Patents

Literature

117results about How to "Reduce product defect rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

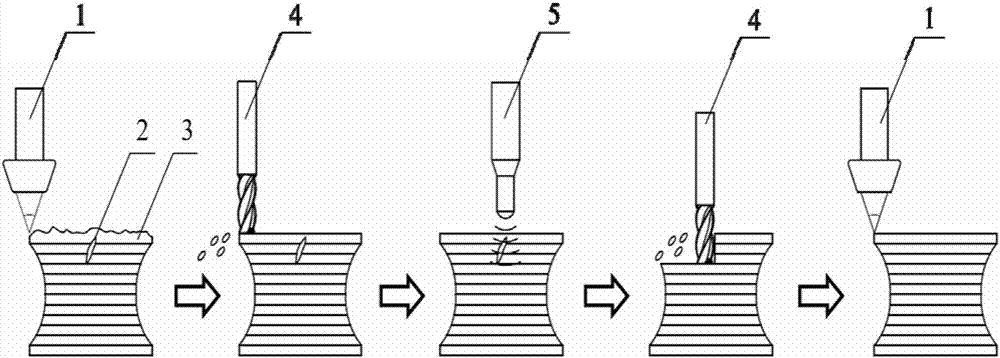

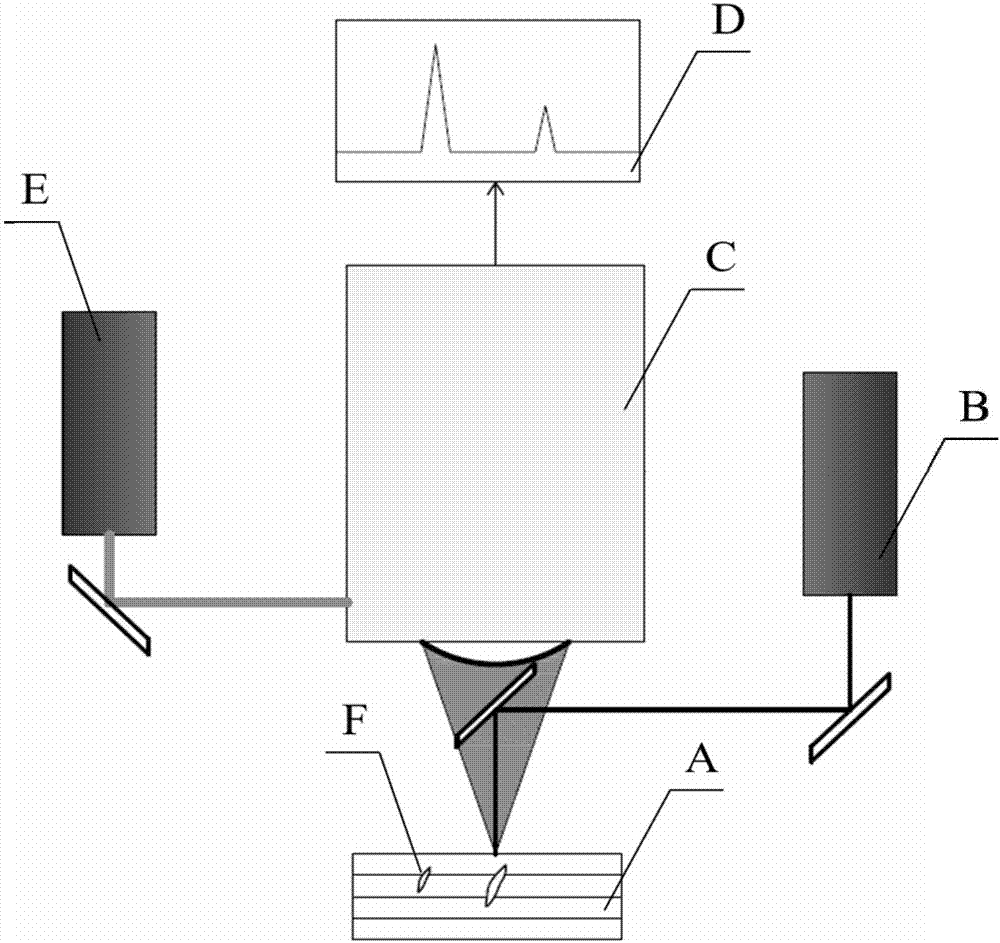

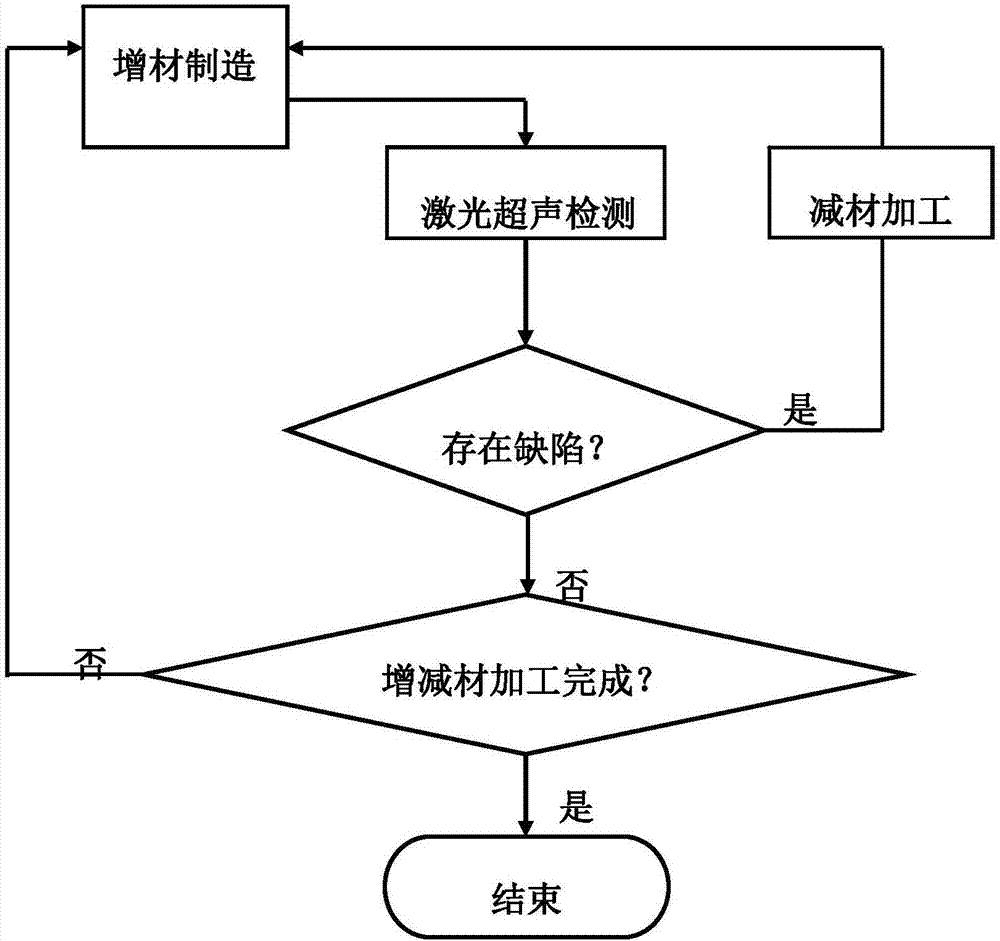

Metal material high-energy-beam additive/subtractive material and on-line laser ultrasonic detection composite processing method

ActiveCN107102061AReduce product defect rateSave time and costAnalysing solids using sonic/ultrasonic/infrasonic wavesNondestructive testingSuperficial mass

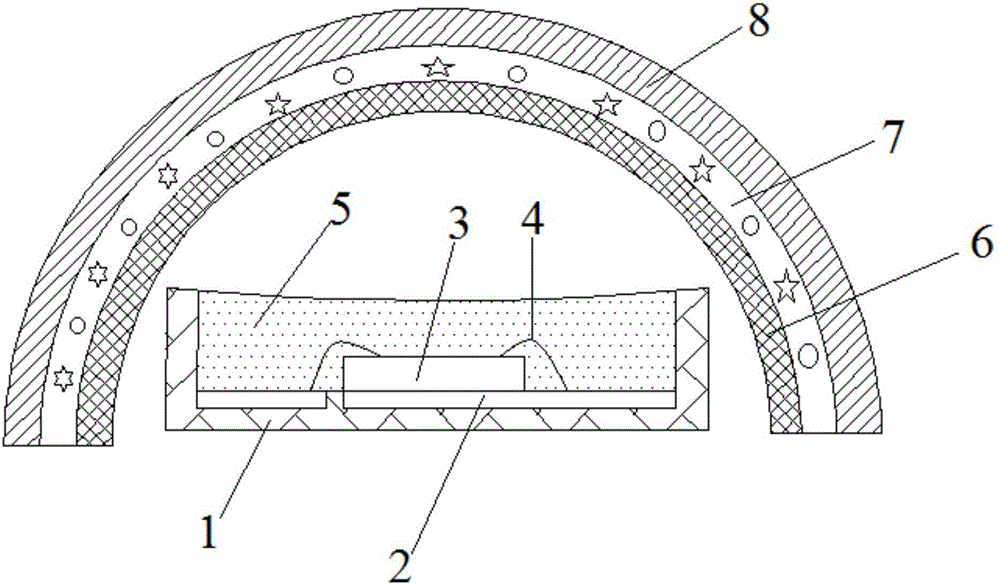

The invention relates to a metal material high-energy-beam additive / subtractive material and on-line laser ultrasonic detection composite processing method and belongs to the field of metal material additive / subtractive composite manufacturing (3D printing). The processing method includes the following steps: S1) additive moulding: performing layer-by-layer fusion / solidification stacking with a high-energy-beam fused metal material according to a predetermined route; S2) subtractive processing: performing subtractive processing to the deposited and shaped material to prepare a detection plane having high size-precision and surface quality; S3) laser ultrasonic detection: carrying out laser ultrasonic nondestructive detection on the surface to determine whether defects exist on the surface of or in interior of the material and determine the positions of the defects; and S4) detection determination and treatment: removing excessive surface or subsurface defects through subtractive processing, and adjusting an additive process to perform additive deposition until the whole metal component is completed, and if no defect exists, directly completing the on-line detection and performing high-quality work piece shaping circularly and repeatedly. The method solves a problem that a process of single additive manufacturing of components cannot achieve on-line detection and repair, and can reduce defection rate of products and save cost.

Owner:DALIAN UNIV OF TECH

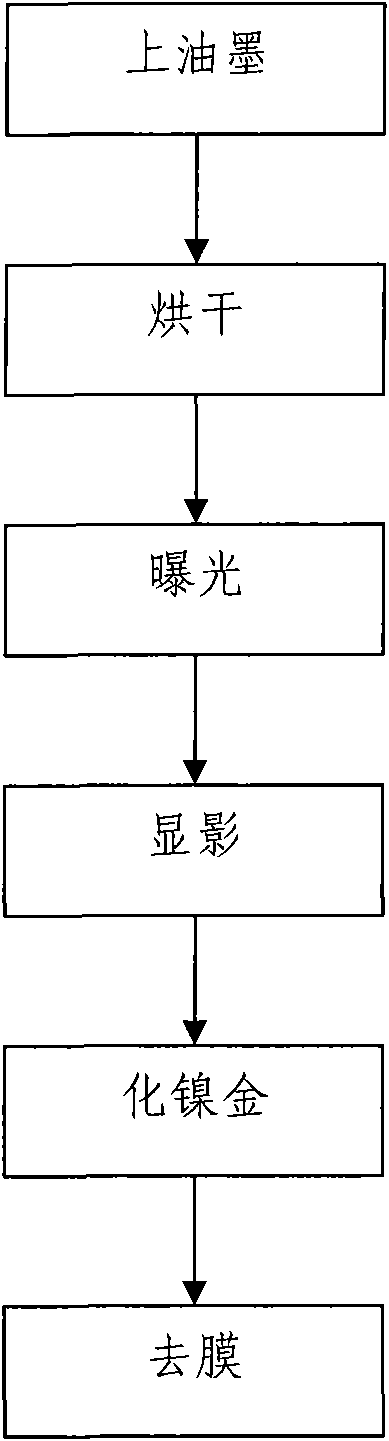

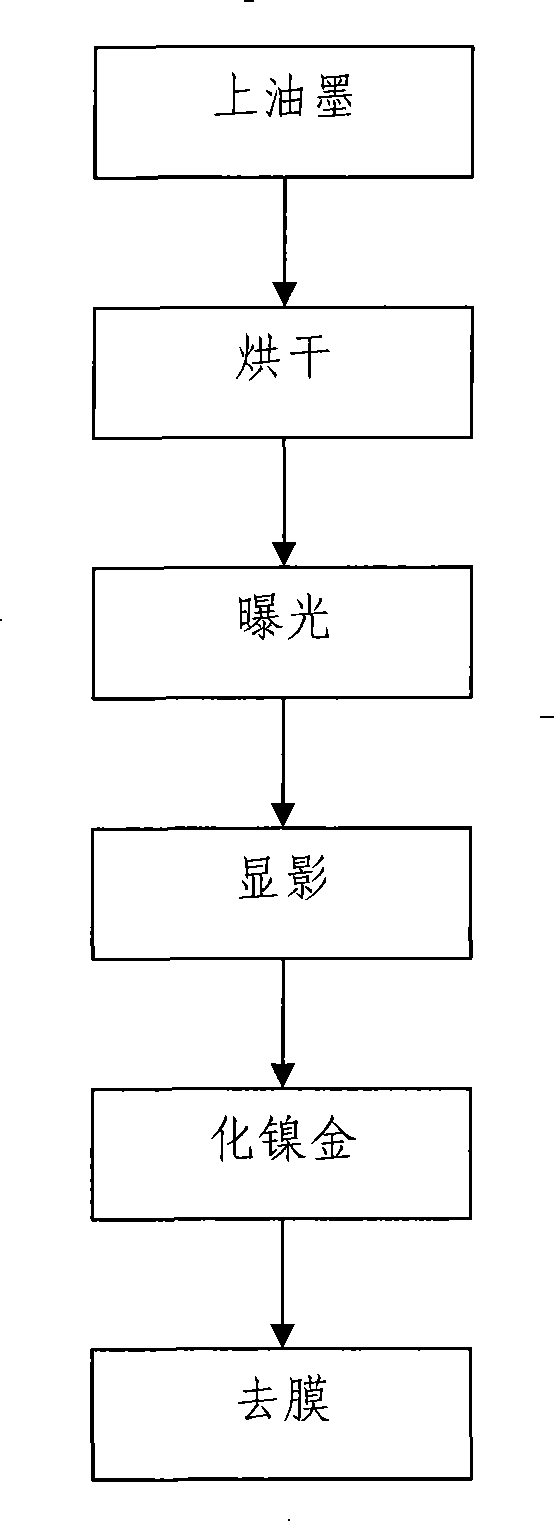

Method for melting nickel alloy by selective ink instead of dry film

InactiveCN101562943AEmission reductionImprove protectionConductive material chemical/electrolytical removalScreen printingEcological environment

The invention discloses a method for melting a nickel alloy by a selective ink instead of a dry film, which comprises the following steps: (1) selectively coating ageing resistant nickel alloy ink on a circuit board by a screen printing technology to form a wet film; (2) drying the ink; (3) exposing the ink; (4) developing the wet film so as to expose the required copper surface; (5) performing nickel alloy melting on the circuit board; and (6) removing the wet film. The selective ink instead of the dry film is used for selective nickel alloy melting, so the cost is greatly reduced, and the combination effect of the wet film and the board surface is superior to the combination effect of the dry film and the board surface, unfavorable phenomena such as diffusion coating and the like can beeffectively prevented, the defective rate of production is reduced and the quality of products is ensured. In addition, the method simplifies the manufacturing flow, saves the ink, greatly reduces theemission of pollutants, saves the expenses of wastewater treatment and is simultaneously favorable for the protection of ecological environment.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +1

