Patents

Literature

356 results about "Trimellitic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimellitic acid (benzene-1,2,4-tricarboxylic acid) is a chemical compound with the molecular formula C₆H₃(СООН)₃. It is one of the isomers of benzenetricarboxylic acid.

Ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material and preparation method thereof

ActiveCN101875747ALower embrittlement temperatureMeet construction requirementsPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

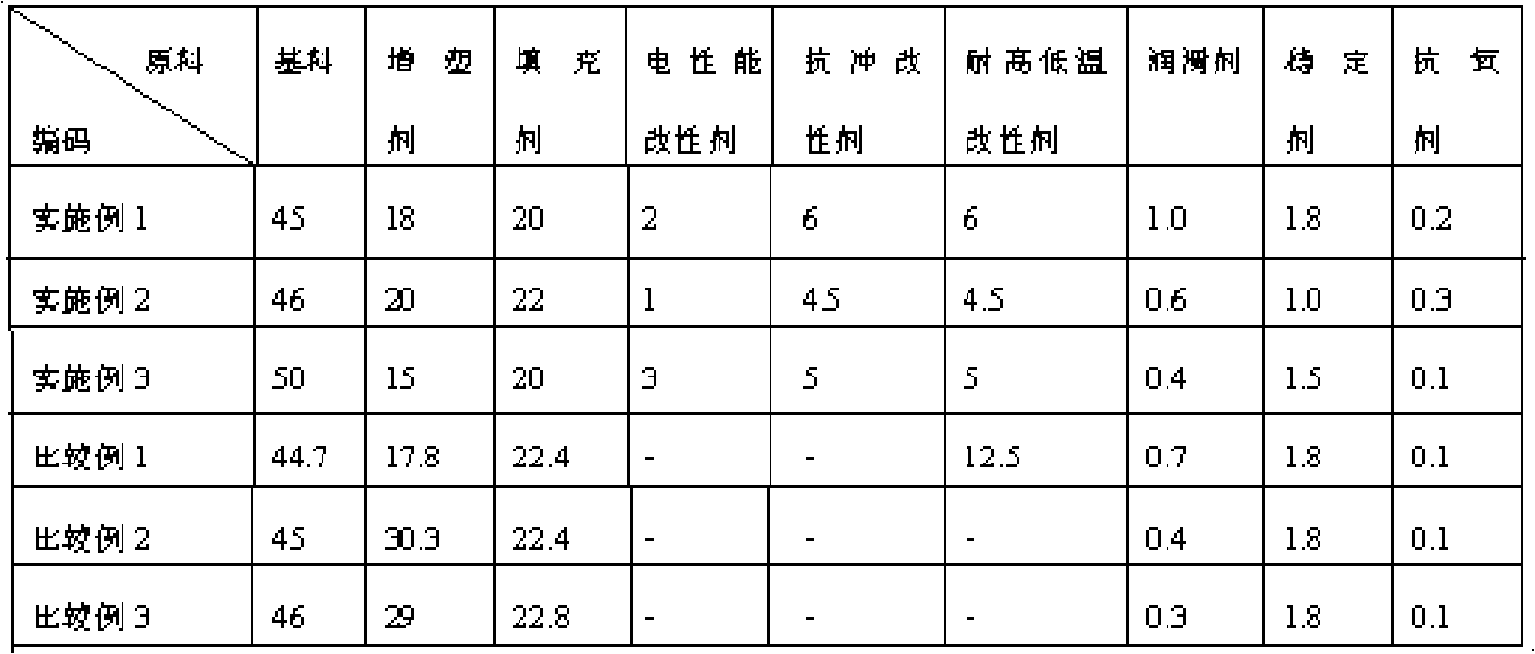

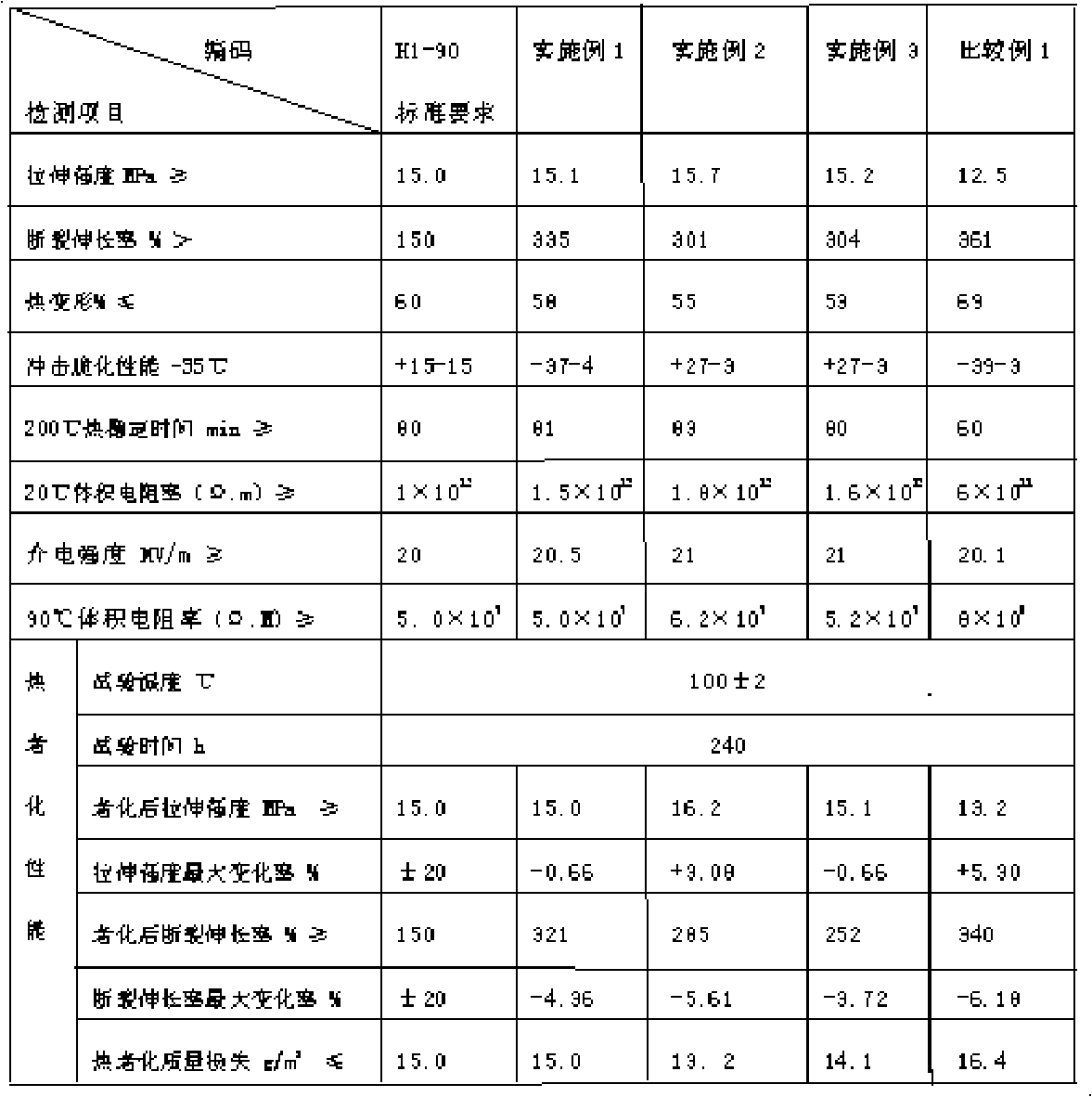

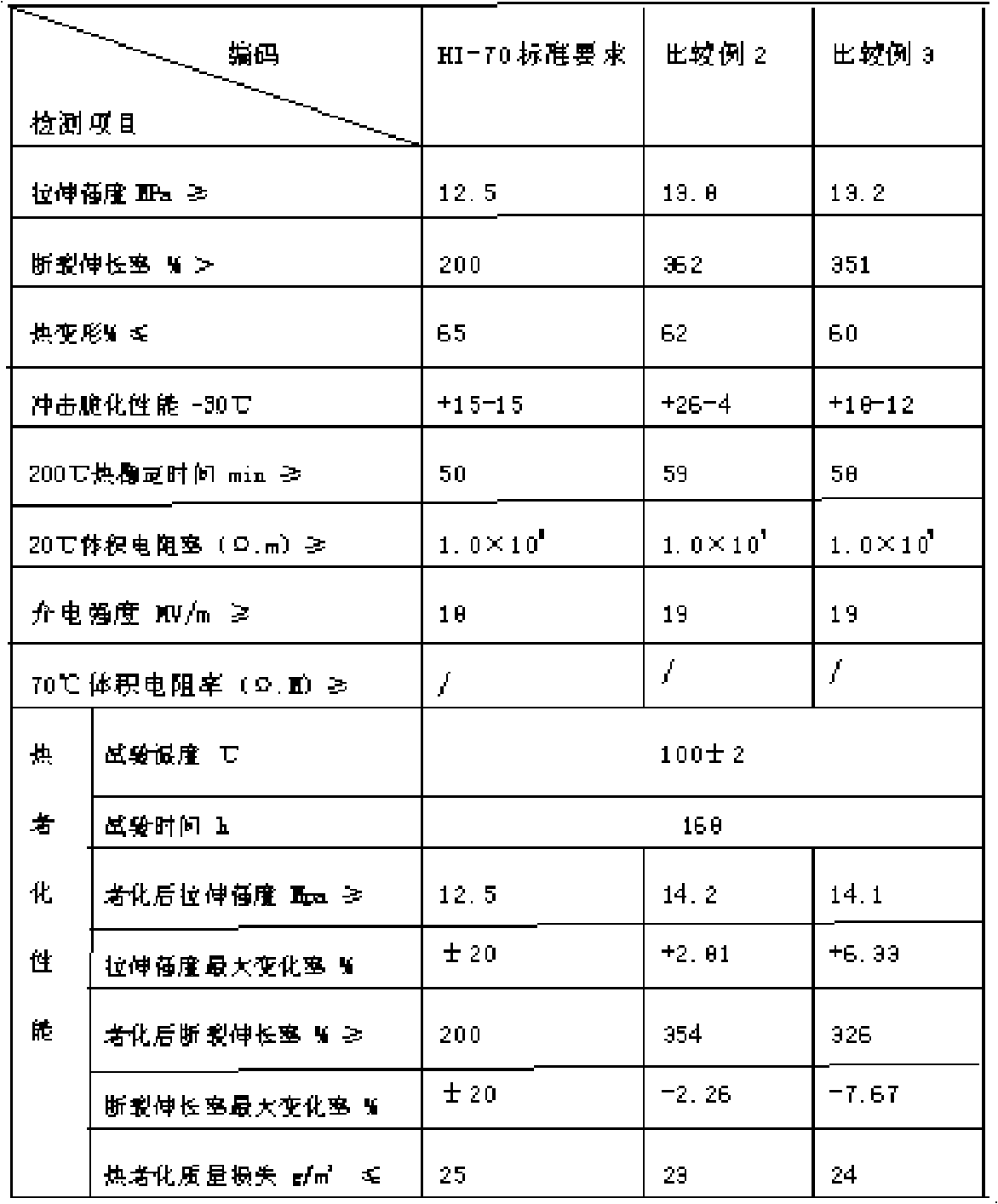

The invention discloses an ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material, belonging to the field of materials. The cable material is mainly prepared from the following raw materials in percentage by weight: 45-50% of PVC resin, 15-20% of plasticizer, 20-25% of filler, 1-3% of electrical property modifier, 9-15% of impact resistant and high and low temperature resistant modifier, 0.4-2.2% of lubricant, 1.0-2.0% of stabilizer and 0.1-0.3% of antioxidant, wherein the plasticizer is a mixture of more than two of phthalate, terephthalate or trimellitate; and the lubricant is a mixture of a composite lubricant and oxidized polyethylene wax. The invention also provides a preparation method of the cable material. The cable material provided by the invention has the advantages of low brittle temperature and good insulating property, wherein the brittle temperature can reach -35 DEG C; and simultaneously, the preparation method of the cable material is simple and is convenient for industrialized production.

