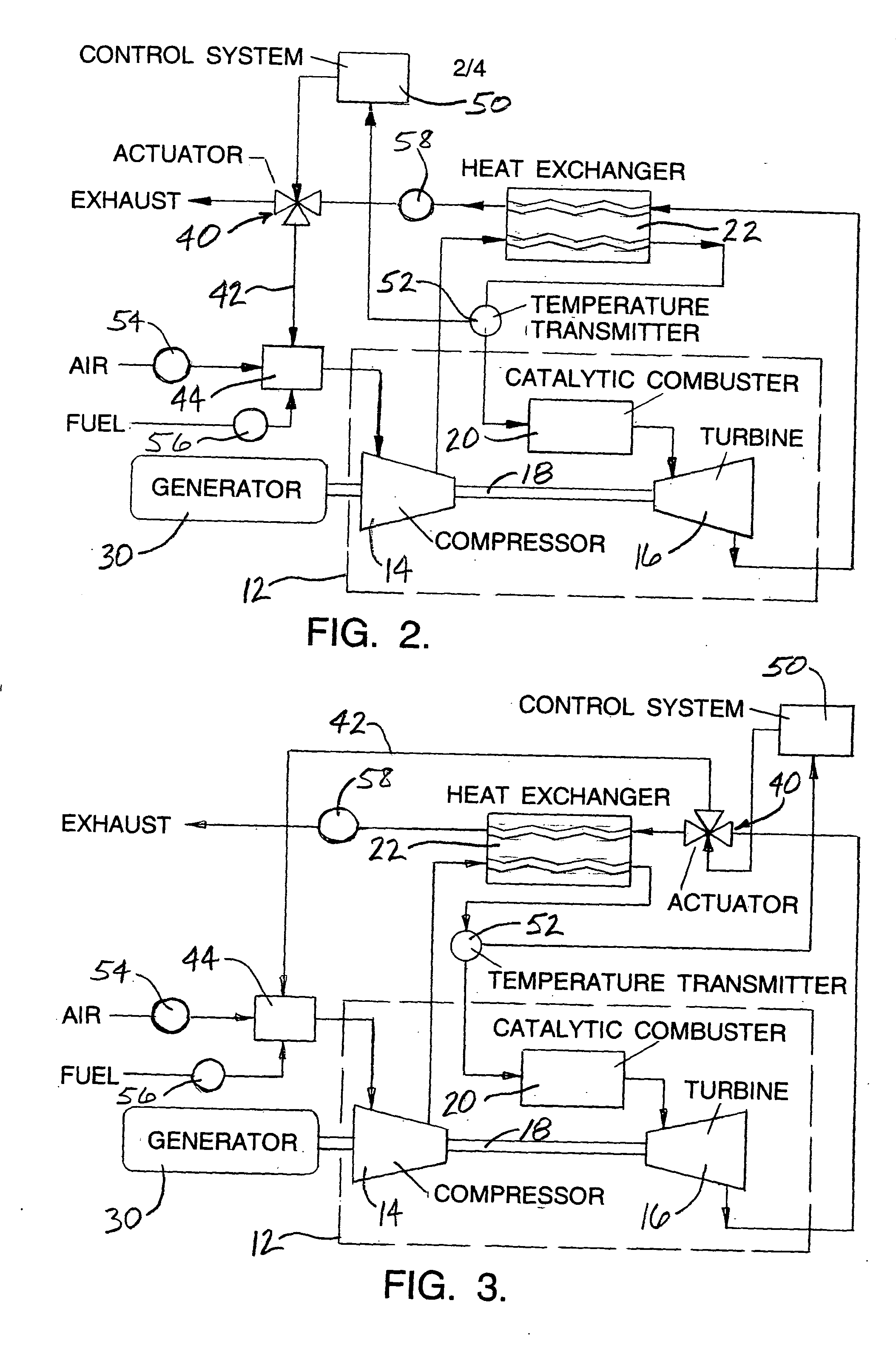

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

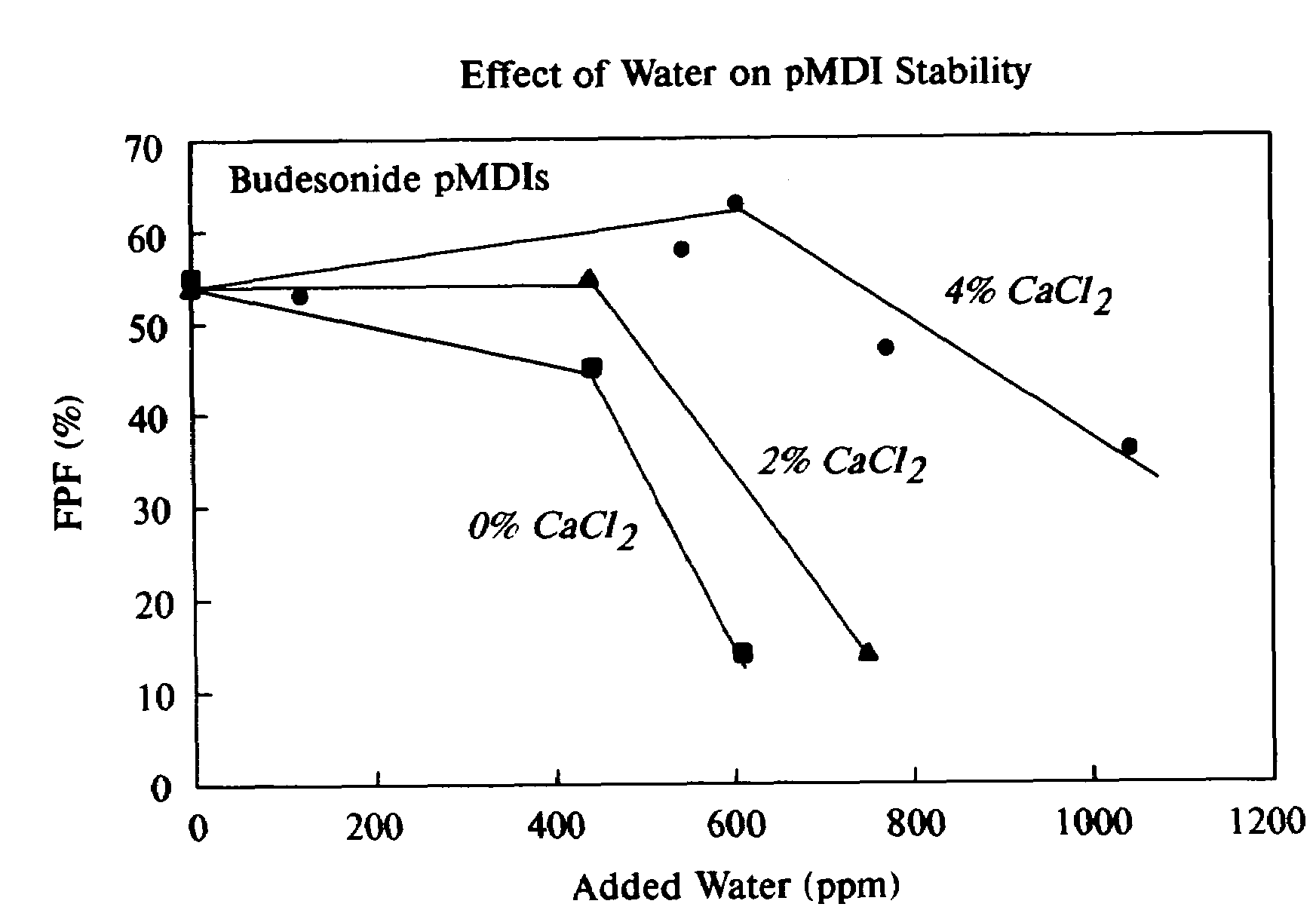

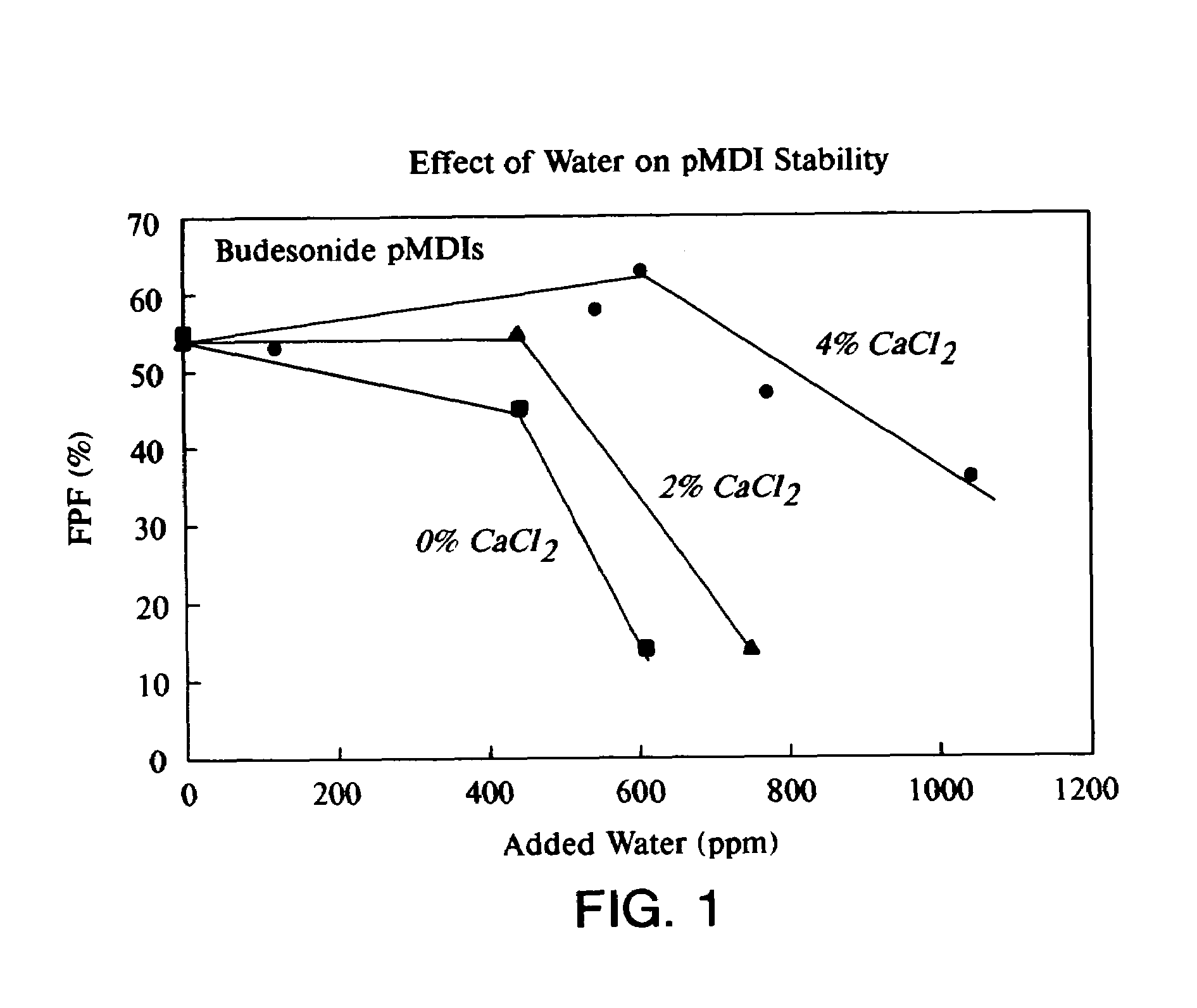

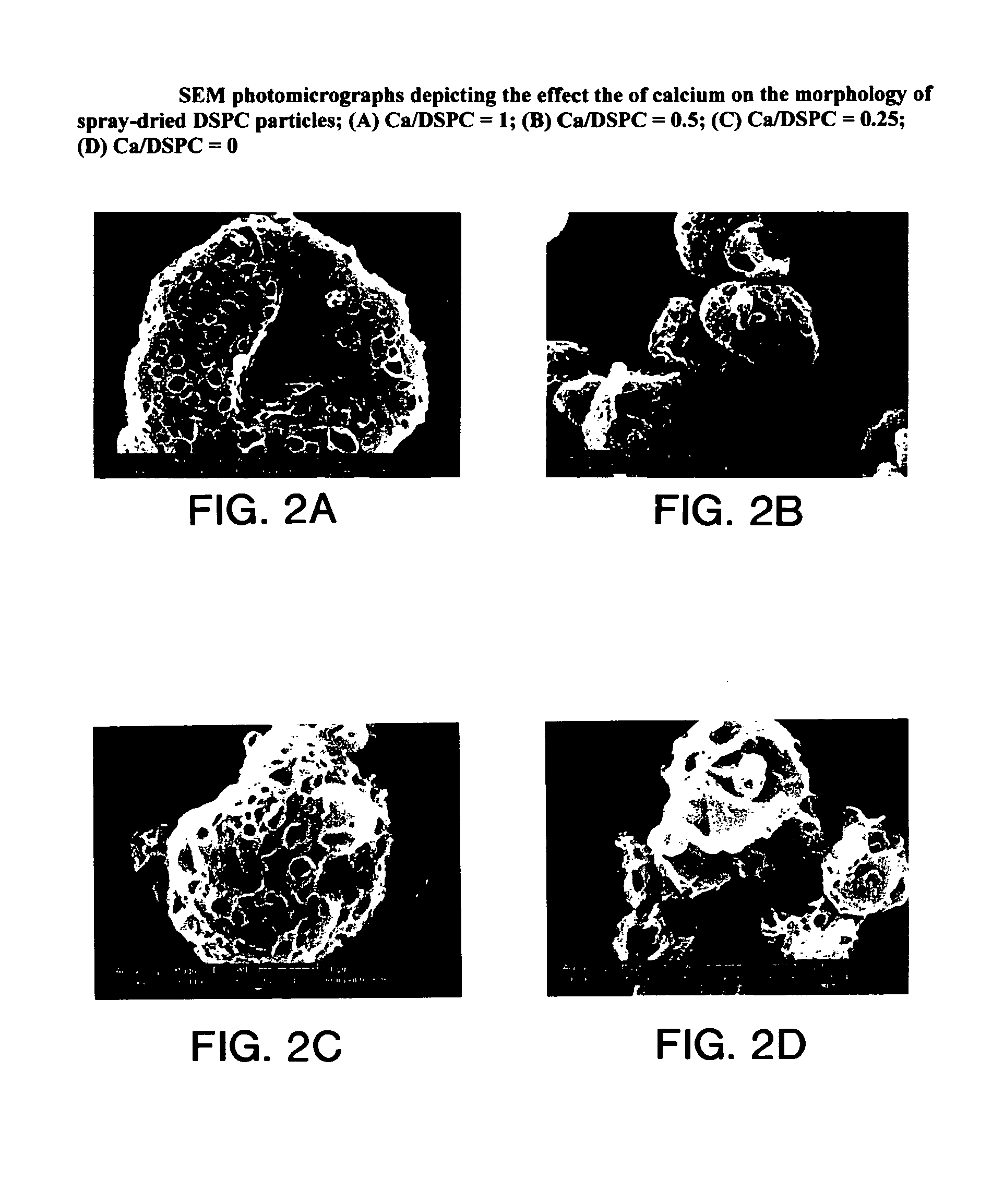

Phospholipid-based powders for drug delivery

InactiveUS7442388B2Raise the inlet temperatureRaise the outlet temperaturePowder deliveryBiocidePrillMedicine

Phospholipid based powders for drug delivery applications are disclosed. The powders comprise a polyvalent cation in an amount effective to increase the gel-to-liquid crystal transition temperature of the particle compared to particles without the polyvalent cation. The powders are hollow and porous and are preferably administered via inhalation.

Owner:NOVARTIS AG

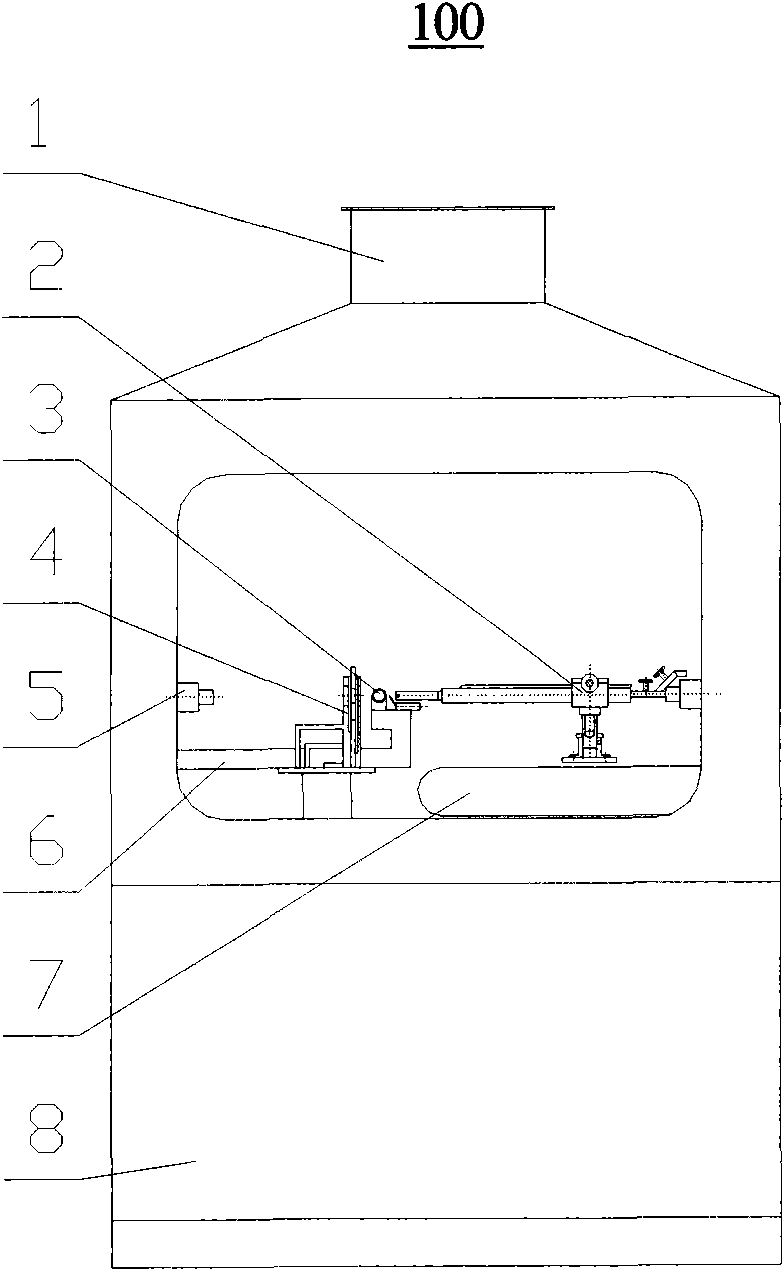

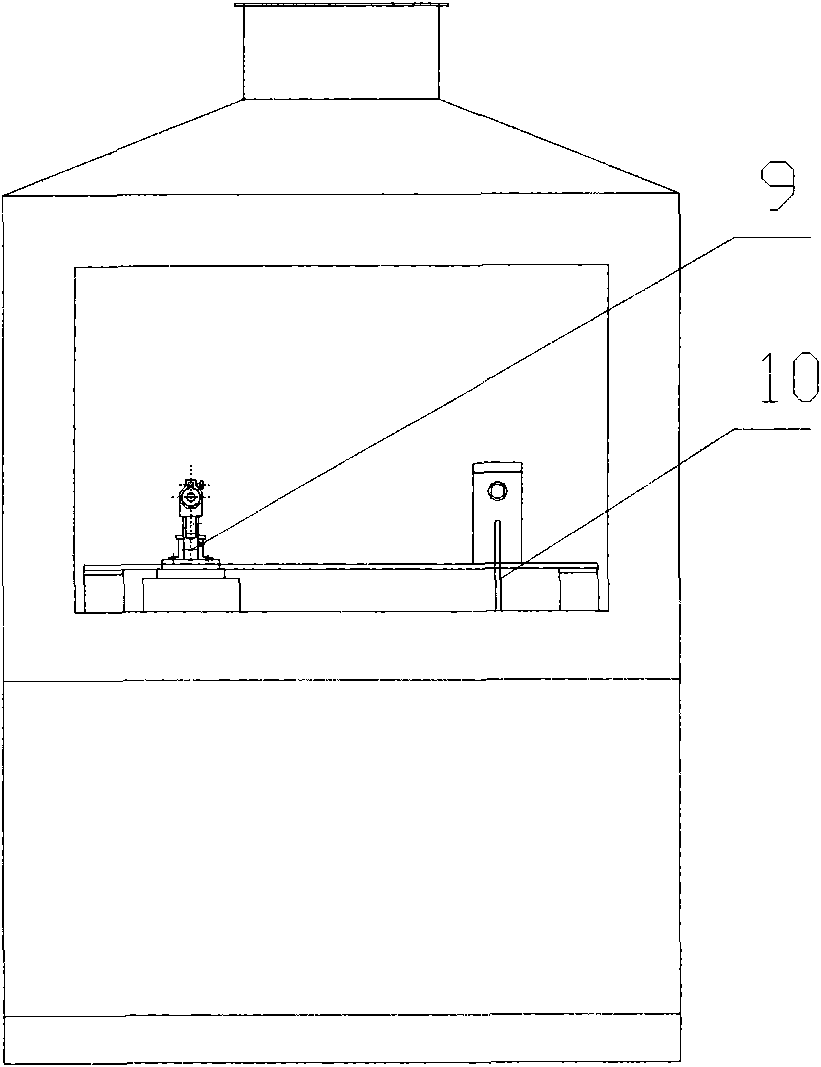

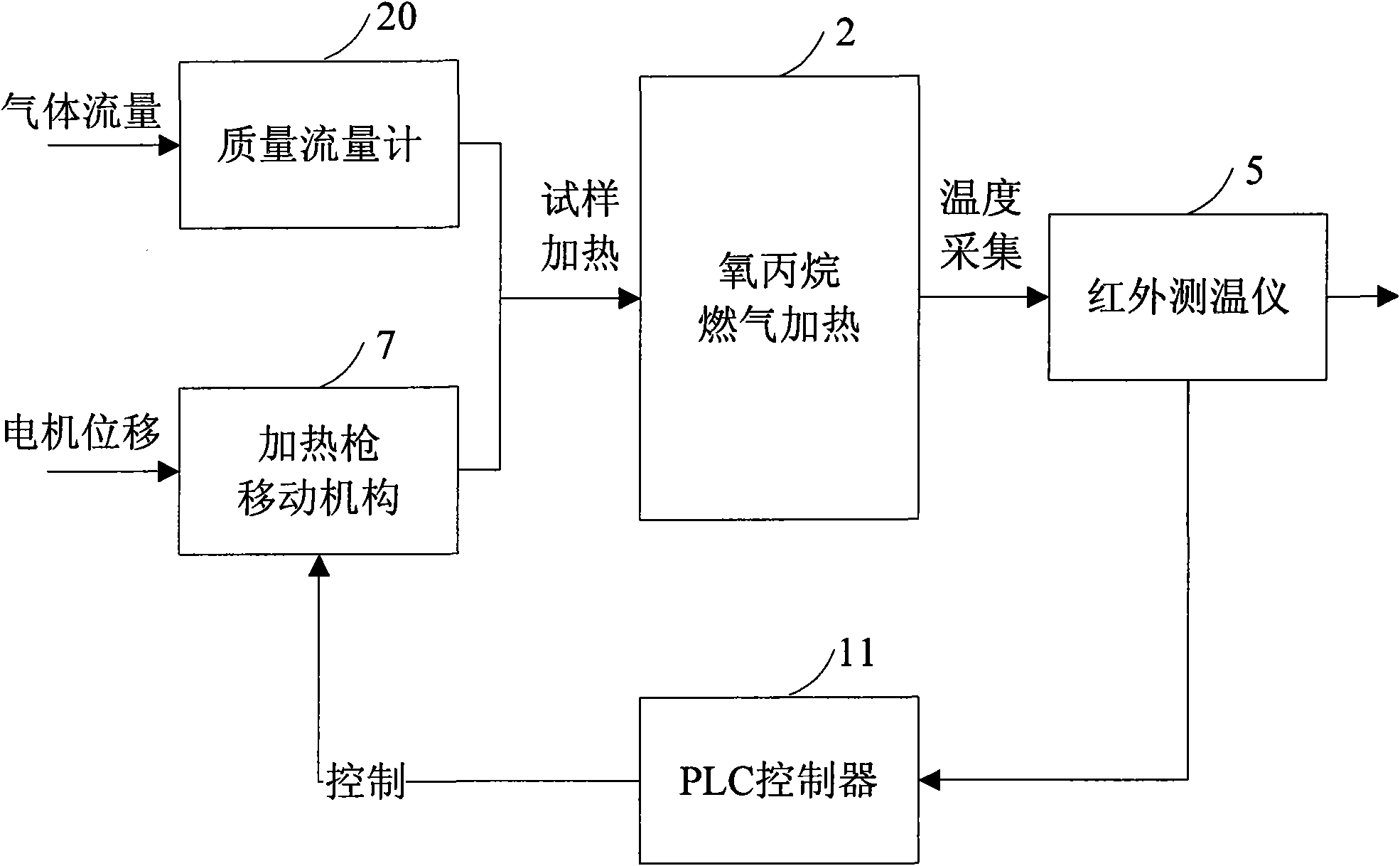

Device and method for testing thermal cycling performance of thermal barrel coating

ActiveCN101644650ATest qualityLife expectancyRadiation pyrometryStrength propertiesComputer caseHolding time