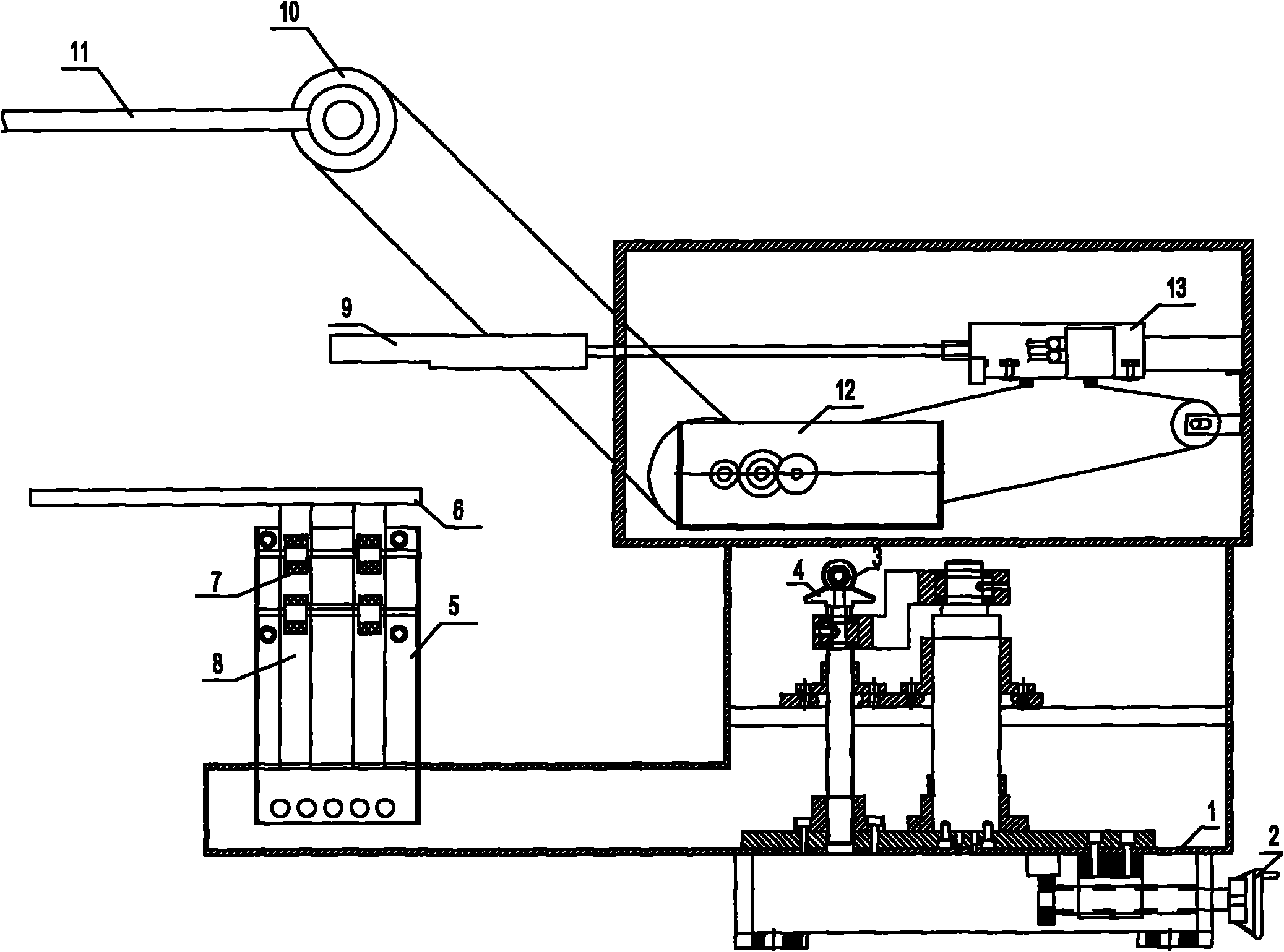

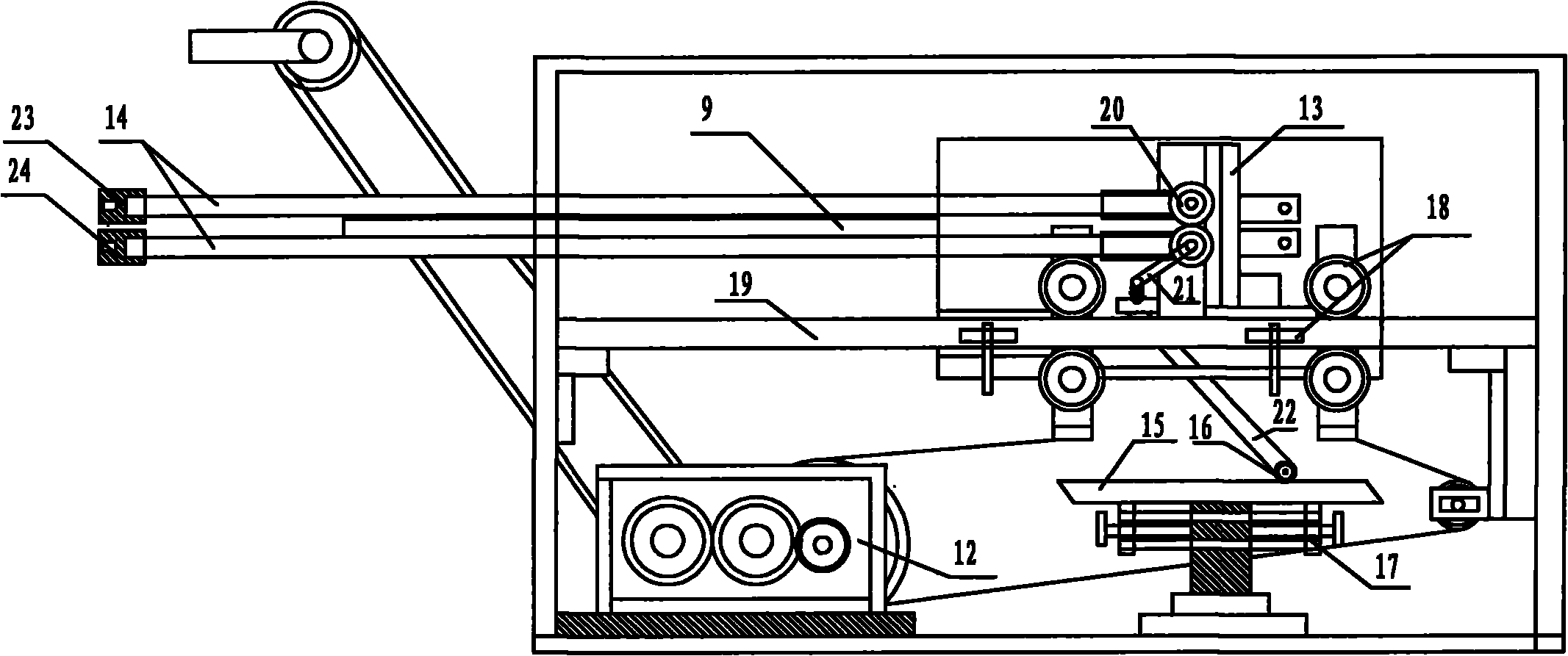

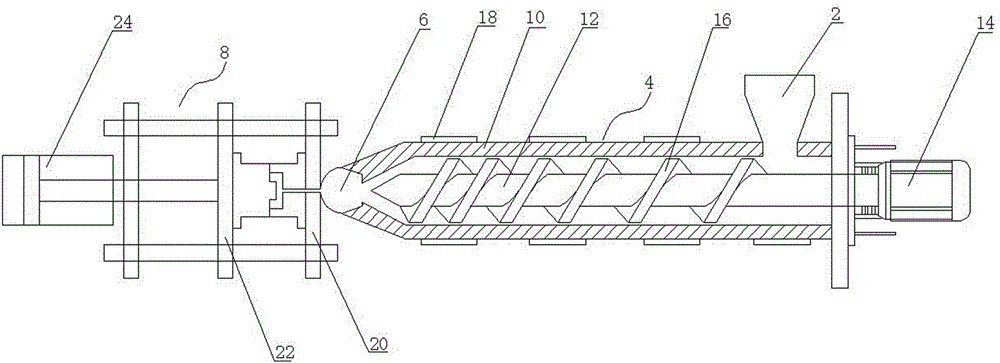

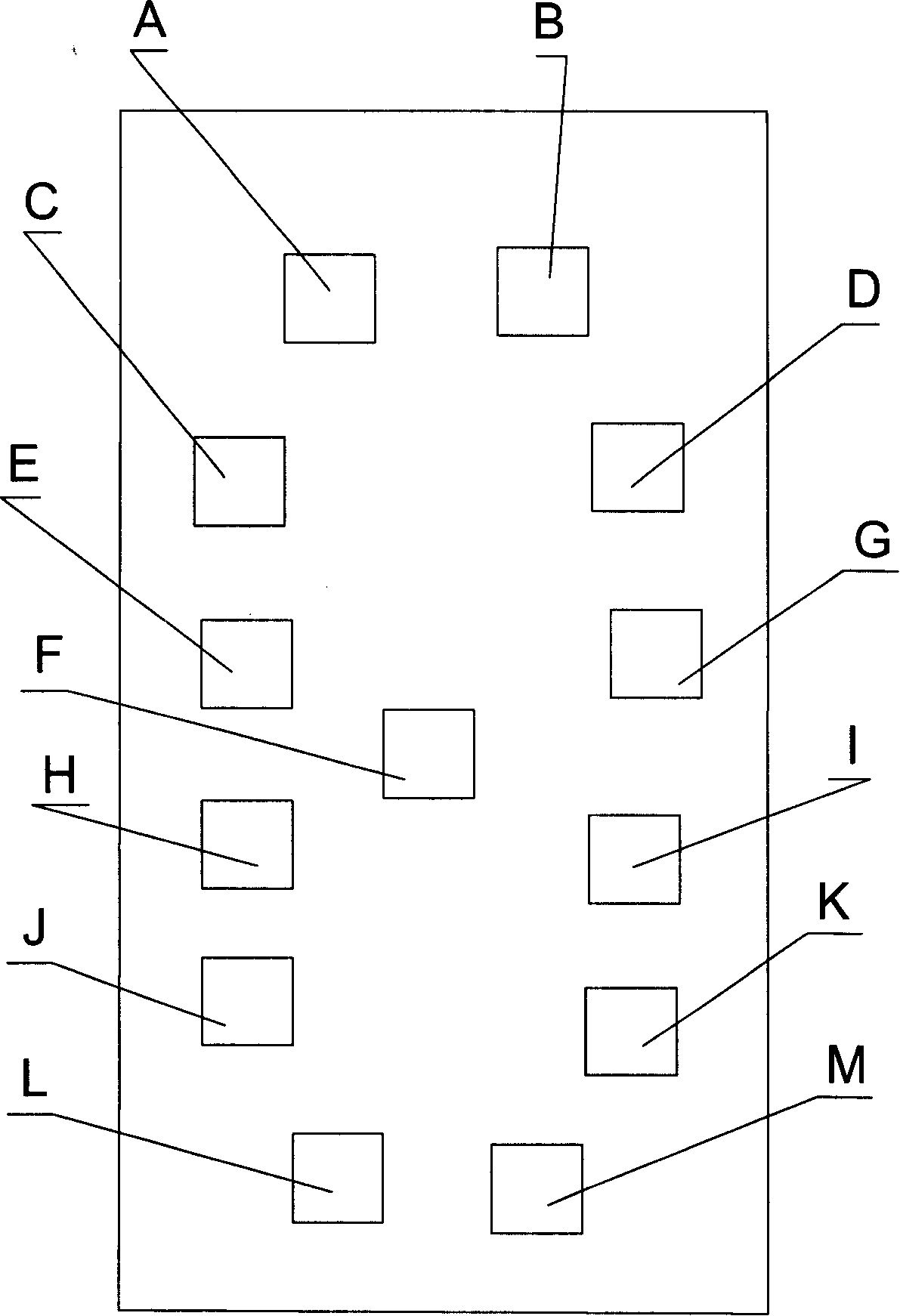

Automatic feeder for punch

InactiveCN101804436AAvoid personal injuryReduce product defect rateMetal-working feeding devicesPositioning devicesEngineeringPower transmission

The invention relates to an automatic feeder for a punch, belonging to the field of punching equipment of flaky material parts. The invention particularly relates to an automatic feeding mechanism for a punch, which is used for carrying out subsequently punch forming for many times on flakes subjected to punch forming once. The automatic feeder comprises a stand (1), a stand regulating mechanism, a stacking plate (6), a supporting frame (5), a pushing and feeding mechanism and a power transmission mechanism, wherein the stand regulating mechanism is installed at the bottom of the stand (1), the stacking plate (6) is arranged at the front end of the stand (1), the supporting frame (5) is arranged below the stacking plate (6), and the pushing and feeding mechanism and the power transmission mechanism are arranged above the stacking plate (6). The automatic feeder is characterized in that two pushing arms (9) are fixed at the front end of a sliding comprehensive support (13) side by side; two feeding arms (14) are respectively fixed at the left side and the right side of the sliding comprehensive support (13); the feeding arms (14) comprise an upper clamping part (23) and a lower clamping part (24); bidirectional transmission shafts (20) are respectively arranged at the tail ends of the upper clamping part (23) and the lower clamping part (24); gears are correspondingly arranged on the two bidirectional transmission shafts (20); and an upper gear and a lower gear are meshed to drive the upper clamping part (23) and the lower clamping part (24) to rotate oppositely. The automatic feeder of the invention can automatically push and feed materials safely and synchronously together with the punch, can be directly driven by the working power of the punch, does not need an additional power source, and has the advantages of energy saving and high efficiency.

Owner:王冬永

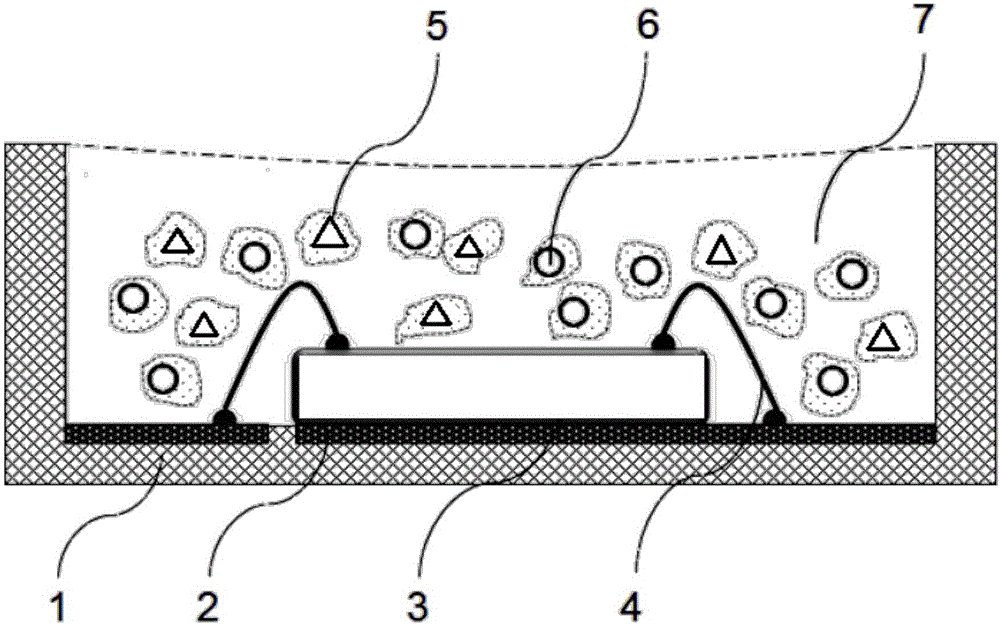

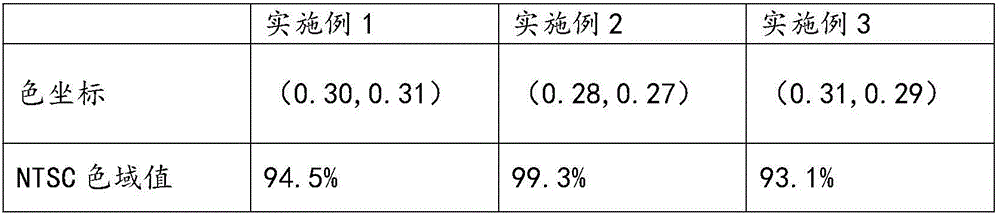

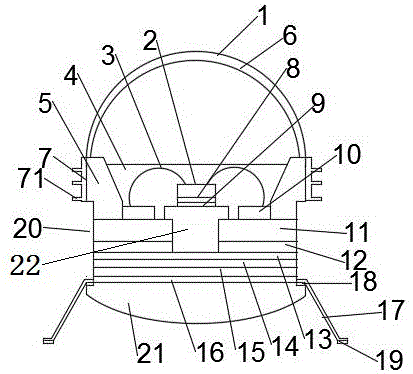

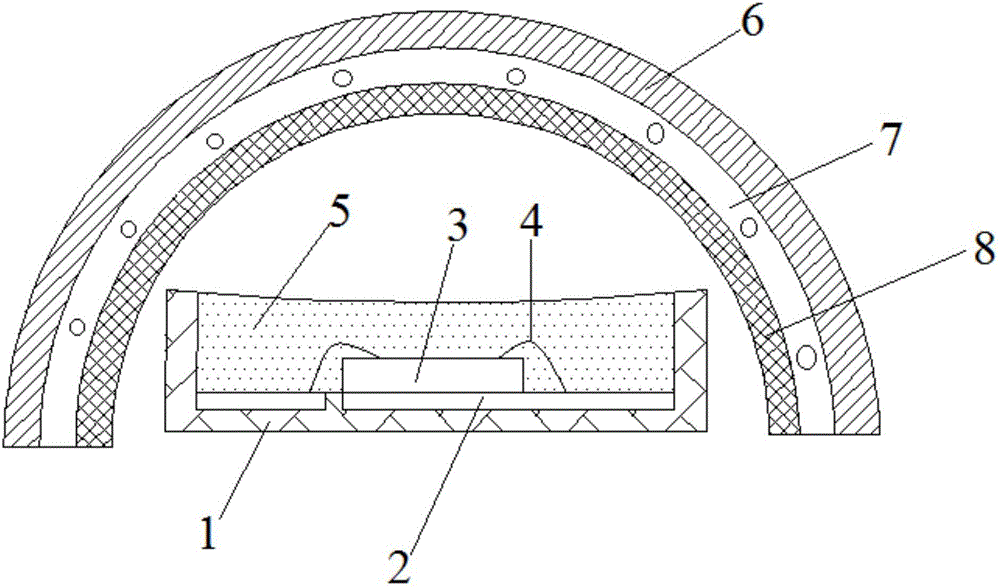

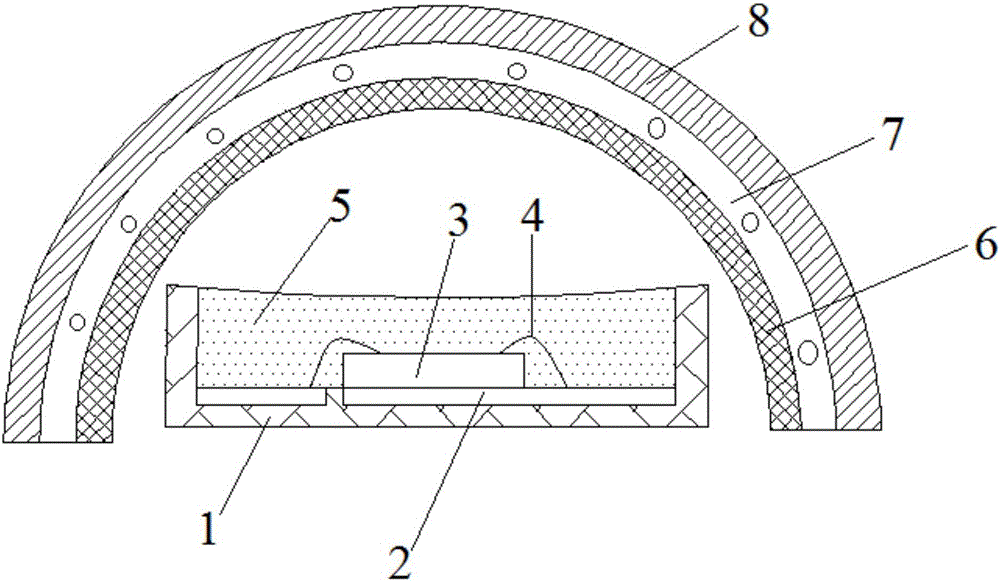

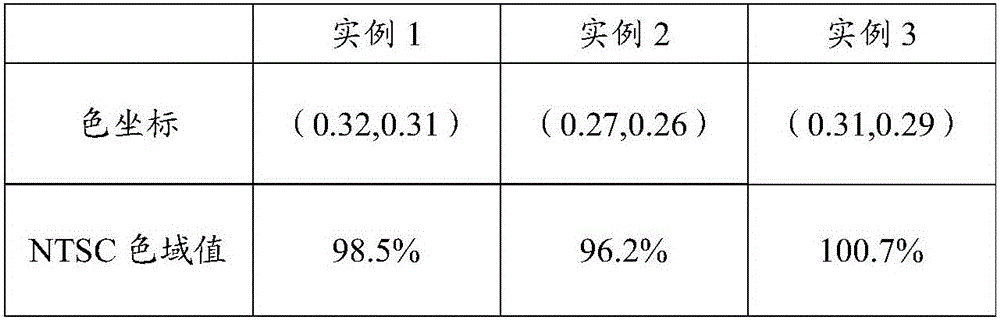

Method for packaging layered quantum dot LED lamp beads

InactiveCN106558644AIncrease color gamutImprove reliabilitySemiconductor devicesLayered structureQuantum dot

The invention belongs to the field of LED backlight processing, and more particularly to a method for packaging layered quantum dot LED lamp beads. The half-wave width of a quantum dot material used in the method is narrow, and the color gamut value of the LED lamp bead can be greatly increased to be more than NTSC 94%. The quantum dot fluorescent powders and other luminescent materials are injected into the LED step by step to form a layered structure. The method can avoid a case that a variety of luminescent materials react to each other in a later lamp bead lighting process and thus results in damage to the structure of quantum fluorescent powders and light attenuation. The method can improve the reliability of LED lamp beads. Since the quantum dot fluorescent powders of a white LED lamp bead prepared from the quantum dot fluorescent powders have high excitation efficiency and have low concentration in a packaging process, packaging difficulty and product reject ratio are reduced so that the method is suitable for large-scale industrial production and has great market prospects and economic value.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

