Patents

Literature

80results about "Tungsten halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hybrid Catalyst for Olefin Metathesis

InactiveUS20120289617A1Easy to separateHigh selectivityCation exchanger materialsLithium organic compoundsOrganic chemistryOlefin metathesis

Owner:SAUDI ARABIAN OIL CO

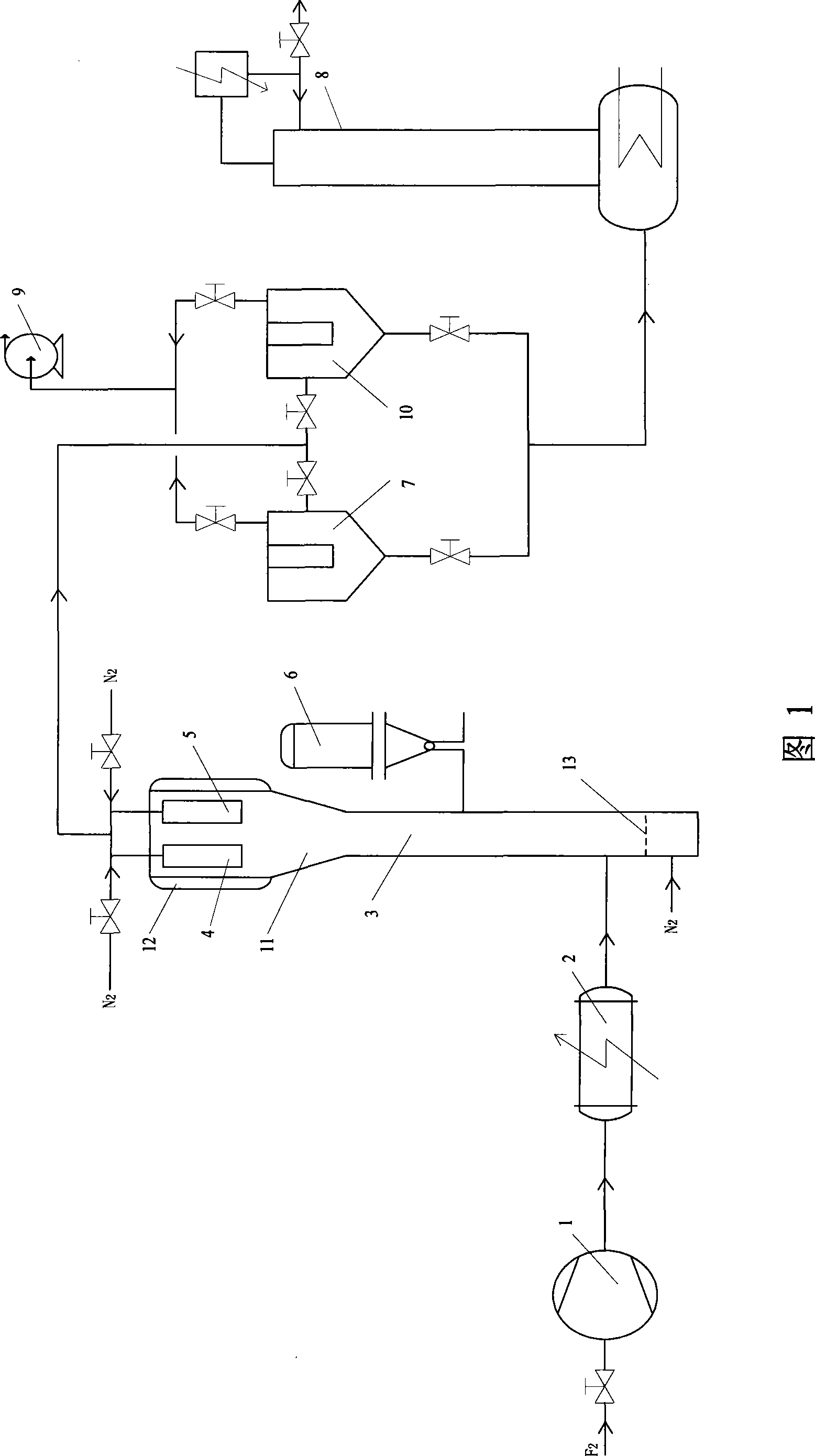

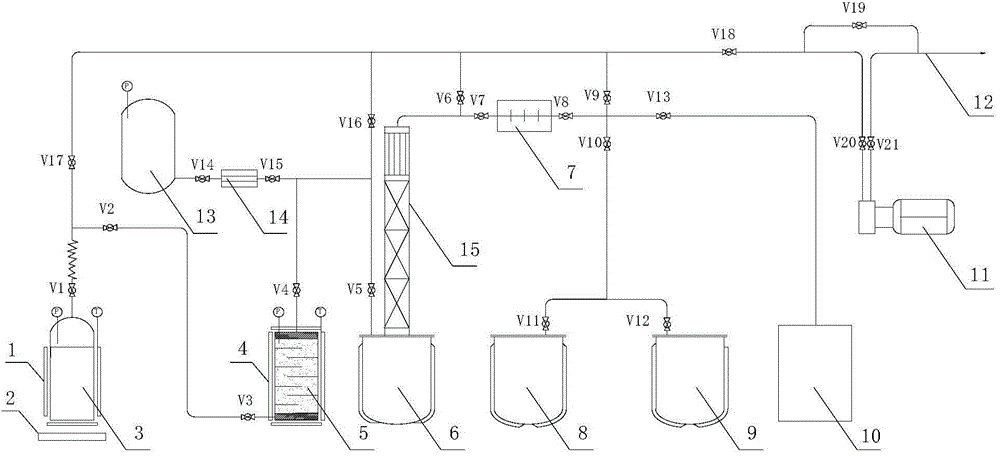

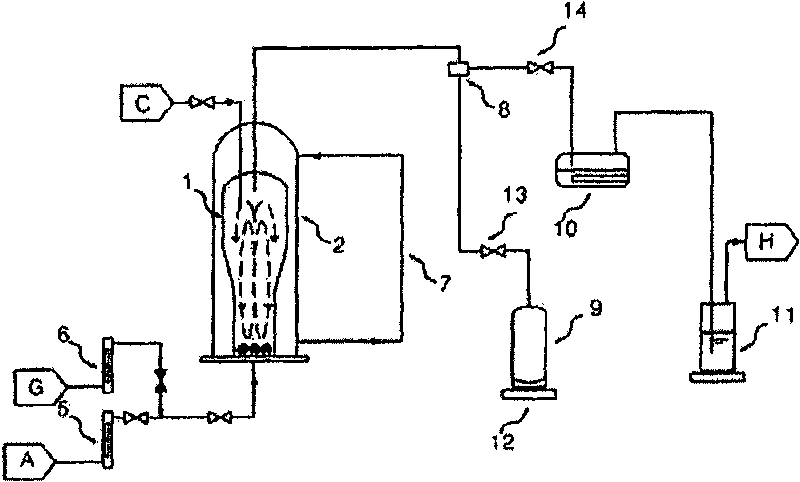

Method for producing high-purity tungsten hexafluoride with fluidized bed and equipment thereof

InactiveCN101428858AImprove mass transfer efficiencyImprove heat transfer efficiencyTungsten halidesTemperature controlFluidized bed

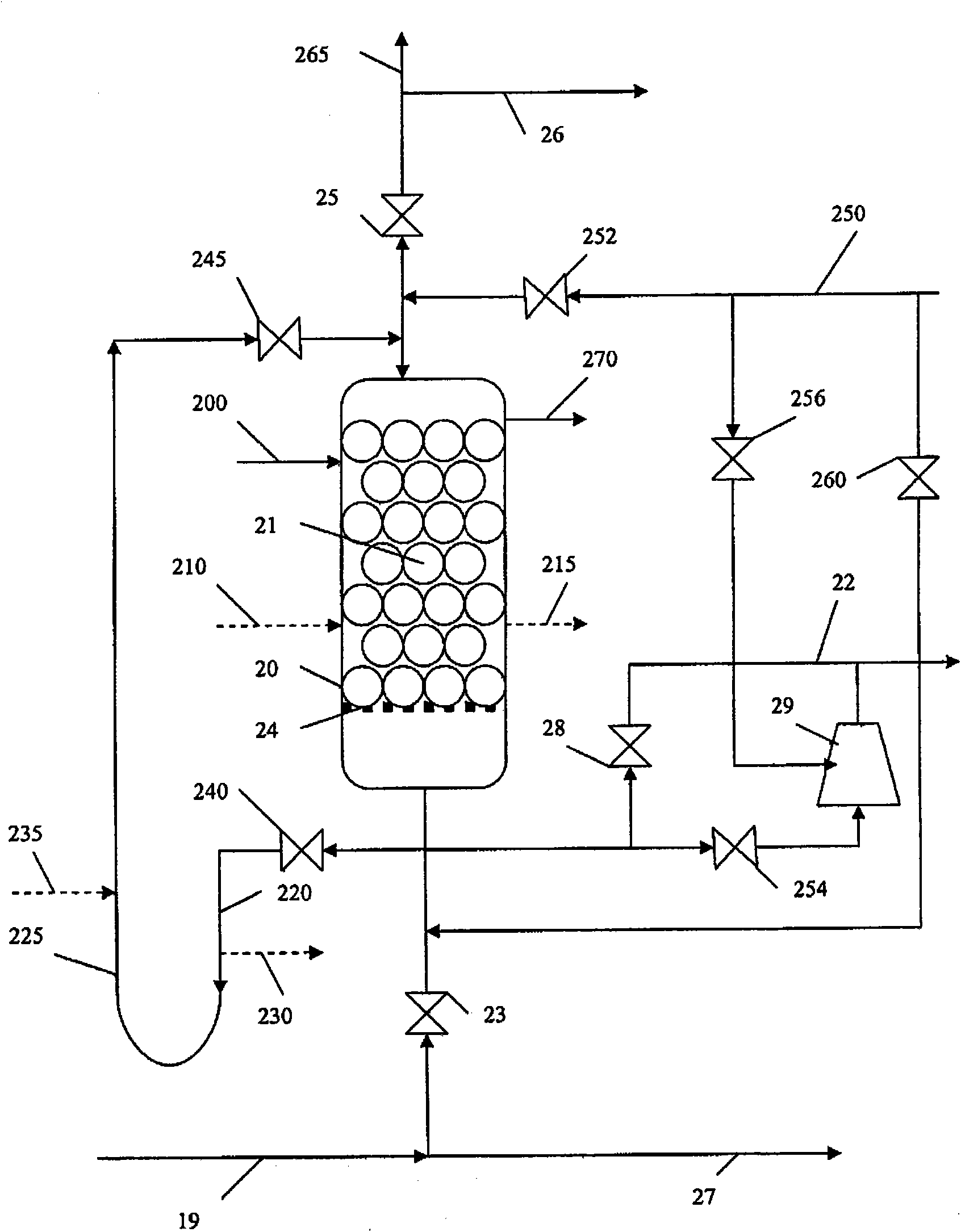

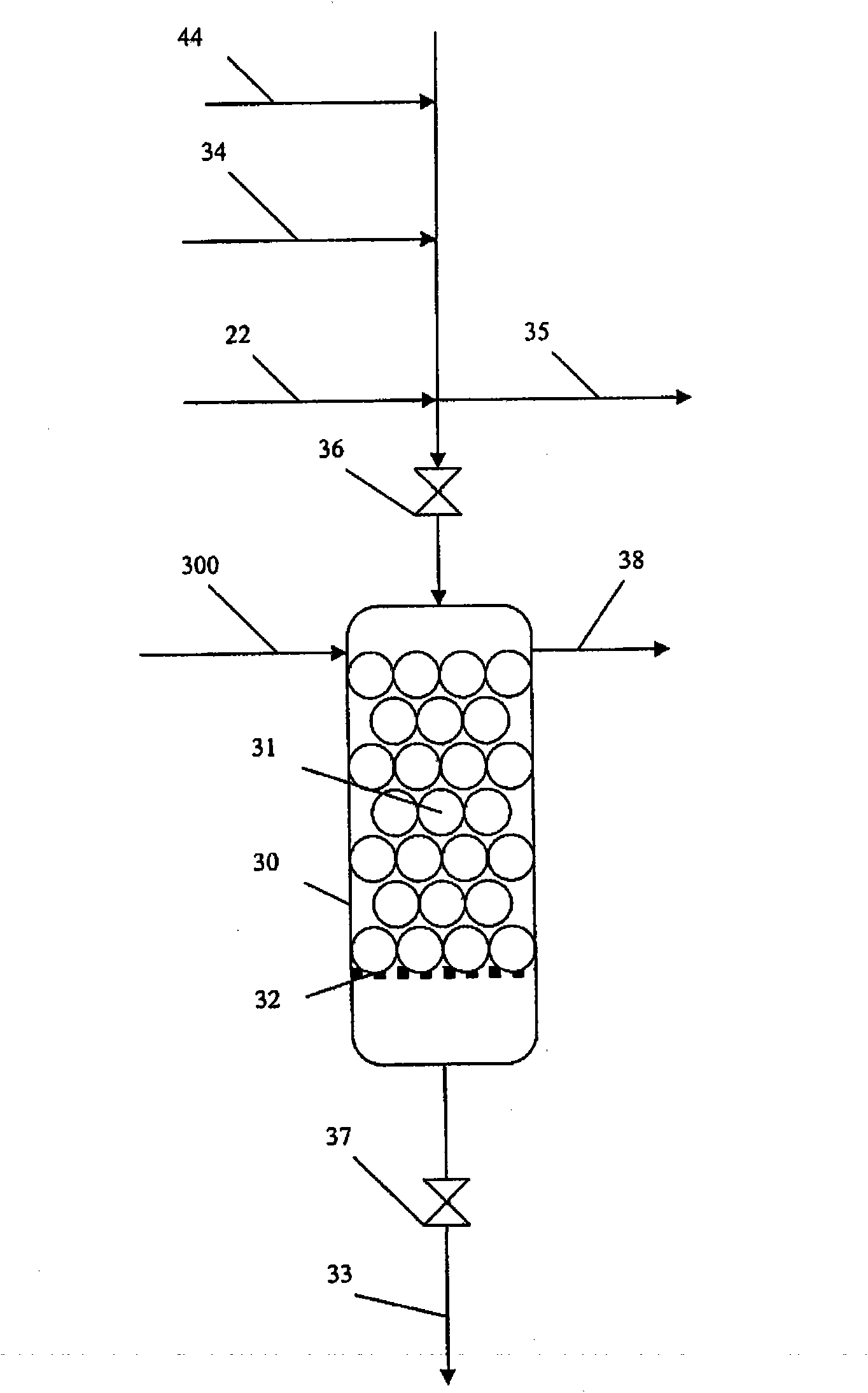

The invention discloses a method for preparing high-purity tungsten hexafluoride by a fluidized bed, and a device thereof. The method comprises the following steps: leading fluorine gas into a pre-heater and pre-heating to the temperature of 50 to 200 DEG C; allowing the pre-heated gas to enter a fluidized bed reactor, wherein, the temperature inside the fluidized bed is 200 to 400 DEG C, and the pressure is 0.1 to 0.5 MPa; continuously adding metered tungsten powder to the middle part of the reactor; allowing crude tungsten hexafluoride product obtained at the upper part of the reactor to enter a freezing collector, wherein, the freezing temperature is minus 35 to 0 DEG C; vacuumizing the top part of the collector so as to remove non-condensable gas impurity; and liquefying the obtained tungsten hexafluoride solid and allowing the tungsten hexafluoride solid to enter a rectifying tower so as to remove the heavy-component impurity, wherein, the purity of the prepared tungsten hexafluoride gas is as high as above 99.99%. The technique can realize automatic temperature control and automatic material feeding of the reactor; the operation is easy to control, safe and reliable; and filter pipes are internally arranged in the reactor which is equipped with a nitrogen backflow device, thereby preventing the product from carrying the tungsten powder.

Owner:LIMING RES INST OF CHEM IND

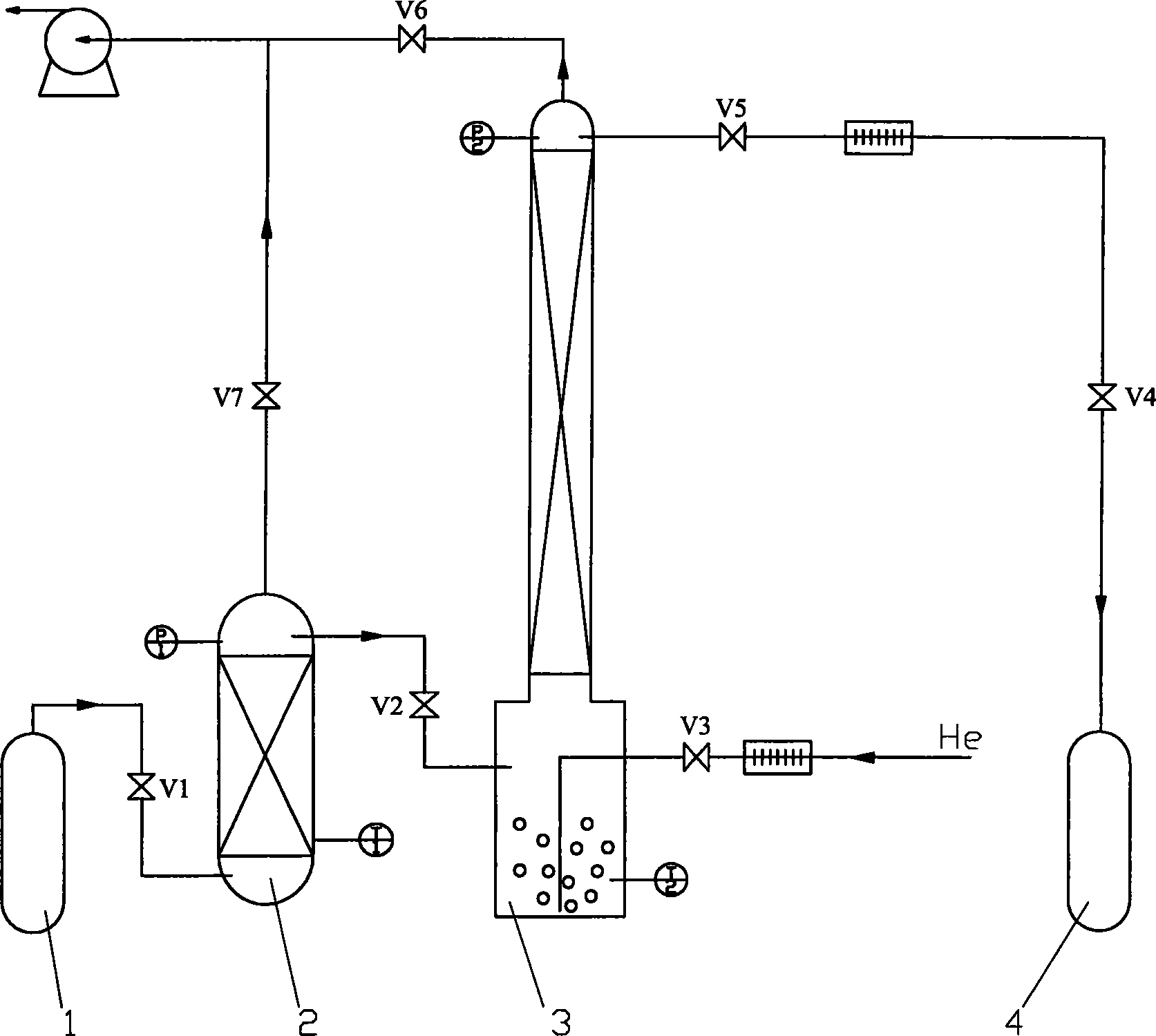

Method for purifying tungsten hexafluoride

The invention relates to a kind of purification method of tungsten hexafluoride gas. First, put impure tungsten hexafluoride gas in the storage tank of crude product into the bottom of absorption column where there are multihole spherical filling of sodium fluoride or potassium fluoride, remove the most impurity of hydrogen fluoride under temperature of 10-80 degree C,put it into rectifying column through pipe and fluidify it, stop entering tungsten hexafluoride gas after fluidifing it for 5kg-50kg, put helium gas of high purity into bottom of tungsten hexafluoride liquid and keep it boiling under temperature between 3 degree C and 20 degree C,the vaporized gas enter rectification column and rises, it gradually gets into condensation and circumfluence during the process of rising ,continues to rectify it to remove impurity, check it with gas chromatography, when concentration of impurity of gas discharged from tower top whose boiling point is higher than that of tungsten hexafluoride gas reduce to the request index, stop entering helium gas of high purity, and when helium gas's index reaches the request, collect tungsten hexafluoride gas of high purity into storage tank of quality product.

