Patents

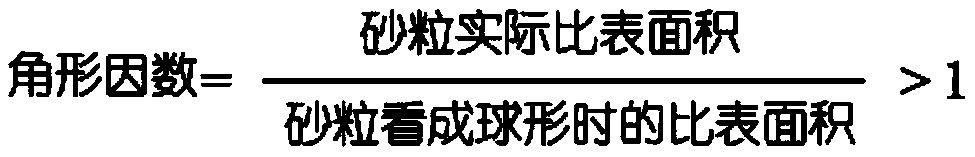

Literature

57results about How to "Reduce solid waste discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Online dechlorination technology of chlorination process tailing slag extracted titanium

InactiveCN105271857AReduce solid waste dischargeReduce contentSolid waste managementSlagWater content

The invention discloses a processing technology of chlorination process tailing slag extracted titanium and belongs to the metallurgical field. The invention provides an online dechlorination technology of chlorination process tailing slag extracted titanium. The technology includes the following steps that firstly, the chlorination process tailing slag extracted titanium enters a beating tank through a slag discharge port of a chlorination furnace, and the temperature of the chlorination process tailing slag extracted titanium is 400-550 DEG C; secondly, the chlorination process tailing slag extracted titanium and water in the beating tank are stirred and beaten for form sizing agents, and the mass ratio of the water to the slag in the sizing agents is controlled to be 3.2-4:1; thirdly, by means of a slurry pump, the sizing agents are conveyed to a slag yard through a pipeline, and therefore integration of dechlorination and tailings conveying can be achieved; fourthly, the beaten tailing slag extracted titanium naturally settles in the slag yard till the water content of tailings is 12-20% and the chlorine ion content is lower than 0.3%; fifthly, the tailings where natural settlement is performed directly enter a rotary kiln through a belt and are calcinated for 20-40 min at the temperature of 600-700 DEG C. By means of the online dechlorination technology, the chlorine ion content of the chlorination process tailing slag extracted titanium is smaller than or equal to 0.08%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

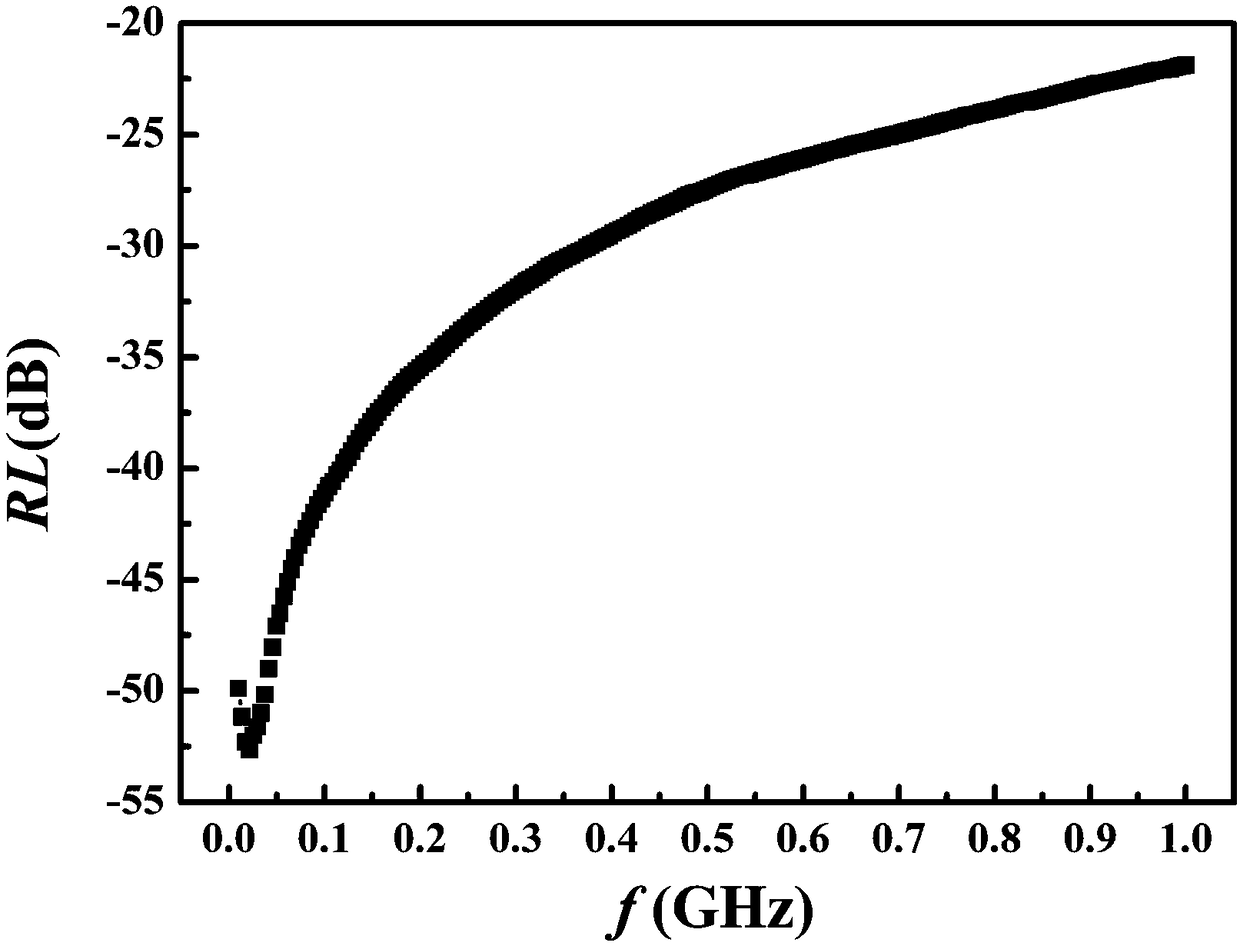

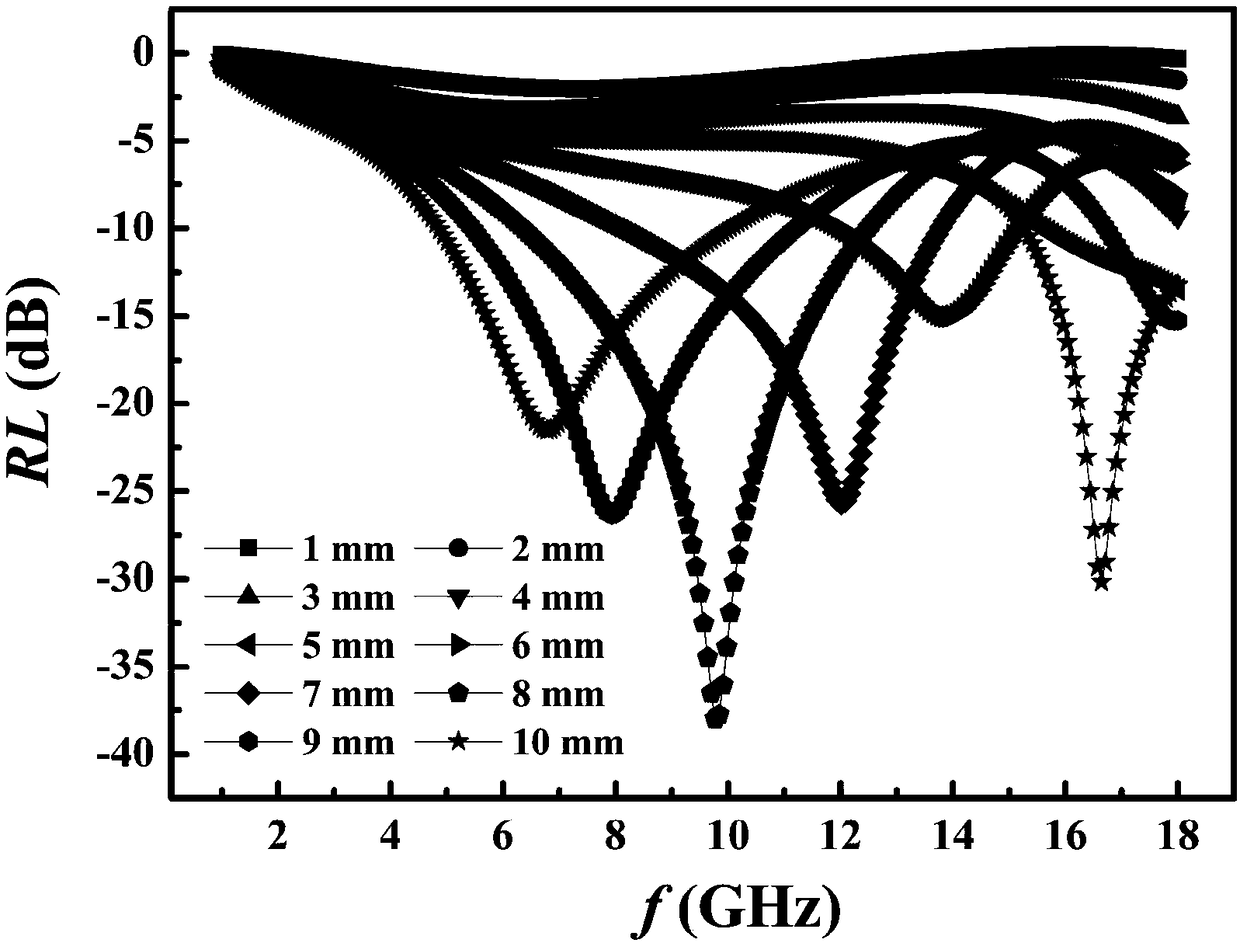

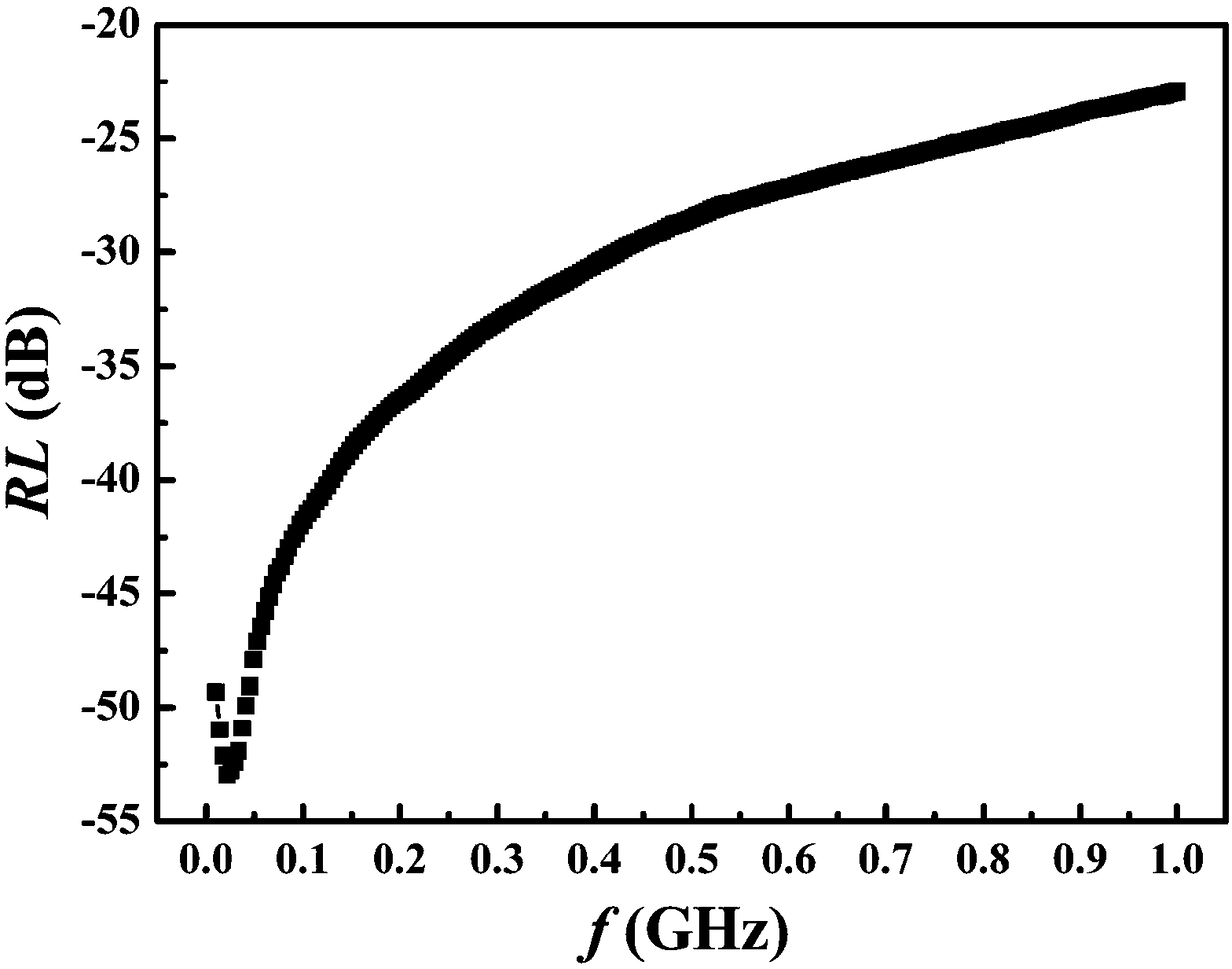

Preparation method of electromagnetic wave absorption material based on ferrite solid wastes

ActiveCN108102393AReduce manufacturing costConducive to environmental protection and recyclingWax coatingsMagnetic/electric field screeningCarbon compositesVolumetric Mass Density

The invention discloses a preparation method of an electromagnetic wave absorption material based on ferrite solid wastes. The electromagnetic wave absorption material with a composite structure is obtained by taking the ferrite solid wastes produced by grinding in a soft magnet magnetic core production link as a magnetic base body and covering carbon on a crystal boundary. A ferrite / carbon composite electromagnetic wave absorption material prepared by the preparation method has anti-oxidization and anti-corrosion capabilities; an interface carbon material is added so that the density of a wave absorption body can be reduced and light and thin wave absorption products are easy to produce; the mechanical properties also can be stabilized and reinforced. The electromagnetic wave absorption material prepared by the preparation method disclosed by the invention has wide applicability, is suitable for being used for absorbing electromagnetic waves with the frequency band of DC-42.5GHz and can be used for products including blocks, patches, pyramids, conoids, coatings, thin films and the like.

