Patents

Literature

120 results about "Ammonia vapor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonia appears in nature as a natural substance that results from decomposition. Ammonia vapor is a colorless gas with a pungent odor. Ammonia exists as a vapor at atmospheric conditions. Ammonia vapor is lighter than air and tends to rise when released to atmosphere.

Method for recycling ammonia from low concentration ammonium chloride wastewater

The invention discloses a method for recovering ammonia from low-concentration ammonium chloride wastewater, which comprises the following steps that: an alkaline substance is added into the low-concentration ammonium chloride wastewater to prepare mixed slurry containing ammonia water and chloride salt; the mixed slurry is subjected to the separation and concentration of the ammonia water in an ammonia water distillation concentration tower to obtain ammonia vapor and a drained waste liquid; the ammonia vapor is conveyed to an ammonia water cooler for cooling treatment, and the ammonia water obtained by the cooling treatment is stored for standby; and the drained waste liquid is subjected to solid-liquid separation to obtain solid-phase residue and a waste liquid containing the chloride salt. The method evaporates the ammonia in the low-concentration ammonium chloride wastewater and concentrates the ammonia to an industrial grade concentration, and has the advantages of broad source of auxiliary materials, low cost, completely sealed technical process, and low energy consumption; and drained substances meet the requirement of no pollution and no nuisance.

Owner:包头市西骏环保科技有限公司

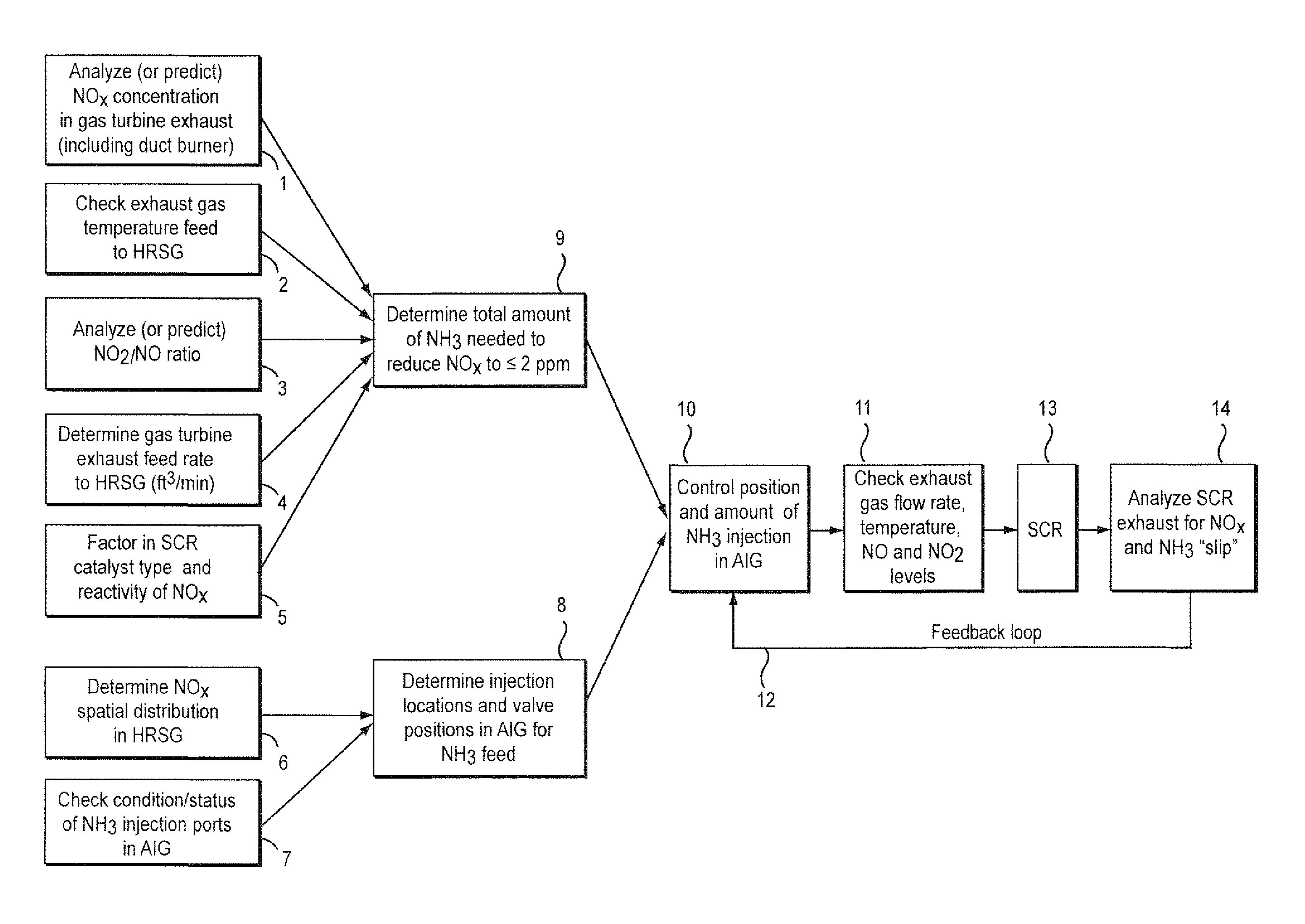

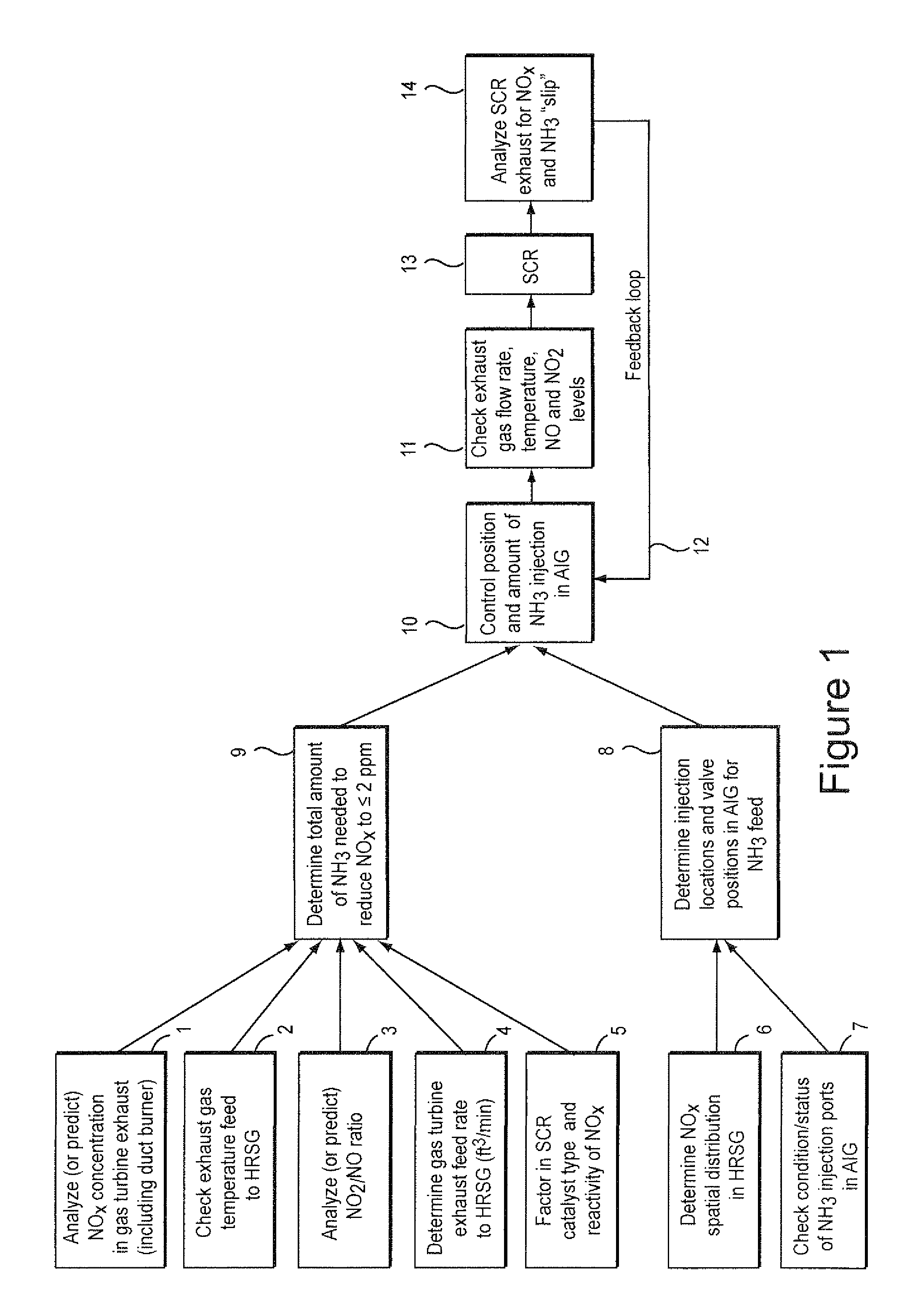

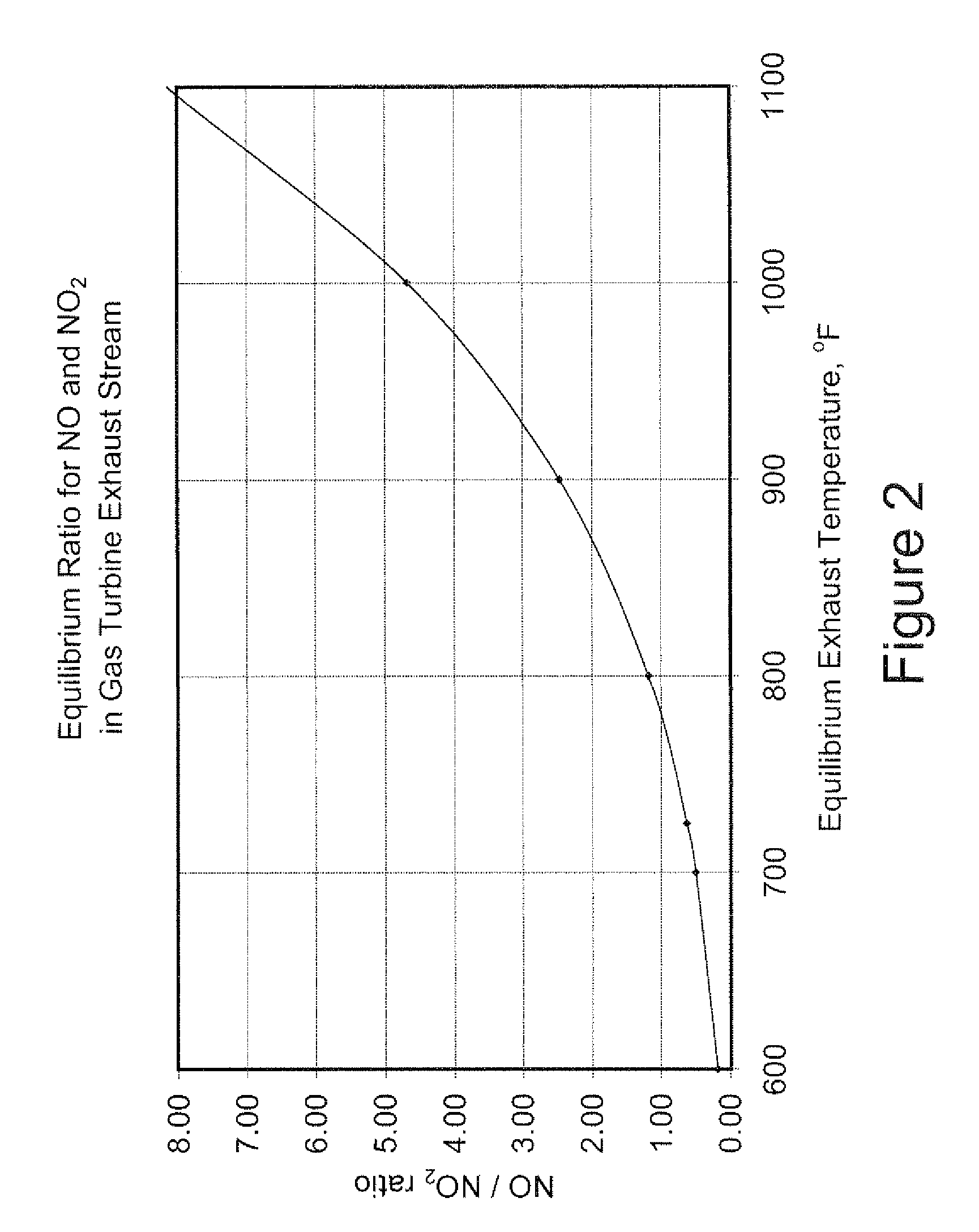

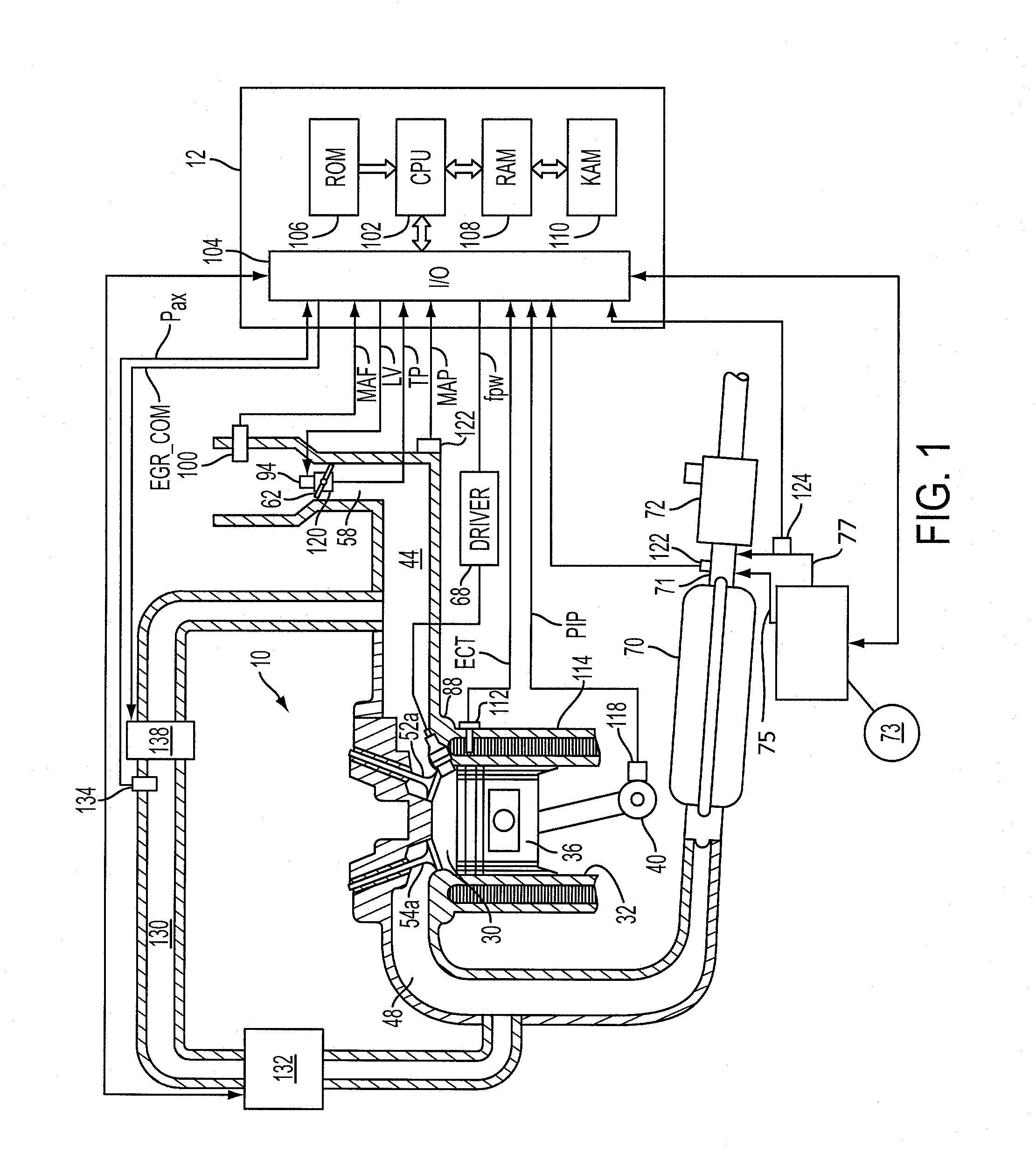

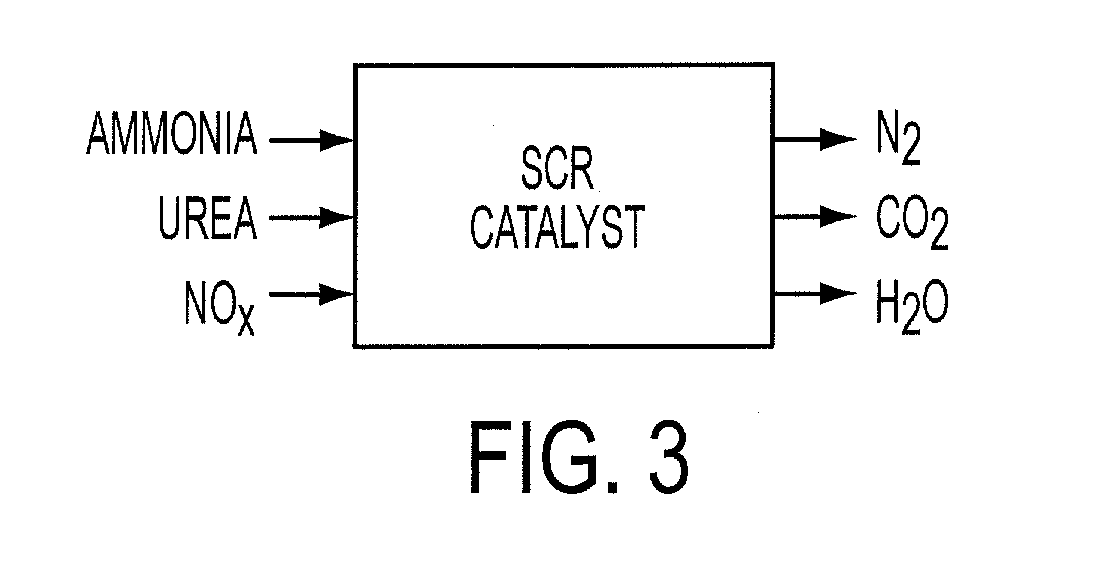

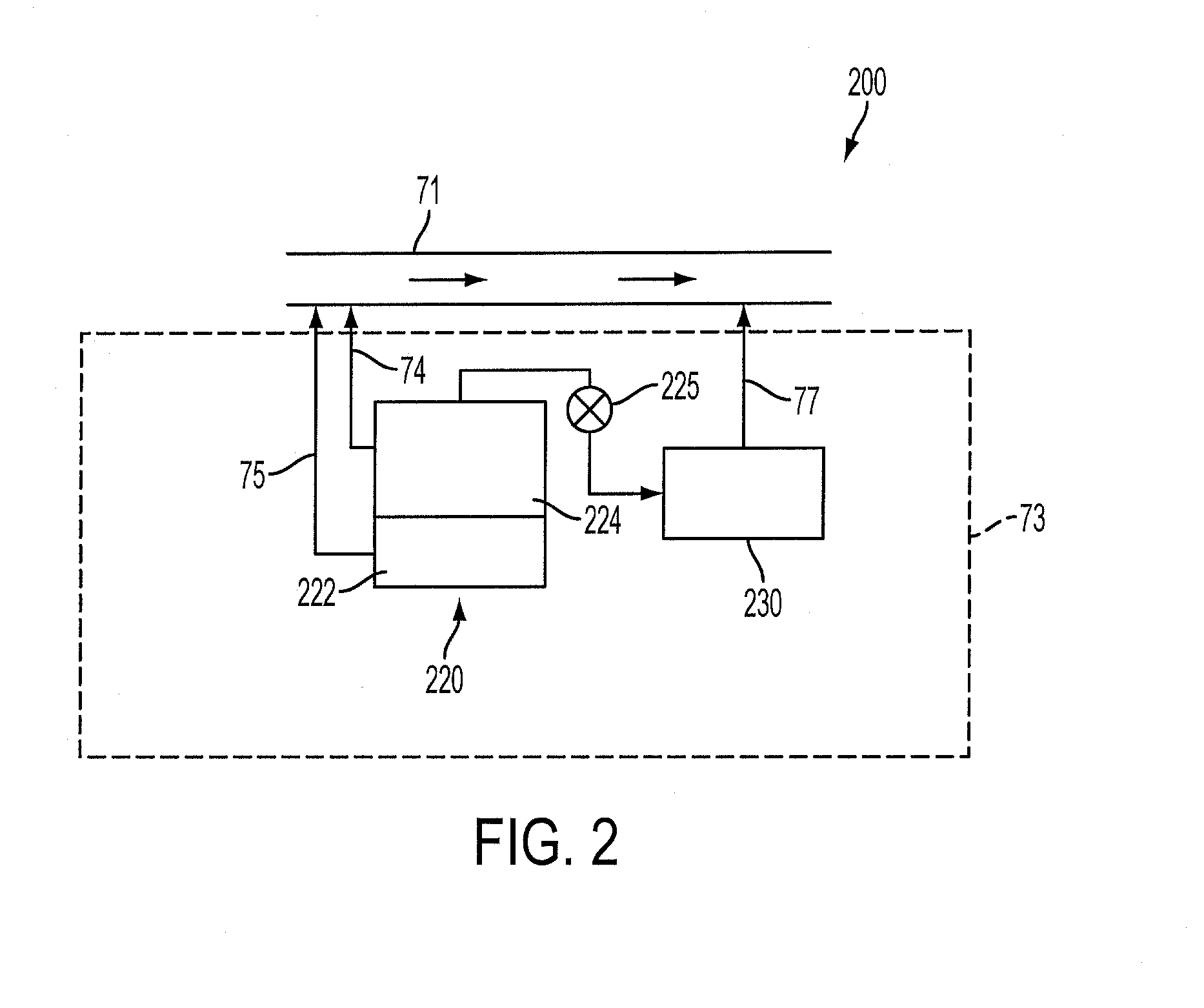

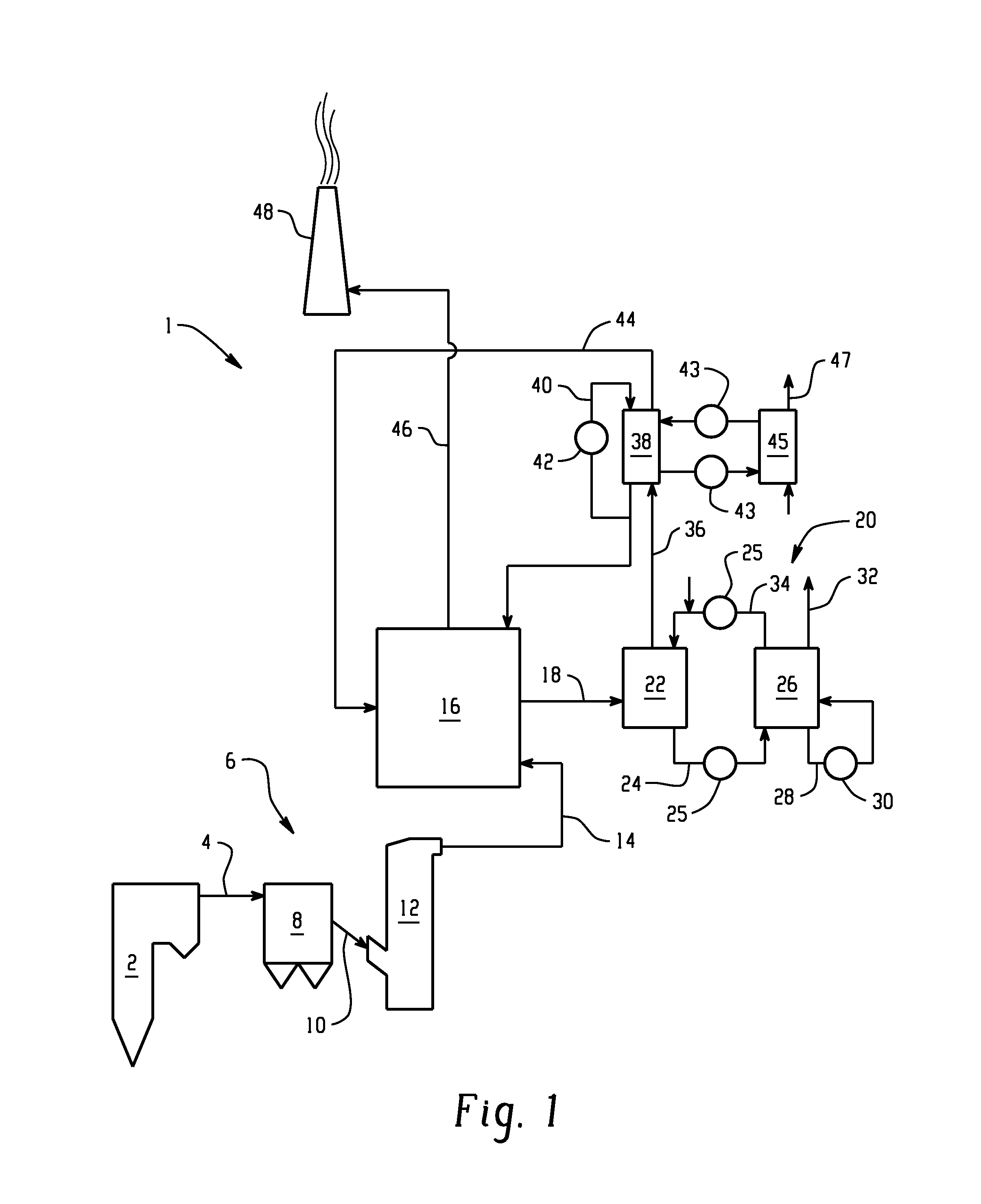

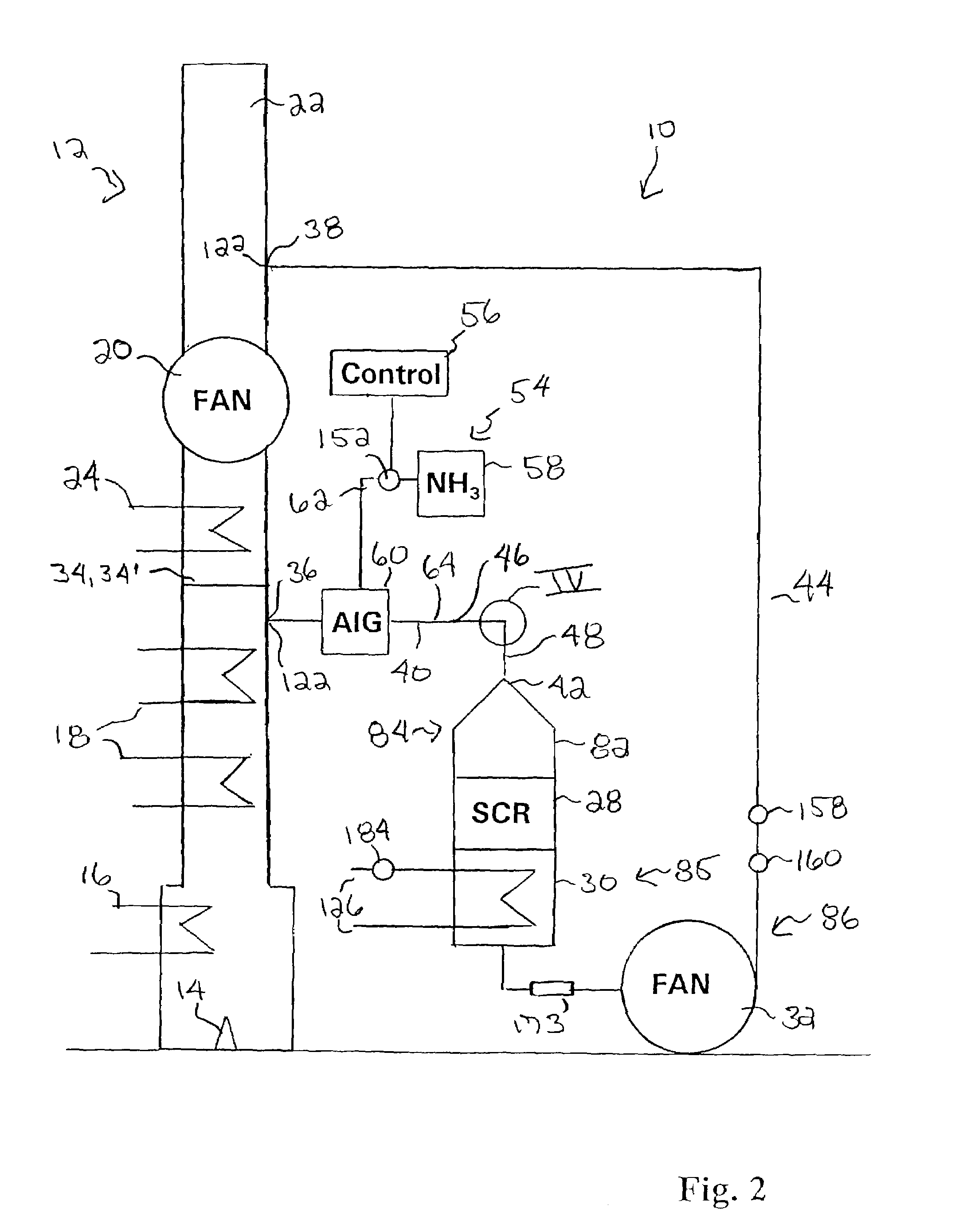

Model-based tuning of ammonia distribution and control for reduced operating cost of selective catalytic reduction

ActiveUS7824636B1Reduce the amount requiredNitrogen compoundsExhaust apparatusOperational costsCombustion

A method and system for reducing the amount of nitrogen oxides (NOx) in a combustion gas waste stream by (1) analyzing the waste stream to determine the amount of NOx; (2) determining the stoichiometric amount of ammonia required to reduce the NOx concentration down to a required level or less; (3) determining the flow rate profile of NOx components across the combustion gas waste stream upstream of an ammonia injection grid; (4) selecting specific locations within the ammonia injection grid to activate ammonia valves; (5) injecting controlled amounts of ammonia vapor into the gas stream at grid locations corresponding to the location of NOx in the gas stream; and (6) treating the gas stream using a selective catalytic reduction unit to reduce the amount of NOx down to acceptable levels.