Owner:ZHEJIANG DEYU TECH

Preparation method of polyester resin for mixing type powdery coating

InactiveCN1962717AReduce melt viscosityUniform molecular weightPowdery paintsPolyester coatingsPolymer sciencePolymer resin

Owner:GUANGZHOU QINGTIAN INDAL

Method for preparing functional environmentally-friendly paint

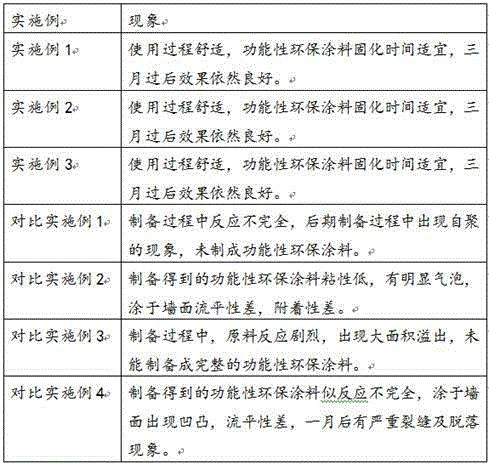

The invention relates to a method for preparing a functional environmentally-friendly paint. The preparation method comprises: adding 10-100 parts of glycerol, 10-100 parts of pentaerythritol, 5-80 parts of trimethylolpropane, 20-200 parts of phthalate, 3-60 parts of adipic acid, 10-80 parts of trimellitic anhydride, and 15-150 parts of maleic acid into a reactor; heating the reactor to make the substances therein react; after a complete reaction, adding in 0.03-3 parts of a defoamer; cooling the reactants, and gradually adding in 0.05-2 parts of hydrogenated castor oil and 0.05-2 parts of a polymerization inhibitor during the cooling process; adding in 8-95 parts of styrene to modify a product; and adding in 4-60 parts of triethylamine, 3-70 parts of a solvent, 15-230 parts of a pigment and a filler, 0.01-2 parts of a leveling agent, 0.5-6 parts of a catalyst, 3-7 parts of a first solid additive, 1.5-6 parts of a second solid additive, 6-9 parts of a first composite modifier, 7-11 parts of a second composite modifier, and 8-14 parts of a third composite modifier to obtain the functional environmentally-friendly paint. The functional environmentally-friendly paint prepared by the method is stable in performance, little in environmental effect, and suitable for large-scale popularization.

Owner:ANJI QILONG NEW BUILDING MATERIAL

Subluminous weather-resistant coating powder and preparation thereof

InactiveCN1613935AHigh glass transition temperatureGood weather resistancePowdery paintsPolyester coatingsAdipic acidTrimethylolpropane

A low lustre weather resisting powdery paint is composed of polyester resin A and B. The weight percent of the composition of A is : the new pentadiol 80-100, 2-methyl-1,3-propylene glycol 0-20, 1,4-cyclohexane dimethyl alcohol 0-10,1,6-hexylene glycol 0-5,trimethylolpropane 0-3, terephthalic acid 100-130, m-phthalic acid 10-50, adipic acid 0-5,dibutyl tin oxidate 0.1-0.3; and the B is :the new pentadiol80-100, 2-methyl-1,3-propylene glycol 0-10, 1,4-cyclohexane dimethyl alcohol 0-5, 1,6-hexylene glycol 0-5, trimethylolpropane 0-10, terephthalic acid 120-150, m-phthalic acid 10-50, adipic acid 0-8, dibutyl tin oxidate 0.1-0.3. The A and B are of high transformation temperature, good stability and so on, The paint has the lustre domain of 15-40%.

Owner:GUANGZHOU QINGTIAN INDAL

Universal refrigerant resistant solvent-free impregnating resin for high and low voltage motor and preparation method thereof

ActiveCN102604384ASolve defects such as inability to be used universallyLow VOC contentLow voltageSolvent free

The invention relates to a universal refrigerant resistant solvent-free impregnating resin for a high and low voltage motor and a preparation method thereof. The impregnating resin is composed of 45-65 parts of unsaturated polyesterimide resin solution with 65-75% of solid content, 15-35 parts of oxazolidone resin solution with 75-85% of solid content, 10-25 parts of environment-friendly dilutingagent, 3-8 parts of curing agent, 1-3 parts of initiating agent and 0.01-0.06 part of polymerization inhibitor; the raw material formula of an unsaturated polyesterimide resin comprises a first monomer, a second monomer and a third monomer, wherein the first monomer is selected from one or multiple of neopentyl glycol, propoxylation bisphenol A and trihydroxyethyl isocyanurate; the second monomeris selected from one or multiple of isophthalic acid, hexanedioic acid, trimellitie anhydride and maleic anhydride; and the third monomer is a compound containing imide groups. The resin provided by the invention has low content of VOC (Volatile Organic Compounds), resists novel refrigerating fluids such as R134a and is universal for the high and low voltage motor.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

