Patents

Literature

62 results about "Enriched uranium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enriched uranium is a type of uranium in which the percent composition of uranium-235 has been increased through the process of isotope separation. Natural uranium is 99.284% ²³⁸U isotope, with ²³⁵U only constituting about 0.711% of its mass. U is the only nuclide existing in nature (in any appreciable amount) that is fissile with thermal neutrons.

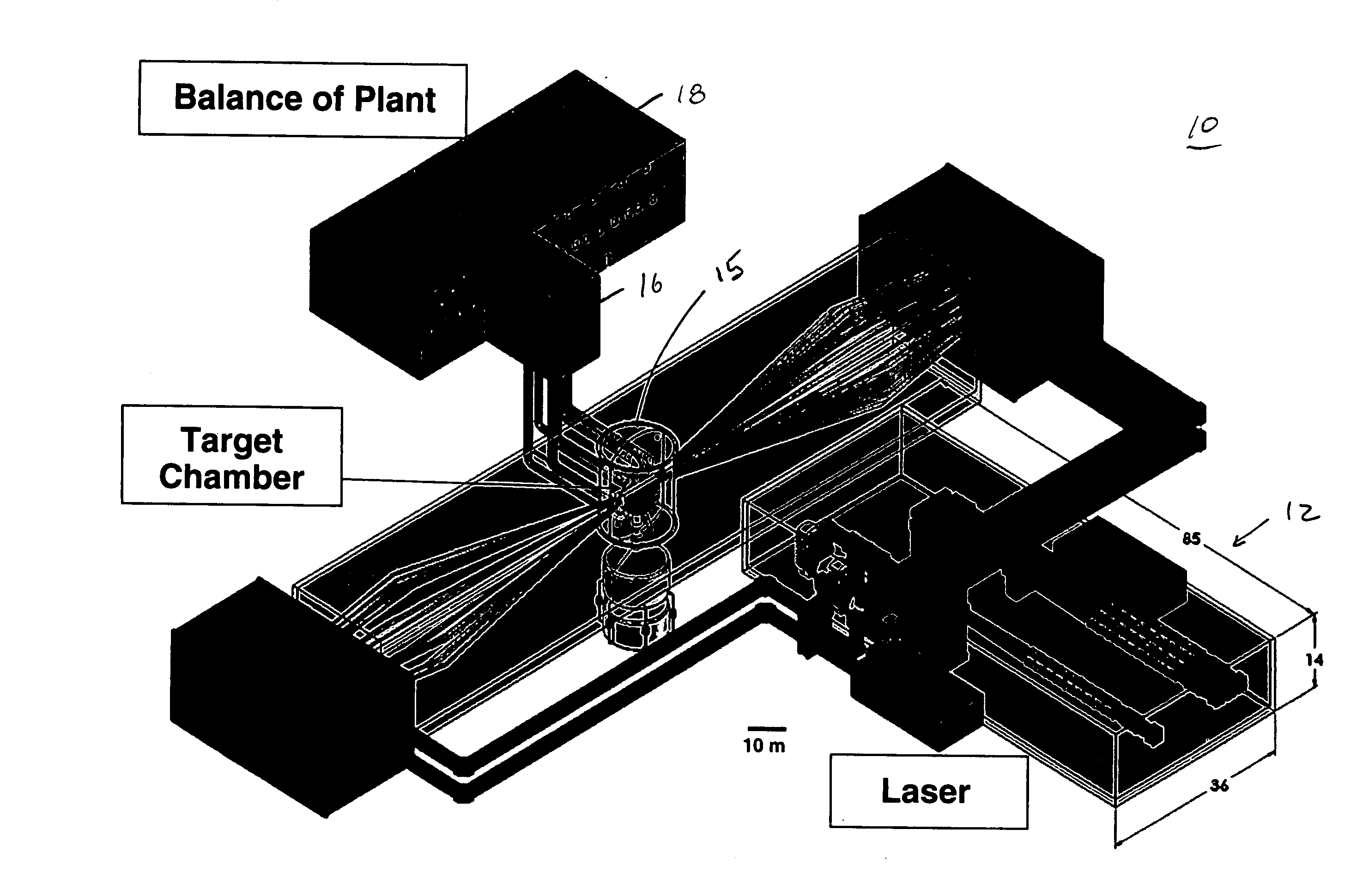

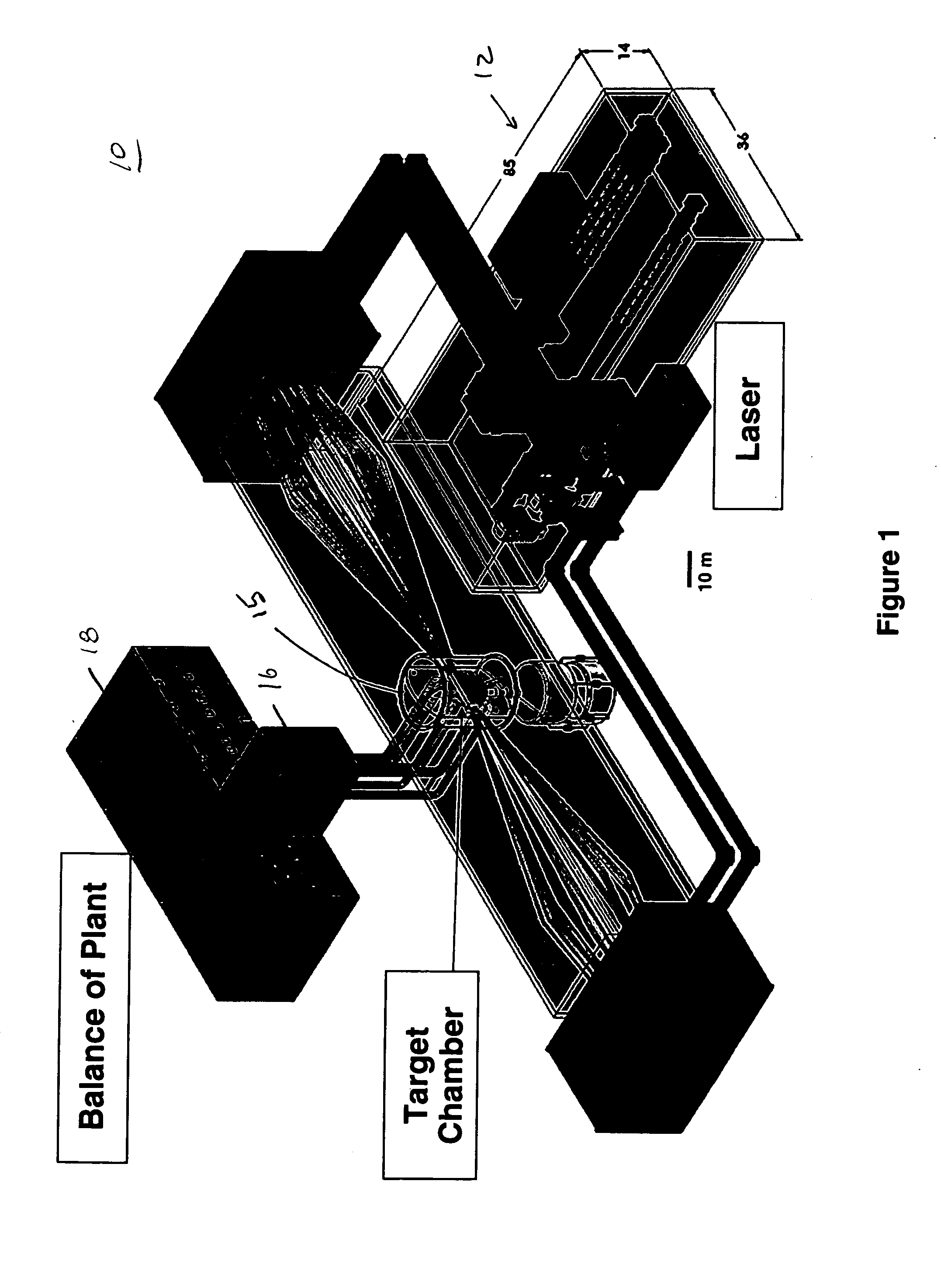

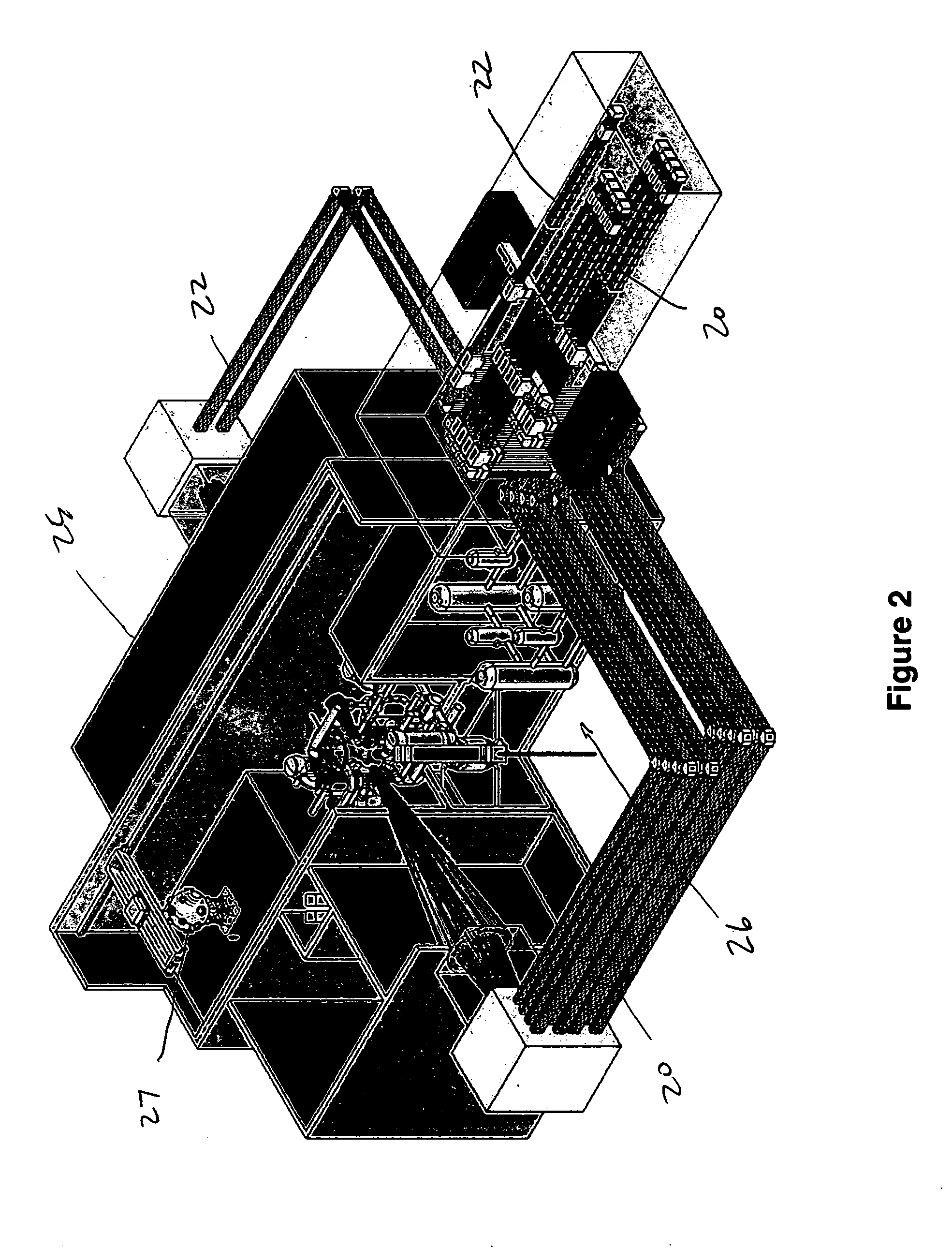

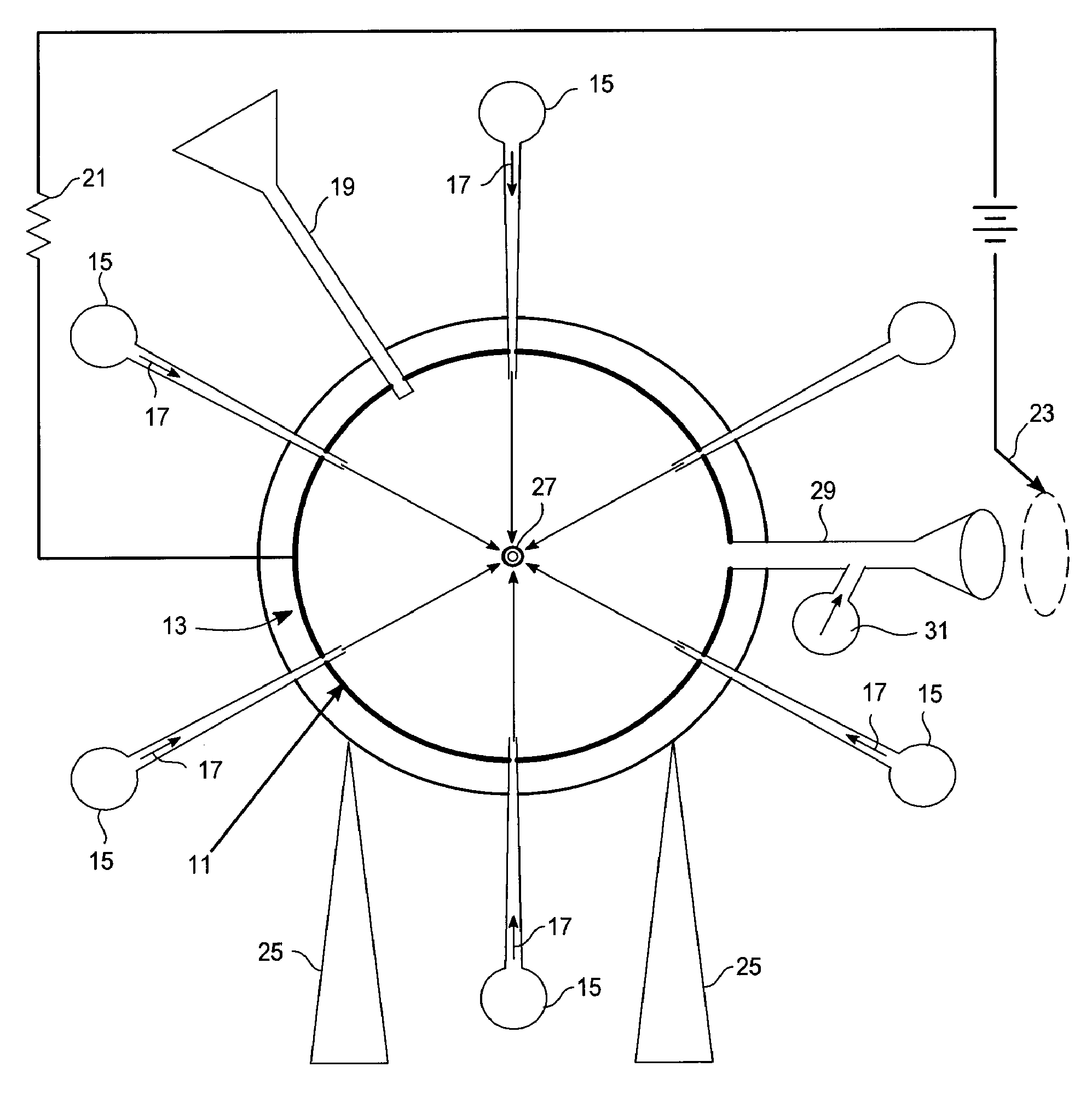

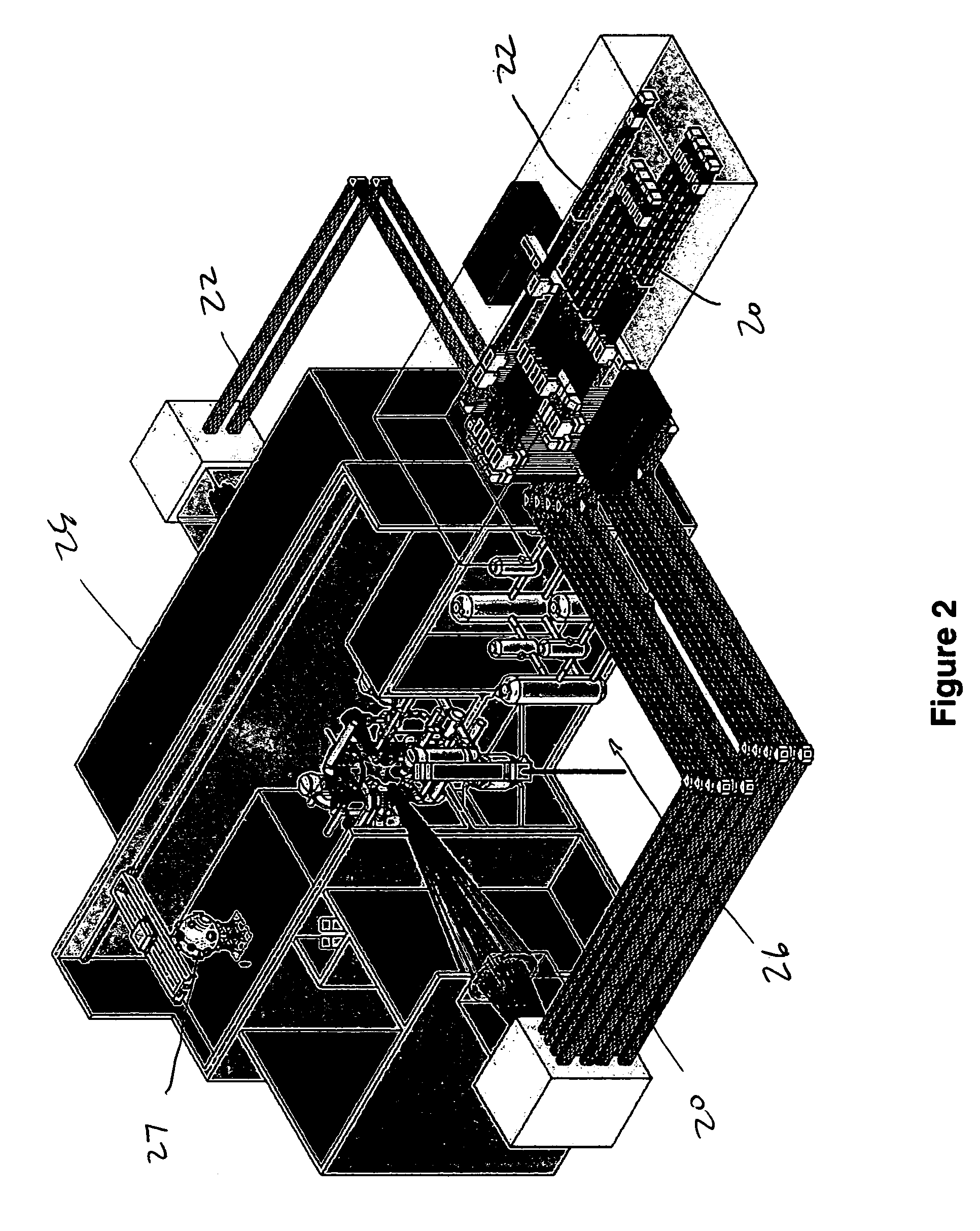

Control of a Laser Inertial Confinement Fusion-Fission Power Plant

ActiveUS20110286563A1Extended service lifeReduce spreadNuclear energy generationWaste based fuelFusion fissionEngineering

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Thermonuclear plasma reactor for rocket thrust and electrical generation

InactiveUS20090000268A1Easy to triggerDownsize working reactionCosmonautic vehiclesNuclear energy generationHigh energyNuclear engineering

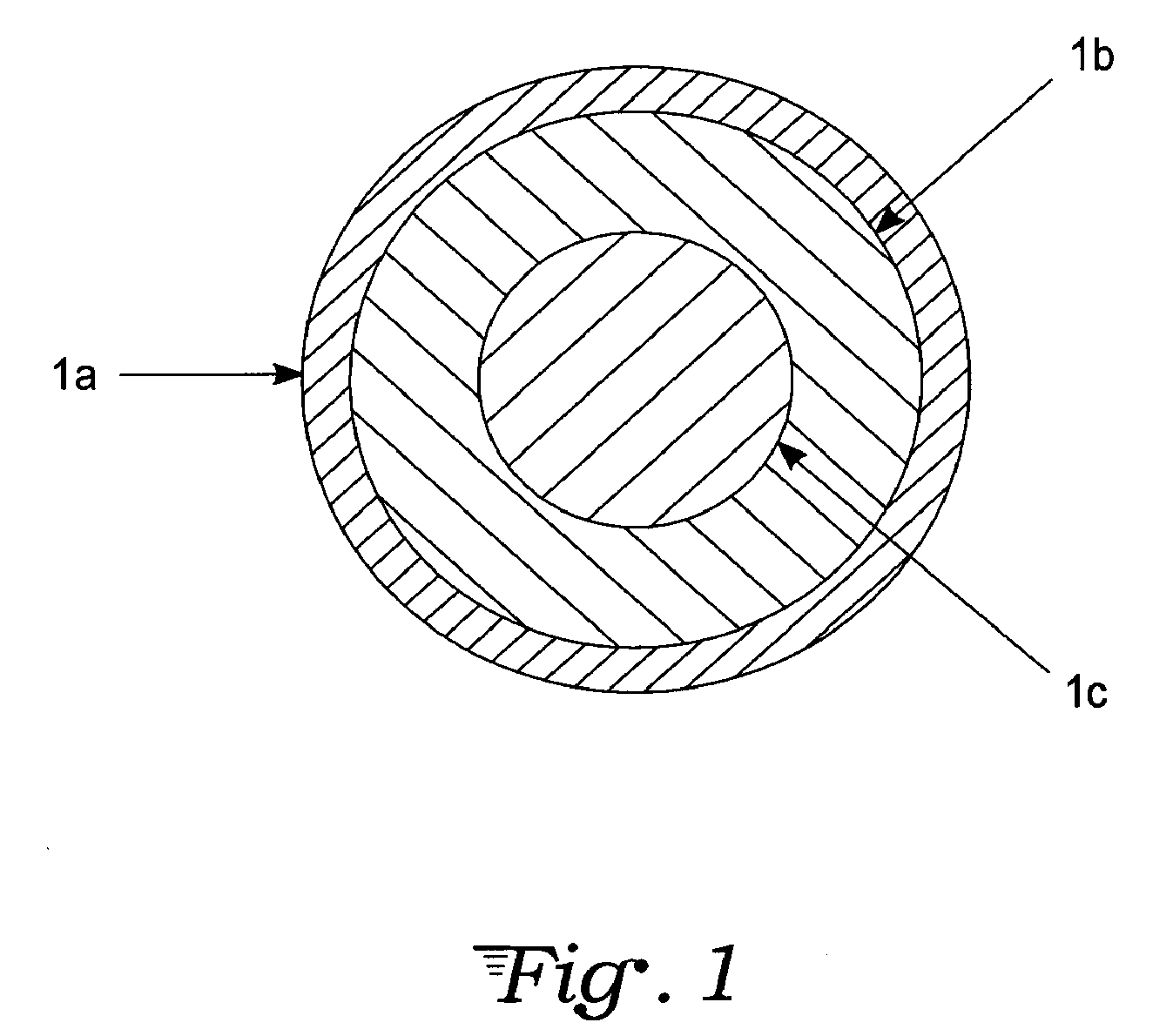

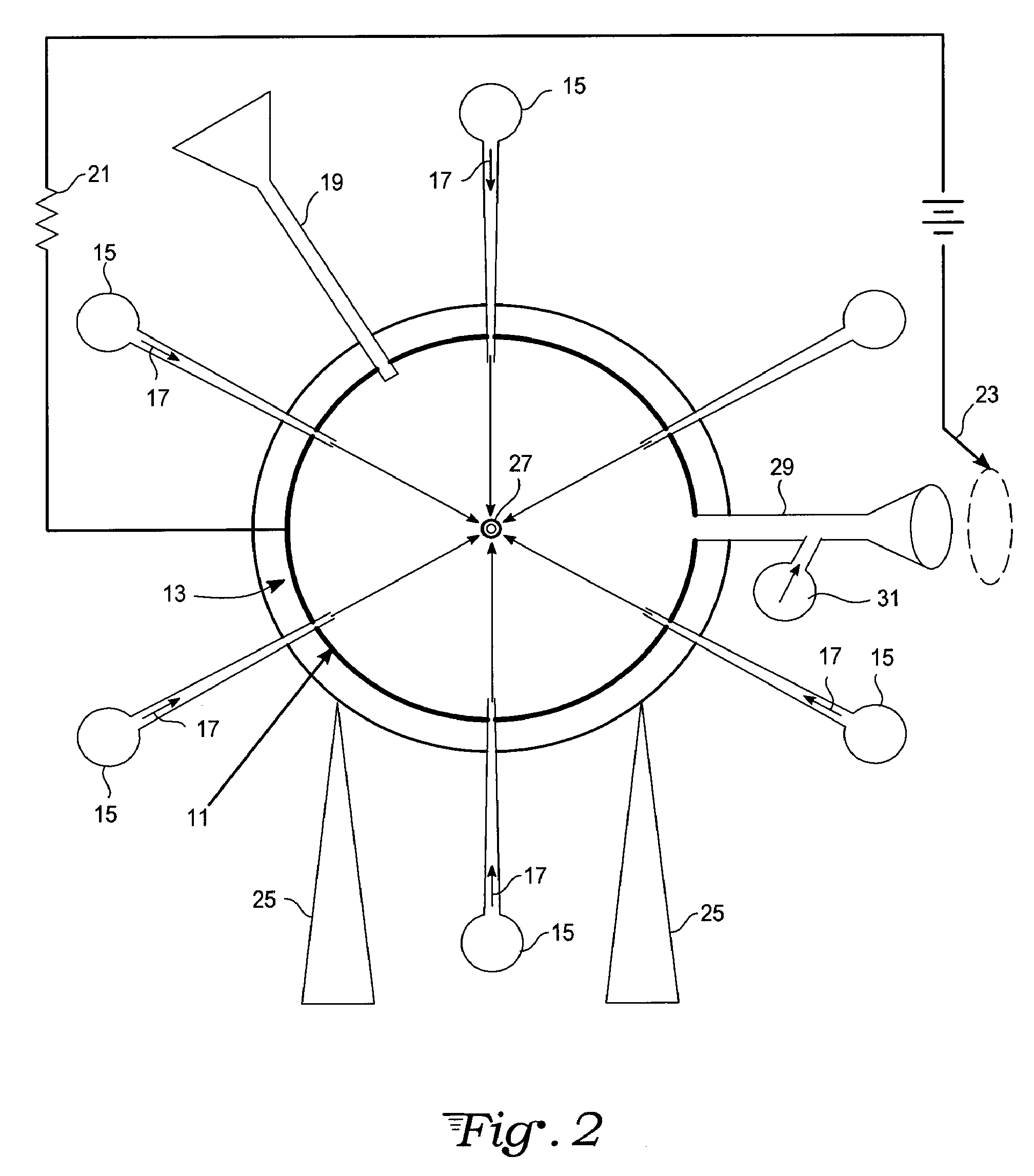

A reactor system produces plasma rocket thrust using alpha-initiated atomic fuel pellets without the need for a critical mass of fissionable material. The fuel pellets include an outer layer reactive material to alpha particles to generate neutrons (e.g., porous lead or beryllium), an under-layer of fissionable material (e.g., thorium or enriched uranium), and an optional inner core of fusion material (e.g., heavy water ice, boron hydride). The pellets are injected one at a time into a charged reaction chamber containing a set of alpha beam channels, possibly doubling as ion accelerators, all directed toward a common point. Alpha particles converging on each successive pellet initiate an atomic reaction in the fissionable under-layer, via a neutron cascade from the pellet outer layer, producing plasma that is confined within the chamber. This may be enhanced by atomic fusion of the optional inner core. The resulting high-energy plasma creates electrostatic pressure on the chamber and is allowed to exit the chamber through a port. An ion accelerator at the exhaust port of the chamber accelerates outgoing plasma ions, possibly with added reaction mass, to generate the rocket thrust. An electric circuit that includes the charged chamber may collect the electrons in the plasma to help power the ion accelerator(s).

