Novel solar PV/T building integration curtain wall component and multi-energy-complementary energy supplying system

A technology of solar energy and components, applied in building components, heating systems, building structures, etc., can solve problems such as waste, low power generation efficiency, and large thickness of photovoltaic curtain wall maintenance structures, and achieve the goal of increasing inlet temperature and reducing maintenance structure costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

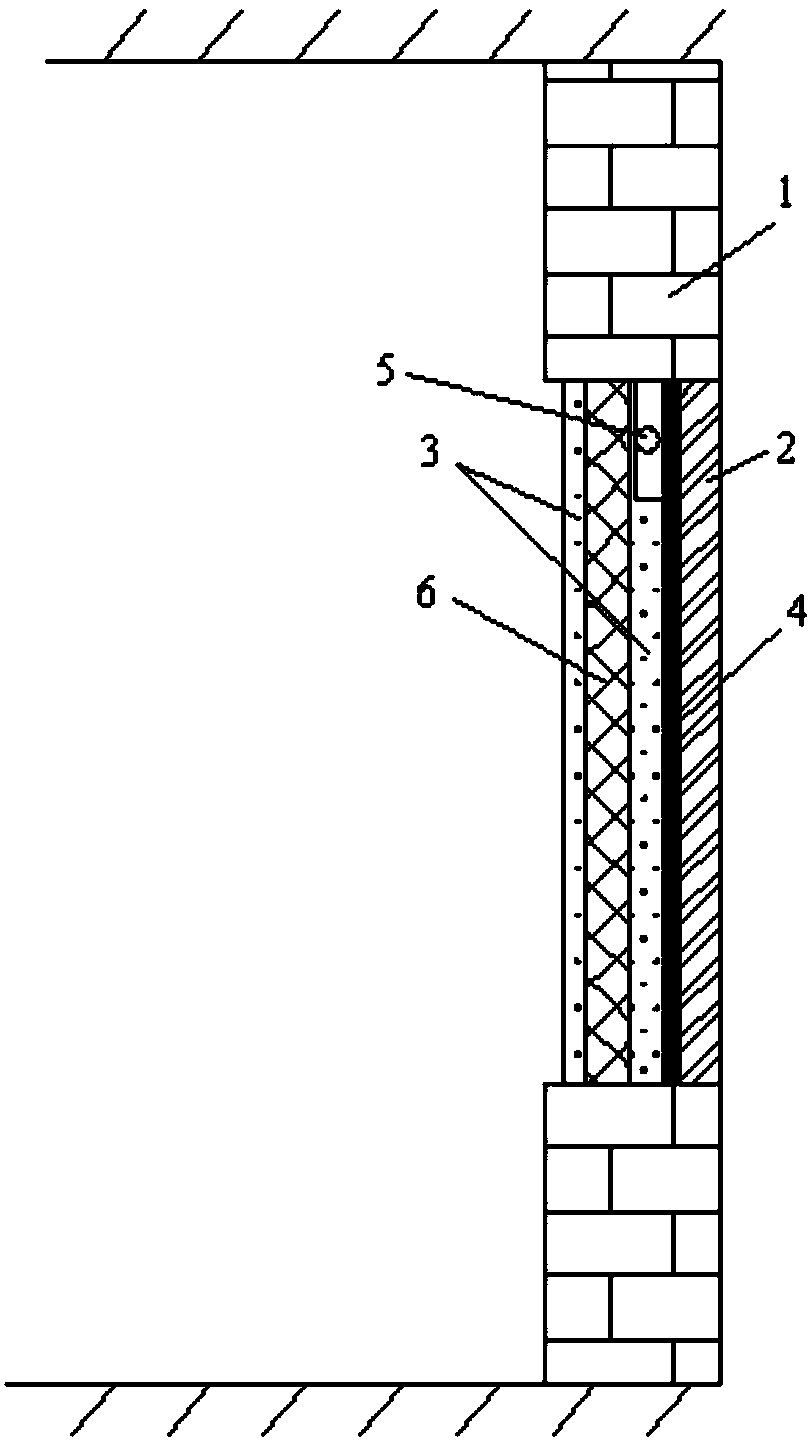

[0044] Such as figure 1 with Figure 2a As shown, a solar PV / T building-integrated curtain wall component of this embodiment is a water-cooled module (hereinafter referred to as a water-cooled BIPV / T module), which includes a solar panel 2 and a heat exchange unit in sequence from outdoor to indoor. and insulation layer 3. Wherein the solar cell panel 2 is located at the outdoor side to absorb solar energy, and is composed of a solar cell panel, the material is a monocrystalline silicon battery, and placed vertically. The heat exchange unit includes 6 micro-heat pipe arrays 4 and heat-taking pipes 5. Each micro-heat pipe array 4 is an integrally extruded metal plate structure with arrays of micro-heat pipes arranged side by side, with an average of 2-40 micro-heat pipes per 1 cm. As for the micro heat pipes, one side plane of each micro heat pipe array 4 is attached to the back plate of the solar cell panel 2 , and the top of the opposite side plane is horizontally attached ...