Owner:GENERAL ELECTRIC CO

Catalyst for preparing phenylethane from dilute ethylene and benzene alkylation and method for preparing same

ActiveCN101584993AIncrease profitHigh activityMolecular sieve catalystsCatalyst activation/preparationReaction temperatureHigh activity

The invention aims to provide a catalyst for preparing phenylethane from dilute ethylene and benzene alkylation and a method for preparing the same. The catalyst is characterized in that the crystal is formed by a small crystal grain ZSM-5 molecular screen with the crystal grain size of between 0.15 and 0.8 mircometer and a bonding agent of aluminum oxide and silicon dioxide, and then prepared by steps of vapor / ammonia vapor treatment and acid treatment, wherein the relative mass ratio of the ZSM-5 molecular screen to the bonding agent of the aluminum oxide and the silicon dioxide is (5-9):(1-5). When the catalyst is used for preparing the phenylethane from the dilute ethylene and the benzene alkylation in dry gas, because the crystal grain size of the used molecular screen is small, the number of acidic sites and the acidic utilization ratio of the catalyst are high, and simultaneously the pore canal of the molecular screen is short, which is favorable for dispersion of reactants and products, so that the catalyst has the characteristics of high activity, low reaction temperature, high selectivity of target products, low content of xylene impurity in the product and good satiability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

