Patents

Literature

476results about How to "Suitable for mass industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High heat-resisting ceramic cooking cook ware suitable for electromagnetic induction furnace

InactiveCN101077274ADeliciousImprove heat utilizationCooking-vessel materialsLithiumThermal stability

The present invention discloses one kind of high temperature resistant ceramic cooker suitable for use in electromagnetic induction furnace. The high temperature resistant ceramic cooker is produced with the main materials, including lithium-containing mineral material, quartz, kaolin, etc, and through grinding, mixing, forming, drying, glazing and high temperature baking to obtain the ceramic body; coating far infrared radiation layer, electromagnetically inducing eddy flow heating layer and far infrared reflecting layer to the bottom of the ceramic body; and roasting. It has high heat stability, no cracking even in no-water cooking state, high heat utilization rate and long service life. It is especially suitable for cooking in electromagnetic induction furnace.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Blackening method for lithium tantalite crystal substrate

ActiveCN105463581AEasy to control resistivityUniform colorPolycrystalline material growthAfter-treatment detailsNon oxidativeReducing atmosphere

The invention discloses a blackening method for a lithium tantalite crystal substrate. According to the method, a fluoride material and the to-be-treated lithium tantalite crystal substrate are contacted sufficiently, and the lithium tantalite crystal substrate is subjected to reductive heat treatment at the temperature of 450-600 DEG C in non-oxidative reducing atmosphere for 5-24 h. The volume resistivity of the lithium tantalite crystal substrate after blackening is 10<9>-10<12> omega cm. The method has the advantages that the method is simple, reliable and easy to operate, and the obtained lithium tantalite crystal substrate has good resistivity repeatability and low cost and is applicable to batch production.

Owner:上海召业申凯电子材料有限公司

Epigallo-catechin gallate (EGCG) with high purity and preparation method thereof

ActiveCN101643466AThe process route is simple and easySuitable for mass industrial productionAntibacterial agentsIon-exchange process apparatusCrystallizationChemistry

The invention provides an epigallo-catechin gallate (EGCG) with high purity and a preparation method thereof. The EGCG content is 98.0 percent to 99.9 percent. The preparation method mainly comprisesthe working procedures of extracting, separating by a chromatography and crystallizing. The invention has favorable reproducibility of preparation process, high acquired EGCG content, low cost and stable and controllable quality and is suitable for industrialized production.

Owner:JIANGSU TIANSHENG PHARMA

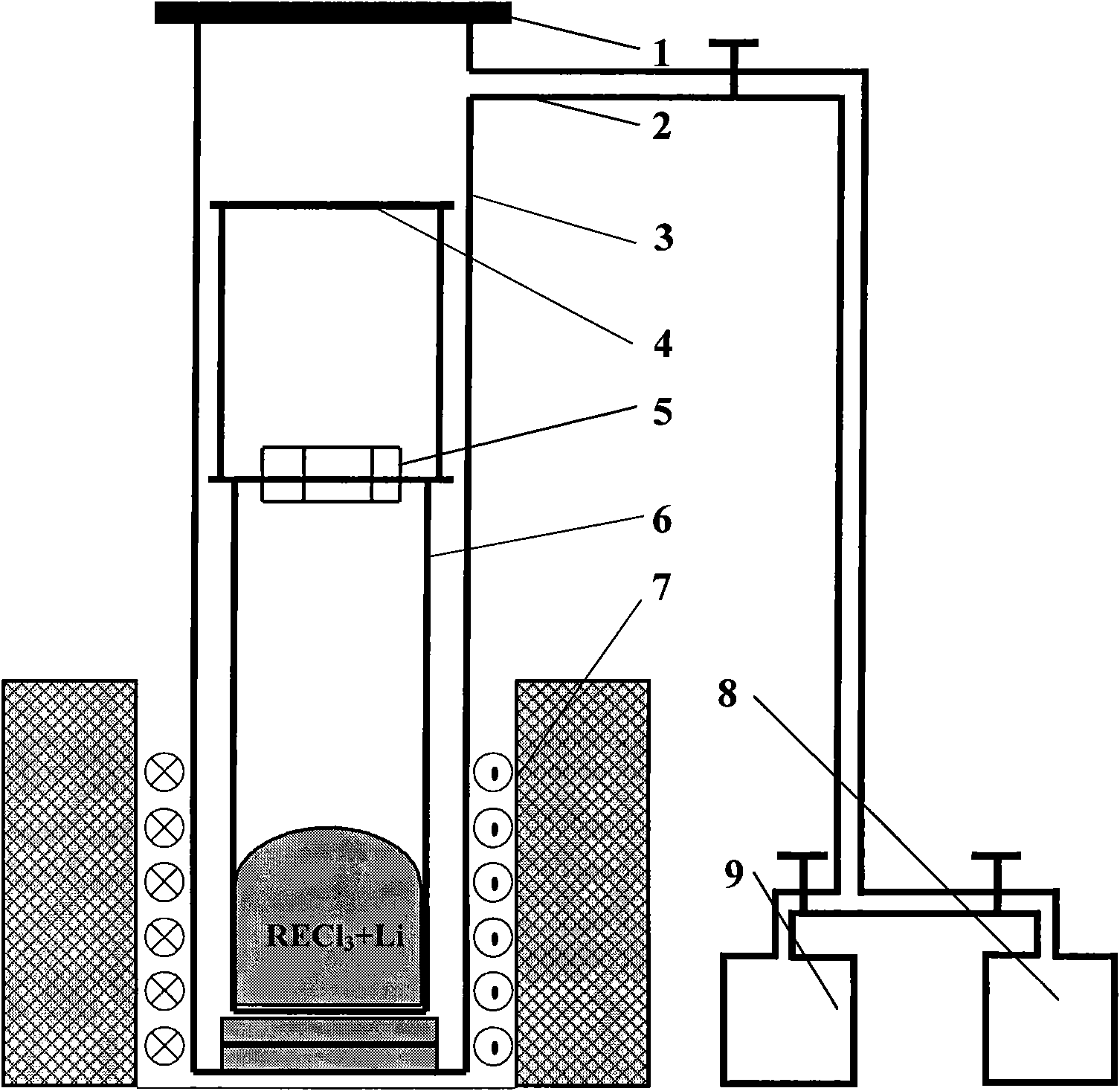

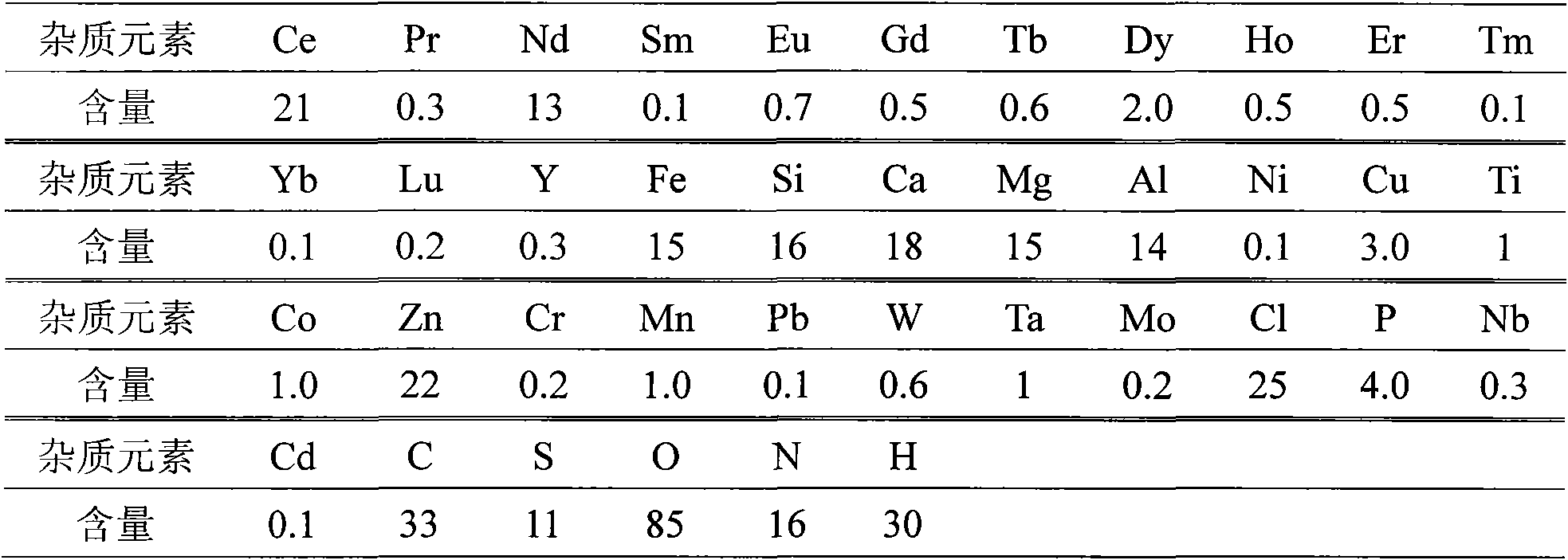

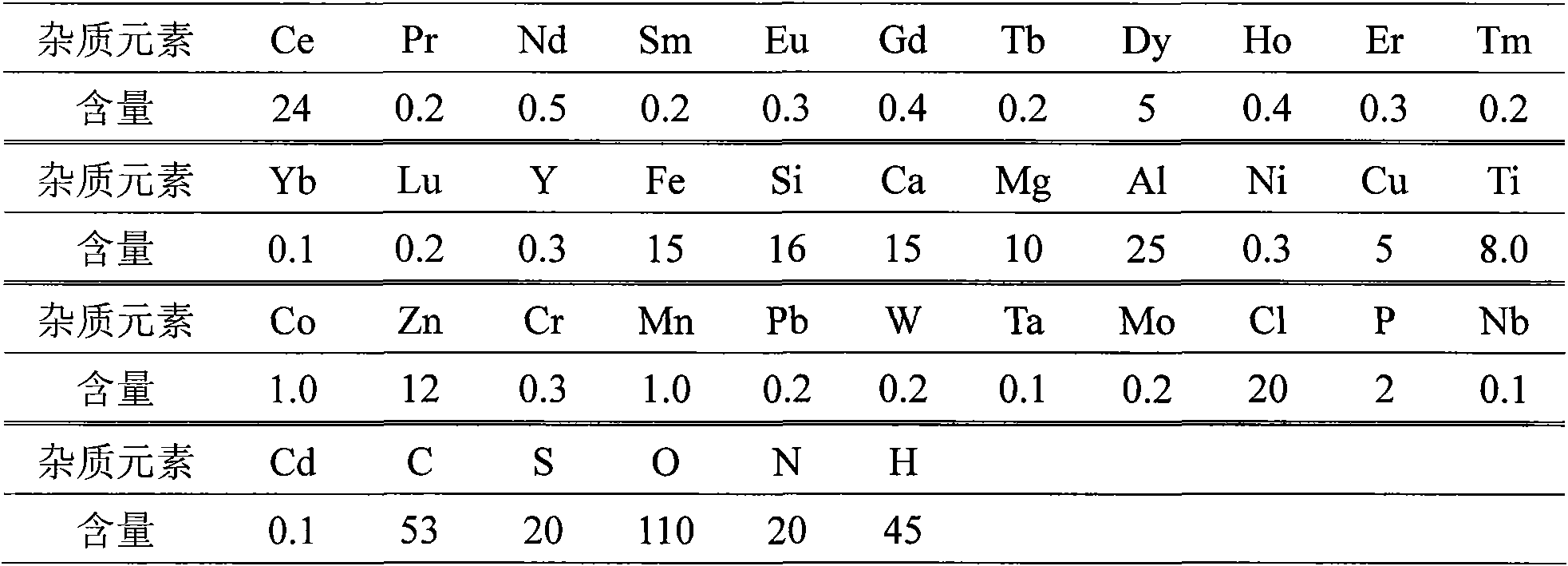

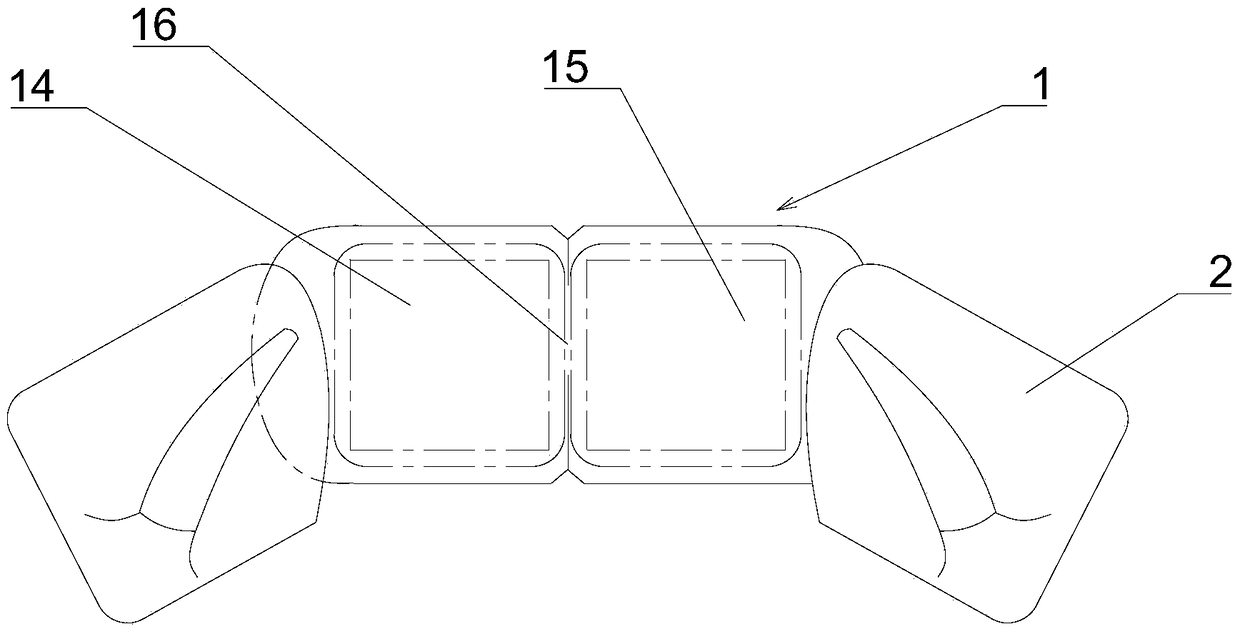

Method for preparing high purity rare earth metal and its apparatus

InactiveCN102465210AAvoid pollutionHigh purityProcess efficiency improvementChemistryDisplacement reactions

The invention relates to a method for preparing a high purity rare earth metal and its apparatus, which is characterized in that a lithium thermal reduction-vacuum distillation combined technology is used for preparing the high purity rare earth metal. The method comprises the following steps: taking rare earth chloride as a raw material and lithium metal as a reducing agent, placing in a reaction container, in a reaction system, carrying out a liquid-liquid displacement reaction of lithium metal and rare earth chloride under the inert gas protection (the pressure is 0.1-0.5 MPa) and the temperature of 850-1100 DEG C, then vacuum-pumping the reaction system to 10<-1>-10<-3> Pa, wherein the temperature is controlled at 900-1200 DEG C, evaporating lithium metal and lithium chloride, separating slag and metal to obtain the high purity rare earth metal. The reaction apparatus is composed of a furnace cover (1), a communicating pipe (2), a collector (3), a furnace body (4), a thermal baffle (5), a reactor (6), a heating device (7), an inflation system (8) and a vacuum system (9). The invention has the advantages of short process flow, high yield of rare earth metal and low production cost; the purity of the prepared rare earth metal is high. The used apparatus is simple and is easy to enlarge, and is suitable for large batch of industrial production.

Owner:GRIREM ADVANCED MATERIALS CO LTD

3D printing photosensitive resin material

InactiveCN107868443ALow viscosityReduce the smellAdditive manufacturing apparatusOligomerReactive diluent

The invention discloses a 3D printing photosensitive resin material. The 3D printing photosensitive resin material comprises the following components in parts by weight: 10-50 parts of a low-viscosityphotosensitive resin oligomer, 10-50 parts of organosilicone modified epoxy acrylate, 30-50 parts of a reactive diluent, 1-5 parts of a photoinitiator, 1-5 parts of an auxiliary agent and 0.01-1 partof a pigment. The 3D printing photosensitive resin material is very low in viscosity and odor, high in curing rate, high in precision of a printed product and universal in universality; meanwhile, the organosilicone modified epoxy acrylate resin is obtained by grafting silicon onto a molecular chain of epoxy resin, so that the polarity of an organosilicone component is reduced and the compatibility thereof in the photosensitive resin material can be improved; in addition, the content of the organosilicone is high, and the organosilicone component in a branched-chain state contributes to movement of the molecular chain and can easily migrate to an interface between a 3D printing trough and the photosensitive resin material, so that the 3D printing photosensitive resin material shows excellent release capability.

Owner:HUIZHOU YOUHENGKE 3D MATERIAL TECH CO LTD

Preparing method for in-situ synthesis TiC-Ti5Si3 particle reinforcement Ti-based composite material

The invention relates to the field of Ti-based composite materials, in particular to a preparing method for an in-situ synthesis TiC-Ti5Si3 particle reinforcement Ti-based composite material. The preparing method includes the specific steps that firstly, materials are weighed; secondly, mixed powder of Ti powder and SiC powder is prepared; thirdly, loading is conducted; and fourthly, vacuum induction melting is conducted, and the in-situ synthesis TiC-Ti5Si3 particle reinforcement Ti-based composite material is obtained after cooling. According to the preparing method, the in-situ synthesis Ti-based composite material high in performance can be prepared by adjusting the content of reinforcement phases and components of a titanium alloy base body, and secondary molding can also be conducted with the combination of the technology of hot forging, hot rolling, hot extruding and the like. The preparing method has the advantages that the technology is simple, cost is low, and industrial production is easy to achieve.