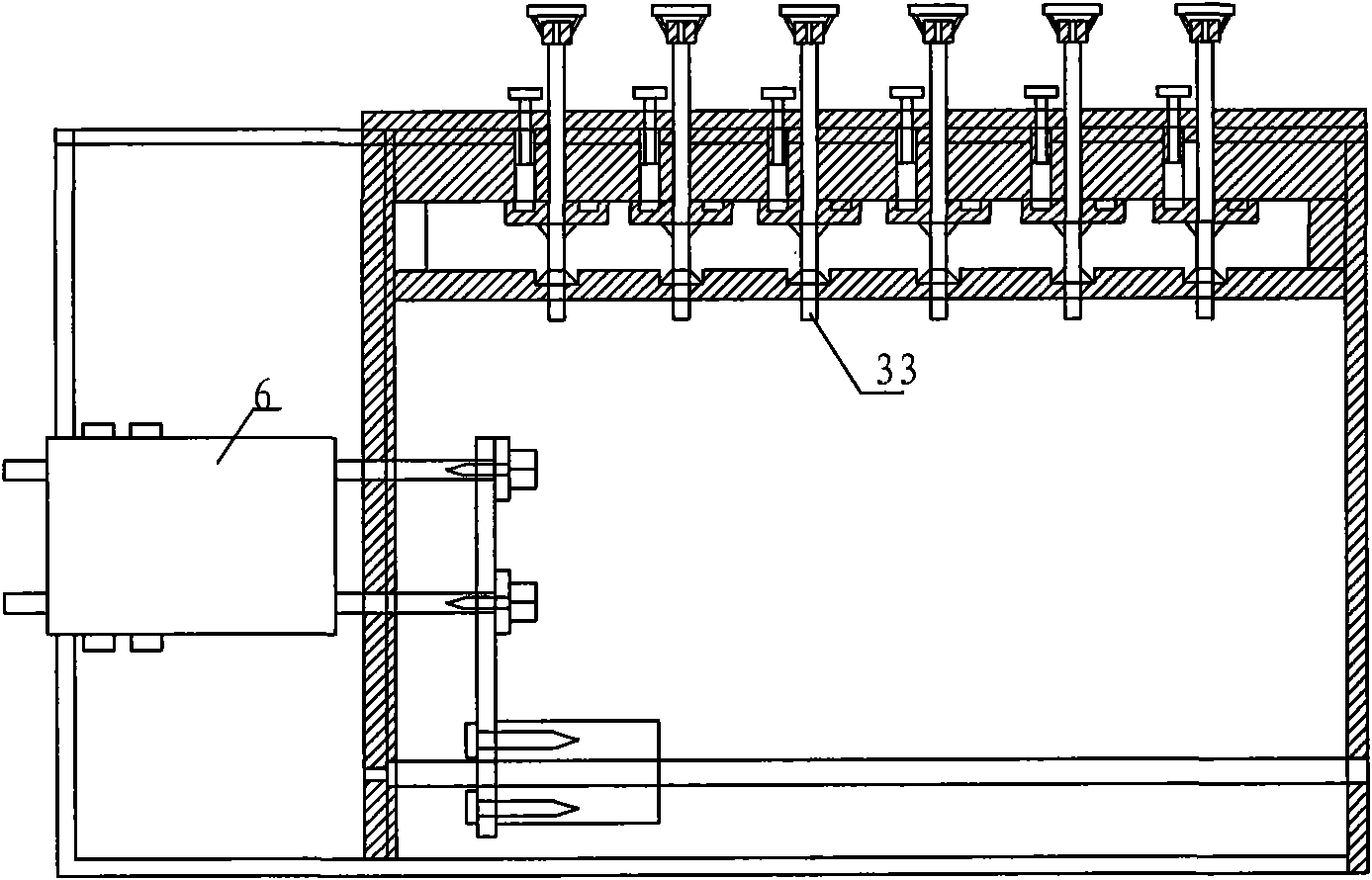

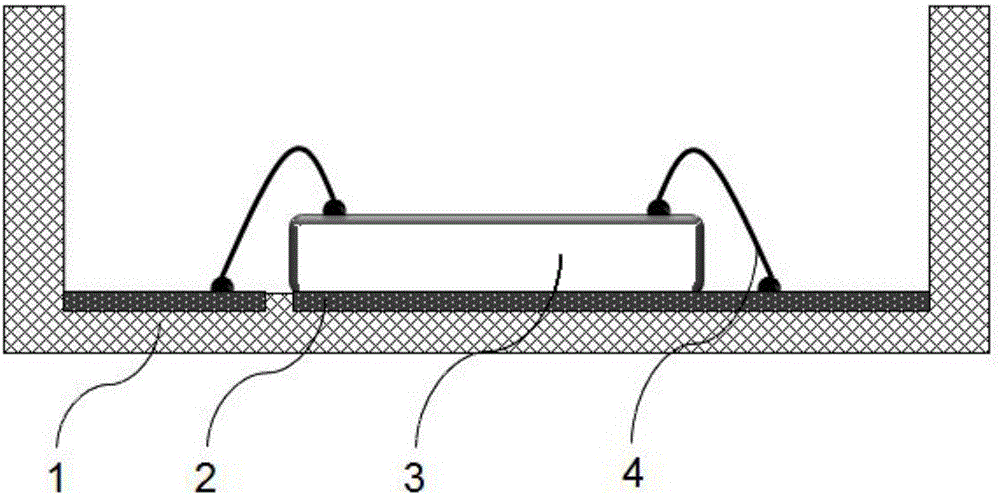

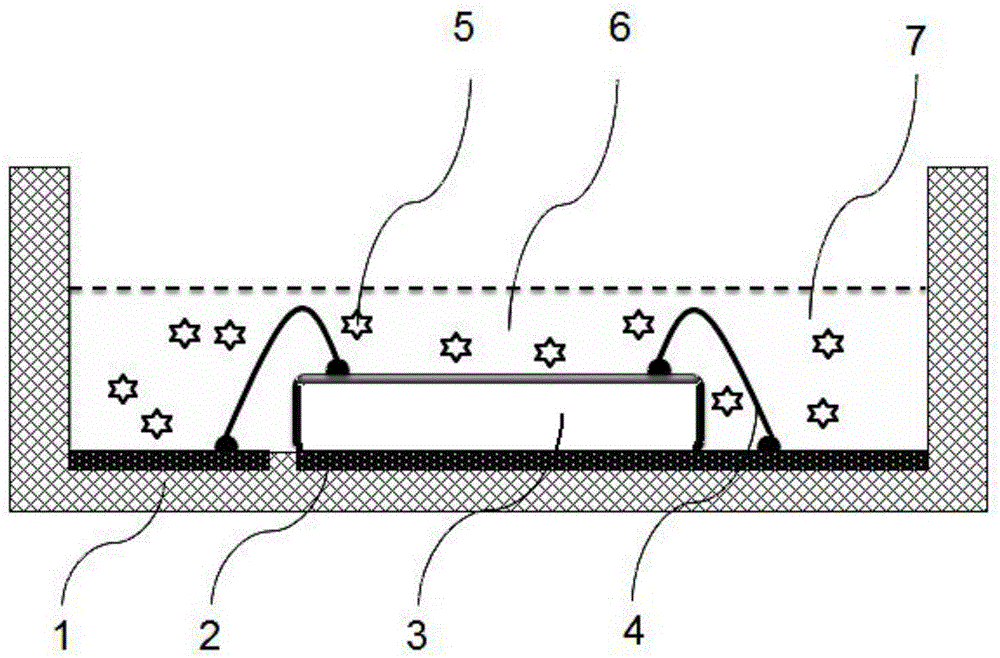

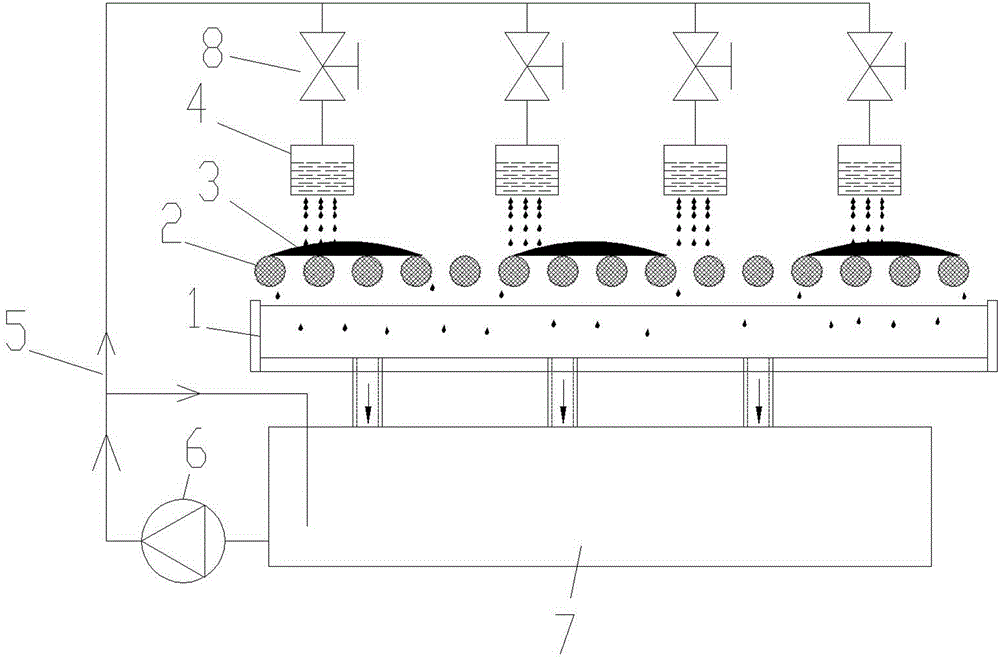

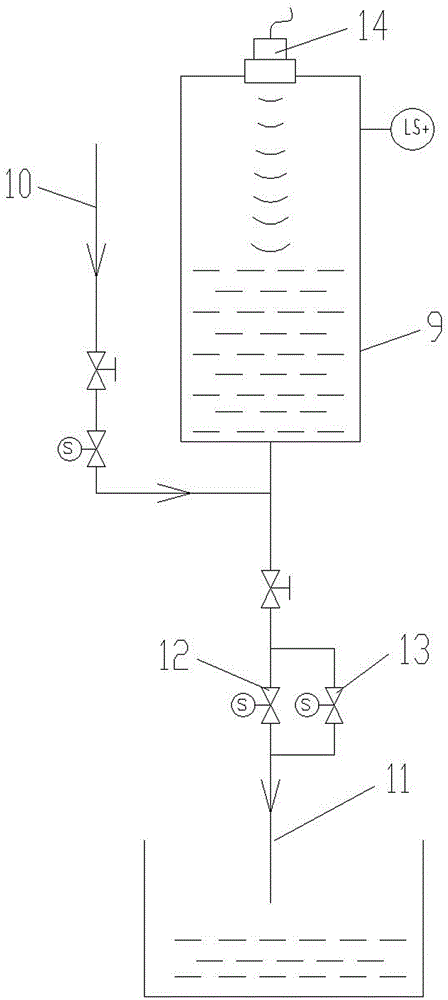

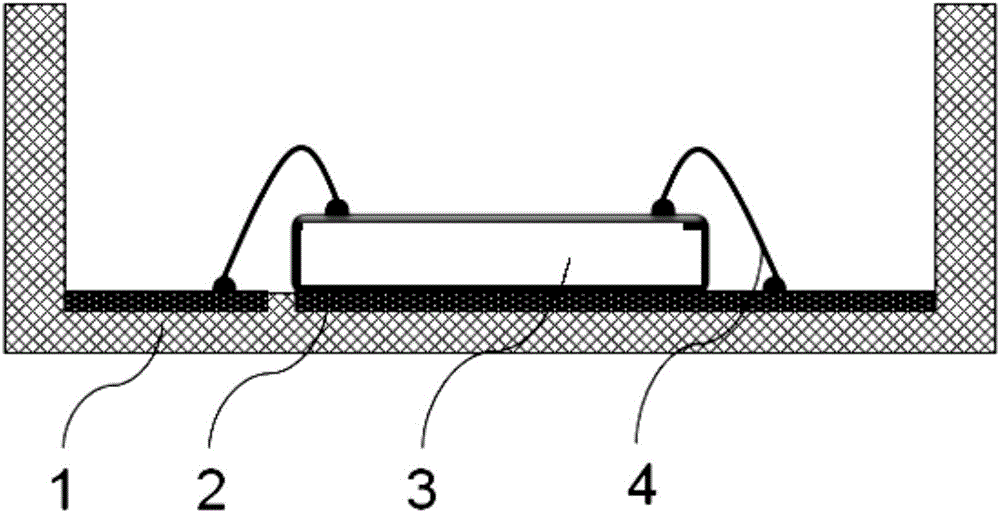

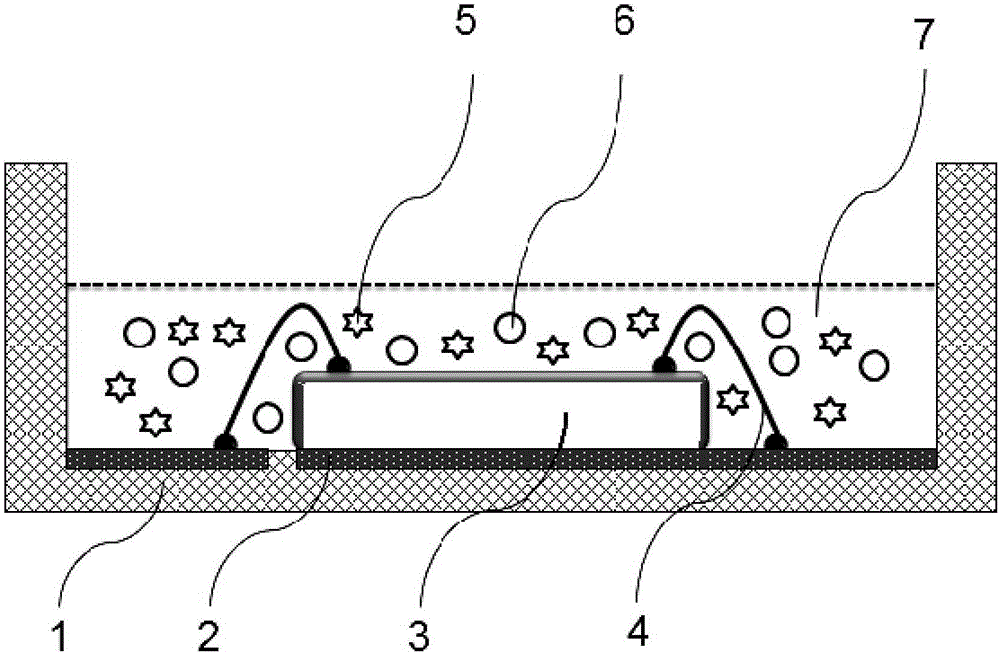

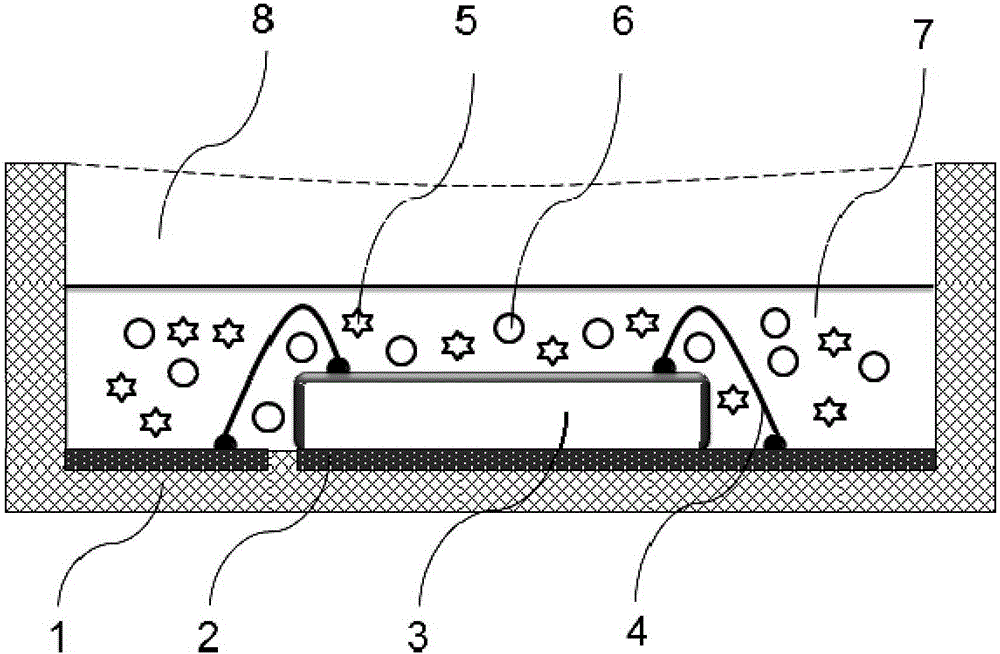

Showering-type wet-process velvet making equipment with solar silicon chips and method

ActiveCN104538503ATake advantage ofImprove product qualityFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon chip

The invention discloses showering-type wet-process velvet making equipment with solar silicon chips. The showering-type wet-process velvet making equipment comprises a conveying component for conveying the silicon chips forwards, a spraying component arranged above the conveying component and a liquid supplying component arranged under the conveying component. The silicon chips are placed on the conveying component at interval, and are conveyed forwards by the conveying component, and a spraying box sprays liquid medicine downwards; and the liquid medicine flowing from the conveying component is polymerized in a liquid receiving groove. The invention also provides a method for carrying out wet-process velvet making by utilizing the showering-type wet-process velvet making equipment. The showering-type wet-process velvet making equipment and method disclosed by the invention have the advantages that corrosive liquid is sprayed or dripped on the silicon chips by a showering mode, and redundant liquid medicine and reaction products flow to the liquid receiving groove, so that the corrosive uniformity of the silicon chips is guaranteed.

Owner:CHANGZHOU S C EXACT EQUIP

Screw injection molding device

The invention provides a screw injection molding device. The device comprises a storage hopper, a plasticizing injection unit communicated with the interior of the storage hopper and a molding unit communicated with an injection nozzle of the plasticizing injection unit. The device is characterized in that the plasticizing injection unit comprises a material barrel communicated with the interior of the storage hopper, a screw penetrating the material barrel and arranged coaxially with the material barrel and a motor driving the screw to rotate around the own axis. A plurality of screw grooves for pushing materials are opened spirally in the outer wall of the screw, and a heating unit is arranged on the outer wall of the material barrel. According to the screw injection molding device, powder is pushed from an inlet to the injection nozzle through the rotation of the screw with the screw grooves and is stirred and mixed fully during rotation, so that the powder is uniformly heated under the action of the heating unit, and the 'laminar-flow'-shaped motion problem of the powder is solved; shear heat is generated for the powder by the rotation screw grooves, so that the powder temperature is further improved, and the powder is in a uniform viscous state before reaching the front end of the material barrel.

