Patents

Literature

251results about "Integral reactors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

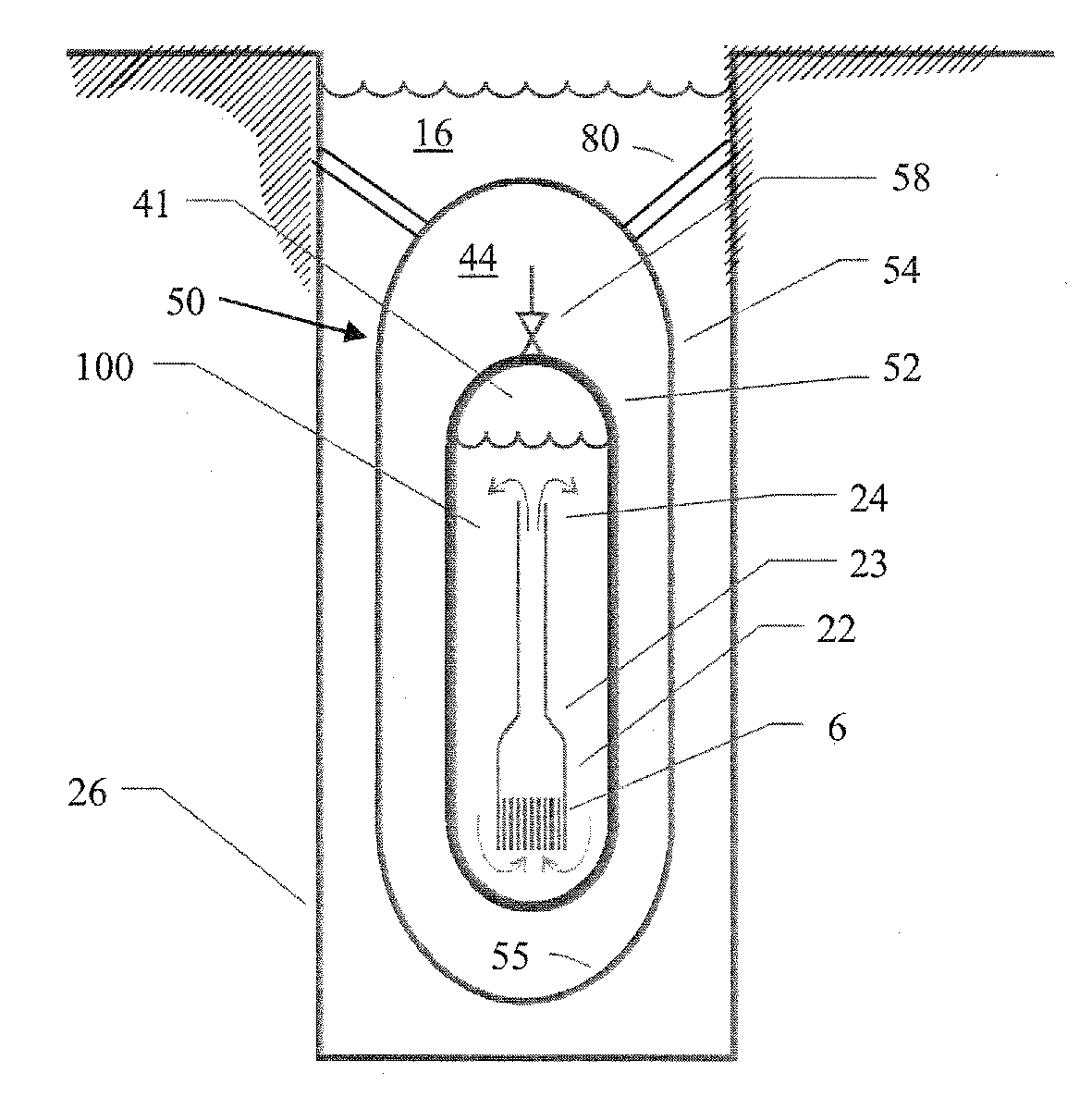

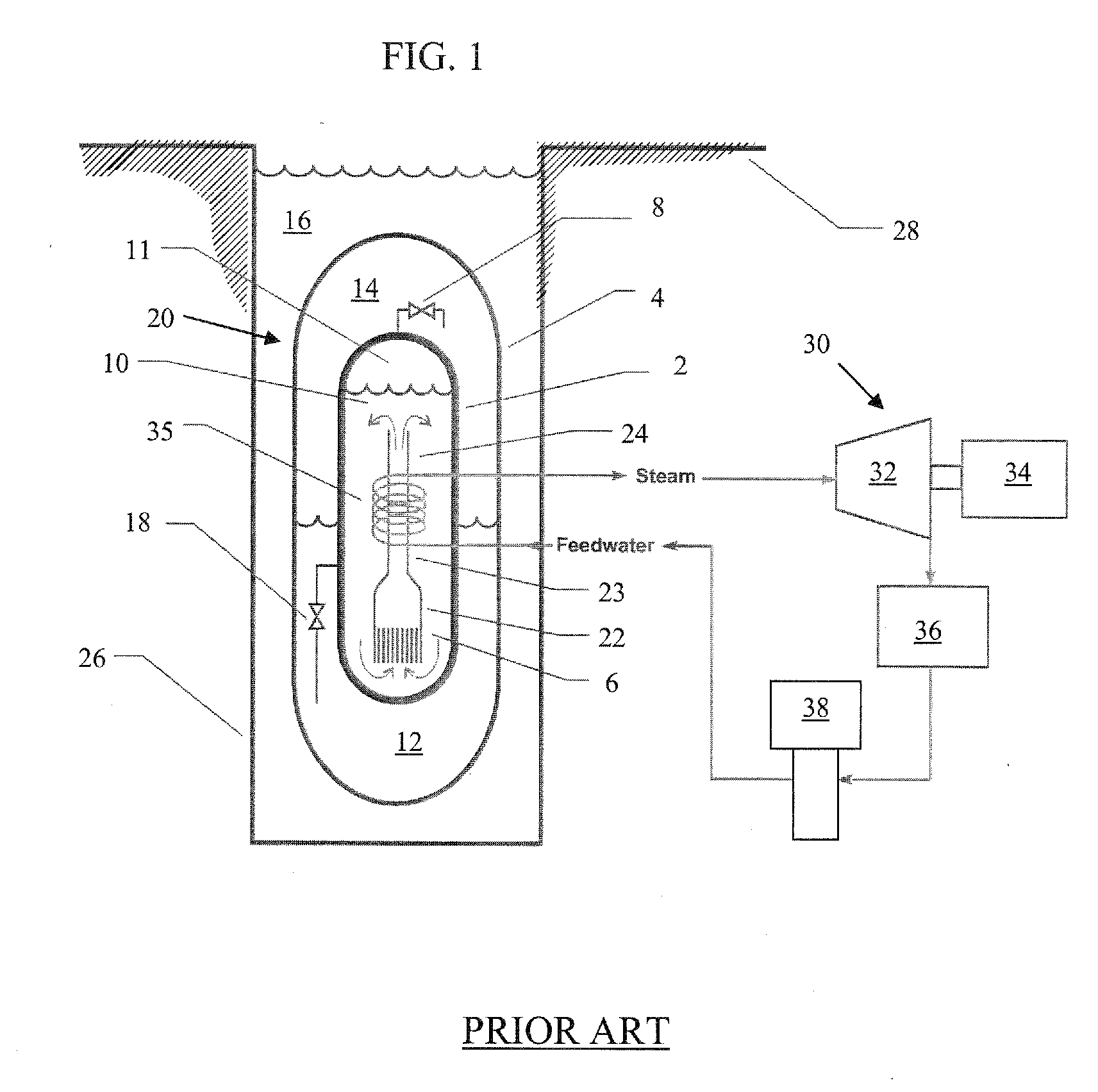

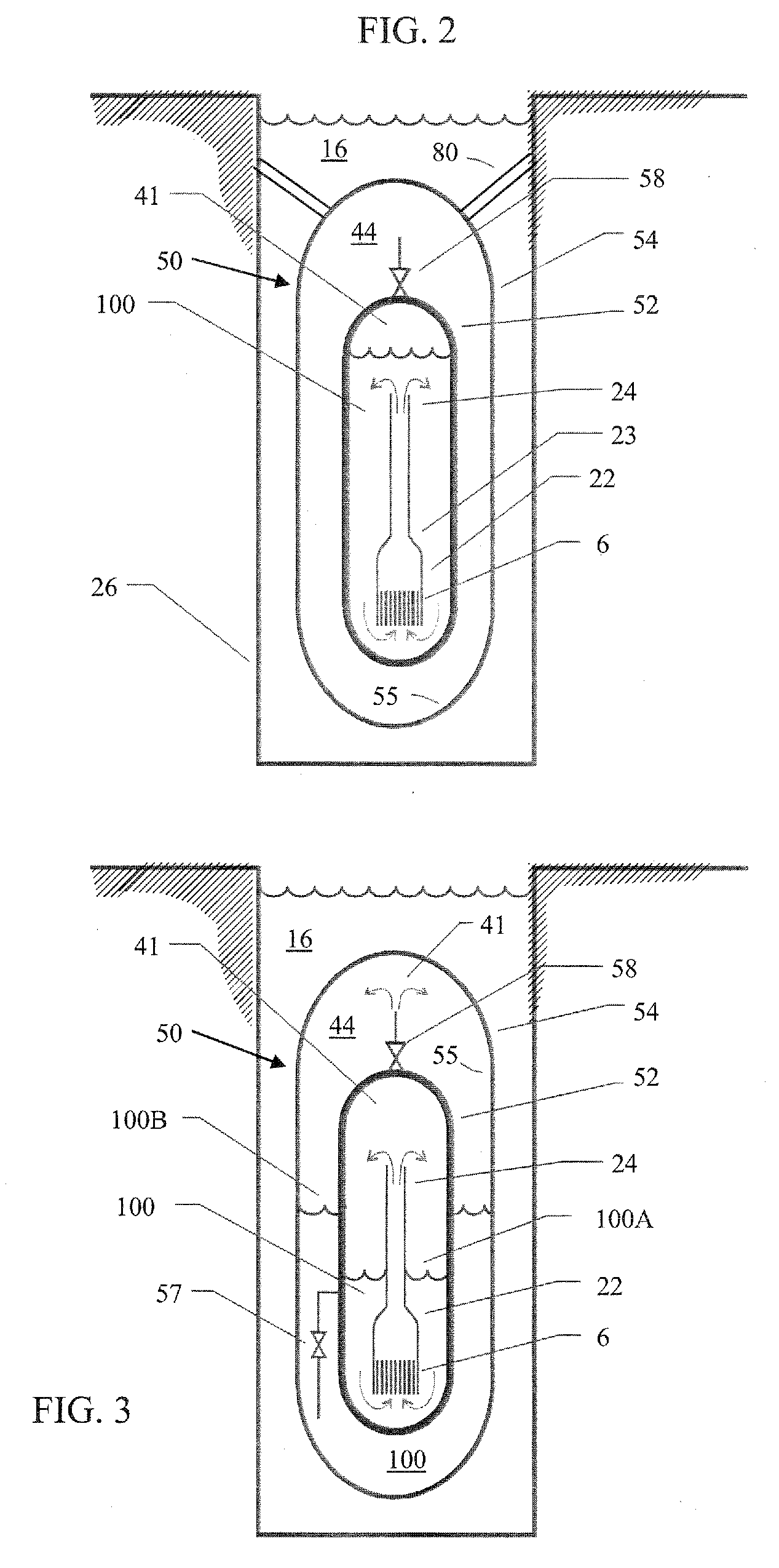

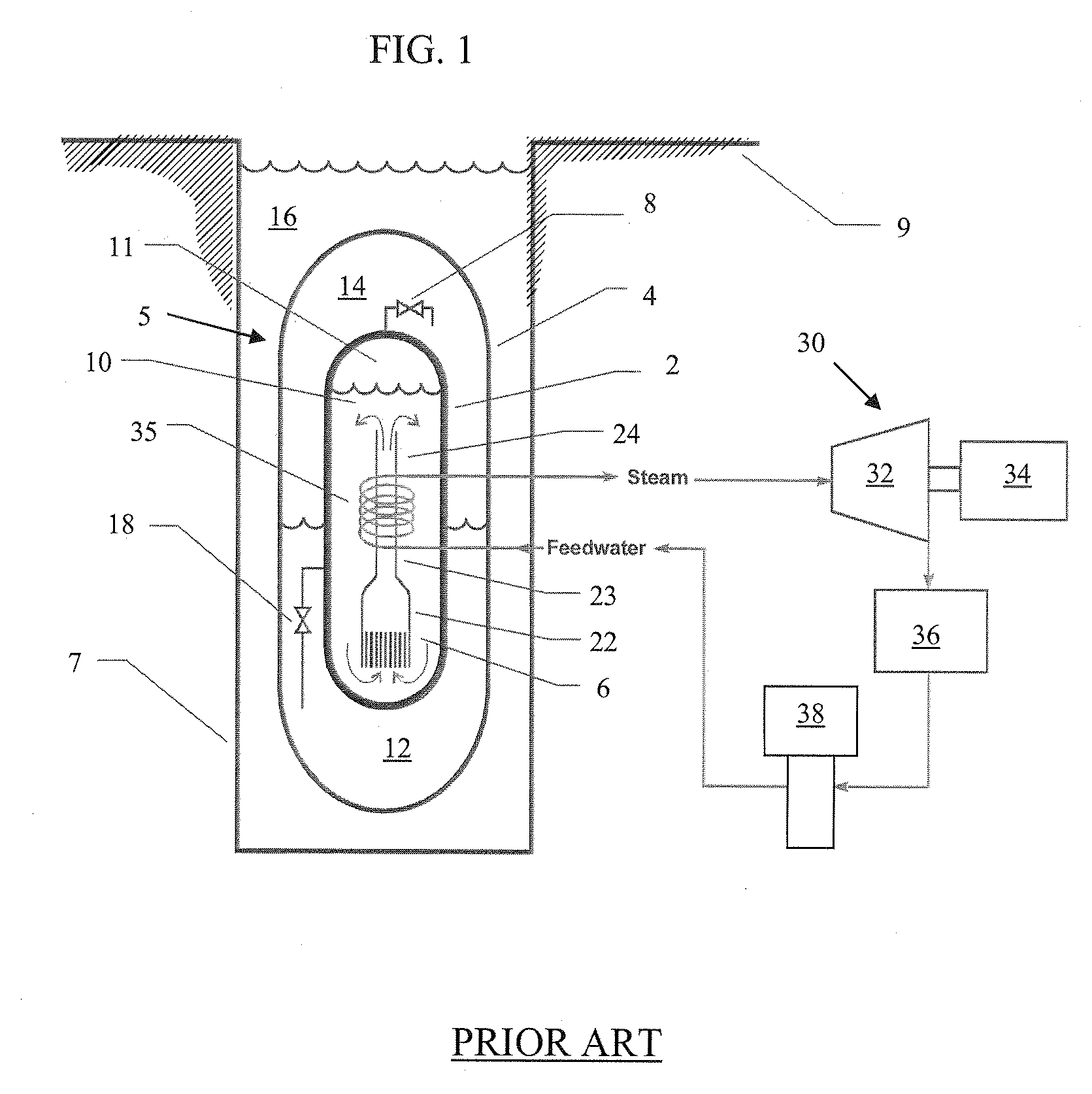

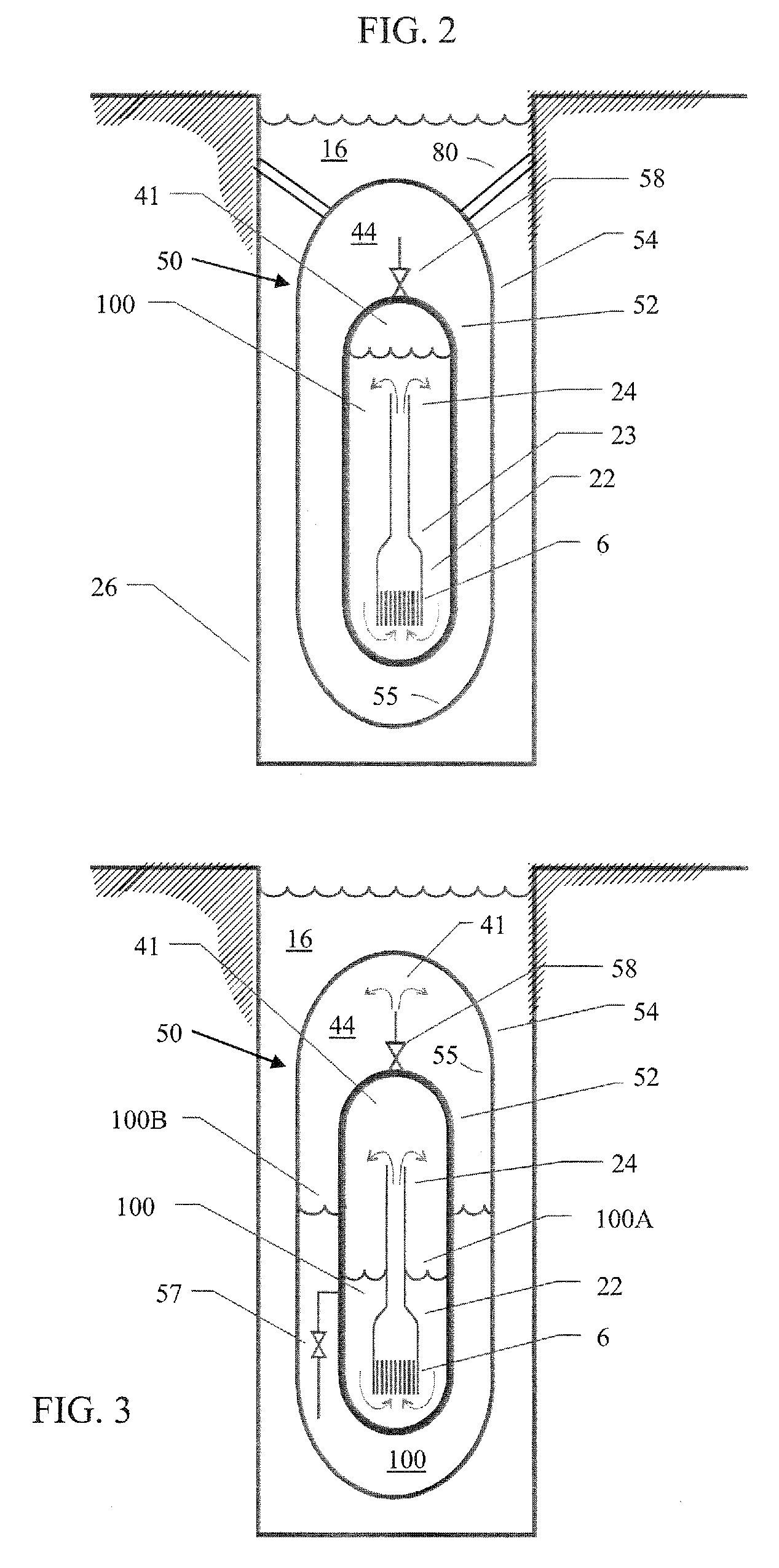

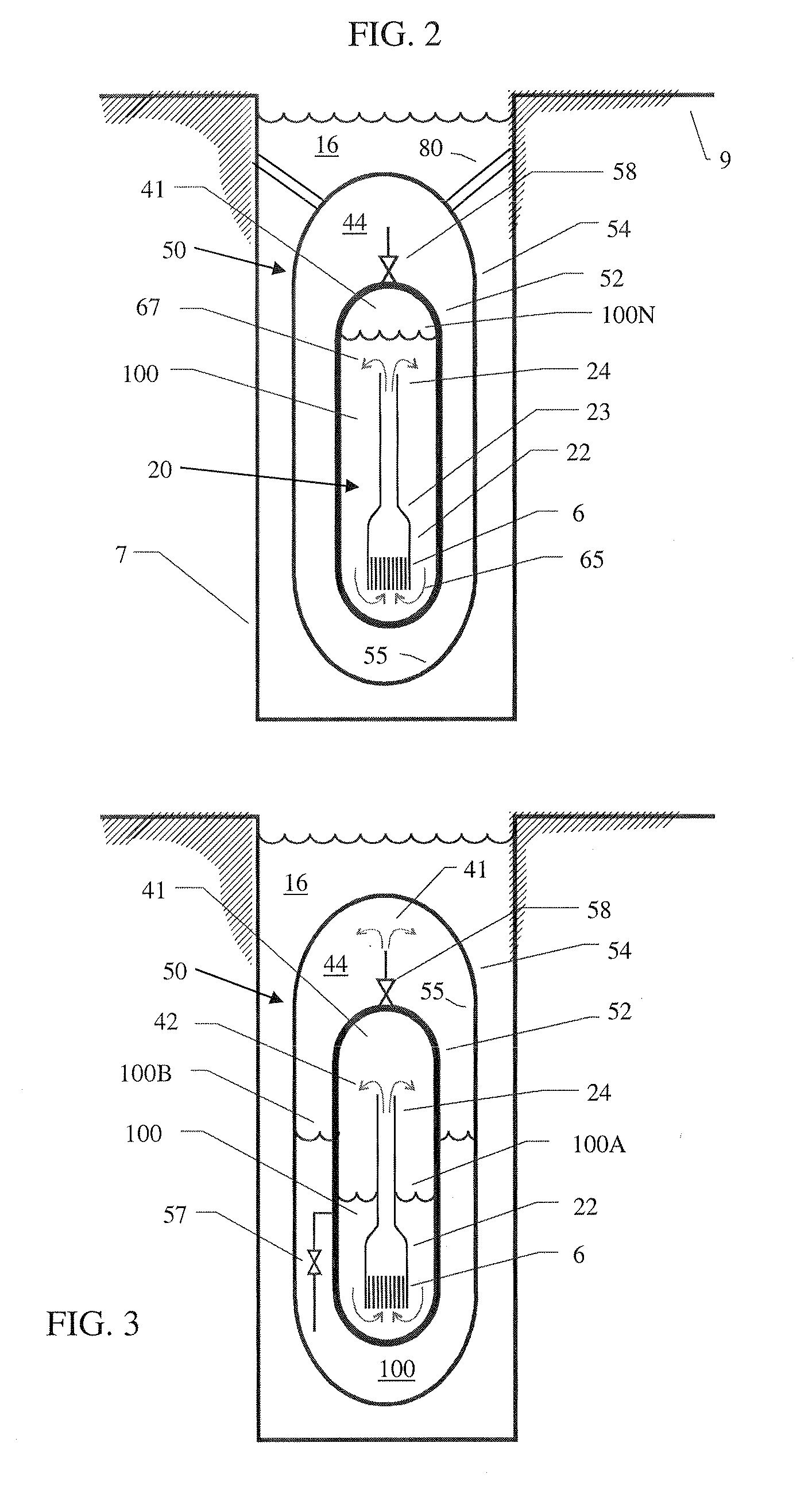

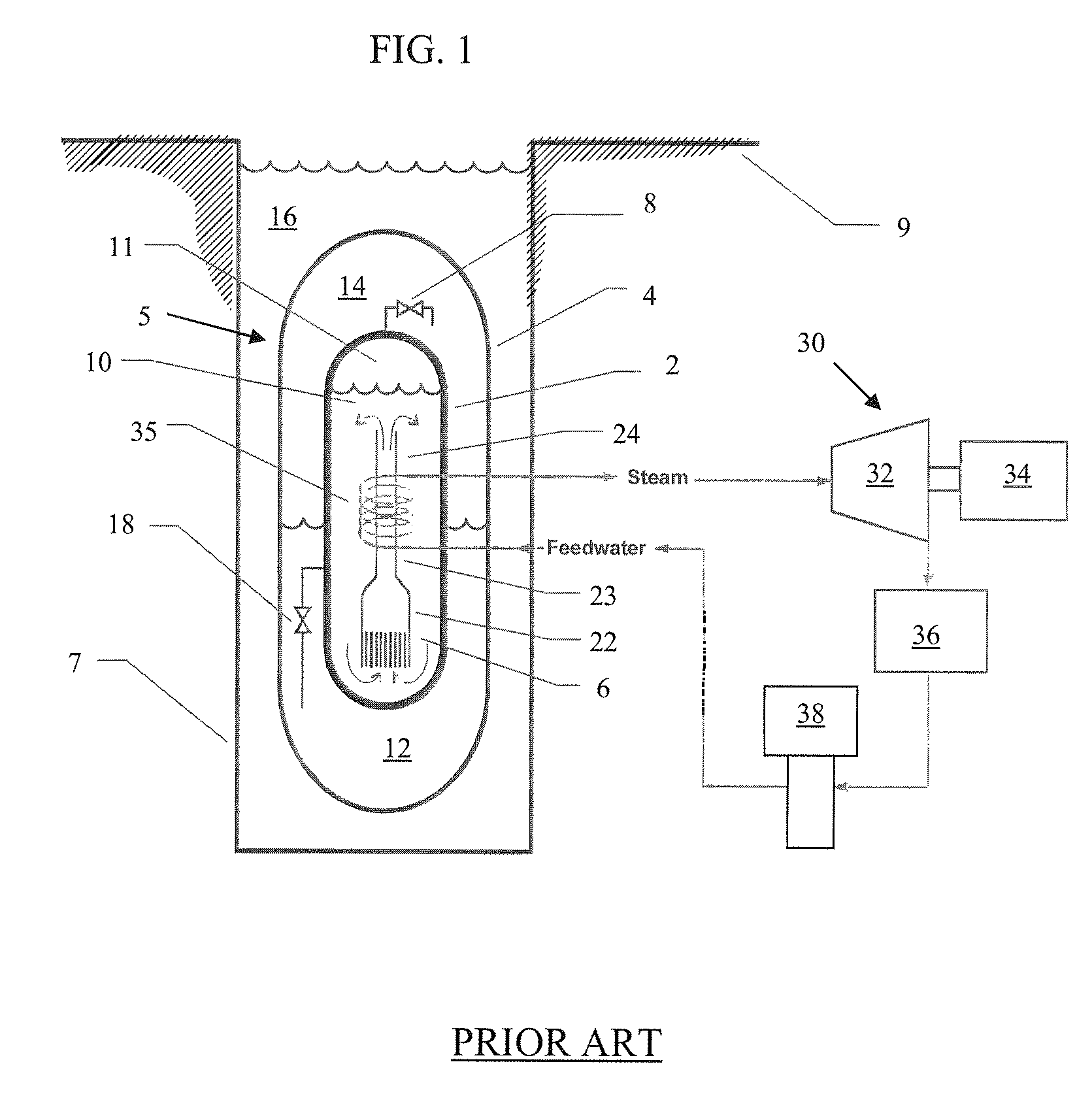

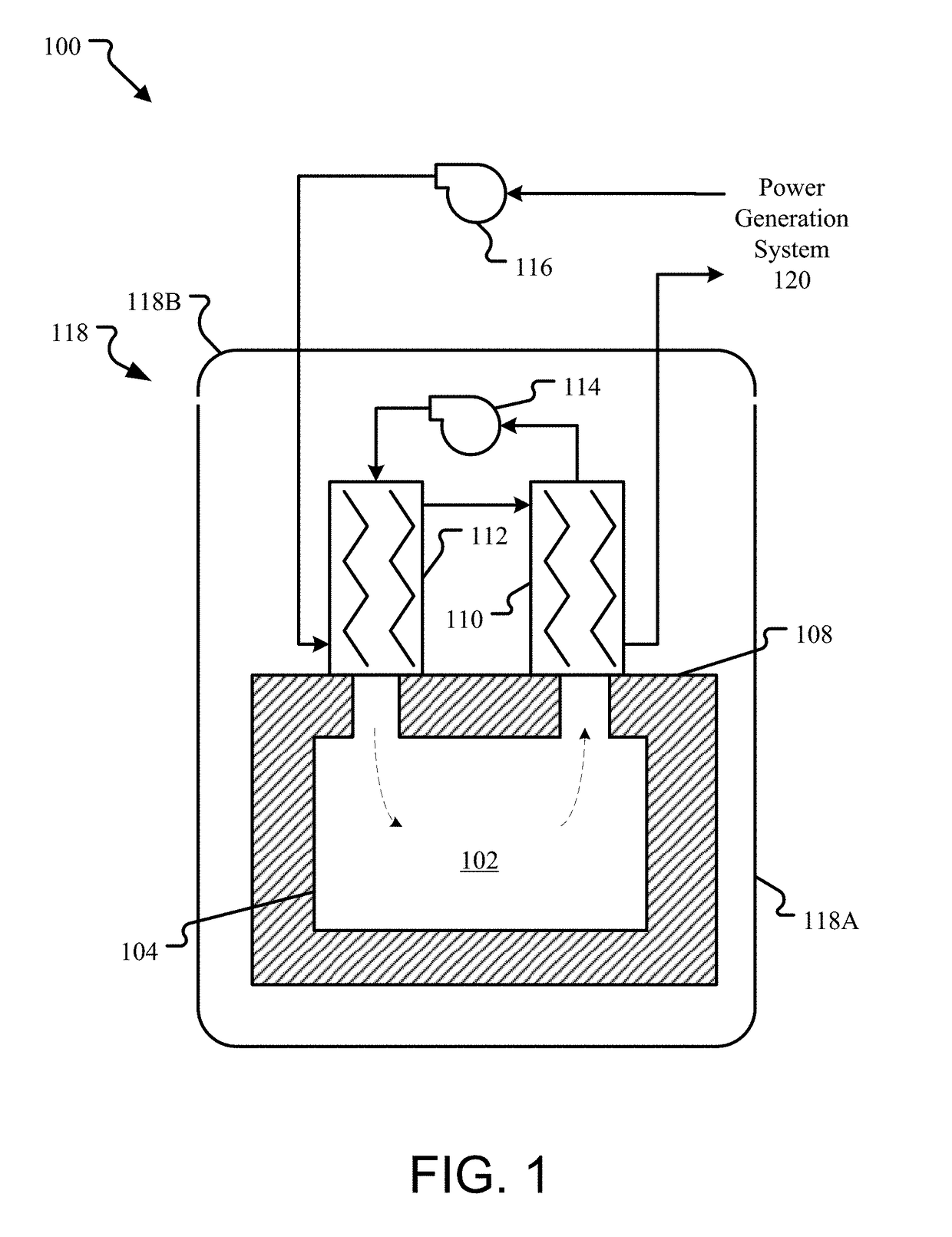

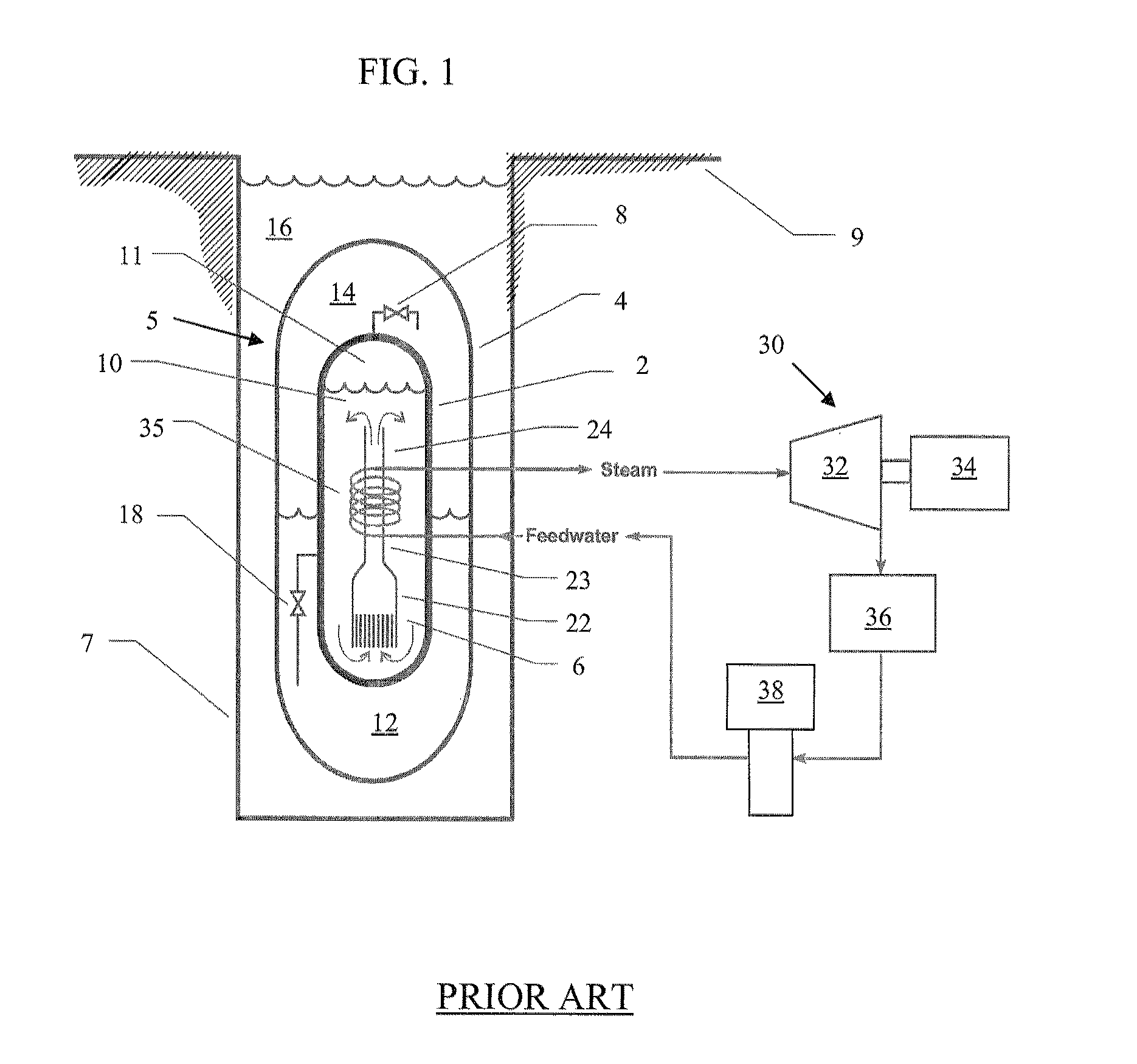

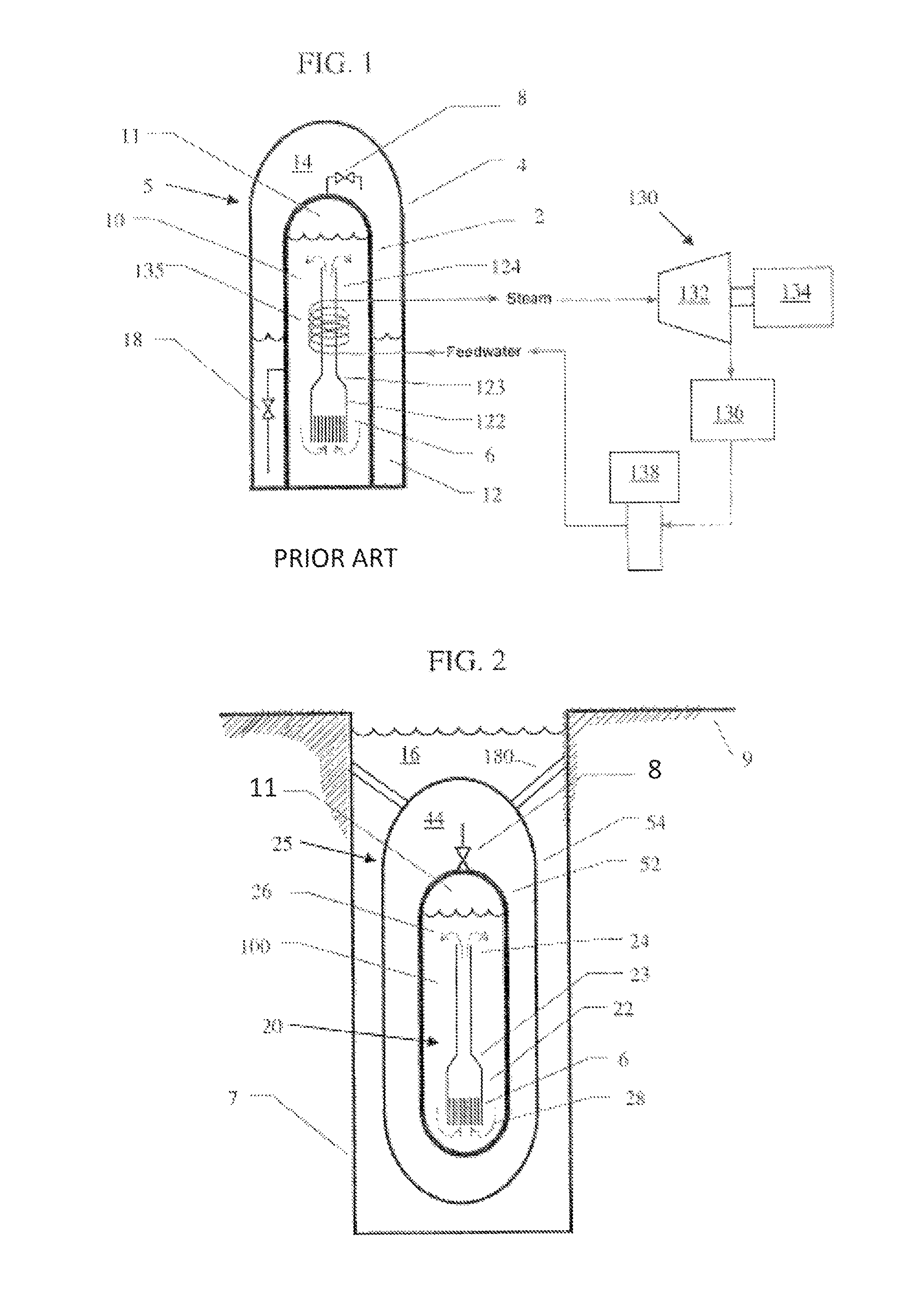

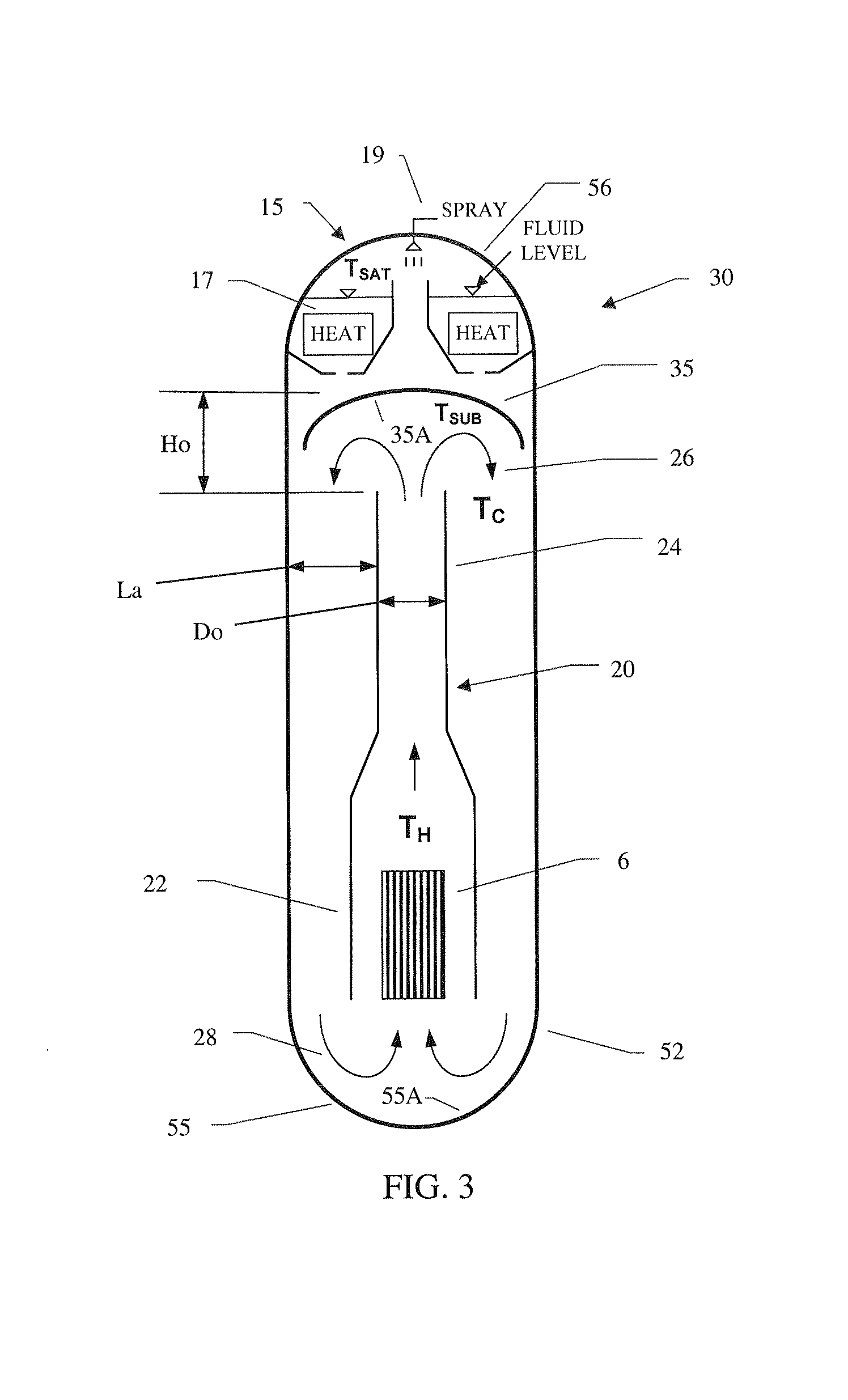

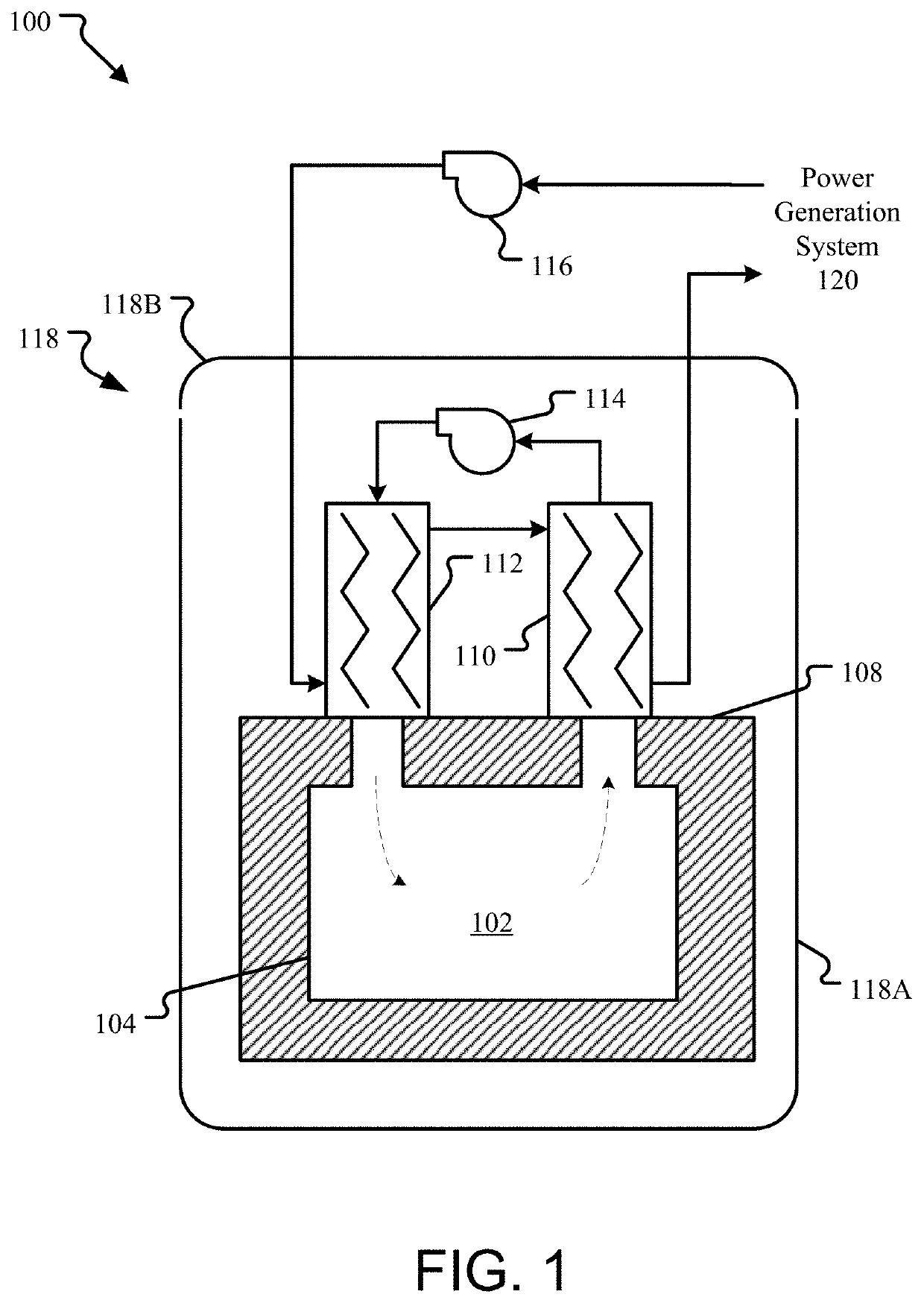

Submerged containment vessel for a nuclear reactor

A power module assembly includes a reactor core immersed in a coolant and a reactor vessel housing the coolant and the reactor core. An internal dry containment vessel submerged in liquid substantially surrounds the reactor vessel in a gaseous environment. During an over-pressurization event the reactor vessel is configured to release the coolant into the containment vessel and remove a decay heat of the reactor core through condensation of the coolant on an inner surface of the containment vessel.