Owner:PERIC SPECIAL GASES CO LTD

Method and apparatus for the production of high purity tungsten hexafluoride

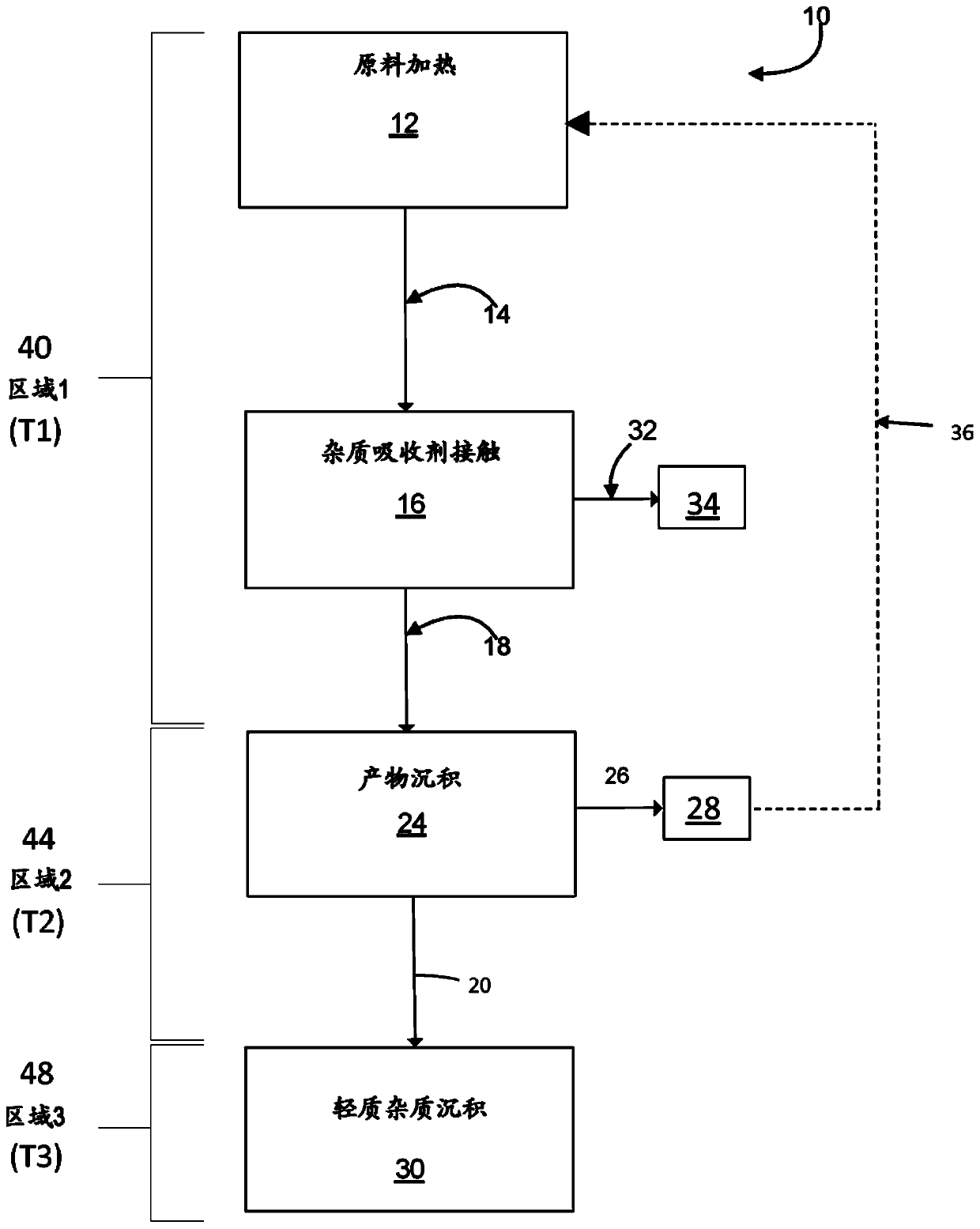

The present Invention provides new and useful apparatus and methods for purifying WF6 gas, and In particular, provides apparatus and methods of using carbonaceous materials to produce high purity WF6by removing substantially all the high volatility gas impurities and troublesome transition metal impurities The present invention is particularly useful for removing chromium and molybdenum impurities from WF6 gas.

Owner:LINDE NORTH AMERICA

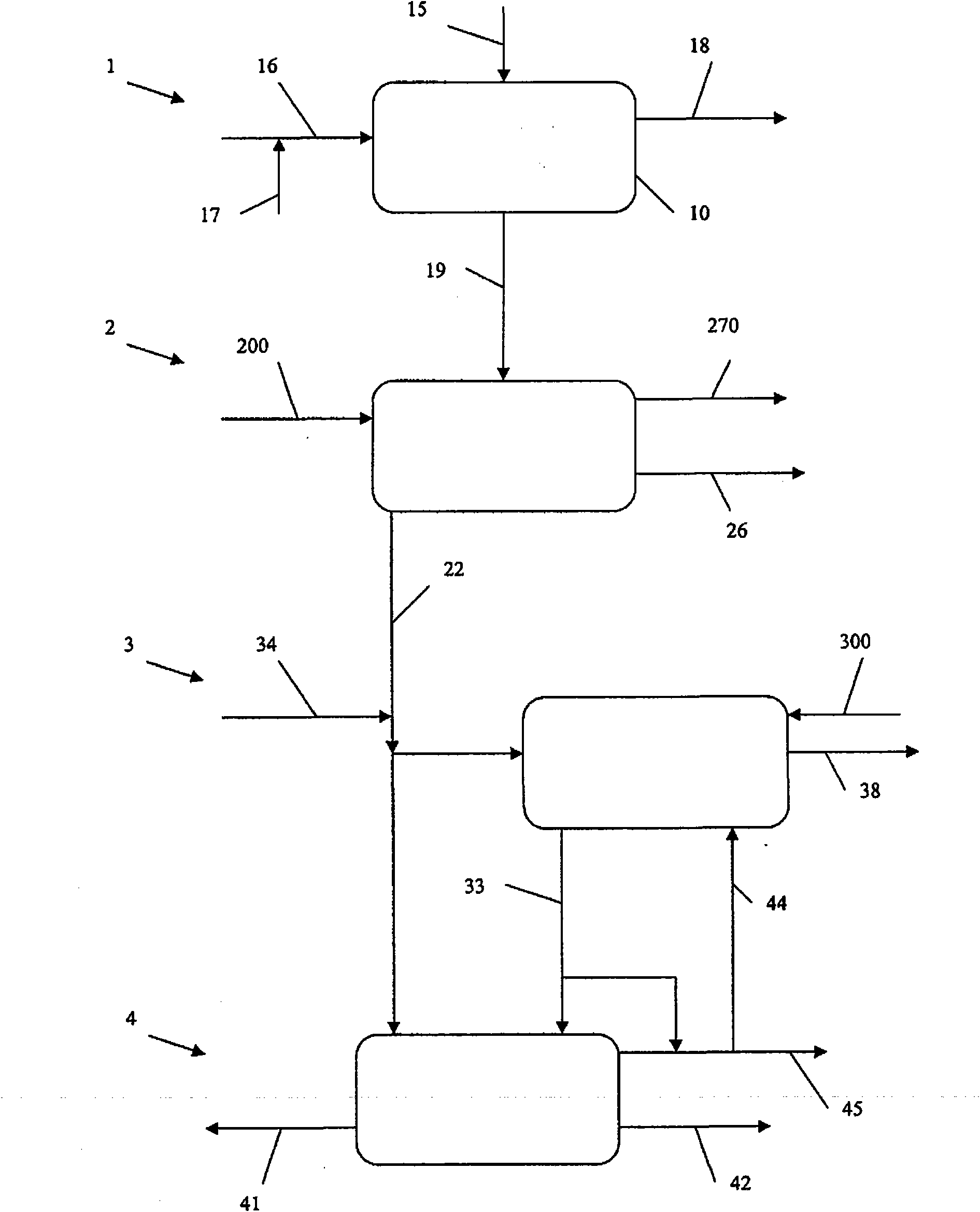

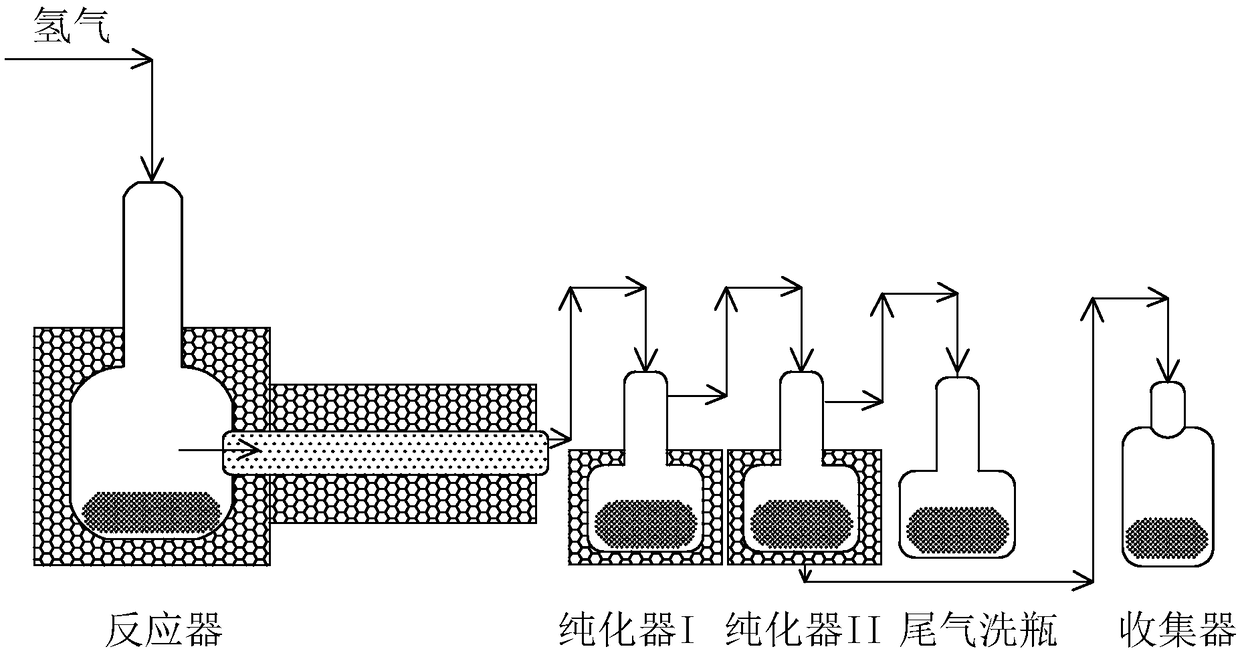

Preparation method for tungsten hexafluoride gas

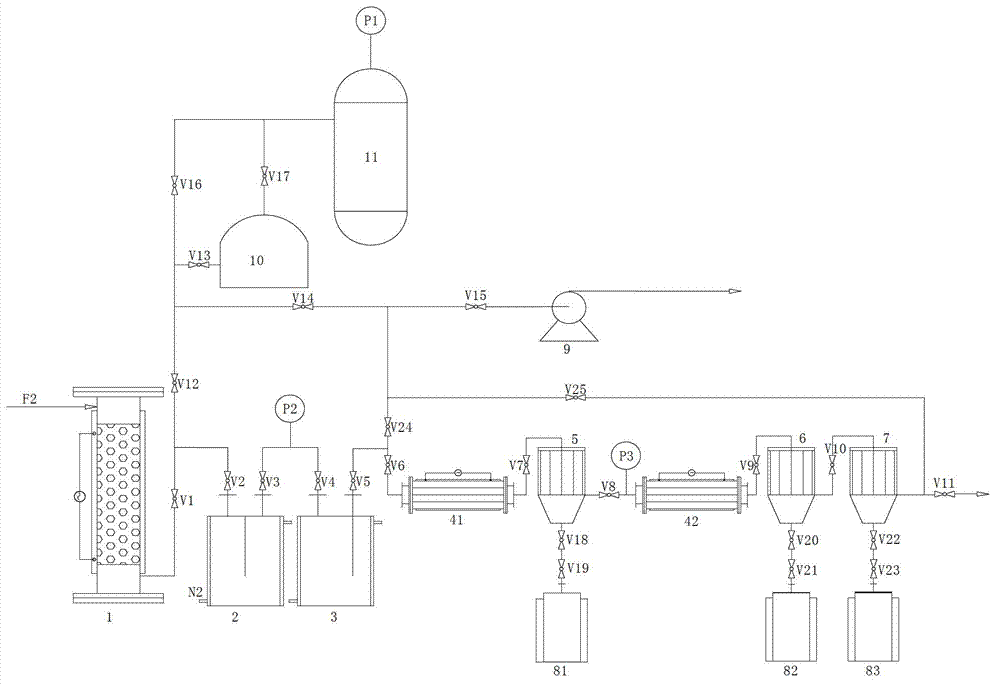

ActiveCN102951684AReduce consumptionFew controllable parametersTungsten halidesHydrogen fluorideElectrolysis

The invention provides a preparation method for tungsten hexafluoride gas, relating to fluoride of tungsten. The preparation method comprises the following steps of accessing hydrogen fluoride into an electrolytic bath to prepare fluorine electrolytically; by passing through a purifying purified tower, a first in-depth cooling tank and a second in-depth cooling tank in sequence, purifying the produced low-purity fluorine gas; accessing the purified fluorine gas to a reaction system to perform reaction, generating a crude product, namely tungsten hexafluoride; accessing the purified fluorine gas to a first horizontal fixed fixing bed reactor and a second horizontal fixed fixing bed reactor which are filled with waste tungsten cutting heads to perform reaction; collecting the prepared tungsten hexafluoride gas by a primary condenser, an intermediate condenser and a senior condenser in sequence; respectively unfreezing the collected tungsten hexafluoride gas to flow to a first storage tank, a second storage tank and a third storage tank to collect, discharging the uncondensed or unreacted impurity gas to a spraying tower through a tail part pipeline to perform alkali liquid absorption, heating the crude product tungsten hexafluoride collected by the first storage tank, the second storage tank and the third storage tank, and distilling the heated tungsten hexafluoride to a rectifying tower through a filter to perform rectifying and purifying. By utilizing the waste tungsten cutting heads, the preparation method provided by the invention has the advantages of safe process operation and high purity.