Owner:SUZHOU MIMO METAL SCI & TECH

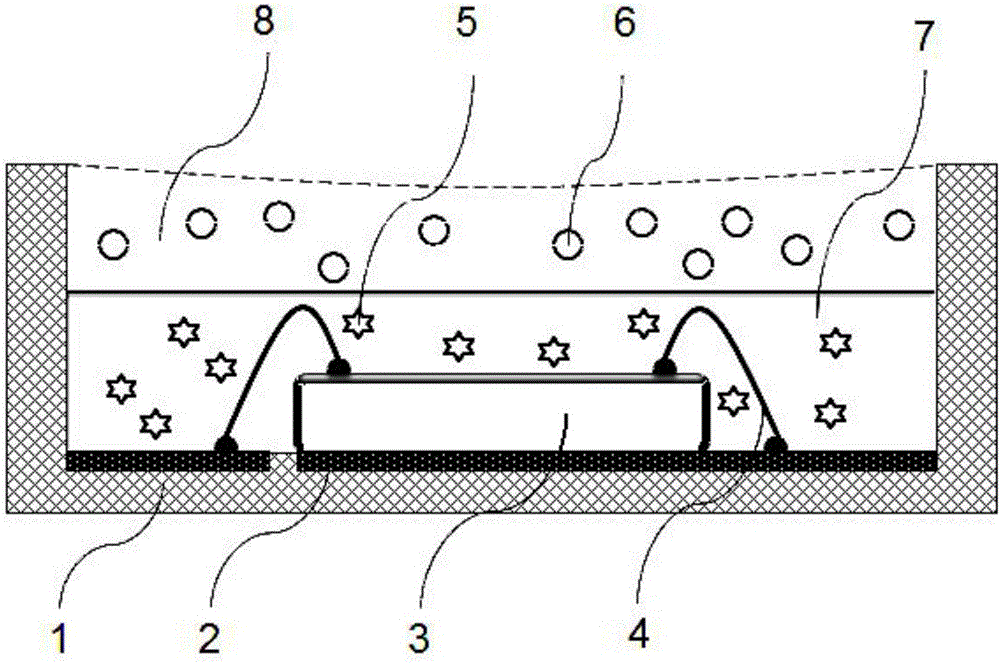

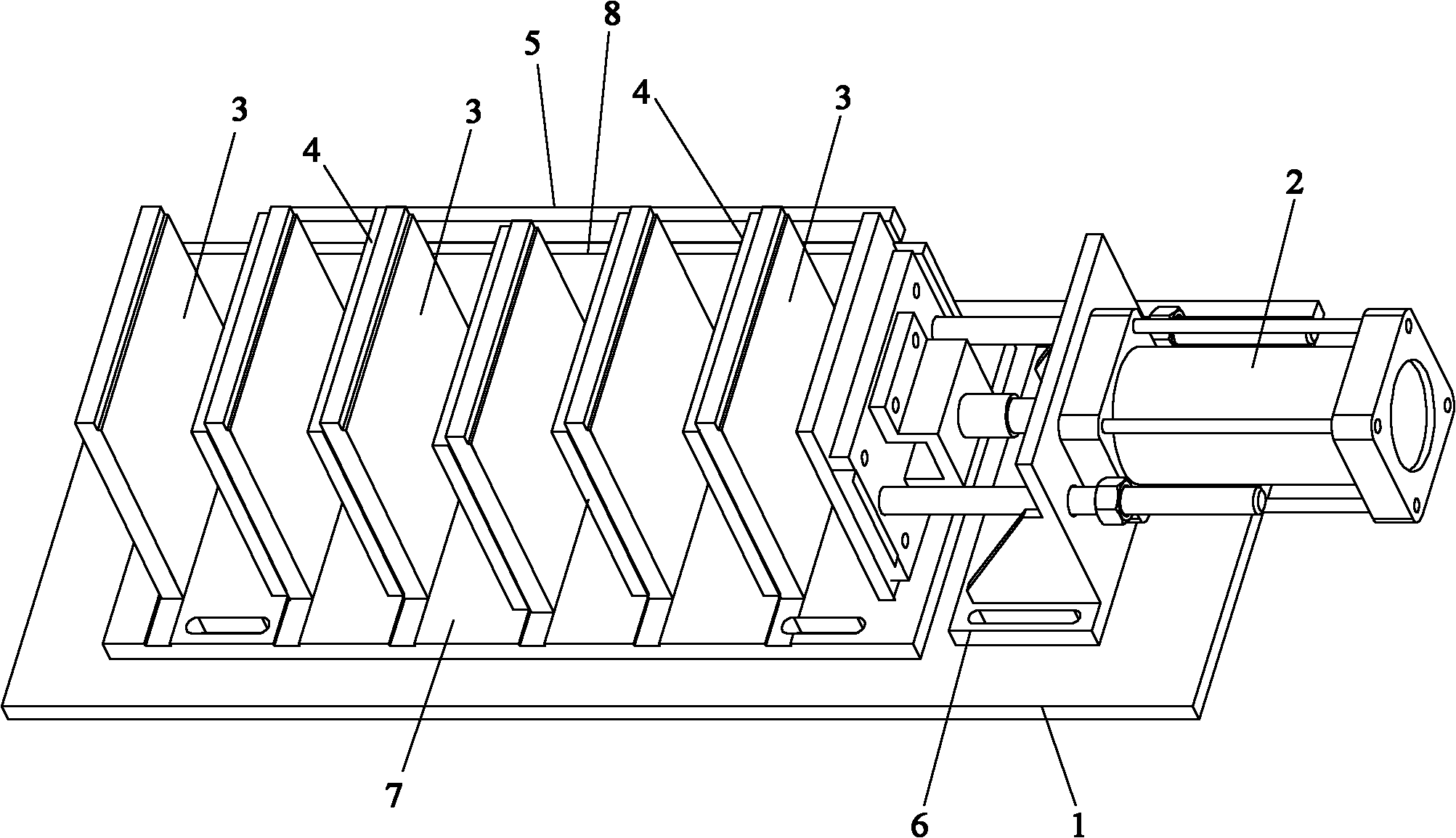

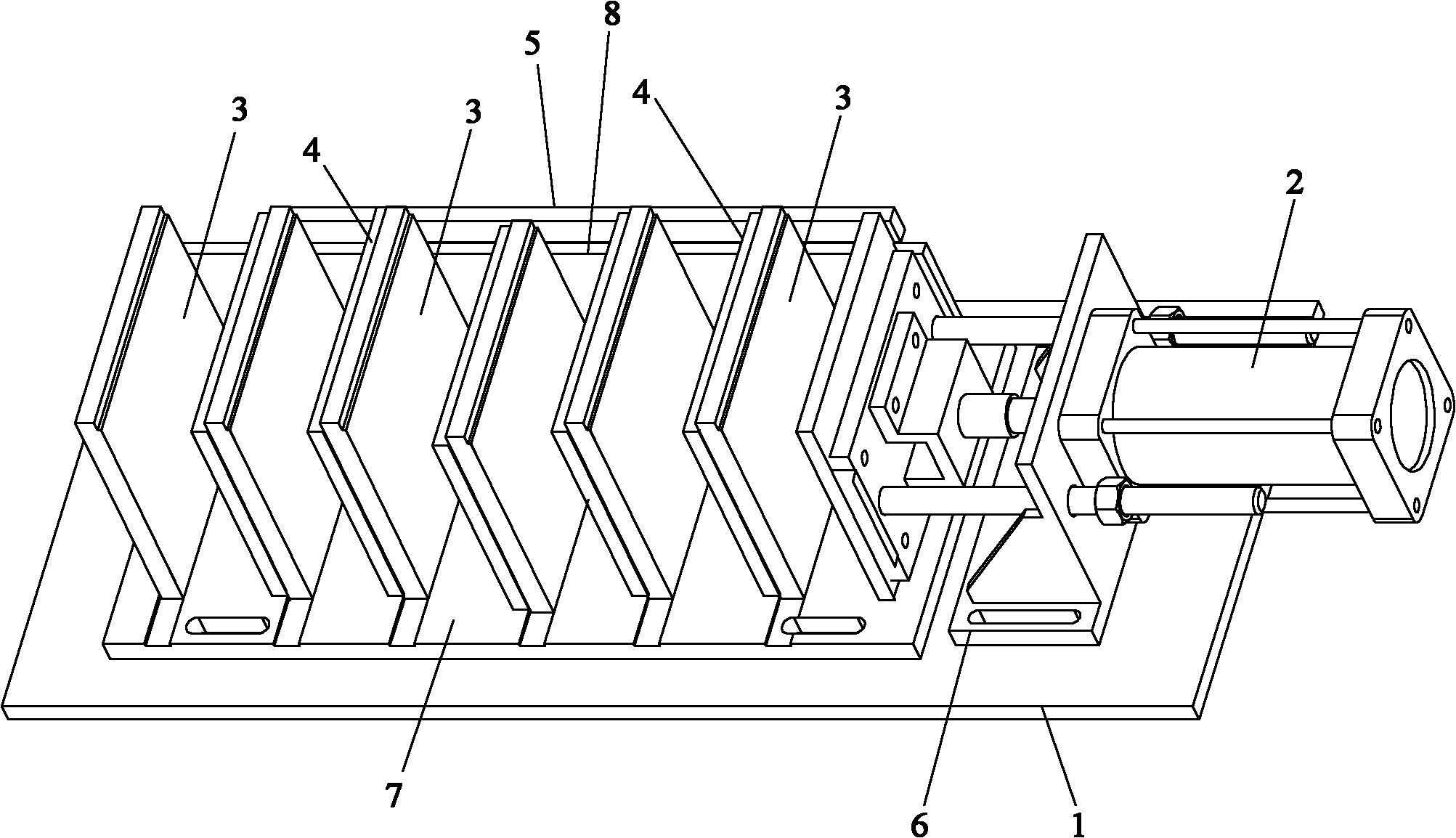

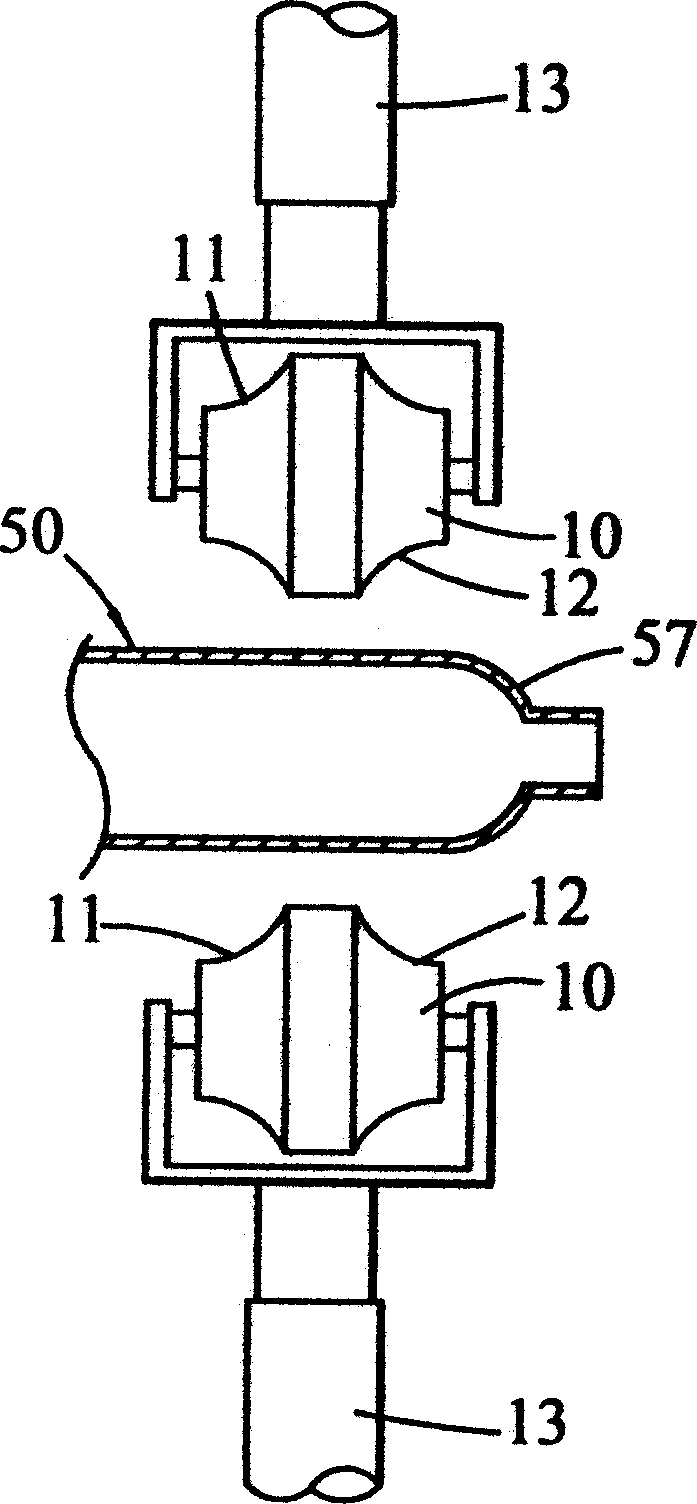

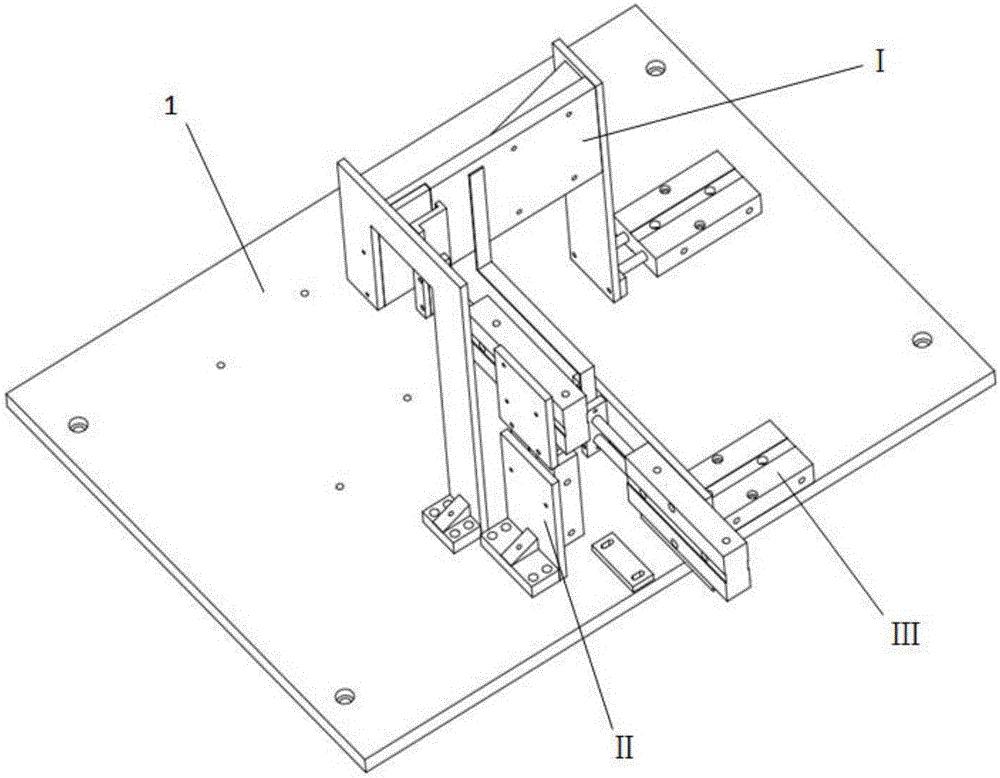

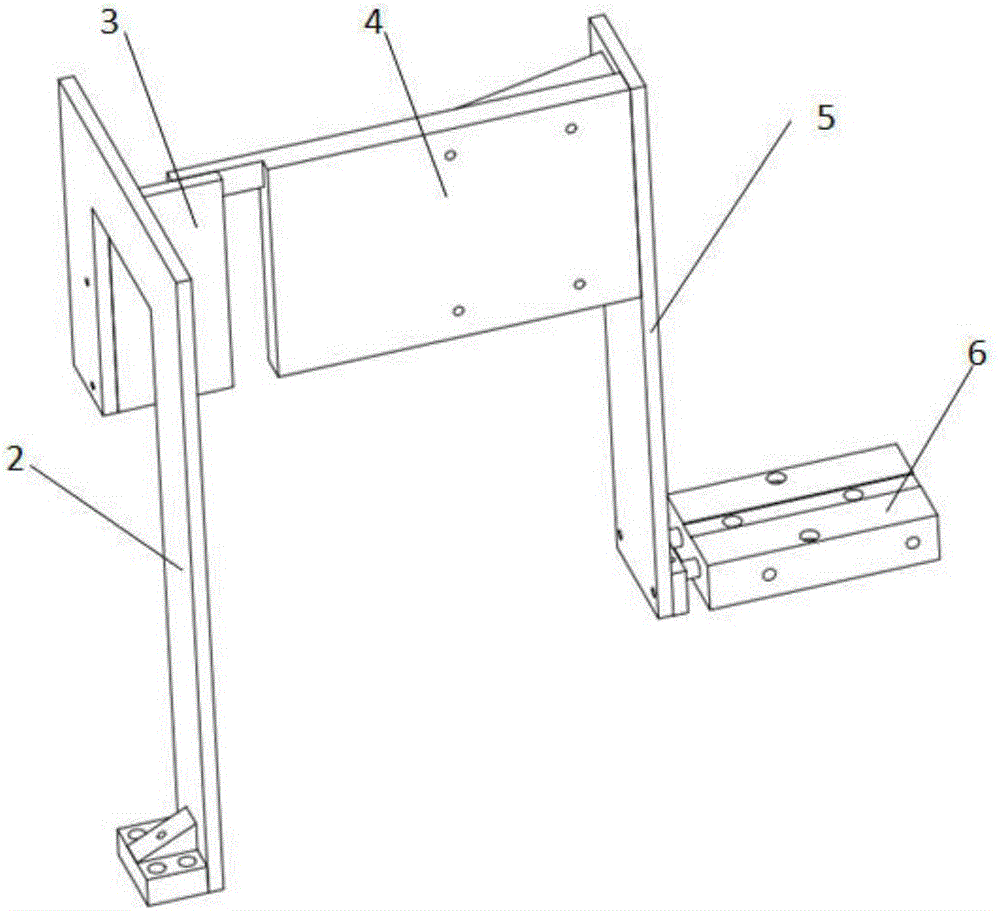

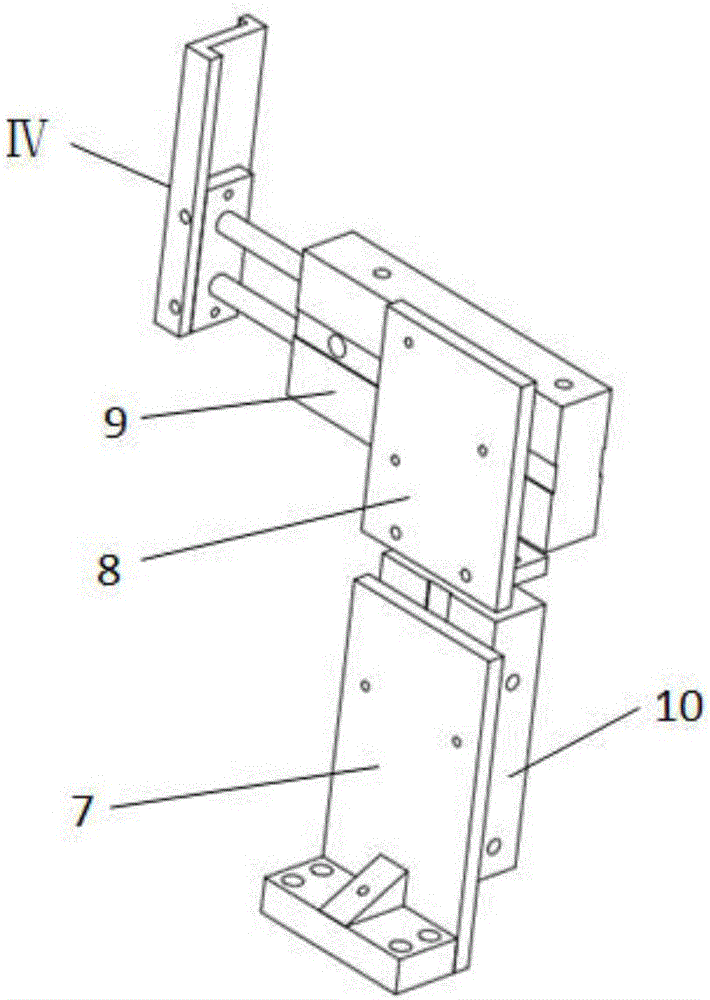

Compression welding device of polar group of battery

InactiveCN102126098AIncrease productivityReduce product defect rateWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceRejection rate

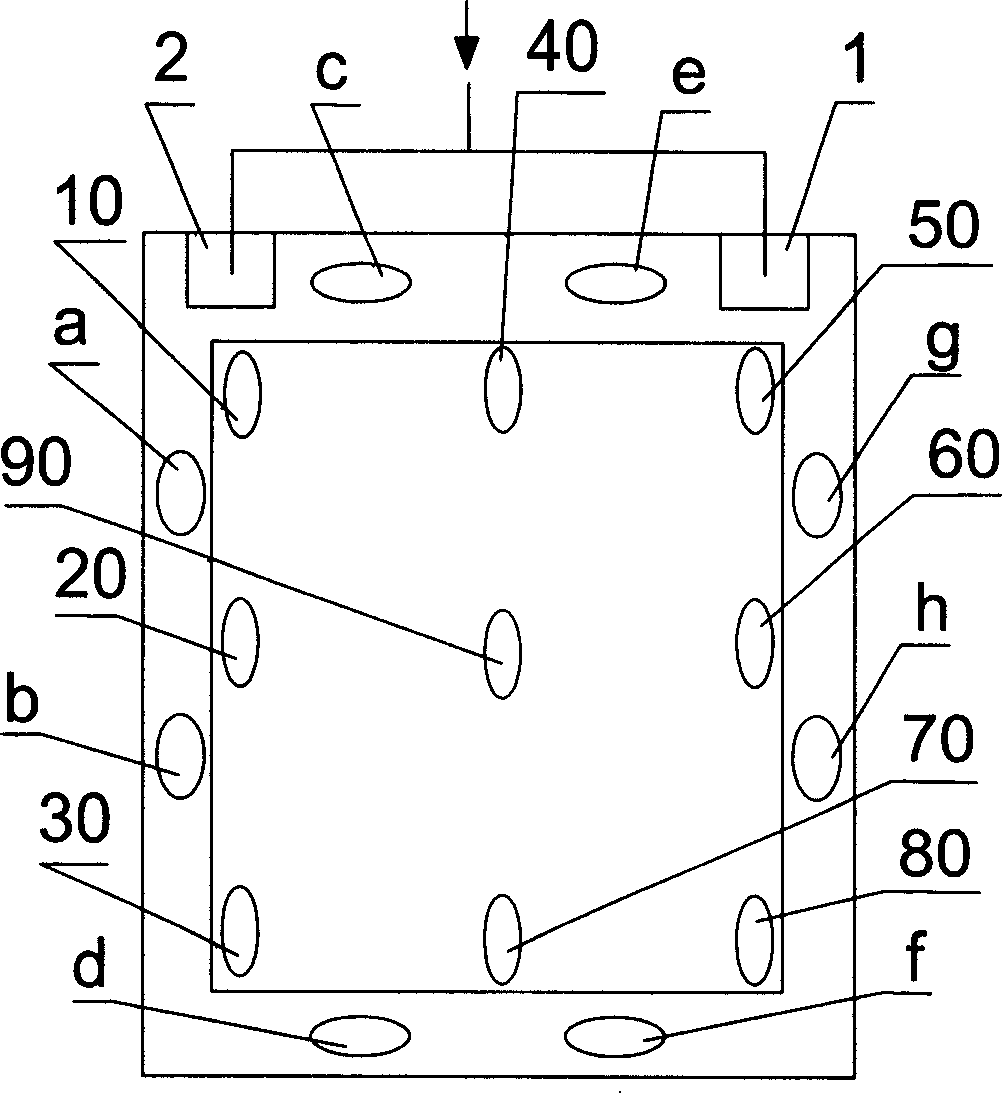

The invention discloses a compression welding device of a polar group of a battery, and the compression welding device comprises a first baseplate (1), a compression device (2), a plurality of fixed plates (3), a plurality of movable plates (4) and moving plate connecting plates (5) for fixing the movable plates (4), wherein the compression device (2) and the fixed plates (3) are fixed on the baseplate (1), the movable plate connecting plates (5) are connected with the compression device (2), and the compression device (2) is used for driving the movable plate connecting plates (5) and the movable plates (4) to move together. By arranging the compression device (2), the plurality of the fixed plates (3) and the plurality of the movable plates (4) on the first baseplate (1), the compression device can be used for driving the movable plates to move so as to perform compression welding on the polar group, thereby being applicable to welding the polar groups in different sizes, greatly improving the production efficiency and reducing the rejection rate of products.

Owner:ANHUI LEOCH BATTERY TECH

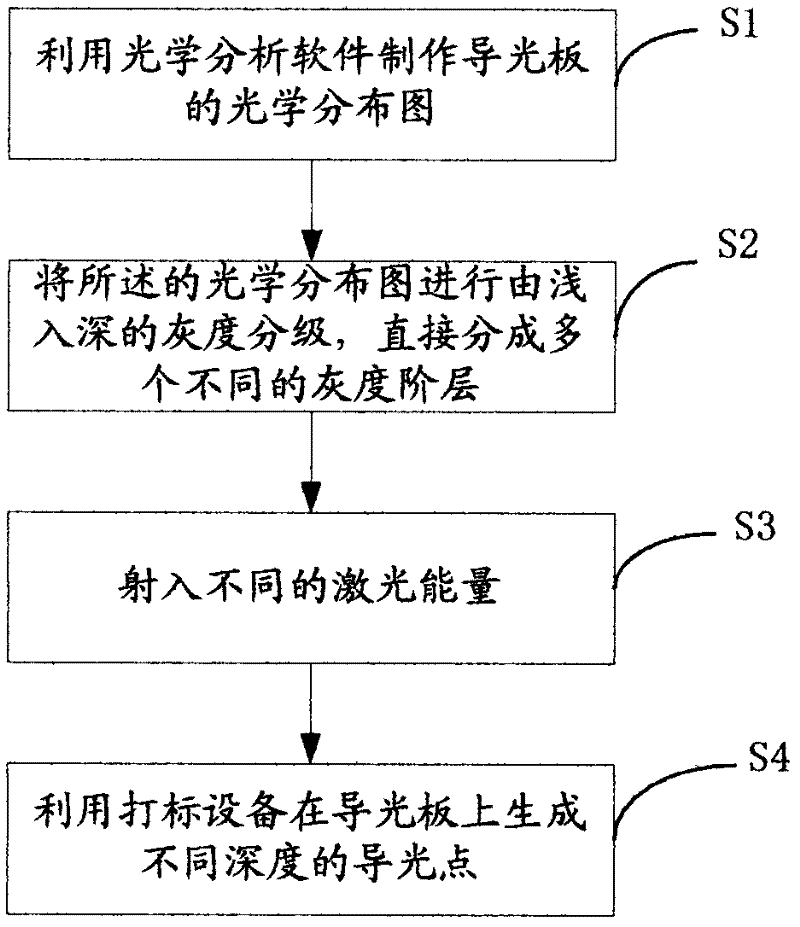

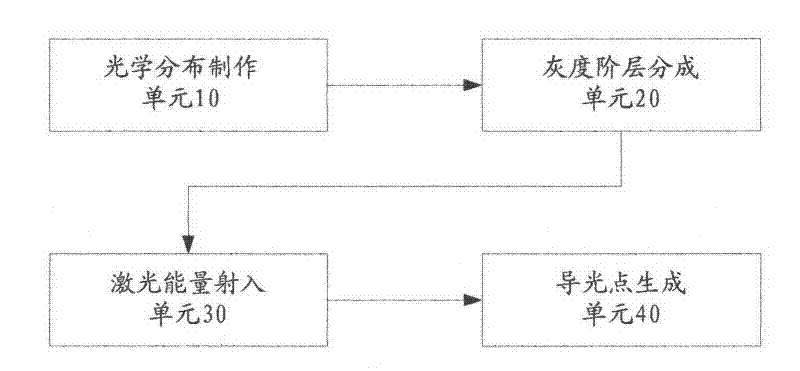

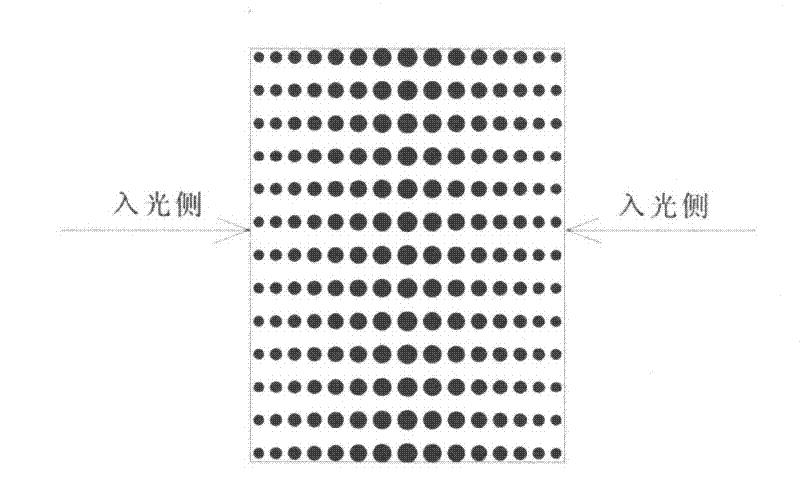

Light guide plate manufacture method and device

ActiveCN102520473ANo chemical pollutionIncrease productivityOptical light guidesGray levelLight guide

The invention discloses a light guide plate manufacture method, which comprises the following steps that: S1, an optical distribution map of a light guide plate is manufactured by using optical analysis software; S2, the optical distribution map is subjected to gray level grading from shallow to deep and is directly divided into a plurality of different gray levels; S3, different laser energy is emitted according to different gray levels; and S4, light guide points with different depths are generated on the light guide plate by labeling equipment according to different laser energy. The invention also discloses a light guide plate manufacture device. When the light guide plate manufacture method and the light guide plate manufacture device provided by the invention are implemented, laser net points are realized by a pure physical method, the environment is protected, no chemical pollution is caused, durability is realized, the production efficiency is greatly improved, the energy is saved, and the light ray material internal loss is reduced.

