Patents

Literature

221 results about "Molten salt reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A molten salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a molten salt mixture. MSRs offer multiple advantages over conventional nuclear power plants, although for historical reasons, they have not been deployed.

Molten nuclear fuel salts and related systems and methods

InactiveUS20160189813A1Improve power densityImprove the level ofFuel elementsNuclear energy generationPresent methodChloride

This disclosure describes nuclear fuel salts usable in certain molten salt reactor designs and related systems and methods. Binary, ternary and quaternary chloride fuel salts of uranium, as well as other fissionable elements, are described. In addition, fuel salts of UClxFy are disclosed as well as bromide fuel salts. This disclosure also presents methods and systems for manufacturing such fuel salts, for creating salts that reduce corrosion of the reactor components and for creating fuel salts that are not suitable for weapons applications.

Owner:TERRAPOWER

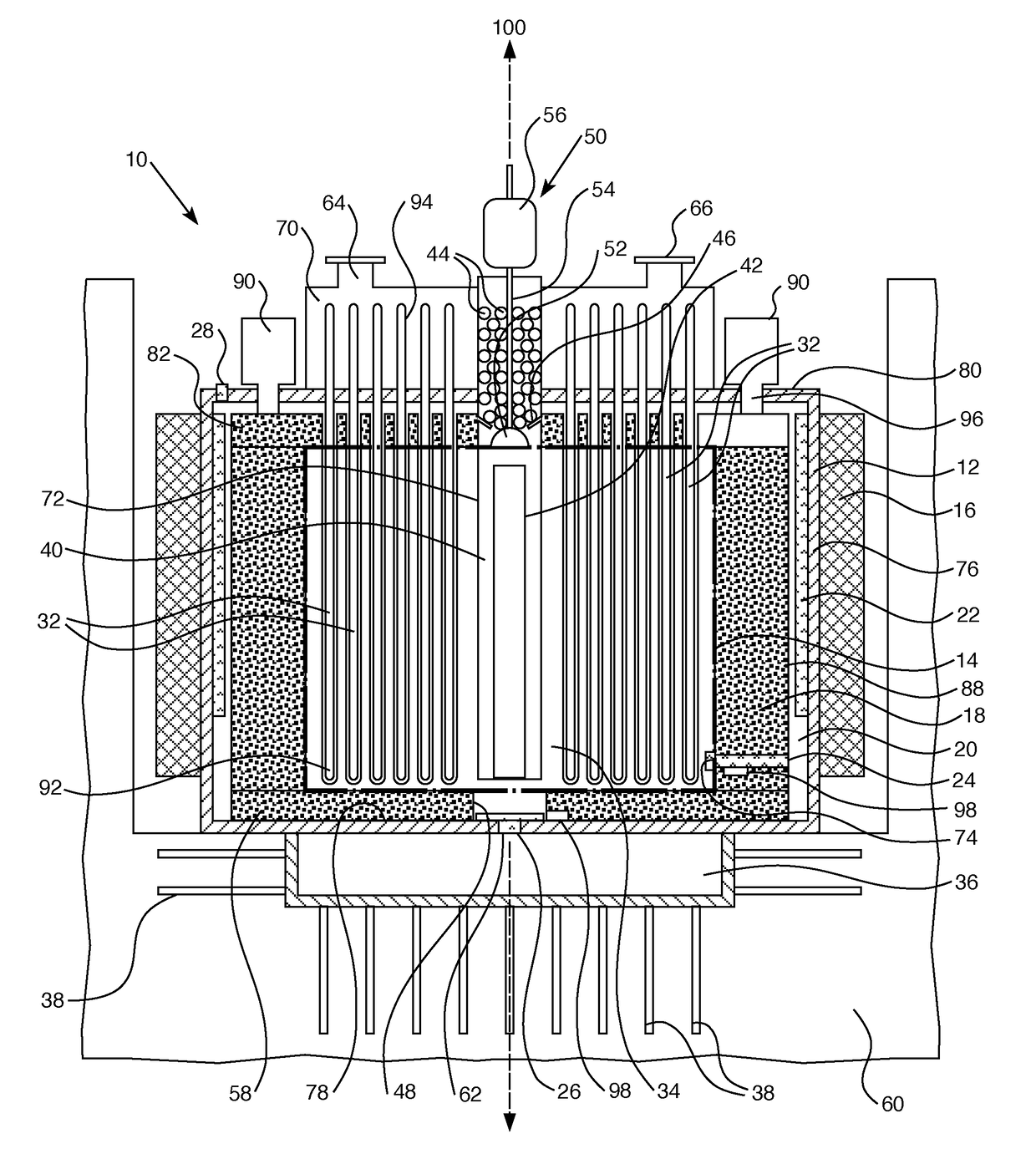

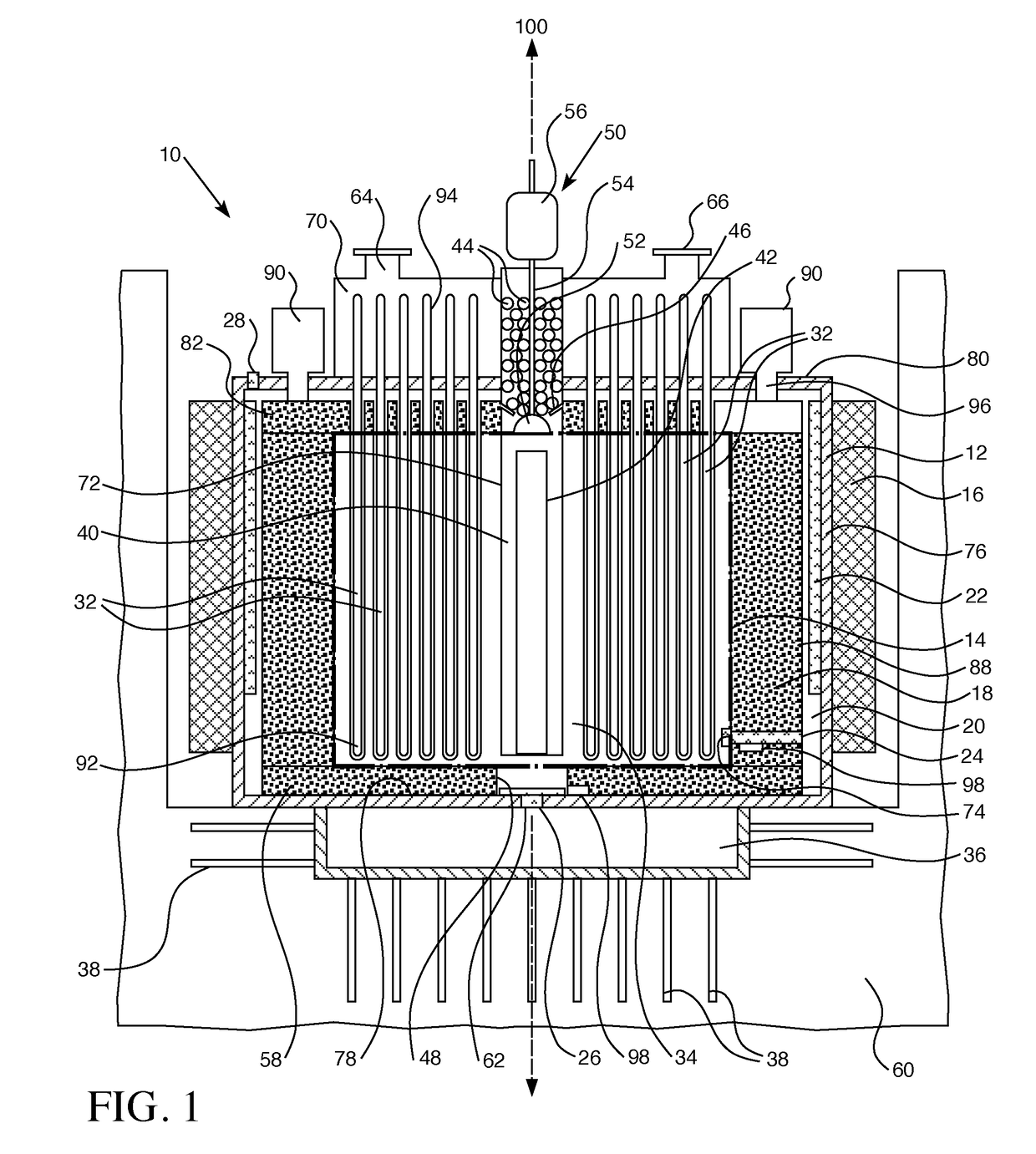

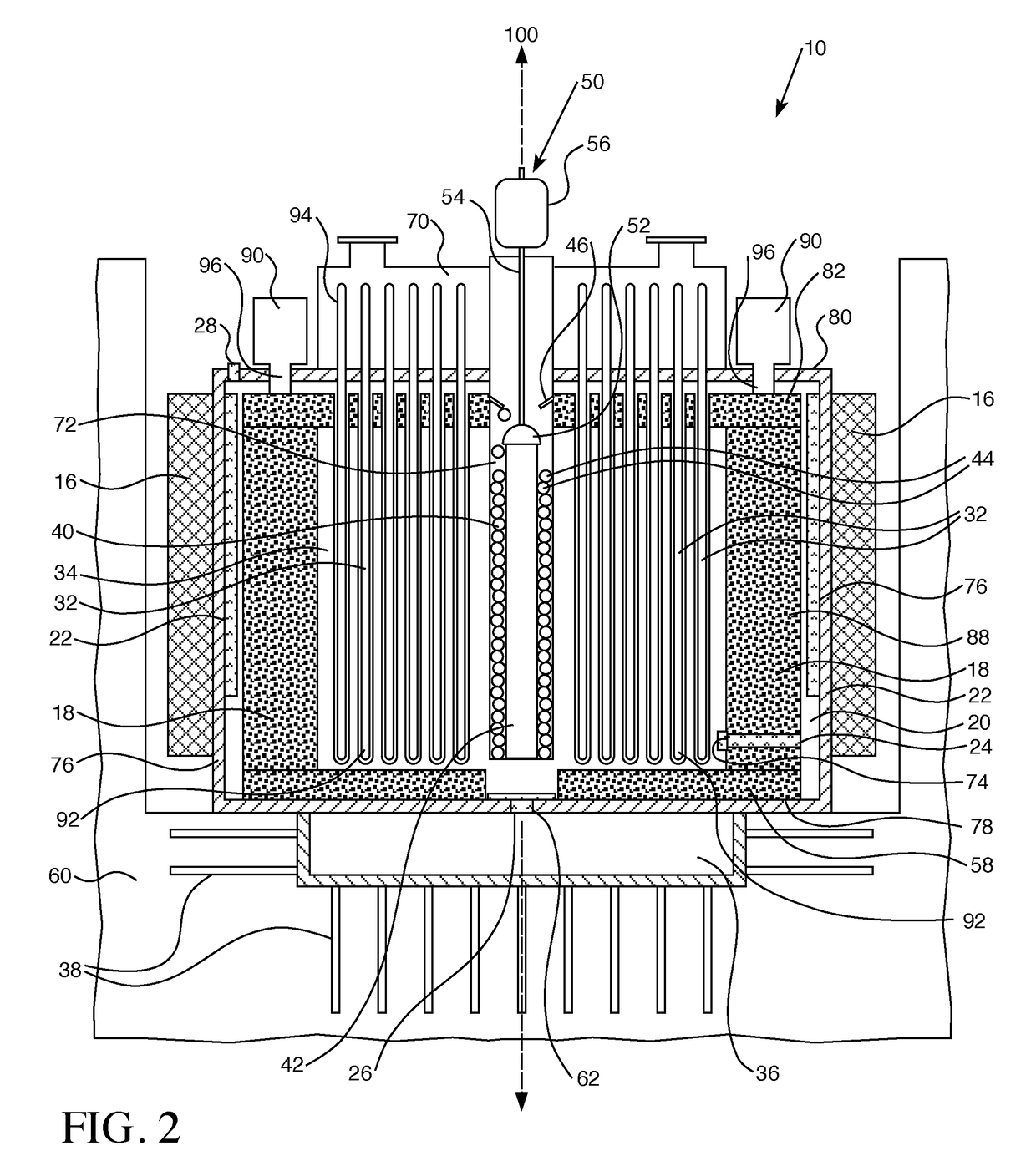

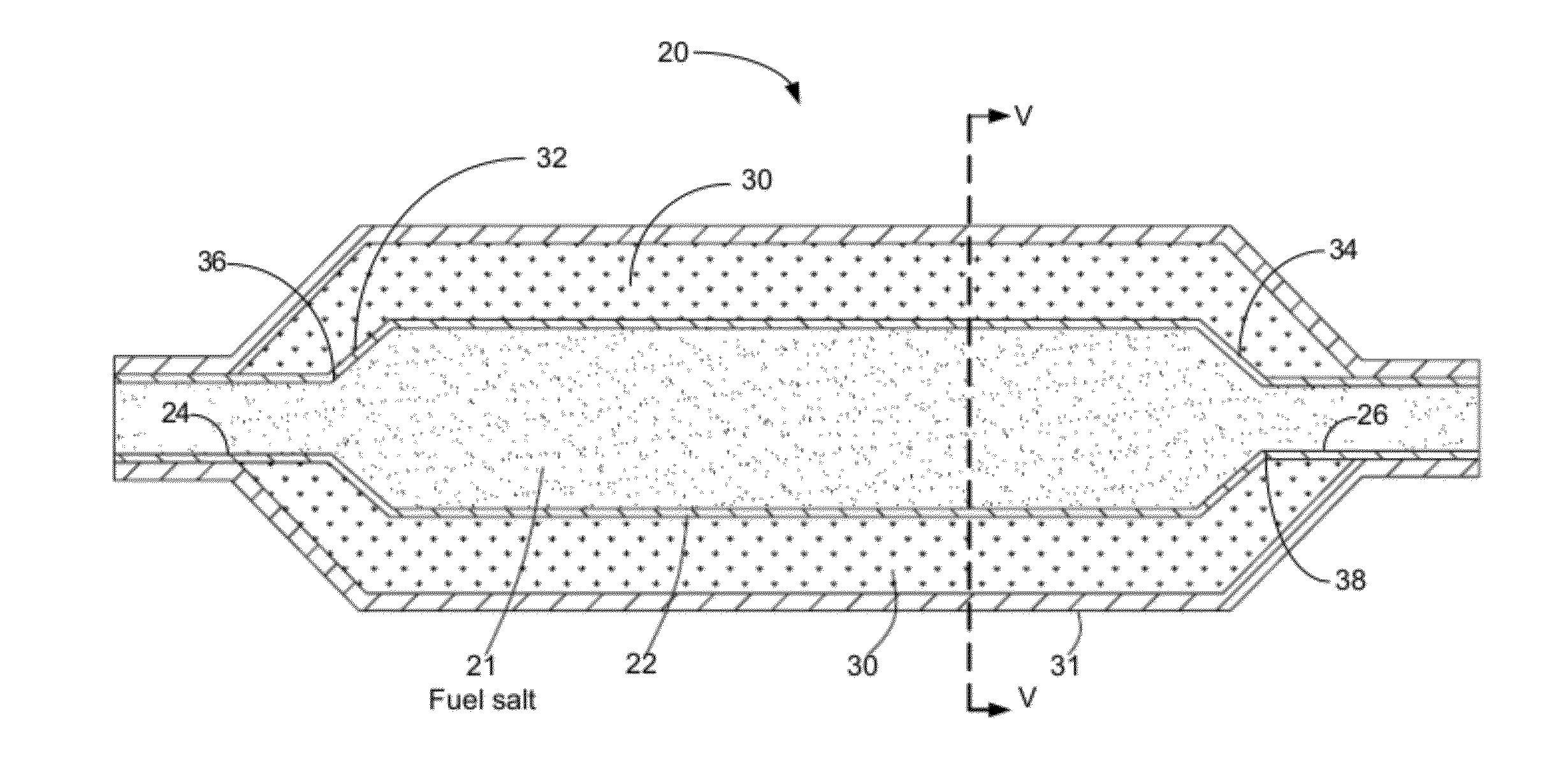

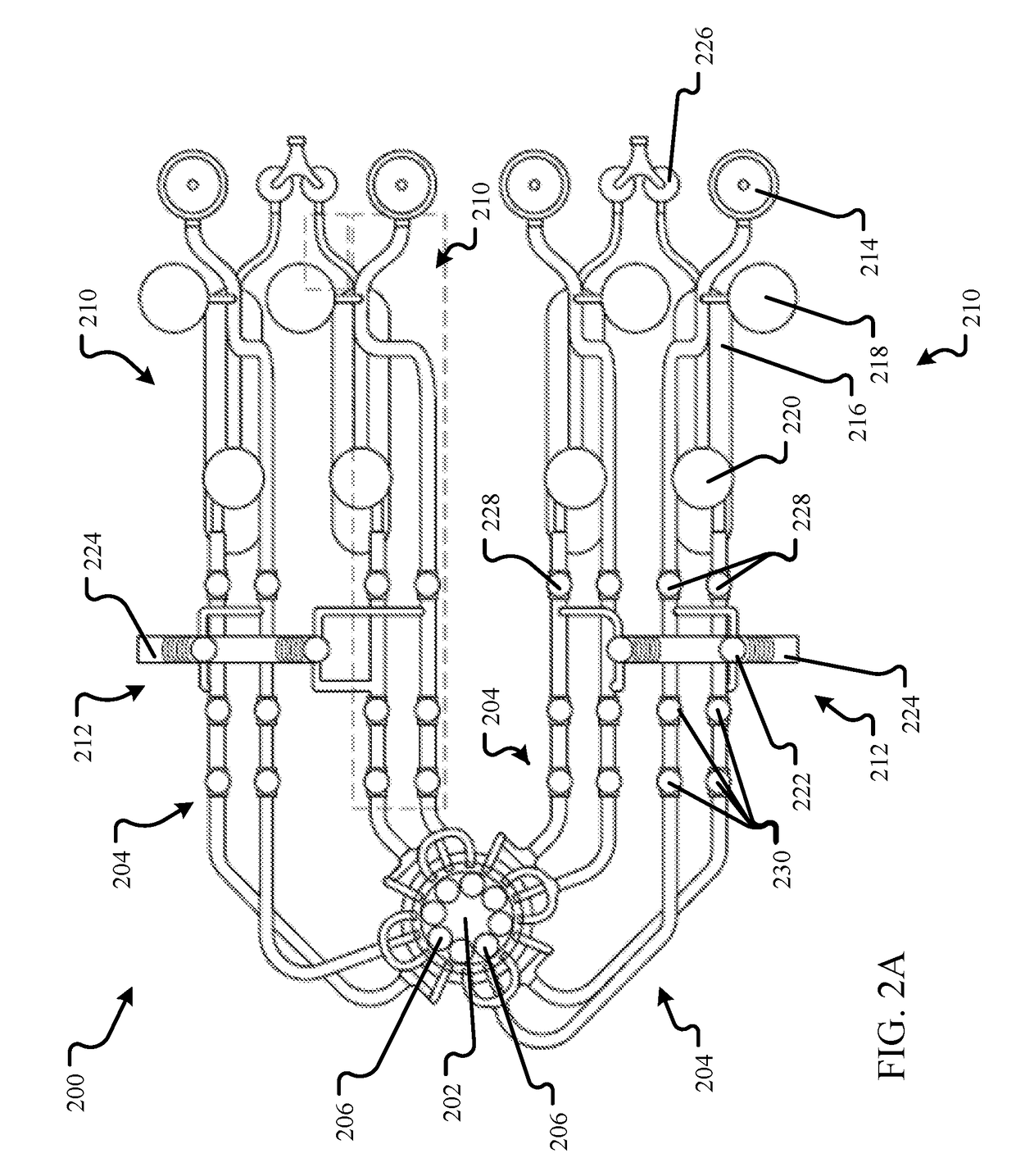

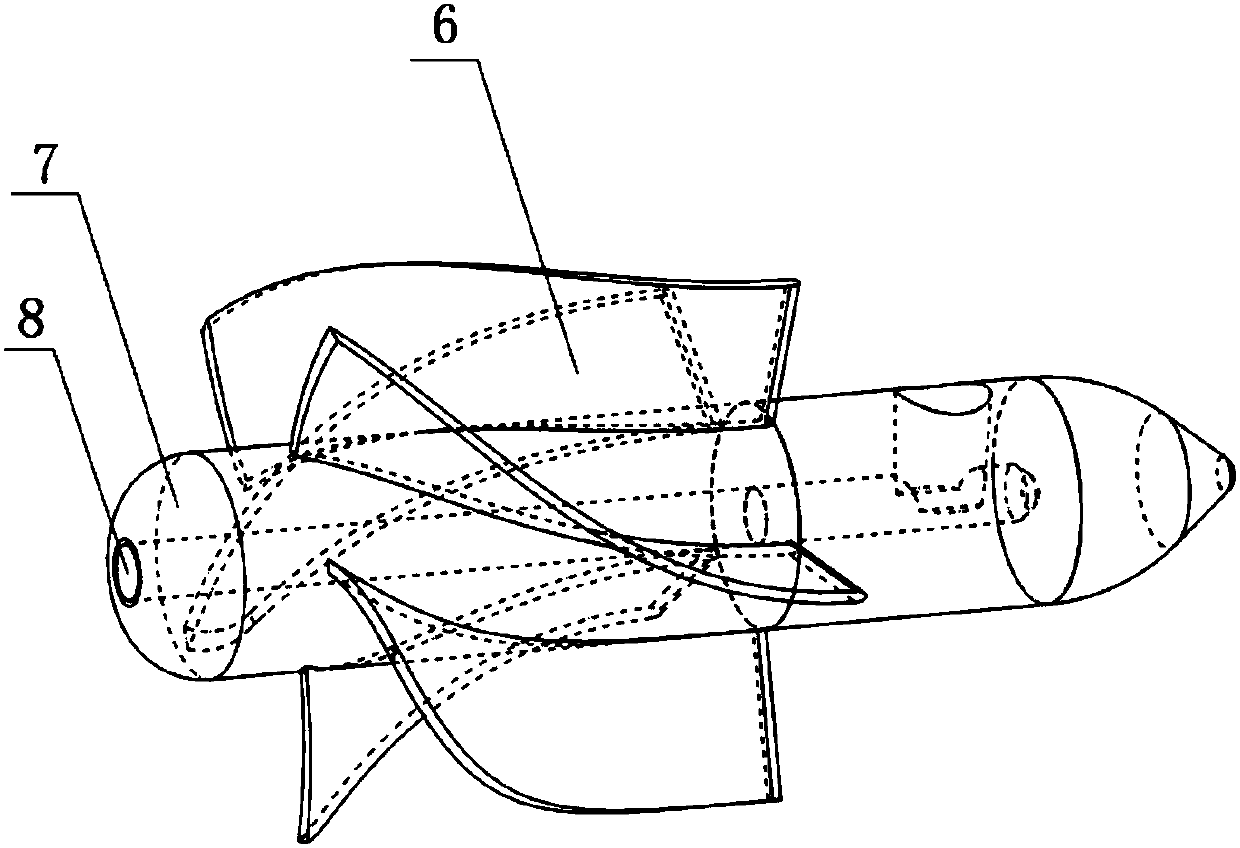

Heat pipe molten salt fast reactor with stagnant liquid core

A molten salt reactor is described that includes a containment vessel, a reactor core housed within the containment vessel, a neutron reflector spaced from the containment vessel and positioned between the core and the containment vessel, a liquid fuel comprised of a nuclear fission material dissolved in a molten salt enclosed within the core, a plurality of heat transfer pipes, each pipe having a first and a second end, wherein the first end is positioned within the reactor core for absorbing heat from the fuel, a heat exchanger external to the containment vessel for receiving the second end of each heat transfer pipe for transferring heat from the core to the heat exchanger, and at least one and preferably two or more reactor shut down systems, where at least one may be a passive system and at least one or both may be an active or a manually operated system. The liquid fuel in the core is kept within the core and heat pipes are used to carry only the heat from the liquid core to the heat exchanger.

Owner:WESTINGHOUSE ELECTRIC CORP

Two-fluid molten-salt reactor

ActiveUS20120051481A1Shut downConversion outside reactor/acceleratorsNuclear energy generationNuclear engineeringMolten salt reactor

A reactor vessel includes a plenum and a reactor core with first and second sets of channels. A blanket salt flows through the first set of channels, and a fuel salt flows through the second set of channels. The plenum receives the blanket salt from the first set of channels. The blanket salt provides a breed-stock for a fission reaction in the fuel salt and transfers heat generated by the fission reaction without mixing with the fuel salt.

Owner:ACAD SINIC +1

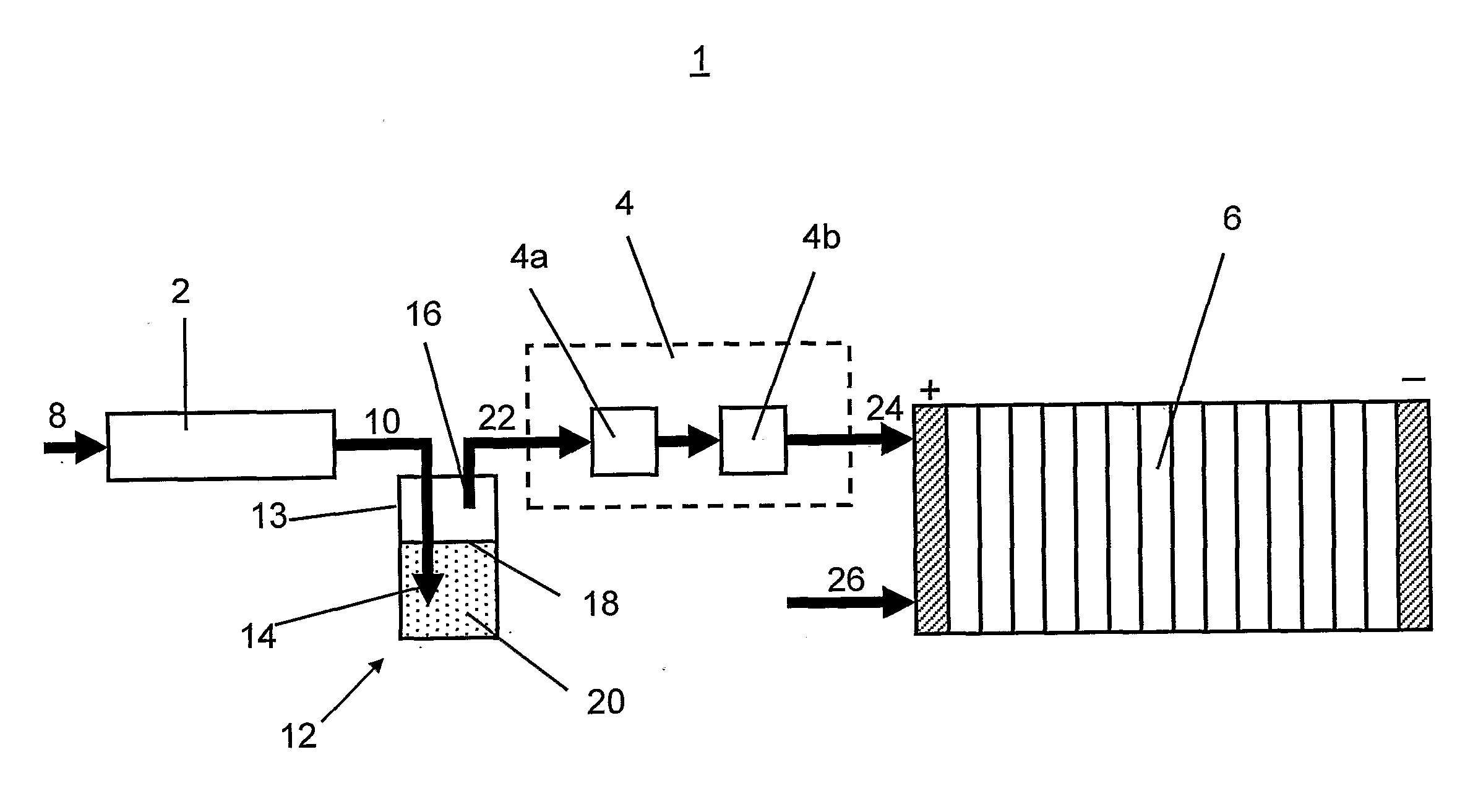

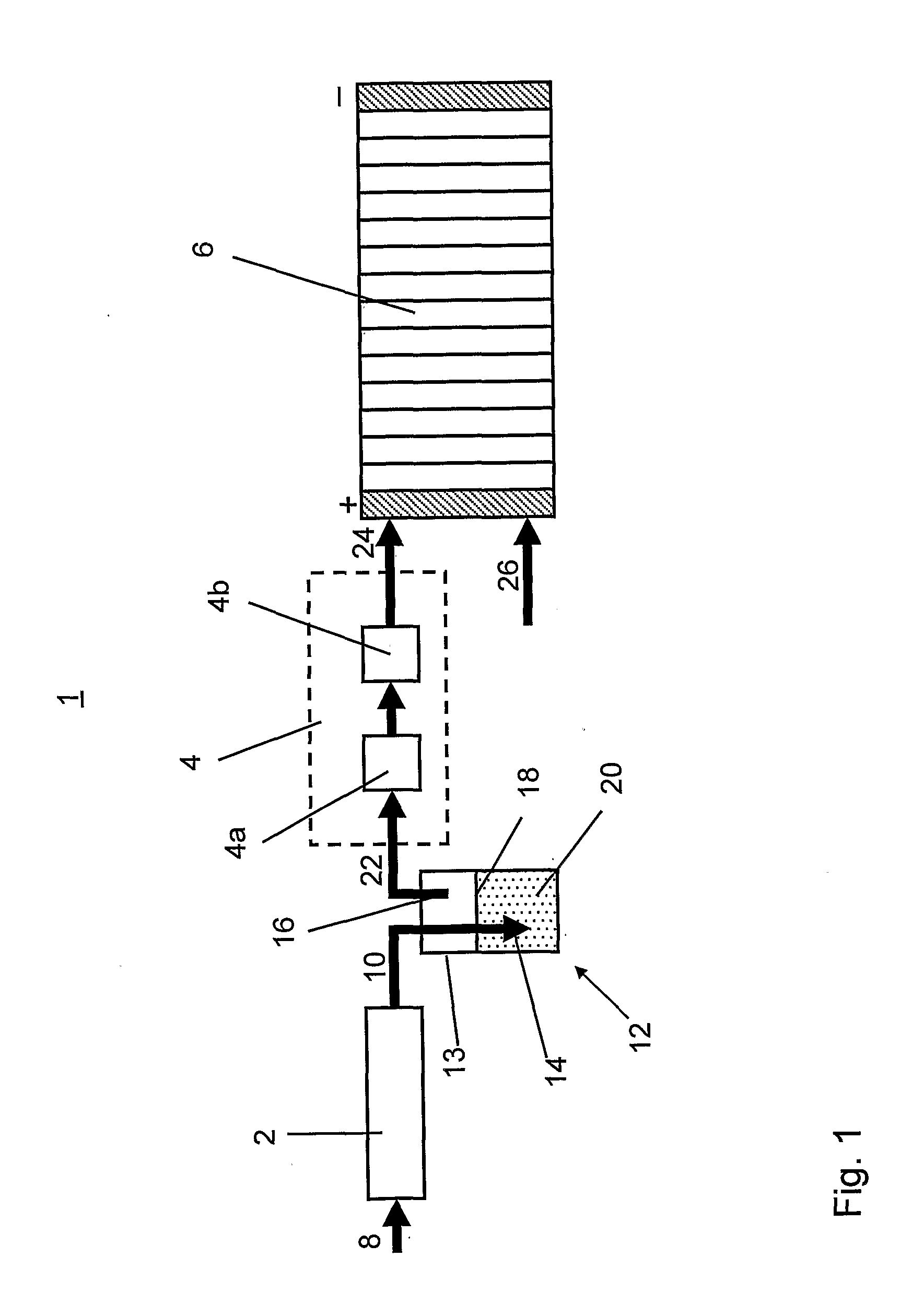

Arrangement and method for generating hydrogen from hydrocarbon fuel

ActiveUS20120028145A1Simplify cleanup processEasy to replaceSamplingHydrogen separation using liquid contactHydrogenAuxiliary power unit

An arrangement and a method are provided for generating hydrogen from hydrocarbon fuel, wherein hydrocarbon fuel is supplied to a fuel reformer for producing hydrogen rich gas including hydrogen, carbon monoxide and possibly unconverted fuel compounds, wherein the amount of carbon monoxide and / or the unconverted fuel compounds is reduced with the help of a molten salt reactor arranged downstream the fuel reformer. An auxiliary power unit including such an arrangement is also provided.