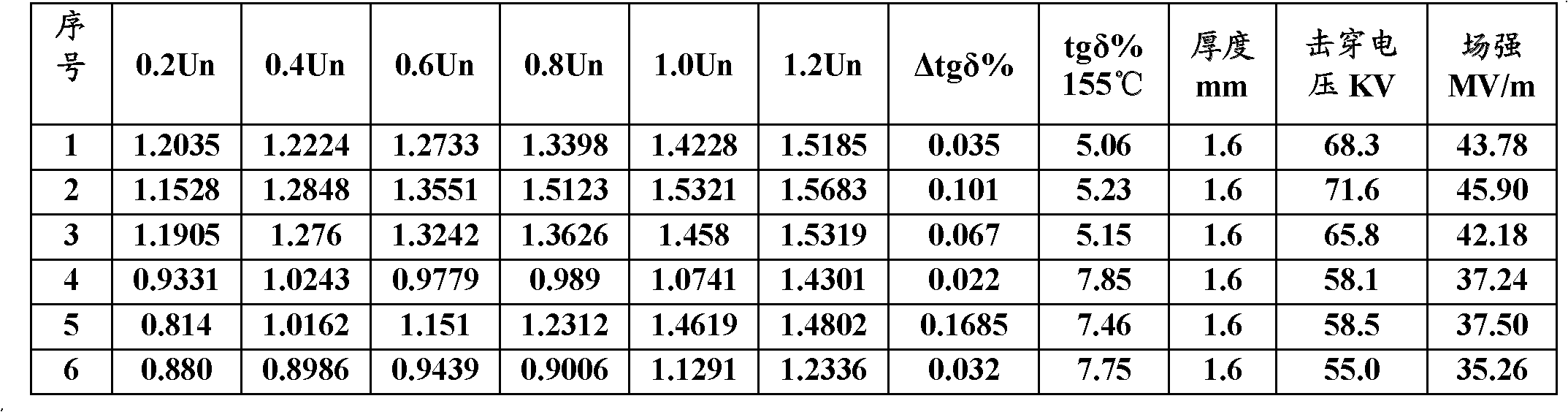

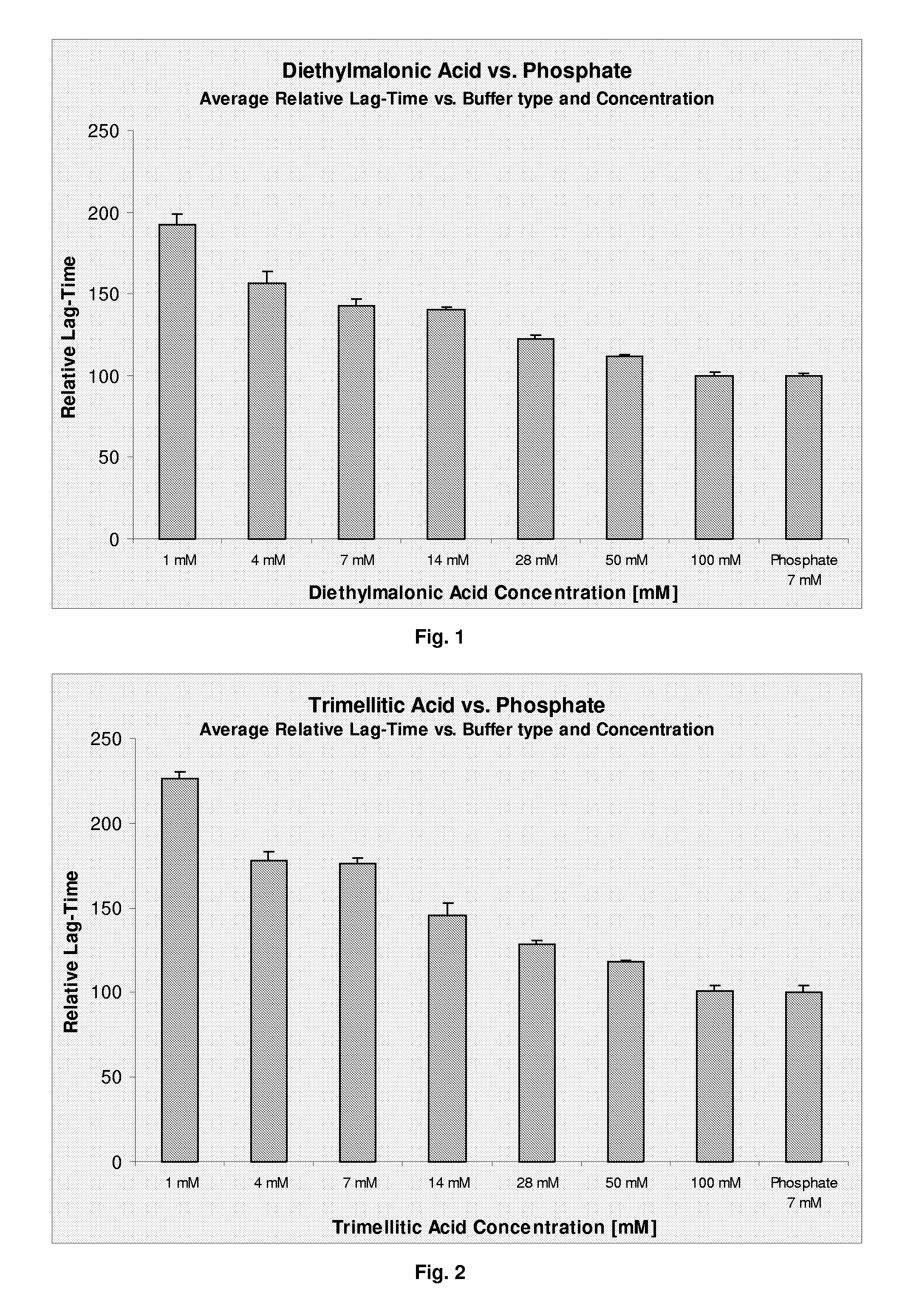

Stabilized Polypeptide Formulations

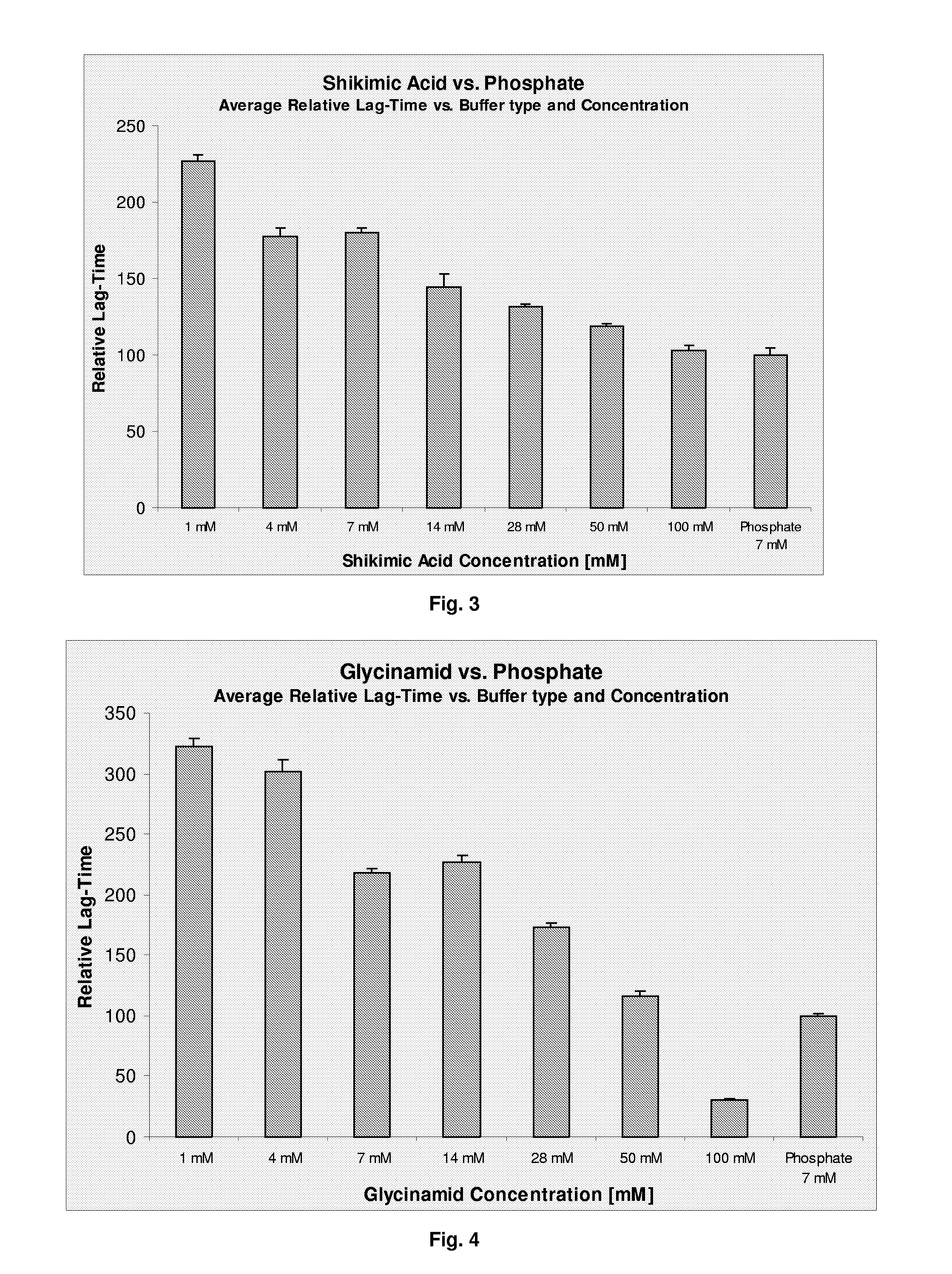

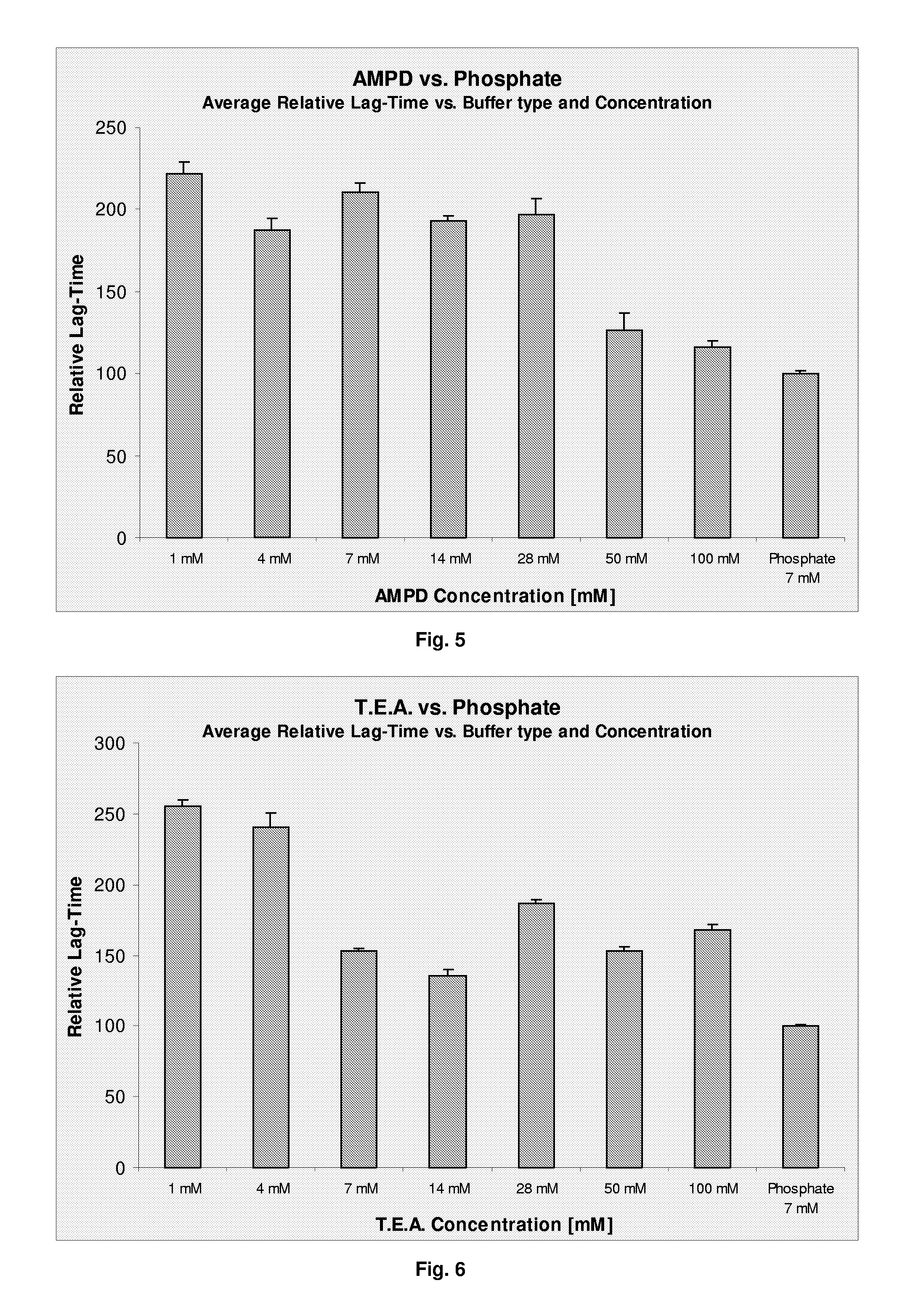

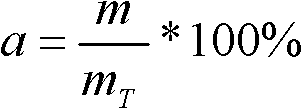

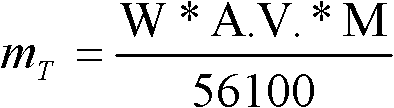

InactiveUS20090060861A1Improve physical stabilityPeptide/protein ingredientsMetabolism disorderEthylmalonic acidShikimic acid

The present invention relates to a pharmaceutical formulation comprising a polypeptide and a buffer selected from the group consisting of diethylmalonic acid, trimellitic acid, shikimic acid, glycinamid, 2-amino-2-methyl-1,3-propanediol (AMPD) and tetraethylammonium (T.E.A.) or salts thereof. Further more the invention relates to a method for improving stability of a polypeptide in a purification process comprising the step of applying a buffer selected from the group consisting of diethylmalonic acid, trimellitic acid, shikimic acid, glycinamid, AMPD and T.E.A. or salts thereof to said purification process.

Owner:NOVO NORDISK AS

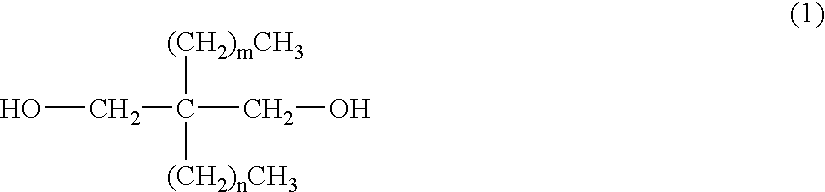

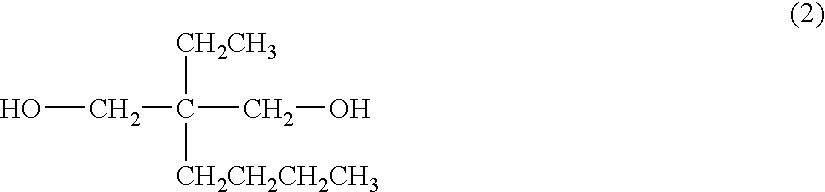

C10/C7 ester mixtures based on 2-propylheptanol

Ester mixture comprising at least one ester of an aliphatic or aromatic di- or tricarboxylic acid having a C10 alcohol component composed of 2-propylheptanol or composed of a C10 alcohol mixture composed of 2-propylheptanol and of at least one of the C10 alcohols 2-propyl-4-methylhexanol, 2-propyl-5-methylhexanol, 2-isopropylheptanol, 2-isopropyl-4-methylhexanol, 2-isopropyl-5-methylhexanol, and / or 2-propyl-4,4-dimethylpentanol, and comprising at least one ester of an aliphatic or aromatic di- or tricarboxylic acid having a C7 alcohol component composed of n-heptanol or composed of an alcohol mixture composed of n-heptanol with at least one of the C7 alcohols 2-methylhexanol and / or 2-ethylpentanol, where the aliphatic or aromatic di- or tricarboxylic acid has been selected from the group consisting of citric acid, phthalic acid, isophthalic acid, terephthalic acid, and trimellitic acid, and polyvinyl chloride composition comprising this ester mixture.

Owner:BASF CORP

High-performance aqueous alkyd resin paint

InactiveCN102604517AGood storage stabilitySave raw materialsPolyester coatingsCooking & bakingCombustion

The invention relates to a high-performance aqueous alkyd resin paint prepared through the steps that: (a) plant oil aliphatic acid is subject to a reaction with polybasic acid and polyol, such that oleiferous alkyd resin is obtained; (b) oleiferous alkyd resin is subject to a reaction with trimellitic anhydride, such that oleiferous alkyd resin with excessive carboxyl is obtained; (c) the oleiferous alkyd resin with excessive carboxyl is neutralized by using a neutralizing agent, such that aqueous alkyd resin is obtained; and (d) the aqueous alkyd resin is mixed with aqueous amino resin and water, and the pH value is regulated, such that the aqueous alkyd resin paint is obtained. The aqueous alkyd resin paint provided by the invention has good storage stability, and a paint film prepared with the paint has good mechanical properties. With the novel preparation method provided by the invention, reaction time is shortened, and production energy consumption is reduced. Water is used as a diluent of the product. The product causes no toxicity, no combustion, and no pollution to the environment. The paint can be used as common industrial baking paint, vehicle top paint, bicycle baking paint, and the like.

Owner:ETERNAL CHEM (CHINA) CO LTD

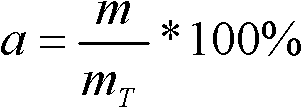

Environment-friendly ethanol migration resistance elastomer sheathing compound and preparation method thereof

InactiveCN103342868AGood mechanical propertiesExcellent resistance to ethanol migrationPlastic/resin/waxes insulatorsInsulated cablesPolyesterElastomer

The invention relates to an environment-friendly ethanol migration resistance elastomer sheathing compound and a preparation method thereof. The environment-friendly ethanol migration resistance elastomer sheathing compound comprises polyvinyl chloride resin, a plasticizer, a stabilizer, a lubricating agent and packing which serve as raw materials, wherein the polyvinyl chloride resin comprises low-polymerization-degree polyvinyl chloride resin powder with the polymerization degree of 1200-1400 and high-polymerization-degree polyvinyl chloride resin powder with the polymerization degree of 2500-3000 according to a weight ratio of 1: (0.8-1.2), and the plasticizer comprises a polyester plasticizer and one or several of trimellitic acid phosphate ester, epoxy soybean oil, dioctyl sebacate, dioctyl phthalate and di-isodecyl phthalate according to a weight ratio of (1.5-15): 1; and the preparation method of the sheathing compound comprises the following steps of: firstly carrying out low-speed kneading, then carrying out high-speed kneading and finally mixing and pelleting. The preparation method can be used for ensuring that the sheathing compound has excellent ethanol migration resistance under the condition of ensuring that the sheathing compound has good mechanical and physical properties and good machining property.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

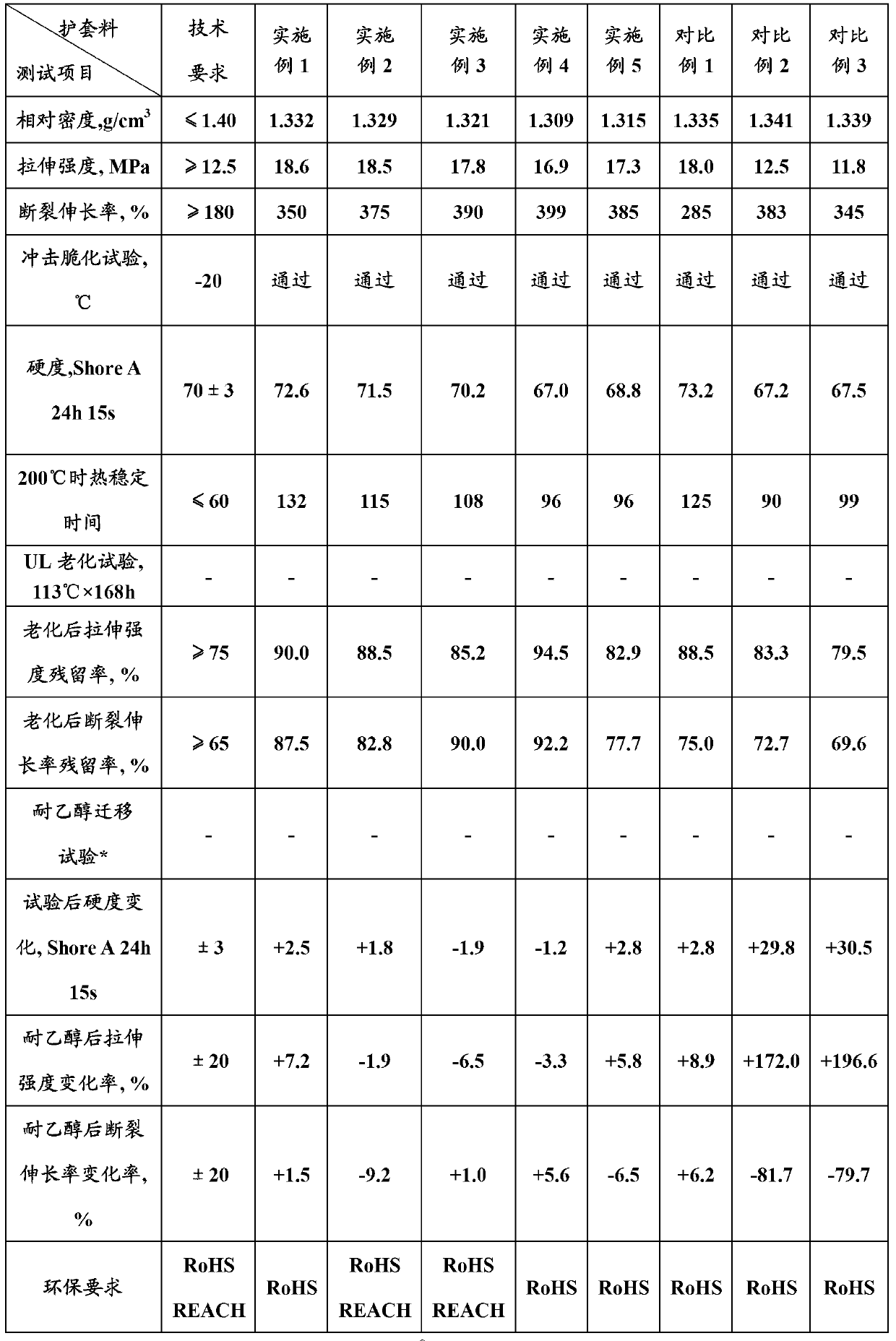

Method for producing meta benzene tricarbonic acid through sequential oxidation by using intermittent multiple cascaded Bubbling oxidation towers