Owner:XIAMEN TUNGSTEN +1

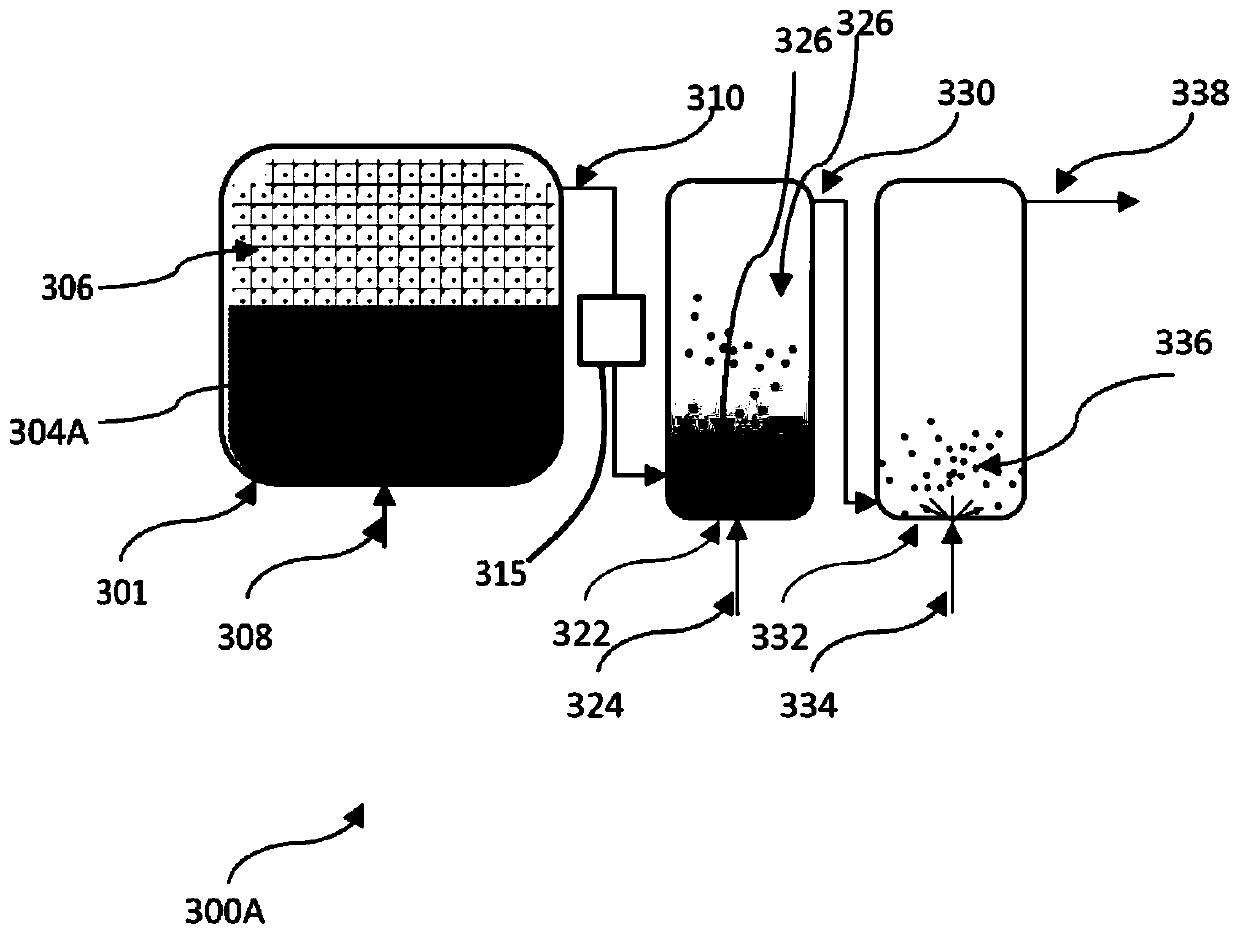

High purity tungsten hexachloride and method for making same

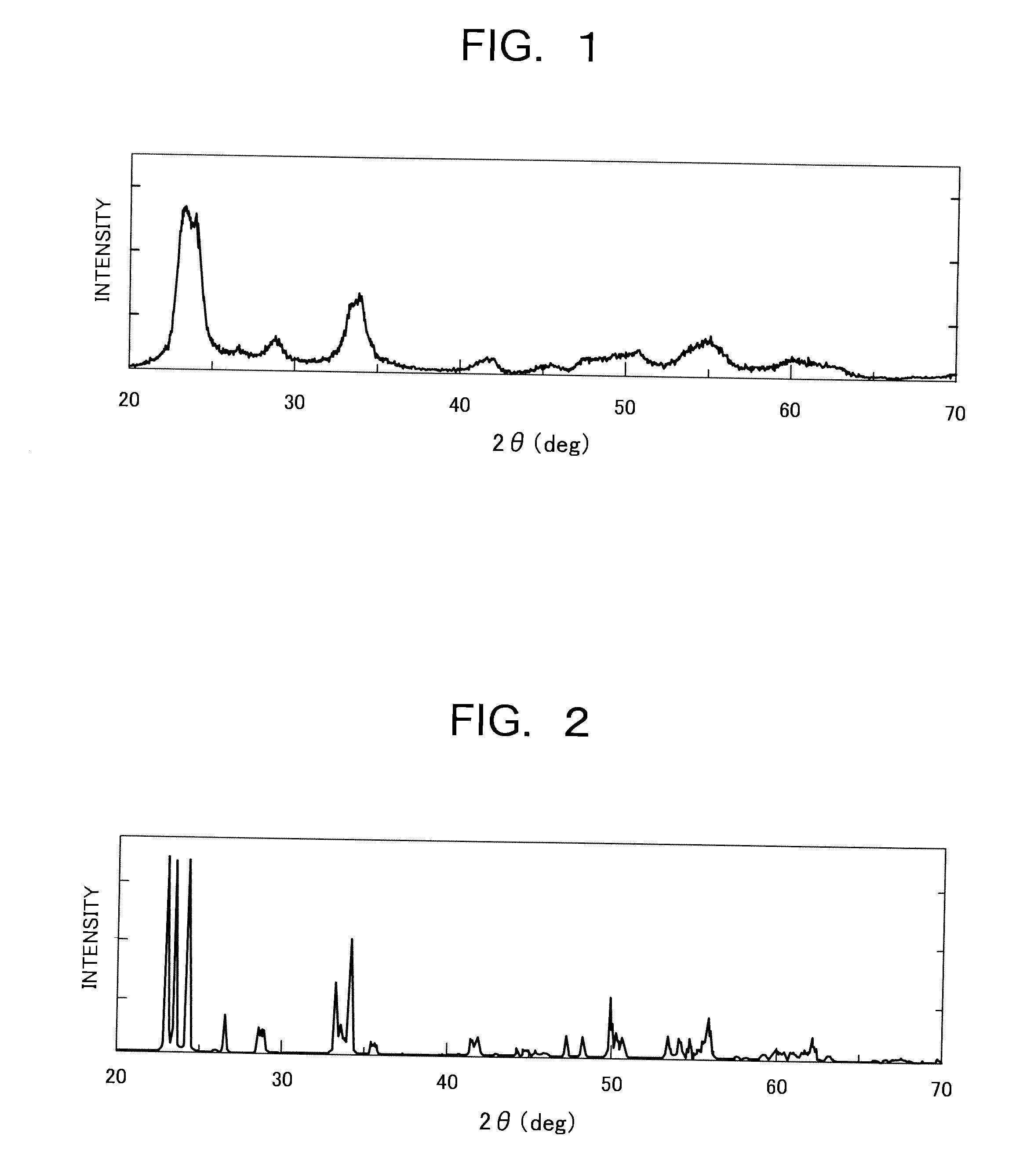

Condensable metal halide materials, such as but not limited to tungsten chloride (WCl6), can be used deposit films metal or metal containing films in a chemical vapor deposition (CVD) or atomic layer deposition process. Described herein are high purity compositions comprising condensable materials and methods to purify condensable materials. In one aspect, there is provided a composition comprising: tungsten hexachloride which is substantially free of at least one impurity and wherein the tungsten hexachloride comprises at least 90%, preferably 95% and more preferably 99% by weight or greater of a β-WCl6 and 5% by weight or less of the α-WCl6 as measured by X-ray diffraction.

Owner:VERSUM MATERIALS US LLC

Purification method of tungsten hexafluoride gas

ActiveCN104973629AEfficient removalReduce gas contentTungsten halidesHydrogen fluoridePurification methods

A purification method of a tungsten hexafluoride gas relates to a fluoride of tungsten. The purification method comprises the following steps: removing oil by equipment, pressurizing with nitrogen, vacuumizing to the limit, turning on a nitrogen heater, introducing the heated nitrogen into a system, and vacuumizing to the limit; filling a hydrogen fluoride removal tower with nitrogen, putting tungsten hexachloride into the hydrogen fluoride removal tower, introducing high-purity tungsten hexafluoride into a finished product gathering tank, reacting with steam adhered to the wall of the tank to generate hydrogen fluoride, sucking-back impure tungsten hexafluoride in the finished product gathering tank into a rectifying still for low-temperature curing after displacement, detecting content of foreign gas, and stopping high-purity tungsten hexafluoride displacement after qualified; heating primary tungsten hexafluoride and carrying out low-temperature curing, vacuumizing the rectifying still, adsorbing tail gas by a basic spray tower, thawing by hot water, and detecting when pressure is stable and rectifying; carrying out reflux condensation on evaporated tungsten hexafluoride gas in the rectifying tower, removing impurities, rectifying primary tungsten hexafluoride gas and gathering, detecting, gathering by the finished product gathering tank, taking a liquid sample, and detecting metal impurities in tungsten hexafluoride.

Owner:XIAMEN TUNGSTEN

Method for delaminating/exfoliating layered materials

InactiveUS20110057156A1Improve solubilityImprove mechanical propertiesTungsten halidesPhysical/chemical process catalystsMaterials science

The present invention relates to a method for producing delaminated / exfoliated non-ionic inorganic materials, to such materials and their use as additives.