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

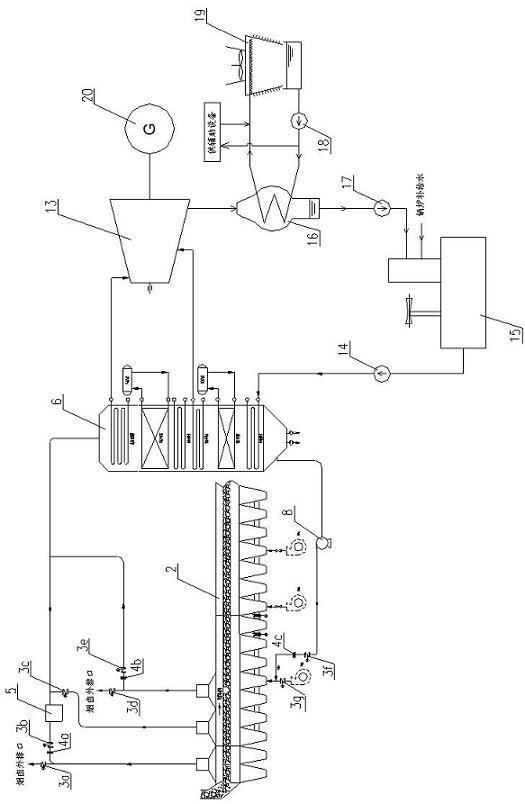

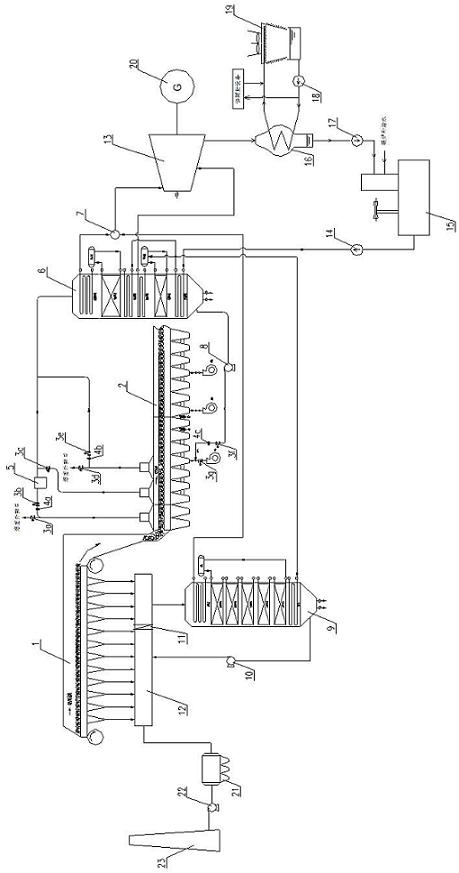

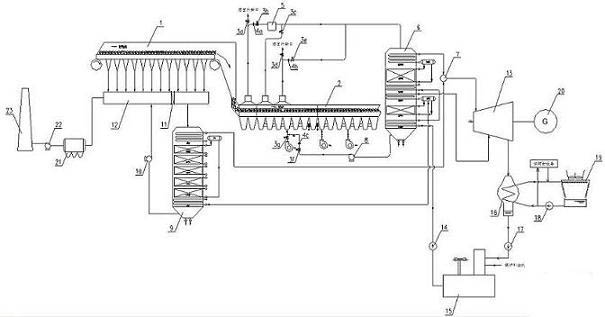

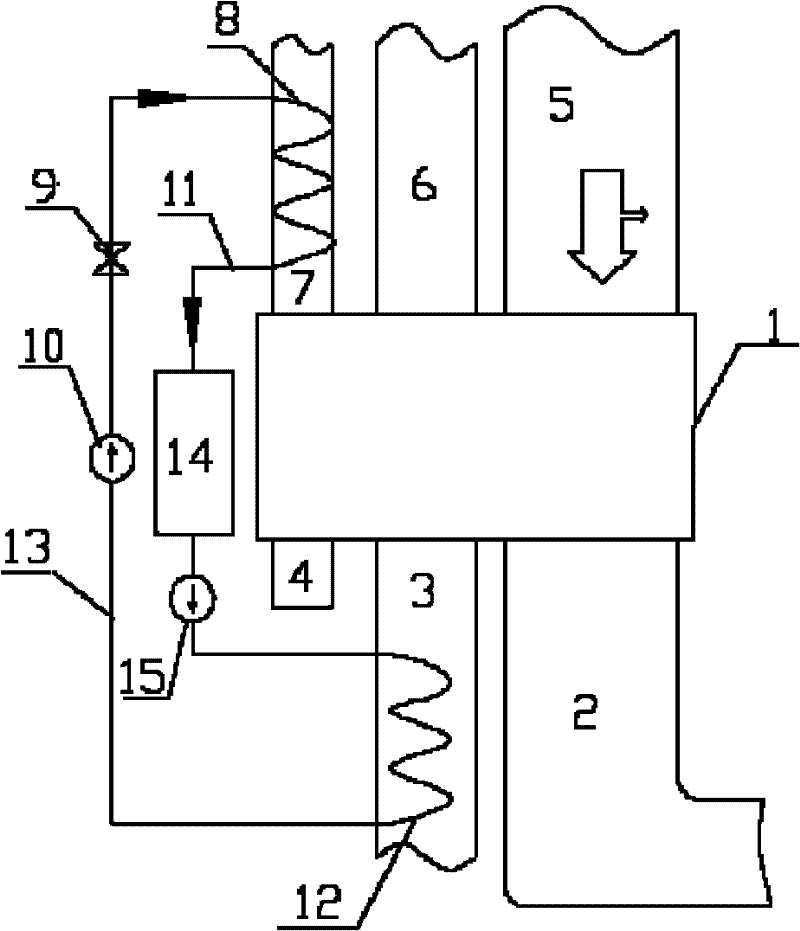

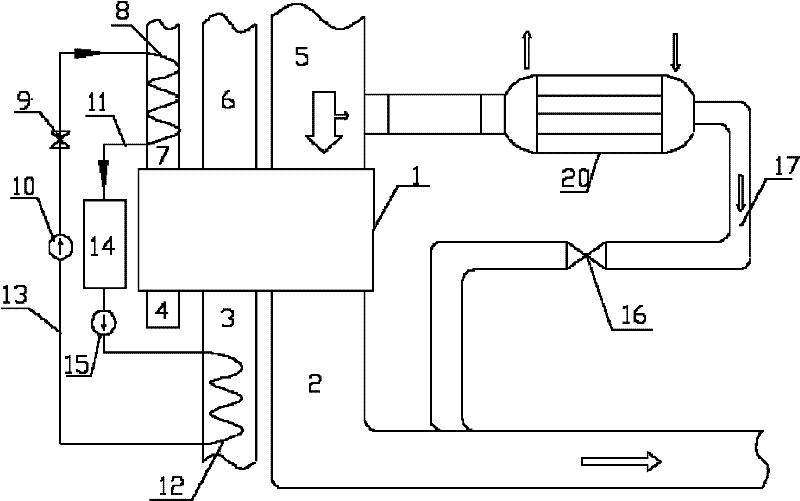

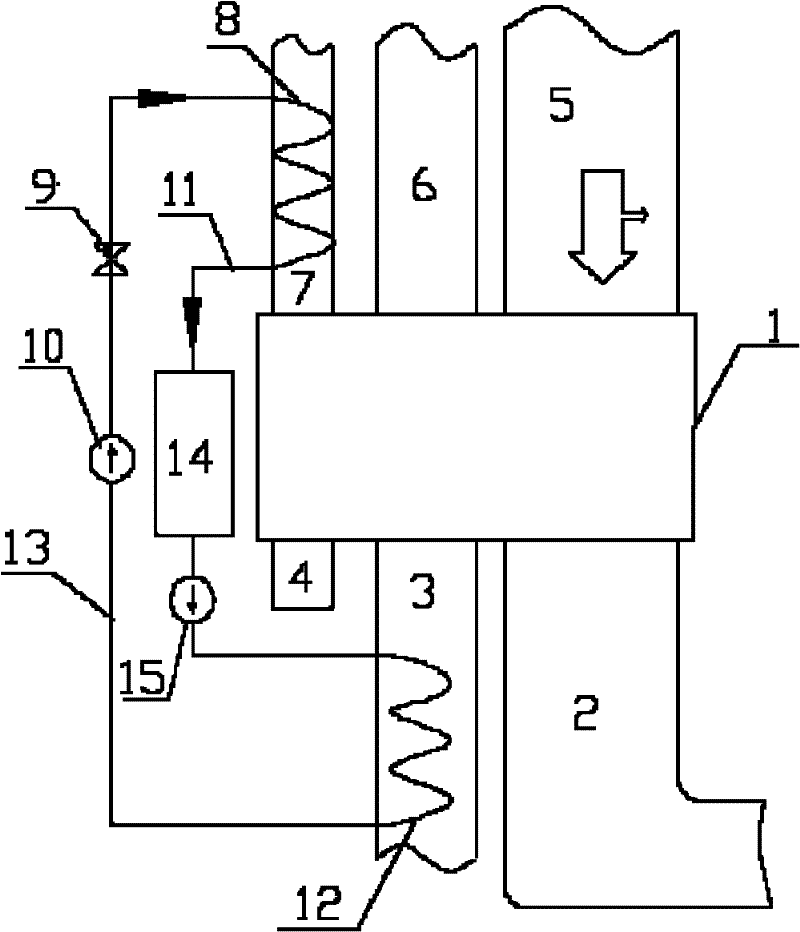

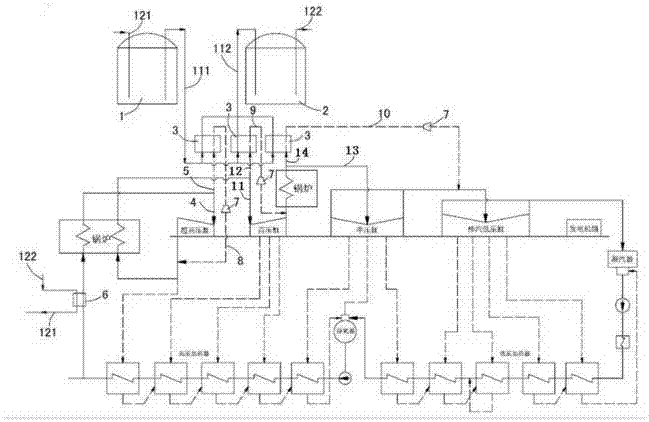

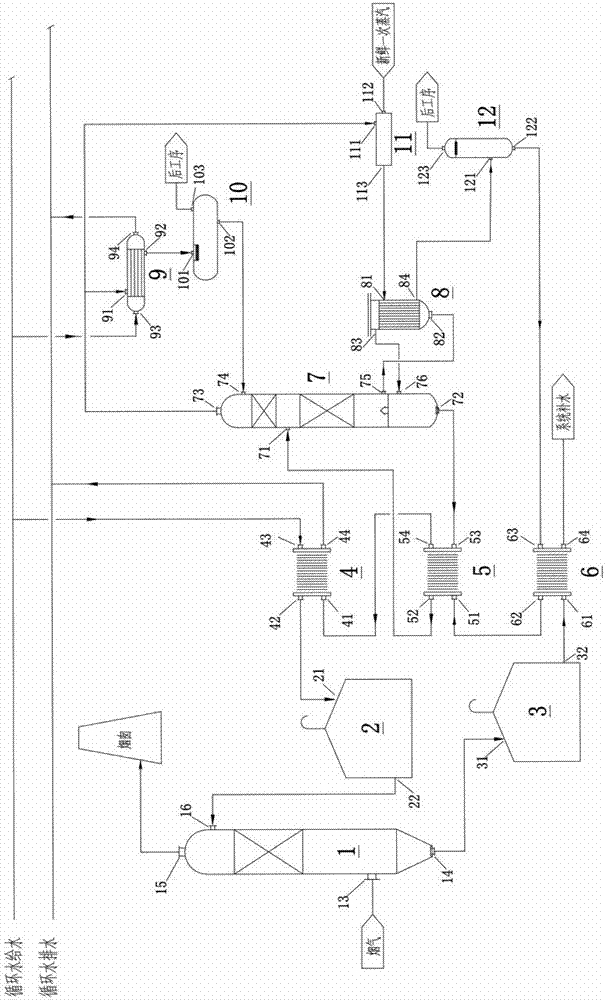

System and method for power generating by jointly recovering waste heat of flue gas of sintering machine and exhaust gas of cooling machine

ActiveCN102012167AImprove the efficiency of waste heat recovery and utilizationIncrease feed water temperatureEnergy industryIncreasing energy efficiencyWaste heat recovery unitIron plant

The invention discloses a system and method for power generating by jointly recovering the waste heat of a flue gas of a sintering machine and an exhaust gas of a cooling machine, belonging to the technical field of power generation by using waste sintering heat of a steel and iron plant. The power generating system comprises a sintering machine flue gas waste heat utilizing system, a cooling machine exhaust gas waste heat utilizing system, a turbine generating system and a relevant auxiliary system, wherein a main waste heat discharging boiler is utilized to recover the waste heat of the flue gas of a high-temperature segment of the tail part of the sintering machine; a cooling machine waste heat boiler is utilized to recover the waste heat of the high-temperature exhaust gas of the cooling machine; and a high-temperature electric butterfly valve is arranged between the high-temperature segment and a low-temperature segment of a large flue positioned on the tail part of the sintering machine to prevent the wind pickup temperature of the flue gas from being reduced because a low-temperature flue gas and a high-temperature flue gas are directly mixed so as to ensure the high-temperature flue gas to enter the main waste heat discharging boiler for waste heat recovery. The system and method effectively utilizes the waste heat resources of the high-temperature flue gas of the machine tail of the sintering machine and a hot gas of the high-temperature segment of the cooling machine, enhances the waste heat recovery and utilization efficiency of a sintering process and increases the power generation capacity of the waste heat power generating system.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Natural gas absorbent regeneration and energy conservation technology and device

InactiveCN103071475AAvoid wastingReduce dosageGaseous fuelsCombustible gas purificationCompressed natural gasNatural gas dehydration

The invention relates to a natural gas absorbent regeneration and energy conservation technology and a natural gas absorbent regeneration and energy conservation device. The technology and the device can overcome the defects that the energy consumption is great and the heating time is long when the absorbent is regenerated. The technical scheme is as follows: a process of two towers is adopted, one tower is used for dehydration of natural gas and the other one is used for regeneration of natural gas. The two towers are switched for dehydration and regeneration of natural gas. During dehydration of natural gas, compressed natural gas first enters into the dehydration tower A to be dehydrated and obtain dried natural gas after being separated by a front filter separator, then the natural gas enters into a gas storage tank after being separated by a back filter separator; during heating and regeneration of absorbent, after flow reduction and depressurization, the regenerated natural gas is first heated in a heat exchanger and a heater and enters into the dehydration tower B to regenerate the absorbent, then, the natural gas enters into the heat exchanger to be cooled, and finally the natural gas enters into a recovery tank after being separated by a condensation separator; and during cold blowing and regeneration of the absorbent, after flow reduction and depressurization, the regenerated natural gas enters into the dehydration tower B to cold blow and reduce the temperature of the absorbent. According to the technology, complementary utilization of energy is achieved, energy consumption in absorbent regeneration is reduced, and energy-saving operation of the device is realized.

Owner:SOUTHWEST PETROLEUM UNIV

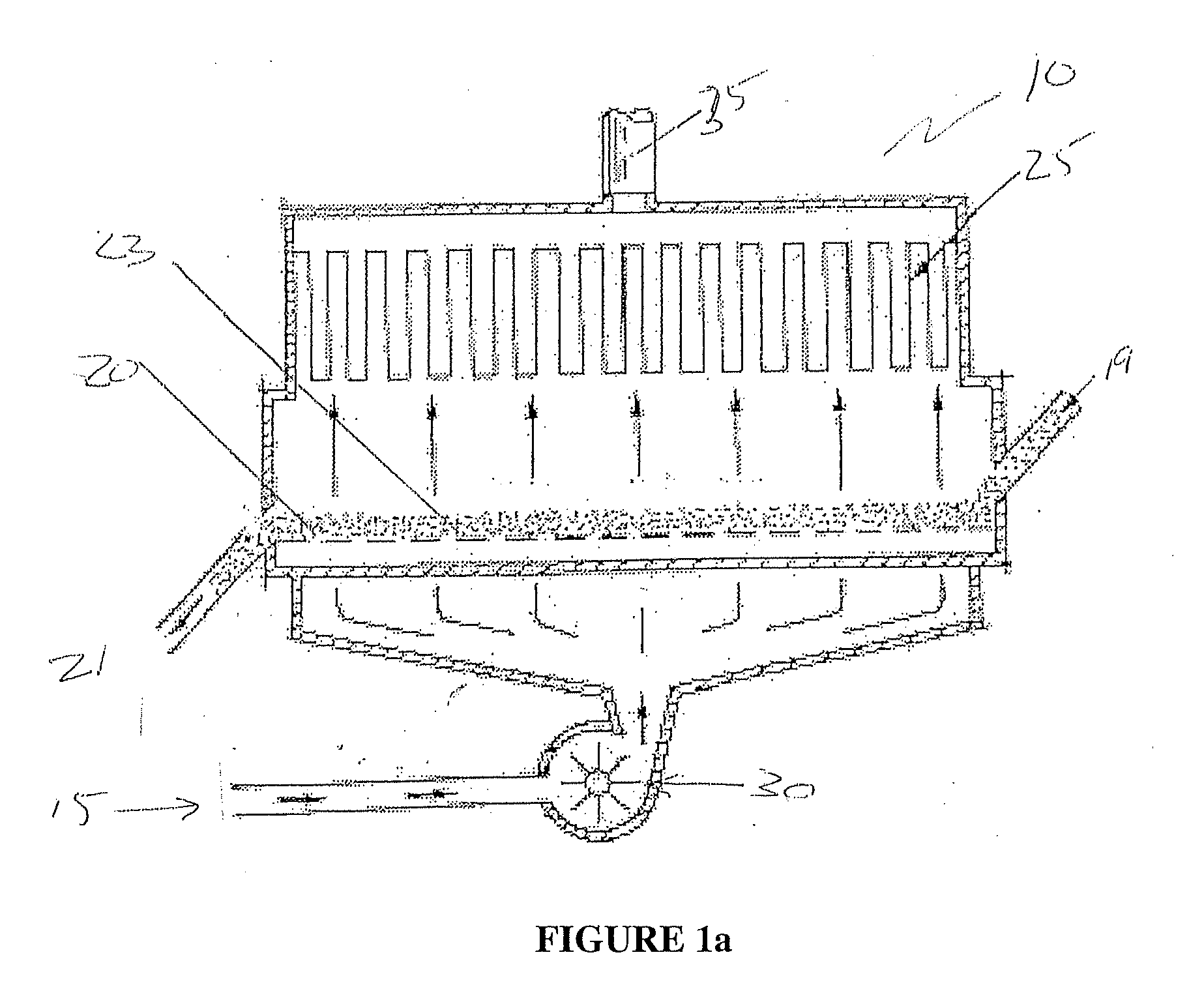

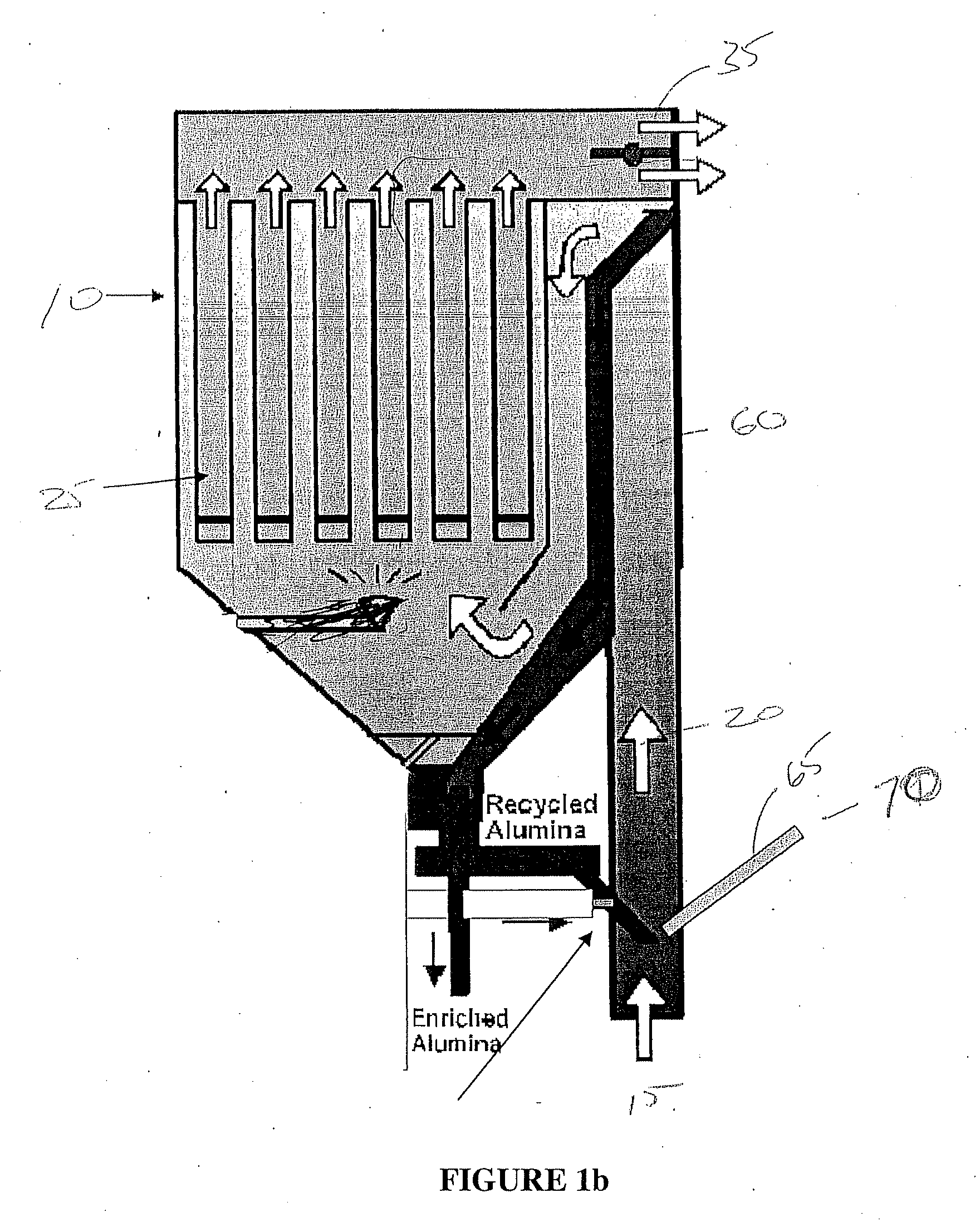

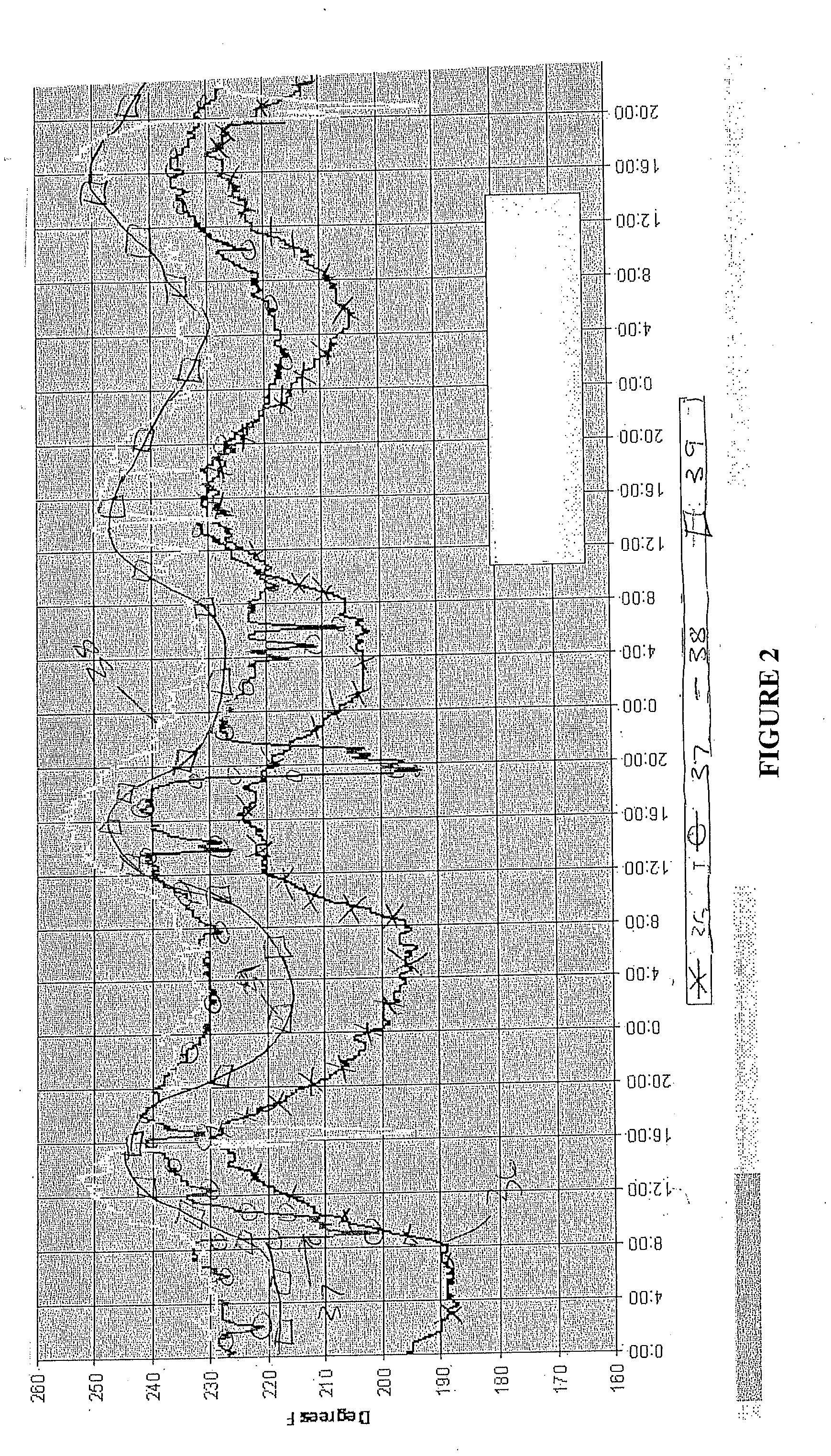

Method For Improving the HF Capture Efficiency of Dry Scrubbers

InactiveUS20080050298A1Improve efficiencyIncrease and decrease in adsorption efficiencyGas treatmentUsing liquid separation agentScrubberInlet temperature

The present invention provides, a method of reducing fluoride emissions from aluminum smelting including the steps of providing alumina at a preselected feed rate to pots containing an aluminum producing molten electrolyte, wherein the aluminum producing molten electrolyte evolves gaseous fluoride byproducts; transporting the gaseous fluoride byproducts to alumina-based dry scrubbers, wherein the alumina scrubbers absorb at least a portion of the gaseous fluoride byproducts; determining the inlet temperature into the dry scrubber; and adjusting the alumina feed rate to the dry scrubber to optimize the capture efficiency of the gaseous fluoride byproducts, wherein adjusting the aluminum feed rate includes increasing the aluminum feed rate to correspond to a first temperature and decreasing the feed rate to correspond to a second temperature, wherein the first temperature is greater than the second temperature.

