Patents

Literature

123 results about "Tungsten hexafluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten(VI) fluoride, also known as tungsten hexafluoride, is an inorganic compound with the formula WF₆. It is a toxic, corrosive, colorless gas, with a density of about 13 g/L (roughly 11 times heavier than air.) It is one of the densest known gases under standard conditions. WF₆ is commonly used by the semiconductor industry to form tungsten films, through the process of chemical vapor deposition. This layer serves as a low-resistivity metallic "interconnect". It is one of seventeen known binary hexafluorides.

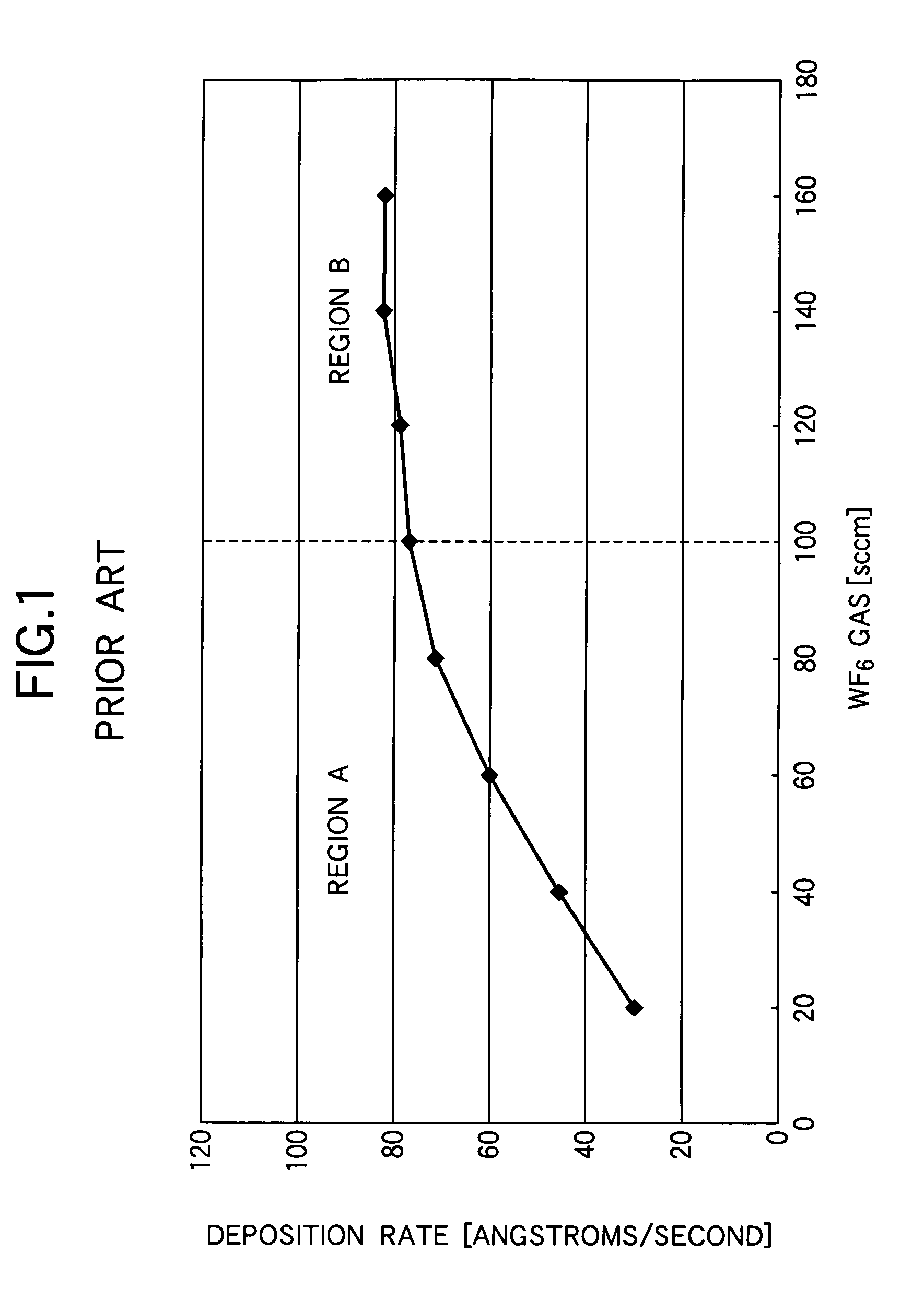

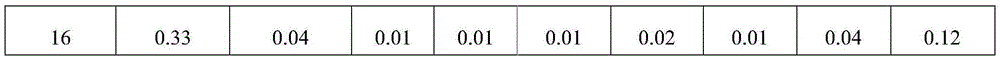

Low temperature high pressure high H2/WF6 ratio W process for 3D NAND application

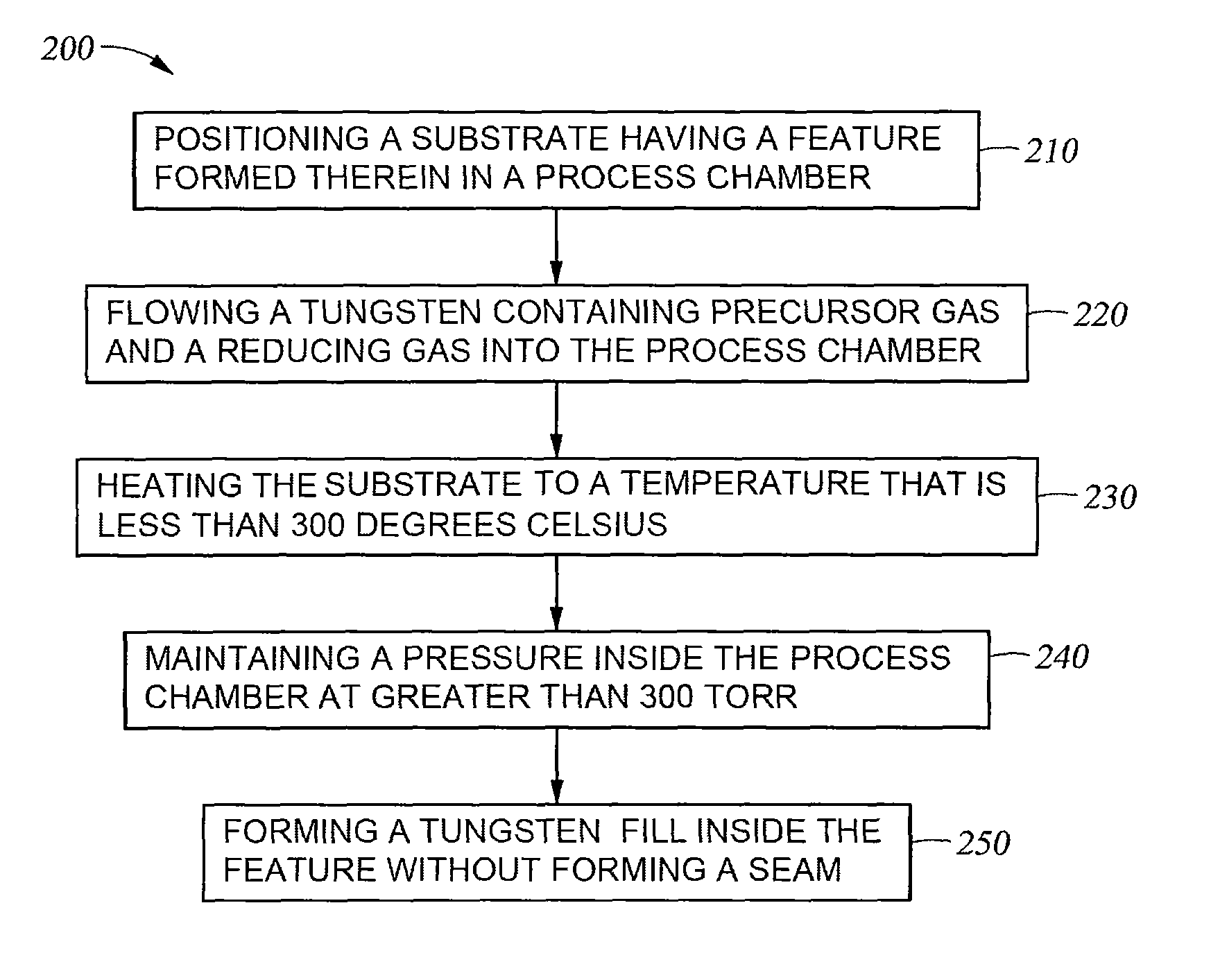

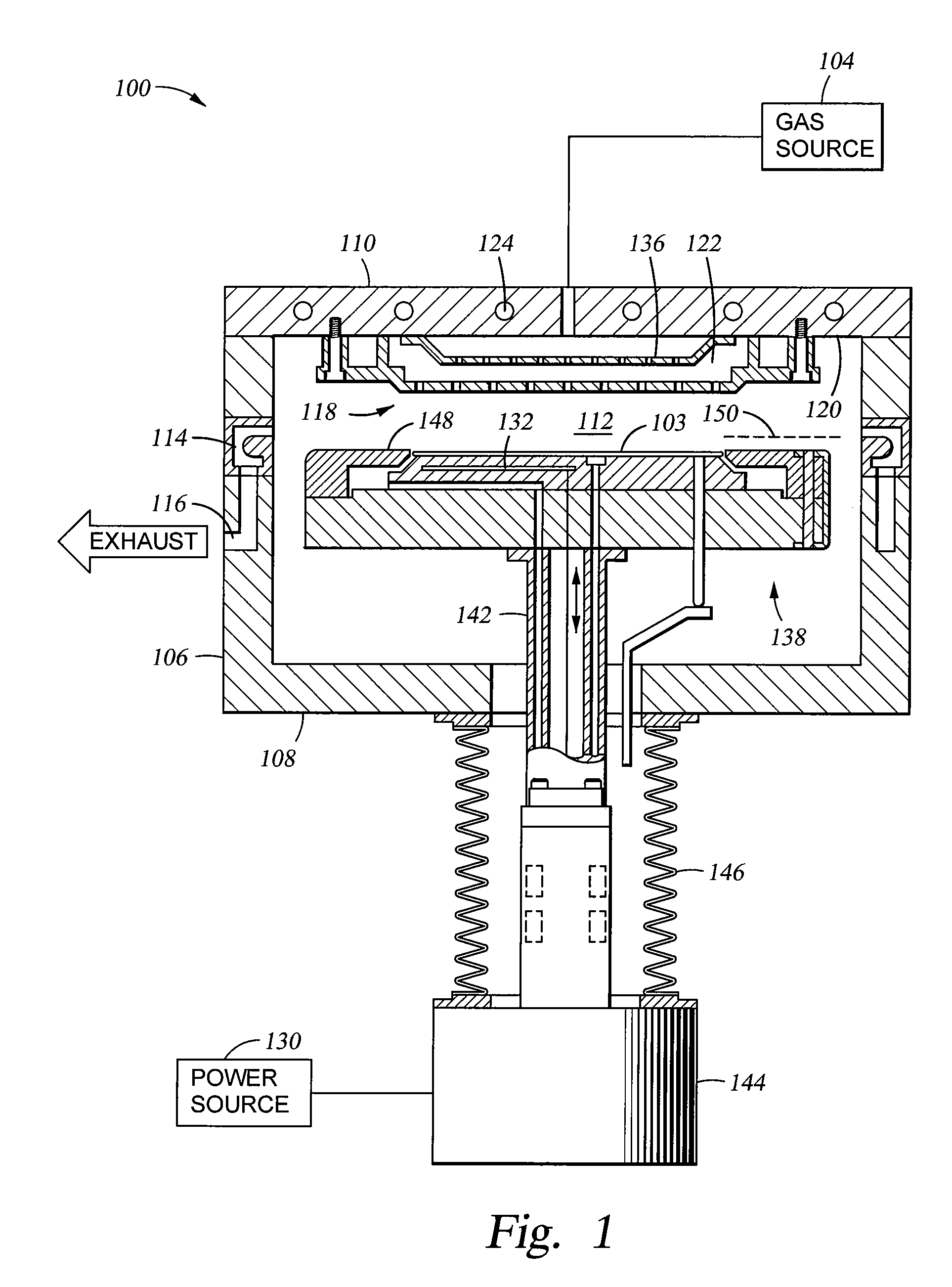

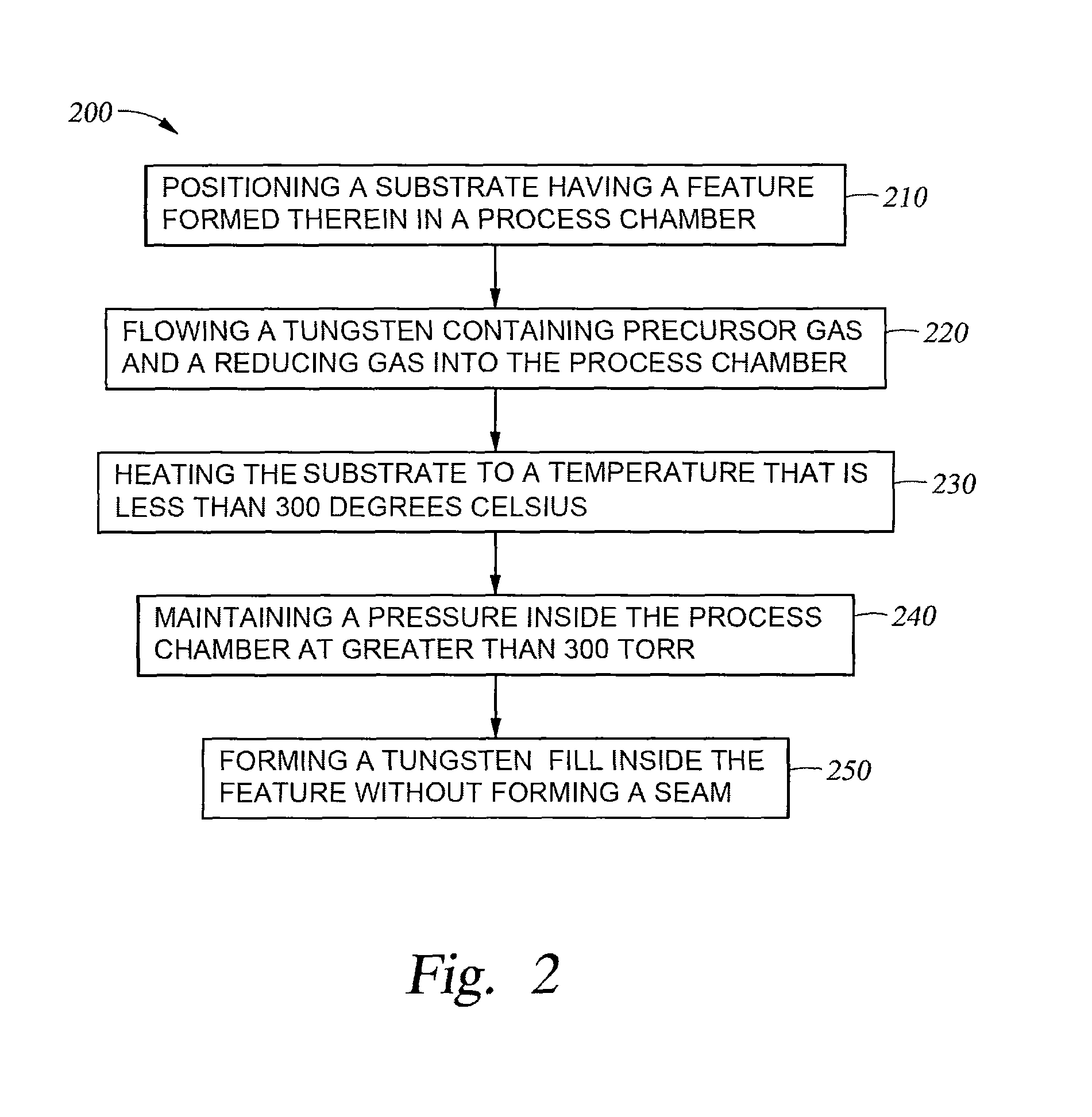

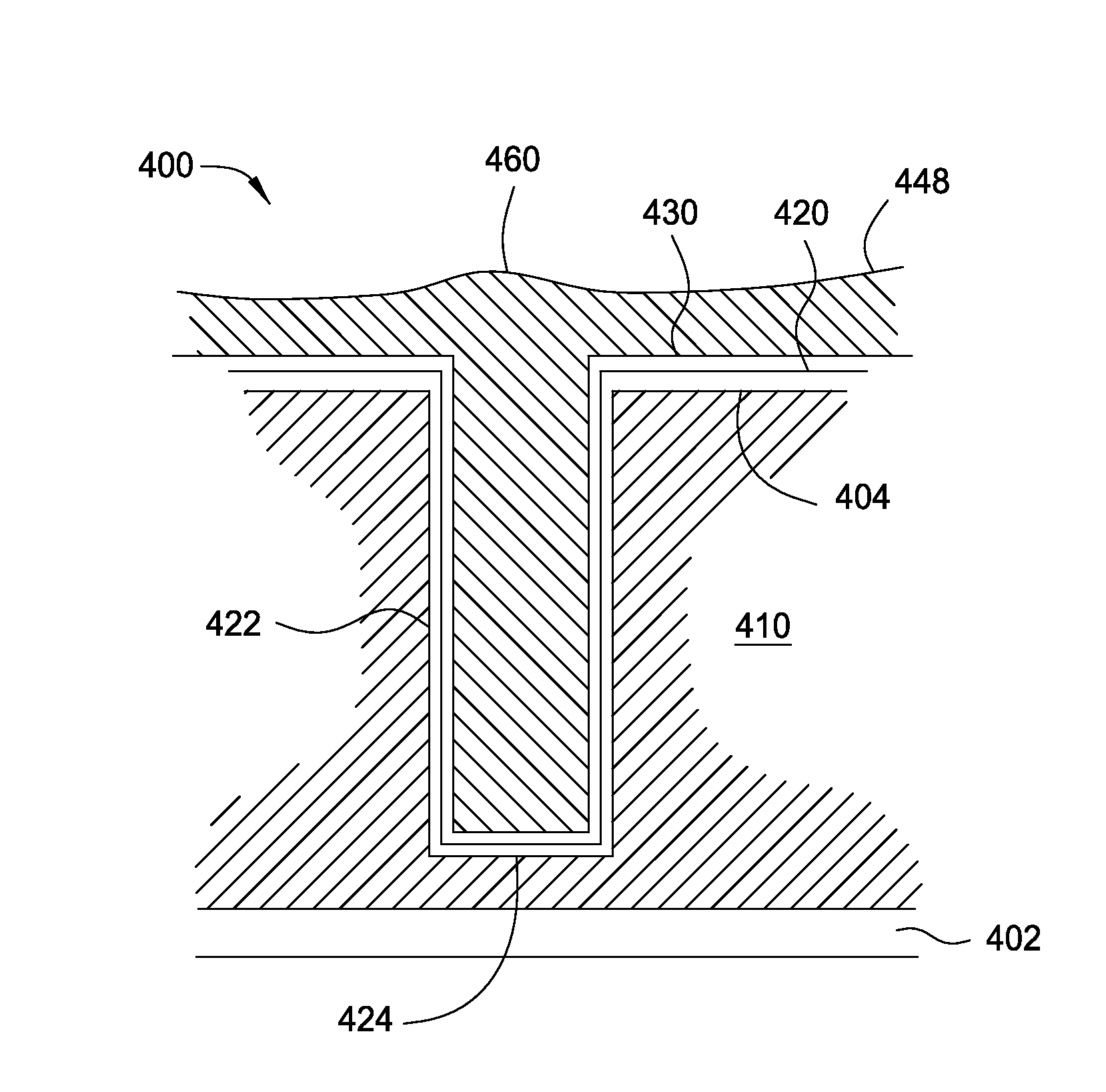

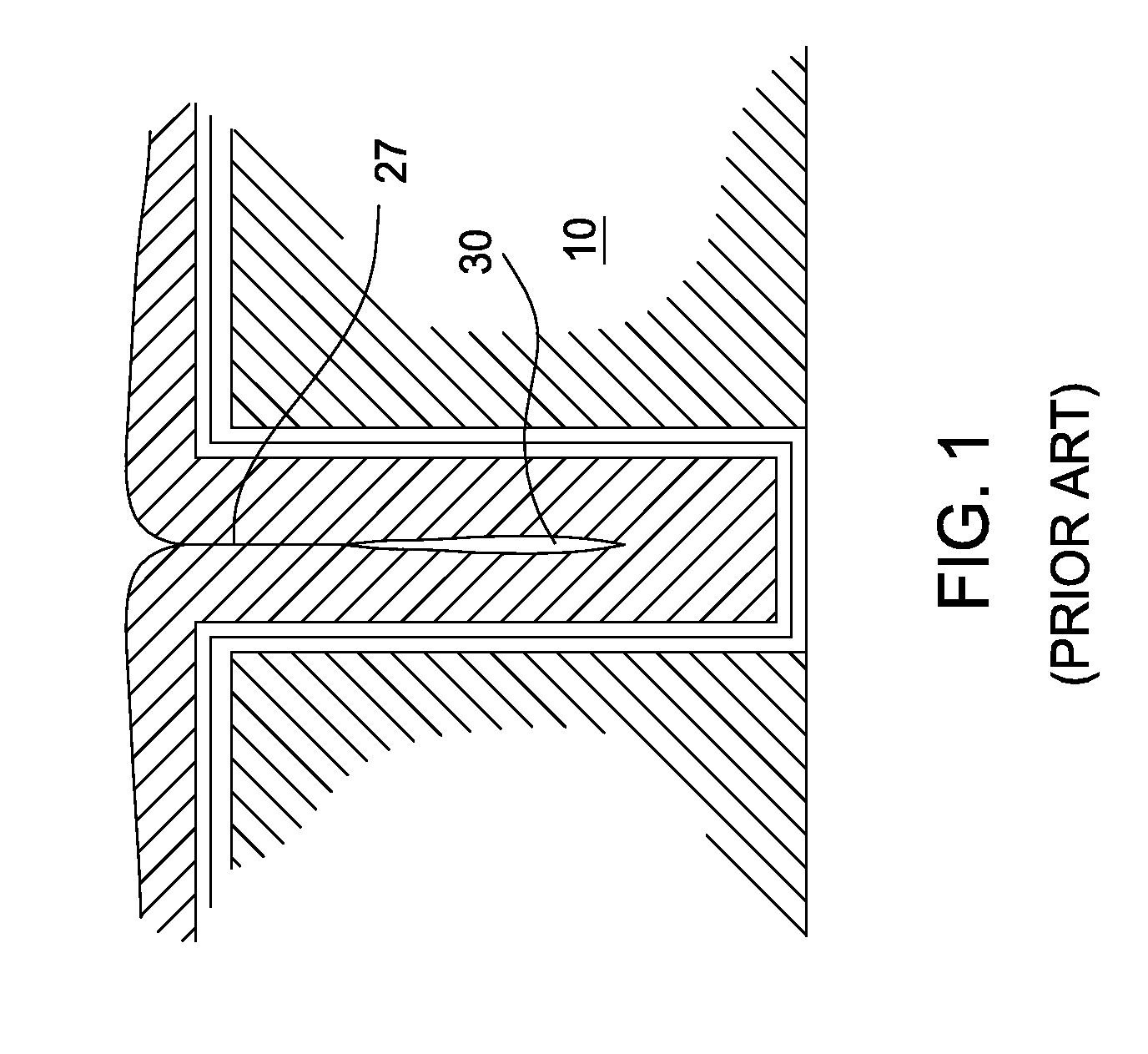

ActiveUS8900999B1Semiconductor/solid-state device manufacturingCelsius DegreeThermal chemical vapor deposition

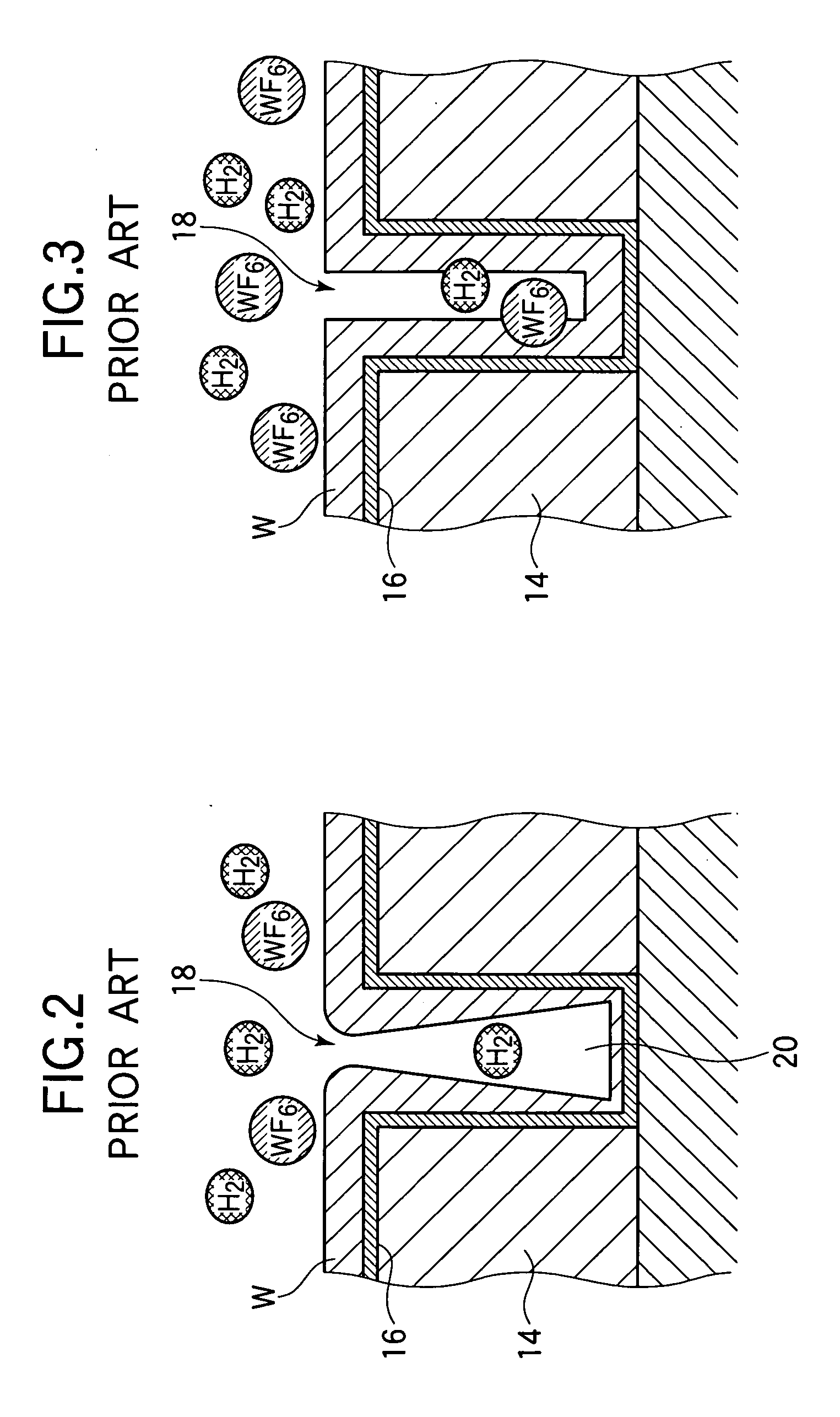

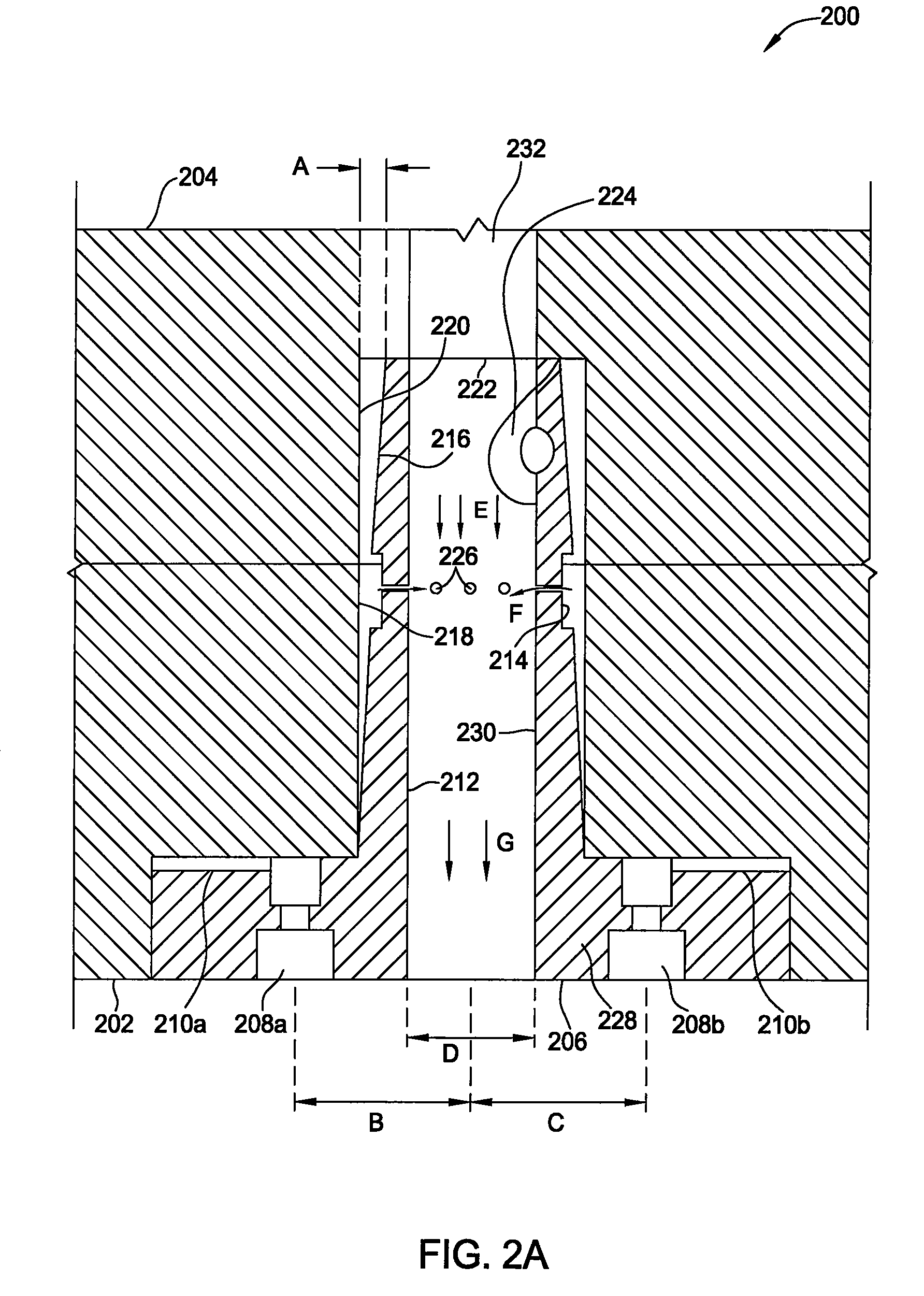

A method of filling a feature in a substrate with tungsten without forming a seam is presented. The tungsten is deposited by a thermal chemical vapor deposition (CVD) process using hydrogen (H2) and tungsten hexafluoride (WF6) precursor gases. The H2 to WF6 flow rate ratio is greater than 40 to 1, such as from 40 to 1 to 100 to 1. The substrate temperature during deposition is less than 300 degrees Celsius (° C.) and the processing pressure during deposition is greater than 300 Torr.

