Patents

Literature

113results about How to "Reduce mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

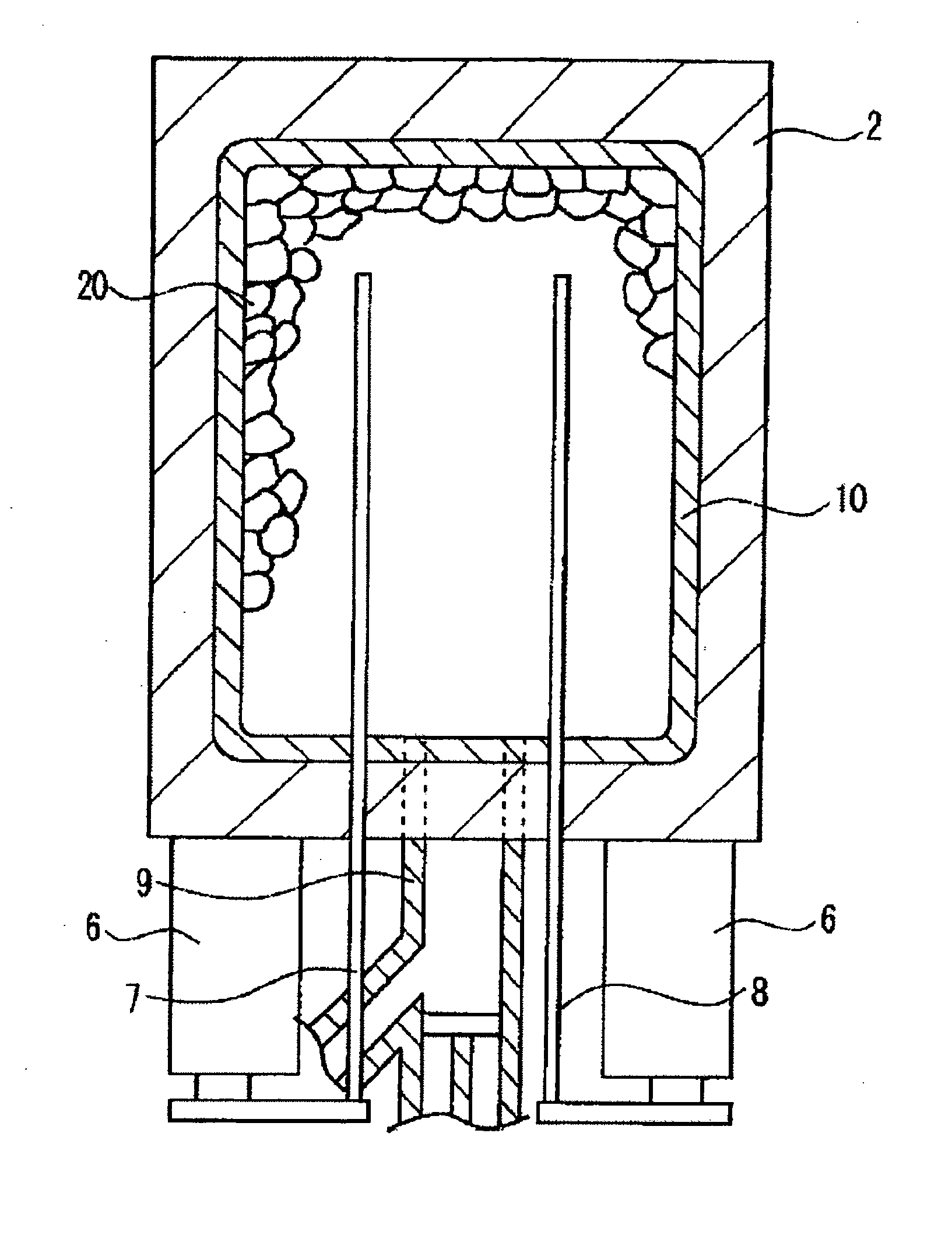

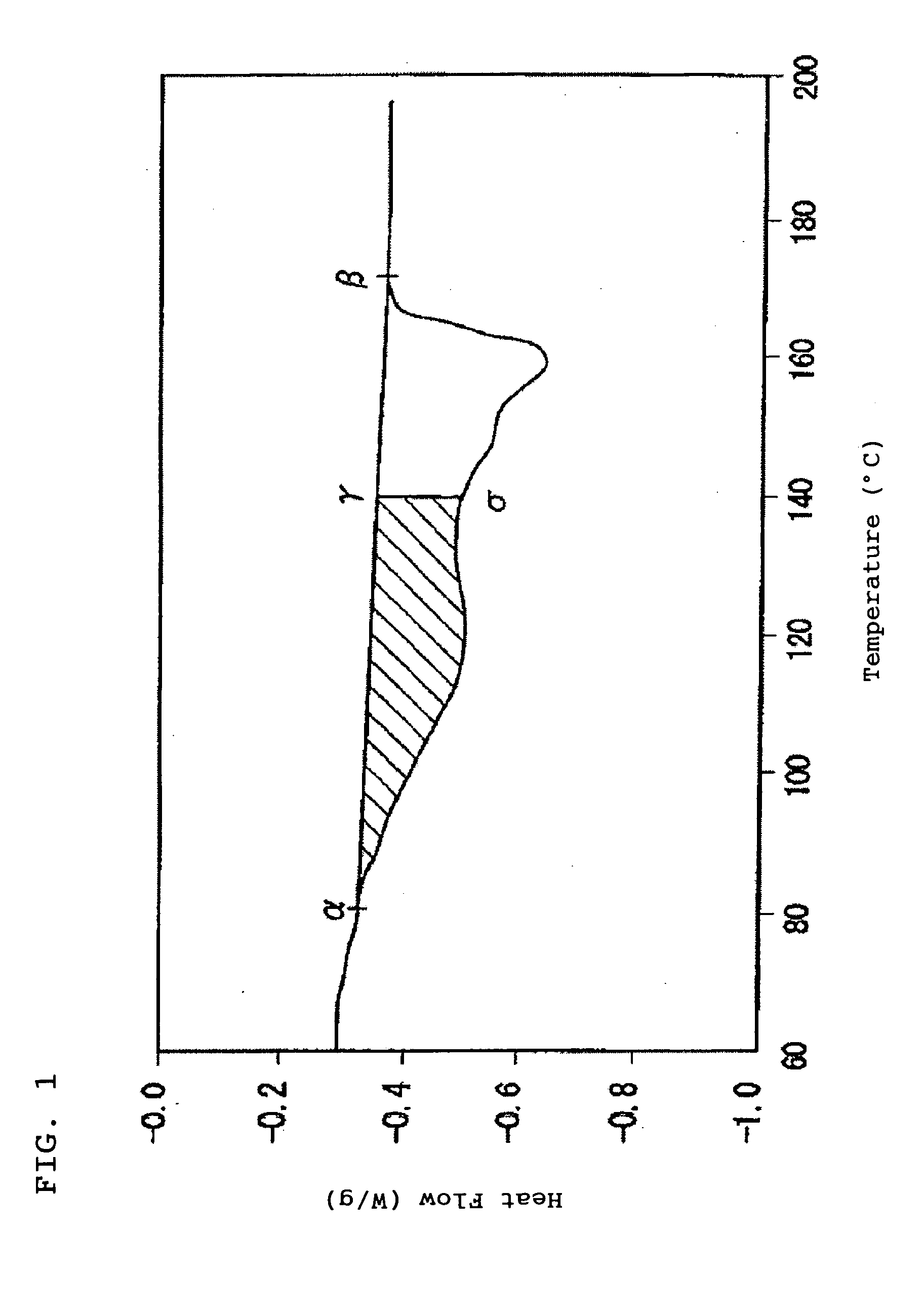

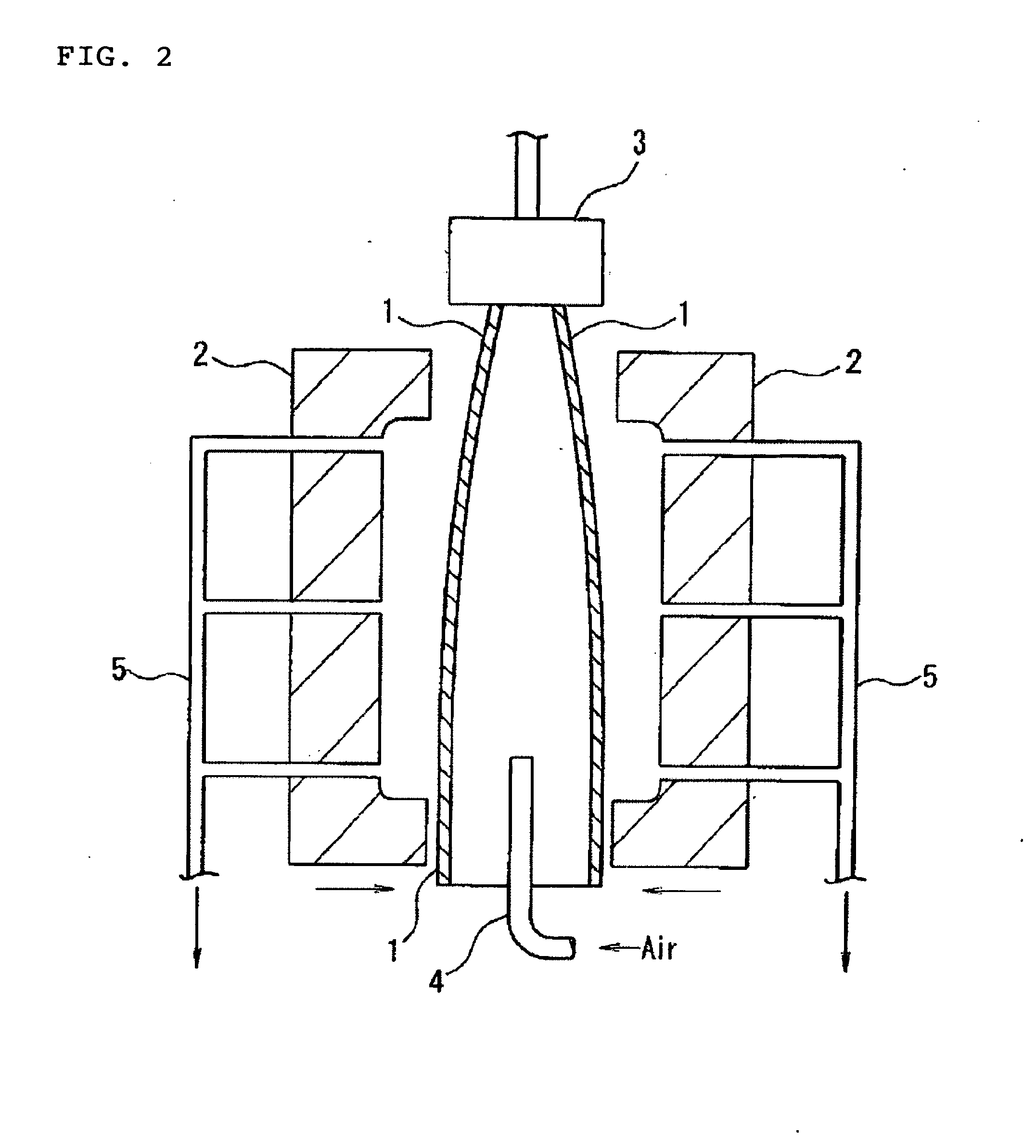

Skin-covered propylene resin foamed molded article

ActiveUS20080275148A1Improve relationshipSmall thicknessThin material handlingApparent densityBlow molding

The present invention pertains to a skin-covered foamed molded article of expanded propylene resin beads having excellent lightness in weight, mechanical properties and appearance.The present invention provides a skin-covered foamed molded article of propylene resin expanded beads, with the skin covering substantially the entire surface of the molded article of the expanded beads. The skin, within which the molded article of expanded propylene resin beads is placed, is a propylene resin hollow molded body obtained by blow molding. A base resin of which the skin is formed comprises a propylene resin having a partial heat of fusion in a temperature range between 80 and 140° C. of at least 15 J / g and a ratio of the partial heat of fusion to a total heat of fusion (partial heat of fusion / total heat of fusion) of at least 0.2 as measured by heat flux differential scanning calorimetry. The skin has a thickness in the range of 0.3 to 3.5 mm, and the molded article of expanded propylene resin beads has an apparent density in the range of 0.015 to 0.15 g / cm3. The skin is fuse-bonded to the molded article of expanded beads, and the expanded beads from which the molded article is formed are fuse-bonded to each other.

Owner:JSP CORP

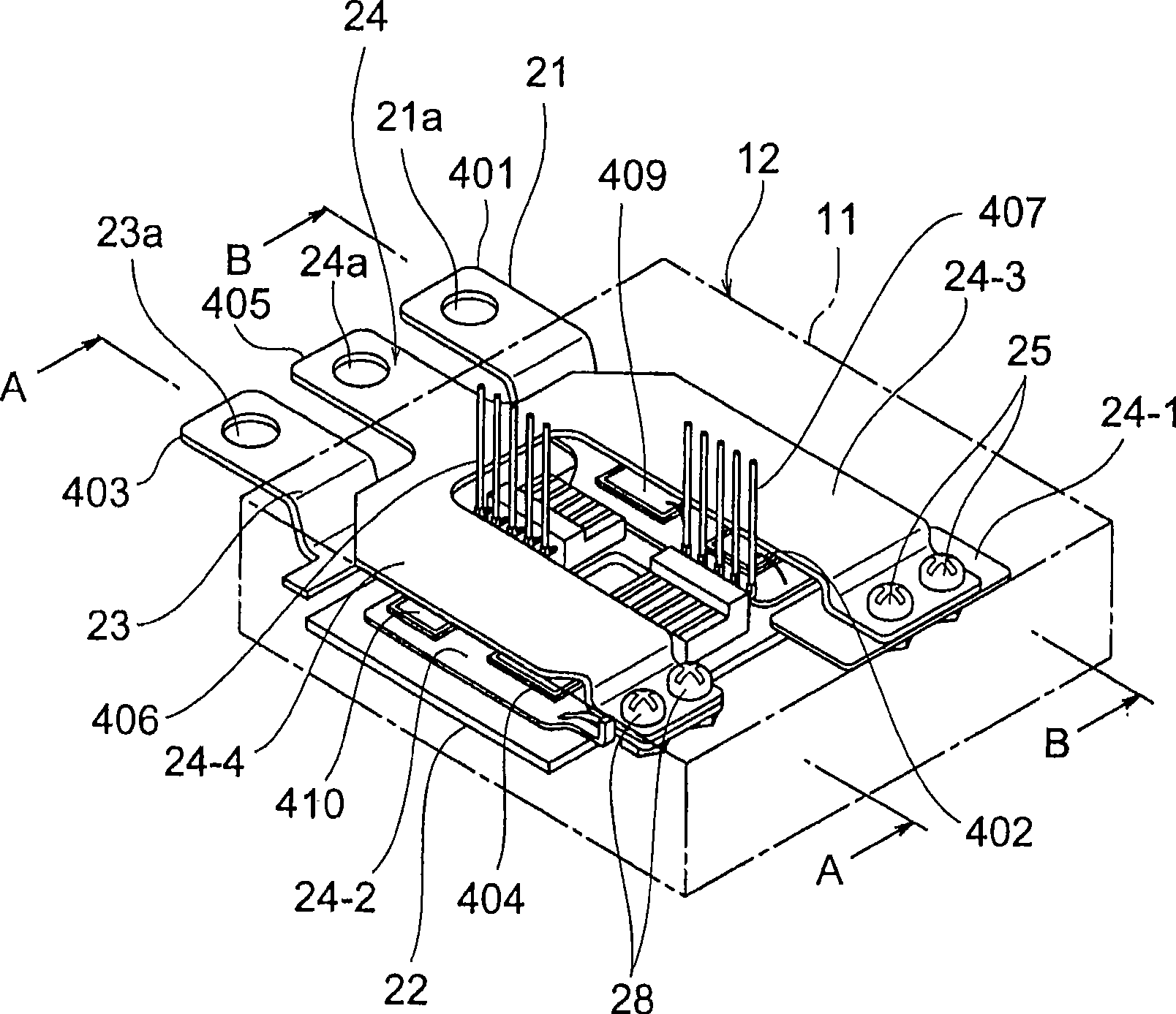

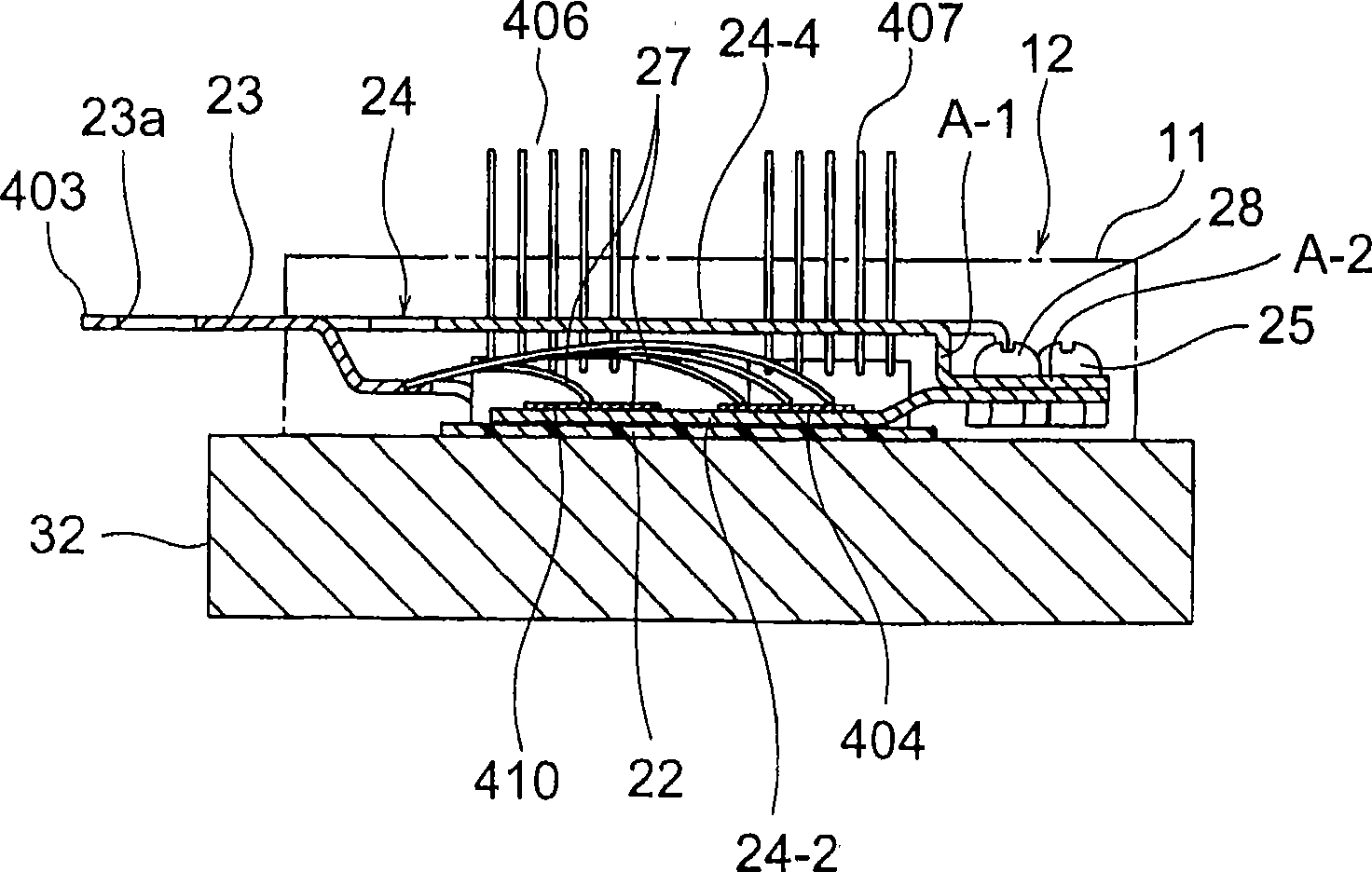

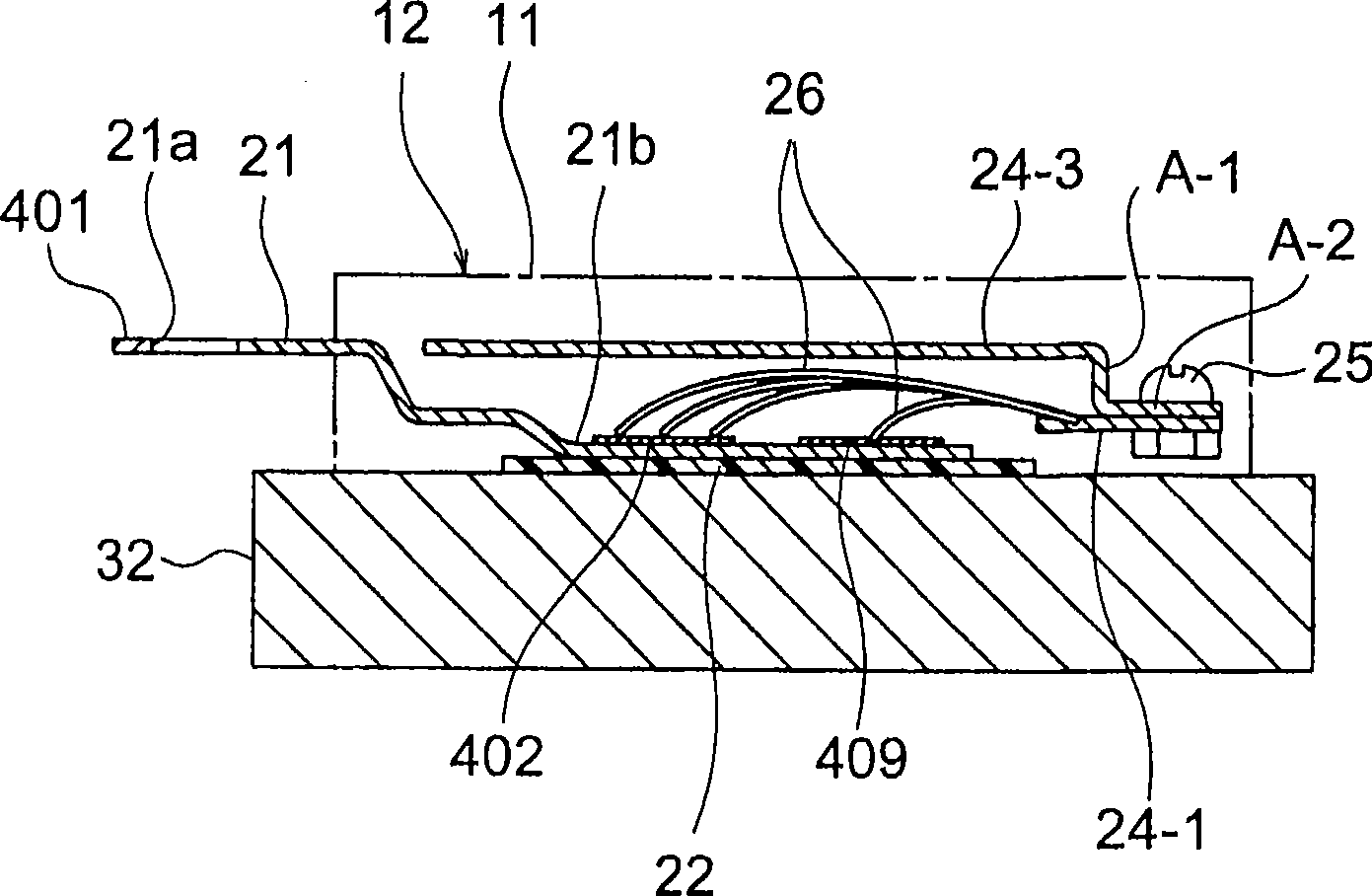

Semiconductor device

InactiveCN101467252AReduce inductanceReduce lossesSolid-state devicesElectric energy managementLow voltageSemiconductor chip

A semiconductor device is composed of a pair of semiconductor chips (402, 404) arranged parallel on the same flat plane; a high voltage bus bar (21) bonded on the surface on the collector side of one semiconductor chip (402); a low voltage bus bar (23) connected to the surface on the emitter side of the other semiconductor chip (404) with a bonding wire (27); a first metal wiring board (24-1) connected to the surface on the emitter side of the semiconductor chip (402) with a bonding wire (26); a second metal wiring board (24-2) bonded on the surface on the collector side of the semiconductor chip (404); a third metal wiring board (24-3) connected to the first metal wiring board (24-1); a fourth metal wiring board (24-4) connected by being bent from an end portion of the second metal wiring board (24-2); and an output bus bar (24) having output terminals (405) extending from each end portion of the third metal wiring board (24-3) and that of the fourth metal wiring board (24-4).

Owner:HONDA MOTOR CO LTD

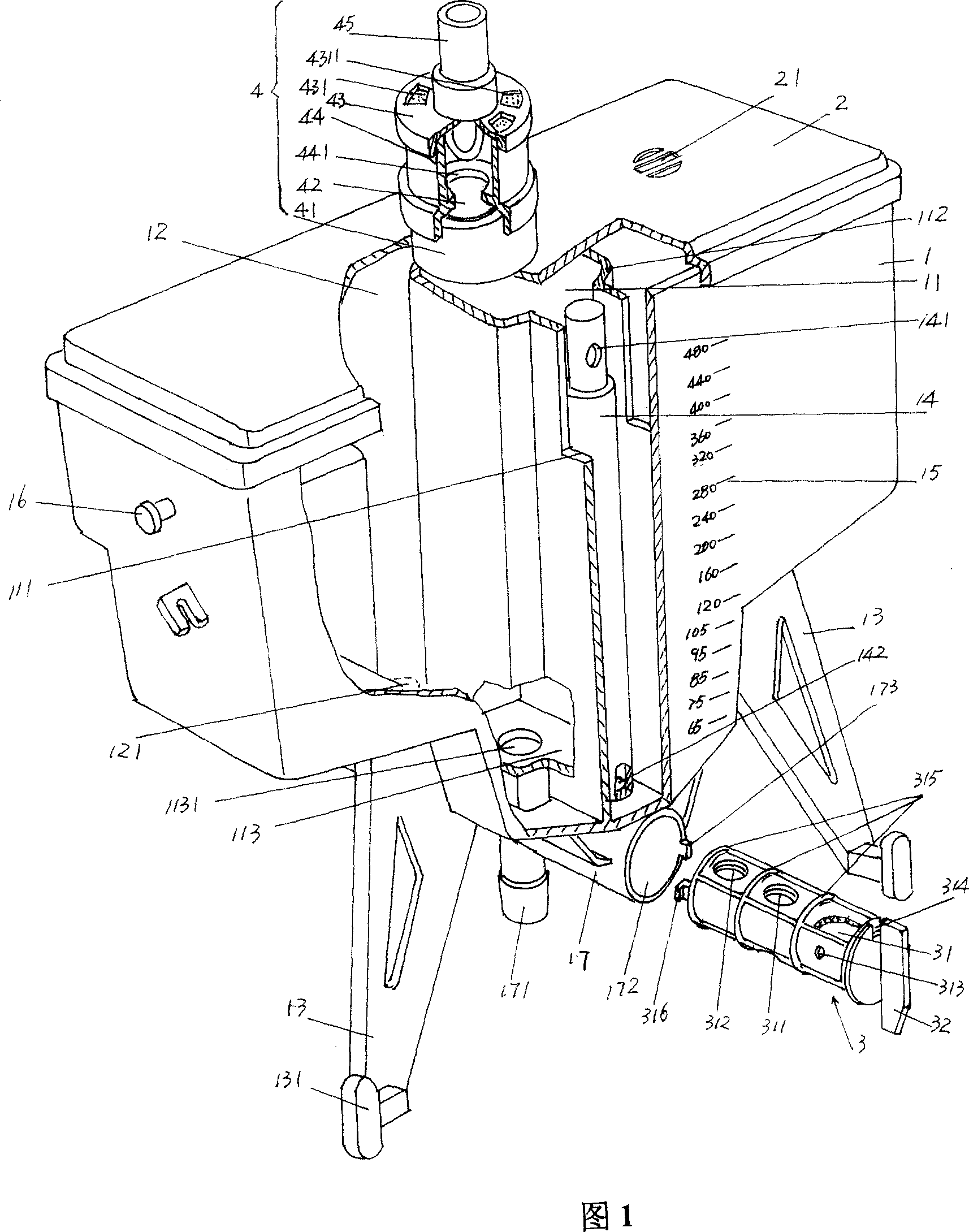

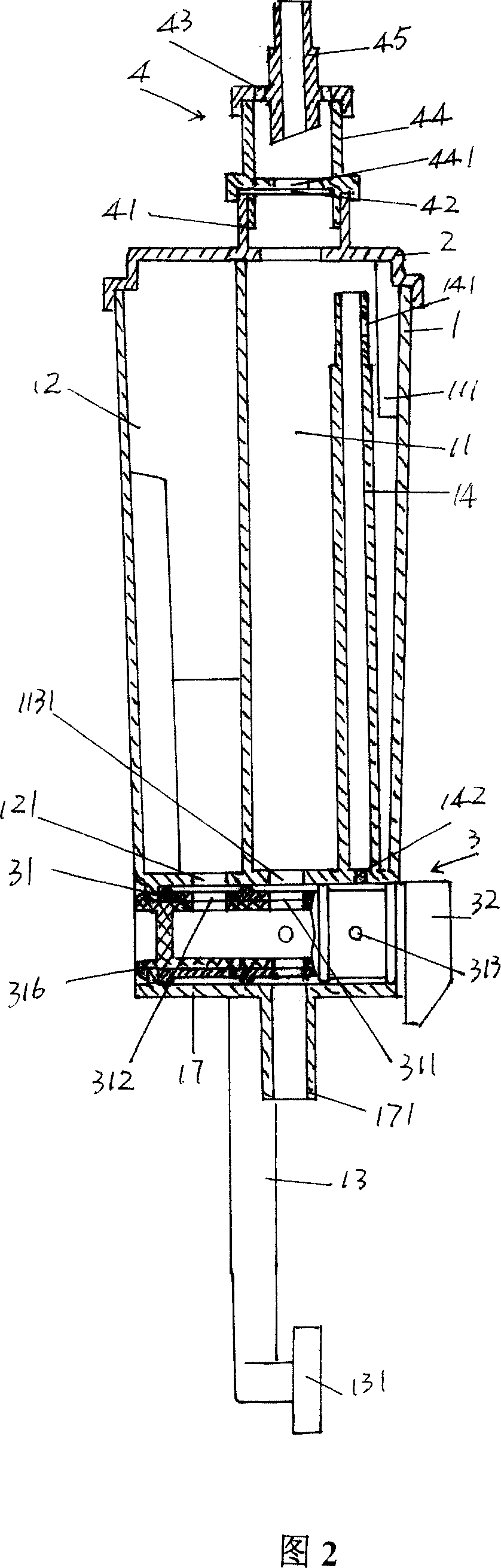

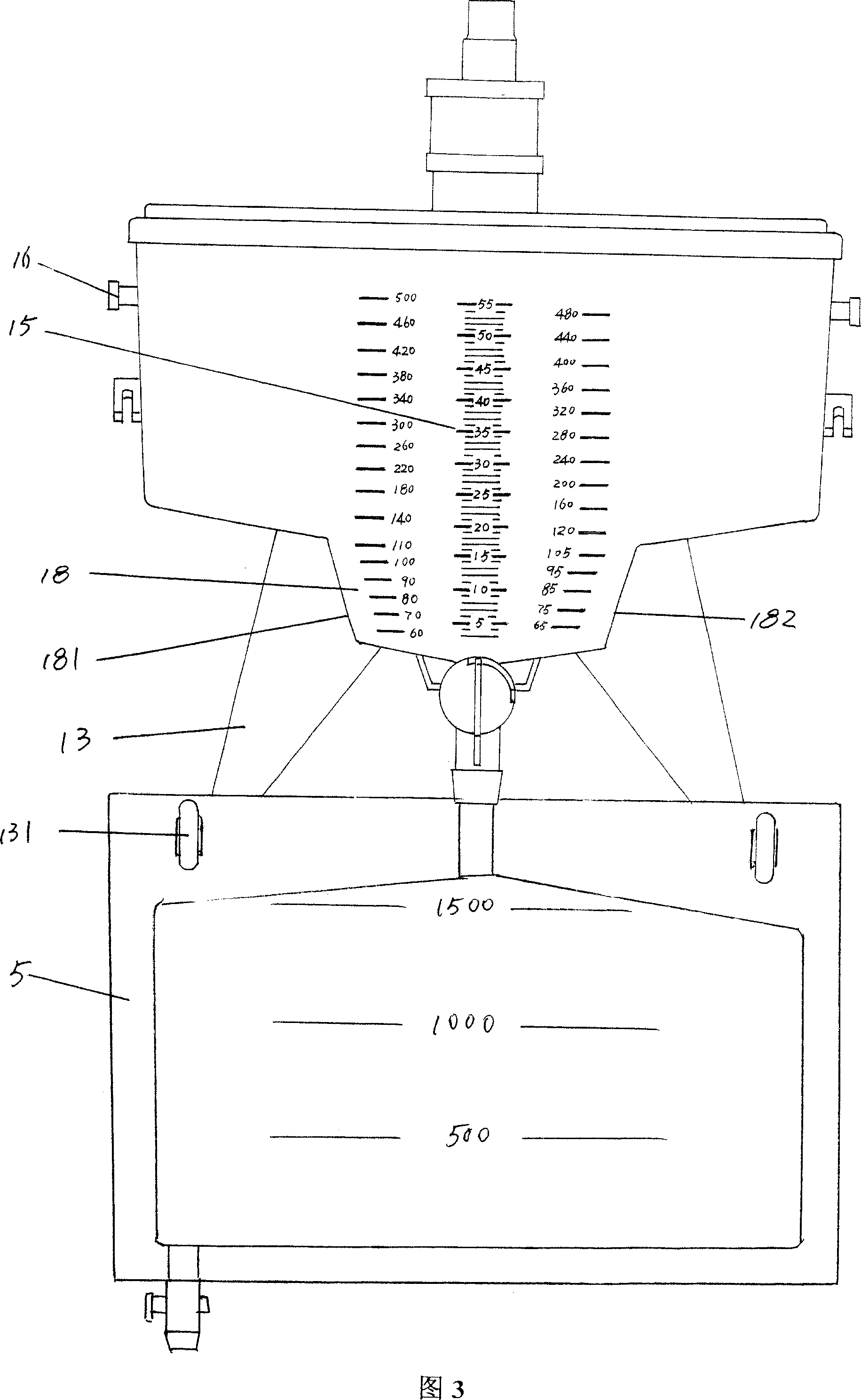

Medical semi-automatic drain liquid metering and storing apparatus

InactiveCN100998540AConducive to exhaustionAccurate measurementVolume measurement and fluid deliveryPharmaceutical containersSemi automaticEngineering

A semi-automatic metering accumulator of drainage fluid for medical purpose is composed of a box body, a box cover with the guide and anti-reflux mechanism of drainage fluid, a panel with a longitudinal metering scale, and a drainage fluid discharging valve. Said box body has a big fluid storage cavity, a cylindrical small fluid storage cavity, and a tubular over-flow cavity arranged vertically in said small fluid storage cavity.