Owner:ARCONIC INC

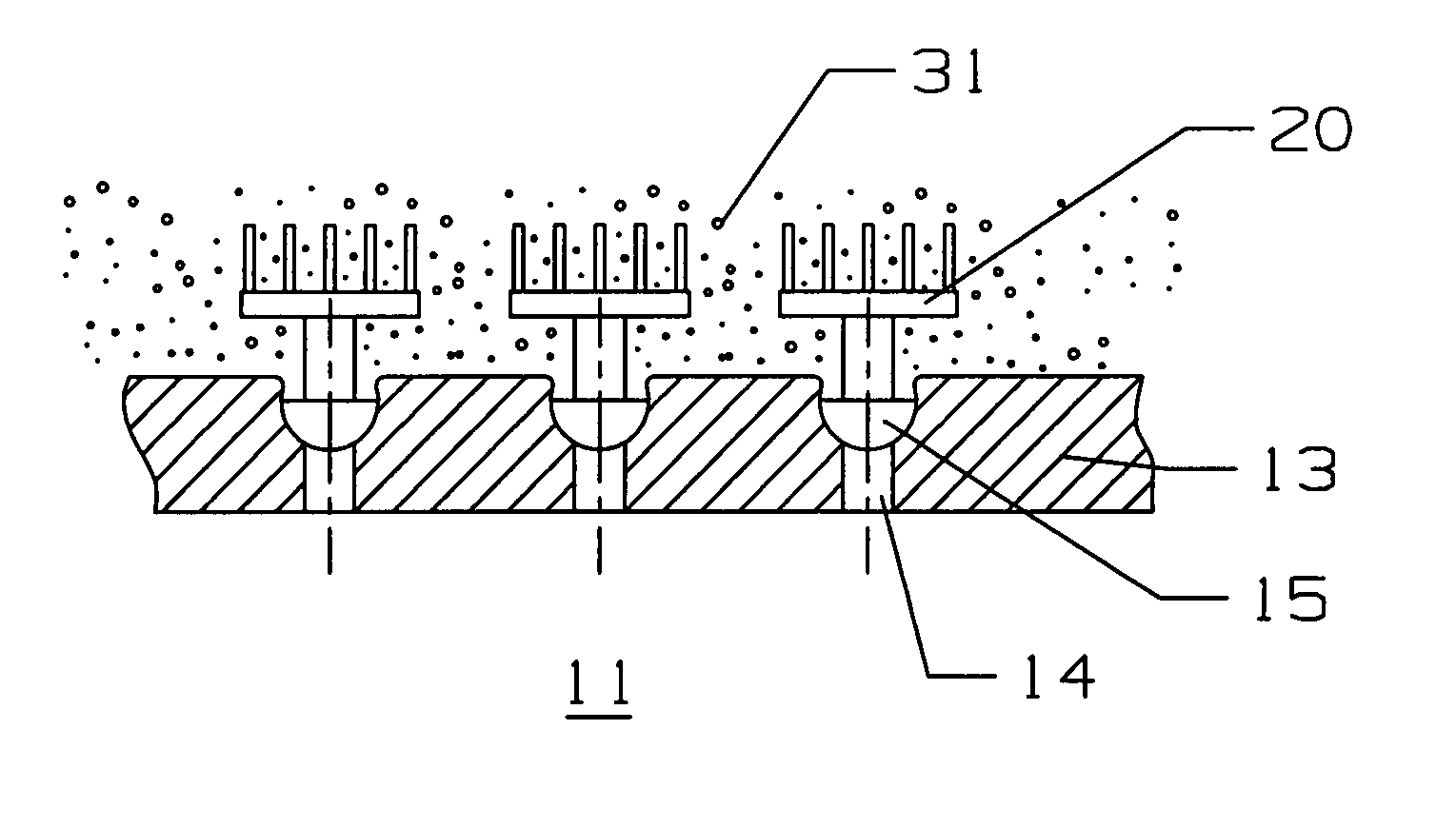

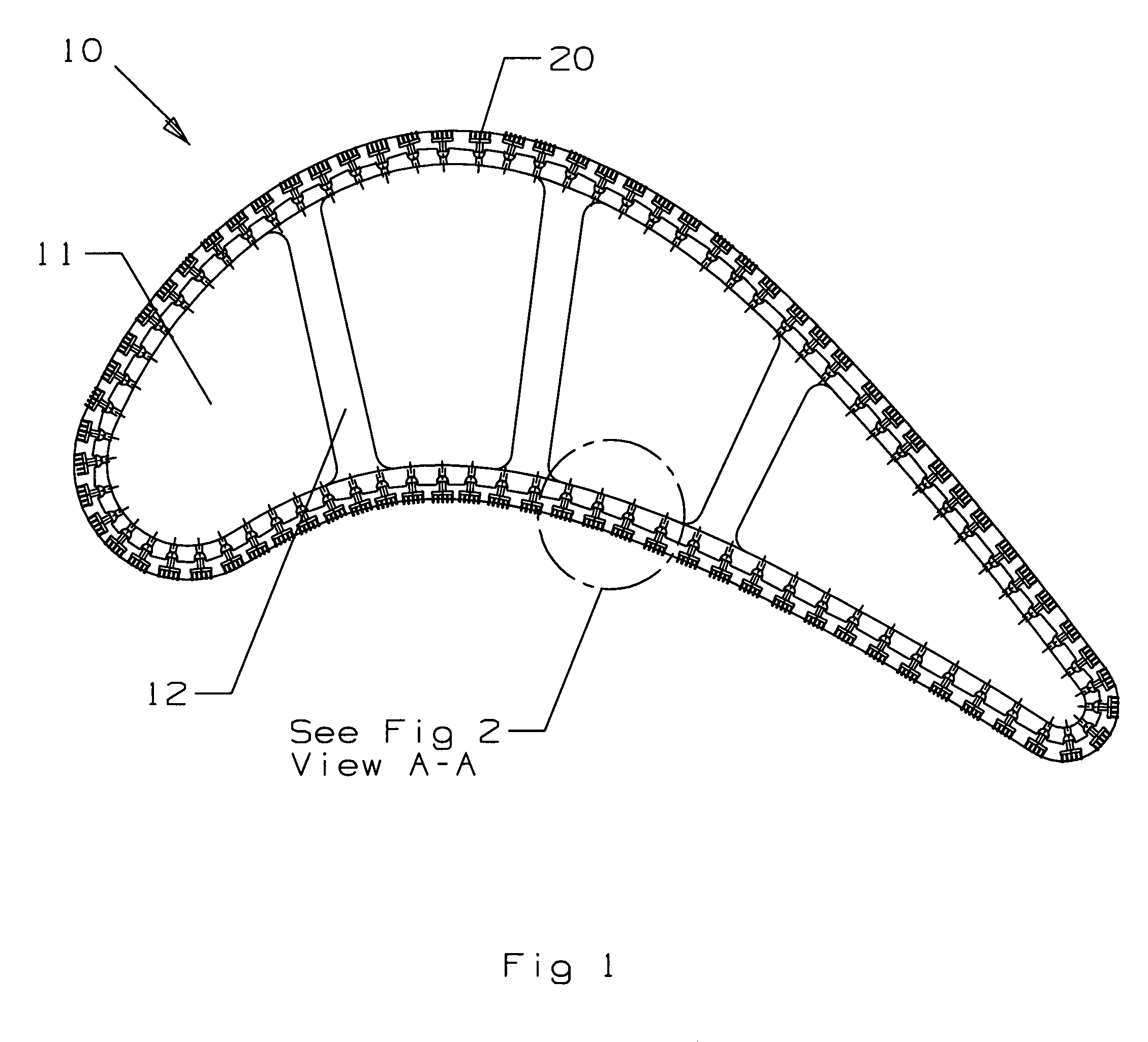

Multi-metering and diffusion transpiration cooled airfoil

InactiveUS7717677B1High-temperature resistant coatingIncreased durabilityPump componentsEngine fuctionsDiffusionCoated surface

A turbine airfoil, or a substrate exposed to a high temperature environment, having a plurality of individual cooling circuits in the airfoil wall, each individual cooling circuit having a first metering hole connecting the cooling circuit to a cooling air supply, a first diffusion cavity, a second metering hole, and a plurality of fine film cooling holes connected between the second diffusion cavity and the surface of a high temperature resistant coating. The coating is a refractory coating to provide higher heat resistance than a ceramic based thermal barrier coating. A process of forming the individual cooling circuits is also disclosed, where a ceramic core representing the above described cooling passages is secured in a “fish bowl” shaped cavity in the substrate wall, the refractory coating is applied to just under the core fingers, and the ceramic core is leached out to leave behind the cooling circuit. The cooling circuit thus formed includes a first metering hole, a first diffusion cavity, a second metering hole, a second diffusion cavity, and a plurality of micro film cooling holes to provide transpiration cooling to the coating surface.

Owner:FLORIDA TURBINE TECH

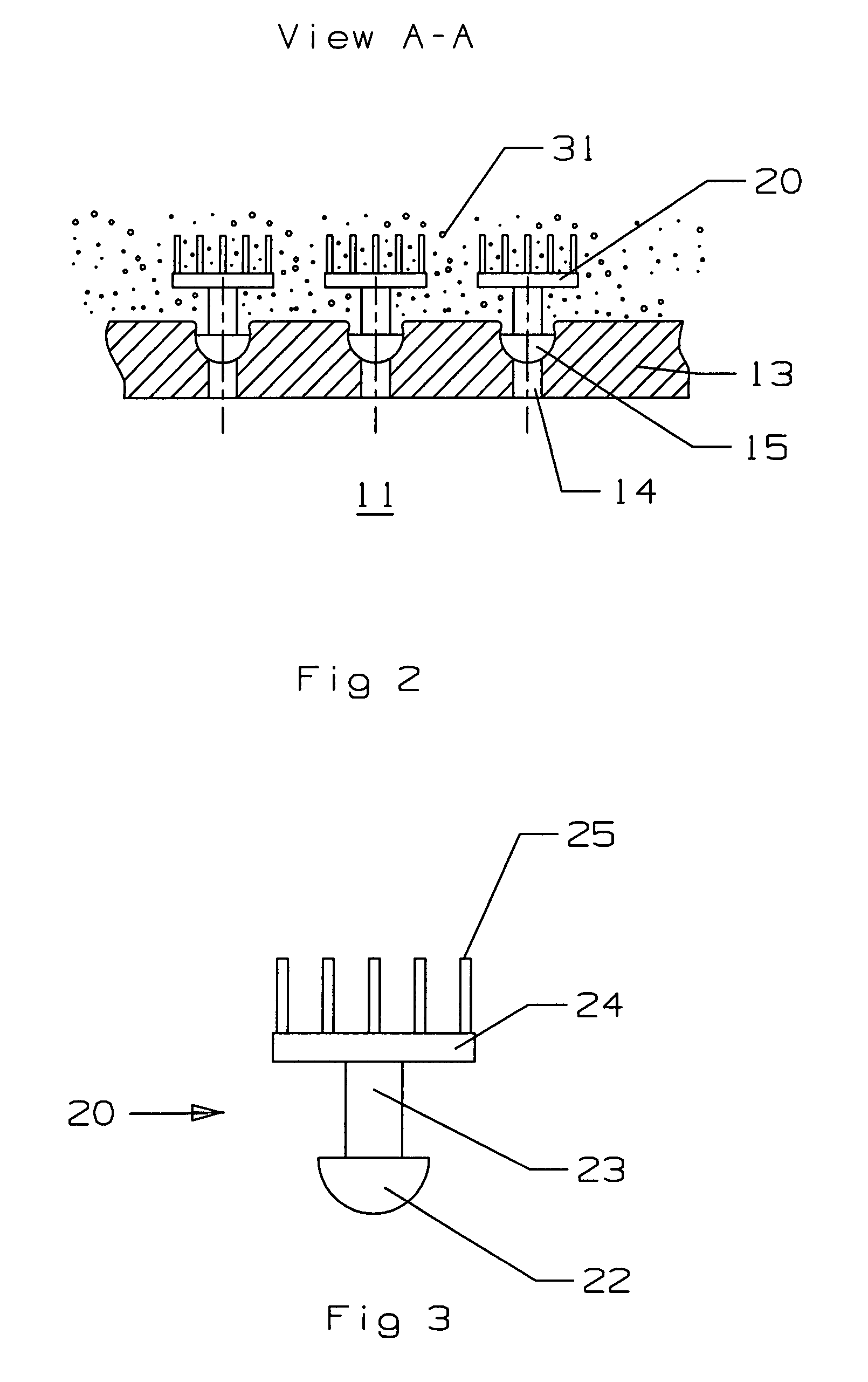

High pressure ratio twin spool industrial gas turbine engine

InactiveUS20160215694A1Reduce the temperatureImprove efficiencyGas turbine plantsEfficient propulsion technologiesNuclear engineeringHigh pressure

An industrial gas turbine engine for electrical power production includes a high pressure spool and a low pressure spool in which the low pressure spool can be operated from full power mode to zero power mode when completely shut off, where the low pressure spool is operated at high electrical demand to supply compressed air to the high pressure compressor of the high pressure spool, and where turbine exhaust is used to drive a second electric generator from steam produced in a heat recovery steam generator. The power plant can operate at 25% of peak load while keeping the unused parts of the power plant hot for easy restart when high power output is required.

Owner:FLORIDA TURBINE TECH

System for reducing discharge smoke temperature of power station boiler

InactiveCN102252339AReduce the temperatureIncrease temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a system for reducing discharge smoke temperature of a power station boiler and belongs to the technical field of waste heat recovery, and the system is characterized that a heat transfer pipeline is arranged in the hot primary air pipeline of the boiler, the two ends of the heat transfer pipeline are respectively connected with a water inlet pipeline and a water outlet pipeline, the other ends of the water inlet pipeline and the water outlet pipeline are connected to a heater on the secondary air inlet air flue of an air pre-heater; and simultaneously a bypass flue is additionally arranged, thus the original smoke is divided into two paths, one path of the original smoke is sent into the air pre-heater through the original flue, and the other path of the originalsmoke is sent into a low-pressure high-temperature economizer through the bypass flue. The hot primary air is utilized to heat the cold secondary air, thereby improving the air temperature of a secondary air inlet; the primary air temperature is controlled by changing the quantity of a cooling medium in the heat transfer pipeline, thereby reducing the amount of the cold primary air doped in a coal pulverizing system; and a method of increasing the amount of the smoke in the bypass flue is adopted, thereby reducing the temperature of the discharge smoke. On the premise of ensuring the temperature of the secondary air, the surplus heat of the primary air is recycled, thus the coal consumption of the boiler and the heat rate of a steam turbine are reduced, and the economical efficiency of a power plant is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

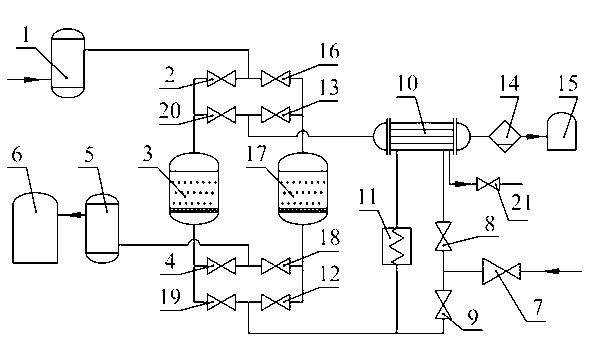

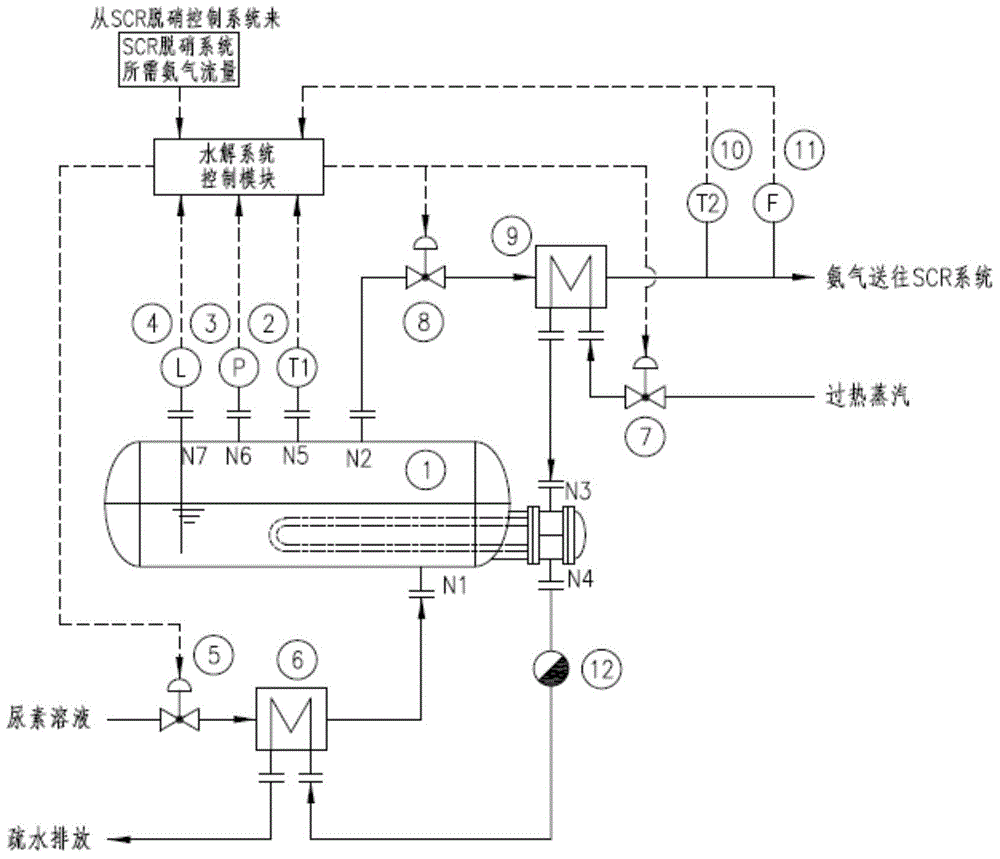

System and control method for producing ammonia gas by hydrolyzing urea solution

InactiveCN103979575ARaise the inlet temperatureImprove utilization efficiencyAmmonia preparation/separationProcess engineeringHydrolysis

The invention discloses a system for producing ammonia gas by hydrolyzing a urea solution. The system comprises a hydrolyzer, a hydrolyzer thermometer T1, a hydrolyzer pressure transmitter P, a hydrolyzer liquidometer L, a urea solution regulating valve A1, a hydrophobic heat exchanger, a steam regulating valve A2, a hydrolyzing gas outlet regulating valve A3, a steam heat exchanger, a hydrolyzing gas outlet thermometer T2, a hydrolyzing gas outlet flowmeter F, a steam hydrophobic valve and a hydrolysis system control module, wherein the hydrolyzer is provided with seven ports respectively connected with the components above; the hydrolysis system control module is respectively connected with the hydrolyzer thermometer T1, the hydrolyzer pressure transmitter P, the hydrolyzer liquidometer L, the urea solution regulating valve A1, the steam regulating valve A2, the hydrolyzing gas outlet regulating valve A3, the hydrolyzing gas outlet thermometer T2 and the hydrolyzing gas outlet flowmeter F through cables. The invention also discloses a control method for producing ammonia gas by hydrolyzing the urea solution, which is implemented through six steps. The system and control method disclosed by the invention are simple and reliable, and easy to control. Steam is taken as a heat source of a hydrolysis system, so that the operation cost and the energy consumption are reduced.

Owner:北京乐道致远技术有限公司

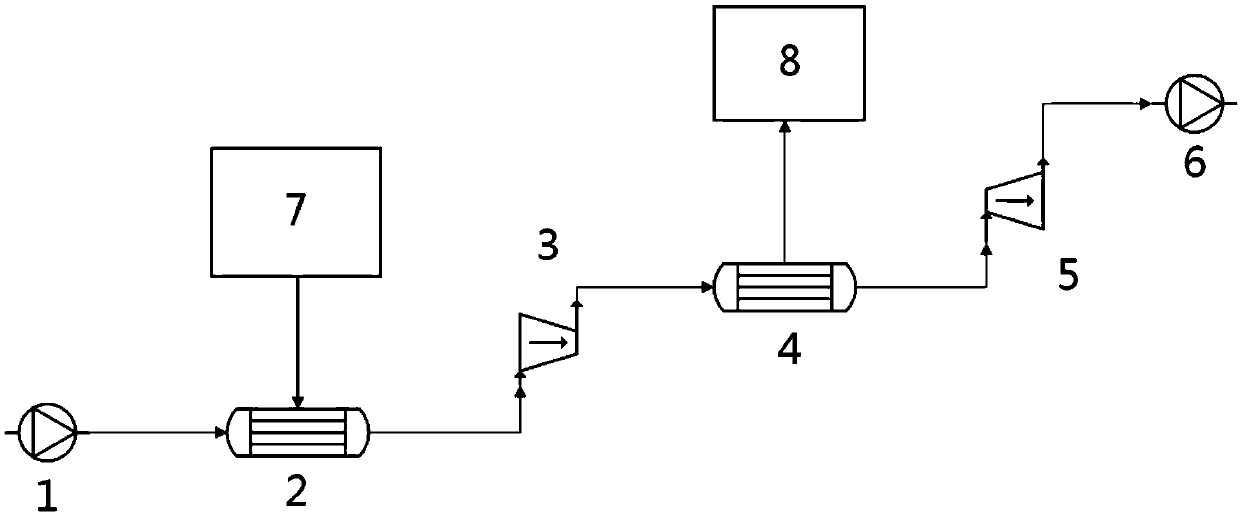

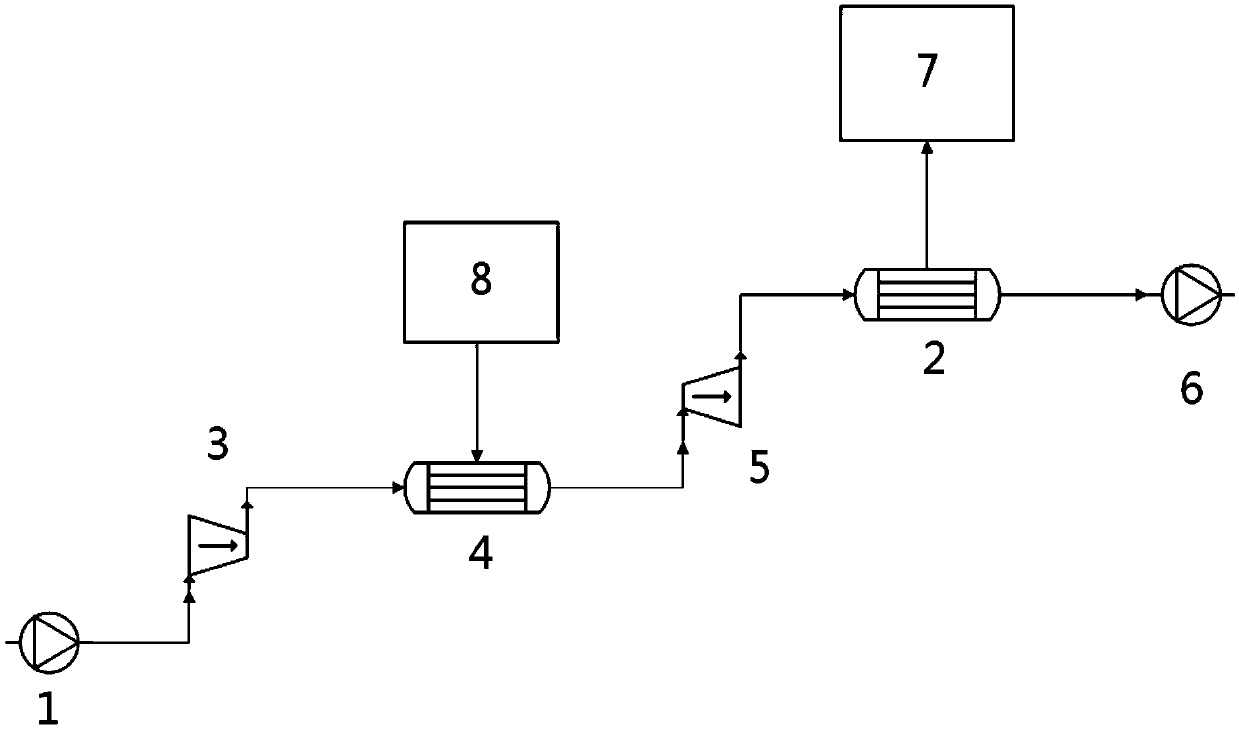

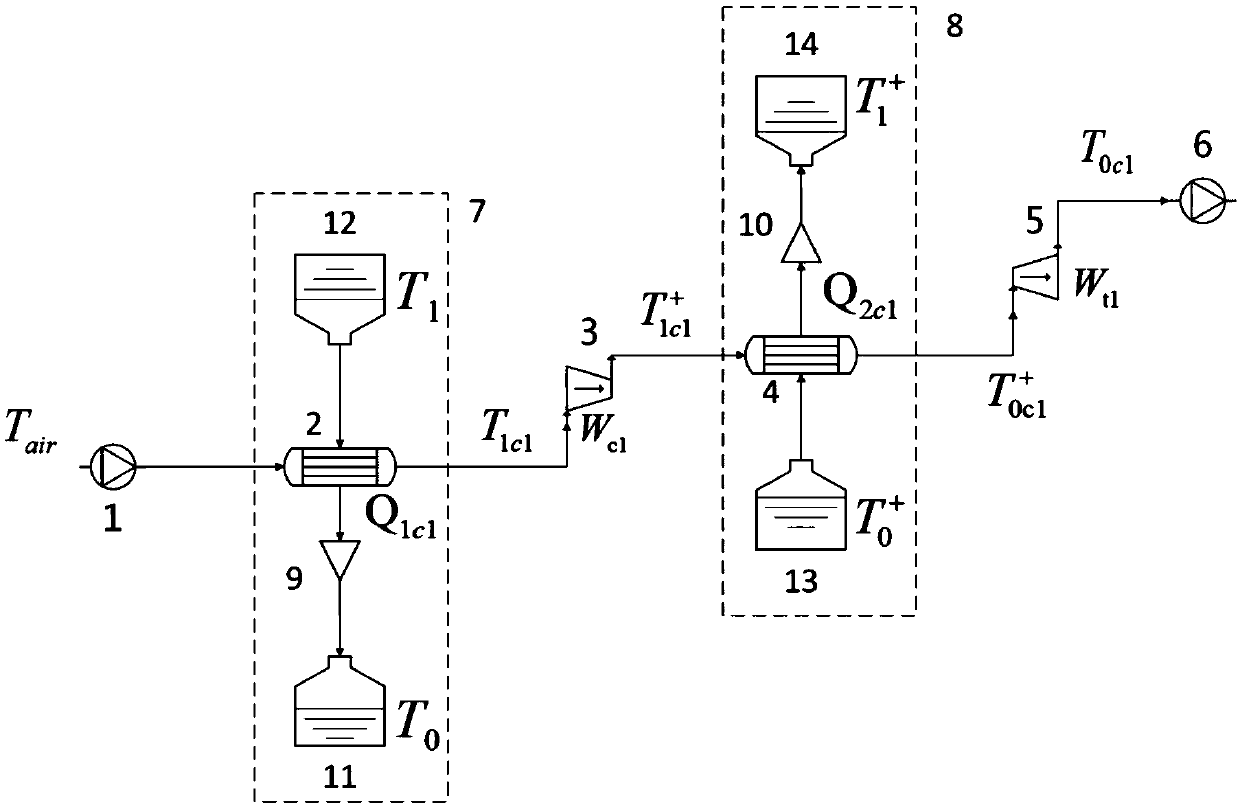

Heat pump type alternating energy storing and power supplying method and device

ActiveCN108731303ARaise the inlet temperatureLow costHeat pumpsHeat storage plantsElectricityEngineering

The invention provides a heat pump type alternating energy storing and power supplying method and device. The heat pump type alternating energy storing ad power supplying method comprises an energy storing and heat supplying mode and a power supplying and heat supplying mode. When the energy storing and heat supplying mode is used, a normal temperature working medium absorbs heat isobarically through a first heat storing system to be adiabatically compressed by a compressor, then releases heat isobarically through a second heat storing system, then enters a turbine for heat insulation and expansion to carry out external work, and finally is released to the outside as a heating supply. The device is sequentially connected in series with an air inlet device, a first heat exchanger, a first heat storing system, a compressor, a second heat exchanger, a second heat storing system, the turbine and an air outlet device in the moving direction of working air. According to the heat pump type alternating energy storing and power supplying method and the device, the problems of wind curtailment and light curtailment in photovoltaic power generation and wind power generation and the problem ofpeak cutting and valley filling in peak-valley electricity are solved; heat supply is achieved when energy storing and power supplying are carried out; and afterheat of waste air is recycled into another heat storing system, and heat-work conversion efficiency is improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Liquid state energy storage system applicable to depth peak load regulation of heat power generating unit

PendingCN106885232AMeet the needs of low-load Internet accessRaise the inlet temperatureSteam engine plantsFeed-water heatersSteam pressureMolten salt