Owner:HEFEI UNIV OF TECH

Method for producing tetracycline by fermentation of streptomyces aureus

ActiveCN103602714AReduce contentEasy to sterilizeMicroorganism based processesFermentationSucroseOxygen

The invention relates to a method for producing tetracycline by fermentation of streptomyces aureus. The method comprises the following steps: slant spore culture, seed culture and fermentation culture of the streptomyces aureus, and is characterized in that dextrin, sucrose, corn pulp, hydrolyzed soybean meal and other medium-effect carbon-nitrogen sources are adopted to replace original late-effect carbon-nitrogen sources; by reducing the contents of starch and bean flour in an original fermentation culture medium and combining with a formula of a mixture in the fermentation process and adjustment of a replenishing method and placing part of the nitrogen sources in the fermentation culture medium into material replenishment in the fermentation process, the concentration of the culture medium in the fermentation process is effectively controlled, the oxygen dissolution condition in the early stage of fermentation is improved, the final residue of the culture medium of fermentation is controlled by material replenishment, the material consumption is reduced, and the emission of solid wastes is reduced; the metabolism velocity in exponential growth phase in the fermentation process of the tetracycline is effectively controlled, the abnormal situations that a fermentation solution turns red and becomes sour and the like in the fermentation process are reduced, and the fermentation level is improved.

Owner:NINGXIA QIYUAN PHARMA

Gold-rich beneficiation method for gold ores and gold waste ores

The invention provides a gold-rich beneficiation method for gold ores and gold waste ores. The gold-rich beneficiation method comprises the following steps that 1, coarsely crushing the waste ores until the maximum particle size is less than 120 mm, so that the coarse crushed ores are obtained; 2, the coarse crushed ores are screened to obtain first gold-rich ores in the particle size below 30 mmand to be sorted ores with the particle size more than 30 mm; 3, the to be sorted ores enables a X-ray sorting machine, the qualitative and quantitative analysis are carried out on the elements in theores to be sorted according to the wavelength and intensity of X rays, and the waste ores and second gold-rich ores are obtained after separating ; 4, the first gold-rich ores and the second gold-rich ores are finely crushed until the particle sizes are smaller than 12 mm, and ore grinding and grading is carried out on the obtained fine products; and 5, the flotation recovery ores are carried outon the obtained ore grinding grading products, and gold concentrate products and tailings are obtained by flotation. The method disclosed by the invention can be used for effectively improving the gold grade of the ores to be grinded in the plant, the ore grinding grading amount is reduced, the ore quantity of the sorting operation is reduced, and the discharge of the tailings is reduced.

Owner:河南黄金产业技术研究院有限公司

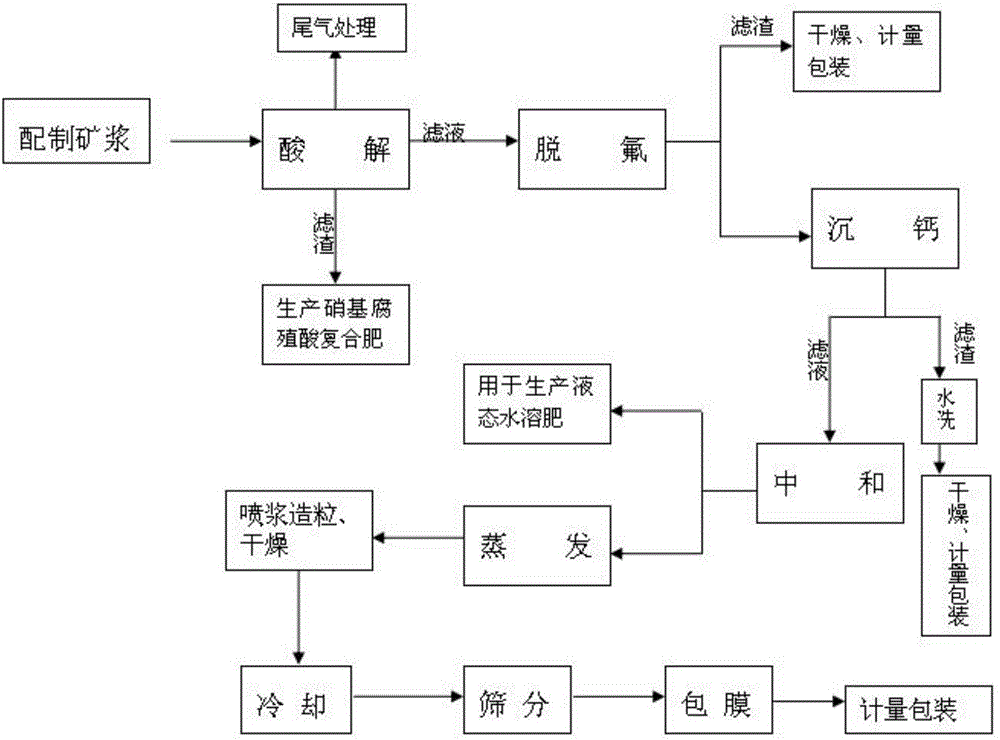

Method for co-production of chemical synthetic fertilizer by industrial calcium products

ActiveCN106517293ASimple product structureSimple structureCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesChemical synthesisNitrohumic acid

The invention relates to a method for co-production of a chemical synthetic fertilizer by industrial calcium products, and belongs to the field of production of agricultural fertilizers. The method comprises the following steps: preparing phosphorite powder into ore pulp by using a raw material slurry method, reacting the ore pulp with nitric acid, and filtering; feeding filter residues to a compound fertilizer workshop to produce a nitrohumic acid compound fertilizer; adding sodium nitrate in the filtrate to remove fluoride; centrifugally dehydrating; drying the filter residues to prepare sodium fluosilicate; adding ammonium sulfate, potassium sulphate or potassium carbonate in the filtrate to deposit calcium; then filtering; preparing the industrial calcium products from the filter residues; and neutralizing, concentrating, guniting, drying, cooling, enveloping, metering and packing the filtrate to obtain the chemical synthetic fertilizer.

Owner:CHONGQING HUAQIANG ECOLOGICAL FERTILIZER IND CO LTD

Method for producing parachlorotoluene through continuous chlorination of methylbenzene

InactiveCN108467333AReduce manufacturing costReduce solid waste dischargeChemical recyclingHalogenated hydrocarbon preparationMolecular sieveDistillation

The invention discloses a method for producing parachlorotoluene through continuous chlorination of methylbenzene. The method comprises the following steps: with an active molecular sieve as a catalyst, performing continuous chlorination on methylbenzene in a static bed, wherein a ratio of parachlorotoluene to o-chlorotoluene in the chlorination products is 1.2-6.0; performing aeration and distillation separation on the chlorination product to obtain high-purity parachlorotoluene, and enabling the separated methylbenzene and raw material methylbenzene to enter the static bed together so as toperform continuous chlorination; periodically reproducing the catalyst in the static bed; and alternately using and activating two groups or more than two groups of static beds. According to the method disclosed by the invention, continuous chlorination production of methylbenzene is realized, the ratio of parachlorotoluene to o-chlorotoluene is 1.2-6.0, the catalyst can be repeatedly used, the production cost is reduced, and solid waste emission is reduced.

Owner:江苏优普生物化学科技股份有限公司

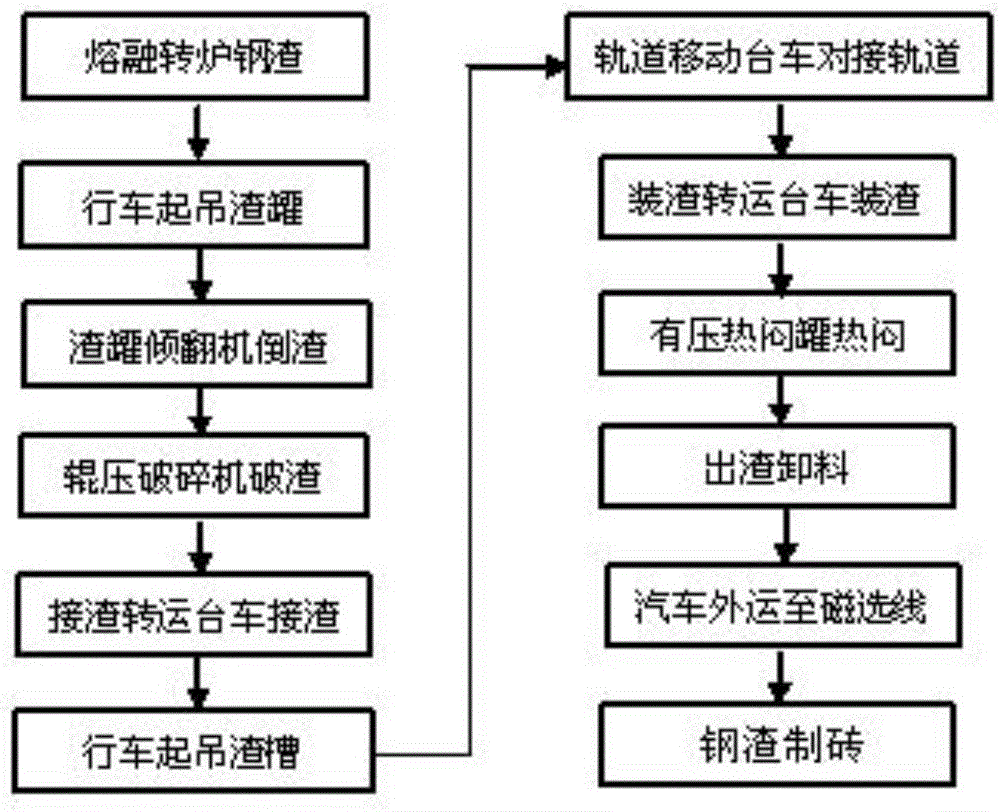

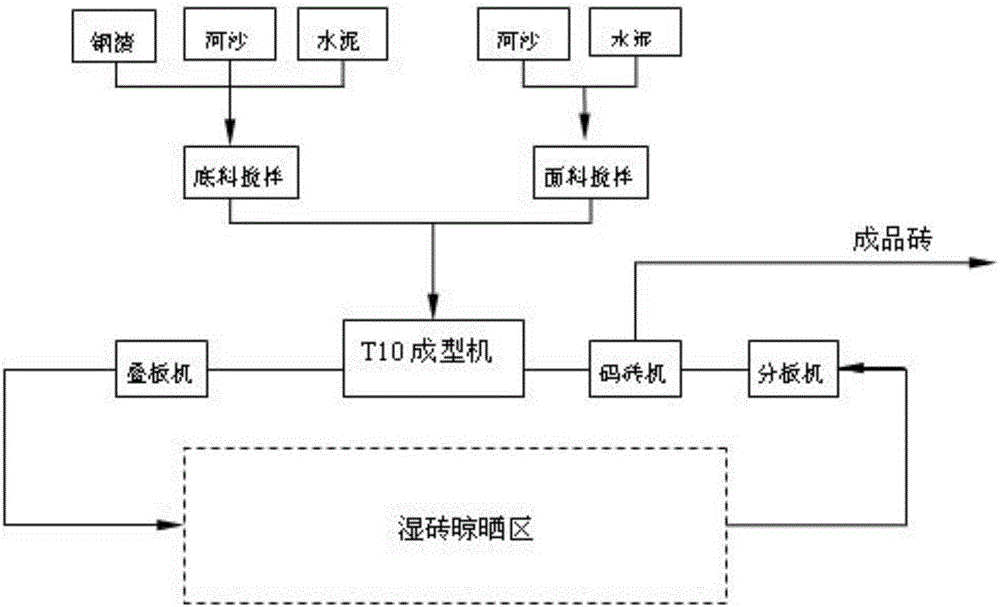

Brickmaking technique for deeply processing waste steel slag

InactiveCN106277951AIncrease the added value of recyclingReduce solid waste dischargeSteelmakingBrick

The invention relates to a brickmaking technique for deeply processing waste steel slag. The steelmaking slag is subjected to rolling and crushing and pressure-hot stew treatment and the magnetically separated waste steel slag is taken as the main aggregate for making brick. The waste steel slag is used for replacing the lime pebble in the traditional brickmaking technique and is mixed with the river sand and cement for making the brick, wherein the steel slag content is 60%-75%, the river sand content is 10%-15% and the cement content is 15%; the end product of brick is acquired through the processes of forming, laminating, airing, separating and brick stacking. According to the brickmaking technique for deeply processing waste steel slag provided by the invention, the additional value of recycling of the waste steel slag is increased, the solid waste discharging is reduced and the brickmaking technique has the advantages of reasonable technique, high economic benefit and environment-friendly and energy-saving effects.

Owner:CANGZHOU CHINA RAILWAY EQUIP MFG MATERIALS CO LTD +1

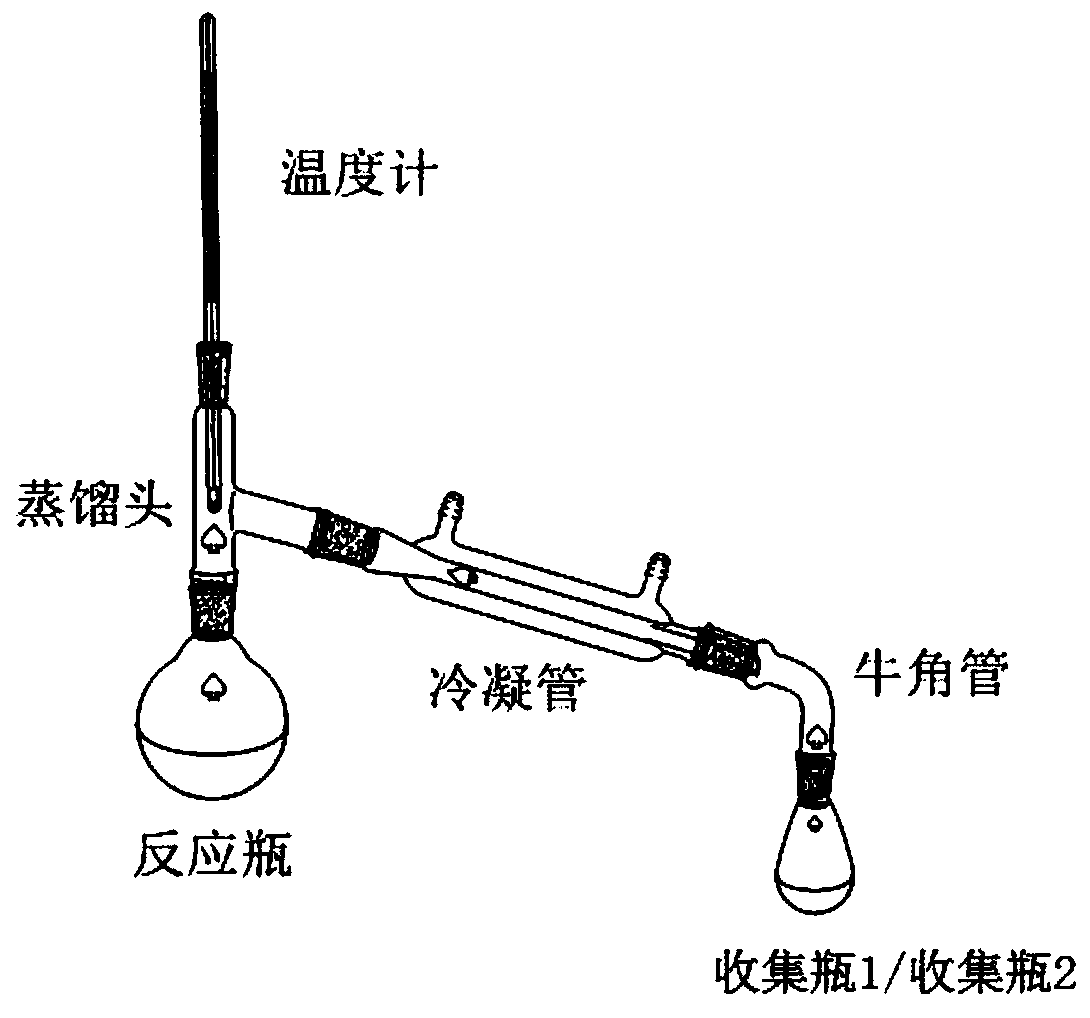

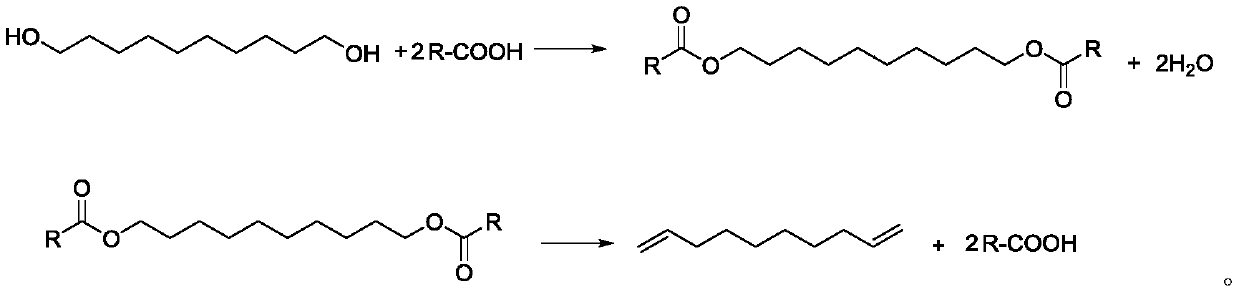

Method for synthesizing 1,9-decadiene

InactiveCN109879712AThe process steps are simple and clearEasy post-processingHydrocarbonsHydrocarbon preparationCarboxylic acidEsterification reaction

