Light guide plate manufacture method and device

A manufacturing method and technology for manufacturing devices, which are applied in the directions of light guides, optics, optical components, etc., can solve the problems of high production environment requirements, large environmental pollution, complex production processes, etc., so as to improve uniformity and light output rate, and reduce production environment requirements. , The effect of reducing the production defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

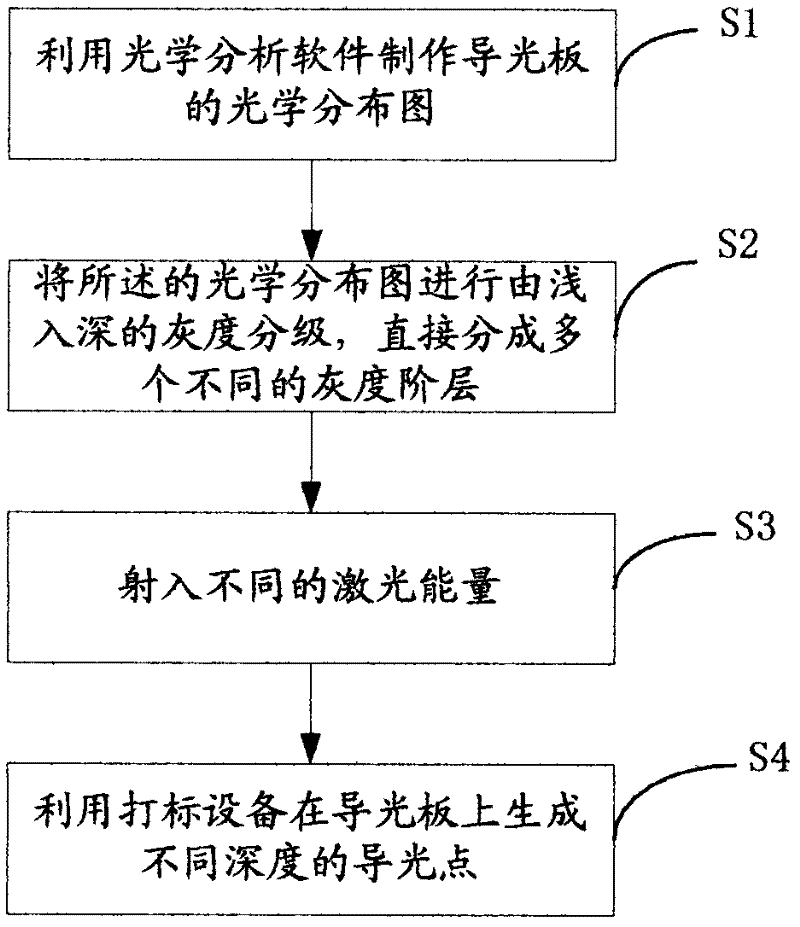

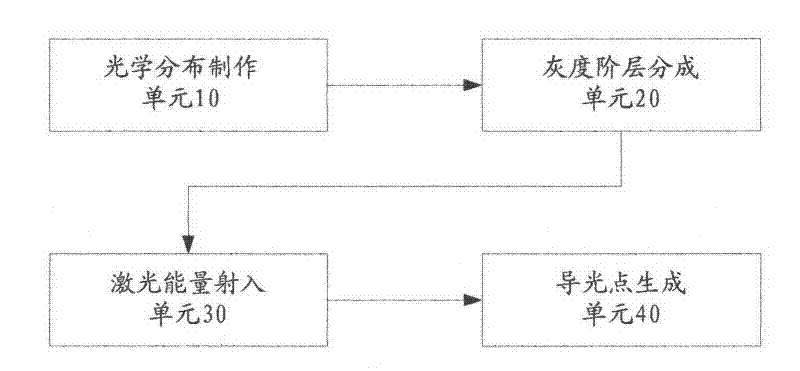

[0044] see figure 1 , a method for manufacturing a light guide plate, comprising:

[0045] S1. Using optical analysis software to make an optical distribution diagram of the light guide plate;

[0046] The optical analysis software may be optical analysis software produced by GTOOLS of Taiwan.

[0047] S2. Carrying out gray-scale grading from shallow to deep on the optical distribution map, and directly dividing it into a plurality of different gray-scale levels;

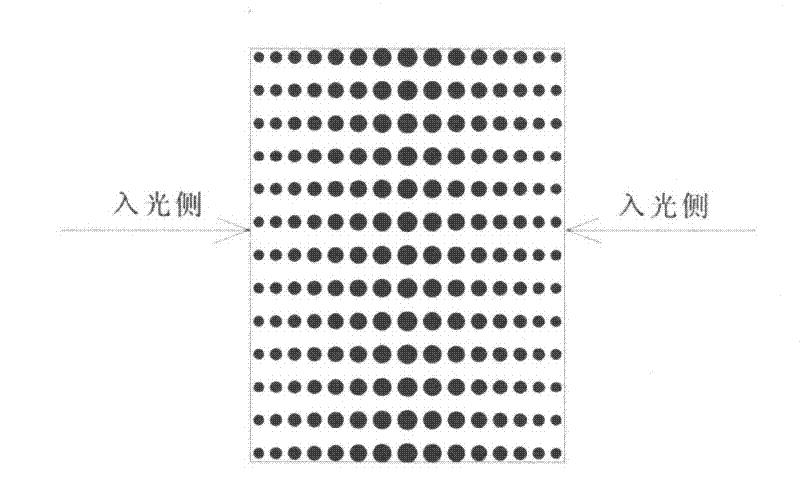

[0048] The light source enters the light guide plate from at least one side of the light guide plate, which can be two sides, three sides or four sides, or more sides depending on the plate material. In short, the place farthest from the light source, The grayscale is the dar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com