Patents

Literature

620results about How to "Improve reaction stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

Nano titanium dioxide/ acrylate composite emulsion and preparation method thereof

InactiveCN102516477AAvoid reunionStable structureCoatingsGraft polymer adhesivesPtru catalystPolymer chemistry

The invention discloses nano titanium dioxide / acrylate composite emulsion and a preparation method thereof. The method comprises the following steps of: hydrolyzing butyl titanate to generate nano titanium dioxide sol in absolute ethanol by using hydrochloric acid as a catalyst, adding a vinyl-containing silane coupling agent for modifying the sol, performing centrifugal washing, drying and grinding on the obtained product to obtain nano titanium dioxide, and thus obtaining the nano titanium dioxide / acrylate composite emulsion by using acrylate monomers of methyl methacrylate, butyl acrylate and the like as reaction monomers and adopting a method combining in-situ emulsion polymerization and seed emulsion polymerization. The nano titanium dioxide / acrylate composite emulsion prepared by the method has good storage stability and is stable in a polymerization reaction process; and a film formed by the composite emulsion has good hardness, impact strength and heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

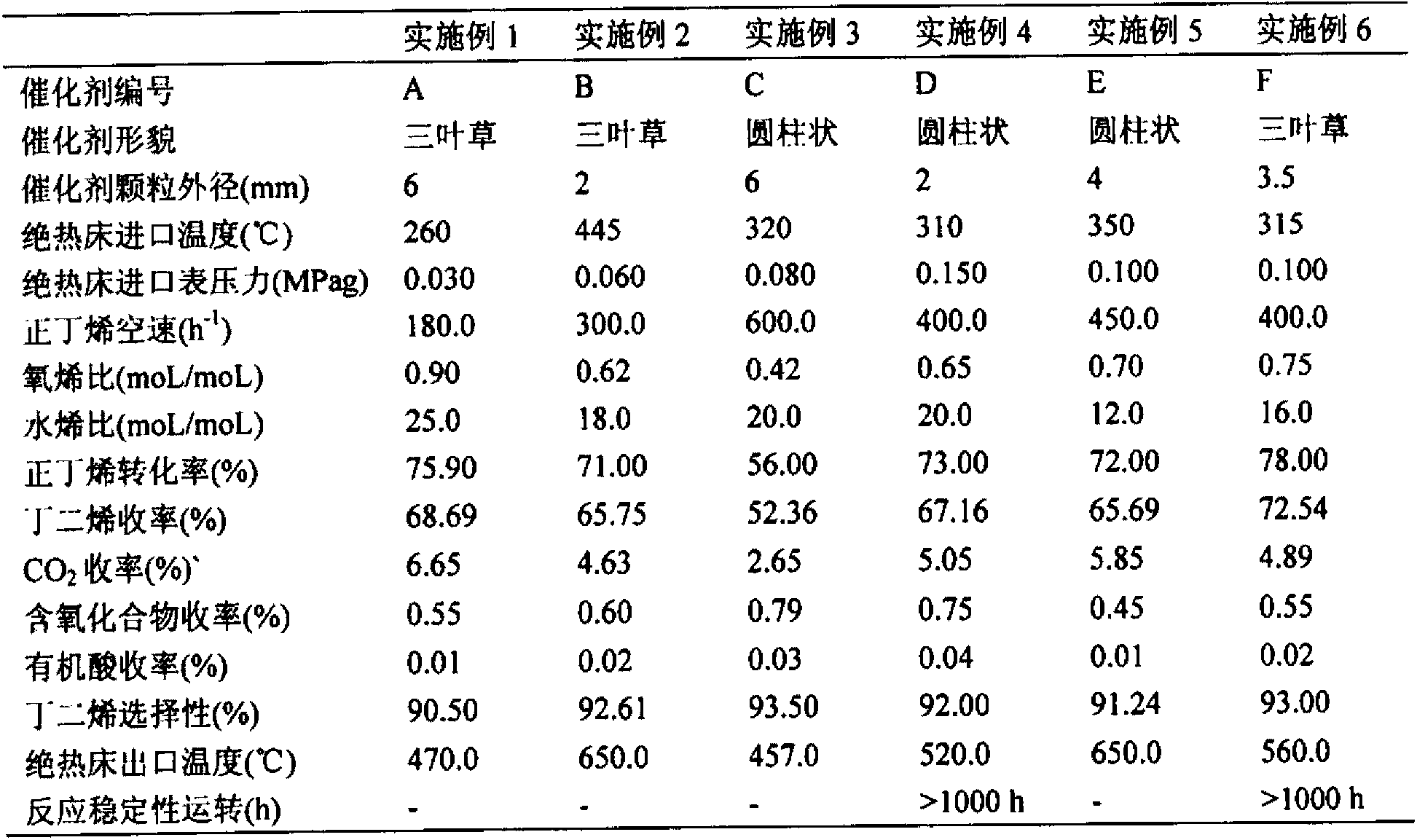

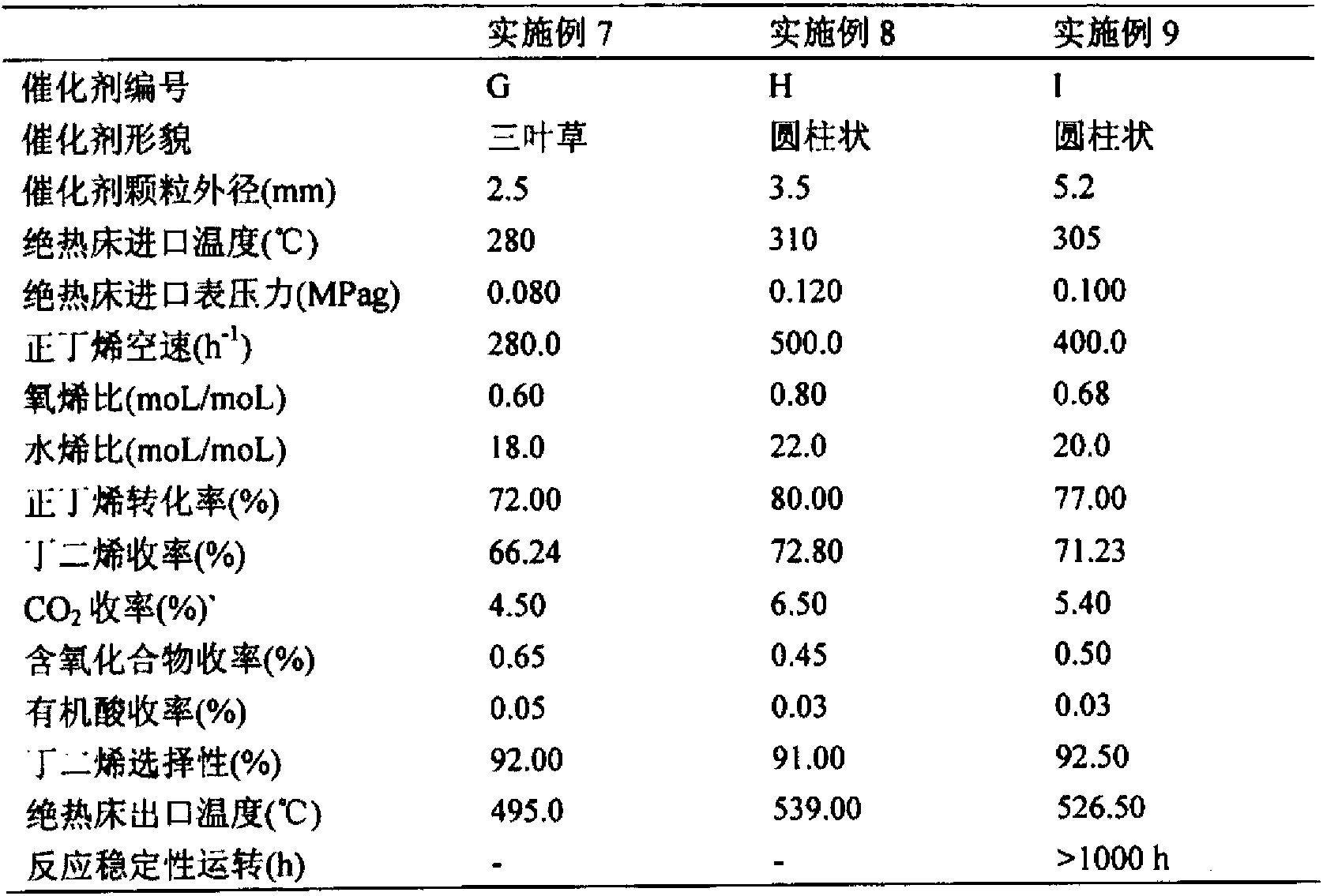

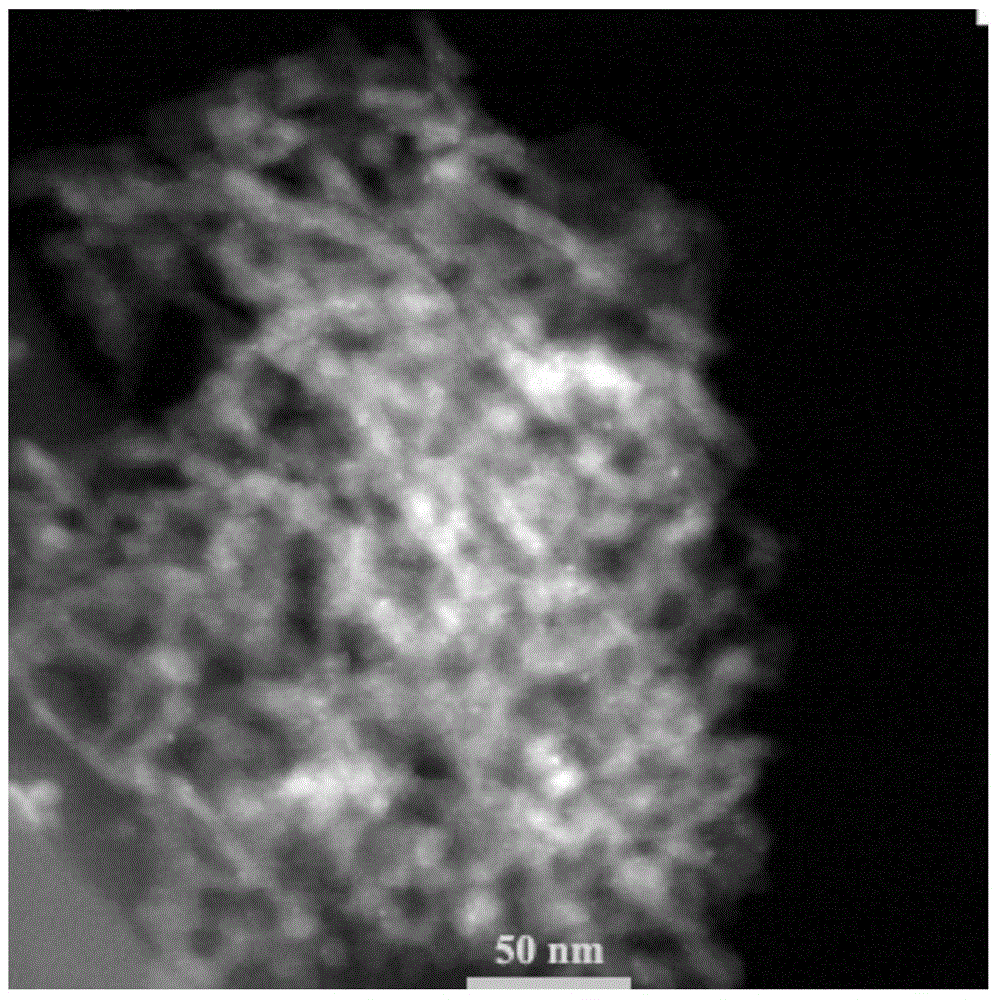

Iron catalyst used in butadiene production through n-butylene oxidation dehydrogenation, and preparation method and application thereof

ActiveCN103055890ASimple preparation processEasy accessHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationFixed bed

The invention relates to an iron catalyst used in butadiene production through n-butylene oxidation dehydrogenation, and a preparation method and an application thereof. The catalyst comprises Fe as a main component, and a co-catalyst comprising Mg, Zn, and other elements. The catalyst is composed of, by mass, 48.80-60.53% of Fe, 0.01-18.00% of Mg, 0-15.00% of Zn, 0-5.00% of other elements, and balance of oxygen element. The catalyst is prepared with a precipitation method. The catalyst is applied in butadiene production through n-butylene oxidation dehydrogenation by using an adiabatic fixed bed. Application conditions comprise: adiabatic fixed bed material inlet temperature is 260.0-445.0 DEG C; molar ratio of inlet oxygen to n-butylene is 0.42-0.90; molar ratio of inlet water to n-butylene is 12.0-25.0; inlet n-butylene volume space velocity is 180-600h<-1>, and an adiabatic fixed bed material outlet temperature is 457.0-650.0 DEG C. Compared with prior arts, the catalyst provided by the invention is suitable for an adiabatic fixed bed, and has the advantages such as high butadiene selectivity, good catalyst reaction stability, and the like.

Owner:WISON ENG

Supported noble metal catalyst and preparation and application thereof

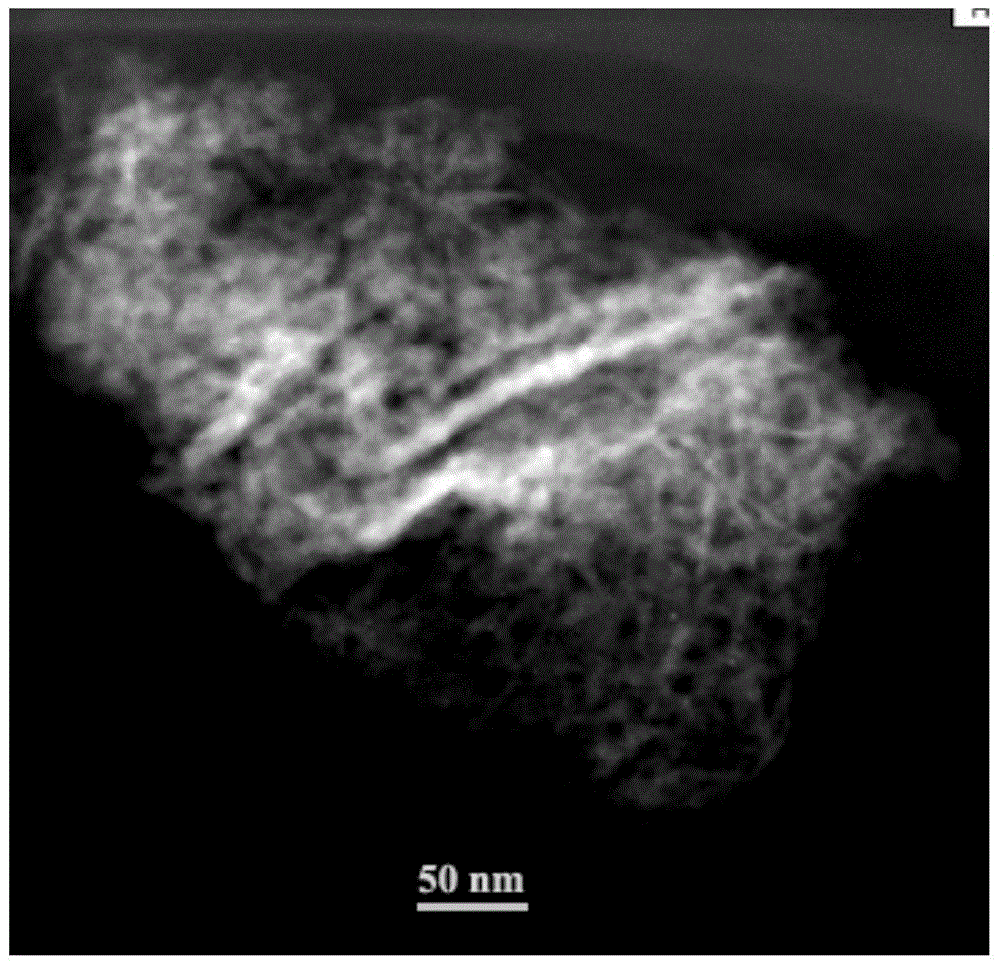

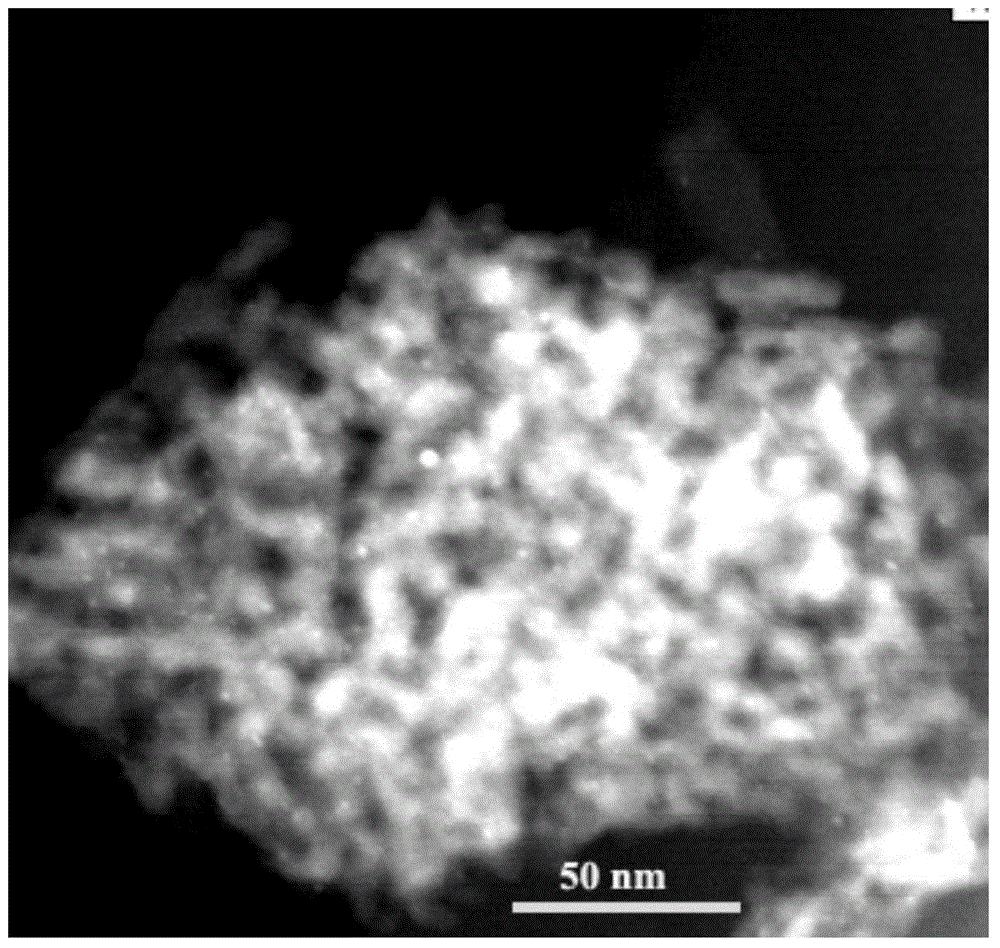

ActiveCN104923225AGood dispersionEnhanced strong interactionHydrocarbon from carbon oxidesDispersed particle separationMethanationHigh activity

The invention relates to a preparation method and a catalytic application of a supported noble metal catalyst. Active components are noble metals Ru, Rh and Pd, and a carrier is MxOy or perovskite MAlO3 or spinel MAl2O4. The composite oxide carrier is prepared by an impregnation method or a coprecipitation method and is roasted under a medium-high temperature condition of 650-1200 DEG C ultimately, so that while the formed MxOy, MAlO3 or MAl2O4 or even a mixture thereof has a closer effect with an Al2O3 carrier, the number of defects and holes on the surface of Al2O3 is greatly increased, and thus prepared noble metal nanoparticles have high dispersion degree and strong stability. The catalyst preparation method has the advantages of simple operation, convenience for production and application, good product repeatability, high activity in a carbon dioxide methanation reaction and a carbon monoxide oxidation reaction, strong stability in a storage state and reaction, and quite good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

