Apparatus for pyrolyzing solid wastes through molten salt, and method thereof

A solid waste and molten salt technology, applied in the direction of solid waste removal, etc., can solve the problems of no proposed molten salt regeneration and reuse method, high equipment requirements, and high reaction temperature, and achieve rapid and efficient decomposition, high thermal conductivity, The effect of increasing the decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Recycling resources of waste circuit boards by pyrolysis of KOH-NaOH mixed molten salt

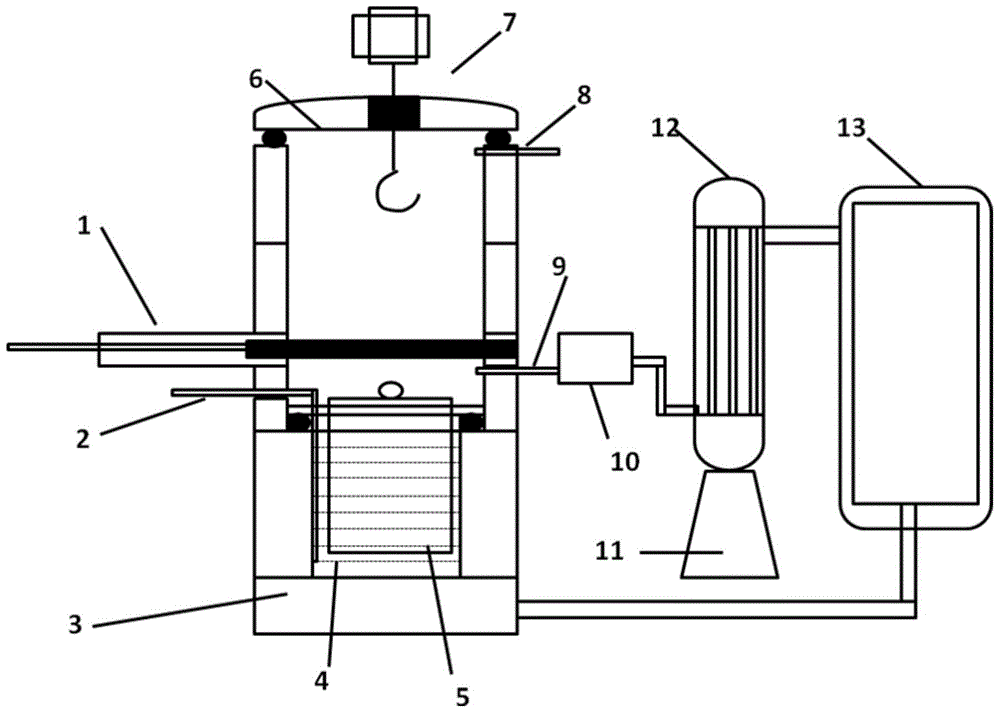

[0016] Open the material retrieving heat preservation door 1 and the reactor sealing cover 6, use the crane 7 to lower the molten salt reaction pool 4 containing 200g 40wt.%NaOH-60wt.%KOH eutectic salt to the lower end of the reaction chamber, and use electric heating to melt the molten salt The salt reaction tank is heated to 500°C and then kept at a constant temperature. The molten salt is in a liquid state, and a small amount of nitrogen gas is introduced to maintain an inert atmosphere. A crane is used to transfer the pyrolysis basket 5 containing 20g of waste circuit boards from the upper end to the upper end of the molten salt reaction tank 4, and close The reactor sealing cover and the air inlet are connected to the volatile matter outlet 9, the volatile matter reformer 10, the condenser 12, the pyrolysis oil collection tank 11 and the gas storage tank 13, check that the airti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com