Patents

Literature

172results about How to "Lower energy level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

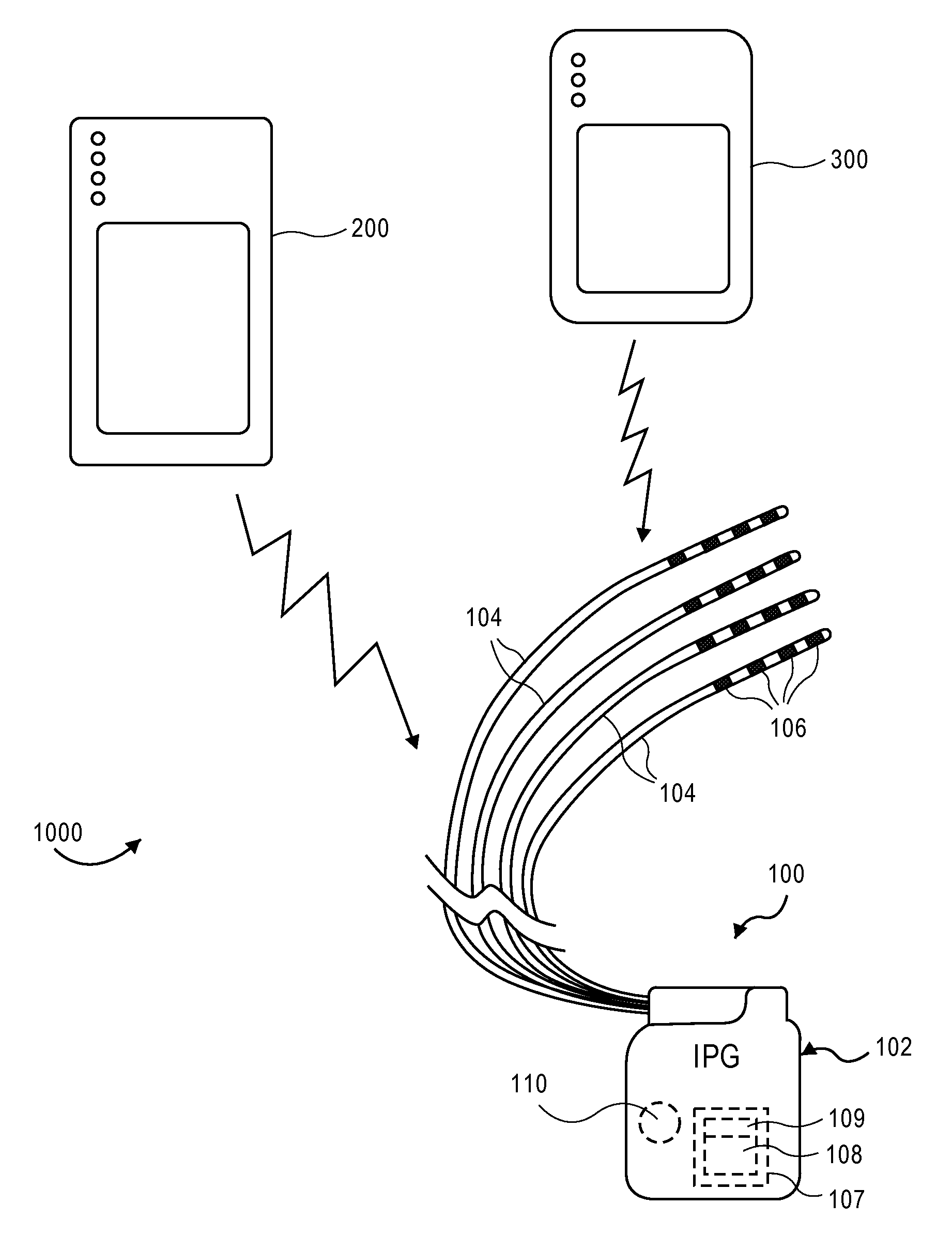

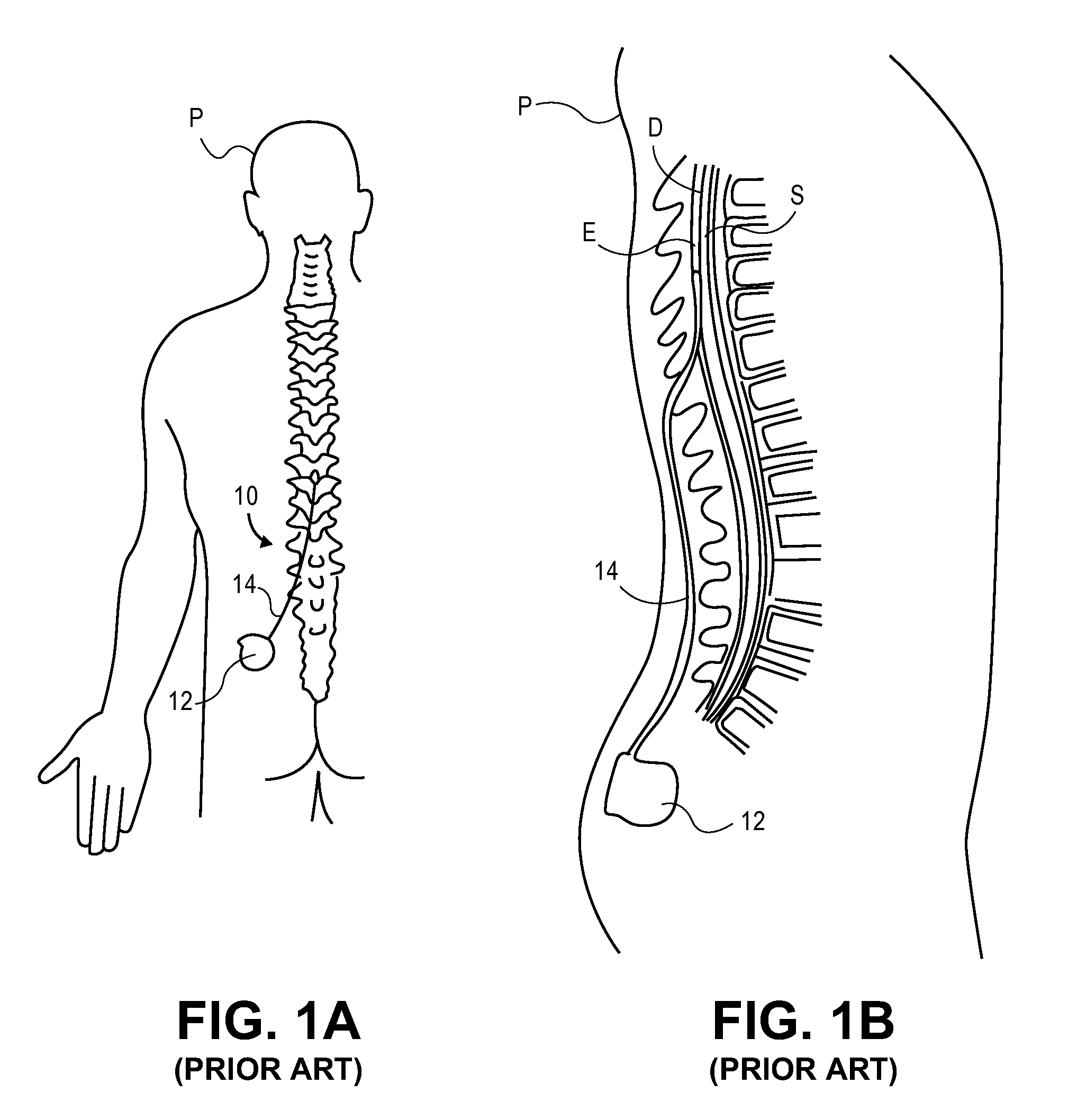

Selective stimulation systems and signal parameters for medical conditions

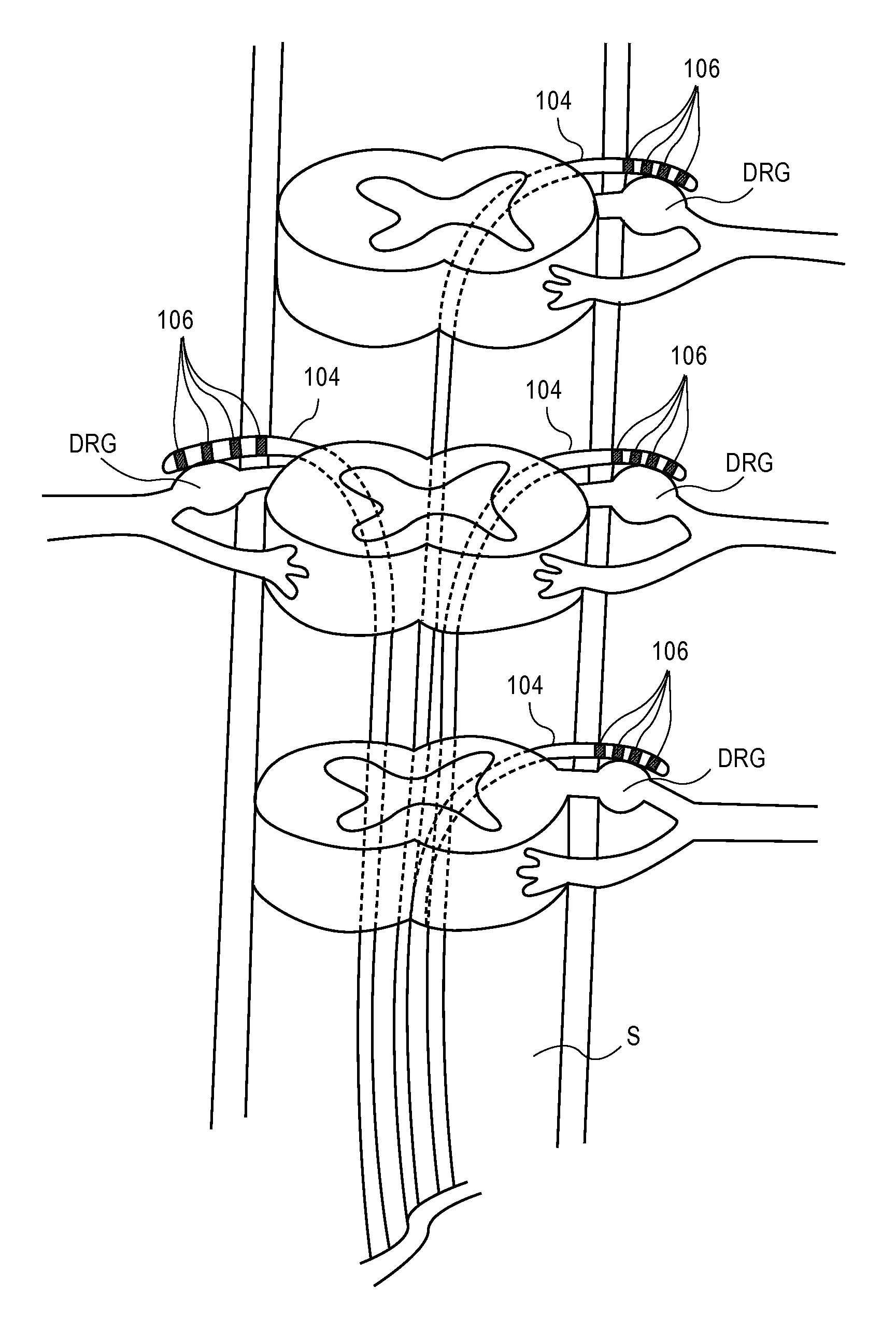

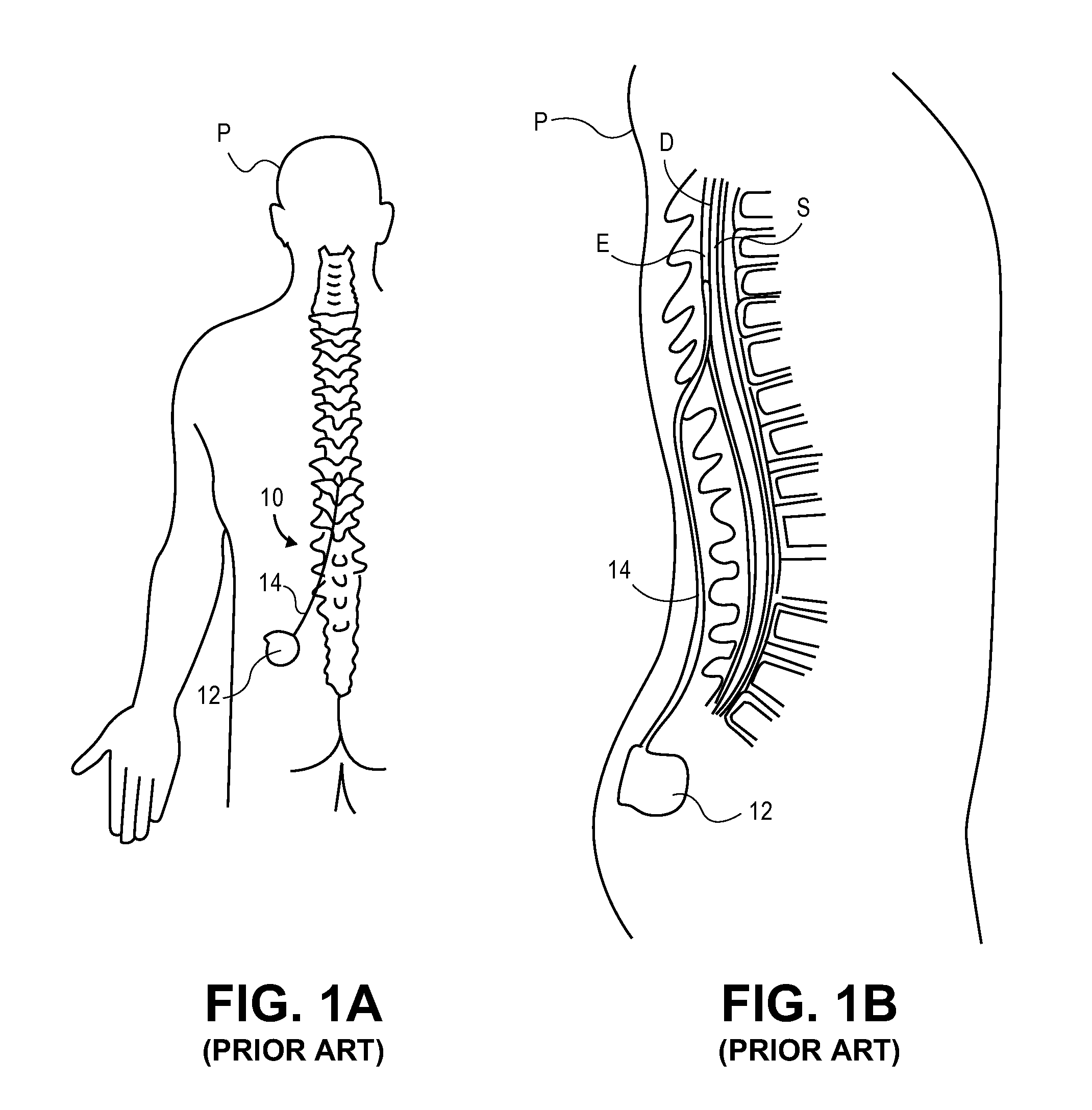

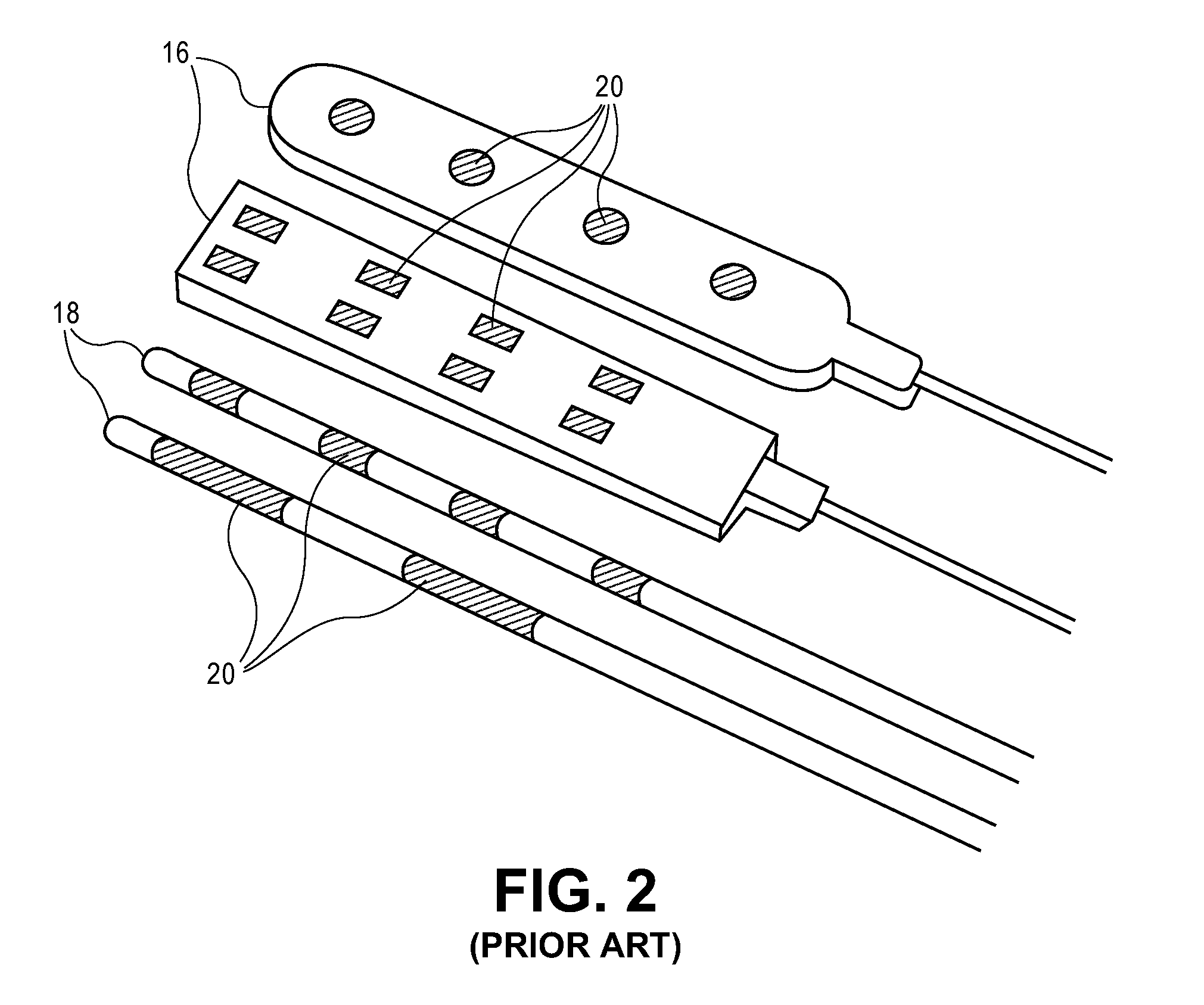

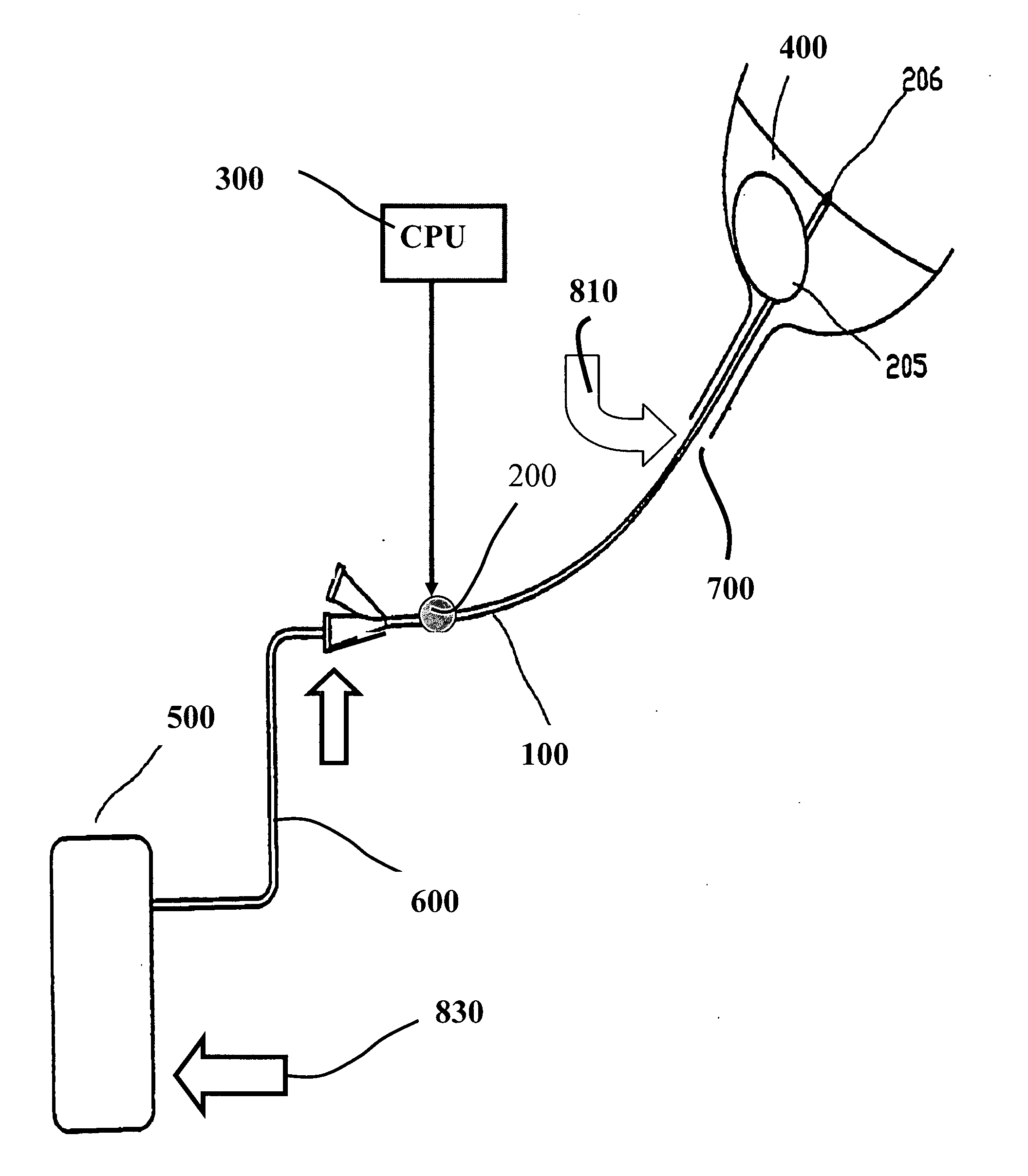

Devices, systems and methods are provided for targeted treatment of a variety of conditions, particularly conditions that are associated with or influenced by the nervous system, such as pain. Targeted treatment of such conditions is provided with minimal deleterious side effects, such as undesired motor responses or undesired stimulation of unaffected body regions. This is achieved by directly neuromodulating a target anatomy associated with the condition while minimizing or excluding undesired neuromodulation of other anatomies.