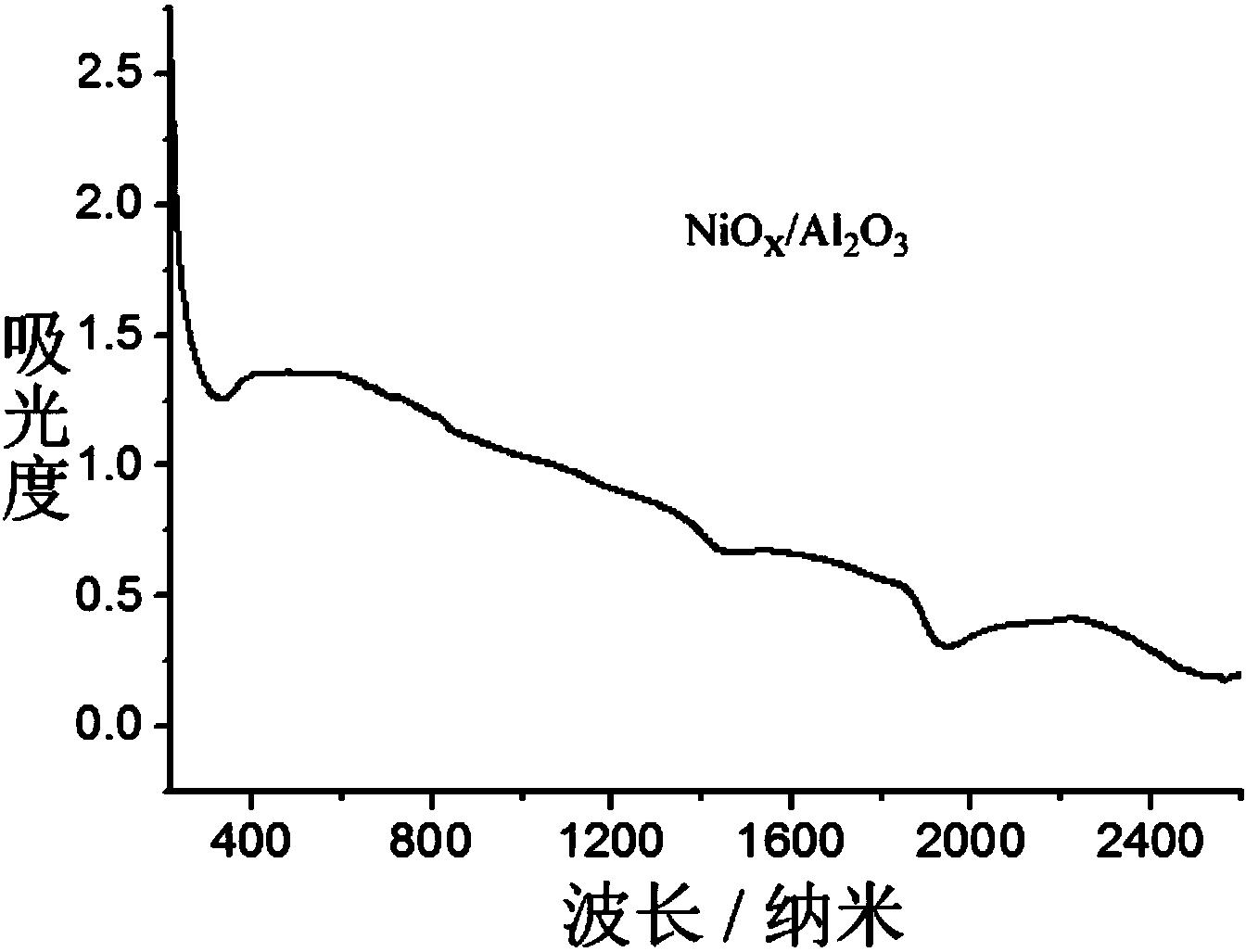

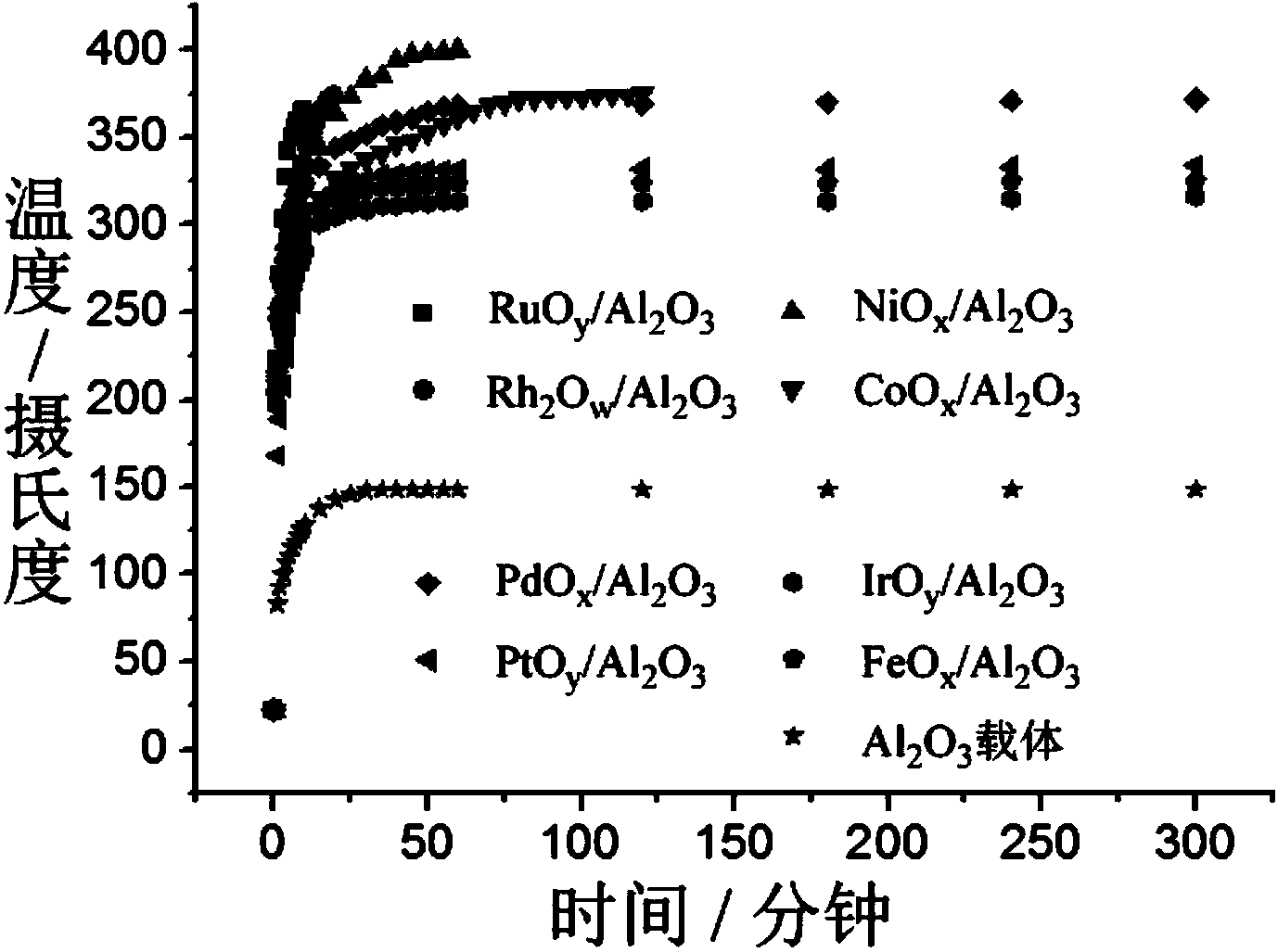

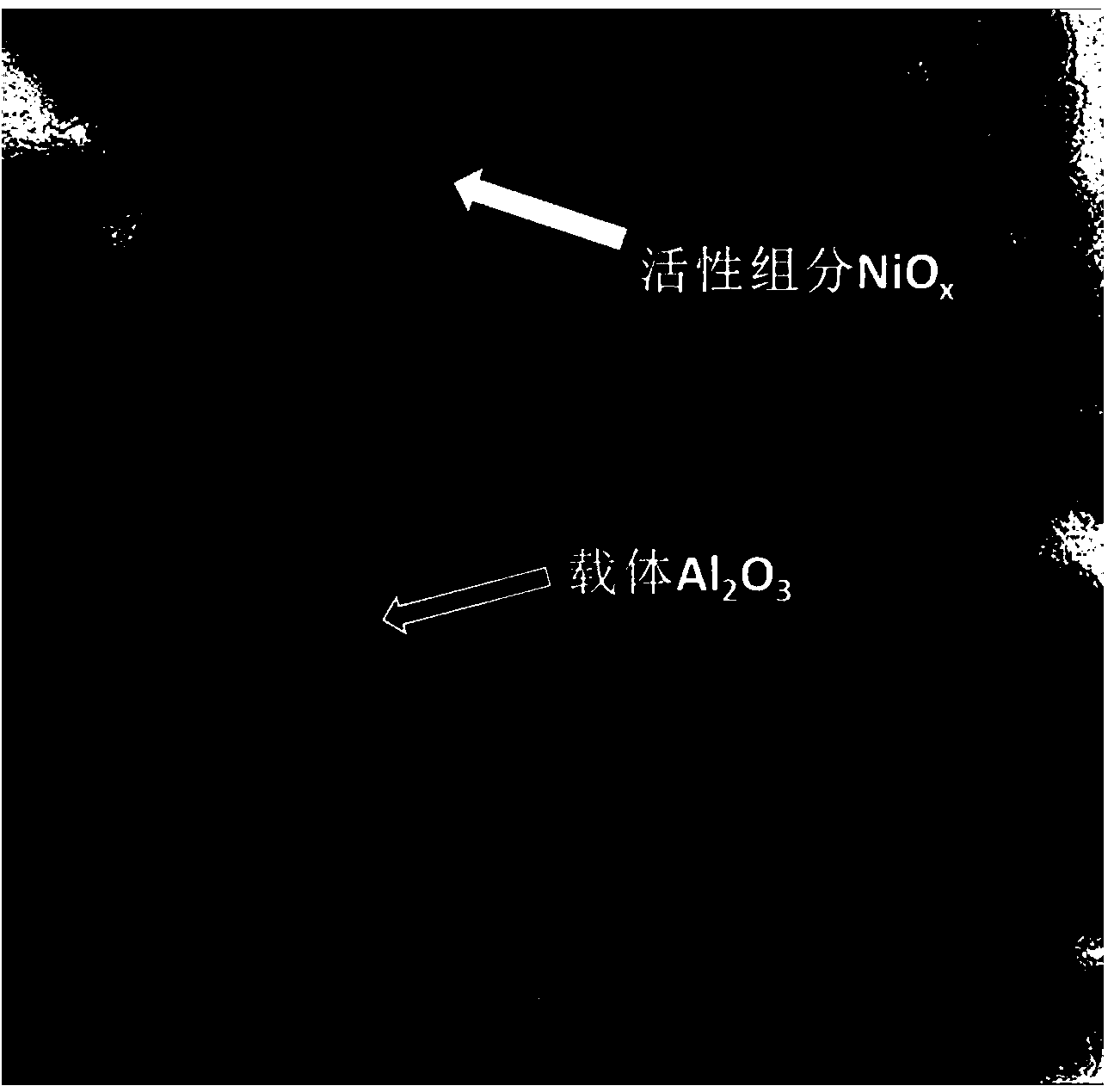

Technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and photothermal catalyst

InactiveCN104016825AReduce energy consumptionHigh reactivityHydrocarbon from carbon oxidesOrganic compound preparationSynthesis methodsUltraviolet lights

The invention discloses a technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and a photothermal catalyst. Sunlight is utilized to supply light and heat for the synthesis and catalytic process of the photothermal catalyst, and the photothermal catalyst can simultaneously absorb and utilize ultraviolet light, visible light and infrared light parts in sunlight, so that a phtothermal catalytic reaction is induced to prepare the organic fuel through reducing carbon dioxide by using hydrogen. The photothermal catalyst comprises the following components: an active component which is a 2-30 nano-scale non-stoichiometric oxide belonging to a VIII-family element in a transition family and a carrier material which is an oxide or carbon material with the specific surface area of 30-1000cm<2> / g, alkaline resistance, high heat conductivity or photocatalytic activity. A steeping and in-situ sintering method or photodepositing and in-situ sintering method is used as a synthesis method so that the energy consumption is low, and the photothermal catalyst has high activity and long service life by using a solar-assisted in-situ sintering technology. The technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and the photothermal catalyst is low in energy consumption in the catalytic process, high in organic fuel production efficiency and stable in catalyst activity.

Owner:TIANJIN UNIV

Molecular sieve catalyst, preparing method and use thereof

InactiveCN1990104AImprove reaction stabilityMolecular sieve catalystsOrganic isomerisationMolecular sieveNH3 compound

A modified molecular sieve catalysts used for olefin aromatization reaction, make up of molecular sieve and adhesive, the adhesive weight is 20 ~ 80% of the catalyst weight. The molecular sieve park in the alkaline solution that the concentration of 0.01 - 5M at room temperature to 100 Deg C for 0.1-50 hours; After washing, drying, and extrusion molding with the adhesive, via ammonia exchange, drying, roasting under 400 ~ 1000 Deg C, obtaining the goal product. Compare With ordinary untreated catalyst, the invention of the modified molecular sieve catalysts show good mixed reaction olefin aromatization Stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

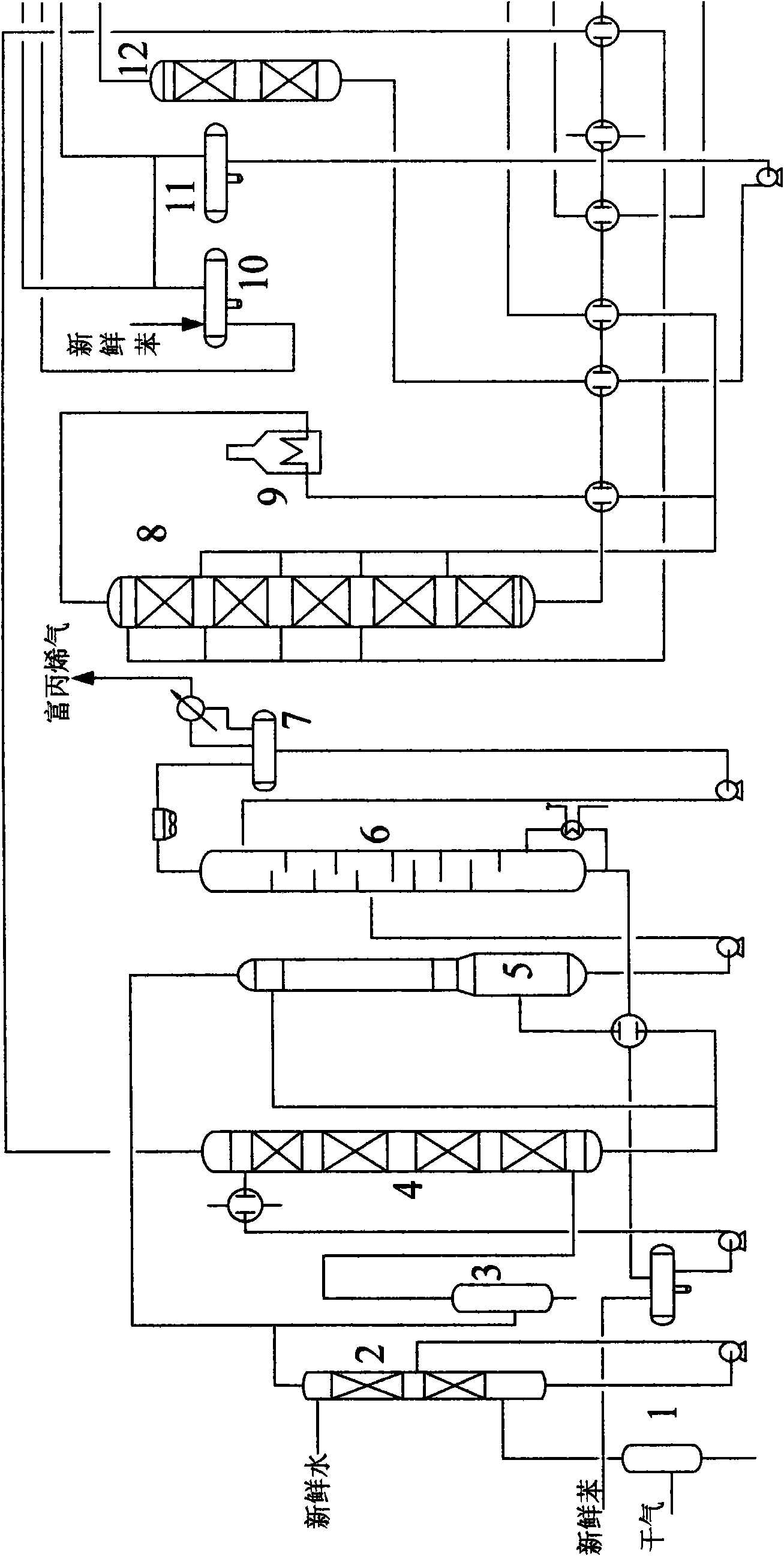

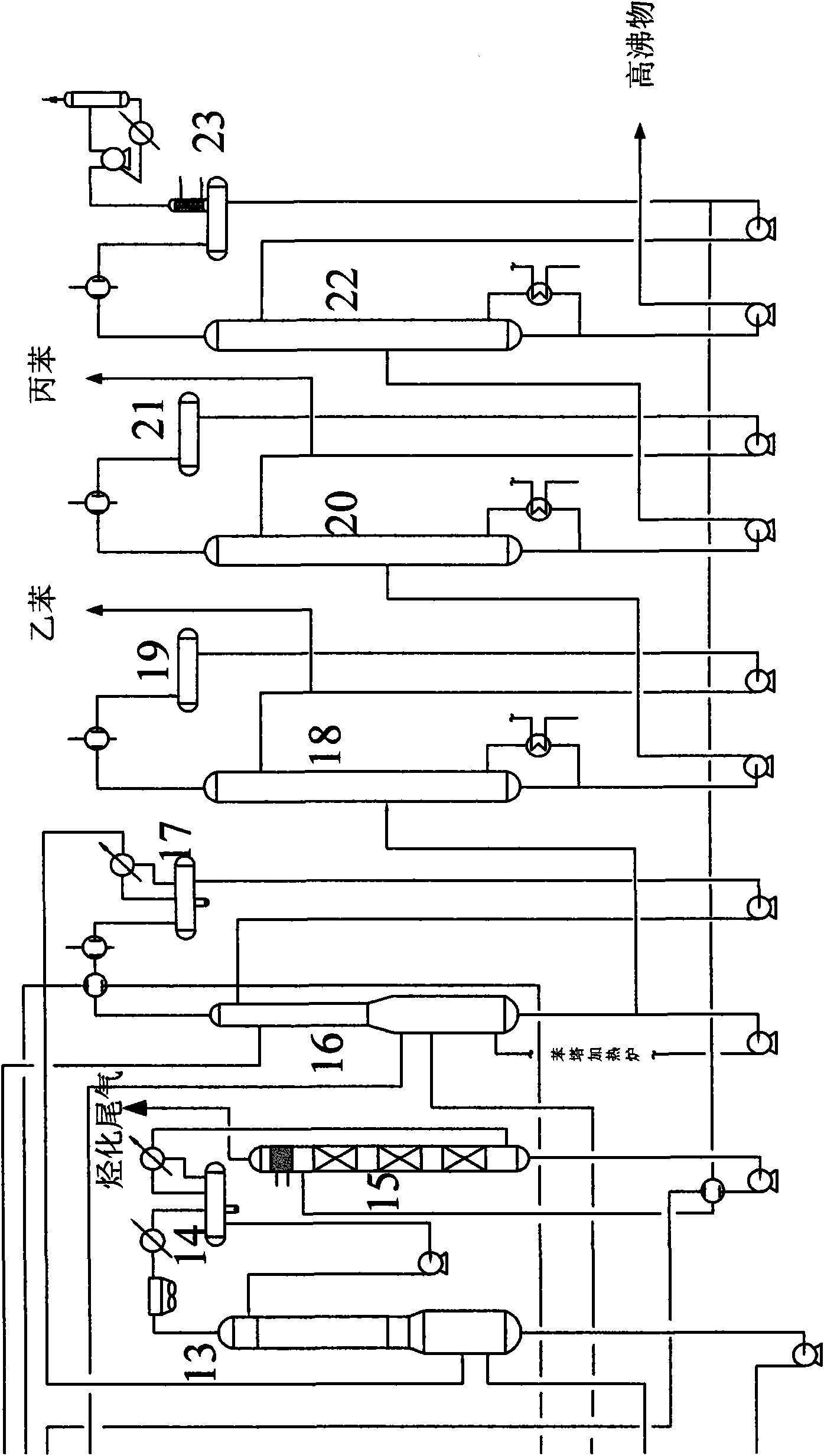

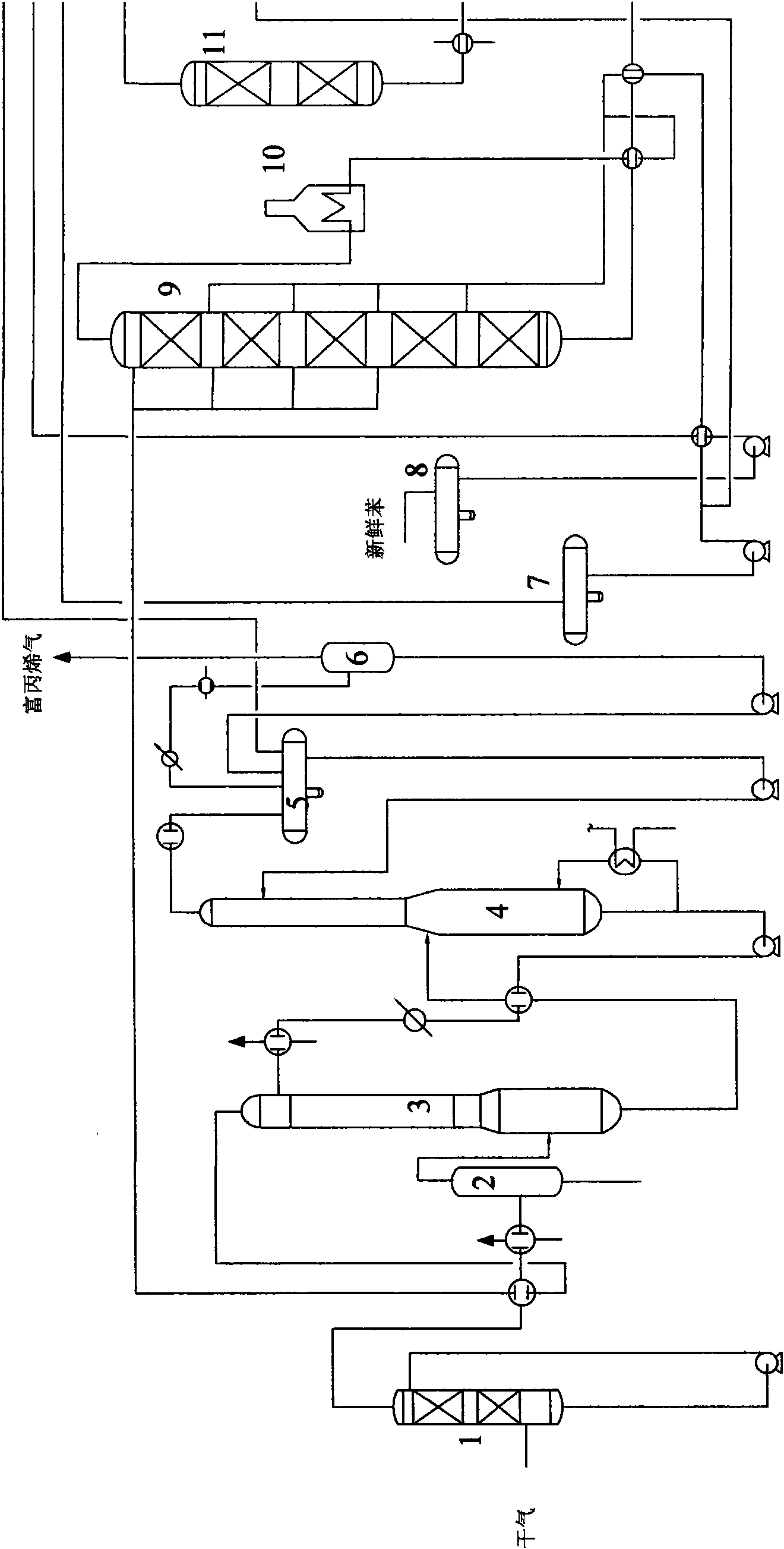

Method for preparing ethylbenzene by reaction of dilute ethylene and benzene

ActiveCN101768043AReduce temperature riseEfficient use ofHydrocarbonsBulk chemical productionVapor liquidLiquid product

