Patents

Literature

175results about How to "Non-stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

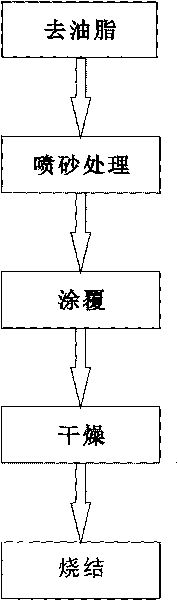

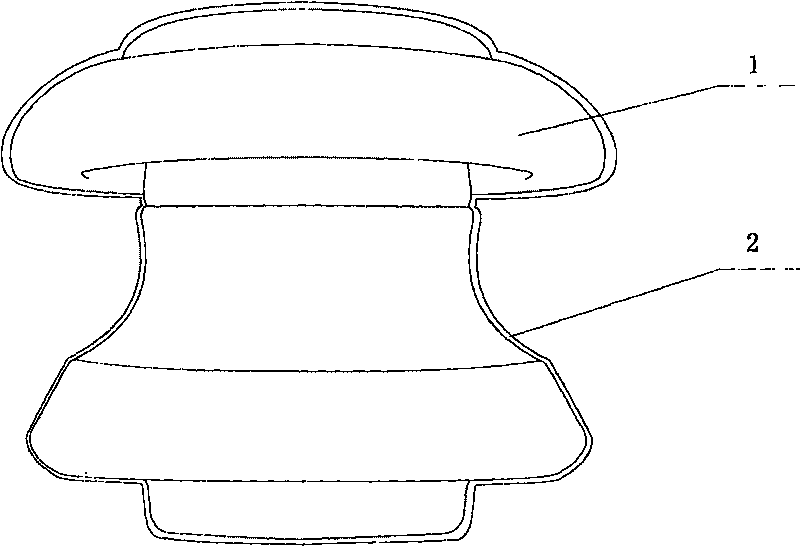

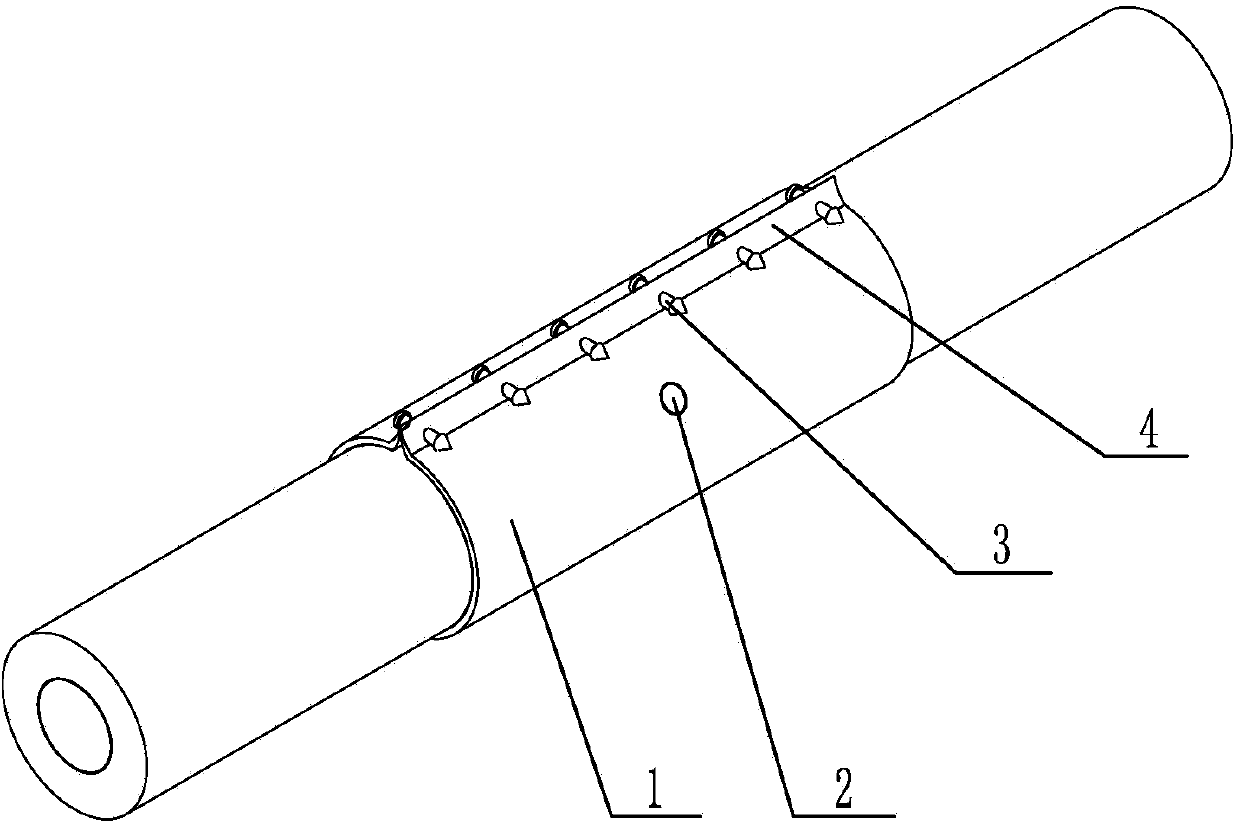

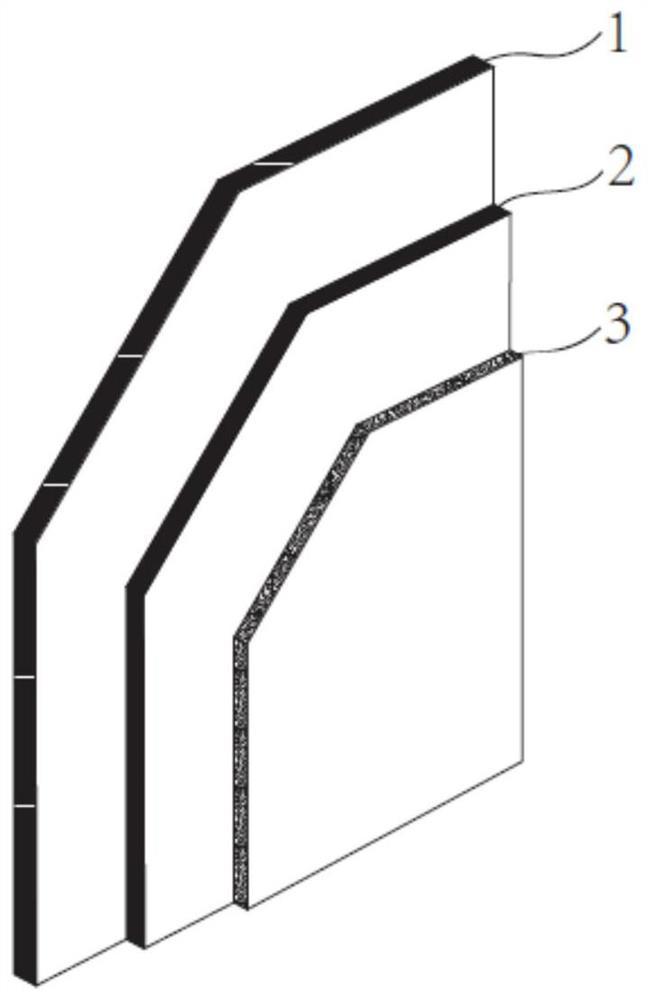

Coating method for wire or electrical insulator with teflon coating

InactiveCN101707103AExcellent heat and low temperature resistanceReduce permeabilityInsulatorsInsulating conductors/cablesTemperature resistanceTransmission line

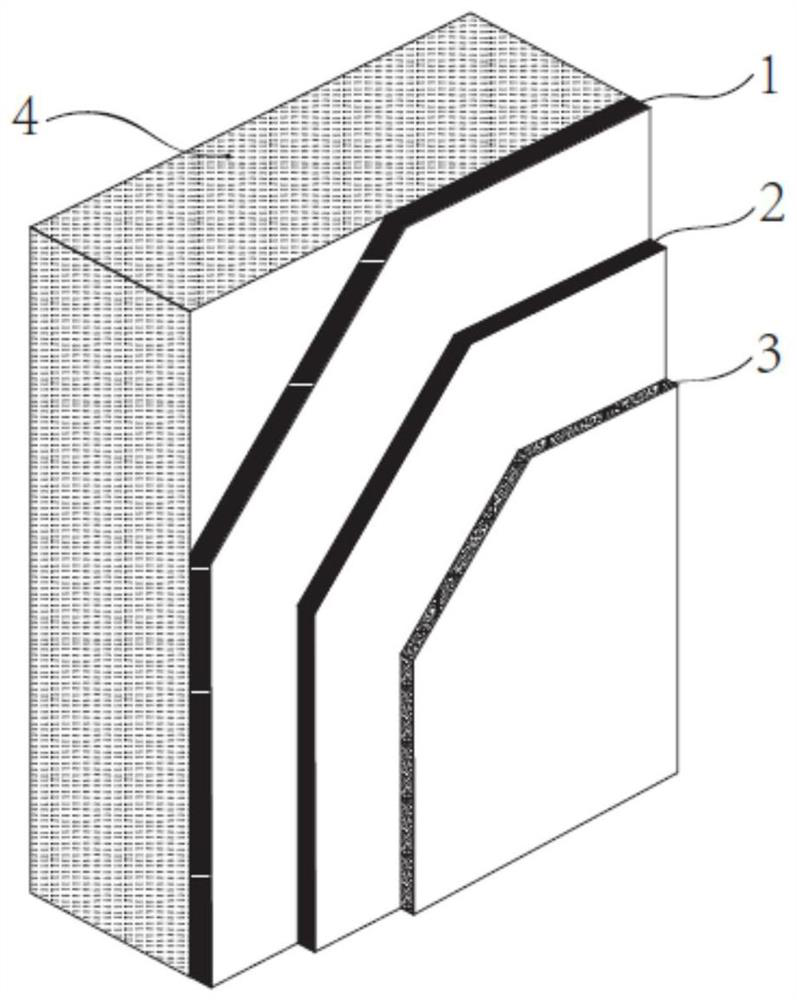

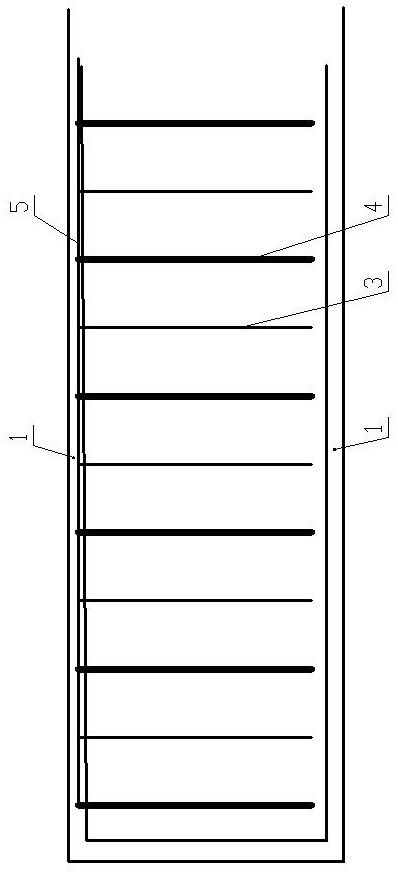

The invention relates to a coating method for a wire or an electrical insulator with a teflon coating, which relates to the technical field of transmission lines. The coating method for the electrical insulator (3) comprises the steps of degreasing, sand-blasting treatment, coating, drying and sintering. The coating method for the wire (1) comprises the steps of degreasing, coating adhesives and spraying the coatings. As the teflon has inadhesion property and moisture resistance, the aim of preventing serious icing can be fulfilled by spraying the teflon on the outsides of the wire and the electrical insulator, and the aim of preventing the pollution flashover can be fulfilled by spraying the teflon on the outside of the electrical insulator. As the teflon coating film has excellent heat resistance and low temperature resistance, the wire or electrical insulator sprayed with the teflon can work normally in a high-temperature environment in summer or a low-temperature environment in winter.

Owner:河南省电力公司洛阳供电公司输电公司

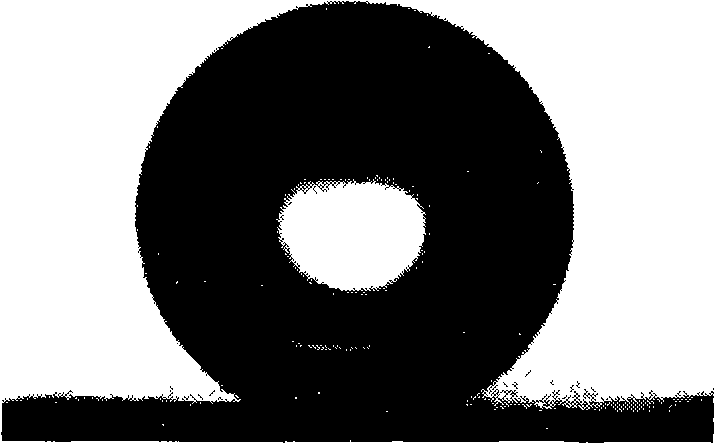

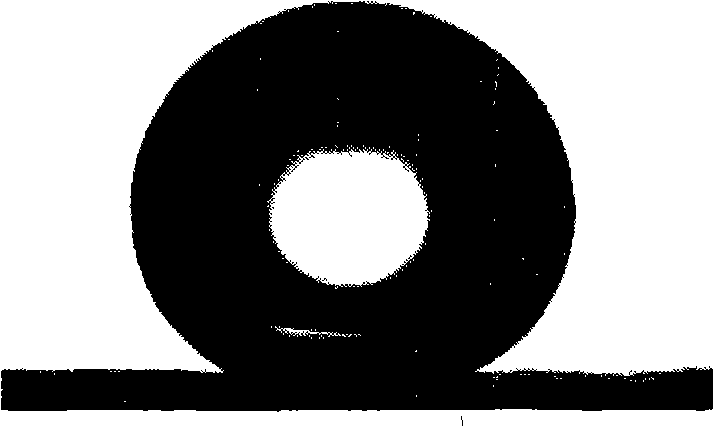

Method for acquiring super-double-thinning property on metallic copper or copper alloy backing material surface

InactiveCN101492815AAvoid corrosionTo achieve the purpose of anticorrosionMetallic material coating processesSurface finishingWork in process

The invention relates to corrosion resistance and self cleaning of a metal surface, in particular to the corrosion resistance and self cleaning realized by obtaining super-amphiphobic property on the surface of copper metal and copper alloy. The method is to clean the copper metal, a copper alloy base material or a base material coated by the copper metal on the surface to be immersed in a perfluorinated aliphatic acid organic solvent with concentration of 0.005-0.05mol / L, thereby obtaining a self-cleaning surface with super-dual hydrophobic property on the surface of the copper metal, the copper alloy base material or the base material coated by the metal copper on the surface. The method has simple operation and low requirement on equipment, is not restricted by the shape of the base material, is also applicable to surface treatment of a finished product and a semi-finished product workpiece, and is easy to realize industrialization. The method can be widely applied to each department of national production and living, such as machinery, shipbuilding, electric power, military, building, kitchenware and the like, and has wide practical value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