Owner:TC1 LLC

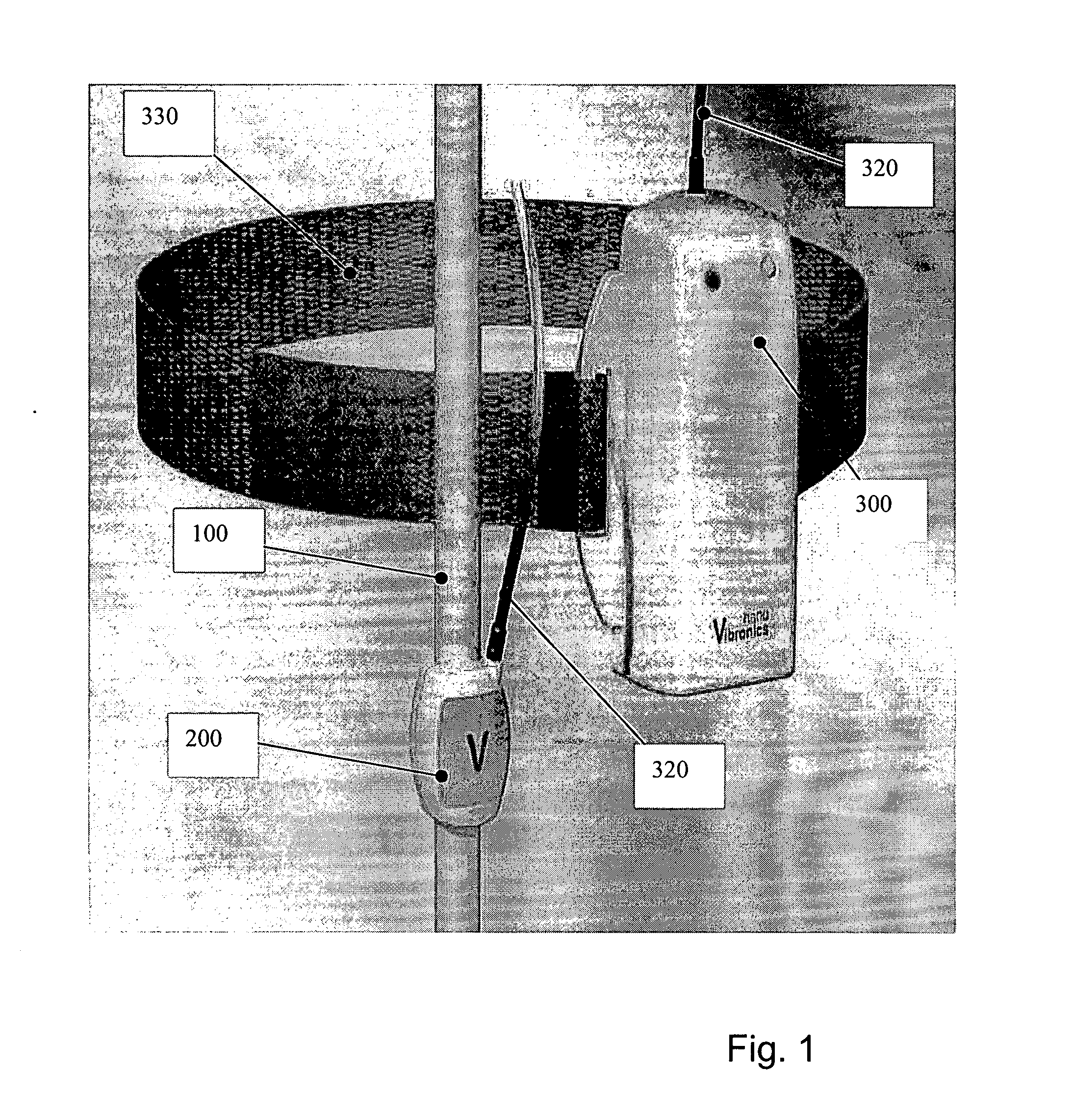

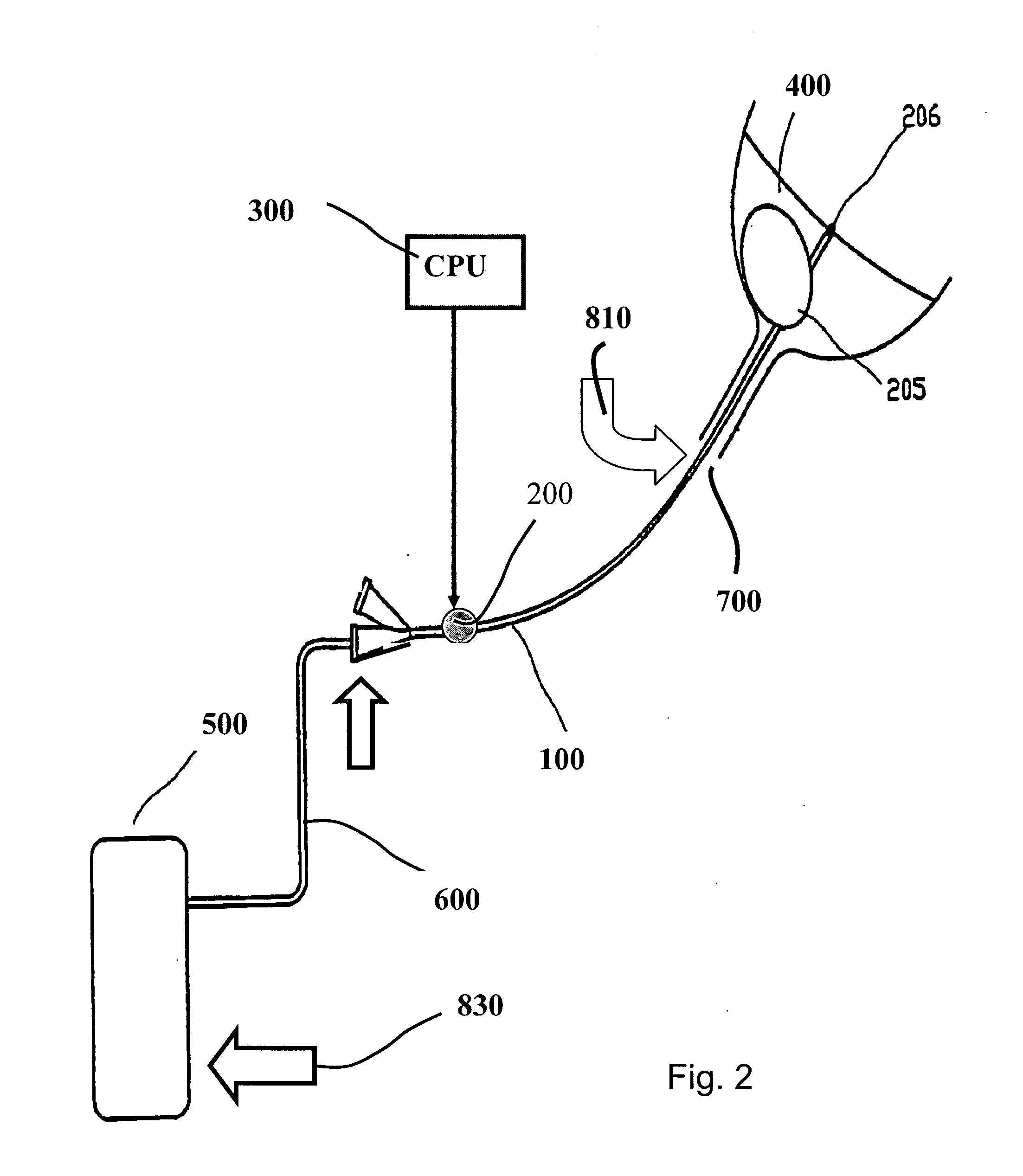

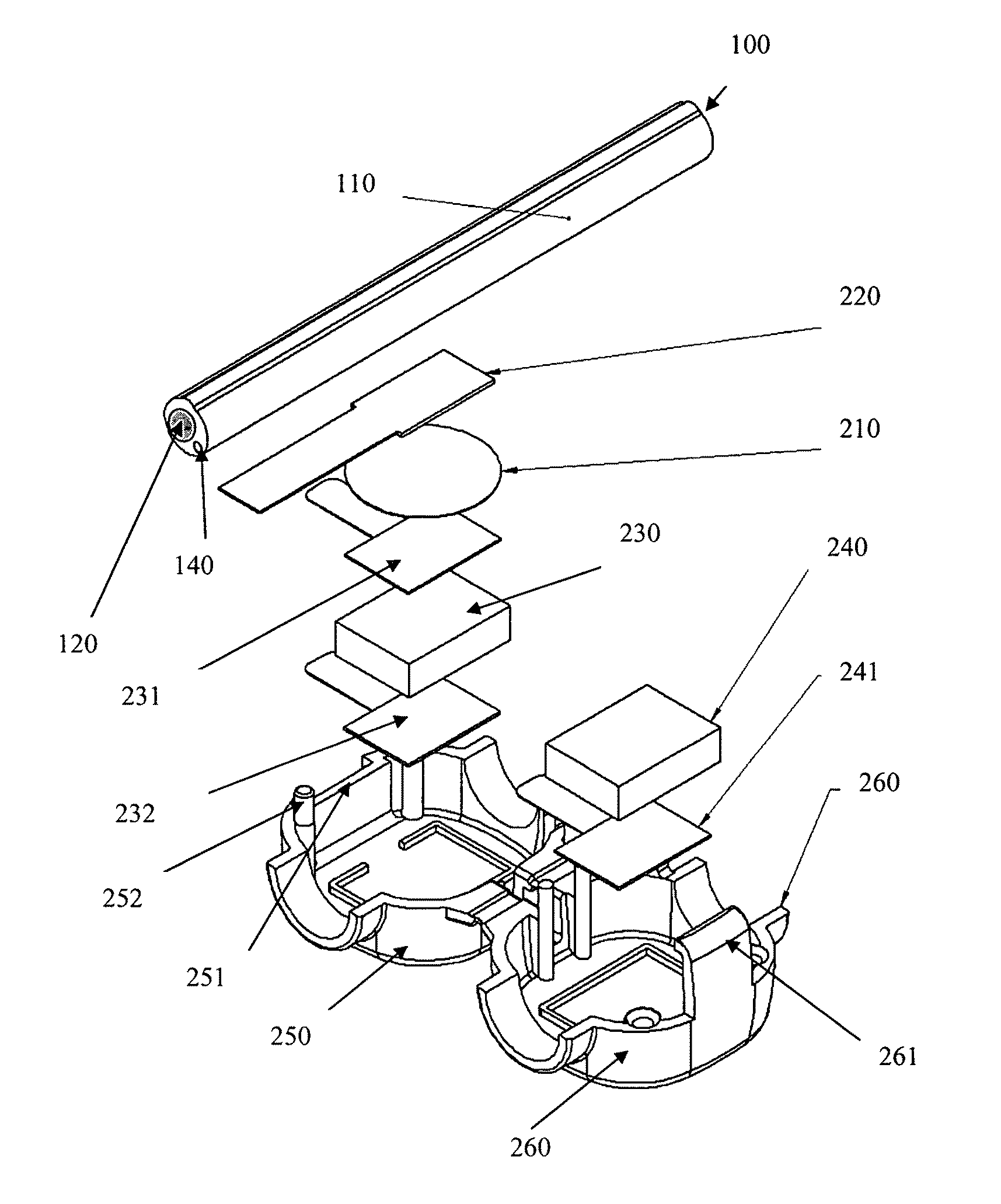

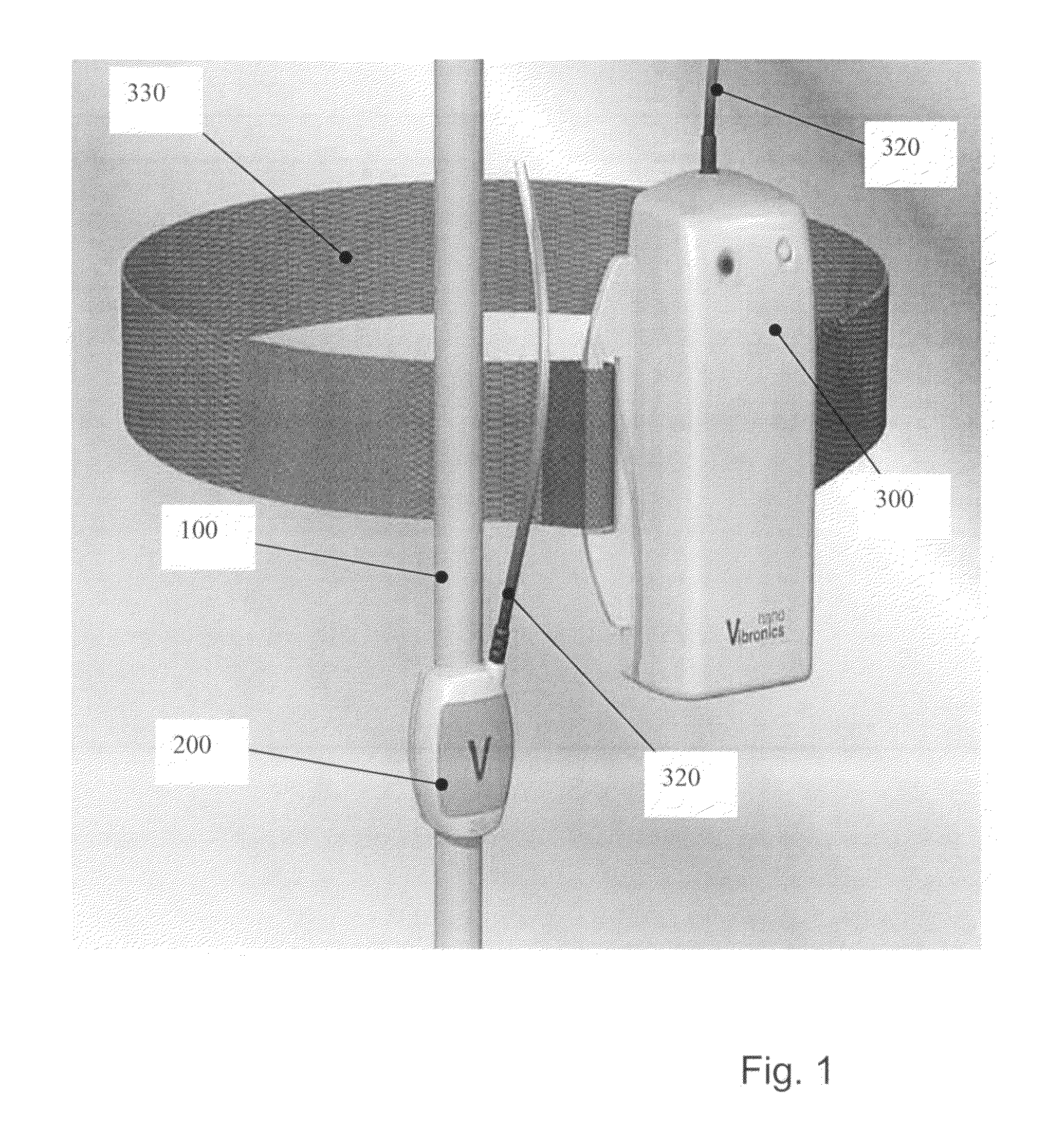

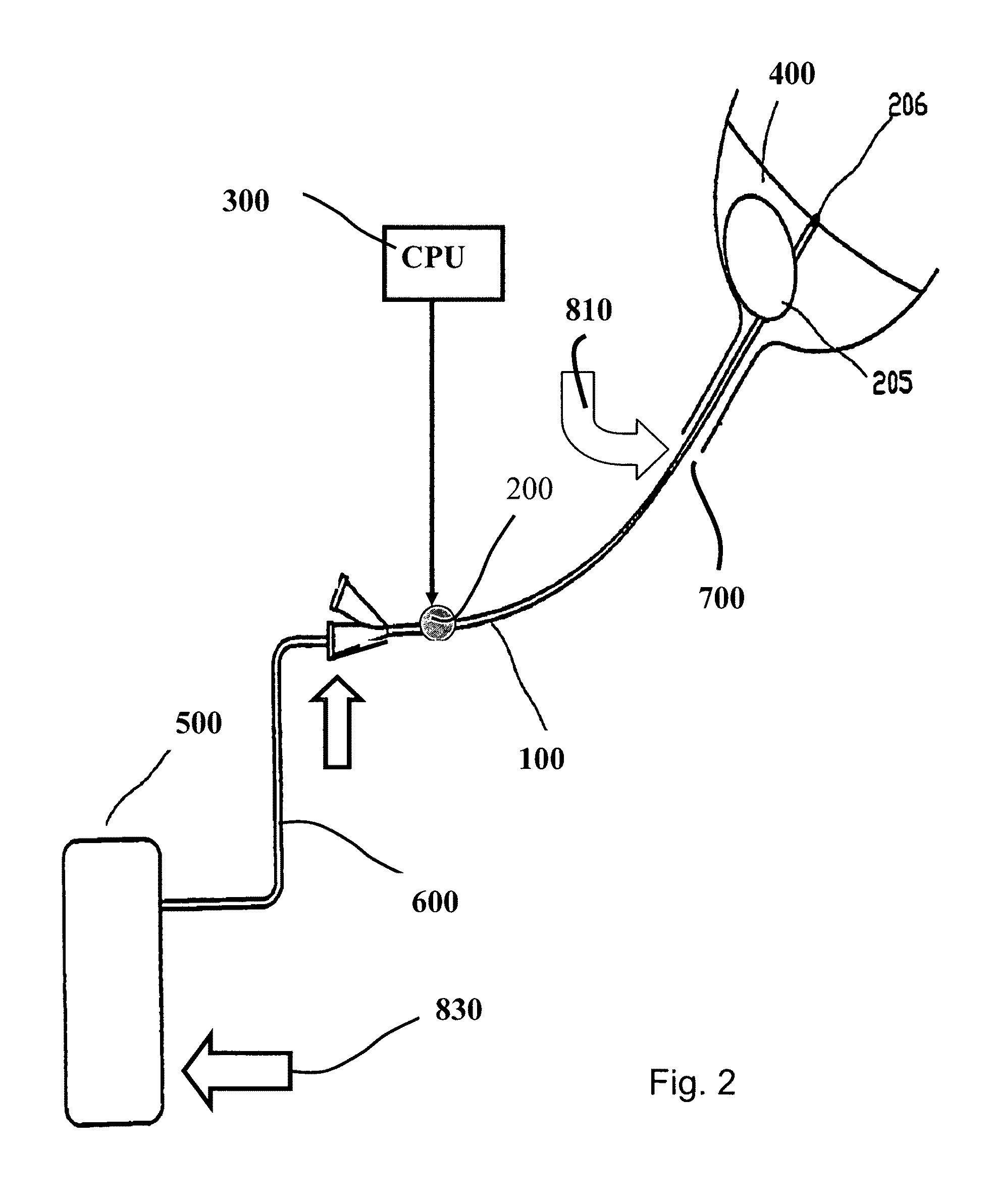

Acoustic add-on device for biofilm prevention in urinary catheter

ActiveUS20070244423A1Shorten connection timeAvoid injuryUltrasonic/sonic/infrasonic diagnosticsSurgeryUrinary catheterMedicine

A urinary catheter clip-on device applies surface acoustic waves of Rayleigh-Lamb and / or Love type to a urinary catheter for preventing biofilms on the catheter surfaces. The bacteria is forced to move relative to the vibrating catheter surface. The amplitudes of bacteria vibrations are in nanometer range. The relative motion of bacteria results in bacteria quorum sensing, and disrupts the bacteria attachment process. The method is preventive as surface acoustic waves create low acoustic energy and bacteria is not killed.