Owner:YURASH GREG J

Control of a laser inertial confinement fusion-fission power plant

ActiveUS9171646B2Extended service lifeNuclear energy generationWaste based fuelFusion fissionEngineering

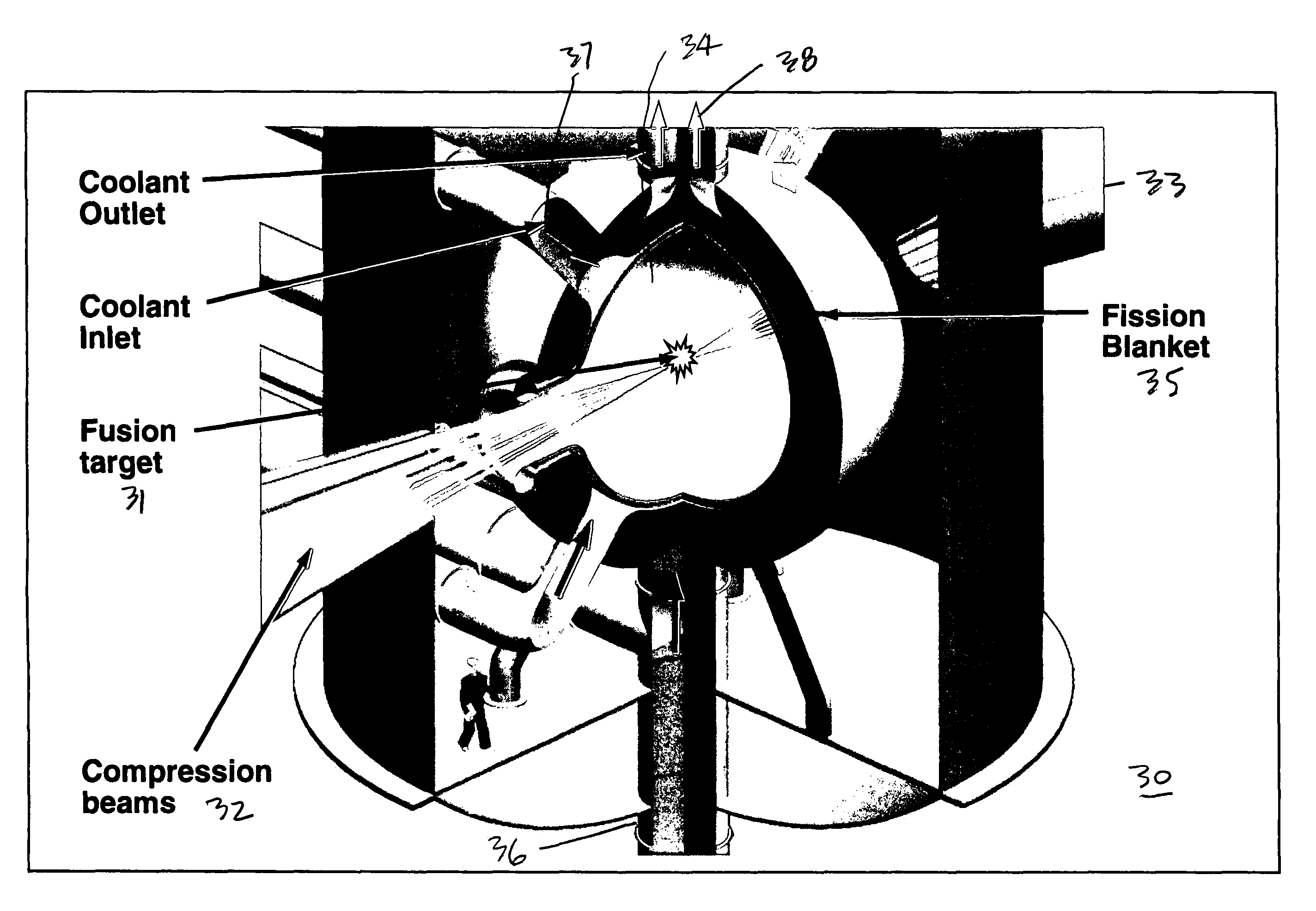

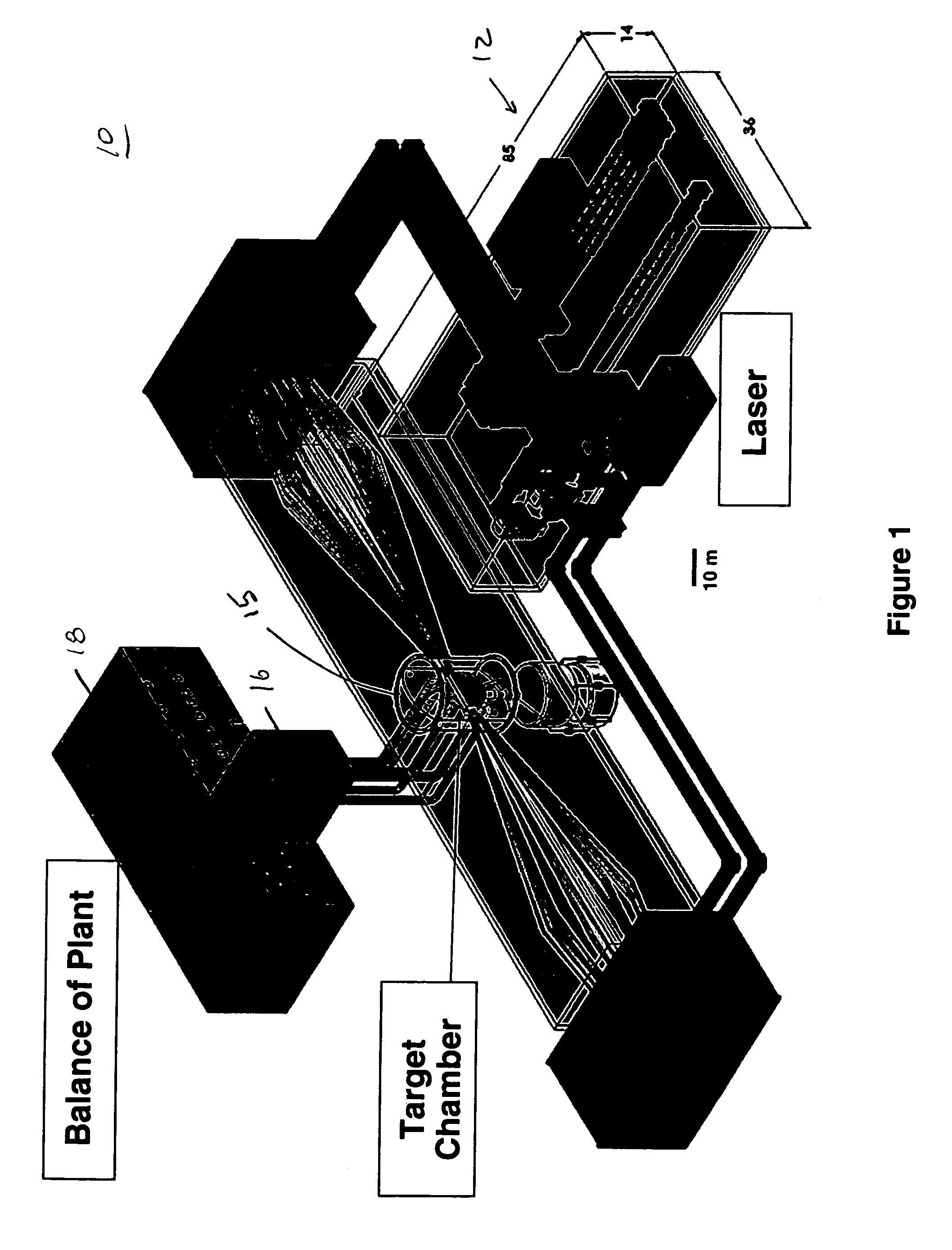

A laser inertial-confinement fusion-fission energy power plant is described. The fusion-fission hybrid system uses inertial confinement fusion to produce neutrons from a fusion reaction of deuterium and tritium. The fusion neutrons drive a sub-critical blanket of fissile or fertile fuel. A coolant circulated through the fuel extracts heat from the fuel that is used to generate electricity. The inertial confinement fusion reaction can be implemented using central hot spot or fast ignition fusion, and direct or indirect drive. The fusion neutrons result in ultra-deep burn-up of the fuel in the fission blanket, thus enabling the burning of nuclear waste. Fuels include depleted uranium, natural uranium, enriched uranium, spent nuclear fuel, thorium, and weapons grade plutonium. LIFE engines can meet worldwide electricity needs in a safe and sustainable manner, while drastically shrinking the highly undesirable stockpiles of depleted uranium, spent nuclear fuel and excess weapons materials.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

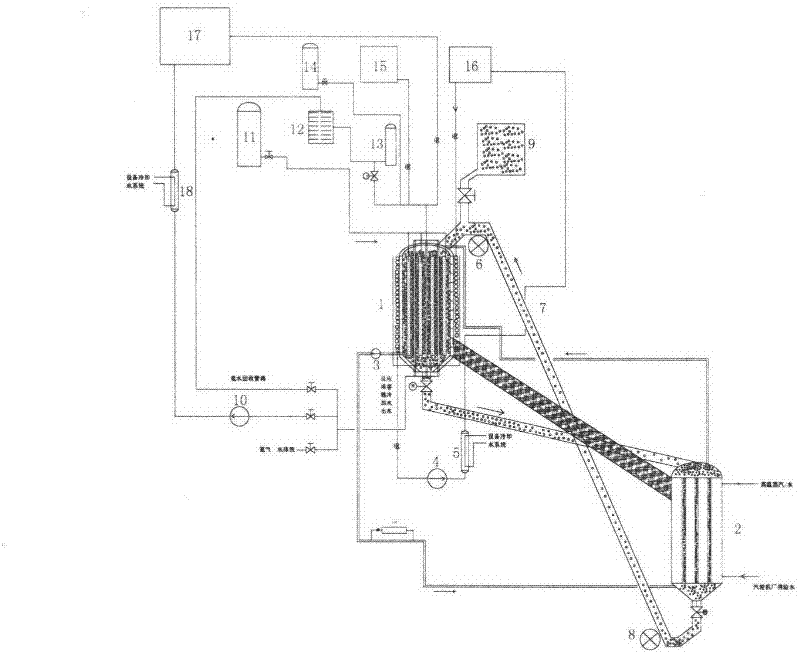

High-temperature supercritical nuclear reactor

InactiveCN102568624AImprove economyTake advantage ofNuclear energy generationCooling arrangementFast-neutron reactorMaterials science

The invention relates to a high-temperature supercritical nuclear reactor. A spherical solid is used as a coolant of the nuclear reactor, which is different from common nuclear reactors that adopt light water, heavy water, gas and liquid sodium. The spherical solid coolant can be graphite spheres coated with silicon carbide, stainless steel spheres, graphite spheres coated with stainless steel and the like. The spherical solid has the characteristic of good rolling ability, so that the spherical solid can roll to a steam generator under the action of gravity after heating in the reactor, and the purpose of transferring heat from the reactor to the steam generator is achieved. The reactor is applicable to both thermal neutron reactor and fast neutron reactor, and natural uranium, low-enriched uranium, plutonium and thorium can be used as nuclear fuel. The temperature of high-temperature steam / water outputted by the steam generator can reach 900 DEG C, the same parameters to a thermal power station can be reached, the requirement of supercritical even ultra-supercritical can be satisfied, and the high-temperature supercritical nuclear reactor has high safety and reliability.

Owner:李正蔚

Portable/mobile fissible material detector and methods for making and using same

InactiveUS20100301196A1Reduce total powerSmall sizeLaser detailsMaterial analysis using wave/particle radiationDelayed neutronPu element

A portable and / or mobile detector for highly enriched uranium (HEU) and weapon grade plutonium (WGPu) is disclosed the detects HEU and / or WGPu based on neutron induced fission of a portion of the HEU and / or WGPu and detecting delayed neutron and / or γ-rays emission from delayed neutron emitters formed from the induced fission reactions.

Owner:CHU WEI KAN +1

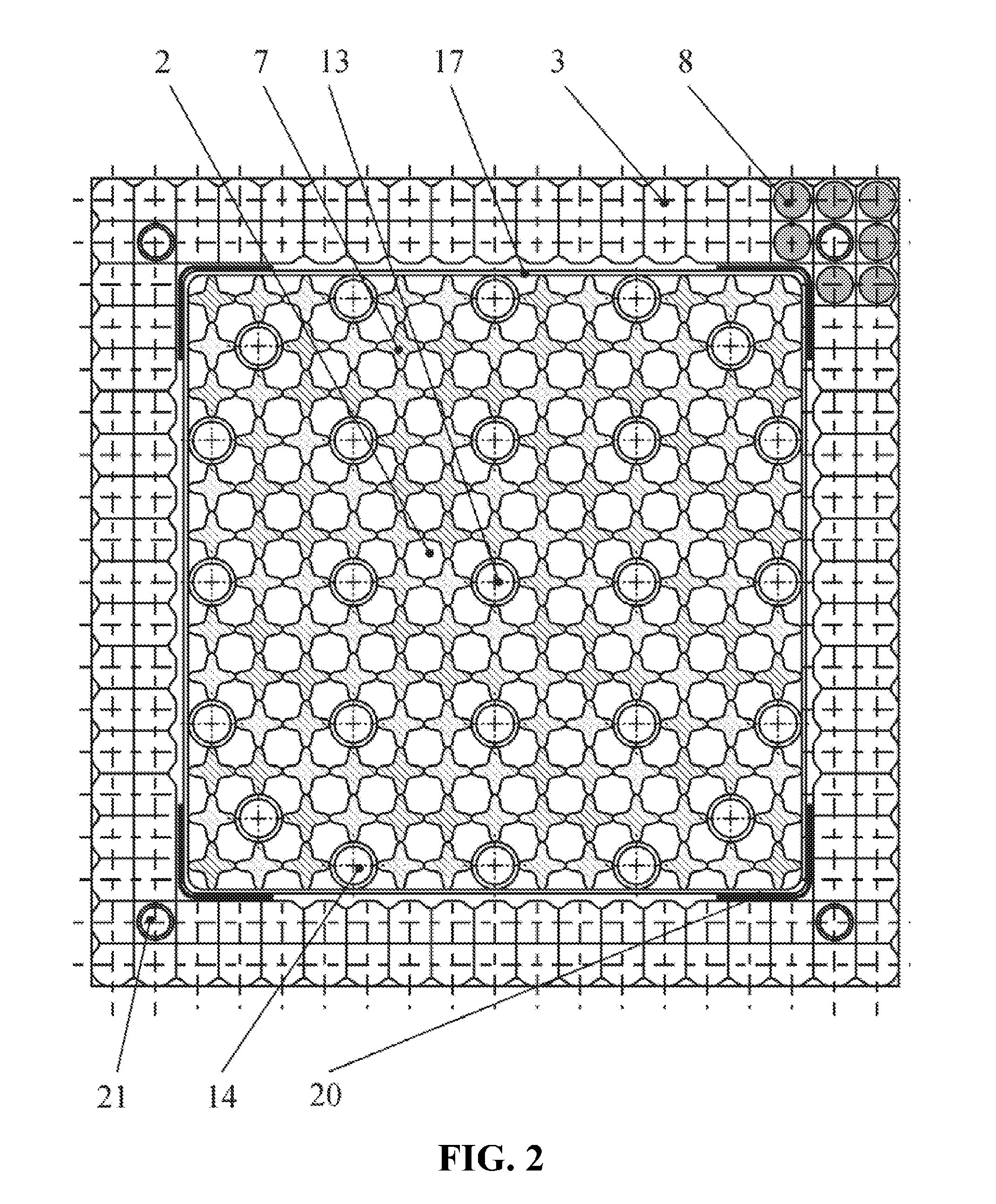

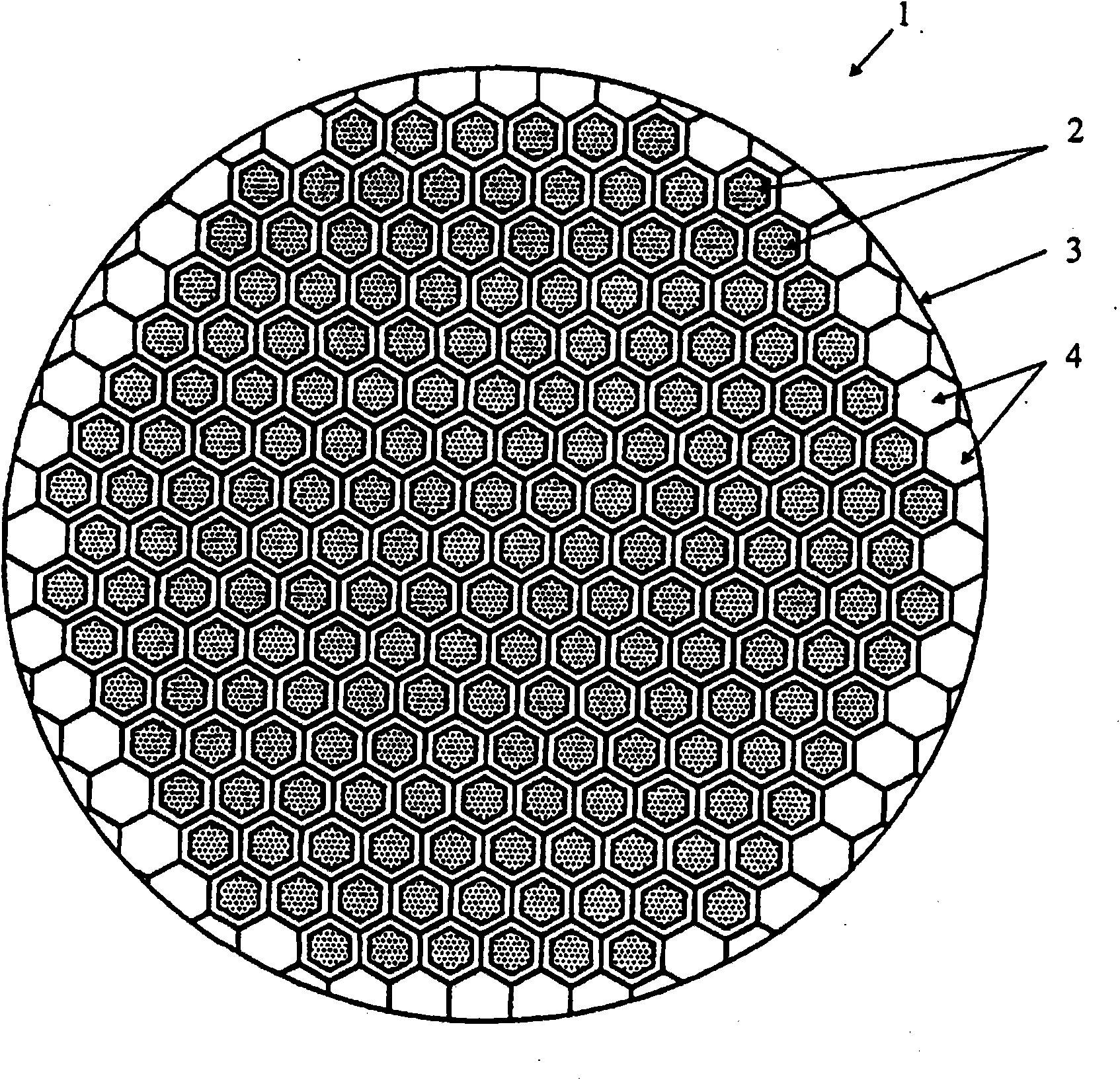

Light-water reactor fuel assembly (alternatives), a light-water reactor, and a fuel element of fuel assembly

ActiveUS20110311016A1Easy to installFreedom of movementFuel elementsNuclear energy generationEngineeringThorium

A 17×17 jacketless fuel assembly for a PWR-type light-water reactor uses thorium as the fuel. The fuel assembly has a square shape in the plan view, a seed region, a blanket region that encircles it, an upper nozzle, and a lower nozzle. The fuel elements of the seed region re arranged in the rows and columns of a square coordinate grid and have a four-lobed profile that forms spiral spacer ribs along the length of a fuel element. The blanket region contains a frame structure within which a bundle of fuel elements made from thorium with the addition of enriched uranium is positioned. The blanket region fuel elements are arranged in the two or three rows and columns of a square coordinate grid.

Owner:THORIUM POWER

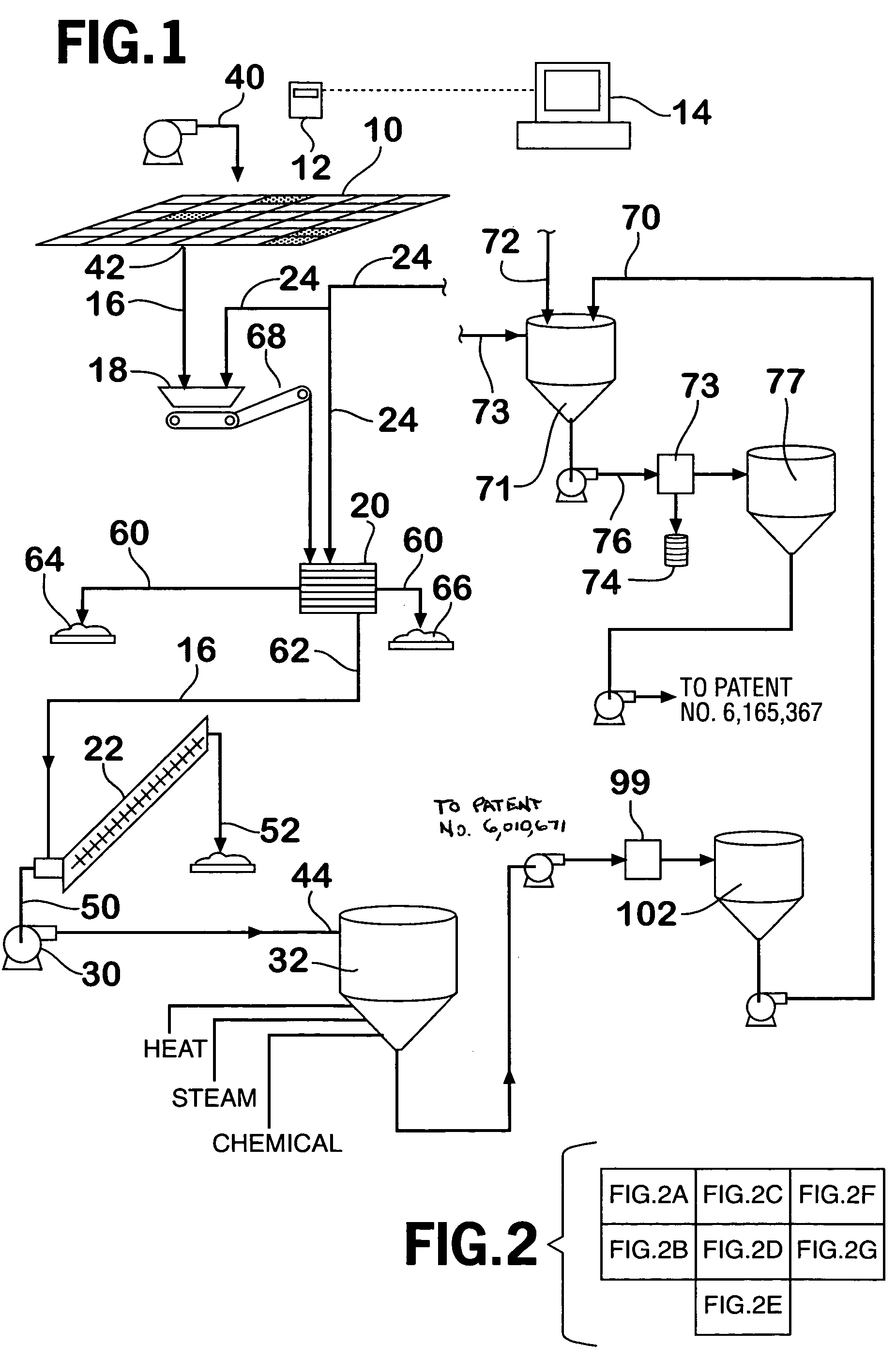

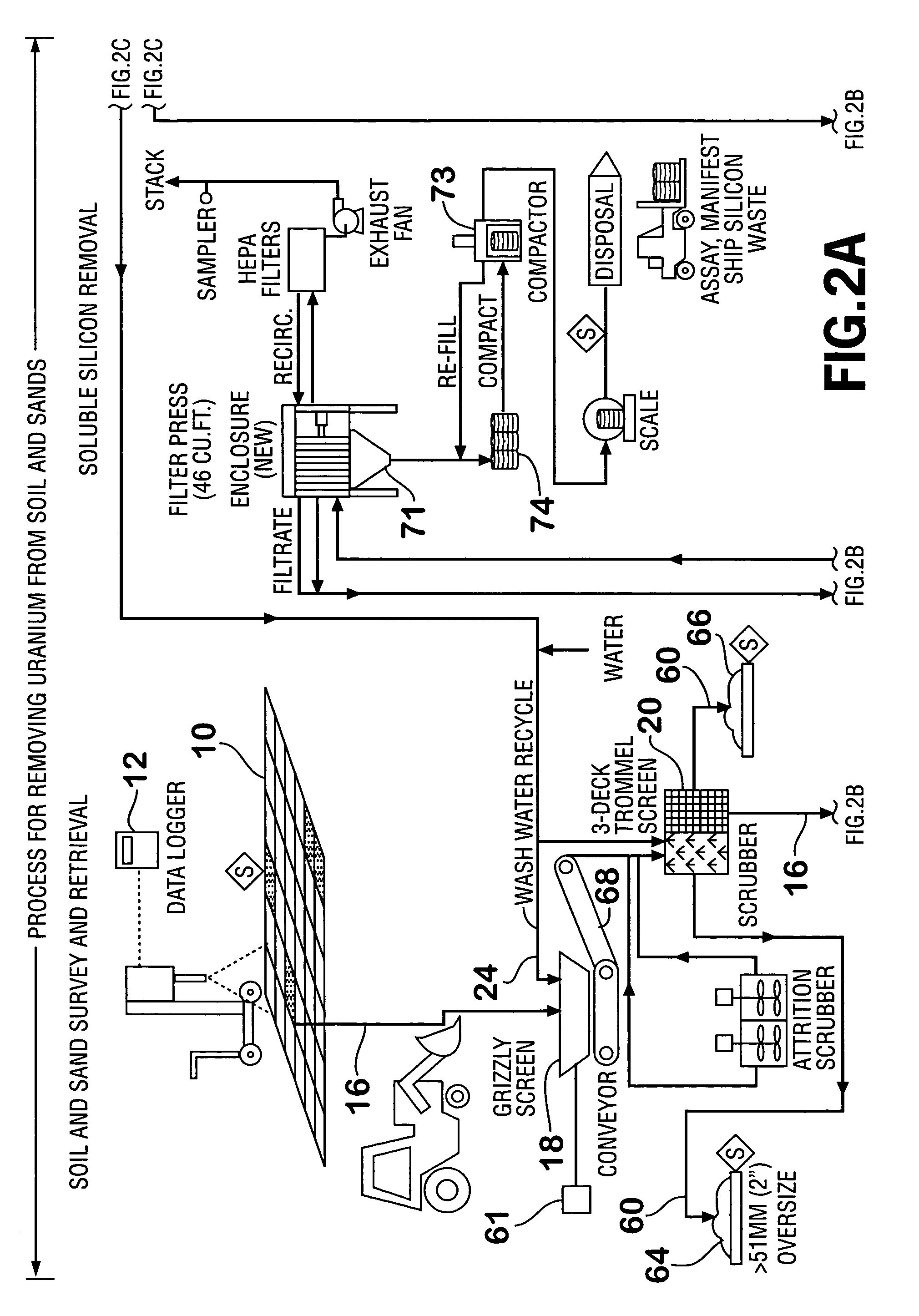

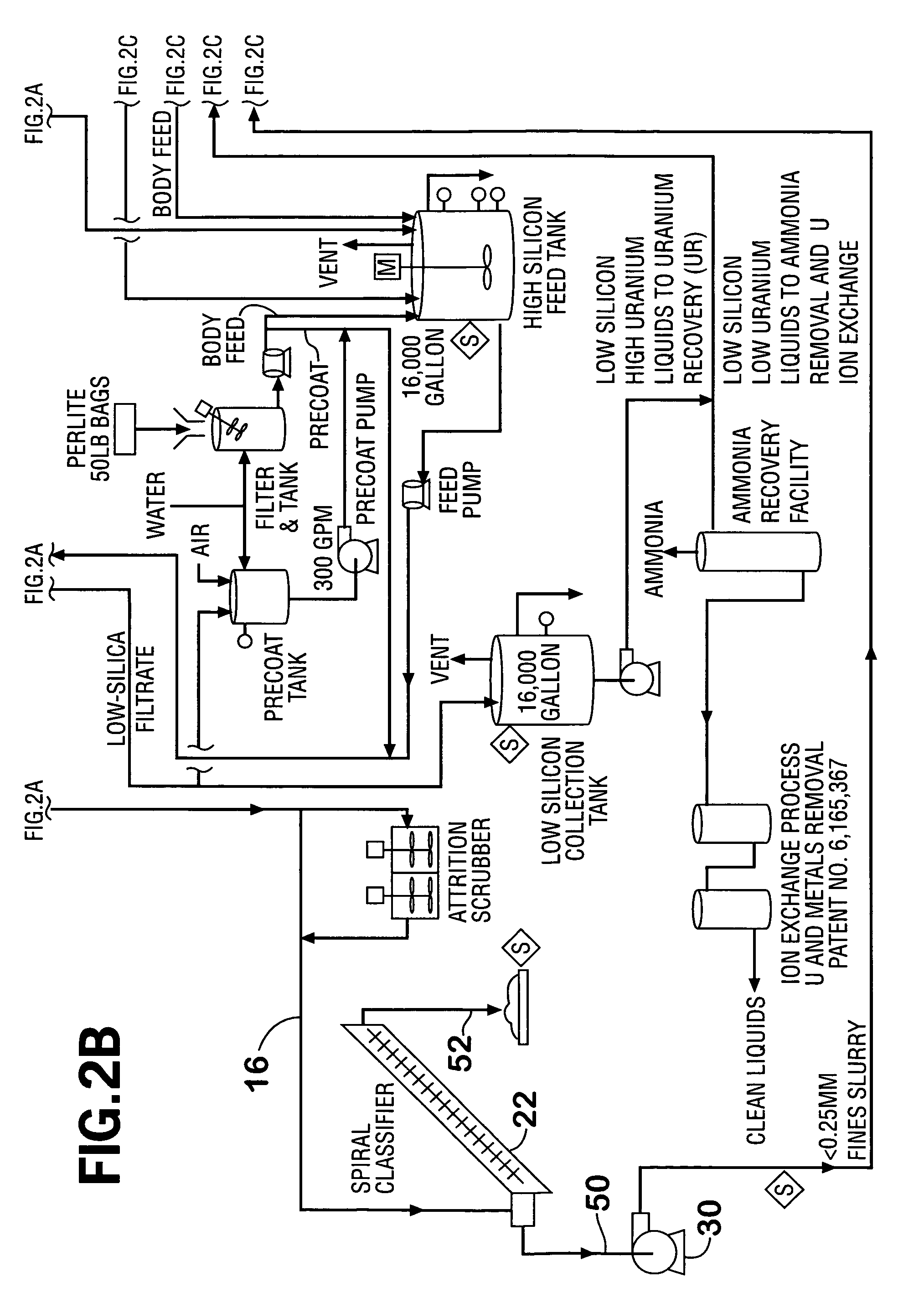

Apparatus and method for aiding in the removal of enriched uranium from soils

ActiveUS7390934B1Limited amountMinimize ultimate disposal volumeSolvent extractionTransuranic element compoundsAmmoniaSilicon

A method and apparatus for removing uranium (IV) and uranium (VI) from sands and soils. The method and device assays a volume of soil and determines a presence and position of uranium enrichment. A concentration of uranium enrichment is determined, and compared to a threshold concentration. The volume of soil is processed and transported to a coarse screen, deck screen and classified in a classifier. In the classifier, the volume of soil is separated into a washed and fines fraction, assayed and transported to a uranium recovery facility, then transported to a silicon removal process and subsequent ammonia and metals removal processes.

