Integrated small molten salt reactor

A molten salt reactor, a small-scale technology, applied in the direction of reactors, greenhouse gas reduction, reactor fuel materials, etc., can solve the problems of short service life, poor safety and reliability, complex structure, etc., to achieve simplified structure, enhanced core heat exchange capacity, The effect of simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment takes an integrated small molten salt reactor with a thermal power of 1 MWt as an example.

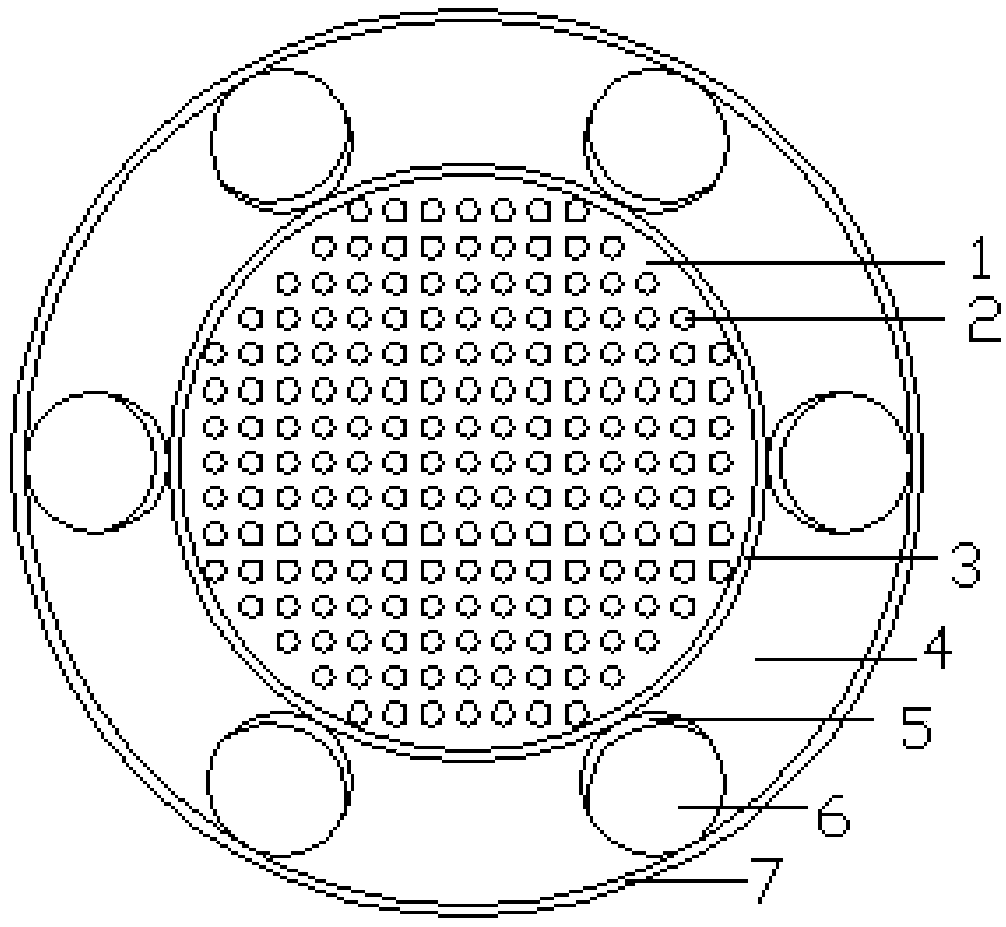

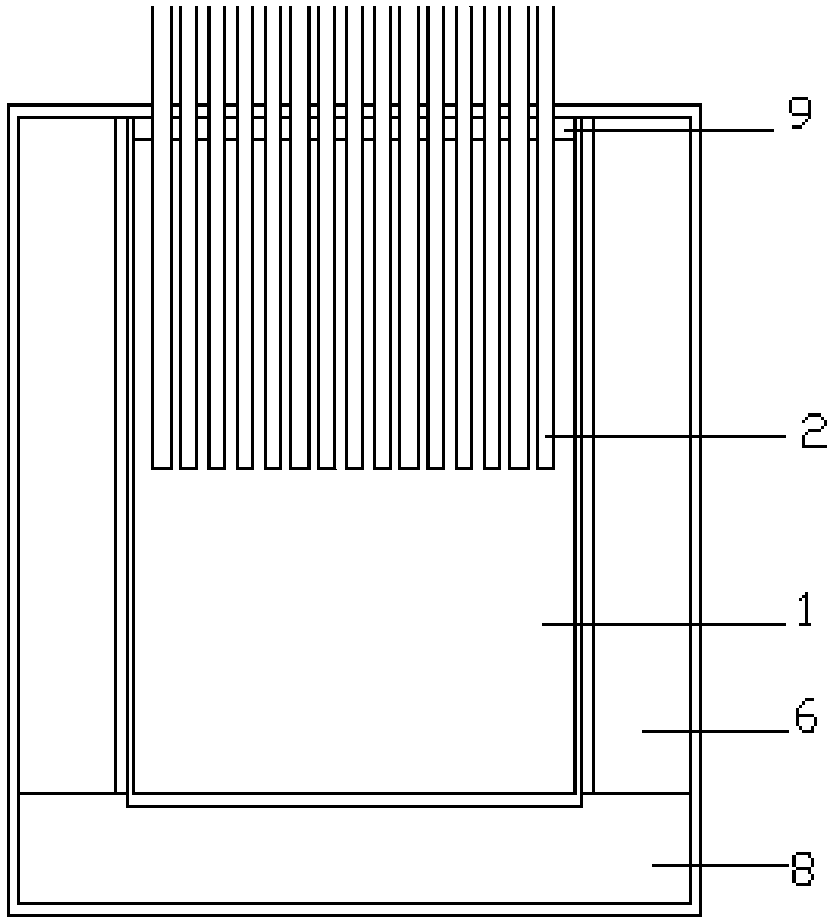

[0027] like figure 1 and figure 2 As shown, the core of an integrated small molten salt reactor includes a fuel salt 1, a heat pipe 2, a core vessel 3, a side reflector 4, a neutron absorber 5, a control drum 6, a cladding 7 and a lower reflector 8 . The heat pipe 2 and the core vessel 3 are designed in an integrated manner. The heat pipe 2 is partially inserted into the core vessel 3 and fixed with the core vessel 3. The fuel salt 1 fills the interior of the core vessel 3. A cavity 9 is formed between the liquid surfaces, the outer wall of the core vessel 3 is provided with a side reflection layer 4, the side reflection layer 4 is provided with a control drum 6, and the side of the control drum 6 close to the core vessel 3 is provided with a center. The sub-absorber 5 and the bottom of the core vessel 3 are provided with a lower reflection layer 8 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com