Compression-absorption-diffusion combined refrigerating plant and its refrigeration cycle method

A refrigeration device and refrigeration cycle technology, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of refrigeration equipment driven by small and low-grade waste heat, and use restrictions, etc. The effect of lowering, less heat load, and lower power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The device and its refrigeration method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

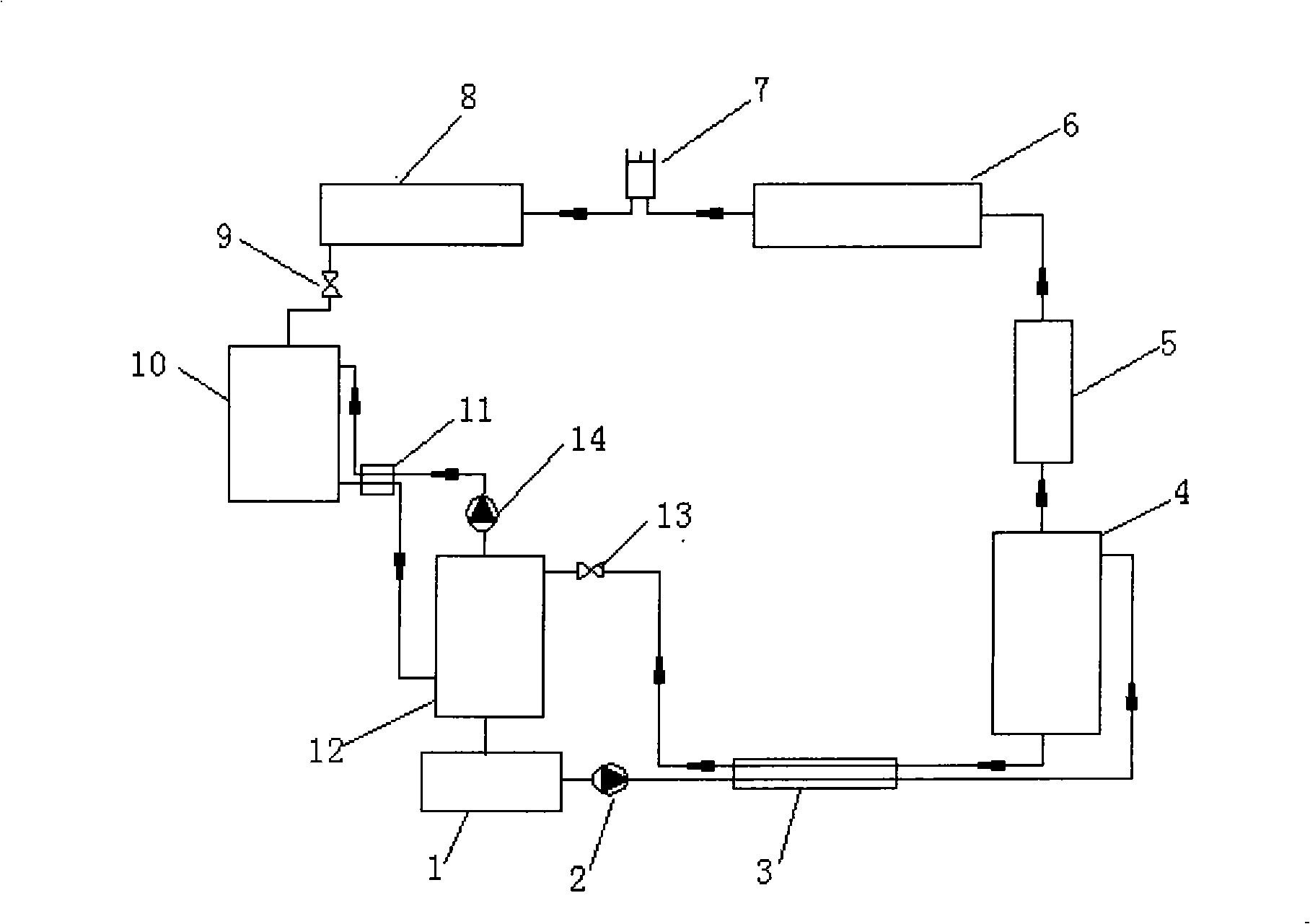

[0012] like figure 1 As shown, liquid receiver 1, solution pump 2, solution heat exchanger 3, generator 4, rectifier 5, primary condenser 6, secondary condenser 8, refrigerant throttle valve 9, evaporator 10, The absorber 12 is welded and communicated with pipelines of seamless steel pipe or stainless steel in turn, and the bottom of the generator 4 is connected with the upper part of the absorber 12 through the solution heat exchanger 3 to form a circulation path. In the liquid reservoir 1, add Refrigerant has completed the processing of the ammonia water absorption refrigeration system mechanism for ammonia-water; a compressor 7 is arranged between the first-stage condenser 6 and the second-stage condenser 8, and the outlet of the first-stage condenser 6 is connected to the compressor 7 The suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com