Owner:NUSCALE

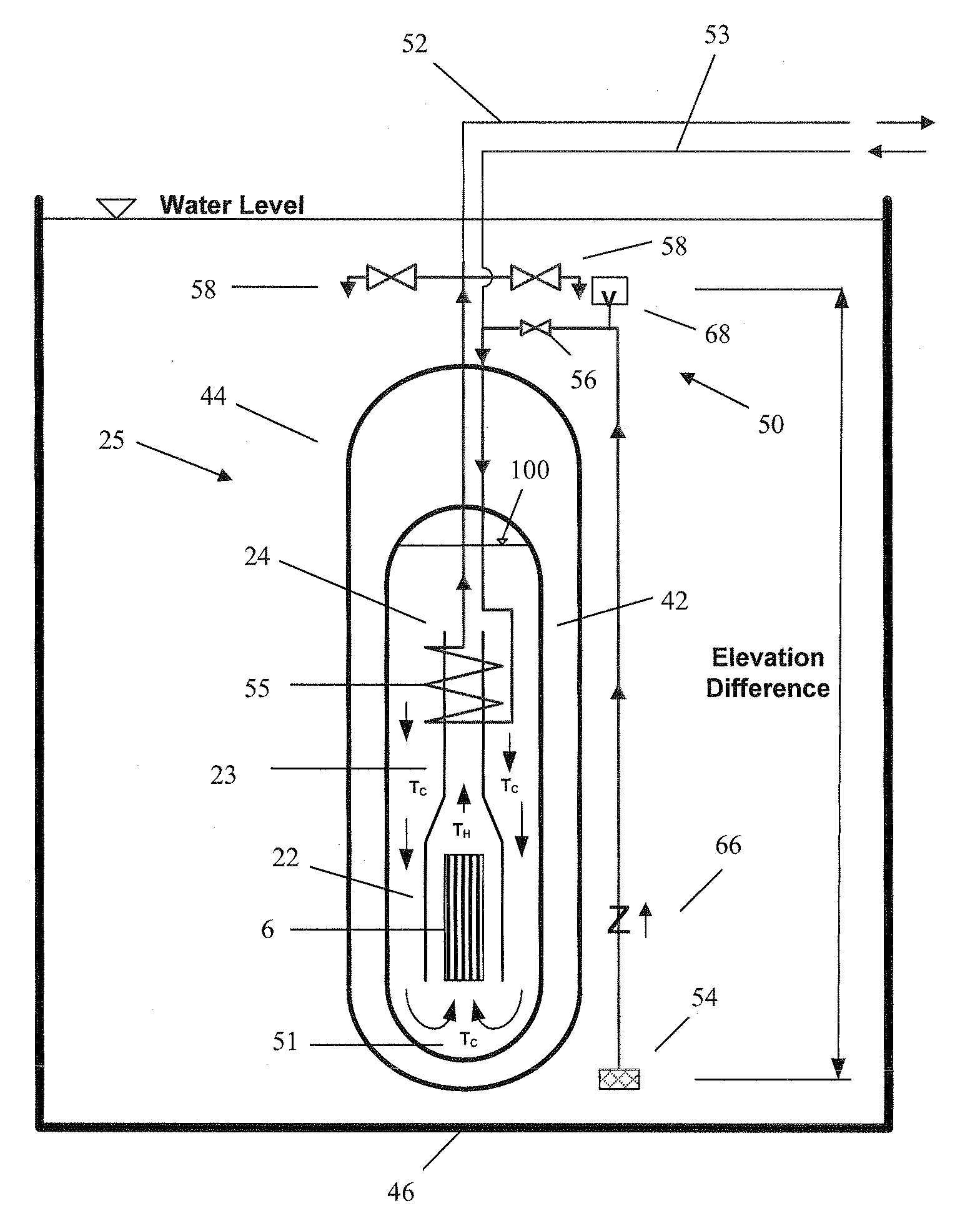

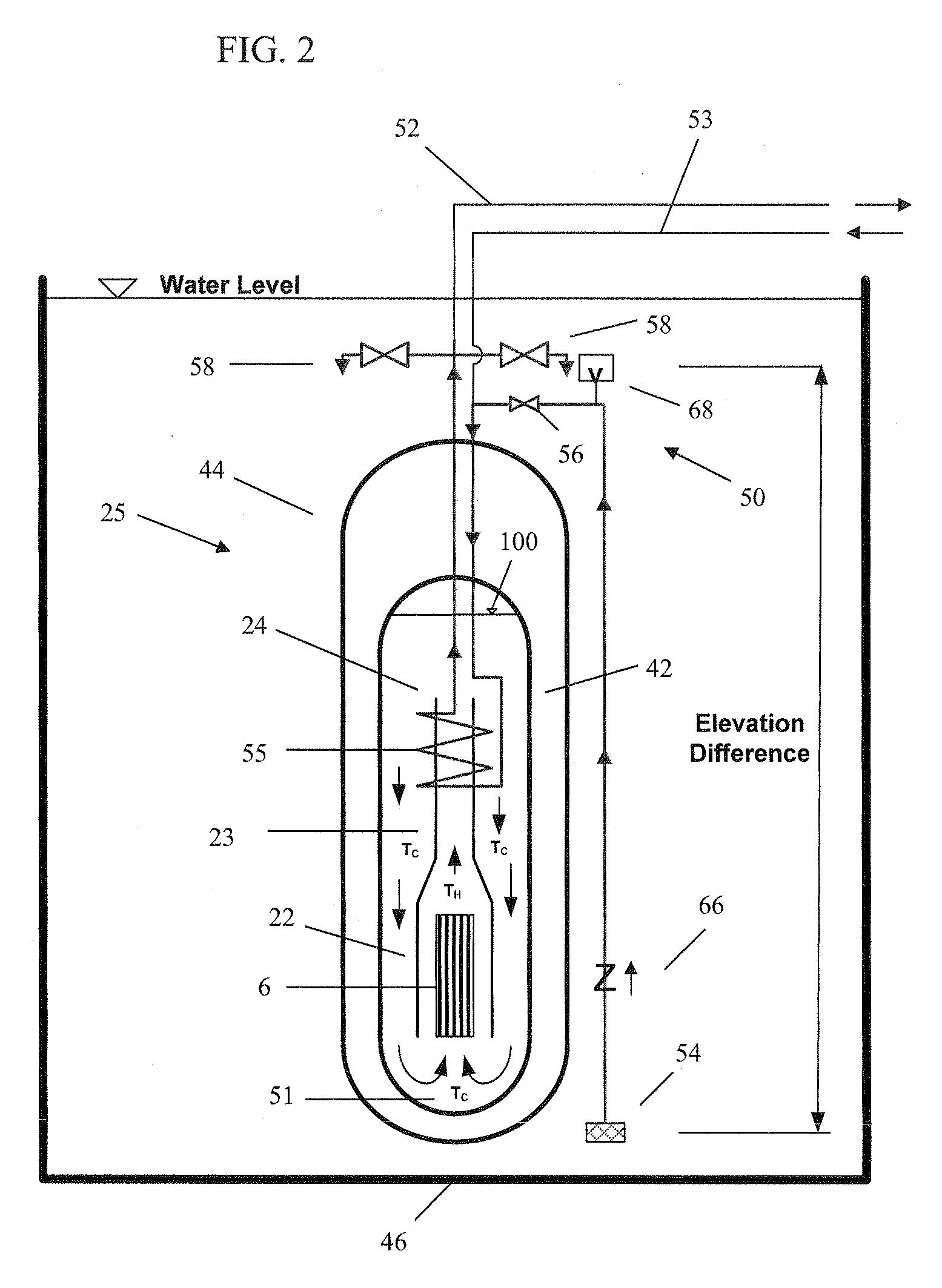

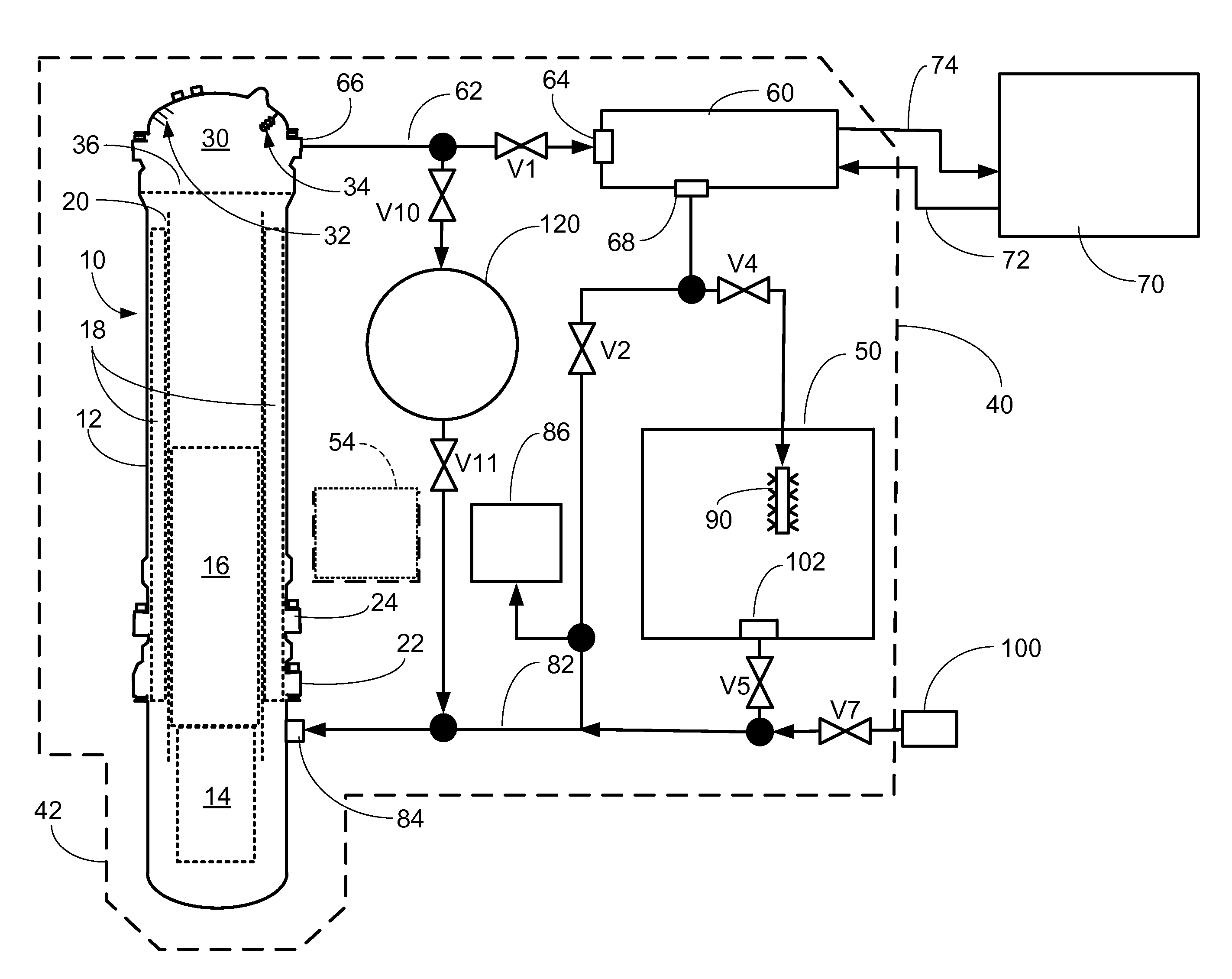

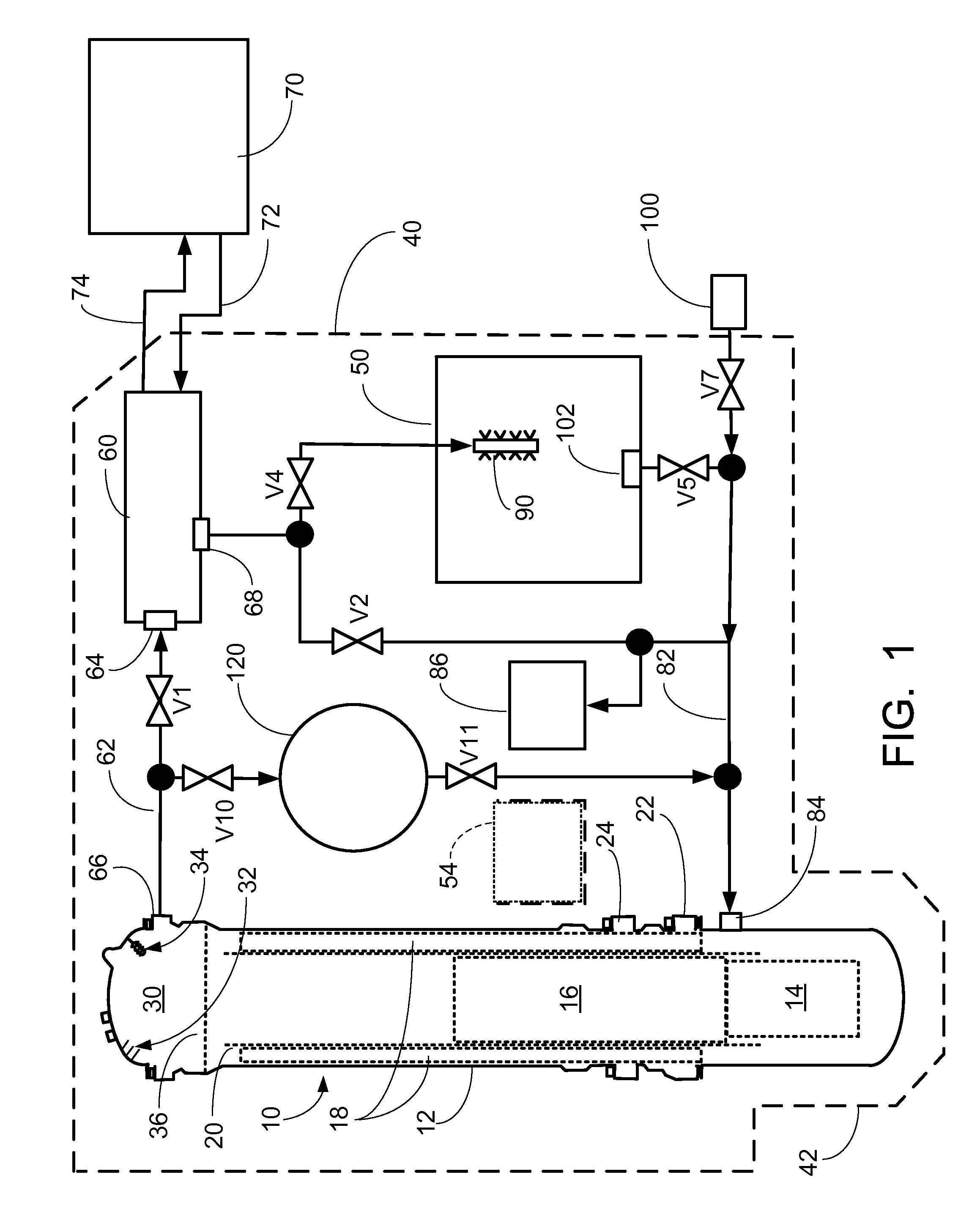

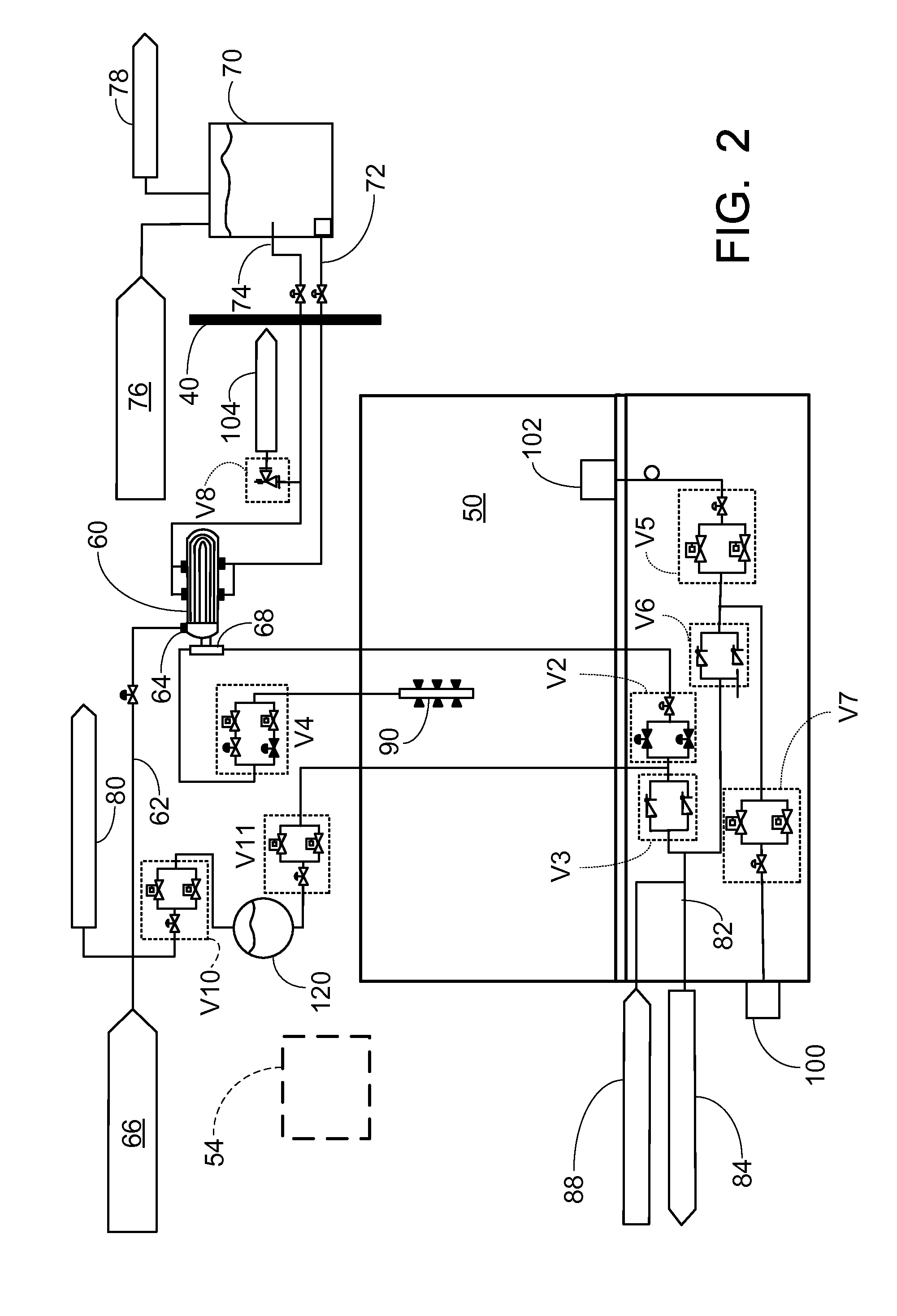

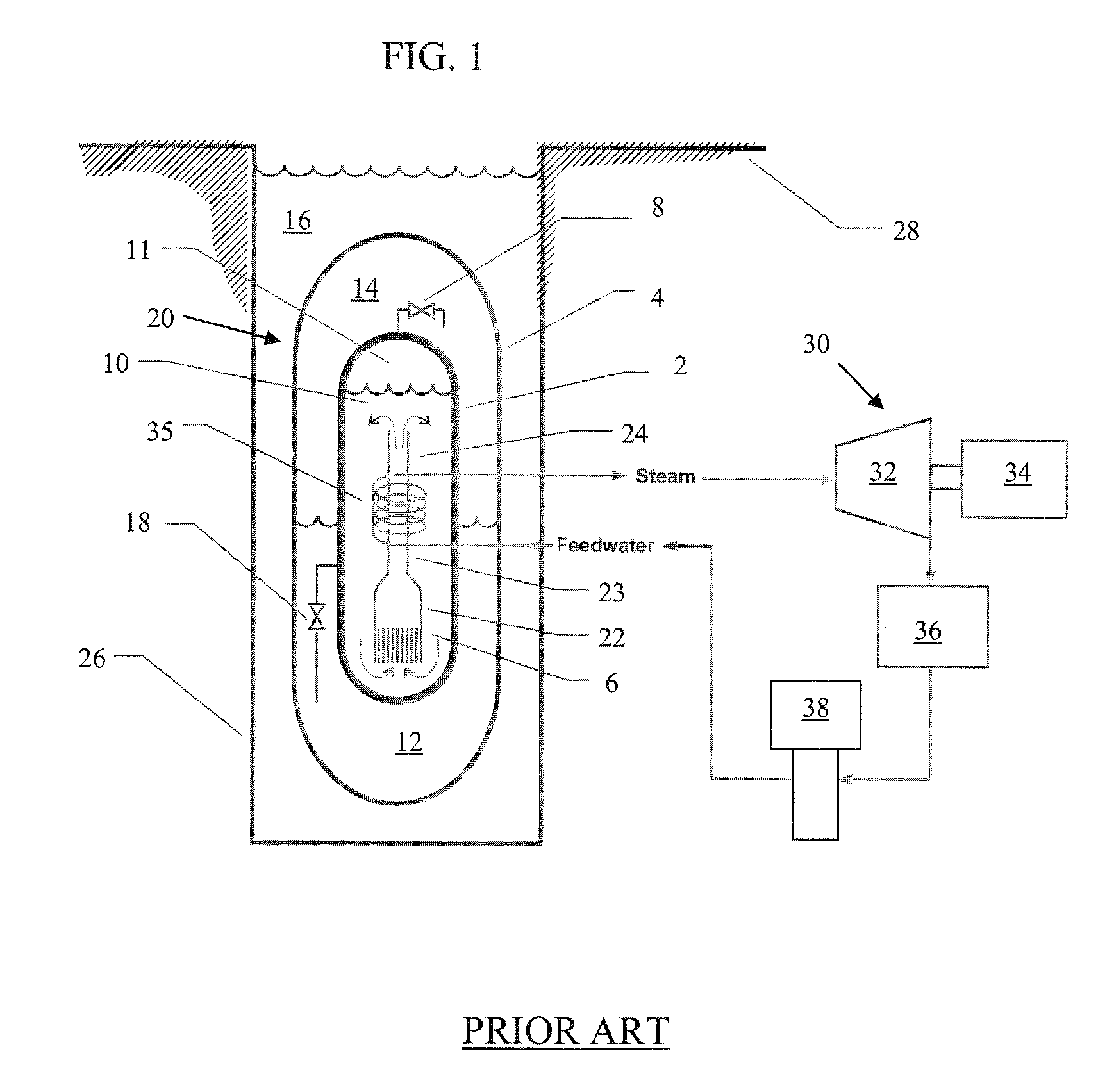

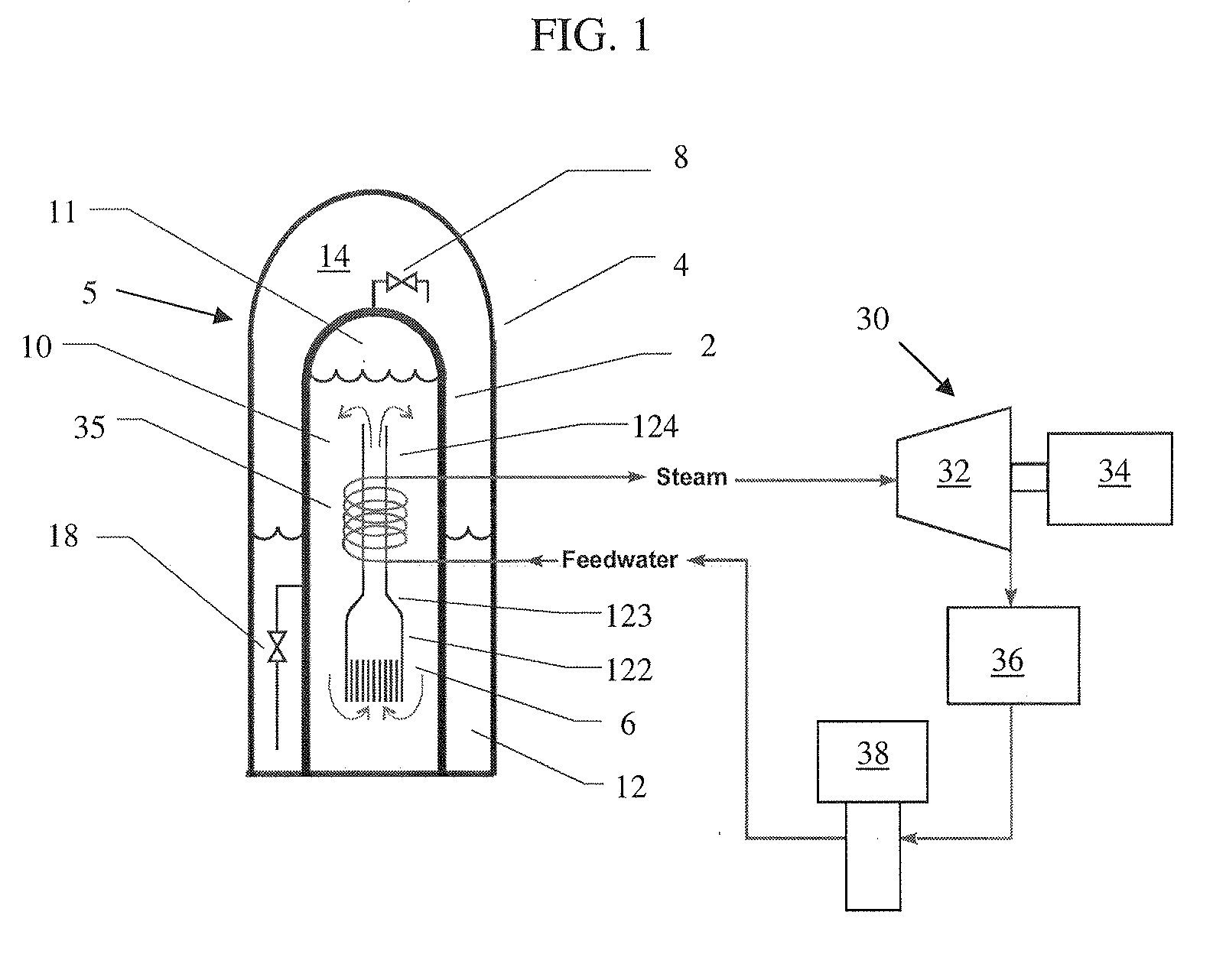

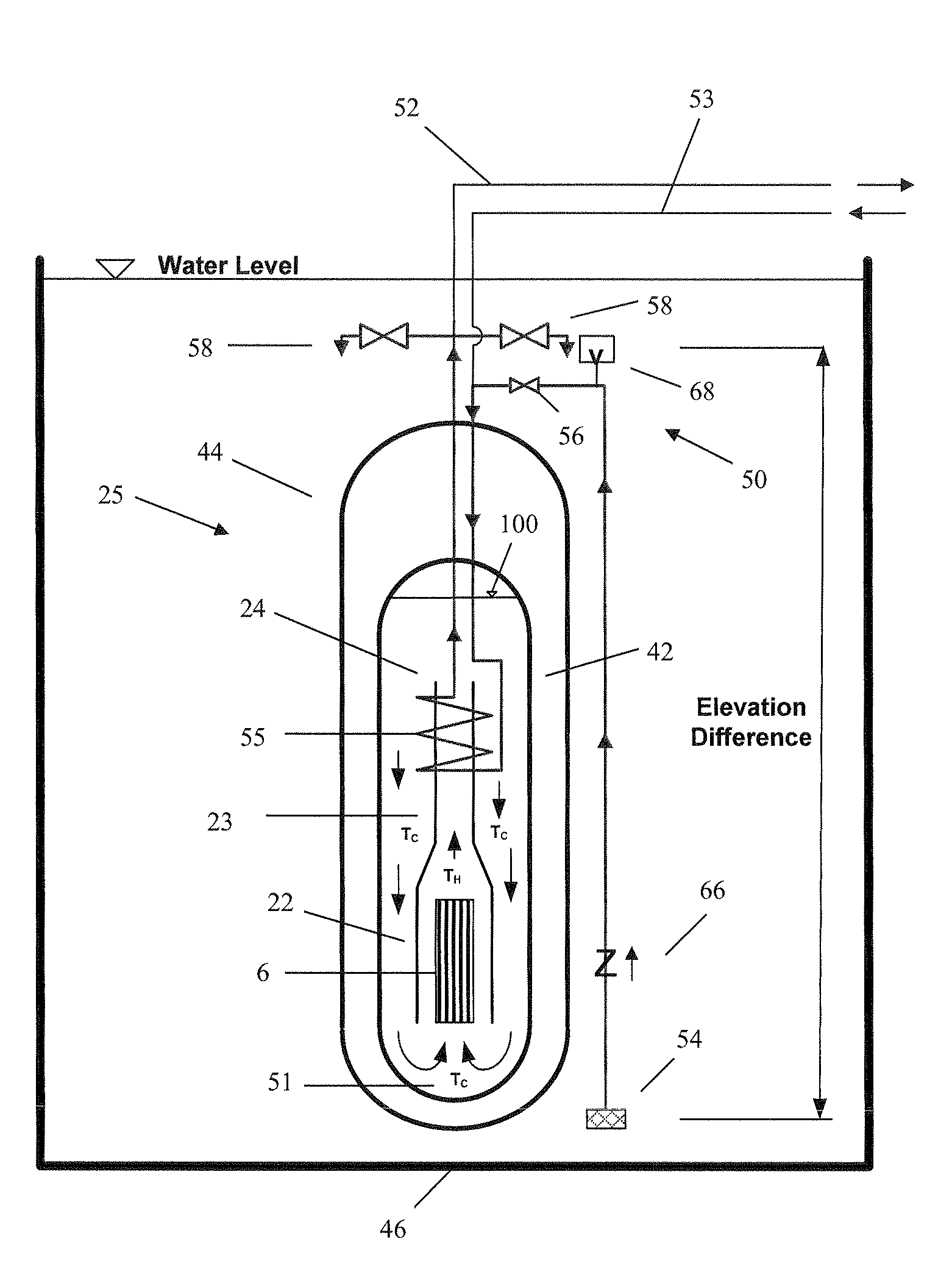

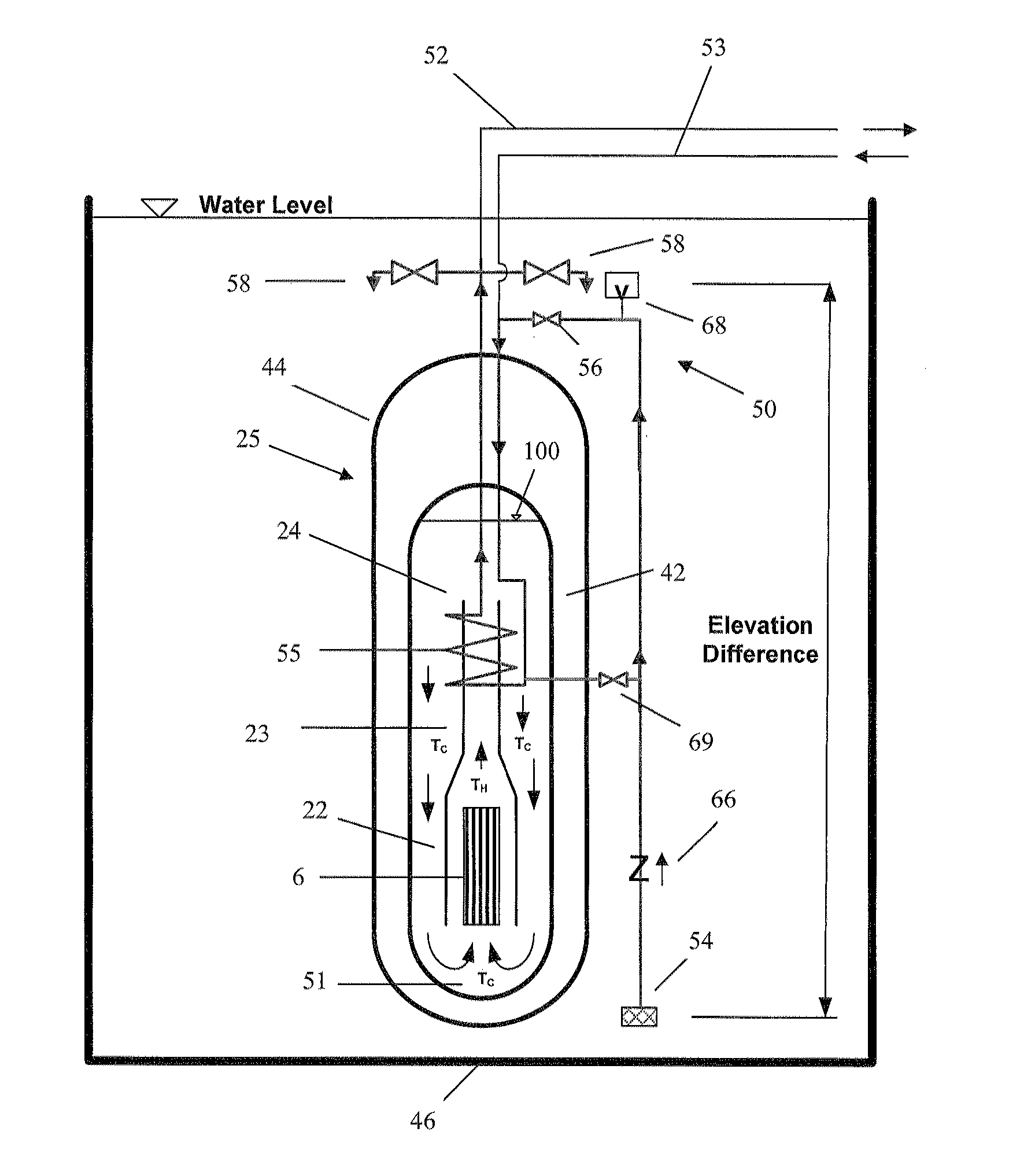

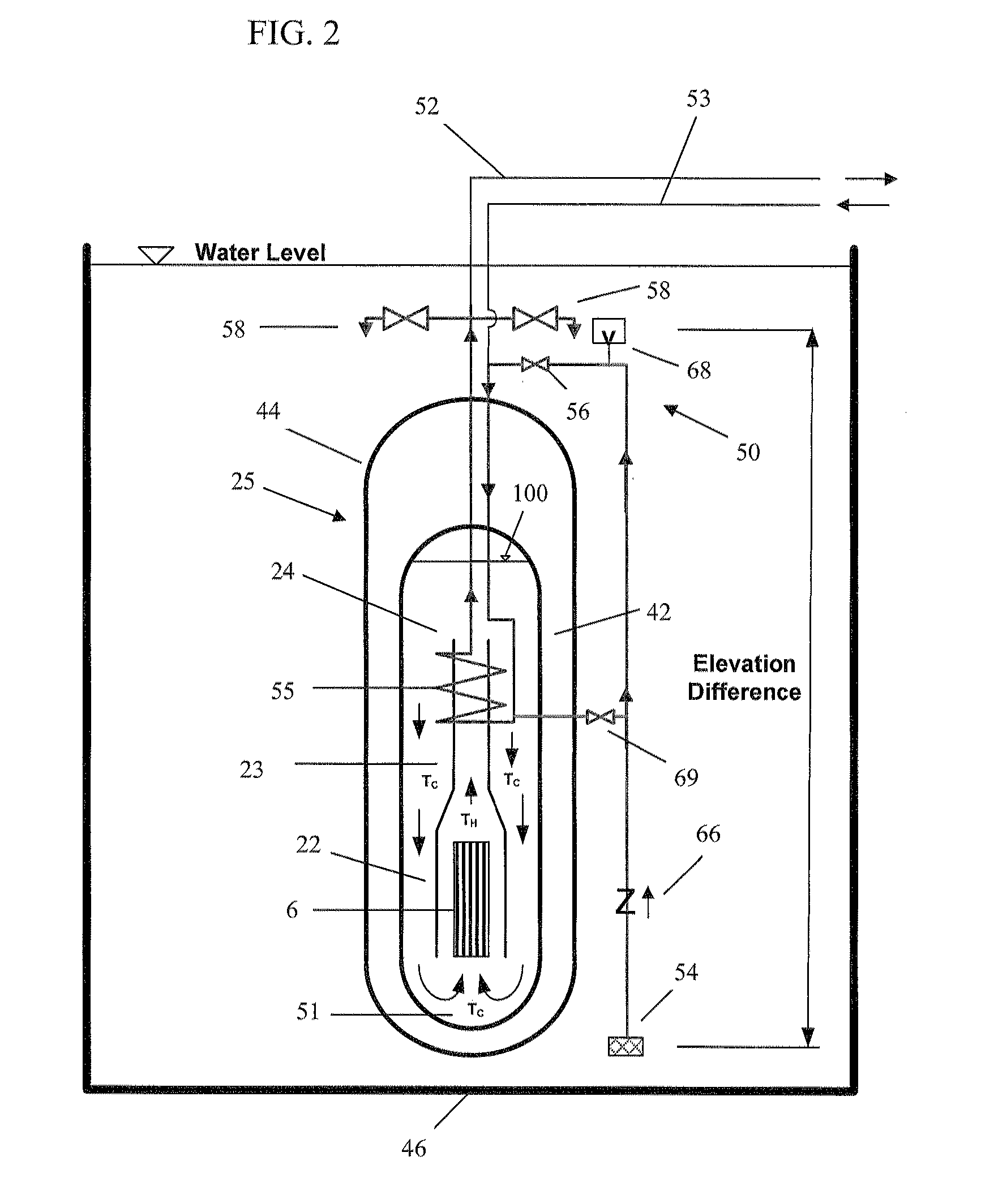

Passive emergency feedwater system

A power module assembly includes a reactor vessel containing a reactor core surrounded by a primary coolant. A containment vessel is adapted to be submerged in a containment cooling pool and to prohibit a release of the primary coolant outside of the containment vessel. A secondary cooling system is configured to remove heat generated by the reactor core. The heat is removed by circulating liquid from the containment cooling pool through the primary coolant.

