Active agent for laser welding and method for laser welding by utilizing same

A technology of laser welding and active agent, which is applied in laser welding equipment, welding medium, welding equipment, etc., and can solve the problems of reduced laser energy utilization rate and low laser absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

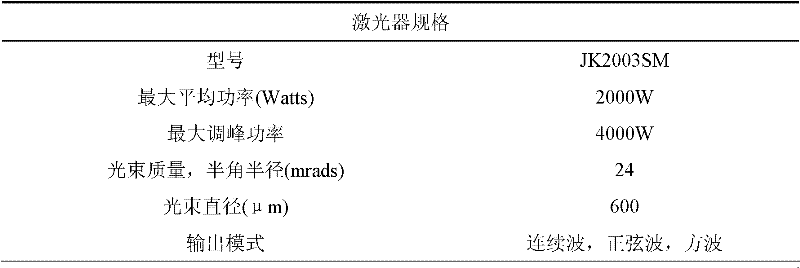

[0031] Weigh 8g of lithium chloride powder (80 mesh) and 2g of potassium fluoride powder (50 mesh) and mix evenly, then add 8g of water and mix to make a paste coating agent, and use No. 400 sandpaper to polish the surface of the welding test piece deal with. Apply the adjusted paste coating agent on the surface of the welded test piece, and dry it. The thickness of the coating layer is 0.6mm. Use the above welding equipment for laser welding, and the shielding gas is argon.

Embodiment 2

[0033] Take by weighing lithium chloride powder (50 mesh) 5g, sodium chloride powder (80 mesh) 2g, potassium chloride powder (80 mesh) 3g, potassium fluoride powder (50 mesh) 5g mix uniformly, then add 9g water to mix and adjust Make a paste coating agent, and use No. 400 sandpaper to polish the surface of the welded test piece. Apply the adjusted paste coating agent on the surface of the welded test piece, and dry it. The thickness of the coating layer is 0.6mm. Use the above welding equipment for laser welding, and the shielding gas is argon.

Embodiment 3

[0035]Weigh 10g of sodium chloride powder (100 mesh) and 5g of sodium fluoride powder (100 mesh) and mix evenly, then add 12g of water and mix to make a paste coating agent, and use No. 80 sandpaper to polish the surface of the welding test piece deal with. Apply the adjusted paste coating agent on the surface of the welded test piece, and dry it. The thickness of the coating layer is 0.5mm. Laser welding is carried out by using the above-mentioned welding equipment, the shielding gas is a mixed gas of argon and oxygen, and the volume percentage of oxygen is 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com