Owner:APPLIED MATERIALS INC

Tungsten deposition with tungsten hexafluoride (WF6) etchback

ActiveUS20150050807A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseContinuous flow

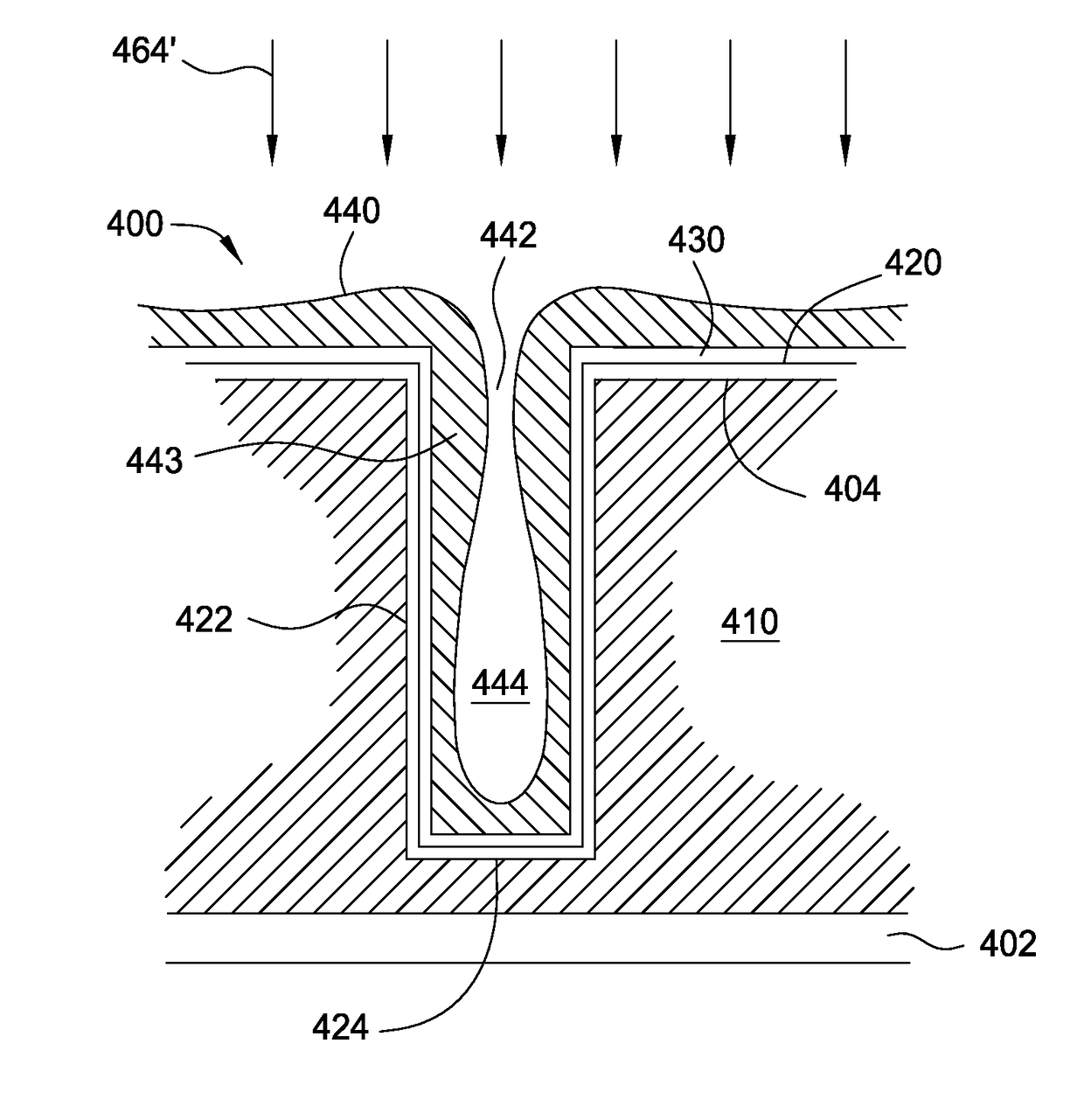

Implementations described herein generally relate to methods for forming tungsten materials on substrates using vapor deposition processes. The method comprises positioning a substrate having a feature formed therein in a substrate processing chamber, depositing a first film of a bulk tungsten layer by introducing a continuous flow of a hydrogen containing gas and a tungsten halide compound to the processing chamber to deposit the first tungsten film over the feature, etching the first film of the bulk tungsten layer using a plasma treatment to remove a portion of the first film by exposing the first film to a continuous flow of the tungsten halide compound and an activated treatment gas and depositing a second film of the bulk tungsten layer by introducing a continuous flow of the hydrogen containing gas and the tungsten halide compound to the processing chamber to deposit the second tungsten film over the first tungsten film.

Owner:APPLIED MATERIALS INC

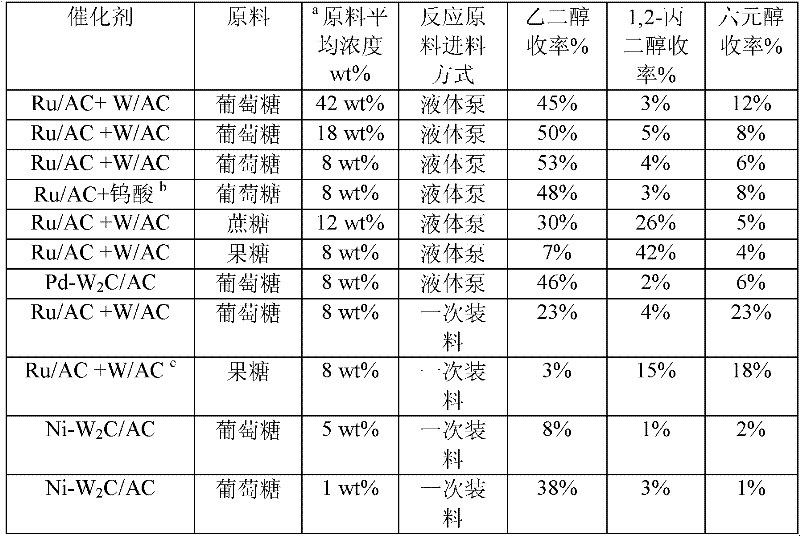

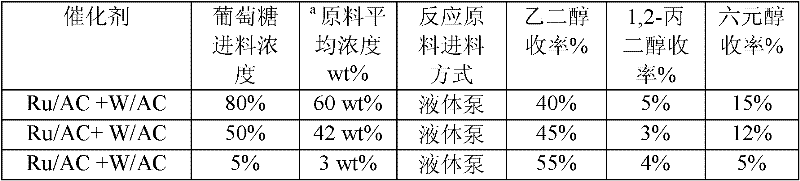

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

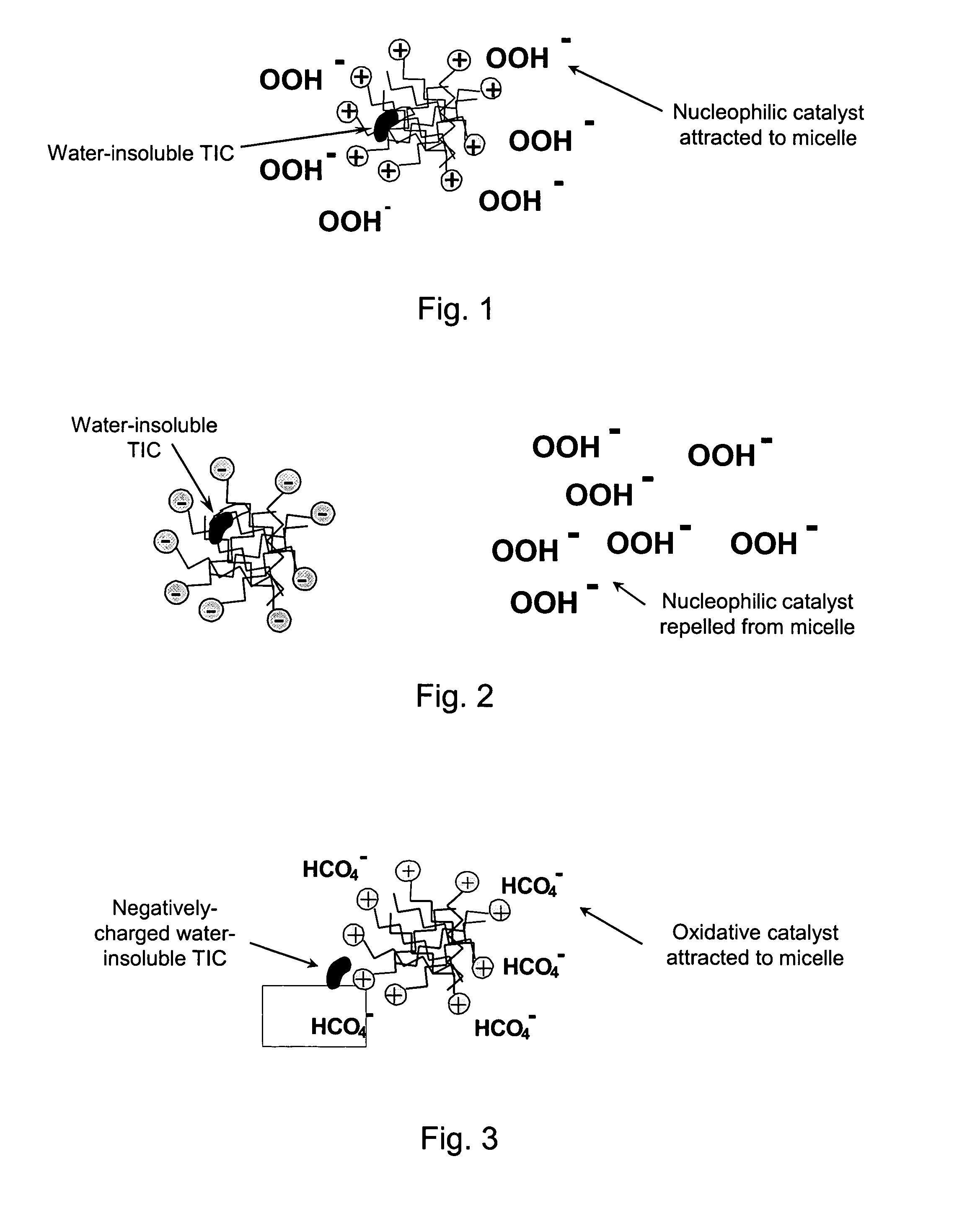

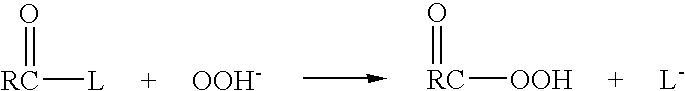

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

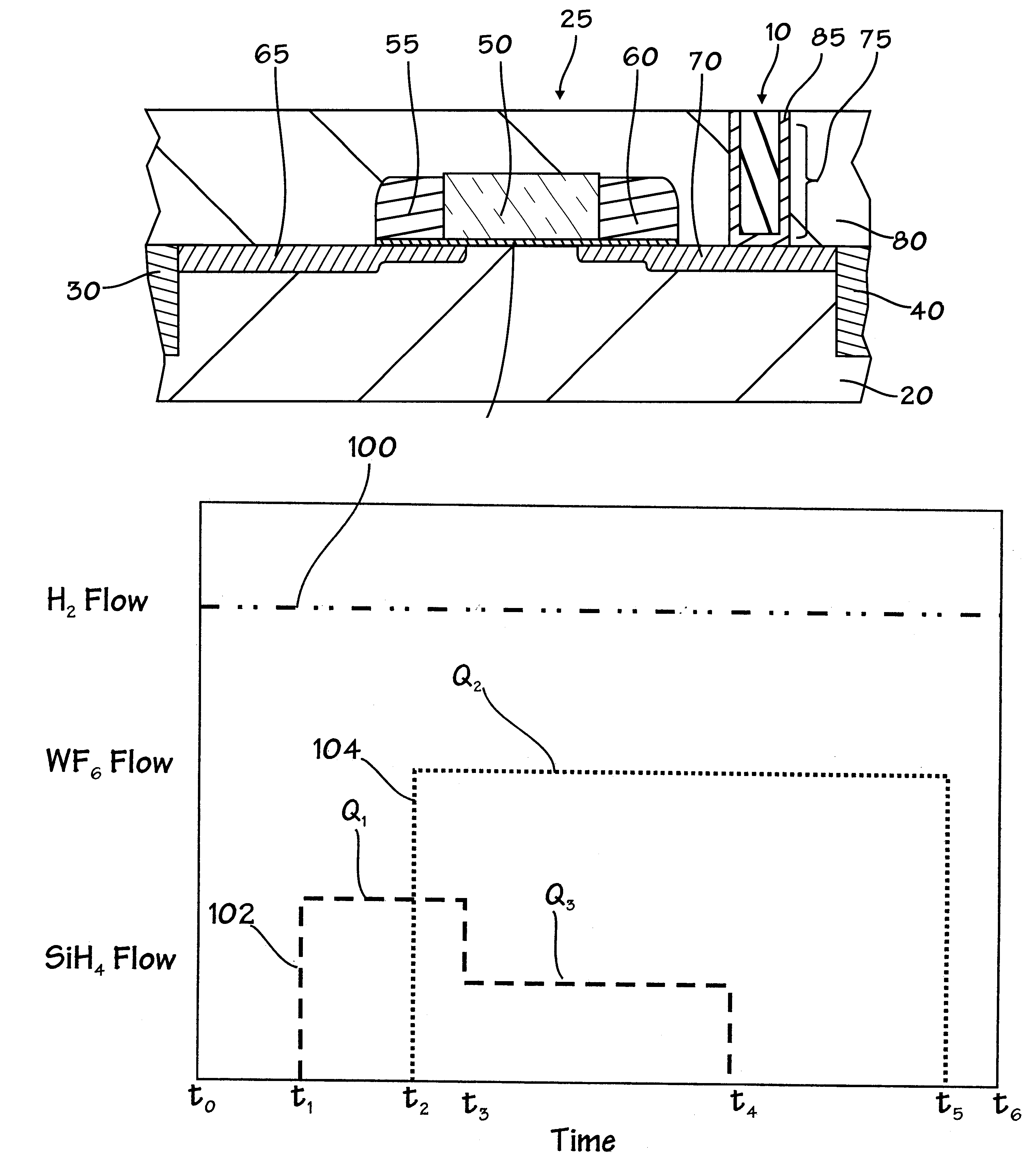

Two-level silane nucleation for blanket tungsten deposition

InactiveUS6277744B1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingElectrical conductorSilanes

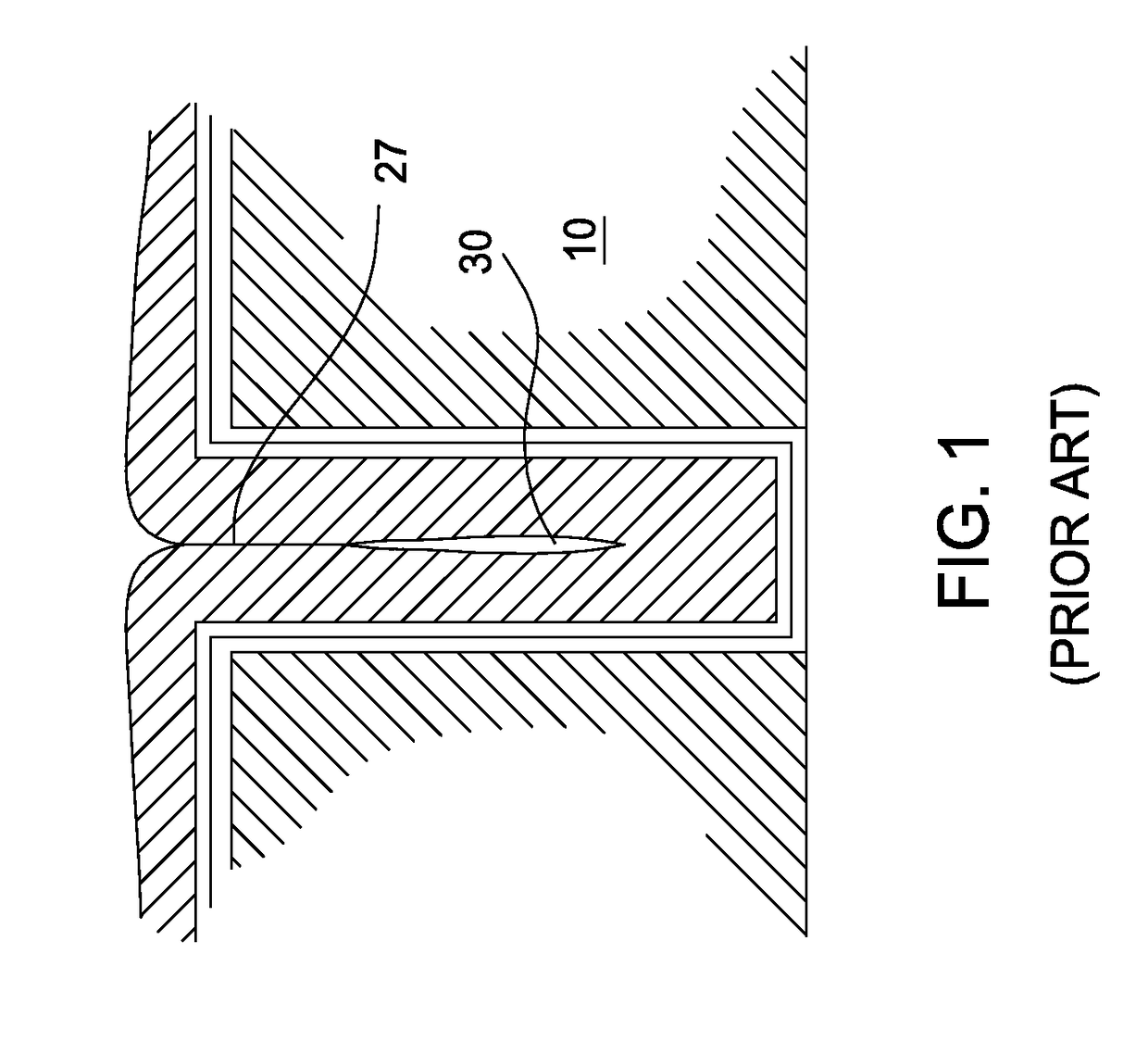

Various methods of fabricating a tungsten conductor structure are provided. In one aspect, a method of fabricating a tungsten conductor structure in an opening in an insulating film is provided that includes forming a titanium nitride film in the opening and heating the a titanium nitride film. The titanium nitride film is exposed to a flow of hydrogen gas and a flow of an inert carrier gas. The titanium nitride film is exposed to a flow of silane at a first flow rate for a first time interval and to a flow of tungsten hexafluoride for a second time interval that begins after the beginning but prior to the end of the first time interval. The flow of silane is reduced at the end of the first time interval to a second flow rate and maintained at the second flow rate for a third time interval. Fluorine diffusion into the titanium nitride film and the potential for void formation due to non-conformal tungsten deposition are reduced.

Owner:ADVANCED MICRO DEVICES INC

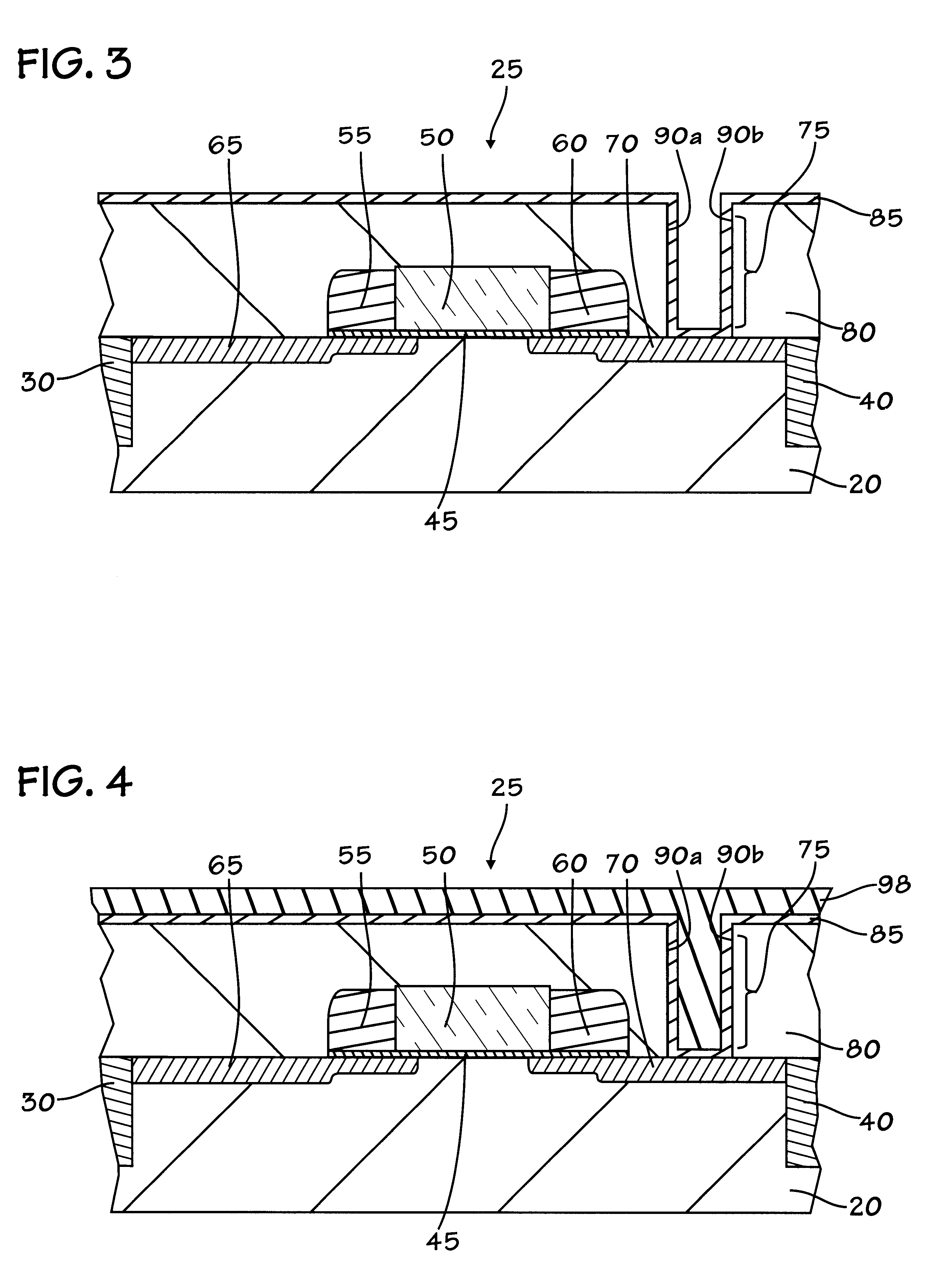

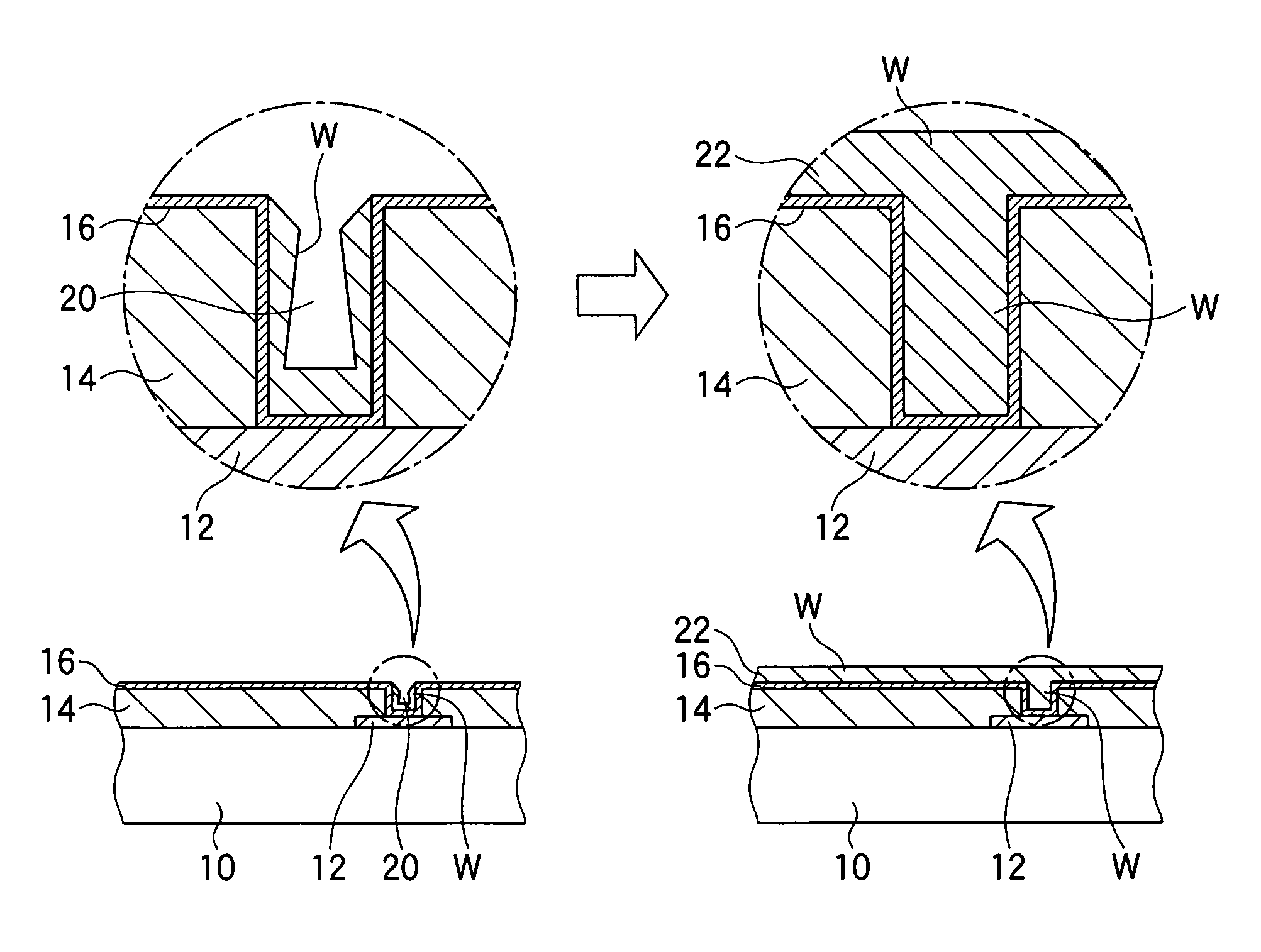

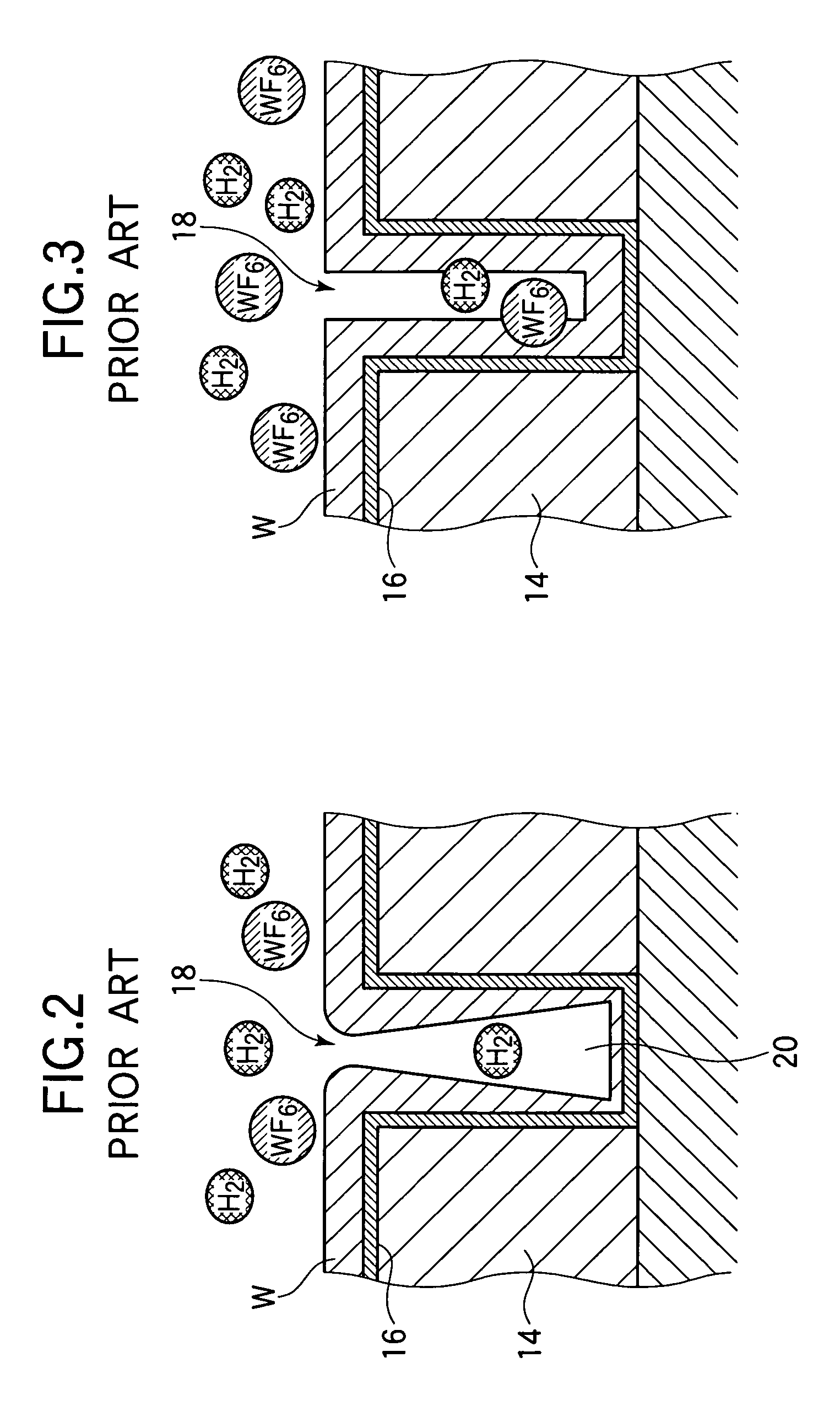

Method of manufacturing a semiconductor device

InactiveUS20100240212A1Novel process is simple and inexpensiveSimple and inexpensiveSemiconductor/solid-state device detailsSolid-state devicesHigh volume manufacturingSemiconductor

A semiconductor device manufacturing method includes a process for filling holes in a dielectric film with tungsten. The process deposits tungsten in the holes, partially etches the deposited tungsten, and then deposits additional tungsten in the holes. Voids that may be left by the first tungsten deposition step are made accessible by openings formed in the etching step, and are then filled in by the second tungsten deposition step. Tungsten hexafluoride may be used as both a deposition source gas and an etching gas, providing a simple and inexpensive process that is suitable for high-volume production.

