Propenyl phenoxy compounds with three-branch aromatic structure and preparation method thereof, and bismaleimide resin modified by propenyl phenoxy compounds

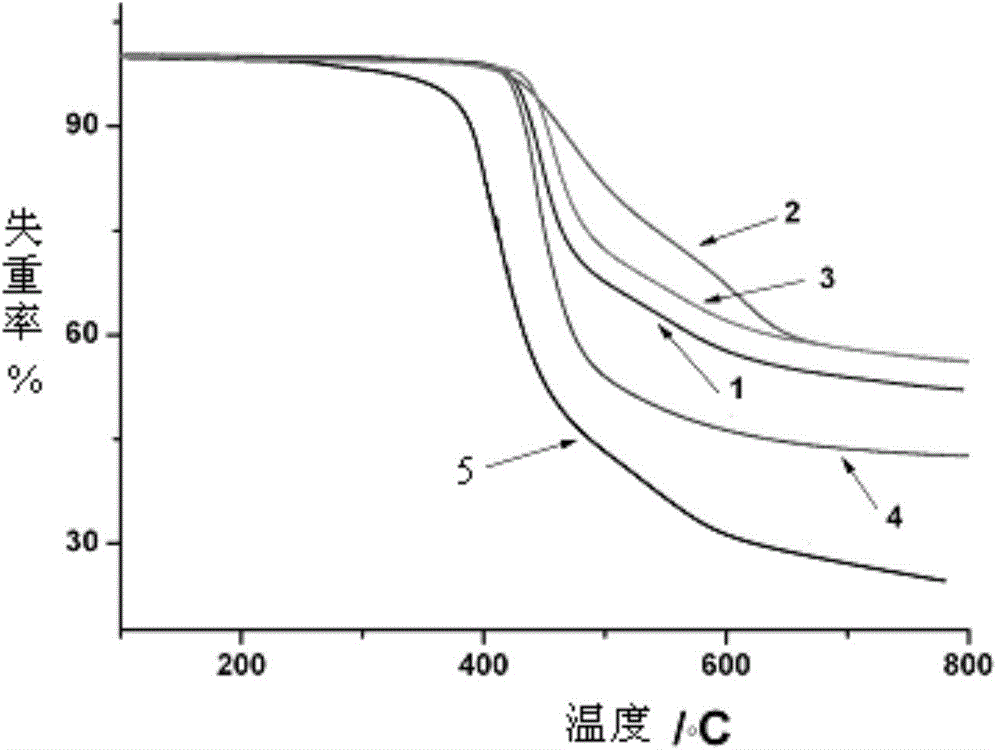

A technology of bismaleimide resin and propylene phenoxy, which is applied to the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of poor thermal aging, high curing temperature and post-curing temperature problem, achieve the effect of small mass loss, reduce curing reaction temperature and time, and increase crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025]Specific embodiment 1: The general structural formula of a three-branched aromatic structure propenylphenoxy compound in this embodiment is:

[0026]

[0027] The R 1 for

[0028] The R 2 -H, -CH 3 、-OCH 3 or -CF 3 .

[0029] The propenylphenoxy compound of the three-branched aromatic structure in this specific embodiment is mainly tris(2-propenyl-5-methoxyphenoxy-4'-benzoyl)benzene, and its structural formula is:

[0030]

specific Embodiment approach 2

[0031] Embodiment 2: The preparation method of a three-branched aromatic structure propenylphenoxy compound described in this embodiment is carried out according to the following steps:

[0032] Mix the trifunctional fluoroketone and allylphenol to obtain the mixture, then add the mixture and the catalyst to the solvent, then raise the temperature of the reaction system to 150°C-205°C, and reflux at 150°C-205°C for 5h-8h , to obtain a crude product, filter the crude product, add ice water dropwise to the filtrate to cool the filtrate to a temperature of 0°C to 5°C, and precipitate at a temperature of 0°C to 5°C for 3h to 5h, finally filter and wash with water until The pH value of the washing solution is neutral, and the washed product is dried to obtain an alkenylphenoxy compound with a three-branched aromatic structure;

[0033] The molar ratio of the trifunctional fluoroketone to allylphenol is 1:(3~3.8); the molar ratio of the trifunctional fluoroketone to the catalyst is ...

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the trifunctional fluoroketone is

[0035]

[0036] The allyl phenol is Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com