A preparation method of electromagnetic wave absorbing material based on ferrite solid waste

A technology of absorbing materials and ferrites, applied in the direction of magnetic materials, inorganic materials, unspecified rubber coatings, etc., can solve the problems of electromagnetic impedance imbalance, insufficient dielectric loss, uneven size, etc. The effect of small solid waste discharge and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

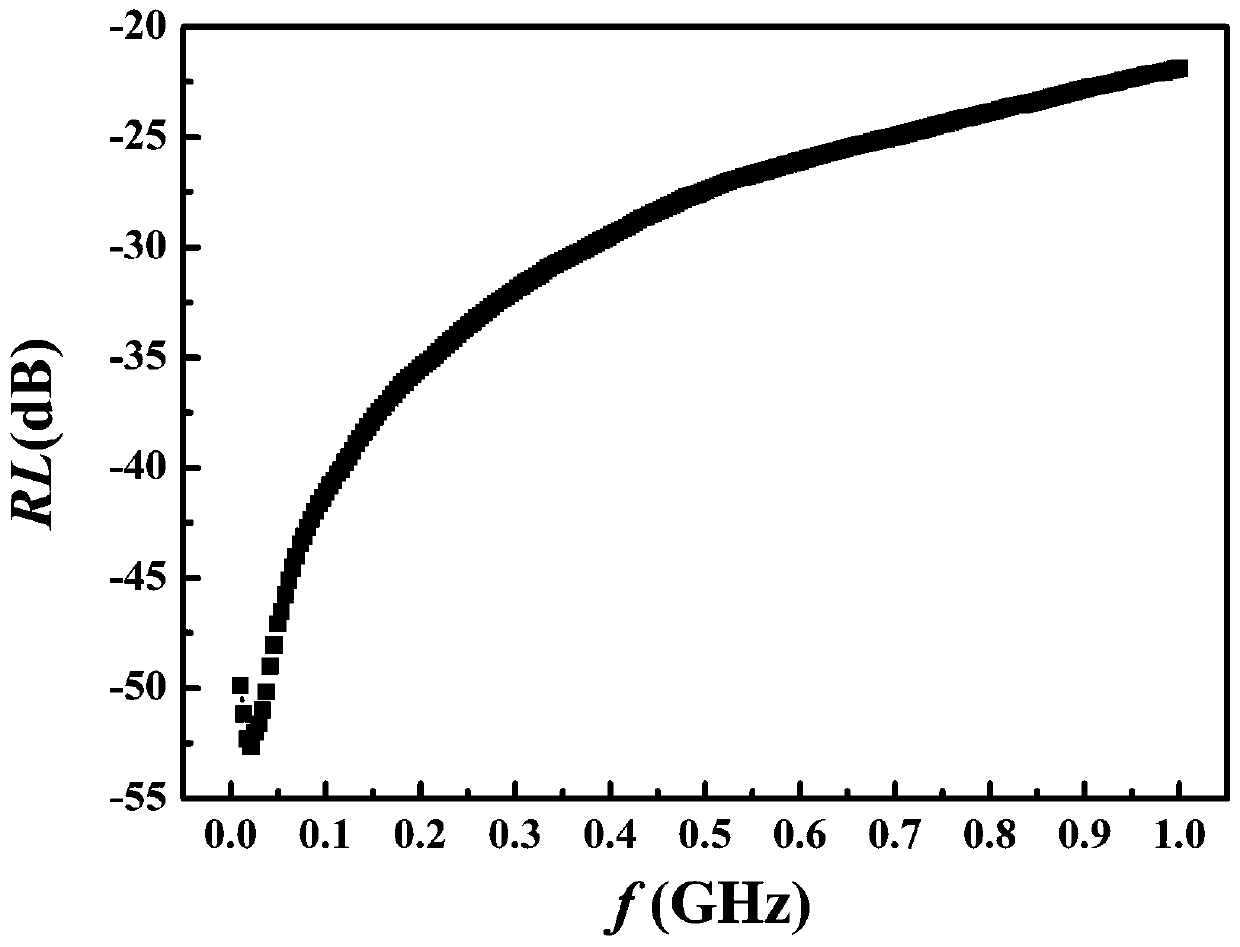

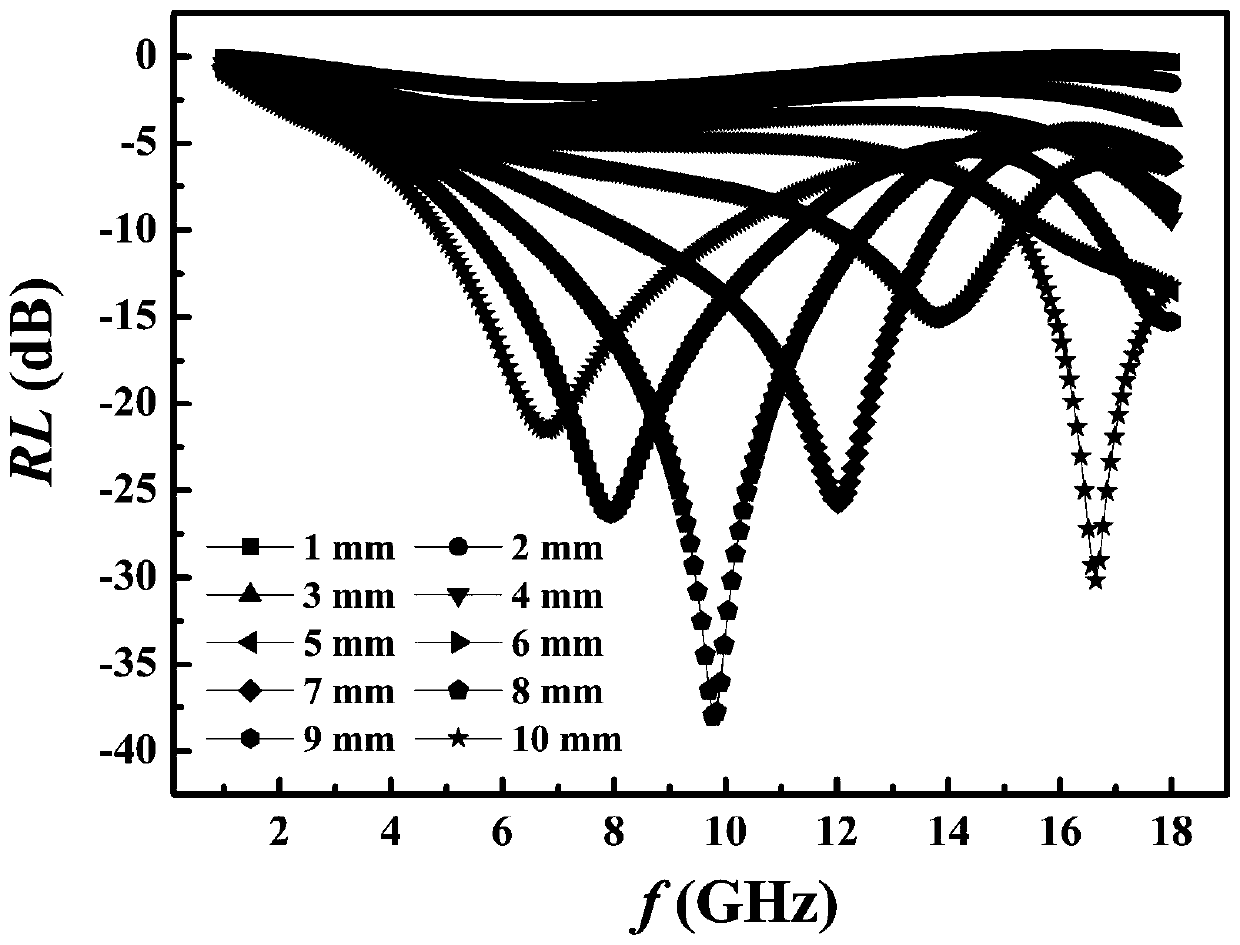

Embodiment 1

[0035] In this embodiment, the manganese-zinc ferrite industrial solid waste recovered by the soft magnetic core production line is used as the precursor, and the solid waste is prepared with a mass ratio of solid waste and glucose of 1:1 through the steps of purification, ball milling, and hydrothermal carbon coating. The ferrite / carbon composite electromagnetic wave absorbing material specifically includes the following steps:

[0036] 1. Purification of solid waste

[0037] Place 3g of untreated manganese-zinc ferrite agglomerated and ground solid waste recovered from the magnetic core production line in a mortar and grind it thoroughly until it becomes powder; disperse the solid waste powder of manganese-zinc ferrite in 30ml In deionized water, mechanically stir to mix uniformly to form a suspension; the suspension is ultrasonically treated for 20 minutes to make the ferrite particles and impurities in the solid waste powder uniformly dispersed in the water; a 0.2T permanent ma...

Embodiment 2

[0045] In this embodiment, the manganese-zinc ferrite industrial solid waste recovered by the soft magnetic core production line is used as the precursor, and the solid waste is prepared with a mass ratio of solid waste and glucose of 1:3 through the steps of purification, ball milling, and hydrothermal carbon coating. The ferrite / carbon composite electromagnetic wave absorbing material specifically includes the following steps:

[0046] 1. Purification of solid waste

[0047] Place 3g of untreated manganese-zinc ferrite agglomerated and ground solid waste recovered from the magnetic core production line in a mortar and grind it thoroughly until it becomes powder; disperse the solid waste powder of manganese-zinc ferrite in 30ml In deionized water, mechanically stir to mix uniformly to form a suspension; the suspension is ultrasonically treated for 20 minutes to make the ferrite particles and impurities in the solid waste powder uniformly dispersed in the water; a 0.2T permanent ma...