Owner:LAPIS SEMICON CO LTD

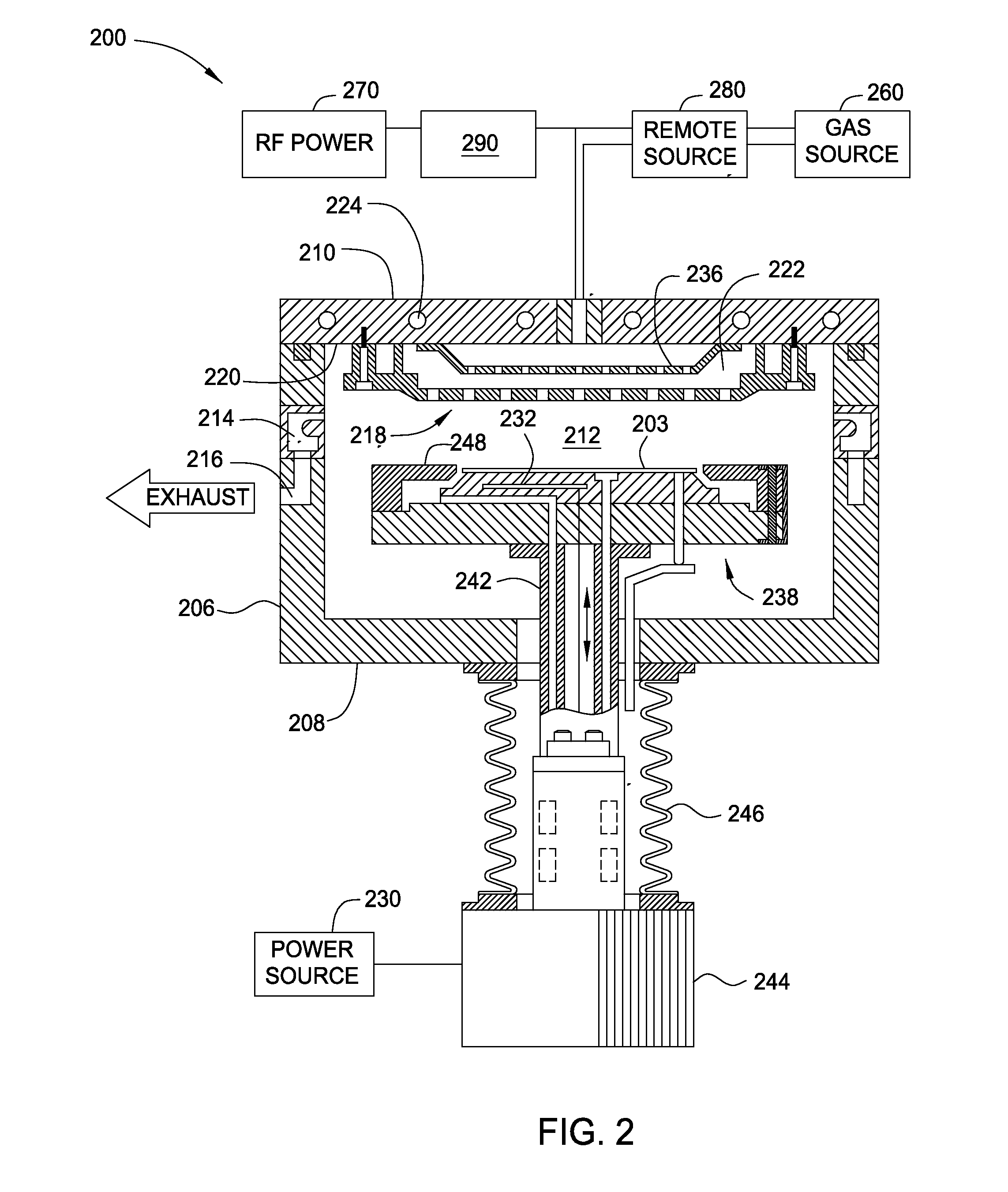

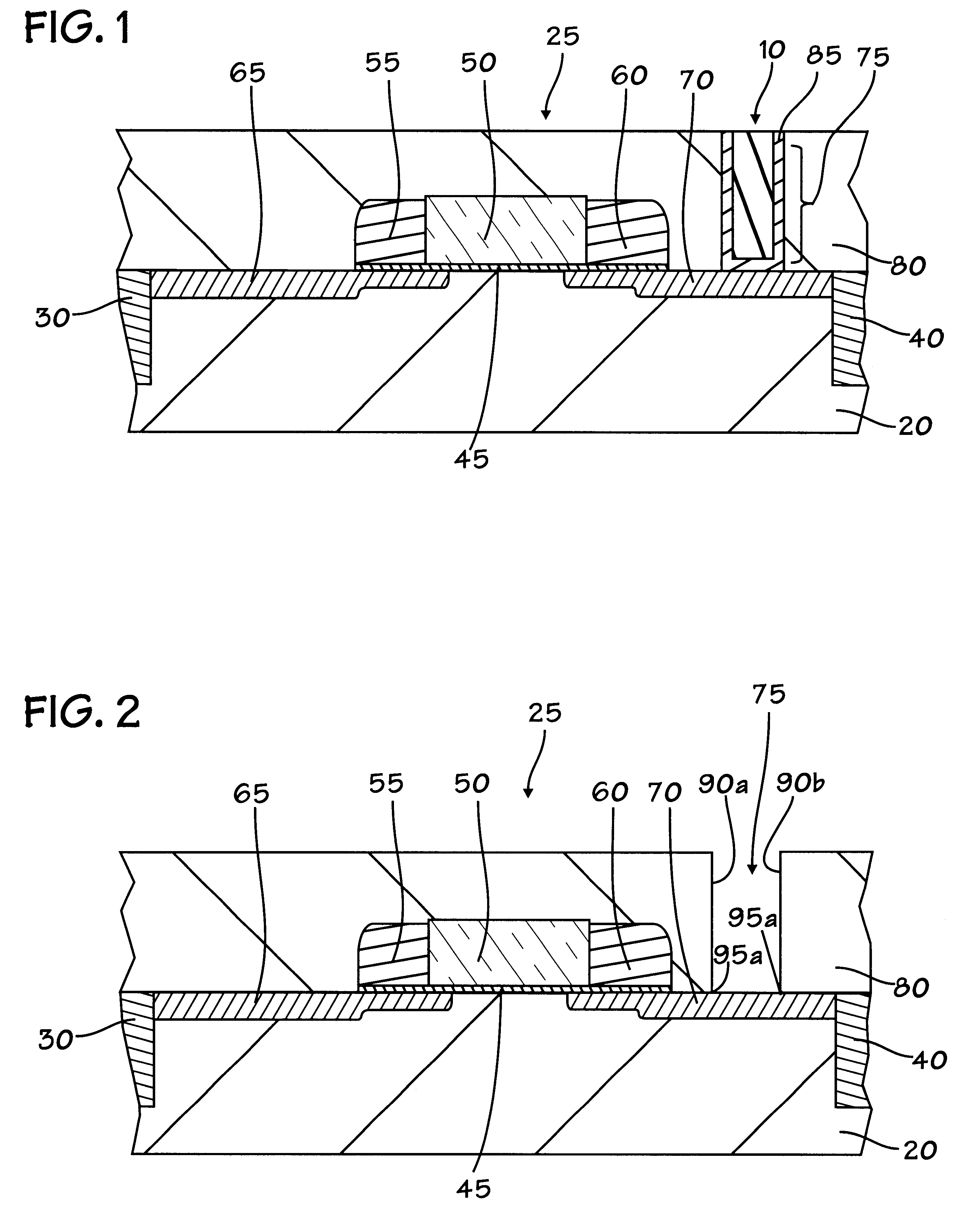

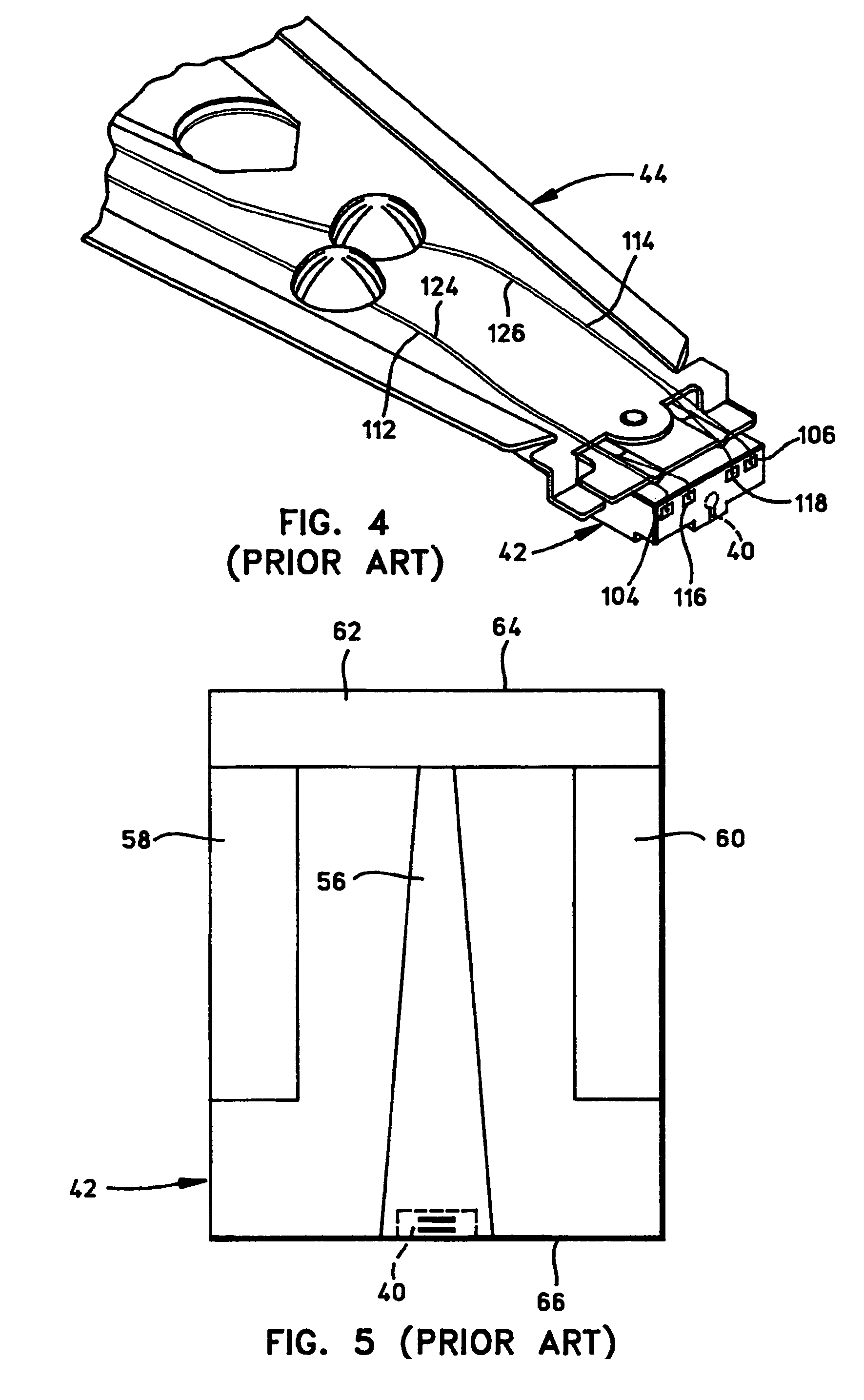

Temperature controlled lid assembly for tungsten nitride deposition

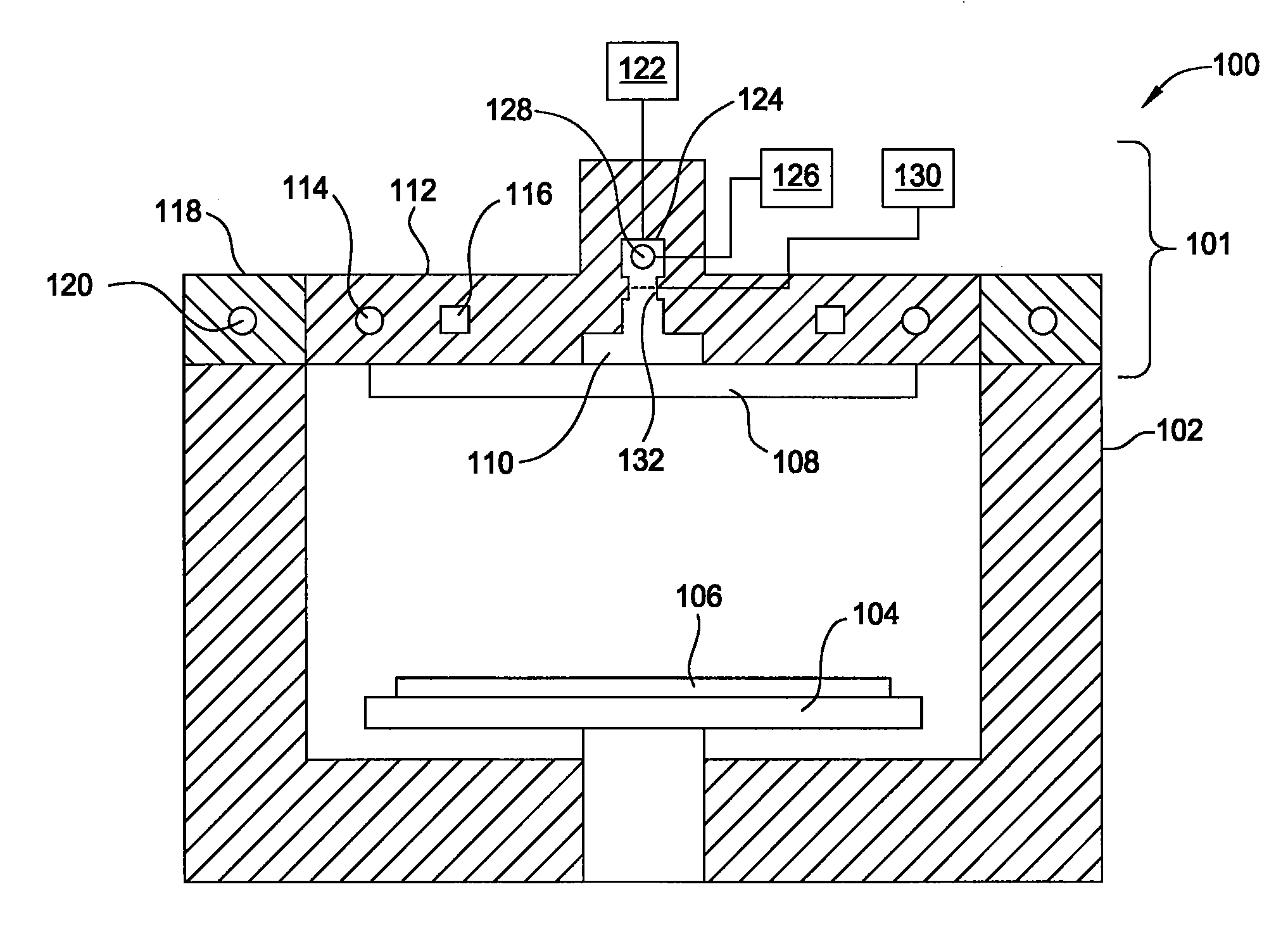

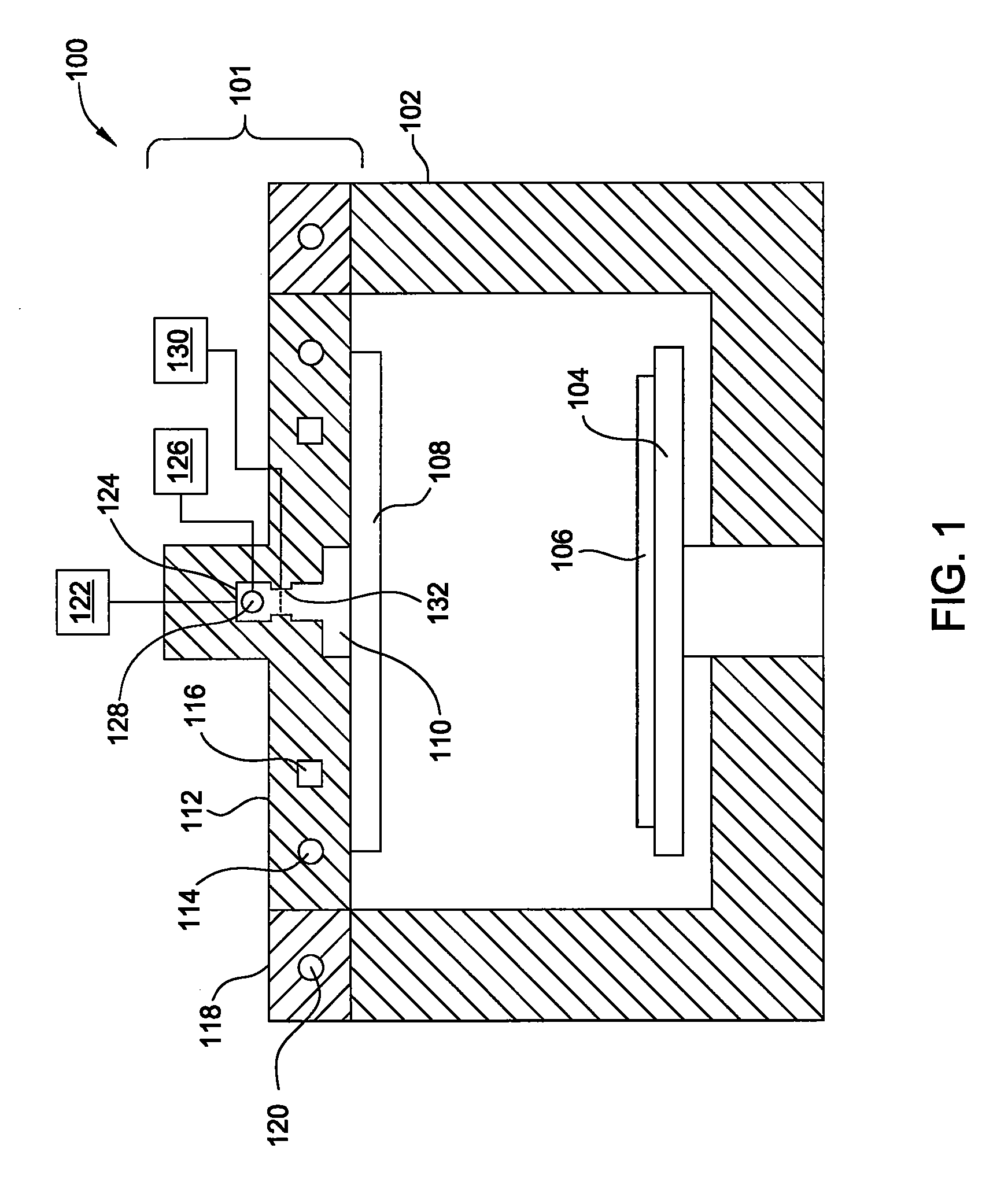

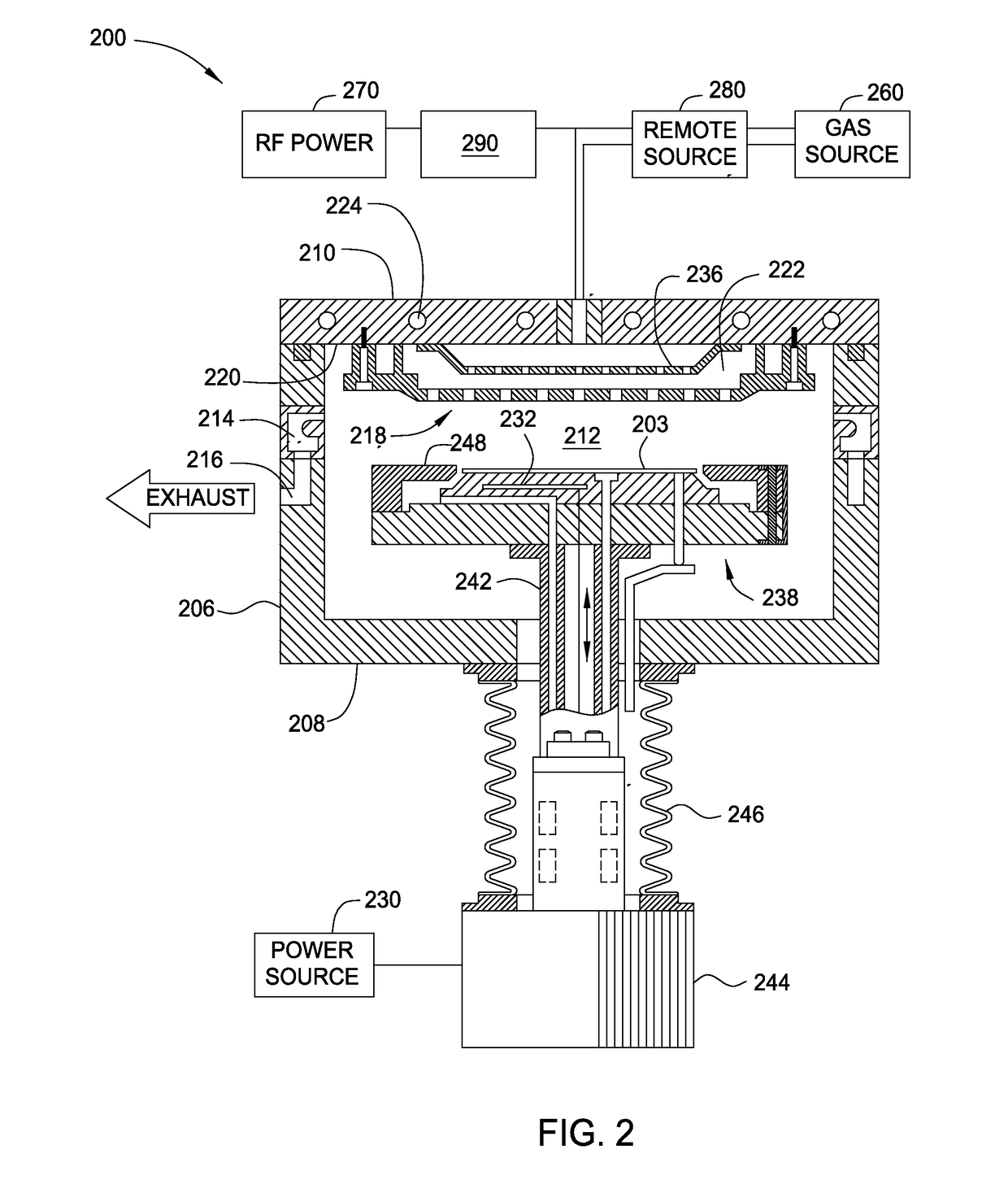

InactiveUS20080202425A1Fast heatingFast coolingChemical vapor deposition coatingTemperature controlElectrical resistance and conductance

Embodiments of the invention provide apparatuses for vapor depositing tungsten-containing materials, such as metallic tungsten and tungsten nitride. In one embodiment, a processing chamber is provided which includes a lid assembly containing a lid plate, a showerhead, a mixing cavity, a distribution cavity, and a resistive heating element contained within the lid plate. In one example, the resistive heating element is configured to provide the lid plate at a temperature within a range from about 120° C. to about 180° C., preferably, from about 140° C. to about 160° C., more preferably, from about 145° C. to about 155° C. The mixing cavity may be in fluid communication with a tungsten precursor source containing tungsten hexafluoride and a nitrogen precursor source containing ammonia. In some embodiments, a single processing chamber may be used to deposit metallic tungsten and tungsten nitride materials by CVD processes.