Owner:AREVA NP INC

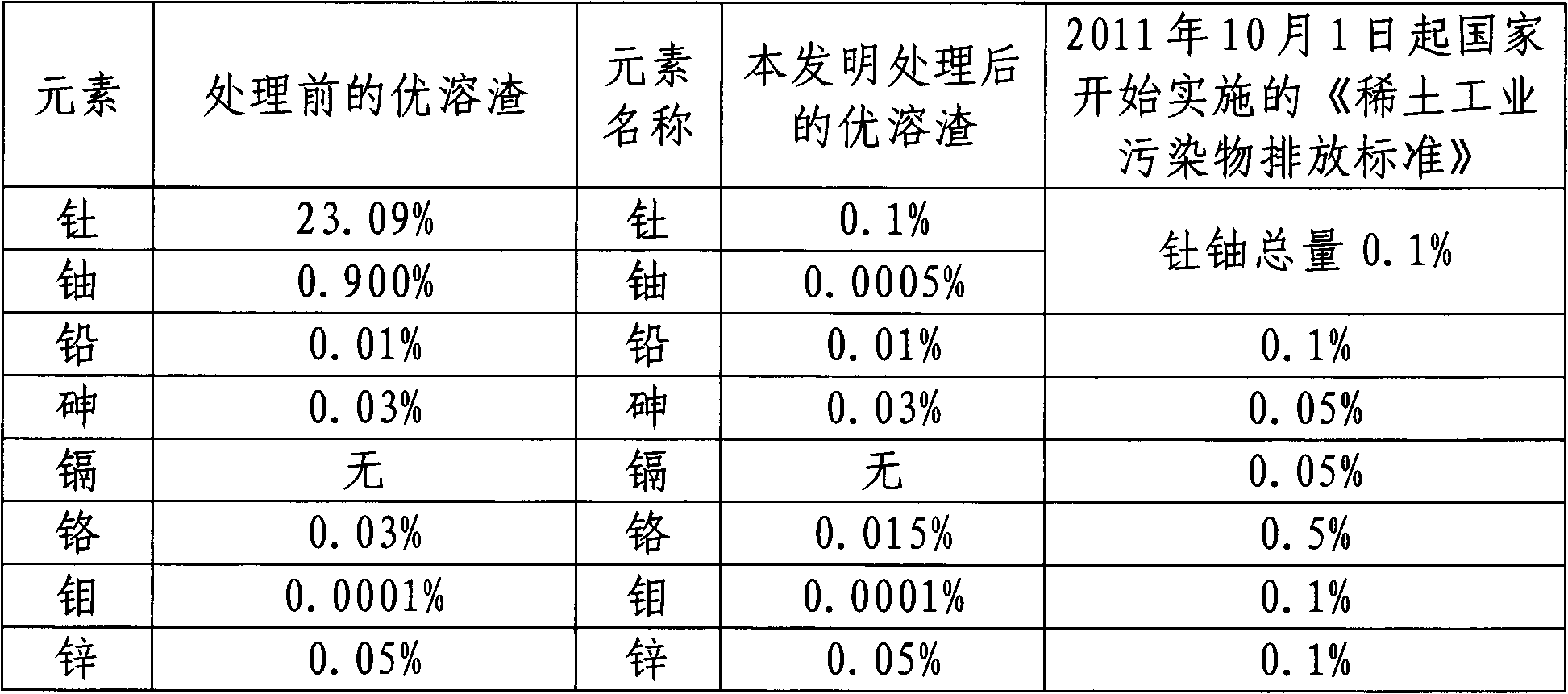

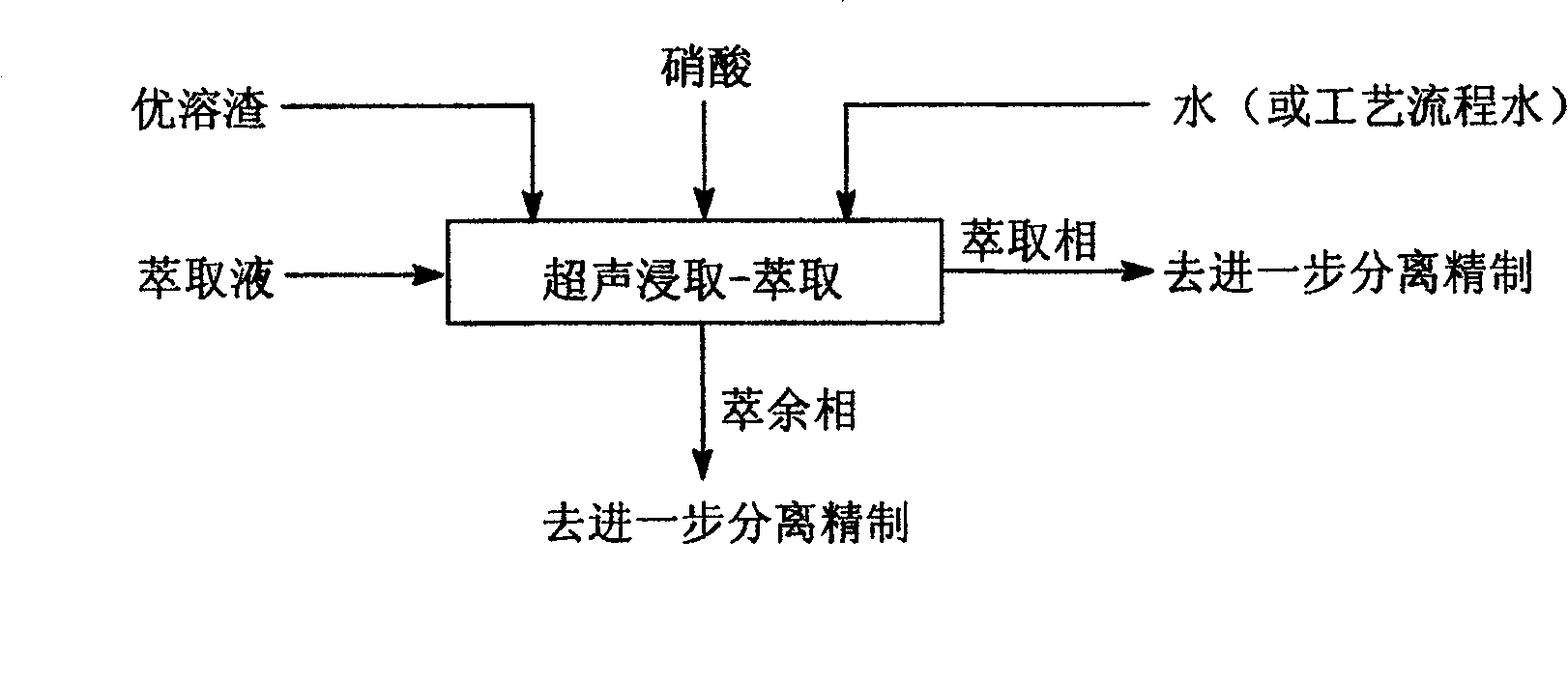

Method for separating and extracting uranium and thorium from superior molten slag

InactiveCN102154560ASimple processEasy to operateProcess efficiency improvementSeparation technologyRare earth

The invention relates to the field of hydrometallurgy, in particular to a method for separating enriched uranium and thorium from rare earth superior molten slag. In the method for separating the enriched uranium and thorium from the superior molten slag, disclosed by the invention, the technical scheme for performing alkaline leaching on the superior molten slag, performing acid leaching on precipitated uranium and separating precipitated thorium is adopted, so that the precipitate of uranyl and precipitate of thorium are obtained respectively. Due to the adoption of a separation technology of stepwise leaching and precipitating, complete separation of thorium and uranium is realized, the equipment and process flow are simple, the operation is convenient, raw material are readily available, and the environmental pollution is reduced.

Owner:王北华

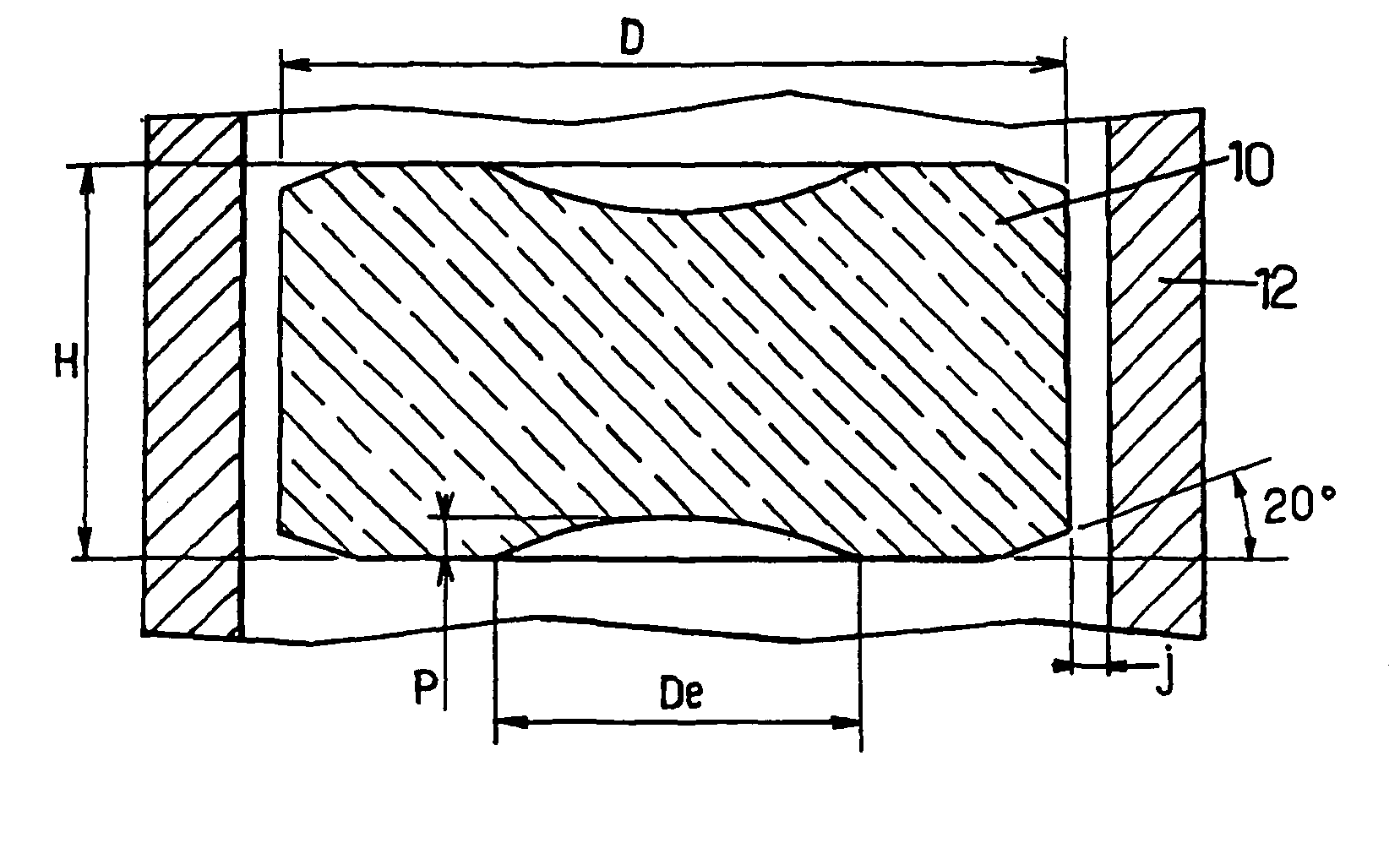

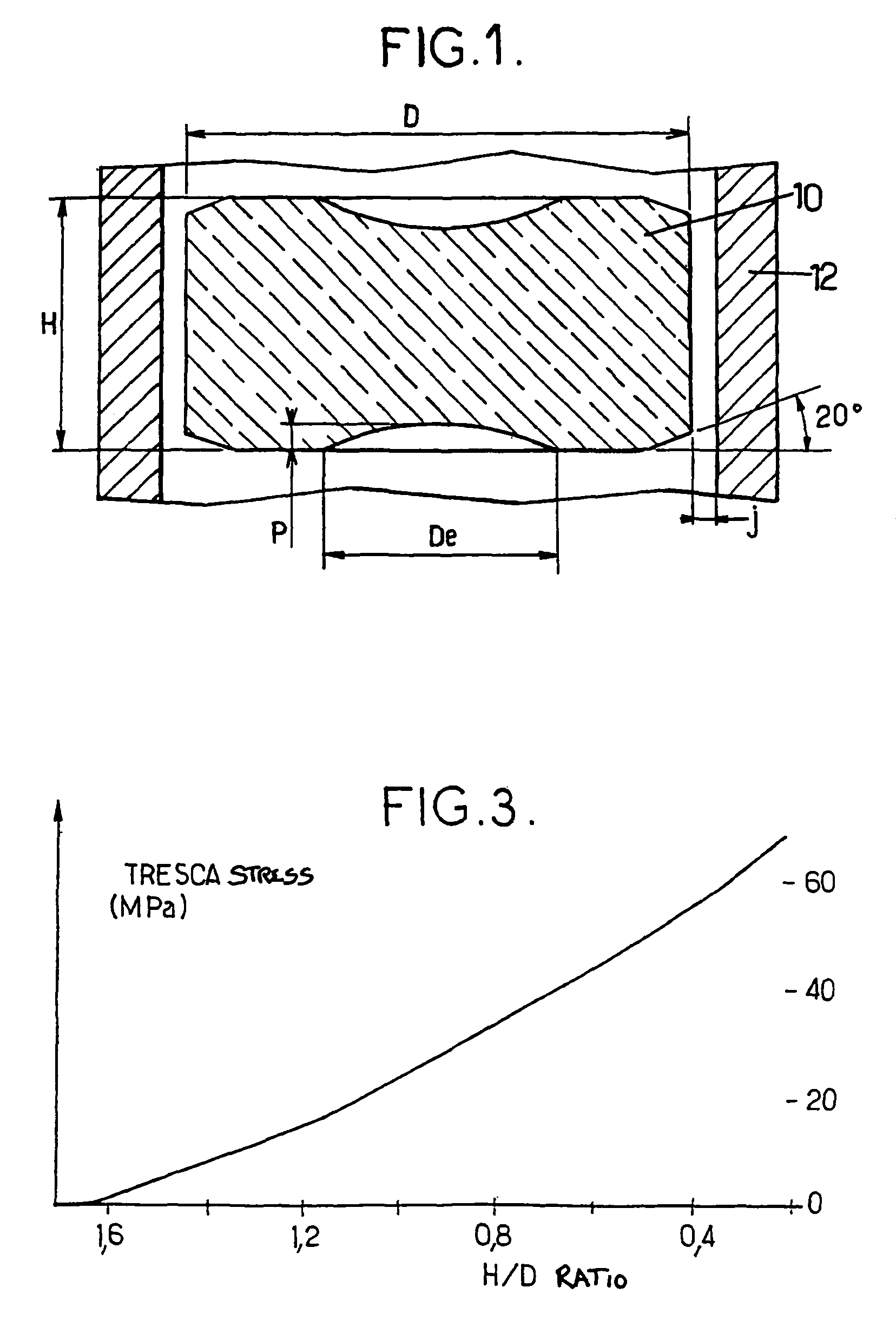

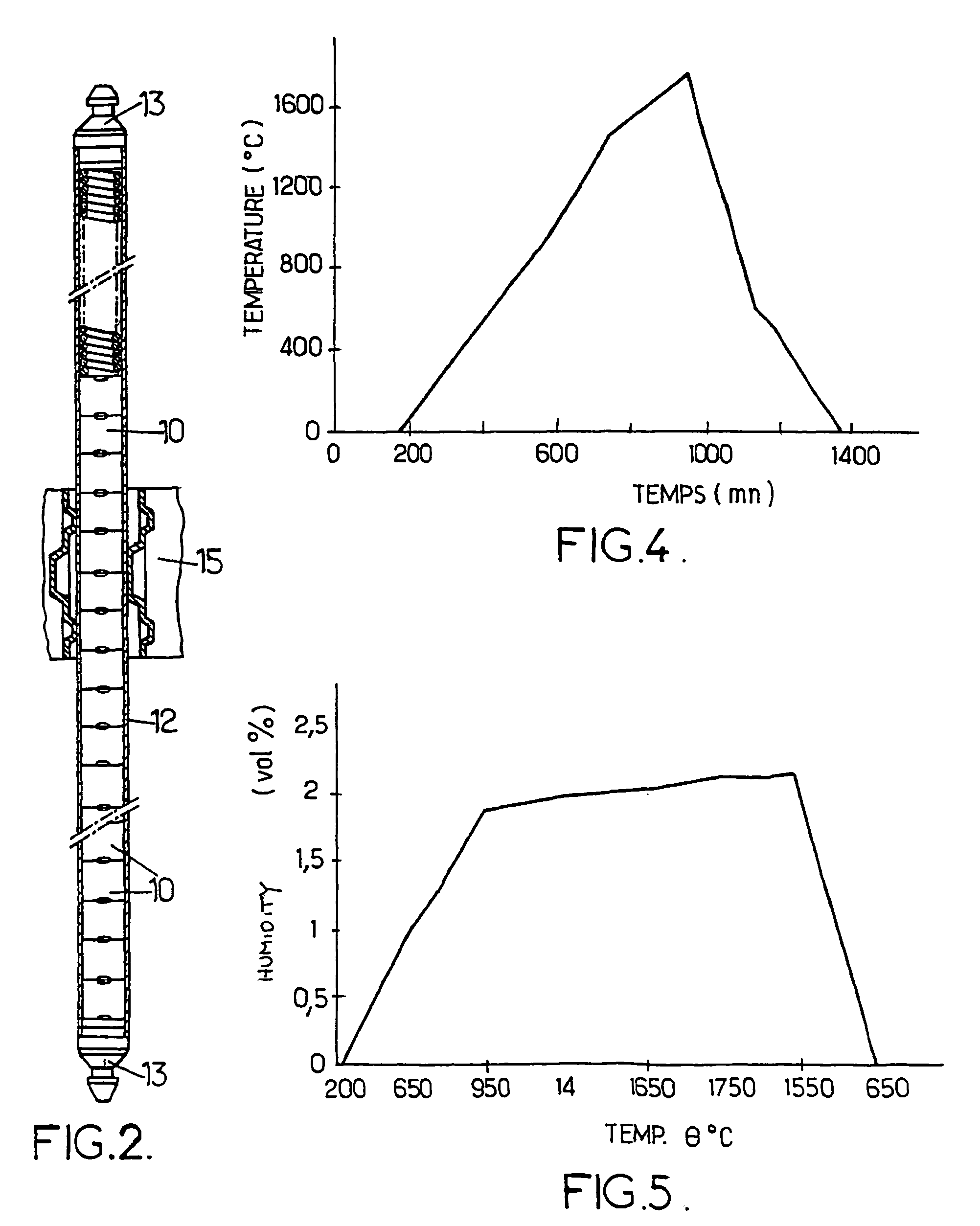

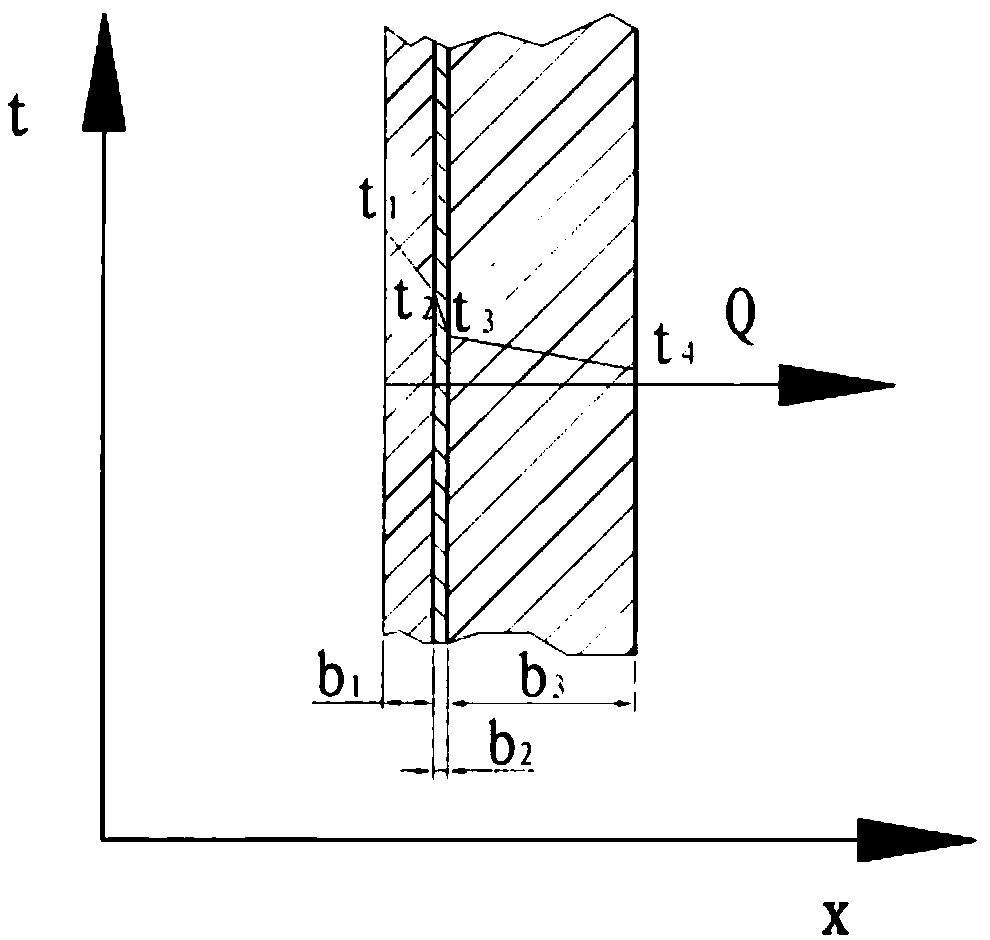

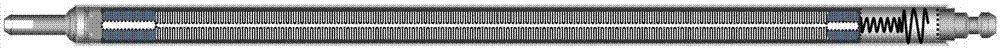

Pencil comprising a stack of oxide nuclear fuel pellets

InactiveUS9053830B2Reduce hoop stressImprove creepFuel elementsNuclear energy generationUranium oxideEnriched uranium

The rod contains substantially cylindrical oxide nuclear fuel pellets based on enriched uranium oxide. The H / D ratio of the height over the diameter of the pellets lies in the range 0.4 to 0.6. The initial diametral clearance between the pellets and the cladding does not exceed 200 μm.

Owner:FRAMATOME ANP

Method for separating enriched uranium, thorium mixture and rare earth from preferred slag

The invention discloses a separating method of enriched uranium and thorium composition and rare earth, which comprises the following steps: leaching slag; extracting; separating extracting phase, residual phase and insoluble solid; obtaining the product.

Owner:YANGZHOU UNIV +2

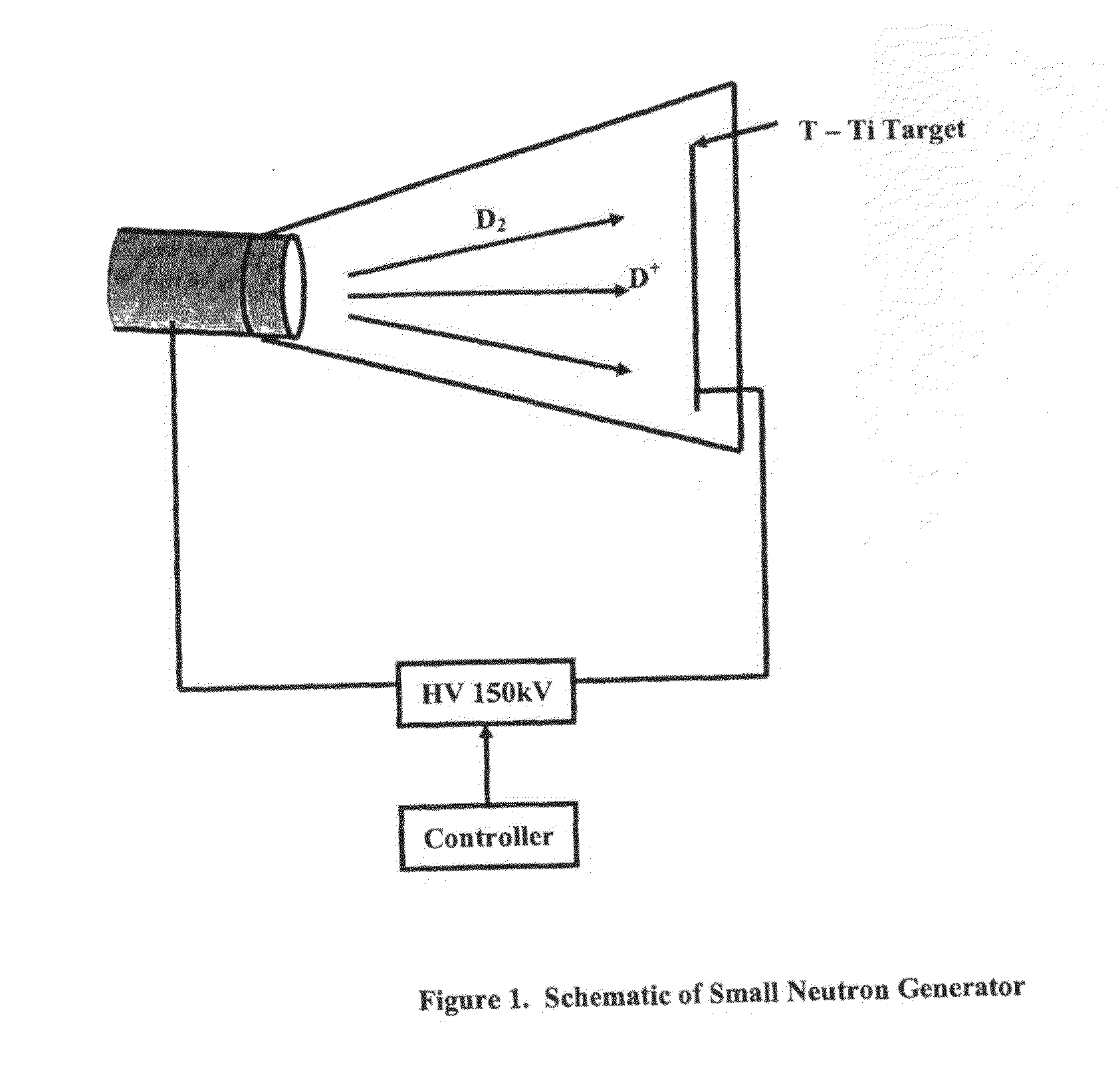

Miniature Neutron Generator for Active Nuclear Materials Detection

InactiveUS20100193685A1Reduce power consumptionEasy maintenanceMaterial analysis using wave/particle radiationNuclear energy generationTransport systemActive detection