Owner:DET SELVEJENDE INSTITUT CISMI FOND

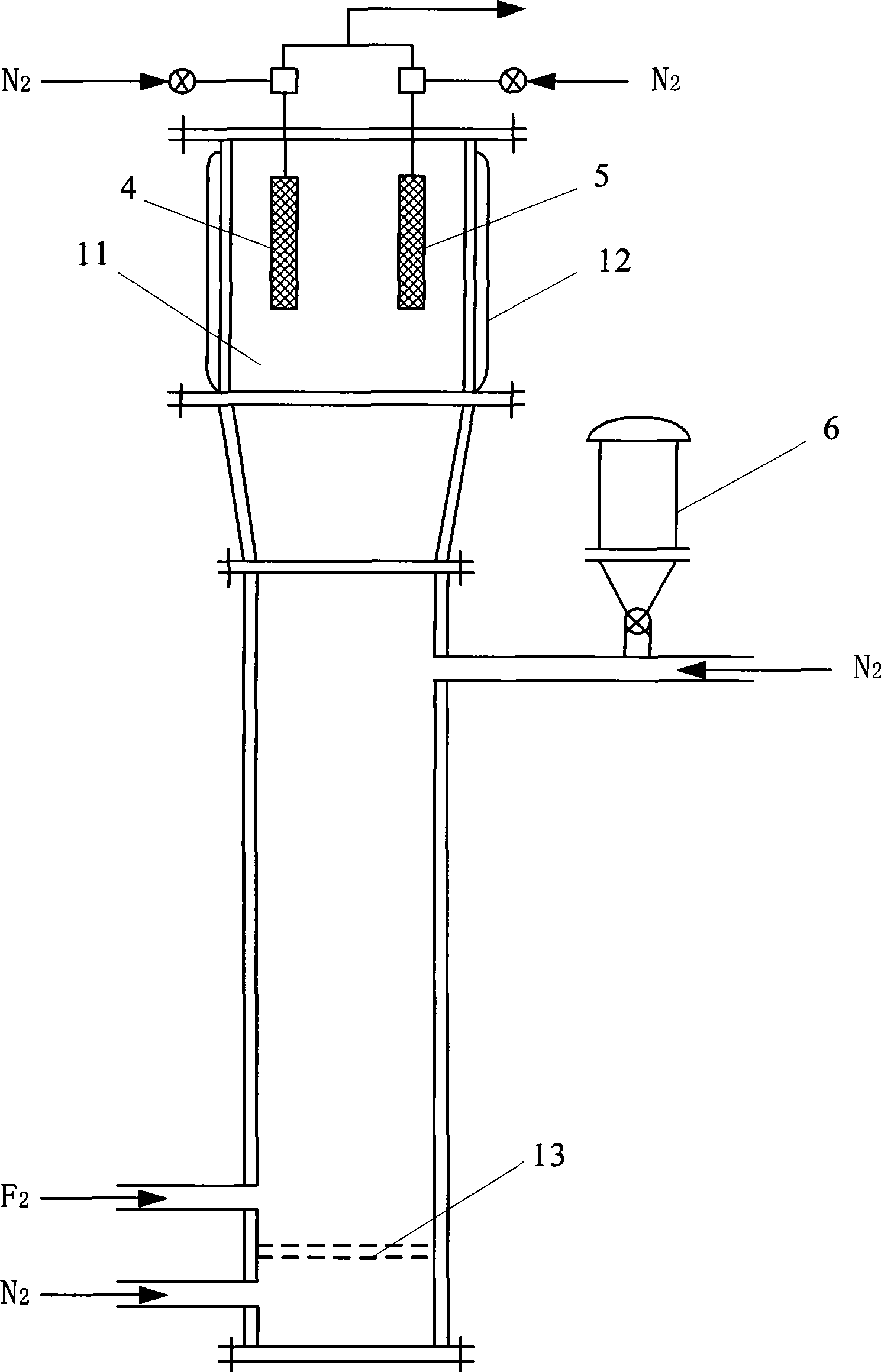

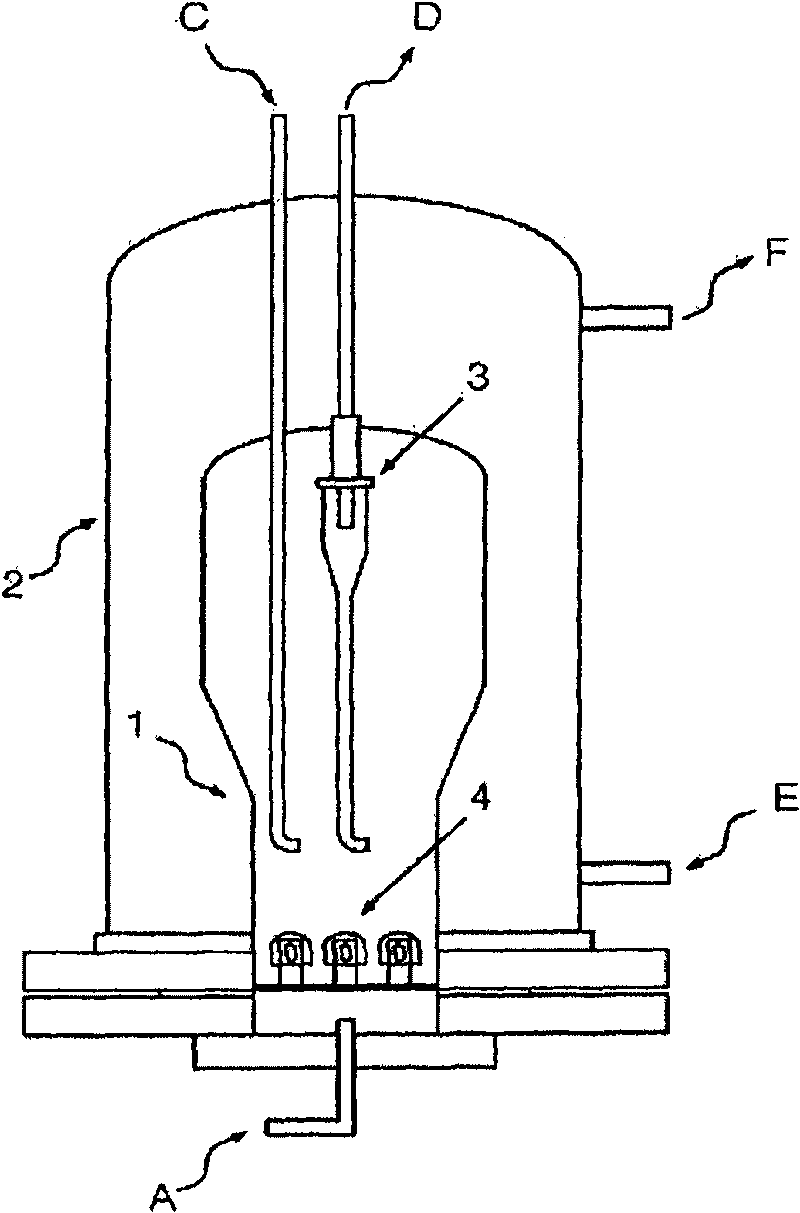

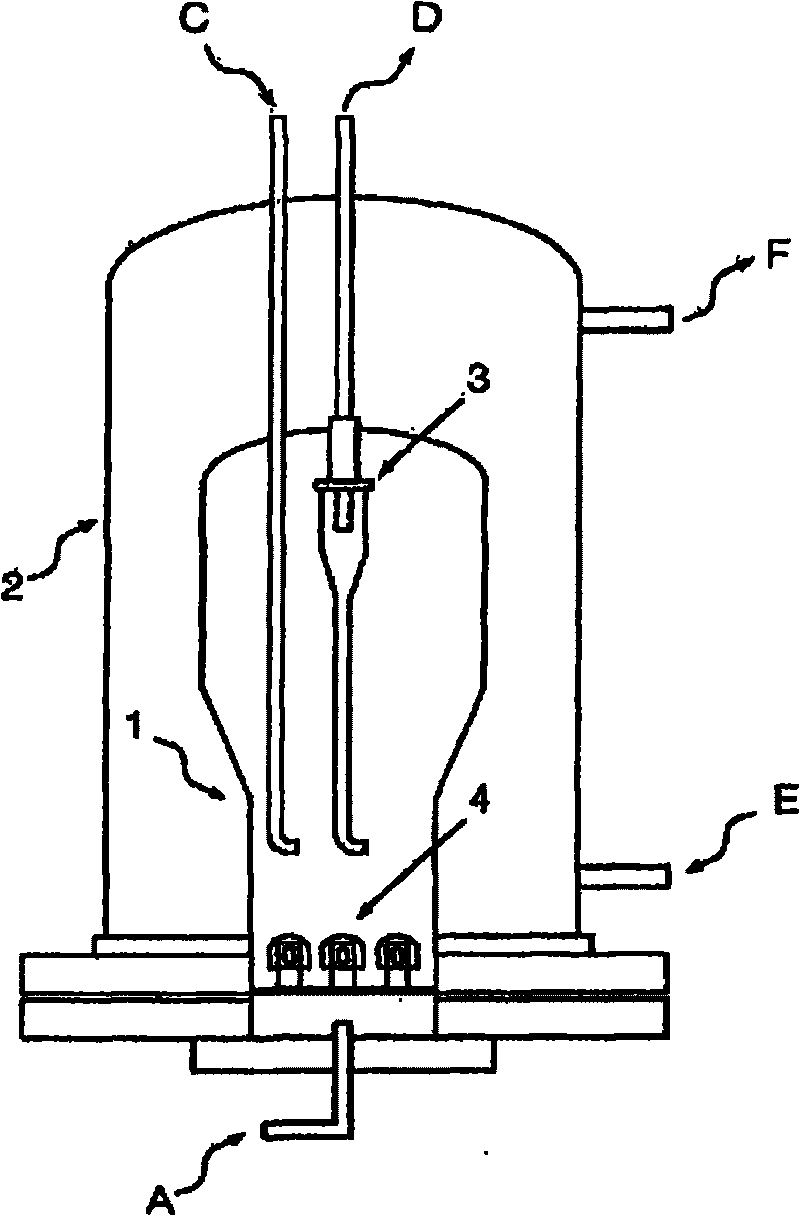

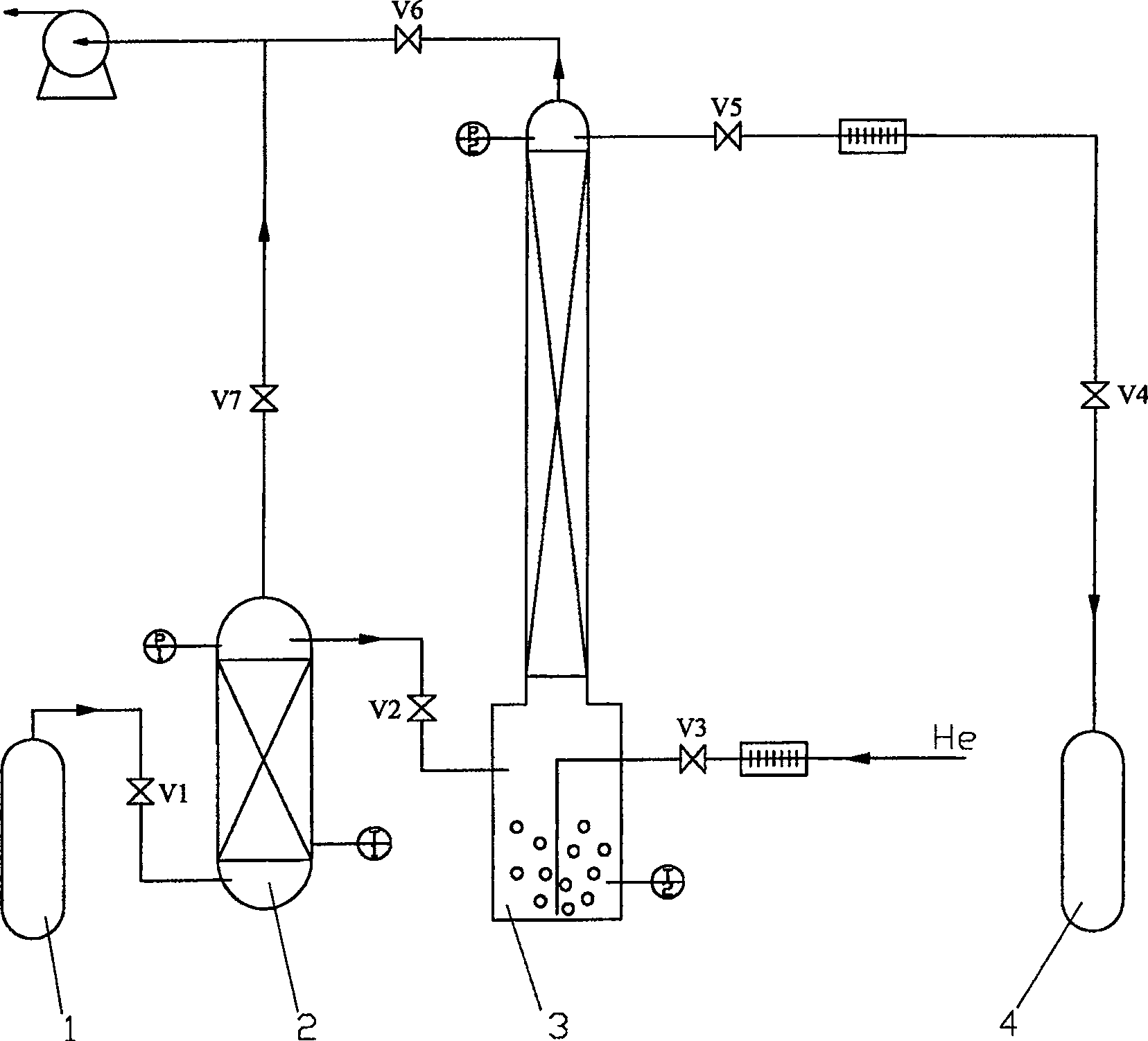

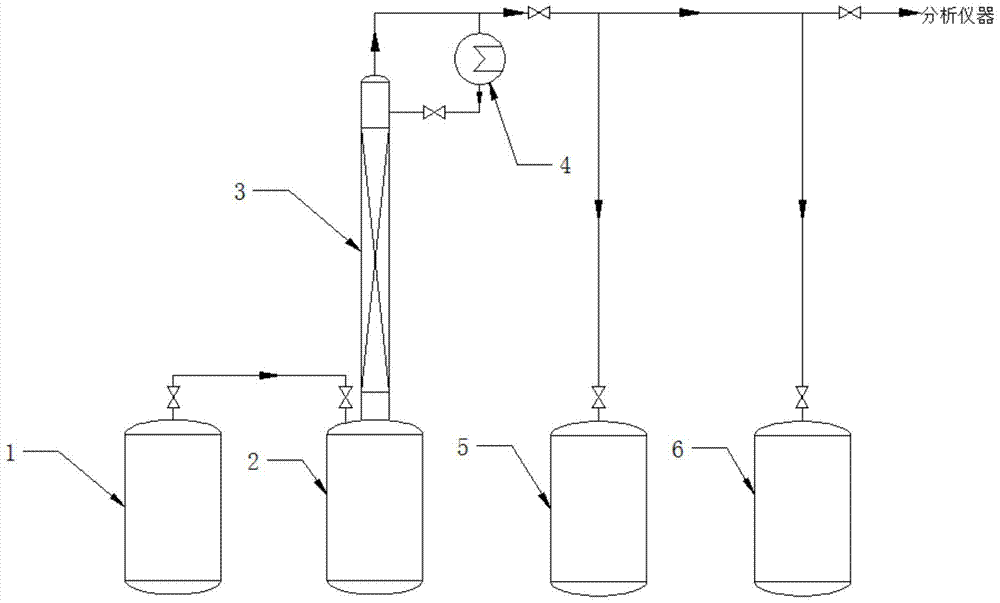

Method and apparatus for preparing tungsten hexafluoride using a fluidized bed reactor

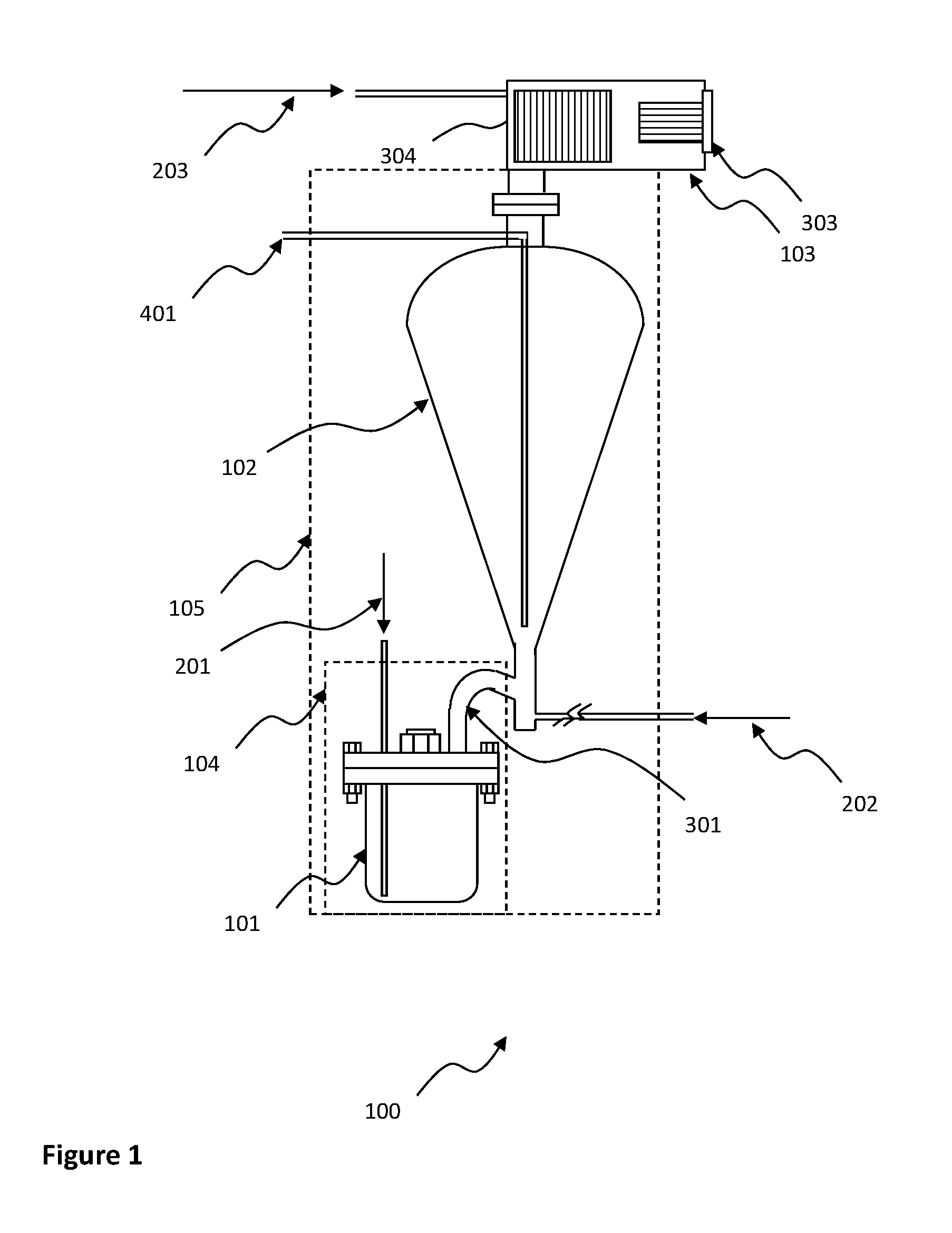

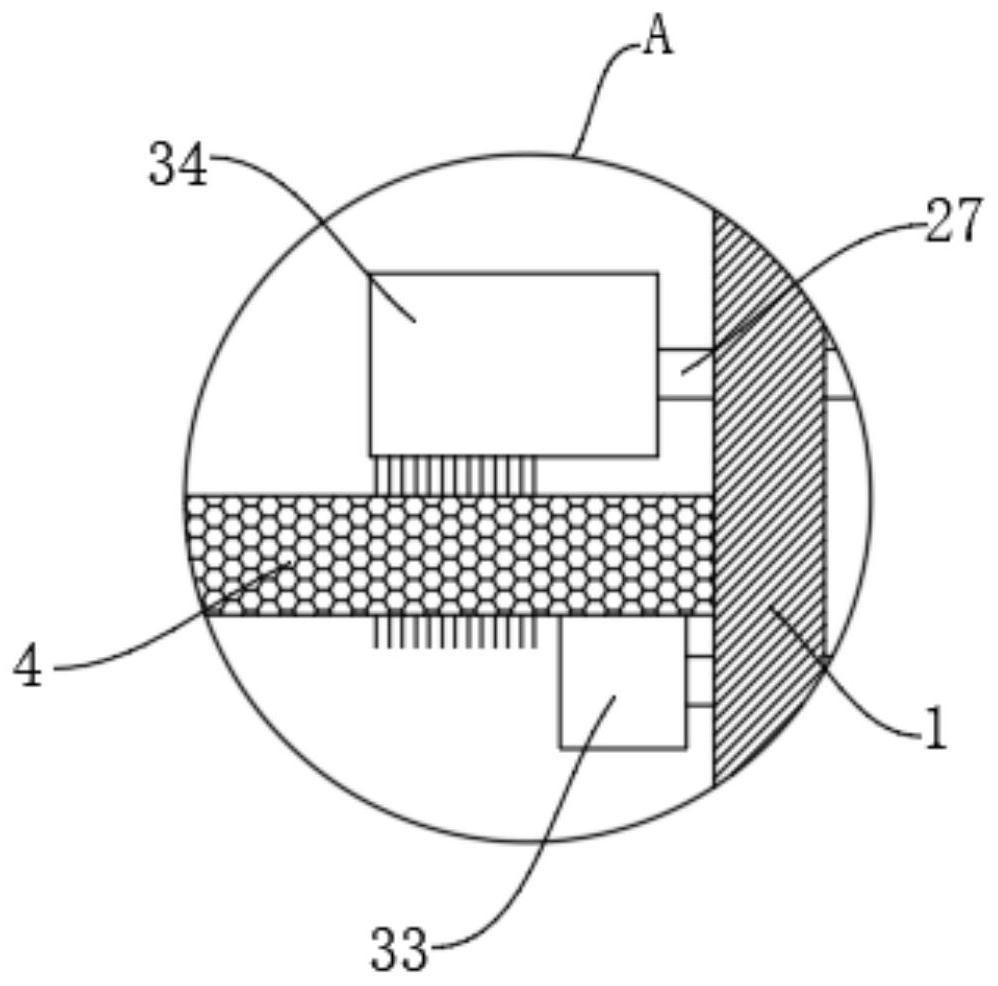

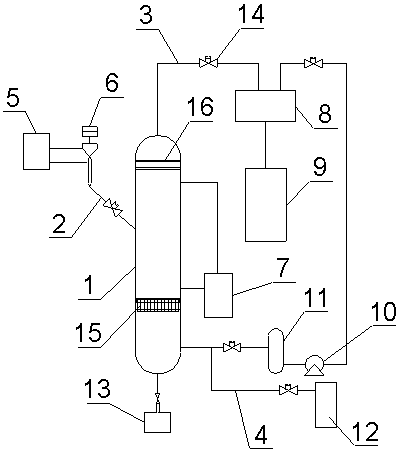

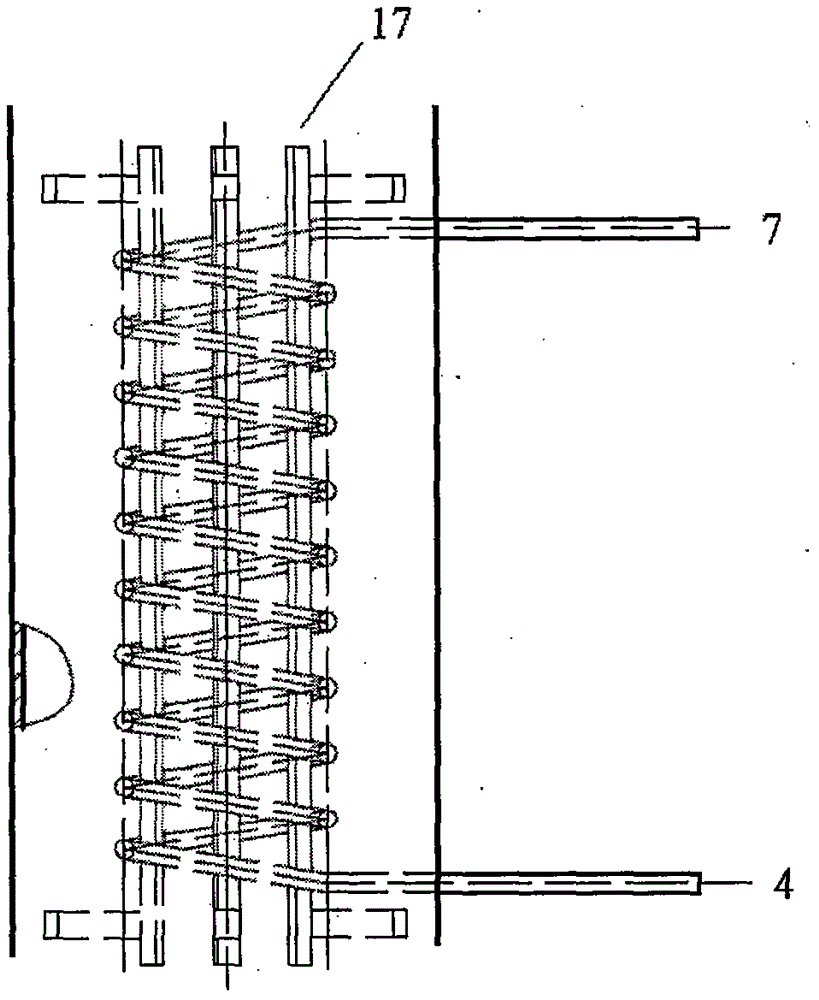

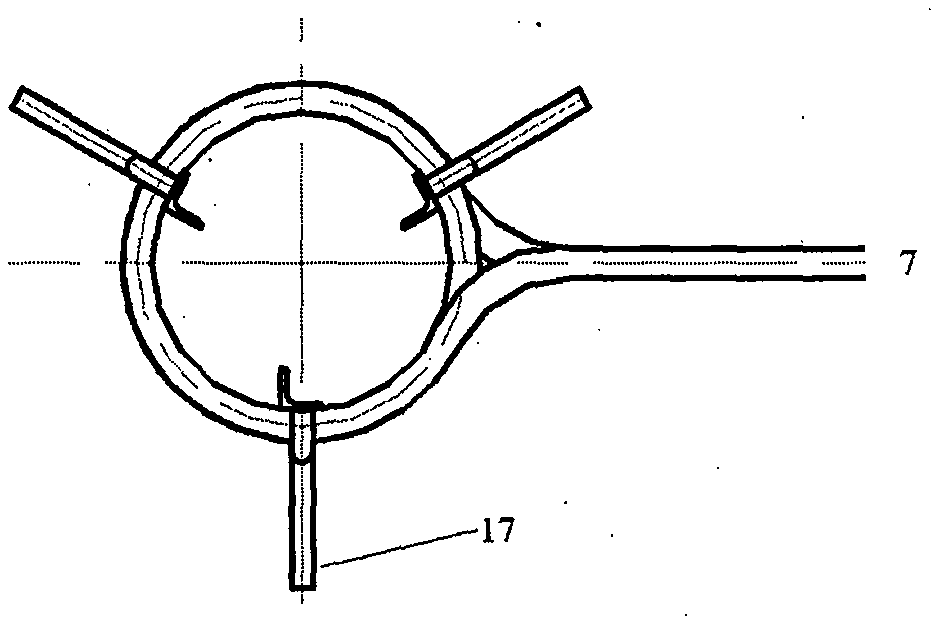

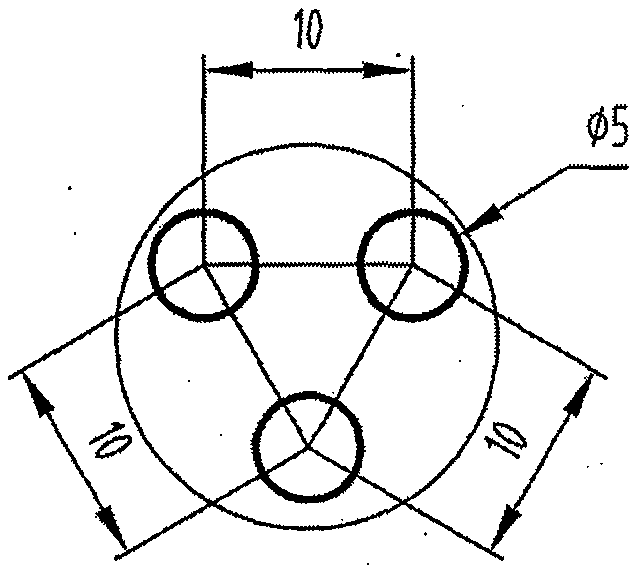

InactiveCN101723465AReduce volumeIncrease contact areaTungsten halidesFluoride preparationFluidized bedReaction system

The invention provides a reaction system for preparing tungsten hexafluoride, capable of making the tungsten with specific gravity of 19.25g / cm3 uniformly distributed in the whole reactor, maximizing the contact area of the tungsten and the reaction gas, obviously reducing the volume of the reactor and more easily controlling the reaction heat and obviously improving the reaction efficiency. The invention also provides a method of preparing tungsten hexafluoride by using a fluidized bed reactor through contacting the tungsten with fluorizating agent, comprising the following steps: inputting a tungsten powder into a closed reactor, fluidizing the tungsten powder by injecting pressured inert gas in the reactor and continuously supplying the pressured gaseous fluorizating agent and tungsten powder to make them contact and then react with each other at the fluidized state.