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

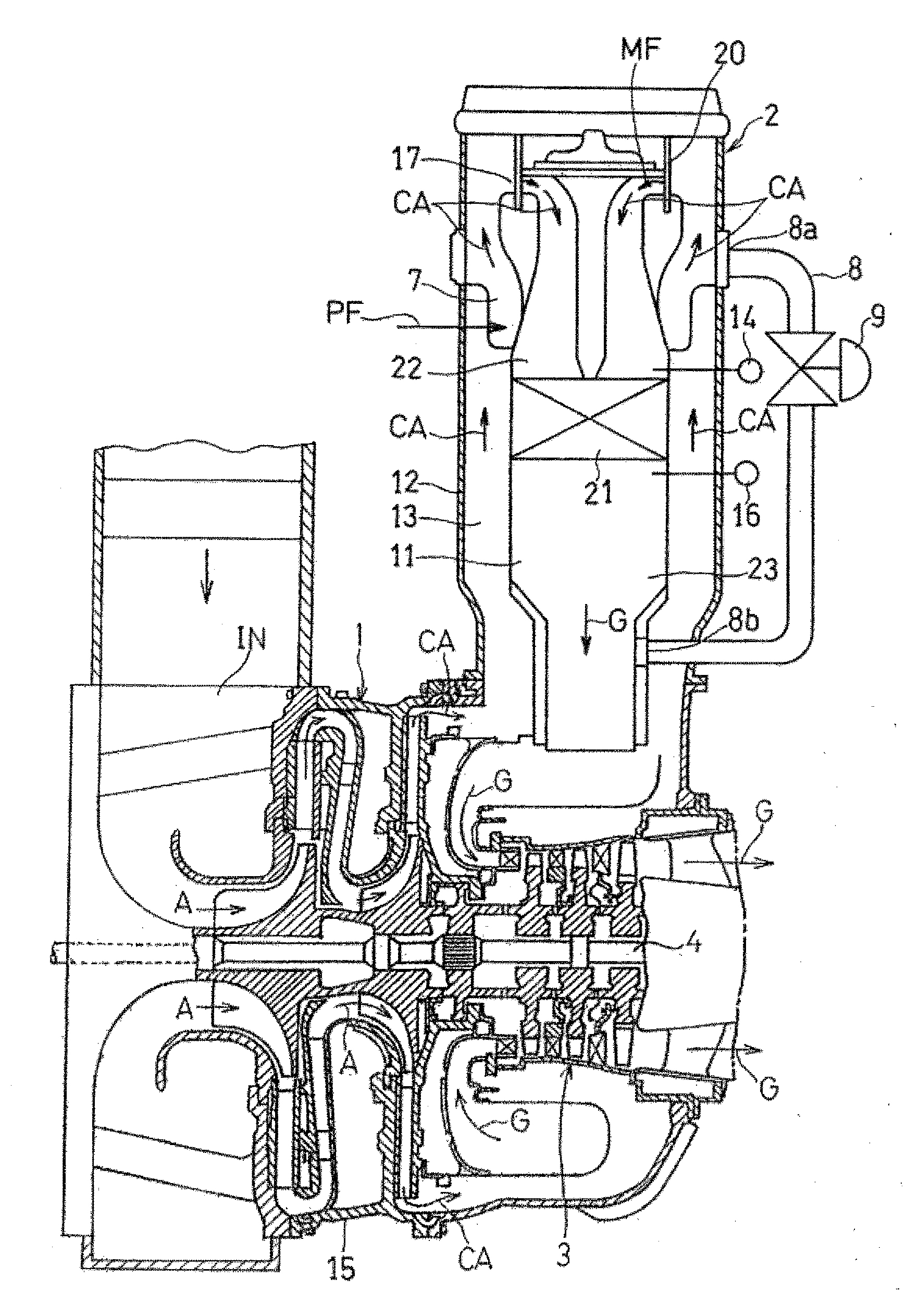

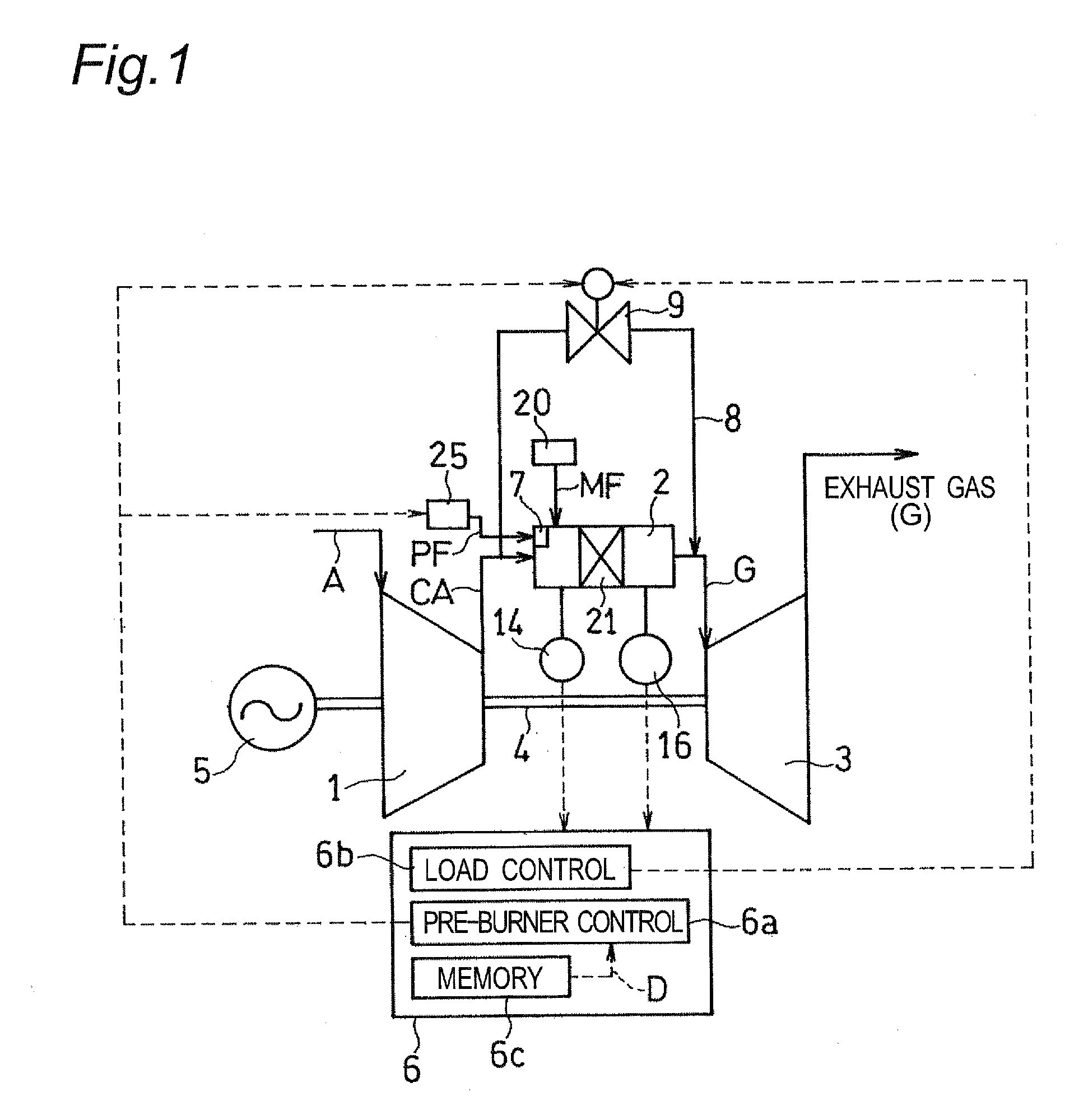

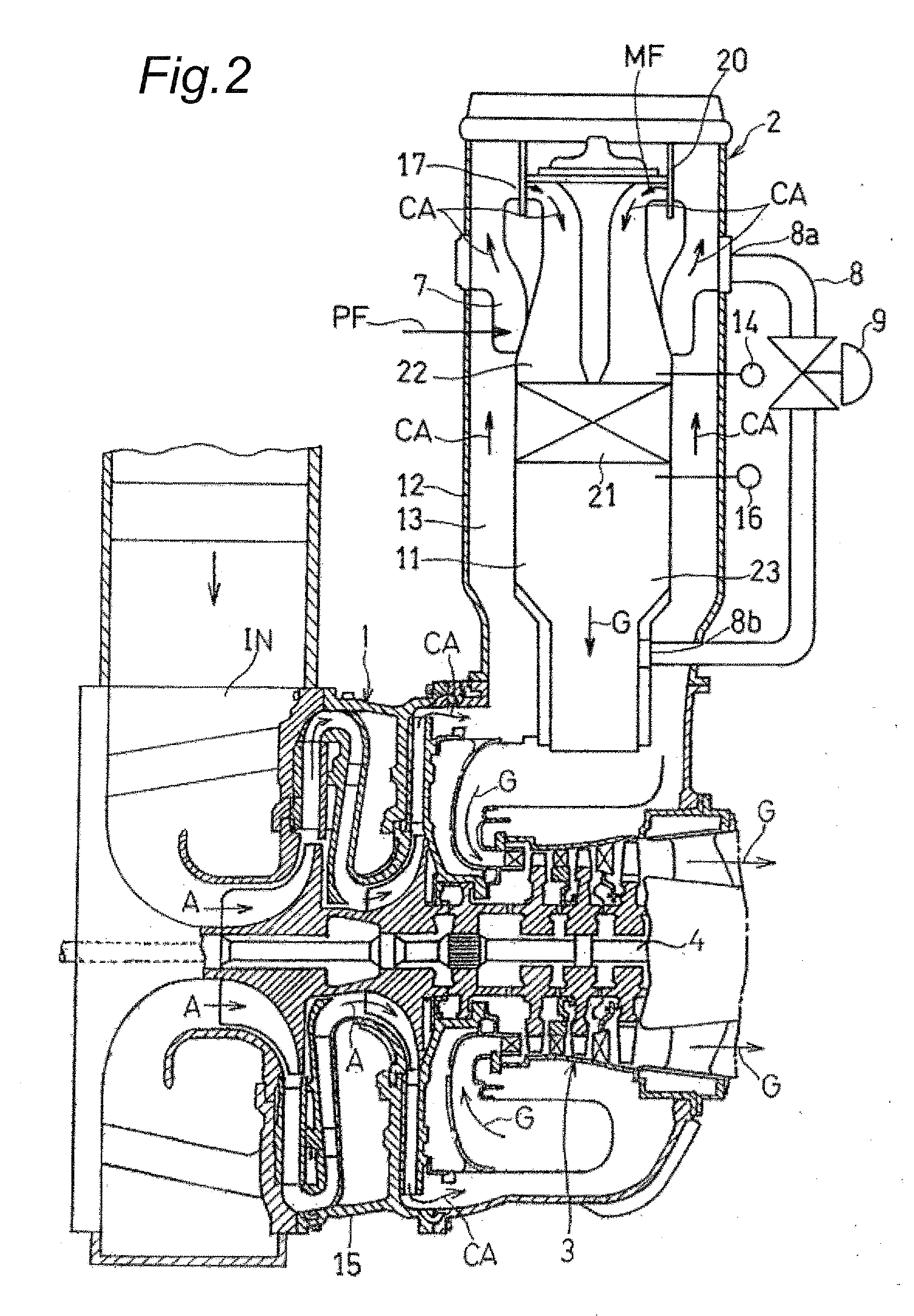

Controller for use with gas turbine engine

InactiveUS20130025254A1Reduce the amount requiredIncrease carbon monoxide concentrationFuel supply regulationContinuous combustion chamberCombustorTemperature difference

Provided is a controller for use with a gas turbine engine, which ensures a stable combustion regardless of the deterioration of the catalyst and elevated characteristics of the exhaust gas. The controller 6 is used in the engine which comprises a combustor 2 for combusting a mixture of compressed air from a compressor 1 and a fuel under the existence of catalyst, the combustor having a catalytic combustion unit 21 bearing the catalyst and a pre-burner 7 provided on an upstream side of the catalytic combustion unit with respect to a flow of the compressed air for supplying and combusting a pre-heating fuel PF with the compressed air CA. The controller comprises a memory 6c for memorizing an initial temperature difference D between inlet and outlet temperatures t1, t2 measured at inlet and outlet of the catalytic combustion unit with non-deteriorated catalyst accommodated therein, and a pre-burner control for calculating a present temperature difference between the inlet and outlet temperatures measured in an operation of the gas turbine engine and controlling an amount of the fuel to be supplied to the pre-burner according to a deterioration Δd of the catalyst which is provided by a difference between the initial and present temperature differences D and d.

Owner:KAWASAKI HEAVY IND LTD

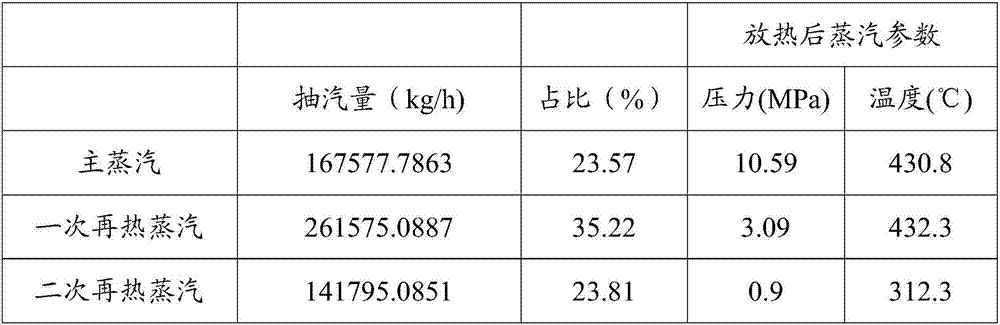

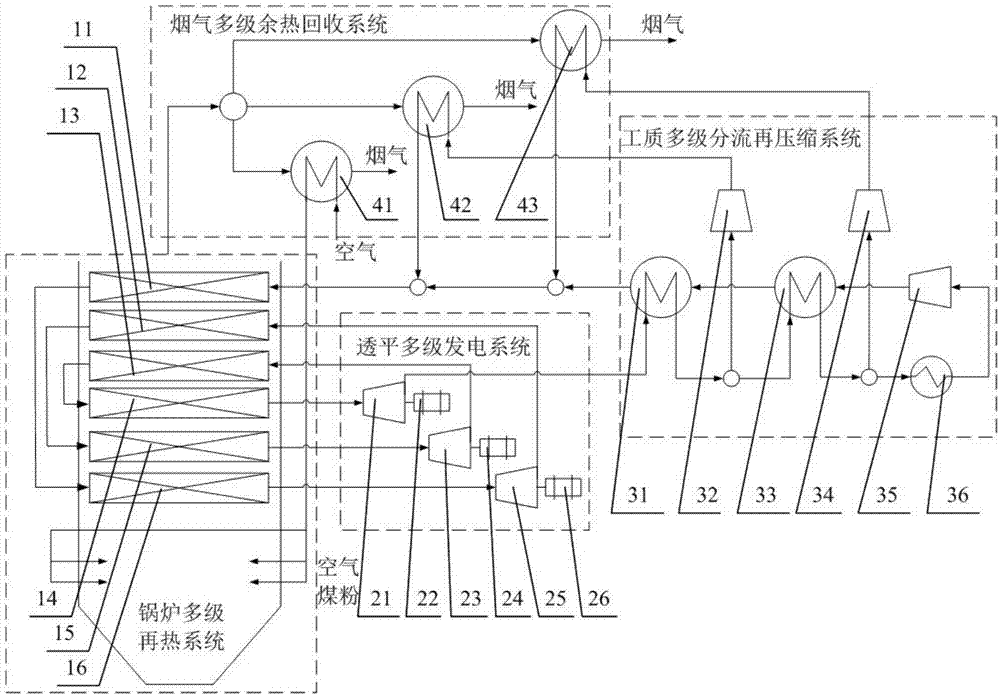

Coal-based novel supercritical working medium multistage distribution reheat efficient power generation system

ActiveCN104727868AImprove efficiencyAvoiding Pinch Heat Transfer Worsening EffectsSteam useFeed-water heatersCombustionSingle stage

The invention discloses a coal-based novel supercritical working medium multistage distribution reheat efficient power generation system. The coal-based novel supercritical working medium multistage distribution reheat efficient power generation system comprises a multistage boiler reheat system, a multistage turbine power generation system, a multistage working medium distribution and recompression system and a multistage fume waste heat recovery system. The multistage working medium distribution and recompression system comprises a main compressor, multistage re-compressors, all stages of regenerators and pre-coolers, wherein the main compressor and the re-compressors are arranged in a distributed mode, and the regenerators and the pre-coolers are arranged on all distribution branches. By utilizing the system, a working medium is divided into multiple stages for respective compression, and heat is recovered through the multistage regenerators, and therefore the efficiency of all stages of compressors is improved. Meanwhile, as all the stages of regenerators can effectively adjust the flow ratio, the pinch point heat transfer deterioration effect of a traditional single-stage system is effectively avoided, and heat transfer efficiency is improved. The multistage fume waste heat recovery system utilizes system waste heat resources in a stepped mode and meanwhile heats a new working medium and combustion air, and therefore the utilization efficiency of energy is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

