Convertible shoe body

A shoe upper and shoe body technology, applied in footwear, clothing, applications, etc., can solve problems such as cost consumption, increased component defect rate, and increased number of molds, so as to reduce molds and consumables, reduce outsole defect rate, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

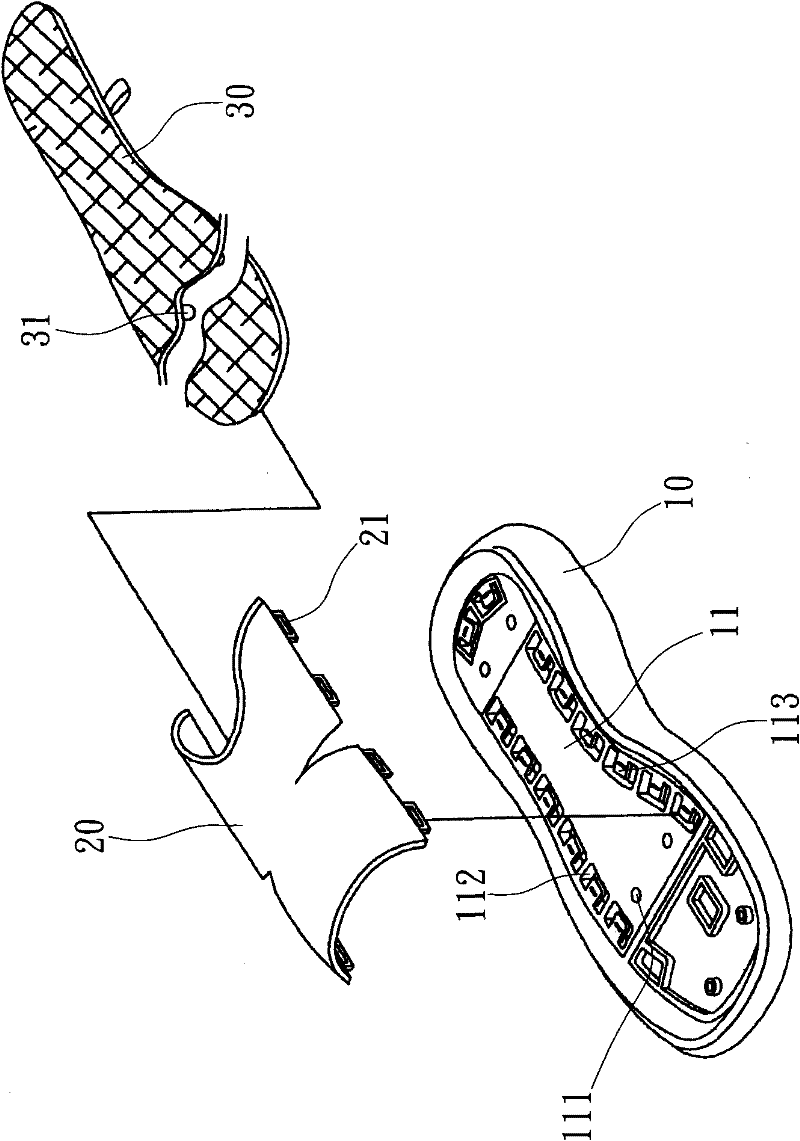

[0039] In order to enable your examiner to have a better understanding of the present invention, hereby cite a preferred embodiment together with the accompanying drawings, and describe it in detail as follows:

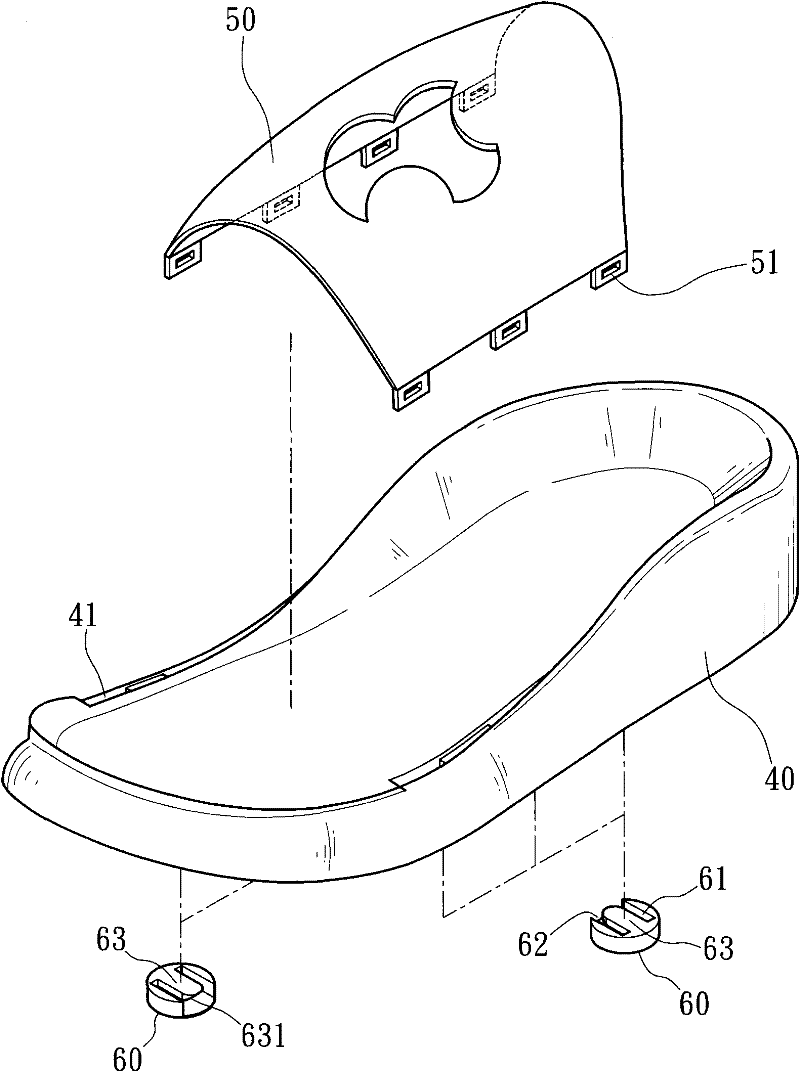

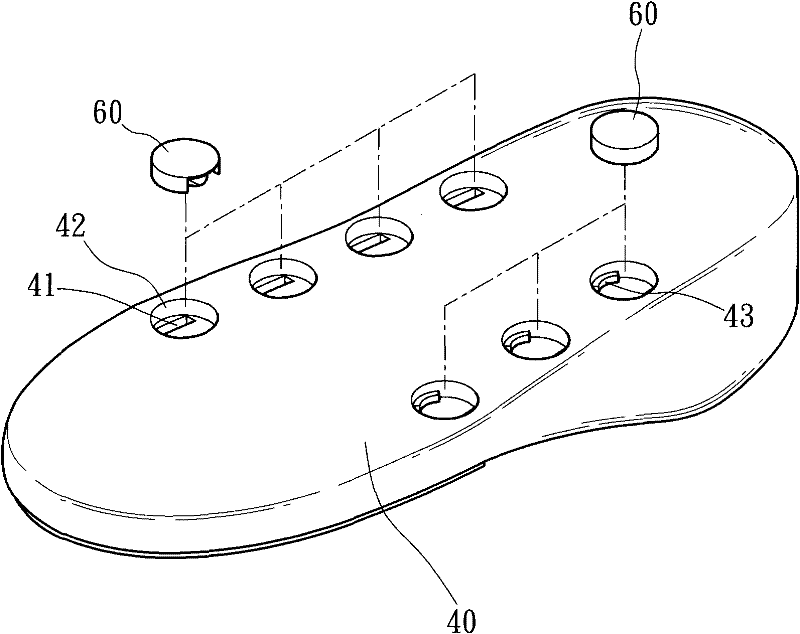

[0040] see figure 2 , image 3 The shoe body of the present invention includes a large bottom 40, a vamp 50 and a plurality of positioning parts 60. The large bottom 40 is a shoe shape and can be made of different materials. In this embodiment, the large bottom 40 is The rubber material is integrally injection-molded, and a plurality of perforations 41 through the bottom surface are provided on both sides of the top surface, and grooves 42 are provided on the bottom surface corresponding to the positions of the perforations 41. In this embodiment, each groove 42 is roughly It is circular, and the inner ring surface has an appropriate slope, and an arc-shaped guide block 43 is protruded on the inner top surface. The shoe upper 50 can be in different shapes. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com