Method for processing surface of touch control element

A technology for surface processing and touch components, which can be applied to devices for coating liquids on surfaces, plating of superimposed layers, and metal material coating processes, etc. injuries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

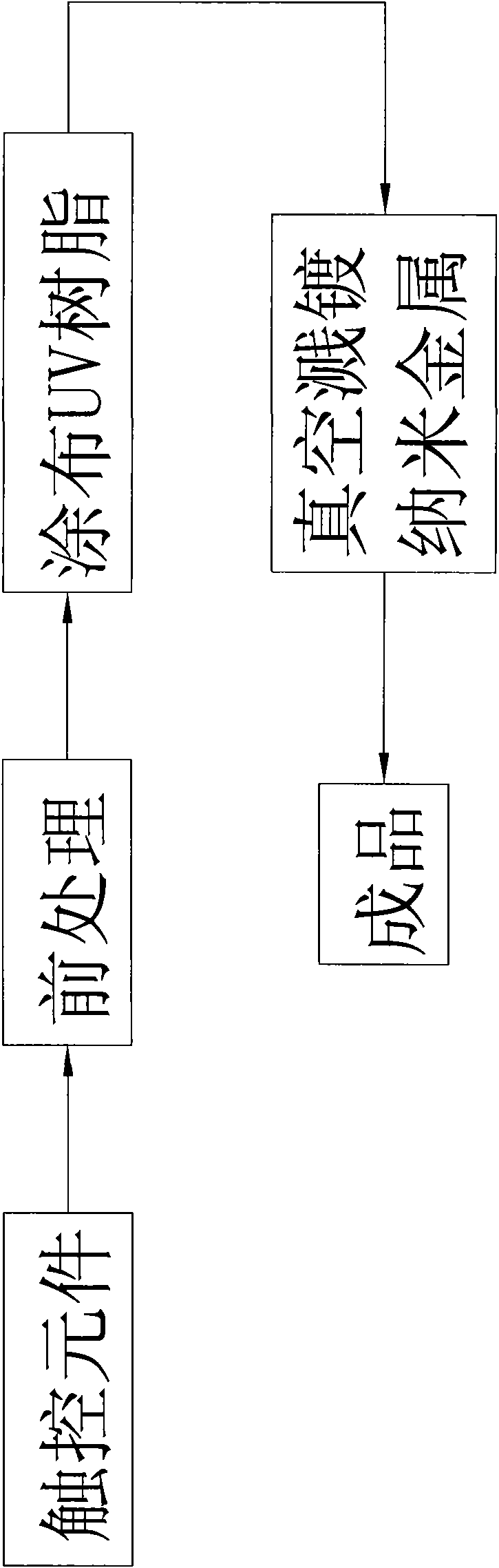

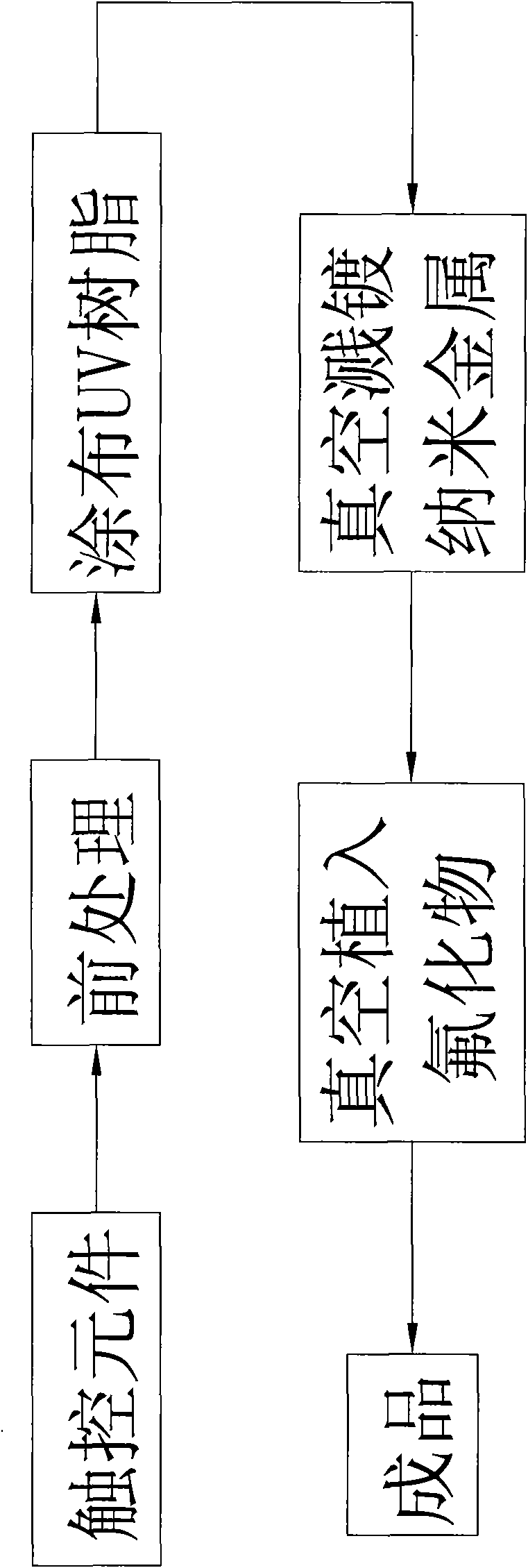

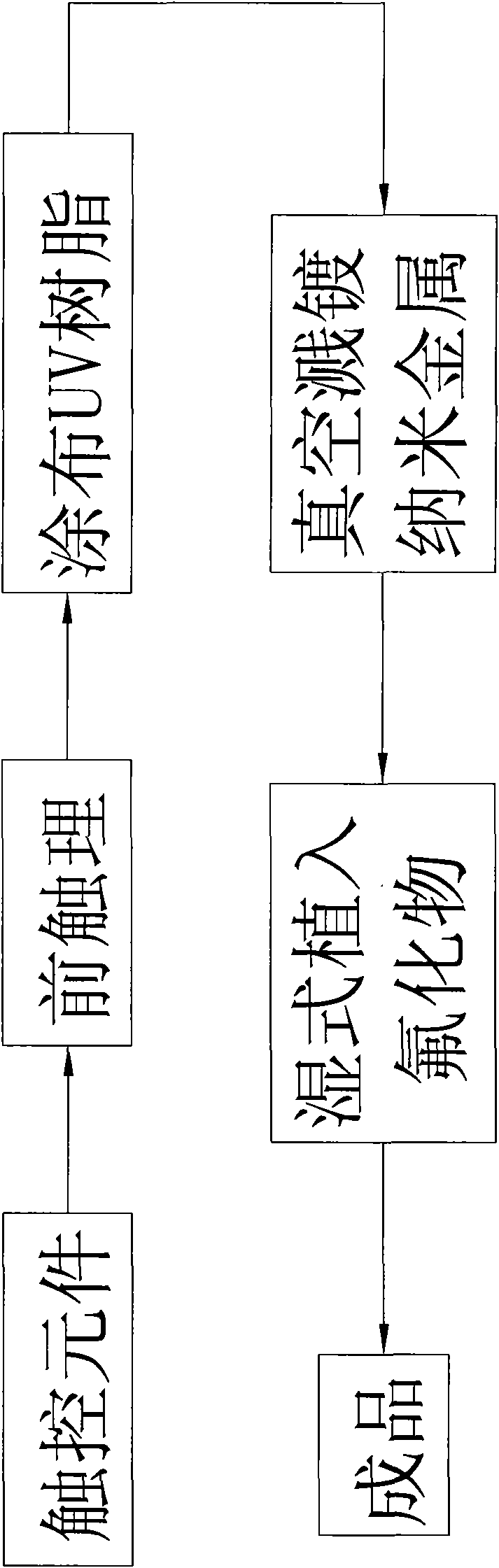

[0035] First of all, figure 1 Shown as a preferred embodiment of the method for processing the surface of the touch element of the present invention, the processing steps include:

[0036] Pre-treatment: After the touch workpiece is formed, the surface is usually rough or contains oil and other impurities. Therefore, according to the surface roughness or the oil and other impurities, first use chemical agents (such as scouring oil, alcohol, etc.) to remove the workpiece Impurities on the surface, and / or use physical methods such as surface grinding or corona (arc) to clean and smooth the surface of the workpiece to increase the surface tension of the workpiece;

[0037] Coating UV resin: First coat the surface of the touch workpiece with at least one layer of film with a hardness of 1H or higher and containing UV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com