Pressurizer surge-line separator for integral pressurized water reactors

a separator and pressurizer technology, applied in nuclear reactors, nuclear elements, greenhouse gas reduction, etc., can solve the problems of increasing the rate of nuclear reaction and core power, reducing the extent of neutron absorption, and the traditional method of separation of pressurizer from reactor coolant loop is not possibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

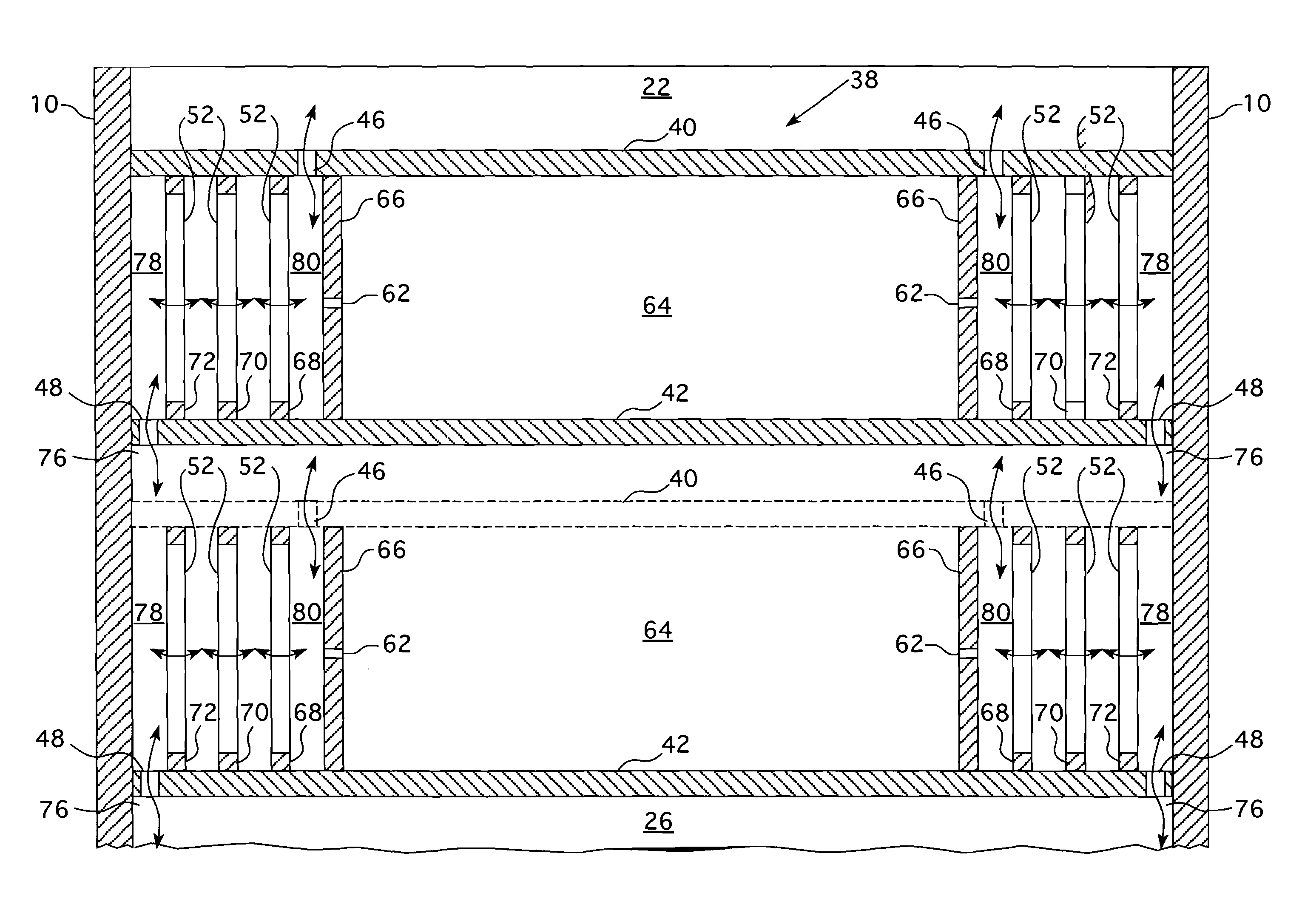

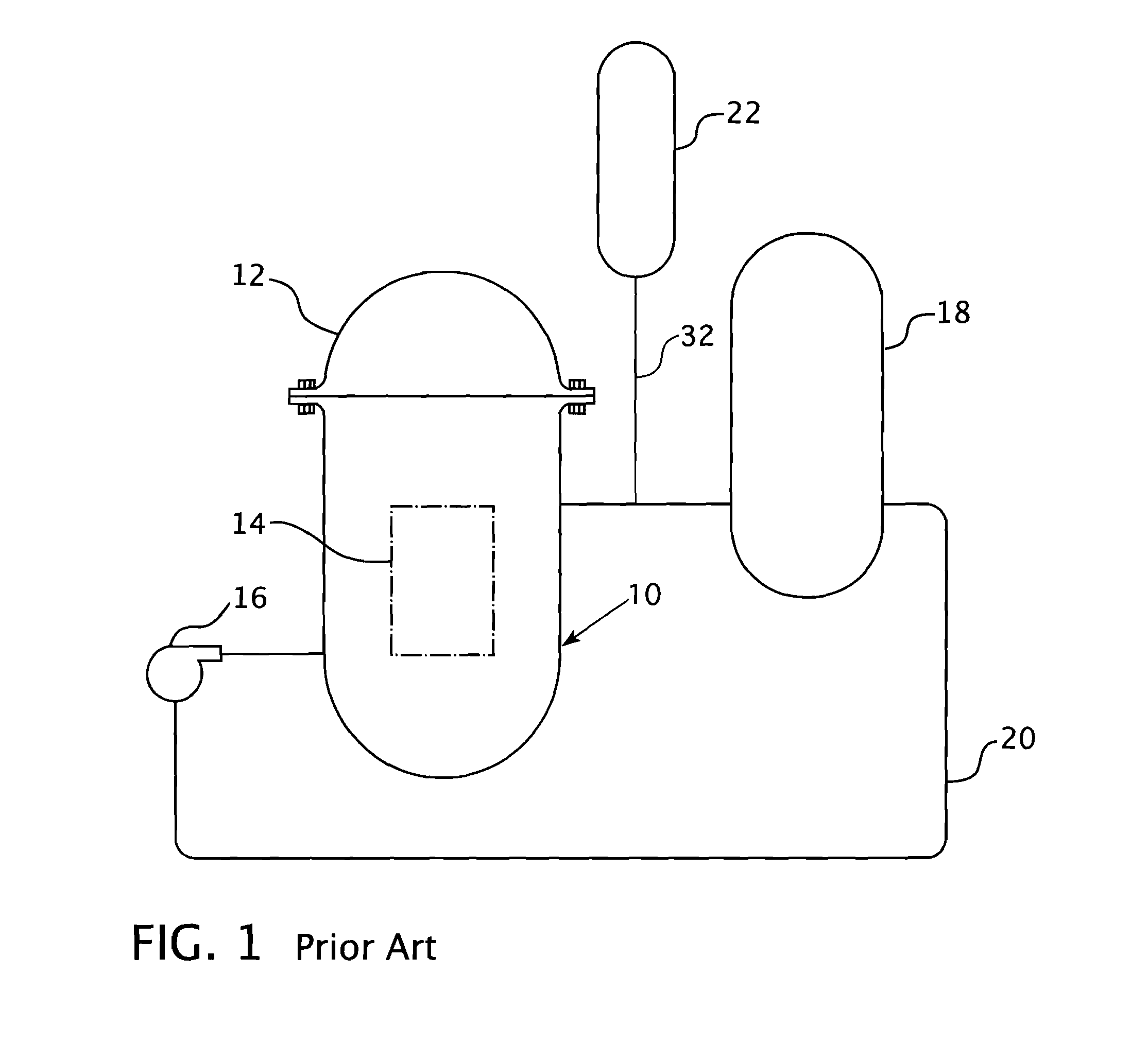

