Fuel filter

A fuel filter and filter technology, applied in the direction of machines/engines, liquid fuel feeders, engine components, etc., can solve the problem of damaging the filter base structure, reducing the service life of the filter, and the cost of the filter element assembly Advanced problems, to achieve the effect of being suitable for frequent replacement, improving sealing performance, and facilitating production and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

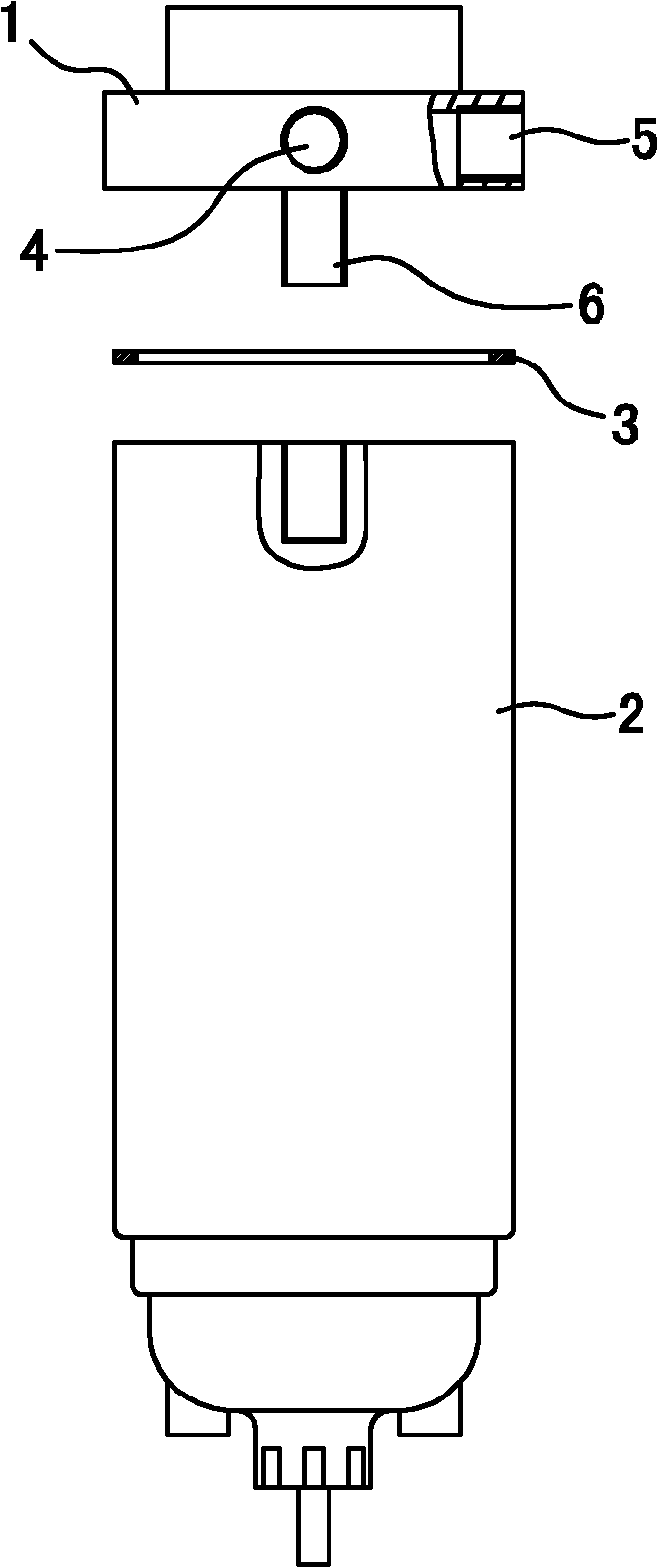

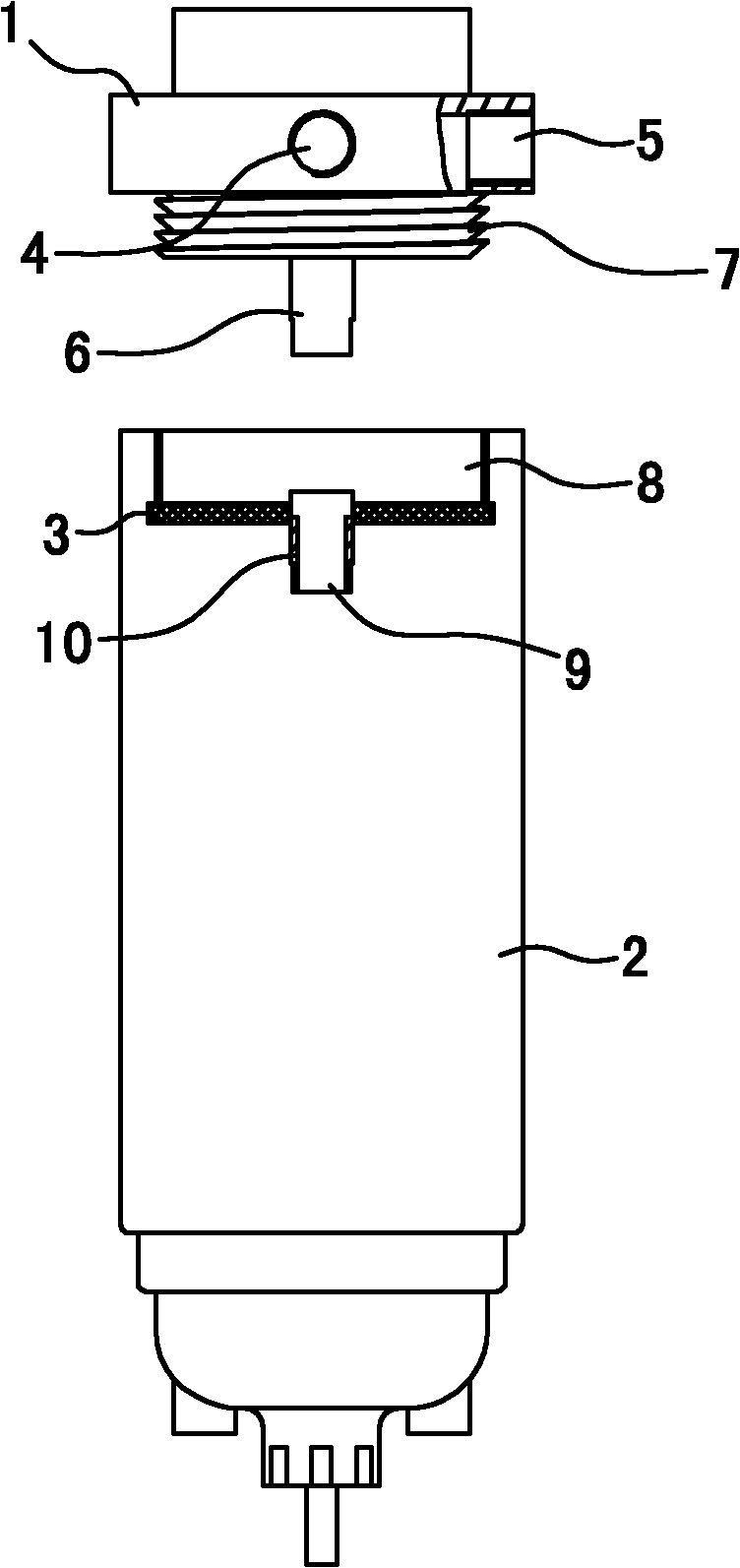

