Patents

Literature

991 results about "Potassium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium fluoride is the chemical compound with the formula KF. After hydrogen fluoride, KF is the primary source of the fluoride ion for applications in manufacturing and in chemistry. It is an alkali halide and occurs naturally as the rare mineral carobbiite. Solutions of KF will etch glass due to the formation of soluble fluorosilicates, although HF is more effective.

Process for preparing 2,3,5,6-Tetrafluoro-para-xylyl alcohol

InactiveCN1458137AOrganic compound preparationHydroxy compound preparationSulfolanePotassium fluoride

The preparation process of 2, 3, 5, 6-tetrafluoro-para-xylyl alcohol with 2, 3, 5, 6-tetrachloro-p-phenyl diformyl chloride as material includes fluorination with potassium fluoride, etc. as fluorination agent, sulfolane, etc. as solvent and calixarene, etc. as catalyst and at 40-230 deg.c; esterification of ester with fatty alcohol or aromatic alcohol as esterifying agent and at 20-120 deg.c; reduction of ester with sodium borohydride, etc. as reductant and sulfolane, etc. as solvent, and at -10 deg.c to 60 deg.c; bromination with HBr acid as brominating agent and dichloromethane as solvent and at 30-160 deg.c; and reduction of bromide with magnesium powder, etc as reductant and fatty alcohol, water, chloride, etc as solvent, and at -10 deg.c to 50 deg.c. The present invention has the advantages of simple process, low production cost, high product yield and purity, and is suitable for industrial production.

Owner:TIANJIN UNIV

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

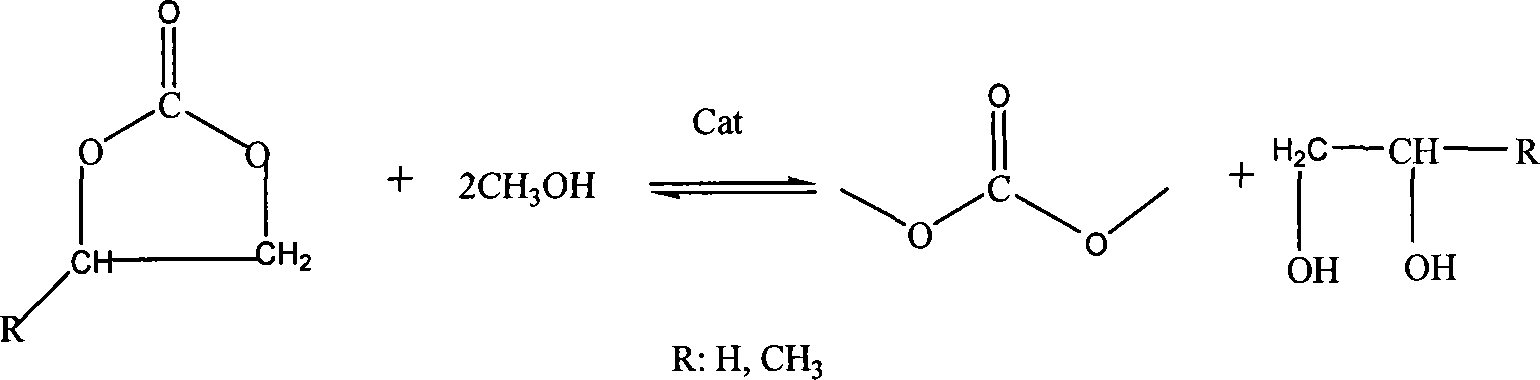

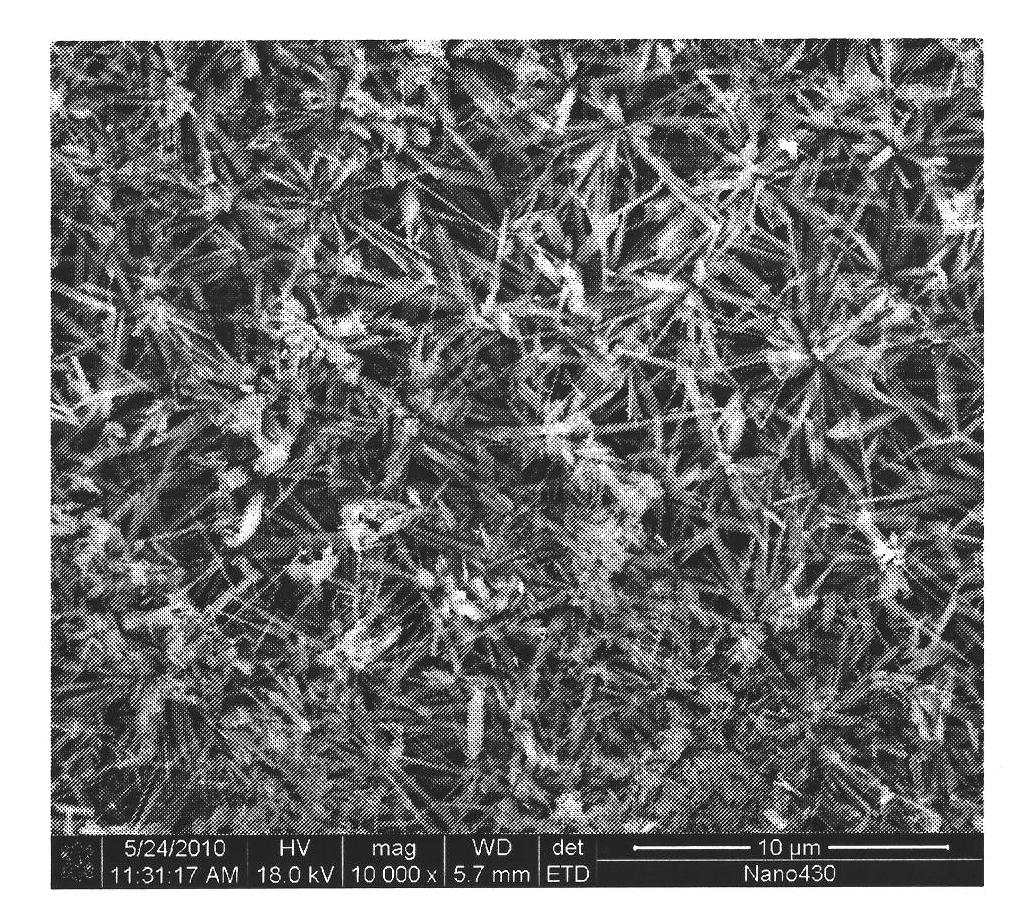

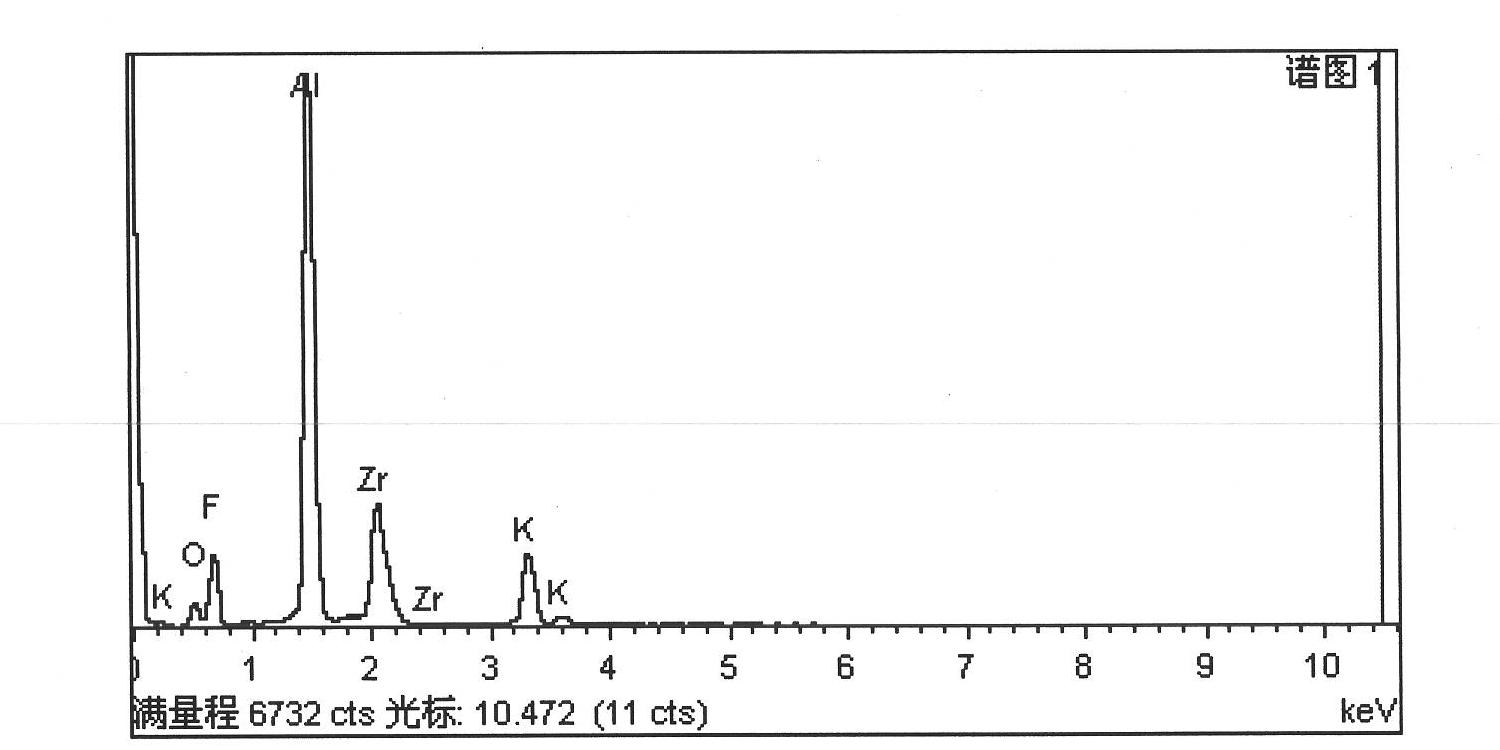

Load type solid body base catalyst of synthesizing dimethyl carbonate and method of preparing the same

InactiveCN101249452AEasy to makeEasy to preparePhysical/chemical process catalystsPreparation from organic carbonatesMethyl carbonatePotassium fluoride