ActiveCN1915960AAvoid easy-to-block problemsLess prone to damageOrganic compound preparationCarboxylic compound preparationSlurrySolvent

This invention relates to a method for preparing trimellitic acid with series intermediate bubble oxidization columns by continuous oxidation. The method comprises: (1) mixing 1,2,4-trimethylbenzene with solvent and catalyst in a kettle, heating for mixing, and sending to a series of three oxidization columns for reaction; (2) introducing the reaction products into a crystallization kettle, crystallizing to obtain mixed slurry of trimellitic acid crystal, acetic acid and water, sending to a centrifugation separator for separation, and sending the w trimellitic acid granules to the anhydridization process; (3) sending the mixture of acetic acid and water to a concentration column, and recovering acetic acid for recycling; (4) recovering trimellitic acid from the concentration column bottom product in a flash evaporation column. The series oxidization columns have such advantages as low investment, no leakage, no blockage at the inlet / outlet, continuous operation, high productivity, high yield, low raw material consumption and low energy consumption.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

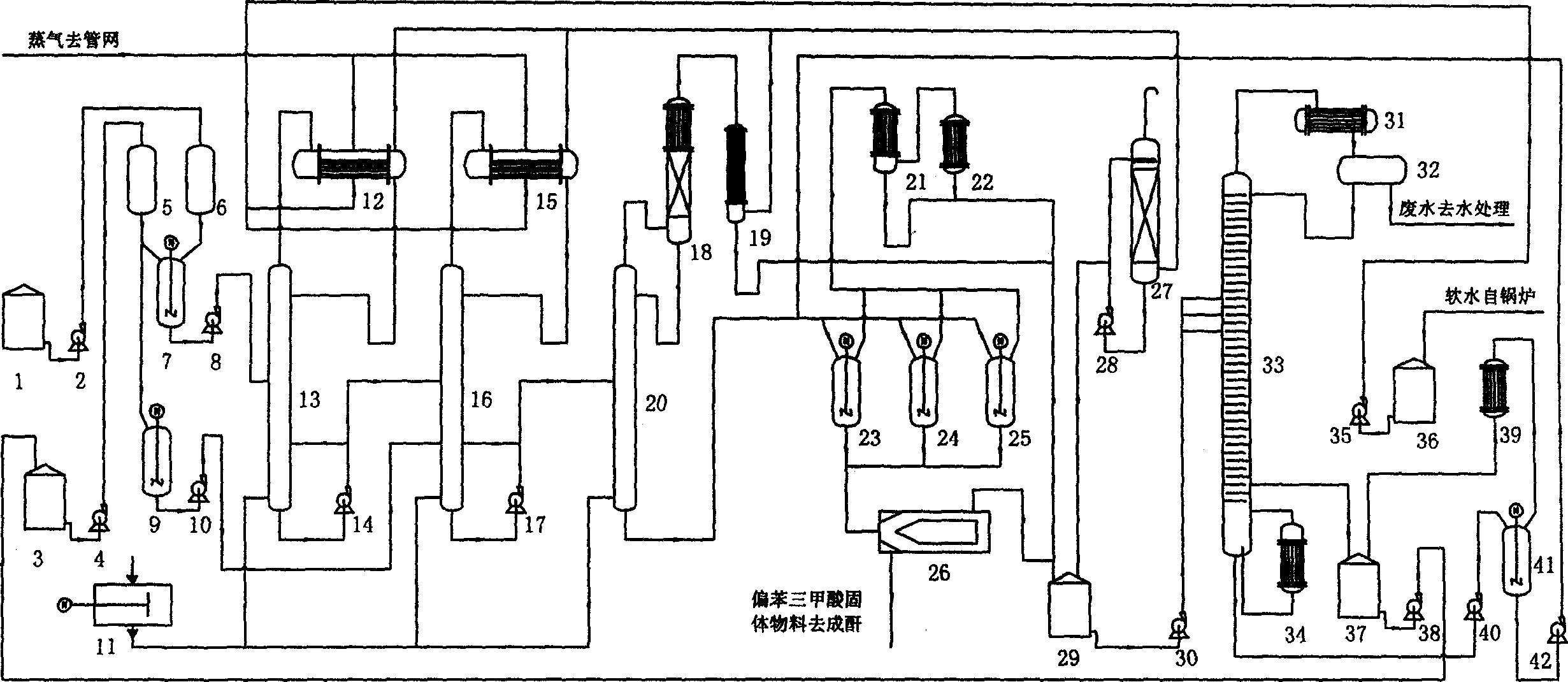

Precipitation modifying method for cellulose type solid enteric coatings

The invention relates to an improved precipitation method for the cellulose-based solid enteric-coating material; wherein, the solid enteric-coating material comprises a series of cellulose ether esters such as hydroxypropyl methylcellulose of phthalate ester (HPMCP), hydroxypropyl methylcellulose of acetic acid succinate (HPMCAS) and hydroxypropyl methylcellulose of trimellitic ester. The improved precipitation method is characterized in that the mixed solution of diluent and bleaching agent with a certain quantity is added in the reaction system at the later reaction phase, then the product is enabled to form even powdery particles in the viscous system via cooling and adding purified water for continuous precipitation. The improved precipitation method for the cellulose-based solid enteric-coating material has the advantages that the content of free acid in the product is greatly reduced; the dense and powdery particles do not need to be grinded; and dissolution rate of the product is improved to a great extent.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

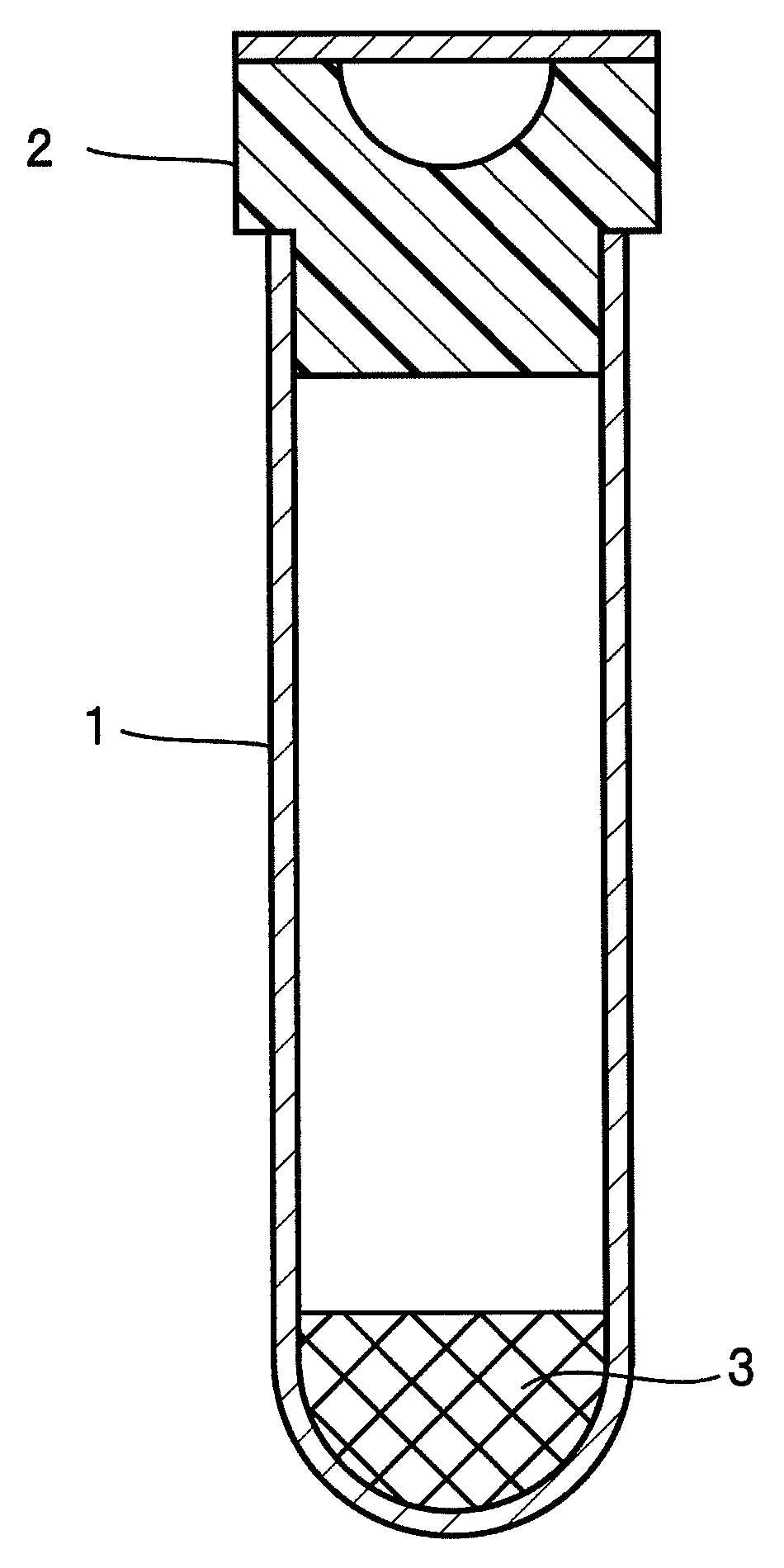

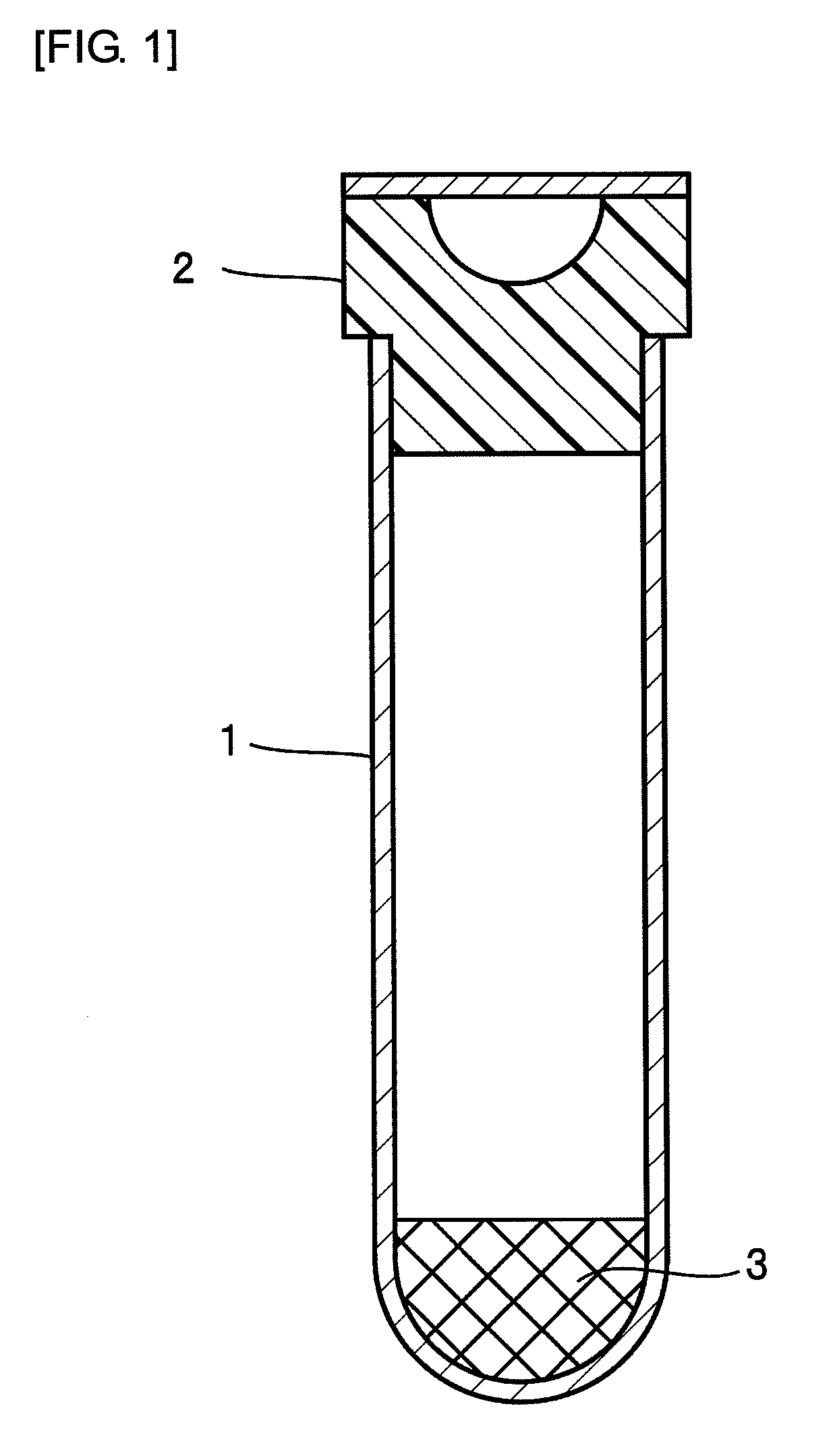

Composition for separation of serum or plasma and container for blood test

ActiveUS20090146099A1Improve compatibilityEasy to separateAnalysis material containersDifferential sedimentationAdditive ingredientBlood plasma