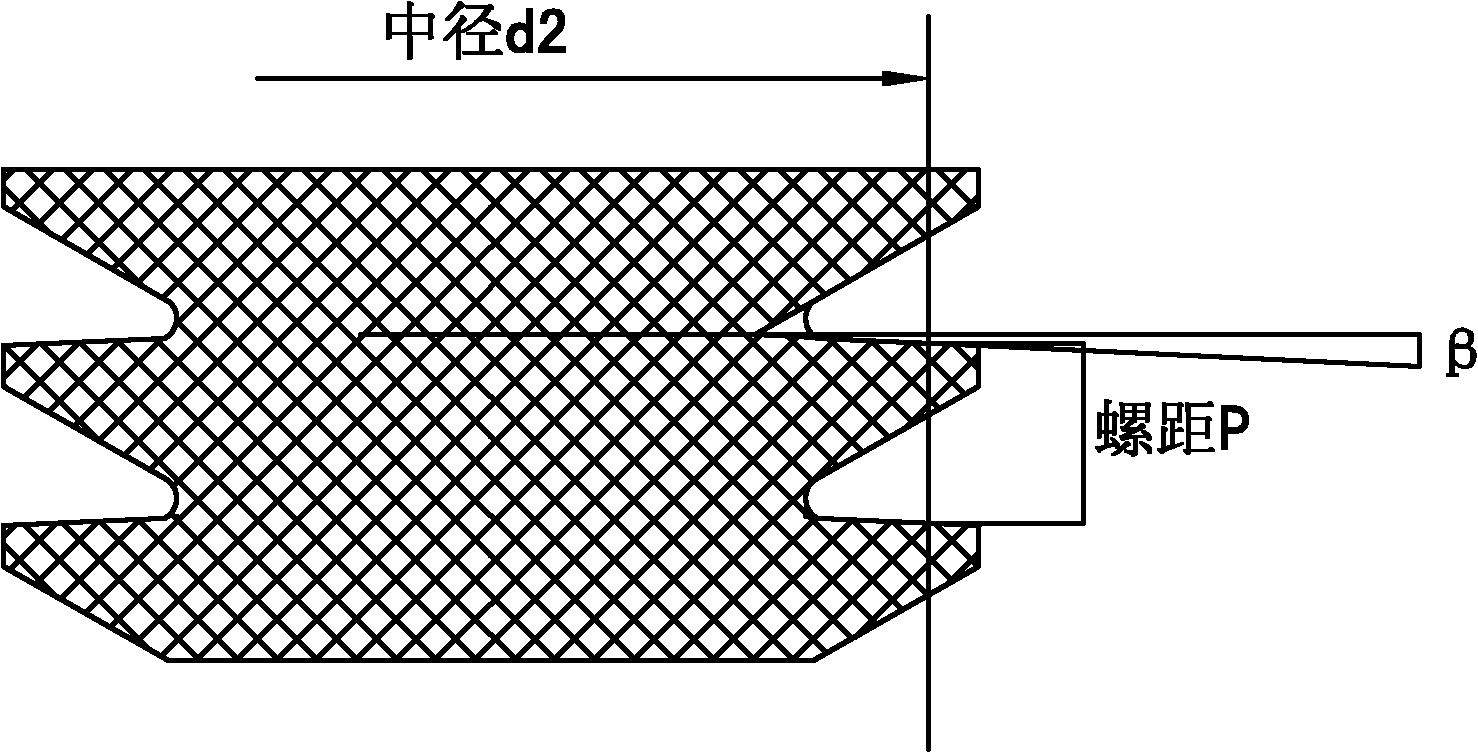

[0025] see Figure 2~3 As shown, a fuel filter includes a filter base 1, a filter element assembly 2 and a sealing ring 3. The filter base is provided with an inlet 4 and an outlet 5; the center of the bottom of the filter base is provided with a protruding The connecting rod 6 is also provided with a connecting section 7 coaxial with the connecting rod between the bottom of the filter base and the connecting rod, the diameter of the connecting section is greater than the diameter of the connecting rod, and the connecting section is provided with external threads; the filter element The center of the top of the assembly is provided with a groove 8 that matches the connecting section, and the inner wall of the groove is provided with a matching internal thread; the bottom of the groove of the filter element assembly is provided with a connecting groove 9 that cooperates with the connecting rod 6; The connecting rod 6 is a round table structure with a large top and a small botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com