Owner:NUSCALE

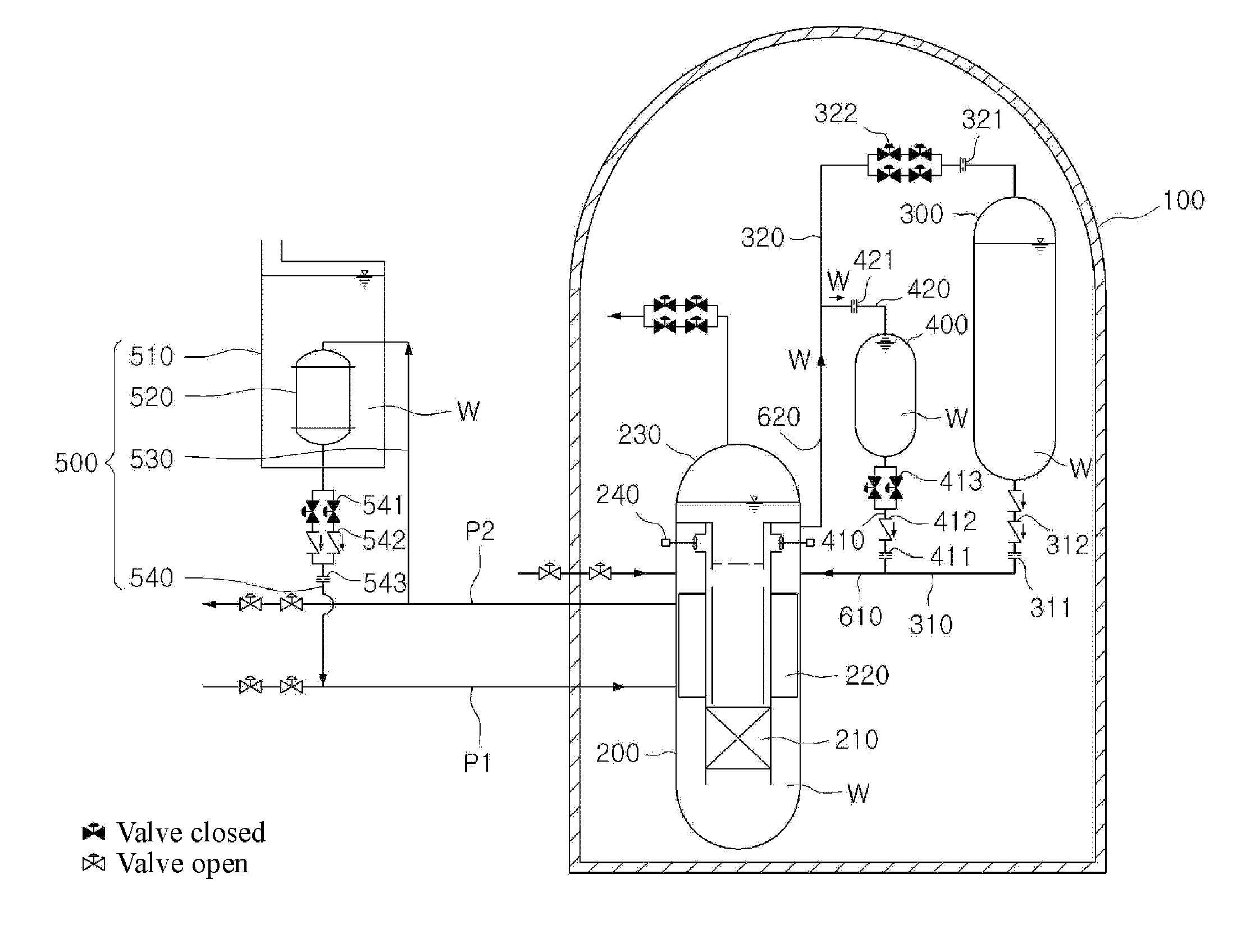

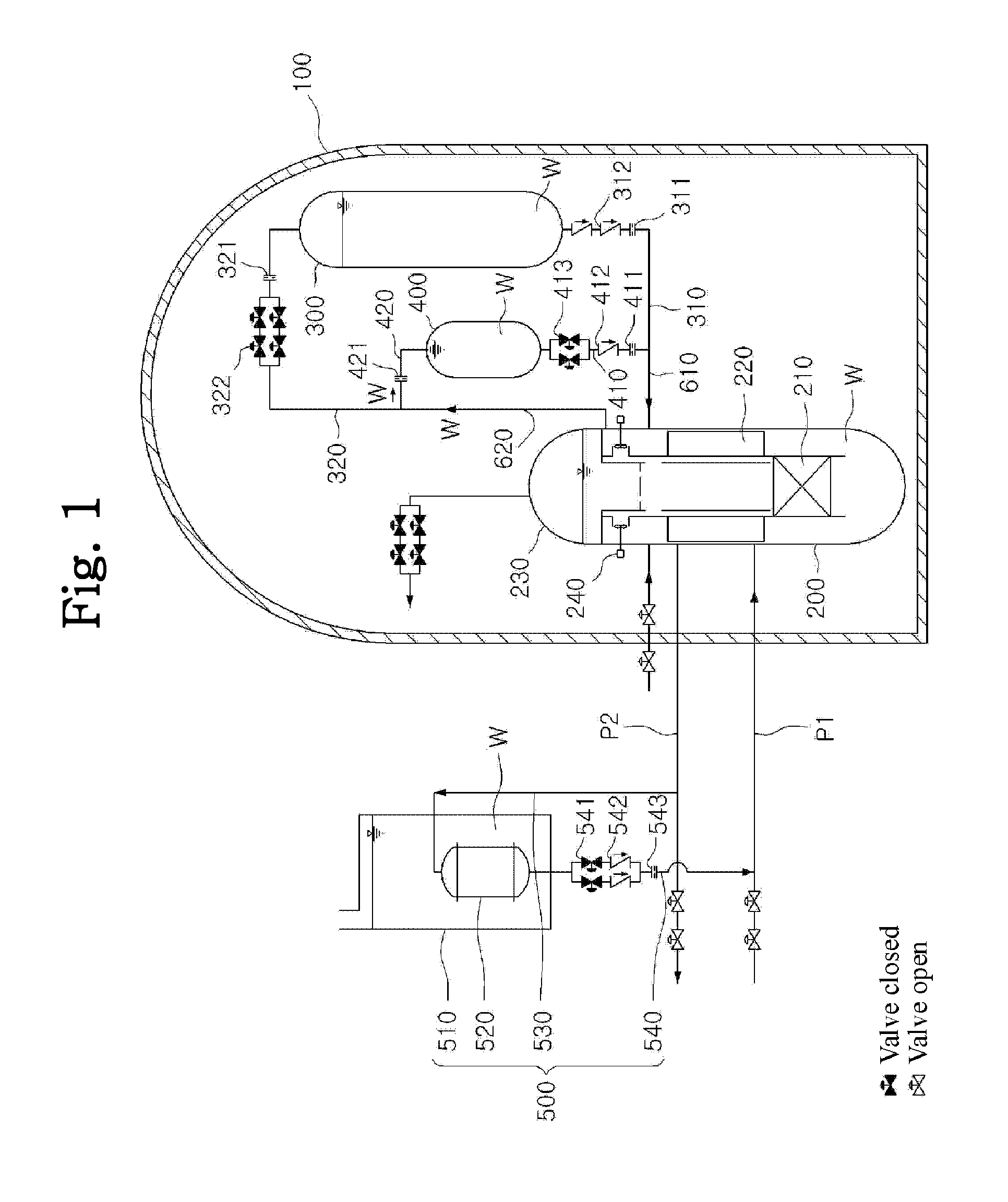

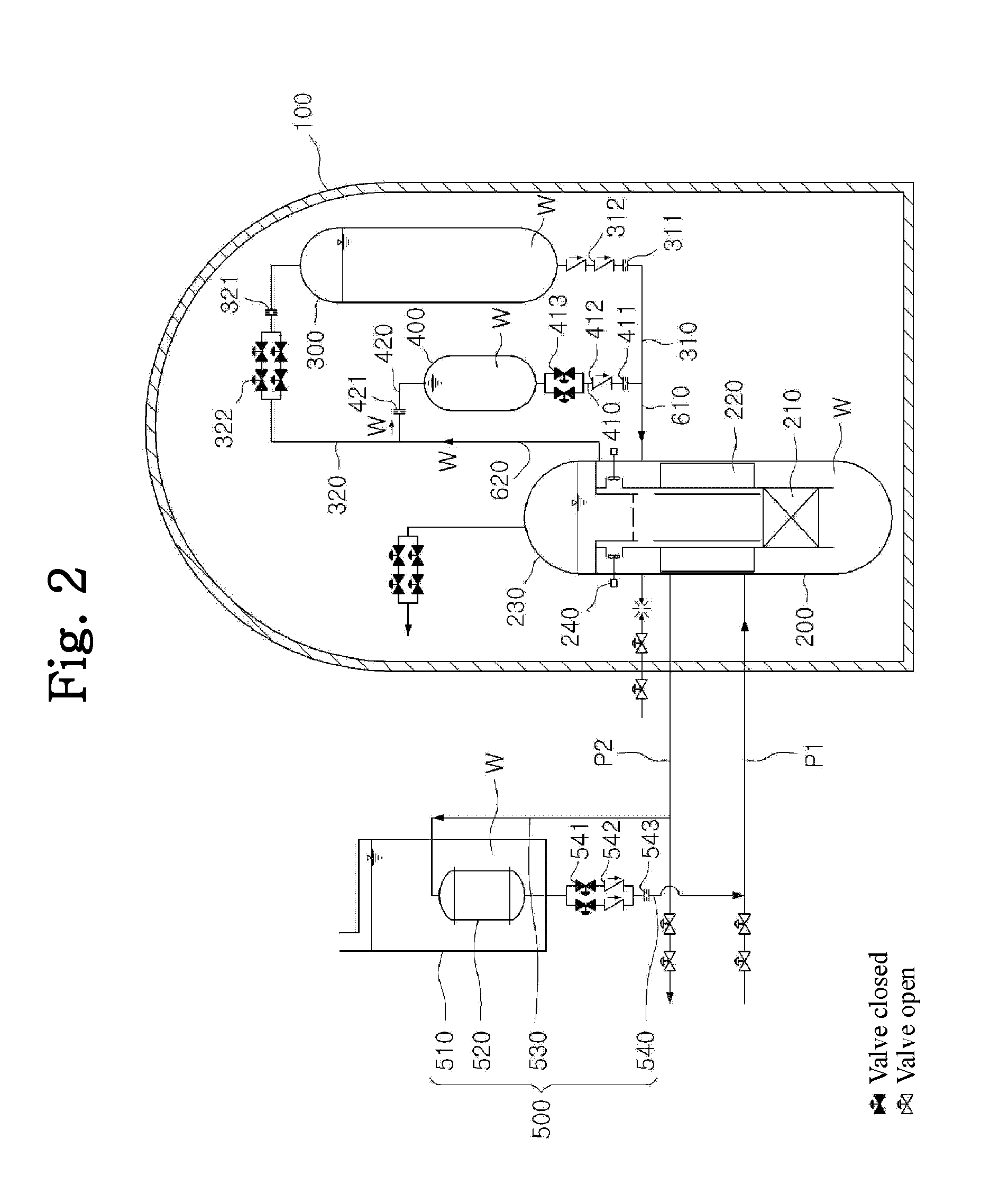

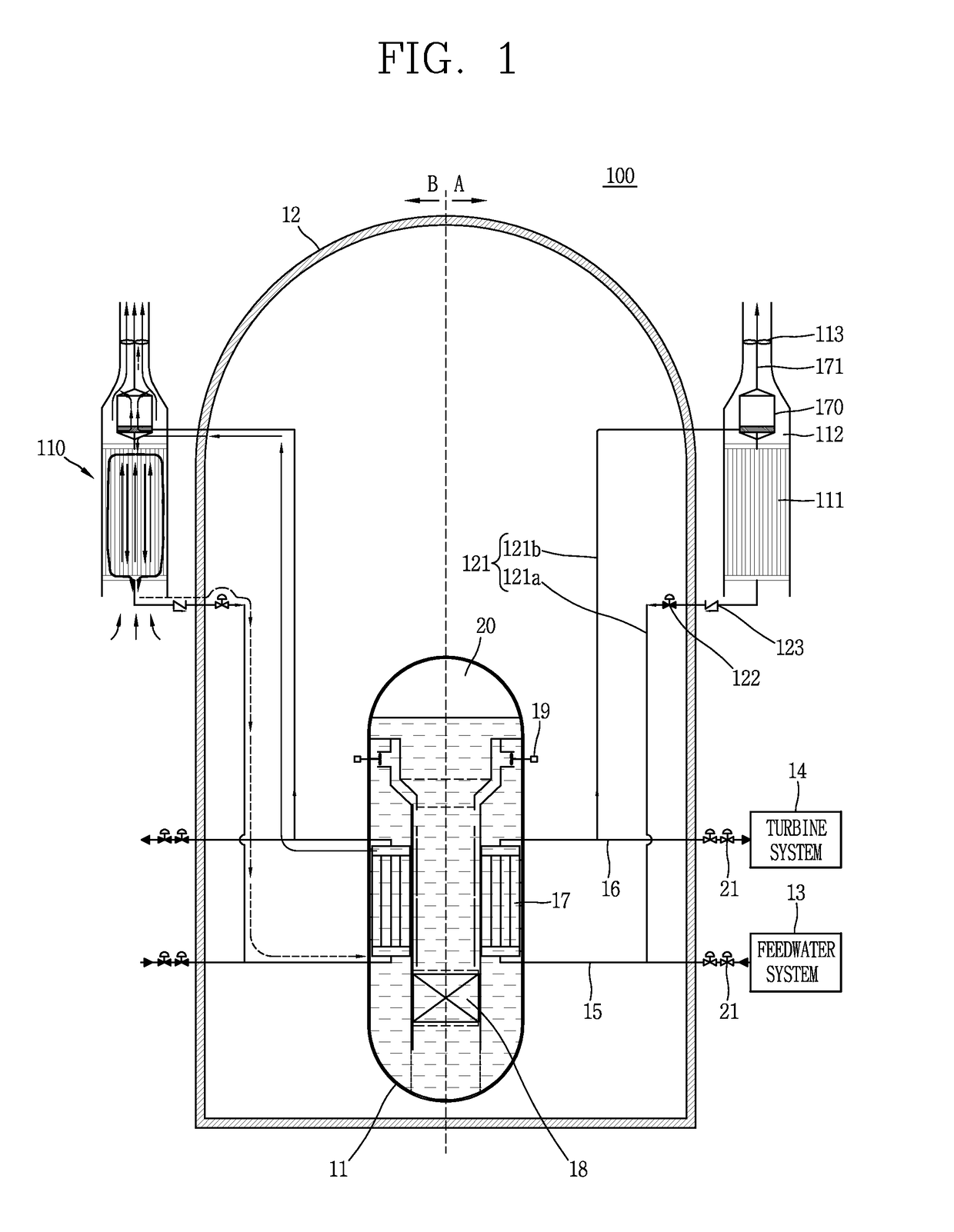

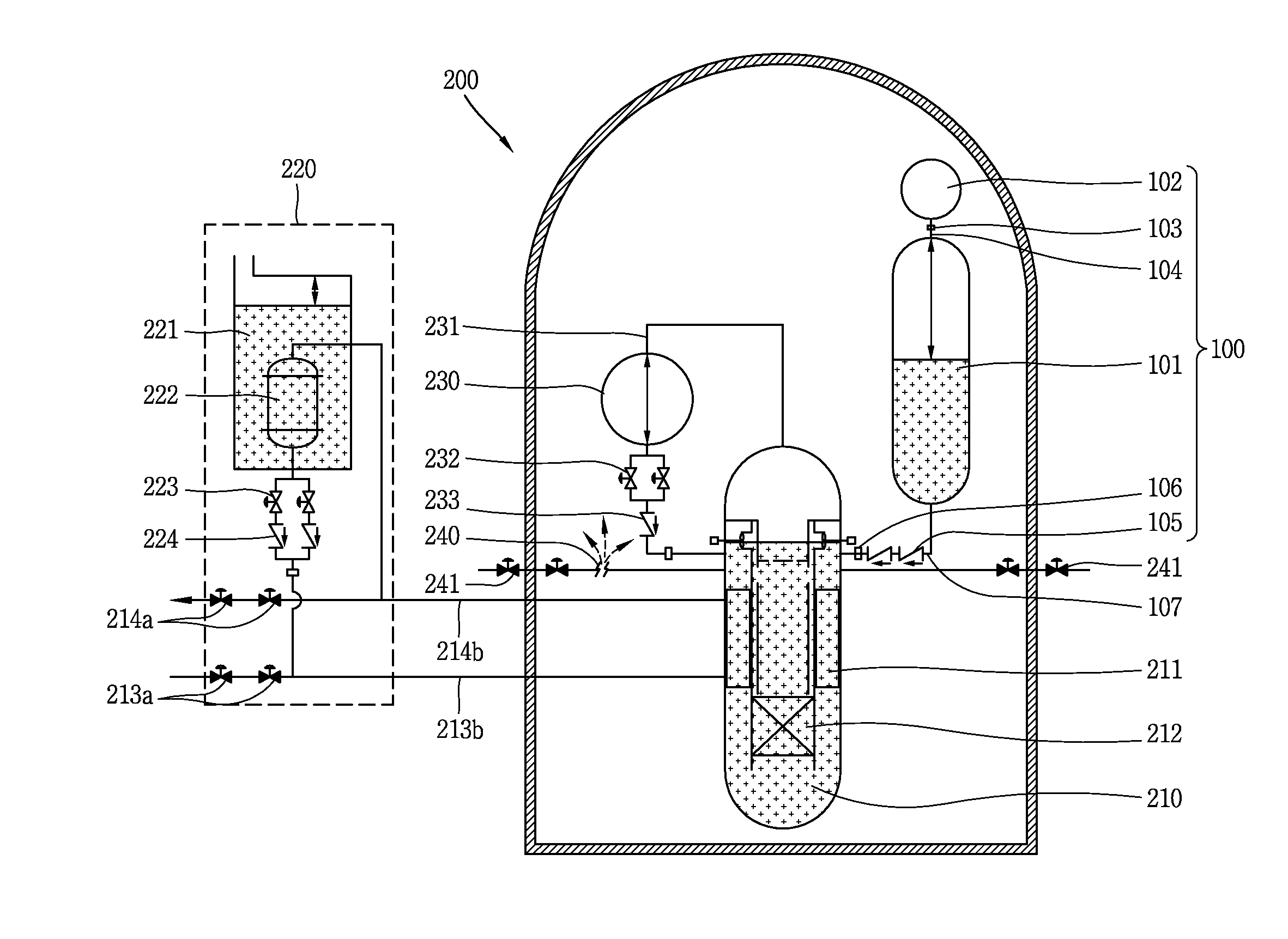

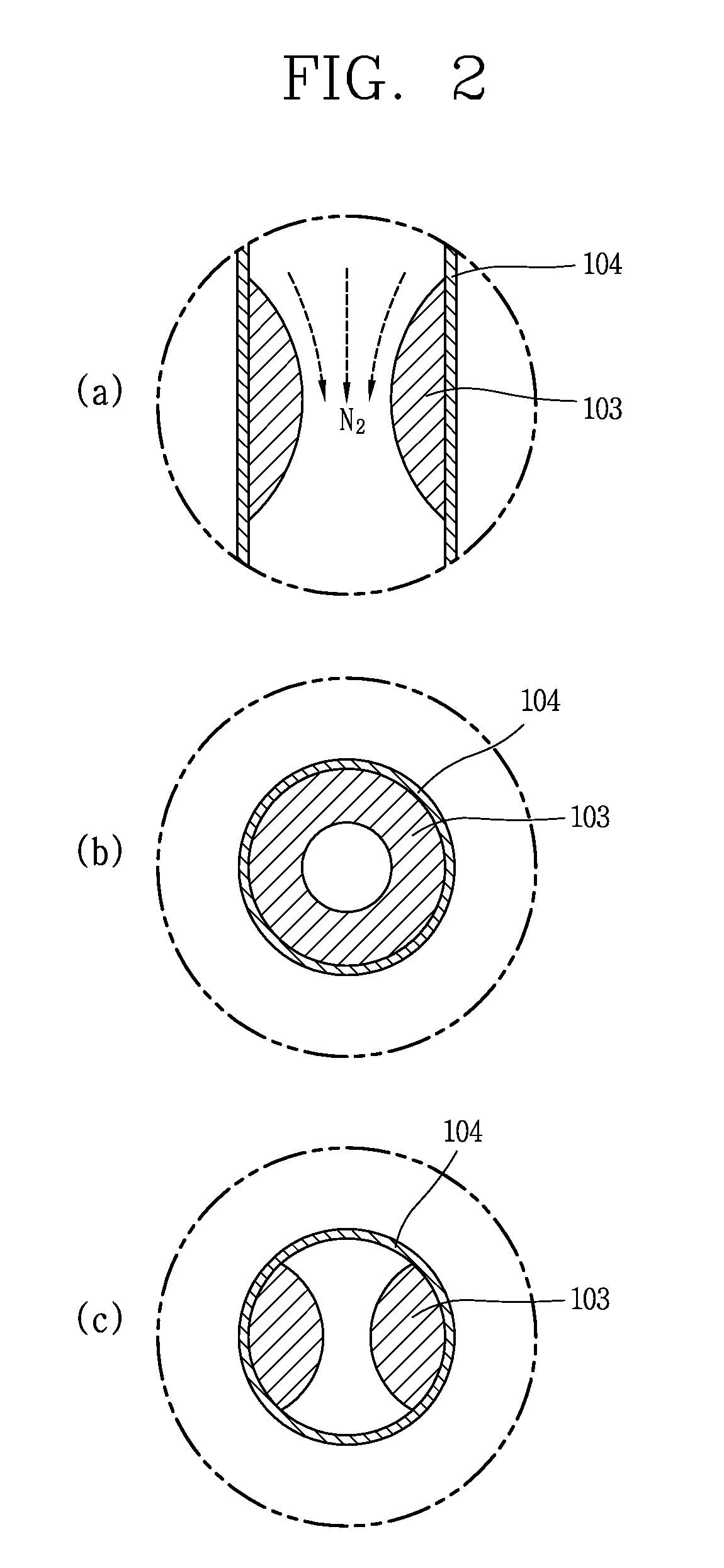

Passive safety system of integral reactor

ActiveUS20140016734A1Maintain water levelSimple facilitiesPower plant safety arrangementIntegral reactorsNuclear engineeringNitrogen gas

A passive safety system includes a containment, a reactor in the containment, a plurality of safety injection tanks connected with the reactor and having water and nitrogen gas to supply water thereof into the reactor through a safety injection line communicating to the first safety injection line upon a loss of coolant accident, a plurality of core makeup tanks connected with the reactor to supply water thereof into the reactor through a second safety injection line communicating to a safety injection line upon the loss of coolant accident, and a plurality of passive residual heat removal systems to remove residual heat from the reactor upon the loss of coolant accident or a non-loss of coolant accident. The water in each of the safety injection tank is stably supplied to the reactor for many hours by a differential head resulting from gravity or gas pressure.