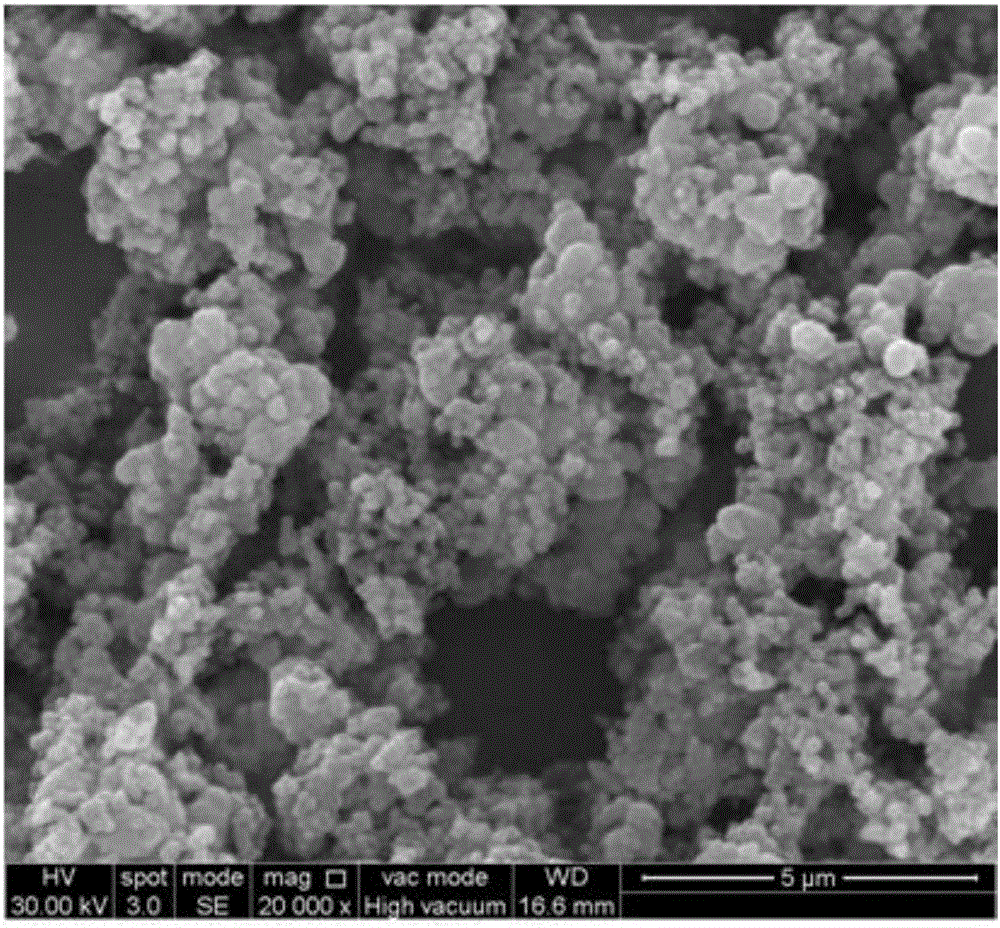

The invention relates to a carrier type solid base catalyst for synthesizing dimethyl carbonate, which belongs to the technical field of catalytic material. The catalyst's formula is KF / M<2+>-N<3+>-(O), wherein M<2+>-N<3+>-(O) represents the composite metal oxide, M<2+> can be divalent metal ion (Mg<2+> or Ca<2+> ) and N<3+> can be trivalent metal ion (Fe<3+> and / or Al<3+>). The catalyst is prepared from potassium fluoride and composite metal oxide at a certain weight ratio by immersing the potassium fluoride into the composite metal oxide, wherein the composite metal oxide is prepared from hydrotalcite precursor and in nucleation / crystallization isolation method by calcining at a certain temperature. The catalyst has the advantages of nanoscaled particle size, high specific surface area and high activity, selectivity in catalytic reaction and simple preparation, and can be reused as it can be centrifugally separated after reacting.

Owner:BEIJING UNIV OF CHEM TECH

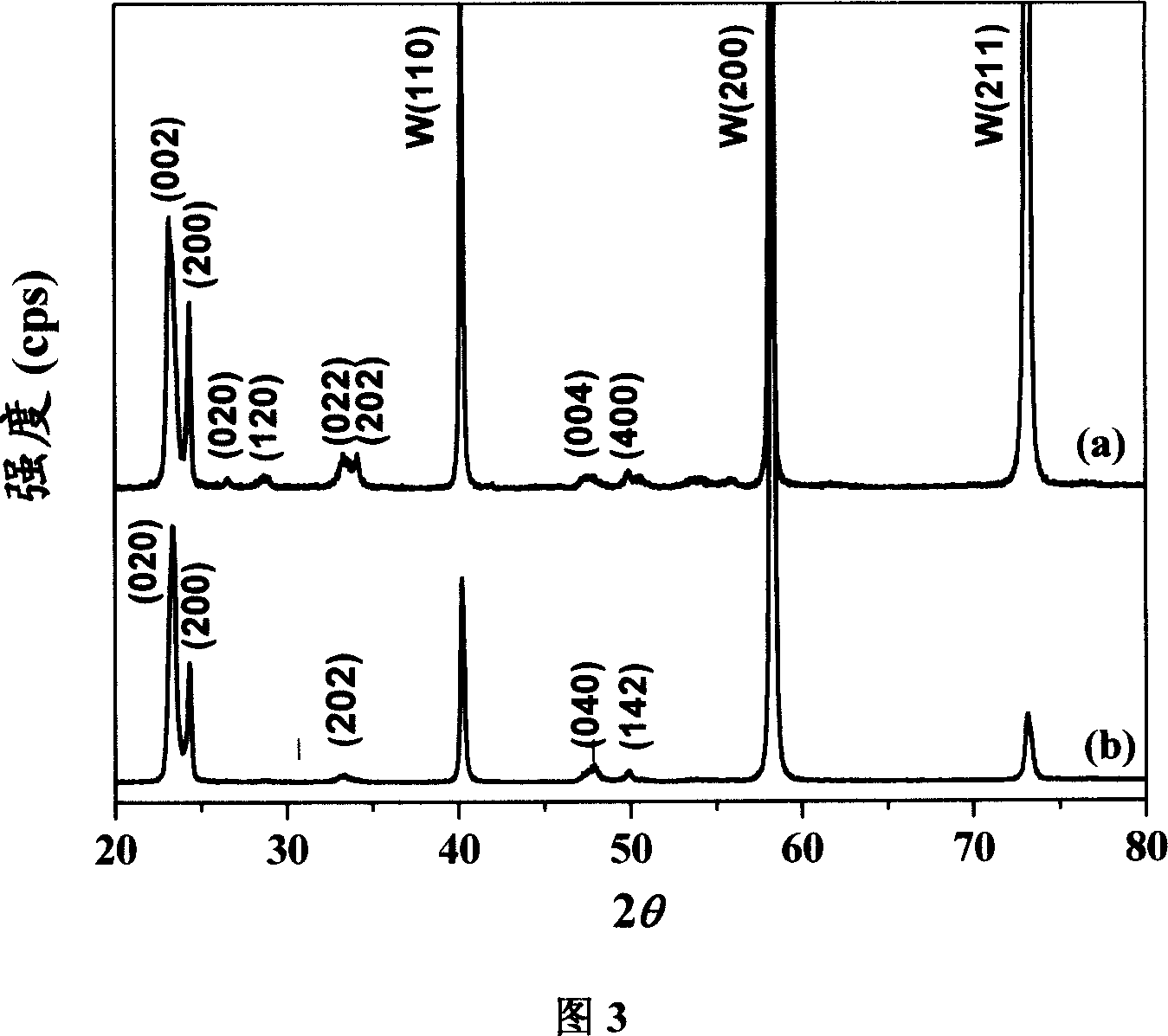

Nanometer porous tungsten trioxide material and its prepn and application

InactiveCN1974890ALower surface energyImprove surface topographyPolycrystalline material growthSurface reaction electrolytic coatingPotassium fluorideStrong acids

Owner:DALIAN UNIV OF TECH

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

Plating solution of magnesium alloy nickle sulfate main salt and technology of chemical plating thereof

InactiveCN1598053ALow priceReduce manufacturing costLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a plating solution of magnalium alloy Nickel sulfate and its chemical plating technique. The plating solution is made up of: (1) 5 to 40g.dm-3 of Nickel sulfate, (2) 10 to 50g.dm-3 of reducing agent of hypo-phosphite sodium; (3) one or several of the 2.5 to 30g.dm-3of the citric acid or tri-sodium citric acid, 2.5 to 30g.dm-3of the lactic acid, 2.5 to 30g.dm-3of the acetic acid, 2.5 to 30g.dm-3of the malic acid, 2.5 to 30g.dm-3 of the third acid and 2.5 to 30g.dm-3of the buta-acid; (4) one or several of the 5 to 30g.dm-3of Potassium fluoride, 5 to 30g.dm-3of sodium fluoride, 5 to 30g.dm-3of lithium fluoride and 5 to 30g.dm-3of NH4HF2; (5) 0.1 to 3g.dm-3of sulphur carbamide. The plating steps include: washing with ultrasonic->washing with alkali->washing with acid->activation->dipping it in the zinc solution->getting rid of the activation solution->secondary dipping it in the zinc solution->chemical plating->passivation and sealing the holes. The invention is featured by little pollution to the environment, low cost, uniform film and simpel technique.

Owner:HUNAN UNIV

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

Brazing flux without corrosion for aluminum and aluminum alloy brazing

InactiveCN101439449ASimple preparation processLow costWelding/cutting media/materialsSoldering mediaPotassium fluorideTin Fluorides

The invention relates to a corrosion-free soldering flux used for braze welding aluminium and aluminium alloy. Counted by weight percentage, the soldering flux used for braze welding the aluminium and aluminium alloy comprises the following components: 32.0-34.0 percent of cesium fluoride, 44.0-46.5 percent of aluminium fluoride, 20.5-23.5 percent of potassium fluoride, 0.5-2.5 percent of one, two or three materials selected from tin fluoride, zinc fluoride and lithium fluoride. The corrosion-free soldering flux of the invention has low melting point and better soldering performance.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

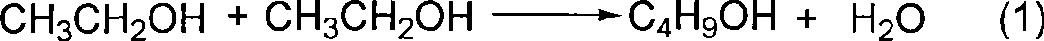

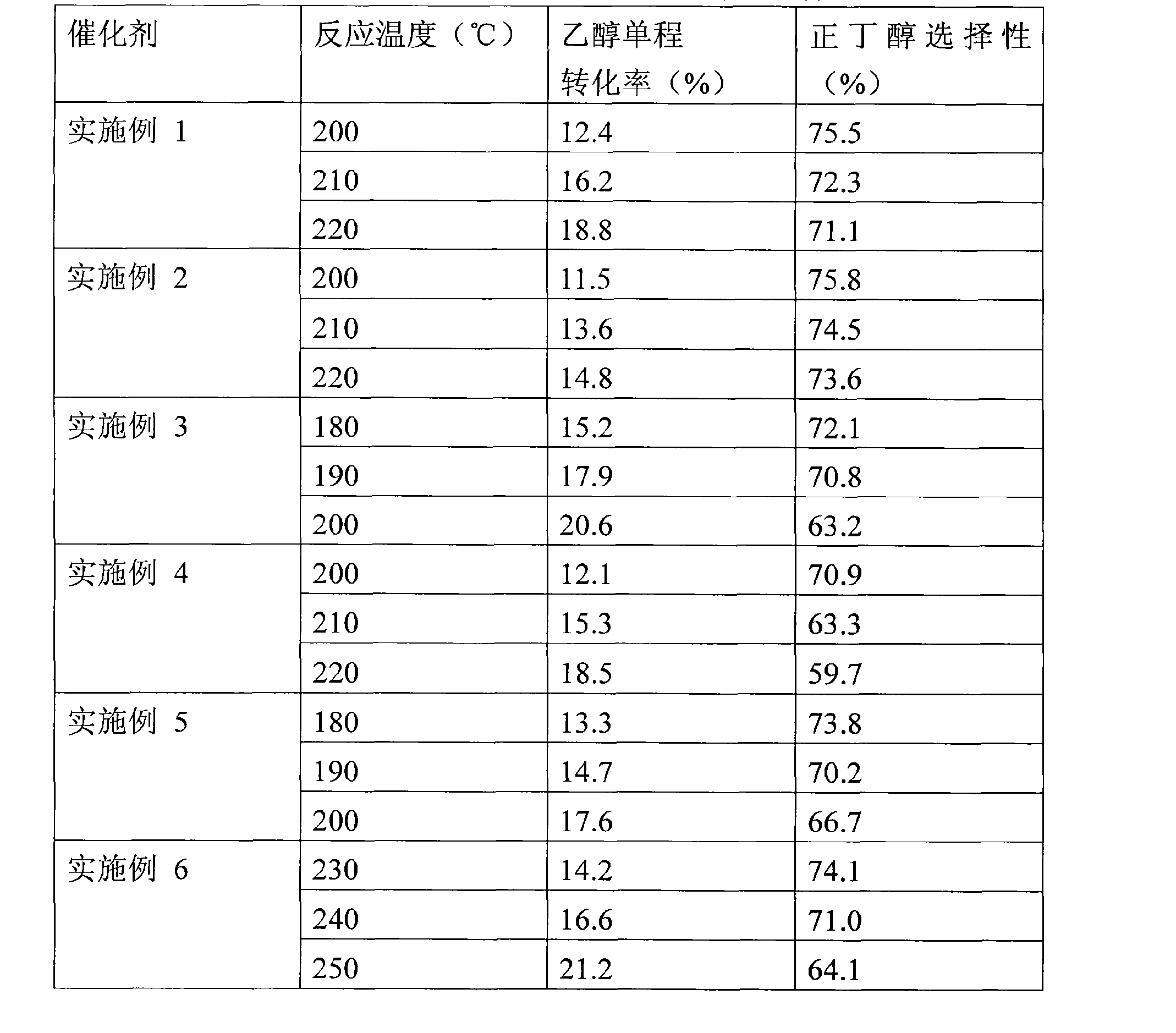

Bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof

InactiveCN101530802ASimple methodLow costOrganic compound preparationHydroxy compound preparationPotassium fluorideGram

The invention discloses a bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof. The main active ingredients of the catalyst are as follows by weight percentage content: 2%-10% nickel, 0.5%-9% cocatalyst MgO or KF. The preparing method comprises the steps of: directly dipping 30-50 grams of granulose gamma-Al2O3 into nickel acetate or nickel nitrate aqueous solution with consistency being 0.5-1.0 mol / L, dipping for 2 to 4 days, occasionally stirring, evaporating, drying under 130 degrees centigrade, then dipping into magnesium nitrate or potassium fluoride aqueous solution with consistency being 0.1-1.0 mol / L for 2 to 3 days, evaporating, drying under 130 degrees centigrade to prepare the bi-component supported catalyst of ethanol condensed n-butanol. The method of preparing bi-component supported catalyst in the invention is simple and has low cost; the catalytic activity is higher than that of the single component nickel supported catalyst; the selectivity of the n-butanol in the products can achieve above 70% and has wildly industrialized application prospect.