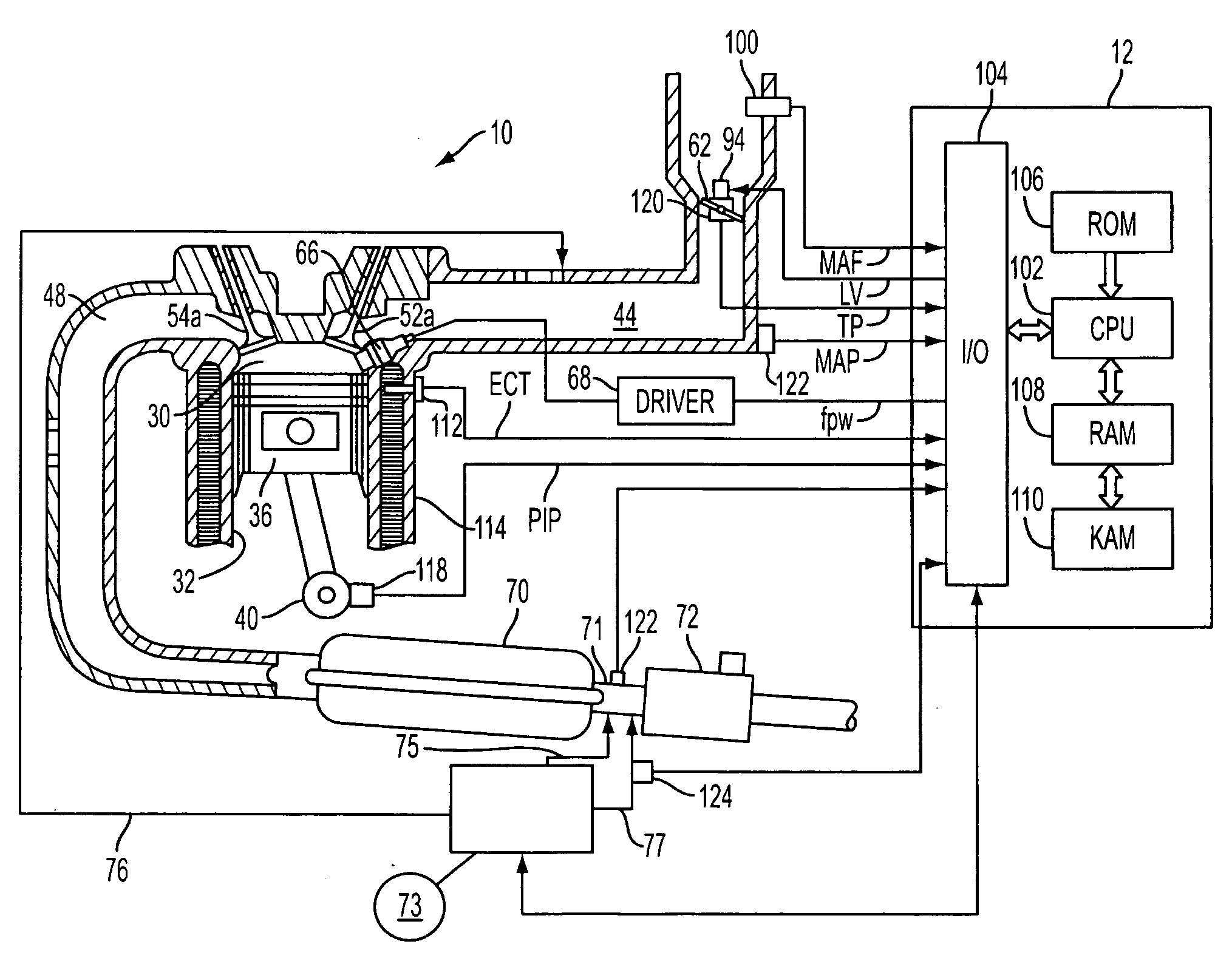

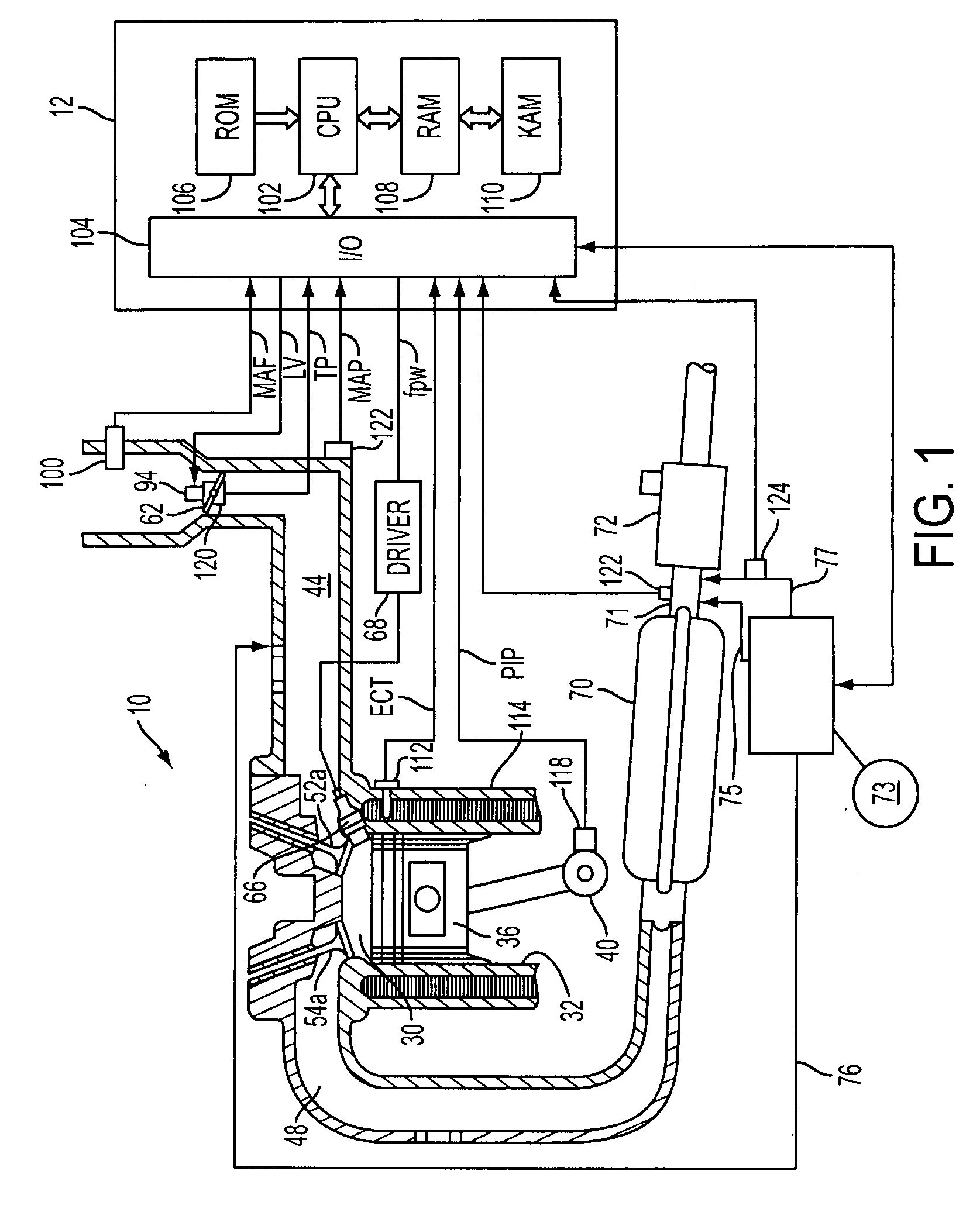

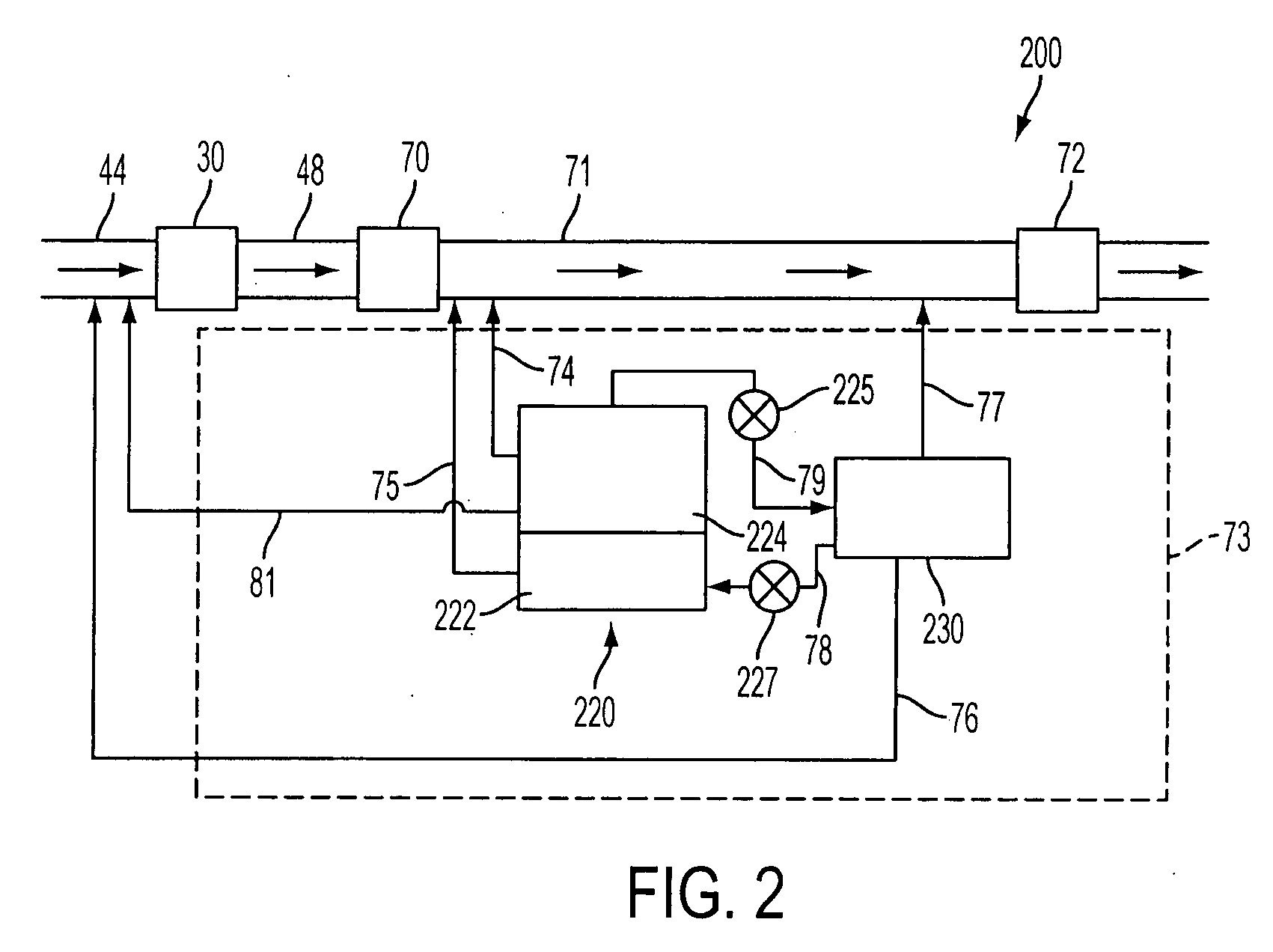

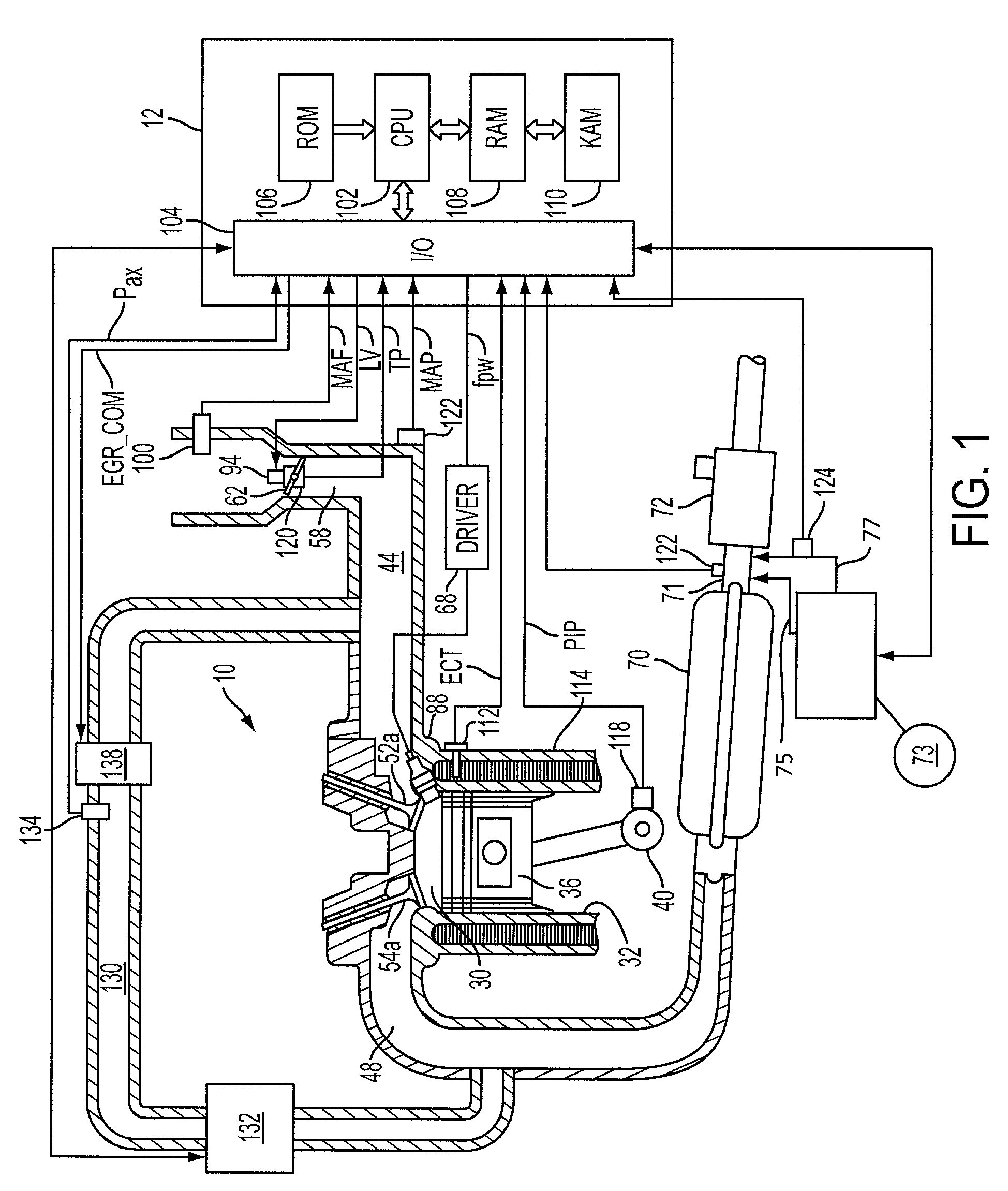

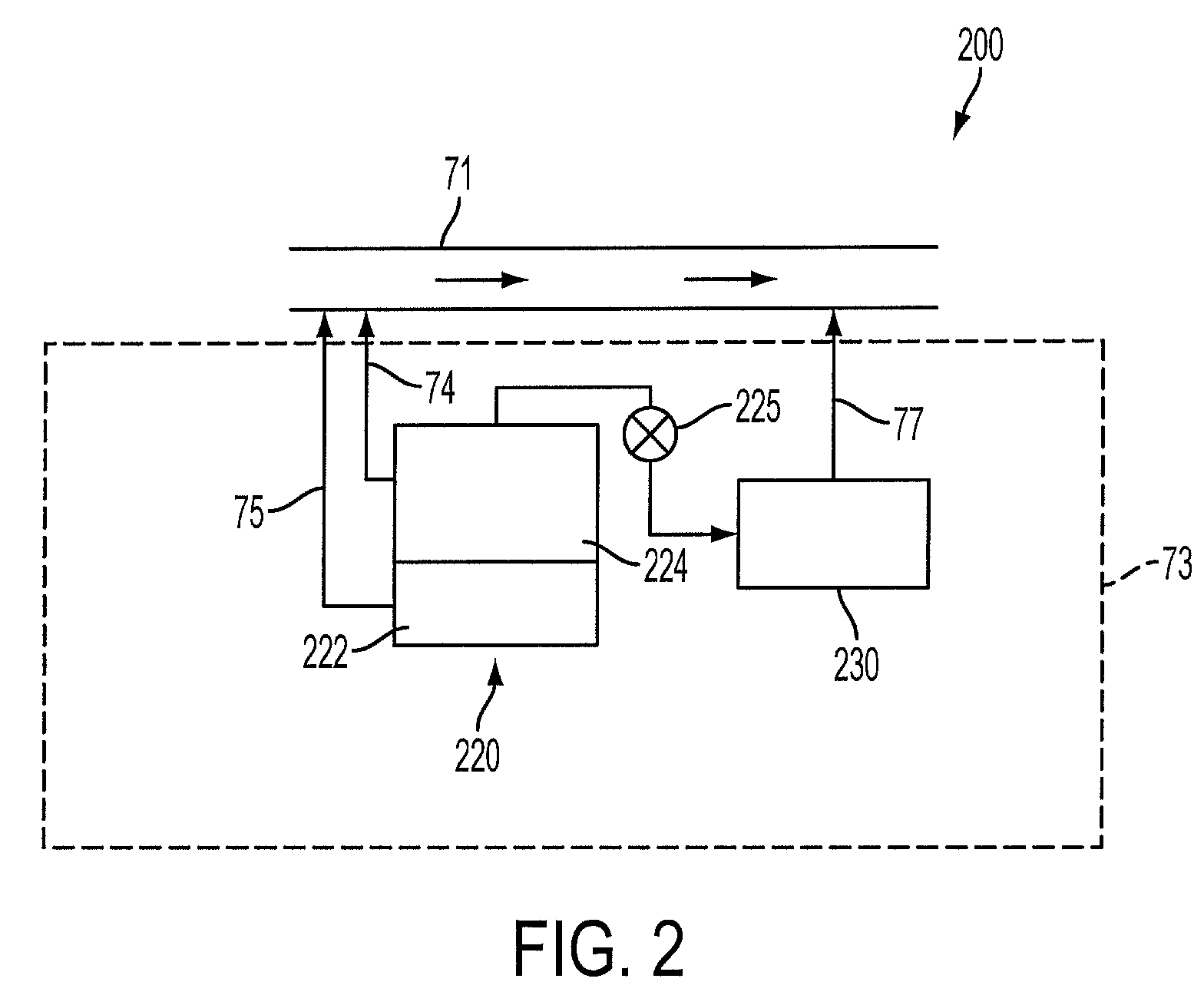

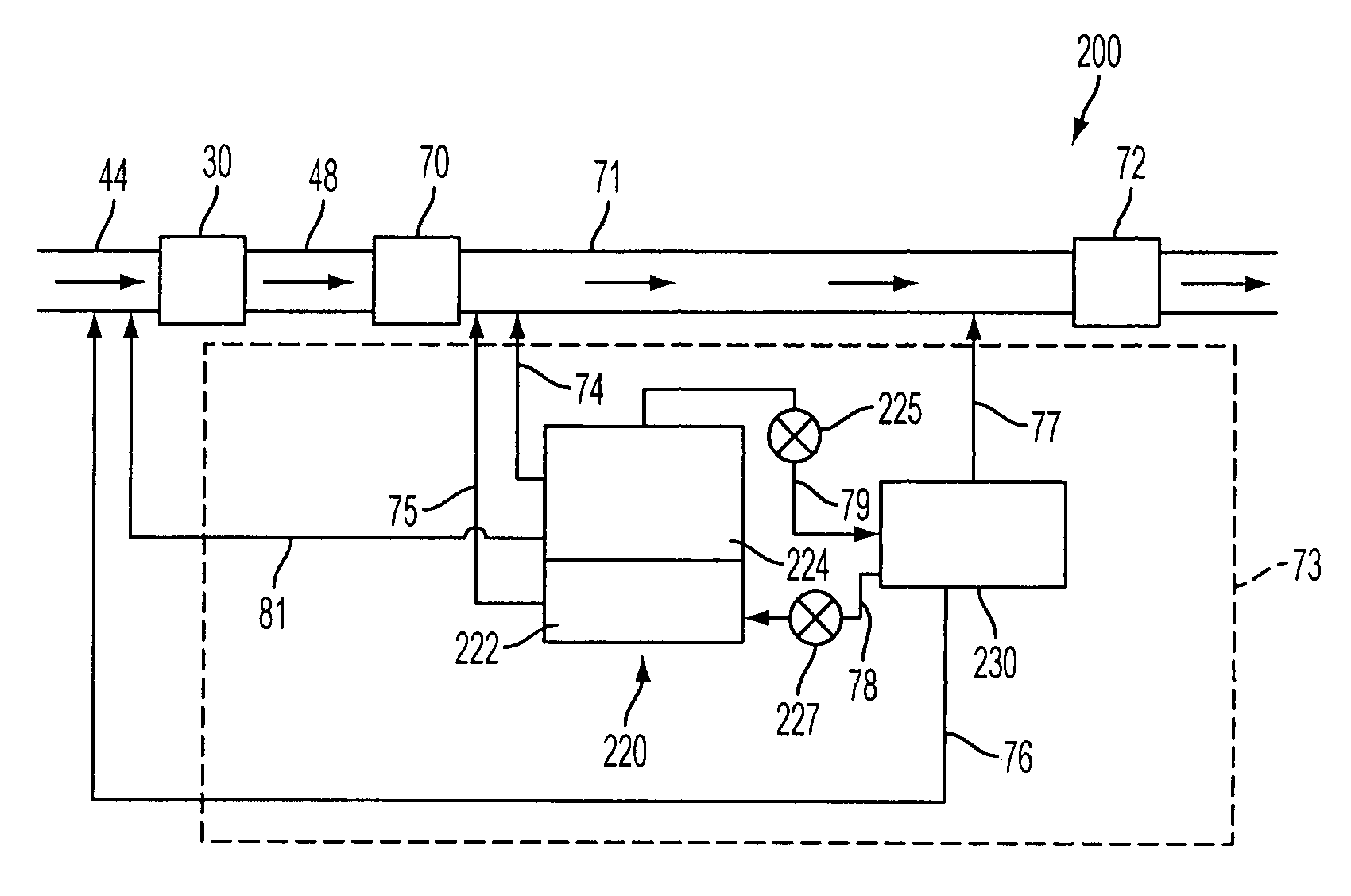

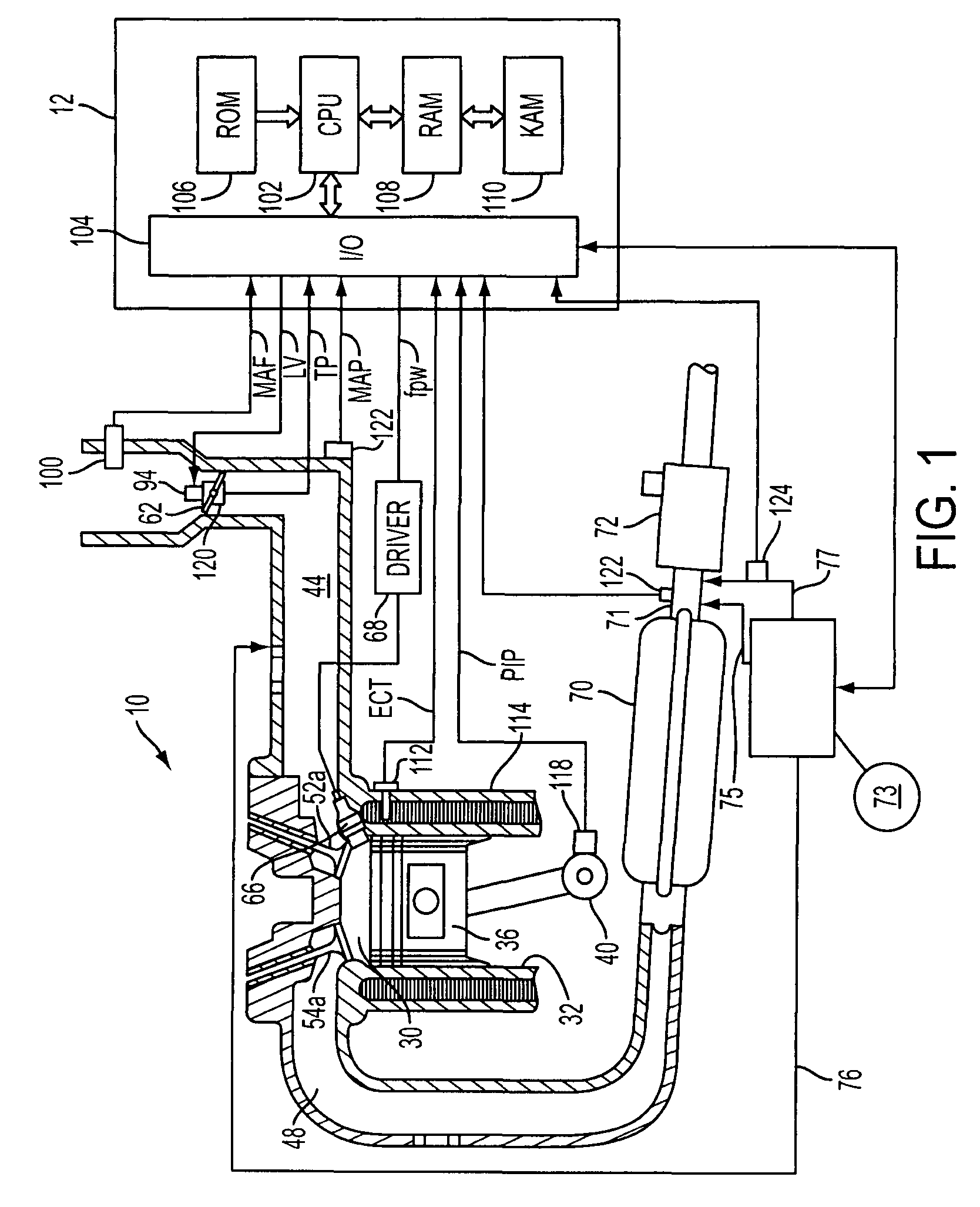

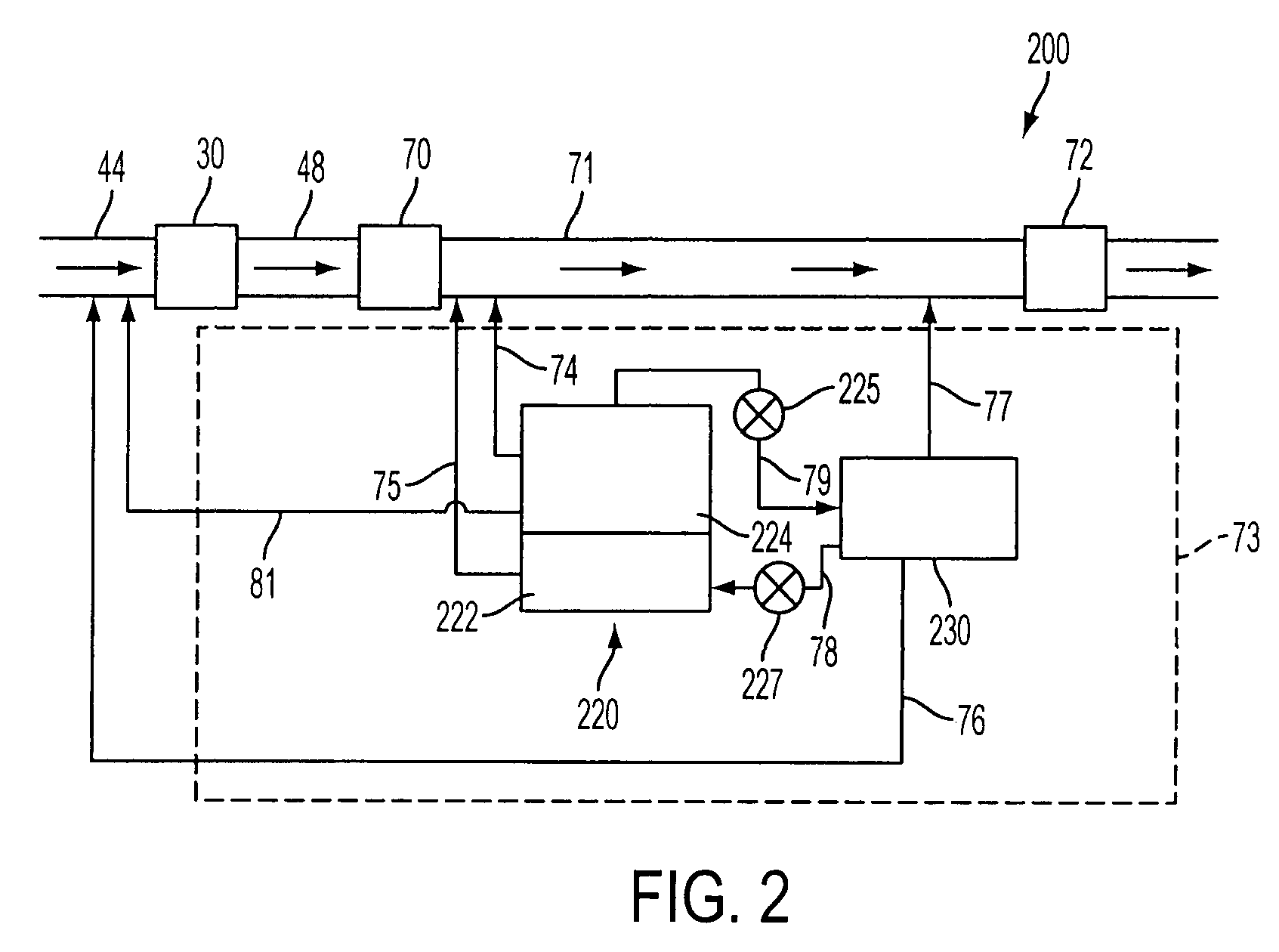

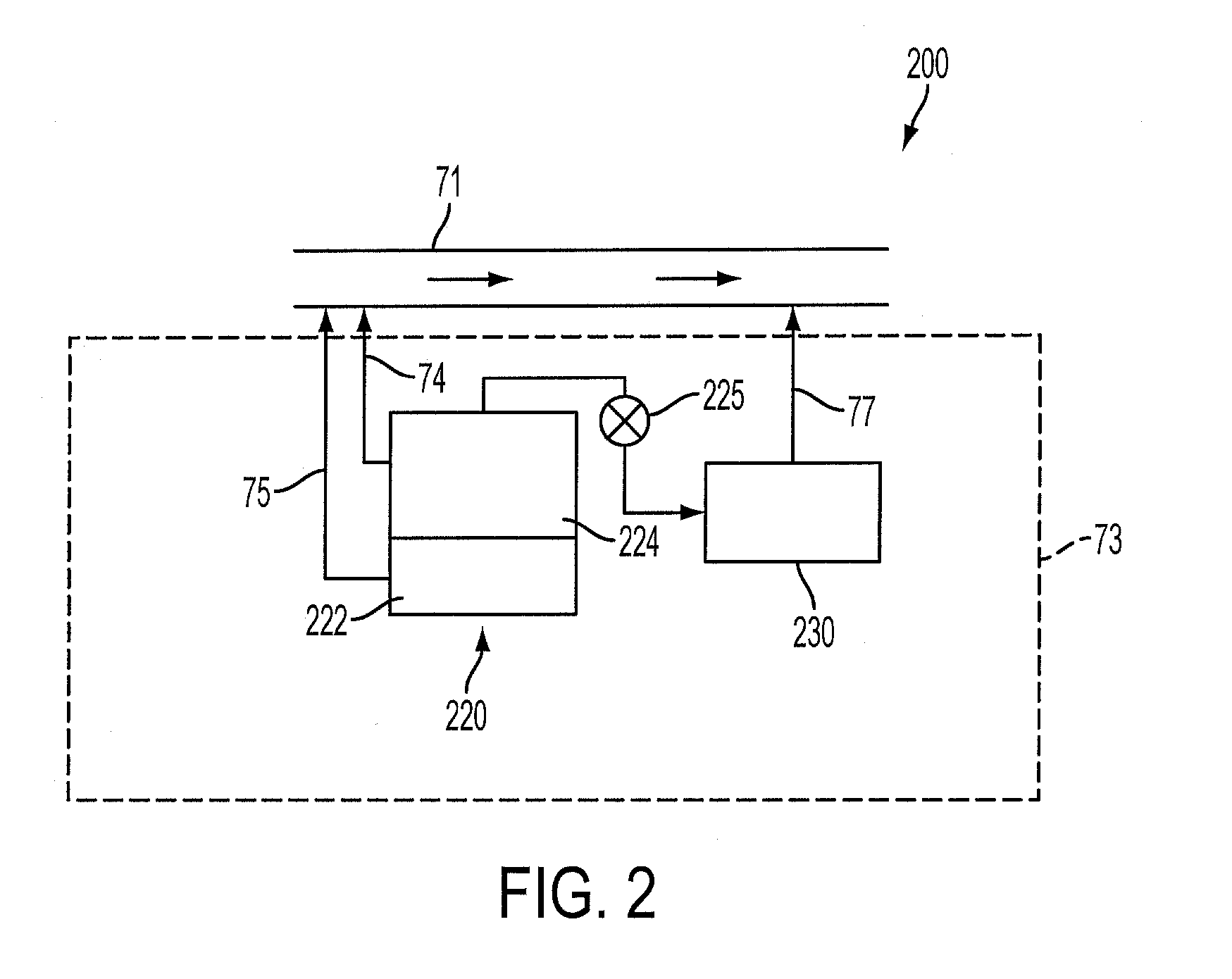

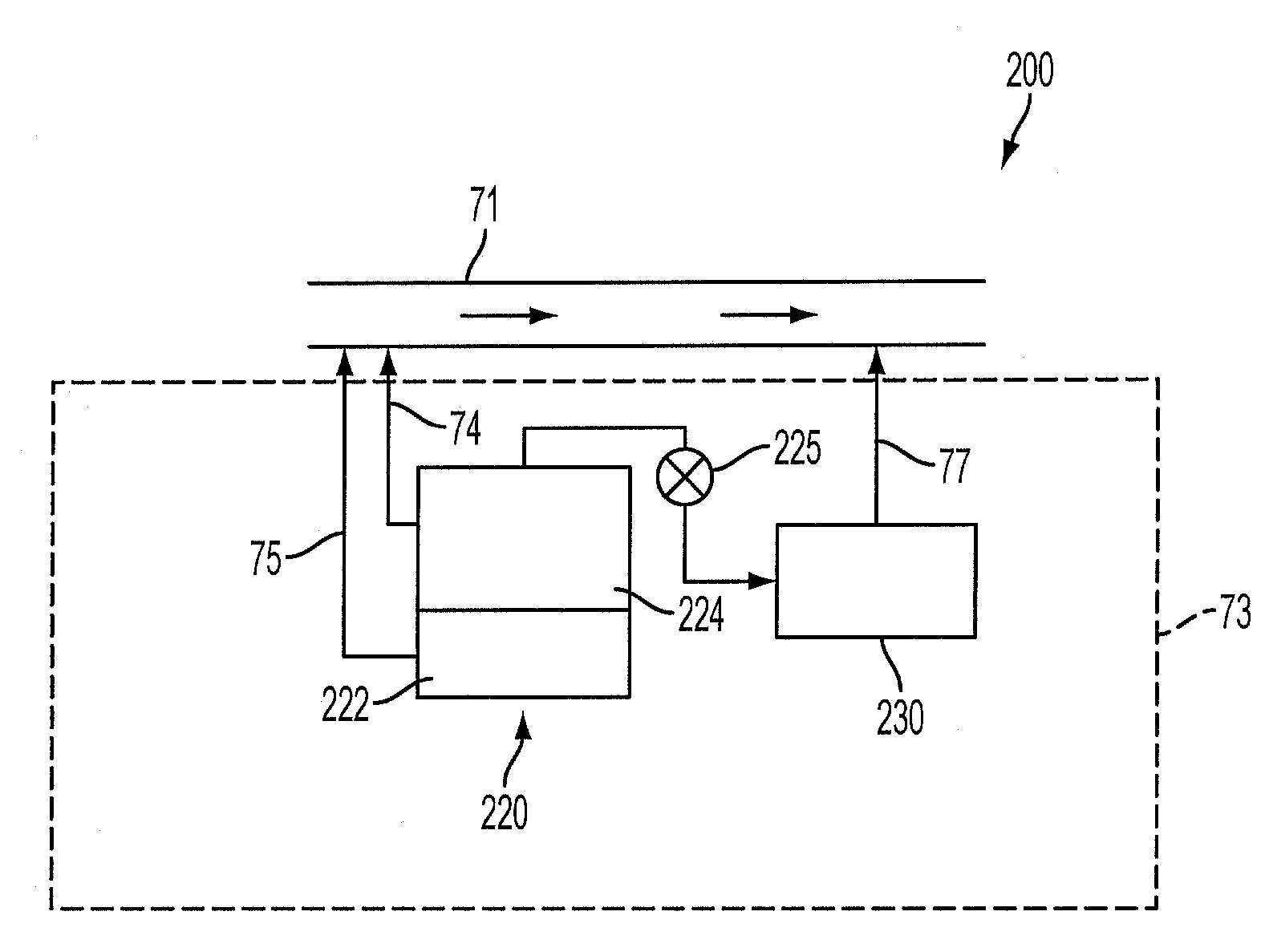

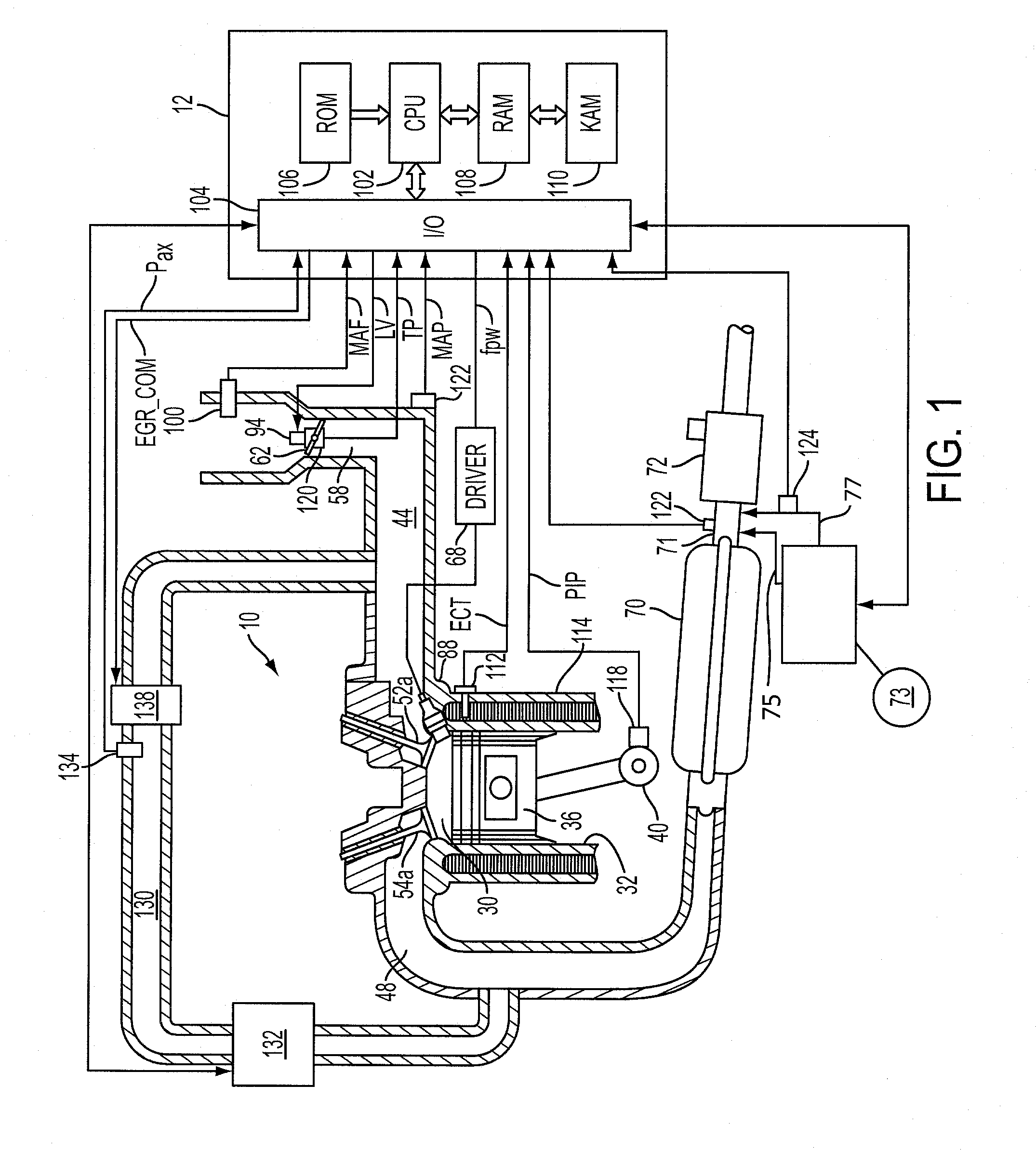

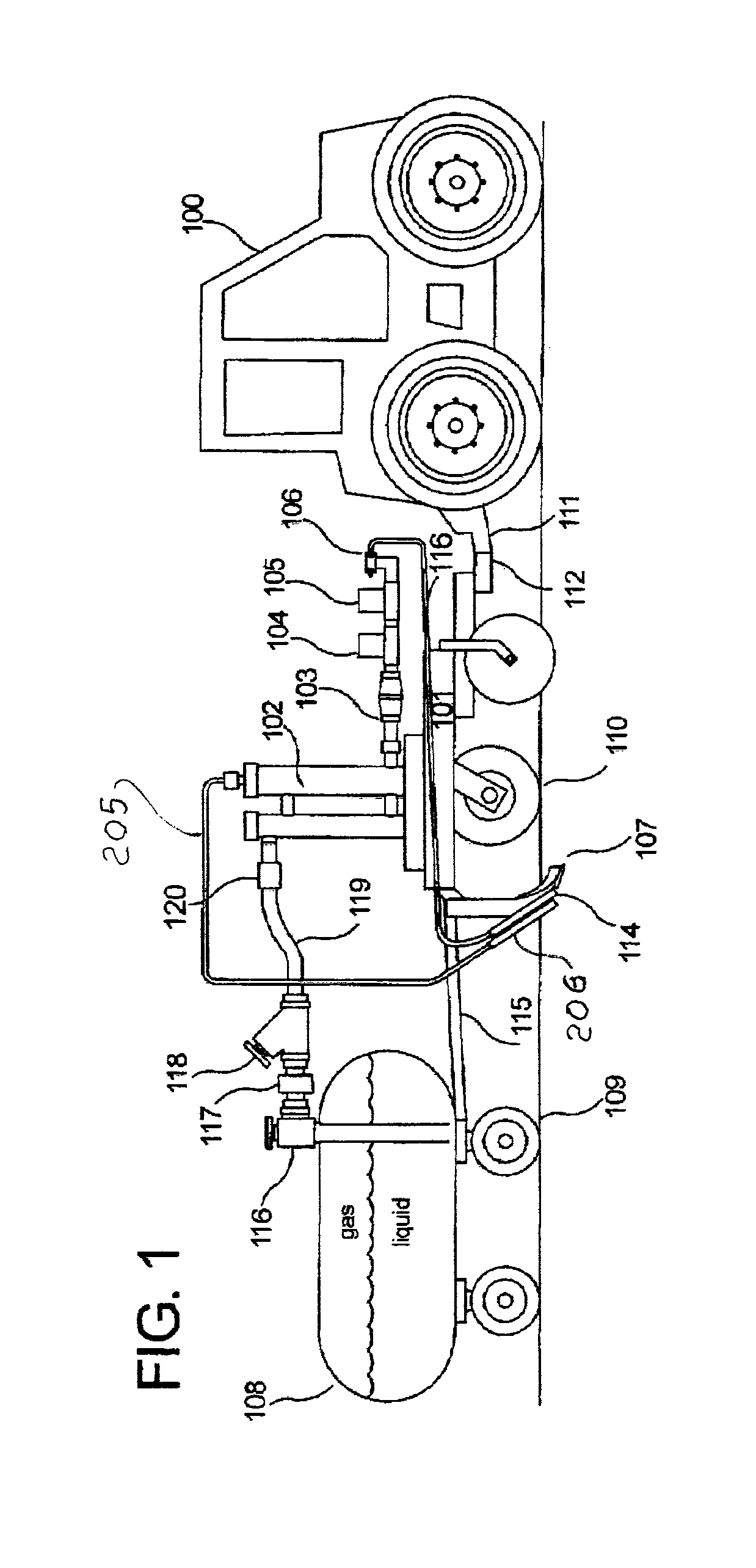

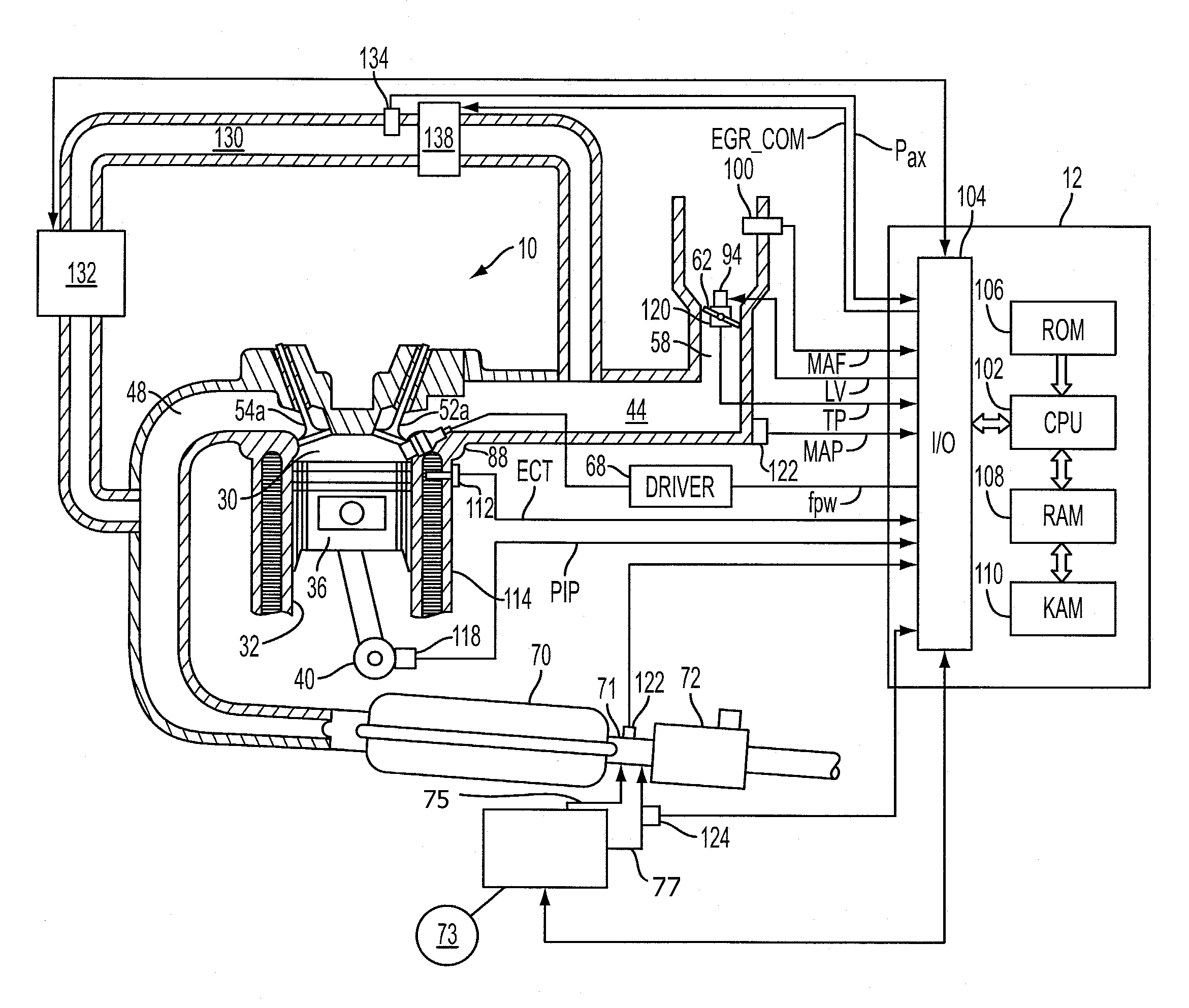

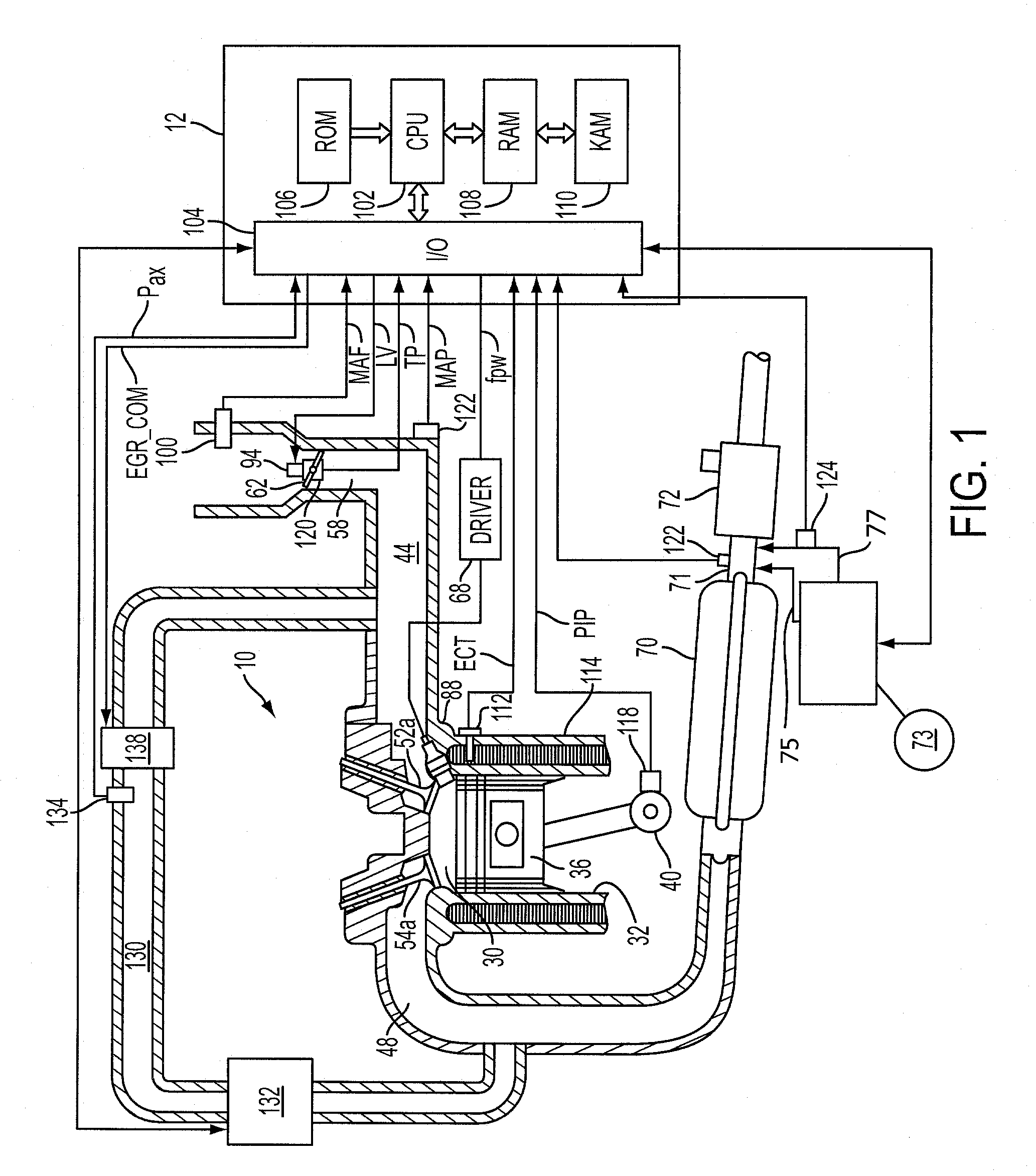

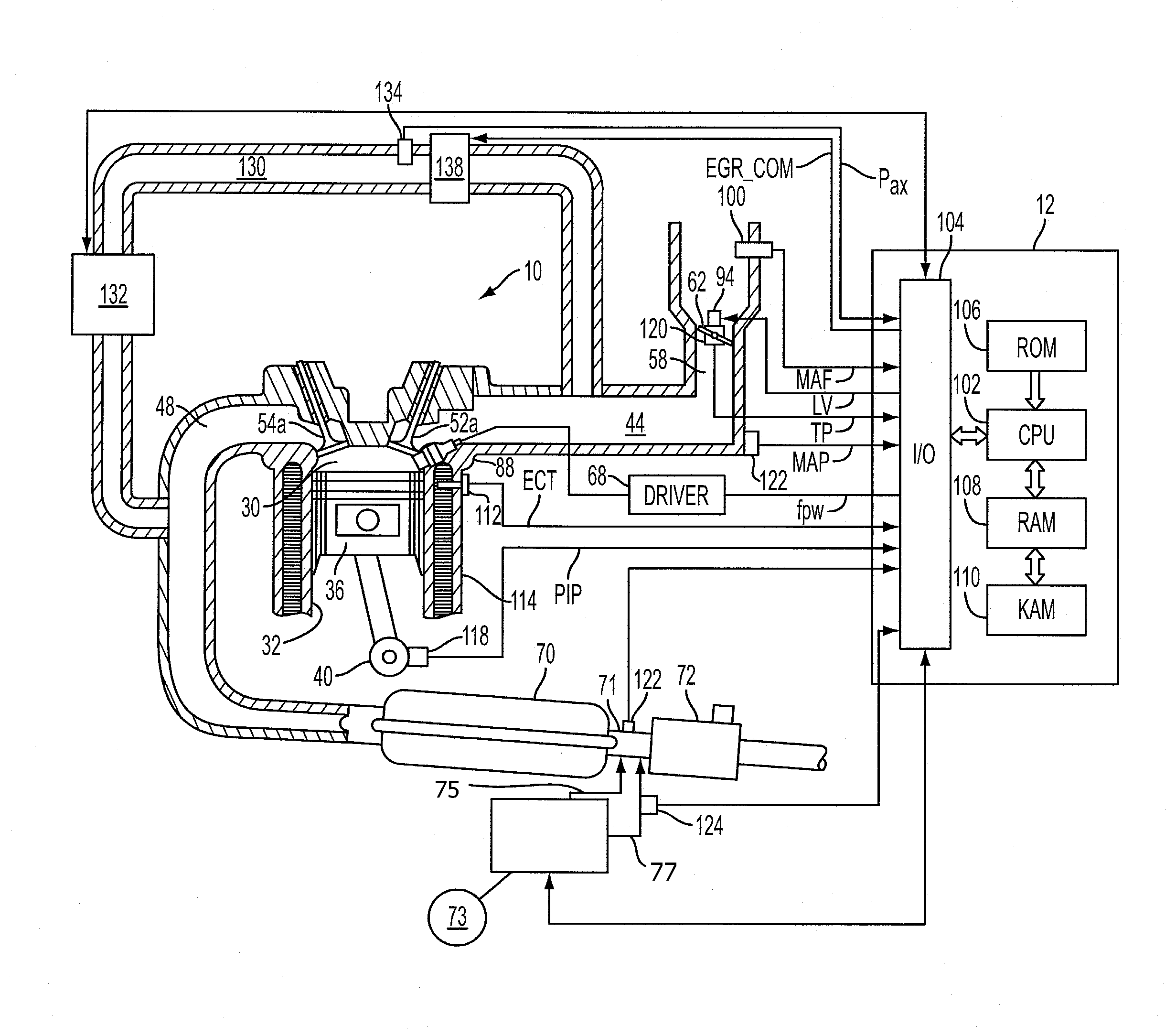

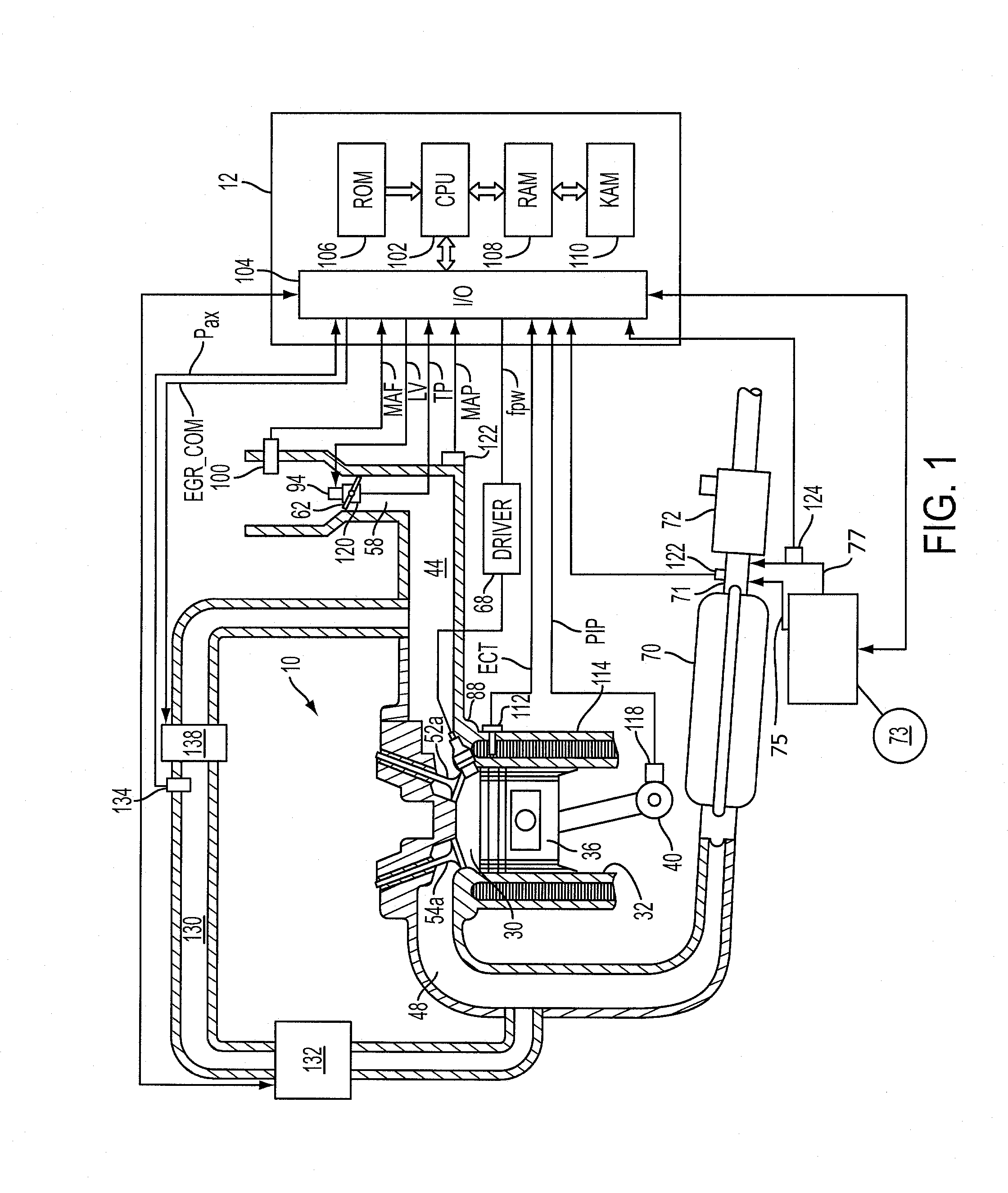

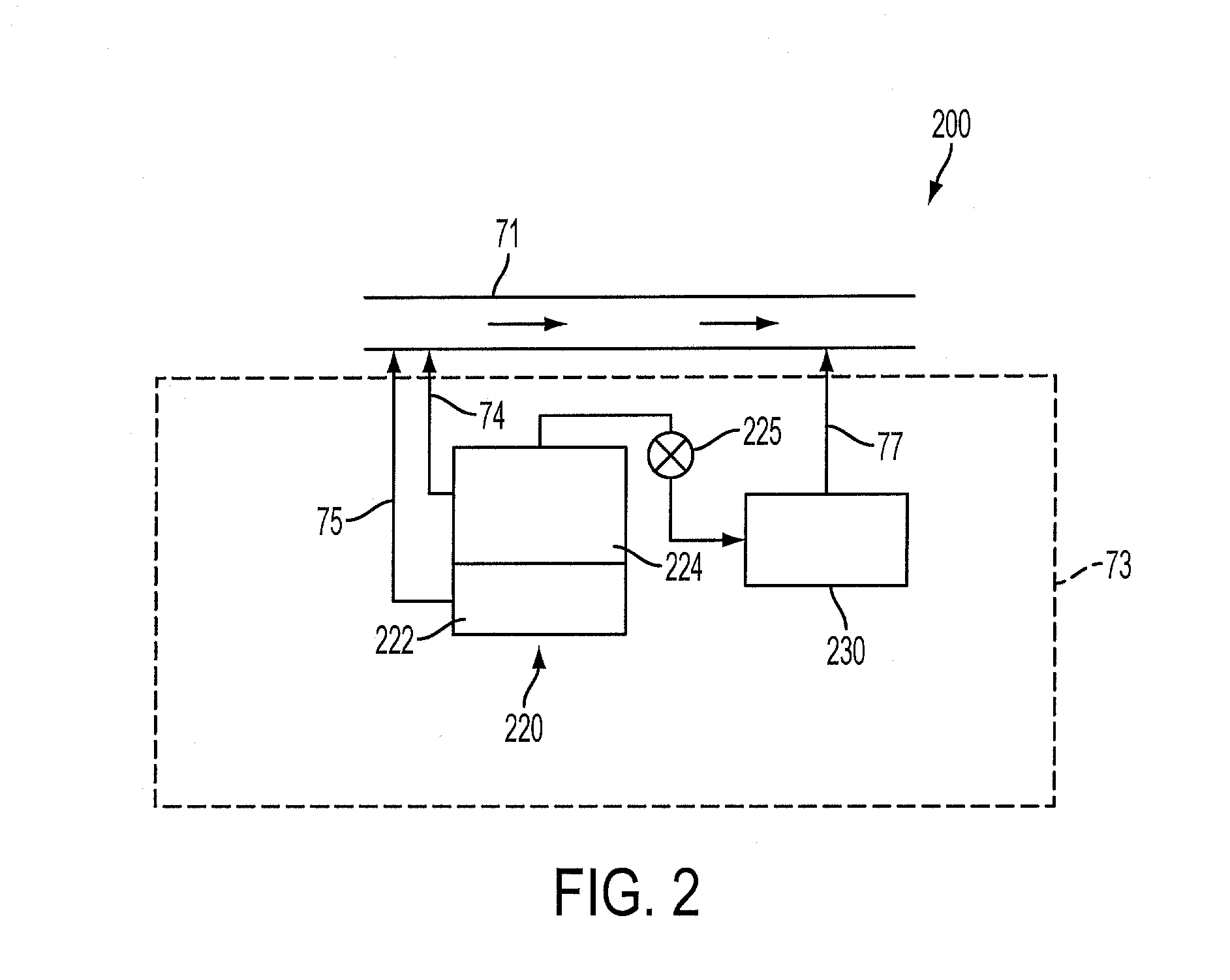

Ammonia vapor management system and method

InactiveUS20080223021A1Reduce first amountReduce the amount requiredNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberDelivery system

A method of managing vapors generated from an ammonia-containing reductant delivery system for an engine, comprising of storing an ammonia-containing fluid in a first storage device; generating ammonia vapors in the first storage device and storing said generated ammonia vapors in a second storage device; and purging said stored vapors from the second storage device to upstream of a combustion chamber of the engine during a first condition and downstream of the combustion chamber during a second condition.