Owner:FOOSUNG

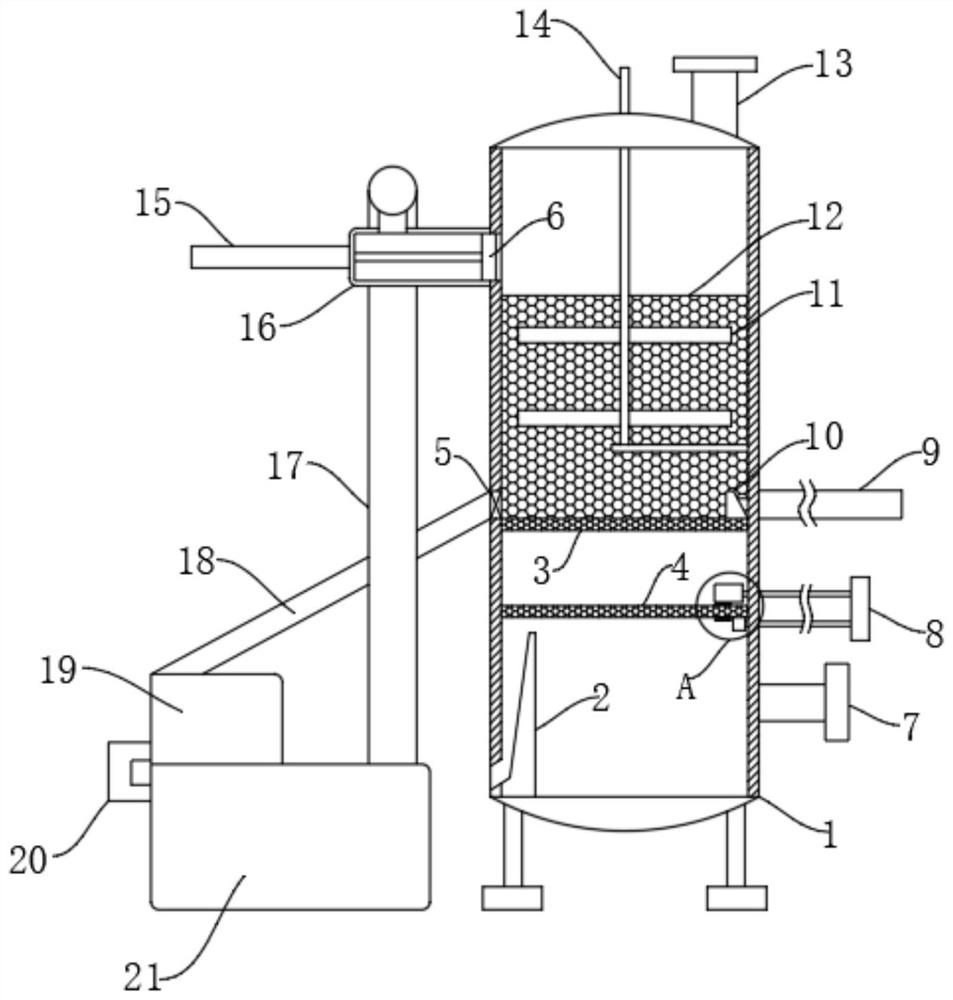

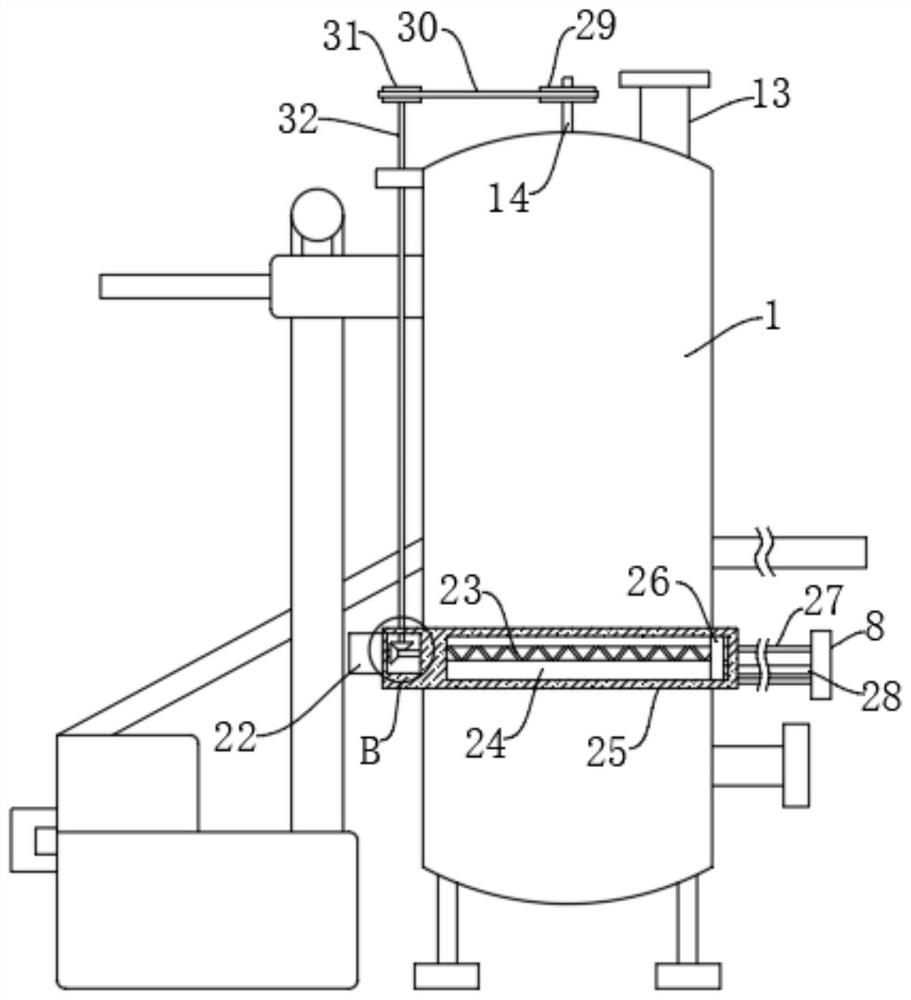

Adsorption tower for preparing high-purity tungsten hexafluoride

PendingCN111729468AGuaranteed adsorption effectIncrease profitTungsten halidesGas treatmentMetallurgyPhysical chemistry

The invention relates to an adsorption tower for preparing high-purity tungsten hexafluoride, and belongs to the technical field of tungsten hexafluoride preparation. The adsorption tower comprises anadsorption tower body, an adsorbent, a feeding mechanism and a discharging mechanism, and can further comprise at least one of a stirring mechanism, a cyclic utilization mechanism and a cleaning mechanism. A baffle net and a filter screen are sequentially arranged in the adsorption tower body from top to bottom; the baffle net is filled with adsorbent particles capable of adsorbing HF; filter screen for filtering granular impurities, the feeding mechanism is used for adding new adsorbent particles into the adsorption tower body; the discharging mechanism is used for discharging adsorbent particles with high utilization rate at the bottom of the adsorbent filled on the baffle net, the stirring mechanism is used for stirring the adsorbent particles filled on the baffle net, the cyclic utilization mechanism is used for desorbing the discharged adsorbent particles for cyclic utilization, and the cleaning mechanism is used for cleaning the filter net. According to the adsorption tower, through reasonable structural design, the utilization rate of an adsorbent can be greatly increased, and the adsorption effect can be improved.

Owner:PERIC SPECIAL GASES CO LTD

Visible-light-responsive photocatalyst powder, and visible-light-responsive photocatalytic material, photocatalytic coating material and photocatalytic product each using the same

ActiveUS20100204041A1Improve photocatalytic performanceGood reproducibilityMaterial nanotechnologyGlass/slag layered productsMetallurgyLight responsive

A visible-light-responsive photocatalyst powder includes a tungsten oxide powder. The tungsten oxide powder has color whose a* is −5 or less, b* is −5 or more, and L* is 50 or more when the color of the powder is expressed by an L*a*b* color system. Further, the tungsten oxide powder has a BET specific surface area in a range of 11 to 820 m2 / g.

Owner:KK TOSHIBA +1

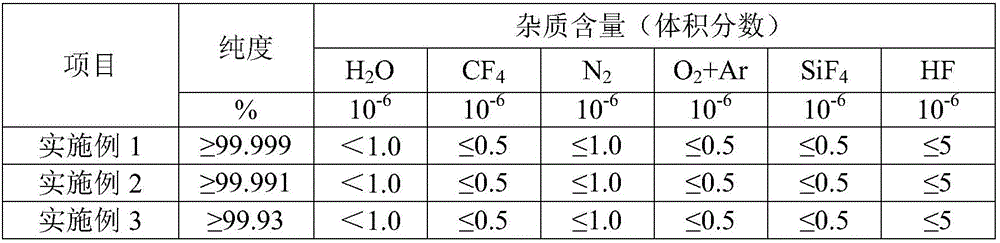

Preparation method of high-purity tungsten hexafluoride

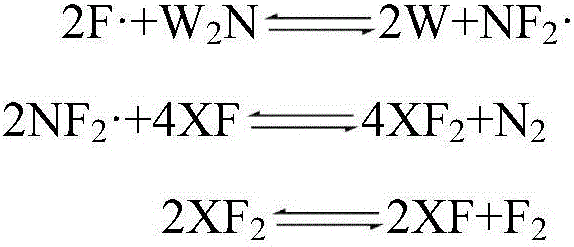

ActiveCN106587159AThe preparation method is safe and economicalEnsure safetyTungsten halidesChemical industryEnvironmental resistance

The invention relates to a preparation method of high-purity tungsten hexafluoride, and belongs to the technical field of fluorine chemical industry. The preparation method comprises the following steps: introducing nitrogen trifluoride gas into a cracker containing a catalyst to perform cracking; then enabling a fluorine-nitrogen mixture obtained by cracking to react with tungsten powder; performing condensation to obtain a tungsten hexafluoride crude product; and performing distillation and rectification to obtain tungsten hexafluoride of which the purity reaches 99.999%. The preparation method provided by the invention is safe and economical, the introduction of the catalyst ensures that nitrogen is not needed to be additionally introduced into a feed gas to ensure the safety of reaction, the purity of the obtained product reaches a 6N level, and the subsequent treatment cost is reduced, so that the preparation method is economical and environment-friendly and has great industrial application values.

Owner:南大光电(淄博)有限公司

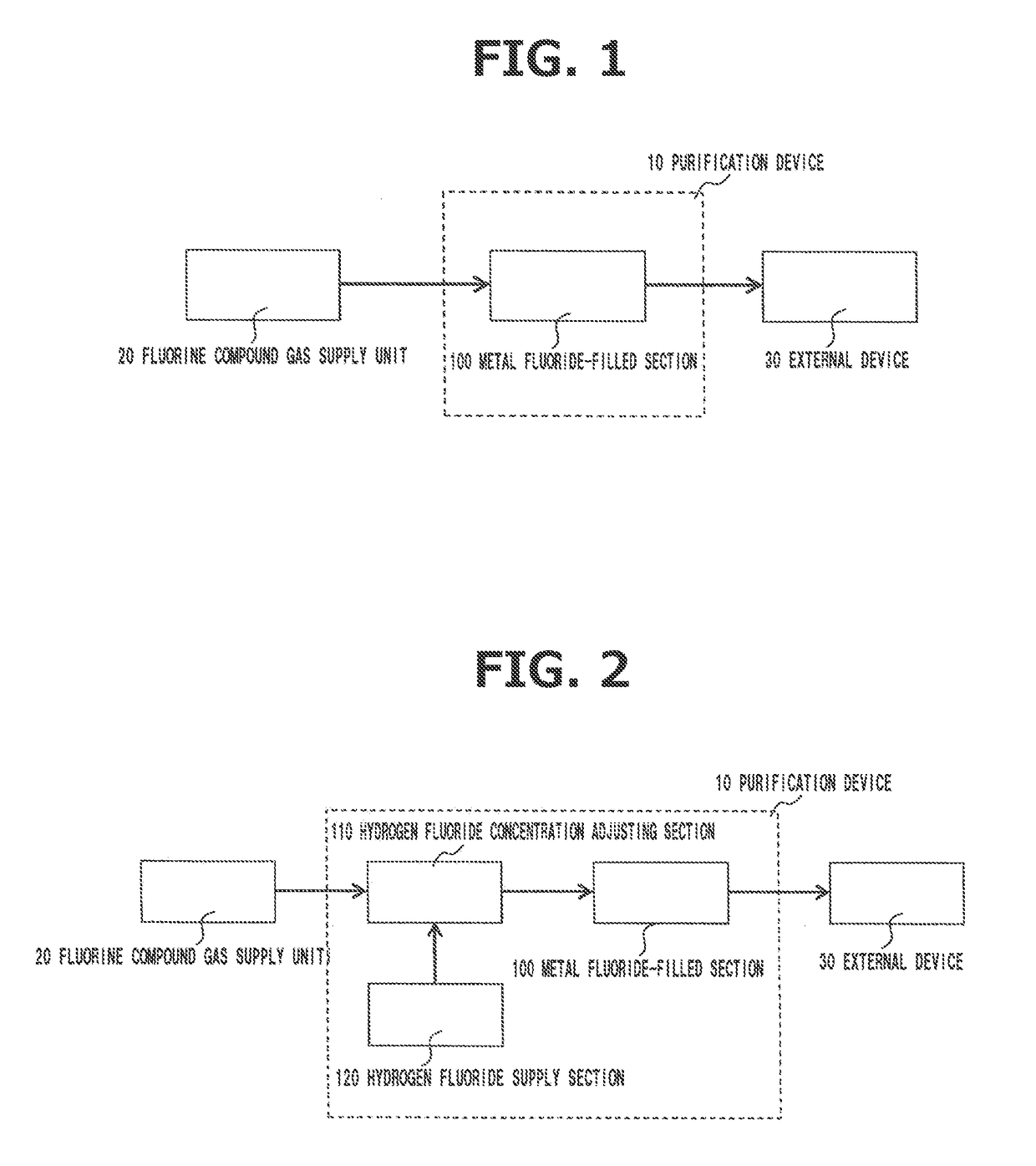

Method for Purifying Fluorine Compound Gas

ActiveUS20190046917A1Easy to disassembleSimple structureTungsten halidesGas treatmentHydrogen fluoridePurification methods

Disclosed is a purification method for removing a metal component from a fluorine compound gas containing hydrogen fluoride and a metal component. This method includes a removing step for removing the hydrogen fluoride and the metal component therefrom by bringing the fluorine compound gas into contact with a solid metal fluoride to adsorb the hydrogen fluoride and the metal component on the metal fluoride. It is preferable for the fluorine compound gas to contain at least one kind selected from the group consisting of CIF, CIF3, IF5, IF7, BrF3, BrF5, NF3, WF6, SiF4, CF4, SF6 and BF3. It is also preferable for the metal fluoride to be an alkali metal fluoride or an alkali earth metal fluoride. Surprisingly, the presence of hydrogen fluoride in a fluorine compound gas makes it possible to remove a metal component therefrom as an impurity as a result of adsorption thereof by a metal fluoride.

