Technology and device for continuously removing light-component ammonia nitrogen organic matters and salts

A technology for light components and organic matter, applied in water pollutants, centrifugal separation water/sewage treatment, water/sludge/sewage treatment, etc., can solve incomplete treatment, impure treatment products, failure to achieve waste utilization, etc. problems, to achieve the effect of reducing water consumption, reducing solid waste discharge, and reducing energy consumption for device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

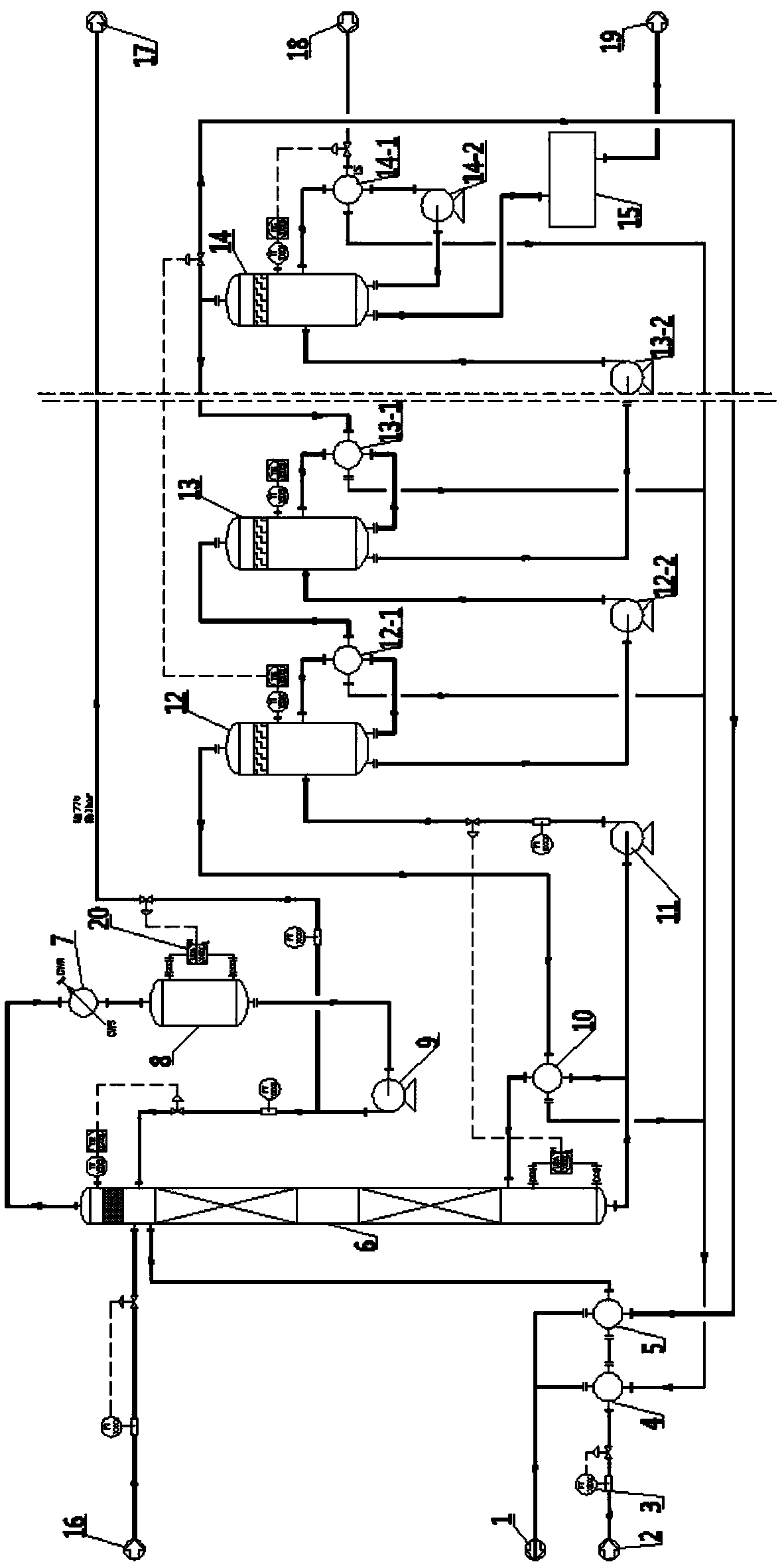

[0030] Accompanying drawing is a kind of specific embodiment of the present invention.

[0031] The technique for continuously removing ammonia nitrogen light component organic matter and salt of the present invention comprises the following process steps:

[0032] Step 1: Distillation in the rectification tower kettle: the waste water from outside the boundary area is heated by the preheater, and then transported to the rectification tower kettle for rectification treatment. The ammonia vapor is introduced into the condenser from the top of the rectification tower kettle to condense After treatment, it is evaporated through the evaporating tank of the tower kettle, and the ammonia gas outlet and the upper part of the rectification tower kettle are branched and pressed into the ammonia gas outlet and the upper part of the rectification tower kettle through the tower kettle. ; The bottom liquid of the rectification tower kettle is pressed into the rectification tower kettle thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com