The invention discloses a method for preparing ethylbenzene by reaction of dilute ethylene and benzene, which uses the dilute ethylene in dry gas of oil refinery as raw material, water washing and selective removal of propylene are conducted for the dry gas before the dry gas enters an alkylation reactor in sections, alkylation reaction of the dilute ethylene in dry gas and the benzene proceeds under the circumstances that zeolite catalyst exists, the dry gas and / or low-temperature gas-phase benzene are utilized for taking heat during the alkylation reaction, and the reaction temperature rising is reduced; after the vapor-liquid separation of the alkylation reaction product, tail gas is discharged from the device through low-temperature absorption, and cycle benzene, ethylbenzene, propyl benzene, diethylbenzene and heavy component are sequentially separated from the liquid product through a separation system; the diethylbenzene and the benzene are mixed and enter an anti-alkylation reactor and anti-alkylation reaction proceeds on molecular sieve catalyst for further converting to the ethylbenzene. The invention effectively reduces the benzene consumption and the energy consumption during the course of preparing ethylbenzene by dilute ethylene, the ethylene conversion rate is more than or equal to 99%, the total selectivity of generating ethylbenzene is more than or equal to 99%, the recovery rate of benzene carried by the tail gas is more than or equal to 99.5%, and the xylene content in the ethylbenzene is less than 800 ppm.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

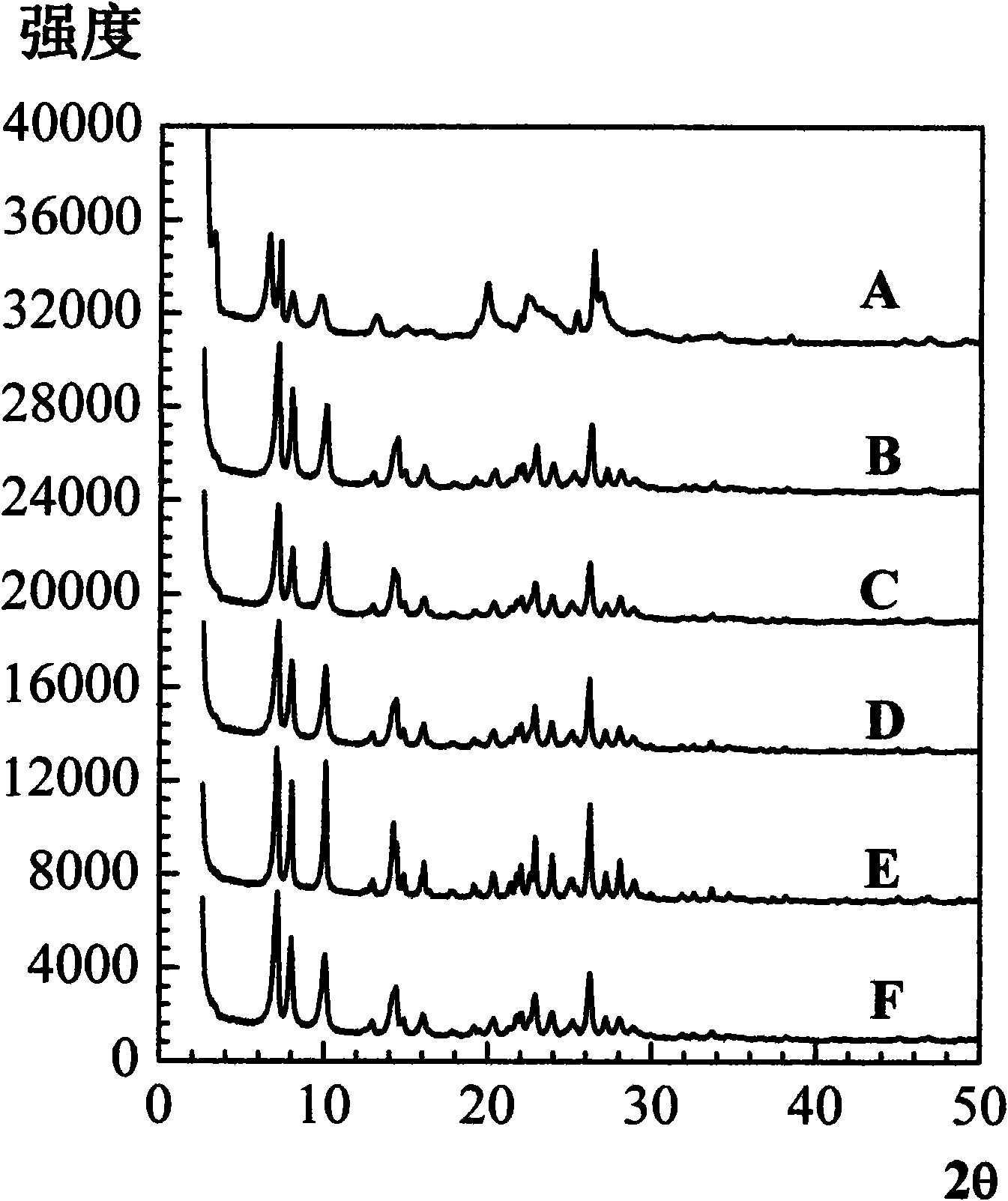

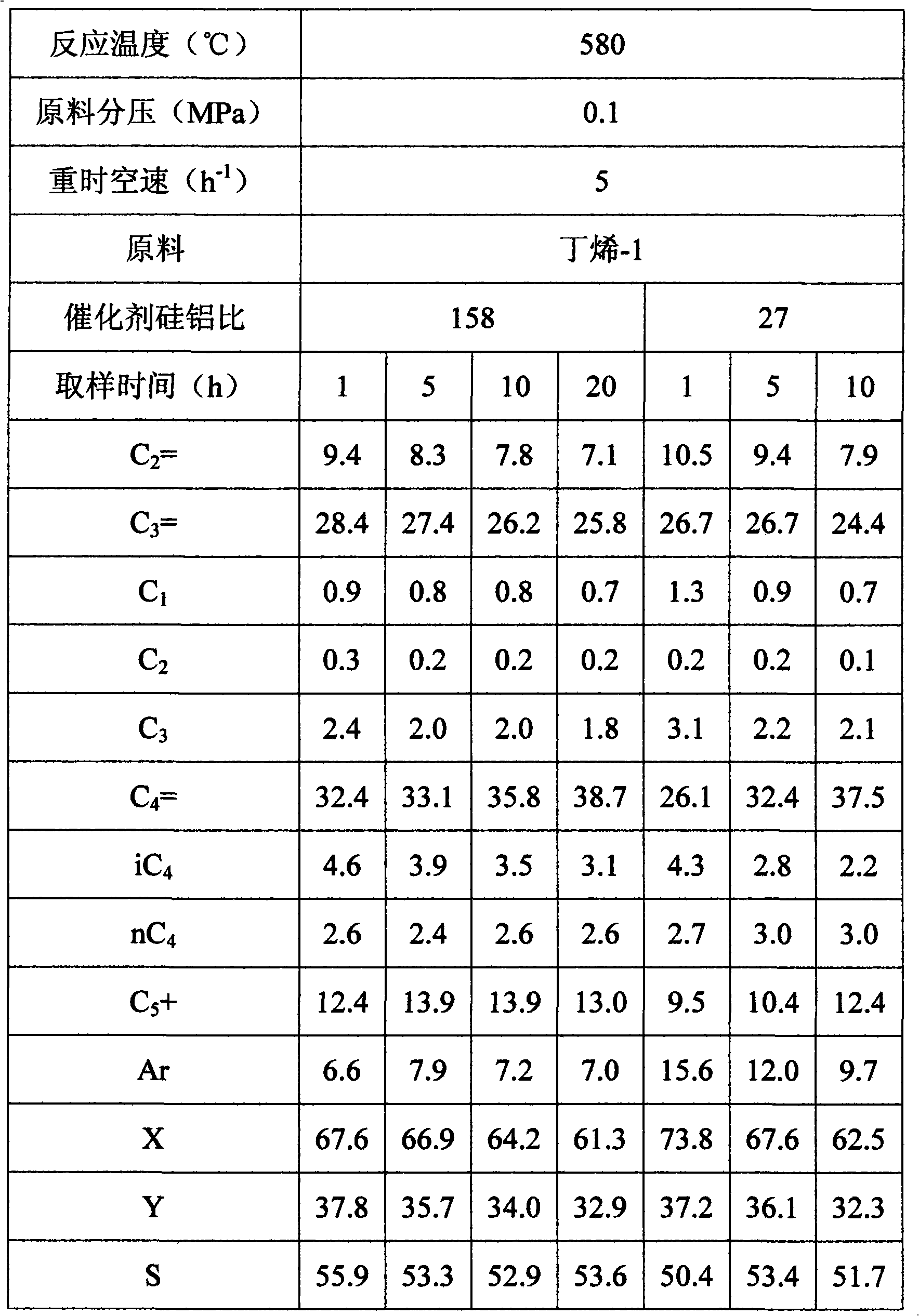

Preparation method of high silica alumina ratio MCM-22 molecular sieve catalyst

InactiveCN101554592AReduce aluminum contentLess acidic surfaceMolecular sieve catalystsHydrocarbon by hydrocarbon crackingAir atmosphereIon exchange

The invention provides a preparation method of a high silica alumina ratio MCM-22 molecular sieve catalyst. The method comprises the following steps: raw materials of sodium source, silicon source, aluminium source, boron source, templeting agent and deionized water are put in a synthesis reactor according to the mixture ratio and statically or dynamically crystallized for 1-20 days at the crystallization temperature of 110-200 DEG C, and the product is filtered, washed and dried to obtain molecular sieve initial powder; and the obtained molecular sieve initial powder is roasted in the air atmosphere at the high temperature of 450-750 DEG C so as to remove the templeting agent and is exchanged into an ammonium type molecular sieve by an ammonium ion exchange method, the ammonium type molecular sieve is roasted at the temperature of 450-750 DEG C to obtain a corresponding hydrogen type molecular sieve, and the hydrogen type molecular sieve is prepared into the high silica alumina ratio MCM-22 molecular sieve catalyst after being molded. By using the method, the MCM-22 molecular sieve catalyst with controllable silica alumina ratio, high crystallization degree and high silica alumina ratio can be prepared, and the invention breaks through the range of the silica alumina ratio of the MCM-22 molecular sieve catalyst of the conventional method and overcomes the problem of descending of crystallization degree generally existing in the post-processing method.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

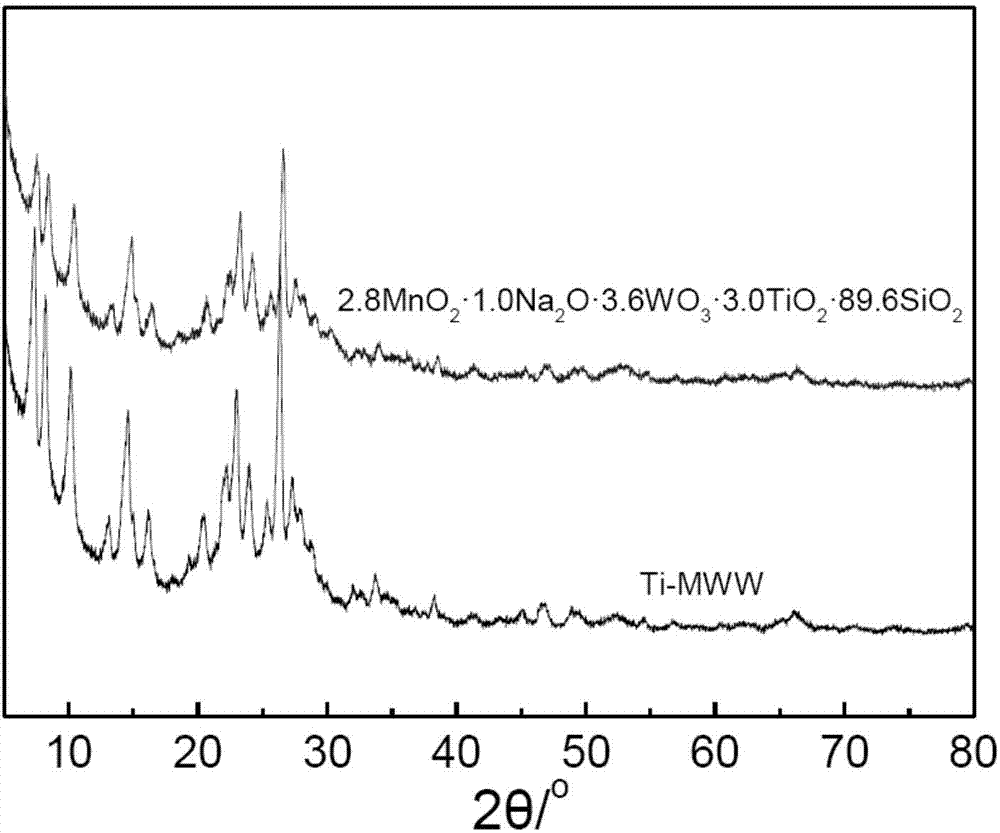

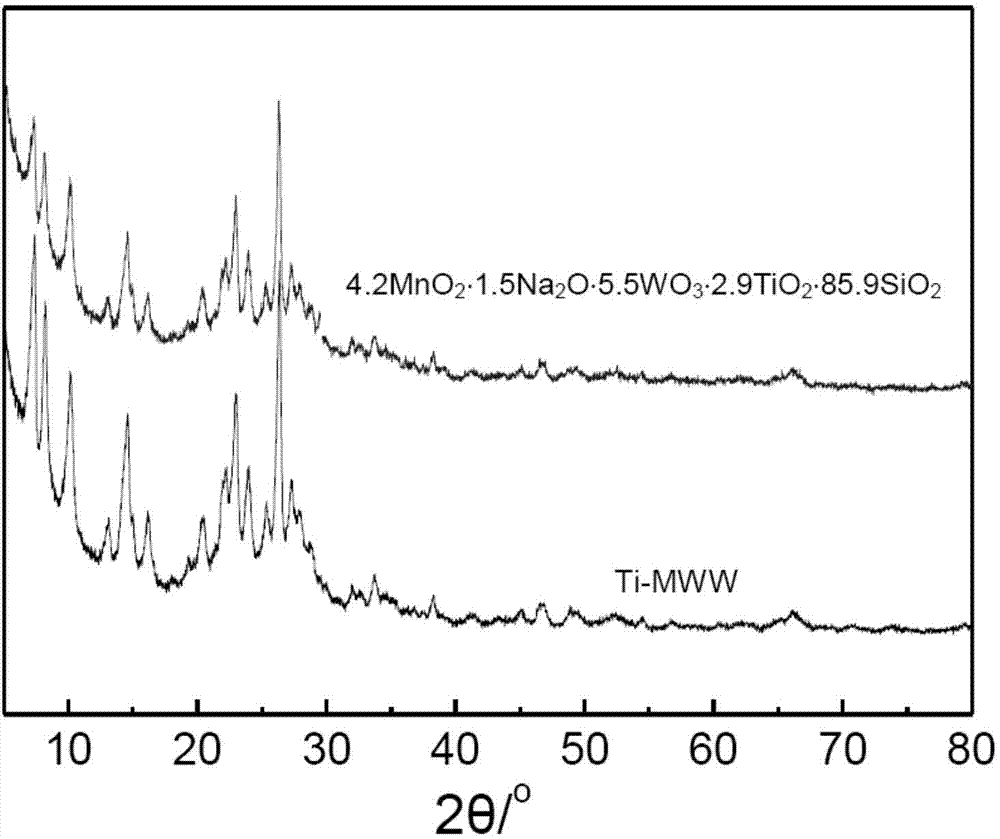

Methane oxidation coupling catalyst and preparation method thereof

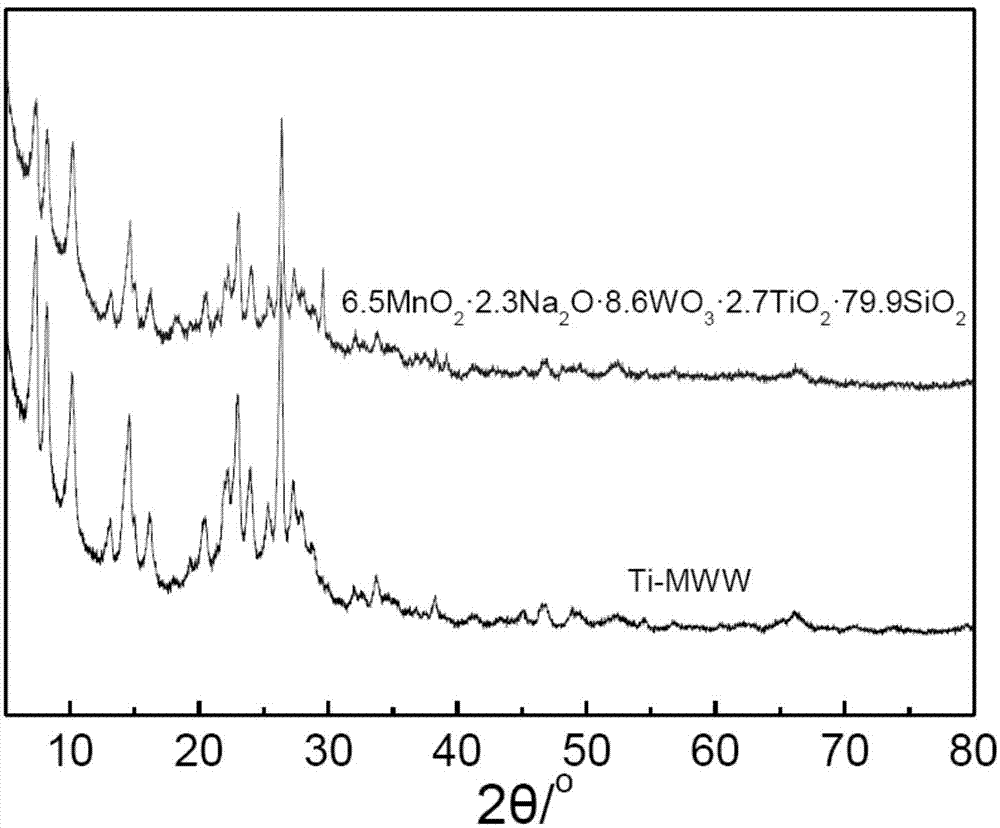

ActiveCN104759291AGood activity at low temperatureHigh selectivityMolecular sieve catalystsHeterogenous catalyst chemical elementsManganese oxideStructural formula

The present invention discloses a manganese-sodium-tungsten-silicon composite oxide oxidative coupling of methane catalyst containing or not containing titanium, obtained by loading manganese-sodium-tungsten onto a titanium-silicon molecular sieve or a pure silicon molecular sieve by means of a step-by-step impregnation method and calcination. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium has the following structural formula: vMnO2·xNa2O·yWO3·zTiO2·(100-v-x-y-z)SiO2, the v, x, y, and z respectively representing the fractional quality occupied by metal manganese oxide, sodium oxide, tungsten oxide and titanium oxide, 0.3≤v≤16, 0.1≤x≤5, 0.6≤y≤21, 0.0≤z≤4. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium set forth in the present invention is used for oxidative coupling of methane reactions, having excellent low-temperature catalytic activity and ethylene / propylene selectivity generation and reaction stability.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

Hydrogenation dechlorinating catalyst for synthesizing trifluoroethylene and novel preprocessing process of carrier of catalyst

ActiveCN102211028AHigh selectivityImprove stabilityPreparation by dehalogenationCatalyst activation/preparationChemistryActivated carbon

The invention discloses a catalyst used for preparing trifluoroethylene by hydrogenating and dechlorinating trifluorochlor oethylene, comprising a first catalyst, a second catalyst and an assistant, wherein the first catalyst is one or combination of more than two of palladium, ruthenium and platinum, the second catalyst is Fe and / or Cu, and the assistant is selected from one or combination of more than two of V, Bi and K. The invention also discloses an activated carbon carrier preprocessing method of the catalyst for preparing the trifluoroethylene by hydrogenating and dechlorinating the trifluorochlor oethylene and an application of the prepared catalyst in trifluoroethylene preparation. The catalyst prepared by the method disclosed by the invention has the advantages of high catalytic activity and catalyst efficiency, good trifluoroethylene selectivity, strong reaction stability, mild reaction condition, simple catalyst preparation and processing process and the like.

