Patents

Literature

105results about How to "Gentle preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

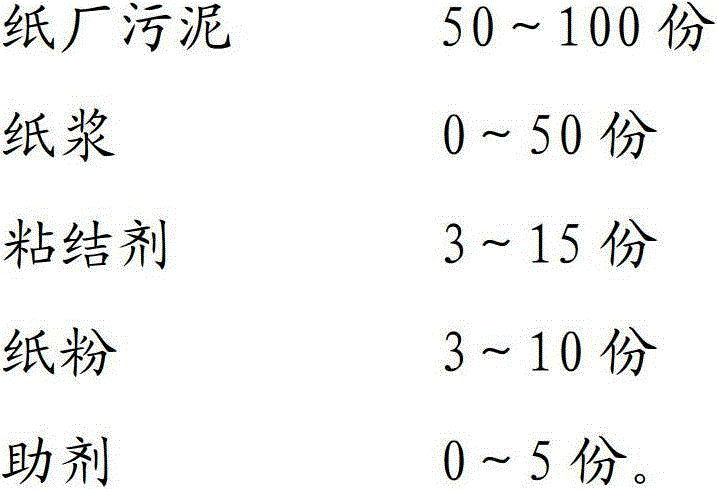

Cat litter for pets and preparation method of cat litter

The invention relates to the technical field of articles for pet garbage cleaning, in particular to cat litter for pets and a preparation method of the cat litter. The cat litter for pets comprises the following ingredients in parts by weight: 50 to 100 parts of paper plant sludge, 0 to 50 parts of paper pulp, 3 to 10 parts of bonding agents, 3 to 5 parts of paper dust and 0 to 5 parts of auxiliary agents, wherein the paper fiber length in the paper pulp is 1.5 to 3mm, and the paper fiber length in the paper dust is 0.5 to 1.5mm. The cat litter for pets has the advantages that the specific gravity is light, the adsorption capacity is high, the caking effect is good, the processing is easy, the environment protection is excellent, and in addition, the cost is low. The flow process of the preparation process of the cat litter is continuous, the time is saved, during the raw material stirring homogenization and granulation, the process is mild, and the operation is easy.

