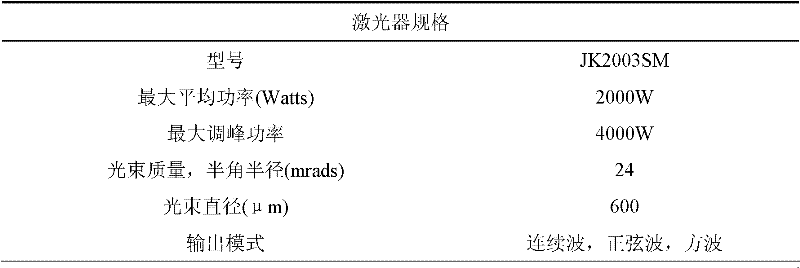

Patents

Literature

1650 results about "Lithium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium chloride is a chemical compound with the formula LiCl. The salt is a typical ionic compound, although the small size of the Li⁺ ion gives rise to properties not seen for other alkali metal chlorides, such as extraordinary solubility in polar solvents (83.05 g/100 mL of water at 20 °C) and its hygroscopic properties.

Process for extracting lithium from salt lake brine by adsorptive method

InactiveCN1511964AEasy to makeNo pollutionProcess efficiency improvementLithium chlorideLithium carbonate

The present invention relates to adsorption process of extracting lithium from salt lake brine, and the process is suitable for producing lithium carbonate and lithium chloride with lithium-containing Qinghai saline lake brine, including concentrated lithium-containing Qinghai saline lake brine. The process includes sun shining saline lake brine to obtain concentrated lithium containing brine, adsorption of lithium ion with aluminum salt adsorbent, eluting adsorbed lithium ion with water, and refining and concentrating the elutriant to obtain material for preparing lithium carbonate and lithium chloride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Nano-filtration method for separating magnesium and enriching lithium from salt lake brine

InactiveCN1542147AEfficient recyclingSimple processSemi-permeable membranesLithium compoundsIon contentLithium chloride

The nanofiltration process is suitable for Mg-Li separation and Li enriching of Li containing bittern or Li containing solution from salt lake to prepare lithium carbonate or lithium chloride with the Li enriching bittern. Nanofiltration membrane is used in separating and enriching lithium from lithium containing bittern, which contains Mg, Ca and other cations and sulfate radical and other anions and has Li ion concentration of 0.1-11.5 g / L and Mg / Li ion weight ratio 1-200, to obtain lithium enriched bittern suitable for preparing lithium carbonate or lithium chloride. The said process is effective, and can obtain lithium enriched bittern with Mg / Li ion weight ratio 0.6-5 and Li ion content of 0.6-20 g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Dehumidizer for air dehumidification, air dehumidification method and device

InactiveCN102335545AEfficient removalQuick removalLighting and heating apparatusDispersed particle separationLithium chlorideWater vapor

The invention discloses a dehumidizer for air dehumidification. The dehumidizer provided by the invention is an ionic liquid solution formed by dissolving an ionic liquid in water, wherein the ionic liquid is formed by organic positive ions and inorganic negative ions, and the melting point of the ionic liquid is close to or is lower than room temperature. In addition, the invention further discloses a method and a device for air dehumidification by the adoption of the above dehumidizer. In comparison with traditional salting liquids (lithium bromide, lithium chloride and calcium chloride aqueous solutions and the like), the dehumidizer provided by the invention has the following advantages: 1) the applied ionic liquid solution is in the liquid state at normal temperature, is intermiscible with water, and will not be crystallized during operation, so as to guarantee the reliable operation of a system; 2) the applied ionic liquid solution has similar or lower water vapor pressure than a traditional dehumidifying salting liquid so as to raise the dehumidifying efficiency; 3) the applied ionic liquid solution will not corrode metal equipment such as steel equipment such that the equipment has low cost and long service life; 4) the dehumidizer has nonvolatility so as to reduce the environmental pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