Owner:CENT GLASS CO LTD

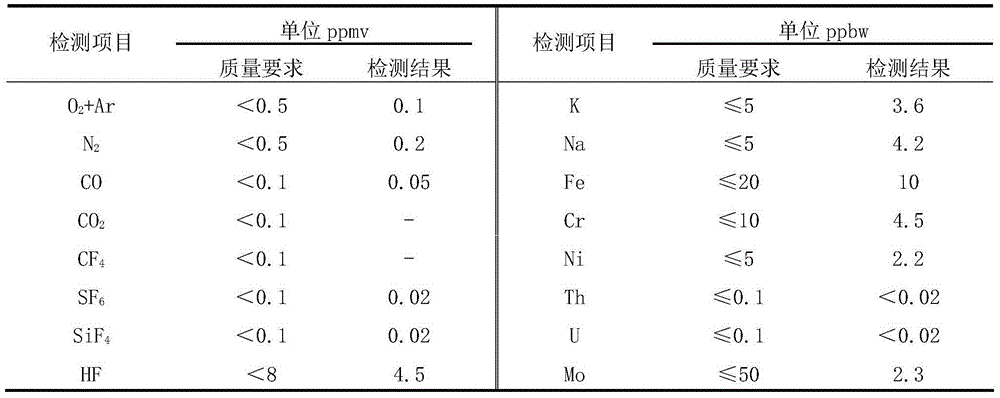

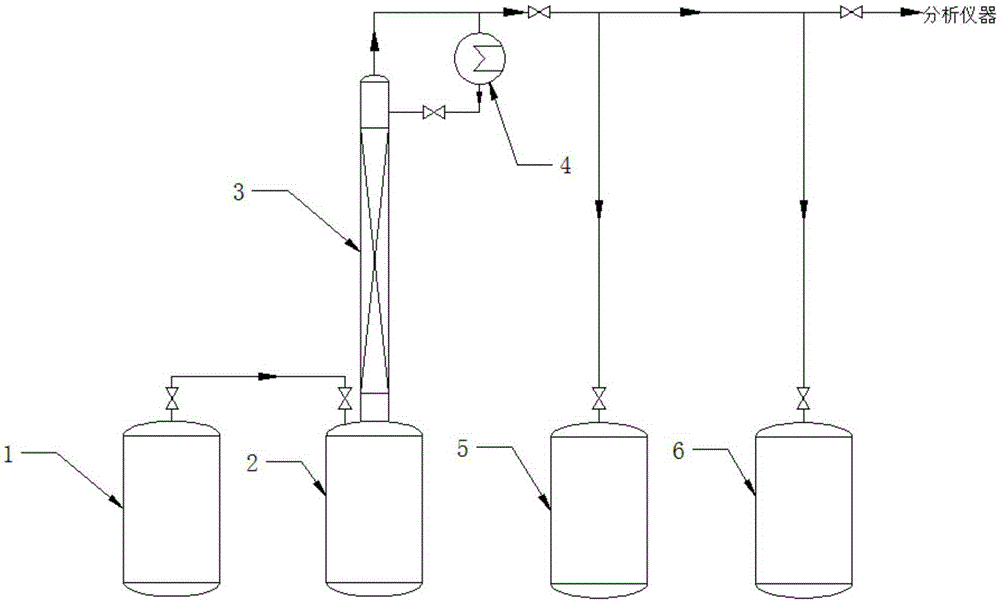

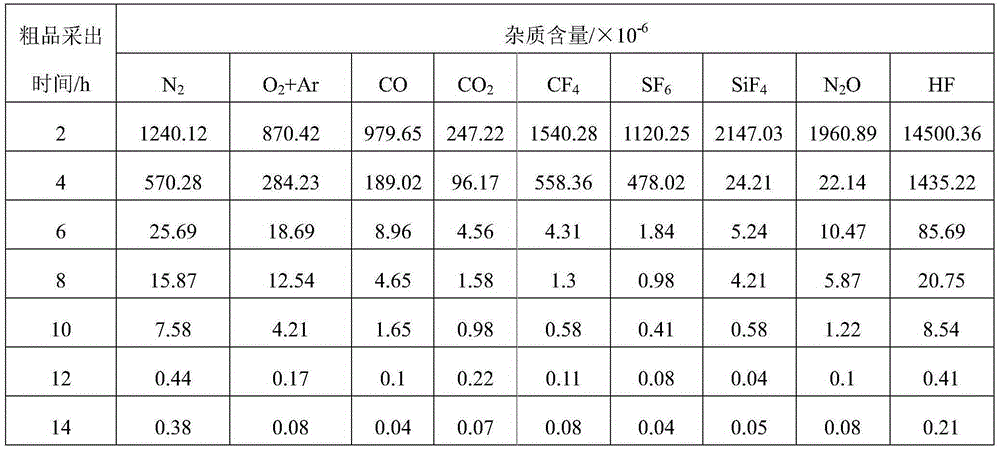

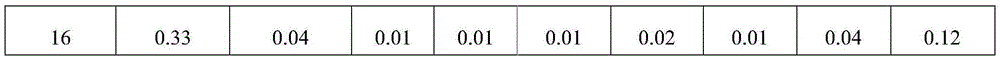

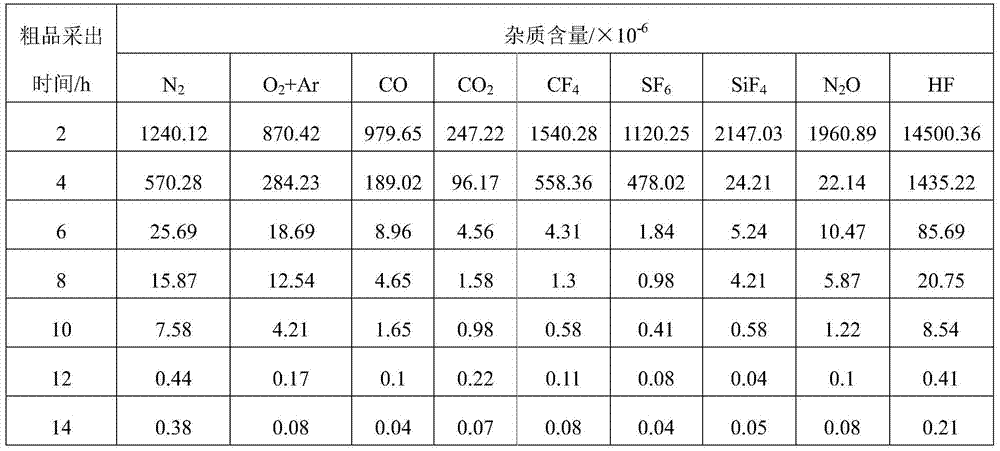

Tungsten hexafluoride gas purifying device and method

ActiveCN105417583AHigh yieldLow costTungsten halidesSpecific gas purification/separationGas phaseLiquid phase

The invention relates to a tungsten hexafluoride gas purifying device and method and belongs to the field of chemical engineering separation. The device is mainly composed of a rectification kettle, a rectification column and a condenser. Crude product WF6 gas with the purity smaller than or equal to 99% and the HF content being 1-10% is introduced into the rectification kettle, the temperature of the rectification kettle is controlled to be 30-60 DEG C, pressure is controlled to be 0.10-0.40 MPa, the temperature of the condenser is 20-50 DEG C, pressure is 0.05-0.35 MPa, the WF6 liquid is vaporized to rise and liquified to flow back, mass transfer separation happens to WF6 of a gas phase and a liquid phase in the rectification column, and therefore the purpose of removing N2, O2, CO, CO2, CF4, SiF4, SF6, N2O and HF impurities is achieved. The method is simple in technology and low in cost, 99.9999% high-purity WF6 gas can be obtained with gas low in purity and high in HF content as raw materials, and the HF content can be lowered to 0.5*10<-6> or below.

Owner:PERIC SPECIAL GASES CO LTD

Process for chlorinating resources containing recoverable metals

A process for chlorinating ore, slag, mill scale, scrap, dust and other resources containing recoverable metals from the groups 4-6, 8-12, and 14 in the periodic table. The process comprises: a) forming a liquid fused salt melt consisting essentially of aluminum chloride and at least one other metal chloride selected from the group consisting of alkali metal chlorides and alkaline earth metal chlorides, wherein the aluminum chloride content in the liquid salt melt exceeds 10% by weight; b) introducing the recoverable metal resources into said liquid salt melt: c) reacting the aluminum chloride as chlorine donor with said recoverable metal resource to form metal chlorides, which are dissolved in the salt melt; and d) recovering the formed metal chlorides from the salt melt.

Owner:P M TECH

Tungsten hexafluoride purifying device prepared from bismuth doped low-temperature-resistant material

InactiveCN108658129AEfficient removalImprove mechanical propertiesTungsten halidesHydrogen fluorideMetal impurities

The invention relates to a tungsten hexafluoride purifying device prepared from a bismuth doped low-temperature-resistant material. According to the tungsten hexafluoride purifying device prepared from the bismuth doped low-temperature-resistant material, hydrogen fluoride gas is removed effectively by sodium fluoride adsorption and deep freeze separation, then by combination with a series of purification means such as vacuum removal of light-components, rectification and the like, a large amount of volatile foreign gas and a large quantity of non-volatile metal impurities can be removed, anda tungsten hexafluoride product with purity being 99.999% or higher is produced; by means of the bismuth doped low-temperature-resistant material, the device has good low-temperature-resistant mechanical properties and coefficient of thermal expansion and can work for a long time under repeated ultralow-temperature conditions.

Owner:宁波高新区诠宝绶新材料科技有限公司

Method for purifying tungsten hexafluoride

The invention relates to a kind of purification method of tungsten hexafluoride gas. First, put impure tungsten hexafluoride gas in the storage tank of crude product into the bottom of absorption column where there are multihole spherical filling of sodium fluoride or potassium fluoride, remove the most impurity of hydrogen fluoride under temperature of 10-80 degree C,put it into rectifying column through pipe and fluidify it, stop entering tungsten hexafluoride gas after fluidifing it for 5kg-50kg, put helium gas of high purity into bottom of tungsten hexafluoride liquid and keep it boiling under temperature between 3 degree C and 20 degree C,the vaporized gas enter rectification column and rises, it gradually gets into condensation and circumfluence during the process of rising ,continues to rectify it to remove impurity, check it with gas chromatography, when concentration of impurity of gas discharged from tower top whose boiling point is higher than that of tungsten hexafluoride gas reduce to the request index, stop entering helium gas of high purity, and when helium gas's index reaches the request, collect tungsten hexafluoride gas of high purity into storage tank of quality product.

Owner:PERIC SPECIAL GASES CO LTD

High purity tungsten hexachloride and method for making same

Condensable metal halide materials, such as but not limited to tungsten chloride (WCl6), can be used to deposit metal films or metal containing films in a chemical vapor deposition (CVD) or atomic layer deposition process. Described herein are high purity compositions comprising condensable materials and methods to purify condensable materials. In one aspect, there is provided a composition comprising: tungsten hexachloride which is substantially free of at least one impurity and wherein the tungsten hexachloride comprises at least 90%, preferably 95% and more preferably 99% by weight or greater of a β-WCl6 and 5% by weight or less of the α-WCl6 as measured by X-ray diffraction.

Owner:VERSUM MATERIALS US LLC

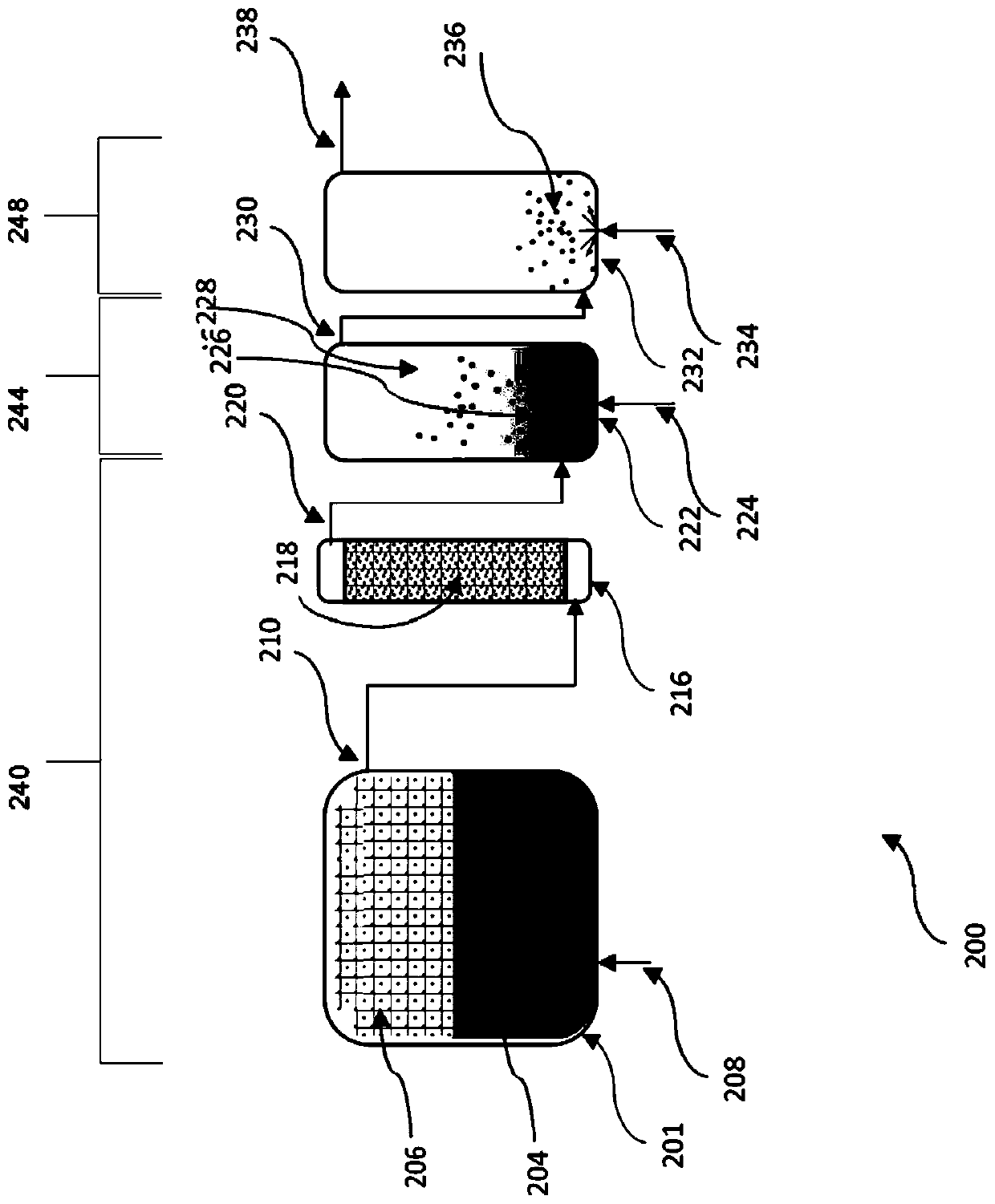

Ultra-high purity tungsten chlorides

Condensable metal halide materials, such as but not limited to tungsten hexachloride and tungsten pentachloride can be used deposit films metal or metal containing films in a chemical vapor deposition(CVD) or atomic layer deposition process. Described herein are high purity tungsten hexachloride and tungsten pentachloride systems and methods to purify tungsten hexachloride and tungsten pentachloride raw materials. There is provided a purified tungsten hexachloride and tungsten pentachloride containing less than 10 ppm, preferably less than 5 ppm, more preferably less than 1 ppm, and most preferably less than 0.5 ppm of iron and / or molybdenum; and less than 10 ppm, preferably less than 5 ppm of all other trace metals combined including but not limited to aluminum, potassium and sodium.

Owner:VERSUM MATERIALS US LLC

Method for preparing tungsten pentachloride

ActiveCN108298586AImprove conversion rateAvoid decompositionTungsten halidesDeposition temperatureHydrogen

The invention discloses a method for preparing tungsten pentachloride. The method includes the steps of grinding and transferring raw material tungsten hexachloride into a reactor, introducing high-purity hydrogen to perform reduction reaction on tungsten pentachloride, wherein the reaction temperature is 280-400 DEG C, the reaction pressure is 0.01-0.5 MPa and the reaction duration is 2-5 s, andobtaining crude tungsten pentachloride with a concentration of 95% or above, wherein the conversion rate of tungsten pentachloride is larger than 80%; by sublimation and deposition, purifying the crude tungsten pentachloride, wherein the sublimation temperature is in a range of 200-250 DEG C, the deposition temperature is in a range of 100-150 DEG C, and the purity of the collected high-purity tungsten pentachloride can reach 99.99% or above. According to the method, the reduction reaction process is precisely regulated, the stability and purification rate of the product tungsten pentachlorideare improved, the method is simple, convenient, practical, high in controllability and low in cost, and large-scale industrial production is easy.

Owner:绿菱电子材料(天津)有限公司

Method for adsorbing and purifying tungsten hexafluoride

ActiveCN105668639AImprove the ability to adsorb gaseous impuritiesTungsten halidesTungsten compounds preparationFiberCarbon fibers

The invention relates to a method for adsorbing and purifying tungsten hexafluoride.The method comprises the steps of adding fluorinated carbon fibers into a reaction kettle, and conducting on-load operation, so that adsorbent is obtained; adsorbing industrial-grade tungsten hexafluoride with a chromatographic column filled with the adsorbent, so that a tungsten hexafluoride product is obtained.