Owner:FORD GLOBAL TECH LLC

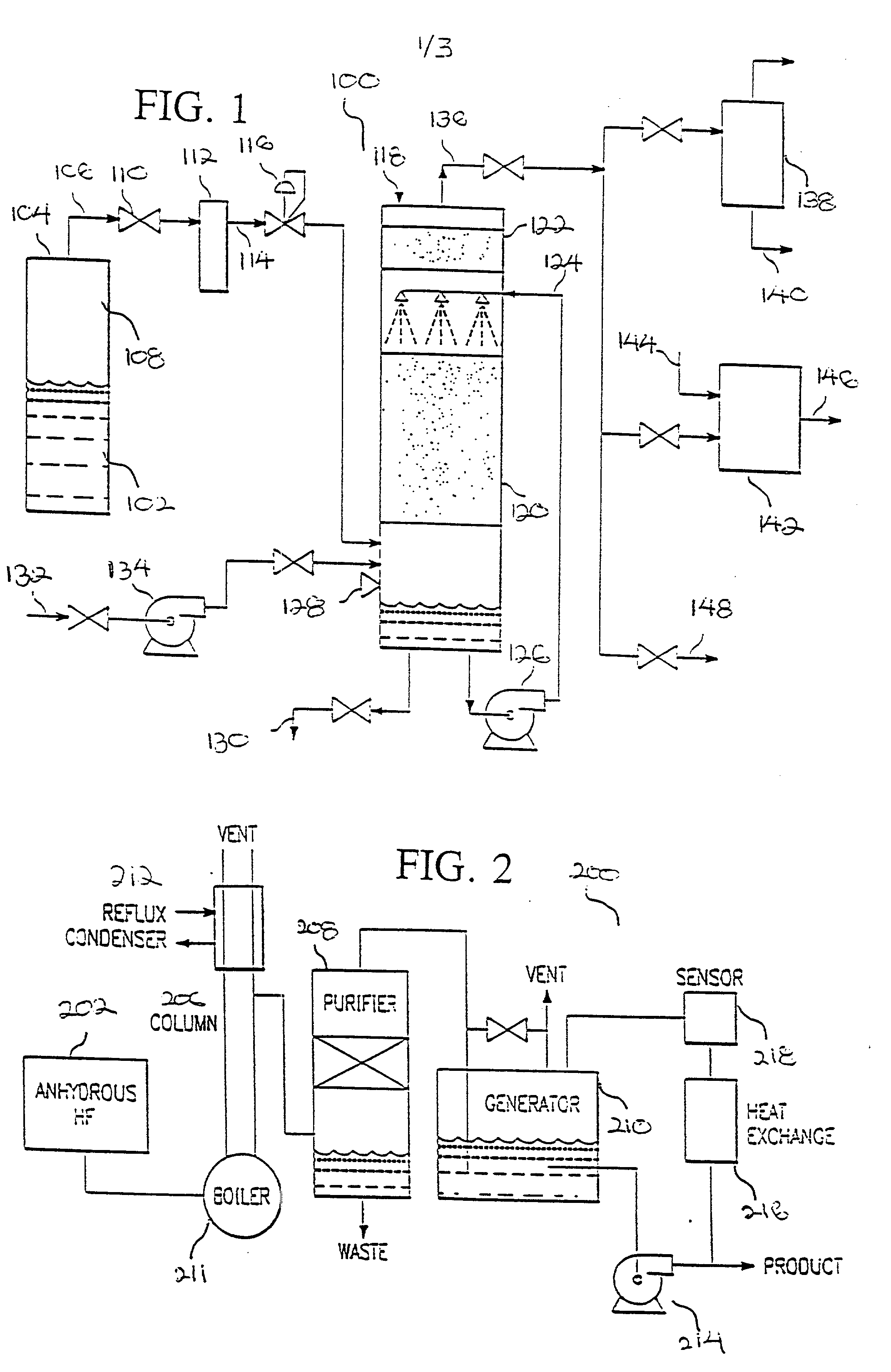

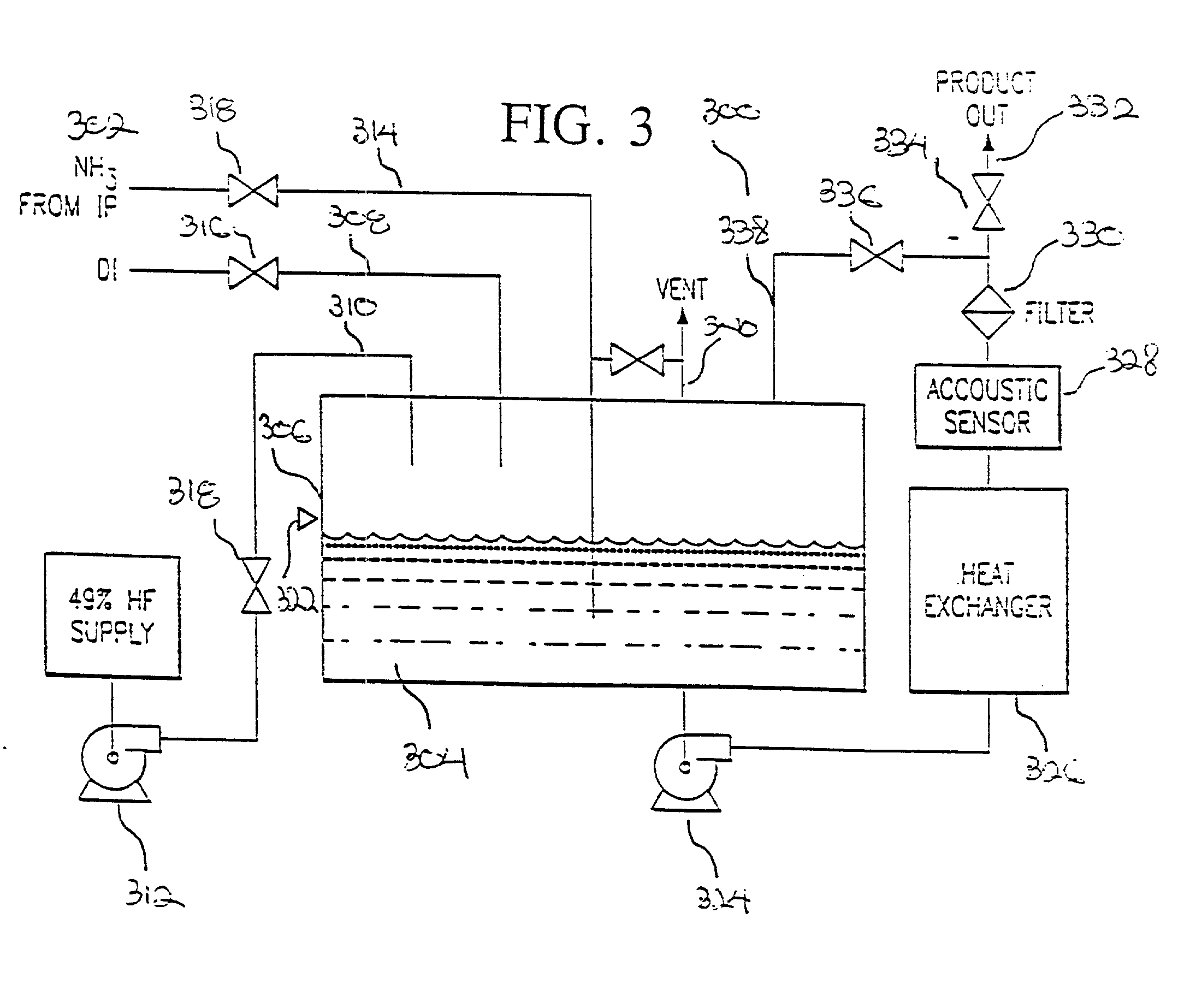

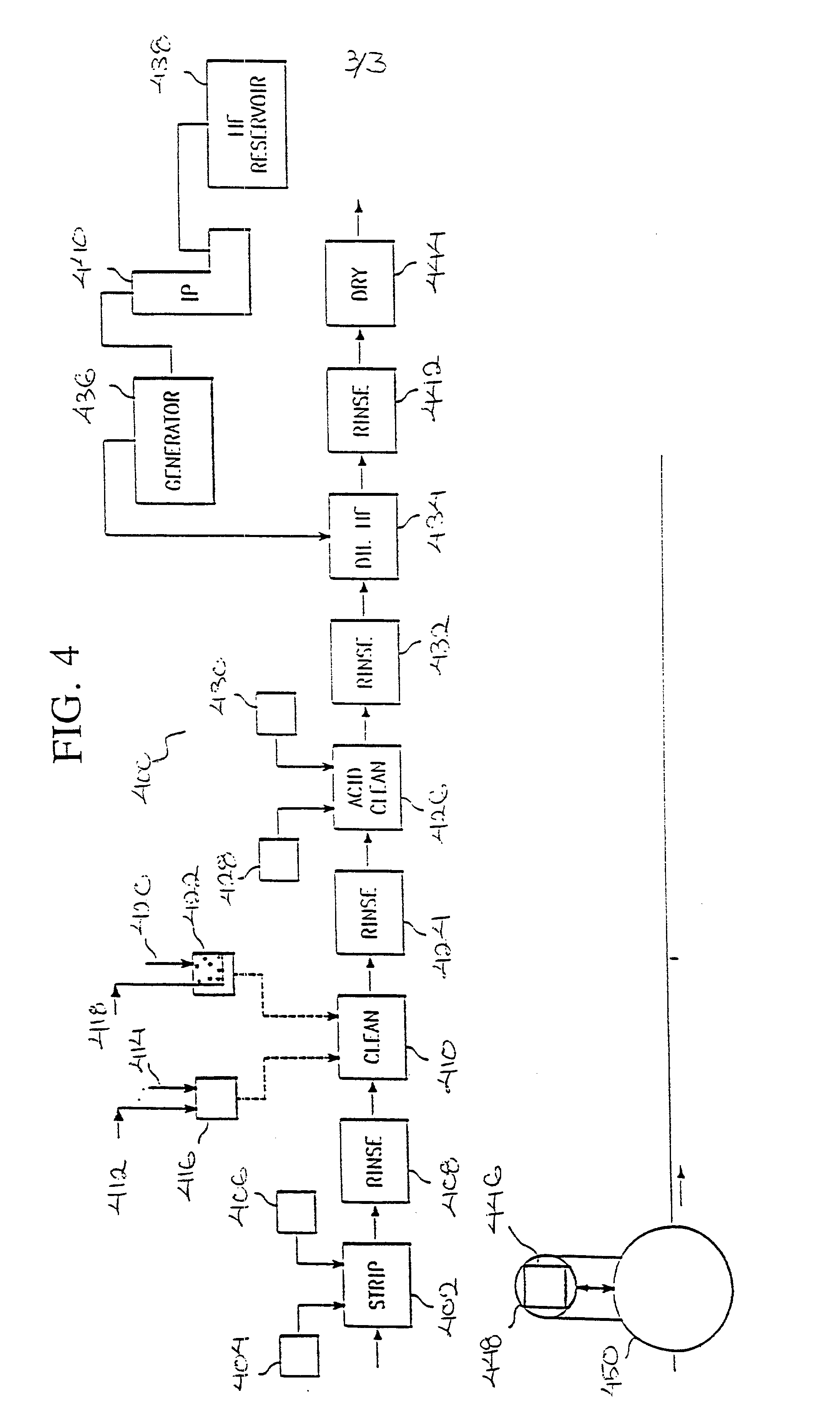

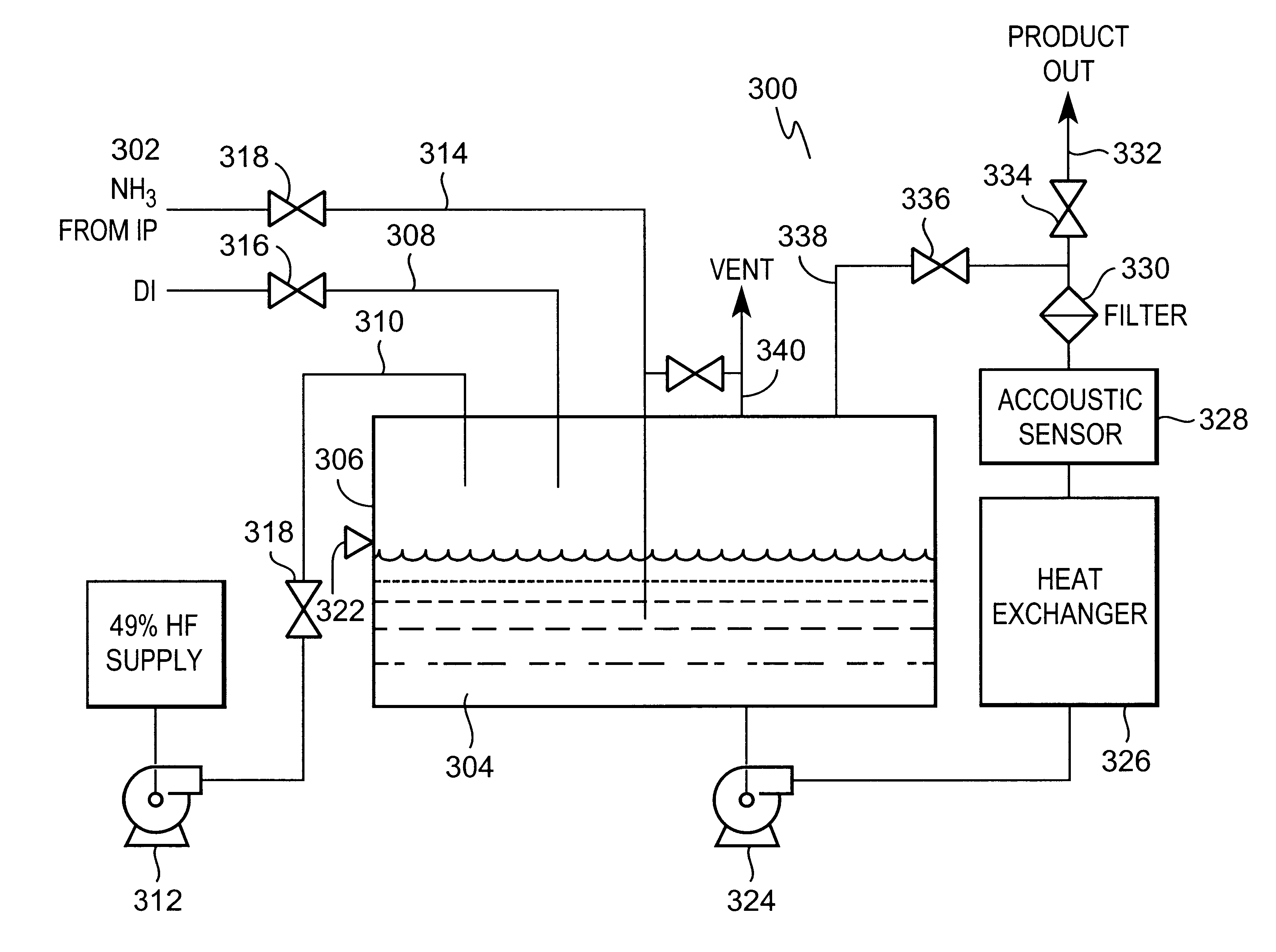

On-site generation of ultra-high-purity buffered-hf and ammonium fluoride

InactiveUS20010051128A1Low impurity contentImprove device characteristicsChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration. The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