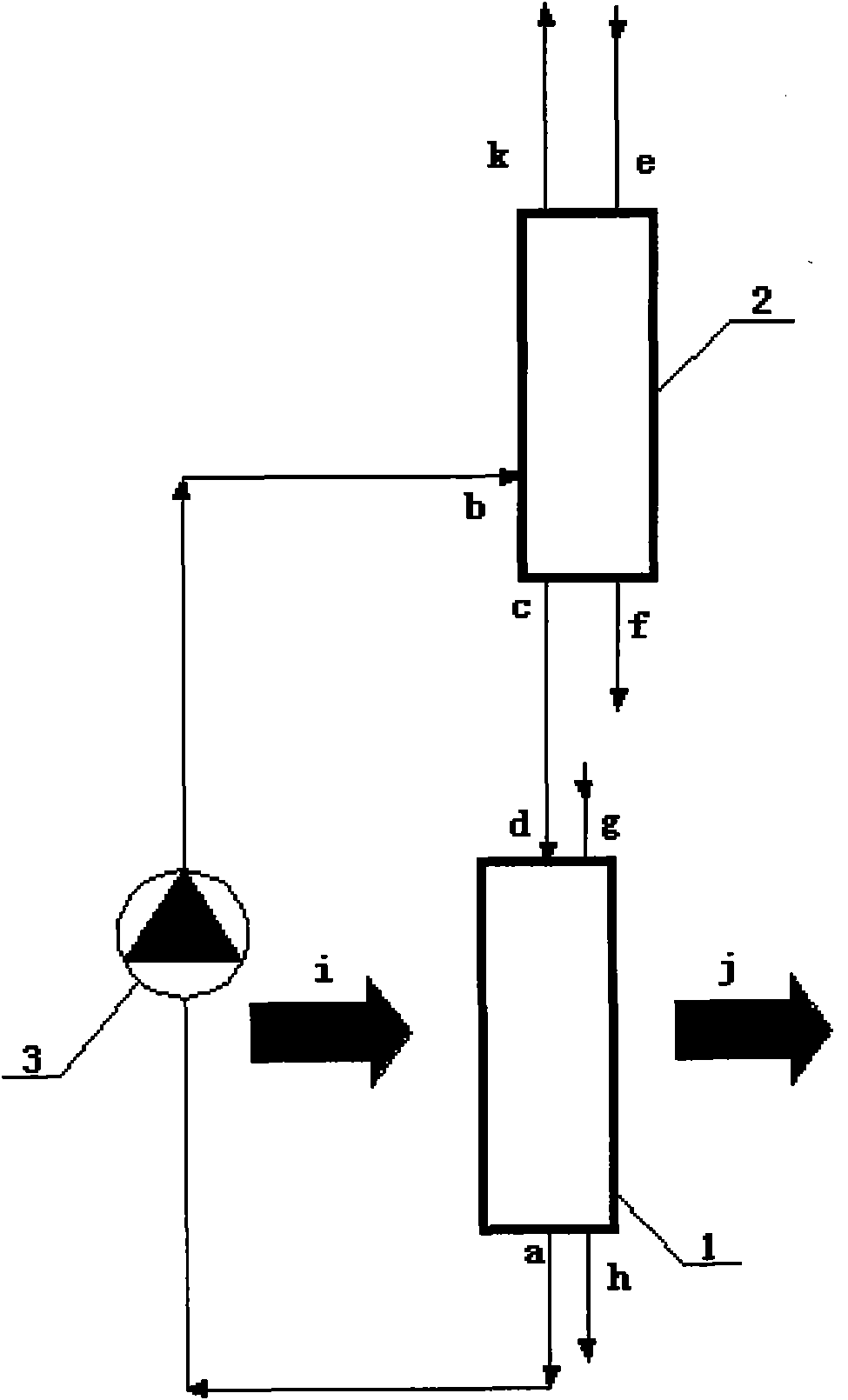

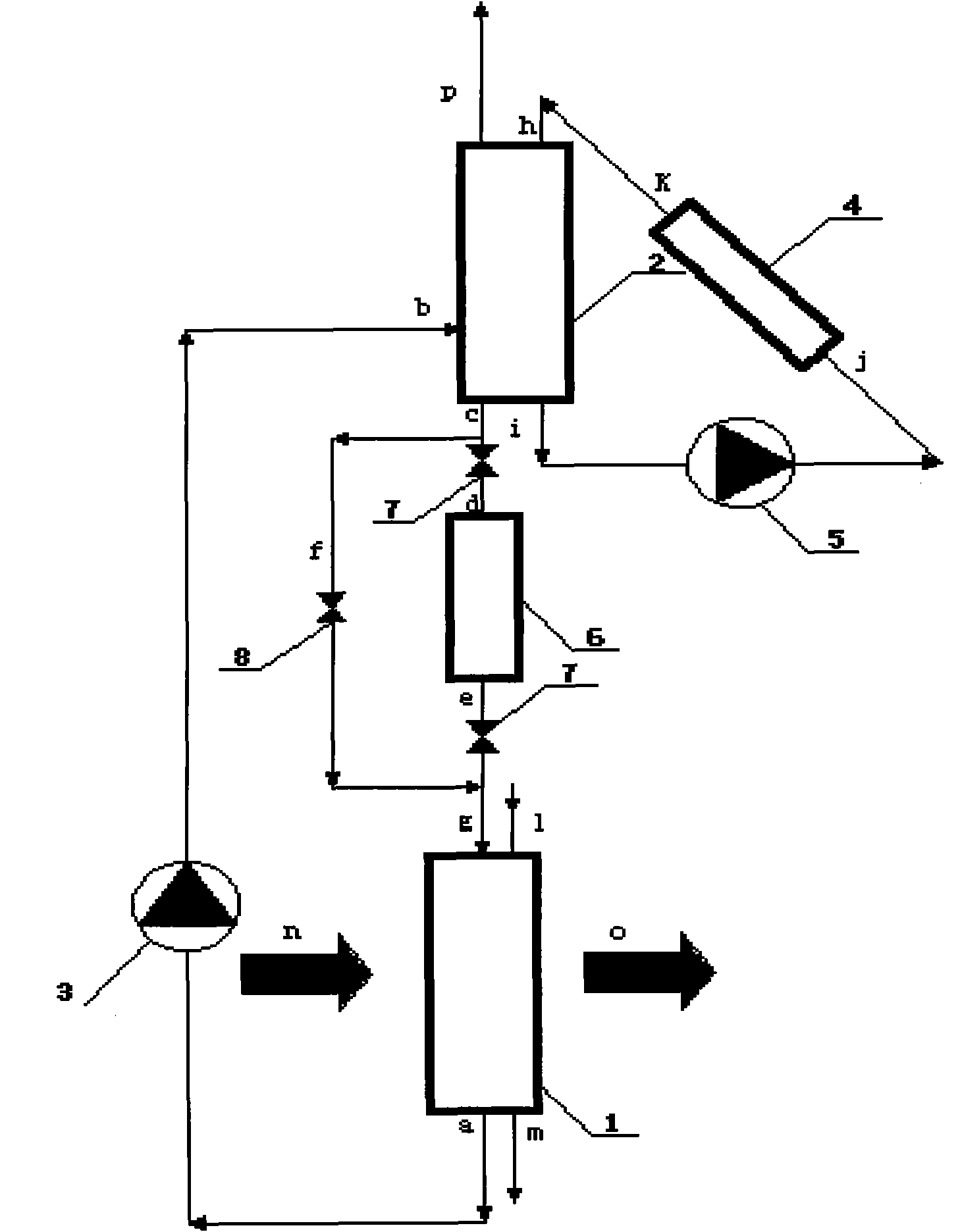

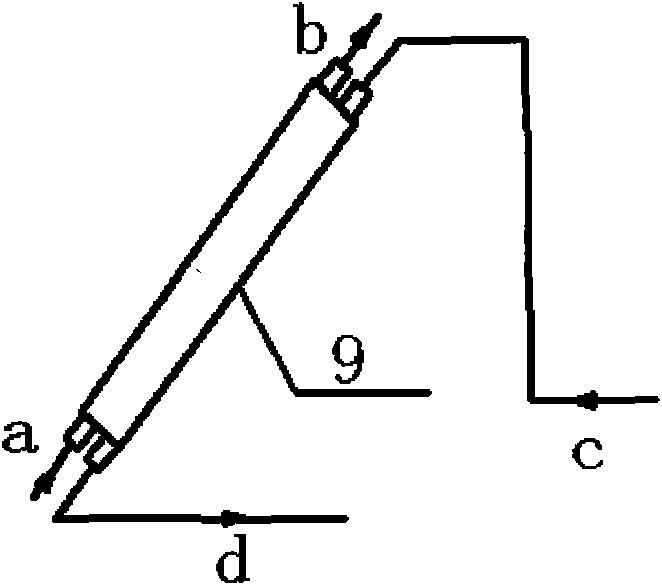

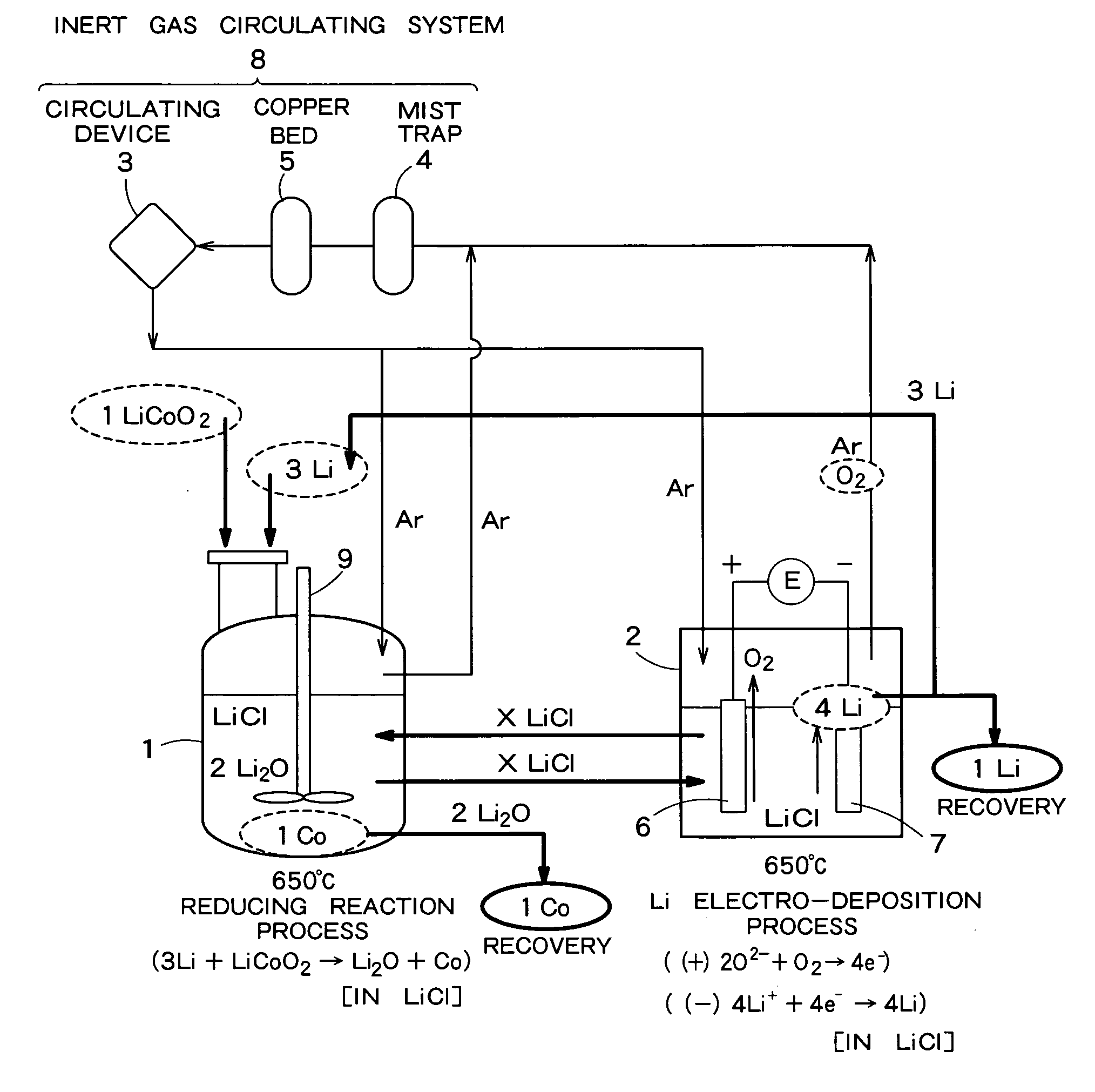

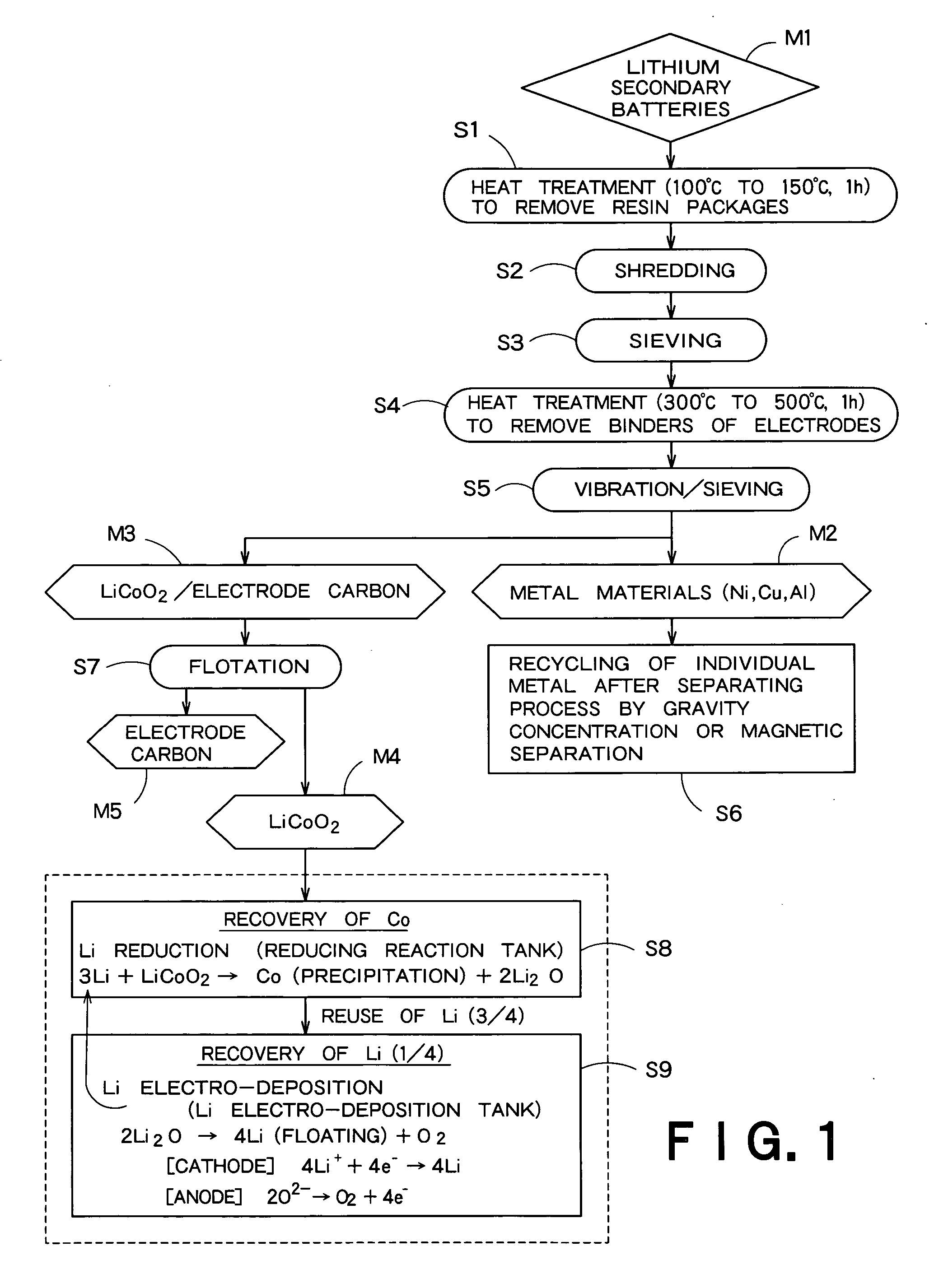

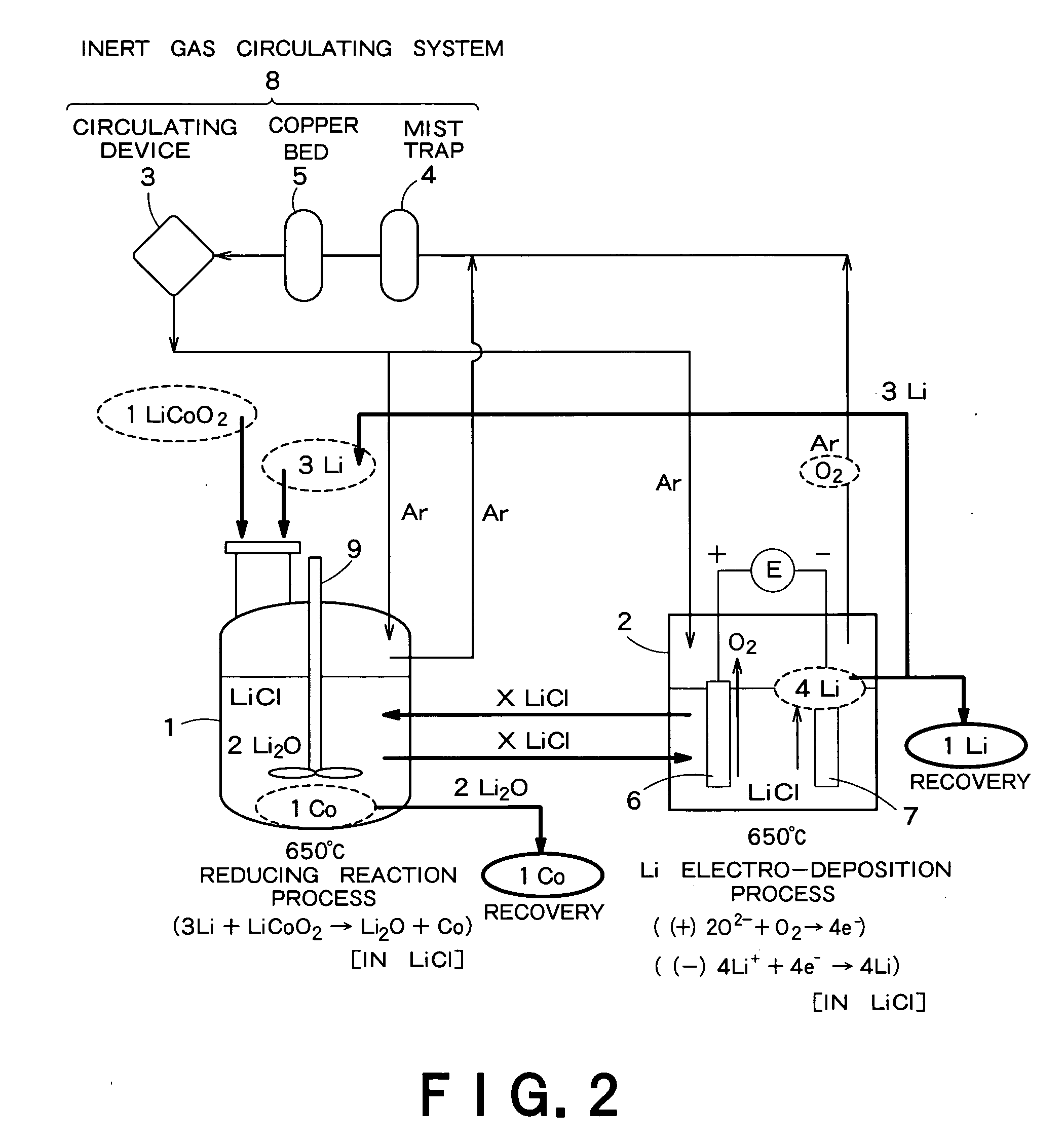

Method and apparatus for recycling electrode material of lithium secondary battery

ActiveUS20050241943A1Reduce equipment costsReduce operating costsCellsPhotography auxillary processesLithium oxideLithium chloride

Lithium cobaltate forming the positive electrode of a lithium secondary battery is subjected together with lithium metal to reducing reaction in molten lithium chloride to produce lithium oxide and to precipitate and separate cobalt or cobalt oxide. The lithium oxide is subjected to electro-deposition in molten lithium chloride contained in a lithium electro-deposition tank provided with an anode and a cathode to recover lithium metal deposited on the cathode.