The invention discloses a method for synthesizing 1,9-decadiene. The method sequentially comprises the following steps: adding carboxylic acid and 1,10-decadienol into a reaction container, heating the container until the 1,10-decadienol is dissolved, adding a catalyst, carrying out an esterification reaction at 120-200 DEG C, and collecting water evaporated in the esterification reaction; continuously heating the container to 300-350 DEG C after no water is produced in the esterification reaction, carrying out a reaction for 5-8 h, and evaporating and collecting a mixed solution of 1,9-decadiene and carboxylic acid; and respectively post-processing the mixed of 1,9-decadiene and carboxylic acid to obtain carboxylic acid and 1,9-decadiene respectively. The method for preparing 1,9-decadiene is efficient, economical and green, and meets industrial production requirements.

Owner:ZHEJIANG UNIV

Composite profile made from waste dry film and preparation method thereof

The invention provides a composite profile made from a waste dry film and a preparation method thereof. The composite profile comprises, by weight, 25-35 parts of dry film fines, 35-45 parts of wastecircuit board resin powder, 5-20 parts of polyethylene plastic and / or dry wood powder, 5-10 parts of waste glass fiber reinforced plastic, and 10-15 parts of an auxiliary agent, wherein the dry film fines is obtained from alkali treatment on a waste dry film and contains no more than 3% by mass of colloid. Through resource utilization of the waste dry film, waste circuit board resin powder and waste glass fiber reinforced plastic, a composite profile with excellent mechanical properties is obtained. The composite profile has significant economic and social benefit.

Owner:常州厚德再生资源科技有限公司

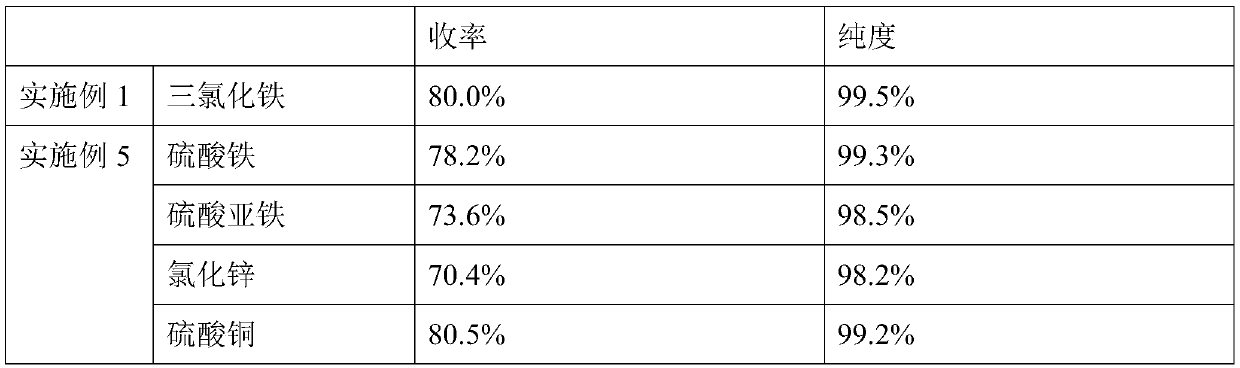

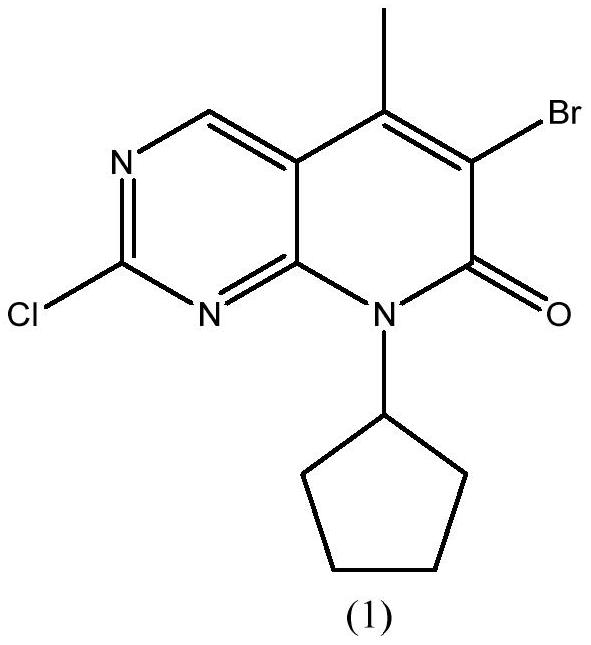

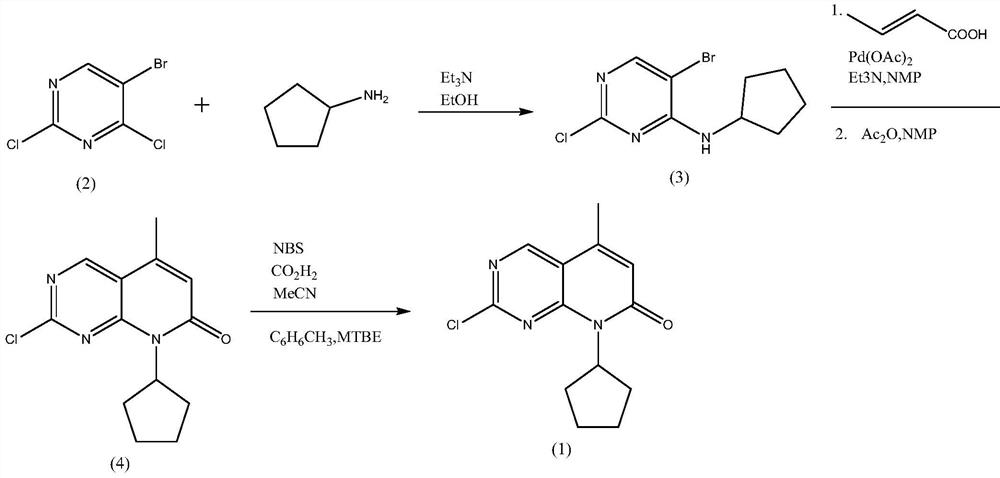

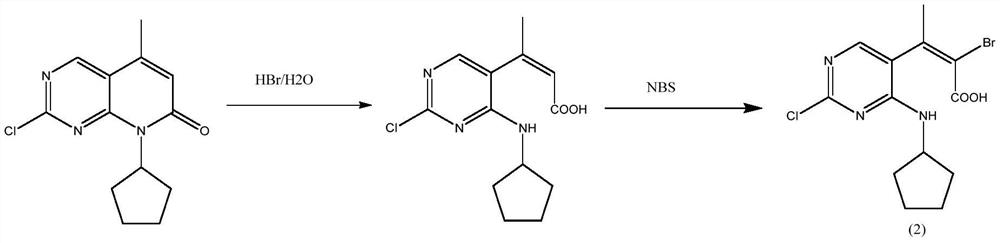

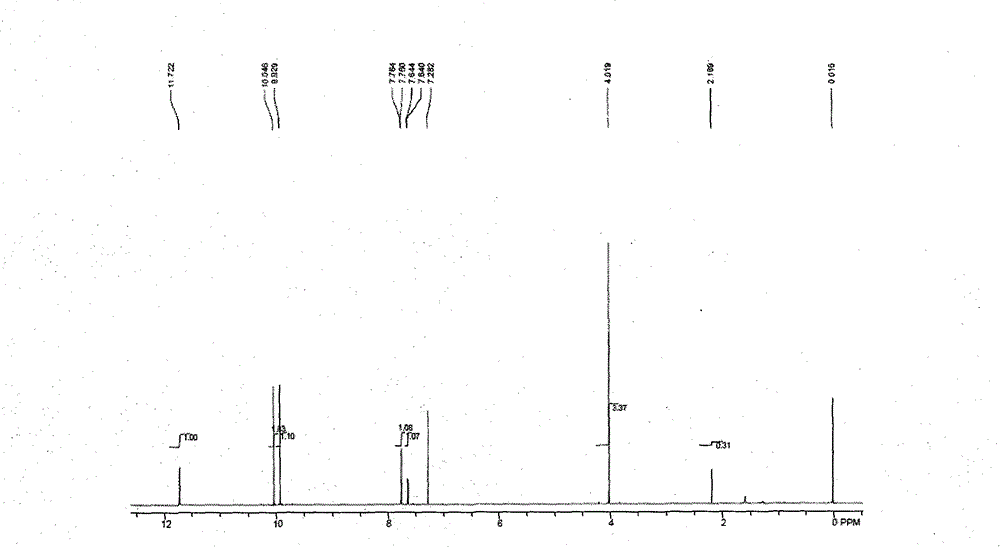

Preparation method of palbociclib intermediate

ActiveCN112661753AReduce the discharge of three wastesReduce solid waste dischargeOrganic chemistryOXALIC ACID DIHYDRATEKetone

The invention discloses a preparation method of a palbociclib intermediate, which comprises the following steps: by using 2-chlorine-8-cyclopentyl-5-methylpyrido [2, 3-D] pyrimidine -7 (8H) -ketone as a raw material, carrying out NBS bromination and cooling crystallization centrifugation under the catalysis of oxalic acid and acetic anhydride to obtain 6-bromine-2-chlorine-8-cyclopentyl-5-methylpyrido [2, 3-D] pyrimidine -7 (8H) -ketone; meanwhile, waste liquid generated in the preparation process is fully reutilized, three wastes are reduced, and the preparation method which is high in quality, low in cost, environmentally friendly and suitable for industrial production is provided.

Owner:SHANDONG BOYUAN PHARM CO LTD

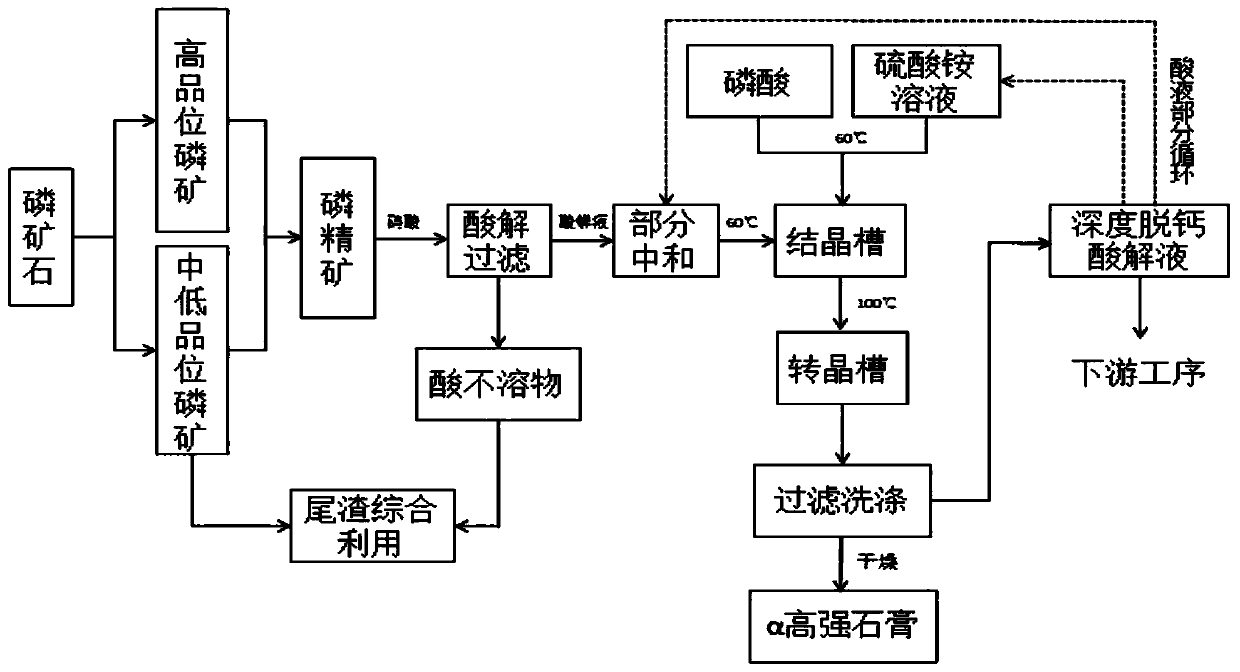

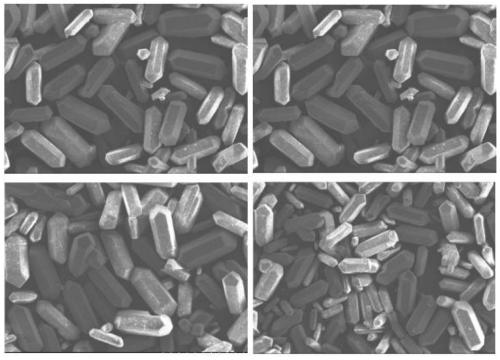

Method for decomposing phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum

ActiveCN111533154AReduce manufacturing costTake advantage ofCalcium/strontium/barium sulfatesPhosphoric acidChemical industryO-Phosphoric Acid

The invention discloses a method for decomposing a phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum. The method comprises: decomposing phosphoriteby nitric acid, filtering out acid insoluble substances, partially neutralizing the acidolysis liquid, regulating and controlling the concentration of calcium ions in the acidolysis liquid, adding the acidolysis liquid into a crystallization tank containing a mixed solution of additional phosphoric acid and ammonium sulfate, controlling the reaction temperature to be 50-70 DEG C and the reactiontime to be 0.5-2 hours to firstly generate dihydrate gypsum, then, making the reaction slurry flow into a crystal transformation tank, and raising the temperature to 95 to 110 DEG C for reacting for aperiod of time so that an alpha-type high-strength gypsum product can be produced as a byproduct. According to the invention, the acidolysis liquid can be used for producing products such as fine phosphate, high-water-solubility phosphate fertilizer and the like, meanwhile, calcium resources in the acidolysis liquid are converted into an alpha high-strength gypsum product, solid waste phosphogypsum is changed into product phosphogypsum, environmental risks caused by the fact that a large amount of solid waste phosphogypsum is produced as a byproduct in the ammonium phosphate industry are eliminated, the phosphorus compound fertilizer industry is promoted to adjust the product structure, solid waste emission is reduced, and sustainable development of the phosphorus chemical industry is promoted.