Owner:APPLIED MATERIALS INC

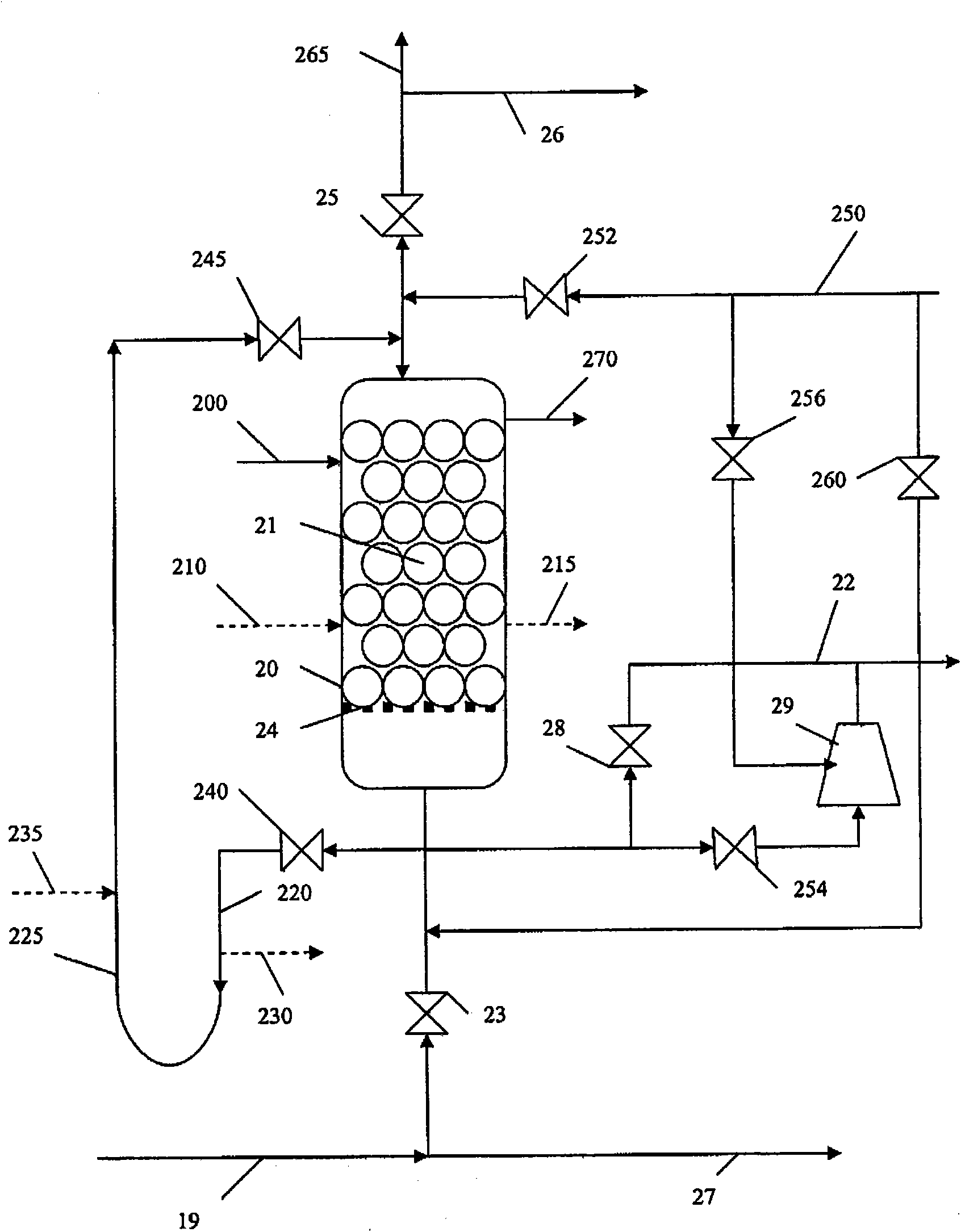

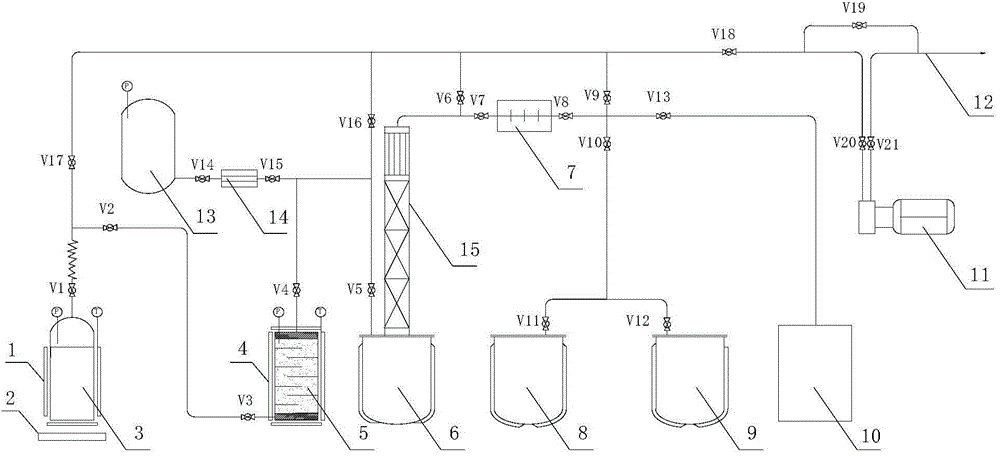

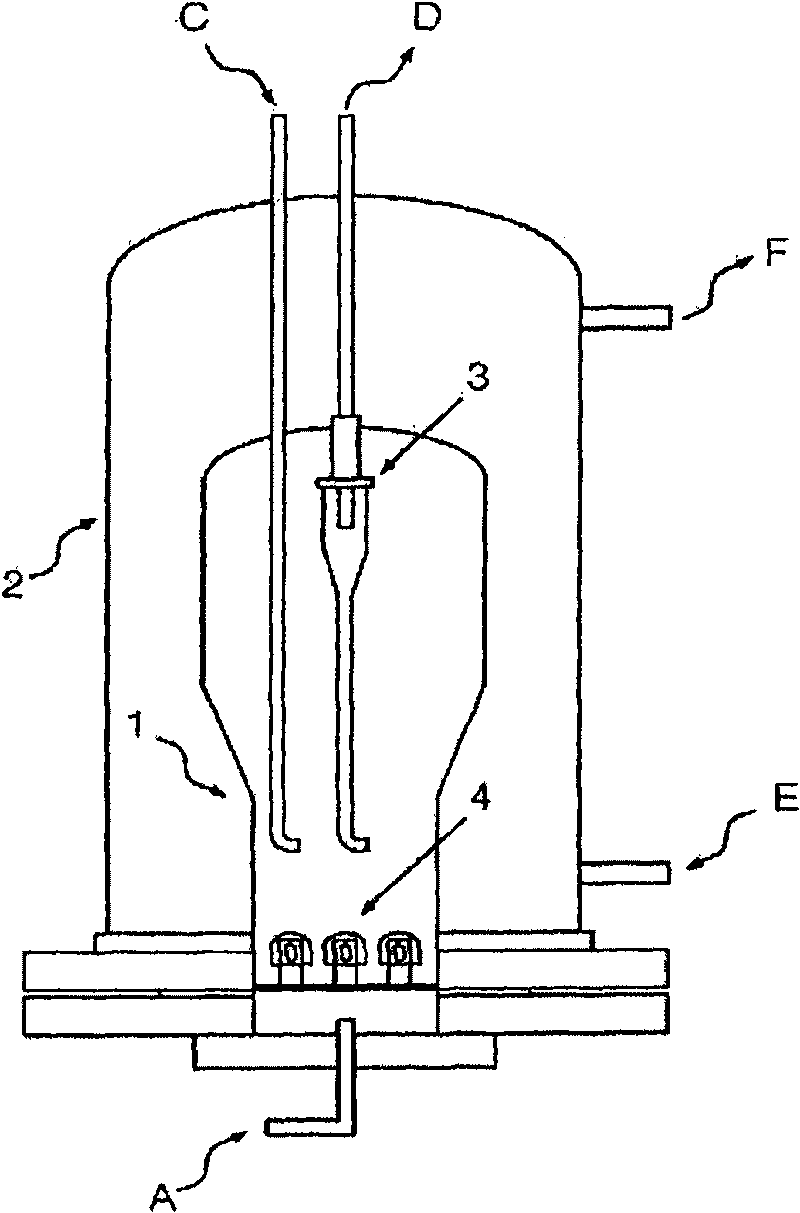

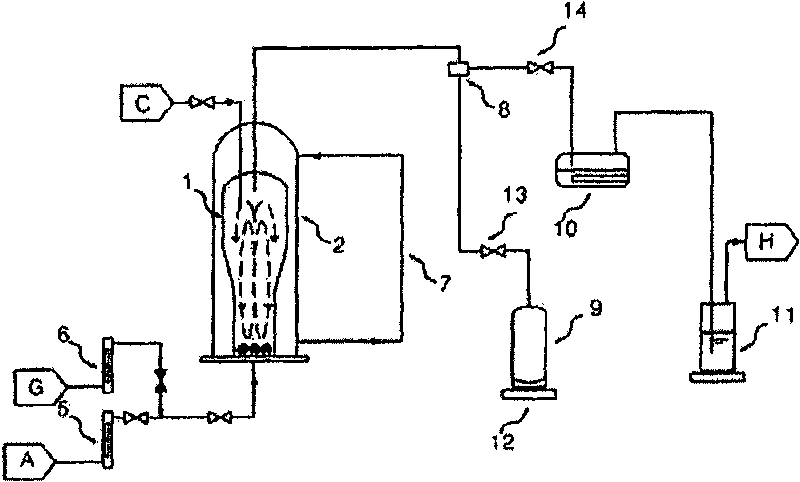

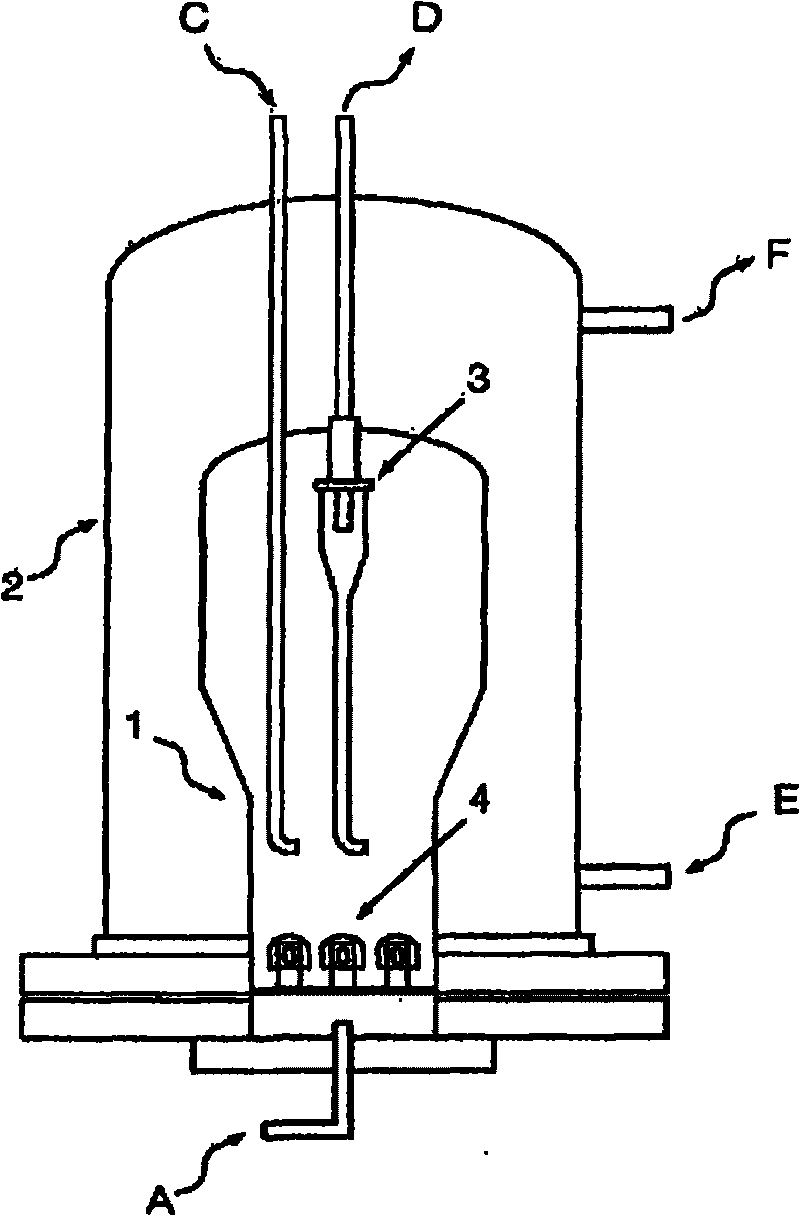

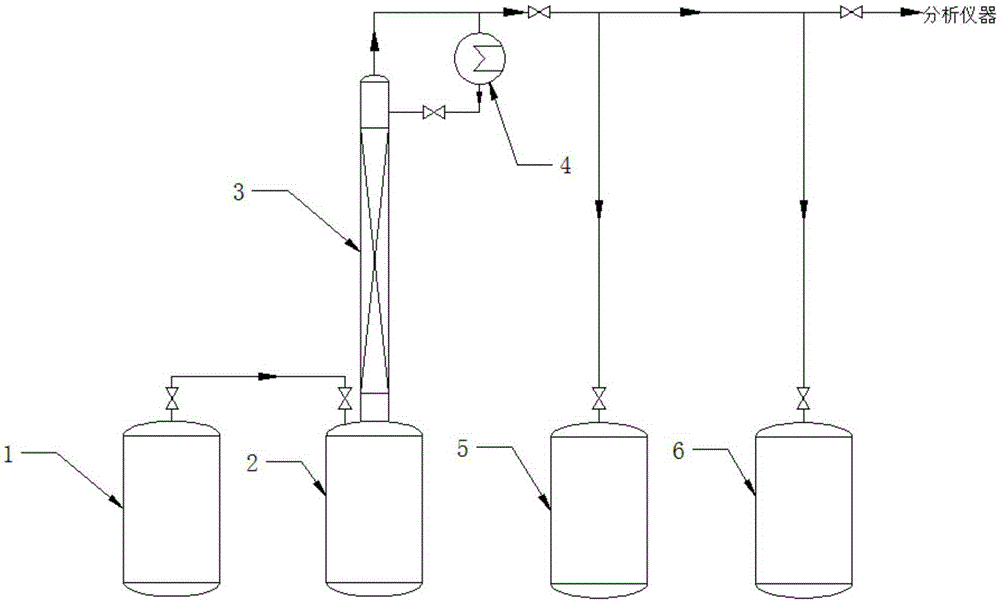

Method for producing high-purity tungsten hexafluoride with fluidized bed and equipment thereof

InactiveCN101428858AImprove mass transfer efficiencyImprove heat transfer efficiencyTungsten halidesTemperature controlFluidized bed

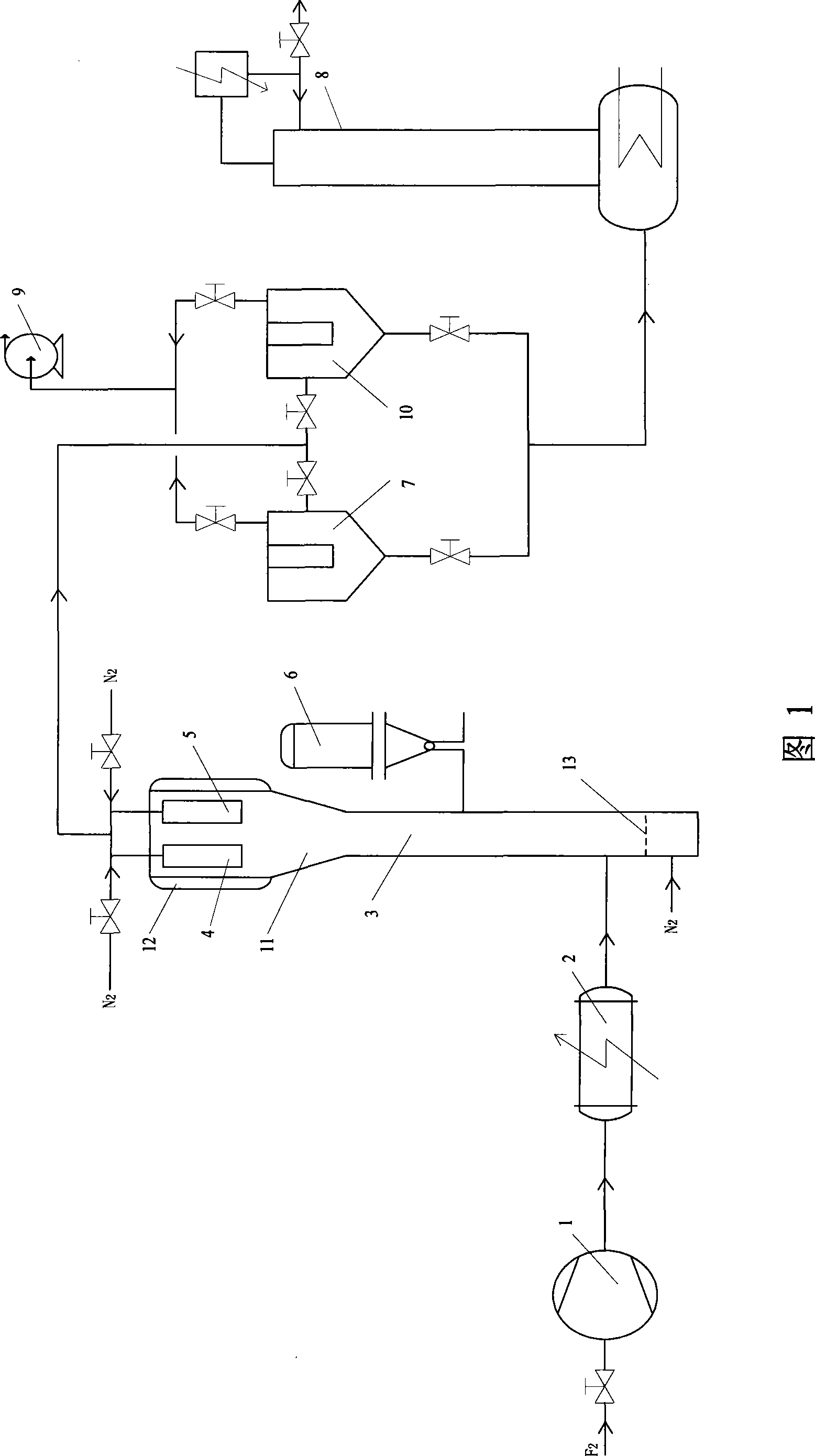

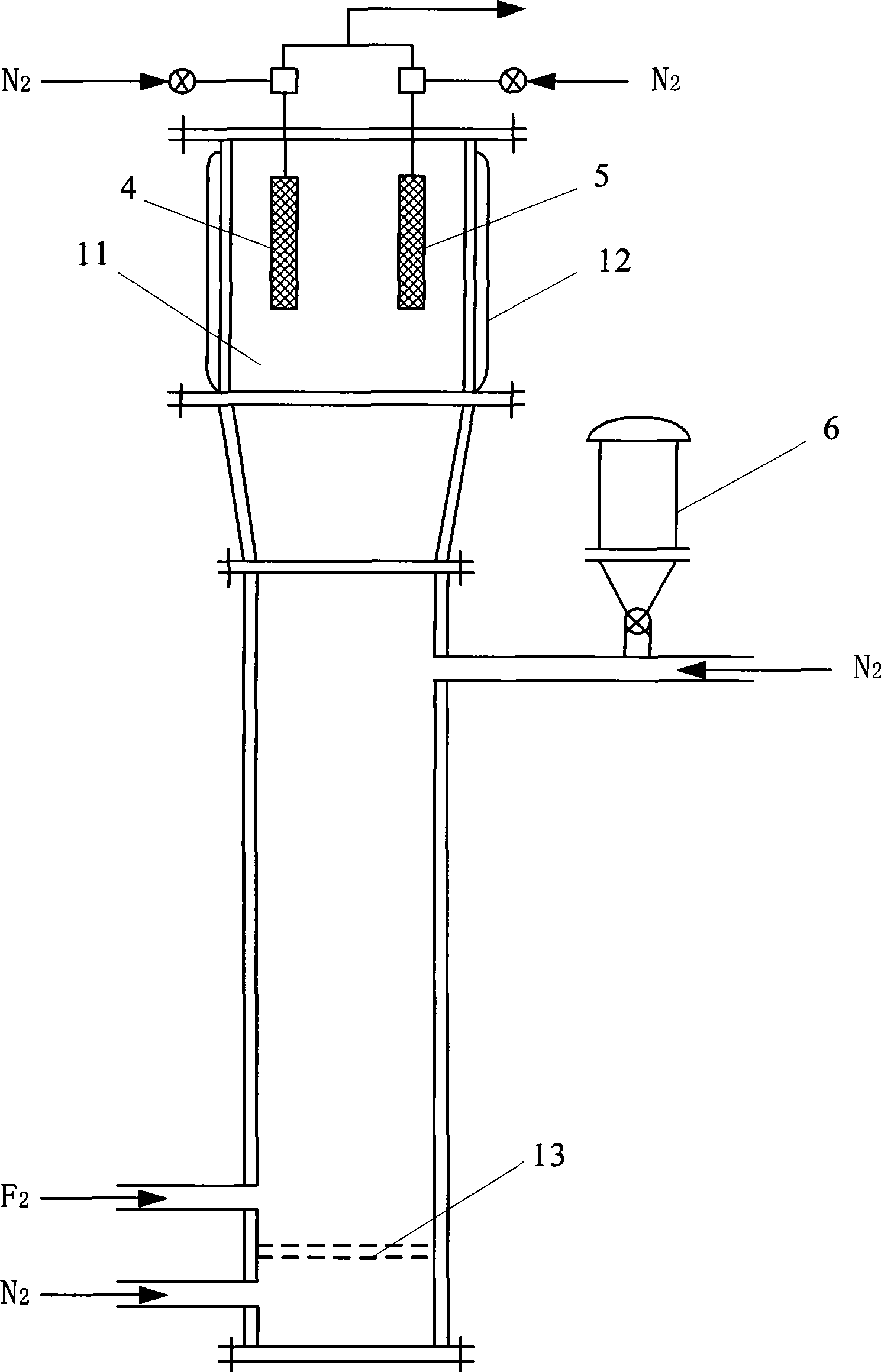

The invention discloses a method for preparing high-purity tungsten hexafluoride by a fluidized bed, and a device thereof. The method comprises the following steps: leading fluorine gas into a pre-heater and pre-heating to the temperature of 50 to 200 DEG C; allowing the pre-heated gas to enter a fluidized bed reactor, wherein, the temperature inside the fluidized bed is 200 to 400 DEG C, and the pressure is 0.1 to 0.5 MPa; continuously adding metered tungsten powder to the middle part of the reactor; allowing crude tungsten hexafluoride product obtained at the upper part of the reactor to enter a freezing collector, wherein, the freezing temperature is minus 35 to 0 DEG C; vacuumizing the top part of the collector so as to remove non-condensable gas impurity; and liquefying the obtained tungsten hexafluoride solid and allowing the tungsten hexafluoride solid to enter a rectifying tower so as to remove the heavy-component impurity, wherein, the purity of the prepared tungsten hexafluoride gas is as high as above 99.99%. The technique can realize automatic temperature control and automatic material feeding of the reactor; the operation is easy to control, safe and reliable; and filter pipes are internally arranged in the reactor which is equipped with a nitrogen backflow device, thereby preventing the product from carrying the tungsten powder.

Owner:LIMING RES INST OF CHEM IND

Method for purifying tungsten hexafluoride

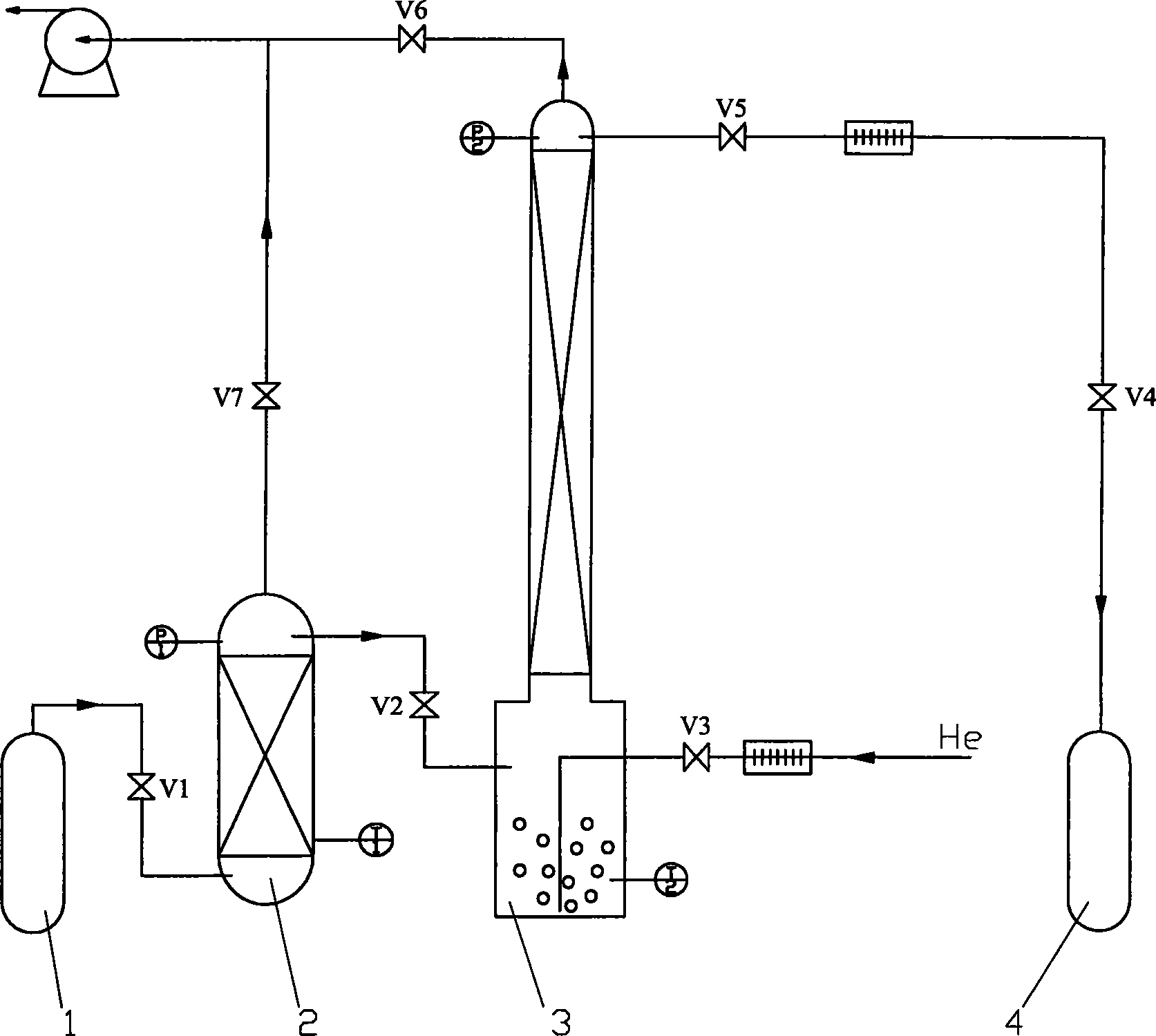

The invention relates to a kind of purification method of tungsten hexafluoride gas. First, put impure tungsten hexafluoride gas in the storage tank of crude product into the bottom of absorption column where there are multihole spherical filling of sodium fluoride or potassium fluoride, remove the most impurity of hydrogen fluoride under temperature of 10-80 degree C,put it into rectifying column through pipe and fluidify it, stop entering tungsten hexafluoride gas after fluidifing it for 5kg-50kg, put helium gas of high purity into bottom of tungsten hexafluoride liquid and keep it boiling under temperature between 3 degree C and 20 degree C,the vaporized gas enter rectification column and rises, it gradually gets into condensation and circumfluence during the process of rising ,continues to rectify it to remove impurity, check it with gas chromatography, when concentration of impurity of gas discharged from tower top whose boiling point is higher than that of tungsten hexafluoride gas reduce to the request index, stop entering helium gas of high purity, and when helium gas's index reaches the request, collect tungsten hexafluoride gas of high purity into storage tank of quality product.

Owner:PERIC SPECIAL GASES CO LTD

Method and apparatus for the production of high purity tungsten hexafluoride

The present Invention provides new and useful apparatus and methods for purifying WF6 gas, and In particular, provides apparatus and methods of using carbonaceous materials to produce high purity WF6by removing substantially all the high volatility gas impurities and troublesome transition metal impurities The present invention is particularly useful for removing chromium and molybdenum impurities from WF6 gas.