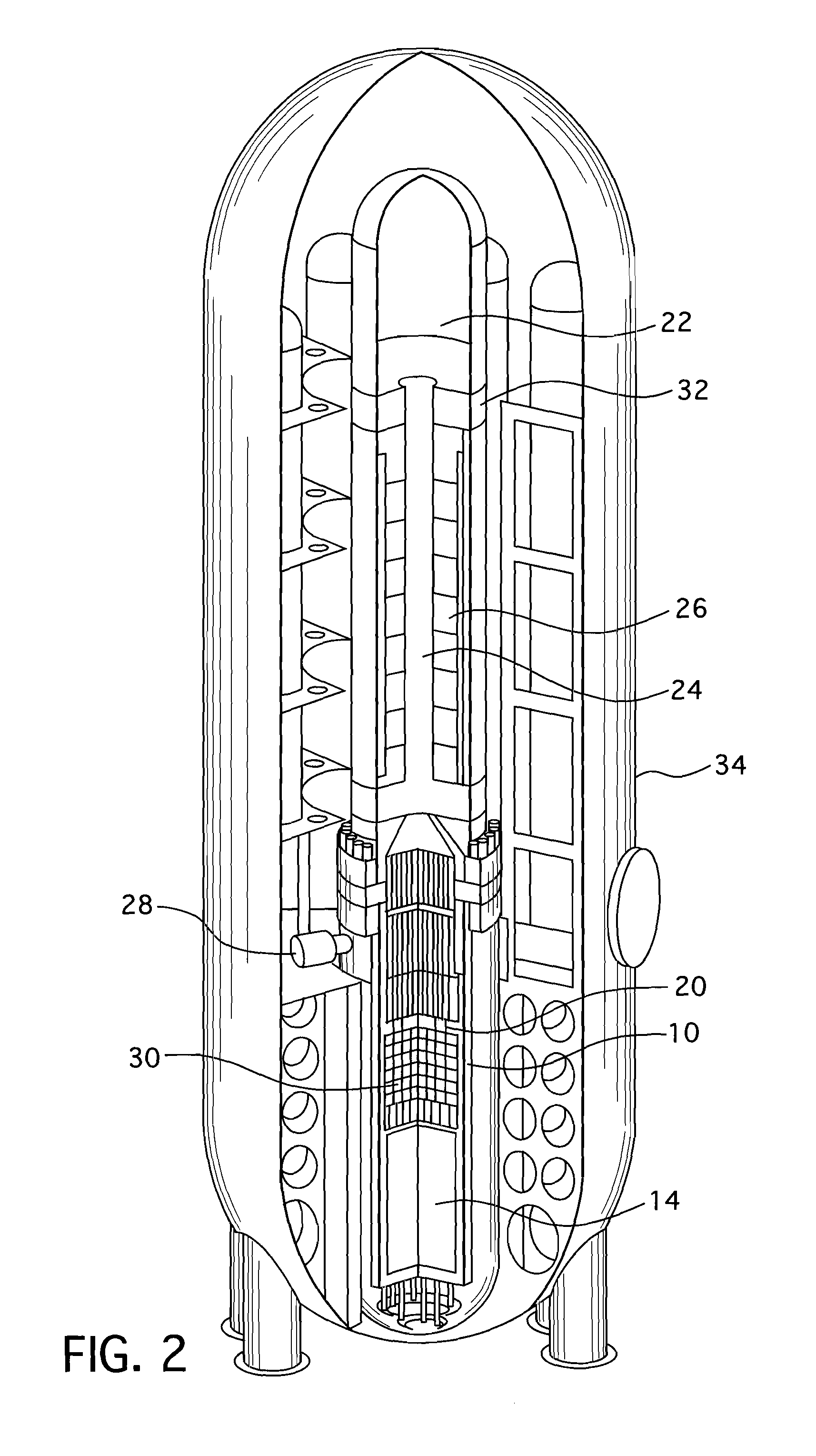

[0028]FIGS. 2 and 3 illustrate a small modular reactor design which can benefit from the surge separator design claimed hereafter. FIG. 2 shows a perspective view, partially cut away, to show the pressure vessel and its integral, internal components. FIG. 3 is an enlarged view of the pressure vessel shown in FIG. 2. Like reference characters are used among the several figures to identify corresponding components. The pressurizer 22 shown in FIGS. 2 and 3 above the surge separator 38 is of conventional construction and is integrated into the upper portion of the reactor vessel head 12 and eliminates the need for a separate component. A hot leg riser 24 which forms part of the hot leg of the reactor coolant primary loop, directs primary coolant from the core 14 to a heat exchanger 26 which surrounds the hot leg riser 24. A plurality of reactor coolant pumps 28 are circumferentially spaced around the reactor vessel at an elevation near the upper end of the upper internals 30. The react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com