Owner:SINOCHEM LANTIAN

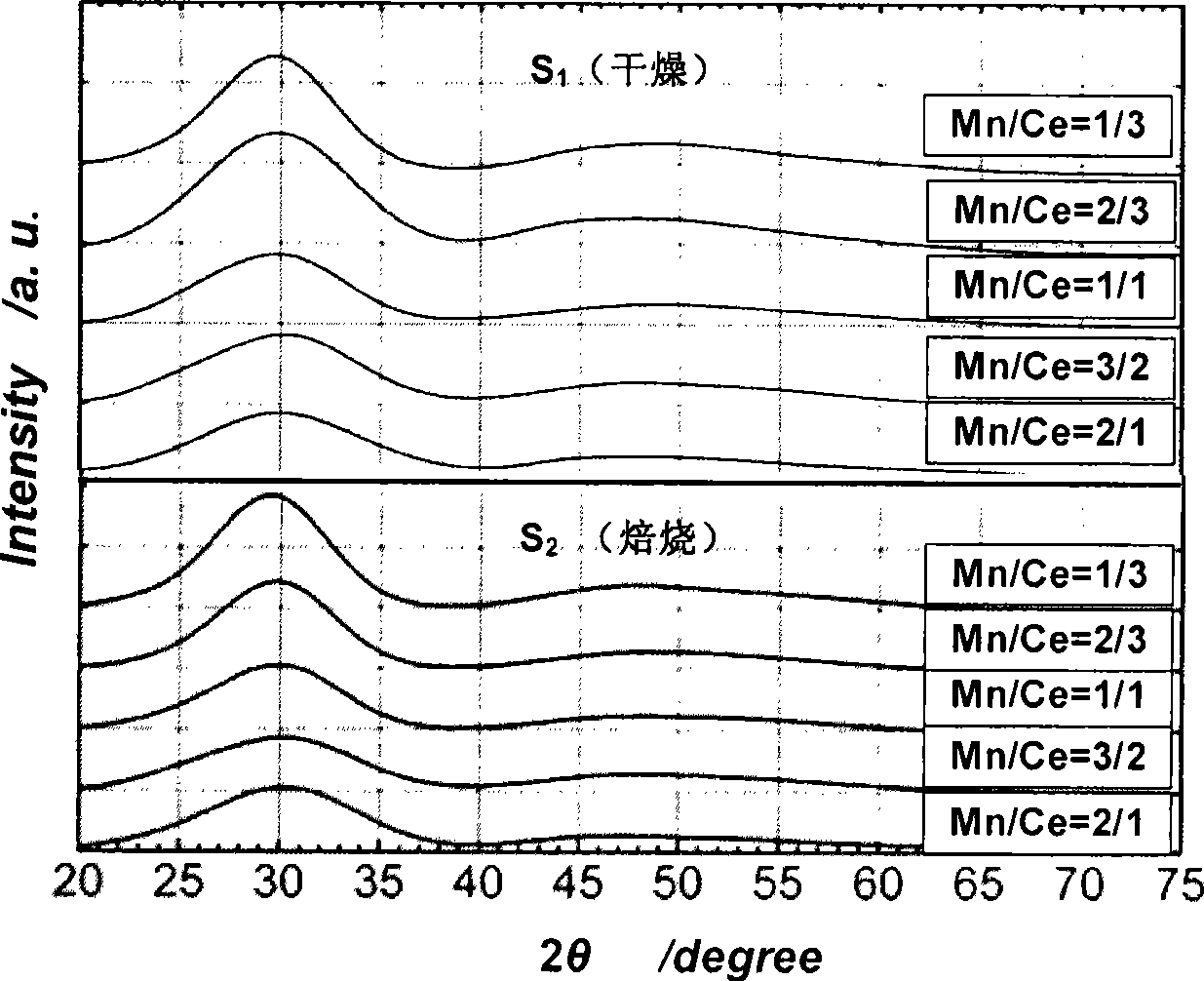

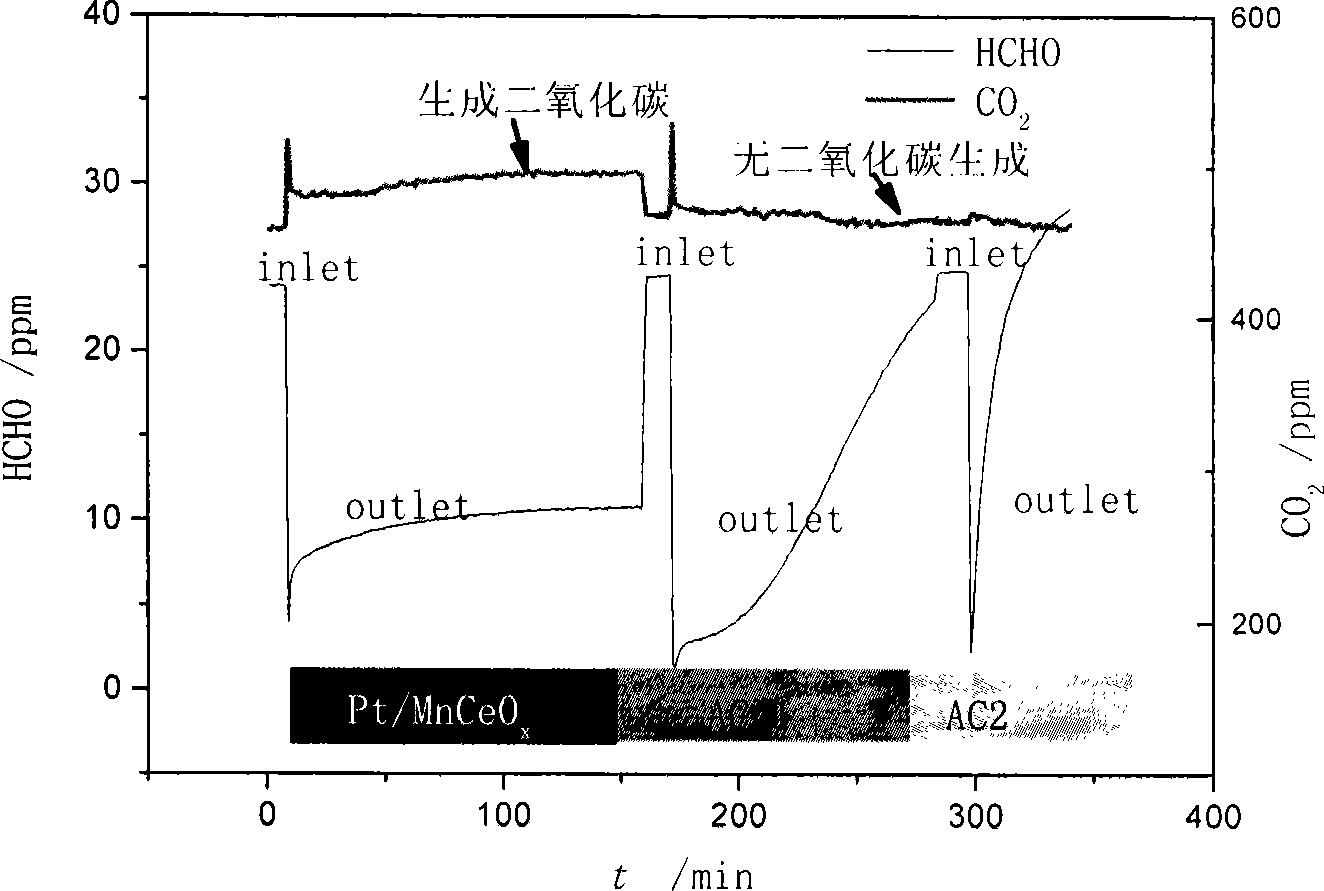

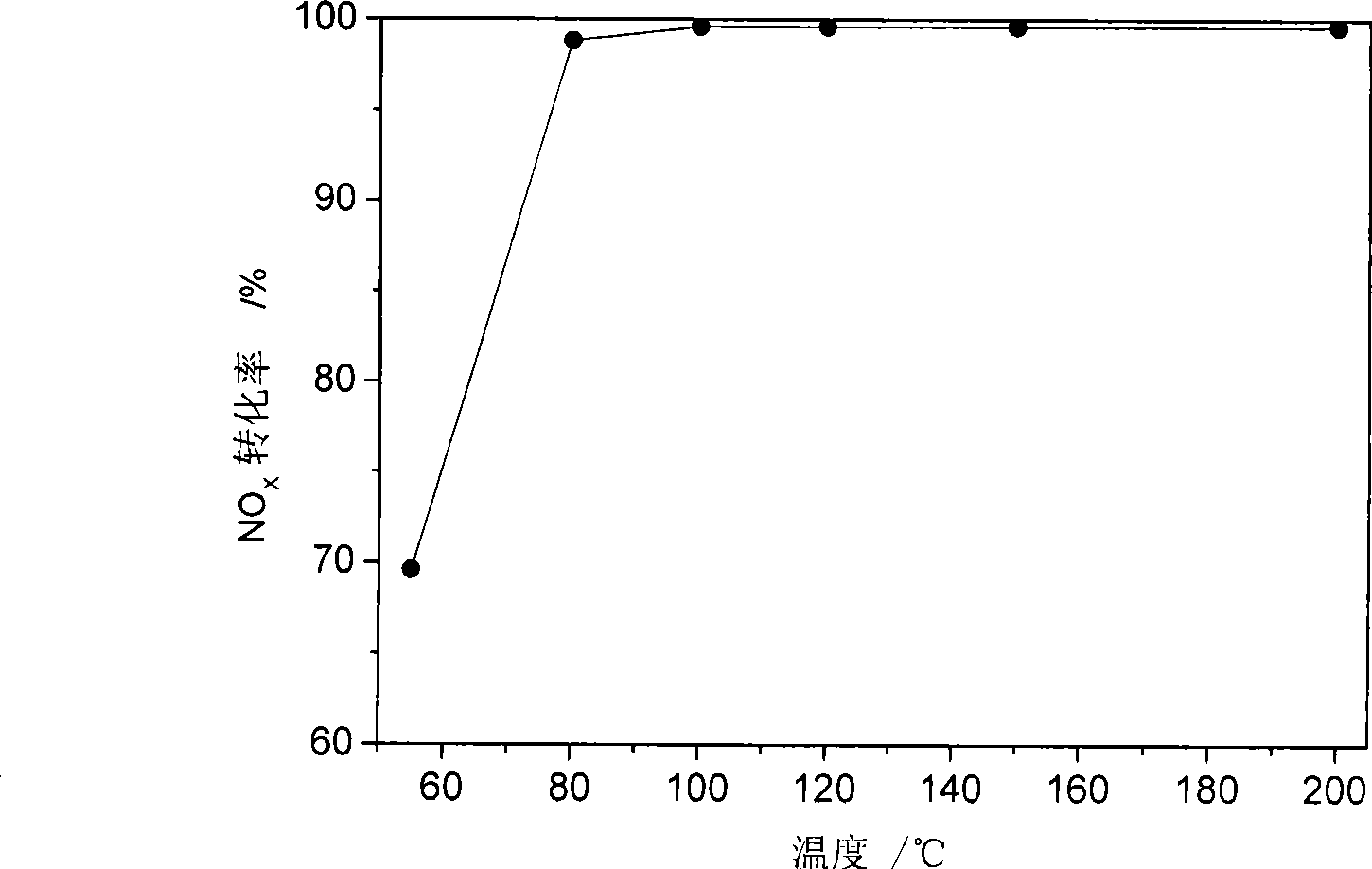

High-dispersion manganese-cerium composite oxides and preparation method thereof

ActiveCN101462049AGentle preparation processGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention discloses manganese-cerium composite oxide, which is prepared in one step through the oxidation reduction-precipitation process among Mn<VII>, Mn<II> and Ce<III> ions, wherein components, namely MnO2 and CeO2 of the manganese-cerium composite oxide have high dispersion on a near molecular scale, the mol ratio of Mn to Ce is randomly adjusted, and the composite oxide has good oxidation reduction and oxygen affinity. As a catalyst carrier of reactions of formaldehyde oxidation at room temperature and low-temperature selective catalytic reduction of nitrogen oxide, the use of the composite oxide can ensure that a catalyst has higher activity, and the stability of the composite oxide is more superior to those of other carriers.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

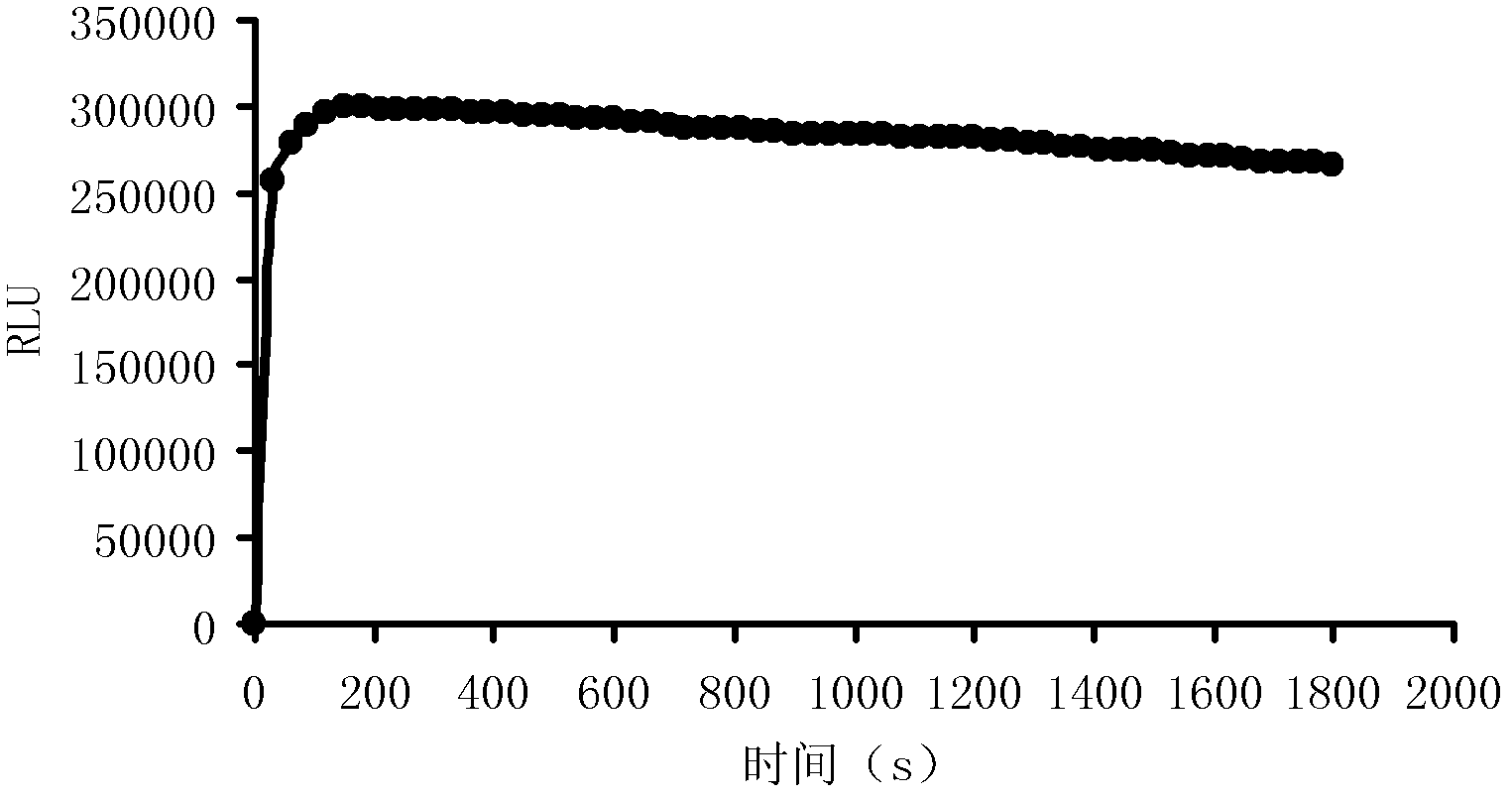

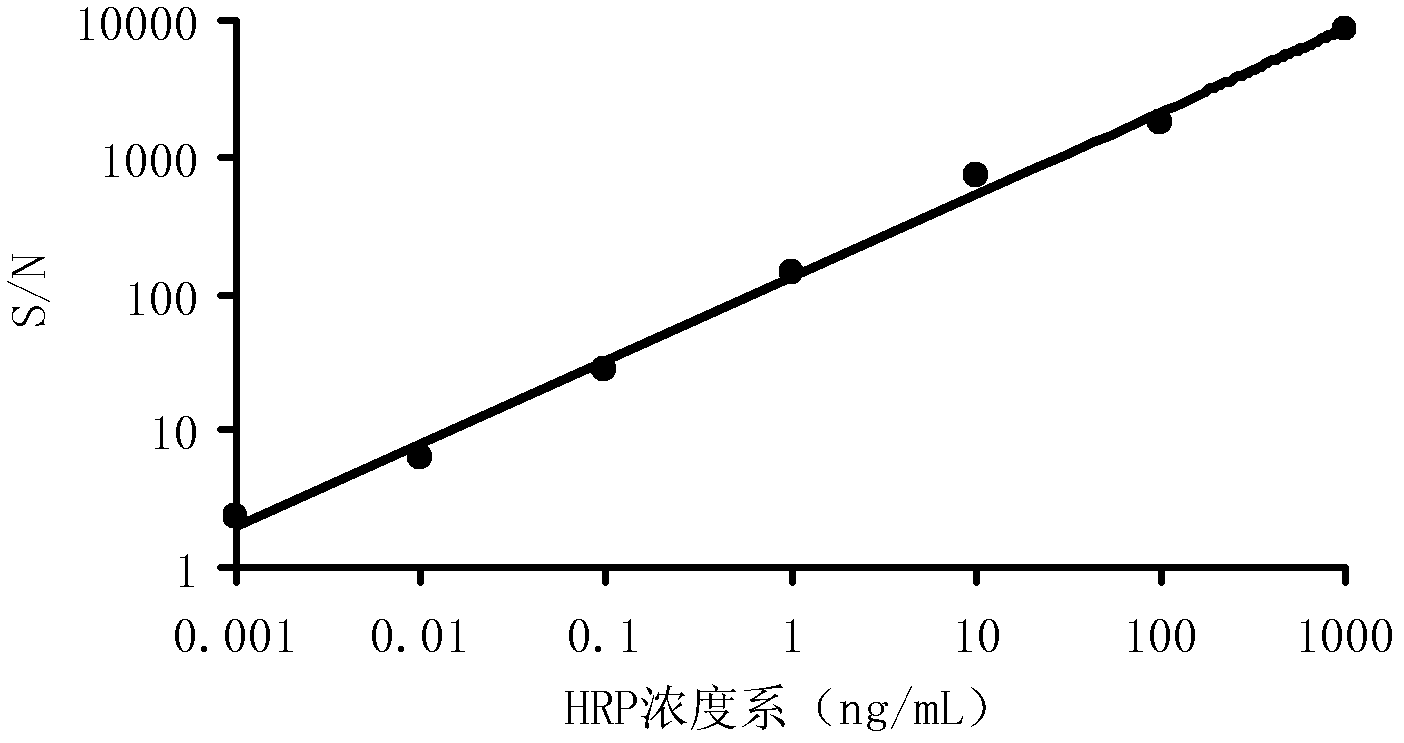

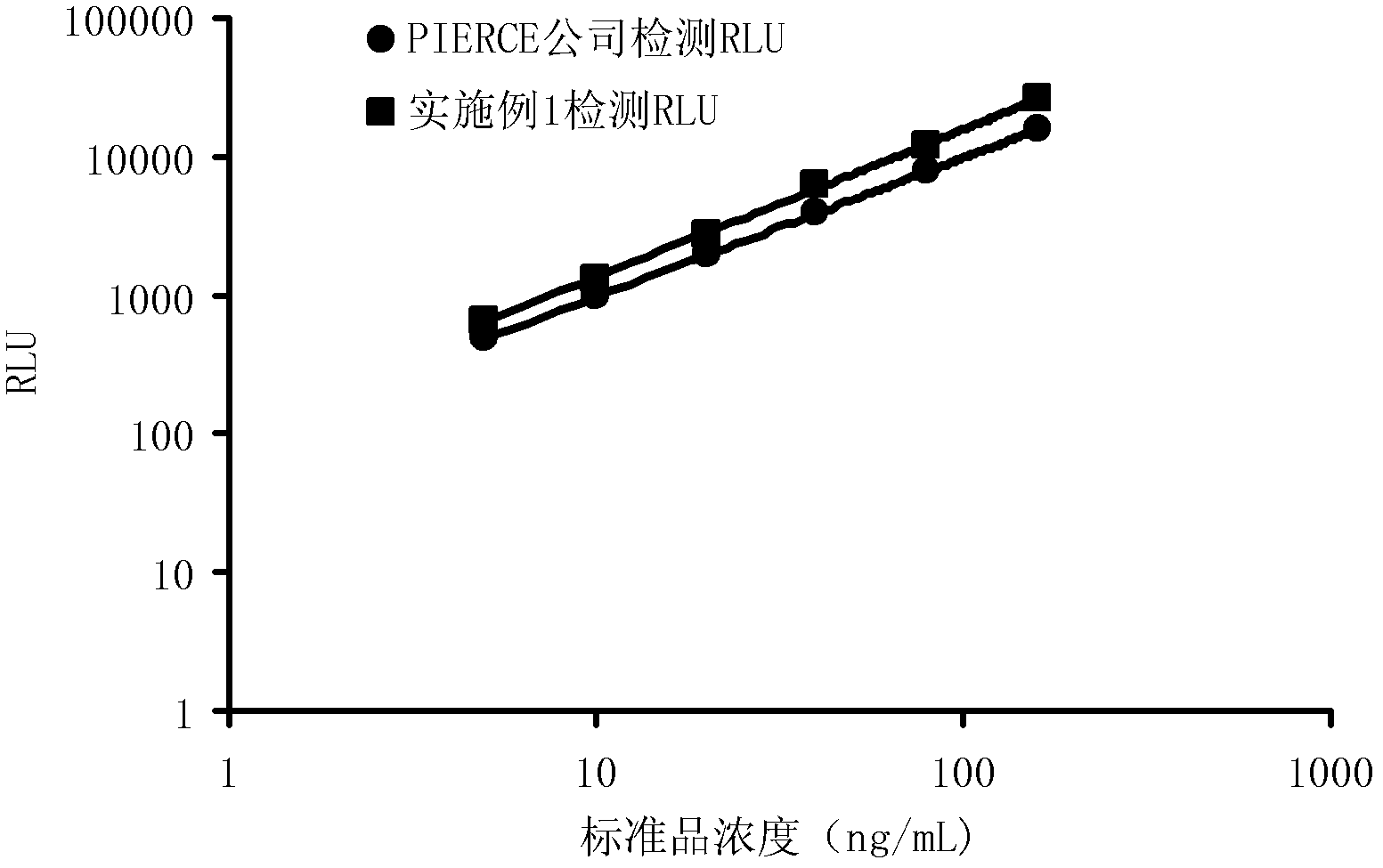

Stable HRP enzymatic enhanced chemiluminescent substrate solution

ActiveCN102435598AImprove reaction stabilityHigh Luminous Intensity ValuesChemiluminescene/bioluminescenceBiological testingPHENOL LIQUIDLuminol

The invention discloses a stable HRP enzymatic enhanced chemiluminescent substrate solution. The stable enzymatic enhanced chemiluminescent substrate solution is composed of a luminescent agent solution A and an oxidizing agent solution B, which are mixed in volume ratios of 2:3-3:2. The luminescent agent solution A contains a luminescent agent: luminol or luminol derivatives, and a reinforcing agent: p-iodo-pheno, 4-(1, 2, 4-triazole-1-radical) phenol, etc., and the oxidizing agent solution B contains sodium perborate, hydrogen peroxide, etc. The stable HRP enzymatic enhanced chemiluminescent substrate solution of the invention is applied in an HRP enzymatic reaction with the characteristics of short reaction time and long platform period, can be stably preserved for 2 years at 4-8 EDG C, and is widely used in a kit using HRP as the detection object.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Metal modified HZSM-5 molecular screen catalyst and its preparation method and uses in preparing methyl formate

InactiveCN1836778AImprove conversion rateHigh yieldMolecular sieve catalystsOrganic compound preparationMolecular sieveCatalytic oxidation

The present invention discloses one kind of metal modified HZSM-5 molecular sieve catalyst and its preparation process and application in preparing methyl formate. The metal modified HZSM-5 molecular sieve catalyst is V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ag, Mg, Ba, Ca, Pb, Sn, Mo, W, Sr, Zr, La or Bi modified HZSM-5 molecular sieve catalyst. After the catalyst is set inside a continuously flowing immobilized bed reactor, dimethyl ether, oxygen and inert gas in certain weight proportion are introduced to react at certain temperature to prepare methyl formate. The catalyst results in high dimethyl ether converting rate and high methyl formate yield, and this proves the high reaction activity, high stability and high target product selectivity of the catalyst.