Owner:KAWASAKI HEAVY IND LTD +1

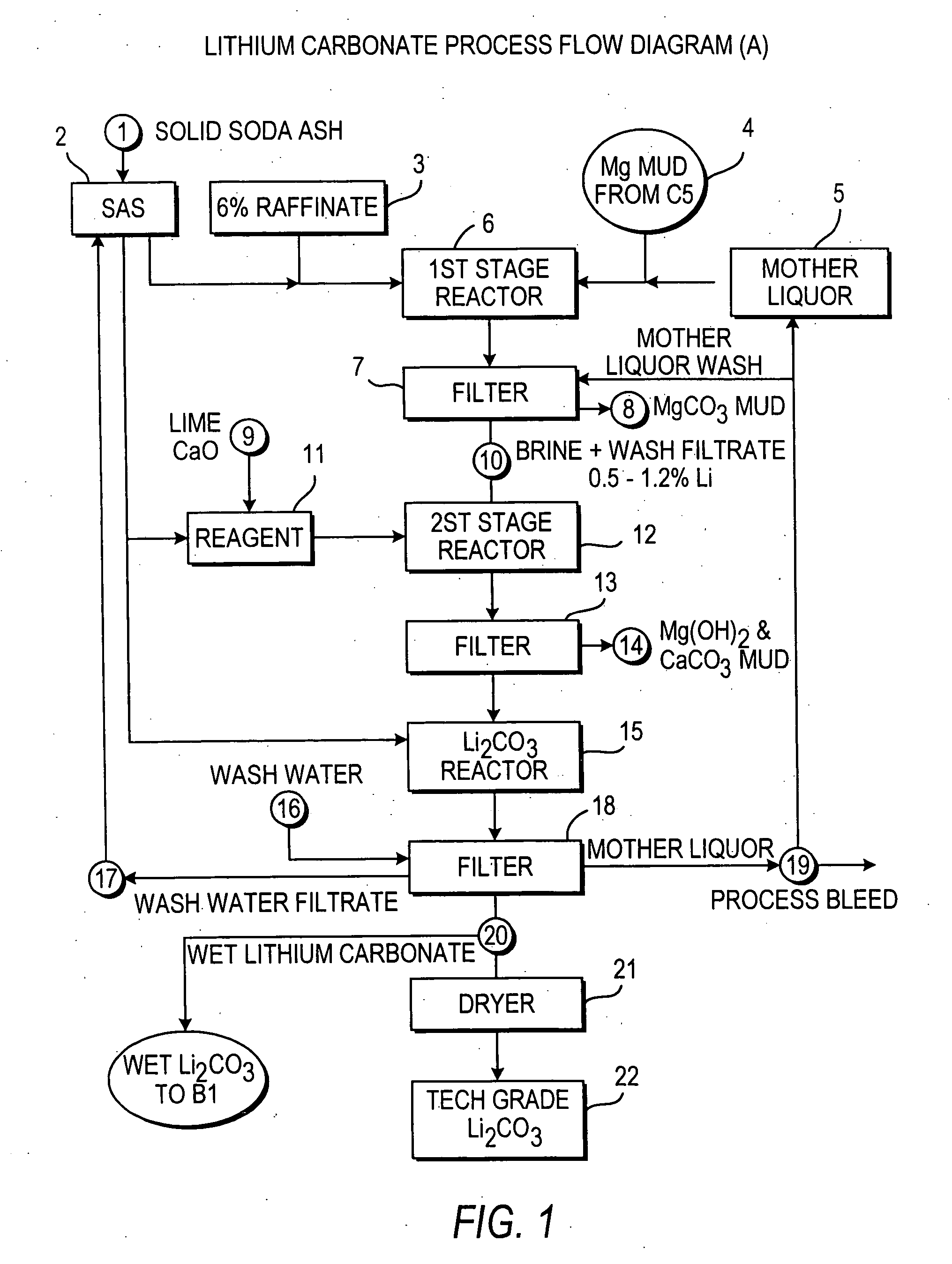

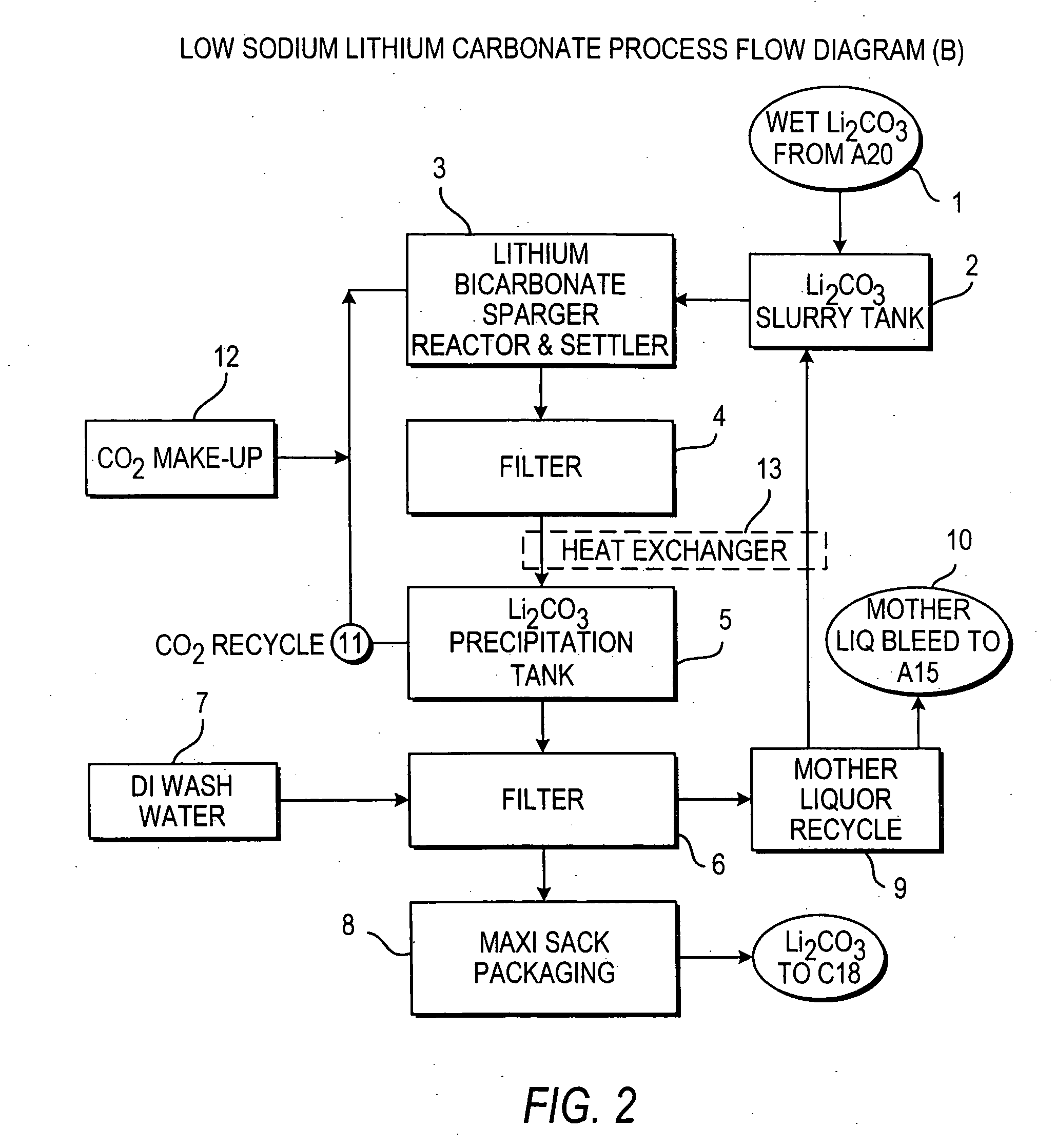

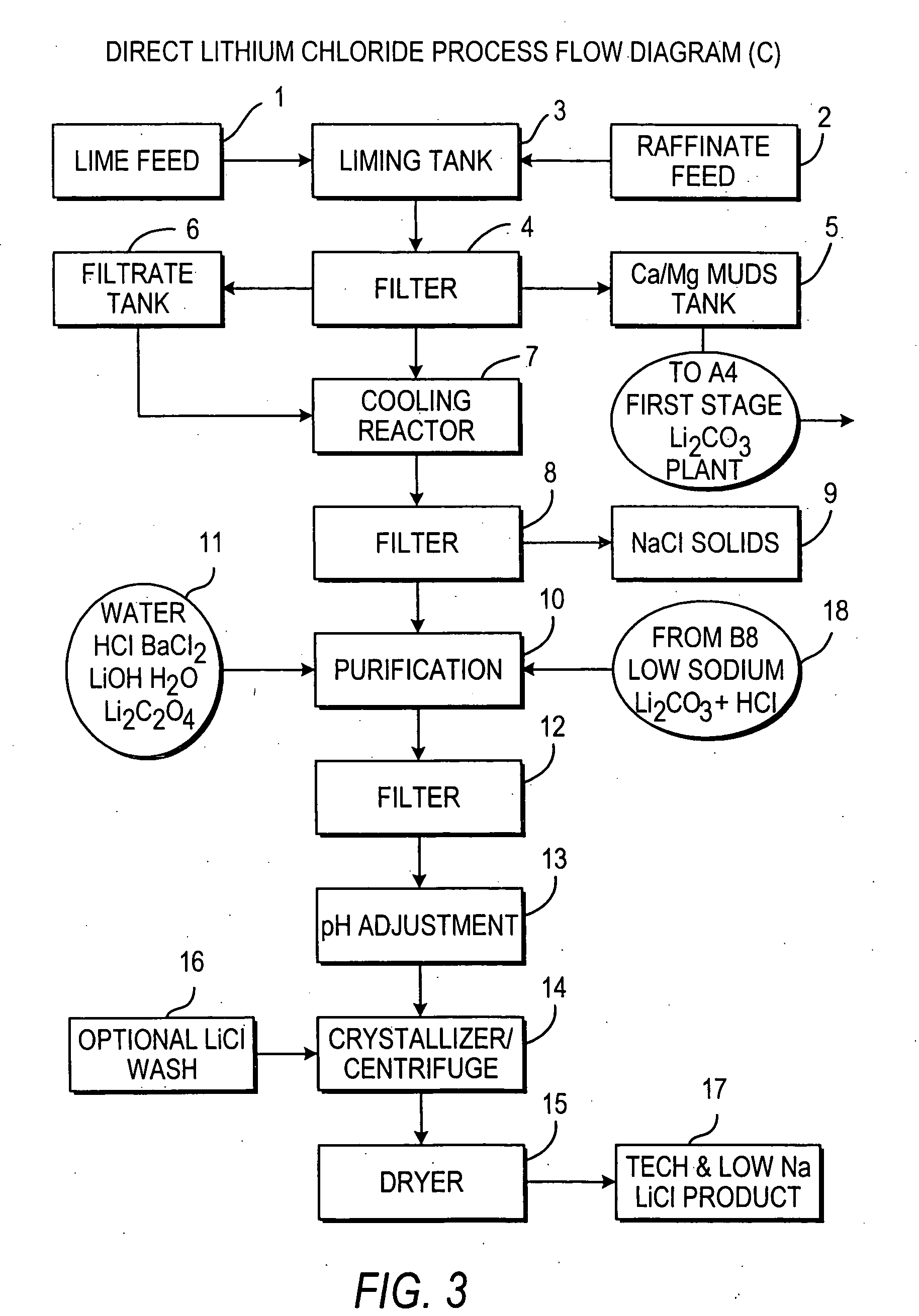

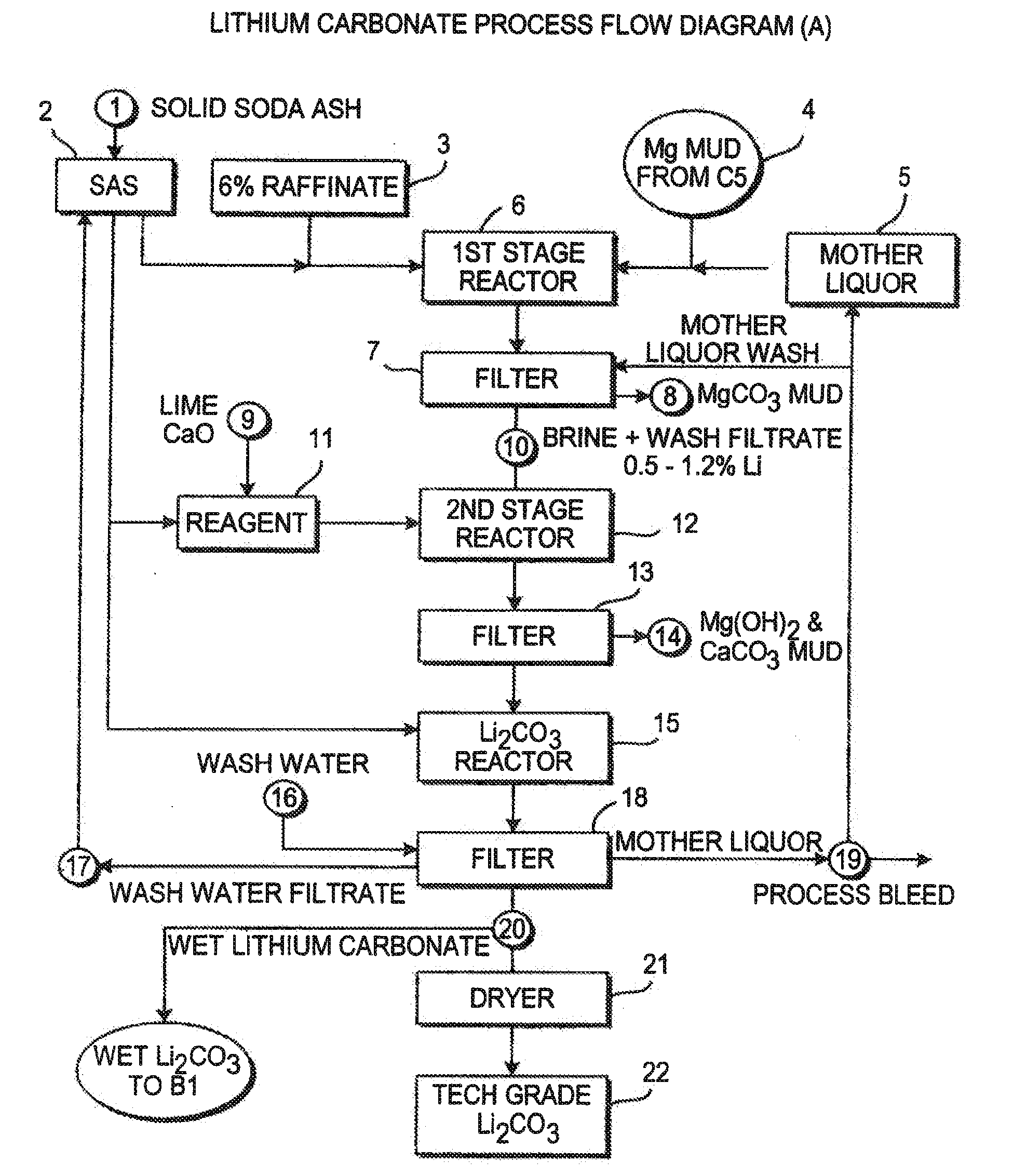

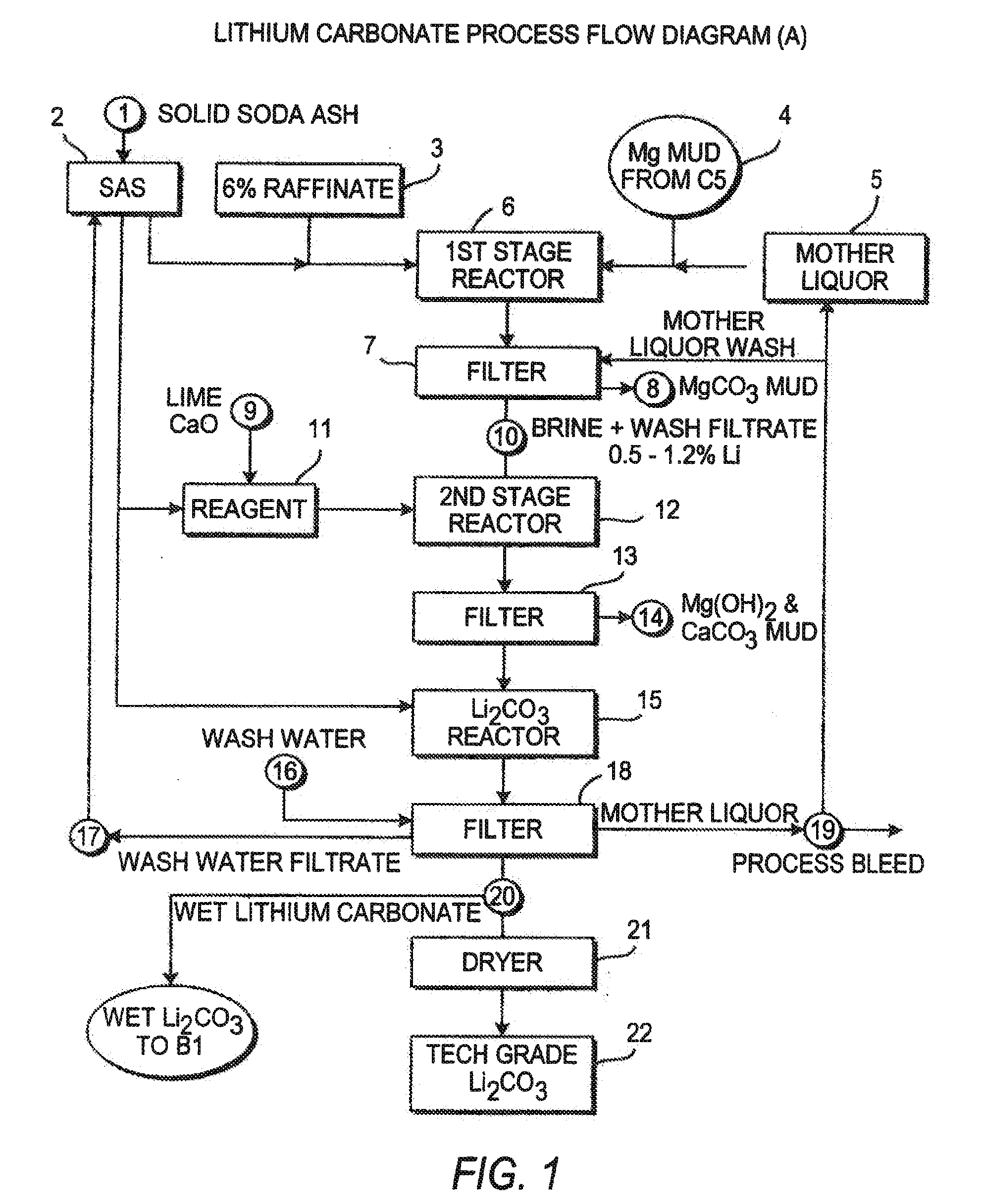

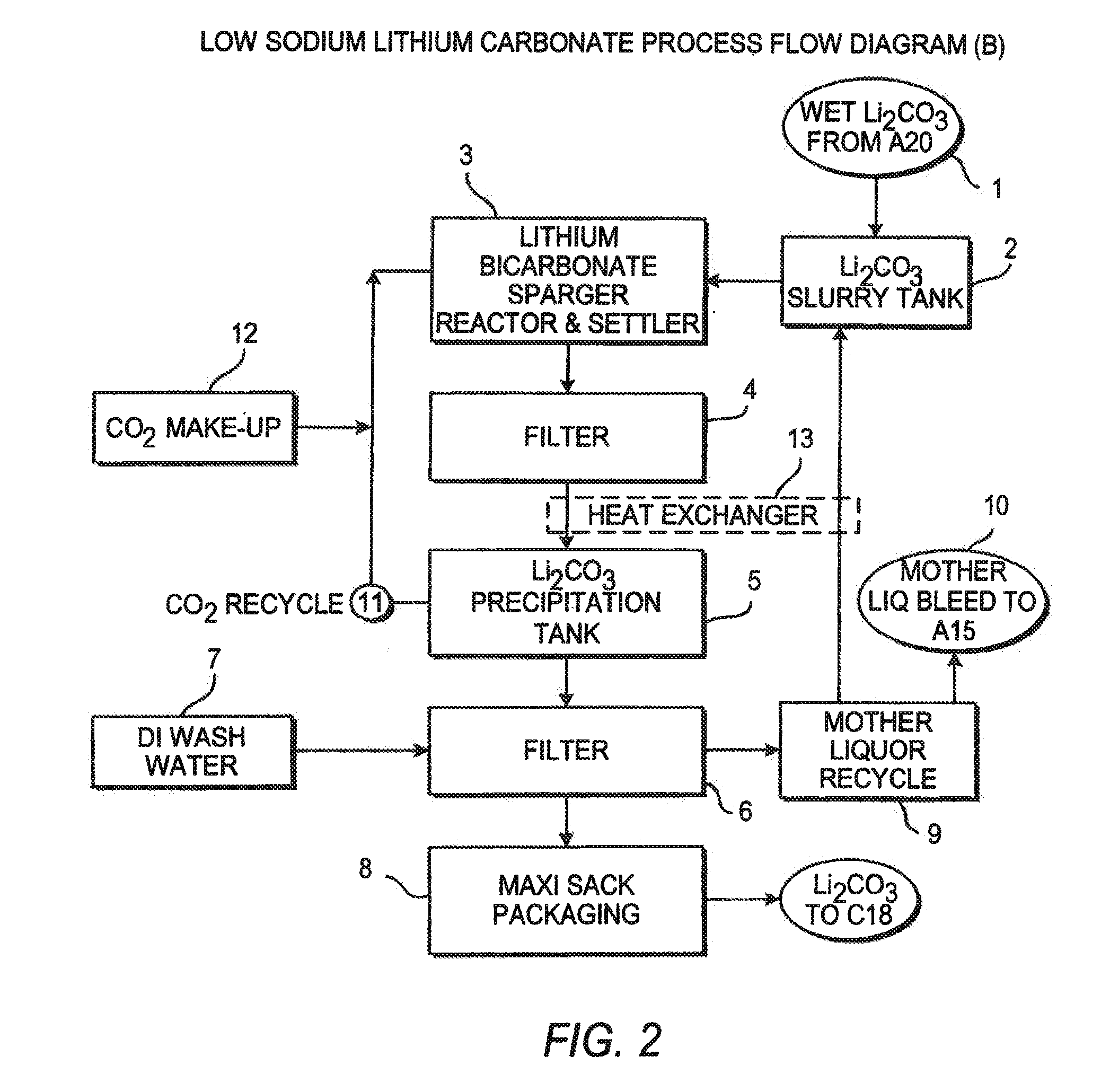

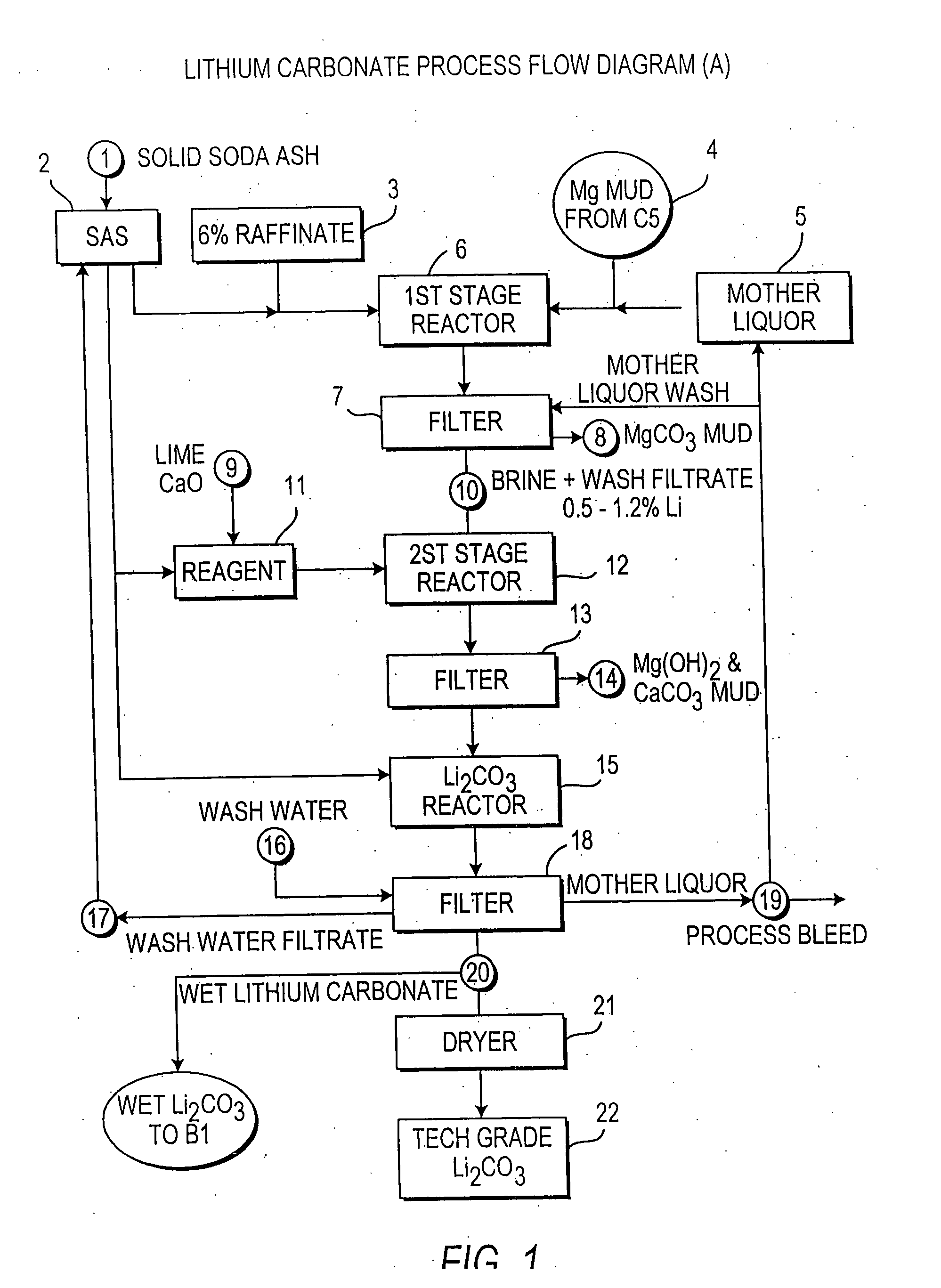

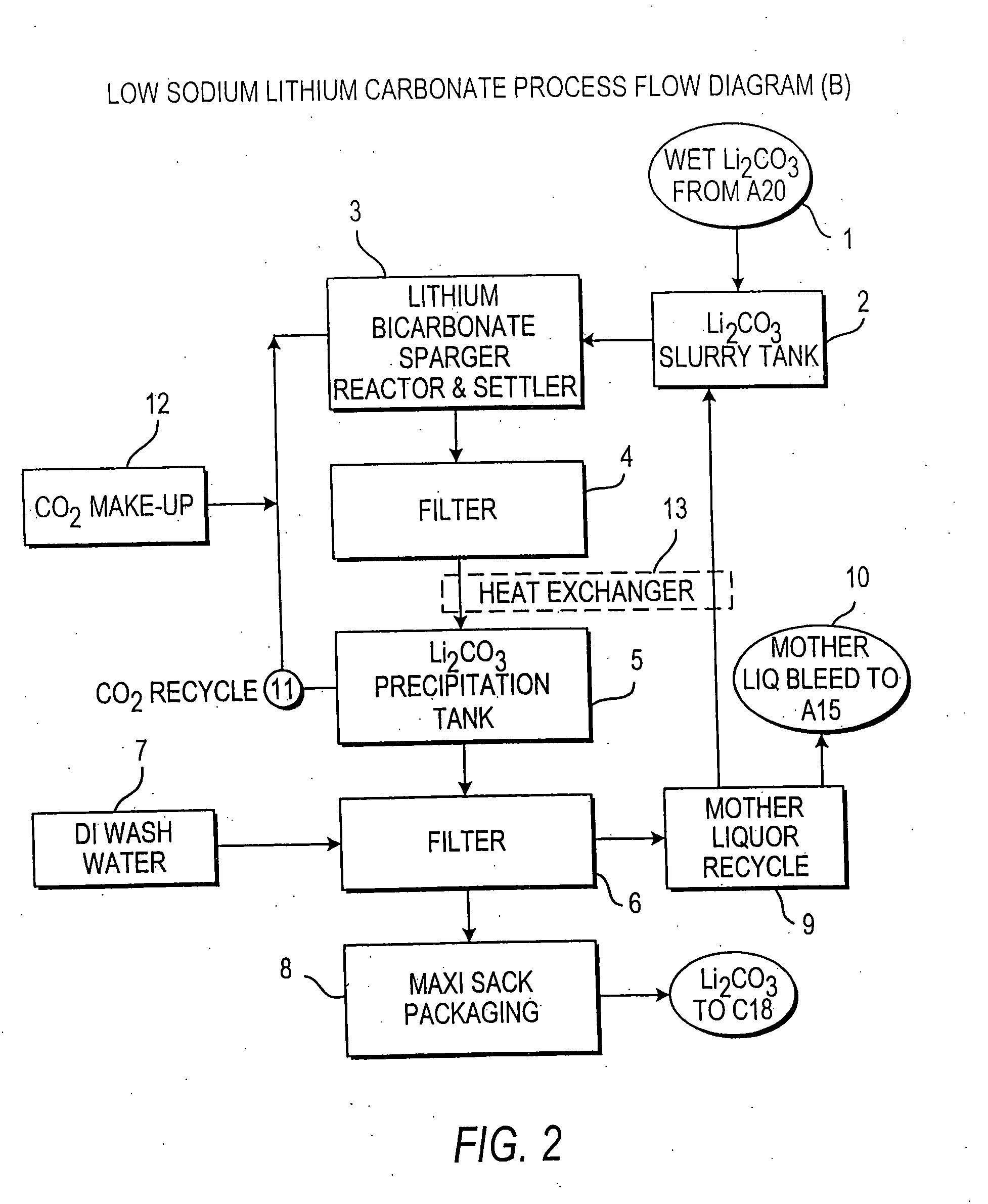

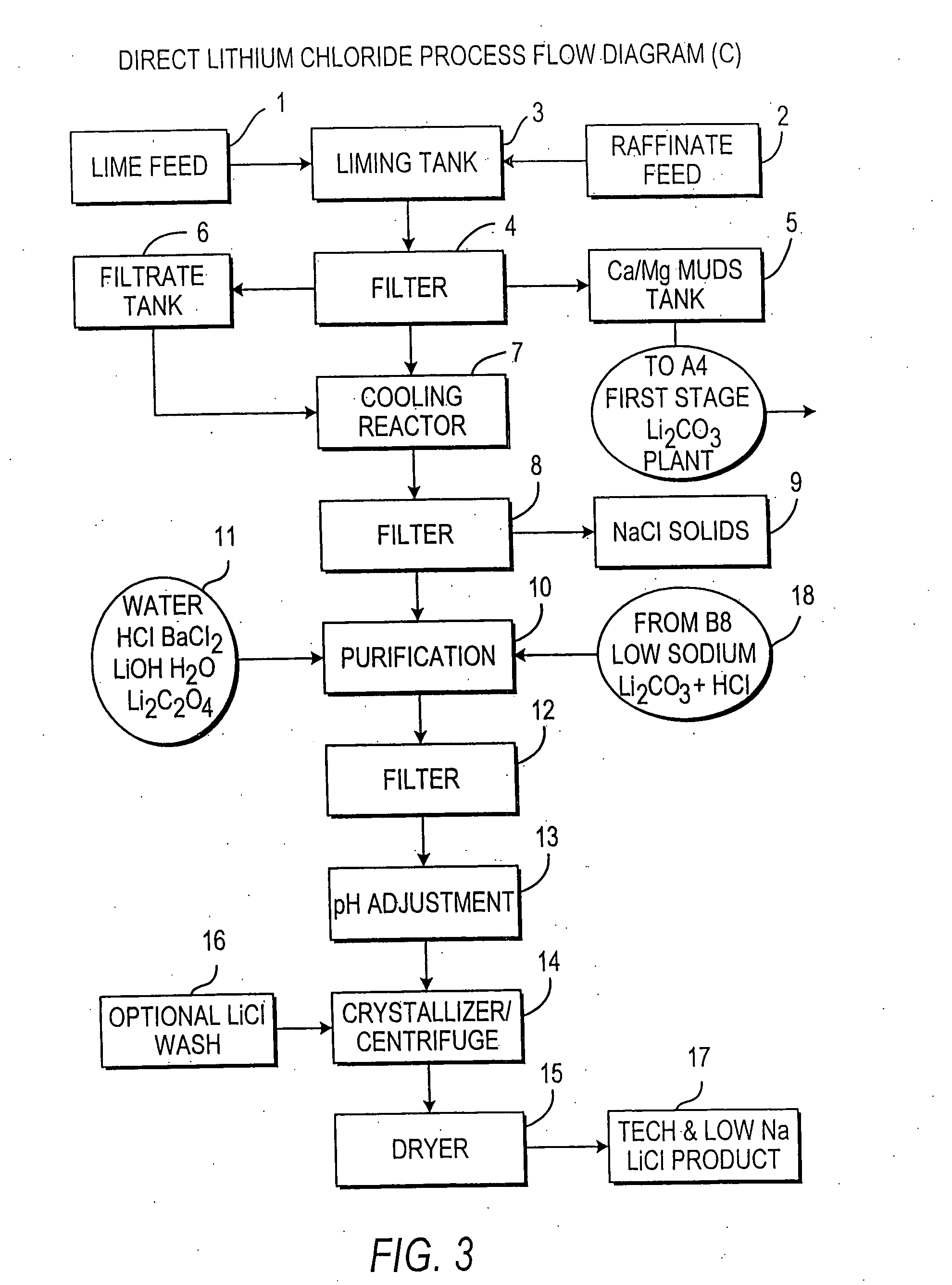

Production of lithium compounds directly from lithium containing brines

InactiveUS20060115396A1Promote absorptionConstant liquid volumeCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:BORYTA DANIEL ALFRED +2