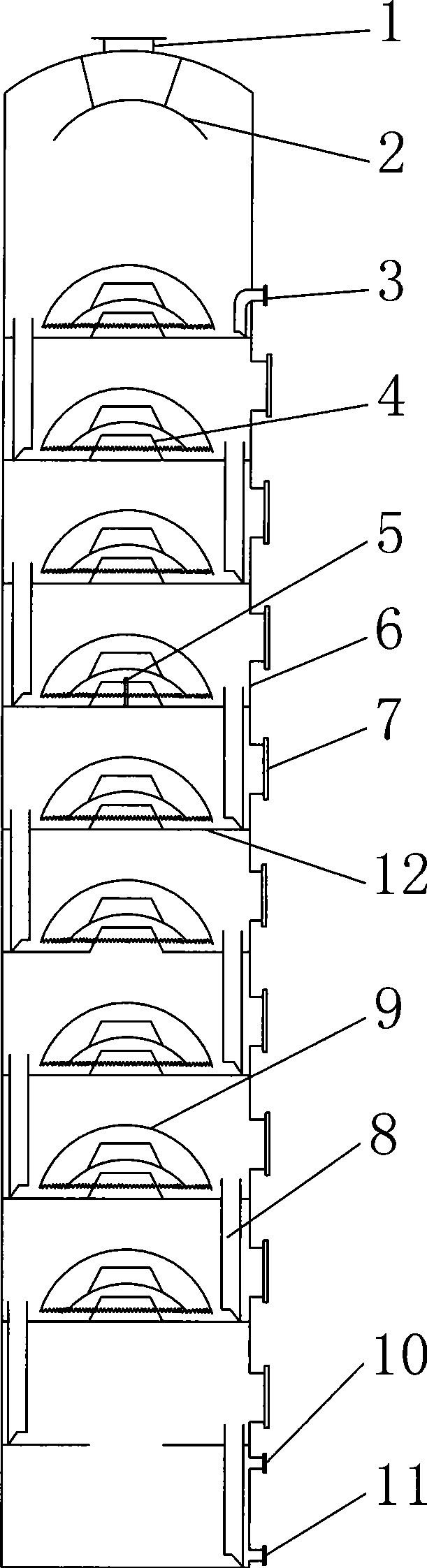

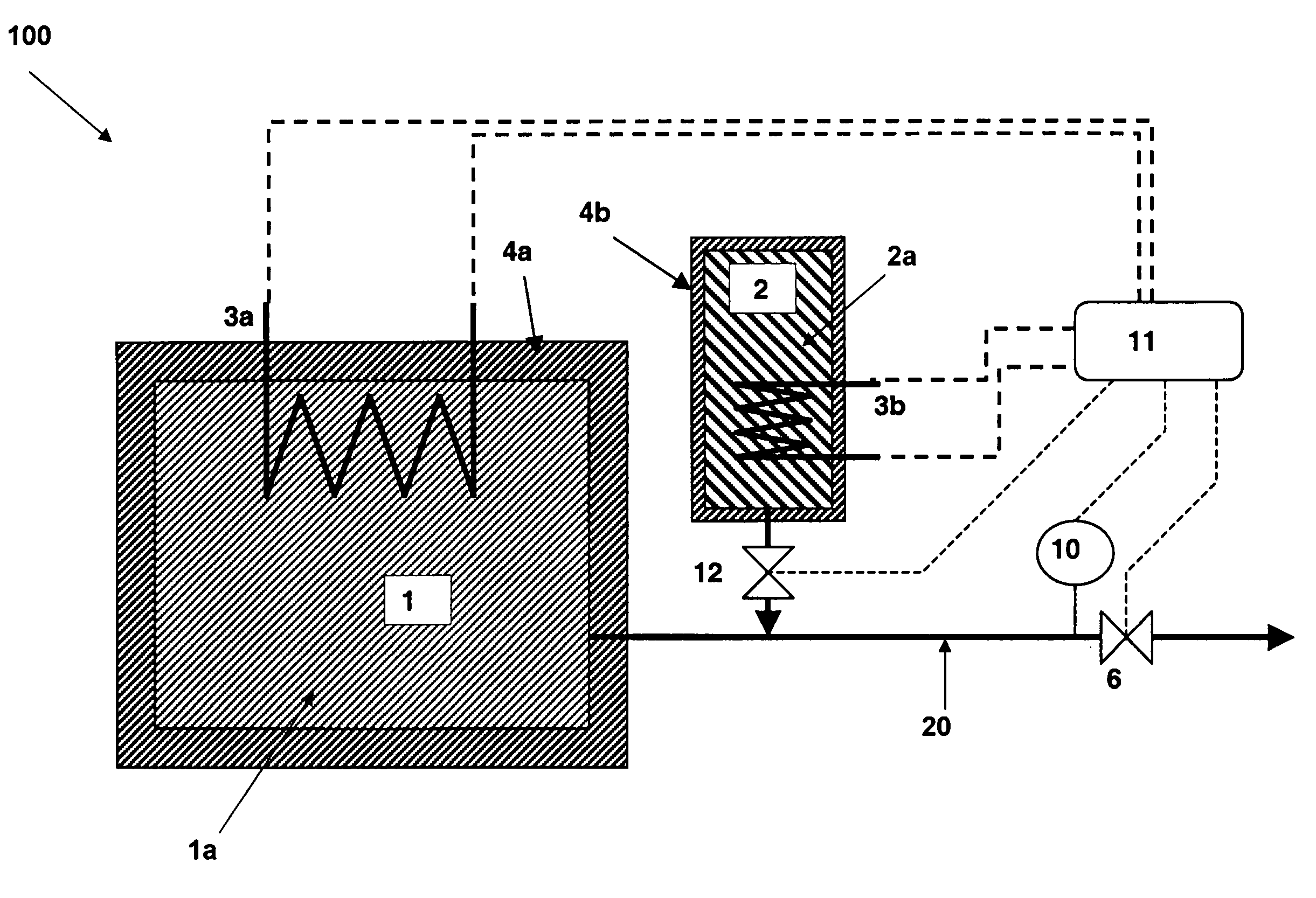

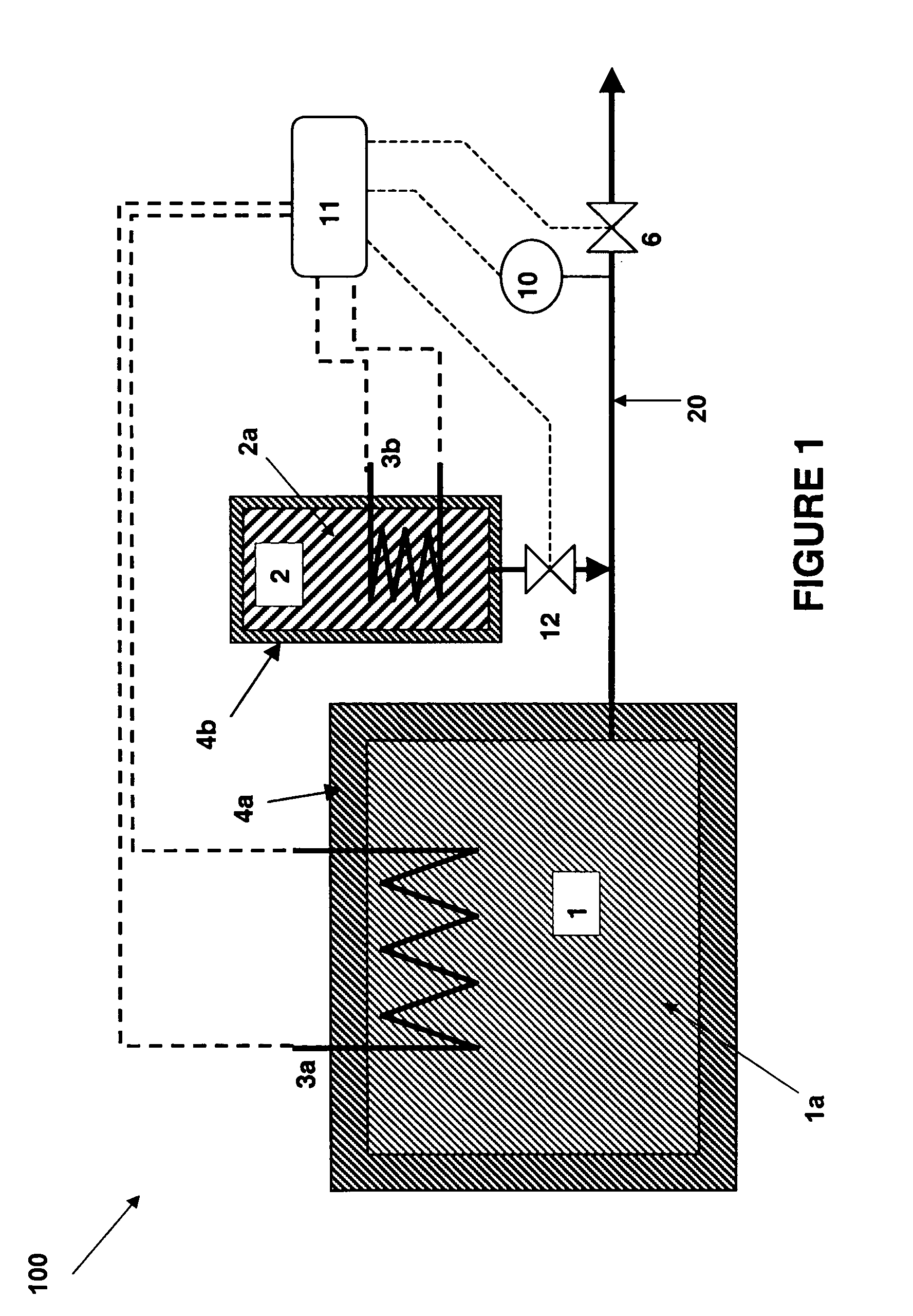

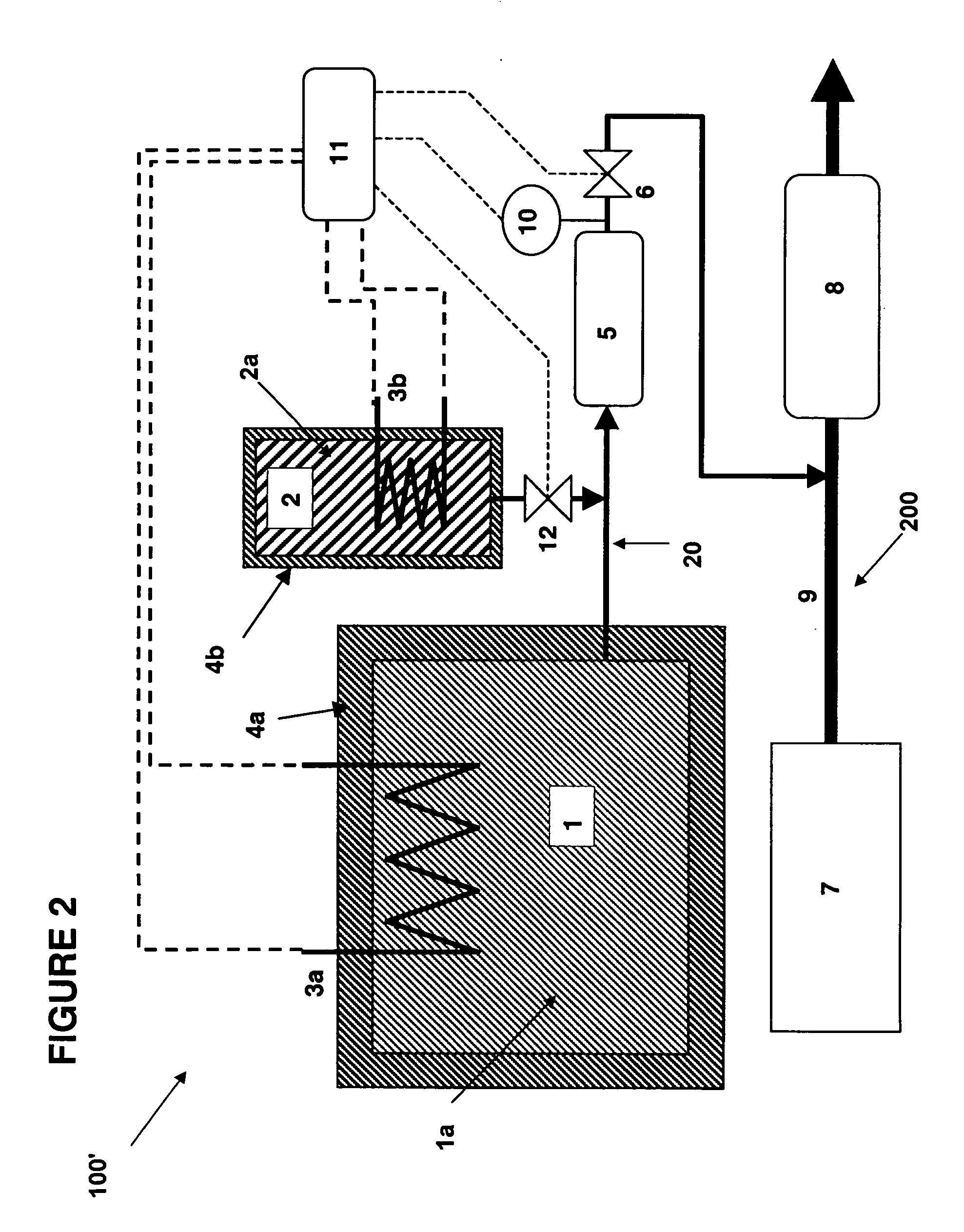

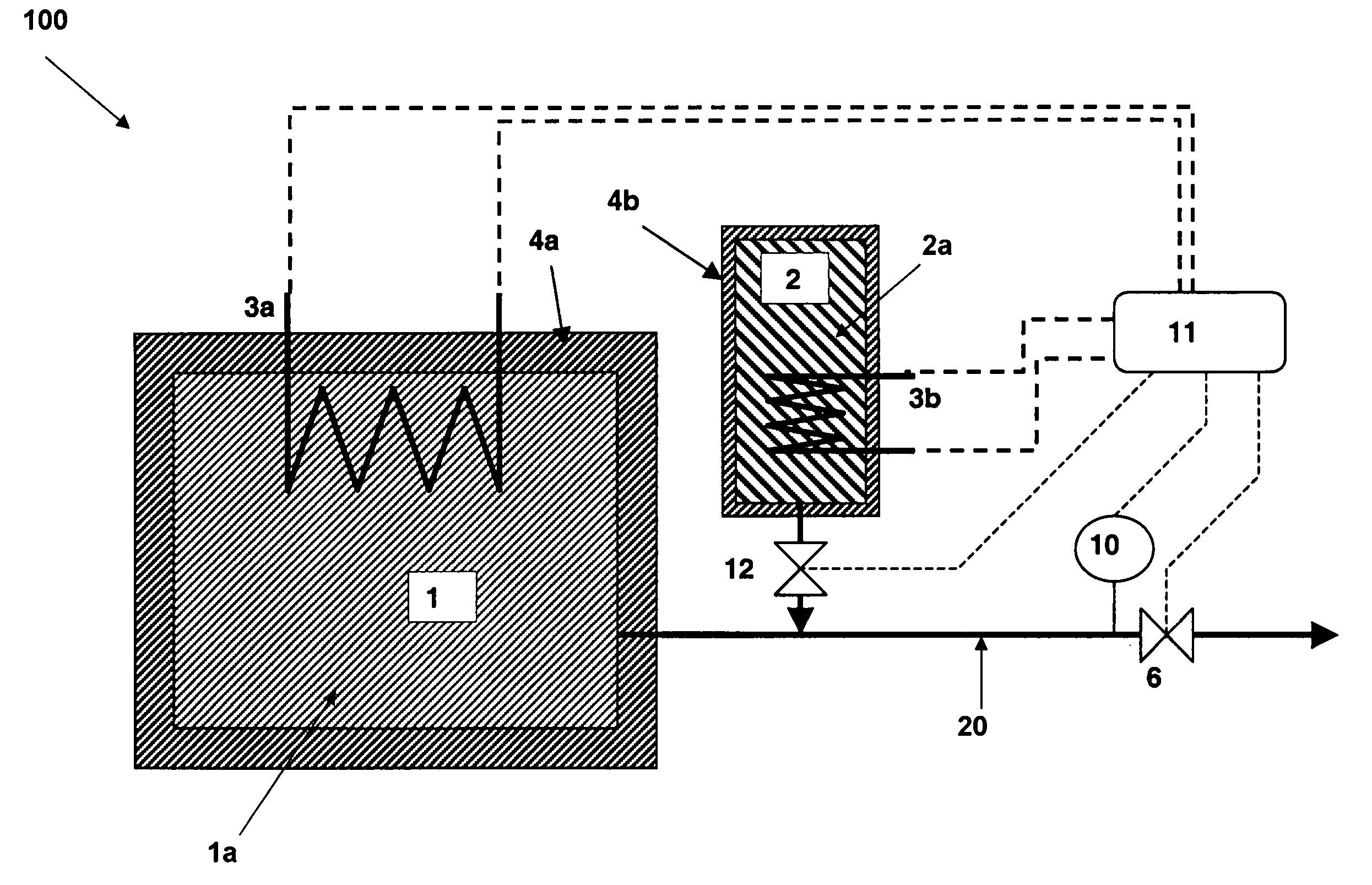

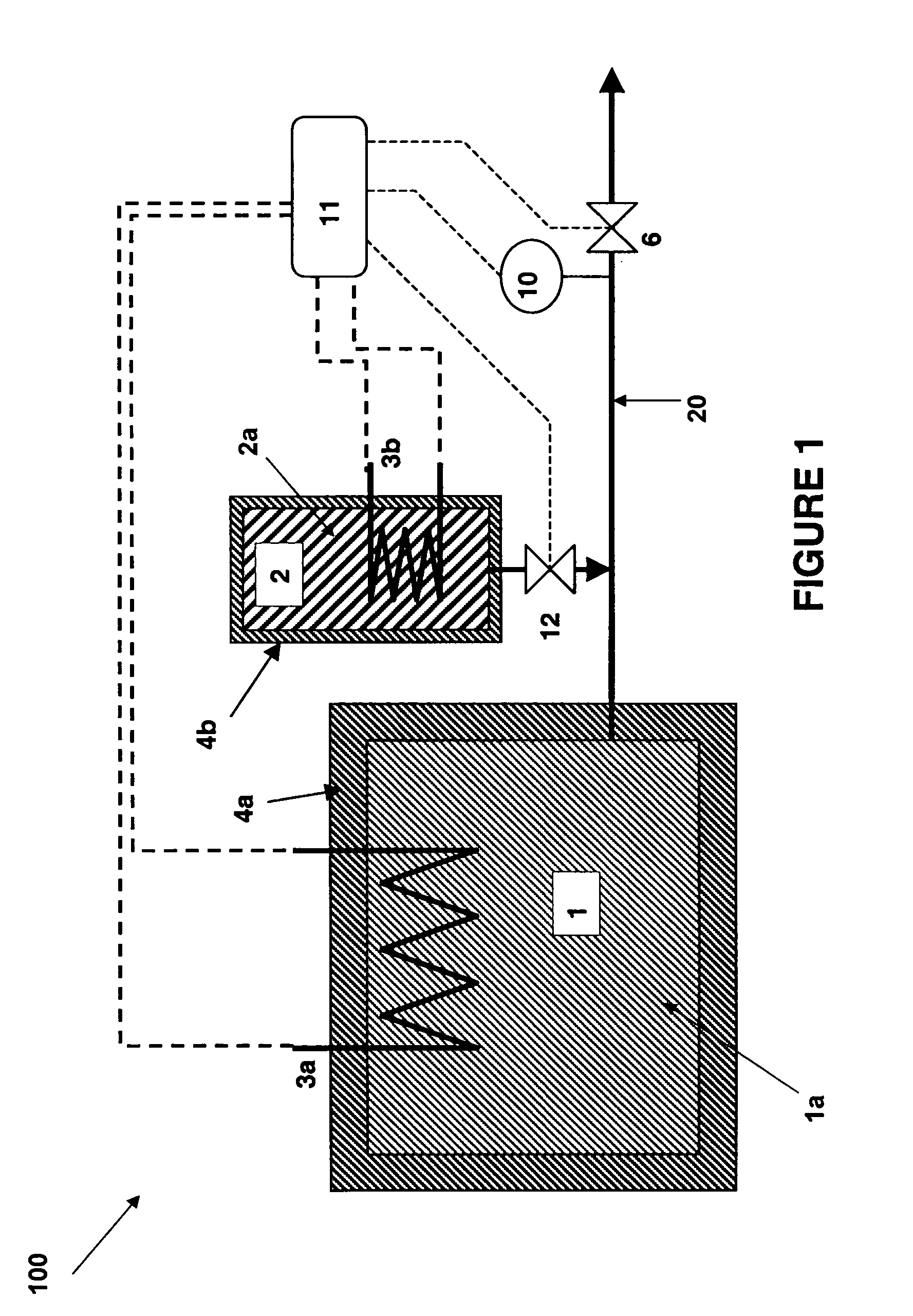

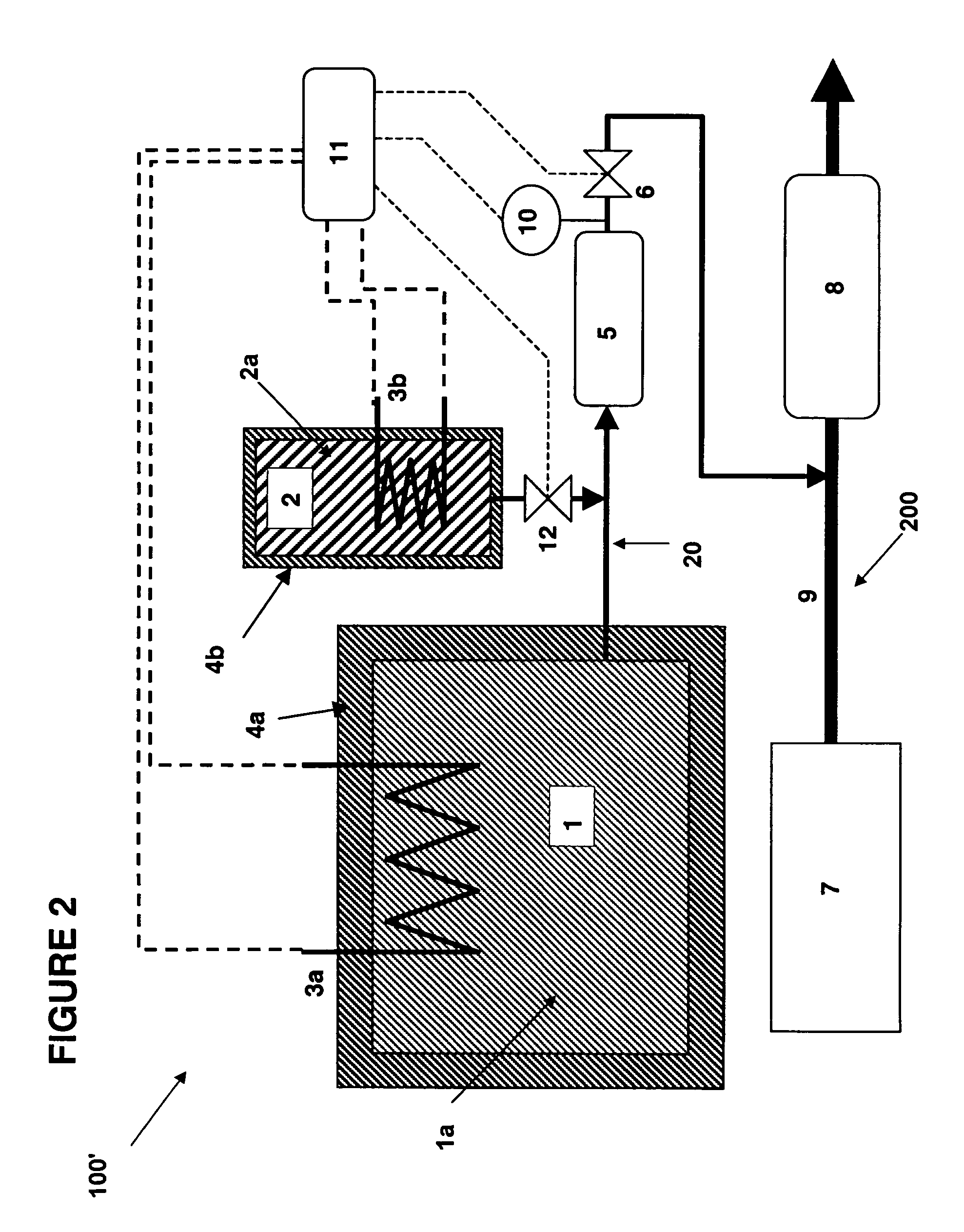

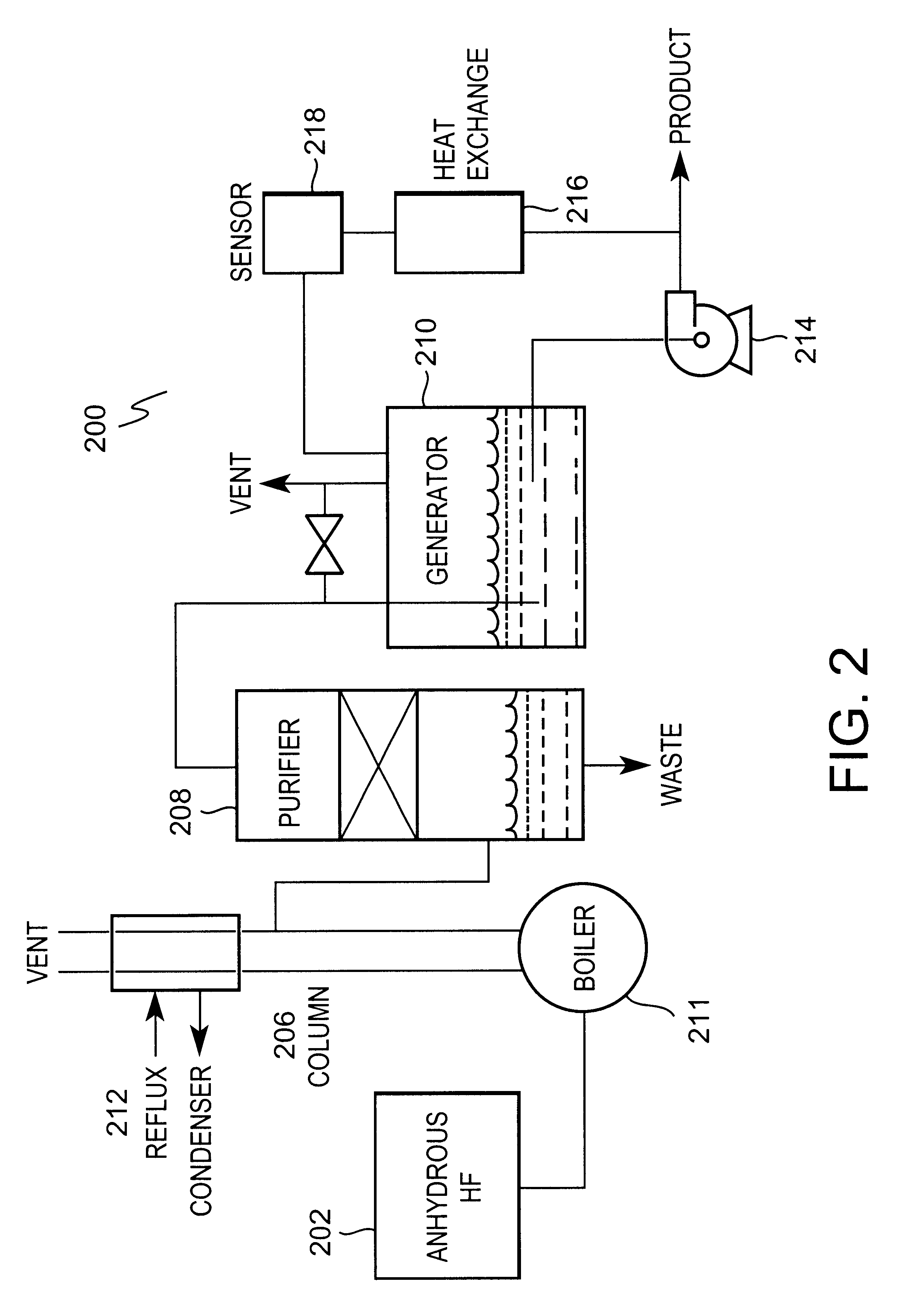

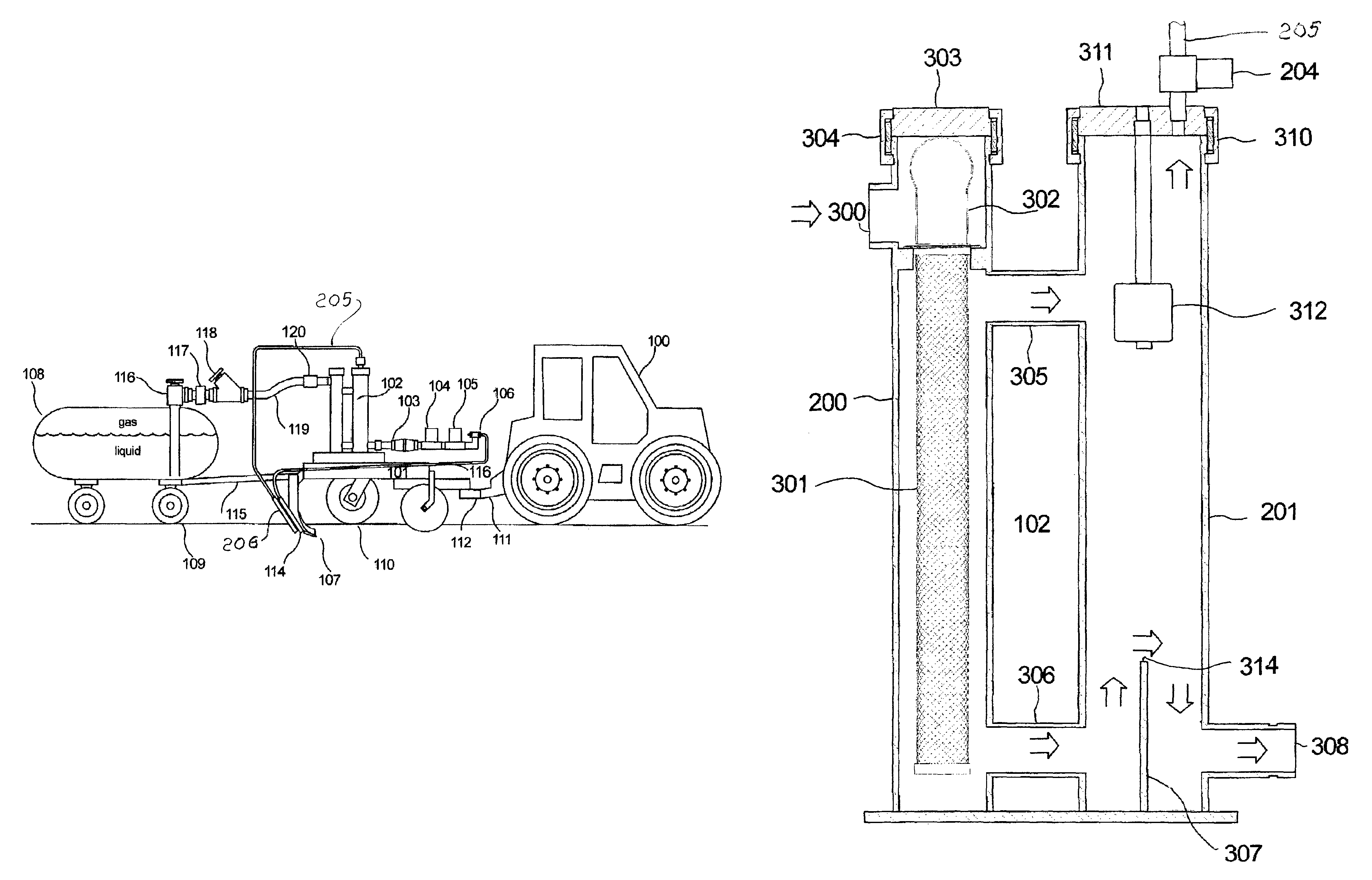

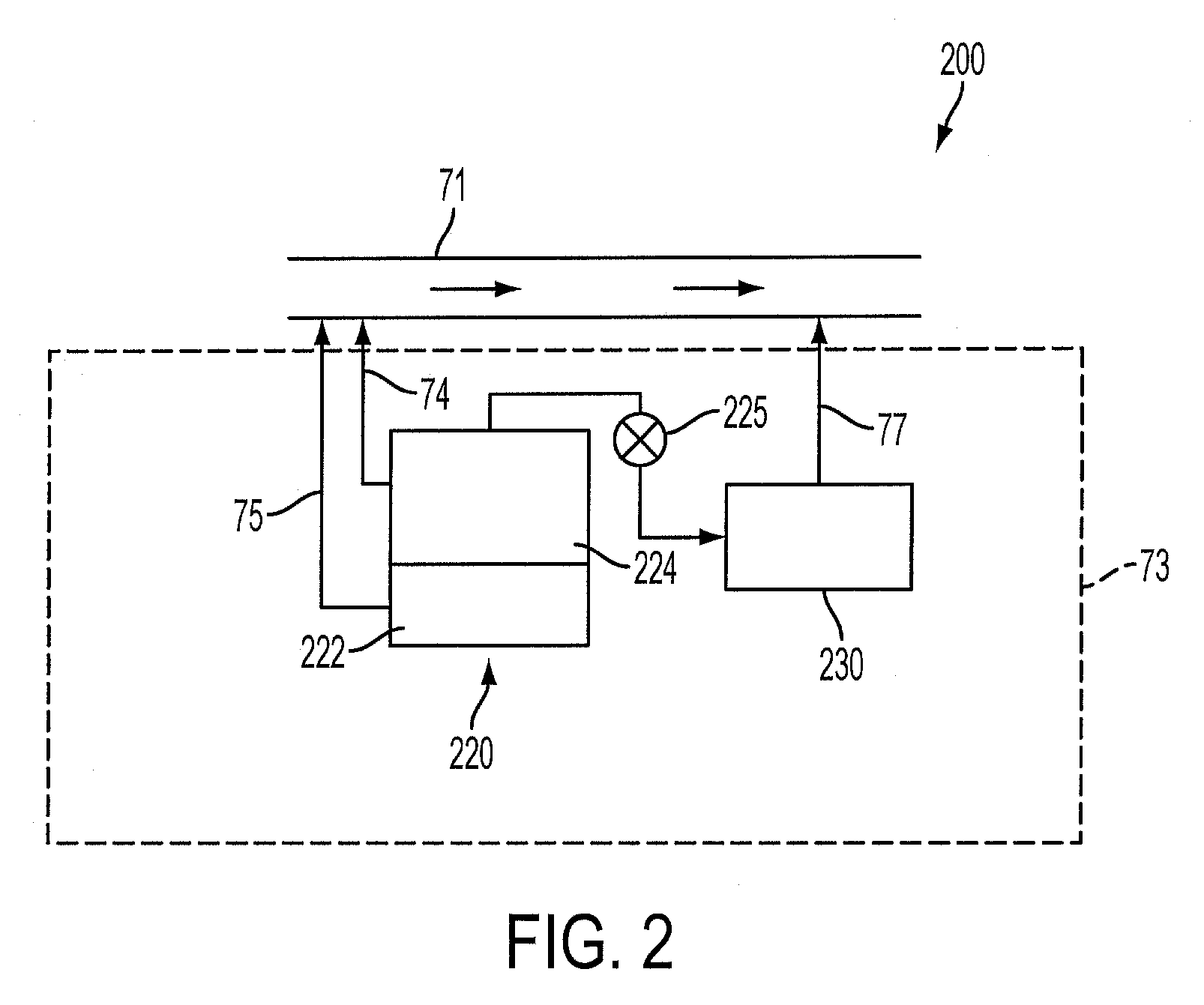

Method and Device for Safe Storage and Use of Volatile Ammonia Storage Materials

There is described a method and apparatus (100, 100′) for storing and delivering ammonia wherein at least two ammonia storage materials (1a, 2a) capable of reversibly adsorbing or absorbing ammonia having different ammonia vapor pressures are used. Ammonia storage material (2a) having a lower vapor pressure, which is only partially saturated with ammonia or void of ammonia, is brought into fluid communication with ammonia storage material (1a) having a higher ammonia vapor pressure to adsorb or absorb ammonia released from the ammonia storage material (1a) having a higher ammonia vapor pressure when the latter is higher than a pressure threshold. An automotive NOx treatment system (200) comprising such apparatus (100, 100′) is also described.

Owner:AMMINEX

Method and device for safe storage and use of volatile ammonia storage materials

There is described a method and apparatus (100, 100′) for storing and delivering ammonia wherein at least two ammonia storage materials (1a, 2a) capable of reversibly adsorbing or absorbing ammonia having different ammonia vapor pressures are used. Ammonia storage material (2a) having a lower vapor pressure, which is only partially saturated with ammonia or void of ammonia, is brought into fluid communication with ammonia storage material (1a) having a higher ammonia vapor pressure to adsorb or absorb ammonia released from the ammonia storage material (1a) having a higher ammonia vapor pressure when the latter is higher than a pressure threshold. An automotive NOx treatment system (200) comprising such apparatus (100, 100′) is also described.

Owner:AMMINEX

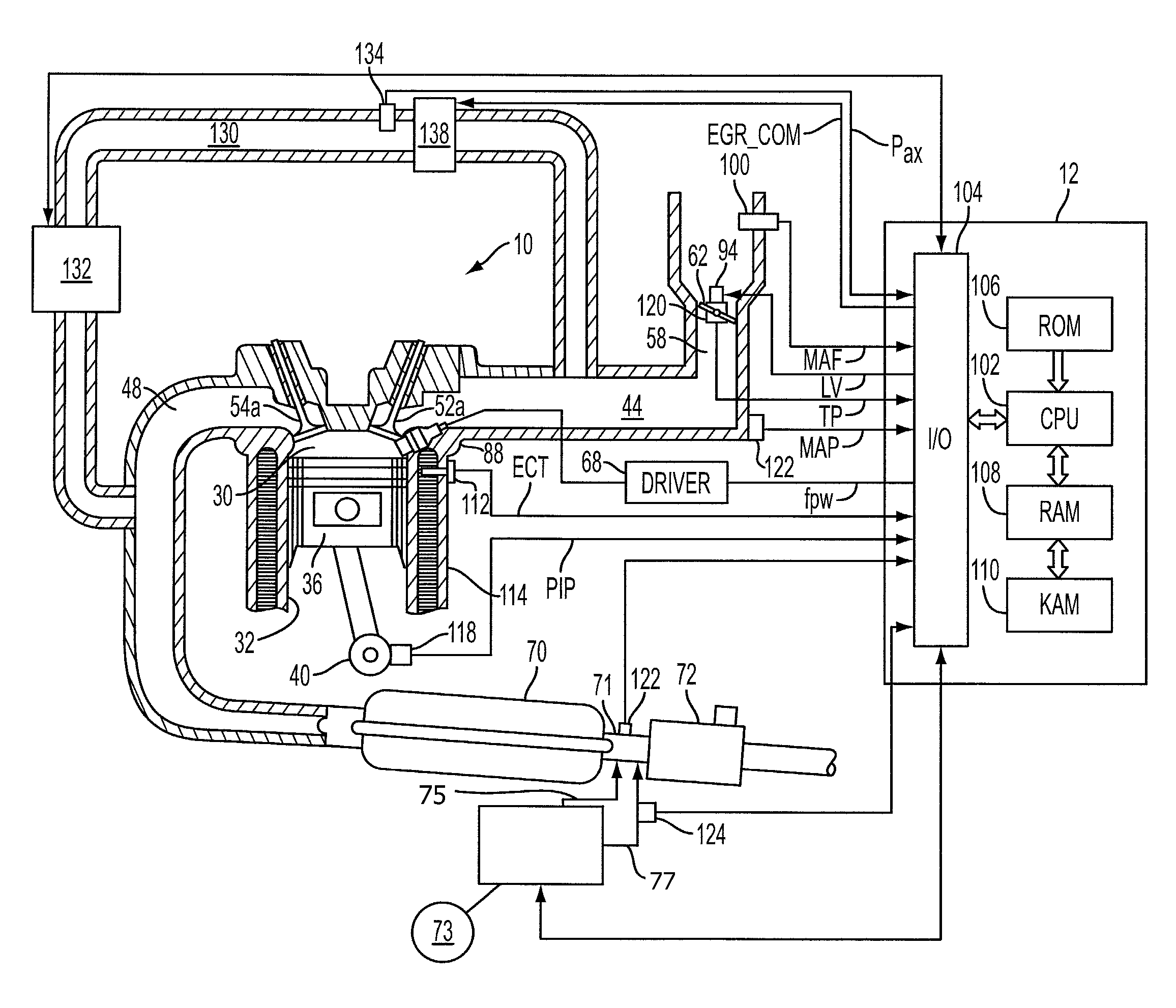

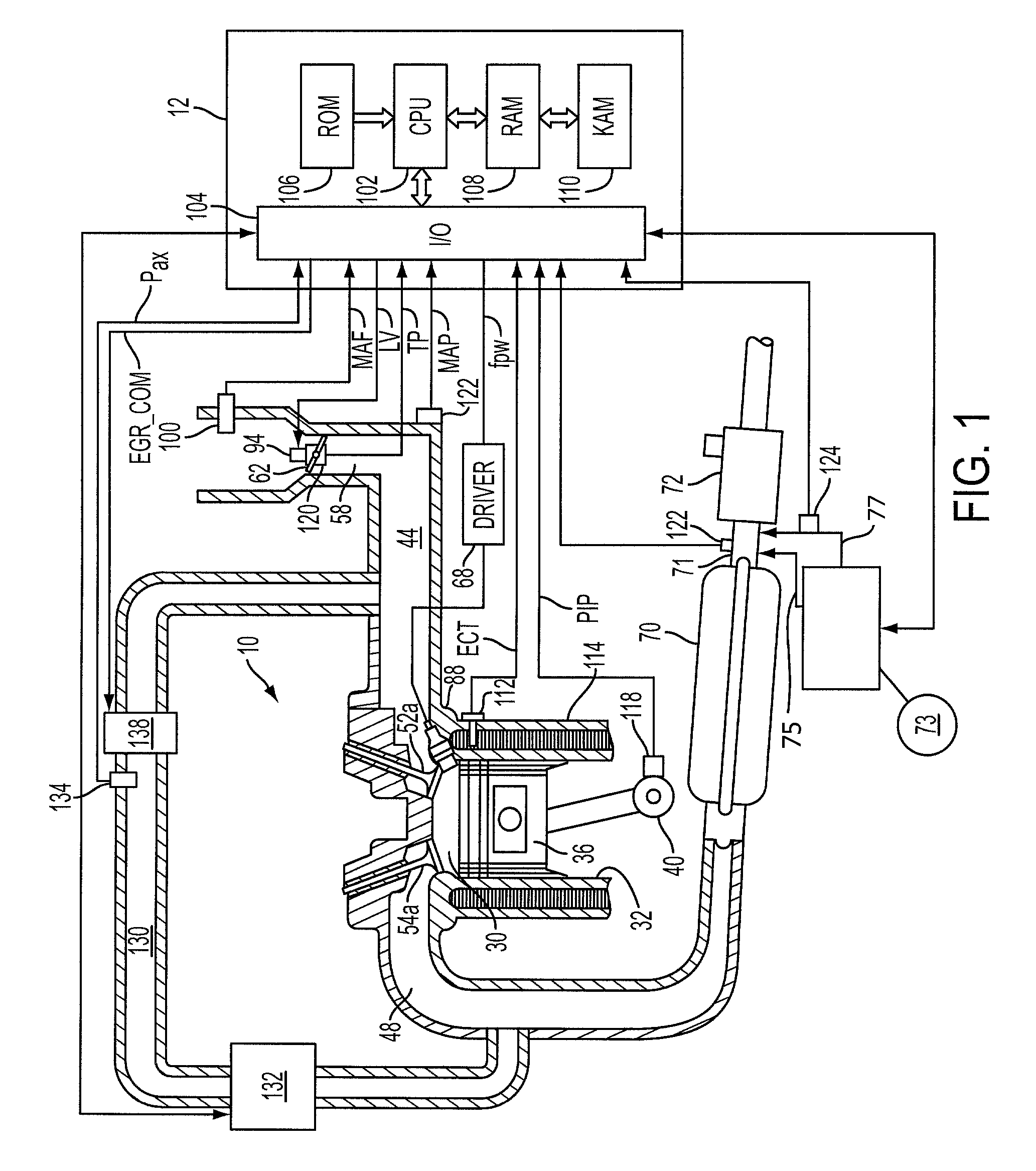

Engine-off ammonia vapor management system and method

A method of managing vapors generated from an ammonia-containing reductant delivery system for an engine of a vehicle, comprising of during at least a portion of engine-off conditions, storing ammonia containing vapors generated in the reductant delivery system, and after said storing and during at least a portion of engine operation, purging said stored ammonia into an exhaust of the engine to react in a catalyst in the exhaust flow.

Owner:FORD GLOBAL TECH LLC

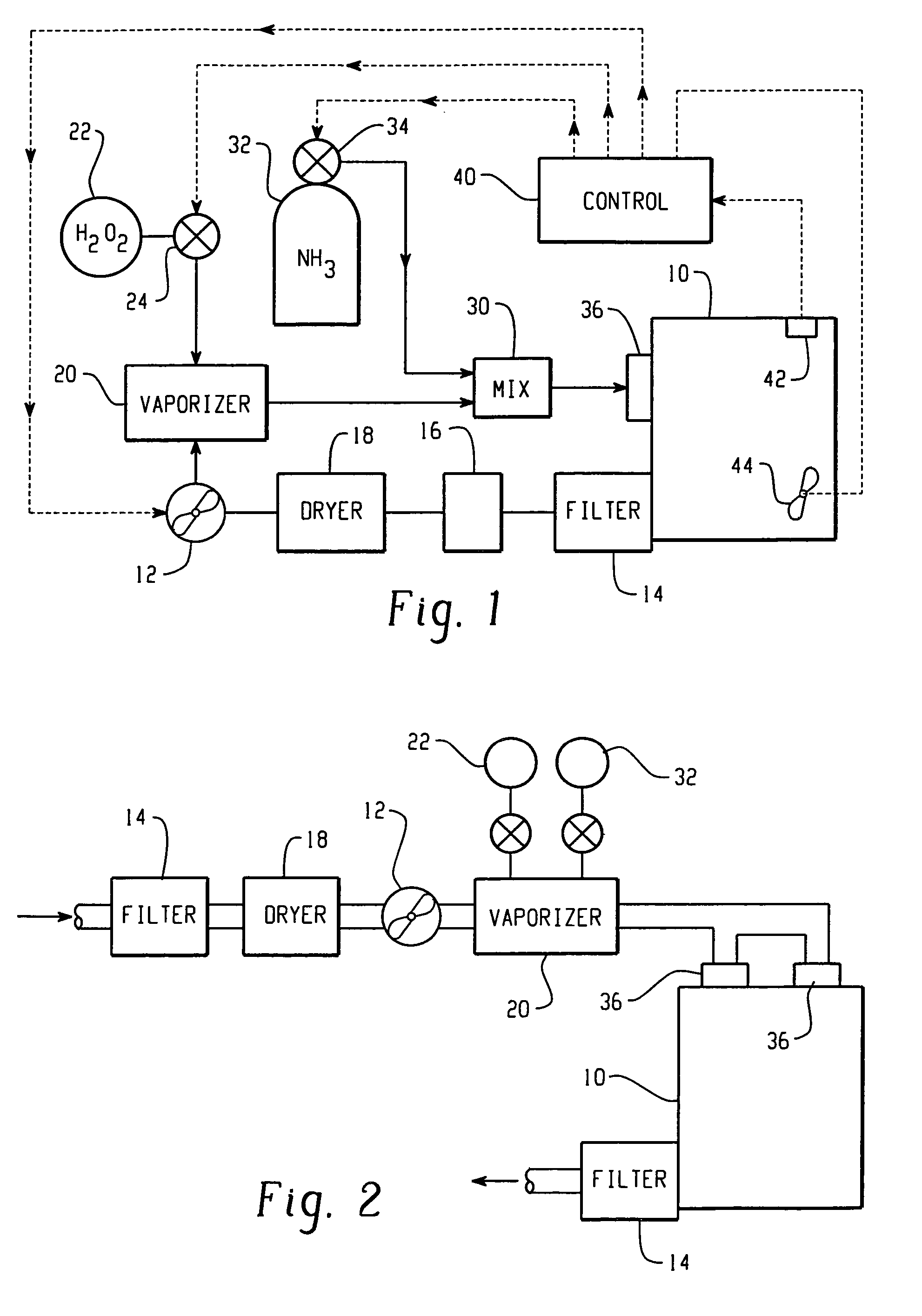

Activated vapor treatment for neutralizing warfare agents

ActiveUS7102052B2Effectiveness againstEasy to cleanPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDisinfectionSporeAccelerant

Hydrogen peroxide is vaporized (20) and mixed (30) with ammonia gas in a ratio between 1:1 and 1:0.0001. The peroxide and ammonia vapor mixture are conveyed to a treatment area (10) to neutralize V-type, H-type, or G-type chemical agents, pathogens, biotoxins, spores, prions, and the like. The ammonia provides the primary deactivating agent for G-type agents with the peroxide acting as an accelerator. The peroxide acts as the primary agent for deactivating V-type and H-type agents, pathogens, biotoxins, spores, and prions. The ammonia acts as an accelerator in at least some of these peroxide deactivation reactions.