Owner:KOREA ATOMIC ENERGY RES INST

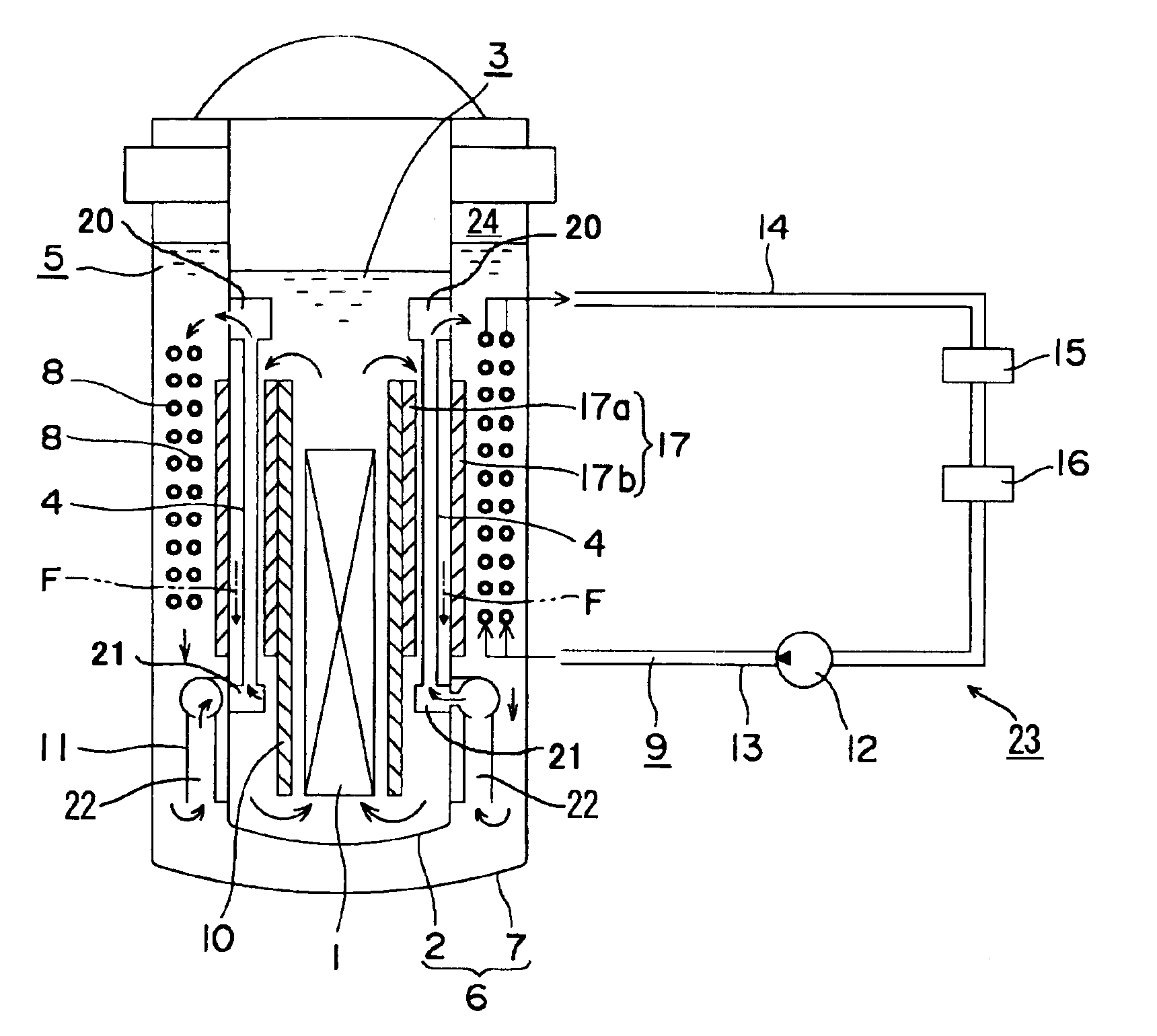

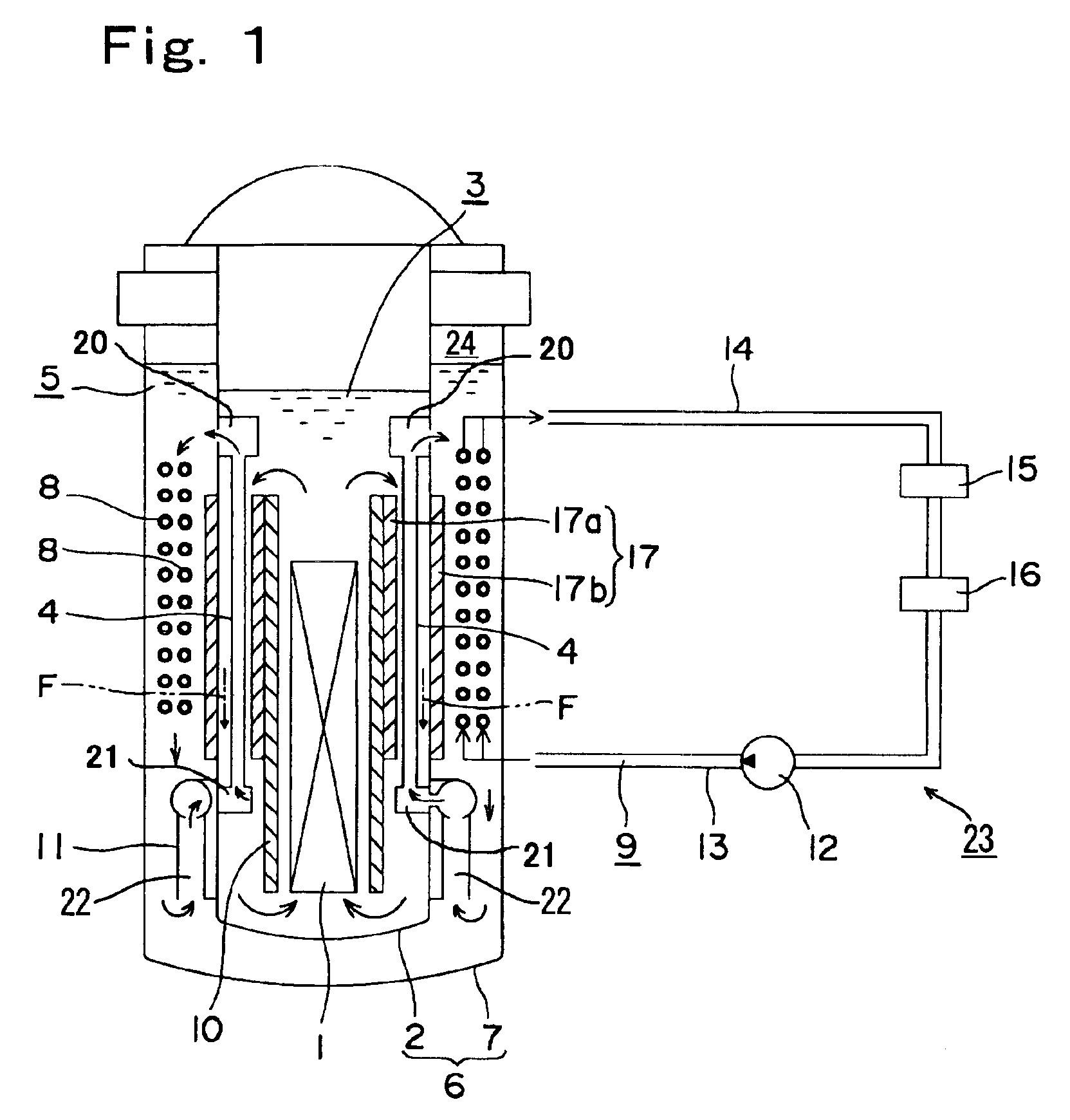

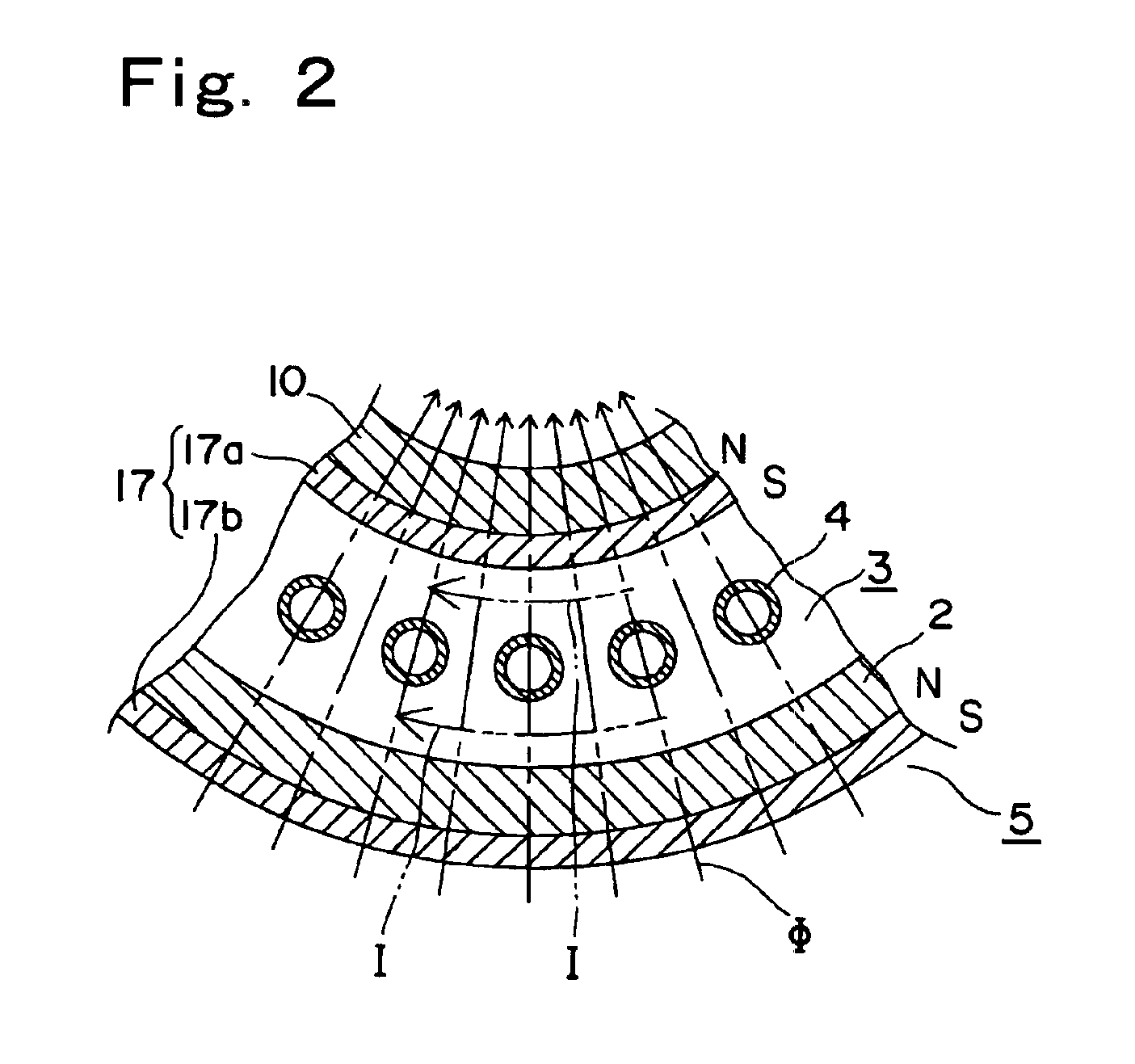

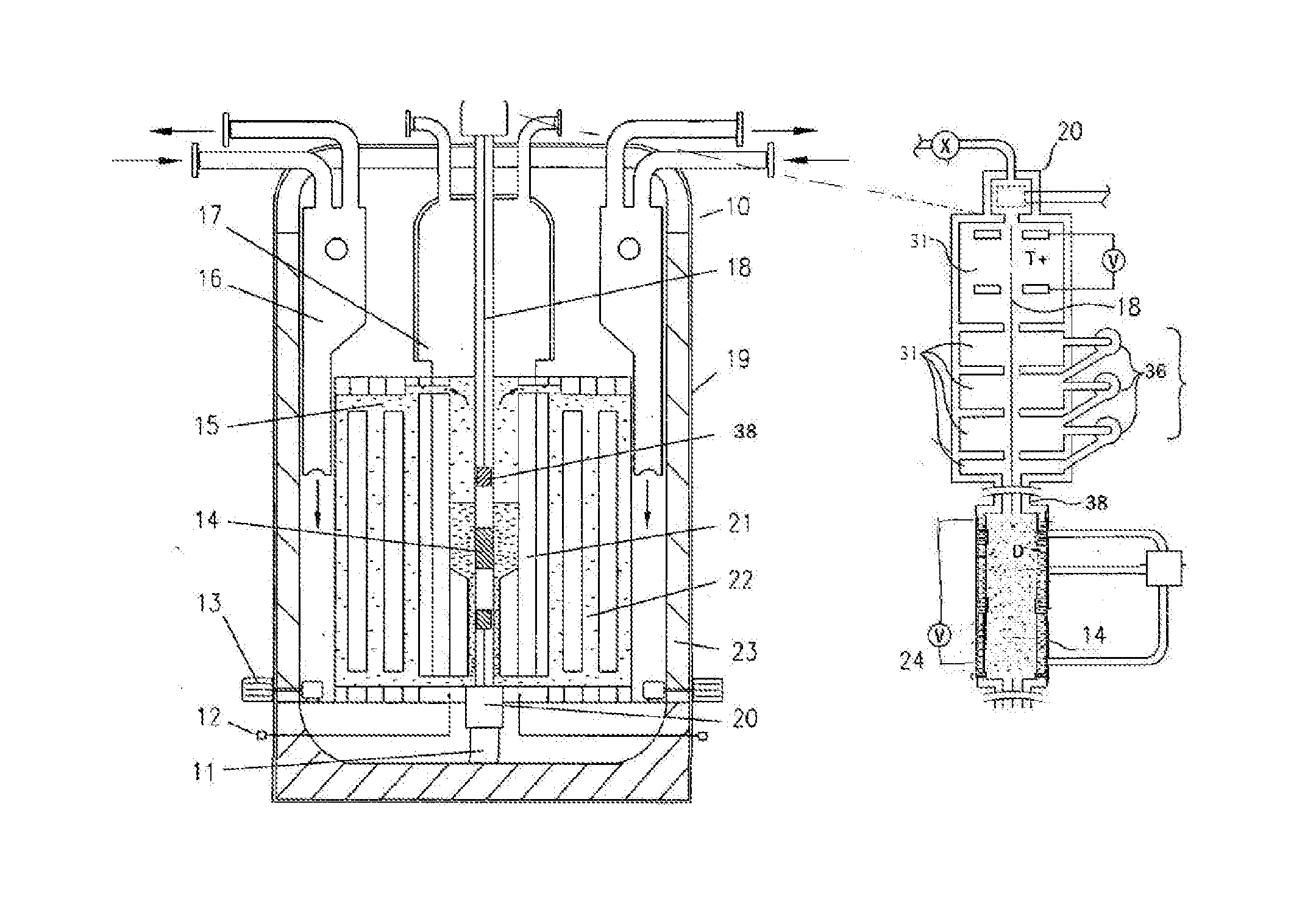

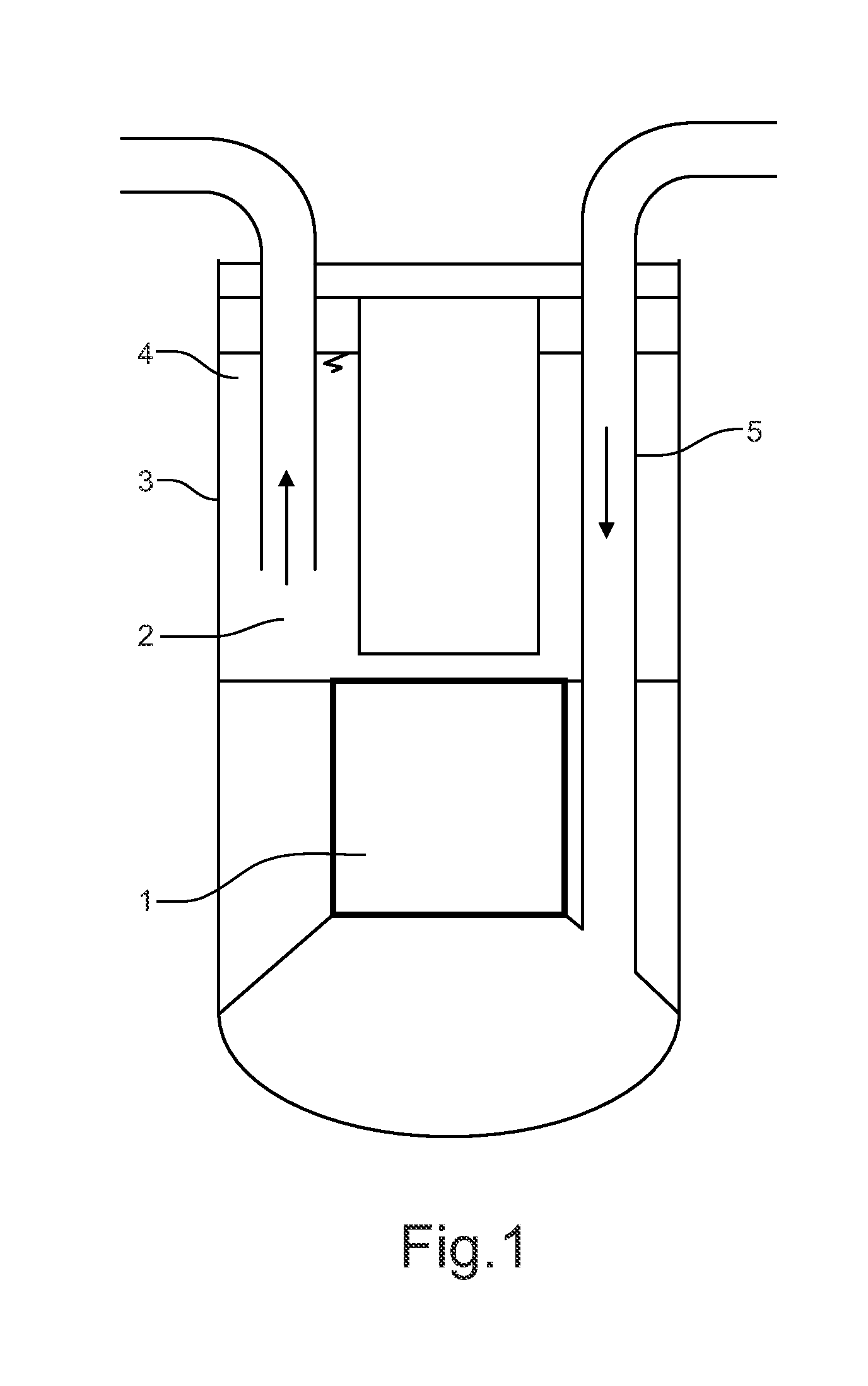

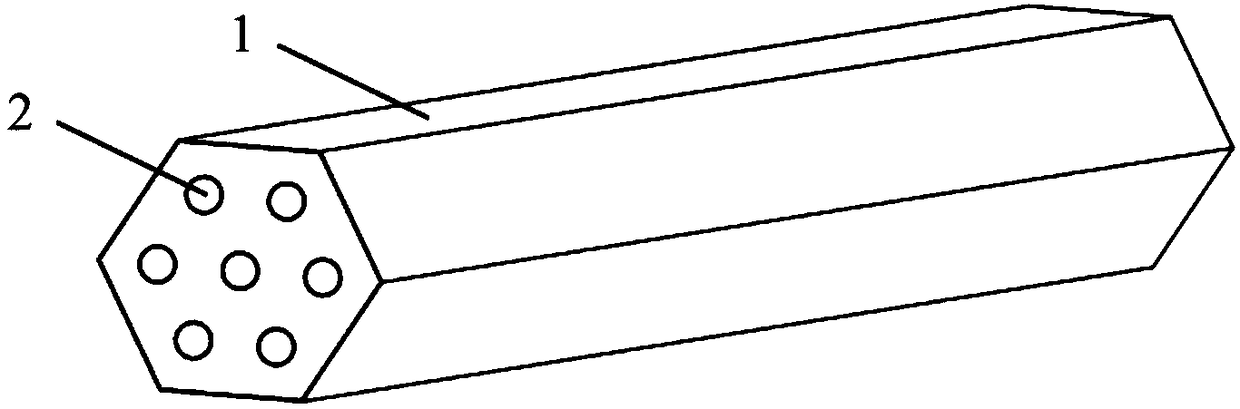

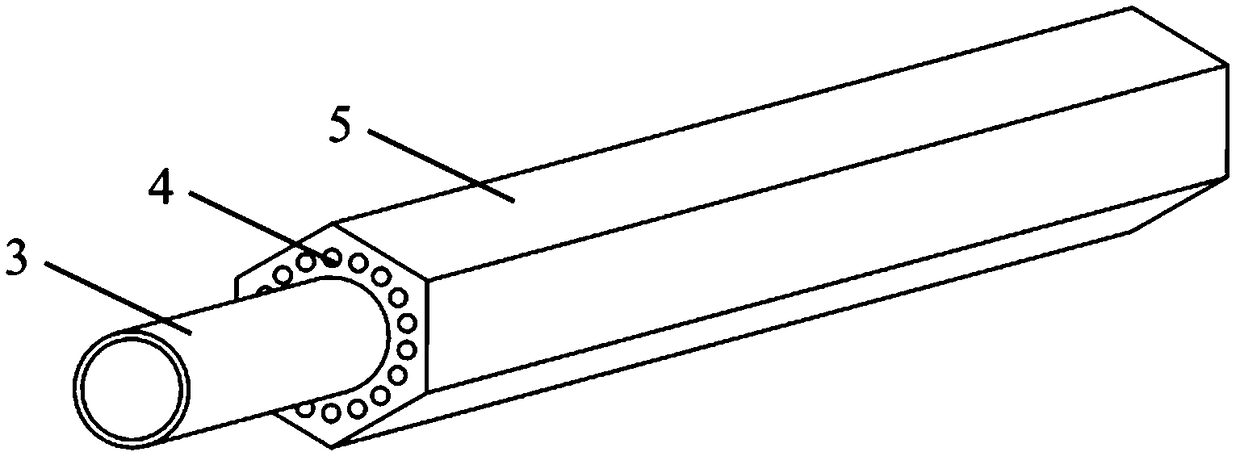

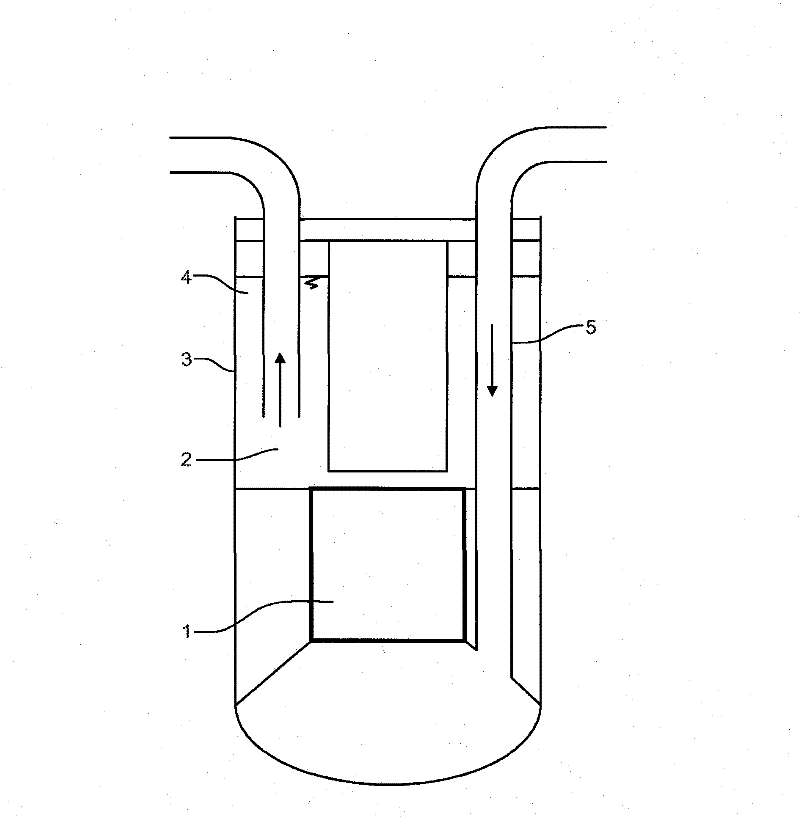

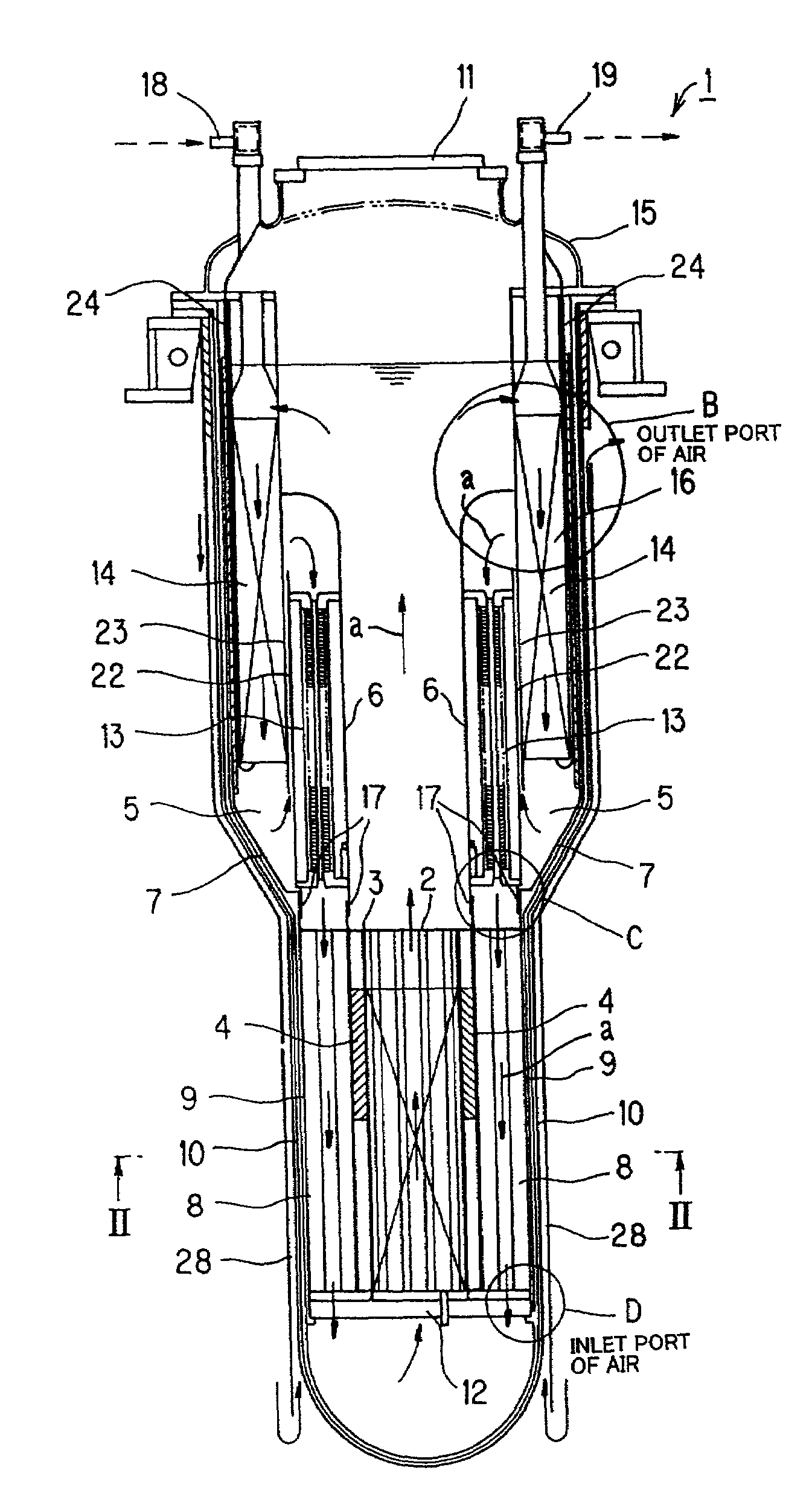

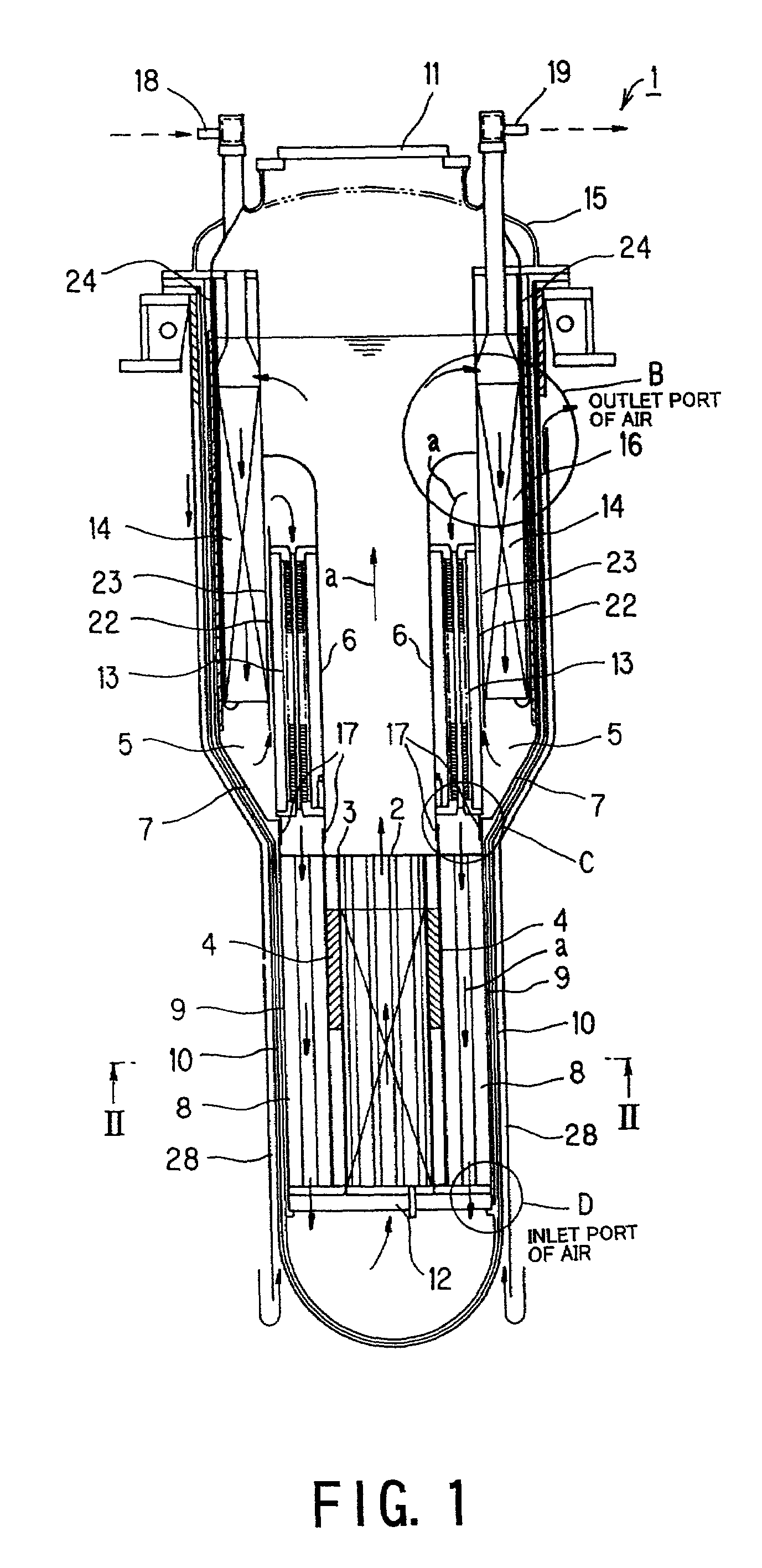

Nuclear reactor

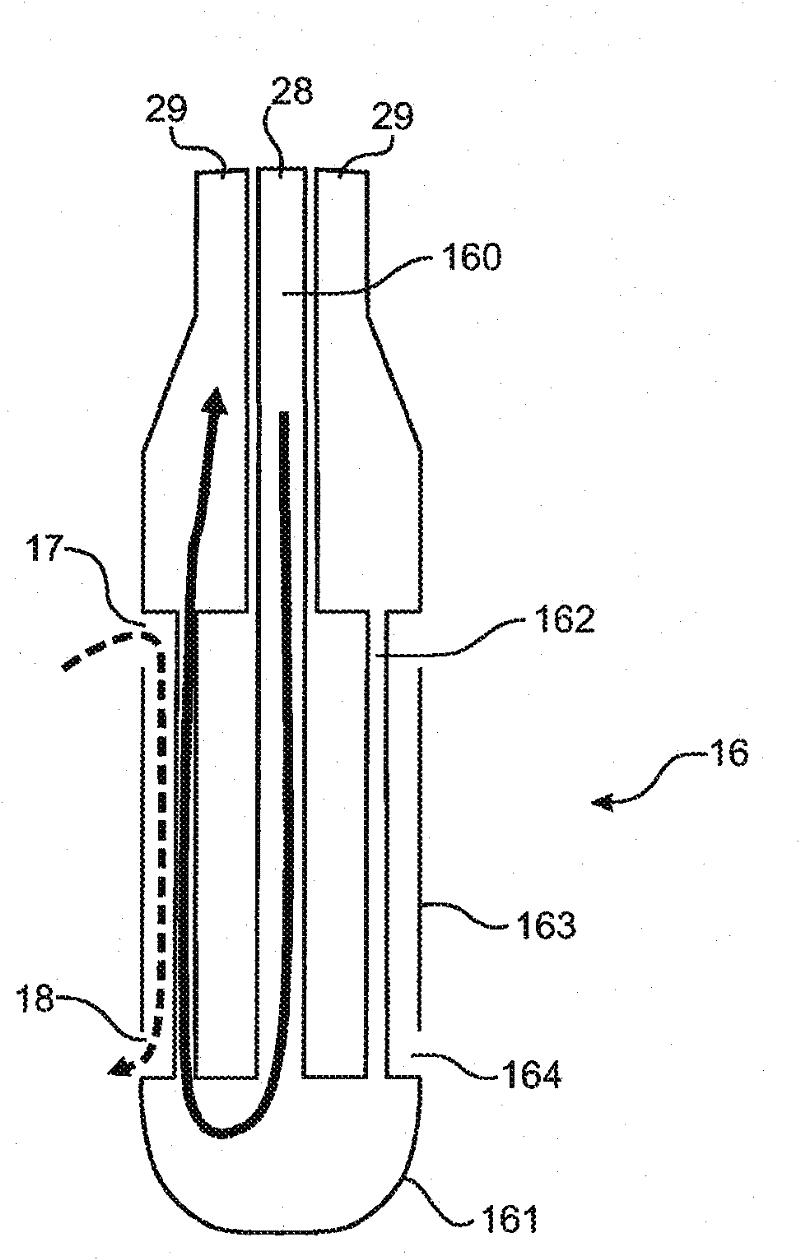

InactiveUS6944255B2Small sizeReduce manufacturing costIntegral reactorsNuclear energy generationNuclear reactorHeat transfer tube

A nuclear reactor in which a secondary or tertiary coolant system of a nuclear steam supply system is simplified, comprising: a reactor vessel (2) which integrates a reactor core (1); a first coolant (3) which is stored in the reactor vessel (2) and heated by the reactor core (1) to convect; a first heat transfer tube (4) which is arranged in the reactor vessel (2) and comes into contact with the first coolant (3); and a second coolant (5) which is supplied from the outside of the reactor vessel (2) to the first heat transfer tube (4), cools the first coolant (3) and led to the outside of the reactor vessel (2).

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

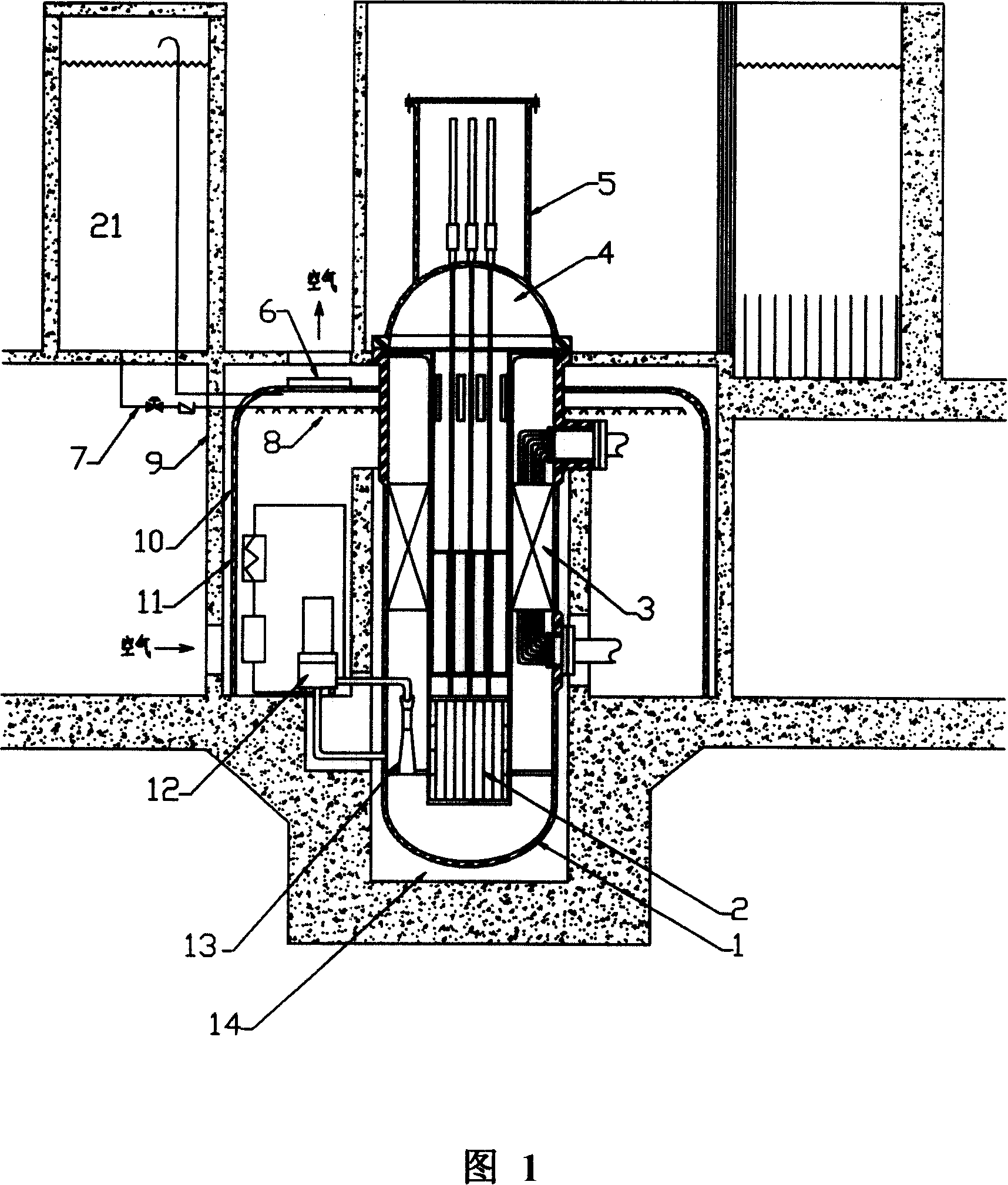

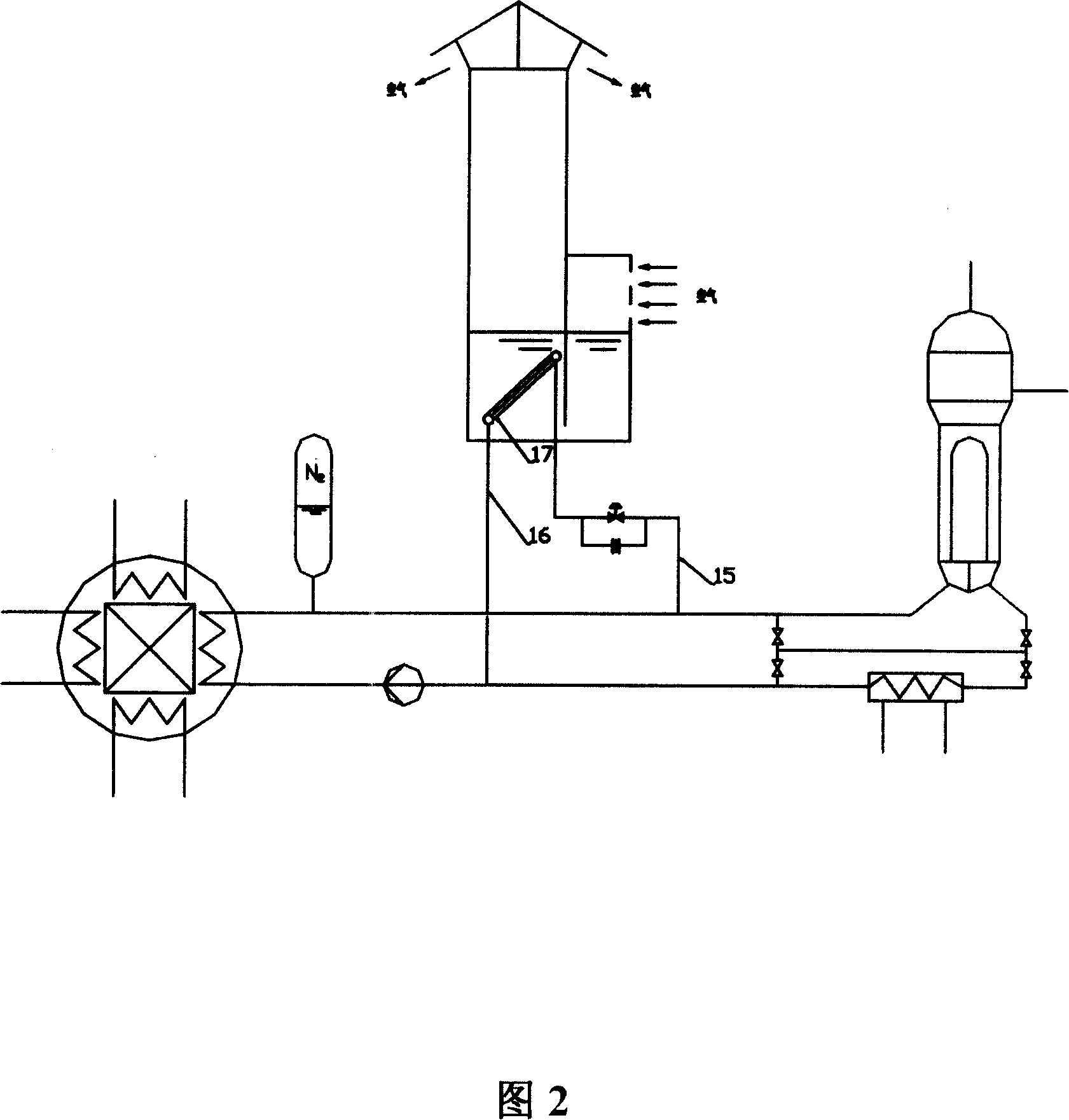

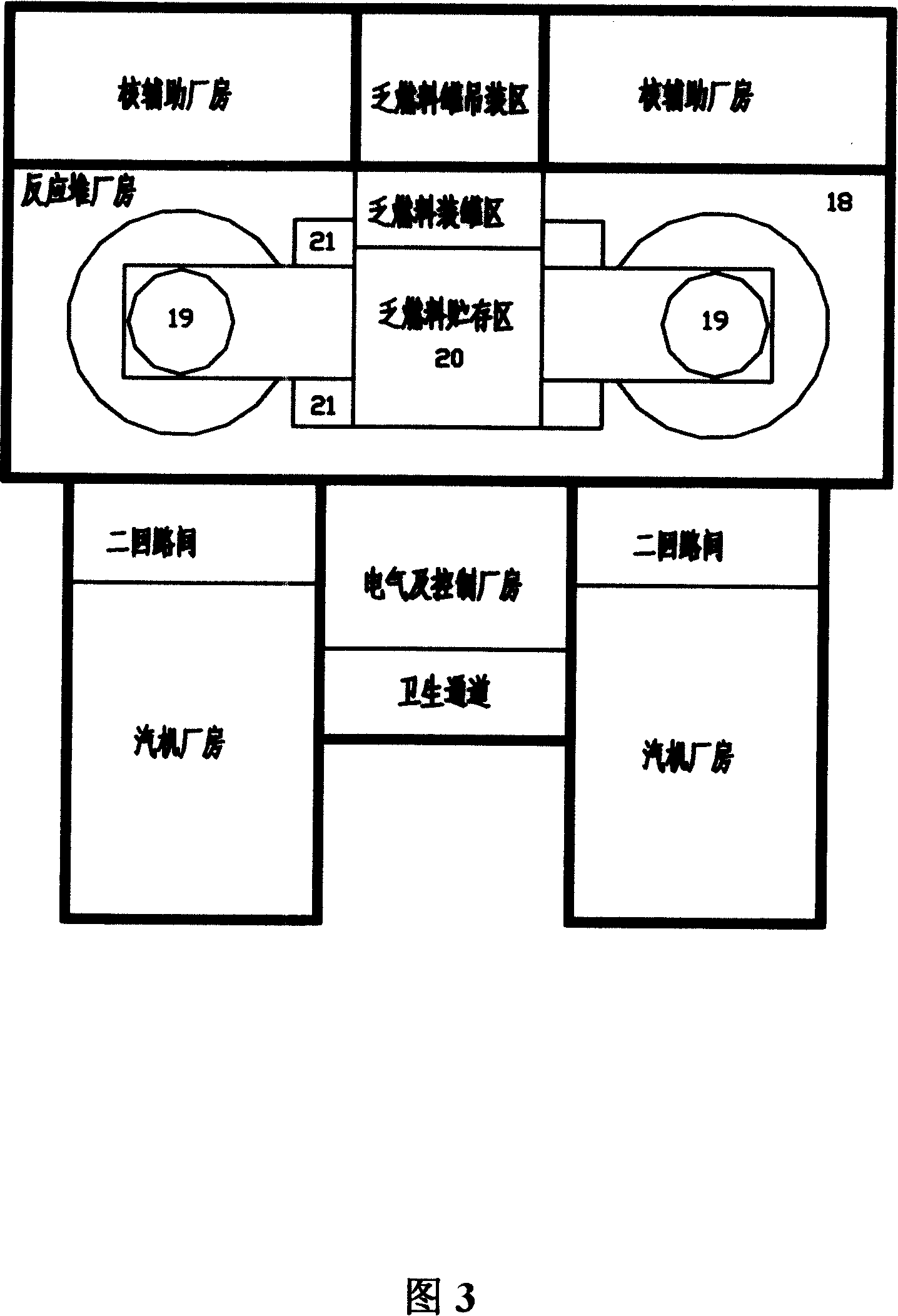

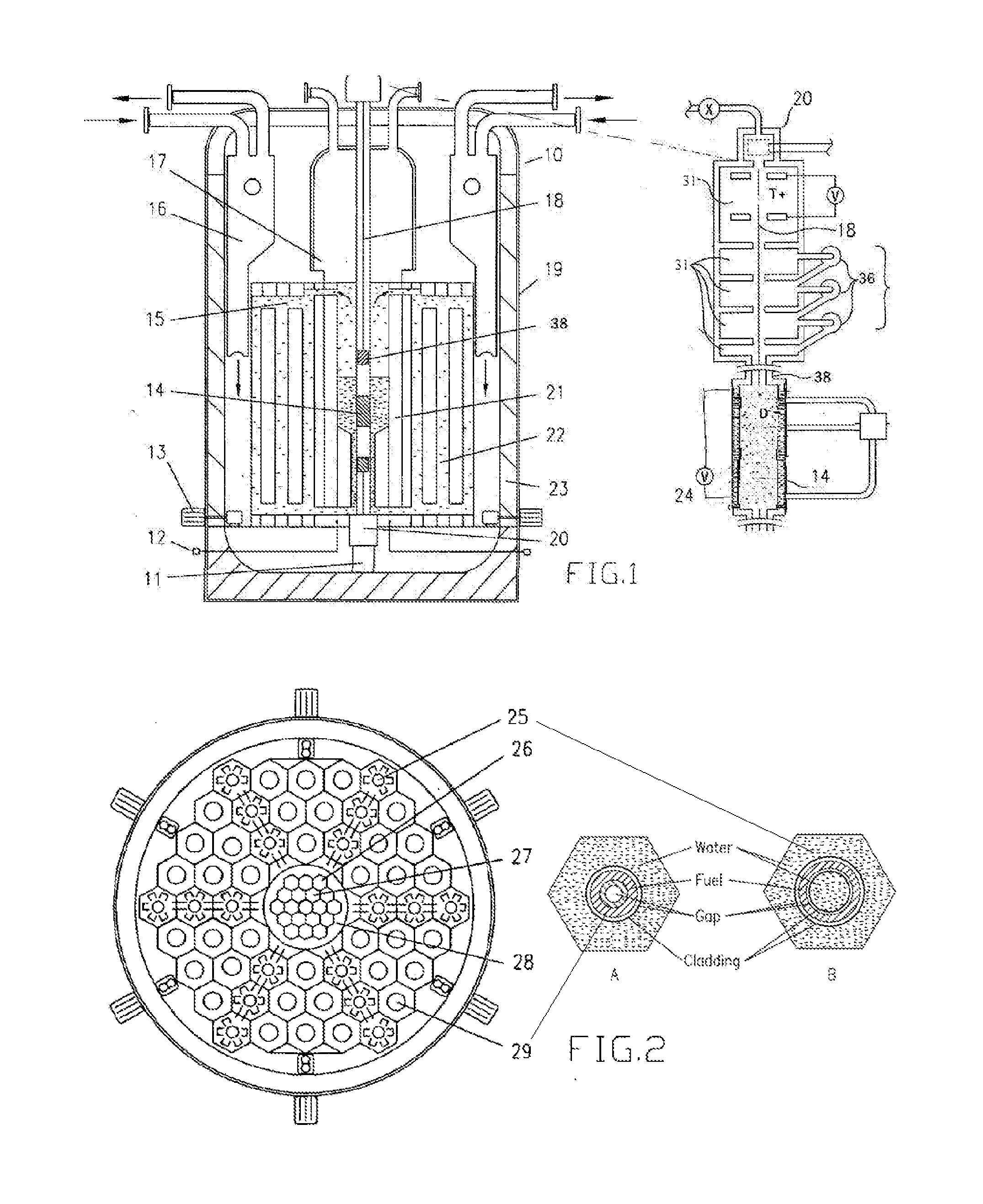

Integrated low-temperature nuclear heat supplying pile

ActiveCN101154472ASmall sizeCompact layoutIntegral reactorsNuclear energy generationReactor pressure vesselPressurized water reactor

The invention discloses an integral low-temperature nuclear heat reactor with the circuit equipment adopting integral arrangement and belonging to the low- and medium-parameter pressurized-water reactor, wherein, a reactor core adopts the mature nuclear power plant fuel component and control rod component; a main heat exchanger is of integral coil type; a voltage stabilizer is a built-in nitrogen partial pressure control voltage stabilizer; coolant circulation is completed by a built-in jet apparatus and the equipment of an external drive circuit; the drive circuit and the equipment and a main circuit auxiliary system are arranged at the circumference of a reactor pressure vessel; a containment vessel consists of a reactor body containment vessel and a reactor top containment vessel; the reactor body containment vessel which is a structure combined by a reactor vault of reinforced concrete structure and a casing of steel structure is connected with a sealed refueling water storage pool through a pipe and a valve. The thermal power of the reactor can be selected between 50MW and 500MW at will and the outlet temperature of the reactor can be selected between 100 DEG C to 200 DEG C according to application, requirement and power.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

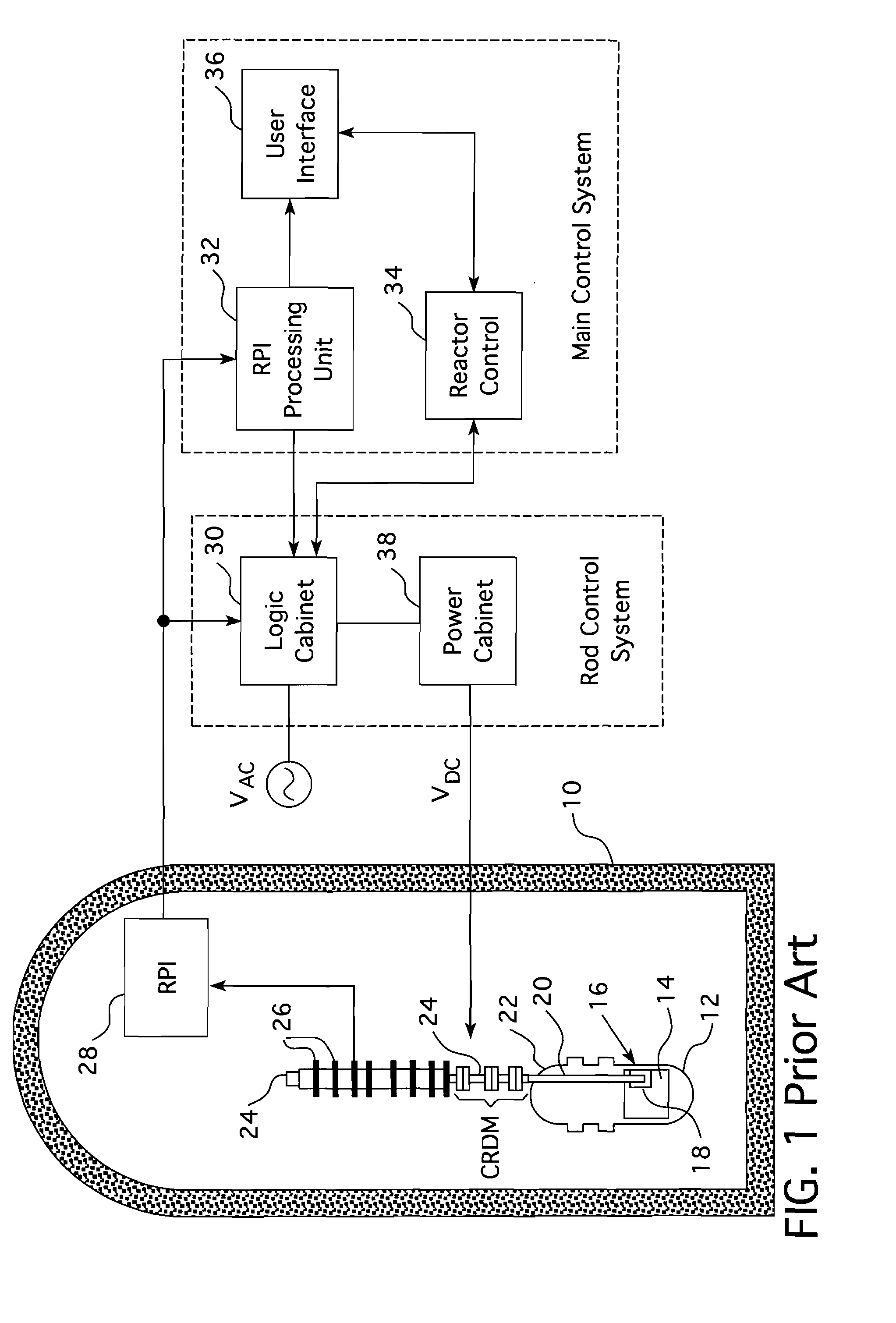

Instrumentation and control penetration flange for pressurized water reactor

A nuclear reactor having a penetration seal ring interposed between the reactor vessel flange and a mating flange on the reactor vessel head. Radial ports through the flange provide passage into the interior of the reactor vessel for utility conduits that can be used to convey signal cables, power cables or hydraulic lines to the components within the interior of the pressure vessel. A double o-ring seal is provided on both sides of the penetration flange and partial J-welds on the inside diameter of the flange between the flange and the utility conduits secure the pressure boundary.