Owner:UNIV HOUSTON SYST

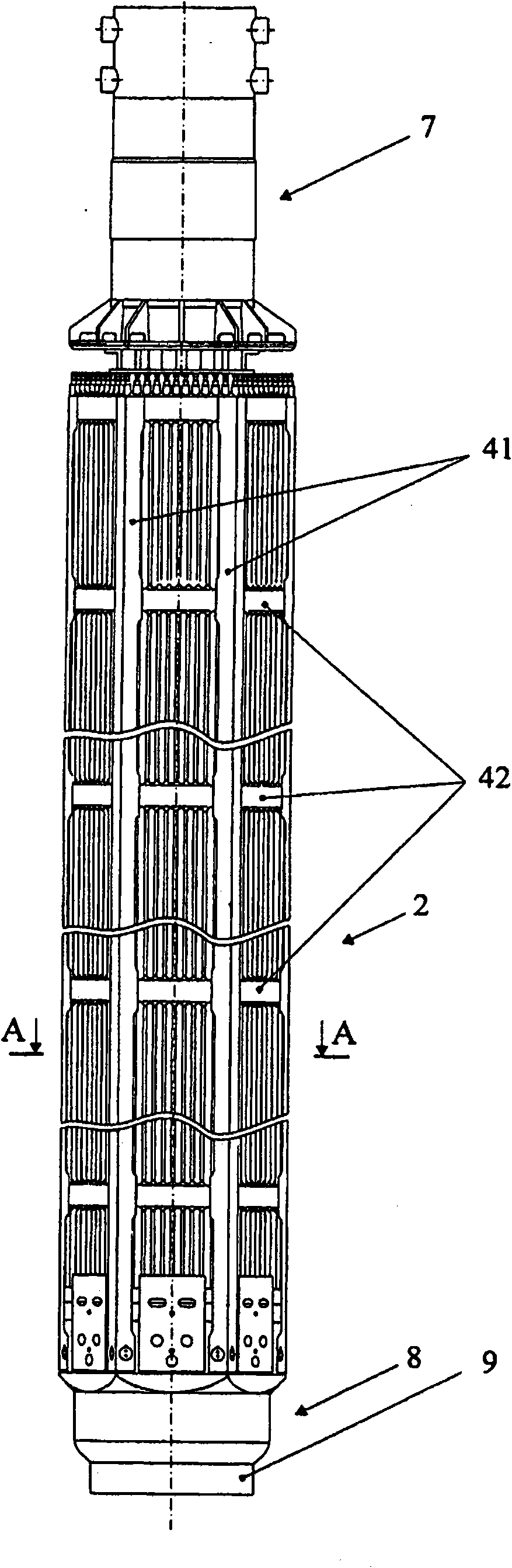

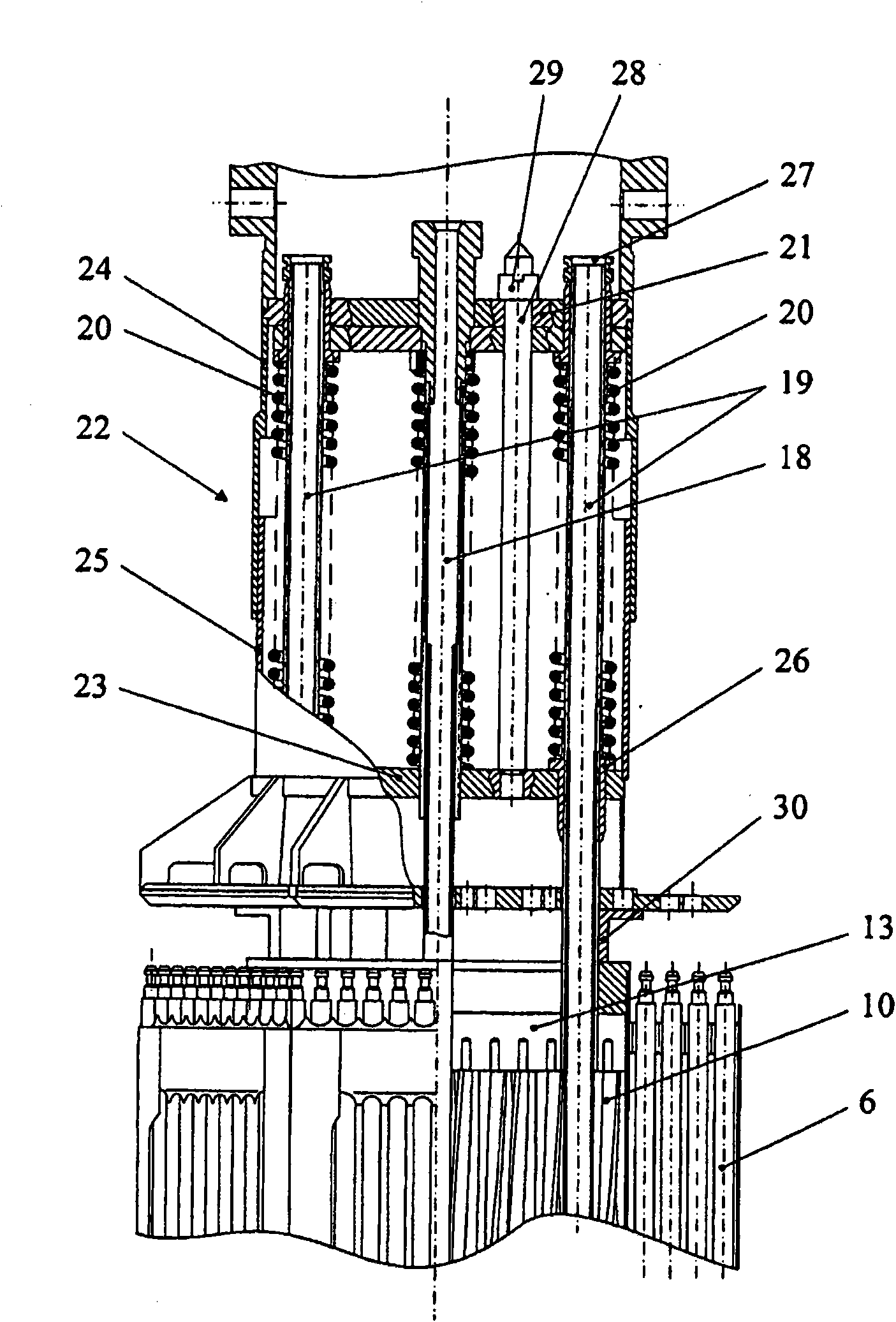

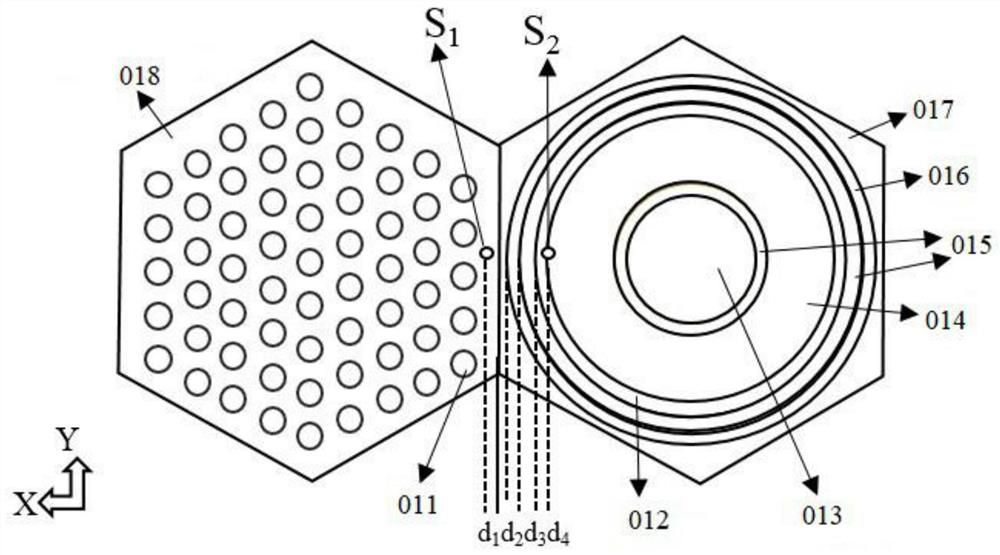

Nuclear reactor (variants), fuel assembly consisting of driver-breeding modules for a nuclear reactor (variants) and a fuel cell for a fuel assembly

The invention relates to a structural design for light-water-moderated nuclear reactors using a thorium fuel, in particular to the structural design for caseless fuel assemblies constituting the cores of water moderated power-producing reactors, such as a WWER-1000 reactor. A thorium fuel in a breeding module together with a conventional reactor fuel containing unshaped enriched uranium or power producing plutonium in a driver module are burned in the core of a nuclear reactor which comprises a fuel assembly consisting of a driver and breeding modules. The driver module comprises a bundle of three leaf-shaped fuel cells forming screw spacer ribs. The driver and breeding modules can be coupled to each other by means of a spigot joint or be free of a rigid mechanical coupling. The inventive structural design of the fuel assembly provides the total compatibility thereof with existing fuel assemblies used in the WWER-1000 reactors. The fact that the two-section fuel assembly can be disassembled makes it possible to individually reload the driver module.

Owner:THORIUM POWER

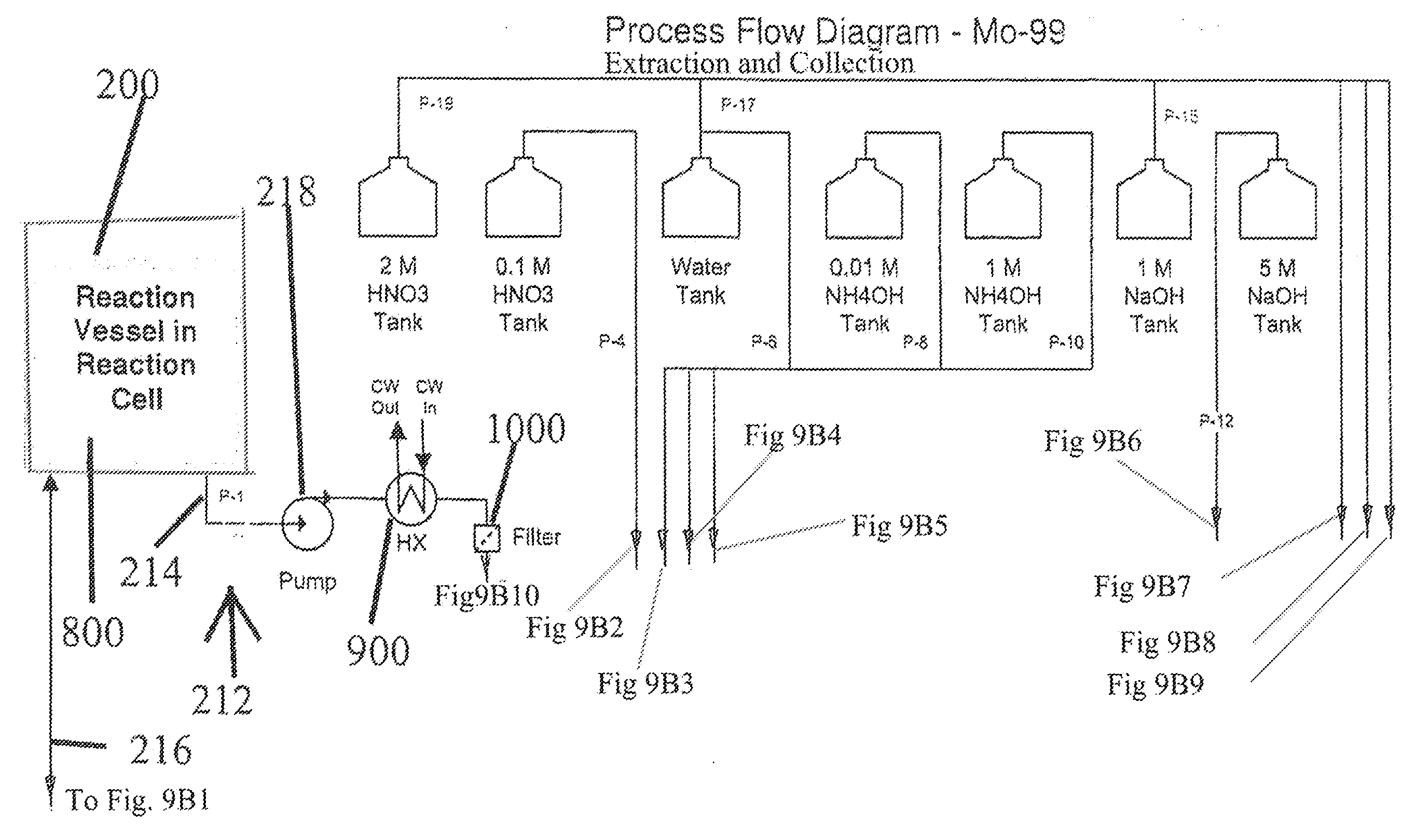

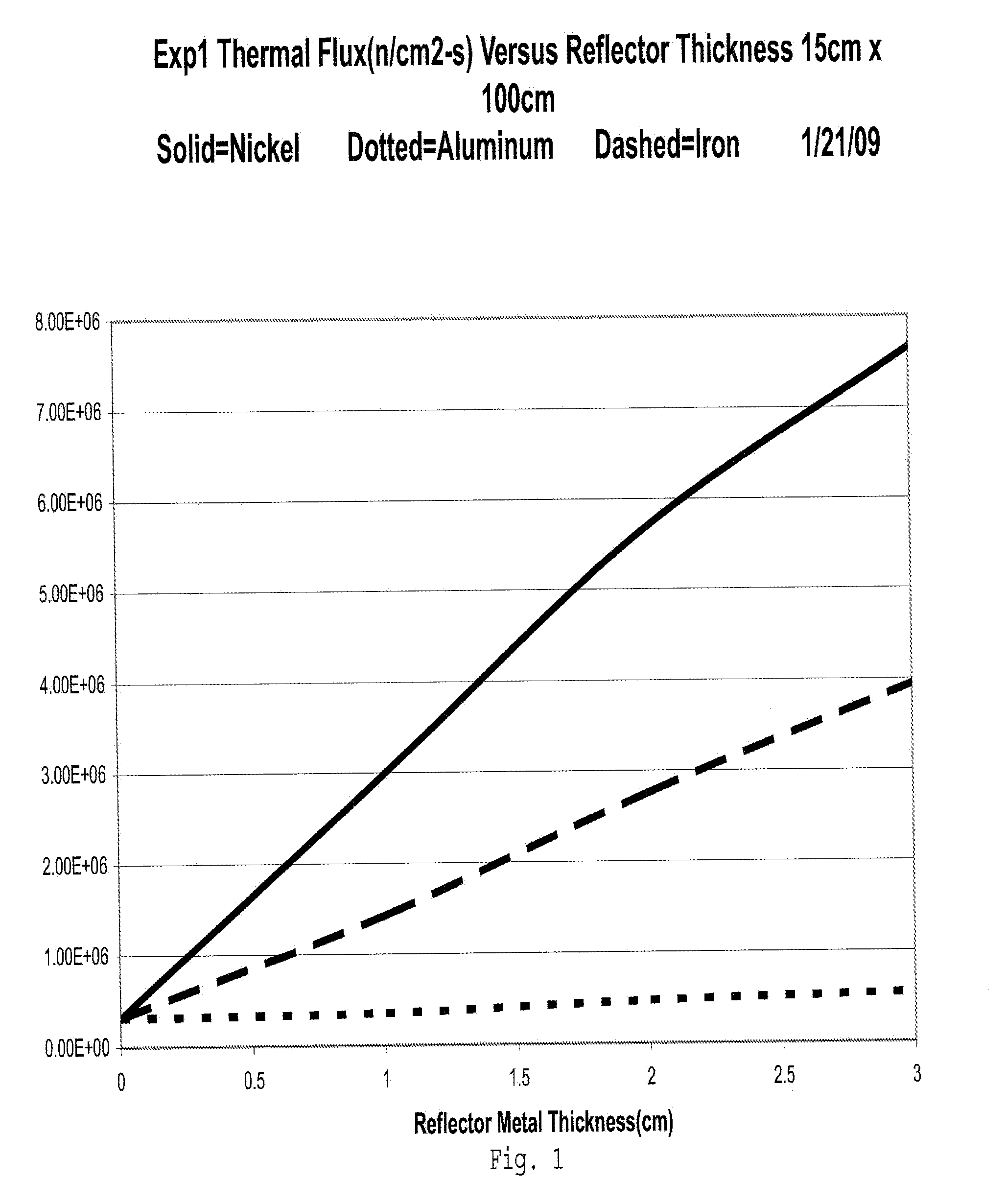

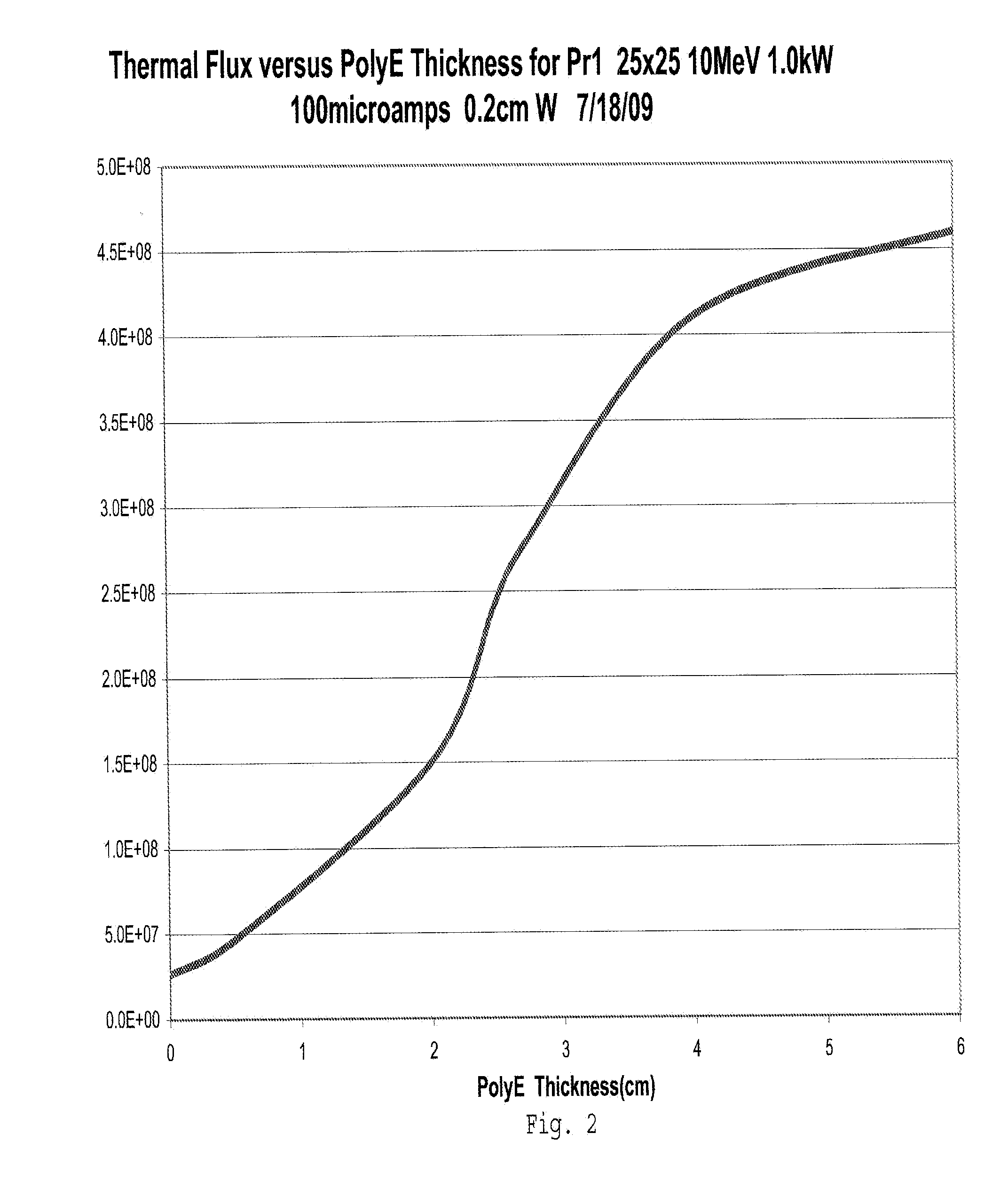

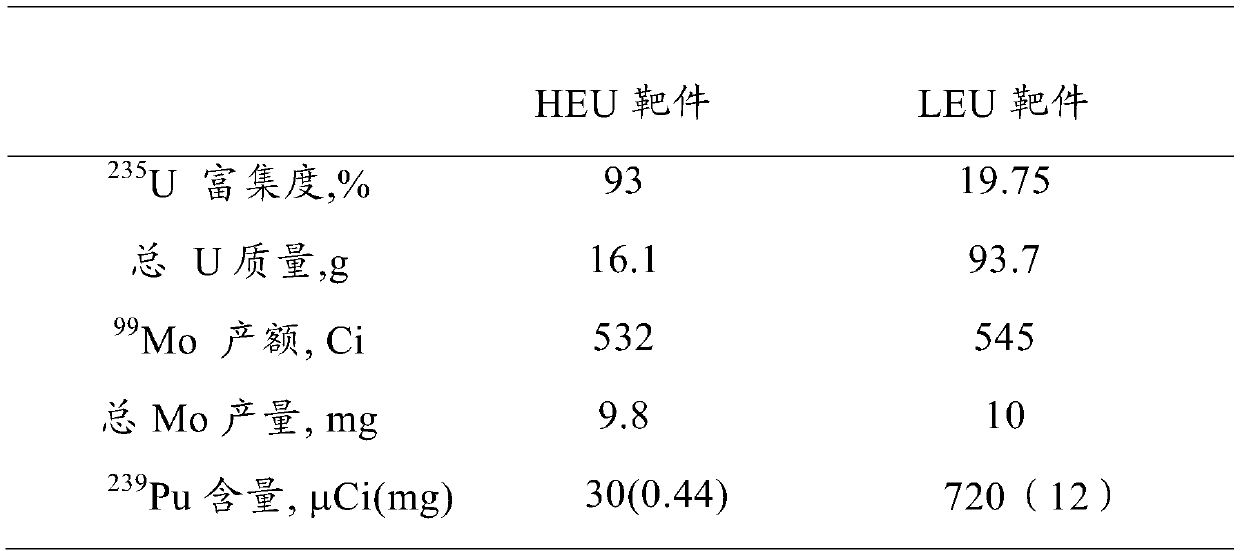

Advanced once-through processing for extracting molybdenum-99 from deuterium and low enriched uranium solutions

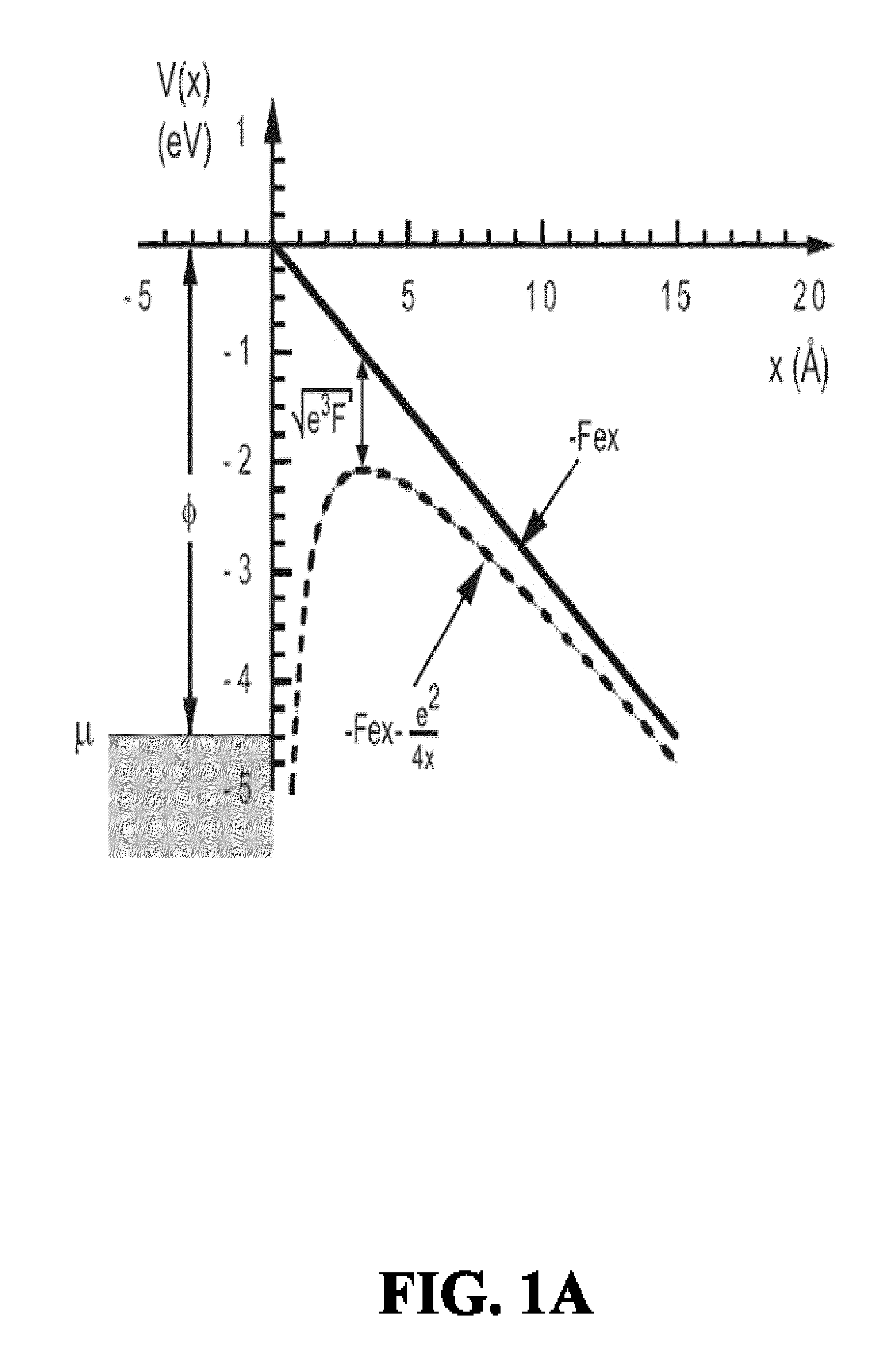

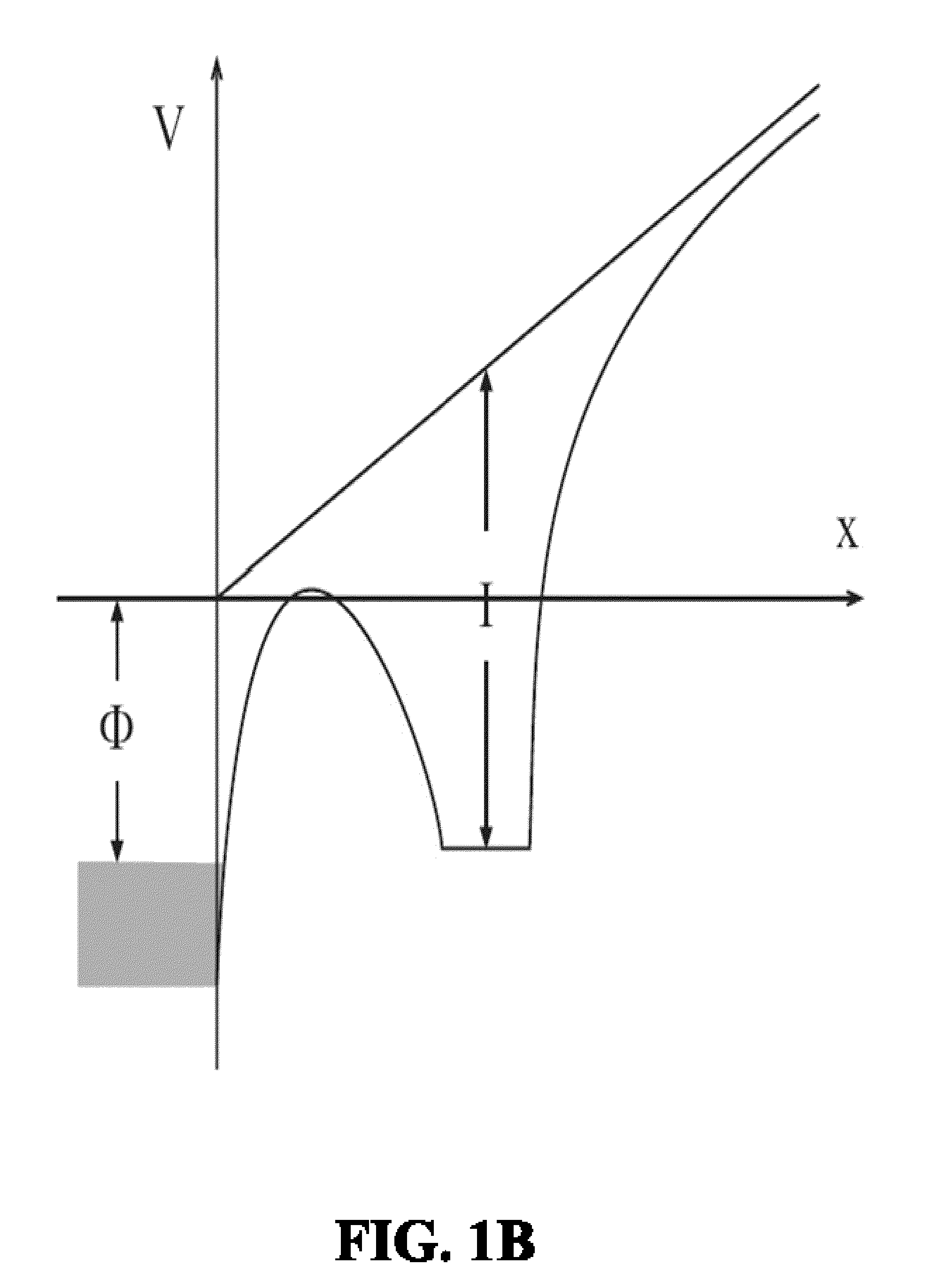

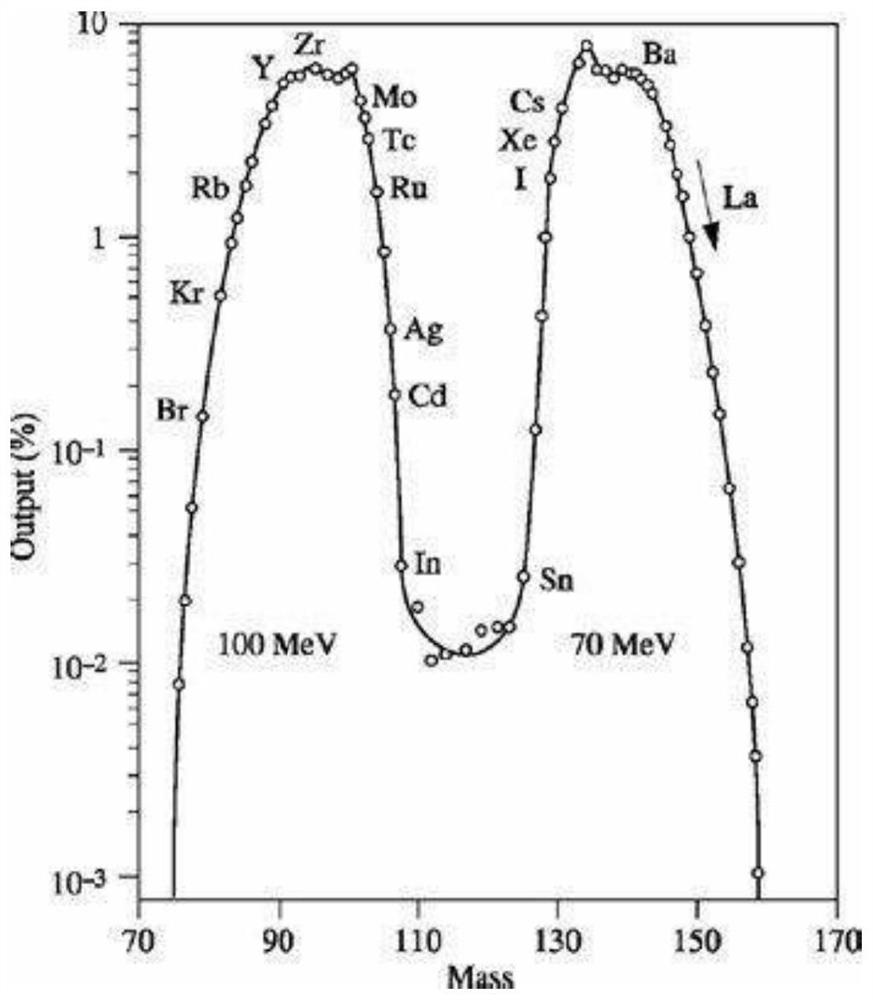

InactiveUS20110305308A1Increase heightLower energy levelConversion outside reactor/acceleratorsSpherical shapedElectron

A large enhancement of neutron flux is realized when a primary target of D2O and H2O is contained in a vessel, is irradiated by an electron beam incident on a gamma converter and where the vessel is enclosed within a neutron reflector material including Nickel and Polyethylene. A very large enhancement of neutron flux is realized when a secondary target of LEU is mixed with the primary target resulting in a very large enhanced production of Molybdenum-99. The primary target and the secondary target is contained in cylindrical or spherical vessels. A process for extracting produced Mo-99 from the reaction vessel solution.