Owner:POWERCELL SWEDEN AB

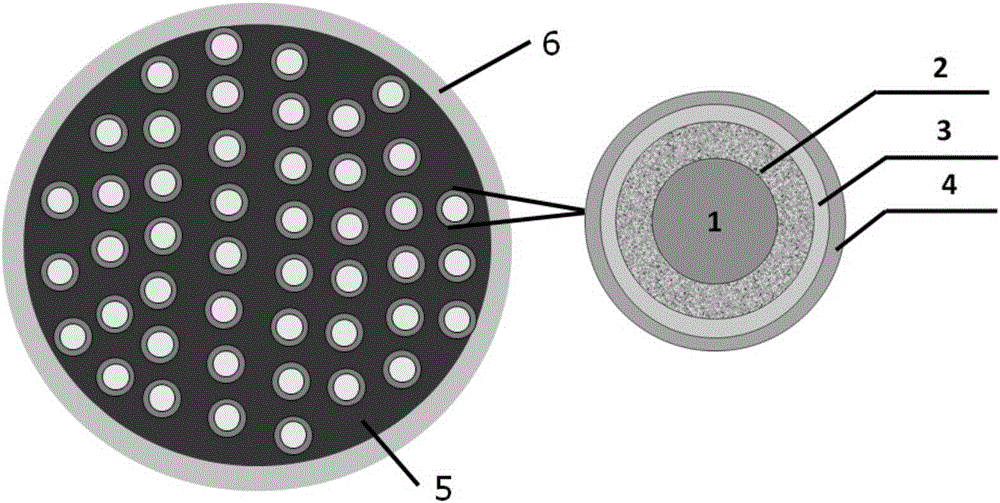

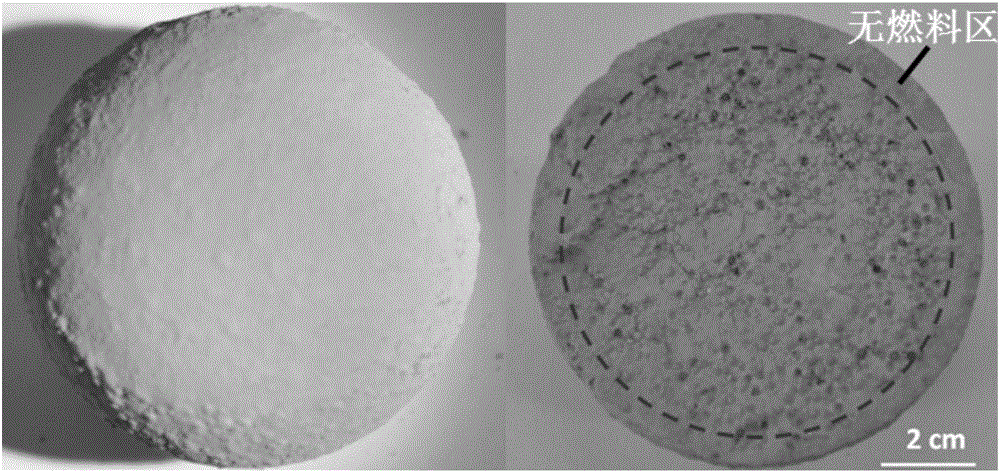

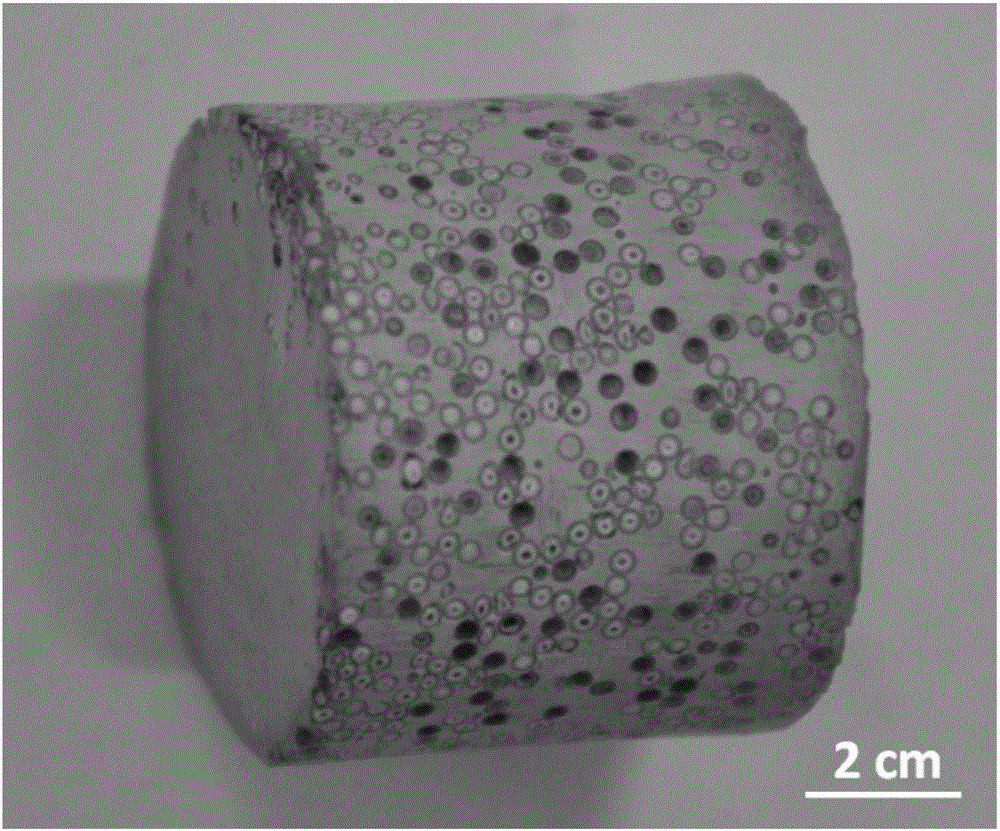

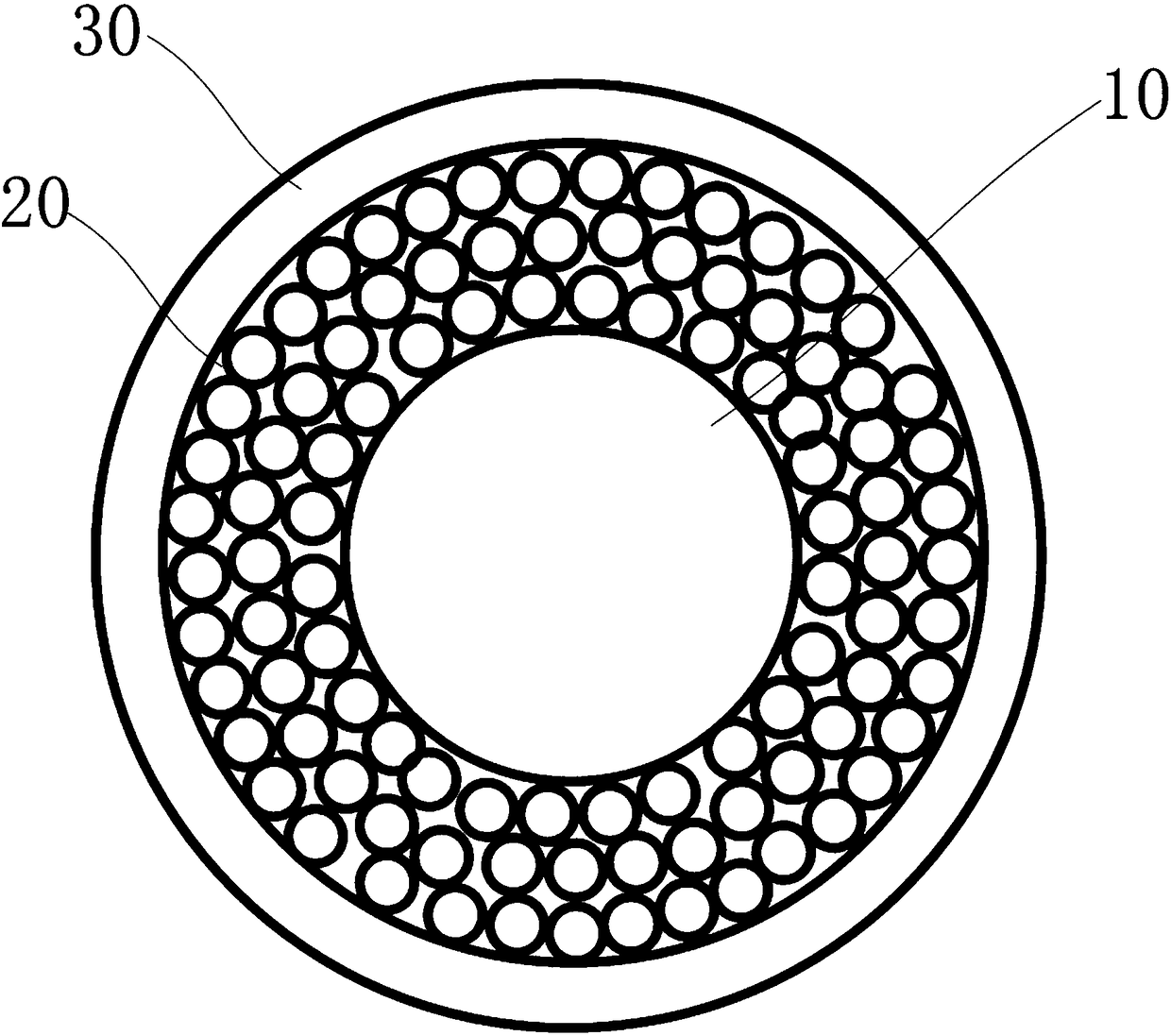

Full ceramic type covering fuel particle, preparation method of full ceramic type covering fuel particle and fuel element

ActiveCN105185418ASimple processEasy to operateFuel elementsNuclear energy generationGas-cooled fast reactorMolten salt reactor

The invention relates to a full ceramic type covering fuel particle, a preparation method of the full ceramic type covering fuel particle and a fuel element prepared from the full ceramic type covering fuel particle. The full ceramic type covering fuel particle comprises a nuclear fuel core, a loose silicon carbide layer, a silicon carbide transition layer and a compact silicon carbide layer, wherein the loose silicon carbide layer, the silicon carbide transition layer and the compact silicon carbide layer sequentially cover the outside of the nuclear core. The full ceramic type fuel element is prepared by dispersing and distributing covering fuel particles in a silicon carbide substrate. When the fuel element provided by the invention is used, the problems of oxidation and corrosion of the existing covering fuel particles and the fuel element during air and water injection under the condition of reactor accidents can be solved. The fuel element can be used for the reactor types such as high-temperature air-cooled reactors, gas-cooled fast reactors, molten salt reactors, space reactors and pressurized water reactors.

Owner:TSINGHUA UNIV

Molten salt nuclear reactor

InactiveUS20120183112A1Maximize probabilityFuel elementsConversion outside reactor/acceleratorsNuclear reactor coreBreeder reactor

A molten salt breeder reactor that has fuel conduit surrounded by a fertile blanket. The fuel salt conduit has an elongated core section that allows for the generation of electrical power on a scale comparable to commercially available nuclear reactors. The geometry of the fuel conduit is such that sub-critical conditions exist near the input and output of the fuel salt conduit and the fertile blanket surrounds the input and output of the fuel salt conduit, thereby minimizing neutron losses.

Owner:OTTAWA VALLEY RES ASSOCS

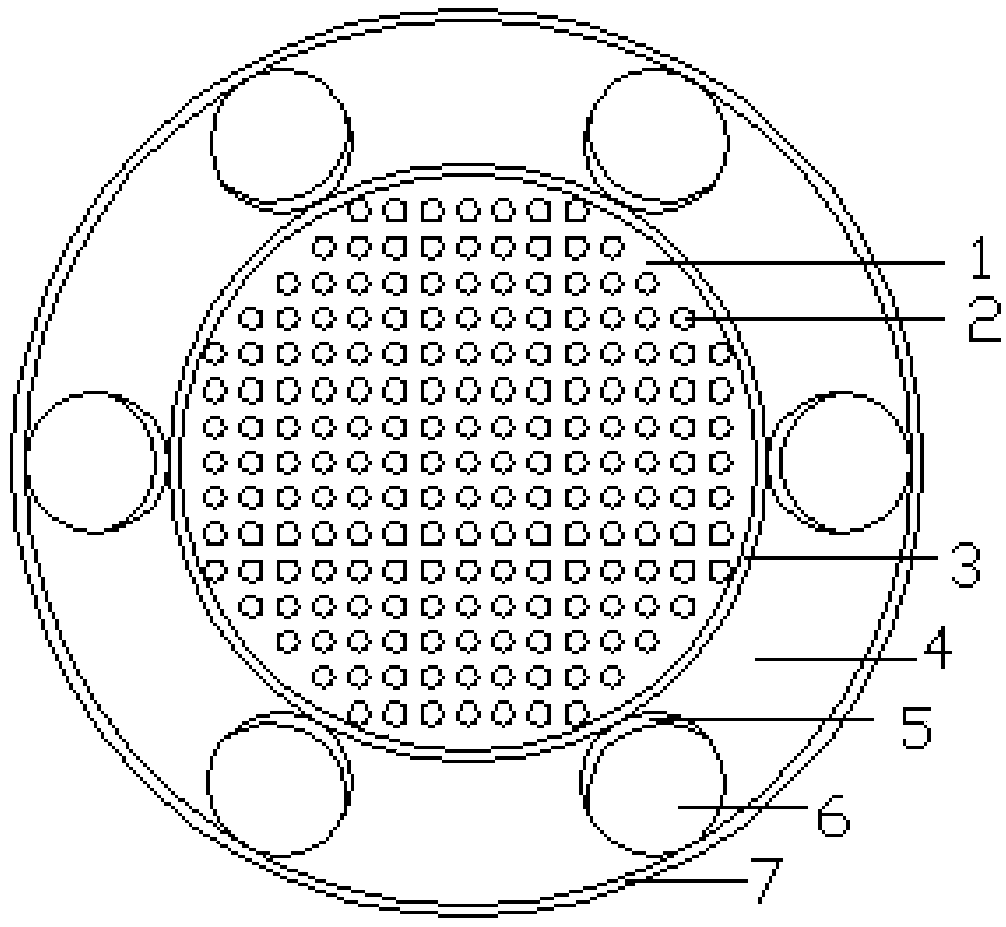

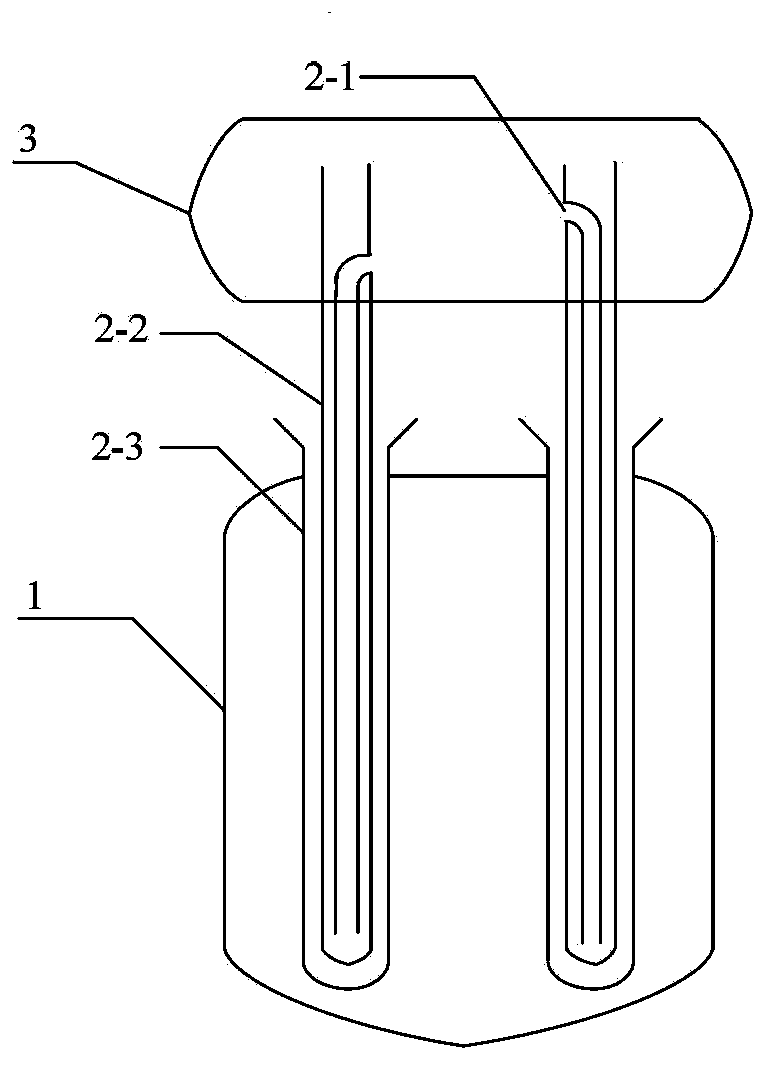

Integrated small molten salt reactor

ActiveCN107945887AImprove heat transfer effectLong-term efficient and stable transmissionFuel elementsNuclear energy generationNuclear engineeringNatural convection

The invention discloses an integrated small molten salt reactor. The reactor body of the integrated small molten salt reactor comprises a fuel salt, heat tubes, a core container, a side reflection layer, neutron absorbers, control drums, a shell and a lower reflection layer, wherein the heat tubes and the core container are integrally designed, the heat tubes are partly or fully inserted into thecore container, the core container is filled with the fuel salt, a cavity is formed between the core container and the liquid surface of the fuel salt, the outer wall of the core container is surrounded with the side reflection layer, the control drums are arranged in the side reflection layer, the neutron absorbers are arranged at one sides of the control drums, the lower reflection layer is arranged at the bottom of the core container, and the shell surrounds the external of the side reflection layer and the lower reflection layer. A heat tube technology is applied to the molten salt reactorin order to greatly simplify the structure of the above system, and natural circulation or natural convection is generated to realize the long-term efficient and stable transmission of heat and improve the safety and the reliability of the system.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

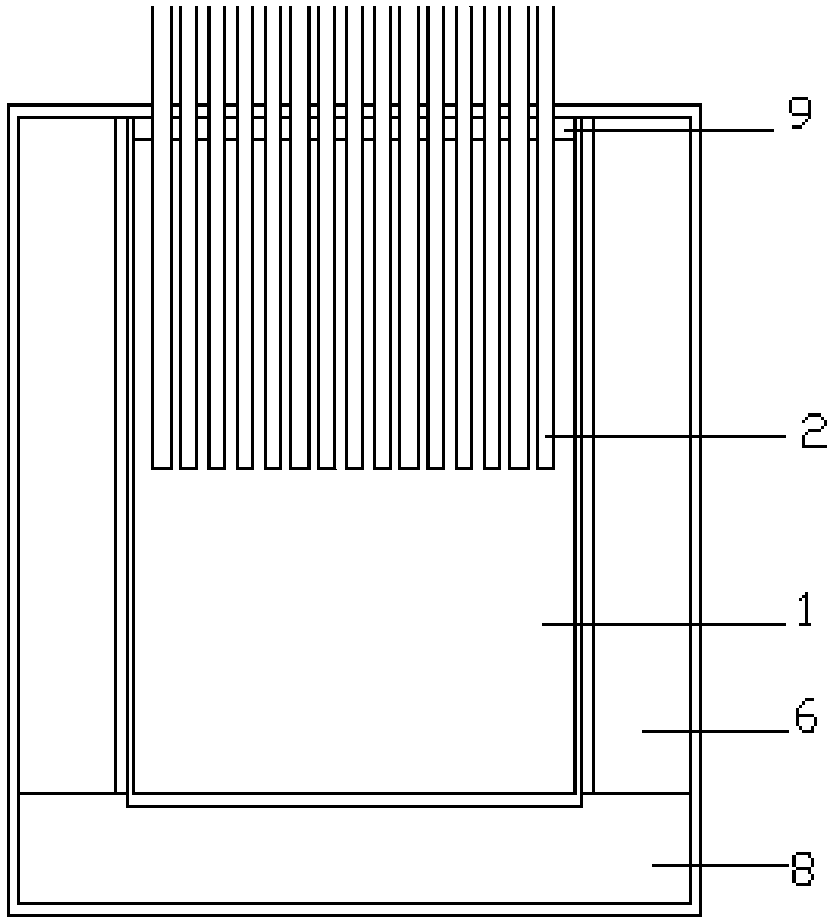

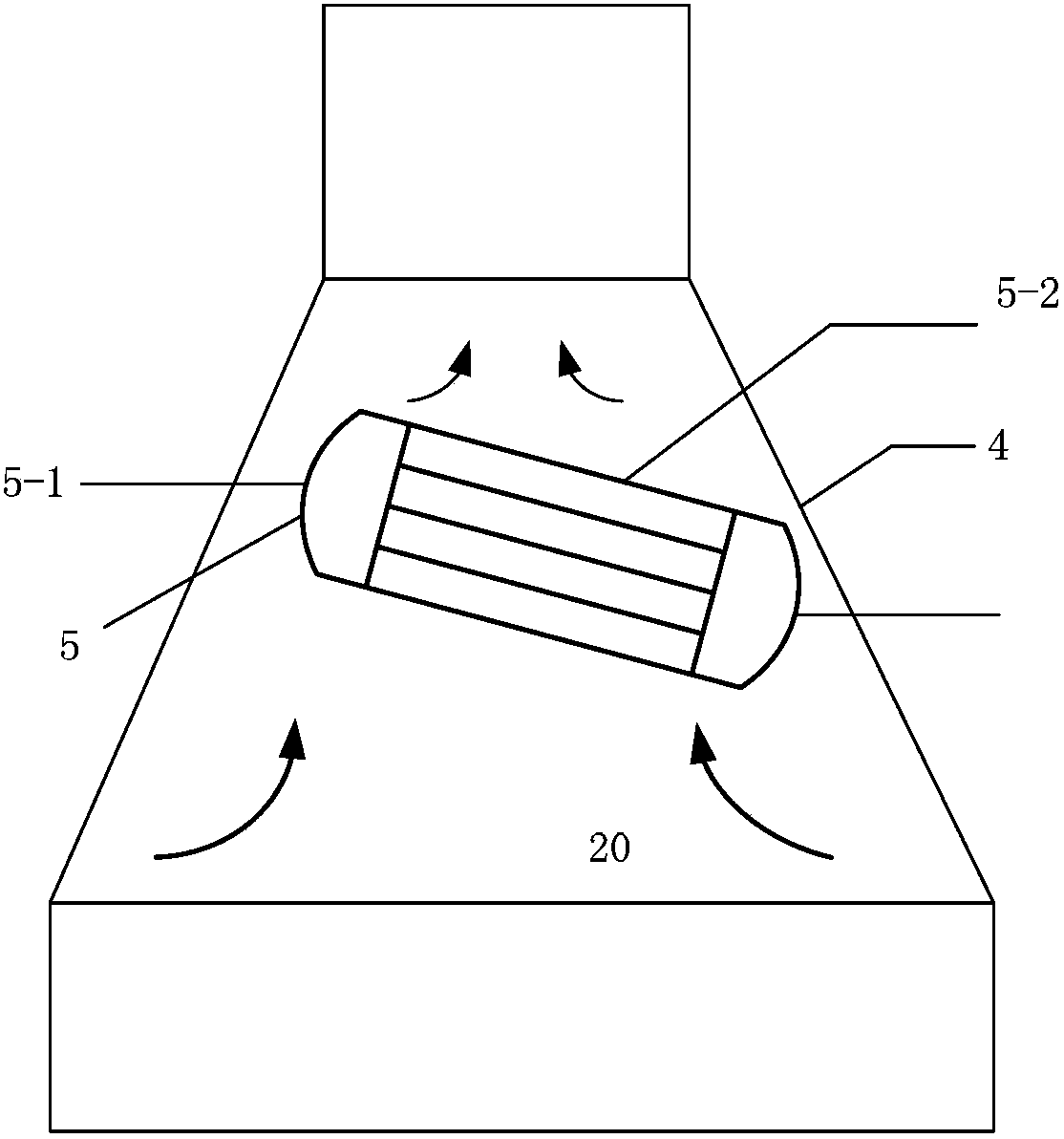

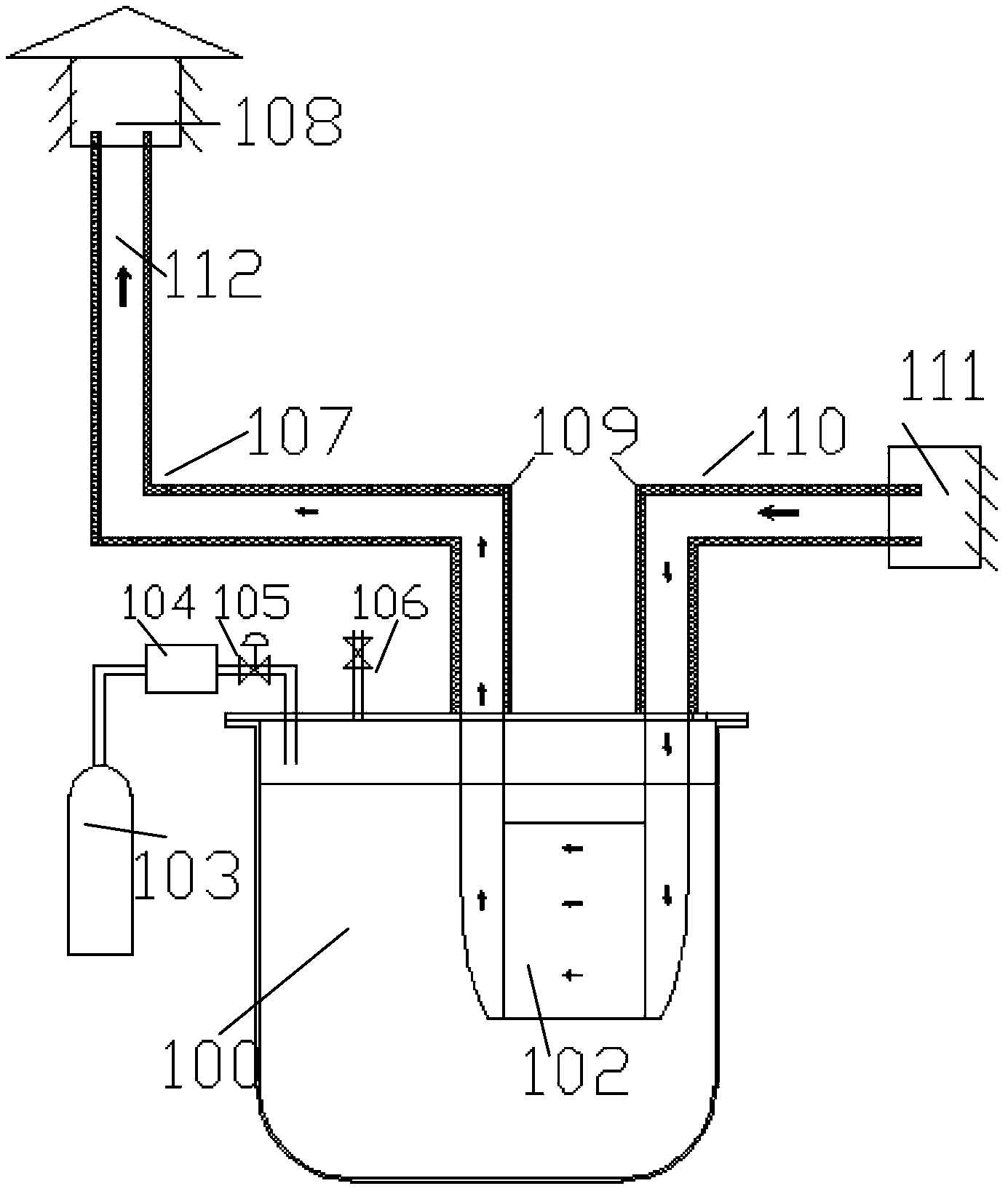

Passive residual heat exhausting system for molten salt reactor

InactiveCN103400608AImprove intrinsic safetyIncrease cooling powerNuclear energy generationCooling arrangementSystems designEngineering

The invention aims to provide a passive residual heat exhausting system for a molten salt reactor. The passive residual heat exhausting system comprises a salt discharging pot, heat exchanging elements, a steam pocket and a ventilator, wherein the upper part of each heat exchanging element is located in the steam pocket, the lower part of each heat exchanging element is located in the salt discharging pot, and other parts of each heat exchanging element are located between the steam pocket and the salt discharging pot; each heat exchanging element comprises a heat transferring pipe; each heat transferring pipe is internally provided with a middle sleeve; each middle sleeve comprises an inner wall and an outer wall; a channel for steam to flow through is formed between each inner wall and the corresponding outer wall; a water inlet pipeline is formed in the inner wall of each middle sleeve, a water inlet is formed in the top of each water inlet pipeline, and the bottom end of each water inlet pipeline is disconnected and is communicated with the corresponding channel; the ventilator is internally provided with an air cooler; an air cooler inlet is formed in the end part of the air cooler and a fin pipe is arranged in the middle of the air cooler; the steam pocket is communicated with the air cooler inlet. According to the passive residual heat exhausting system for the molten salt reactor provided by the invention, the passive working capability of the system is improved, the problems of high fault rate and the like caused by the design of an active system are solved, and therefore, the safety of the residual heat exhausting system for the molten salt reactor is improved.

Owner:HARBIN ENG UNIV

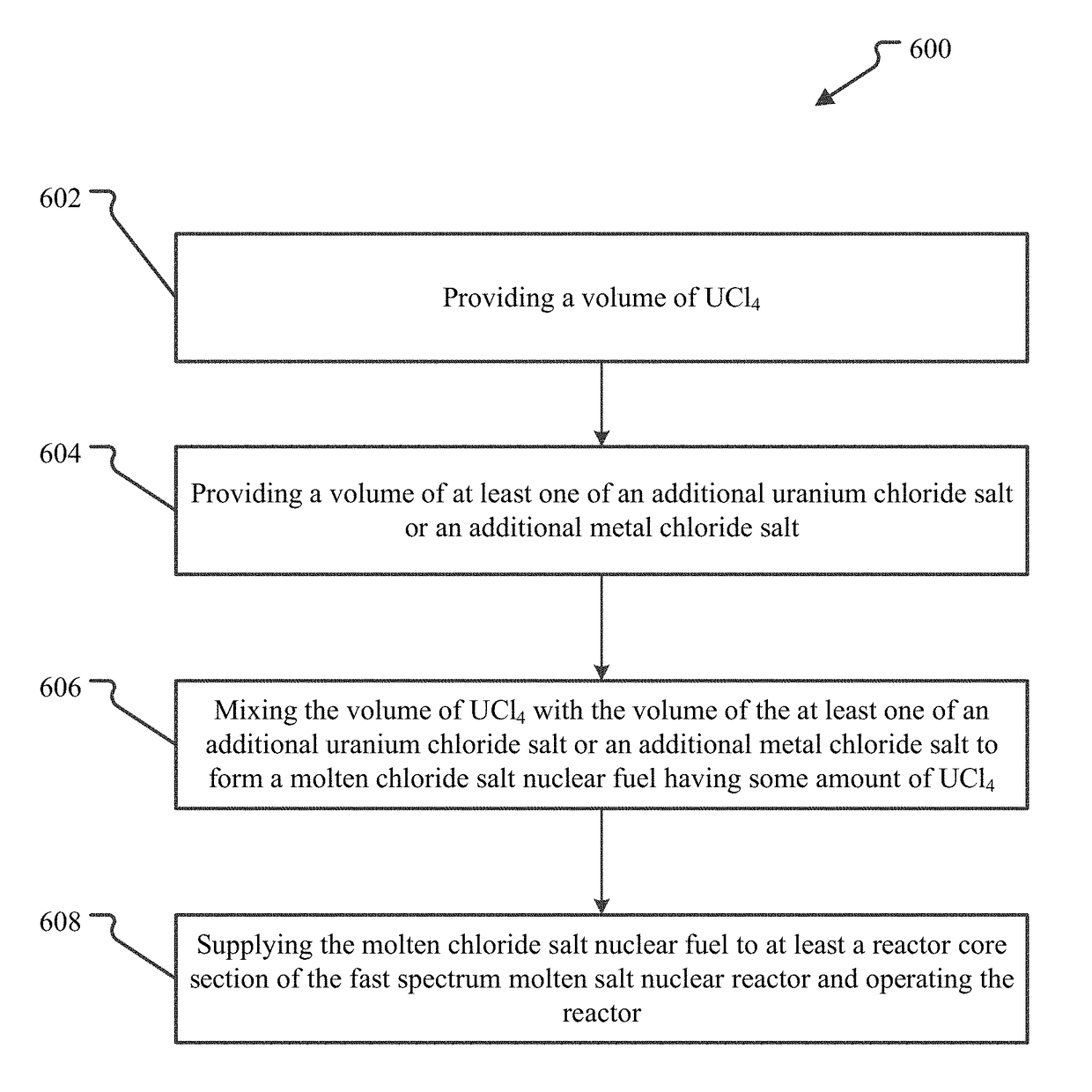

Nuclear fuel salts

InactiveUS20170301413A1Improve power densityImprove the level ofFuel elementsNuclear energy generationPresent methodChloride

This disclosure describes nuclear fuel salts usable in certain molten salt reactor designs and related systems and methods. Binary, ternary and quaternary chloride fuel salts of uranium, as well as other fissionable elements, are described. In addition, fuel salts of UClxFy are disclosed as well as bromide fuel salts. This disclosure also presents methods and systems for manufacturing such fuel salts, for creating salts that reduce corrosion of the reactor components and for creating fuel salts that are not suitable for weapons applications.