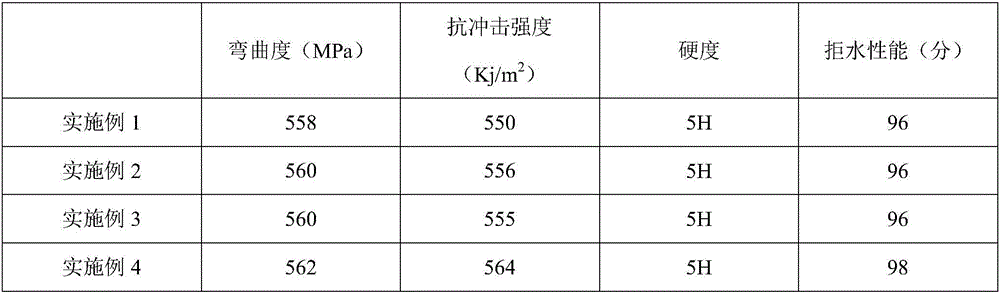

High-abrasion-resisting glass fiber fabric and preparation method thereof

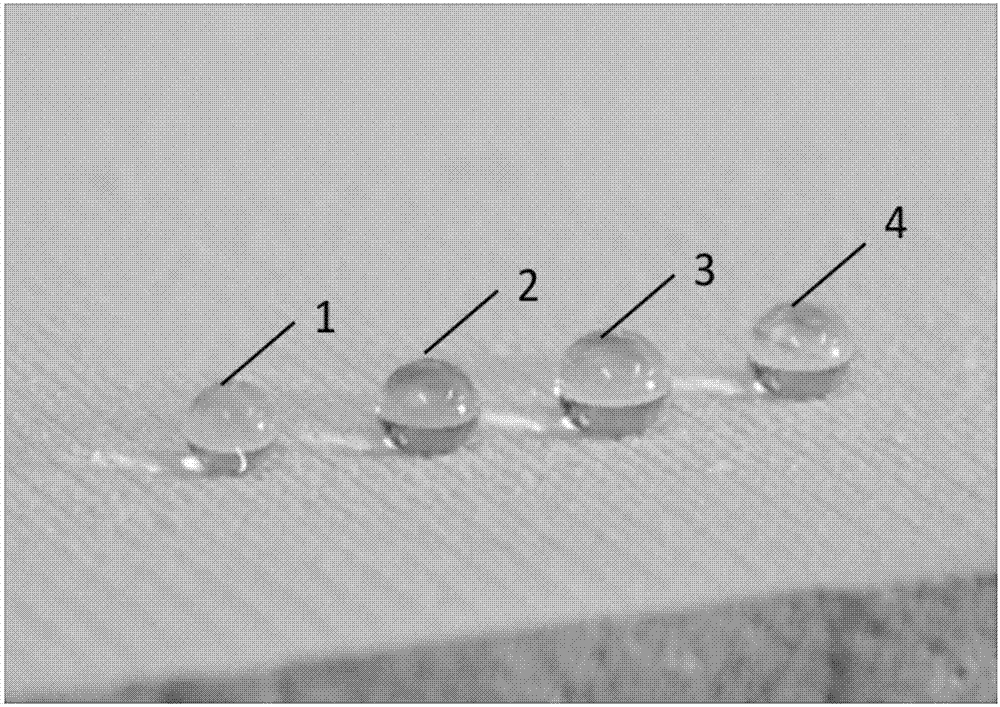

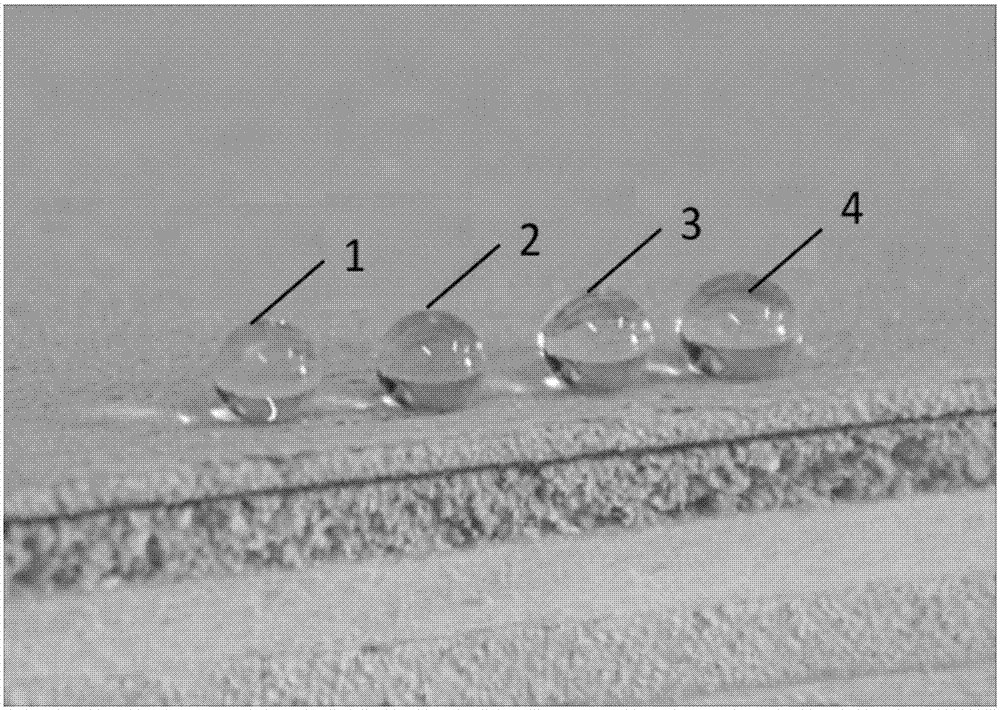

The invention discloses a high-abrasion-resisting glass fiber fabric and a preparation method thereof. The preparation method comprises the steps that 1, glass fiber monofilaments are plain-woven to obtain a basic glass fiber fabric; 2, the basic glass fiber fabric is put in a sizing agent to be dipped for 2-3 hours; 3, the excessive sizing agent on the basic glass fiber fabric is extruded out, and air bubbles are removed to obtain a preformed glass fiber fabric; 4, the glass fiber monofilaments are parallelly concentrated to obtain protofilaments, the protofilaments are cut according to the length of 60-70 mm and are randomly and uniformly laid on the preformed glass fiber fabric, then a bonder is applied, and heating and curing are performed to obtain a basic material; 5, the sizing agent in the step 2 is uniformly applied to two sides of the basic material in a coated mode, and then ultraviolet curing is conducted on the basic material to obtain the high-abrasion-resisting glass fiber fabric. The high-abrasion-resisting glass fiber fabric has high hardness, good mechanical strength and a high water-repellency performance value, and good abrasion resistance is reflected. The curvature and anti-impact strength are ideal, and it is indicated that the high-abrasion-resisting glass fiber fabric has good water repellency.

Owner:嘉兴杰特新材料股份有限公司

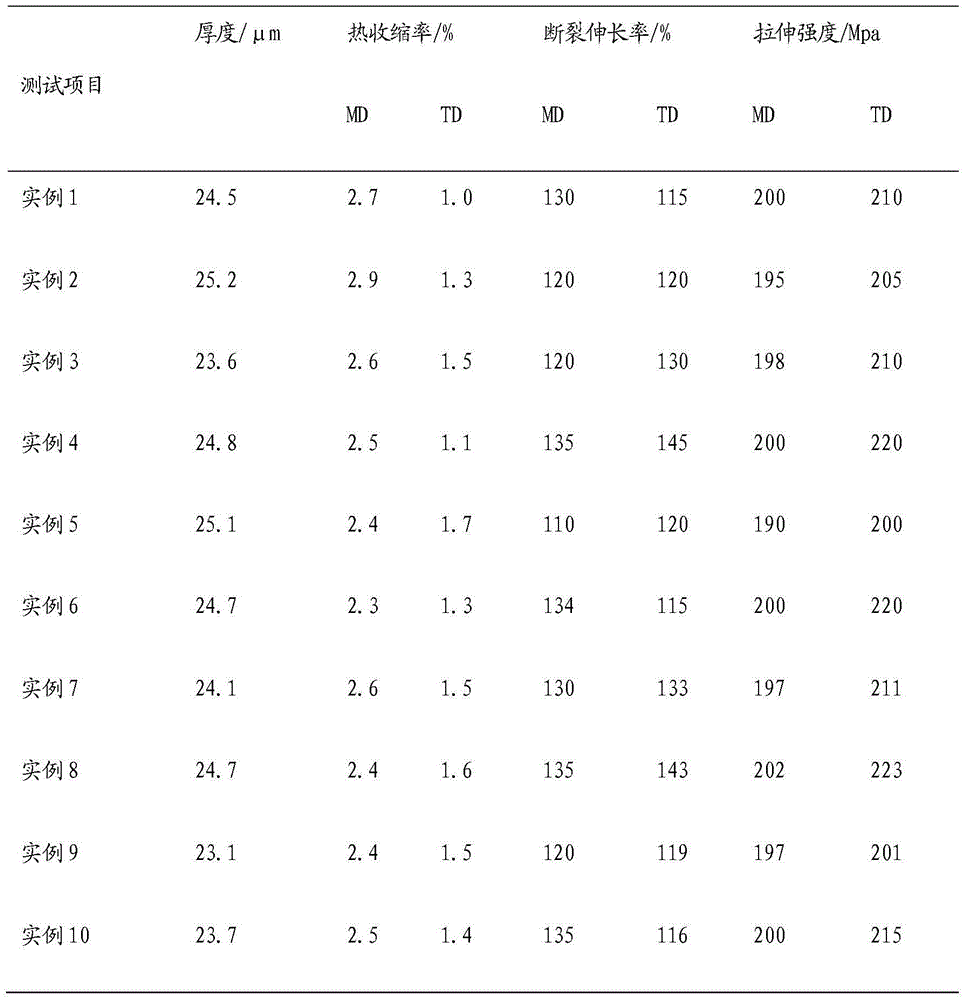

Polyester thin film used for being directly thermal-compounded with metal surface and preparation method of same

The invention belongs to the technical field of polyester thin films and provides a polyester thin film used for being directly thermal-compounded with a metal surface and a preparation method of the same. The polyester thin film is prepared by copolymerizing terephthalic acid, isophthalic acid, ethylene glycol and a fourth component and bidirectionally stretching the co-polymer, wherein the molar ratio of the terephthalic acid, the ethylene glycol, the isophthalic acid to the fourth component is 135-165:148-194:11-15:0.01-12. The fourth component is selected from one or more of isophthalic-5-sulfonate, 1,4-cyclohexane dimethanol, neo-pentanediol and trimellitic acid. The polyester thin film is free of high temperature deformation, has good insulation property, is corrosion resistant, is easy to print, has a durable surface tension force and is not liable to strip off when being laminated with the metal surface, is free of escaped substances at high temperature and has no pollution on content, is free of adhesion and is safe and sanitary.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Preparation method of sustainable anti-icing super-amphiphobic coating

ActiveCN107116017AImproved long-lasting anti-icing performanceLong-lasting anti-icing performancePretreated surfacesAnti-corrosive paintsEpoxySilanes

The invention relates to the field of preparation of super-hydrophobic or super-amphiphobic coatings, in particular relates to a preparation method of a sustainable anti-icing super-amphiphobic coating. The method comprises the following steps: 1, cleaning a substrate surface and carrying out sand-blasting roughening treatment; 2, blending epoxy resins, epoxy resin curing agents and a first solvent to obtain an epoxy resin solution; 3, dispersing submicron particles and nanoparticles into a second solvent, and then adding fluoroalkyl silane to obtain particle composite suspension liquid; 4, spraying substrate surface subjected to the treatment in step 1 with the epoxy resin solution obtained in step 2, and carrying out semi-curing on the epoxy resin adhesive; 5, spraying the substrate surface subjected to the treatment in step 4 with the particle composite suspension liquid obtained in step 3, and carrying out complete curing; 6, obtaining the sustainable anti-icing super-amphiphobic coating. The method has the advantages that the super-amphiphobic coating prepared on all substrate surfaces has good durability and fastness, and has sustainable anti-icing performance.