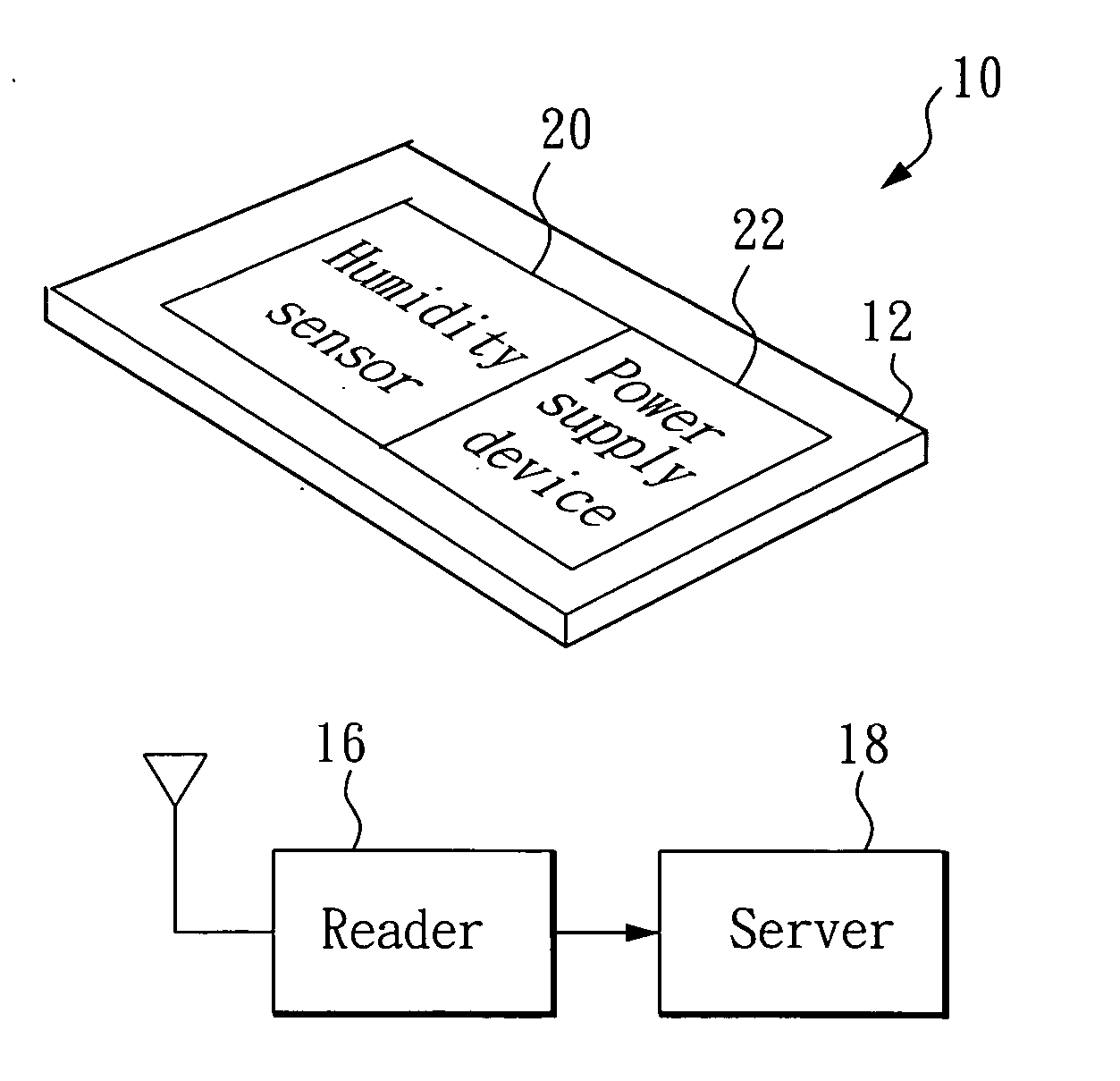

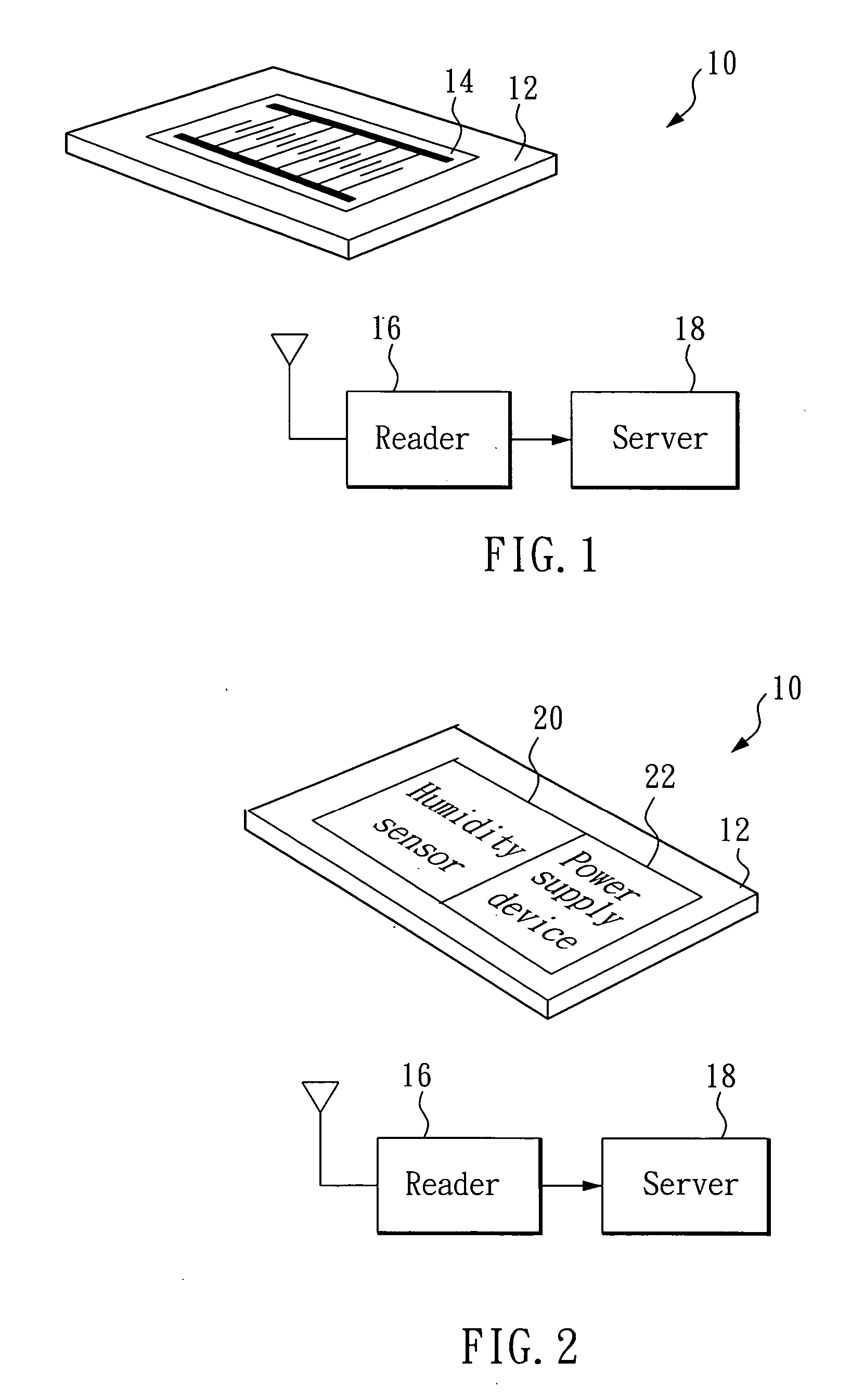

Remote humidity monitoring system

A remote humidity monitor system for detecting a targeted object utilizes a humidity sensor to detect humidity and sends a result to a reader via the wireless communication device; a server can execute monitor management. The humidity sensor can be a mass hygrometer, an optical condensation dew-point hygrometer, a psychrometer (wet-and-dry bulb thermometer), a hair hygrometer, an electrolysis humidity sensor, a lithium chloride humidity sensor, an aluminum oxide humidity sensor, a high polymer humidity sensor, or an infrared hygrometer.

Owner:THINKFAR NANOTECH CORP

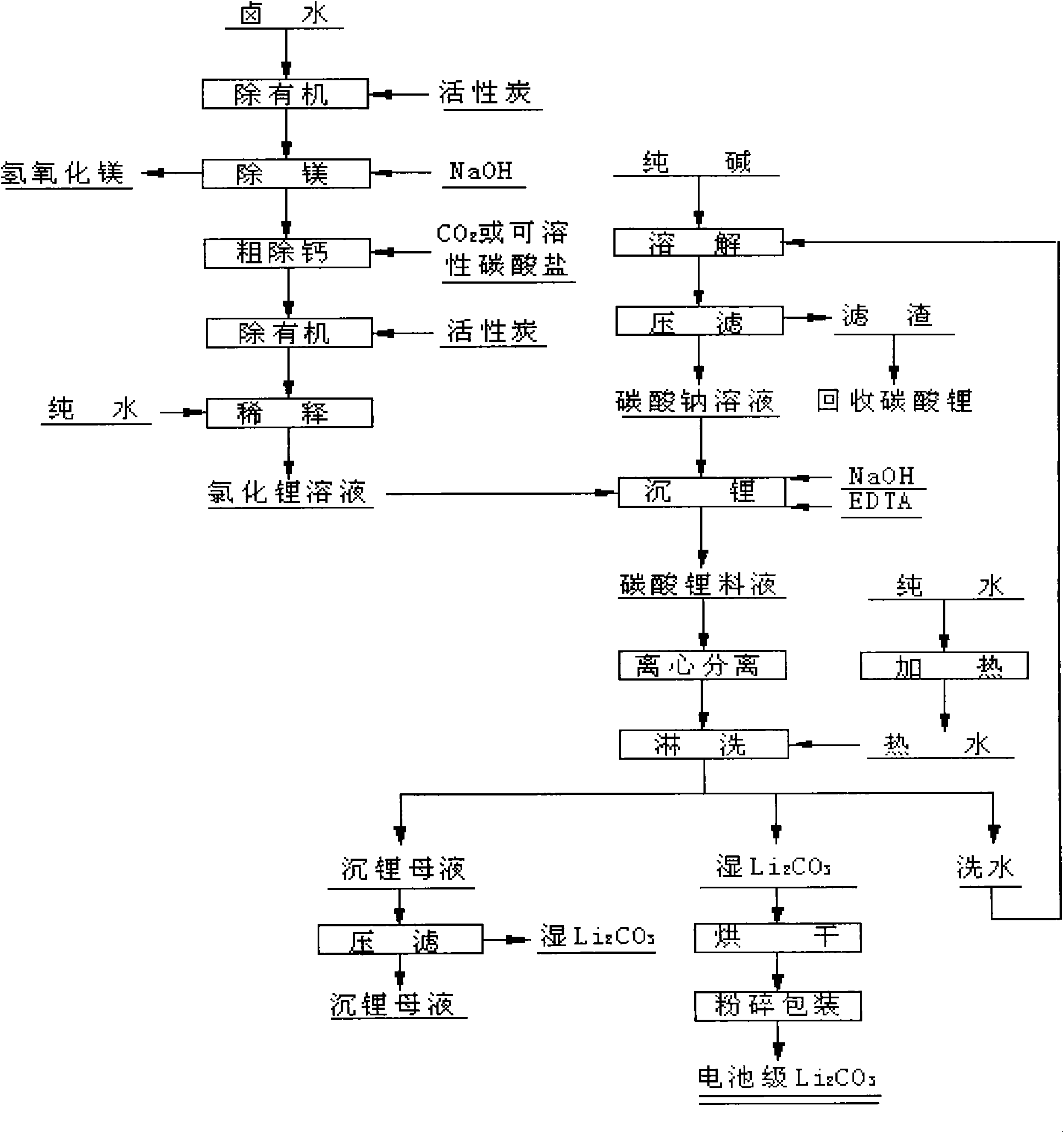

Method for extracting ultrahigh-purity lithium carbonate from salt lake brine with high magnesium-lithium ratio

The invention discloses a method for extracting ultrahigh-purity lithium carbonate from chloride brine with a high magnesium-lithium ratio. The method comprises the following steps of: preparing a lithium chloride concentrated solution by an adsorption, desorption and evaporation concentration process; purifying, and precipitating lithium carbonate by using ammonium bicarbonate pulp; and converting into a lithium bicarbonate solution, filtering, and decarburizing. By improving steps and parameters of the conventional process, the purity of a product is more than 99.99 weight percent and the total amount of major impurities is not more than 0.002 weight percent without the introduction of additional high-cost purification steps such as ion exchange resin / membranes; and additional sodium ions are not introduced in the production process, byproducts at all stages can be recycled, and only an extremely small amount of waste solution is generated.

Owner:JIANGSU HAILONG LITHIUM IND TECH

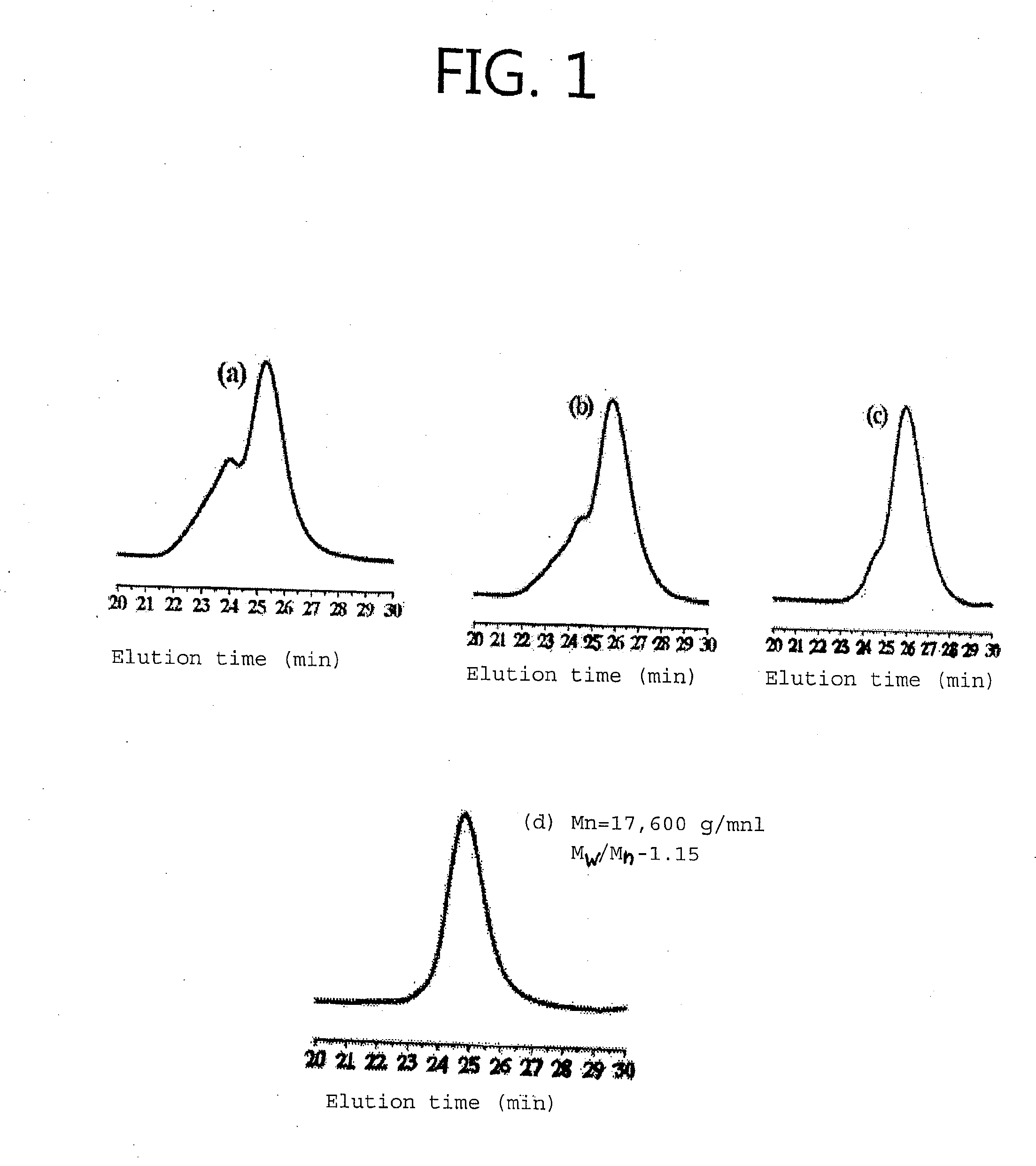

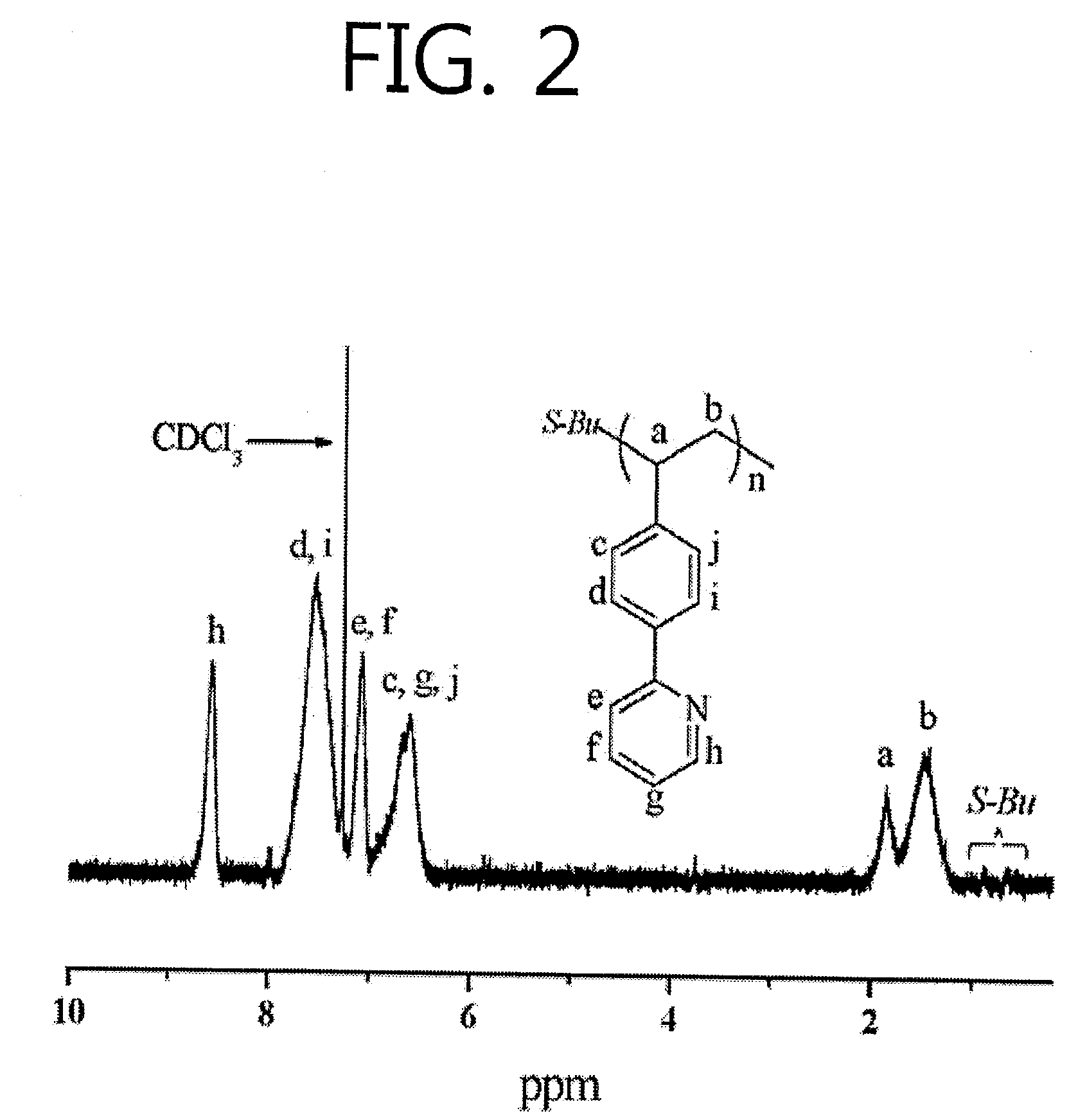

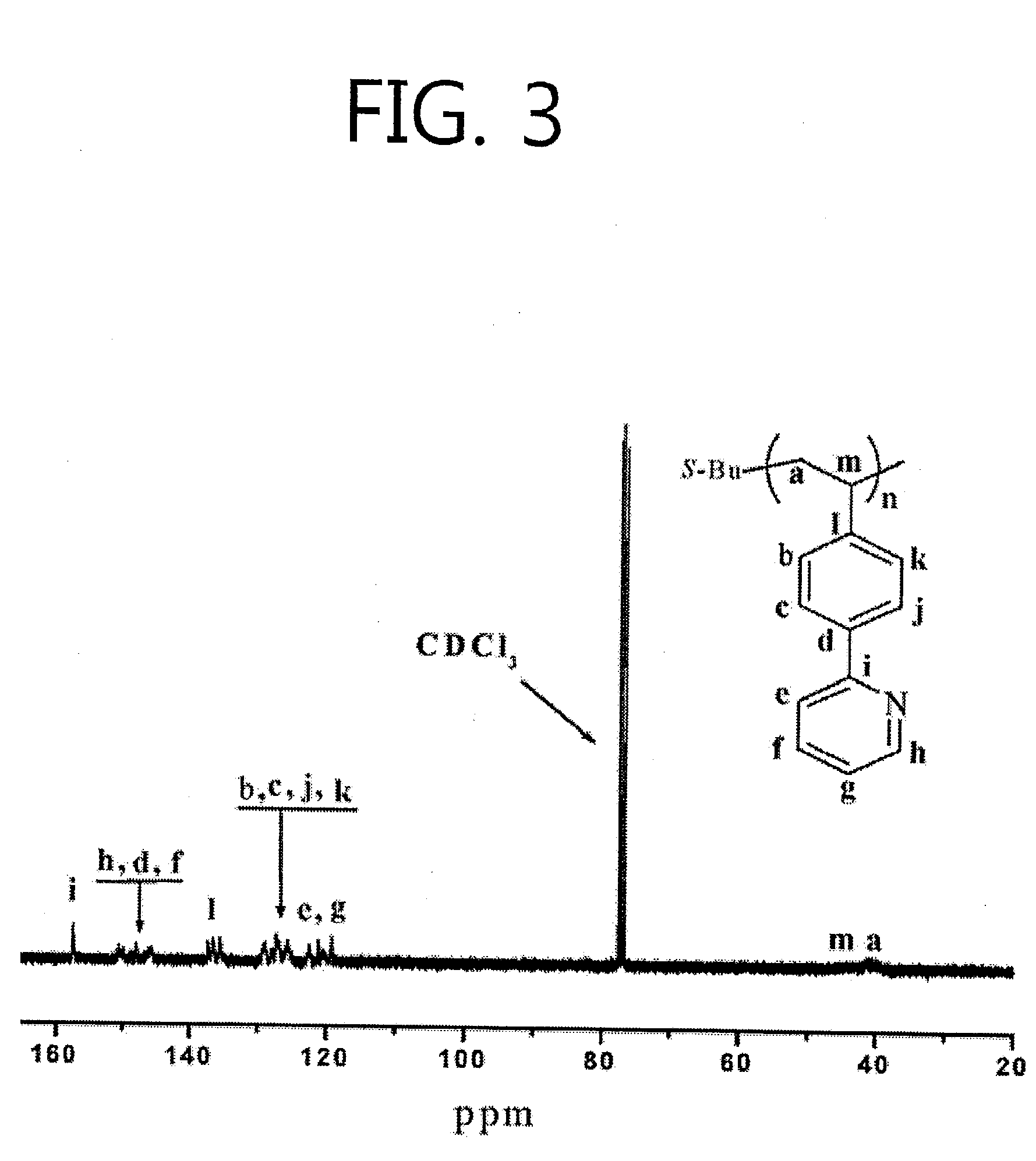

Anionic polymerization method for styrene derivative containing pyridine as functional group