Owner:LINDE NORTH AMERICA

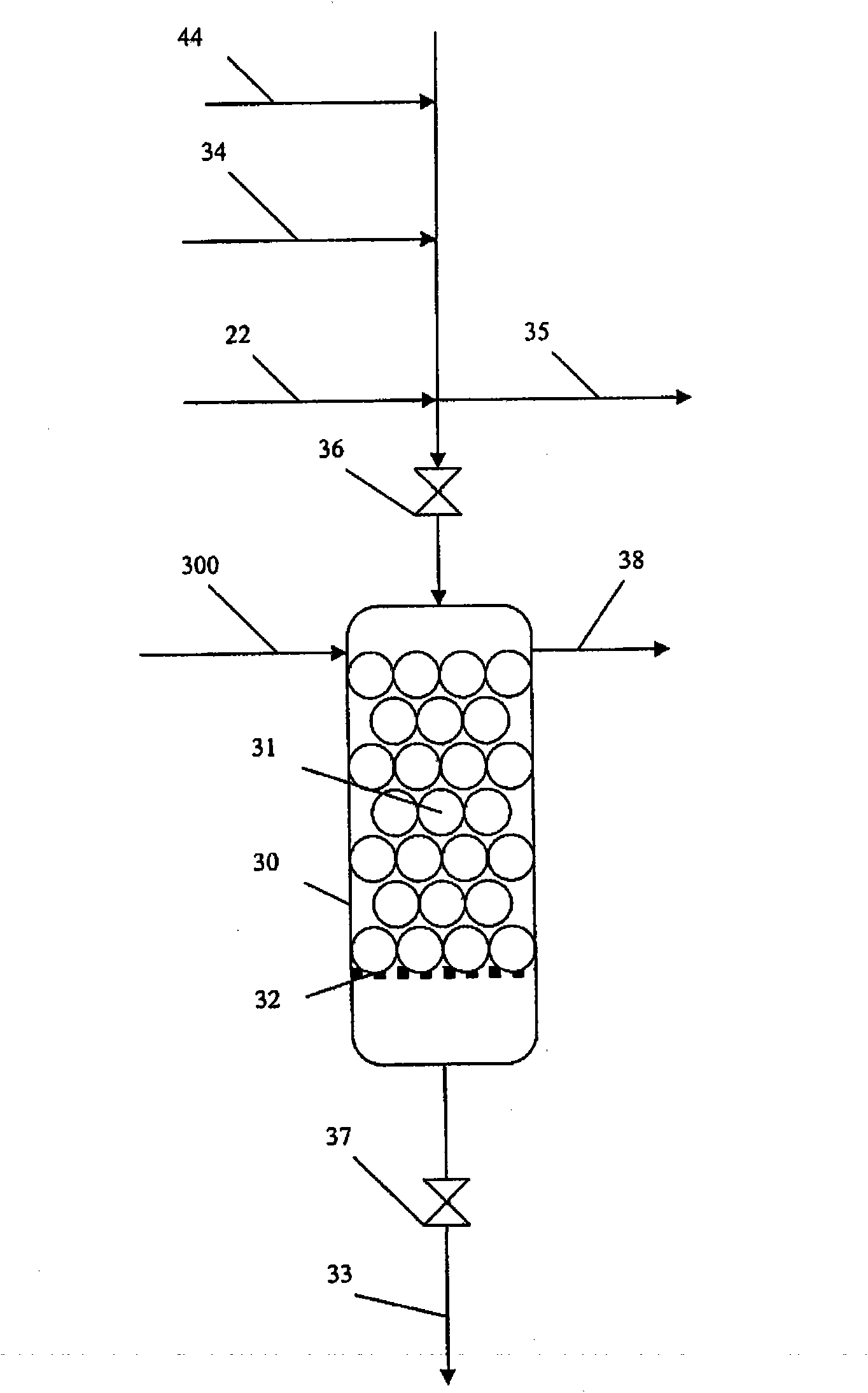

Preparation method for tungsten hexafluoride gas

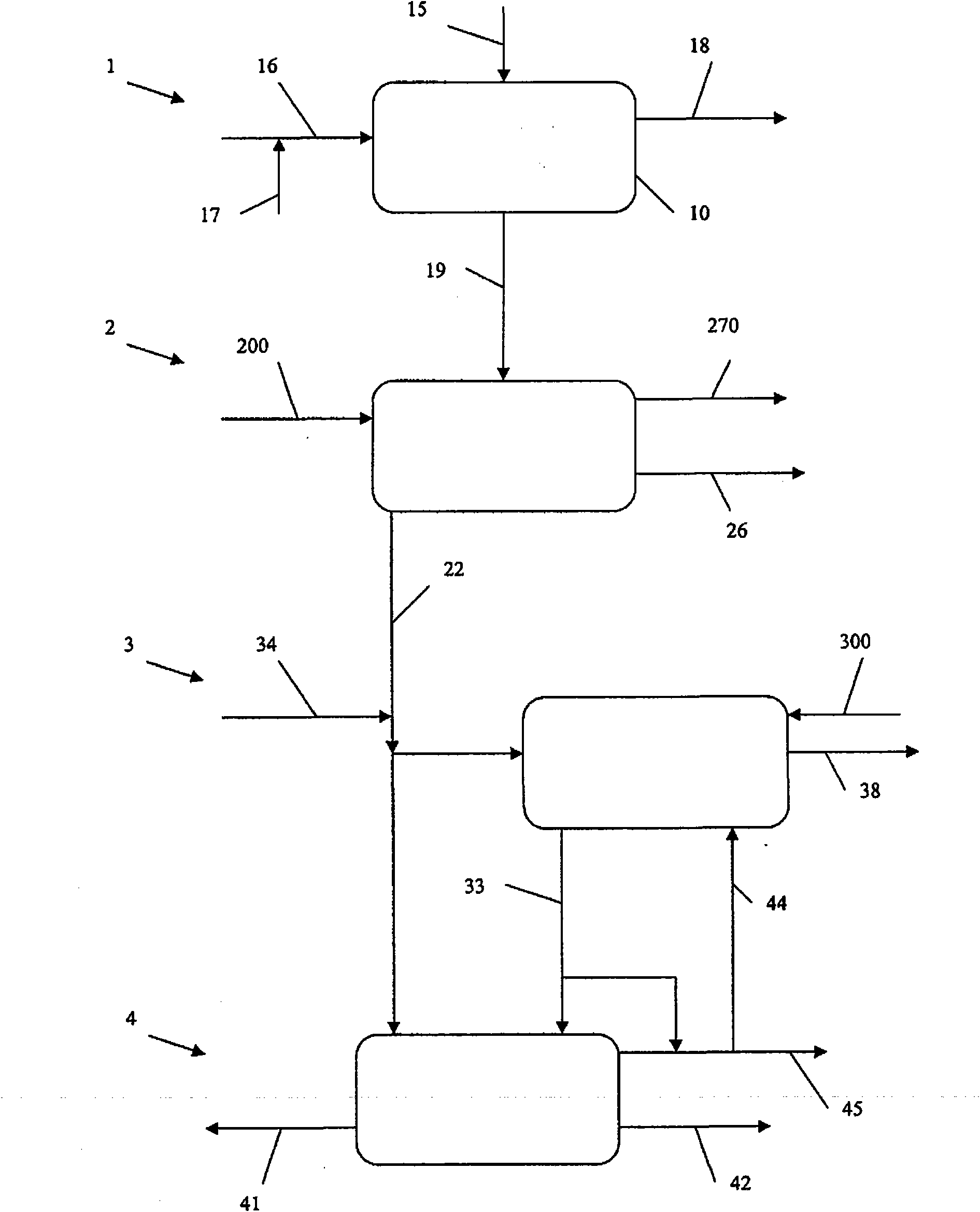

ActiveCN102951684AReduce consumptionFew controllable parametersTungsten halidesHydrogen fluorideElectrolysis

The invention provides a preparation method for tungsten hexafluoride gas, relating to fluoride of tungsten. The preparation method comprises the following steps of accessing hydrogen fluoride into an electrolytic bath to prepare fluorine electrolytically; by passing through a purifying purified tower, a first in-depth cooling tank and a second in-depth cooling tank in sequence, purifying the produced low-purity fluorine gas; accessing the purified fluorine gas to a reaction system to perform reaction, generating a crude product, namely tungsten hexafluoride; accessing the purified fluorine gas to a first horizontal fixed fixing bed reactor and a second horizontal fixed fixing bed reactor which are filled with waste tungsten cutting heads to perform reaction; collecting the prepared tungsten hexafluoride gas by a primary condenser, an intermediate condenser and a senior condenser in sequence; respectively unfreezing the collected tungsten hexafluoride gas to flow to a first storage tank, a second storage tank and a third storage tank to collect, discharging the uncondensed or unreacted impurity gas to a spraying tower through a tail part pipeline to perform alkali liquid absorption, heating the crude product tungsten hexafluoride collected by the first storage tank, the second storage tank and the third storage tank, and distilling the heated tungsten hexafluoride to a rectifying tower through a filter to perform rectifying and purifying. By utilizing the waste tungsten cutting heads, the preparation method provided by the invention has the advantages of safe process operation and high purity.

Owner:XIAMEN TUNGSTEN +1

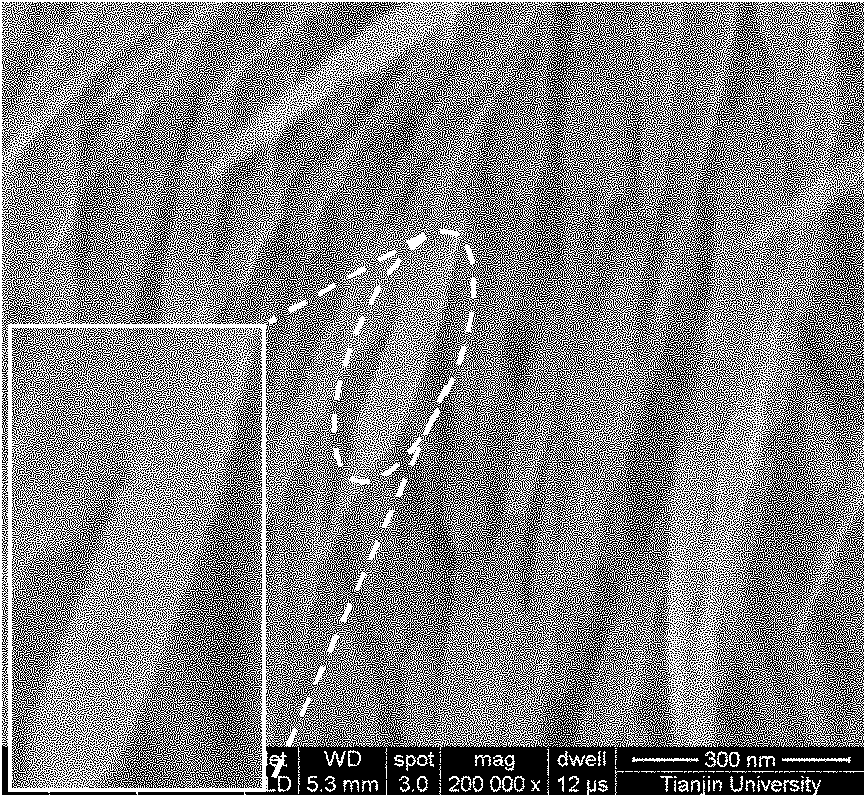

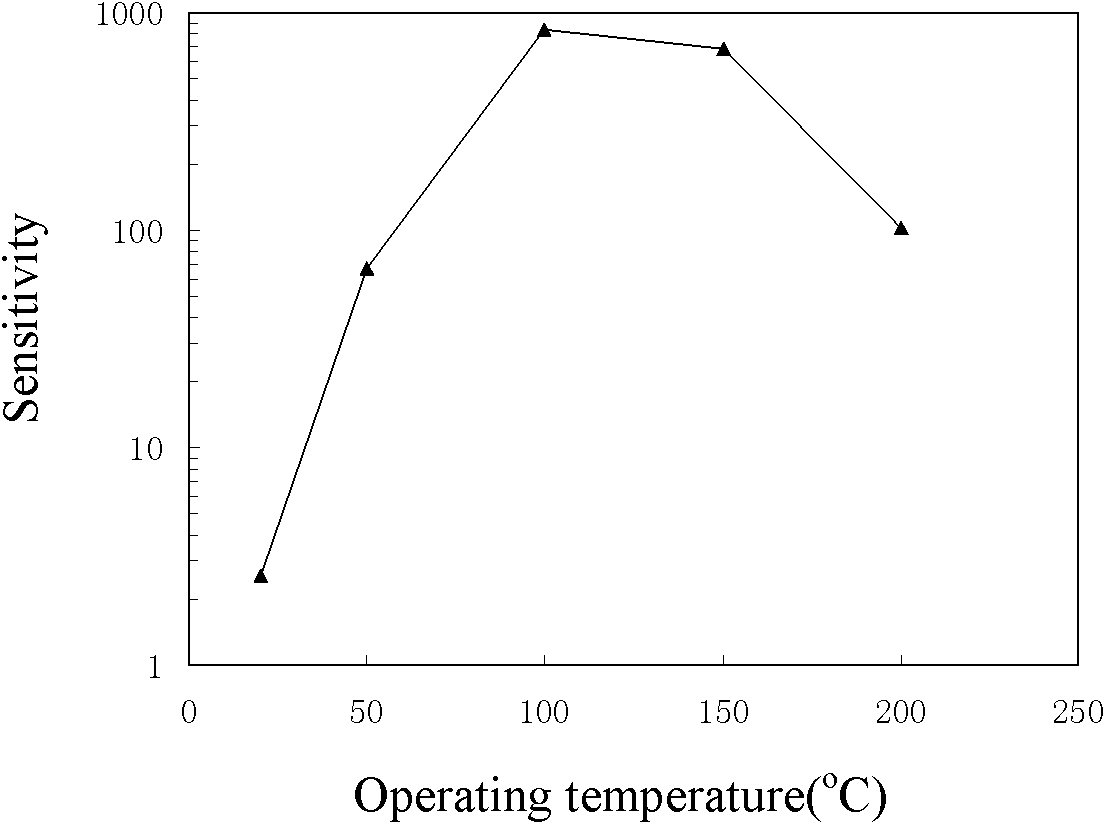

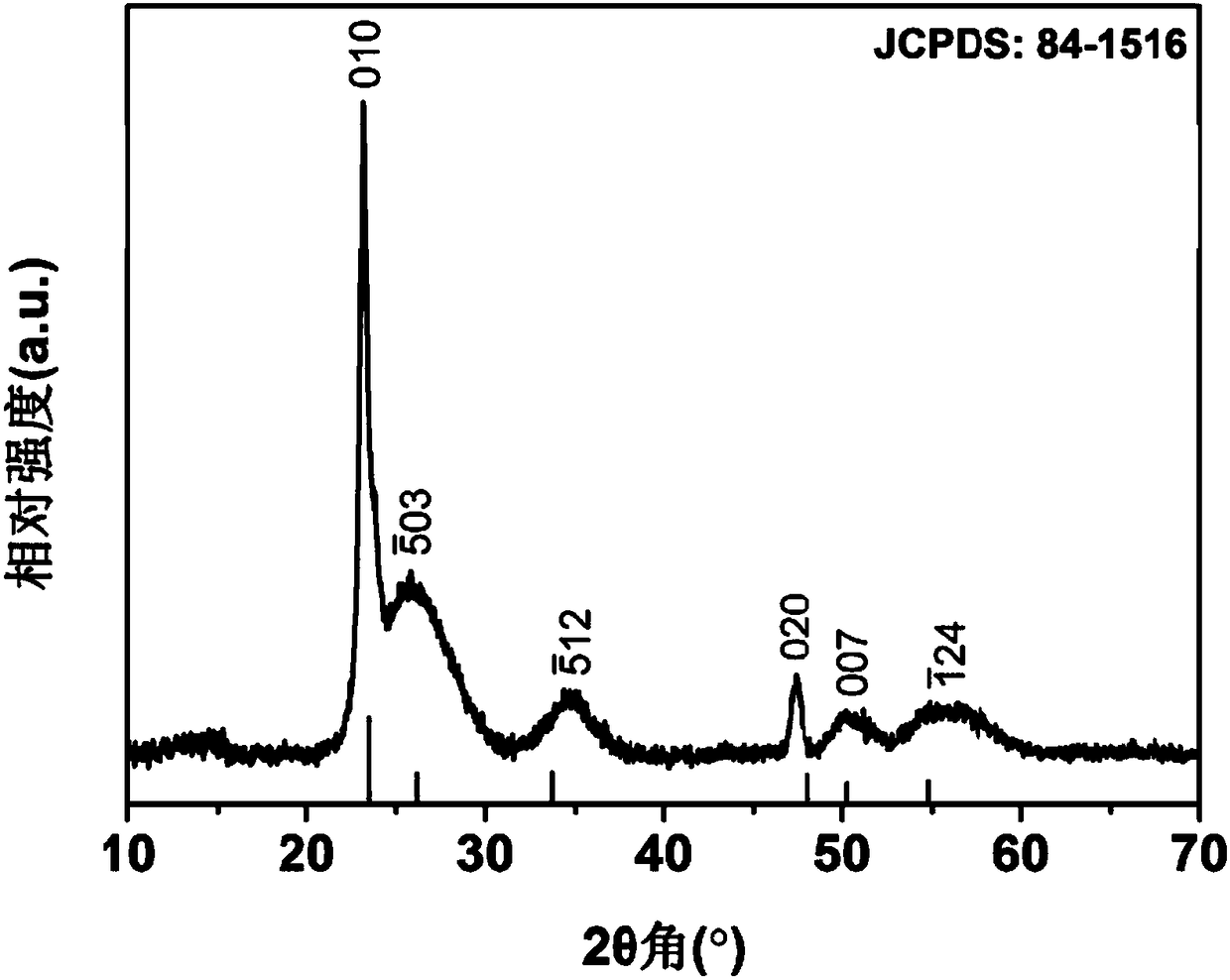

Preparation method of nitric oxide gas sensor element based on pseudodirected tungsten trioxide nano tape

InactiveCN102012386ALower working temperatureReduce power consumptionMaterial resistanceNitrogen oxidesWorking temperature

The invention discloses a preparation method of a nitric oxide gas sensor element based on a pseudodirected tungsten trioxide nano tape, which comprises the steps of: 1, preparing a tungsten hexachloride solution; 2, regulating the mol concentration of tungsten hexachloride to be 0.003-0.012M; 3, synthesizing a pseudodirected tungsten oxide nano wire; 4, preparing a pseudodirected tungsten oxide nano wire; 5, preparing a sensitive material slurry; and 6, preparing the sensor element based on the pseudodirected tungsten trioxide nano tape. The sensor element based on the pseudodirected tungsten trioxide nano tape, prepared by using the method, has the advantages of high sensitivity, high selectivity, low working temperature and low power consumption for the low-concentration nitric oxide gas detection.

Owner:TIANJIN UNIV

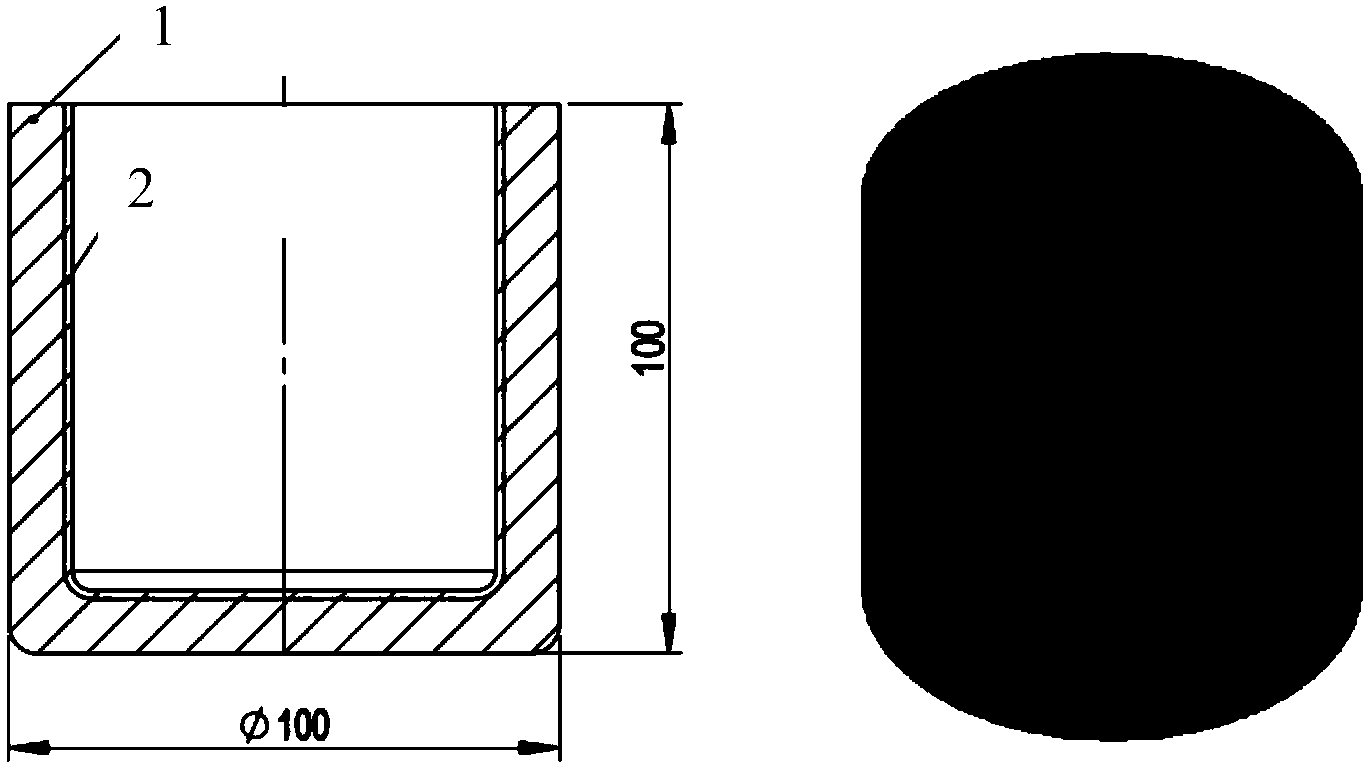

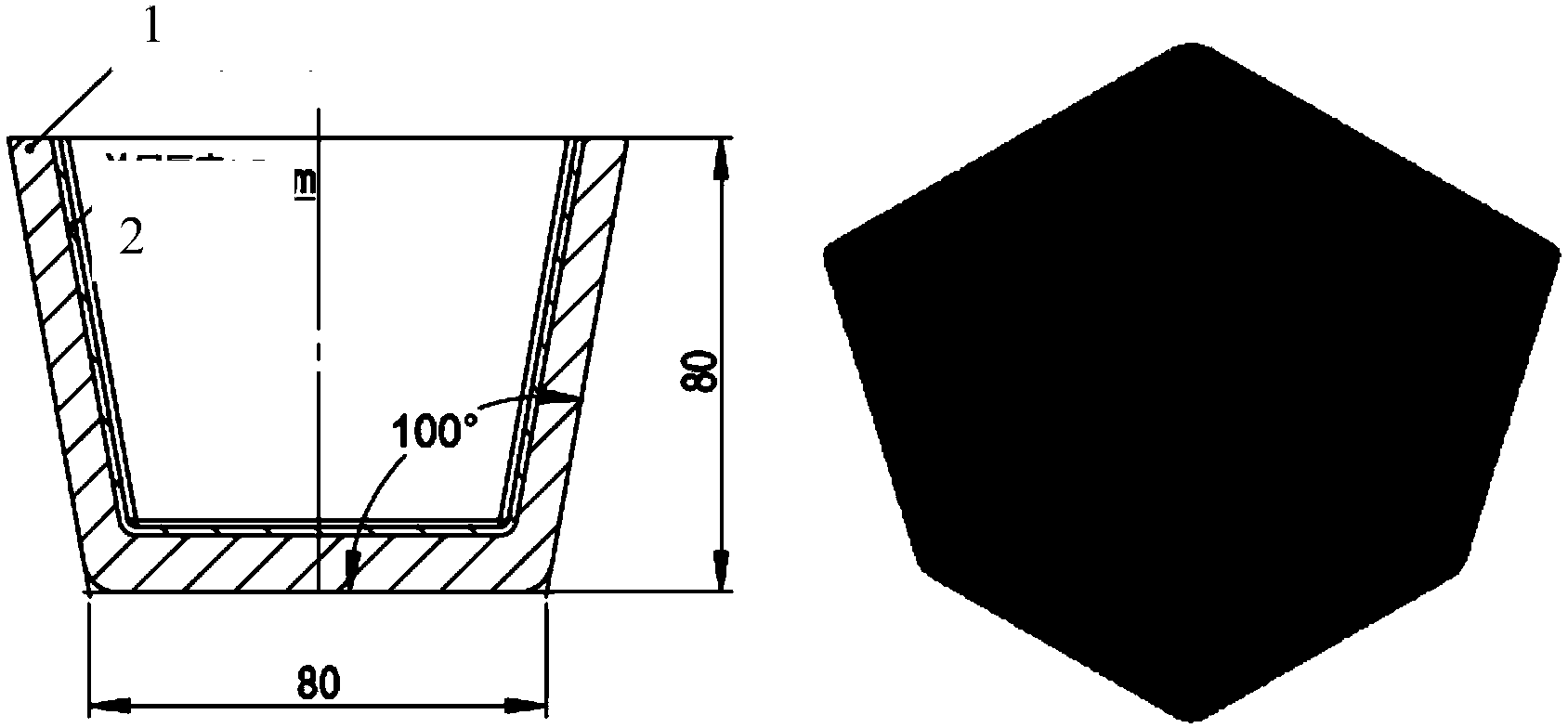

Preparation method of crucible with tungsten coating

ActiveCN104213096AImprove corrosion resistanceExtended service lifeChemical vapor deposition coatingCrucibleAlloy

The invention discloses a preparation method of a crucible with a tungsten coating. The preparation method comprises the following steps: (1) a needed pure tungsten, pure molybdenum or molybdenum alloy crucible base material is obtained through a specific processing technology according to a needed size; (2) a certain degree of surface roughening treatment is performed for the obtained crucible base material; and then, the surface is cleaned to remove an oxide layer; and (3) tungsten hexafluoride serves as a raw material, hydrogen serves as reducing gas, and the chemical vapor deposition (CVD) is performed for the surface of the crucible base material under the condition of the base material temperature of 350-600 DEG C to form a tungsten coating layer with the thickness of 0.01-3 mm so as to obtain a crucible product coated with the tungsten coating layer. The CVD tungsten coating layer with high purity and high compactness has excellent metal or nonmetallic solution corrosion resistance, so that the protecting effect on the crucible basal body is achieved, and the service life and the performance of the crucible under such high-temperature environments as metal or nonmetal smelting and crystal growth are prolonged and improved.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

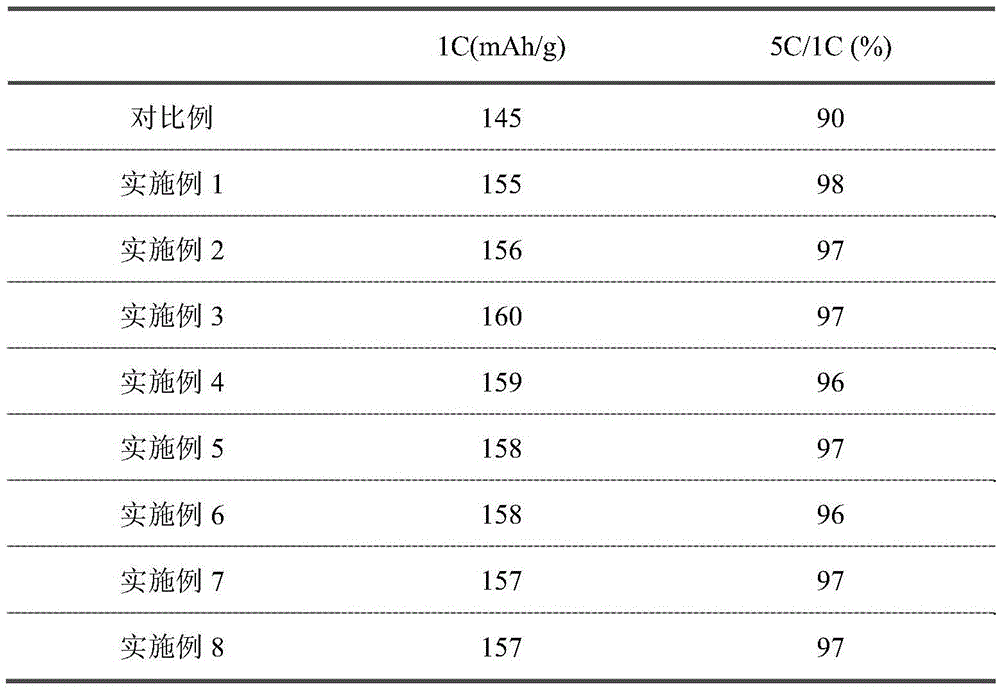

Tungsten carbide shell layer coated lithium iron phosphate positive electrode material and preparation method therefor

InactiveCN105633362AImprove bindingImproved magnification performanceCell electrodesSecondary cellsVacuum pumpingLithium iron phosphate

The invention discloses a tungsten carbide shell layer coated lithium iron phosphate positive electrode material and a preparation method therefor. The tungsten carbide shell layer coated lithium iron phosphate positive electrode material is prepared by the steps of putting lithium iron phosphate into a reaction chamber, performing vacuum pumping, and carrying out heating to 200-500 DEG C; taking tungsten hexafluoride and methane at a volume ratio of 1:1-1.5 as the gas raw materials and injecting the gas raw material into the reaction chamber; maintaining the total gas pressure intensity in the reaction chamber at 10-100Pa, and performing reaction for 10-60min to obtain the positive electrode material, wherein the power supply output power of the radio frequency plasma is 400-800W. The tungsten carbide shell layer coated lithium iron phosphate prepared by the invention has an excellent rate capability.

Owner:SIHUI DABOWEN IND CO LTD

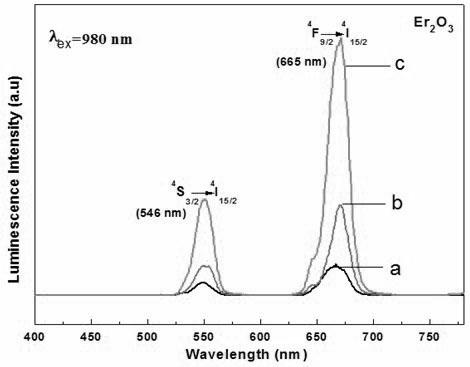

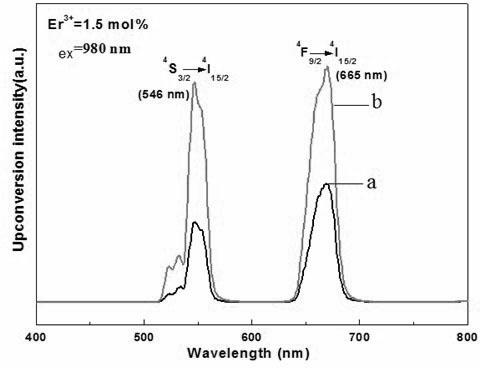

Preparation method of rare earth ion doped tungsten oxygen fluoride silicate up-converted luminescent glass

The invention discloses a preparation method of rare earth ion doped tungsten oxygen fluoride silicate up-converted luminescent glass. The preparation method comprises the steps of: firstly, uniformly mixing silicon dioxide, germanium dioxide, aluminum oxide, tungsten oxide, calcium fluoride, titanium dioxide and rare earth oxide in a mortar; and then preparing the Er<3+>-Yb<3+> rare earth ions doped tungsten oxygen fluoride silicate up-converted luminescent glass by adopting a high-temperature melting annealing method. The method disclosed by the invention is simple in preparation method, low in raw material cost and simple in required device without a special device; and the overall preparation process is carried out in air atmosphere. According to the invention, tungsten oxide is introduced into an oxygen fluoride silicate glass substrate for the first time, and the further solution of the problems that the oxygen fluoride silicate glass is poor in chemical stability and mechanical strength after tungsten oxide is introduced is facilitated, so that the glass product has the advantages of low phonon energy of fluoride and good crystallization stability of oxide, thereby obtaining strong up-converted red and green light output visible to naked eyes.