Owner:朱群

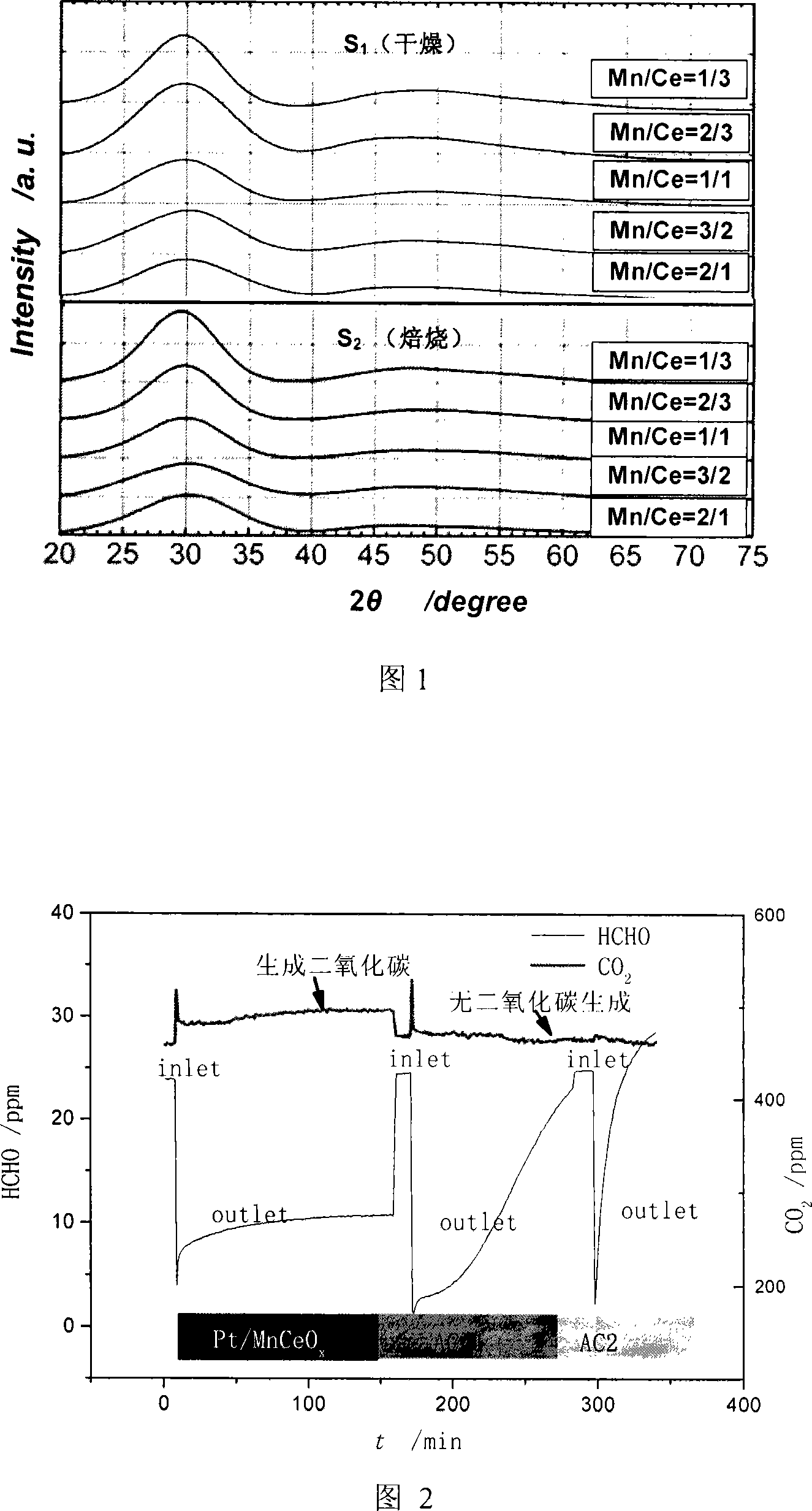

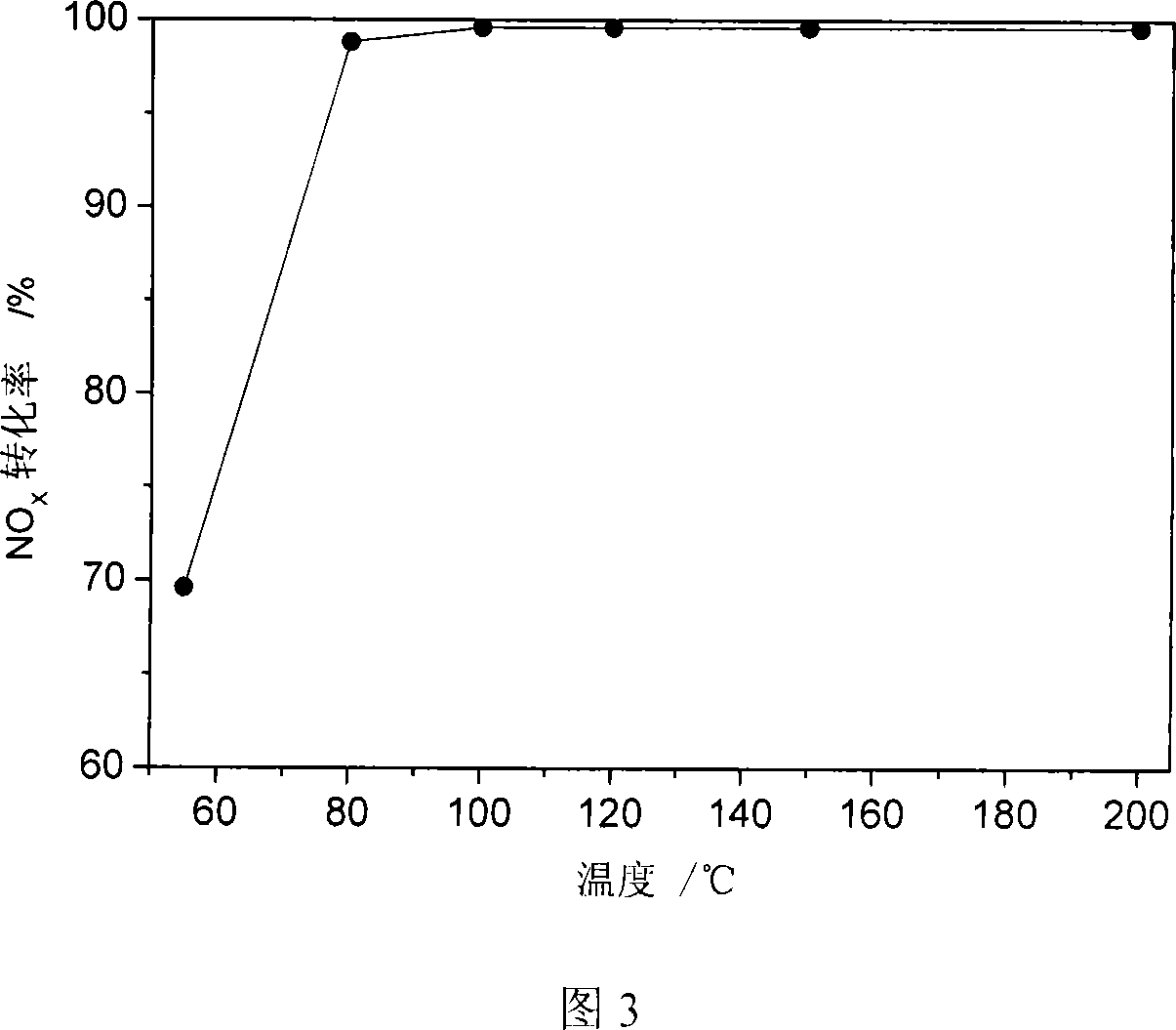

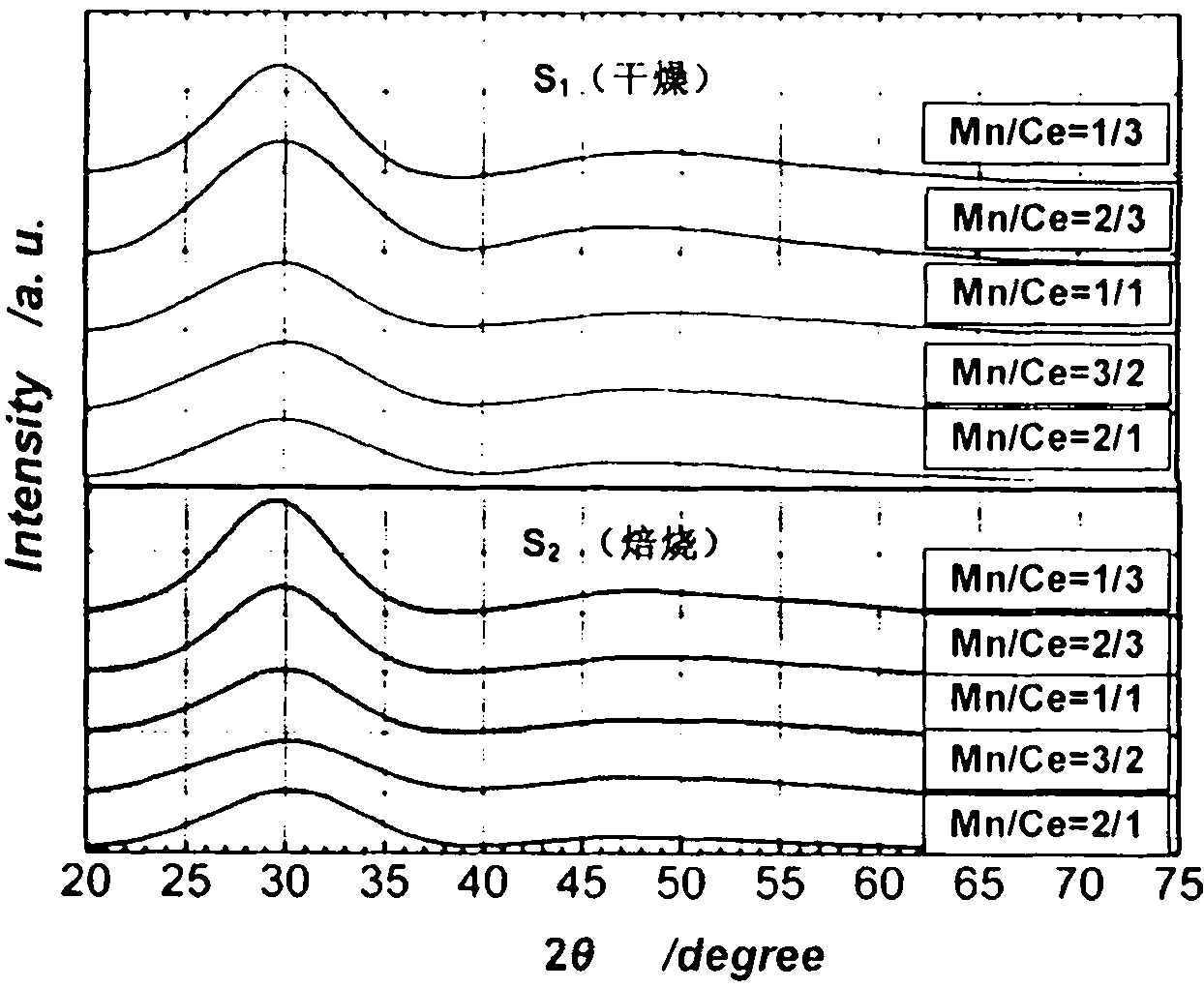

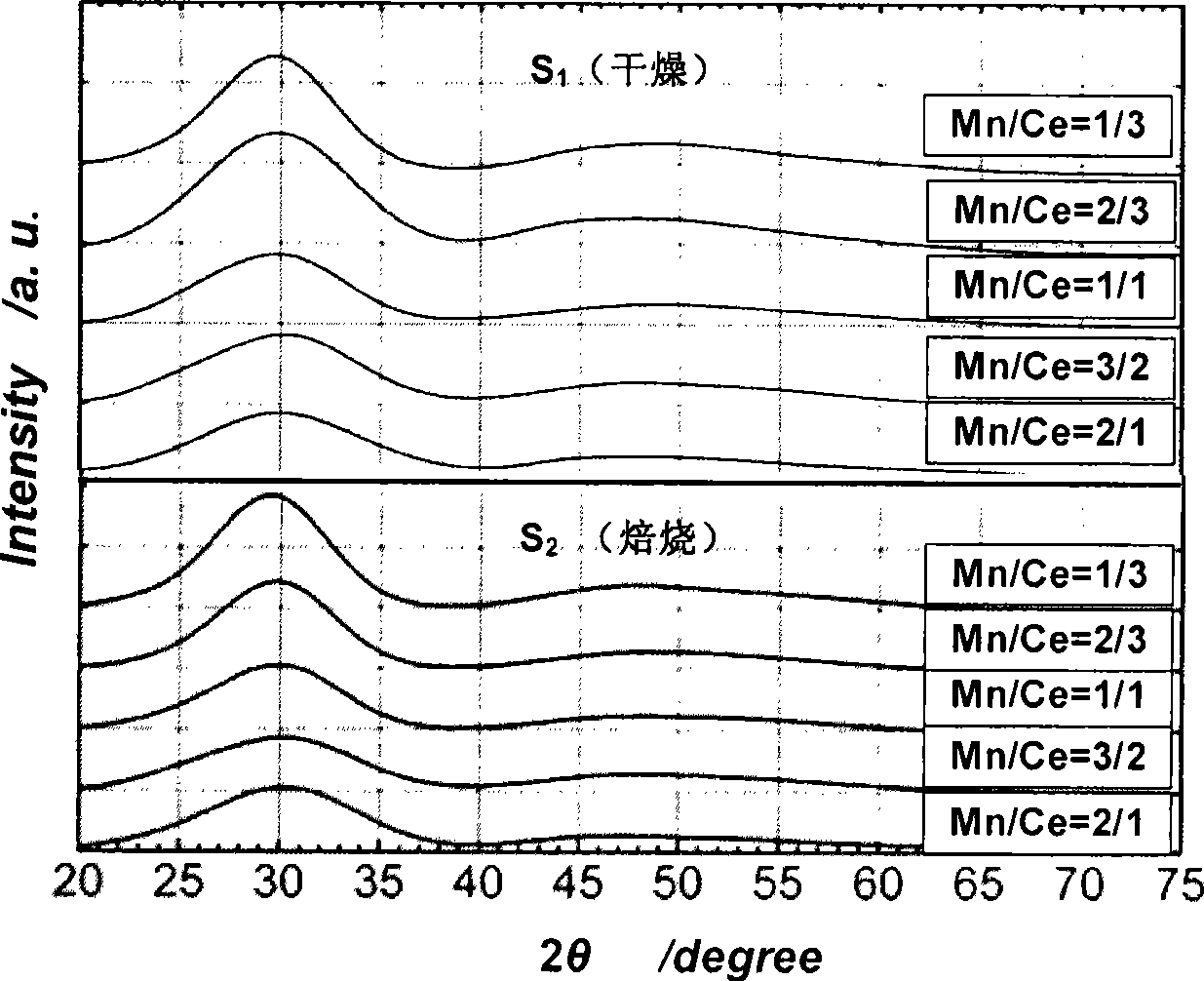

High-dispersion manganese-cerium composite oxides and preparation method thereof

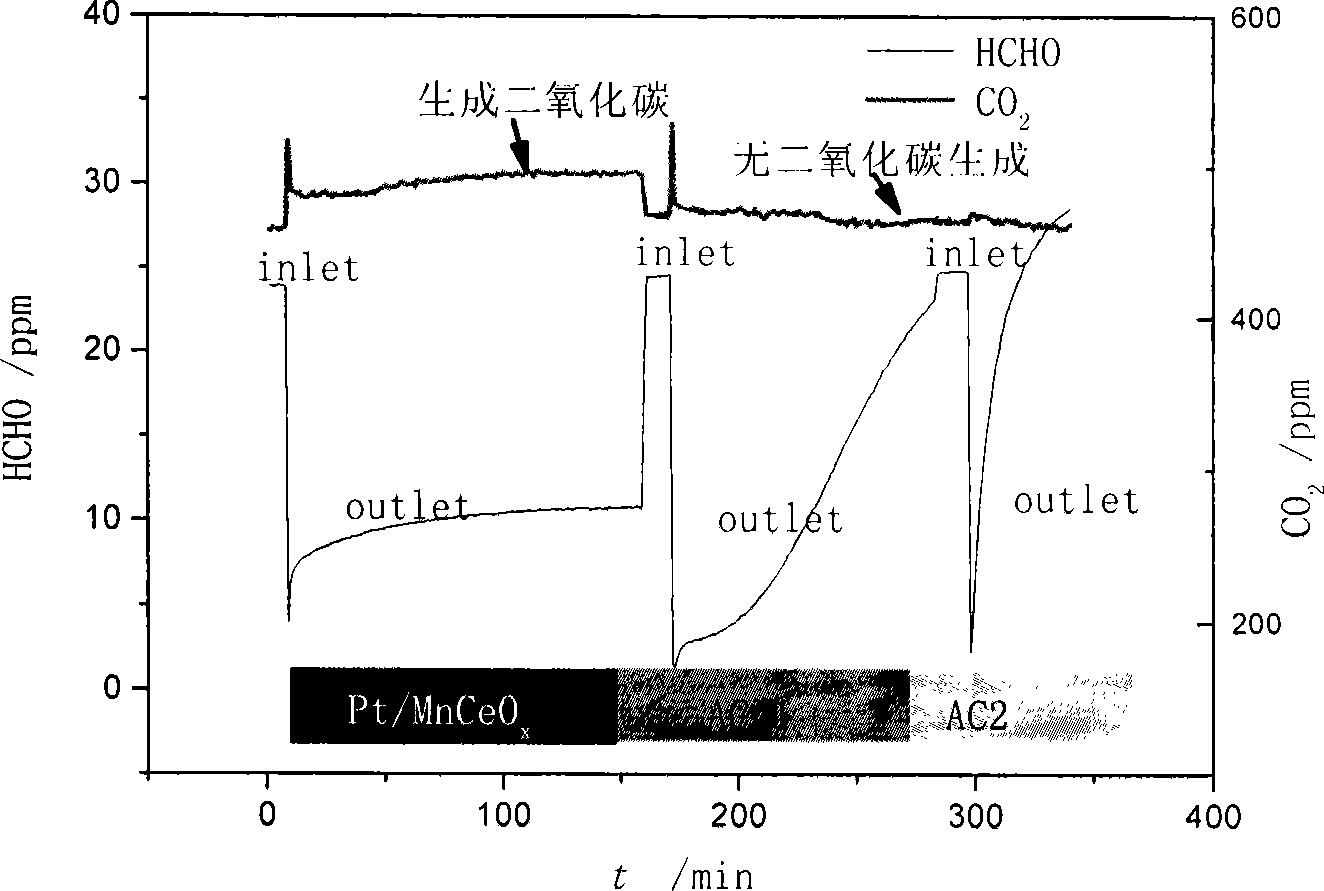

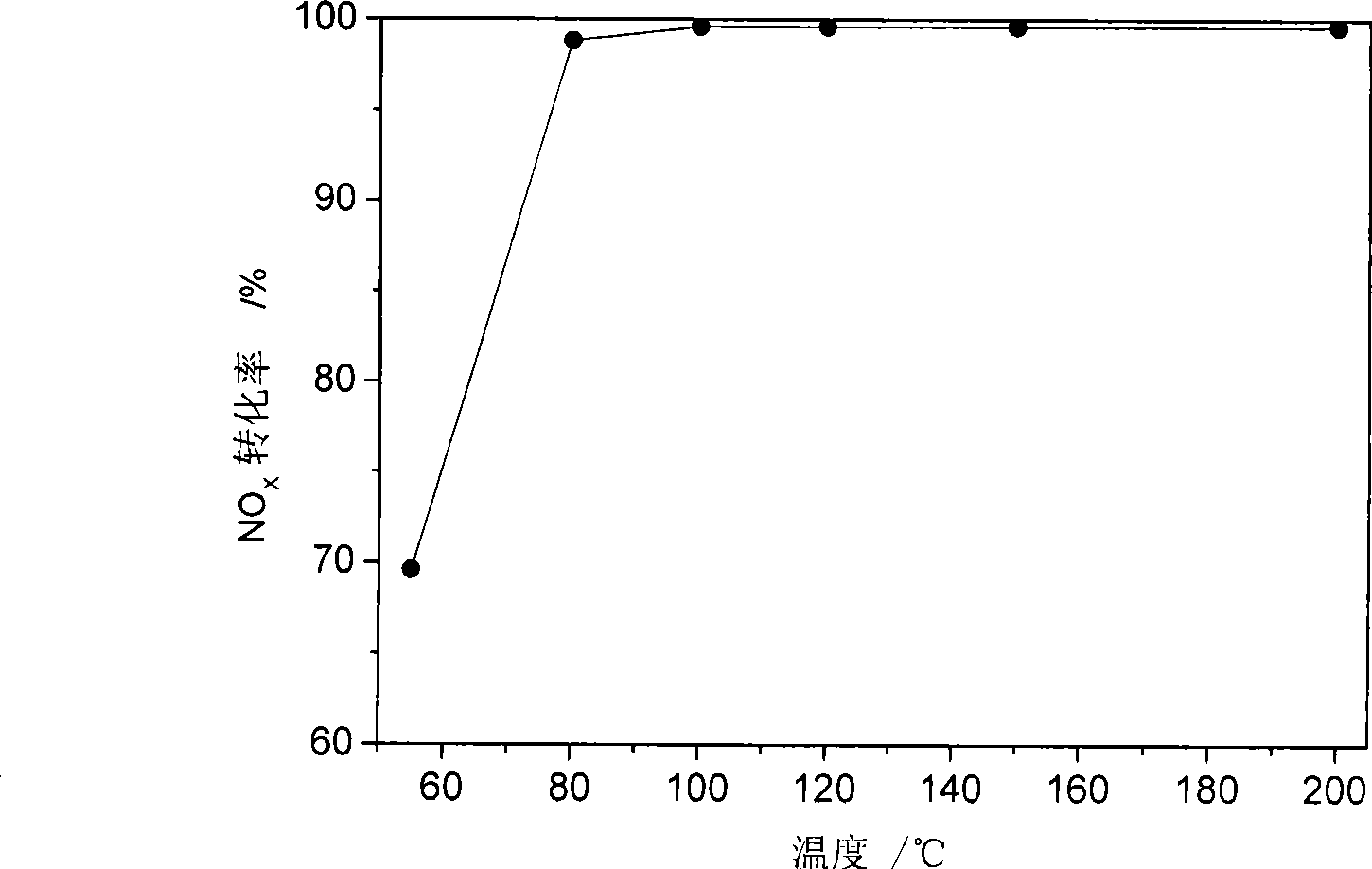

ActiveCN101462049AGentle preparation processGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention discloses manganese-cerium composite oxide, which is prepared in one step through the oxidation reduction-precipitation process among Mn<VII>, Mn<II> and Ce<III> ions, wherein components, namely MnO2 and CeO2 of the manganese-cerium composite oxide have high dispersion on a near molecular scale, the mol ratio of Mn to Ce is randomly adjusted, and the composite oxide has good oxidation reduction and oxygen affinity. As a catalyst carrier of reactions of formaldehyde oxidation at room temperature and low-temperature selective catalytic reduction of nitrogen oxide, the use of the composite oxide can ensure that a catalyst has higher activity, and the stability of the composite oxide is more superior to those of other carriers.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