Owner:TERRAPOWER

Two-fluid molten-salt reactor

ActiveUS8594268B2Conversion outside reactor/acceleratorsNuclear energy generationNuclear engineeringMolten salt reactor

A reactor vessel includes a plenum and a reactor core with first and second sets of channels. A blanket salt flows through the first set of channels, and a fuel salt flows through the second set of channels. The plenum receives the blanket salt from the first set of channels. The blanket salt provides a breed-stock for a fission reaction in the fuel salt and transfers heat generated by the fission reaction without mixing with the fuel salt.

Owner:ACAD SINIC +1

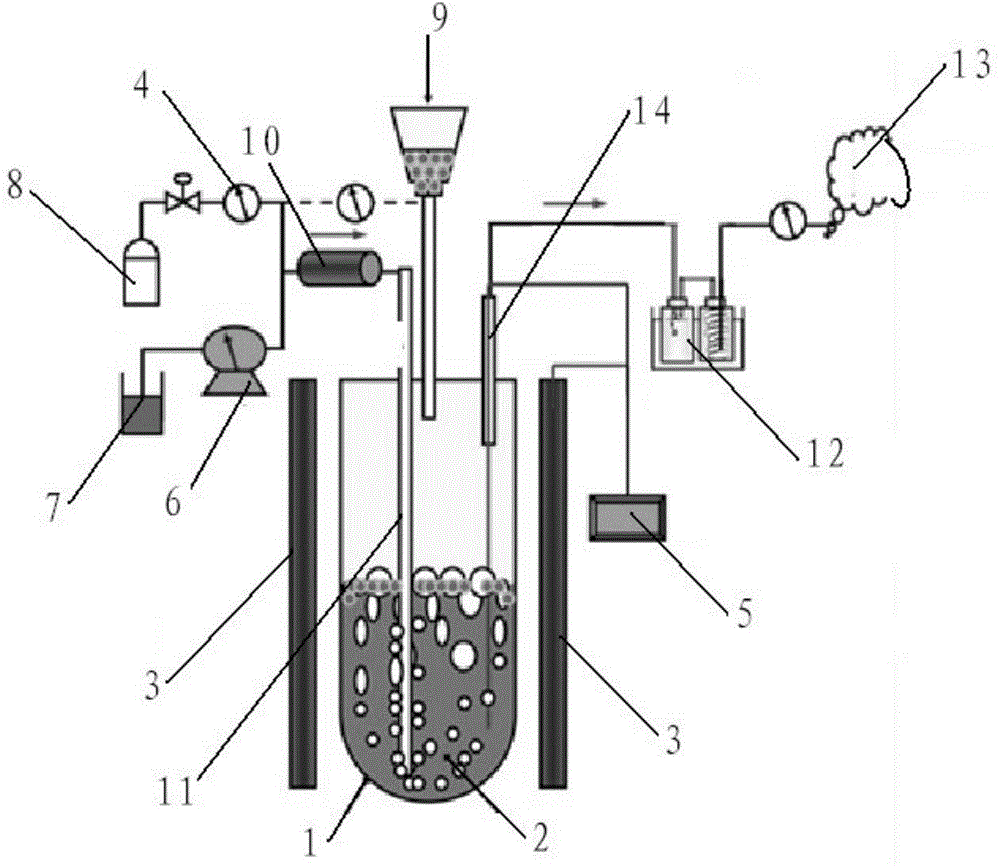

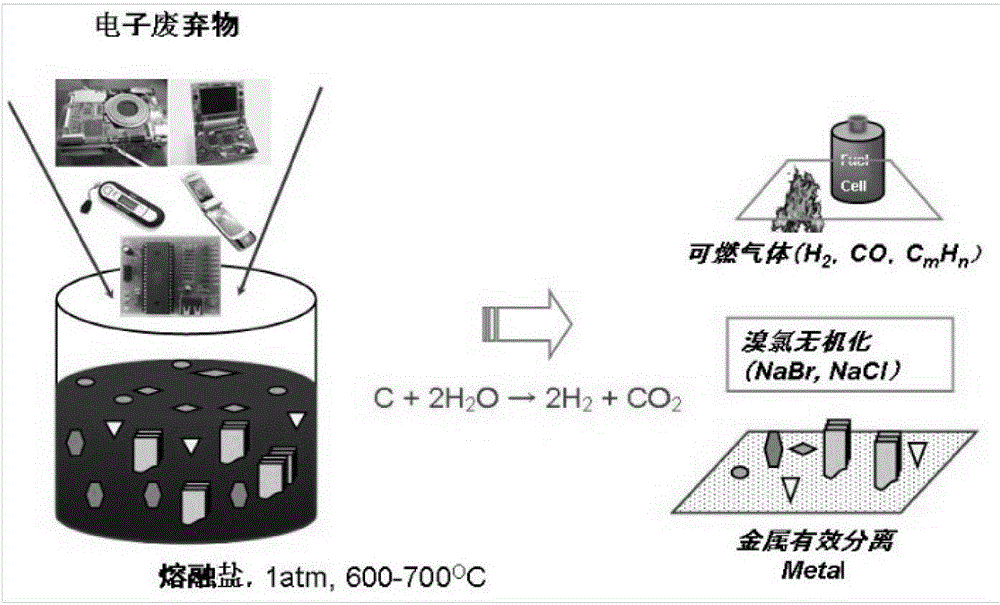

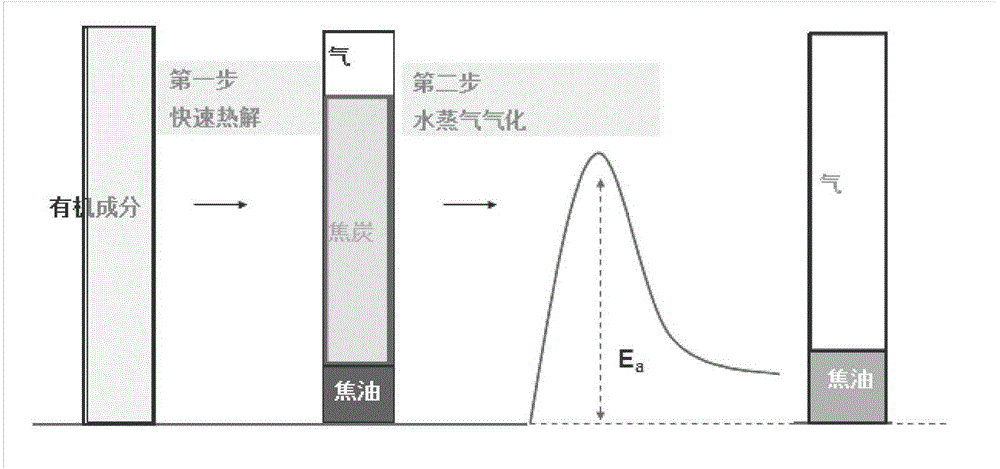

Water-vapor gasification separation apparatus and method for waste printed circuit boards

InactiveCN104479756AEasy to separateImprove recycling efficiencySolid waste disposalTransportation and packagingWater vaporReaction temperature

The invention provides a water-vapor gasification separation apparatus and a method for waste printed circuit boards. The method comprises the following steps: (1) adding a molten salt into a reaction furnace, pouring waste printed circuit boards into the reaction furnace under a normal pressure in an oxygen-free atmosphere, and controlling the reaction temperature to be 600-700 DEG C, so as to rapidly pyrolyze organics on circuit boards in the molten salt bath and generates products of an organic gas, coke and tar; and (2) performing water gas reaction on coke generated through pyrolysis and water vapor, so as to generate hydrogen and carbon dioxide. Metals in the circuit boards can be effectively separated and recovered after organics in the waste circuit boards are pyrolyzed and gasified. Hydrogen and the organic gas generated in the pyrolysis gasification separation process of the waste circuit boards in the salt bath can be used as fuels, and toxic halides contained in the waste circuit boards are absorbed by the molten salt and is converted into stable inorganic salts.

Owner:JIANGXI UNIV OF SCI & TECH

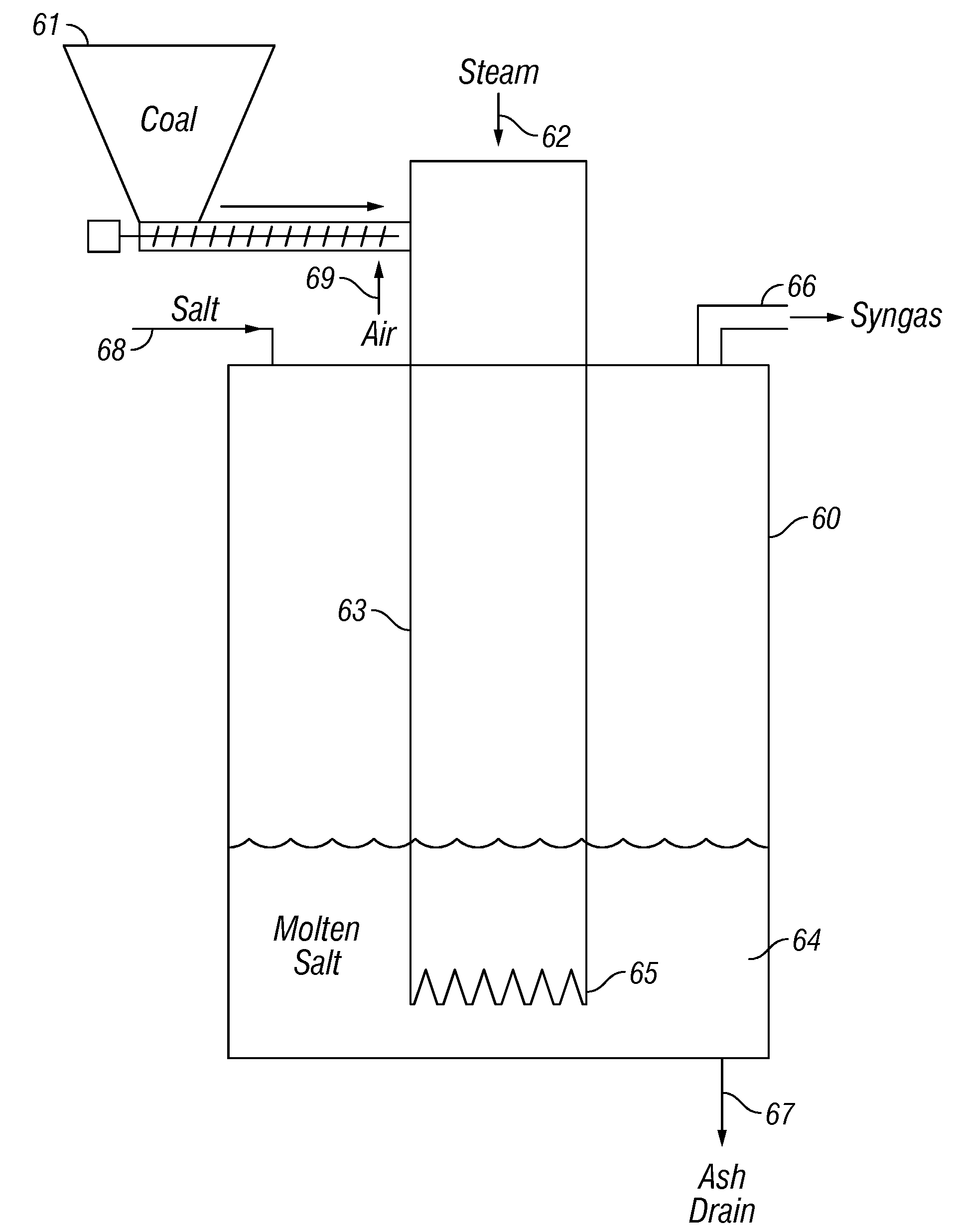

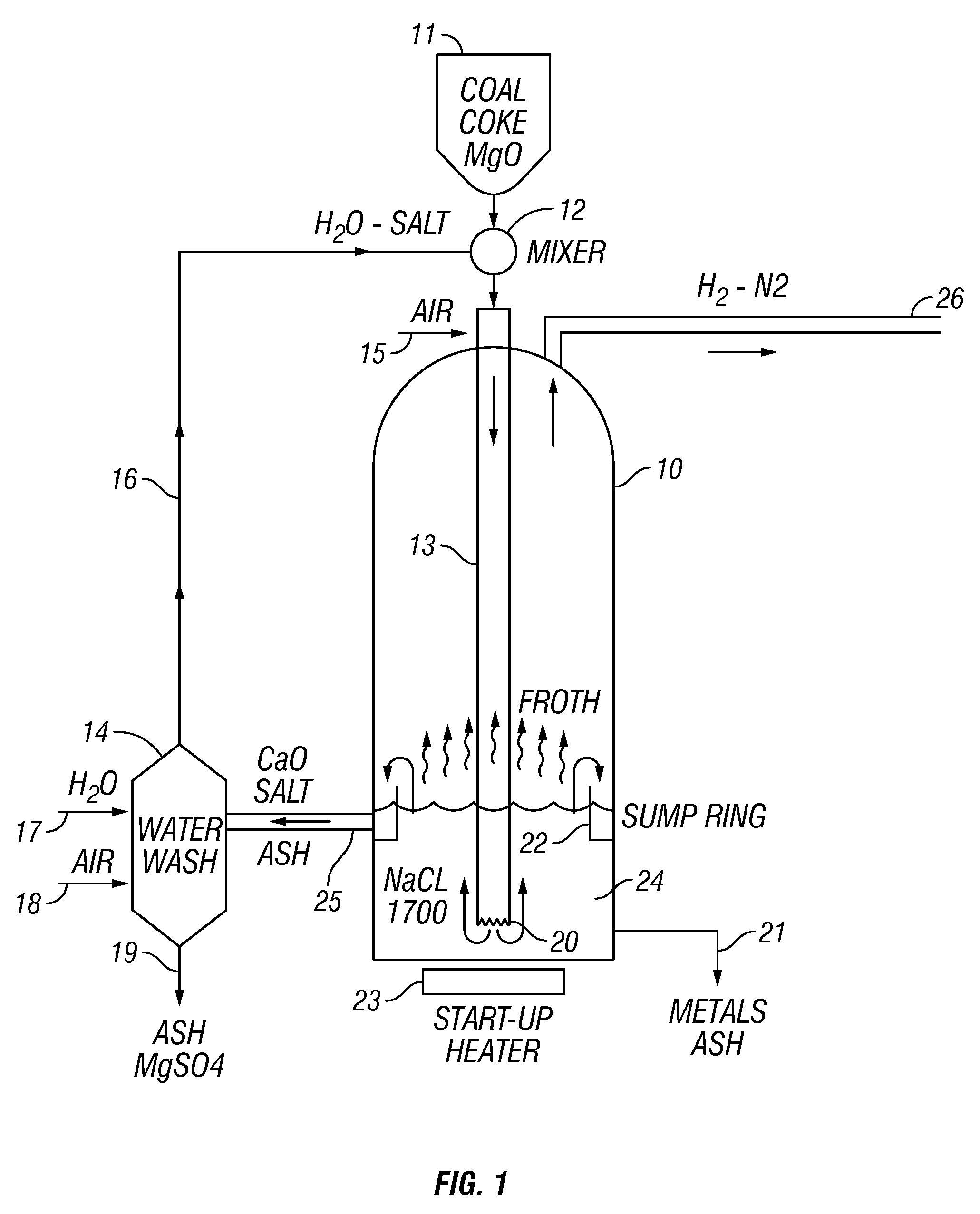

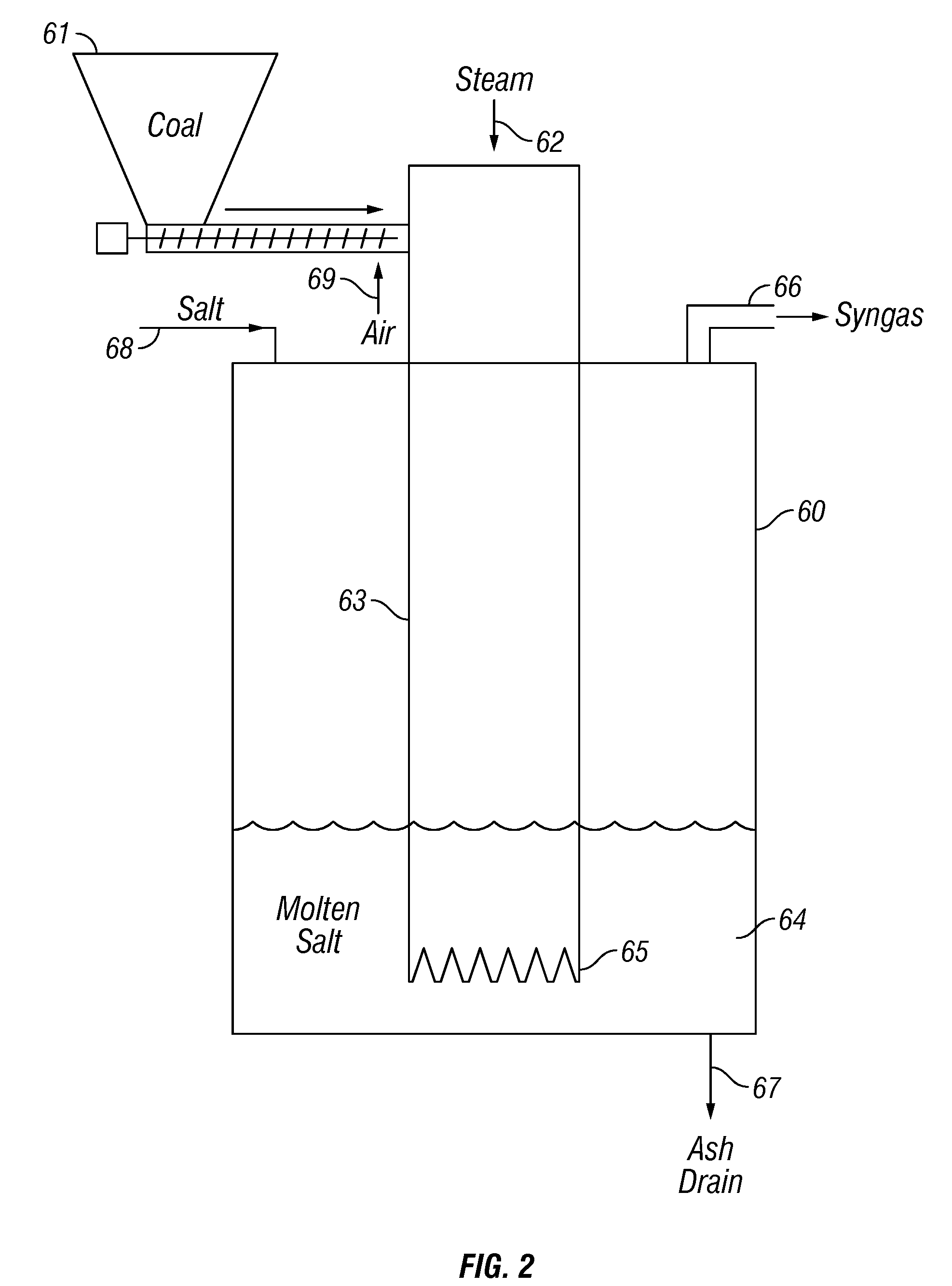

Process for production of hydrogen from coal and other fossil fuels

InactiveUS20090074656A1Improve heat transfer performanceGasifier feeding meansHydrogen separation using solid contactHydrogenMolten salt reactor

A process for converting coal or other fossil fuel to hydrogen by reacting the fossil fuel or coal with water in a molten salt reactor at elevated temperatures in the presence of a magnesium silicate wherein the magnesium silicate reacts with the CO2 produced in the reaction, thus removing it from the hydrogen gas product.

Owner:BILLINGS CALVIN

Welding flux for molten salt corrosion resistant nickel-base superalloy fusion welding

ActiveCN106077997AIncrease resistanceFacilitate preparation controlWelding/cutting media/materialsSoldering mediaRare-earth elementFusion welding

The invention discloses a welding flux formolten salt corrosion resistant nickel-base superalloy fusion welding and belongs to the technical field of welding materials. The welding flux comprises the following components in percentage by weight: 0.03%-0.06% of C, 0.04%-0.10% of Mn, 0.3%-0.5% of Si, not greater than 0.10% of Cu, not greater than 0.20% of Co, not greater than 0.015% of P, not greater than 0.015% of S, 0.01%-0.05% of rare earth element, 1.0%-5.0% of Fe, 6.0%-8.0% of Cr, 12.0%-18.0% of Mo, not greater than 0.3% of Al, not greater than 0.2% of Ti, 1.0%-2.0% of Nb and the balance of Ni, wherein Ti+Nb+Al is not greater than 2%. The invention also discloses a welding material for molten salt corrosion resistant nickel-base superalloy fusion welding, a connecting method of a molten salt corrosion resistant nickel-base superalloy and a structural member of the molten salt corrosion resistant nickel-base superalloy. According to the welding flux for molten salt corrosion resistant nickel-base superalloy fusion welding, the toughness and the oxidation resistance of a welded joint can be effectively improved, the excellent molten salt corrosion resistance and the excellent high temperature mechanical property can be guaranteed, the usage demands of molten salt and radiation environments with high usage temperature and performance requirements can be satisfied, and the welding flux is suitable for welding of a molten salt reactor structural material.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

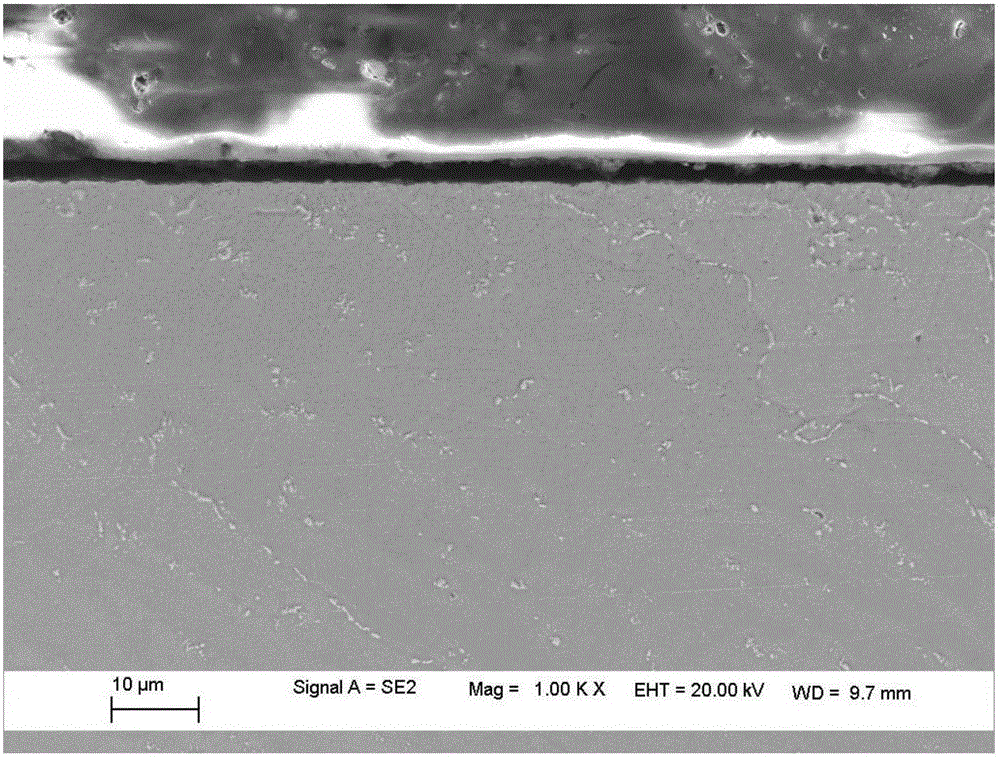

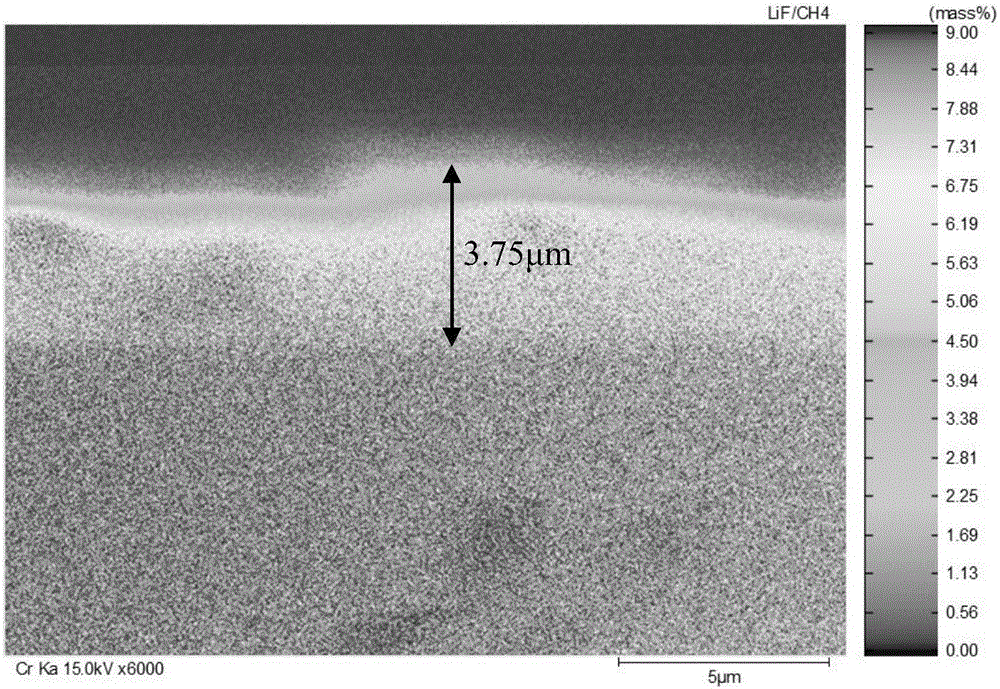

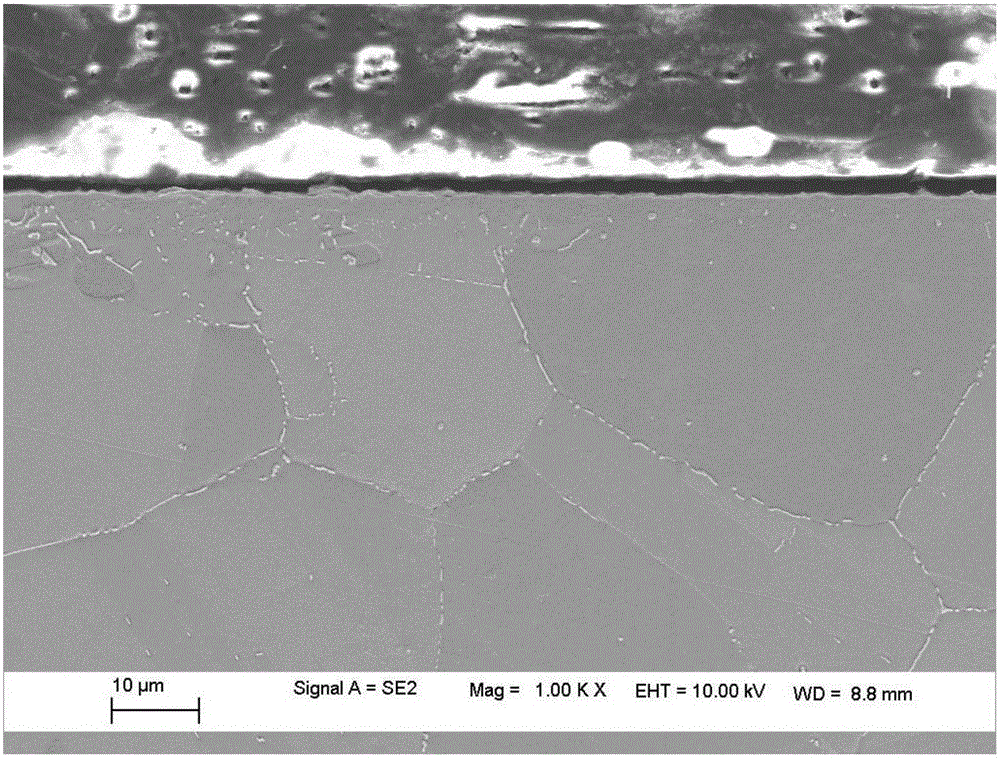

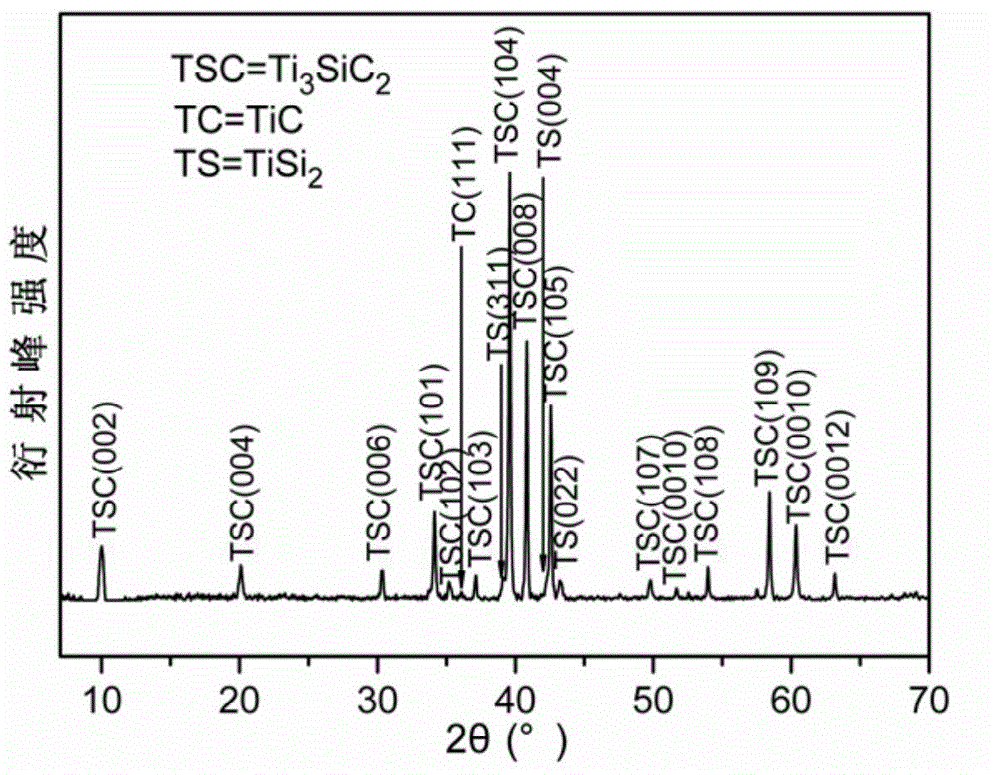

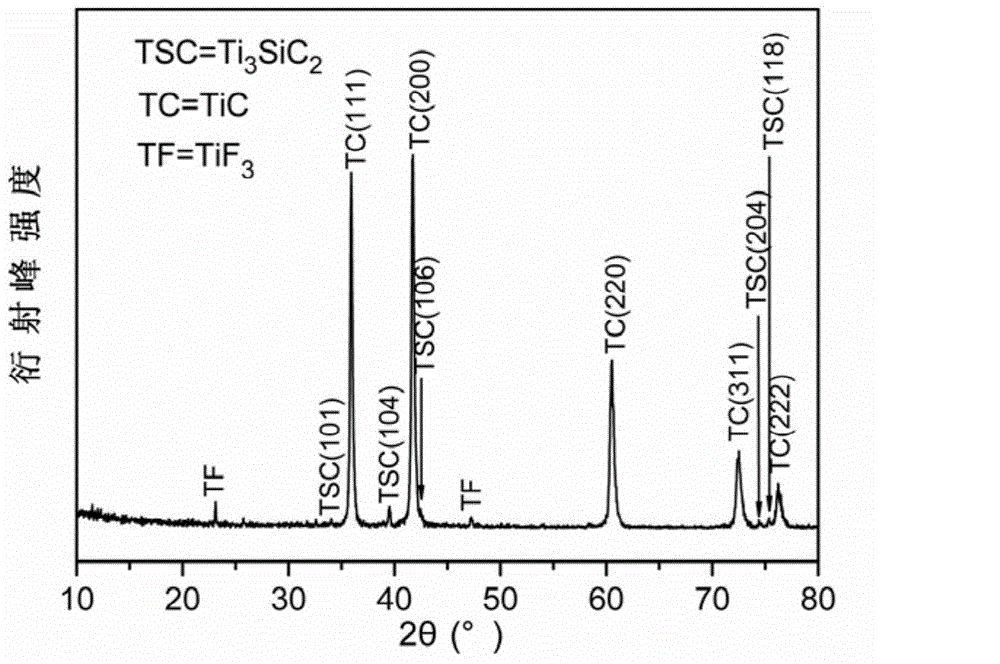

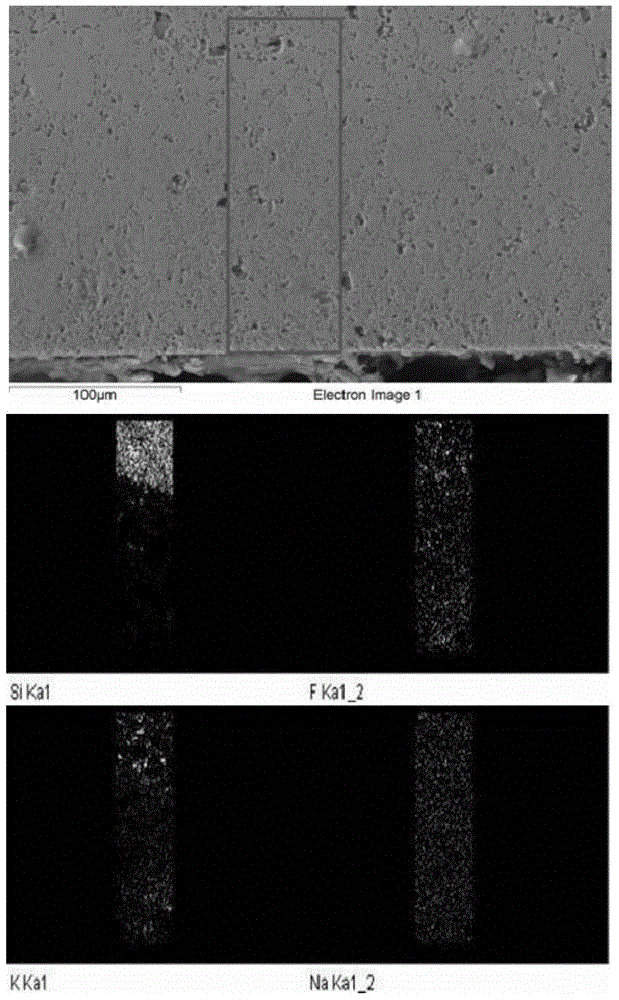

Application of Ti3SiC2 based ceramic material as melted fluorine salt corrosion resistant material