Owner:ZHEJIANG BRITECH CO LTD

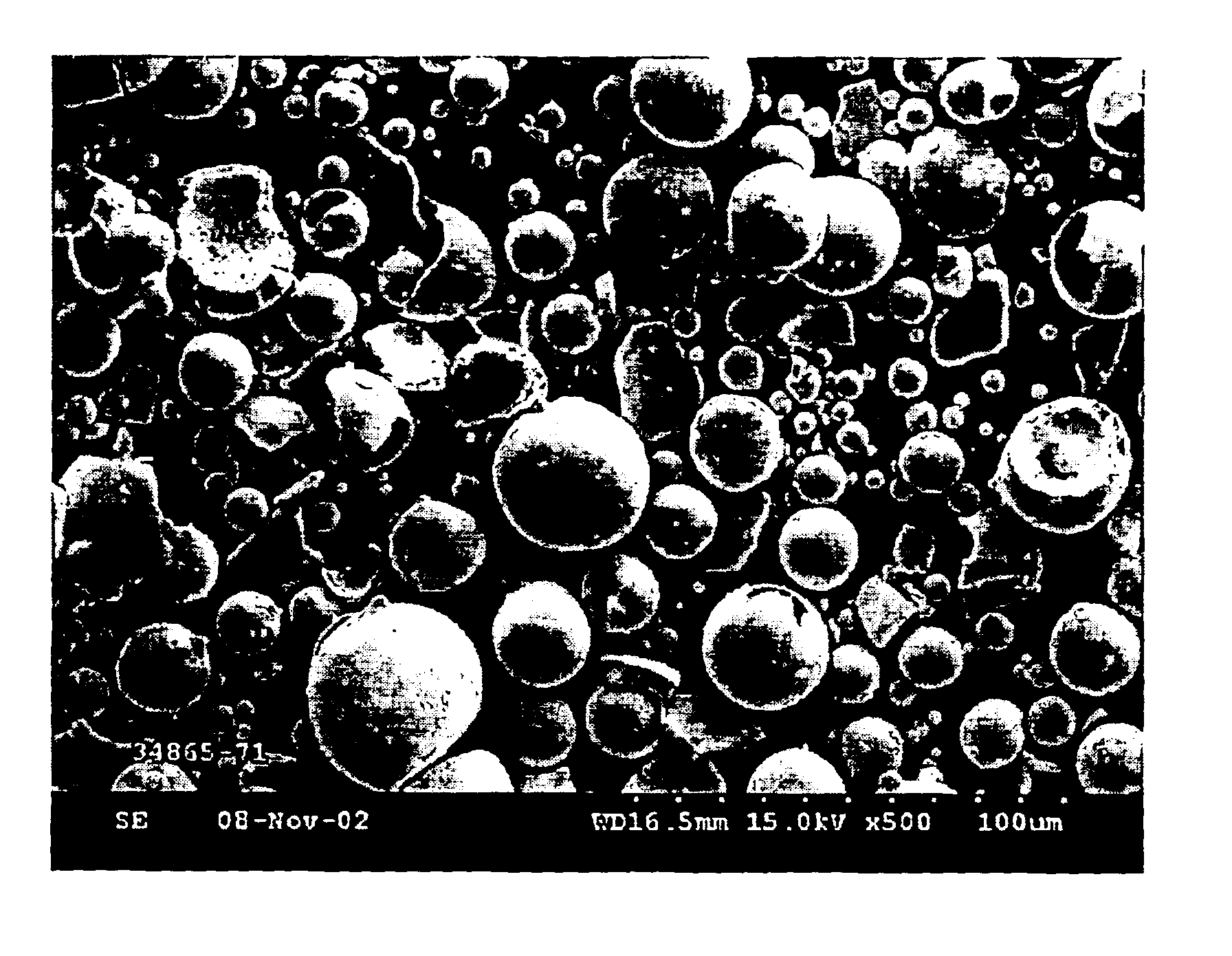

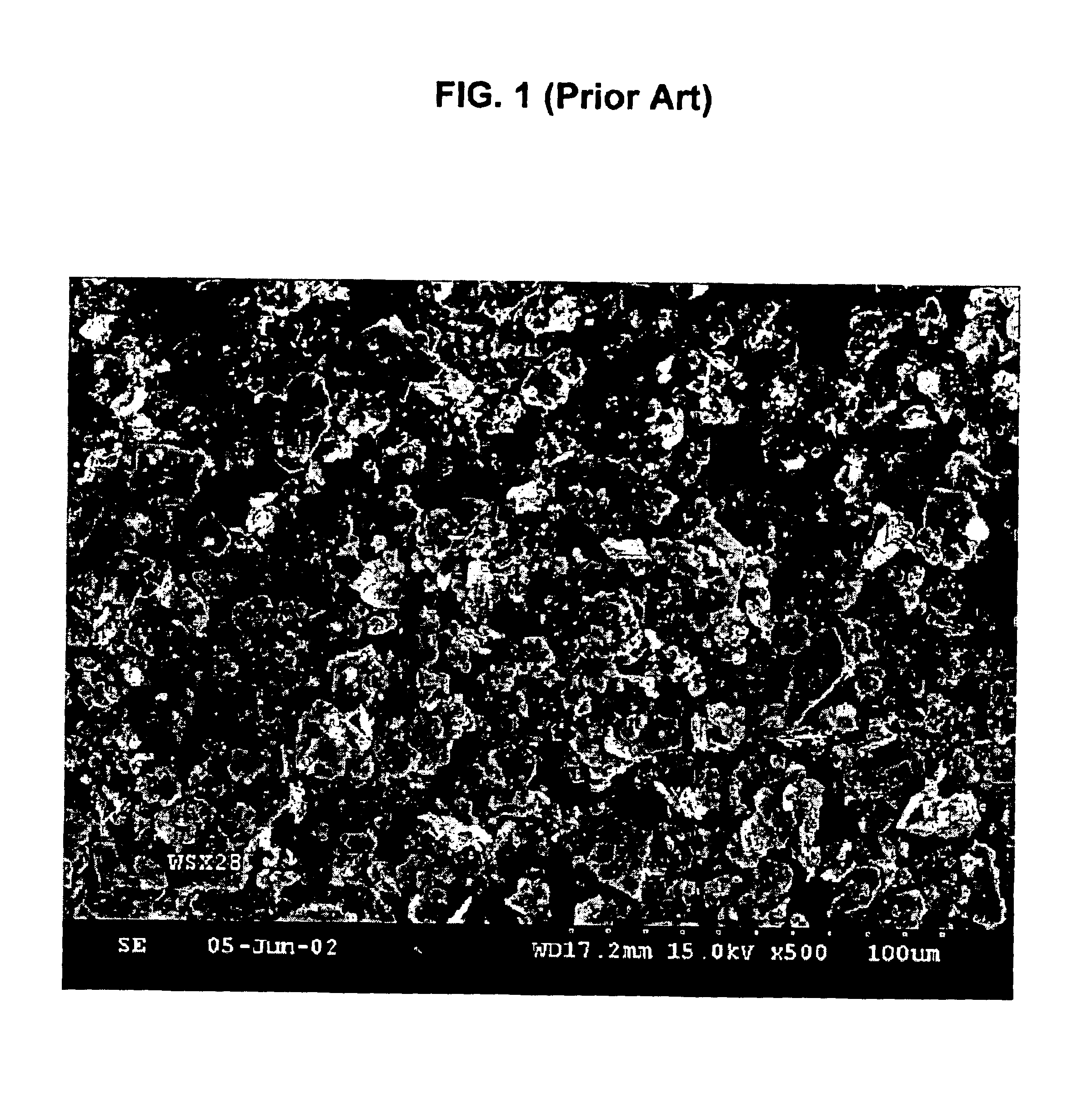

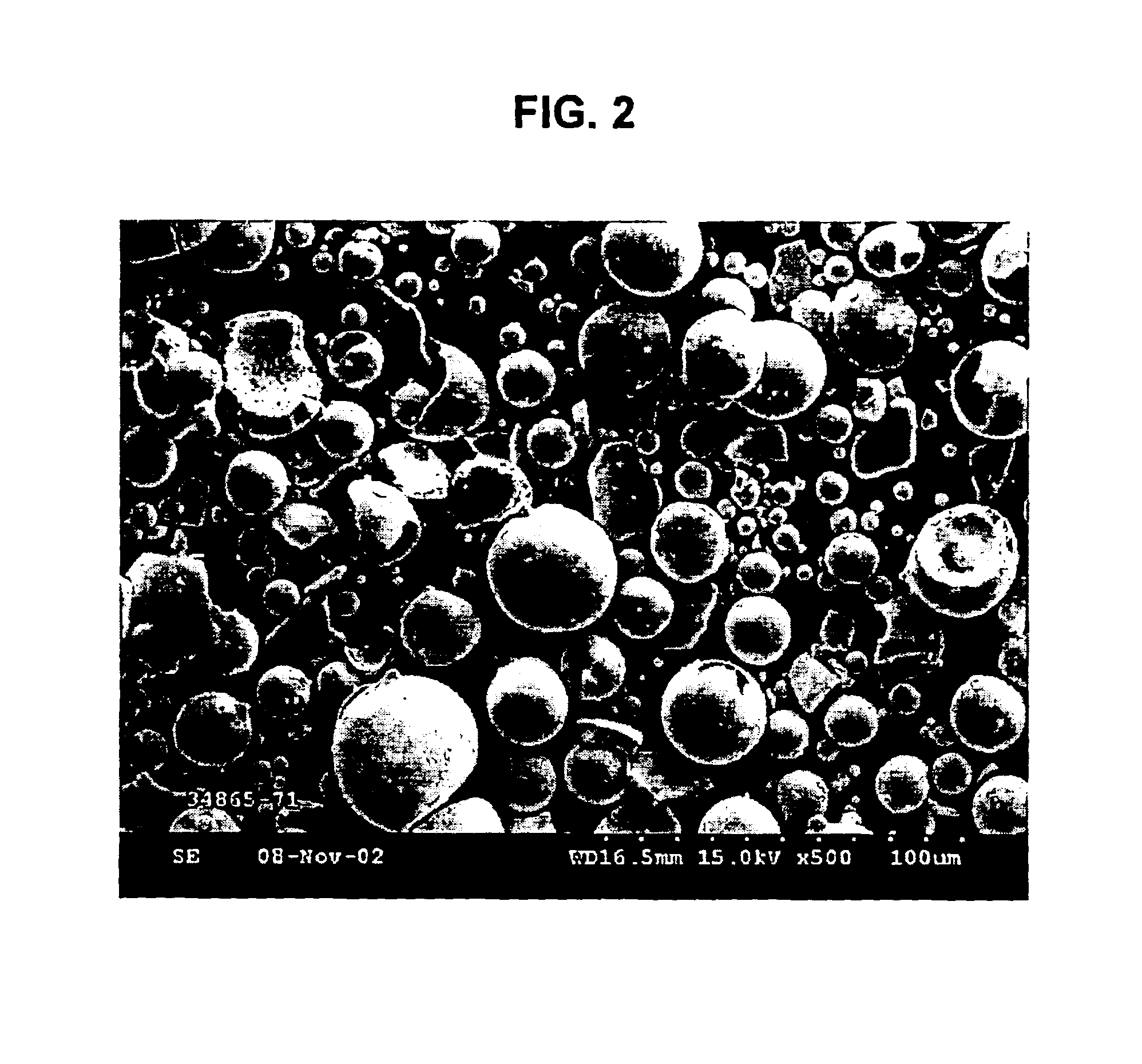

Spherical tungsten disulfide powder

A tungsten disulfide powder comprised of macro-spherical particles of tungsten disulfide having an average particle diameter of from about 5 to about 50 micrometers is prepared by successively treating spray-dried powders of ammonium metatungstate with heat in air and sulfidizing the resultant tungsten trioxide in a carbon disulfide-containing atmosphere at about 750° C. The tungsten disulfide powder may also be formed to have a bimodal particle size distribution of the macro-spherical particles and smaller, dispersed micro- to submicron-sized fine particles.

Owner:GLOBAL TUNGSTEN & POWDERS CORP

A purification device and method for tungsten hexafluoride gas

ActiveCN105417583BHigh yieldLow costTungsten halidesSpecific gas purification/separationGas phaseImpurity

The invention relates to a tungsten hexafluoride gas purifying device and method and belongs to the field of chemical engineering separation. The device is mainly composed of a rectification kettle, a rectification column and a condenser. Crude product WF6 gas with the purity smaller than or equal to 99% and the HF content being 1-10% is introduced into the rectification kettle, the temperature of the rectification kettle is controlled to be 30-60 DEG C, pressure is controlled to be 0.10-0.40 MPa, the temperature of the condenser is 20-50 DEG C, pressure is 0.05-0.35 MPa, the WF6 liquid is vaporized to rise and liquified to flow back, mass transfer separation happens to WF6 of a gas phase and a liquid phase in the rectification column, and therefore the purpose of removing N2, O2, CO, CO2, CF4, SiF4, SF6, N2O and HF impurities is achieved. The method is simple in technology and low in cost, 99.9999% high-purity WF6 gas can be obtained with gas low in purity and high in HF content as raw materials, and the HF content can be lowered to 0.5*10<-6> or below.

Owner:PERIC SPECIAL GASES CO LTD

High purity tungsten pentachloride and method for synthesizing same

The purpose of the present invention is to safely synthesize high purity tungsten pentachloride at a higher yield and at a higher purity than in prior art. This method for producing tungsten pentachloride includes: a step of mixing a reducing agent selected from the group consisting of Bi, Hg, Sb, Ti, Al, P, and As with tungsten hexachloride uniformly in an inert atmosphere with a molar ratio of the tungsten hexachloride to the reducing agent being 2.8:1.0 to 3.2:1.0 to obtain a mixture; a step of heating the mixture of the reducing agent and the tungsten hexachloride to 80 to 210° C. at 13 Pa or lower and reducing the same; a step of heating the reduced product of the mixture of the reducing agent and the tungsten hexachloride to 120 to 290° C. at 66 Pa or lower and vacuum distilling the same to remove impurities; and a step of heating the reduced product from which impurities have been removed by the vacuum distillation to 140 to 350° C. at 13 Pa or lower and purifying the same by sublimation to obtain the tungsten pentachloride.

Owner:JX NIPPON MINING& METALS CORP

Synthesis method of tungsten hexafluoride

The method discloses a synthesis method of tungsten hexafluoride, comprising the following steps: putting tungsten powder and metal fluoride into a reactor, sufficiently mixing, introducing fluorine under a reaction condition, reacting to synthesize the tungsten hexafluoride, enabling the raw material fluorine which is not completely reacted and the product tungsten hexafluoride to be subjected tocondensation gas liquid separation, and then returning to the reactor for circular reaction. According to the synthesis method, the circulated fluorine and tungsten powder are used for reacting in the presence of the metal fluoride, the reaction efficiency is effectively improved, the waste of the raw material fluorine is reduced, and the needed size of the reactor is effectively reduced.

Owner:欧中电子材料(重庆)有限公司

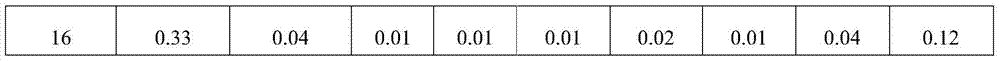

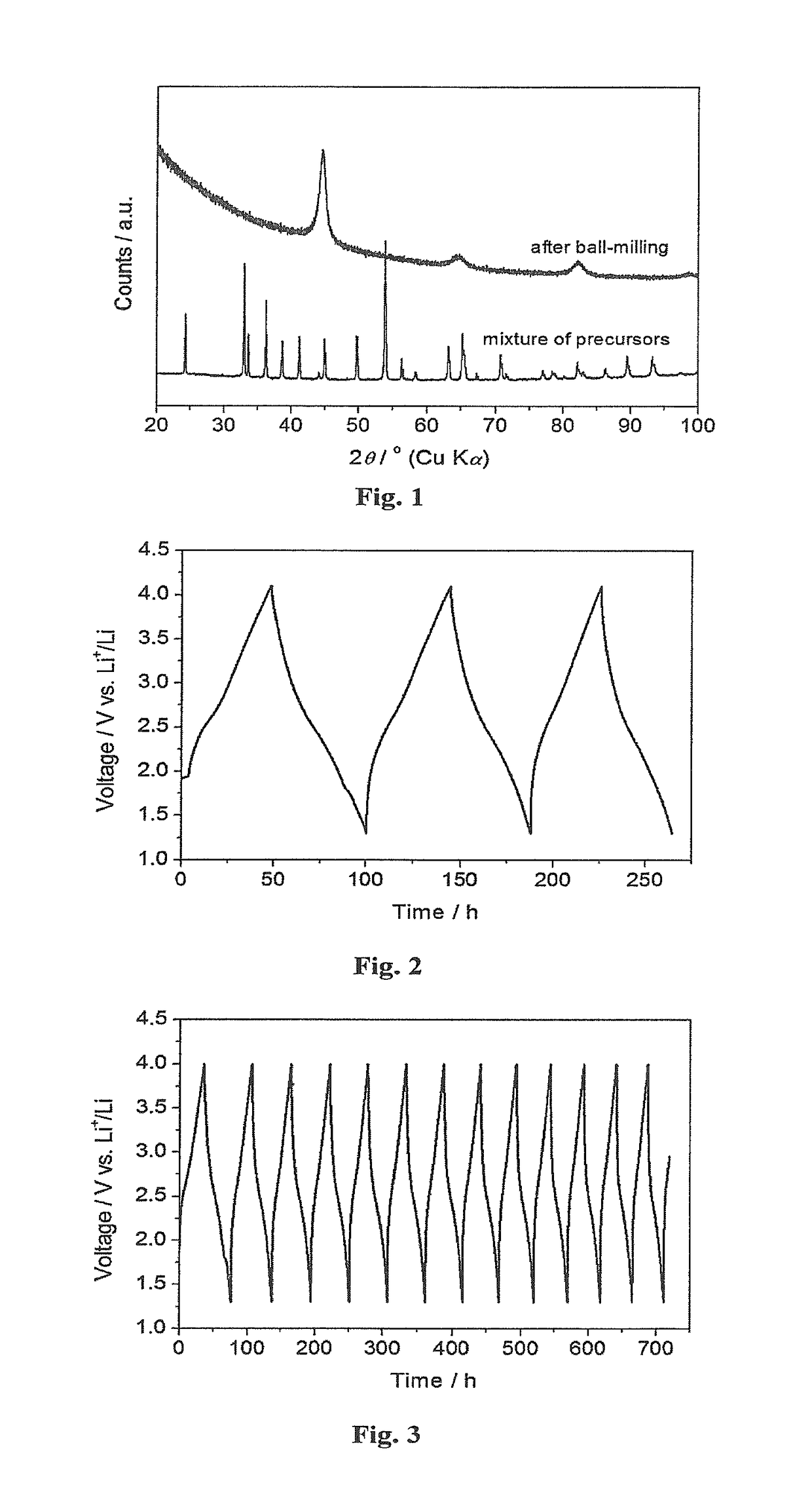

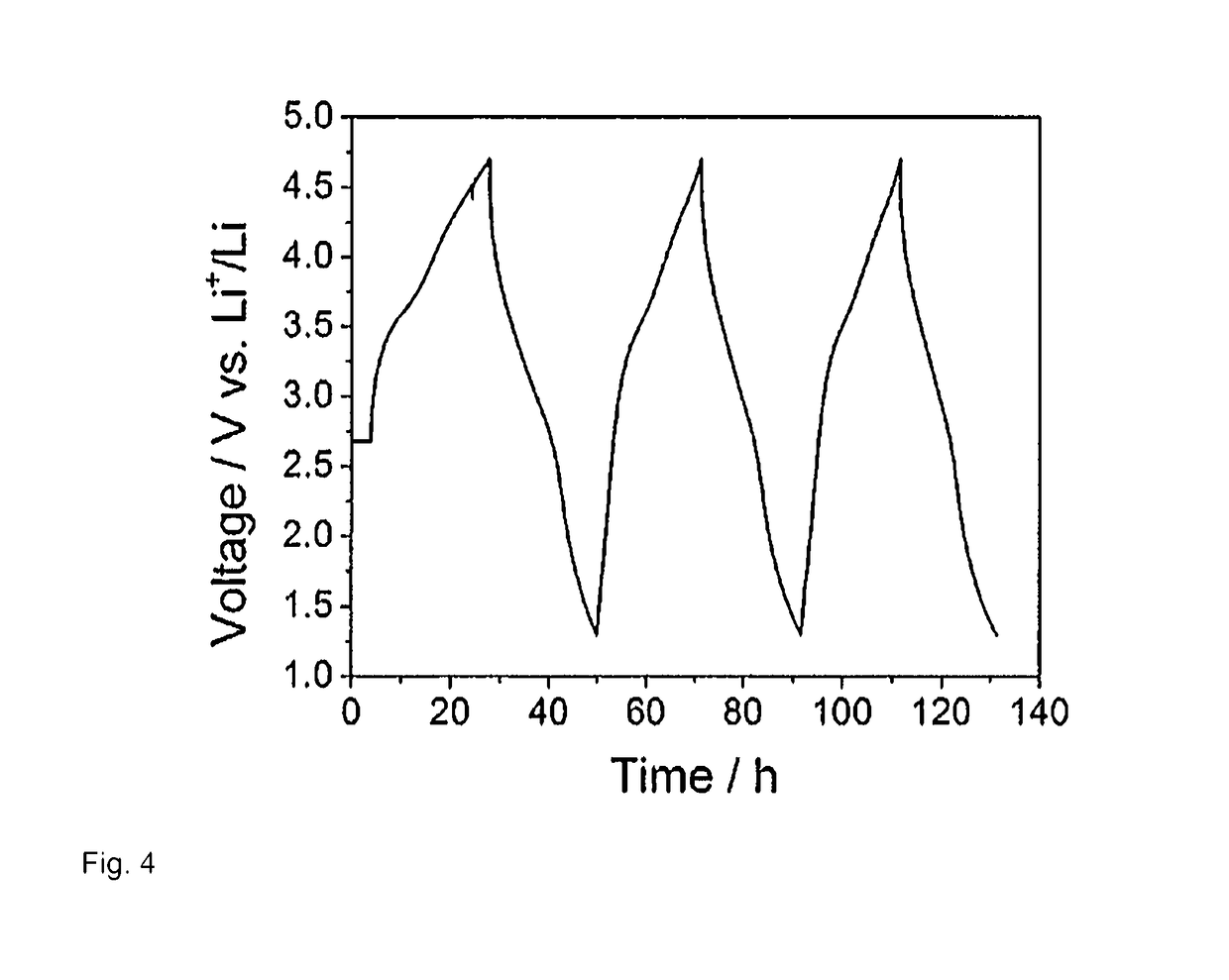

Oxyfluoride compounds for lithium-cells and batteries

InactiveUS10199647B2Improve featuresHigh materialTungsten halidesTungsten oxides/hydroxidesMedicinal chemistryCathode material

The present invention concerns specific new compounds of formula Li(2−x)Na(x)MO(2−y / 2)F(1+y) (where 0≤x≤0.2 and −0.6≤y≤0,8 and M is a transition metal), cathode material comprising the new compounds, batteries and lithium-cells comprising said new compound or cathode material, a process for the production of the new compound and their use.