Owner:ZHEJIANG UNIV

Method of manufacturing a semiconductor device

InactiveUS8399351B2Simple and inexpensiveSuitableSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceHigh volume manufacturing

Owner:LAPIS SEMICON CO LTD

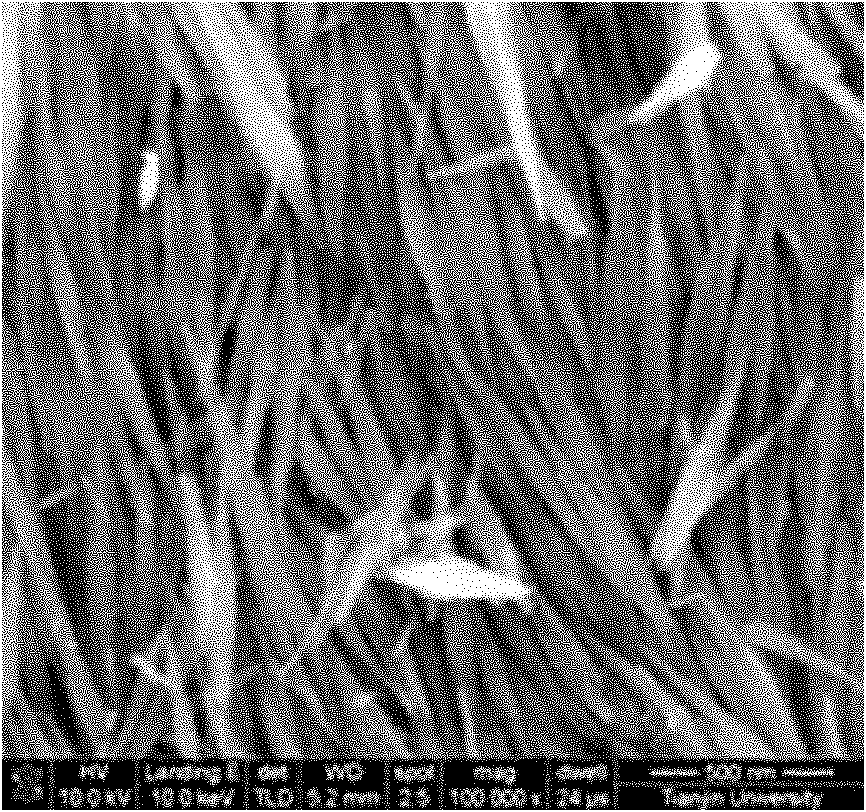

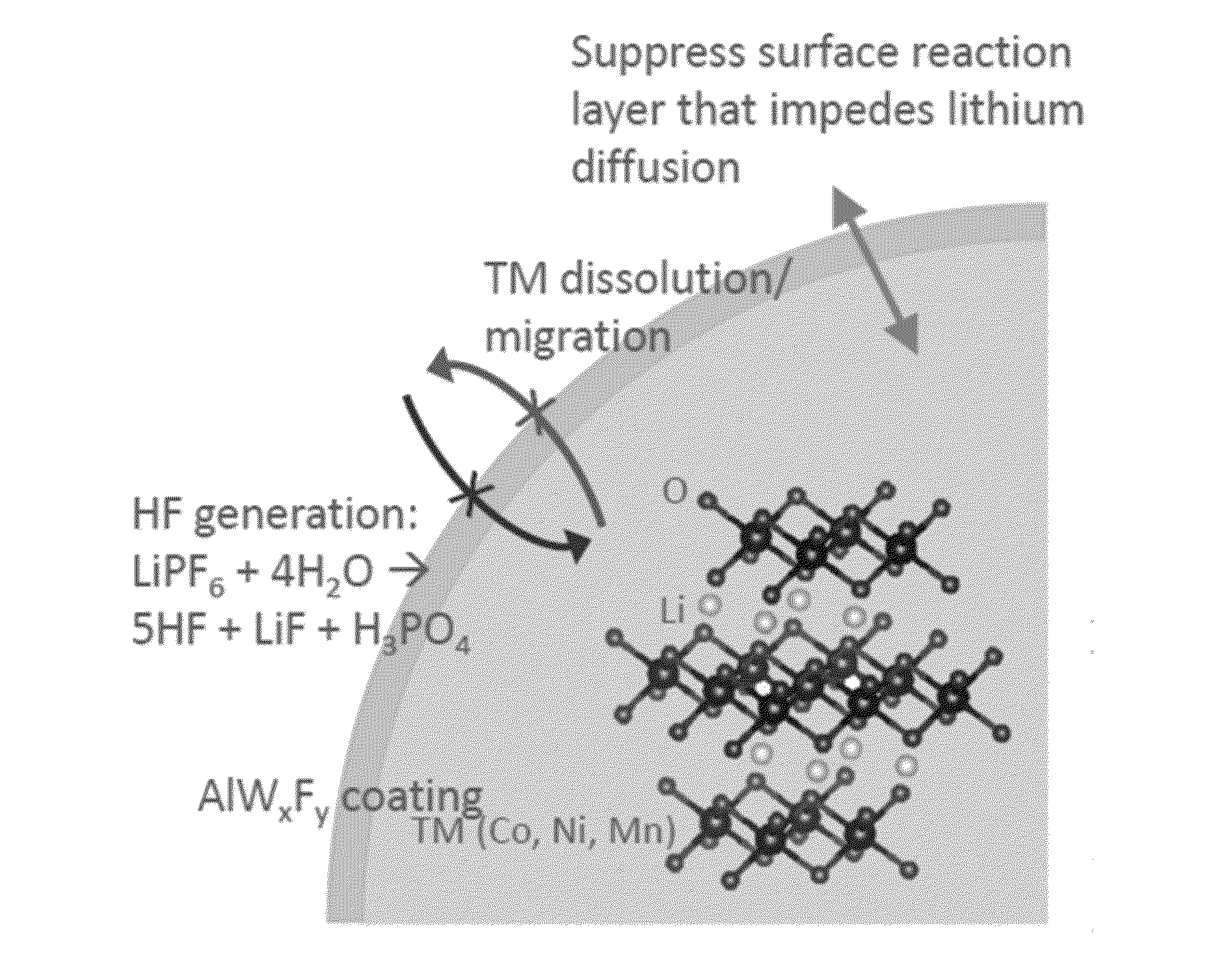

METAL FLUORIDE PASSIVATION COATINGS PREPARED BY ATOMIC LAYER DEPOSITION ON LiCoO2 FOR LI-ION BATTERIES

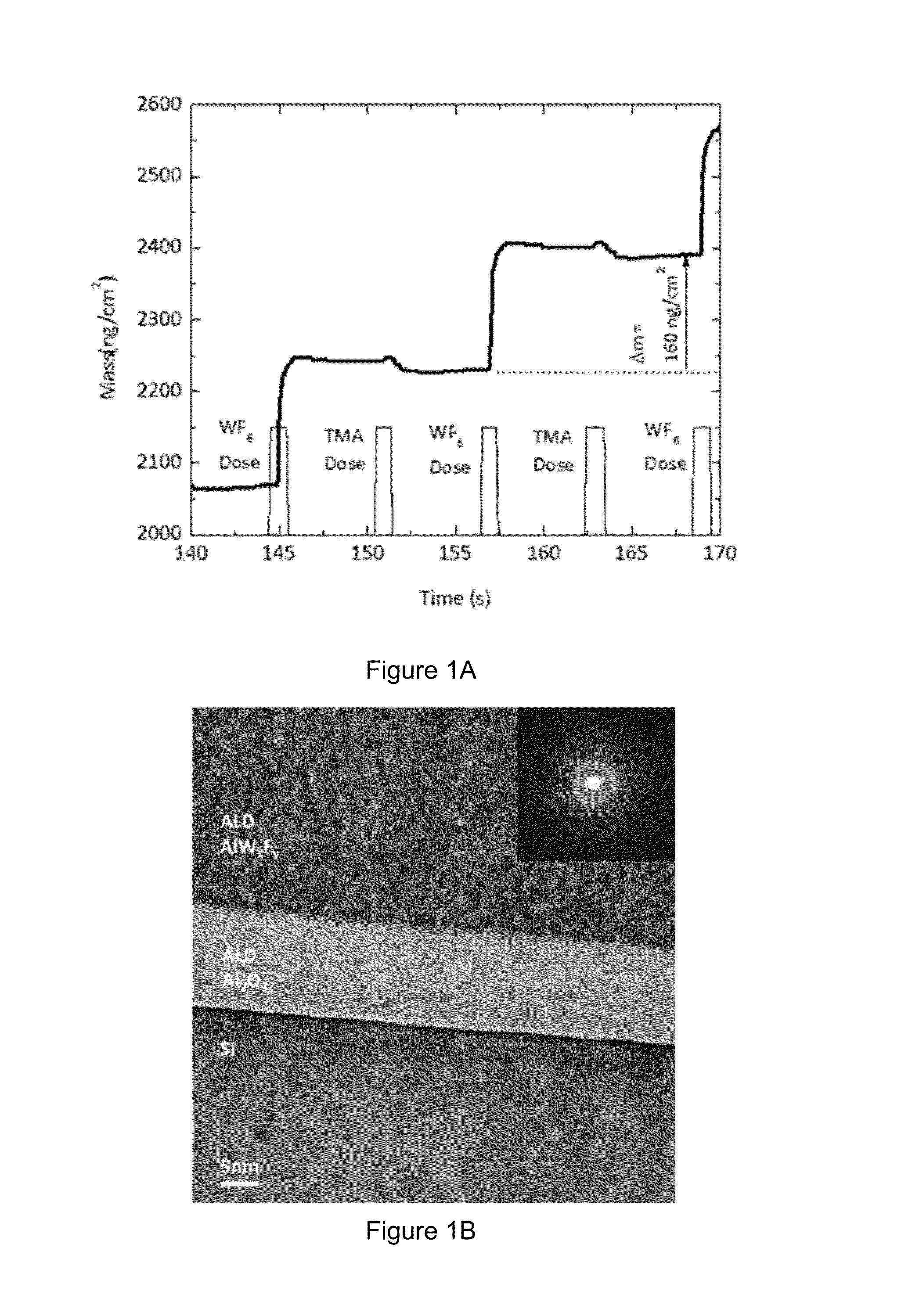

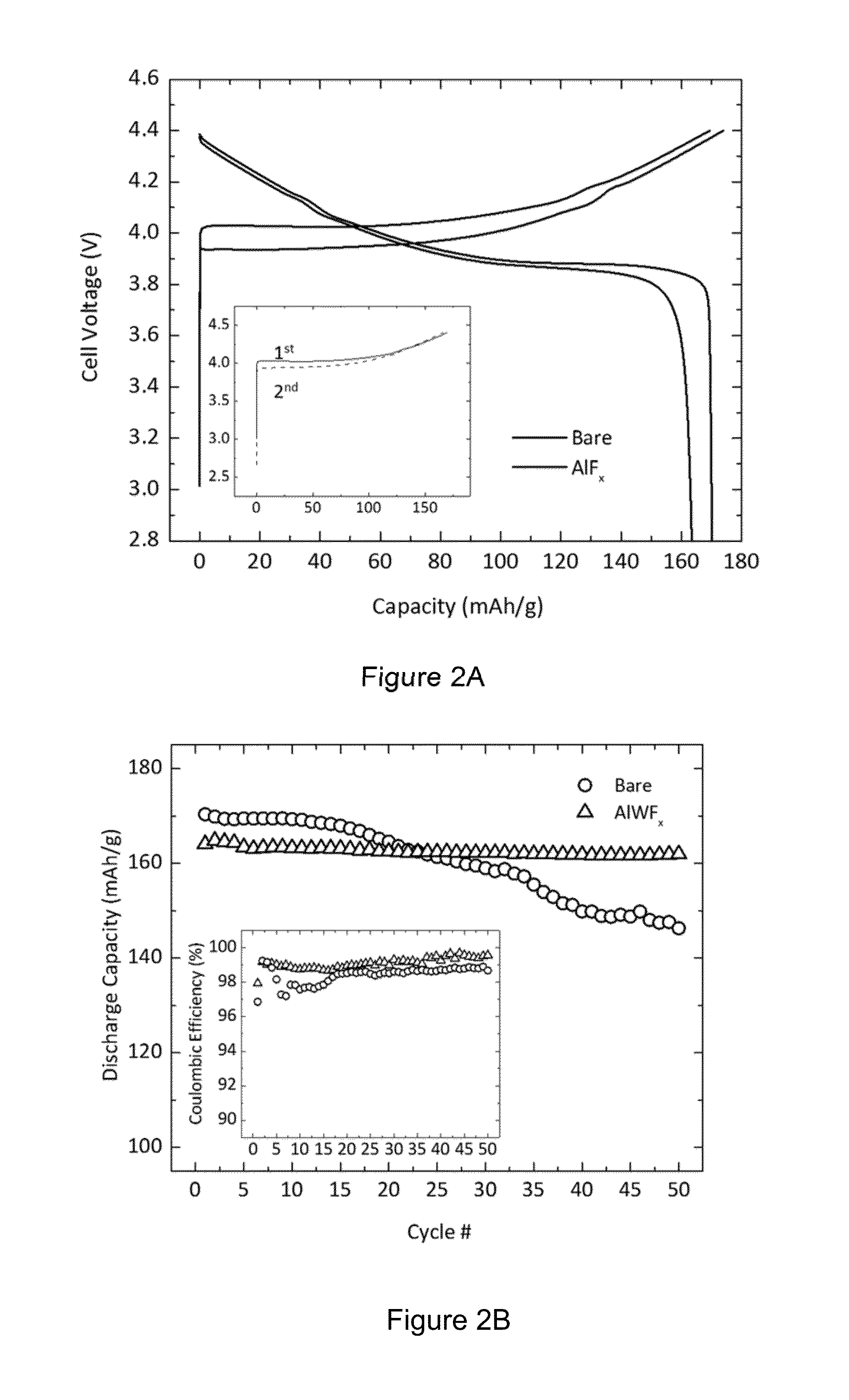

The fabrication of robust interfaces between transition metal oxides and non-aqueous electrolytes is one of the great challenges of lithium ion batteries. Atomic layer deposition (ALD) of aluminum tungsten fluoride (AlWxFy) improves the electrochemical stability of LiCoO2. AlWxFy thin films were deposited by combining trimethylaluminum and tungsten hexafluoride. in-situ quartz crystal microbalance and transmission electron microscopy studies show that the films grow in a layer-by-layer fashion and are amorphous nature. Ultrathin AlWxFy coatings (<10 Å) on LiCoO2 significantly enhance stability relative to bare LiCoO2 when cycled to 4.4 V. The coated LiCoO2 exhibited superior rate capability (up to 400 mA / g) and discharge capacities at a current of 400 mA / g were 51% and 92% of the first cycle capacities for the bare and AlWxFy coated materials. These results open new possibilities for designing ultrathin and electrochemically robust coatings of metal fluorides via ALD to enhance the stability of Li-ion electrodes.

Owner:UCHICAGO ARGONNE LLC

Purification method of tungsten hexafluoride gas

ActiveCN104973629AEfficient removalReduce gas contentTungsten halidesHydrogen fluoridePurification methods

A purification method of a tungsten hexafluoride gas relates to a fluoride of tungsten. The purification method comprises the following steps: removing oil by equipment, pressurizing with nitrogen, vacuumizing to the limit, turning on a nitrogen heater, introducing the heated nitrogen into a system, and vacuumizing to the limit; filling a hydrogen fluoride removal tower with nitrogen, putting tungsten hexachloride into the hydrogen fluoride removal tower, introducing high-purity tungsten hexafluoride into a finished product gathering tank, reacting with steam adhered to the wall of the tank to generate hydrogen fluoride, sucking-back impure tungsten hexafluoride in the finished product gathering tank into a rectifying still for low-temperature curing after displacement, detecting content of foreign gas, and stopping high-purity tungsten hexafluoride displacement after qualified; heating primary tungsten hexafluoride and carrying out low-temperature curing, vacuumizing the rectifying still, adsorbing tail gas by a basic spray tower, thawing by hot water, and detecting when pressure is stable and rectifying; carrying out reflux condensation on evaporated tungsten hexafluoride gas in the rectifying tower, removing impurities, rectifying primary tungsten hexafluoride gas and gathering, detecting, gathering by the finished product gathering tank, taking a liquid sample, and detecting metal impurities in tungsten hexafluoride.

Owner:XIAMEN TUNGSTEN

Preparation method of thick tungsten coating material and tungsten coating material

InactiveCN103484830AHigh densityHigh hardnessChemical vapor deposition coatingMetal layered productsGradient materialThermal expansion

The invention relates to a preparation method of a thick tungsten coating material. Chemical vapor deposition method is used, and a tungsten coating is deposited on a base material by using hydrogen for reduction of tungsten hexafluoride. The deposition rate is 0.4-1 mm / h, and the tungsten coating thickness is greater than or equal to 1 mm. The invention also relates to a tungsten coating material including pure copper or copper alloy, an adaptation layer and the tungsten coating; the adaptation layer is 1-5 layers of a tungsten copper gradient material, and the thickness of each layer is 0.5 - 1.5mm; the tungsten content of the tungsten copper gradient material closed to the tungsten coating side is 50-90wt.%; the tungsten contents of the middle layers of tungsten copper gradient material decrease successively, and the copper contents increase successively; and the copper content of the tungsten copper gradient material closed to the copper or copper alloy side is 50-90wt.%. In the tungsten coating material, a pure tungsten coating-adaptation layer-copper based material method is used, through adoption of the adaptation layer, the thermal expansion coefficient mismatch problem between tungsten and copper can be solved, and the thermal stress of the coating and the base can be reduced.

Owner:SOUTHWESTERN INST OF PHYSICS +1

Method and apparatus for preparing tungsten hexafluoride using a fluidized bed reactor

InactiveCN101723465AReduce volumeIncrease contact areaTungsten halidesFluoride preparationFluidized bedReaction system

The invention provides a reaction system for preparing tungsten hexafluoride, capable of making the tungsten with specific gravity of 19.25g / cm3 uniformly distributed in the whole reactor, maximizing the contact area of the tungsten and the reaction gas, obviously reducing the volume of the reactor and more easily controlling the reaction heat and obviously improving the reaction efficiency. The invention also provides a method of preparing tungsten hexafluoride by using a fluidized bed reactor through contacting the tungsten with fluorizating agent, comprising the following steps: inputting a tungsten powder into a closed reactor, fluidizing the tungsten powder by injecting pressured inert gas in the reactor and continuously supplying the pressured gaseous fluorizating agent and tungsten powder to make them contact and then react with each other at the fluidized state.

Owner:FOOSUNG

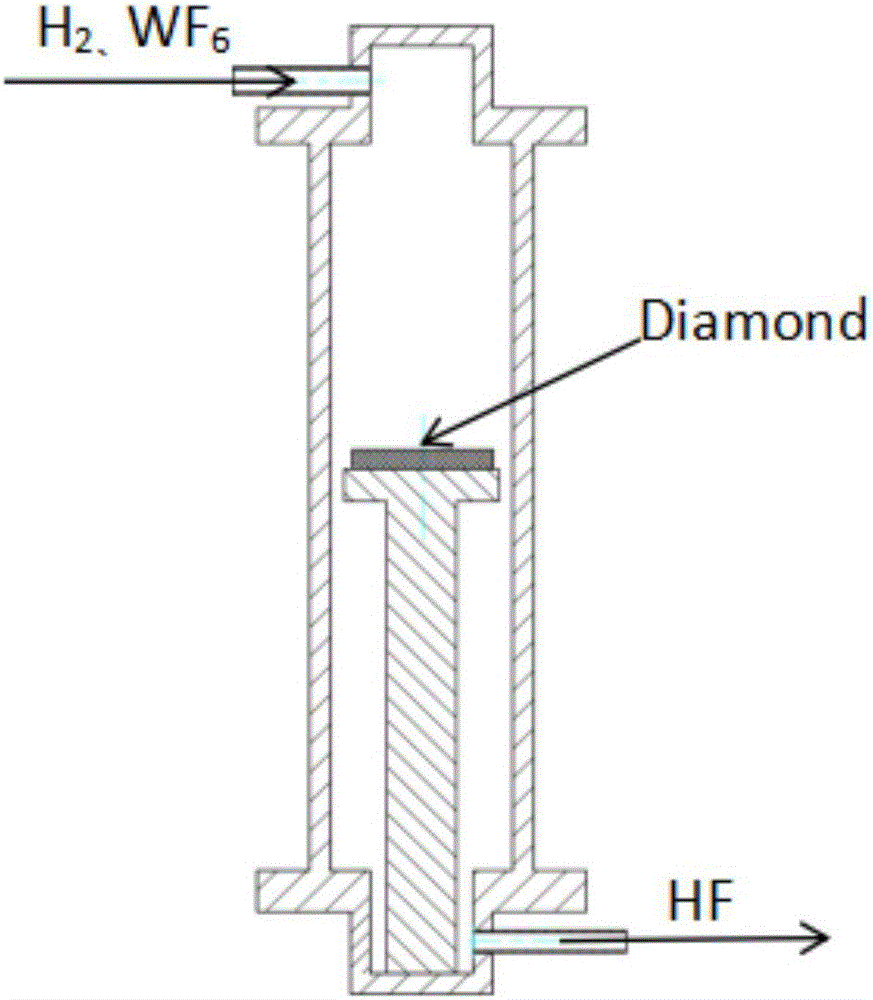

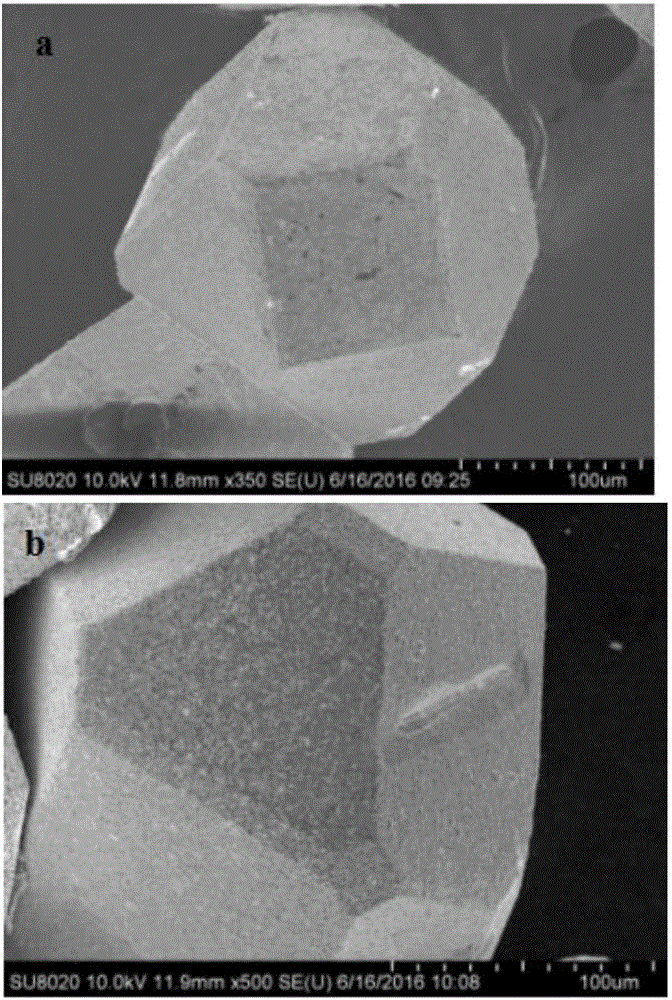

Method for plating tungsten on diamond powder surface

InactiveCN106521451AEasy to operateFast depositionTransportation and packagingMetal-working apparatusDeposition temperatureGas phase

The invention discloses a method for plating tungsten on a diamond powder surface, and belongs to the technical field of coating. The method adopts a chemical vapor-deposition tungsten coating method, and belongs to the technical field of coating. The method comprises the following steps of: carrying out treatment of removing organic substances, removing oil, roughening and drying on the diamond powder surface; uniformly spreading the dried diamond powder on a heating platform, putting the platform in a heating furnace, and carrying out temperature preserving for 10-60 minutes after heating the platform to a temperature ranging from 550 DEG C to 700 DEG C under a hydrogen-gas atmosphere; within a deposition temperature range from 550 DEG C to 700 DEG C, forming a tungsten coating on the diamond powder surface by utilizing reduction reaction between tungsten hexafluoride and hydrogen gas; and slowly cooling the tungsten coating to the room temperature. After chemical vapor-deposition plating, the uniform compact coating can be formed on the diamond powder surface, the coating is low in impurity content, and a phase of the coating is alpha-W; after being subjected to hot-pressing sintering, the tungsten-plated diamond powder is improved by 38.6% in bending strength compared with a diamond sample not plated with tungsten; and moreover, a thermal expansion coefficient of a pressure block is reduced to some extent in comparison with that of the pressure block with common diamond.