Owner:GUIZHOU UNIV

Method for synthesizing o-vanillin through utilizing 5-aldehyde vanillin

InactiveCN103145538AReduce solid waste dischargeImprove economic efficiencyOrganic compound preparationCarbonyl compound preparationChemistryAldehyde

The invention discloses a method for converting 5-aldehyde vanillin to o-vanillin. The method is characterized in that a byproduct 5-aldehyde vanillin generated in the vanillin production process through crystallization, distillation or rectification, separation and recovery undergoes catalytic aldehyde removal under a reduced pressure condition to convert to o-vanillin, vanillin and guaiacol. The method realizes the reduction of the discharge of solid wastes, realizes the recycle of the solid wastes generated in the production of vanillin through a glyoxylic acid method, and improves the economic benefit.

Owner:JIAXING ZHONGHUA CHEM

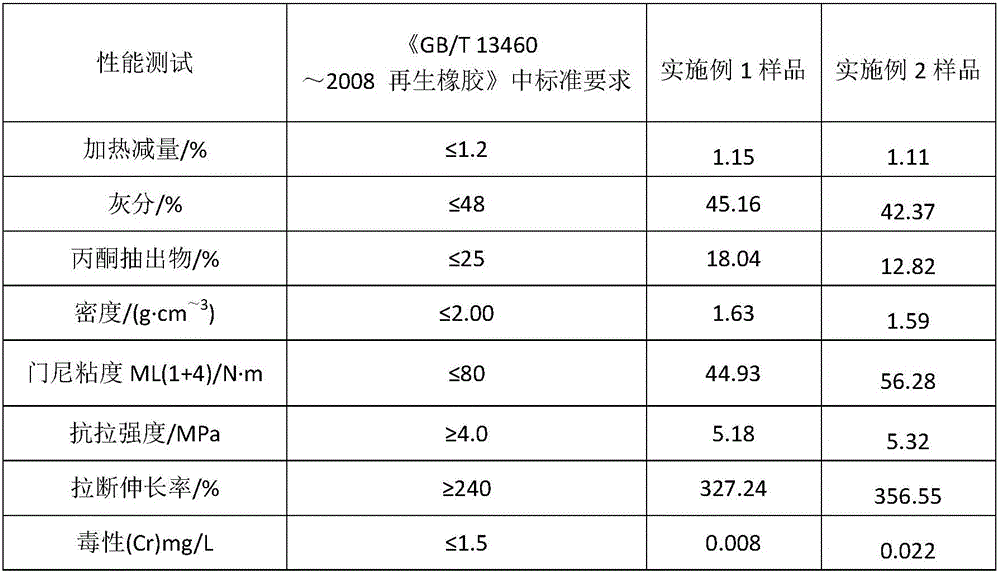

Reclaimed rubber prepared from oil field oil sludge and production method thereof

InactiveCN106188613AImprove qualityImprove vulcanization activityPlastic recyclingTarTherapeutic effect

The invention belongs to the field of oil field oil sludge resourceful treatment, especially discloses reclaimed rubber prepared from oil field oil sludge as a main raw material, and also discloses a production method. The reclaimed rubber prepared from the oil field oil sludge is composed of the raw materials by the mass percentage: 50%-65% of oily sludge, 5%-20% of a waste tire rubber powder, 20%-40% of clay, 0.1%-0.4% of an activator 420, 0.1%-0.3% of ethylene tar, and 0.1%-0.3% of alkyl phenol disulfide. According to the reclaimed rubber prepared with oil field oil sludge, through formula optimization design, the content of the oily sludge is increased significantly, the consumption of the oil field sludge is increased, and the oil field oil sludge resourceful treatment effect is increased by 20% or more; with use of the waste tire rubber powder, the use amount is only 5%-20% and is significantly reduced, and the production cost is saved; the reclaimed rubber has relatively short reclaiming reaction time and has high degree of desulfurization, and the reclaimed rubber properties all reach national corresponding reclaimed rubber standards.

Owner:青岛三聚猫环保能源科技有限公司

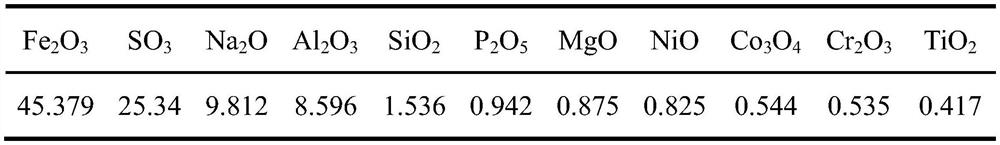

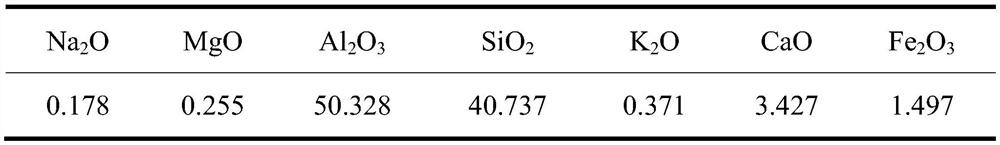

Method for preparing synthetic gas from C1 chemical fuel in multivariate conjugation manner

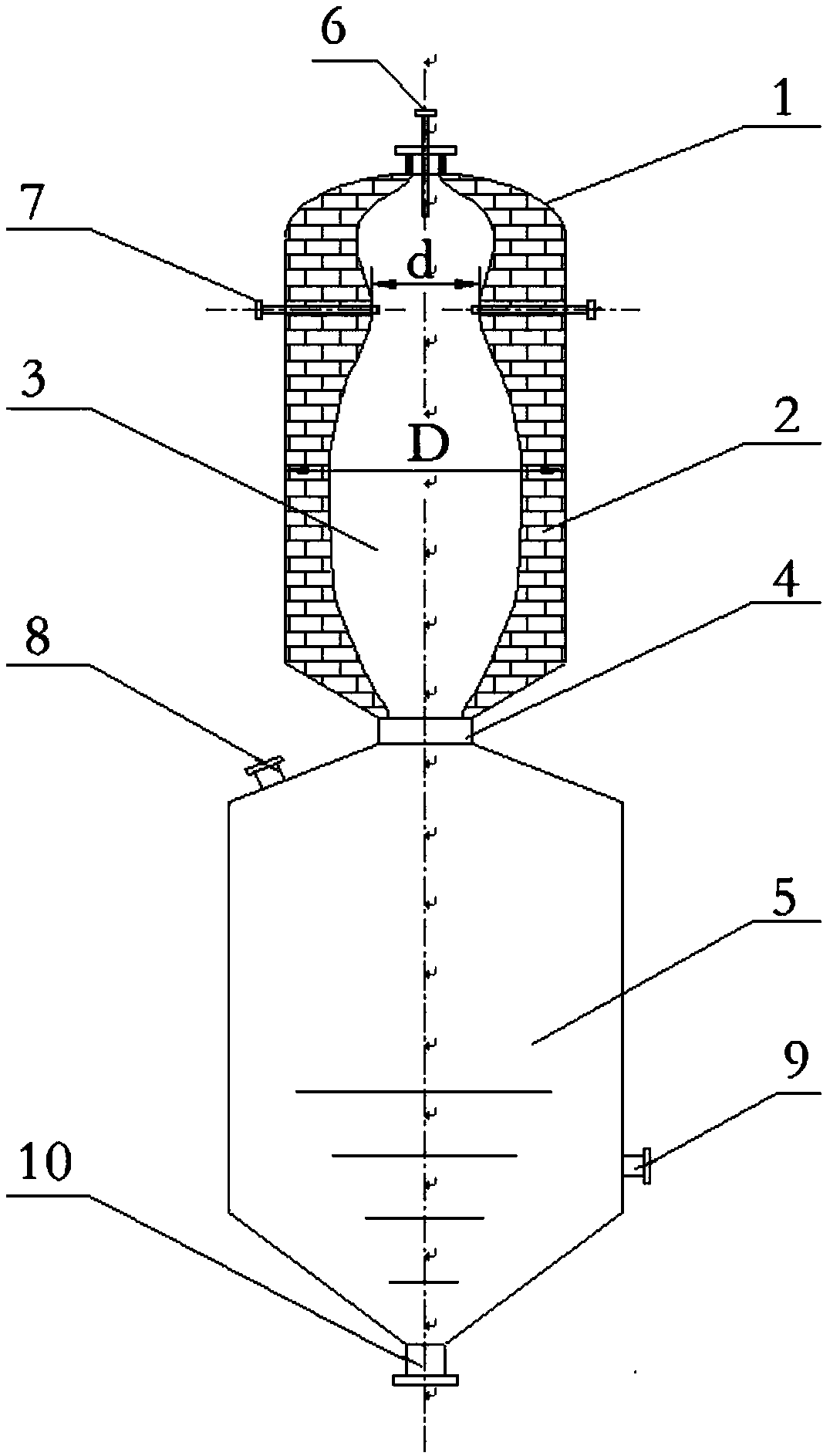

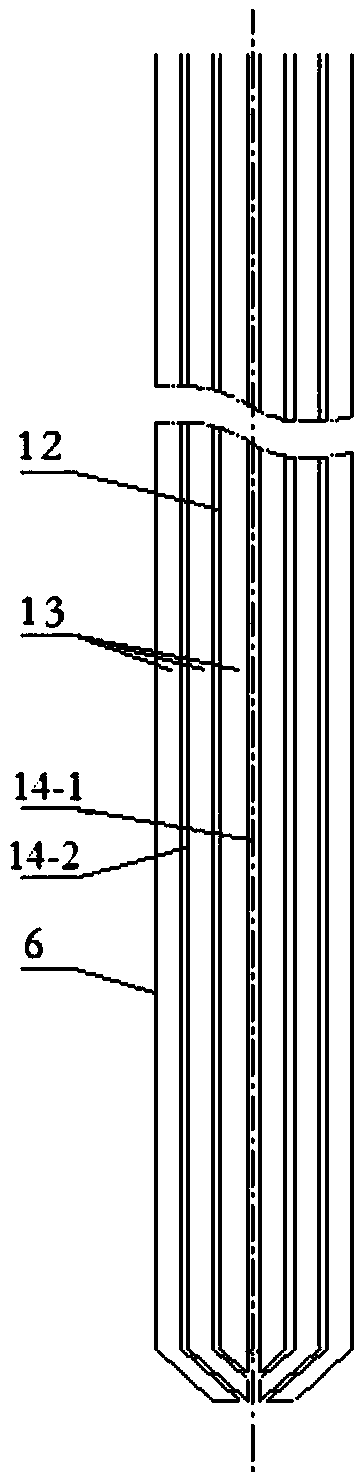

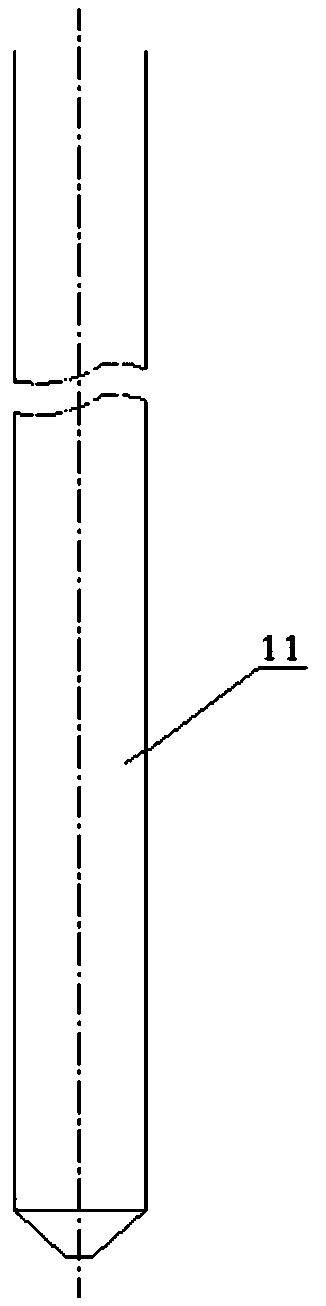

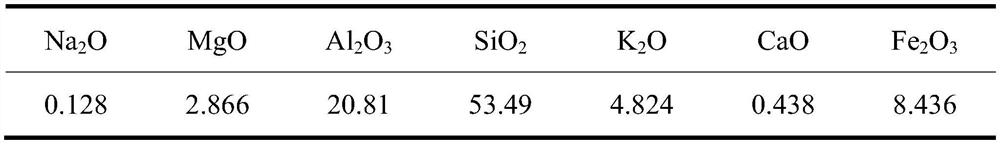

ActiveCN109486533AEfficient mass transferImprove conversion rateGasification processes detailsGasification apparatus detailsHigh concentrationSpray nozzle

The invention discloses a method for preparing synthetic gas from C1 chemical fuel in a multivariate conjugation manner. The method comprises the following steps: 1, baking in an oven; 2, introducingC1 gas-state fuel and C1 solid-state fuel slurry into a gasification furnace respectively to be mixed with an oxidant, and reacting to generate crude synthetic gas, wherein a reaction cavity is of a flat and long gourd shape, a relation between the diameter d of a fine neck part of the reaction cavity and the diameter D of the thickest part of a web part is as follows: d=0.382D, and the ratio of axial heights of upper and lower sections of chambers of the reaction cavity taking the fine neck part as the boundary is 1 to 3; and 3, quenching the crude synthetic gas and unreacted solid residues,and discharging the crude synthetic gas with overheated gas. According to the method disclosed by the invention, the reaction cavity of the gasification furnace and a spraying nozzle are designed andan actual reaction space of the reaction cavity of the gasification furnace is matched with a flow field for reaction of raw materials, so that C1 raw materials are mixed in the reaction cavity in a high-strength manner and are in sufficient contact; the mass transfer effect is improved, and the high-concentration crude synthetic gas taking CO and H2 as main raw materials is obtained; and the utilization efficiency of a C1 fuel resource is improved.