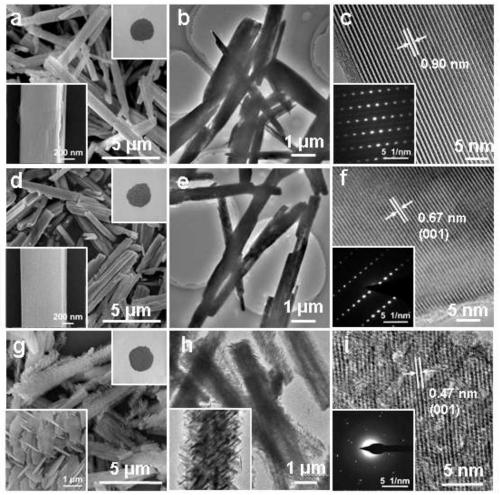

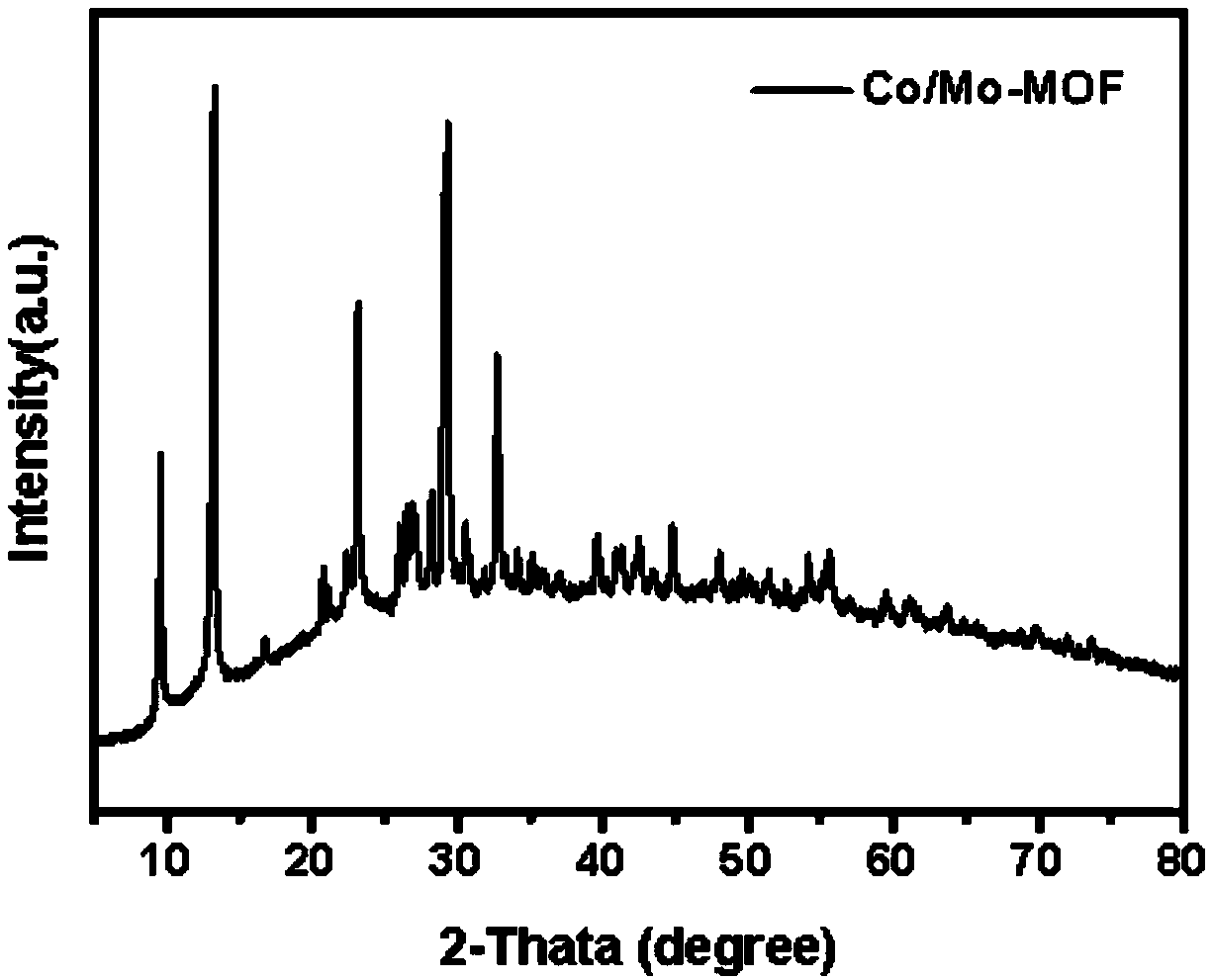

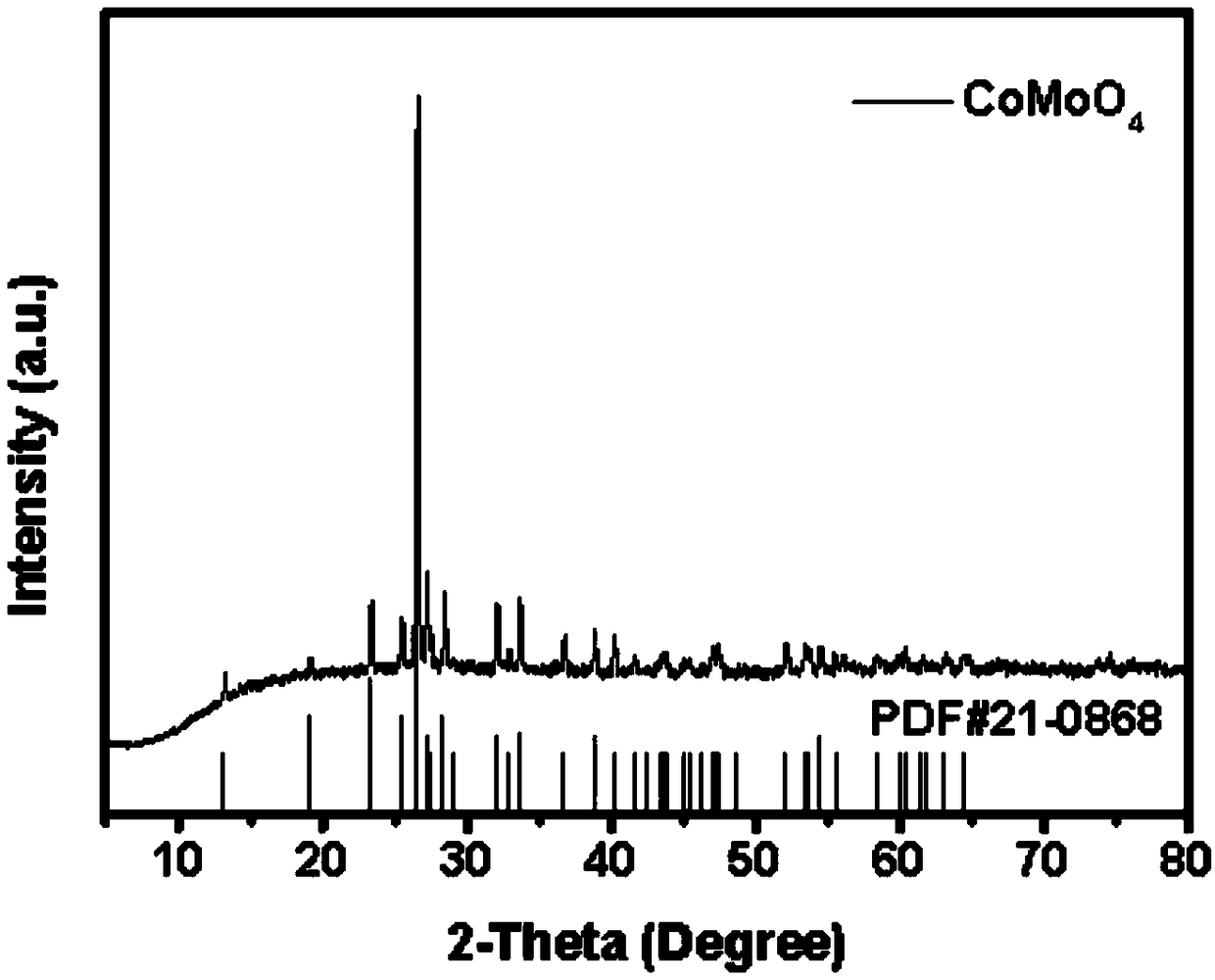

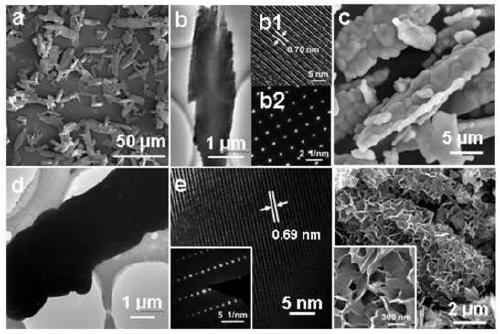

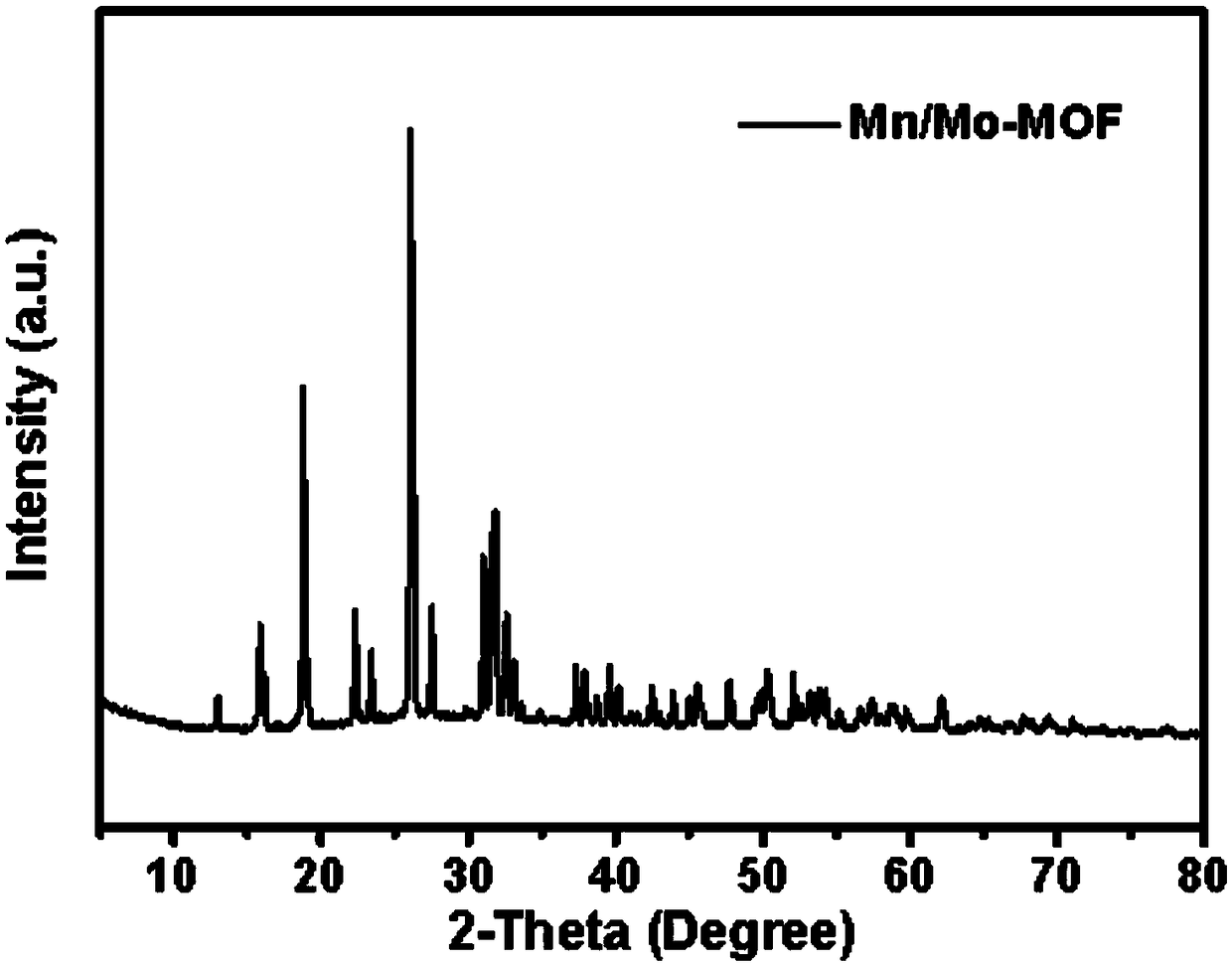

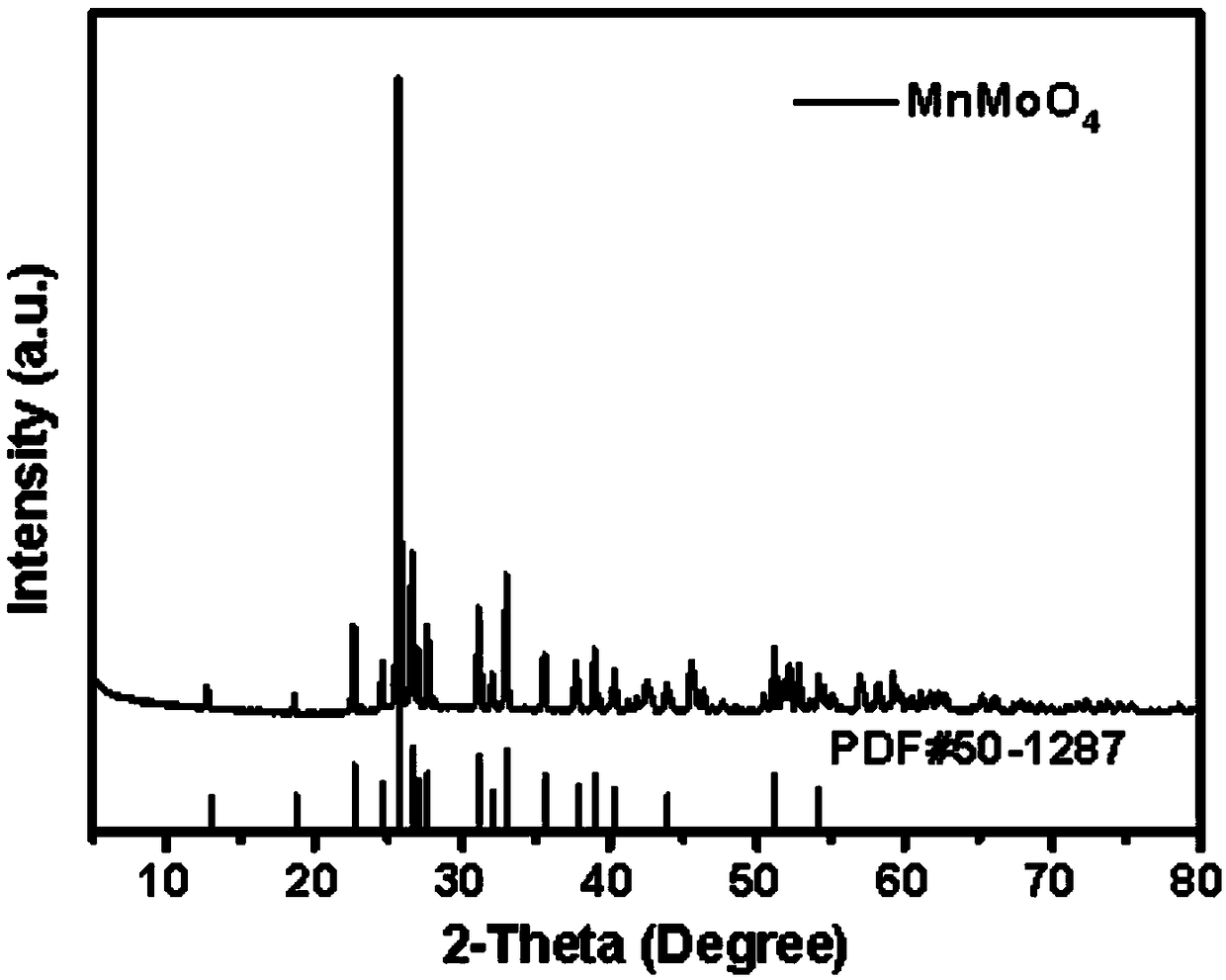

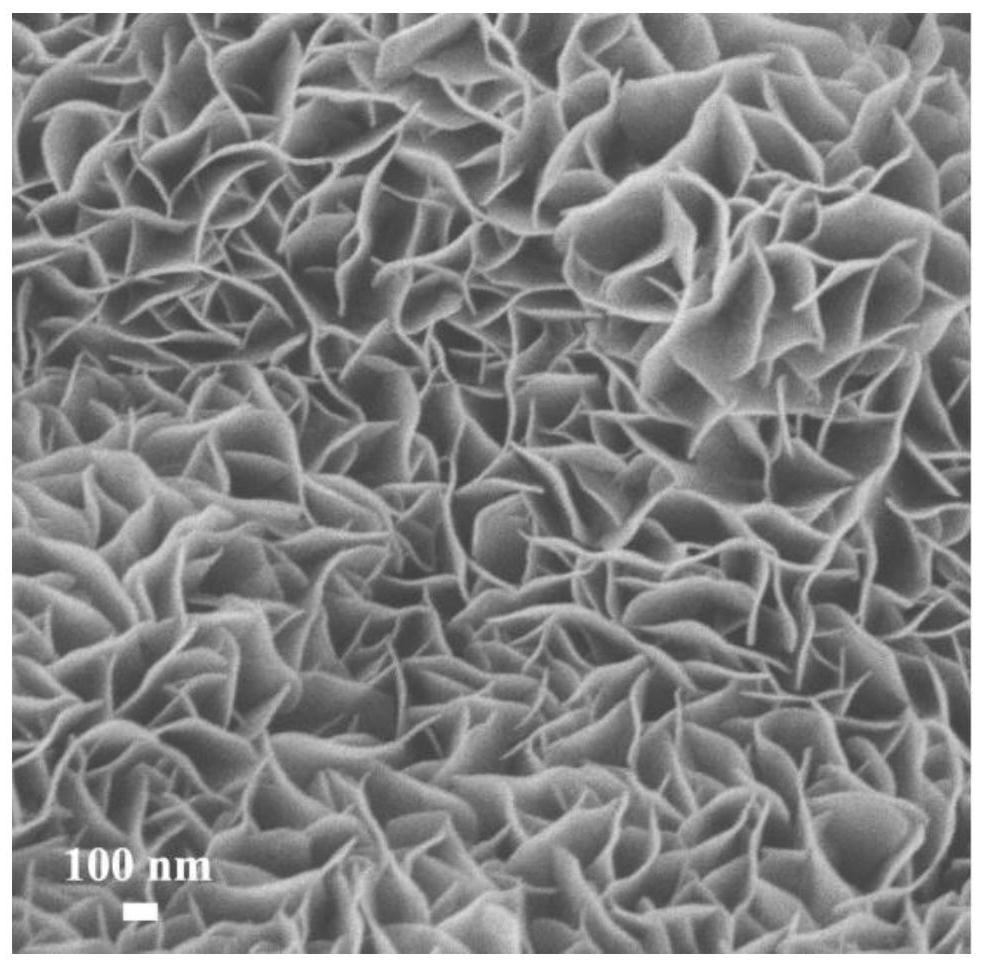

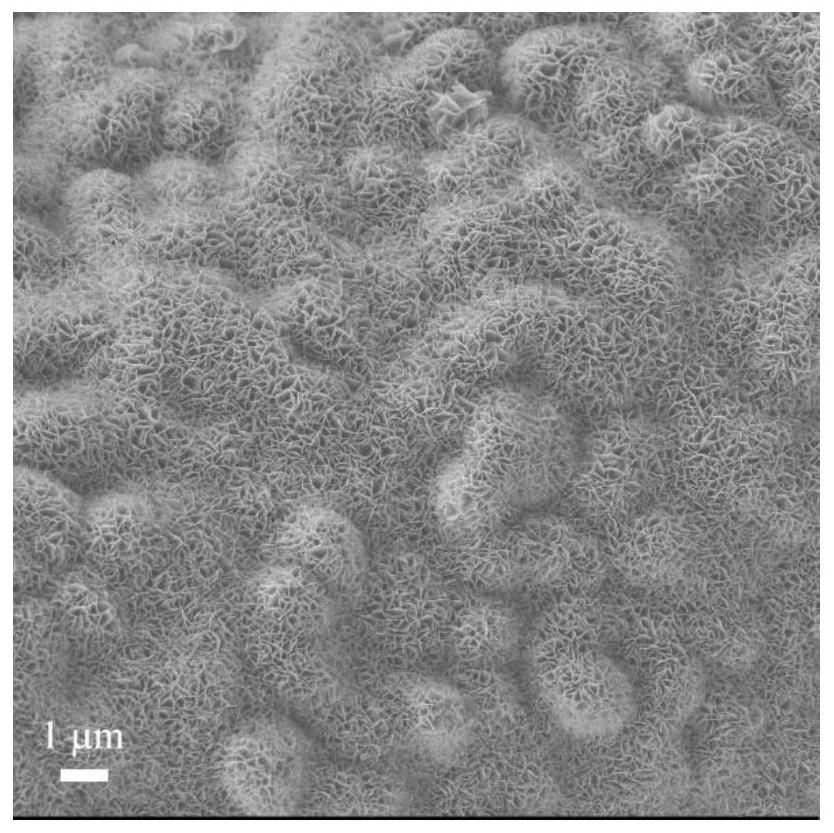

Method for preparing metal hydroxide multi-stage structure through MOF derivative bimetallic oxide template

ActiveCN109133193ASimple preparation processGentle preparation processNickel oxides/hydroxidesCobalt oxides/hydroxidesSURFACTANT BLENDMetal hydroxide

The invention relates to the technical field of nanometer materials, in particular to a method for preparing a metal hydroxide multi-stage structure through an MOF derivative bimetallic oxide template. Alkali treatment is conducted on the MOF derivative bimetallic oxide template to obtain the metal hydroxide multi-stage structure, M is set into metal in the metal hydroxide multi-stage structure, the MOF derivative bimetallic oxide template is set into MMoO4-MOF derivative bimetallic oxide, and the metal hydroxide multi-stage structure is M(OH)x. The method is simple, mold and universal in preparing process, has no special requirements for equipment, does not use surfactants, and can conduct large-scale industrial production; the metal hydroxide multi-stage structure prepared through the method is uniform in size, stable in structure and even in component distribution and has excellent OER performance and constant-current stability.

Owner:ZHEJIANG UNIV OF TECH

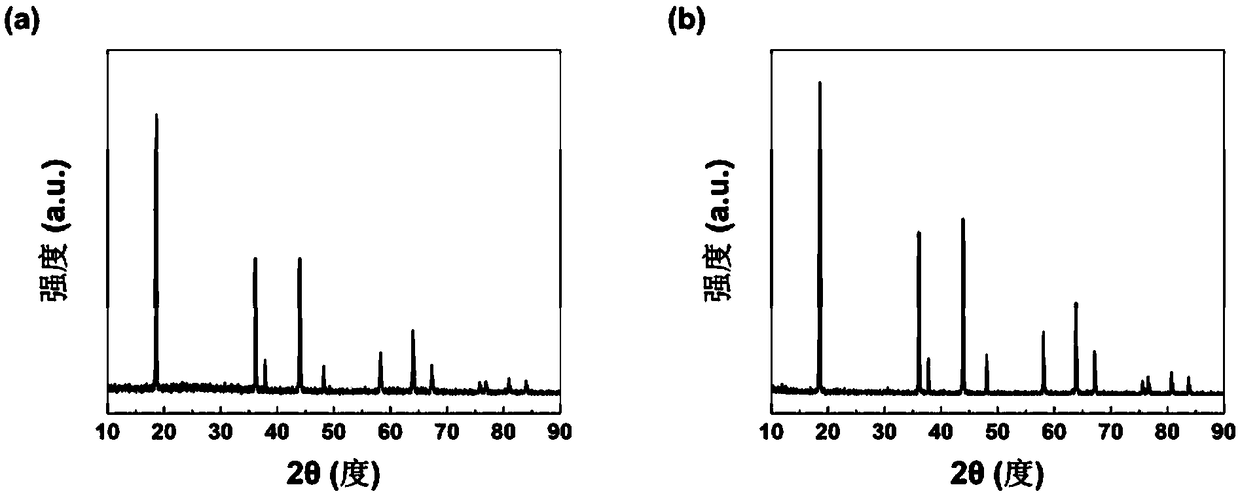

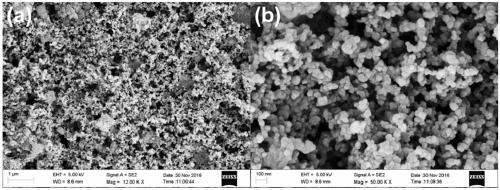

Preparation method of graphene-supported stannic oxide quantum dot negative electrode material for lithium ion battery

InactiveCN103441254ATight and evenly attachedHigh lithium storage capacityCell electrodesLithium-ion batteryReducing agent

The invention discloses a preparation method of a graphene / stannic oxide quantum dot composite electrode material for a lithium ion battery. In the sample preparation process, that graphene-supported stannic oxide quantum dots are synthesized under relatively mild experiment conditions by utilizing a wet chemical method, and urea is adopted as a reducing agent to reduce graphite oxide, so that the preparation method has the advantages of simple and controllable reaction conditions and low production cost; by introducing graphene, not only can the conductivity of the composite material be improved but also volume change in the stannic oxide charge-discharge process can be effectively buffered; therefore the composite material shows good cycling stability.

