Multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with thermometal compound box body structure

A box structure, energy-saving control technology, applied in the direction of air-conditioning systems, heating and ventilation control systems, heating methods, etc., can solve the problems that cannot meet the requirements of radiation resistance, corrosion resistance, sealing, and earthquake resistance, and achieve small volume, metal Less consumption, full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

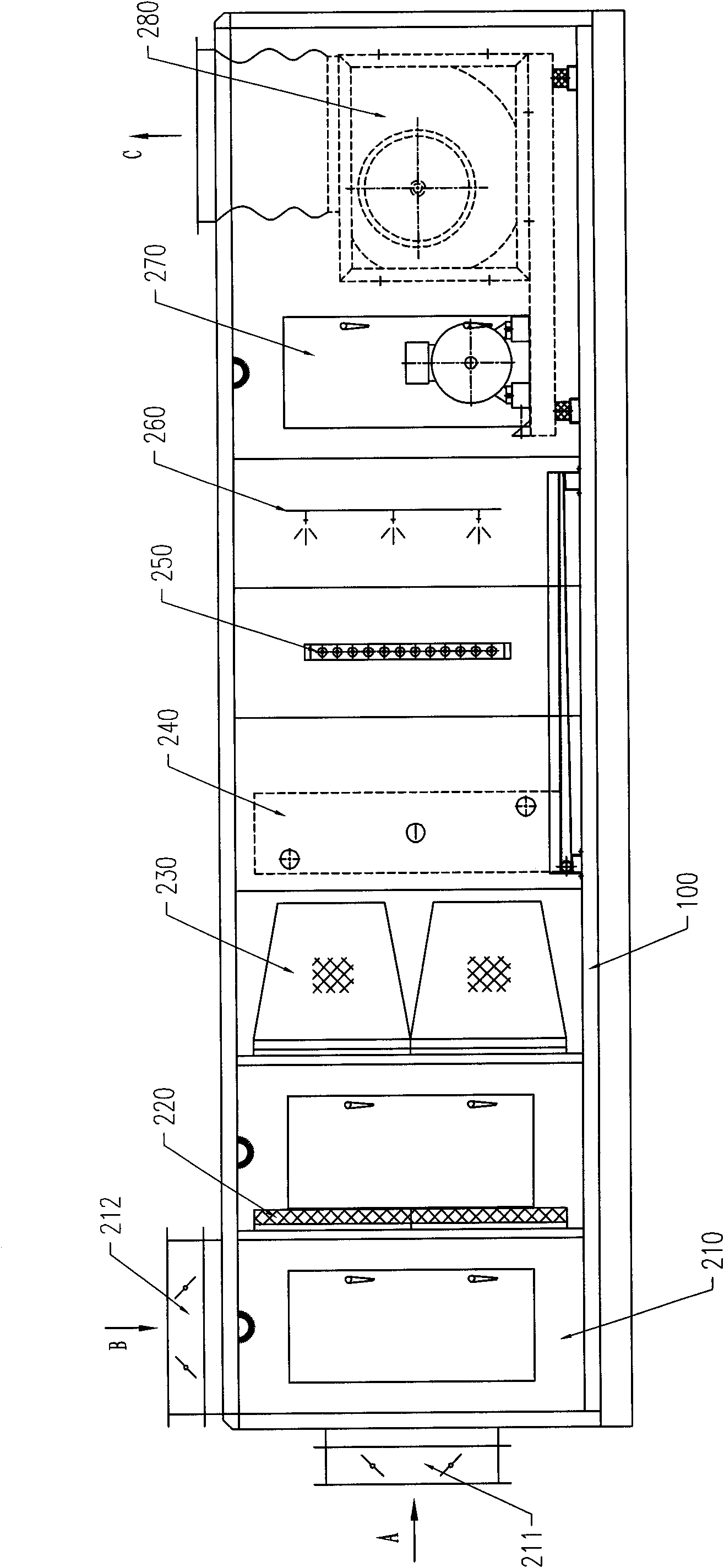