Owner:哈尔滨毓干科技有限公司

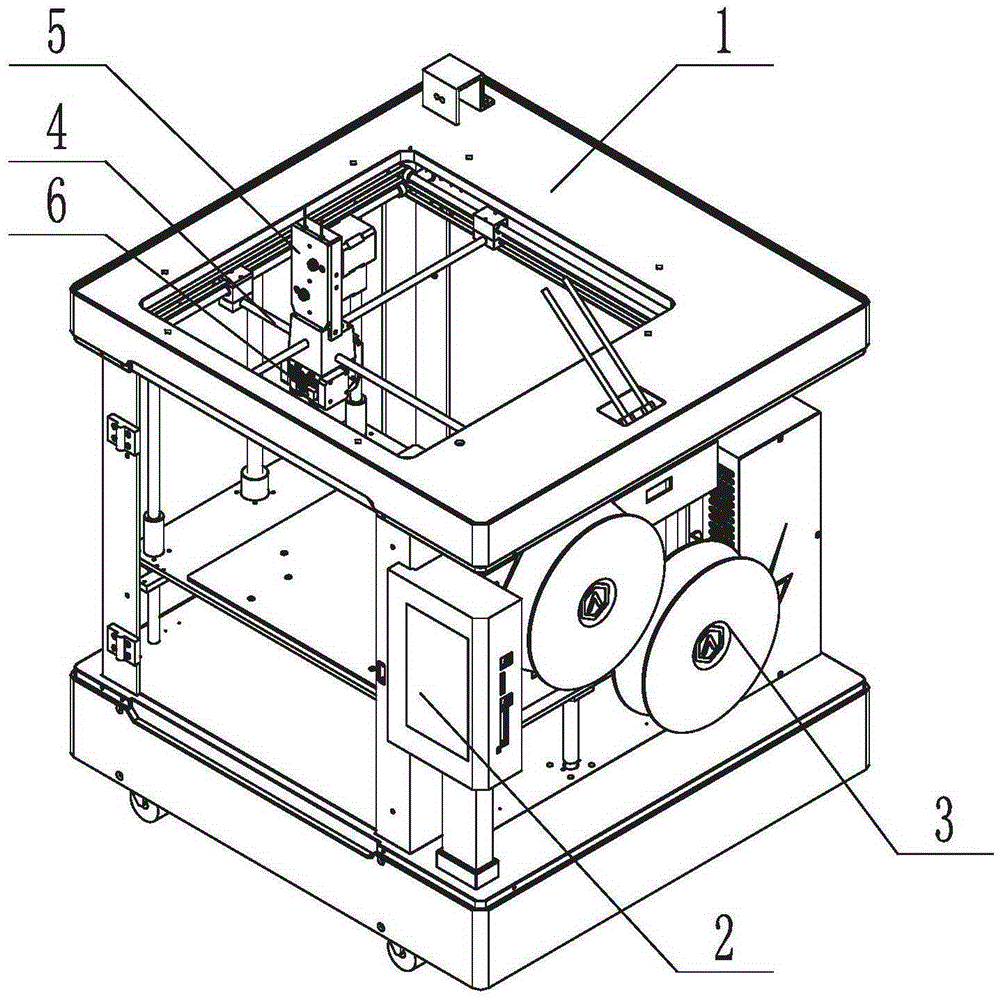

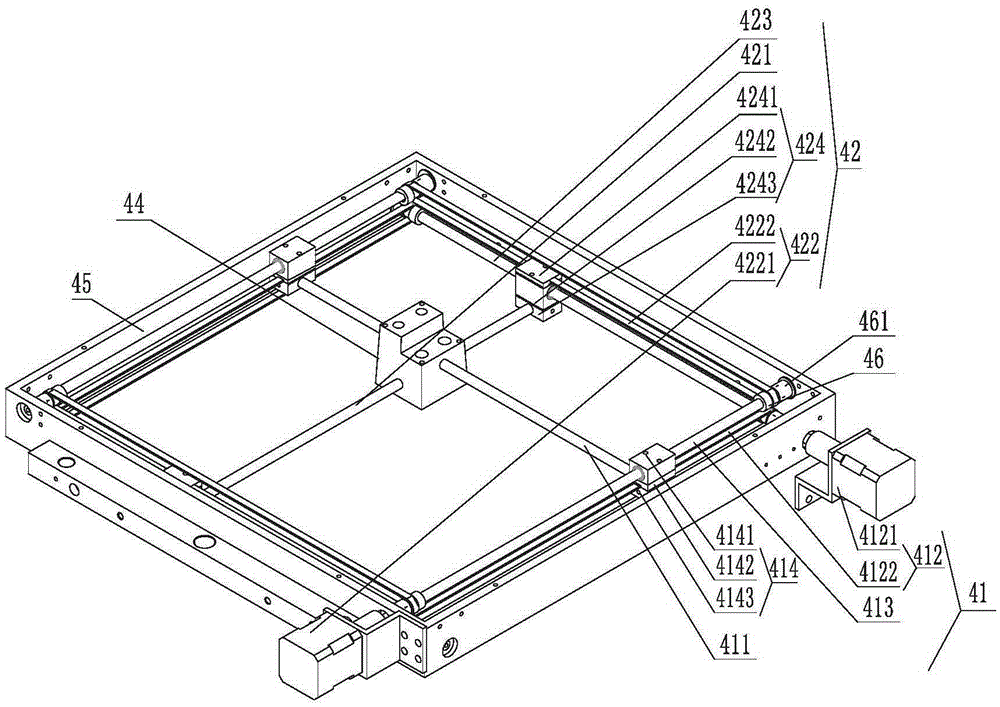

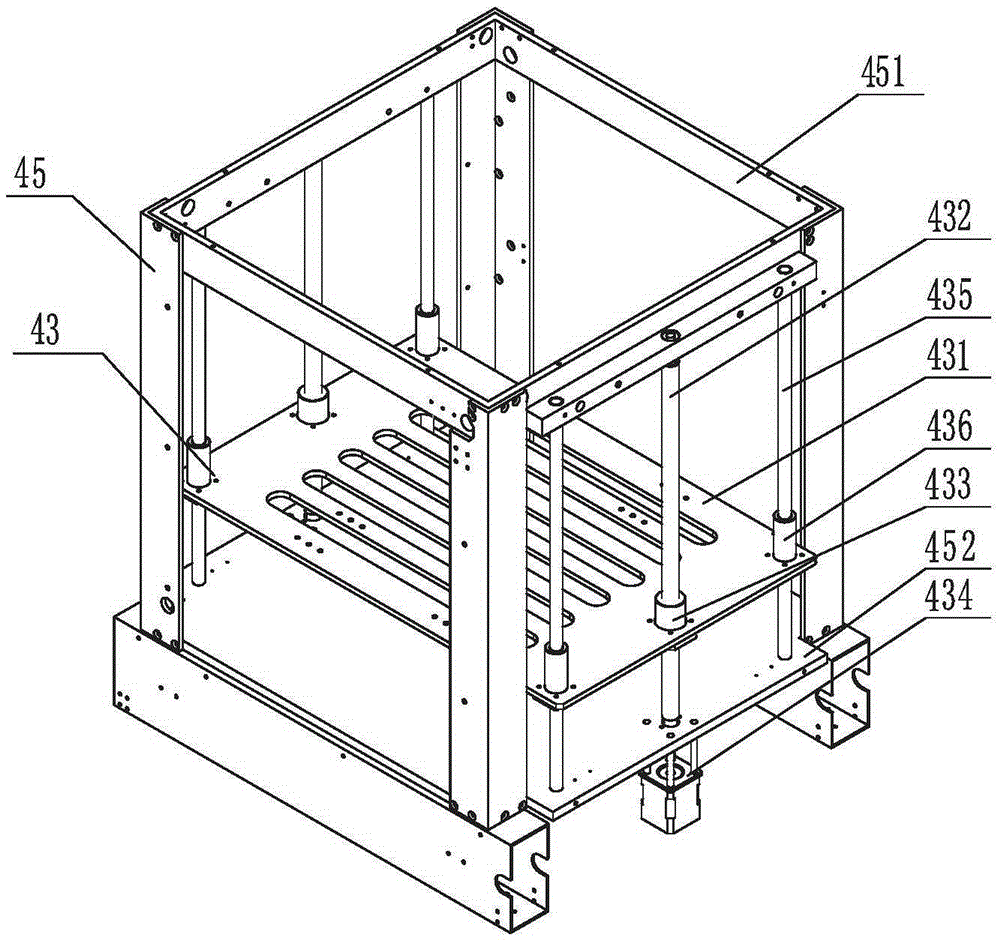

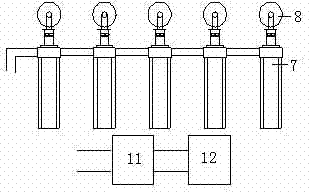

Desktop-level 3D printer

InactiveCN105252776AReasonable structural designHigh precisionAdditive manufacturing apparatusElectricityColor printing

The invention discloses a desktop-level 3D printer. The desktop-level 3D printer comprises a machine frame, a controller, a material conveying device, an X,Y and Z axis movement device, a feeding device and a spraying nozzle device, wherein the material conveying device and the X,Y and Z axis movement device are installed on the machine frame; the feeding device and the spraying nozzle device are installed on the X,Y and Z axis movement device; the material conveying device is connected with the feeding device; the feeding device is connected with the spraying nozzle device; the controller is electrically connected with the material conveying device, the X,Y and Z axis movement device, the feeding device and the spraying nozzle device. The desktop-level 3D printer can realize effective multi-color printing, a printed model is high in accuracy, the printing effect is good, and color switching nearly without errors can be achieved. Meanwhile, the environmental characteristic that materials like acrylonitrile butadiene styrene (ABS) need to be printed at a constant temperature can be realized, so that technical support is provided for clients needing to print the ABS. The products with the biggest effective printing area are included, and requirements of various clients can be met.

Owner:SHANGHAI FUSION TECH CO LTD

Aerial insulation wire electrification repairing method

ActiveCN104009421ANon-stickReduce the temperatureApparatus for repairing insulation/armouring cablesSilicone tapeElectrical tape

The invention relates to an aerial insulation wire electrification overhauling method, in particular to an aerial insulation wire electrification repairing method. The method comprises the steps that polyimide adhesive tape is wrapped on the exposed part of an aerial insulation wire through a half fold packaging method, the outer side of the exposed part wrapped by the polyimide adhesive tape is coated with a layer of teflon coating film, an injection hole is formed in the middle of the teflon coating film, and a spray gun sprays a polyurethane foam joint mixture to the position between the teflon coating film and the polyimide adhesive tape through the injection hole for joint filling. According to the aerial insulation wire electrification repairing method, the problems that the insulation performance of the aerial wire is lowered, and a grounded short circuit accident is caused due to the facts that the aerial wire is exposed and the insulation adhesive tape is aged, unglued and chapped are effectively prevented, large-area power failure is avoided, power supply reliability is provided for reducing interphase short circuits and ground faults, and hidden dangers existing when workers work are avoided.

Owner:STATE GRID CORP OF CHINA +1

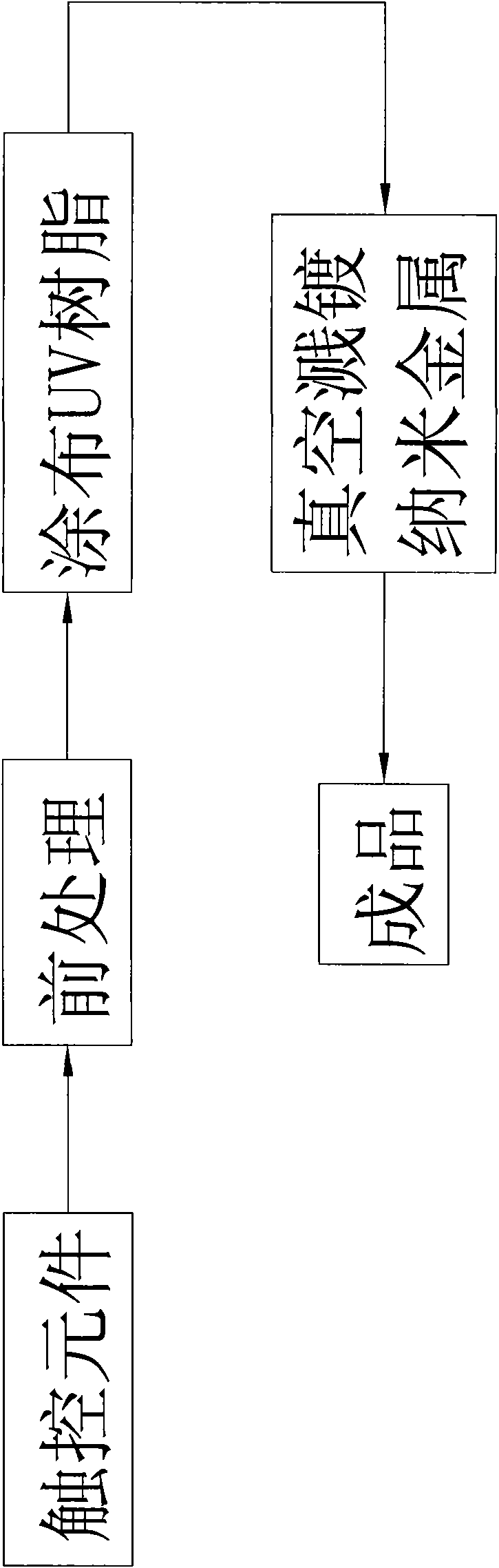

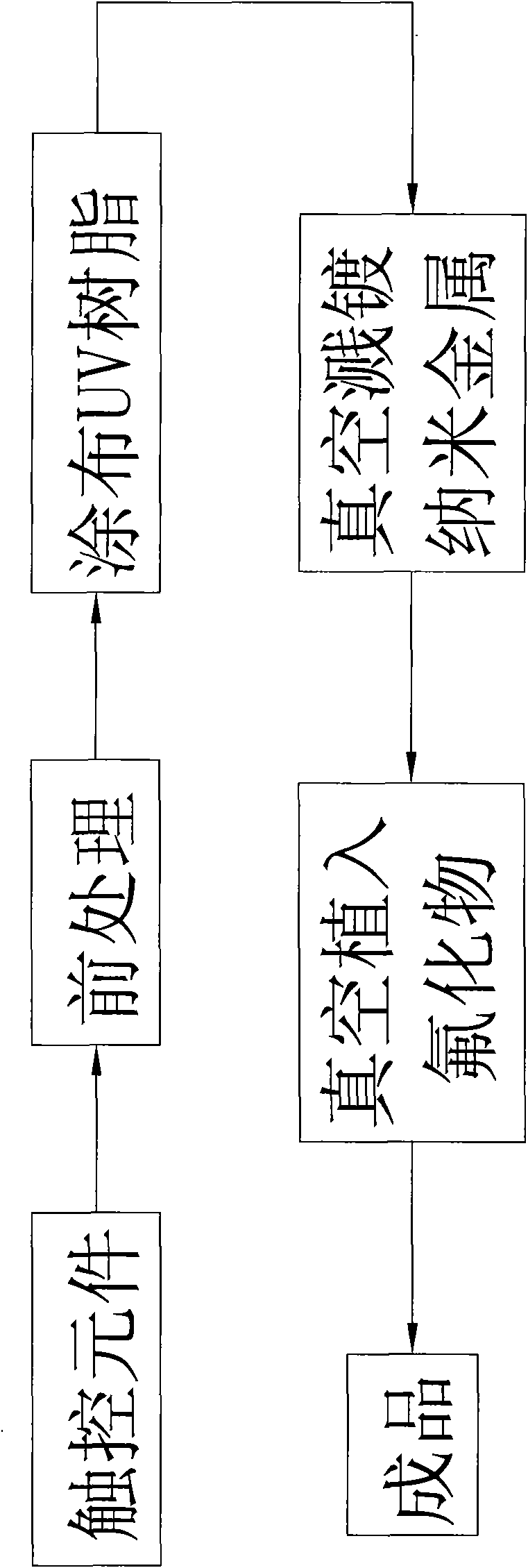

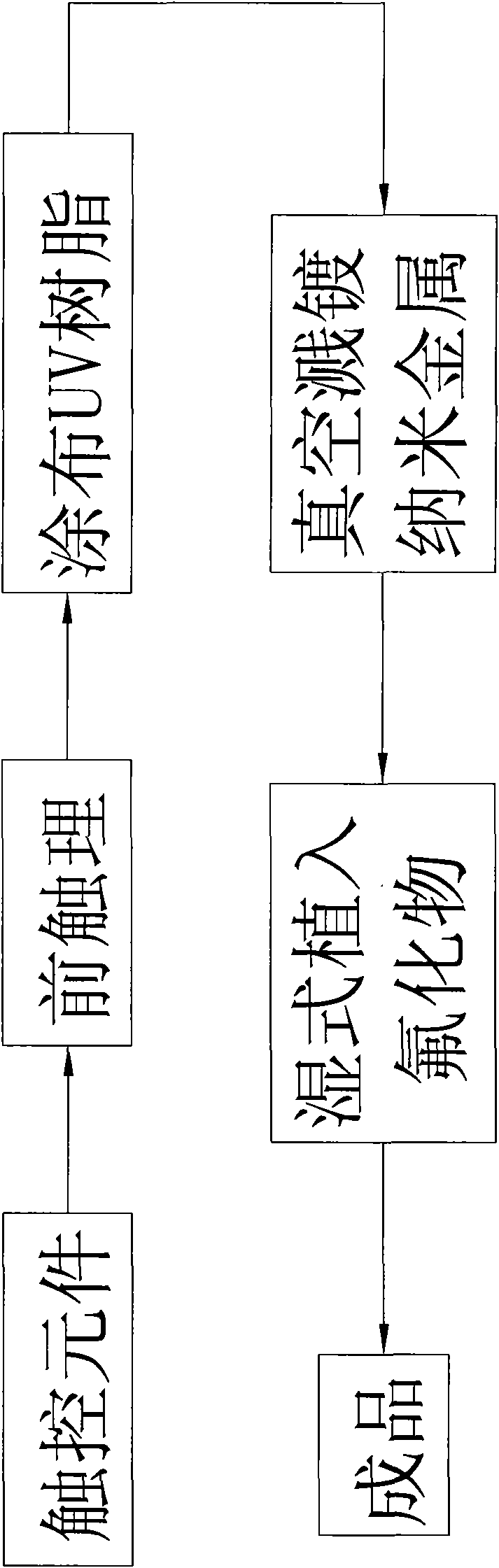

Method for processing surface of touch control element

InactiveCN101768740ANon-stickAntistaticLiquid surface applicatorsVacuum evaporation coatingSputteringTectorial membrane

The invention relates to a method for processing the surface of a touch control element, which comprises the following steps of: coating a touch control workpiece with a thin film having the hardness higher than 1 H and containing UV resin; then, sputtering inorganic nanometer metal on the surface of the coated thin film containing the UV resin to form a nanometer oxide protection film; and finally, implanting fluorocarbon into the nanometer oxide protection film by vacuum sputtering or a wet method to form a nanometer fluorocarbon antifouling film. By sputtering the inorganic nanometer metal on the surface of the thin film containing the UV resin to form the protection film, or further implanting the fluorocarbon into the nanometer oxide protection film to form the antifouling film containing fluorocarbon, the coated surface of the touch control workpiece has improvement in the efficacy of antifouling property, no contamination, antistatic property, wear resistance, good sticking tendency, no luster difference before and after use, and the like.