Owner:常熟市神灵医用器材有限公司

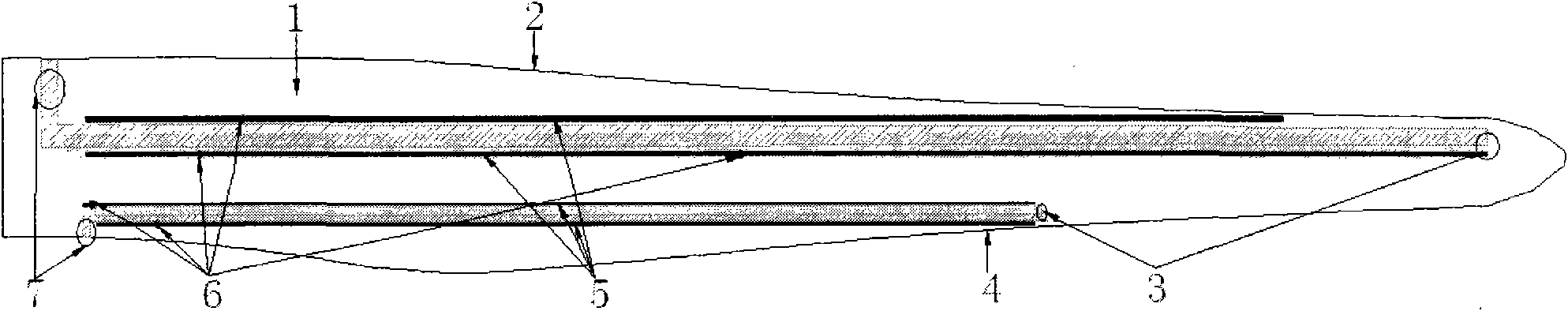

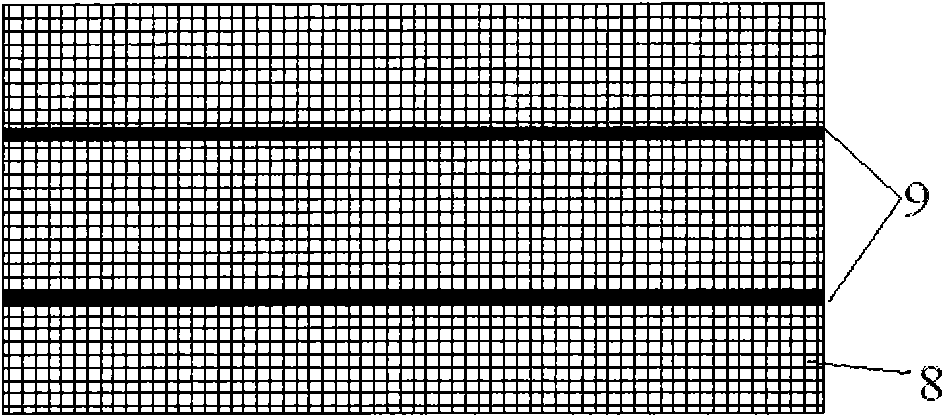

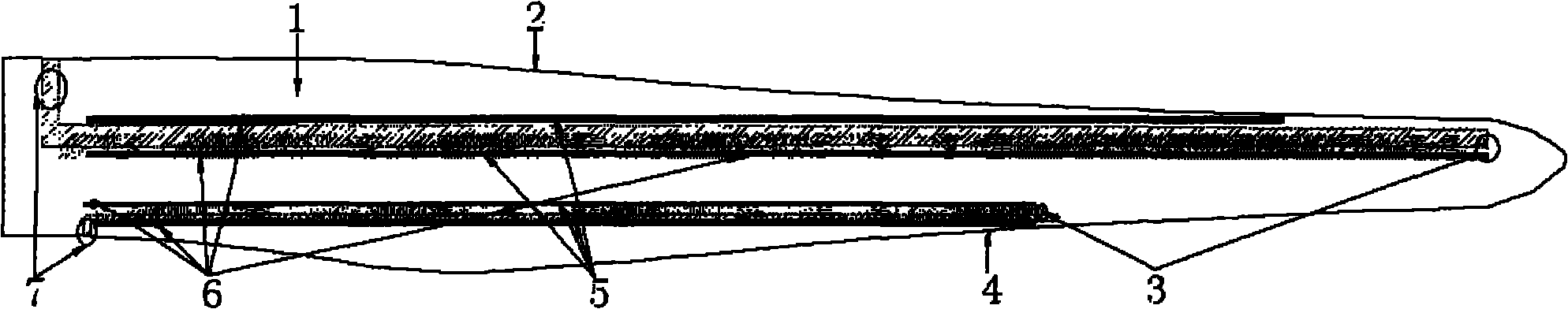

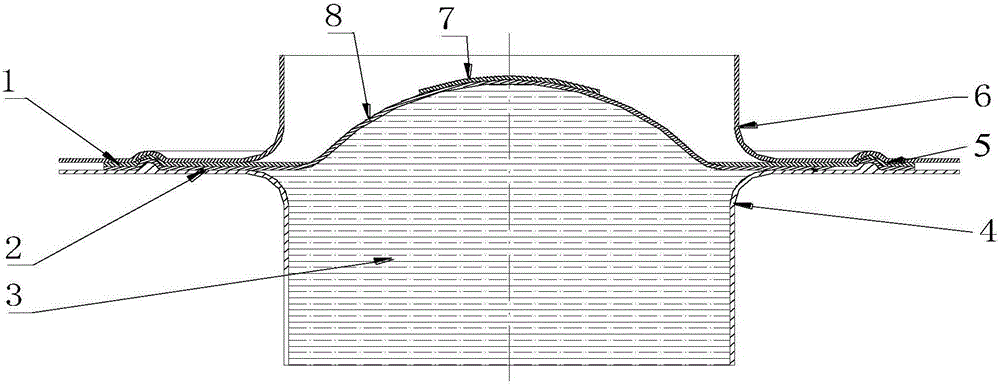

Method for preparing large-scale composite-material aerogenerator blade

The invention relates to the molding technology of nonmetal composite materials, and provides a method for preparing large-scale composite-material aerogenerator blades; the method mainly relates to the following steps: preparing an upper and a lower housing of the blade; directly laying a crossbeam (3) in the blade housing body when laying the blade housing; completing the preparation of the blade housing by an integral forming process of the crossbeam (3) and the blade housing; during vacuum perfusion, setting different rapid diversion zones and flow obstruction zones (7) according to the change of the permeation rate of a resin in fibers so as to allow the resin to infiltrate the whole laid layer more rapidly and much better; laying a diversion net on the upper surface of the laid blade housing; setting a certain interval between diversion media for the arrangement of the obstruction zones (7), and laying a flow obstruction belt (9) on the diversion media where flow obstruction is needed; or directly laying the flow obstruction belt on the upper surface of the blade housing; adding continuous strand mats into the interior part of the crossbeam layer so as to accelerate the permeation rate of the resin in the layer.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

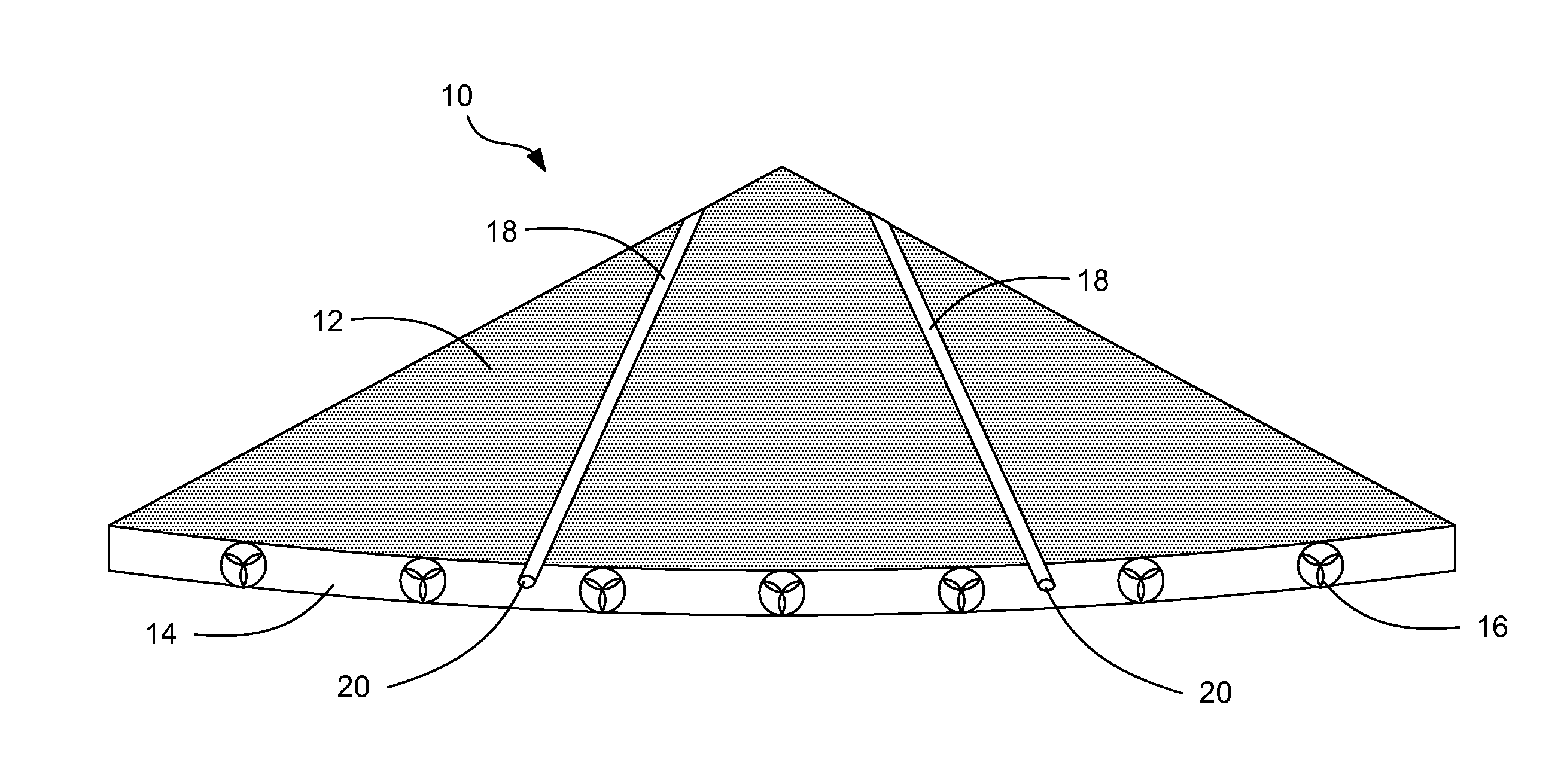

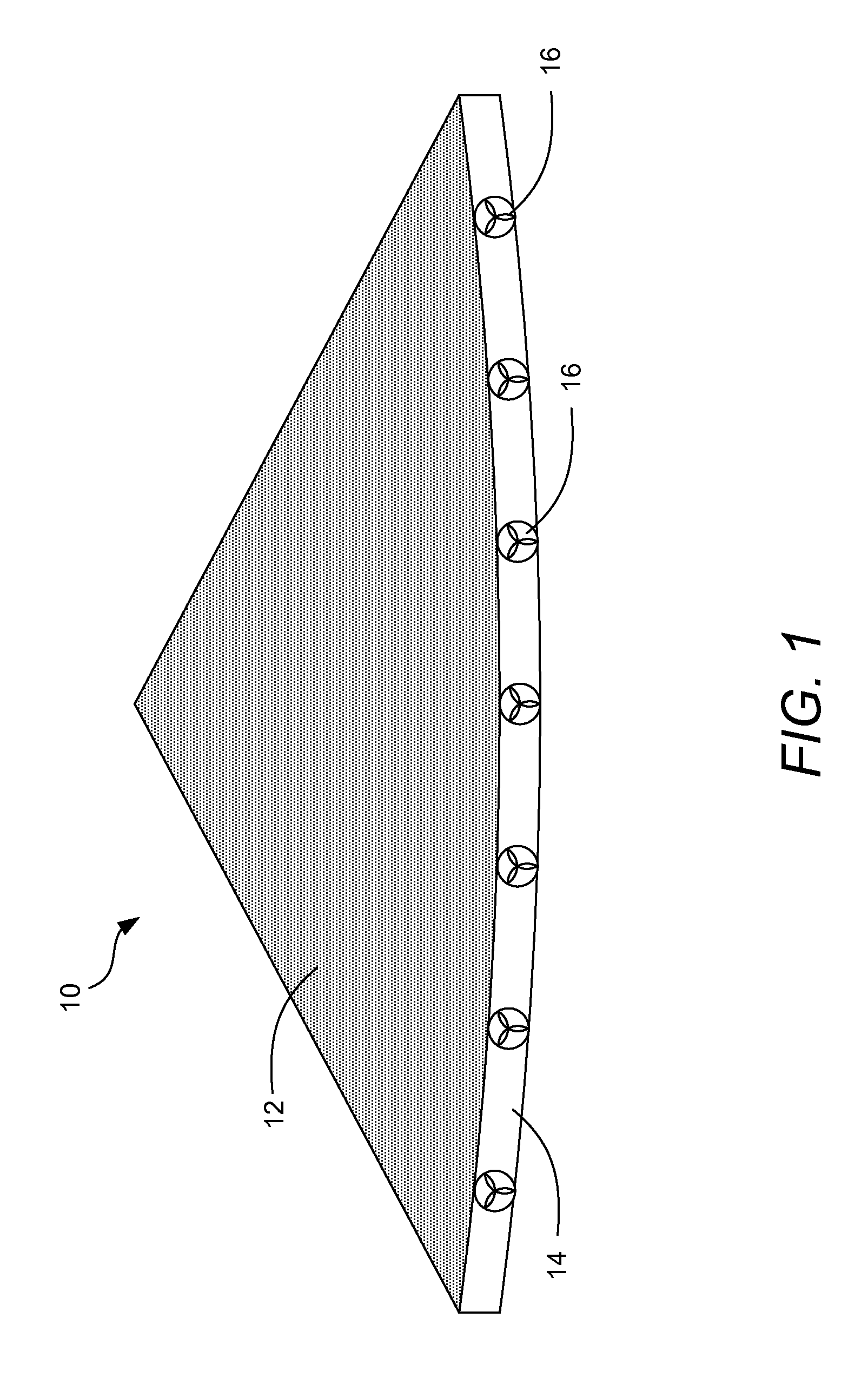

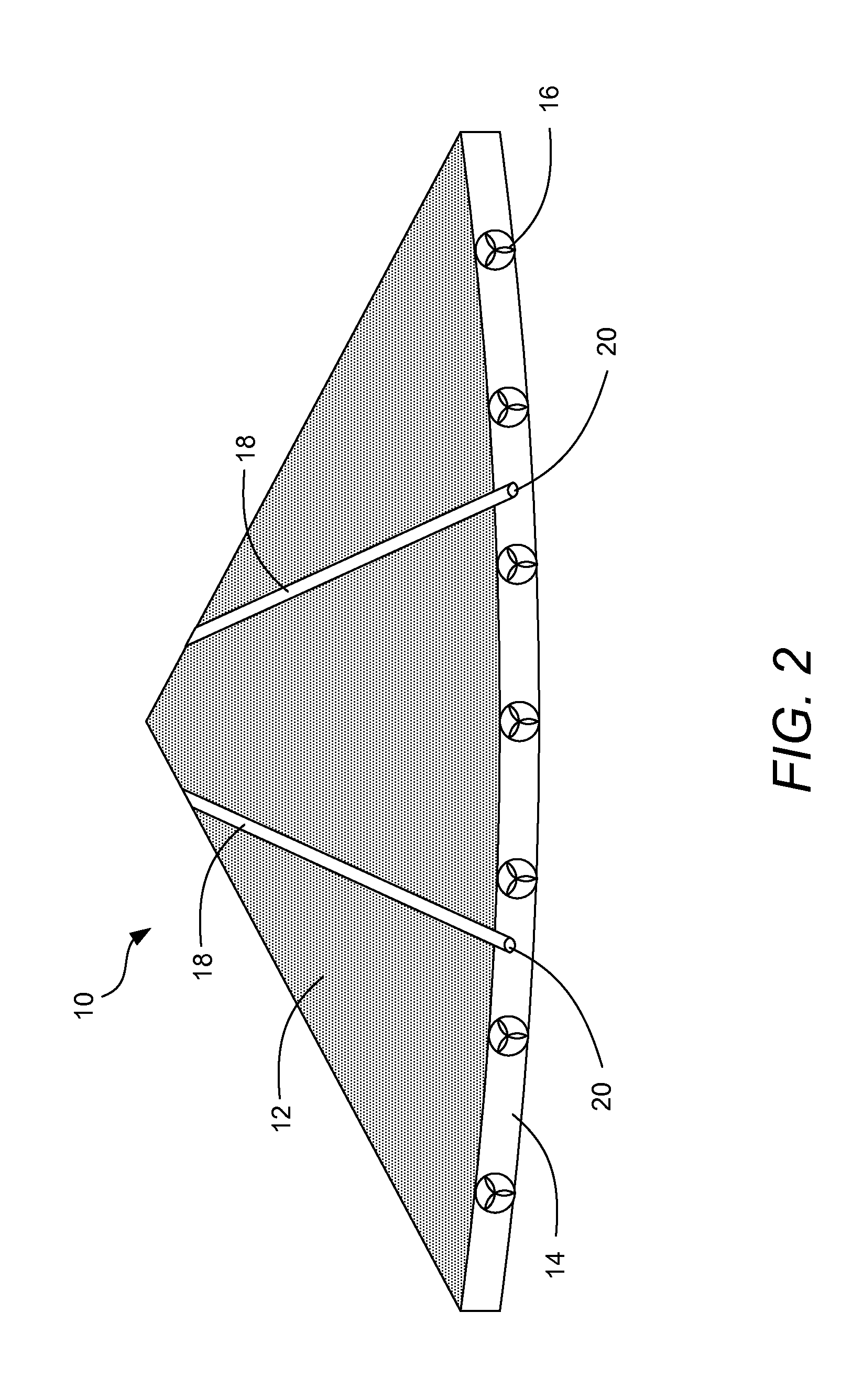

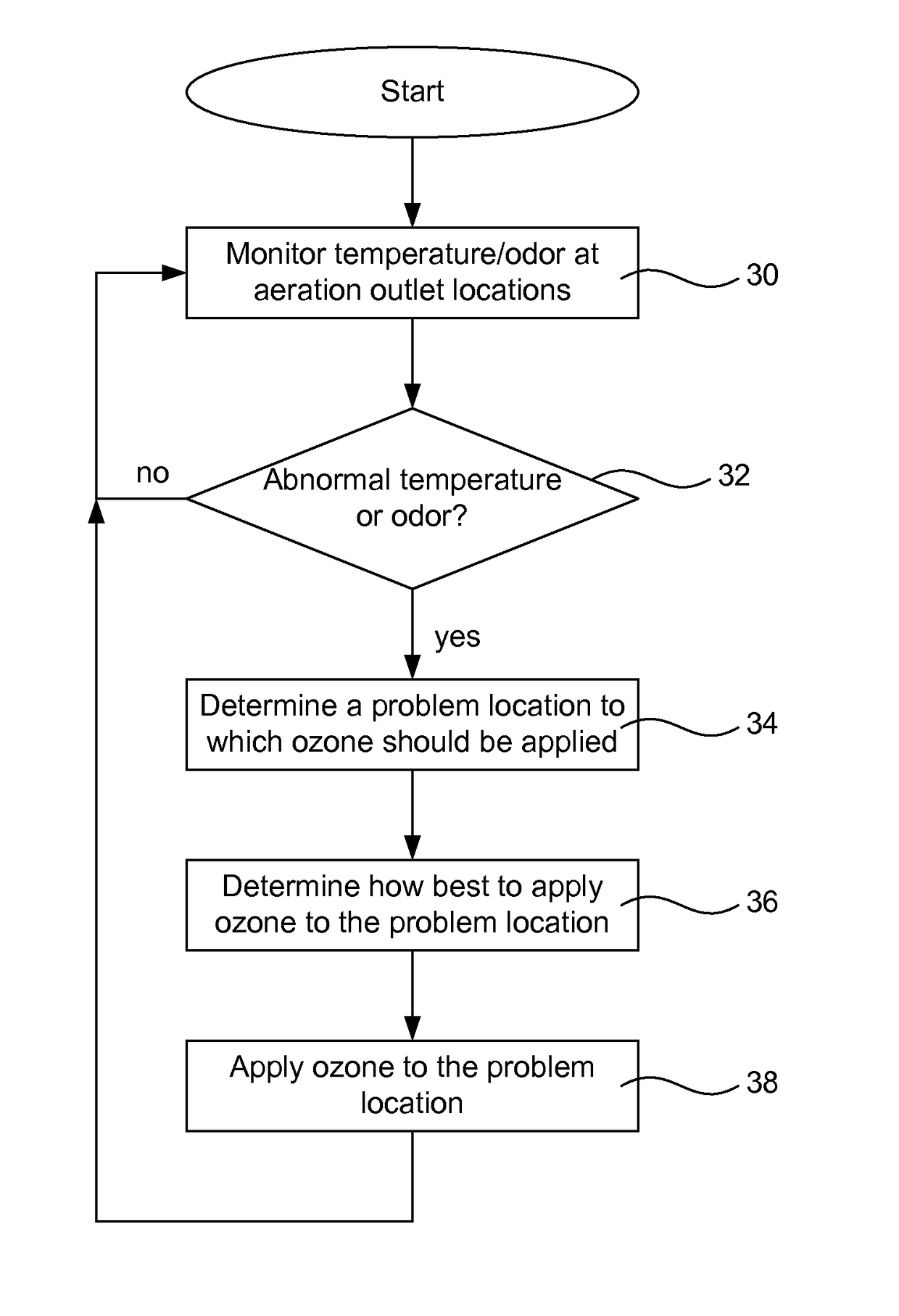

Systems and Methods for Ozone Treatment of Grain in Grain Piles

ActiveUS20110151073A1Minimize nascent problemReduce moldSeed preservation using chemicalsAvicultureToxinProblem location

Systems and methods for treating grain stored in a grain pile with ozone are effective for treating grain for toxins, insects, mold, and / or odor. A method according to embodiments of the invention involves monitoring at least one of temperature and odor at a plurality of aeration outlet locations spaced around the grain pile. When an abnormal temperature variance or odor is detected at one or more of the aeration outlet locations, a determination is made as to a problem location within the grain pile where a treatment of ozone should be applied, and a further determination is made as to how best to apply ozone to the problem location. Ozone is then applied to the problem location within the grain pile to minimize nascent problems in the grain pile. The ozone treatment may reduce molds and toxins.

Owner:ARCHER DANIELS MIDLAND CO

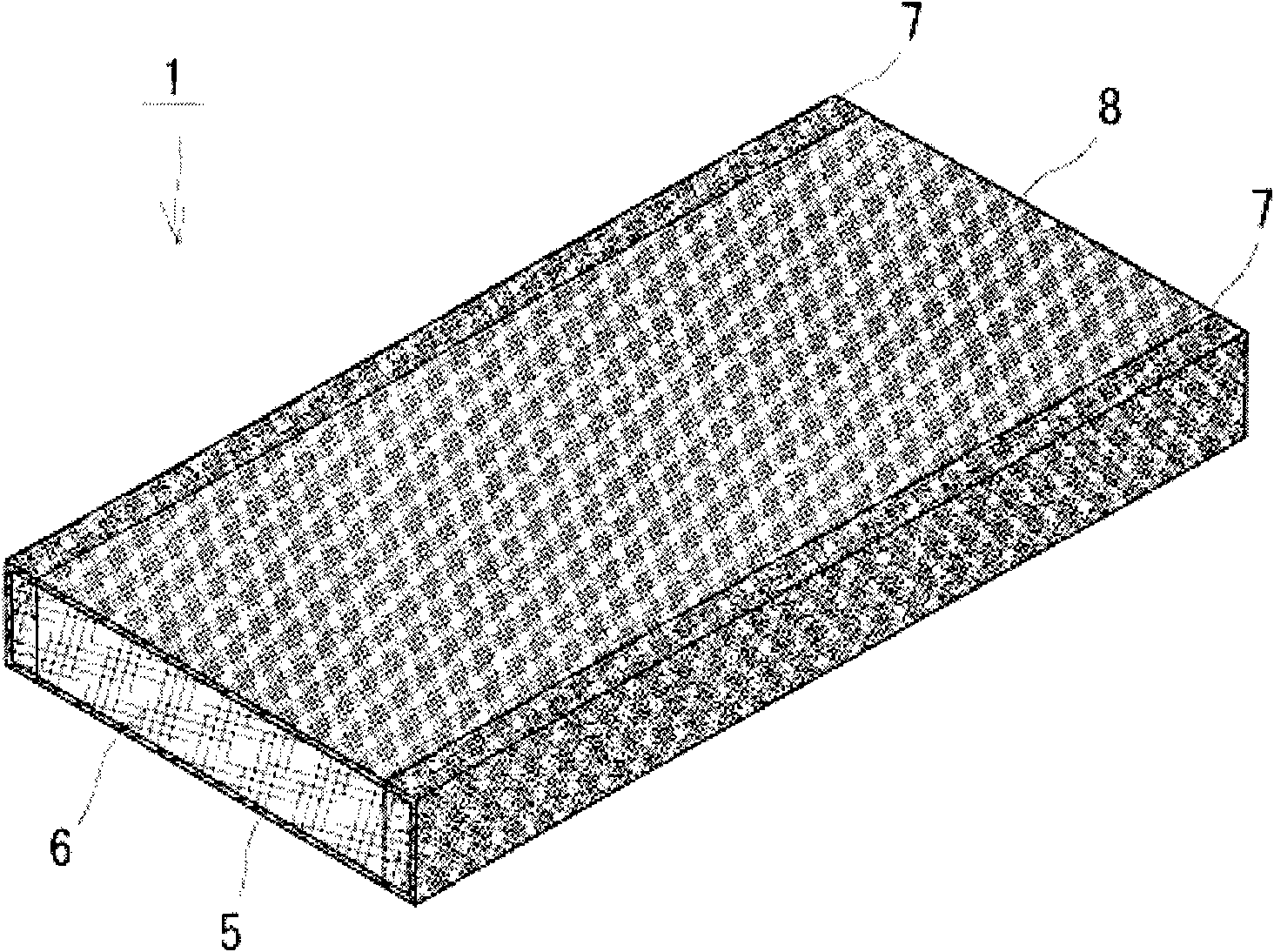

Damp-proof mattress and manufacture method thereof

InactiveCN101874691AGood for healthBeneficial antibacterial effectUpholstery manufactureStuffed mattressesApparent densityEngineering

The invention provides a good mattress capable of preventing dewing and dispensing, characterized in that: the thermal plasticity resin as the raw material or the main raw material melts to be extruded into lines and a large amount of lines are wounded out of order and welded into annular aggregates of the lines and the aggregates are formed into the plate-like shape and then cooled and solidified, therefore a three-dimensional net structure is formed. The left, right relatively-long side-surfaces have side-surface firmness parts with high apparent density.