An anionic polymerization method for styrene derivative containing pyridine as functional group is provided. The method includes forming a complex of (vinylphenyl)-pyridine and lithium chloride and performing anionic polymerization. Accordingly, a polymer of styrene derivative containing pyridine can be obtained. The polymer has excellent optical properties, and its molecular weight and molecular weight distribution can be controlled.

Owner:GWANGJU INST OF SCI & TECH

Production of lithium compounds directly from lithium containing brines

InactiveUS20110123427A1Reduce in quantityPromote absorptionVarying alkali metal carbonate water contentRubidium/caesium/francium compoundsLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

Production of lithium compounds directly from lithium containing brines

InactiveUS20070160516A1Promote absorptionConstant liquid volumeCrystallization separationCarbonate/bicarbonate preparationLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

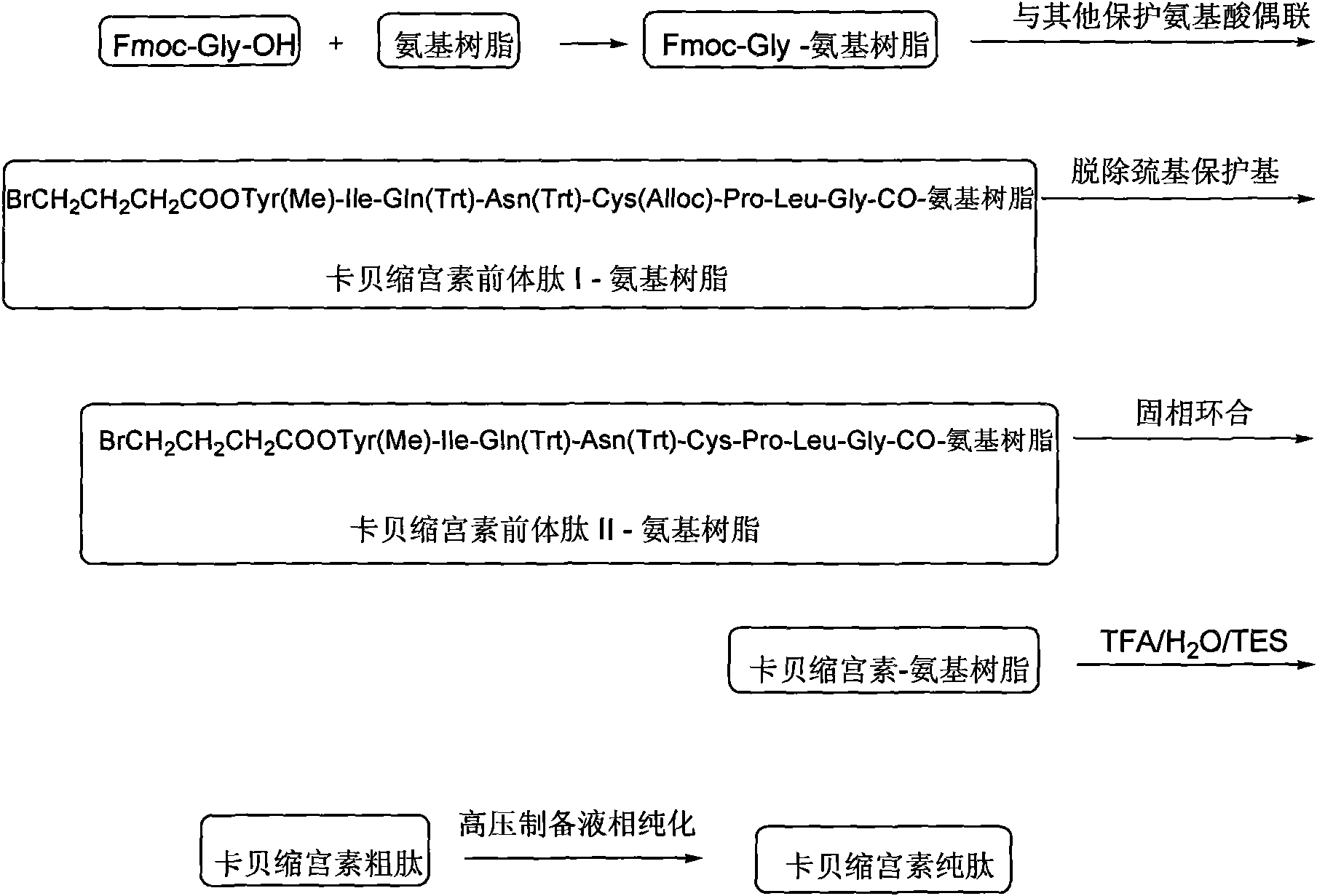

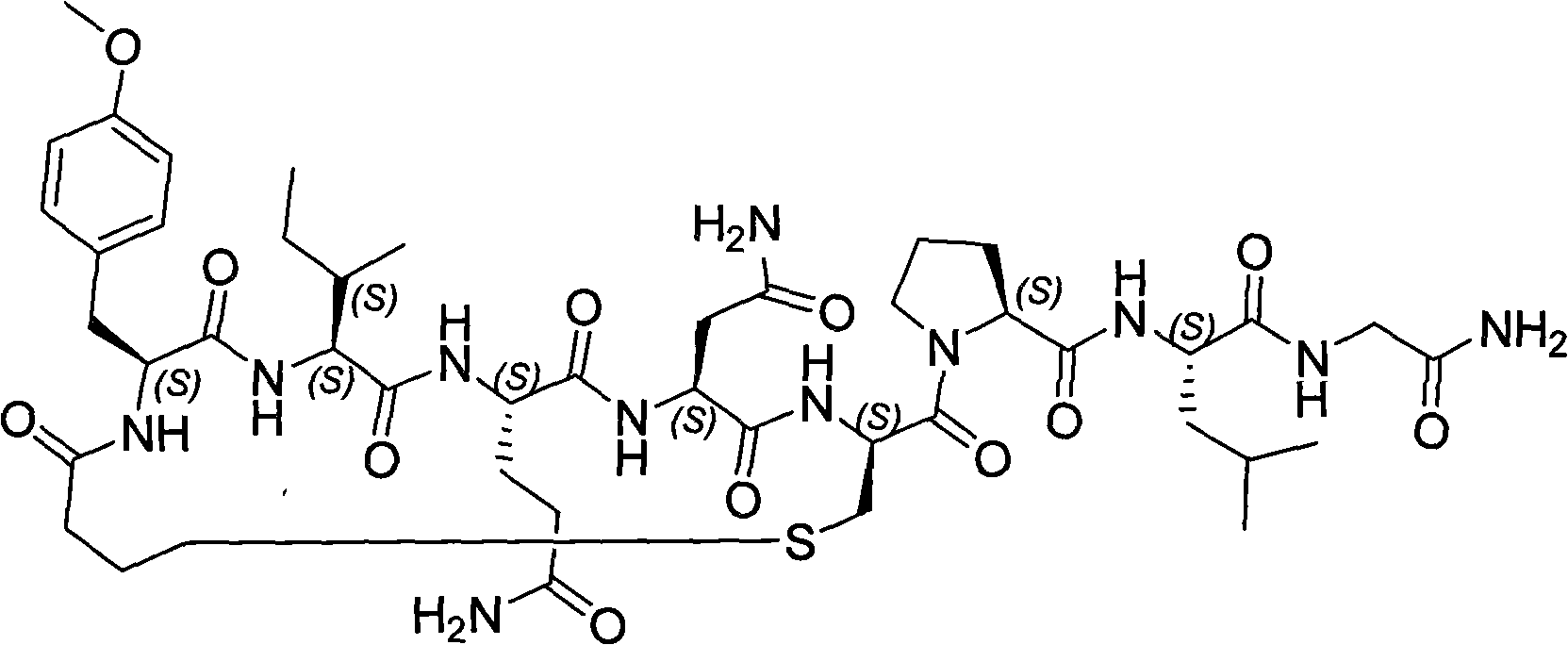

Solid phase preparation method of carbetocin

ActiveCN101555272AReduce investmentEasy to operatePeptide preparation methodsSexual disorderLithium chlorideFreeze-drying

The invention discloses a solid phase synthesis method of carbetocin. The technical proposal comprises the following steps of: obtaining Fmoc-Gly-amino resin by reaction of Fmoc-Gly-OH and amino resin with the substitutability being 0.2 mmol / g-0.9 mmol / g; sequentially connecting amino acids with Fmoc protecting groups by the solid phase synthesis method to obtain carbetocin precursor peptide I-amino resin; stripping off cysteine side chain protecting groups to obtain carbetocin precursor peptide II-amino resin; adding organic alkali and lithium chloride in solvent for cyclization to obtain carbetocin-amino resin; cracking to obtain carbetocin crude peptide; and purifying and freeze-drying to obtain the carbetocin. The method adopts the amino resin to synthesize carbetocin by the solid phase cyclization technology. The process is characterized by simple operation, easy post-treatment, high yield, low cost, and the like, and has considerable economical and practical value and broad application prospect.

Owner:HYBIO PHARMA

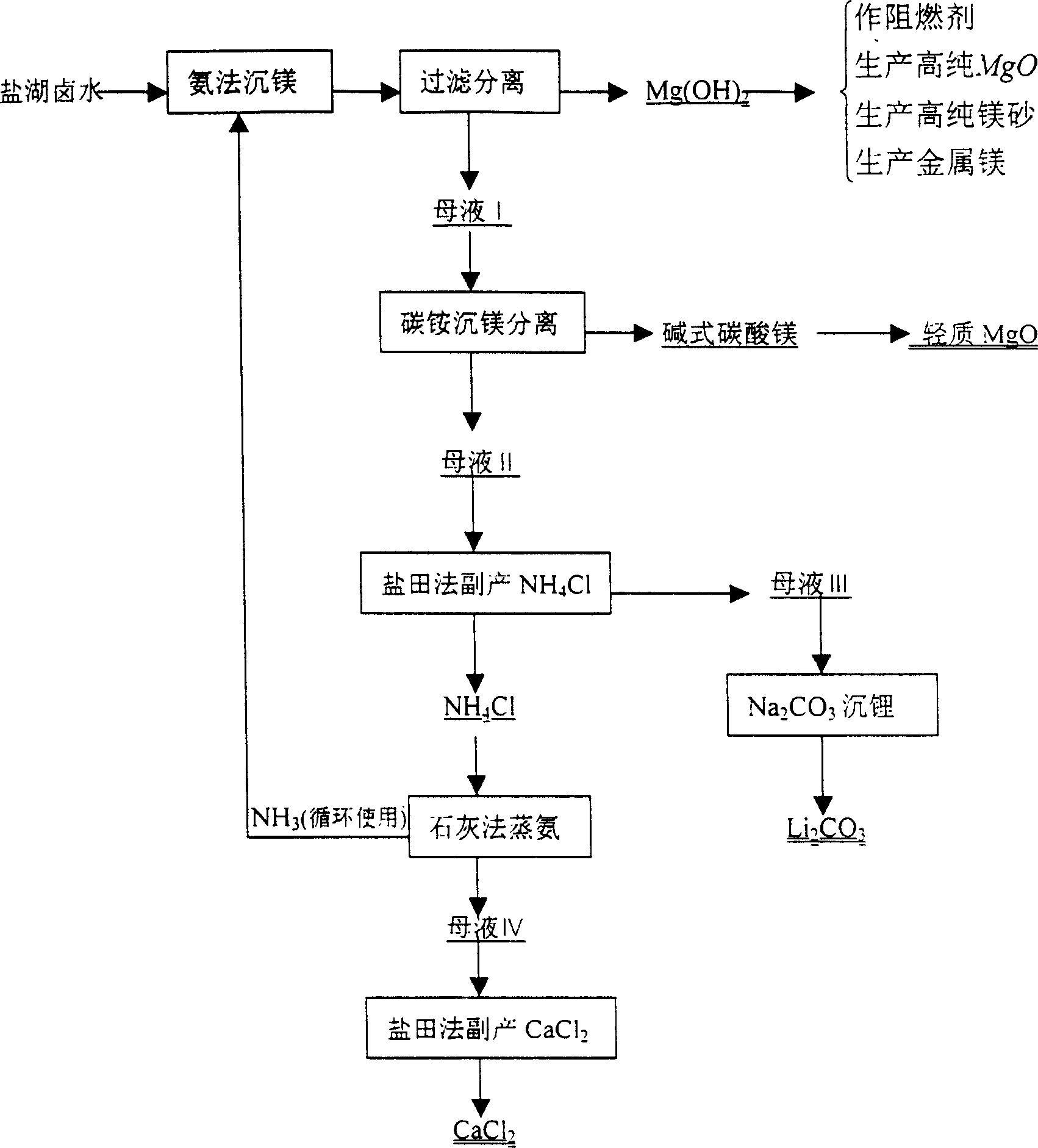

Method of combined extraction of magnesium and lithium in salt lake bittern

A process for extracting Mg and Li from the brine of salt lake features that the ammonia and ammonium dicarbonate are used to implement two stages of magnesium deposition. For the first stage, the crystal seeds (5-10%) are added and the efficiency of magnesium deposition is controlled to 80-85%. For the second stage, the solid ammonium dicarbonate is added for reaction to obtain more than 98% of Mg extraction rate. The ammonium chloride in the mother liquid can be converted to ammonia for reuse. The lithium chloride solution enriched from the mother liquid can be used to prepare lithium carbonate. The extraction rate of Li is more than 95%.

Owner:CENT SOUTH UNIV

Process for extracting lithium from salt lake brine by manganese dioxide

The present invention is manganese dioxide process of extracting lithium from salt lake brine, and the process is suitable for producing lithium carbonate and lithium chloride with lithium-containing Qinghai saline lake brine, including concentrated lithium-containing Qinghai saline lake brine. The process includes sun shining saline lake brine to obtain concentrated lithium containing brine, selective adsorption of lithium ion with MnO2 adsorbent, eluting adsorbed lithium ion with hydrochloric acid solution, and refining and concentrating the elutriant to obtain material for preparing lithium carbonate and lithium chloride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

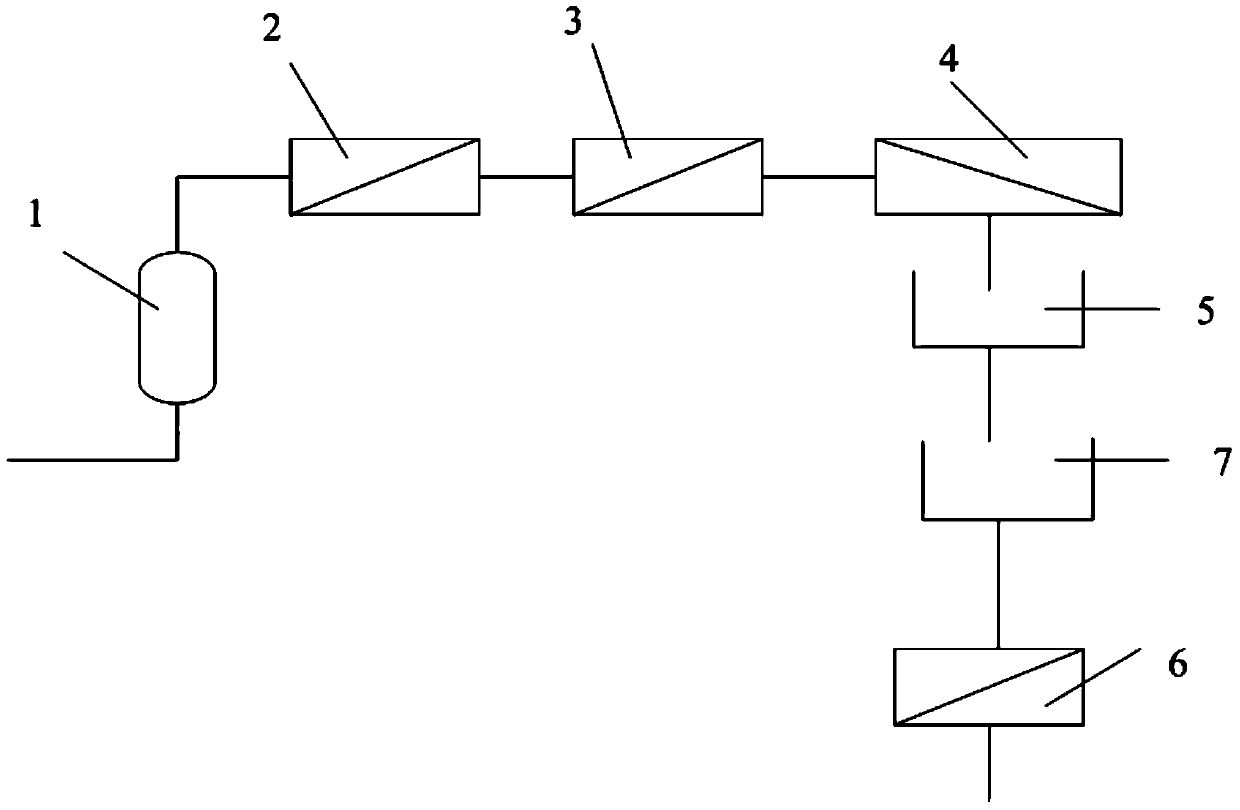

Coordinate extracting system for extracting lithium from salt lake brine with extraction method

