Molten salt corrosion resistant high-temperature composite material and reactor core structural part of molten salt reactor

A technology of molten salt corrosion and composite materials, applied in the field of metal-based reinforcing materials, can solve the problems of inability to meet the needs of long-term use, poor high temperature mechanical properties, difficult to replace, etc., to improve high temperature radiation resistance, good plasticity, Avoid swollen effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

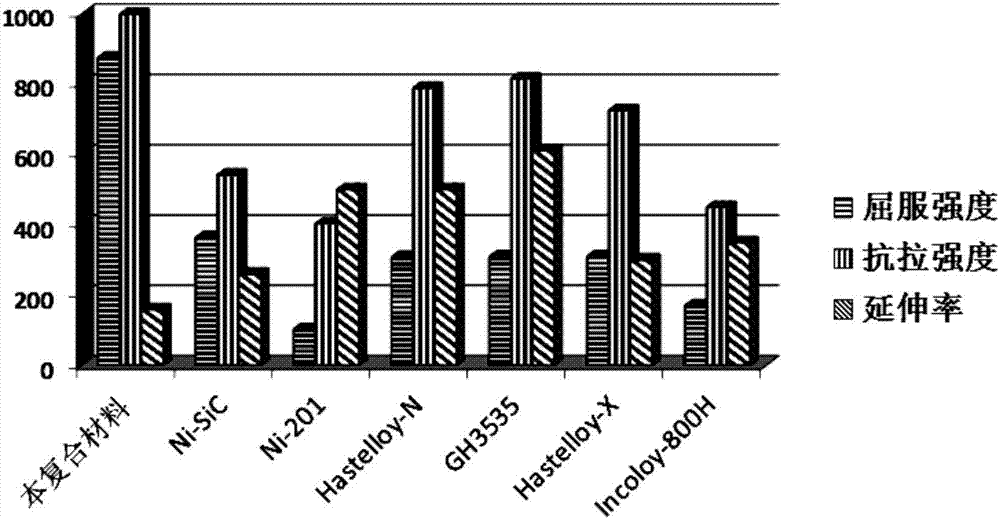

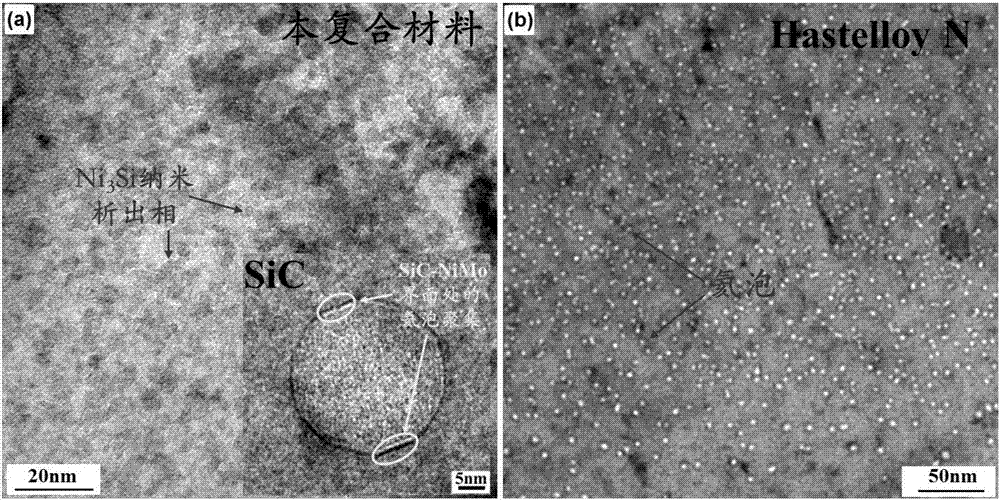

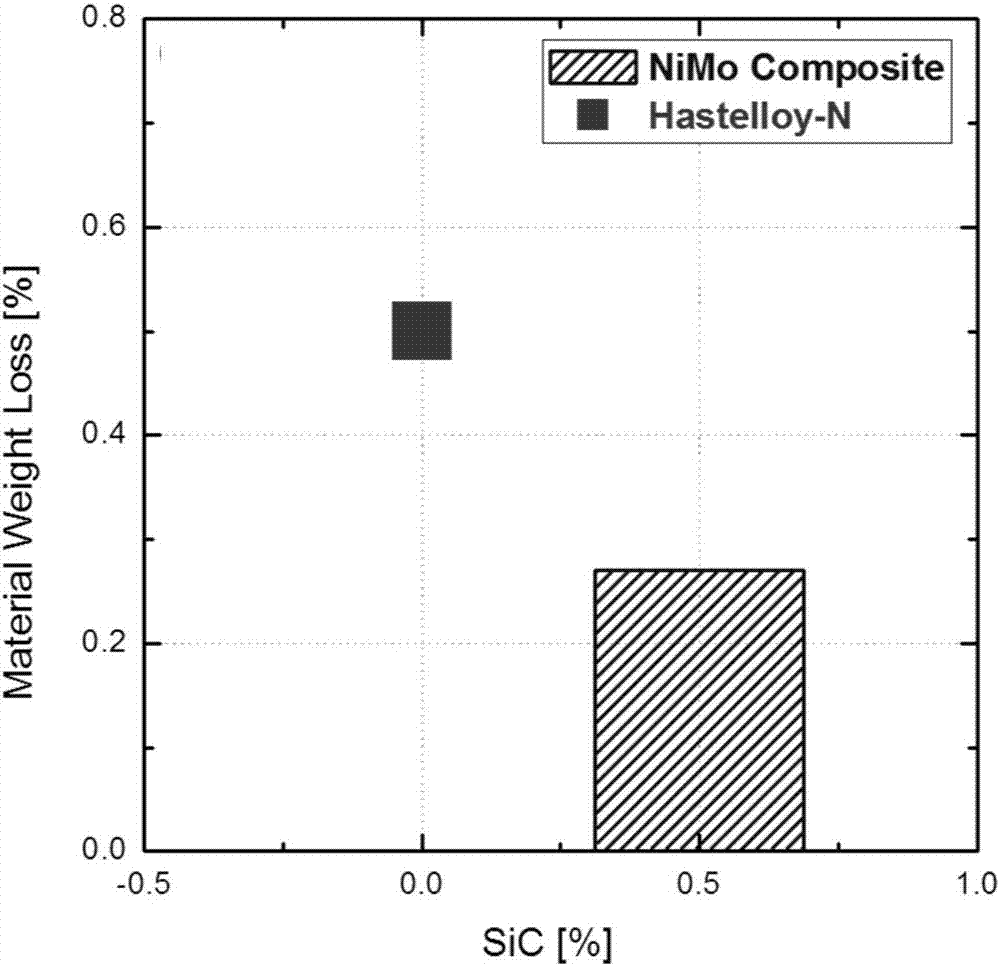

[0029] Although nickel-based alloys have been explored for use in molten salt reactors as early as the 1960s, nickel easily undergoes a transmutation reaction with neutrons to generate helium, which in turn forms helium bubbles inside the nickel-based alloy. The massive accumulation of helium bubbles at the grain boundaries will reduce the bonding force between the alloy grain boundaries and cause direct embrittlement of the material; the helium bubbles formed inside the alloy grains will pin the free movement of the dislocation lines, resulting in hardening and hardening of the alloy. Embrittlement; the formation of helium bubbles will also cause swelling of the material, which will affect the service performance of the alloy. In addition, ORNL's report also clearly pointed out that the maximum allowable temperature of Hastelloy N alloy is only 704°C. Combined with its helium embrittlement problem, it clearly opposes the use of nickel-based alloys in the core. Per Peterson poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com