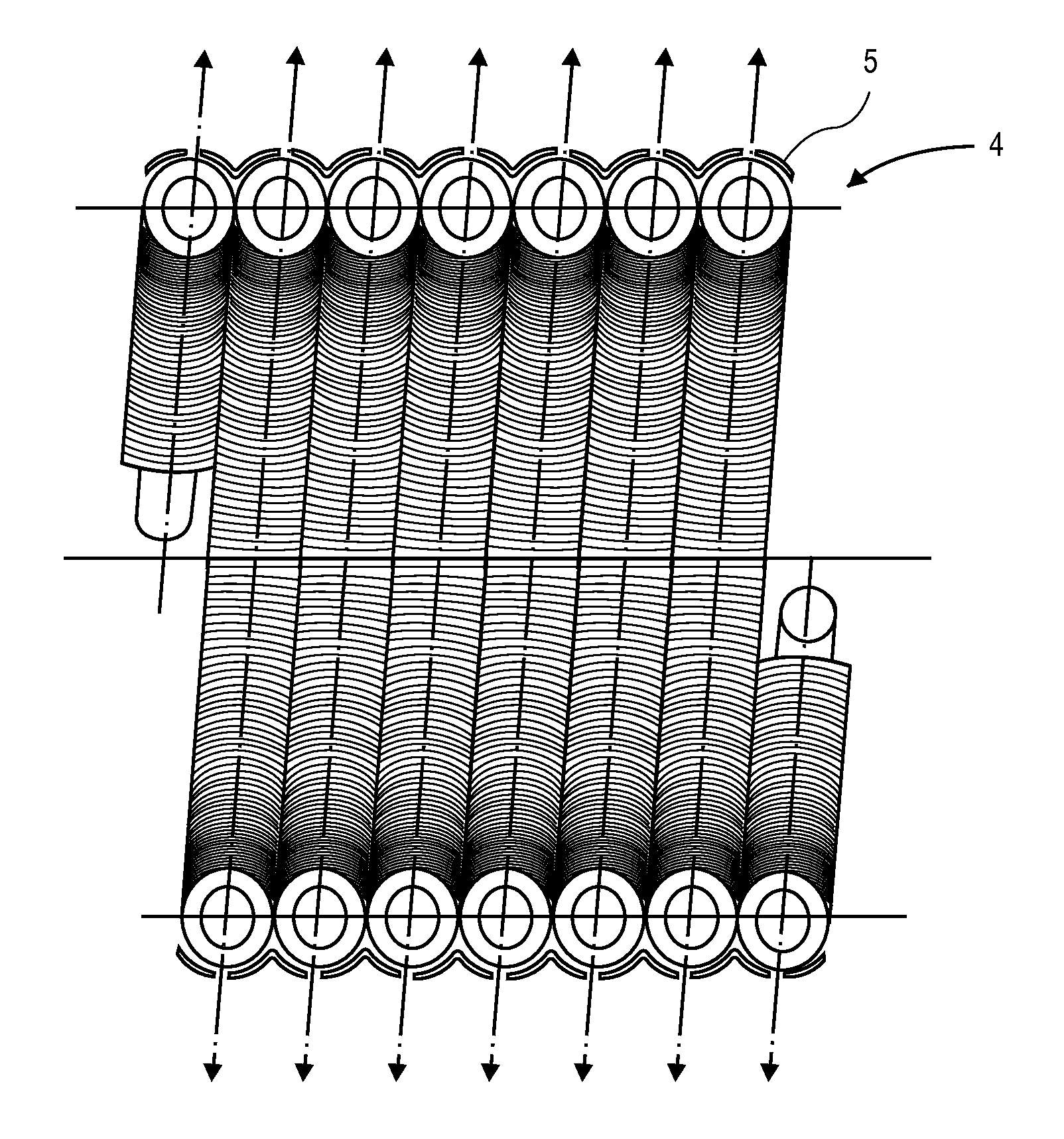

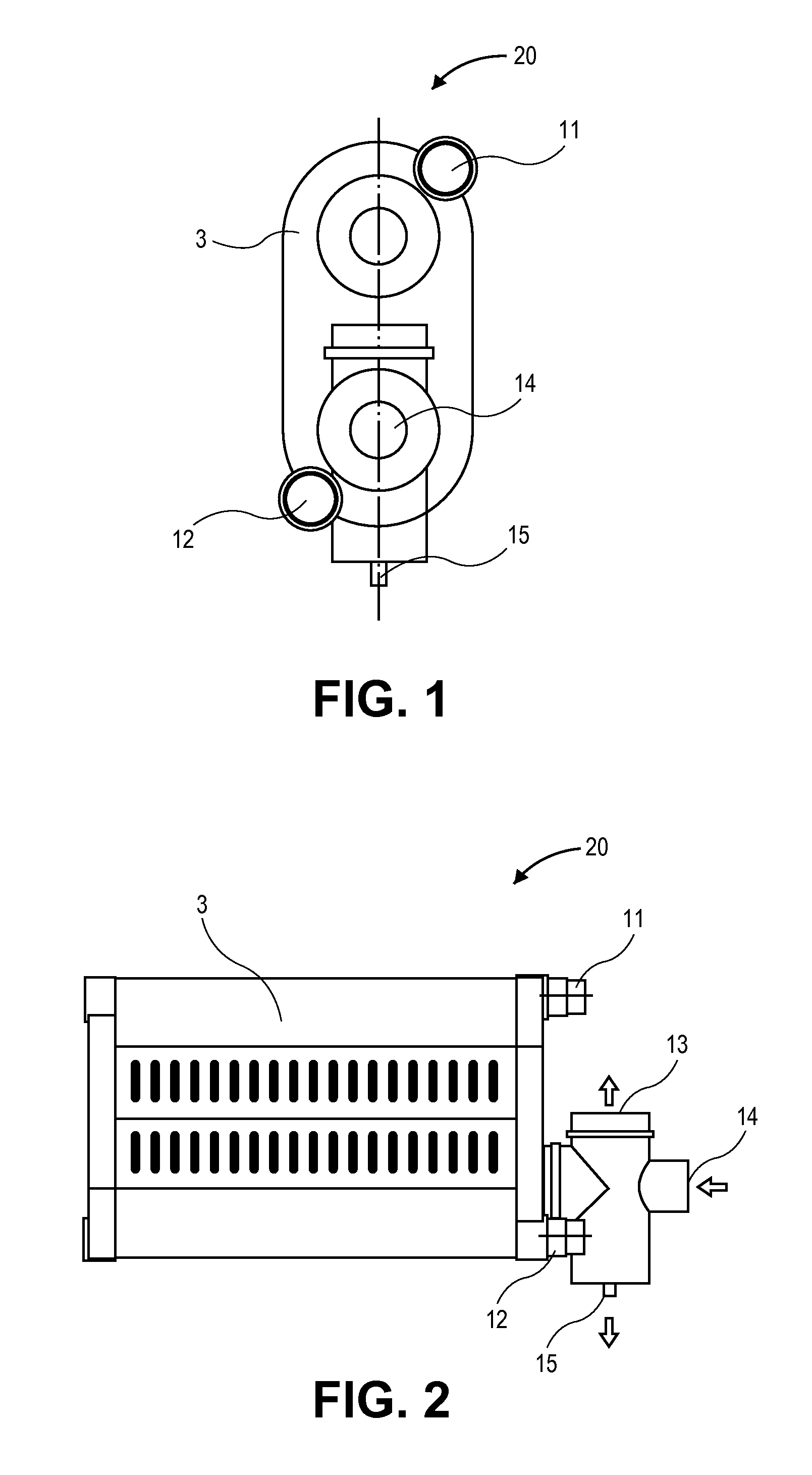

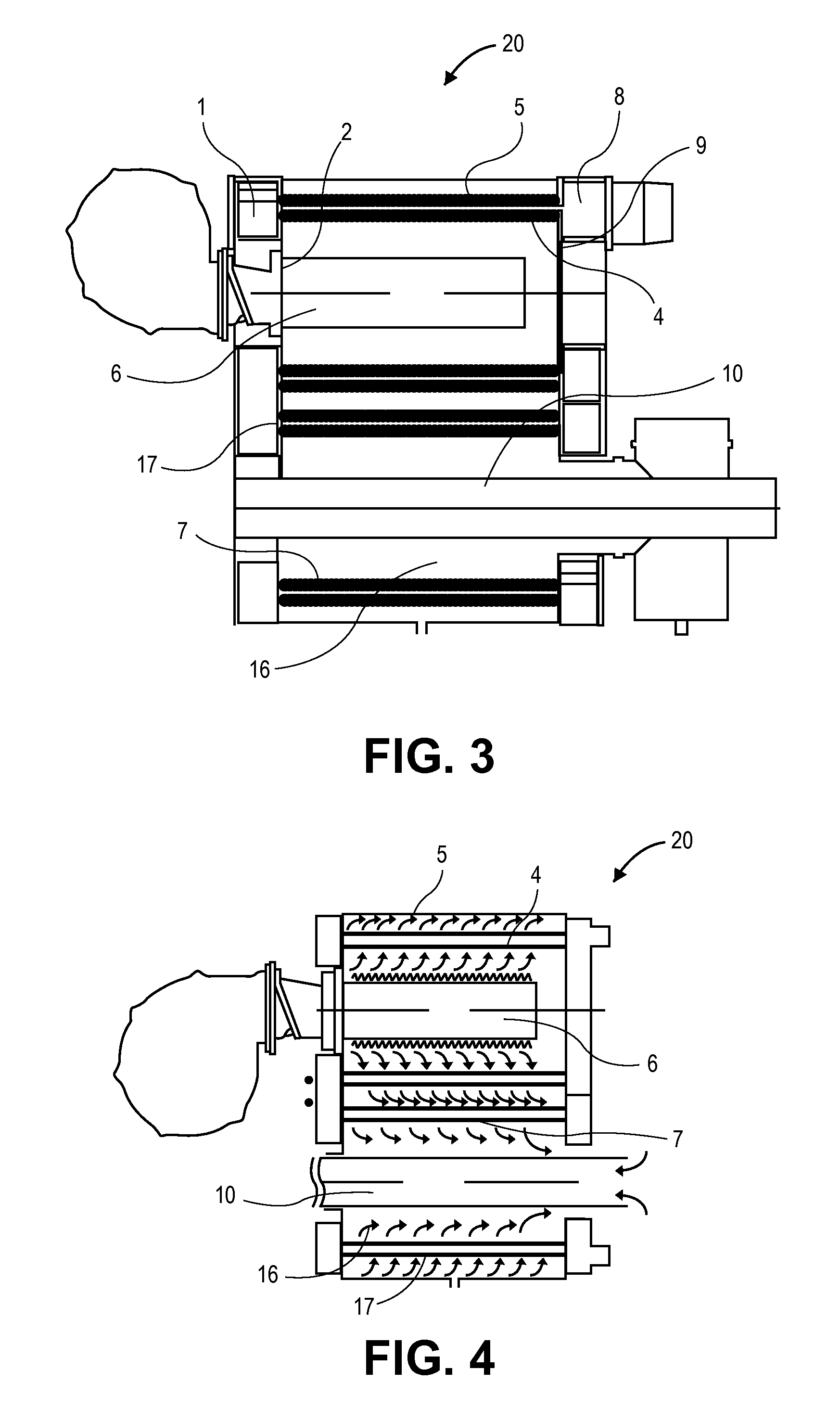

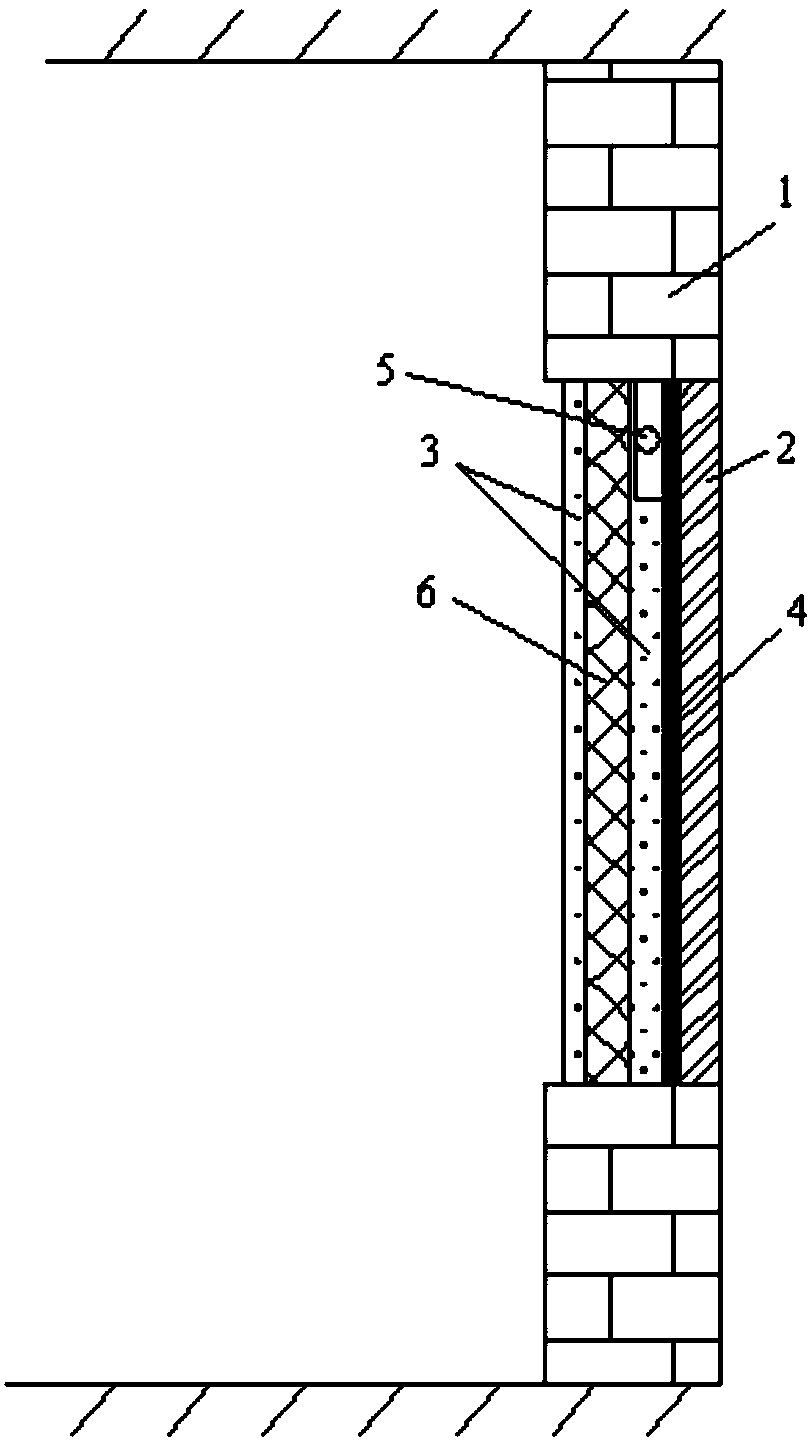

Spiral finned coil condensing heat exchanger

InactiveUS20150007779A1Improving heat transfer structureRaise the inlet temperatureAir heatersStationary tubular conduit assembliesPlate heat exchangerCombustor

A heat exchanger for supplying heat includes a housing, a bundle of helical fin-coil tubes, and a flue channel. The housing includes a burner, a water inlet, a water outlet and a flue gas outlet. The burner is disposed on a top portion of the housing and connected to an air / gas mixture unit. The bundle of helical fin-tube coils is disposed tightly, circularly, and coaxially around the burner. The flue channel is disposed below the burner and is formed by a plurality of helical fin-tube coils. A flow of flue gas vents from the flue channel to the flue gas outlet. The water inlet is connected to the plurality of helical fin-tube coils which forms the flue channel below the burner. The plurality of helical fin-tube coils below the burner are connected to the bundle of helical fin-tube coils. The bundle of helical fin-tube coils are connected to the water outlet.

Owner:SUZHOU CQ HEAT EXCHANGER

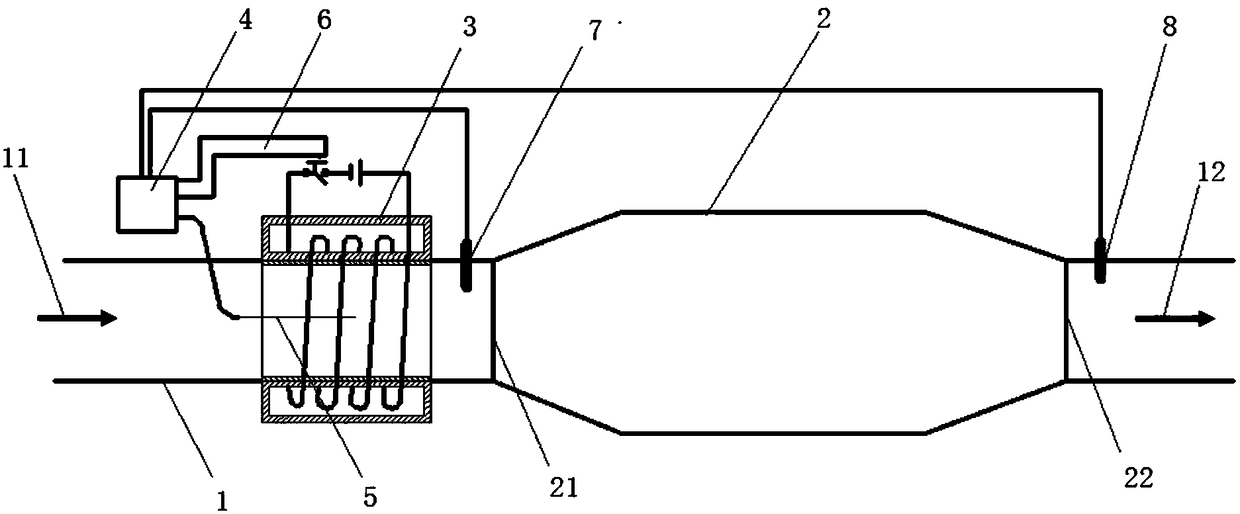

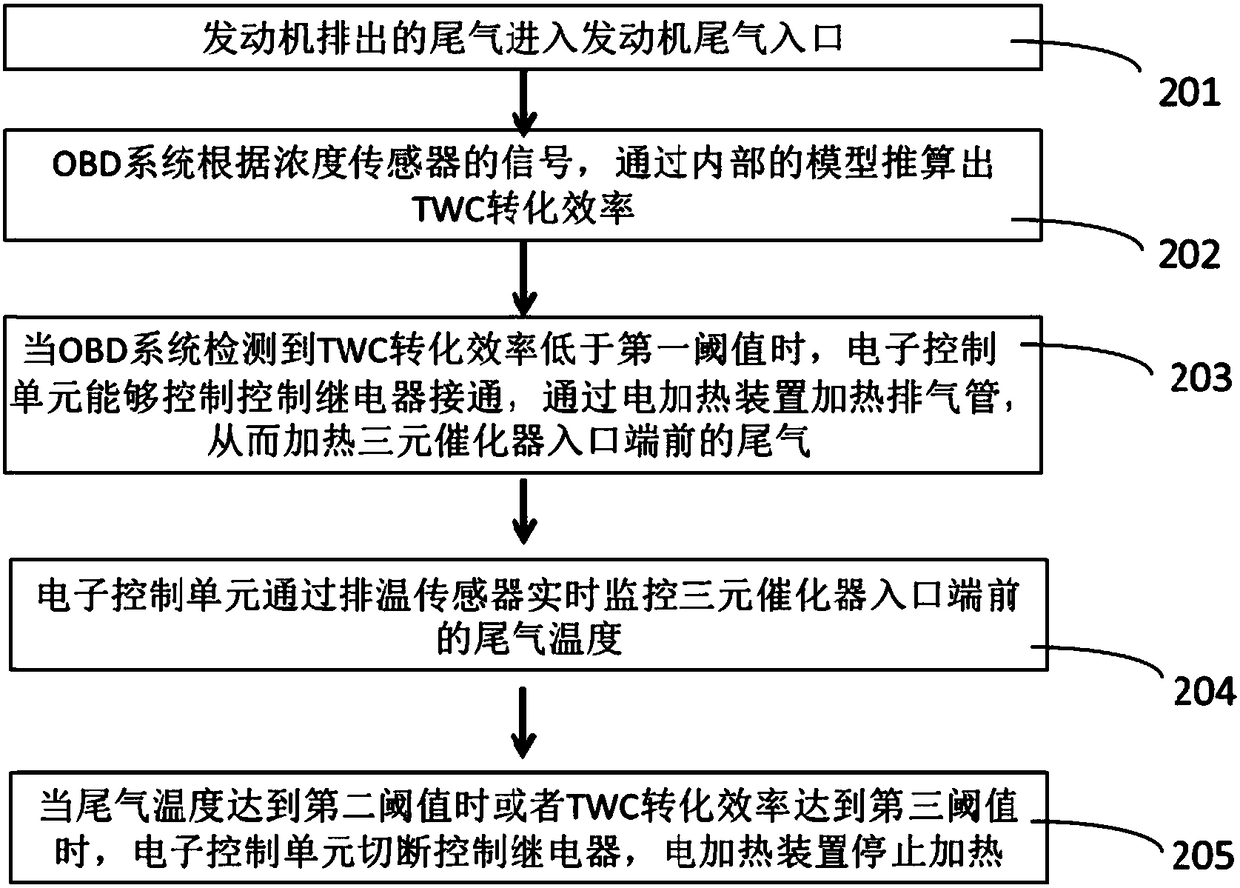

Device and method for controlling inlet temperature of three-way catalytic converter according to OBD monitoring efficiency

ActiveCN108590827ARaise the inlet temperatureShorten light-off timeInternal combustion piston enginesExhaust apparatusElectricityElectronic control system

The invention discloses a device and method for controlling the inlet temperature of a three-way catalytic converter according to OBD monitoring efficiency. The device comprises an exhaust pipe, a three-way catalytic converter, an electric heating device and an engine electronic control system, wherein the exhaust pipe comprises an engine exhaust gas inlet end; the inlet end of the three-way catalytic converter is connected with the engine exhaust gas inlet end; the electric heating device is arranged at the outer part of the exhaust pipe, distributed close to the inlet end of the three-way catalytic converter and used for heating exhaust gas before the inlet end of the three-way catalytic converter; and the engine electronic control system comprises an electronic control unit, an OBD system, an exhaust temperature sensor, a concentration sensor and a control relay, wherein the electronic control unit is separately electrically connected with the exhaust temperature sensor, the controlrelay and front and rear oxygen sensors, and the electronic control unit can control the working state of the electric heating device by controlling the connection and disconnection of the control relay. According to the device, the inlet temperature of the three-way catalytic converter can be raised in the cold starting and machine heating process of the engine, and the converting efficiency ofthe three-way catalytic converter is increased.

Owner:GUANGXI YUCHAI MASCH CO LTD

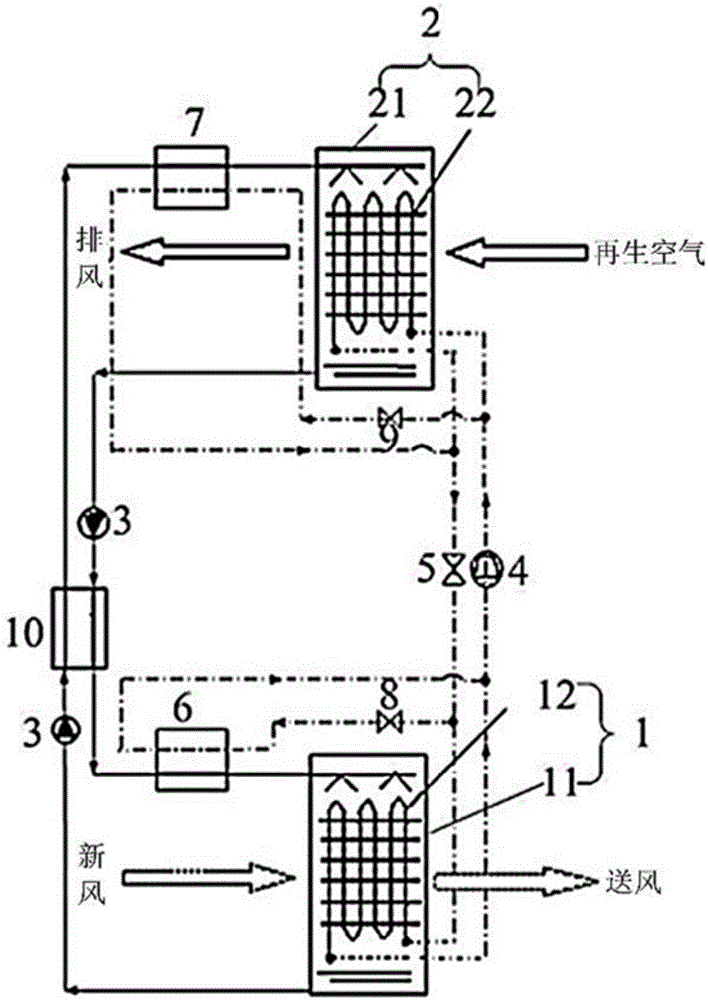

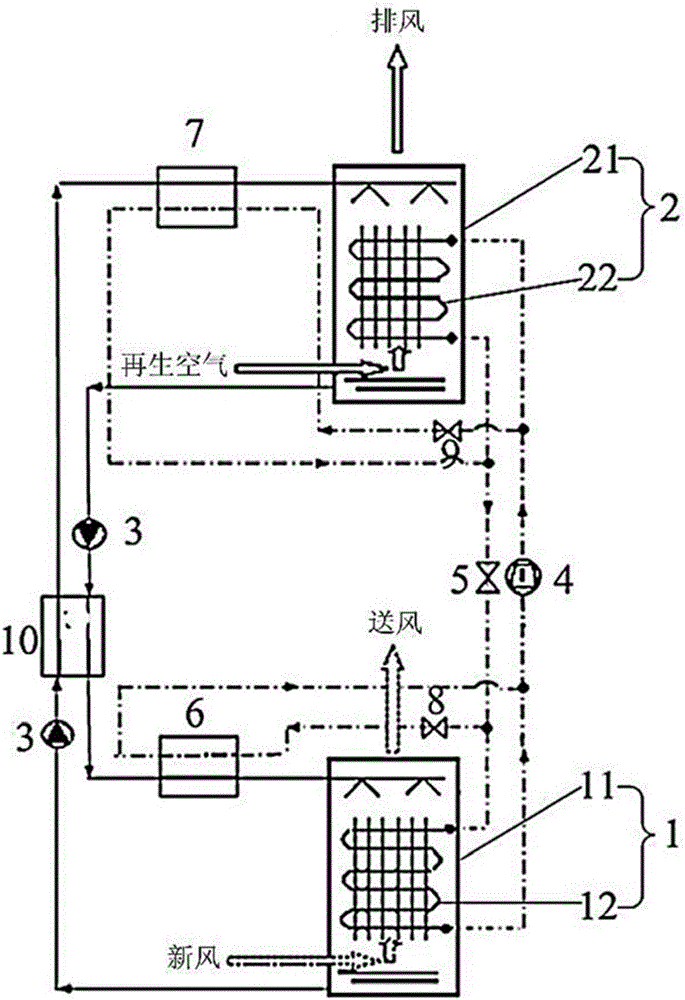

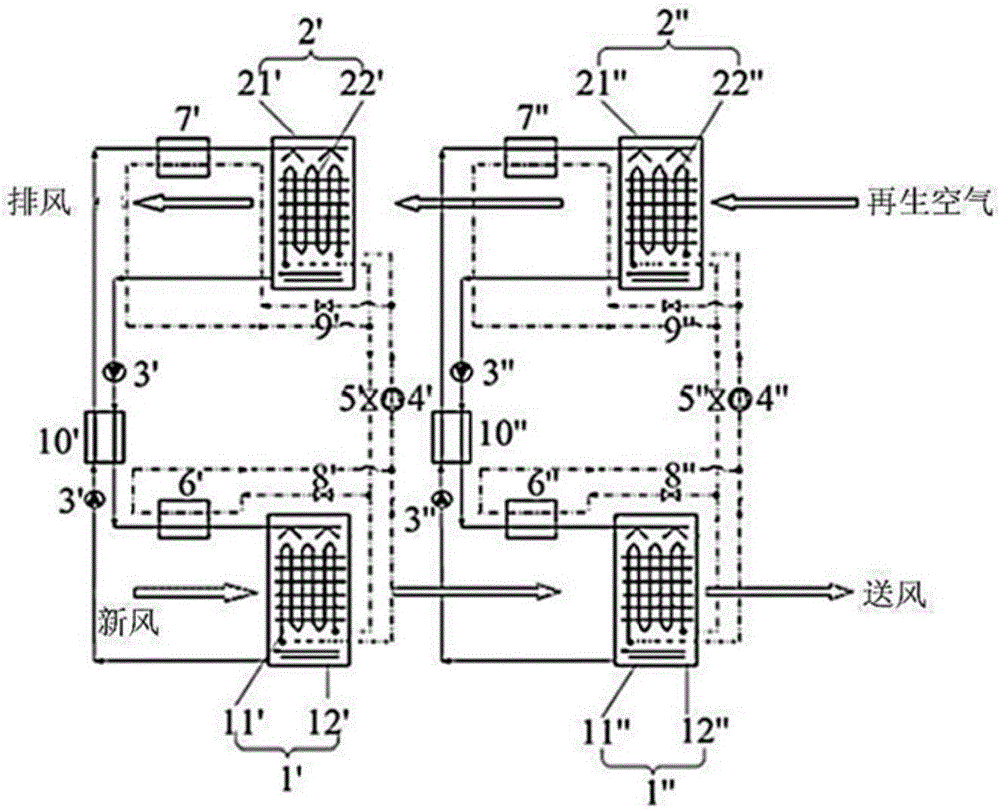

Heat pump driven precooling and internal-cooling solution dehumidification air conditioning unit

InactiveCN107525166AImproved moisture absorption and concentrated regeneration capacityReduce heat exchange linksMechanical apparatusHeat pumpsHVACEvaporator

The invention relates to the technical filed of heating ventilation air conditioning (HVAC), and particularly to a heat pump driven precooling and internal-cooling solution dehumidification air conditioning unit. The solution dehumidification air conditioning unit comprises a solution circulation system formed by an internal-cooling dehumidification module and an internal-heating regeneration module and a heat pump system, wherein the solution circulation system is an inter-stage solution circulation circuit formed by connecting a dehumidification spray device and a regeneration spray device through a solution circulation pump; the inter-stage solution circulation circuit is filled with a moisture absorption solution; and the heat pump system comprises a refrigeration circuit formed by connecting a dehumidification internal-cooling evaporator, a compressor, a regeneration internal-heating condenser and a throttle valve in sequence, a solution precooling heat exchanger used for precooling the solution at the inlet of the dehumidification spray device and a solution preheating heat exchanger used for preheating the solution at the inlet of the regeneration spray device. The heat pump driven precooling and internal-cooling solution dehumidification air conditioning unit integrates the characteristics of adiabatic and internal-cooling (heating) solution dehumidification devices, can control the temperature of the solution at the inlet of the dehumidification (regeneration) spray device, and can also improve the dehumidification (regeneration) capacity of the dehumidification (regeneration) spray device.

Owner:TSINGHUA UNIV

Flue gas desulfurization method and system

ActiveCN104208985AAchieve cycle balanceReduce consumptionDispersed particle separationThermodynamicsFlue gas

The invention discloses a flue gas desulfurization method and a flue gas desulfurization system; the flue gas desulfurization method comprises the steps that: flue gas including SO2 is in countercurrent contact with barren liquor of absorption liquid to form rich liquor, after temperature of the rich liquor raises, the rich liquor is in countercurrent contact with secondary steam in a desorber to complete desorbing and regeneration, the steam including the SO2 exhausted from the top of the tower forms a regenerative primary steam under the injection effect of fresh primary steam to serve as a hot source of a reboiler for heating the barren liquor in the desorber, and then secondary steam is generated for continuously steam stripping SO2. The flue gas desulfurization comprises an absorption tower, a rich liquor pre-heater, a rich-barren liquor heat exchanger and a desorber, wherein the desorber is connected to a steam coupling regeneration device and a condenser respectively, and the steam coupling regeneration device is connected to a reboiler that is also connected to the desorber. The flue gas desulfurization method and system provided by the invention has the advantages of being capable of improving temperature of rich liquor of absorption liquid entering the desorber, achieving circular steam balance, saving steam consumption and reducing thermal load of condenser.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

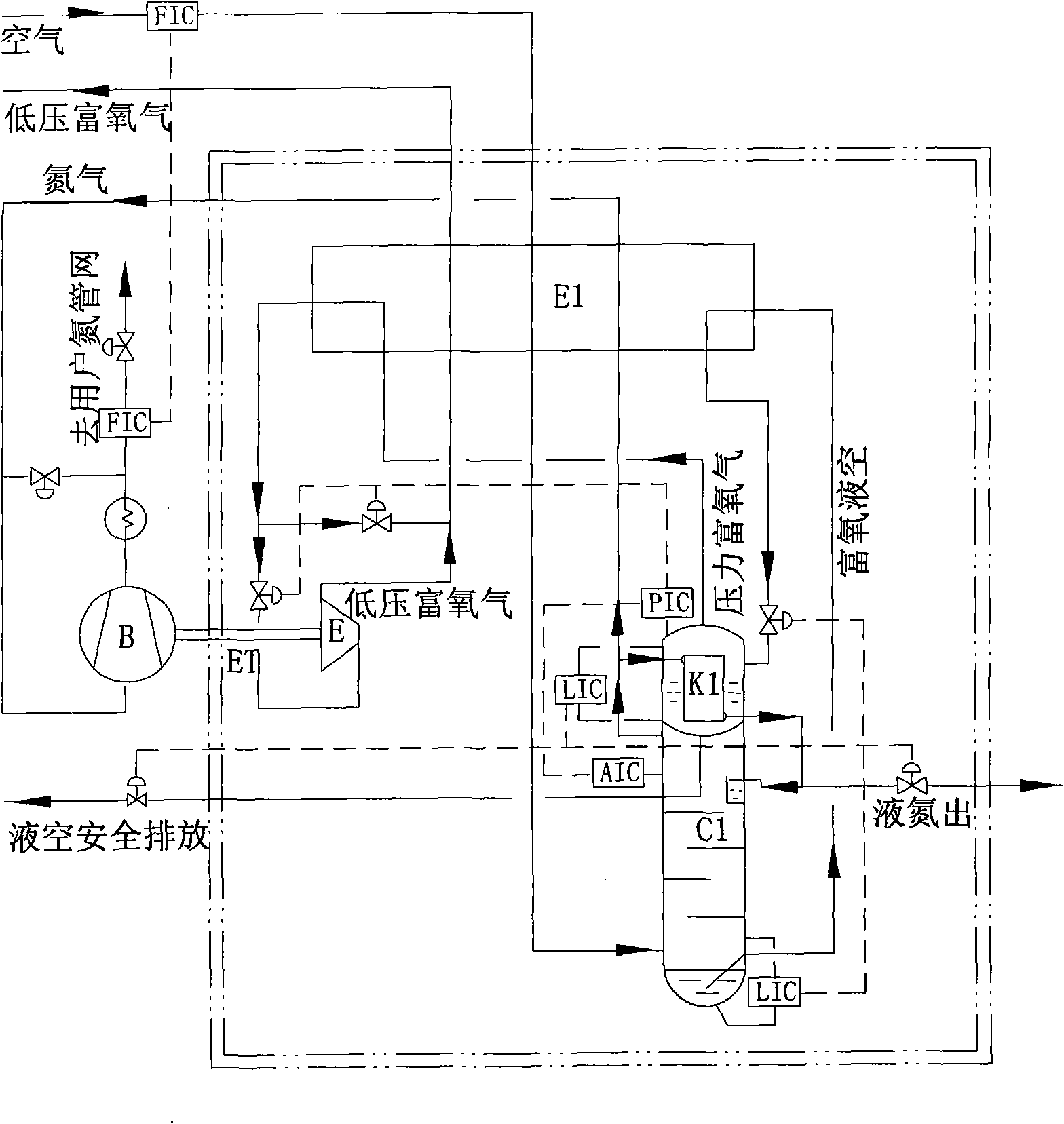

Low-energy consumption nitrogen production method and apparatus

ActiveCN101492156ARaise the inlet temperatureFull recoveryNitrogen purification/separationSolidificationOxygenNitrogen gas

The invention relates to a method and a device for preparing nitrogen in low energy consumption. The method comprises that: the nitrogen is obtained on the top of a rectifying tower after the air is cooled, and one part of the nitrogen is condensed into liquid nitrogen, wherein one part of the liquid nitrogen is taken as a product liquid nitrogen and the rest liquid nitrogen is taken as a backflow liquid to return the top of the tower; the other part of the nitrogen enters a heat exchanger, is heated again to normal temperature and pressurized by a pressure-increasing end of an expander, and is sent into a user nitrogen conveying pipe network; the liquid air rich in oxygen is obtained on the bottom of the tower, enters the heat exchanger, is supercooled by cold fluid and throttled, and enters a condenser / evaporator as a cold source to carry out heat exchange with the nitrogen; the vaporized air rich in oxygen enters the heat exchanger, is heated again, and enters the expander for expansion refrigeration; and the low-pressure air rich in oxygen after the expansion enters the heat exchanger, and is heated again and led out. The method increases the pressure of the nitrogen through work outputted by the expansion of the air rich in oxygen, and reduces pressure discharge of a compressor so as to reduce energy consumption; the liquid air is subjected to heat exchanging and supercooling by various cold fluid such as the low-pressure air rich in oxygen, the nitrogen, the pressurized air rich in oxygen, and the like, so the humidity content of the air is reduced to improve extraction yield, the energy consumption is reduced by 15 to 23 percent, the water consumption is reduced by 14 to 22 percent, and the economic benefit is significant.