Owner:广州市金明激光科技有限公司

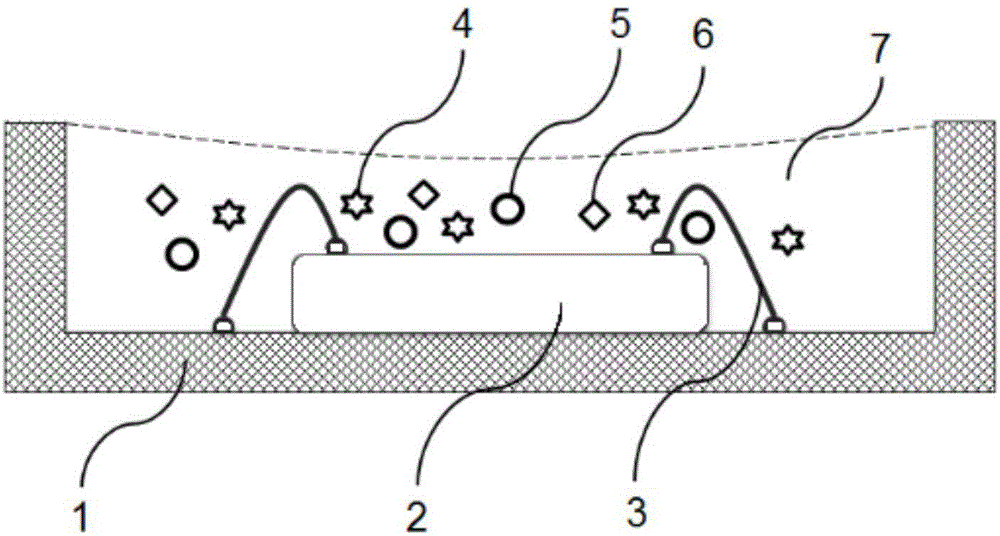

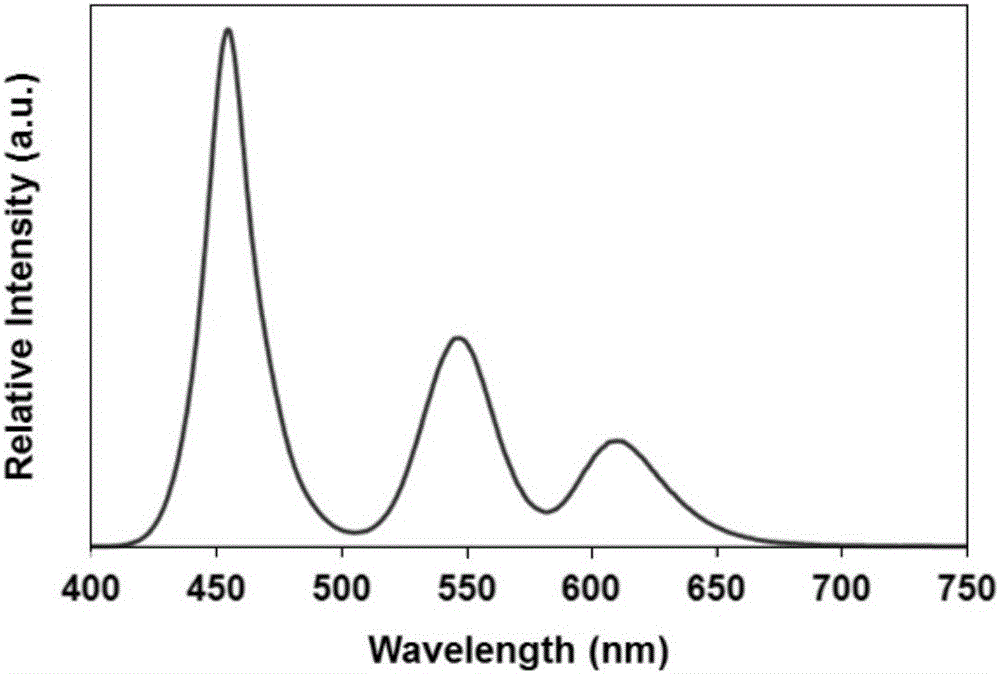

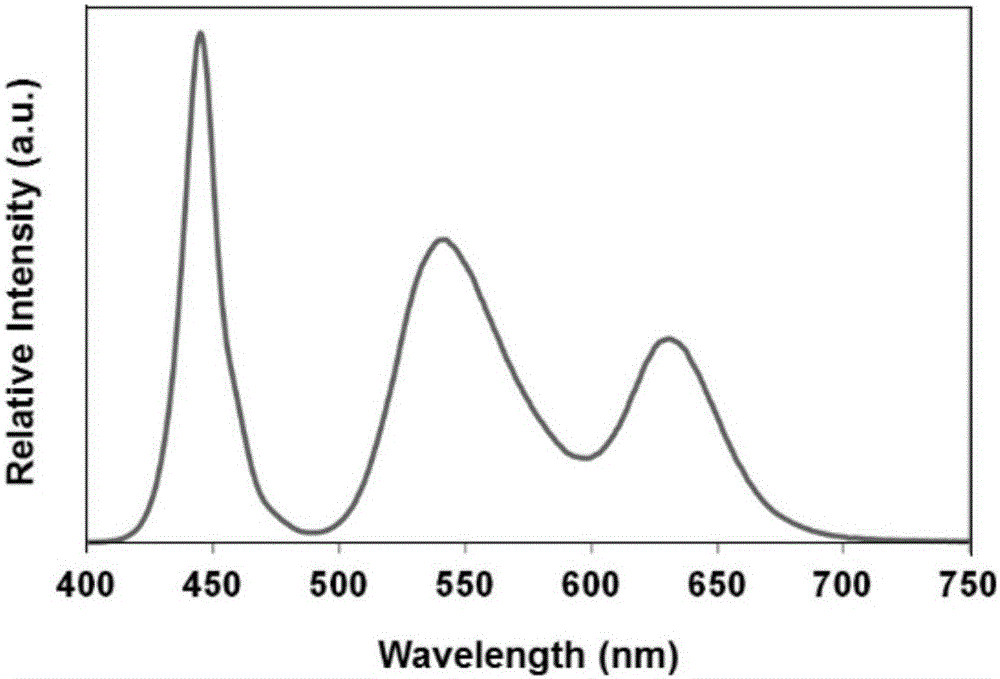

Ultraviolet light and multi-quantum dot combined high-gamut white light implementation mode

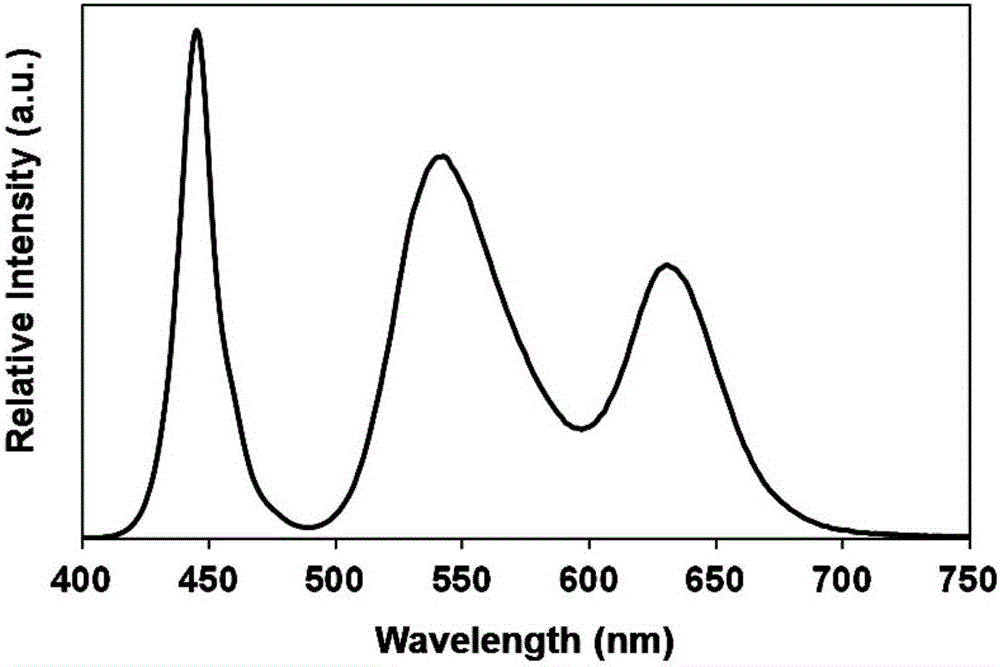

ActiveCN105742462AImprove color gamutImprove excitation efficiencyLuminescent compositionsSemiconductor devicesFluorescenceUltraviolet lights

The invention discloses an ultraviolet light and multi-quantum dot combined high-gamut white light implementation mode. The mode comprises the following steps of (a) respectively adding an organic solvent to red-light quantum-dot fluorescent powder, green-light quantum-dot fluorescent powder and blue-light quantum-dot fluorescent powder; (b) processing a solution with ultrasound; (c) preparing a hybrid quantum-dot solution; (d) adding a hybrid package glue into the hybrid quantum-dot solution and uniformly stirring the mixed solution; (e) removing the organic solvent; and (f) dropwise adding a hybrid fluorescent glue into a light emitting diode (LED) support fixed with an ultraviolet chip, and baking and curing the LED support to obtain an LED lamp bead. By the white-light implementation mode, high-gamut white-light LED is obtained, and the gamut value of the LED backlight lamp bead is greatly increased and can reach over NTSC 94%; by taking the organic solvent as a connection bridge, quantum dots and the package glue are uniformly mixed; and moreover, the phenomenon that the quantum-dot fluorescent powder is failure to be agglomerated is avoided, and the quality of the high-gamut white-light LED lamp bead is remarkably improved.

Owner:惠州市聚飞光学材料有限公司

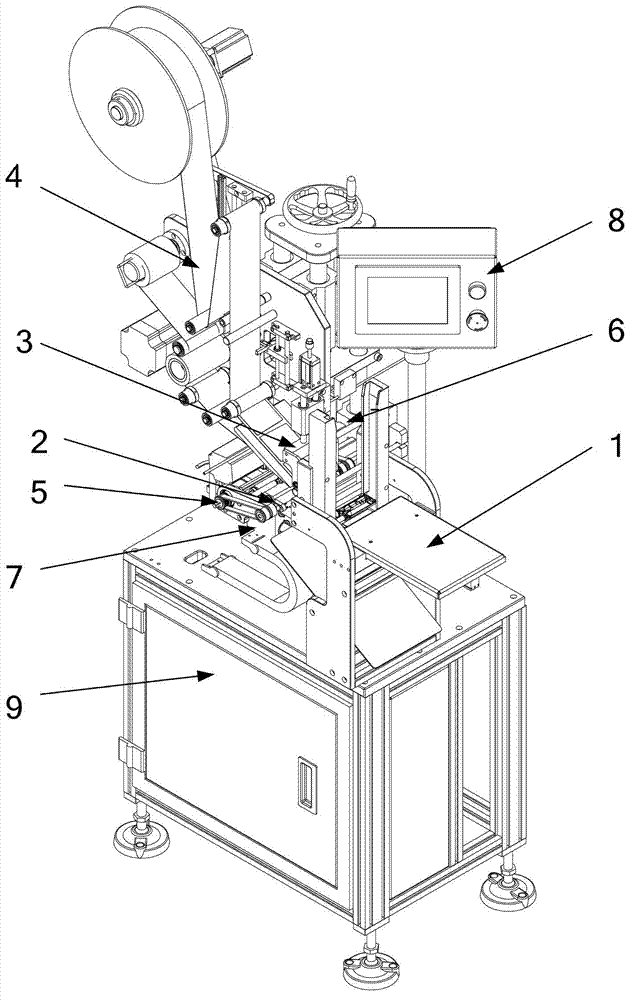

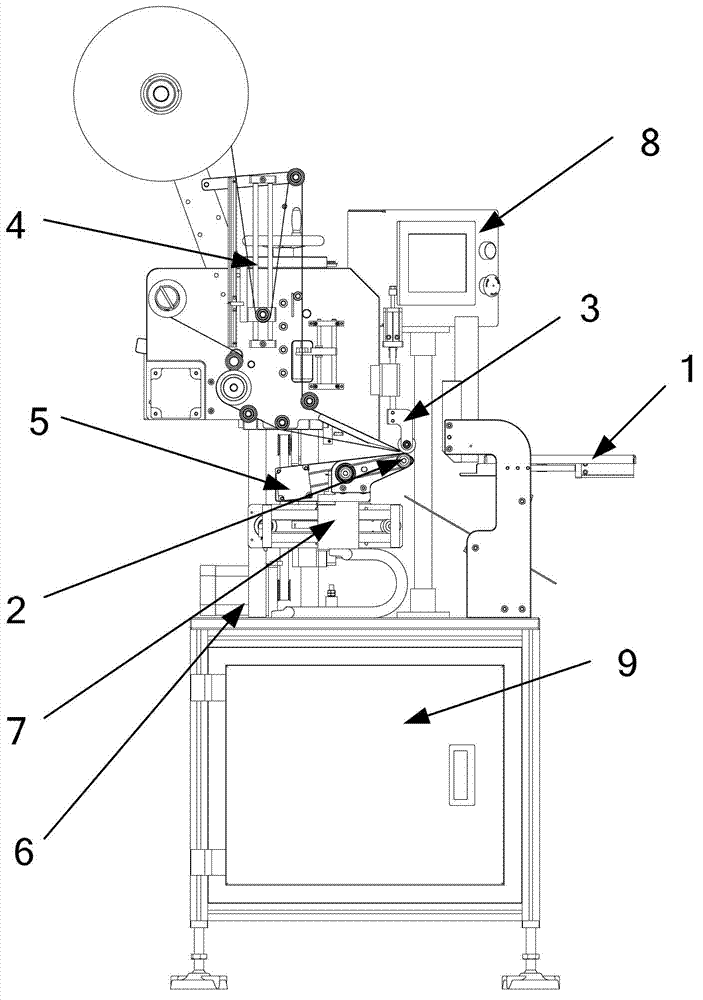

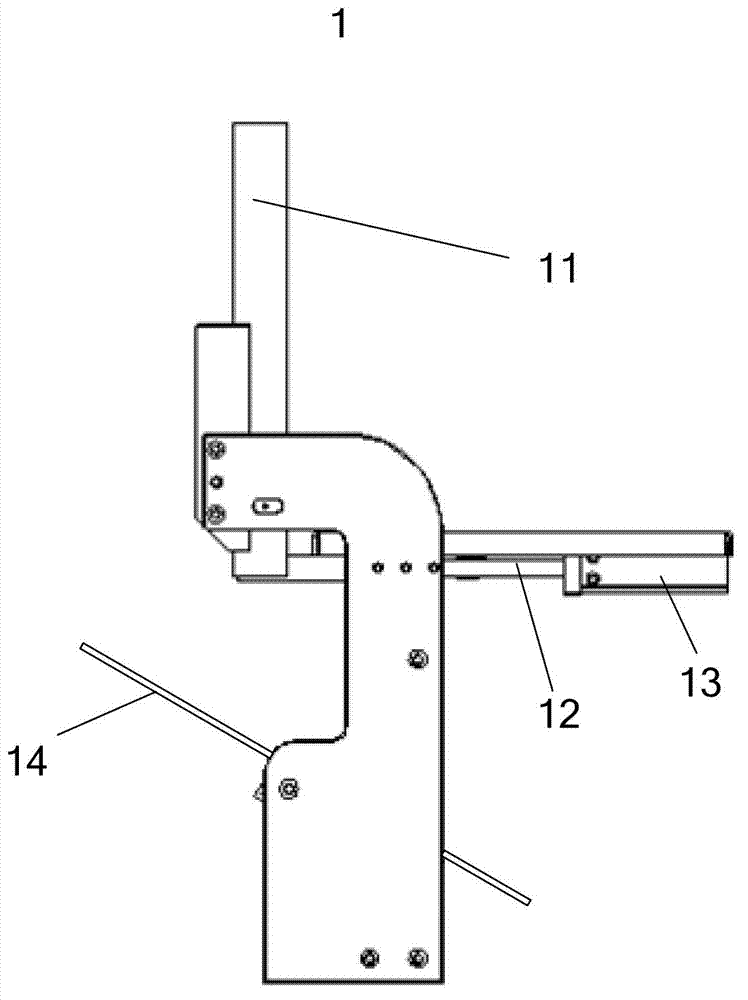

Paper wrapping machine and paper wrapping method

ActiveCN103043237AEliminate flatnessEliminates easy creasesWrapping with article rotationPulp and paper industryNumerical control system

The invention provides a paper wrapping machine which comprises a feeding device, a clamping device, a pressing device, a wrapping paper supply device, a rotating device, a lifting device, a transferring device and a numerical control system. The feeding device, the clamping device, the pressing device, the wrapping paper supply device, the rotating device, the lifting device and the transferring device are connected with the numerical control system. The feeding device, the clamping device, the pressing device, the wrapping paper supply device, the rotating device, the lifting device, the transferring device and the numerical control system are installed on a machine frame. A paper wrapping method is further provided. The paper wrapping machine and the paper wrapping method can effectively improve paper wrapping efficiency of a product, reduce labor intensity of workers, eliminate the defect that wrapping paper is uneven and easy to winkle and has bubbles and the like, reduce reject ratio of the product, and improve quality of the product.

Owner:XINHAI TECH GRP CO LTD

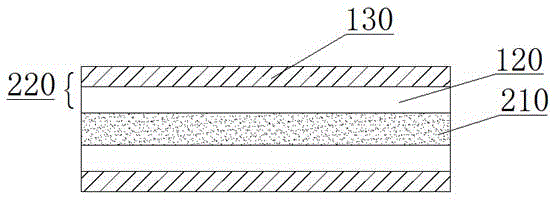

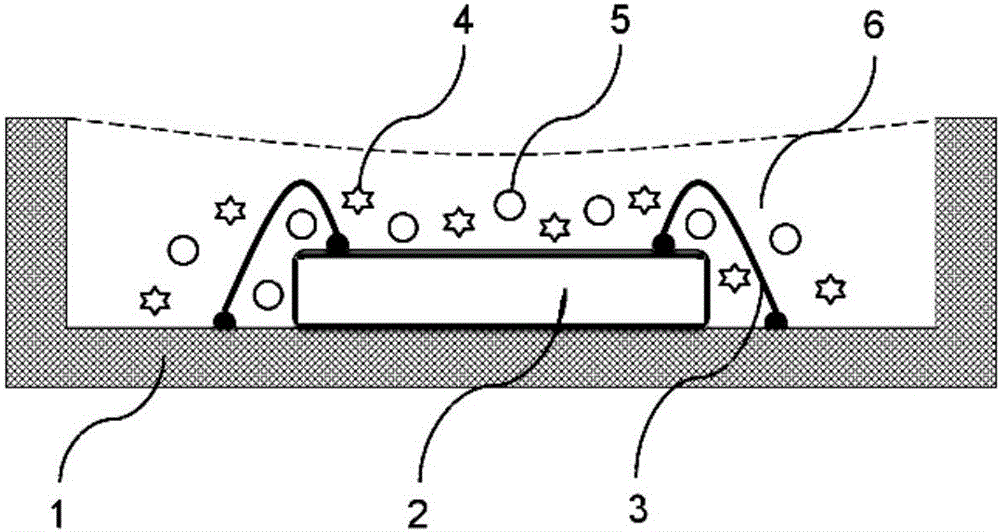

Cladding type quantum dot LED lamp bead packaging method

The invention belongs to the LED backlight processing field, and specifically relates to a cladding type quantum dot LED lamp bead packaging method; the half-wave width of the employed quantum dot material is relatively narrow, thus greatly improving LED lamp bead color gamut value, and the color gamut value of the obtained LED lamp bead can be above NTSC93%; epoxy resin is used to wrap the quantum dot material in an early stage, thus isolating external moisture and oxygen from eroding the quantum dot material, and improving the lamp bead reliability; quantum dot phosphor is employed to obtain the white light LED lamp bead; the quantum dot phosphor is high in excitation efficiency, and the phosphor concentration is low in a packaging working process, thus reducing the packaging work difficulty and product fraction defective; the cladding type quantum dot LED lamp bead packaging method is suitable for mass industrialization production, and can provide great market prospect and economic values.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

Making method of anti-static lamination type support pad for protecting LCD panel

ActiveCN104589769AReduce pollutionReduce incidenceSynthetic resin layered productsLaminationForeign matterPolyolefin

The invention relates to a making method of an anti-static lamination type support pad for protecting an LCD panel. According to the making method, a polyolefin film of an anti-static layer is at least formed on one surface or two surfaces of a polyolefin or polyurethane foam sheet by virtue of lamination. The lamination type support pad made by using the making method can be used as a panel lamination type support pad which is used for preventing the surface from being scraped, polluted and impacted and is especially sensitive to static electricity when a liquid crystal display panel is stored and conveyed, and can be used for effectively preventing the edge of the lamination type support pad from fluffing, further effectively reducing the dust generation rate and preventing foreign matters from permeating between the lamination type support pads.

Owner:纳诺化学技术株式会社 +2

Manufacturing method of direct-light-type LED backlight

InactiveCN106784260AThe production process is simpleImprove light conversion efficiencySolid-state devicesSemiconductor devicesFluorescenceLight conversion efficiency

The present invention discloses a manufacturing method of a direct-light-type LED backlight. The method comprises: mixing mixed phosphors including quantum dot fluorescent powder with photocuring glue to obtain quantum dot fluorescent glue, coating the quantum dot fluorescent glue at the surface of a LED lens in the LED backlight, and coating a photocuring glue protective layer at the surface of the fluorescent glue after the fluorescent glue is solidified. The manufacturing method of direct-light-type LED backlight is simple in manufacturing technology, and the half-wave width of the quantum dot fluorescent glue made of quantum dot materials is small so as to greatly improve the color gamut value of the LED backlight, the color gamut value of the direct-light-type LED backlight can reach above 97% of NTSC, and the light conversion efficiency of a light source obtained through the technology is high, and the production cost is low. The photocuring glue protective layer can effectively reduce the erosion of moisture and oxygen for the quantum dot materials, can prevent the quantum dot materials from directly contacting a luminous chip, and is not liable to high-temperature influence of the luminous chip so as to improve the reliability of the LED light source.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

Method for controlling plating layer thickness distribution in FPC making process

InactiveCN101193501APromotes even distributionImproved thickness distribution capabilityPrinted circuit manufactureEngineeringOperability

The invention discloses a method for controlling the thickness distribution of a clad layer in the process of manufacturing an FPC, Especially a first electroplating area with an opening is formed on the coating film of each FPC single product during the process of manufacturing the FPC, and a second electroplating area with an opening is formed simultaneously on the outside of the first electroplating area and on the coating films. The method can improve the equal distribution of current and overcome the relatively strong edge effect, thereby achieving the control of the thickness distribution of the clad layer; besides, the invention presents good operability and no influence on the production cost.

Owner:BYD CO LTD

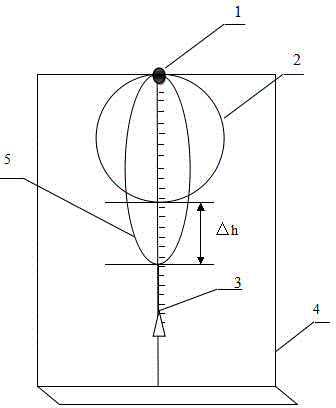

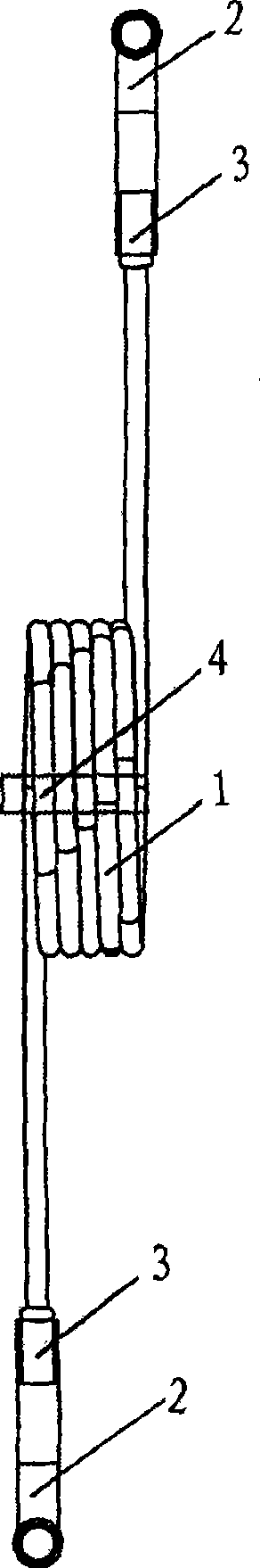

Detection method for softness of steel wires

InactiveCN104568598AEasy to operateThe detection device is simpleMaterial strength using tensile/compressive forcesEngineeringStandard samples

The invention discloses a detection method for the softness of steel wires. The detection method comprises the following steps that (1) a steel wire sample to be detected is circled into a certain circle diameter according a standard sample circle, and a sewing head is fixed on a detection plate with a dial; (2) a gravity source with certain weight is suspended at the lowest point of the steel wire sample to be detected, so that the steel wire sample to be detected is naturally drawn, the elongation delta h of the steel wire sample is recorded, and M is the mass of the suspended gravity source; and (3) the value of the softness is calculated according to a formula R=delta h / M, wherein R is the softness. The detection method disclosed by the invention has the advantages that the operation is simple and fast, the used equipment is simple, the detection cost is low, the softness of the steel wire can be rapidly and effectively reflected on a production site in a direct manner, so that whether the processability of the steel wire for a steel cord meets the requirement or not can be rapidly and comprehensively detected out; and the detection device is simple and is convenient in use, so that the production can be better guided and the defective rate in production can be reduced.