Owner:兆震实业股份有限公司

Heat preservation device with ceramic inner container

The invention provides a heat preservation device with a ceramic inner container, for further improving the heat preservation effect of existing vacuum cups, kettles and drinking cups, and overcoming the defects that stainless steel cups easily precipitate harmful substances and glass inner containers or ceramic inner containers are easily broken. The heat preservation device with the ceramic inner container is better in heat preservation effect, more attractive, unlikely to damage, better in corrosion resistance, easy to clean and good in mouthfeel when being used for accommodating water. The heat preservation device comprises a stainless steel outer container, a stainless steel vacuum inner container and a ceramic coating, wherein the ceramic coating is positioned on the inner wall of the stainless steel vacuum inner container; the ceramic coating is prepared from the following raw materials: 30-40 parts of silica sol, 25-50 parts of silane coupling agent, 2-8 parts of iron ions, 2-8 parts of manganese ions, mixed acid and 50-80 parts of white steel; and the mixed acid comprises acetic acid and acrylic acid. The heat preservation device, which has good attrition, acid, alkali, cold, heat and corrosion resistance, is suitable for popularization and application.

Owner:陈守伟 +1

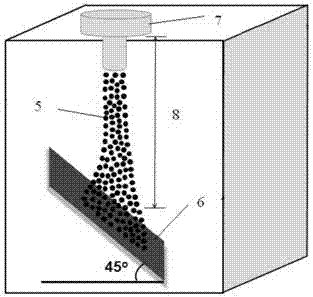

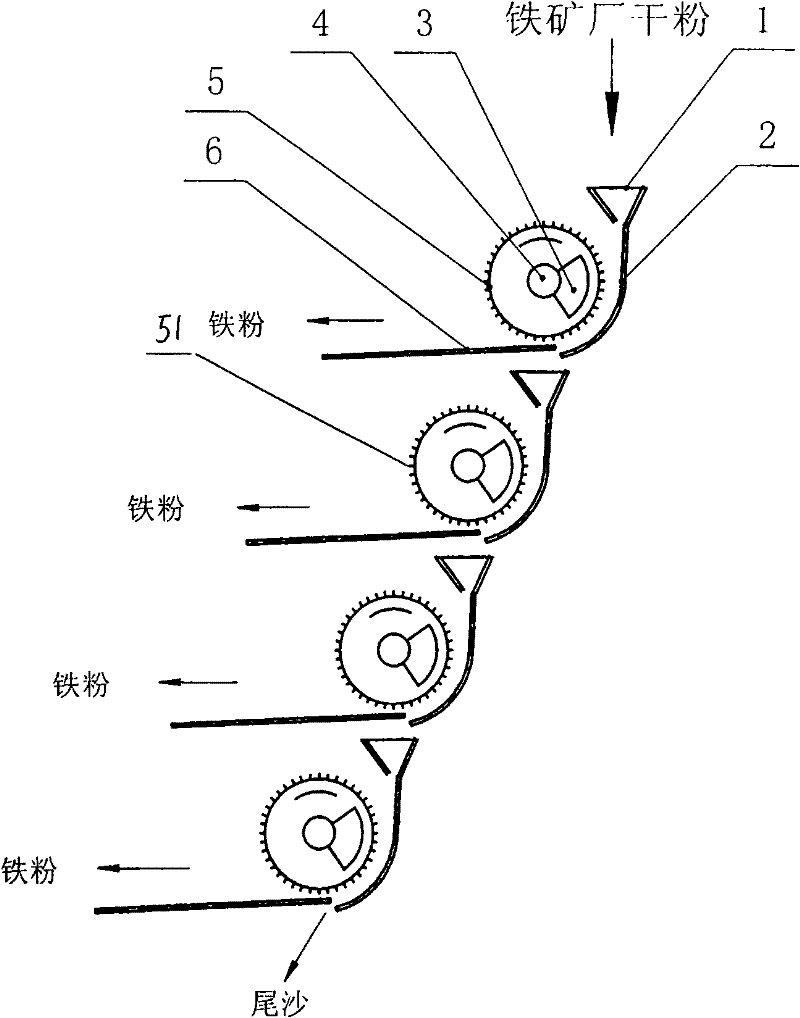

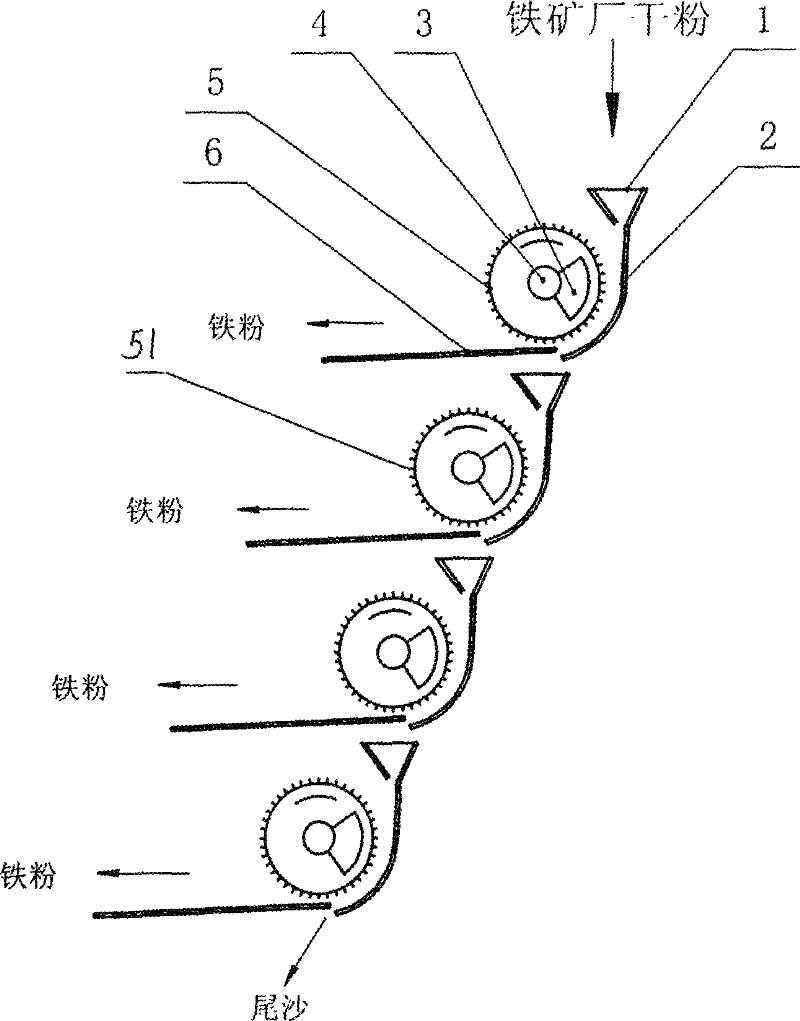

An iron ore dry powder magnetic separation process and equipment

InactiveCN101954311BImprove adsorption capacityMeet the requirements of adsorptionMagnetic separationElectricityIron powder

Owner:吴跃进

Preparation method of aluminum alloy non-stick pan coating

InactiveCN102677119AHigh bonding strengthExtended service lifeAnodisationPretreated surfacesMicro arc oxidationThermal insulation

The invention discloses a preparation method of an aluminum alloy non-stick pan coating, and relates to a preparation method of a non-stick pan coating. The invention solves the problems of poor scratch resistance, poor heat resistance, short service life and poor thermal insulation effect of the conventional aluminum alloy non-stick pan coating. The preparation method is realized by the following steps: 1, preparing alkaline solution; 2, preparing a film through micro-arc oxidization; 3, spraying a non-stick coating; and 4, drying. By adopting the aluminum alloy non-stick pan coating prepared by the method provided by the invention has the characteristics of good scratch resistance, high use temperature, long service life and good thermal insulation effect, and the preparation method can be applied to the technical field of surface treatment of light metal material.

Owner:HARBIN INST OF TECH

Method for processing polyurethane mold surface through Teflon coating

The invention discloses a method for processing a polyurethane mold surface through a Teflon coating. The method comprises the steps that the polyurethane mold surface is degreased; sand blasting is carried out on the degreased polyurethane mold surface, and then the Teflon coating is sprayed on the polyurethane mold surface; the Teflon coating sprayed on the polyurethane mold surface is heated; 5, the Teflon coating is sprayed on the polyurethane mold surface for the second time on which melting processing is carried out; and 6, the Teflon coating on the polyurethane mold surface processed in the step 5 is molten. The Teflon coating has the advantages of inadhesion, heat resistance, sliding performance, moisture resistance, abrasion resistance and corrosion resistance. The polyurethane mold surface coated with the Teflon coating which can be used repeatedly after coating is performed one time. The trouble that coating of a mold release agent needs to be carried out every time molds are released is saved; the production process is simplified, production efficiency is improved, production cost is reduced, and no harm is produced to the human body and environment.

