Light-weight high-strength ceramic plate and preparation method thereof

A ceramic plate and high-strength technology, applied in the field of ceramics, can solve the problems of not conforming to outdoor high-altitude curtain walls, short service life, poor frost resistance, etc., to achieve convenient construction, save installation costs, and reduce building loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0124] Correspondingly, the present invention also provides a method for preparing a lightweight high-strength ceramic plate, comprising the following steps:

[0125] 1. Mix the raw materials according to the formula to obtain the mixture;

[0126] 2. Put the mixture into a ball mill for ball milling to obtain mud;

[0127] 3. Spray and granulate the ball-milled slurry to obtain powder;

[0128] 4. Press and form the powder to obtain a green body;

[0129] 5. Drying the compacted green body;

[0130] 6. Surface treatment is carried out on the dried green body to obtain the primary product;

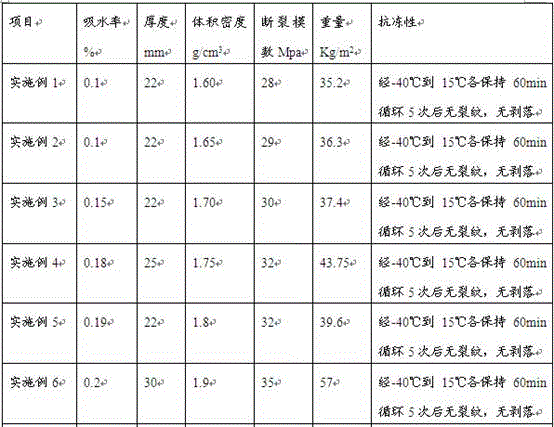

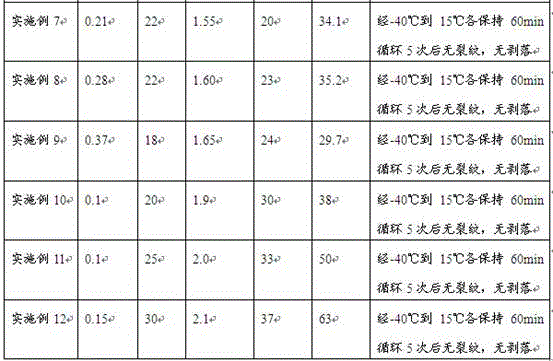

[0131] 7. Sinter the primary product at a temperature of 1050-1120 degrees Celsius to obtain a bulk density of 1.55-2.1g / cm 3 , a finished product with a thickness of 18-30mm and a water absorption rate of 0.1-0.5%.

[0132] Preferably, the preparation method of the lightweight high-strength ceramic plate is as follows:

[0133] 1. Mix the raw materials according to the formula to ob...

Embodiment 1

[0142] Example 1 - artificial granite hanging boards for outdoor high-altitude curtain walls

[0143] (1) Formula: 1.5 parts of silicon carbide, 25 parts of ceramic waste solids, 10 parts of sludge or bottom sludge, 10 parts of bentonite, 0.1 part of body strengthening agent, and 0.1 part of debonding agent.

[0144] (2) Preparation method:

[0145] 1. Mix the raw materials according to the formula to obtain the mixture;

[0146] 2. Put the mixture into a ball mill for ball milling to obtain a slurry with a moisture content of 12%;

[0147] 3. Spray and granulate the ball-milled slurry to obtain a powder with a moisture content of 1%;

[0148] 4. Press and form the powder to obtain a green body;

[0149] 5. Drying the compacted green body to obtain a green body with a moisture content in the range of 0.1%;

[0150] 6. The dried green body is distributed by a special material truck for granite, and then 3D inkjet printing is carried out, so that the green body can restore t...

Embodiment 2

[0152] Example 2 - artificial marble hanging boards for outdoor high-altitude curtain walls

[0153] (1) Formula: 1.6 parts of silicon carbide, 28 parts of ceramic waste solids, 15 parts of sludge or bottom sludge, 15 parts of bentonite, 0.5 parts of body strengthening agent, and 0.2 parts of debonding agent.

[0154] (2) Preparation method:

[0155] 1. Mix the raw materials according to the formula to obtain the mixture;

[0156] 2. Put the mixture into a ball mill for ball milling to obtain a slurry with a moisture content of 13%;

[0157] 3. Spray and granulate the ball-milled slurry to obtain a powder with a moisture content of 1.5%;

[0158] 4. Press and form the powder to obtain a green body;

[0159] 5. Drying the compacted green body to obtain a green body with a moisture content in the range of 0.2%;

[0160] 6. The dried green body is clothed by a special marble material truck, and then 3D inkjet printing is carried out to restore the natural marble temperament o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com