Owner:ZHEJIANG UNIV

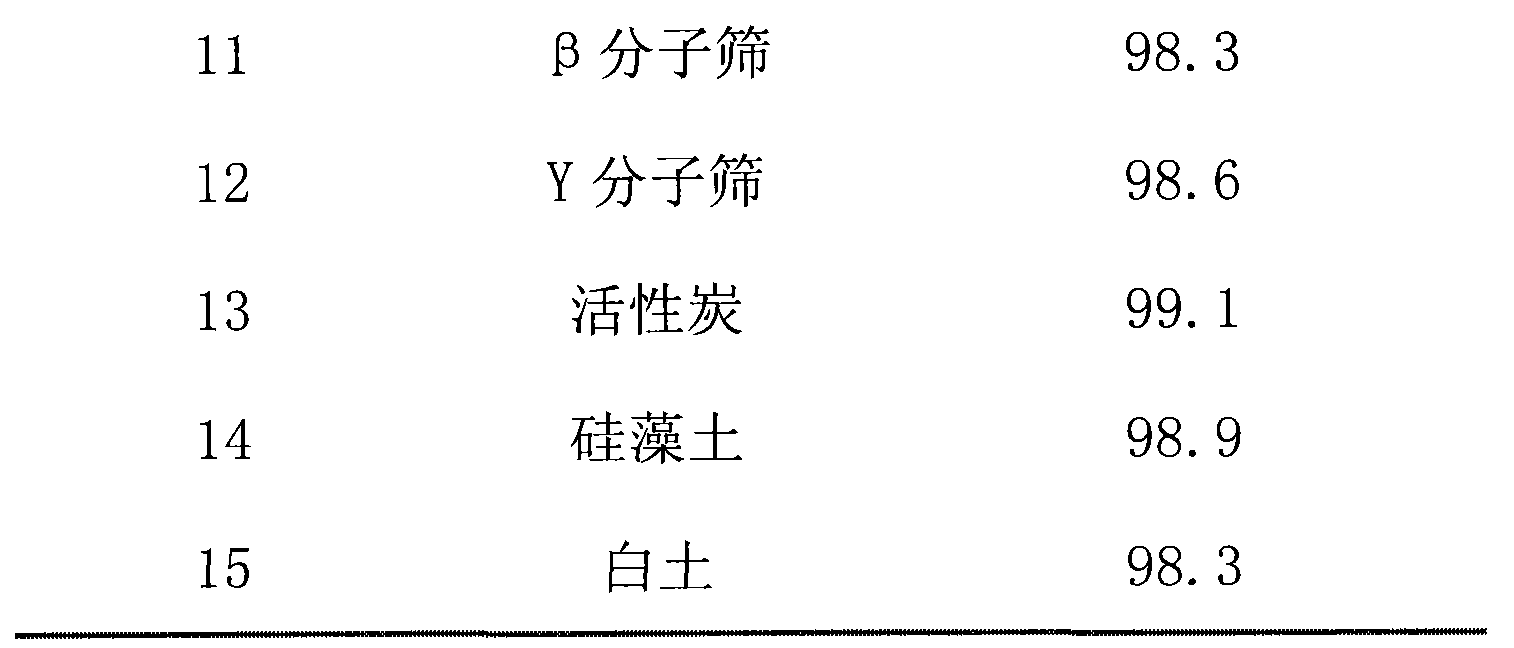

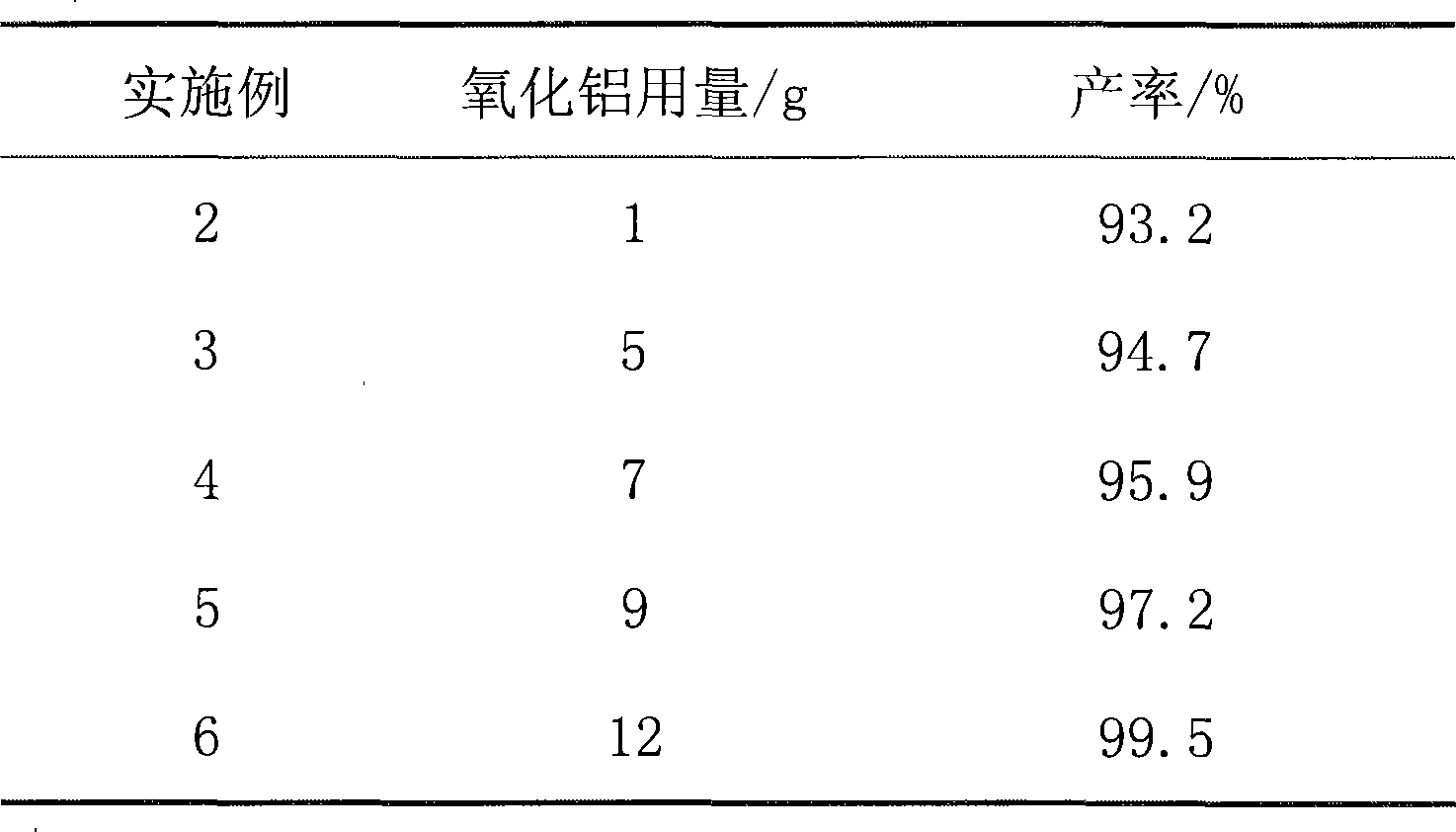

Novel solid body base catalyst and applications for biological diesel oil synthesizing

InactiveCN101249449AEasy to makeReduce energy consumptionMolecular sieve catalystsBiofuelsOil and greaseActivated carbon

The invention discloses a novel solid base catalyst and application thereof in the preparation of biodiesel oil. The catalyst is prepared by loading potassium fluoride as an active component on carriers; and calcining at a high temperature. The carrier is alumina, activated carbon or diatomite. The biodiesel oil is prepared by transesterification including adding oil and fat, low carbon alcohol and the solid base catalyst into a three-neck container; refluxing under heating and stirring; filtering to remove the catalyst; demixing the filtrate; separating glycerol at the lower layer, adding NaHCO3 solution into the mixture at the upper layer; washing until a neutral condition; drying with anhydrous MgSO4; and reduced pressure distilling. The application of the catalyst in the preparation of biodiesel oil has the advantages of high yield, cheap catalyst, small catalyst consumption, mild reaction conditions, short reaction time, reutilization of catalyst, environment friendliness and low requirement to raw material.

Owner:EAST CHINA NORMAL UNIV

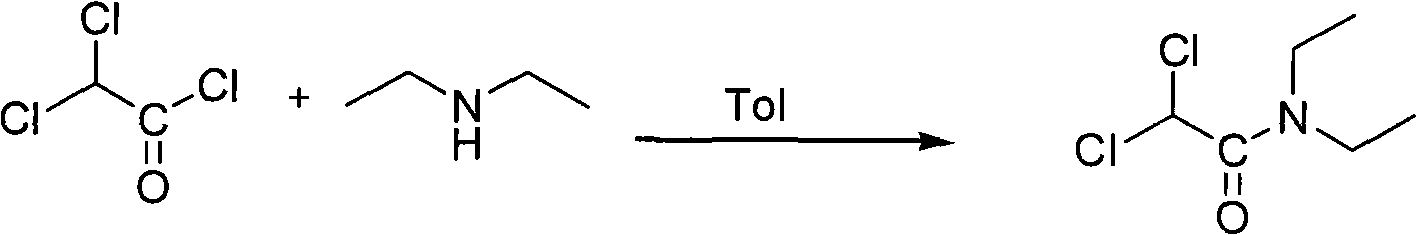

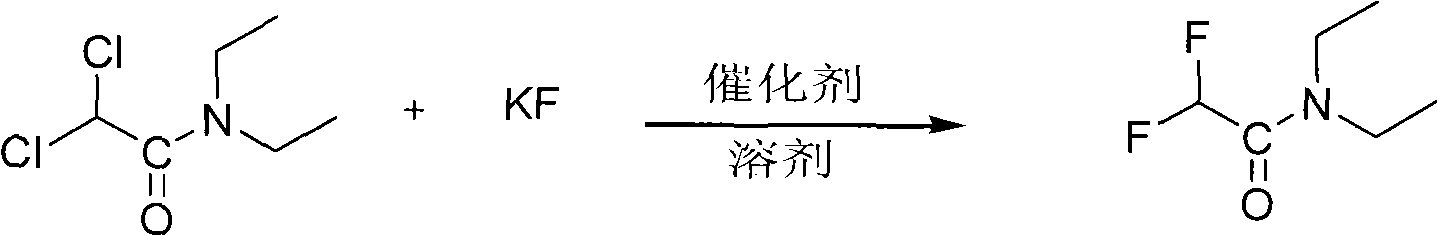

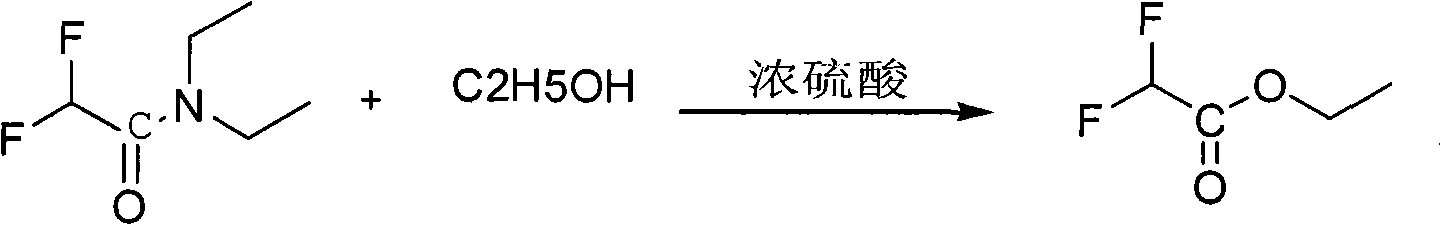

Processing technique of ethyl difluoroacetate

InactiveCN102311343AHigh yieldHigh product yieldOrganic compound preparationCarboxylic acid esters preparationPotassium fluorideAmination