Owner:WESTINGHOUSE ELECTRIC CORP

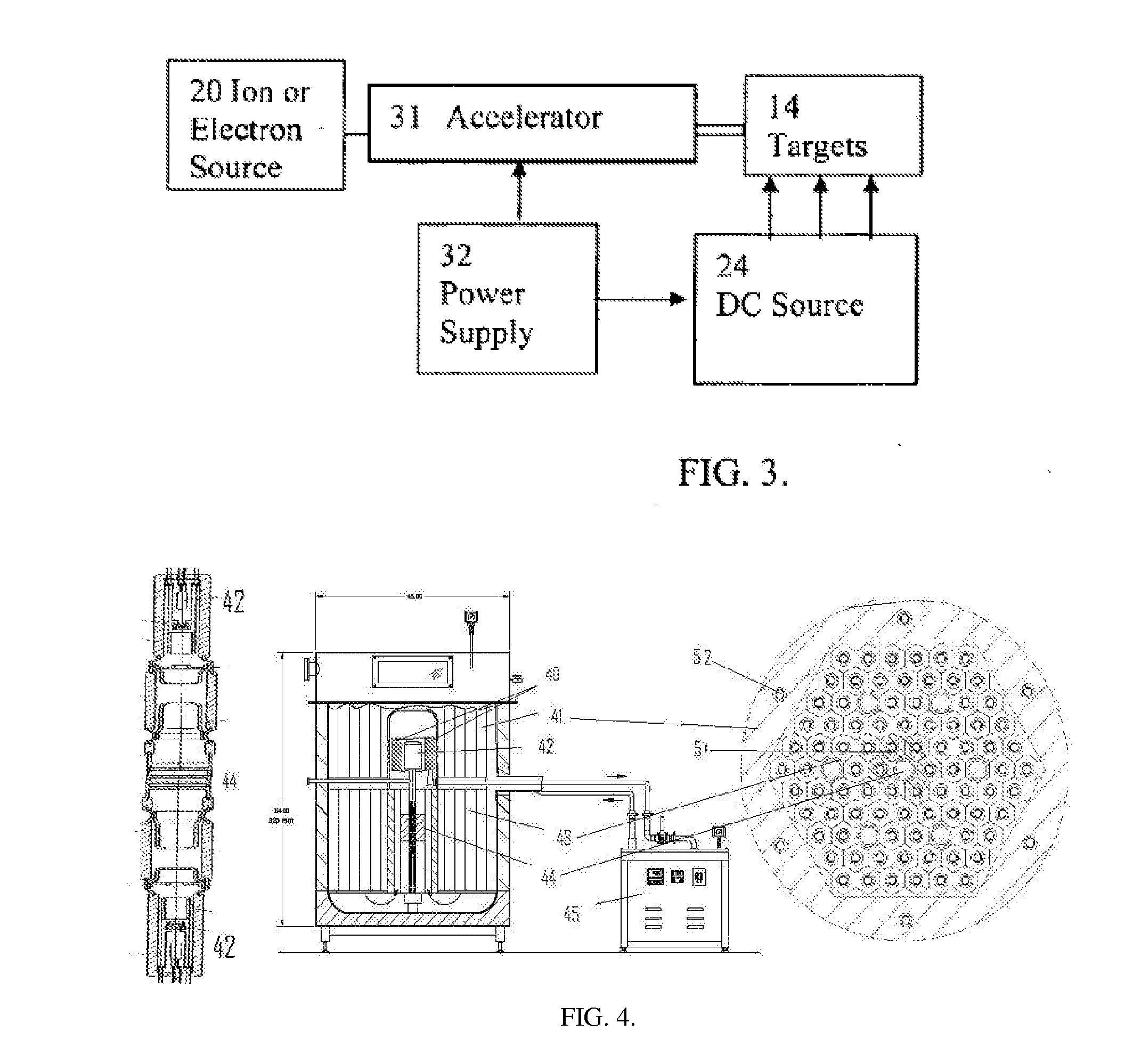

Sustainable Modular Transmutation Reactor

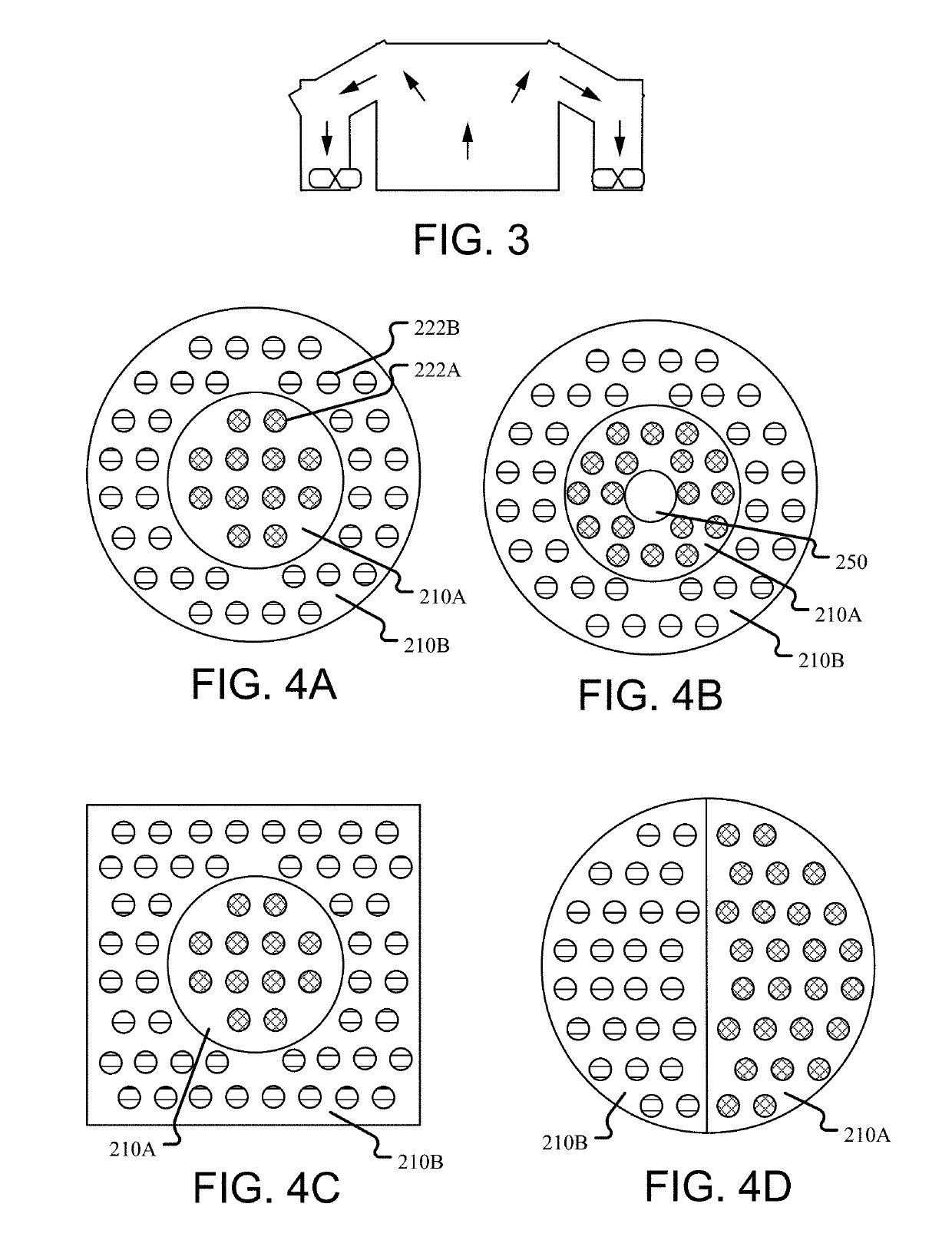

InactiveUS20150098544A1Improve distributionImprove economyIntegral reactorsConversion outside reactor/acceleratorsFission fusionDelayed neutron

A light water reactor to safely convert depleted uranium into a fuel source that could be used as a sustainable source of energy for centuries. The reactor is a type of breed-burn reactor uniquely combined with a proliferation-resistant fuel cycle with no uranium enrichment and no plutonium isolation. It is comprised of a compact factory-produced fast region and a thermal region that produces about 95% of the core power and contains the passageways for transports of delayed-neutron emitters to the fast region, where they can provide additional neutrons (source-based mode) or all the necessary excitation without an external neutron source (self-regulating mode). A second embodiment of the invention is a small unit driven by a neutron source with beam recycling for propulsion, electrical power or radioisotope production. It could also serve as a demonstration facility for the transmutation reactor with fission-fusion fuel.

Owner:BLANOVSKY ANATOLY

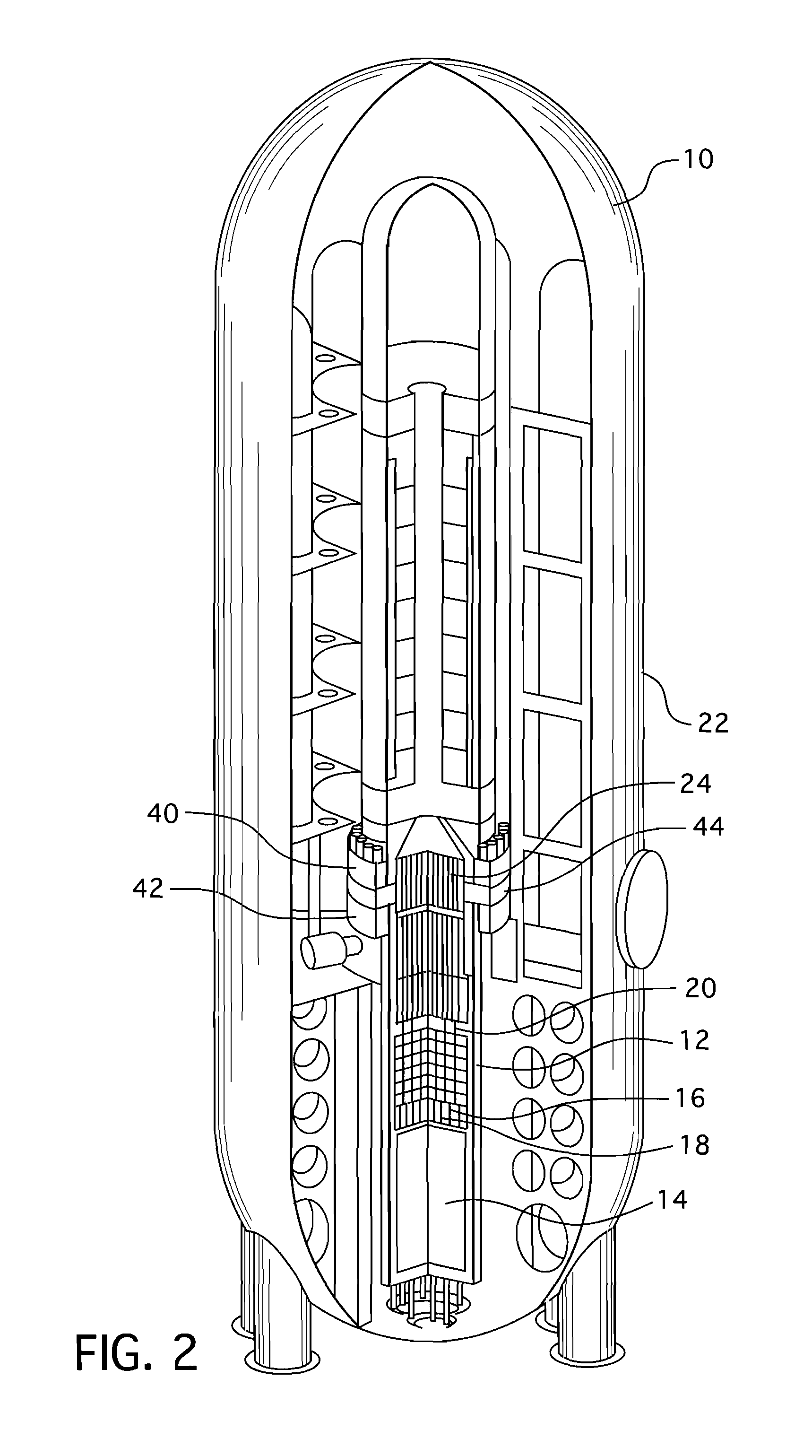

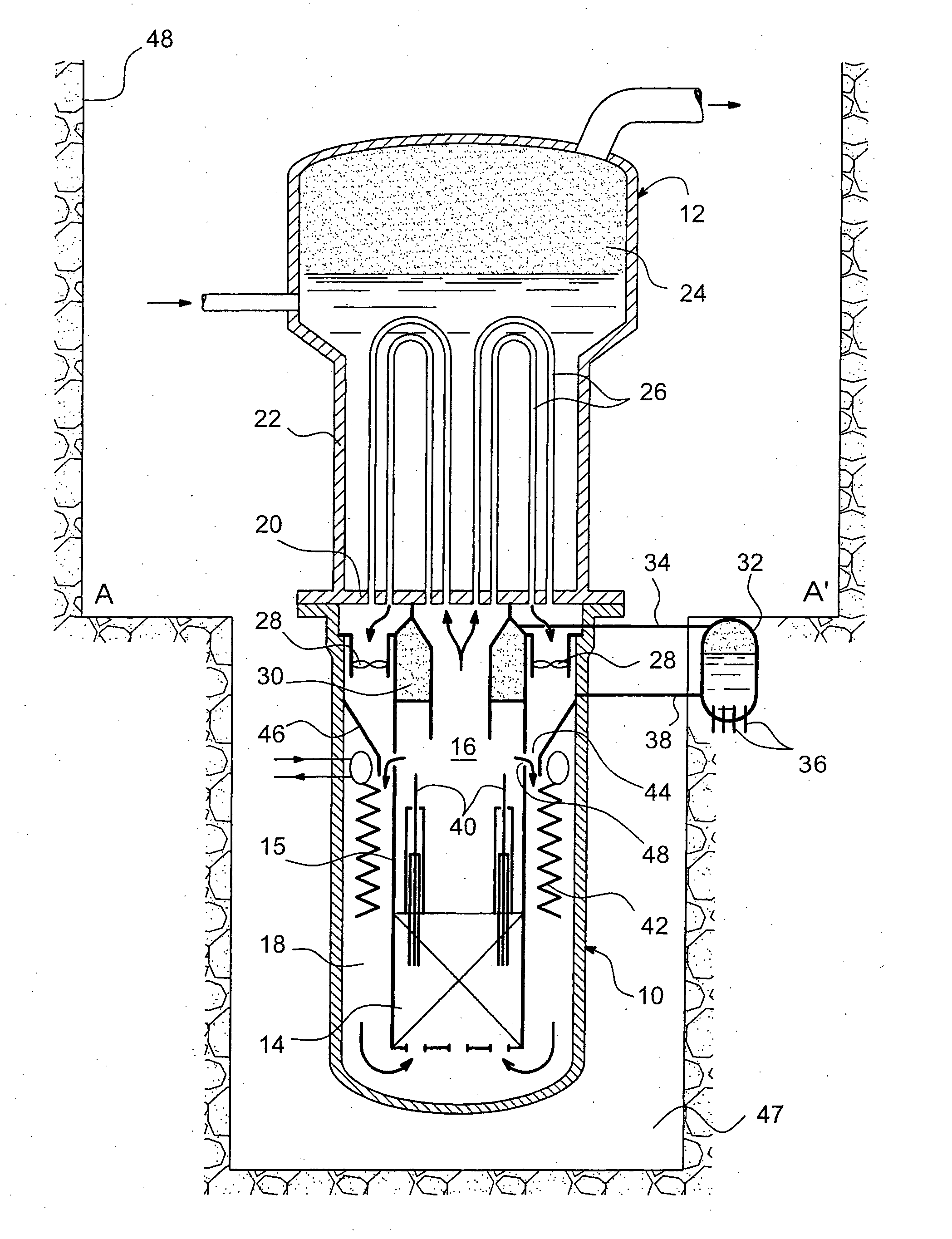

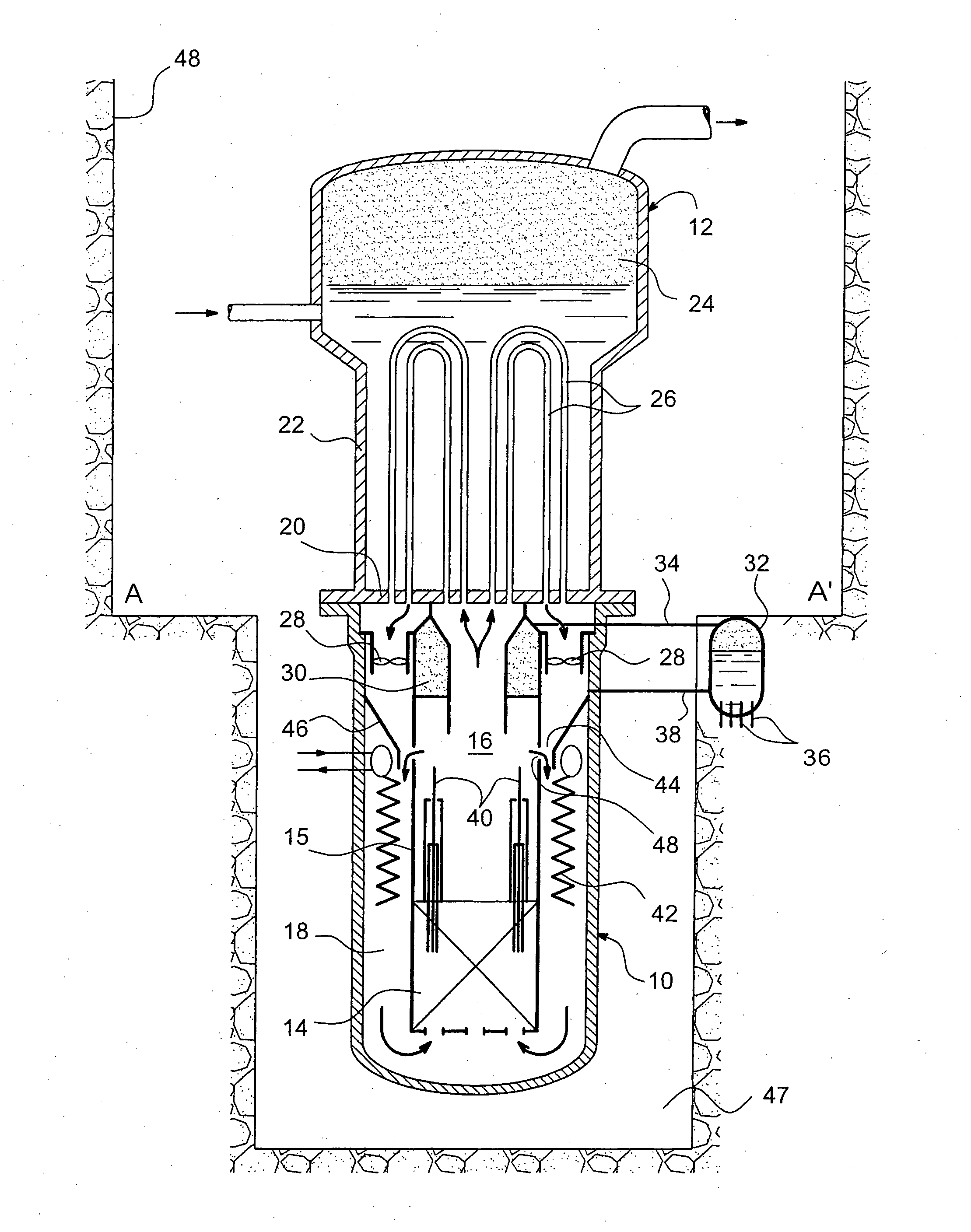

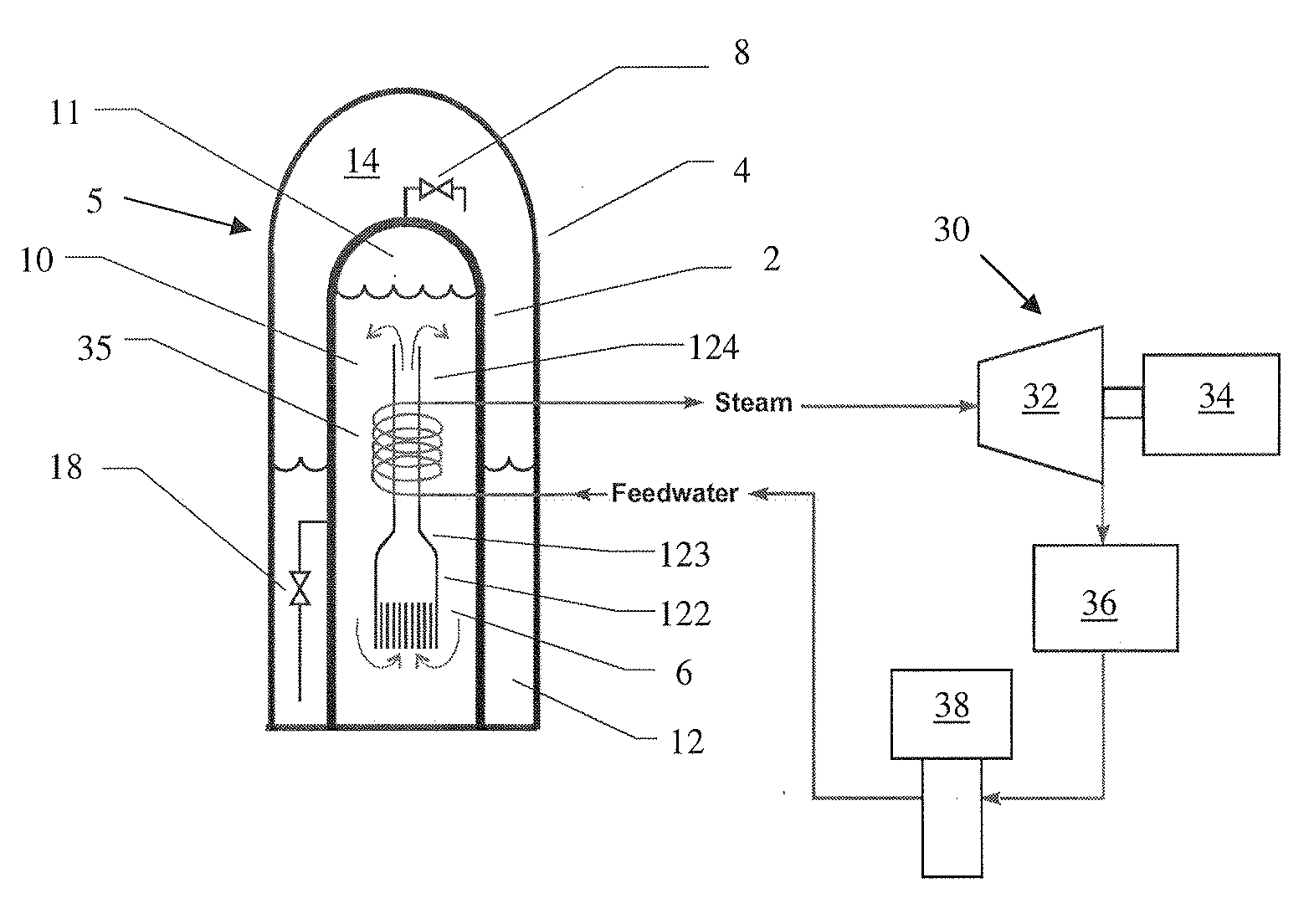

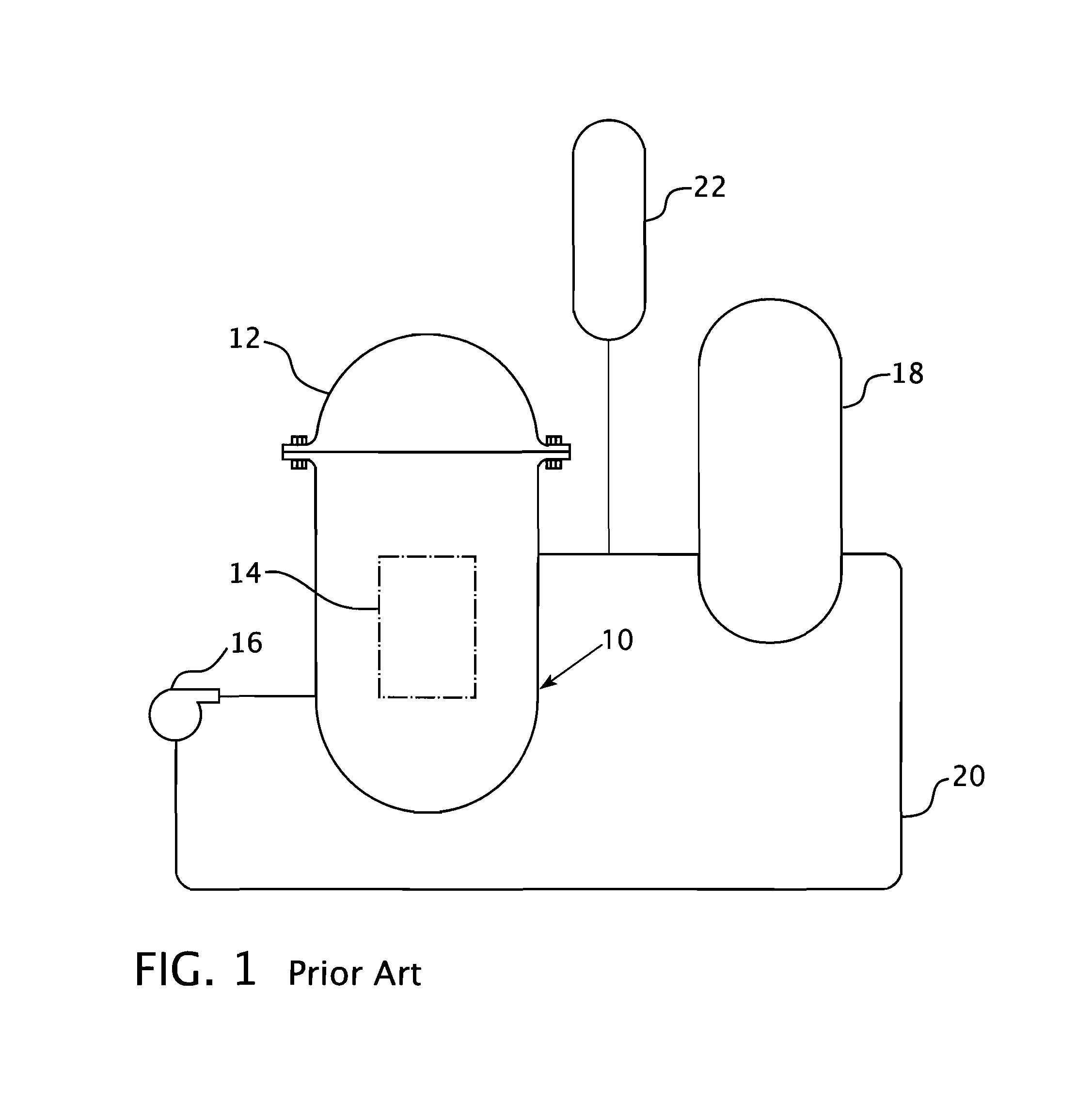

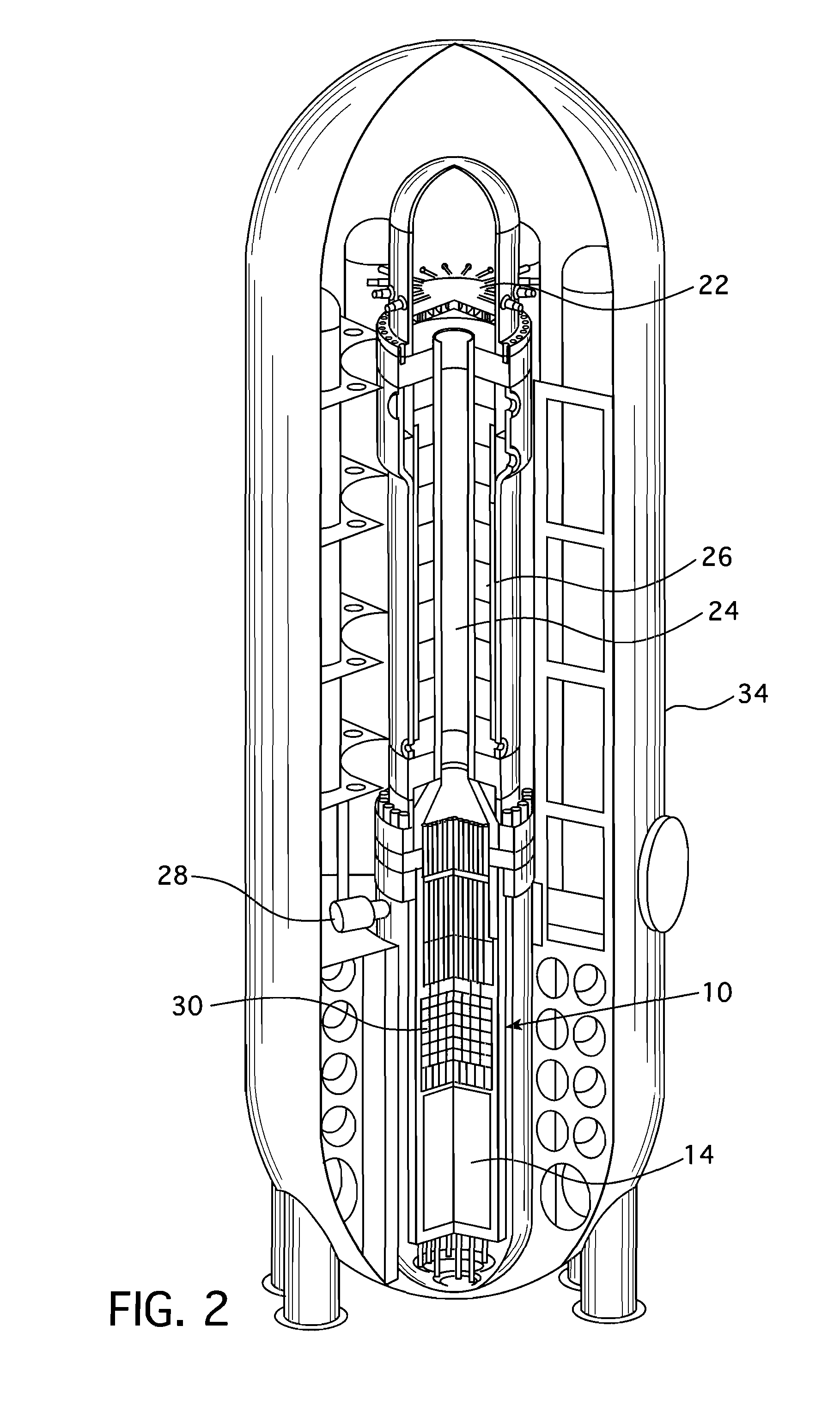

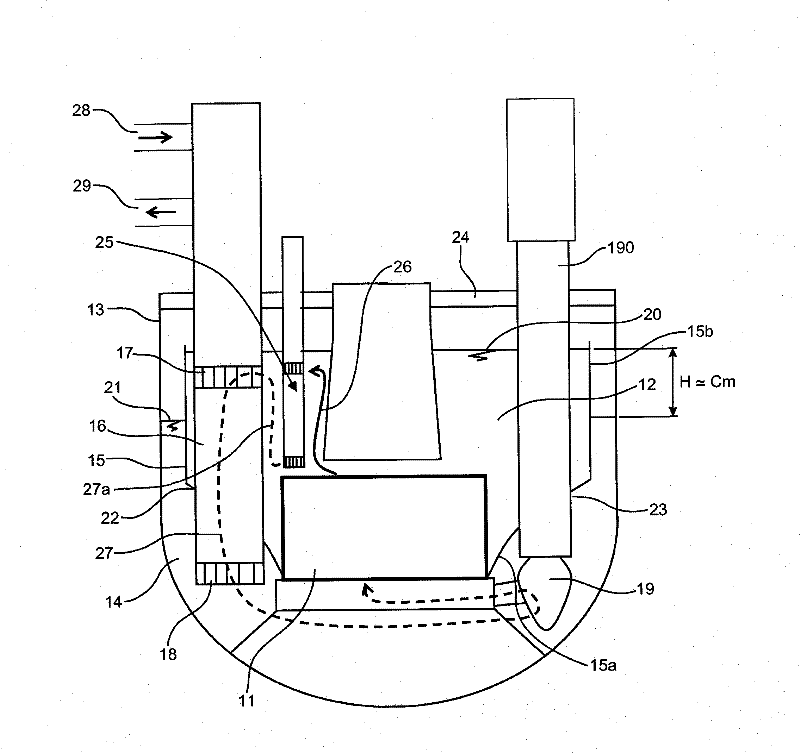

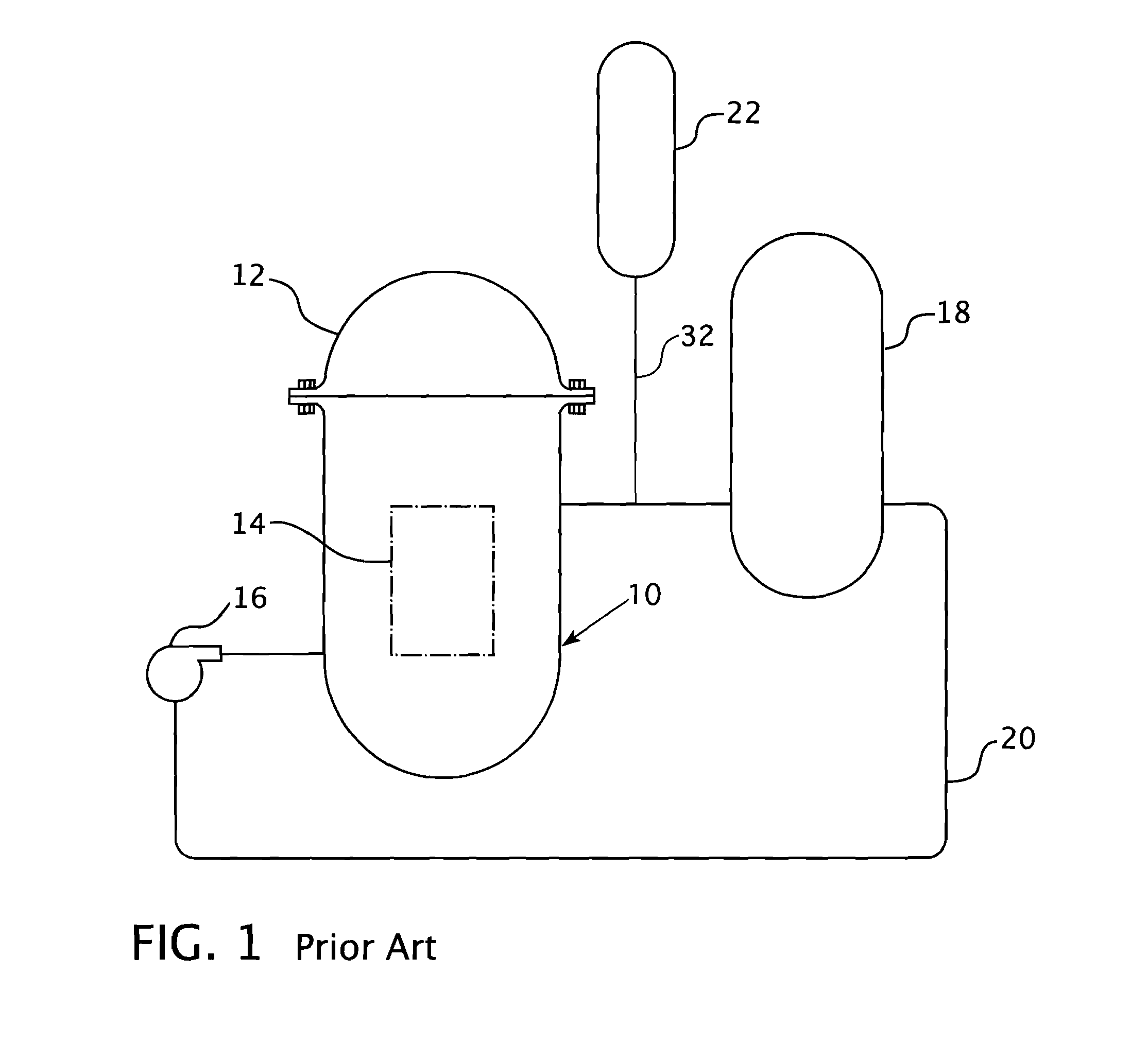

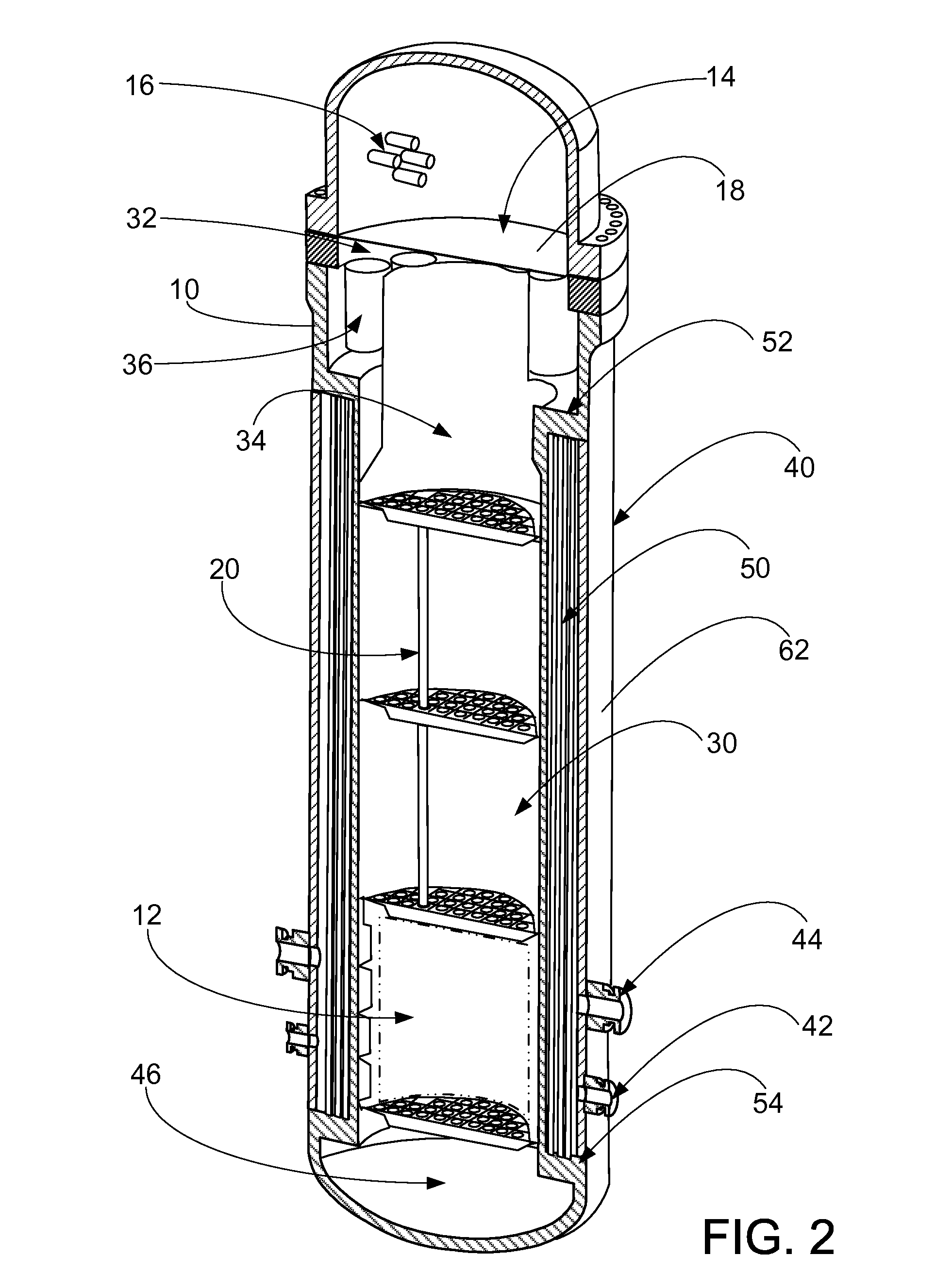

Compact pressurized water nuclear reactor

InactiveUS20050018806A1Low investment costEasy to buildIntegral reactorsNuclear energy generationNuclear reactorWater circulation

A compact pressurised water nuclear reactor comprises a primary circuit fully integrated into the reactor vessel (10). Thus, a single steam generator (12) forms the cover of the vessel (10) and the pressuriser (30) and the primary pumps (28) are housed in the vessel (10). The same is true for the control mechanisms of the control rods (40). Finally, a venturi system (44) is also provided in the vessel (10) to create water circulation if there is a failure of the primary pumps (28).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Emergency core cooling system for pressurized water reactor

ActiveUS20120243651A1Power plant safety arrangementIntegral reactorsCondensed waterPressurized water reactor

A pressurized water nuclear reactor (PWR) has an internal pressurizer volume containing a steam bubble and is surrounded by a containment structure. A condenser is disposed inside the containment structure and is operatively connected with an external heat sink disposed outside of the containment structure. A valve assembly operatively connects the PWR with the condenser responsive to an abnormal operation signal such that the condenser condenses steam from the steam bubble while rejecting heat to the external heat sink and returns the condensed water to the PWR. A quench tank contains water with dissolved neutron poison. A valved tank pressurizing path selectively connects the steam bubble to the quench tank to pressurize the quench tank, and a valved soluble poison delivery path selectively connects the quench tank to the PWR such that the quench tank under pressure from the steam bubble discharges water with dissolved neutron poison into the PWR.