Owner:THE NORTHWEST RES INST OF CHEM IND

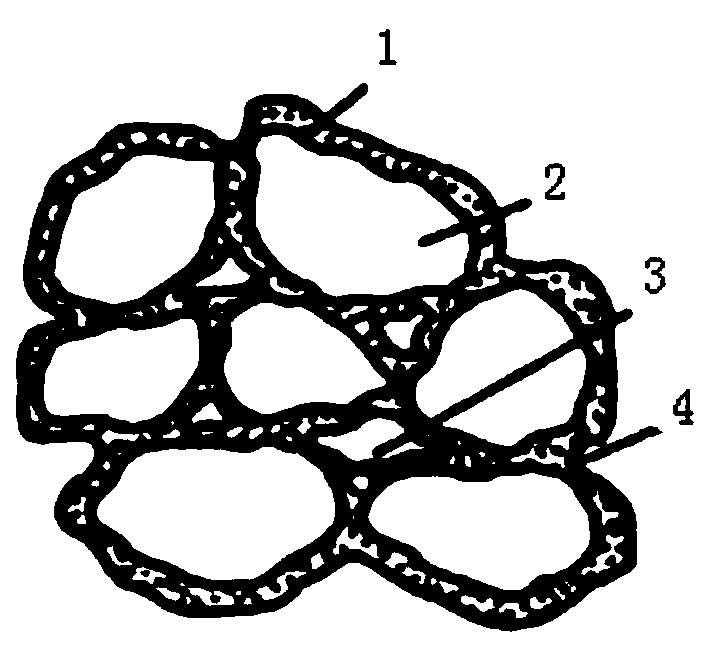

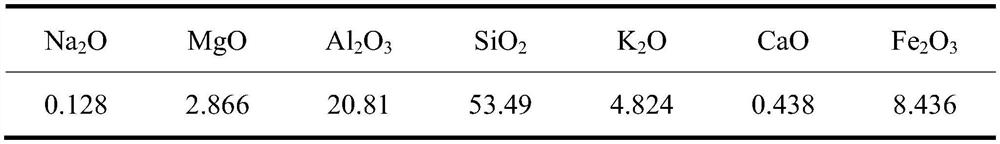

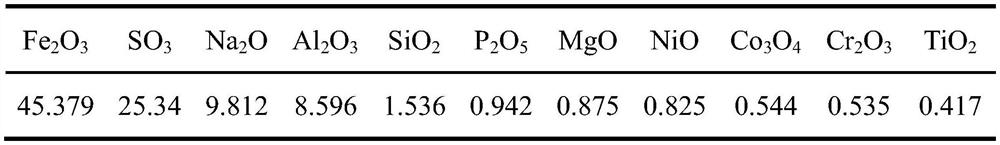

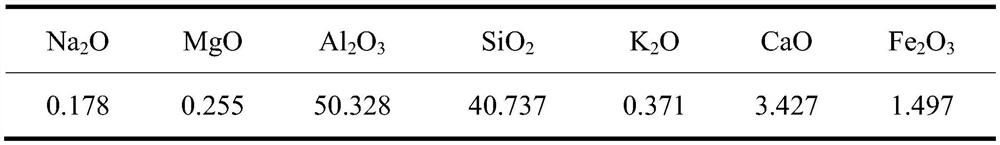

Composition for preparing ultralight ceramsite, ceramsite and preparation method thereof

The invention discloses a composition for preparing ultralight ceramsite, which comprises the following components in parts by weight: 60-100 parts of shale, 0-40 parts of fly ash and 2-20 parts of jarosite slag. 0.22% of silicon carbide is also added on the basis of the total weight of the shale, the coal ash and the jarosite slag. By matching the components, effective utilization of waste resources such as shale and jarosite slag is realized, solid waste discharge is reduced, ultralight ceramsite with stacking density below 400kg / m < 3 > and low water absorption can be obtained, the raw material cost is low, the added value of the product is high, and high-valued utilization of wastes is realized. The invention also discloses ceramsite prepared by taking the composition as a raw materialand a preparation method of the ceramsite.

Owner:长沙中瓷资源循环利用有限公司 +1

Casting paint composition prepared by industrial dust

ActiveCN109865795AReduce solid waste dischargeImprove high temperature strengthFoundry mouldsFoundry coresSodium fluosilicateEther

The invention provides a casting paint composition prepared by industrial dust. The casting paint composition comprises the components of the industrial dust, carrier liquid, silicon carbide, alkali phenolic resin, amphiphilic cellulose ether, attapulgite, porcelainizing agent, calcium phosphate, sodium fluosilicate, polycarboxylate and acetylenic diol; and the mass parts of the components are asfollows: 100 parts of industrial dust, 40-70 parts of carrier liquid, 5-15 parts of silicon carbide, 5-15 parts of alkali phenolic resin, 0.2-0.6 part of amphiphilic cellulose ether, 2-10 parts of attapulgite, 4-12 parts of porcelainizing agent, 2-6 parts of calcium phosphate, 3-7 parts of sodium fluosilicate, 0.2-0.6 part of polycarboxylate and 0.1-0.3 part of acetylenic diol. Casting paint is prepared by fully using effective components of casting resin sand regenerative dust and thinner strength characteristic; the prepared casting paint is excellent in performances, and can meet the requirements of the casting paint; meanwhile, the recycling of the industrial dust is achieved; the environmental pollution is reduced; the production cost is reduced; and the comprehensive and cyclic utilization of resources is achieved.

Owner:GANSU KOCEL CHEM

Method for recovering steel ladle cast residues by using converter

InactiveCN106834590AHigh yieldReduce solid waste dischargeManufacturing convertersRecycling and recovery technologiesScrapMetal

The invention discloses a method for recovering steel ladle cast residues by using a converter, and belongs to the technical field of production of medium-thickness plates. The method includes the steps of proportioning converter raw materials, wherein the raw materials comprise 100-102t of molten iron, 3-5t of plate-edge steel scraps and 3-5t of solid steel ladle cast residues; adding 500-1000kg of lime and 2000-3000kg of limestone in a first batch material when blowing is started, carrying out blowing for 3-6min, and adding 2000-2500kg of the limestone into a second batch material; and adopting bottom blowing operation in the blowing process, wherein the gun position is 1.2-1.3m, and the final temperature is controlled to be 1650-1670DEG C. The method for recovering the steel ladle cast residues by using the converter has the advantages that solid waste emission is reduced, and the yield of metal materials is increased, the utilization rate of slagging agents is increased, and the smelting cost is reduced.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL

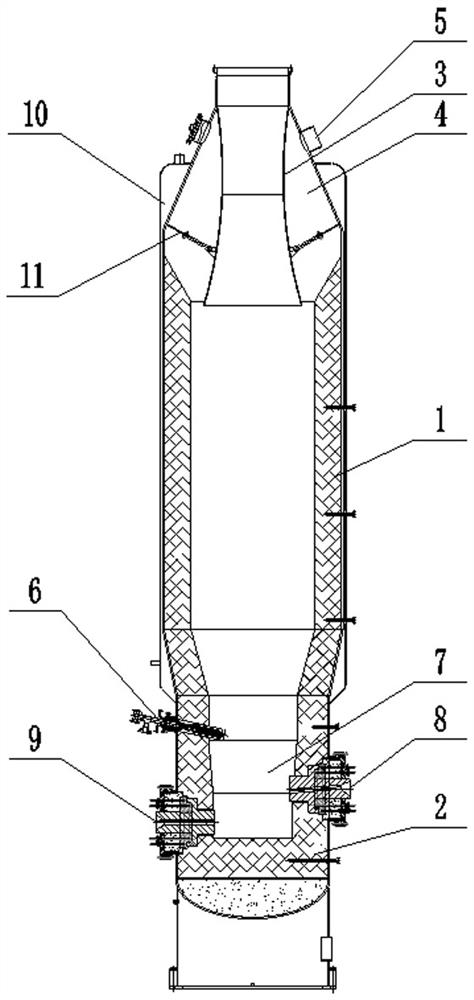

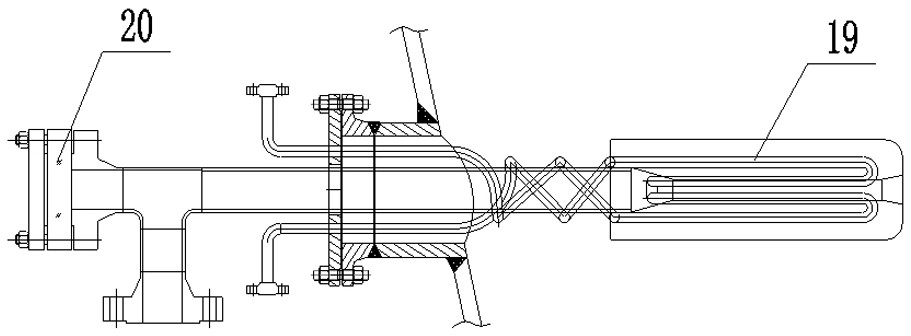

Pressurized moving bed oxygen thermal method calcium carbide gas integrated production equipment

ActiveCN111874908AReasonable qualityGuaranteed qualityCalcium carbideGas dust removalCarbideMoving bed

The invention relates to pressurized moving bed oxygen thermal method calcium carbide gas integrated production equipment. The equipment comprises a calcium carbide gasifier, a first gasifier body isarranged above the waist of a gasifier body of the calcium carbide gasifier, and a second gasifier body is arranged below the waist. The top of the first furnace body is of a frustum body structure, and a distribution cylinder with a hyperbolic section is longitudinally arranged in the middle of the frustum body structure; and an annular gas collection chamber is formed by a cavity between the material distribution cylinder and the inner wall of the frustum body structure. The bottom of the gas collecting chamber is communicated with the furnace chamber of the first furnace body, and the top of the gas collecting chamber is provided with a gas collecting chamber outlet for outputting calcium carbide furnace gas to the outside of the furnace body. The plurality of oxygen nozzles are arranged around the waist of the furnace body. A hearth for accommodating liquid calcium carbide is arranged in the second furnace body; a calcium carbide outlet is formed in the second furnace body; a heavycalcium carbide outlet is formed in the bottom of the second furnace body. According to the invention, fully-closed safe operation of calcium carbide production can be realized, raw material and power consumption is reduced, carbon emission is reduced, and the environment is improved.

Owner:北京海卓康低碳技术有限公司

Environment-friendly process for quizalofop-p-ethyl production

ActiveCN107739343AHigh recovery rateIncrease profitOrganic chemistryEthyl lactateHydroquinone Compound

The invention relates to an environment-friendly process for quizalofop-p-ethyl production. The environment-friendly process is characterized by comprising the following steps: firstly enabling hydroquinone to react with sodium hydroxide to prepare sodium salt of the hydroquinone, then reacting with 2,6-dichloroquinoxaline to obtain 4-(6-chloro-2-quinoxalinyloxy) and reacting with ethyl lactate p-toluenesulfonate to obtain the quizalofop-p-ethyl; then performing alkaline hydrolysis and acidification on produced quizalofop-p-ethyl butter and recovering 6-chloro-2-quinoxalinone. The synthetic process has the advantages that as the reaction and the post-treatment are performed in an organic solvent, the alkalinity of a reaction system is reduced, the defect that impurities are easy to generate due to too strong aqueous phase reaction alkalinity is overcome, and the hydrolysis of 2,6-dichloroquinoxaline as a raw material is reduced, so that the content of 4-(6-chloro-2-quinoxalineoxy) phenol reaches 98 percent or above, and the yield reaches 92 percent or above; 6-chloro-2-hydroxyquinoxaline in the quizalofop-p-ethyl butter is recovered, so that the solid waste discharge amount is reduced, the environment is protected, and the intermediate cost of the quizalofop-p-ethyl is reduced.