The invention mainly discloses a processing technique of ethyl difluoroacetate, which mainly comprises the following steps of: preparing an intermediate product dichloroacetyl diethylamine through an amination process; carrying out fluorination with anhydrous potassium fluoride and the dichloroacetyl diethylamine as raw material under the action of a solvent and a phase transfer catalyst to prepare difluoro-acetyl diethylamine; and carrying out esterification to prepare the ethyl difluoroacetate. The processing technique of the ethyl difluoroacetate is characterized in that the solvent in the fluorination is sulfolane, and the esterification is a direction reaction of ethanol and the difluoro-acetyl diethylamine. The processing technique of the ethyl difluoroacetate specifically has the advantages of improving the final yield by changing the solvent during the fluorination and improving the production rate by carrying out the direct esterification after the fluorination.

Owner:RUGAO JINLING CHEM

Treating fluid for preparing zirconium-containing coloring passive film on surface of aluminum alloy and treating method thereof

InactiveCN101985750AHigh bonding strengthImprove the protective effectMetallic material coating processesPotassium fluorideCompound (substance)

The invention discloses a treating fluid for preparing a zirconium-containing coloring passive film on the surface of an aluminum alloy and a treating method thereof. The zirconium chemical passive treating fluid comprises the following main components of: potassium fluoride, a pH value regulator, fluorozirconate and / or potassium fluozirconate; and the pH value of the treating fluid is between 2.5 and 4.5, and the film can be formed within 3 to 10 minutes. The color of the passive layer prepared by the method is black gray; the film layer is tightly combined with a substrate; and the film layer has high strength and high corrosion resistance. The method is simple in operating process, and a coating does not contain hexavalent chromium which is harmful to the environment and human bodies.

Owner:SOUTH CHINA UNIV OF TECH

Differential arc oxidation electrolytic solution and differential arc oxidation method

ActiveCN101476143AImprove corrosion resistanceImprove dirt resistanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a micro-arc oxidation electrolyte which is a water solution comprises phosphate and silicate, and has 6-12 PH value. The electrolyte has characteristics that the electrolyte also comprises colorant, the colorant comprises A and B components, wherein, A comprises one or some of potassium fluoride, sodium fluoride, sodium sulfate and borax, B comprises cupric pyrophosphate and / or bluestone. The micro-arc oxidation electrolyte and the method for micro-art oxidating provided by the invention can make micro-arc oxidation film of light metal material obtaining uniform color for having beautiful decorating effect. At the same time, the obtained micro-arc oxidation film of light metal material surface has better stain resistance and compactness that increases additive value and practical using value of magnesium alloy greatly.

Owner:BYD CO LTD

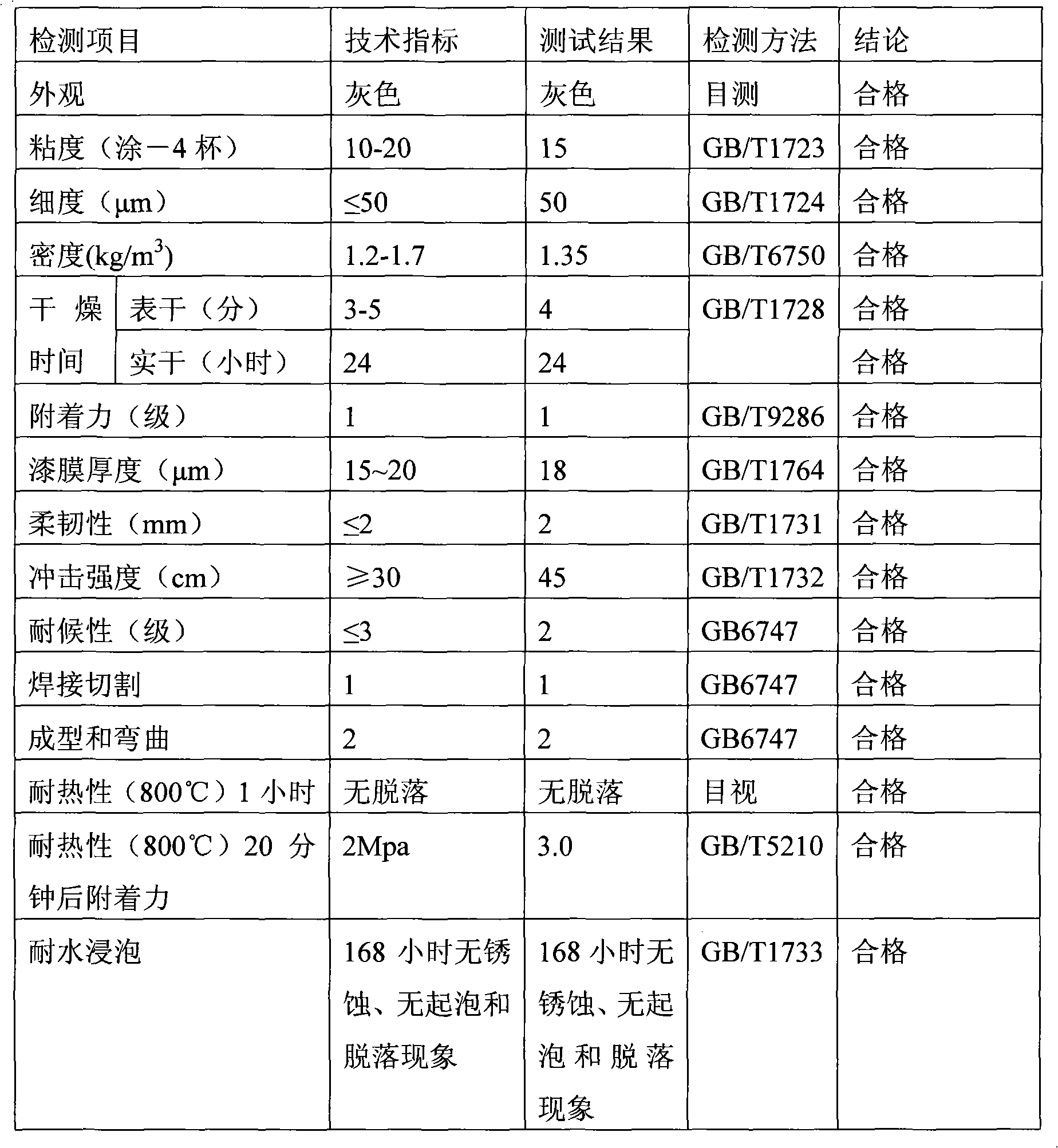

High-temperature resistant workshop primer and preparation process thereof

InactiveCN101619195AImprove high temperature resistanceReduce foggingAnti-corrosive paintsSodium BentoniteGas phase

The invention discloses a high-temperature resistant workshop primer, which consists of curing agent and slurry according to a weight ratio of 1:2-4, wherein the slurry comprises the following components in portion by weight: 10 to 30 portions of isopropanol, 0.5 to 4 portions of bentonite, 0.1 to 2 portions of nano gaseous silica, 0 to 5 portions of precipitated silica, 2 to 10 portions of butanol, 1 to 10 portions of industrial ethanol, 50 to 70 portions of zinc powder, 5 to 15 portions of dimethyl benzene, 0 to 20 portions of ferro-phosphorus powder, 0 to 10 portions of ferrotitanium powder, 0 to 5 portions of stainless steel powder, 0 to 2 portions of nickel powder, 0 to 2 portions of titanium white powder, 0 to 2 portions of alumina powder, 0 to 2 portions of precipitated barium sulfate, 0 to 5 portions of feldspar powder, and 0 to 2 portions of aluminum paste. The curing agent comprises the following components in portion by weight: 0 to 2 portions of ammonia water, 0 to 2 portions of sodium ethylate, 0 to 2 portions of potassium fluoride, 15 to 50 portions of ethyl silicate, 0 to 2 portions of AMP-95, 0.05 to 1 portion of sulfuric acid, 0 to 0.5 portion of potassium hydroxide, 3 to 15 portions of distilled water, 5 to 10 portions of industrial ethanol, 15 to 60 portions of isopropanol, and 0 to 10 portions of silicon resin. The temperature resistance of the high-temperature workshop primer can reach 800 DEG C, and the burned area of the workshop primer in welding seams and fire areas can be reduced after high-temperature processing such as welding, cutting, fire correcting and the like.

Owner:上海暄洋化工材料科技有限公司

Additive for aluminum alloy melting

The invention discloses an additive for aluminum alloy melting. The additive comprises: by mass, 65 to 75% of metal powder having granularity of 80 to 100 meshes, 20 to 30% of one or more halide salt cosolvents, 1 to 3% of paraffin powder and 1 to 3% of a moisture-proofing agent. The metal powder is at least one of iron powder, copper powder, manganese powder, titanium powder and nickel powder. The one or more halide salt cosolvents are selected from potassium chloride, potassium fluoride, potassium iodide, potassium fluosilicate and potassium fluoroaluminate. Through use of the paraffin powder and the one or more halide salt cosolvents, good bonding effects on metal powder are obtained; pulverization of metal powder is prevented effectively; an additive falling speed is reduced; and a melting speed is obviously improved. The additive provided by the invention solves the problems of a high additive melting temperature and a low metal powder absorption rate, realizes a high metal powder absorption rate reaching to 99%, and improves the quality of an aluminum alloy ingot casting.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

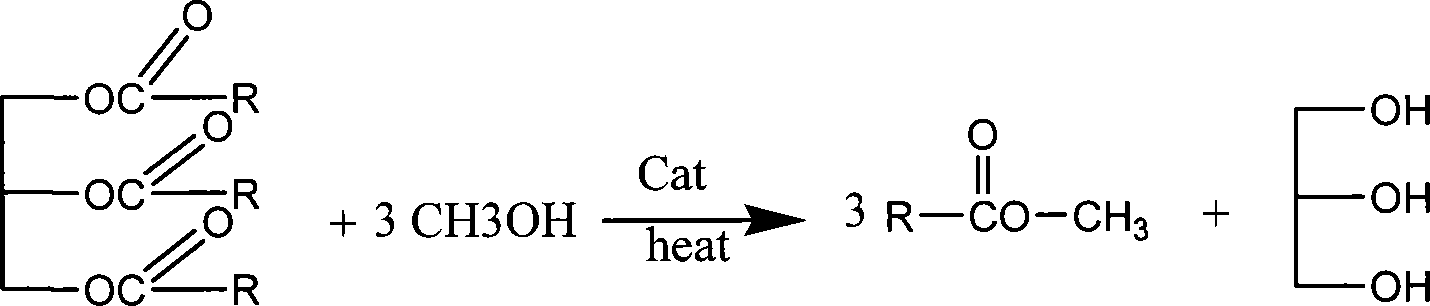

Method for preparing polyol by using bio-oil and application

ActiveCN104341297AWide variety of sourcesPromote degradationOrganic compound preparationPolyureas/polyurethane adhesivesPtru catalystPotassium fluoride

The invention discloses a method for preparing polyol by using bio-oil. The method comprises the following steps: firstly performing methyl esterification, namely, performing ester exchange on biolipid and methanol under the catalysis of potassium fluoride loaded magnesium oxide solid alkali, converting the obtained product into fatty acid methyl ester with small molecular weight and byproduct glycerol, filtering to recycle the catalyst, and separating lower-layer glycerol; performing epoxidation on upper-layer fatty acid methyl ester in 30% of hydrogen peroxide under the catalysis of ionic liquid so as to form epoxidized fatty acid methyl ester.; then adding the glycerol in the methyl esterification process, continuously performing alkoxide ring-opening under the catalysis of ionic liquid, introducing hydroxyl, and finally separating liquid to recycle the ionic liquid catalyst, reducing pressure and distilling the upper-layer to remove water so as to obtain low-viscosity bio-oil-based polyol. The raw material is easily available, recyclable and good in biodegradability, the preparation process is environmental friendly, the industrial three-waste emission is small, the product structure and a hydroxyl value are adjustable, the application range is wide, and the environment influence level is low.