Embodiment 2

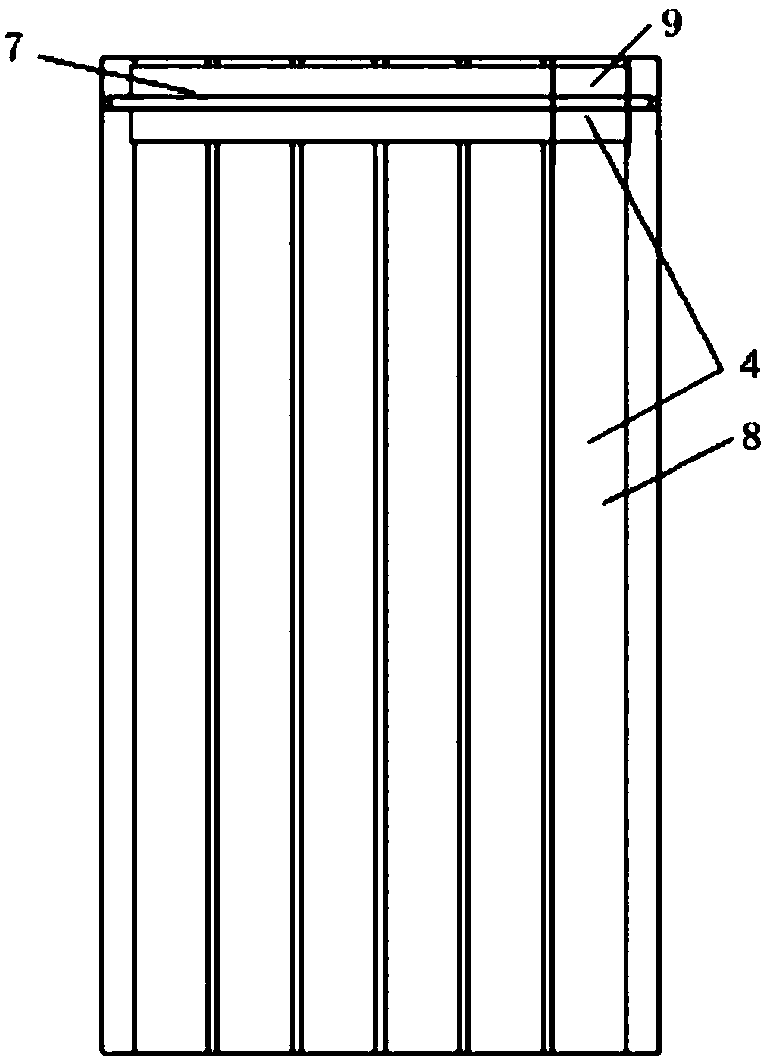

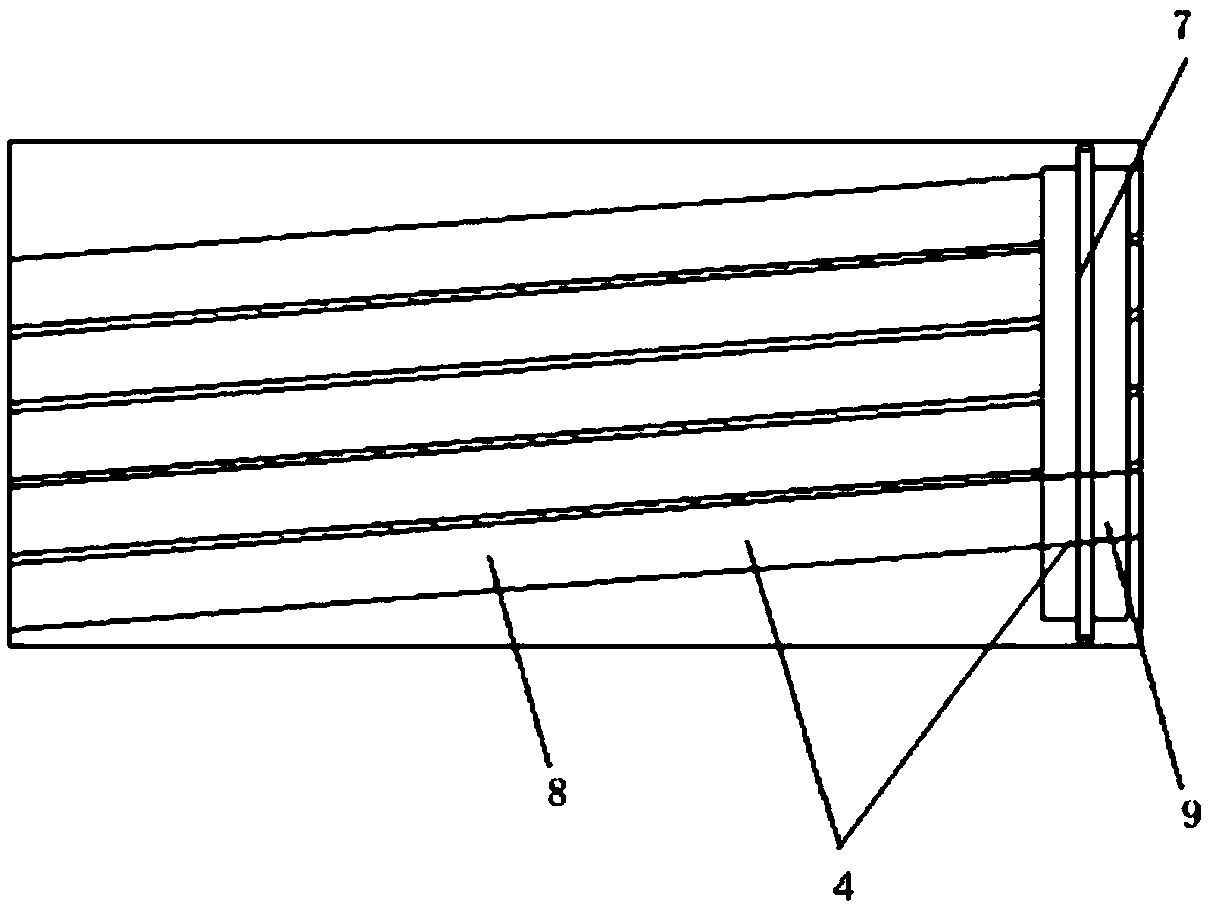

[0051] Such as Figure 2b As shown, this implementation is also a water-cooled BIPV / T module. The difference from Example 1 is that, according to the different requirements for the appearance of the building curtain wall, the battery panels are placed horizontally or obliquely, and the micro heat pipe array 4 is 5 pieces. The array 4 is inclined at a certain angle along the horizontal direction. In order to ensure the normal operation of the micro heat pipe, the inclination angle should not be less than 1°. In this embodiment, it is 10°. On the other side of the junction box, that is, the condensation section 9 is placed vertically to obtain heat. water pipe7. In addition, the water-cooled BIPV / T module of this embodiment also includes an interior decoration layer, which is attached to the indoor side of the insulation layer 3, and the interior decoration layer can be decorative substances such as stickers that play an aesthetic role.

Embodiment 3

[0053] This embodiment can be based on embodiment 1 or embodiment 2, the difference is that in order to increase the heat exchange efficiency, the hot water pipe 7 is set as a flat sink type cold water pipe 10 . Such as Figure 5 As shown, the main body of the flat trough cold water pipe 10 is extruded or stamped from an aluminum alloy and has an array structure of ten branch channels 11 arranged side by side along the length direction of the water pipe. Each of the two ends of the structure has a rectangular end cover 12 with a circular dry pipe 13, and the end cover 12 is sealingly connected with the two ends of the main structure, and each branch channel 11 is connected in the end cover 12. The side surfaces of each end cover 12 are connected to the main pipe 13 respectively, and are arranged diagonally, with low entry and high exit, so that the water in each branch channel 11 can converge into the main pipe 13. The internal equivalent diameter of the branch channel 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com