Owner:QINGDAO UNIV OF SCI & TECH

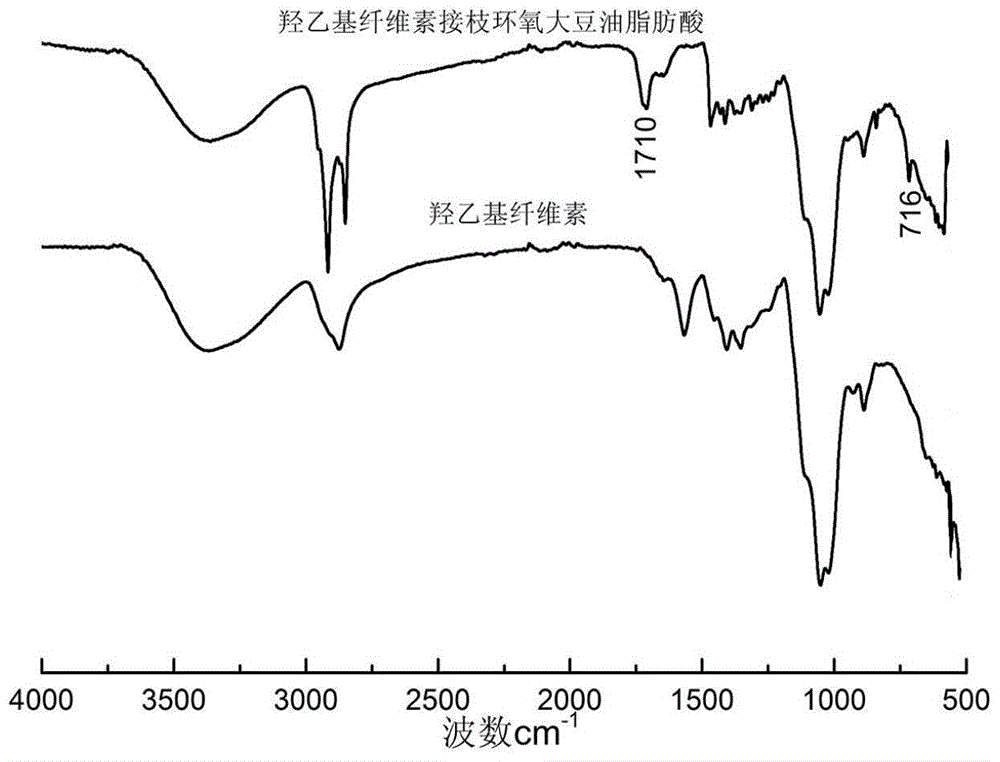

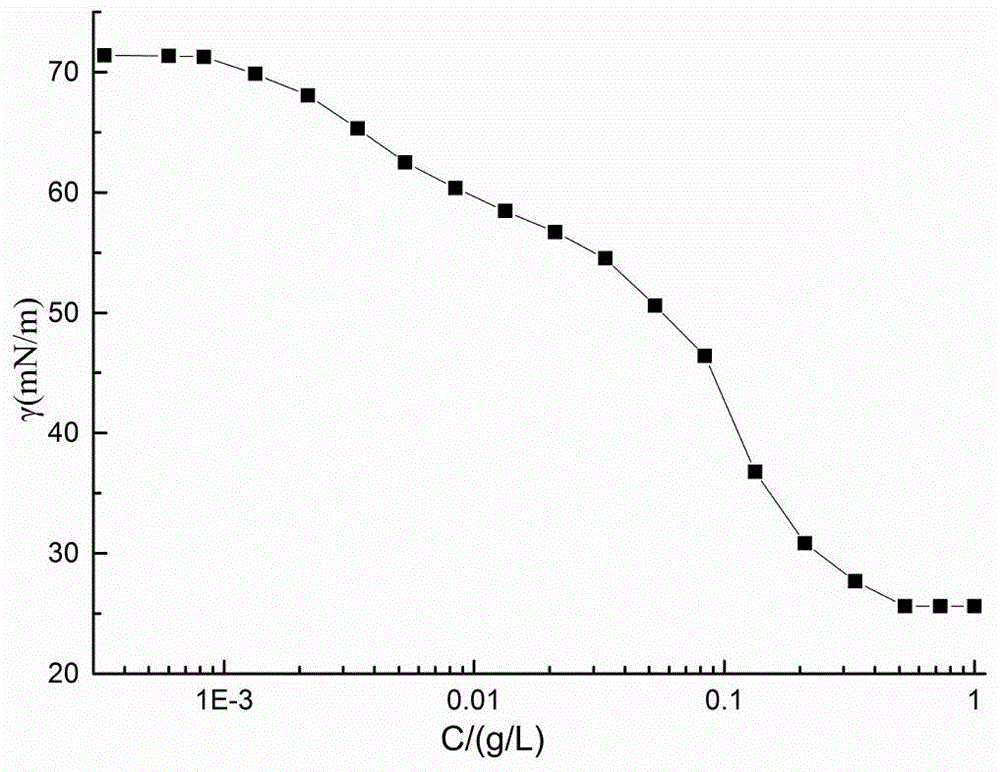

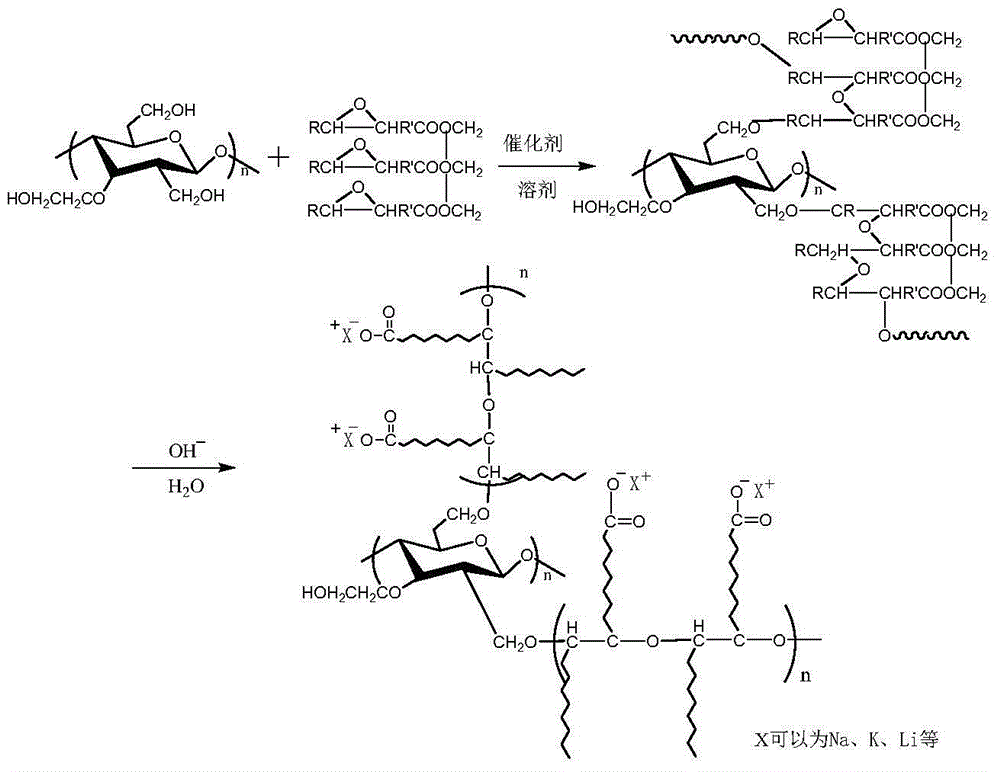

Cellulose grafted epoxy vegetable fat anionic polymeric surfactant and preparation method thereof

The invention discloses a preparation method of a cellulose grafted epoxy vegetable fat anionic polymeric surfactant. The preparation method comprises the following sequentially-connected steps: fully dissolving a cellulose material in a solvent, stirring, heating to 30-70 DEG C, adding epoxy vegetable fat, dropwise adding an initiator solution, reacting for 1-2 h under the condition of heat preservation, and removing the solvent, so that a cellulose grafted epoxy vegetable fat product is obtained; hydrolyzing the cellulose grafted epoxy vegetable fat product under the action of a catalyst, and purifying the obtained object, so that a cellulose grafted epoxy vegetable fatty acid is obtained; and dispersing the cellulose grafted epoxy vegetable fatty acid in water, adjusting the pH value to 7-11, and carrying out distillated dehydration on the obtained product, so that the cellulose grafted epoxy vegetable fat anionic polymeric surfactant is obtained. The preparation method is wide in raw material sources and low in price, the prepared surfactant is biodegradable, mild in synthetic conditions and simple in preparation process, has less pollution to the environment, and accords with the concept of sustainable development.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preparing metal oxide multistage structure by MOF-derived bimetallic oxide template

ActiveCN109205567ASimple preparation processUniform sizeOxide/hydroxide preparationZinc oxides/hydroxidesOxideMetal

The invention relates to the technical field of nanomaterials, and in particular, relates to a method for preparing a metal oxide multistage structure by an MOF-derived bimetallic oxide template; theMOF-derived bimetallic oxide template is treated by an alkali to obtain the metal oxide multistage structure; M is set as a metal in the metal oxide multistage structure, the MOF-derived bimetallic oxide template is MMoO4-MOF-derived bimetallic oxide, and the metal oxide multistage structure is MxOy. The preparation process is simple, mild and universal, has no special requirements for equipment,does not use surfactants, and can be industrialized and produced in large scale. The metal oxide multi-stage structure prepared by the method is uniform in size, stable in structure and uniform in component distribution.

Owner:ZHEJIANG UNIV OF TECH

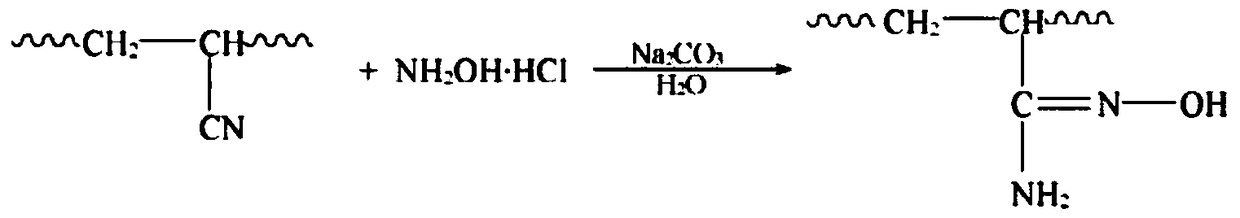

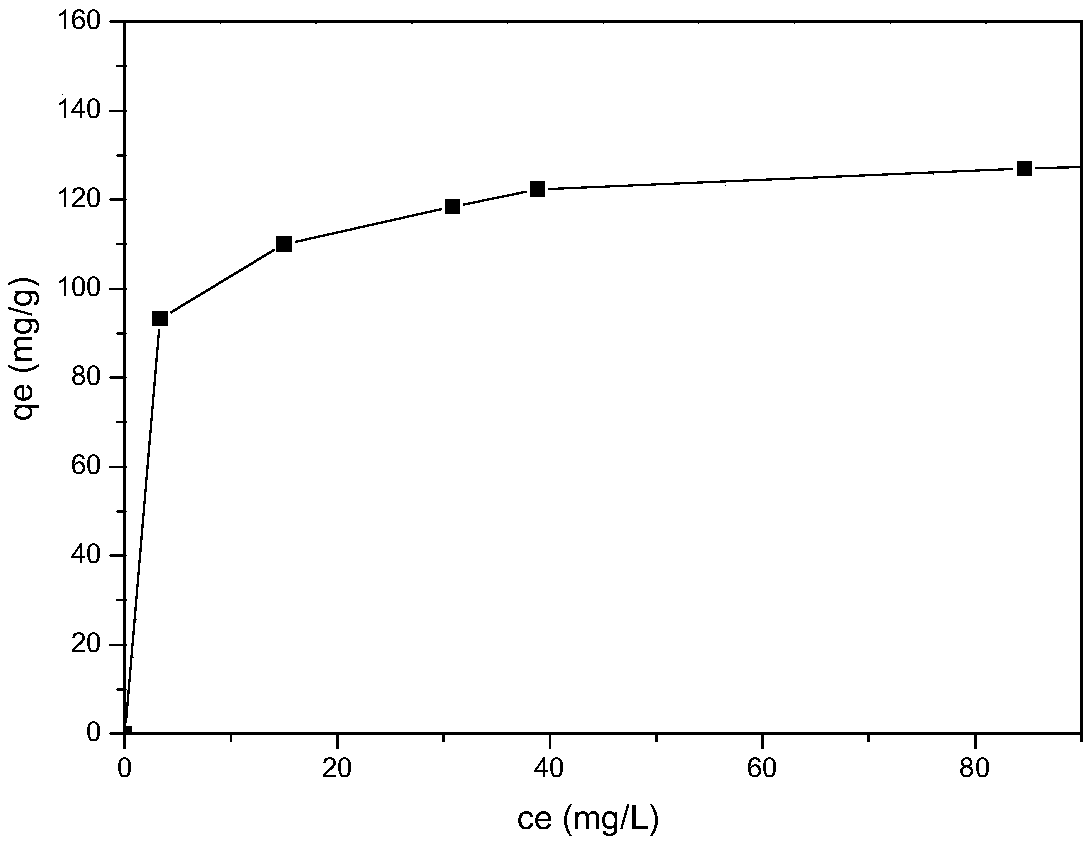

Modified polyacrylonitrile for treating wastewater containing antimony and preparation method thereof

InactiveCN109364891ARich sourcesEasy to prepareOther chemical processesWater contaminantsWater bathsSorbent

The invention discloses modified polyacrylonitrile for treating wastewater containing antimony and a preparation method thereof and relates to the field of adsorbents. The preparation method includesthe following steps: S1) immersing a polyacrylonitrile substrate in an aqueous solution of hydroxylamine hydrochloride, adding anhydrous sodium carbonate and stirring; S2) after the anhydrous sodium carbonate is completely dissolved, heating a mixed solution in the step S1) in a water bath to start reaction and conducting amidoximation on the polyacrylonitrile substrate in situ; conducting the reaction in the step S2) for 4-12 hours, taking a product out, immersing and washing the product with deionized water, drying the washed product in an oven and vacuum-dehydrating the dried product; S4) grinding the product obtained in the step S3). A modified polyacrylonitrile particle adsorbent prepared has the following advantage that raw materials can be derived from discarded PAN fiber filamentsand rags; the preparation method is simple and the process is mild; the adsorption capacity to the antimony is high and the maximum adsorption amount is large; the desorption effect is good, and the modified polyacrylonitrile can be recycled for many times.

Owner:SHANGHAI JIAO TONG UNIV

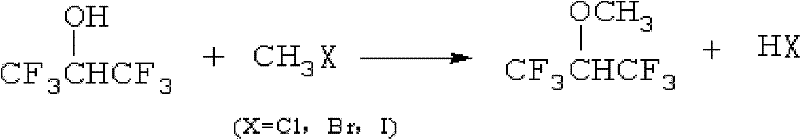

Preparation method of hexafluoroisopropyl methyl ether

The invention discloses a preparation method of 1,1,1,3,3,3-hexafluoroisopropyl methyl ether. In the preparation method, hexafluoroisopropyl alcohol and halogenated methane are taken as raw materials to synthesize the 1,1,1,3,3,3-hexafluoroisopropyl methyl ether under the action of a base catalyst, wherein, the halogenated methane has the following general formula: CH3X, wherein, X is chosen from Cl, Br or I. The preparation method has the advantages of available raw materials and mild preparation process, and is simple in operation; and the obtained 1,1,1,3,3,3-hexafluoroisopropyl methyl ether can be taken as an intermediate to synthesize the methyl fluoride-1,1,1,3,3,3- hexafluoroisopropyl ether.

Owner:SINOCHEM LANTIAN +1

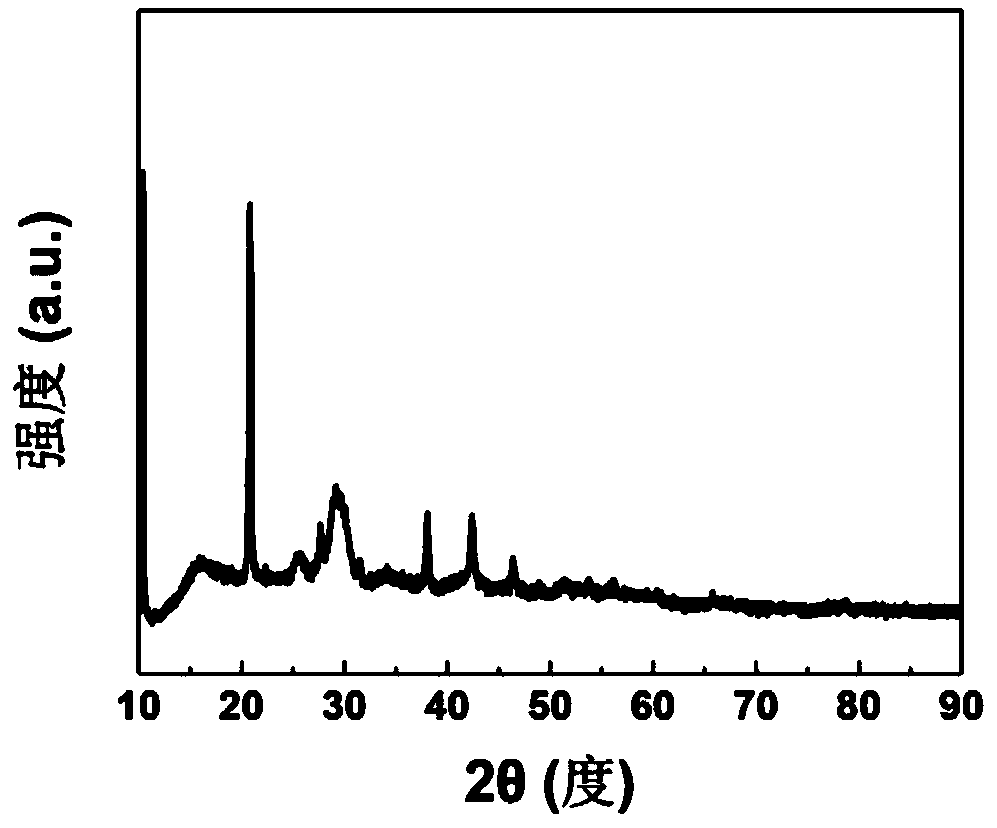

Preparation method of ammonia removal material

ActiveCN103055833AGentle preparation processGood repeatabilityOther chemical processesAluminium silicatesMolecular sieveSewage

The invention discloses a preparation method of an ammonia removal material. The preparation method comprises the steps of: uniformly mixing NaY molecular sieves, ammonia removal effective constituents and a lubricating agent, then adding a binder and deionized water for kneading, carrying out extrusion forming, and drying to obtain the ammonia removal material, wherein the weight ratio of the NaY molecular sieves, the ammonia removal effective constituents and the lubricating agent is 1:0.2-0.7:0.02-0.15:0.1-0.7. The ammonia removal material has the advantages of being mild in a preparation technology, efficient and economic, having high repeatability and high strength, resisting high temperature and being suitable for removal of ammonia gas in industrial exhaust gas, sewage treatment plants and interior of rooms. The ammonia removal material provided by the invention is safe, non-toxic and low in cost. The invention provides an effective solution for ammonia pollution problem.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

