Method for preparing metal hydroxide multi-stage structure through MOF derivative bimetallic oxide template

A double metal oxide and hydroxide technology, applied in the field of nanomaterials, can solve problems such as dependence on surfactants, unfavorable industrialization, complex hydroxide preparation process, etc., and achieve excellent constant current stability and uniform component distribution , the effect of excellent OER performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

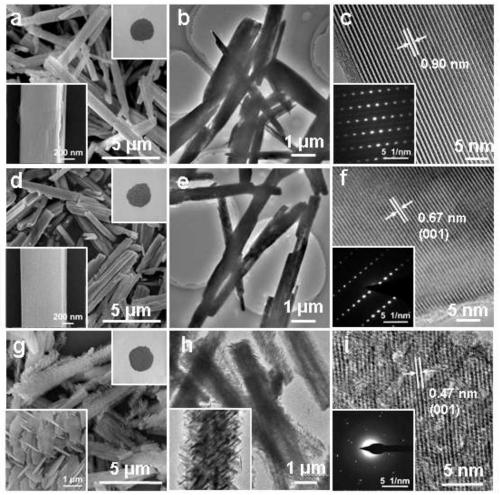

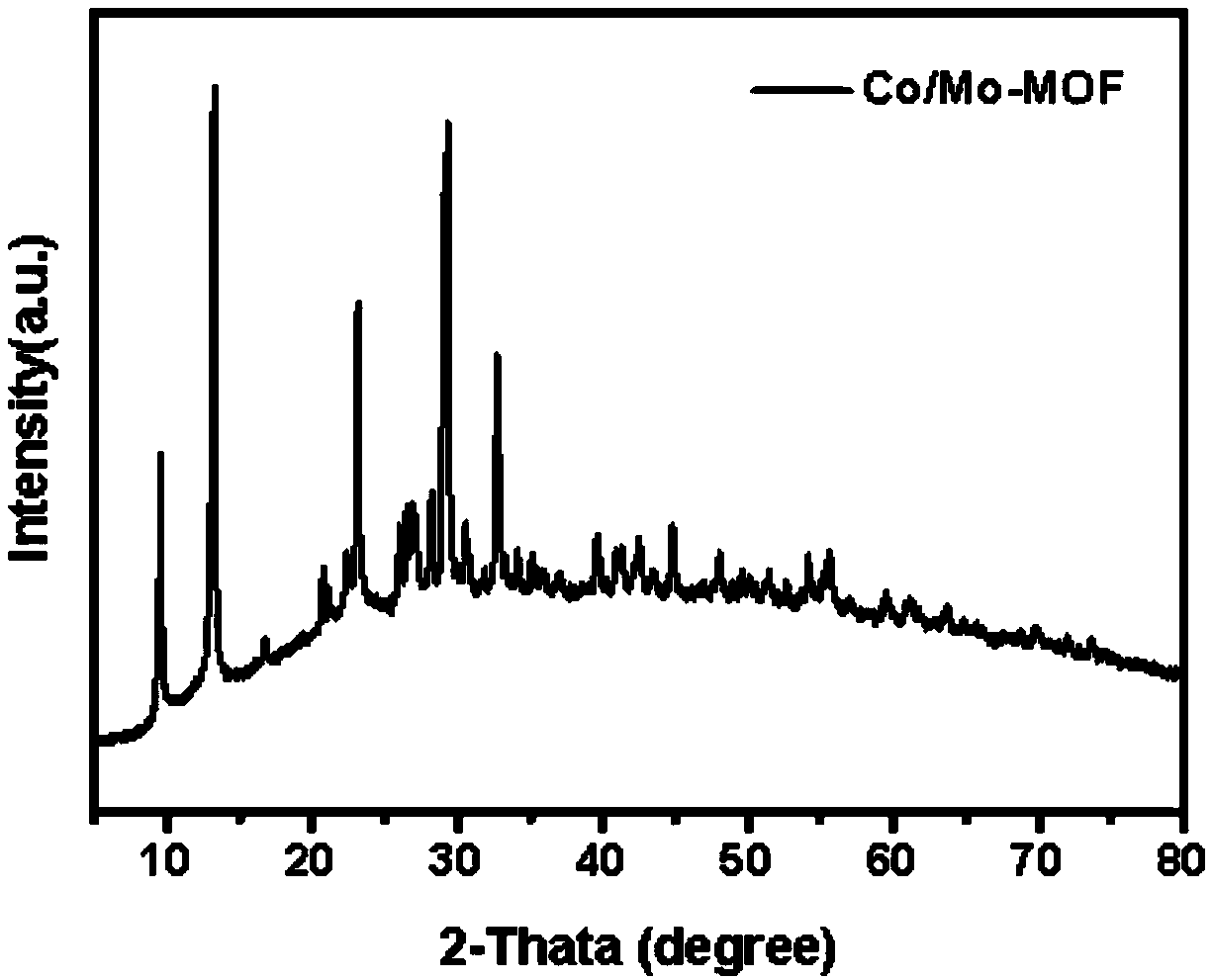

[0038] (1) Take a clean beaker, add 25ml deionized water, weigh 0.5g MoO 3 Pour it into deionized water, weigh 0.475g of 2-methylimidazole, pour it into deionized water, and ultrasonically dissolve it. Take another clean beaker, add 25ml deionized water, weigh 0.3gCo(NO 3 ) 2 ·6H 2 O was poured into deionized water, dissolved ultrasonically, and the cobalt nitrate solution was added to MoO 3 in solution. Heat the oil bath to 120°C, stir for 12 hours, and cool down to room temperature naturally after the reaction stops. Centrifugal washing with deionized water, repeated three times, and vacuum drying at 60°C for 12 hours to obtain Co / Mo-MOF;

