Method for preparing high purity rare earth metal and its apparatus

A rare-earth metal, high-purity technology, applied in the direction of improving process efficiency, can solve the problems of small removal effect, low production efficiency, high content of metal gas impurities and non-rare earth metal impurities, so as to reduce the content of gas impurities and improve utilization The effect of improving the efficiency and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

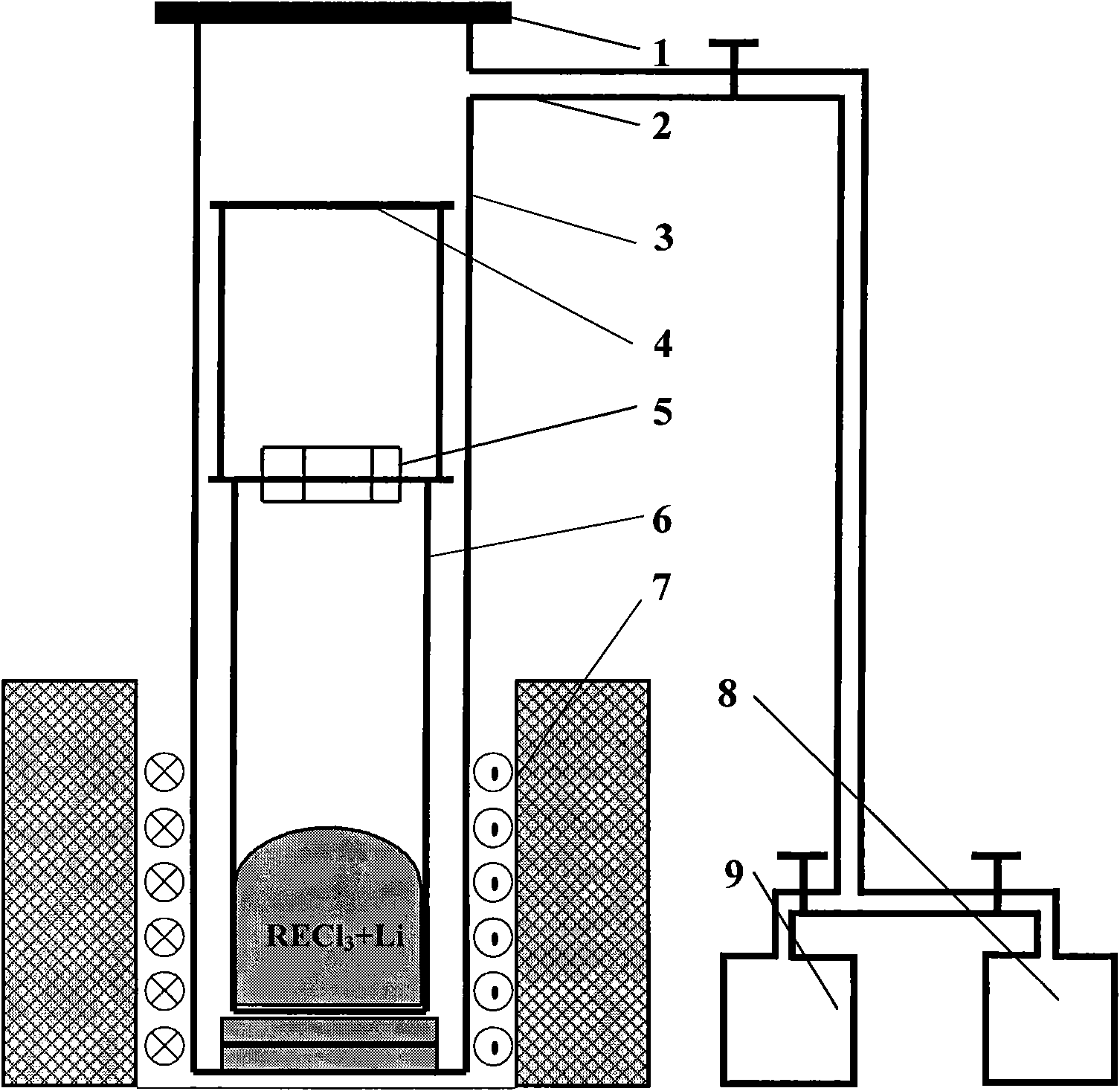

[0031] Attached Figure 1 The equipment and device shown, add 500g of anhydrous lanthanum chloride with a purity of 99.9wt.% and 45g of lithium metal with a purity of 99.9wt.