Owner:US SEC THE ARMY THE +1

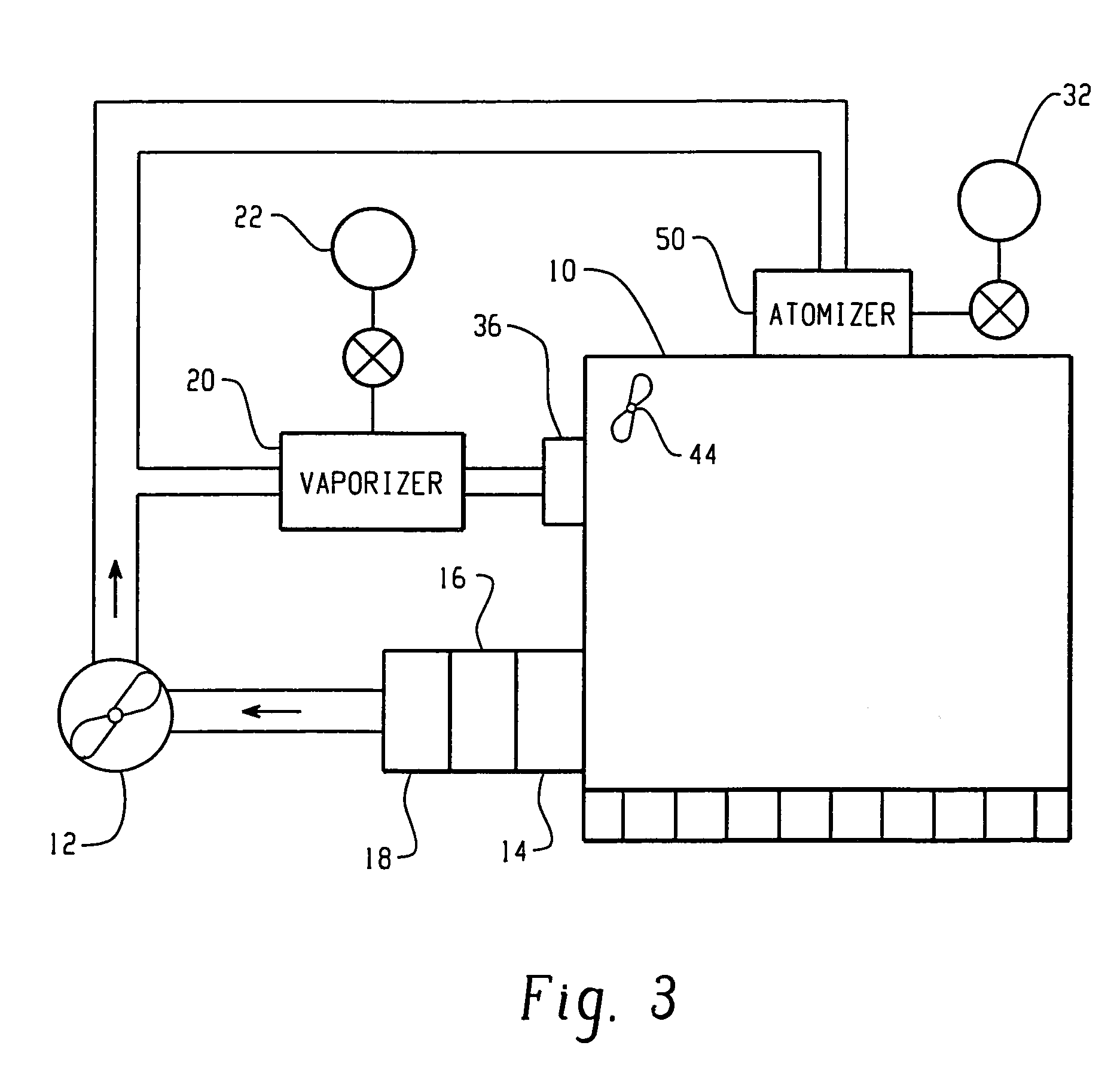

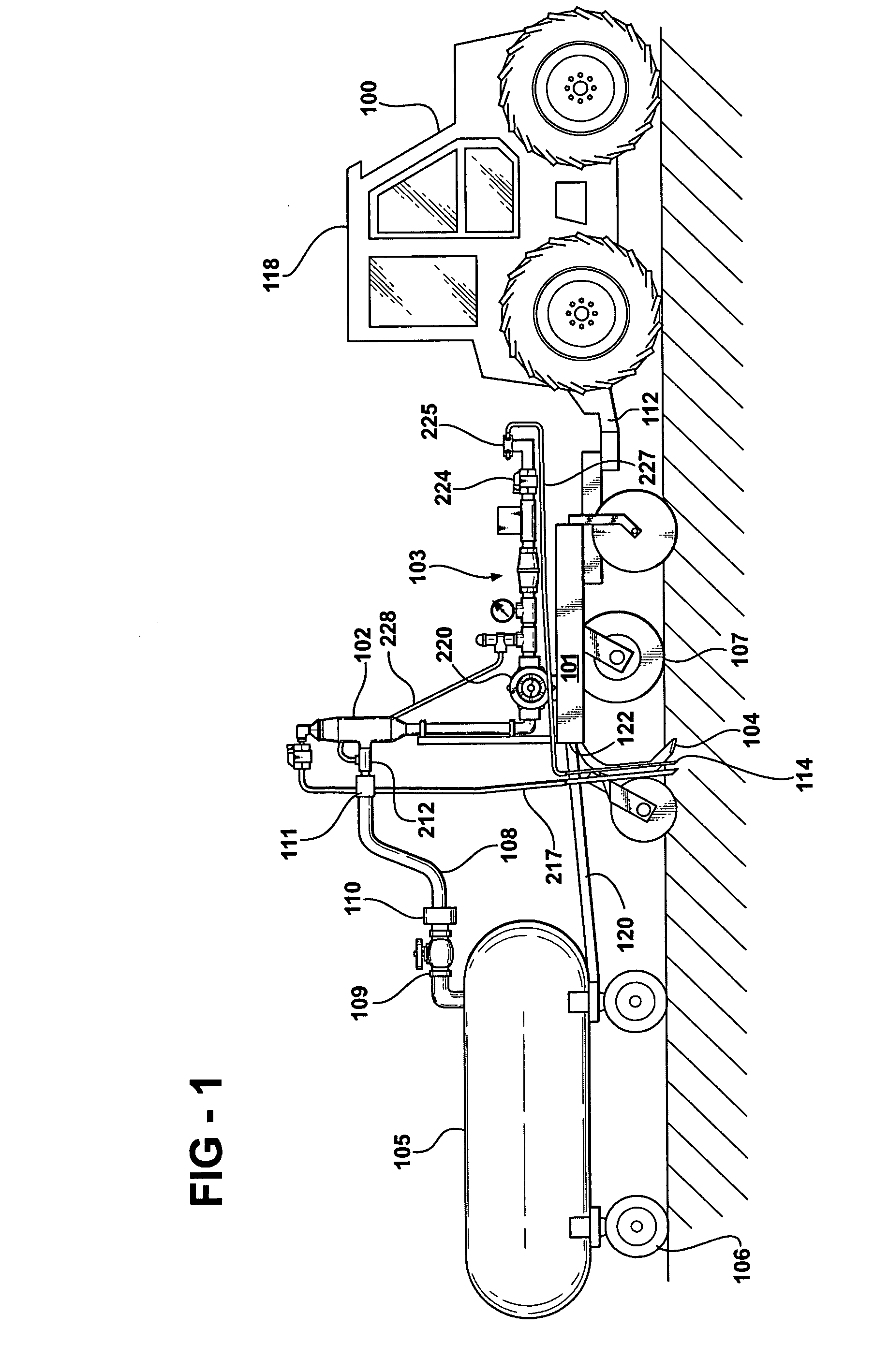

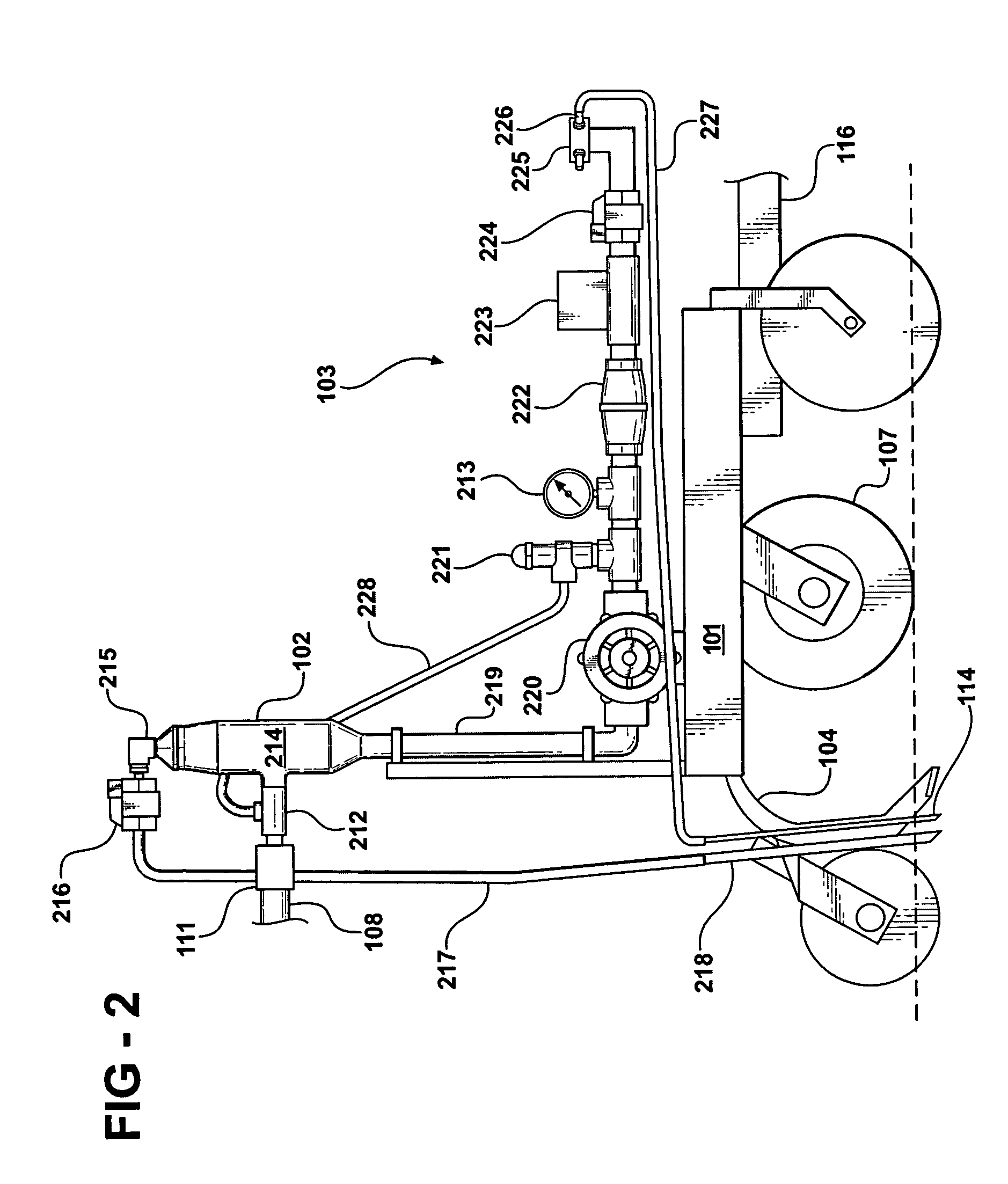

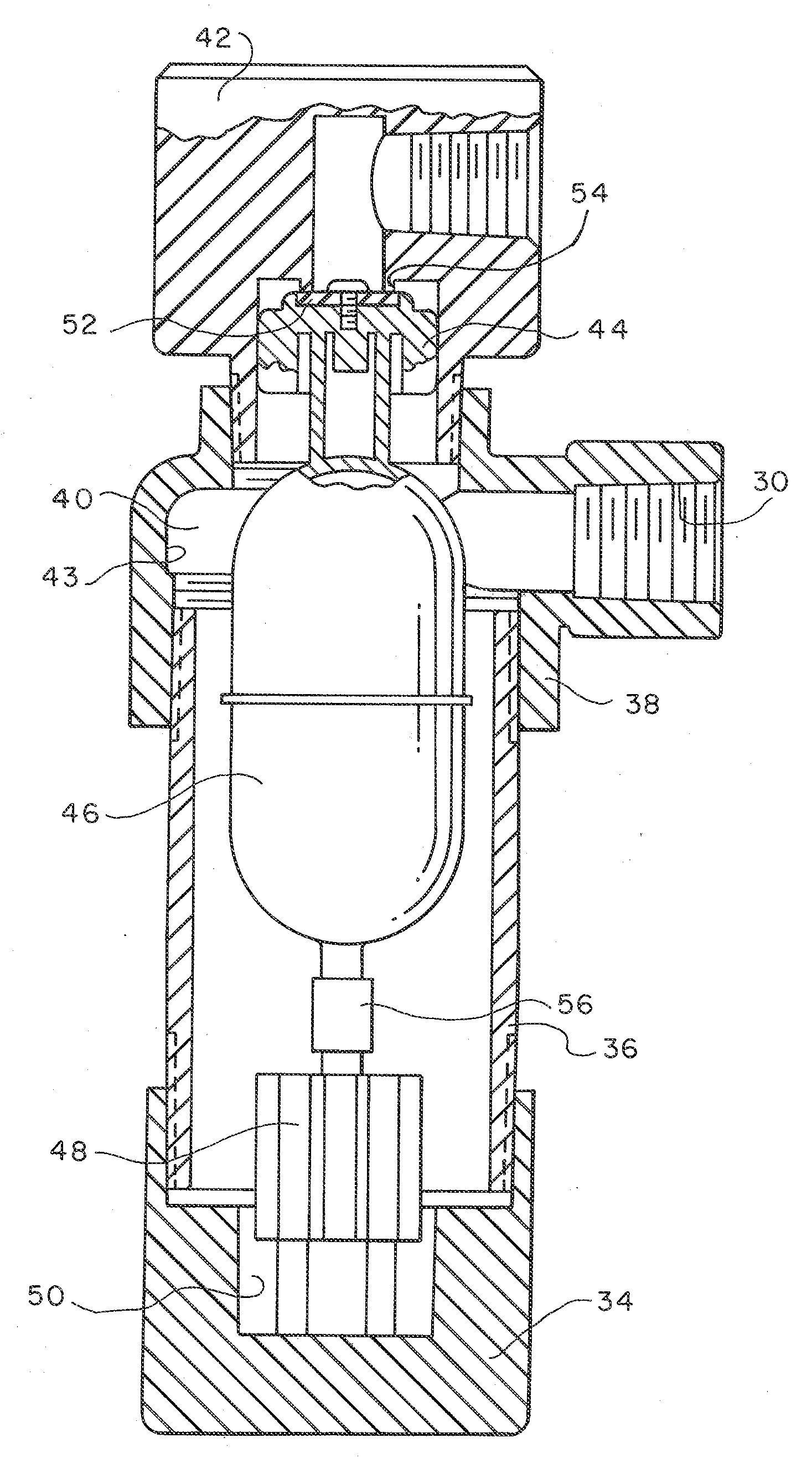

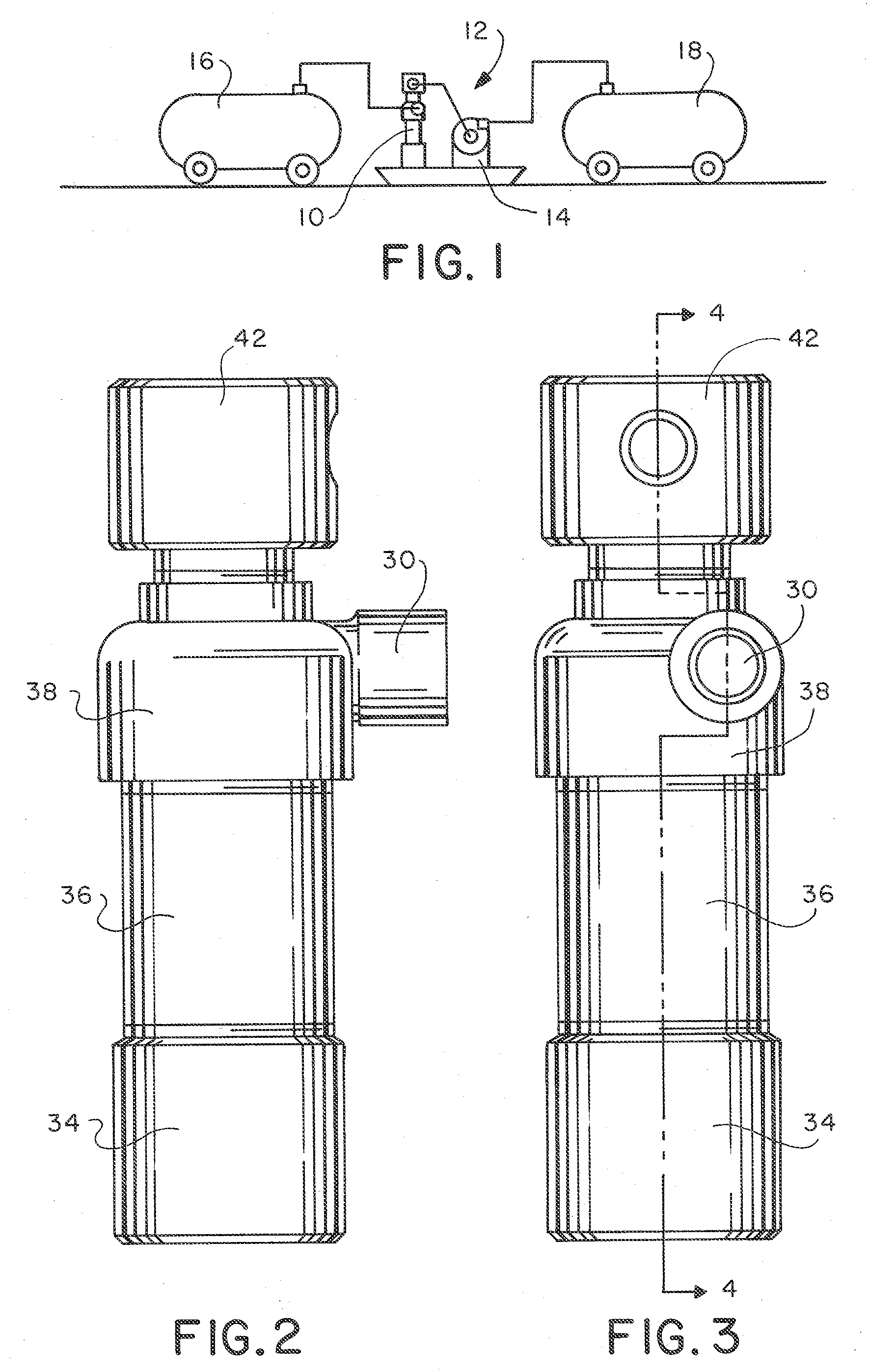

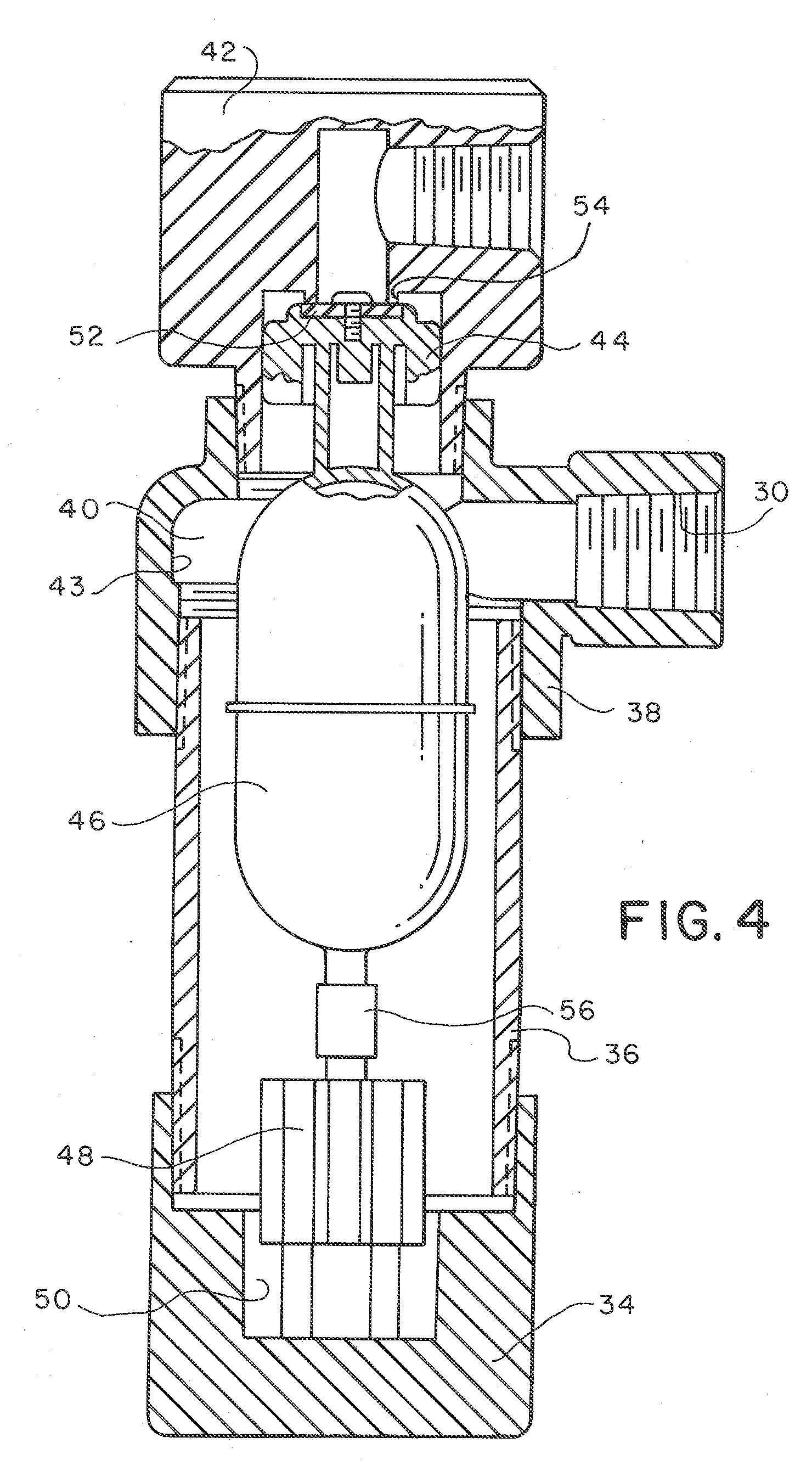

Anhydrous ammonia fertilizer flow control apparatus and method

ActiveUS7096802B1Reduce the amount requiredIncrease volumePlantingLiquid fertiliser distributionControl systemEngineering

A method and apparatus for supplying liquid anhydrous ammonia to a pump or other flow control system whereby a separation chamber removes vapor generated by friction in the flow path from a storage tank containing saturated anhydrous ammonia. Additionally, liquid ammonia in the separation chamber creates a static head pressure. The difference in height between the inlet near the top of the separation chamber and the outlet at the bottom causes the static head pressure. The static head assures pure liquid at the bottom since absolute pressure exceeds saturation pressure. As a result, the feed stream to the pump or other flow control system is free of ammonia vapor.

Owner:360 YIELD CENT

On-site generation of ultra-high-purity buffered-HF and ammonium fluoride

InactiveUS6350425B2Reduce processingLow impurity contentChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Wastewater treatment method

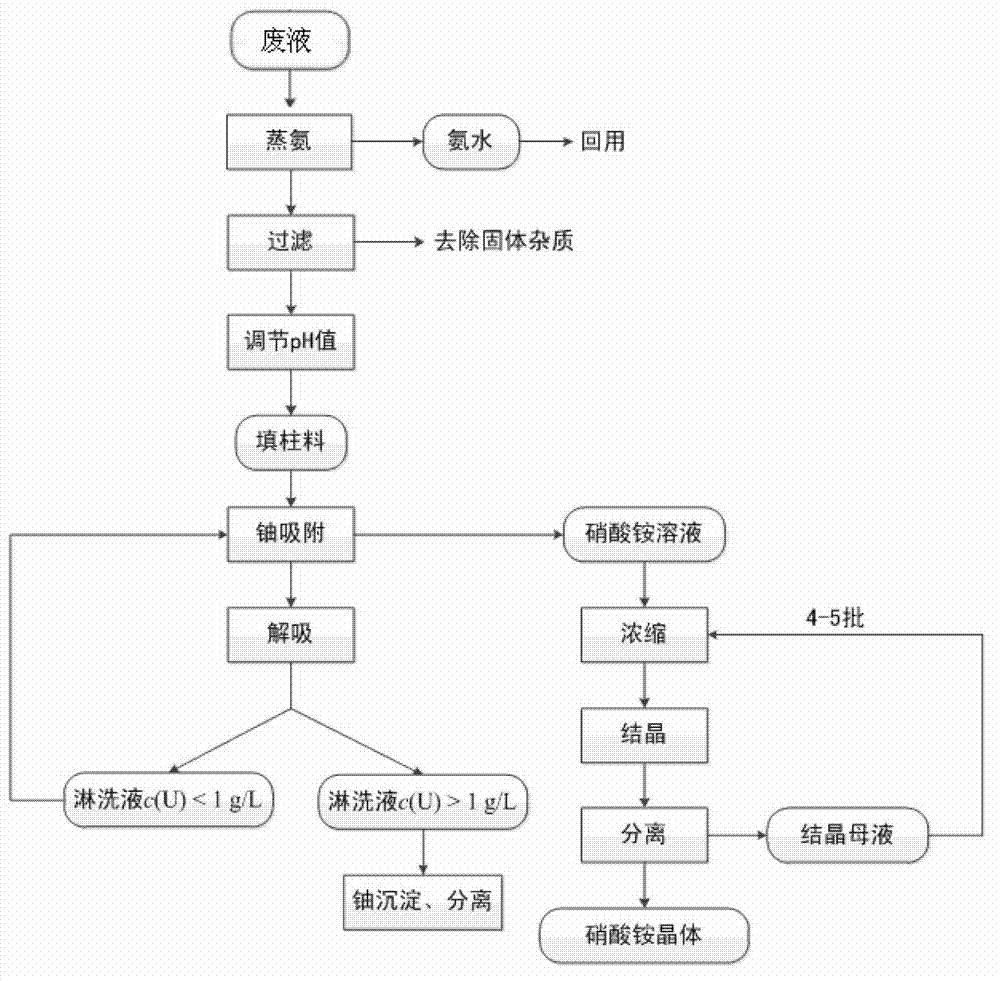

The invention provides a treatment method of low-radioactivity wastewater with complex components and high salt content. The wastewater treatment method comprises the following steps of: removing ammonia by evaporating, and recycling ammonia vapor; removing solid substances and macromolecular substances in the wastewater by removing; adsorbing uranium after pre-treating the filtrate; leaching adsorbent, desorbing the uranium and regenerating the adsorbent; and carrying out concentration crystallization separation onto the uranium-removed wastewater to obtain the solid ammonium nitrate. The wastewater treatment method is capable of realizing the recycling of useful substances ammonia, uranium and ammonium nitrate without generating secondary liquid waste and waste.

Owner:TSINGHUA UNIV

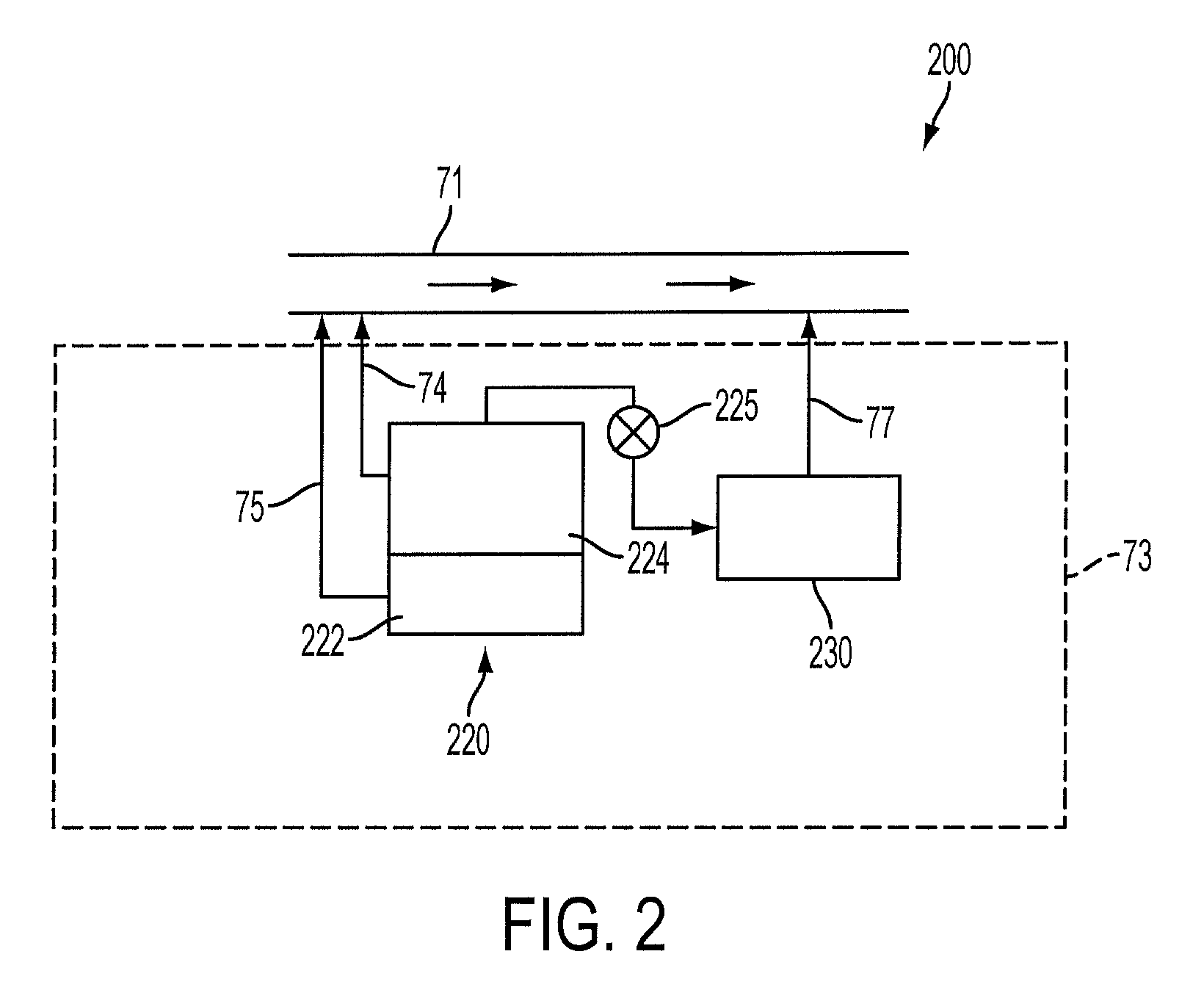

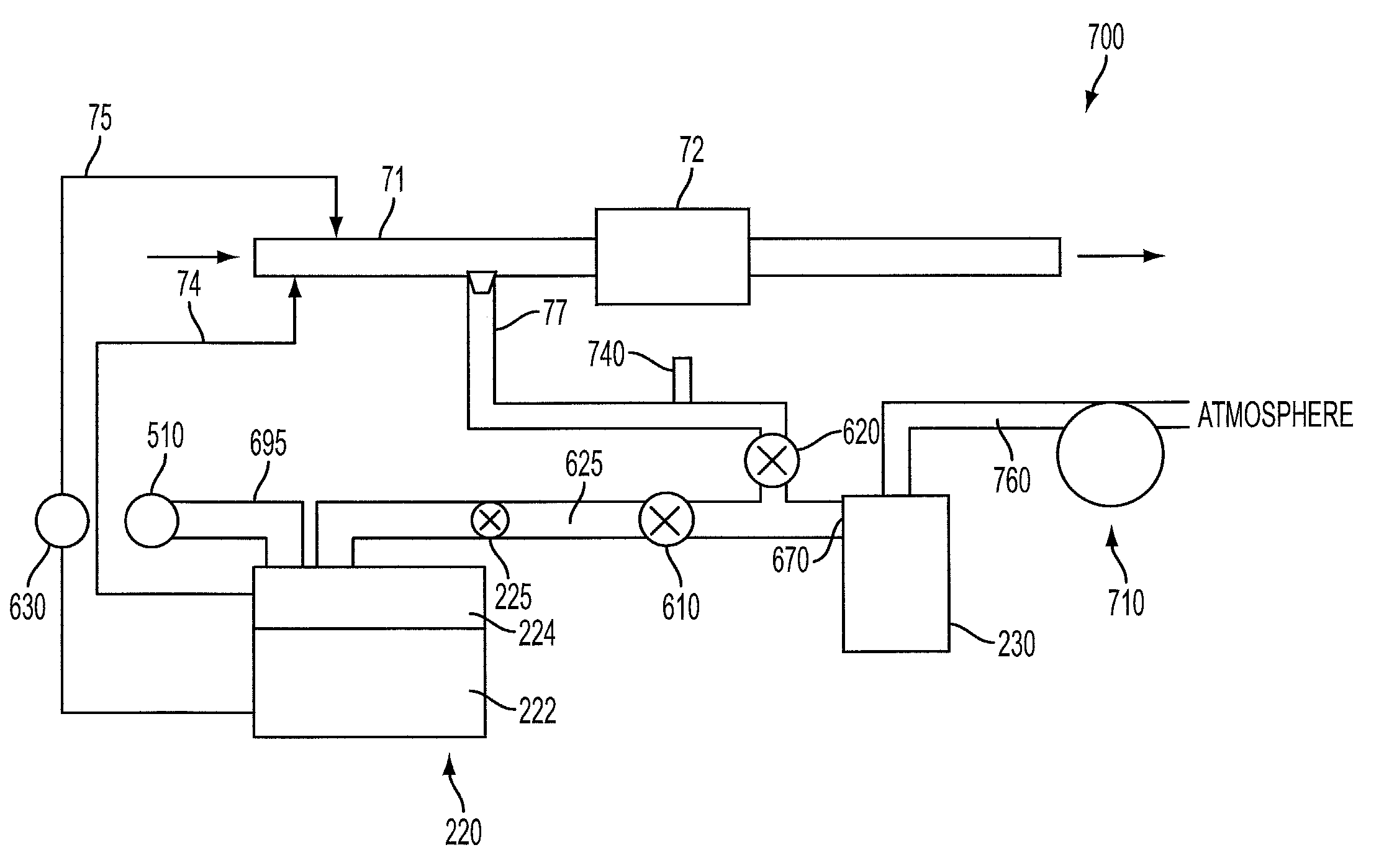

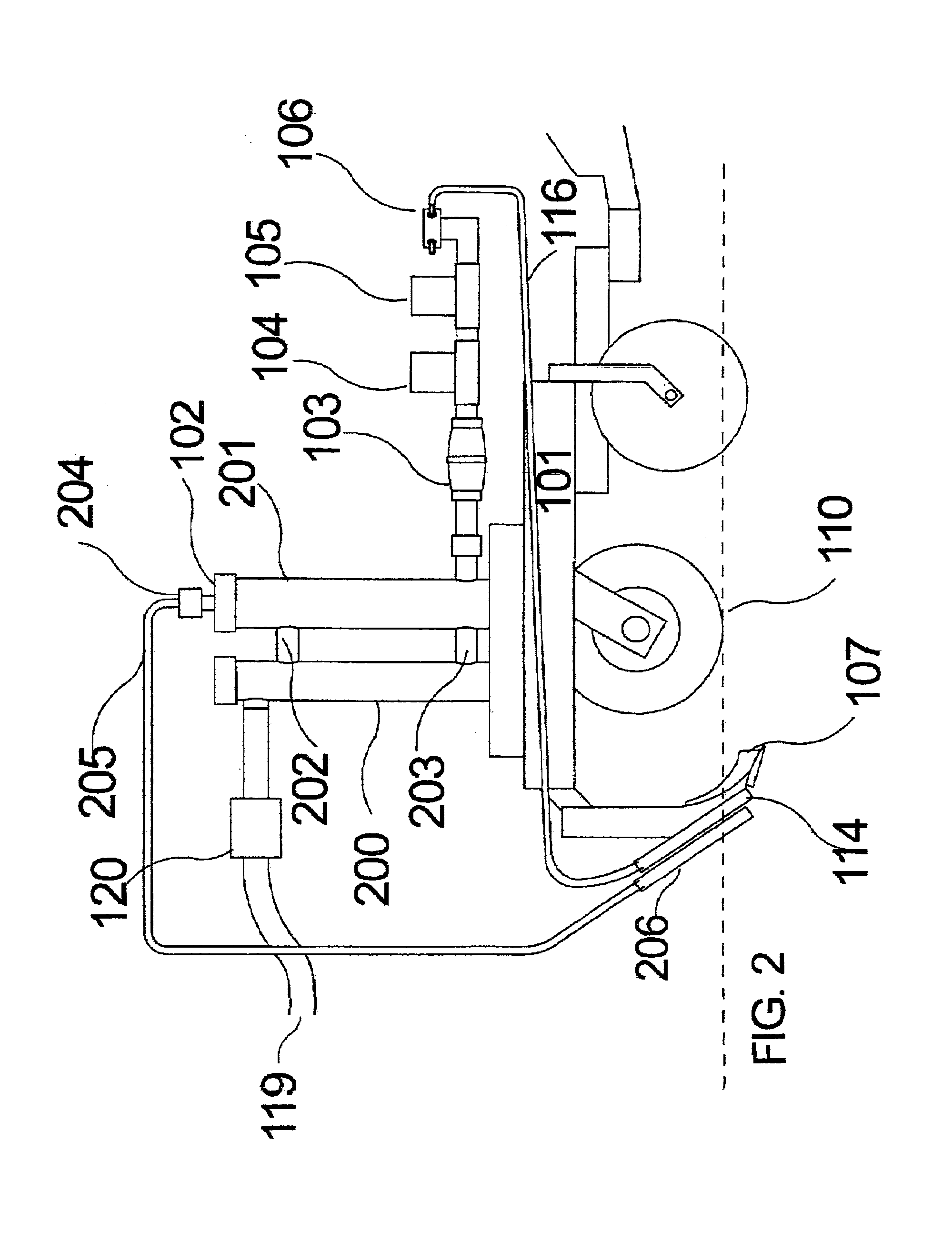

Management of a plurality of reductants for selective catalytic reduction

ActiveUS8015801B2Relieve pressureRelieving vacuum build-upInternal combustion piston enginesExhaust apparatusReducing agentSelective catalytic reduction

A method of operating a reductant delivery and storage system of a vehicle, comprising of storing an ammonia-containing fluid in a first storage device, generating ammonia vapors in the first storage device, storing said generated ammonia vapors in a second storage device, purging said stored vapors from the second storage device to an exhaust of the engine, and relieving pressure or vacuum build-up during at least one of said storing and purging is provided via an atmospheric vent coupled in the reductant delivery and storage system.