ActiveCN104637551AImproving corrosion resistance to molten fluoride saltsHigh densityLiquid surface applicatorsNuclear energy generationMolten salt reactorElectrolyte

The invention provides an application of a Ti3SiC2 based ceramic material as a melted fluorine salt corrosion resistant material. Through a large amount of experiments, the inventor finds that the corrosion speed of the Ti3SiC2 based ceramic material is extremely low in melted fluorine salt, and the melted fluorine salt corrosion resistant performance of the Ti3SiC2 based ceramic material is in the same level as that of inert metal nickel and nickel-based high-temperature alloy which are the best melted fluorine salt corrosion resistant materials. Thus the Ti3SiC2 based ceramic material can be used to build the structure of a molten salt reactor such as a shell, a container, a pipeline, and the like. The Ti3SiC2 based ceramic material can also be used as a functional electrode material in the post treatment of a spent fuel dry process taking fluorine salt as the electrolyte and can be painted on the alloy surface to form a film or coating so as to prevent melt fluorine salt corrosion.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Residual heat removal system for molten salt reactor buffer salt accident

InactiveCN103337264AExtended service lifeOptimize layoutNuclear energy generationCooling arrangementExpansion tankNatural ventilation

The invention provides a residual heat removal system for a molten salt reactor buffer salt accident. The residual heat removal system for the molten salt reactor buffer salt accident system comprises a cooling tower, a main loop system and a salt filling and eliminating system, wherein a natural ventilation heat exchanger is arranged in the air cooling tower; a heater is arranged on the periphery of the natural ventilation heat exchanger; the main loop system is formed by connecting a molten salt pond, a heat tube section, the natural ventilation heat exchanger and a cooling tube section in sequence; a reactor core is arranged in the molten salt pond which is filled with molten salt; one tail ends of the heat tube section and the cooling tube section are respectively immersed in the molten salt in molten salt pond; the highest position of the heat tube section of the main loop system is connected with an expansion tank; the salt filling and eliminating system is connected with the molten salt pond directly. According the system, a passive design concept is adopted, the external power is not required, the passive elimination of the molten salt reactor residual heat under accidental working condition is realized by relaying on the natural circulation of the air and molten salt, besides, the space of the molten salt is saved by the system, and the arrangement of the other components is convenient.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

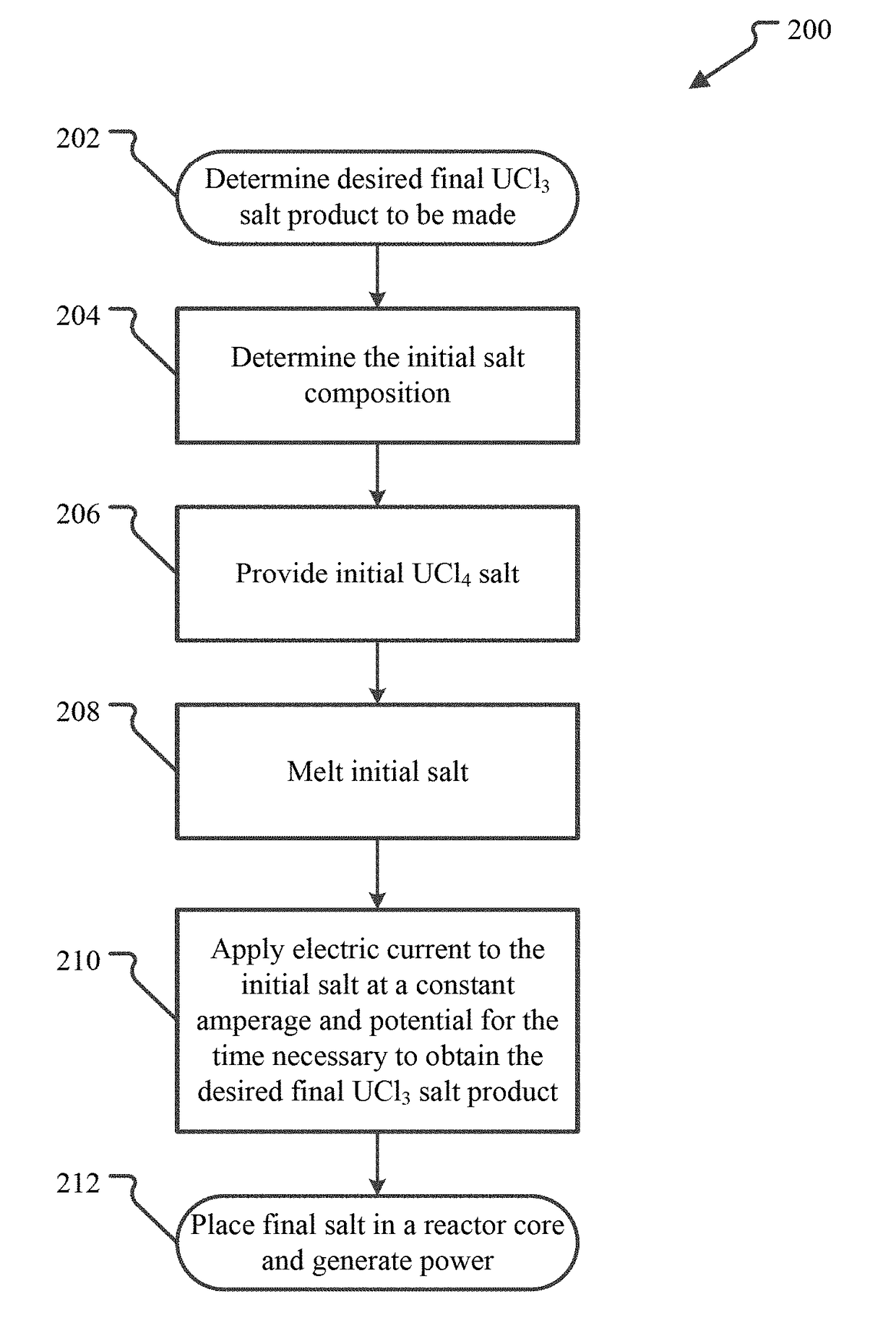

Electro-synthesis of uranium chloride fuel salts

ActiveUS20180047467A1Improve power densitySave on fuel costsCellsNuclear energy generationChlorideElectrochemistry

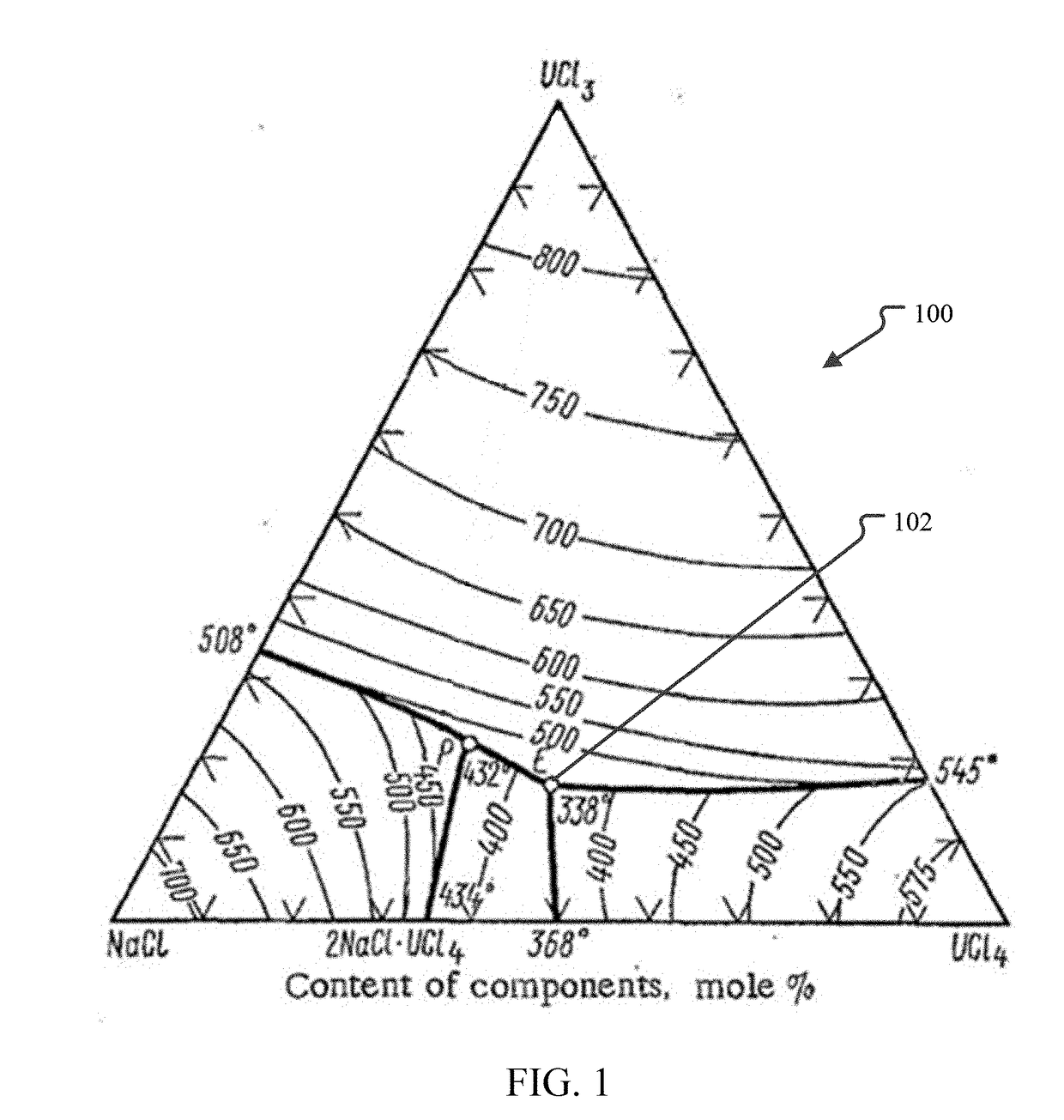

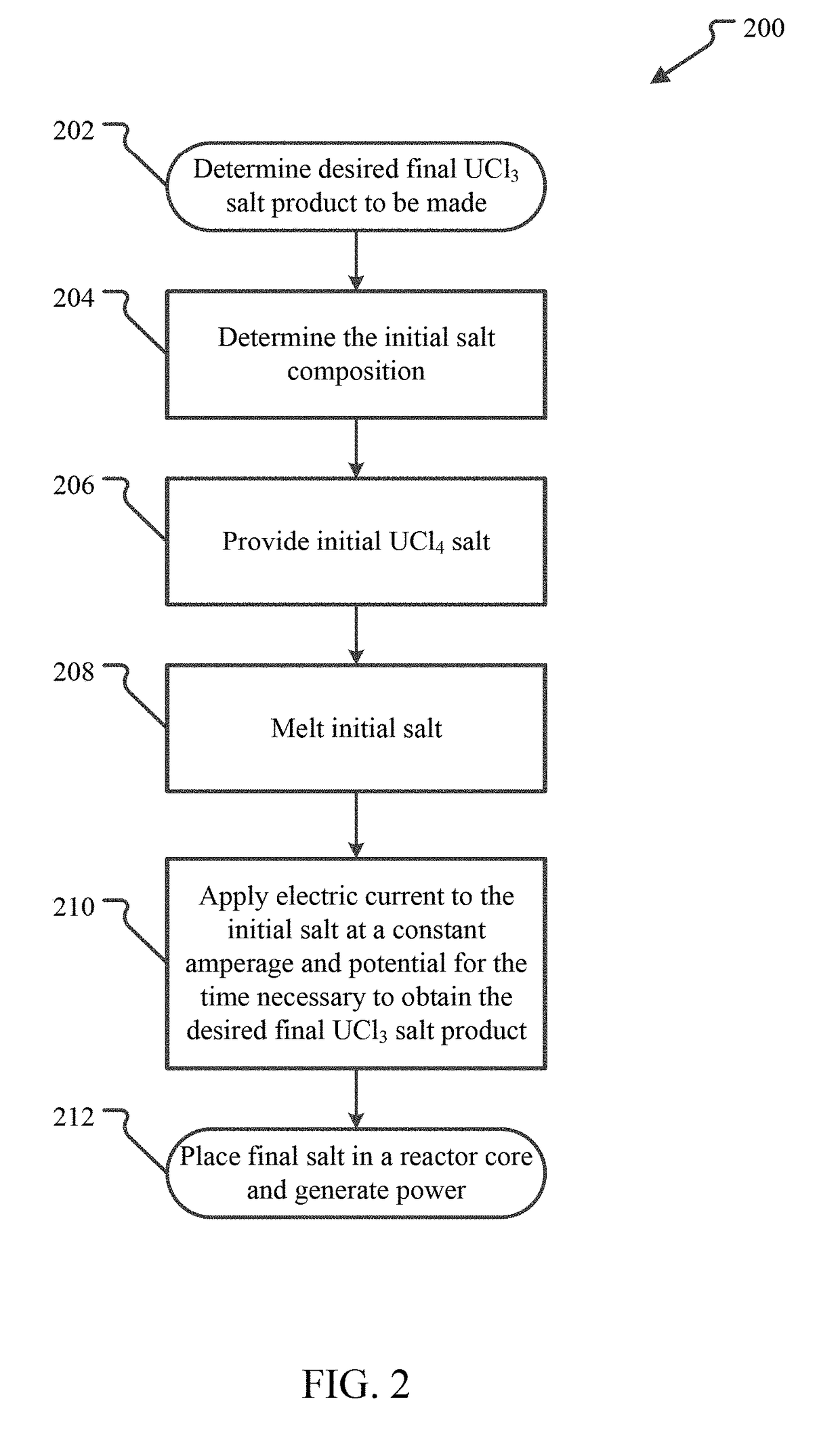

This disclosure describes systems and methods for synthesizing UCl3 from UCl4. These systems and methods may also be used to directly synthesize binary and ternary embodiments of uranium salts of chloride usable as nuclear fuel in certain molten salt reactor designs. The systems and methods described herein are capable of synthesizing any desired uranium chloride fuel salt that is a combination of UCl4, UCl3 and one or more non-fissile chloride compounds, such as NaCl. In particular, the systems and methods described herein are capable of synthesizing any UCl3—UCl4—NaCl or UCl3—NaCl fuel salt composition from UCl4—NaCl.

Owner:TERRAPOWER

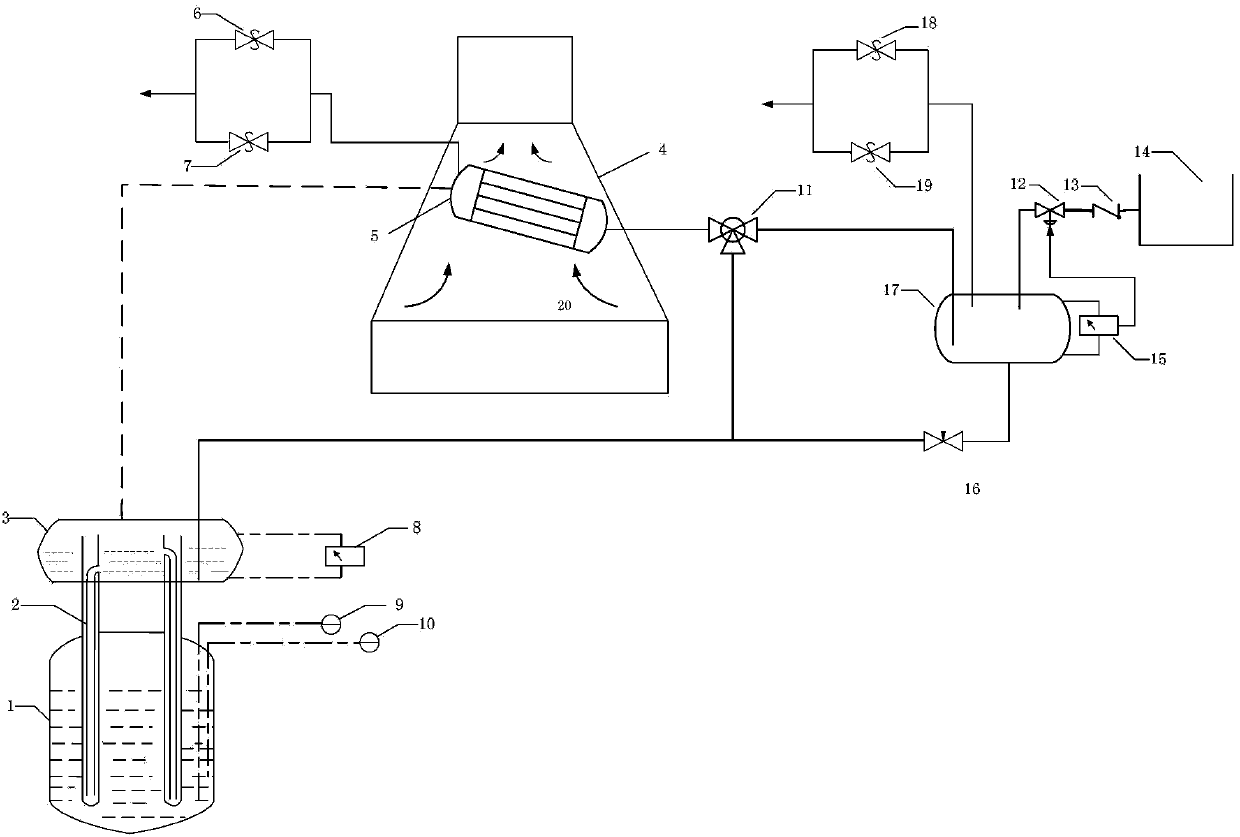

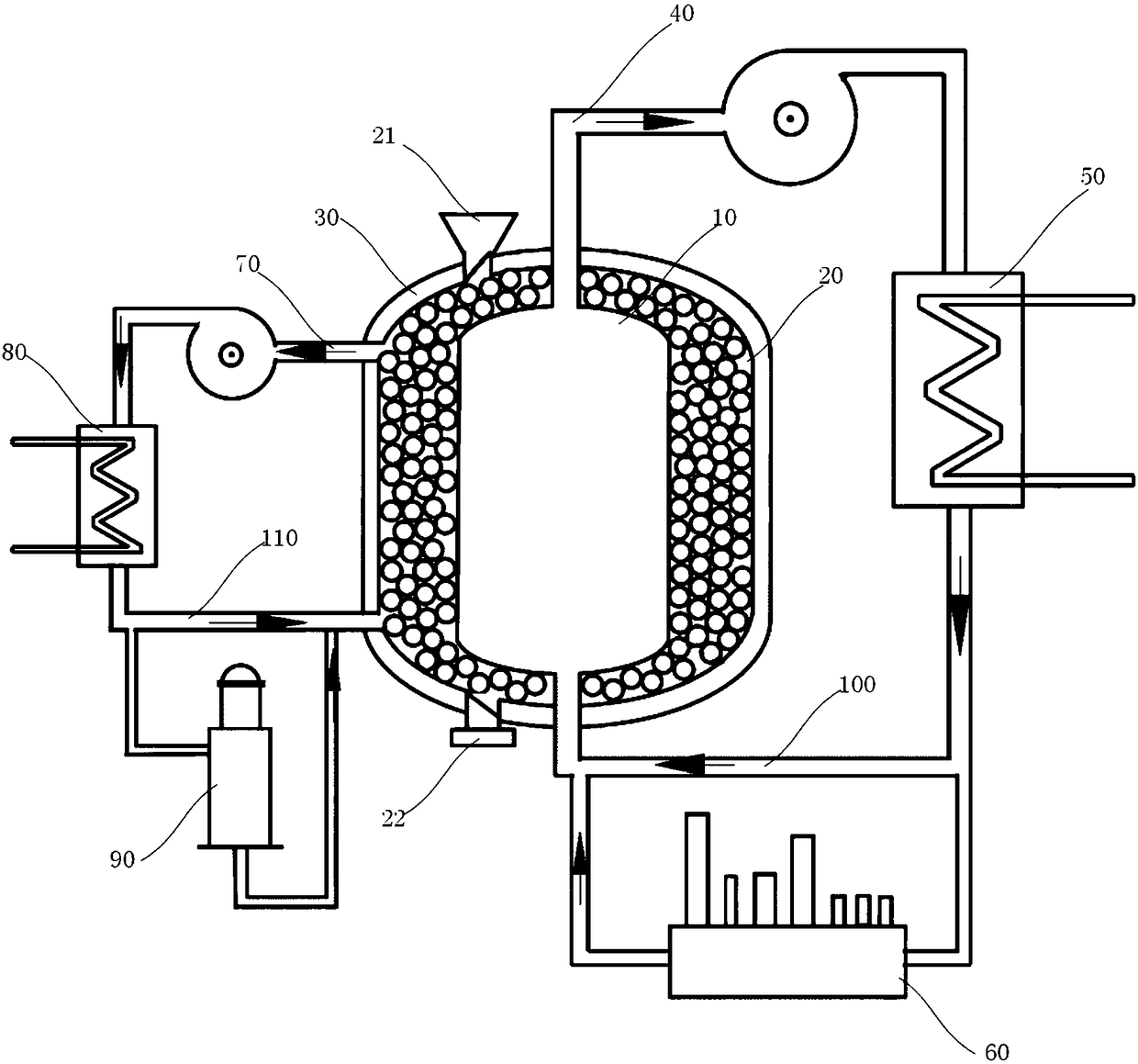

Comprehensive experiment loop system for working medium forced circulation of heat conduction oil

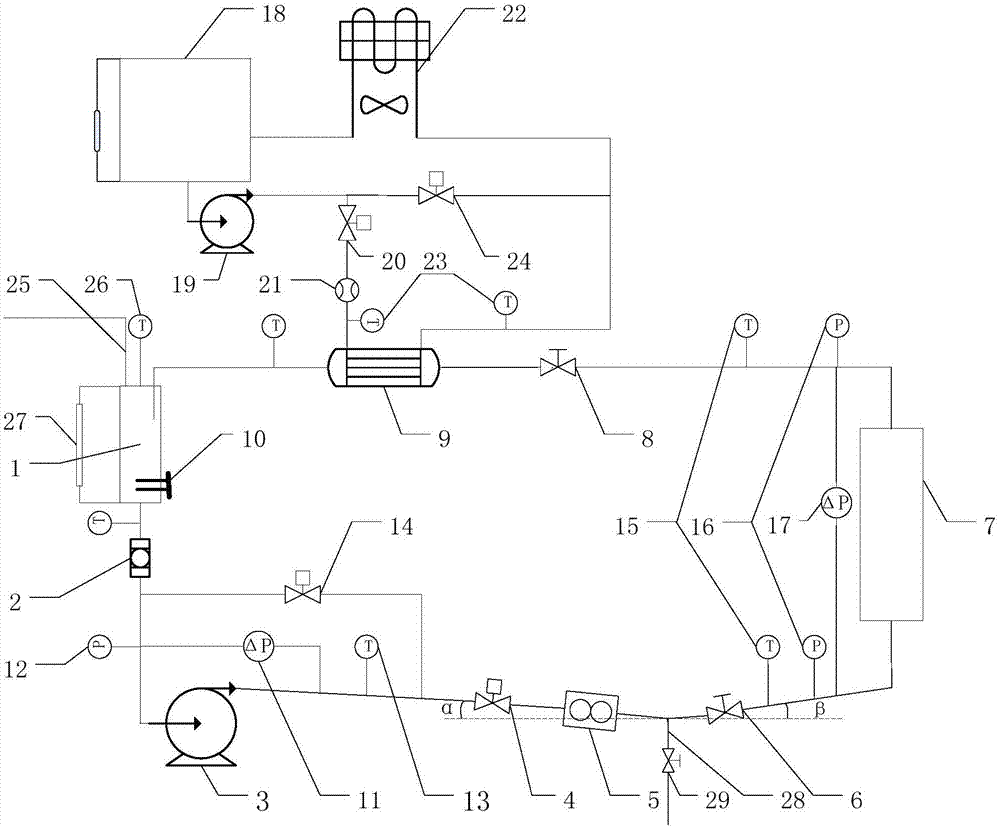

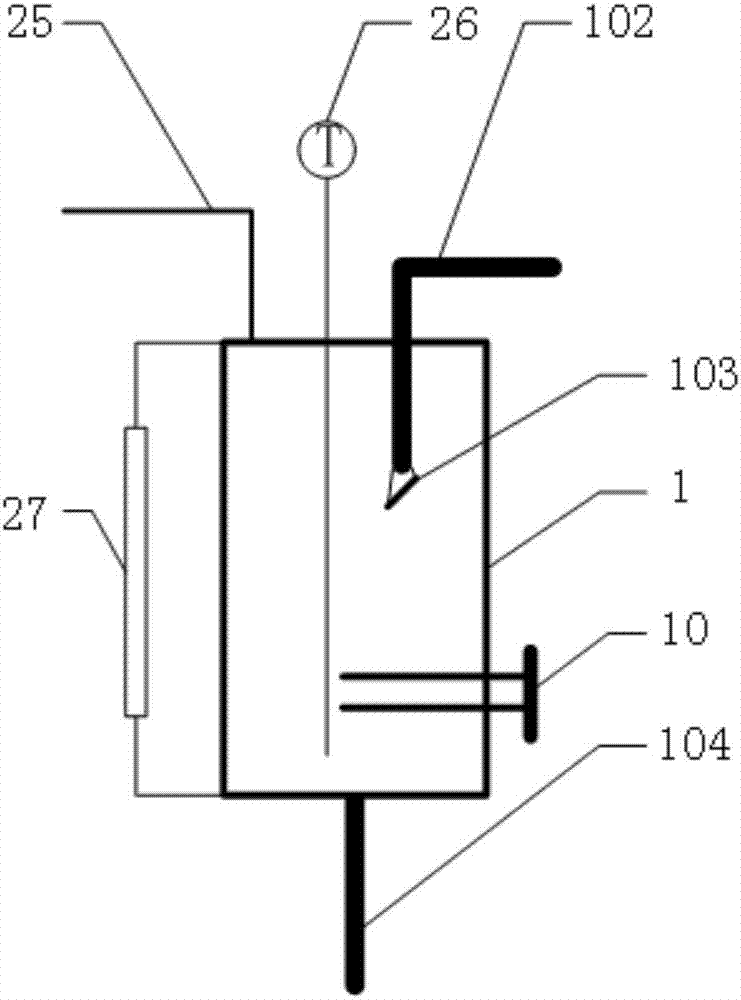

ActiveCN107238627AReduce the difficulty of experimental operationHigh measurement accuracyMaterial heat developmentHydrodynamic testingCooling towerFuel tank

The invention relates to a comprehensive experiment loop system for working medium forced circulation of heat conduction oil. The comprehensive experiment loop system comprises a main experiment loop, a cooling circulation loop and a data collection and control system, wherein Dowtherm-A heat conduction oil is taken as a working mechanism of the main experiment loop, and water is taken as a working mechanism of the cooling circulation loop; the main experiment loop comprises an oil conduction oil tank, a centrifugal pump, an regulating valve, a flow meter, an experiment body section and a heat exchanger are connected according to the working mechanism flow direction; and the cooling circulation loop comprises a cooling agent tank, a centrifugal pump, an regulating valve, a flow meter, a heat exchanger and an air cooling tower. The heat conduction oil is guided out from the oil conduction oil tanks through the centrifugal pumps, enters an experiment body through the flow meters after being subjected to flow regulation through the regulating valves, finally is cooled through the heat exchanges and flows back to the oil conduction oil tank so as to form closed forced circulation flow; the cooling circulation loop is connected with the main experiment loop through the heat exchangers, and heat of the main experiment loop is discharged. The comprehensive experiment loop system can simulate the flow heat exchanging property of FLiBe, is easy to operate, economic, safe and high in measurement accuracy and can be used for implementing the experimental study on core stacking of a molten salt reactor ball bed, heat convection of pipelines and flow resistance of key equipment.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

