Preparation process of modified chitosan composite gel moisture retention adhesive bandage

A composite gel and preparation technology, which is applied in the field of medical devices, can solve problems such as limited application range, achieve good antibacterial effect, good moisturizing and moisture absorption performance, and relieve physical and mental pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

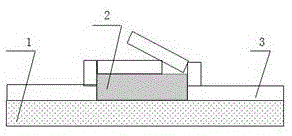

Image

Examples

Embodiment 1

[0031] 1. Weigh 50g of carbomer neutralized with NaOH for later use.

[0032] 2. Weigh 4 g of hydroxypropyl chitosan aqueous solution with a concentration of 1.5 mg / ml for subsequent use.

[0033] 3. Weigh 0.3g aluminum glyoxate and 3g NP700, dissolve with 15g glycerol for later use.

[0034] 4. Weigh 0.2g of citric acid and 0.2g of tartaric acid, add 25g of water to dissolve and set aside.

[0035] 5. Add 2 and 3 into 1 and stir evenly;

[0036] 6. Slowly add 4 to 1, stir evenly, and fully react.

Embodiment 2

[0038] 1. Weigh 40g of carbomer neutralized with NaOH for later use.

[0039] 2. Weigh 4 g of hydroxypropyl chitosan aqueous solution with a concentration of 1.5 mg / ml for subsequent use.

[0040] 3. Weigh 0.3g aluminum glyoxate and 4.5g NP700, and dissolve them with 20g glycerol for later use.

[0041] 4. Weigh 0.4g of lactic acid and 0.1g of tartaric acid, add 30g of water to dissolve and set aside.

[0042] 5. Add 2 and 3 into 1 and stir evenly;

[0043] 6. Slowly add 4 to 1, stir evenly, and fully react.

Embodiment 3

[0045] 1. Weigh 60g of carbomer neutralized with NaOH for later use.

[0046] 2. Weigh 2 g of hydroxypropyl chitosan aqueous solution with a concentration of 1.5 mg / ml for subsequent use.

[0047] 3. Weigh 0.3g aluminum glyoxate and 4g NP700, and dissolve them with 12g glycerol for later use.

[0048] 4. Weigh 1.3g lactic acid, 0.2g citric acid, 0.2g tartaric acid, add 20.2g water to dissolve and set aside.

[0049] 5. Add 2 and 3 into 1 and stir evenly;

[0050] 6. Slowly add 4 to 1, stir evenly, and fully react.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com