Owner:TAIYUAN UNIV OF TECH

Package method for high-gamut white-light quantum-dot light emitting diode (LED)

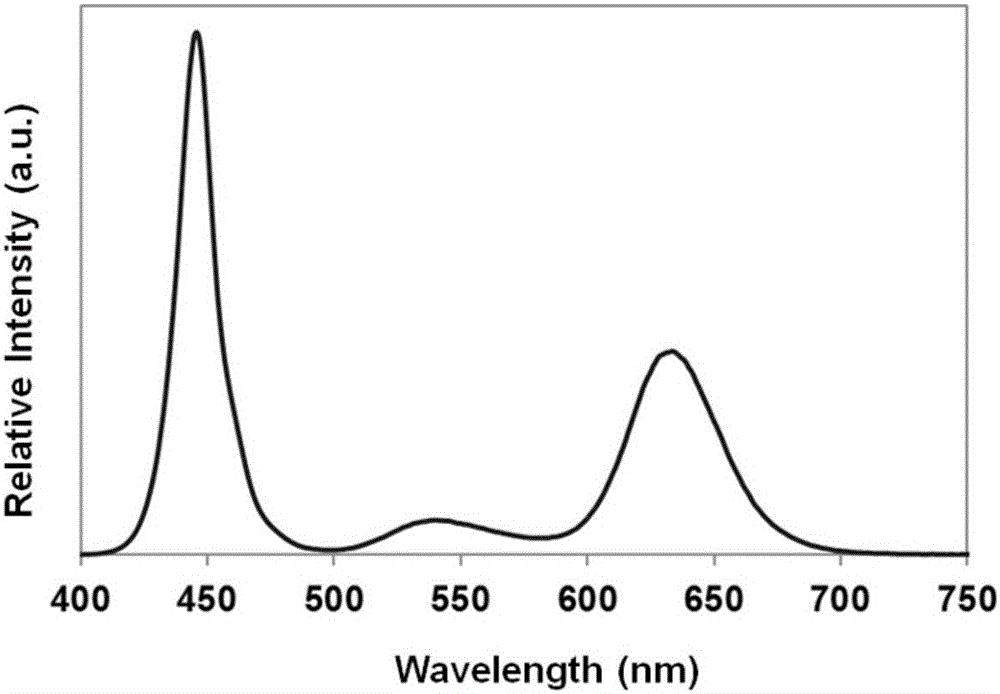

ActiveCN105870302AImprove color gamutReduce concentrationNanoopticsEnergy efficient lightingOrganic solventGamut

The invention discloses a package method for a high-gamut white-light quantum-dot light emitting diode (LED). The package method comprises the following steps of (a) separately adding an organic solvent to red-light quantum-dot fluorescent powder and blue-light quantum-dot fluorescent powder; (b) carrying out ultrasonic processing on the solution; (c) preparing a mixed quantum-dot solution; (d) adding package glue to the mixed quantum-dot solution, and uniformly stirring the package glue; (e) removing the organic solvent; (f) adding green-light rare-earth fluorescent powder; and (g) dropping the mixed fluorescent glue to an LED support fixed with an ultraviolet chip, roasting and curing the mixed fluorescent glue to obtain an LED light bead. By the package method, the high-gamut white-light LED is obtained, and the gamut value of the LED back-light bead is greatly increased and can reach over 92% of NTSC; the organic solvent is taken as a connection bridge, so that quantum dots and the package glue are uniformly mixed, the agglomeration failure phenomenon of the quantum dot fluorescent powder is prevented, and the quality of the high-gamut white-light LED bead is remarkably improved.