Owner:ZHEJIANG HENGFENG NEW MATERIAL

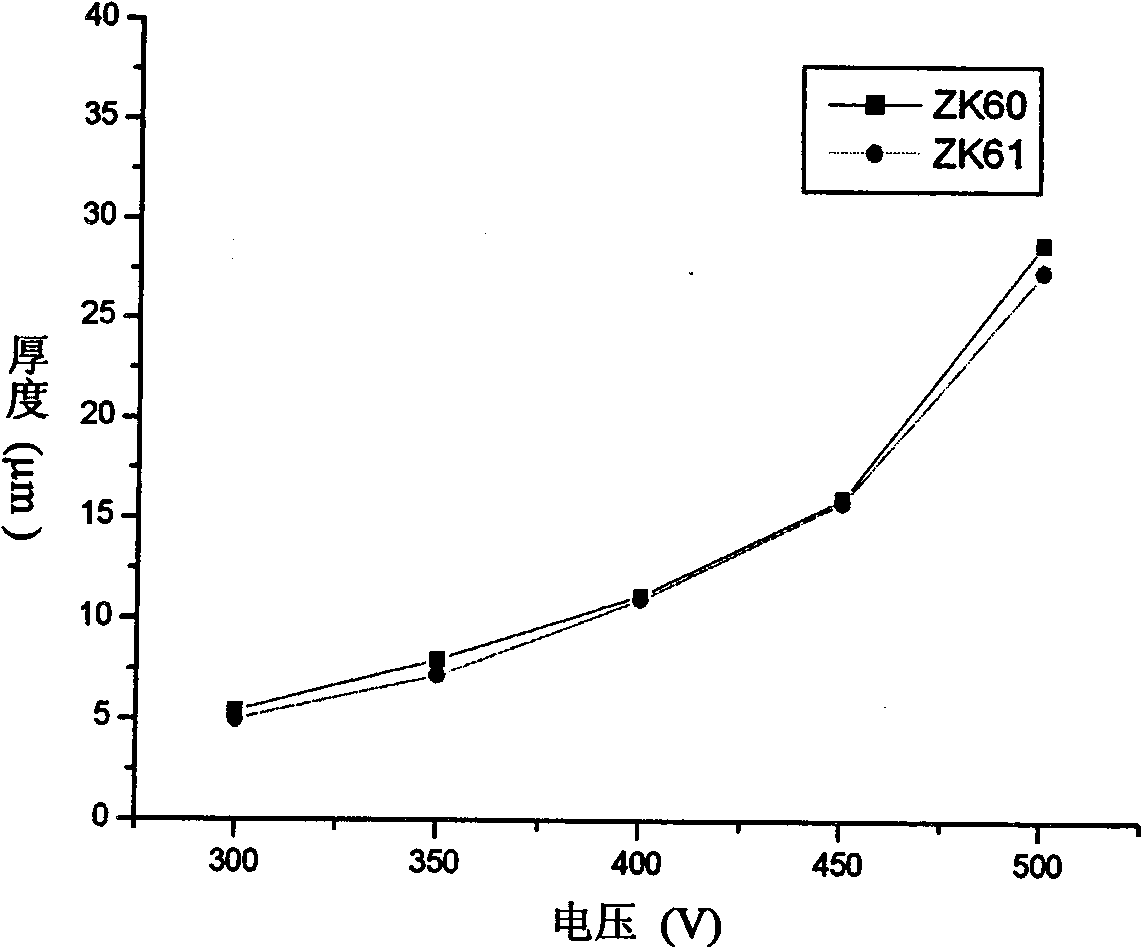

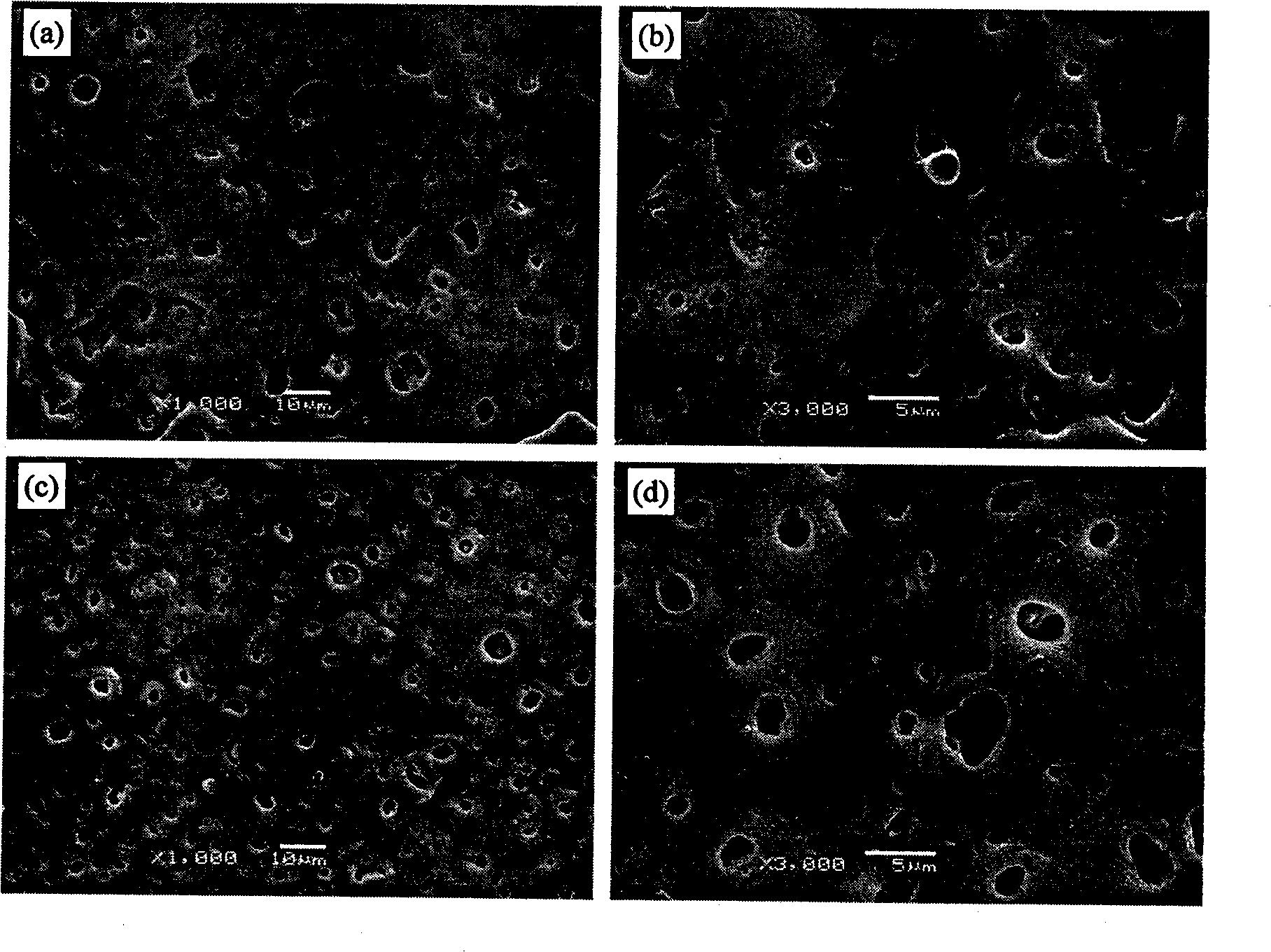

Magnesium base degradable implant material and preparation method thereof

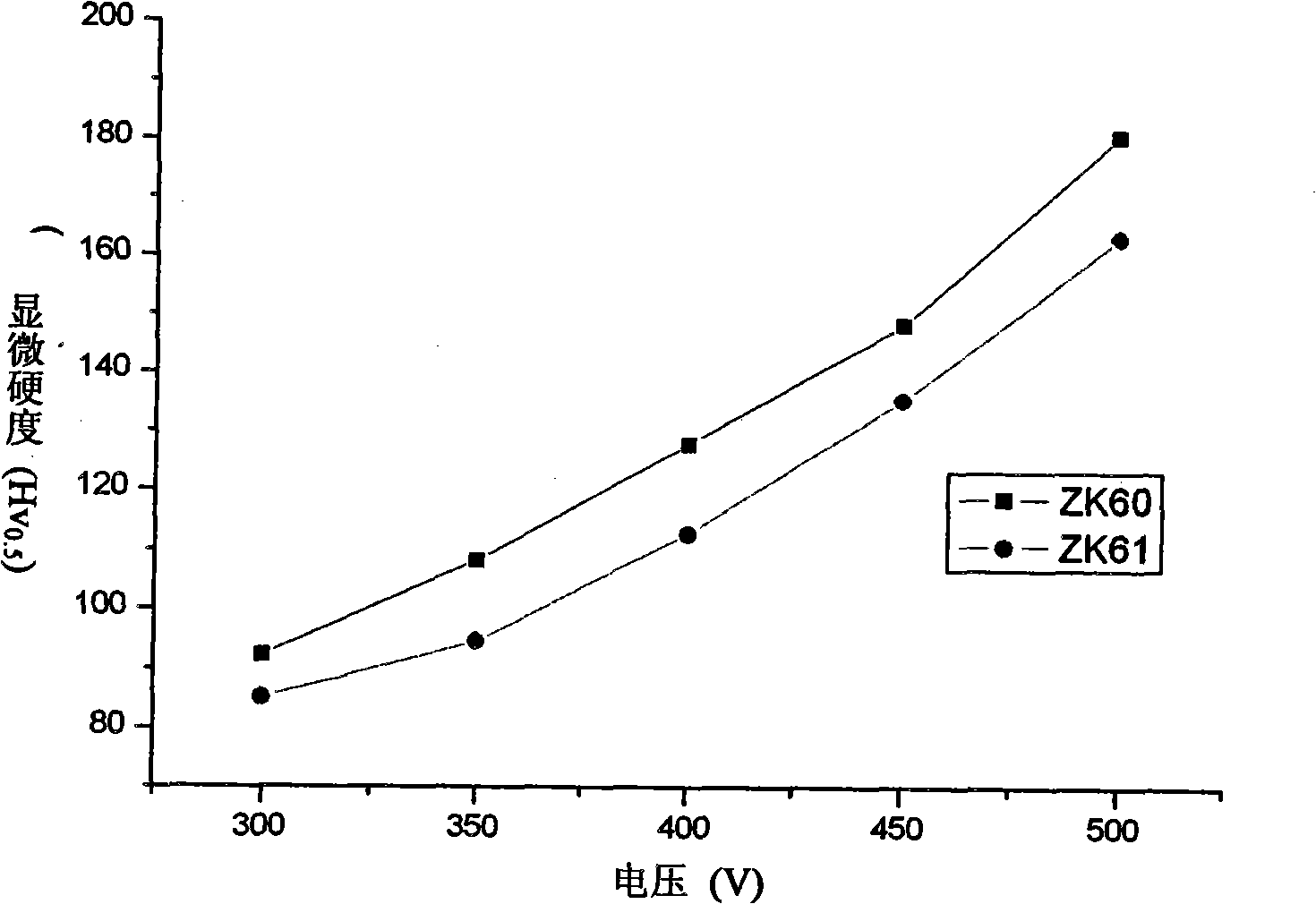

InactiveCN101559239AImprove biological activityIncreased microhardnessAnodisationProsthesisMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a magnesium base degradable implant material, belonging to the technical field of biological materials. The implant material is composed of Mg-Zn-Zr alloy matrix and micro-arc oxidation coating; the micro-arc oxidation coating is formed by micro-arc oxidation treatment by electrolyte formed by solving the sodium silicate, potassium hydroxide, potassium fluoride, soluble phosphate and trolamine in pure water; each liter of electrolyte contains 12-18g of sodium silicate, 3-8g of potassium hydroxide, 2-7g of potassium fluoride, 5-20g of soluble phosphate and 5-10ml of trolamine. The implant material has not only high micro hardness but also excellent decay resistance; and after dipping in simulated body fluid, the surface has phosphorite deposition, which shows that the material has certain biological activity.

