Polyester thin film used for being directly thermal-compounded with metal surface and preparation method of same

A polyester film, metal surface technology, applied in the field of polyester film, can solve the problems of difficult metal surface bonding, difficult to have lasting surface tension of polyester film, etc., and achieve the effects of low cost, easy printing, and good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

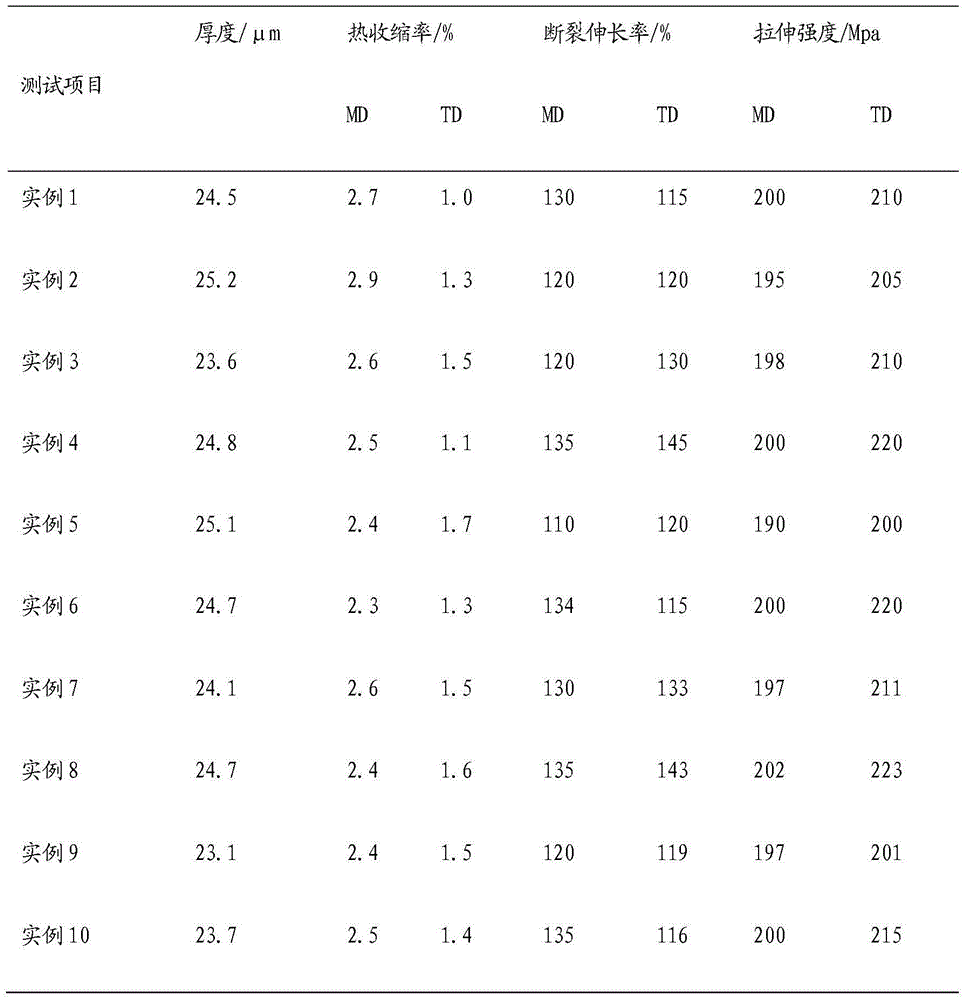

Examples

Embodiment 1

[0034] The experiment was carried out in a 10L reactor, and terephthalic acid, isophthalic acid, and ethylene glycol were added to the In the reactor, add catalyst, 1,4-cyclohexanedimethanol and dimethyl isophthalate-5-sodium sulfonate, antimony trioxide (molar content is 80ppm) is catalyst, wherein 1,4- The molar content of cyclohexanedimethanol is 3.5%, and the molar content of dimethyl-5-sodium isophthalate-5-sulfonate is 0.01%, and N2 is used as a protective gas, and the temperature is raised with stirring under a gas pressure of 0.1 MPa. Control the temperature at 185°C. After about two hours, when the esterification water is significantly reduced, release the pressure to normal pressure to complete the esterification reaction. Next, the temperature is raised and the pressure is lowered. The temperature in the reactor is raised to 280°C, and the pressure drops to 100 Pa to start vacuum polycondensation. The polycondensation takes 1.8 hours to obtain a polyester melt, whic...

Embodiment 2

[0038] The experiment was carried out in a 10L reactor. Terephthalic acid, isophthalic acid, and ethylene glycol were added to the In the reactor, add catalyst and isophthalic acid-5-sodium sulfonate, antimony trioxide (molar content is 40ppm), titanate (molar content is 3ppm) are catalyst, wherein isophthalic acid-5- The molar content of sodium sulfonate is 3.8%, with N 2 Substitution, stirring and heating under a gas pressure of 0.1MPa. Control the temperature at 175°C, and after about 1.5 hours, when the water to be esterified decreases significantly, release the pressure to normal pressure to complete the esterification reaction. Next, the temperature is raised and the pressure is lowered. The temperature in the reactor is raised to 280°C, and the pressure drops to 100 Pa to start vacuum polycondensation. The polycondensation takes 1.8 hours to obtain a polyester melt, which is cooled in a water tank and pelletized to obtain a chemically modified polyester. The titanate ...

Embodiment 3

[0041] The experiment was carried out in a 10L reactor, and terephthalic acid, isophthalic acid, and ethylene glycol were added to the In the reactor, add catalyst and trimellitic acid and isophthalic acid-5-sodium sulfonate again, antimony trioxide (molar content is 40ppm), titanate (molar content is 3ppm) is catalyst, wherein The total molar content of triformic acid and isophthalic acid-5-sodium sulfonate is 2.5%, replaced with N2, stirred and heated under a gas pressure of 0.1 MPa. Control the temperature at 175°C, and after about 1.4 hours, when the water to be esterified decreases significantly, release the pressure to normal pressure to complete the esterification reaction. Next, the temperature is raised and the pressure is lowered. The temperature in the reactor is raised to 270°C, and the pressure drops to 100 Pa to start vacuum polycondensation. The polycondensation takes 1.8 hours to obtain a polyester melt, which is cooled in a water tank and pelletized to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com