Owner:ADVANCED MEDICAL ISOTOPE

Method for extracting uranium and thorium from southern ionic rare-earth lixivium

The invention relates to a method for extracting uranium and thorium from a southern ionic rare-earth lixivium, which is characterized by comprising the following steps: (1) carrying out uranium and thorium extraction separation by using a 15-25 vol% naphthenate-15-25 vol% octanol or isooctanol-50-70 vol% kerosene extractant and a southern ionic rare-earth lixivium in a volume ratio of (0.5-5):1; and (2) carrying out back extraction on the loaded organic phase obtained in the step (1) and a 2-5 mol / L sulfuric acid, hydrochloric acid or nitric acid solution in a volume ratio of (0.1-10):1, wherein the organic phase after the back extraction returns to the step (1) for repeated use, and the water phase, which is the solution with enriched uranium and thorium, is used for recycling uranium and thorium. The method provided by the invention can selectively separate uranium and thorium from the rare-earth lixivium, has the advantages of fewer extraction stages, simple technique, favorable separating effect, no influence on subsequent rare-earth separation technique, and high extraction ratio of uranium and thorium.

Owner:GUANGDONG INST OF RARE METALS

Sleeve pipe type low-enriched uranium nuclear fuel assembly

ActiveCN101727992ASimple processEasy to useOptical rangefindersFuel elementsUpper jointControl engineering

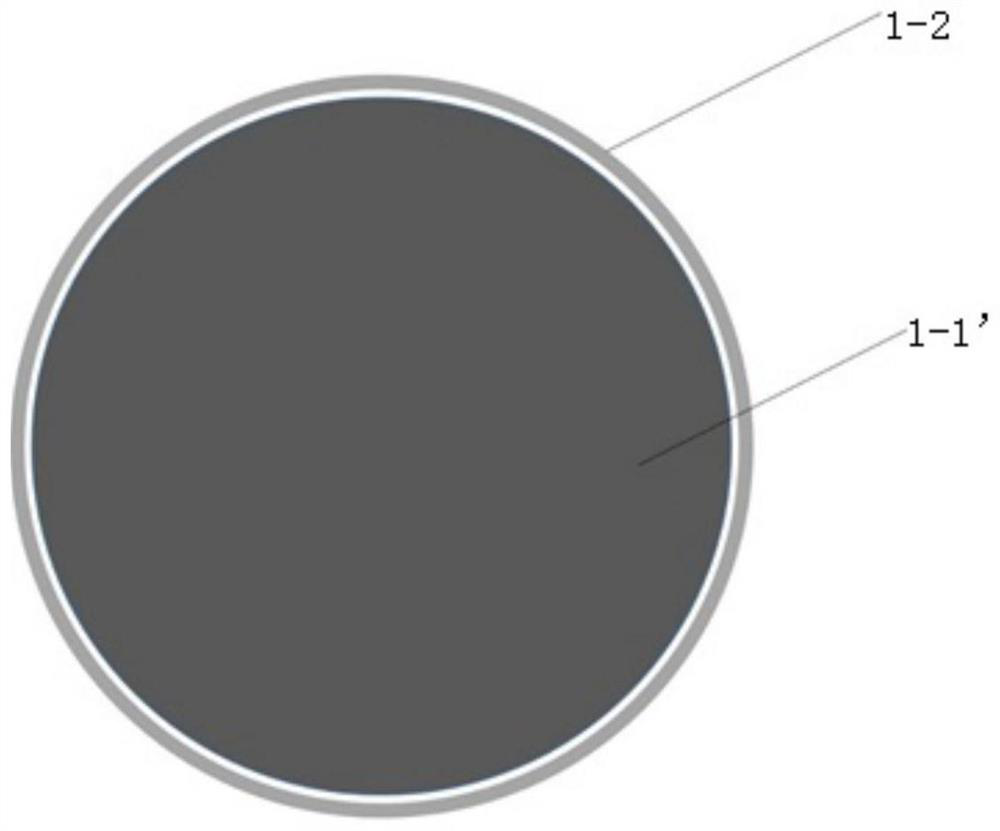

The invention discloses a sleeve pipe type low-enriched uranium nuclear fuel assembly which comprises an inner sleeve pipe, an outer sleeve pipe, a multilayer nuclear fuel sleeve pipe between the inner sleeve pipe and the outer sleeve pipe, an upper positioning tooth block, an upper joint, a lower joint and a lower positioning tooth block, wherein the inner sleeve pipe and the outer sleeve pipe are concentric; the upper positioning tooth block is fixedly connected with the upper end of the multilayer nuclear fuel sleeve pipe and arranged at the top of the outer sleeve pipe; the upper joint is fixed at the upper port of the upper positioning tooth block; the lower joint is sleeved on the lower port of the outer sleeve pipe; the lower positioning tooth block is arranged in the outer sleeve pipe and fixedly connected with the lower end of the multilayer nuclear fuel sleeve pipe; and each layer of nuclear fuel sleeve pipe comprises an aluminum alloy inner shell, an aluminum alloy outer shell and a U3Si2-Al nuclear fuel core which is arranged between the inner shell and the outer shell and forms metallurgical bonding with the aluminum alloy shells. The invention adopts a coextrusion process and has integral manufacture and simple process; a nuclear fuel sleeve pipe shell material is made of aluminum alloy and has favorable matching performance with the nuclear fuel core in use; the nuclear fuel core, the inner shell and the outer shell are extruded to form the fuel sleeve pipe of which the outer surface is provided with three ridge ribs, and the core and the shells form the metallurgical bonding, thereby improving the structural strength and the safe reliability.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

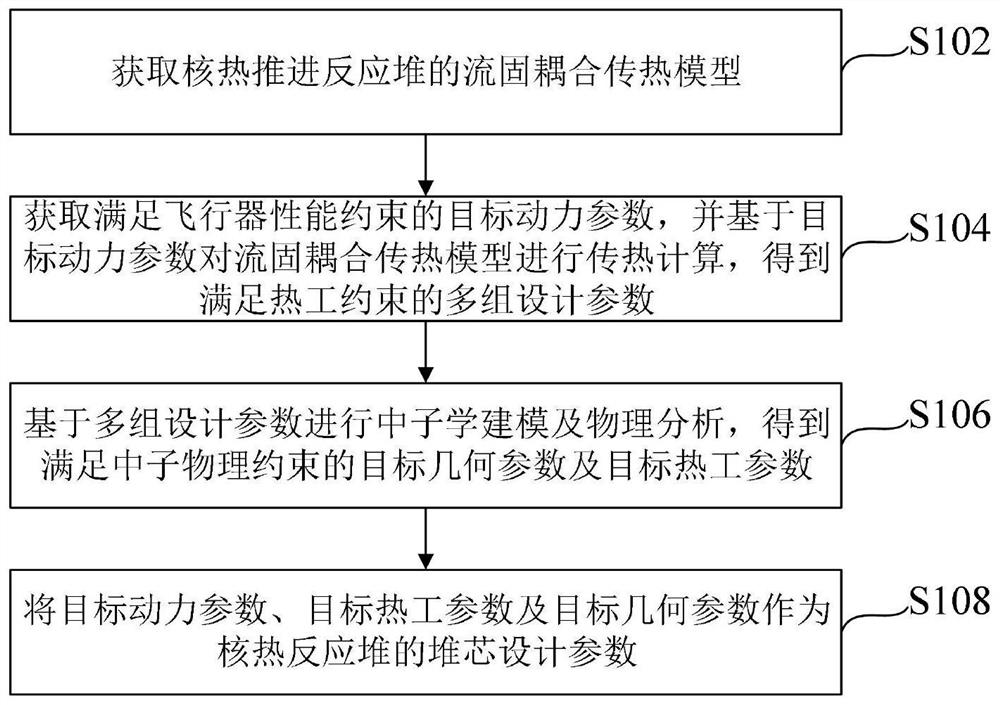

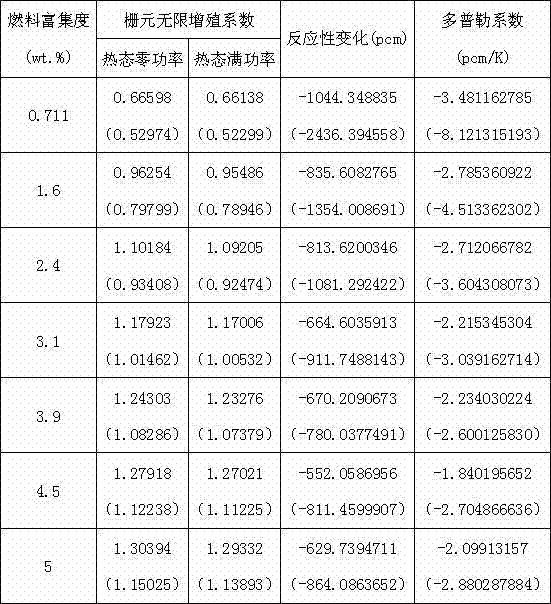

Method and device for determining reactor core parameters of nuclear thermal propulsion reactor

ActiveCN112199811AImprove reliabilityGuaranteed validityAircraft navigation controlNuclear energy generationNuclear engineeringFluid solid coupling

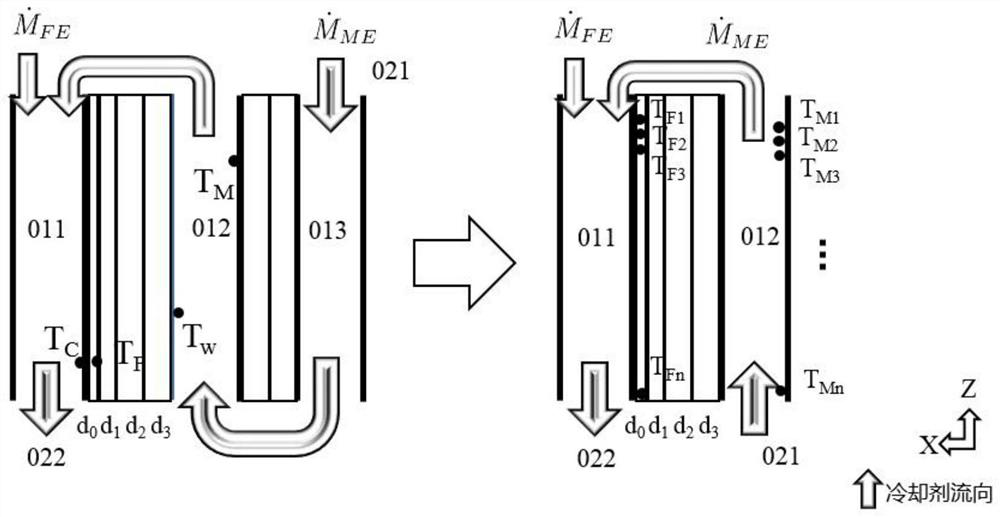

The invention provides a method and a device for determining reactor core parameters of a nuclear thermal propulsion reactor, and relates to the technical field of nuclear thermal propulsion, whereinthe method comprises the steps: acquiring a fluid-solid coupling heat transfer model of the nuclear thermal propulsion reactor; acquiring a target power parameter meeting aircraft performance constraints, and performing heat transfer calculation on the fluid-solid coupling heat transfer model based on the target power parameter to obtain multiple groups of design parameters meeting thermal constraints, wherein each group of design parameters comprises geometric parameters and thermal parameters; performing neutronics modeling and physical analysis based on the multiple groups of design parameters to obtain target geometric parameters and target thermal parameters meeting neutron physical constraints; and taking the target power parameters, the target thermal parameters and the target geometric parameters as reactor core design parameters of the nuclear thermal reactor. According to the method, the reliability of reactor core parameter design in the low-enrichment-degree concentrated uranium nuclear thermal propulsion reactor can be improved.

Owner:SHANGHAI JIAO TONG UNIV

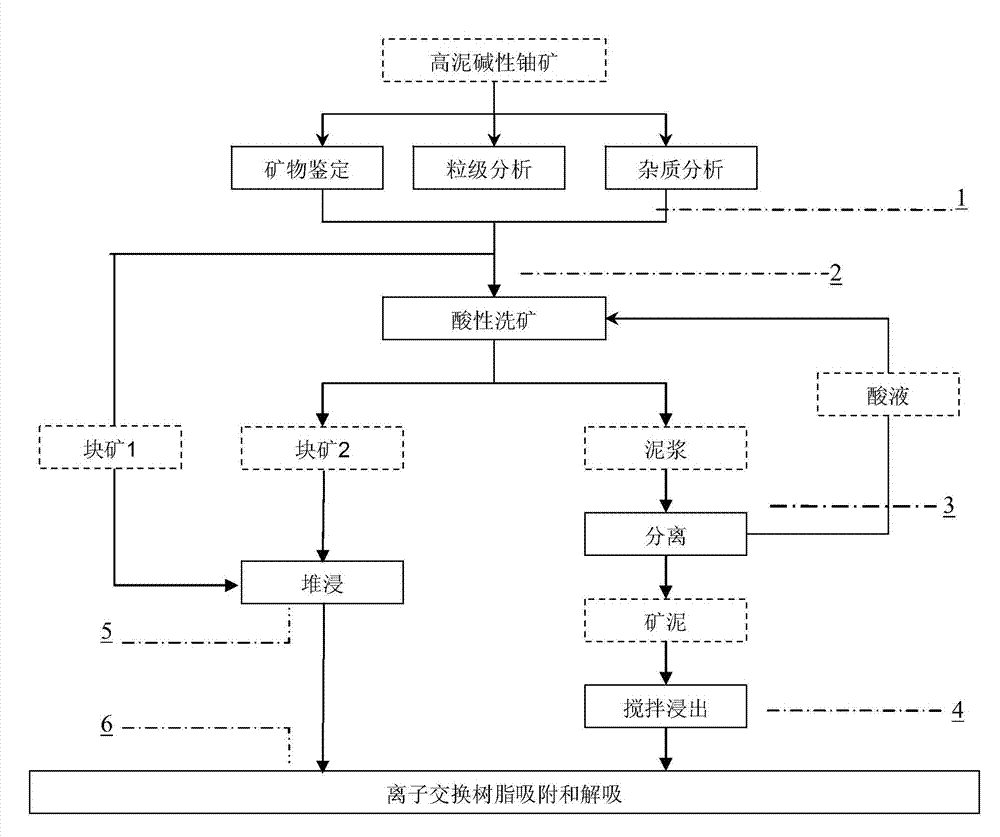

Acid ore washing biological leaching process used for high mud alkaline uranium ore

An acid ore washing biological leaching process used for high mud alkaline uranium ore comprises the following main steps: after crushing and screening of raw ore, sending + 30 mm particle grade ore into a heap field for heap construction, and performing acid ore washing treatment on-30mm particle grade ore. Sulfuric acid is added into a washing solution, then part of basic gangue is removed by ore washing, the washing solution is separated and precipitated, and an acid solution can be recycled. After processing by the acid ore washing system, + 0.074mm particle grade sand ore is sent to the heap field for heap construction, and-0.074mm particle grade sand ore enter the intensive agitation leaching process. An agitation leaching solution and a heap leaching solution are merged, and enter ion exchange resin adsorption desorption process, and finally a qualified enriched uranium product is obtained. According to the process, in the ore washing process, the part of basic gangue easy to dissolve is removed by neutralization, the problems of poor heap leaching permeability, low uranium leaching rate and the like caused by existence of mud ore and dissolution precipitation of the basic gangue can be solved, the uranium recovery rate is improved, high mud alkaline uranium ore mineral resources can be comprehensively utilized, and greater economic benefits can be obtained.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Nuclear fuel element doped with technetium-99

InactiveCN102831939ADoppler coefficient enhancementReduce outputNuclear energy generationReactor fuel susbtancesTechnetium-99Engineering

The invention relates to a nuclear fuel element doped with technetium-99, which is characterized in that fuel pellets are overlapped to be placed into a zirconium quaternary alloy cladding pipe, after being compressed by a compression spring, two end ports of the cladding pipe are sealed and fixed by an end plug, and the nuclear fuel element is characterized in that each fuel pellet is a mixture of tachnetiuim-99 and uranium dioxide, wherein a ratio of the nuclear density of the technetium-99 and the sum of the nuclear density of technetium-99 and uranium-238 in the uranium dioxide is 10 percent to 90 percent. The resonance characteristic of the technetium-99 is utilized, and the technetium-99 is used for partially substituting the uranium-238 in the enriched uranium fuel, so that three purpose for enhancing the Doppler coefficient, reducing minor actinides nuclide so as to really reduce the minor actinides, guaranteeing the prompt negative temperature coefficient and transforming the nuclear waste technetium-99, and the safety of a reactor can be enhanced.

Owner:NANHUA UNIV

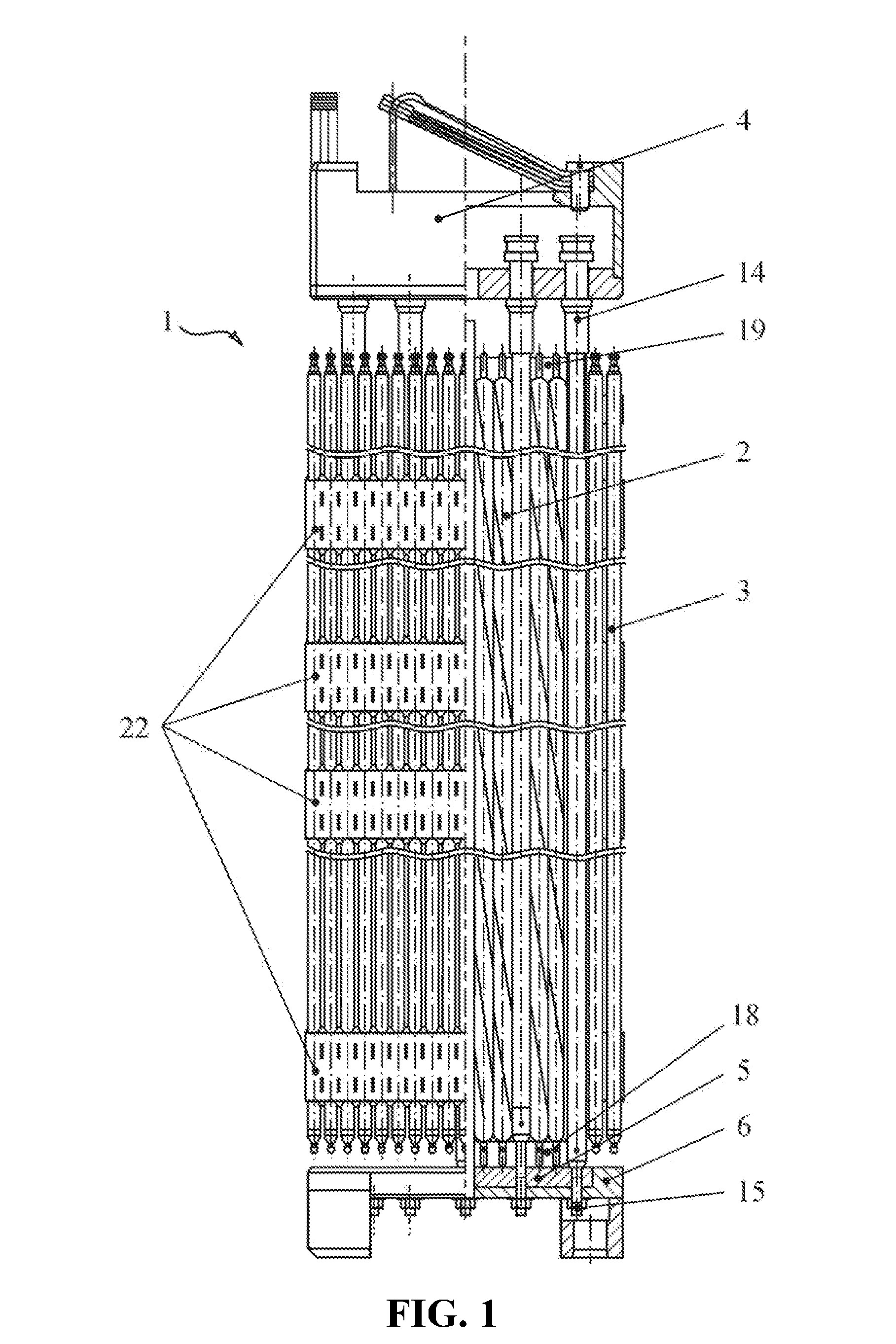

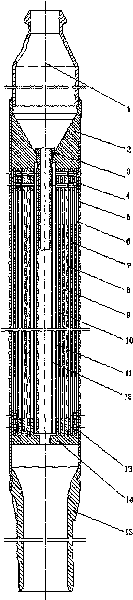

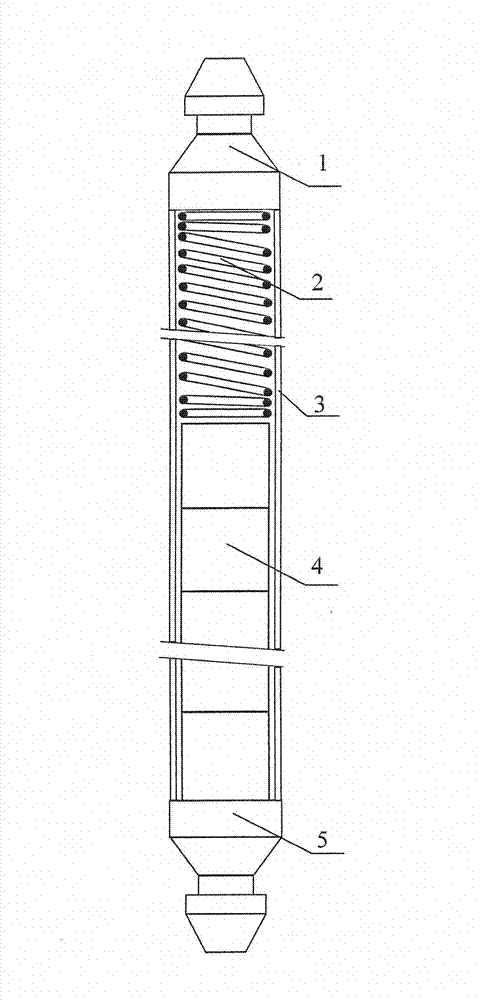

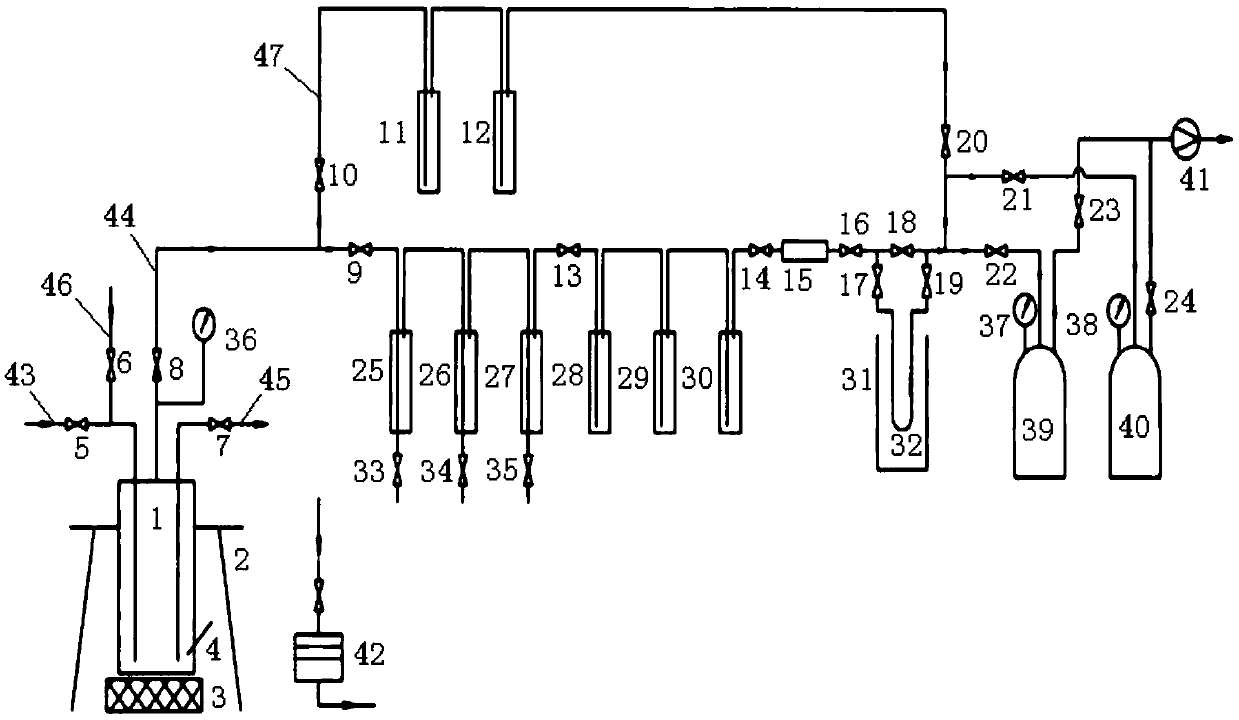

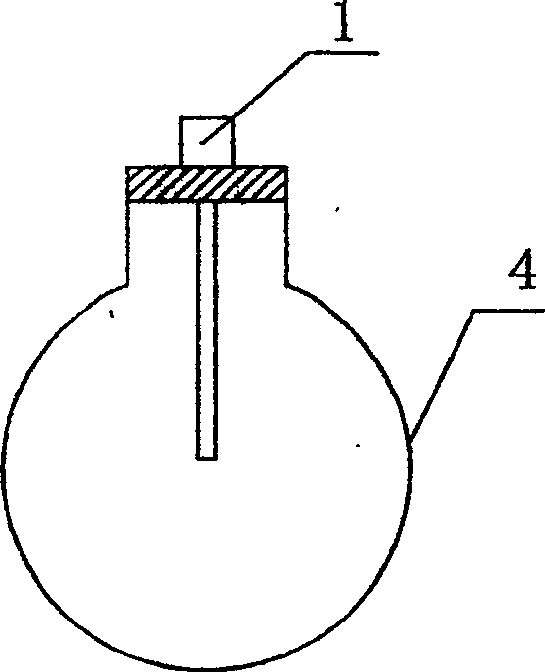

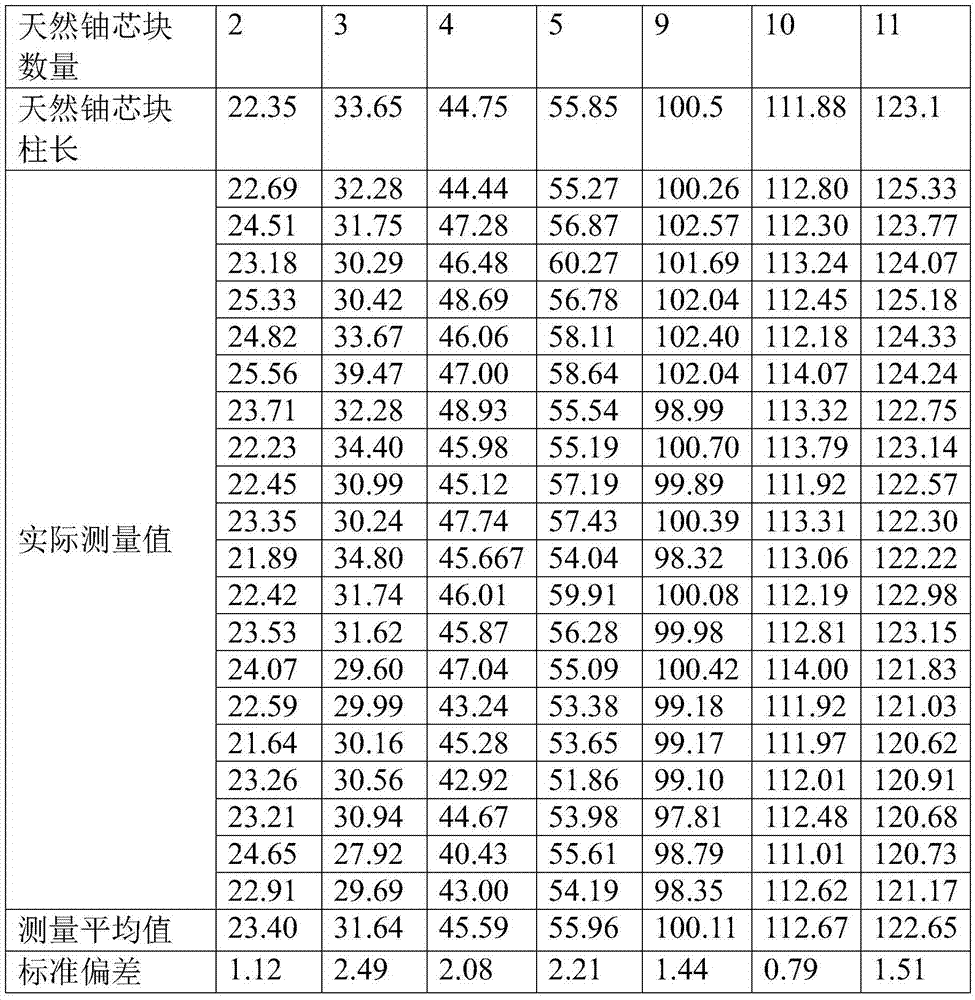

Uranium foil dissolving device for irradiated LEU (low-enriched uranium) foil target