Owner:NANOVIBRONIX INC CO P M G MEDICA LTD

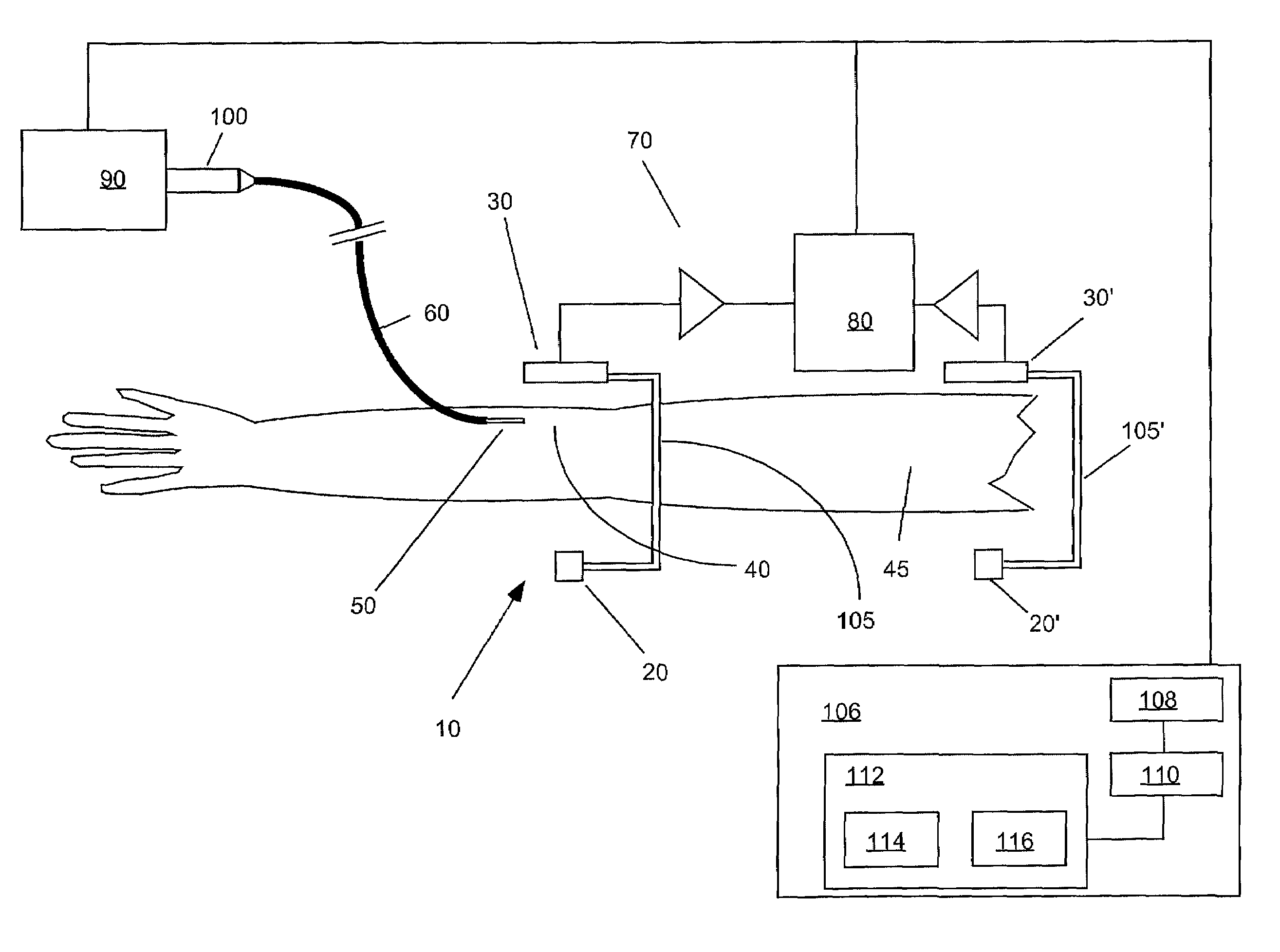

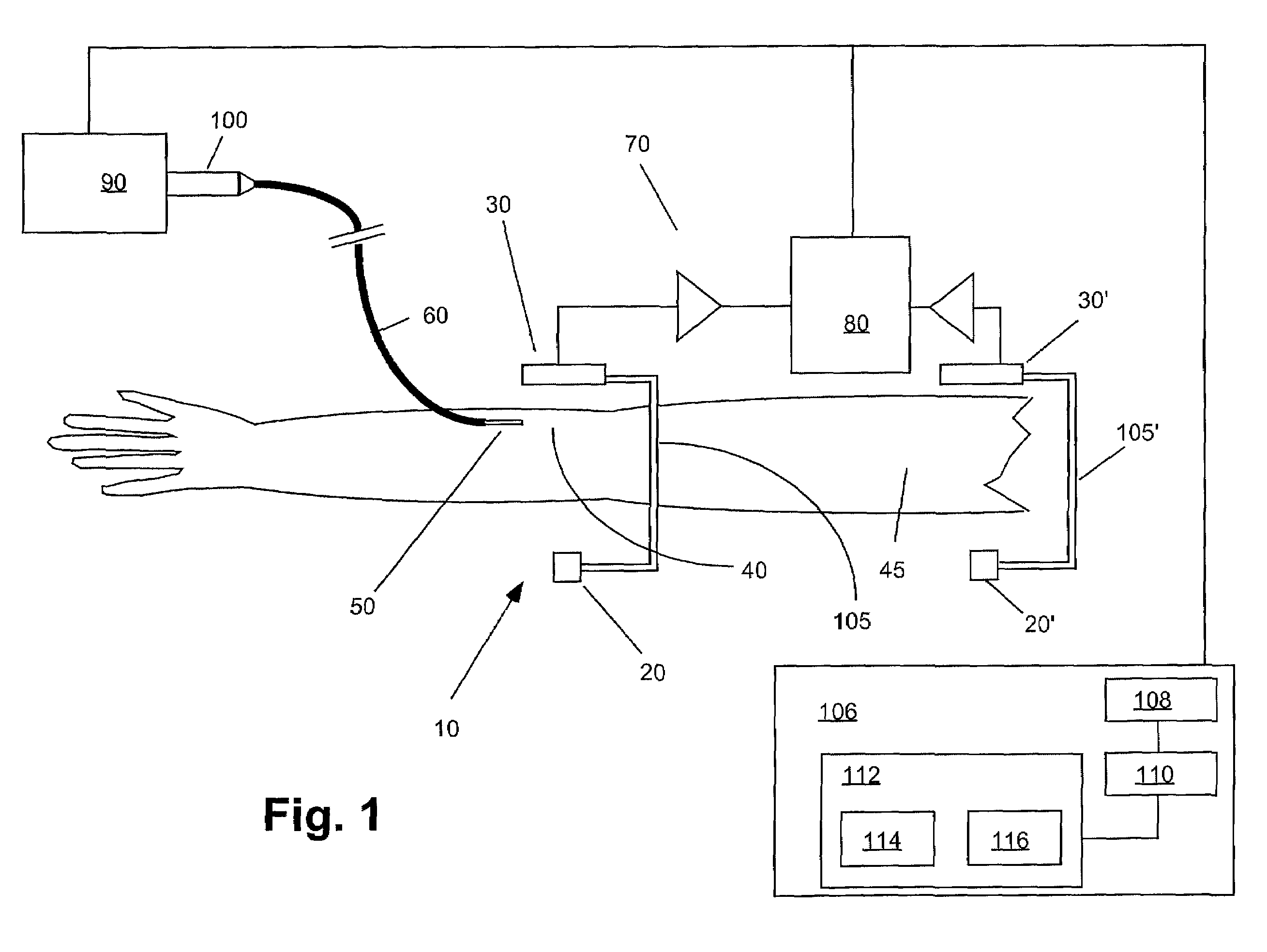

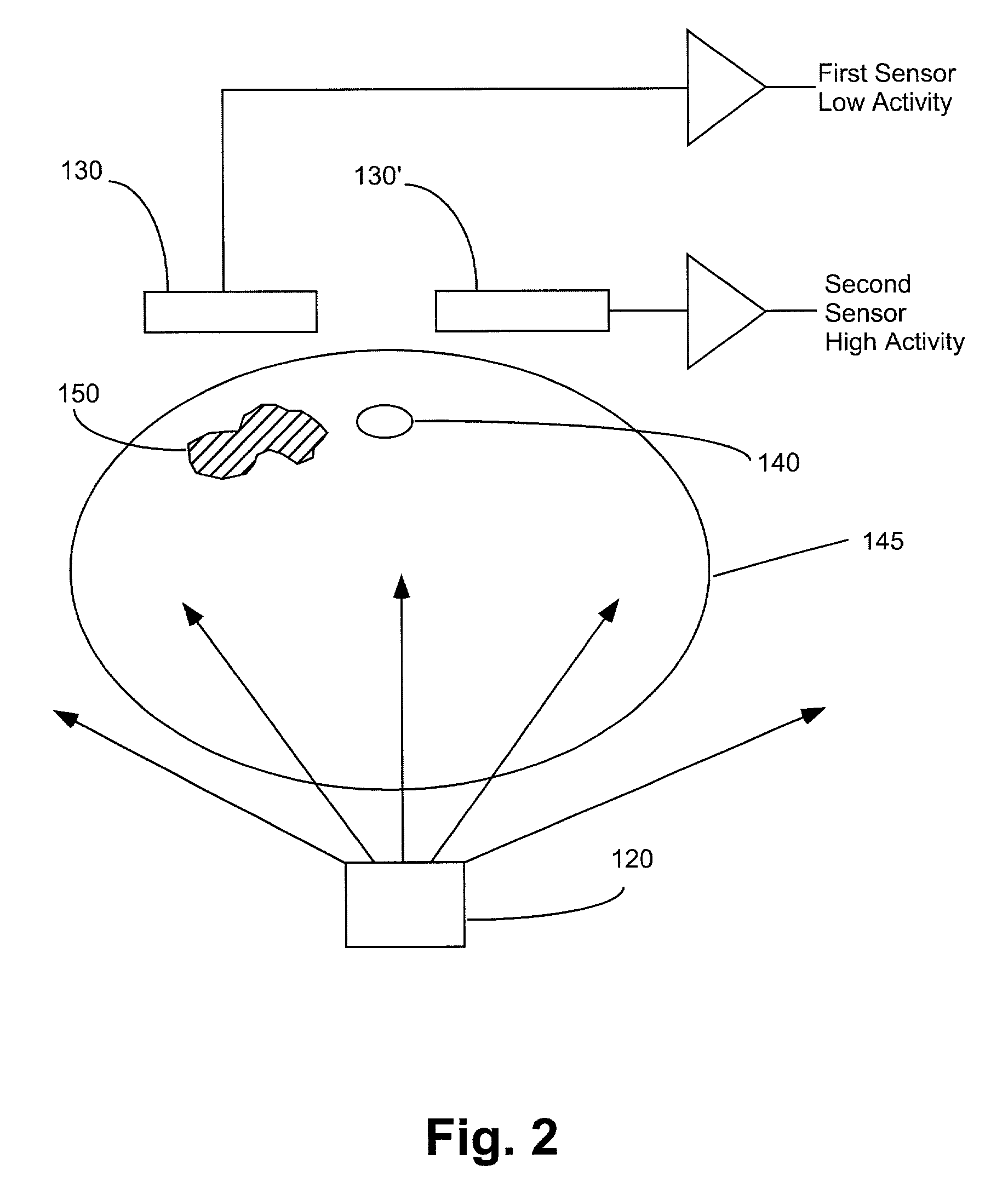

Apparatuses, systems and methods for extravasation detection

InactiveUS7047058B1Enhance the imageSensitive measurementUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using microwave meansMedicineX-ray

An apparatus for the detection of extravasation in an imaging procedure includes at least a first source of energy to supply imaging energy to tissue in the vicinity of a site and at least a first sensor to measure a signal resulting from the energy supplied to the tissue by the first imaging energy source. In preferred embodiment, the energy may be one of X-ray, gamma ray or ultrasound energy.