Owner:BEIJING UNIV OF TECH

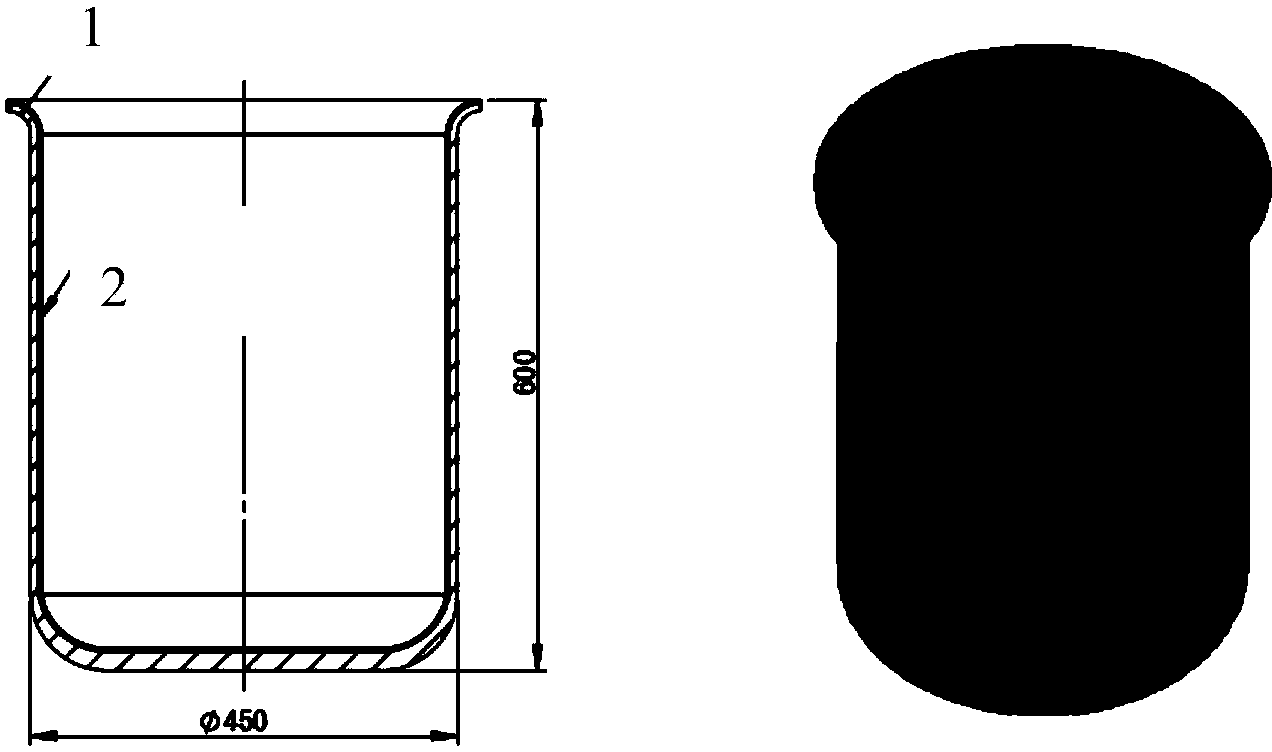

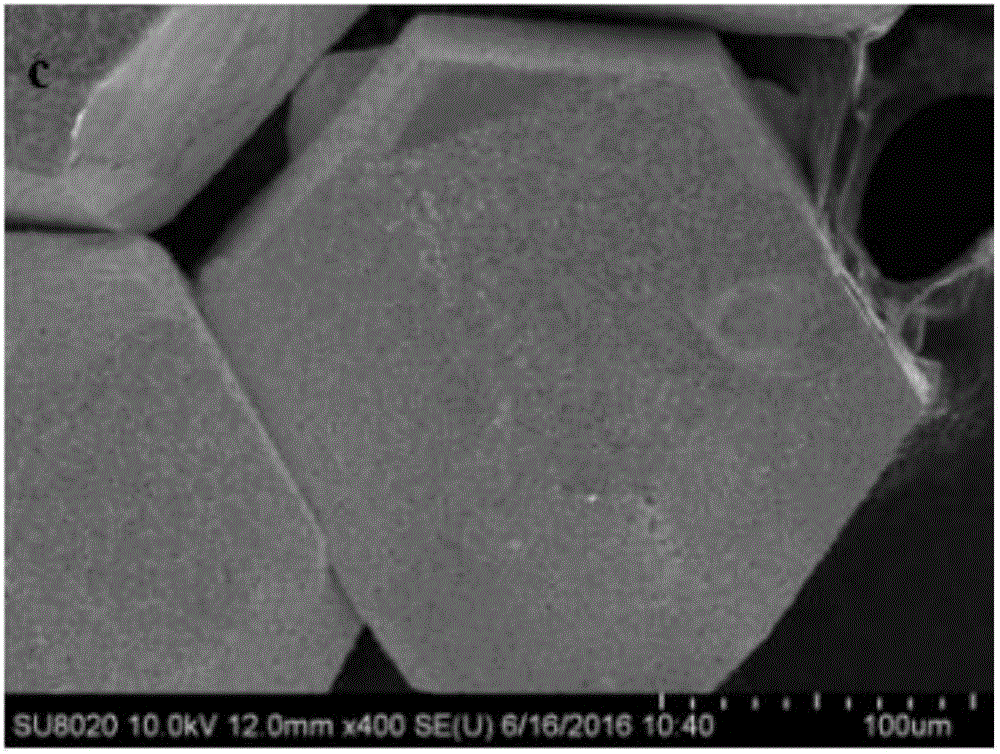

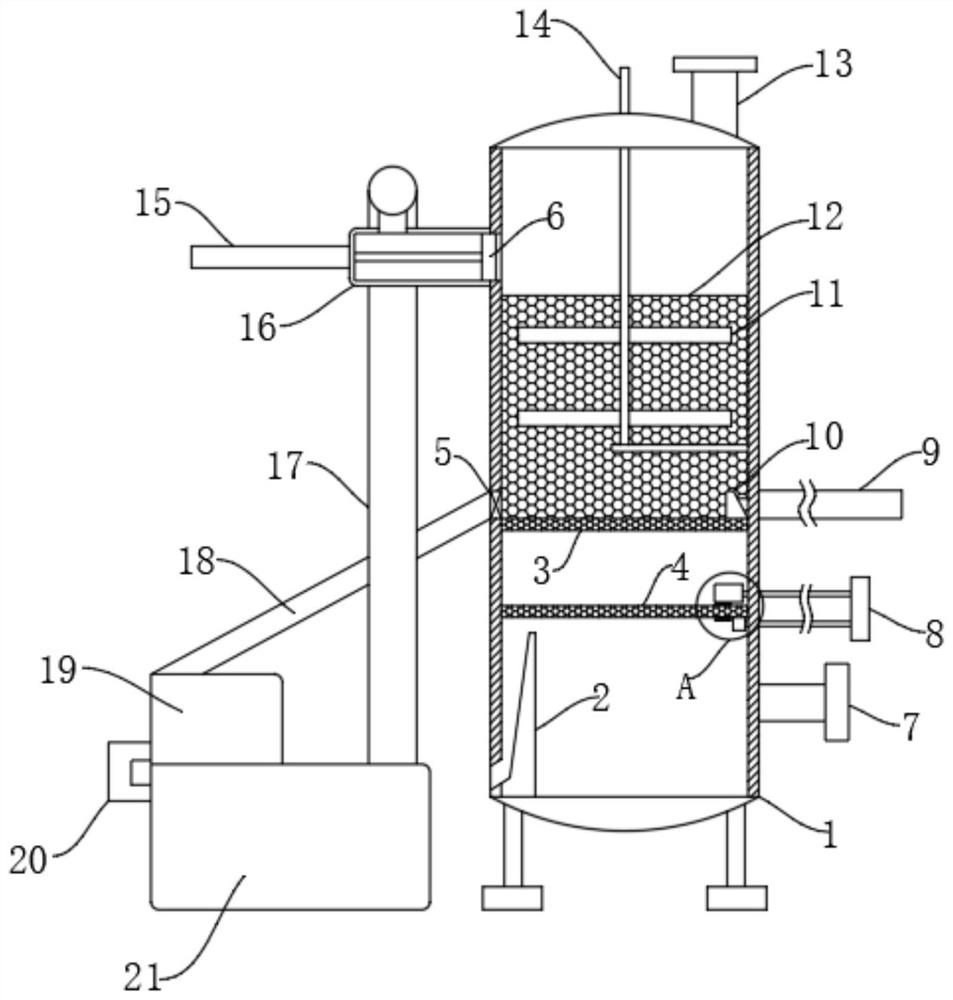

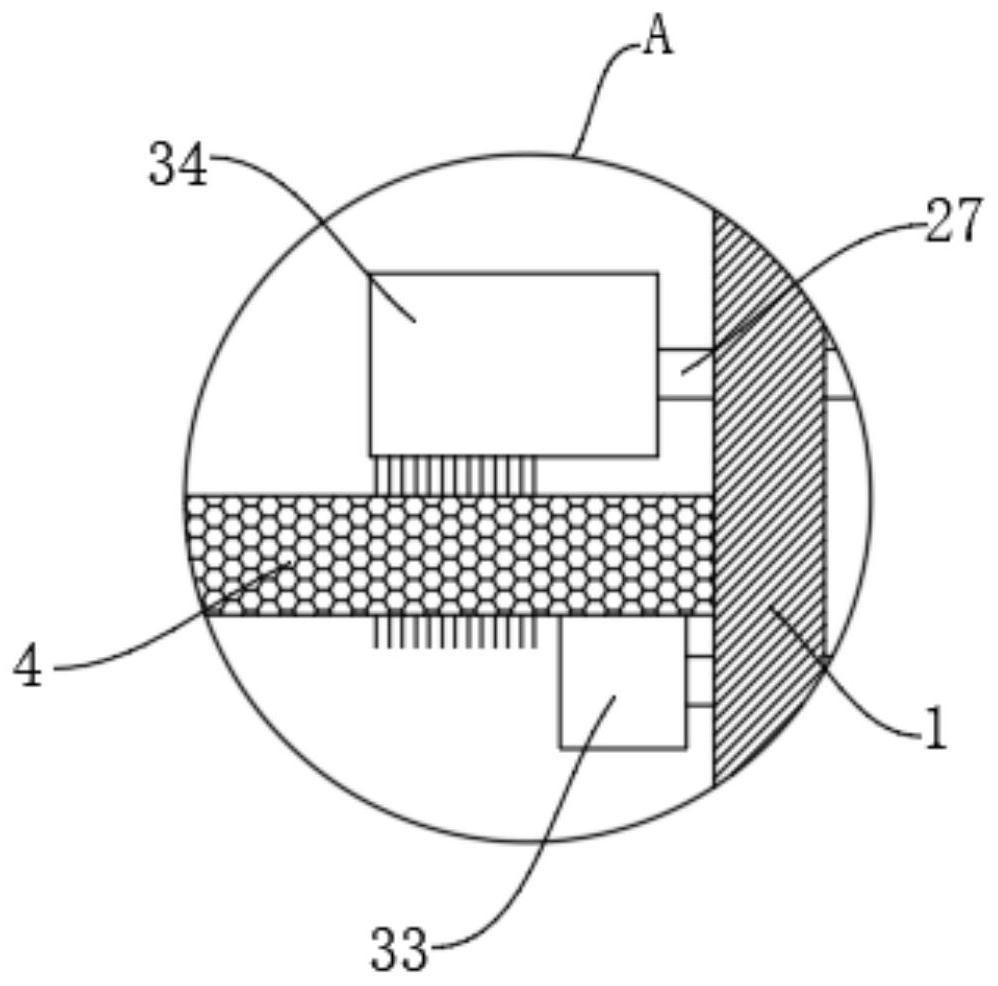

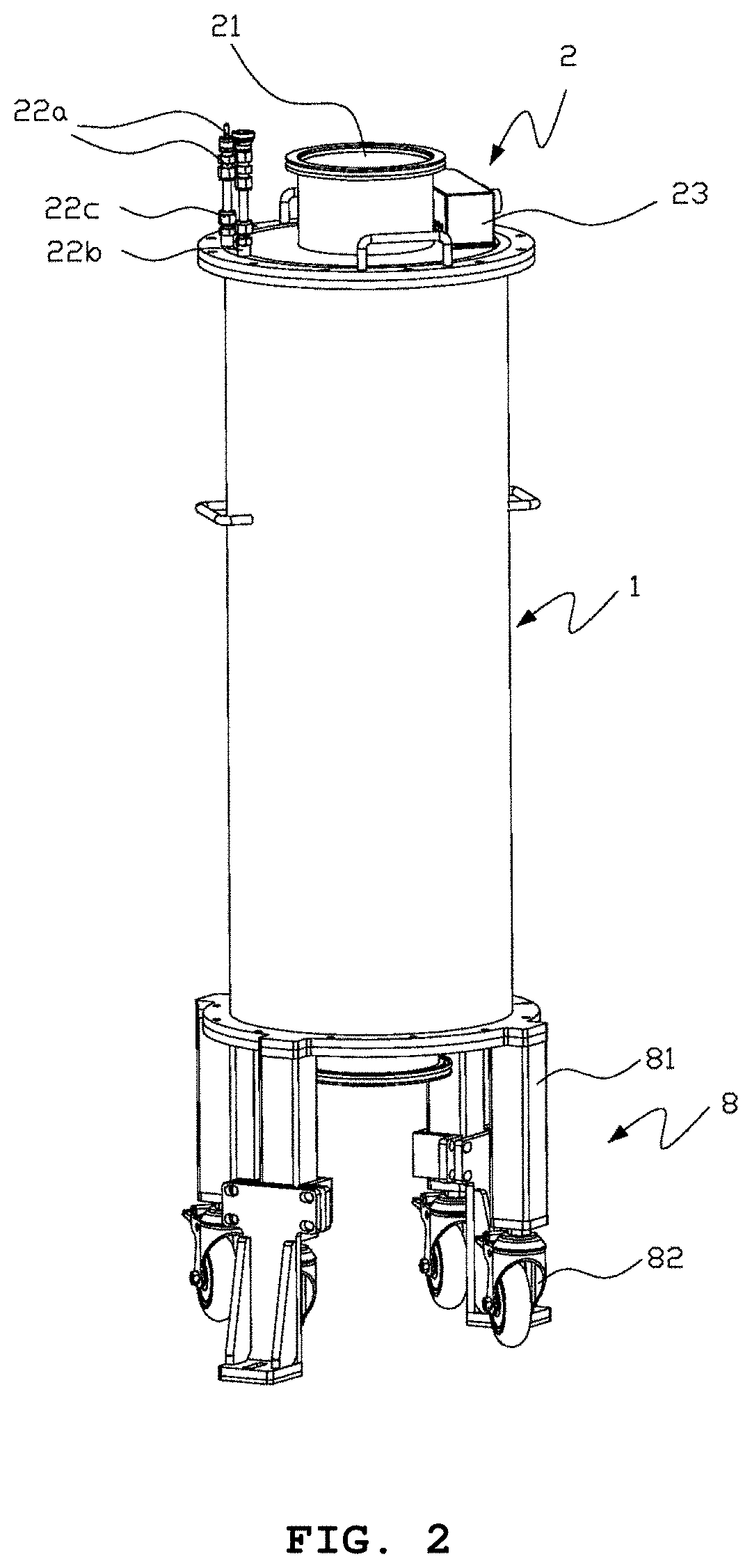

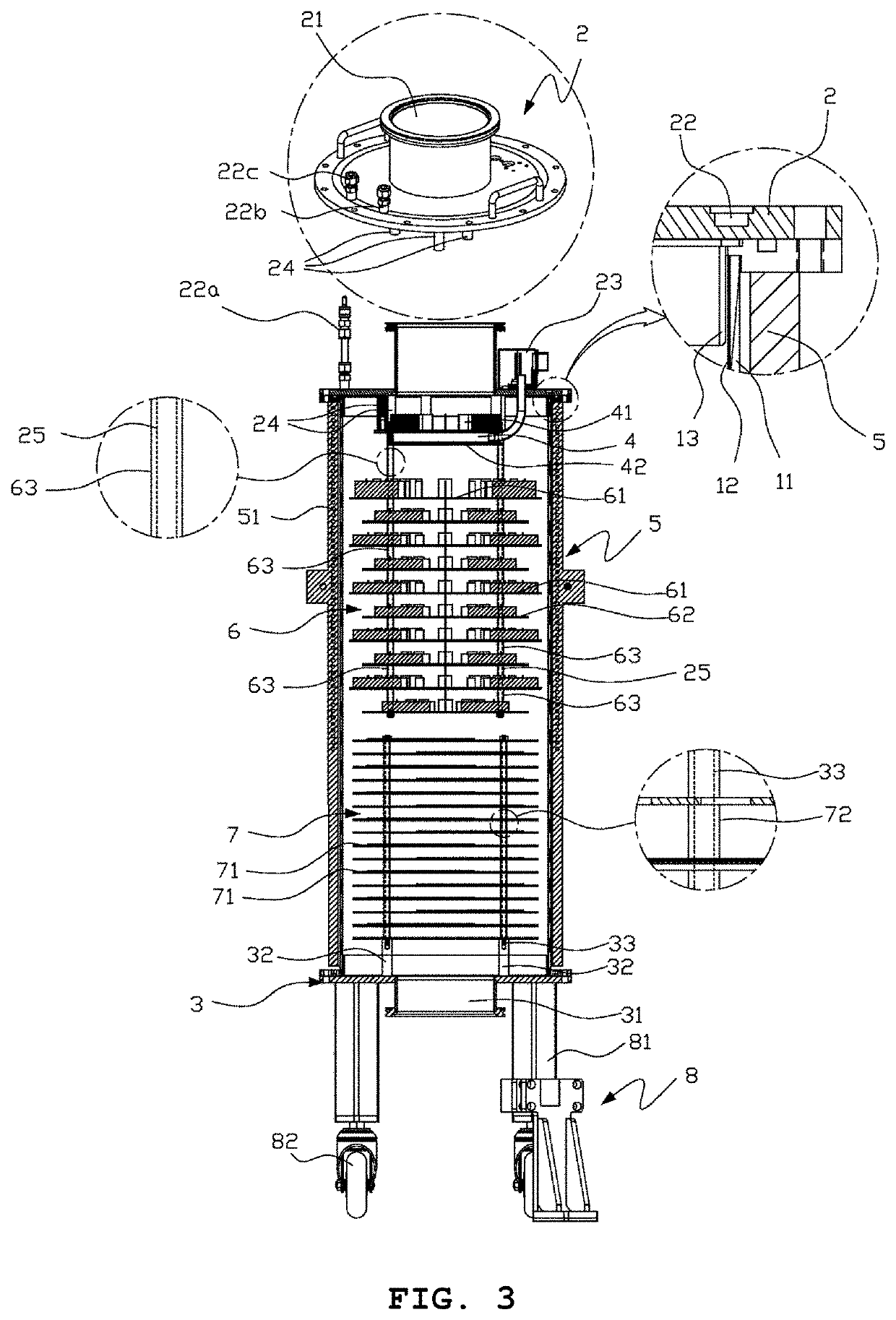

Adsorption tower for preparing high-purity tungsten hexafluoride

PendingCN111729468AGuaranteed adsorption effectIncrease profitTungsten halidesGas treatmentMetallurgyPhysical chemistry

The invention relates to an adsorption tower for preparing high-purity tungsten hexafluoride, and belongs to the technical field of tungsten hexafluoride preparation. The adsorption tower comprises anadsorption tower body, an adsorbent, a feeding mechanism and a discharging mechanism, and can further comprise at least one of a stirring mechanism, a cyclic utilization mechanism and a cleaning mechanism. A baffle net and a filter screen are sequentially arranged in the adsorption tower body from top to bottom; the baffle net is filled with adsorbent particles capable of adsorbing HF; filter screen for filtering granular impurities, the feeding mechanism is used for adding new adsorbent particles into the adsorption tower body; the discharging mechanism is used for discharging adsorbent particles with high utilization rate at the bottom of the adsorbent filled on the baffle net, the stirring mechanism is used for stirring the adsorbent particles filled on the baffle net, the cyclic utilization mechanism is used for desorbing the discharged adsorbent particles for cyclic utilization, and the cleaning mechanism is used for cleaning the filter net. According to the adsorption tower, through reasonable structural design, the utilization rate of an adsorbent can be greatly increased, and the adsorption effect can be improved.

Owner:PERIC SPECIAL GASES CO LTD

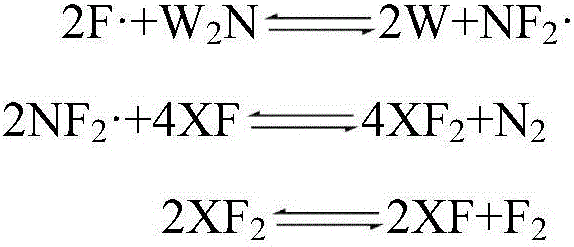

Preparation method of high-purity tungsten hexafluoride

ActiveCN106587159AThe preparation method is safe and economicalEnsure safetyTungsten halidesChemical industryEnvironmental resistance

The invention relates to a preparation method of high-purity tungsten hexafluoride, and belongs to the technical field of fluorine chemical industry. The preparation method comprises the following steps: introducing nitrogen trifluoride gas into a cracker containing a catalyst to perform cracking; then enabling a fluorine-nitrogen mixture obtained by cracking to react with tungsten powder; performing condensation to obtain a tungsten hexafluoride crude product; and performing distillation and rectification to obtain tungsten hexafluoride of which the purity reaches 99.999%. The preparation method provided by the invention is safe and economical, the introduction of the catalyst ensures that nitrogen is not needed to be additionally introduced into a feed gas to ensure the safety of reaction, the purity of the obtained product reaches a 6N level, and the subsequent treatment cost is reduced, so that the preparation method is economical and environment-friendly and has great industrial application values.

Owner:南大光电(淄博)有限公司

Method for separating molybdenum and tungsten from molybdenum-tungsten concentrate

ActiveCN102864300AReduce consumptionSimple methodProcess efficiency improvementNitrogenMolybdenum chloride

A method for separating molybdenum and tungsten from molybdenum-tungsten concentrate is characterized by including well mixing molybdenum-tungsten concentrate with reducing agent; introducing nitrogen for chloridizing roasting; allowing molybdenum and tungsten to volatilize in chloride form; collecting molybdenum and tungsten chlorides and adding the chlorides into water or dilute hydrochloric acid solution to form tungsten chloride precipitate and molybdenum chloride solution; filtering and cleaning to separate the molybdenum and tungsten. The molybdenum-tungsten concentrate is decomposed by one-step chlorination process, and molybdenum and tungsten are separated by taking the advantage of property difference between the molybdenum chloride and the tungsten chloride. The method can be used to process concentrates different in molybdenum and tungsten content, and has the advantages of simplicity, low reagent consumption and the like.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

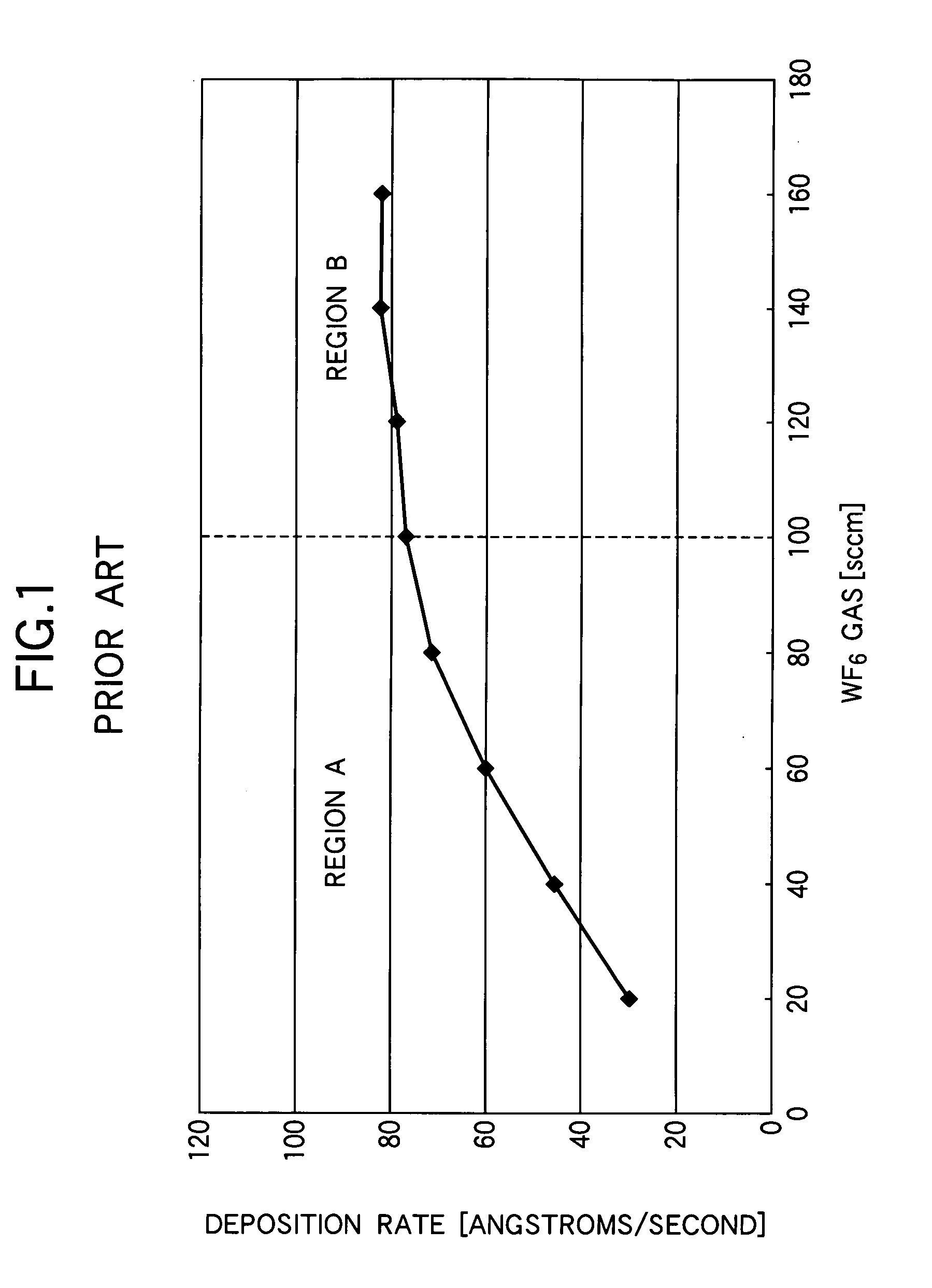

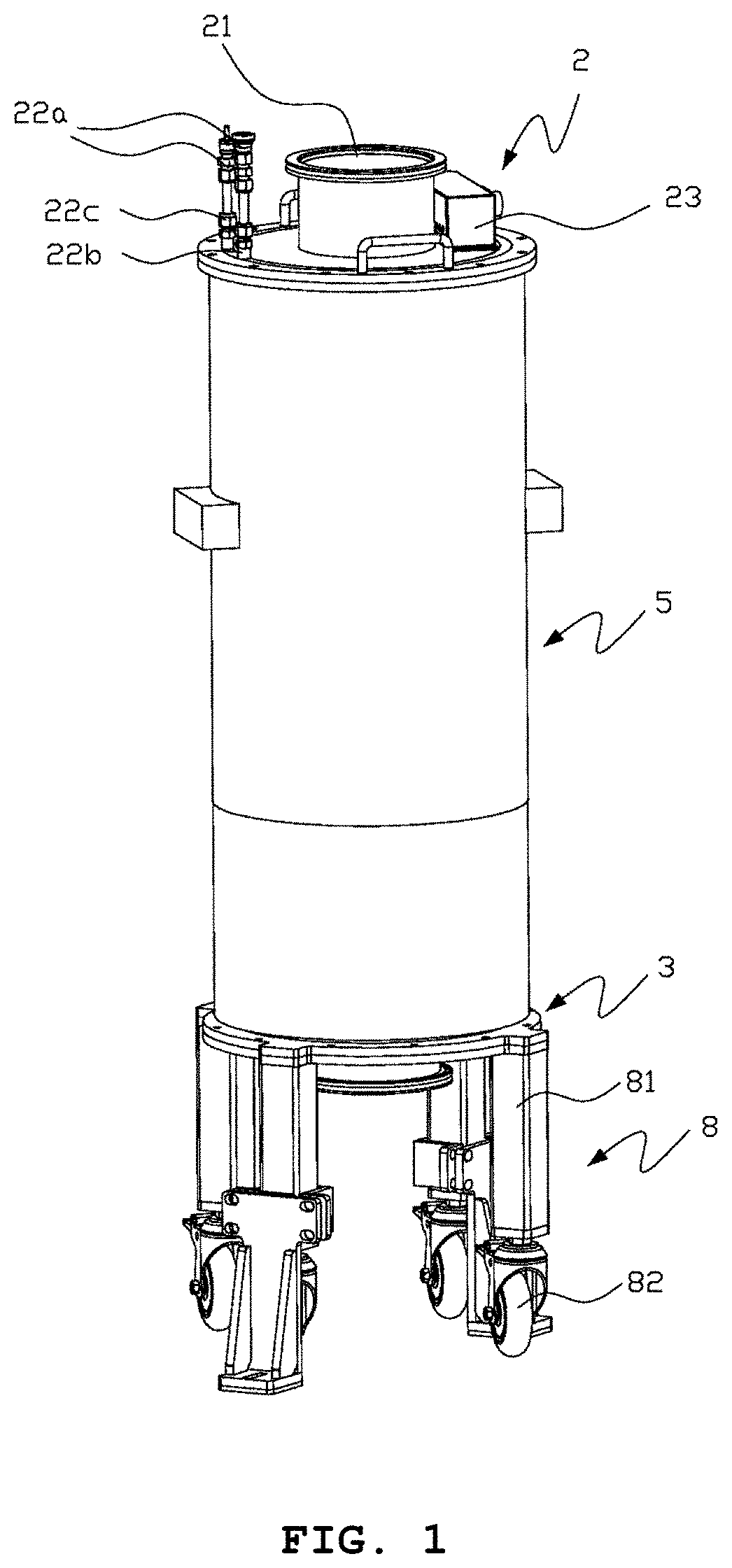

Apparatus for collecting by-product of semiconductor manufacturing process

ActiveUS20200321226A1Efficient collectionIncrease contact areaGas treatmentAuxillary pretreatmentMechanical engineeringSemiconductor

Disclosed is an apparatus for collecting a by-product in a semiconductor manufacturing process, the apparatus including: a heating jacket provided detachably along an outer circumference of a housing unit to provide a uniform temperature in a space into which exhaust gas containing tungsten hexafluoride (WF6) discharged after being used in a semiconductor manufacturing process flows; an upper internal collecting tower having first collecting plates and second collecting plates alternately arranged at regular intervals in a vertical direction to realize sufficient moving path and time in a narrow space; and a lower internal collection tower having third collecting plates arranged at regular intervals in the vertical direction, the third collecting plates having different regions on each surface thereof such that each of the third collecting plates is misaligned with a next third collecting plate to realize sufficient moving path and time in a narrow space.

Owner:MILAEBO

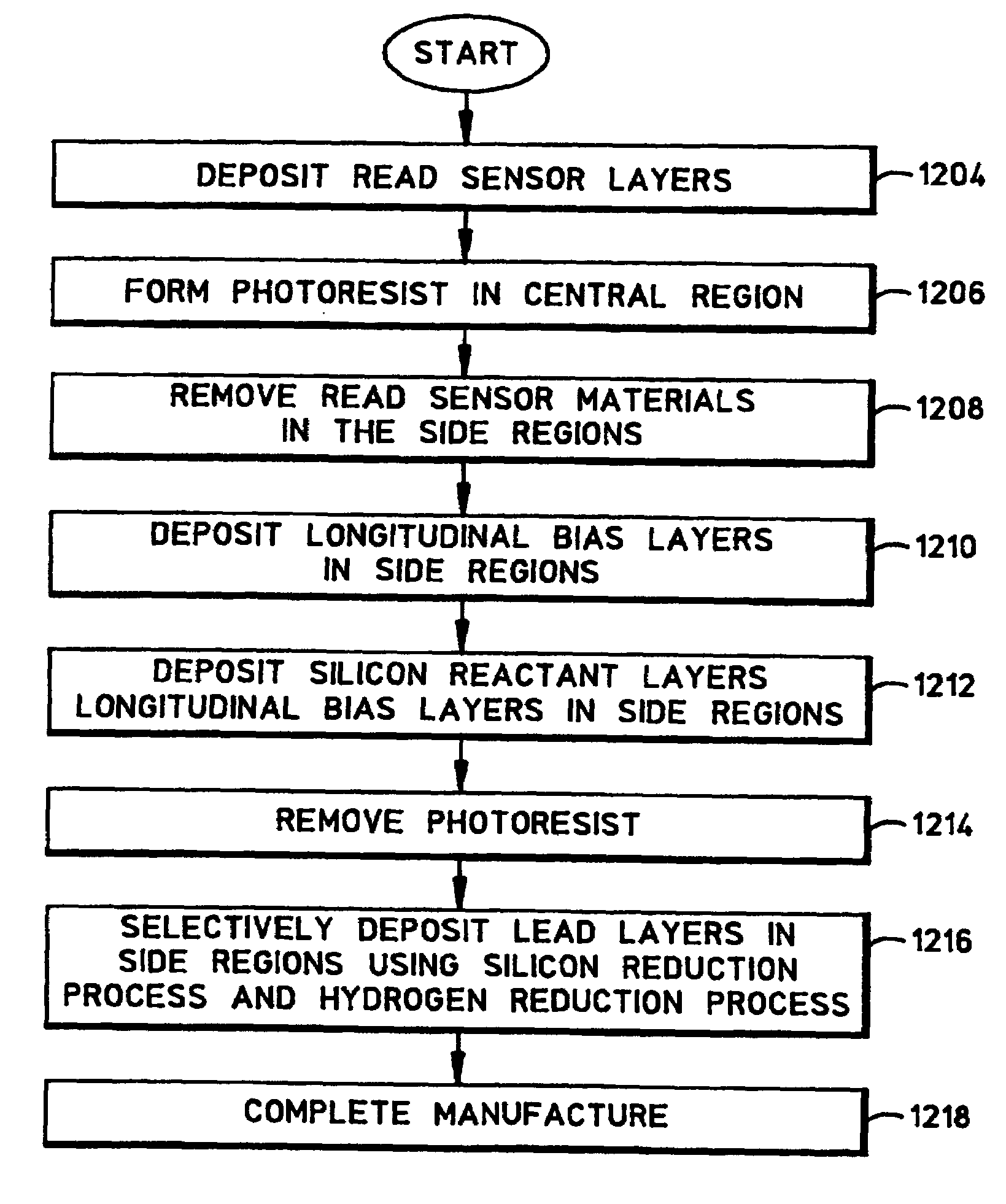

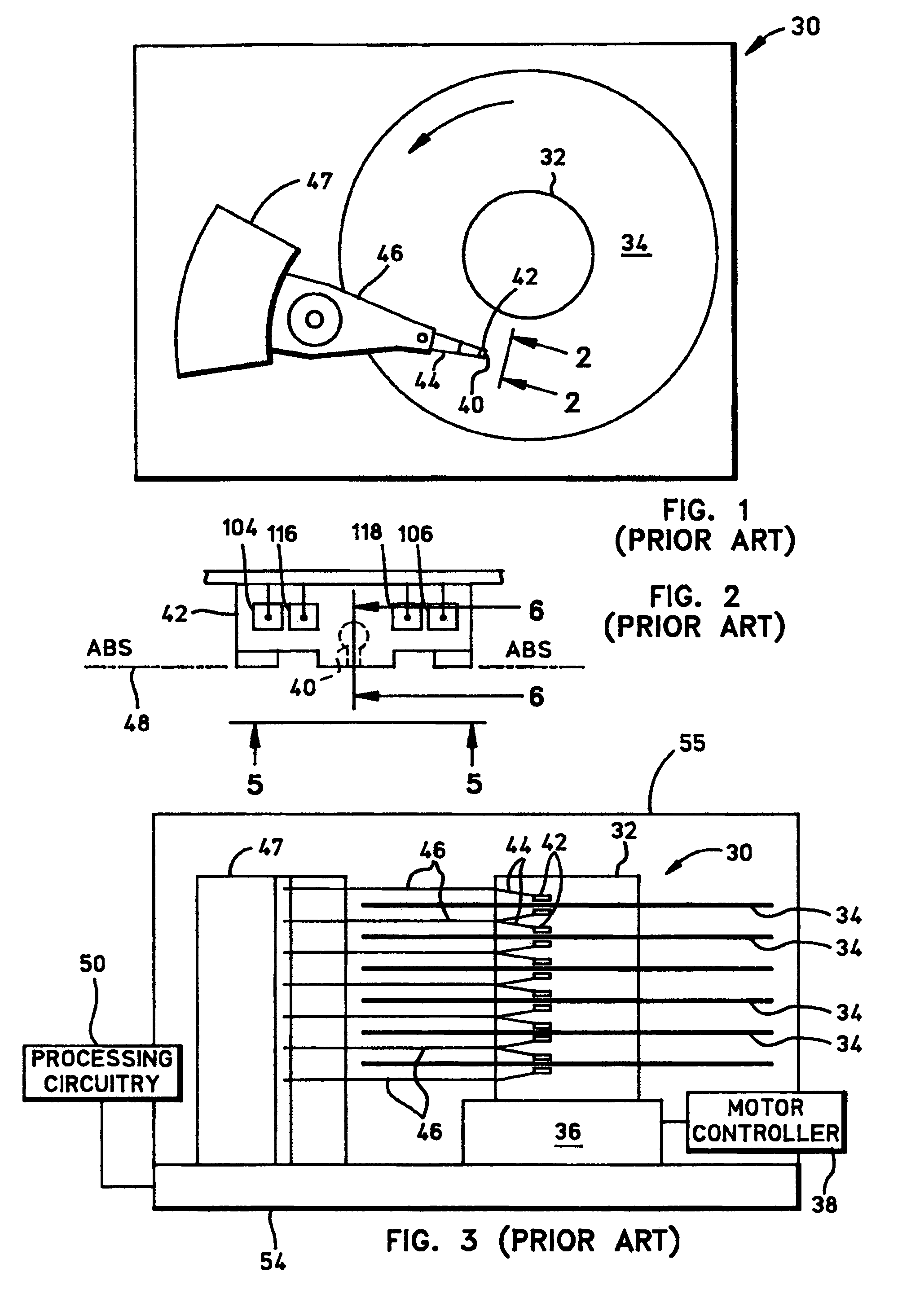

Method for use in making a read head

Methods of making a read sensor with a selectively deposited lead layers are disclosed. In one illustrative example, the method includes the acts of forming a plurality of read sensor layers over a wafer; forming a monolayer photoresist to mask the plurality of read sensor layers in a central region; ion milling to remove the unmasked plurality of read sensor layers in side regions to thereby form a read sensor in the central region; depositing longitudinal bias layers in the side regions; and depositing a silicon reactant layer over the longitudinal bias layers in the side regions. After removing the monolayer photoresist, a silicon reduction process and a hydrogen reduction process are sequentially performed for the selective depositions of the lead material. In the silicon reduction process, tungsten hexafluoride (WF6) and argon (Ar) gases are passed over the wafer to thereby selectively deposit a relatively thin W film only on the Si reactant layer in the side regions through the following chemical reaction: 2WF6+3Si→2W+3SiF4. In the hydrogen reduction process, WF6 and hydrogen (H2) gases are passed over the wafer to thereby selectively deposit a relatively thick W film only on the W film in the side regions through the following chemical reaction: WF6+3H2→W+6HF.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