The invention relates to a uranium foil dissolving device for an irradiated LEU (low-enriched uranium) foil target. The uranium foil dissolving device comprises a dissolver (1), wherein a heater (3) is arranged at the bottom of the dissolver (1); a liquid inlet pipeline (43), a gas absorbing pipeline (44) and a liquid outlet pipeline (45) are arranged in the dissolver (1) in a penetrating manner; a pressure limiting check valve (8), a gas absorbing unit and a gas storage unit are sequentially arranged on the gas absorbing pipeline (44). With the adoption of the dissolving device, irradiated LEU can be quickly dissolved, and gas waste produced in a system can be processed and stored, so that safe emission of gas produced in the dissolution process is guaranteed, and safety of operators and the environment are guaranteed; impurities are removed from the completely dissolved target, and a foundation is laid for acquisition of <99>Mo through further separation and extraction.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

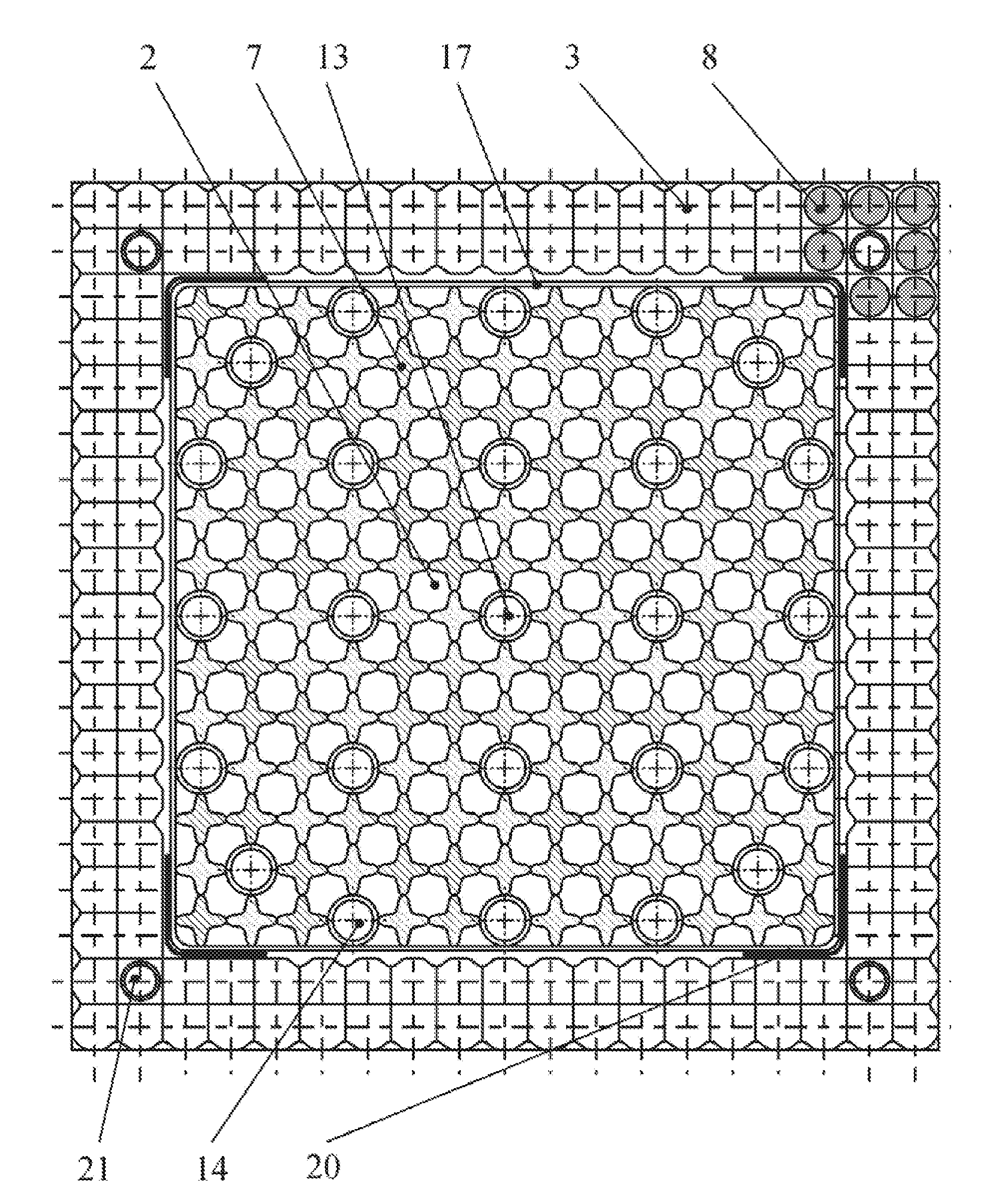

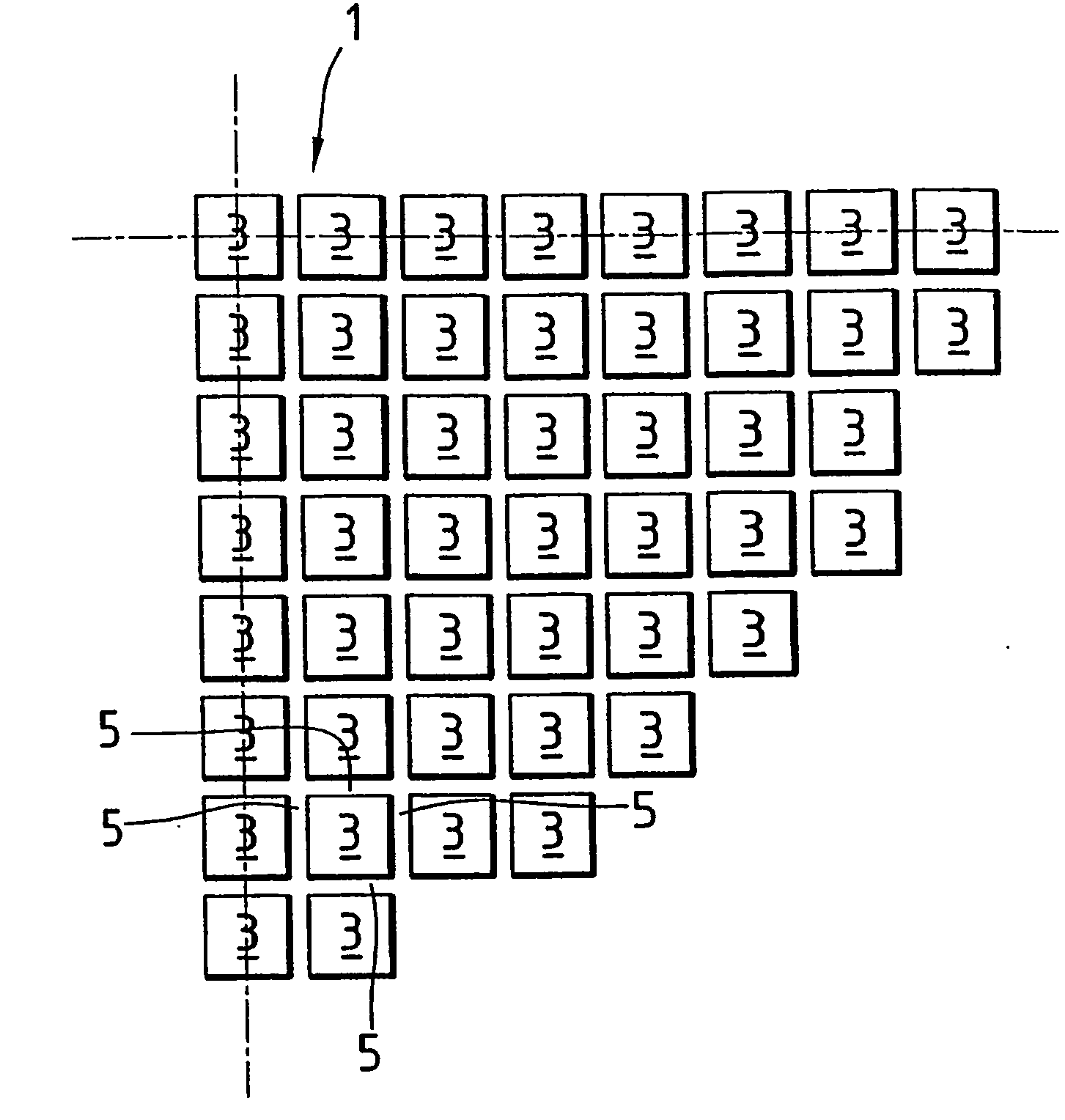

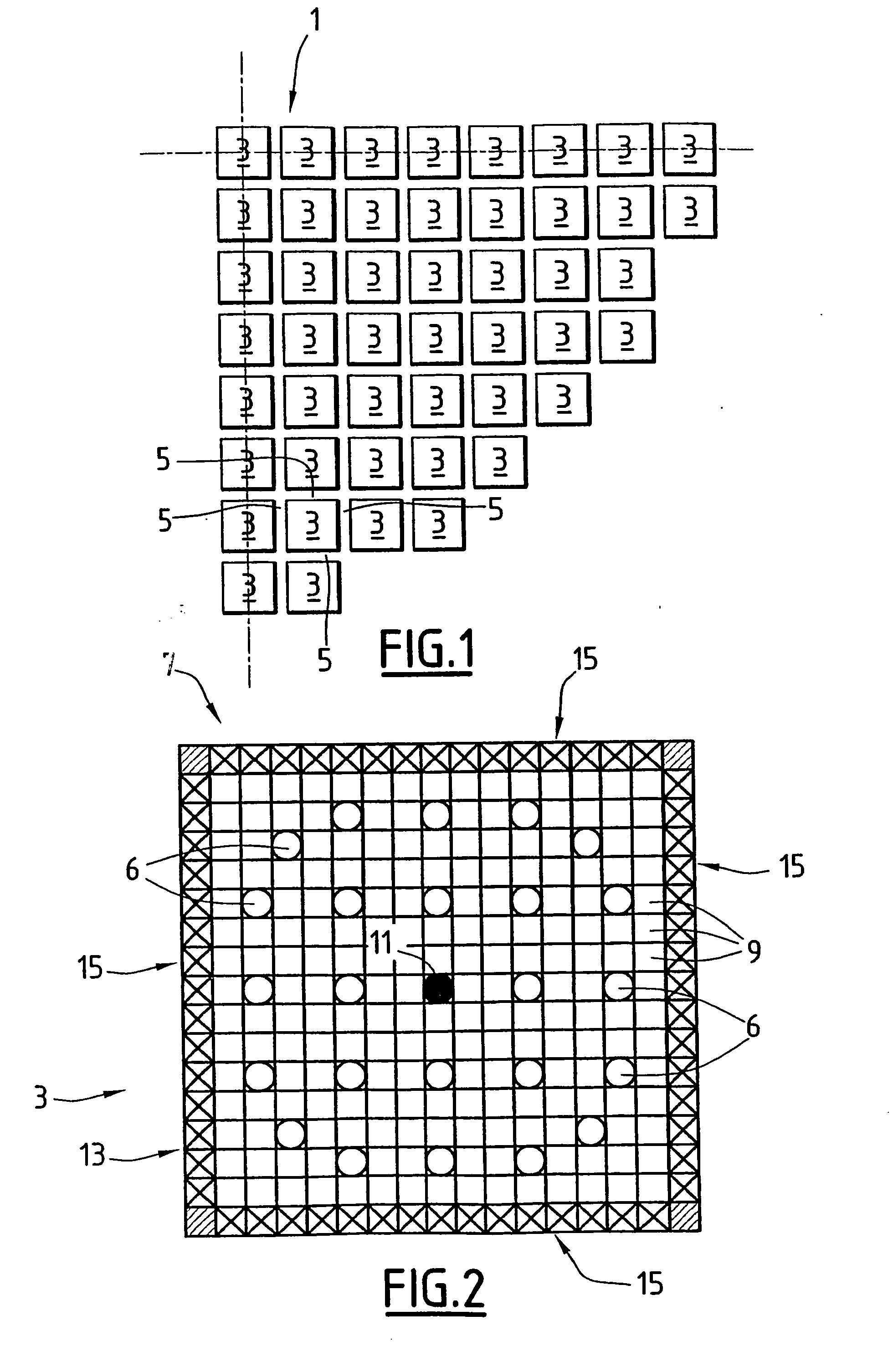

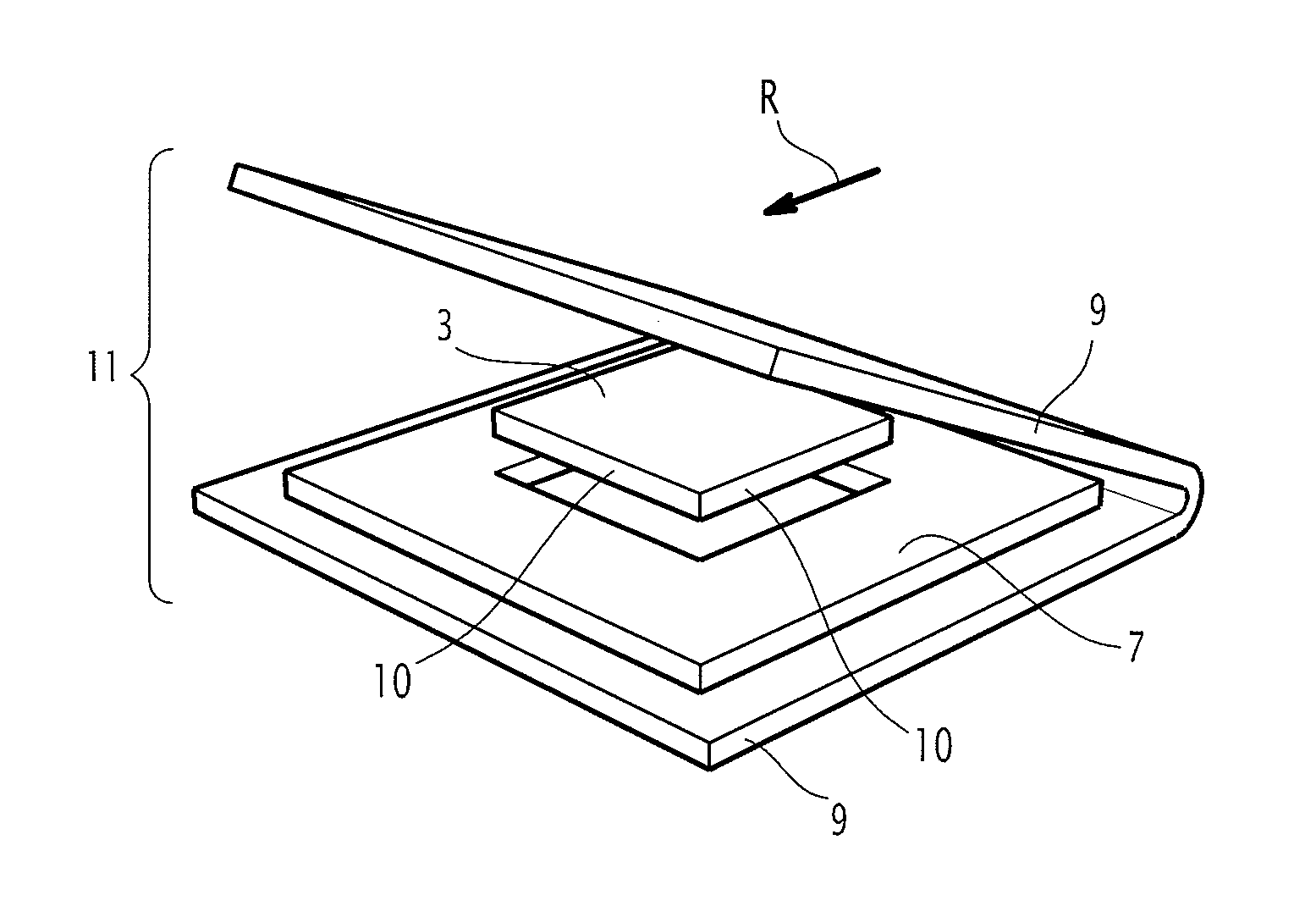

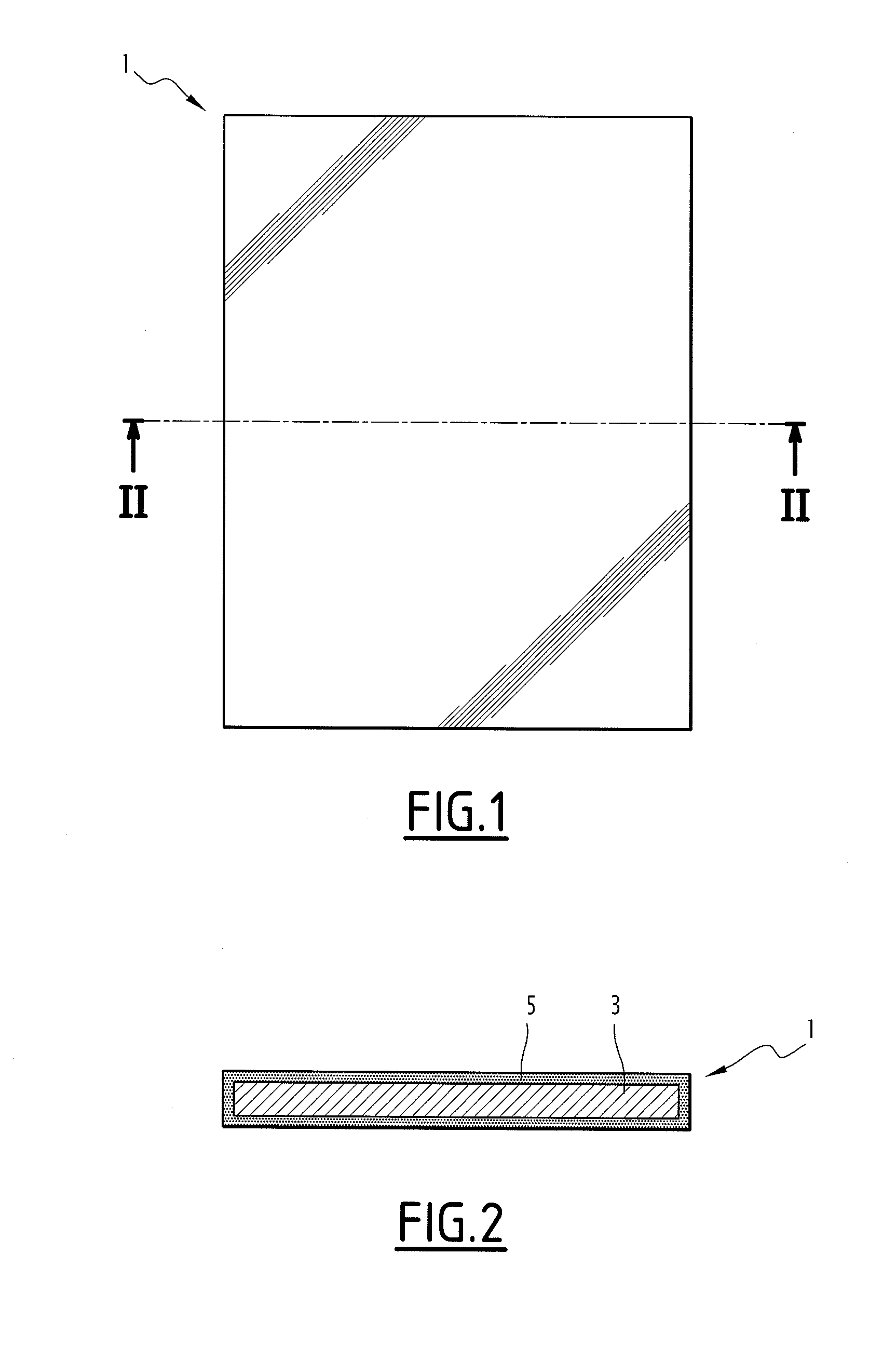

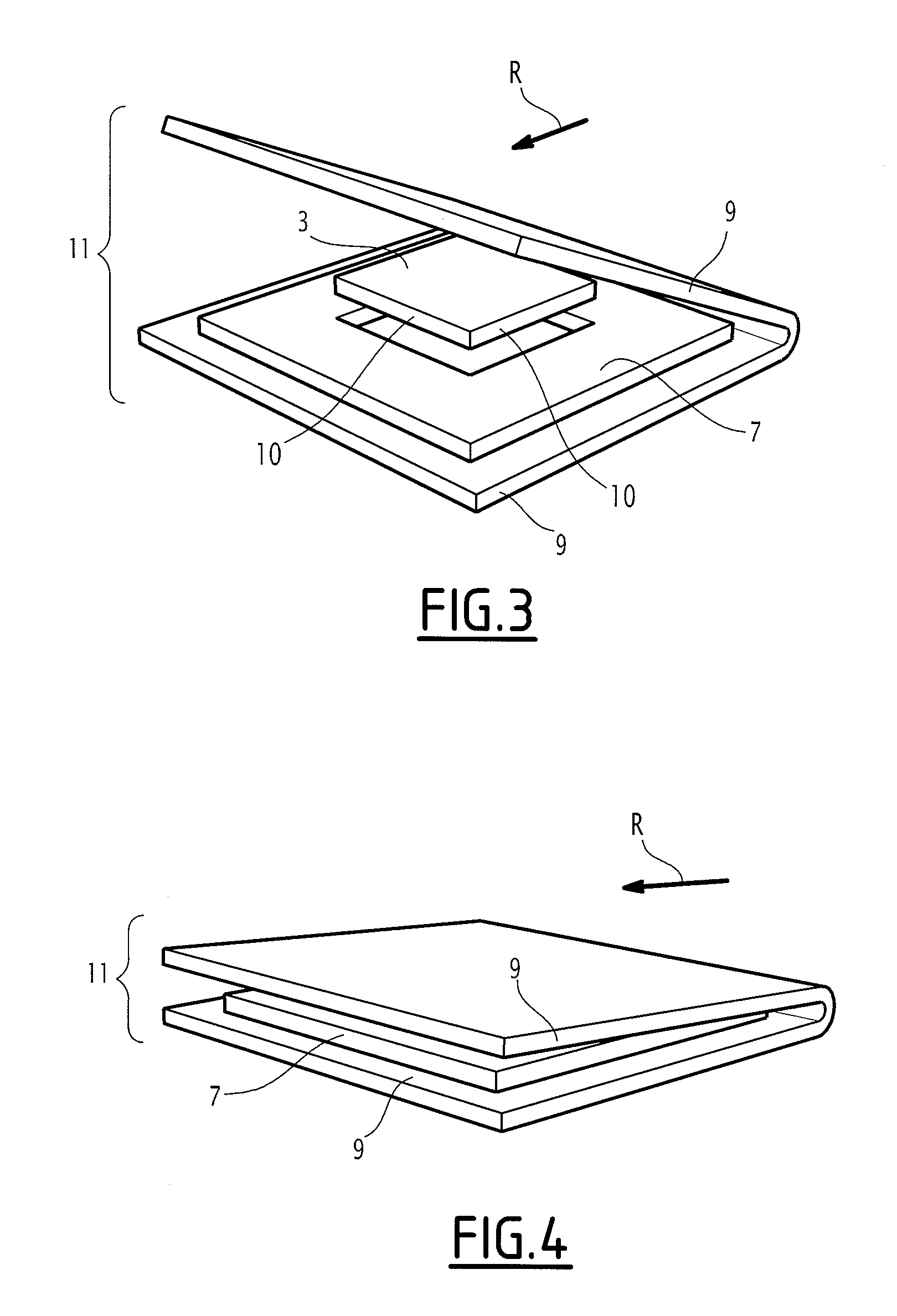

Fuel Assembly For A Pressurized Water Nuclear Reactor Containing Plutonium-Free Enriched Uranium

InactiveUS20070195919A1Reduce riskNuclear energy generationFuel element assembliesNuclear reactorIsotope

This fuel assembly (3) for a pressurised water nuclear reactor comprises fuel rods which are arranged at the nodes of a substantially regular network which has a polygonal outer contour, the fuel rods containing uranium which is enriched in isotope 235 and not containing any plutonium before the assembly is used in a reactor. The rods are distributed in at least: a first central group which is constituted by fuel rods which have a first level of nuclear reactivity, and an outer peripheral layer (13) of fuel rods which have a level / levels of nuclear reactivity which is / are strictly less than the first level of reactivity.