Owner:JIANGSU XINGDA STEEL TYPE CORD

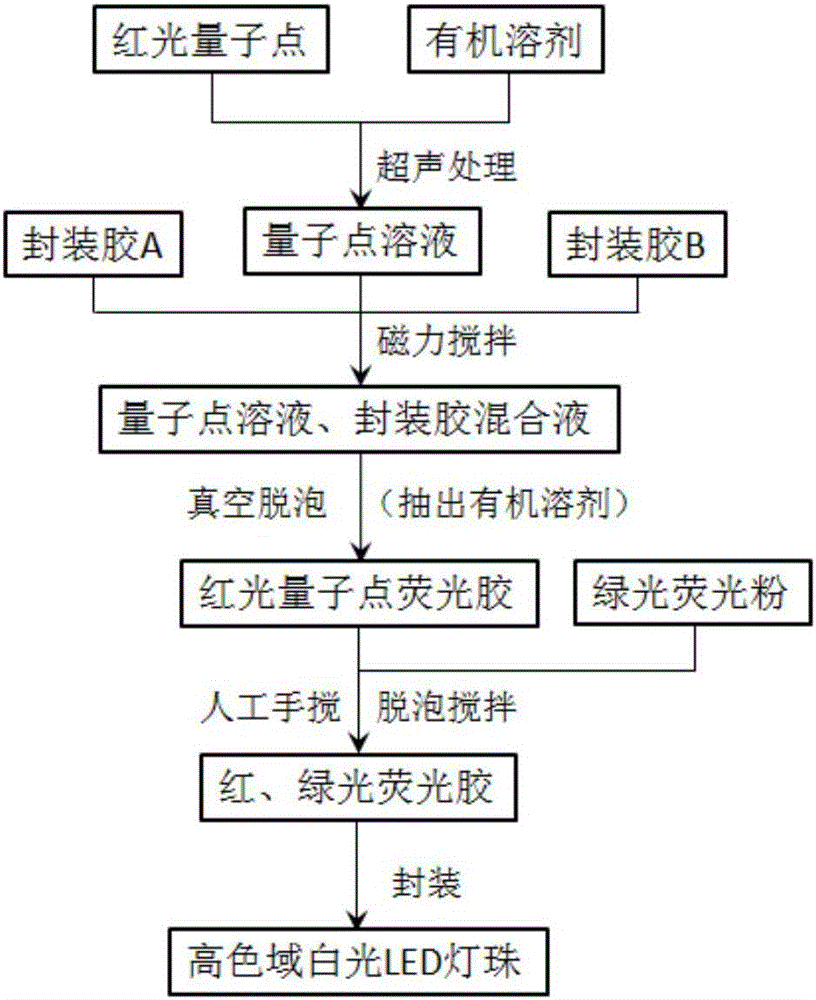

Manufacture method of red quantum dot-based high-color gamut white-light LED lamp bead

ActiveCN105679894AImprove color gamutReduce concentrationSolid-state devicesSemiconductor devicesGamutOrganic solvent

The invention belongs to the LED backlight processing field and relates to a manufacture method of a red quantum dot-based high-color gamut white-light LED lamp bead. According to the manufacture method of the invention, red quantum dot fluorescent powder is utilized, an organic solvent is adopted as a bridge, a mode according to which dissolution and extraction are performed sequentially is adopted encapsulate the red quantum dot fluorescent powder in a backlight LED lamp bead; and a blue light chip is adopted to carry out excitation, so that high-color gamut white light can be obtained. Through related technical means, the difficulty of encapsulation work is greatly reduced, and technological problems of little possibility of mixing the quantum dot fluorescent powder with encapsulation glue, high possibility of the failure of the agglomeration of the quantum dot fluorescent powder and little possibility of the solidification of the encapsulation glue due to the influence of organic matters can be solved. The manufacture method has a bright market prospect and a high economic value.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

Method for melting nickel alloy by selective ink instead of dry film

InactiveCN101562943BEmission reductionImprove protectionConductive material chemical/electrolytical removalScreen printingEcological environment

The invention discloses a method for melting a nickel alloy by a selective ink instead of a dry film, which comprises the following steps: (1) selectively coating ageing resistant nickel alloy ink on a circuit board by a screen printing technology to form a wet film; (2) drying the ink; (3) exposing the ink; (4) developing the wet film so as to expose the required copper surface; (5) performing nickel alloy melting on the circuit board; and (6) removing the wet film. The selective ink instead of the dry film is used for selective nickel alloy melting, so the cost is greatly reduced, and the combination effect of the wet film and the board surface is superior to the combination effect of the dry film and the board surface, unfavorable phenomena such as diffusion coating and the like can be effectively prevented, the defective rate of production is reduced and the quality of products is ensured. In addition, the method simplifies the manufacturing flow, saves the ink, greatly reduces the emission of pollutants, saves the expenses of wastewater treatment and is simultaneously favorable for the protection of ecological environment.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +1

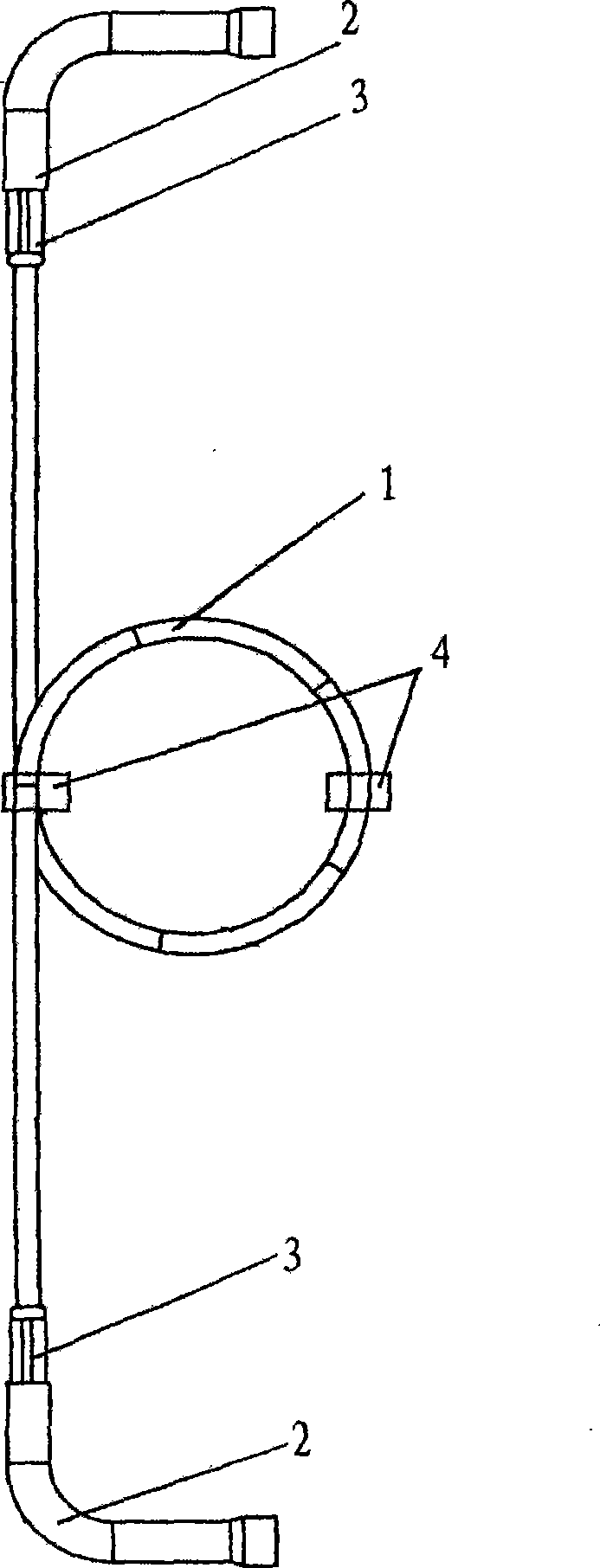

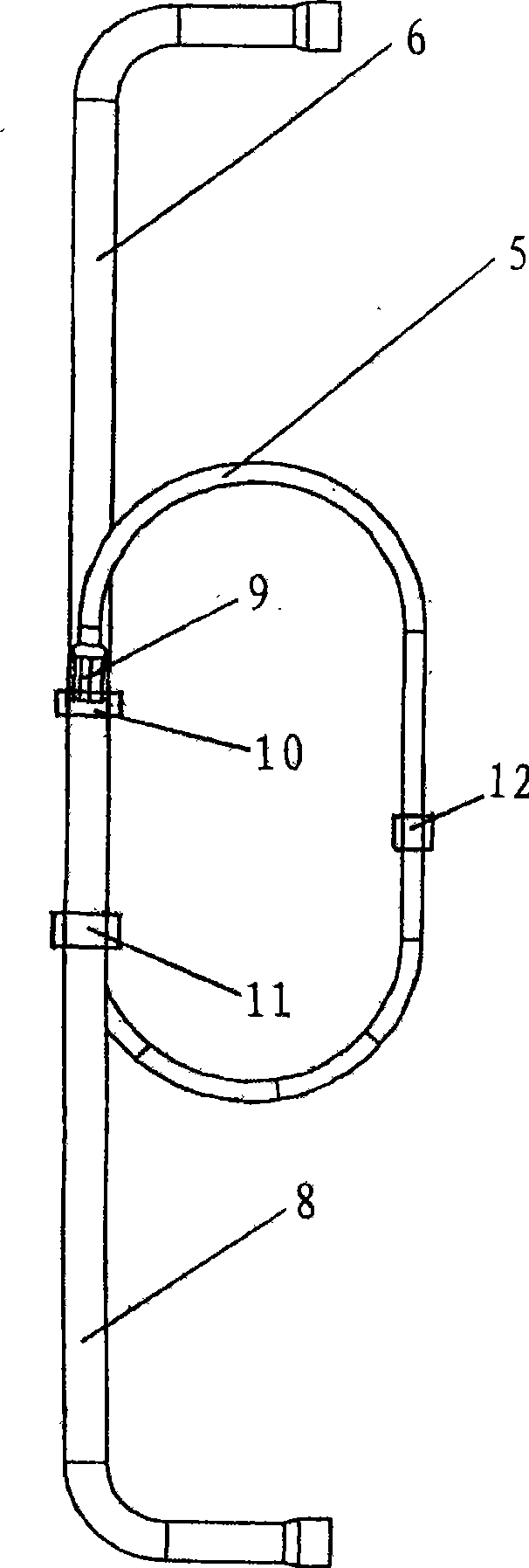

Throttle capillary tube fixing structure of air conditioner

InactiveCN101464079AReduce product defect rateOvercome leaksMechanical apparatusFluid circulation arrangementEngineeringThrottle

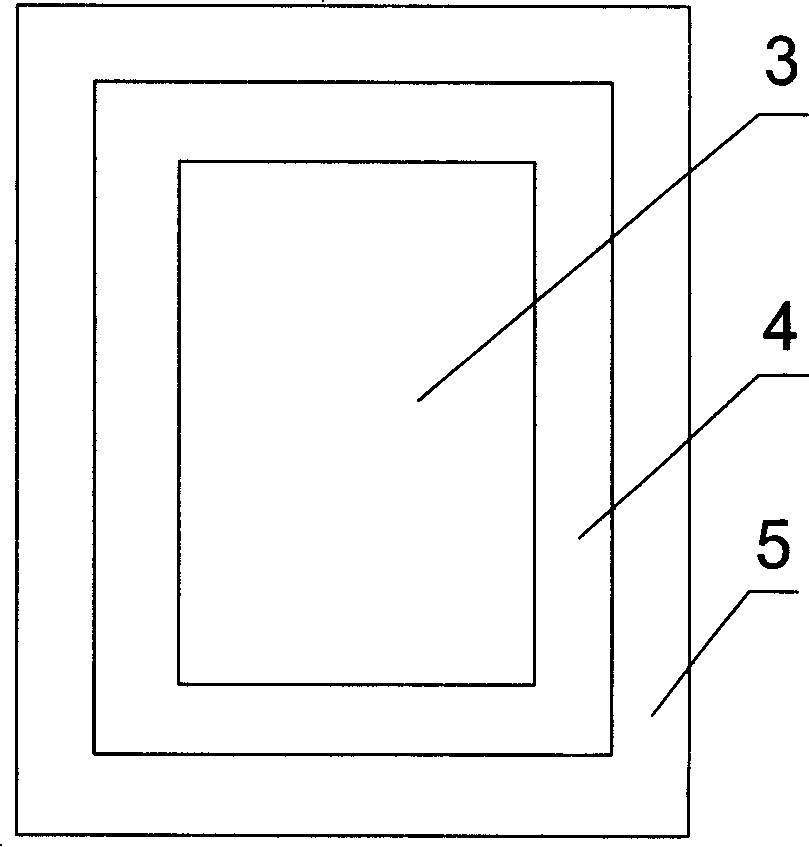

The invention relates to a fixing structure of a throttling capillary of an air conditioner. The fixing structure comprises the capillary which is wound into an oval pipe with orderly arrangement and two lengthened connecting pipes, the two ends of the capillary are respectively welded with the connecting pipes, the two connecting pipes and the capillary which is wound into the oval pipe are fixed together by wire clamps. Three wire clamps are utilized for fixing the connecting pipes and the capillary, wherein, two wire clamps are arranged on one side of the oval pipe with the orderly arrangement for respectively fixing welds between one connecting pipe and the other connection pipe and between the connecting pipe and the capillary; the other wire clamp is arranged on the other side of the oval pipe with the orderly arrangement for fixing the capillary.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

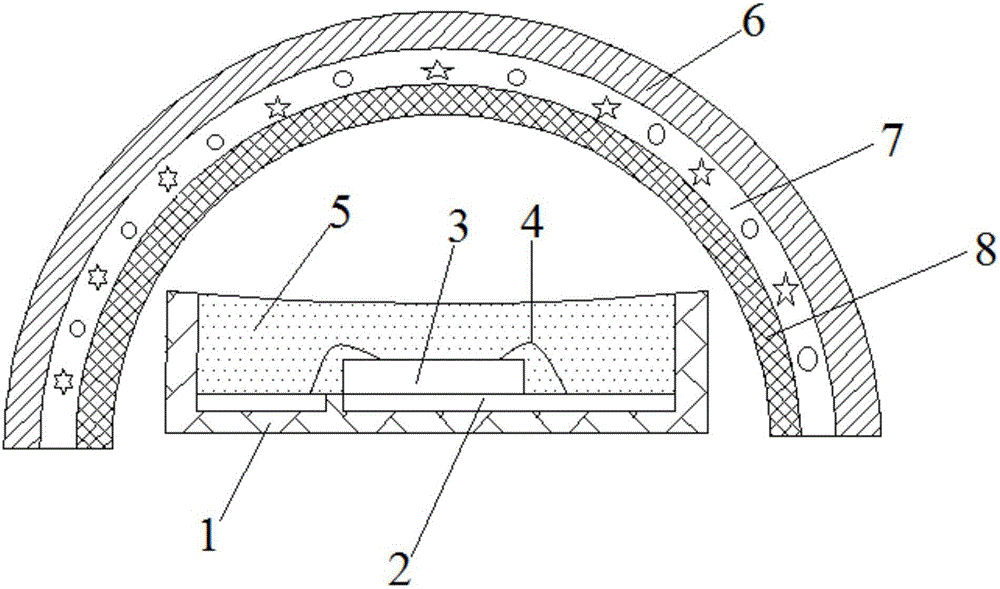

Packaging method for quantum dot LED bead

ActiveCN106784177AIncrease color gamutImprove reliabilitySemiconductor devicesQuantum dotQuantum dot laser

The invention belongs to the field of LED backlight processing, and particularly relates to a packaging method for a quantum dot LED bead. The method has the advantages that a prepared quantum dot material achieves a smaller half-wave width, so that the color gamut of the LED bead can be greatly improved (the color gamut of the obtained LED bead can exceed NTSC 95%); secondary glue dispensing is adopted, that is, a layer of packaging glue is additionally arranged on quantum dot fluorescent powders, so that corrosion of moisture and oxygen to the quantum dot material in the LED bead is reduced, and the bead is more reliable; the white LED bead is obtained through the quantum dot fluorescent powders, and the concentration of the quantum dot fluorescent powders is low during packaging because of a high excitation efficiency of the quantum dot fluorescent powders, so that packaging difficulties and the product rejection ratio are reduced, and the applicability for mass industrial production is achieved; and enormous market prospects and economic value are achieved.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

Ultraviolet-excited white light LED lamp bead of perovskite fluorescent powder

ActiveCN107437575AGood light decay consistencyImprove luminous efficiencySemiconductor devicesLuminous intensityHeat conducting

The invention discloses an ultraviolet-excited white light LED lamp bead of perovskite fluorescent powder. The internal structure is compact, the stability is good, light of the bottom can be reflected to a packaging lens by a high-temperature-resistant reflector plate, and the illumination intensity is improved. The heat is radiated by a mode of combined radiation of an outer heat conductive coat, a heat conducting sheet, inner heat conductive silica gel, a bottom copper foil and an aluminium substrate, so the heat dispersion is guaranteed. A base is installed and convenient for rapid replacing. The fluorescent powder is uniformly coated on the inner wall of the packaging lens, and the fluorescent powder is a perovskite structure. The fluorescent powder is the single-phase fluorescent powder which can be excited for emitting the white light by the ultraviolet light with the shorter wavelength, and the light intensity of the fluorescent powder is high. The problems of the defect and the low light effect caused by the mixed fluorescent powder are overcome. The preparation method is simple, the production cost is low, and the energy consumption is less. The white fluorescent powder has the stable chemical property, better humidity resistance and better light failure consistency. The perovskite has the characteristics of high luminous efficiency and higher photochromic adjustability.

Owner:苏州轻光材料科技有限公司

Manufacturing method of life cultivation and health preservation dark-red enameled pottery

InactiveCN112851296AReduce product defect rateReplace at any timeDomestic vesselsClaywaresSurface finishMachining

The invention relates to the technical field of dark-red enameled pottery, and discloses a manufacturing method of a life cultivation and health preservation dark-red enameled pottery, which solves the technical problem of low production and processing yield of the current dark-red enameled pottery, and comprises the following steps: 1, preparation; including preparation of pug, preparation of tools and preparation of modeling; 2, manufacturing; a main method for forming the dark-red enameled pottery is manual pinching and impression, each part of the dark-red enameled pottery and the dark-red enameled pottery are manufactured firstly, then the parts are bonded together, and then surface finish machining is carried out, and the method comprises the following steps that 1, a mud block is beaten into mud pieces with the average thickness; (2) making a kettle body; (3) manufacturing a kettle handle, a spout and a kettle cover; (4) assembling; (5) performing finish machining; and (6) decorating; 3 firing; the prepared teapot is firstly dried in the shade, moisture in a teapot blank is removed, and the teapot blank is put into a sagger and fired in a kiln after being dried in the shade; and 4, subsequent working procedures. According to the technical scheme, the purpose of improving the processing yield of the dark-red enameled pottery is achieved by using a processing method of firstly manufacturing each component, then adhering each component together and then performing surface finish machining.

Owner:上海荧视包装设计有限公司

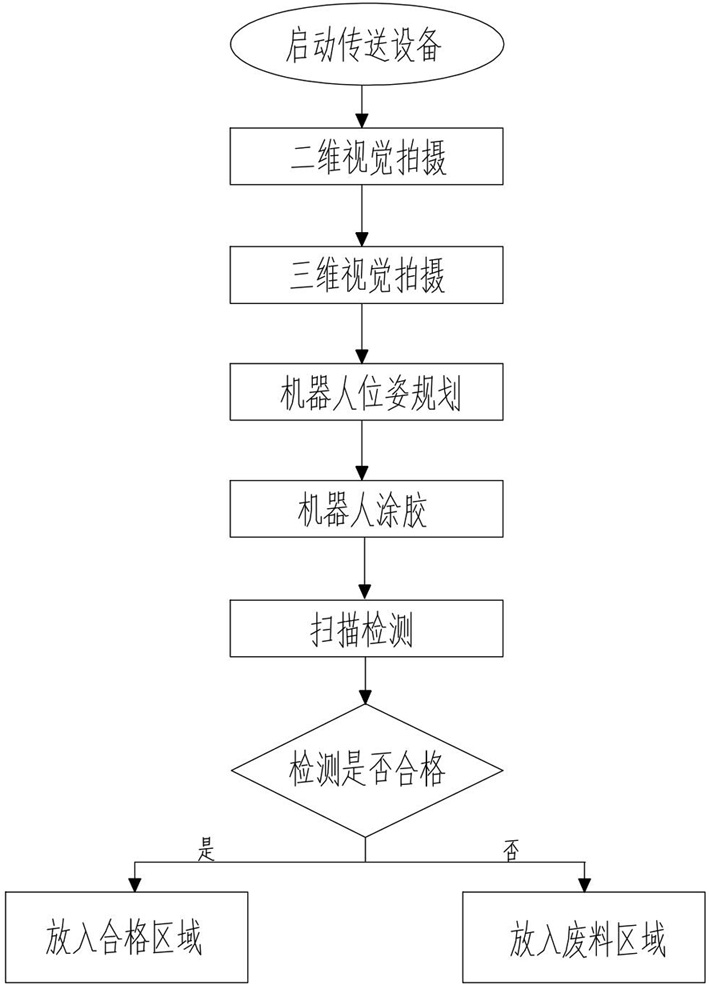

Robot gluing path planning method

InactiveCN113290556AIncrease productivityReduce product defect rateProgramme-controlled manipulatorLiquid surface applicatorsContour matchingEngineering

The invention relates to a robot gluing path planning method, which comprises the following steps of: starting conveying equipment, and driving a to-be-glued object by a conveying belt to enter a two-dimensional visual shooting area; then, photographing the to-be-glued object by a camera in the two-dimensional visual shooting area, and comparing two-dimensional drawings in a database according to the photographed picture so as to identify the corresponding product type; after collection is completed in the two-dimensional visual shooting area, driving the to-be-glued object by the conveying equipment to enter a three-dimensional visual shooting area, scanning the to-be-glued object by three-dimensional shooting equipment to obtain shape and size parameters of the to-be-glued object, and performing contour matching and comparison according to a database three-dimensional model to determine a gluing position; planning the pose of a robot by control equipment, and at the moment, the robot starting to perform gluing operation on the to-be-glued object; and driving the gluing object by the conveying equipment to enter a scanning detection area. According to the invention, the robot gluing path planning method, which is high in gluing precision, high-efficiency in mechanical gluing operation and wide in application range, can be provided.