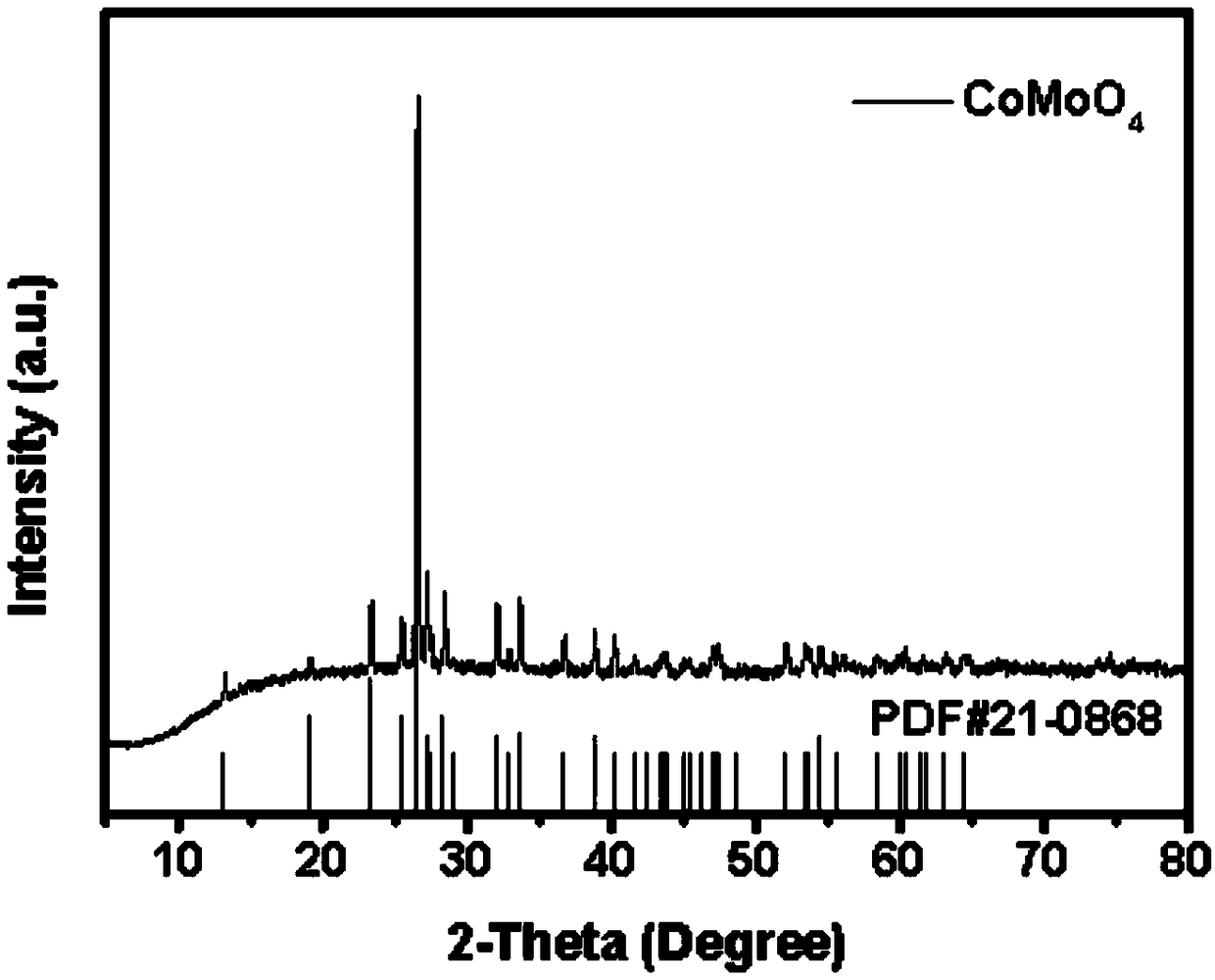

[0039] (2) Take an appropriate amount of Co / Mo-MOF and place it in a boat-shaped crucible, place the crucible in the middle of a quartz tube, and oxidize it in a tube furnace at 500 °C for 3 hours in an air atmosphere with a heating rate of 10 °C / min to obtain CoMoO 4 -MOF crystal powder;

[0040] (3) Take 10mg CoMoO 4 Put the MOF...

Embodiment 2

[0056] (1) Take a clean beaker, add 25ml deionized water, weigh 0.5g MoO 3 Pour it into deionized water, weigh 0.475g of 2-methylimidazole, pour it into deionized water, and ultrasonically dissolve it. Take another clean beaker, add 25ml deionized water, weigh 0.3gNi(NO 3 ) 2 ·6H 2 O was poured into deionized water, ultrasonically dissolved, and nickel nitrate solution was added to MoO 3 in solution. Heat the oil bath to 80°C, stir for 18 hours, and cool down to room temperature naturally after the reaction stops. Centrifugal washing with deionized water was repeated three times. and vacuum drying at 60°C for 12 hours to obtain Ni / Mo-MOF crystal powder;

[0057] (2) Take an appropriate amount of Ni / Mo-MOF and place it in a boat-shaped crucible, place the crucible in the middle of a quartz tube, and oxidize it in a tube furnace at 900 °C for 1 h in an air atmosphere with a heating rate of 20 °C / min to obtain NiMoO 4 - MOF crystal powder;

[0058] (3) Take 10mg of NiMoO ...

Embodiment 3

[0070] Take a clean beaker, add 25ml deionized water, weigh 0.5g MoO 3 Pour it into deionized water, weigh 0.475g of 2-methylimidazole, pour it into deionized water, and ultrasonically dissolve it. Take another clean beaker, add 25ml deionized water, weigh 0.3g Co(NO 3 ) 2 ·6H 2 O was poured into deionized water, dissolved ultrasonically, and the cobalt nitrate solution was added to MoO 3 in solution. Heat the oil bath to 180°C, stir for 10 hours, and cool down to room temperature naturally after the reaction stops. Centrifugal washing with deionized water, repeated four times, and vacuum drying at 60°C for 12 hours to obtain Co / Mo-MOF;

[0071] (2) Take an appropriate amount of Co / Mo-MOF and place it in a boat-shaped crucible, place the crucible in the middle of a quartz tube, and oxidize it in a tube furnace at 300°C for 24 hours in an air atmosphere with a heating rate of 1°C / min to obtain CoMoO 4 - MOF crystal powder;

[0072] (3) Take 10mg CoMoO 4 -MOF crystal pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com