Disclosed is a composition for the separation of a serum or plasma, which comprises a cyclopentadiene oligomer, can be used for separating a serum or plasma by utilizing the difference in specific gravity among blood components, and enables to provide a serum or plasma having no oily component floating therein after centrifugal separation. The composition comprises a trimellitic acid ester and / or a pyromellitate ester and a cyclopentadiene oligomer. Alternatively, the composition comprises an aromatic esterified compound and a cyclopentadiene oligomer as the main ingredients and additionally comprises an inorganic micropowder and an organic gelling agent as thixotropy-imparting agents, wherein the organic gelling agent is contained in an amount of less than 0.06 parts by weight relative to 100 parts by weight of the cyclopentadiene oligomer.

Owner:SEKISUI CHEM CO LTD

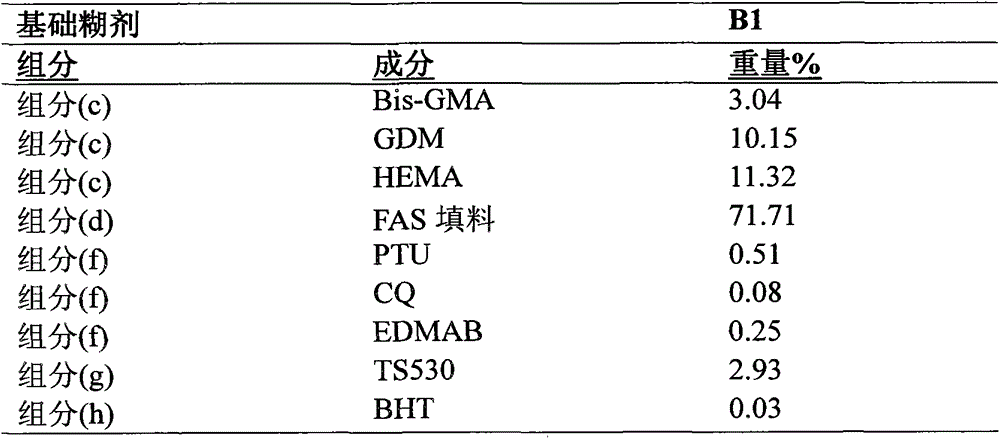

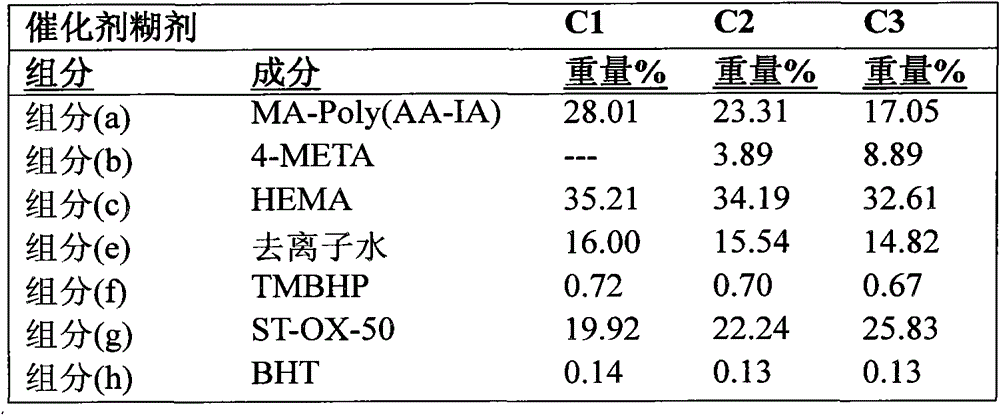

Dental resin modified glass-ionomer composition

The dental resin modified glass-ionomer composition includes an acidic polymer; an acidic polymerizable monomer selected from 4-(meth)acryloxyalkyltrimellitic anhydride, 4-(meth)acryloxyalkyltrimellitic acid, and a combination thereof; a non-acidic polymerizable monomer; a fluoroaluminosilicate glass filler; water; and at least one polymerization initiator system. The dental resin modified glass-ionomer composition is useful for a dental restorative composition, an endodontic composition, and / or an orthodontic composition, and provides significantly enhanced adhesive property toward tooth structure.

Owner:THE KERR

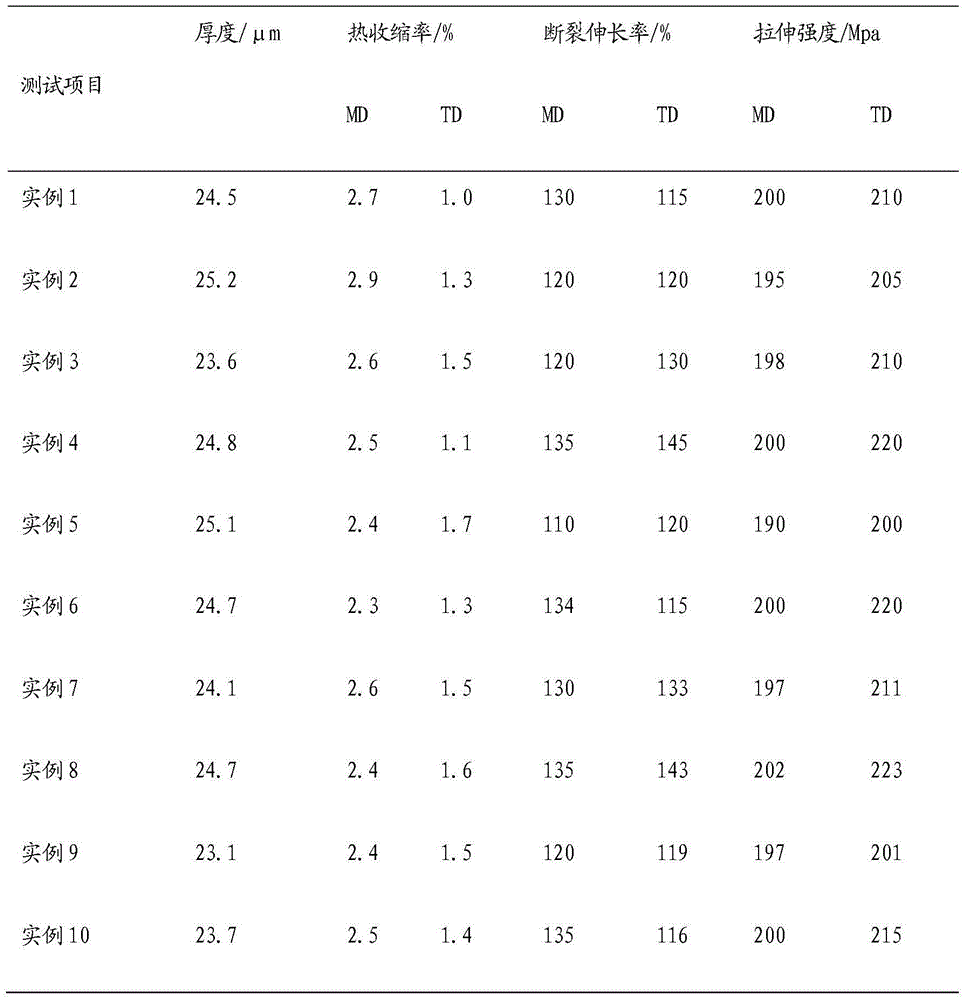

Polyester thin film used for being directly thermal-compounded with metal surface and preparation method of same

The invention belongs to the technical field of polyester thin films and provides a polyester thin film used for being directly thermal-compounded with a metal surface and a preparation method of the same. The polyester thin film is prepared by copolymerizing terephthalic acid, isophthalic acid, ethylene glycol and a fourth component and bidirectionally stretching the co-polymer, wherein the molar ratio of the terephthalic acid, the ethylene glycol, the isophthalic acid to the fourth component is 135-165:148-194:11-15:0.01-12. The fourth component is selected from one or more of isophthalic-5-sulfonate, 1,4-cyclohexane dimethanol, neo-pentanediol and trimellitic acid. The polyester thin film is free of high temperature deformation, has good insulation property, is corrosion resistant, is easy to print, has a durable surface tension force and is not liable to strip off when being laminated with the metal surface, is free of escaped substances at high temperature and has no pollution on content, is free of adhesion and is safe and sanitary.

Owner:BAOSHAN IRON & STEEL CO LTD +1

High-hardness, wear-resistant and heat-resistant material for cell phone cases

The invention discloses a high-hardness, wear-resistant and heat-resistant material for cell phone cases. The high-hardness, wear-resistant and heat-resistant material comprises the following raw materials in parts by weight: 80-120 parts of modified ethylene propylene diene monomer, 30-50 parts of styrene-butadiene rubber, 30-50 parts of epoxy resin, 30-50 parts of coumarone resin, 20-50 parts of polycarbonate, 5-15 parts of wollastonite, 2-8 parts of nano calcium carbonate, 1-5 parts of magnesium carbonate, 3-6 parts of trioctyl trimellitate, 4-8 parts of 2,6-di-tert-butyl-4-methylphenol, 2-9 parts of dicumyl peroxide, 3-4 parts of phthalic anhydride, 2-6 parts of an anti-stress-cracking agent, 2-6 parts of a lubricant, 1-5 parts of a flame retardant, 2-6 parts of a foaming agent and 2-5 parts of a toughening agent. The high-hardness, wear-resistant and heat-resistant material for the cell phone cases, disclosed by the invention, is high in hardness and good in wear resistance and heat resistance.

Owner:安徽酷米智能科技股份有限公司

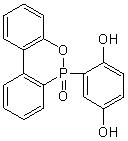

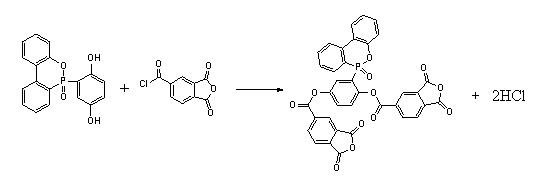

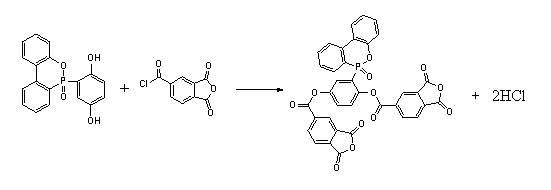

Phosphorous epoxy resin curing agent and preparation method thereof

InactiveCN102070770AImprove thermal stabilityHigh char formation rateGroup 5/15 element organic compoundsEpoxyTrimellitic anhydride chloride

The invention provides a phosphorous epoxy resin curing agent and a preparation method thereof, relating to a curing agent and a preparation method thereof. In the preparation method for synthesizing the phosphorous epoxy resin curing agent BPA-ODOPE, the mole ratio of trimellitic anhydride chloride to ODOPB ranges from (2:1) to (10:1), organic solvents are benzene, toluene and the like, inert gases are nitrogen, argon and helium, and the inert solvents for precipitation and washing are petroleum ether, pentane and the like. The preparation method comprises the following steps of: 1, adding the trimellitic anhydride chloride and the ODOPB in a reactor, adding the organic solvents, stirring under the protection of the inert gases, and obtaining the compound BPA-ODOPE; and 2, cooling the reaction mixing liquid, precipitating in the inert solvents to separate out the BPA-ODOPE, vacuum filtering, washing the precipitate with the inert solvents, drying, and obtaining white or yellowish powder-shaped product. The compound can be used as a curing agent applied in epoxy resin and also as halogen-free fire retardant.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for producing trioctyl trimellitate with trimellitic acid

ActiveCN101429126ATemperature is not harshLower requirementOrganic compound preparationCarboxylic acid esters preparationTrimellitic acidOctanol