Owner:C ENG CO LTD

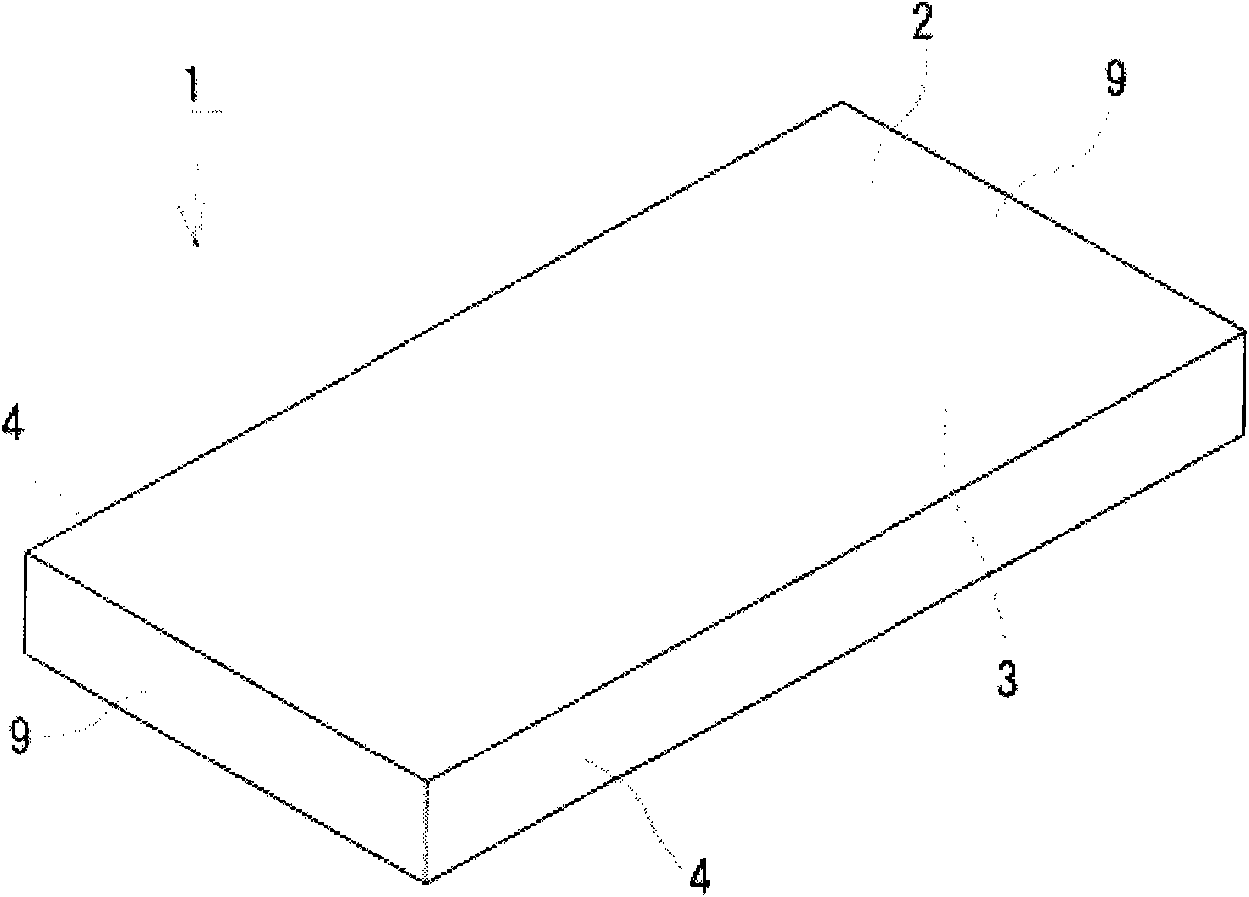

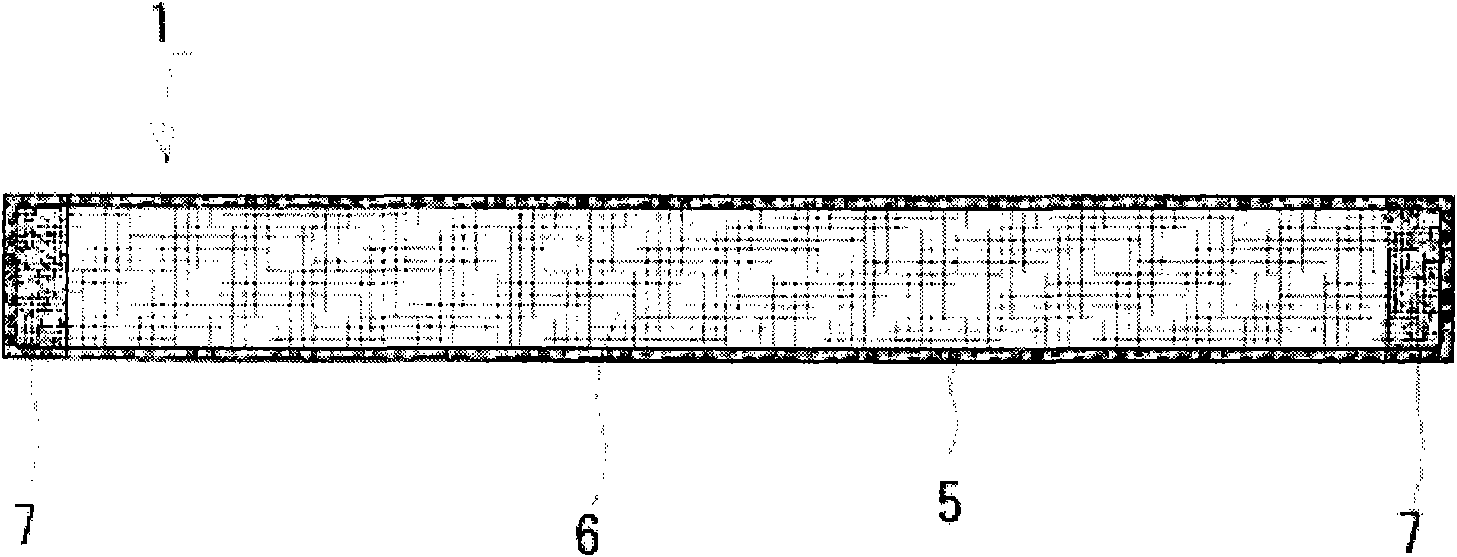

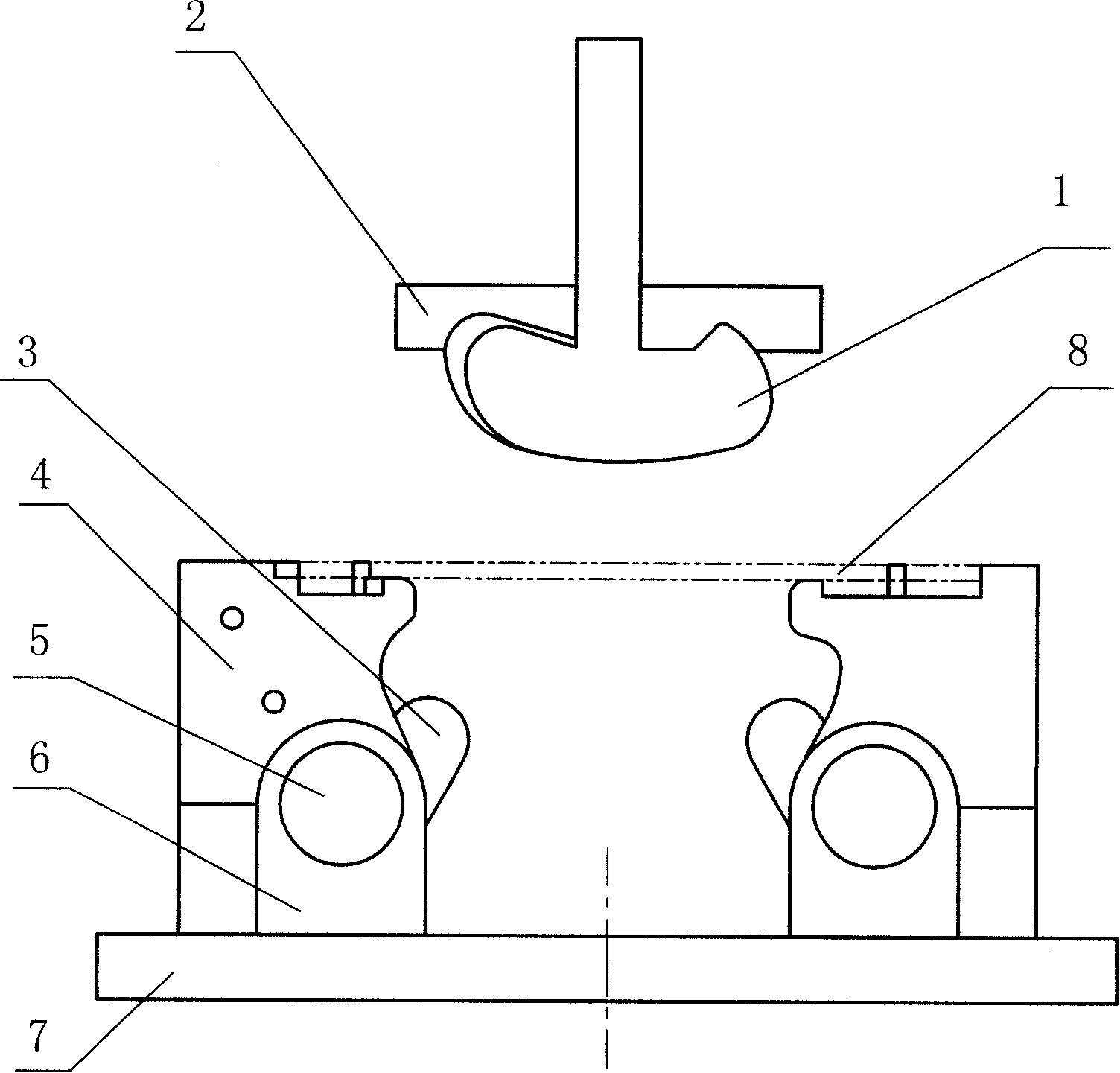

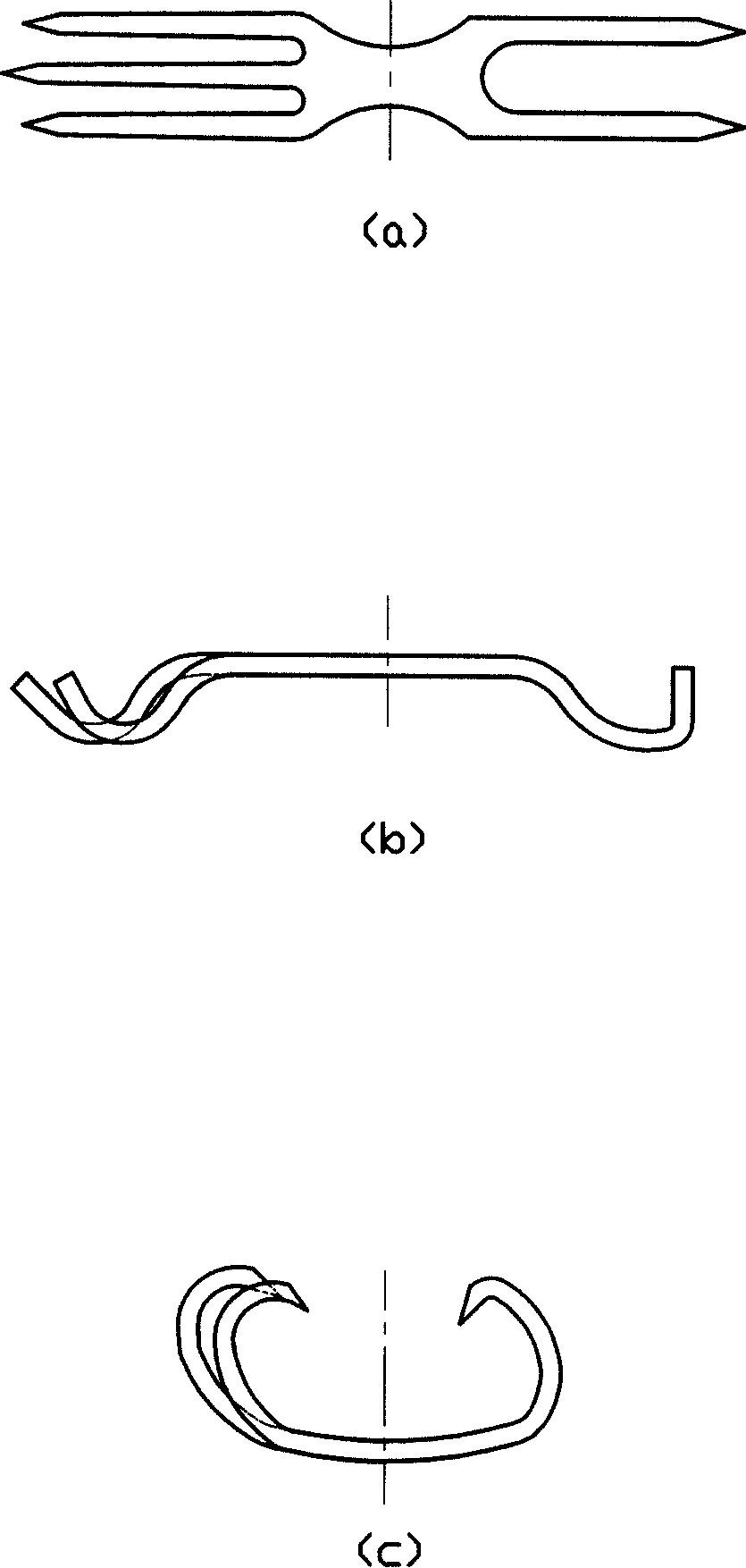

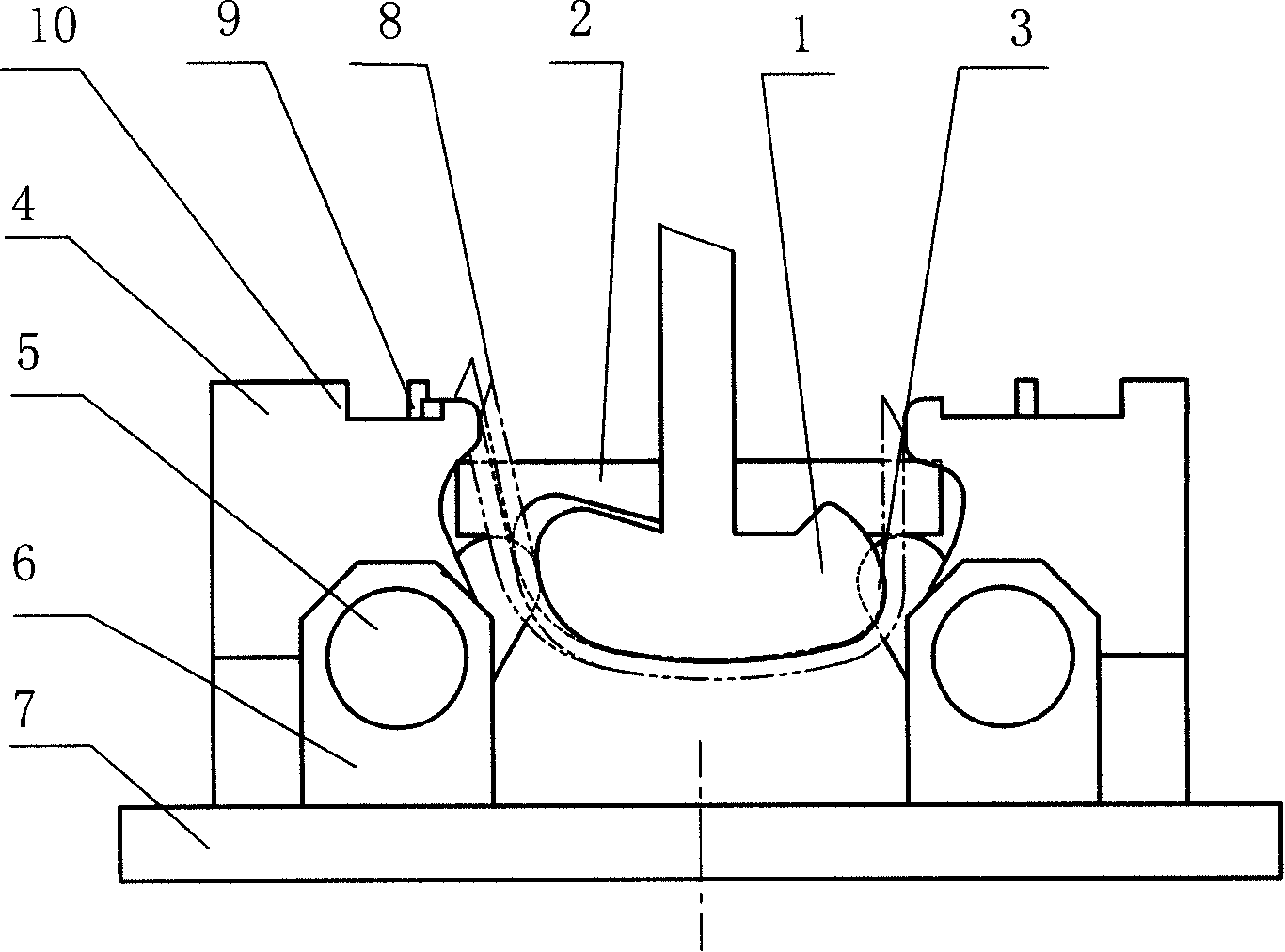

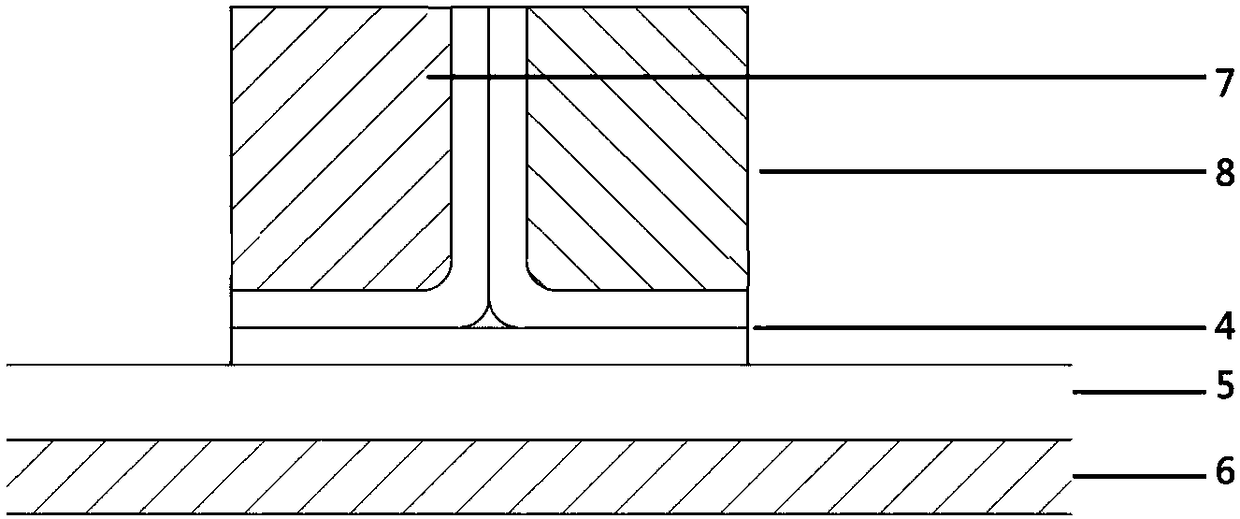

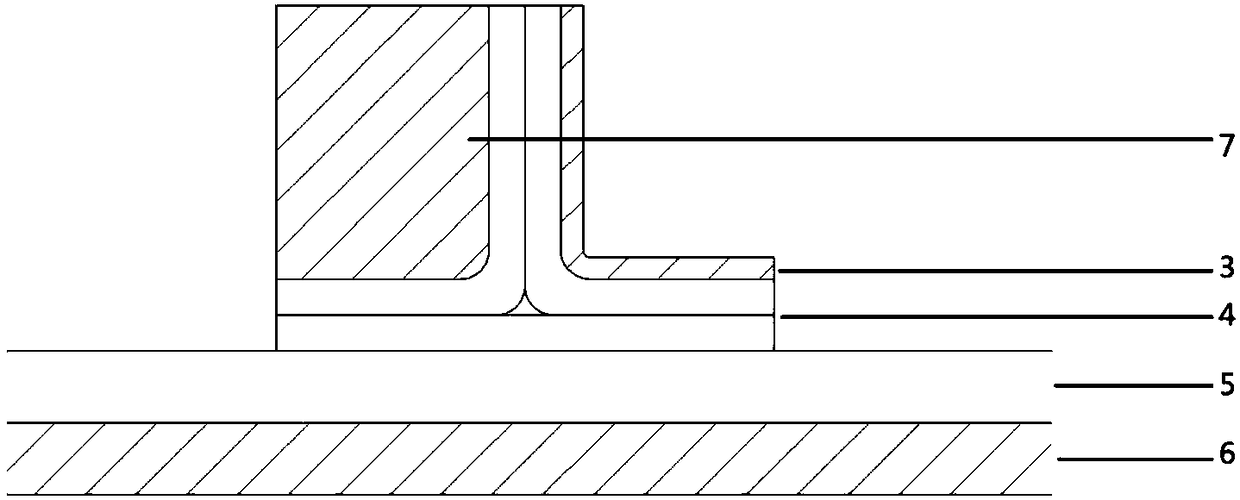

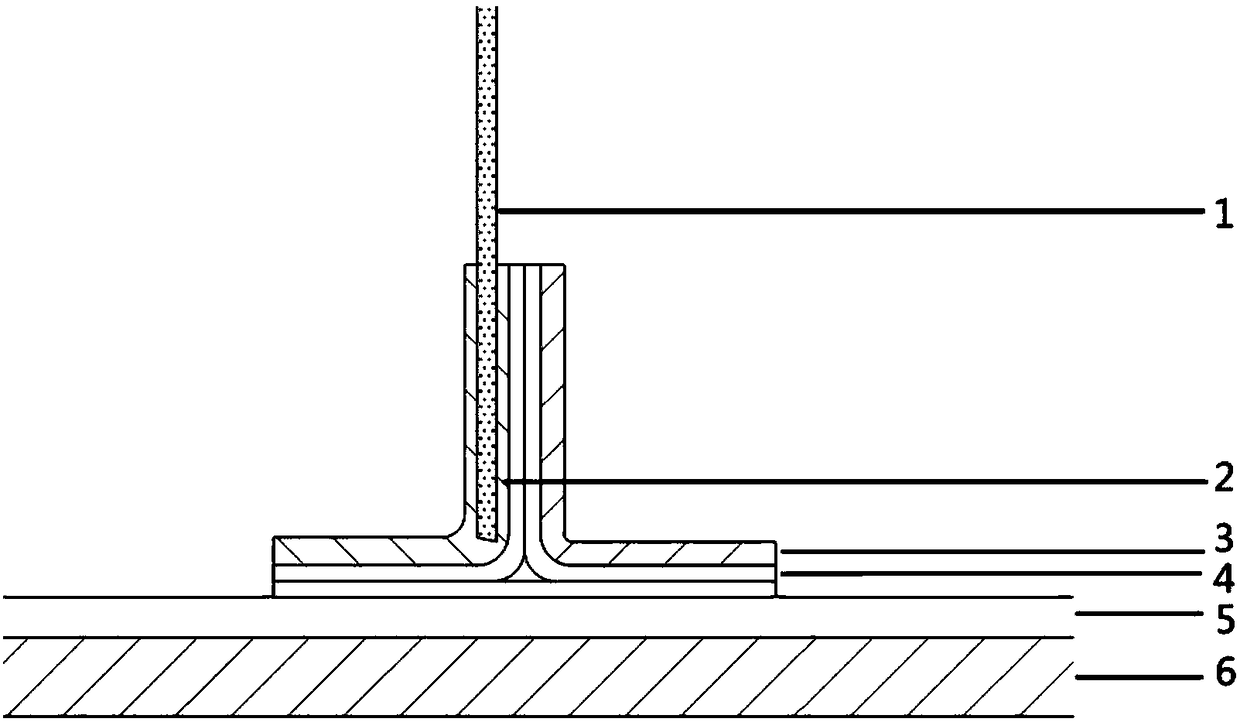

One-time thermoform composite mold for nickel-titanium shape memory alloy patellar concentrator and operation method thereof

InactiveCN101172294AReduce the number of forming operationsReduce moldShaping toolsBone implantComputer moduleAlloy

The invention relates to a compound die assembly of a fixing device for processing the human body skeleton and an operating method thereof. The compound die assembly comprises an upper male die and a lower concave die, the upper male mould comprises a concave module (1) and a press plate (2), wherein, the concave module (1) is matched with the shape of a patella collection device (8), and a vacant groove is arranged between an m claw and an n claw. The lower concave die comprises a concave module (4), a cam (3) and a lever shaft (5), the concave module (4) presents a cuboid, the upper surface is a plane for placing the flat-plate material, the side face of the concave module (4) presents a C character shape, the lever shaft (5) is arranged at the lower part of the concave module (4), the upper male die moves downwards and presses in the lower concave die in the way of two sections, the press plate (2) lies hard upon the cam (3) and drives the rotation of the concave module (4), the flat-plate material is bent and formed on the concave module (1), and a finished product is laterally taken out from the groove of the concave module (1). The invention reduces the numbers of forming and processing, reduces the cost and improves the working efficiency. A blank only is under a linear stress state during the forming process of the patella collection device, the stress state is improved, and the strength, the rigidity and the products quality are improved.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

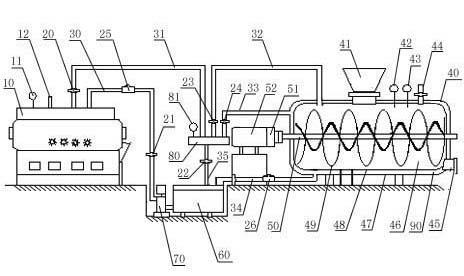

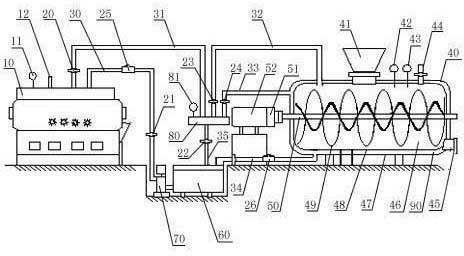

Feed maturation method and high-temperature maturation device

The invention discloses a feed maturation method and a high-temperature maturation device. The feed maturation method includes the following steps that: steam generated by a boiler is delivered to a maturation pot filled with materials; the materials are constantly stirred so that the materials can be fully matured; the matured materials are taken out and dried; and finally, fragmentation is carried out on the resulting materials to obtain a finished product. A novel feed processing technology and a device are provided in the present invention, being characterized in that the raw materials of feed after maturation, can make starch more easily digestible, protein content higher and protein more easily absorbed; and being advantaged in simple operation, energy conservation, low carbon, environmental protection and greatly reduced cost of feed processing.

Owner:明雷

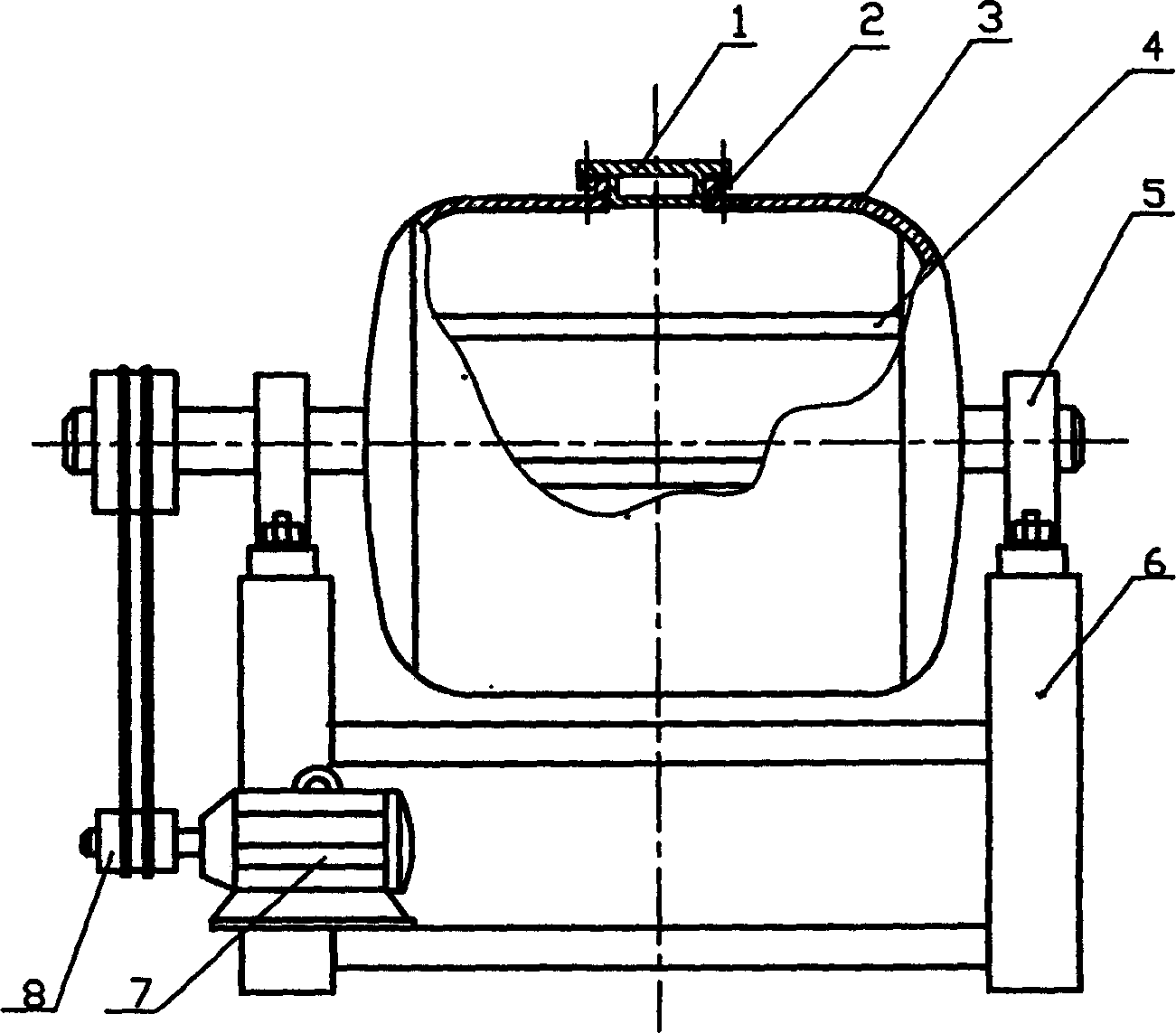

Energy-saving and effect-enhancing type rolling and kneading machine

InactiveCN1559233AUniform structureStructural symmetryMeat tenderisingEngineeringMechanical engineering

An energy-saving rolling and kneading machine has a drum body with feeding opening, a cover of said opening, and the material kneading plates in said drum body. Its advantages are high volume and high stability.