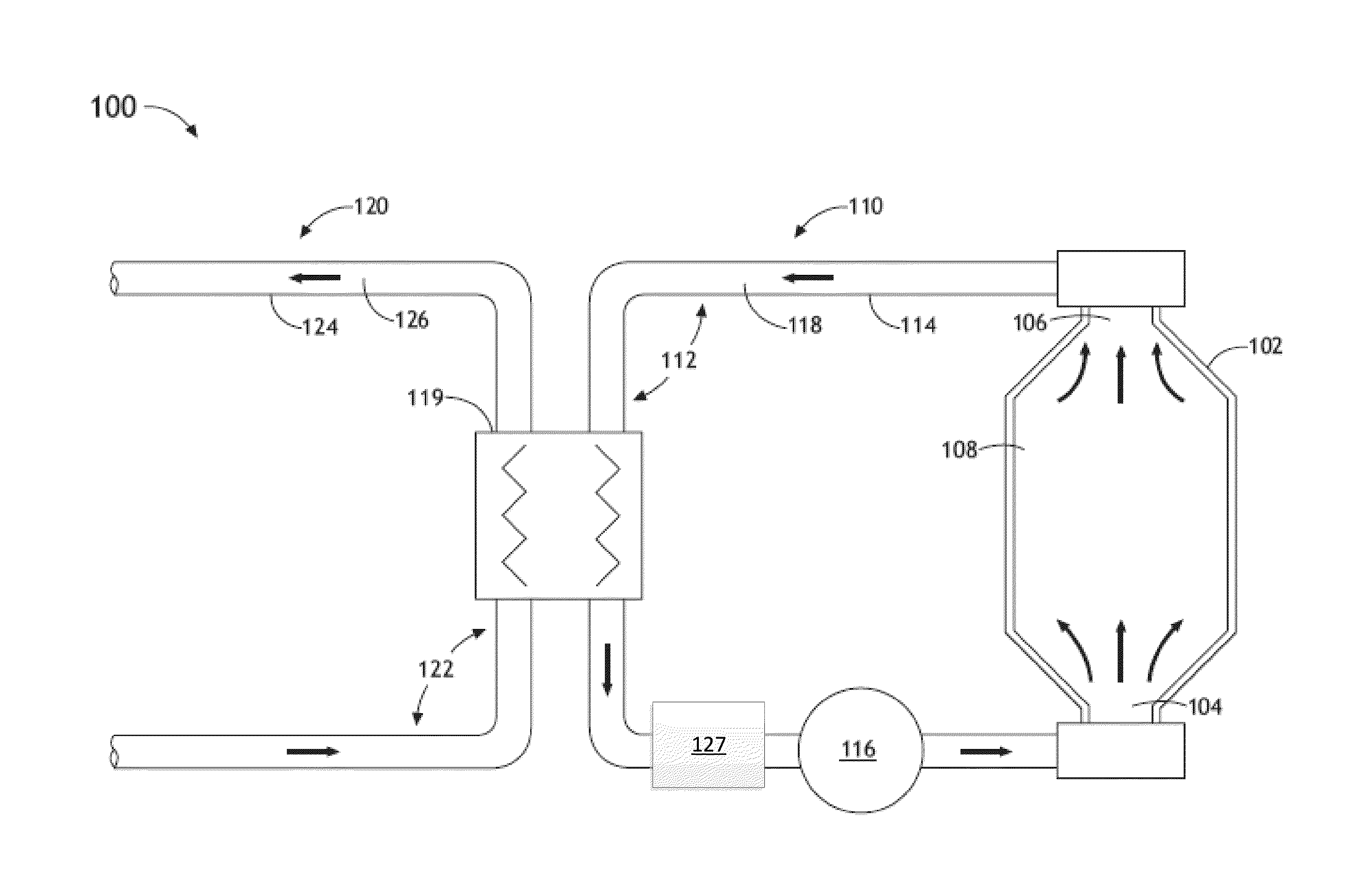

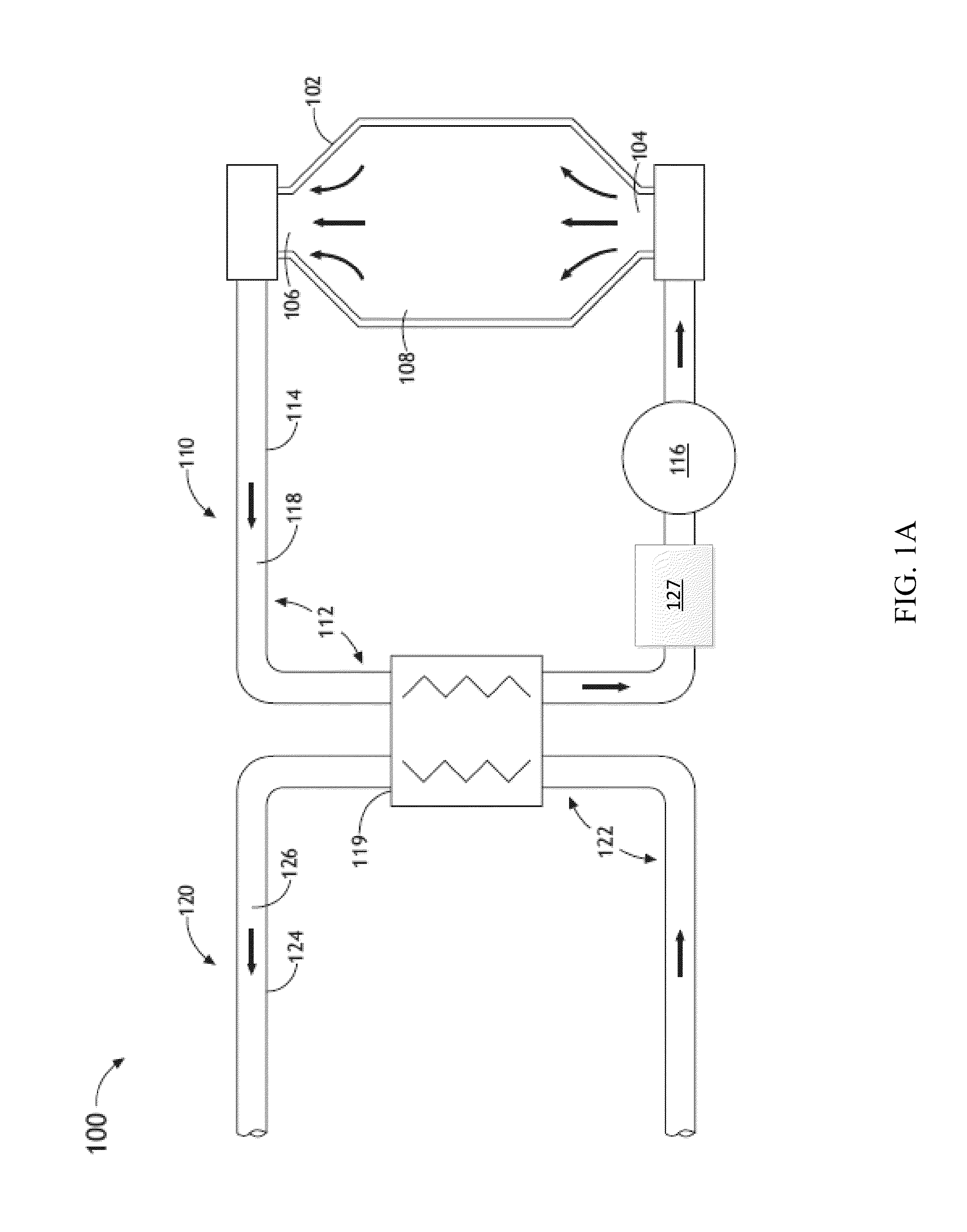

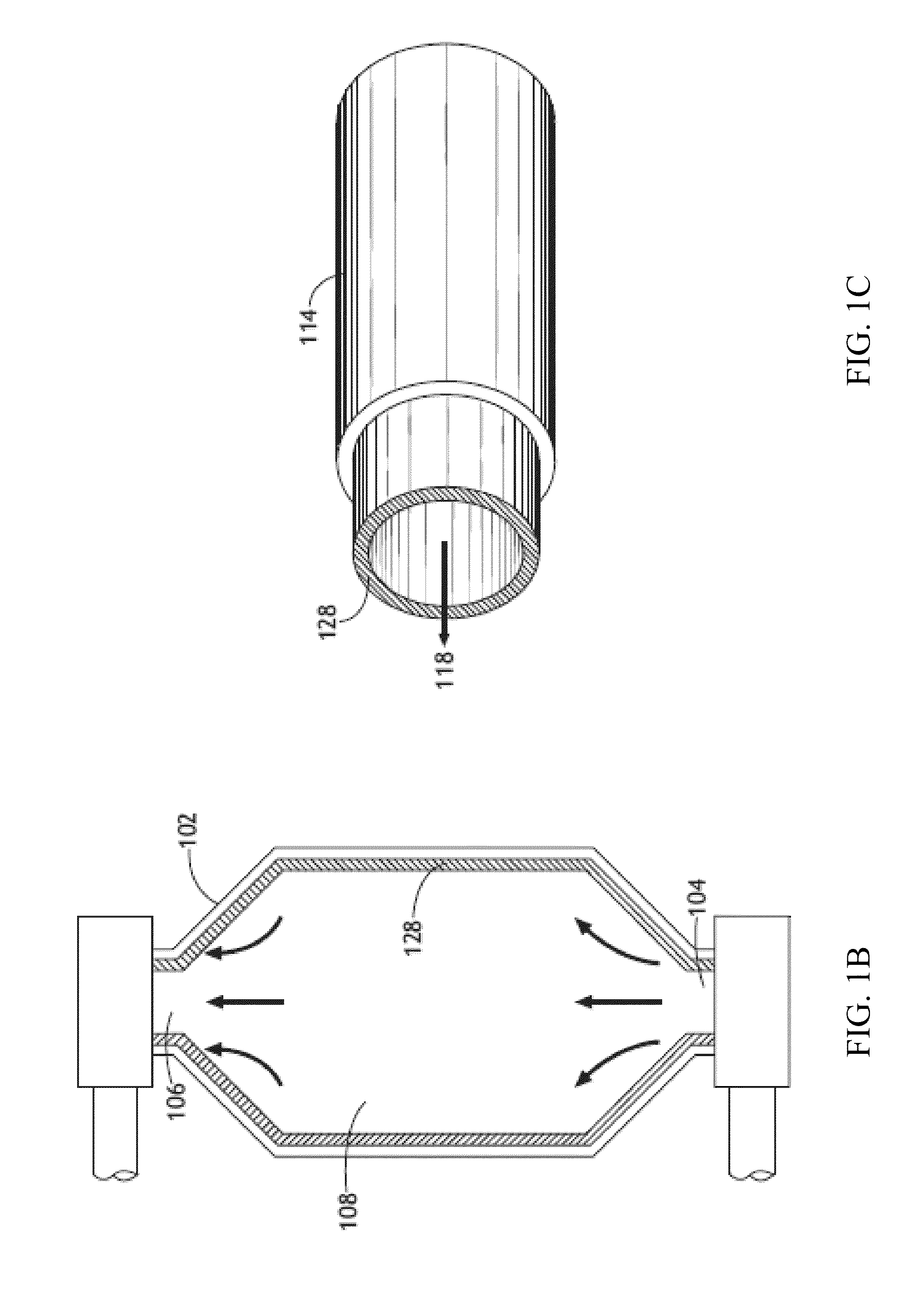

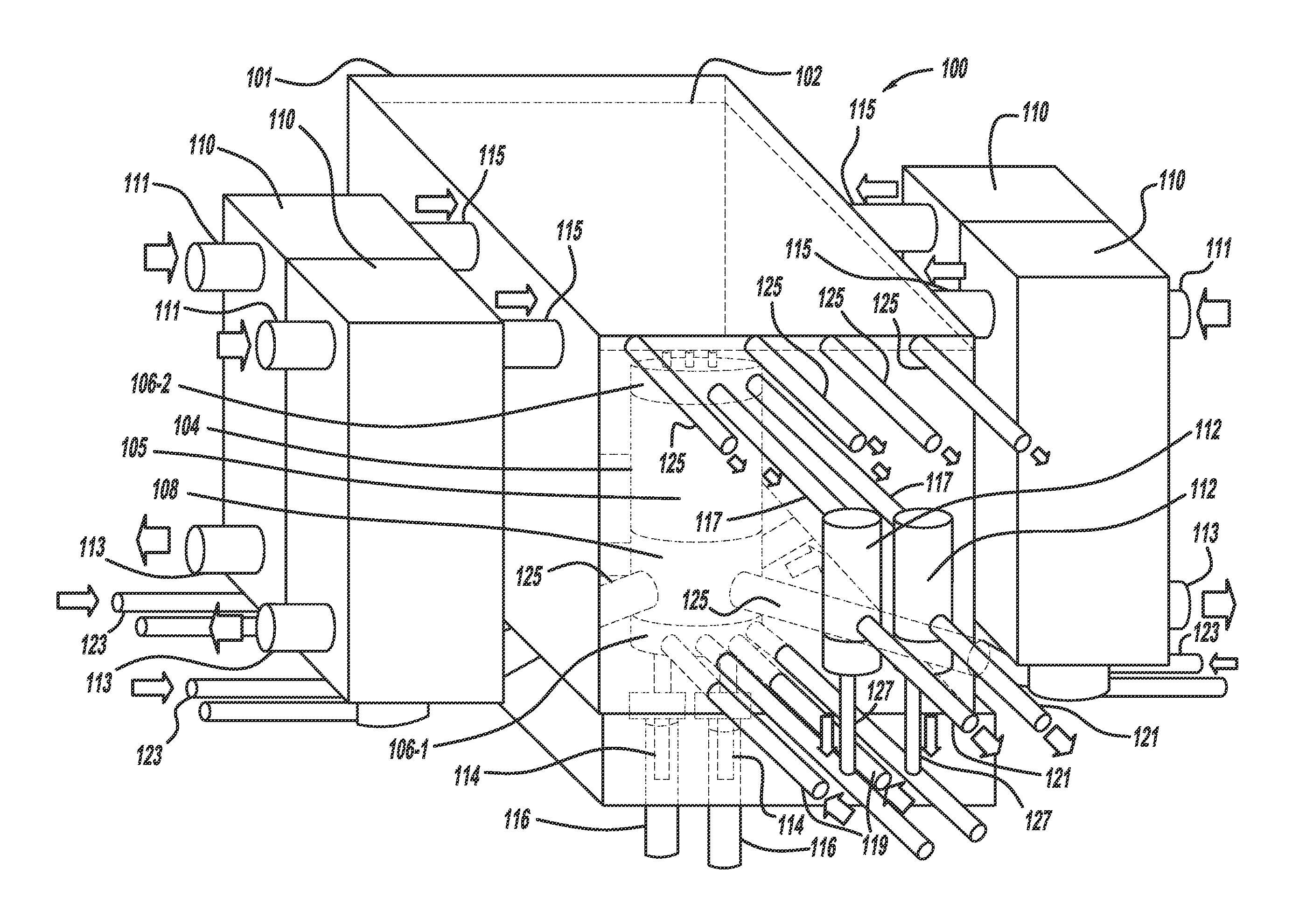

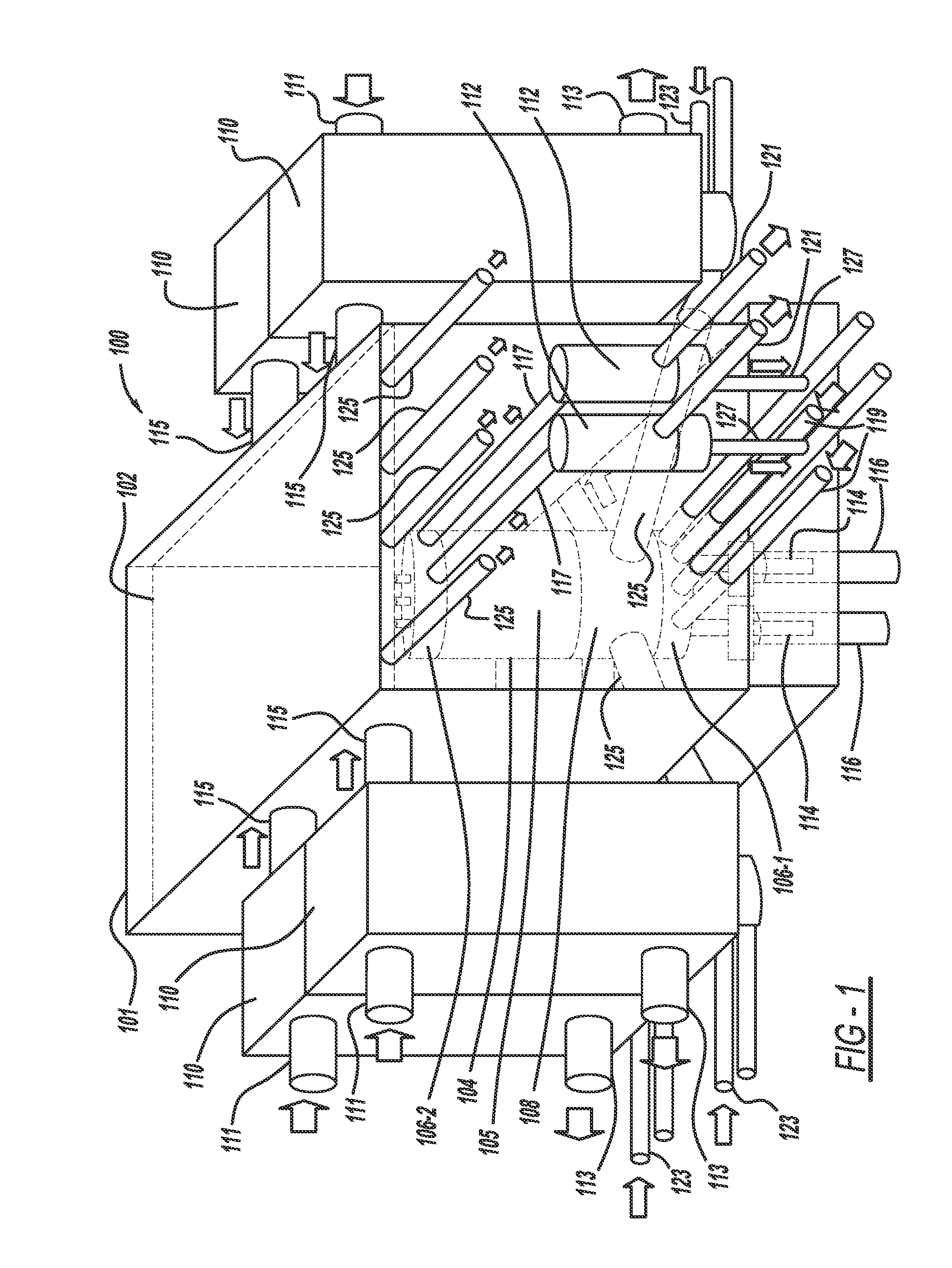

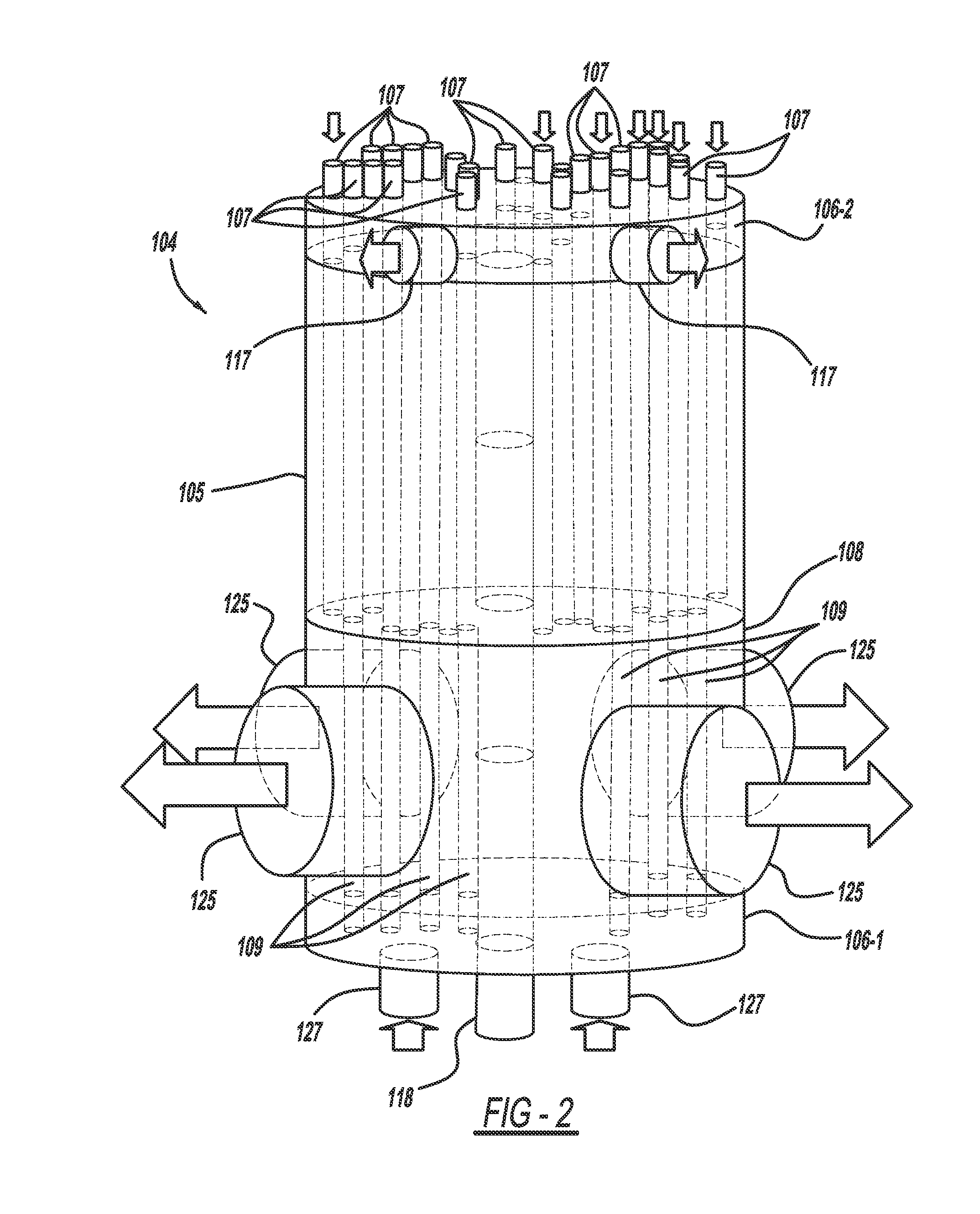

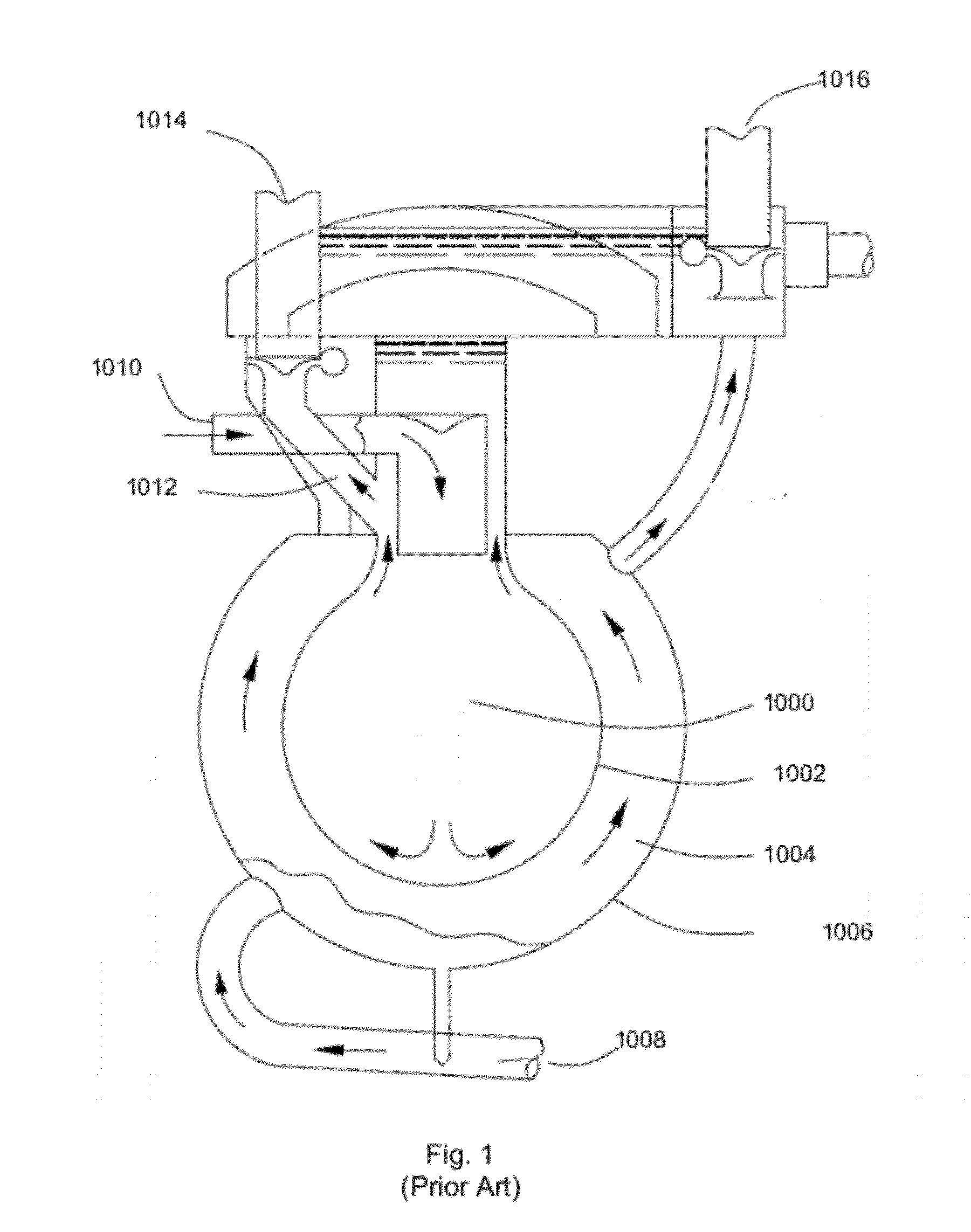

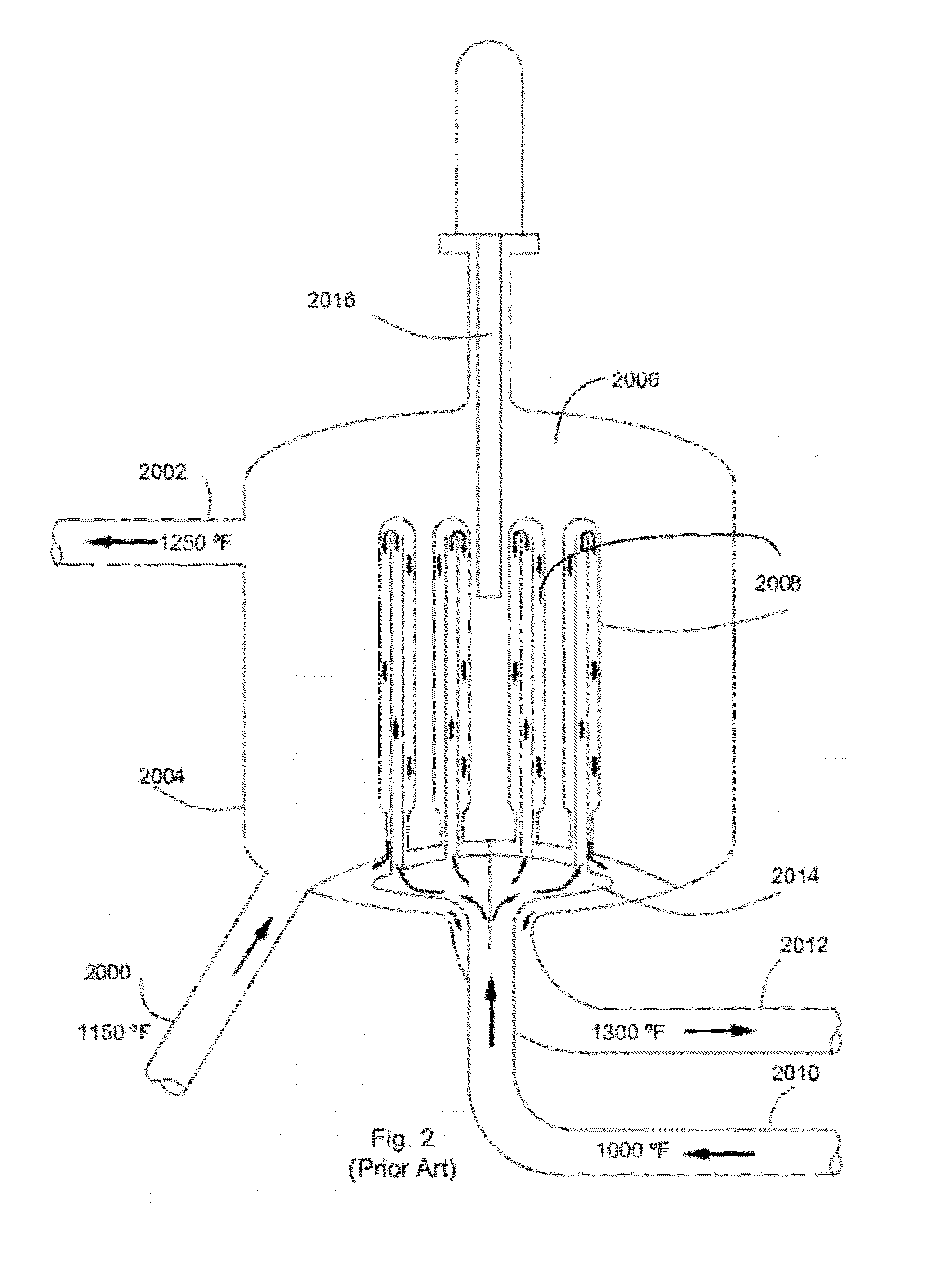

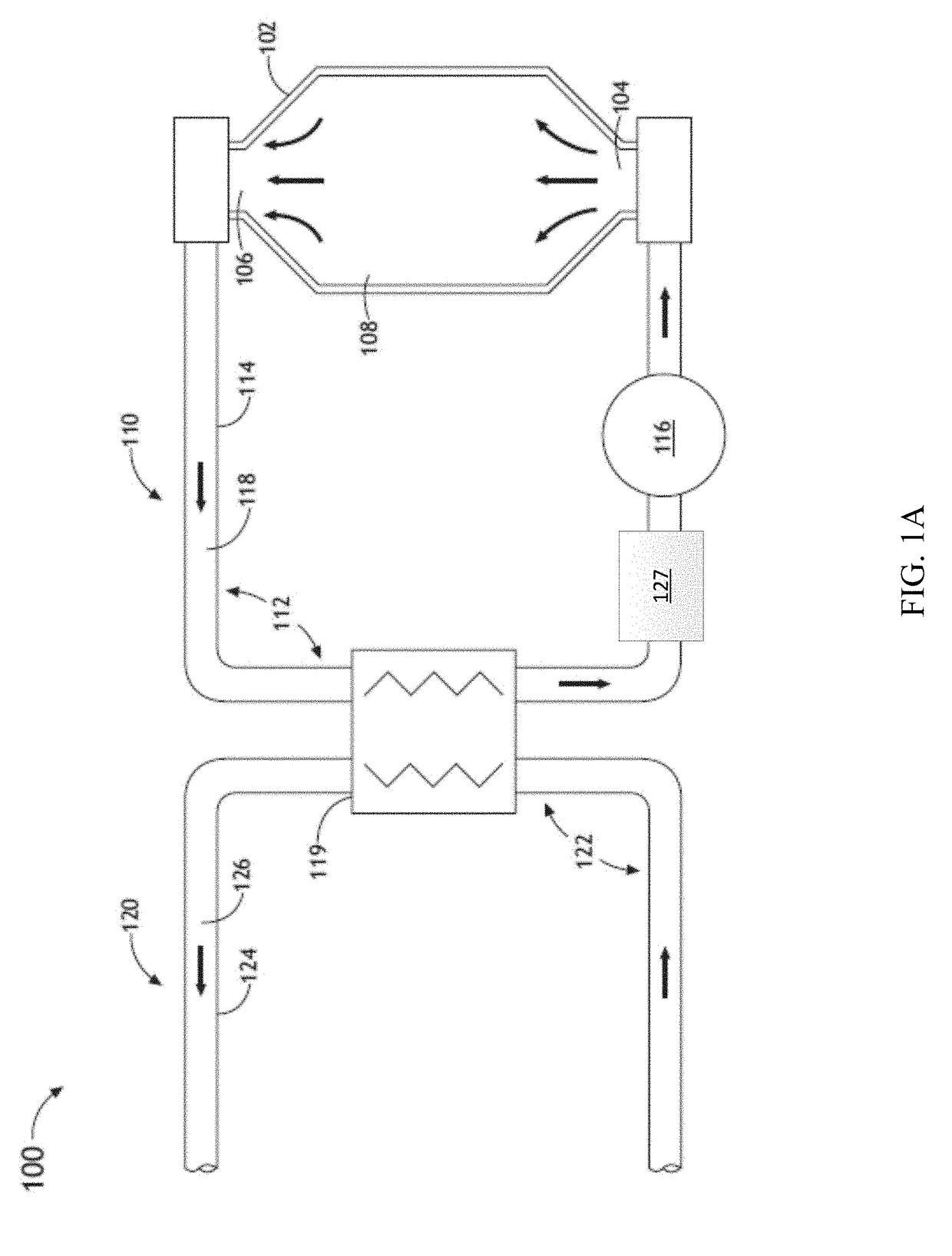

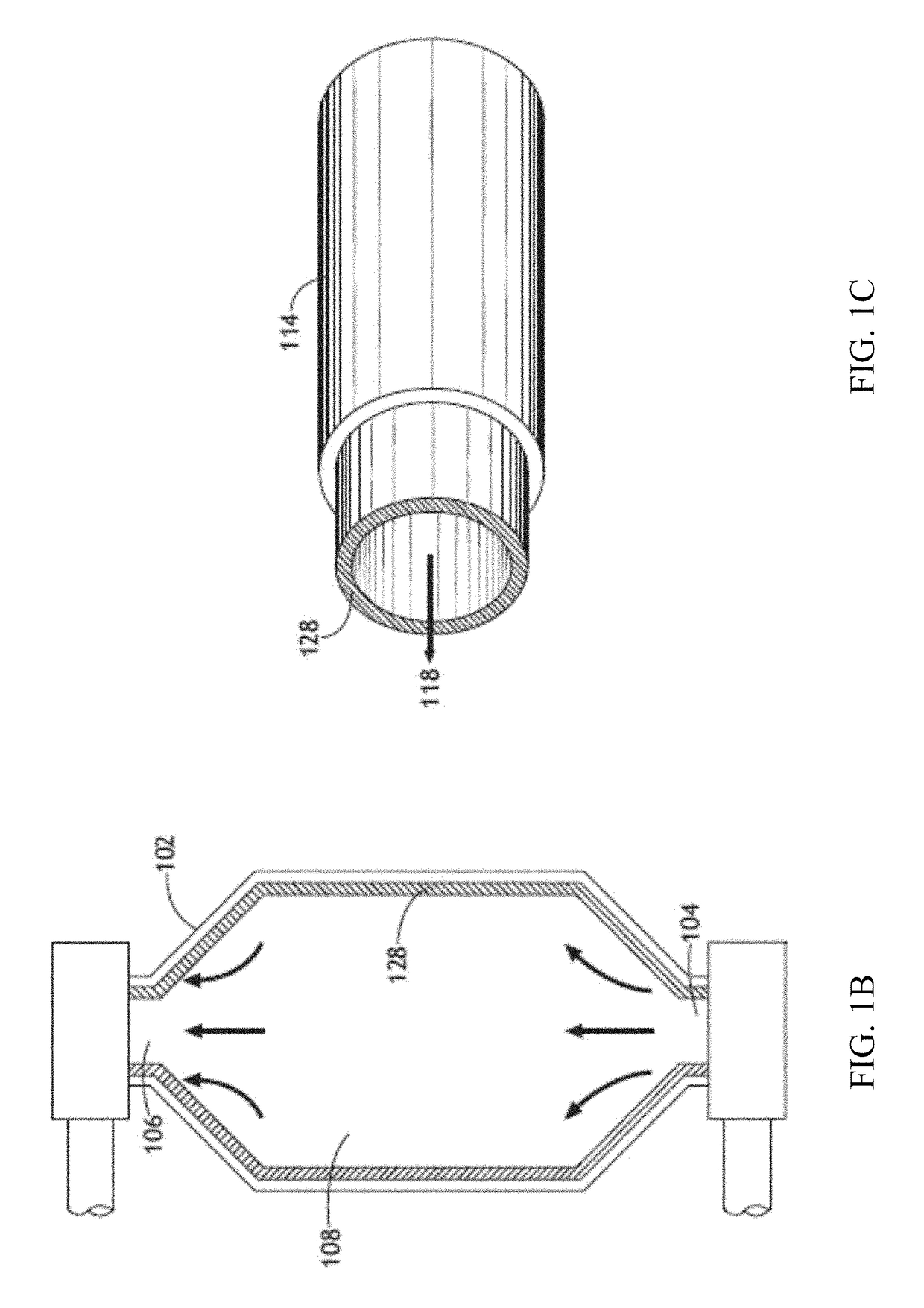

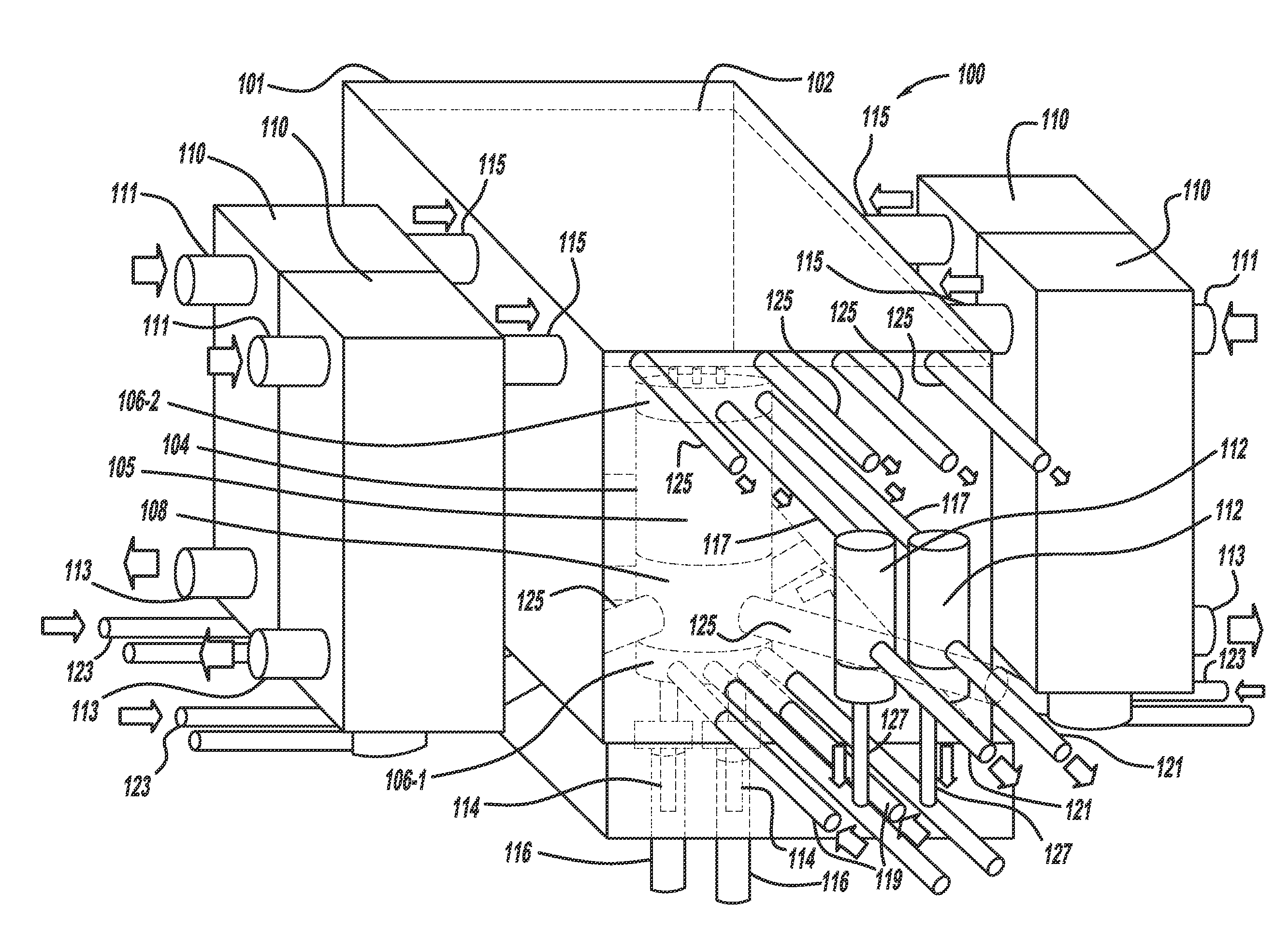

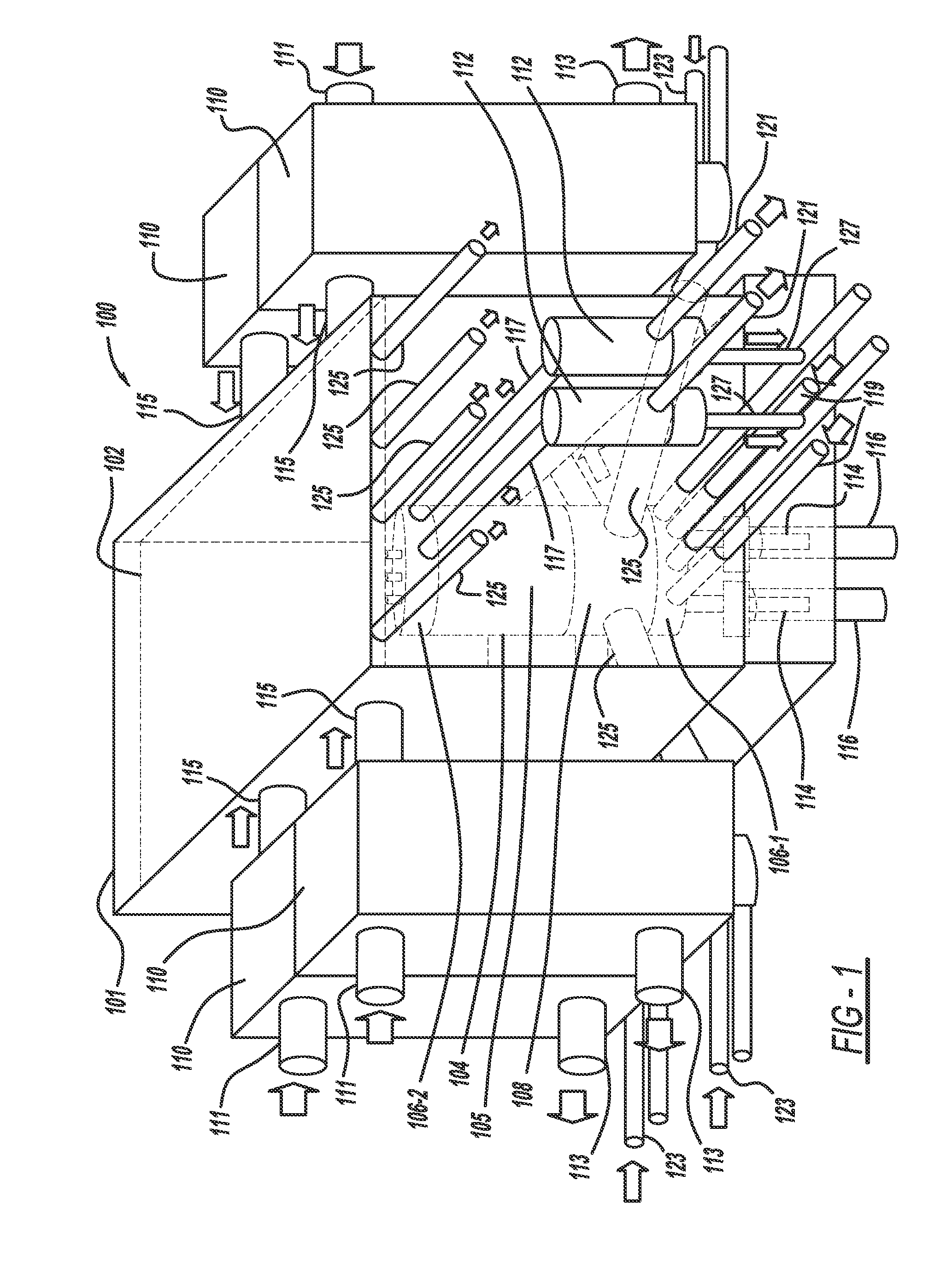

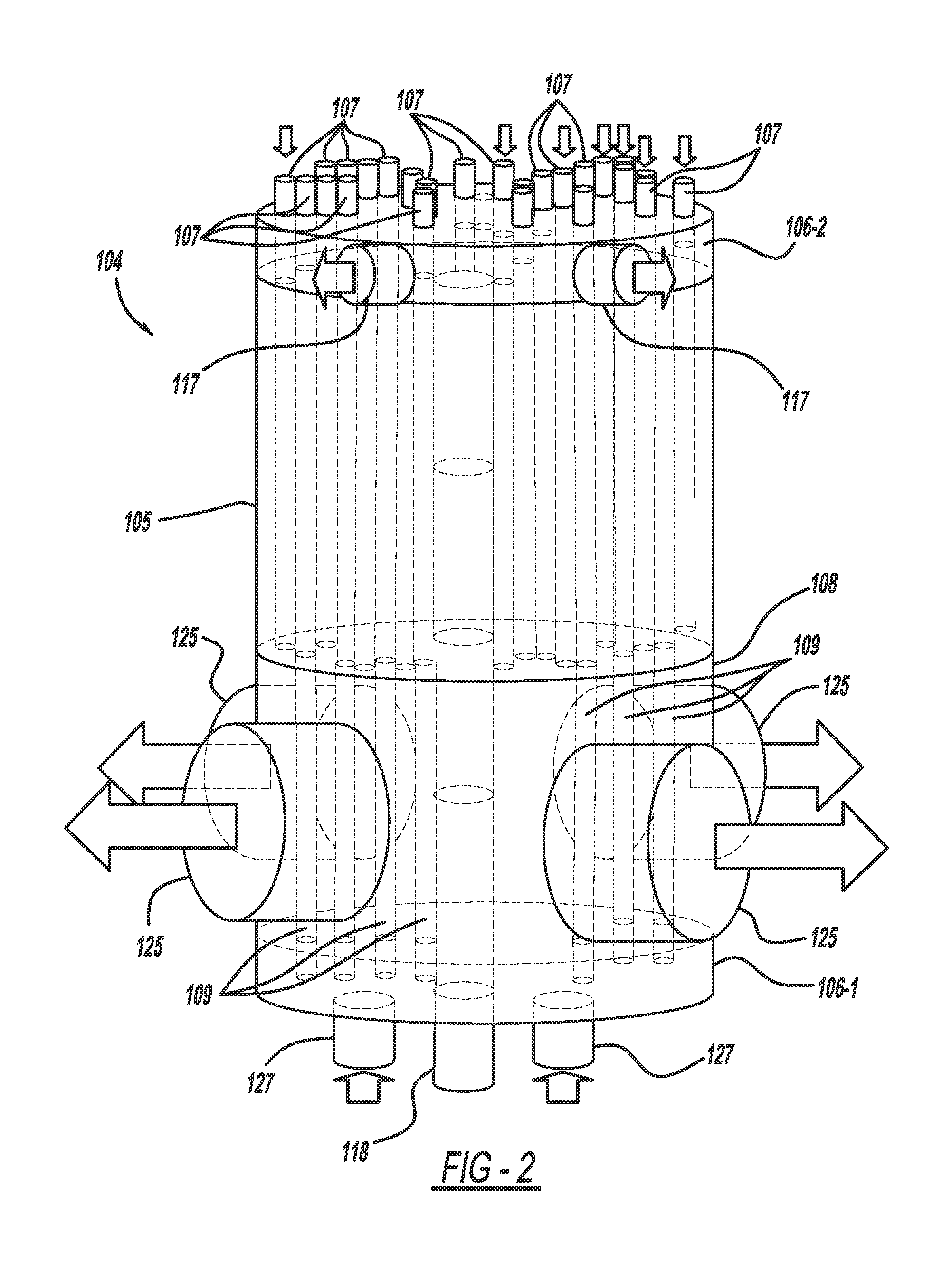

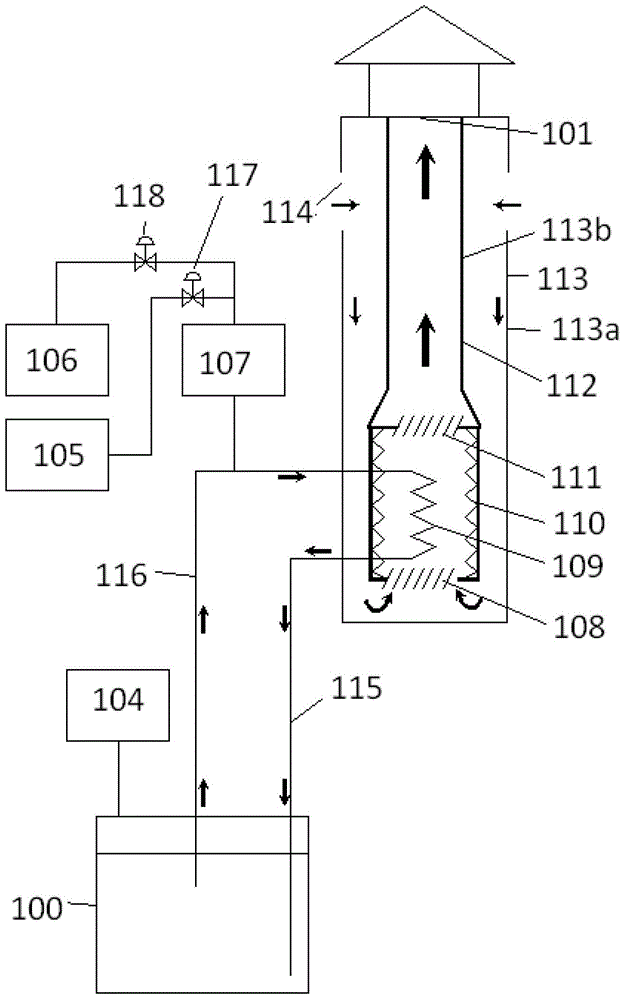

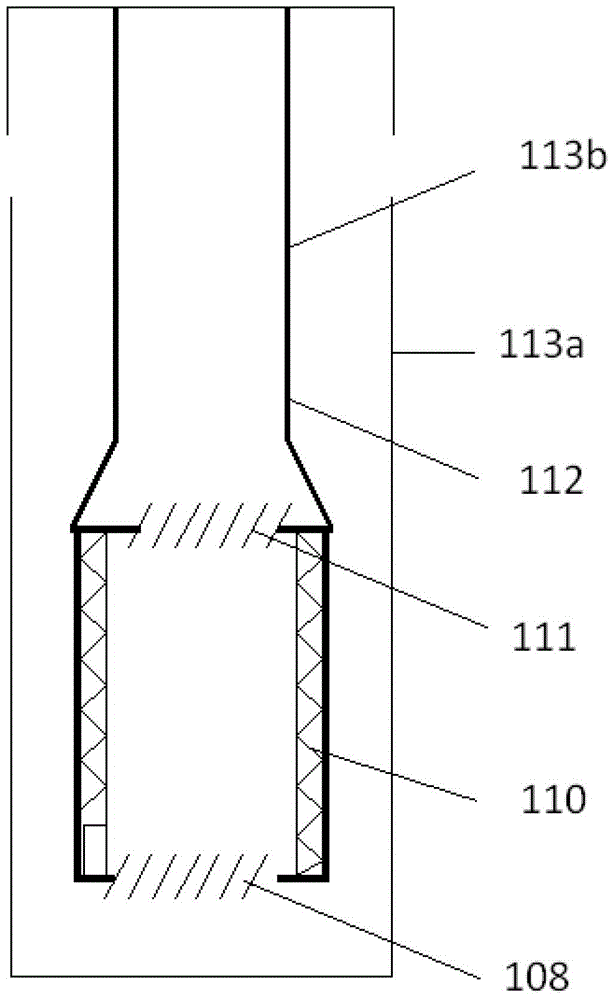

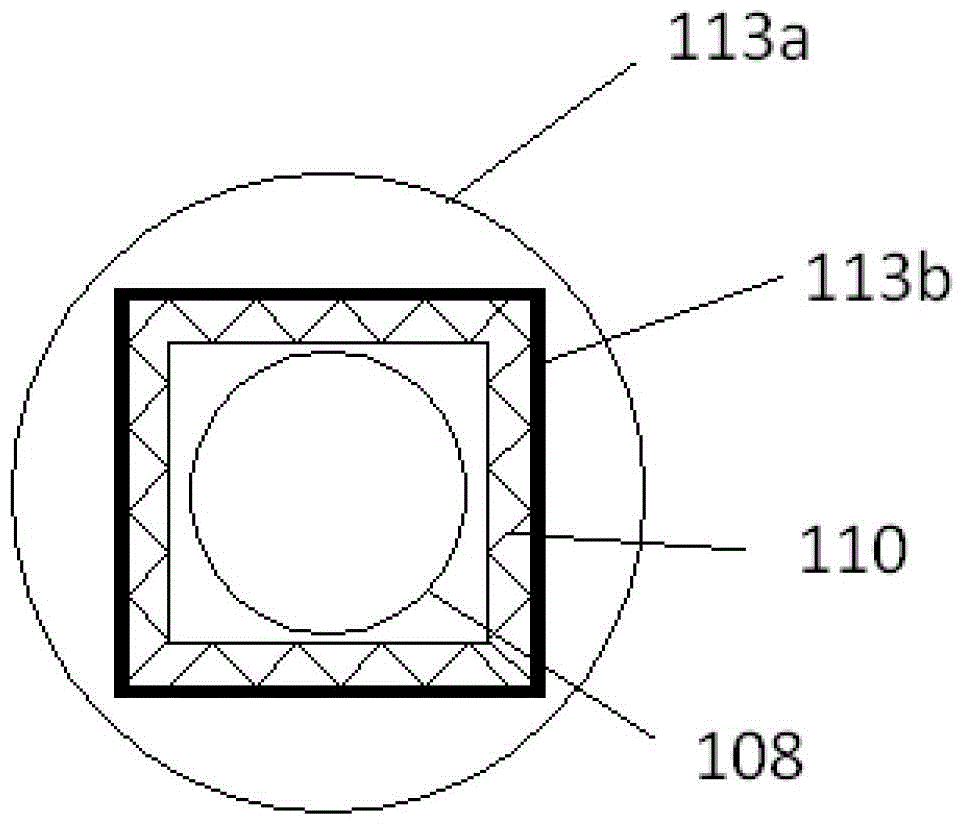

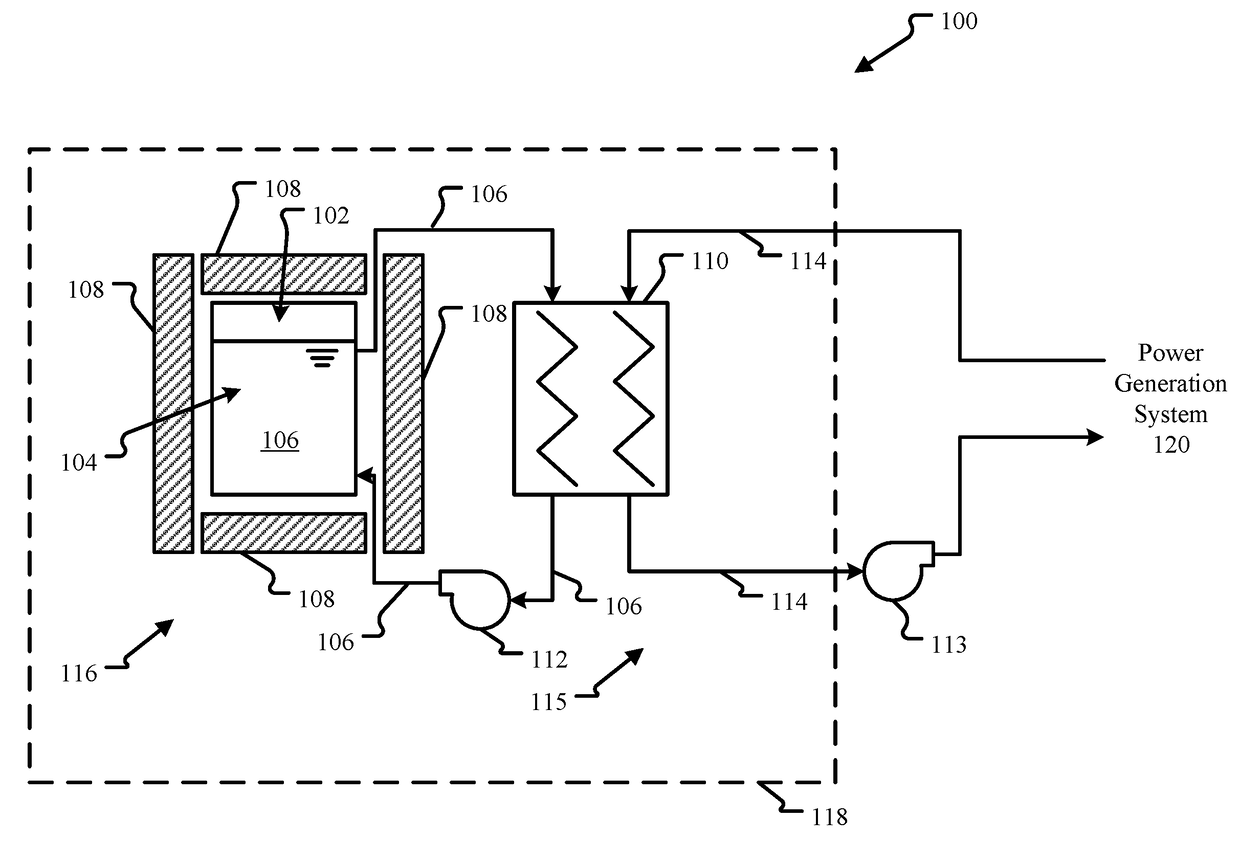

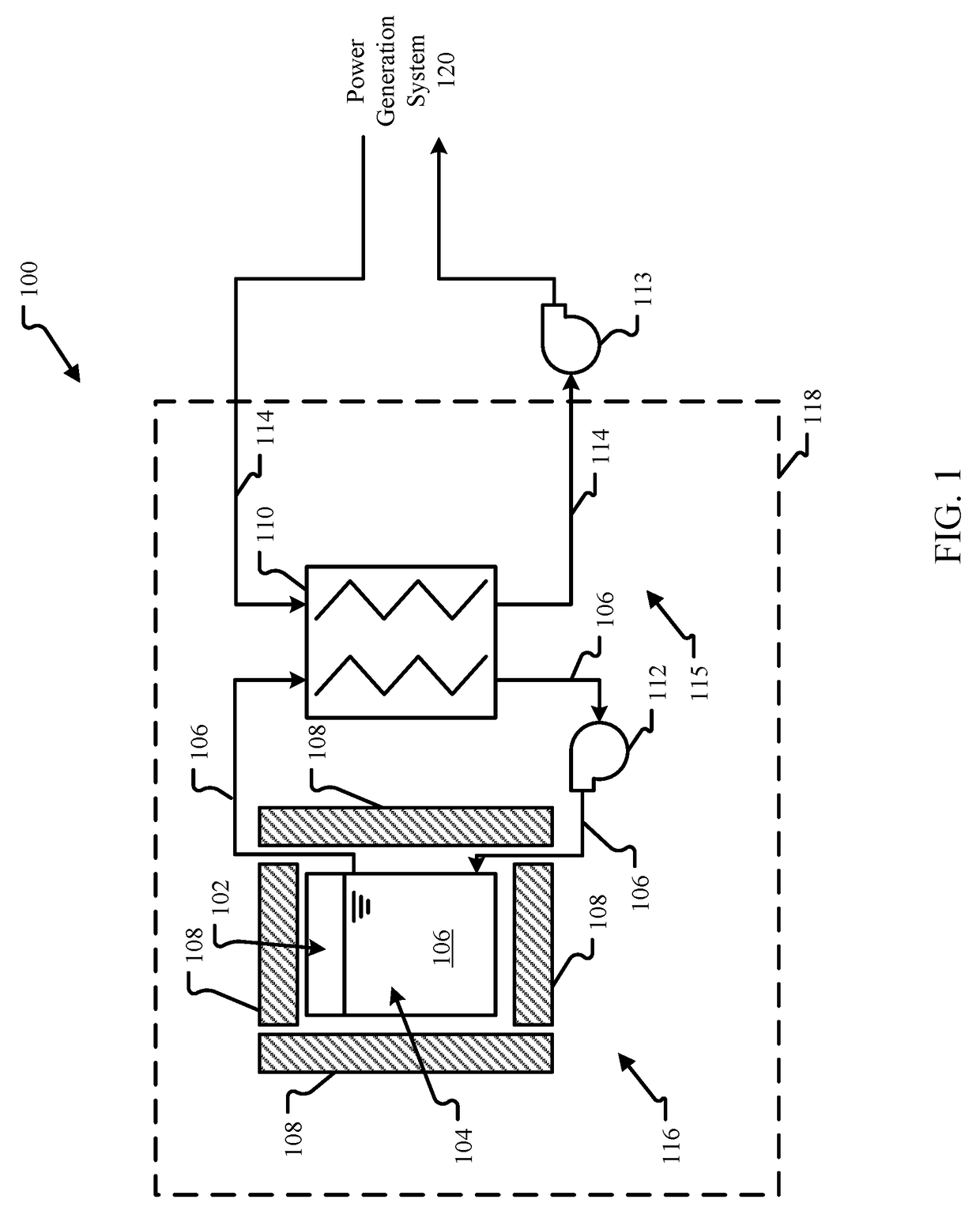

Molten fuel reactor cooling and pump configurations

ActiveUS20170316841A1Improve power densitySave on fuel costsIntegral reactorsFuel elementsDecay heatMolten salt reactor

Configurations of molten fuel salt reactors are described that include an auxiliary cooling system which shared part of the primary coolant loop but allows for passive cooling of decay heat from the reactor. Furthermore, different pump configurations for circulating molten fuel through the reactor core and one or more in vessel heat exchangers are described.