% to a titanium crucible made of titanium with a purity of 99.5wt.%, in a 99.999% argon atmosphere (>0.1MPa), raise the temperature to 950°C (the pressure of the reaction system is kept below 0.5MPa during the heating process), and keep it warm for 1 hour, then pump the system down to below 0.1Pa for distillation and removal of impurities, and keep it warm for 3 hours at 1100°C After finishing the distillation, refill with argon and cool to room temperature. Reduction obtained 263.4g of metal lanthanum, the yield was 93%, and the absolute purity of lanthanum was 99.957%. The analysis results are as follows:

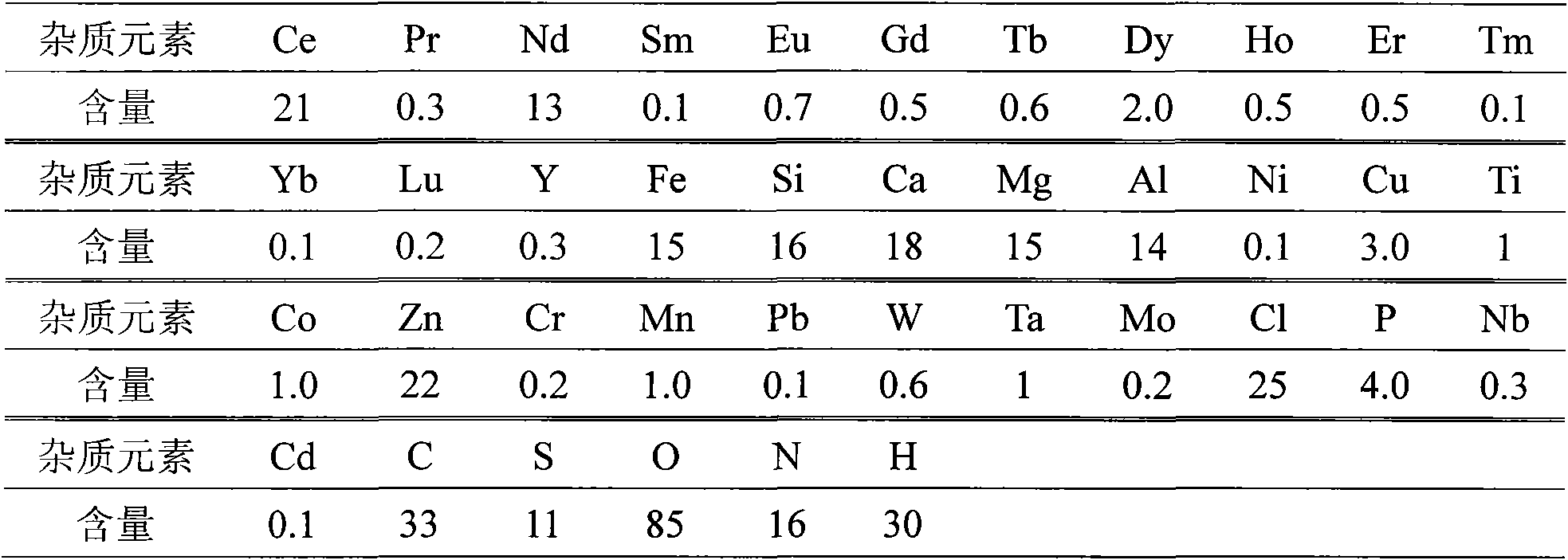

[0032] Table 1 Metal Lanthanum Composition Analysis Unit: ppm (wt.)