Owner:FORD GLOBAL TECH LLC

Ammonia vapor management system and method

InactiveUS7954311B2Reduce the amount requiredEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberDelivery system

A method is described for managing vapors generated from an ammonia-containing reductant delivery system. The method may include generating ammonia vapors in a first storage device and storing said generated ammonia vapors in a second storage device. Further, the method may include purging the stored vapors from the second storage device to upstream of a combustion chamber of the engine during a first condition and downstream of the combustion chamber during a second condition.

Owner:FORD GLOBAL TECH LLC

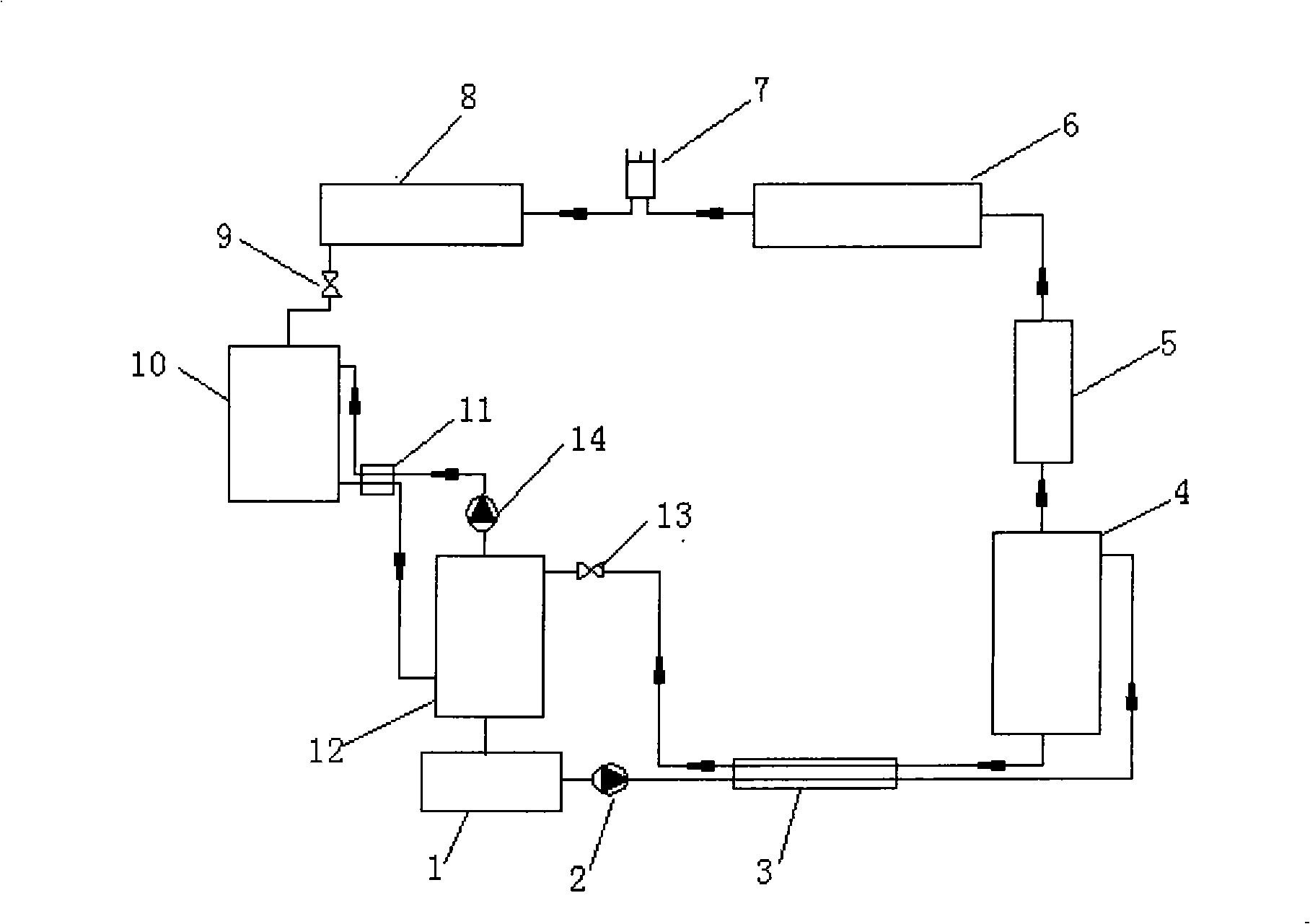

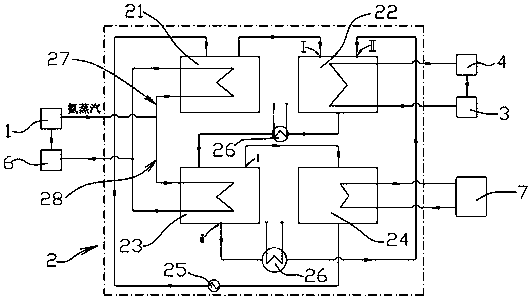

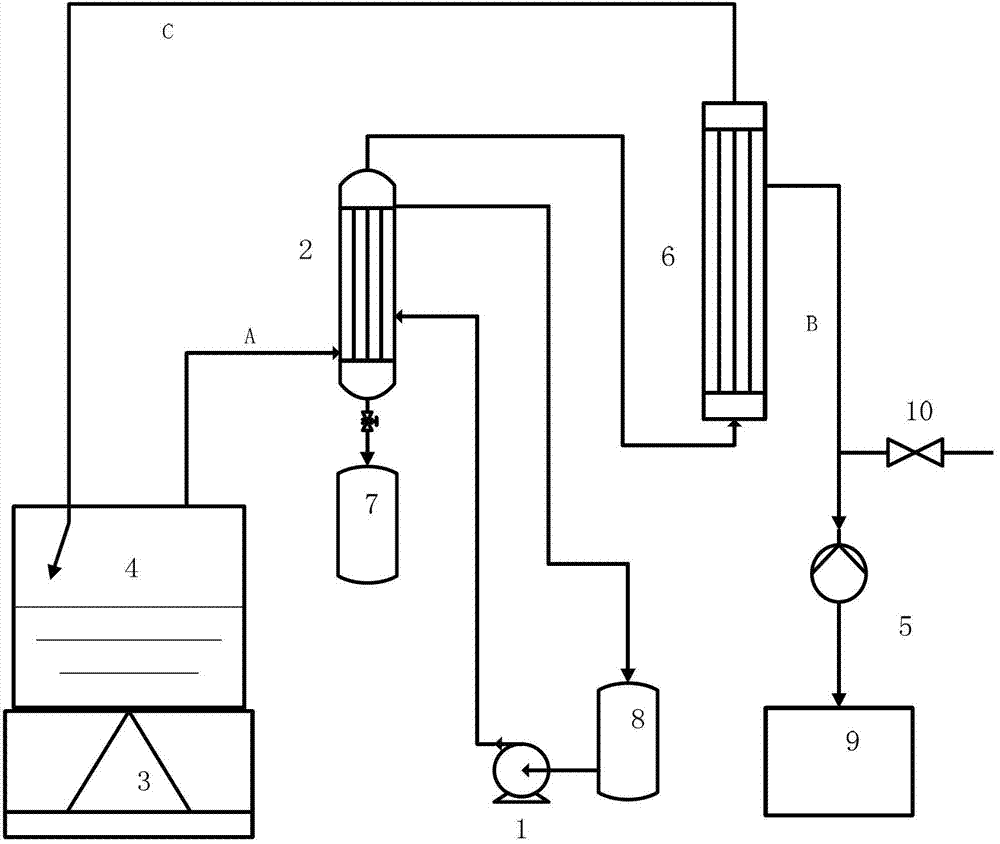

Compression-absorption-diffusion combined refrigerating plant and its refrigeration cycle method

InactiveCN101344345AImprove efficiencyRelieve pressureRefrigeration machinesEngineeringRefrigeration plant

The invention provides a compression-absorption-diffusion composite refrigeration device and a refrigeration circulation method which adopts the device, while the device and the method belong to the technical field of refrigeration devices. The device is coupled in a series connected way by an absorption refrigeration system, a compression refrigeration system and a diffusion refrigeration system and is composed of a common heat exchange device, a throttling device and a refrigeration working medium; and the device comprises a liquid storage device, a solution pump, a generator, a rectifier, a first-stage condenser, a second-stage condenser, a compressor, a throttle valve, an evaporator and an absorber. Ammonia vapor completes first pressure increase in the diffusion refrigeration system and the absorption refrigeration system and enters the compressor through a pipeline after entering the first-stage condenser for completing second pressure increase, after that, the ammonia vapor enters the second-stage condenser to be cooled to liquid ammonia, the liquid ammonia enters the evaporator through the throttle valve, the evaporation and the refrigeration are carried out under the role of a diffusing agent of the evaporator, the liquid ammonia is further mixed with the diffusing agent to enter the absorber, ammonia in the absorber is absorbed, and the diffusing agent is returned back to the evaporator along the pipeline. The device of the invention is applicable to small-scale low-grade waste heat refrigeration occasions.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for Recycling Ammonia from Low-Concentration Ammonium Chloride Wastewater

InactiveUS20170101326A1Reduce power consumptionEasy to processCalcium/strontium/barium chloridesTreatment involving filtrationLiquid wasteSlag

A method for comprehensively treating low-concentration ammonia-nitrogen wastewater by completely recycling is disclosed. The low-concentration ammonia-nitrogen wastewater and carbide slag or quick lime are mixed and reacted to obtain a mixed solution containing ammonia water and ammonium chloride. The mixed solution is transferred into an ammonia-water evaporative concentration tower to separate the ammonia water and thus obtain an ammonia vapor and a calcium chloride waste solution. The ammonia vapor is transferred into an ammonia-water cooler, and the calcium chloride waste solution is introduced into an aging pool for aging, and then filtered to obtain a purified calcium chloride solution; and the purified calcium chloride solution is introduced into an MVR triple-effect evaporator for evaporation, so as to obtain distilled water and a concentrated calcium chloride solution. The concentrated calcium chloride solution is introduced into a fluidized bed for spray granulation, so as to obtain an anhydrous calcium chloride product.

Owner:BAOTOU CITY XIJUN ENVIRONMENTAL SCI & TECH CO LTD

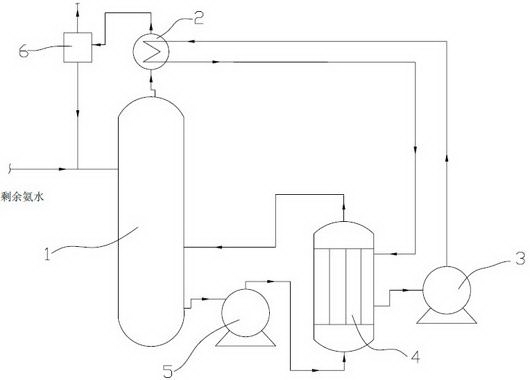

System for recovering residual heat of ammonia vapor on top of surplus ammonia water ammonia still

InactiveCN103803668ALow renovation costWater/sewage treatment by heatingWater/sewage treatment by degassingVapor–liquid separatorFluid phase

The invention discloses a system for recovering residual heat of ammonia vapor on the top of a surplus ammonia water ammonia still. The system comprises an ammonia still, a heat pump unit, a circulating hot water pump, a reboiler, a waste water pump and a gas-liquid separator, wherein the heat pump unit is an absorptive heat pump unit which comprises an evaporator end, an absorber end, a generator end and a condenser end. The heat pump unit is placed on the top of the ammonia still and is used for recycling latent heat of ammonia vapor on the top of the still to heat circulating hot water, the heated circulating hot water is used for heating ammonia distilling waste water at the bottom of the still through the reboiler to produce saturated vapor, and the saturated steam returns into the ammonia still to supply distillation energy and realize recycling of energy, so that the consumption of coal gas or vapor is lowered, and the utilization ratio of recovered residual heat is increased. The ammonia vapor is subjected to gas-liquid separation after recovery of the latent heat, and liquid-phase ammonia water returns into the ammonia still for serving as reflux liquid.

Owner:JIGANG GRP

Fishing boat tail gas refrigerating unit

InactiveCN101865560ARealize comprehensive utilizationReduce consumptionClimate change adaptationEnergy efficient heating/coolingWater vaporLiquid storage tank

The invention discloses a fishing boat tail gas refrigerating unit, which adopts the principle of ammonia-water absorption refrigeration and uses the waste heat of fishing boat tail gas to drive a system to work so as to finally realize a refrigeration process. The refrigerating unit realizes low temperature, high efficiency and high power. The system mainly comprises a generating and rectifying device, a condenser, an ammonia throttle valve, a liquid storage tank, an evaporator, an absorber, a solution pump, a solution throttle valve, a solution heat exchanger and the like. Aqueous solution of ammonia is heated at a generating part of the generating and rectifying device to evaporate a large amount of ammonia vapor and a small amount of water vapor, the water vapor is rectified at a rectifying part of the generating and rectifying device, the rest ammonia vapor is condensed in the condenser to form liquid ammonia, the liquid ammonia is throttled and decompressed by the throttle valve and then enters the liquid storage tank, and the liquid ammonia is evaporated and refrigerated in the evaporator to provide cold energy for fresh keeping for a fishing boat. The refrigerating unit reduces the ice load of the fishing boat, effectively improves the freshness of fishes, and has significance for realizing energy conservation and emission reduction on the fishing boat.

Owner:HAINAN RARE AGRI CO LTD

Ammonia Vapor Storage and Purge System and Method

InactiveUS20080069750A1Efficient removalEasy to controlNitrogen compoundsInternal combustion piston enginesReducing agentNH3 compound

A method of operating a reductant delivery and storage system of a vehicle, comprising of storing an ammonia-containing fluid in a first storage device, generating ammonia vapors in the first storage device and storing said generated ammonia vapors in a second storage device, purging said stored vapors from the second storage device to an exhaust of the engine, delivering said ammonia-containing fluid to said exhaust of the engine, and adjusting at least one of an amount of ammonia-containing fluid delivered and an amount of vapors purged to said exhaust based on the other of said at least one of said amount of ammonia-containing fluid delivered and said amount of vapors purged to said exhaust.

Owner:FORD GLOBAL TECH LLC

Engine-Off Ammonia Vapor Management System and Method

InactiveUS20080066452A1Internal combustion piston enginesExhaust apparatusEngineeringManagement system

A method of managing vapors generated from an ammonia-containing reductant delivery system for an engine of a vehicle, comprising of during at least a portion of engine-off conditions, storing ammonia containing vapors generated in the reductant delivery system, and after said storing and during at least a portion of engine operation, purging said stored ammonia into an exhaust of the engine to react in a catalyst in the exhaust flow.

Owner:FORD GLOBAL TECH LLC

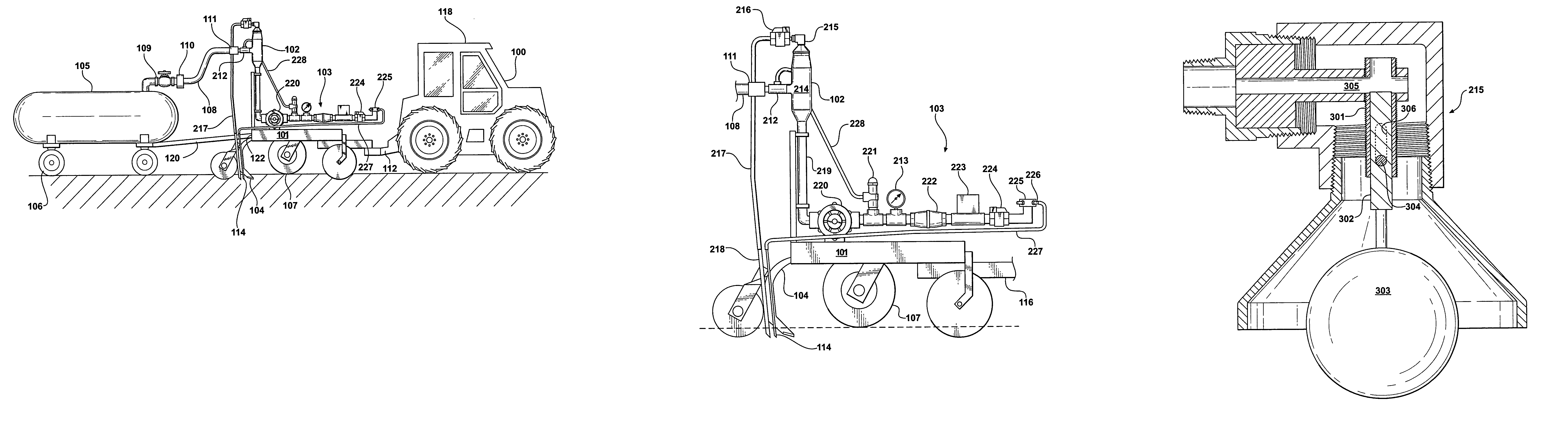

Anhydrous ammonia fertilizer liquid and vapor separator

InactiveUS8667916B1Prevent excessive fertilizer applicationReduce productionLiquid fertiliser distributionVertical tubeTower

The vapor exhaust assembly, for anhydrous ammonia, includes a closed filter tower and a closed exhaust tower with vertical tubes. The filter tower is connected to the vapor tower by a vapor upper pipe and a liquid lower pipe. A filter tube is mounted in the filter tower. Ammonia enters the filter tower above an open end of the filter. Ammonia vapor moves from the filter tower through the vapor upper pipe to a vapor chamber in the vapor tower. Liquid moves from the filter tower through the liquid pipe to the vapor tower. Liquid received in the vapor tower is moved upward by a dam. Vapor in the liquid moves upward to the vapor chamber. Liquid moves downward from the dam top to a liquid discharge exit. A vapor discharge valve in the top of the vapor tower is opened to discharge vapor and increase liquid in both towers.

Owner:360 YIELD CENT

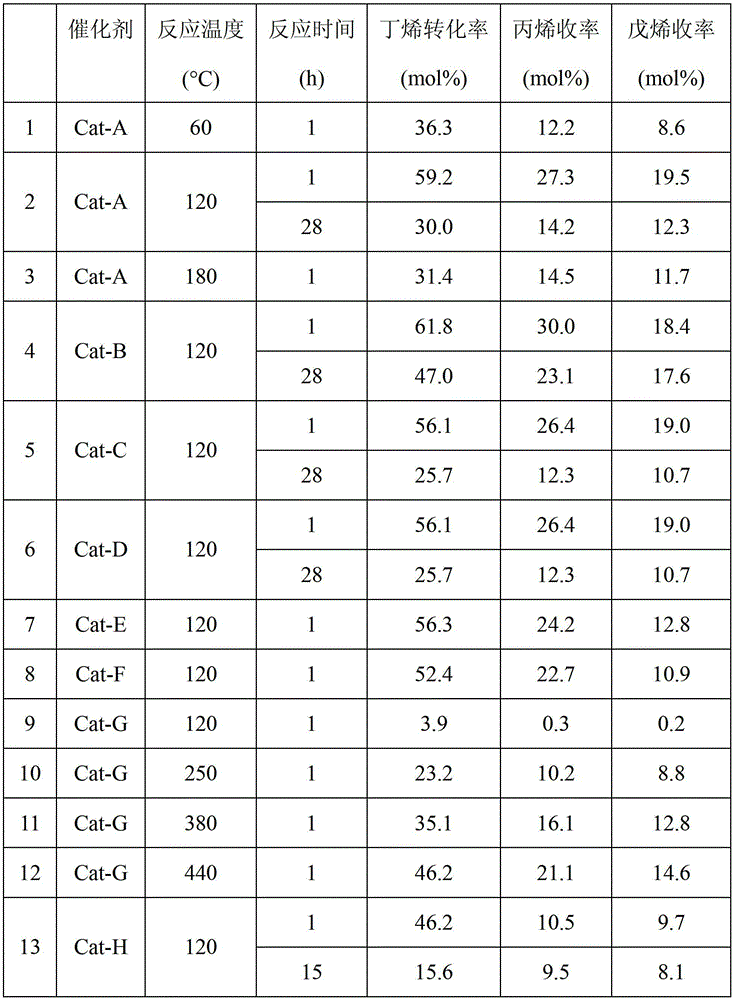

Molybdenum supported catalyst for 1-butylene disproportionation reaction and preparation method

ActiveCN104056651AHigh yieldImprove reaction stabilityMolecular sieve catalystsHydrocarbon by metathesis reactionButeneMolecular sieve

The invention provides a molybdenum supported catalyst for 1-butylene disproportionation reaction and a preparation method; the catalyst comprises two parts, an active metal component and a composite carrier, wherein the composite carrier is a compound of a mesoporous SBA-15 molecular sieve and alumina, and the supported active metal component is an oxide of molybdenum; the preparation method of the catalyst comprises the following steps: firstly removing templates from a mesoporous SBA-15 molecular sieve, coating the mesoporous SBA-15 molecular sieve with an alumina precursor by methods of water vapor-induced hydrolysis, ammonia vapor-induced hydrolysis, and the like to prepare a composite carrier with different ratios; then performing isovolumetric impregnation of the composite carrier in a molybdenum element-containing solution to obtain a supporting amount of metal molybdenum of 1-30%, drying and roasting to obtain the molybdenum supported catalyst. The catalyst provided in the invention can be used in reactions for preparing propylene and pentene by 1-butylene disproportionation, can improve the conversion rate of 1-butylene, and prolong the service life of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

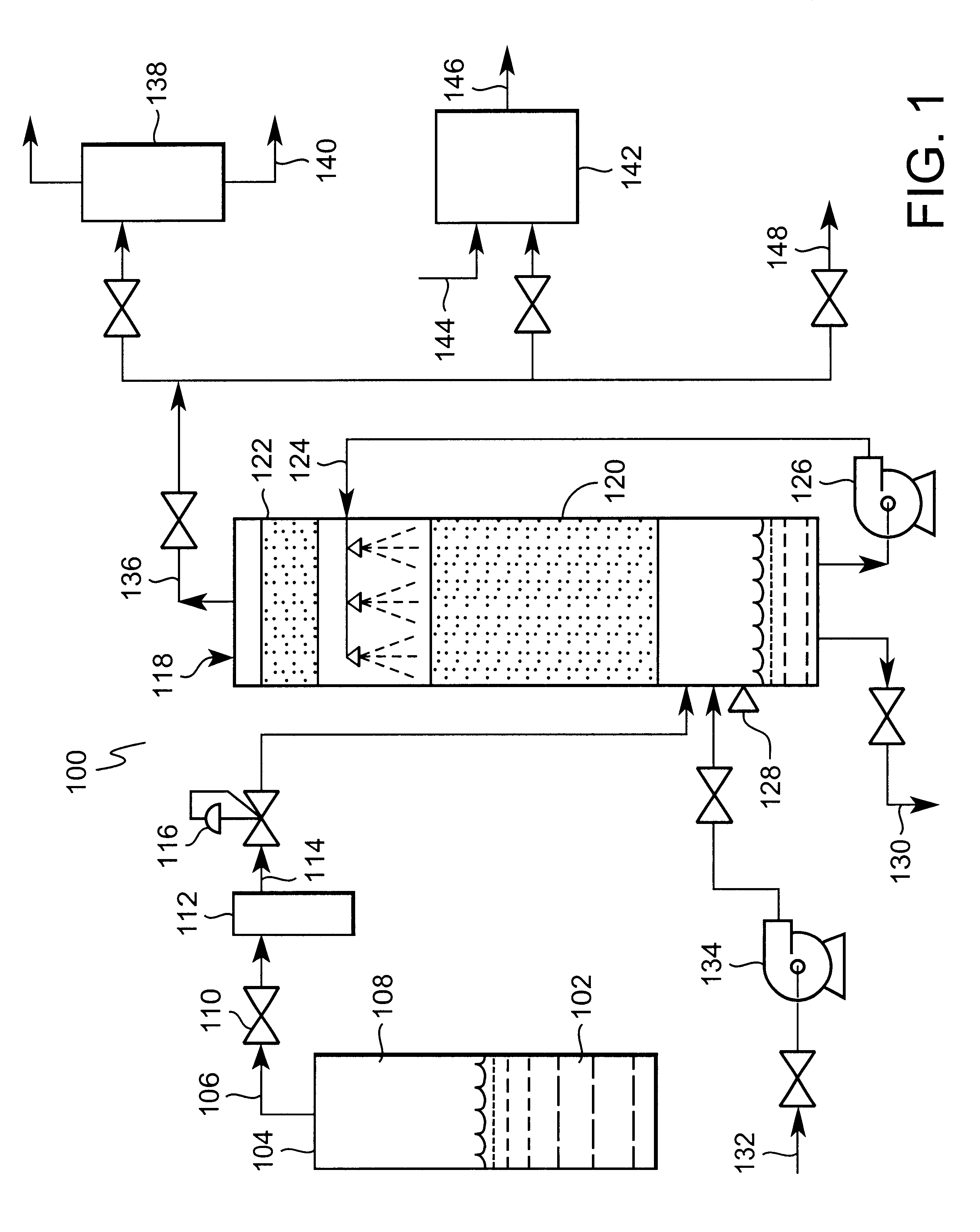

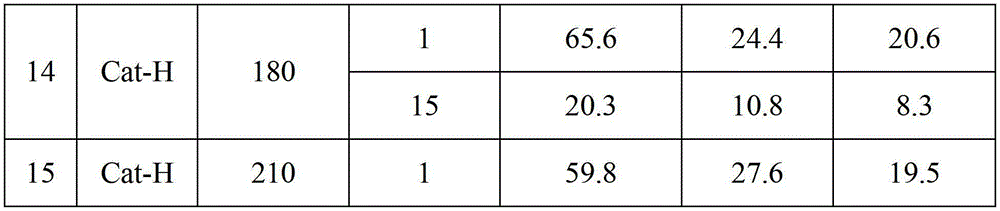

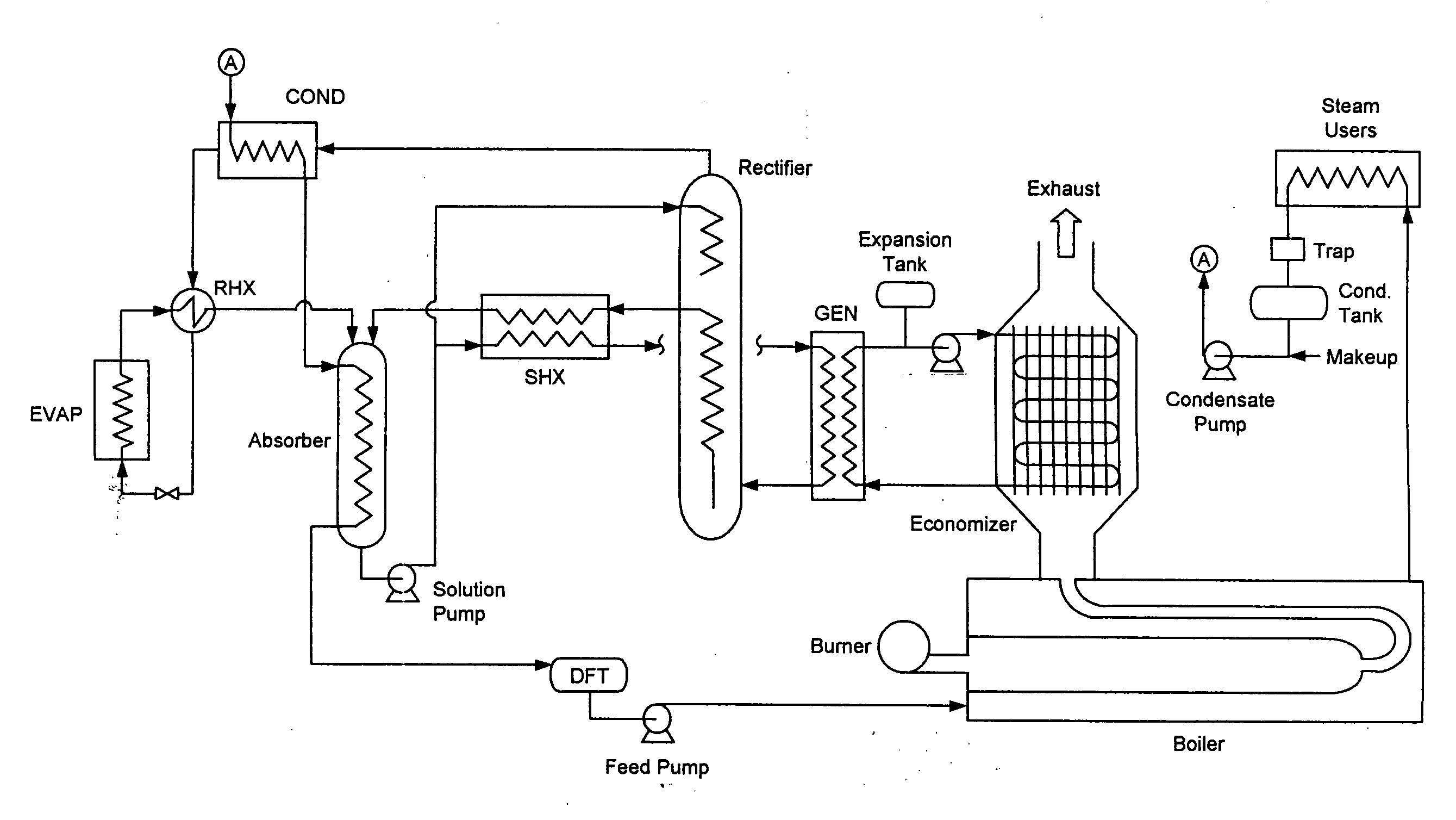

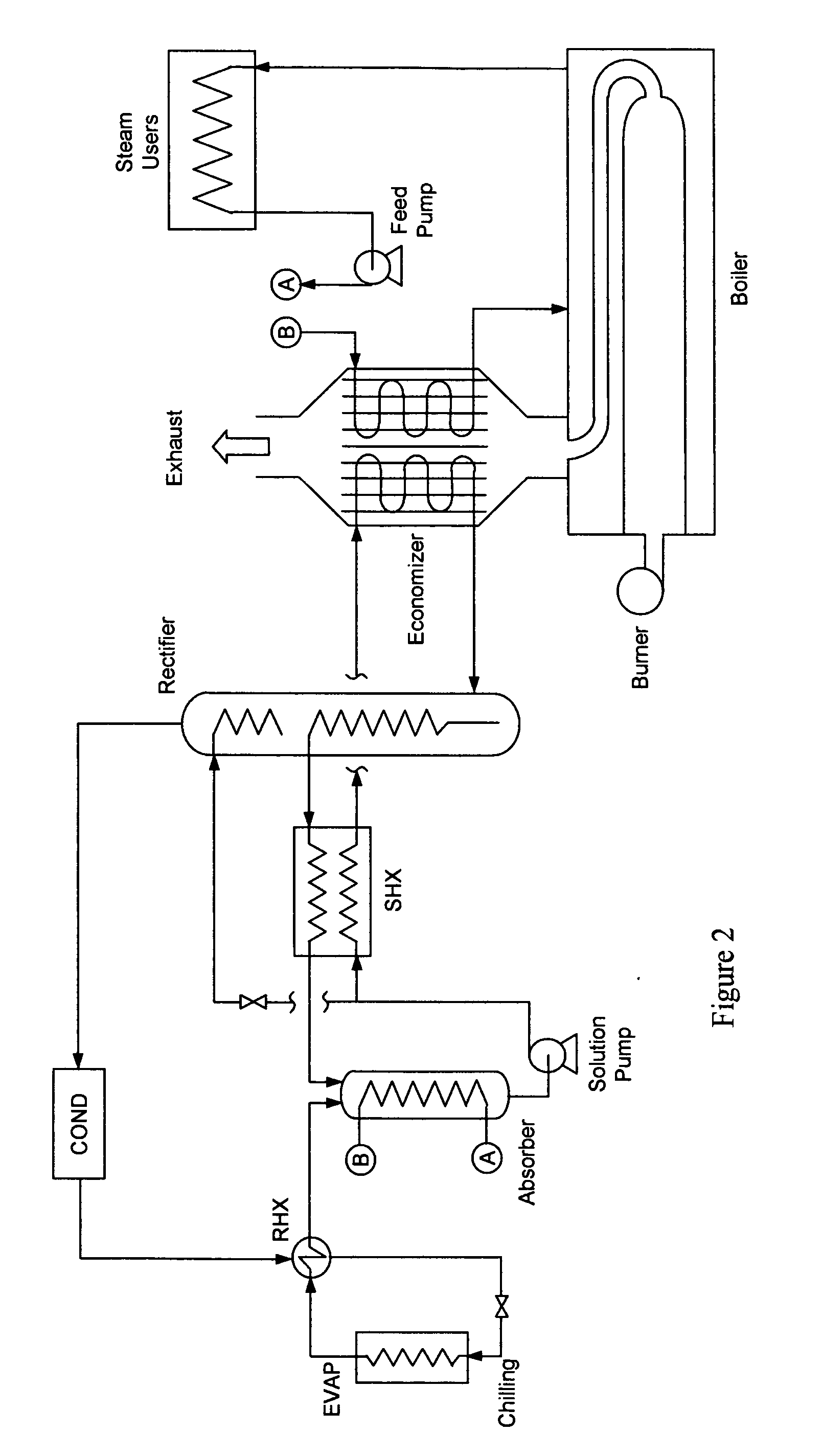

Chilling economizer

InactiveUS20100229594A1Increase volumeReduce the amount requiredEnergy efficient heating/coolingClimate change adaptationWorking fluidEngineering

Chilling is produced from heat that is normally wasted in the economizer section of a steam boiler. A thermally-activated ammonia-water absorption chiller is powered by a heat recovery unit. The heat recovery unit supplies boiler exhaust heat to desorb the working fluid of the chiller. That can be directly, such that the heat recovery unit is a heat recovery vapor generator that can be colocated with an economizer, in parallel or series. The exhaust heat can alternatively be supplied to the AARC indirectly, via a heat transfer loop and a separate generator. The desorbed ammonia vapor is rectified, condensed, and then used to produce the chilling. The heat released in the chiller when low pressure ammonia vapor is re-absorbed is used to preheat the boiler feedwater.

