Method for producing high-purity tungsten hexafluoride with fluidized bed and equipment thereof

A technology of tungsten hexafluoride and fluidized bed, which is applied in the direction of tungsten halide, etc., can solve the problems of easy entrainment of tungsten powder in the product, difficulty in continuous production, and low efficiency of the reactor, so as to avoid entrainment of tungsten powder in the product and easy reaction temperature The effect of high control and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

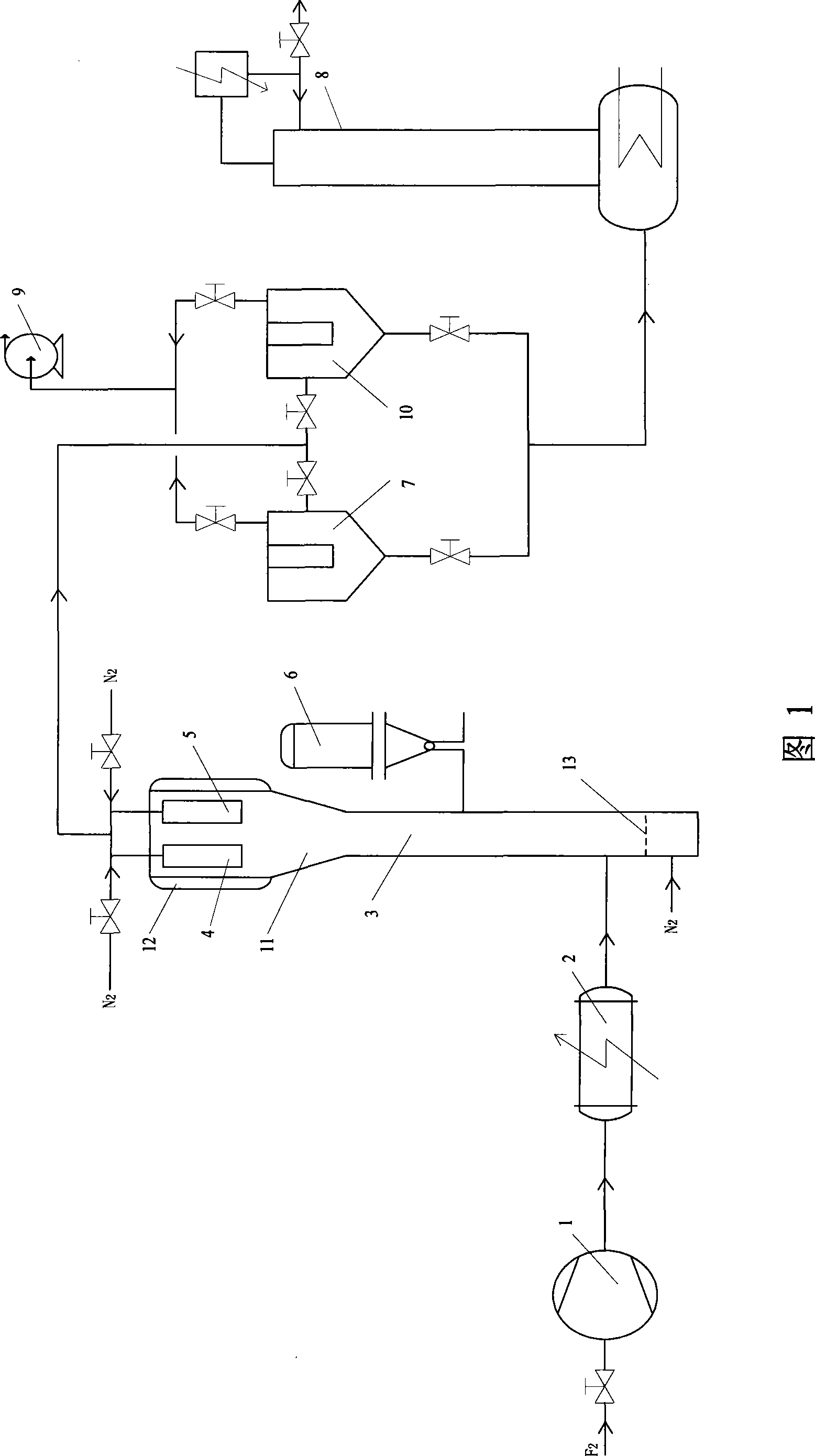

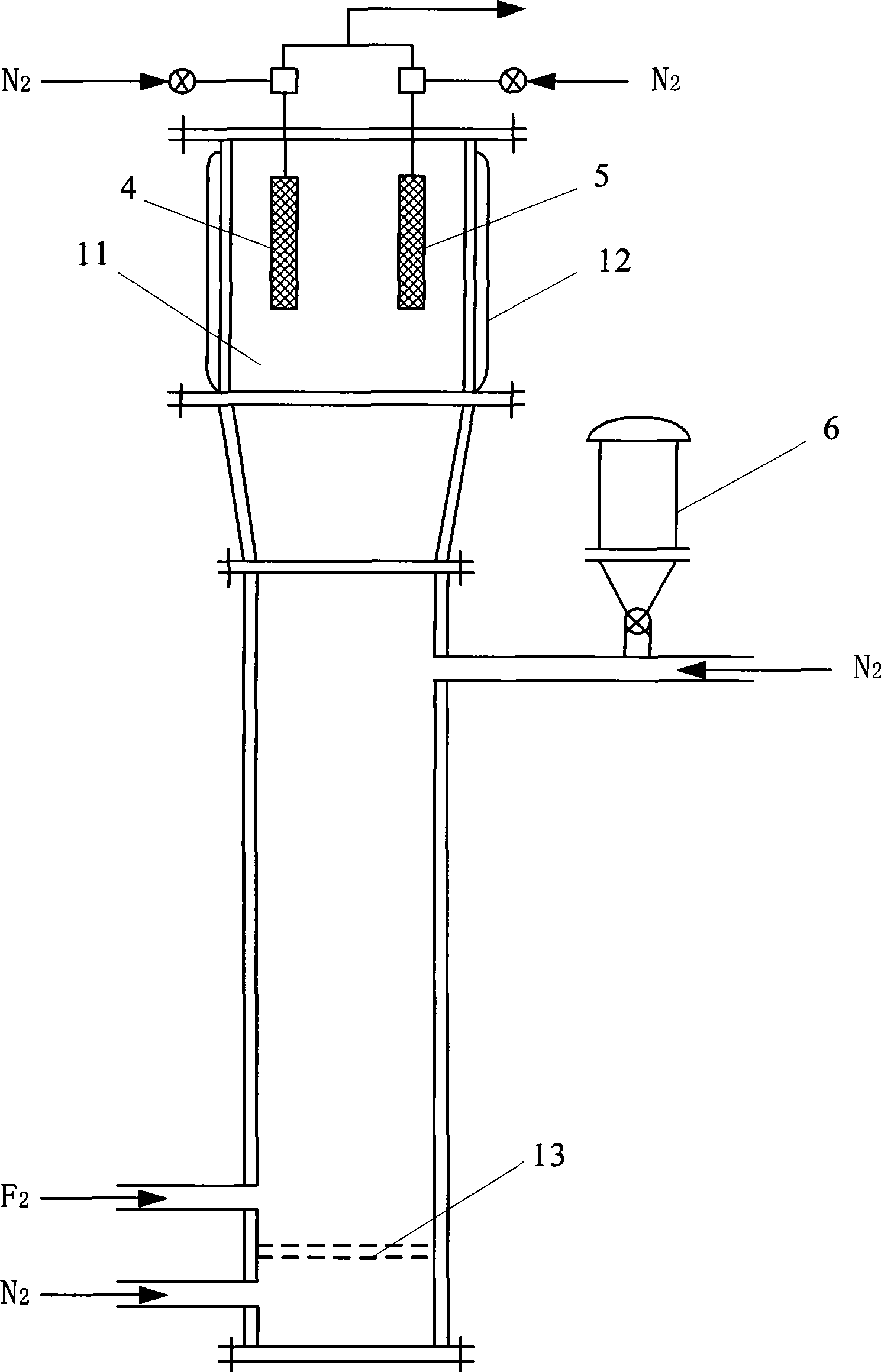

[0029] Using the reaction process shown in Figure 1, the reaction system was purged with inert gas and vacuumized before the reaction. The fluidized bed reactor is made of Monel alloy, with a diameter of 100mm and a height of 1500mm. The purity of the fluorine gas is 99%, the hydrogen fluoride content is below 20ppmv, and the feed rate of the fluorine gas is 0.8-1.6mol / min. The fluorine gas enters the preheater 2 after being pressurized by the compressor 1. The temperature of the preheater is 150°C and the pressure is 0.1-0.15Mpa. The preheater is made of Monel alloy with a diameter of 100mm and a height of 1000mm. After preheating, the gas enters the fluidized bed reactor 3, and the tungsten powder is controlled by the feed bin 6 through the discharge valve, and is fed under the action of nitrogen at a feed rate of 0.05-0.1kg / min, and is fed by the gas distributor 13 The fed nitrogen is fluidized into a fluid state, the purity of the tungsten powder is 99.95%, and the partic...

Embodiment 2

[0032] The feed rate of fluorine gas is 1.6~3.2mol / min. The particle size of tungsten powder is 270~600 mesh, the feed rate of tungsten powder is 0.1~0.2kg / min, the temperature is 350±10℃, and the reaction pressure is 0.1~0.2MPa. Other Simultaneous Example 1.

[0033] The purity of the obtained product tungsten hexafluoride is greater than 99.99%, wherein the content of hydrogen fluoride is 20ppmv, and other impurities are not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com