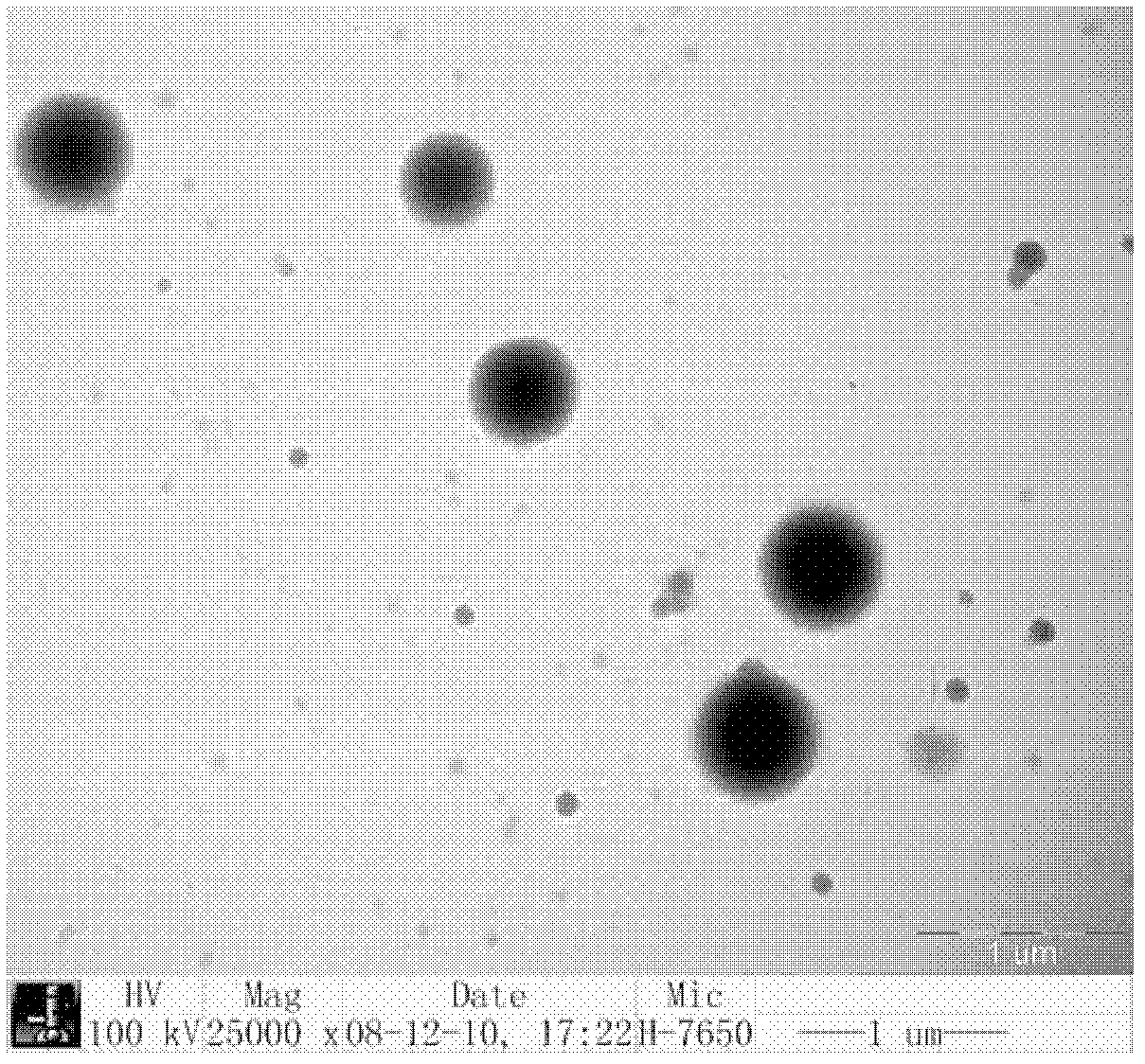

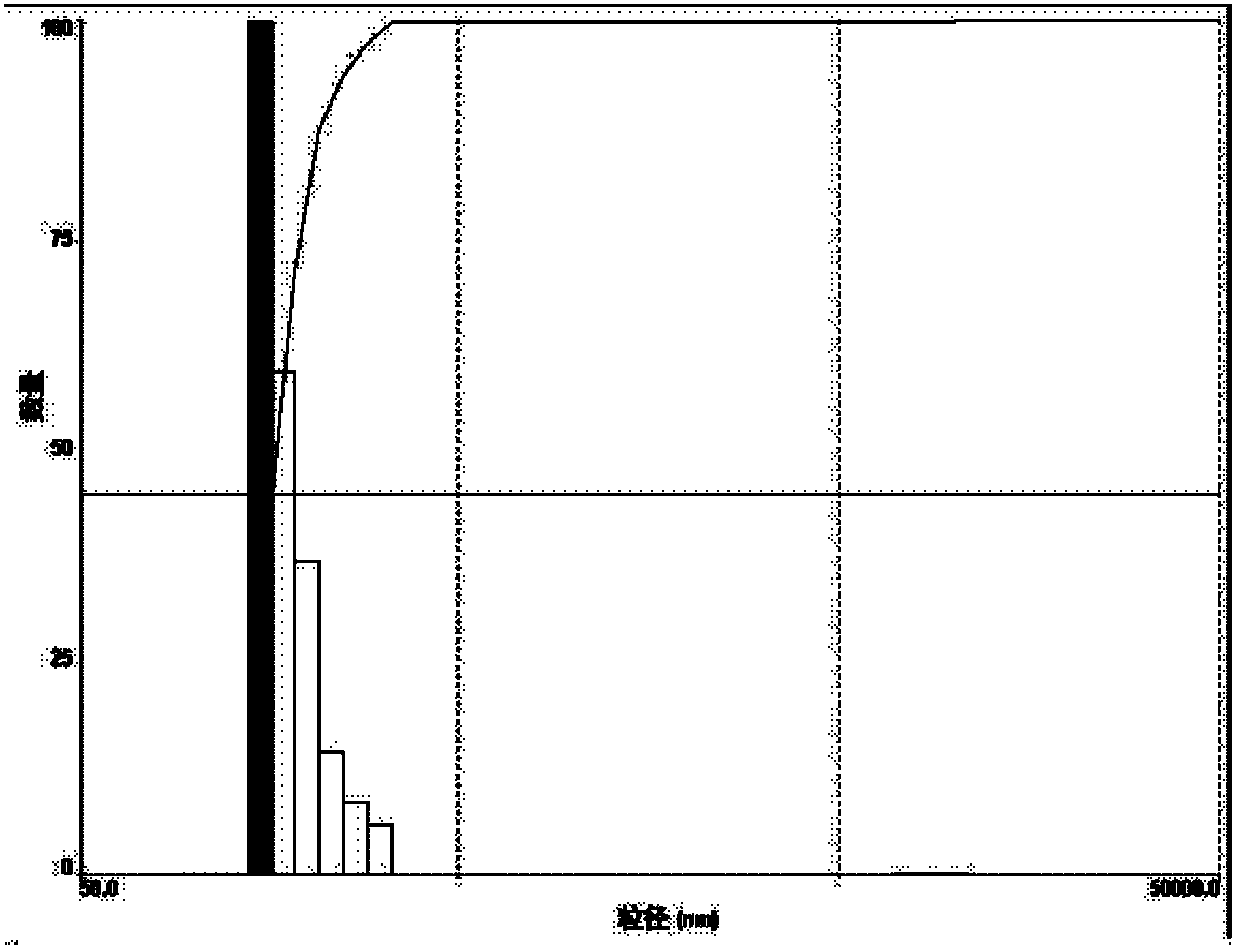

Method for preparing nanoparticle oil adjuvant vaccine

InactiveCN102580083ASmall particle sizeLarge particle sizeViral antigen ingredientsAntiviralsOil adjuvantNewcastle disease virus NDV

The invention relates to a method for preparing a nanoparticle oil adjuvant vaccine. The method comprises the following steps of: adding newcastle disease virus liquid into a chitosan solution or an N-2-hydroxypropyl trimethyl ammonium chloride chitosan solution to obtain a solution A; adding sodium tripolyphosphate and a phosphate buffer solution (PBS) into the solution A, stirring, adding span-80 to obtain a solution B; centrifuging the solution B, extracting supernate to obtain a solution B1, suspending precipitation by using deionized water, and performing suspension to obtain a solution B2; sterilizing white oil for injection at high temperature, adding the span-80 and cooling to obtain a solution C1; adding tween-80 into the solution B1 to obtain a solution C2; adding the solution C2 into the solution C1, and stirring to obtain a solution C; and adding the solution B2 into the solution C, and stirring to obtain the nanoparticle oil adjuvant vaccine. The nanoparticle oil adjuvant vaccine is small in particle sizes of virus-loaded nanoparticles, high in envelop rate and large in medicine-carrying quantity, and the method has a mild preparation condition and a simple preparation process, and is low in production cost.

Owner:HEILONGJIANG UNIV

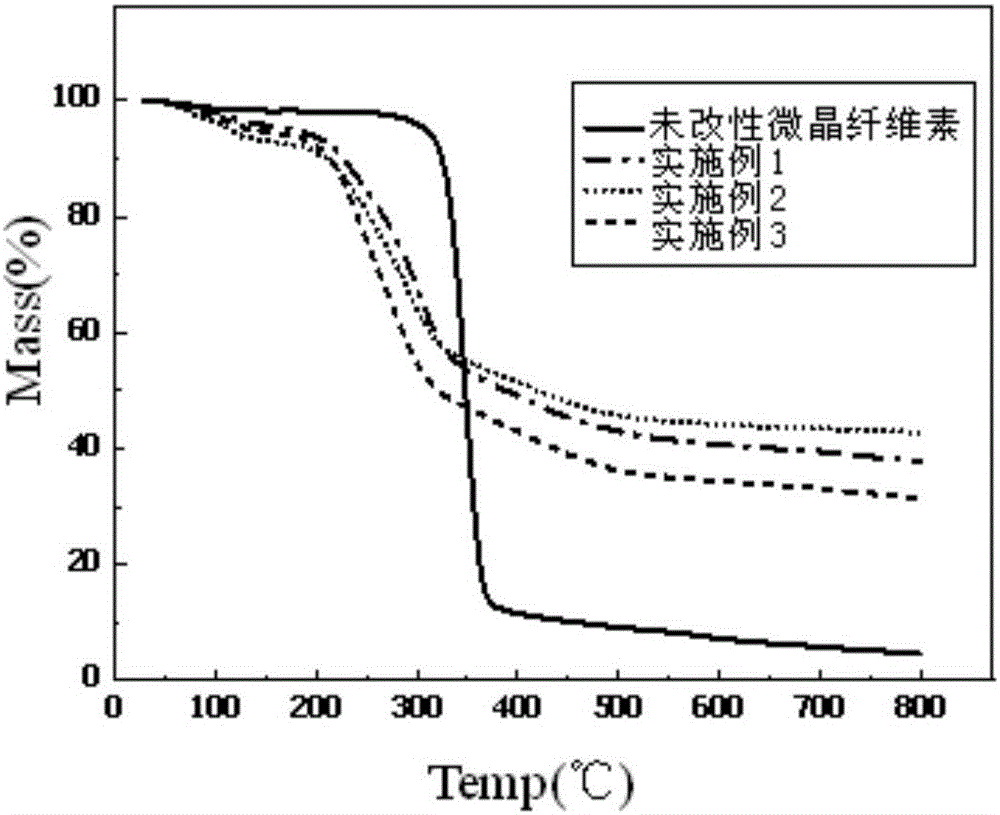

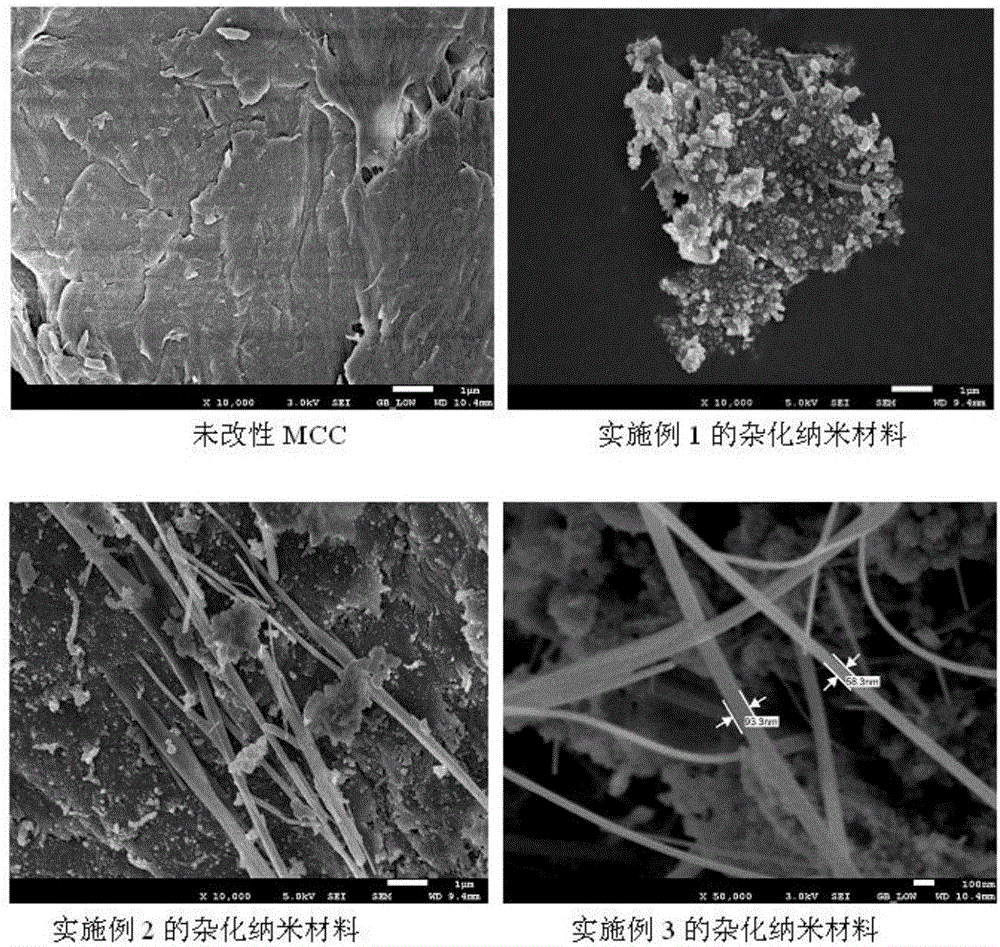

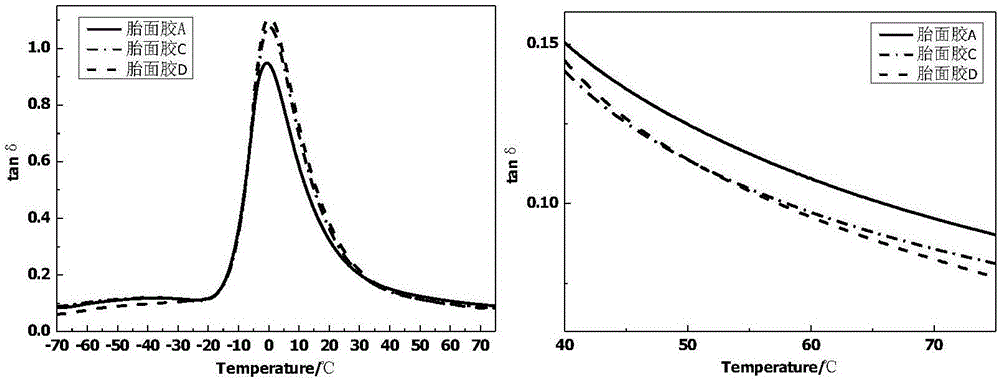

Microcrystalline cellulose-nanometer silicon dioxide hybrid material and preparing method and application thereof

InactiveCN106519352AUniform refiningEvenly mixedSpecial tyresRolling resistance optimizationDispersityRolling resistance

The invention relates to the field of microcrystalline cellulose hybrid nanometer materials and discloses a microcrystalline cellulose-nanometer silicon dioxide hybrid material and a preparing method and application thereof. According to the method, through adopting a micro-reactor technology in combination with a sol-gel technology, a catalyst NaOH needed by a sol-gel reaction is introduced into micro-reactors formed on the surface and in the interior of microcrystalline cellulose, and the sol-gel reaction is catalyzed. The adopted preparation technology of the microcrystalline cellulose-nanometer silicon dioxide hybrid material is simple and mild, and pollution to environment is small. Dispersity of the microcrystalline cellulose-nanometer silicon dioxide hybrid material prepared through the preparing method in a rubber matrix can be improved remarkably, and the reinforcement efficiency can be brought into full play. The finished microcrystalline cellulose-nanometer silicon dioxide hybrid material product partially or totally replaces white carbon black in tire tread rubber, themogenesis of the tread rubber can be reduced remarkably, and rolling resistance is reduced while wet skid resistance of the tread rubber is improved.

Owner:QINGDAO UNIV OF SCI & TECH

High concentrated paste-shaped detergent

ActiveCN103484264AGood decontamination effectGood decontamination and cleaning effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsThermal energyAcrylonitrile

The invention discloses a high concentrated paste-shaped detergent. A preparation method for the detergent comprises the following steps: adding 25-40 wt% of deionized water, 3-5 wt% of caustic soda flakes, 15-30 wt% of AES (acrylonitrile-ethylene-styrene), 20-40 wt% of sulfonic acid, 3-5 wt% of 6501, 1-2 wt% of sodium hypochlorite, 3-7 wt% of urea, 1-3 wt% of edible alcohol, 1-3 wt% of a thickener prepared by mixing 15-25 wt% of hydroxypropyl methyl cellulose, 70-82 wt% of salt and 3-5 wt% of water, and essences into a pot, mixing into a paste body, and discharging from the pot. Under the condition that the same thickening effect is kept, the raw material cost and the packaging cost are reduced and the reduced cost per ton can reach more than 150 yuan; a liquid detergent can be adopted for packaging the paste-shaped detergent; the high concentrated paste-shaped detergent is good in cleaning effect, moderate in performance, green, environment-friendly, simple in preparation process, free from heat consumption and low in production cost.

Owner:周元材

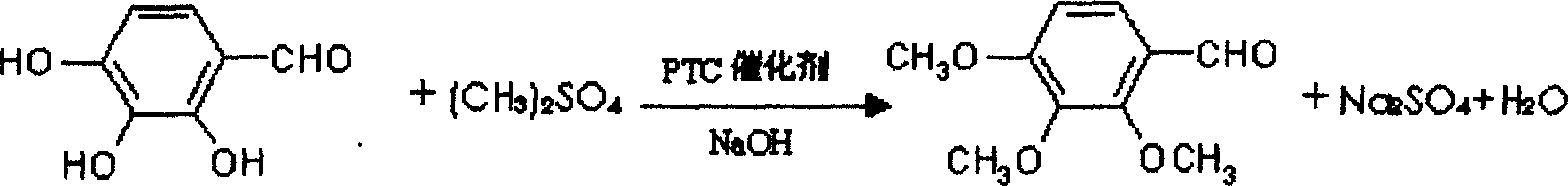

Preparation method of medical intermediate 2,3,4-trimethoxy benzaldehyde

ActiveCN1556086AAbundant resourcesLow costOrganic compound preparationCarbonyl compound preparationBenzaldehydePhase-transfer catalyst

A process for preparing the 2,3,4-trimethoxyphenyl formaldehyde as the intermediate of medicine includes the methylating reaction between 2,3,4-trihydroxyphenyl formaldehyde, dimethyl sulfate, quaternary ammonium salt and sodium hydroxide at 50-70 deg.C, laying aside for layering, taking the upper oily layer, water washing, vacuum distilling, cooling and crystallizing. Its advantages are high output rate and high purity.