Owner:BAYER HEALTHCARE LLC

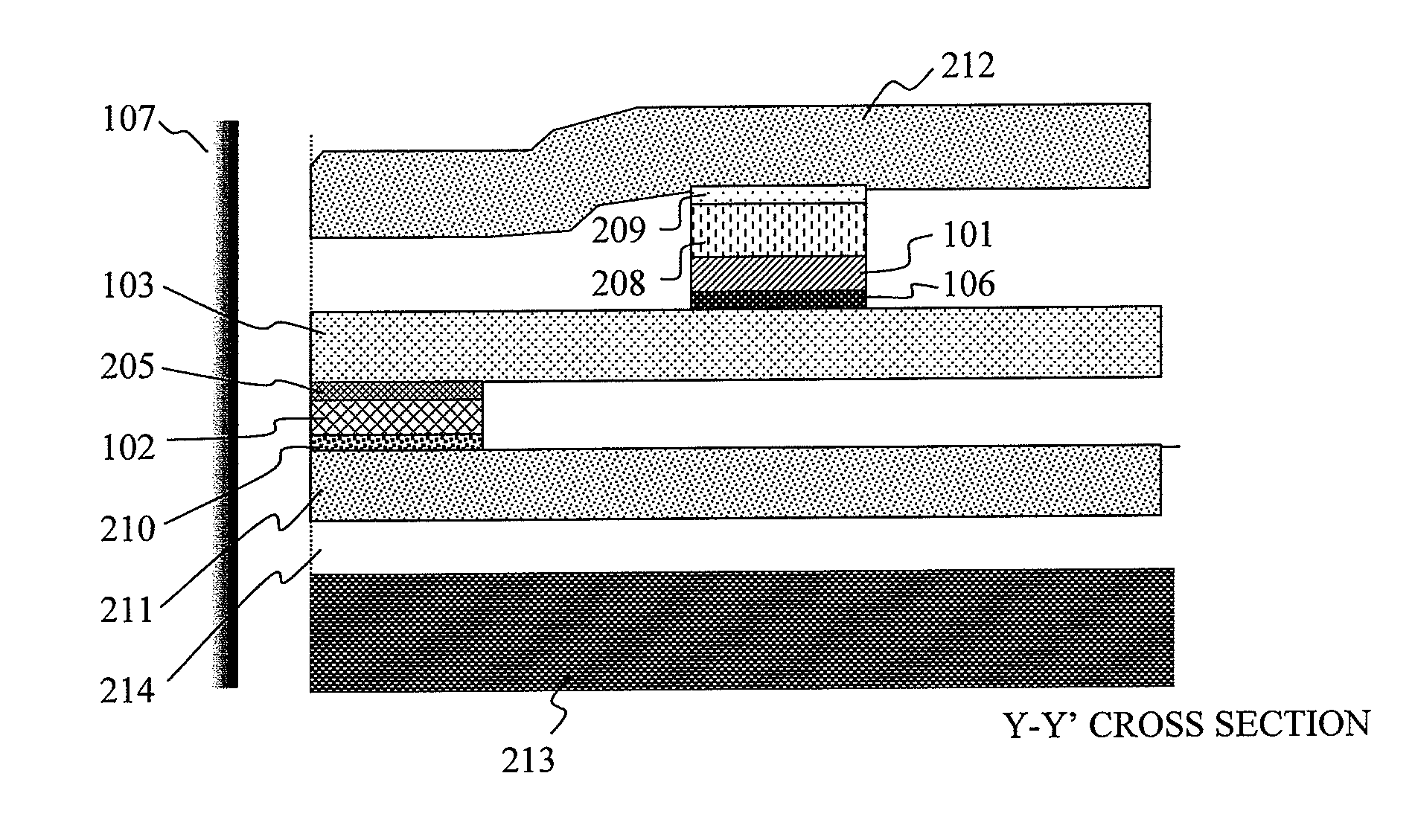

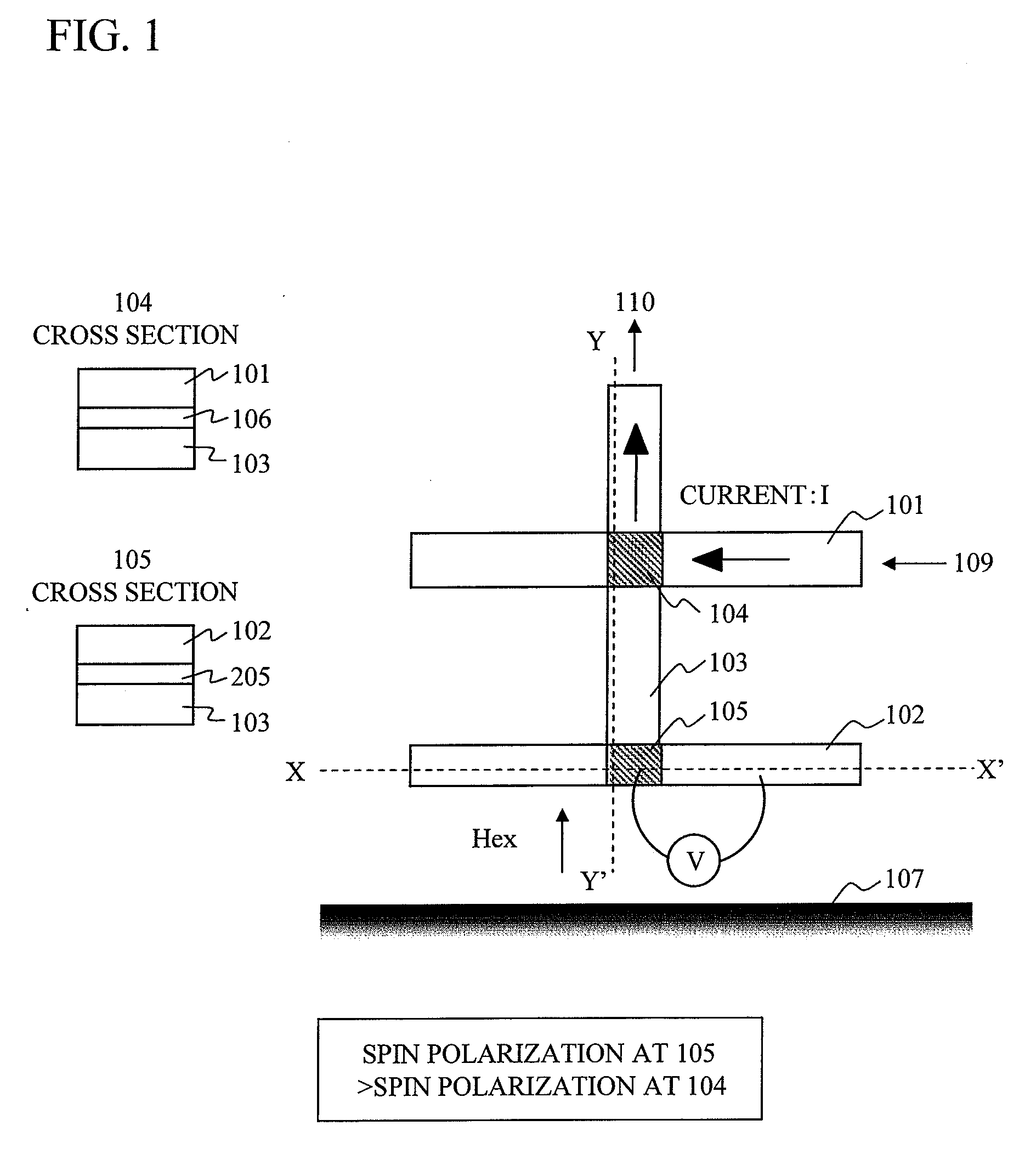

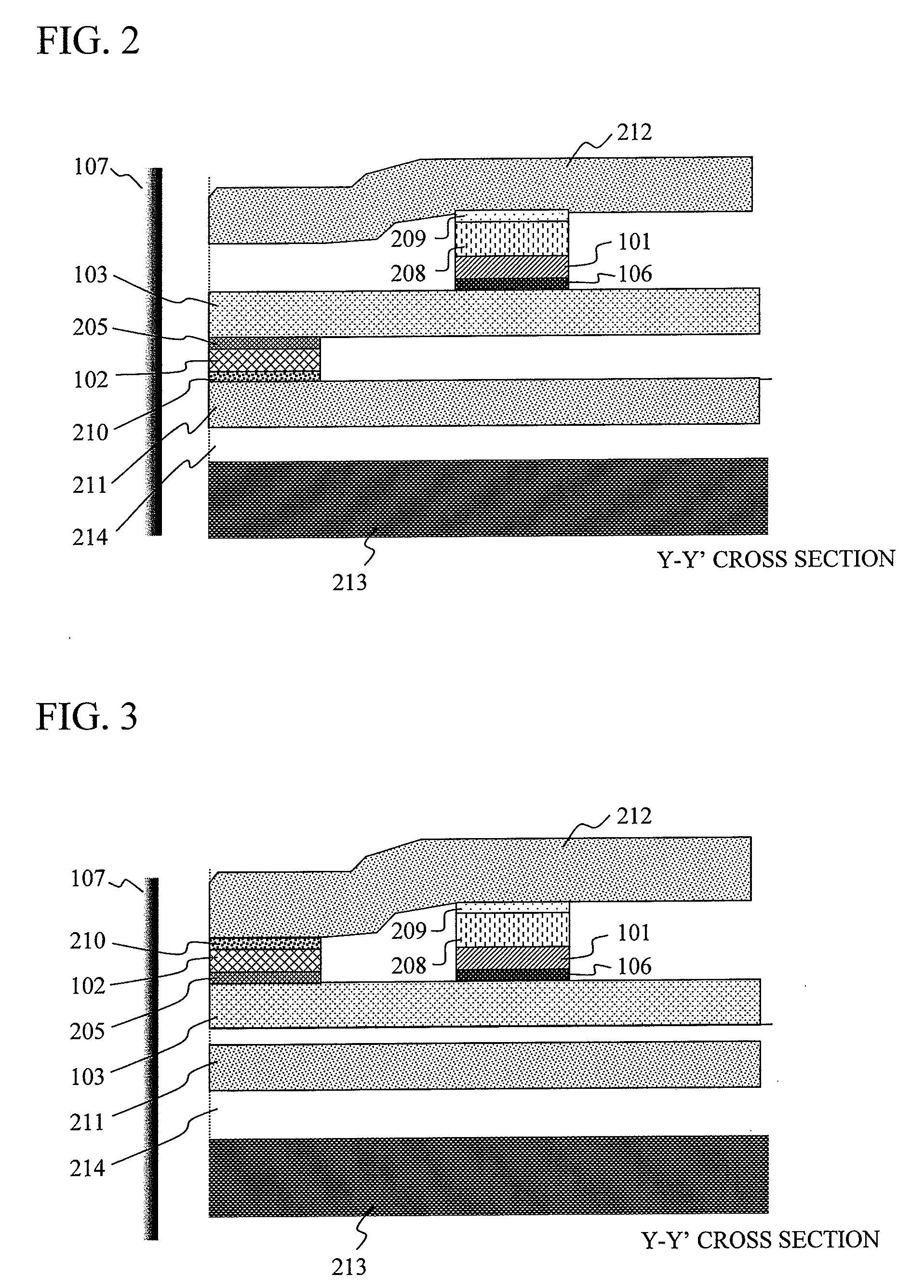

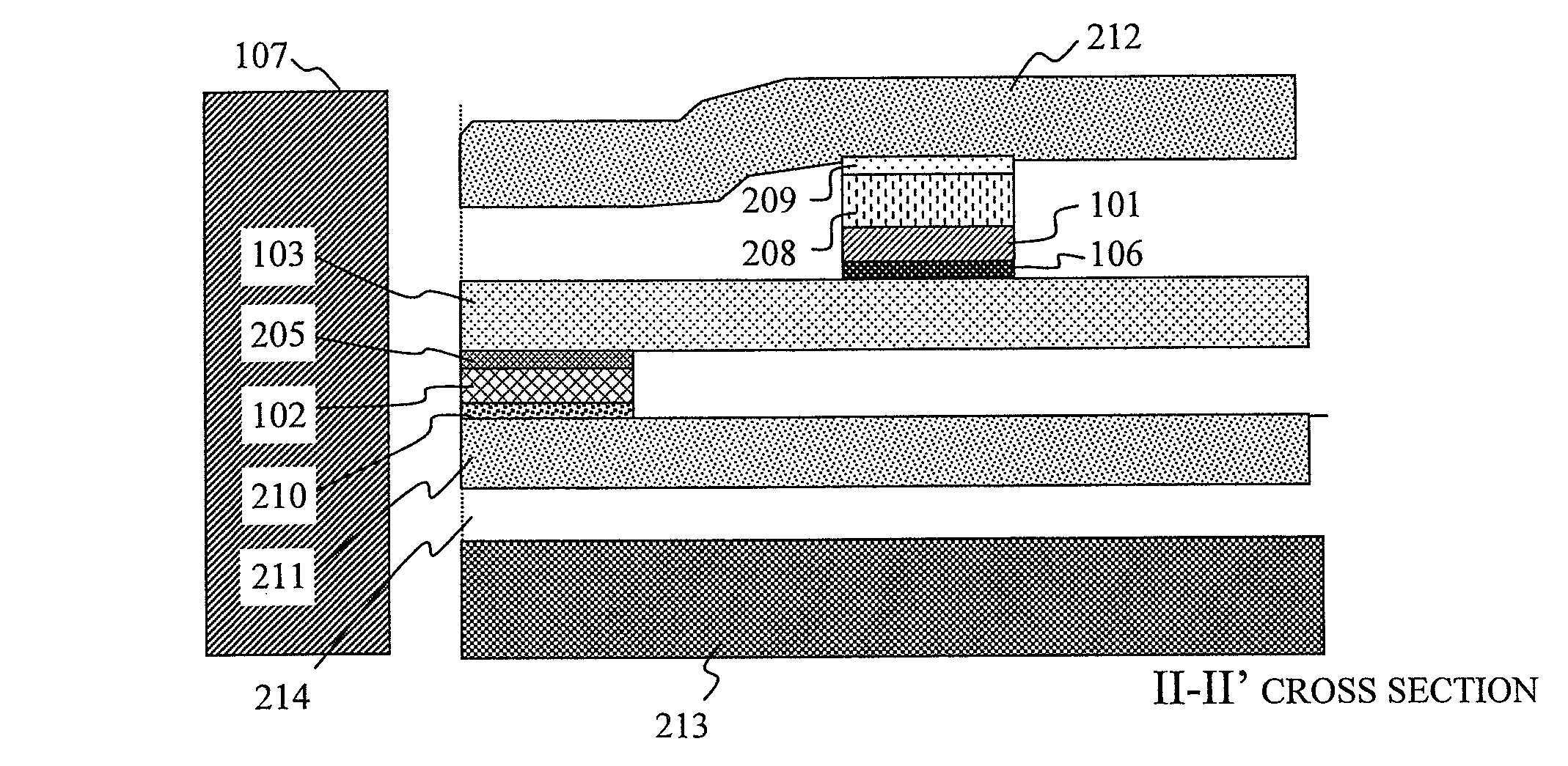

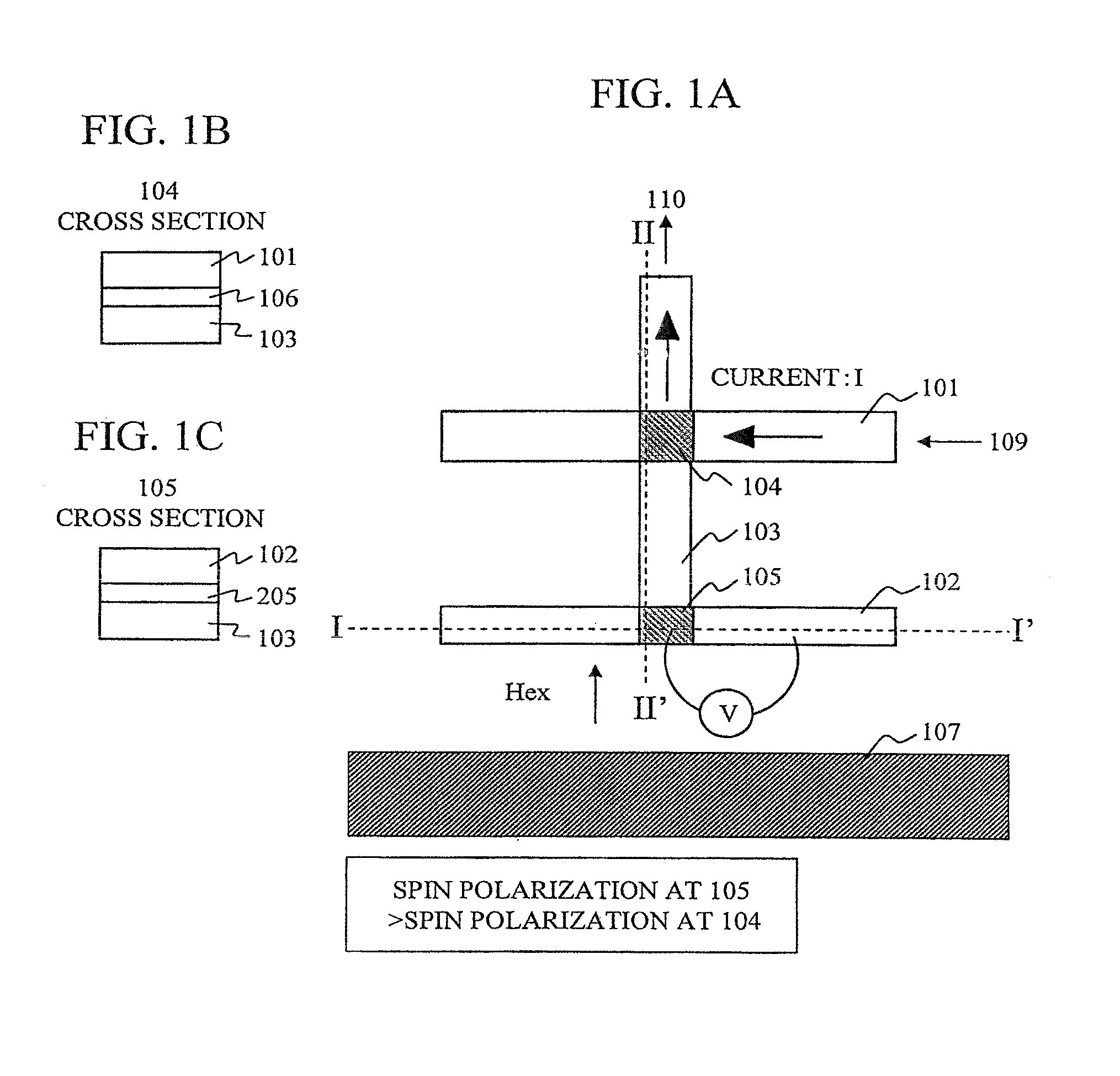

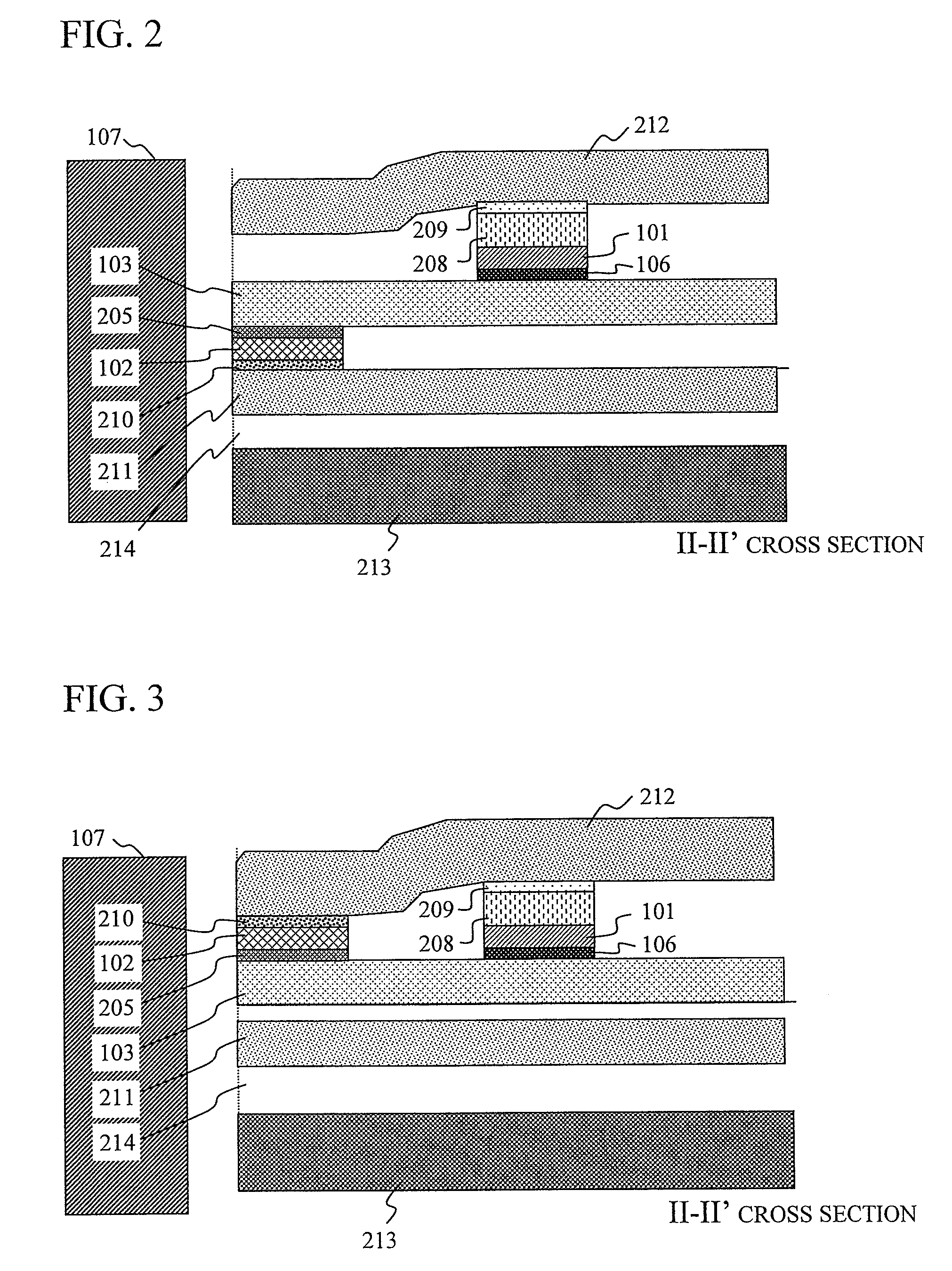

Magnetic reading head

InactiveUS20070253116A1High magneto-resistive ratioLarge outputNanomagnetismMagnetic measurementsPhysicsSpin polarization

A magnetic head includes a pair of ferromagnetic electrodes, namely, a first ferromagnetic electrode layer which is in contact with a portion of a first electrode layer with a first insulating barrier layer interposed in between; and a second ferromagnetic electrode layer which is in contact with another portion of the first electrode layer with a second insulating barrier layer interposed in between. The first electrode layer and the first ferromagnetic layer collectively constitute part of a current-supplying circuit. Moreover, the first electrode layer and the second ferromagnetic layer which are in contact with the first electrode layer with the second insulating barrier layer interposed in between in a region where the two layers are not in contact with the first insulating barrier layer, collectively constitute part of a voltage-measurement circuit. Spin-polarization at the interface in an intersecting region of the second ferromagnetic layer and the second insulating barrier layer, is greater than spin-polarization at the interface in an intersecting region of the first ferromagnetic layer and the first insulating barrier layer.