Owner:刘长雁

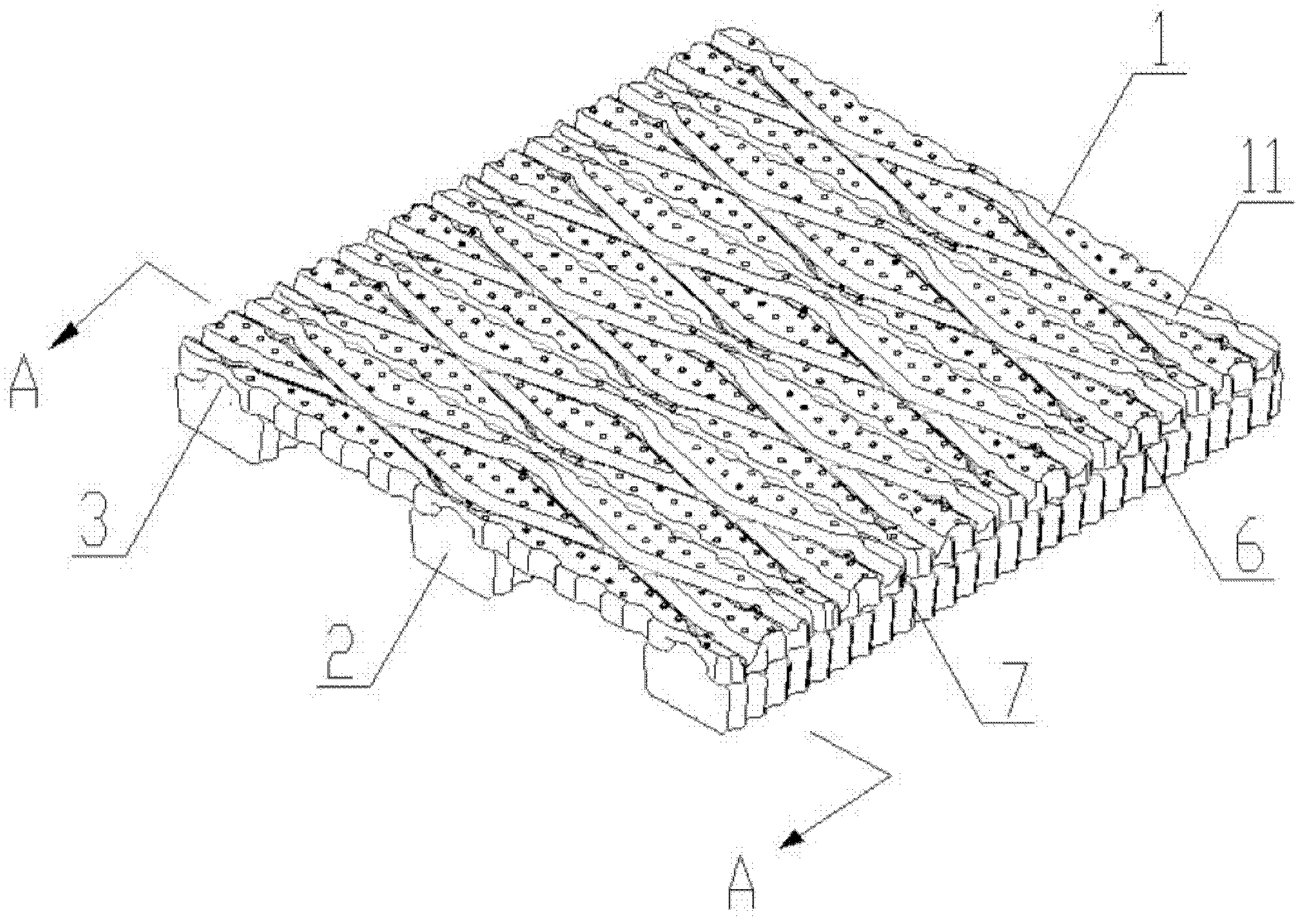

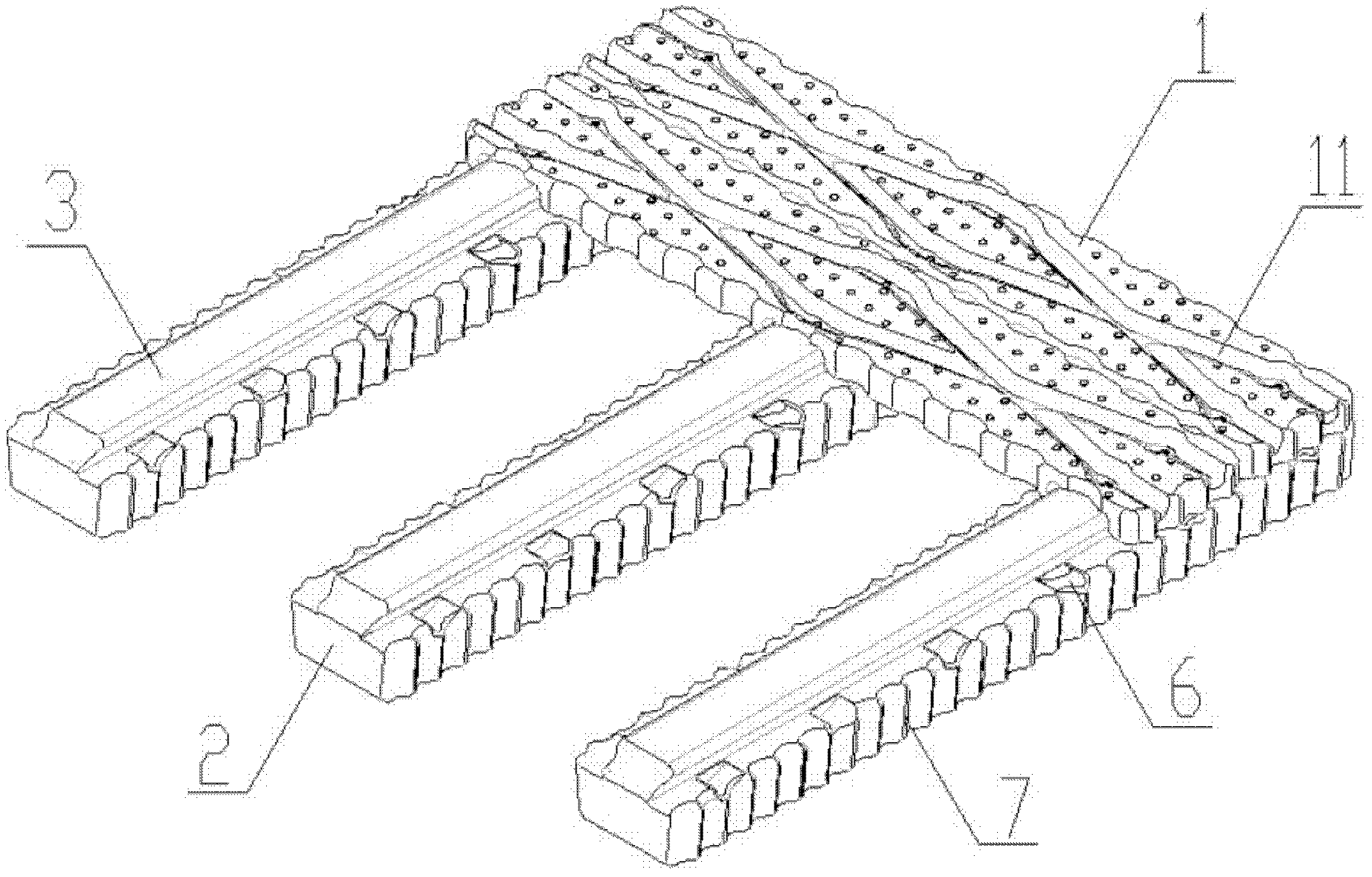

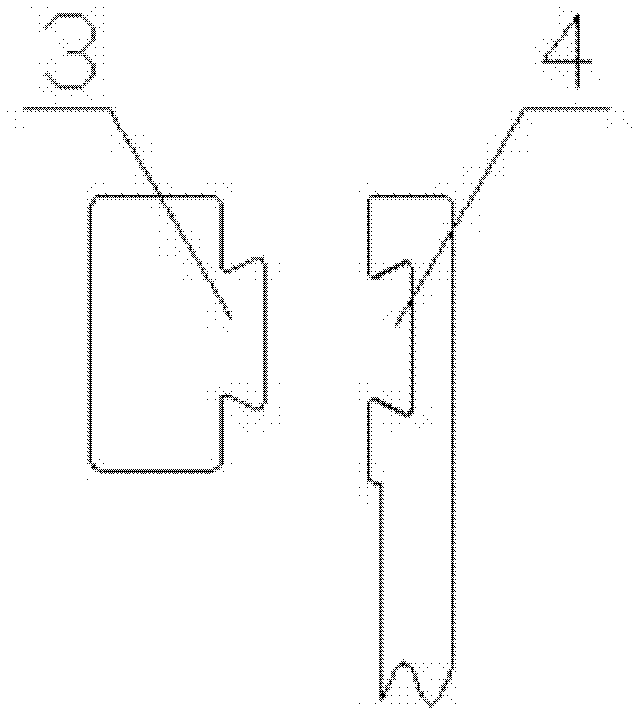

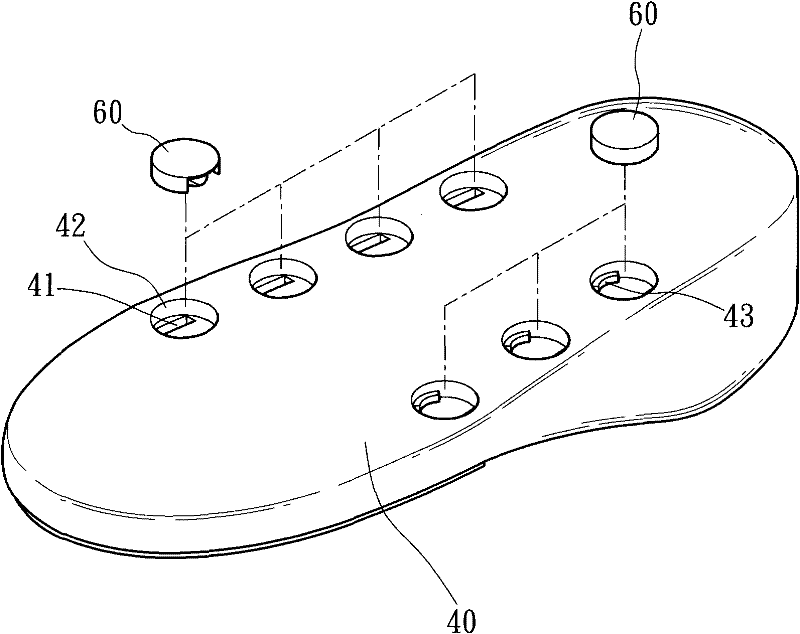

Combined blow-molding tray

InactiveCN102556466AImprove carrying capacityReduce production processRigid containersBlow moldingMortise and tenon

The invention relates to a blow-molding tray, in particular to a combined blow-molding tray comprising a panel and supporting legs, wherein the panel is formed by combining panel units, the panel units are vertical to the supporting legs, the panel units are spliced and combined with the supporting legs through grooves in the panel units and corresponding raised structures on the supporting legs in a preferable way of a mortise and tenon structure, and a splicing and matching surface of the panel and the supporting legs is provided with a reverse backstop pin; and the upper surfaces of the panel units are provided with crossed grooves, the peripheral vertical faces of the panel units and the supporting legs are of wavy structures, vertex angles of waves are of circular arc shapes, and the bottoms of the panel units are provided with reinforcing ribs. Due to the adoption of the structure, the combined blow-molding tray can be freely dismounted and mounted, can be replaced after being damaged and has the advantages of high bearing capacity, long service life, low using cost, low cost of machining equipment and low energy consumption in manufacturing.

Owner:张然

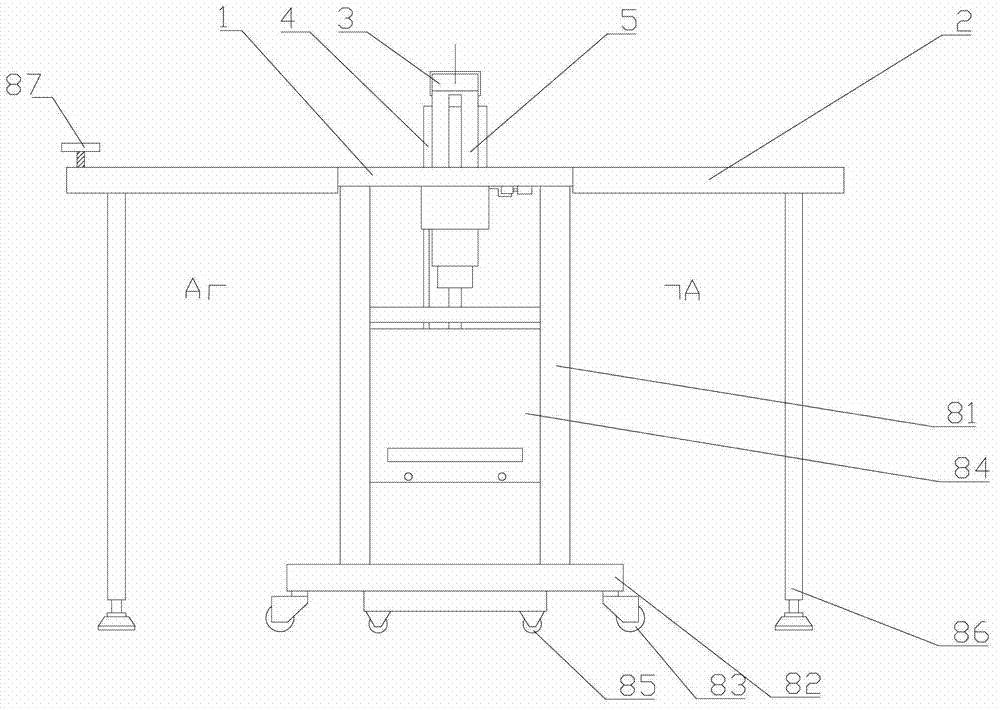

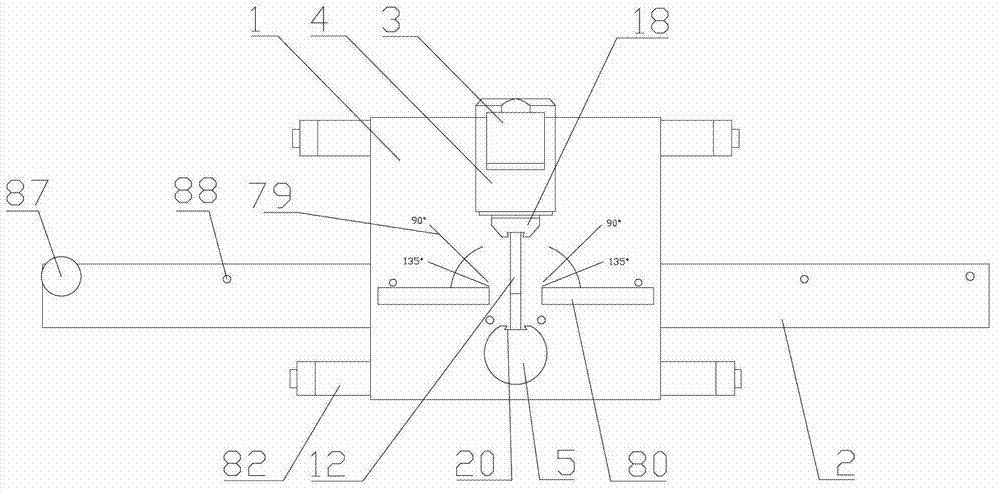

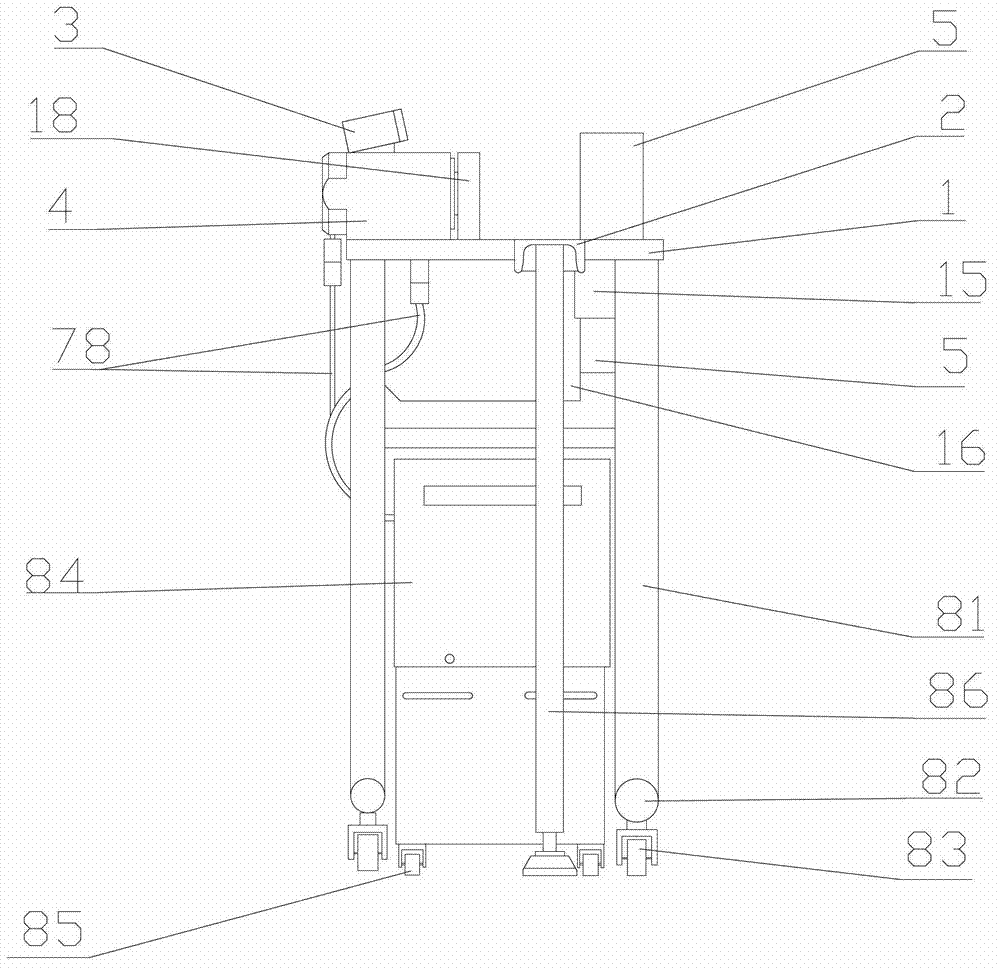

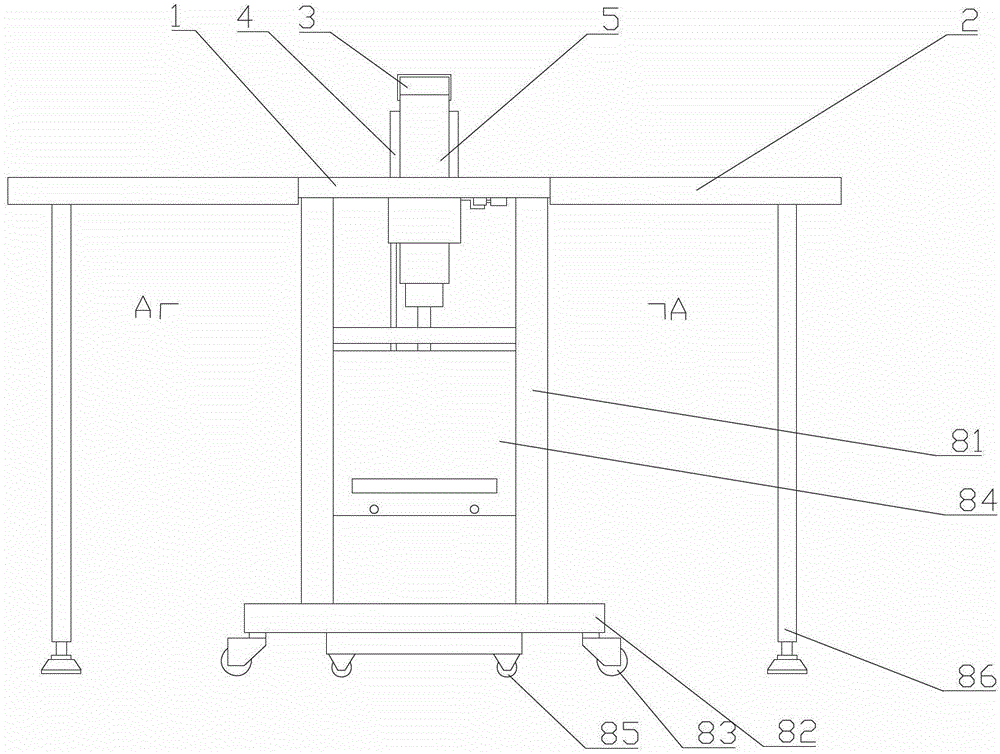

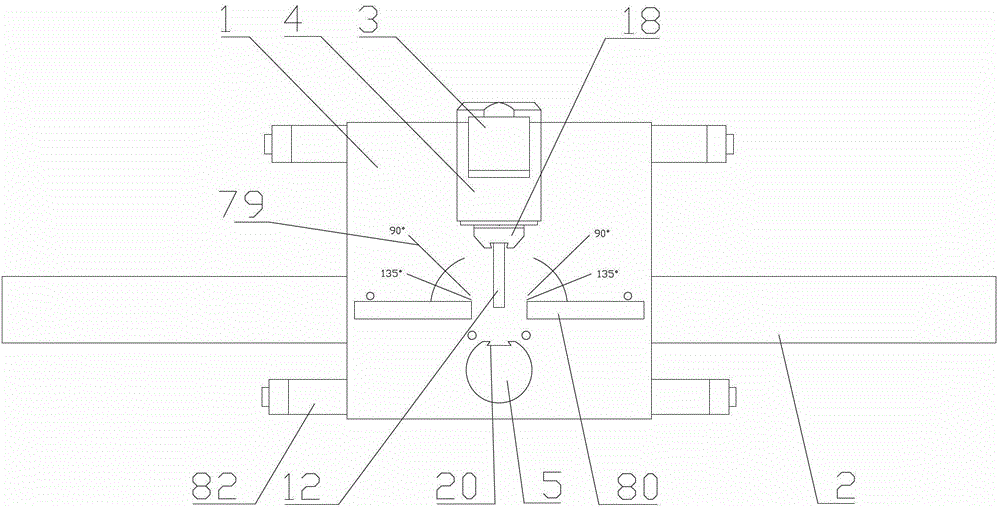

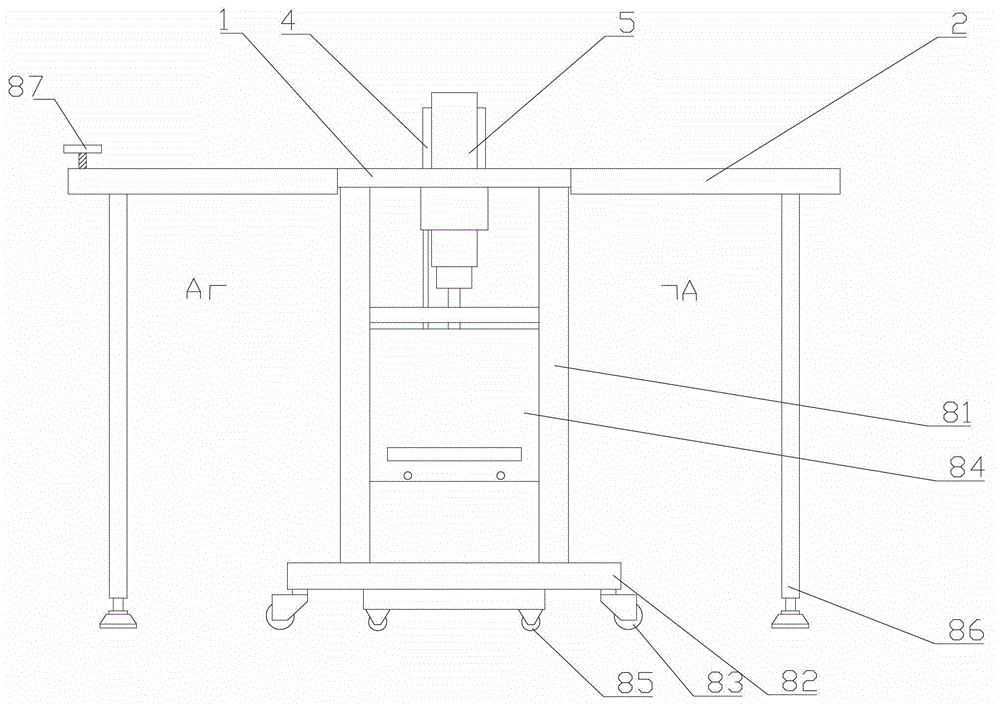

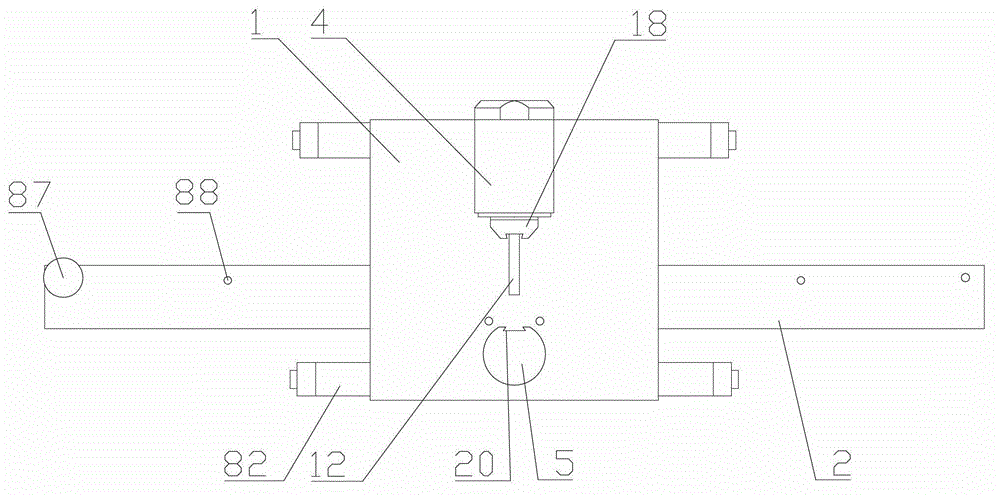

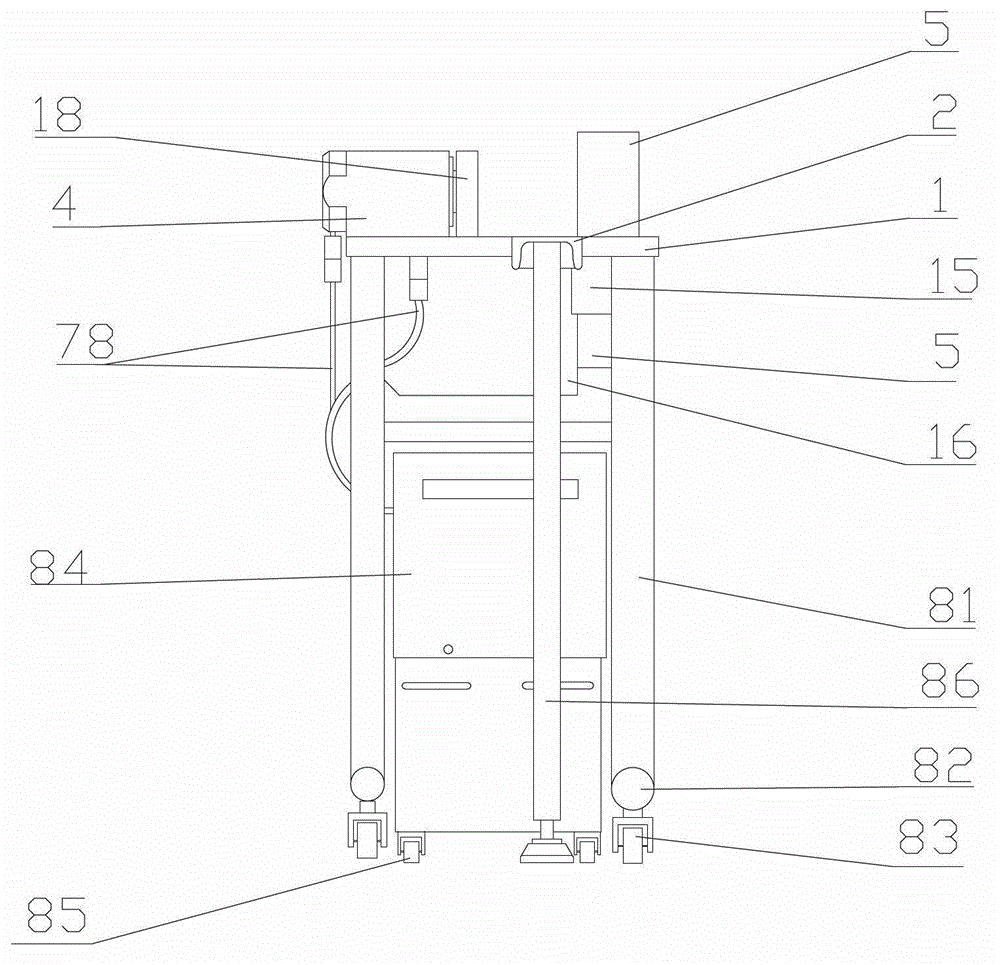

Small light numerically-controlled bus processing machine

The invention relates to a small light numerically-controlled bus processing machine. The small light numerically-controlled bus processing machine comprises a platen, supporting plates, a grating controller, an oil cylinder, a pressure head, an upright column, a shearing mold, a punching mold and a bending mold, wherein an oil cylinder insertion hole, a guide groove and an upright column fixing hole are formed in the platen respectively, the oil cylinder is inserted in the oil cylinder insertion hole and fixed on the platen, and the upright column is fixed on the platen; a strengthening plate is connected with the lower wall surface of the platen, the upright column and a strengthening sleeve; a falling object chute is formed in the strengthening plate, a section of the guide groove is correspondingly formed above the falling object chute, the pressure head is arranged at the front end of a piston rod of the oil cylinder, a first dovetail groove is formed in the pressure head, a second dovetail groove is formed in the upright column, and the supporting plates are positioned on two sides of the platen; a grating scale is connected below the pressure head, and arranged on the lower bottom surface of the platen; and a shearing stripping groove penetrating a middle shaft of the upright column and the whole upright column is formed in the side surface of the upright column, and an opening on one side of the shearing stripping groove is positioned in the second dovetail groove. The small light numerically-controlled bus processing machine has the advantages of functional diversity, simplicity, light weight, small size and the like.

Owner:陈伟民

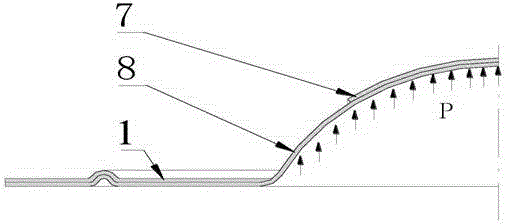

Forming method suitable for T-shaped and L-shaped composite material wall plates

The invention belongs to the technical field of forming of composite materials, and relates to a forming method suitable for T-shaped and L-shaped composite material wall plates. A forming mode combining a soft film positioning plate and a soft film is adopted, a fit clearance does not exist, pressure transmission is uniform, and the internal quality of formed wall plates is good. There are only afew molds in a vacuum bag, heat transferring is uniform, and the uniformity of a temperature field is good. The number of molds entering a tank is small, a soft film forming mold is low in precisionand does not need to enter the tank, and the overall mold cost is low. The assembling clearance is small, the forming quality is good, and the forming method is suitable for wall plates with large skin thickness change or large skin shape change. By means of the forming method suitable for T-shaped and L-shaped composite material wall plates, the internal quality of composite material wall platesformed through the method is high, studs are high in position precision, and the forming method is particularly suitable for forming wall plates with complex surfaces and many variable-thickness areas, and lays a certain technical foundation for development of composite materials.