[0033]

Embodiment 2

[0035] Attached Figure 1 For the equipment and device shown, add 500g of anhydrous lanthanum chloride with a purity of 99.9wt.% and 48g of lithium metal with a purity of 99.9wt.% to a tantalum crucible made of a tantalum material with a purity of 99.9wt.%, in a 99.999% argon atmosphere (>0.1MPa), raise the temperature to 950°C (the pressure of the reaction system is kept below 0.5MPa during the heating process), and keep it warm for 1 hour, then pump the system down to below 0.1Pa for distillation and removal of impurities, and keep it warm for 3 hours at 1100°C After finishing the distillation, refill with argon and cool to room temperature. The reduction obtained 265.1 g of metal lanthanum, the yield was 93.6%, and the absolute purity of lanthanum was 99.964%. The analysis results are as follows:

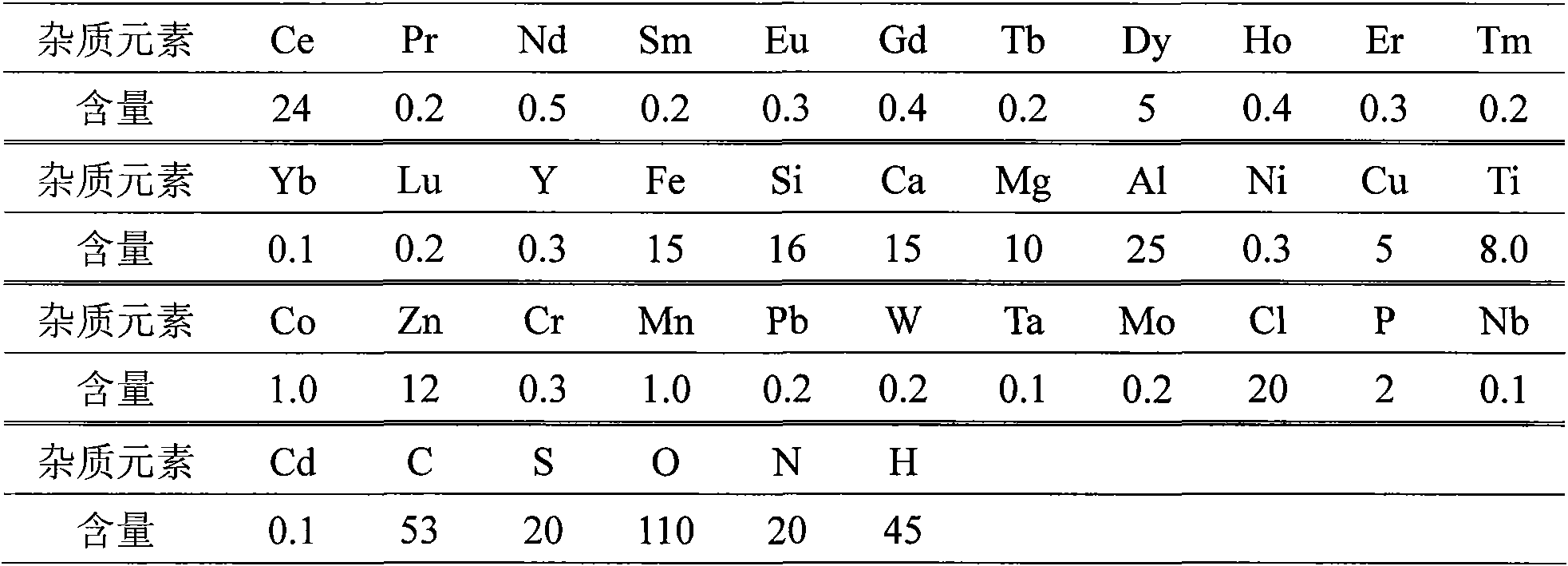

[0036] Table 2 Analysis of metal lanthanum components Unit: ppm (wt.)

[0037]

Embodiment 3

[0039] Attached Figure 1 The equipment and device shown, add 500g of anhydrous neodymium chloride with a purity of 99.9wt.% and 45g of lithium metal at 99.9wt.% to a titanium crucible made of titanium with a purity of 99.5wt.%, in a 99.999% argon atmosphere (>0.1MPa), raise the temperature to 1050°C (the pressure of the reaction system is kept below 0.5MPa during the heating process), and keep it warm for 1 hour, then pump the system down to below 0.1Pa for distillation and removal of impurities, and keep it warm for 3 hours at 1100°C After finishing the distillation, refill with argon and cool to room temperature. The reduction obtained 264.4g of neodymium metal, the yield was 92%, and the absolute purity of neodymium was 99.952%. The analysis results are as follows:

[0040] Table 3 Analysis of metal neodymium composition Unit: ppm (wt.)

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com