Owner:ERICKSON DONALD CHARLES

Ammonia vapor storage and purge system and method

InactiveUS7770384B2Efficient removalEasy to controlNitrogen compoundsInternal combustion piston enginesEngineeringReducing agent

A method of operating a reductant delivery and storage system of a vehicle, comprising of storing an ammonia-containing fluid in a first storage device, generating ammonia vapors in the first storage device and storing said generated ammonia vapors in a second storage device, purging said stored vapors from the second storage device to an exhaust of the engine, delivering said ammonia-containing fluid to said exhaust of the engine, and adjusting at least one of an amount of ammonia-containing fluid delivered and an amount of vapors purged to said exhaust based on the other of said at least one of said amount of ammonia-containing fluid delivered and said amount of vapors purged to said exhaust.

Owner:FORD GLOBAL TECH LLC

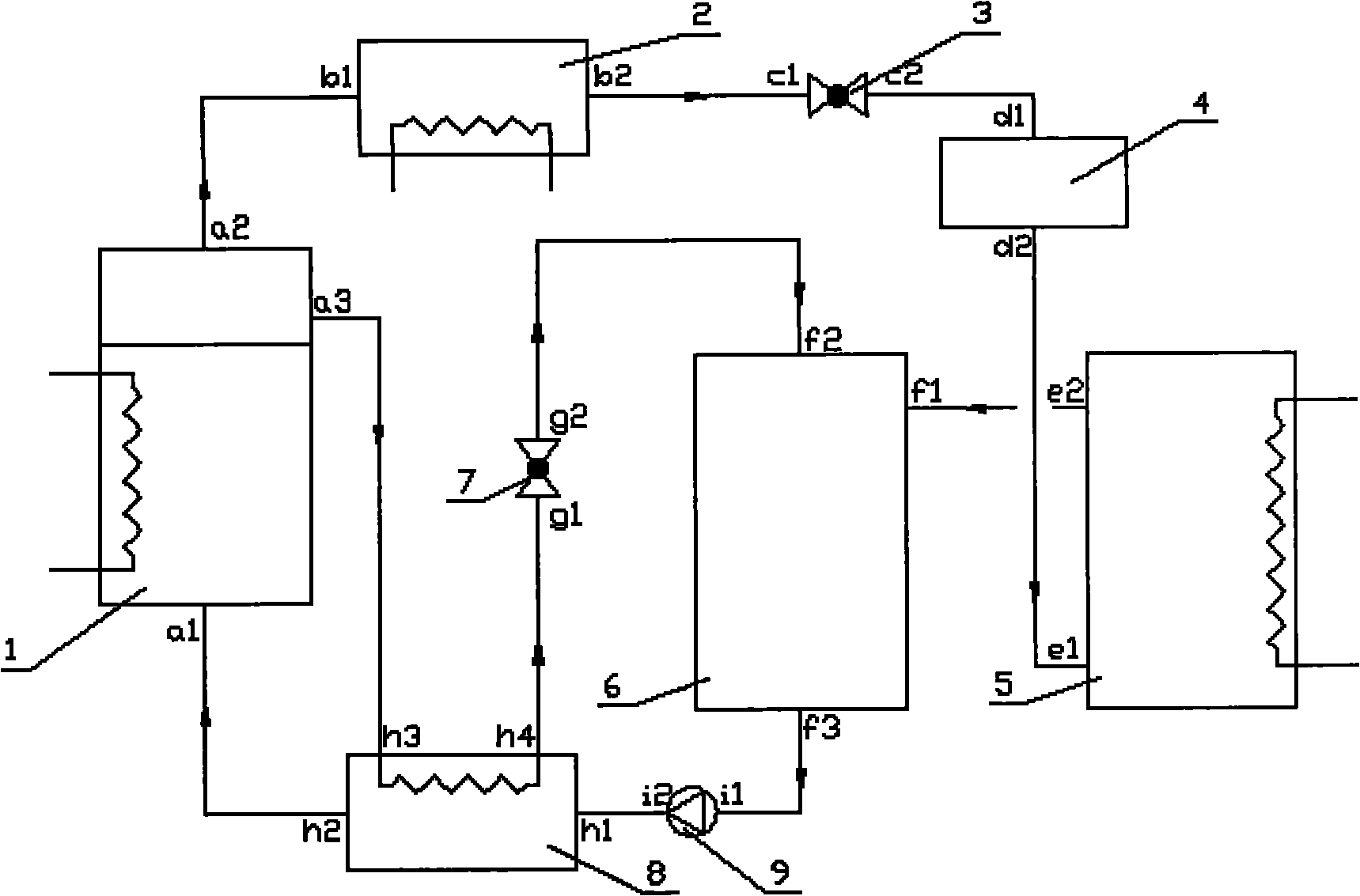

Method for preparing high-concentration ammonia by separating and purifying low-concentration aqueous ammonia

ActiveCN103112871AImprove product valueNo cloggingAmmonia preparation/separationTemperature controlHigh concentration

The invention provides a method for preparing high-concentration ammonia by separating and purifying low-concentration aqueous ammonia and relates to separation and purification of aqueous ammonia. The method comprises the following steps of: turning on a circulating pump and carrying out circulating cooling to a pre-separator by the ice water in a chiller; injecting the dilute aqueous ammonia into a temperature control heater and heating the dilute aqueous ammonia; turning on a vacuum pump and adjusting to the preset vacuum degree for vacuumizing a film distiller; rising the temperature of the dilute aqueous ammonia by the temperature control heater according to the set heating rate to the preset final temperature; cooling and separating out water drops after the ammonia / water vapor generated by heating the dilute aqueous ammonia in the temperature control heater enters into the pre-separator; discharging the water dops in condensation from the lower part to a condensate water receiver and discharging the ammonia vapor from the outlet at the upper part to the inner side of the film distiller; making the ammonia of the ammonia vapor entering into the inner side of the film distiller enter into the outer side of the film under the action of negative pressure, and taking out by the vacuum pump to an ammonia receiver to obtain high-purity ammonia; insulating after the temperature of the temperature control heater rises to the preset final temperature, stopping heating and vacuumizing; and discharging the residual aqueous ammonia from the temperature control heater for ammonia absorption in the waste ammonia after the heat exchange.

Owner:XIAMEN HUANKANG ENVIRONMENTAL PROTECTION TECH

Separating liquid shut-off for ammonia vapor transfer system

InactiveUS20100319788A1Operating means/releasing devices for valvesVenting valvesTransfer systemChemistry

A separating liquid shut-off for an ammonia vapor transfer system has a centrifugal liquid-vapor separator and a float-actuated shut-off valve.

Owner:WARD DAVID P

Ammonia vapor storage and purge system and method

InactiveUS20100319317A1Efficient removalEasy to controlInternal combustion piston enginesExhaust apparatusEngineeringReducing agent

A method of operating a reductant delivery and storage system of a vehicle, comprising of storing an ammonia-containing fluid in a first storage device, generating ammonia vapors in the first storage device and storing said generated ammonia vapors in a second storage device, purging said stored vapors from the second storage device to an exhaust of the engine, delivering said ammonia-containing fluid to said exhaust of the engine, and adjusting at least one of an amount of ammonia-containing fluid delivered and an amount of vapors purged to said exhaust based on the other of said at least one of said amount of ammonia-containing fluid delivered and said amount of vapors purged to said exhaust.

Owner:FORD GLOBAL TECH LLC

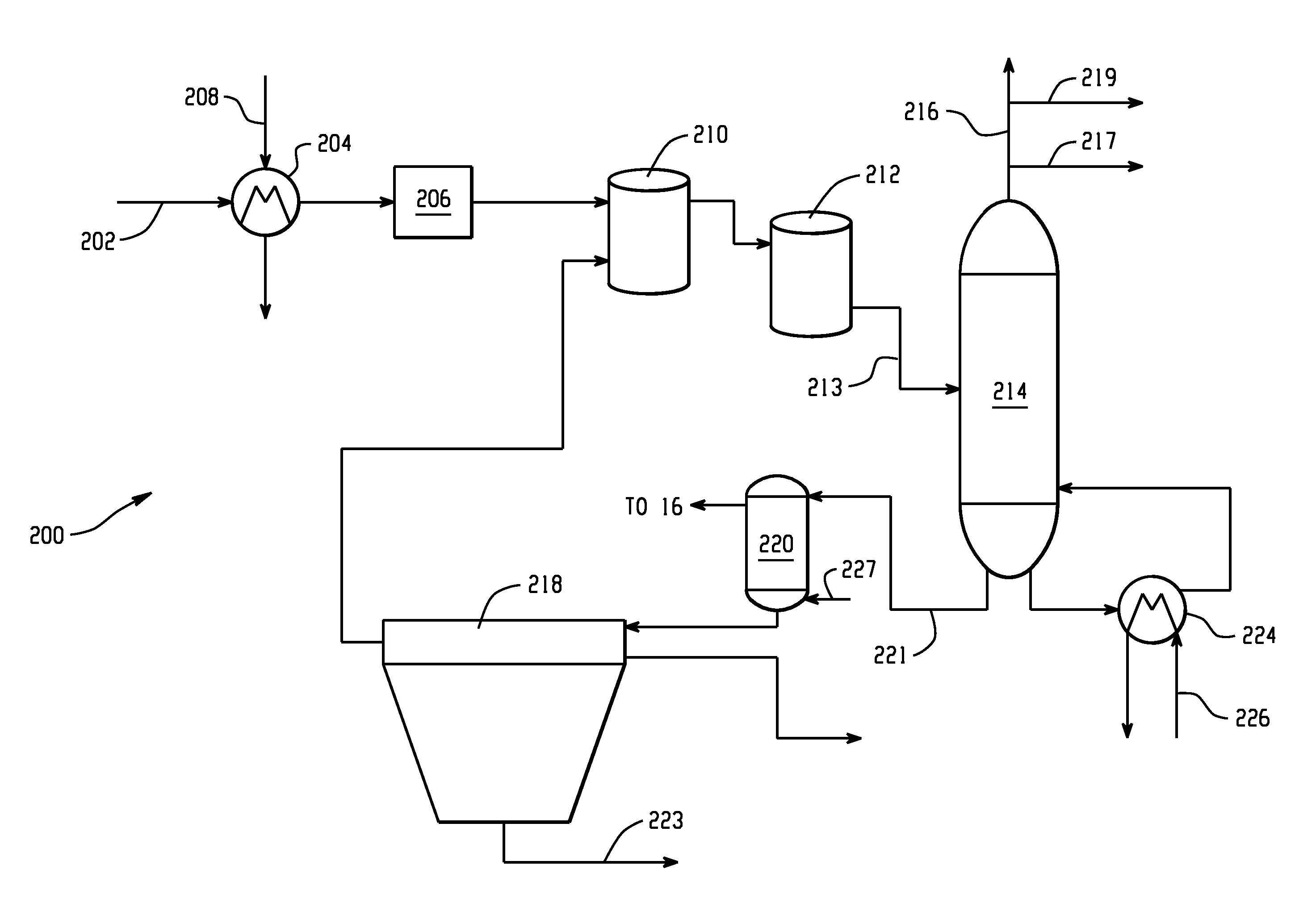

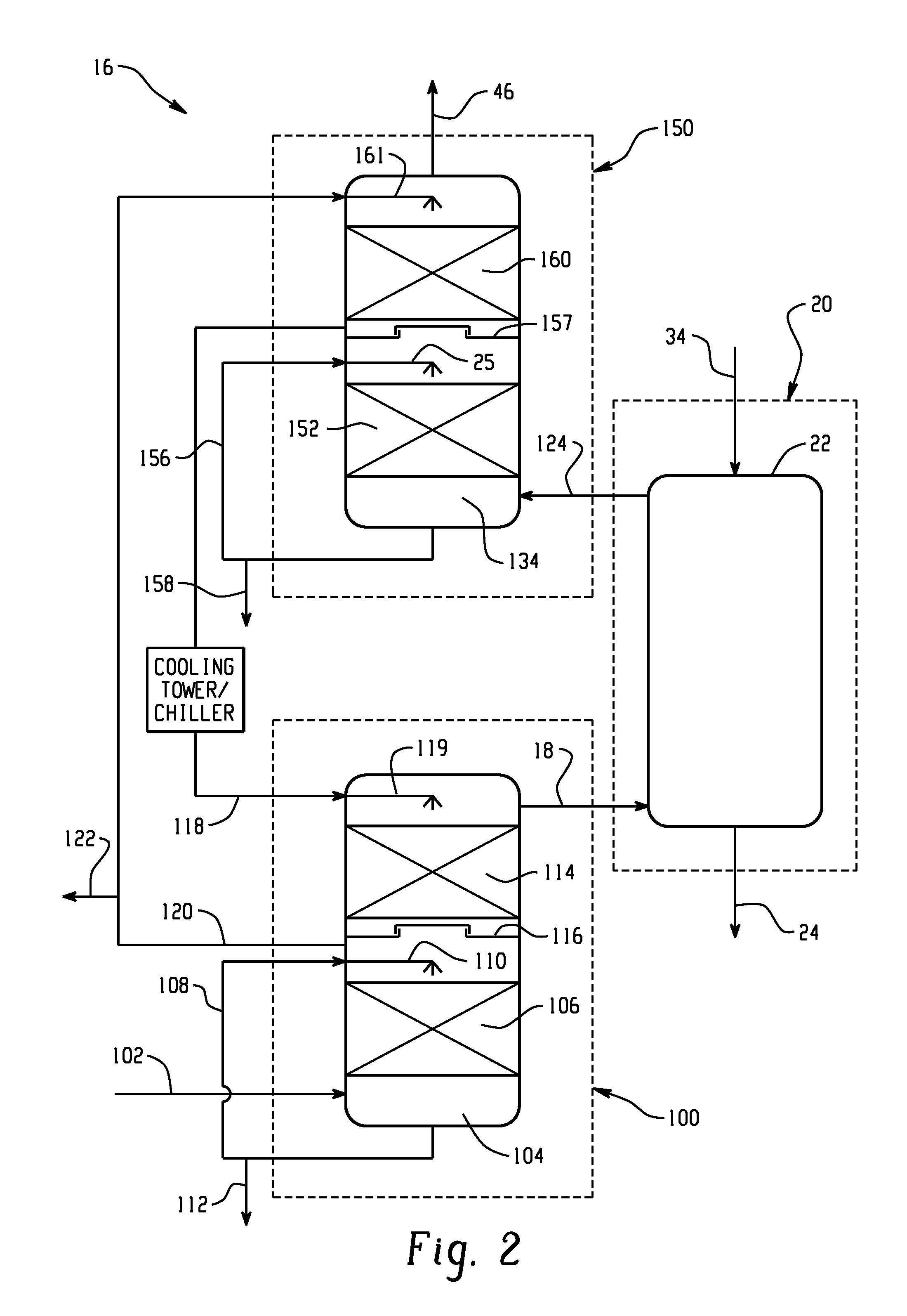

Chilled ammonia based co2 capture system with ammonia recovery and processes of use

ActiveUS20130004400A1Easy to understandUsing liquid separation agentAlkali metal oxides/hydroxidesSulfateSlurry

Processes for recovering ammonia from an ammonium sulfate stream include reacting the ammonia sulfate stream with a lime slurry to form a slurry comprising calcium sulfate and ammonia; providing the slurry comprising calcium sulfate and ammonia to a stripper configured to recover the ammonia from the slurry; utilizing a heat source from a chilled ammonia process to the stripper; and extracting an ammonia vapor stream from the stripper. Also disclosed are systems for performing the processes.

Owner:GENERAL ELECTRIC TECH GMBH

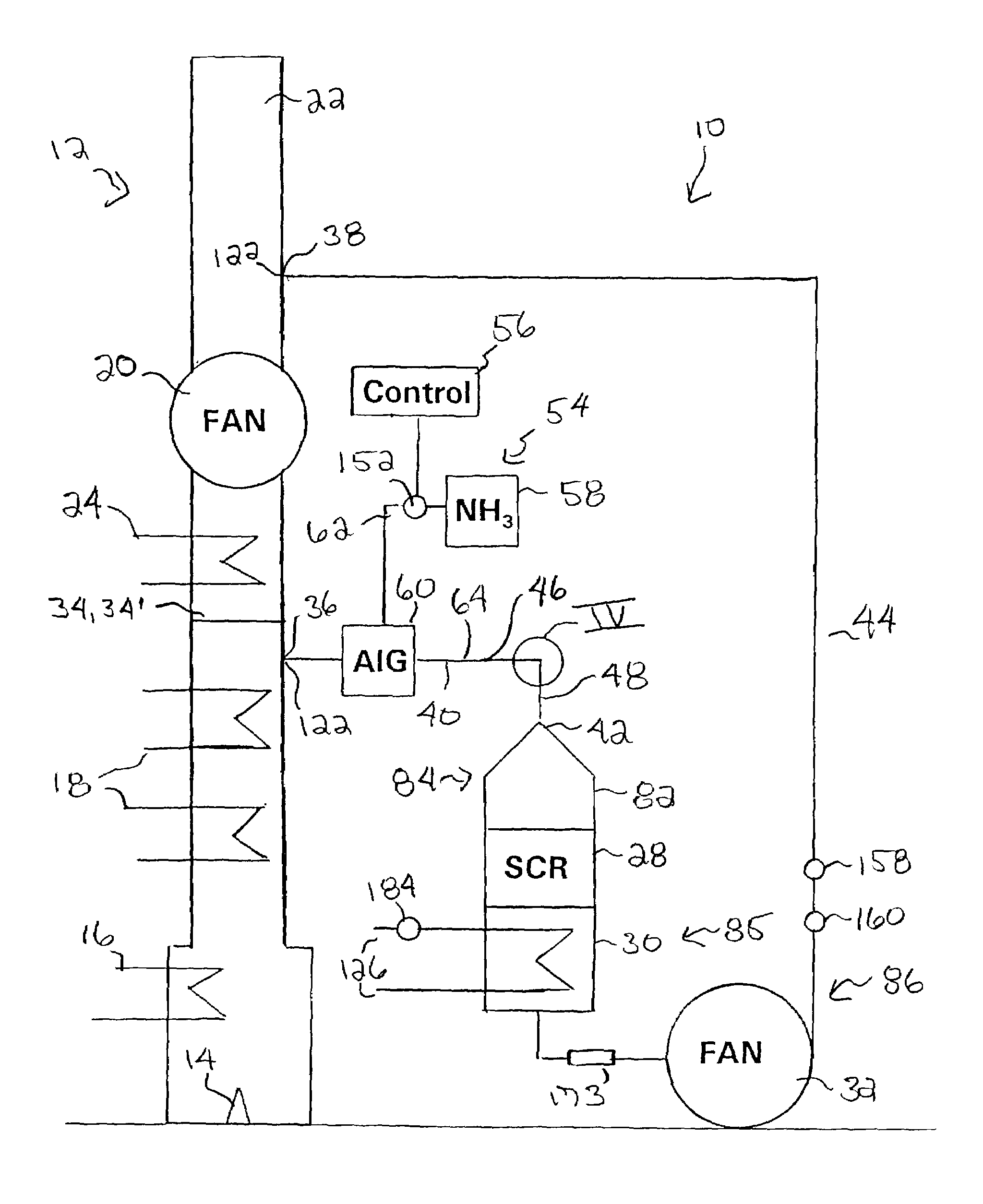

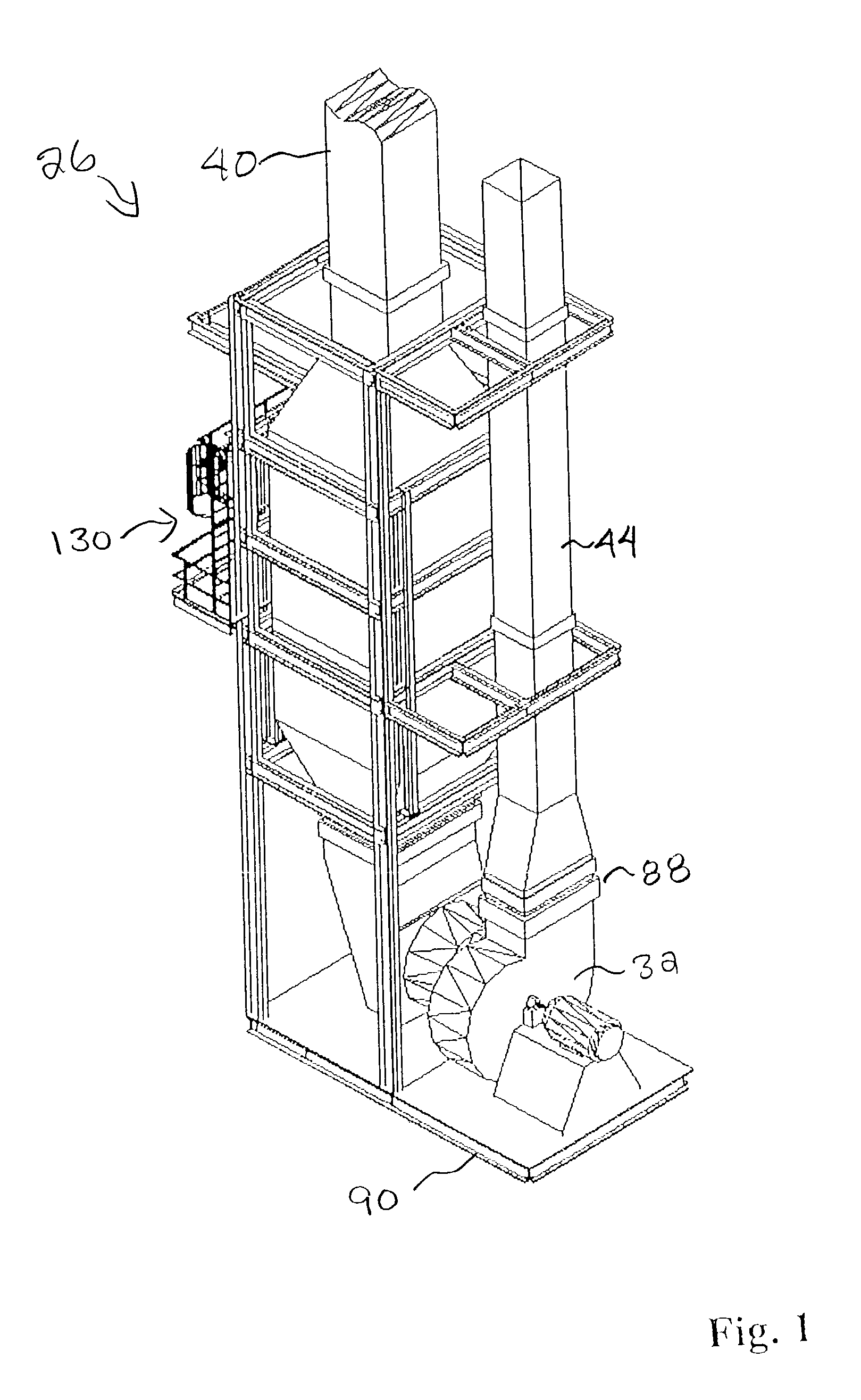

Emission treatment system

ActiveUS7056478B1Lower overall pressure dropCombination devicesNitrogen compoundsFlue gasEngineering

An emission treatment system for removing NOx from flue gas includes a diversion member that closes the stack at a position intermediate the inlet and outlet ends. A major component module includes a first sub-module, having an inlet and an SCR segment, a second sub-module, having a heat exchange segment, and a third sub-module, having an ID fan and an outlet, forming a flue gas flow path extending from the inlet to the outlet. Inlet ductwork, which is in fluid communication with the stack at a position intermediate the inlet end of the stack and the diversion member, provides a passageway from the stack to the inlet. Outlet ductwork, which is in fluid communication with the stack at a position intermediate the diversion member and the outlet end of the stack, provides a passageway from the outlet to the stack. An ammonia addition subsystem injects ammonia vapor into the inlet ductwork.

Owner:GENERAL ELECTRIC TECH GMBH

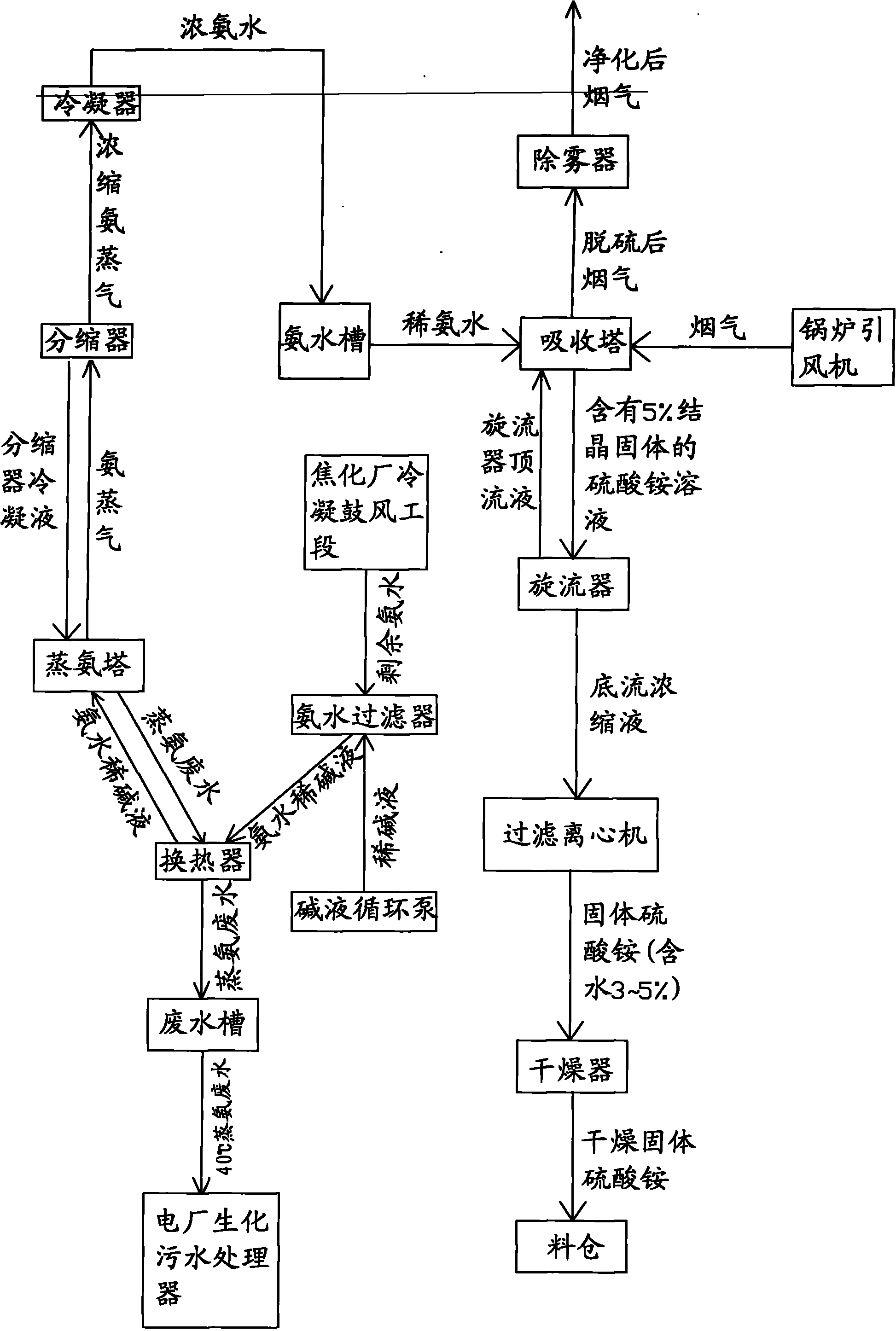

Process for removing SO2 in smoke from boiler of coking plant by utilizing residual coked ammonia water

ActiveCN102101006AReduce procurement costsRealize the purpose of circular economyDispersed particle separationWastewaterEvaporation

The invention discloses a process for removing SO2 in smoke from a boiler of a coking plant by utilizing residual coked ammonia water, and the process comprises the following steps: (1) heat exchange of the residual ammonia water; (2) ammonia evaporation in an ammonia evaporation tower; (3) concentration and condensation of ammonia vapor; (4) ammonia evaporation and waste water treatment; (5) stronger ammonia water dilution; (6) desulfuration in an absorption tower; (7) thick separation in a swirler; and (8) drying, warehousing and packaging. According to the invention, the residual coked ammonia water is fully utilized, so that the wet ammonia flue gas desulfurization can be realized, thus the purposes of treating waste by waste, saving energy, reducing emission, reducing secondary pollution and realizing recycling economy can be achieved; and meanwhile, the procurement cost of sulfuric acid for treating the waste ammonia water of the coking plant can be reduced.

Owner:内蒙古庆华集团乌斯太能源化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com