Hyperbranched surfactant and preparation method thereof

A surfactant, hyperbranched technology, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve the problems of complex process, complex process and high cost of terminal group modification, and achieve the reaction conditions. The effect of mildness, simple preparation process and strong emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

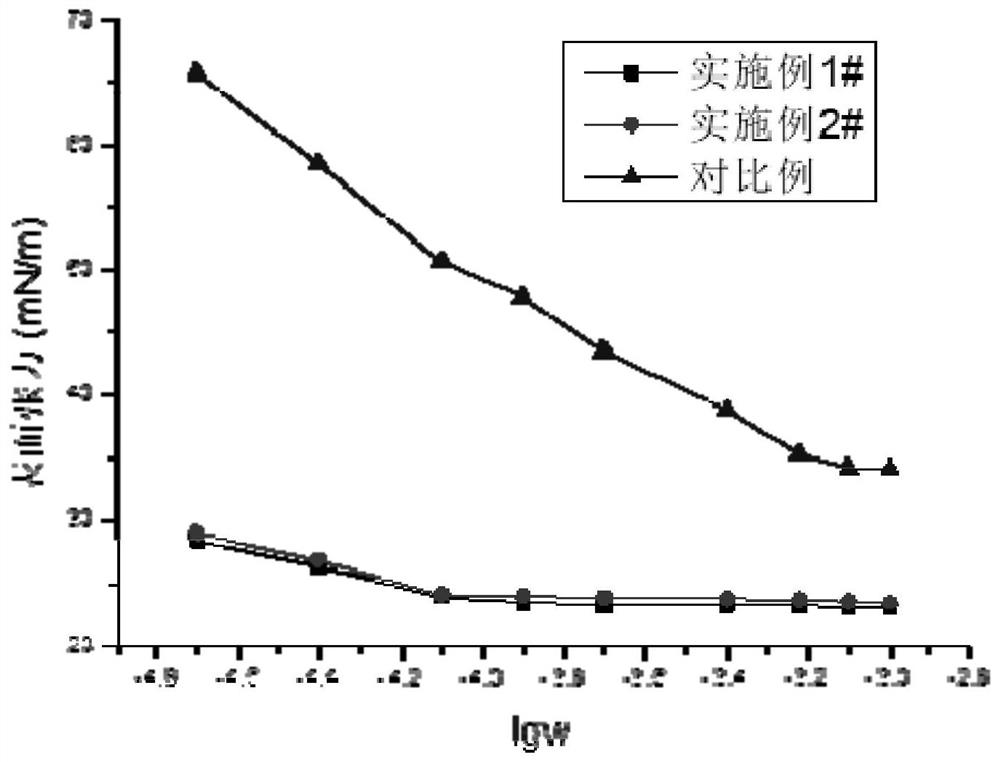

[0063] The preparation of embodiment 1 hyperbranched surfactant 1#

[0064] Step (1) Synthesis of hyperbranched polyester amine: Polyethylene glycol (200) diacrylate and N-aminoethylpiperazine are mixed in a reaction vessel with deionized water according to the amount of substance at 1:1 to obtain a solid content of 30% of the reaction solution, the reaction container is sealed, the reaction temperature is 30 ° C, and the reaction time is 6 days under stirring conditions. After the reaction is completed, a hyperbranched polyester amine solution is obtained;

[0065] Step (2) hyperbranched surfactant synthesis: take by weighing 2-acryloyl fatty amino dodecyl sodium dodecylsulfonate by 0.5 times of the amount of substance in step (1) and dissolve in In ionized water, a solution with a solid content of 30% was obtained, which was added to the reaction vessel in step (1) in situ, the reaction vessel was sealed, the reaction temperature was 30°C, and the reaction time was 1d under ...

Embodiment 2

[0066] The preparation of embodiment 2 hyperbranched surfactant 2#

[0067] Step (1) Synthesis of hyperbranched polyester amine: Polyethylene glycol (400) diacrylate and N-aminoethylpiperazine are mixed in a reaction vessel with deionized water according to the amount of substance at 1:1 to obtain a solid content of 30% of the reaction solution, the reaction container is sealed, the reaction temperature is 25 ° C, and the reaction time is 5 days under stirring conditions. After the reaction is completed, a hyperbranched polyester amine solution is obtained;

[0068] Step (2) hyperbranched surfactant synthesis: N-aminoethylpiperazine is weighed 2-acryloyl fatty amino octadecyl sodium sulfonate by 0.5 times of the amount of substance in step (1) and dissolved in In deionized water, a solution with a solid content of 30% was obtained, which was added to the reaction vessel in step (1) in situ, and the reaction vessel was sealed at a reaction temperature of 25°C. Under stirring co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com