The invention relates to a coordinate extracting system for extracting lithium from salt lake brine with extraction method, which comprises the following steps of (1) acidity of raw material liquid adjustment: adding hydrochloric acid to the salt lake brine to adjust the pH value of the raw material liquid to 1 to 5 so that the raw material liquid is obtained; (2) extracting lithium: carrying out three-stage extraction on the raw material liquid obtained in step (1) by using TBP-BA-FeCl3 solvent naphtha as an extracting agent to obtain an organic phase; (3) organic phase washing: carrying out three-stage washing to the organic phase obtained in the step (2) by using the hydrochloric acid as a washing agent; (4) organic phase reextraction: carrying out three-stage extraction on the organic phase obtained in the step (3) by using hydrochloric acid as a reextraction agent to obtain lithium chloride solution. The invention has the advantages of simple technique, easy control, low reextraction acidity, low requirements on reextraction equipment materials and concentration of lithium in the material brine, and no need of evaporation concentration of thin lithium solution, thereby saving energy, reducing consumption, decreasing the production cost, and simultaneously improving the total recovery rate of the lithium effectively.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

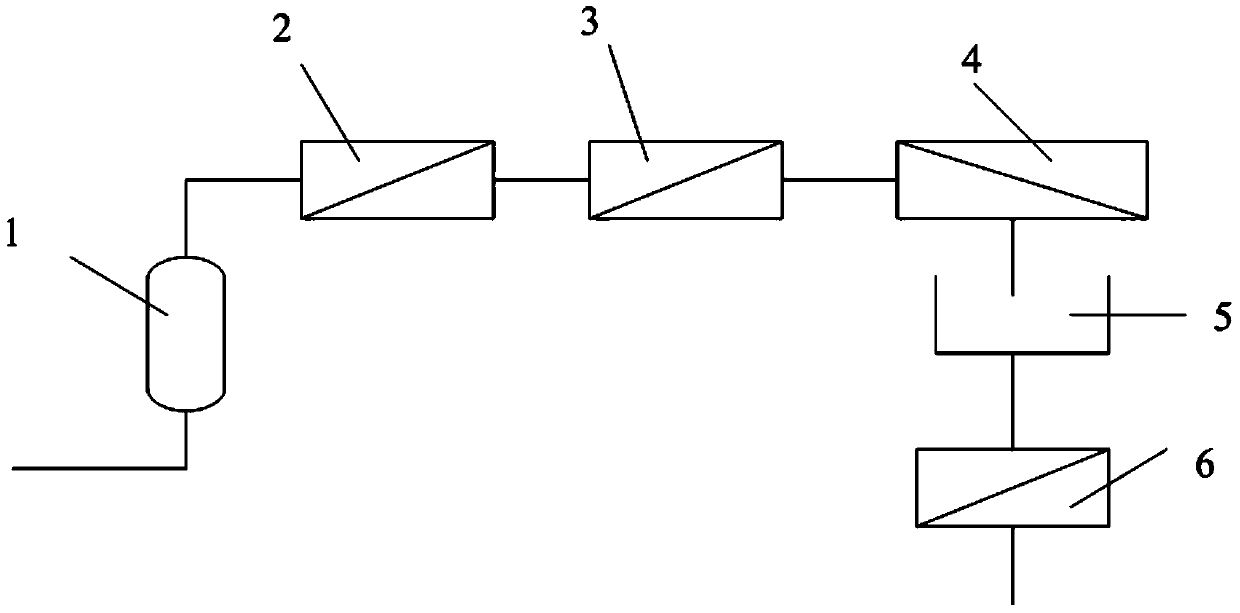

Method and device for extracting bitten lithium chloride

The invention relates to a method and a device for extracting bitten lithium chloride. The method specifically comprises the steps: 1, adsorbing lithium ions by bittern in a lithium-containing salt lake old brine pool through an aluminum salt adsorbing agent, desorbing by using water to obtain a desorbing solution; 2, filtering the desorbing solution by using a coarse filter; 3, filtering permeate of the coarse filter by using a nanofiltration membrane to obtain permeate of the nanofiltration membrane; 4, concentrating the permeate of the nanofiltration membrane by using a reverse osmosis membrane to obtain a reverse osmosis concentrated solution; and 5, carrying out baysalt or evaporating on the reverse osmosis concentrated solution to obtain lithium-containing concentrated brine. According to the method, the problems that the concentration multiple in a reverse osmosis station can not be increased, the baysalt efficiency is low and a plenty of reagents are consumed in precipitation in a conventional process for extracting lithium from brine can be solved, and the obtained lithium chloride solution is high in yield and high in purity.

Owner:JIANGSU JIUWU HITECH

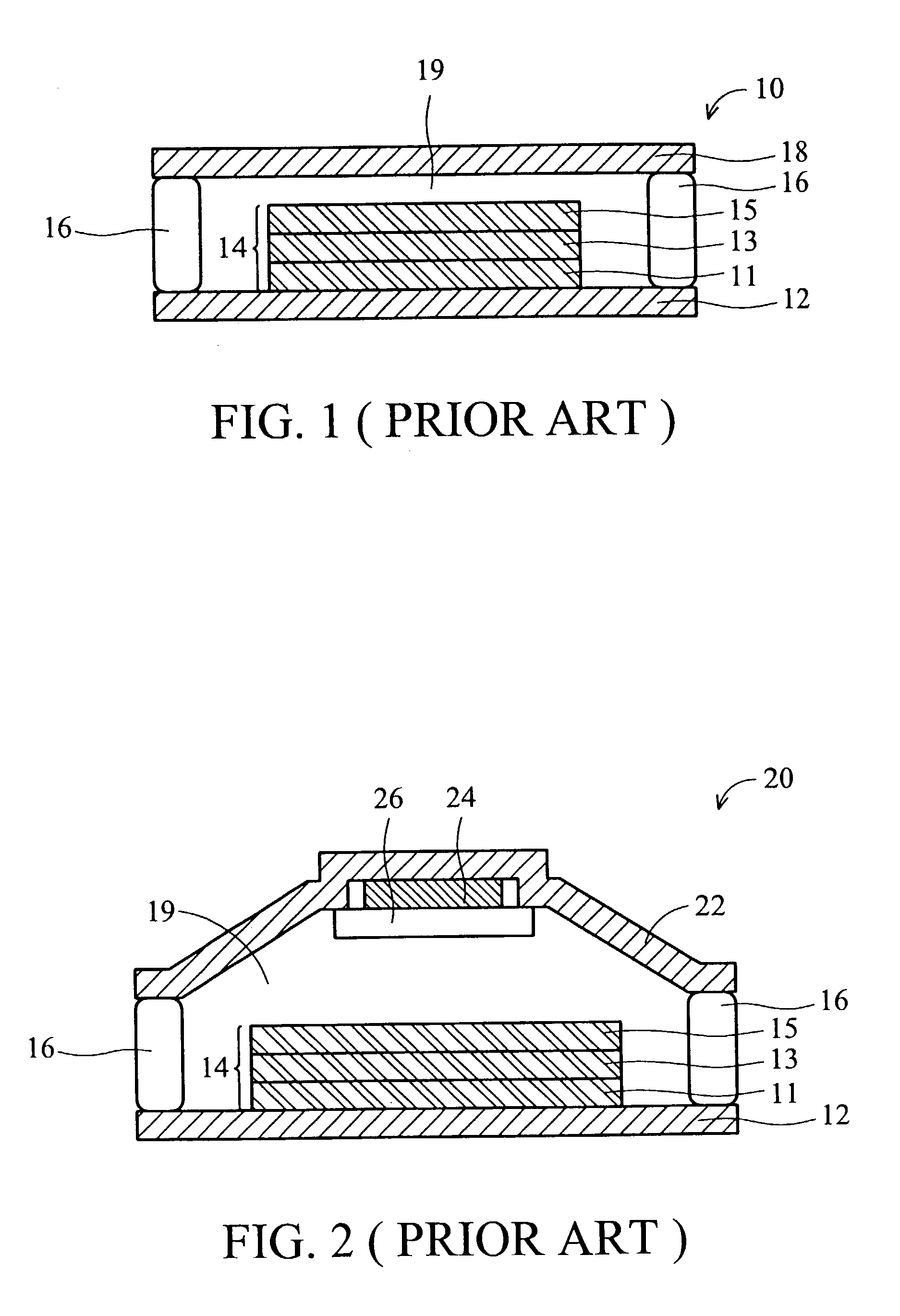

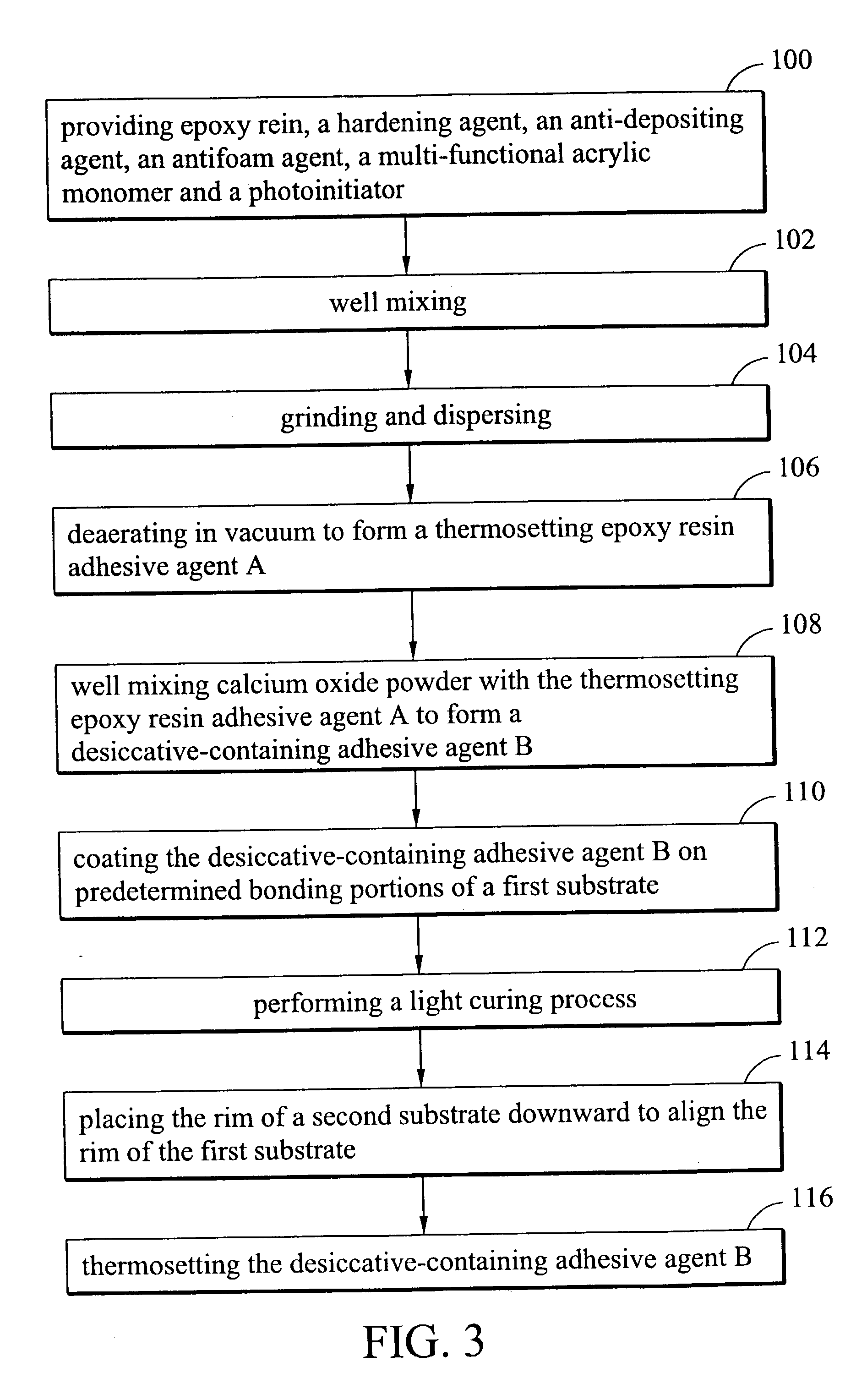

Packaging material used for a display device and method of forming thereof

InactiveUS20040084686A1Non-macromolecular adhesive additivesSemiconductor/solid-state device detailsZinc bromideAlkaline earth metal

A packaging material used for a display device which is a desiccative-containing adhesive agent. The desiccative-containing adhesive agent is composed of a liquid-state organic material selected from a group including epoxy resin, polyurethane, bakelite, polyamide, acrylic resin and polysiloxane, and a solid-state desiccative selected from a group including alkaline metal oxide, alkaline-earth metal oxide, metallic halide, barium oxide, calcium oxide, calcium sulfate, calcium chloride, lithium chloride, calcium bromide, potassium Carbonate, aluminum oxide, magnesium oxide, copper sulfate, zinc chloride, zinc bromide, cobalt chloride, silica gel, zeolite and molecular sieve.

Owner:DELTA OPTOELECTRONICS +1

A kind of separation and recovery method of NMP and catalyst lithium chloride in polyphenylene sulfide production

The invention relates to a separation and recovery method for n-methylpyrrolidone (NMP) and a lithium chloride catalyst during polyphenylene sulfide producing. The method is characterized by: directly carrying out vacuum distillation for a polyphenylene sulfide polycondensation mother liquid until the polyphenylene sulfide polycondensation mother liquid is dried to recover a solvent of the NMP, wherein the NMP can be used in the next recycling production; adding water to the distilled residues, then heating to a temperature of 40 DEG C, carrying out stirring and completely dissolving the distilled residues, carrying out filtering and washing the filter residues, mixing the resulting filtrate and the washing solution, and analyzing lithium content in the mixed solution; adding the mixed solution to a phosphoric acid solution or a sodium aluminate solution, wherein the phosphoric acid solution or the sodium aluminate solution has a lithium reaction equivalent of 105-115%, then completely stirring to enable lithium phosphate or lithium aluminate to be precipitated completely, then carrying out steps of filtering, washing, drying for the lithium phosphate or the lithium aluminate to recover the lithium salt having a purity more than 97%. According to the present invention, the operation of the method is simple; the cost is low; the recovered NMP and the recovered lithium salt havehigh purities.

Owner:NANJING UNIV

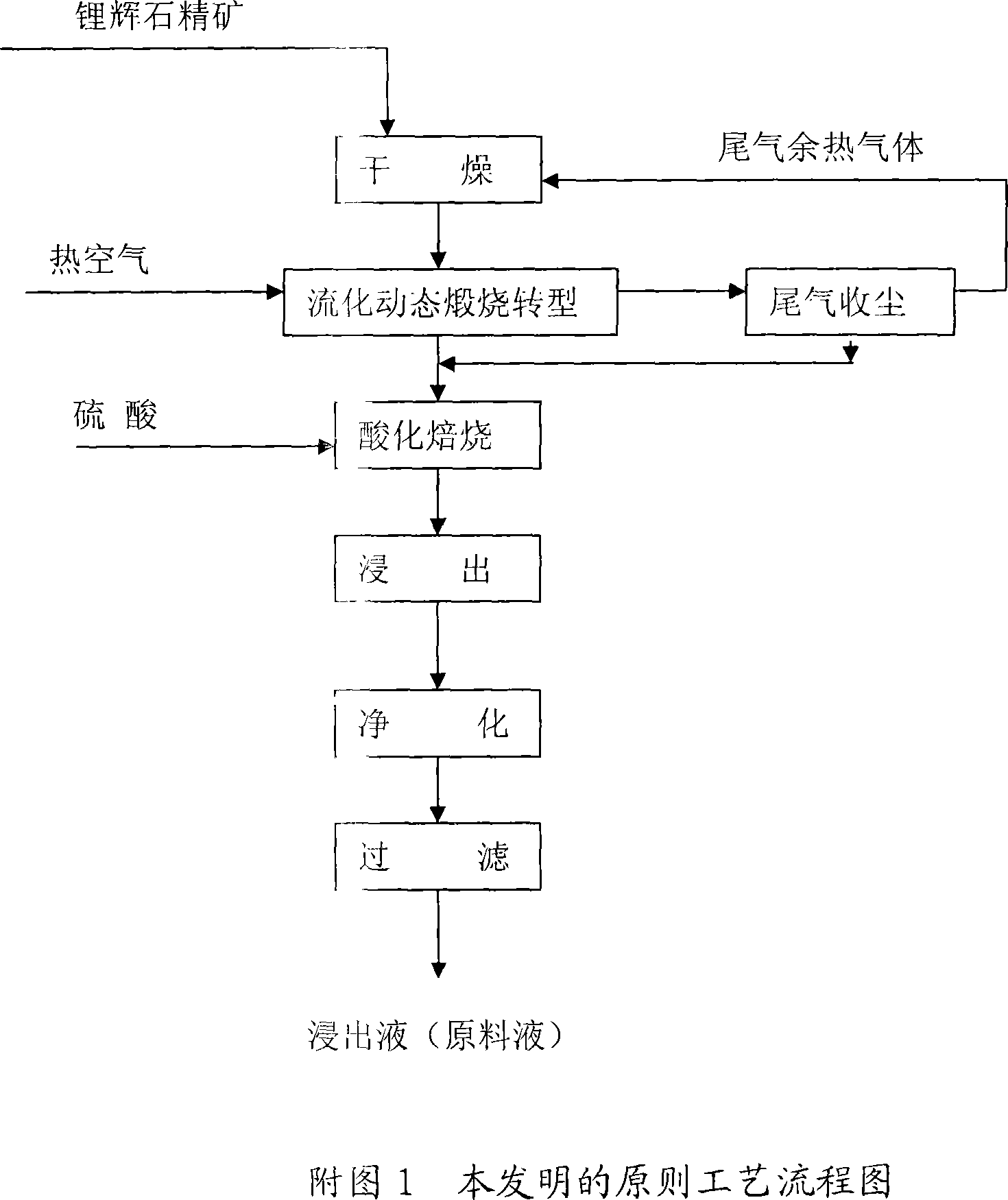

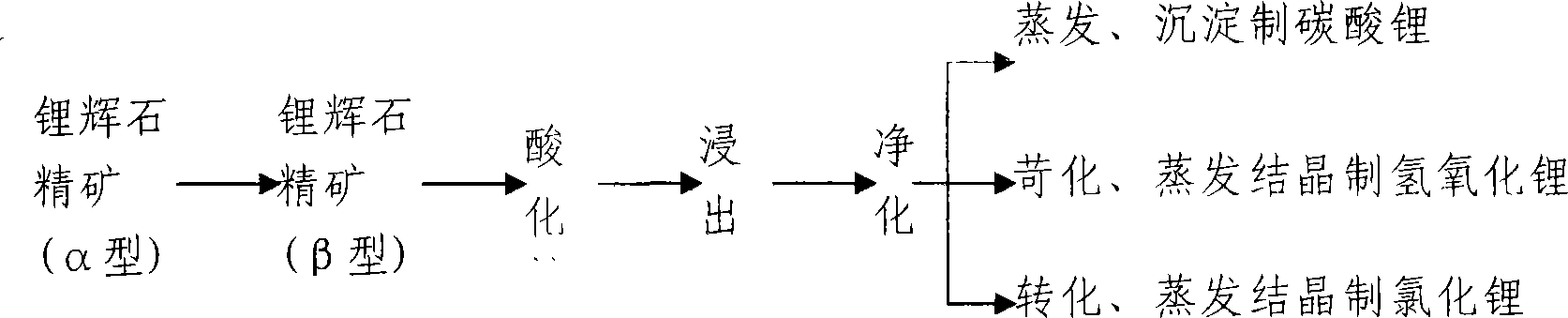

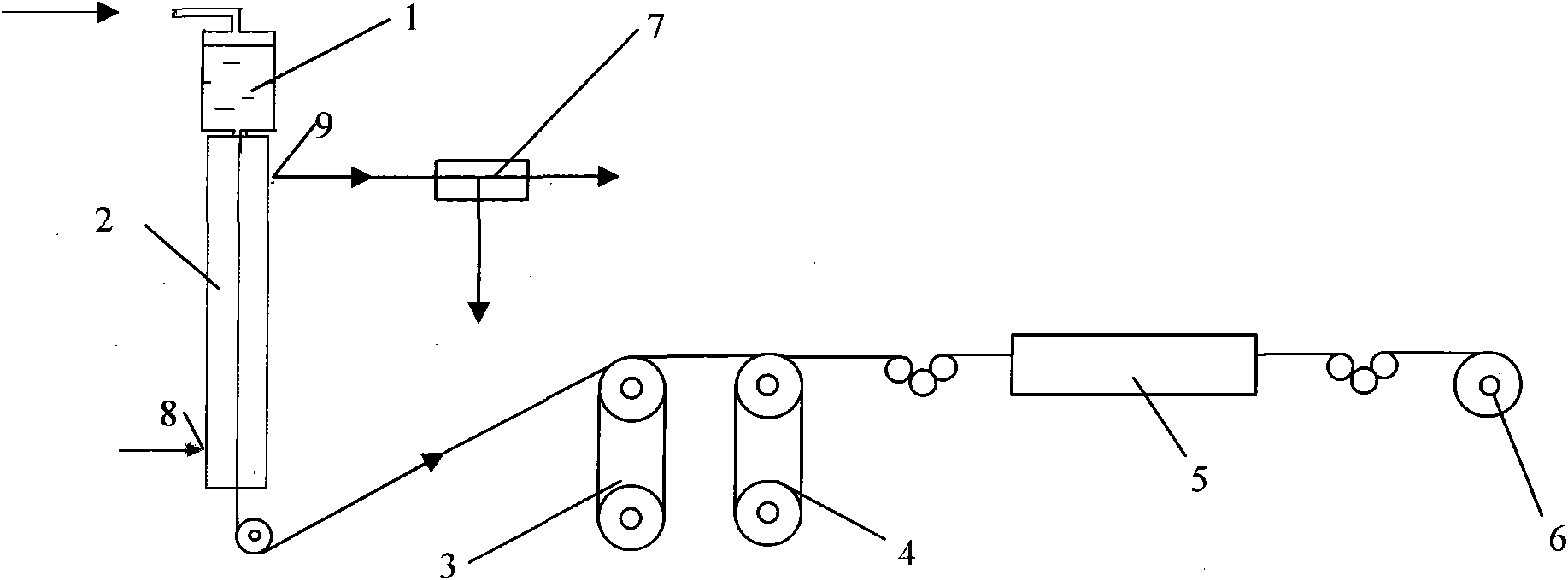

Novel method for spodumene calcining transformation

InactiveCN101224900AEvenly heatedFast heat transferChemical industryLithium halidesLithium chlorideLithium hydroxide