The invention relates to a method for producing trioctyl trimellitate through using trimellitic acid. Intermediate products of trimellitic acid and methanol in the process of producing the trimellitic anhydride are esterified to generate trimethyl trimellitate; the trimethyl trimellitate and 2-ethylhexanol (commonly called asoctanol) are subjected to ester exchange to produce trimellitate (2-ethyl) trihexyl ester (trioctyl trimellitate). The method of methyl esterification and ester exchange can reduce requirement on a technology and equipment so that the intermediate product of the trimellitic acid in the process of producing the trimellitic anhydride is flexibly utilized.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

Brushing method of functional environment-friendly paint

InactiveCN104962183AAntioxidantFunctionalLiquid surface applicatorsAnti-corrosive paintsGlycerolAdipic acid

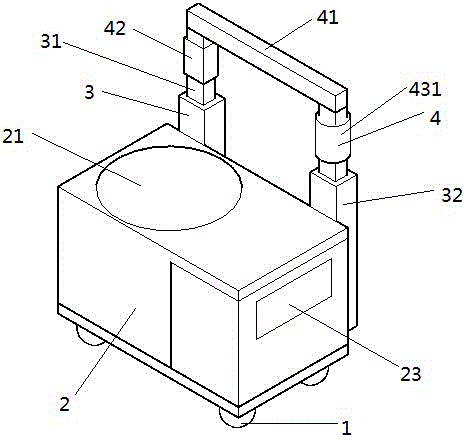

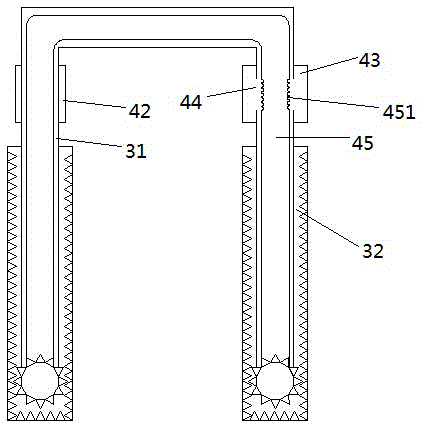

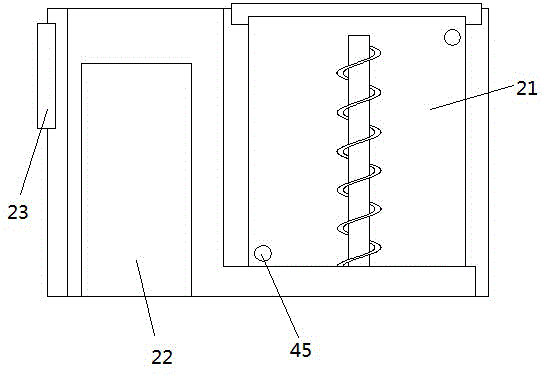

The invention discloses a brushing method of a functional environment-friendly paint, which comprises a mobile device, a carrying box arranged on the mobile device, a lifting device and a wall brushing device, wherein the lifting device is arranged on one side in the carrying box and used for lifting; the wall brushing device is arranged on the lifting device and used for wall brushing; a containing cavity for containing the paint and a power unit are arranged in the carrying box; one side of the carrying box is provided with a display control system; the lifting device comprises a first lifting bracket and a second lifting bracket; and the functional environment-friendly paint is automatically brushed on the wall surface through an automatic wall brushing machine. The paint comprises a raw material glycerol, pentaerythritol, trimethylolpropane, phthalic acid, adipic acid, trimellitie anhydride, maleic acid, triethylamine, a first solid additive, a second solid additive, a first composite regulator, a second composite regulator and a third composite regulator. The method has the advantages of low manufacturing cost and favorable wall brushing effect, and is suitable for wide application in the market.

Owner:ZHEJIANG QIAOXING CONSTR GRP

Preparation method of hyper-branched bio-based epoxy resin

The invention relates to a preparation method of hyper-branched bio-based epoxy resin. The method comprises the following steps: initiating ring-opening polymerization of lactide by a coinitiator polyol to obtain hydroxyl-terminated polylactic acid with a low molecular weight, synthesizing carboxyl-terminated hyper-branched polyester from trimellitic anhydride and the obtained polylactic acid, and synthesizing the hyper-branched epoxy resin from chloropropylene oxide and the obtained hyper-branched polyester. Lactide is from corn, potato and other crops, has wide sources, and is in favor of reducing the consumption of petroleum resources and the discharge of CO2, and the obtained epoxy resin is a novel functional material with excellent performances, has the advantages of low viscosity, high solid content, easy film formation, and good adhesion and thermal stability, has good toughening and manufacturability improving effects when blended with common epoxy resin, can be used in adhesives, coatings and composite materials as a matrix, and is suitable for molding technologies of various composite materials, so the hyper-branched bio-based epoxy resin has very wide application prospect.

Owner:JIANGSU SUPLA BIOPLASTICS CO LTD

Touch screen protective ink

The invention discloses a touch screen protective ink, which is prepared by mixing the following raw materials in portion: 100 to 250 portions of chlorethylene-vinyl acetate copolymer fluororesin, 100 to 300 portions of polyvinyl chloride A, 150 to 300 portions of polyvinyl chloride B, 1 to 3 portions of C23H16n8Cu, 20 to 60 portions of non-migrating macromolecular polyester plasticizer, 120 to 300 portions of diisononyl trimellitate, 20 to 70 portions of butyl benzyl phthalate, and 30 to 80 portions of dioctyl phthalate. The touch screen protective ink is used for protecting the surfaces of an ITO film and ITO glass in a raw material for preparing a touch screen. The touch screen protective ink plays a role in protection after heat curing or ultraviolet irradiation after printing and can be completely peeled off after use; and the touch screen protective ink has no residual adhesive bright edges, good toughness, no color change, easy peeling off, no holes, no residues and the like when peeled off after use. The touch screen protective ink can be applied to all ITO films and ITO glass on markets.

Owner:刘恒全

Modified natural rubber composite material for tire treads

The invention discloses a modified natural rubber composite material for tire treads, relating to the technical field of natural rubber processing. The modified natural rubber composite material is prepared from the following raw materials in parts by quality: 80-100 parts of natural rubber, 10-15 parts of carbon nanotube, 5-10 parts of magnesium carbonate, 3-8 parts of calcium silicate, 2-6 parts of diphenyl silanediol, 3-8 parts of coumarone indene resin, 1-5 parts of rosin, 2-5 parts of trioctyl metabenzenetricarboxylate, 2-3.5 parts of kaolin, 0.5-3 parts of zinc dialkyl dithiophosphate, 1-2 parts of titanium white, 3-8 parts of benzoperoxide, 2-6 parts of superfine magnesium hydroxide and 1-5 parts of zinc borate. By using the carbon nanotube to modify the natural rubber, the prepared rubber composite material has the advantages of high temperature resistance, wear resistance, slip resistance, aging resistance and favorable mechanical properties.

Owner:ANHUI ZHONGMA RUBBER & PLASTIC PROD

Method for refining tri-n-octyl trimellitate and used refining agent thereof

InactiveCN102320975AAvoid investmentEliminate high vacuum refining stepsOrganic compound preparationCarboxylic acid esters preparationTrimellitic acidSilicon dioxide

The invention relates to a method for refining tri-n-octyl trimellitate and a used refining agent thereof. The refining agent comprises the following components in the following mass ratio: calcium oxide: magnesia: active carbon: silicon dioxide=1:1:2:1. The method for preparing the tri-n-octyl trimellitate comprises the following refining steps of: adopting the refining agent, adding the refining agent to a crude product of the tri-n-octyl trimellitate with the mass ratio of the refining agent to trimellitic acid being 0.05-0.1:1, stirring and refining for one hour, and filtering refined mixed liquid to obtain a finished product of the tri-n-octyl trimellitate. A high-vacuum refining step is omitted in the preparation method during production, thereby the input of high-vacuum pump equipment is avoided, so that the investment of the equipment is saved, the production cost is lowered, and the market competitiveness of the product is improved.