Owner:南京龙源天然多酚合成厂

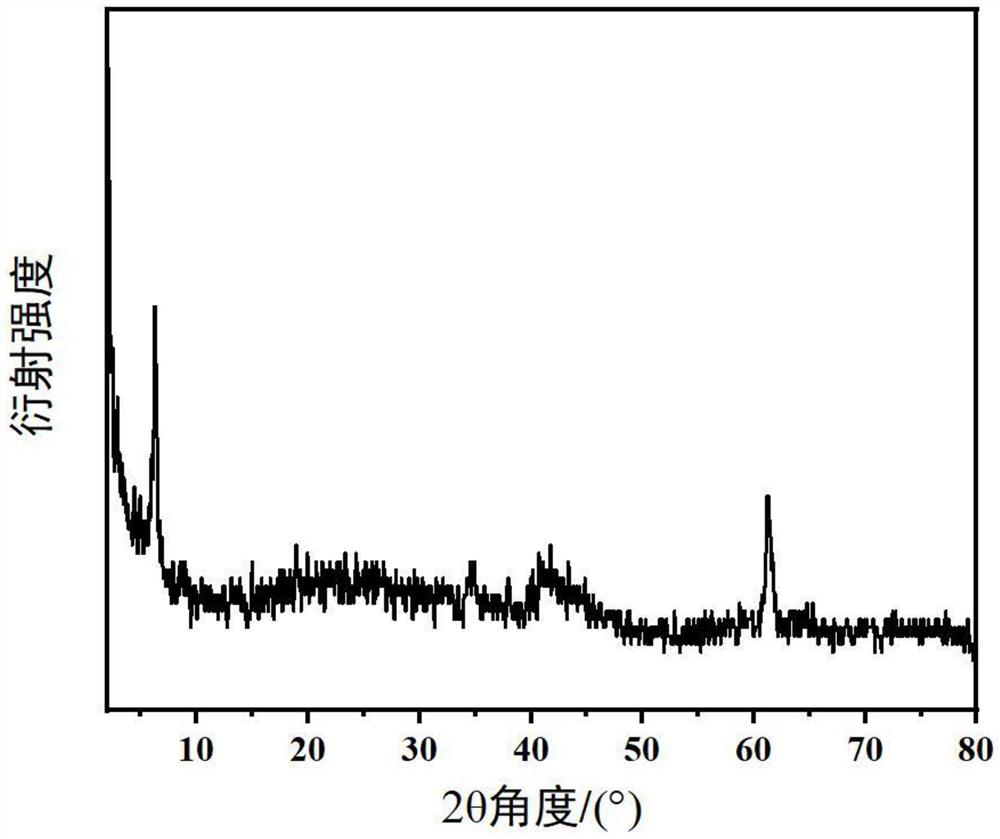

ZIF-67@MXene composite material as well as preparation method and application thereof

ActiveCN112680746AStable structureSimple preparation processElectrodesMethyl palmoxirateElectronic conductivity

The invention provides a ZIF-67@MXene composite material as well as a preparation method and application thereof, belonging to the technical field of nanomaterials. The preparation method comprises the following steps: etching MAX powder with hydrofluoric acid to synthesize MXene with a layered structure, adding Co salt and 2-methylimidazole to grow ZIF-67 on an MXene lamella, and performing a series of treatment procedures including ultrasonic treatment, stirring, centrifuging, washing and vacuum drying treatment in the period so as to finally obtain the ZIF-67@MXene composite material. Benefited from the advantages of large specific surface area, adjustable porosity and the like of ZIF-67 and excellent electronic conductivity and surface hydrophilicity of MXene, the composite material is expected to be further improved in performance in an electrocatalysis process. In addition, the preparation method for the composite material is simple in process, low in cost and suitable for industrial production.

Owner:DALIAN UNIV OF TECH

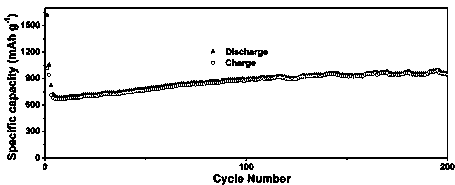

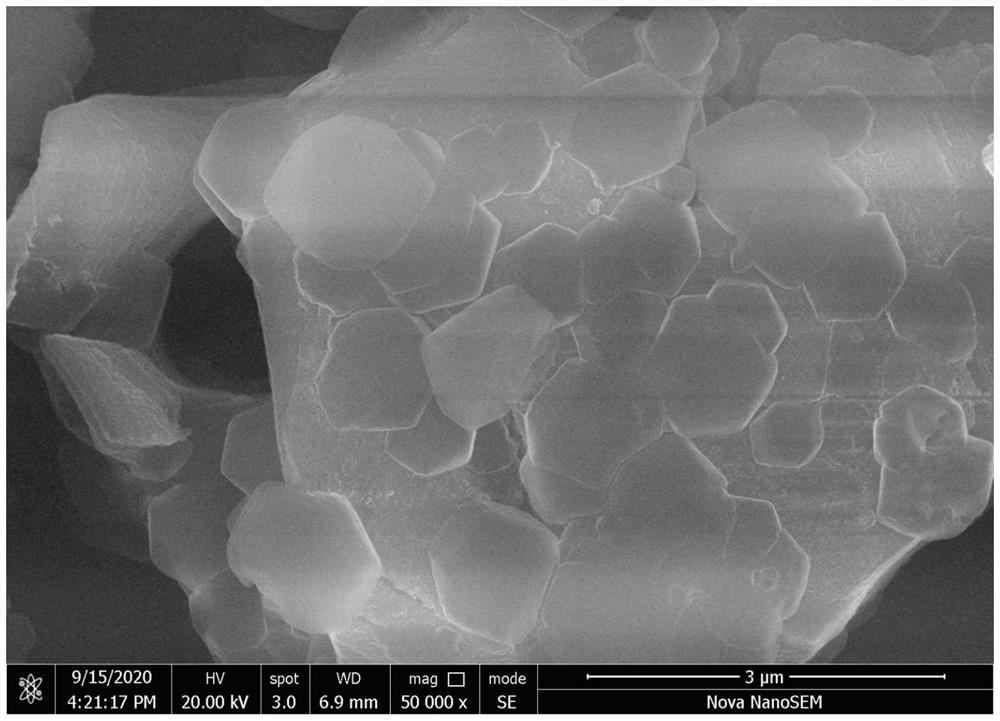

Spherical porous lithium manganate and preparation method and application thereof

ActiveCN109319845AGentle preparation processStable structureCell electrodesSecondary cellsSolventTrimesic acid

The invention discloses spherical porous lithium manganate and a preparation method and application thereof. The method comprises the following steps that 1, a manganese source and an organic ligand are added into a solvent according to a set ratio, and a mixture is mixed evenly for reaction to obtain an organic compound of manganese, wherein the organic ligand is one or a mixture of at least twoof trimesic acid, trimellitic acid, terephthalic acid, isophthalic acid, benzoic acid, methylimidazole and polyvinylpyrrolidone; 2, after the separated dried organic compound of the manganese and a lithium source are mixed evenly, calcination is conducted to obtain the spherical porous lithium manganate. A preparation technology of the lithium manganate is mild, environmentally friendly, controllable and suitable for large-scale production, and raw material kinds of the manganese source and the lithium source are numerous.

Owner:SHANDONG UNIV

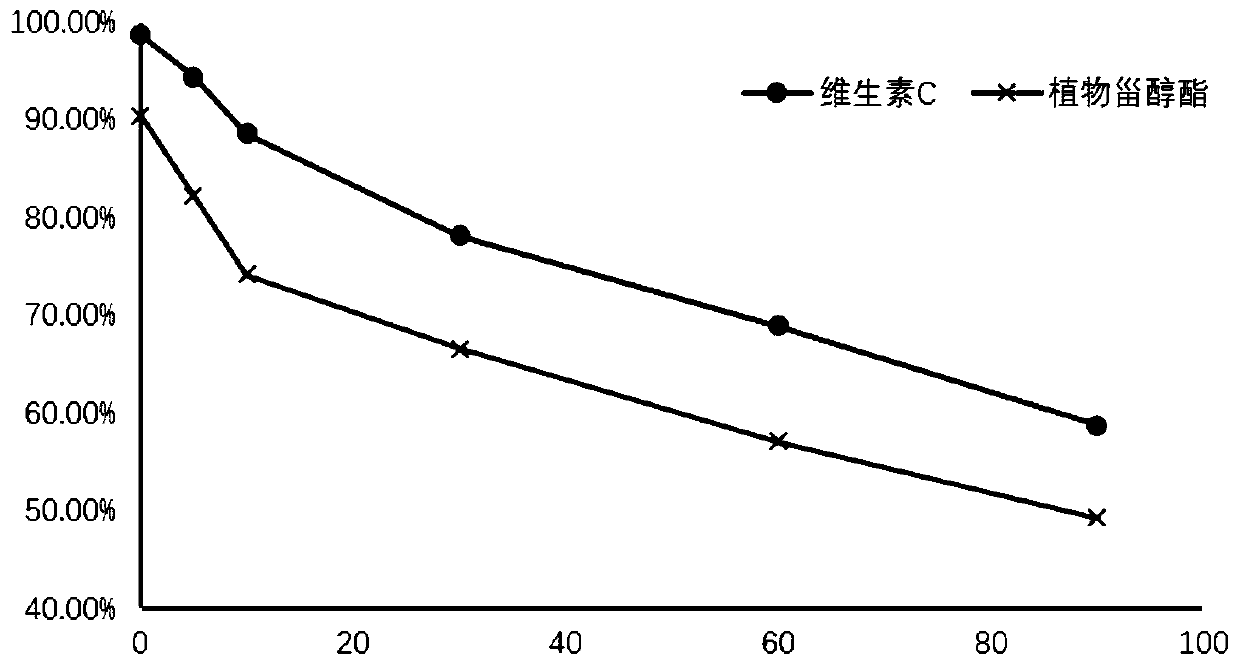

Phytosterol ester microcapsule and preparation method and application thereof

ActiveCN110721643AImprove stabilityProtects against oxidative rancidityOrganic active ingredientsAntinoxious agentsPolymer sciencePhytosterol esters

The invention belongs to the field of fine chemical industry, and particularly relates to a phytosterol ester microcapsule and a preparation method and application thereof. According to the method, avitamin C aqueous solution is used as a water phase, phytosterol ester is used as an oil phase, a stable W / O emulsion is prepared by assisting of an emulsifier, then the W / O emulsion is used as a corematerial, negatively charged polymers arabic gum and pectin, and a positively charged polymer chitosan are used as a wall material, and a complex coacervation reaction is carry out to obtain the stable phytosterol ester microcapsule. The microcapsule is resistant to high-temperature and high-humidity, and has the slow-release effect, the method is simple, and the reaction is mild.

Owner:广东蔚莱生物科技有限公司

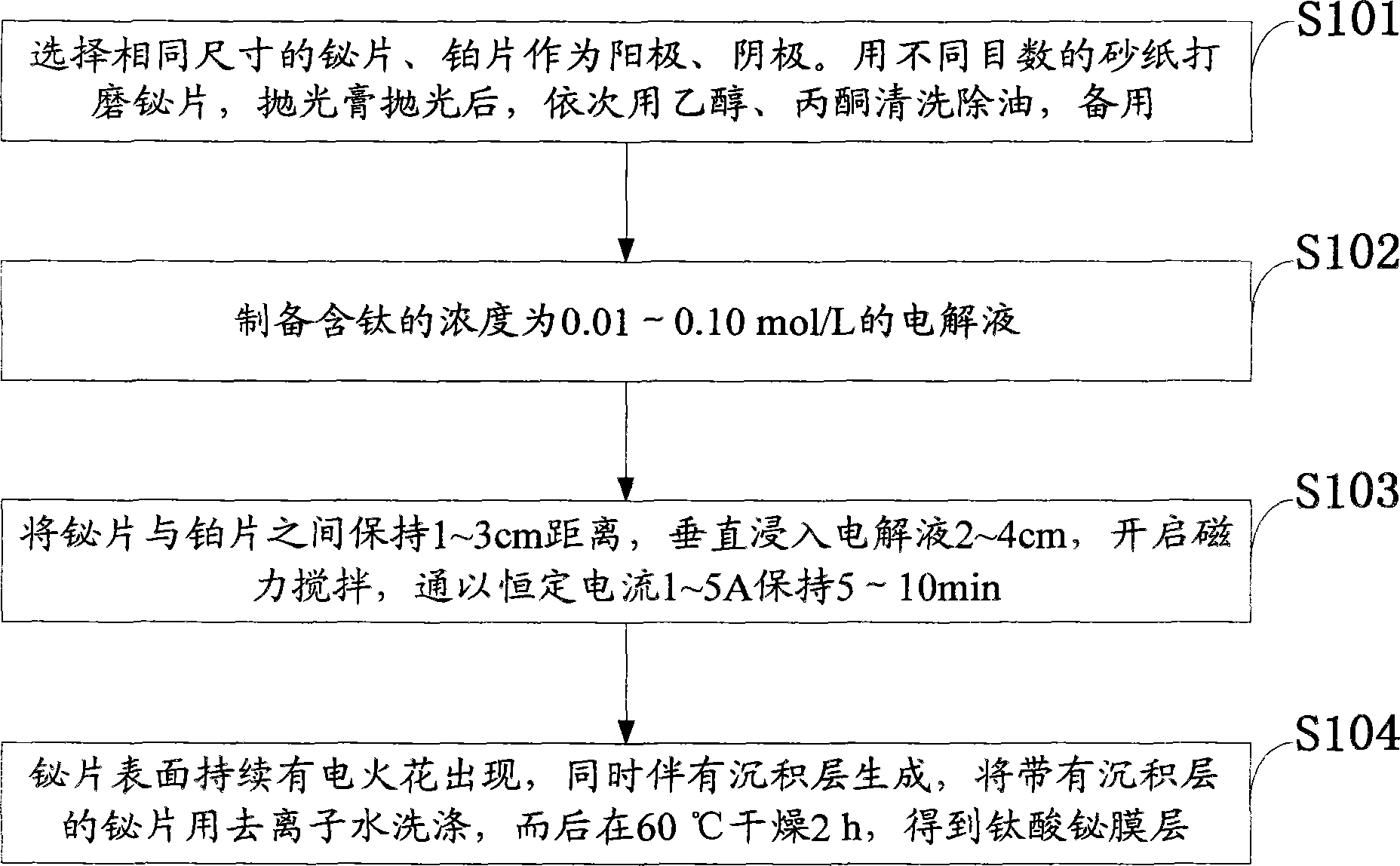

Preparation method for bismuth titanate film layer on basis of micro-arc oxidation technology

InactiveCN103409781AAvoid the use of organic solventsThe preparation process is simpleSurface reaction electrolytic coatingMicro arc oxidationIon

The invention discloses a preparation method for a bismuth titanate film layer on the basis of micro-arc oxidation technology. The preparation method comprises the following steps: a bismuth sheet and a platinum sheet which are the same in size are respectively used as an anode and a cathode; the bismuth sheet is burnished with several pieces of sand paper with different meshes and polished with a polishing paste, and the cleaning and oil removal of the bismuth sheet are performed sequentially via alcohol and acetone for standby; electrolyte with titanium concentration of 0.01-0.10 mol / L is prepared; the bismuth sheet keeps a distance of 1-3 cm from the platinum sheet, the bismuth sheet and the platinum sheet are vertically immersed into the electrolyte in a depth of 2-4 cm, magnetic agitation is started, and 1-5A constant current is electrified for 5-10 min; electric sparks are continuously generated on the surface of the bismuth sheet, a deposition layer is synchronously generated, and the bismuth sheet with the deposition layer is flushed with ion water and then dried at a temperature of 60 DEG C for 2 h, as a result, a bismuth titanate film layer is obtained. The bismuth titanate film layer preparation method is mild in synthesis conditions, can be completed under the conditions of normal temperature and normal pressure, and is quick in reaction speed and simple in operation steps; used bismuth is an environmental-friendly raw material, the process is safe, and no hazardous substance is leaked and discharged, so that environmental protection is facilitated.

Owner:QINGDAO AGRI UNIV

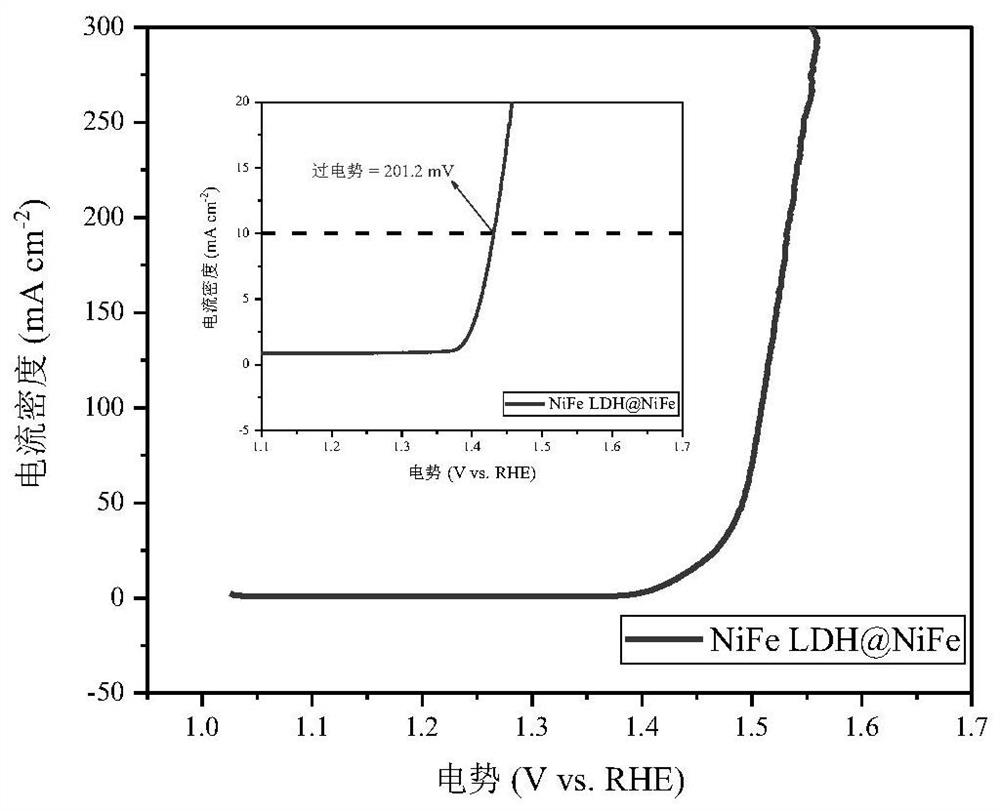

Preparation method and application of self-supporting catalytic electrode

ActiveCN112921351AImprove connection characteristicsSlow acid etchMaterial nanotechnologyElectrodesAcid etchingOxygen evolution

The invention discloses a preparation method and application of a self-supporting catalytic electrode, which belong to the technical field of hydrogen and oxygen preparation through water electrolysis. The method comprises the following steps of immersing the ferro-nickel alloy into an acidic aqueous solution containing ethylene glycol, taking out, cleaning, and airing in air. The preparation process is realized through a one-step acid etching method, the preparation process is simple, and production can be carried out only by immersing cleaned foamed ferronickel into an ethylene glycol aqueous solution of sulfuric acid; conditions are mild, safety is high, raw materials are low in price, pollutant emission is avoided, and the prepared electrode has high catalytic oxygen evolution activity, can effectively reduce water electrolysis energy consumption and has batch manufacturing feasibility.