Owner:AVIC COMPOSITES

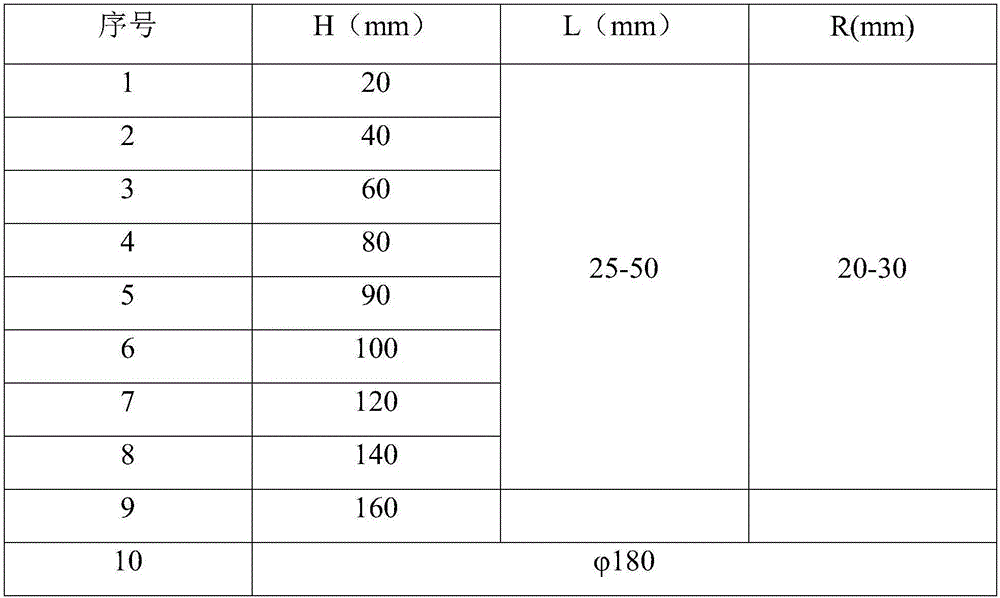

Test method based on forming limit diagrams for plate hydroforming

ActiveCN106111780AReduce coefficient of frictionStable deliveryMetal working apparatusForming limit diagramEngineering

Provided is a test method based on forming limit diagrams for plate hydroforming. The method comprises the steps that a series of test plates, assistant plates and laminated assistant plates of different width dimensions and specific shapes are overlapped on a female mold in a specific mode; the plates are subjected to forming limit testing in an overlapped plate hydroforming mode; the forming performance of the laminated assistant plates is higher than that of materials of the test plates, and it is ensured that the test plates enter an unstable rupture state firstly; and then all second principal strain positive portions and second principal strain negative portions under linear loading are obtained by measuring test-pieces of different widths, and accordingly all the complete hydroforming limit diagrams are obtained. The test method based on the forming limit diagrams for plate hydroforming carries out quasi-complement on the vacancy of the forming limit diagrams for plate hydroforming. The method has the advantage of overlapped plate formation so that pressure transfer of a hydraulic chamber can be guaranteed. In the hydroforming process, completeness of brake beads is ensured through the assistant plates, gap uniformity is ensured, and the plates are prompted to deform sufficiently. The test method has the advantages of being high in efficiency, small in number of molds, low in cost, safe and convenient to operate, and the like.

Owner:BEIHANG UNIV

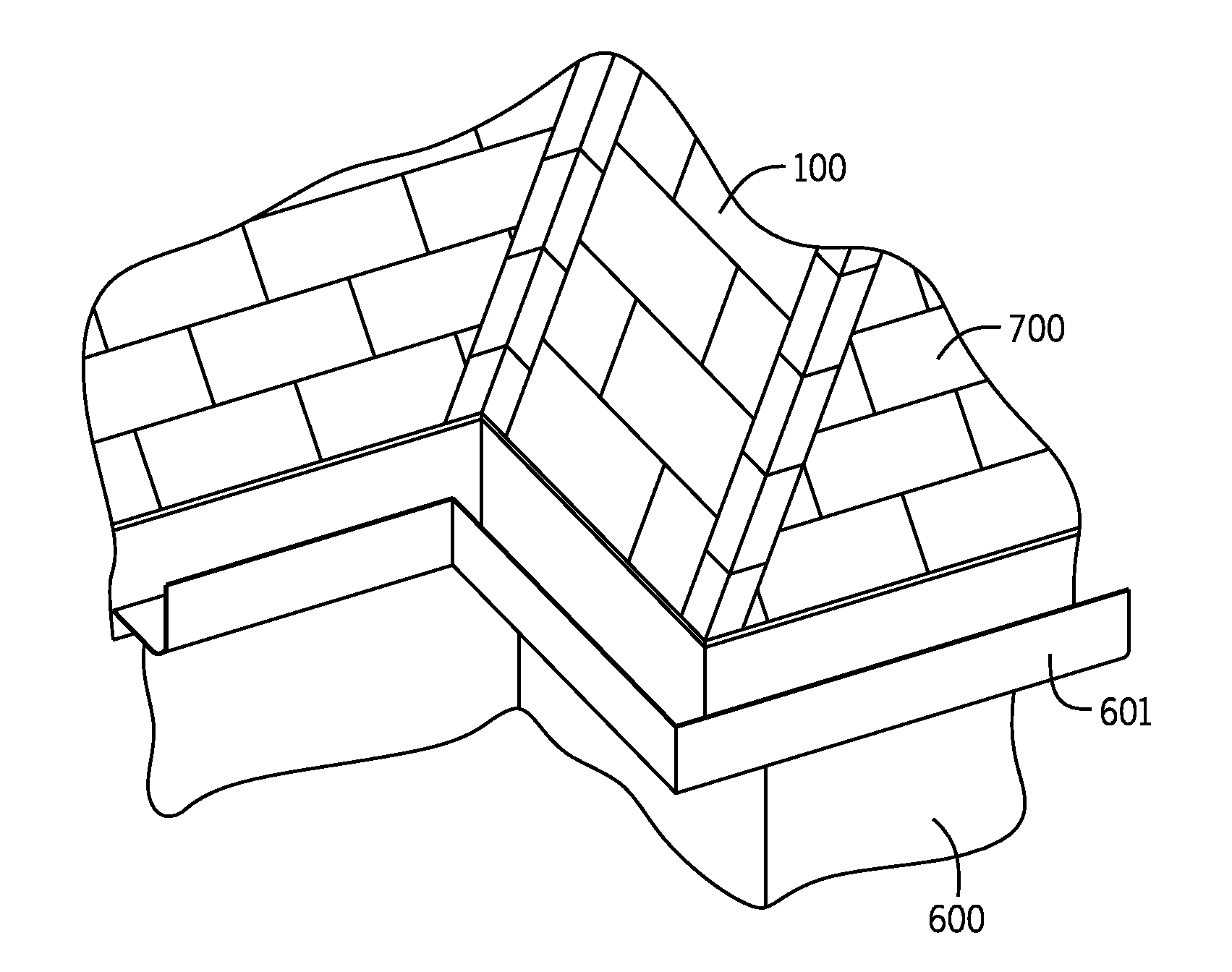

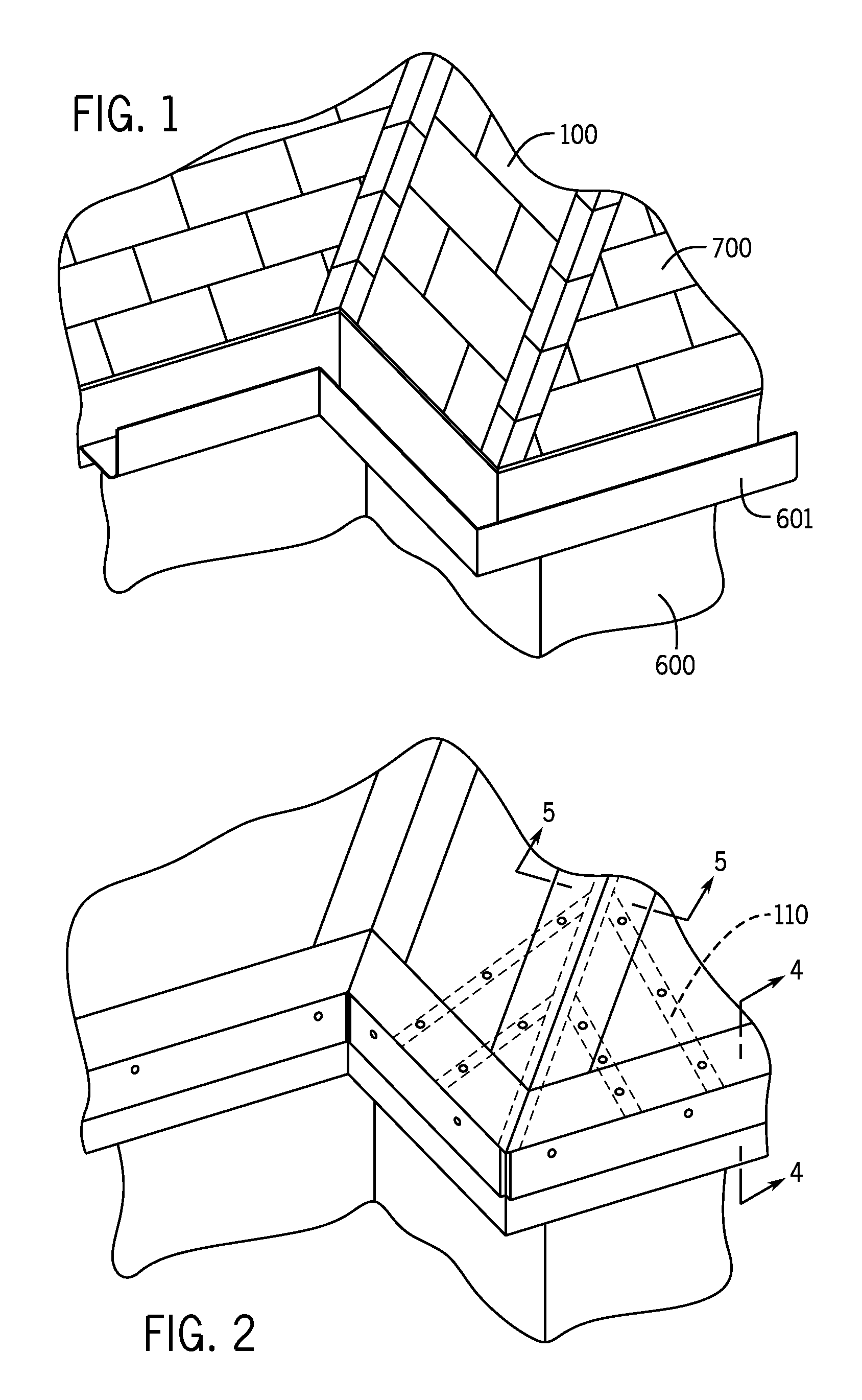

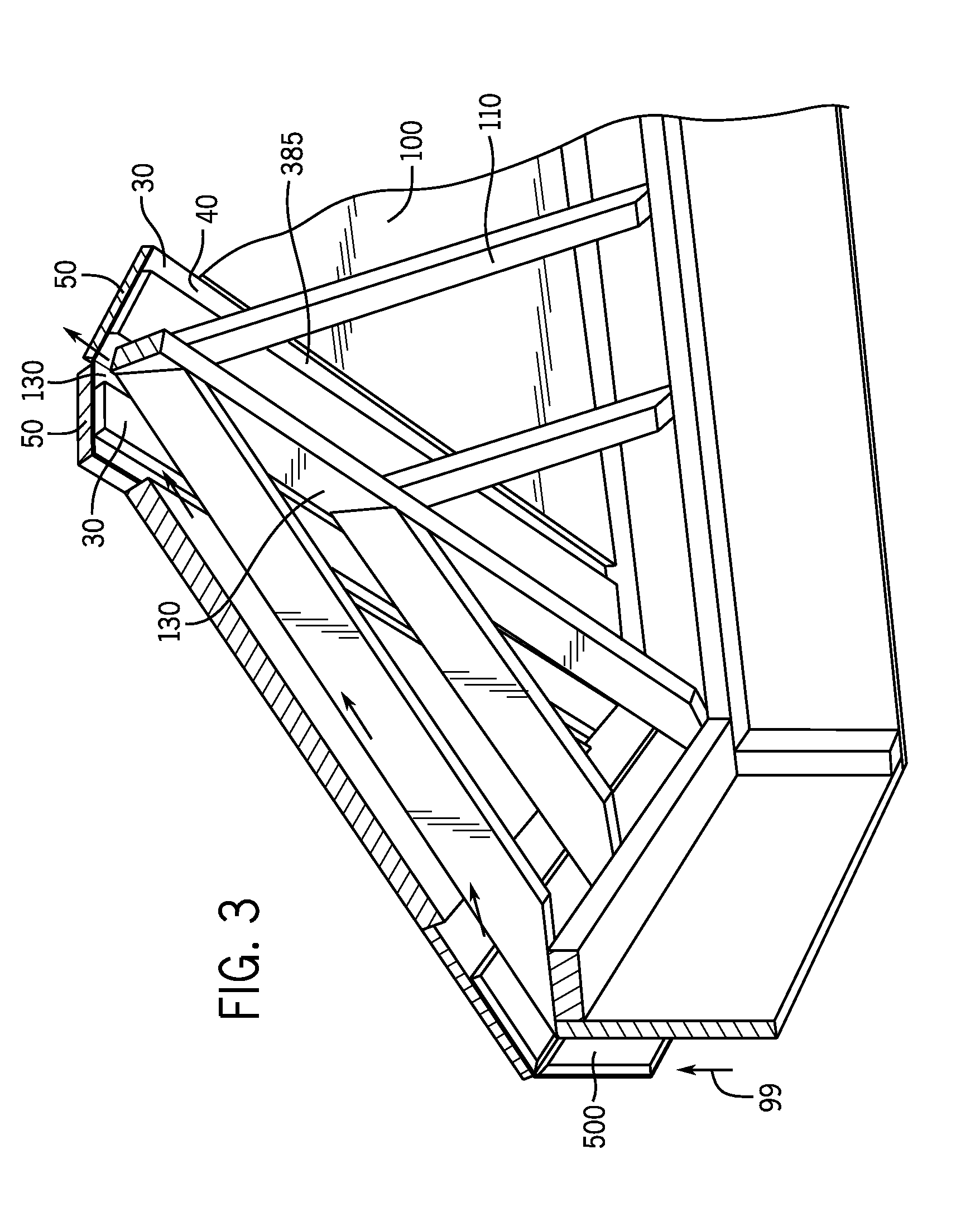

Systems and methods for ozone treatment of grain in grain piles

ActiveUS9808021B2Minimize nascent problemReduce moldSeed preservation using chemicalsAvicultureEngineeringToxin

Systems and methods for treating grain stored in a grain pile with ozone are effective for treating grain for toxins, insects, mold, and / or odor. A method according to embodiments of the invention involves monitoring at least one of temperature and odor at a plurality of aeration outlet locations spaced around the grain pile. When an abnormal temperature variance or odor is detected at one or more of the aeration outlet locations, a determination is made as to a problem location within the grain pile where a treatment of ozone should be applied, and a further determination is made as to how best to apply ozone to the problem location. Ozone is then applied to the problem location within the grain pile to minimize nascent problems in the grain pile. The ozone treatment may reduce molds and toxins.

Owner:ARCHER DANIELS MIDLAND CO

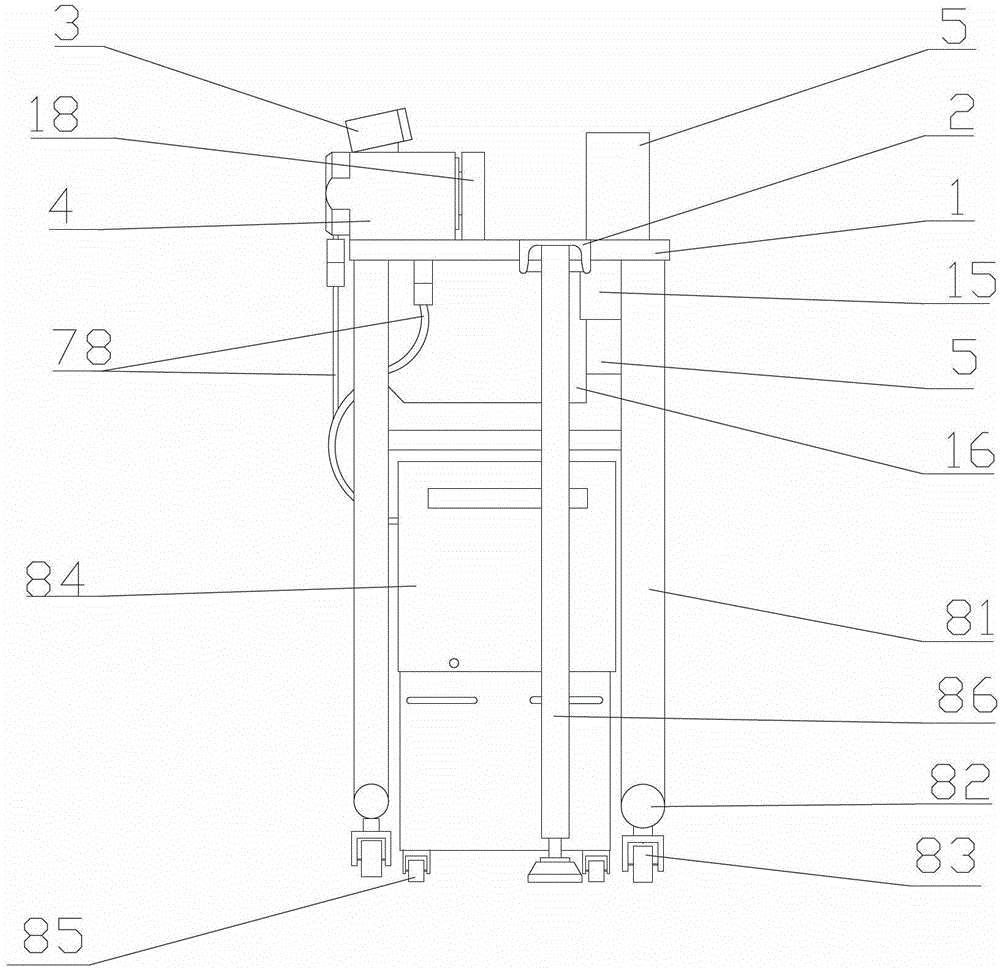

Light-small type numerical-control bus bar bending machine

The invention relates to a light-small type numerical-control bus bar bending machine, comprising a table plate, support plates, a grating controller, an oil cylinder, a press head, a vertical column and a bending die, wherein the oil cylinder and the vertical column are fixed on the table plate, a reinforcing plate is arranged on the lower wall surface of the table plate, and the reinforcing plate is connected with the vertical column and a reinforcing sleeve; a material-falling inclined groove is formed on the reinforcing plate; a section of guide groove is correspondingly formed above the material-falling inclined groove, and is through from top to bottom, the press head is arranged at the front end of the oil cylinder; a first dovetail groove is formed on the press head, and a second dovetail groove is formed on the vertical column, a slide foot is arranged below the press head, a connecting foot is connected below the slide foot, a connecting rod extending along the left side or the right side of the table plate is connected below the connecting foot, a connecting plate is connected to the other end head of the connecting rod, the connecting plate is connected to a grating ruler, and the bending die comprises a bending convex die and a bending concave die; and a swallow tail E3 is arranged on the side of the bending convex die, and a swallow tail F is arranged on the side of the bending concave die. The light-small type numerical-control bus bar bending machine disclosed by the invention has the advantages of being accurate in bending angle, high in efficiency, small in die, light in machine body, firm in table plate, easy to carry, and the like.

Owner:陈伟民

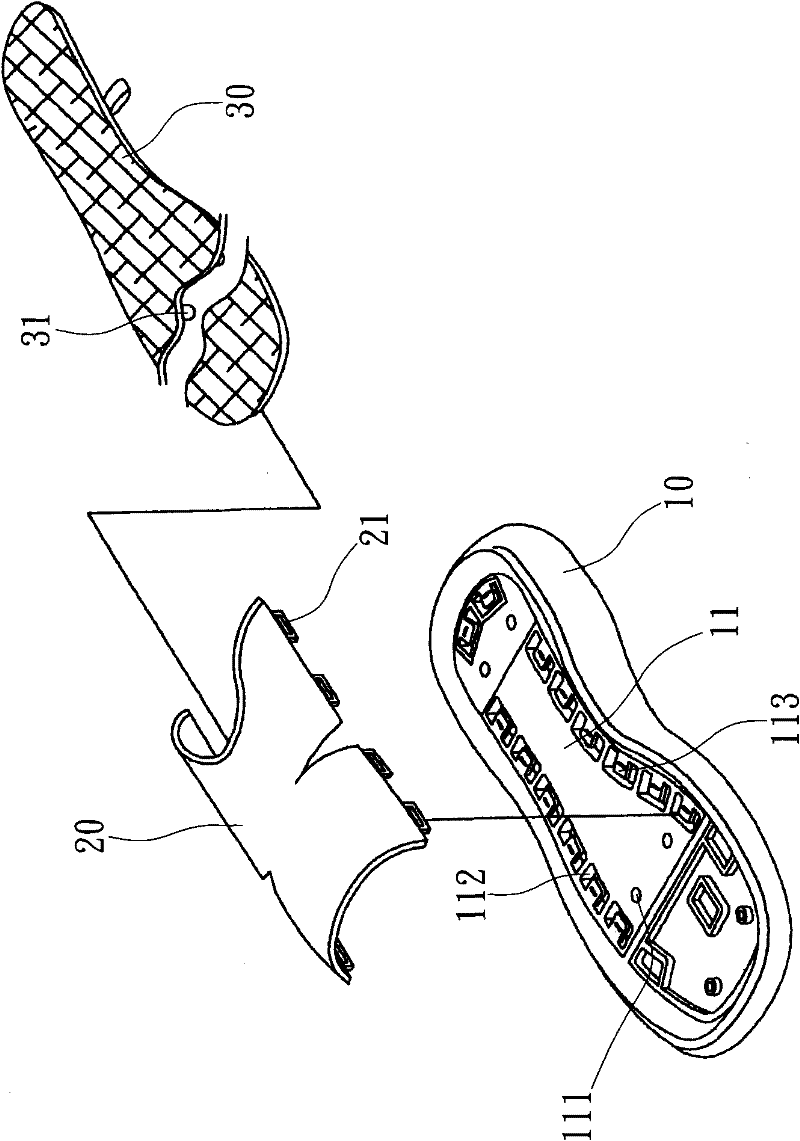

Convertible shoe body

Owner:杨成义

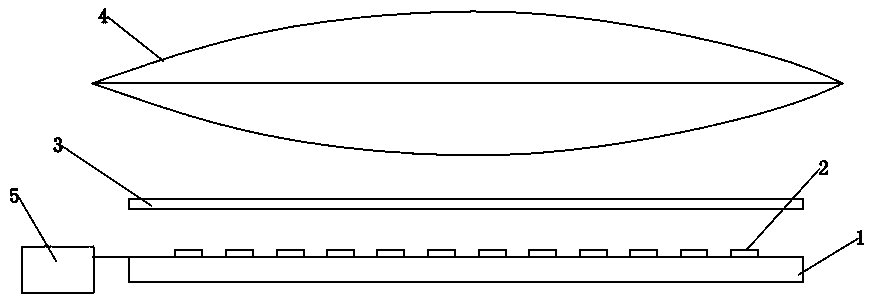

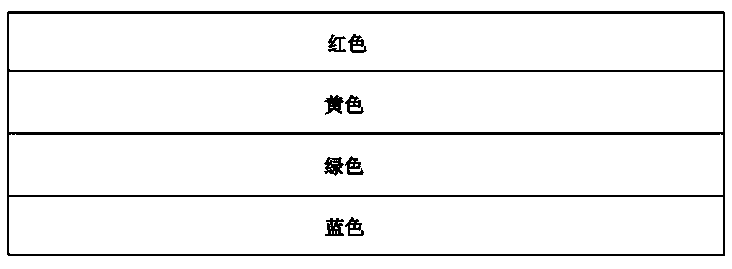

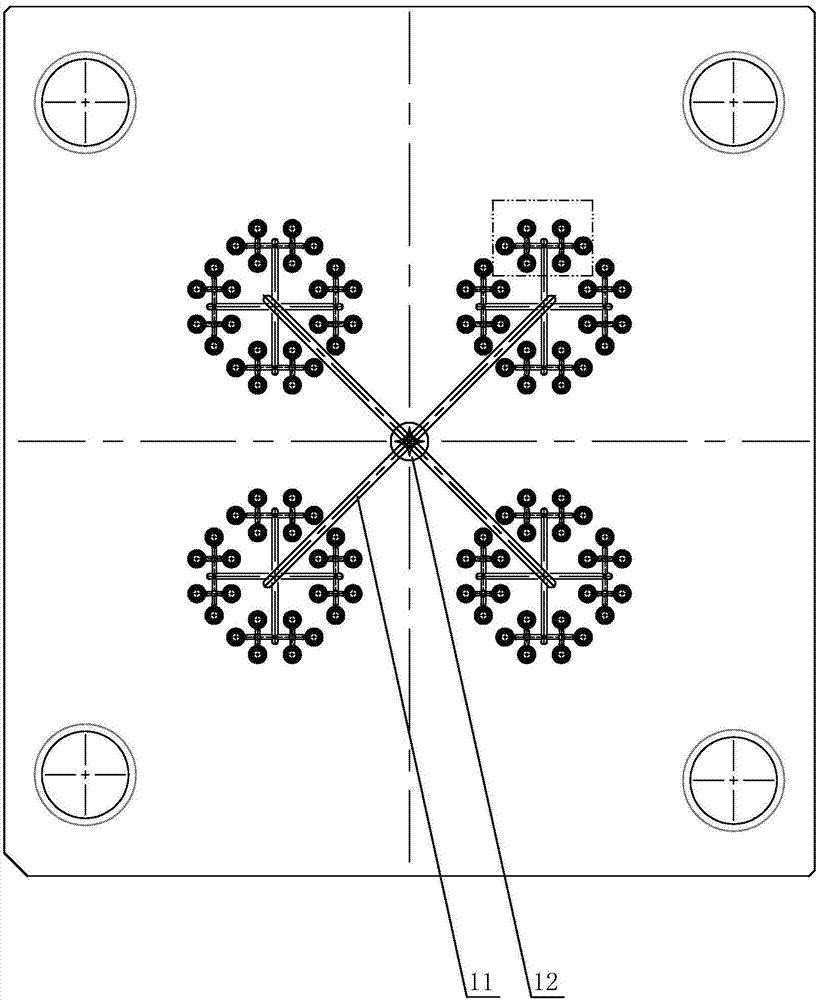

Preparation and application of full-spectrum intelligent plant lamp

InactiveCN110112128AHigh nutritional valueEasy to disinfectSolid-state devicesSaving energy measuresFluorescenceEngineering

The invention discloses preparation and application of a full-spectrum intelligent plant lamp. The full-spectrum intelligent plant lamp comprises a substrate, a purple light chip, a fluorescence conversion layer, a lens and a driving power supply. The preparation process of the full-spectrum intelligent plant lamp comprises the following steps of: (a) performing die bonding of the purple light chip on the substrate in a flip eutectic welding mode; (b) fixing the fluorescence conversion layer on the substrate in the step (a) in a plane coating mode, and performing curing to obtain a package full-spectrum plant lamp light source; and (c) fixing the lens on the substrate in a riveting mode, and accessing the driving power supply into the substrate circuit to obtain the full-spectrum intelligent plant lamp. The preparation is simple, and the plant can have light capable of promoting photosynthesis and can promote the establishment of the light form.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