Owner:ZHEJIANG ZHENYANG COLD INSULATION TECH CO LTD

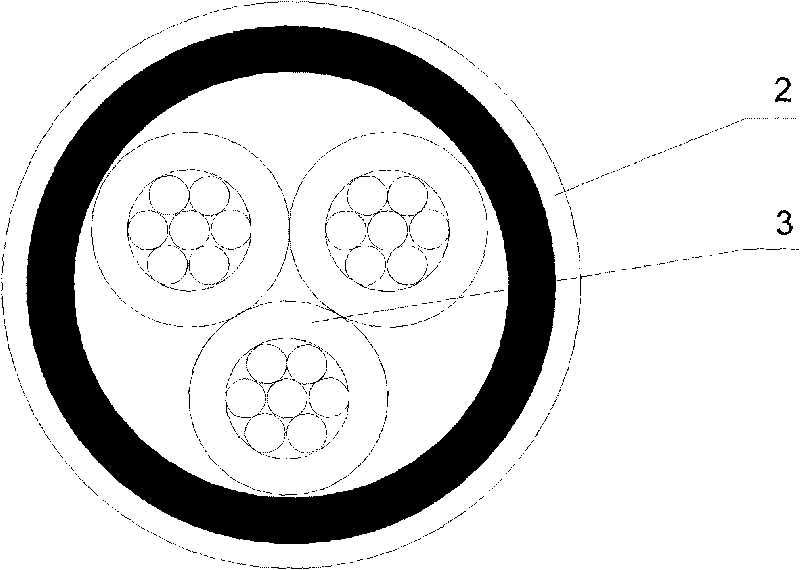

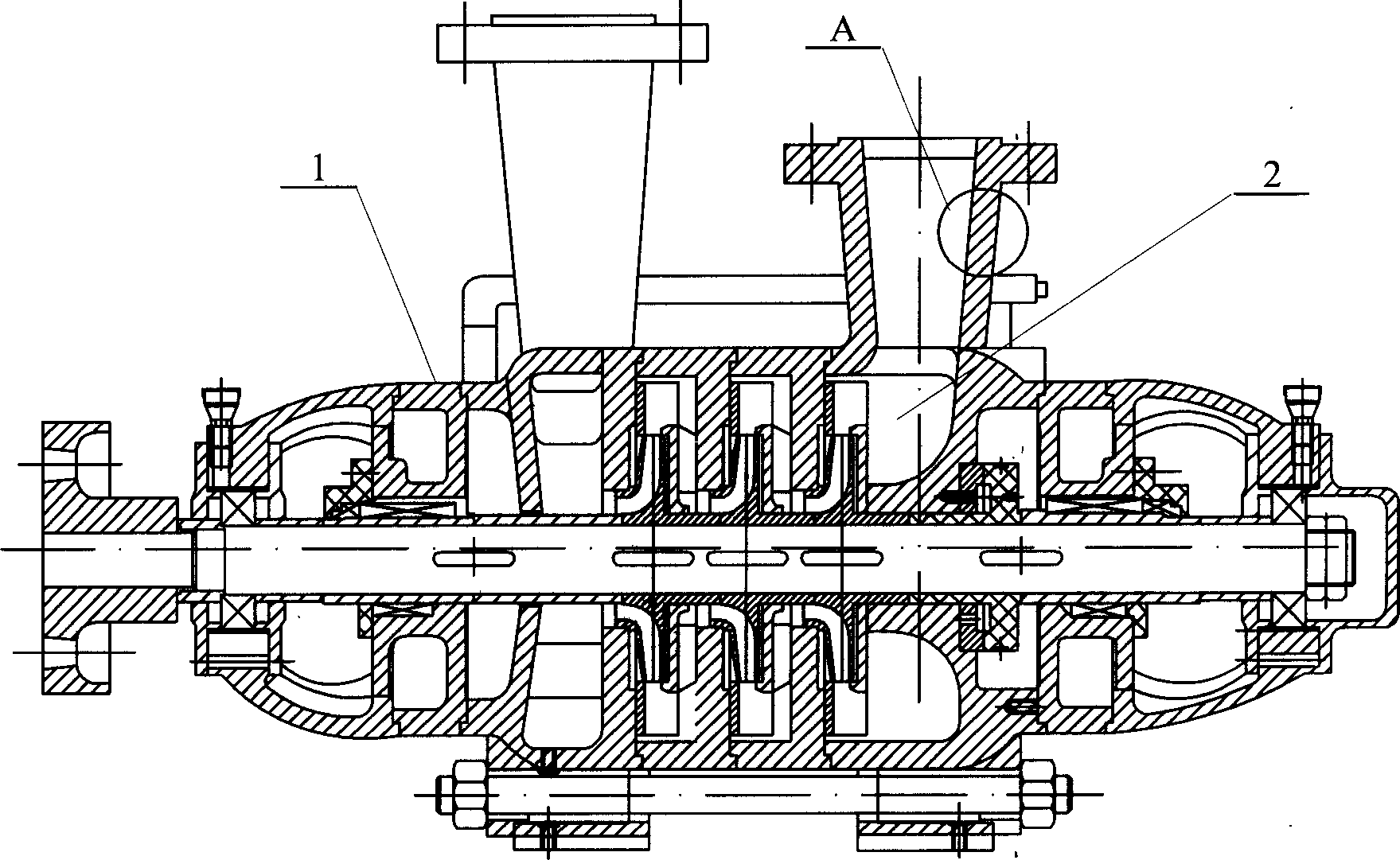

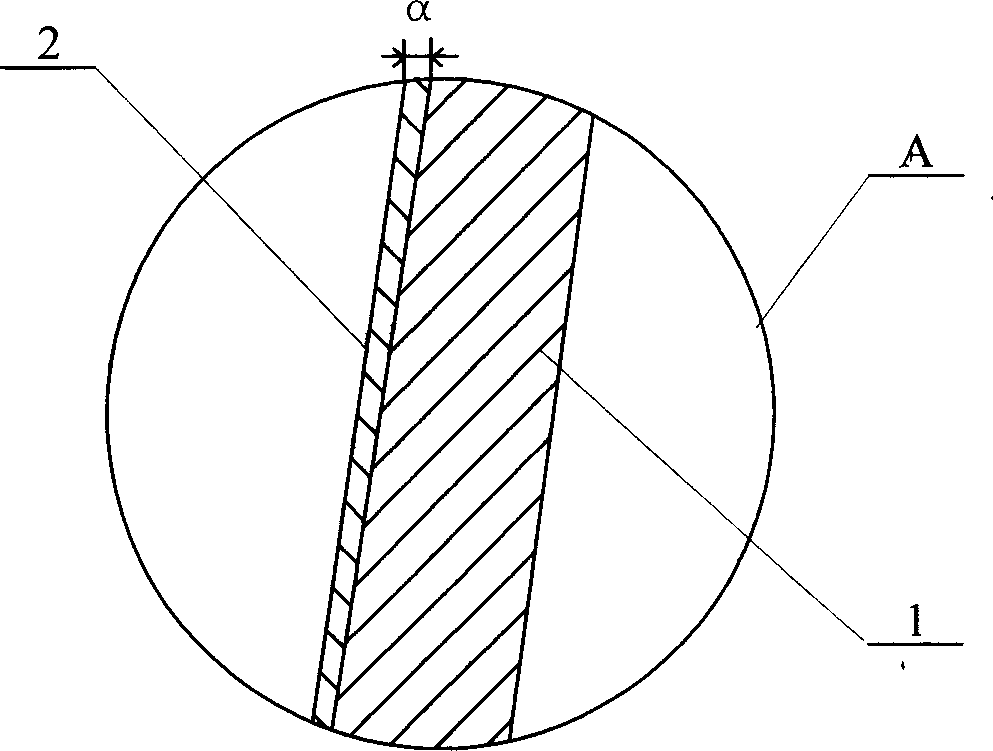

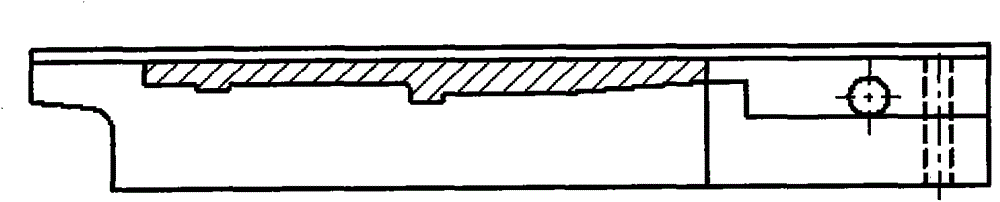

Pump with polytetrafluoroethylene or F46 inner coating and method for processing the coating

InactiveCN1828062ANon-stickLubriciousSpecific fluid pumpsPump componentsCoated surfaceMaterials science

The invention relates to a pump with politef or F46 coat and relative producing method, which solve the problem for plating politef inside the pump, with high producing cost. The thickness of politef or F46 inner coat (2) of pump flow section (a) is 0.1-50um. The producing method comprises: sintering the pump plated with politef or F46 coat in 280-350Deg. C for 2-4 hours. The invention has the advantages as thin coat and better resistance. It has simple process, smooth surface and small friction parameter.

Owner:康庆刚

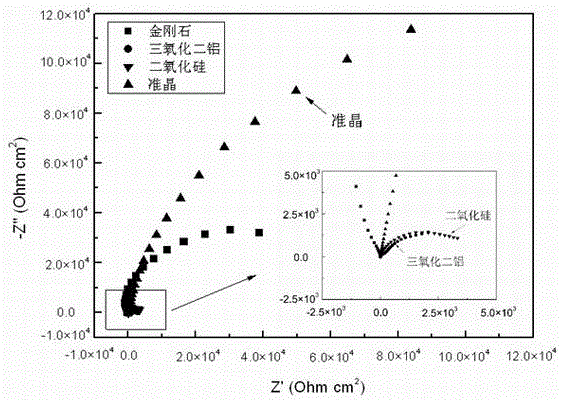

Method for preparing aluminium based composite material enhanced by AlCuFe through extrusion casting method

A method of preparing AlCuFe Quasicrystalline Particles Reinforced Al base Composites. The present invention adopts the method of high pressure inert gases atomization to prepare the powder of AlCuFe. The Quasicrystalline Particles which is 20 - 100 micron after sift out, is heat treated in order to get single phase of Quasicrystalline Press it in cold, and then press it into prefabrication in the ratio of design. Heat preservation the prefabrication and die, and fusion the aluminium alloy at the same time. Press and penetrate it after heat preservation in order to prepare Quasicrystalline Particles Reinforced Al base Composites. The present invention has simple technics and low cost.

Owner:SHANGHAI JIAO TONG UNIV

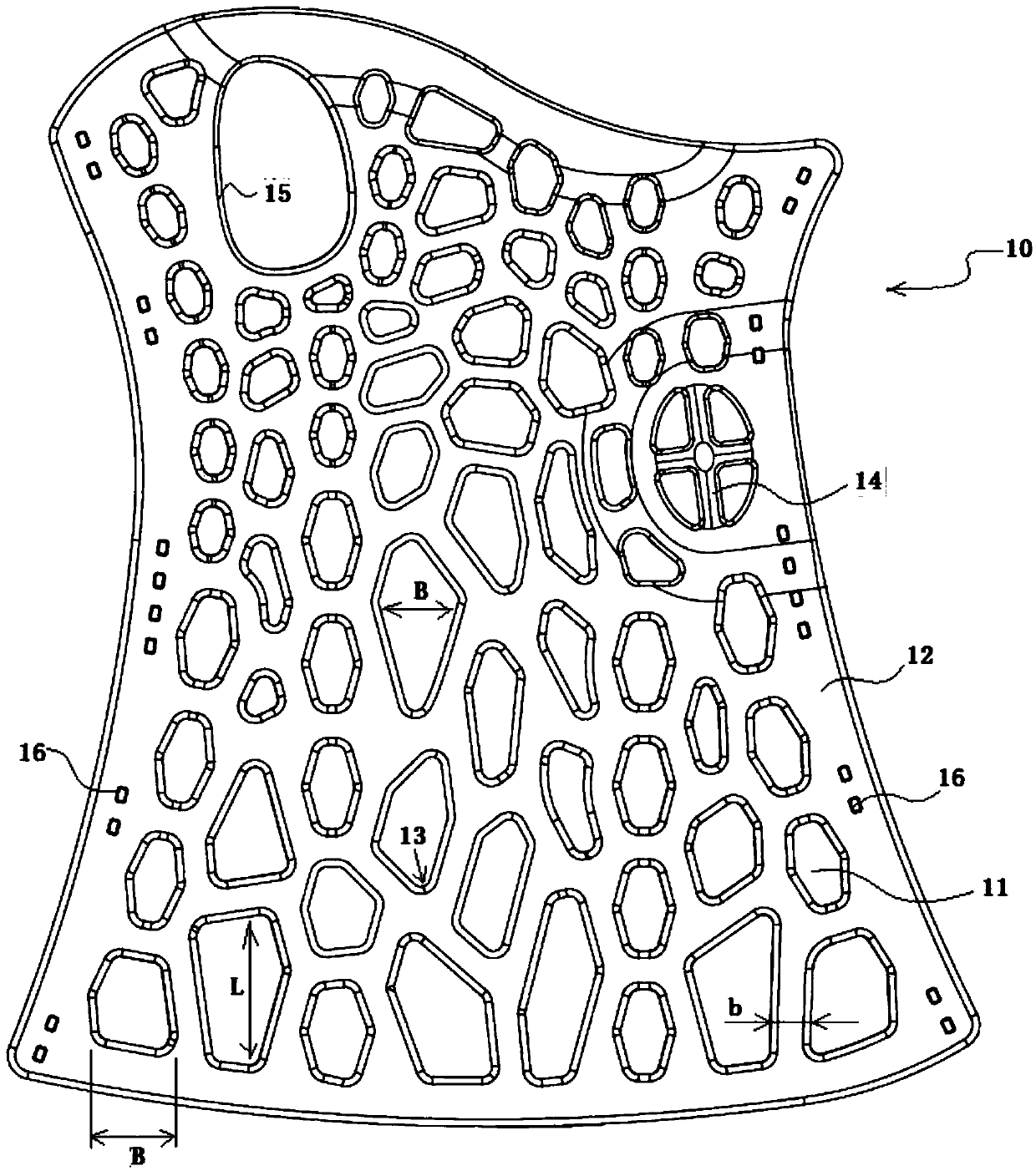

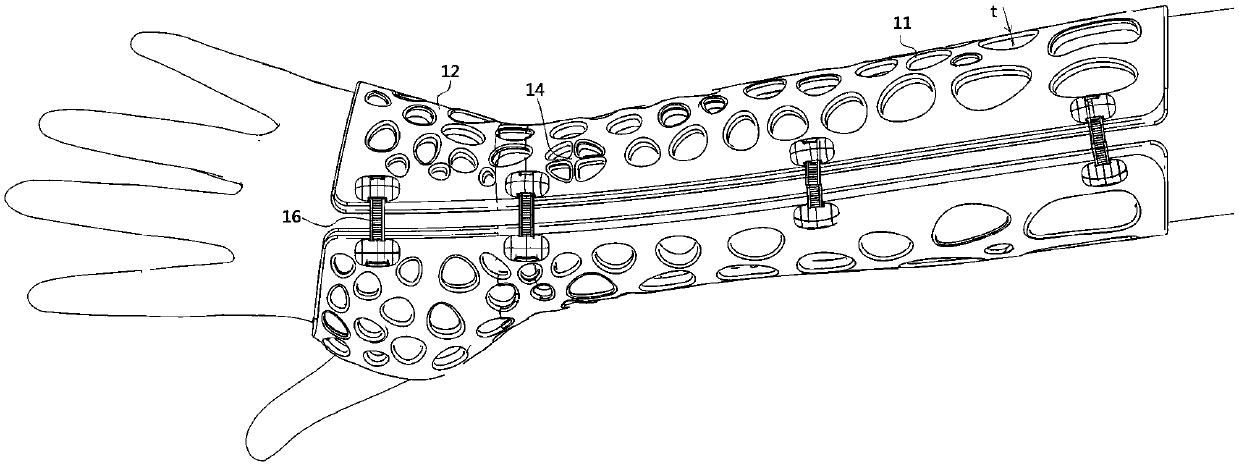

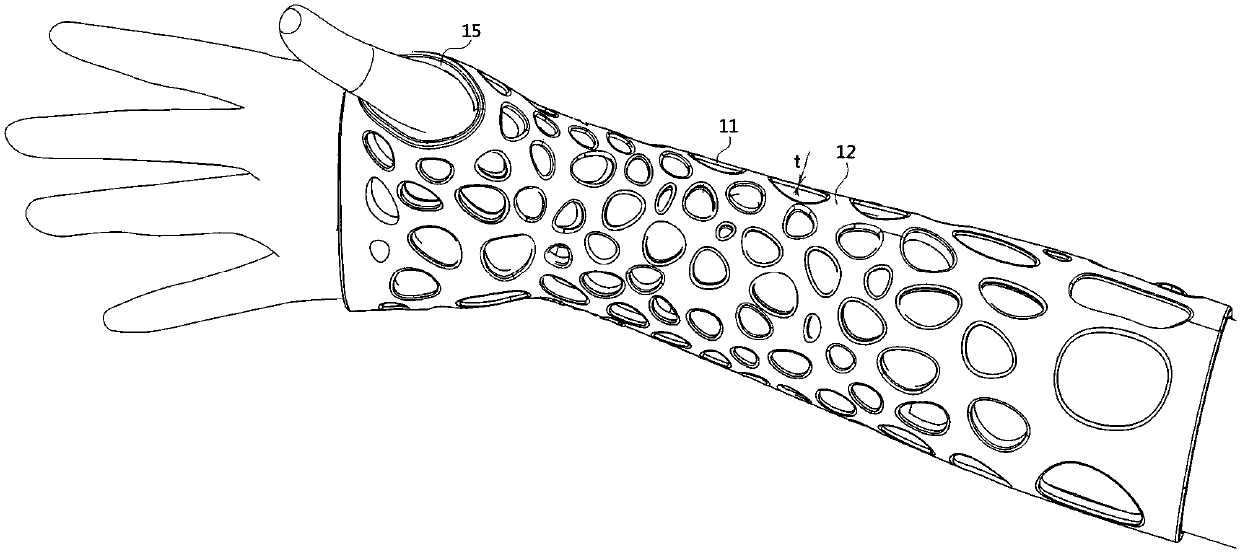

Adjustable outer fixing support and its material formula, preparation method and use method

Owner:WUHAN XUNSHU TECH CO LTD

Carbon tetrafluoride aluminum single board

ActiveCN102627005AHigh temperature resistantLow temperature resistanceSynthetic resin layered productsCoatingsGlycolurilCalcium silicate

The invention relates to an aluminum single board, in particular to a carbon tetrafluoride aluminum single board. The carbon tetrafluoride aluminum single board comprises an aluminum base board layer, a chromizing film layer and a carbon tetrafluoride layer which are sequentially arranged from inside to outside. The carbon tetrafluoride aluminum single board is formed by electrostatically spraying carbon tetrafluoride powder coatings which are composed of the following components in part by weight: 30-60 parts of arcarbon tetrafluoride resin, 5-20 parts of acrylic resin, 1-5 parts of hydroxylalkyl acyl, 3-8 parts of tetramethoxy methyl glycoluril, 1-8 parts of zirconium oxide, 2-6 parts of calcium silicate, 2-5 parts of magnesium oxide, 1-3 parts of silicon-aluminum oxide, 1-25 parts of paint and 1-5 parts of accessory ingredient. The carbon tetrafluoride aluminum single board provided by the invention has excellent chemical resistance, weather resistance, adhesive force and gloss.