Owner:BWXT MPOWER INC

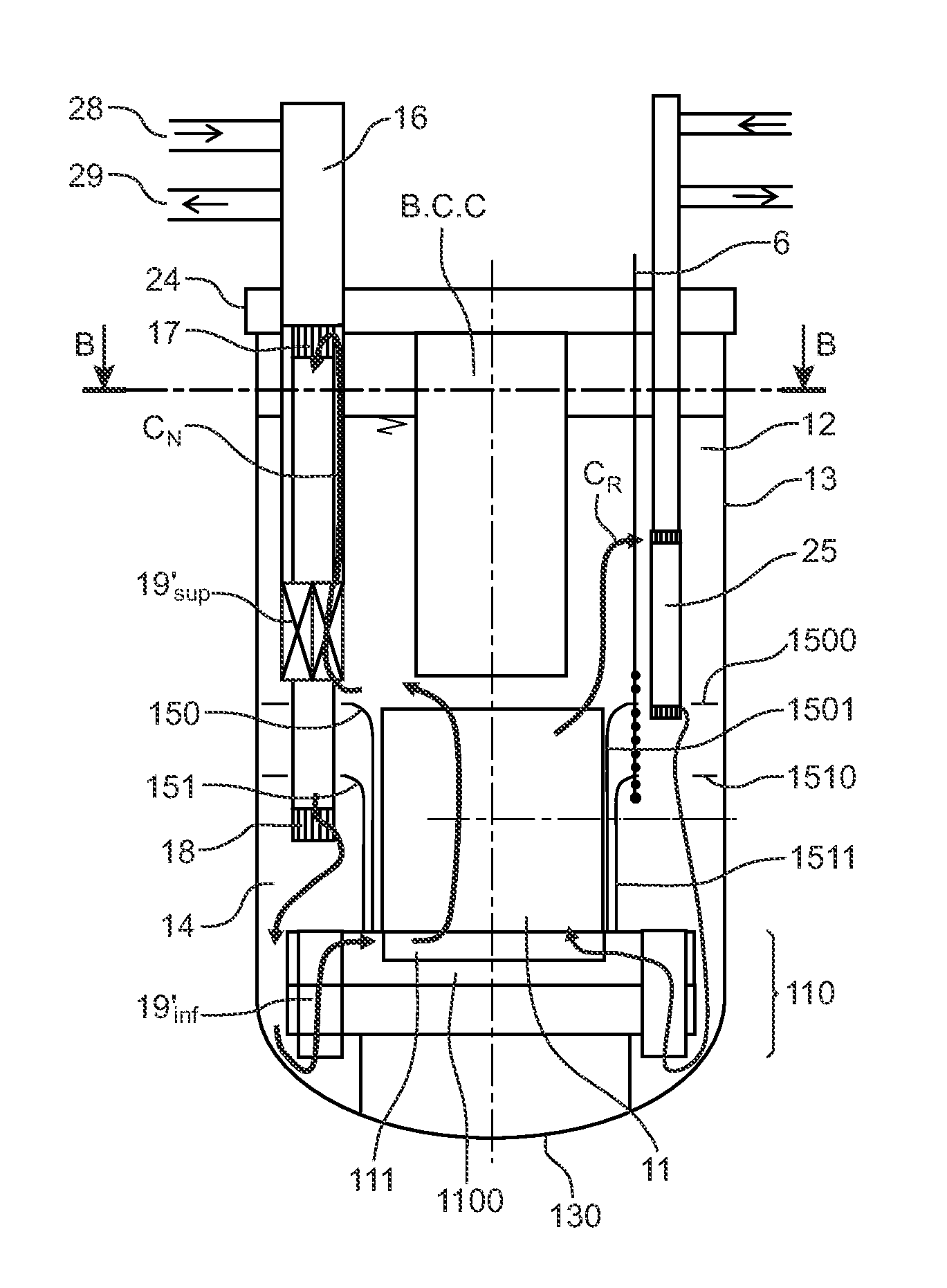

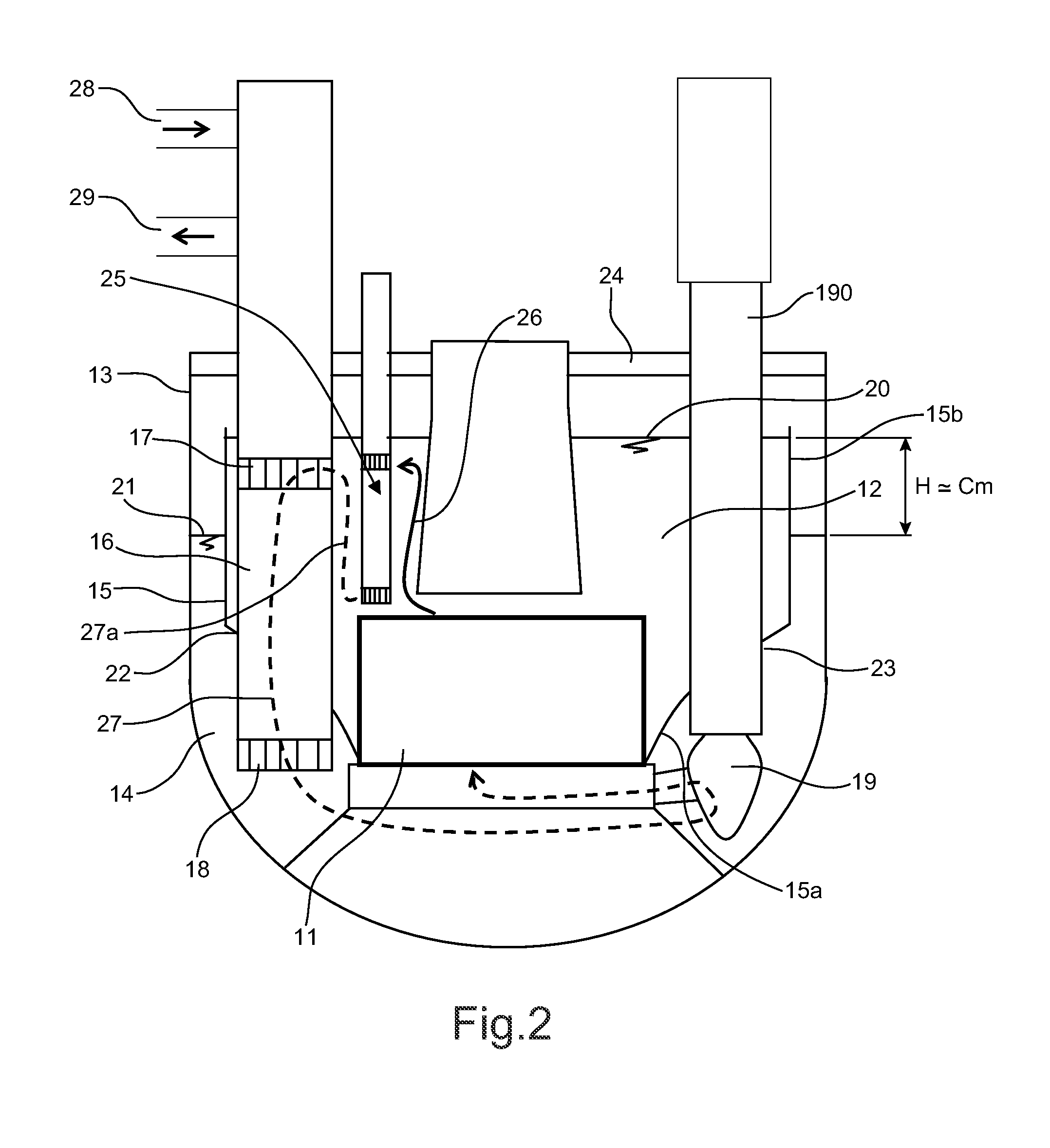

Sfr nuclear reactor of the integrated type with improved compactness and convection

The invention relates to a novel architecture for a nuclear reactor of the integrated type.The invention comprises:realising the hot area and cold area separation device for the primary sodium flow in the form of two walls with cuts,providing two pumping groups hydraulically in series, one for the flow of sodium from the hot area to the cold area through the intermediate exchangers and the other in the cold area;providing outlet windows of the intermediate exchangers below the lower wall;providing outlet windows of the removal exchangers of the decay heat above the cold area, wherein all of clearances between the walls with cuts and the heat removal exchangers and the height between the two walls with cuts are previously determined so as to, during normal operation, take up differential movements between the walls, exchangers and vessel and to make it possible to establish during normal operation a thermal stratification of the primary sodium in the space defined between the horizontal portions of the two walls and so as to reduce, in case of an unexpected stop of a single pumping group, the mechanical stress applied to the walls and due to the portion of the primary sodium flow passing between said clearances.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

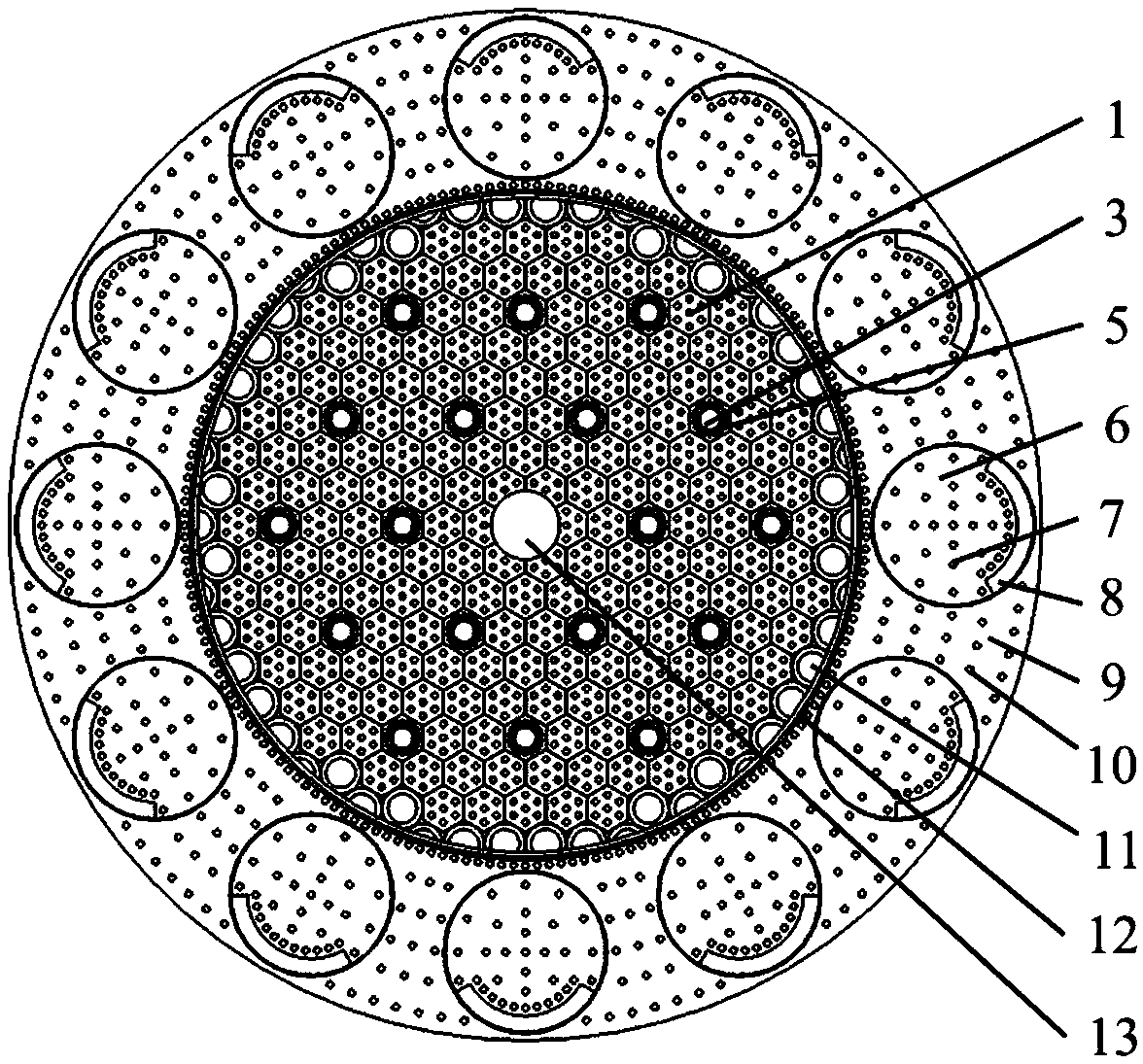

Heating pipe-type dual-mode space nuclear reactor core

PendingCN109192329AAvoid damageReduce complexityIntegral reactorsNuclear energy generationNuclear reactor coreNuclear reactor

The invention belongs to the technical field of nuclear reactors and discloses a heating pipe-type dual-mode space nuclear reactor core. The reactor core comprises a reactor core active zone, a reactor core cylinder, a radial reflection layer, an axial reflection layer and a control drum. The reactor core active zone is located in the reactor core cylinder. The axial reflection layer is located above the reactor core active zone. The axial reflection layer is a hollow cylindrical structure. The reactor core active zone, the axial reflection layer and a heating pipe are located in the cavity ofthe radial reflection layer. The reactor core can effectively prevent the heat pipe overheating and has the beneficial effects of safety and reliability such as passive and non-single point failure.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

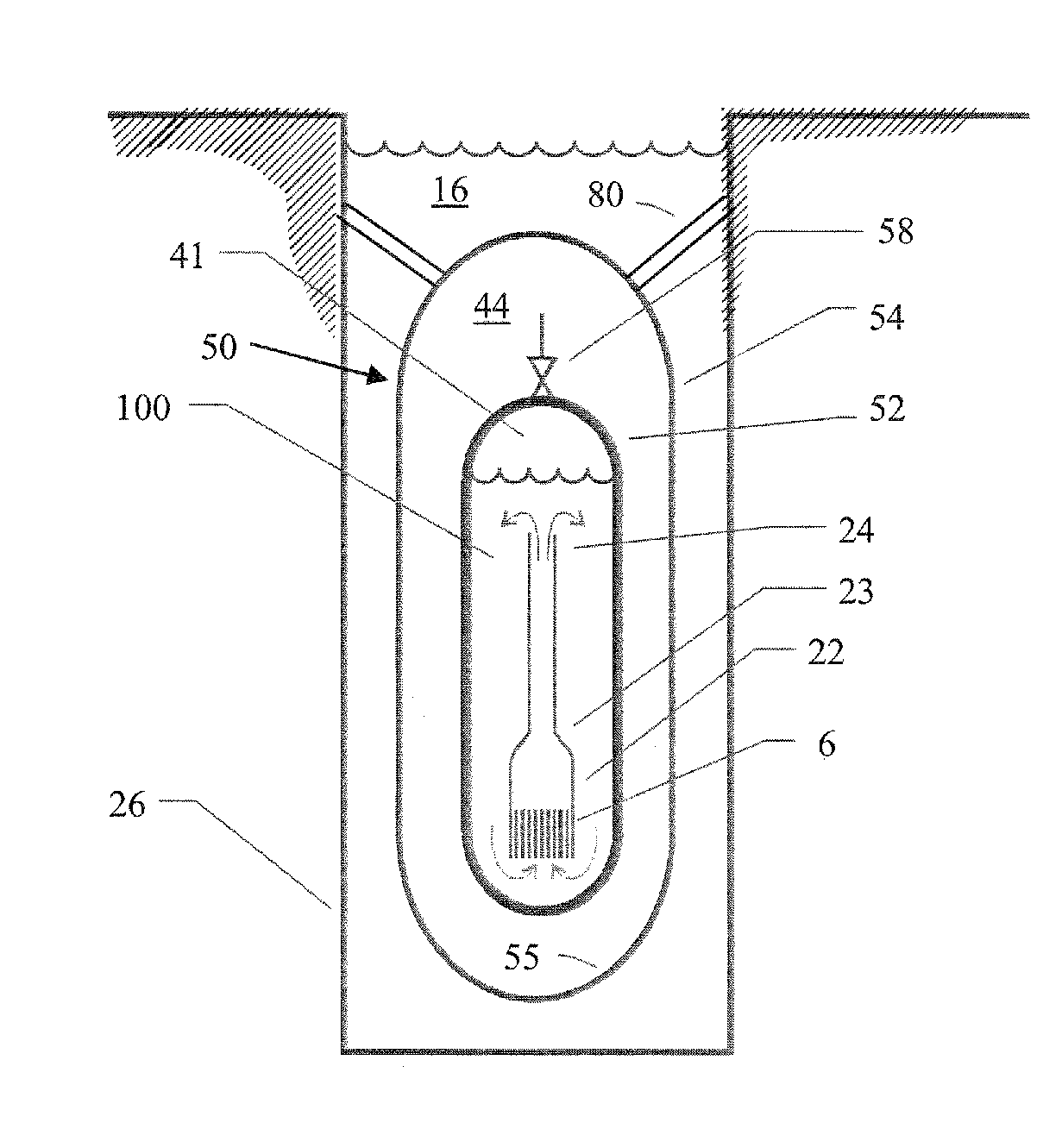

Internal dry containment vessel for a nuclear reactor

A power module assembly includes a reactor core immersed in a coolant and a reactor vessel housing the coolant and the reactor core. An internal dry containment vessel submerged in liquid substantially surrounds the reactor vessel in a gaseous environment. During an over-pressurization event the reactor vessel is configured to release the coolant into the containment vessel and remove a decay heat of the reactor core through condensation of the coolant on an inner surface of the containment vessel.

Owner:NUSCALE

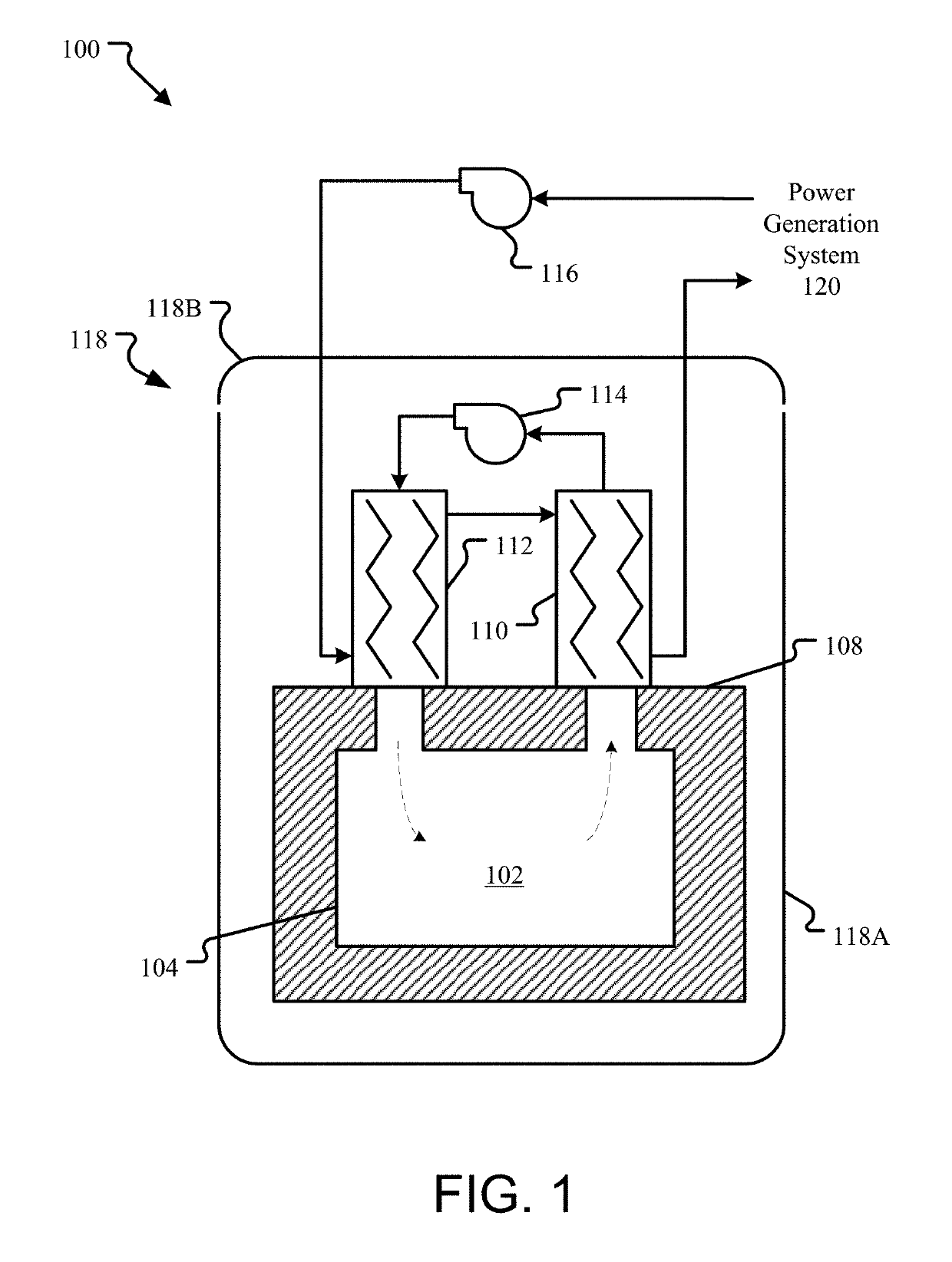

Steam generator flow by-pass system

A nuclear reactor module includes a reactor vessel and a reactor housing mounted inside the reactor vessel, wherein the reactor housing comprises a shroud and a riser located above the shroud. The nuclear reactor module further includes a heat exchanger proximately located about the riser, and a reactor core located in the shroud. A steam generator by-pass system is configured to provide an auxiliary flow path of primary coolant to the reactor core to augment a primary flow path of the primary coolant out of the riser and into the shroud, wherein the auxiliary flow path of primary coolant exits the reactor housing without passing by the heat exchanger.

Owner:NUSCALE

Pressurized water reactor compact steam generator

ActiveUS20130336442A1Facilitate natural recirculation of recirculatingBoiler drums/headersIntegral reactorsPressurized water reactorSteam drum

A steam generator system for a pressurized water reactor which employs an external to containment steam drum and recirculation loop piping. The steam generator system changes the arrangement of a typical pressurized water reactor recirculation steam generator by relocating the functions of steam separation and feedwater preheating outside of the reactor coolant system. The steam generator system and thermal hydraulic conditions are selected in order to minimize the size of the steam generator heat exchanger component volume inside of the containment. The external steam drum component can be isolated in accident conditions when desired and is used as a source of secondary fluid inventory for improved decay heat removal capability and tolerance for loss of feedwater events. Thus, the steam generator component volume inside of the containment is reduced and the amount of maintenance required for the reactor coolant system components are similarly reduced.

Owner:WESTINGHOUSE ELECTRIC CORP

Compact pressurized water nuclear reactor

A compact pressurised water nuclear reactor comprises a primary circuit fully integrated into the reactor vessel (10). Thus, a single steam generator (12) forms the cover of the vessel (10) and the pressuriser (30) and the primary pumps (28) are housed in the vessel (10). The same is true for the control mechanisms of the control rods (40). Finally, a venturi system (44) is also provided in the vessel (10) to create water circulation if there is a failure of the primary pumps (28).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Passive emergency feedwater system

A power module assembly includes a reactor vessel containing a reactor core surrounded by a primary coolant. A containment vessel is adapted to be submerged in a containment cooling pool and to prohibit a release of the primary coolant outside of the containment vessel. A secondary cooling system is configured to remove heat generated by the reactor core. The heat is removed by circulating liquid from the containment cooling pool through the primary coolant.

Owner:NUSCALE LLC

Integrated sfr nuclear reactor with enhanced convective operation

InactiveCN102282625ASuitable for operationSmall diameterIntegral reactorsNuclear energy generationNuclear reactorHot zone

The invention relates to a novel architecture for a nuclear reactor of the integrated type. The invention comprises: realising the hot area and cold area separation device for the primary sodium flow in the form of two walls with cuts, providing two pumping groups hydraulically in series, one for the flow of sodium from the hot area to the cold area through the intermediate exchangers and the other in the cold area; providing outlet windows of the intermediate exchangers below the lower wall; providing outlet windows of the removal exchangers of the decay heat above the cold area, wherein all of clearances between the walls with cuts and the heat removal exchangers and the height between the two walls with cuts are previously determined so as to, during normal operation, take up differential movements between the walls, exchangers and vessel and to make it possible to establish during normal operation a thermal stratification of the primary sodium in the space defined between the horizontal portions of the two walls and so as to reduce, in case of an unexpected stop of a single pumping group, the mechanical stress applied to the walls and due to the portion of the primary sodium flow passing between said clearances.

Owner:COMMISSARIAT À L ÉNERGIE ATOMIQUE & AUX ÉNERGIES ALTERNATIVES FR

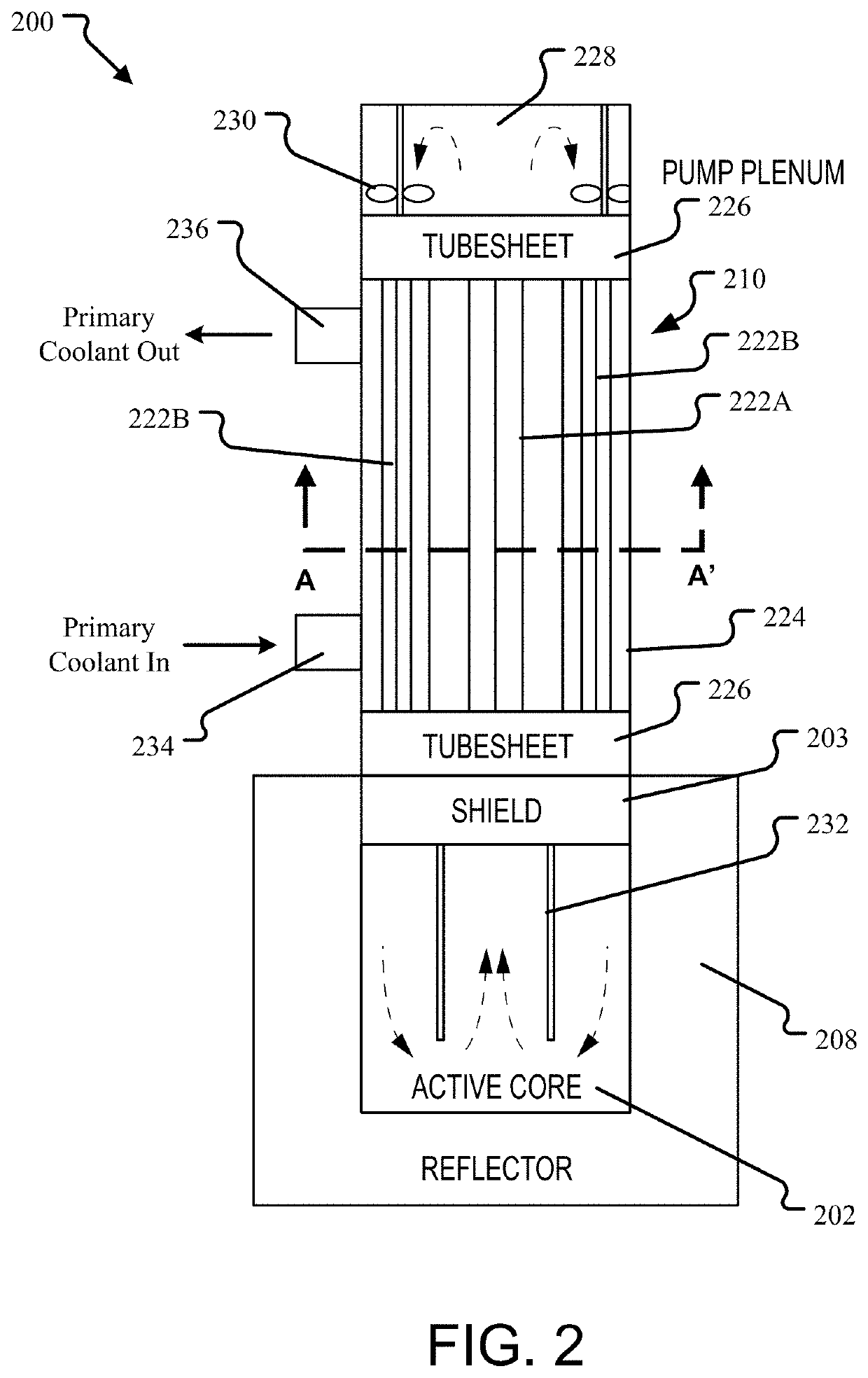

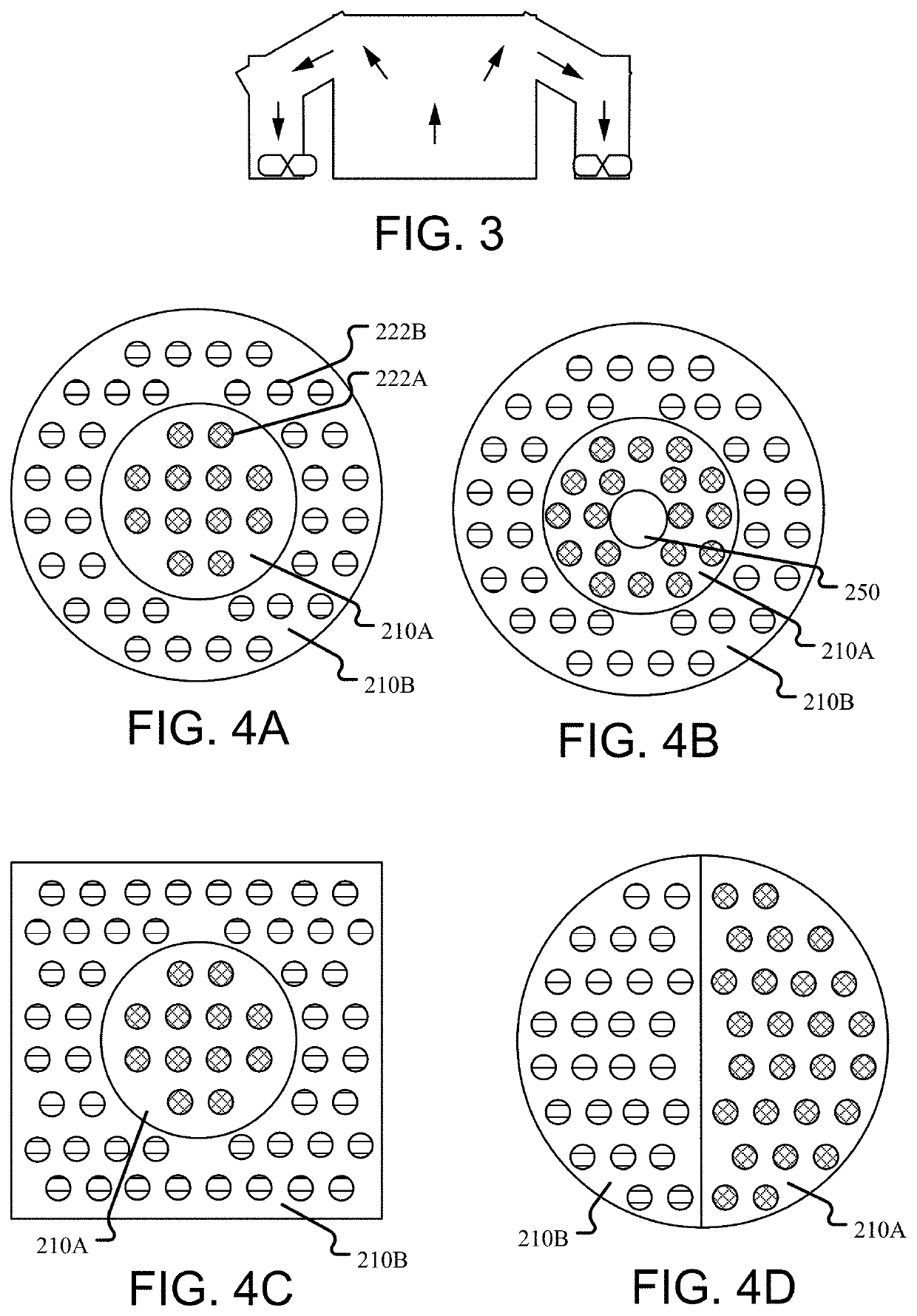

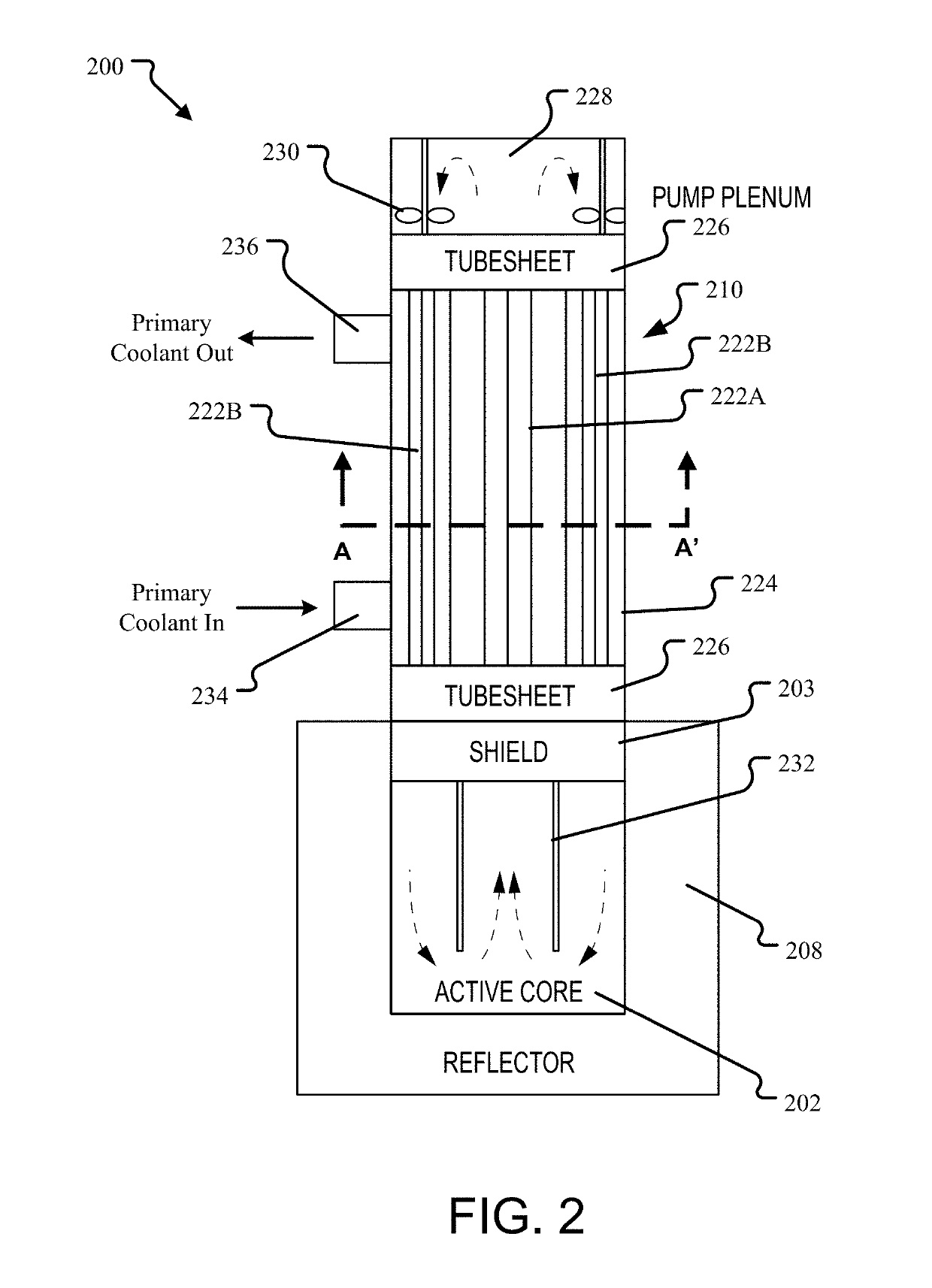

Vertically-segmented nuclear reactor

ActiveUS20180019025A1Improve power densitySave on fuel costsIntegral reactorsFuel elementsNuclear reactor coreNuclear reactor

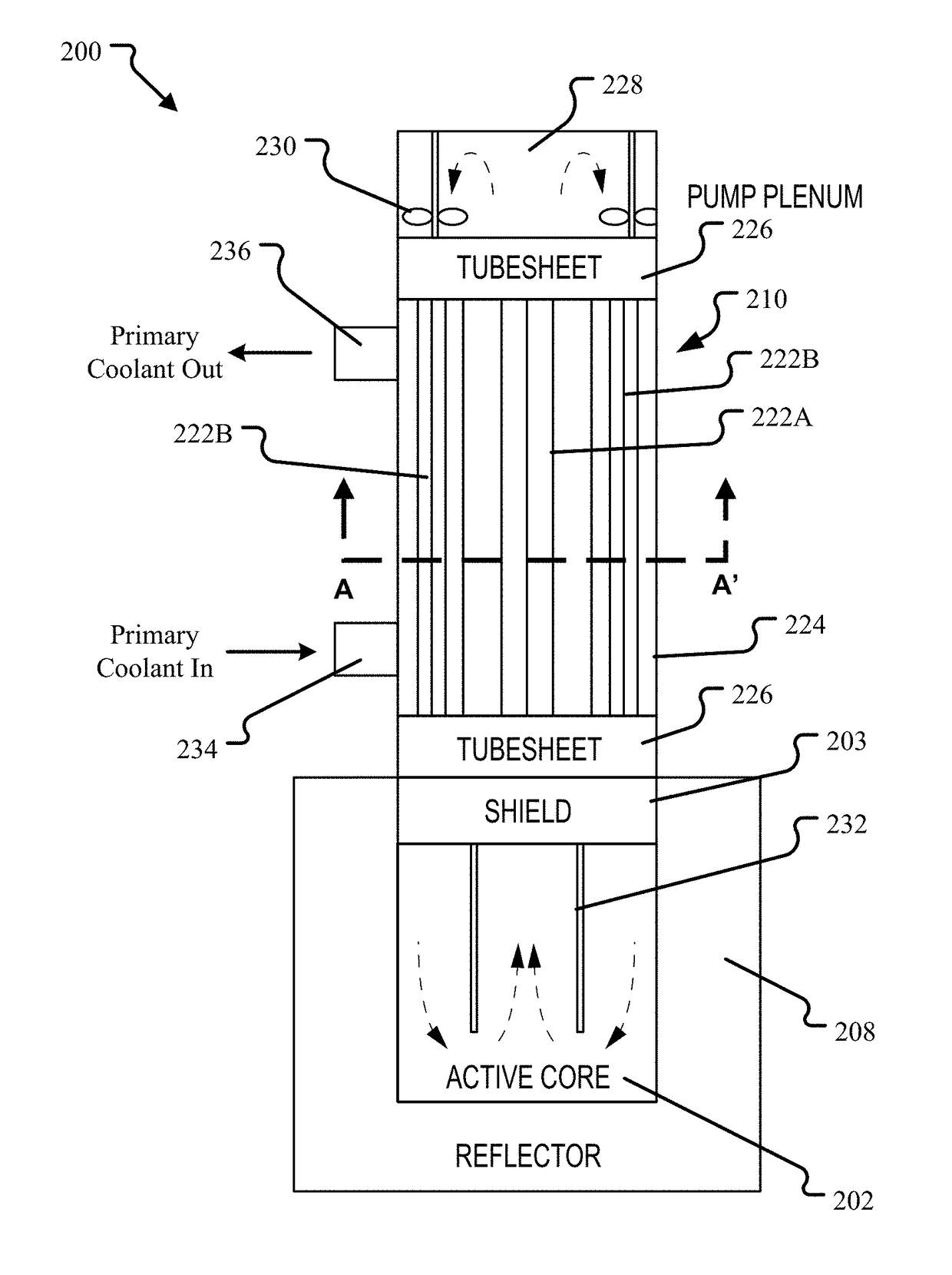

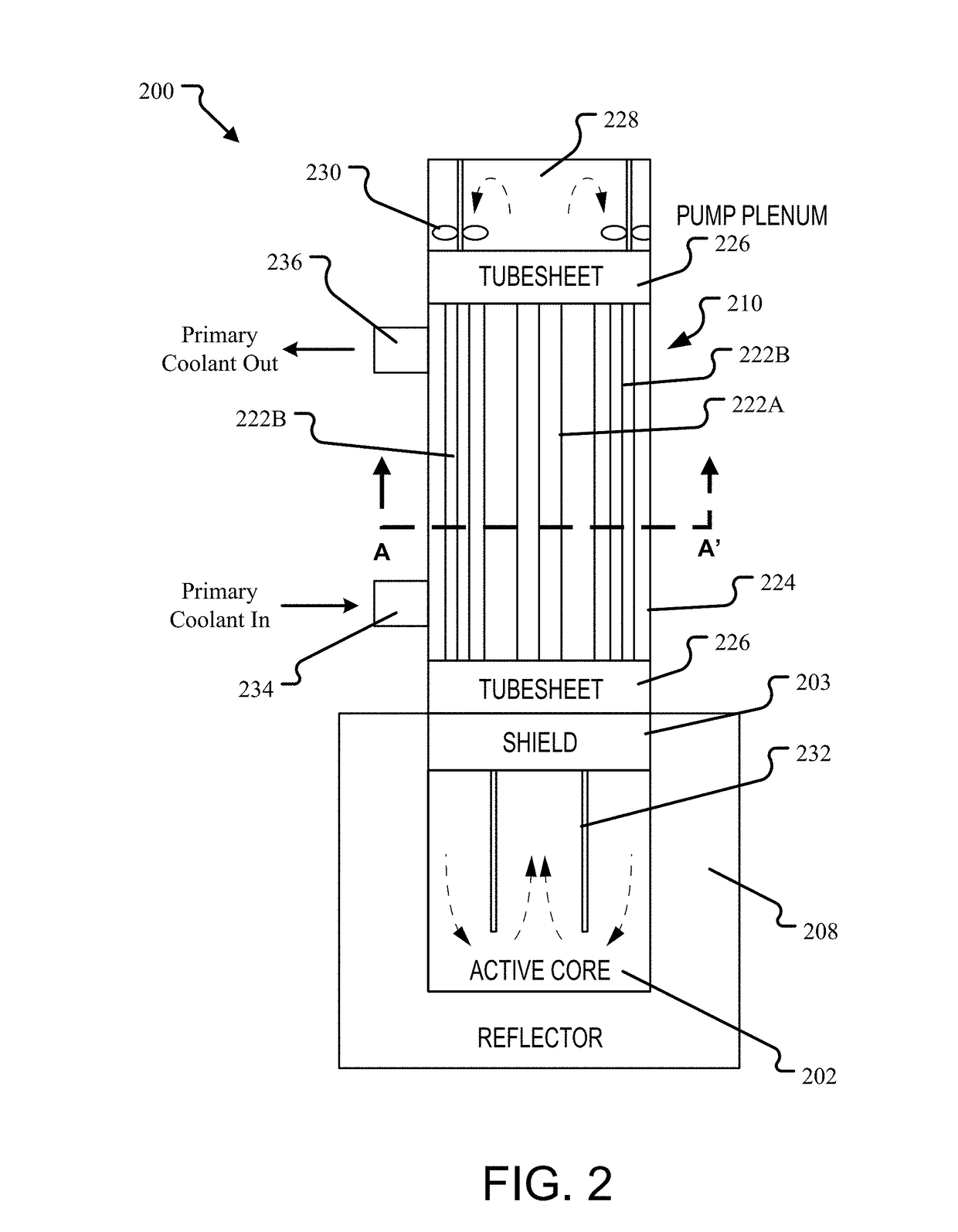

This disclosure describes various configurations and components of a molten fuel fast or thermal nuclear reactor in which one or more primary heat exchangers are located above the reactor core of the nuclear reactor.