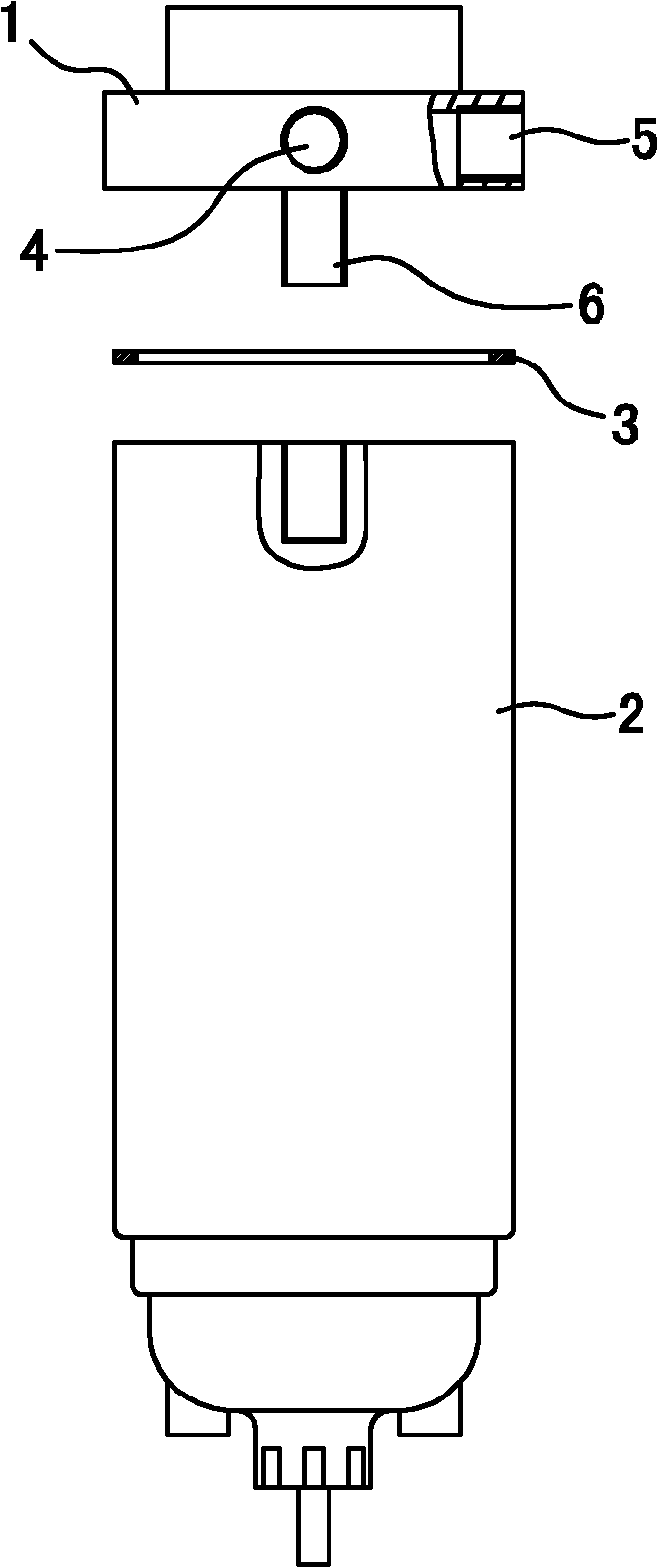

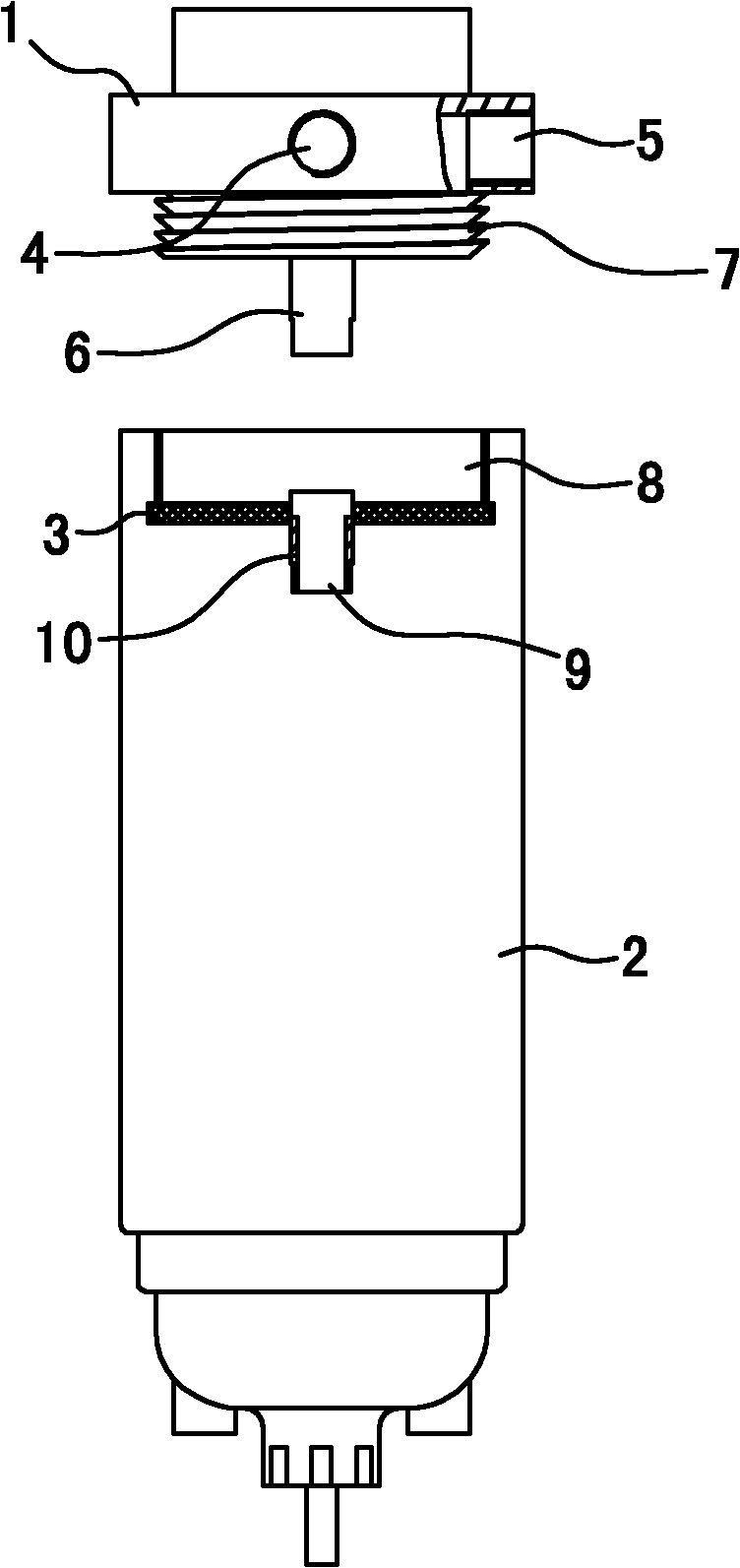

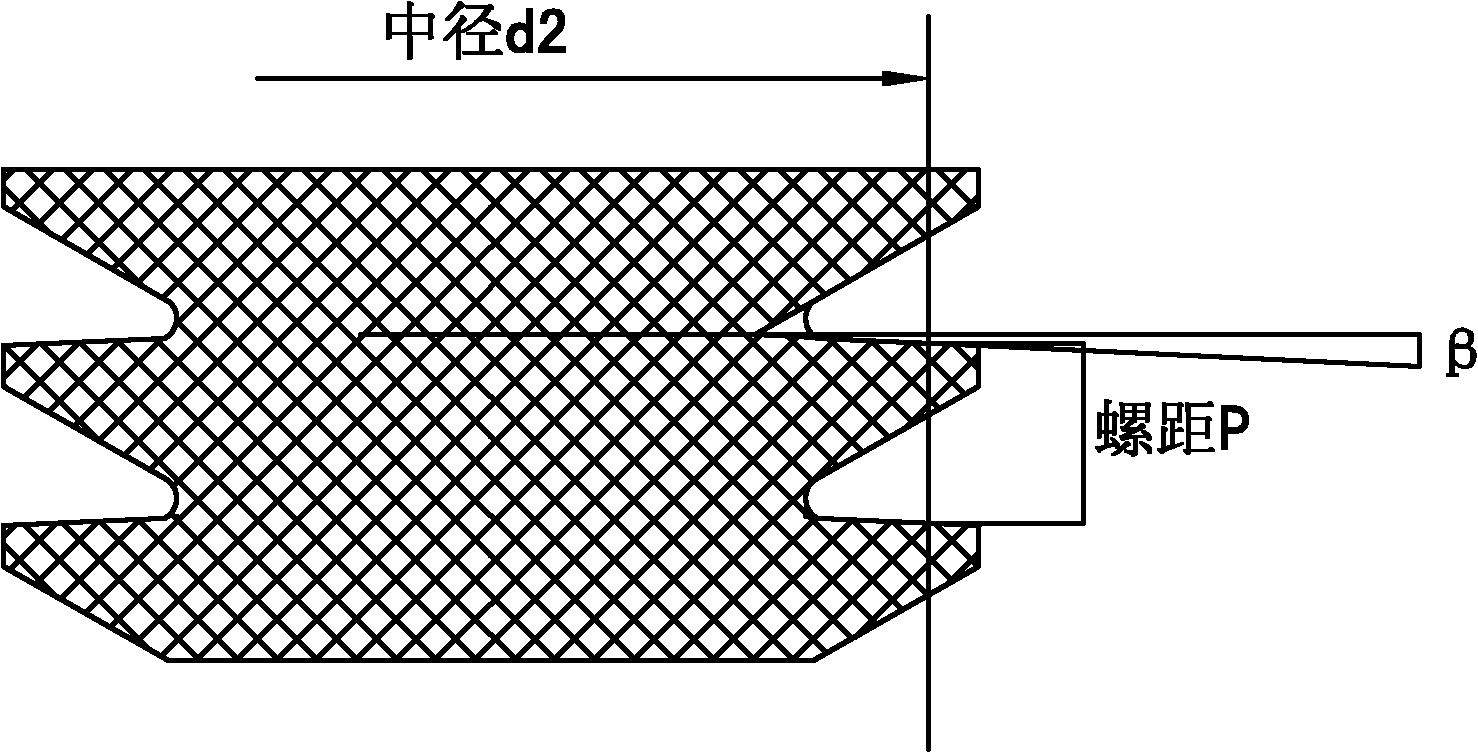

Fuel filter

InactiveCN101988450AEasy to assemble and disassembleEasy to replaceMachines/enginesLiquid fuel feedersEngineeringFuel filter

The invention discloses a fuel filter which comprises a filter base, a filter element assembly and a seal ring, wherein the center of the bottom of the filter base is provided with a convex connecting rod; a connecting section is also arranged between the bottom of the filter base and the connecting rod; the diameter of the connecting section is larger than that of the connecting rod, and outer threads are arranged on the connecting section; the center of the top of the filter element assembly is provided with a groove which is matched with the connecting section, and the inner wall of the groove is provided with matched inner threads; a connecting groove which is matched with the connecting rod is arranged under the groove of the filter element assembly; the connecting rod has a circular truncated cone structure with a top down design; and the seal ring is arranged at the bottom of the groove of the filter element assembly, the outer edge is abutted against the groove, and the inner edge is matched with the connecting groove in the size. The double-seal structure of the invention has favorable seal performance, can ensure the seal performance of the fuel filter without tightly screwing an end cover and a filter element on purpose when a filter element is assembled or replaced, solves the problem brought by tightly screwing and is convenient to assemble, disassemble and replace the filter element of the filter.

Owner:SANY HEAVY MACHINERY

Bus bar punching machine

The invention relates to a bus bar punching machine, comprising a table plate, support plates, an oil cylinder, a press head, a vertical column and a punching die, wherein an oil cylinder insertion hole, a guide groove and a vertical column fixing hole which are longitudinally arrayed are sequentially formed on the table plate; the oil cylinder and the vertical column are fixed on the table plate; a reinforcing plate is arranged on the lower wall surface of the table plate; a material-falling inclined groove which is formed towards a side surface is formed on the upper surface of the reinforcing plate; a section of guide groove is correspondingly formed above the material-falling inclined groove, and is through from top to bottom; the press head is arranged at the front end of the piston rod of the oil cylinder and towards the direction of the vertical column; a first dovetail groove is formed at one side facing the vertical column, of the press head, and a second dovetail groove is formed at one side facing the press head, of the vertical column; the support plates are located at the both sides of the table plate; a slide foot is arranged below the press head and arranged in the guide groove, and can be used for guiding the press head to slide back and forth along the direction of the guide groove; and the punching die is arranged on the press head of the oil cylinder and the vertical column. The bus bar punching machine disclosed by the invention has the advantages of being simple, light and small in structure, small in die, light in machine body, firm in table plate and easy to carry.

Owner:陈伟民

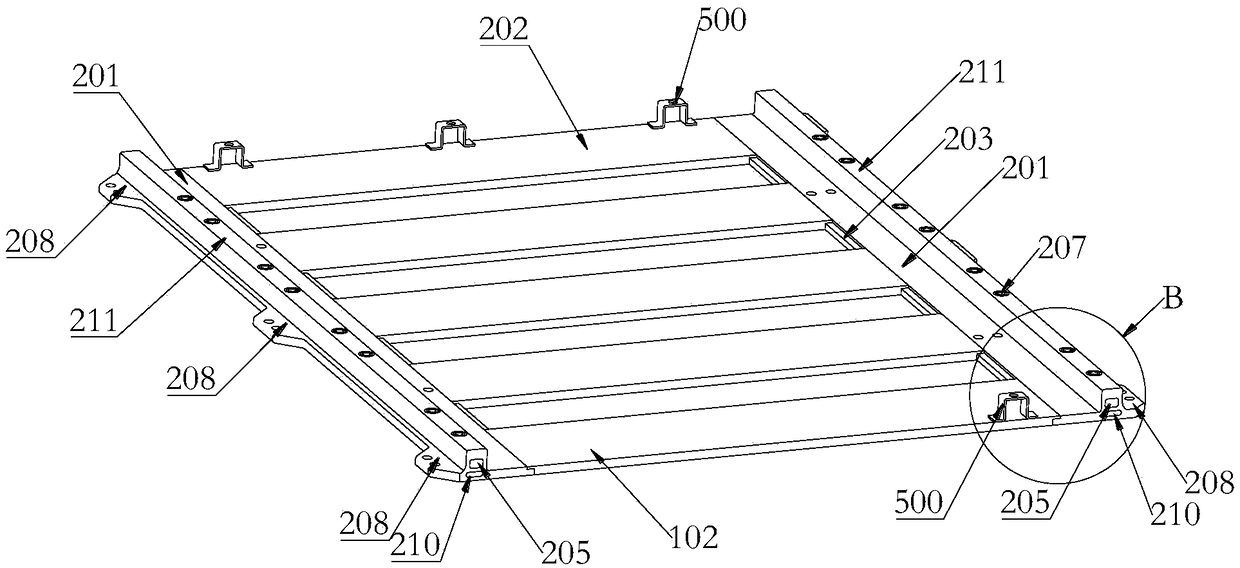

Tailor-welded type aluminum alloy module tray and battery pack

The invention relates to a tailor-welded type aluminum alloy module tray and a battery pack. The tailor-welded aluminum alloy module tray comprises two fixed beams and a plurality of beams; two fixedbeams are arranged in parallel and connected with a battery box body; two ends of each beam are respectively welded on two fixed beams; the fixed beams and the beams are molded through an extrusion mold by adopting aluminum alloy material and are in tailor-welded connection. The tailor-welded type aluminum alloy module tray disclosed by the invention is formed by performing the tailor-welded on the parts molded through the extrusion mold by adopting the aluminum alloy material; the mold is cheap and easy to acquire; the development cots is reduced, the production efficiency is high, the tray can be suitable for the large-scale production demand, and the economic benefit is increased.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

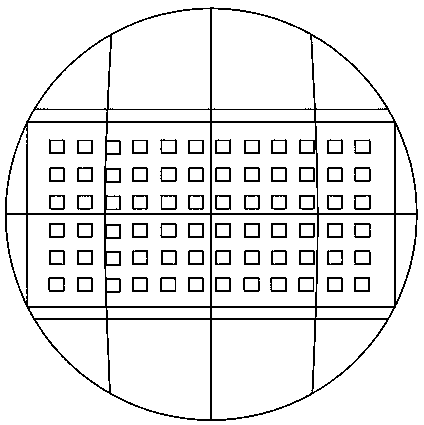

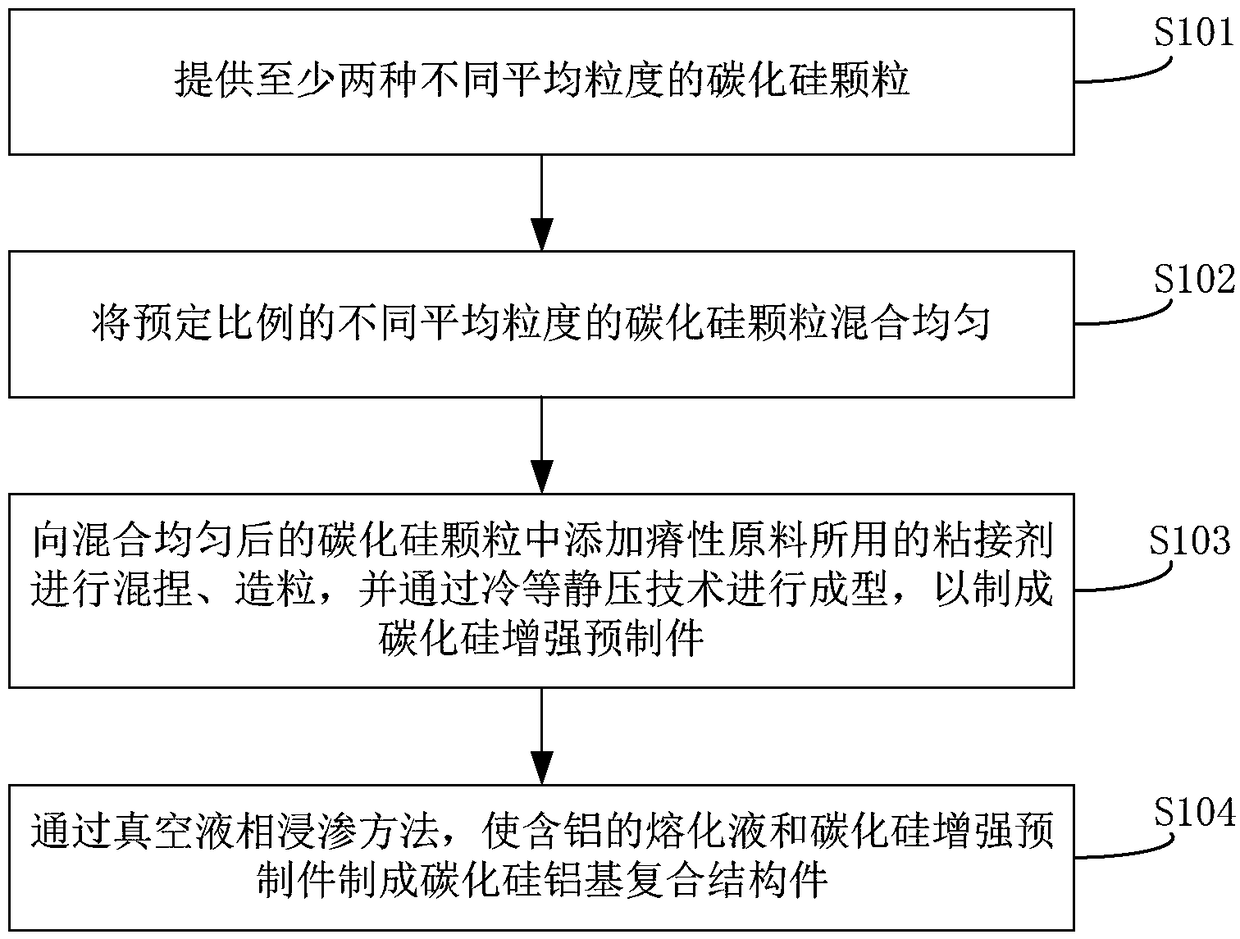

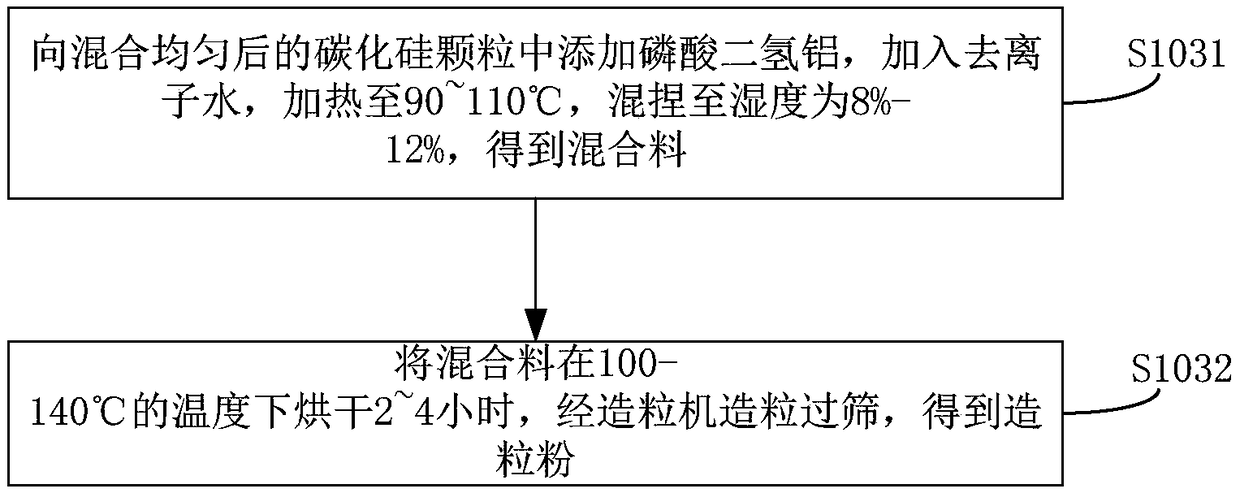

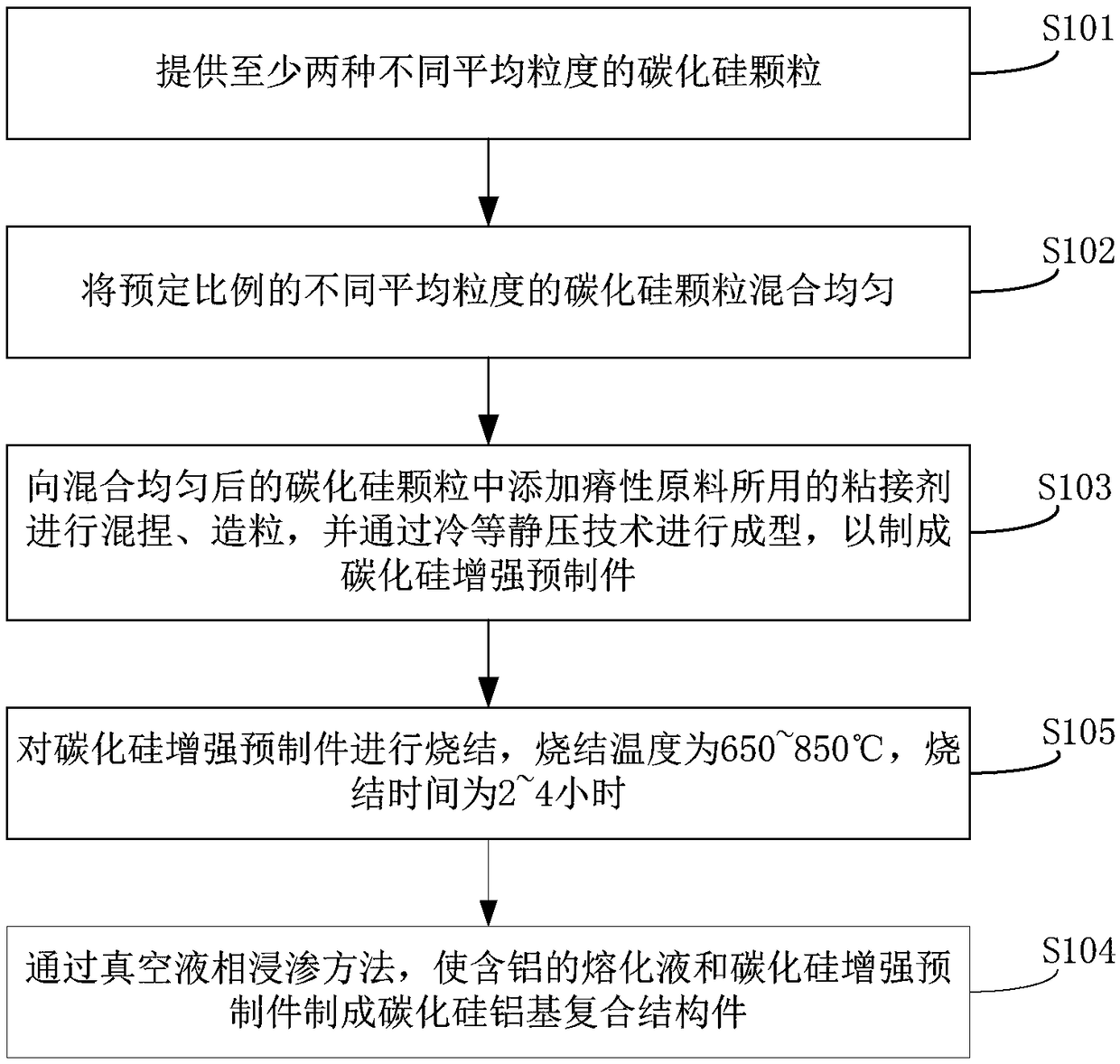

Method for preparing silicon carbide aluminum-based composite structural member and silicon carbide reinforced preform

The present application discloses a method for preparing a silicon carbide aluminum-based composite structural member and a silicon carbide reinforced preform, the method comprising: providing at least two silicon carbide particles having different average particle sizes; uniformly mixing the silicon carbide particles having different average particle sizes in a predetermined ratio; adding a binder containing an inert material to the uniformly mixed silicon carbide particles for kneading and granulating, and performing cold isostatic pressing technology to form a silicon carbide reinforced preform; and making the aluminum-containing melt liquid and the silicon carbide reinforced preform into the silicon carbide aluminum-based composite structural member by using avacuum liquid phase infiltration method. In this way, the method is capable of producing complex parts or providing technical support for the complex parts, and the plasticity requirements for the powder are not high.

Owner:ANHUI TATFOOK TECH CO LTD

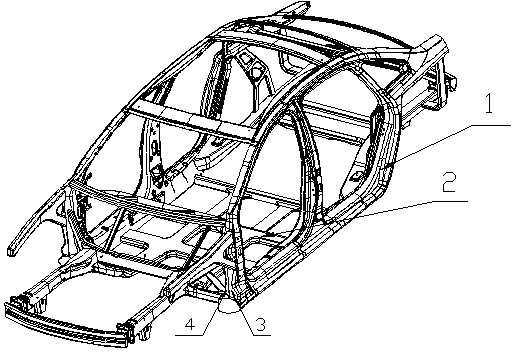

Integral car body frame

InactiveCN103879455AReduce moldReduce FixturesSuperstructure subunitsSuperstructure connectionsVehicle frameEngineering

The invention relates to a car component, in particular to an integral car body frame. The integral car body frame comprises an integral side wall frame and a lower car body intermediate frame at the bottom of the integral side wall frame, and the integral side wall frame comprises an integral side wall frame outer board and an integral side wall frame inner board which are formed via full-length welding by a laser. The integral car body frame has the advantages that parts are reduced, costs on dies, clamps and test tools in a developing process are reduced, and lightening of an integral car and oil consumption reduction are benefited.

Owner:湖南湖大三佳车辆技术装备有限公司

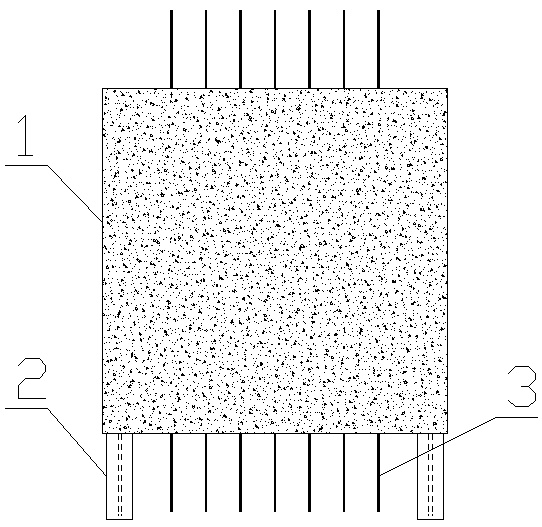

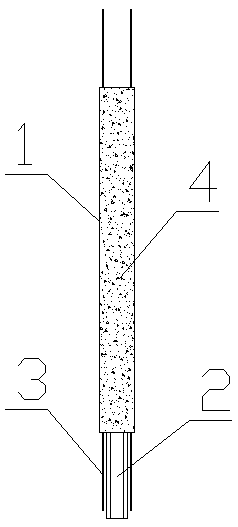

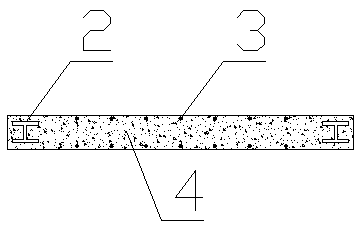

Construction method of vertical connection of fabricated shear wall plate

The invention relates to the technical field of building construction, in particular to a construction method of vertical connection of a fabricated shear wall plate. The construction method comprisesthe steps that a wall body is precast, and the wall body is composed of concrete, reinforcing bars and I-shaped steel; the wall body is lifted to an installation site and fixed well through diagonalsupport, and the I-shaped steel plays a role of temporary support; the reinforcing bars are poured after reinforcing bar joints at the bottom of the wall body are bound; a formwork is erected to a post-cast section at the bottom of the wall body after binding of the reinforcing bars is completed and concrete is poured; and the formwork can be removed after the concrete reaches strength. The formwork for manufacturing the bottom post-cast section and later removal work are reduced, later mending work is reduced, artificial and material costs are saved, the construction period is shortened, andthe construction efficiency is improved.