Owner:四川空分设备(集团)有限责任公司

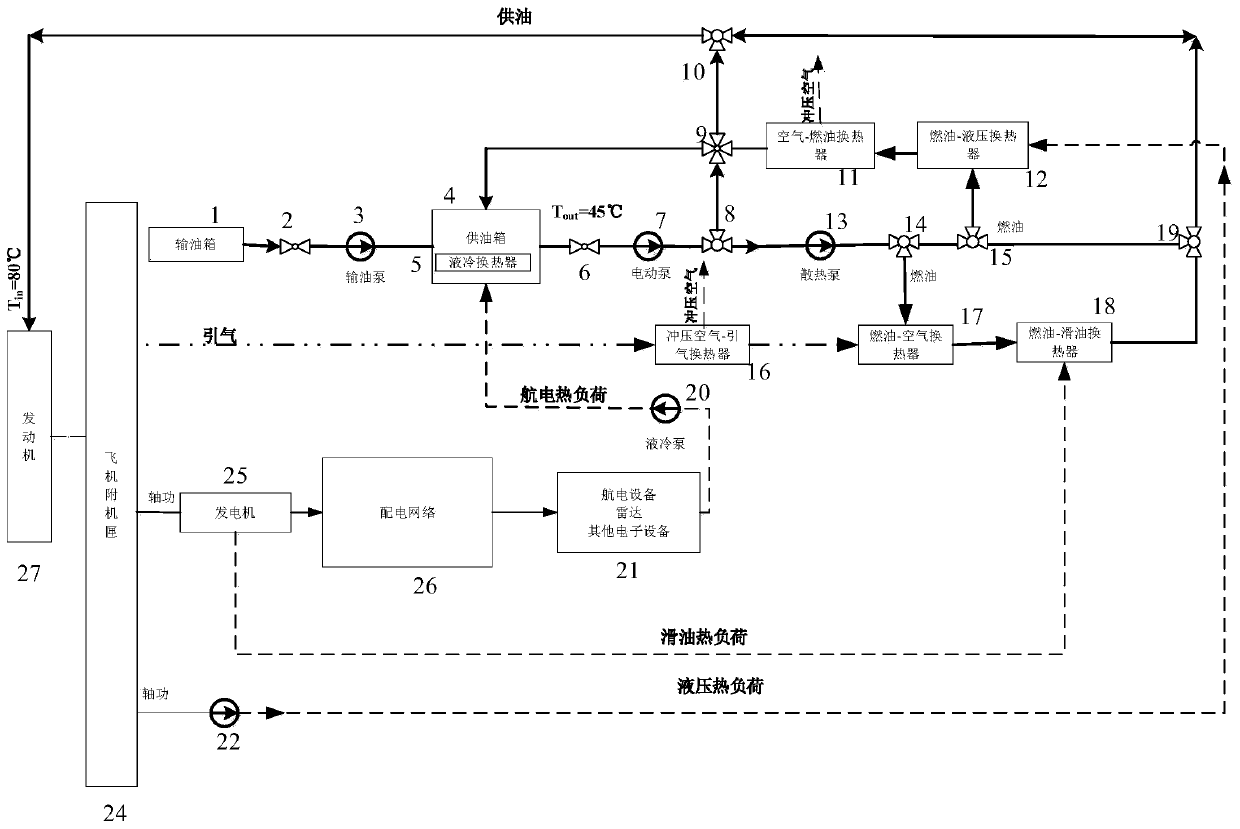

Airplane comprehensive thermal management adjusting system

ActiveCN110920914AAvoid the disadvantages of a single heat sinkGuaranteed fuel quantityPower plant cooling arrangmentsConditioning fuel arrangementsFour-way valveFuel tank

The invention discloses an airplane comprehensive heat management adjusting system. The system comprises an oil delivery tank, a first valve, an oil supply tank, a second valve, a first three-way valve, a third three-way valve, a fourth three-way valve, a fifth three-way valve, a second three-way valve and an engine which are sequentially connected through an oil pipeline, a fuel oil-air heat exchanger and a fuel oil-lubricating oil heat exchanger are sequentially connected between the third three-way valve and the fifth three-way valve through oil way pipelines. A fuel oil-hydraulic heat exchanger and an air-fuel oil heat exchanger are further sequentially connected between the fourth three-way valve and the oil supply tank through an oil way pipeline, a four-way valve is further arrangedon the oil way pipeline between the air-fuel oil heat exchanger and the oil supply tank, and the four-way valve is further communicated with the first three-way valve and the second three-way valve through an oil way pipeline. Airborne fuel oil and external ram air are reasonably utilized, and energy is saved; the fuel flow is reasonably distributed by adjusting the opening degree of the electromagnetic valve, the fuel quantity required by the aircraft engine is guaranteed, the purpose of heat dissipation is achieved, the temperature of an inlet of the engine is prevented from being too high,and the service life of the aircraft engine is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

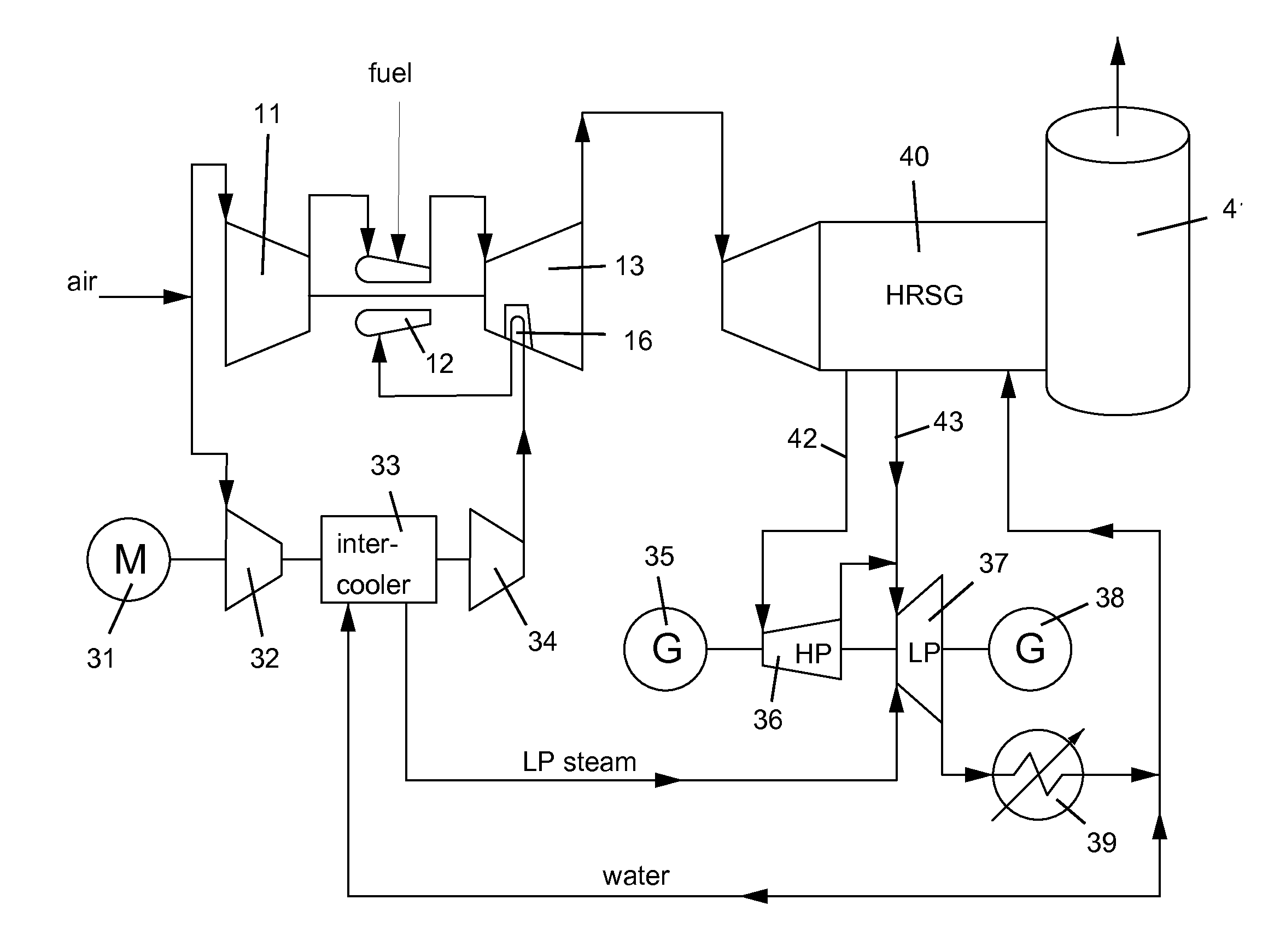

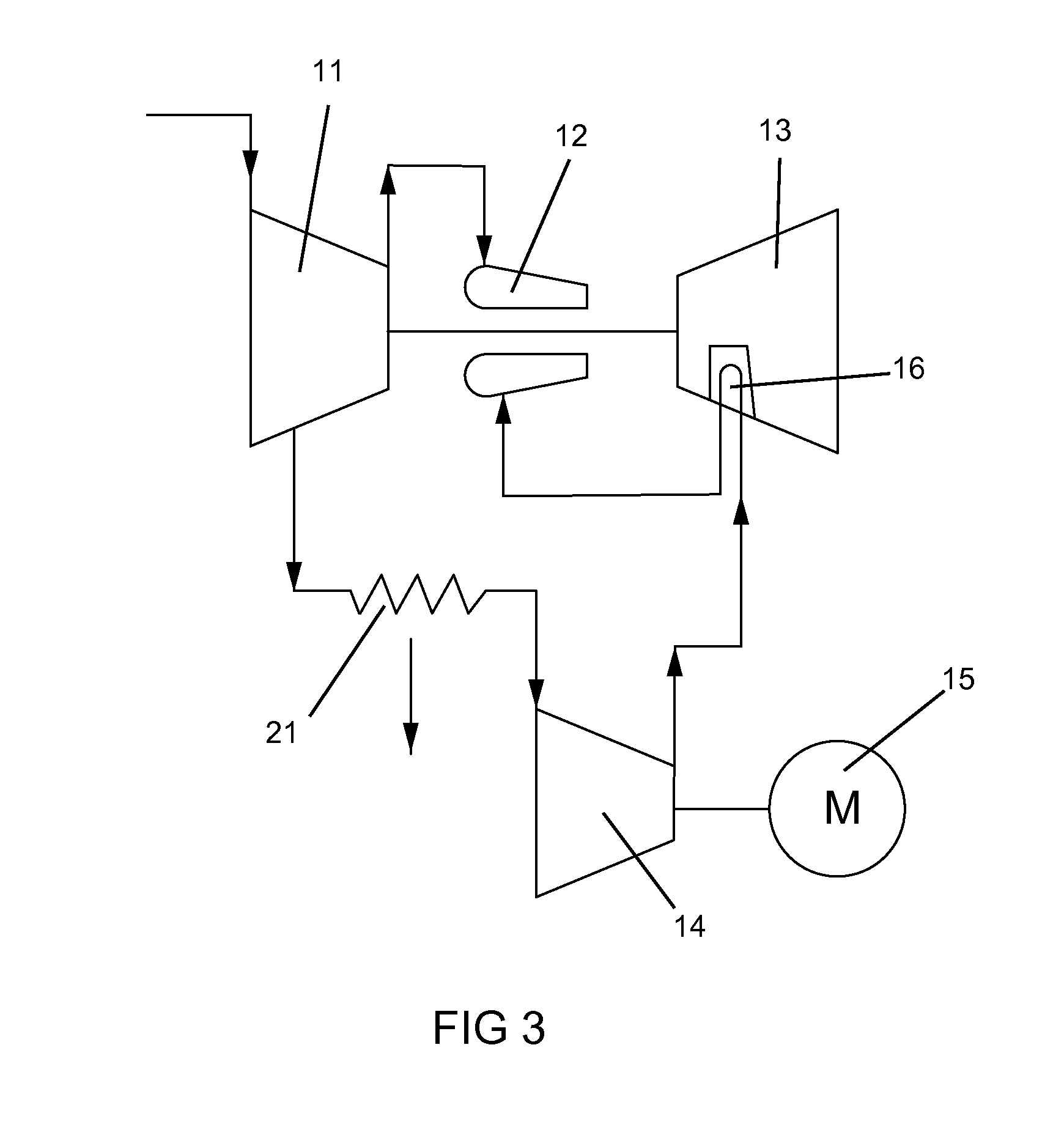

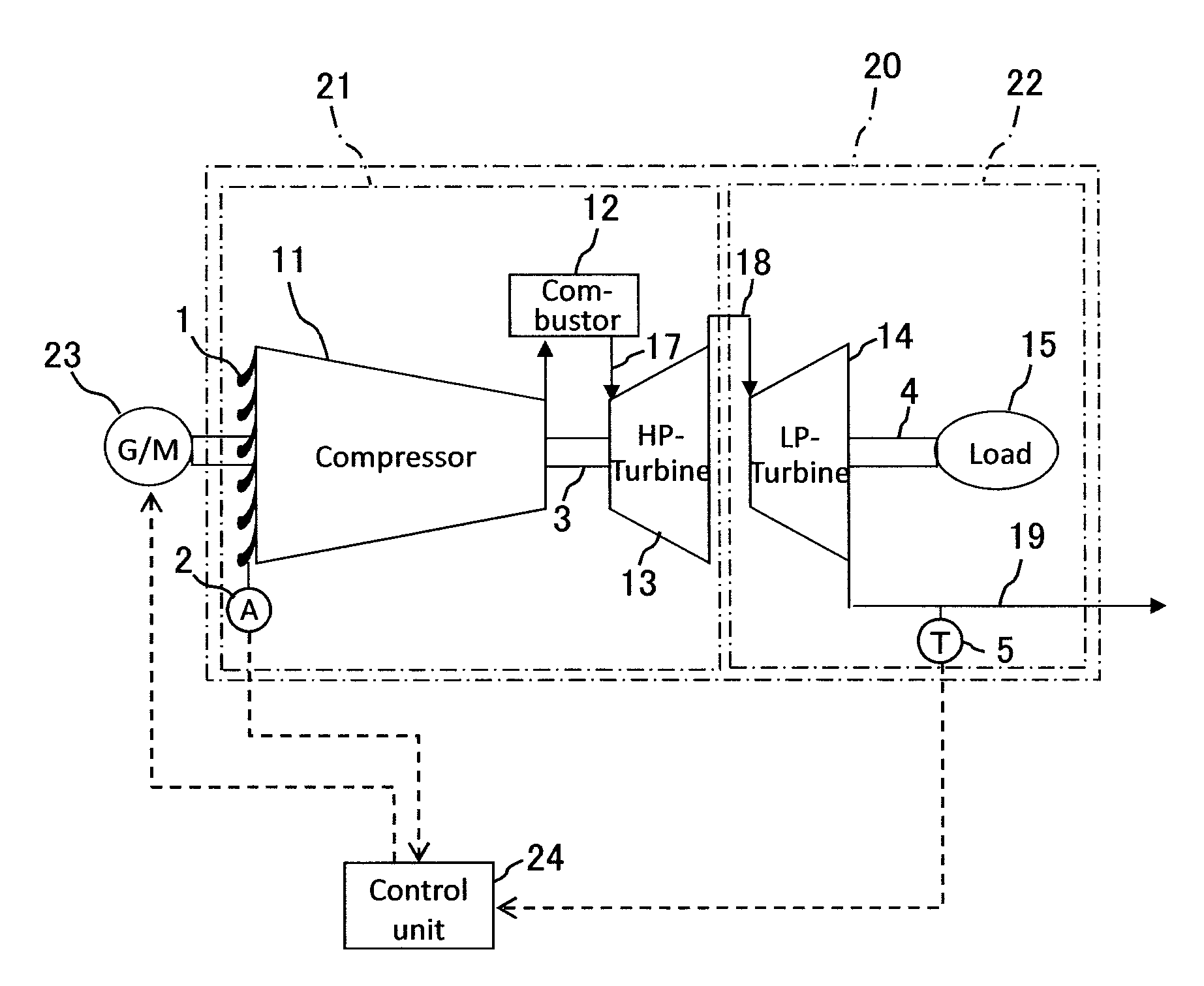

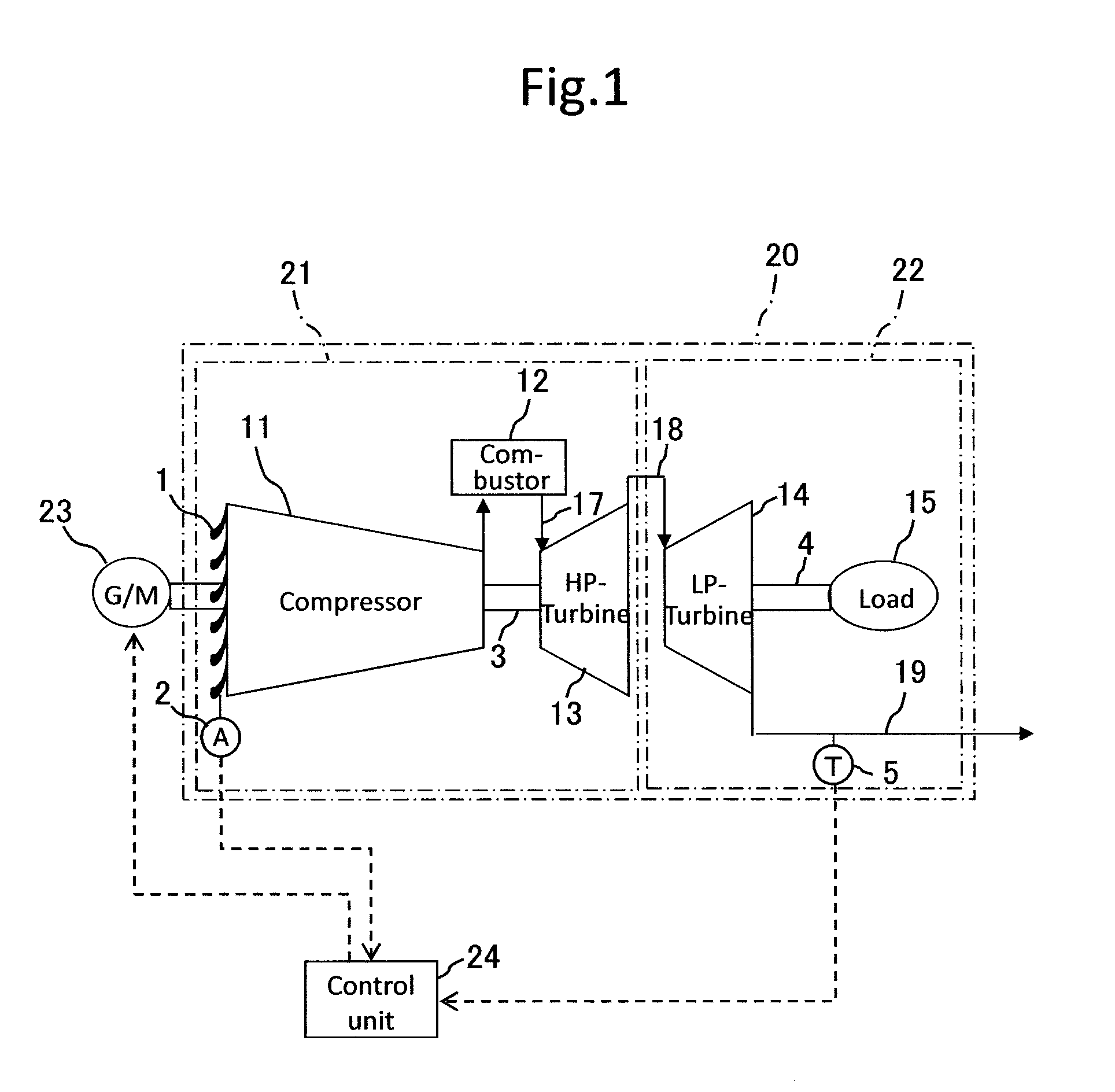

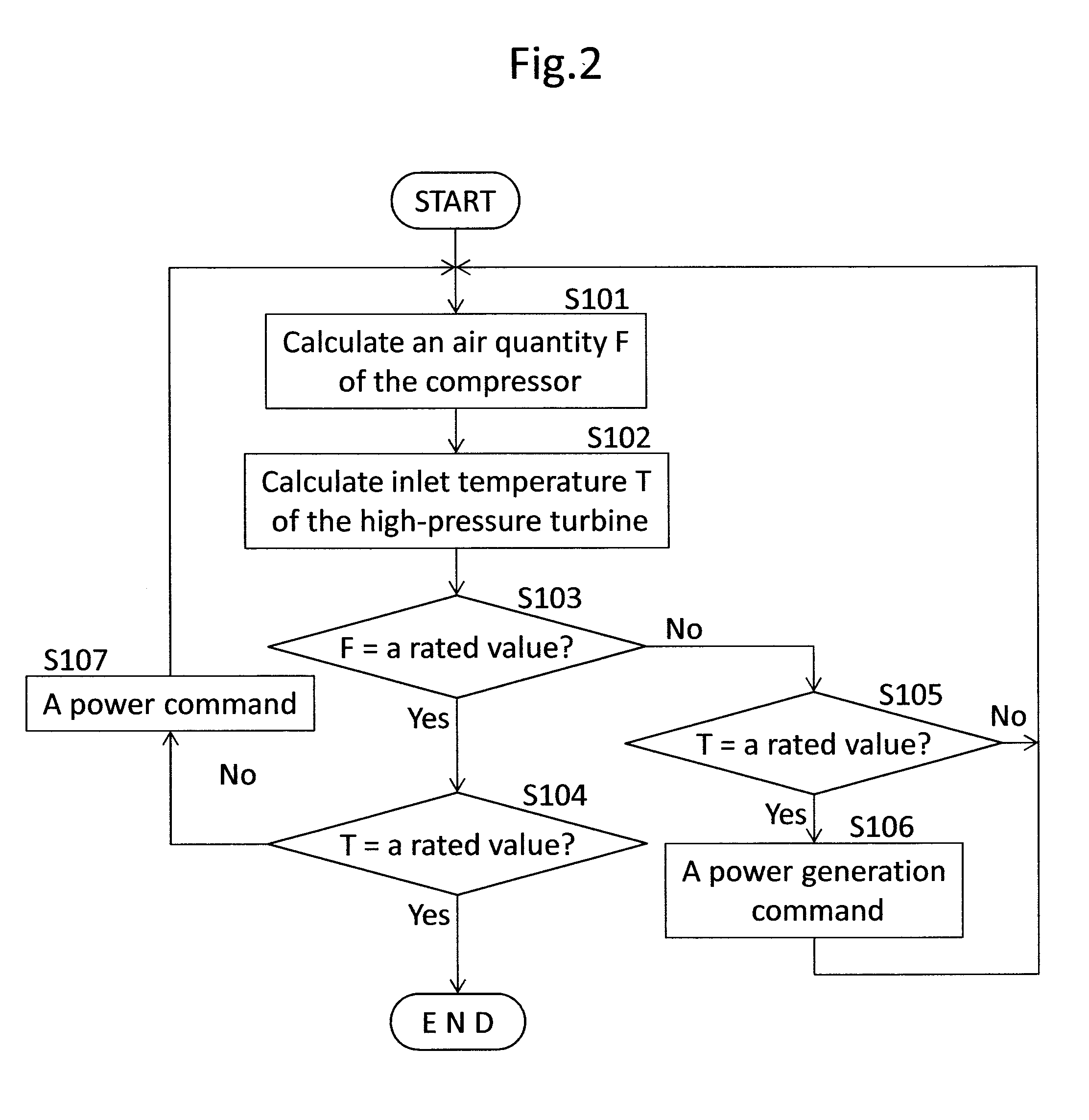

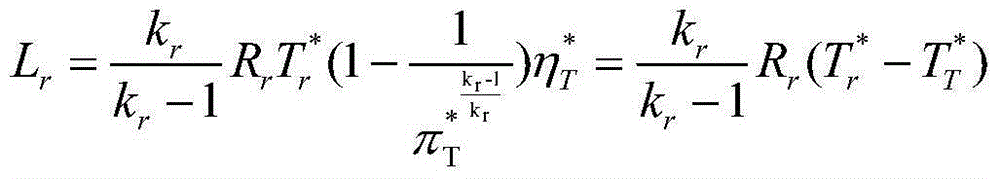

Two-Shaft Gas Turbine

InactiveUS20140352320A1Change the balanceRaise the inlet temperatureGas turbine plantsTurbine/propulsion fuel controlCombustorAtmospheric temperature

A two-shaft gas turbine is provided that can raise an inlet temperature of a high-pressure turbine and the air quantity of a compressor to respective rated values at any atmospheric temperature without using a variable stator vane in the initial stage of a low-pressure turbine.The two-shaft gas turbine includes a power generator 21 having a compressor 11, a combustor 12 and a high-pressure turbine 13; a low-pressure turbine 14 driven by exhaust gas from the high-pressure turbine 13; a generator motor 23 connected to the gas generator 21; and a control unit 24. When either one of a value of the inlet temperature of the high-pressure turbine 13 and a value of the air quantity of the compressor 11 reaches a rated value before the other value reaches a rated value, the control unit 24 drives the generator motor 23 to bring the other value close to the rated value.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