Owner:GUANGDONG UNIV OF TECH

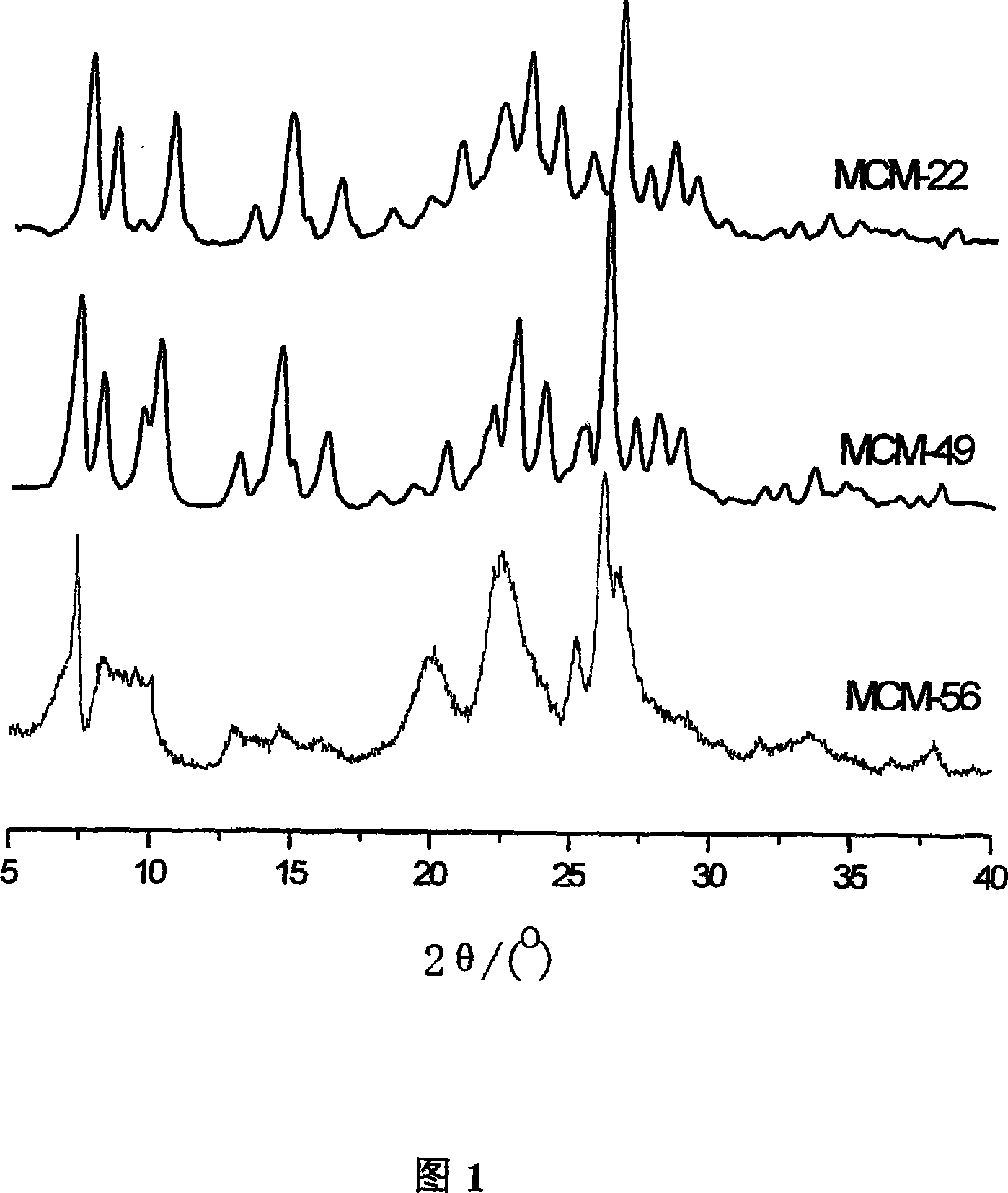

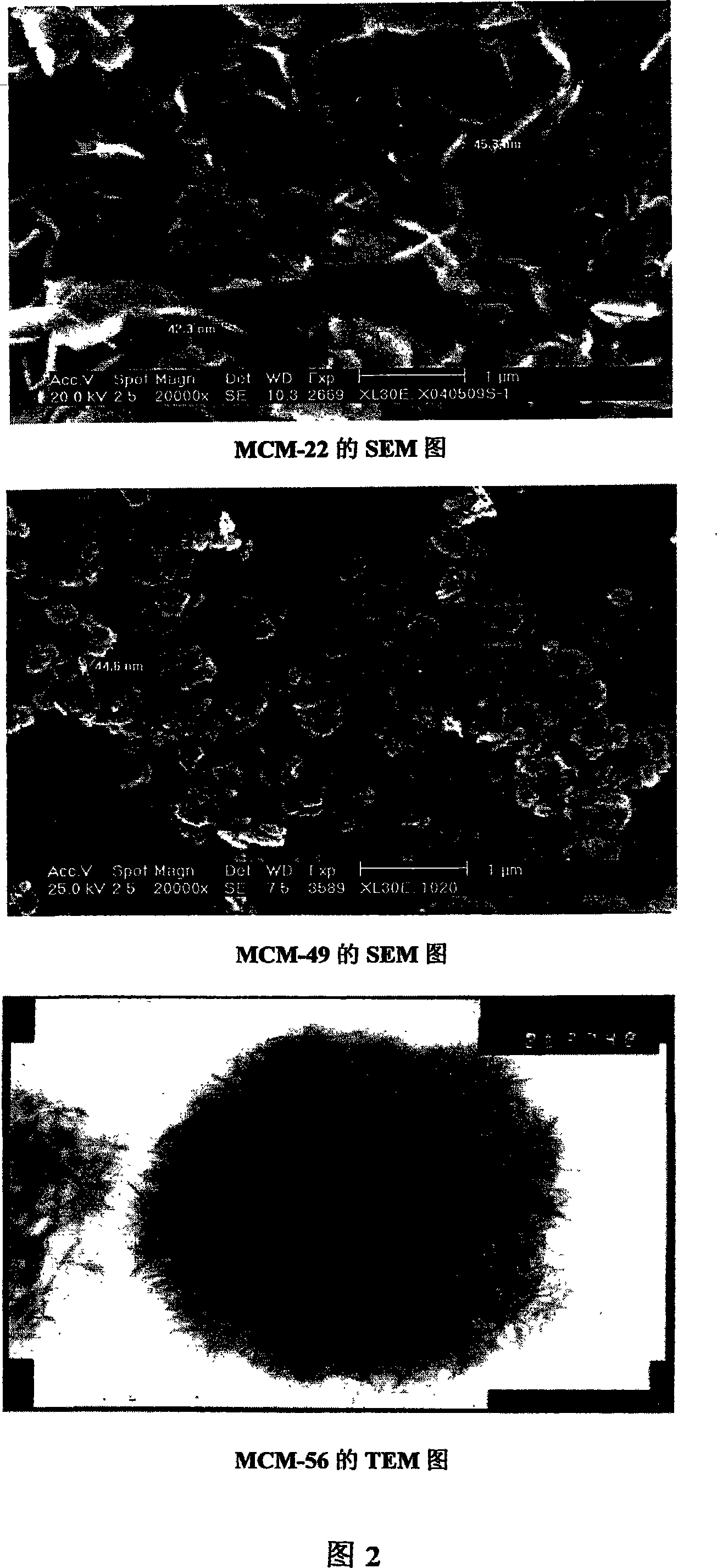

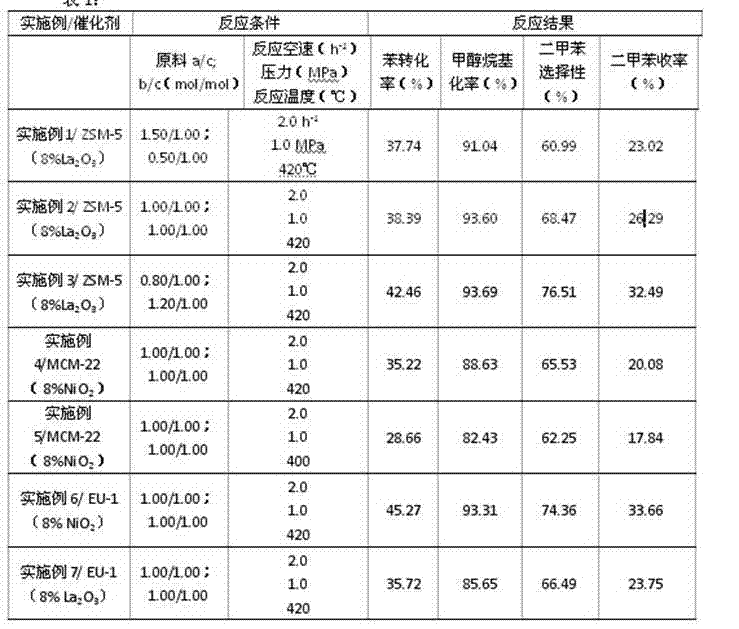

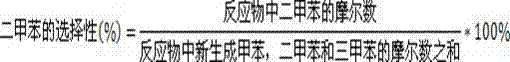

Application of nano molecular sieve catalyst in alkylation reaction of arene

ActiveCN101054334AImprove conversion rateHigh selectivityMolecular sieve catalystsHydrocarbonsMolecular sieveAliphatic alcohol

The invention provides an application of nanometer molecular screen in aromatic hydrocarbons alkylation reaction, and a method for generating mono-substituted, disubstituted and polysubstituted benzene by alkylation reaction of aromatic hydrocarbons with olefin hydrocarbon or alcohol on molecular sieve catalyst, wherein aromatic hydrocarbons is benzene, toluol, ethylbenzene or cumene; olefin hydrocarbon is ethylene, propone, butene or isobutene; alcohol is C1 to C4 aliphatic alcohol; molecular screen is high high crystallinity sheet MCM-22, MCM-49 or MCM-56 crystal powder in which the thickness is smaller than 50nm, and sizes is between 300 and 500nm.The nanometer molecular sieve catalyst provided in present invention has high conversion rate of alkylation reaction and high selectivity, and it has fine stability, which is capable of being used for manufacturing production.

Owner:SHANGHAI HUAYI NEW MATERIAL

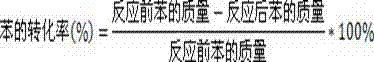

Method for high selectively synthesizing dimethylbenzene through benzene and methanol alkylation reaction

ActiveCN102964201AImprove reaction stabilitySuppress generationHydrocarbon by hydrocarbon and non-hydrocarbon condensationBulk chemical productionPtru catalystReaction temperature

The invention relates to a method for high selectively synthesizing dimethylbenzene through benzene and methanol alkylation reaction. The method takes the benzene as a raw material a, a toluene is taken as a raw material b, the methanol is taken as a raw material c, according to the molar ratio, a / c equals to 0.50-3.00 / 1.00, b / c equals to 0.60-3.00 / 1.00, under the conditions that the reaction temperature is between 380 and 480 DEG C, the reaction pressure is between 0.50 and 6.0 mega pascals, the reaction space velocity is between 0.5 and 5.0 h<-1> and the carrier gas is H2, N2 or CO2, the dimethylbenzene is produced in a fixed bed reactor under the catalysis of molecular sieve based catalysts, the catalysts are one or a plurality of molecular sieves of zeolite socony mobile-5 (ZSM-5), USY, mobile composite of matter (MCM)-22 or EU-1, a load metallic oxide is Mo, Ni or La metallic oxide, and the load of the metallic oxide is 0.50-10.00%. The method utilizes the benzene with relative surplus capacity and the inexpensive methanol to produce the dimethylbenzene with high industrial added value. The appropriate molecular sieve based catalyst is adopted, the utilization ratio of the methanol alkylation reaction for high selectively synthesizing the dimethylbenzene cannot be less than 90%, and the catalyst stability can satisfy industrial application requirements. Moreover, the toluene is added into the reaction raw materials, so that toluene byproducts can be inhibited from being produced; and in addition, an H2, N2 or CO2 carrier gas atmosphere is adopted, so that the reaction stability of the catalyst is enhanced.

Owner:TONGJI UNIV

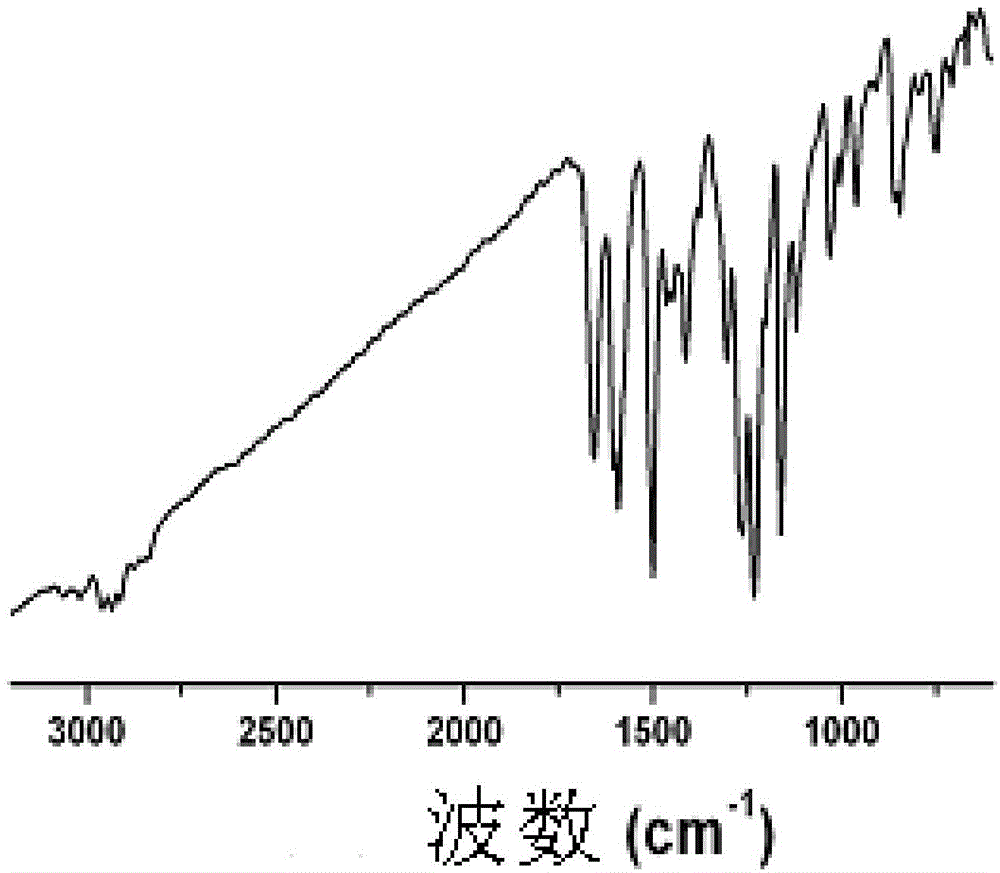

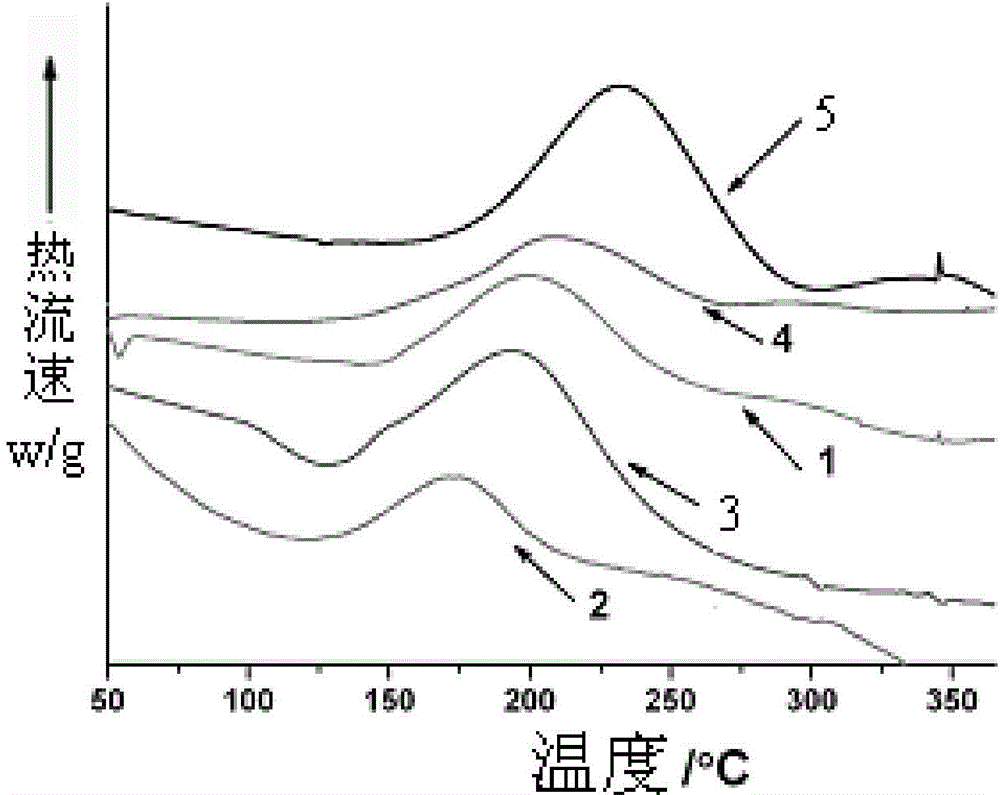

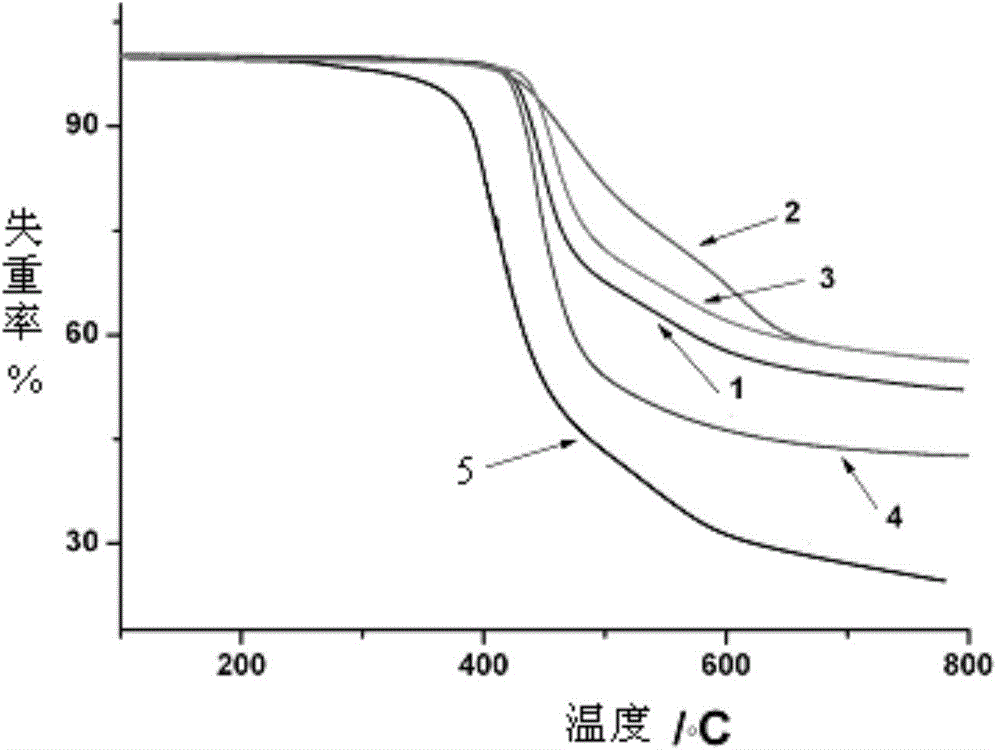

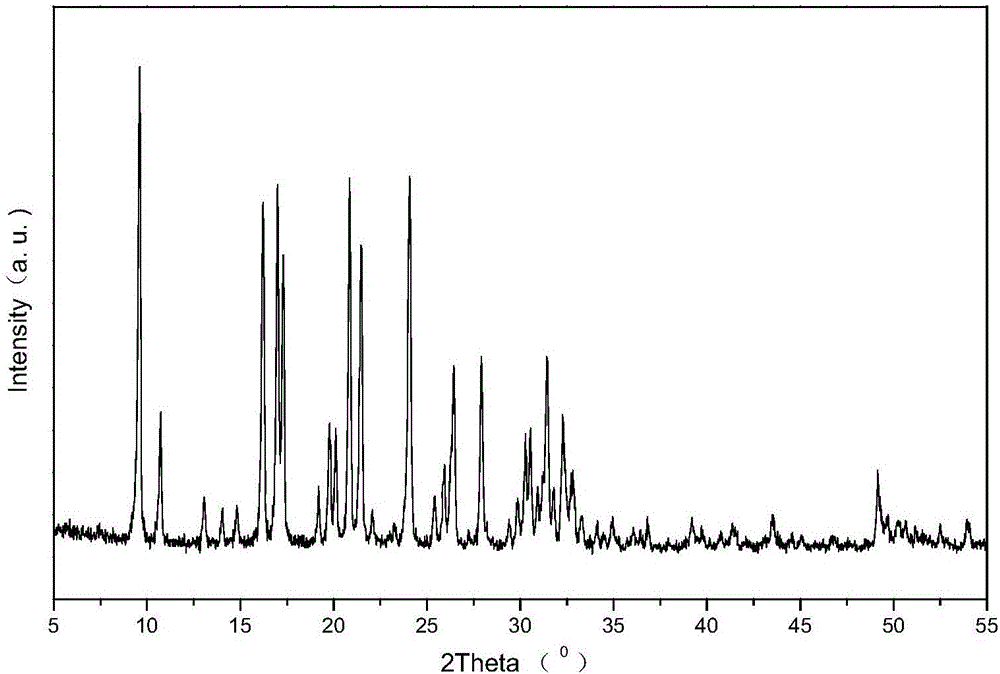

Propenyl phenoxy compounds with three-branch aromatic structure and preparation method thereof, and bismaleimide resin modified by propenyl phenoxy compounds

ActiveCN104628544ALower curing temperature effectIncreased reactivity collision chanceOrganic compound preparationCarbonyl compound preparationCooking & bakingReflux

The invention provides propenyl phenoxy compounds with a three-branch aromatic structure and a preparation method thereof, and a bismaleimide resin modified by the propenyl phenoxy compounds, relating to the field of thermosetting resins and adhesives for high-temperature-resistant composite materials. The invention aims to solve the problems of higher curing temperature and higher after-treatment temperature in the existing bismaleimide resin and the problem of poor long-time thermal aging resistance of the cured resin at high temperature. The structural general formula is disclosed in the specification. The preparation method comprises the following steps: adding trifunctional fluoro ketone, allyl phenol and a catalyst into a solvent, heating to react under reflux, filtering, cooling, precipitating, washing with water and baking. The bismaleimide resin modified by the propenyl phenoxy compounds is prepared from bismaleimide, propenyl phenoxy compounds with three-branch aromatic structure, and diallylphenyl compounds. The invention mainly discloses a propenyl phenoxy compounds with three-branch aromatic structure and a preparation method thereof, and a bismaleimide resin modified by the propenyl phenoxy compounds.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

High-silica-alumina-ratio SSZ-39 zeolite, and synthesis and application thereof

ActiveCN106745031AHigh crystallinityOvercome problems such as decreased crystallinityMolecular sieve catalystsOther chemical processesDispersityFiltration

The invention discloses a preparation method of a high-crystallinity high-dispersity adjustable-silica-alumina-ratio high-silicon SSZ-39 molecular sieve catalyst. The method comprises the following steps: proportionally adding a sodium source, a silicon source, an aluminum source, fluorine ions, a template, a growth polymerization inhibitor and deionized water into a synthesis kettle, carrying out dynamic or static crystallization in different temperature sections, and carrying out filtration, washing and drying on the product to obtain molecular sieve raw powder; and carrying out high-temperature roasting to remove the template, carrying out ion exchange, and carrying out high-temperature roasting to obtain the high-silica-alumina-ratio SSZ-39 molecular sieve. The high-silica-alumina-ratio SSZ-39 molecular sieve has appropriate acid site, heat stability and pore size. The high-crystallinity high-dispersity controllable-silica-alumina-ratio SSZ-39 molecular sieve can be used for MTO (methanol to olefins) reaction for catalytically converting organic oxides (such as methanol and / or dimethyl ether and the like) into low-carbon olefins, and has the advantages of very high reaction activity and high selectivity for ethylene and propylene.