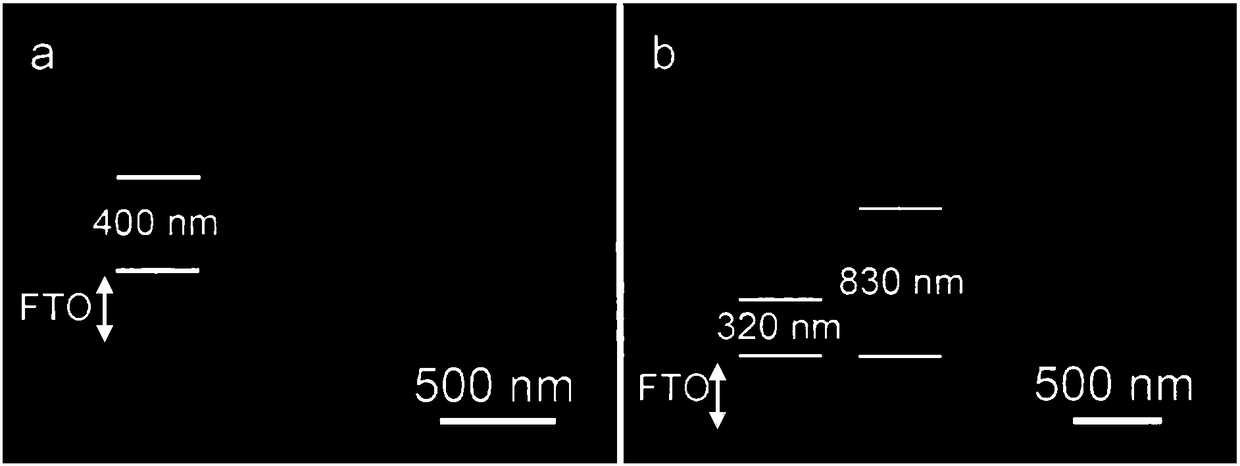

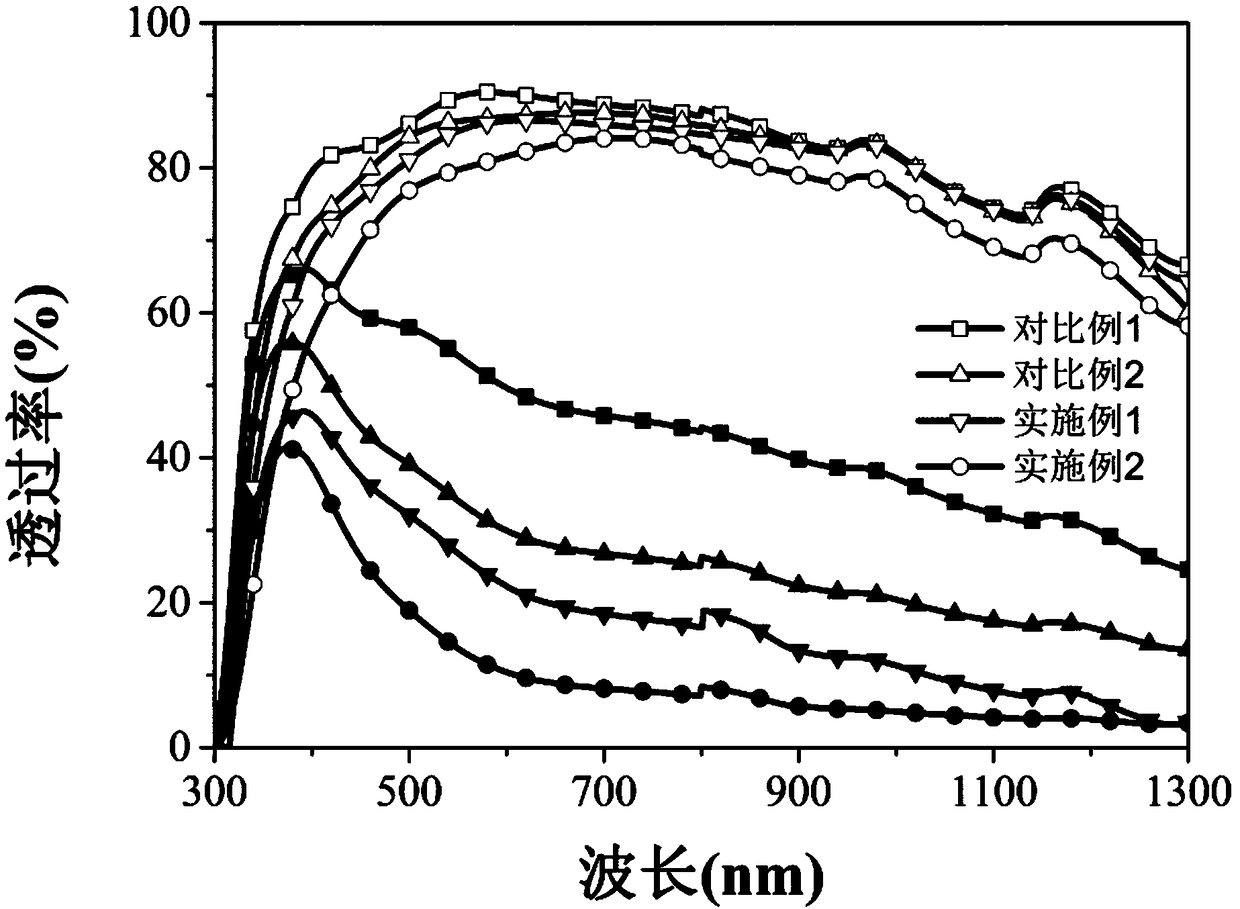

Tungsten oxide electrochromic film with high spectral adjustment range and preparation method thereof

The invention discloses a preparation method of a tungsten oxide electrochromic film with a high spectral adjustment range. The method includes: adopting tungsten hexachloride and oxalic acid as the raw materials to prepare a precursor solution, and then carrying out solvothermal reaction to obtain the product. In the precursor solution, the concentration of tungsten hexachloride is 1-15g / L. According to the preparation method of the tungsten oxide electrochromic film with a high spectral adjustment range provided by the invention, oxalic acid is introduced as a structural adjustment agent toincrease the adhesion amount of the tungsten oxide electrochromic film on a conductive substrate under a low W source concentration, thus effectively enhancing the spectral adjustment range and increasing the raw material utilization. The preparation method is simple, is low in cost, and is safe and reliable.

Owner:ZHEJIANG UNIV

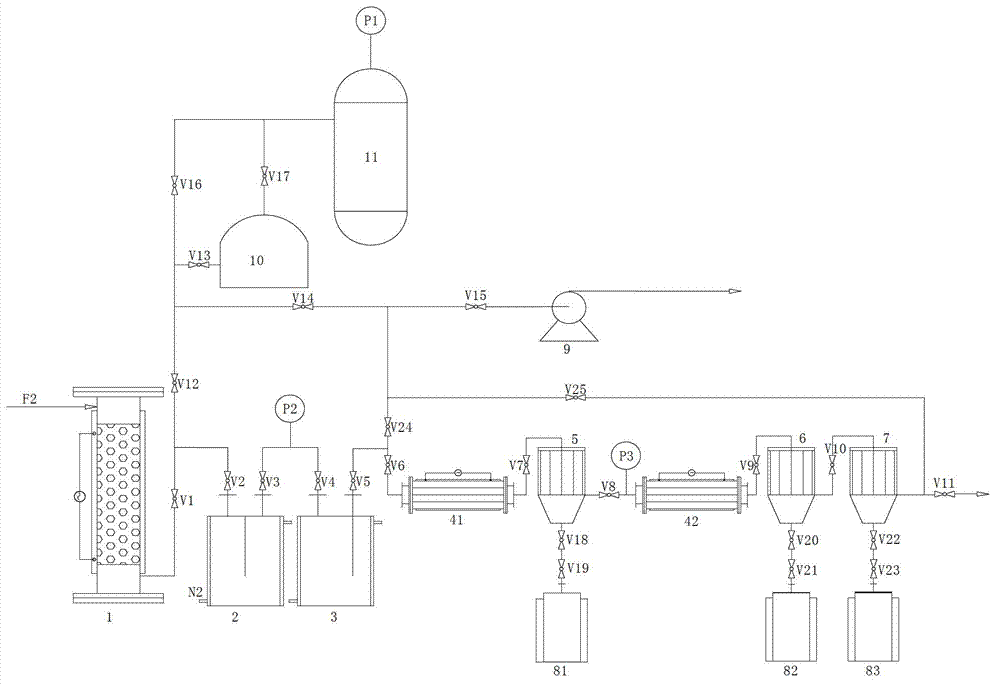

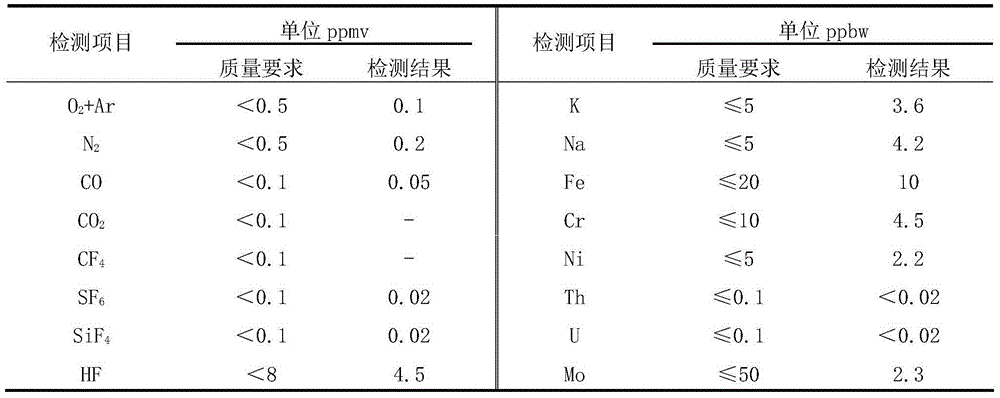

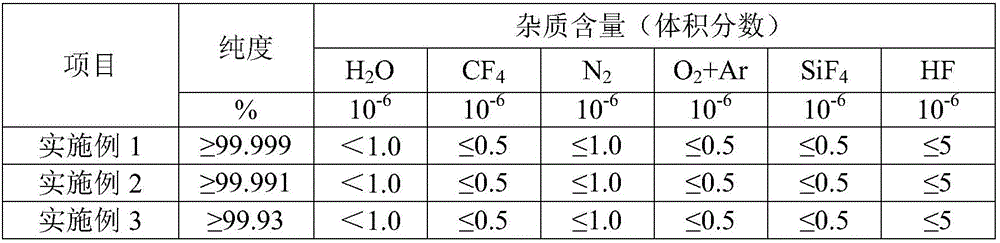

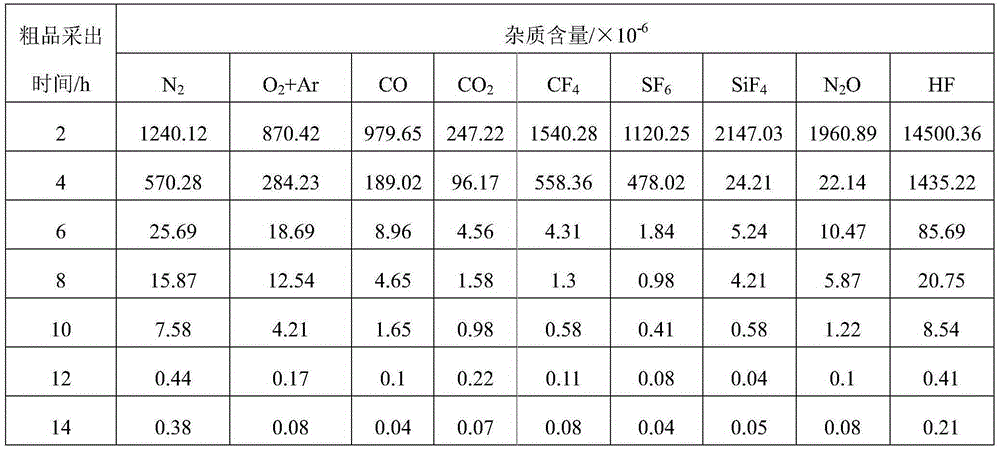

Tungsten hexafluoride gas purifying device and method

ActiveCN105417583AHigh yieldLow costTungsten halidesSpecific gas purification/separationGas phaseLiquid phase

The invention relates to a tungsten hexafluoride gas purifying device and method and belongs to the field of chemical engineering separation. The device is mainly composed of a rectification kettle, a rectification column and a condenser. Crude product WF6 gas with the purity smaller than or equal to 99% and the HF content being 1-10% is introduced into the rectification kettle, the temperature of the rectification kettle is controlled to be 30-60 DEG C, pressure is controlled to be 0.10-0.40 MPa, the temperature of the condenser is 20-50 DEG C, pressure is 0.05-0.35 MPa, the WF6 liquid is vaporized to rise and liquified to flow back, mass transfer separation happens to WF6 of a gas phase and a liquid phase in the rectification column, and therefore the purpose of removing N2, O2, CO, CO2, CF4, SiF4, SF6, N2O and HF impurities is achieved. The method is simple in technology and low in cost, 99.9999% high-purity WF6 gas can be obtained with gas low in purity and high in HF content as raw materials, and the HF content can be lowered to 0.5*10<-6> or below.

Owner:PERIC SPECIAL GASES CO LTD

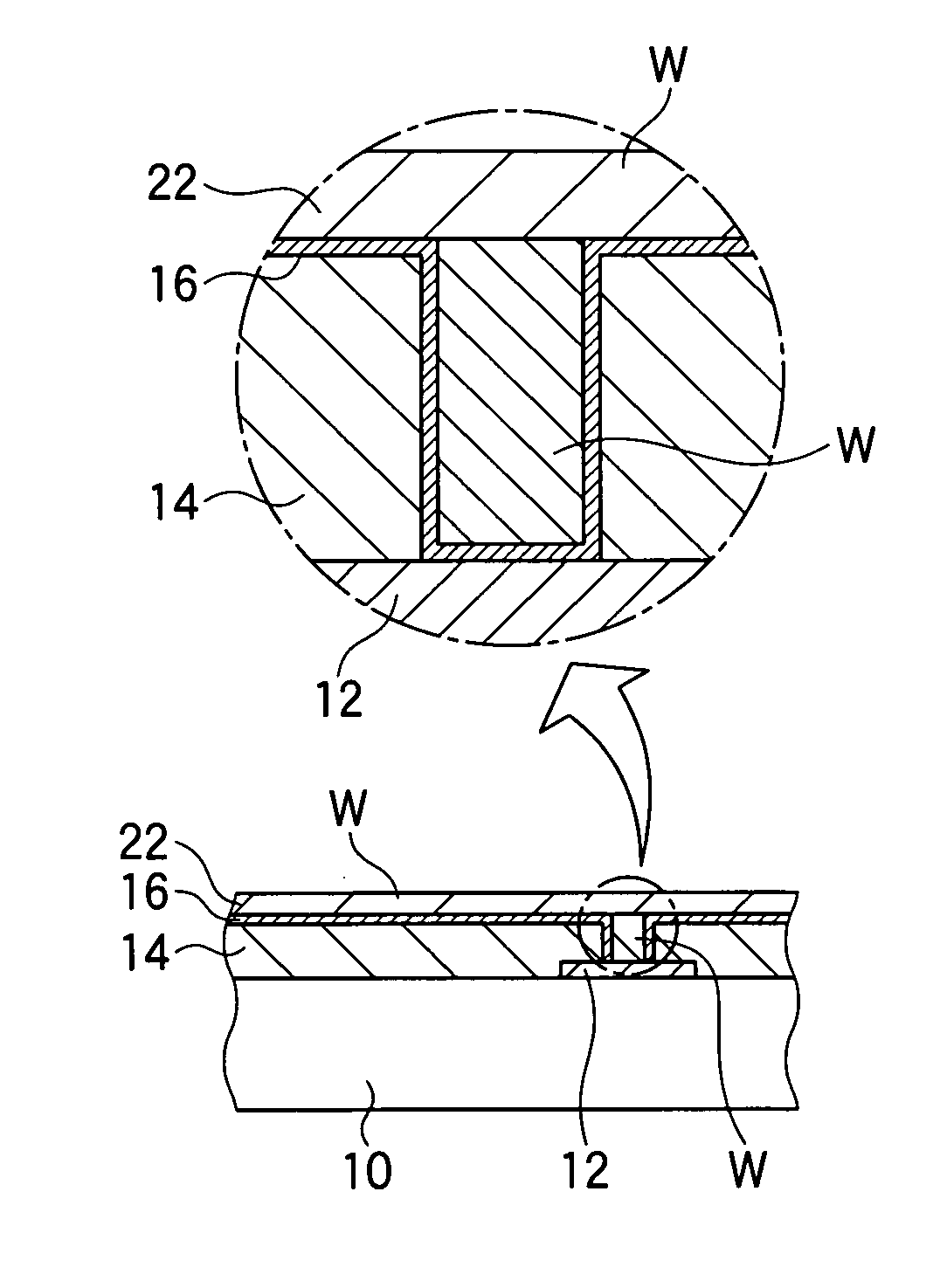

Method for forming metallic tungsten film

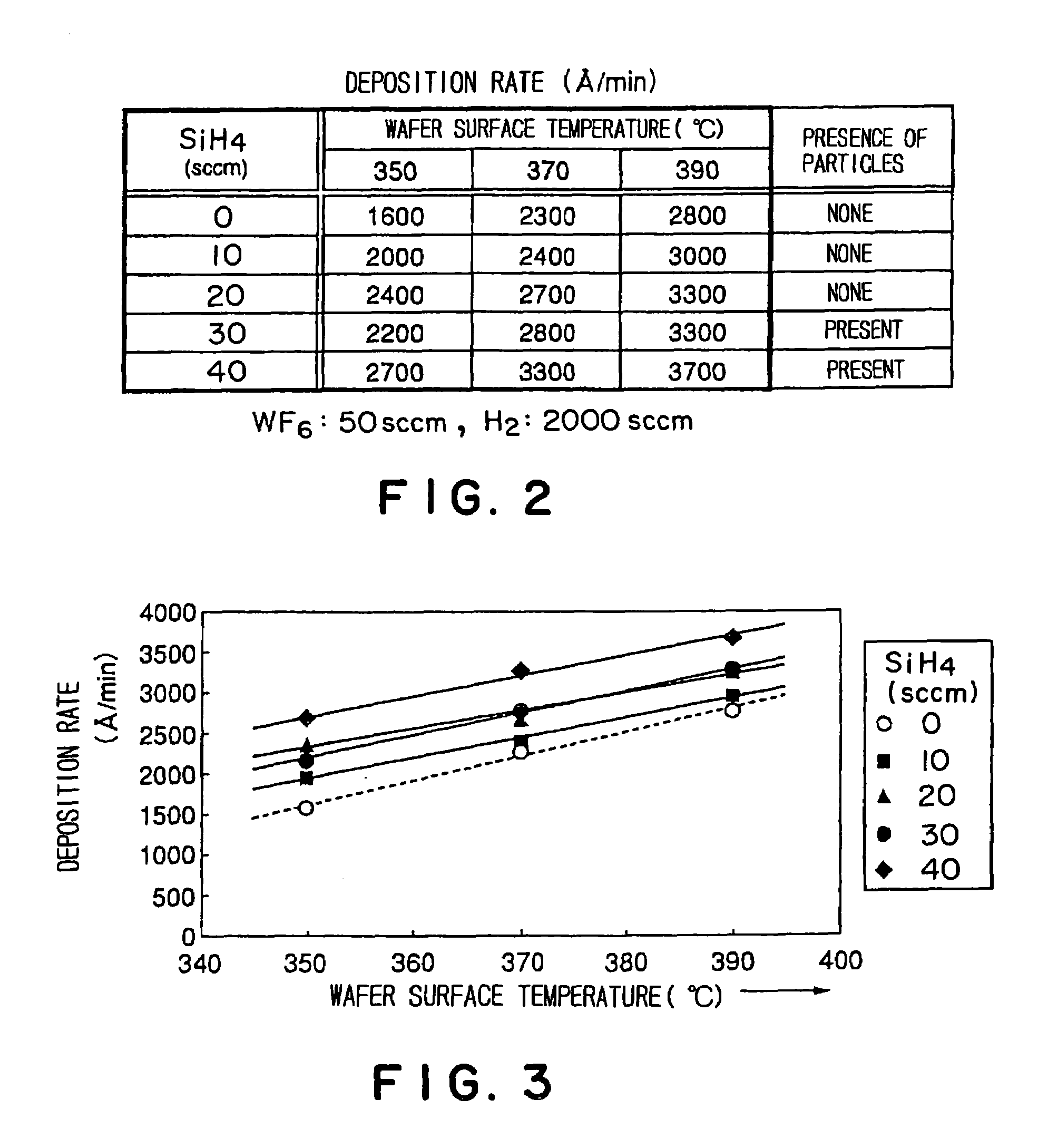

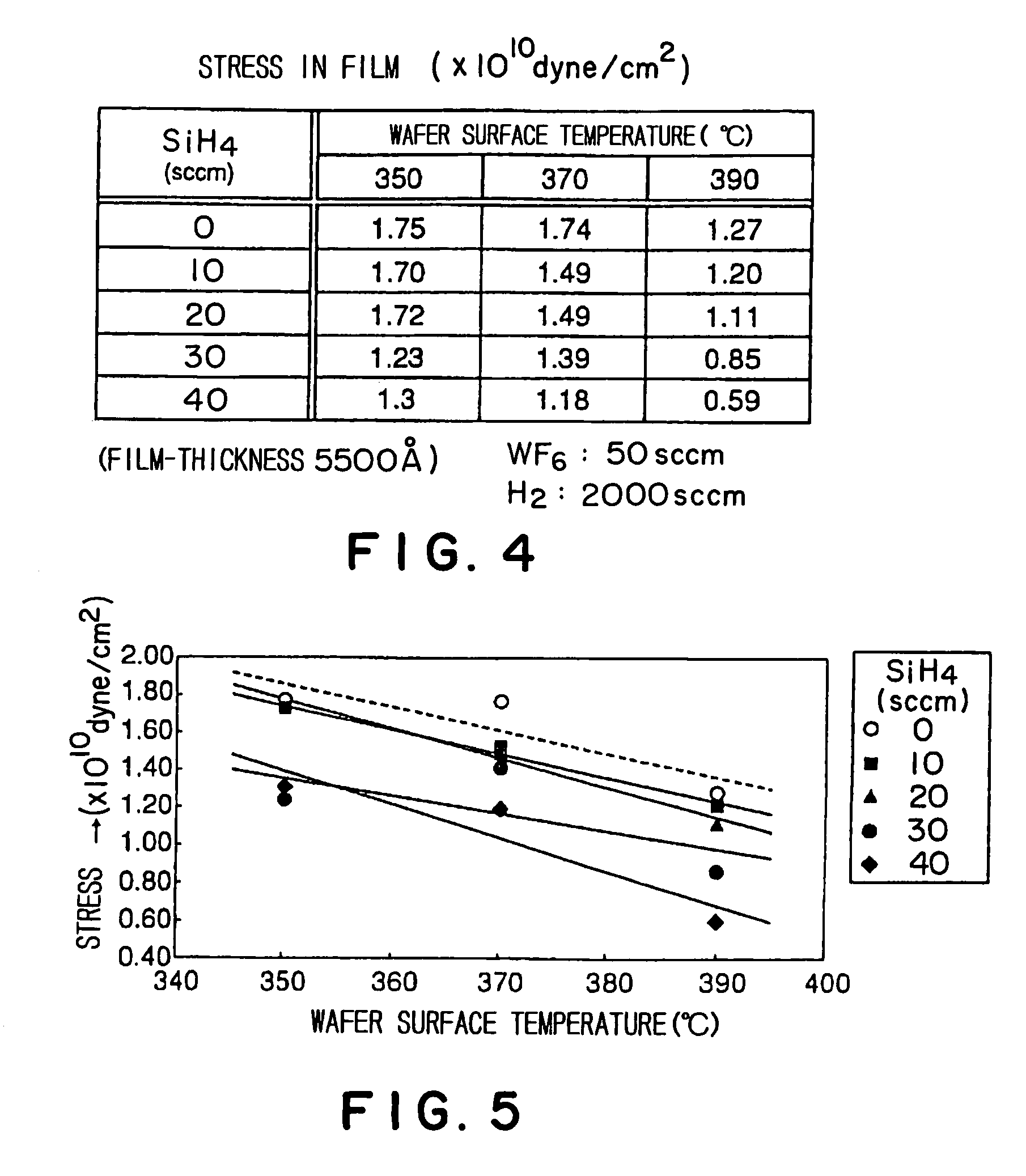

InactiveUS6964790B1Efficient solutionRelieve pressureVacuum evaporation coatingSputtering coatingProduct gasReduced properties

A deposition method for supplying process gases into an evacuated processing vessel to deposit a metal tungsten film on the surface of an object to be processed. The processing gases include tungsten hexafluoride gas, hydrogen gas, and a reducing gas which has a richer reducing property than that of the hydrogen gas, the amount of the reducing gas being smaller than that of the hydrogen gas. Thus, it is possible to form a metal tungsten film without increasing stress in the film so much even in a low temperature region of about 400° C. and without decreasing a deposition rate so much.

Owner:TOKYO ELECTRON LTD

Tungsten deposition with tungsten hexafluoride (WF6) etchback

ActiveUS9748105B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseContinuous flow

Implementations described herein generally relate to methods for forming tungsten materials on substrates using vapor deposition processes. The method comprises positioning a substrate having a feature formed therein in a substrate processing chamber, depositing a first film of a bulk tungsten layer by introducing a continuous flow of a hydrogen containing gas and a tungsten halide compound to the processing chamber to deposit the first tungsten film over the feature, etching the first film of the bulk tungsten layer using a plasma treatment to remove a portion of the first film by exposing the first film to a continuous flow of the tungsten halide compound and an activated treatment gas and depositing a second film of the bulk tungsten layer by introducing a continuous flow of the hydrogen containing gas and the tungsten halide compound to the processing chamber to deposit the second tungsten film over the first tungsten film.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com