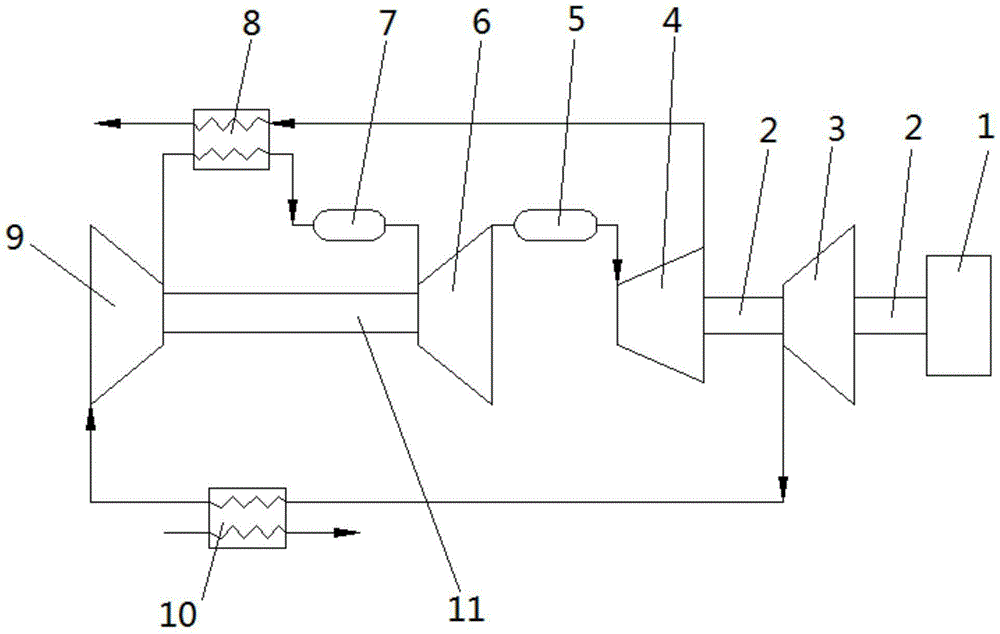

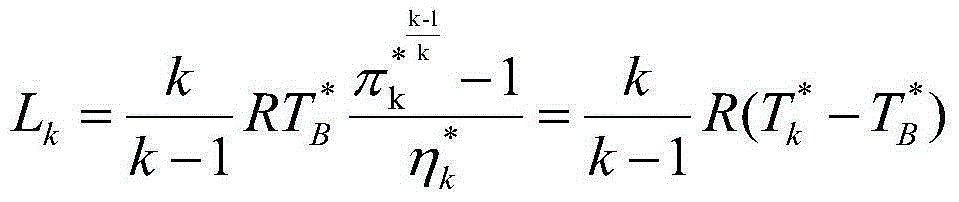

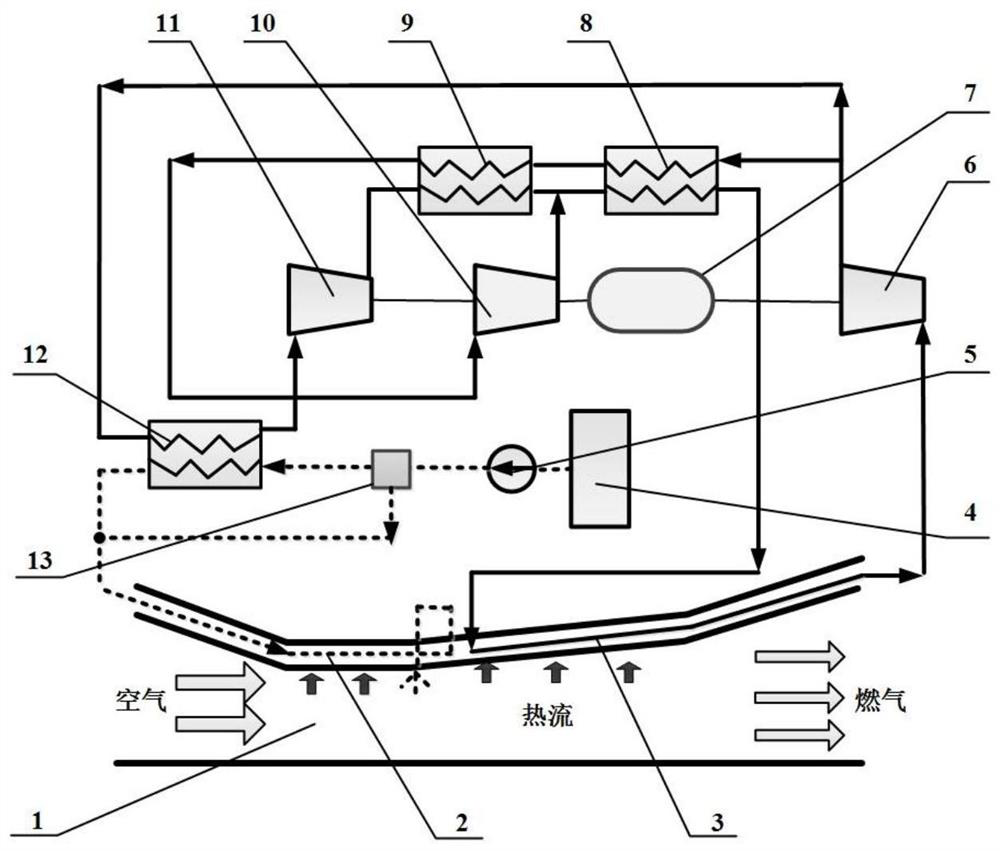

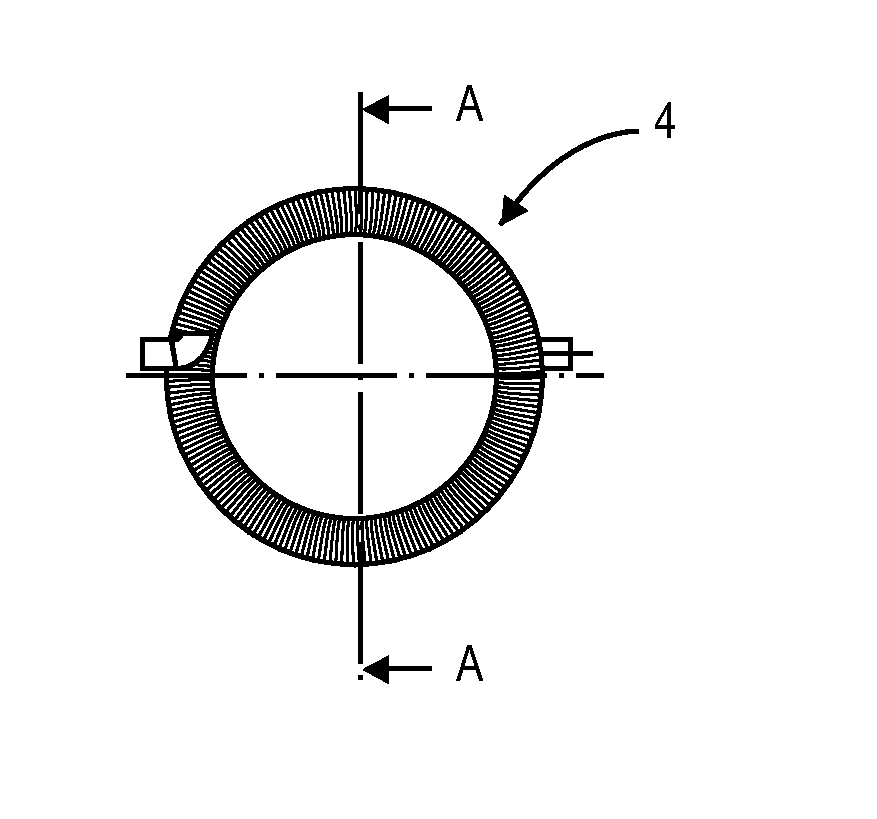

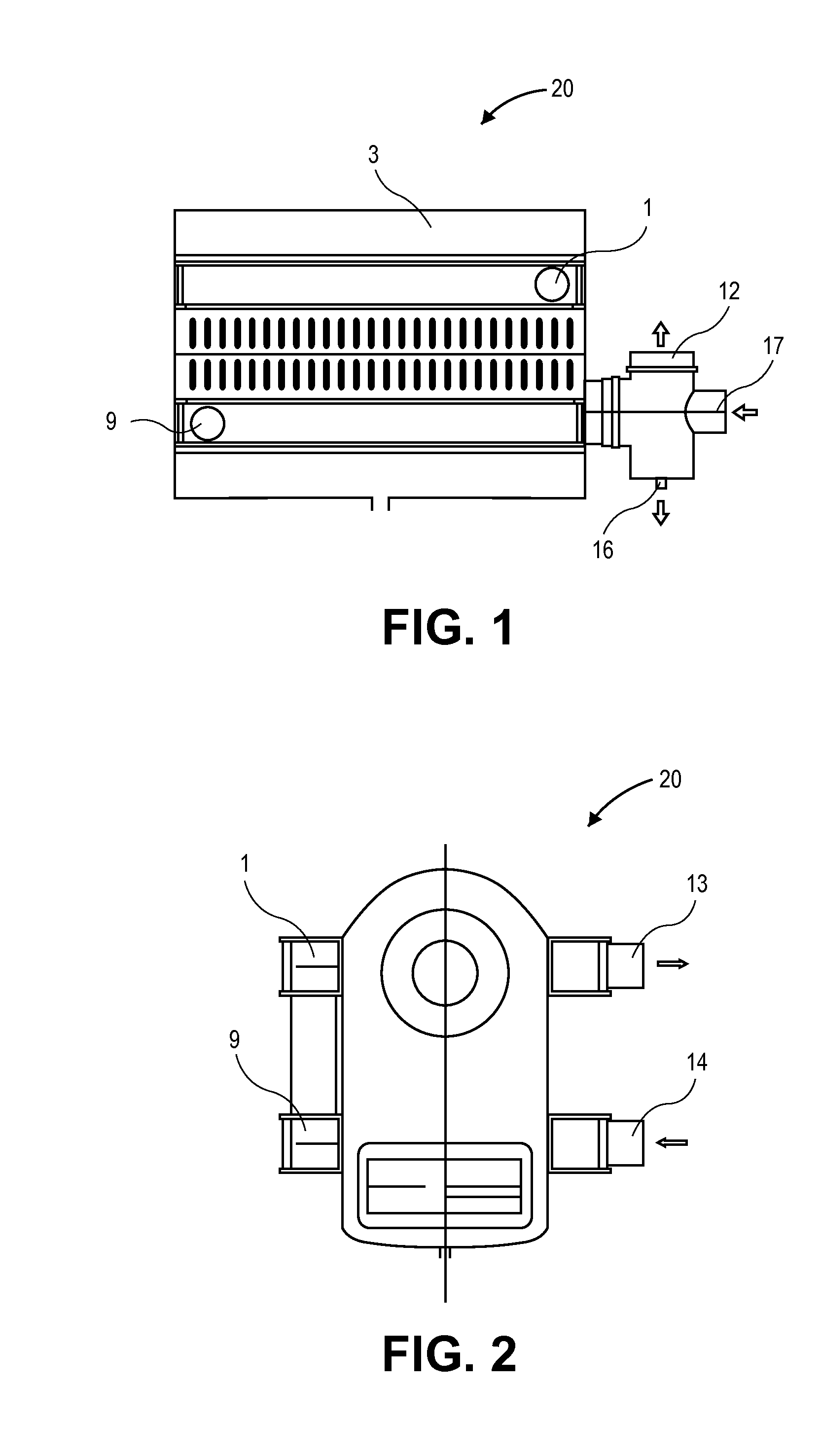

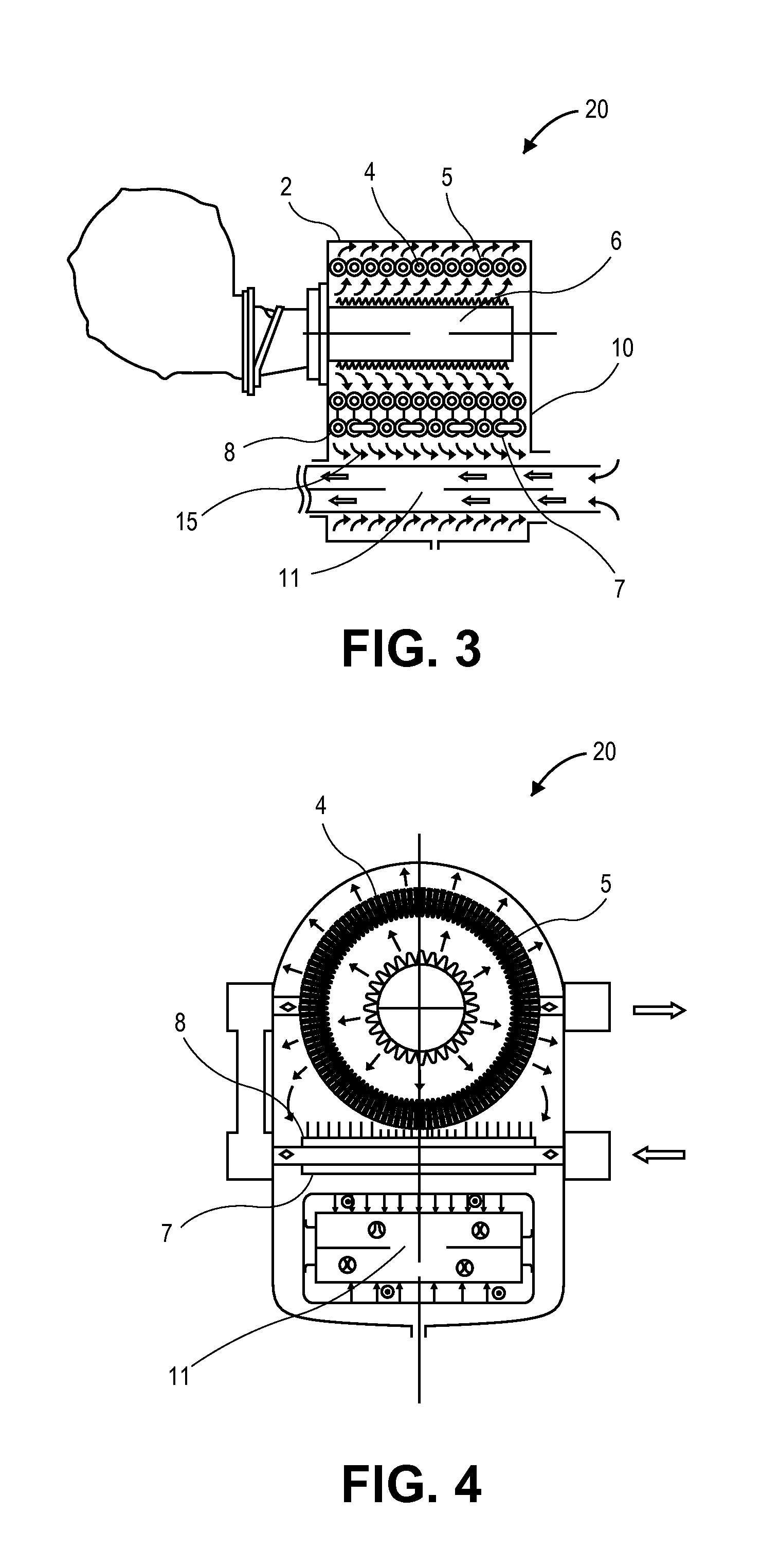

Intercooling regenerative cycle combustion gas turbine system

InactiveCN105221262AIncrease air pressureRaise the inlet temperatureGas turbine plantsJet propulsion plantsExhaust gasAutomotive engineering

The invention discloses an intercooling regenerative cycle combustion gas turbine system and relates to the technical field of combustion gas turbines. The intercooling regenerative cycle combustion gas turbine system comprises a high-pressure turbine, a regenerator, a low-pressure turbine, a power turbine and an afterburning combustion chamber, wherein the afterburning combustion chamber is arranged between the high-pressure turbine and the low-pressure turbine; fuel gas exhausted out of the high-pressure turbine is burnt and heated again through the afterburning combustion chamber, and the temperature of fuel gas entering the low-pressure turbine is increased; fuel gas drives the power turbine after being subjected to expansion work through the low-pressure turbine; heat energy of exhausted gas of the power turbine is absorbed by the regenerator. The intercooling regenerative cycle combustion gas turbine system has the advantages that the afterburning combustion chamber is added between the high-pressure turbine and the low-pressure turbine, fuel gas flowing out of the high-pressure turbine is heated again, the temperature of an inlet of the low-pressure turbine can be increased, the temperature of tail gas recycled by the regenerator is high, and high-pressure air exhausted out of a high-pressure compressor is further heated. Circulation work of the combustion gas turbine is enlarged, the power is improved, and the heat efficiency keeps at a high level.

Owner:AECC SHENYANG ENGINE RES INST

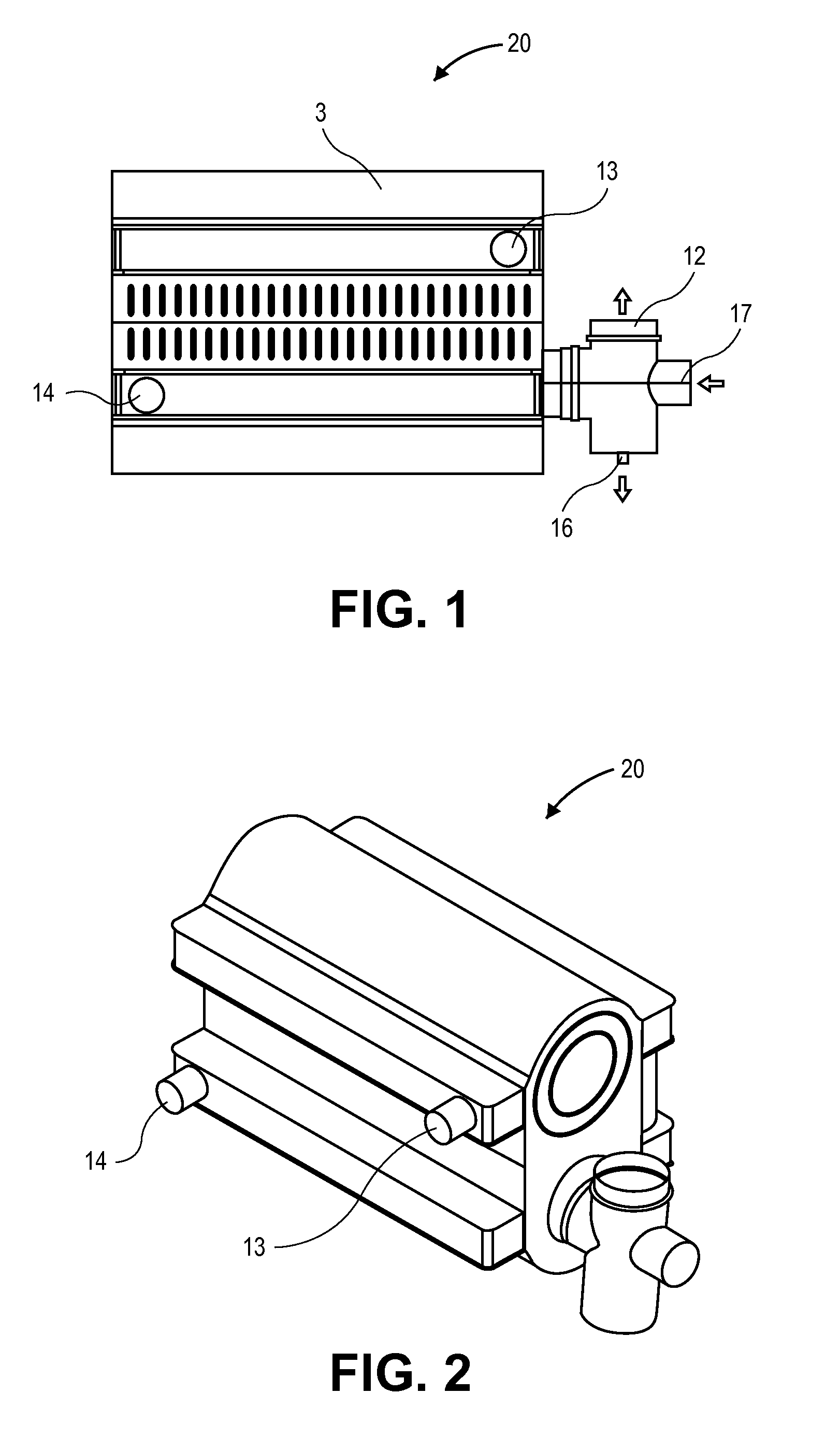

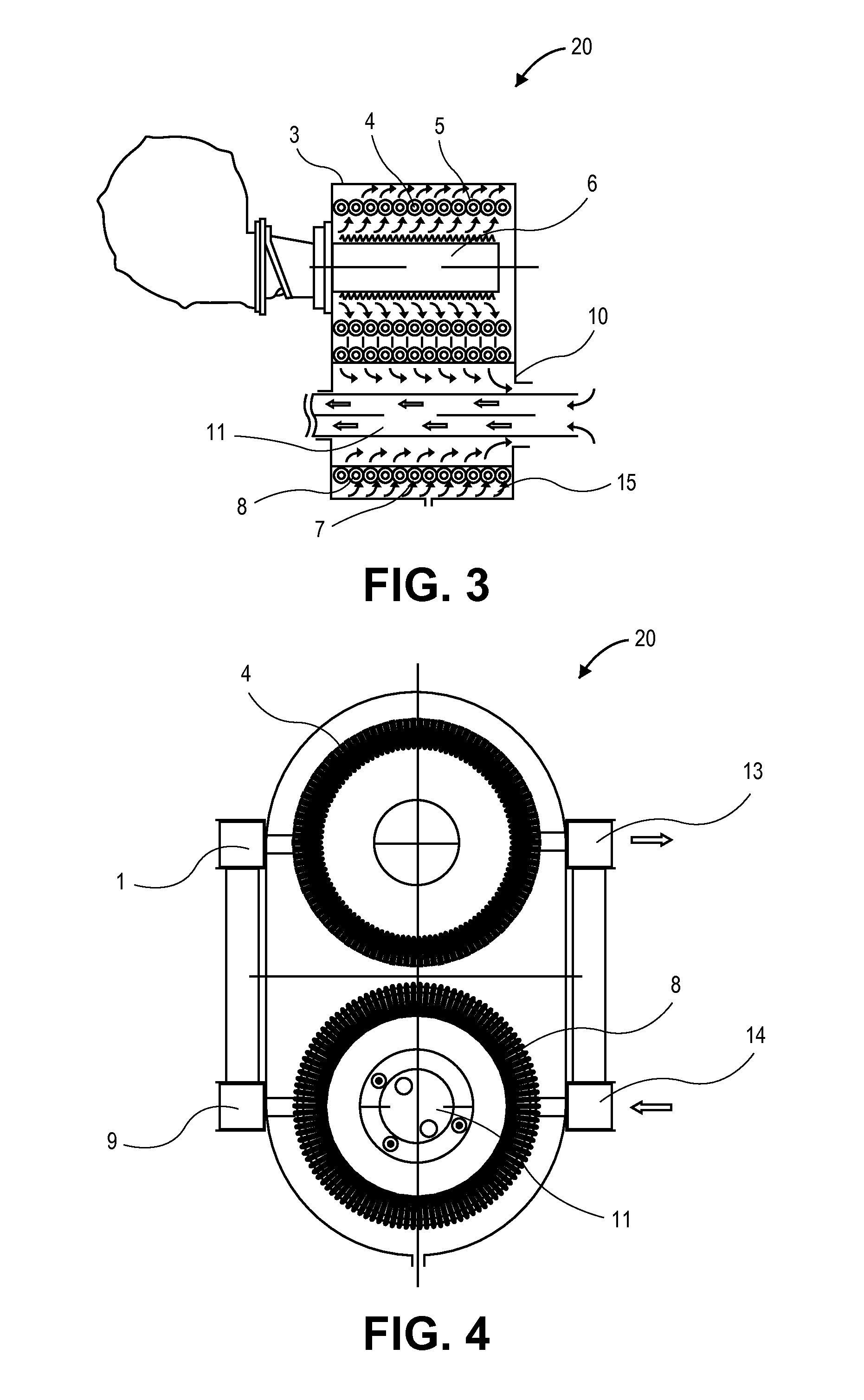

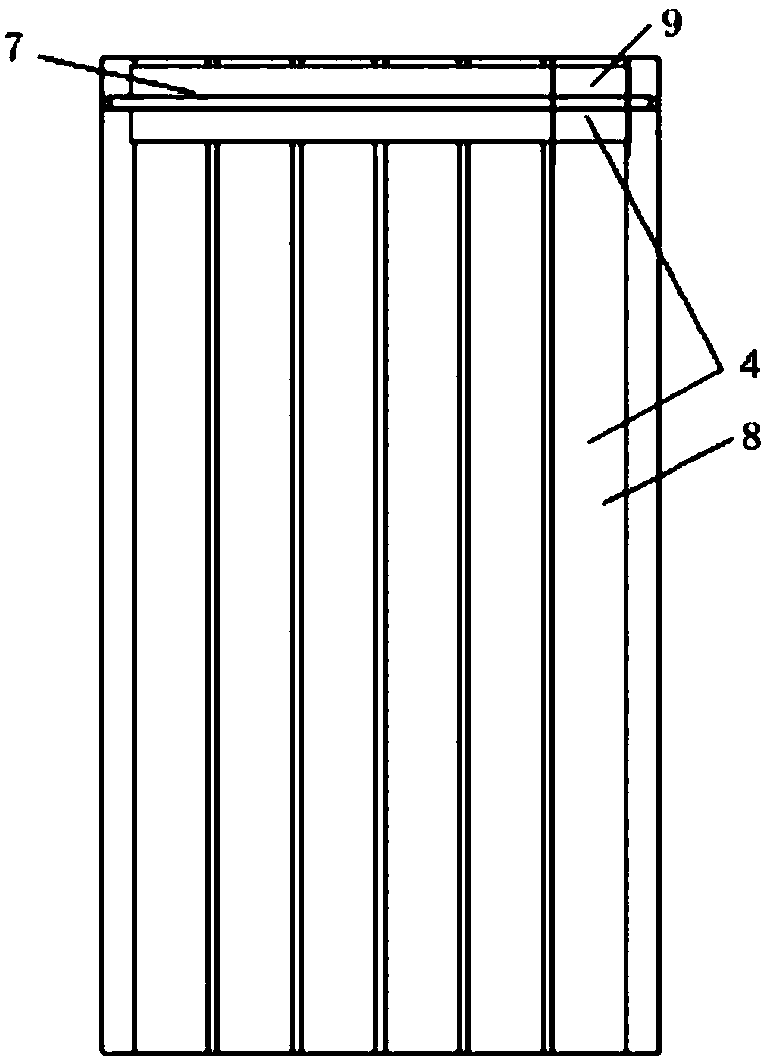

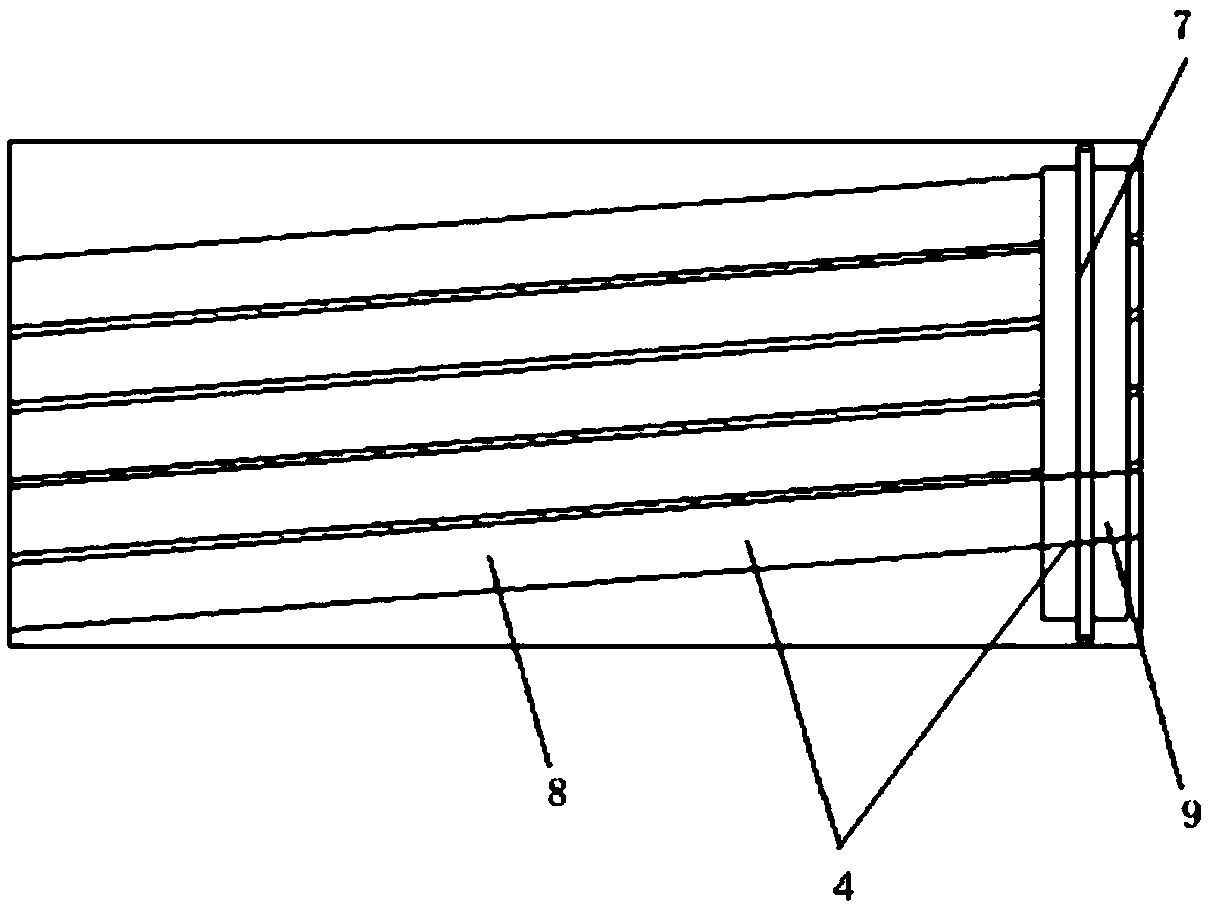

Dual-ring and straight fin tube condensing

ActiveUS20150184888A1Improving heat transfer structureRaise the inlet temperatureAir heatersIndirect heat exchangersCombustorFlue gas

A heat exchanger for supplying heat includes a housing, a bundle of dual-ring, straight fin-coil tubes, and a flue channel. The housing includes a burner, a water inlet, a water outlet and a flue gas outlet. The burner is disposed on a top portion of the housing and connected to an air / gas mixture unit. The first group of fin tubes is disposed tightly, circularly, and coaxially around the burner. The flue channel is disposed below the burner and is formed by a second group of fin tubes. A flow of flue gas vents from the flue channel to the flue gas outlet. The water inlet is connected to the first group of fin tubes which forms the flue channel below the burner. The second group of fin tubes below the burner is connected to the first group of fin tubes. The first group of fin tubes is connected to the water outlet.