Owner:东阿蓝天七色建材有限公司

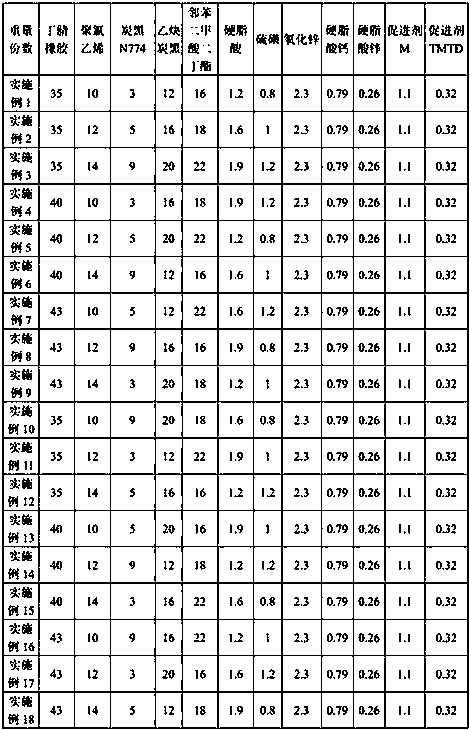

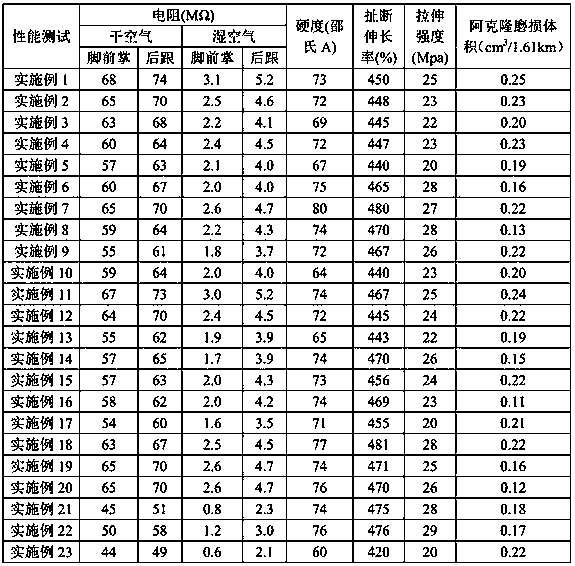

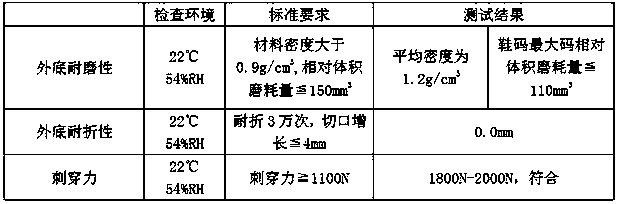

Anti-static shoe sole

The invention relates to the field of shoe soles, in particular to an anti-static shoe sole. The technical scheme is that the anti-static shoe sole is prepared from, by weight, 35-43 parts of nitrilerubber, 10-15 parts of polyvinyl chloride, 2.1-2.8 parts of active agent, 0.5-1.1 parts of calcium stearate, 0.1-0.5 part of zinc stearate, 3-9 parts of carbon black N774, 12-20 parts of acetylene black, 16-22 parts of dibutyl phthalate, 0.7-1.3 parts of promoter M, 0.2-0.5 part of promoter TMTD, 0.8-1.2 parts of sulphur. The shoe sole has very good anti-static performance and wear resistance, andcan meet the requirement of military shoes and improve the service life. Components in the formula are toxic-free and environment-friendly, and good for body health.

Owner:浙江恒诚鞋业有限公司

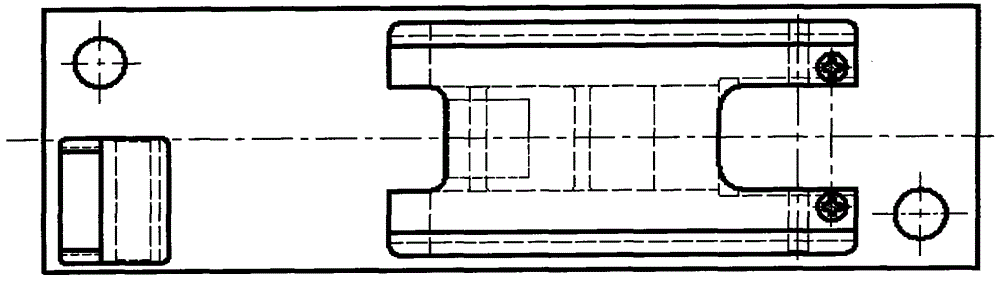

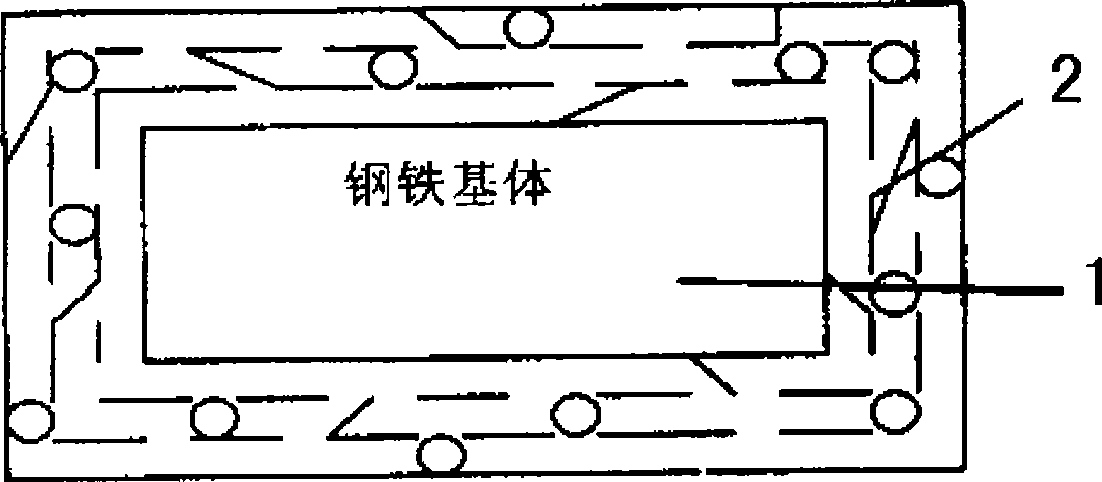

Self-lubricating slide plate and manufacturing method thereof

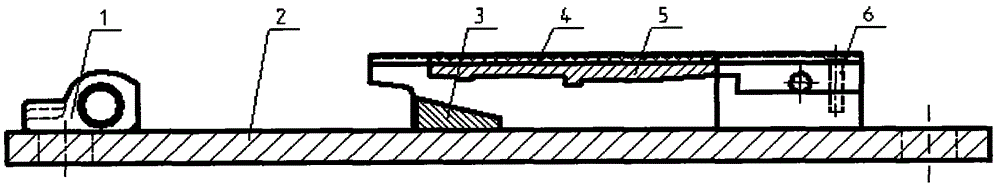

The invention discloses a self-lubricating slide plate and a manufacturing method thereof. The self-lubricating slide plate comprises a bottom plate, an iron base, a platen, an iron guide, an anti-friction plate and countersunk screws. The anti-friction plate is embedded into a slot in the surface of the platen and fixed onto the upper surface of the platen through the countersunk screws; the iron base, the platen and the iron guide are welded on the bottom plate. The self-lubricating slide plate reduces switching resistance and displacement insufficiency of a point rail, ensures normal working of a point switch and maintains good linearity for a turnout, enables a train to safely pass through the turnout, effectively reduces the construction cost and the maintenance cost, achieves high reliability, releases the labor load of working personnel for daily maintenance and reduces environmental pollution.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

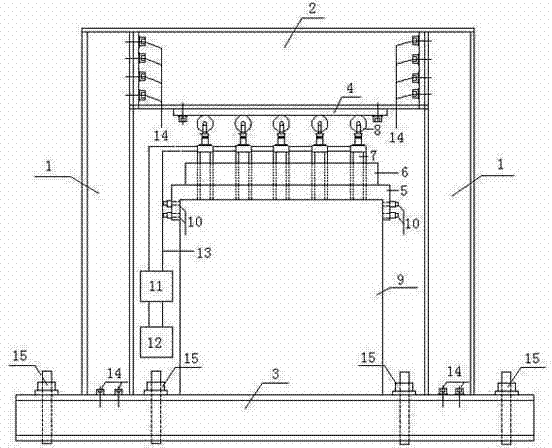

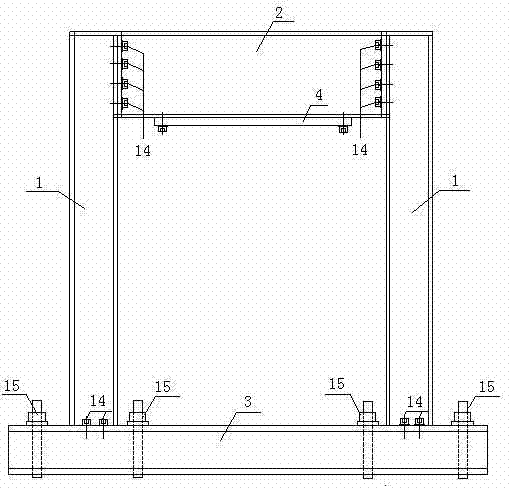

Vertical load loading device for shear wall

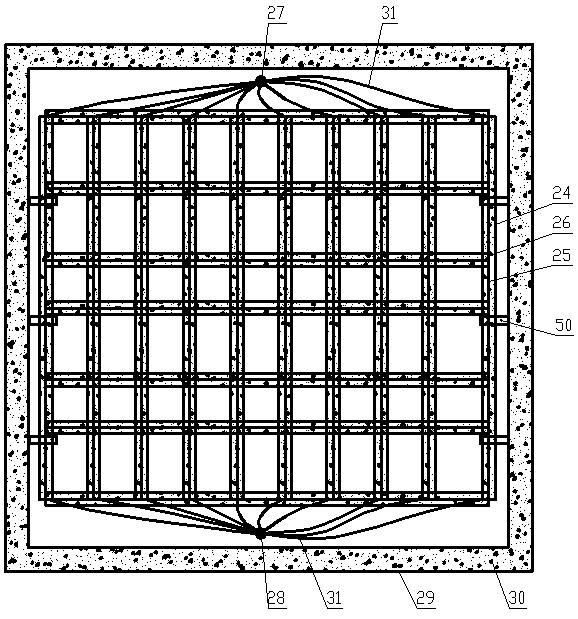

InactiveCN103207096AIncrease the number ofConstant loadStructural/machines measurementHysteresisConstant load

The invention discloses a vertical load loading device for a shear wall. The vertical load loading device comprises a shear wall test piece, a polyfluortetraethylene plate, a bearing plate with concave holes on the top portion, more than five hydraulic jacks of the same specification, an antidumping net rack, pulleys and adjusting bolts which are in a counter-force system. The bearing plate with the concave holes on the top portion is arranged on the top portion of the shear wall test piece, the adjusting bolts are arranged on the left side and the right side of the bearing plate, the hydraulic jacks are arranged in the concave holes of the bearing plate and fixed through the antidumping net rack, the hydraulic jacks are connected in series through an oil pipe and connected with a hydraulic oil source and a pressure stabilizing system, the pulleys are arranged on the top portions of the hydraulic jacks, and the top portions of the pulleys are contacted with the polyfluortetraethylene plate at the bottom of a counter-force beam. The vertical load loading device is simple in structure, convenient to detach, suitable for exerting of vertical constant load during hysteresis performance testing of the shear wall test piece.

Owner:HOHAI UNIV +1

Manufacturing method of ceramic vacuum cup

InactiveCN103222766AAvoid influenceAntimicrobial resistantDrinking vesselsMetallurgyThermal insulation

The invention relates to daily hardware, in particular to a manufacturing method of a ceramic vacuum cup. A layer of ceramic is applied to the inner container of a stainless steel vacuum cup, so that the thermal insulation performance of the stainless steel vacuum cup is effectively improved, water scale deposition is avoided and the cleanliness of the vacuum cup is improved.

Owner:JINHUA VOCATIONAL TECH COLLEGE

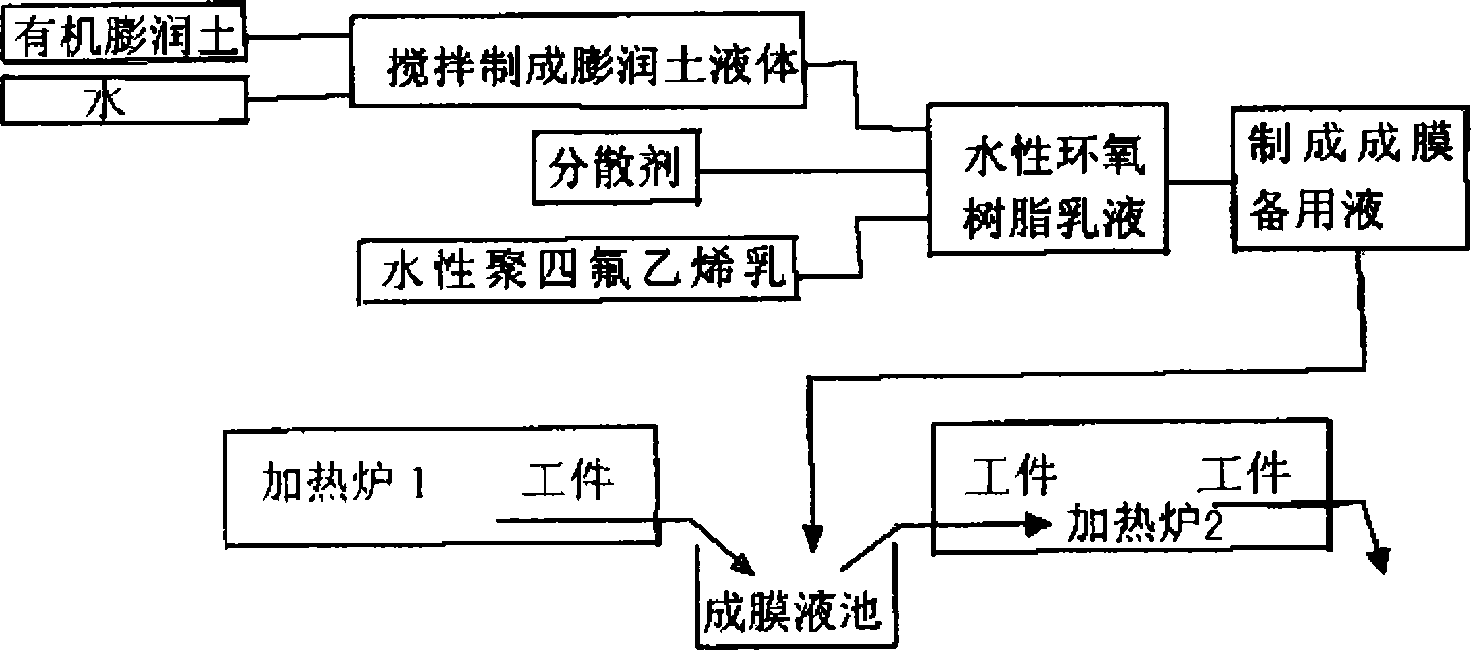

Method for preparing composite organic protective film on surface of steel

InactiveCN101543814AImprove heat resistanceImprove corrosion resistancePretreated surfacesEpoxy resin coatingsCompound organicTectorial membrane

The invention discloses a method for preparing a composite organic protective film on the surface of steel, which belongs to the technical field of steel surface protection. The method comprises the following steps: mixing a water borne epoxy resin emulsion, water or water borne color paste, and stirring the mixture evenly to prepare a water borne epoxy resin film-forming liquid for standby; adding a dispersant and an antifrictional, corrosion resistant and heat-resisting material into the film-forming liquid; then forming a film on a workpiece by excess heat: heating up a steel workpiece, keeping the temperature so that the workpiece is heated thoroughly, taking out the workpiece and soaking the workpiece into a water borne epoxy resin film-forming liquid tank for 5 to 30 seconds, taking the workpiece out of the tank, and heating and drying the workpiece, or reheating the steel workpiece coated by a layer of protective film, keeping the temperature, taking out the steel workpiece, and cooling the steel workpiece in air or water to prepare a layer of composite organic protective film. The composite organic protective film prepared by the method has high heat resistance and corrosion resistance, and the frictional coefficient thereof is greatly reduced. The protective film has the characteristic of not being wetted so that various performances of the protective film are improved. The protective film has strong bonding force with steel materials without flaking off and can be applied widely.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete

The invention relates to a nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete, which is characterized by comprising a bi-component high-molecular polymer mortar bonding bottom coating, a bi-component high-strength polymer mortar middle coating and a nano anti-corrosion and anti-fouling protective surface coating, wherein the bi-component high-molecular polymer mortar bonding bottom coating, the bi-component high-strength polymer mortar middle coating and the nano anti-corrosion and anti-pollution protective surface coating are sequentially stacked together. The coating structure has the advantages of corrosion prevention, seepage prevention and pollution resistance, good effect, good stability, easiness in cleaning, lasting effect, good applicability and the like.

