Wastewater treatment method

A wastewater treatment and treatment method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve uneconomical, inability to achieve effective separation and recovery, increase ion exchange method and Membrane wastewater treatment difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

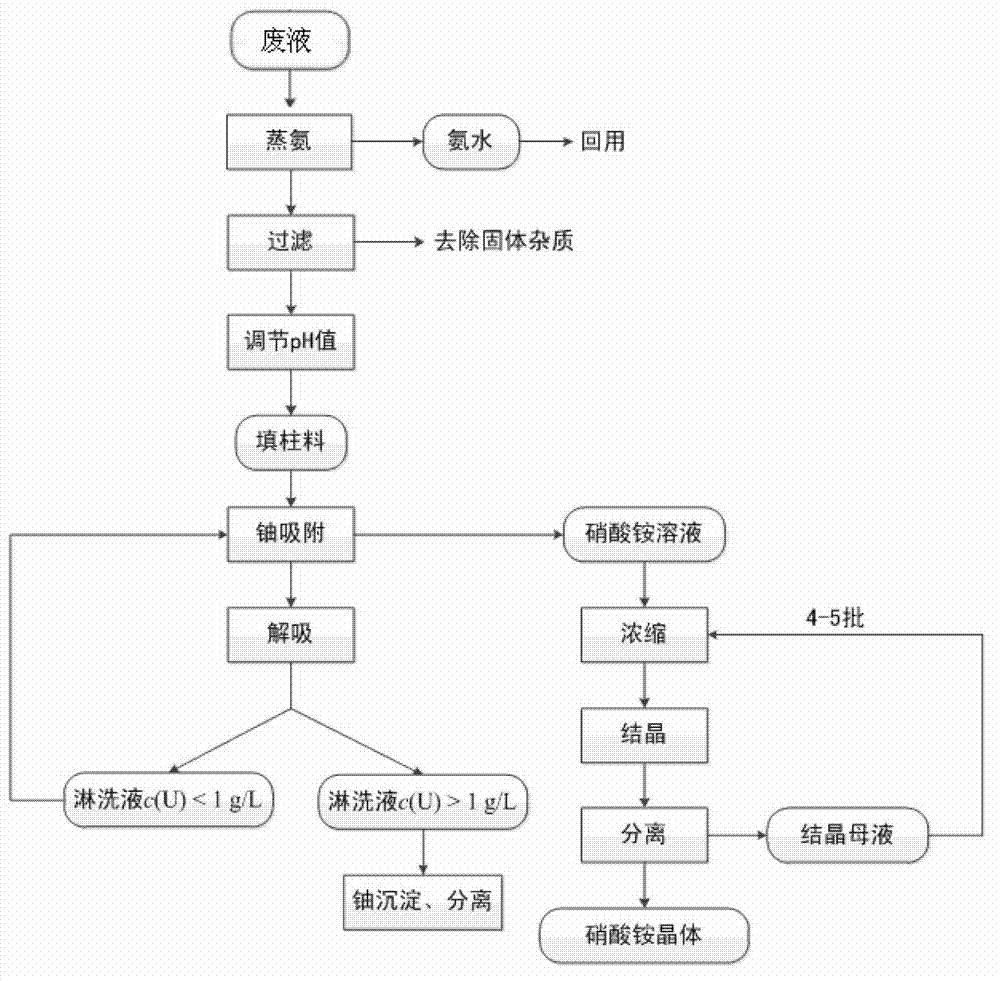

[0037] During the production of a certain batch of fuel elements, about 250 liters of ammonia-containing process wastewater needs to be treated. NH in the raw water 3 - The mass concentration of N is 8.9%, the concentration of uranium is about 10mg / L, the concentration of ammonium nitrate is 12.4g / L, and the COD value of organic matter is 4×10 4 . In order to realize the removal and recovery of the main components in wastewater, the following schemes are adopted: recovery of ammonia by evaporation → filtration to remove solid impurities and organic macromolecules → adsorption on silica gel → recovery of uranium by desorption → recovery of ammonium nitrate by crystallization (such as figure 1 shown).

[0038] The waste water is firstly heated by the evaporator in the evaporative ammonia removal device, and the evaporated ammonia is absorbed with deionized water. After ammonia removal, the mass concentration of ammonia in the wastewater is reduced to 0.9%, and the recycled amm...

Embodiment 2

[0044] During the production process of a certain batch of sol-gel preparation process to prepare uranium oxide ceramic particles, about 200 liters of ammonia-containing process wastewater needs to be treated, and the NH in the raw water 3 - The mass concentration of N is 1.3%, the concentration of uranium is about 50mg / L, the concentration of ammonium nitrate is 5g / L, and the COD value of organic matter is 4×10 5 . In order to realize the removal and recovery of the main components in the wastewater, the following schemes are adopted: recovery of ammonia by evaporation → filtration to remove solid impurities and organic macromolecules → adsorption on silica gel → recovery of uranium by desorption → recovery of ammonium nitrate by crystallization.

[0045] The waste water is firstly heated by the evaporator in the evaporative ammonia removal device, and the evaporated ammonia is absorbed with deionized water. After ammonia removal, the mass concentration of ammonia in the was...

Embodiment 3

[0051] About 100 liters of ammonia-containing process wastewater needs to be treated during the production of uranium oxide ceramic particles prepared by a certain batch of sol-gel preparation process, and the NH in the raw water 3 -The mass concentration of N is 5.7%, the concentration of uranium is about 0.05mg / L, the concentration of ammonium nitrate is 50g / L, and the COD value of organic matter is 10 3 . In order to realize the removal and recovery of the main components in the wastewater, the following schemes are adopted: recovery of ammonia by evaporation → filtration to remove solid impurities and organic macromolecules → adsorption on silica gel → recovery of uranium by desorption → recovery of ammonium nitrate by crystallization.

[0052] The waste water is firstly heated by the evaporator in the evaporative ammonia removal device, and the evaporated ammonia is absorbed with deionized water. After ammonia removal, the mass concentration of ammonia in the wastewater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com