Owner:TSINGHUA UNIV

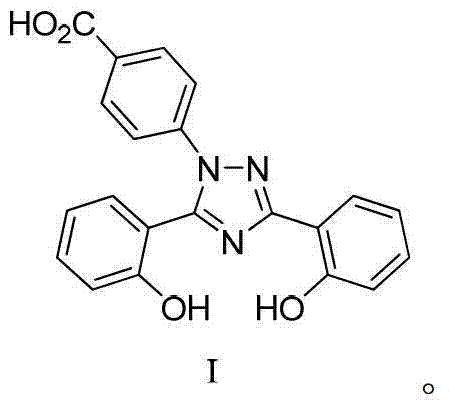

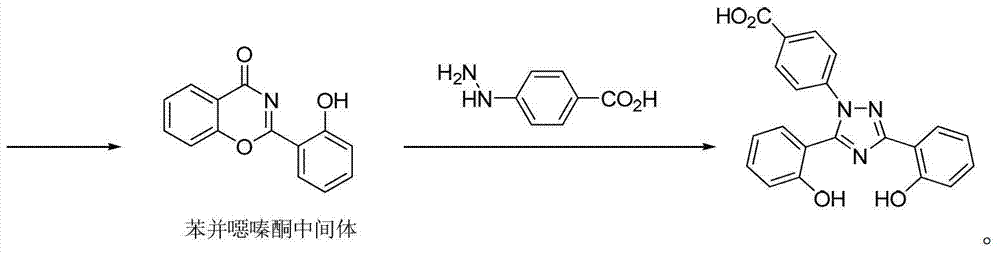

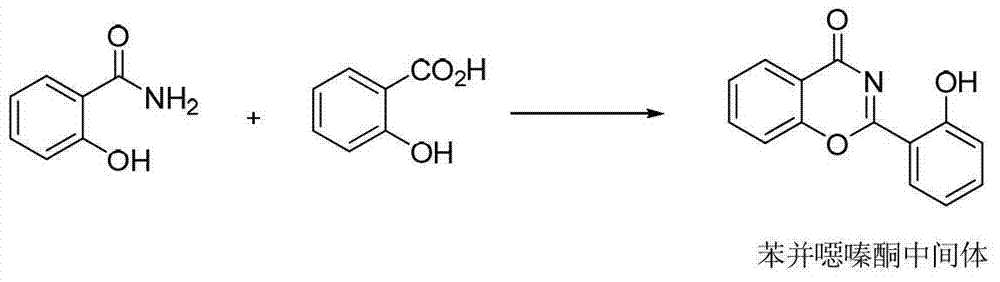

Preparation method of deferasirox and intermediate compound of deferasirox

ActiveCN103396373AGentle preparation processThe preparation process has mild reaction conditionsOrganic chemistryChlorideDeferasirox

The invention belongs to the field of pharmaceutical chemicals, provides a preparation method of deferasirox which is an iron-overloaded medicament and particularly provides a method for preparing deferasirox mainly from salicyloyl chloride, o-benzyloxy cyanophenyl, p-hydrazinobenzoic acid (or hydrochlorides thereof) under mild conditions. The method for preparing the deferasirox is mild in condition and simple to operate; the deferasirox product is high in purity.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Preparation method of light/biological dual-degradation high-water-absorption resin based on natural polymer

The invention relates to a preparation method of light / biological dual-degradation high-water-absorption resin based on natural polymer. According to the method, with cyclohexane as the solvent, a Span-series surface active agent as the dispersing agent, potassium persulfate as the initiator and N,N-methylenebis acrylamide as the crosslinking agent, by means of a reverse-phase suspension polymerization method, starch or carboxymethylcellulose or chitosan or other natural polymer reacts with acrylic acid and acrylamide monomer to prepare the light / biological dual-degradation high-water-absorption resin. According to the high-water-absorption resin, with natural polymer as the biological degradation source and nanometer TiO2 particles as the light degradation source, the nanometer TiO2 particles are evenly distributed in the high-water-absorption resin, the problem that ordinary high-water-absorption resin is difficult to degrade can be effectively solved, and the environment pollution problem is solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing analogue of carnosine

This invention discloses a method for preparing carnosine analog. The method uses enzyme as the catalyst, and does not need group protection or condensation agent during the reaction, thus having such advantages as simple process, mild reaction conditions, easy operation, complete utilization of resources, no pollution and low cost. The prepared canosine analog has high purity (93.5-95.5%), good quality and strong antioxidative effect, and can be used as antioxidative active substances in medicine, food, health product, cosmetic and feed.

Owner:CHONGQING UNIV

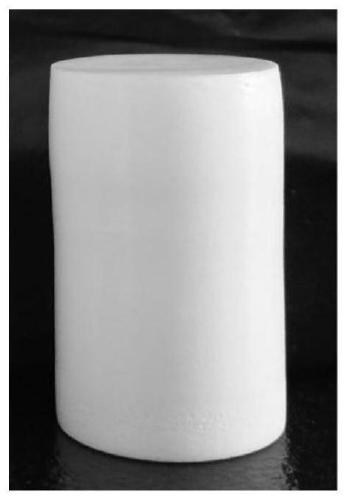

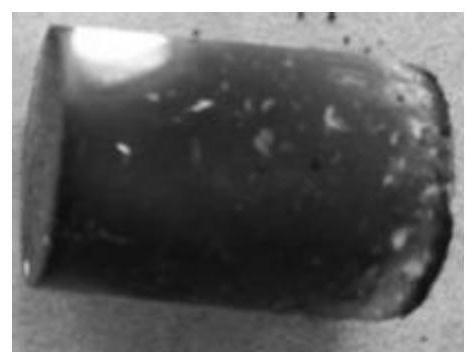

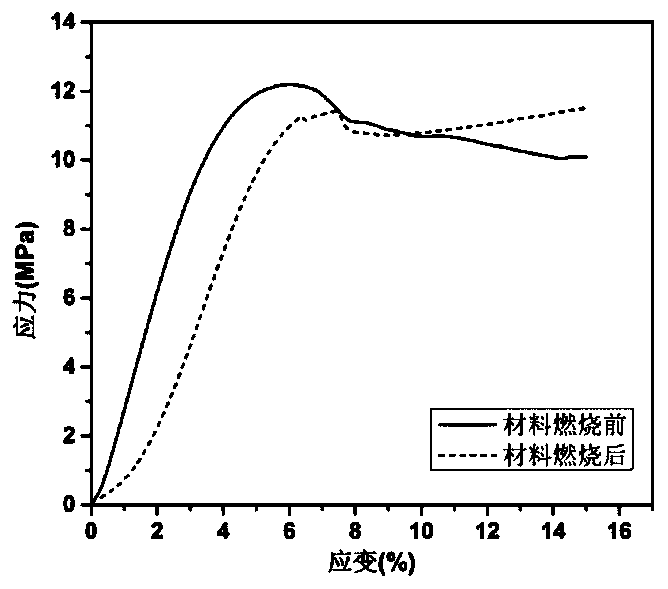

Flame-retardant smoke-inhibition light-weight high-strength high-molecular material, and preparation method thereof

The invention provides a flame-retardant smoke-inhibition light-weight high-strength high-molecular material, and a preparation method thereof. The flame-retardant smoke-inhibition light-weight high-strength high-molecular material comprises following steps: 1, a gelatinizing agent, an oil phase reaction monomer, an oil phase crosslinking agent, an initiator, and a composite flame-retardant smoke-inhibition agent are mixed, and are stirred to be uniform, a dispersion phase is added for emulsification so as to form a uniform fine gel emulsion which is stagnant in upside down position; the gel emulsion is subjected to thermal induced polymerization reaction, and after reaction drying is carried out so as to obtain the flame-retardant smoke-inhibition light-weight high-strength high-molecularmaterial. The flame resistance of the flame-retardant smoke-inhibition light-weight high-strength high-molecular material is capable of reaching V-0 grade or higher only with slightly reduced mechanical performance.

Owner:SHAANXI NORMAL UNIV

PVC (Polyvinyl Chloride) flocking composite material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride) flocking composite material and a preparation method thereof. The PVC flocking composite material is prepared from the following components in parts by mass: 70-90 parts of PVC, 20-30 parts of short fibers, 5-15 parts of triphenyl phosphate, 0.2-0.6 part of paraffin, 0.5-1.5 parts of stearate, 5-10 parts of chlorinated paraffin, 1-3 parts of dioctyl phthalate, 5-10 parts of polyvinyl ester, 1-3 parts of epoxy linseed oil, 3-8 parts of light calcium carbonate, 2-5 parts of an antistatic agent, 1-3 parts of an antioxidant, 0.1-1.0 part of a dispersant and 0.1-0.5 part of a de-foaming agent. The PVC flocking composite material has the characteristics of inflaming retarding, water prevention, no deformation, no fading and high strength, is produced by a machine and can be continuously molded; the PVC flocking composite material can be used as a novel high-grade indoor decorative material; after the PVC flocking composite material is used for decorating, the hand feeling is soft, the third dimension is strong and the sound absorption and heat preservation are realized.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

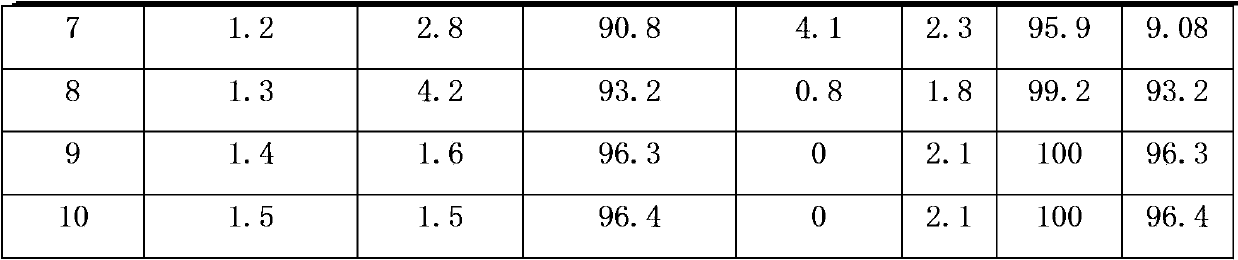

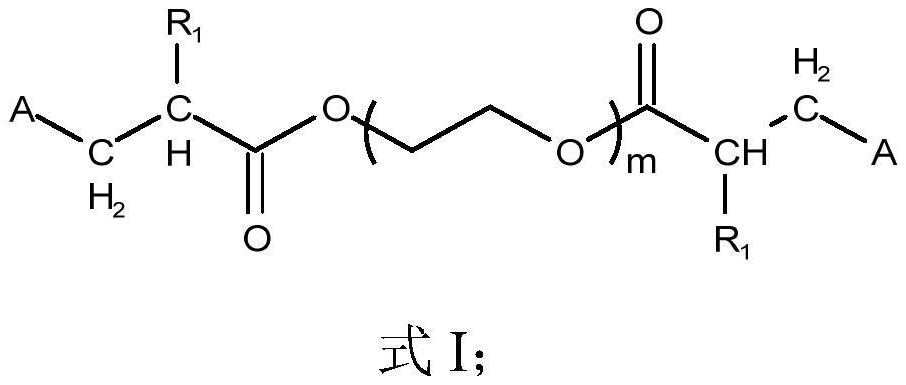

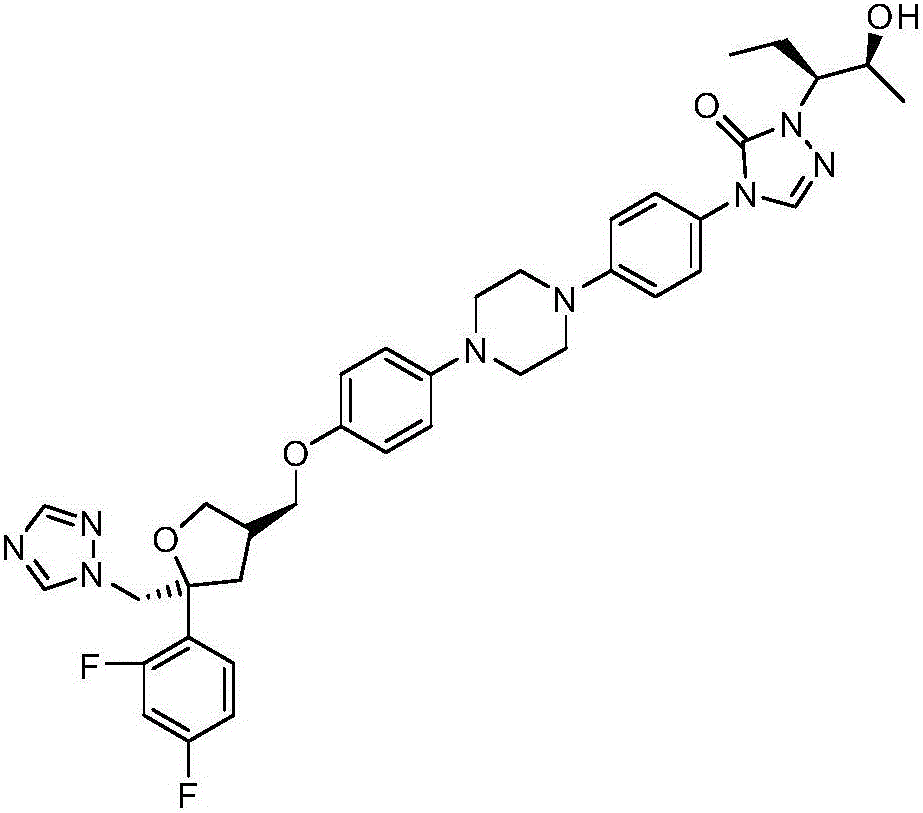

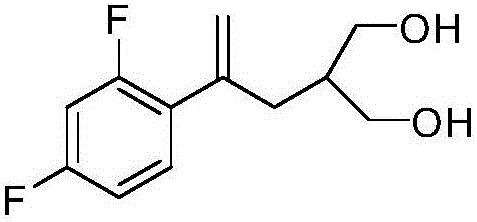

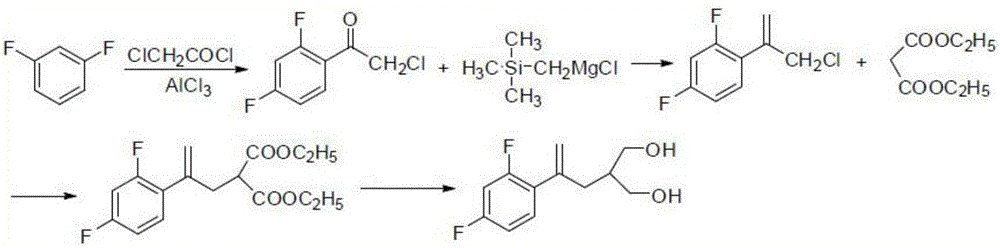

Synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate

ActiveCN105622413AReduce manufacturing costGentle preparation processOrganic compound preparationCarboxylic acid esters preparationHydrogen SulfateChlorobenzene

The invention relates to a synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate. The synthesis method comprises the following steps: mixing 3-chloro-1,2-propanediol and 1,3-difluorobenzene, and adding a catalyst to react; adding the mixture into a hydrochloric acid solution at 5 to -5 DEG C, stirring uniformly, extracting 3-5 times by using dichloromethane as an extractant, and washing the extracting solution with a saturated NaHCO3 solution, water and a saturated saline solution; drying with anhydrous Na2SO4, filtering, evaporating the dichloromethane to obtain 1-chloro-2-(2,4-difluorophenyl)-3-propanol, mixing the 1-chloro-2-(2,4-difluorophenyl)-3-propanol and potassium hydrogen sulfate into chlorobenzene, and heating under reflux for 10-16 hours; and washing with water to a neutral state, drying with anhydrous Na2SO4, filtering, distilling to obtain 1-(1-chloromethylvinyl)-2,4-difluorobenzene, dissolving in DMSO (dimethyl sulfoxide), adding diethyl malonate and hydroxide to react, extracting, washing and carrying out reduced pressure distillation to obtain the target product. The synthesis route is disclosed in the specification.