Owner:韦尔狄(广州)生物工程科技有限公司

Special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels and preparation method of special grinding fluid

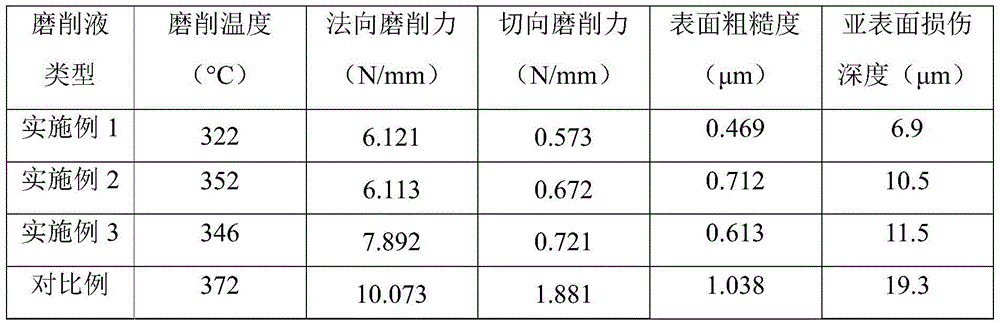

ActiveCN105586142AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsDimethyl siloxaneMachining process

The invention relates to a special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels. The special grinding fluid comprises 4.8%-6.2% of fatty acid methyl ester polyoxyethylene ether, 2.5%-2.9% of an alkyl synthol alkoxy compound, 2.2%-2.5% of tungsten disulfide, 4.2%-4.4% of cyclopentasiloxane, 3.5%-3.7% of an anti-wear reagent at extreme pressure, 2.3%-3% of a corrosion inhibitor, 2.5%-3.5% of a friction modifier and the balance of deionized water. The special grinding fluid for grinding of the silicon carbide ceramic by the diamond grinding wheels has excellent lubricating, cooling and cleaning effects, has the long service cycle and can substantially reduce the grinding temperature, the normal grinding force and the tangential grinding force in the machining process of the silicon carbide ceramic, reduce abrasions of the grinding wheels, effectively improve surface quality and precision of ground surfaces of the silicon carbide engineering ceramic and the like.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

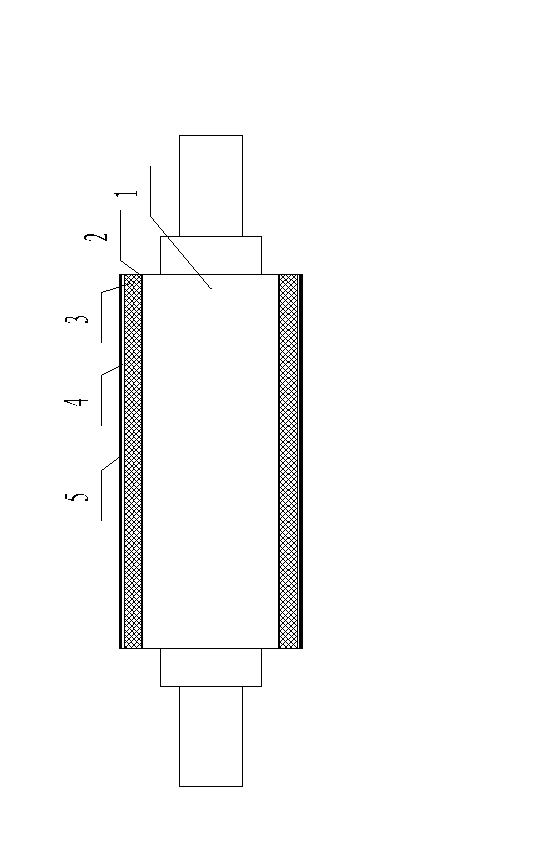

Teflon rubber roller and production method thereof

The invention relates to a Teflon rubber roller and a production method thereof. In order to solve the technical problem that the current rubber roller is high in cost and poor in wear resistance, the invention provides the Teflon rubber roller which comprises a roller core and a rubber layer coving the roller core. The Teflon rubber roller is characterized in that a Teflon coating is arranged on the surface of the rubber layer. Through arranging the Teflon coating on the surface of the rubber roller, the rubber roller has non-adhesion property and high-wearing feature, so that the service life of the roller is greatly prolonged to 18-24 months, which is improved by over 50% compared with that of a silicon rubber roller. The production method of the Teflon rubber roller provided by the invention is reasonable in process and strong in operability, and can be widely applied to the production process of Teflon rubber rollers.

Owner:WEIHAI FENGTAI NEW MATERIAL SCI & TECH

Low-wear abrasive capable of improving corrosion resistance capability of stainless steel surface and preparation method of low-wear abrasive

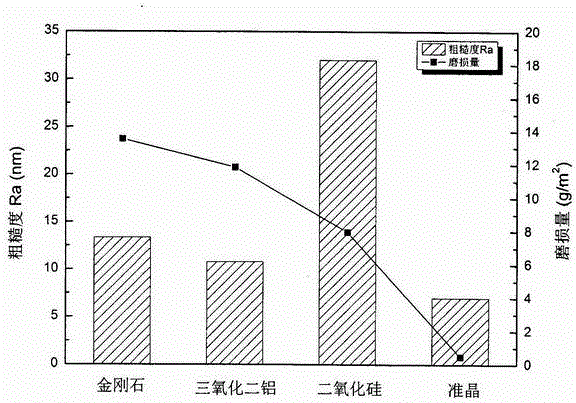

InactiveCN105154004AImprove surface corrosion resistanceHigh hardness ratioOther chemical processesSurface corrosionQuasicrystal

The invention discloses a low-wear abrasive capable of improving corrosion resistance capability of the stainless steel surface and a preparation method of the low-wear abrasive and belongs to the technical field of grinding and polishing finish machining for stainless steel surface machining. The low-wear abrasive capable of improving the corrosion resistance capability of the stainless steel surface forms a quasicrystal and approximates and comprises components as follows: Al-(Li,Cu,Fe,Co,Cr,V,Mn,Ru,Re,Os), TiZrNi, (Zn / Cd)-Mg-(Y,Yb,Gd,Tb,Dy,Ho,Er,Sc) and Cd-(Ca,Y,Gd,Tb,Tm,Ho,Dy,Er,Yb), and the content of the quasicrystal and the approximates is larger than 50%. The abrasive is used for grinding and polishing the stainless steel surface and also can realize low-wear polishing and finish machining of stainless steel and rapidly improve the surface corrosion resistance capability.

Owner:DALIAN UNIV OF TECH

Preparation process of modified chitosan composite gel moisture retention adhesive bandage

InactiveCN105079861APromote healingLighten the bodyAdhesive dressingsMedical applicatorsPolymer sciencePolymer chemistry

The present invention relates to a preparation process of a modified chitosan composite gel moisture retention adhesive bandage, which comprises a nonwoven layer, a moisture retention layer and a protective layer from bottom to top, wherein the moisture retention layer consists of a modified chitosan gel. The preparation process designs the preparation method of the adhesive bandage. The adhesive bandage has the characteristics of bacteriostasis, inflammation relief, bleeding and pain stopping, and no wound adhesion, and provides a moist environment to accelerate wound healing, and mitigates the physic and spirit pain of the patients.