The invention relates to a method for producing lithium carbonate, lithium hydroxide and lithium chloride with spodumene. Aiming at the defect of the calcination transformation technology of the spodumene concentrate, the invention provides a new method of the fluidization and dynamic calcination transformation of the spodumene concentrate: the spodumene concentrate from a concentration plant is dried and milled to granules with the granularity of minus 250 meshes to minus 350 meshes; then a fluidization dynamic calcinator is adopted to carry out high temperature calcination transformation to the concentrate, the material temperature is controlled between 900 and 1200 DEG C; because the material in the furnace is fluidized and transfers heat and is delivered in the form of air delivery with hot air, the process is rapid in heat transfer rate, high in efficiency and short in calcination time, which overcomes the technical defect of the existing calcination technology that the material is easy to be agglomerated and avoids cooling and ball-milling procedures. When the calcined material is treated by the procedures of leaching, purging, filtering, etc., the obtained filtrate (raw material liquid) can be utilized for producing products such as lithium carbonate, lithium hydroxide, lithium chloride and so on by adopting existing different technologies.

Owner:钟辉

Method for preparing high-purity lithium carbonate and other available byproducts from salt lake brine

InactiveCN101712481ATake advantage ofCalcium/strontium/barium carbonatesLithium halidesLithium chlorideLithium carbonate

The invention relates to a method for preparing high-purity lithium carbonate and other available byproducts from salt lake brine. The method comprises the following steps: (1) separating potassium and sodium by exposing salt in a salt field, (2) separating boron by an acidification method, (3) separating magnesium by a sedimentation method, (4) separating calcium by the sedimentation method, (5) preparing lithium chloride, and (6) preparing the lithium carbonate. The preparation method of the invention can purify the potassium, sodium, boron, magnesium and calcium ions respectively besides obtaining the lithium carbonate product of which the purity is over 99.5 percent so as to fully utilize the salt lake brine resource.

Owner:DALIAN LICHANG NEW MATERIAL CO LTD

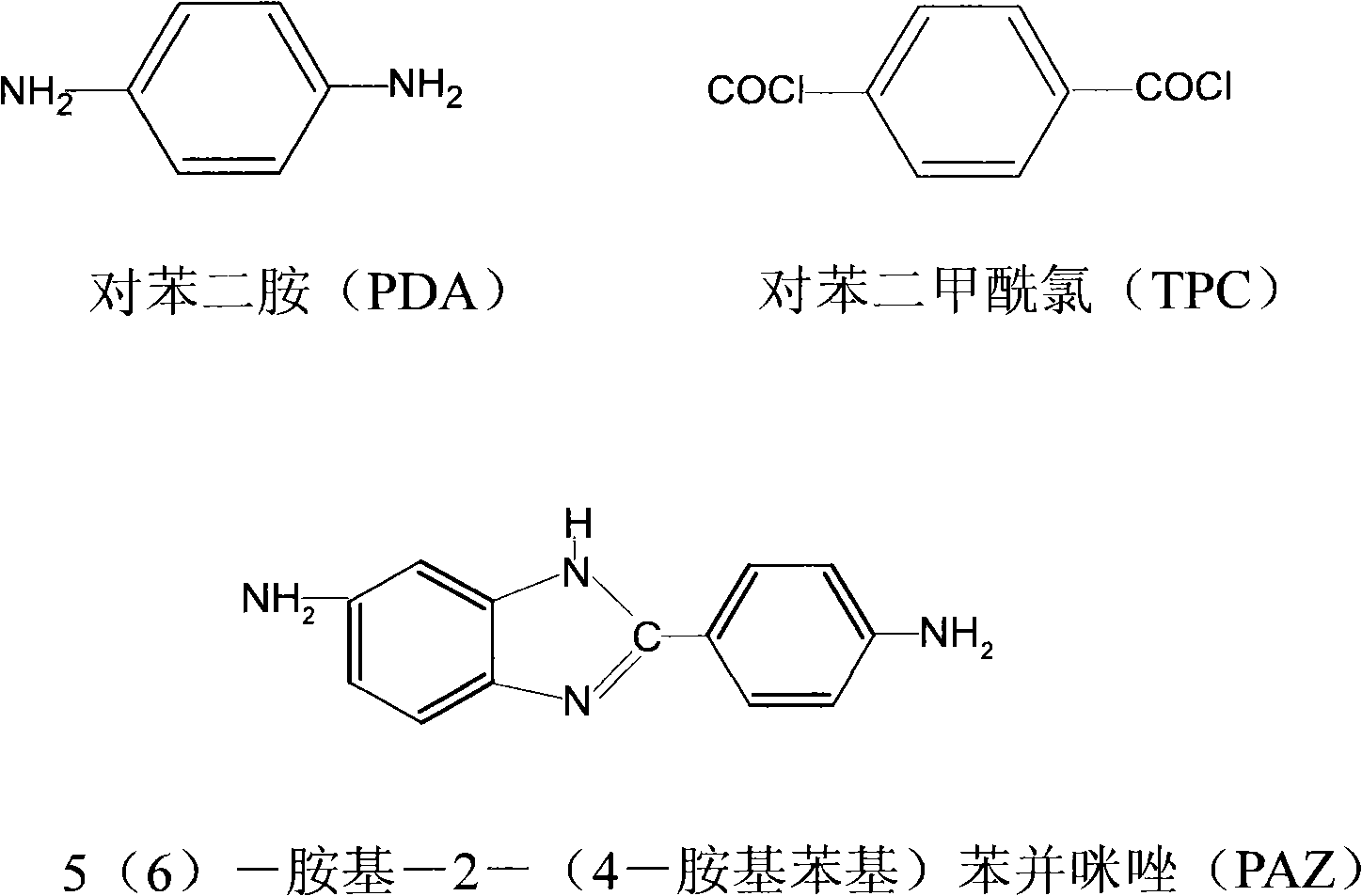

Method for preparing aramid IIII fiber

InactiveCN101851809AImprove spinning efficiencyLow investment costMonocomponent copolyamides artificial filamentDry spinning methodsYarnLithium chloride

The invention relates to a method for preparing an aramid IIII fiber, which comprises the following steps of: (1) synthesizing a spinning stock solution, carrying out low-temperature copolymerization by adopting three monomers of p-phenylenediamine, paraphthaloyl chloride and 5(6)-amido-2-(4-amidophenyl)benzimidazole as raw materials and adopting dimethylacetylamide / lithium chloride as a solvent; (2) spinning by adopting a dry method spinning process, i.e. leading the spinning stock solution obtained in the previous step to pass through a spinneret and directly enter a hot inert gas channel and evaporating and removing the solvent in the spinning stock solution by utilizing a hot inert gas to obtain cured raw yarn; and (3) carrying out water washing and heat treatment on the raw yarn and winding to obtain the aramid IIII fiber. The method has high solid content of the spinning stock solution, high spinning speed, great improvement of spinning efficiency, obvious reduction of fiber manufacturing cost, improved mechanical performance of the manufactured aramid IIII fiber and wide application prospect.

Owner:SINOSELEN HI TECH

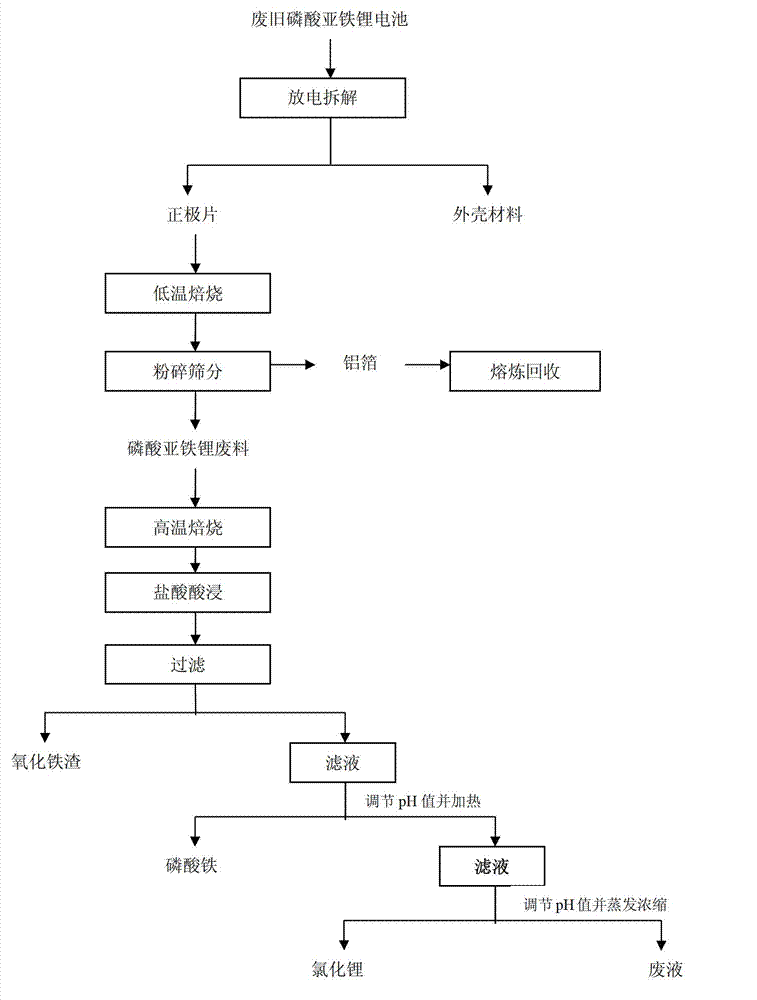

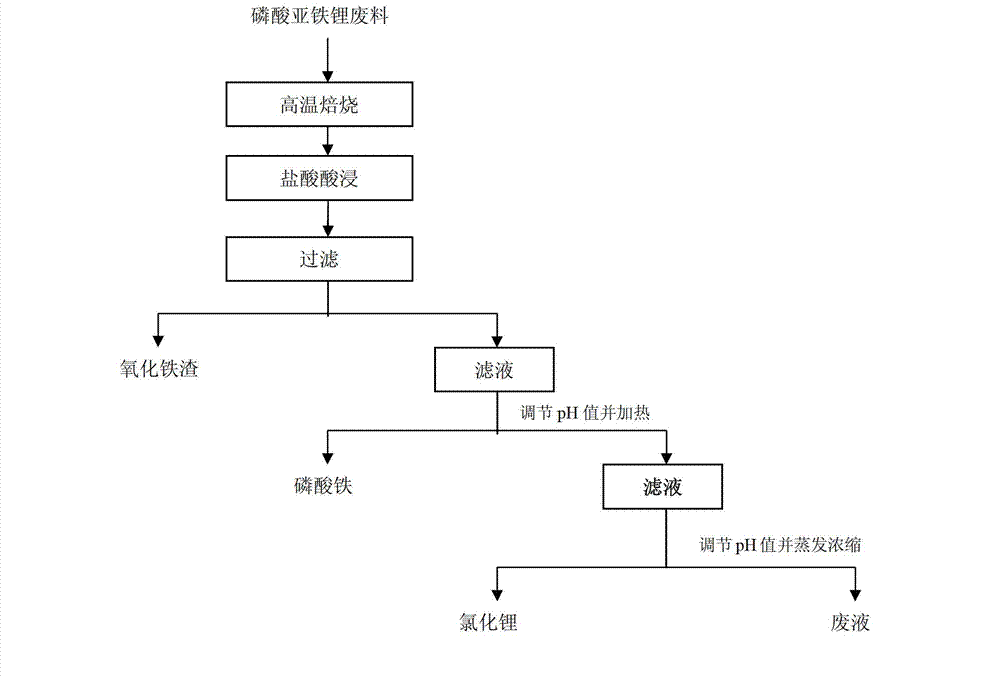

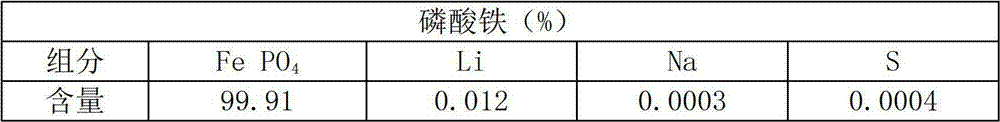

Method for recycling lithium chloride from waste lithium iron phosphate

ActiveCN102891345ASolve the problem of resource recyclingWaste accumulators reclaimingBattery recyclingLithium chlorideIron(III) chloride

The invention relates to a method for recycling lithium chloride from waste lithium iron phosphate, belongs to the technical field of waste and old lithium ion battery recycle, and solves the technical problem that the method for recycling lithium chloride from the waste lithium iron phosphate is provided. The method comprises the following steps of: roasting the waste lithium iron phosphate for 1-4hours under the temperature of 500-800 DEG C; leaching the materials after roasting by using hydrochloric acid, wherein the pH value is controlled to be within 0.5-1 during leaching; filtering so as to obtain a mixing liquid of lithium phosphate, iron phosphate and ferric chloride; heating the obtained mixing liquid to be at 80-100 DEG C; adjusting the pH value to be 2-2.5; reacting for 1-4hours; filtering; washing; drying so as to obtain the iron phosphate; adjusting the pH value of obtained filtrate to be 6-7; adding calcium chloride to perform phosphorous removal; and filtering; evaporating, concentrating, crystallizing, washing and drying the obtained filtrate to obtain lithium chloride.

Owner:天齐锂业(江苏)有限公司 +2

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

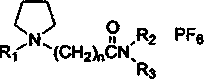

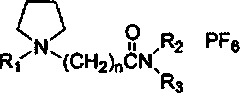

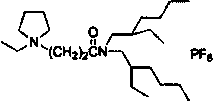

Lithium extraction system

ActiveCN106498184AReduce usageEasy material selectionProcess efficiency improvementSolvent extractionLithium chlorideKerosene

The invention provides a system from extracting lithium from salt lake brine, comprising ionic liquid, a co-extracting agent and a diluent; the ionic liquid is pyrrole hexafluorophosphate ionic liquid comprising lithium extraction functional groups, and the diluent is from solvent gasoline, sulfonated kerosene and petroleum ether. The use of the co-extracting agent iron trichloride is avoided in the lithium extraction system, adjusting pH of brine is not required, at least 5 tons of industrial hydrochloric acid and 2 tons of sodium hydroxide may be saved per ton of lithium chloride produced, and the production cost is greatly reduced; saponifying step, pickling step and deironing step are omitted from the technique, and therefore, the system is easier to use in industrial large-scale production.

Owner:青海柴达木兴华锂盐有限公司

Cellulose acetate/functionalized graphene mixed media hollow fiber positive osmotic membrane

InactiveCN104906966AImprove performanceImprove hydrophilicitySemi-permeable membranesFiberLithium chloride

The invention discloses a cellulose acetate / functionalized graphene mixed media hollow fiber positive osmotic membrane. 0.05-3.0% (w / w) of graphene is added into a solution composed of N-methyl-pyrrolidone or dimethylacetamide or dimethylformamide and 1,4-dioxane, 2.0-20.0% (w / w) of a polyethylene glycol or polyvinylpyrrolidone / lithium chloride composite additive with a volume ratio of 7:1 is added, stirring is carried out for 15-60min, then 10.0-35.0% (w / w) of cellulose acetate is added, stirring is carried out, the mixture is allowed to stand, and a casting film solution. The casting film solution is squeezed into an annular gap of a nozzle, goes through an air gap of 2-20cm, and goes into deionized water with a temperature of 20-60 DEG C, solidification is carried out, and a positive osmotic membrane is obtained after washing. When 1M of NaCl is employed as a drive liquid and deionized water is employed as a raw material liquid, the water flux is 18.3L / m2h, the reverse salt flux is less than 3.3g / m2h, and the contact angle is 57.5 degrees.