Owner:WUHU JUFEI PHOTOELECTRIC TECH CO LTD

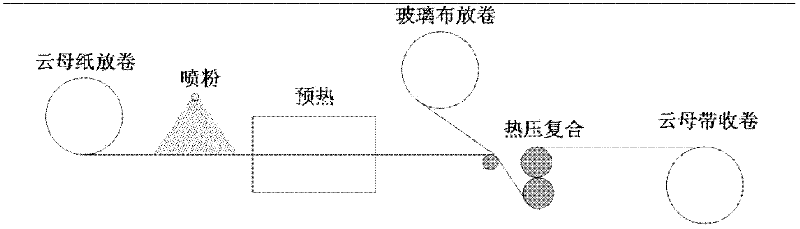

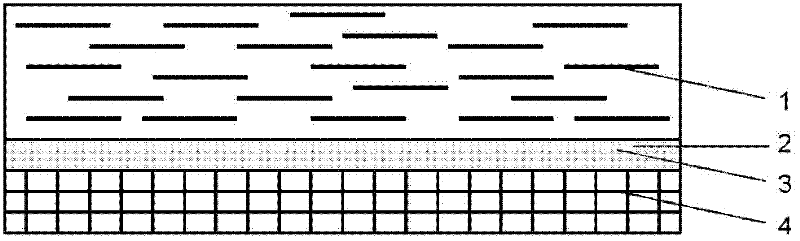

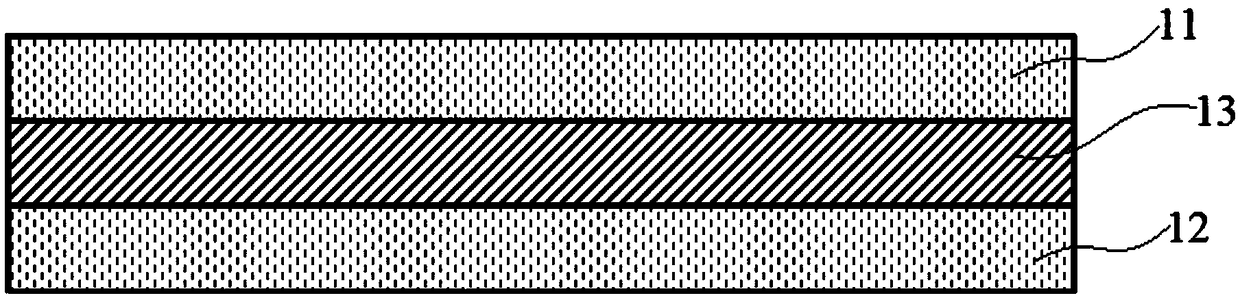

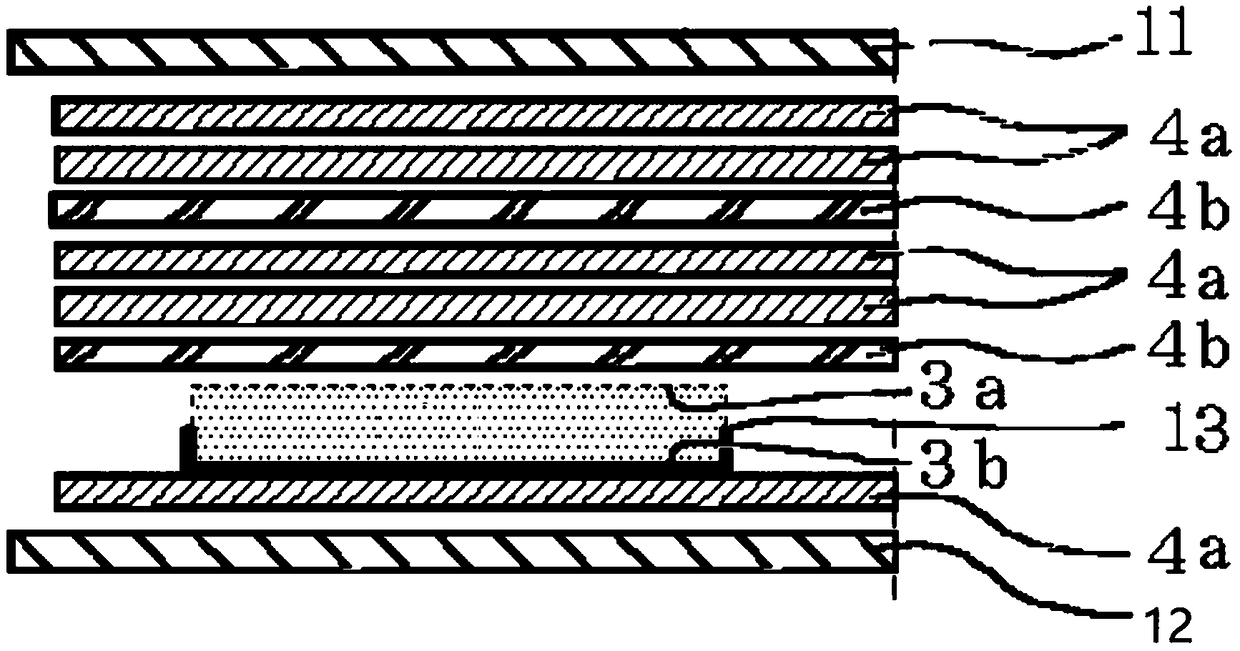

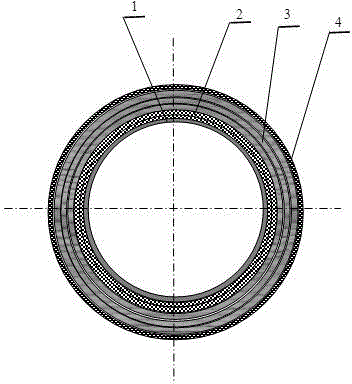

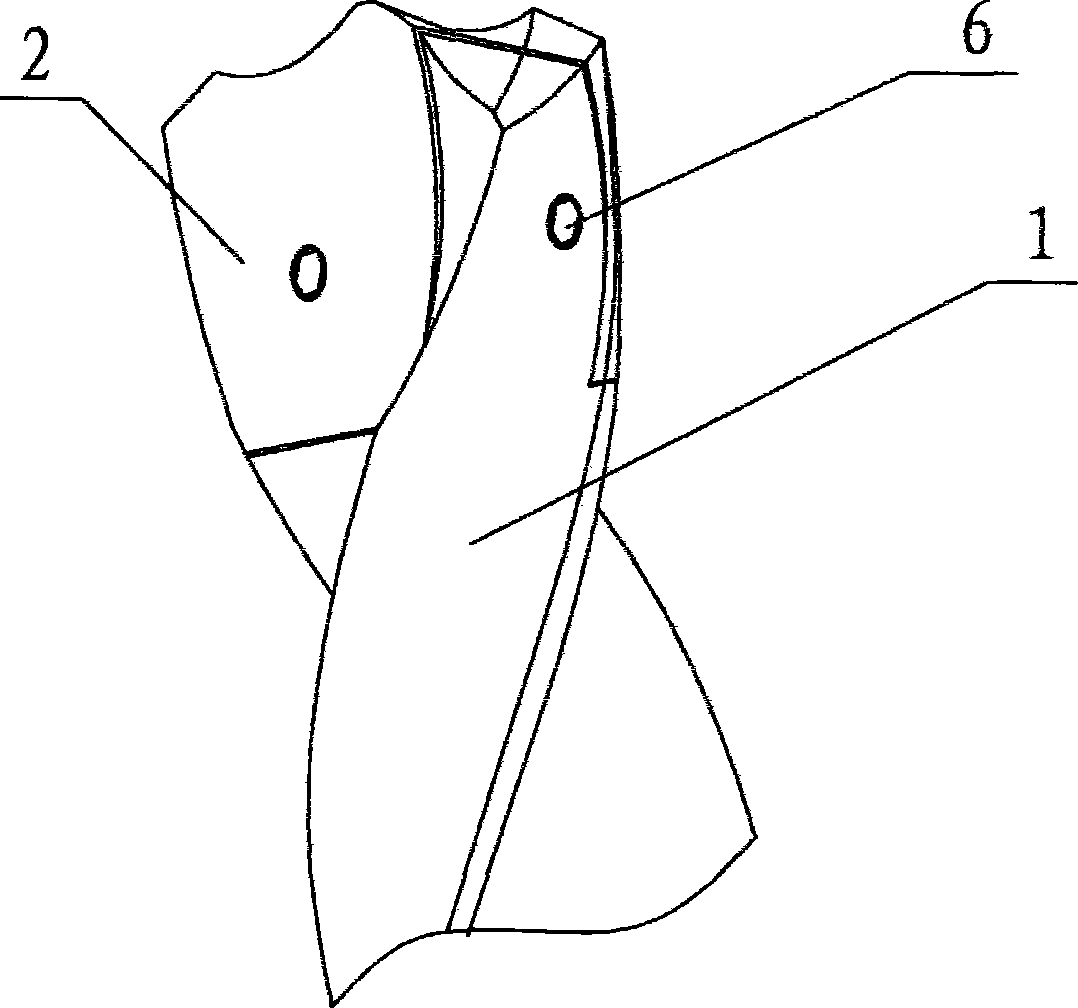

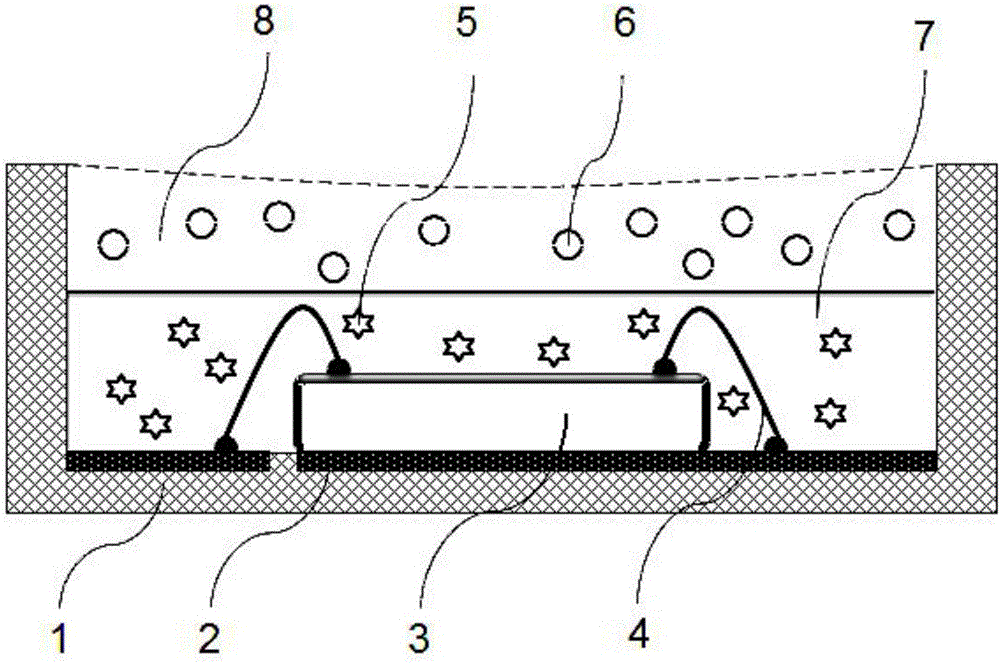

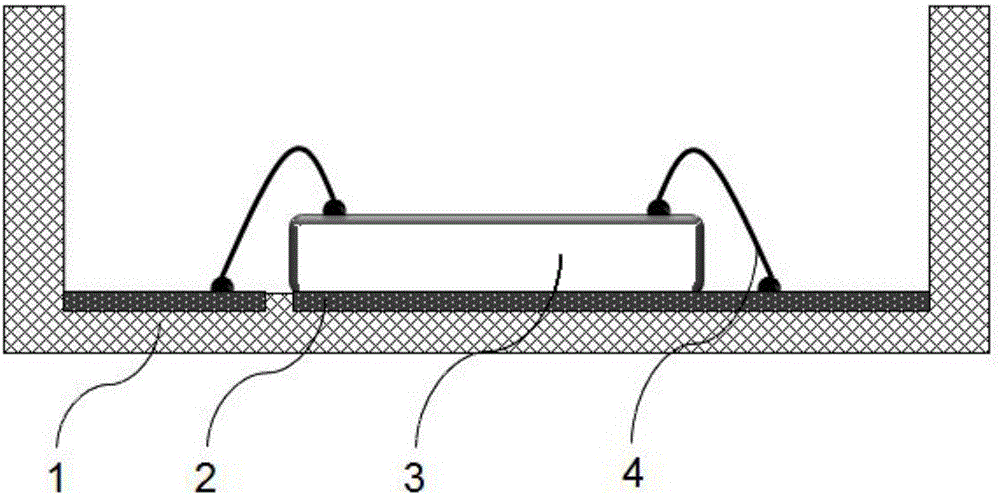

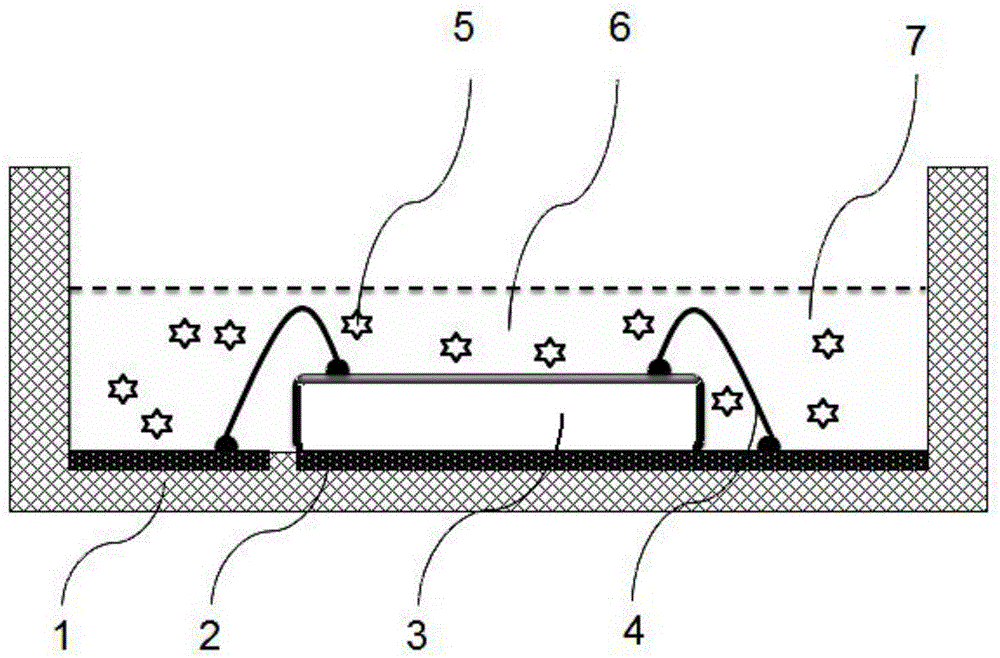

Preparation method of high-permeability mica tape

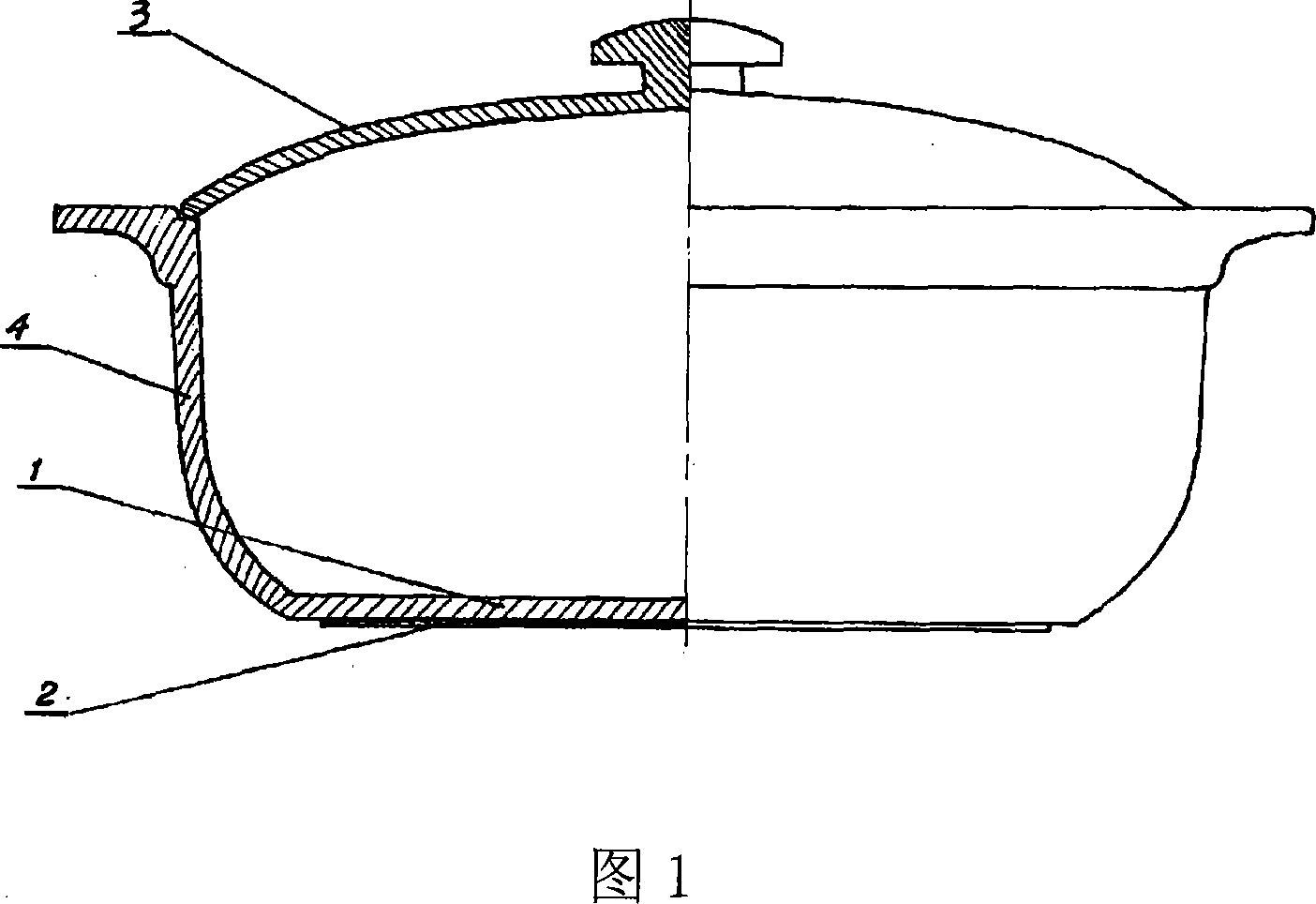

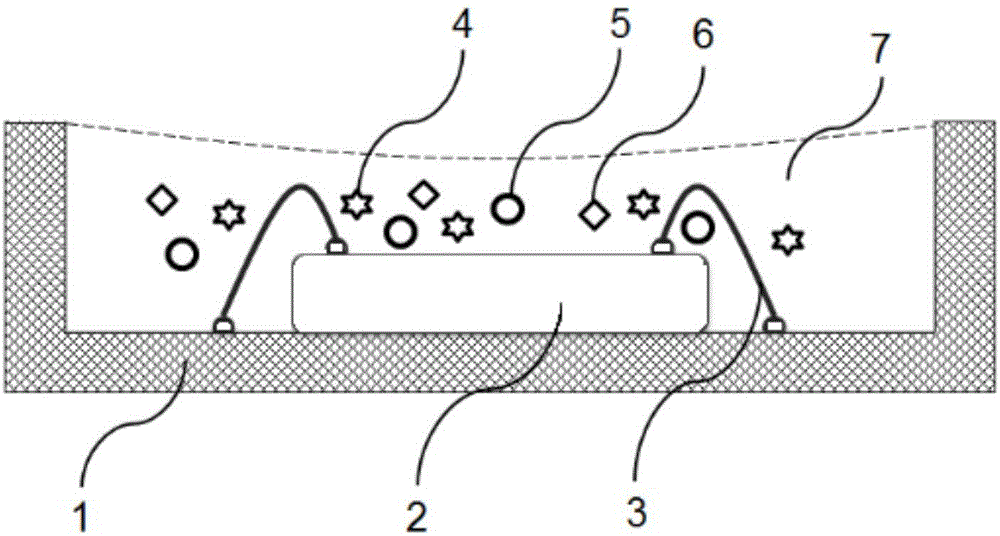

ActiveCN102412041ALong-term softnessWon't penetrateInsulatorsNatural mineral layered productsEngineeringSolvent

The invention discloses a preparation method of a high-permeability mica tape. The high-permeability mica tape comprises: a mica paper layer (1) and a reinforcement material layer (4). The high-permeability mica tape is characterized in that: an adhesive layer (2) is sprayed between the mica paper layer (1) and the reinforcement material layer (4); the mica paper layer (1) is mica paper possessing the high permeability; the adhesive layer (2) is a solventless powdered resin which forms point distribution and a large amount of pore channels (3) exist between the pointlike resin. The method comprises the following steps: (1) respectively rewinding the mica paper and the reinforcement material and spraying the solventless adhesive resin powder on the mica paper; (2) after the mica paper sprayed with the adhesive resin powder is preheated, performing hot pressing and compositing, winding and cutting to the mica paper and the reinforcement material so as to obtain the high-permeability mica tape. The prepared mica tape possesses the high permeability. Adhesive contents are small. Flexibility is good. A caking property of the reinforcement material and the mica paper is good. The mica tape can be stored for a long time, can not harden and can not be crisp. A winding technology is good and the mica tape has many other advantages. The mica tape is suitable for insulation processing of various kinds of motors or electric appliance products and especially suitable for a large high-voltage generator set, whose voltage range is 13.8-27Kv. The mica tape is suitable for a main insulation VPI processing technology of a coil (stator bar) with a unilateral insulation thickness of 4-8mm. Soakage time can be shortened.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

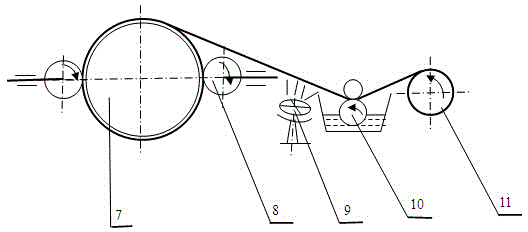

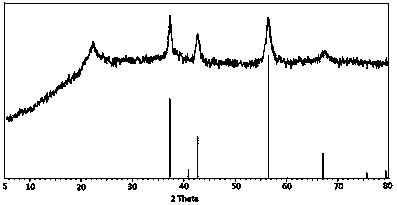

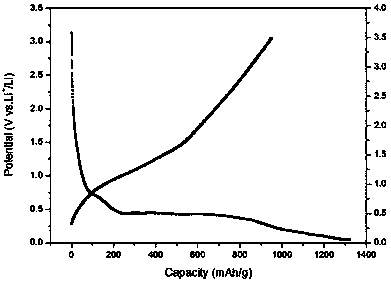

Preparation method of lithium iron phosphate material

InactiveCN103258995AImprove mixing uniformityGood repeatabilityCell electrodesPhosphorus compoundsLithium iron phosphateLithium-ion battery

The invention discloses a preparation method of a high-tap density lithium iron phosphate material. The method comprises the following steps: mechanically mixing iron orthophosphate, a lithium source and a composite carbon source, transferring to a wet stirring ball milling device, adding a certain amount of deionized water and dispersant to form uniform suspension liquid, carrying out nano-ball milling on the obtained suspension liquid, spray-drying to obtain a precursor, and firing and crushing the obtained precursor to obtain the high-tap density lithium iron phosphate material. The lithium iron phosphate material prepared by the method disclosed by the invention has the characteristics of good processability, excellent electrochemical properties and the like when being used as a positive pole material of a lithium ion battery, and the preparation method is low in production cost, free of exhaust pollution, and convenient for commercial mass production.

Owner:郑州瑞普生物工程有限公司

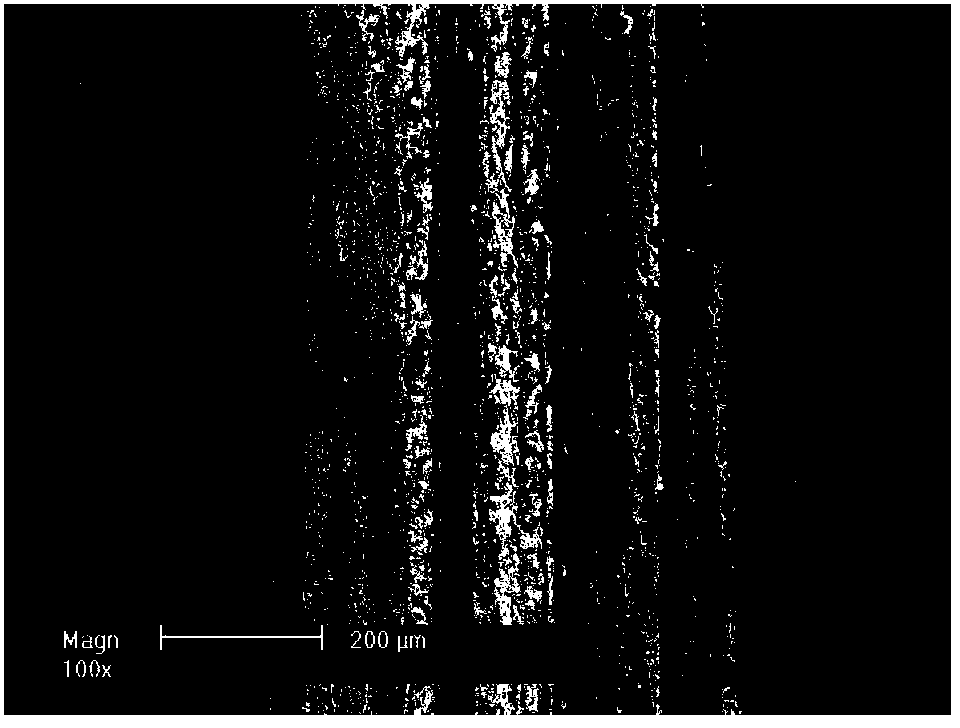

Method for preparing Fe-Mn-Si shape memory alloy coating via laser cladding

InactiveCN103409748ASimple preparation processSuitable for mass industrial productionMetallic material coating processesShape-memory alloyAlloy

The invention discloses a method for preparing a Fe-Mn-Si shape memory alloy coating via laser cladding. The Fe-Mn-Si shape memory alloy coating comprises raw materials including pure iron powder, nickel power, manganese powder, silicon powder, chromium powder, vanadium powder, terrae rare, quartz, wood flour, starch and the like, via the laser cladding way, the Fe-Mn-Si shape memory alloy coating prepared by the method has an excellent mechanical property, and particularly has the characteristics of good abrasion resistance, low stress residue, high fatigue strength. The self-designed cladding power preparation process is simple and suitable for industrial mass production, the cladding process is simple and easy to implement, and the obtained functional coating has greater market application prospects.