Owner:AREVA NP SAS

Fuel preparation for use in the production of medical isotopes

The present invention relates generally to the field of medical isotope production by fission of uranium-235 and the fuel utilized therein (e.g., the production of suitable Low Enriched Uranium (LEU is uranium having 20 weight percent or less uranium-235) fuel for medical isotope production) and, in particular to a method for producing LEU fuel and a LEU fuel product that is suitable for use in the production of medical isotopes. In one embodiment, the LEU fuel of the present invention is designed to be utilized in an Aqueous Homogeneous Reactor (AHR) for the production of various medical isotopes including, but not limited to, molybdenum-99, cesium-137, iodine-131, strontium-89, xenon-133 and yttrium-90.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

Target-fueled nuclear reactor for medical isotope production

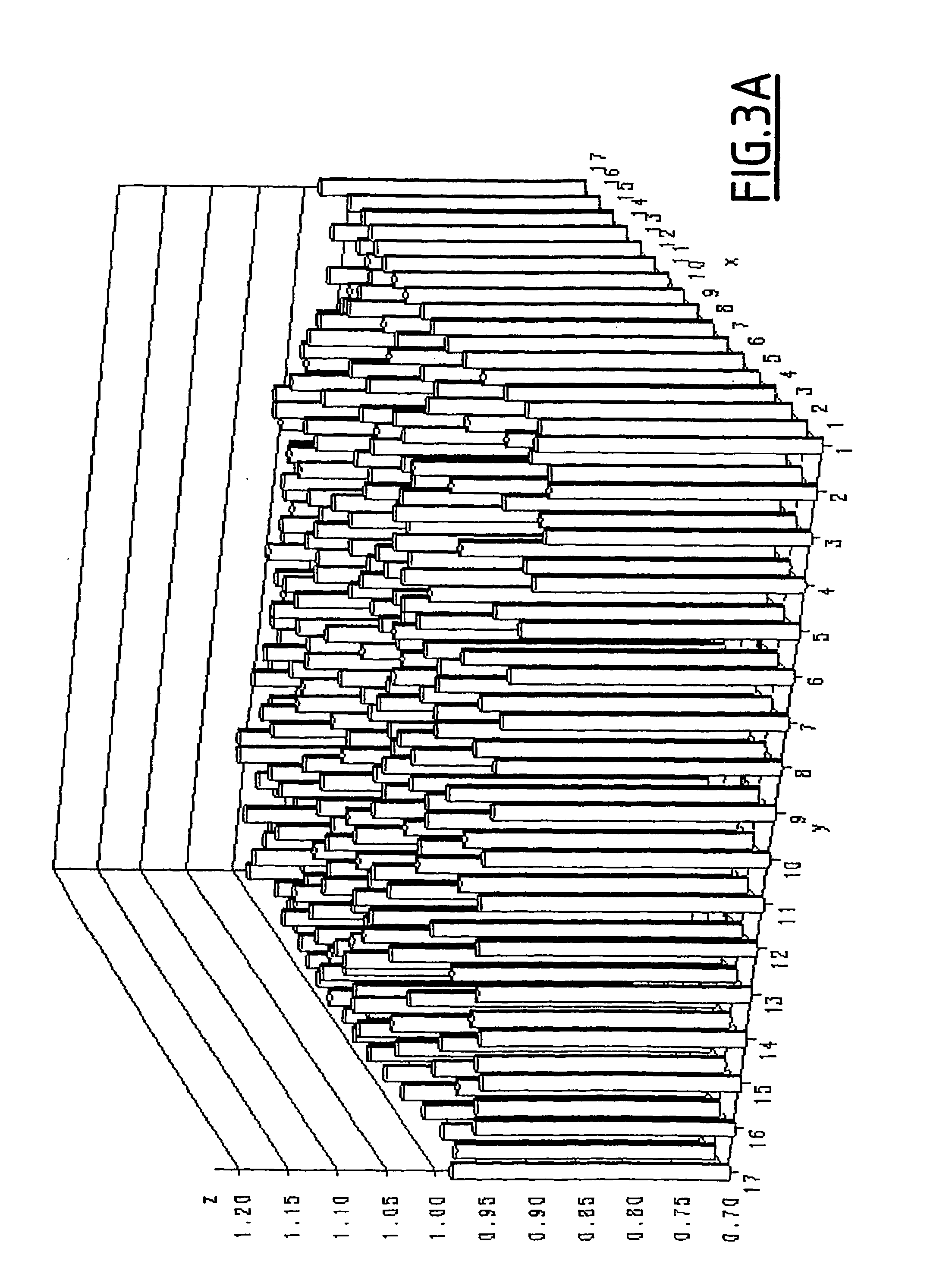

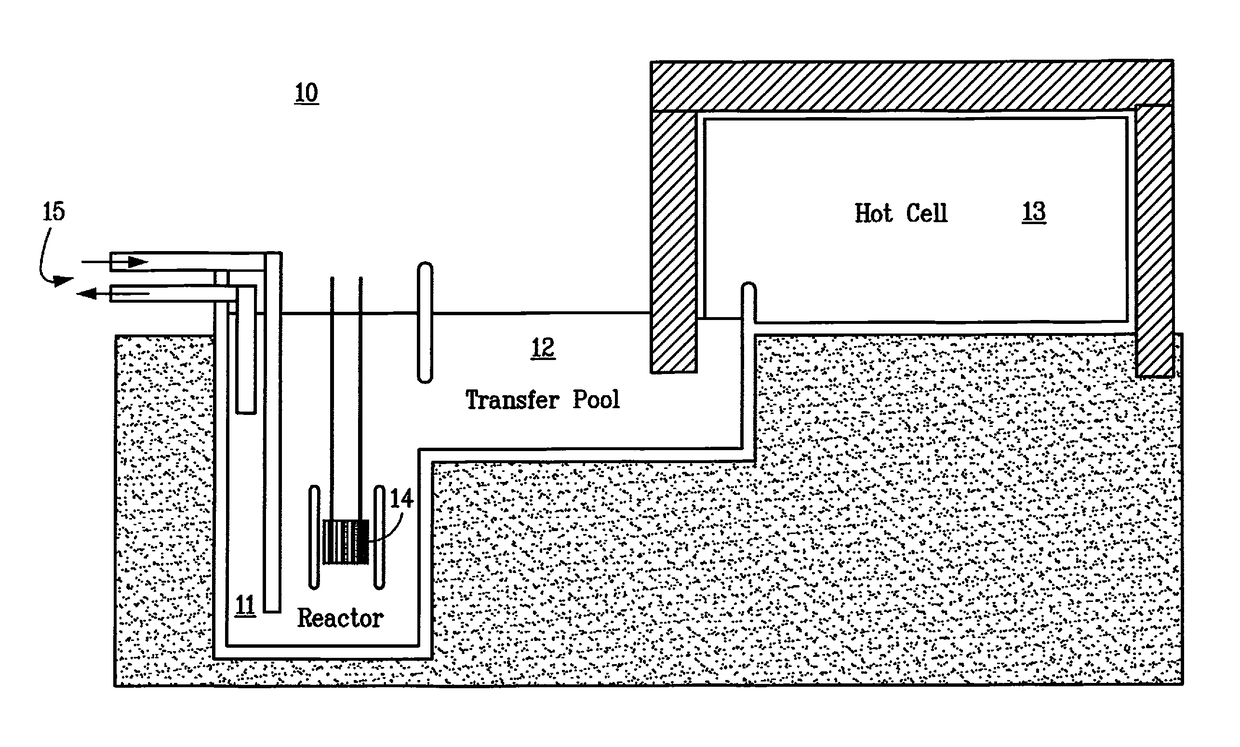

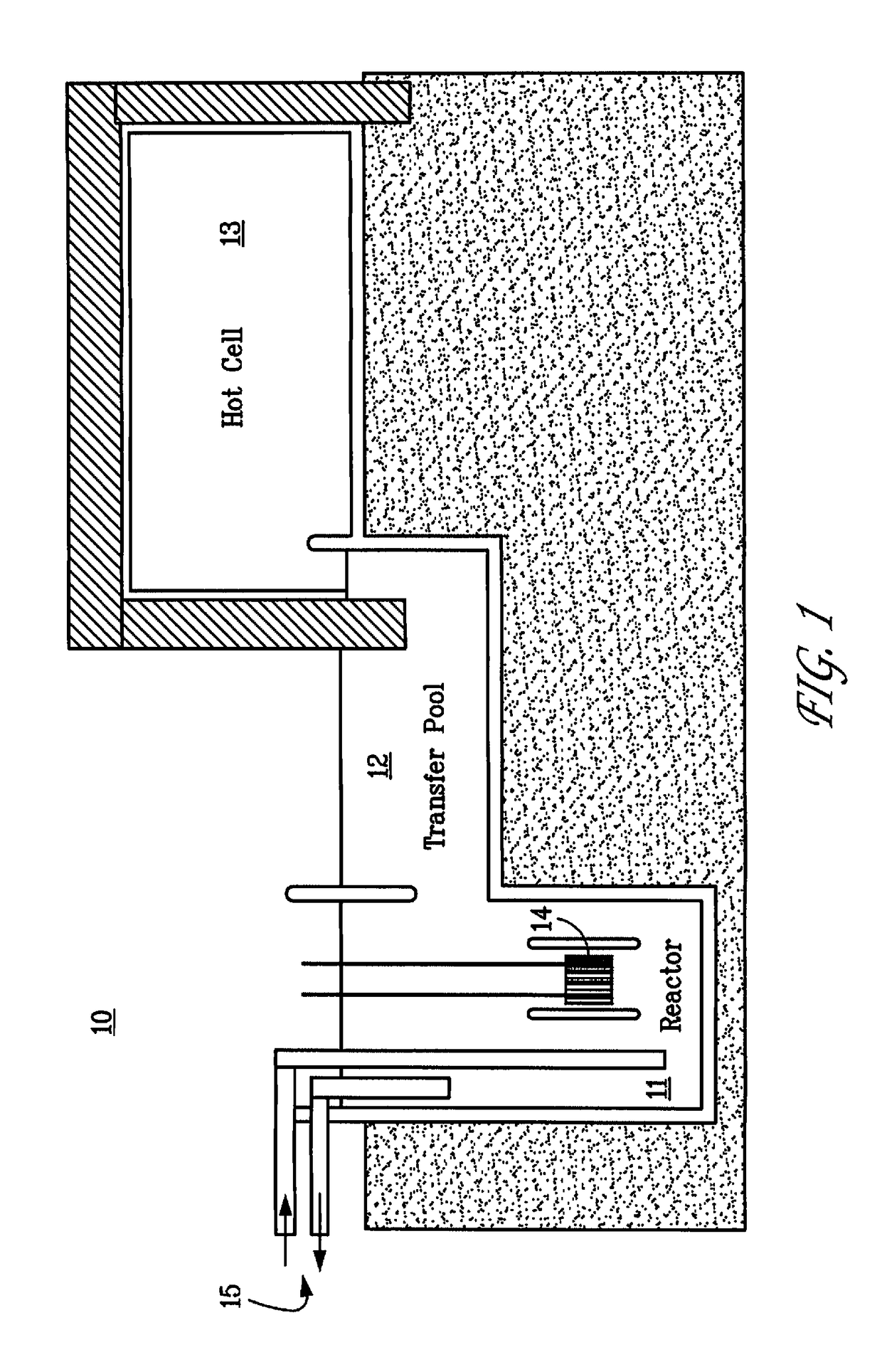

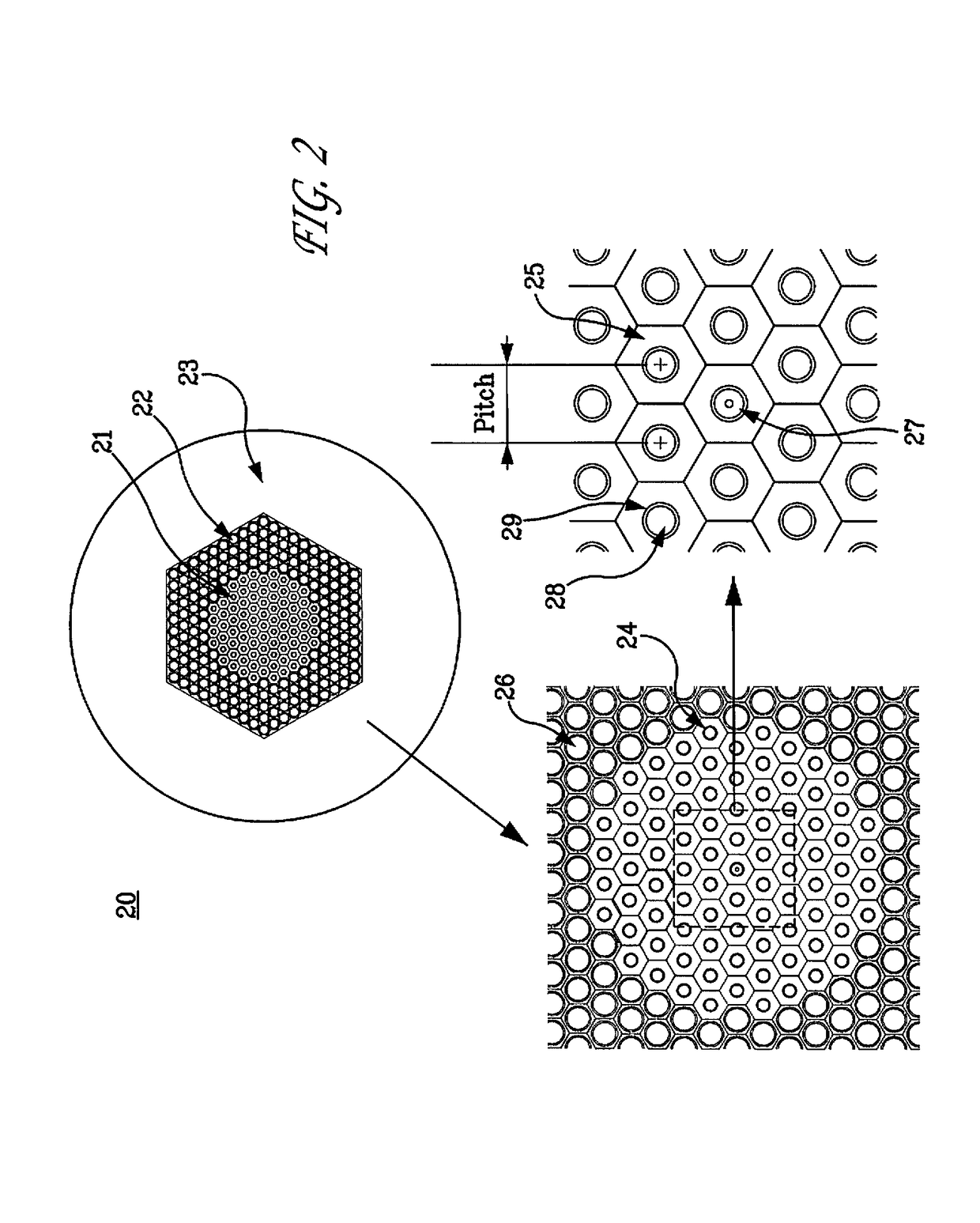

ActiveUS9691511B1Improve uniformityImprove automationConversion outside reactor/acceleratorsConversion in nuclear reactorNuclear reactor coreNuclear reactor

A small, low-enriched, passively safe, low-power nuclear reactor comprises a core of target and fuel pins that can be processed to produce the medical isotope 99Mo and other fission product isotopes. The fuel for the reactor and the targets for the 99Mo production are the same. The fuel can be low enriched uranium oxide, enriched to less than 20% 235U. The reactor power level can be 1 to 2 MW. The reactor is passively safe and maintains negative reactivity coefficients. The total radionuclide inventory in the reactor core is minimized since the fuel / target pins are removed and processed after 7 to 21 days.

Owner:SANDIA

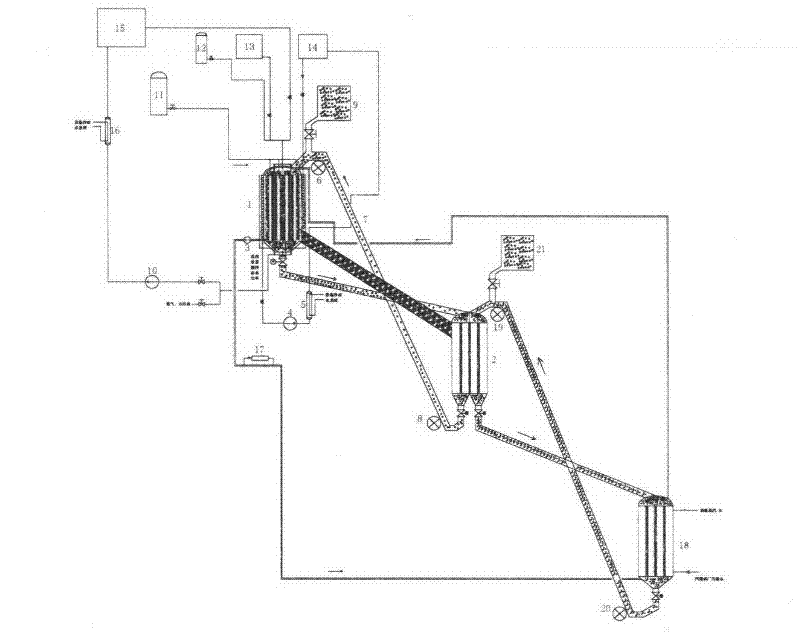

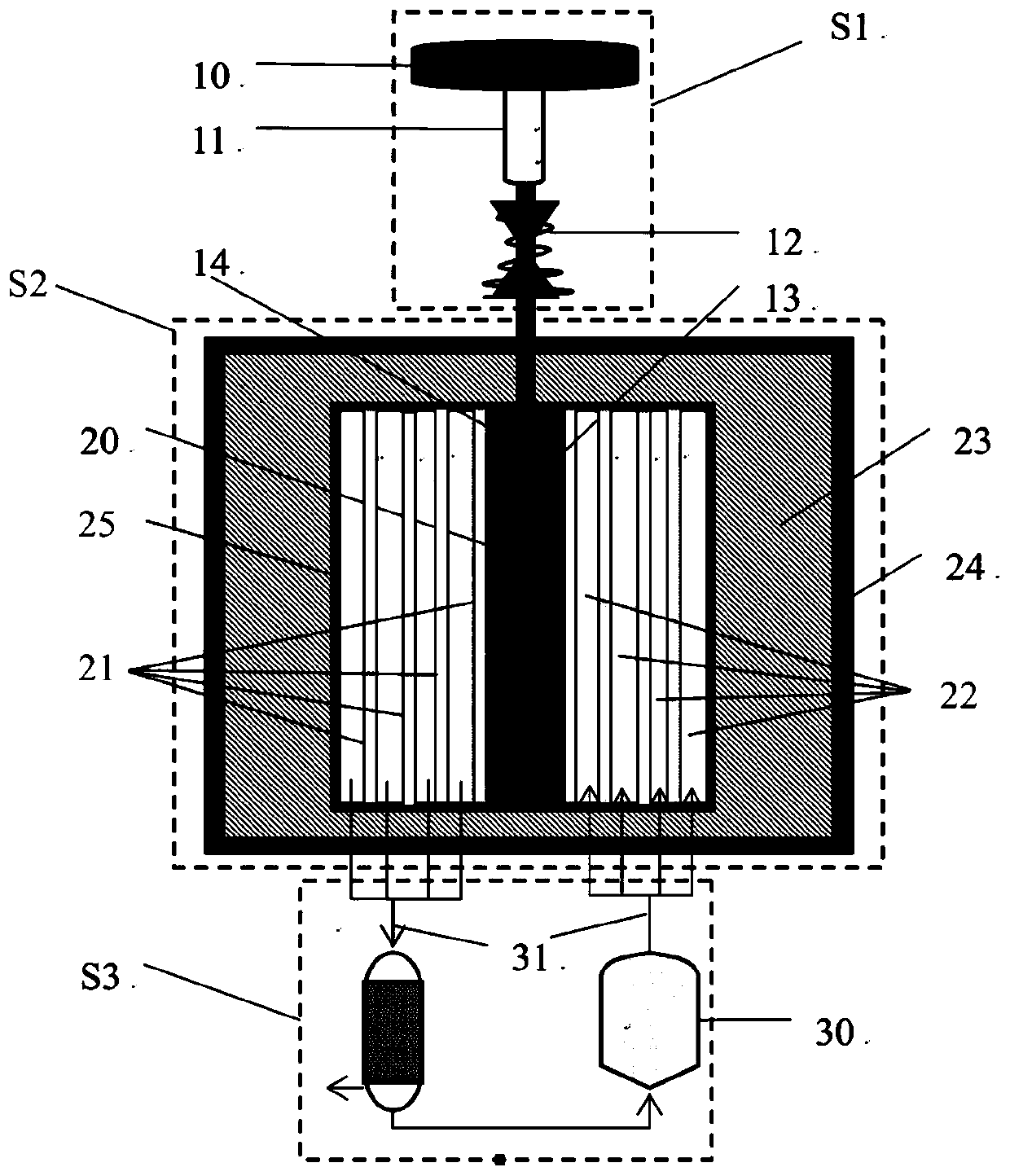

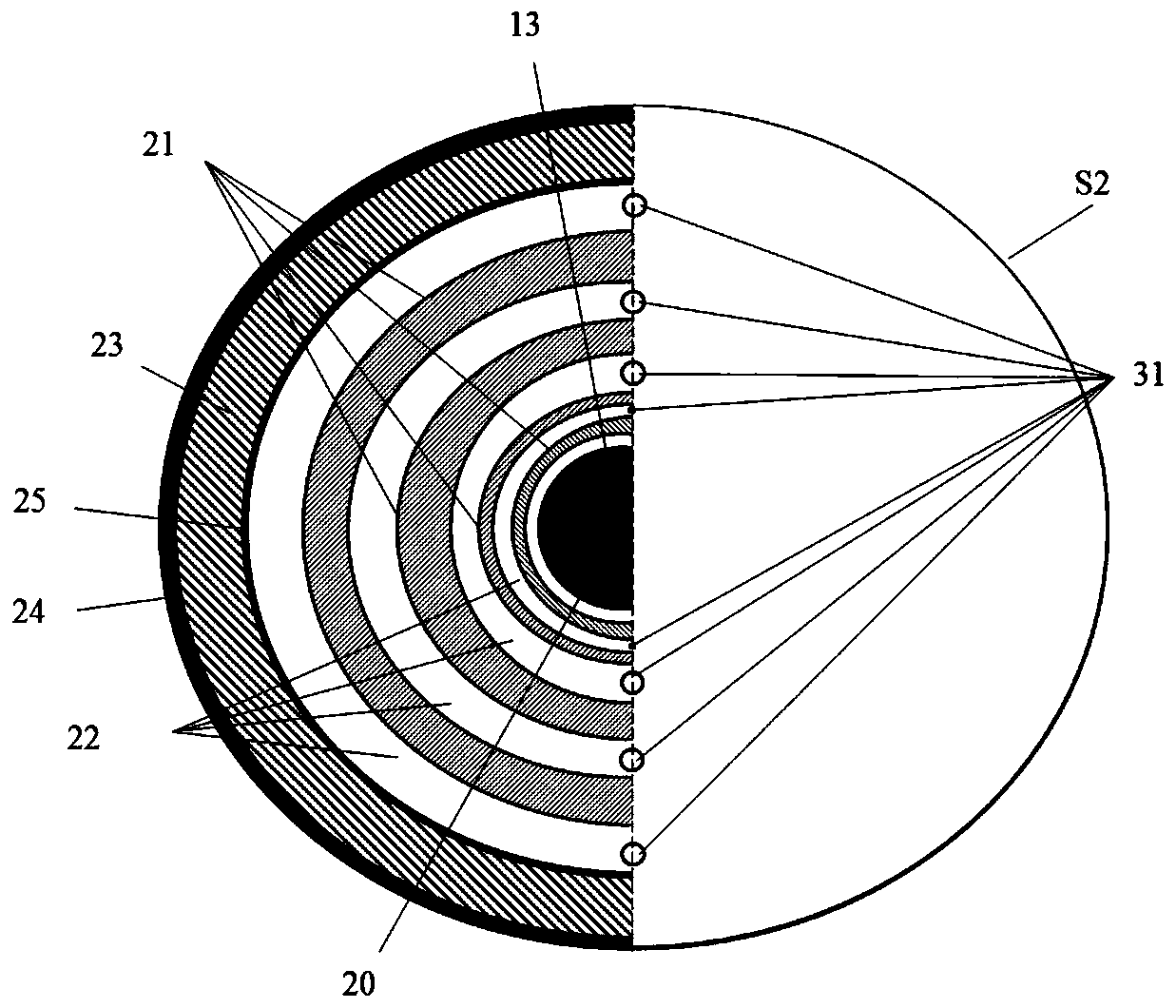

<99>Mo sub-critical production device and method based on accelerator driving

ActiveCN110706840AReduce lossesImprove utilization efficiencyConversion outside reactor/acceleratorsNeutron irradiationNuclear engineering

The invention discloses a <99>Mo sub-critical production device and method based on accelerator driving. The <99>Mo sub-critical production device based on accelerator driving comprises an acceleratorunit, a radiation production unit and a separation and purification unit; the accelerator unit sequentially comprises a high-energy particle source, a collimator, an accelerator, a target and a target cavity in an output direction; the high-energy particle source accurately bombards the target positioned in the target cavity at the center of the radiation production unit through the collimator and the accelerator to generate neutron; the radiation production unit adopts a concentric cylindrical structure and sequentially comprises neutron slowing layer, a neutron multiplying layer, a low enriched uranium salt solution and a neutron reflecting layer from inside to outside; and the low enriched uranium salt solution is placed into a fission reaction container to be sealed, the reflecting neutron generated by the target in the target cavity passes through the neutron slowing layer and the neutron multiplying layer to obtain high neutron flux and react with the low enriched uranium salt solution, the solution after reaction enters the separation and purification unit through a pipeline, and the neutron reflecting layer and a shielding layer are arranged sequentially from inside to outside, are positioned on an outer layer and are used for reducing neutron loss.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

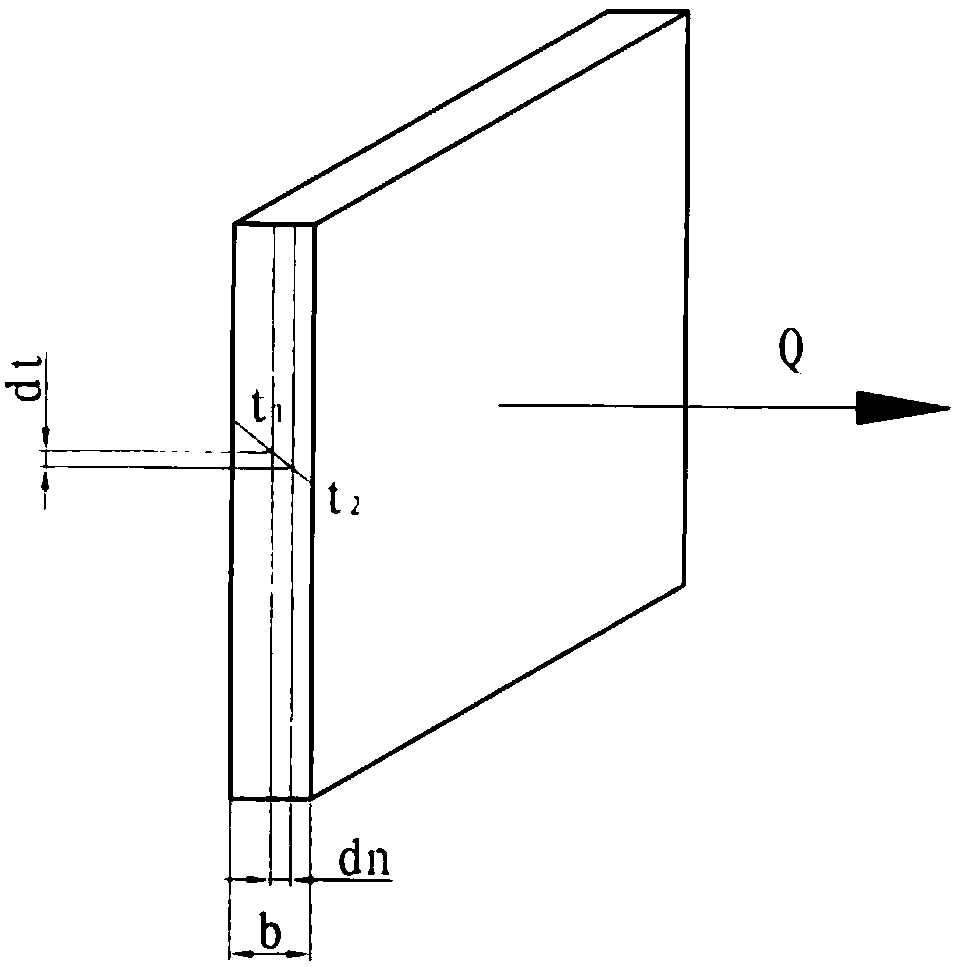

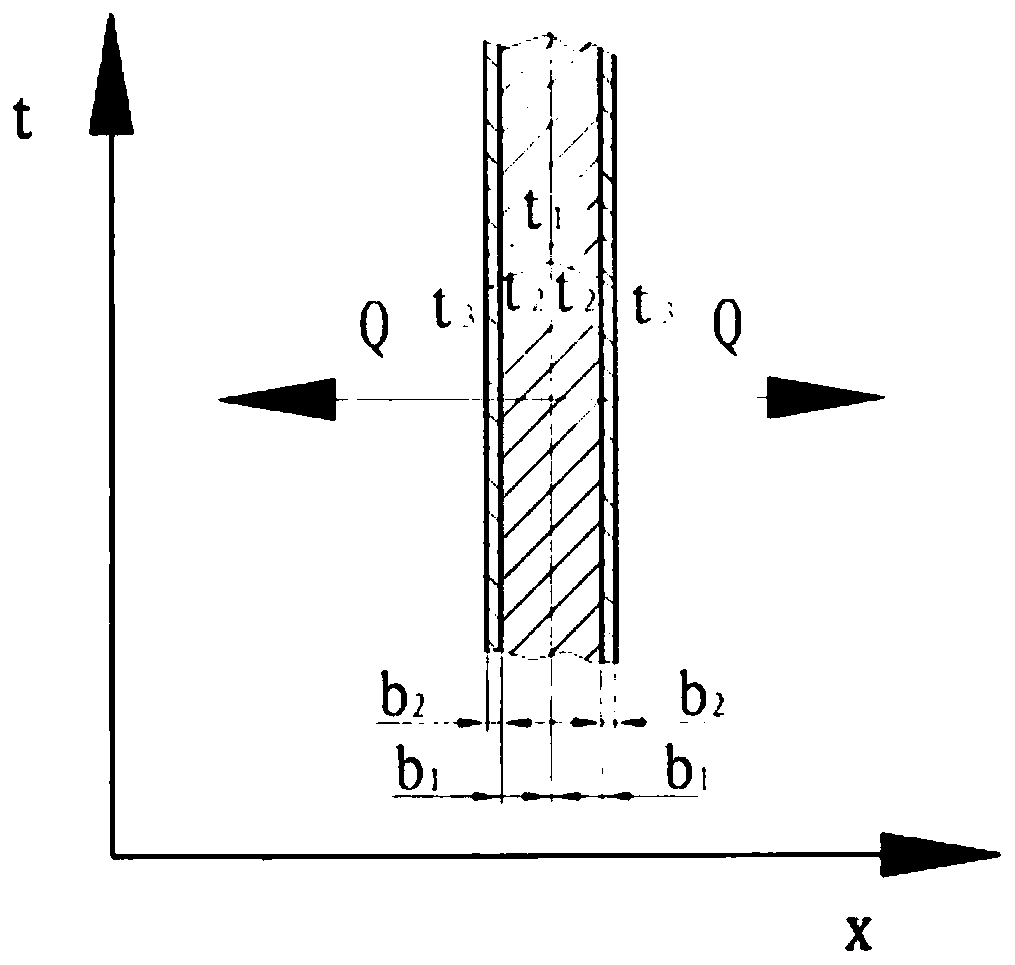

Freely combined low enriched uranium foil target with multiple single pieces

InactiveCN109147965AEnsure radiation safetySimple manufacturing processOptical rangefindersFuel elementsRadioactive agentIrradiation

The invention belongs to the technical field of radioactive substance preparation, and relates to a freely combined low enriched uranium foil target with multiple single pieces. The freely combined low enriched uranium foil target is used for producing fission <99> Mo by means of irradiation. The freely combined low enriched uranium foil target comprises a target barrel, low enriched uranium foils, a target core plug, a pressure plug and sealing covers. The target core plug is placed in the hollow target barrel, so that the multiple pieces of freely combined low enriched uranium foils can be compressed between the inner wall of the target barrel and the target core plug; the target core plug is compressed by the pressure plug in the target barrel from the upper side of the target core plug; two ends of the target barrel are sealed by the sealing covers by means of welding. The freely combined low enriched uranium foil target with the multiple single pieces has the advantages that processes for preparing the freely combined low enriched uranium foil target can be simplified, the irradiation efficiency can be improved, self-shielding can be reduced, the freely combined low enriched uranium foil target is safe in reactor irradiation periods and is easy to release in follow-up procedures, and the quality of the produced <99> Mo can be guaranteed.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for producing nuclear fuel products with a high loading of leu and corresponding nuclear fuel product

ActiveUS20150340110A1Improved Mo9 recoveryA large amountOptical rangefindersFuel elementsEngineeringEnriched uranium

A method of producing a nuclear fuel product is provided. The method includes the steps of providing a core comprising aluminium and low-enriched uranium; and sealing said core in a cladding. The core has a low-enriched uranium loading strictly higher than 3.0 gU / cm3 and includes less than 10 wt % of aluminium phase and / or aluminium compounds other than UAl2 phase, than UAl3 phase, and than UAl4 phase. A corresponding nuclear fuel product is also provided.