Owner:SHANDONG UNIV

High-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux

ActiveCN105127618AHigh activityStrong ability to remove filmWelding/cutting media/materialsSoldering mediaPotassium borohydridePotassium fluoride

The invention discloses a high-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux. The high-strength and high-toughness composite silver solder ring comprises a silver solder ring body of a hollow structure. The silver solder ring body is formed by winding composite silver solder formed by a silver solder pipe and a flux core with which the silver solder pipe is filled. The flux core is prepared from boron micro-powder, sodium borohydride or potassium borohydride, potassium fluoborate, boric anhydride or boric acid, potassium fluoride or sodium fluoride or lithium fluoride, potassium bifluoride and potassium fluoroaluminate according to a certain proportion. The purpose of in-situ synthesis of the soldering flux through the boron micro-powder in the flux core and metal elements in the silver solder pipe is achieved, so that the content of the flux core is reduced, and when the content of the flux core is low, the solder still achieves good brazing manufacturability; meanwhile, due to the fact that the wall thickness of the solder pipe is increased, good toughness and high stiffness are achieved, the processing performance of the solder is greatly improved, the minimum diameter can be reduced to 0.8 mm, the solder can be easily wound into the solder ring with the intermediate diameter below 6 mm, and application and popularization of the automatic brazing process are facilitated.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

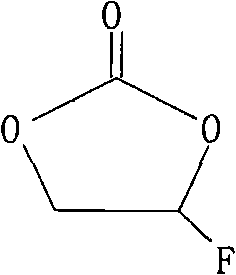

Method for synthesizing fluoroethylene carbonate by phase-transfer catalysis

InactiveCN101870687AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHalogenPotassium fluoride

The invention relates to a method for synthesizing fluoroethylene carbonate by phase-transfer catalysis. The fluoroethylene carbonate is produced by performing halogen exchange reaction on chloroethylene carbonate and potassium fluoride under the catalysis of crown ether serving as a phase-transfer catalyst in aprotic solvent.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for linked producing potassium fluoride white carbon black

A process for preparing potassium fluoride and white carbon black simultaneously includes such steps as reaction between fluorosilicic acid (or potassium fluorsilicate) and potassium hydroxide to obtain the slurry of white carbon black and potassium fluoride solution, filtering, washing to obtain white carbon black paste and potassium fluoride solution, and respectively preparing white carbon black and potassium fluride from them.

Owner:DO FLUORIDE CHEM CO LTD

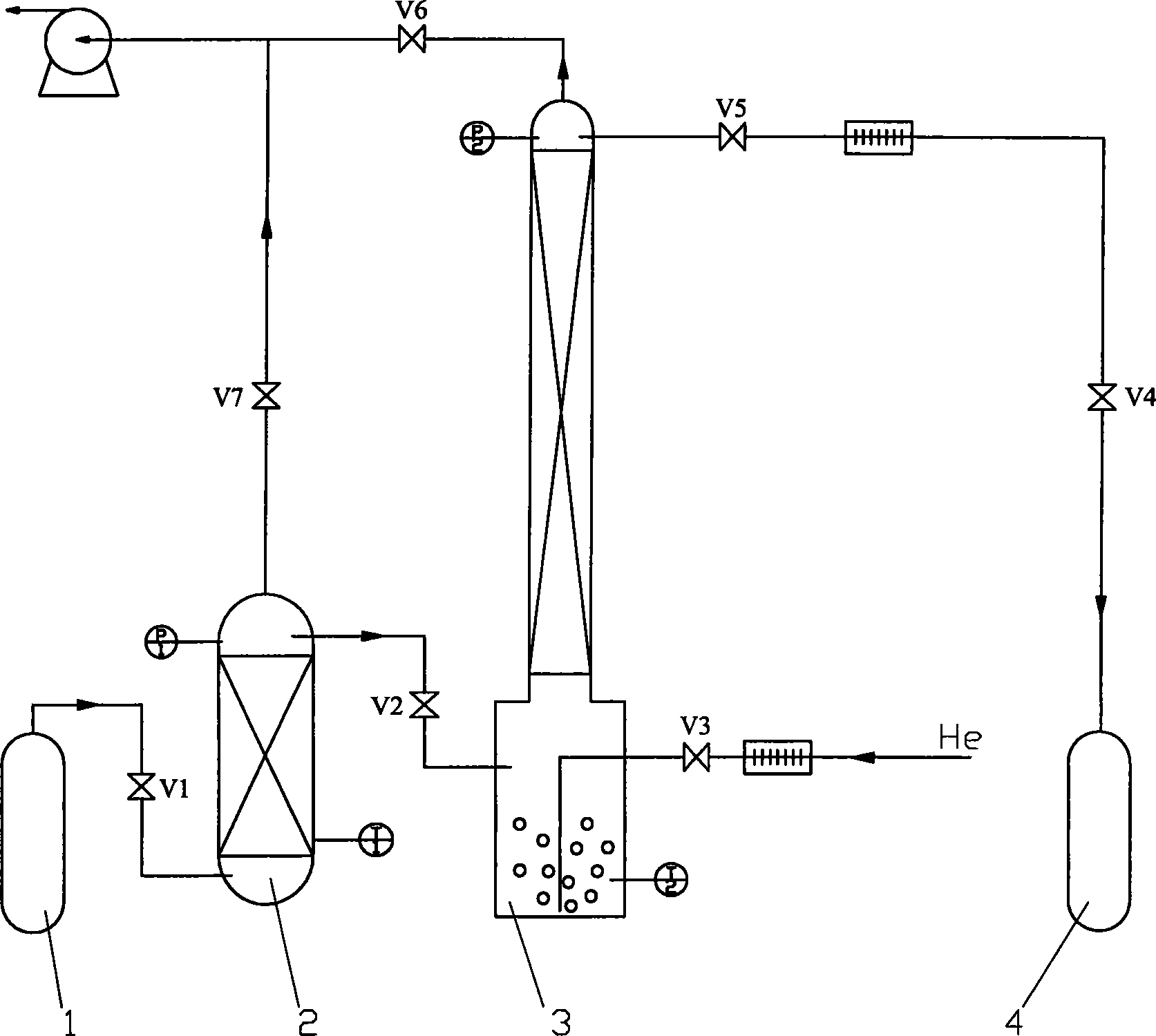

Method for purifying tungsten hexafluoride

The invention relates to a kind of purification method of tungsten hexafluoride gas. First, put impure tungsten hexafluoride gas in the storage tank of crude product into the bottom of absorption column where there are multihole spherical filling of sodium fluoride or potassium fluoride, remove the most impurity of hydrogen fluoride under temperature of 10-80 degree C,put it into rectifying column through pipe and fluidify it, stop entering tungsten hexafluoride gas after fluidifing it for 5kg-50kg, put helium gas of high purity into bottom of tungsten hexafluoride liquid and keep it boiling under temperature between 3 degree C and 20 degree C,the vaporized gas enter rectification column and rises, it gradually gets into condensation and circumfluence during the process of rising ,continues to rectify it to remove impurity, check it with gas chromatography, when concentration of impurity of gas discharged from tower top whose boiling point is higher than that of tungsten hexafluoride gas reduce to the request index, stop entering helium gas of high purity, and when helium gas's index reaches the request, collect tungsten hexafluoride gas of high purity into storage tank of quality product.

Owner:PERIC SPECIAL GASES CO LTD

Supported solid alkali catalyst for synthesis of propylene glycol

InactiveCN1762578AHigh selectivityImprove conversion rateOrganic chemistryChemical recyclingPotassium nitrateIsomerization

The carrier-type solid base catalyst to synthesize propylene glycol comprises: carrier selected at least one from potassium fluoride, potassium nitrate and potassium carbonate; and metal oxide. This invention is simple, can filter the catalyst for recycle, and has high activity and selectivity and isomerization proportion.

Owner:MAOMING COLLEGE

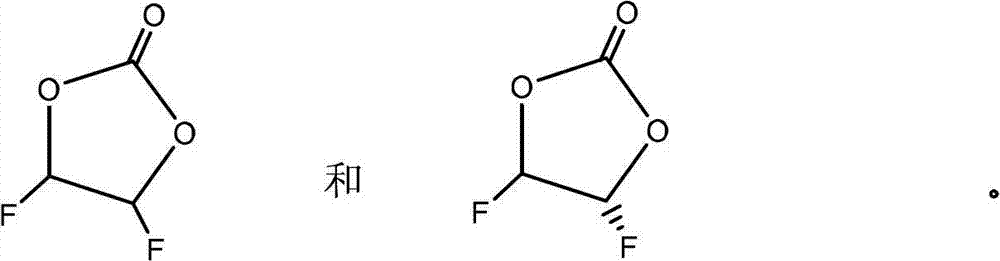

Preparation method of difluoroethylene carbonate

InactiveCN102766130AMeet the requirements of green environmental protectionMild reaction conditionsOrganic chemistryOrganic solventPotassium fluoride

The invention relates to a preparation method of difluoroethylene carbonate. According to the method, replacement reaction is carried out on dichloroethylene carbonate to generate the difluoroethylene carbonate. The replacement reaction is implemented by the steps of: dripping the dichloroethylene carbonate into a mixed system of anhydrous fluoride, catalyst and organic solvent at the temperature which is controlled within a range of 40-100 DEG C to react; after the reaction, sequentially carrying out solid-liquid separating, alkali washing and neutralizing, and distilling to obtain the difluoroethylene carbonate, wherein the fluoride is potassium fluoride or sodium fluoride or a mixture of the potassium fluoride and the sodium fluoride, and the adding mol ratio of the dichloroethylene carbonate to the fluoride is 1: (2-10); and the catalyst is tetra(diethylin)phosphorus bromide and the adding amount of the catalyst is 0.001-0.1 time as much as the total mass of the dichloroethylene carbonate and the fluoride. The preparation method disclosed by the invention has the advantages of moderate reaction conditions, simplicity and safety, high reaction selectivity, greatly-shortened reaction time and obvious economic benefits, and is suitable for industrial production.