Owner:青岛高新区尚达医药研究所

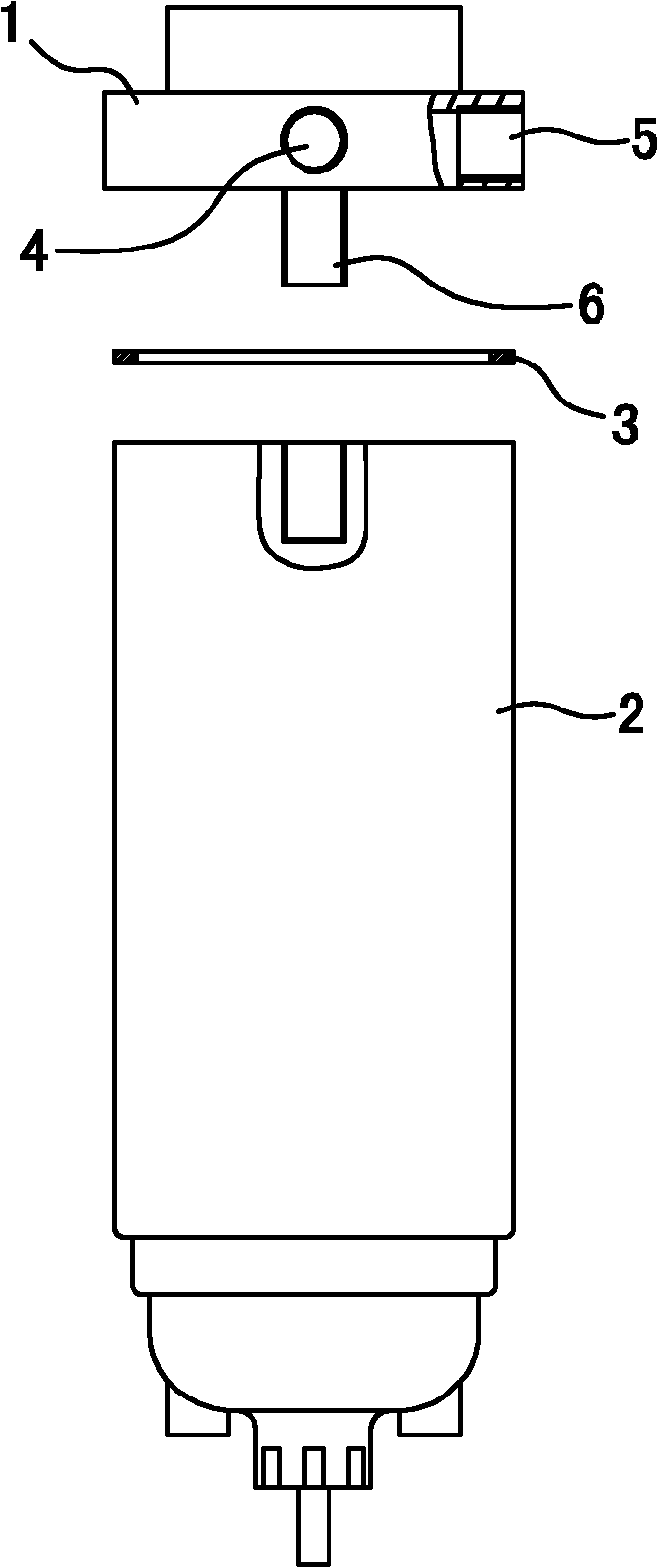

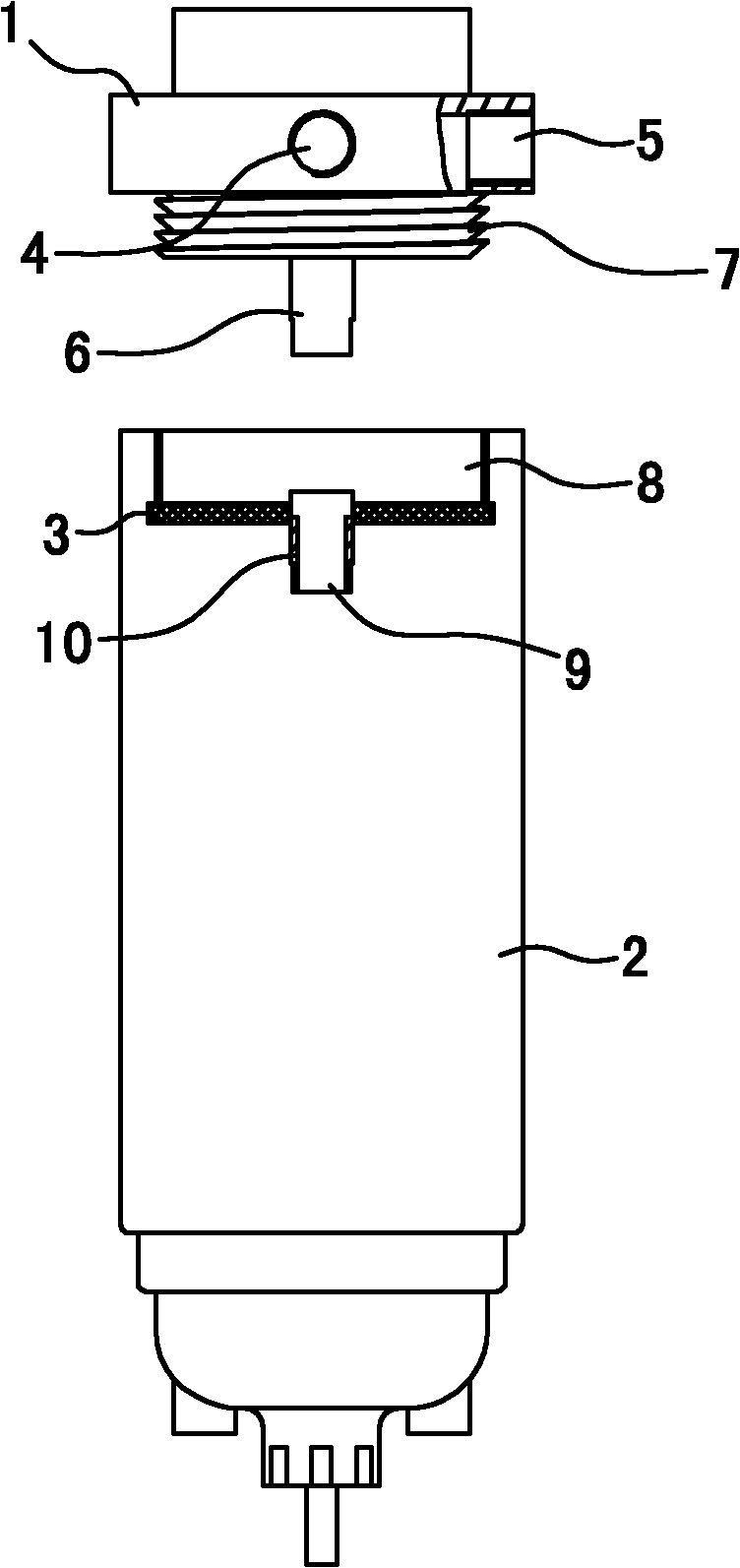

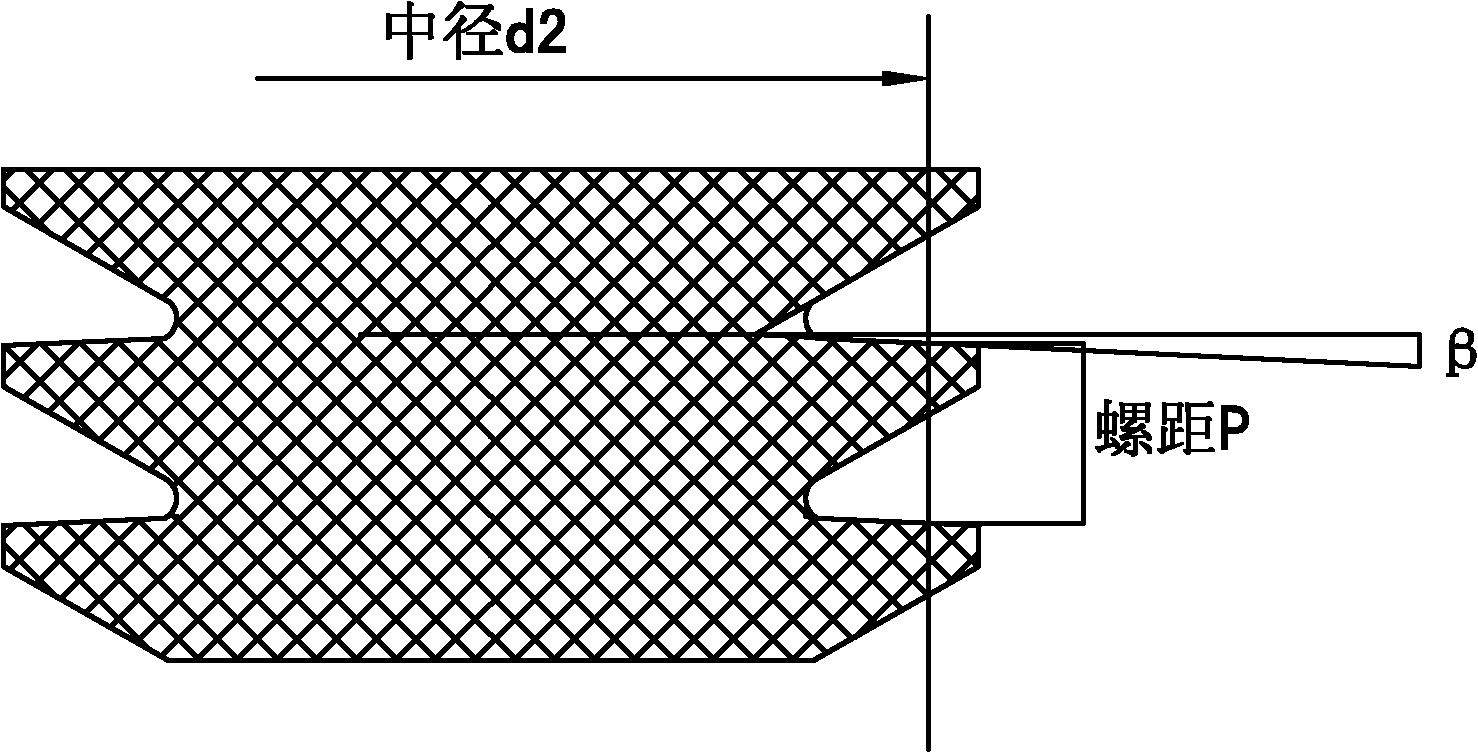

Fuel filter

InactiveCN101988450AEasy to assemble and disassembleEasy to replaceMachines/enginesLiquid fuel feedersEngineeringFuel filter

The invention discloses a fuel filter which comprises a filter base, a filter element assembly and a seal ring, wherein the center of the bottom of the filter base is provided with a convex connecting rod; a connecting section is also arranged between the bottom of the filter base and the connecting rod; the diameter of the connecting section is larger than that of the connecting rod, and outer threads are arranged on the connecting section; the center of the top of the filter element assembly is provided with a groove which is matched with the connecting section, and the inner wall of the groove is provided with matched inner threads; a connecting groove which is matched with the connecting rod is arranged under the groove of the filter element assembly; the connecting rod has a circular truncated cone structure with a top down design; and the seal ring is arranged at the bottom of the groove of the filter element assembly, the outer edge is abutted against the groove, and the inner edge is matched with the connecting groove in the size. The double-seal structure of the invention has favorable seal performance, can ensure the seal performance of the fuel filter without tightly screwing an end cover and a filter element on purpose when a filter element is assembled or replaced, solves the problem brought by tightly screwing and is convenient to assemble, disassemble and replace the filter element of the filter.

Owner:SANY HEAVY MACHINERY

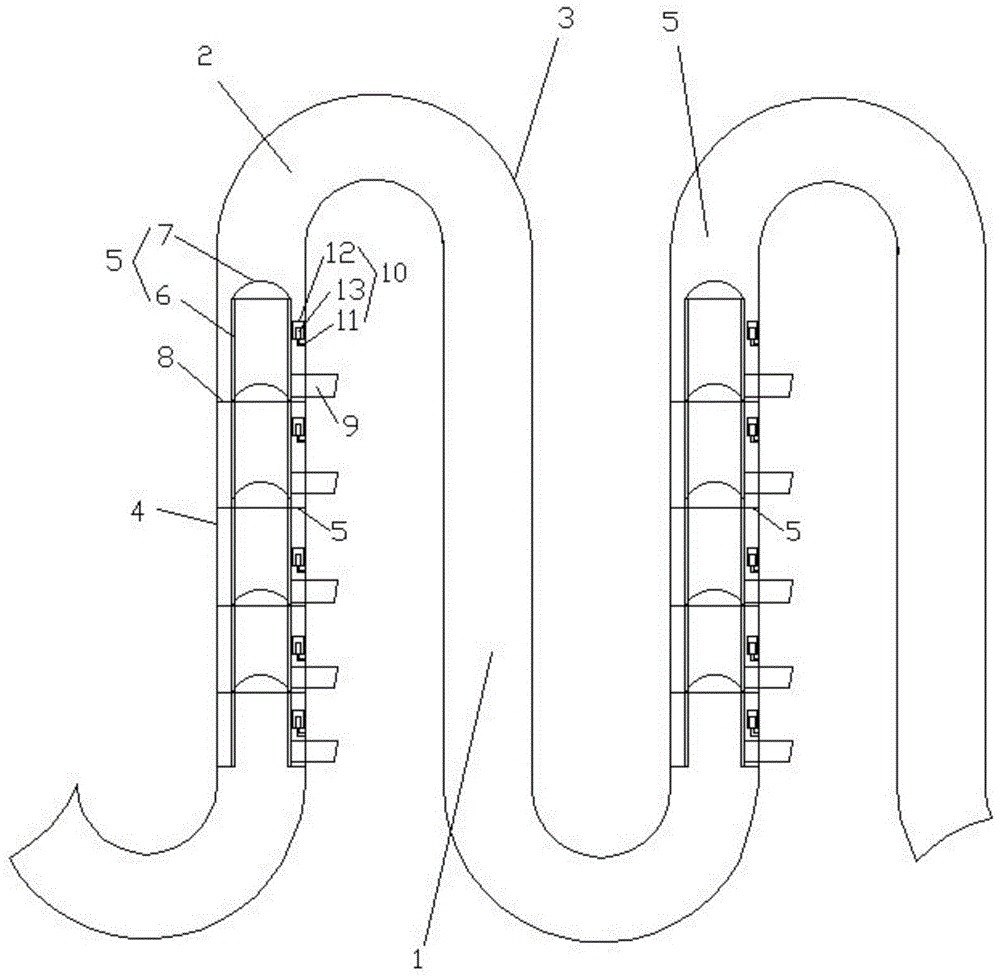

Sewage treatment pipeline with filter devices

InactiveCN105688494AAvoid cloggingReduce replacement timeMembrane filtersStationary filtering element filtersWater flowSewage treatment

The invention discloses a sewage treatment pipeline with filter devices.The sewage treatment pipeline comprises a pipeline.The pipeline comprises at least one U-shaped pipeline and inverted-U-shaped pipelines, liquid outlet ends of the U-shaped pipelines of the pipeline are connected with liquid inlet ends of the adjacent inverted-U-shaped pipelines, and ascending pipelines, where water flow flows from bottom to top, of the pipeline are ascending pipelines.The sewage treatment pipeline has the advantages that at least one Teflon filter screen with a downward opening is arranged in each ascending pipeline, the water flow flows through the Teflon filter screens with the downward openings from bottom to top, the Teflon filter screens are made of Teflon, accordingly, the filter time can be prolonged, the filter screens can be prevented from being blocked, and excellent filter effects can be realized; the sewage treatment pipeline is provided with shaking devices, accordingly, the filter effects can be improved, impurities adhered on the Teflon filter screens can be reduced, and the Teflon filter screen replacing and cleaning time can be shortened.

Owner:北京普仁生态技术有限公司

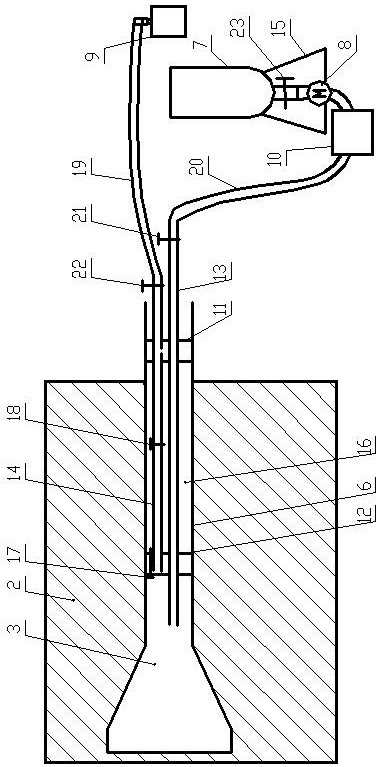

Method for enhancing permeability and promoting drainage by combining hydraulic hole making and hole drilling heat injection in mining-coal bed

ActiveCN112412417ANo pollution in the processImprove thermal stressInsulationLiquid/gas jet drillingThermodynamicsPunching

The invention provides a method for enhancing permeability and promoting drainage by combining hydraulic hole making and hole drilling heat injection in a mining-coal bed. The method comprises the following steps that crossheading drilling is carried out on a working face crossheading, wherein the distance between every two adjacent drill holes is 7-10m, and any two adjacent drill holes are namedas a heat injection hole and a drainage hole respectively; drainage pipes are arranged in the drill holes, and a special hole packer is sent into the second drainage pipe for hole sealing; high-temperature and high-pressure nitrogen is injected into the heat injection holes through the special hole packer, the adjacent drainage holes are always in normal gas drainage, and gas escaping from heatedcoal is pumped away in time; the drainage pipes in the heat injection holes are connected with a drainage system for gas drainage work, and the gas drainage effect is further enhanced. In conclusion,the method is scientific in principle, tight in hole sealing, safe and reliable, the heat injection improving drainage promoting effect is greatly enhanced by combining hydraulic punching; and the method can be widely applied to rock cross-cut coal uncovering, fault crossing, permeability enhancement and drainage promotion of excavation working faces, enhanced gas drainage and other work and is wide in application prospect.

Owner:HENAN POLYTECHNIC UNIV

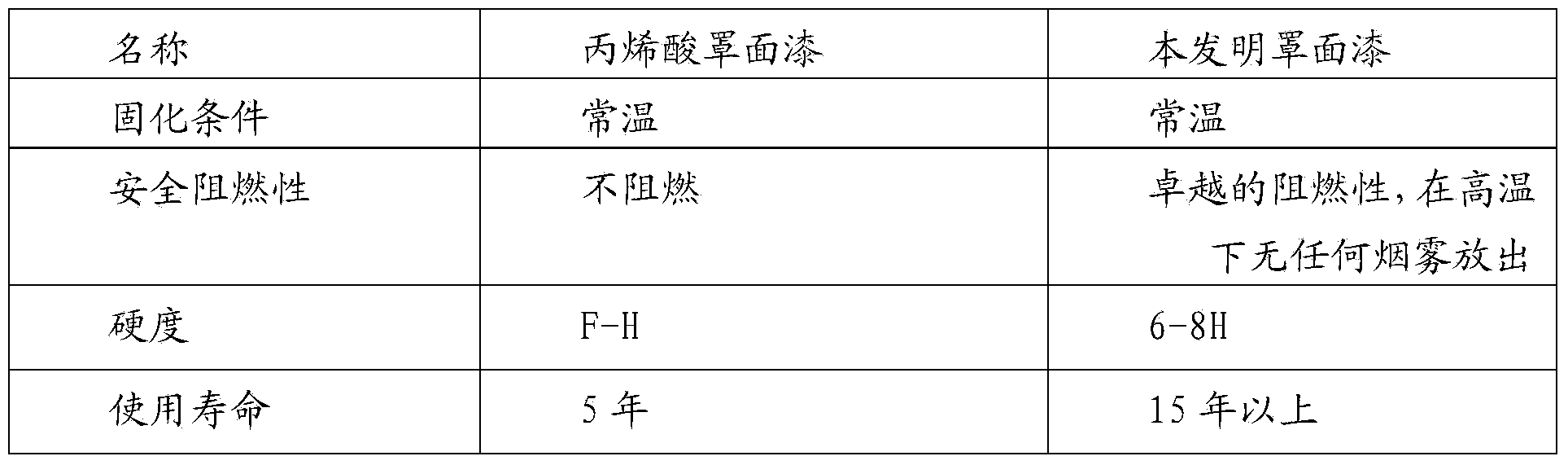

Inorganic overcoat resin and preparation method thereof

The invention discloses an inorganic overcoat resin which comprises an inorganic nano material having a solid content of 42-46%, wherein the inorganic nano material is synthesized through a sol-gel method process from the following components in parts by weight: 1-30 parts of ethyl orthosilicate, 1-10 parts of methyltrimethoxy silane, 1-50 parts of mixture of silicon dioxide, aluminum oxide, titanium dioxide and zirconium dioxide and 1-50 parts of water-alcohol mixture; the weight ratio of the silicon dioxide, aluminum oxide, titanium dioxide and zirconium dioxide in the mixture thereof is 50:20:20:10; and the water-alcohol weight ratio of the water-alcohol mixture is 65:35. According to the invention, the inorganic overcoat resin is prepared from the pure inorganic nano material, and the service life can be kept at 15 years or above; and the composition adopts a methyl introduction manner, so that the overcoat has hydrophobic / oleophobic properties, thus ensuring that self cleaning of a decorative layer can be realized by rainfall.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com