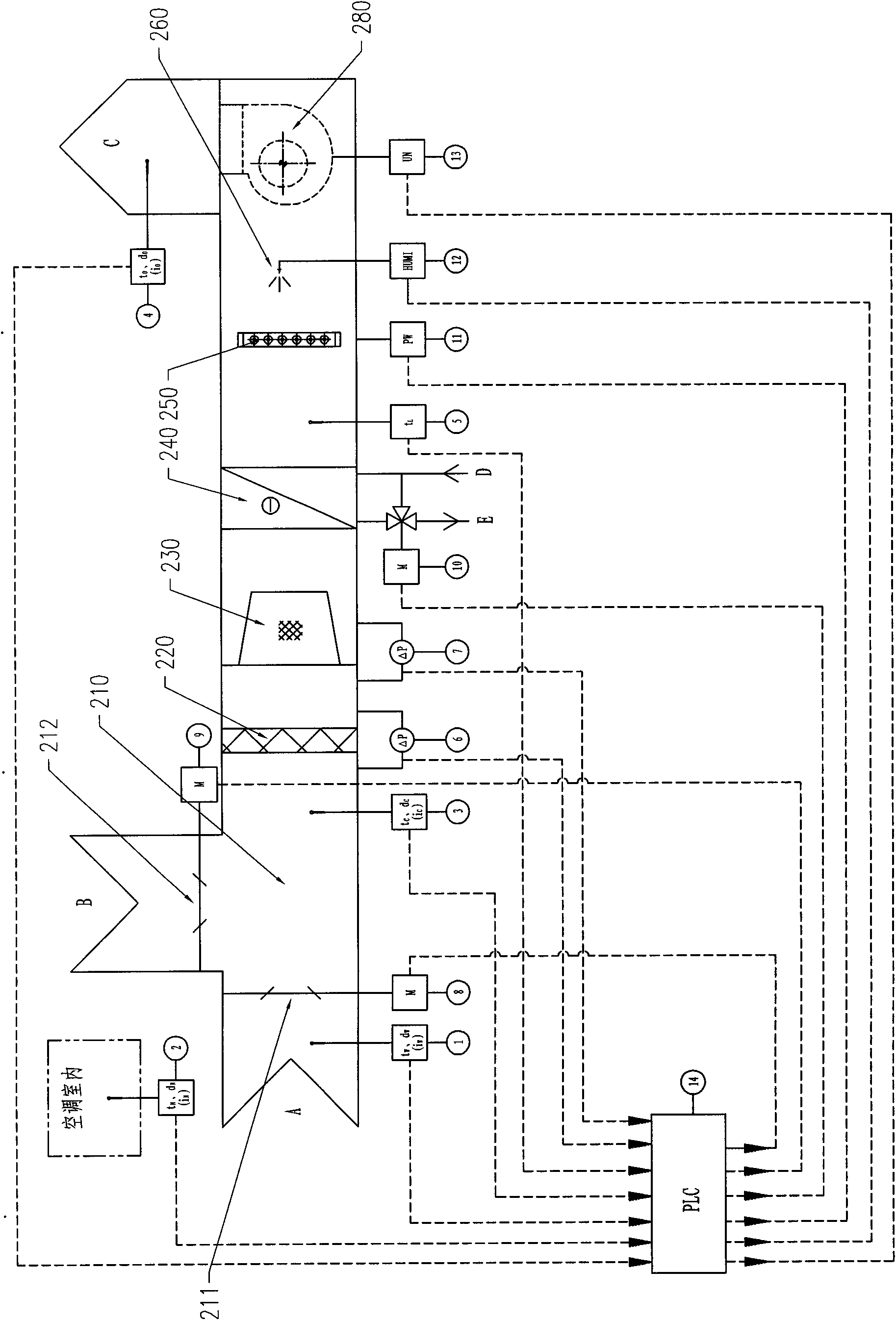

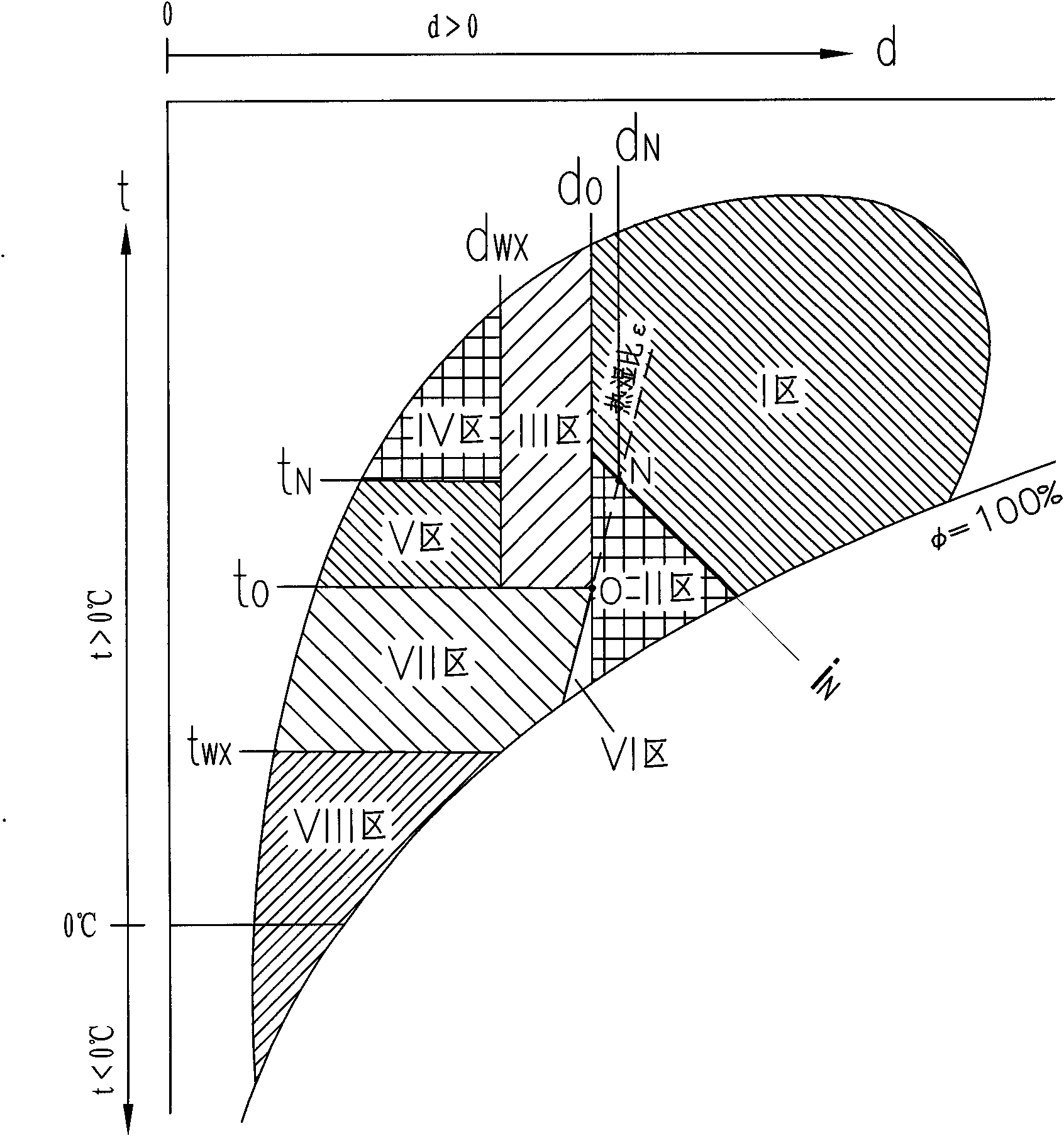

[0056] refer to Figure 1-Figure 3 , a combined constant temperature and humidity air conditioner with multi-working condition energy-saving control of a bimetallic composite box structure, including a control system and a box structure. In the box 100, a primary filter 220 and a medium filter 230 are arranged in sequence. , surface cooler 240, heater 250, humidifier 260 and air supply device, the fresh air and return air mixing section 210 is located in front of the primary filter, and the fresh air proportional valve 211 and the return air proportional valve 211 are set at the entrances of fresh air A and return air B respectively Valve 212, the air supply device includes air supply motor 270 and air supply blower 280, and described control system adopts programmable controller PLC14, and the complex number input end of programmable controller PLC14 is connected with outdoor fresh air temperature t respectively. W , humidity d W , enthalpy i w Value measuring device 1; roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com