Owner:TERRAPOWER

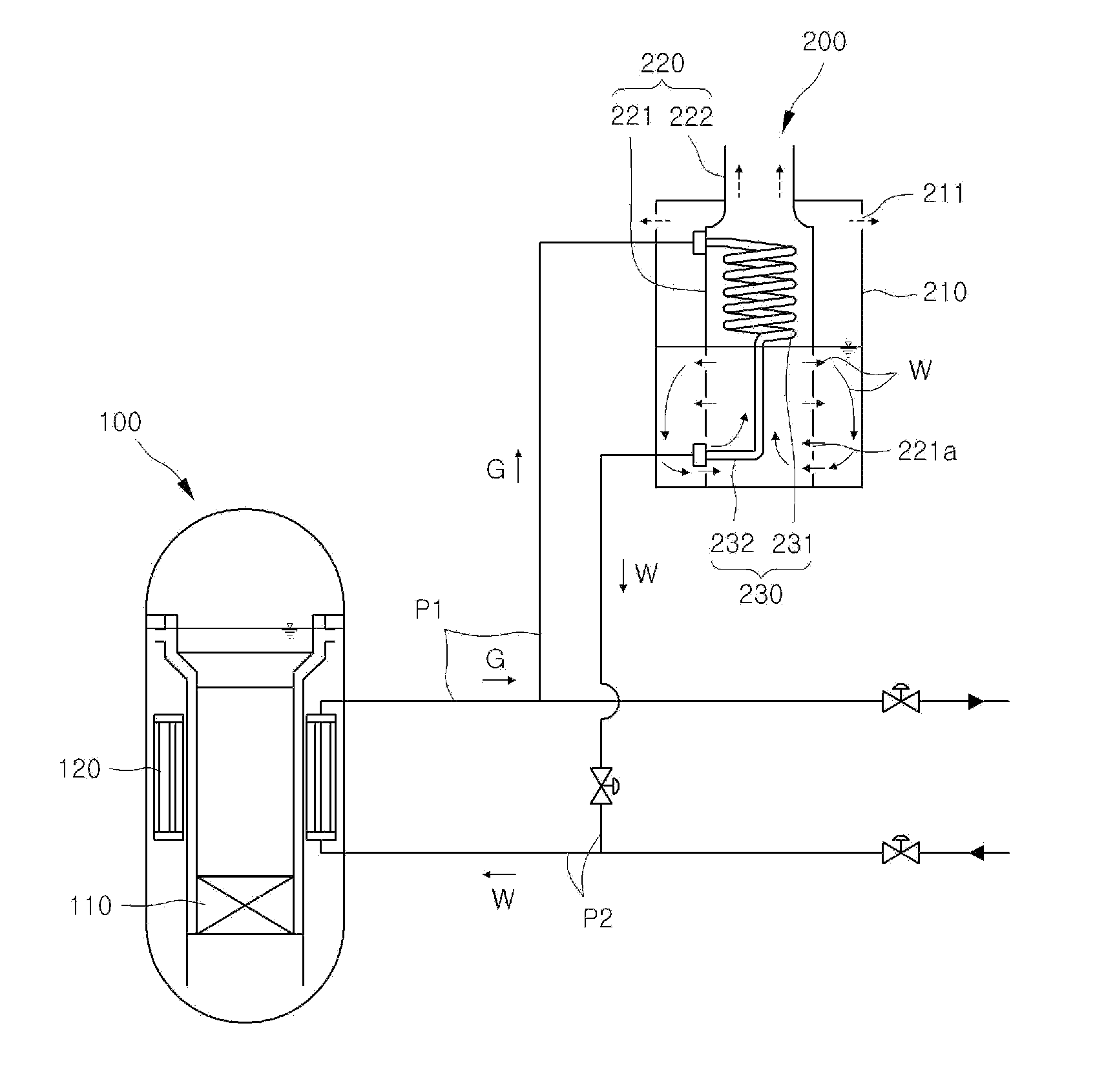

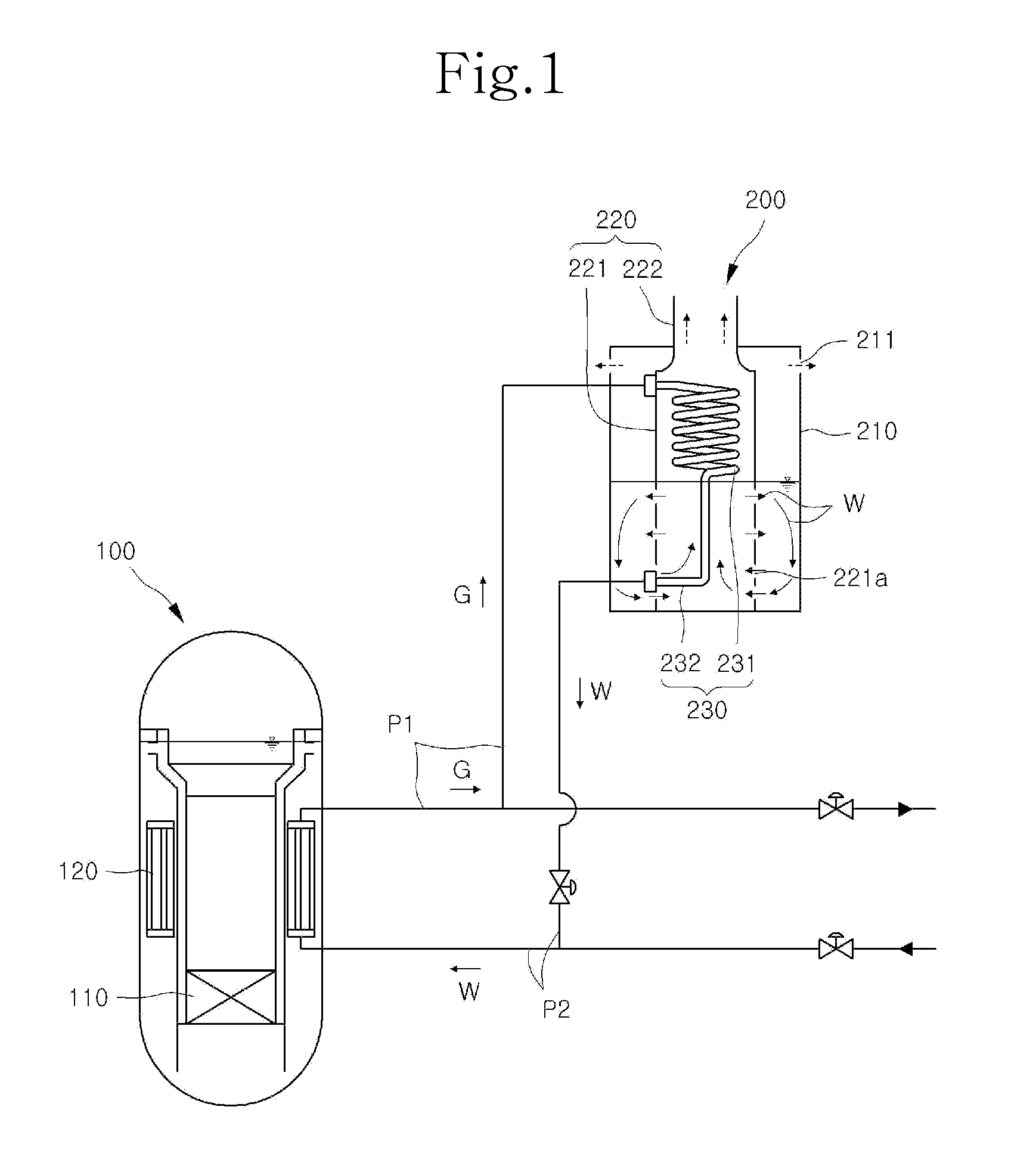

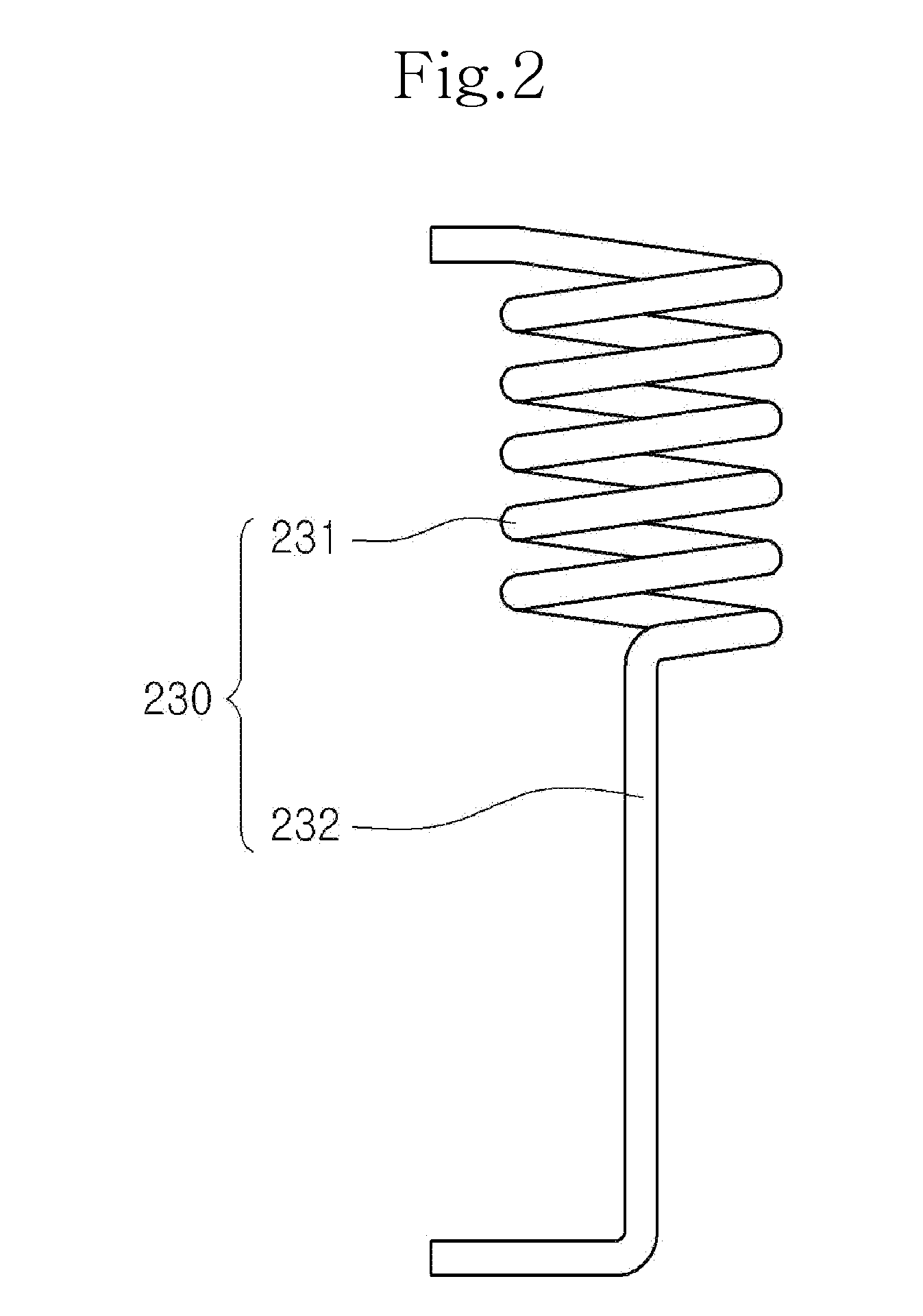

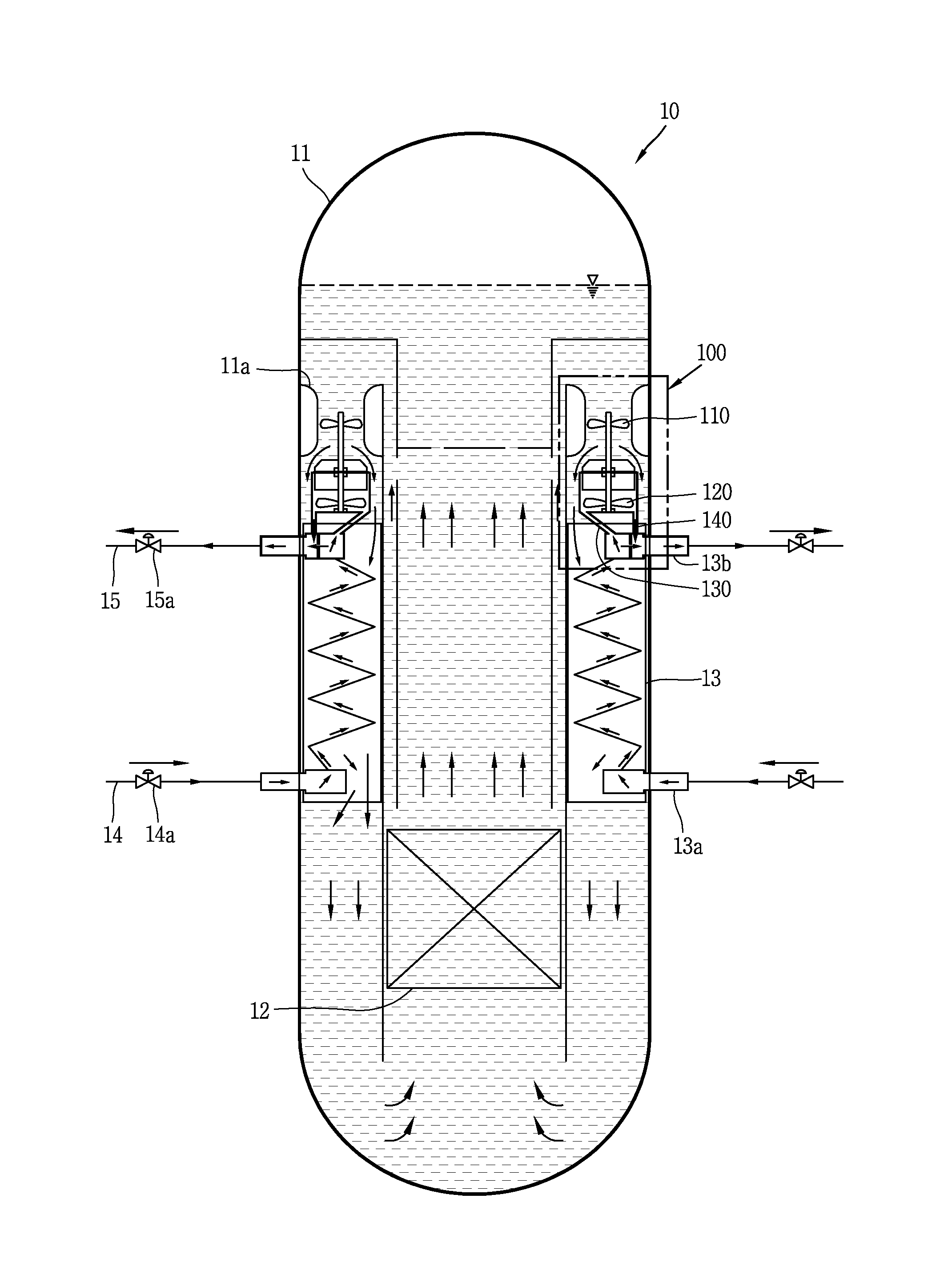

Heat exchanger for passive residual heat removal system

ActiveUS20130343504A1Efficient removalMaintain securityIntegral reactorsNuclear energy generationNuclear reactor coreNuclear reactor

Disclosed is a heat exchanger for a passive residual heat removal system, which improves heat transfer efficiency by expanding a heat transfer area. A heat exchange tube includes a first member connected to a steam pipe through which steam generated from a steam generator of a nuclear reactor circulates, and a second member connected to both of the first member and a feed water pipe used to supply water to the steam generator provided in the nuclear reactor, and the first member has the shape different from that of the second member, thereby expanding the heat transfer area so that the heat transfer efficiency is improved.

Owner:KOREA ATOMIC ENERGY RES INST

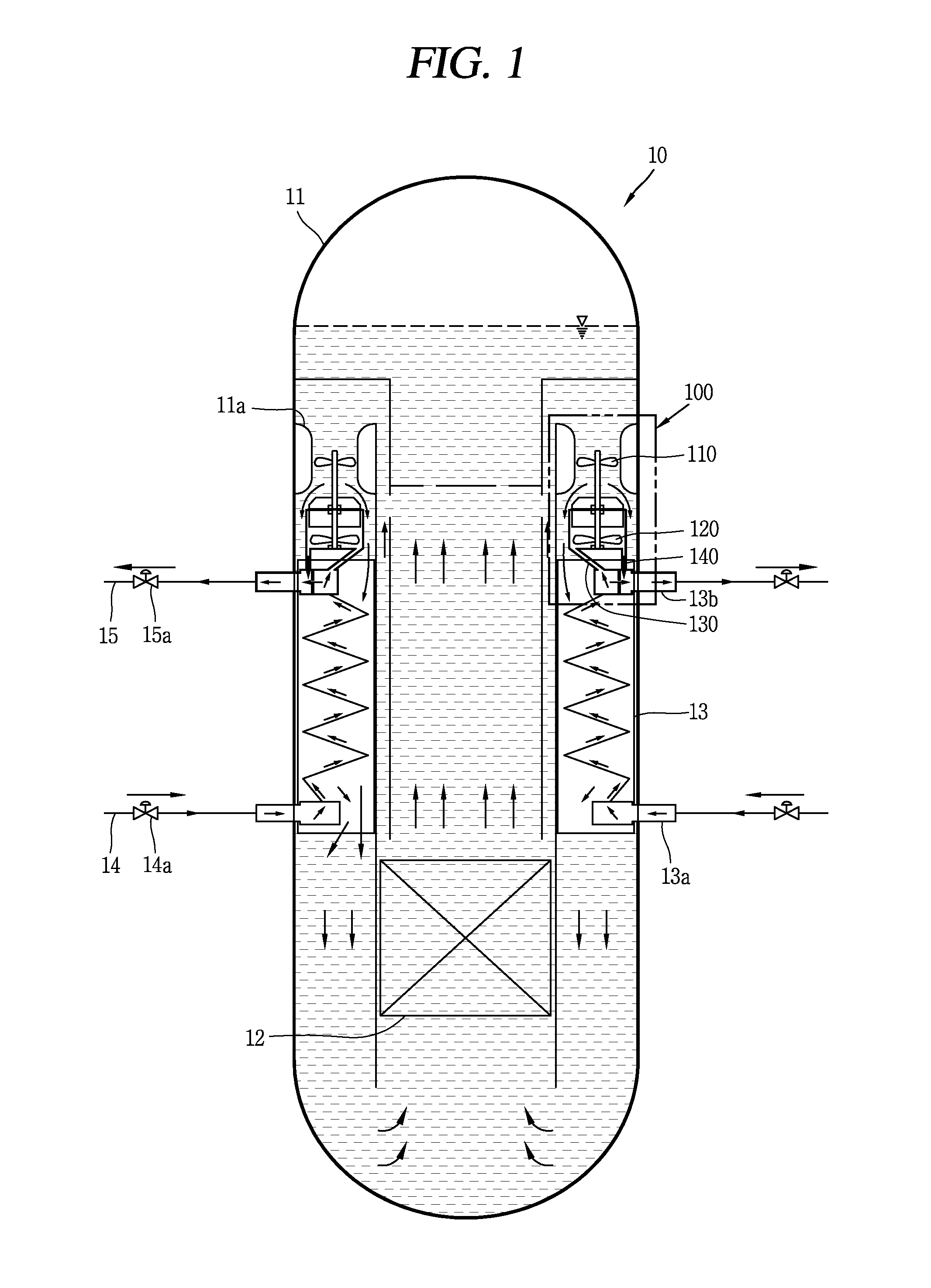

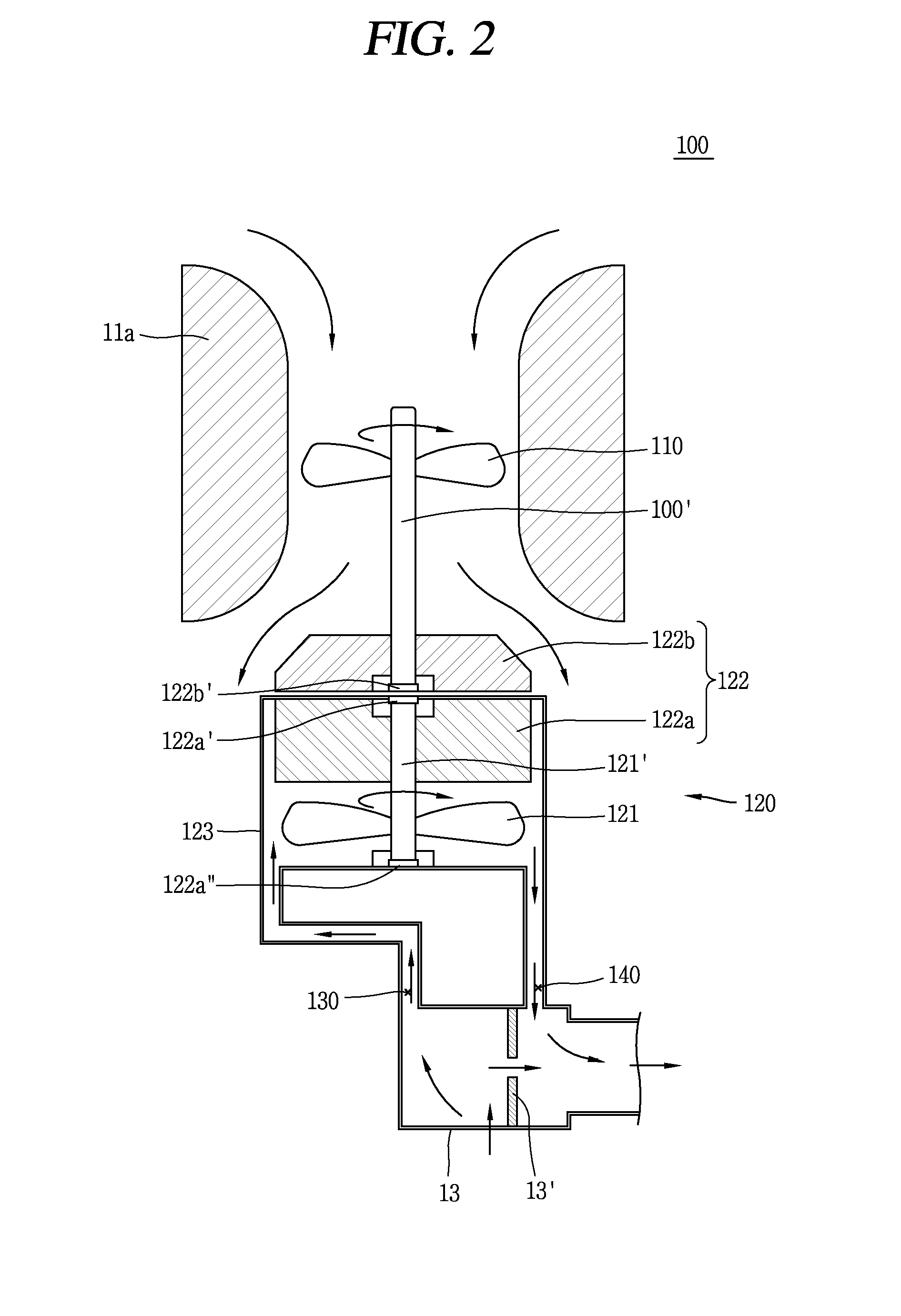

Nuclear reactor coolant pump and nuclear power plant having same

ActiveUS20160260509A1Energy lossElectrical degradationIntegral reactorsNuclear energy generationNuclear reactor coreImpeller

The present invention discloses a nuclear reactor coolant pump that does not rely on an electric motor, but is operated by means of driving force generated inside a nuclear power plant, so a to be capable of maintaining the safety of the nuclear reactor when the nuclear reactor is operating normally and also in the event of an accident in the nuclear reactor. The nuclear reactor coolant pump comprises: a pump impeller rotatably installed in a first fluid passage of a nuclear reactor coolant system to circulate a first fluid inside the nuclear reactor coolant system; a drive unit receiving steam from a steam generator to generate driving force to rotate the pump impeller, and rotating about the same rotating shaft as the pump impeller to transfer the generated driving force to the pump impeller; and a steam supplying unit forming a passage between the steam generator and the drive unit to supply at least a portion of the steam released from the steam generator to the drive unit.

Owner:KOREA ATOMIC ENERGY RES INST

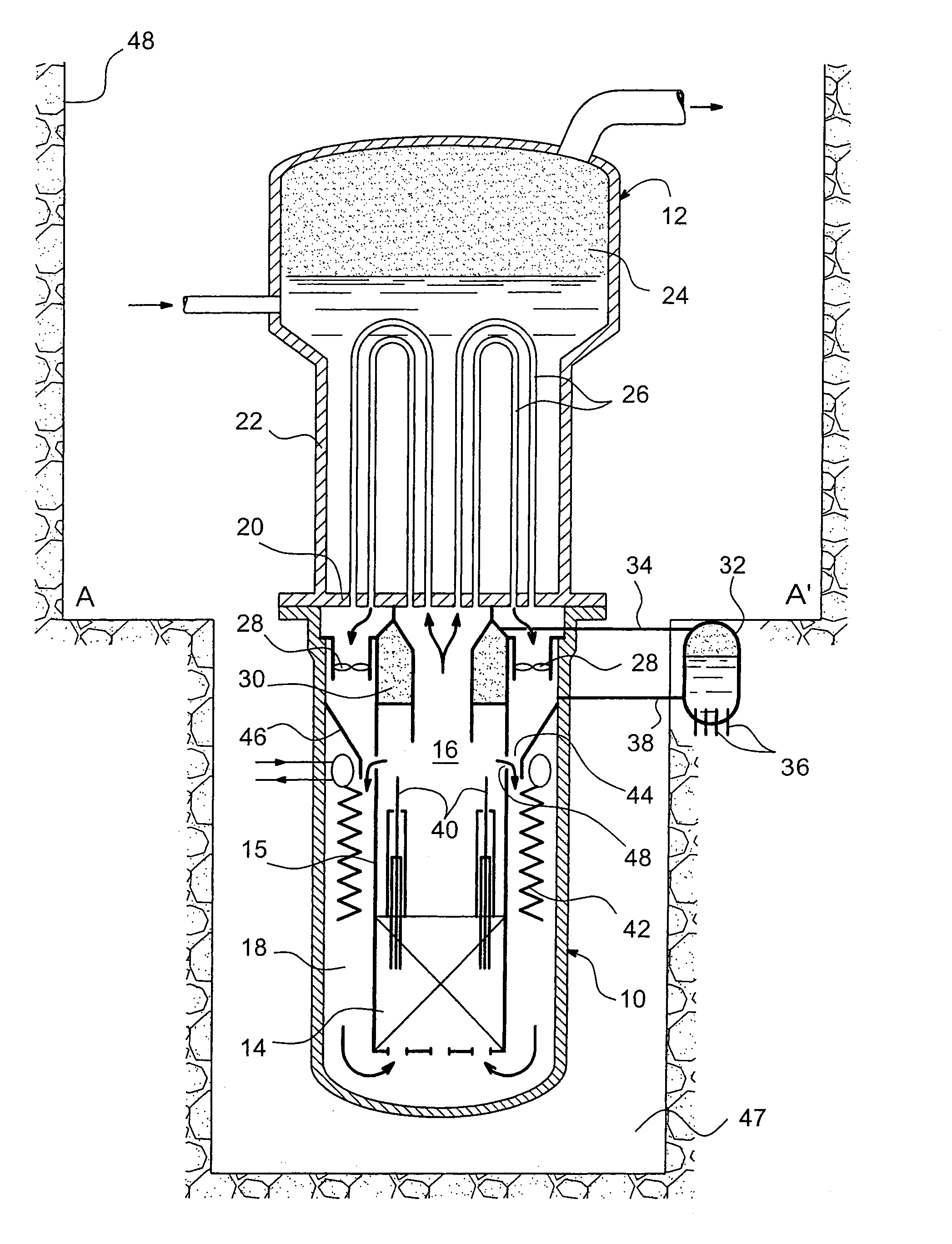

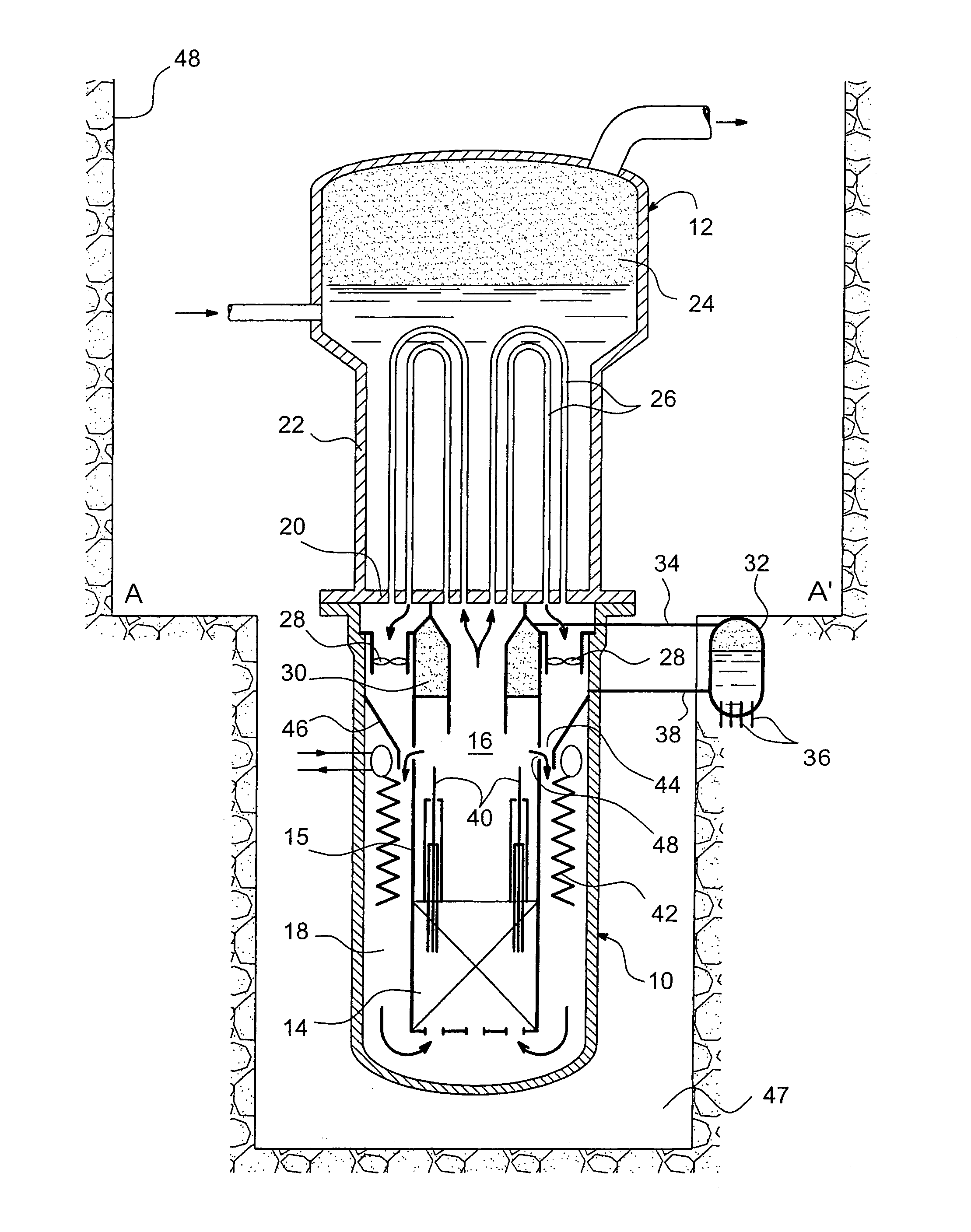

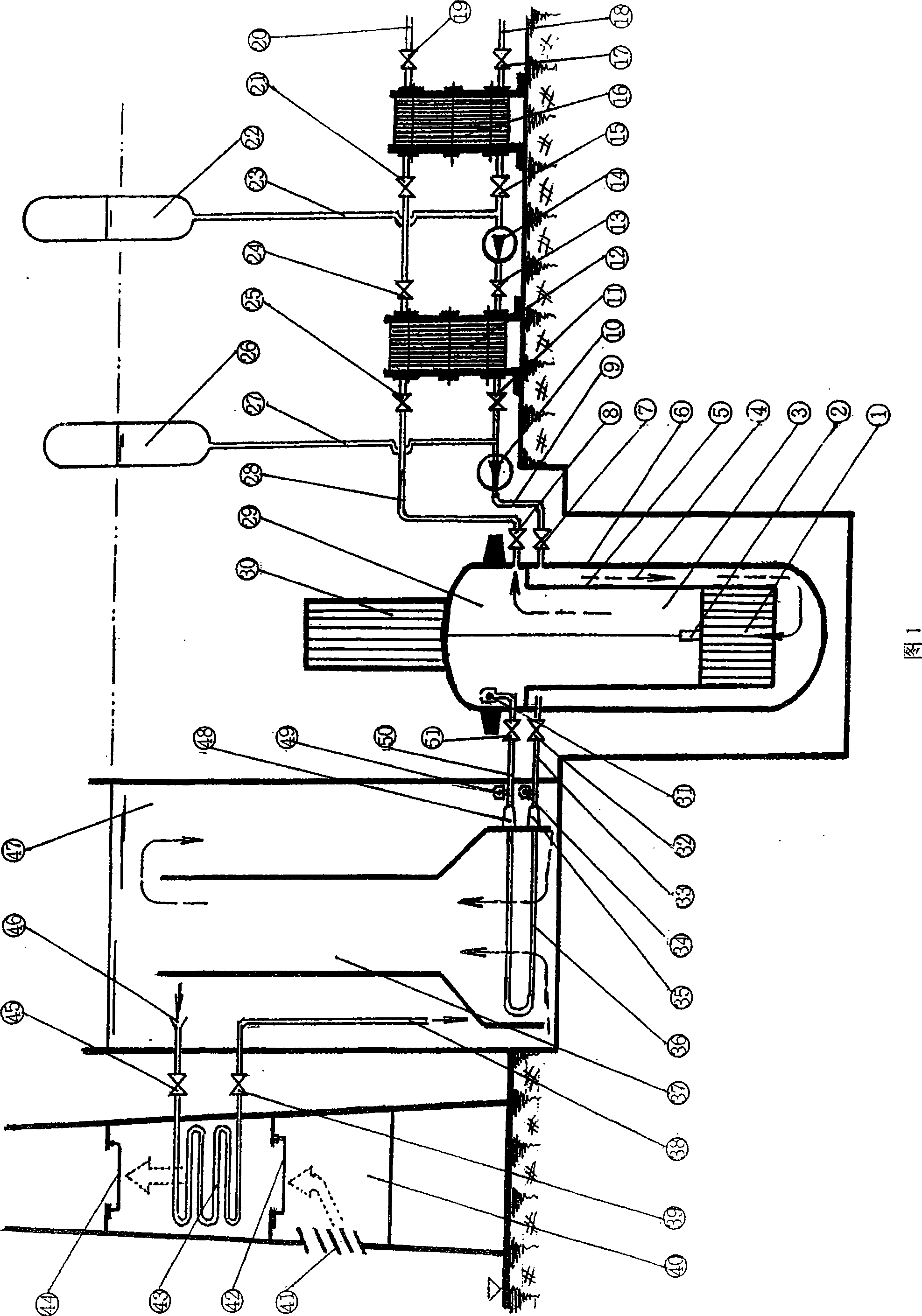

Inherent safety pool case combination low-temperature stack nuclear heating station apparatus and operational procedure thereof

InactiveCN101441902AIncreased average volume specific powerReduce initial loadIntegral reactorsNuclear energy generationInherent safetyPressurized water reactor

The present invention provides an inherent security pool-shell combination low temperature nuclear heating device and an operation program thereof, which belongs to nuclear energy centralized heat-supply field. The invention mainly comprises the following procedures: adopting separated layout, forced circulation and high effective small temperature difference heat exchange in primary loop of reactor; under the precondition that parameter requirements of centralized heat-supply by big cities heat supply network satisfied, reducing work temperature of shell-type heating reactor as far as possible; meanwhile optimized layout of equipment, and organic combination of normal pressure pool in large volume (47) and shell-style heating reactor(29) remove accident possibility of water loss and coldness loss of reactor core (1). Complete inherent safety principle is carried out in the invention. Thus, absolute security of nuclear heating can be guaranteed by using mature pressurized water reactor technology, and enterprises have develop nuclear station pressurized water reactor experience can possibly jump over research and develop stage and enter into nuclear heating market directly, and make a real contribution for energy-saving and emission-reduction and improving country energy structure.

Owner:肖宏才

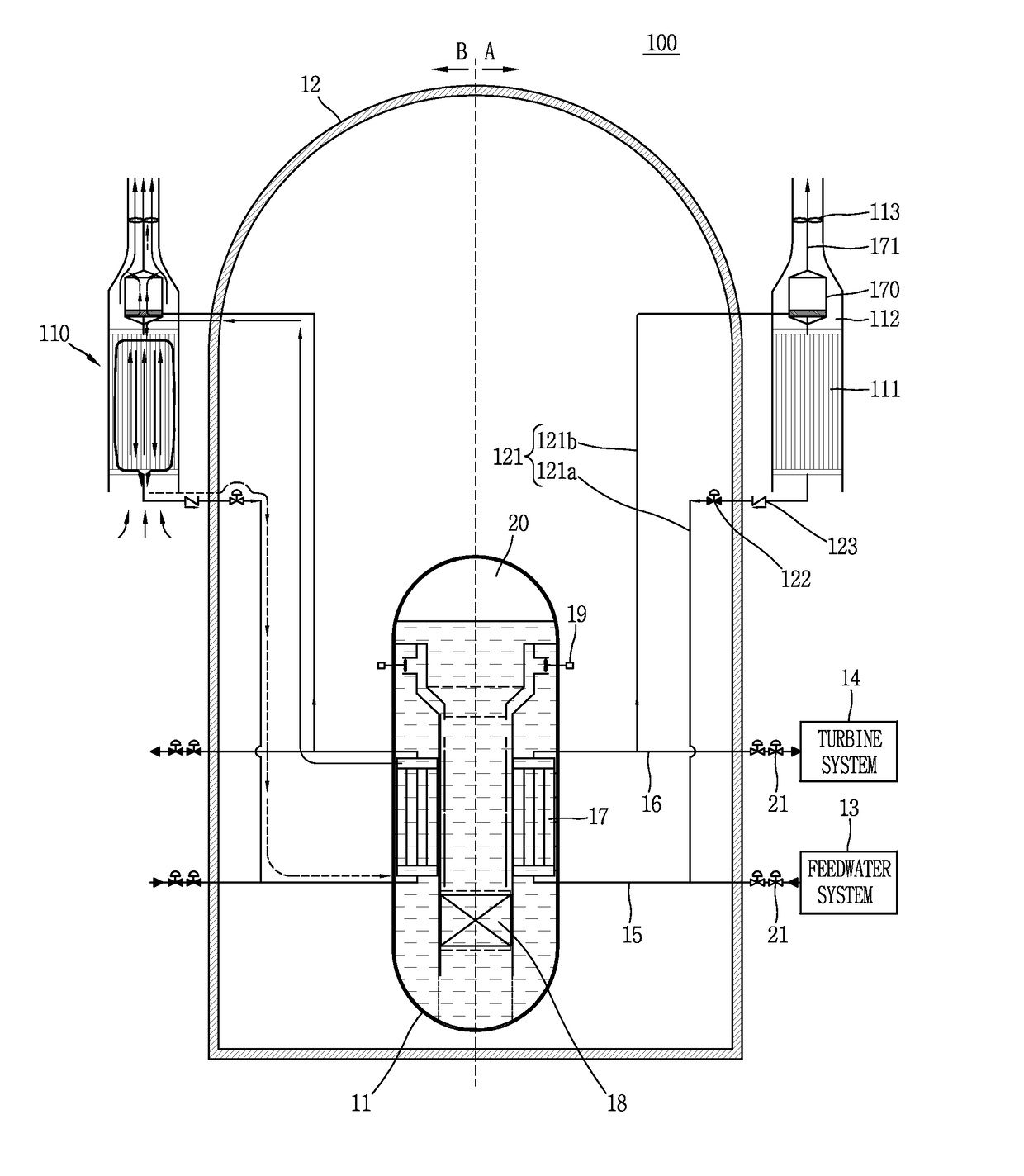

Nuclear power plant

ActiveUS20180233240A1Improve reliabilityImprove efficiencyPower plant safety arrangementIntegral reactorsNuclear powerNuclear engineering

Disclosed is a nuclear power plant which drives a Stirling engine by means of heat generated in nuclear power plant safety systems during an accident, uses the resulting power directly or generates electric power so as to supply the power to the safety systems, and thus can improve economic efficiency as well as the reliability of safety systems, such as a passive safety system, by operating the safety systems without an emergency diesel generator or external electric power.