Owner:TIANJIN CHEM REAGENT RES INST

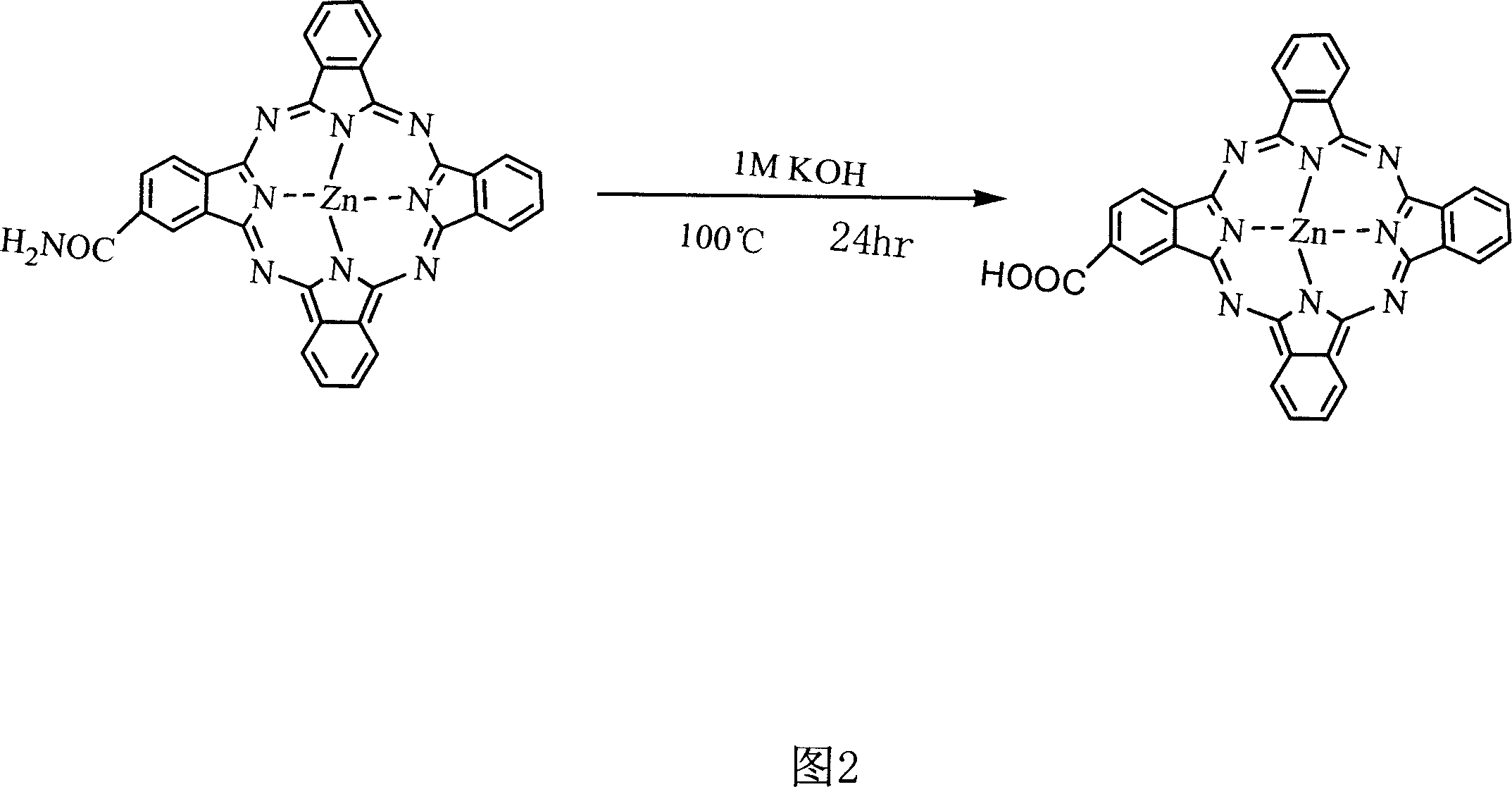

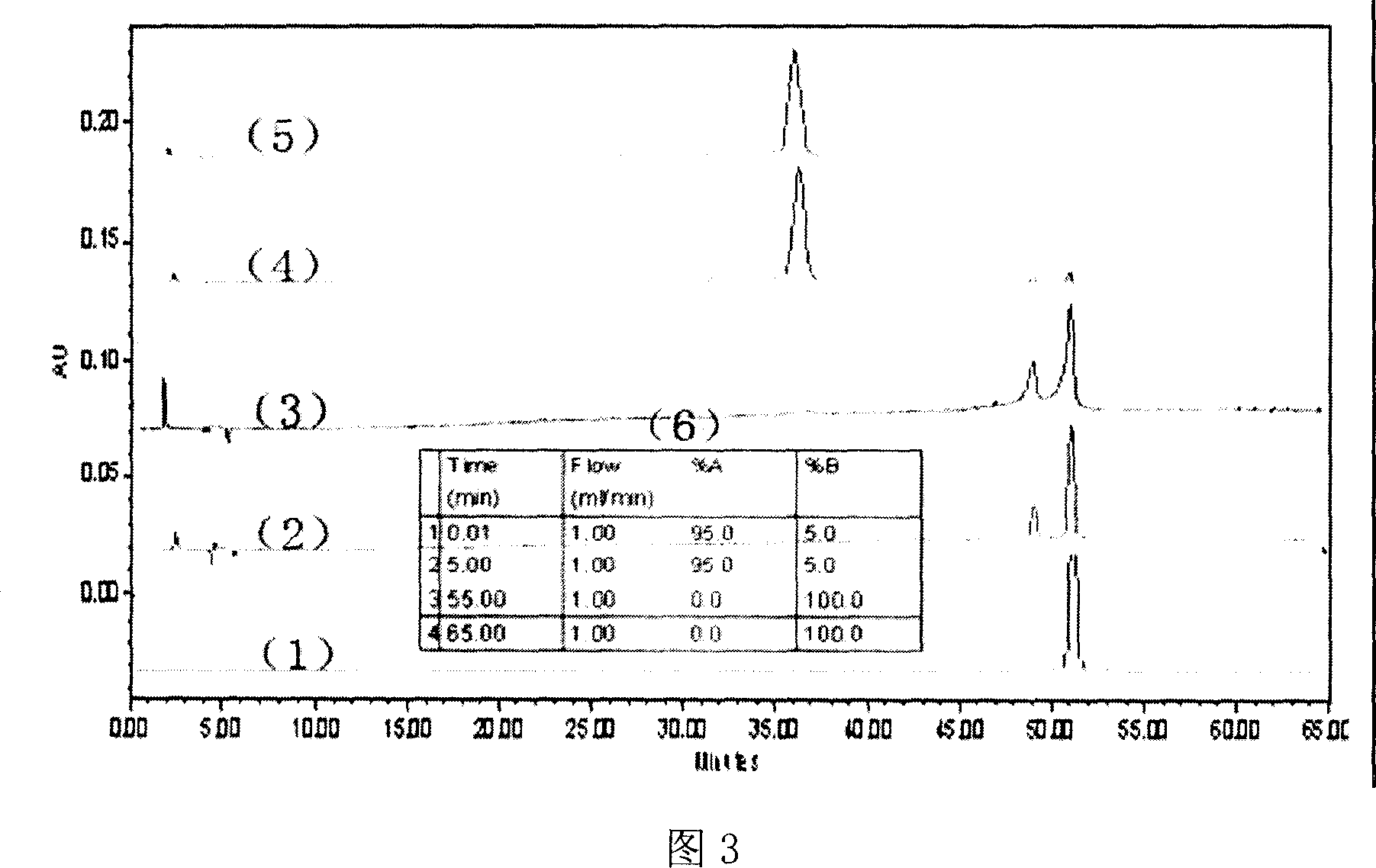

Low-toxic and broad-spectrum phthalocyanine bactericide, its production and use

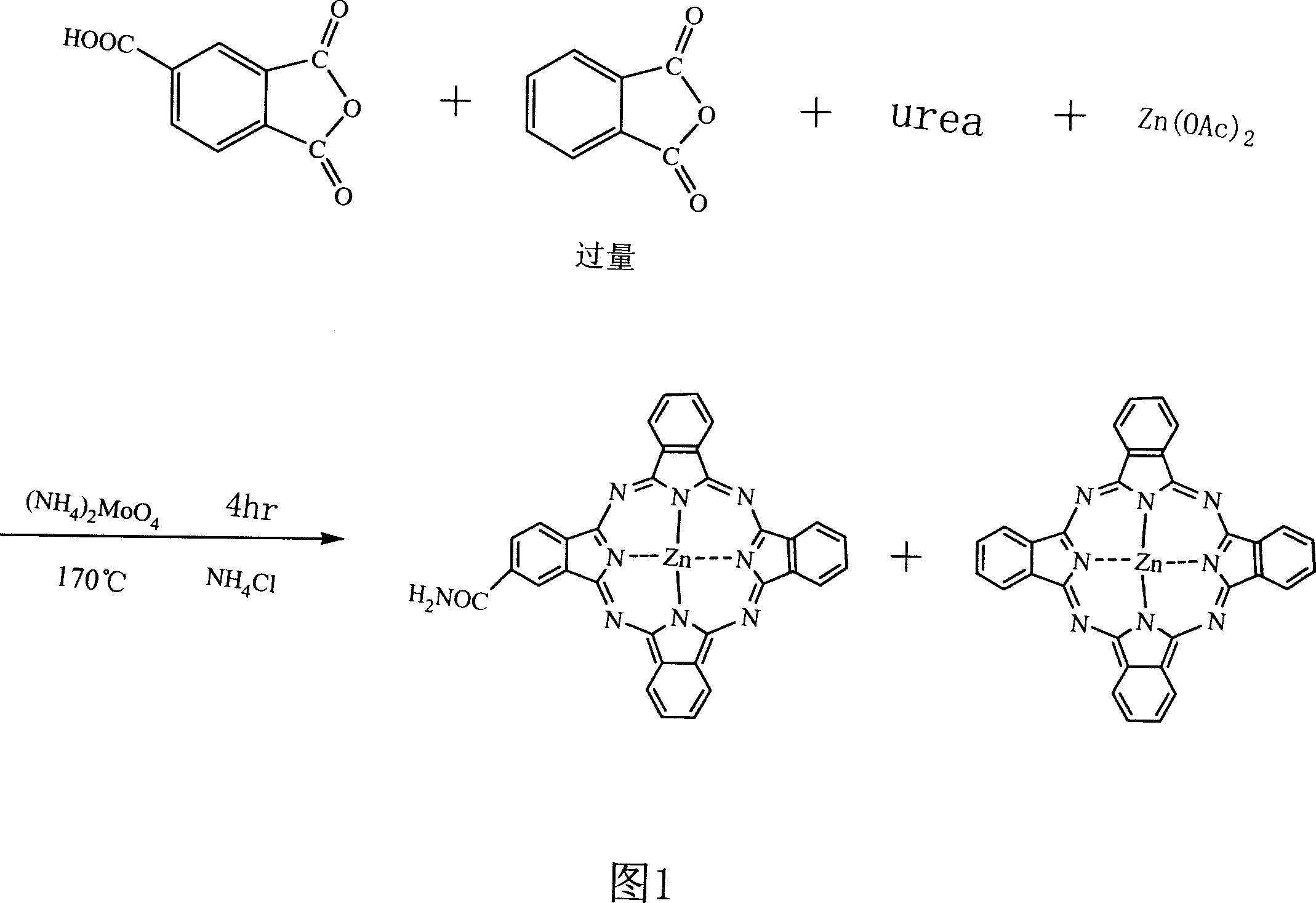

2-monocarboxyl substituted zinc phthalocyanine-oligopoly lysine coupler, its production and use are disclosed. The process is carried out by taking zinc acetate, phthalic anhydride and metaben anhydride triformate as initial raw materials, solid-phase synthesizing, chromatograph column separating to obtain pure 2-monocarboxy substituted zinc phthalocyanine, coupling it with oligopoly lysine to obtain the final product. It's multi-functional, non-toxic and has excellent broad-spectrum performance. It can be used to treat periodontal diseases.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI +2

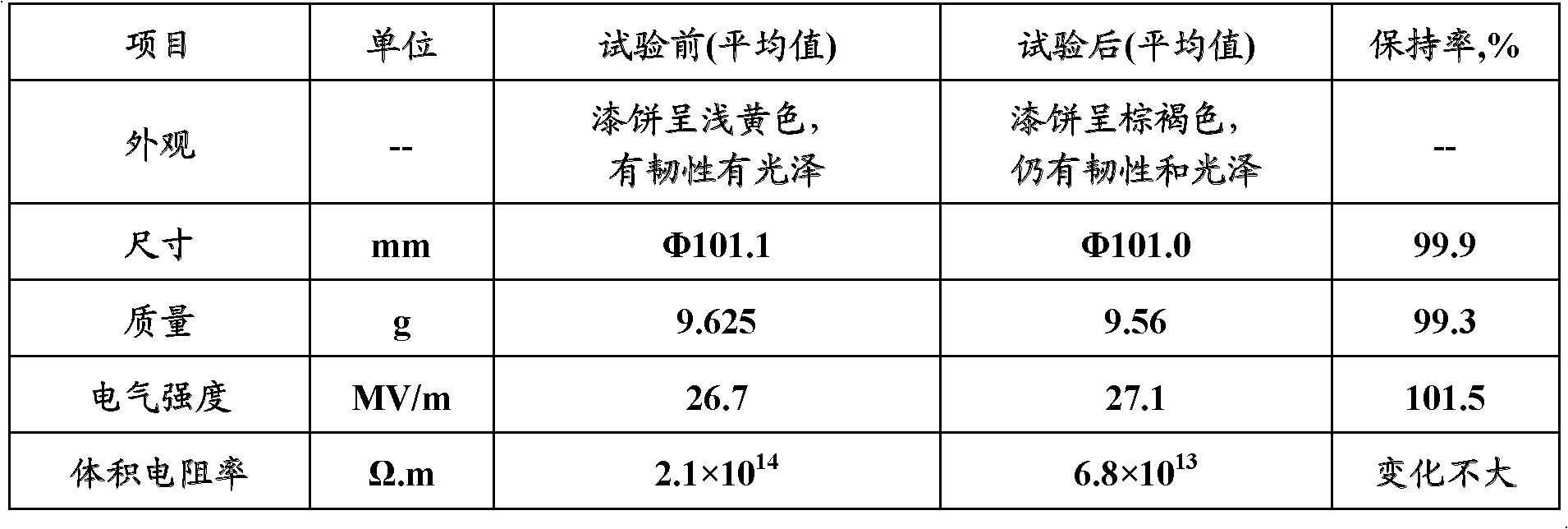

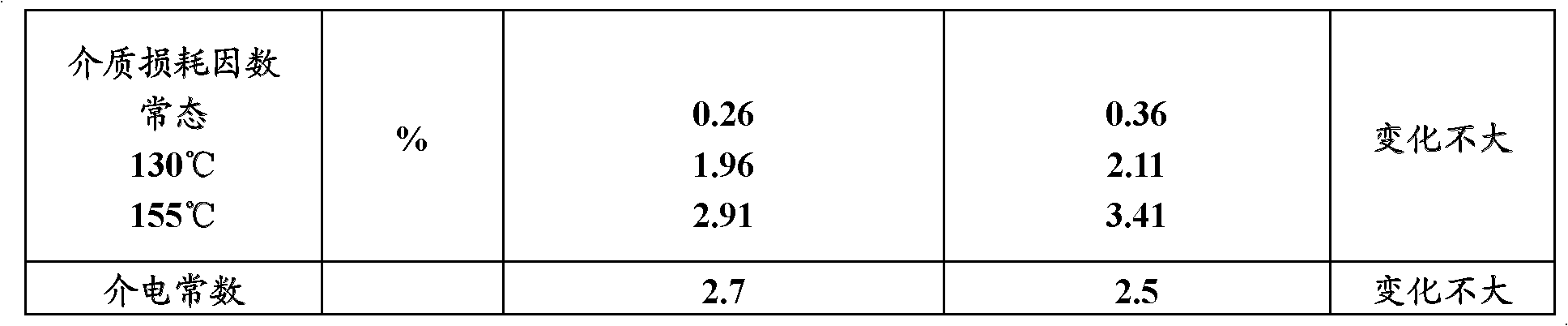

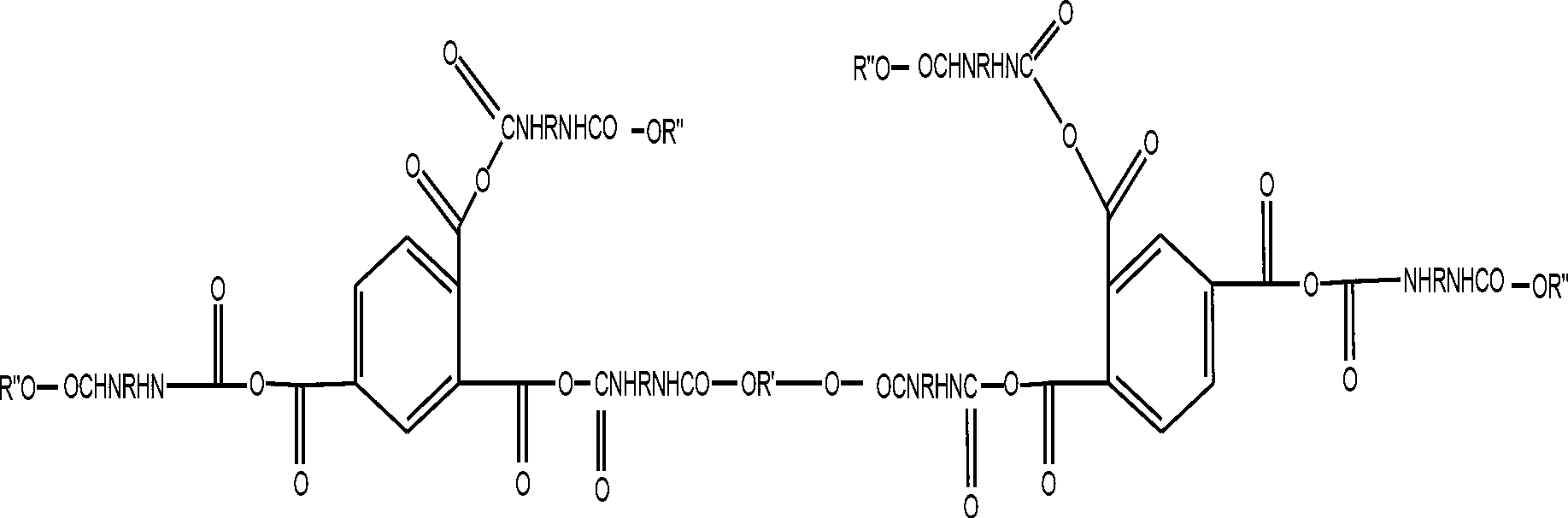

Environmentally-friendly modified heat-resistant polyester enameled wire paint and preparation method thereof