Owner:TIANSHENG PHARMA GROUP

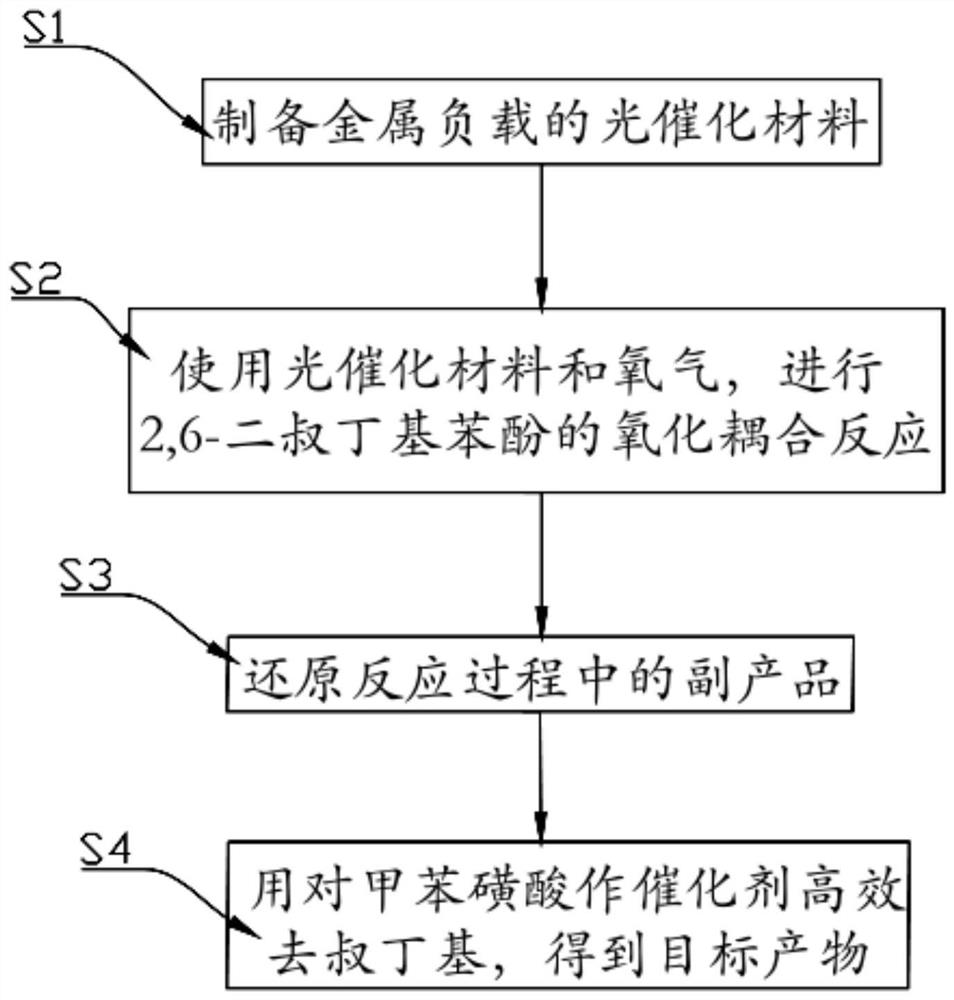

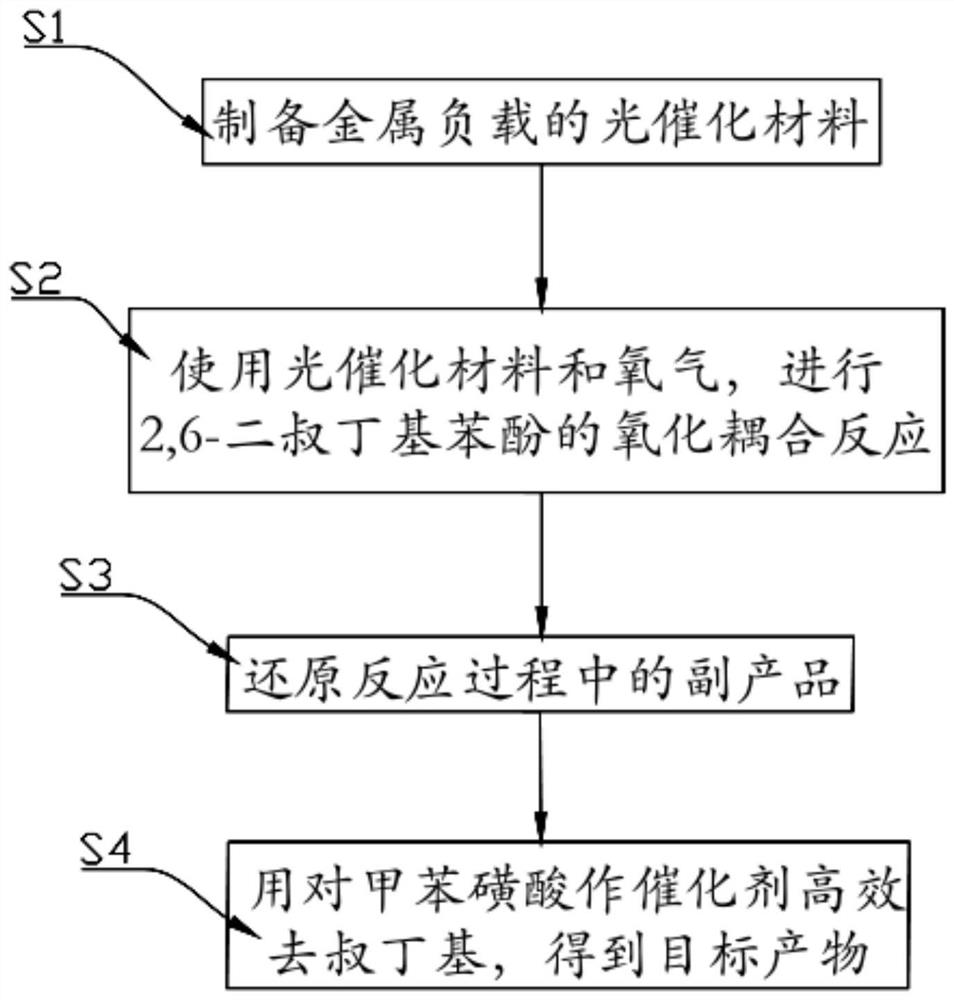

Preparation method of high-yield 4, 4'-biphenol

PendingCN113956135AFast responseImprove conversion rateOrganic chemistryOrganic compound preparationAluminum trichlorideOrganic synthesis

The invention relates to the technical field of organic synthesis, and concretely relates to a preparation method of high-yield 4, 4'-biphenol. According to the preparation method, a metal-loaded semiconductor material is used as a catalyst, oxygen is used as an oxidizing agent, an oxidative coupling reaction of 2, 6-di-tert-butylphenol is realized, the reaction is carried out at normal temperature, the reaction speed is high, the conversion rate is high, and then a small amount of by-products are reduced into 4, 4 '-biphenol through a reduction reaction, purification and filtration are performed, tert-butyl is efficiently removed from the filtered product with p-toluenesulfonic acid as a catalyst, the target product is obtained, and the obtained 4, 4'-biphenol is high in yield and good in quality. The metal-loaded semiconductor material can be recycled, and a large amount of organic medium solvent and a large amount of aluminum trichloride are not used in the preparation process, so the method has the advantages of low environmental pollution, easiness in product purification, mild reaction conditions, low equipment requirements and good application prospects, and meets the requirements of large-batch production and manufacturing.

Owner:宁夏清研高分子新材料有限公司

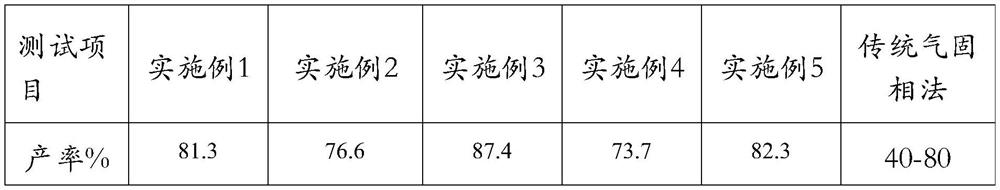

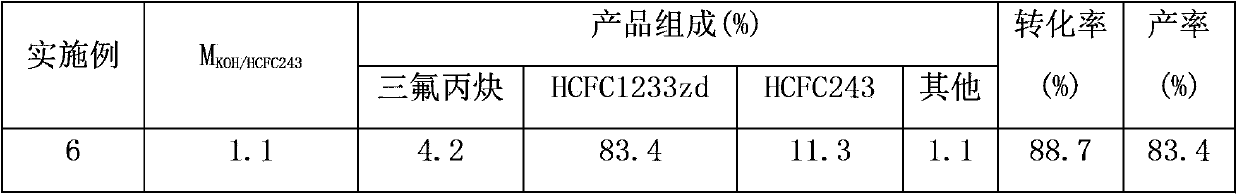

Preparation method of 1-chloro-3,3,3-trifluoropropene

InactiveCN103864570ALow reaction temperatureRaw materials are easy to getPreparation by hydrogen halide split-offEthyl ChloridePhase-transfer catalyst

Owner:SINOCHEM LANTIAN +1

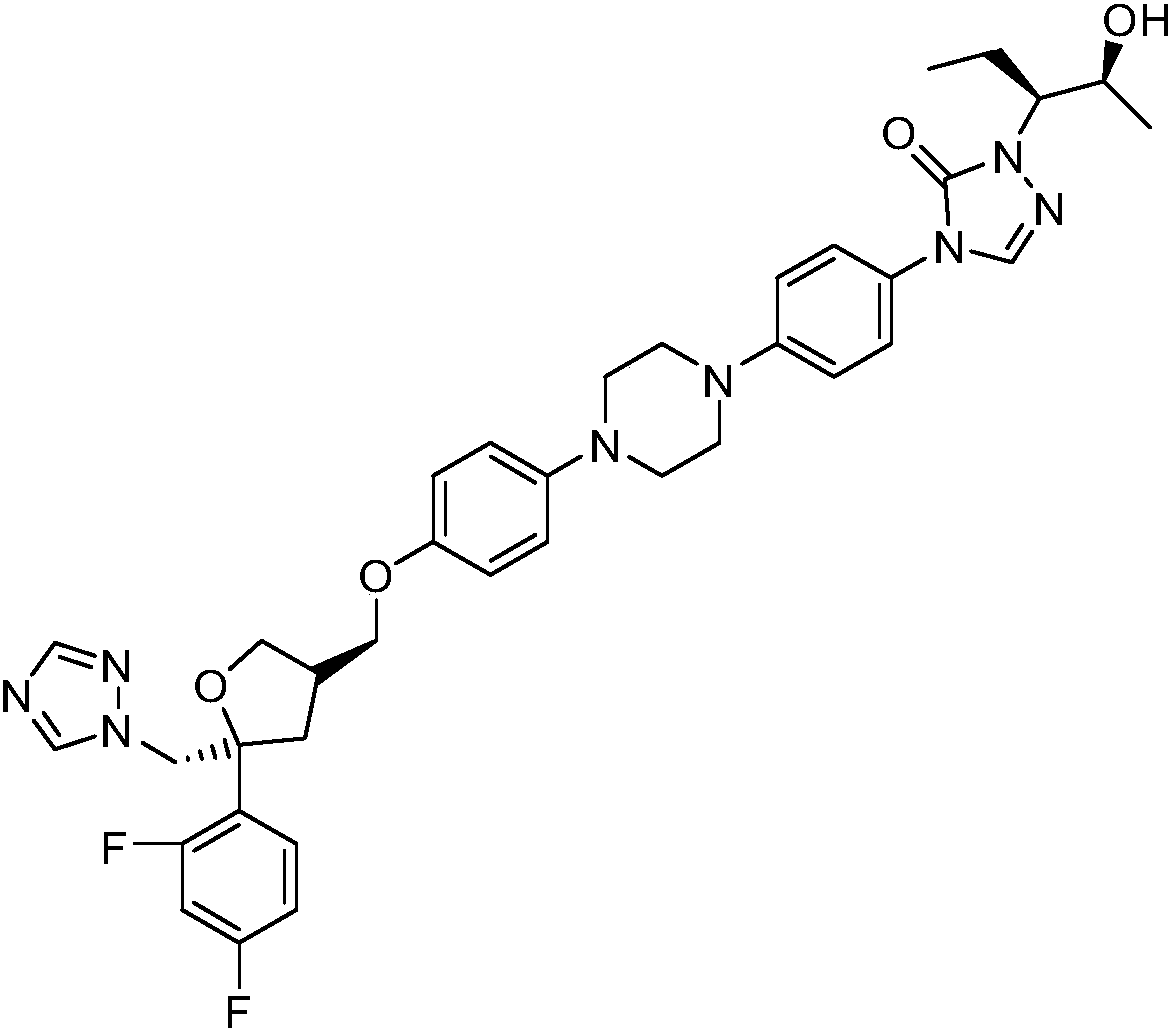

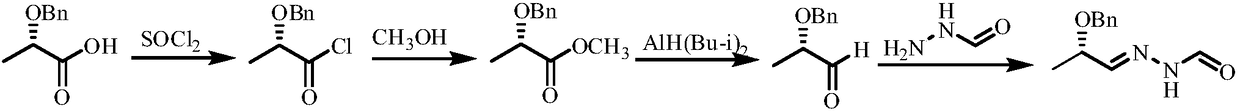

Method of synthesizing (S)-N'-(2-benzyloxy propylidene) formylhydrazine

ActiveCN108191703AFew preparation stepsLess side effectsOrganic compound preparationHydrazide preparationEthylenediaminePropanoic acid

The invention discloses a method of synthesizing (S)-N'-(2-benzyloxy propylidene) formylhydrazine. The method comprises the steps of: (1) allowing (S)-2-benzyloxy propionic acid and ethidene diamine to react to form (S)-2-(1-benzyloxy ethyl)-4,5-dihydro-1H-imidazole, (2) dissolving (S)-2-(1-benzyloxy ethyl)-4,5-dihydro-1H-imidazole in absolute ethyl alcohol, adding metallic sodium for stirring andreaction under nitrogen protection, removing alcohol after the reaction, slowly adding residue into a saturated oxalic acid solution under the nitrogen protection, giving a backflow reaction after uniform stirring, performing extraction, drying and filtration after the reaction, and removing a solvent to form (S)-2-benzyloxy propionaldehyde, and (3) allowing (S)-2-benzyloxy propionaldehyde and formylhydrazine to react, removing a solvent after the reaction and performing post treatment to form the product (S)-N'-(2-benzyloxy propylidene) formylhydrazine. The method has the advantages that anorgano-aluminum compound that is high in price and unsafe is not used, the preparation cost is low, the post treatment is simple, and the method is easy and simple to operate.

Owner:东营睿港投资服务有限责任公司

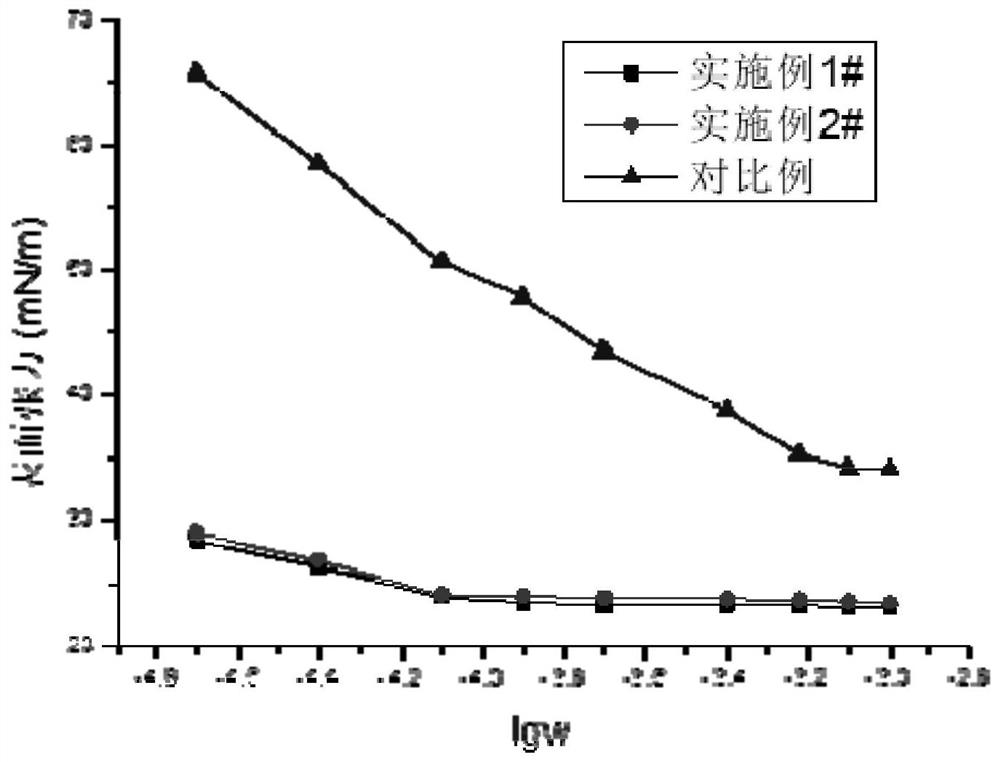

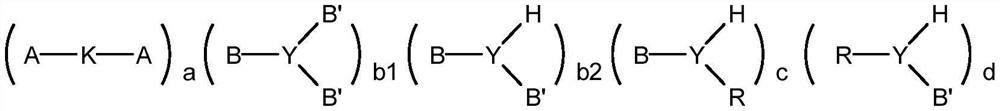

Hyperbranched surfactant and preparation method thereof

ActiveCN114106853ASimple preparation processMild reaction conditionsTransportation and packagingMixingAmino terminalActive agent

The invention discloses a hyperbranched surfactant and a preparation method thereof. According to the invention, a hyperbranched polyesteramine polymer with an amino terminal is synthesized, and the amino terminal is subjected to active chain segment modification, so that a hyperbranched surfactant with the hyperbranched polymer as an inner core and an active chain segment as a shell can be obtained. The hyperbranched surfactant provided by the invention has a spatial three-dimensional structure and a unique hole structure, so that the hyperbranched surfactant has good surface / interface activity, thereby having great advantages in the aspects of wetting, washing, emulsifying, compatibilizing and the like. The hyperbranched surfactant is simple in preparation method, environment-friendly in process and excellent in performance.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST CO LTD

Preparation method of high-dispersion manganese-cerium composite oxides

ActiveCN101462049BGentle preparation processGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention discloses manganese-cerium composite oxide, which is prepared in one step through the oxidation reduction-precipitation process among Mn<VII>, Mn<II> and Ce<III> ions, wherein components, namely MnO2 and CeO2 of the manganese-cerium composite oxide have high dispersion on a near molecular scale, the mol ratio of Mn to Ce is randomly adjusted, and the composite oxide has good oxidation reduction and oxygen affinity. As a catalyst carrier of reactions of formaldehyde oxidation at room temperature and low-temperature selective catalytic reduction of nitrogen oxide, the use of the composite oxide can ensure that a catalyst has higher activity, and the stability of the composite oxide is more superior to those of other carriers.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

Synthesis method of 2-[2-(2,4-diflurophenyl)-2-propen-1-yl)-1,3-propanediol

InactiveCN105777486AReduce pollutionReduce the impact on physical healthOrganic compound preparationCarboxylic acid esters preparationEpoxyHydrogen Sulfate

The invention relates to a synthesis method of 2-[2-(2,4-diflurophenyl)-2-propen-1-yl)-1,3-propanediol. The synthesis method comprises the following steps: mixing 2-chloromethyl epoxy propane with 1,3-difluorobenzene to perform reaction under an effect of catalyst to obtain 2-(2,4-diflurophenyl)-1-chloro-3-propanol; mixing 2-(2,4-diflurophenyl)-1-chloro-3-propanol with potassium hydrogen sulfate and chlorobenzene to perform reaction to obtain 1-(1-chloromethylvinyl)-2,4-difluorobenzene; enabling 1-(1-chloromethylvinyl)-2,4-difluorobenzene to react with diethyl malonate to obtain a product 2-[2-(2,4-diflurophenyl)propenyl]-1,3-diethyl malonate; dissolving 2-[2-(2,4-diflurophenyl)-2-propen-1-yl]-1,3-diethyl malonate in mixed solvent formed by isopropanol and water to react with borohydride to obtain a target product 2-[2-(2,4-diflurophenyl)-2-propen-1-yl)-1,3-propanediol; a synthesis route is as shown in the accompanying drawing.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate Synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate](https://images-eureka.patsnap.com/patent_img/341f27e5-eb73-4ef6-9f6b-c359352d68e4/BDA0000906329540000011.PNG)

![Synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate Synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate](https://images-eureka.patsnap.com/patent_img/341f27e5-eb73-4ef6-9f6b-c359352d68e4/BDA0000906329540000012.PNG)

![Synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate Synthesis method of diethyl 2-[2-(2,4-difluorophenyl)allyl]-1,3-malonate](https://images-eureka.patsnap.com/patent_img/341f27e5-eb73-4ef6-9f6b-c359352d68e4/BDA0000906329540000021.PNG)