Owner:HITACHI LTD

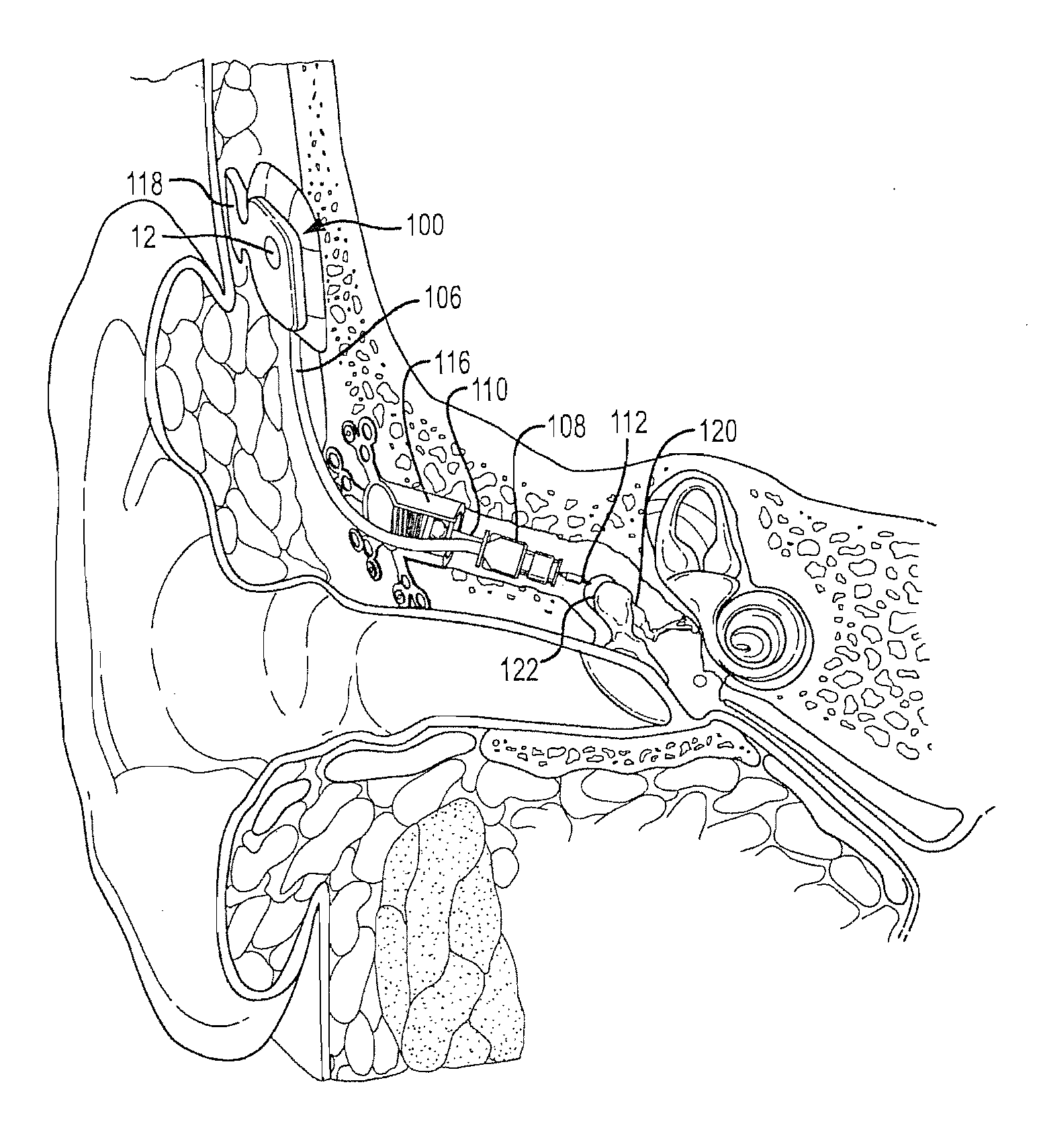

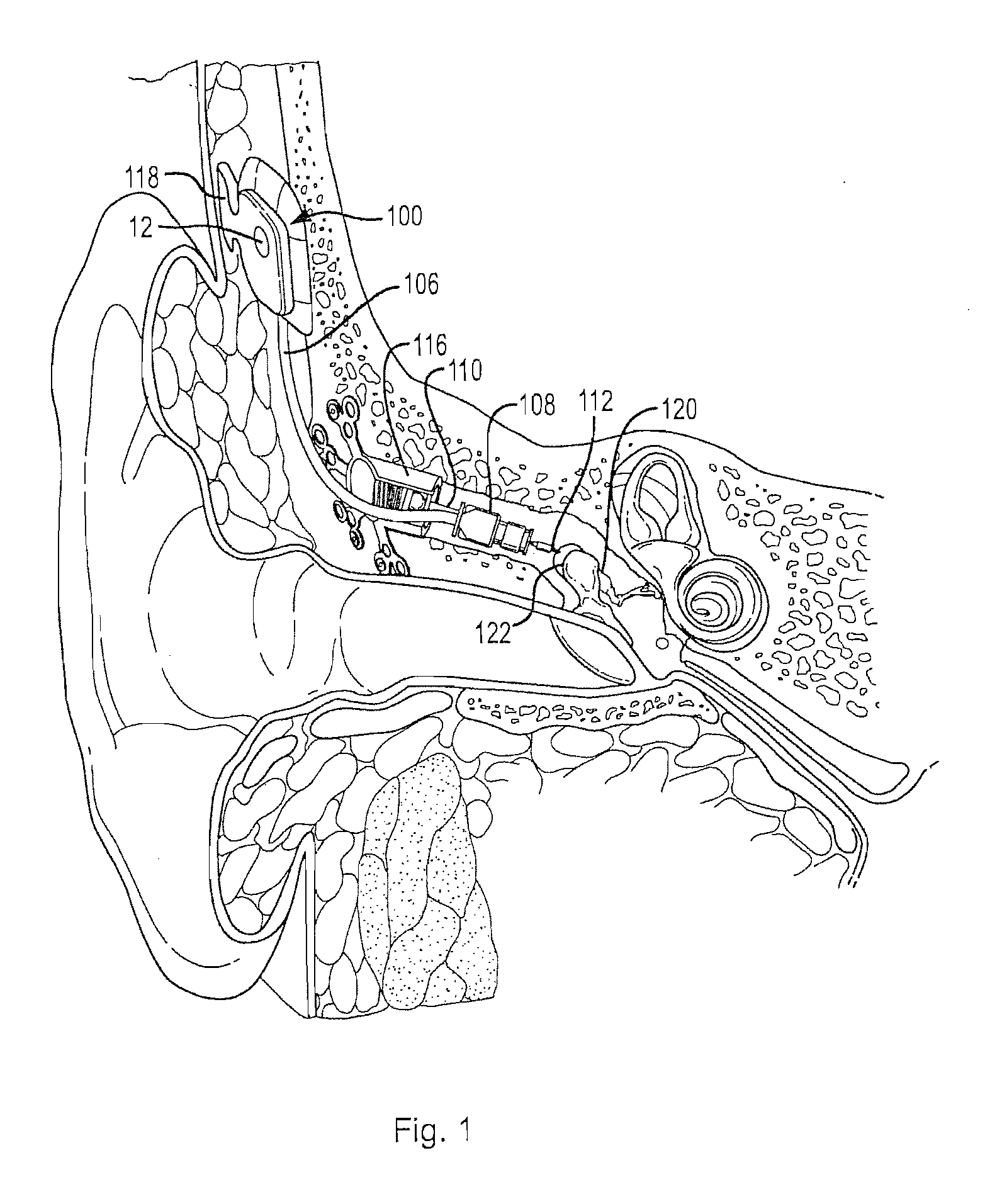

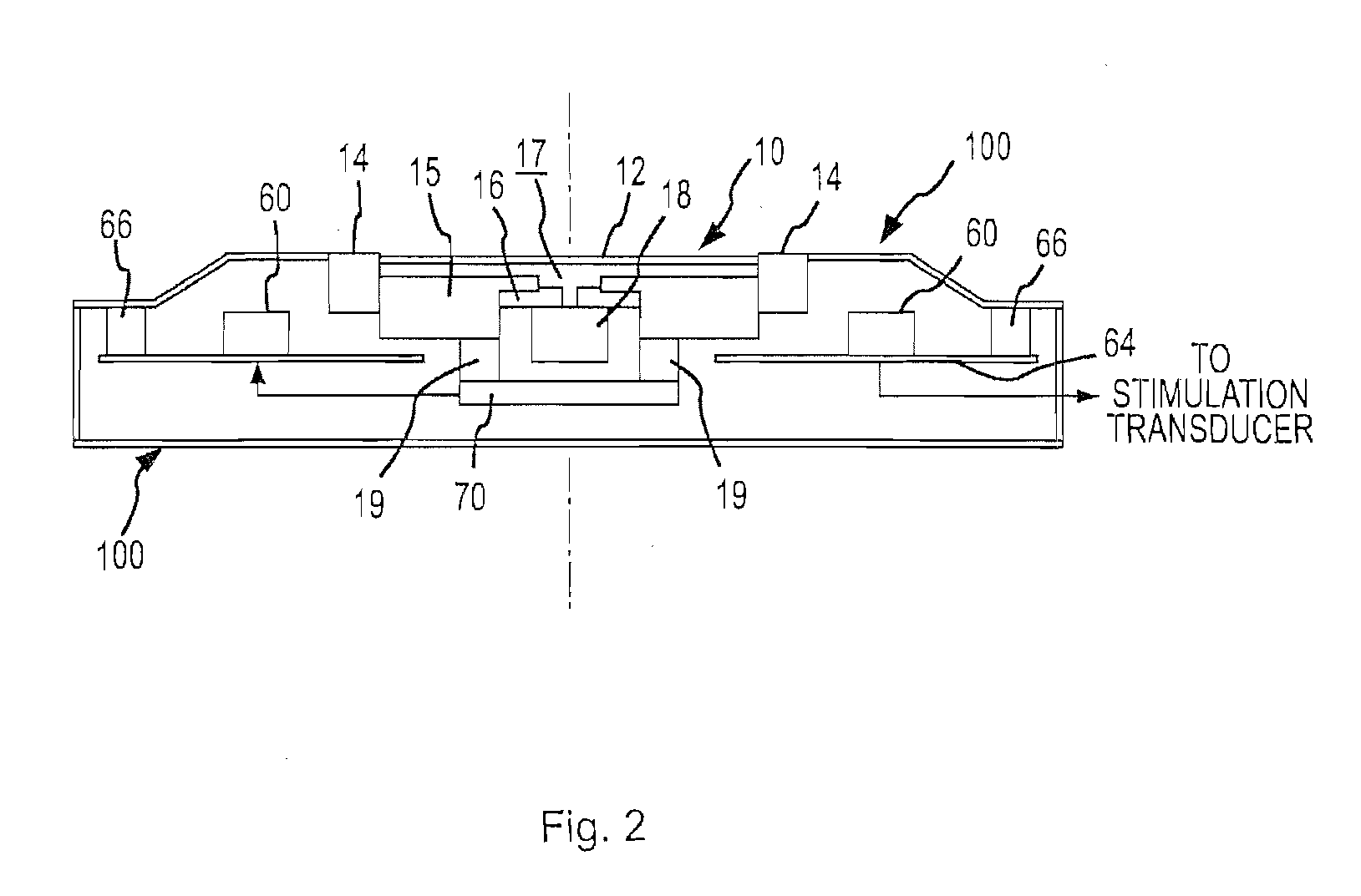

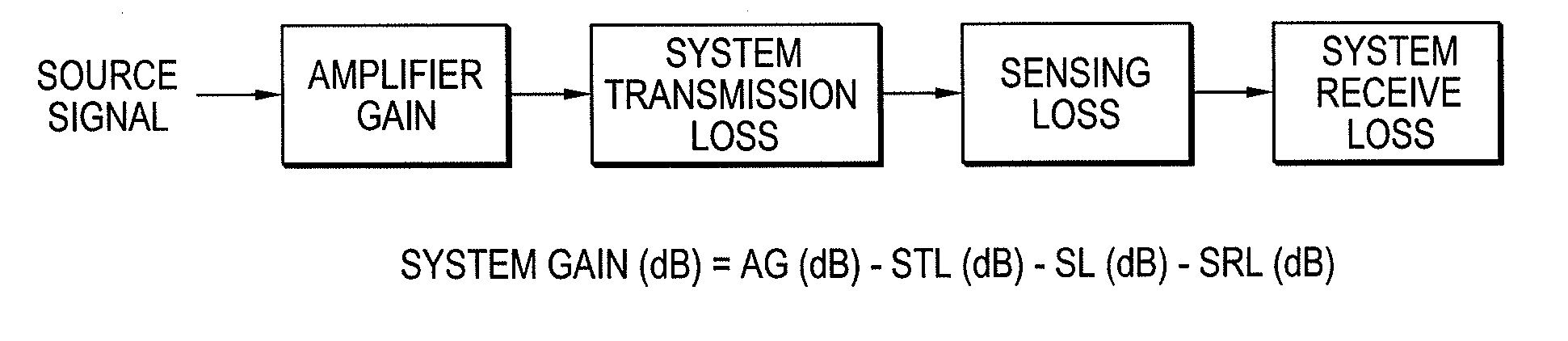

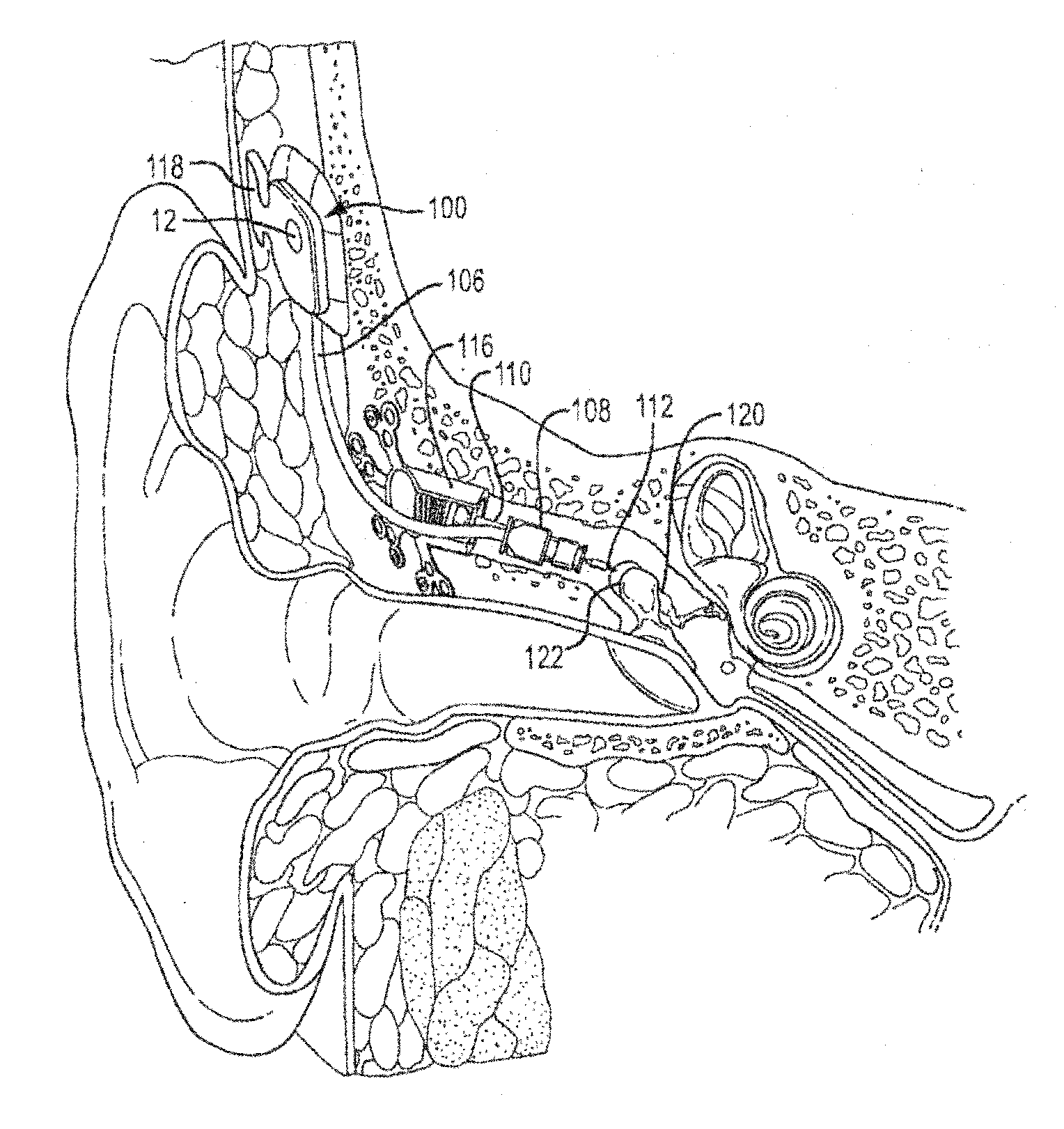

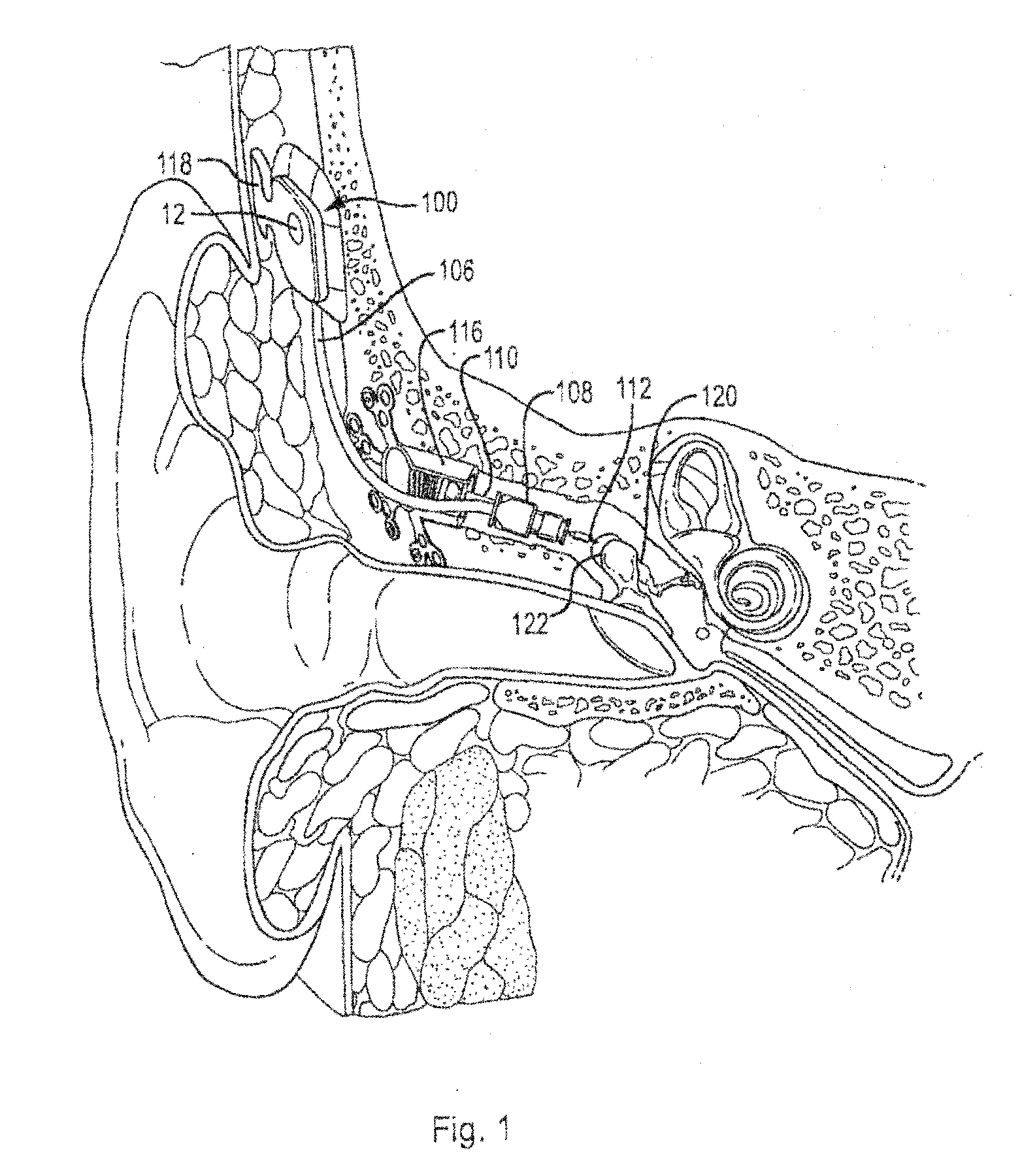

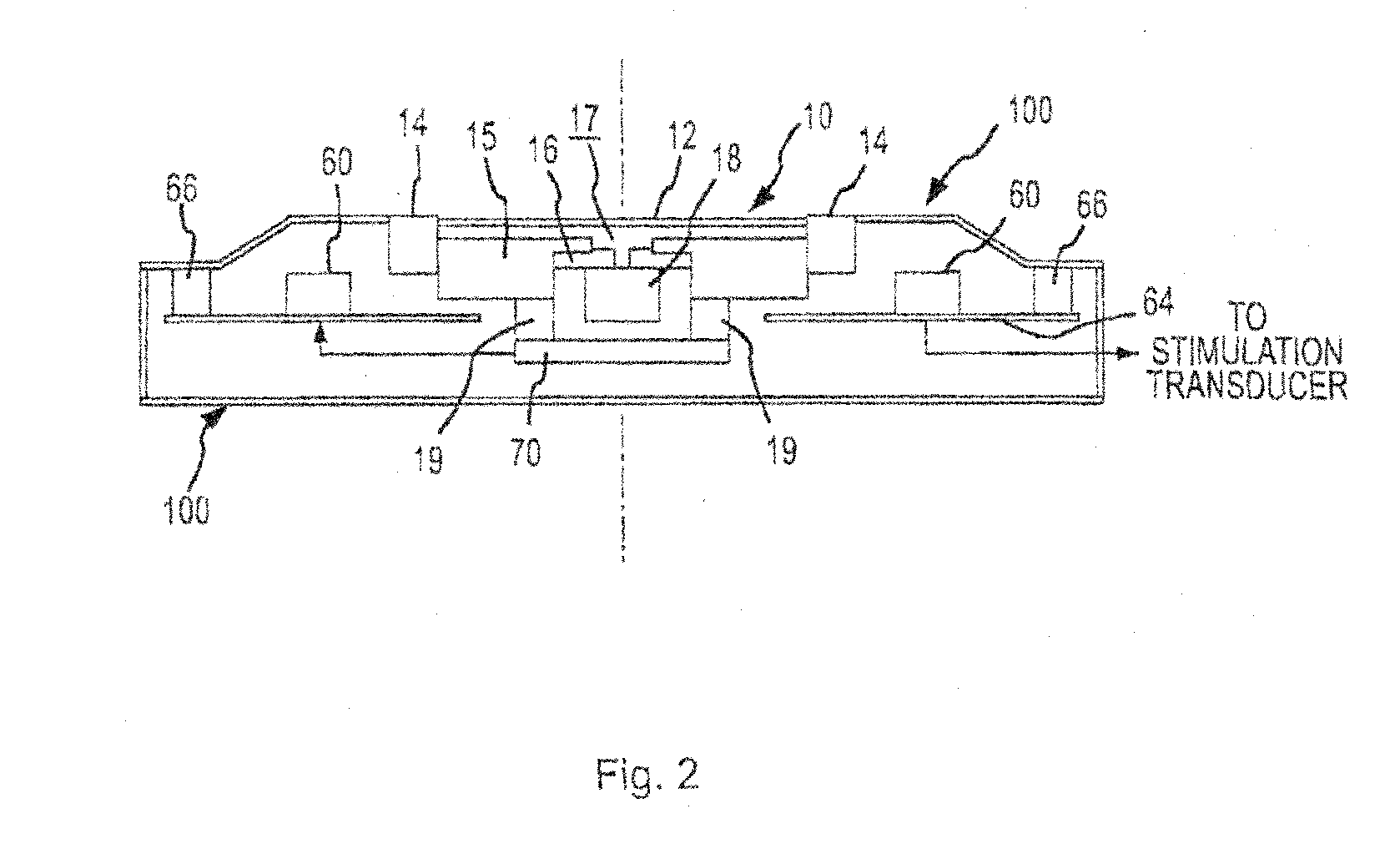

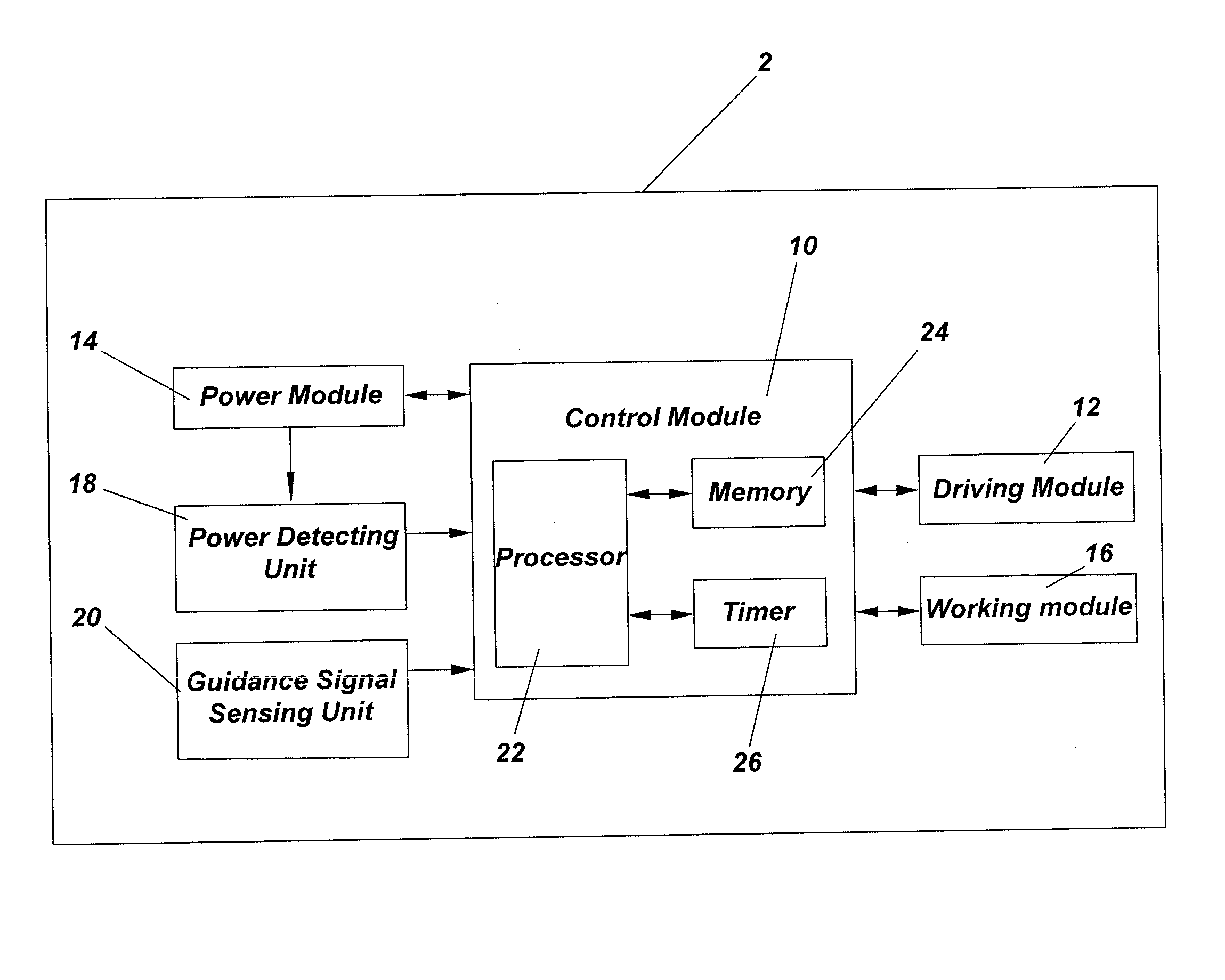

Adaptive cancellation system for implantable hearing instruments

The invention is directed to an implanted microphone having reduced sensitivity to vibration. In this regard, the microphone differentiates between the desirable and undesirable vibration by utilizing at least one motion sensor to produce a motion signal when an implanted microphone is in motion. This motion signal is used to yield a microphone output signal that is less vibration sensitive. In a first arrangement, the motion signal may be processed with an output of the implantable microphone transducer to provide an audio signal that is less vibration-sensitive than the microphone output alone. Specifically, the motion signal may be scaled to match the motion component of the microphone output such that upon removal of the motion signal from the microphone output, the remaining signal is an acoustic signal.

Owner:COCHLEAR LIMITED

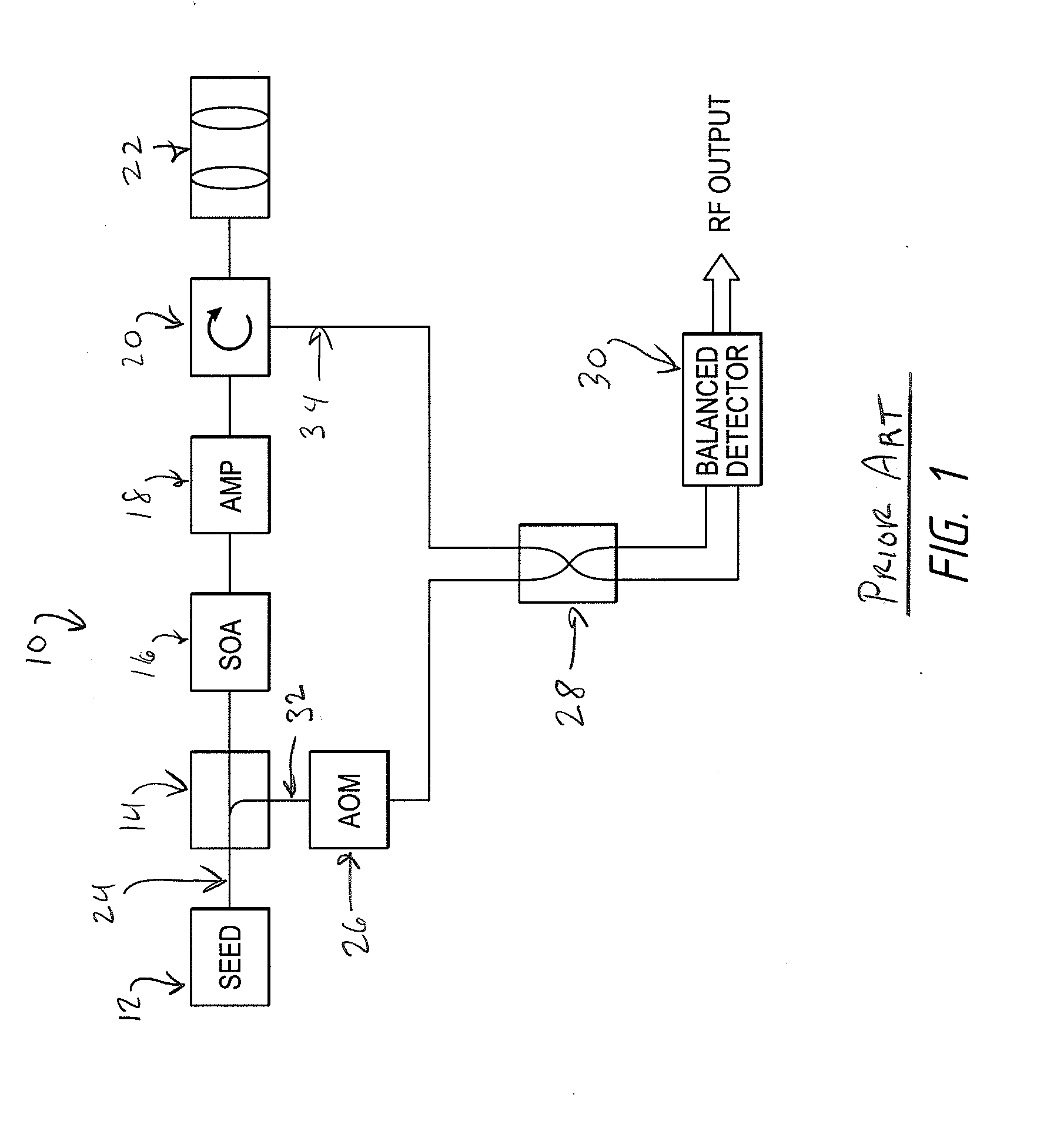

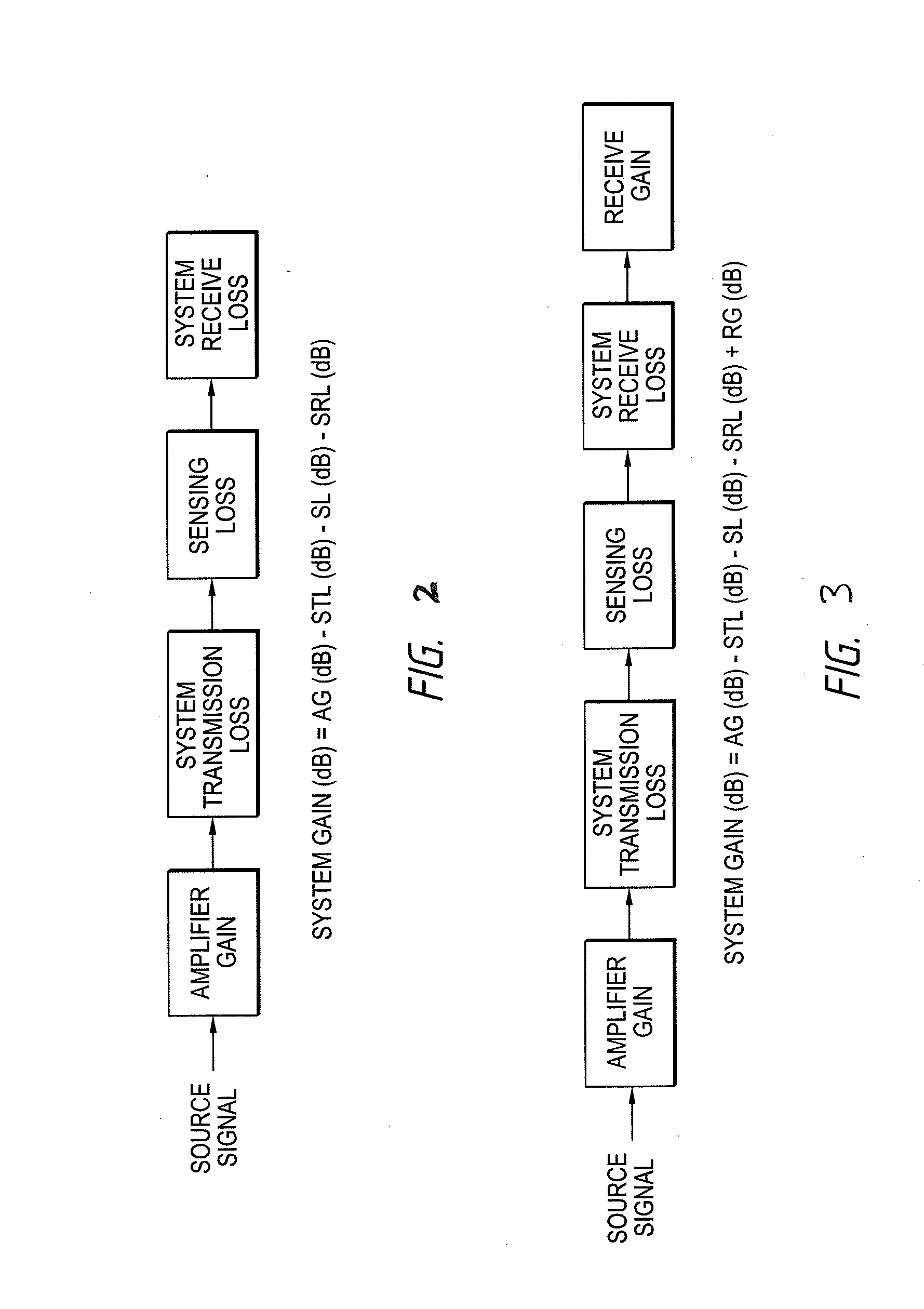

Amplified optical circuit

InactiveUS20150109605A1Certain costLower energy levelFibre transmissionActive medium shape and constructionMultiplexingAudio power amplifier

An optical circuit can include a bidirectional amplifier connected so as to amplify source light prior to emission through an output device such as a telescope as well as amplification of reflected light received by the telescope. Such an optical circuit can be used in laser doppler velocimeter applications as well as other applications. The optical circuit can also include passive splitters or active switches to provide for advantageous multiplexing.