ActiveCN103059702AGenerate molecular weight growthCarbamic acid derivatives preparationOrganic compound preparationEnvironmental resistanceMass ratio

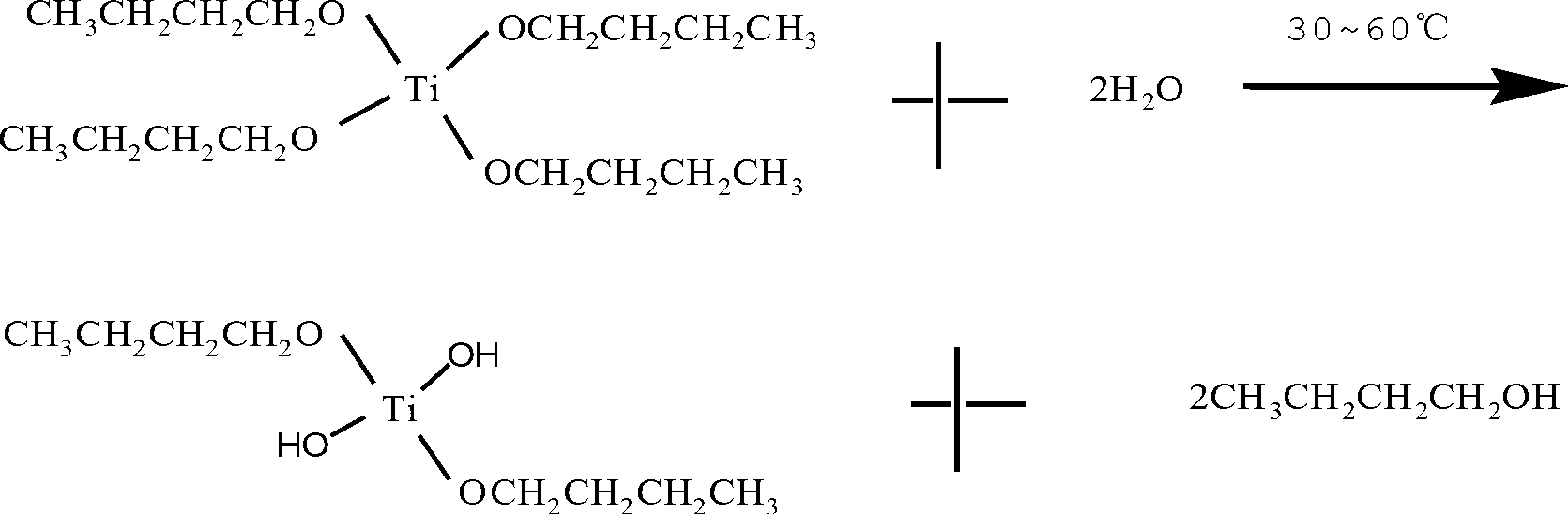

The invention discloses environmentally-friendly modified heat-resistant polyester enameled wire paint and a preparation method thereof. The environmentally-friendly modified heat-resistant polyester enameled wire paint is prepared by mixing TMA-D intermediate resin synthesized by trimellitic anhydride, water, a diisocyanate compound, dihydric alcohol and a hydroxyl compound with low-density heat-resistant polyester resin B, a curing agent, a leveling agent and the like; the mass ratio of TMA-D intermediate resin A to low-density heat-resistant polyester resin B to ether modified tTitanate compound C to leveling agent to a alcohols solvent is (100-150):(800-1000):20:(1-1.5):(50-80); and the solid content of the liquid paint reaches up tp 65-70 percent; and the viscosity is controlled within the scope of 1500-3000 mpas. The environmentally-friendly modified heat-resistant polyester enameled wire paint and the preparation method thereof have the benefits that no material which contains aromatic hydrocarbon and is difficult to degrade is used as a main solvent, the damage to a human body and the pollution to the environment during the production can be effectively reduced, and an environmentally-friendly product with good performance, low toxicity, high solid and less solvent is provided.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Material based on cellulose acetate with plasticisers and manufactured article produced therewith

ActiveUS20130169921A1Comparable in costFramesOrganic non-macromolecular adhesivePlastic materialsPlasticizer

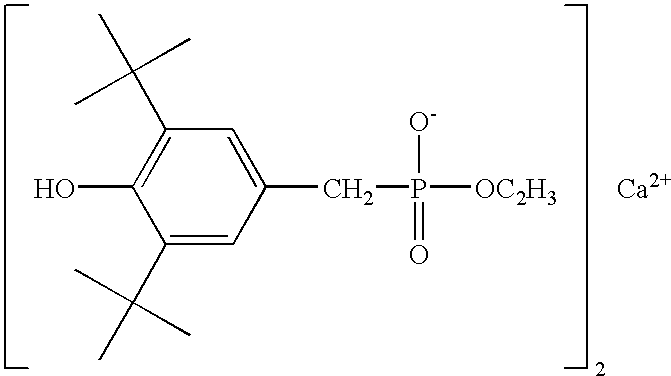

A plastic material based on cellulose acetate, including at least one plasticizer, in which the plasticizer includes a mixture of a first plasticizer including citric acid esters and at least one second plasticizer selected from the group of organic phosphates, glycerol esters and trimellitic acid esters, the content of the first plasticizer being equal to or greater than the second plasticizer and the aforementioned mixture of plasticizers constituting overall 25-35% by weight of the plastic material.

Owner:MAZZUCCHELLI 1849

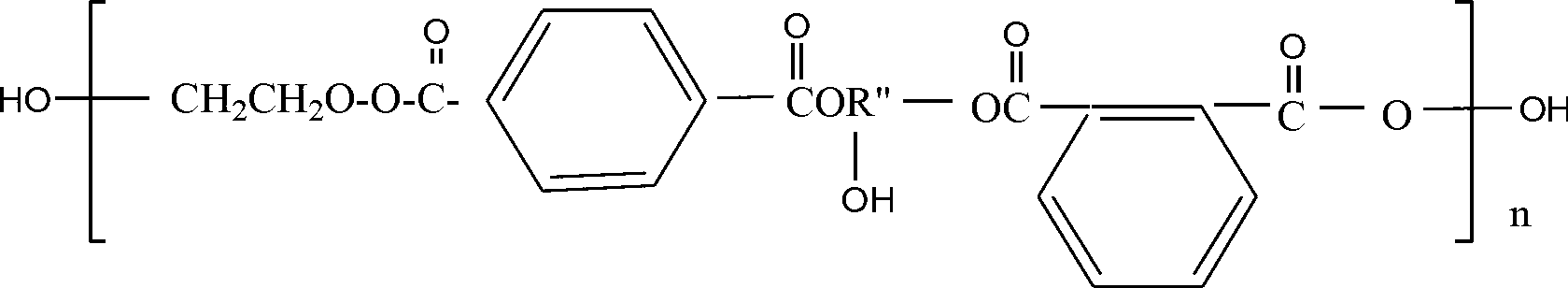

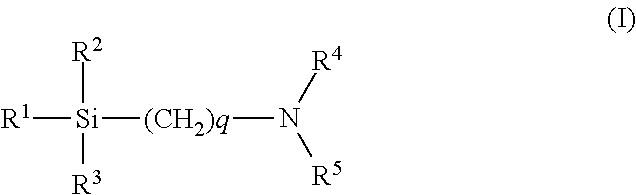

Copolyester with improved extrusion processing and color for extrusion blow molding

InactiveUS20030096942A1Organic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsPolymer scienceReaction rate

To a copolyester reacted essentially by terephthalic acid components and ethylene glycol units, adding 1% to 15 weight % of specific diol unit selected from the group consisting of at least one of 2-butyl-2-ethyl-1,3-propanediol, 3-methyl-1,5-pentanediol, 2,4-diethyl-1,5-pentanediol and hydroxypivalyl hydroxypivalate; or adding 0 to 1.0 mole % of mulfunctional group components consisting of at least one or more of trimellitic acid, trimellitic anhydride and trimethylol propane; and adding 0.01 to 0.5 weight % of compound represented by the following formula: can improve the color hue of the copolyester, and increase the reaction rate of the copolyester subjecting to solid phase polymerization, therefore improve the color hue of the shaped articles produced therefrom; furthermore, reduce the decline degree of the intrinsic viscosity after melt processing.

Owner:NANYA PLASTICS CORP

Process for making aromatic aldehydes

InactiveCN1323287AOrganic compound preparationOrganic chemistry methodsBoiling pointTrimellitic acid

Alkyl aromatic compounds are converted to alkyl aromatic aldehydes by a carbonylation reaction. The carbonylation catalyst can be a high boiling point carbonylation catalyst which allows for the separation of the aldehyde product by selective volatilization. Alternatively, the carbonylation catalyst can be selected from perfluoroalkyl sulfonic acids having 2 to 18 carbon atoms, perfluoroether sulfonic acids having 2 to 18 carbon atoms, BF3.(ROH)x wherein R represents CH3 or H and X is a number within the range of from 0.2 to 2, GaBr3, GaCl3, TaF5, NbF5, and NbBr5, with the proviso that when the catalyst is TaF5, NbF5, or NbBr5, then the reaction takes place in the absence of added HF. Preferably, all of the carbonylation reactions take place in the absence of added HF. The alkyl aromatic aldehydes can be oxidized to form an aromatic acid. A mixed xylene feed stock can be converted to a mixture of diemthylbenzaldehydes and then oxidized to form trimellitic acid without the need to separate the xylene or dimethylbenzaldehyde isomers.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst for synthesizing trioctyl trimellitate from trimellitic anhydride or trimellitic acid and octanol through esterification and application thereof

ActiveCN103007920ALight colorHigh volume resistivityOrganic compound preparationCarboxylic acid esters preparationWastewaterOctanol

The invention discloses a catalyst for synthesizing trioctyl trimellitate from trimellitic anhydride or trimellitic acid and octanol through esterification and application thereof. The catalyst is a solid oxide and has excellent catalytic effect so that prepared trioctyl trimellitate is shallow in color and has high volume resistance. Furthermore, as the catalyst is a non-acid catalyst, no neutralizing water washing operation is needed in the production process; therefore, the posttreatment procedure is simplified; no wastewater is discharged in the production process and no pollution is caused on the environment; and the production process is clean and meet the national related industrial policy requirements for energy saving and emission reduction of the chemical engineering industry.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Preparation method of high-flowability positive ion modified copolyester

The invention relates to a preparation method of high-flowability positive ion modified copolyester. Binary acid I, dihydric alcohol I and high-flowability branched structure modifiers are uniformly mixed and then subjected to esterification reaction, and isophthalic acid-5-sodium sulfonate and dihydric alcohol II esterification products are led in after esterification reaction and subjected to pre-condensation reaction and final polycondensation reaction to prepare the high-flowability positive ion modified copolyester. The high-flowability branched structure modifiers are more than one of pyromellitic anhydride, cyclopentane tetracarboxylic anhydride, benzophenone tetracarboxylic dianhydride, trimellitic anhydride, mellophanic dianhydride, pyromellitic acid, cyclopentane tetracid, benzophenone tetracid, trimellitic acid and mellophanic acid, and the dihydric alcohol II is more than one of butanediol, pentanediol, hexanediol, heptanediol, octylene glycol, nonanediol and decanediol. Two modified components are introduced, so that flow-activation energy is remarkably reduced, acting force of the copolyester and tube walls in the flowing process is reduced, and melt viscosity loss iseffectively controlled.

Owner:DONGHUA UNIV

Rubber composition and pneumatic tire

Provided are a rubber composition that achieves a balanced improvement in grip performance during the initial to late phases of running and abrasion resistance, and a pneumatic tire formed from the rubber composition. The present invention relates to a rubber composition containing a rubber component, sulfur, and a molten mixture of a solid resin and a plasticizer, the solid resin having an SP value of 9.2 to 13 and / or a softening point of 130° C. or higher, the plasticizer including at least one compound selected from the group consisting of phosphoric acid esters, phthalic acid esters, aliphatic polybasic acid esters, trimellitic acid esters, acetic acid esters, and ricinoleic acid esters, the solid resin being present in an amount of 1 part by mass or more per 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com