Owner:SUZHOU HUAYI NEW ENERGY TECH CO LTD

Method for preparing dense fluoride ceramic films on magnesium surface and magnesium alloy surface

InactiveCN101845636AUniform thicknessImprove bindingAnodisationMetallic material coating processesPhosphatePotassium fluoride

The invention relates to a method for preparing dense fluoride ceramic films on a magnesium surface and a magnesium alloy surface and belongs to the technical field of metal surface treatment. The method comprises the following steps of: chemically passivating a magnesium alloy; preparing a single-pulse ceramic film; and preparing a double-pulse ceramic film. In a chemically passivating process, solution such as hydrofluoric acid, phosphoric acid, hydrogen fluoride amine and the like are used; the preparations of the single-pulse ceramic film and the double-pulse ceramic film are mainly performed in a fluoride electrolyte-containing system, wherein potassium fluoride (sodium) is taken as a main salt; phosphate is taken as an additive; and citrate or tartrate is taken as a main stabilizing agent. The fluoride ceramic film obtained by the method is complete and dense, has high hardness, is firmly combined with a substrate, can be separately used as a protective layer and can be prepared into a composite surface functional layer which has higher corrosion resistance, higher wearing resistance and high hardness after subsequent processing treatment. The overall process of the method has the advantages of simple flow, low equipment cost, environment friendliness and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

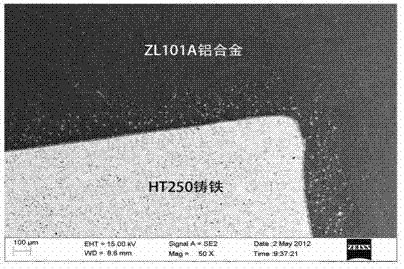

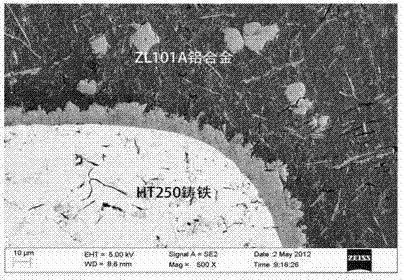

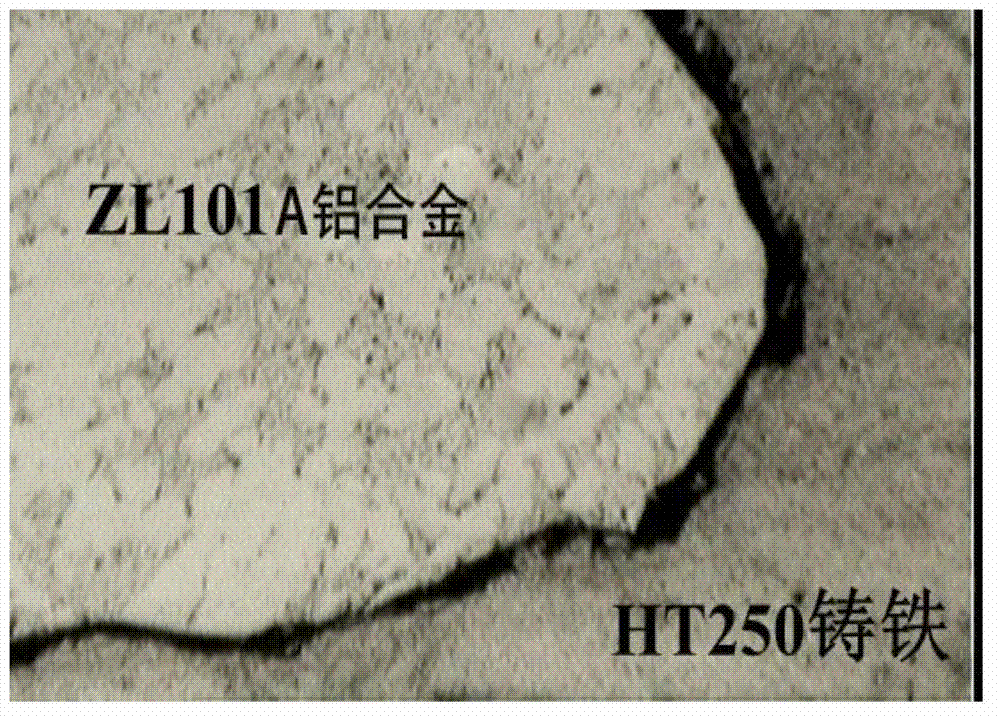

Preparation process of dual-metal engine cylinder composite material

InactiveCN102773463AGuaranteed physical propertiesEnhanced interface bindingPotassium fluorideMetallic materials

The invention relates to a preparation process of a dual-metal engine cylinder composite material, the preparation process comprises the following steps of: firstly, acid-washing a HT250 cast iron cylinder liner and carrying out surface degreasing and derusting treatment on the HT250 cast iron cylinder liner; then dipping the HT250 cast iron cylinder liner into a prepared proportional saline solution, so that the surface of the HT250 cast iron cylinder liner is soaked in the saline solution; then drying the HT250 cast iron cylinder liner, and putting the HT250 cast iron cylinder liner in a ZL101A aluminum alloy melt body for hot immersion plating; fixing the immersion-plated HT250 cast iron cylinder liner in a mold cavity of a metal mold casting mold, casting, melting and cooling a ZL101A aluminum alloy, wherein concentration of the saline solution is 100-200g / L, the saline solution is prepared by mixing water together with potassium fluoride KF, potassium chloride KCl, sodium chloride NaCl, calcium fluoride CaF2, and calcium chloride CaC12 according to a mass ratio of 39-46:16-26:15-21:6-15:5-10. According to the preparation process, the engine cylinder composite material is obtained through treating the ZL101A aluminum alloy and HT250 cast iron by a self-prepared surfactant and implementing a dual-metal composite casting process on the ZL101A aluminum alloy and the HT250 cast iron, wherein two metal materials of the ZL101A aluminum alloy and the HT250 cast iron are not mixed and kept with original physical properties; but the ZL101A aluminum alloy and the HT250 cast iron obtain an extremely perfect combination interface, so that casting metallurgical bonding of 99.5 percent and above is achieved.

Owner:烟台路通精密科技股份有限公司 +1

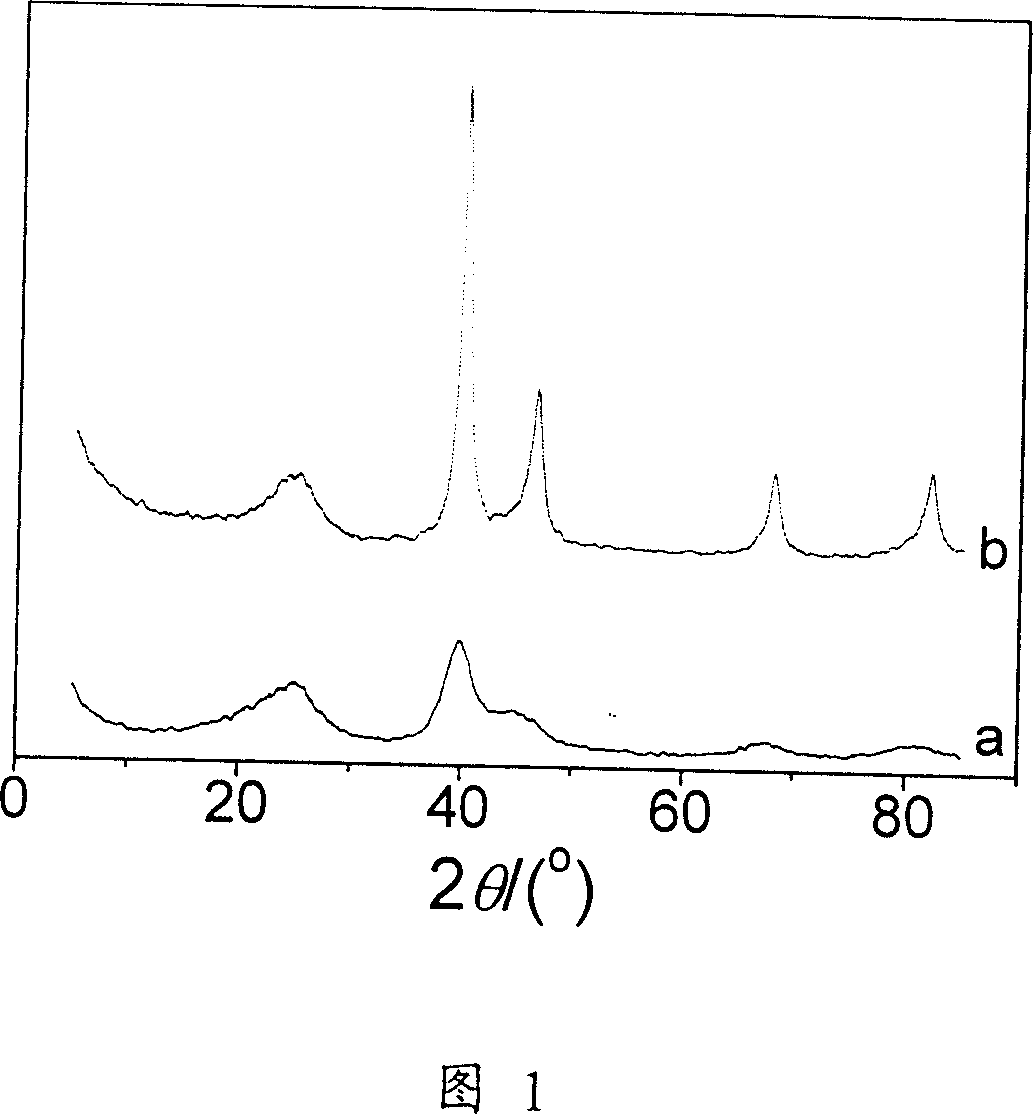

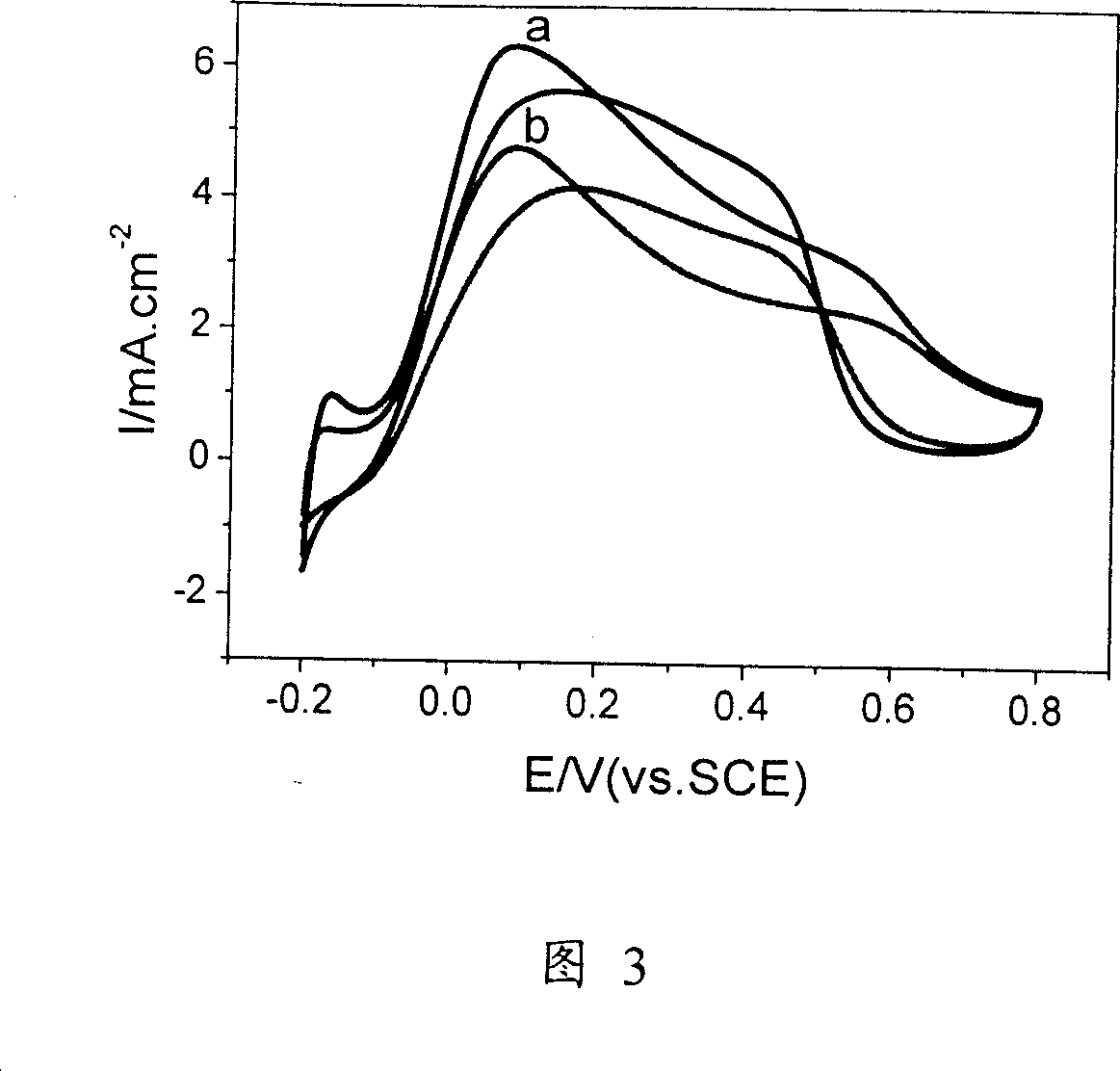

Ultra-fine, highly dispersed Pd/C catalyst for direct aminic acid fuel battery and method for making same