Owner:C E R C A CIE POUR LETUD & LA REAL DE

Method for separating enriched uranium, thorium mixture and rare earth from preferred slag

The invention discloses a separating method of enriched uranium and thorium composition and rare earth, which comprises the following steps: leaching slag; extracting; separating extracting phase, residual phase and insoluble solid; obtaining the product.

Owner:YANGZHOU UNIV +2

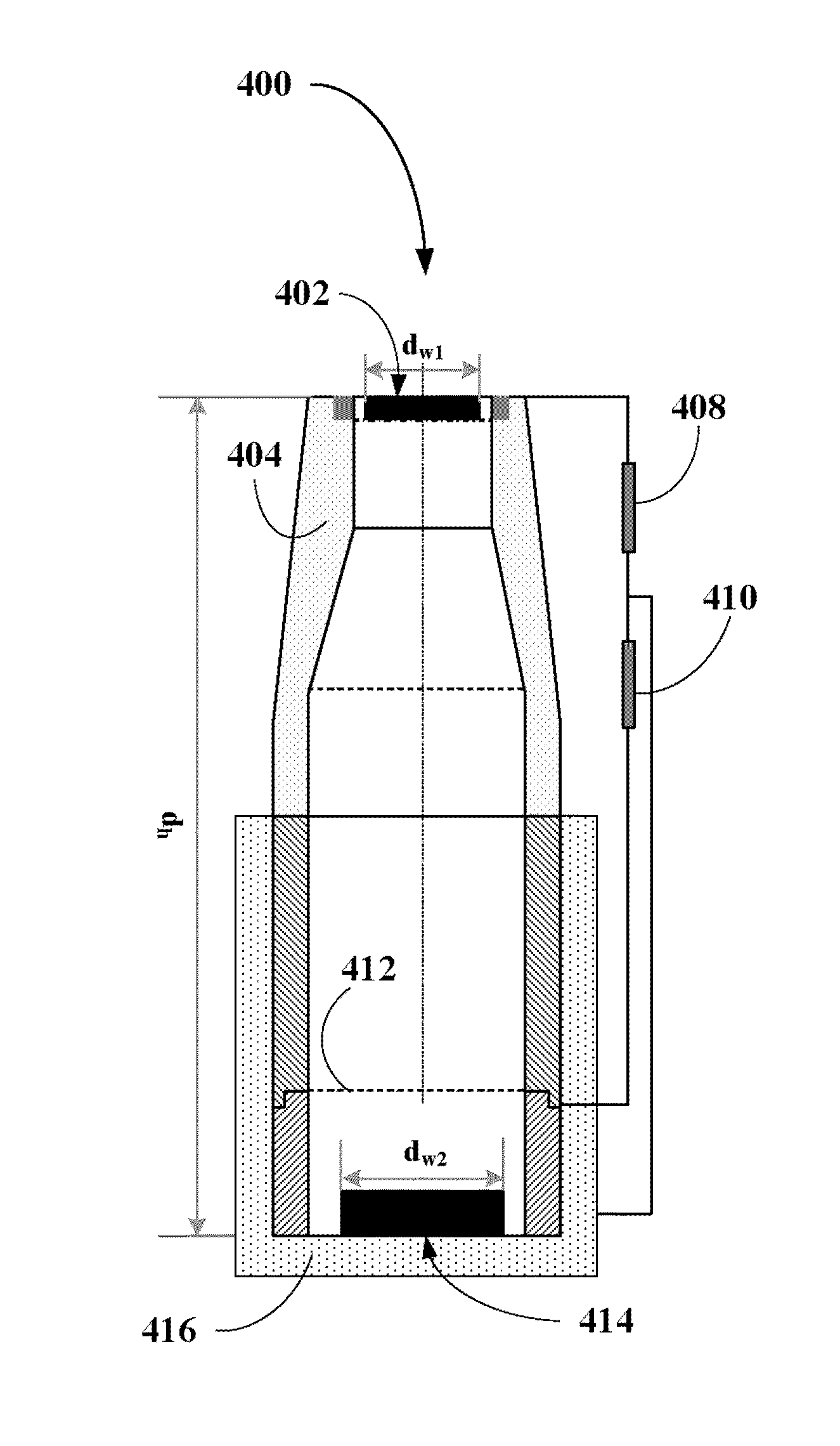

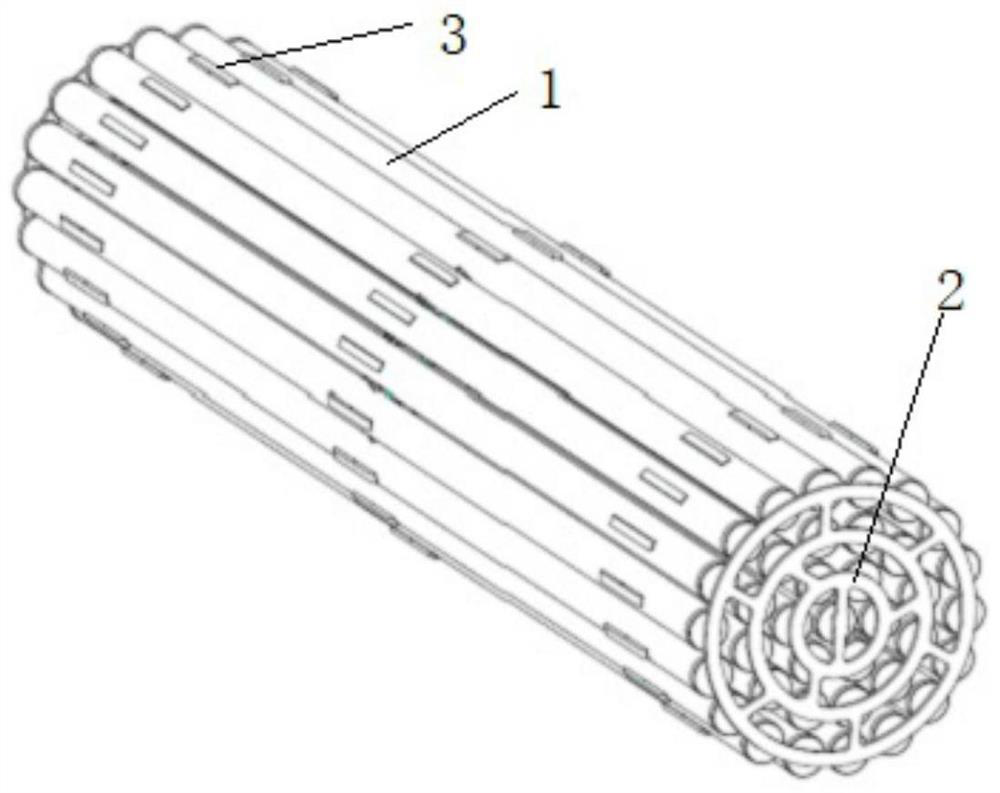

Support rod-containing irradiation target for producing molybdenum-99 isotope in heavy water reactor

PendingCN112951472AReduce the impact of power generationImprove efficiencySpecific isotope recoveryConversion in nuclear reactorNuclear plantNuclear reactor

The invention relates to the technical field of fission type nuclear reactors, in particular to a support rod-containing irradiation target for producing a molybdenum-99 isotope in a heavy water reactor. The irradiation target comprises a fuel rod bundle; the fuel rod bundle comprises a plurality of fuel elements and end plates welded to the two ends of the fuel elements; and at least one fuel element comprises a supporting rod and uranium enrichment cores, at least two through holes are formed in the supporting rod, the uranium enrichment cores are embedded in the through holes of the supporting rod, the uranium enrichment core is made of a uranium enrichment material with the <235>U enrichment degree ranging from 15.0 wt% to 20.0 wt%, and the through holes are formed in the axial direction of the supporting rod. Compared with the prior art, the irradiation target disclosed by the invention has the advantages that the characteristic that the heavy water reactor is refueled without stopping the reactor is fully utilized, the <99>Mo with short half-life period can be continuously produced by utilizing an existing reactor, a new irradiation facility does not need to be specially constructed, and the <99>Mo produced by using the enriched uranium is high in efficiency and good in quality, namely high in specific activity; and when the irradiation target is used for producing <99>Mo, the influence on power generation of a nuclear power plant can be reduced to the maximum extent.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

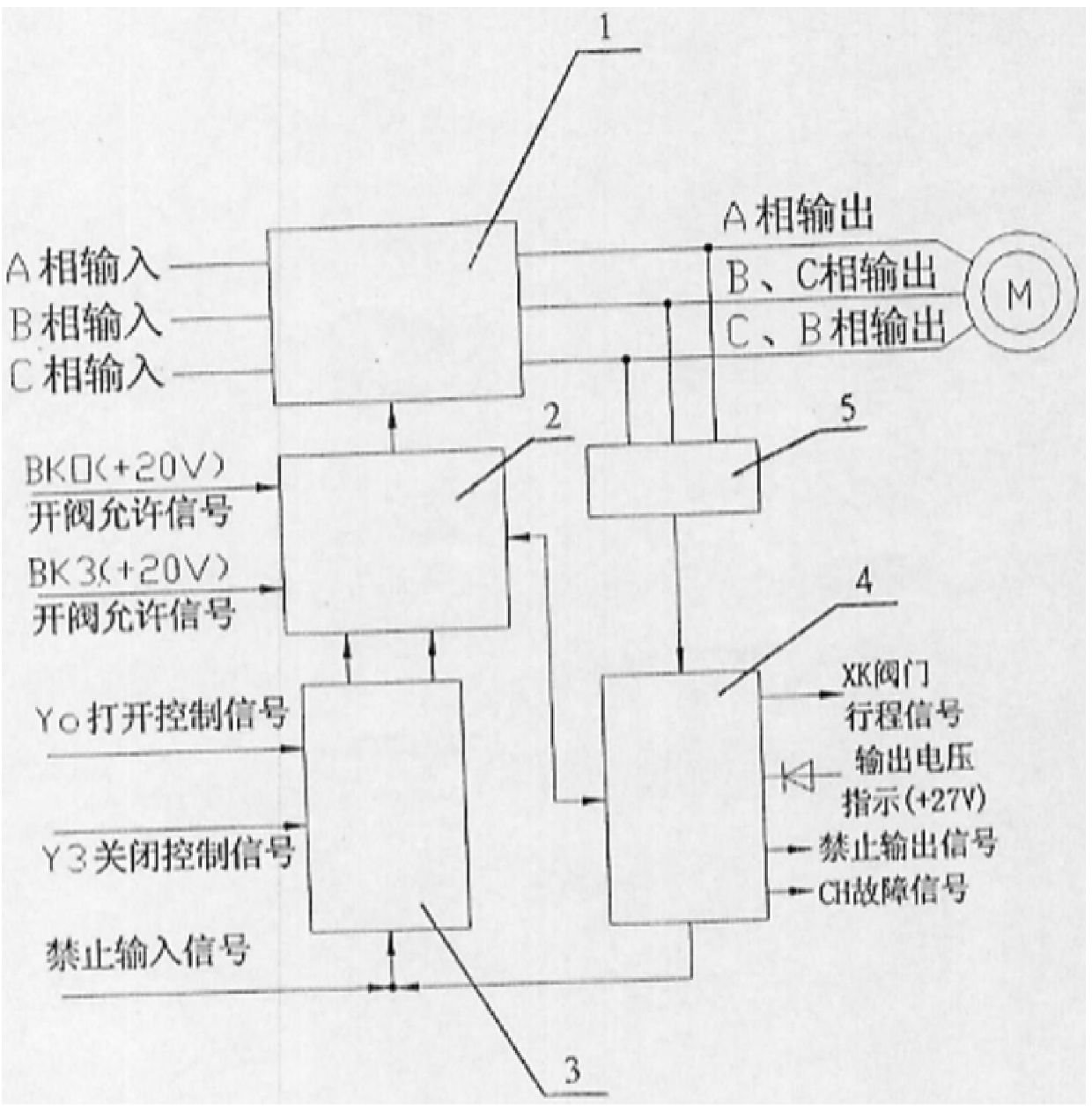

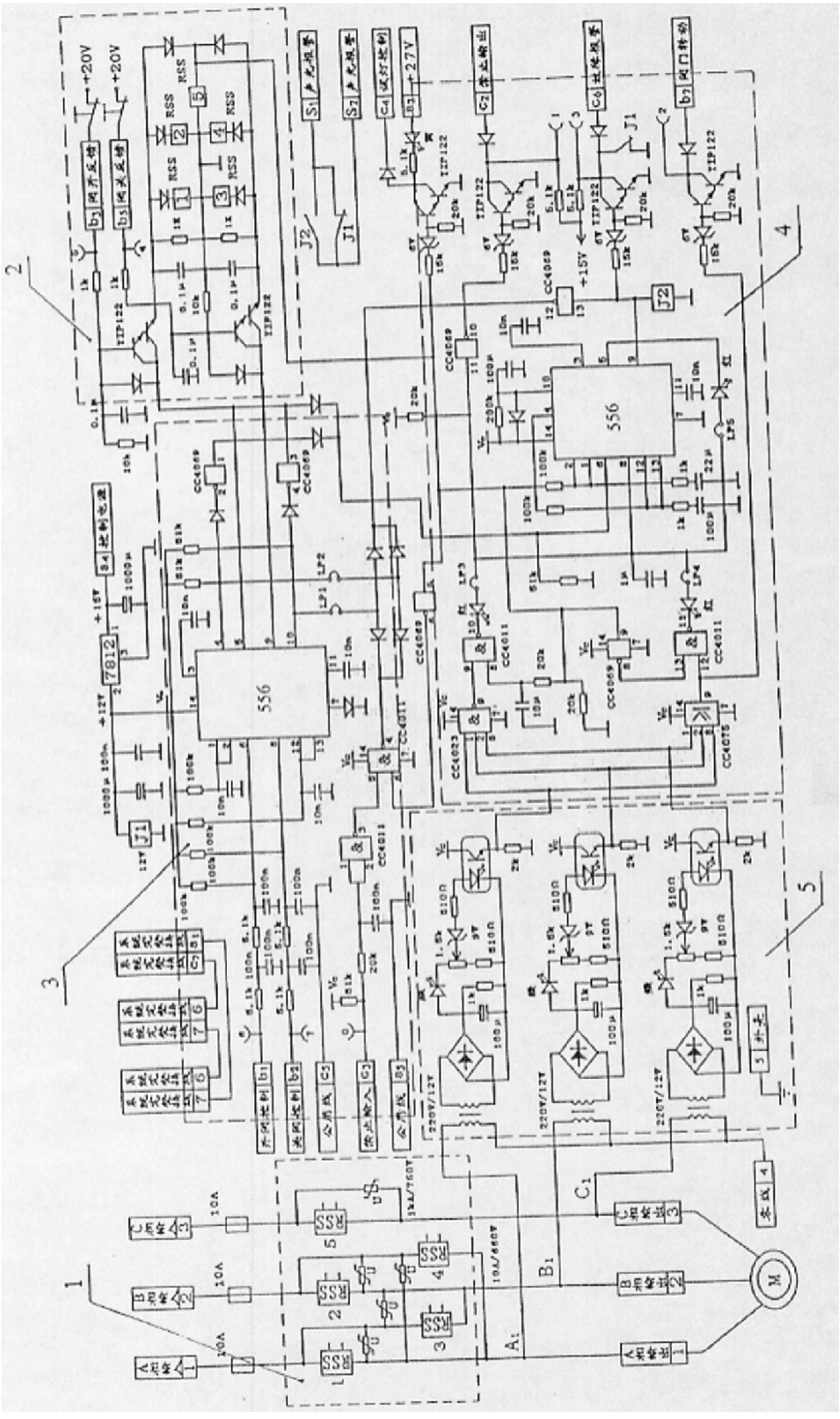

Valve control unit of automatic control system of uranium enrichment plant

ActiveCN106507882BLow costEasy to debugOperating means/releasing devices for valvesElectric controllersAutomatic controlControl signal

The invention belongs to the technical field of automatic control, and in particular relates to a valve control unit of an automatic control system in a uranium enrichment device manufactured by a centrifugal method. It includes a solid-state relay control circuit for controlling the solid-state relay switching circuit. The solid-state relay control circuit is respectively connected with a control chain circuit for discriminating control signals and a protection circuit for protecting the valve motor when a mechanical failure occurs in the valve. The protection circuit is connected with the valve motor. The output detection circuit used to detect the output signal is connected; the solid-state relay control circuit is connected to the valve terminal switch to receive the valve opening or closing permission signal issued by the valve terminal switch, and the control chain circuit is connected to the main control system to receive the signal from the main control system. External control signal, according to the external control signal, the valve control unit can connect the load motor to the circuit under the condition that the valve opening permission signal exists. The valve control unit has low cost, high reliability, easy operation and maintenance.

Owner:CNNC LANZHOU URANIUM ENRICHMENT

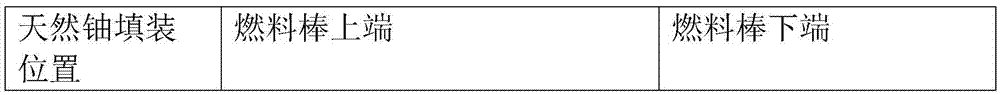

Method for measuring lengths of multiple kinds of enriched uranium pellet columns in nuclear rods

ActiveCN106935292ARealize measurementMeet the measurement requirementsNuclear energy generationNuclear monitoringNatural uraniumEngineering

The invention belongs to the technical field of fuel assemblies and particularly relates to a method for measuring lengths of multiple kinds of enriched uranium pellet columns in nuclear rods. The method includes the specific steps of manufacturing a standard rod, determining a gamma count value, performing data fitting and detecting actually. The method solves the technical problem that an existing measurement method fails to measure the lengths of the natural uranium pellet columns, is capable of measuring the lengths of the natural uranium pellet columns through a gamma-ray energy spectrum measurement method, solves the problem that a gamma absorption method fails to measure and meets the requirements on measuring the lengths of the natural uranium pellet columns in the TVS-2M fuel rods.

Owner:CNNC JIANZHONG NUCLEAR FUEL

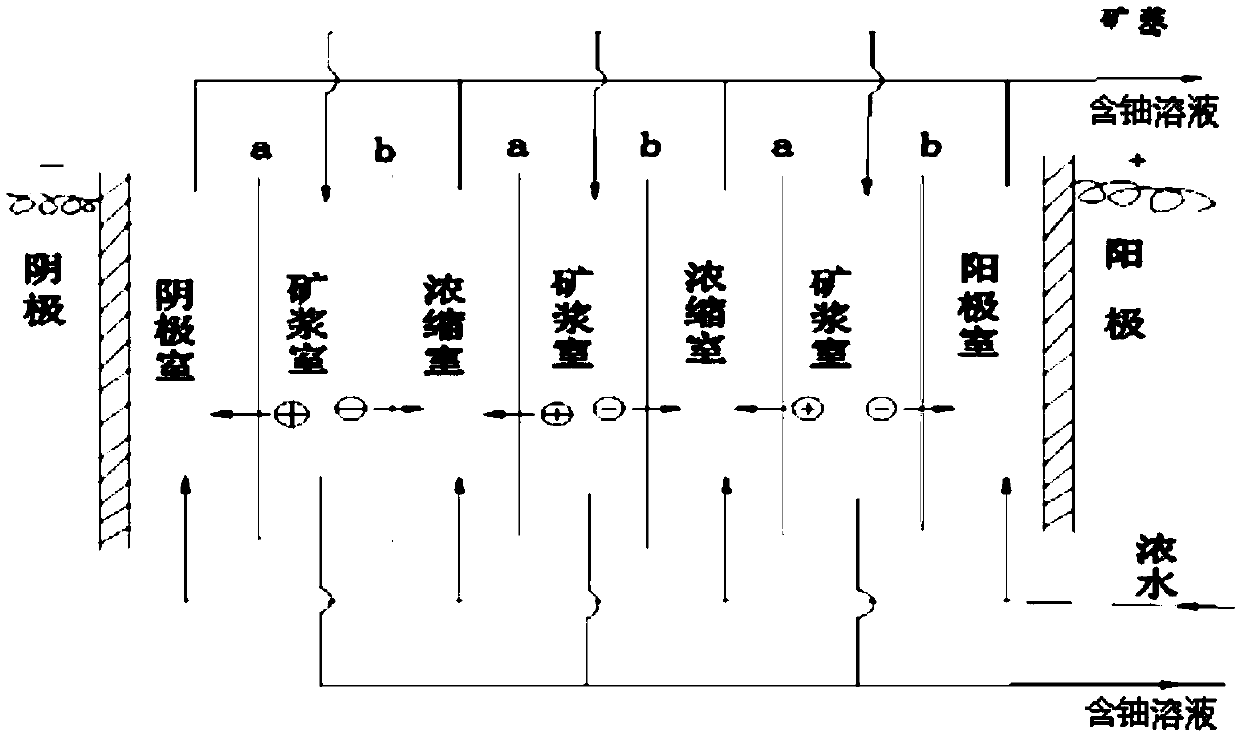

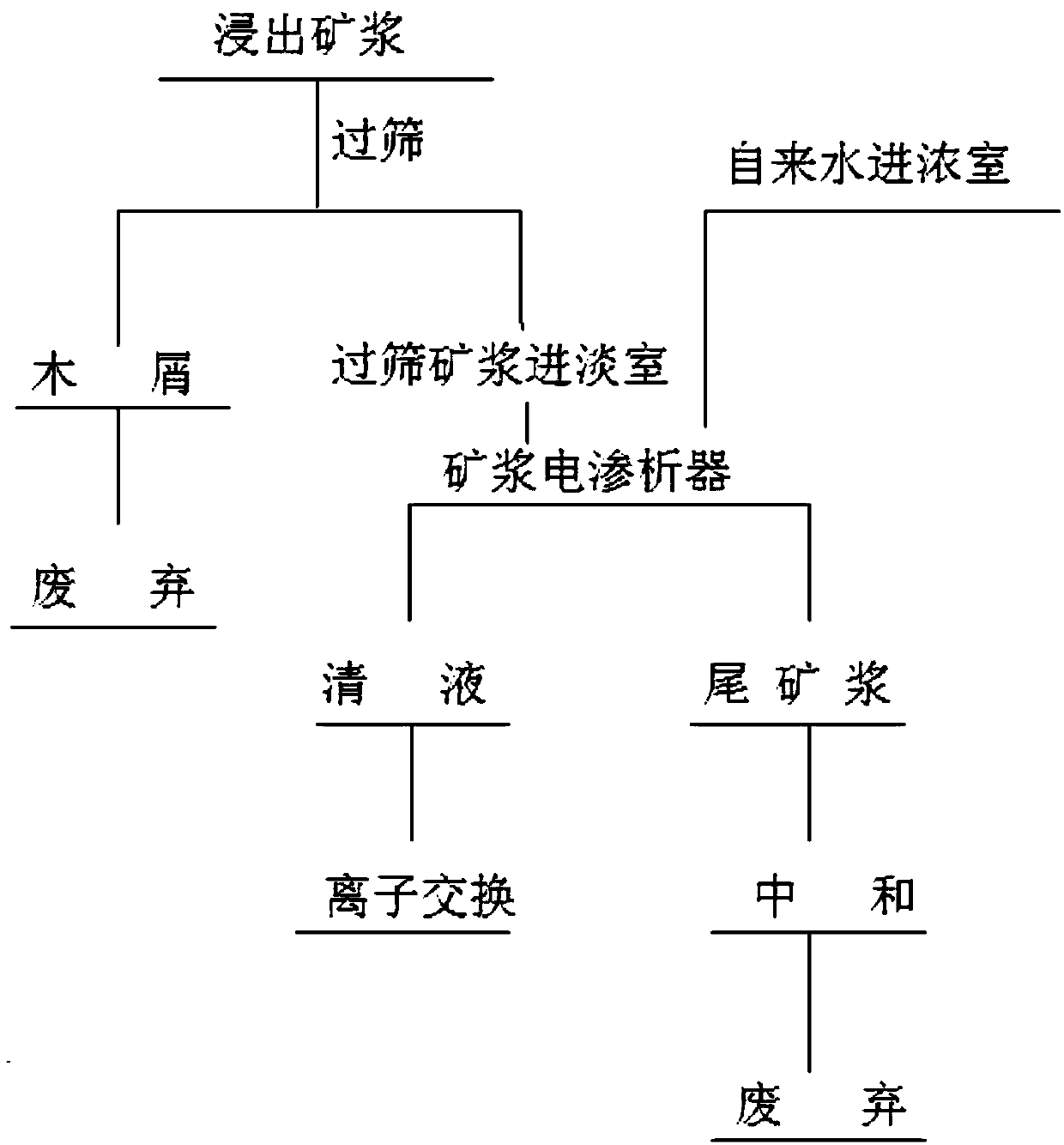

Method for separating uranium from uranium ore pulp with electrodialysis method

The invention provides a method for separating uranium from uranium ore pulp with an electrodialysis method. The method includes the following steps that a uranium-containing ore sample is subjected to agitation leaching with a leaching agent, and the uranium-containing ore pulp is obtained; and uranium is separated from the uranium-containing ore pulp with the electrodialysis method, and a uranium-rich solution and tailings are obtained. According to the method, a thickener or a spiral classifier or a hydrocyclone or other equipment is not needed, enriched uranium can be separated only with the electrodialysis method, and the process is simple; the method has a high uranium separation rate; by means of the method, no reagent needs to be added, and environmental pollution is fundamentallyeliminated; and by means of the method, the occupied area is small. The experimental result shows that the uranium separation rate of the method is 93.0-96.0%.

Owner:NANHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com