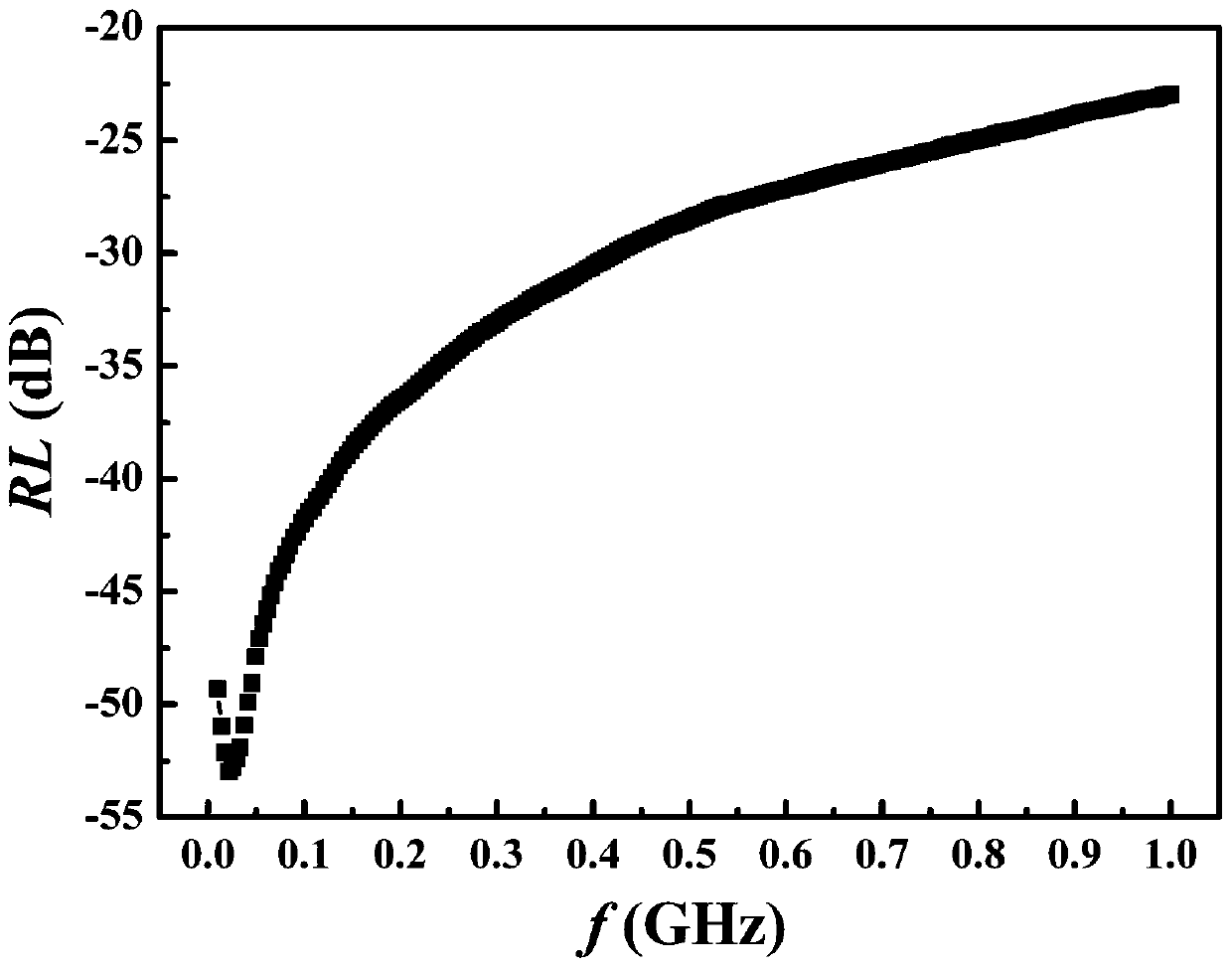

Embodiment 3

[0055] In this embodiment, the manganese-zinc ferrite industrial solid waste recovered by the soft magnetic core production line is used as the precursor, and the solid waste is prepared with a mass ratio of solid waste and glucose of 1:5 through the steps of purification, ball milling, and hydrothermal carbon coating. The ferrite / carbon composite electromagnetic wave absorbing material specifically includes the following steps:

[0056] 1. Purification of solid waste

[0057] Place 3g of untreated manganese-zinc ferrite agglomerated and ground solid waste recovered from the magnetic core production line in a mortar and grind it thoroughly until it becomes powder; disperse the solid waste powder of manganese-zinc ferrite in 30ml In deionized water, mechanically stir to mix uniformly to form a suspension; the suspension is ultrasonically treated for 20 minutes to make the ferrite particles and impurities in the solid waste powder uniformly dispersed in the water; a 0.2T permanent ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com