Owner:CHINA 22MCC GROUP CORP

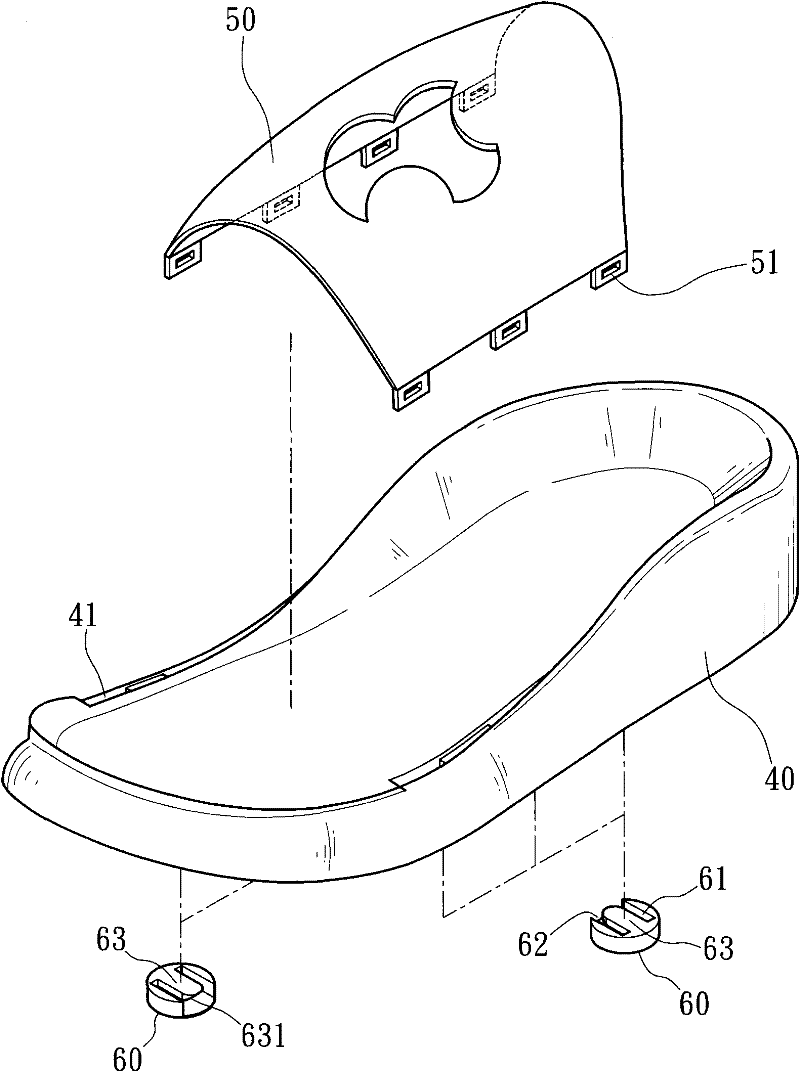

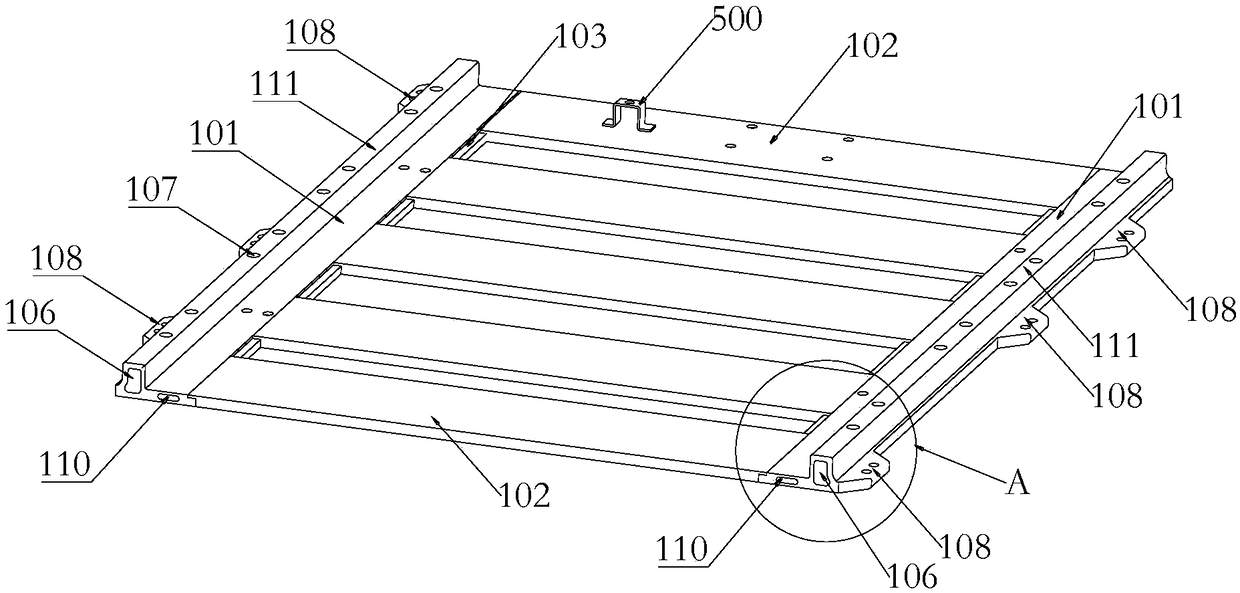

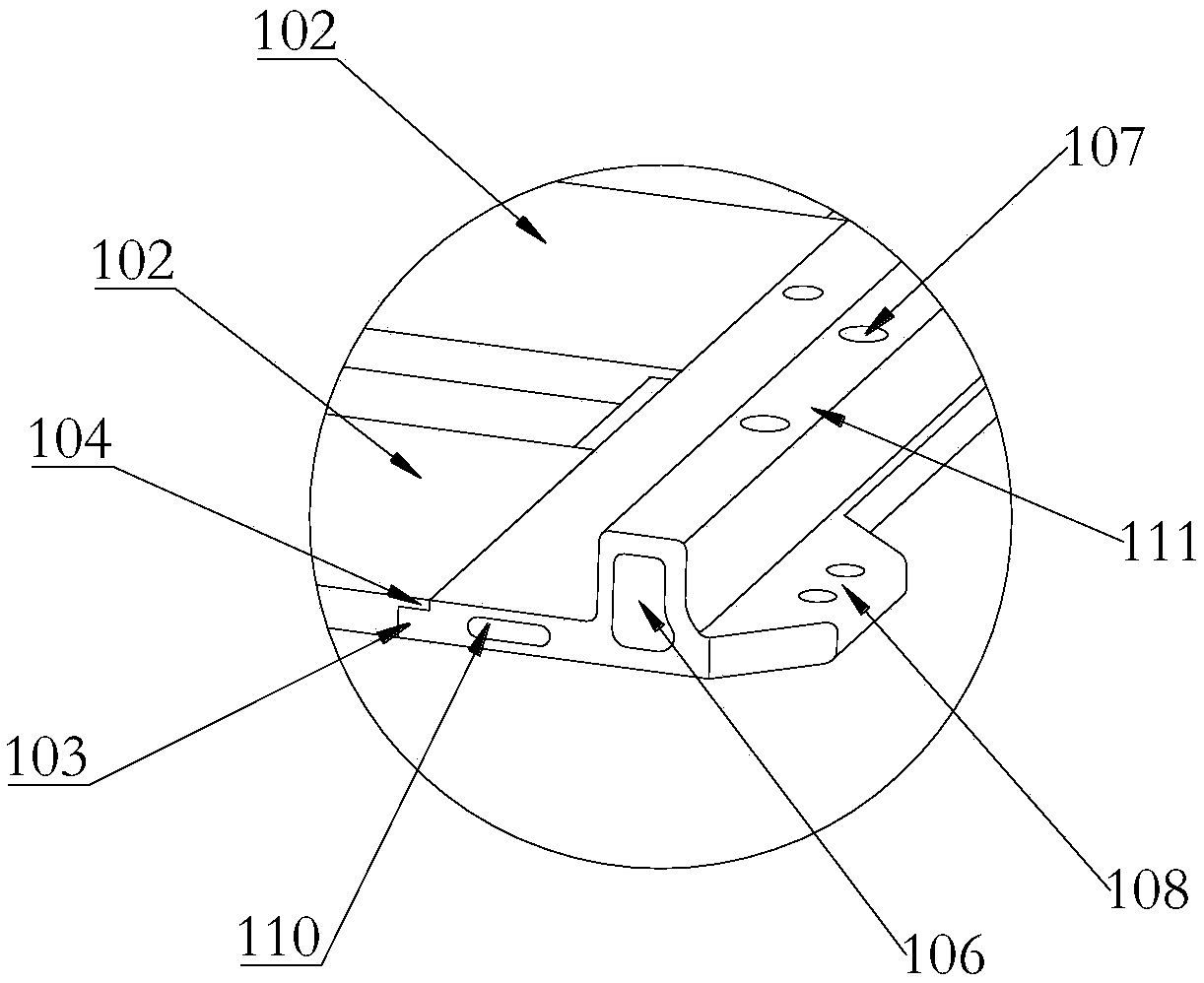

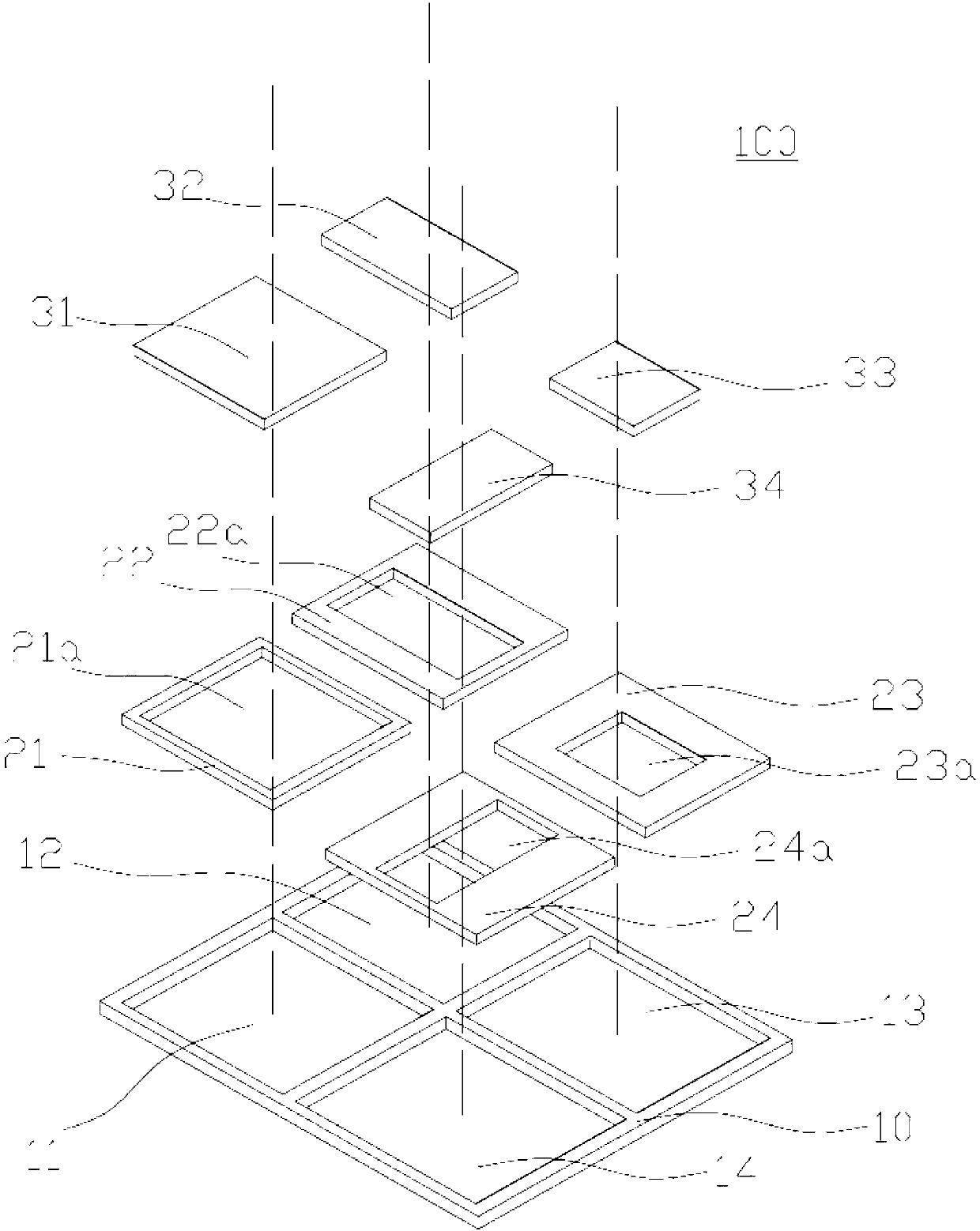

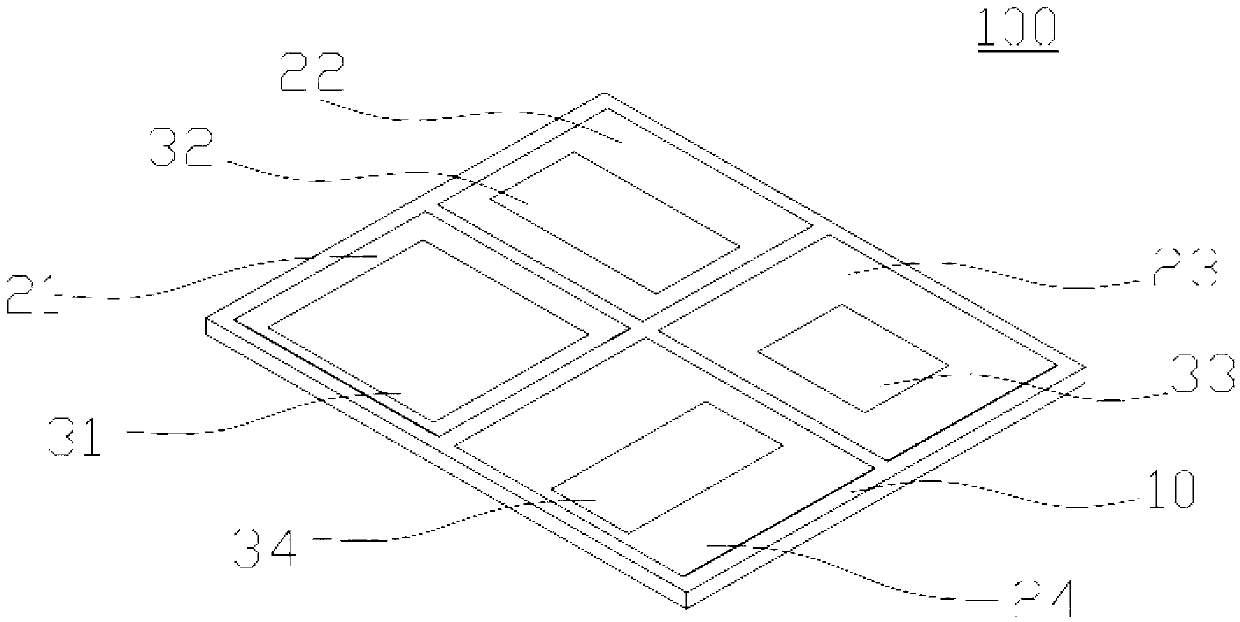

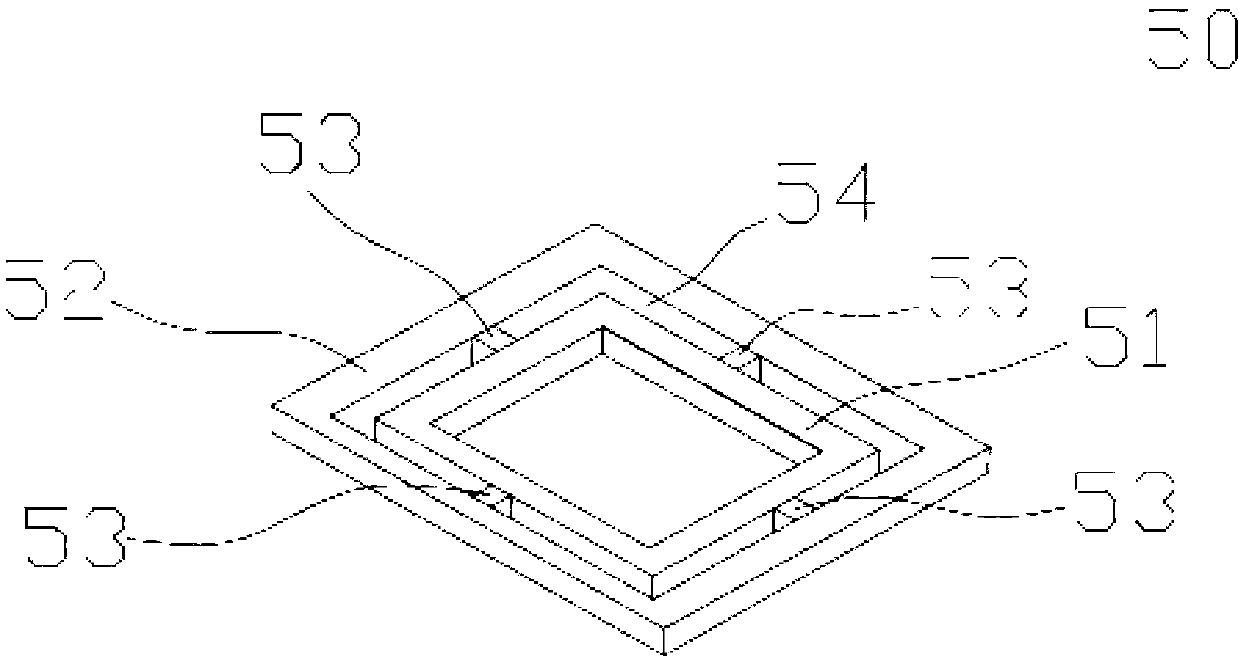

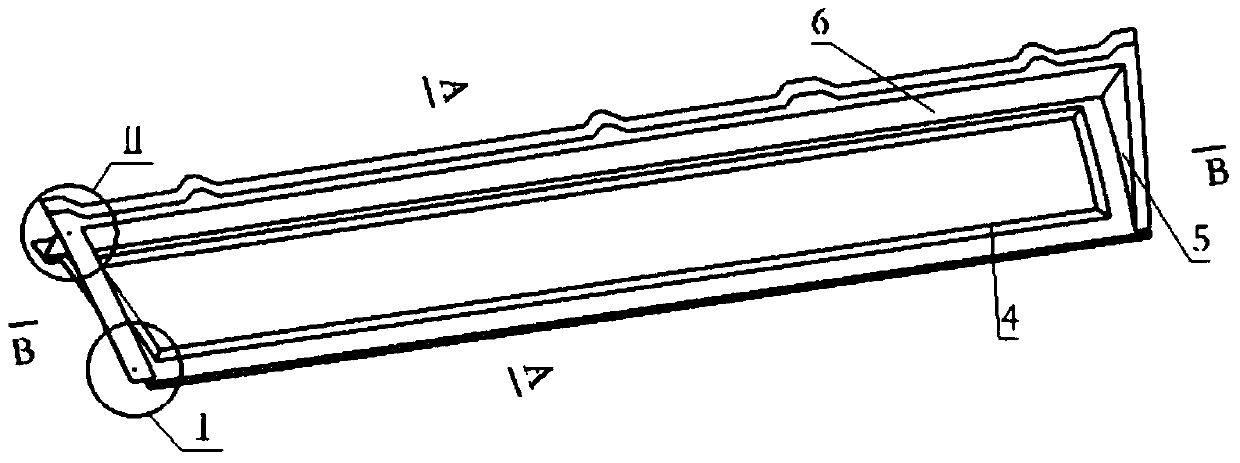

Adjustable packaging mat

InactiveCN103342199AGood versatilityReduce moldDamagable goods packagingLiquid-crystal displayLiquid crystal

The invention provides an adjustable packaging mat. The adjustable packaging mat comprises a first body and a second body. The middle of the first body is hollowed out to form a first containing area for containing a liquid crystal display panel with a first size; the middle of the second body is hollowed out to form a second containing area for containing a liquid crystal display panel with a second size, the first size is smaller than the second size, the first body is nested into the second body and arranged in the second containing area, and the first body is connected to the inner contour of the second body through first connecting portions. When the adjustable packaging mat is used for packaging the liquid crystal display panel with the first size, the liquid crystal display panel with the first size is placed in the first containing area; when the adjustable packaging mat is used for packaging the liquid crystal display panel with the second size, the first body is removed from the first connecting portions, and the liquid crystal display panel with the second size is placed in the second containing area. The adjustable packaging mat can be adjusted according to the sizes of the liquid crystal display panels and has good universality.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

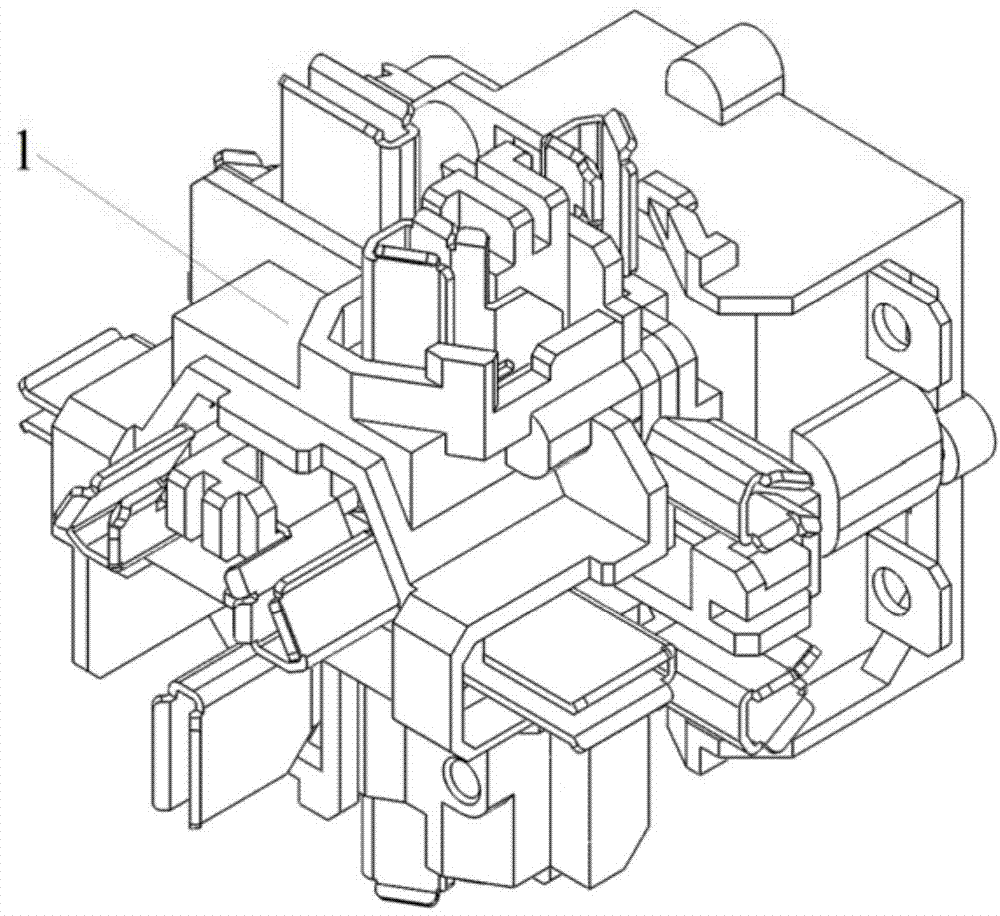

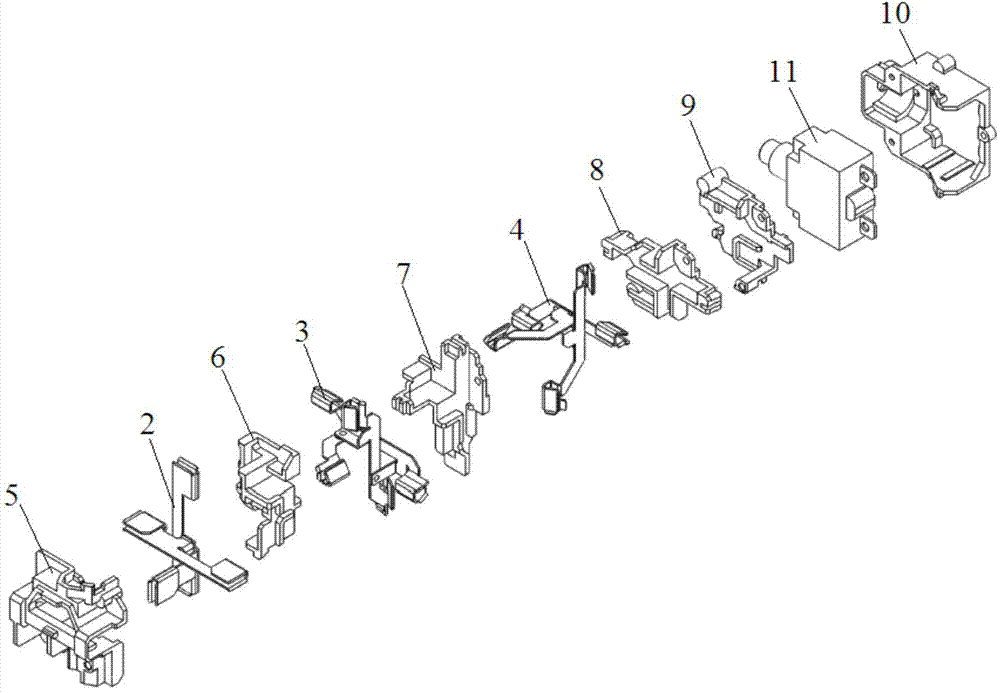

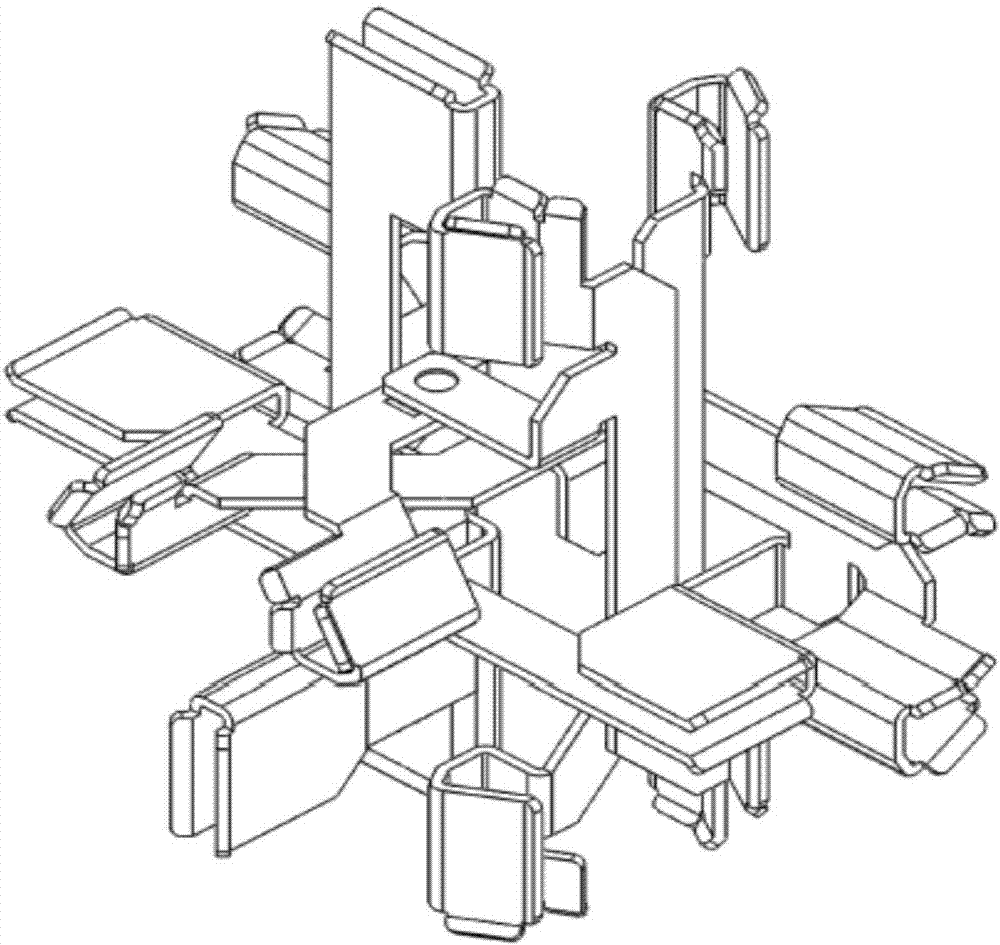

Interior structure of square socket

ActiveCN104716488ASave materialReduce in quantitySecuring/insulating coupling contact membersCoupling contact membersElectrical polarityElectric wire

The invention relates to an interior structure of a square socket. The interior structure is arranged in a square socket shell, the square socket is of a hexahedron structure, and socket apertures are arranged on the faces of the square socket; the interior structure comprises a plurality of plastic connecting pieces and three bending metal sets, the three bending metal sets are relatively independent and are used for being connected with a ground wire, a zero wire and a live wire of an electric wire respectively, a whole is formed by connecting the three bending metal sets through the plastic connecting pieces in the center of the socket, the zero wire and the live wire are distributed in an intersected mode, and it is guaranteed that the socket apertures with the same polarity are located on the same side of each face of the socket. Compared with the prior art, the interior structure has the advantages of being compact in structure, high in durability and high in universality, saving the assembly time and the like.

Owner:SUZHOU BOTELI HARDWARE ILLUMINATION ELECTRIC APPLIANCE CO LTD

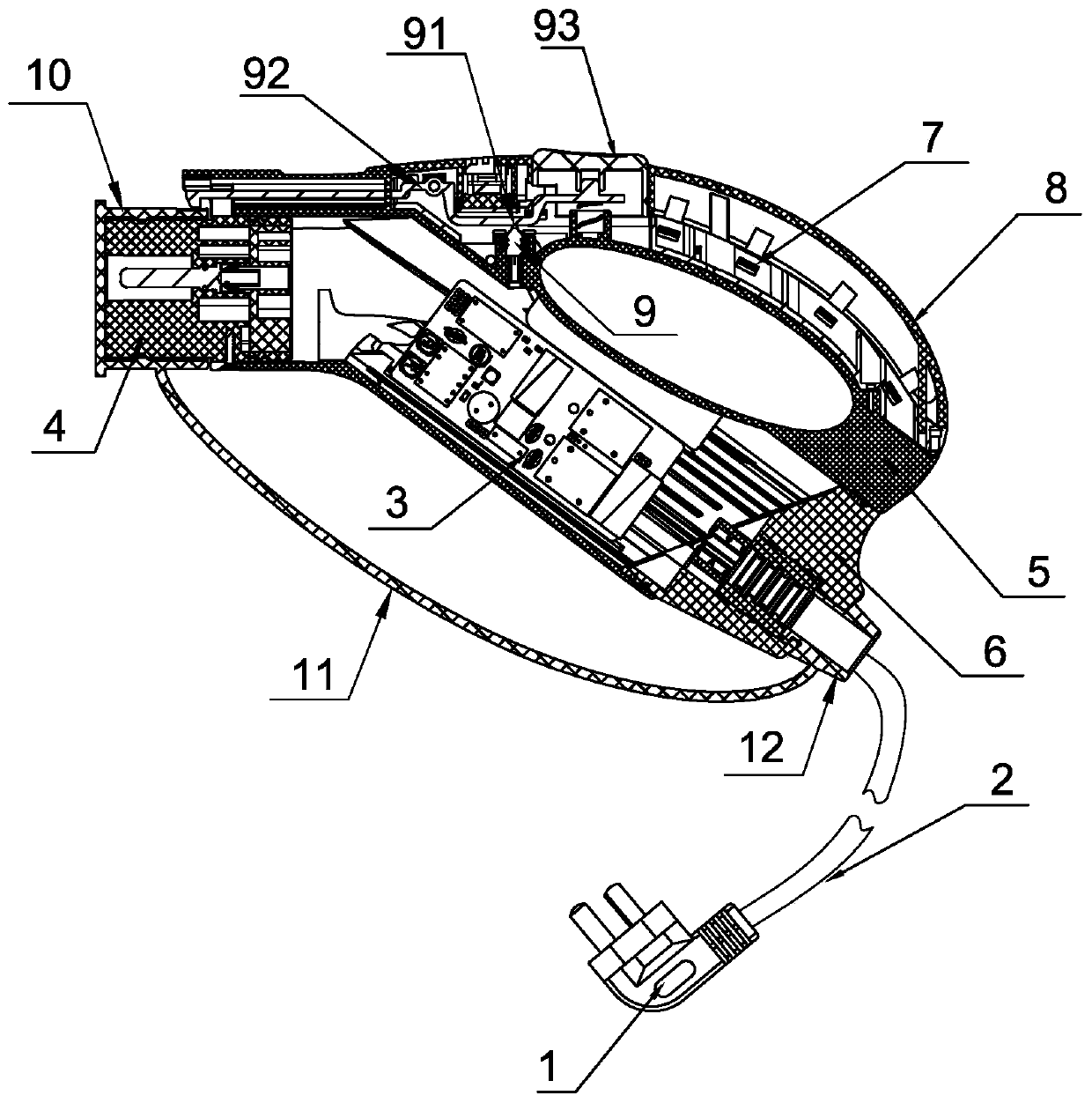

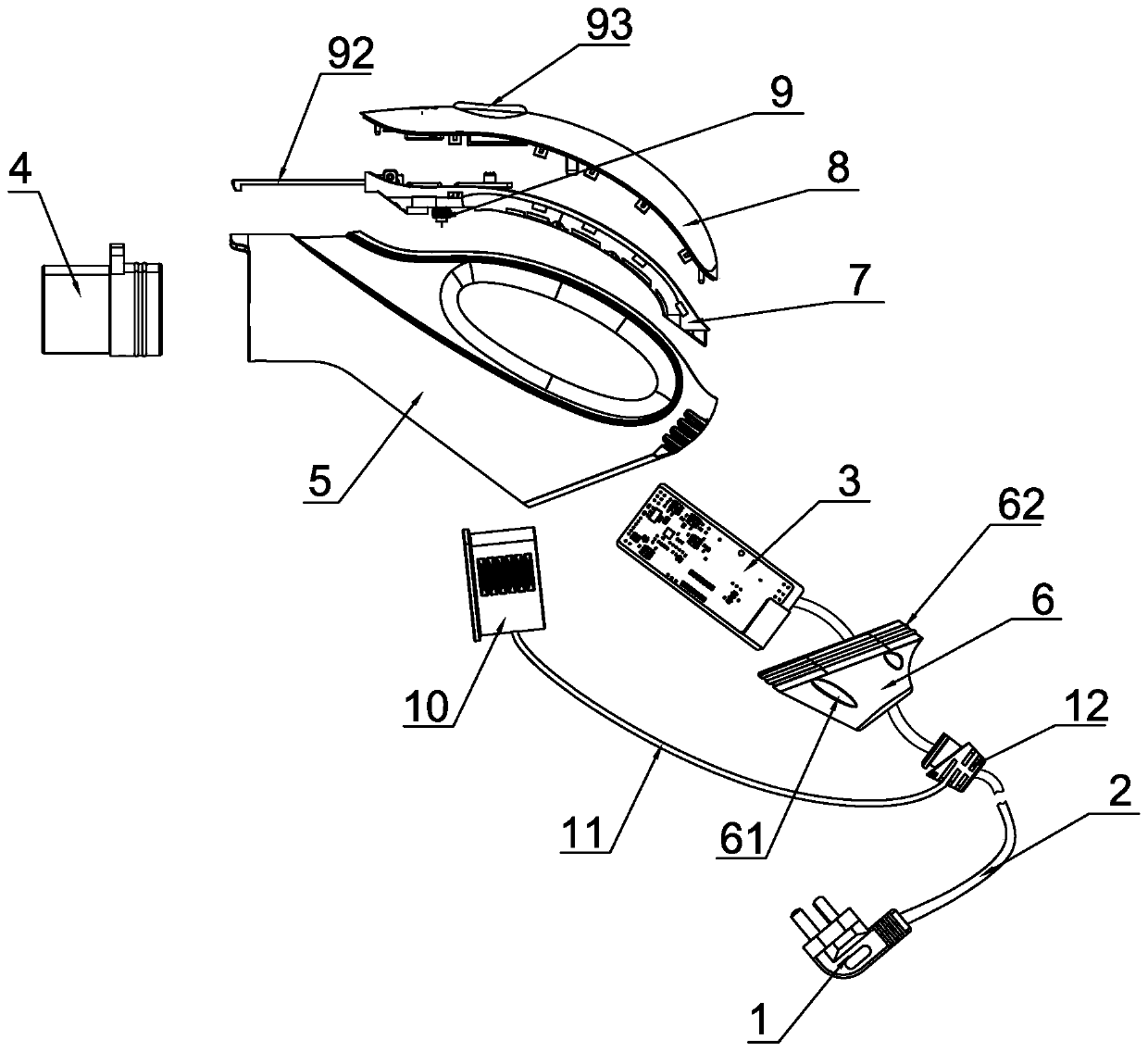

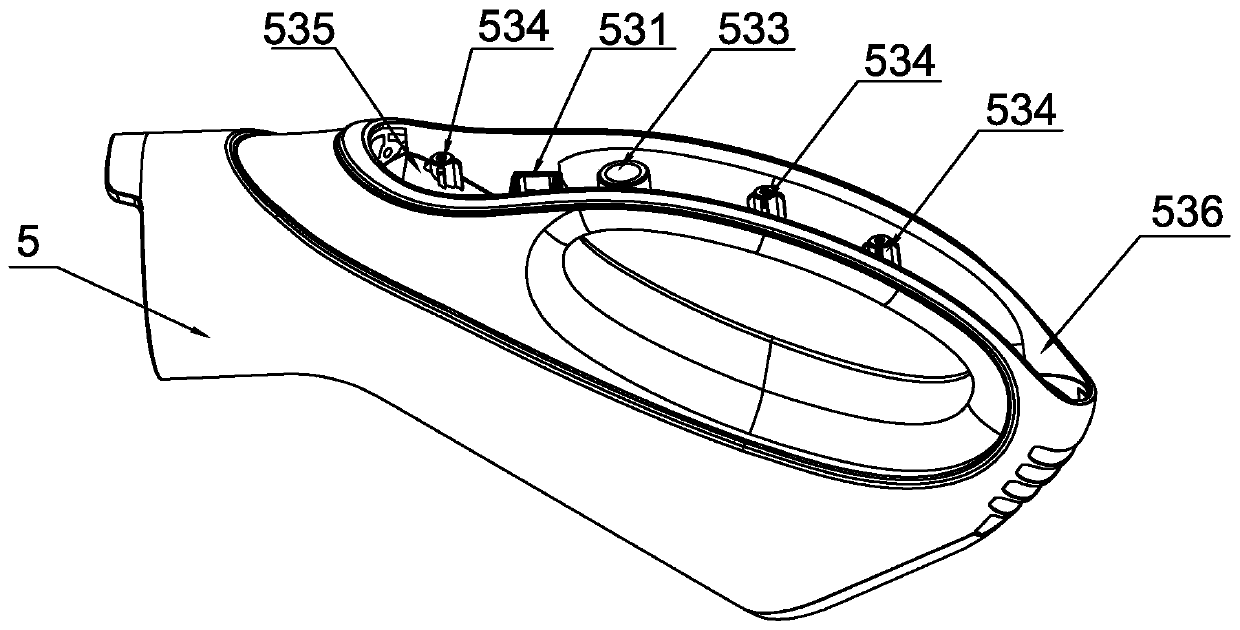

Electric vehicle alternating current charging gun with integrated control circuit hidden in gun body

PendingCN110364896AEliminate the upper and lower shellsReduce moldVehicle connectorsCharging stationsLeaking waterElectricity

The invention discloses an electric vehicle alternating current charging gun with a control circuit hidden in a gun body. The charging gun comprises a power plug, a gun connecting electric wire, a charging control circuit component, a charging plug assembly, a gun body, a tail cover, a connecting plate and a cover plate. The power plug, the gun connecting electric wire, the charging control circuit component and the charging plug assembly are electrically connected, and the charging plug assembly and the charging control circuit component are both arranged in the charging gun body. The charging control circuit part is integrated in the gun body, so that an upper shell and a lower shell of a charging control box are omitted, cost is reduced, and the charging gun is miniaturized and integrated. The electric plug assembly, the tail cover, the connecting plate, a switch and the gun body are sealed, so all connecting positions of the charging gun are sealed, and the protection level is improved to IP67 from existing IP55. Drain holes are formed in the lowest positions of the front-end low-position cavity and the tail low-position cavity of the gun body, so even if a small amount of leaked water exists, the leaked water can be drained in time, short circuit of a control circuit cannot be caused, and the service life of the charging gun is prolonged.