Owner:SENSTHYS INC

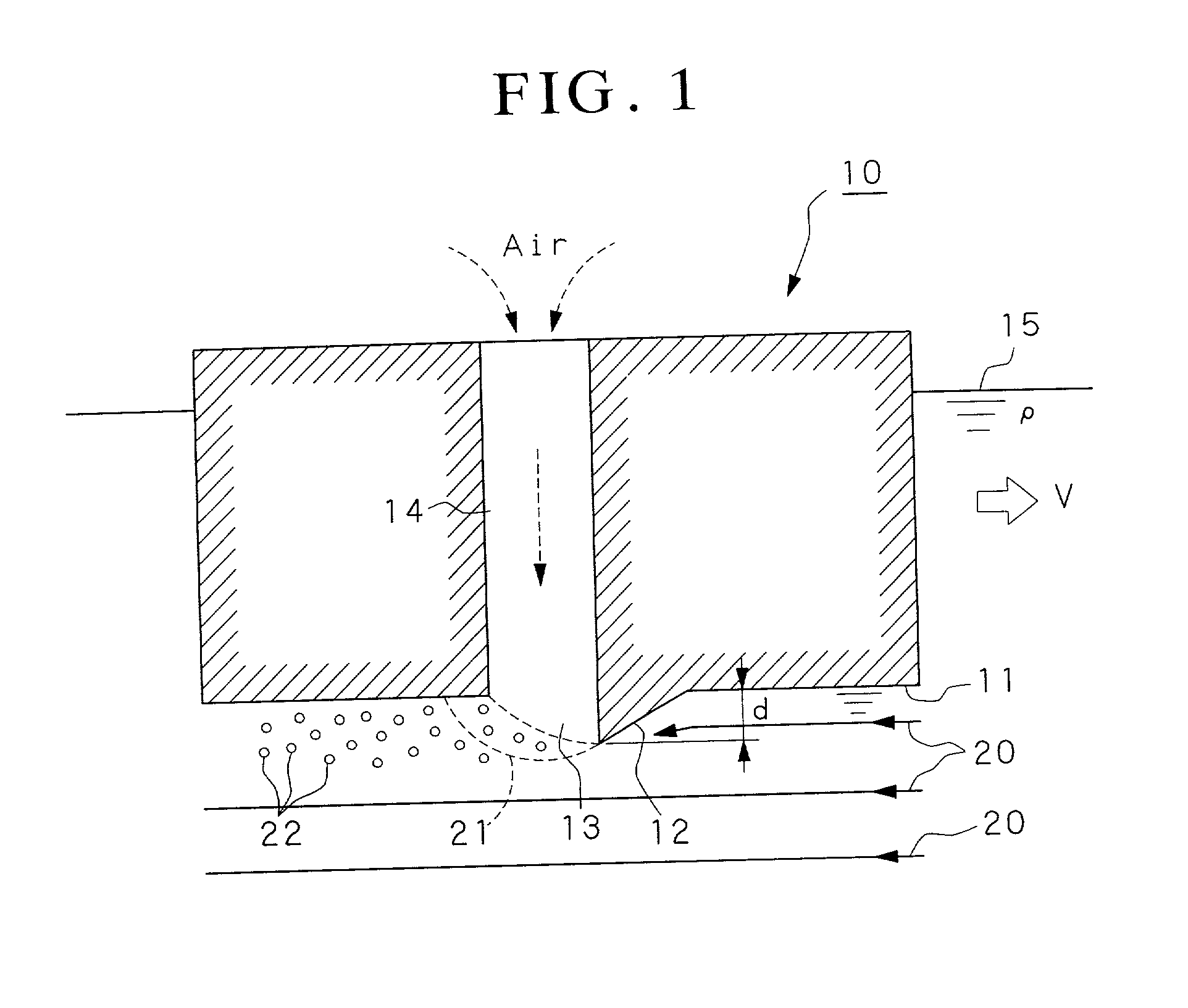

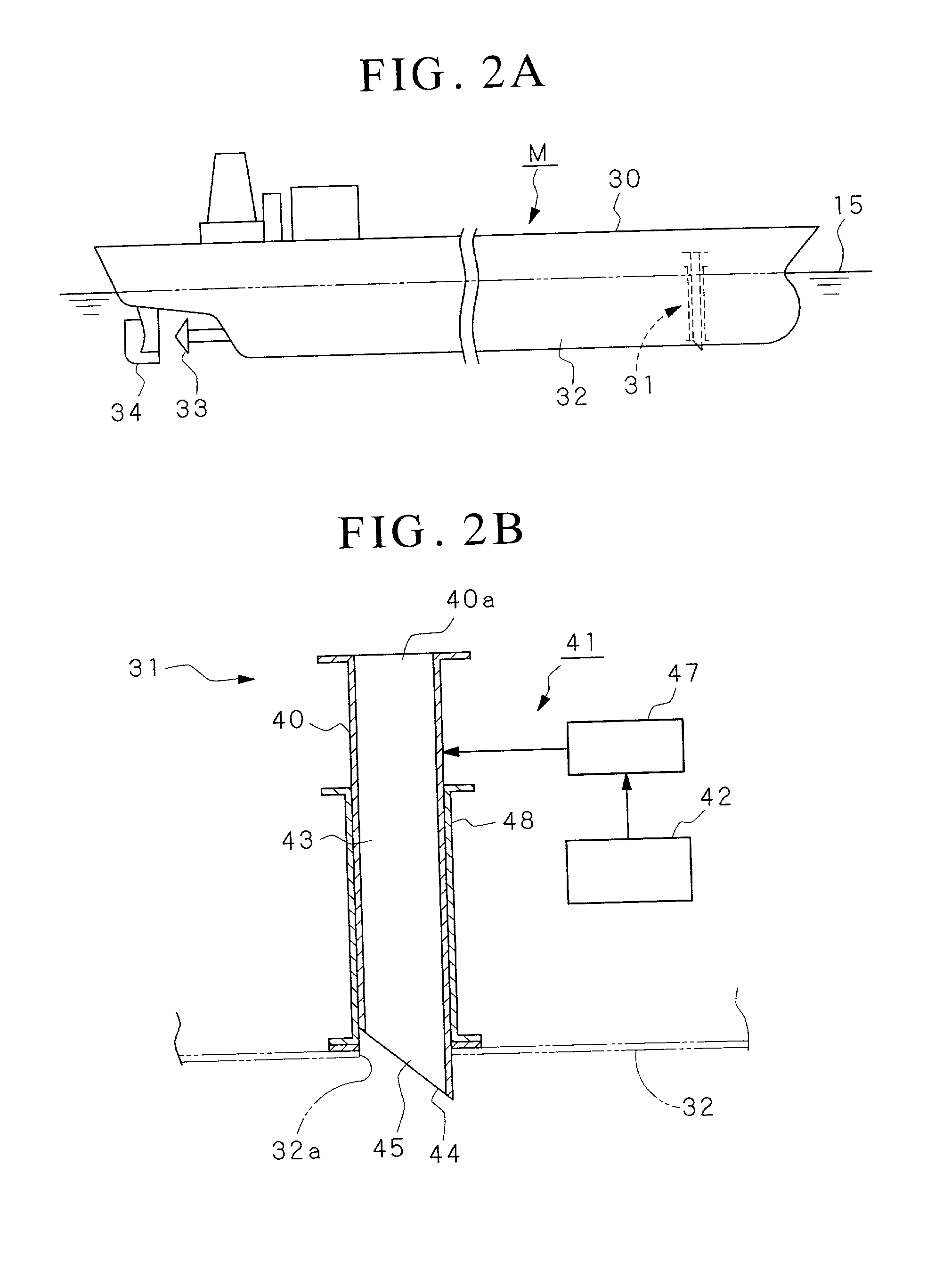

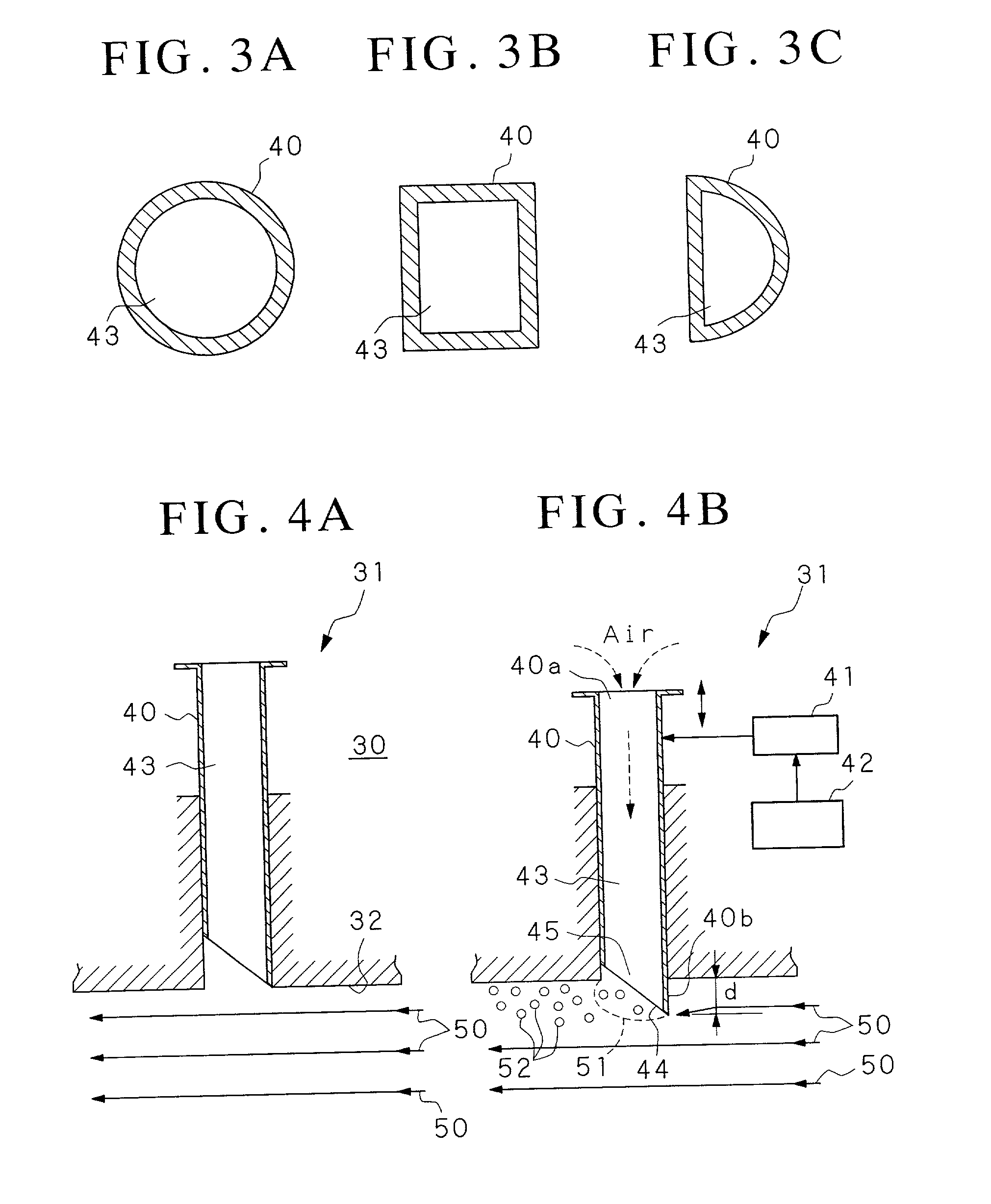

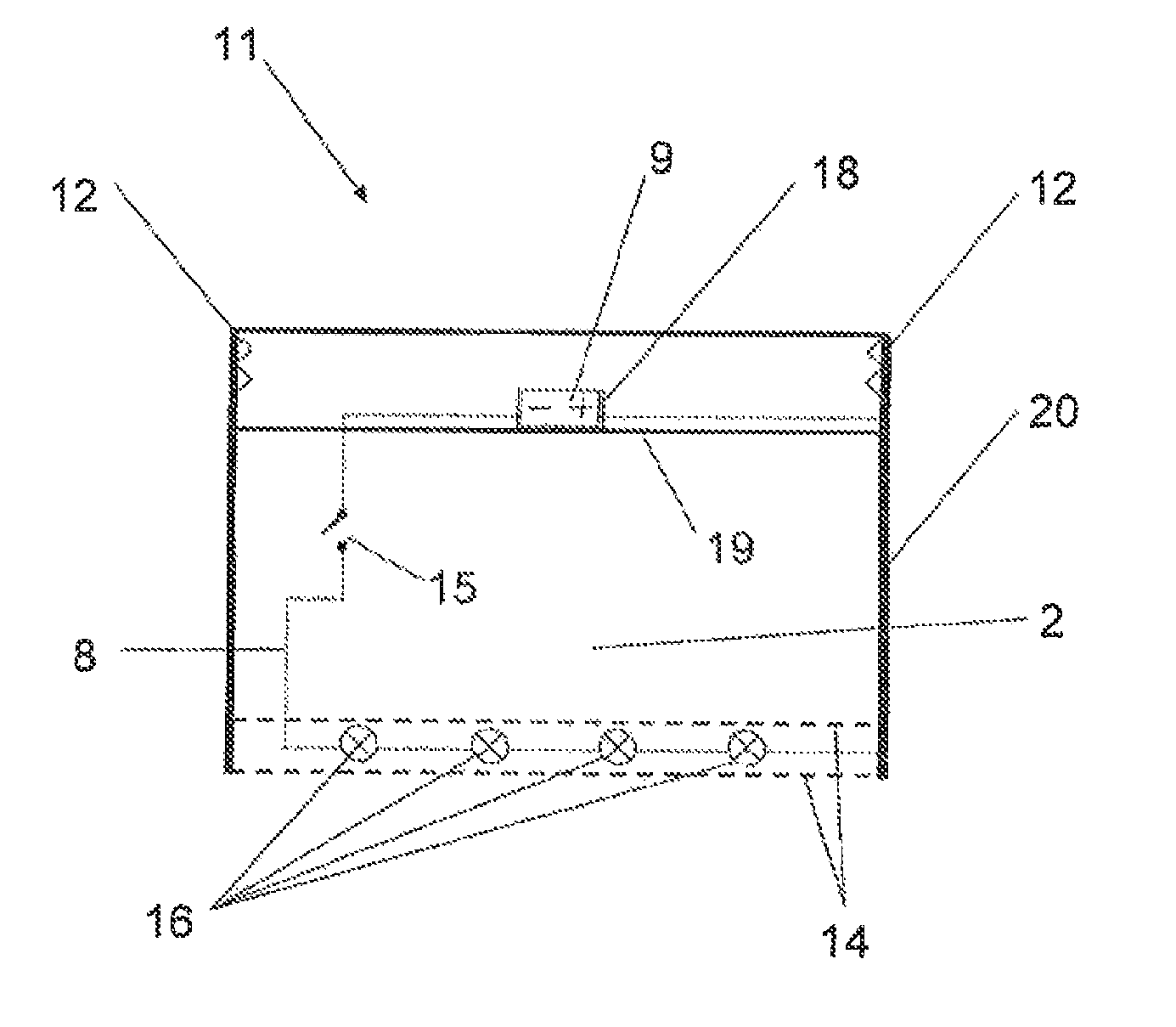

Frictional resistance reducing vessel and a method of reducing frictional resistance of a hull

InactiveUS20010022152A1Easy to operateReduce frictional resistanceWatercraft hull designFloating buildingsProduct gasEngineering

The object of the present invention is to provide a frictional resistance reducing vessel and method of reducing the frictional resistance of a hull that are able to effectively conserve energy consumed during operation by reducing frictional resistance at a low level of energy consumption. In the present invention, a negative pressure region (51), which is at low pressure relative to a gaseous space, is formed in the water accompanying operation of a hull (30), and together with bubbles being guided to this negative pressure region (51) in the water from the gaseous space, the state of this negative pressure region (51) is changed based on changes in vessel velocity.