Owner:中海亚环保材料有限公司

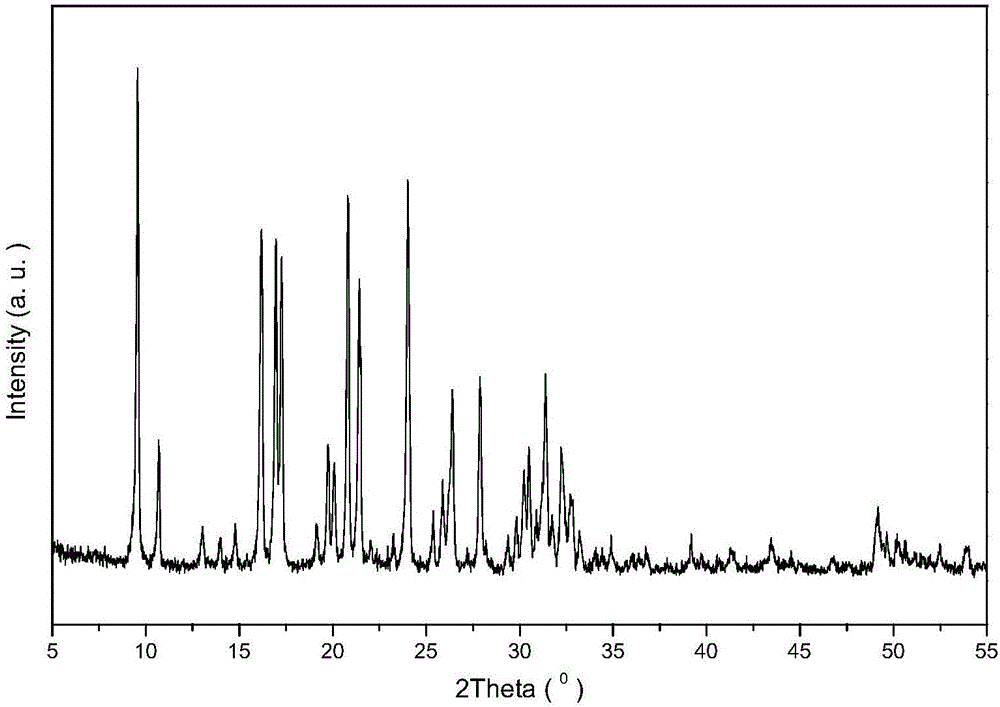

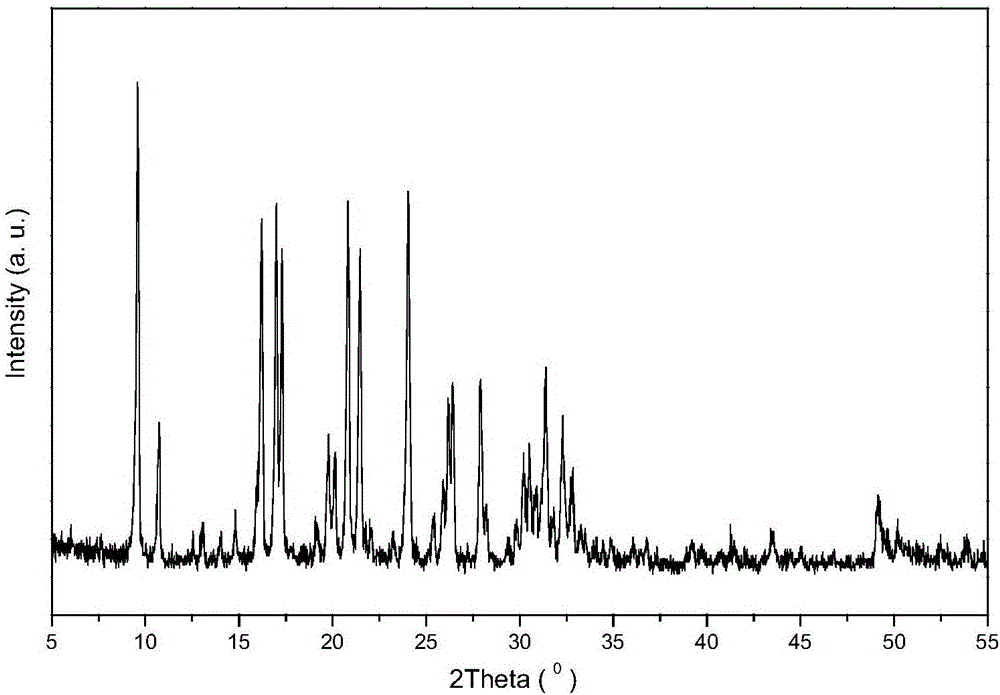

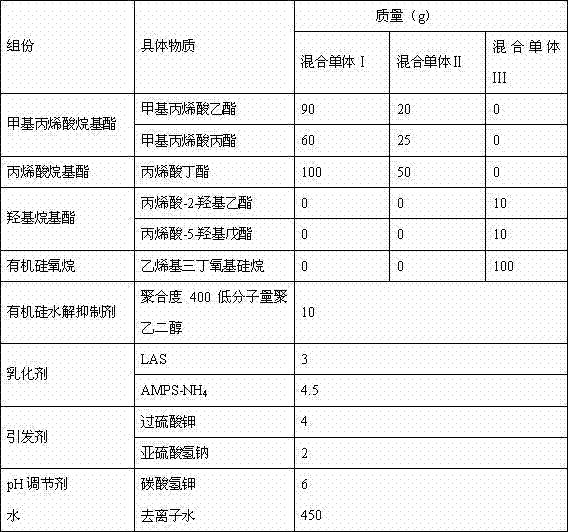

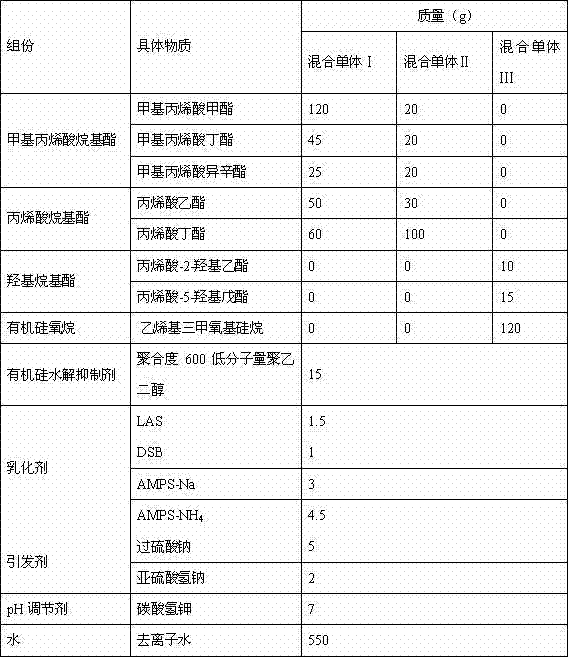

Self-crosslinking silicone-acrylate copolymer emulsion and preparation method

The invention relates to the organic compound technical field, which solves the problems of poor stability of the silicone-acrylate copolymer emulsion and poor water resistance and stain resistance performances of a film due to low silicon content. The invention relates to a self-crosslinking silicone-acrylate copolymer emulsion which comprises the following components by mass percentages: 10.0-30.0% of methacrylic acid alkylester, 15.0-30.0% of alkyl acrylate, 5-15% of organosiloxane, 0.5-2.5% of alkyl ester, 1.0-5.0% of organosilicone hydrolysis inhibitor, 0.5-2.0% of pH modifier, 0.5-2.0% of emulsifier, 0.5-1.0% of initiator and 40.0-60.0% of water. The emulsion good reaction and storage stability, the silicon content used for constituting colloidal particles and its functional group distribution is gradually increased from 60-80% of colloidal particle radius to the surface, the organosilicone segment function can fully performed, and the cost performance of product is enhanced.

Owner:建德市新安有机硅新材料研究所

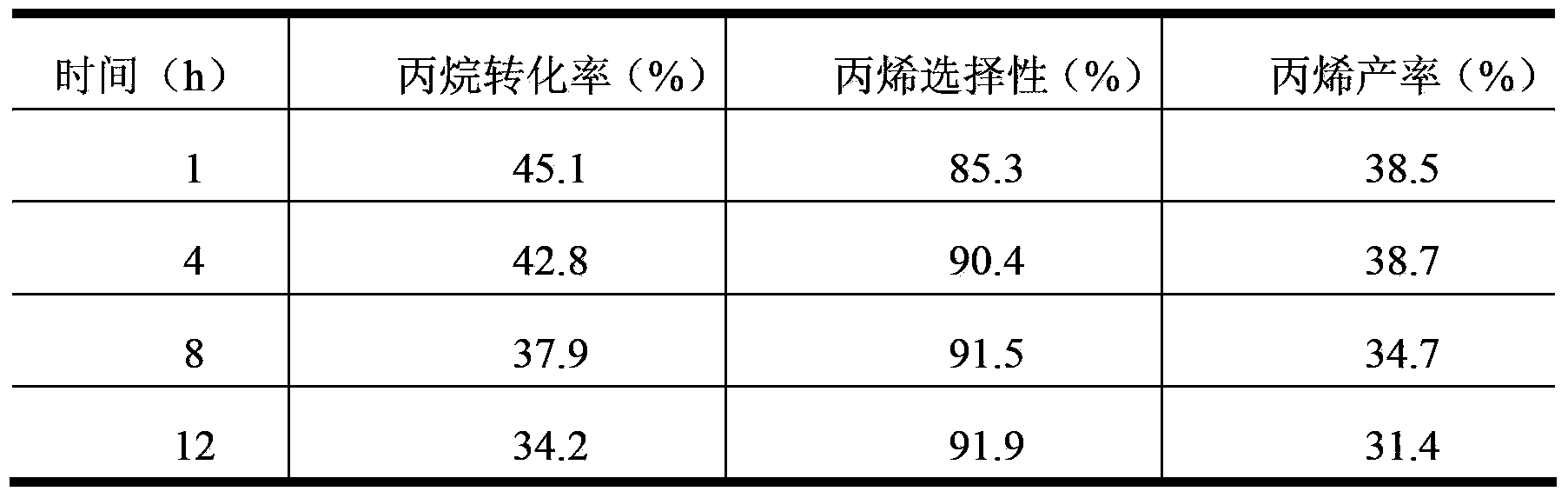

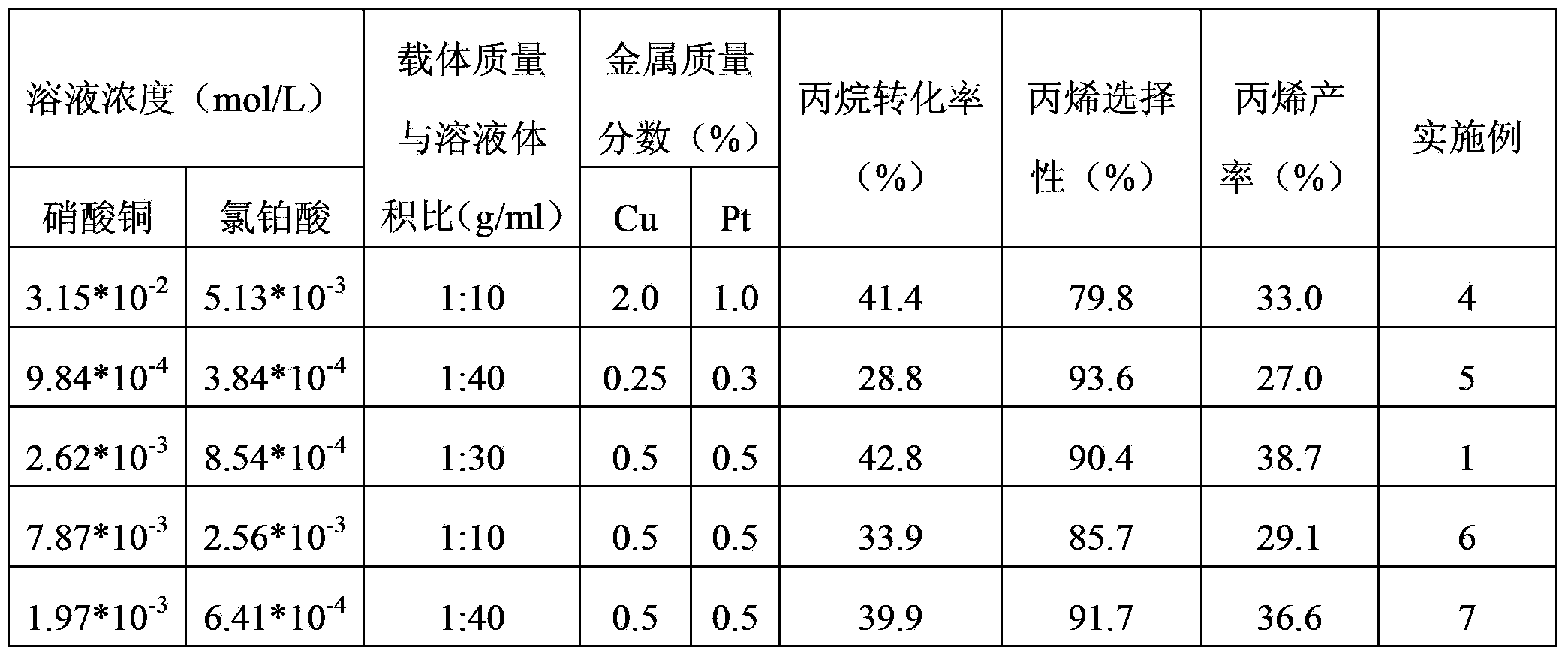

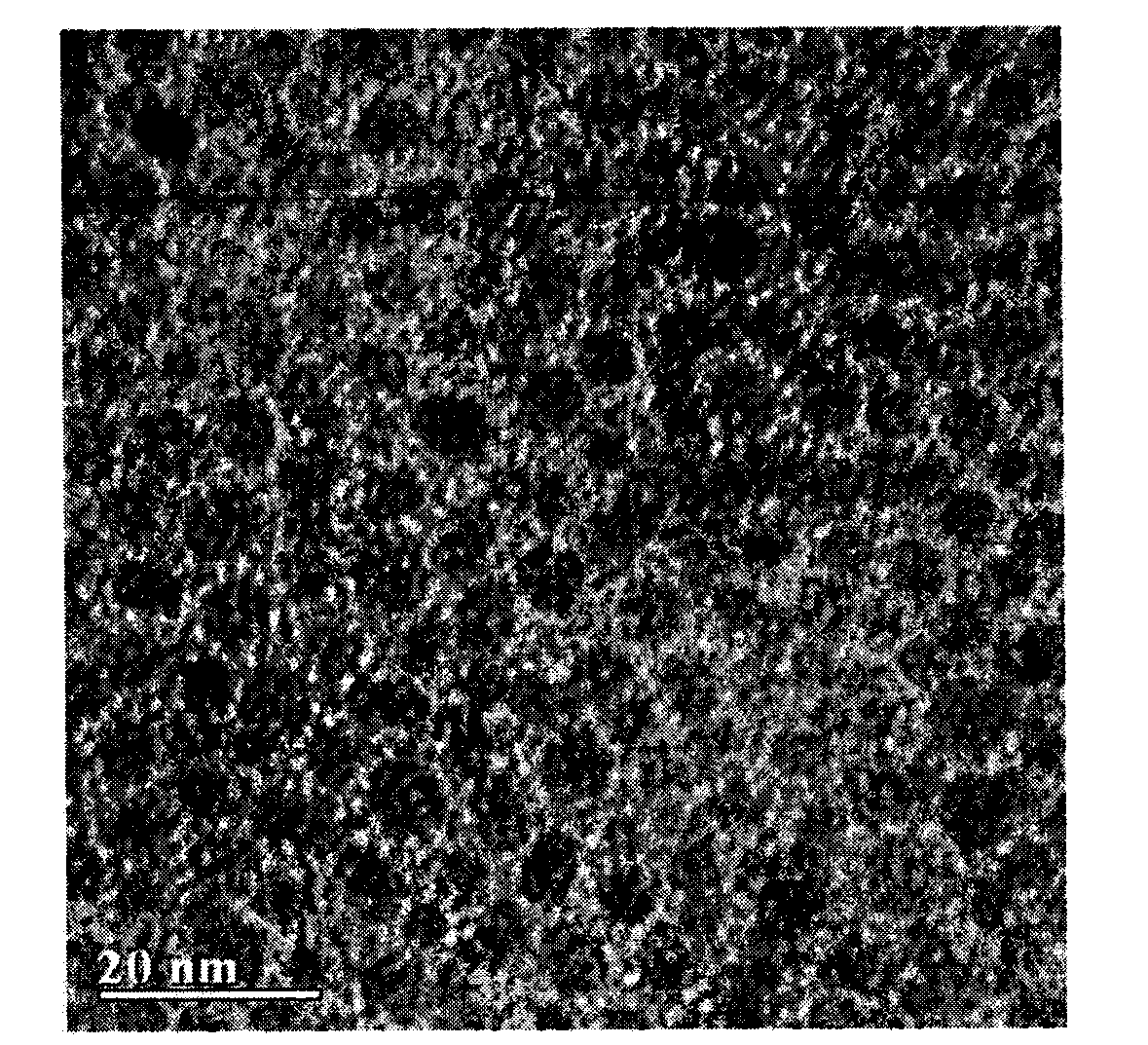

Platinoid bi-component catalyst as well as preparation method and application thereof

InactiveCN103349988AImprove conversion rateEvenly distributedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPlatinumActive component

The invention discloses a platinoid bi-component catalyst as well as a preparation method and application thereof. In the catalyst, gamma-Al203 is taken as a carrier, platinum is taken as an active component, and copper is taken as auxiliary agent. The preparation method includes the following steps: dipping the carrier gamma-Al203 powder in Cu(NO3)2 water solution, removing solvent, drying and roasting, placing the obtained copper-loaded catalyst in H2PtCl6 water solution for dipping, removing solvent, drying and roasting, wherein the platinoid bi-component catalyst can be used in propylene preparation through propane dehydrogenation. According to the invention, copper and platinum in the catalyst interact to change the interaction force between the reactant and the metal surface and between the product and the metal surface, so that better reaction stability at a high temperature in propylene preparation through propane dehydrogenation is guaranteed, the dimethylmethane conversion ratio is higher, the propylene selectivity is excellent; different components of the catalyst can be dipped through the step-by-step dipping method, contents of the components can be controlled easily, and the repeatability is excellent.