Owner:UNIV OF JINAN

Humidity-conditioning building materials capable of automatically adjusting indoor humidity

InactiveCN101234881AReduce moisture contentGood humidity control effectSolid waste managementFiberLithium chloride

The invention discloses humidity conditioning building material which can automatically condition indoor humidity; the components of raw material and weight percentages of the building material are as follows: 60-80 percent of building gypsum, 8-15 percent of plant fiber, 5-15 percent of lithium chloride sol, 3-8 percent of gypsum retarder and 4-9 percent of white cement. The building material has strong humidity conditioning ability, obvious humidity releasing effect, low construction cost and easy-obtained raw materials.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

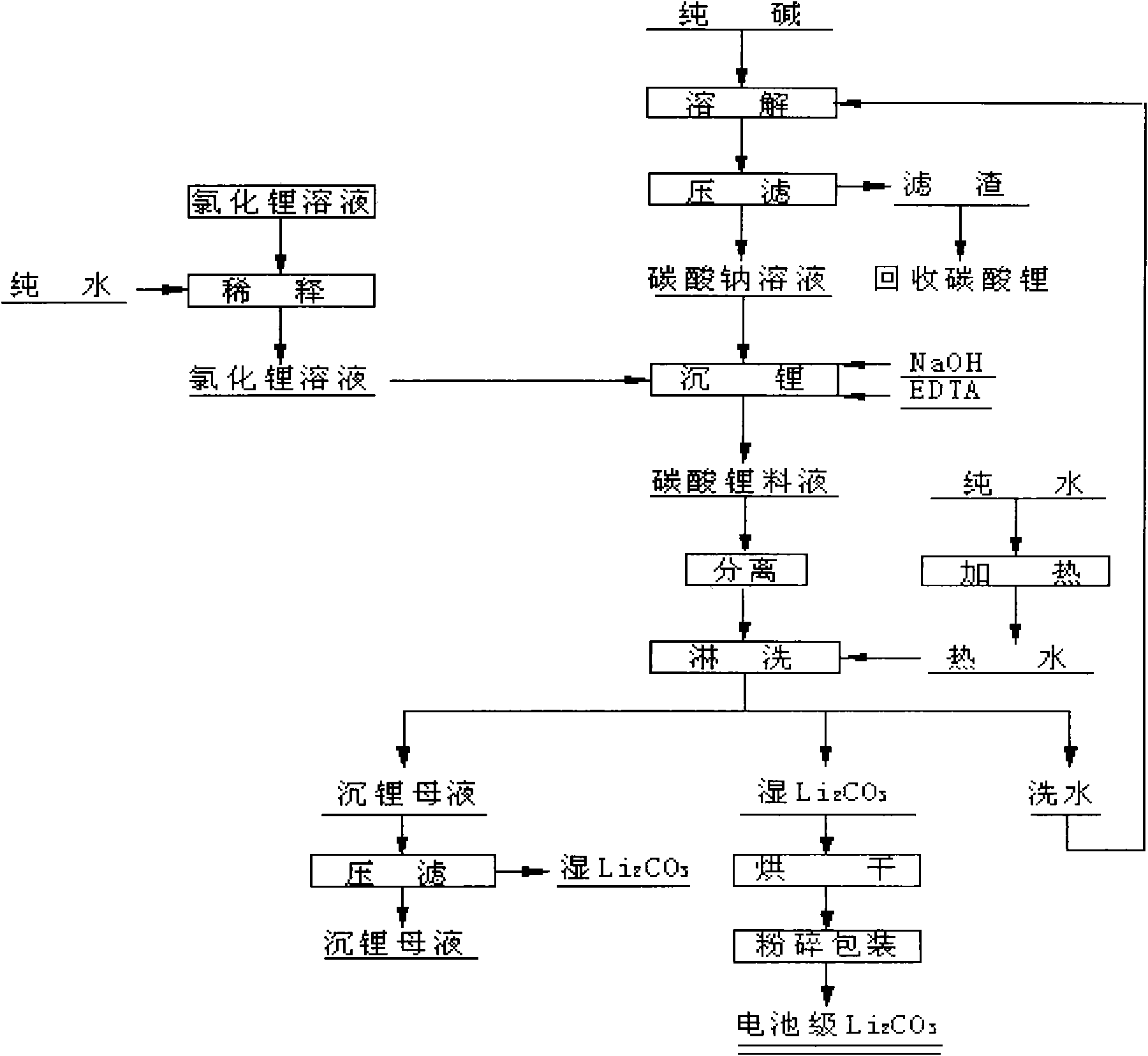

Method for preparing battery level lithium carbonate by using lithium chloride solution

ActiveCN101609888ALow Sulfate ContentQuality improvementElectrode manufacturing processesLithium carbonates/bicarbonatesLithium chlorideSulfate radicals

The invention provides a method for preparing battery level lithium carbonate by using lithium chloride solution. The method includes the steps of the dilution of lithium chloride solution, lithium sedimentation in sodium carbonate, the separation of lithium carbonate, washing, drying, grinding and packing. The method is simple in technology, easy in operation and low in production cost, and the obtained product, namely, battery level lithium carbonate, has the advantages of low sulfate radical content, stable quality, high utilization rate of resources and suitability for the production and application of lithium ion battery raw materials, and has extensive market prospect, as well as favorable economic and social benefit.

Owner:GANFENG LITHIUM CO LTD

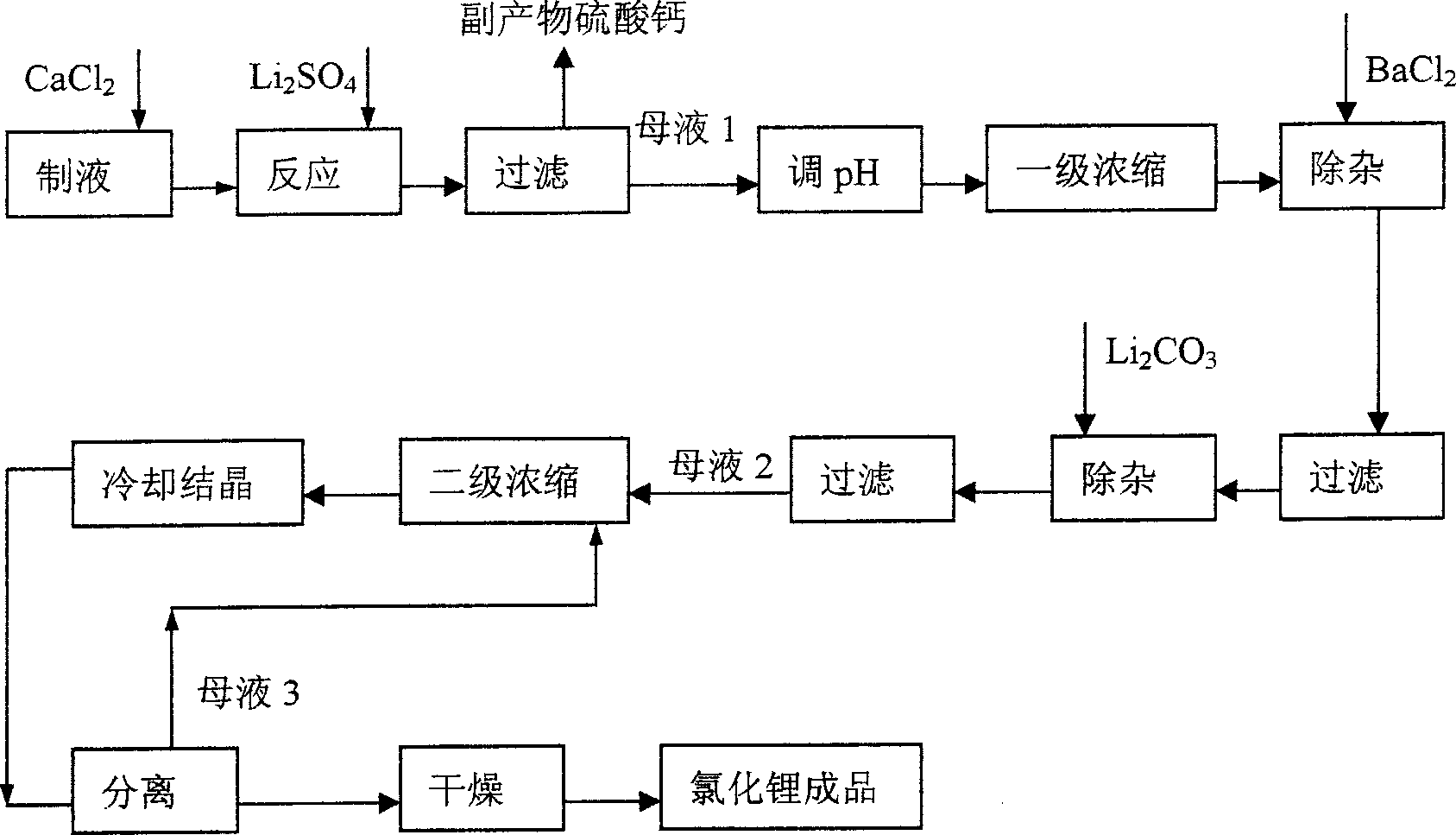

Method for preparing lithium chloride free from water

This invention discloses a method for preparing anhydrous LiCl. The method comprises: (1) adding CaCl2 to Li2SO4 solution to obtain LiCl and CaSO4; (2) filtering and washing to remove CaSO4 and obtain LiCl solution; (3) concentrating, adding BaCl2 solution, reacting, filtering and washing to remove SO42-; (4) adding LiCO3 solution, reacting, filtering and washing to remove Ba2+ and Ca2+; (5) concentrating, cooling, crystallizing, separating and drying to obtain anhydrous LiCl. The method has such advantages as simple process, easy operation, low energy and water consumption, low Li loss, and high LiCl yield.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Solvent and catalyst recovery technology in polyphenyl thioether production

InactiveCN102675683AReduce manufacturing costSave raw materialsChemical recyclingLithium chloridePowder mixture

The invention relates to a solvent and catalyst recovery technology in polyphenyl thioether production, which comprises the steps of: after polycondensation reaction is finished, firstly adding 1-3mol / mol Na2S and fresh NMP (N-methyl pyrrolidone) solvent as a diluting agent, diluting the reaction system with NMP to obtain another mixture, and further treating the mixture by filtering, extraction, evaporation and spiral evaporator to respectively obtain a mixed solution containing NMP and water and a powder mixture containing a cosolvent and byproducts; and evaporating the mixed solution containing NMP and water to remove water to obtain NMP solvent containing certain impurities, further rectifying and purifying the NMP solvent by a rectifying tower to obtain NMP solvent with the purity of 99.98% and the recovery rate of 96-98%to be recycled for polyphenyl thioether resin synthesis, and treating the powder mixture containing the cosolvent and byproducts to obtain catalyst lithium chloride with the purity of 99.95-99.98% and the recovery rate of 98-99%.

Owner:SICHUAN DEYANG ENG PLASTIC DEV

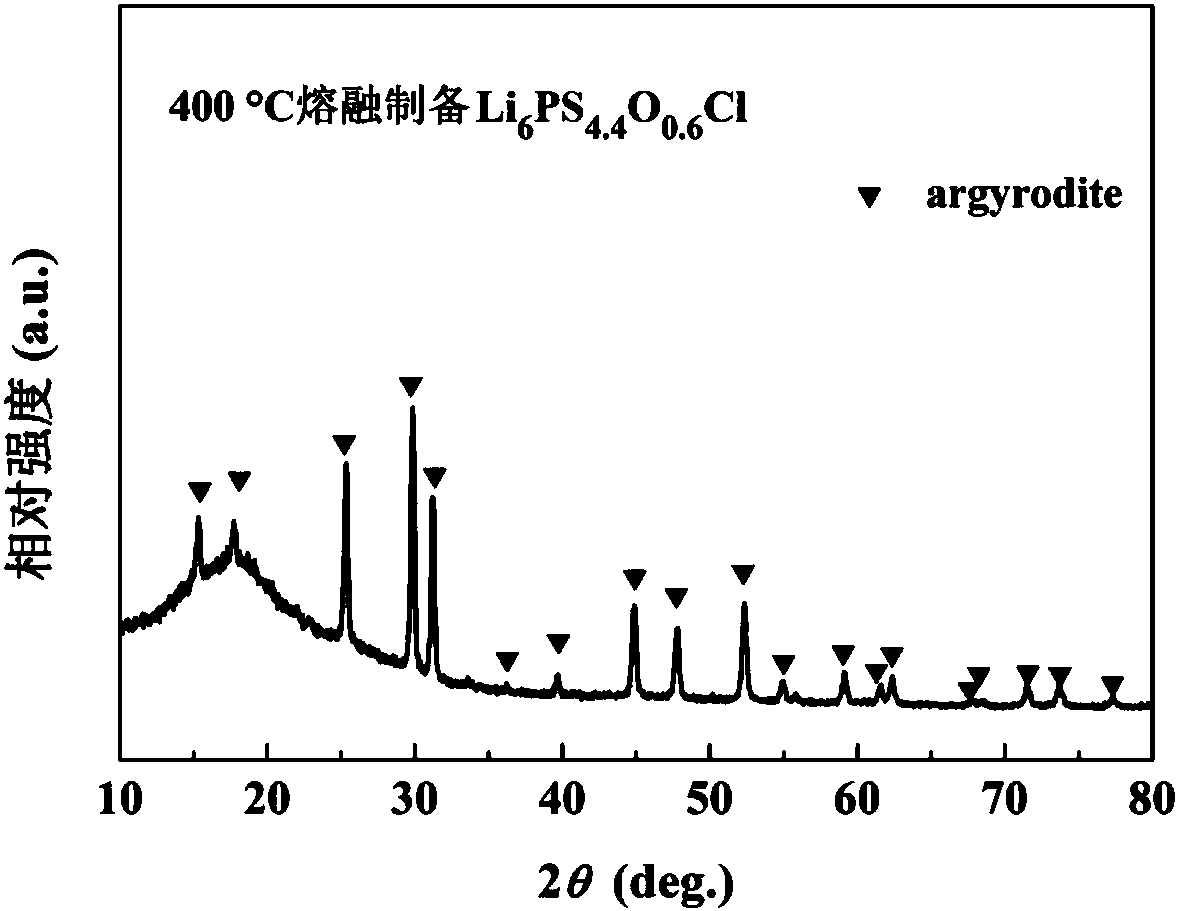

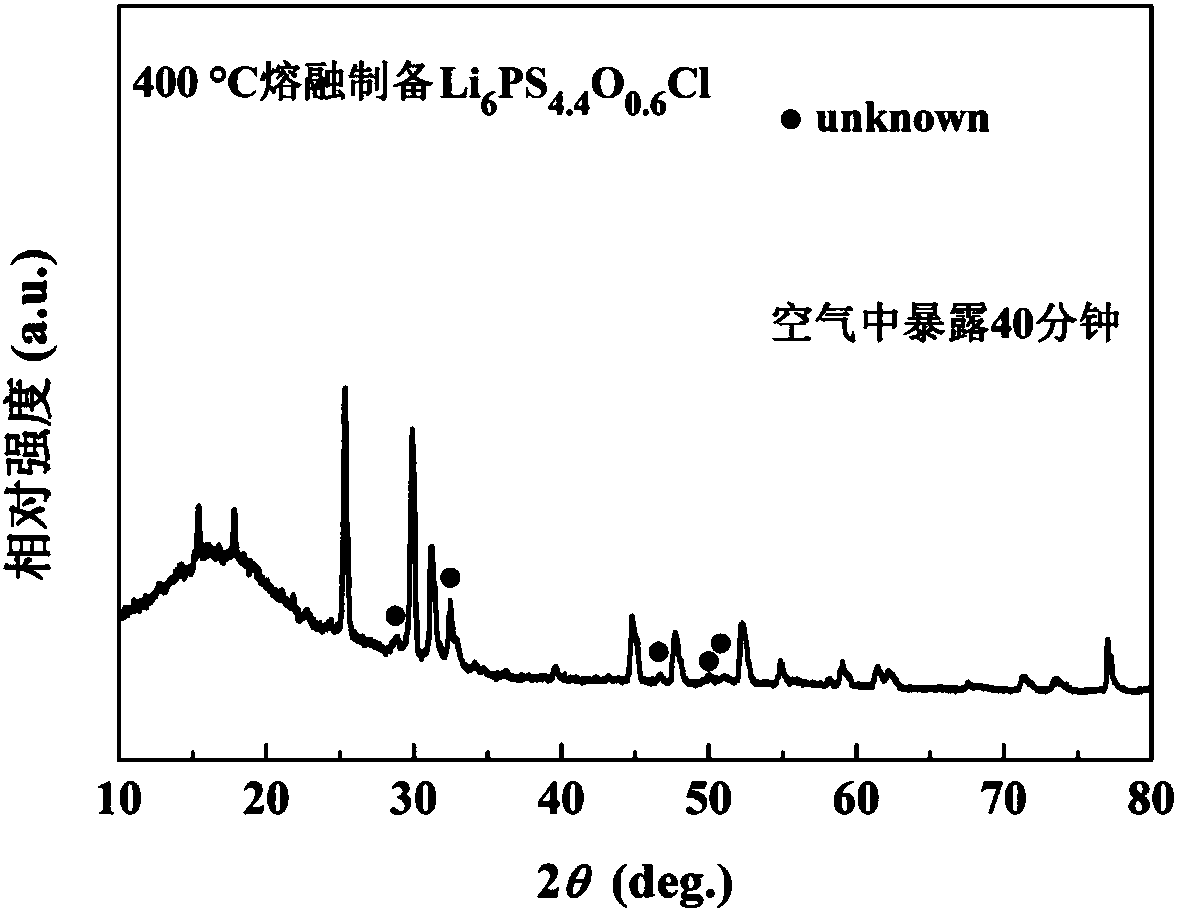

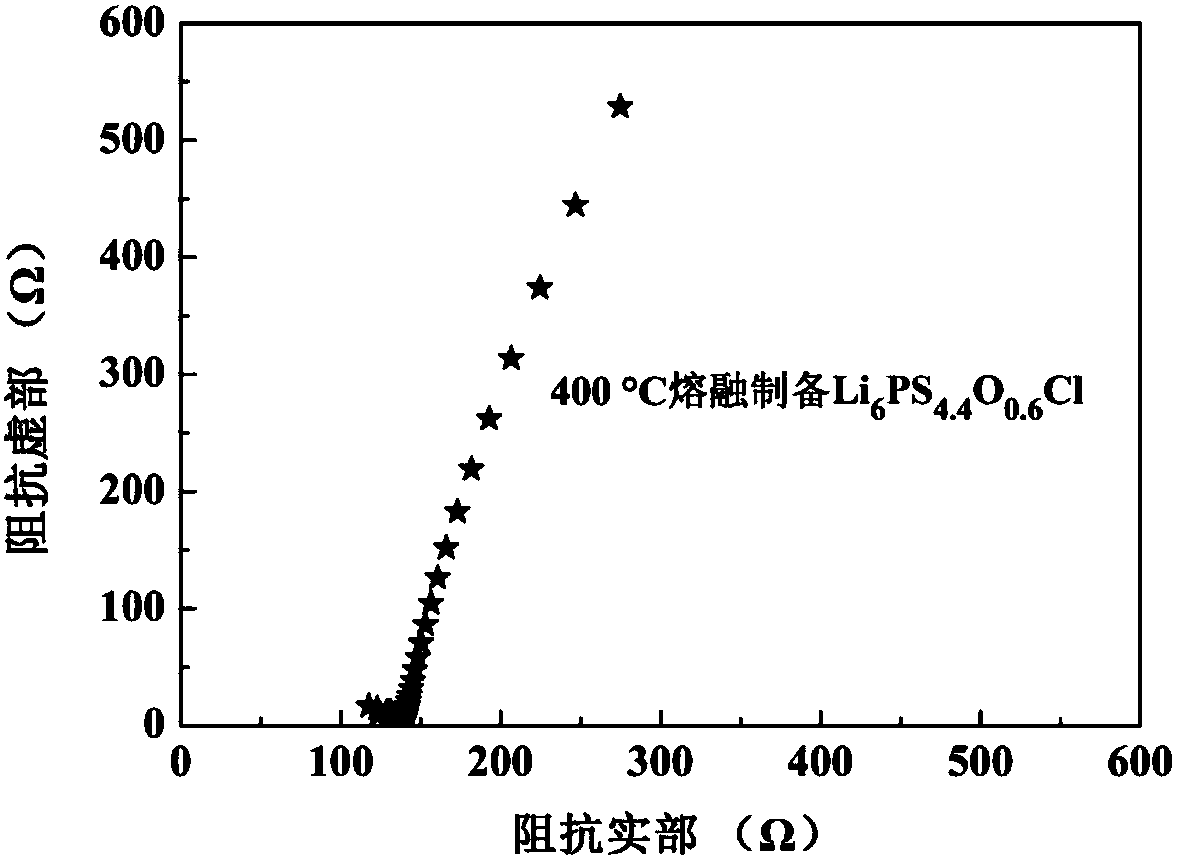

Sulfide solid electrolyte based on oxygen doping and preparation method of sulfide solid electrolyt

ActiveCN108493479AImprove stabilityImprove ionic conductivitySolid electrolytesLi-accumulatorsLithium chloridePhosphorus pentasulfide

The invention provides a sulfide solid electrolyte based on oxygen doping. The sulfide solid electrolyte is prepared from the chemical ingredients, in percentage by mass: 36-60% of lithium sulfide orlithium selenide, 18-48% of phosphorus pentasulfide or phosphorus selenide, 1-23% of metal oxide or specific nonmetallic oxide and 8-37% of lithium chloride, lithium bromide or lithium iodide. The preparation method of the sulfide solid electrolyte mainly comprises the steps that the raw materials are sufficiently blended and subjected to tabletting, then placed in a quartz tube to be burned and sealed, the product is placed in a muffle furnace and heated to be 400-600 DEG C at a slow heating rate, the optimal heating rate is 0.3 DEG C / minute, heat preservation is conducted for 12-48 hours, and then the product is cooled to reach the room temperature; and the product is ground to be powder, and the sulfide solid electrolyte based on oxygen doping is prepared. The sulfide solid electrolyteis easy to prepare and high in repeatability, the prepared solid electrolyte has the high ionic conductivity and good stability to the air and positive and negative electrodes.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com