Owner:IHI CORP

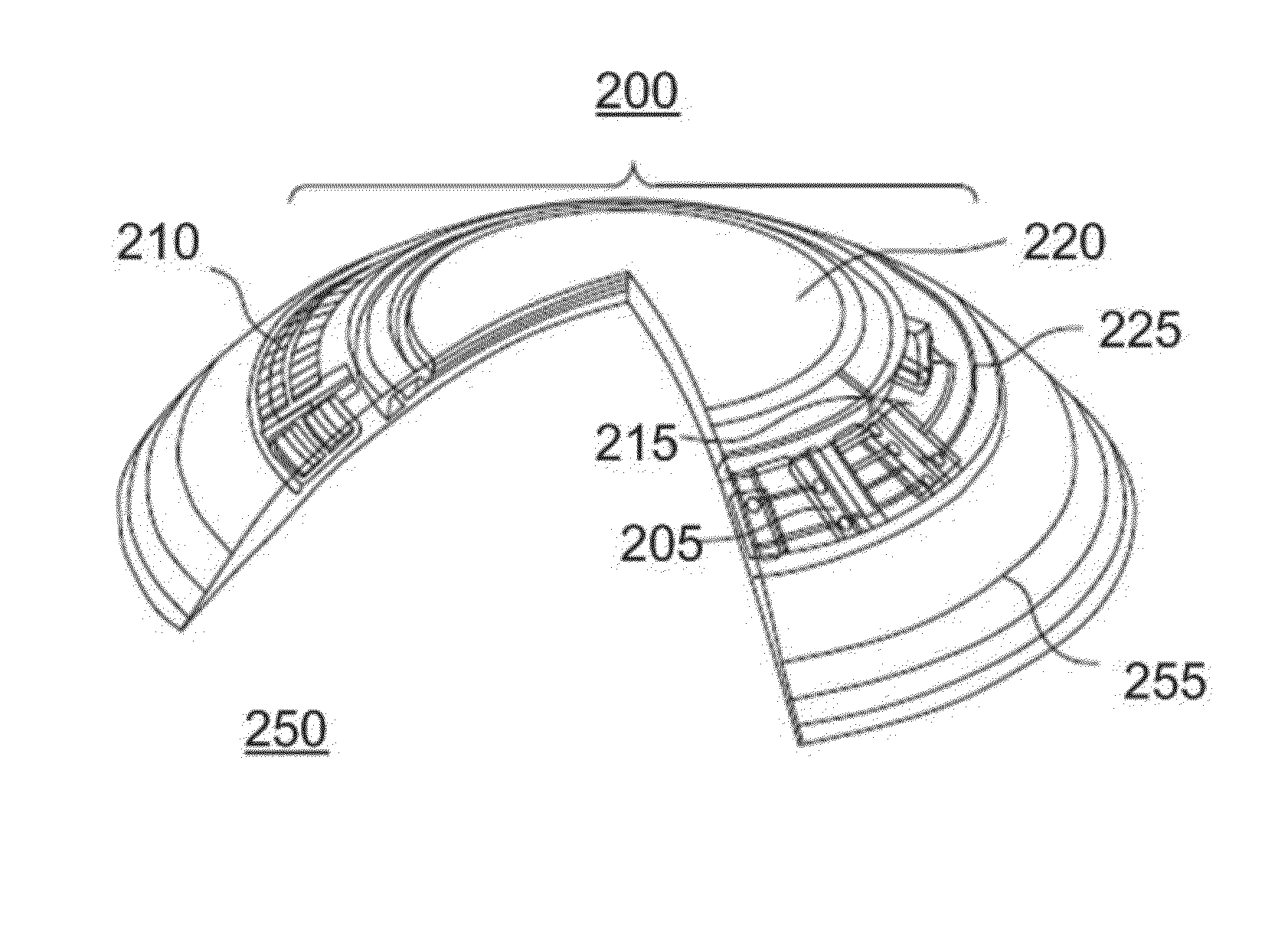

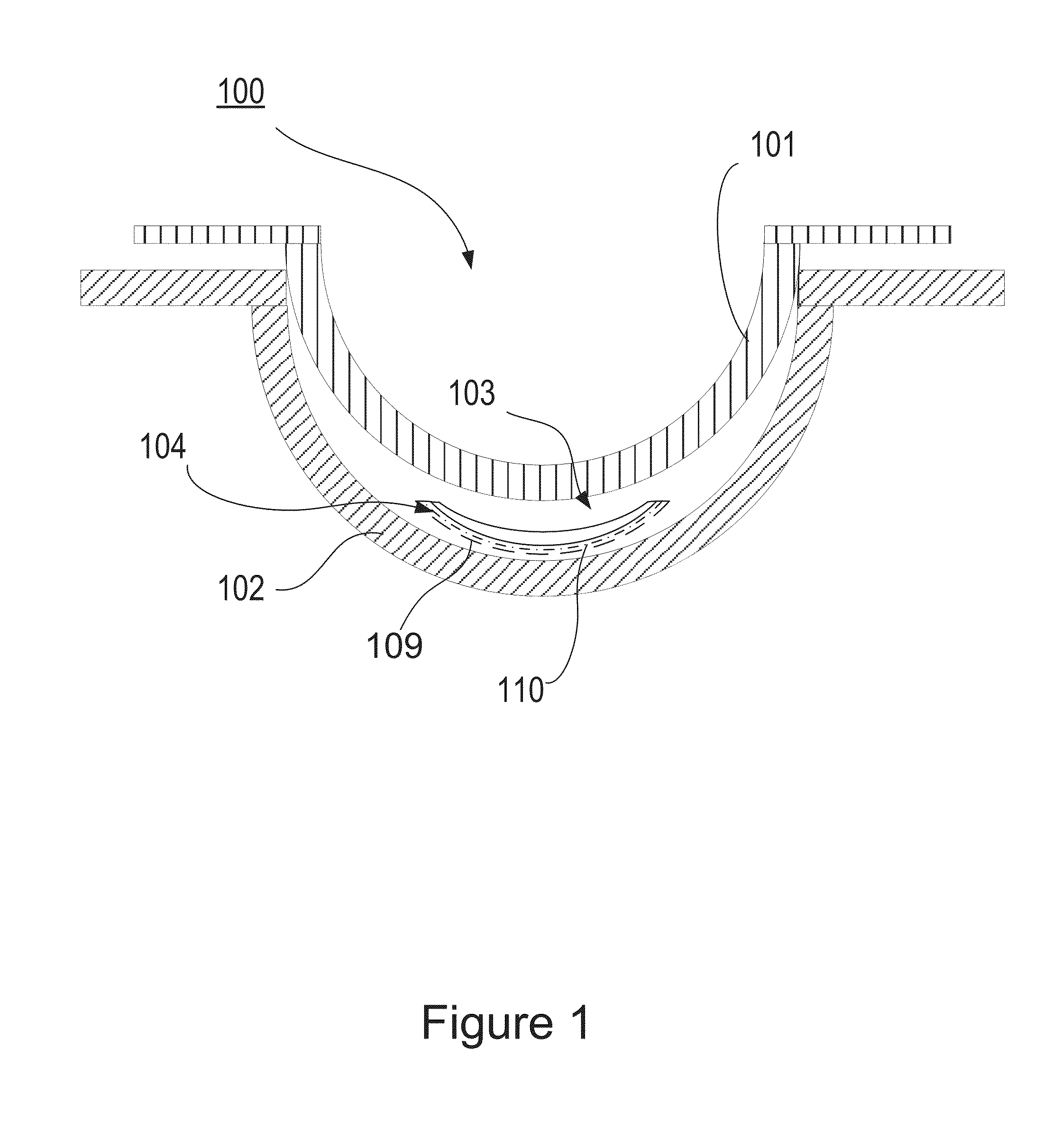

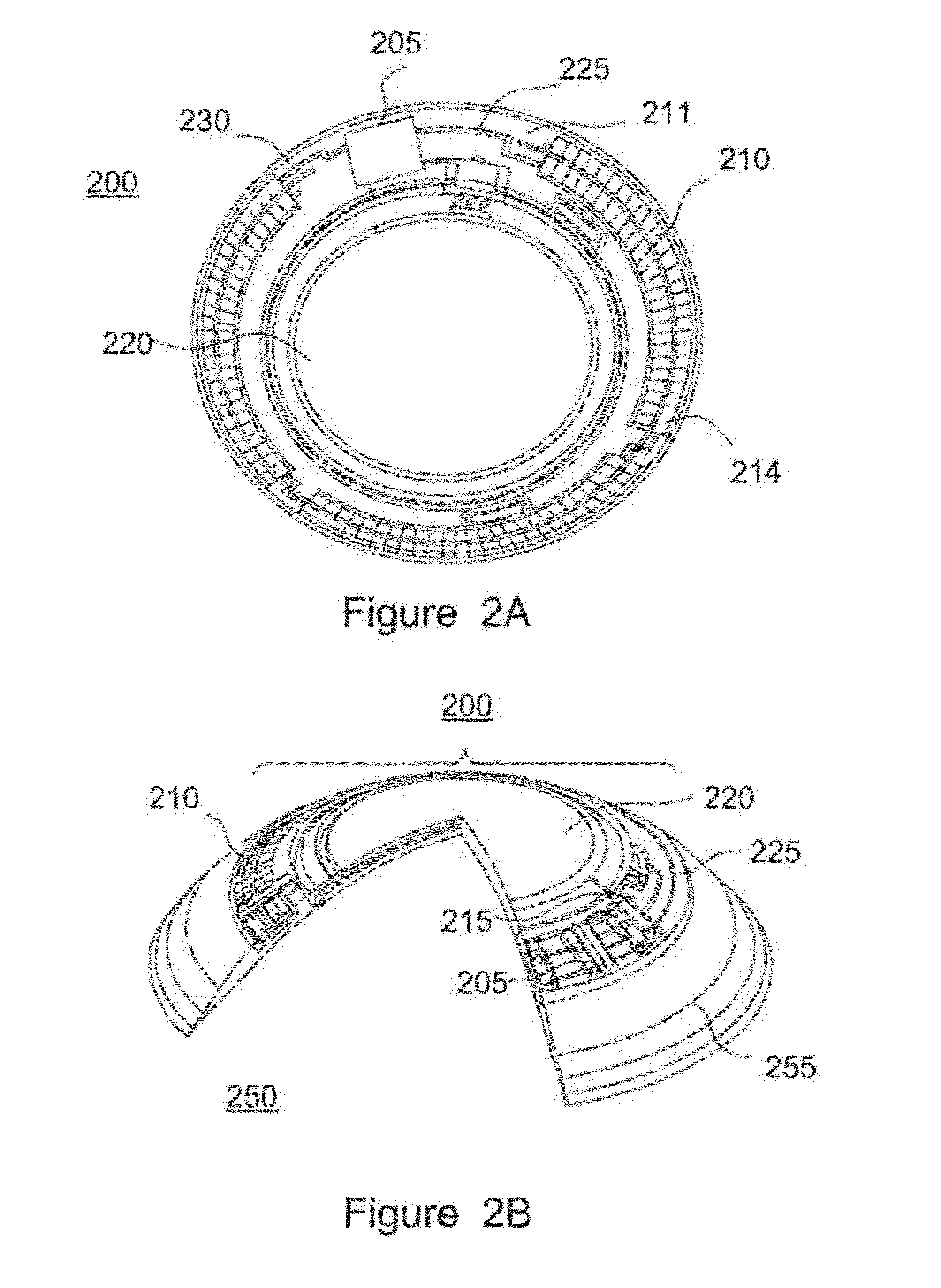

Method and apparatus for ophthalmic devices including hybrid alignment layers and shaped liquid crystal layers

ActiveUS20150077663A1Easy to moveLower energy levelNon-linear opticsOptical partsElectricityOptical property

The present invention discloses methods and apparatus for providing a variable optic insert into an ophthalmic lens. The variable optic insert may have surfaces within that have differing radii of curvature. A liquid crystal layer may be used to provide a variable optic function and in some embodiments, an alignment layer for the liquid crystal layer may be patterned in a hybrid manner. The patterning may allow for the lowering of the minimum electrical potential required to cause a shift in orientation of liquid crystal molecules within the ophthalmic device. An energy source is capable of powering the variable optic insert included within the ophthalmic lens. In some embodiments, an ophthalmic lens is cast-molded from a silicone hydrogel. The various ophthalmic lens entities may include electroactive liquid crystal layers to electrically control optical characteristics.

Owner:JOHNSON & JOHNSON VISION CARE INC

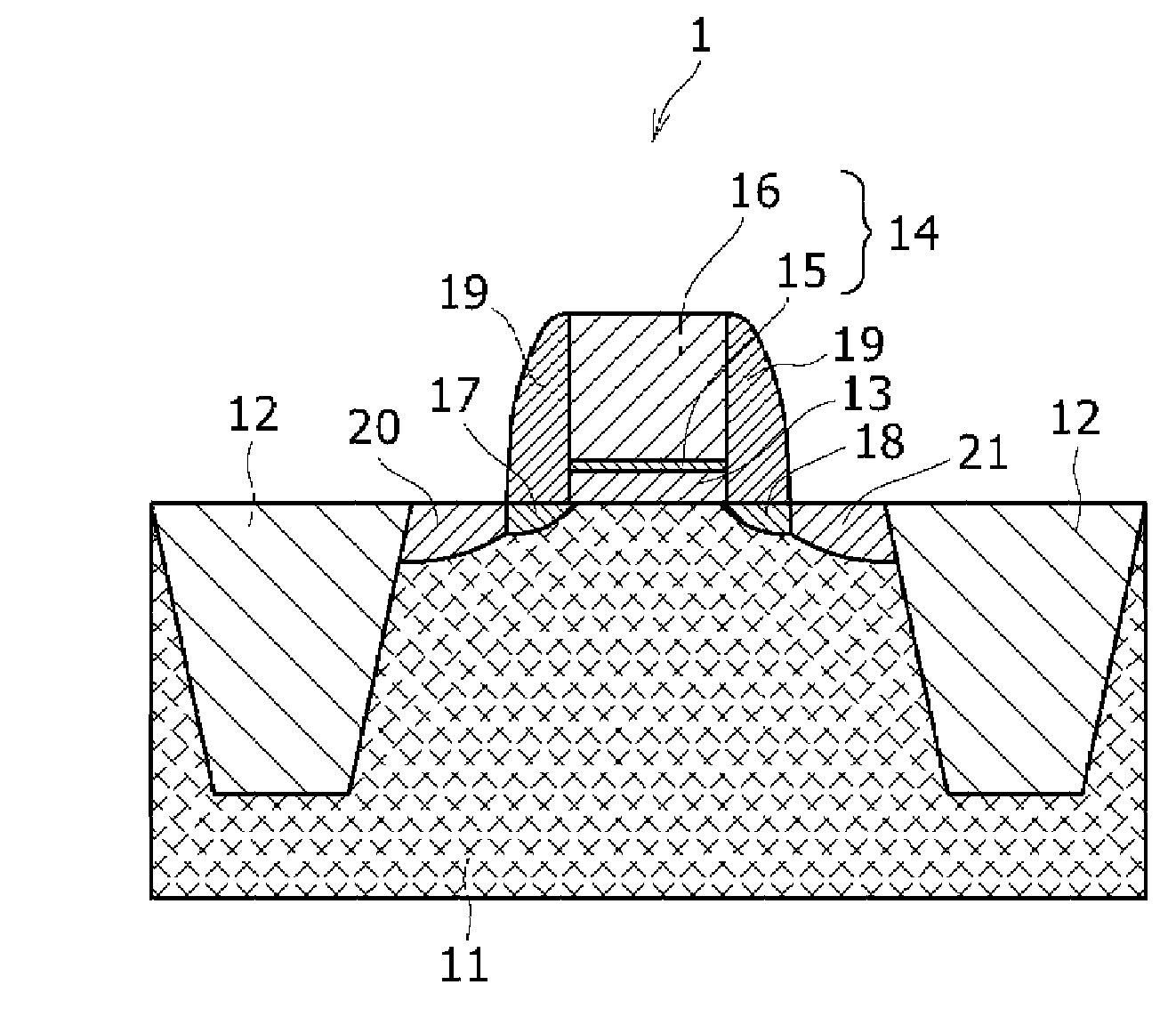

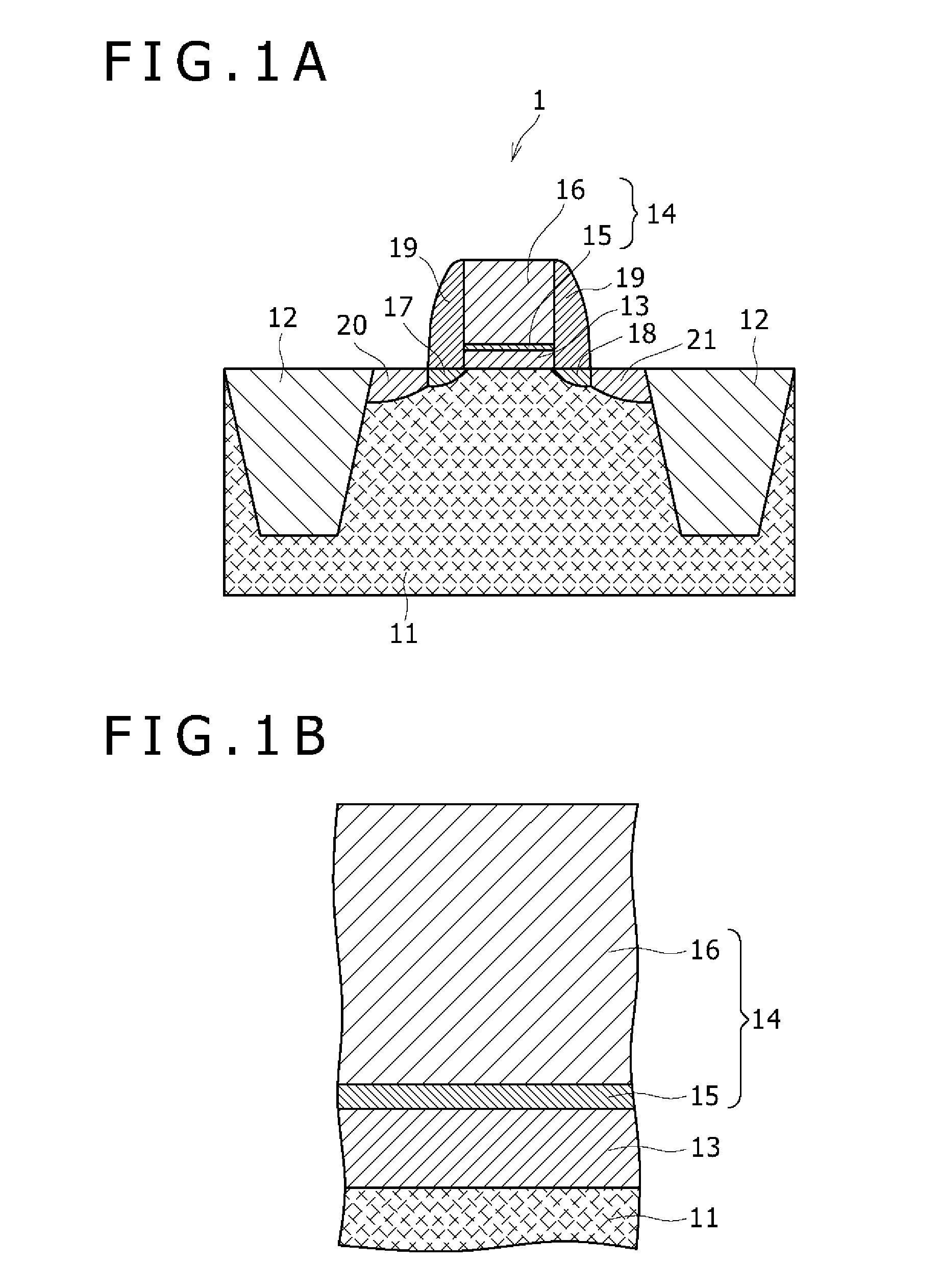

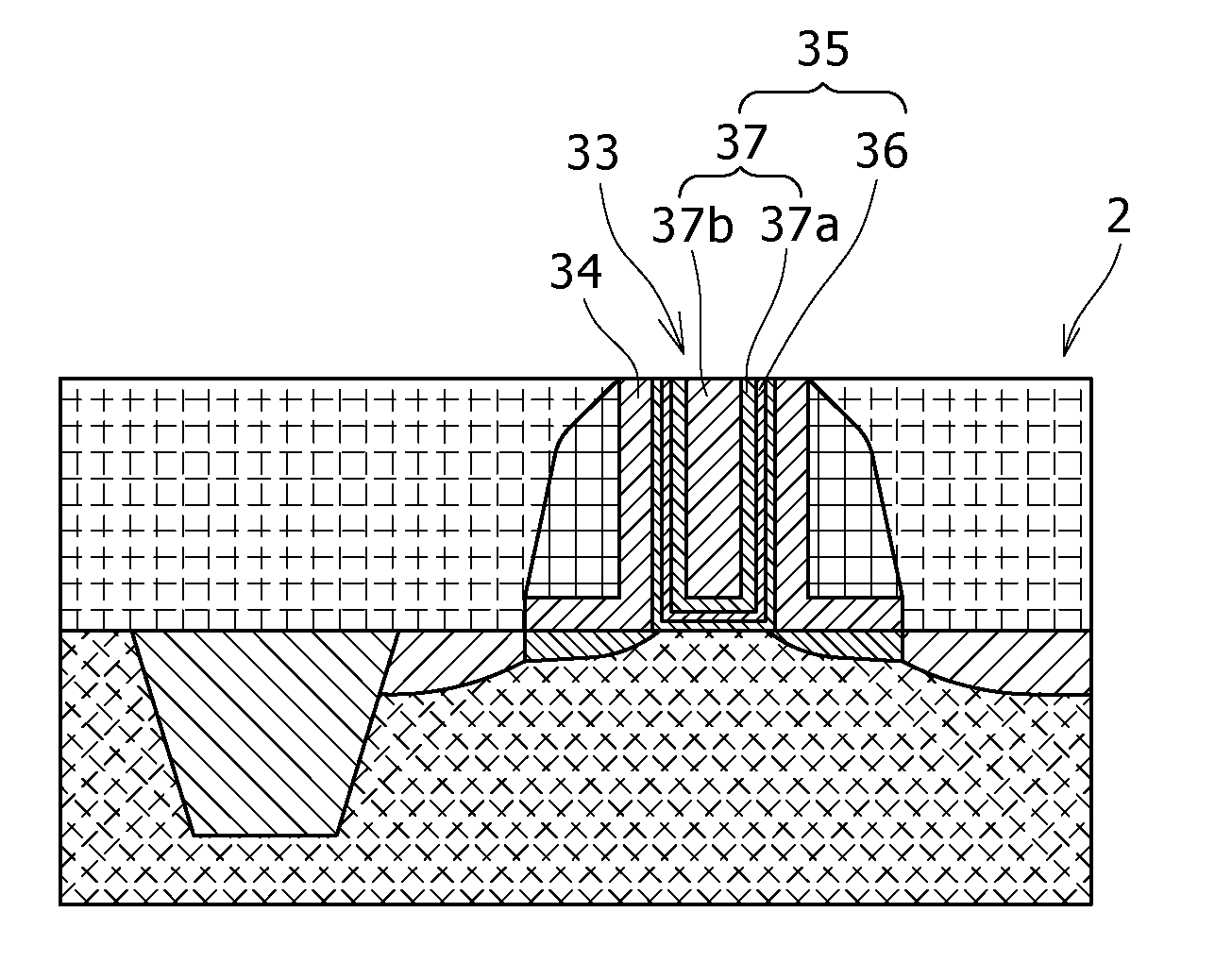

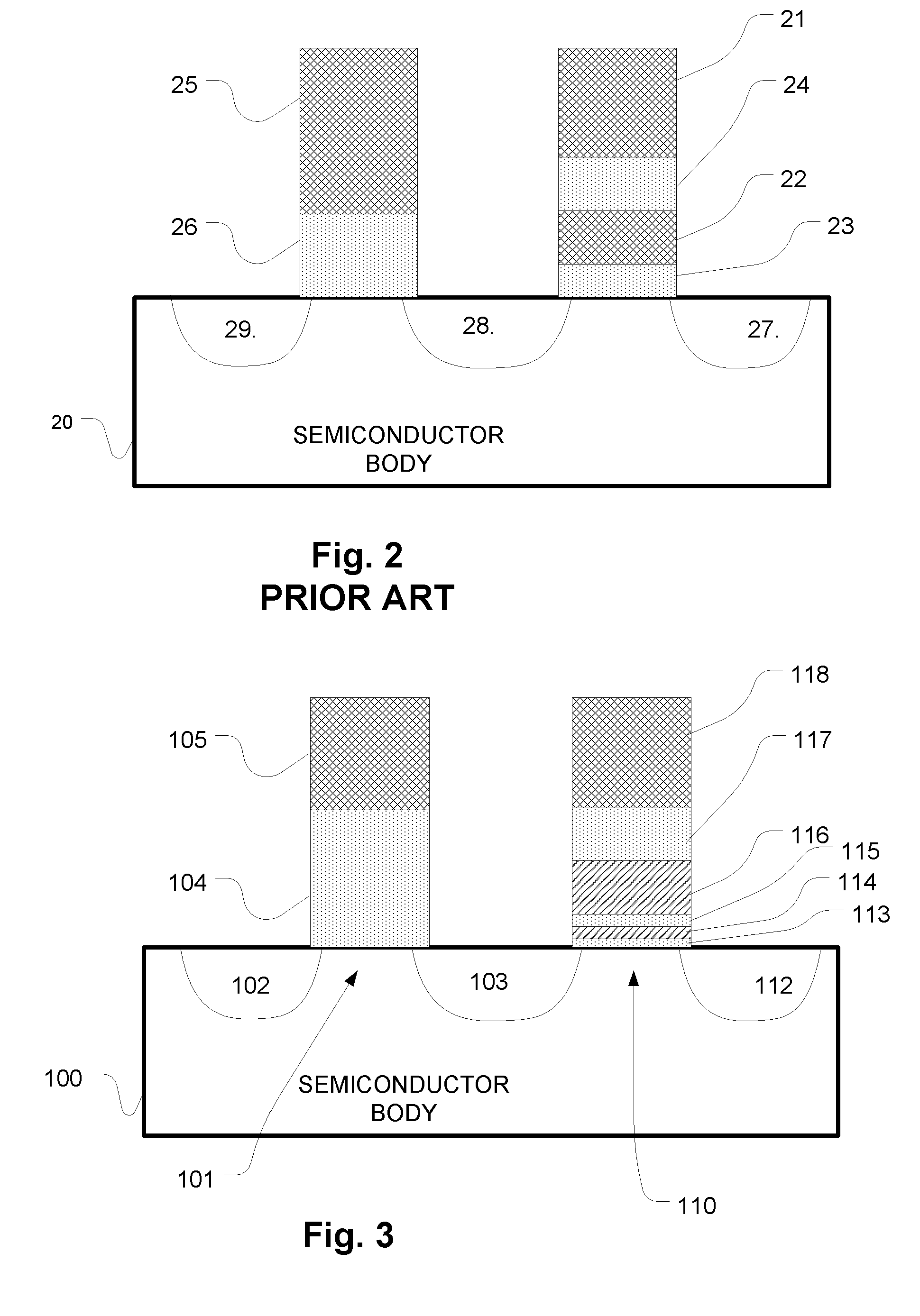

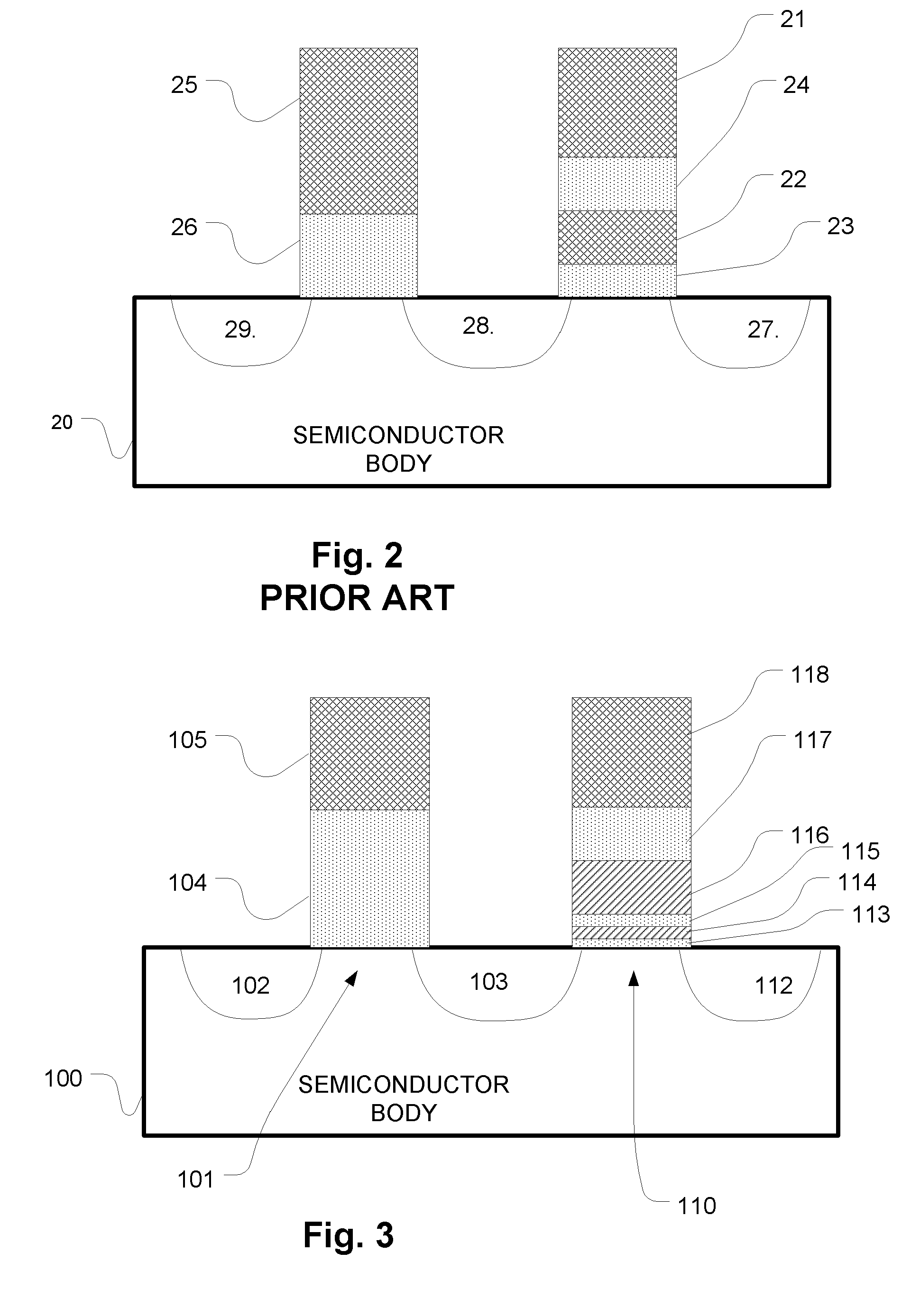

Semiconductor devices and fabrication process thereof

InactiveUS20080105920A1Avoid damageImprove the immunityTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor device has an insulated gate transistor provided with a semiconductor substrate and a gate electrode arranged on the semiconductor substrate via a gate insulating film. The gate electrode includes an electrically-conductive buffer film for preventing any damage, which would occur if a main gate electrode portion were formed directly over the gate insulating film, and the main gate electrode portion formed over the buffer film. A fabrication process for the semiconductor device is also disclosed.