Owner:TIANJIN UNIV

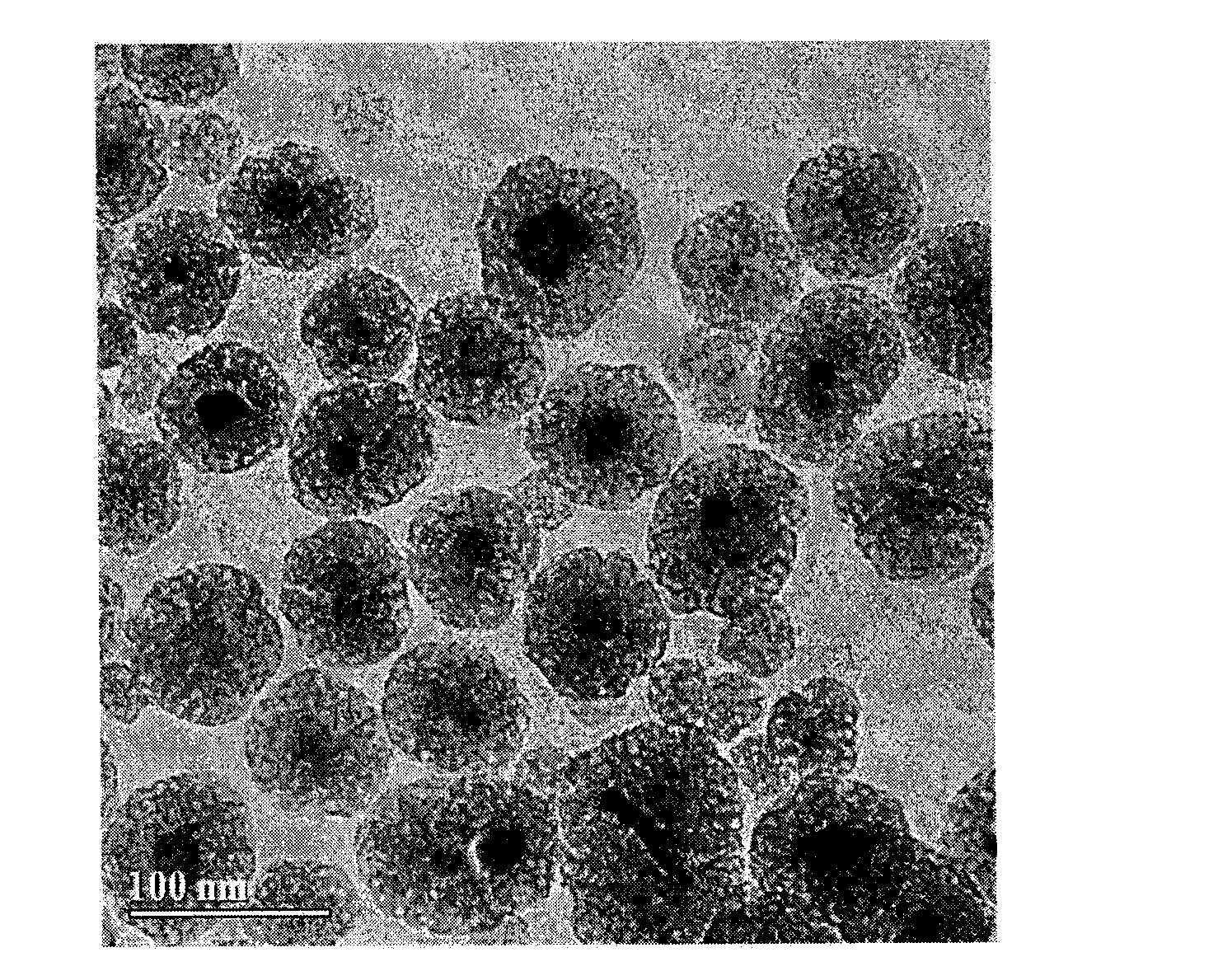

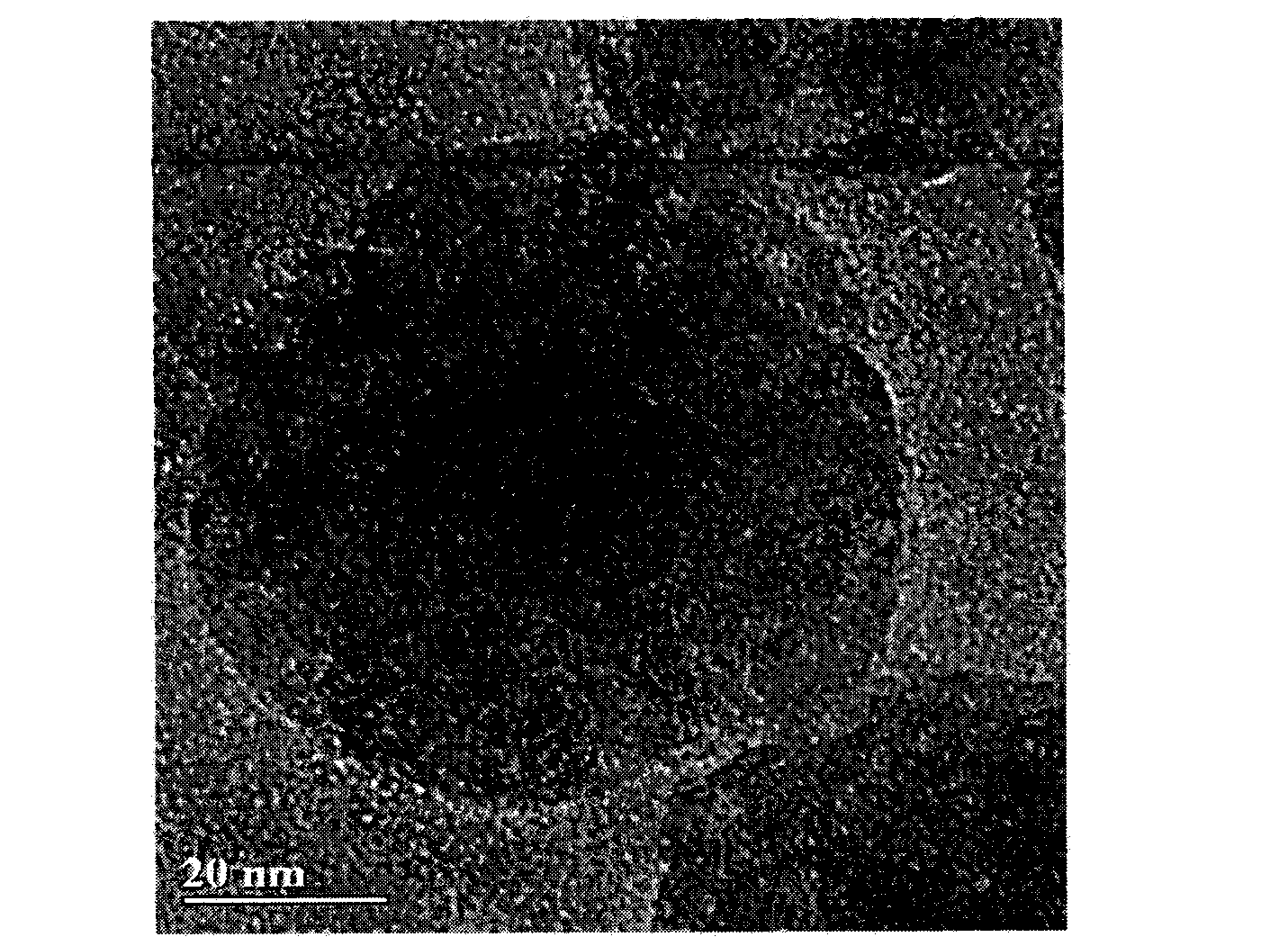

Preparation method of MOx@SiO2 shell-core structure catalyst

ActiveCN103418371AGuaranteed activity and selectivityGood reactivity and stabilityMolecular sieve catalystsDispersed particle separationNano catalystHigh activity

The invention relates to a preparation method of a shell-core structure MOxSiO2, wherein the MOx is one of Mn3O4, Fe2O3, CeO2, Cu2O, or Co3O4. The preparation method comprises following steps: homogenously dispersing 0.01 to 0.1 mol of water-containing inorganic metal salt and 2 to 10 mL of oleic acid into 50 to 100 mL of absolute methanol, then putting the materials in a high-pressure reactor to subject the materials to crystallization reactions for 10 to 48 hours at the temperature of 120 to 240 DEG C, cooling and filtering so as to obtain MOx nano particles, dissolving the MOx nano particles in hexane, adding cetyl trimethyl ammonium bromide solution, subjecting the solution to an ultrasonic treatment, adding sodium hydroxide solution with a concentration of 0.5 M to 2 M, stirring, dropwise adding ethyl orthosilicate, carrying out the reactions at the room temperature for 10 to 24 hours, then subjecting the reaction product to a centrifugation treatment, washing, drying, and burning so as to obtain nano catalyst MOx@SiO2. The preparation method is simple and is easy to be applied to industrial production. The catalyst prepared by the preparation method is applied to the CO oxidation reaction, and has the advantages of low cost, and high activity and stability.

Owner:EAST CHINA UNIV OF SCI & TECH

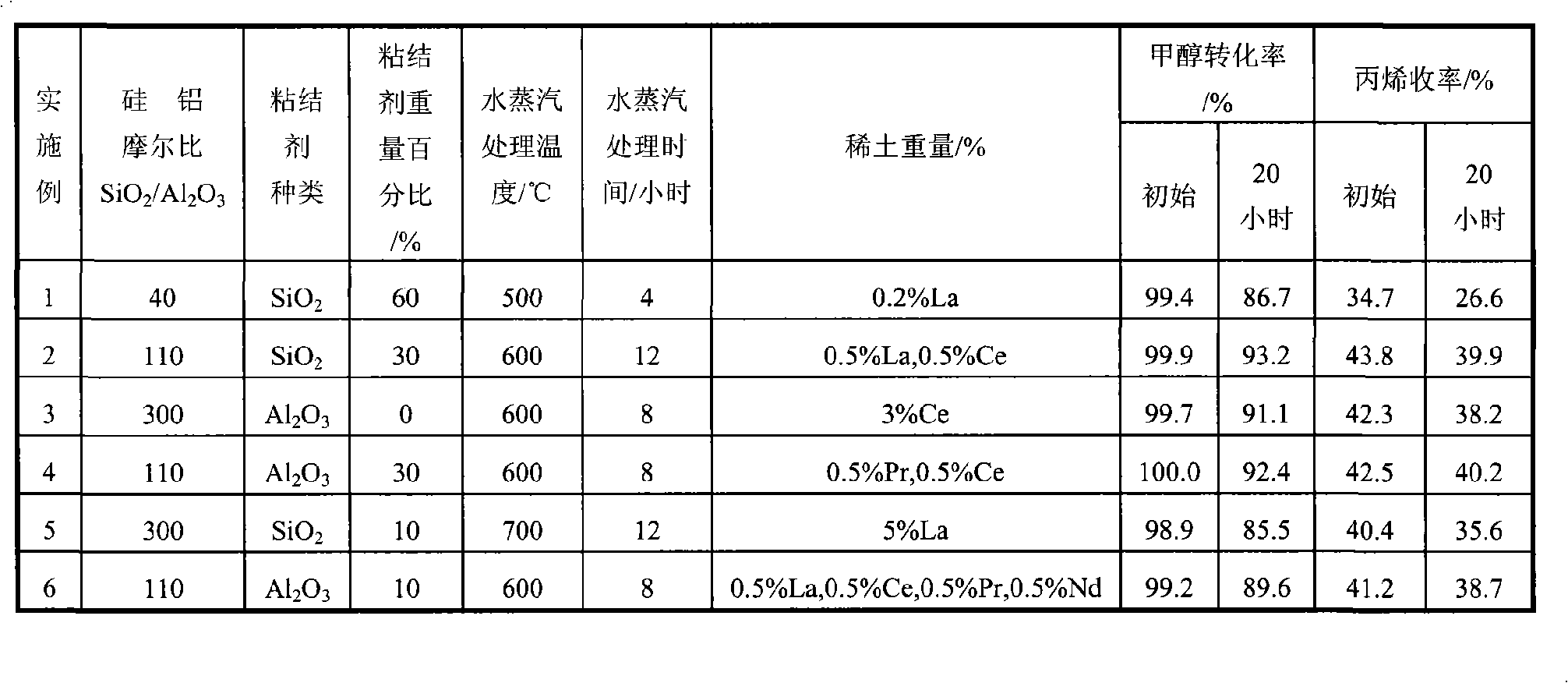

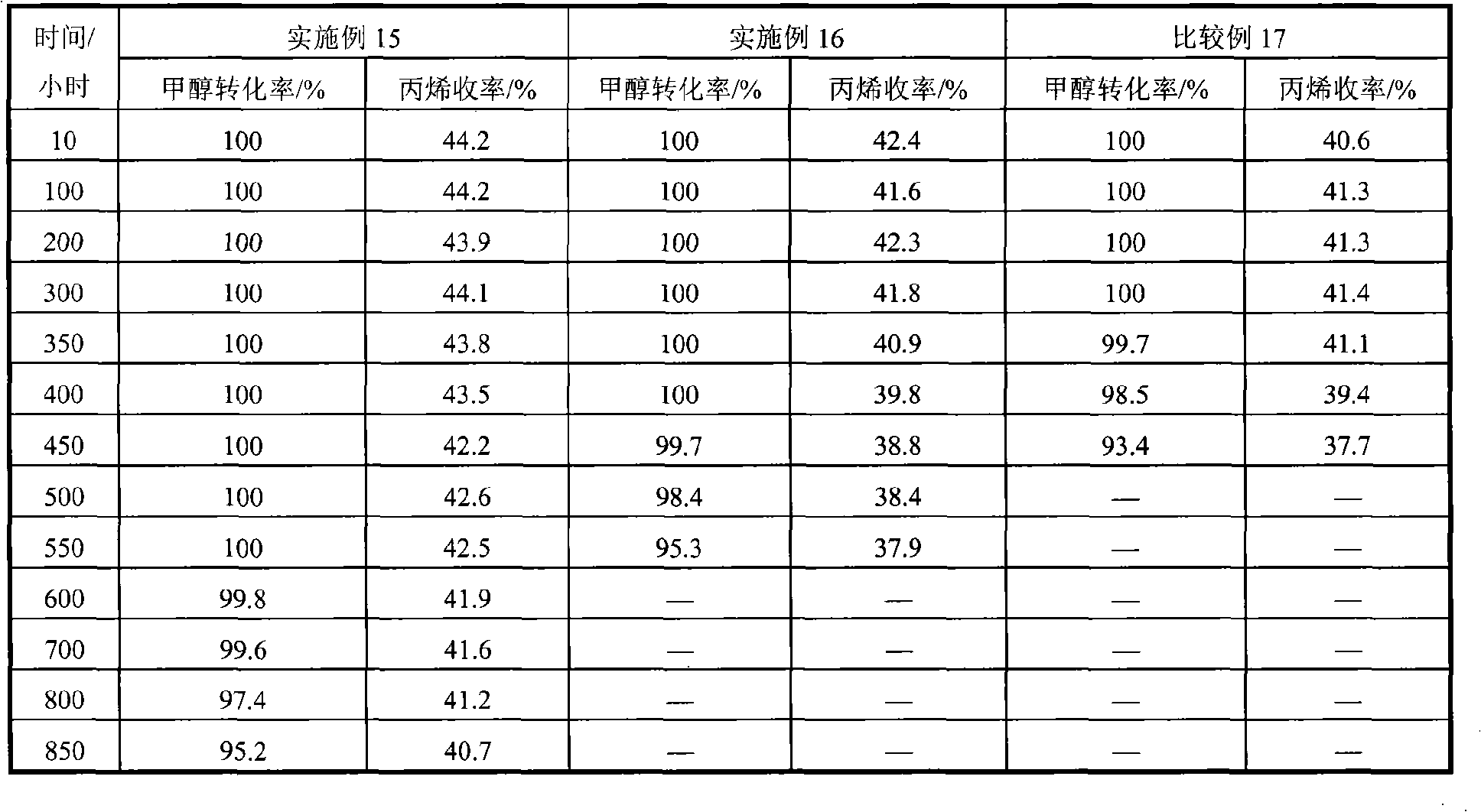

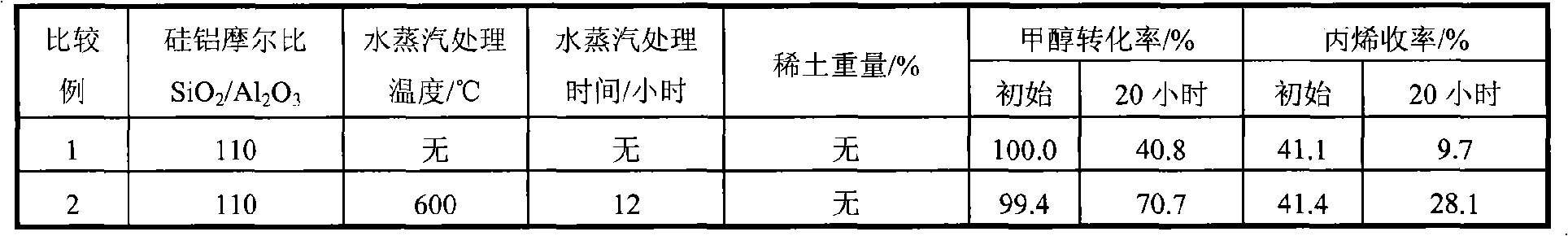

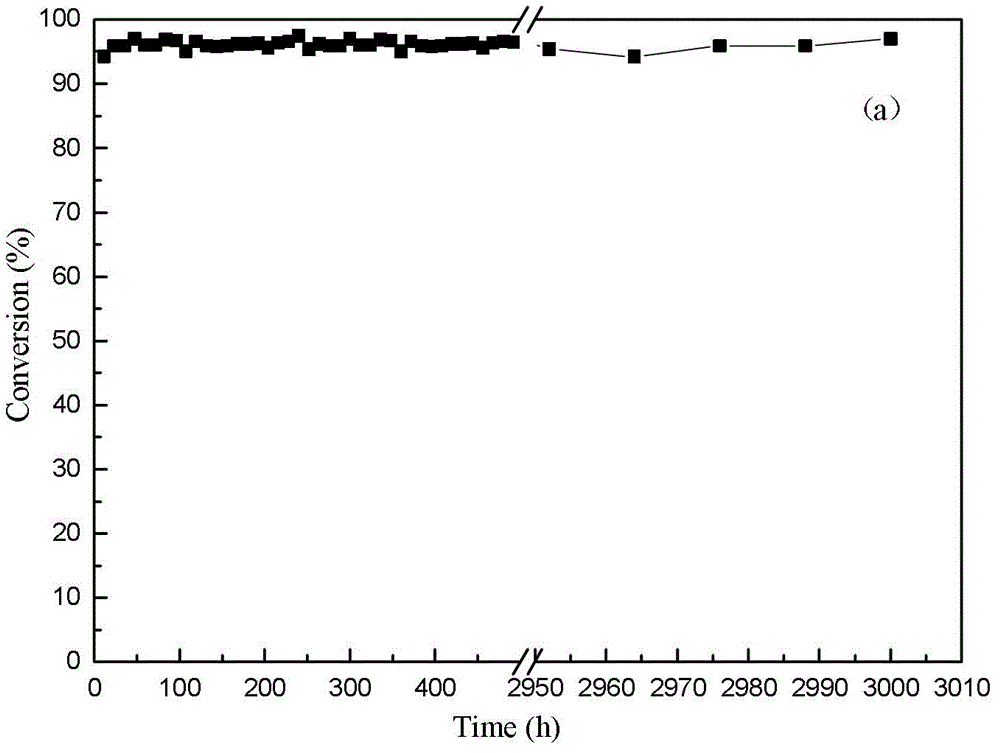

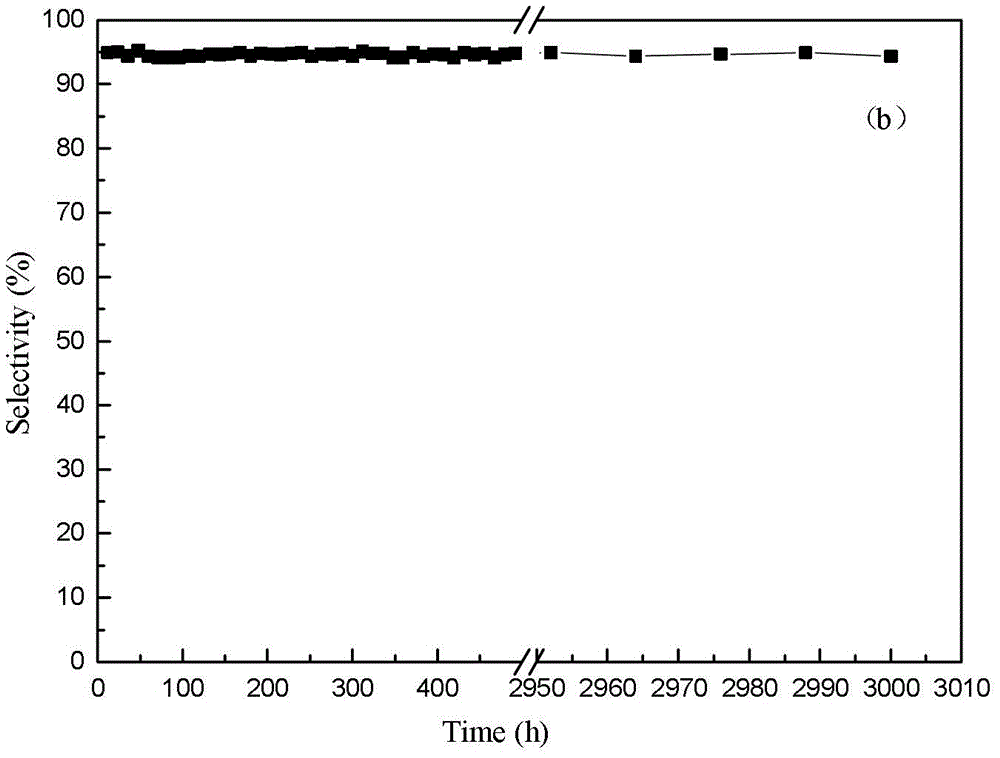

High stability molecular sieve catalyst for preparing propylene transformed from methanol and preparation thereof

ActiveCN101279281AStay acidicImprove anti-coking performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCerium nitratePhosphoric acid

The present invention relates to a high stability molecular sieve catalyst for preparing propylene by being converted from methanol and a preparation method thereof which mainly solve the problems of poor molecular sieve stability and water thermal stability as well as easy coking and deactivation in the prior art. The present invention adopts the technical proposal of adopting the molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 25 to 99.9 percent as well as at least one caking agent from SiO2, clay and Al2O3 to extrude, tablet or spray ball to shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol, phosphoric acid or acetic acid under a temperature of 20 to 90 DEG C; then using 0.1 to 5 percent of at least one liquor selected from lanthanum, cerium nitrate or chloride calculated by weight percentage to treat for 4 to 8 hours under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid, phosphoric acid and maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing alcohol through hydrogenation of acetic acid and preparation method

ActiveCN103331158AExtended service lifeImprove catalytic performanceOrganic compound preparationHydroxy compound preparationPlatinum oxidePalladium oxide

The invention discloses a catalyst for preparing alcohol through hydrogenation of acetic acid, and a preparation method of the catalyst. The catalyst is a multicomponent load catalyst and comprises ingredients a, b and c, and a carrier, wherein the ingredient a is one or more of calcium, potassium, sodium, barium, strontium, calcium oxide, potassium oxide, sodium oxide, barium oxide and strontium oxide; the ingredient b is one or more of tin, cobalt, molybdenum, nickel, iron, tin oxide, cobalt oxide, molybdenum oxide, nickel oxide and iron oxide; the ingredient c is one of platinum, palladium, ruthenium, rhodium, platinum oxide, palladium oxide, ruthenium oxide and rhodium oxide; the carrier is silicon dioxide, cerium dioxide, titanium dioxide, graphite, aluminum oxide or active carbon; and the mass ratio of the ingredient a to the ingredient b to the ingredient c to the carrier is (1-20):(0.5-2):(0.5-1):100. The multicomponent load catalyst is prepared by a multistep impregnation method, and used for preparing alcohol through the hydrogenation of acetic acid, and results prove that the catalyst is excellent in catalytical performance, long in service life and high in reaction stability.