Owner:TERRAPOWER

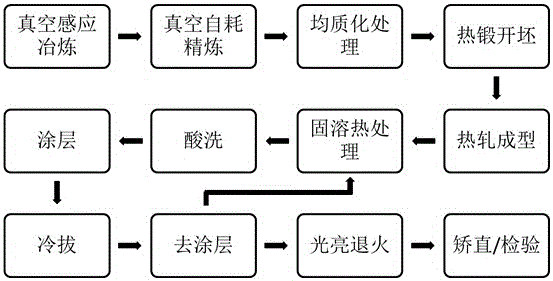

Preparation method of solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding

ActiveCN106181131APrecise content controlReduce lossWelding/cutting media/materialsSoldering mediaSolution treatmentVacuum arc remelting

The invention discloses a preparation method of a solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding, and belongs to the technical field of metal welding. The method includes the technological processes of vacuum smelting, vacuum arc remelting, homogenization, hot forging cogging, hot rolling, solution treatment, acid pickling, coating, cold drawing, coating removal and bright annealing. The invention further discloses the solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding. The solid cored welding wire is prepared through the method. Compared with the prior art, by the adoption of the method, high-quality solid cored welding wires of various diameters for molten-salt corrosion resistance nickel-base superalloy welding can be produced with the extremely-high rolling yield in a batch mode, and the prepared solid cored welding wire can meet the requirement for welding molten-salt reactor structural materials.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