Owner:苏州明图智能科技有限公司

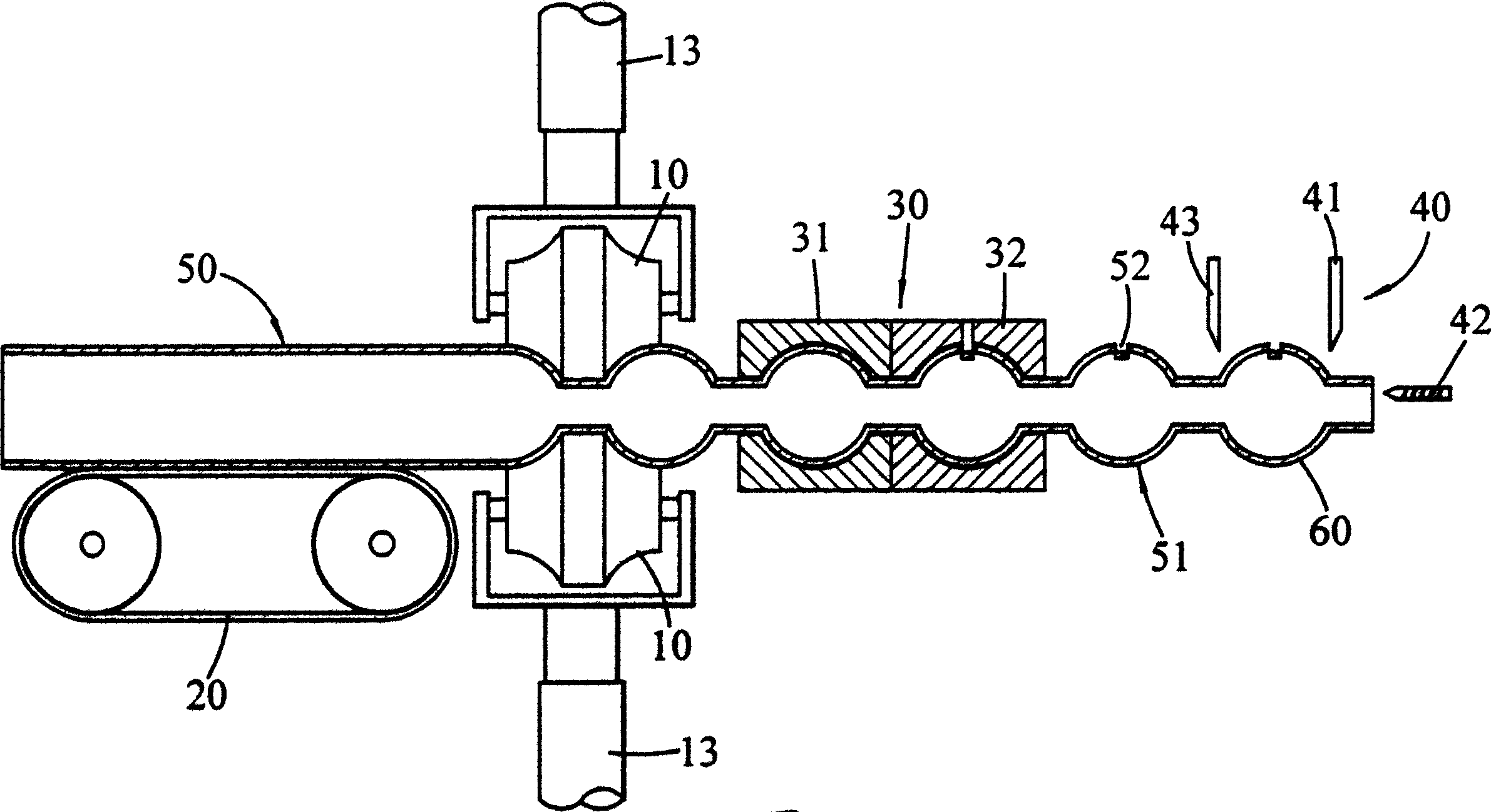

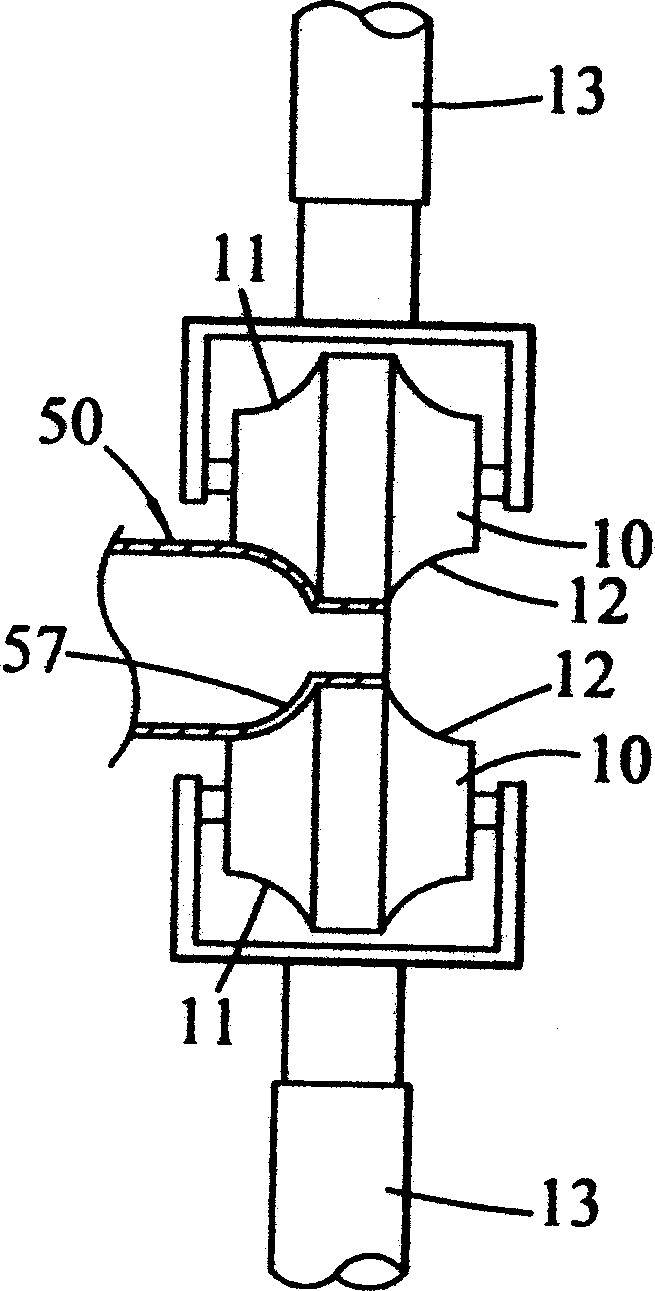

Method for producing ball valve body

The production process of ball valve body is one rolling formation process. Tubular metal material is first rolled into one string of ball valve body blanks, the ball valve body blanks are then punched or milled to form valve rod fixing groove, surface turned and ground to correct degree of sphericity, and the string of ball valve body blanks is finally cut into ball valve bodies with opened ends.

Owner:邱张素月

Wire splitting mechanism

ActiveCN106848798ASimple structureLow costLine/current collector detailsManufacturing wire harnessesUSBAutomation

Provided is a wire splitting mechanism. The mechanism comprises a baffle device, a twisting device and a work table, and the baffle device is adopted as a base plate when multiple core wires of a USB cable are pressed, and provides a support effect for the core wires; the twisting device is used for twisting and scattering the multiple core wires; the baffle device and the twisting device are fixedly connected to the work table separately. Through the wire splitting mechanism, the multiple core wires of the USB cable can be effectively scattered on a plane, and the wire splitting mechanism is simple in structure, low in cost, stable and reliable. Through effective scattering of the wires, automation of the process of packaging the wires into a clamp is effectively promoted, the production efficiency is improved, the production reject ratio is reduced, and meanwhile the production cost is saved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Impregnated tire fabric thermal treatment device and implementing method thereof

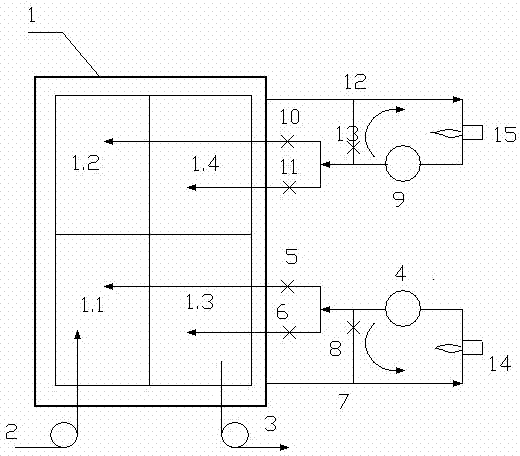

ActiveCN103924410AChange timeChange wind speedTextile treatment machine arrangementsHeating timeThermal treatment

The invention relates to an impregnated tire fabric thermal treatment device and an implementing method thereof. The impregnated tire fabric thermal treatment device comprises a main oven, an outer circulating system, a tire fabric lead-in roll and a tire fabric lead-out roll. The main oven is divided into four drying blocks. The outer circulating system is provided with a fan, hot air of the main oven is provided by a heating device, and the outer circulating system is used for adjusting air speed and heating time when the tire fabric speed is changed. By the modified impregnated tire fabric oven, energy source can be saved, air speed and treatment time of the tire fabric can be adjusted by vehicle speed, production of defective tire fabrics is greatly reduced, automation degree is high and labor intensity of workers is reduced.

Owner:JIANGSU HONGSHENG NEW MATERIAL

Fabrication method of quantum dot lens-type direct LED backlight source

InactiveCN106784238AImprove color gamutSolve the problem of easy reunion failureSolid-state devicesNon-linear opticsGamutAdhesive

The invention discloses a fabrication method of a quantum dot lens-type direct LED backlight source. The method comprises the following steps of firstly preparing a fluorescent adhesive A and dropping the fluorescent adhesive A into an LED bracket; preparing a quantum dot fluorescent adhesive B and coating the surface of an LED lens with the quantum dot fluorescent adhesive B and then coating the surface of the quantum dot fluorescent adhesive B with an ultraviolet-curing adhesive protection layer. A quantum dot fluorescent material is adopted by the quantum dot fluorescent adhesive B and the half-wave width is small, so that the color gamut value of the LED backlight source can be greatly improved and the color gamut value can reach over 96% of NTSC. Quantum dot fluorescent powder is prepared in the fluorescent adhesives, so that the problem of agglomeration and failure of the quantum dot fluorescent powder is solved. The fabrication method is simple in process and low in cost, and industrial production is easy to implement. Meanwhile, the quantum dot fluorescent adhesive B coats the LED lens, and is coated with packaging glue for protection, so that erosion of moisture and oxygen to the quantum dot fluorescent material is reduced, meanwhile, the quantum dot fluorescent material is prevented from being in direct contact with a light-emitting chip and being affected by a high temperature of the light-emitting chip, and the reliability of a lamp bead is improved.