Owner:DALIAN MARITIME UNIVERSITY

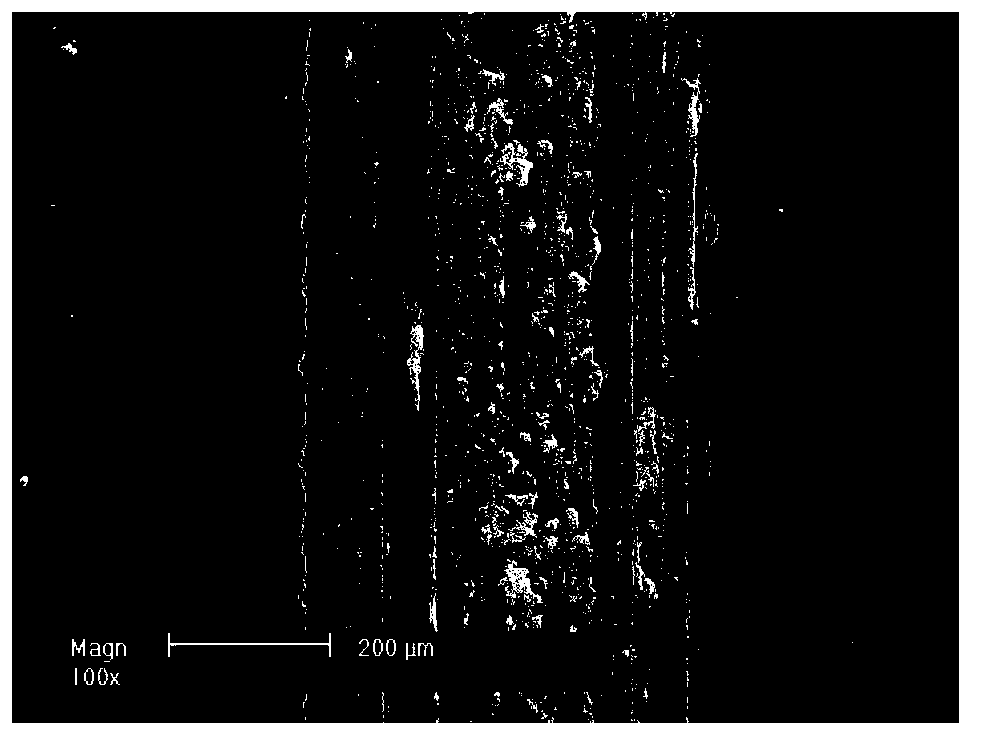

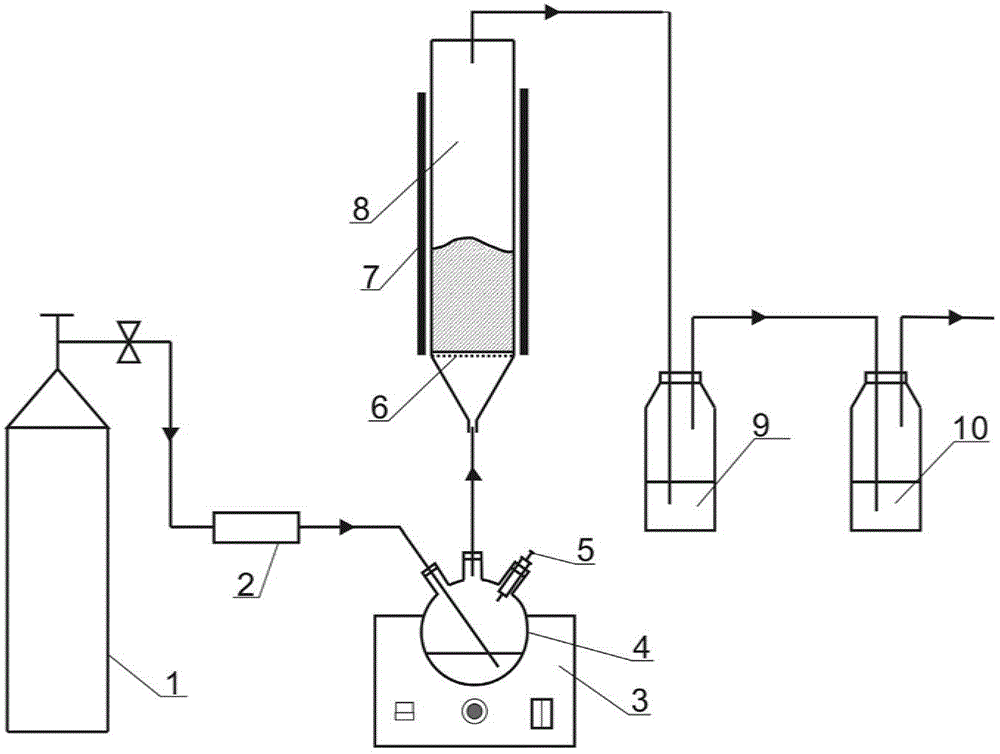

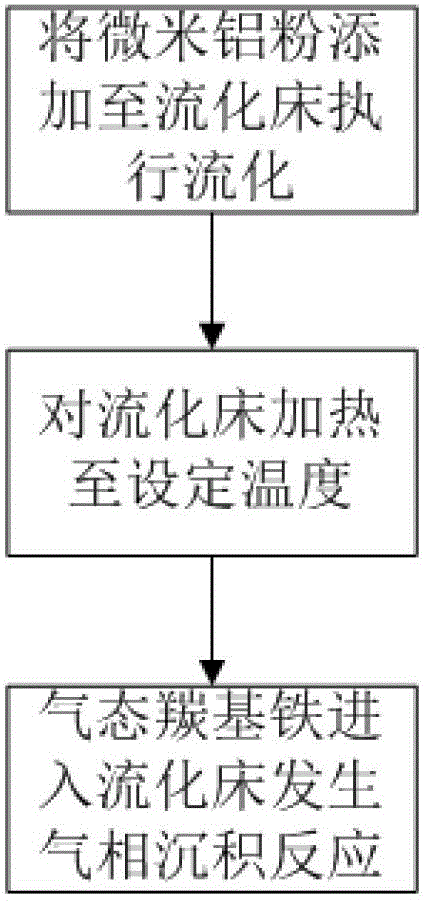

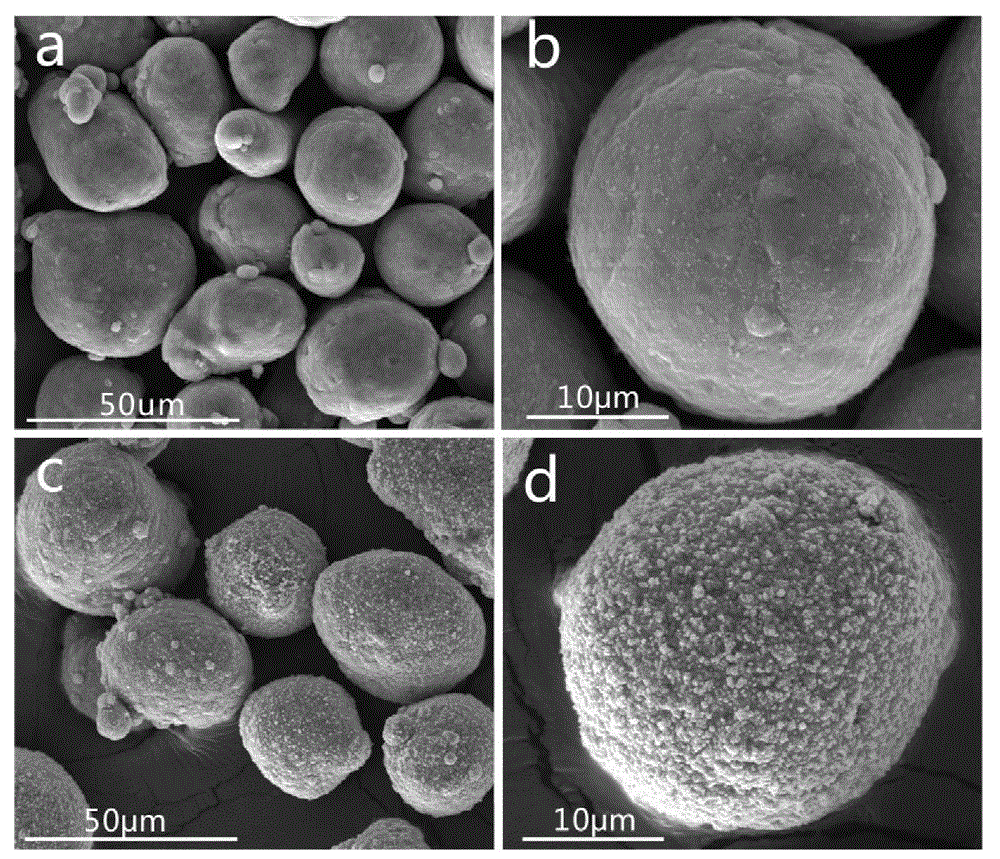

Preparation method of iron-clad aluminum type composite powder and product thereof

InactiveCN103060770AIncrease contact areaHigh mass/heat conversion rateExplosivesChemical vapor deposition coatingSolventAluminum composites

The invention discloses a preparation method of iron-clad aluminum type composite powder. The method comprises the following steps of: (a) adding micron aluminum powder to a fluidized bed and introducing a carrier gas, thereby performing a fluidization process of aluminum powder; (b) continuously introducing the carrier gas to empty air in the fluidized bed, and heating the fluidized bed so as to reach a predetermined temperature; and (c) adding carbonyl iron to a bubbler and heating to volatile carbonyl iron to be brought into the fluidized bed by the carrier gas to generate a vapor deposition reaction, thereby producing an iron-clad aluminum composite powder product. The invention further discloses the corresponding composite powder product and use of the composite powder product. Through the invention, the iron-clad aluminum type composite powder can be prepared without requiring a solvent, later separating and drying steps are saved, the prepared product has a uniform and dense coating layer, excellent thermal properties and good heat release concentration, and is especially applicable to the uses of the aspects in processing energetic materials, laser surface cladding and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

