Preparation method of high-purity tungsten hexafluoride

A tungsten hexafluoride, high-purity technology, applied in tungsten halide and other directions, can solve the problems of uneconomical, cumbersome post-processing, low product purity, etc., and achieve the effect of reducing processing cost, ensuring safety, and having high industrial application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

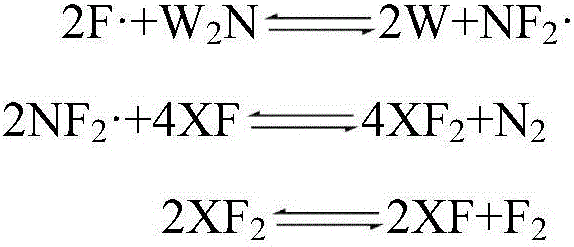

Method used

Image

Examples

Embodiment 1

[0019] NF with a purity of 99.999% 3 into the cracker, in tungsten nitride and copper fluoride (W 2 N:CuF 2 =1:1) under the catalytic action of cracking, the cracking temperature is controlled at 300°C, the cracked gas enters the reactor at a flow rate of 2-3L / min, and reacts with the tungsten powder in the reactor at 500°C, and the reaction pressure is 0.2Mpa, the gas generated by the reaction is collected after condensation, and the crude product of tungsten hexafluoride is obtained. After distillation (10-30°C, 0-0.5Mpa) and rectification (15-30°C, 0-0.2Mpa), high-purity Tungsten hexafluoride gas.

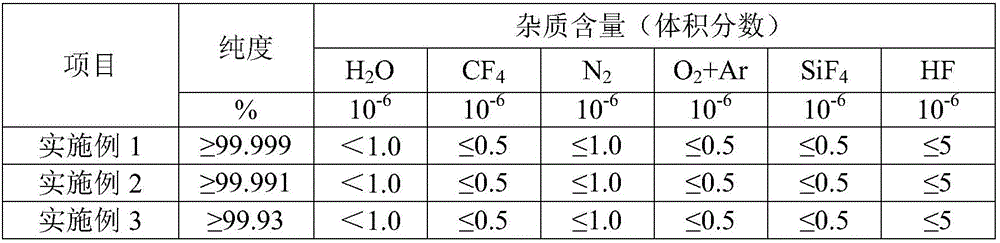

[0020] The purity of the high-purity tungsten hexafluoride gas obtained in this implementation was tested, and the test results are shown in Table 1.

Embodiment 2

[0022] NF with a purity of 99.995% 3 into the cracker, in tungsten nitride and nickel fluoride (W 2 N:NiF 2 =1:8) under the catalytic action of cracking, the cracking temperature is controlled at 280°C, the cracked gas enters the reactor at a flow rate of 2-3L / min, and reacts with the tungsten powder in the reactor at 500°C, and the reaction pressure is 0.2Mpa, the gas generated by the reaction is collected after condensation, and the crude product of tungsten hexafluoride is obtained. After distillation (10-30°C, 0-0.5Mpa) and rectification (15-30°C, 0-0.2Mpa), high-purity Tungsten hexafluoride gas.

[0023] The purity of the high-purity tungsten hexafluoride gas obtained in this implementation was tested, and the test results are shown in Table 1.

Embodiment 3

[0025] NF with a purity of 99.96% 3 into the cracker, in tungsten nitride and ferric fluoride (W 2 N:FeF 3 =1:10) under the catalytic action of cracking, the cracking temperature is controlled at 250°C, the cracked gas enters the reactor at a flow rate of 2-3L / min, and reacts with the tungsten powder in the reactor at 500°C, and the reaction pressure is 0.2Mpa, the gas generated by the reaction is collected after condensation, and the crude product of tungsten hexafluoride is obtained. After distillation (10-30°C, 0-0.5Mpa) and rectification (15-30°C, 0-0.2Mpa), high-purity Tungsten hexafluoride gas.

[0026] The purity of the high-purity tungsten hexafluoride gas obtained in this implementation was tested, and the test results are shown in Table 1.

[0027] Table 1 Test results

[0028]

[0029] It can be seen from Table 1 that the product obtained by the preparation method of the present invention has high purity, and the subsequent treatment process is not complicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com