Preparation method for tungsten hexafluoride gas

A technology of tungsten hexafluoride and gas, which is applied in the field of preparing tungsten hexafluoride by cutting waste tungsten, can solve the problems affecting the purity of high-purity tungsten hexafluoride gas and the high cost of high-purity tungsten hexafluoride, and achieve the recovery rate High, less controllable parameters, less consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

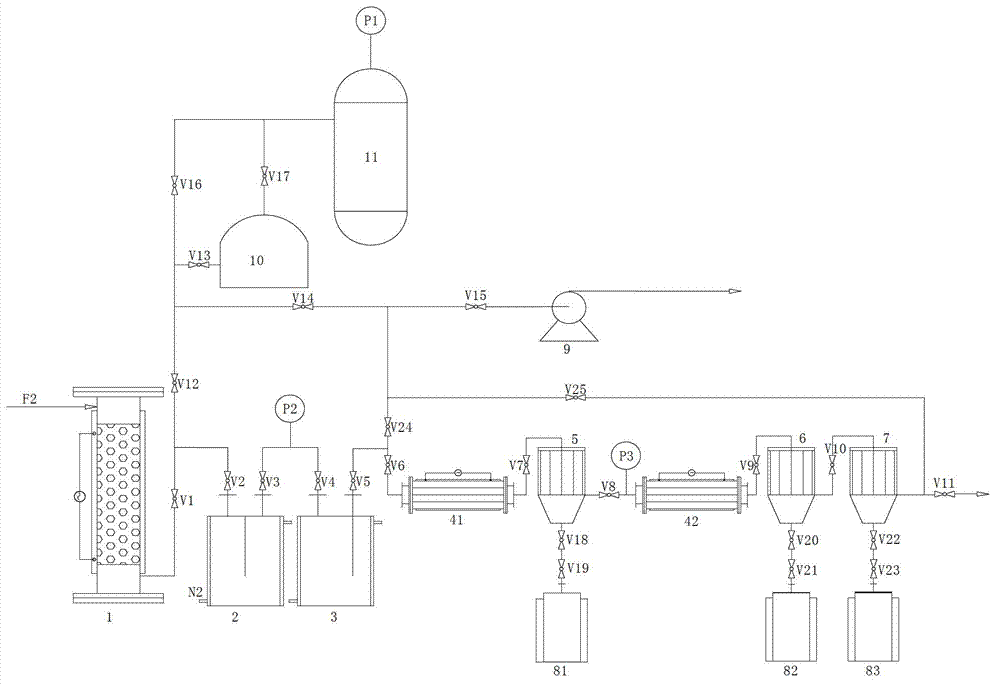

[0024] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0025] seefigure 1 , hydrogen fluoride is passed into the electrolytic cell for electrolytic fluorine production, and the generated low-purity fluorine gas is purified through the purification tower 1, the first cryogenic tank 41 and the second cryogenic tank 42 in sequence, and the purified fluorine gas is passed into the reaction The system reacts to generate crude tungsten hexafluoride, and the raw material tungsten is tungsten scrap; the diameter of the tungsten scrap can be 4-10mm, the length can be 5-20mm, and the purity of the tungsten scrap is above 99.9%. , which is conducive to the preparation of high-purity tungsten hexafluoride gas;

[0026] First degrease the entire tungsten hexafluoride production system equipment and pipelines with acetone, then clean them with ultrapure water, dry them and install them, then put the waste tungsten into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com