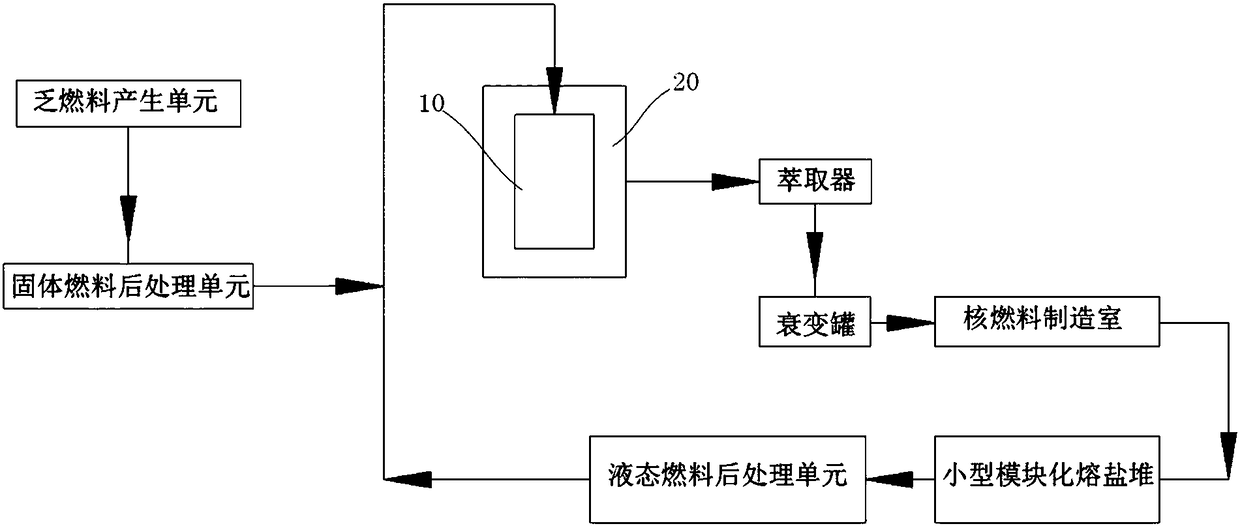

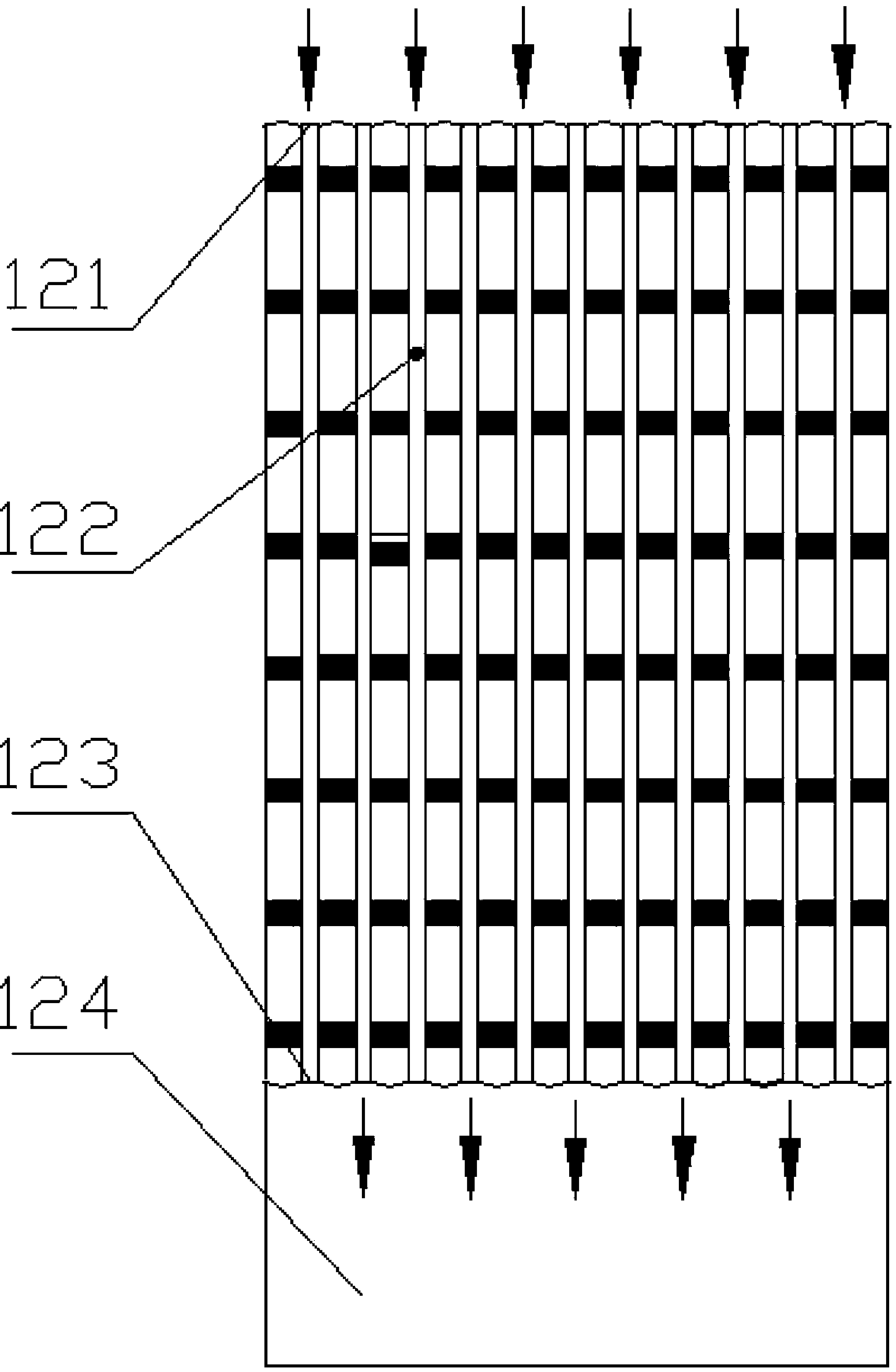

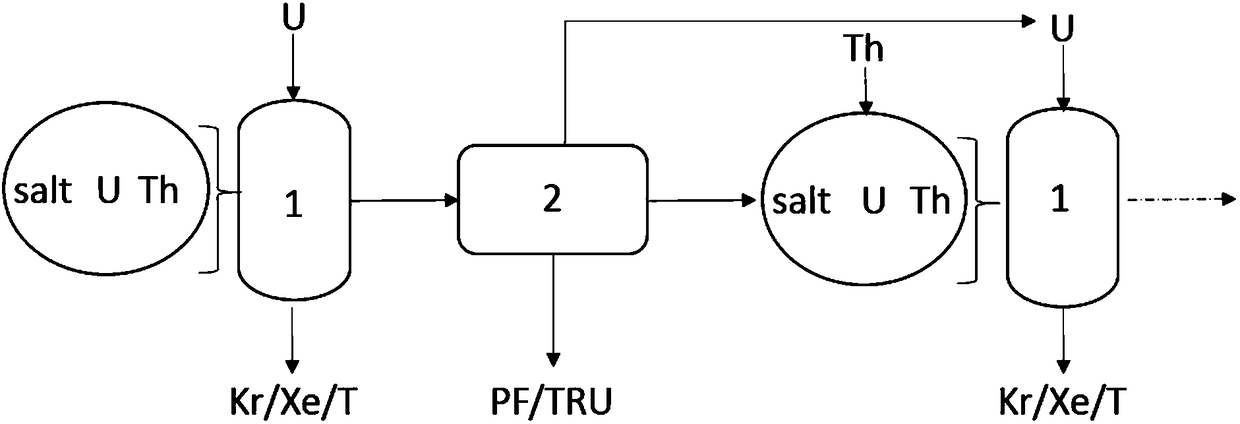

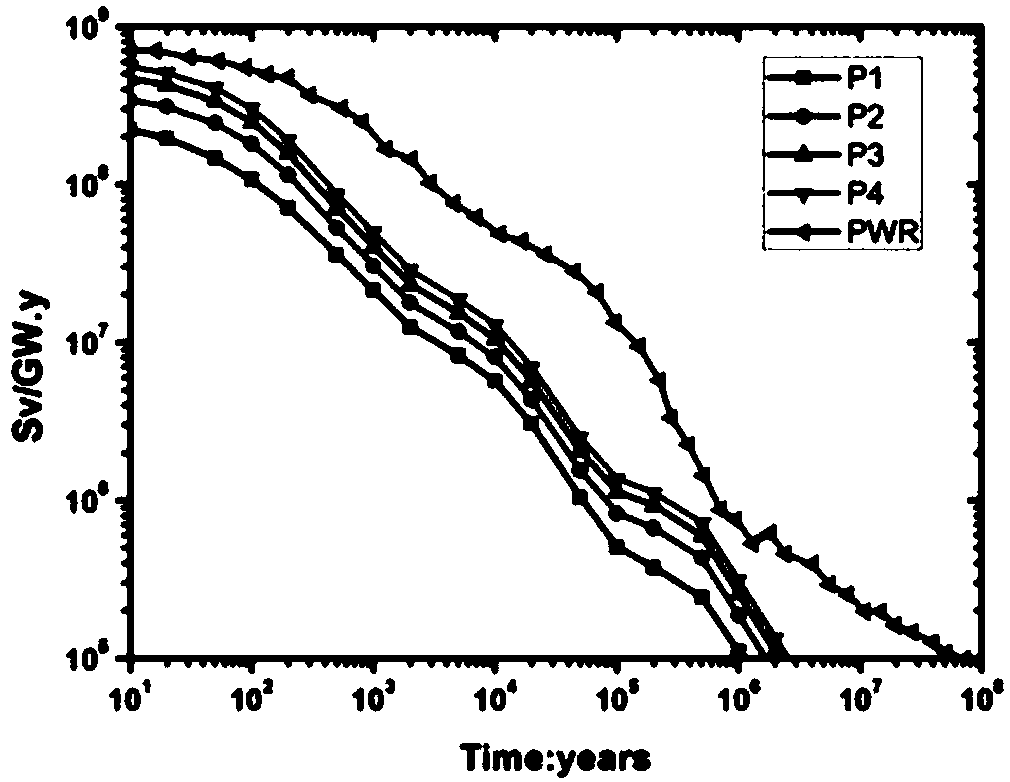

Molten salt reactor core, molten salt reactor system, fuel cycle system and fuel cycle method

ActiveCN108172318AProliferation effect is goodExcellent transmutation abilityNuclear energy generationReactors manufactureGraphiteNeutron

The invention discloses a molten salt reactor core, a molten salt reactor system, a fuel cycle system and a fuel cycle method. An active region of the molten salt reactor core has a respective independent transmutation region and a proliferation region, and the transmutation region is disposed in the proliferation region; the transmutation region is used for fast-spectrum transmutation of tran uranium nuclides under chlorine salt and no moderators conditions, and transferring high residual neutrons obtained by the transmutation to the proliferation region; the proliferation region is used forsuperheating-spectrum proliferation of nuclear fuel thorium under fluoride salt and graphite balls as the moderator conditions. The molten salt reactor core, the molten salt reactor system, the fuel circulation system and the fuel cycle method have an excellent thorium uranium proliferation capability and a transmutation capability, can efficiently transmute TRU in spent fuel, fully utilize the nuclear fuel thorium, and successfully solve current difficulties of shortage of nuclear fuel resources and accumulation of highly active wastes in nuclear development.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Molten salt reactor buffer salt natural circulation cooling system

ActiveCN103366838AIncrease profitAvoid accident riskNuclear energy generationCooling arrangementCooling effectReactor design

The invention relates to a molten salt reactor buffer salt natural circulation cooling system. The system comprises an air natural circulation system and a molten salt natural circulation system which are intersected in an immersion-type plate air cooler. The immersion-type plate air cooler comprises a molten salt inlet, a molten salt runner, and a molten salt outlet sequentially formed on a vertical direction, and an air inlet, an air runner, and an air outlet sequentially formed on a horizontal direction. The air natural circulation system comprises an air inlet pipe and an air outlet pipe connected through the immersion-type plate air cooler. The molten salt natural circulation system comprises a molten salt inlet, a molten salt runner, a molten salt outlet, and a flow guide groove arranged on the downstream of the molten salt outlet. With the system, buffer molten salt can be directly cooled by using air, such that a middle circulation loop of an existing reactor design is eliminated, and cooling effect is improved. The system is maintained safe without dissipating reactor core power. The risk of accidents of a plurality of devices and pipes is avoided, such that system safety is improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

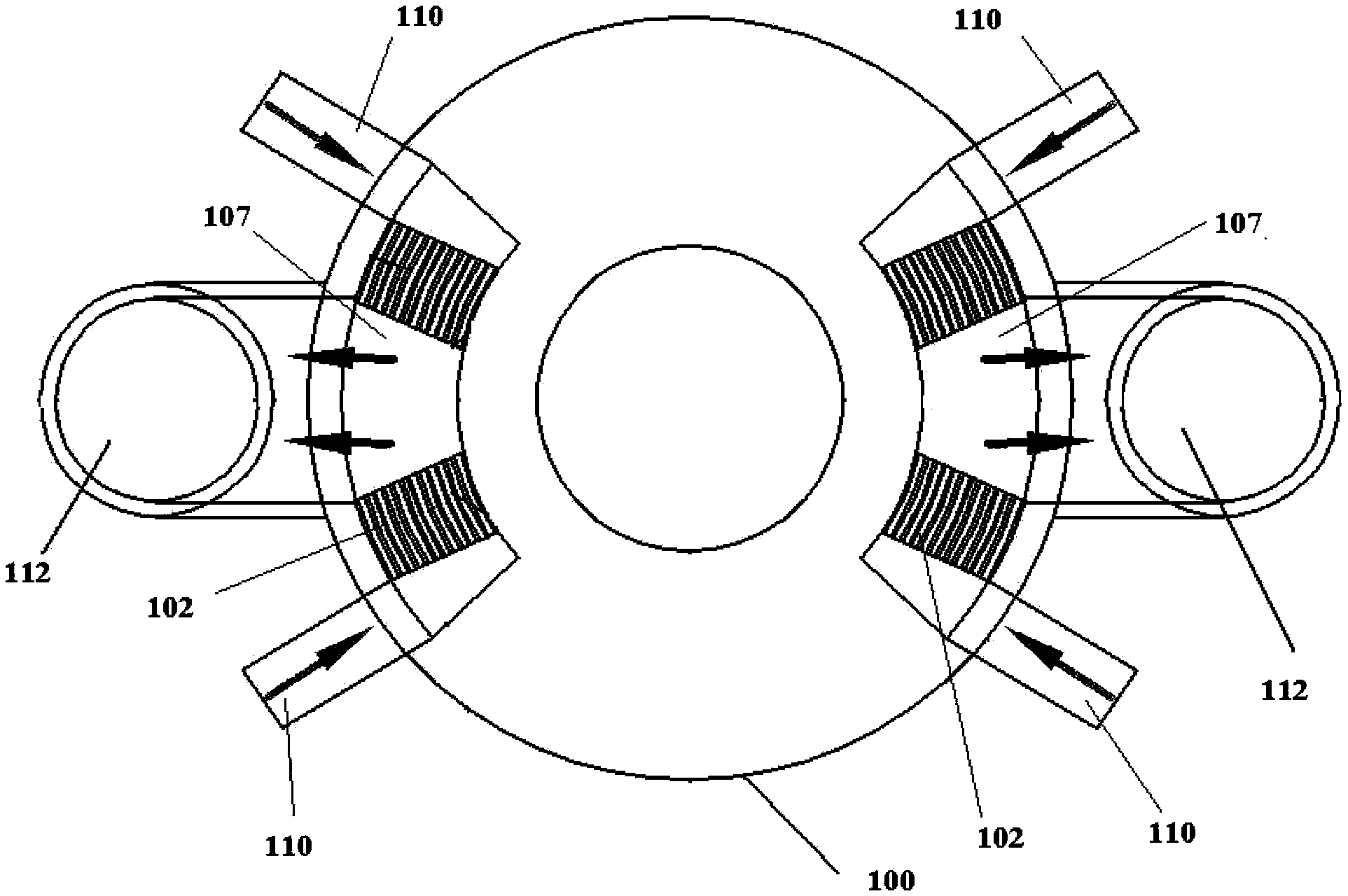

Rotary vane type multistage microbubble screening device

ActiveCN107684983AOptimal bubble sizeOptimal size distributionLiquid degasificationReversed direction vortexImpellerEngineering

The invention provides a rotary vane type multistage microbubble screening device. The device comprises a cylindrical gas-liquid blending cavity, a first-stage bubble separating cavity, a second-stagebubble separating cavity, a third-stage bubble separating cavity and a single-phase liquid cavity which are formed in sequence in the fluid flowing direction. A roiling impeller is arranged between the cylindrical gas-liquid blending cavity and the first-stage bubble separating cavity as well as between the first-stage bubble separating cavity and the second-stage separating cavity and between the second-stage bubble separating cavity and the third-stage bubble separating cavity. A restoring impeller is arranged between the third-stage bubble separating cavity and the single-phase liquid cavity. Axial air outlet mesopores are formed in the roiling impellers and the restoring impeller correspondingly. An air outlet is formed in each axial air outlet mesopore and is connected with a corresponding air outlet branch pipe. The cylindrical gas-liquid blending cavity and the single-phase liquid cavity are provided with pressure sensor detecting holes for a fluid inlet and a fluid outlet. Thepressure sensor detecting holes are used for measuring pressure of the fluid inlet and pressure of the fluid outlet of the microbubble screening device. The rotary vane type multistage microbubble screening device has both the economical efficiency and high efficiency, and online degassing requirements of a molten salt reactor can be met.

Owner:SHANGHAI JIAO TONG UNIV

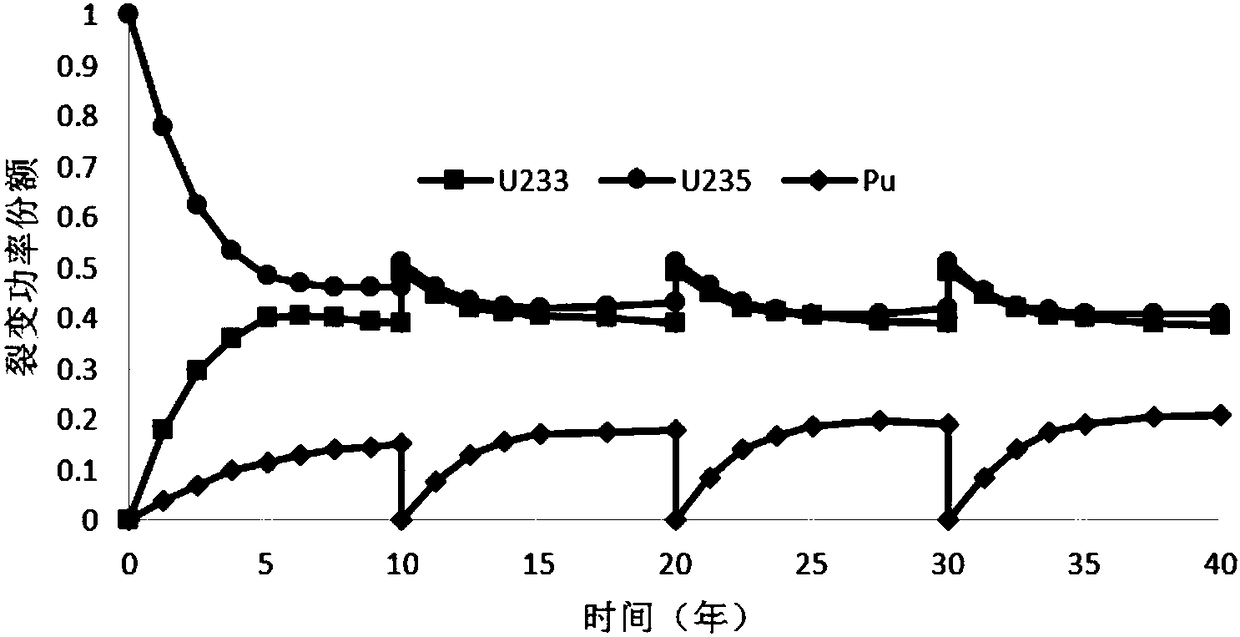

Molten salt reactor thorium fuel cyclic utilization method

InactiveCN108389634AIncrease profitLow radioactivityNuclear energy generationReactor fuel susbtancesEngineeringGraphite

The invention discloses a molten salt reactor thorium fuel cyclic utilization method. A reactor core comprises a graphite assembly and fuel molten salt, wherein the fuel molten salt is filled in a passage formed by the graphite assembly; the fuel molten salt comprises fuel salt and base salt; during operation, the on-line feeding is used; fission gas is cleared in a on-line way; reactor stopping off-line operation is performed, spent fuel is treated; recovered uranium, base salt and thorium are proportioned again and are then loaded into the reactor core for cyclic utilization, wherein the volume ratio of the fuel molten salt to the reactor core is 5 percent to 15 percent; the fuel salt is a mixture of ThF4 and UF4, wherein the U enrichment degree is 15 to 20 percent; the initial mole percentage of the fuel salt in the fuel molten salt is 6 percent to 8 percent; the initial mole percentage of ThF4 in the fuel salt is greater than 80 percent. The method has the advantages that under thecondition without depending an on-line treatment technology, the fission contribution of thorium fuel in the molten salt reactor is improved, so that the utilization rate of U-235 is improved; the radioactivity and the disposal quantity of the spent fuel are reduced.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

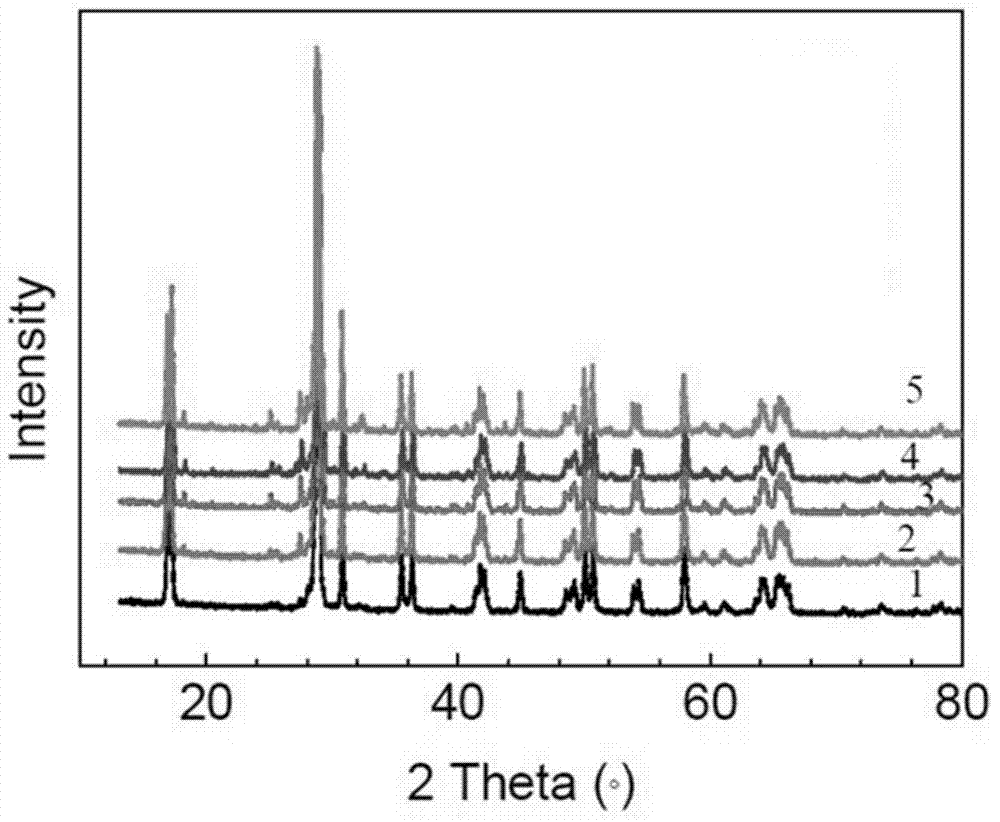

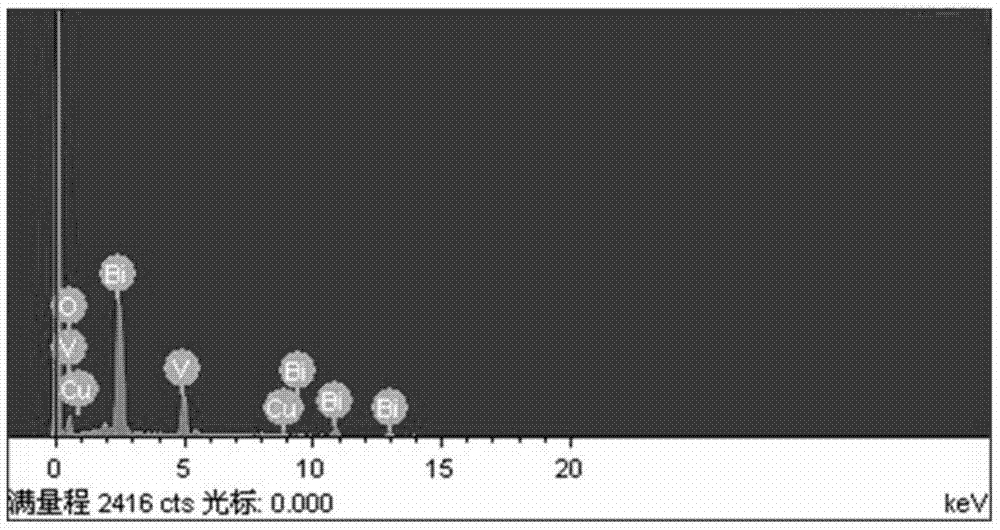

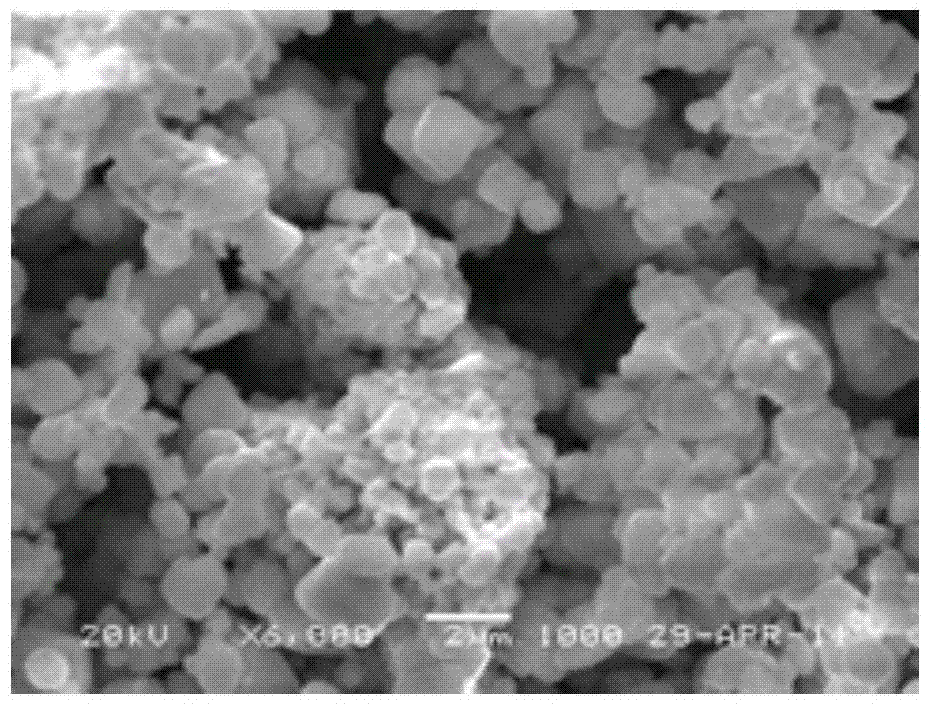

Method for preparing yellow bismuth vanadate pigment via molten salt method

InactiveCN103613132ASimple production processEasy to operateVanadium compoundsBismuth vanadateCalcination

The invention discloses a method for preparing a yellow bismuth vanadate pigment having a monocline structure. The method comprises the following steps: performing ball milling on Bi2O3 and V2O5 which are taken as raw materials and an alkali metal nitrate which is taken as a molten salt medium so as to prepare a powder precursor; and then preparing the yellow bismuth vanadate pigment via the molten salt method. The calcination temperature of the synthesized yellow bismuth vanadate pigment is effectively decreased and the heat preserving time is shortened under a liquid-state environment provided by the molten salt medium, and thus the energy consumption is facilitated; meanwhile, the problem that a large quantity of acids and alkalis are consumed during a liquid-phase precipitation method is avoided, and thus the production cost reduction is facilitated. The method is simple in preparation process; raw materials are easily obtained; the prepared yellow bismuth vanadate pigment is good in quality and uniform in particle distribution. Thus, the method is easy to industrialize.

Owner:HUNAN UNIV OF SCI & TECH

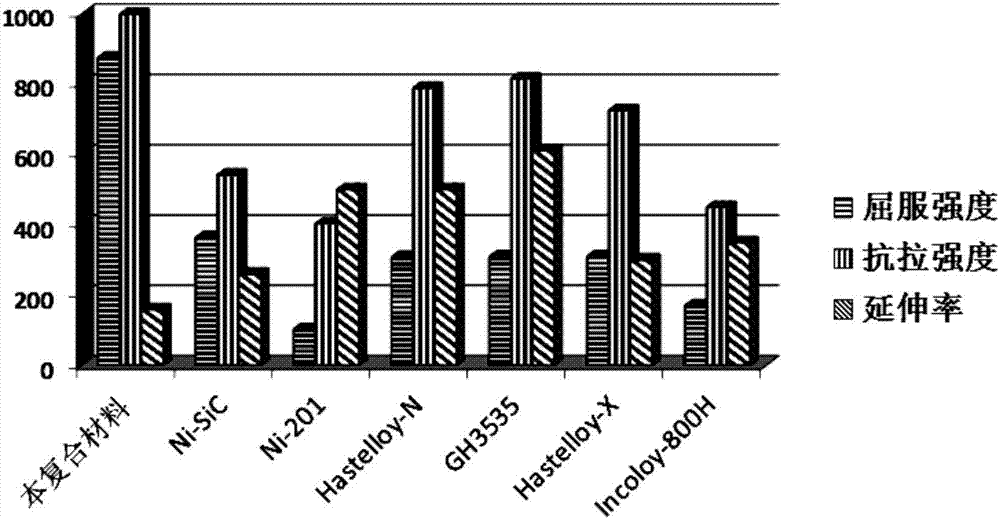

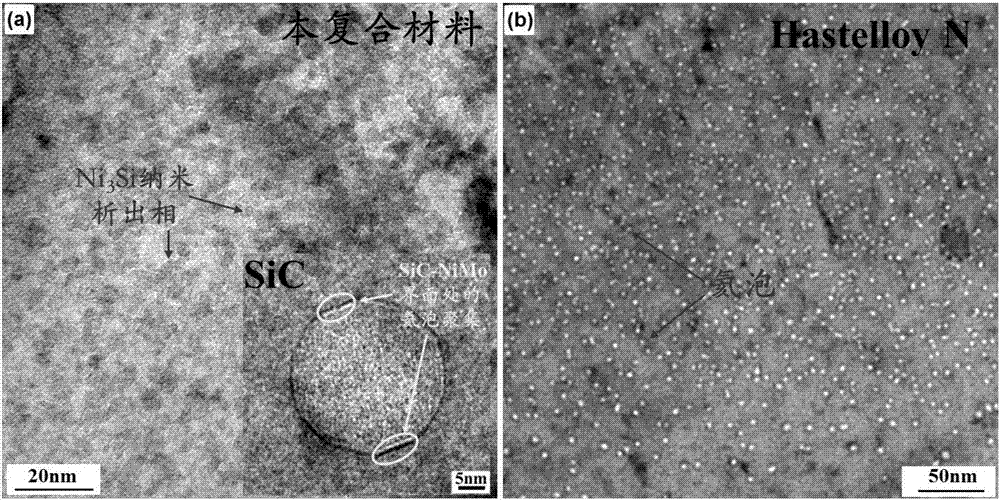

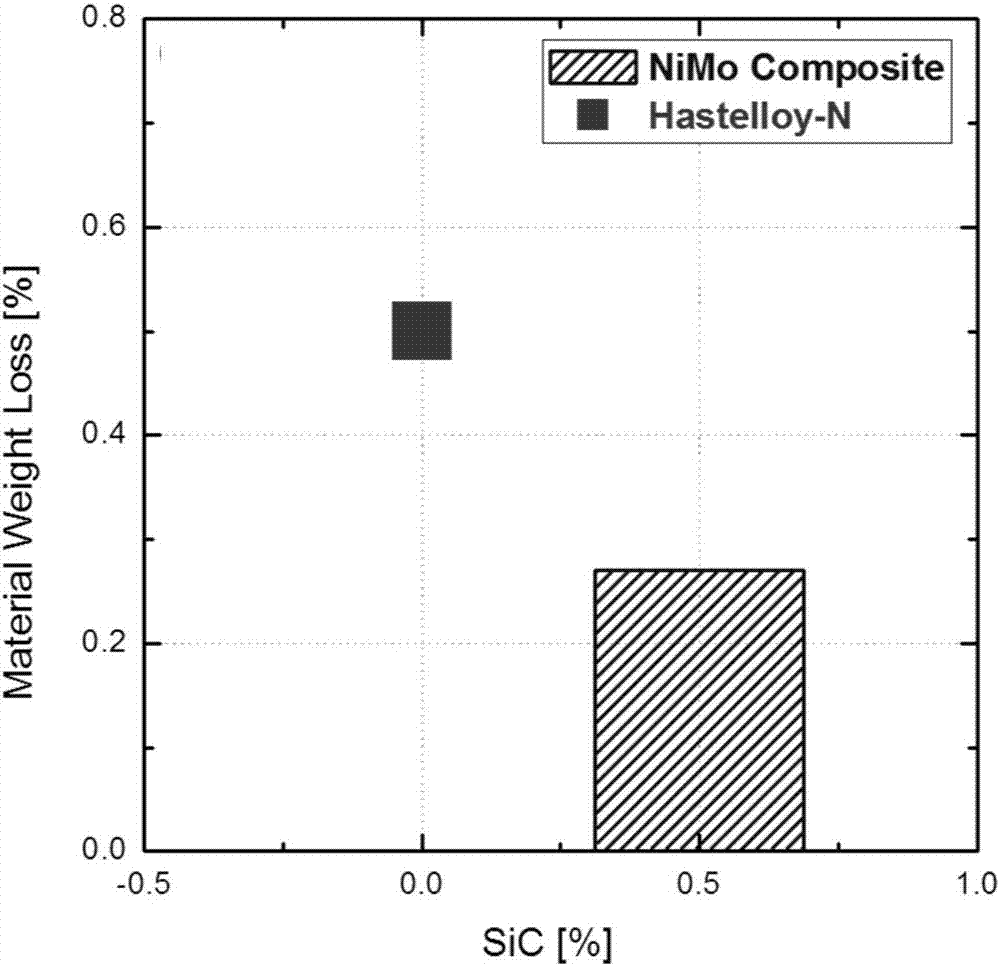

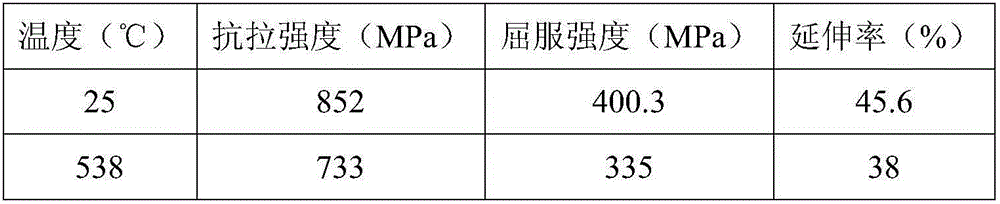

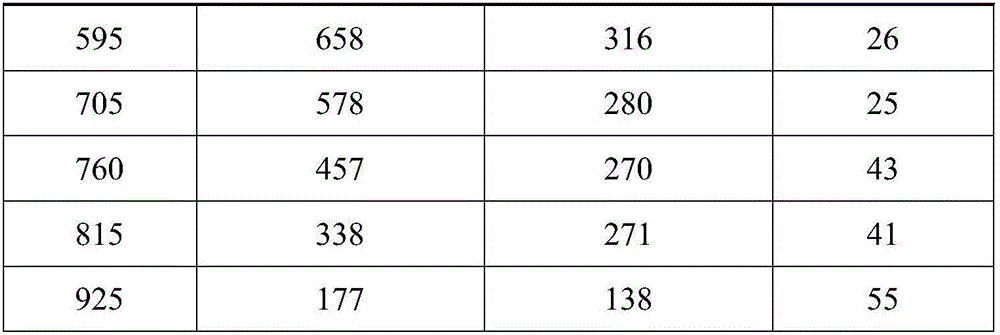

Molten salt corrosion resistant high-temperature composite material and reactor core structural part of molten salt reactor