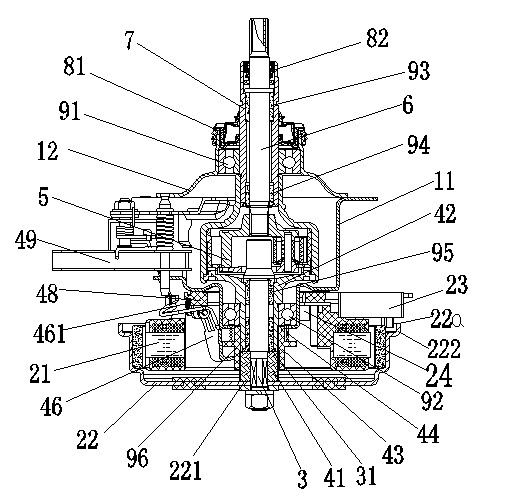

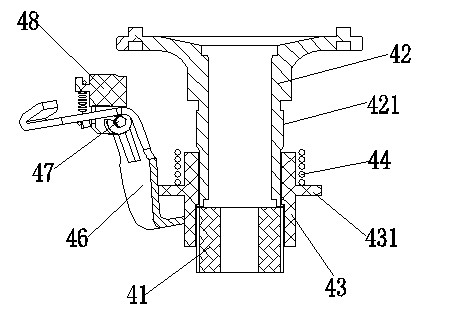

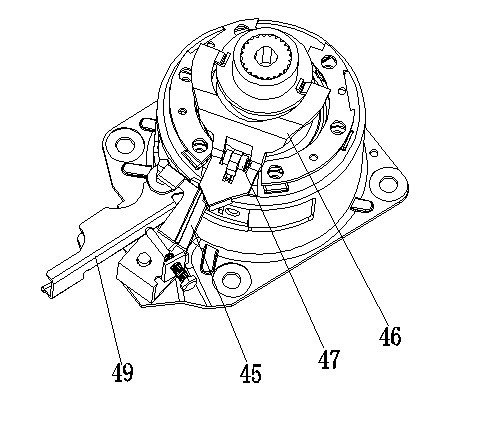

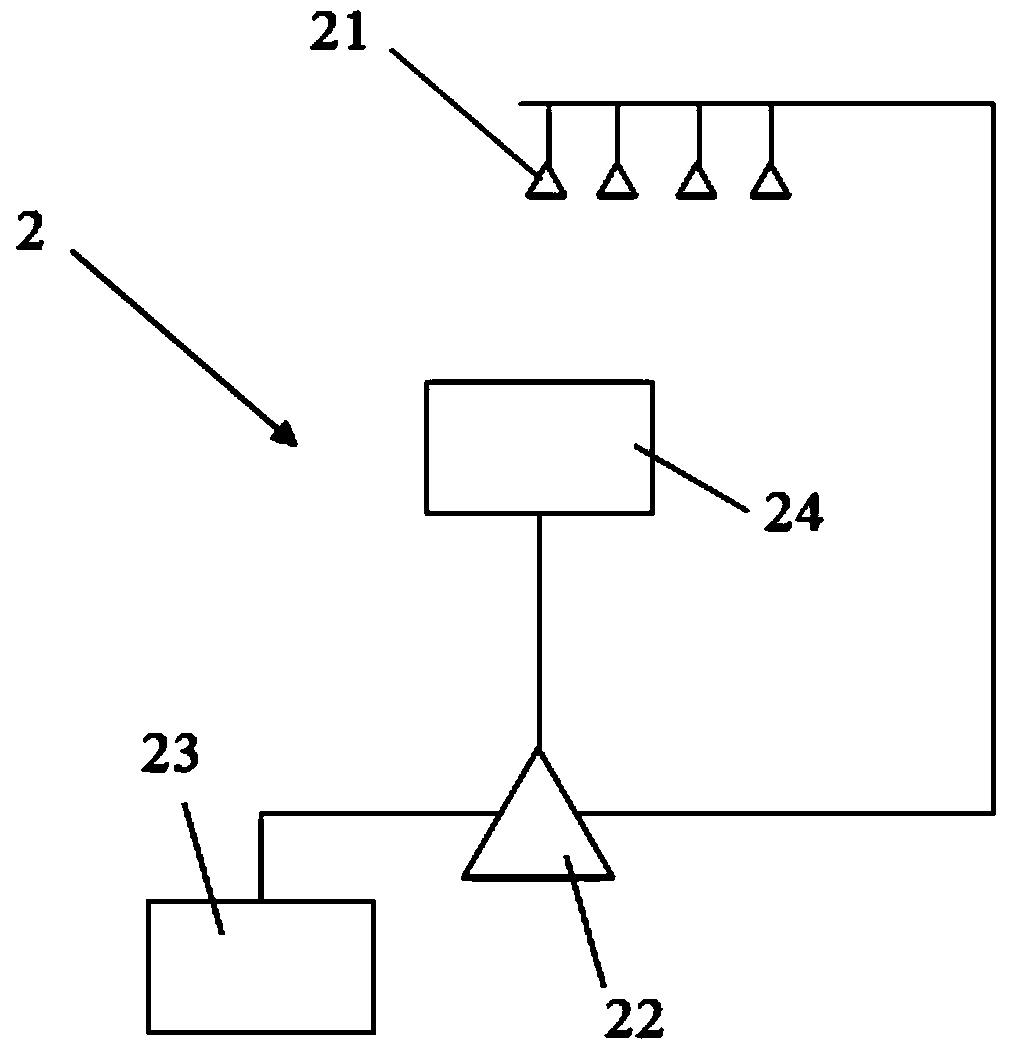

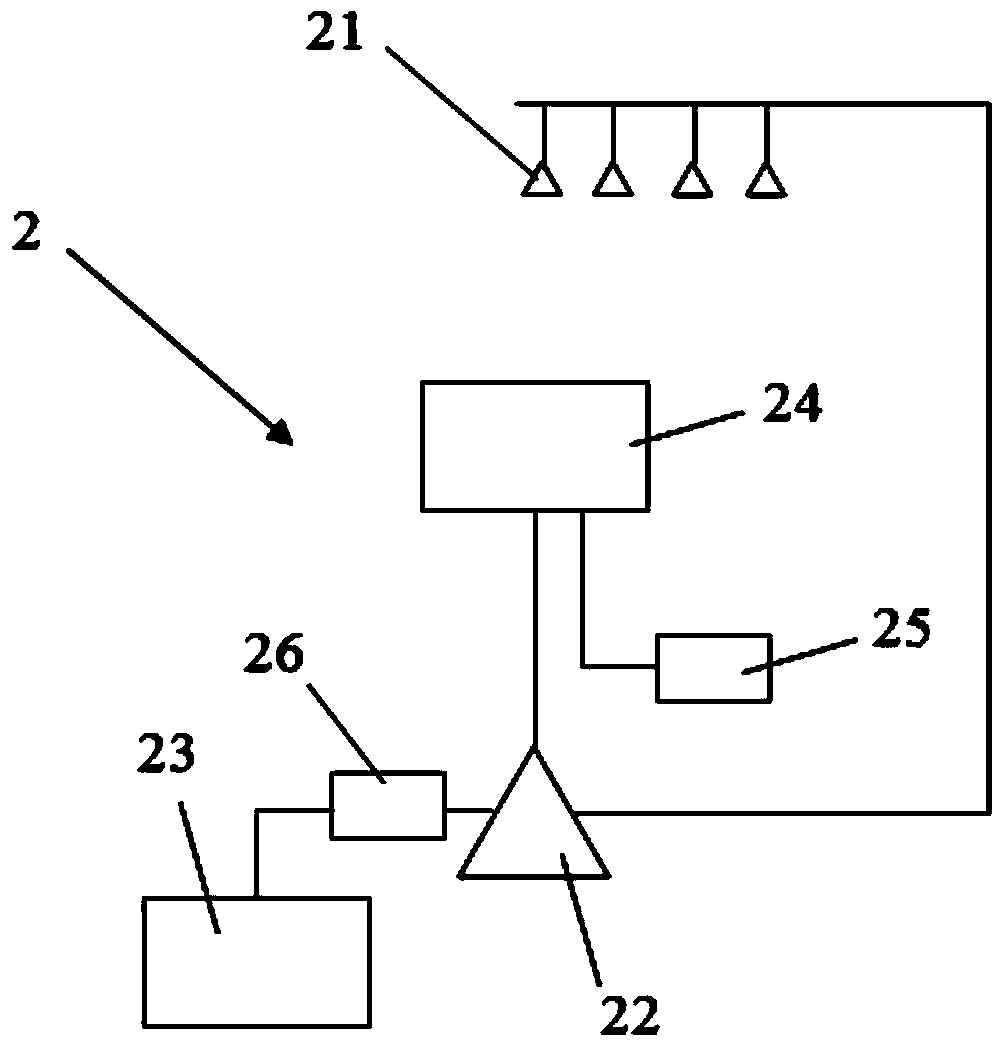

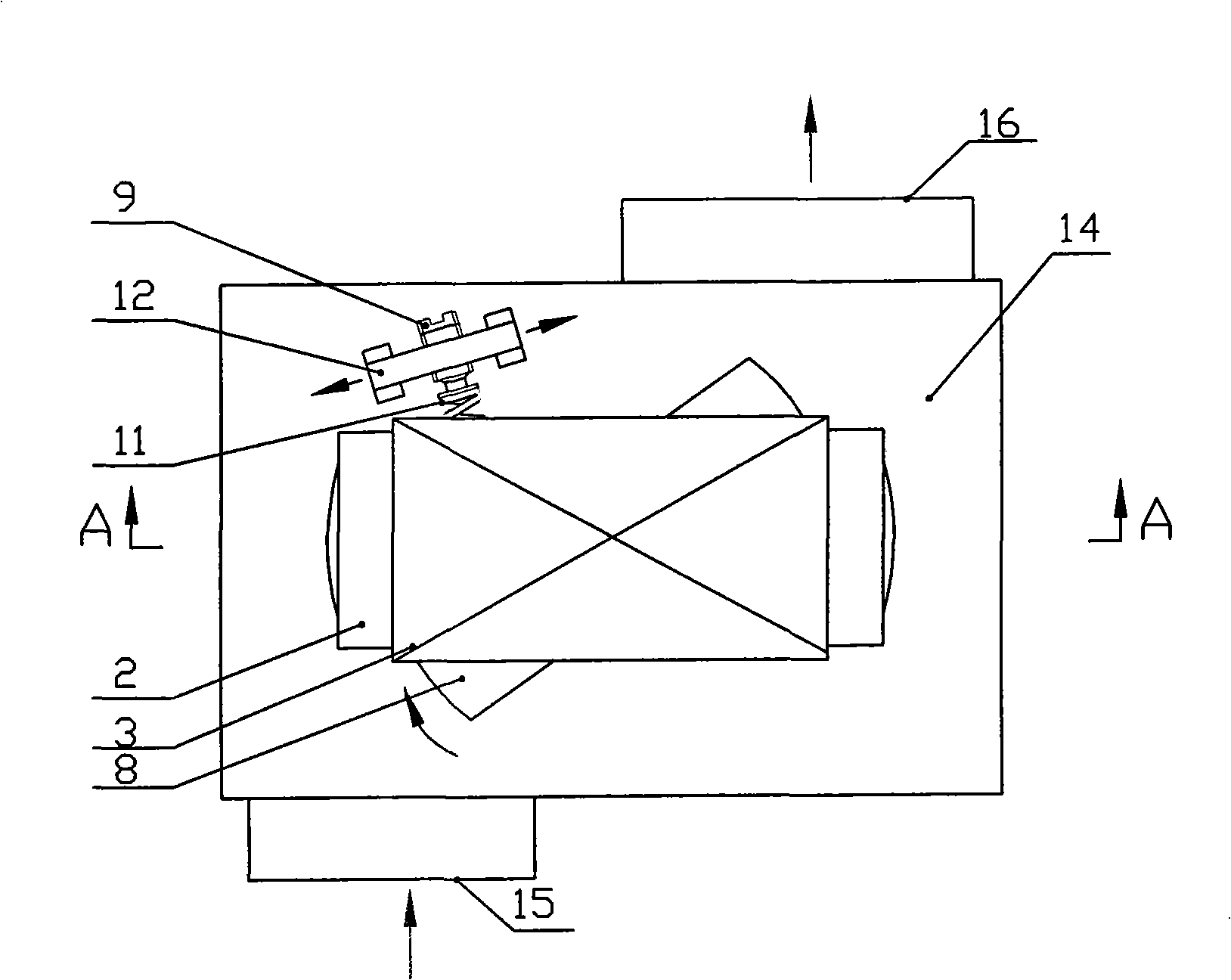

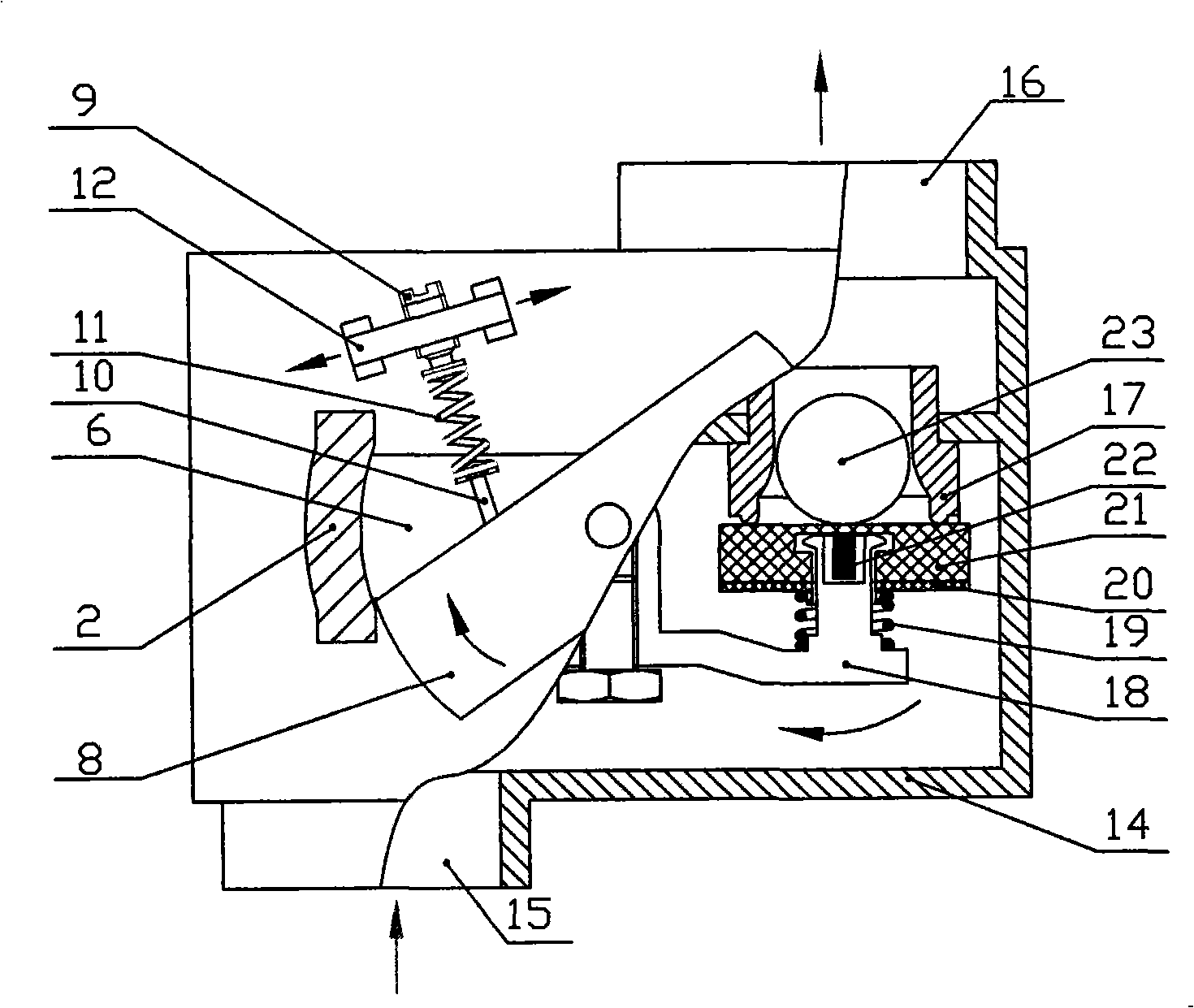

Washing machine bionic hand rub frequency conversion deceleration clutch

ActiveCN102277710AEasy to installImprove insulation performanceOther washing machinesTextiles and paperLow noiseBrushless motors

The invention discloses a variable-frequency speed-reducing clutch of bionic hand rubbing of a washing machine. The clutch provided by the invention comprises a lower shell and an input shaft which are matched; the lower shell is equipped with a stator of a direct-current brushless motor and the end part of the input shaft is connected with an external rotor of the direct-current brushless motor;the stator of the direct-current brushless motor is located at an inner cavity of the external rotor of the direct-current brushless motor and the input shaft is assembled with a sliding clutch mechanism composed of a shaft sleeve, a clutch shaft, a clutch sliding block and a clutch spring; the shaft sleeve covers the input shaft and the clutch shaft is located above the shaft sleeve to rotatablycover the input shaft; the shaft sleeve and the clutch shaft are all provided with peripheral splines; guiding splines on the inner periphery of the clutch sliding block are slidingly matched with the peripheral spline of the clutch shaft; the clutch spring is pressed on an annular lug boss on the periphery of the clutch sliding block and the clutch sliding block is connected with a clutch control mechanism. The clutch provided by the invention realizes the variable-frequency washing of the bionic hand rubbing of the washing machine; and the clutch enriches the washing function and has the advantages of low noise, energy source conversation, good safety performance and the like.

Owner:宁波普尔机电制造有限公司

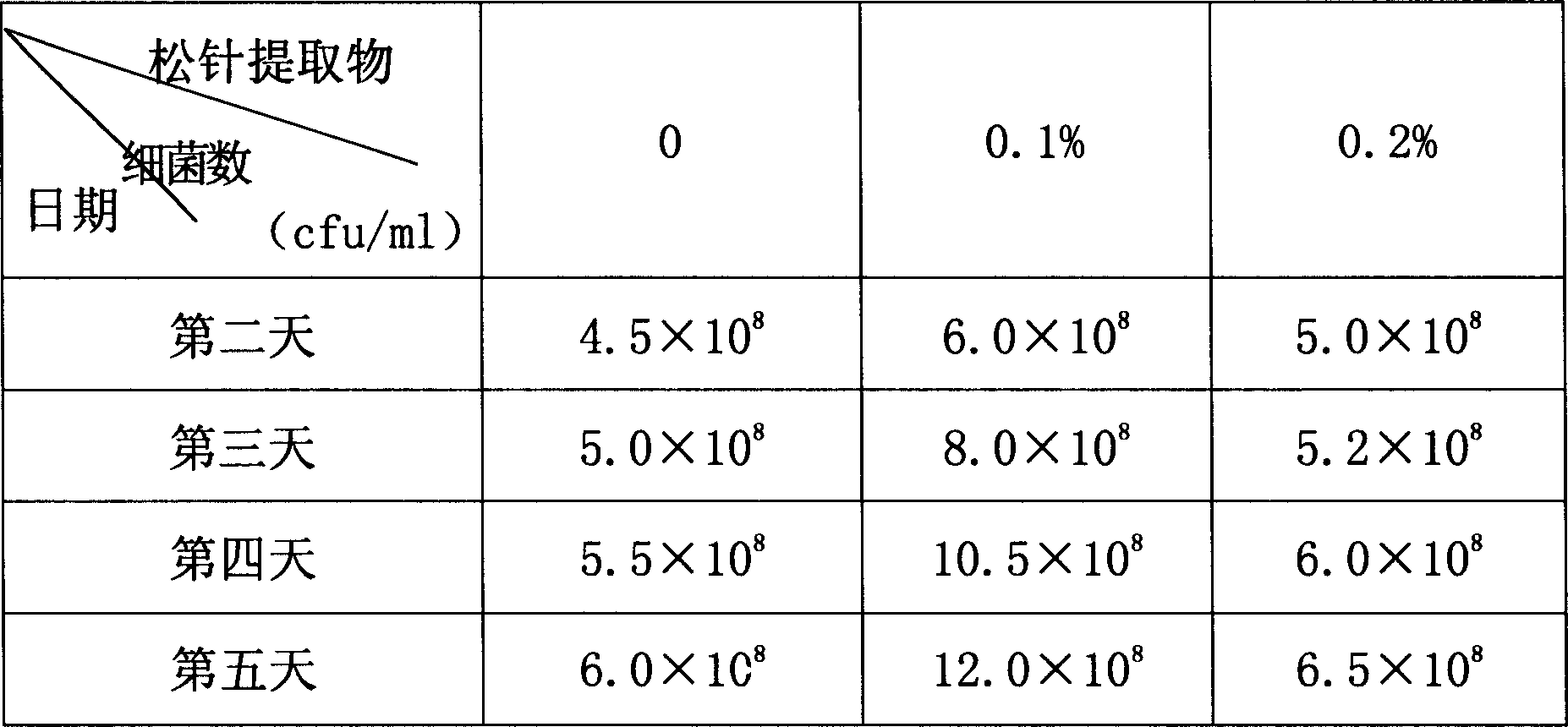

Feed additive for improving animal disease-resistant ability

A feed additive for increasing the resistance of animal to diseases is prepared from the fragments of the plants in pinaceae through pulverizing and extracting in hot water. Its contains polyphenol compound and polyose for regulating the balance between floras in animal's intestinal tract.

Owner:浙江德清利欣生物科技有限公司

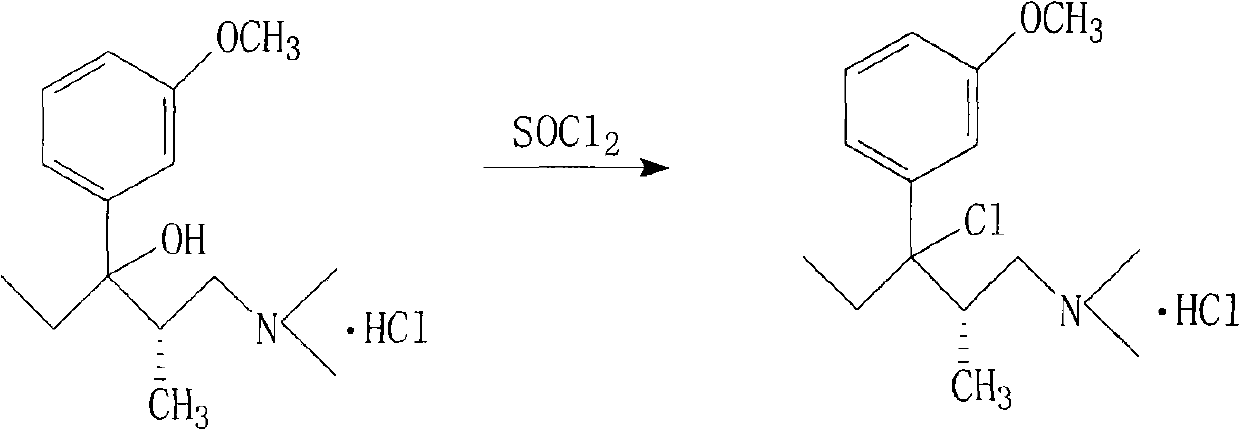

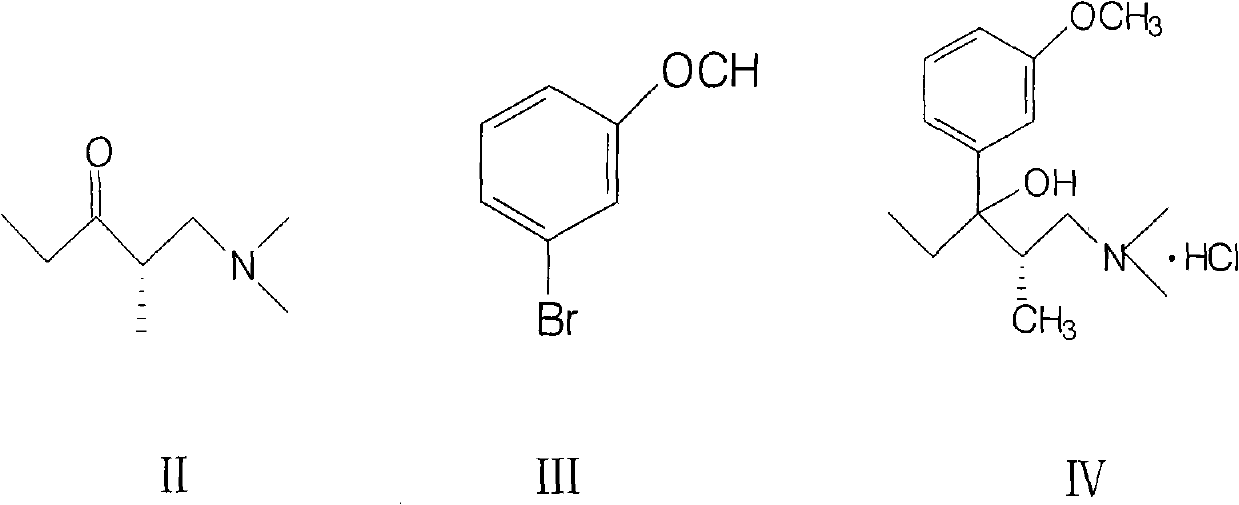

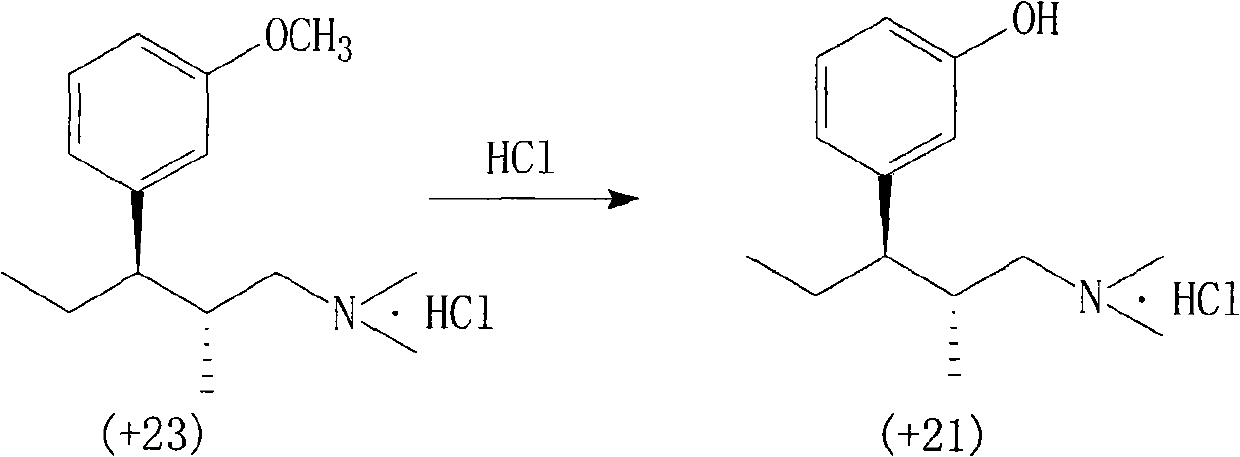

Method for preparing important intermediate of tapentadol hydrochloride analgesic

InactiveCN101948397AReduce manufacturing costSuitable for mass industrial productionOrganic compound preparationAmino-hyroxy compound preparationEnantiomerTapentadol Hydrochloride

The invention relates to a method for preparing an import intermediate of a tapentadol hydrochloride analgesic, which is (2S)-1-dimethylamino-3-(3-methoxyphenyl)-2-methylpentyl-3-ol hydrochloride. The (2S)-1-dimethylamino-3-(3-methoxyphenyl)-2-methylpentyl-3-ol hydrochloride with optical activity is obtained by the Grignard reaction of a compound II with optical activity and a compound III with optical activity. The Grignard reaction is performed by mixing magneson solution of the compound III and the tetrahydrofuran solution of the compound II at 5 to 10 DEG C and standing the mixed solution at room temperature overnight. The molar ratio of the compound II to the compound III is 0.8-1:1.0-1.5. The preparation method of the invention is not limited by a chiral column split instrument, solves the problem of processing enantiomers as waste chemicals, reduces production cost and is more suitable for large-batch industrial production.

Owner:TIANJIN TAIPU PHARMA SCI & TECH DEV

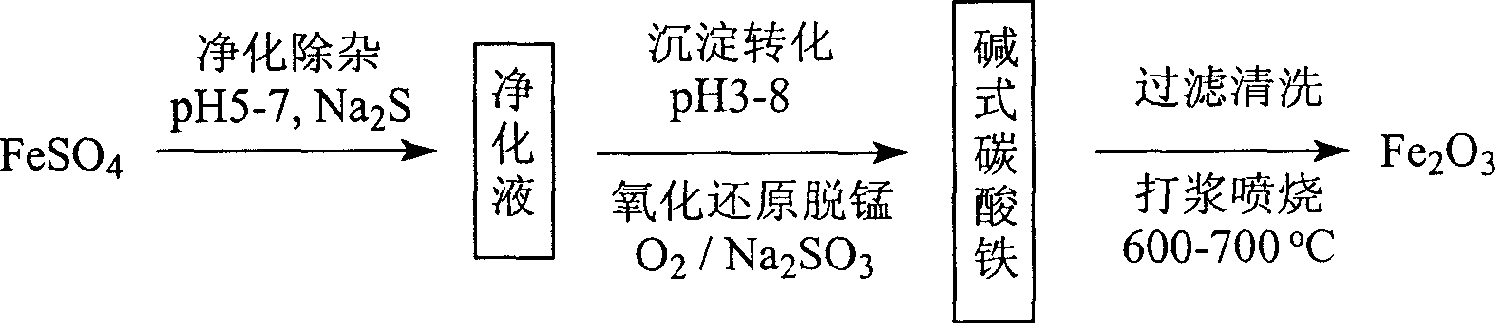

Process for preparing ferric oxide red powder

InactiveCN1491997ASolve the separation problemEasy to producePigmenting treatmentSulfateWhite powder

The present invention relates to the preparation process of ferric oxide red powder. Unlike available technology, which has the demerits of high production cost and low product purity of processed ferrous permanganate, the present invention uses ferrous sulfate as the side product of titanium white powder production as material and produces high purity ferric oxide red powder via purification to eliminate impurity, precipitation to eliminate manganese, water washing, spray burning and other steps. The ferric oxide red powder has impurity content of Si, Al, Ca, Mg, etc. less than 80 ppm, Mn content lower than 0.2 wt% and Fe2O3 content over 99.5 wt%, and is used as soft magnetic material. The present invention has simple technological process, low production cost and high product quality, and may be used in industrial production.

