Application of Ti3SiC2 based ceramic material as melted fluorine salt corrosion resistant material

A ceramic material, melt-resistant technology, applied in the direction of reactor fuel material, device for coating liquid on the surface, coating, etc., can solve the problems of lack of high-temperature strength, high-temperature peeling coating uniformity, etc., and achieve excellent high thermal conductivity, The effect of good high temperature mechanical properties and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, for single-phase Ti 3 SiC 2 The bulk ceramic materials were subjected to the corrosion resistance test of molten fluorine salts.

[0030] The single-phase Ti 3 SiC 2 The block is prepared by powder sintering method, specifically: Weigh an appropriate amount of commercial Ti 3 SiC 2 Powder, the Ti 3 SiC 2 The powder is put into a graphite mold and pressurized in one direction to form a green body, and then put into a spark plasma sintering (SPS) furnace, heated to 1200°C in a vacuum state, and a pressure of 40MPa is applied, and the holding time is 5min.

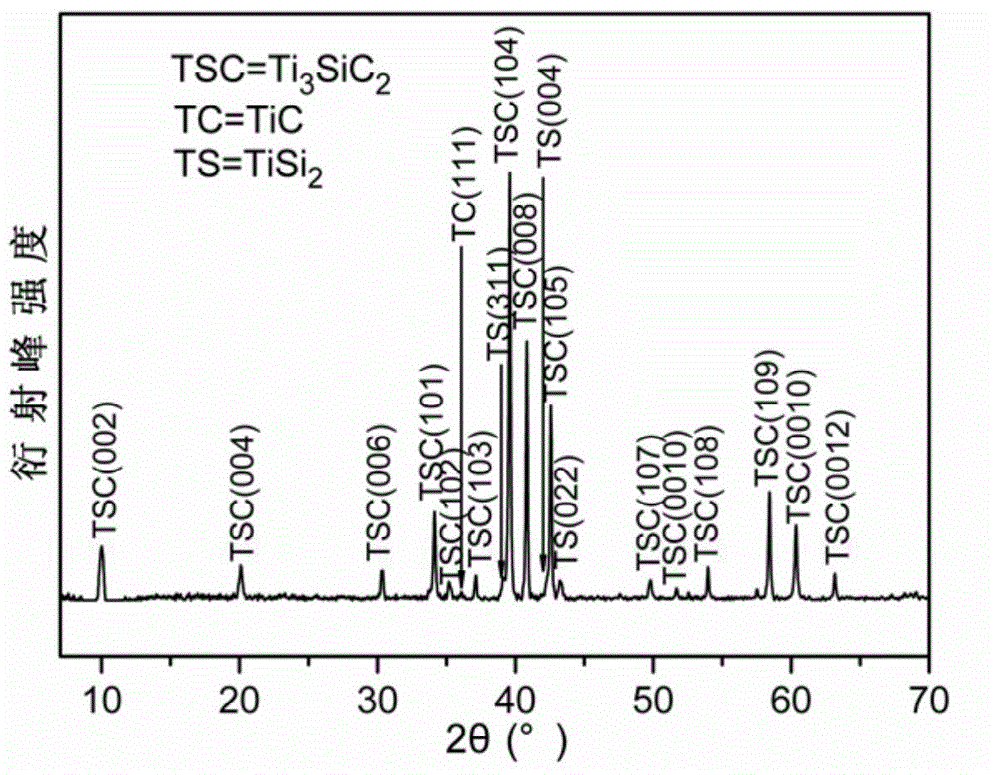

[0031] For the Ti prepared above 3 SiC 2 The phase of the bulk material is measured and analyzed, and its XRD spectrum is as follows figure 1 As shown, it can be seen that the bulk material has high purity and low impurity content.

[0032] The Ti 3 SiC 2 The test method for the corrosion resistance of bulk materials to molten fluorine salts is as follows: the single-phase Ti 3 SiC 2 The ...