Owner:SHANGHAI HUAYI GRP CO

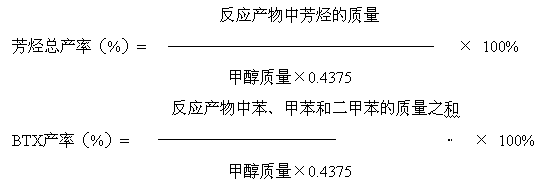

Method for improving the selectivity and reaction stability of arene prepared in methanol aromatization manner

InactiveCN103288582AThe production is conducive toHigh yieldHydrocarbon from oxygen organic compoundsBulk chemical productionMolecular sievePtru catalyst

The invention relates to a method for improving the selectivity and reaction stability of an arene product prepared in a methanol aromatization manner, and is used for preparing the arene in the methanol aromatization manner through the catalysis of a molecular sieve under the action of a carbon dioxide reaction medium. The method comprises the following steps: under the action of the carbon dioxide medium, by taking methanol as a raw material, preparing the arene in the methanol aromatization manner through a molecular sieve based catalyst containing a metal additive under the conditions that the reaction temperature ranges from 340 to 540 DEG C, the methanol reaction airspeed is maintained for 0.1 to 5.0 hours, the reaction pressure ranges from 0.1 to 5.0MPa and the molar ratio of the carbon dioxide to the methanol is 0.5-5.0 (mol / mol). According to the method, a large quantity of excess greenhouse gases, namely the carbon dioxide, serve as the reaction medium; the molecular sieve containing the metal additive serves as the catalyst, so that the selectivity and reaction stability of the arene in a methanol aromatization product are improved effectively. Thus, the method meets the requirement of an industrial application basically.

Owner:TONGJI UNIV

Preparation method of alcohol aromatization catalyst

InactiveCN104841473AImprove diffusion abilityInhibit carbon depositionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsChemistryCarrying capacity

The invention provides a preparation method of an alcohol aromatization catalyst. The preparation method comprises treating a carrier ZSM-5 by acid or alkali so that ZSM-5 aperture sizes are increased, removing organic matter impurities on the carrier surface so that carrier surface purity is improved and hydroxyl-rich mesoporous HZSM-5 is obtained, putting the mesoporous carrier into a reaction chamber of an atomic layer deposition (ALD) device, and coating the surface of the carrier with one or more metal or metal oxide nanometer particles layer by layer by an ALD method. Through control of a reaction chamber substrate temperature, a metal source gasification temperature and unit circulating for repeating atomic layer deposition, catalyst metal carrying capacity and acidity are regulated and controlled. The alcohol aromatization catalyst has accurately controllable catalytic material carrying capacity and high carrier tunnel conformality, effectively inhibits catalyst carbon formation, sintering and active metal seepage, and further realizes alcohol aromatization reaction activity improvement and better reaction stability.

Owner:SOUTHEAST UNIV

Process for preparing ethylene glycol by ethylene oxide catalytic hydration

InactiveCN1566050AGood hydrothermal stabilityReactiveOrganic compound preparationHydroxy compound preparationThermal energyHydration reaction

The invention relates to a process for preparing ethylene glycol by ethylene oxide catalytic hydration, wherein the solid acid catalyst employs niobium compounds as the main active components, at least one of germanium, tin, lead, antimony, phosphor, sulfur, ferrum and cobalt is used as the auxiliary agent for preparing ethylene alcohol at rather low water ratio conditions, the thermal energy needed for processing reacting excess water can be reduced substantially, the catalyst used possesses not only good activity, selectivity, but also fine steadiness.

Owner:CHINA PETROLEUM & CHEM CORP +1

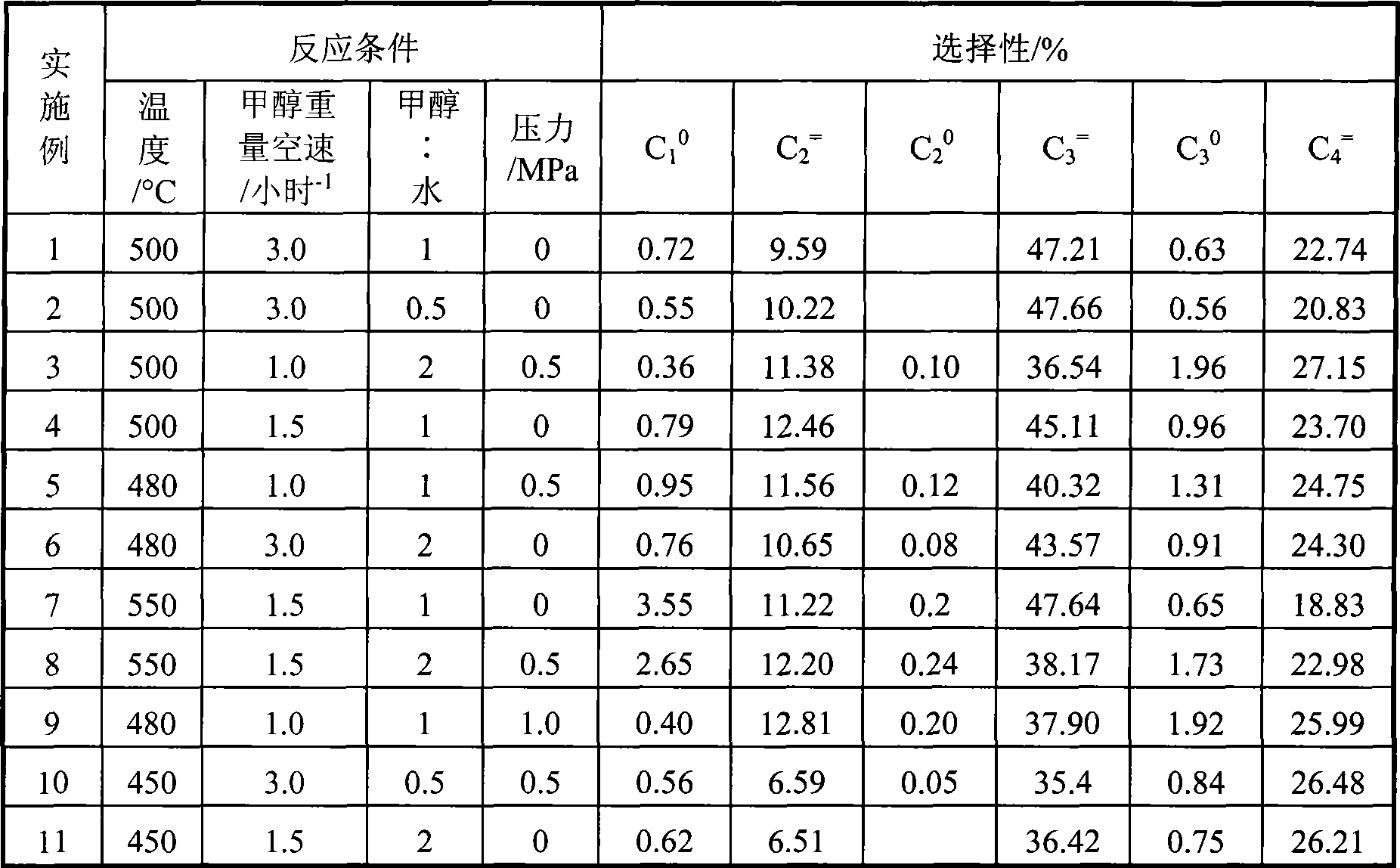

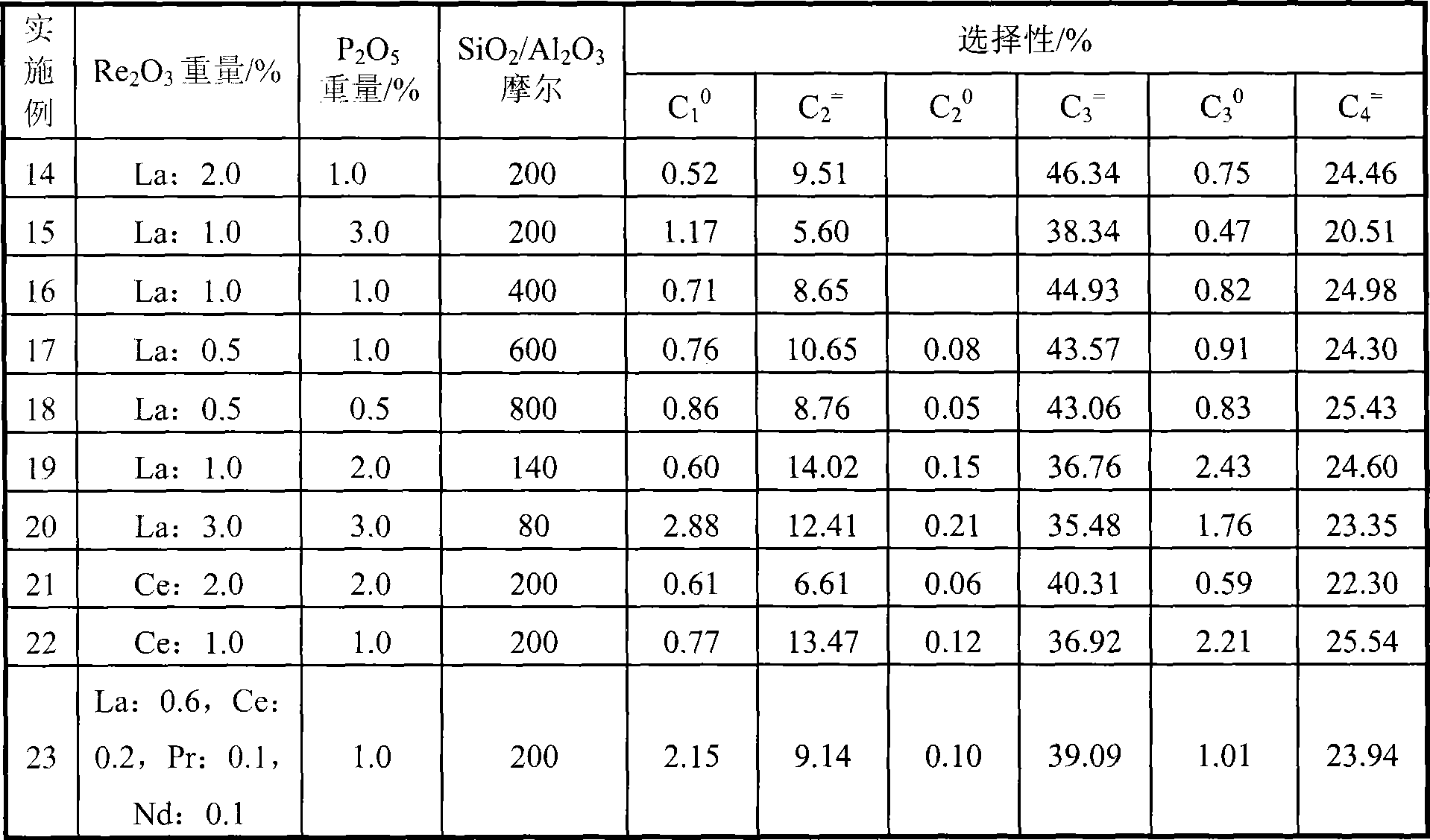

Method for producing propylene, ethylene light olefin hydrocarbon

ActiveCN101429085ARaise the ratioImprove reaction stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveReaction temperature

The invention relates to a method for producing propylene and ethane light olefin by using methanol and / or dimethyl ether as raw materials so as to mainly solve the problems of poor high temperature hydrothermal stability and quick inactivation of a catalyst in the prior reaction process. The method well solves the problems through adopting the technical proposal of using reaction conditions of a molecular sieve containing rare earth and phosphorous oxides as catalysts, at a temperature of between 350 and 650 DEG C, at a pressure of between minus 0.05 and 1.0MPa, according to the weight space velocity of the methanol and / or the dimethyl ether of between 0.2 and 20 hours<-1>, and the weight ratio of water and raw materials of between 0 to 1 and 5 to 1. The method can be used in industrial production of light olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

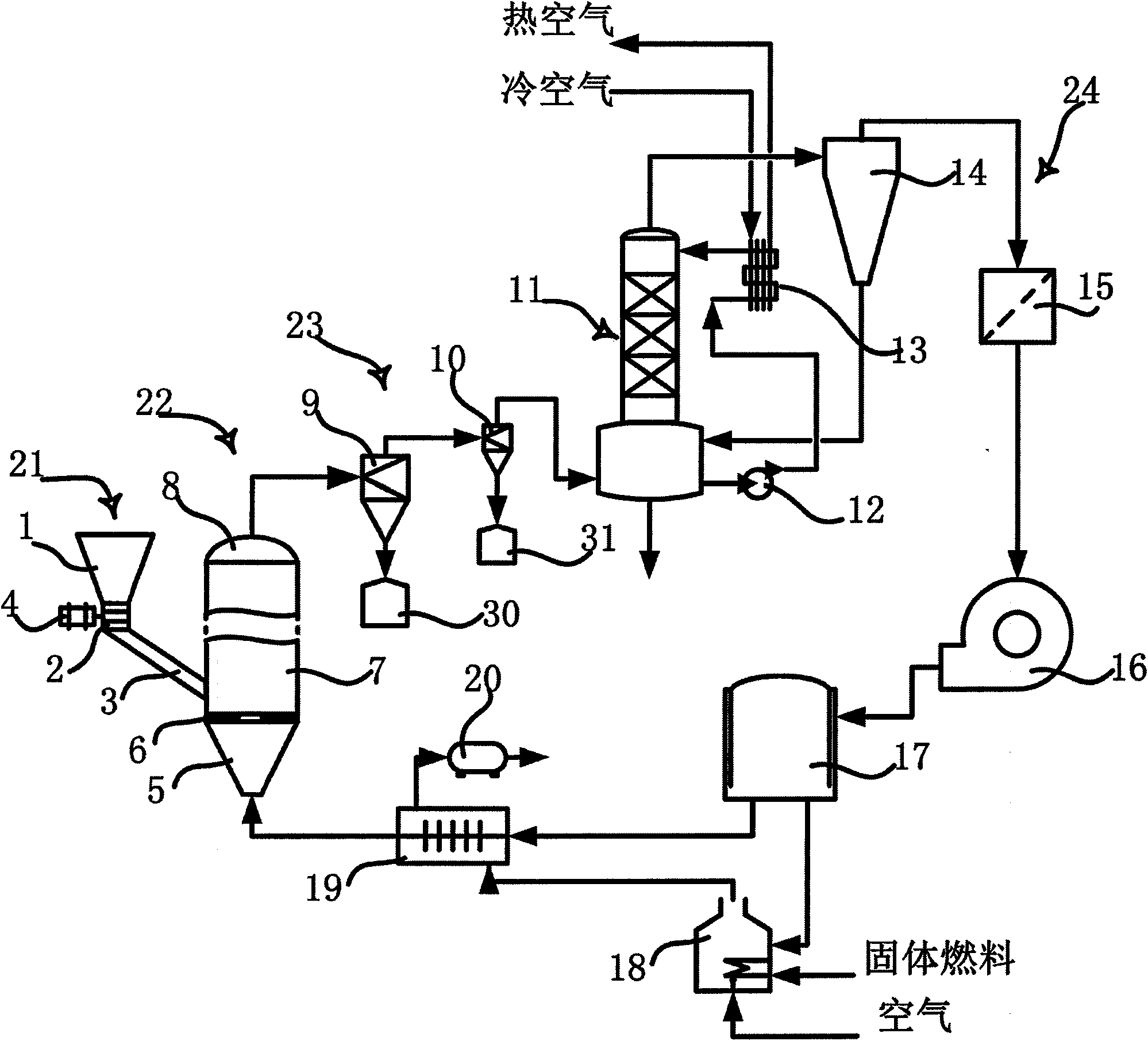

Miniature movable type agricultural and forest biomass fast pyrolysis device

InactiveCN101671570AHeight adjustableAdjust process parametersBiofuelsLiquid hydrocarbon mixture productionCombustionBuffer tank

The invention discloses a miniature movable type agricultural and forest biomass fast pyrolysis device. The device comprises a traveling mechanism (25), a combustion furnace (18), a feeder (21), a fast pyrolysis reactor (22), a gas solid separator (23), a gas condenser (11), a non-condensable gas purifier (24), a fan (16), a gas buffer tank (17) and a gas preheater (19); the height of the fast pyrolysis reactor (22) can be adjusted, the device can be suitable for various agricultural and forest biomass raw materials, and the fluidization quality in the reactor is better due to the arrangementof an inverted-cone-shaped gas flow stabilizer in a top cover of the reactor; the non-condensable gas is taken as gas sources of spouting gas and fluidized gas and heat supply fuel, the entire deviceis simple in structure, small in volume and stable in running, can be hauled to the agricultural and forest biomass for production intensively and has lower production cost; the small-scale movable type operating mode also avoids the problem that the industrial enlargement of a fluid bed reactor is not easy; and the industrial production of agricultural and forest biomass fast pyrolysis is realized in a disguised form.

Owner:BEIJING FORESTRY UNIVERSITY

Catalyst used for hydrating epoxy ethane to prepare ethandiol

ActiveCN100413579CHigh activityHigh selectivityPreparation by hydroxy group additionMetal/metal-oxides/metal-hydroxide catalystsEpoxyHydration reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

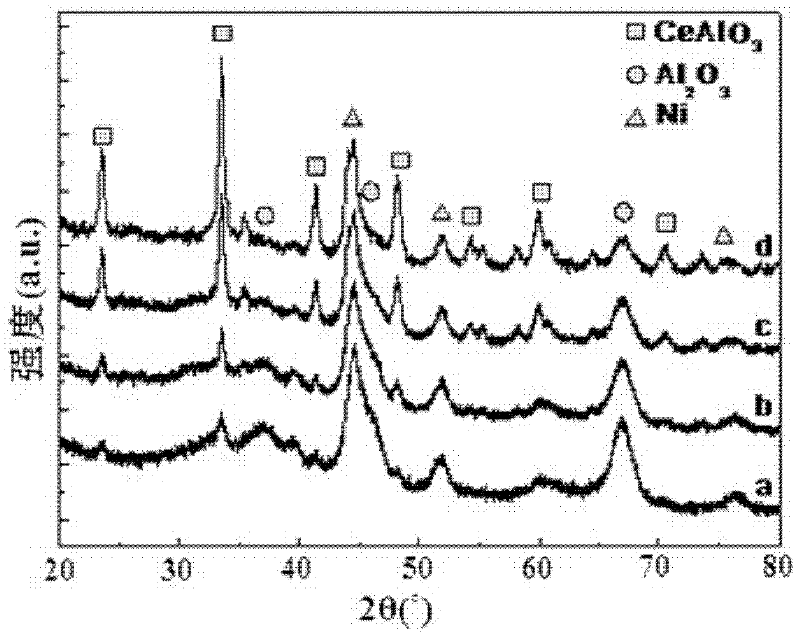

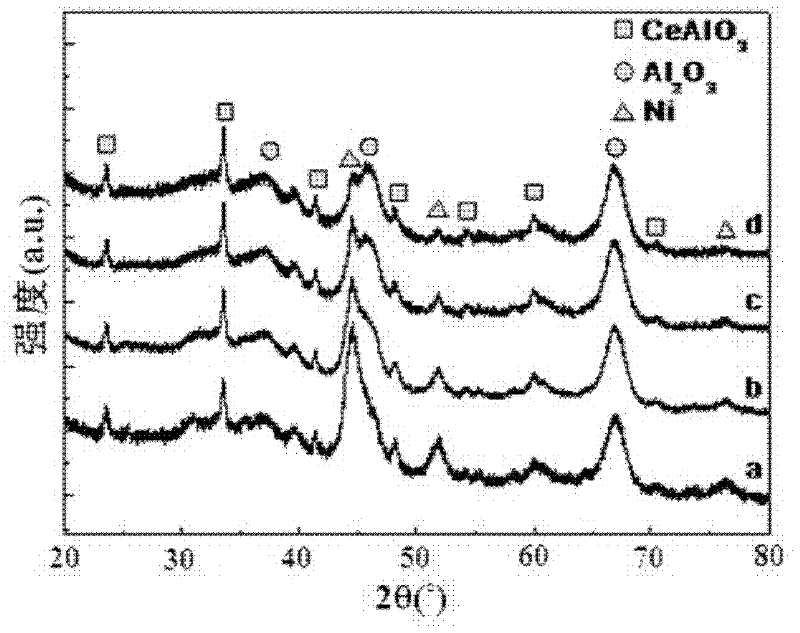

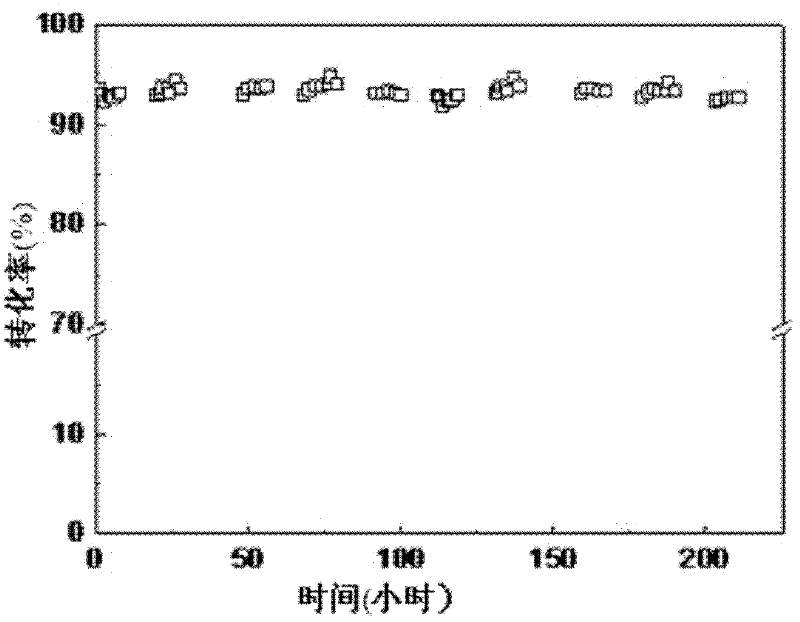

Nickel-based catalyst as well as preparation method and application thereof

InactiveCN102335609AStrong ability to resist carbon depositionHigh reactivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereSyngas

The invention discloses a nickel-based catalyst as well as a preparation method and application thereof. The nickel-based catalyst has the following structural general formula: xNi.yCeAlO3.(100-x-y) Al2O3, wherein 1<=x<=20, 1<=y<=30. The catalyst is prepared by the following steps of: firstly, impregnating dried gamma-Al2O3 in a ceric salt solution at room temperature by using an incipient-wetness impregnation method, drying and roasting at the air atmosphere to obtain a modified carrier; then impregnating the modified carrier obtained at room temperature in a nickel salt solution by using the incipient-wetness impregnation method, drying and roasting at the air atmosphere to obtain a catalyst precursor; and finally, reducing the obtained catalyst precursor in hydrogen gas at 850-1050 DEGC. The catalyst provided by the invention has the advantages of strong coke resistance, good reaction stability and heat stability, high chemical and structural stability and the like and can be usedas the catalyst for preparing synthesis gas from methane.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com