Owner:FUDAN UNIV +1

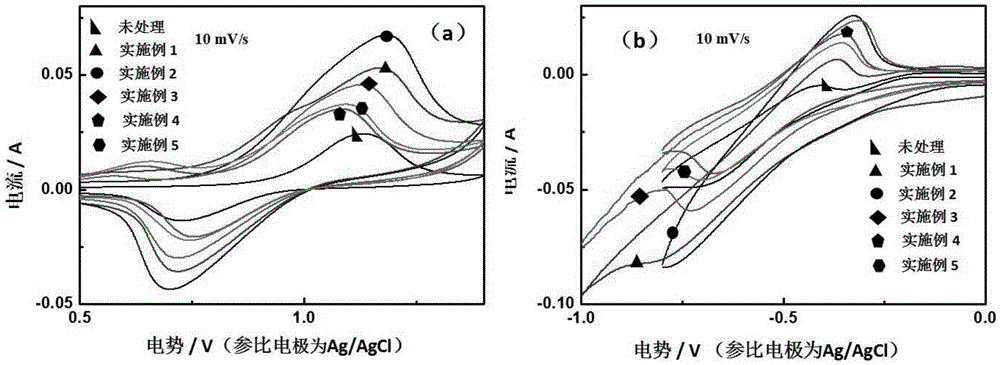

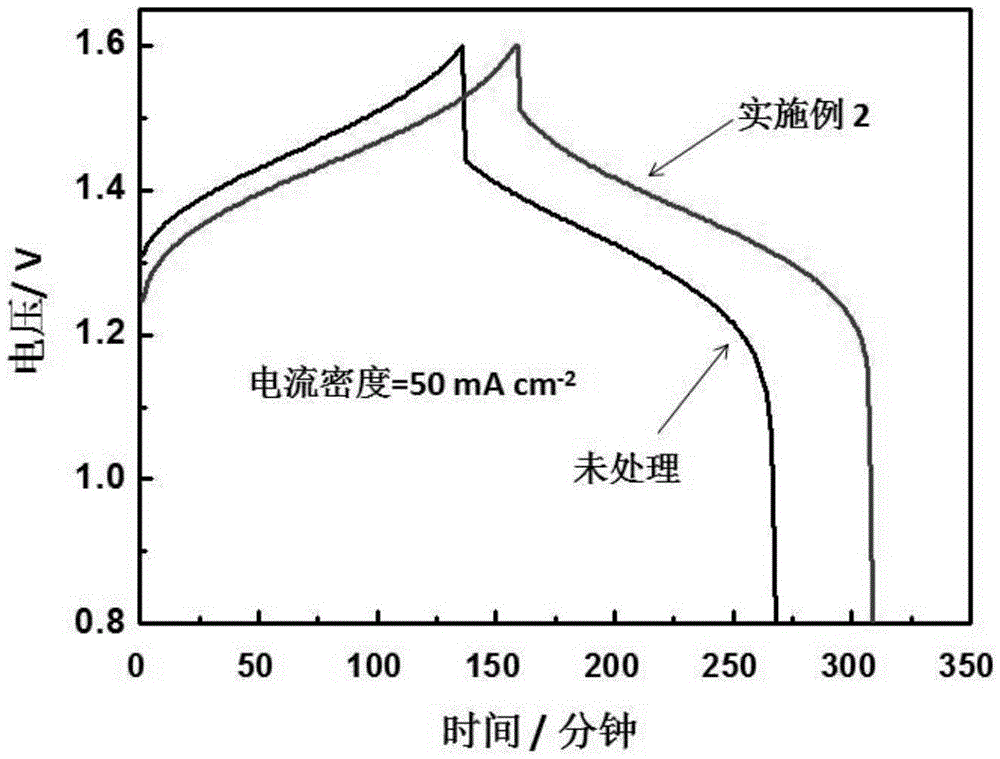

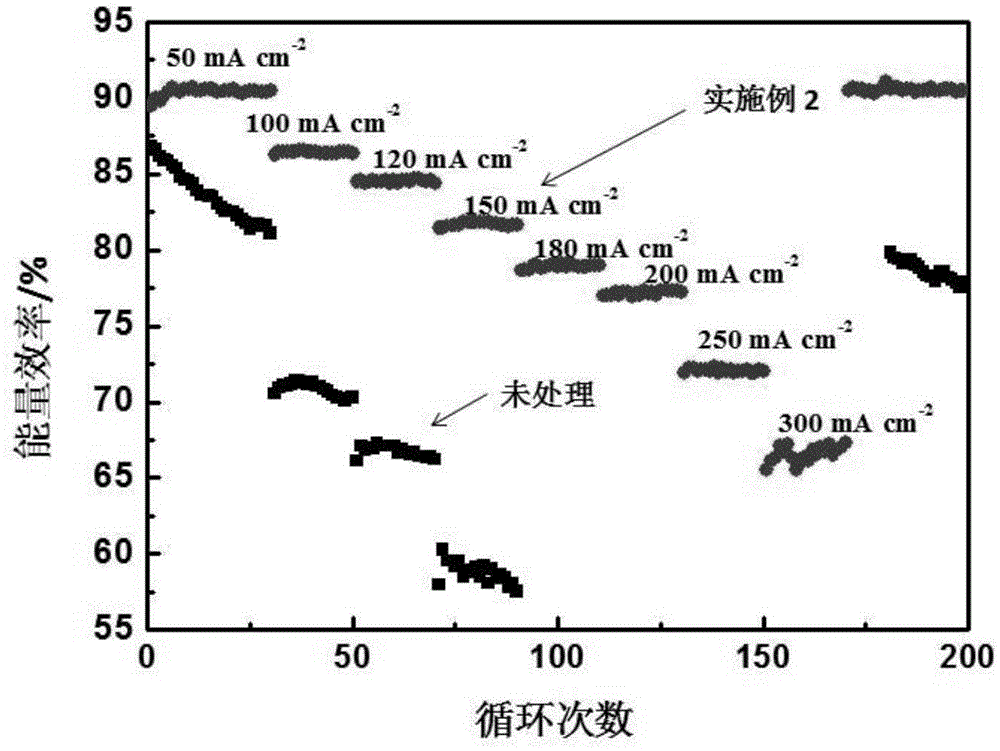

Treatment method for all-vanadium redox flow battery electrode

InactiveCN105529471AOptimize process flowEasy to operateCell electrodesRegenerative fuel cellsHigh current densityCharge discharge

The invention provides a treatment method for an all-vanadium redox flow battery electrode. The method comprises the following steps: with carbon electrode materials of a graphite felt, a carbon felt and the like as raw materials, drying the raw materials after fully soaking in an alkali liquor; carrying out high-temperature activation under protection of an inert gas; and washing and drying the product to prepare the activated carbon electrode materials. The treatment method has the advantages of being simple, simple and convenient to operate and low in cost; the surfaces of the treated carbon electrode materials are etched; the effective reaction area of vanadium ion electron pairs on the electrode surface is increased; the charge transfer impedance of an all-vanadium redox flow battery in a charge-discharge process is greatly reduced, so that the voltage efficiency and the energy efficiency of the all-vanadium redox flow battery under high current density are greatly improved.

Owner:HUNAN YINFENG NEW ENERGY

Steam eye patch and making method thereof

The invention discloses a steam eye patch and a making method thereof. Low-temperature steam at 40-50 DEG C can be generated, heating time can last for 20-40min, and the low-temperature steam can heatperiocular skin, accelerate blood circulation and improve cell activity, so that the steam eye patch has effects of relieving eye fatigue, moisten eyes and removing black eyes and eye bags; diatomitein a heating piece has adsorption performance, thereby being capable of effectively cleaning the periocular skin to enable steam to better permeate skin. The heating piece also contains macromolecular setting fiber, thereby having good setting effect; when in use, the steam eye patch can be adjusted timely according to eye shape of different users to better fit eyes; a healthcare skin lotion coated on the surface of inner-layer nonwoven cloth has good healthcare and skincare effects on human bodies, so that compared with conventional steam eye patches, the steam eye patch is richer in function. The making method is simple in process, mild in condition and suitable for mass industrial production of the steam eye patch.

Owner:WALCH GUANGZHOU COMMODITY

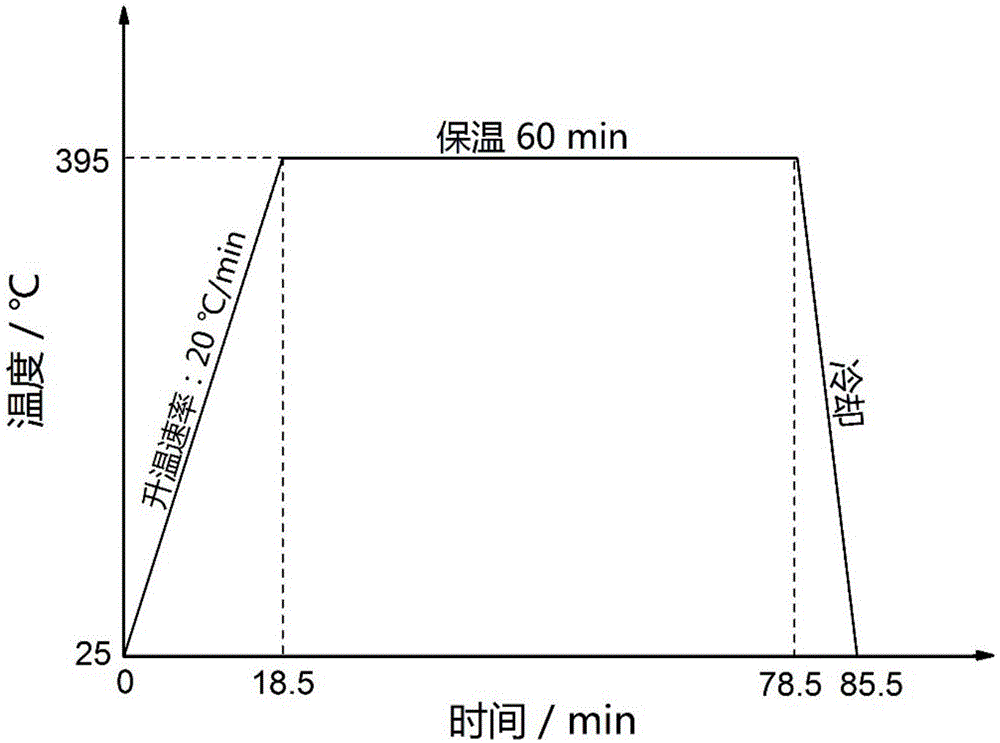

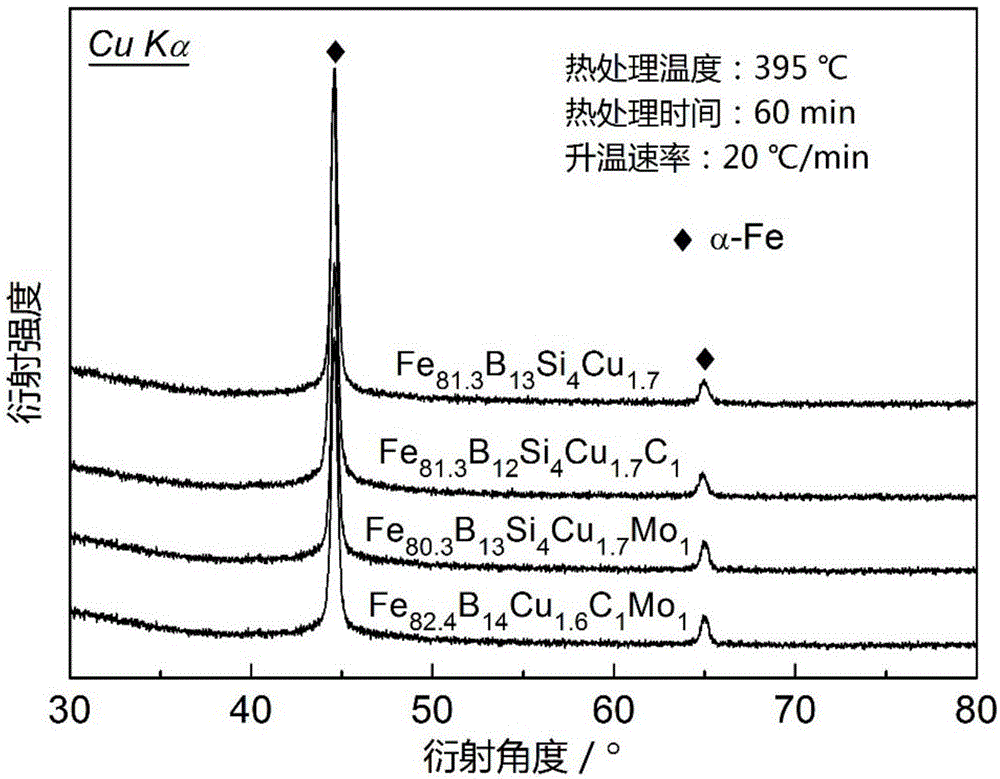

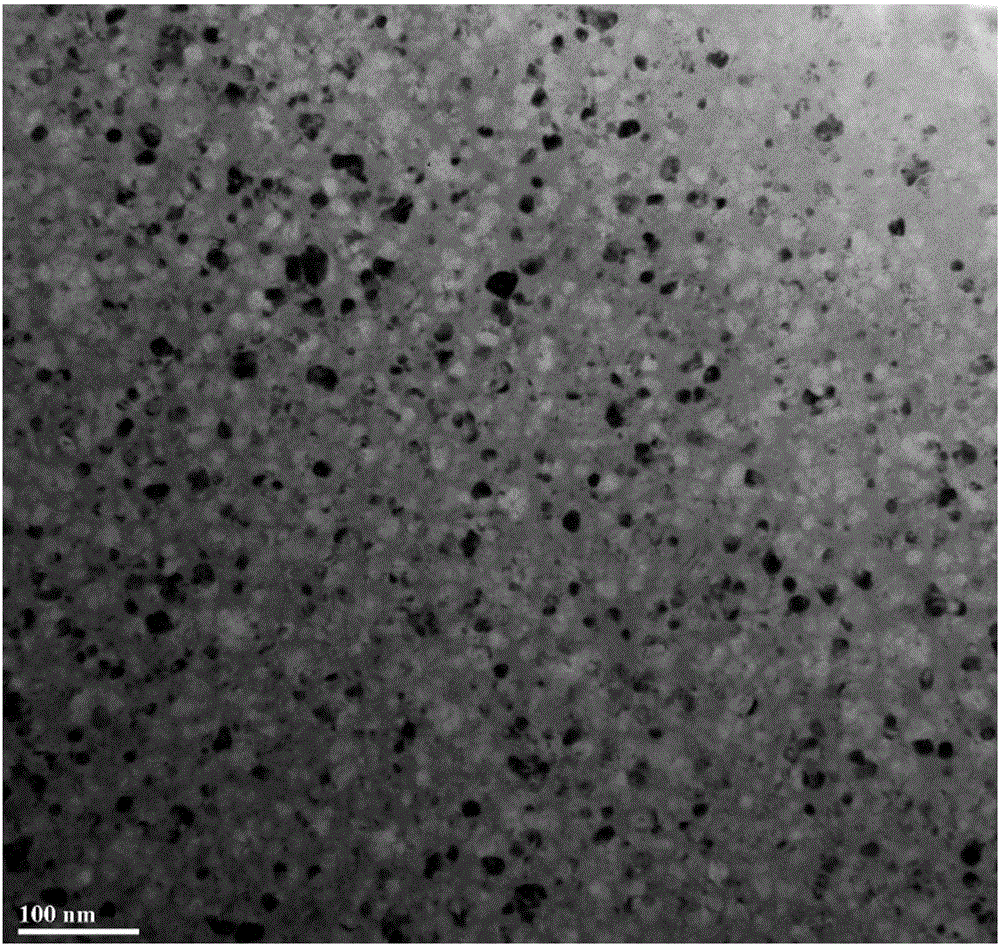

Nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and preparation method therefor

InactiveCN106373690AGood workmanshipHigh saturation magnetic inductionMagnetic materialsThermal insulationAlloy

The invention discloses a nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and a preparation method therefor, and belongs to the technical field of a new material. The chemical formula of the nanocrystal magnetically soft alloy is FeBSi<c>Cu<d>C<e>M<f>Z<g>, wherein M is at least one kind of elements Co or Ni; Z is at least one kind of elements Al, Cr, Mn, Ti, Nb, Ta or Mo; a, b, c, d, e, f and g are atomic percentage contents of corresponding elements, and satisfy the formula as follows: a+f is greater than or equal to 80 and less than or equal to 84; b is greater than or equal to 10 and less than or equal to 15; c is greater than or equal to 0 and less than or equal to 6; d is greater than or equal to 1.6 and less than or equal to 2.2; e is greater than or equal to 0 and less than or equal to 2; f is greater than or equal to 0 and less than or equal to 5; and g is greater than or equal to 0 and less than or equal to 2. The alloy is formed by uniformly dispersing an <alpha>-Fe phase, which is obtained by heat treatment of amorphous stripes and has the crystal grain sizes of less than 50nm, into residual amorphous phase tissues, wherein the saturation magnetic induction strength is greater than 1.7T, and the coercivity is less than 15A / m. The alloy has no volatile phosphorus element; in addition, the heat treatment process is simple, and high temperature-rise rate is not required; the heat treatment temperature range and the thermal insulation time range are wide; industrial production can be realized easily; and the nanocrystal magnetically soft alloy and the preparation method therefor are convenient to popularize and use.

Owner:DALIAN UNIV OF TECH

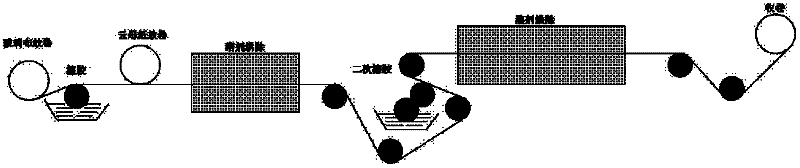

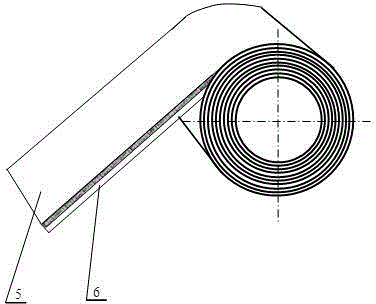

High-performance wood-based composite pressure conveyer pipe and preparation method

InactiveCN104896211AAbundant resourcesEnvironmentally friendlyLaminationLamination apparatusAdhesiveSingle plate

The invention provides a high-performance wood-based composite pressure conveyer pipe. The conveyer pipe is formed by four kinds of functional layers of an inner liner layer 1, a strengthened layer 2, a base layer 3 made of multiple layers of wooden single plates, and an external protection layer 4, which are arranged from inside to outside. The layers are adhered together by selecting special adhesive according to different types of materials, so a firm pipe wall is formed. The manufacturing method comprises following steps of 1) preparation of the inner liner layer; 2) preparation of the strengthened layer; 3) preparation of the wooden base layer; and 4) preparation of high-performance wood-based composite pressure conveyer pipe. The preparation method is advantageous in that strength in all directions of the pipe can be designed and technical requirements of different usage occasions are satisfied; and the conveyer pipe is advantageous in that the conveyer pipe is high in strength, light, convenient to transport and install, and high in environmentally-friendly performance; continuous supplying of main materials can be achieved; and non-renewable mineral resources are hardly consumed.