Owner:华星动力(江苏)有限公司

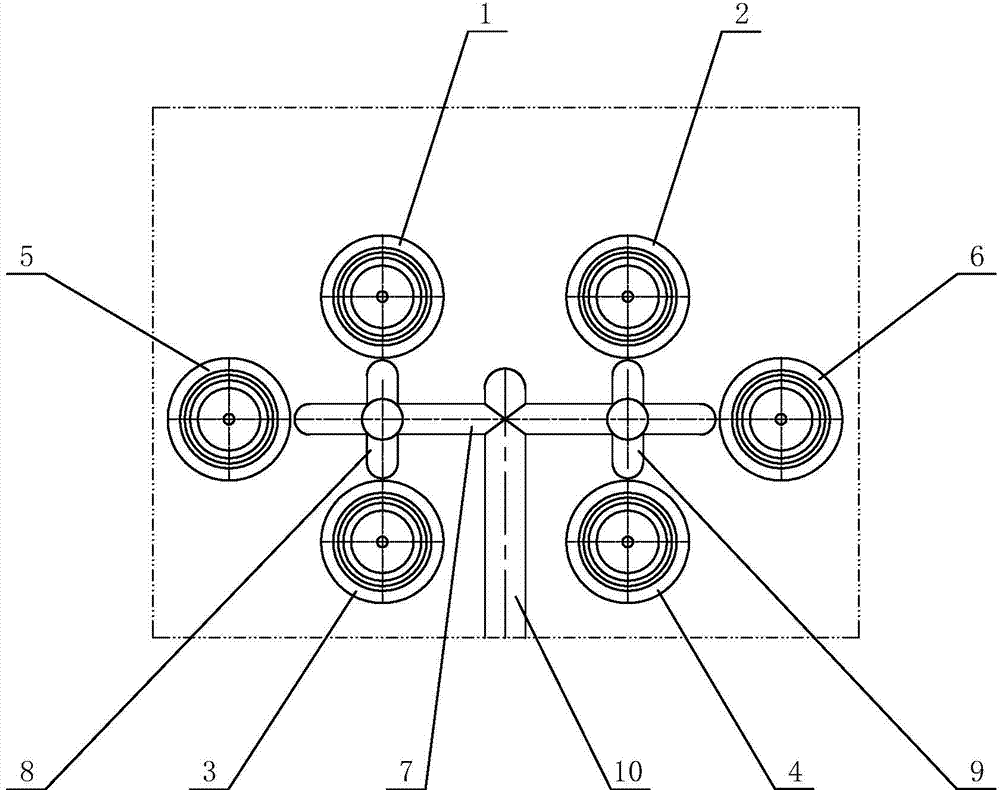

Multi-mold-cavity mold structure

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

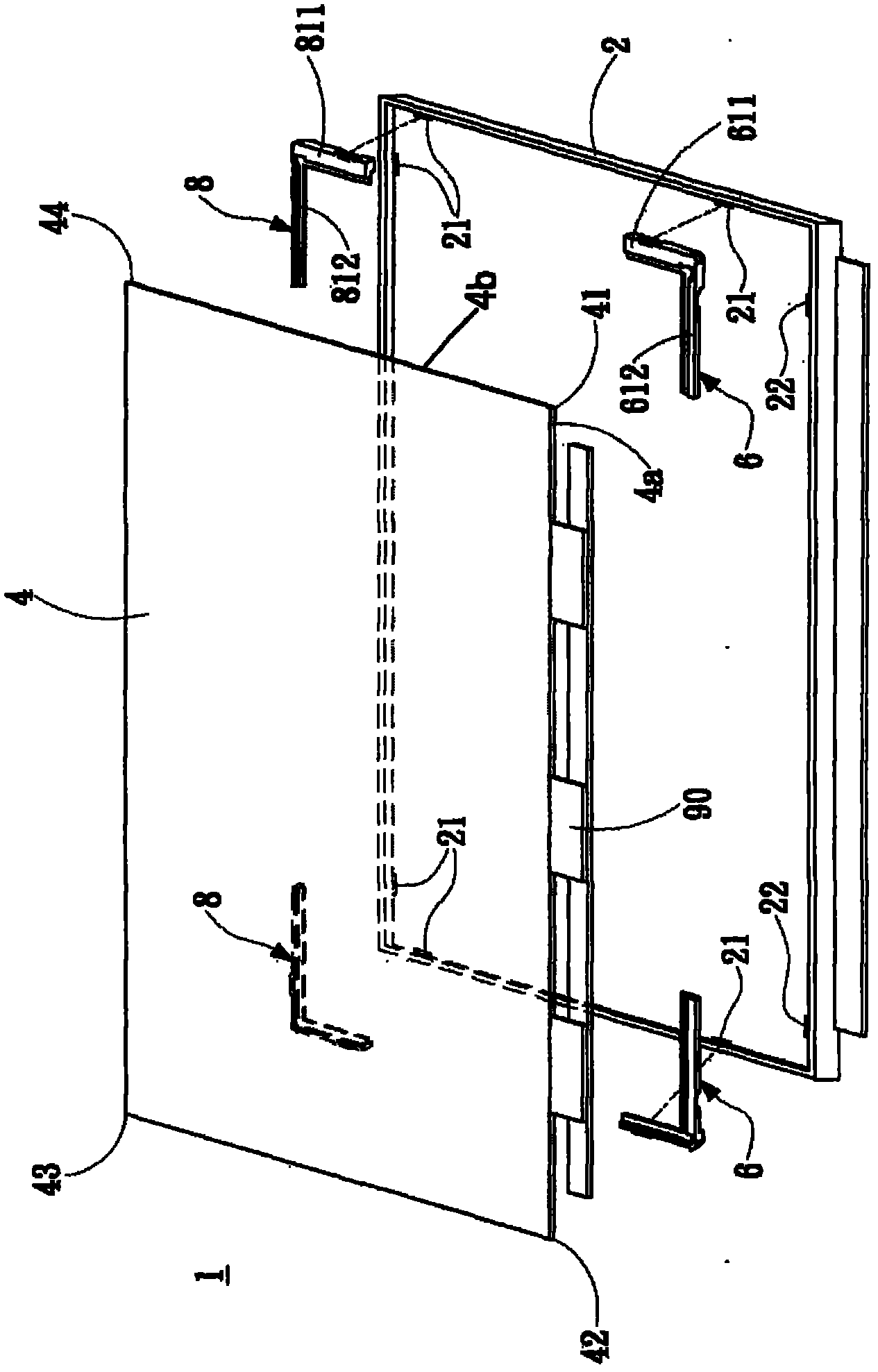

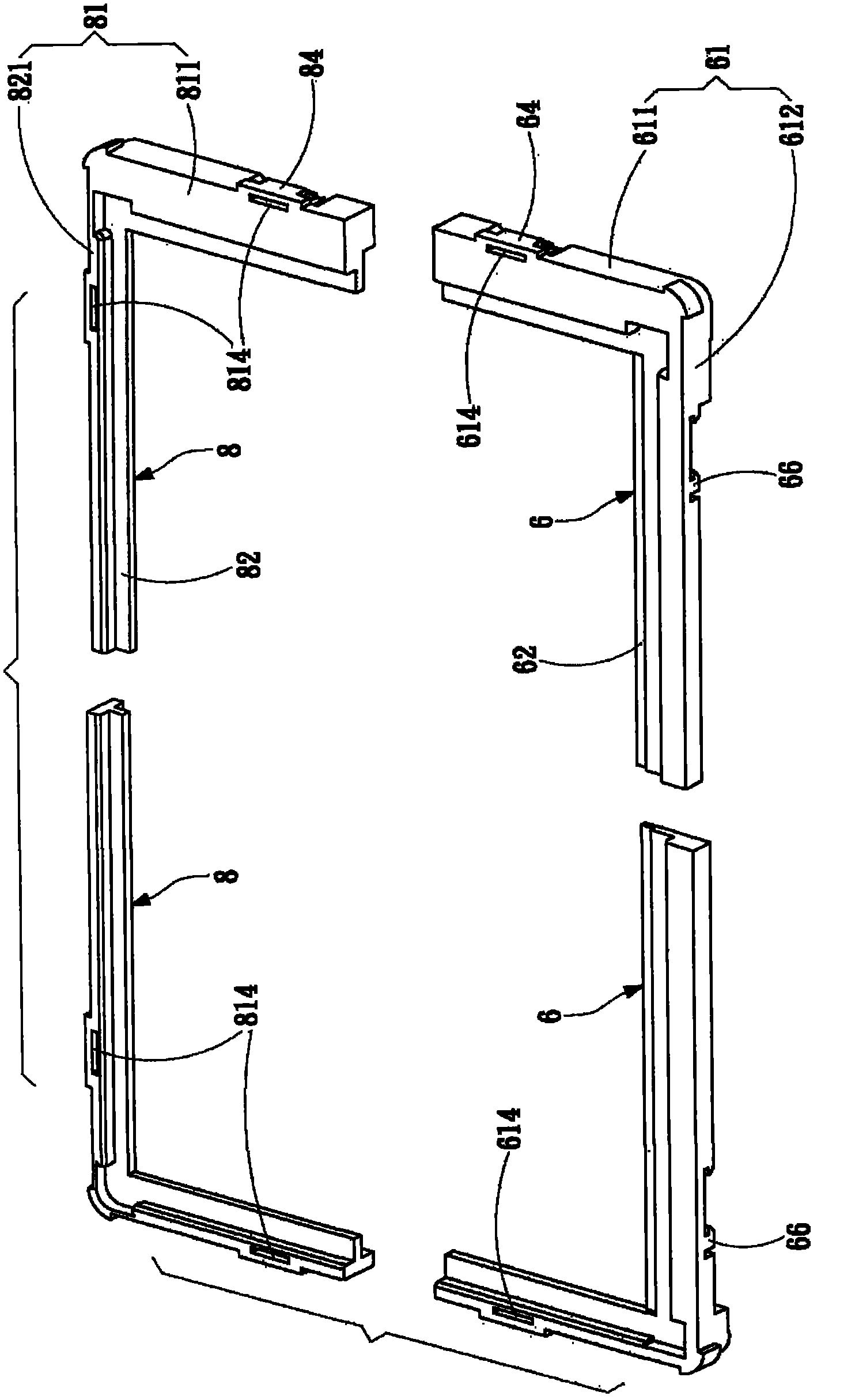

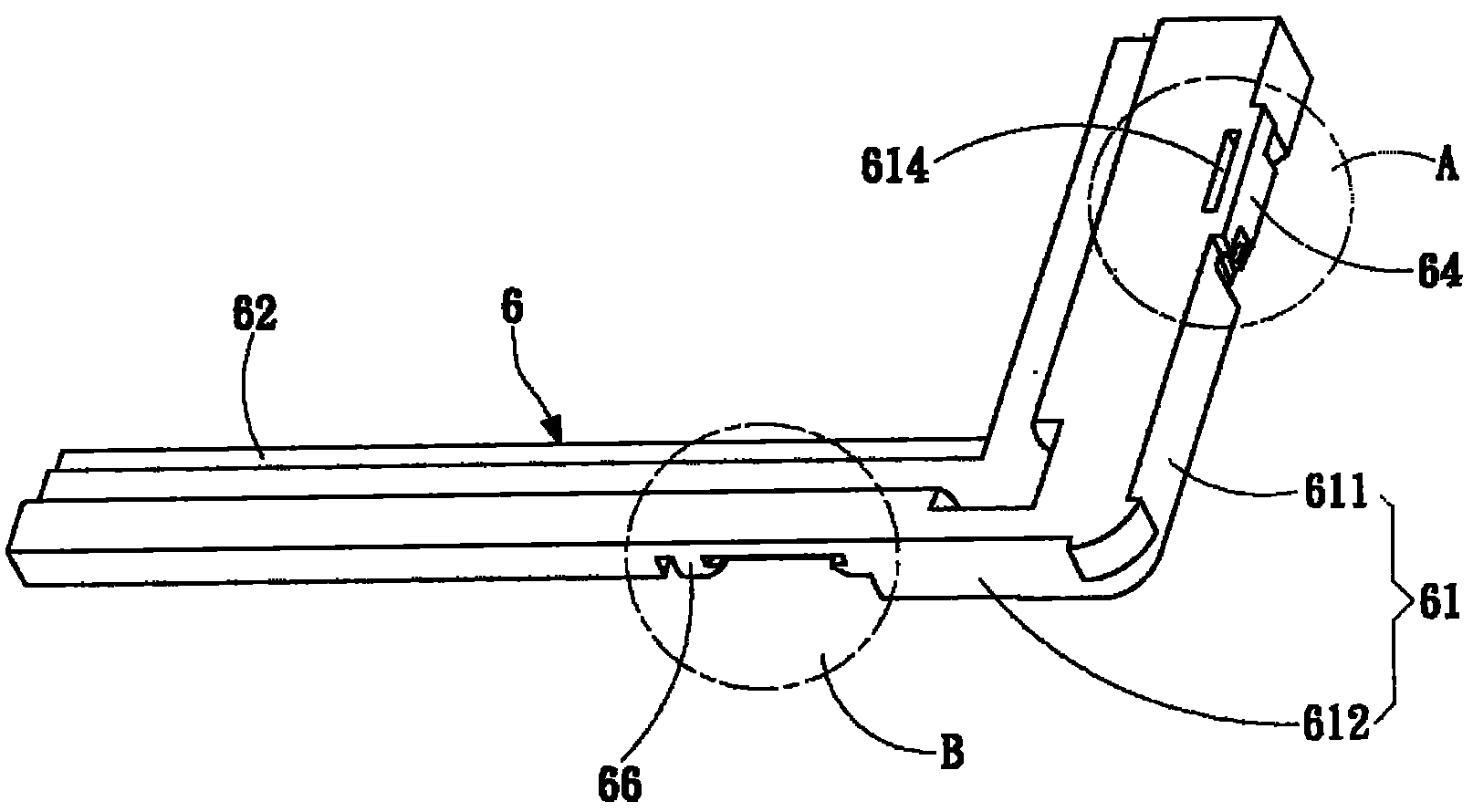

Backlight module and rubber frame structure thereof

InactiveCN102635834AReduce material costsReduce moldMechanical apparatusLight guides for lighting systemsLight guideEngineering

The invention relates to a backlight module and a rubber frame structure of the backlight module. The backlight module comprises a back panel, a light guide plate and the rubber frame structure, wherein the rubber frame structure is used for positioning the light guide plate and the back panel, and consists of two first frames and two second frames which are used for supporting four corners of the light guide plate; the first frame is combined with the back panel by a first positioning piece and a first combination piece; and the second frame is combined with the back panel by a plurality of second positioning pieces. According to the invention, by changing the rubber frame structure into a four-piece design and replacing the known integrated square rubber frame with four L-shaped corner rubber frames, the rubber frame structure is not only applicable to backlight modules with various sizes, but also can save the mold opening cost by utilizing the small volume of the rubber frame, save the material cost of the rubber frame due to minimization of materials required, so as to further achieve the purposes of reducing mold and finished product costs of the rubber frame.

Owner:AU OPTRONICS CORP

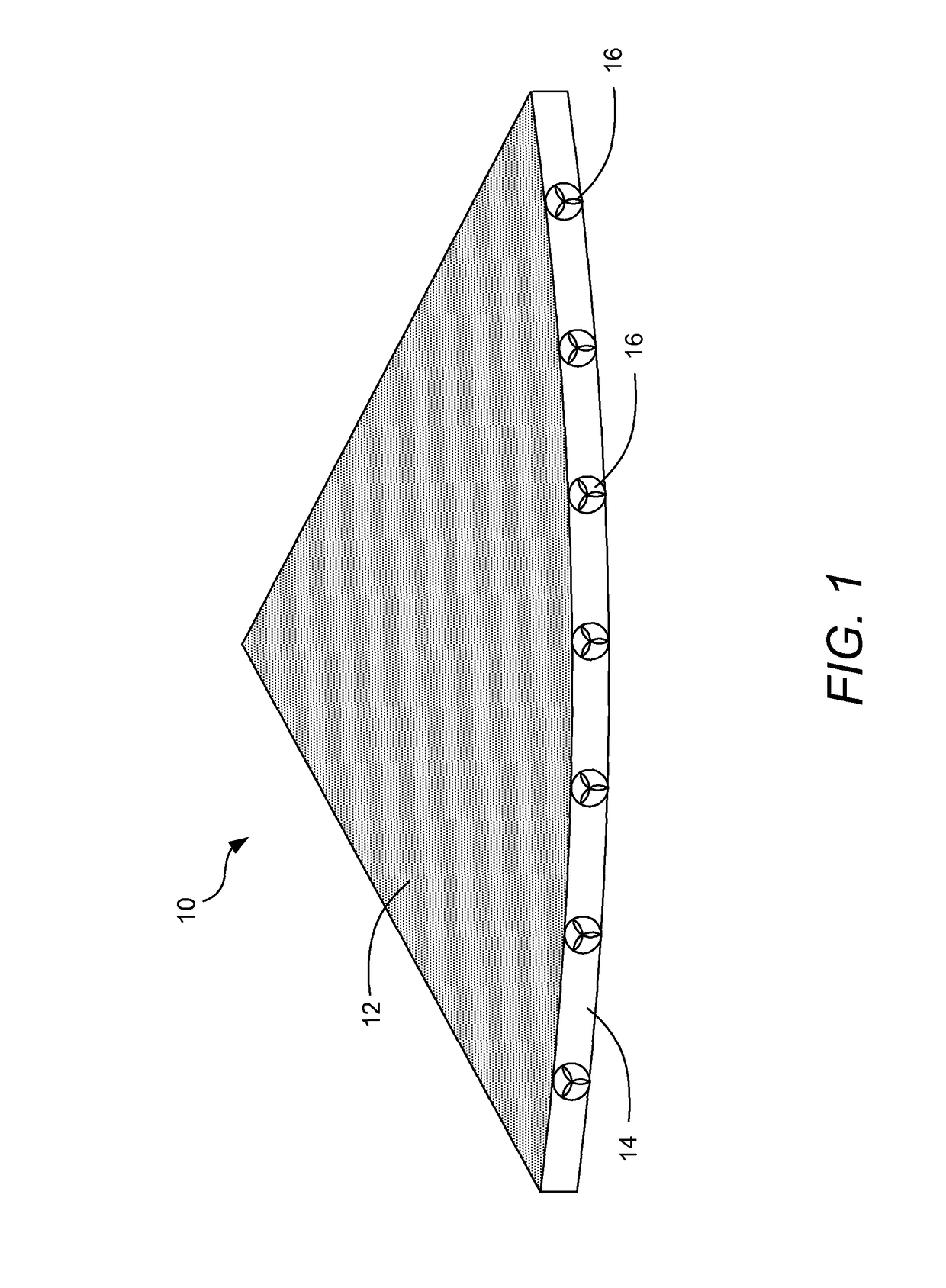

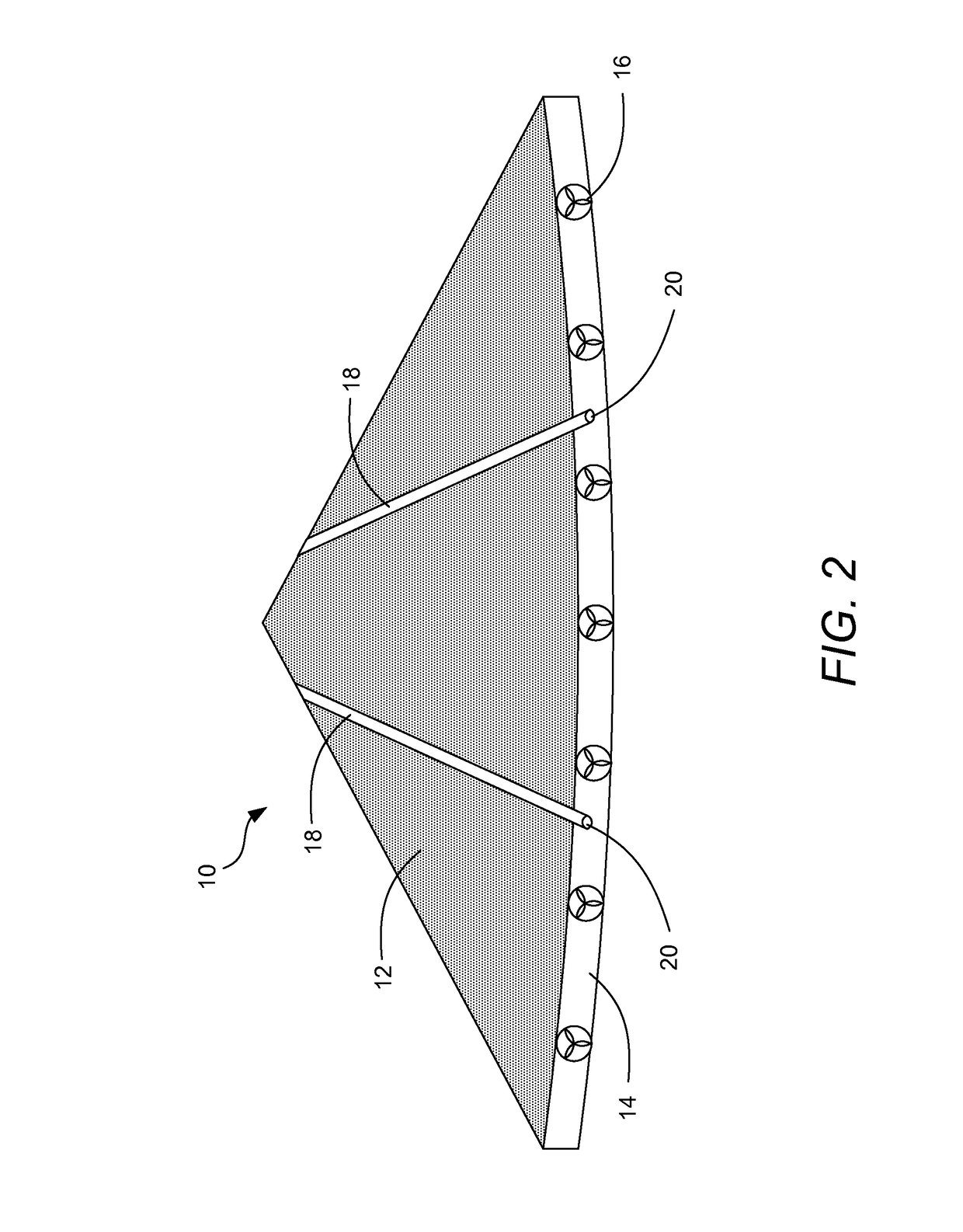

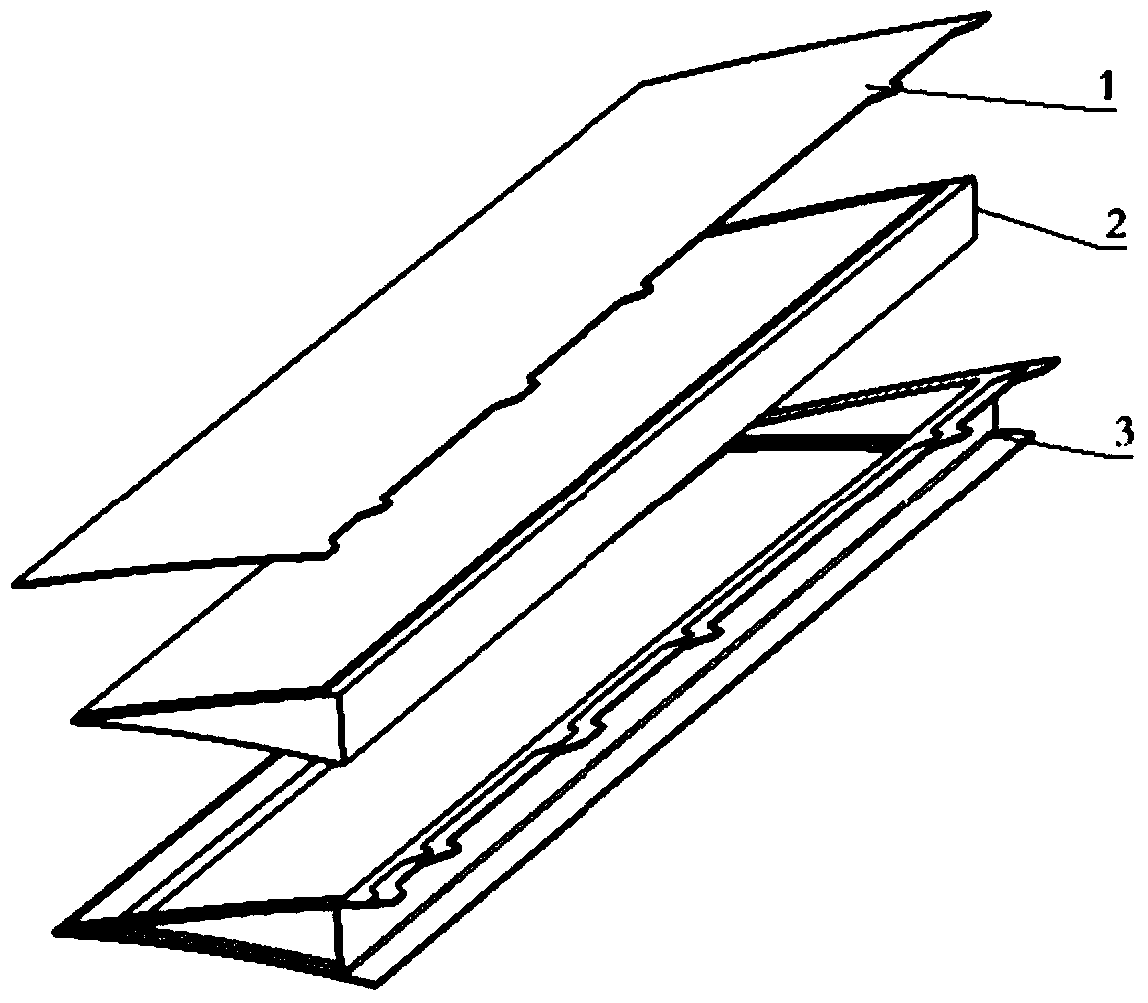

Detachable integral slat trailing edge structure

InactiveCN103466078ALess structural partsReduce moldAircraft controlSandwich constructionsDesign technologyCell trailing edge

The invention belongs to the technical field of structural design of airplanes and particularly relates to a detachable integral slat trailing edge structure. The detachable integral slat trailing edge structure is characterized in that a slat trailing edge takes the shape of a triangular wedge and comprises an upper wall plate (1), a composite enclosing frame (2) and a foam core (3), wherein the upper wall plate (1) is formed by laying carbon fiber fabric; the composite enclosing frame (2) is formed by laying carbon fiber fabric; the foam core (3) is placed in the cavity formed by the upper wall plate (1) and the composite enclosing frame (2); RTM one-step forming is performed after the carbon fiber fabric of all the parts are laid layer by layer. Compared with the traditional composite slat trailing edge, the detachable integral slat trailing edge structure requires fewer parts, fewer manufacturing molds and lower cost; the integral slat trailing edge has higher strength and rigidity than the traditional composite slat trailing edge, is detachable and is easy to maintain and replace.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Construction system for releasing moisture from a hip, valley or gable roof

ActiveUS20150292211A1Avoid formingEasy and efficientBuilding roofsLighting and heating apparatusWater vaporGablet roof

A construction system for releasing moisture from a building is provided. The system is especially suitable for use in buildings having a hip, valley or gable roof. More specifically, the device gives the hip, valley or gable roof adequate ventilation and moisture vapor release portals so as to allow air and water vapor to properly rise through the interior of the hip, valley or gable roof and out through ridge vents without becoming trapped by rafters of the hip, valley or gable roof. The system has a first unit and a second unit, wherein the first unit allows air and water vapor to pass through passageways of the first unit up through the underside of the hip, valley or gable roof up and out through the ridge vent(s) and the second unit allows air from the exterior to pass into the roof cavity to circulate through the roof cavity and into the first unit.

Owner:WICKRIGHT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com