Embodiment 2

[0041] In this example, for Ti 3 SiC 2 -10wt% SiC composite bulk material was tested for corrosion resistance to molten fluorine salts.

[0042] The composite material is Ti 3 SiC 2 -10wt% SiC, the subsequent corrosion test was carried out in FLINAK molten salt at 700 °C, and the corrosion time was 8 days (192h). The specific process is as follows:

[0043] The Ti 3 SiC 2 -10wt%SiC composite bulk material with Ti 3 SiC 2 The ceramic material is used as a matrix, and SiC is used as a composite phase, and the composite phase accounts for 10wt% of the content of the matrix.

[0044] The composite block material is prepared by powder sintering method, specifically: Weigh an appropriate amount of commercial Ti 3 SiC 2 and SiC powder, mixed by ball milling, dried and put into a graphite mold, first pressurized in one direction to form a green body, and then put into a spark plasma sintering (SPS) furnace, heated to 1350°C under the protection of Ar atmosphere, and Apply a...

Embodiment 3

[0052] In this example, for single-phase Ti 3 SiC 2 The bulk ceramic materials were subjected to the corrosion resistance test of molten fluorine salts.

[0053] The single-phase Ti 3 SiC 2 The preparation method of the bulk ceramic material is exactly the same as that of Example 1.

[0054] The Ti 3 SiC 2 The test method of the molten fluorine salt corrosion resistance of the block material is basically the same as that of Example 1, except that the temperature is raised to 850°C, and the corrosion time is 6 days (144h).

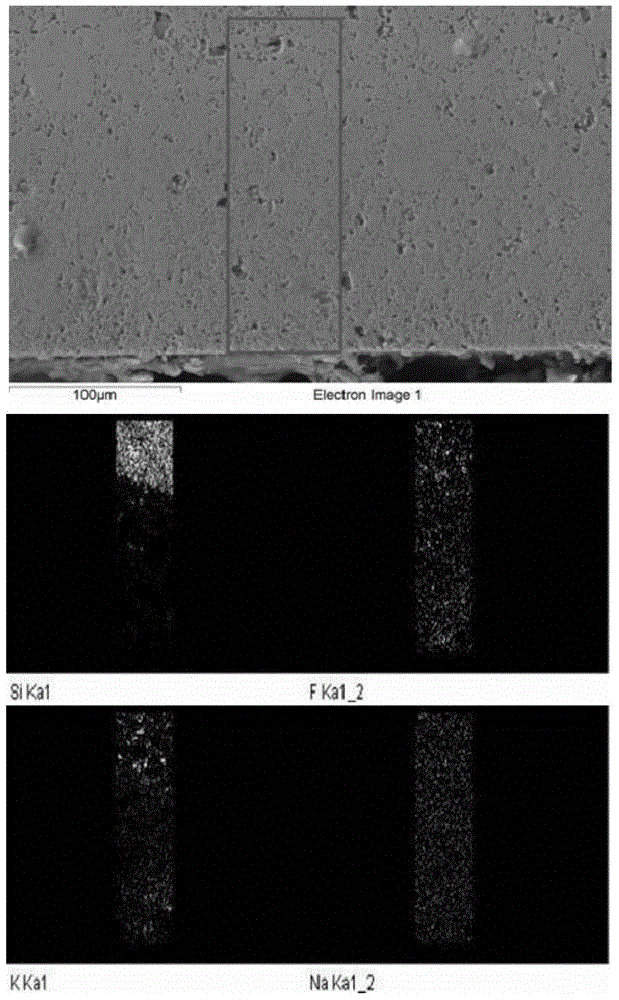

[0055] Result analysis: The size and weight of the sample before and after the molten fluoride salt corrosion test were measured by vernier calipers and analytical balance; the influence of FLINAK molten salt on the surface and section of the sample was observed by SEM; the composition changes of the surface and section of the sample were observed by EDS.

[0056] (1) The above single-phase Ti 3 SiC 2 The size and weight measurement results of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com