Owner:SUZHOU CQ HEAT EXCHANGER

Active cooling and combustion decoupling system of scramjet engine

InactiveCN112377324AAchieve decouplingAvoid high couplingTurbine/propulsion engine coolingGas turbine plantsRamjetCombustion chamber

The invention provides an active cooling and combustion decoupling system of a scramjet engine. According to the active cooling and combustion decoupling system of the scramjet engine, a first wall face cooling channel is arranged on an air inlet channel and an isolation section of the scramjet engine, and a second wall face cooling channel is arranged on a combustion chamber and an exhaust nozzleof the scramjet engine. In the combustion chamber and exhaust nozzle area with high thermal loads, supercritical carbon dioxide is used for absorbing heat and raising the temperature through the second wall face cooling channel. Hydrocarbon fuel is adopted for cooling in he air inlet channel and the isolation section with low thermal loads. According to the system, active cooling and combustion decoupling of the scramjet engine can be achieved, meanwhile, the flow of fuel needed for cooling can be reduced, and the cooling pressure of the scramjet engine is relieved.

Owner:NAT UNIV OF DEFENSE TECH

Coil and serpentine bent fin tube condensing heat exchanger

ActiveUS20150007780A1Improving heat transfer structureRaise the inlet temperatureAir heatersStationary tubular conduit assembliesPlate heat exchangerCombustor

A heat exchanger for supplying heat includes a housing, a bundle of helical fin-coil tubes, and a flue channel. The housing includes a burner, a water inlet, a water outlet and a flue gas outlet. The burner is disposed on a top portion of the housing and connected to an air / gas mixture unit. The bundle of helical fin-tube coils is disposed tightly, circularly, and coaxially around the burner. The flue channel is disposed below the burner and is formed by a plurality of serpentine bent fin-tube coils. A flow of flue gas vents from the flue channel to the flue gas outlet. The water inlet is connected to the plurality of serpentine bent fin-tube coils which forms the flue channel below the burner. The plurality of serpentine bent fin-tube coils below the burner are connected to the bundle of helical fin-tube coils. The bundle of helical fin-tube coils are connected to the water outlet.

Owner:SUZHOU CQ HEAT EXCHANGER

Novel solar PV/T building integration curtain wall component and multi-energy-complementary energy supplying system

PendingCN109235717AThermal insulationThere will be no dilemma of cold winter and hot summerPhotovoltaic supportsWallsBuilding integrationEngineering

The invention discloses a novel solar PV / T building integration curtain wall component and a multi-energy-complementary energy supplying system. The curtain wall component comprises a solar photovoltaic cell panel, a heat exchanging unit and a heat insulating layer which are attached to each other from outdoors to indoors. A load bearing framework is arranged in the heat insulating layer. The heatexchanging unit comprises a micro-heat-pipe array and a heat getting pipe; the micro-heat-pipe array internally comprises a plurality of communicated micro heat pipes arranged side by side and complementarily communicated, and is internally provided with phase change media, one surface of the micro-heat-pipe array is attached to a back board of the cell panel, and one end of the other side of themicro-heat-pipe array is attached to the heat getting pipe; the section, attached to the heat getting pipe, of the micro-heat-pipe array serves as a condensing section, and the other part of the micro-heat-pipe array serves as an evaporating section; fluid is arranged in the heat getting pipe, and one surface of the heat insulating layer is attached to the back faces of the heat getting pipe andthe evaporating section of the micro-heat-pipe array. The assembly has the heat-electricity joint supplying, heat insulation and loading bearing functions, directly serves as a building-outer-wall enclosing structure component, replaces a building outer wall, and has the advantages that the maintenance cost is reduced, the temperature of the cell panel is lowered, electricity generation efficiencyis improved, and the service life is prolonged.

Owner:赵耀华

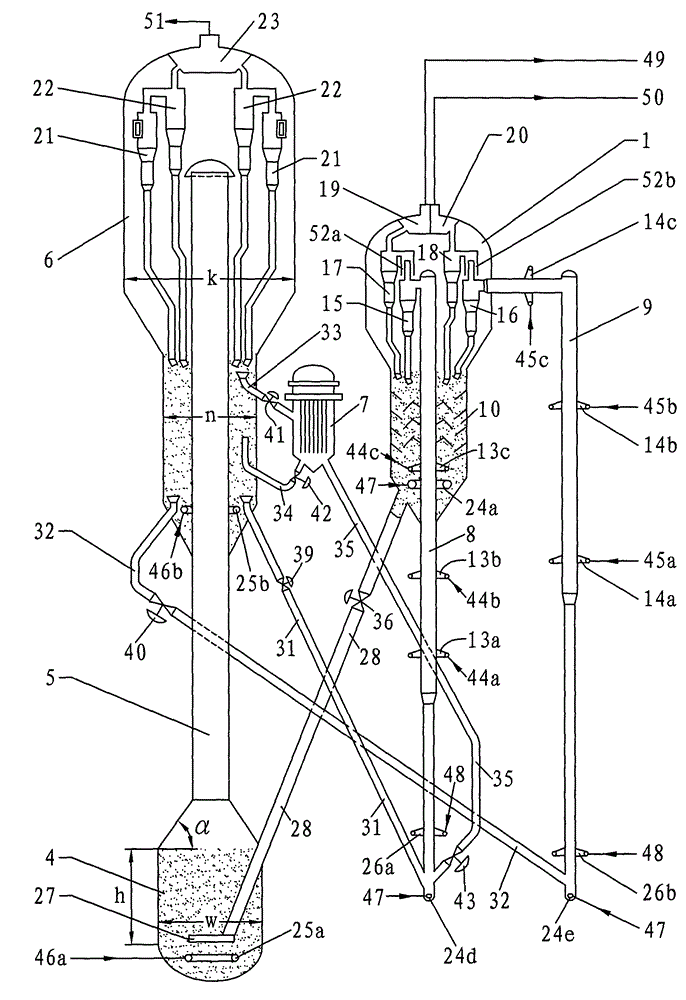

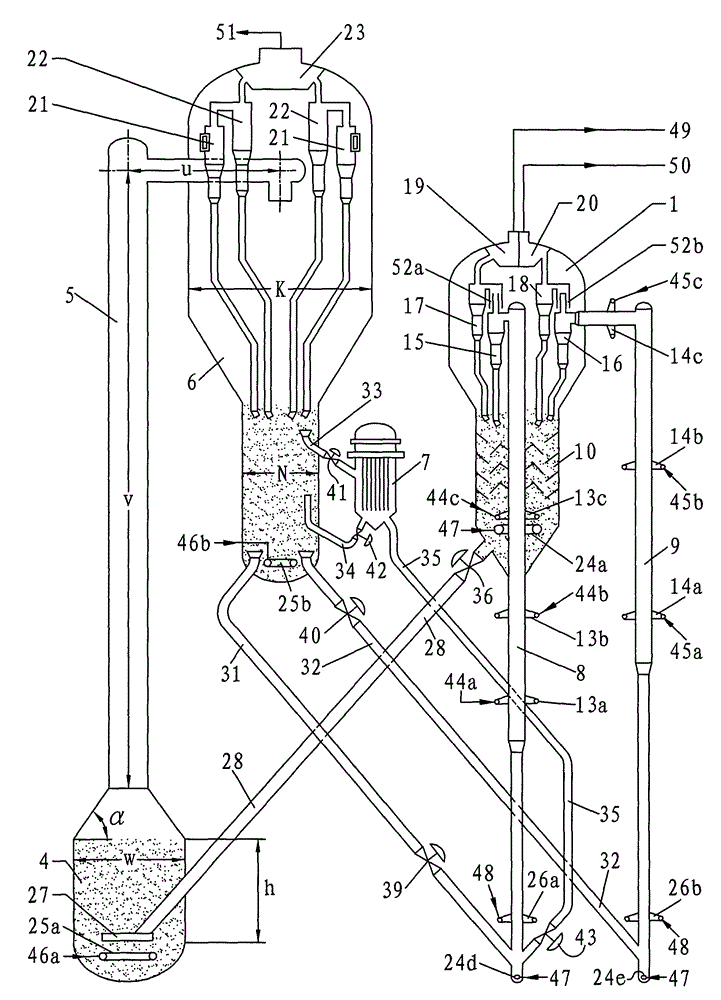

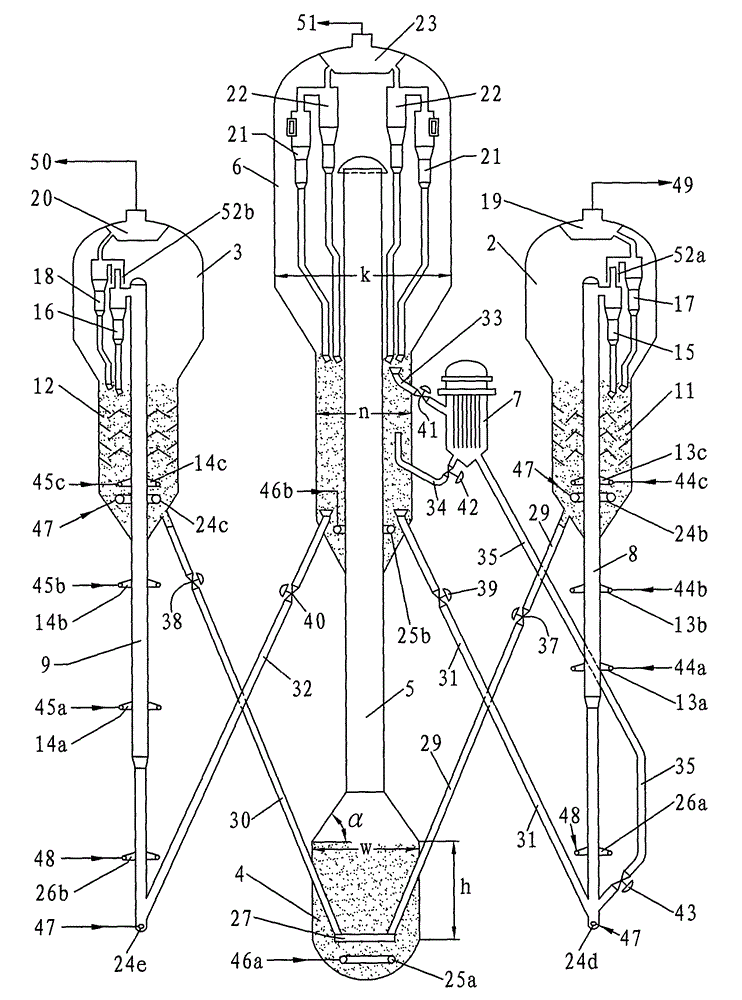

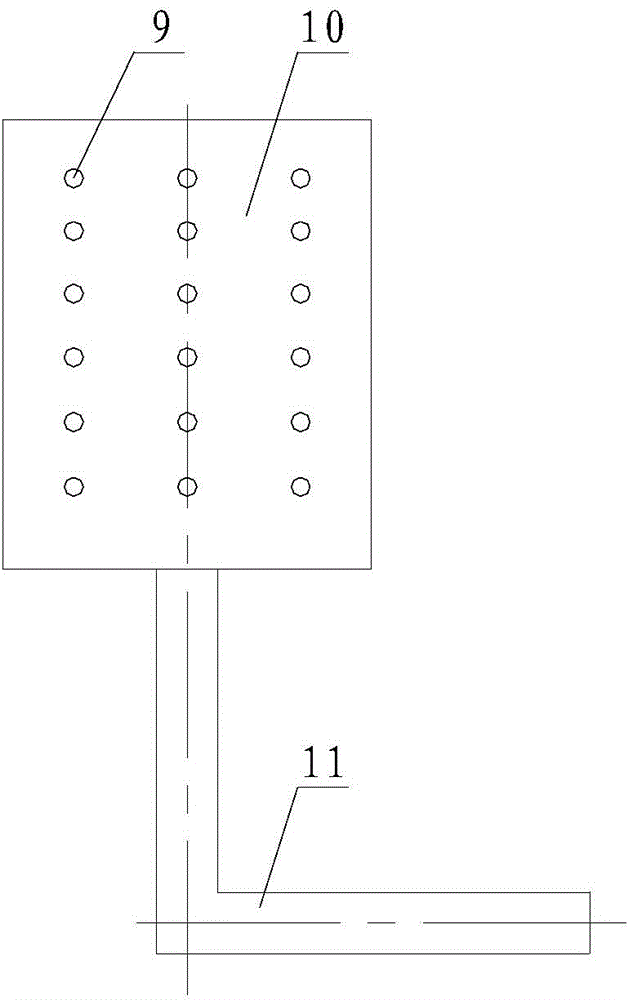

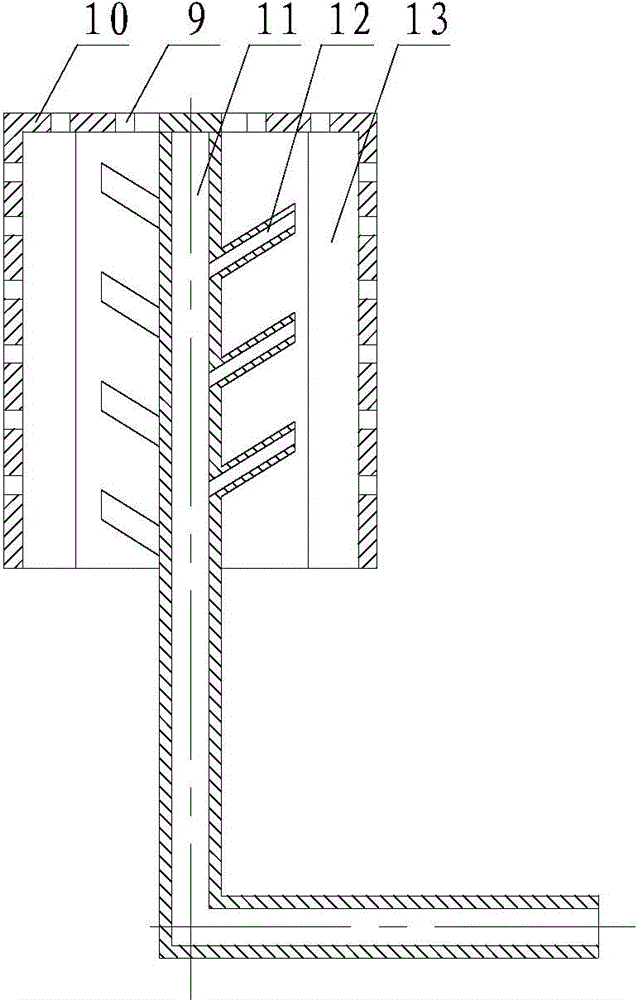

Catalytic cracking method and device employing double lift pipes

ActiveCN104419457ALower dense phase temperatureRaise the inlet temperatureCatalytic crackingHydrocarbon oils treatmentCatalytic reformingContact time

The invention discloses a catalytic cracking method and device employing double lift pipes in the petrochemical industry. The method comprises the following steps: carrying out heavy oil fluid catalytic cracking and light dydrocarbon catalytic reforming by adopting two lift pipes respectively, wherein the heavy oil catalytic cracking oil agent contact time is 0.2-1.5 seconds; carrying out gas-solid separation on two material flows by virtue of special cyclone separators; feeding a spent catalyst into a first turbulent bed regenerator after steam stripping, and contacting main air of the first turbulent bed regenerator in a down-flow manner, so as to burn off 40%-50% of generated coke; lifting a first section of semi-regenerated catalyst by smoke which is generated by the first turbulent bed regenerator to enter a tubular regenerator, and contacting the smoke which is generated by the first turbulent bed regenerator in a down-flow manner, so as to burn off 40%-50% of generated coke; feeding a second section of semi-regenerated catalyst into a second turbulent bed regenerator, and contacting main air of the second turbulent bed regenerator in a countercurrent manner, so as to burn off the residual generated coke; and returning the regenerated catalyst to the two lift pipes to recycle. The invention discloses a catalytic cracking device employing double lift pipes for achieving the method.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

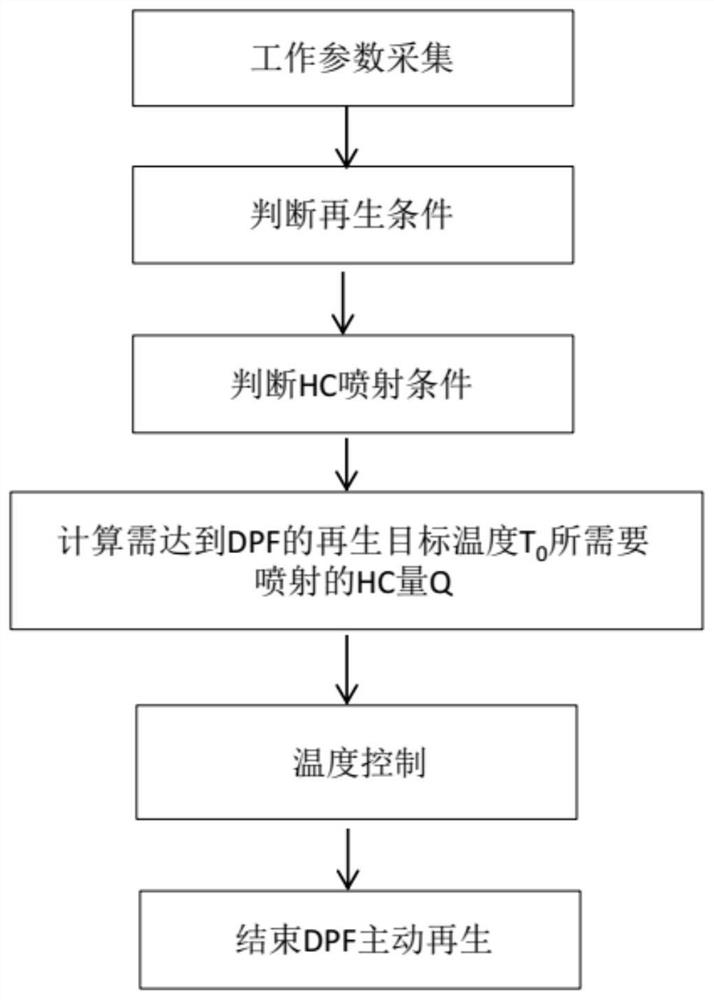

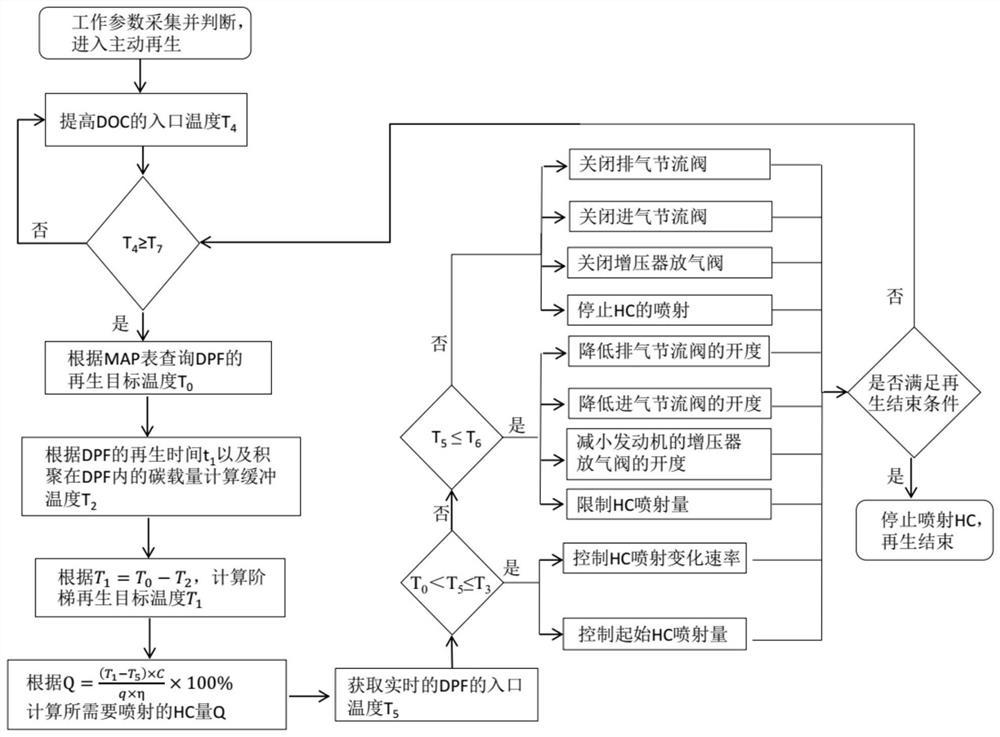

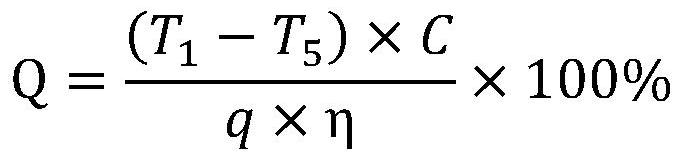

DPF active regeneration safety control method

ActiveCN112963226ARaise the inlet temperatureCarbon load guaranteeInternal combustion piston enginesExhaust apparatusTemperature controlBiochemical engineering

The invention discloses a DPF active regeneration safety control method, and belongs to the technical field of regeneration safety. The DPF active regeneration safety control method comprises the following steps that S10, regeneration conditions are judged; S20, the HC injection condition is judged; S30, the amount of HC needing to be injected to reach T0 is calculated, T1=T0-T2, T2 is the buffer temperature, and T2 is gradually reduced to 0 along with reduction of the carbon loading amount and increase of the regeneration time t1; and S40, temperature control is conducted. In the step S10, when one of operation condition parameters of an engine reaches a regeneration threshold value corresponding to the parameter, a DPF enters active regeneration; in the step S20, when T4 is greater than or equal to T7, the HC injection condition is met; and in the step S40, when T5 is greater than T0 and less than or equal to T3, the initial HC injection amount is reduced, the change rate of HC injection is reduced, when T5 is greater than T3 and less than or equal to T6, the injection amount of HC is reduced, and the amount of tail gas exhausted into the DPF by the engine is increased, and when T6 is less than T5, HC injection is stopped, and the amount of the tail gas exhausted into the DPF by the engine is increased. The DPF active regeneration safety control method has the following beneficial effect that the safety of active regeneration of the DPF can be high.

Owner:FAW JIEFANG AUTOMOTIVE CO

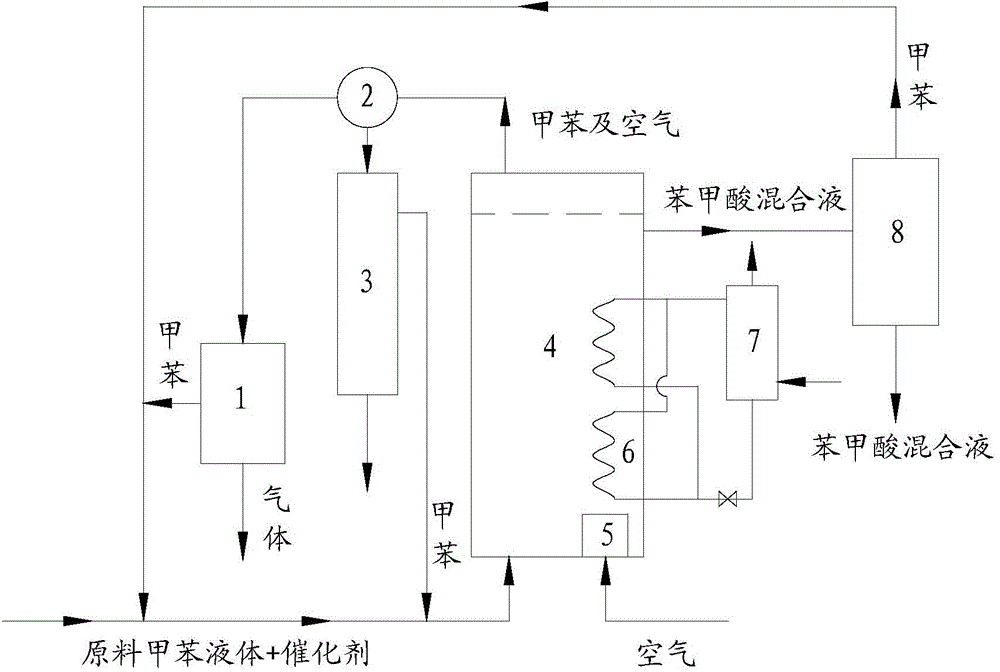

Continuous production process and device of benzoic acid

ActiveCN103601638AHigh selectivityControl reaction temperatureOrganic compound preparationCarboxylic compound preparationBenzoic acidToluene

The invention relates to a continuous production process of benzoic acid. The continuous production process comprises the following steps: (1) introducing toluene liquid and a catalyst; (2) introducing air, wherein the air reacts with the toluene liquid in the presence of a catalyst; (3) controlling temperature; and (4) discharging benzoic acid, and meanwhile, feeding through a feed opening of a reaction tower to realize continuous reaction. Devices used in the process include a reaction tower, a cooling device, an oil-water separator and an absorption tower, wherein a gas-liquid distribution stirrer is installed on the bottom of the reaction tower, two tubular heat exchangers are arranged at the middle part of the reaction tower, and a benzoic acid discharge opening in the upper part of the reaction tower is connected to a benzoic acid flash column. The continuous production process of benzoic acid and the device thereof provided by the invention can be used for improving the selectivity of the catalyst to the benzoic acid product, the gas-liquid mixing and heat exchange and realizing continuous production, thereby reducing the energy consumption in the process, continuously producing low-pressure vapor, improving the product quality and yield, decreasing by-products and reducing the production cost.

Owner:TIANJIN DONGDA CHEM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com