Owner:NANJING FORESTRY UNIV

Preparation method for fixed bed Raney nickel catalyst

The invention discloses a preparation method for a fixed bed Raney nickel catalyst, which comprises the following steps: (1) pretreatment: soaking ketone solvents by using foaming nickel, then taking out and washing the foam nickel by using water; (2) immersing and plating aluminum; immersing the foam nickel obtained from the step (1) into aluminum salt solution, then adding reducing solution into the mixed solution and standing the mixed solution for 1 to 12 hours; (3) baking: washing and drying a sample obtained from the step (2), and baking the sample at a temperature of between 600 and 1,000 DEG C in inert atmosphere for 5 to 600 minutes; and (4) leaching: leaching the sample obtained from the step (3) in sodium hydroxide or potassium hydroxide solution for 1 to 48 hours, and obtaining the fixed bed Raney nickel catalyst. The preparation method has the advantages that the preparation process is simple; and the catalyst prepared by the method has higher catalytic activity, stronger mechanical strength and longer service life. The invention belongs to the technical filed of catalyst preparation.

Owner:HANERGY TECH

Preparation method of hydro-thermal coupling spray pyrolysis MnO2/graphene electrode material

InactiveCN103915613AStable structureWide variety of sourcesMaterial nanotechnologyHybrid capacitor electrodesActive agentGraphene electrode

The invention discloses a preparation method of a hydro-thermal coupling spray pyrolysis MnO2 / graphene electrode material, belonging to the technical field of electrode materials for energy storage systems. The preparation method comprises the following steps: uniformly mixing graphene oxide (GO) prepared by using a Hummer method with an aqueous solution of bivalent manganese salt and a doped metal ion compound, adding a dispersing agent, an oxidant and a surfactant, and ultrasonically dispersing for a certain period of time; putting the mixed solution into a hydrothermal kettle, adjusting the temperature, and keeping for a certain period of time; filtering and washing a reaction product to obtain a precursor; adding the dispersing agent and the surfactant into the precursor, uniformly stirring for mixing, and adjusting the solid-liquid ratio, inlet temperature and outlet temperature to perform spray pyrolysis in order to obtain a metal ion-doped MnO2 / graphene nanometer composite electrode material. According to the nanometer composite electrode material prepared by using the method, components are uniform and the batch stability is high.

Owner:SHANDONG RUNSHENG POWER TECH +1

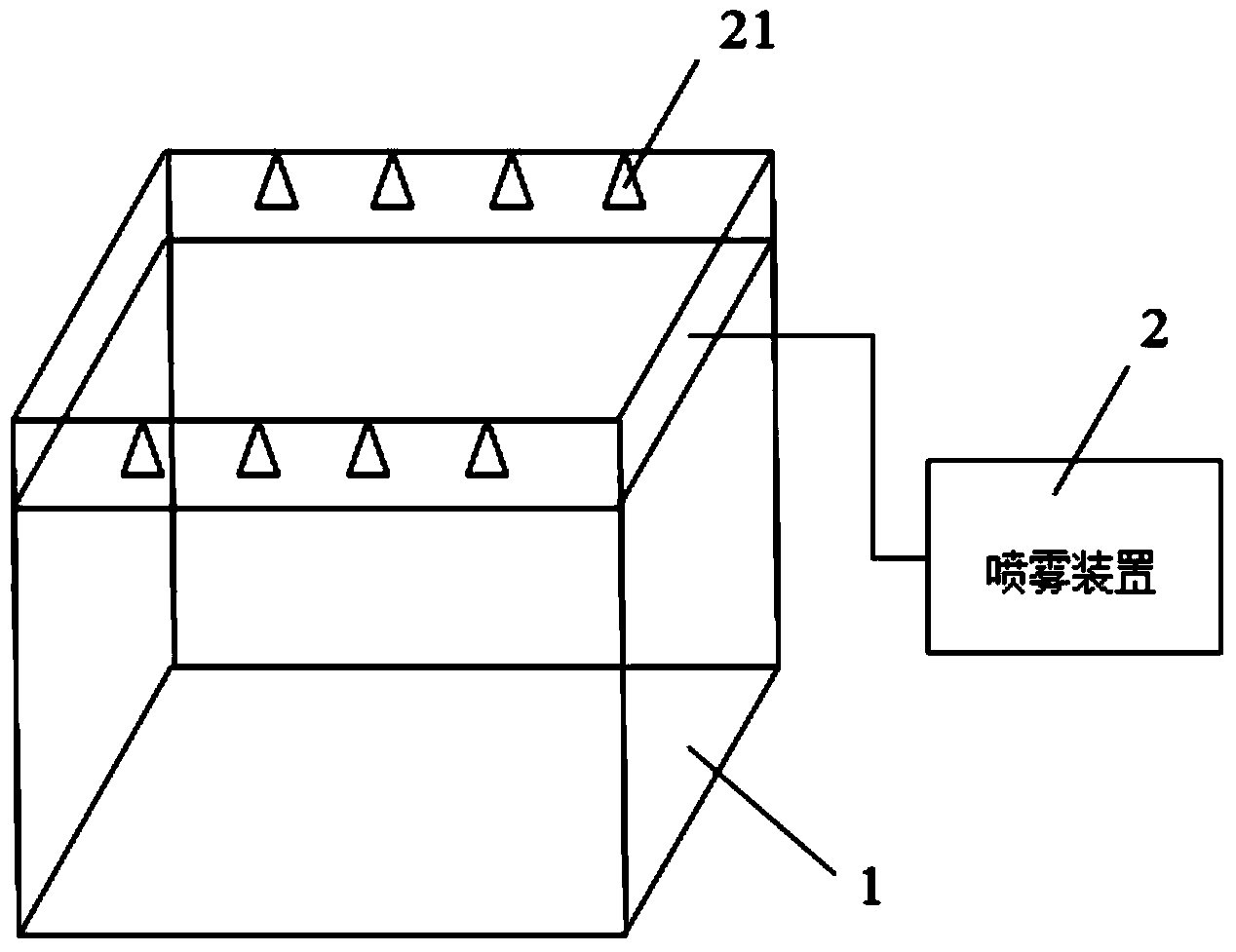

Combined photocatalyst-ClO2 deodorization device and deodorization method adopting same

ActiveCN103721564AEasy to deodorizeSafe DeodorizationDispersed particle separationDeodrantsUltraviolet lightsEngineering

The invention discloses a combined photocatalyst-ClO2 deodorization device which comprises an isolation net and a spraying device, wherein the isolation net is arranged at the periphery of a deodorization space and is loaded with a photocatalyst; the photocatalyst is used for degrading odorous substances in air; the spraying device is used for spraying ClO2 disinfection liquid to the deodorization space. The invention further discloses a deodorization method adopting the deodorization device. The deodorization device can be directly used in the periphery of an animal building and / or a manure pit, is capable of timely treating odor in an odor place and directly disinfecting and deodorizing an open environment without collecting the odor, and so that the odor removing is relatively convenient; in addition, sunlight is taken as a light source, the odorous substances in the air are degraded by adopting the photocatalyst under the condition of visible light irradiation, an ultraviolet light source does not need to be arranged, the odor can be relatively safely removed, and the deodorization cost can be reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

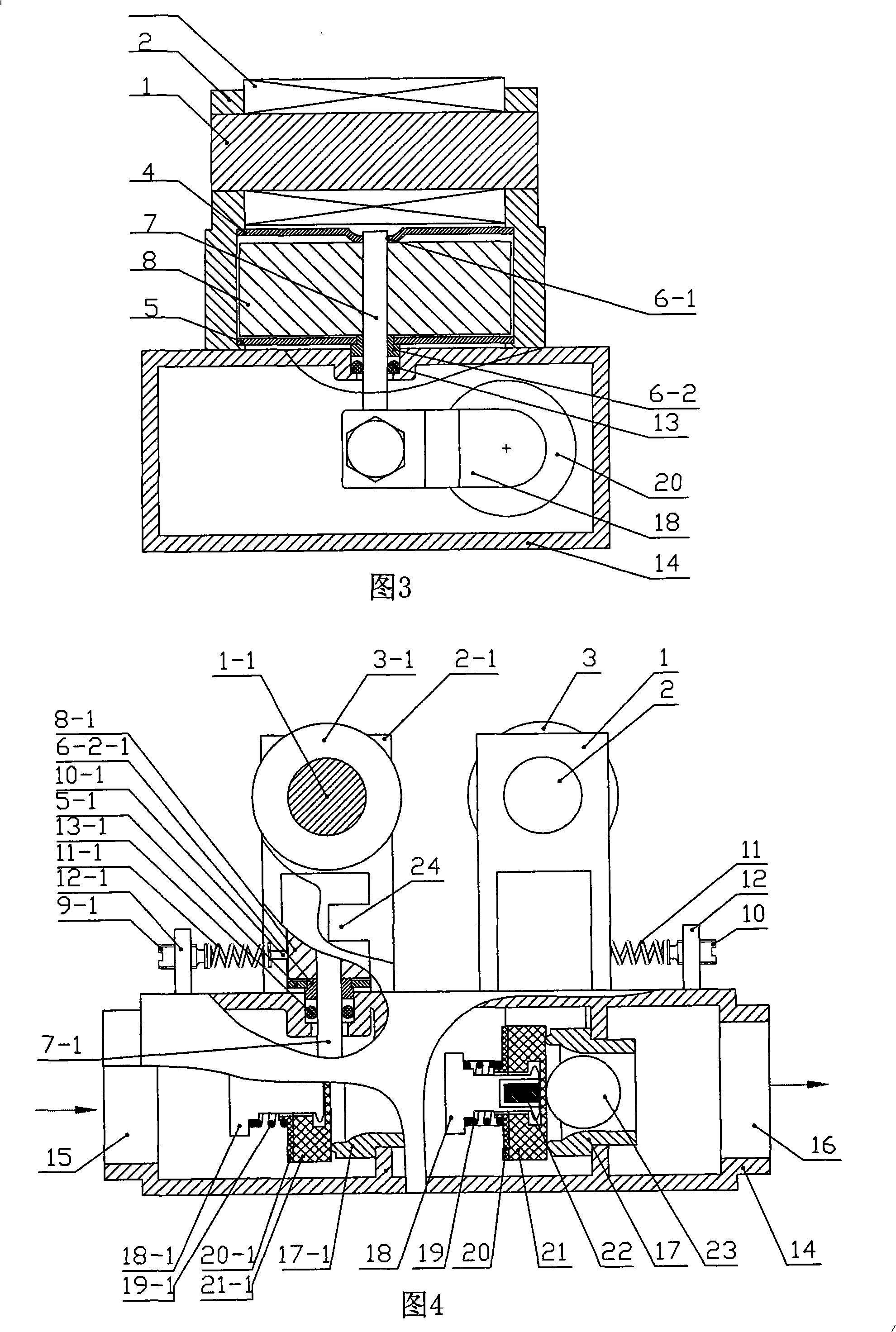

Vertical rotor type gas electromagnetic valve

InactiveCN101493157AReduce dosageSave materialOperating means/releasing devices for valvesSolenoid valveEngineering

The invention discloses a vertical rotor fuel gas solenoid valve, the structure of which can lead a magnetic circuit of the solenoid valve to be shortened and lead the processing technique to be simple, and the concentricity of a rotor and a stator has accurate location and convenient adjustment, and the relation curve of the fuel gas flow rate and current can be adjusted at any time, so the smallest starting point of the fuel gas flow rate can be determined and the adjustment and location are accurate; the solenoid valve can be used for adjusting the fuel gas flow rate and used as a switch, and the solenoid valve can be changed into a strong absorbing valve. The fuel gas solenoid valve comprises a vertical rotor electromagnet, a rotor adjusting bolt, a bracket, a spring and an adjusting bolt; a sealing gasket and a gasket spring are arranged on round lug boss at the external end of a swinging arm which is fixedly connected with a rotor shaft, and the round lug boss is connected with a valve port in a matching way for adjusting the fuel gas flow rate; the transverse positions of the rotor adjusting bolt and the bracket are adjusted for adjusting the relation curve of the fuel gas flow rate and the winding current, and the smallest starting point of the fuel gas flow rate can be determined.

Owner:潘兆铿

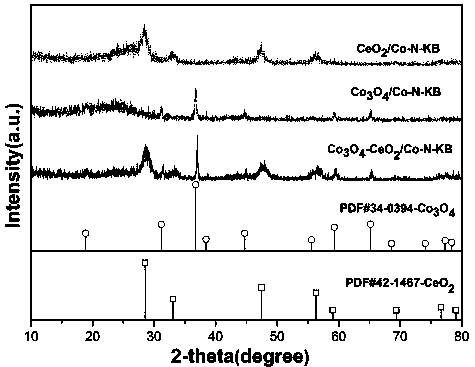

A high -performance Co3O4-CeO2/Co-N-C composite catalyst and preparation method and application thereof

The invention relates to a high-performance Co3O4-CeO2 / Co-N-C composite catalyst and a preparation method and application thereof. The preparation method comprises the following steps: S1, dissolvingcobalt salt and cerium salt, adjusting pH to 7-11, adding a nitrogen-doped carbon carrier, and hydrothermally reacting for 10-20h at 60-100 DEG C; the nitrogen-doped carbon carrier is obtained by reacting a carbon source and a nitrogen source with a mass ratio of 1: 1 to 5; S2: the solution after the reaction of S1 is sucked, filtered, washed, dried and ground to obtain the Co3O4-CeO2 / Co-N-C composite catalyst. The preparation method provided by the invention utilizes a hydrothermal method, wherein the nitrogen-doped carbon carrier, the cobalt source and the cerium source are hydroheated in one pot, the process is simple, the operation is easy, the time is short, and the method is suitable for batch industrial production; and the prepared composite catalyst has excellent catalytic properties for both ORR and OER, and can be used in fuel cells, and metal-air batteries.

Owner:GUANGDONG UNIV OF TECH

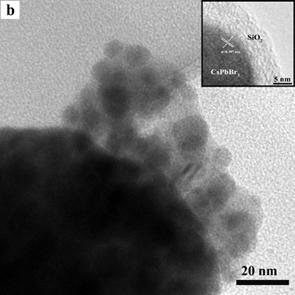

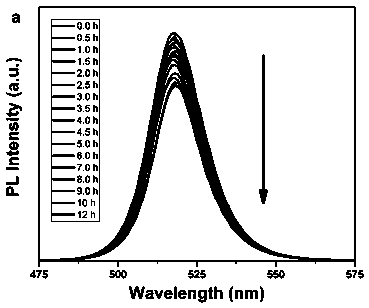

Preparation method of spherical CsPbX3@SiO2 quantum dot with high stability and water solubility

InactiveCN110028950AImprove stabilityGood water solubilityNanoopticsLuminescent compositionsTetraethyl orthosilicateSolubility

The invention discloses a preparation method of a spherical CsPbX3@SiO2 (X=Cl, Br, I) quantum dot with high stability and water solubility. The preparation method adopts an improved thermal injectiontechnology and takes a CsPbX3 quantum dot as a precursor, and mainly comprises the following steps: adding tetramethyl orthosilicate (TMOS) or tetraethyl orthosilicate (TEOS) or a mixture of TMOS andTEOS into a toluene solution containing a trace amount of water, conducting full reacting for a certain time in a stirring state, and carrying out low-speed centrifugation, washing and drying on an obtained precipitate to obtain the high-stability water-soluble spherical CsPbX3@SiO2 (X=Cl, Br, I) quantum dot. Synthesis process is simplified, raw materials are simple, the cost is low, the process equipment requirement is low, other impurity elements are not introduced or generated in the preparation process, the method has the advantages that the purity of the product is improved, the environmental pollution is reduced, the stability and the water solubility of the prepared spherical CsPbX3@SiO2 (X=Cl, Br and I) quantum dot are greatly improved, and conditions are provided for application of full-inorganic perovskite quantum dots in biological and water-based environments.