Owner:JINGBO AGROCHEM TECH CO LTD

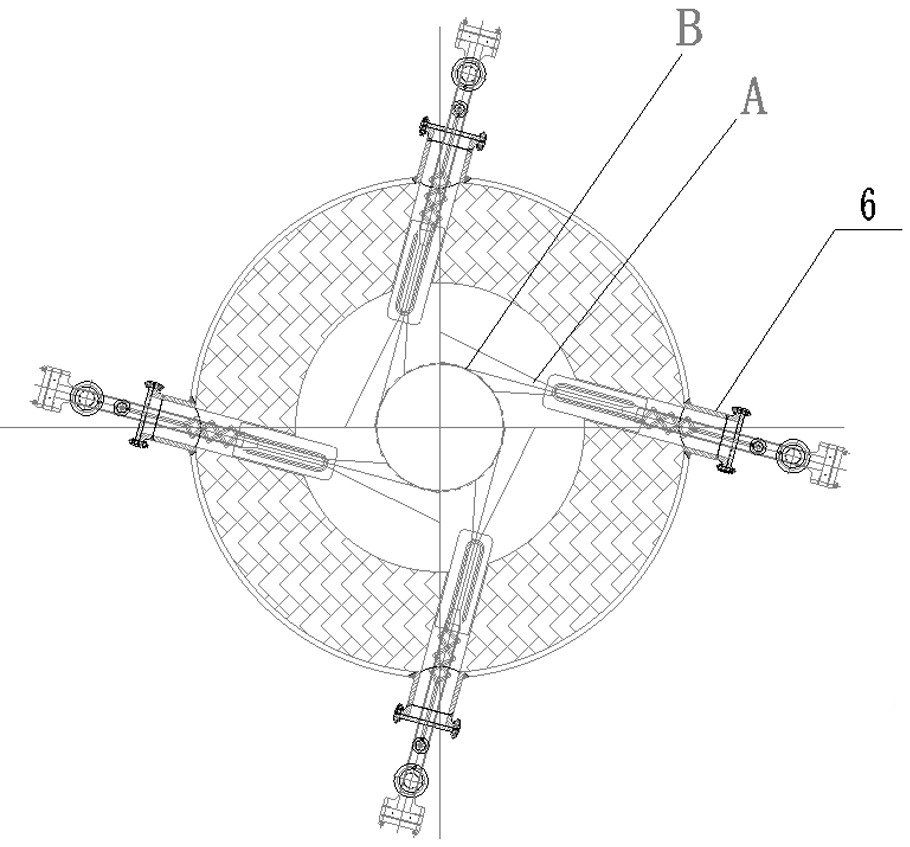

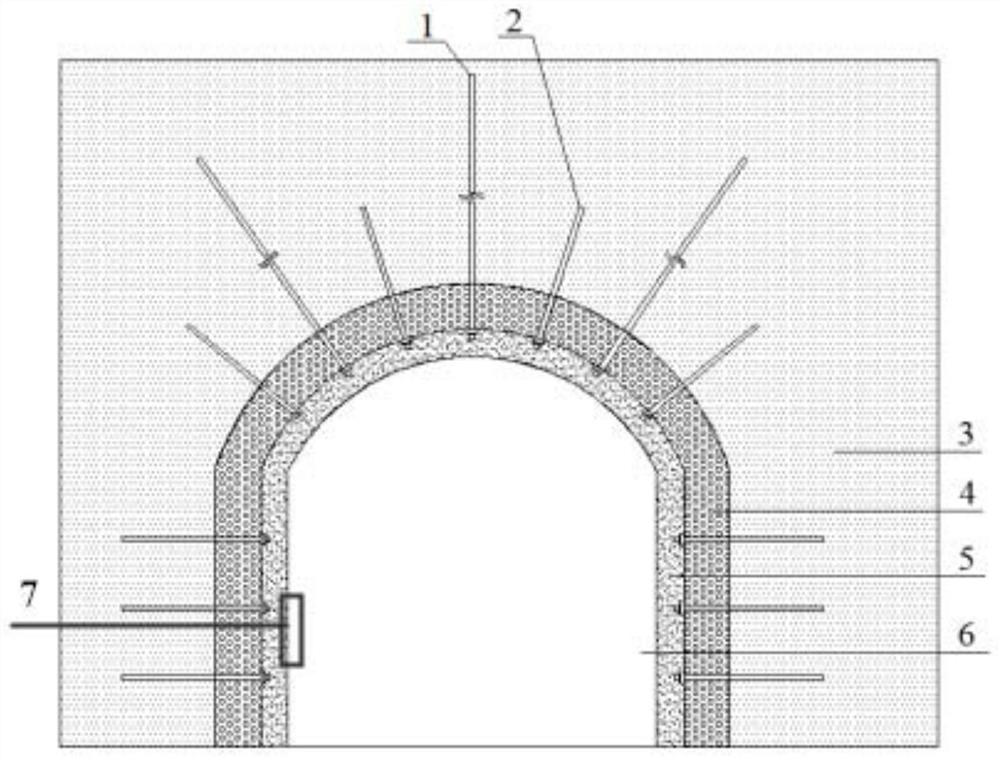

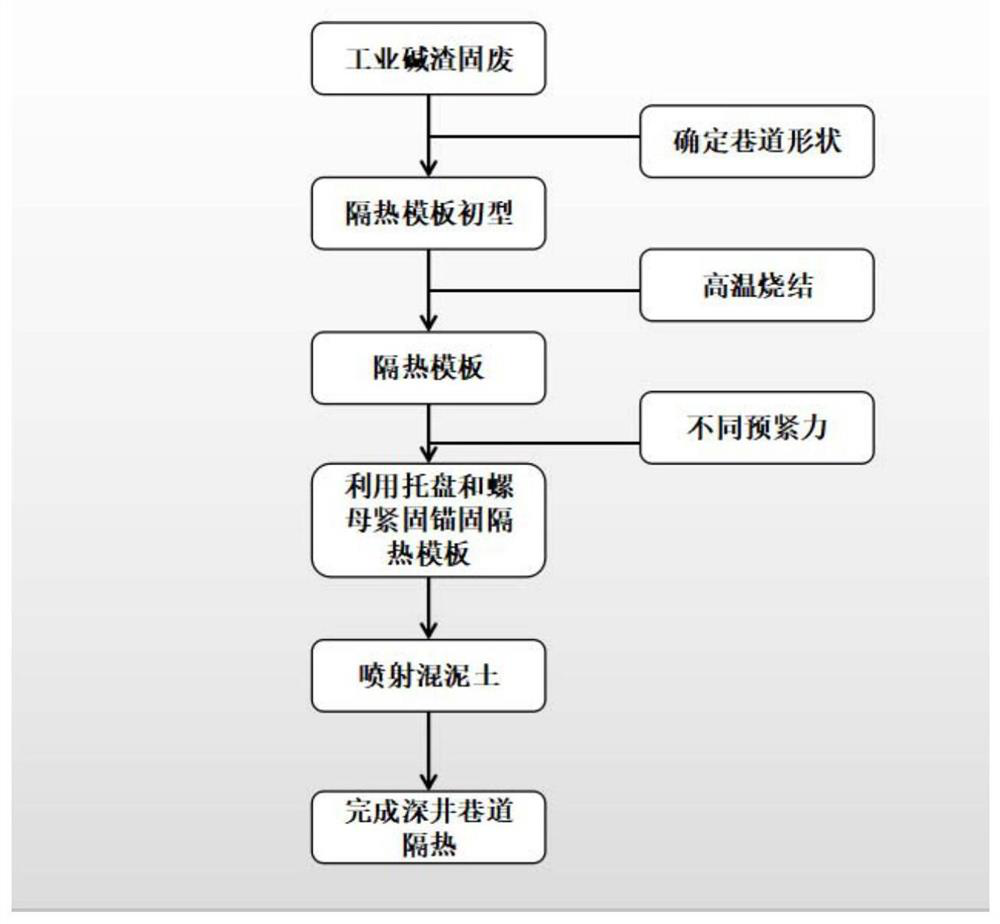

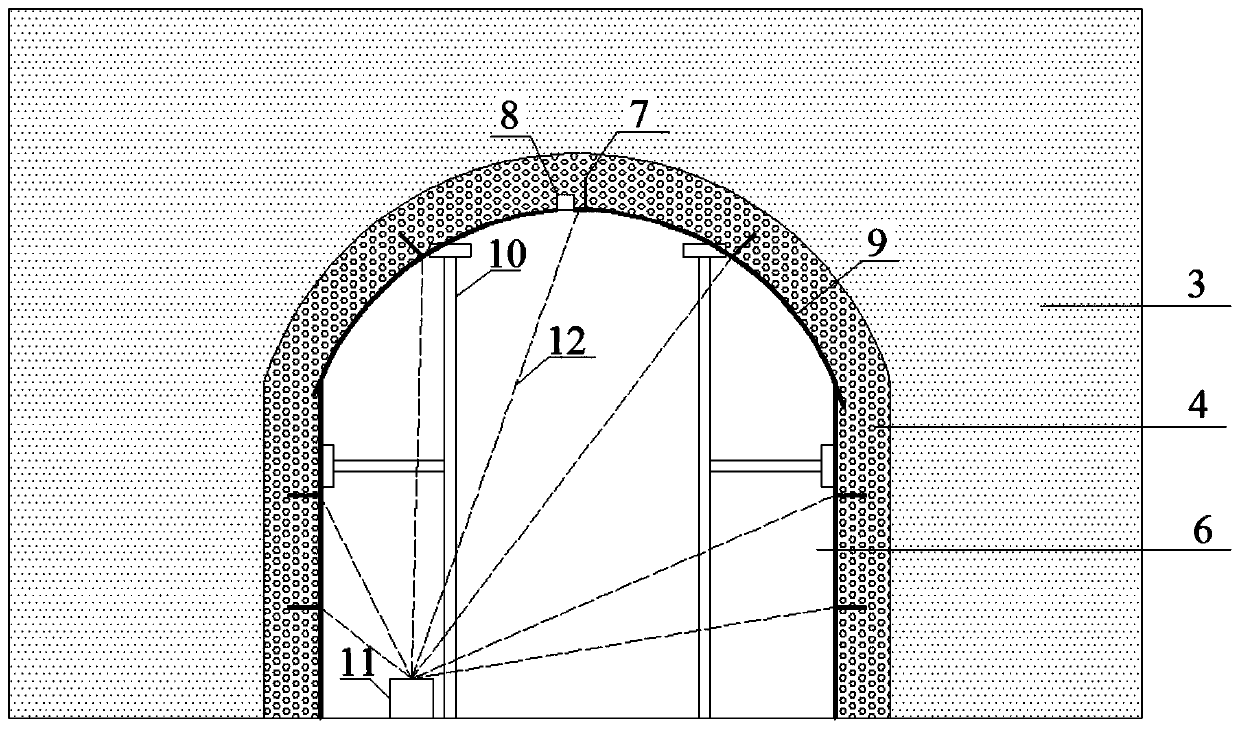

A heat insulation device for mine roadway and its construction method

ActiveCN110863846BGood heat insulationImprove the support effectMining devicesUnderground chambersRock boltWaste material

The invention discloses a heat insulation device for mine roadway and a construction method thereof. The structure of the solid waste heat insulation device includes anchor cables, anchor rods, surrounding rock, solid waste heat insulation templates, concrete layers, roadways, temperature The sensor, the invention utilizes solid waste materials to sinter at high temperature to prepare heat-insulating formwork, the formwork has good heat-insulating performance and supporting function, can reduce solid waste discharge, and reduce the occupied cultivated land area, and 50% of the anchoring pre-tightening force is used in the construction method, It can solve the problem of high preload support failure, heat insulation formwork and surrounding rock separation when the roadway is deformed.

Owner:SHANDONG UNIV OF SCI & TECH

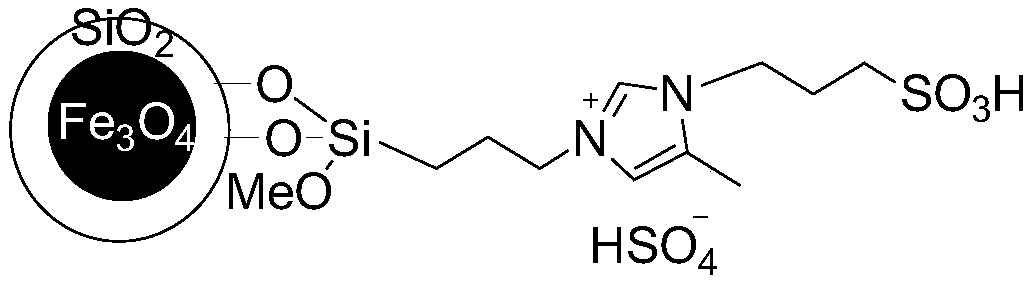

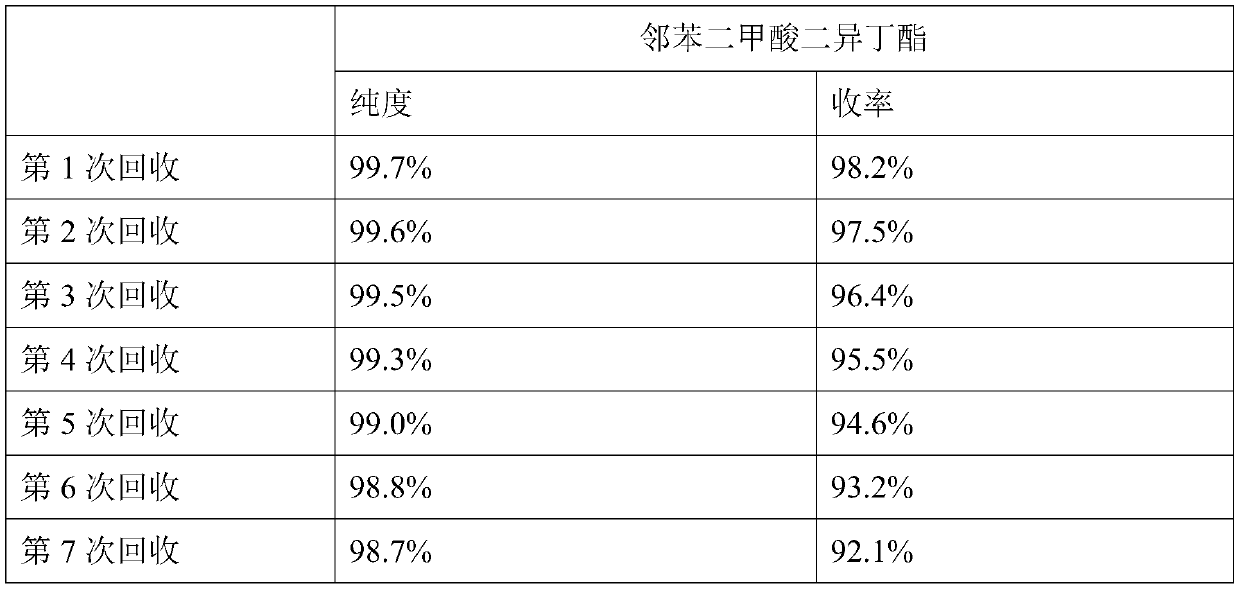

Method for preparing diisobutyl phthalate

ActiveCN110330428AEasy to recycleGood repeatabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolWater discharge

The invention discloses a method for preparing diisobutyl phthalate. The method comprises the following steps: 1, preparing a magnetic nanoparticle-supported acidic ionic liquid used as a catalyst; and 2, preparing the diisobutyl phthalate: carrying out refluxing dehydration condensation on phthalic anhydride and isobutanol under the catalysis of the magnetic nanoparticle-supported acidic ionic liquid for 3-6 h to obtain a diisobutyl phthalate reaction solution, cooling the reaction solution to room temperature, filtering the cooled reaction solution, adsorbing the obtained filtrate I by a solid alkali, performing filtration to obtain a filtrate II and a filter cake respectively, and carrying out reduced pressure dealcoholysis on the filtrate II to obtain the diisobutyl phthalate. The magnetic nanoparticle-supported acidic ionic liquid is used as the catalyst to achieve catalytic synthesis of the diisobutyl phthalate, so the method has the characteristics of high catalysis efficiency,easiness in recovery and reuse of the catalyst, simple process and less waste water discharge.