InactiveCN1921197AOvercoming the larger average particle sizeOvercoming dispersionCatalyst carriersCell electrodesPotassium fluorideHydrazine compound

The invention relates to an ultra-fine high-disperse Pd / C catalyst of formic acid fuel battery. Wherein, it comprises that Pd metal particles are loaded on the carbon carrier while its mass is 1-80% of carbon carrier and its diameter is 3.0nm; and the preparation comprise that adding complexing agent, stabilizer, PdC12 dilute solution and active carbon carrier into water to be vibrated via ultrasonic wave to obtain component A; adding over reducer and vibrating with ultrasonic wave, and the reduced Pd particles are adhered on the carbon carrier, to obtain component B; washing component B, under vacuum or inertia gas, drying it; the complexing agent is ammonium fluoride, sodium fluoride, or potassium fluoride; the stabilizer is selected from boracic acid or borax; and the reducer is NaBH4, KBH4, hydrazine hydrate, and cavaform. The invention has high electric catalyst activity on aminic acid.

Owner:NANJING NORMAL UNIVERSITY

Synthesis method of Favipiravir

ActiveCN104496917ALow impurity contentShort reaction cycleOrganic chemistryPotassium fluorideSynthesis methods

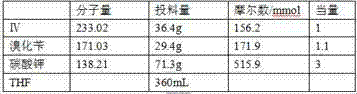

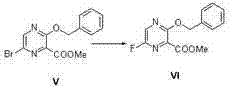

The invention belongs to the field of medicinal chemistry and particularly relates to a new synthesis method of Favipiravir. The method comprises the following steps: carrying out carboxyl protection on raw material shown in the formula (II) to generate a compound (III); carrying out diazotization hydrolysis reaction in the presence of concentrated sulfuric acid and sodium nitriteto generate a compound (IV); carrying out benzyl protection reaction to generate a compound (V), and then generating a compound (VI) in the presence of potassium fluoride and tetrabutylammonium bromide; removing a benzyl protection group to generate a compound (VII); and then adding an aminating agent to carry out amination to generate Favipiravir shown in the formula I. The method disclosed by the invention has the advantages that the reaction cycle is short, the operation is simple, the production cost is low, and the product is high in quality; therefore, the method is suitable for industrial production.

Owner:NANJING HUAWE MEDICINE TECH DEV

Preparation method of perfluoromethyl vinyl ether

The invention relates to a preparation method of perfluoromethyl vinyl ether, and belongs to the field of fluorine-containing plastics. The preparation method comprises the following steps of: preparing CF3OK by using potassium fluoride, carbonyl fluoride and tetrafluoroethylene as initial raw materials and using acetonitrile as a solvent in the absence of a catalyst, and reacting the CF3OK with tetrafluoroethylene in the presence of a little amount of water to prepare the perfluoromethyl vinyl ether serving as a target product. The reaction temperature is normal temperature in the whole process, the reaction of the first step is under normal pressure, and the reaction of the second step does not need external pressure, so the reaction conditions are easily realized and easily controlled;moreover, the equipment used in the preparation process has simple structure, so the cost of the whole production process is low; the intermediate products do not need high-purity separation, so the middle separation step is reduced, and the synthesis cost is reduced; meanwhile, the acetonitrile solvent can be recycled and is not released to the air space, so the method has no pollution and is environment-friendly; therefore, the method can be applied to large-scale industrialized production.

Owner:泉州宇极新材料科技有限公司

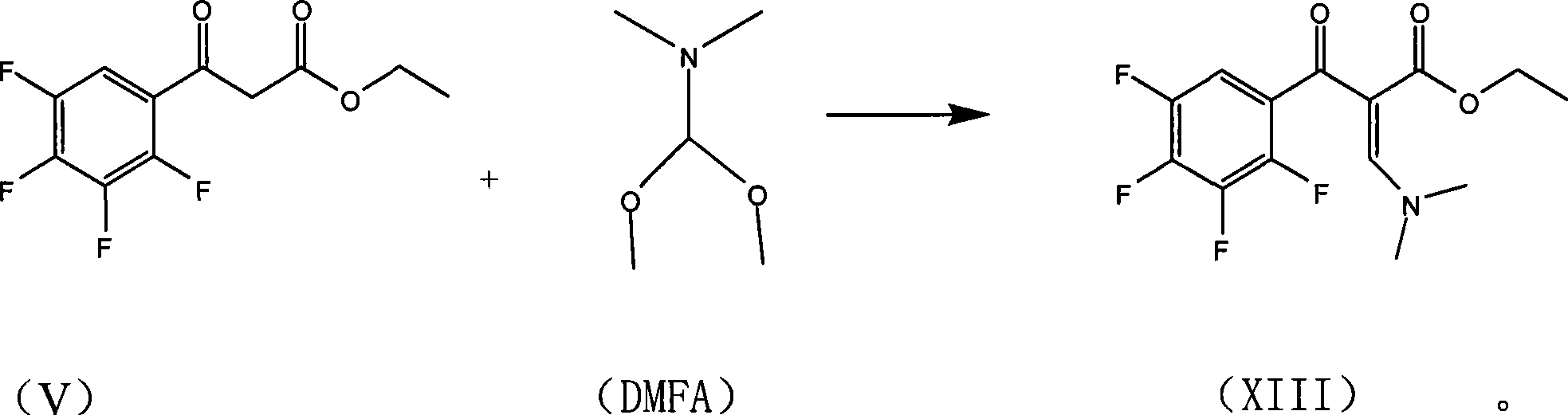

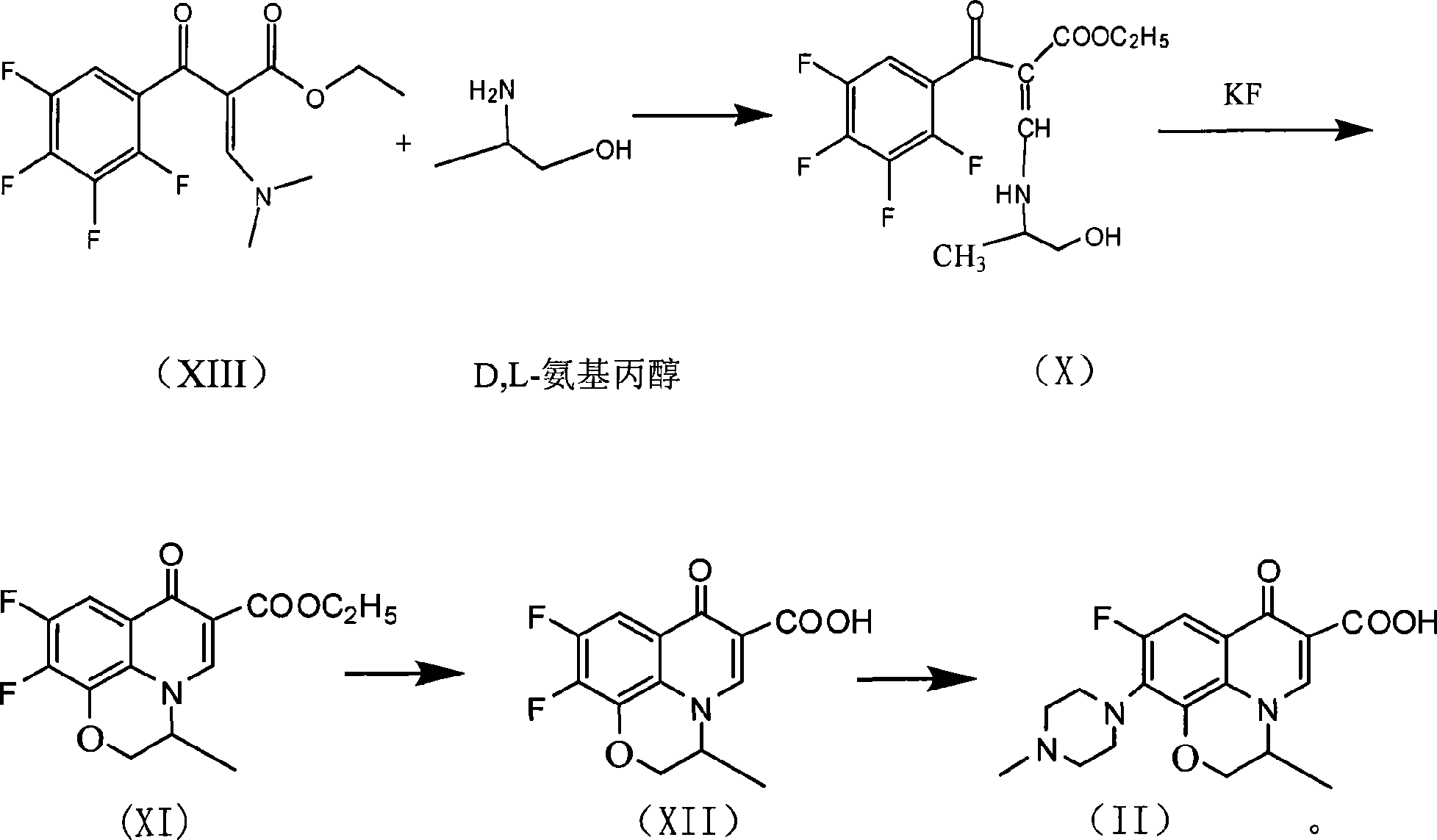

Preparation process of lavo-ofloxacin and ofloxacin

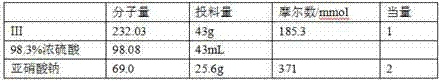

InactiveCN101519361AReduce generationIncrease production levelsOrganic compound preparationAntiinfectivesPotassium fluorideReaction temperature

The invention relates to a preparation process of lavo-ofloxacin and ofloxacin which are anti-infectious medicaments, belonging to the synthetic process with tetrafluorobenzoic aid as raw material. The preparation method is characterized in that (2, 3, 4, 5-phenyl tetrafluoride formyl) ethyl acetate and DMFA react for 1.0-1.5h in toluene at 50-55 DEG C with the existence of acylating catalyst; the reaction product is washed by water, and an aqueous layer is separated; at 30-35 DEG C, L-amino propanol is dripped in an oil layer to carry out replacement reaction for 1.5-2.0h; toluene is decompressed, recovered and dried proper quantity of DMF is added to the oil layer for diluting; the diluted oil layer is dripped into back-flow DMF with the existence of anhydrous potassium fluoride to carry out back-flow reaction for 6h; DMF is recovered, water is added for centrifugation, acid is added to the obtained solid to be hydrolyzed to prepare lavo-perfluorocarboxylic acid, the lavo-perfluorocarboxylic acid reacts with N-methyl piperazine in DMSO at 90-110 DEG C by taking triethylamine as an acid-binding agent, and the lavo-ofloxacin is obtained after the fine purification of the product of reaction. The process improves the reaction condition of (2, 3, 4, 5-phenyl tetrafluoride formyl) ethyl acetate and DMFA, lowers the reaction temperature, shortens the reaction time and improves the reaction yield of lavo-fluoro ester serving as a reaction intermediate by 20 percent.

Owner:HENAN TOPFOND PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com