Owner:KARLSRUHER INST FUR TECH

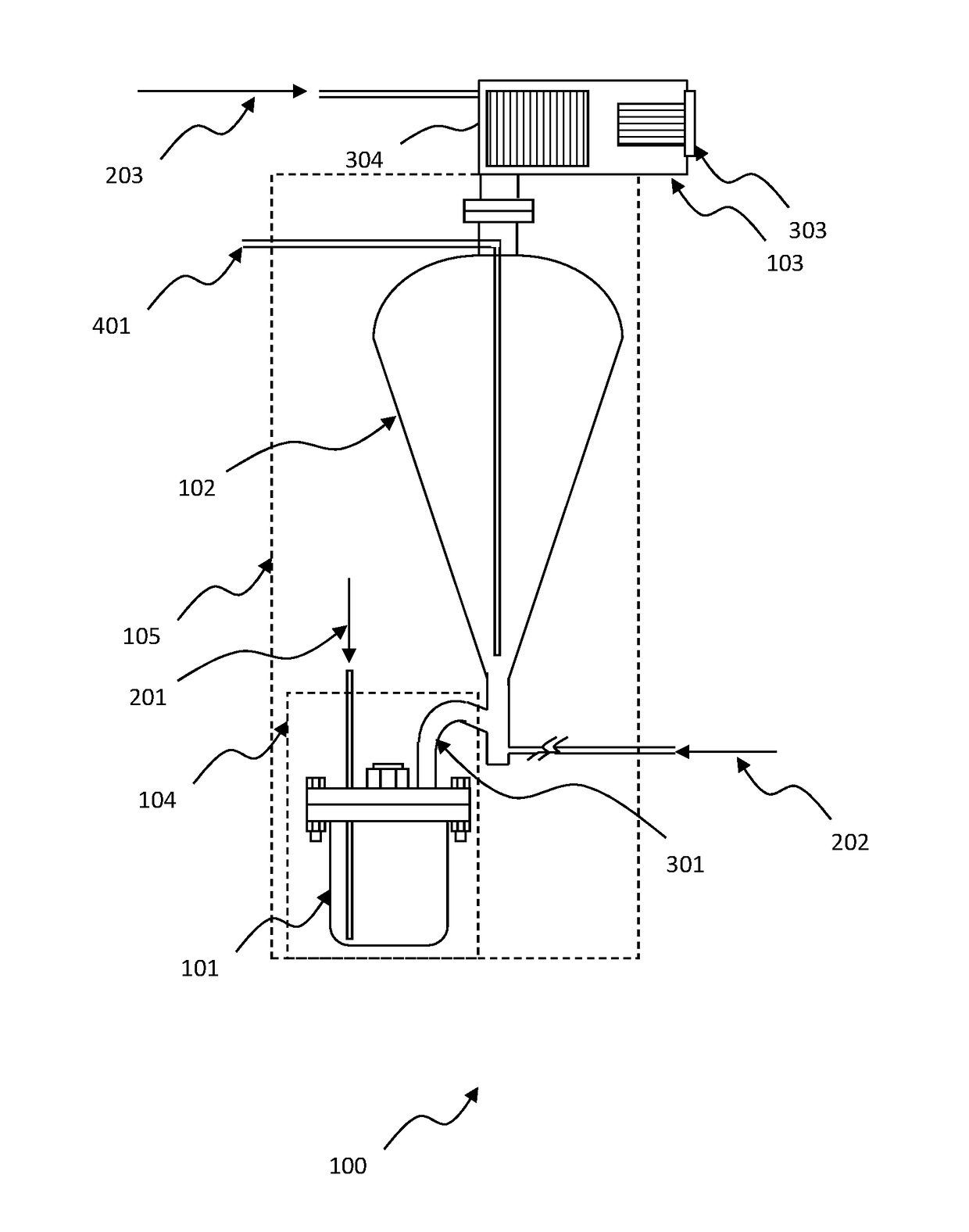

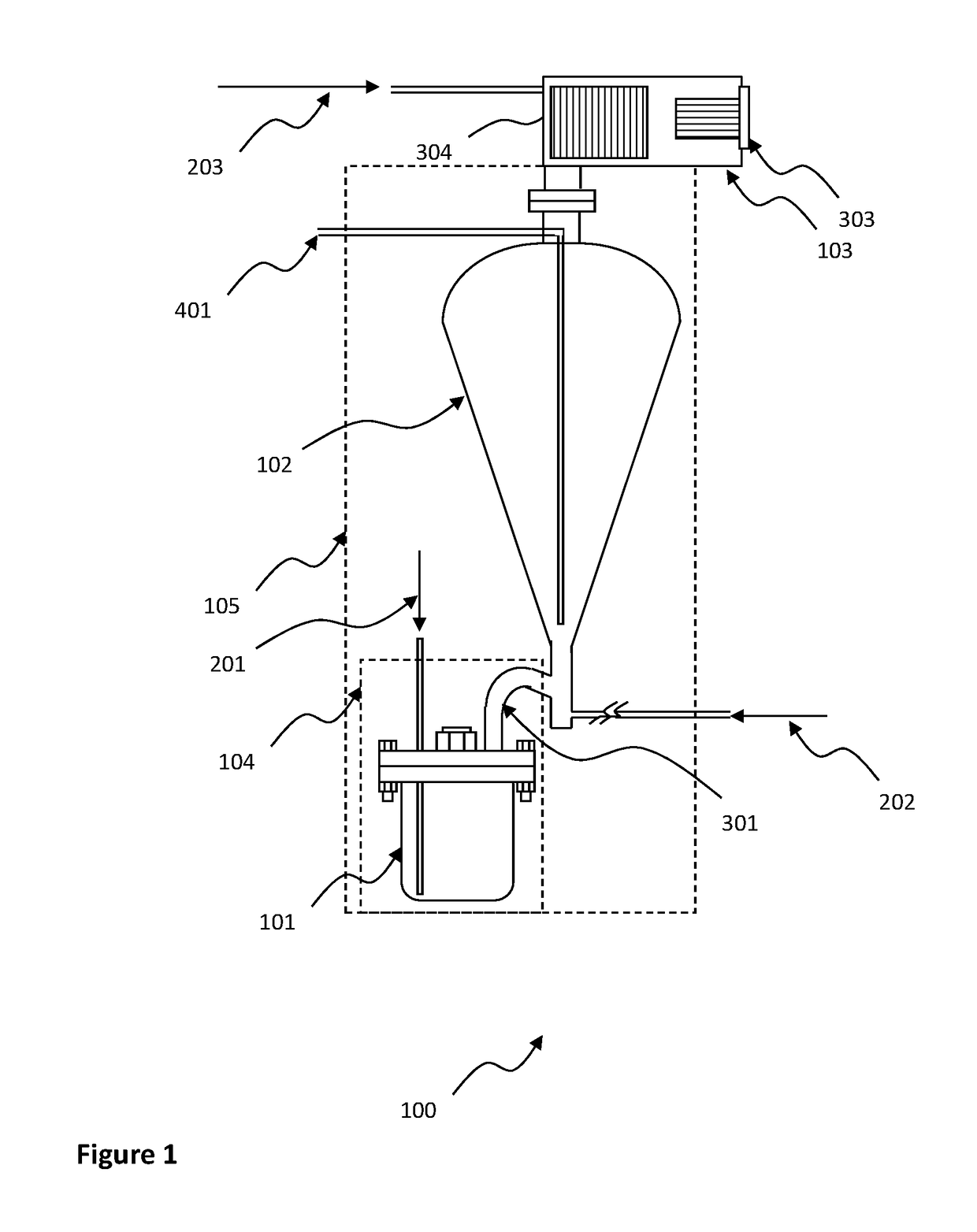

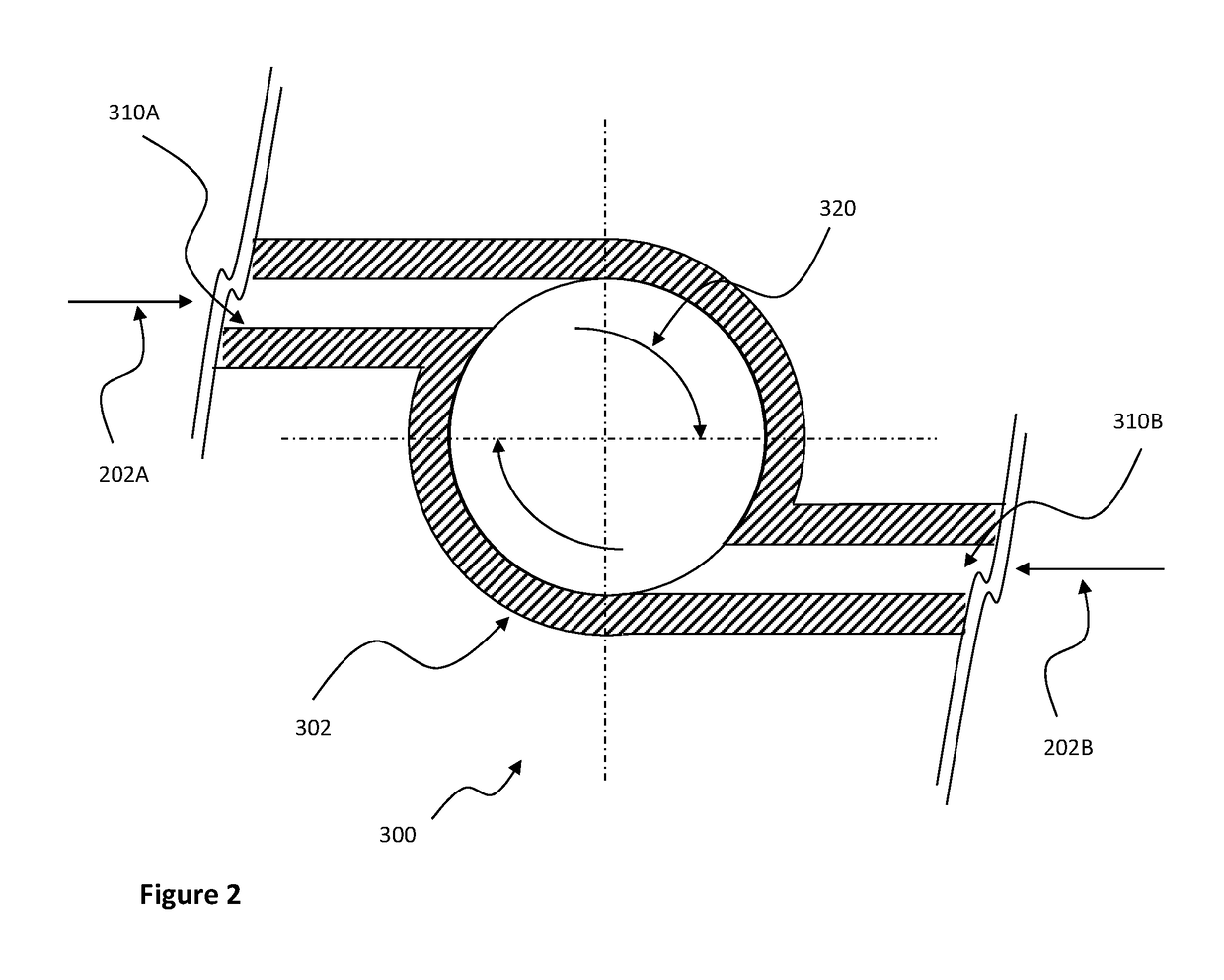

Fluidized bed synthesizing device for tungsten hexafluoride

The invention discloses a fluidized bed synthesizing device for tungsten hexafluoride and belongs to the technical field of preparation devices for tungsten hexafluoride. The fluidized bed synthesizing device comprises a fluidized bed reactor, a material feeding pipe, a material conveying pipe, a gas inlet pipe, a nitrogen purging gas tank, a quantitative hopper, a heater, a condenser, a collecting tank, an air compressor, a buffer tank and a fluorine-containing mixing gas tank, wherein a feeding opening, a gas inlet and an exhaust outlet are formed in the fluidized bed reactor; the feeding opening is connected with the quantitative hopper by the material feeding pipe; the exhaust outlet is connected with the condenser by the material conveying pipe; the gas inlet is connected with the fluorine-containing mixing gas tank by the gas inlet pipe; the nitrogen purging gas tank is communicated with the quantitative hopper by a pipeline; a liquid outlet of the condenser is communicated withthe collecting tank through the pipeline; an outlet in the tail end of the condenser is sequentially connected with the air compressor and the buffer tank through the pipeline; and the buffer tank iscommunicated with the gas inlet pipe through the pipeline. The fluidized bed synthesizing device disclosed by the invention has the advantages that frequent addition of the material is not needed; a metal tungsten powder is in a fluidized state; the preparation efficiency is high and the collection is simple; and no tungsten powder is entrained.

Owner:SHANGHAI HELI IND GAS CO LTD

Adsorption tower for preparing high purity tungsten hexafluoride and using method thereof

The invention discloses an adsorption tower for preparing high purity tungsten hexafluoride and a using method thereof.The adsorption tower is a tower body of a hierarchy structure.The tower body is divided into the upper-level tower body and the lower-level tower body through screen plates.The first-level tower body (14) is formed in the space between the bottom screen plate (15) and the middle screen plate (12).A gas inlet (1) is formed below the bottom screen plate (15).The second-level tower body (6) is formed in the space above the middle screen plate (12).The first-level tower body is filled with metal packing.The second-level tower body is provided with cooling coil (5) and filled with an alkali metal fluoride adsorbing agent.The cooling coil is provided with a refrigerant inlet (4) and a refrigerant outlet (7).The bottom end of the tower body is a sealing head (16).The top end of the tower body is a blind plate (9).A gas outlet (8) is formed in the blind plate.A heating sleeve is arranged on the outer side wall of the tower body in a matched mode.The content of HF and MoF6 in tungsten hexafluoride adsorbed by the adsorption tower is low, and tungsten hexafluoride in the alkali metal fluoride adsorbing agent can be recycled.

Owner:昊华气体有限公司

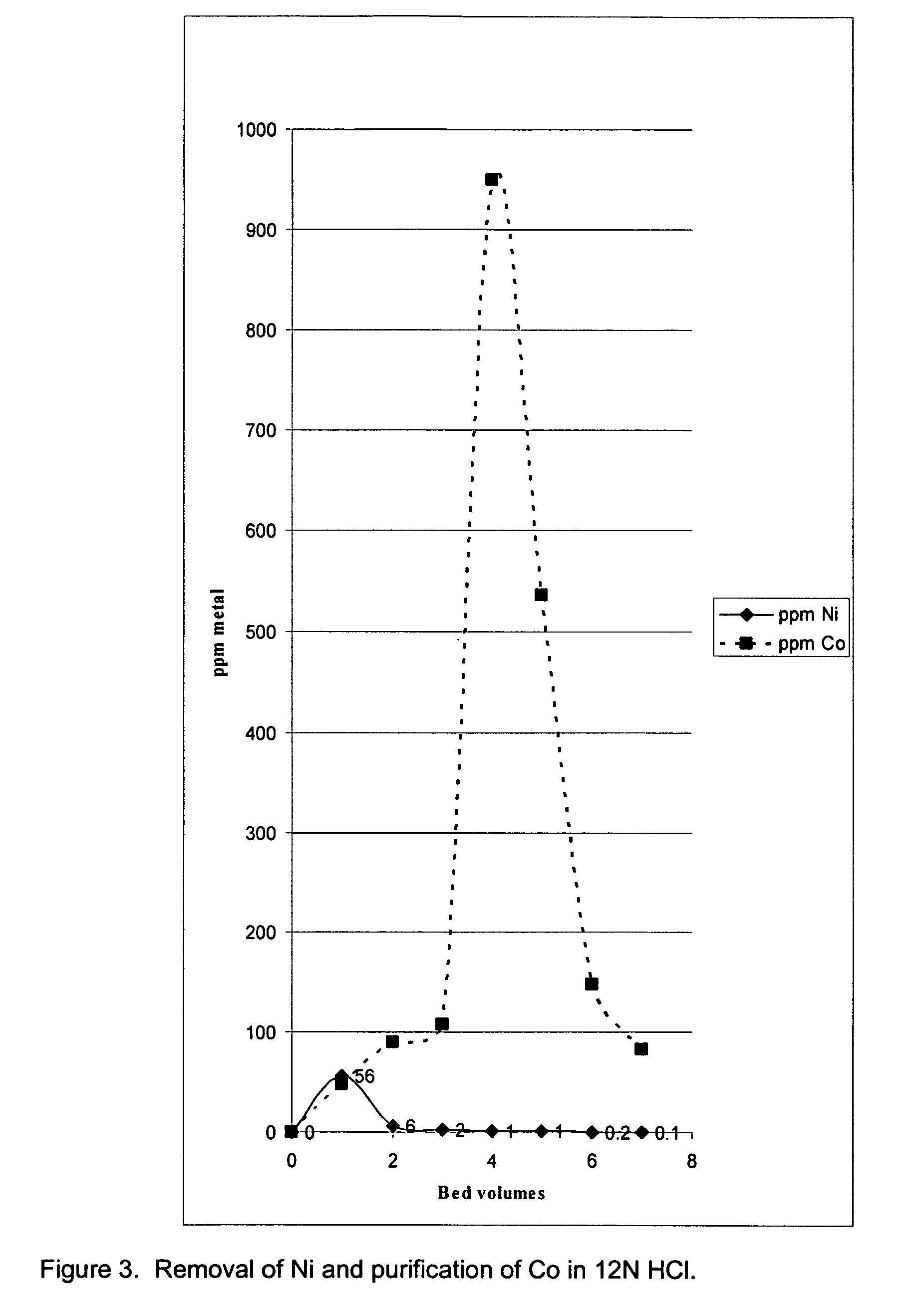

Process for the extraction of specific transition metals with gaseous HCL

A process is disclosed for separation and recovery of vanadium, molybdenum, iron, tungsten, cobalt and nickel from alumina-based materials, mattes, ores, manufacturing by-products and waste. These elements are oxidized. The oxides are reacted with gaseous HCl to form volatile chloride-bearing compounds that subsequently sublimate. The volatile compounds are condensed in a downward-stepped thermal gradient that allows collection of moderate to high purity compounds of individual elements with exception of a nickel-cobalt co-condensate. Nickel is separated from cobalt by precipitation of nickel chloride from concentrated HCl pressurized with gaseous HCl.

Owner:METALS RECOVERY TECH

Tungsten hexafluoride synthesis method

The invention discloses a tungsten hexafluoride synthesis method. The method includes: well mixing tungsten powder with metal fluorides in a reactor; feeding fluorine gas for reactive synthesis of tungsten hexafluoride; after condensation gas-liquid separation of unreacted raw material fluorine gas and product tungsten hexafluoride, returning to the reactor for circular reaction. By reaction of cyclic fluoride gas and tungsten powder in existence of the metal fluorides, reaction efficiency is effectively improved, waste of raw material fluorine gas is reduced, and required volume of the reactor is effectively decreased.

Owner:欧中电子材料(重庆)有限公司

Popular searches

Ion-exchanger regeneration Group 8/9/10/18 element organic compounds Hydrocarbon by metathesis reaction Group 6/16 element organic compounds Titanium halides Bulk chemical production Hydrocarbon by hydrocarbon cracking Tin organic compounds Organic-compounds/hydrides/coordination-complexes catalysts Ruthenium/rhodium/palladium/osmium/iridium/platinum compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com