Owner:UNIV OF JINAN

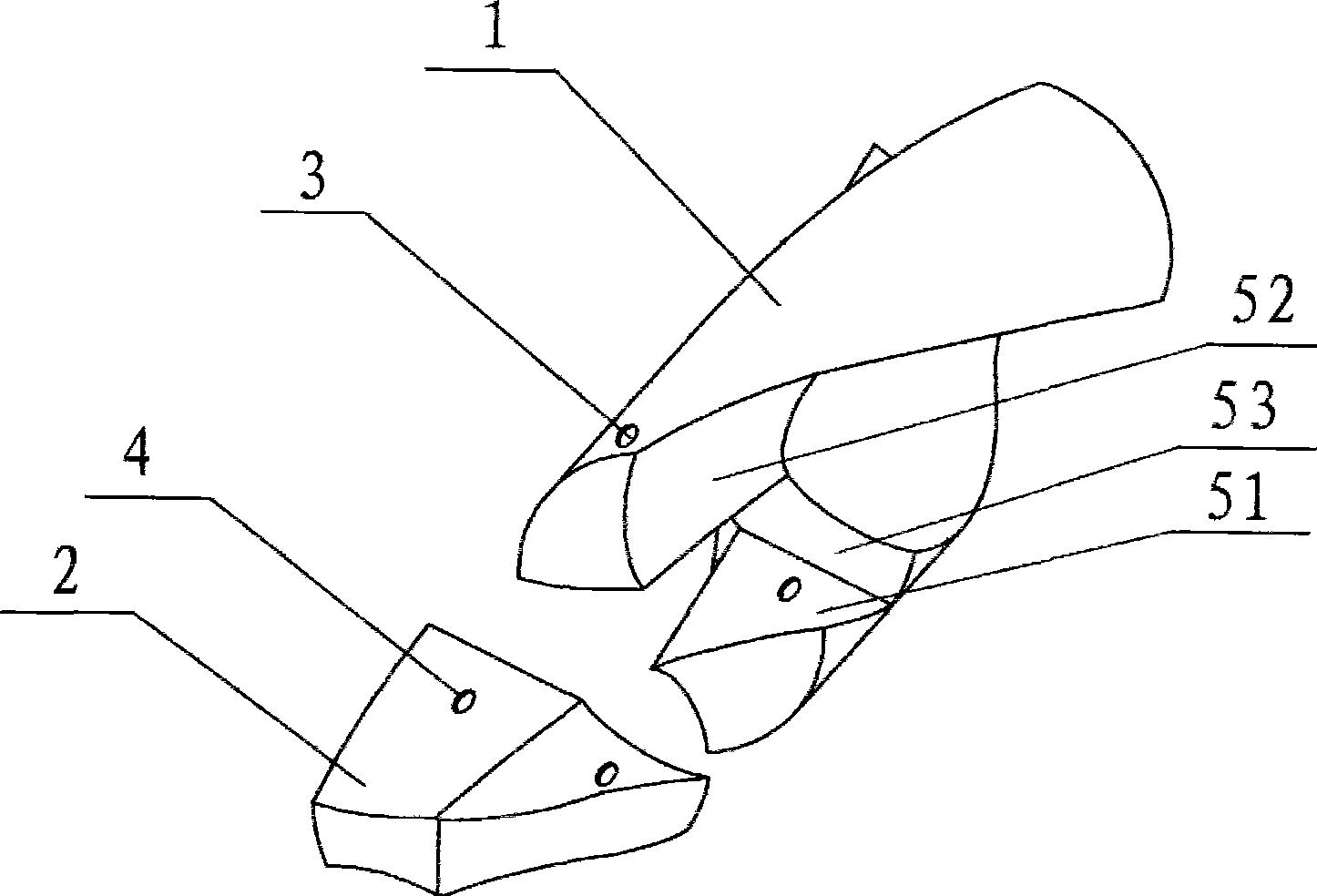

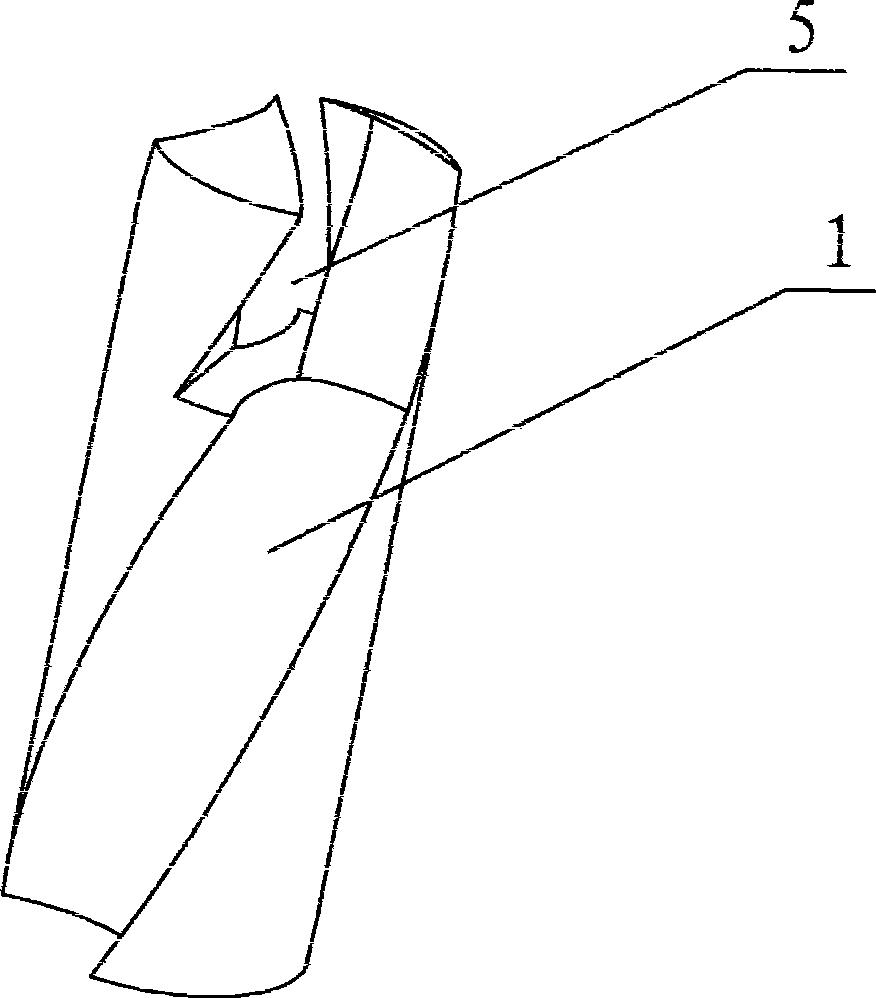

Method for preparing grinding-free drill head and drill head

The invention provides a manufacturing method of a grinding-free drill bit, which comprises a drill body and a detachable cutting blade connected on the front end of the drill body; the manufacturing method is characterized by comprising the following steps: (1) according to the set depth and width, the front end of the drill body is equipped with a spiral groove for holding the cutting blade; both inner side walls of the spiral groove are arcwall faces, and the two arcwall faces are of central symmetry, so that the entire outline of the spiral groove is of S shape; each arcwall surface is a parallelogram after being unfolded; (2) the cutting blade with side walls being two symmetrical arcwall faces and matched with the inner wall shape of the spiral groove is prepared; (3) the cutting blade is placed into the drill spiral groove, and connected to prepare the grinding-free drill bit. No sequence exists between step (1) and step (2). The manufacturing method also provides the grinding-free drill bit prepared by using the method.

Owner:苏茂均

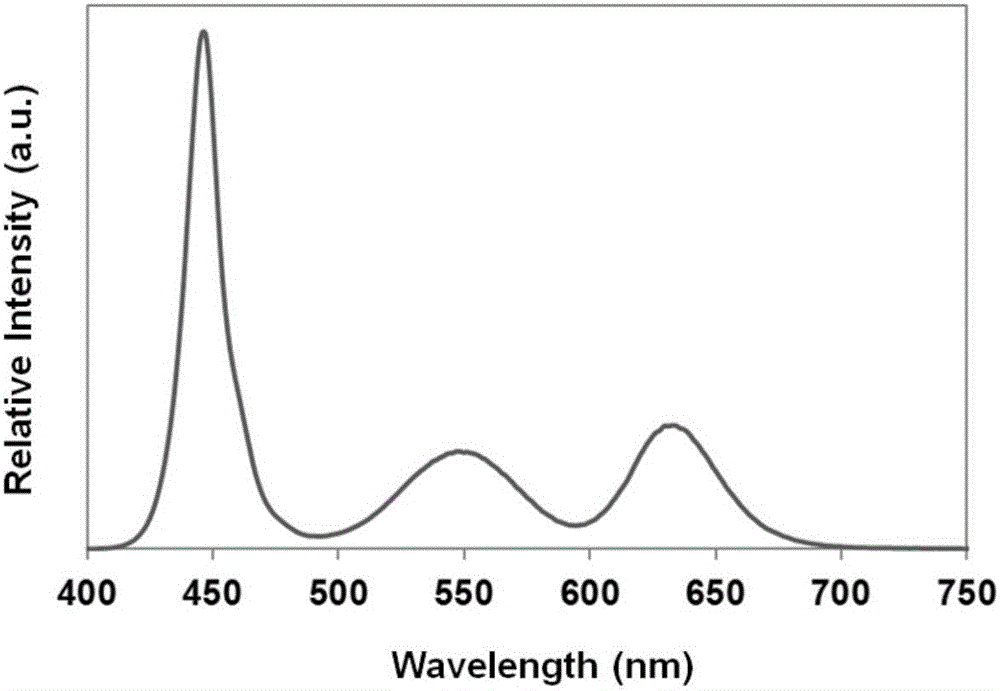

Method for packaging layered quantum dot LED lamp beads

InactiveCN106558644AIncrease color gamutImprove reliabilitySemiconductor devicesLayered structureQuantum dot

The invention belongs to the field of LED backlight processing, and more particularly to a method for packaging layered quantum dot LED lamp beads. The half-wave width of a quantum dot material used in the method is narrow, and the color gamut value of the LED lamp bead can be greatly increased to be more than NTSC 94%. The quantum dot fluorescent powders and other luminescent materials are injected into the LED step by step to form a layered structure. The method can avoid a case that a variety of luminescent materials react to each other in a later lamp bead lighting process and thus results in damage to the structure of quantum fluorescent powders and light attenuation. The method can improve the reliability of LED lamp beads. Since the quantum dot fluorescent powders of a white LED lamp bead prepared from the quantum dot fluorescent powders have high excitation efficiency and have low concentration in a packaging process, packaging difficulty and product reject ratio are reduced so that the method is suitable for large-scale industrial production and has great market prospects and economic value.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

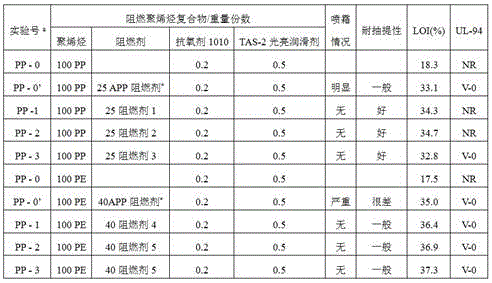

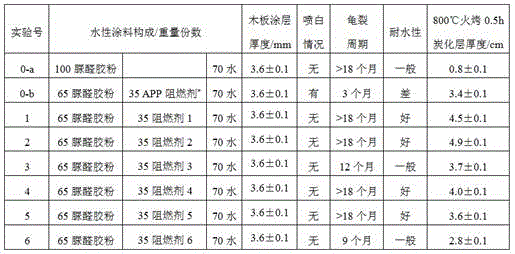

Composite flame retardant and preparation method thereof

ActiveCN106750574AEffective flame retardantGood compatibilityFireproof paintsPolyolefinAcetic anhydride

The invention discloses a composite flame retardant and a preparation method thereof. The composite flame retardant is characterized by being formed by mixing and reacting a chitin compound, a phytic acid compound, acetic anhydride, siloxane, polyamine, white carbon black, urea and water, wherein the chitin compound is at least one of chitin or chitosan; the phytic acid compound is at least one of phytic acid, sodium phytate, potassium phytate, magnesium phytate, calcium phytate, iron phytate, cobalt phytate or zinc phytate. Preparation method of the flame retardant mainly relates to a three-stage mixed reaction process: firstly, uniformly mixing the chitin compound, the phytic acid compound, water, polyamine and white carbon black; then adding acetic anhydride and siloxane to be uniformly mixed; and finally, putting urea to be uniformly mixed, and discharging, cooling and crushing the mixture to obtain a product. The composite flame retardant disclosed by the invention not only can effectively retard flames of polyolefin and woods, but also has good compatibility with polyolefin and an amino resin aqueous coating, and can effectively avoid phenomena of blooming, white spraying, dialyzing and fracturing.

Owner:FUJIAN NORMAL UNIV

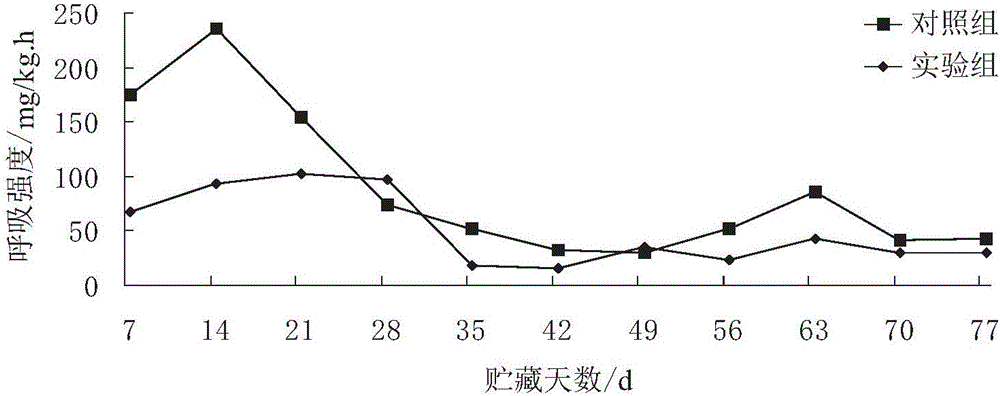

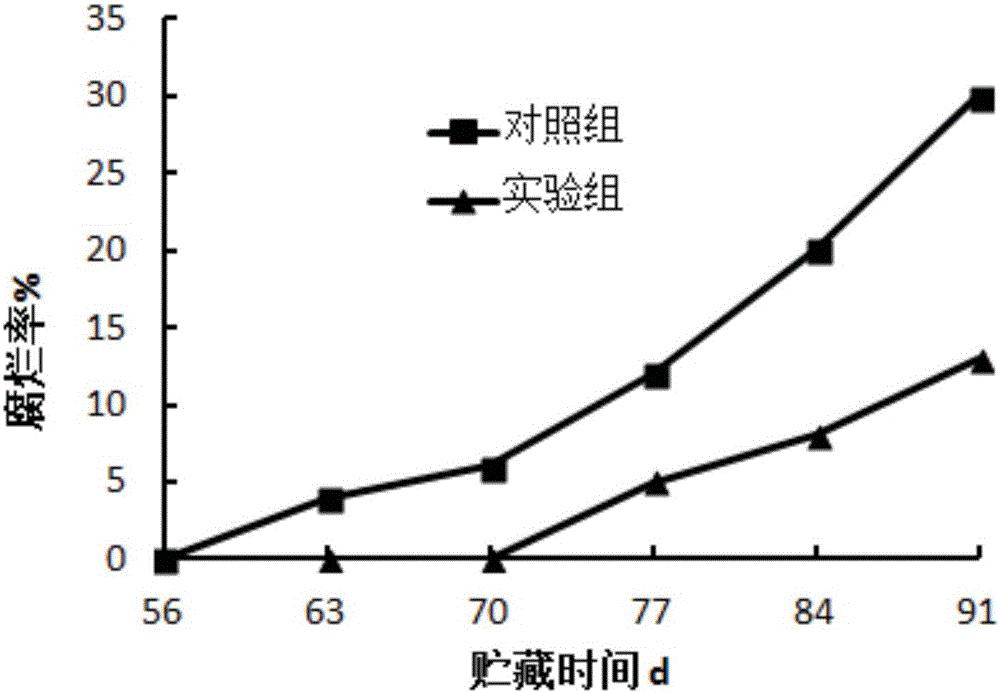

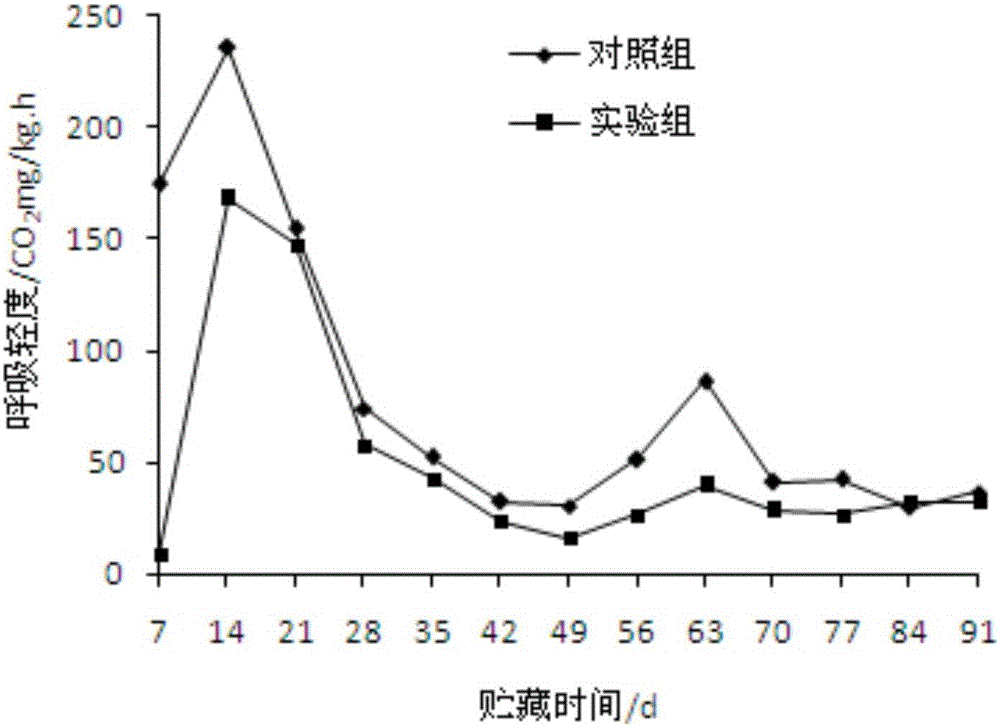

Bacillus subtilis, screening method thereof, application of bacillus subtilis, biological preservative, preparation method thereof and fruit and vegetable preserving method

InactiveCN106148225AStrong broad-spectrum antifungal actionGood broad-spectrum antifungal effectBiocideFruit and vegetables preservationScreening methodBio engineering

The invention relates to the technical field of biological engineering, in particular to a bacillus subtilis, a screening method thereof, an application of the bacillus subtilis, a biological preservative, a preparation method thereof and a fruit and vegetable preserving method. The bacillus subtilis Cy-29 is collected in China General Microbiological Culture Collection Center on December 7th, 2013, and the collection number of the bacillus subtilis is CGMCC 7916. The biological preservative comprises the bacillus subtilis Cy-29. The fruit and vegetable preserving method includes a method for fermenting a product by the bacillus subtilis Cy-29. By planting and growth of the bacillus subtilis Cy-29 and / or antagonism of antibacterial substances generated by the bacillus subtilis Cy-29, respiration of fruits is effectively inhibited, the rotting rate of the fruits is obviously reduced during cold storage, and strong inhibiting effects to various plant pathogenic fungi are achieved.

Owner:SICHUAN AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com