Owner:KOREA ATOMIC ENERGY RES INST

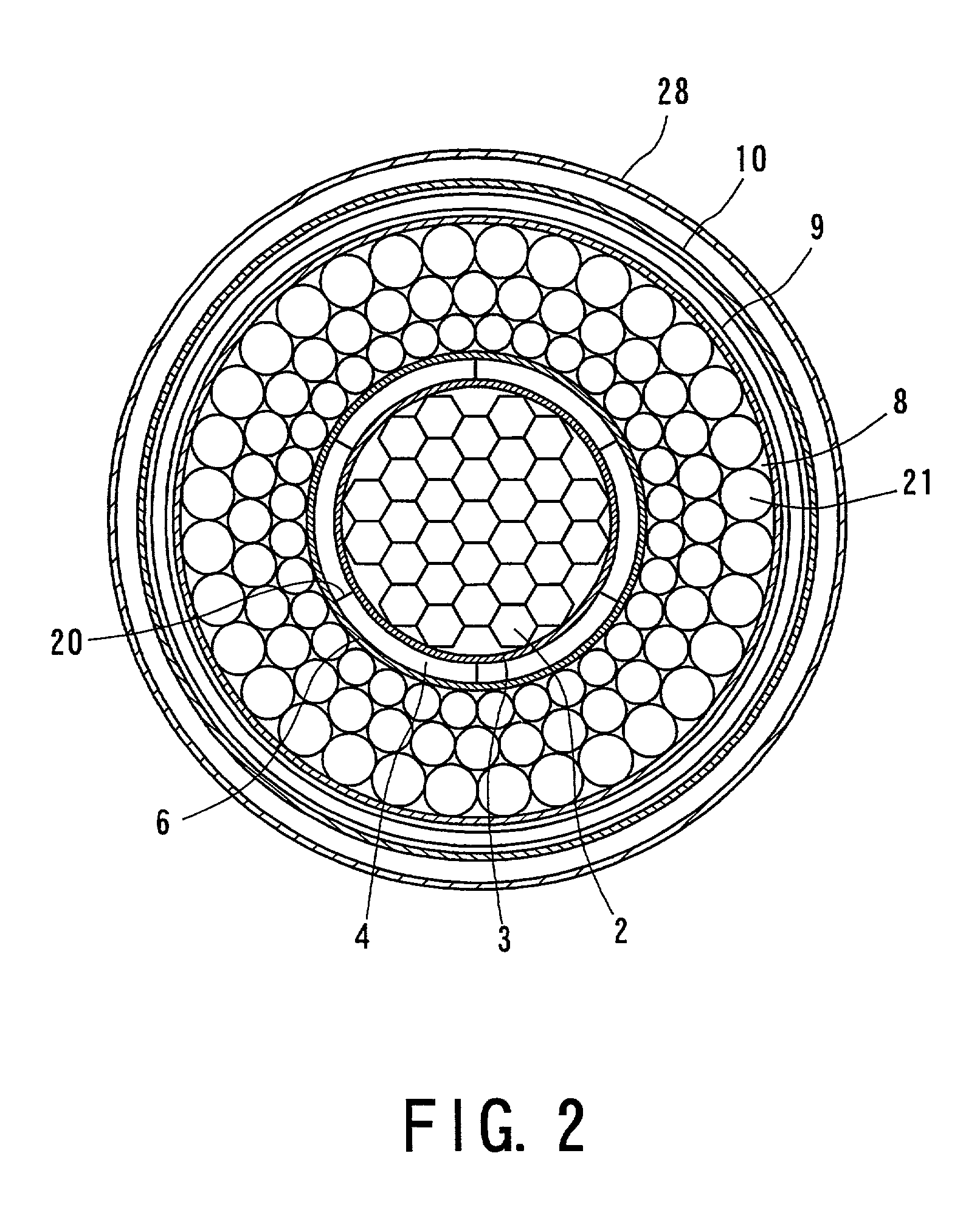

Reactivity control rod for core

InactiveUS7139352B2Prevent liquid leakageReduce the valueIntegral reactorsFuel elementsNuclear engineeringNeutron moderator

A reactivity control rod adapted to be used in a reactor core of a fast reactor and disposed at a substantially central portion of the reactor core for controlling a reactivity therein. The reactivity control rod includes a wrapper tube surrounded by a plurality of fuel rods in a reactor core, and a plurality of neutron absorber rods arranged in the wrapper tube. At least one of the plurality of neutron absorber rods includes a cladding tube and a mixture filled in the cladding tube. The mixture is composed of a neutron absorber that absorbs a neutron and a neutron moderator that moderates the neutron.

Owner:KK TOSHIBA

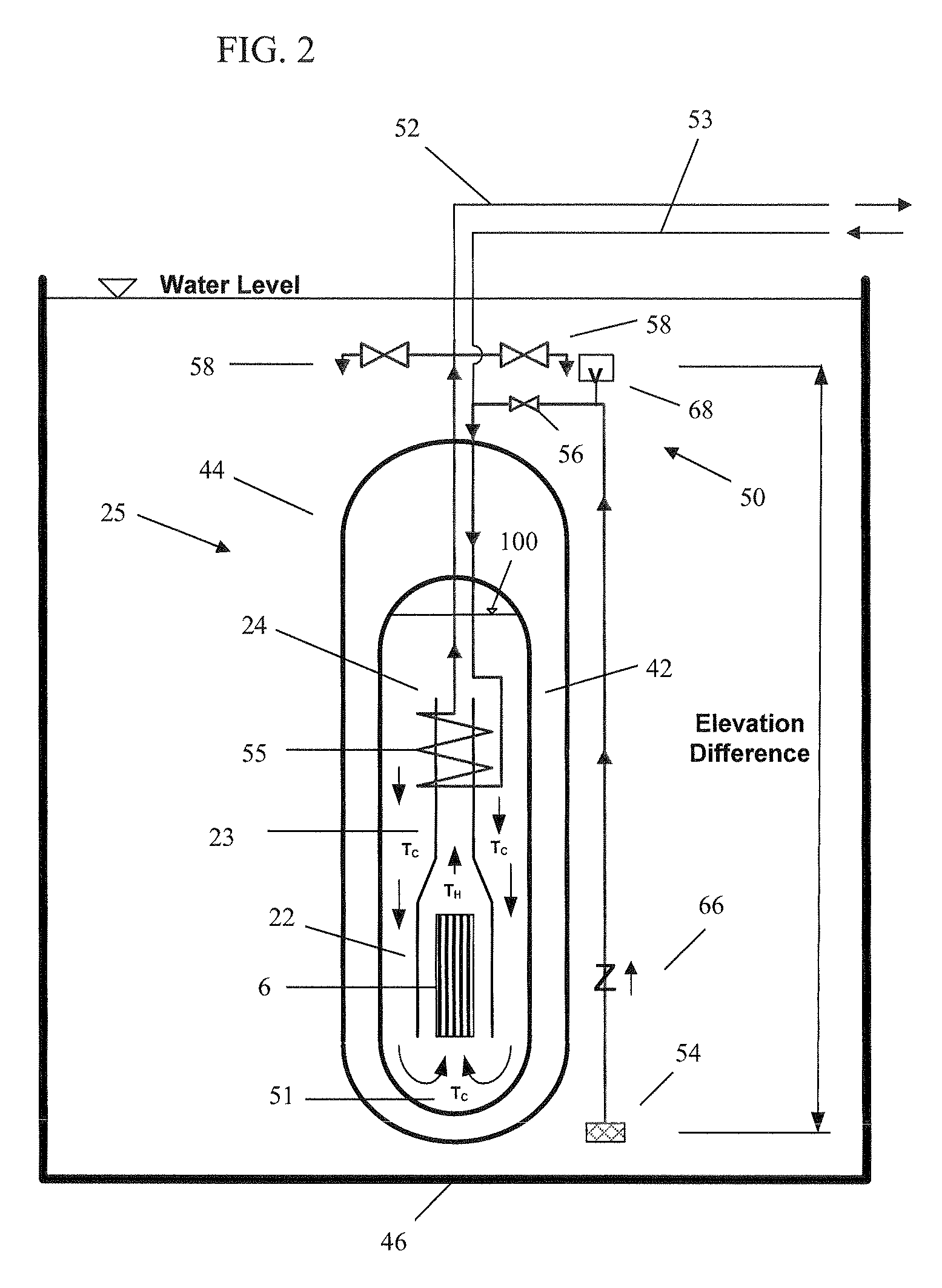

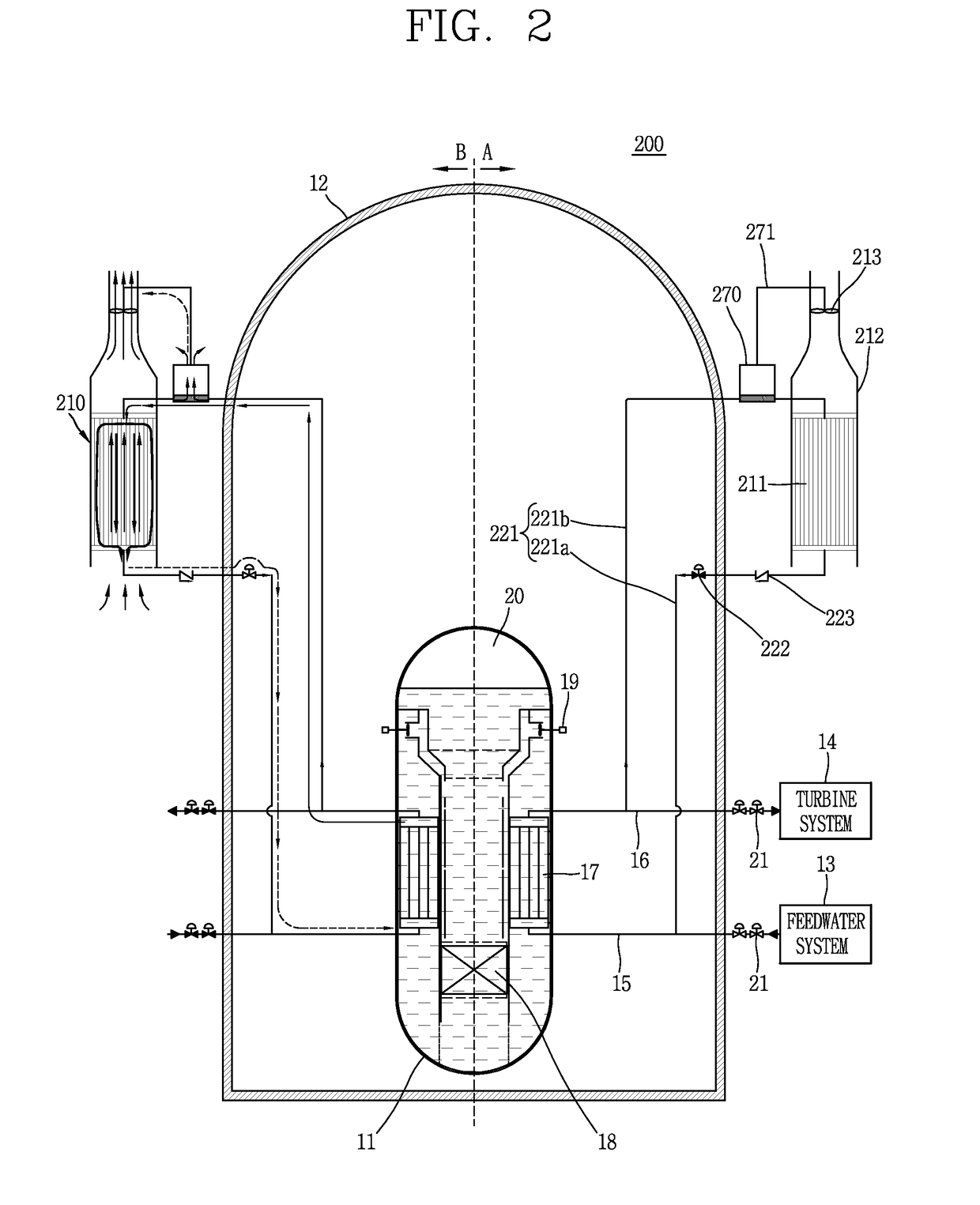

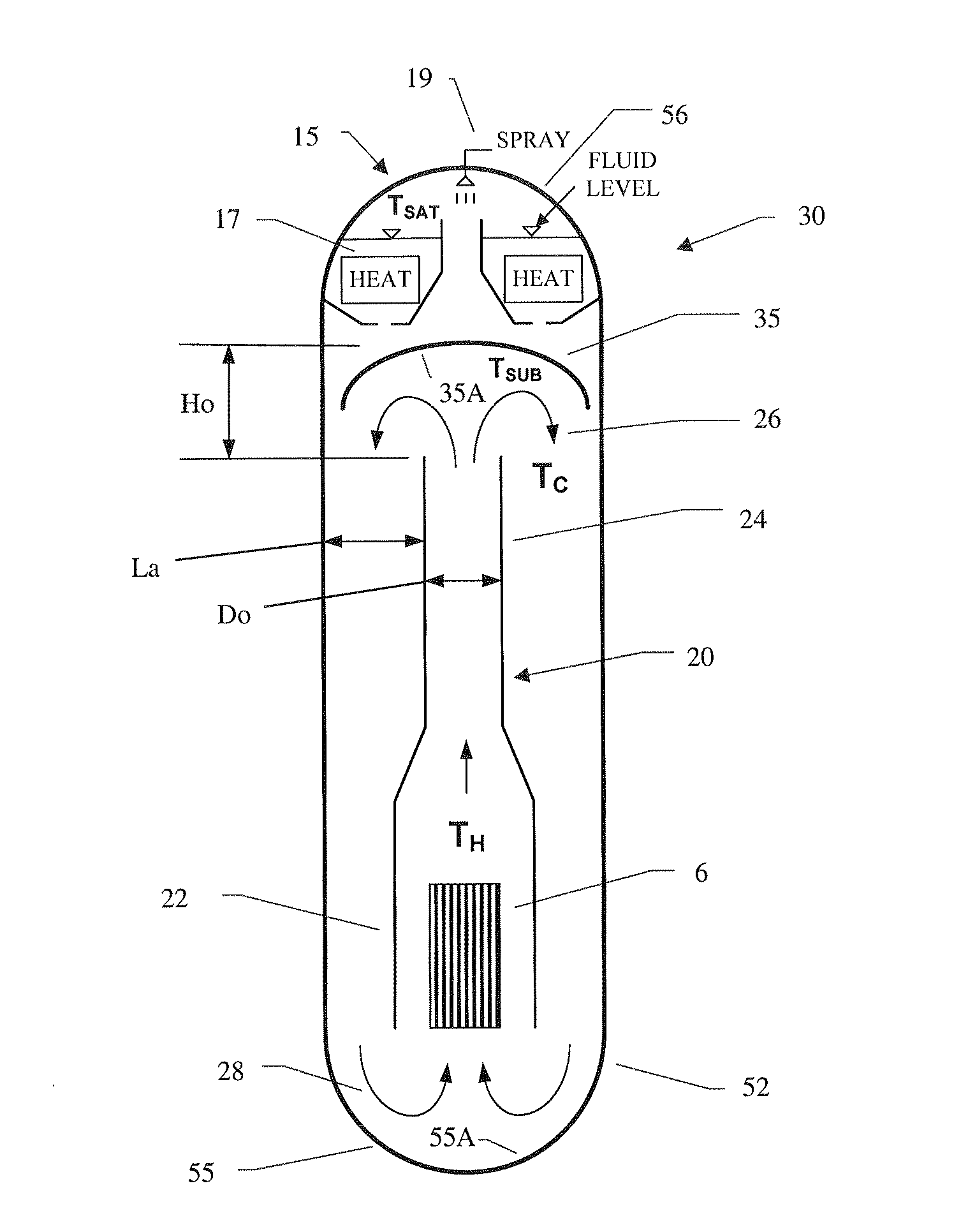

Passive emergency feedwater system

ActiveUS20120177168A1Remove heatIntegral reactorsNuclear energy generationNuclear engineeringCooling pond

A power module assembly may include a reactor vessel containing a primary coolant and one or more inlets configured to draw a secondary coolant from the containment cooling pool in response to a loss of power and / or a loss of coolant. One or more outlets may be submerged in the containment cooling pool and may be configured to vent the secondary coolant into the containment cooling pool. A heat exchanger may be configured to remove heat from the primary coolant, wherein the heat may be removed by circulating the secondary coolant from the containment cooling pool through the heat exchanger via natural circulation.

Owner:NUSCALE

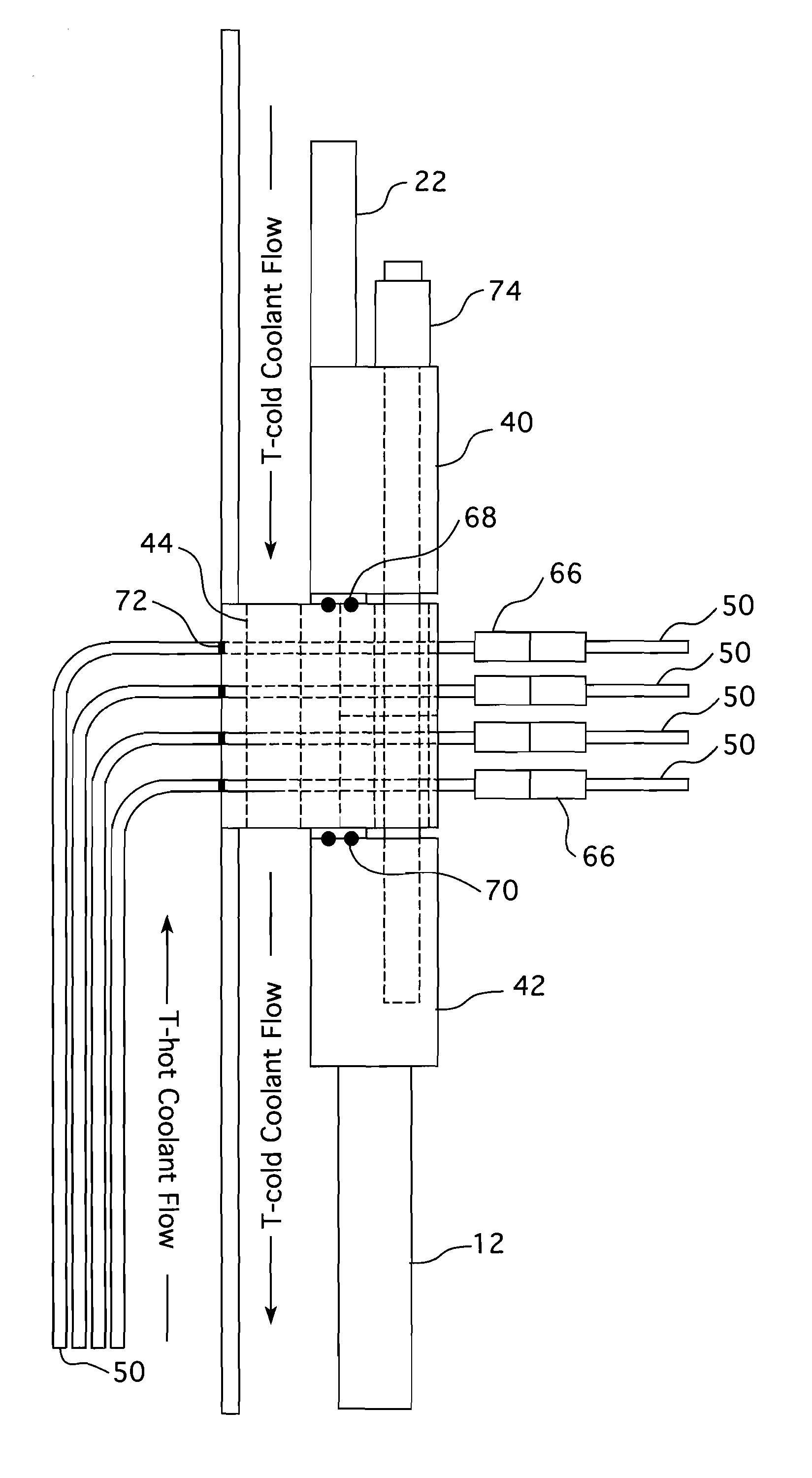

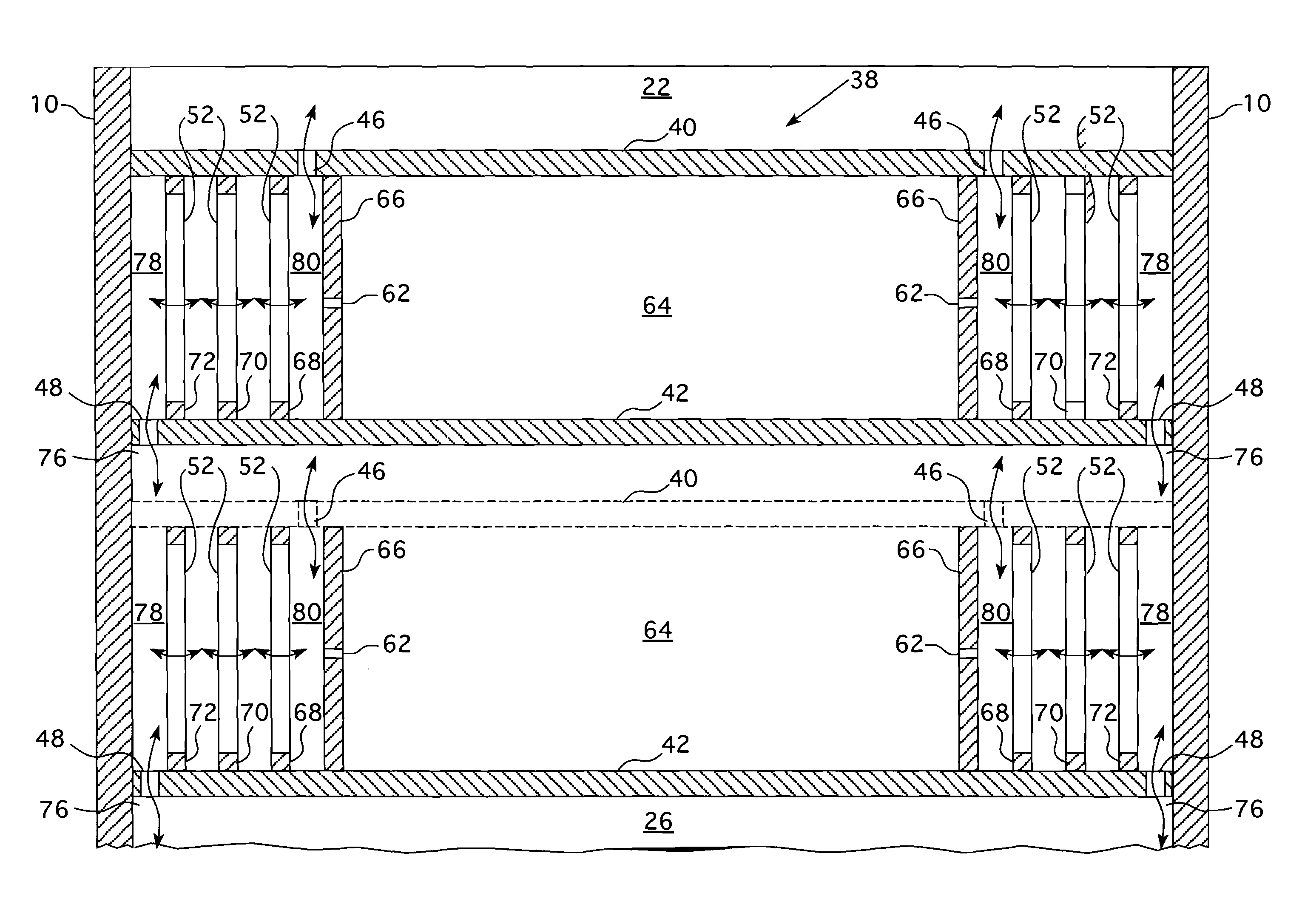

Pressurizer surge-line separator for integral pressurized water reactors

An integral pressurized light water reactor having most of the components of a primary side of a pressurized water reactor nuclear steam supply system housed in a single pressure vessel with a pressurizer separated from the remaining reactor system by a surge separator having multiple layers of separated steel plates with a number of concentric baffles extending therebetween. A circuitous flow path is provided through and between the plates and concentric baffles and a relatively stagnant pool of coolant is maintained within an innermost zone between the plates to provide thermal isolation.

Owner:WESTINGHOUSE ELECTRIC CORP

Reactor vessel coolant deflector shield

A power module includes a reactor vessel containing a coolant and a reactor core located near a bottom end of the reactor vessel. A riser section is located above the reactor core, wherein the coolant circulates past the reactor core and up through the riser section. In one embodiment, a coolant deflector shield includes flow-optimized surfaces, wherein the flow-optimized surfaces direct the coolant towards the bottom end of the reactor vessel. In another embodiment, the reactor housing includes an inward facing portion that varies a flow pressure of the coolant and promotes a circulation of the coolant past a baffle assembly and towards the bottom end of the reactor vessel.

Owner:NUSCALE

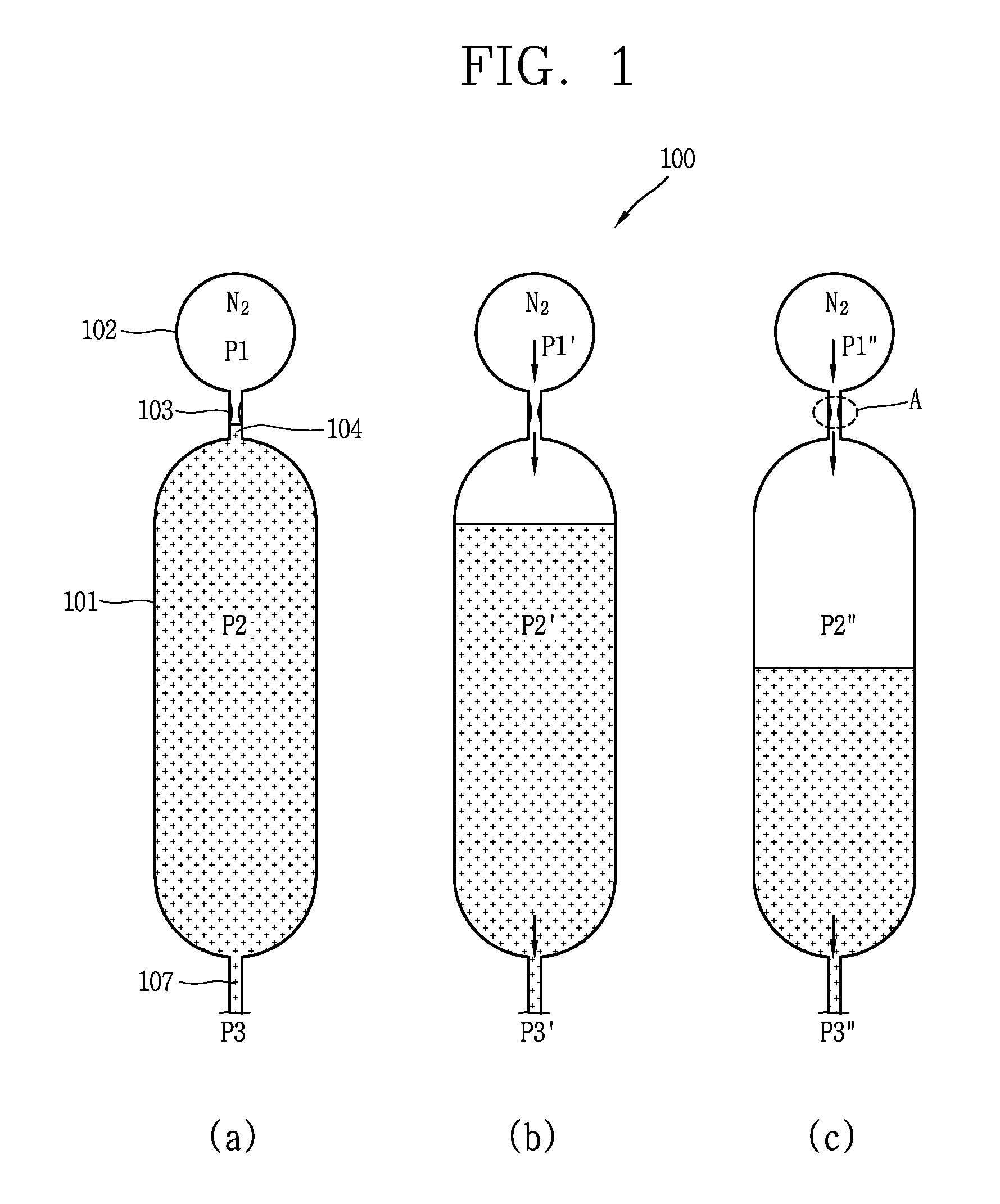

Separate type safety injection tank and integral type reactor having the same

ActiveUS20140050292A1Prevent backflowPower plant safety arrangementIntegral reactorsNuclear engineeringProduct gas

A separate type safety injection tank comprises: a coolant injection unit connected to a reactor coolant system by a safety injection pipe such that coolant stored therein is injected into the reactor coolant system by a pressure difference from the reactor coolant system when a loss-of-coolant-accident (LOCA) occurs; a gas injection unit connected to the coolant injection unit, and configured to pressurize the coolant injected into the reactor coolant system, by introducing gas stored therein to an upper part of the coolant injection unit in the loss-of-coolant-accident; and a choking device disposed between the coolant injection unit and the gas injection unit, and configured to contract a flow cross-sectional area of the gas introduced to the coolant injection unit, and configured to maintain a flow velocity and a flow rate of the gas introduced to the coolant injection unit as a critical flow velocity and a critical flow rate when a pressure difference between the coolant injection unit and the gas injection unit is more than a critical value.

Owner:KOREA ATOMIC ENERGY RES INST

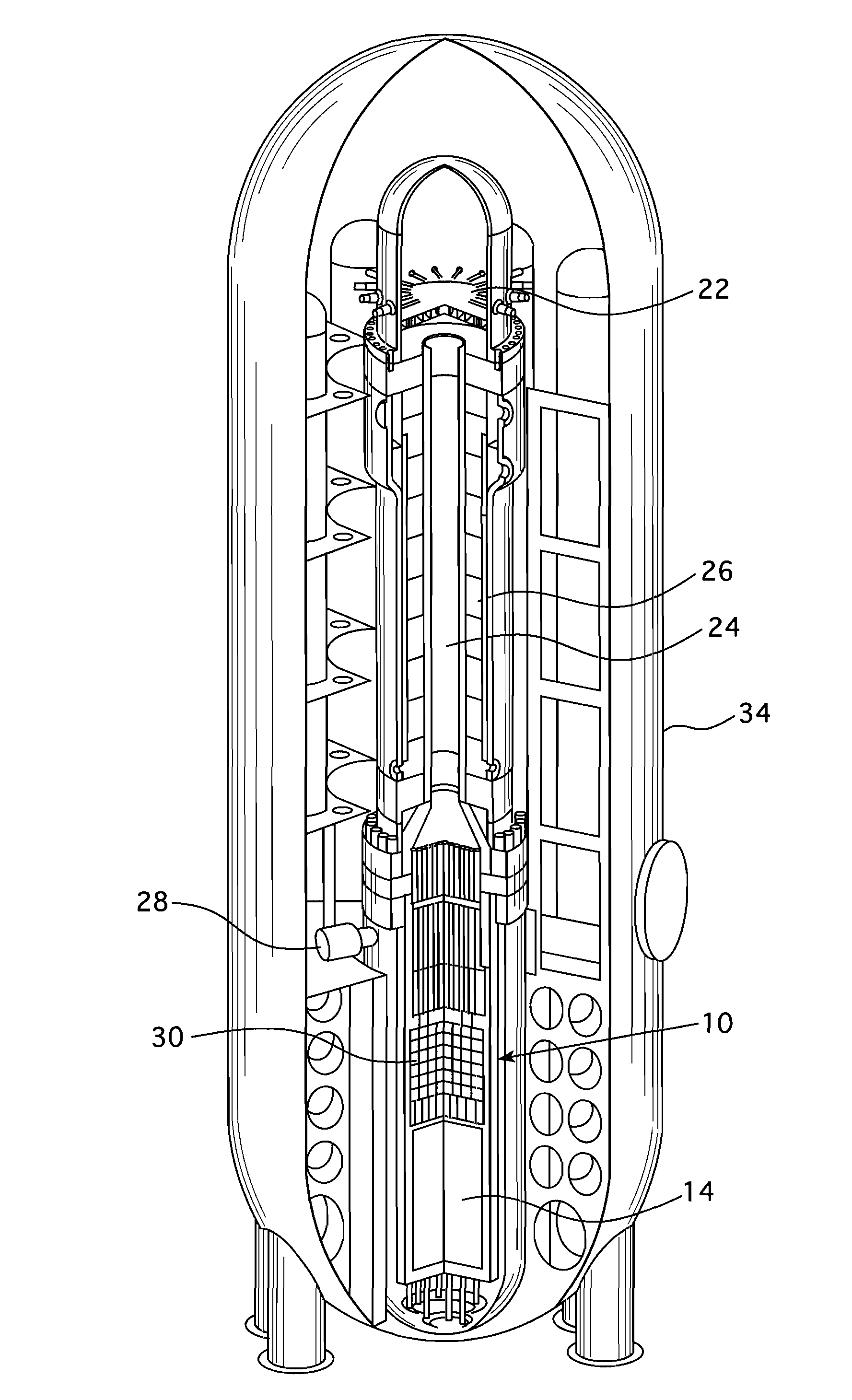

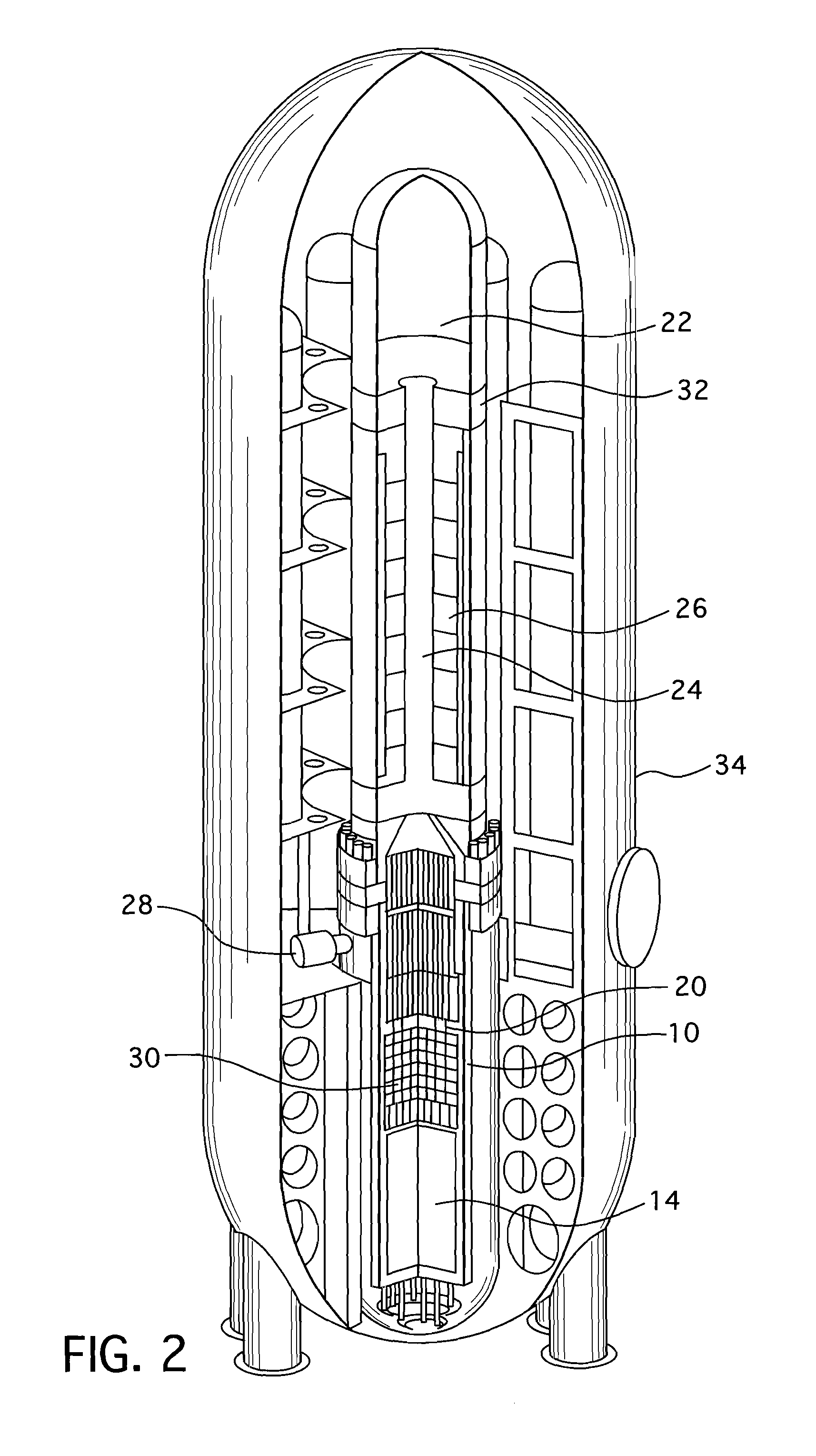

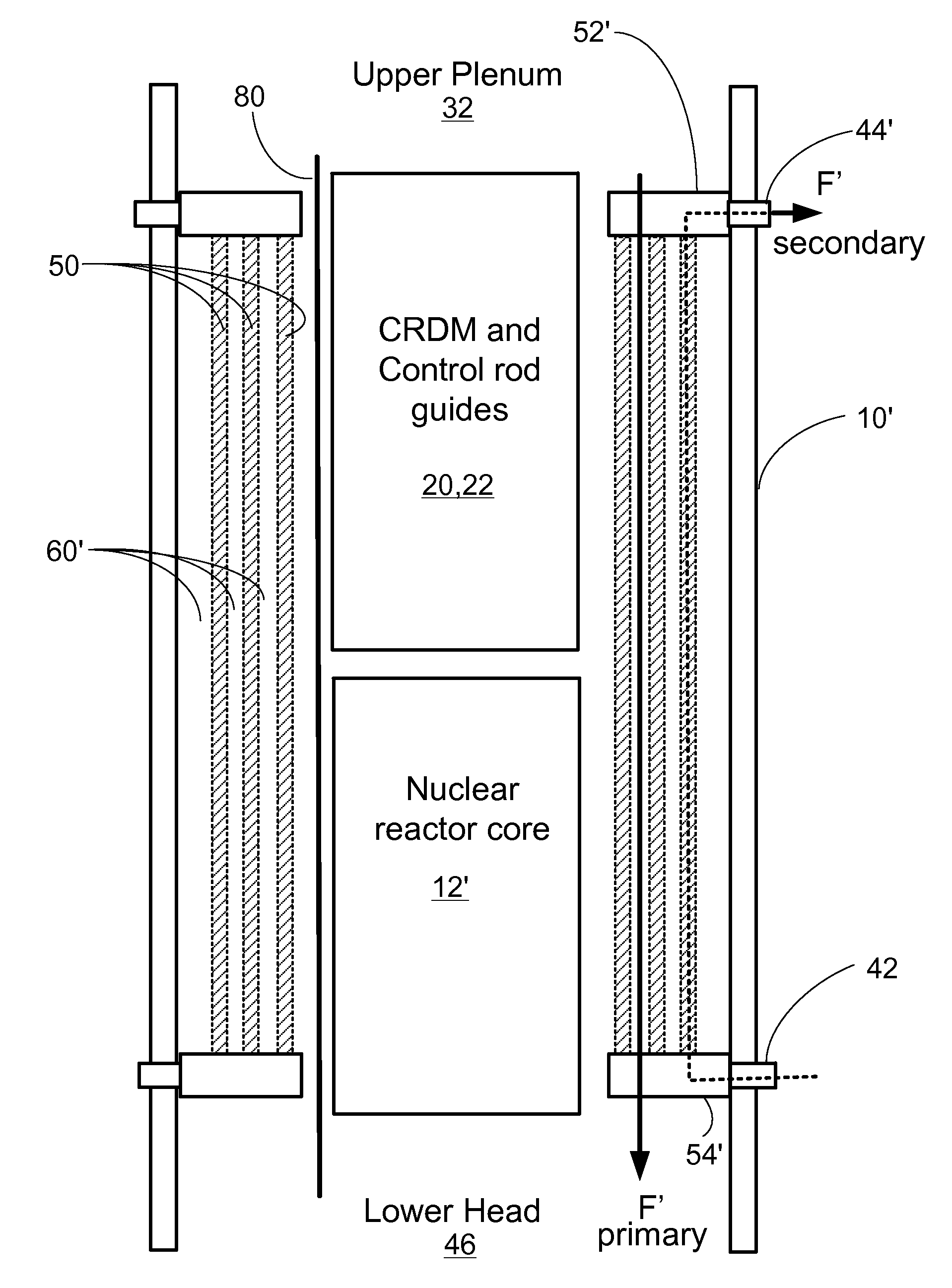

Compact integral pressurized water nuclear reactor

ActiveUS20120263270A1Integral reactorsNuclear energy generationNuclear reactor corePressurized water reactor

A pressurized water reactor (PWR) includes a cylindrical pressure vessel defining a sealed volume, a nuclear reactor core disposed in a lower portion of the cylindrical pressure vessel, one or more control rod drive mechanisms (CRDMs) disposed in the cylindrical pressure vessel above the nuclear reactor core, and an annular steam generator surrounding the nuclear reactor core and the CRDM. In some such PWR, a cylindrical riser is disposed coaxially inside the pressure vessel and inside the annular steam generator and surrounds the nuclear reactor core and the CRDM, and the steam generator is disposed coaxially inside the cylindrical pressure vessel in an annular volume defined by the cylindrical pressure vessel and the cylindrical riser. In other such PWR, the steam generator is disposed coaxially outside of and secured with the cylindrical pressure vessel.

Owner:BWXT MPOWER INC

Vertically-segmented nuclear reactor

ActiveUS20200185114A1Improve power densitySave on fuel costsIntegral reactorsFuel elementsNuclear reactorAtomic physics

This disclosure describes various configurations and components of a molten fuel fast or thermal nuclear reactor in which one or more primary heat exchangers are located above the reactor core of the nuclear reactor.

Owner:TERRAPOWER

Nuclear reactor configured to have molten fuel pass through plural heat exchangers before returning to core

ActiveUS10497479B2Improve power densitySave on fuel costsIntegral reactorsFuel elementsNuclear reactor coreNuclear reactor

This disclosure describes various configurations and components of a molten fuel fast or thermal nuclear reactor in which one or more primary heat exchangers are located above the reactor core of the nuclear reactor.

Owner:TERRAPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com