Owner:ZHEJIANG JIANYE CHEM +1

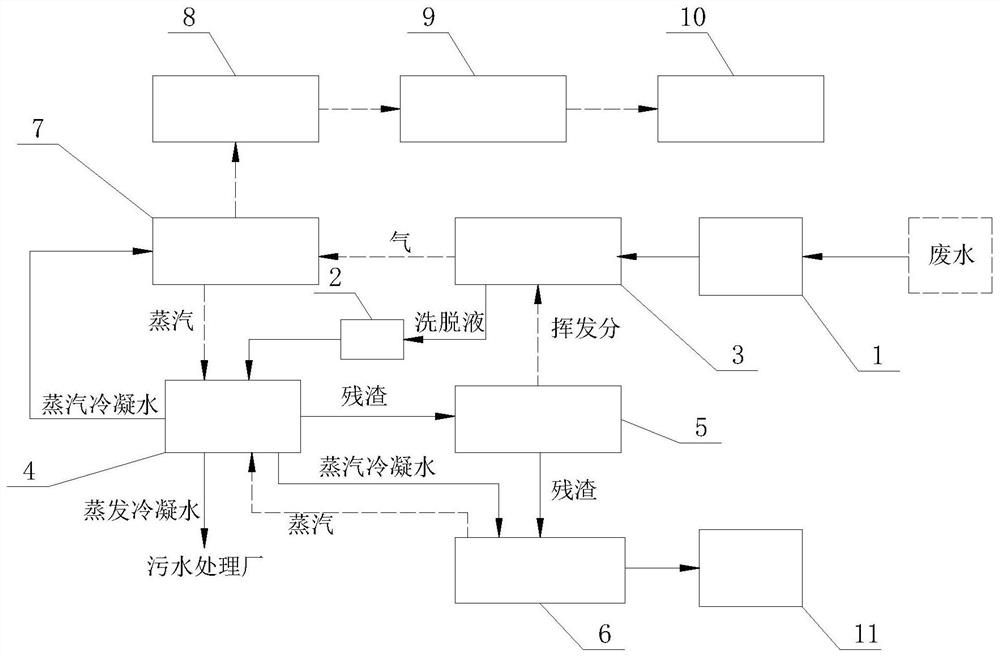

Integrated treatment system and method for high-salt-content and high-concentration organic wastewater

PendingCN114149044ALow process temperatureReduce energy consumptionWater treatment parameter controlSpecific water treatment objectivesCarbonizationWastewater

The invention discloses an integrated treatment system and method for high-salt-content and high-concentration organic wastewater. The integrated treatment system comprises a wastewater pump I, a wastewater pump II, an elution device, an evaporator, a pyrolysis carbonizer, a deslagging cooler, a combustion heat exchanger, a purifier, an induced draft fan and a chimney, according to the invention, an integrated technical scheme of first low-temperature drying and dehydration, then medium-temperature pyrolysis and carbonization, and direct recovery of waste heat of pyrolysis and carbonization products for drying and dehydration of waste water and a structural design of disturbance and dispersion of fillers in a dryer and a pyrolysis carbonizer are adopted; the problems of corrosion and blockage of drying dehydration and pyrolysis carbonization equipment and the problems of high energy consumption and high cost of the system are thoroughly solved, and finally the purpose of treating wastewater and waste salt with low energy consumption and low cost is achieved.

Owner:徐州无废城市技术研究院有限公司

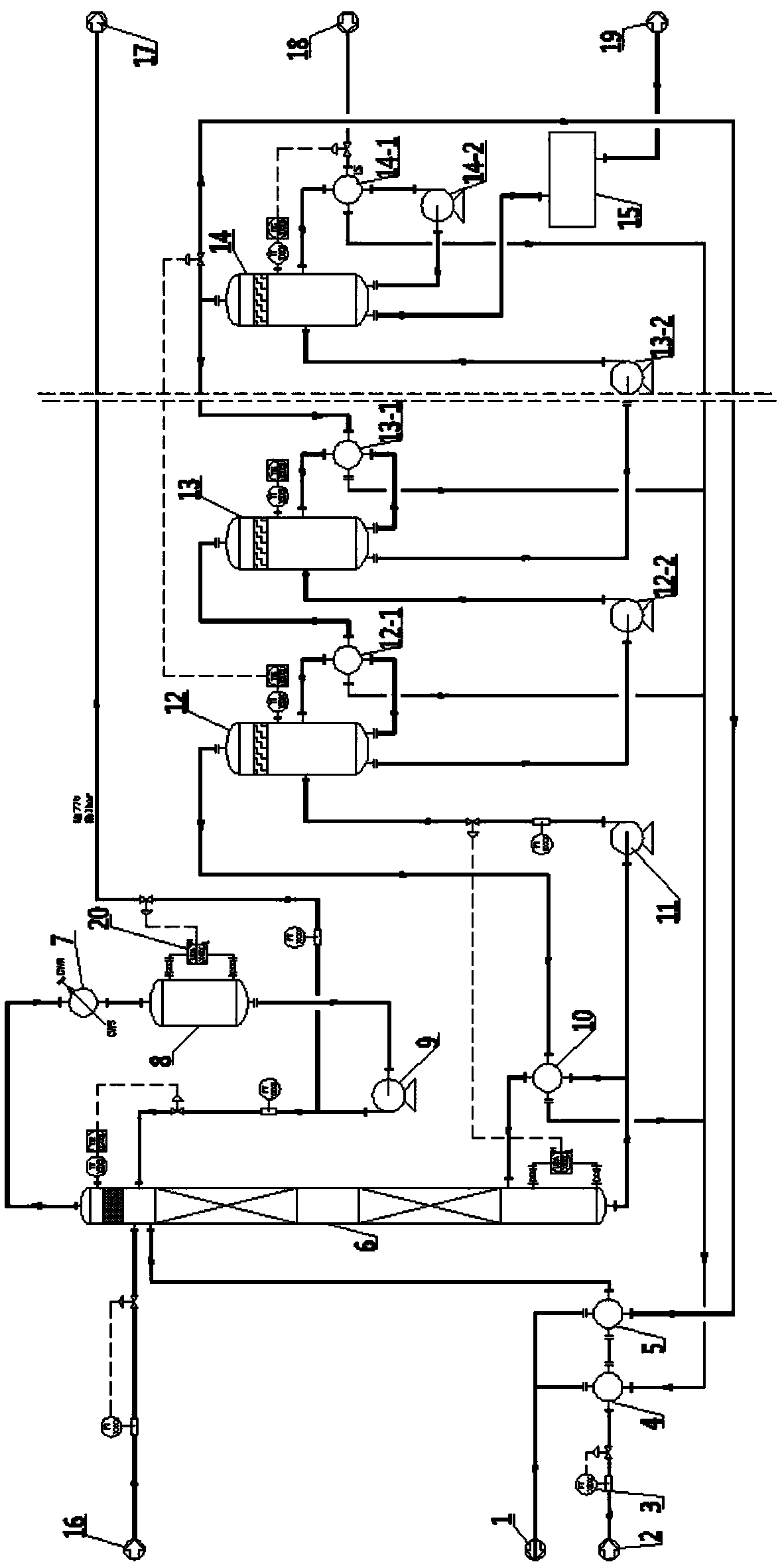

Technology and device for continuously removing light-component ammonia nitrogen organic matters and salts

PendingCN107792904AReduce consumptionHigh purityWater/sewage treatment by centrifugal separationWater contaminantsWater desalinationDistillation

The invention belongs to the technical field of wastewater treatment, and particularly relates to a technology and a system for continuously removing light-component ammonia nitrogen organic matters and salts. A technological method for removing the ammonia nitrogen and the salts from wastewater is characterized by comprising the following technological steps: 1, distilling in a rectifying tower;2, performing first-stage evaporation; 3, performing second-stage evaporation; ...n, performing nth-stage evaporation; n+1, performing final-stage evaporation. An equipment system used by the technology for removing the ammonia nitrogen and the salts from the wastewater comprises the rectifying tower, a first-stage evaporation tank, a second-stage evaporation tank and an nth-stage evaporation tank. The invention has the beneficial effects as follows: 1), the light-component organic matters, especially ammonia water, in the wastewater, are recycled, and the purity is high; 2), the salts in thefinal wastewater are finally converted into solid powder, so that emission of solid wastes is reduced; 3), through coupling of light component removal and heavy component removal, the running energy consumption of a device is reduced by 40-70%; 4), After the light components and the salts are removed from the wastewater, the obtained clean water can return to the system as technological water andis recycled, so that the water consumption is reduced.

Owner:烟台国邦化工机械科技有限公司

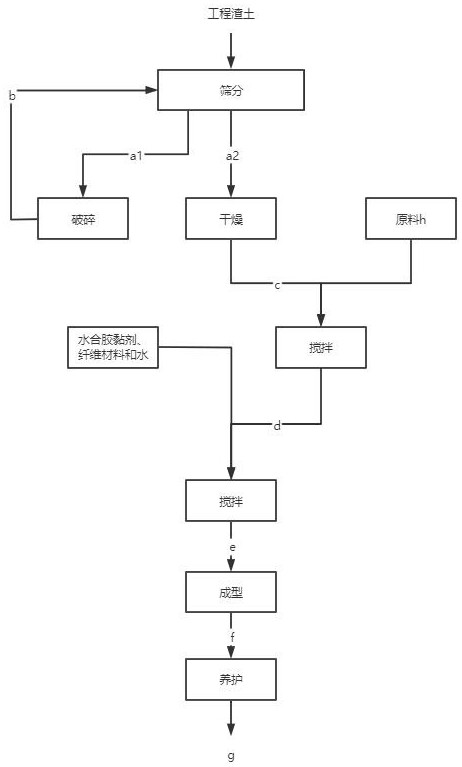

Preparation process of large balancing weight for gravity energy storage made of engineering residue soil

PendingCN114751686AImprove the effective utilization of resourcesReduce solid waste dischargeChemistryScreening procedures

The invention discloses a preparation process of a large balancing weight for gravity energy storage made of engineering residue soil. The preparation process comprises the following steps: (1) a screening procedure: screening the engineering residue soil to obtain a product a1 and a product a2; (2) crushing: crushing the product a1 to obtain a product b; (3) circulation process: mixing the product b into engineering residue soil, and repeating the steps; (4) drying: drying the product a2 to obtain a product c; (5) mixing and stirring: uniformly mixing and stirring the product c and a raw material h to obtain a product d; (6) burdening: mixing the product d with a hydrated adhesive and a fiber material, and uniformly stirring to obtain a product e; (7) a material injection procedure: injecting the product e into a material injection bin; (8) forming: pressing the product e in the injection bin into a forming bin to obtain a semi-finished balancing weight f; and (9) a maintenance procedure: the semi-finished balancing weight f is moved to a maintenance area, and a finished balancing weight g is obtained. The engineering residue soil is used for manufacturing the balancing weight, and the effective utilization rate of resources is increased.

Owner:CHINA TIANYING

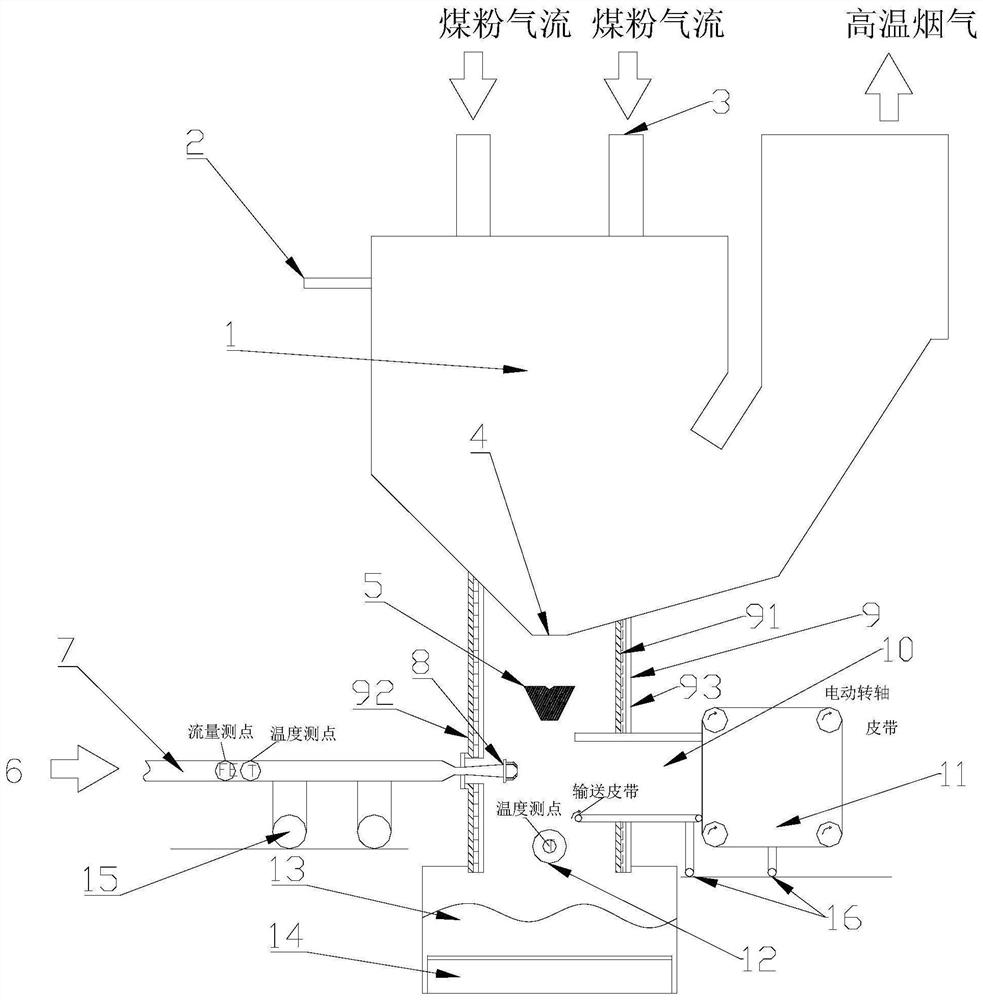

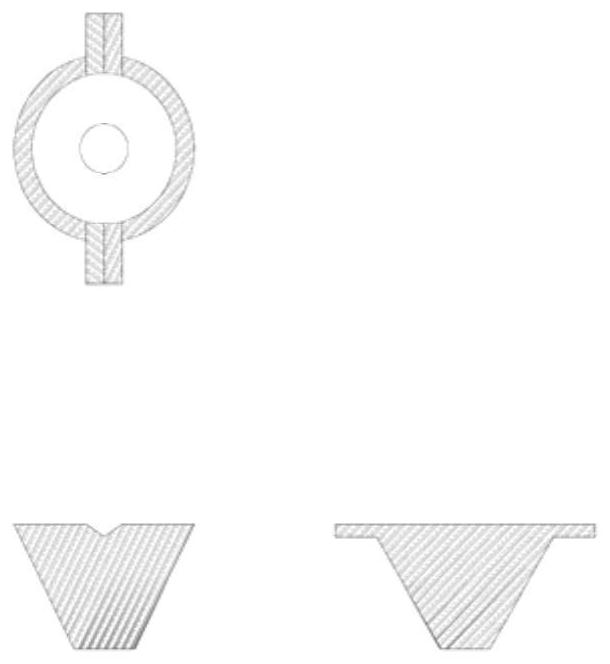

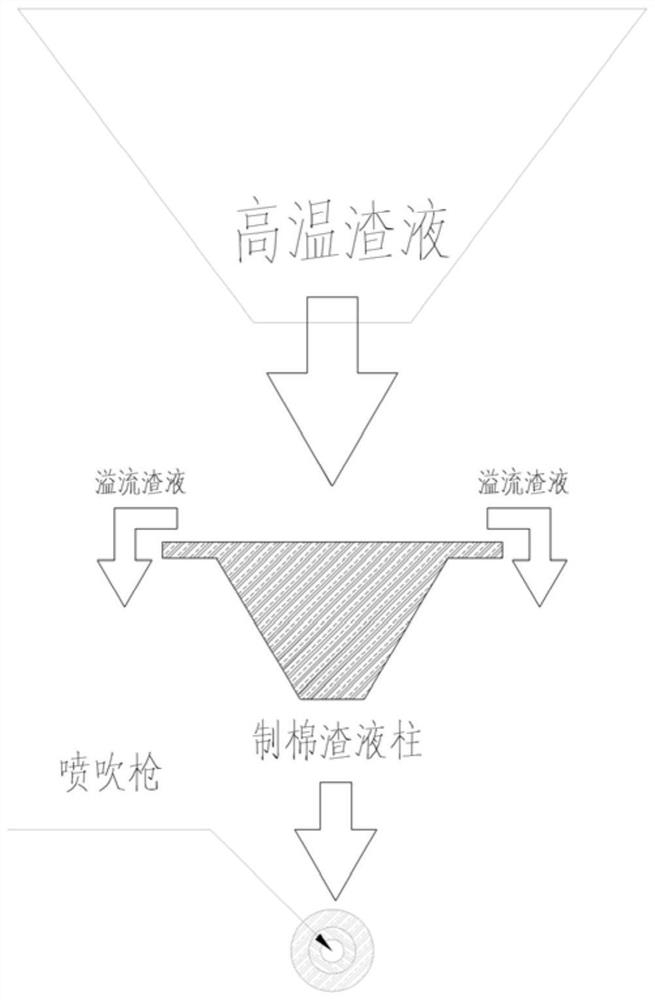

Method and system for producing glass fiber products by using liquid deslagging boiler

InactiveCN113003930AEmission reductionReduce solid waste dischargeWeft knittingGlass furnace apparatusGlass fiberSocial benefits

The invention provides a method and a system for producing glass fiber products by using a liquid deslagging boiler, and relates to the field of waste gas and solid waste treatment. According to the system and the method for producing the glass fiber products through the liquid slagging boiler, the total discharge amount of solid waste of a power plant can be reduced, waste heat of slag liquid can be effectively utilized, meanwhile, steam, pressurized air, electric energy, circulating water and other process products generated by the boiler of the power plant are efficiently utilized, and the production cost is reduced. The solid wastes of the power plant are converted into industrial products by utilizing equipment of the boiler. Compared with a traditional method, the energy utilization efficiency is improved, solid waste emission of a power plant is reduced, pollutant emission is reduced, and economic benefits and social benefits of the power plant are increased.