The invention discloses a molten salt corrosion resistant high-temperature composite material, and belongs to the technical field of metal based reinforcing materials. The molten salt corrosion resistant high-temperature composite material takes 0.5-1.5wt% of nano silicon carbide particles as a reinforcing body, takes 10-20wt% of molybdenum as an additive and takes the balance of nickel as a metal matrix. The invention further discloses a reactor core structural part of a molten salt reactor. The composite material disclosed by the invention can form strengthening effects such as dispersion strengthening of nano silicon carbide particles, solid solution strengthening of molybdenum atoms as well as precipitation strengthening of trinickel silicon nano-sized precipitates (2-5 nm), so that mechanical strength of the matrix is greatly improved, and the obtained composite material has excellent high-temperature strength characteristic, high-temperature irradiation resistance and fluoride salt corrosion resistance, and is a structural material suitable for the reactor core of the molten salt reactor.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Manufacturing method of molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tube

ActiveCN106180254APerformance impactImprove mechanical propertiesNuclear energy generationCooling arrangementMolten salt reactorHeat treated

The invention discloses a manufacturing method of a molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tube. The manufacturing method comprises the steps that firstly, hot extrusion treatment is conducted on a molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy tube blank which is provided with a through hole, so that a pierced billet for cold rolling is obtained, wherein the extrusion temperature of the hot extrusion treatment is 1220-1250 DEG C, and the extrusion ratio is 5-12; secondly, the pierced billet obtained in the first step is cold rolled to be a tube of a required specification, wherein in the cold rolling process, the single-pass rolling reduction of each pass is 20%-70%, and after each pass is completed, intermediate heat treatment and acid pickling are conducted on the tube firstly, and then rolling of the next pass is conducted, wherein the intermediate heat treatment temperature is 1180-1220 DEG C; and thirdly, final heat treatment is conducted on the tube of the required specification in the temperature range from 1180 DEG C to 1220 DEG C. The invention further discloses the molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tube and a structural member for a molten salt reactor. By the adoption of the manufacturing method, various specifications of molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tubes meeting molten salt reactor use requirements can be efficiently manufactured.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI +1

Molten salt treatment system and process

InactiveCN102256693AUsing liquid separation agentHigh temperature liquid-gas reactionEngineeringProduct gas

Owner:TALE & LYLE TECH LTD

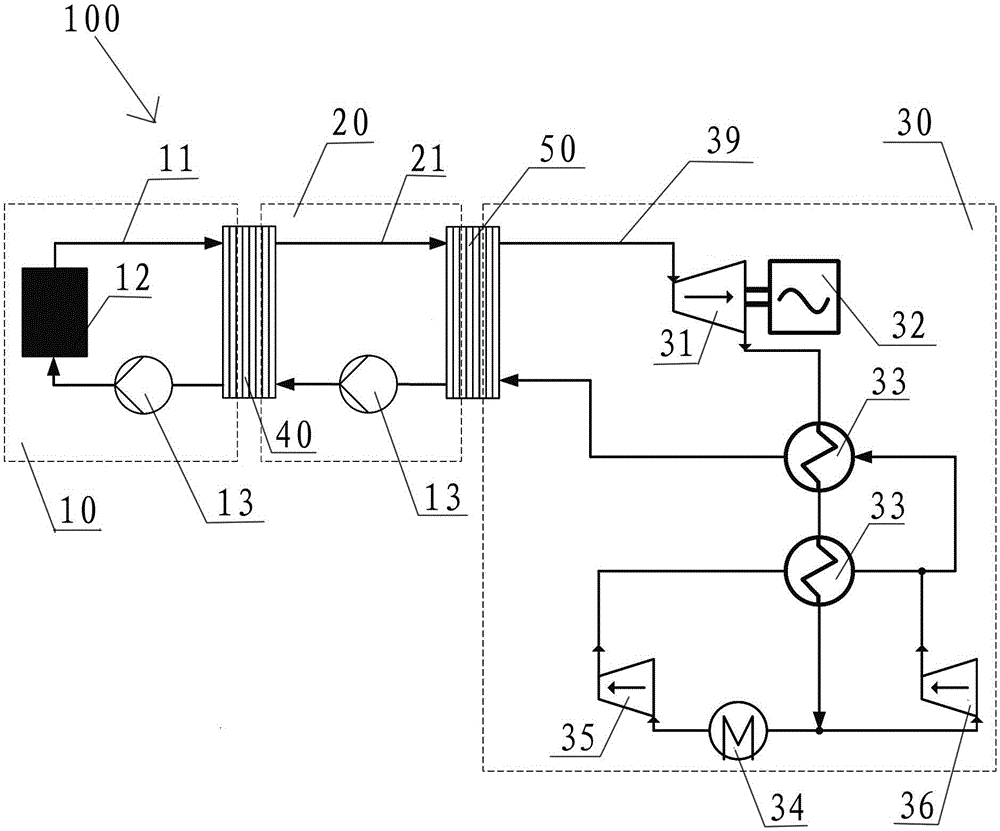

Novel molten salt reactor energy transmission system with supercritical carbon dioxide

InactiveCN105355247AMatch the inlet and outlet temperature parametersImprove economic competitivenessNuclear energy generationSteam engine plantsGas compressorHeat energy

The invention discloses a novel molten salt reactor energy transmission system with supercritical carbon dioxide. The system comprises a loop I providing a heat source, an isolation loop and a loop III converting heat energy into electric energy. A nuclear reactor using fused salt as a coolant is arranged at the loop I; and supercritical carbon dioxide is used as a working medium in the loop III. A turbine, a generator, a regenerator set, a cooler, and a main gas compressor are arranged at the loop III. A secondary side outlet of a second heat exchanger is connected with a secondary side inlet of the second heat exchanger by high-temperature sides of the turbine and the regenerator set and low-temperature sides of the cooler, the main gas compressor, and the regenerator set; and the output terminal of the turbine is connected with the input terminal of the generator. The regenerator set contains at least two regenerators; high-temperature side channels of all regenerators in the regenerator set are communicated and low-temperature side channels of all regenerators in the regenerator set are communicated. According to the invention, with the system, optimization of the generating efficiency can be realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

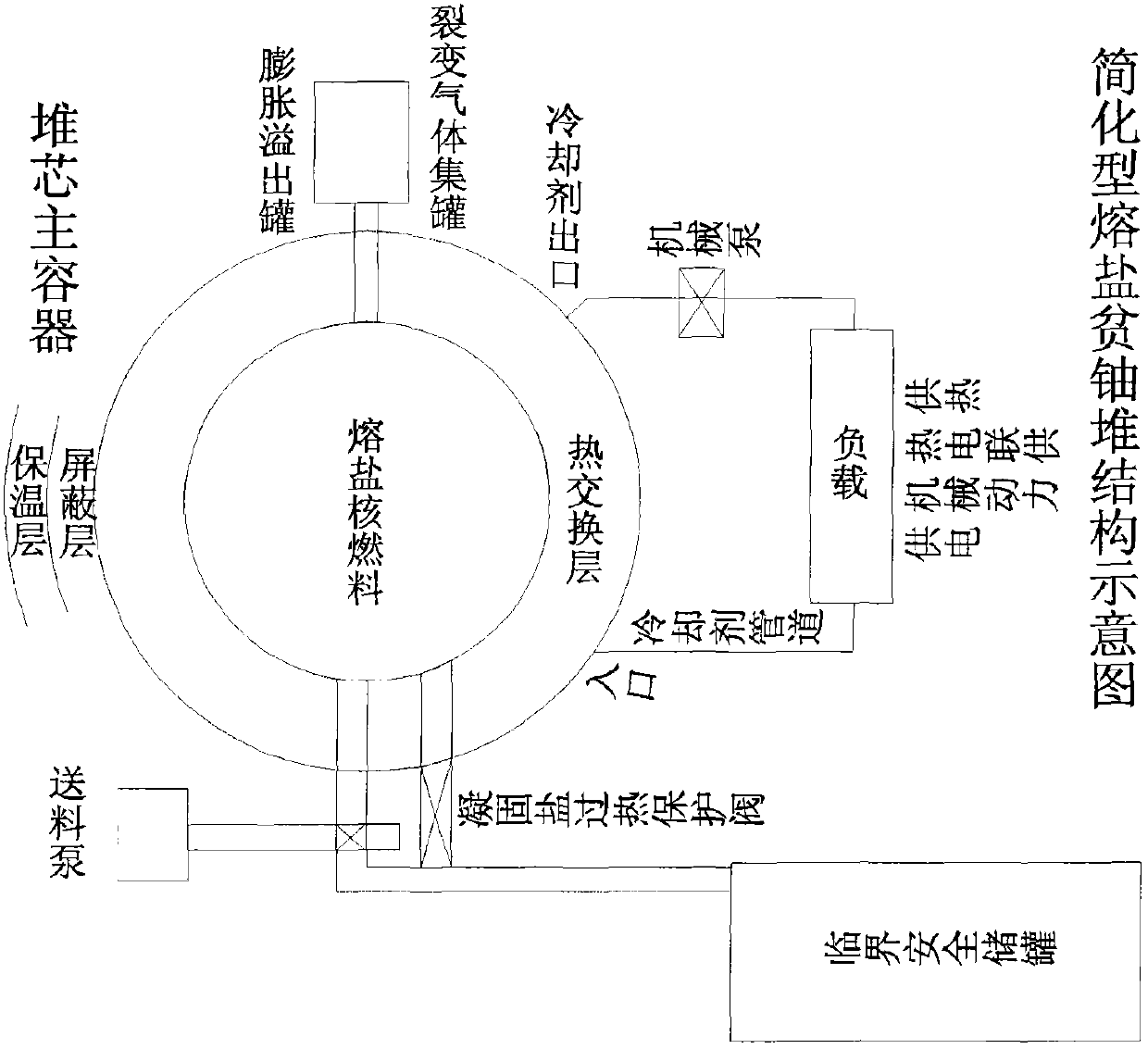

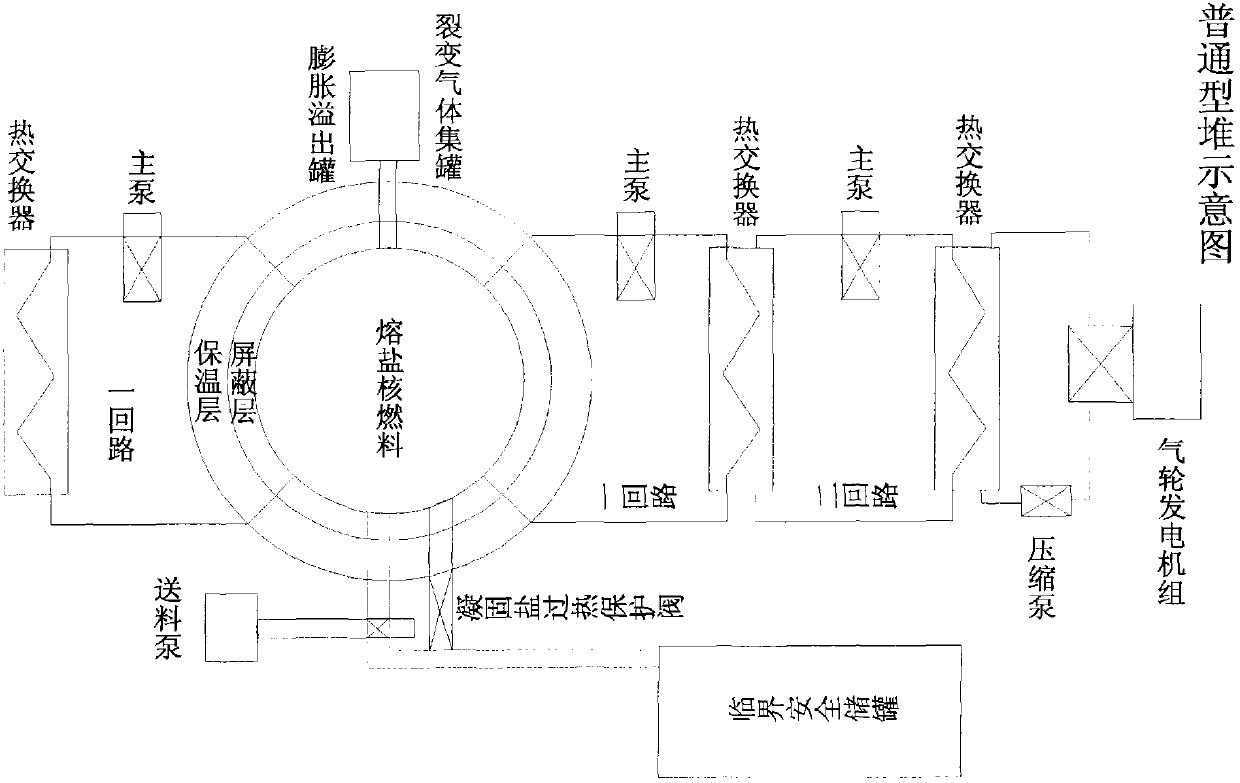

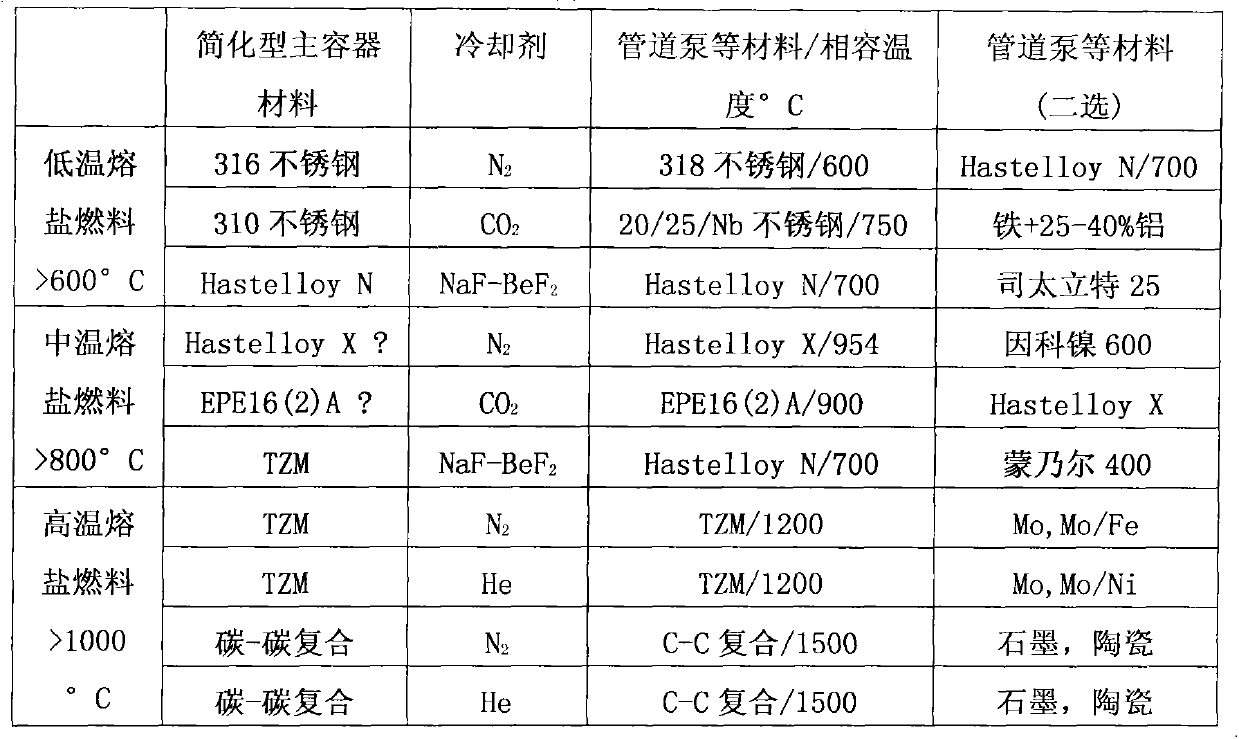

Molten salt depleted uranium reactor

PendingCN104183277AIncrease fuel consumptionSimple structureNuclear energy generationSubcritical reactorsNitrogen gasSteel pipeline

The invention discloses a molten salt depleted uranium reactor, belonging to the technical field of molten salt reactors; fast neutron spectrum, chloride molten salt, uranium plutonium cycle and depleted uranium are used; after start, only by use of a nuclear fuel of self proliferation, long-term stable and safe operation can be achieved, and a supercritical accident may not happen; negative feedback can keep in the critical state; the entire uranium plutonium cycle can be completed in the reactor; normal operation only requires the use of the depleted uranium, the reactor itself does not need uranium enrichment and purification; and high burnup of the depleted uranium can be realized. The reactor has the advantages of simple structure and easy operation, is very suitable for large-scale popularization and application. The reactor is applicable to various types of molten salt formulas and structure materials. The technology, complete set of system technology, engineering and industrialization are feasible. The preferred system is as follows: simplified low temperature IV type + 316 stainless steel main container + nitrogen coolant + 318 stainless steel pipeline pump heat exchanger and the like. Fission nuclear energy can be used to fully meet the national long-term energy needs, at the same time, the problems of the shortage of uranium resources, nuclear criticality safety and low carbon development can be solved, and the reactor is mainly used for heat, electricity or mechanical power supply.

Owner:董保国 +2

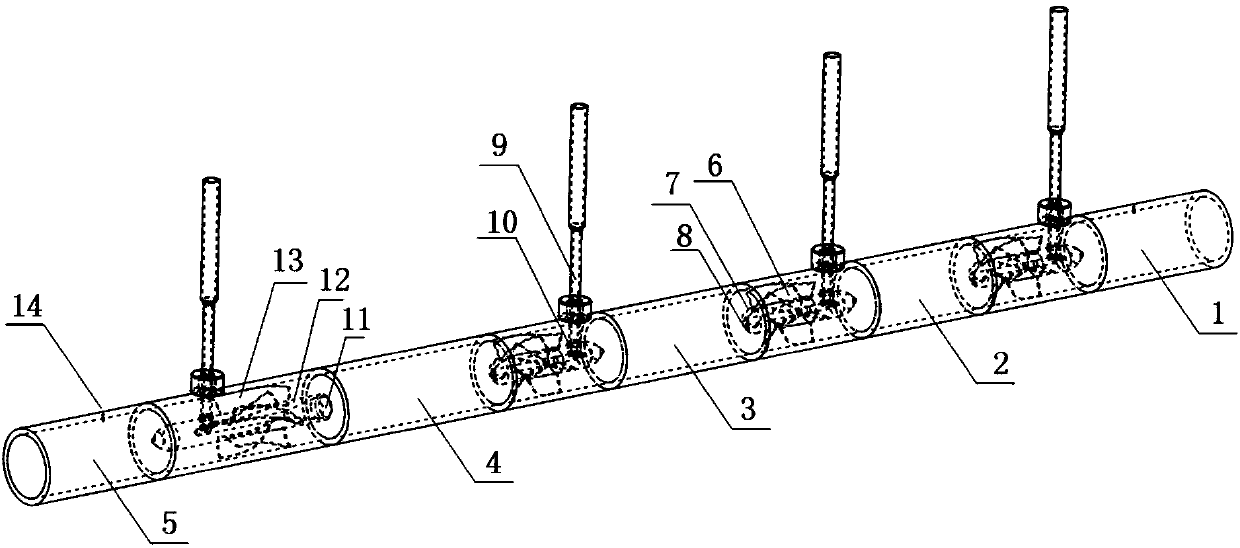

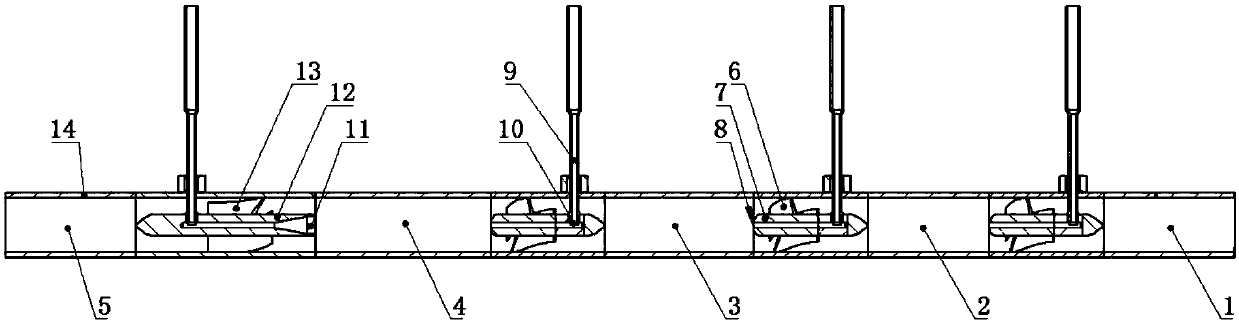

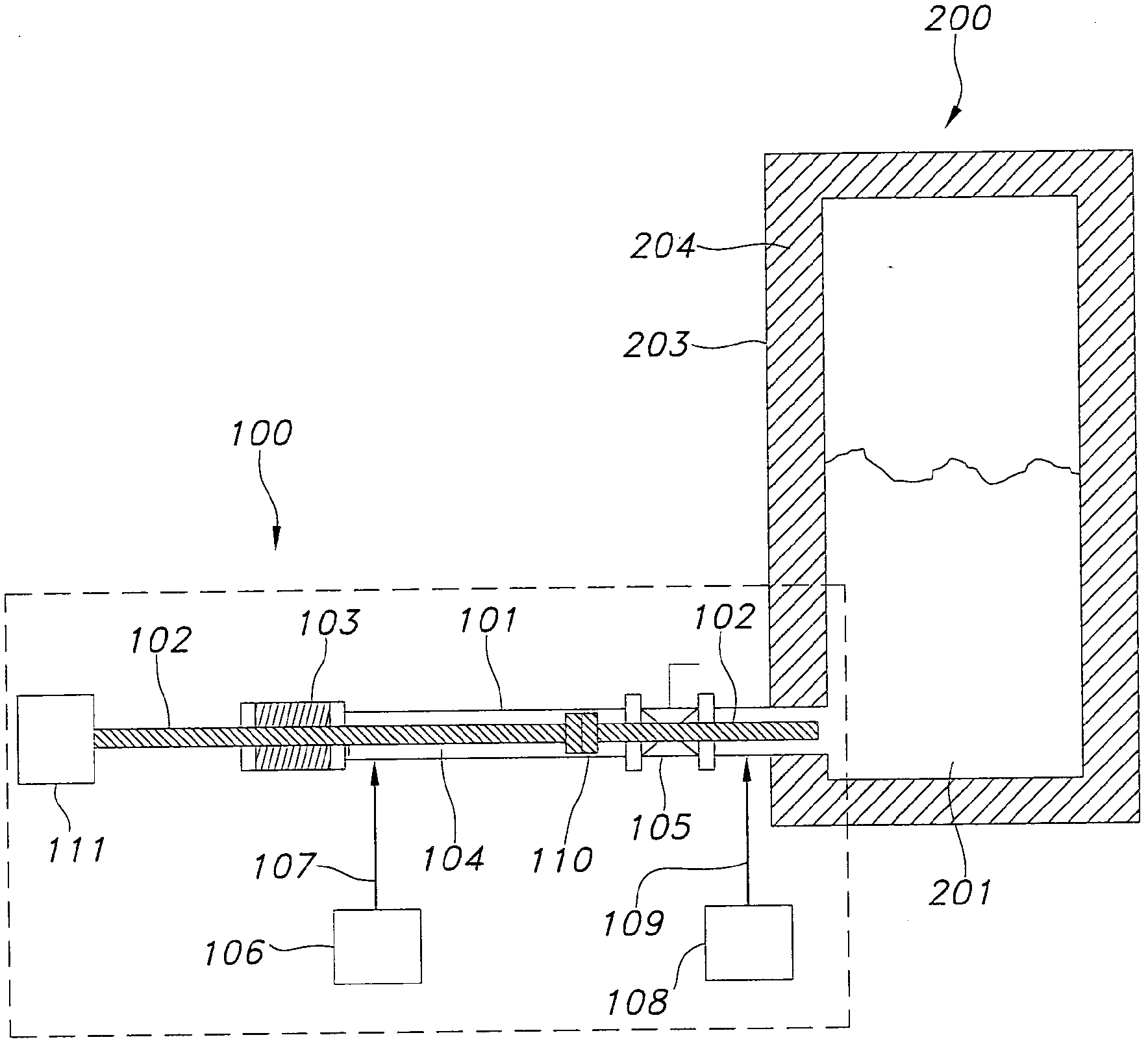

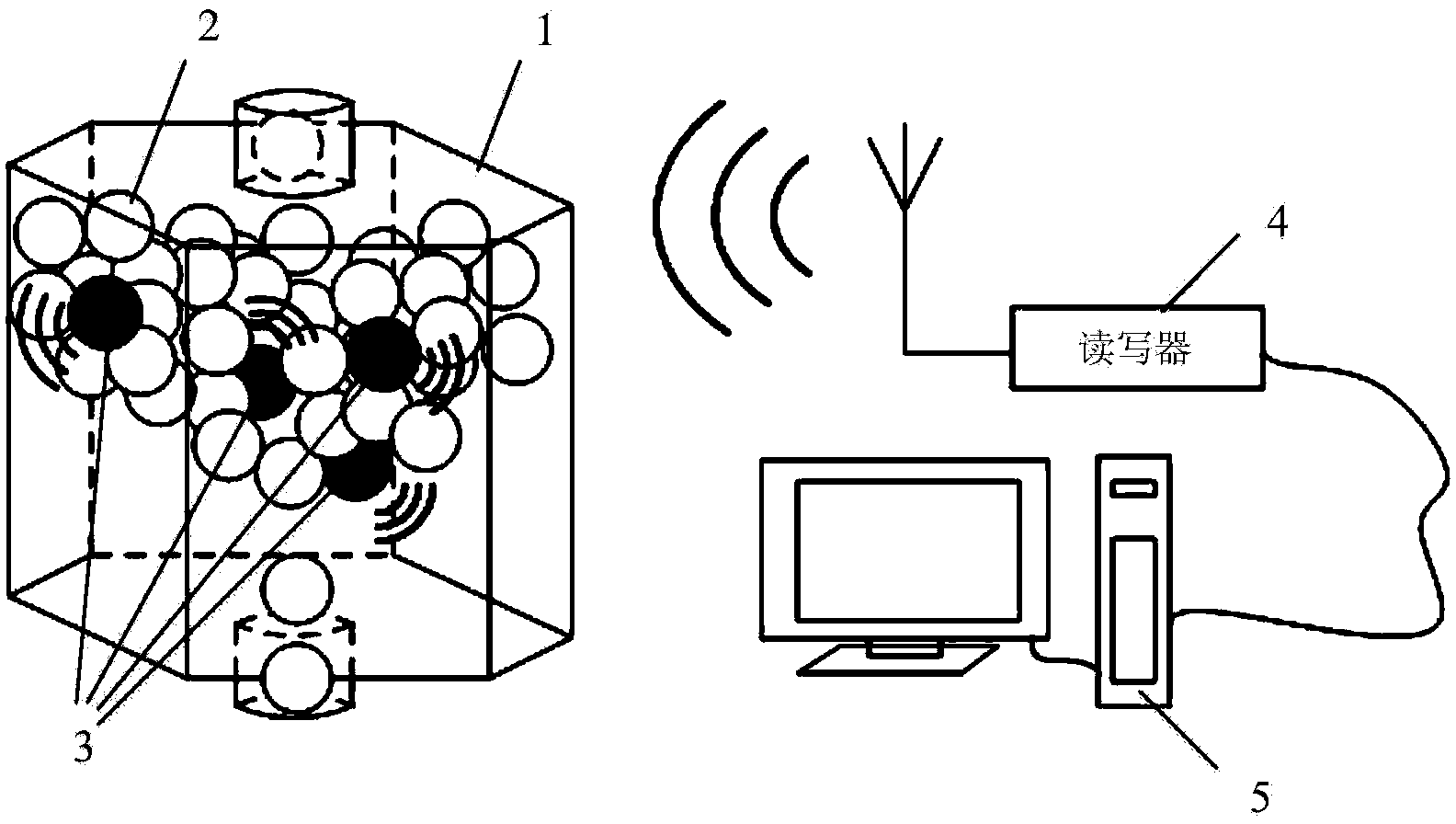

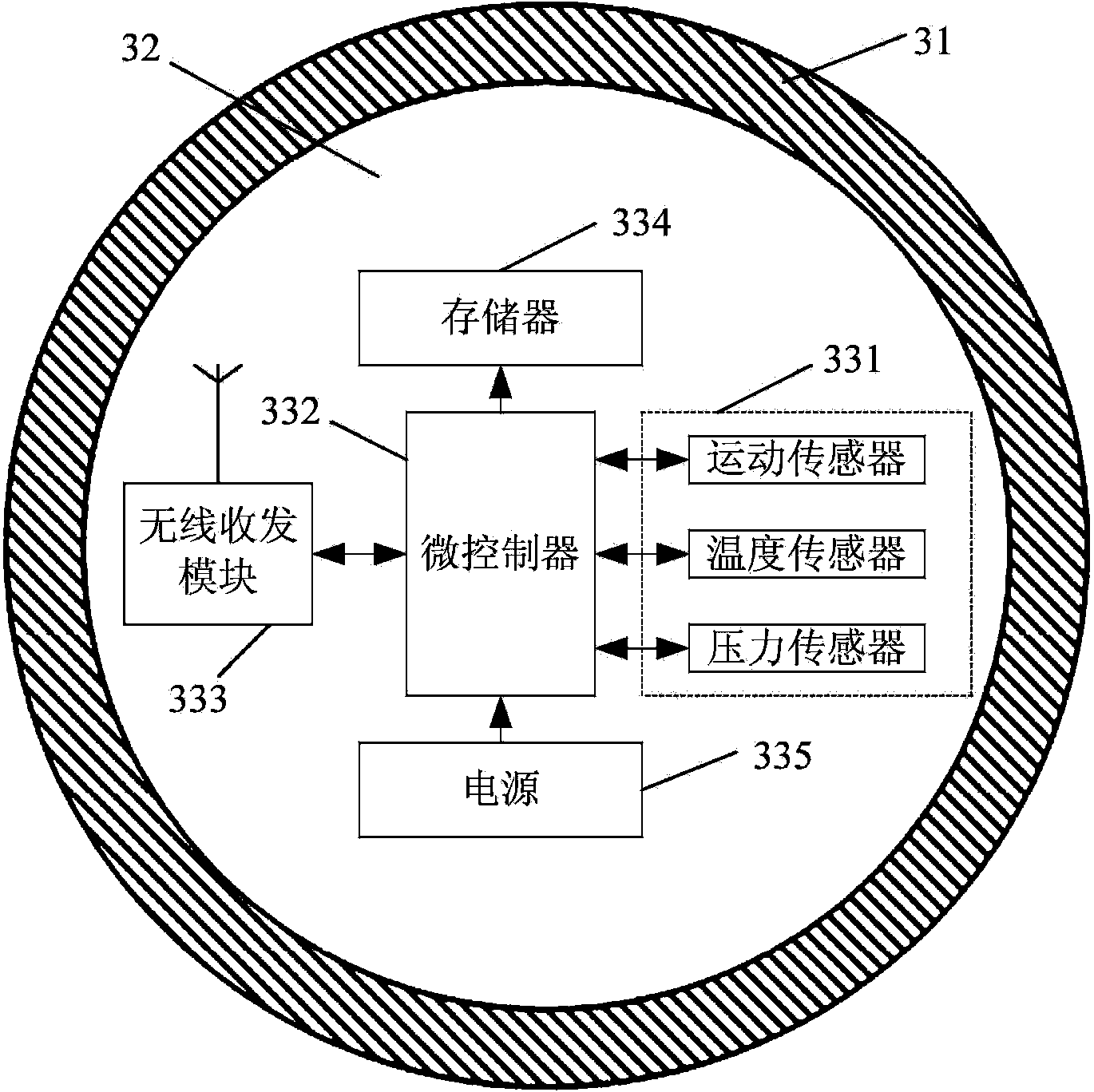

Wireless detection system and method for measuring inner-state parameters of reactor core simulation device

ActiveCN103714371AReal-time measurementAccurate measurementSensing record carriersRecord carriers used with machinesMicrocontrollerState parameter

The invention provides a wireless detection system and method for measuring inner-state parameters of a molten salt reactor core simulation device. The system comprises at least one spherical detection device, wherein the spherical detection device is placed in a reactor core container, comprises a spherical shell, an active RFID electronic tag and fillers, the spherical detection device and a spherical simulation fuel element have the same design parameters, the active RFID electronic tag is arranged in the spherical shell, and the fillers are filled between the spherical shell and the active RFID electronic tag. The active RFID electronic tag comprises a sensor module, a microcontroller and a first wireless transceiving module, wherein the sensor module is used for collecting state parameters of the spherical detection device, the microcontroller is connected to the sensor module, and the first wireless transceiving module is connected to the microcontroller. The wireless detection system further comprises an upper computer and a reader which are arranged outside the reactor core container. By means of the system and method, the inner-state parameters of the reactor core simulation device can be precisely measured in real time on the premise that motion trails of flow fields in the reactor core simulation device and the motion trail of the spherical simulation fuel element are not affected.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com