Owner:WUHU JUFEI PHOTOELECTRIC TECH CO LTD

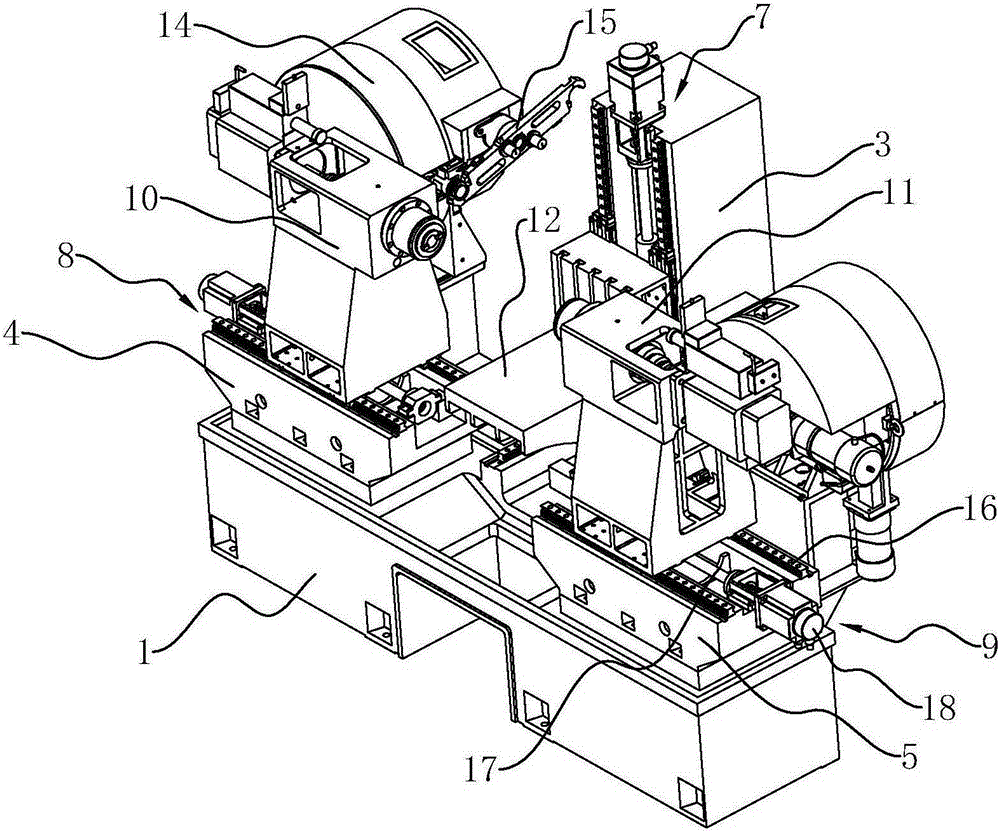

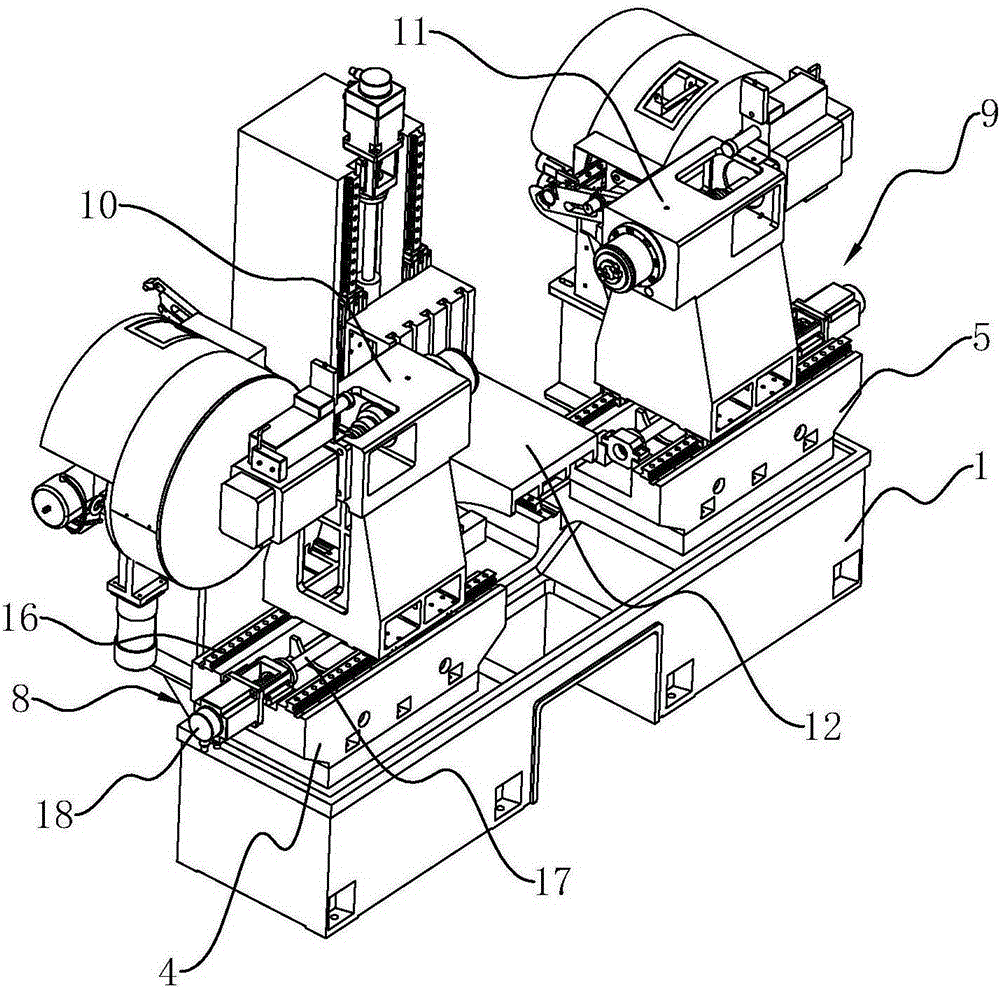

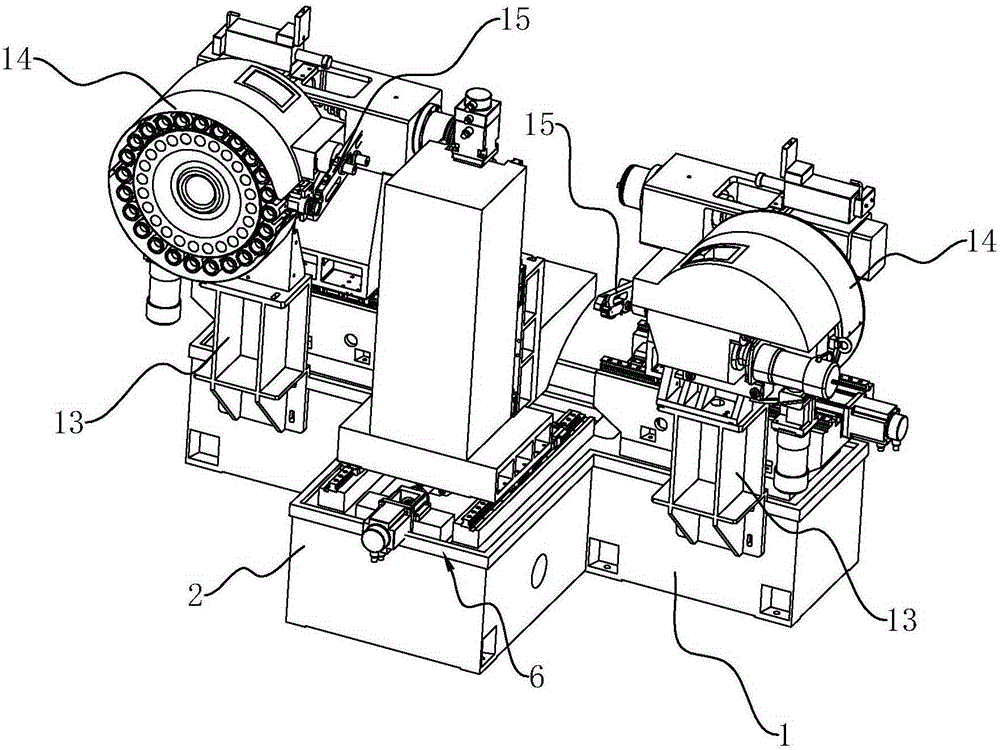

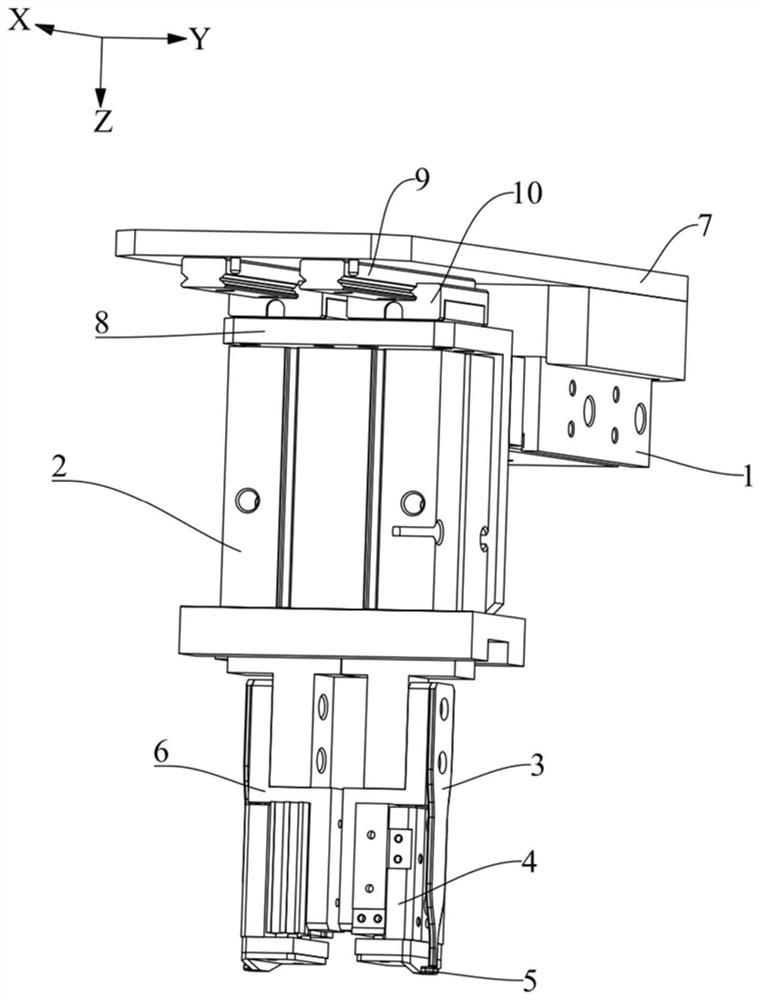

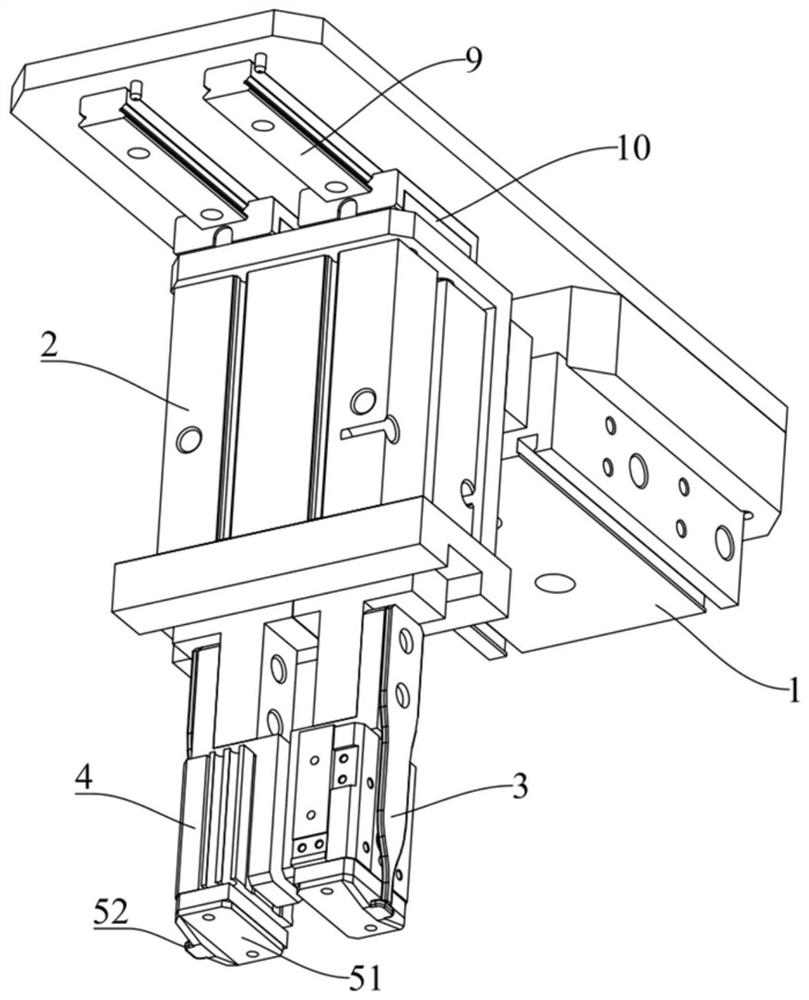

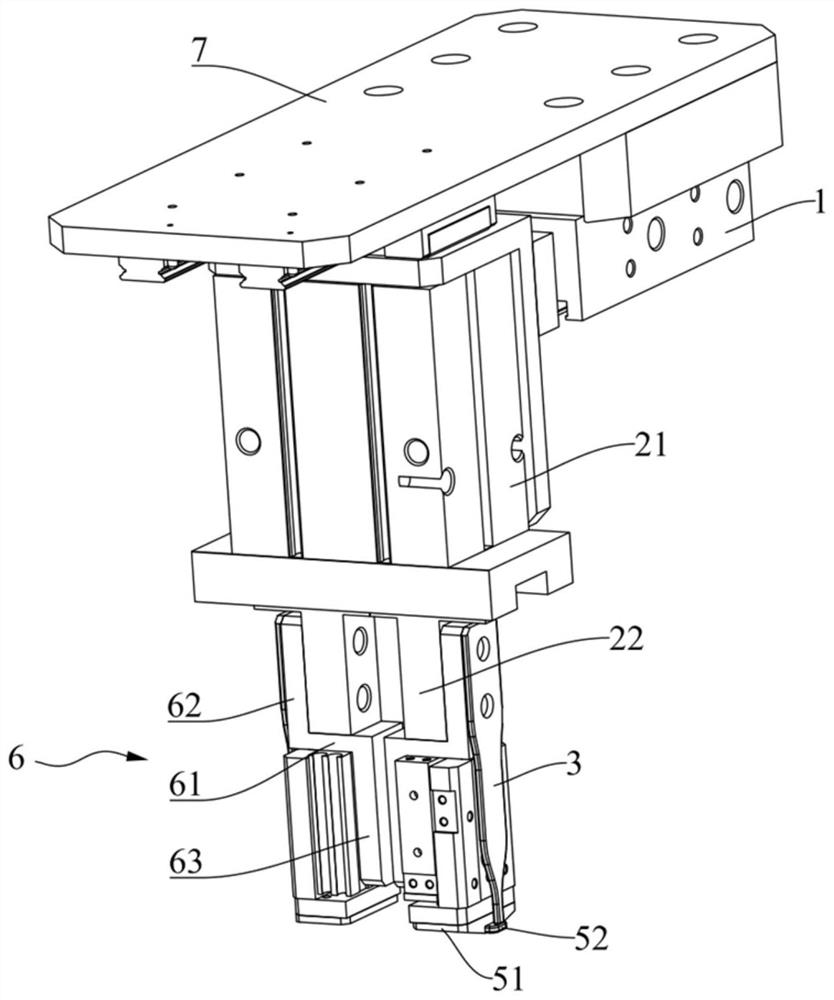

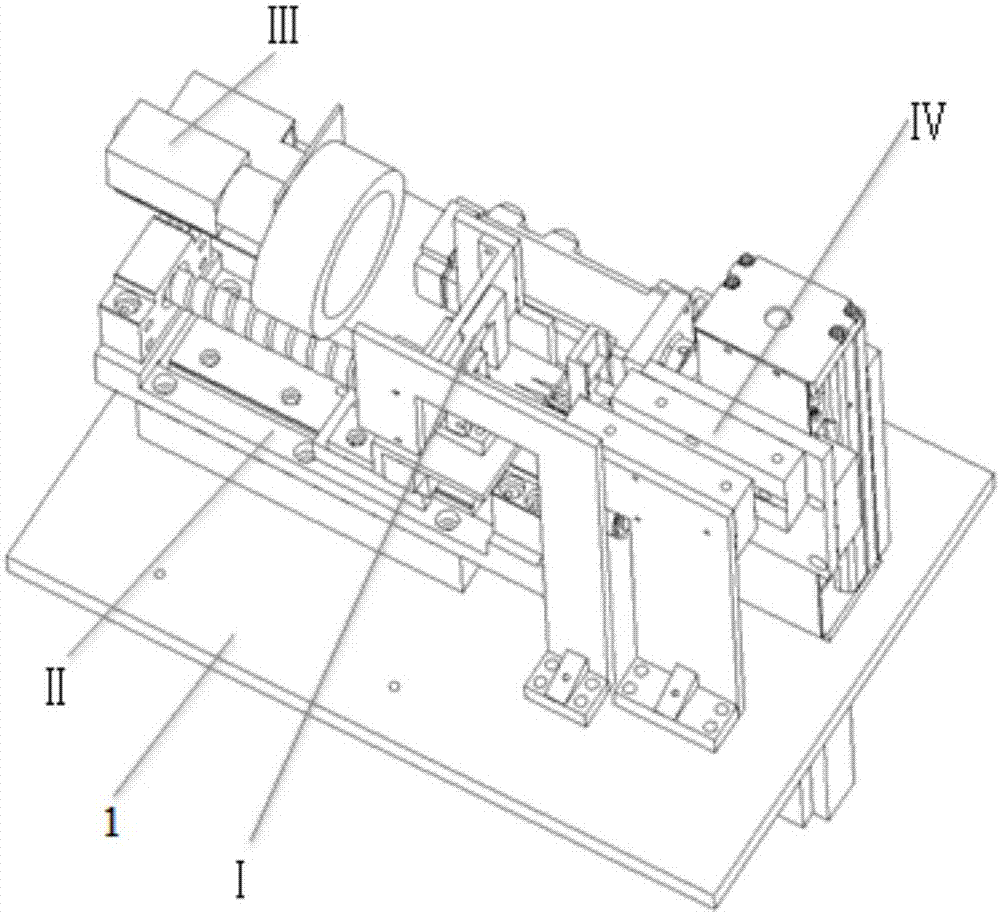

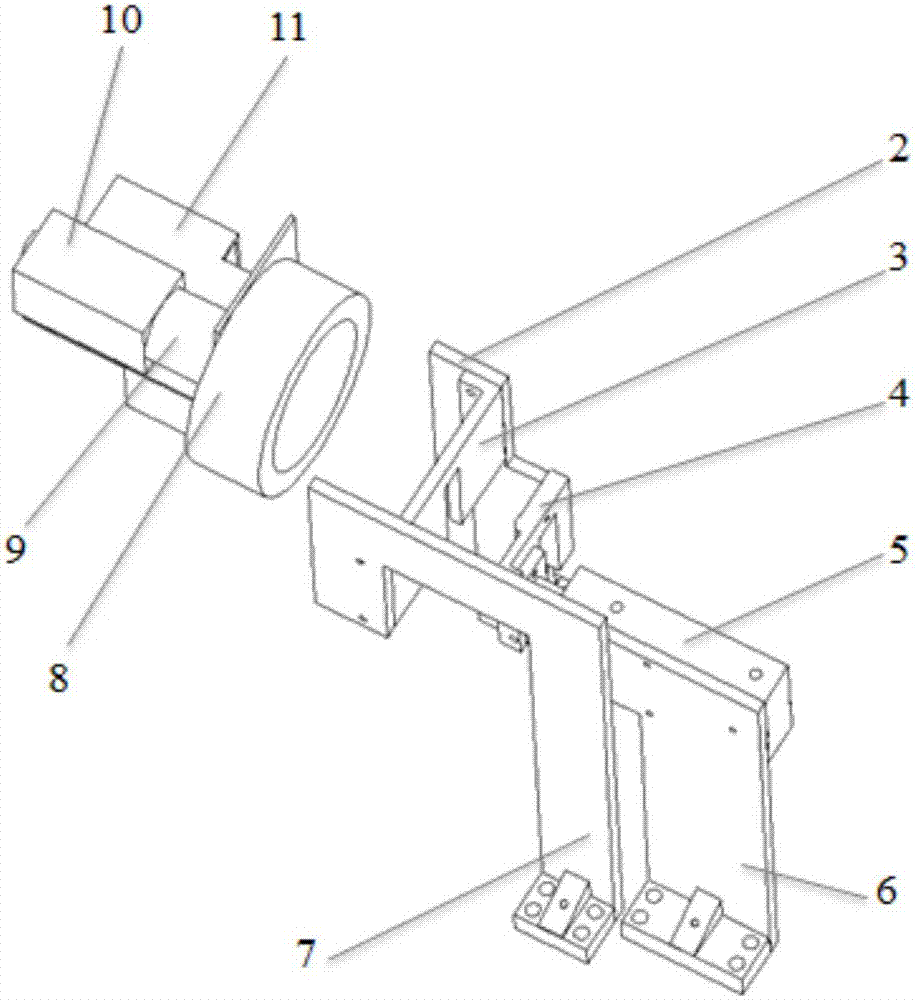

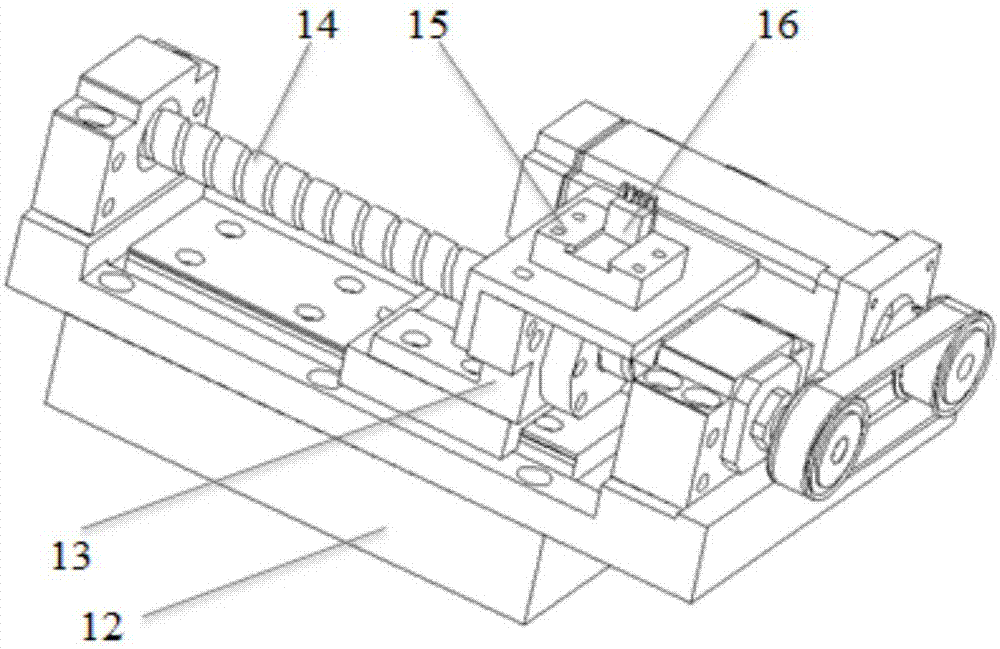

Twin-spindle numerical-control device used for composite sliding block machining

InactiveCN105234749AImprove processing efficiencyImprove machining accuracyMetal working apparatusNumerical controlEngineering

The invention discloses a twin-spindle numerical-control device used for composite sliding block machining. The device comprises a base. An X shaft, a Y shaft, first Z shaft supporting seats and second Z shaft supporting seats are installed on the base. An X shaft linear workbench, a Y shaft linear workbench, a first Z shaft linear workbench and a second Z shaft linear workbench are installed on the X shaft, the Y shaft, the first Z shaft supporting seats and the second Z shaft supporting seats respectively. A Y shaft supporting seat is fixedly installed on the X shaft linear workbench. The movement direction of the Y shaft linear workbench is perpendicular to that of the X shaft linear workbench. A first spindle machining mechanism and a second spindle machining mechanism which are opposite to each other are arranged on the first Z shaft linear workbench and the second Z shaft linear workbench respectively. A workpiece clamping seat is installed on the Y shaft linear workbench. According to the composite sliding block machining device, the first spindle machining mechanism and the second spindle machining mechanism which are opposite to each other can be adopted to machine sliding block ball return holes, threaded holes and chamfers in the two end faces of a sliding block at the same time, the machining efficiency is greatly improved, and the defect that the symmetry is poor due to the fact that clamping is conducted twice is overcome; the machining accuracy is improved, production cost is reduced easily, and the product reject ratio is decreased easily.

Owner:JIANGMEN INTIN NUMERICAL CONTROL MACHINE TOOL CO LTD

Automatic film tearing device and automatic film tearing method

ActiveCN112277433ARealize automatic tear offImprove efficiencyLayered productsLaminationAssembly lineEngineering

The invention discloses an automatic film tearing device and an automatic film tearing method, and belongs to the technical field of electronic product assembly. The automatic film tearing device comprises a first driving mechanism, a second driving mechanism and a clamping assembly, the second driving mechanism is connected to the first driving mechanism, and the first driving mechanism is used for driving the second driving mechanism to move in the X direction; the clamping assembly comprises a first clamping piece, a driving piece and a second clamping piece, the first clamping piece and the driving piece are arranged on a second driving mechanism, the second driving mechanism is used for driving the first clamping piece, the driving piece and the second clamping piece to move in the Ydirection, the second clamping piece is arranged on the driving piece, the driving piece is used for driving the second clamping piece to move in the Z direction, the second clamping piece and the first clamping piece are oppositely arranged in the Z direction so as to clamp the to-be-torn film under driving of the driving piece. According to the automatic film tearing device and the automatic film tearing method, automatic film tearing can be achieved, high film tearing efficiency is achieved, and the automatic film tearing device and the automatic film tearing method are suitable for an automatic assembly line.

Owner:LUXSHARE ITECH(ZHEJIANG) CO LTD

Visual recognition-based usb line splitting and arranging mechanism

The invention discloses a USB line separating and arranging mechanism based on visual identification. The USB line separating and arranging mechanism comprises a workbench, and a line separating device, a line clamp carrying and moving device, a visual detection device and a line clamp loading device which are installed on the workbench. The line separating device is used for separate positioning of USB lines. The line clamp carrying and moving device is used for carrying a line retreating clamp to realize movement of the line retreating clamp. The visual detection device is used for photographing and acquiring color and position information of the USB lines so as to control the movement position of the line clamp carrying and moving device and the line clamp loading device. The line clamp loading device is used for poking the separate USB lines into the line retreating clamp in turn. The mechanism is simple in structure, low in cost and high in production efficiency and can avoid damage of harmful gas to the human body in the welding process.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

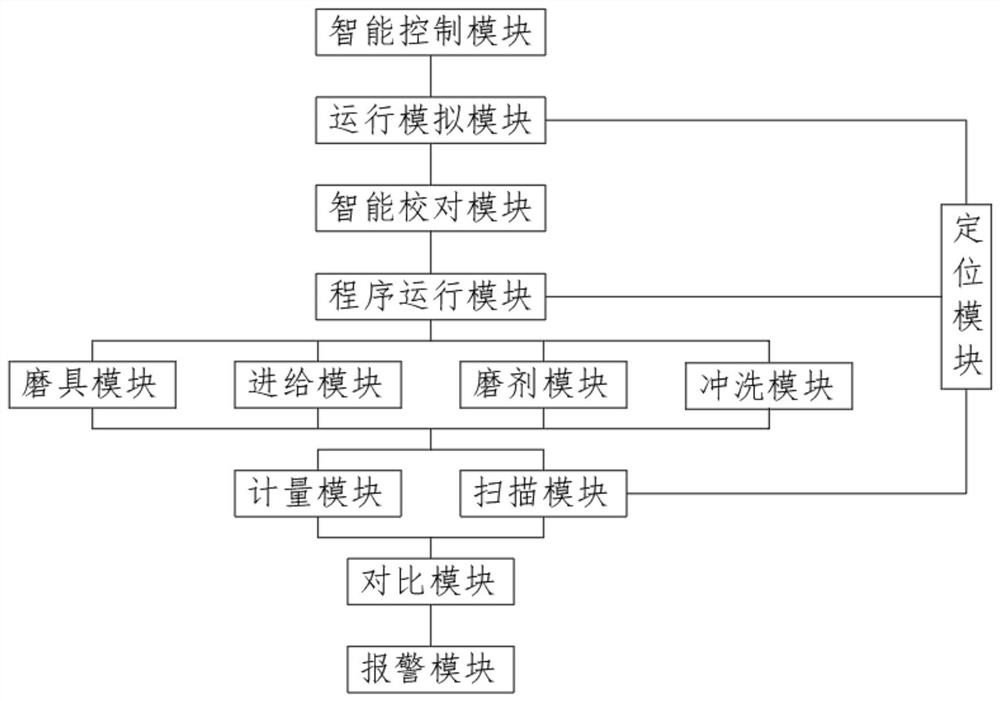

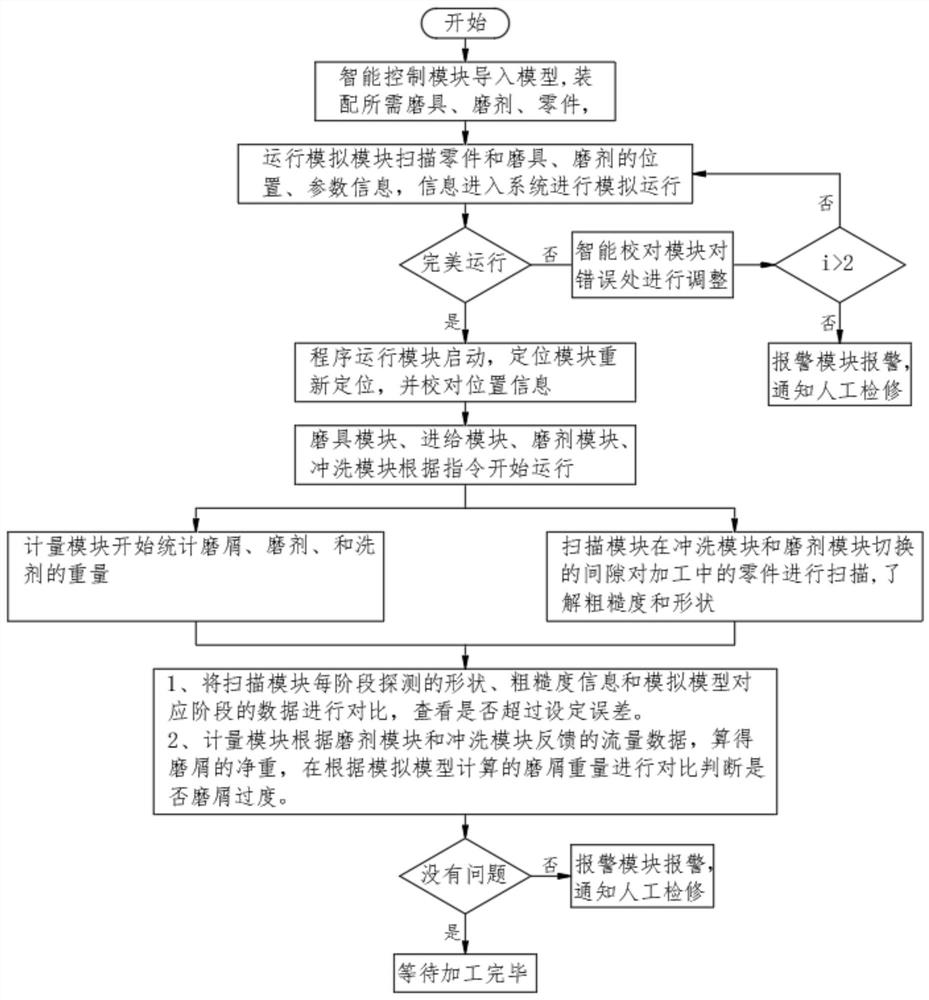

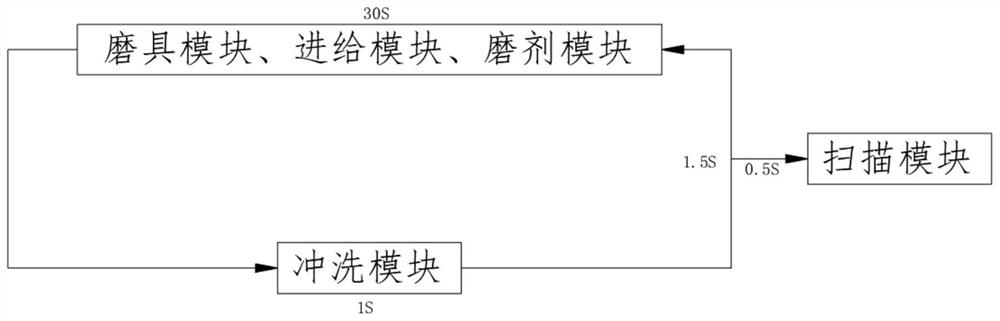

Grinding system of intelligent numerical control platform

ActiveCN113664624AHigh precisionAvoid light reflectionAutomatic grinding controlNumerical controlControl engineering

The invention discloses a grinding system of an intelligent numerical control platform. The grinding system comprises an intelligent control module, an operation simulation module, an intelligent proofreading module, a program operation module, a grinding tool module, a feeding module, a grinding agent module, a flushing module, a metering module, a scanning module, a positioning module and an alarm module, wherein the intelligent control module is used for importing and editing a numerical control program or model and controlling the whole module of the numerical control platform; and the operation simulation module is used for simulating and operating the numerical control program, judging the enforceability of the program and judging whether the position and the model of each module are wrong or not, and timely discovering mistakes, omissions and faults of equipment. According to the grinding system of the intelligent numerical control platform, the flushing module is used in the working process, after grinding is conducted for a period of time, the flushing module is used for flushing the surface of a part, residues of abrasive dust and grinding agent particles are removed, the situation that light reflection of the scanning module is affected by interference factors so that errors of a scanning result are caused is prevented, and therefore the precision of part machining monitoring is improved.

Owner:无锡森导智能工业技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com