Owner:孙叶柱

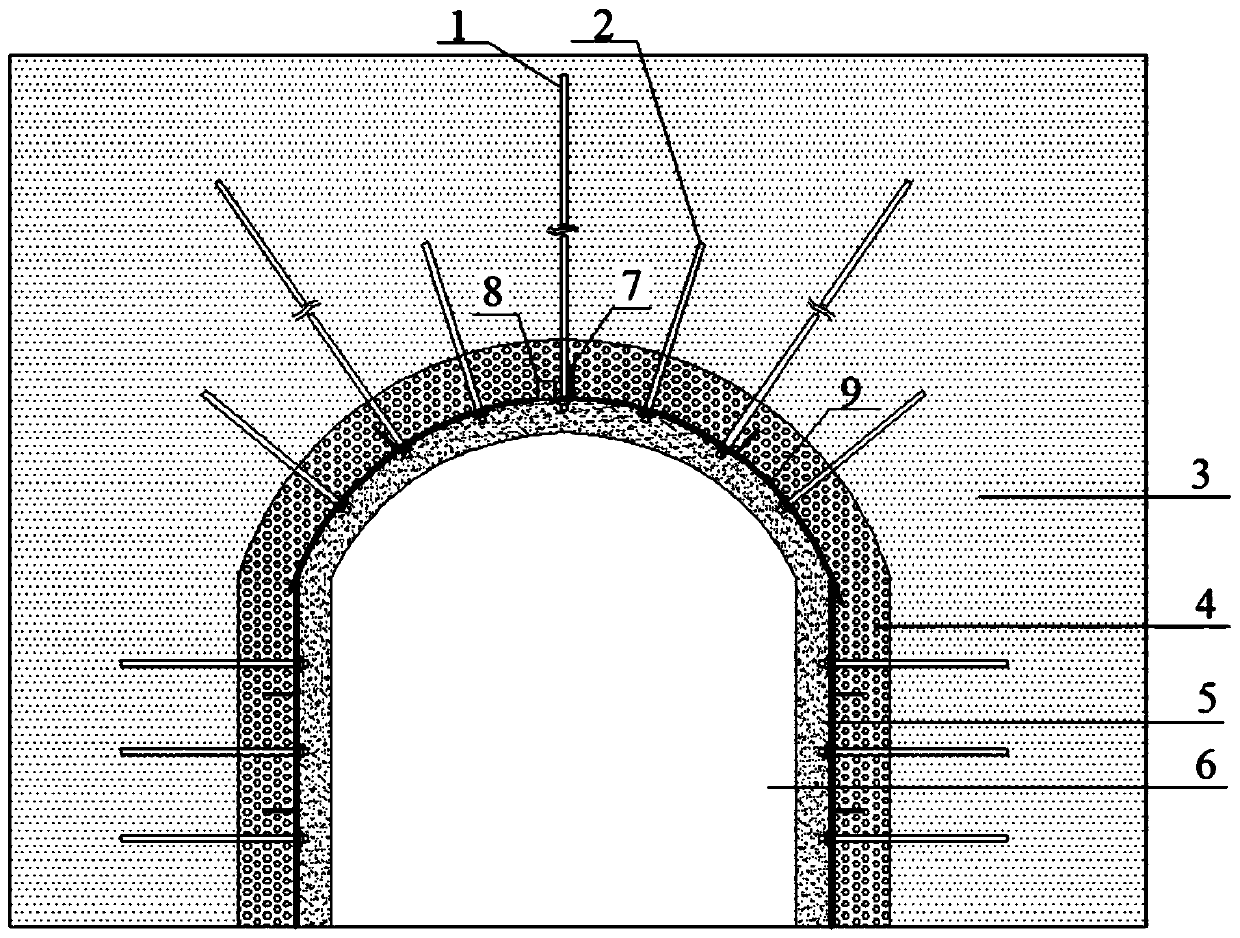

Solid waste heat insulation device for outer surface of surrounding rock of roadway and a construction process thereof

ActiveCN110863847ATightly boundImprove performanceUnderground chambersTunnel liningCarbide siliconHeater Rod

The invention discloses a solid waste heat insulation device for outer surface of surrounding rock of a roadway and a construction process thereof. The solid waste heat insulation device structurallycomprises an anchor cable, an anchor rod, the surrounding rock, a solid waste heat insulation material, a concrete layer, the roadway, a silicon carbide heating rod, a material injection port, a corundum plate, a temporary supporting device, a voltage transformation and temperature rise device and a cable. According to the solid waste heat insulation device, a heat insulation formwork is directlygenerated at high temperature under a well through solid waste slurry, forming is good, the heat insulation formwork is tightly combined with the surrounding rock of the roadway in shape, carrying isnot needed, solid waste is used for preparing the heat insulation formwork, solid waste emission can be reduced, and the occupied cultivated area is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Casting process method for improving sand strength of casting sand grains

The invention relates to a casting process method for improving sand strength of casting sand grains. The casting process method comprises the following steps of 1, preparing raw materials, wherein the raw materials comprise molding sand and a reinforcing agent; 2, adding the raw materials to a casting sand mixing device, adding sand, adding a reinforcing agent, adding the reinforcing agent in a manner of powder or powder concentration into a liquid state, and fully stirring and uniformly mixing the raw materials; 3, adding an adhesive and a curing agent, fully uniformly mixing, then molding and compacting in a sand box, and arranging an overflow port and an air outlet hole on the sand mold; 4, carrying out mold removal after self-hardening, and performing modification; and 5, carrying outbrush coating, box closing, hot air drying, pouring, sand falling and recycling. According to the casting process method, the reinforcing agent material such as the nanoscale refractory material is used for carrying out sand mixing molding production through compatibility with a traditional casting sand production line and equipment, so that the purpose of greatly improving the strength of the sand mold on the premise of not additionally increasing the adding amount of the resin is achieved.

Owner:王海江

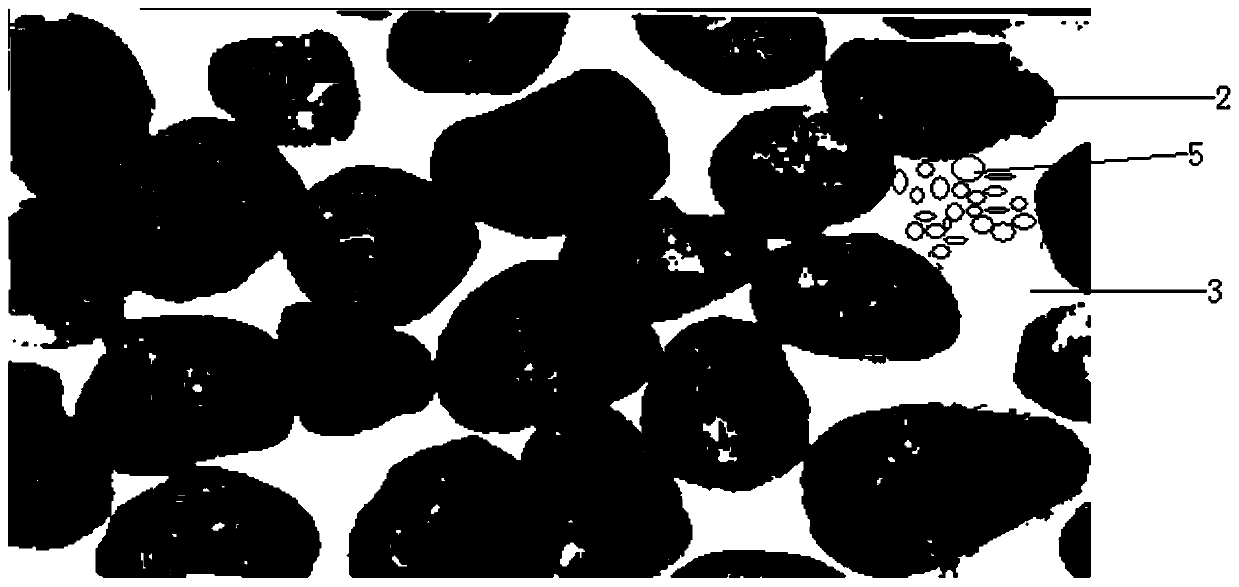

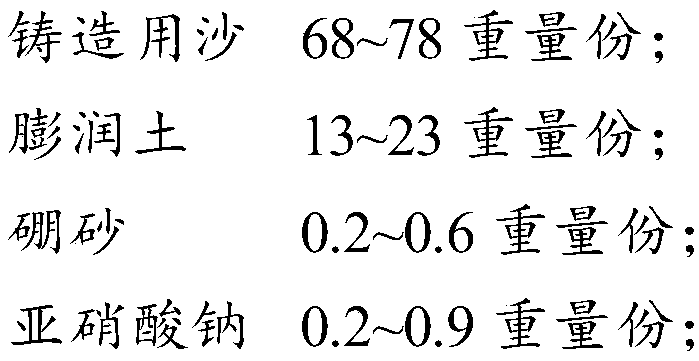

Cast glass sand and preparation method thereof

ActiveCN109175217AGood sand removal performanceReduce solid waste dischargeFoundry mouldsFoundry coresSodium BentoniteMetallurgy

The invention provides cast glass sand. The cast glass sand comprises water as well as, by weight, 60-88 parts of casting sand, 6-30 parts of bentonite and 0.1-0.9 part of borax. The glass sand is prepared from the borax, bentonite and sand, and the borax is used as an anti-sticking additive and cosolvent. The glass sand provided by the invention is a glass body, is molten under high temperature,is used for filling a gap between mold sand, reducing the infiltration angle and preventing molten iron from infiltrating into the mold sand, and achieves the effect of good sand discharging performance. The glass sand has little solid waste emission, can be repeatedly used instead of being abandoned, and is friendly to the environment as being wholly inorganic matter. No gas is generated during casting and pouring, so that no pollution is caused to the environment. The mold sand is prevented from being degraded when cast.

Owner:李新忠

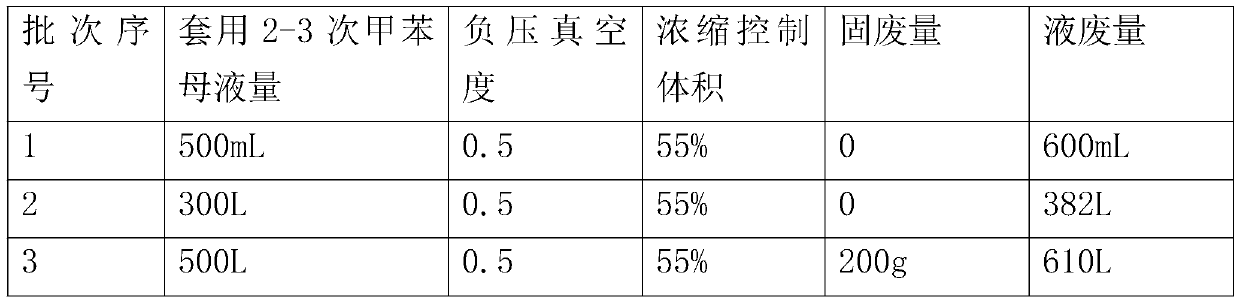

Method for treating toluene mother liquor in order to reducing wastes discharged during preparation of sodium dehydroacetate

InactiveCN109970695AEffective alkaline hydrolysisEfficient removalOrganic chemistryChemistrySodium dehydroacetate

The invention discloses a method for treating a toluene mother liquor in order to reducing wastes discharged during preparation of sodium dehydroacetate. Fine sodium dehydroacetate is obtained by concentrating distillation, negative pressure distillation, coarse crystallization and fine treatment. The method has the following advantages: alkaline hydrolysis of organic impurities can be effectivelycarried out in the manner of alkali lye concentrating distillation and negative pressure distillation, small molecular organic impurities obtained after alkali hydrolysis can be effectively removed by decolorization and recrystallization, decolorizing is carried out to remove impurities in order to form a fine sodium dehydroacetate product, and the emission of solid wastes is effectively reduced.

Owner:经纬精细化工(南通)有限公司

Composition for preparing ultra-light ceramsite, ceramsite and preparation method thereof

The invention discloses a composition for preparing ultra-light ceramsite, which, in parts by weight, comprises 60-100 parts of shale, 0-40 parts of fly ash and 2-20 parts of jarosite slag; Based on the total weight of ash and jarosite slag, 0.2-2% silicon carbide is also added. The combination of components can realize the effective utilization of waste resources such as shale and jarosite slag, reduce the discharge of solid waste, and obtain a bulk density of 400kg / m2 3 Below, the ultra-light ceramsite with lower water absorption at the same time has low raw material cost, high added value of products, and realizes high-value utilization of waste. Also disclosed are ceramsite prepared by using the composition as a raw material and a preparation method of the ceramsite.

Owner:长沙中瓷资源循环利用有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com