Owner:SONY CORP

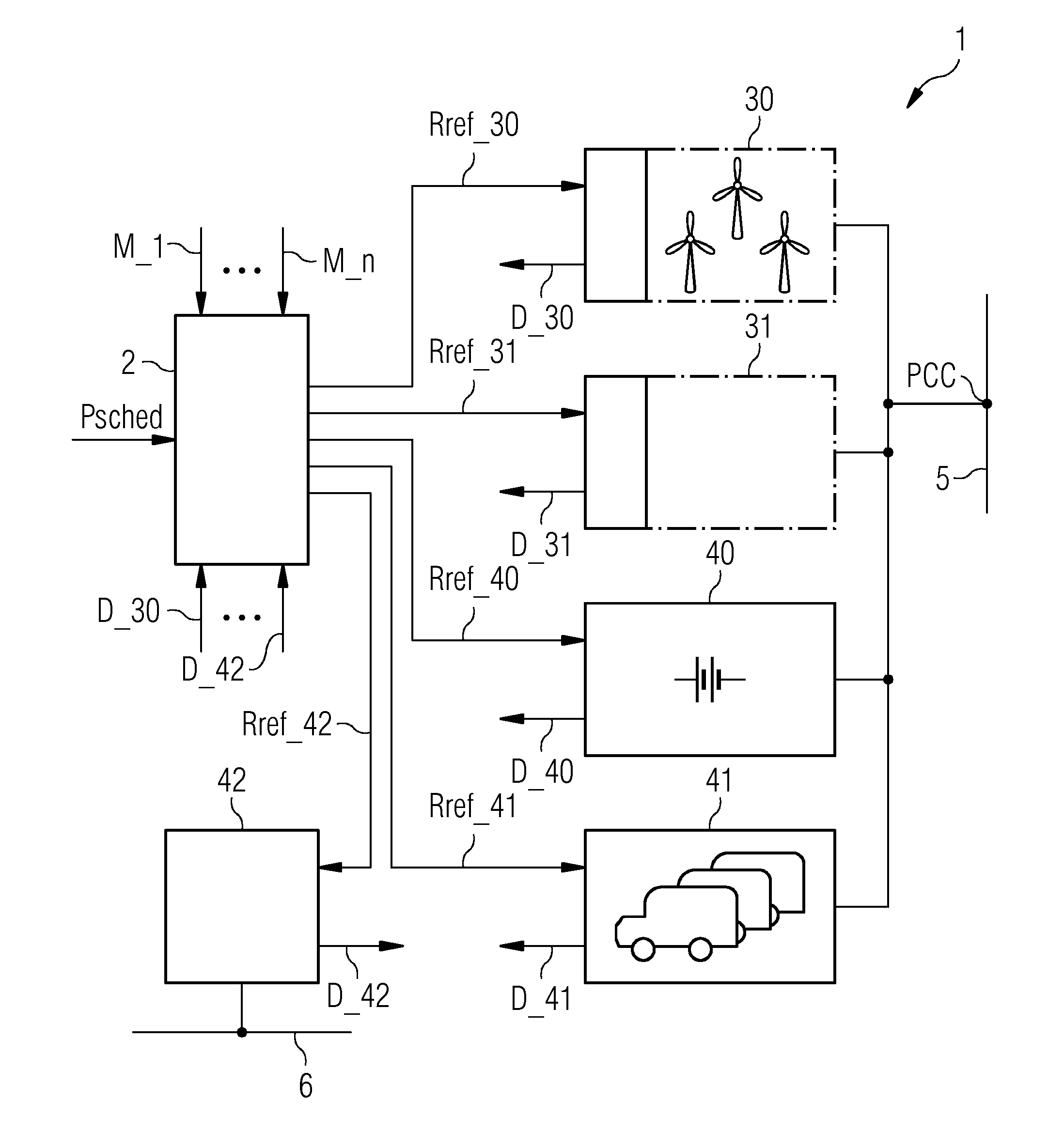

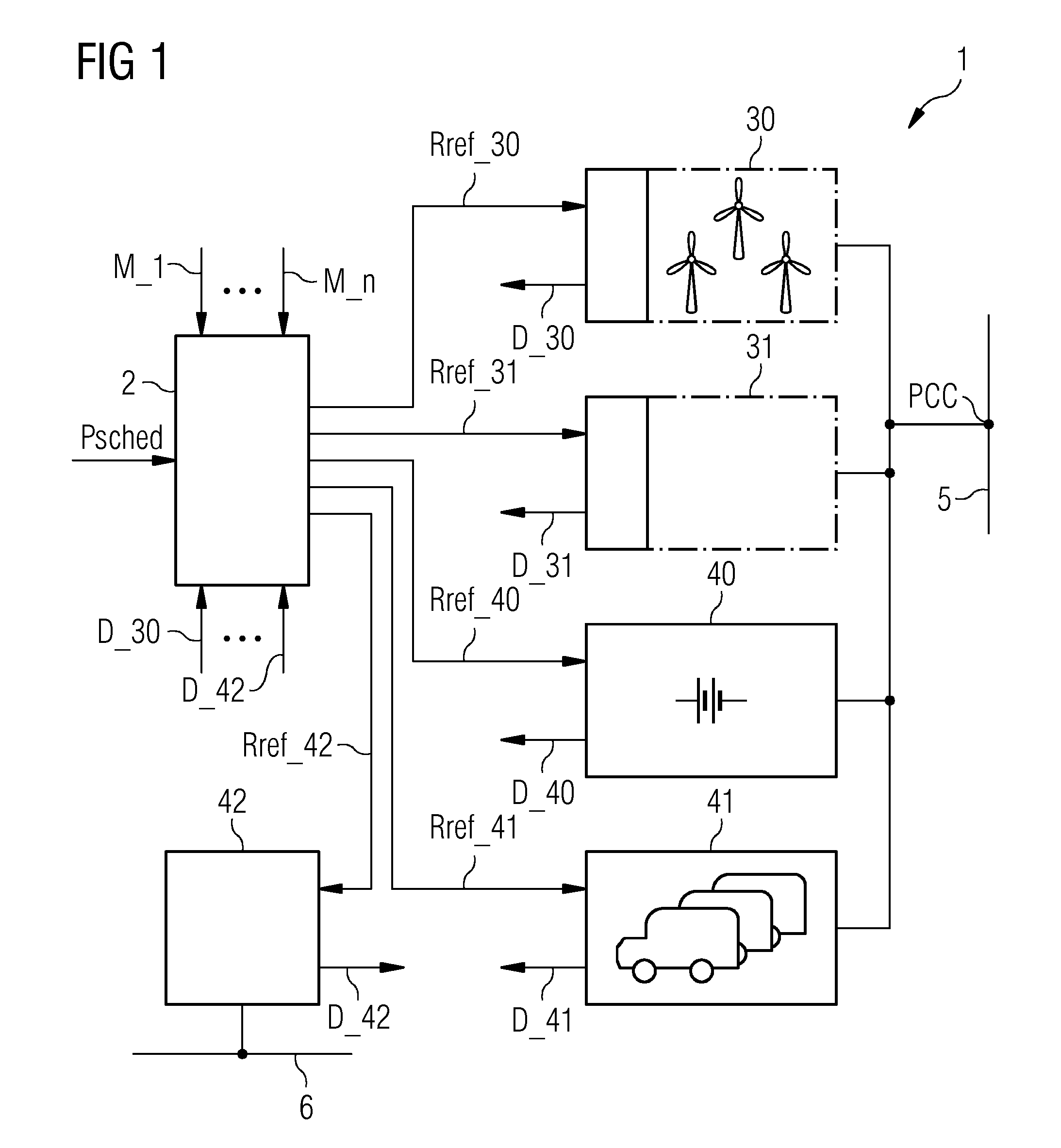

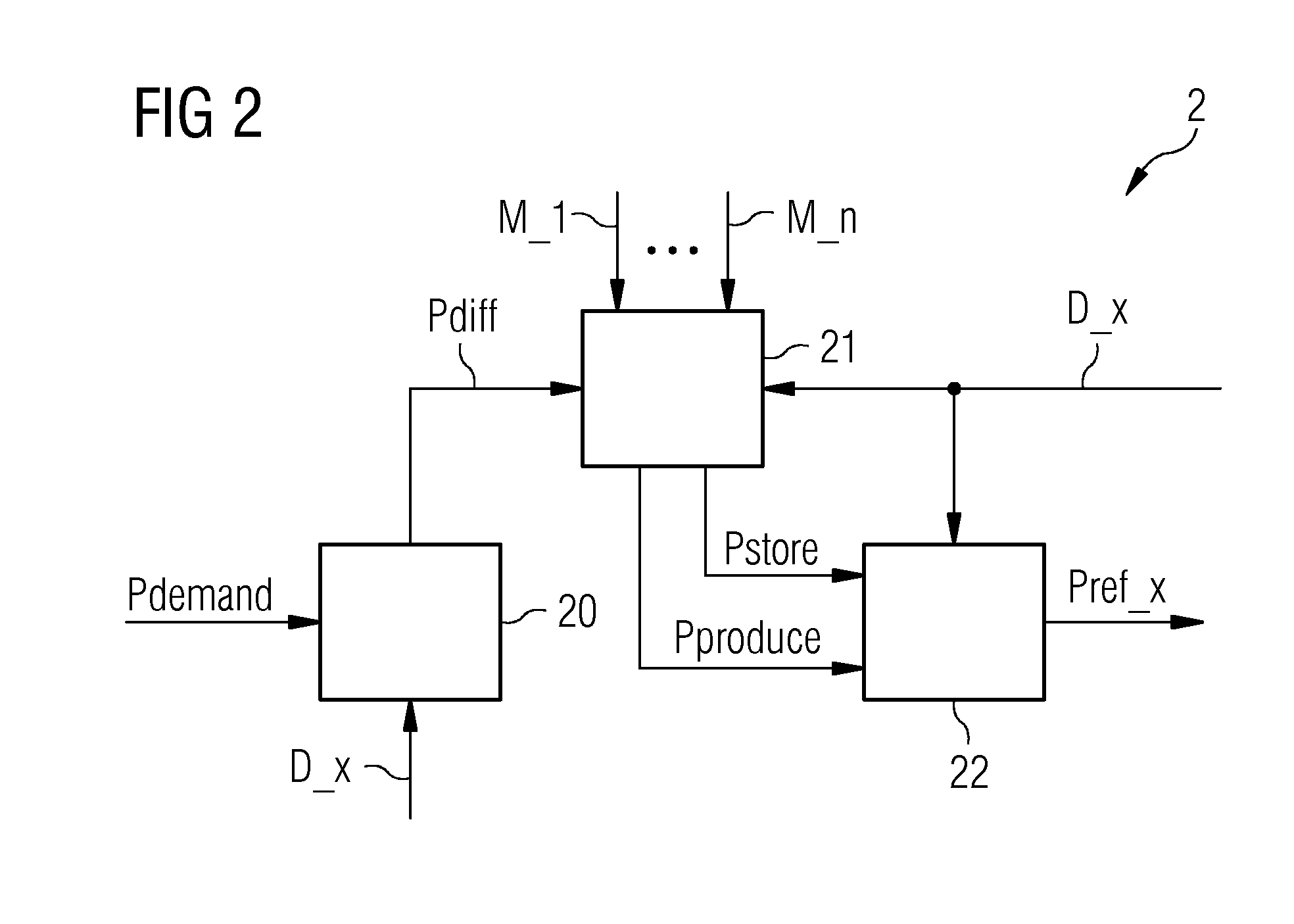

Method of controlling a power network

ActiveUS20140142779A1Way of increaseSmoothen power production of powerLevel controlEmission reduction for energy storagePower gridEngineering

A method is provided for controlling a power network that includes a plurality of power generation facilities connected to an electricity grid and a plurality of power storage facilities connected to the power generation facilities. The method includes monitoring a production capacity of the power generation facilities, monitoring a storage capacity of the power storage facilities and determining an optimal facility control plan on the basis of the storage capacity and the production capacity. The method further includes operating the power network, according to the facility control plan, to feed power from the power generation facilities into the electricity grid and / or to transfer power from the power generation facilities to the power storage facilities and / or to consume power from the power storage facilities.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

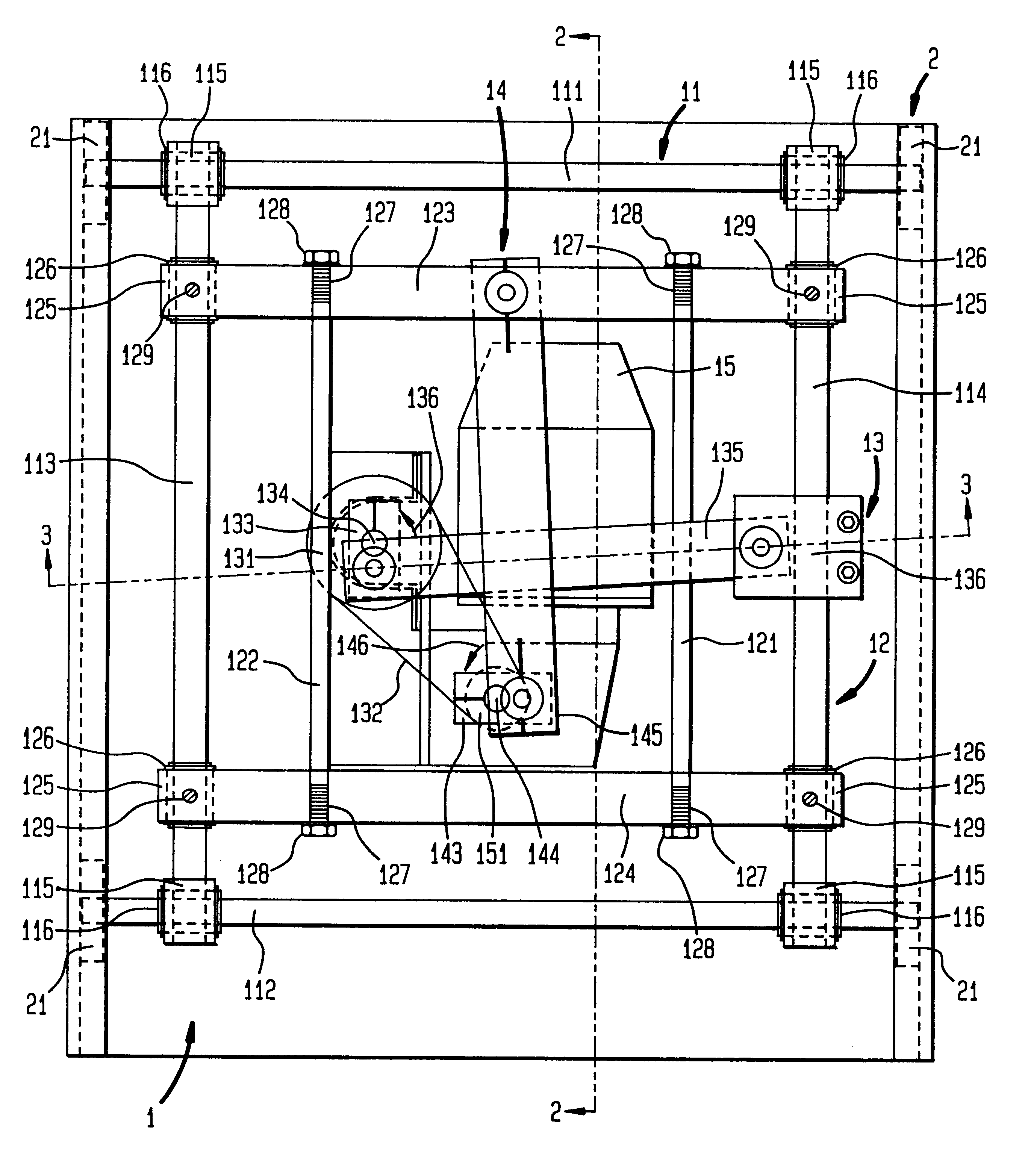

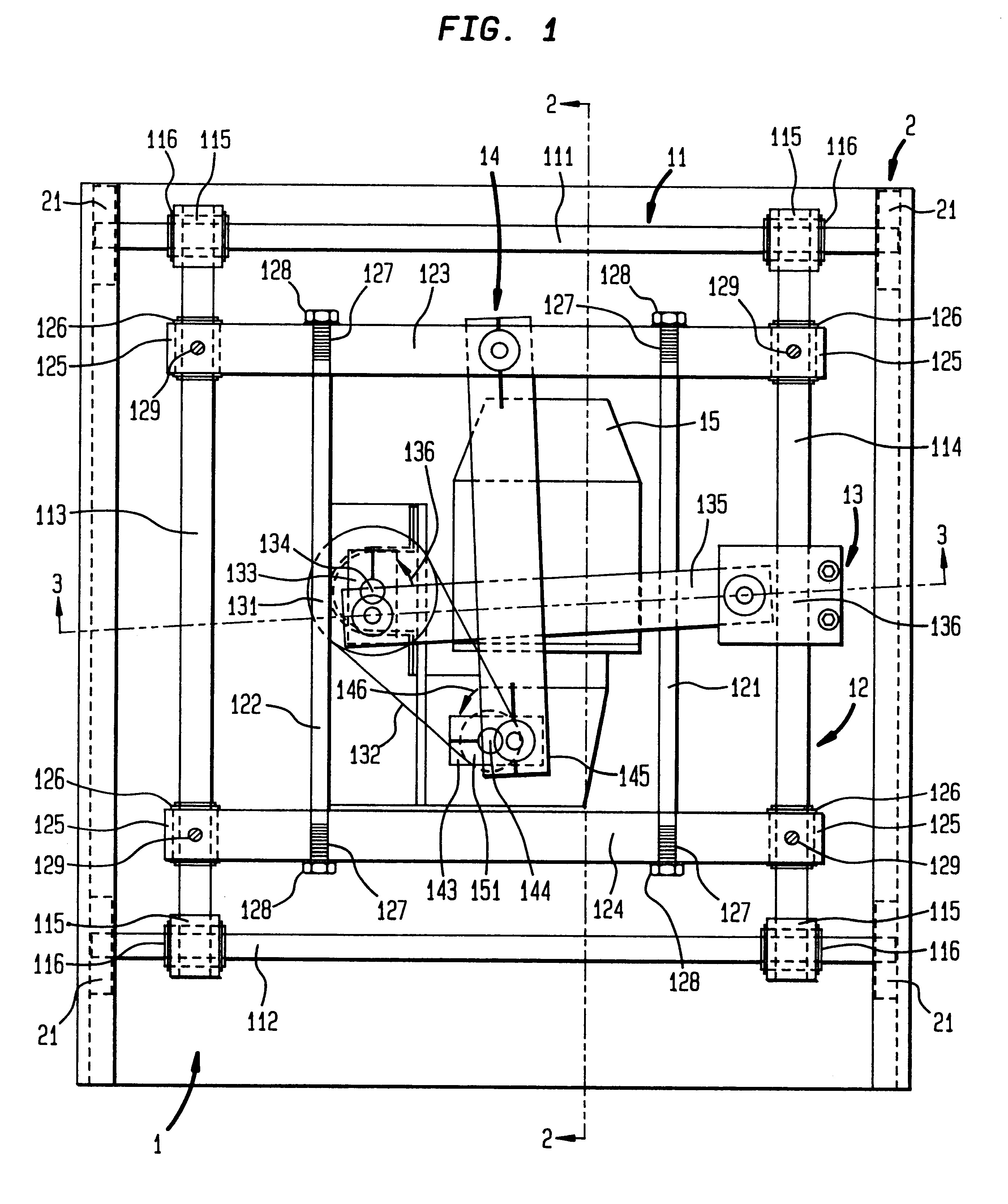

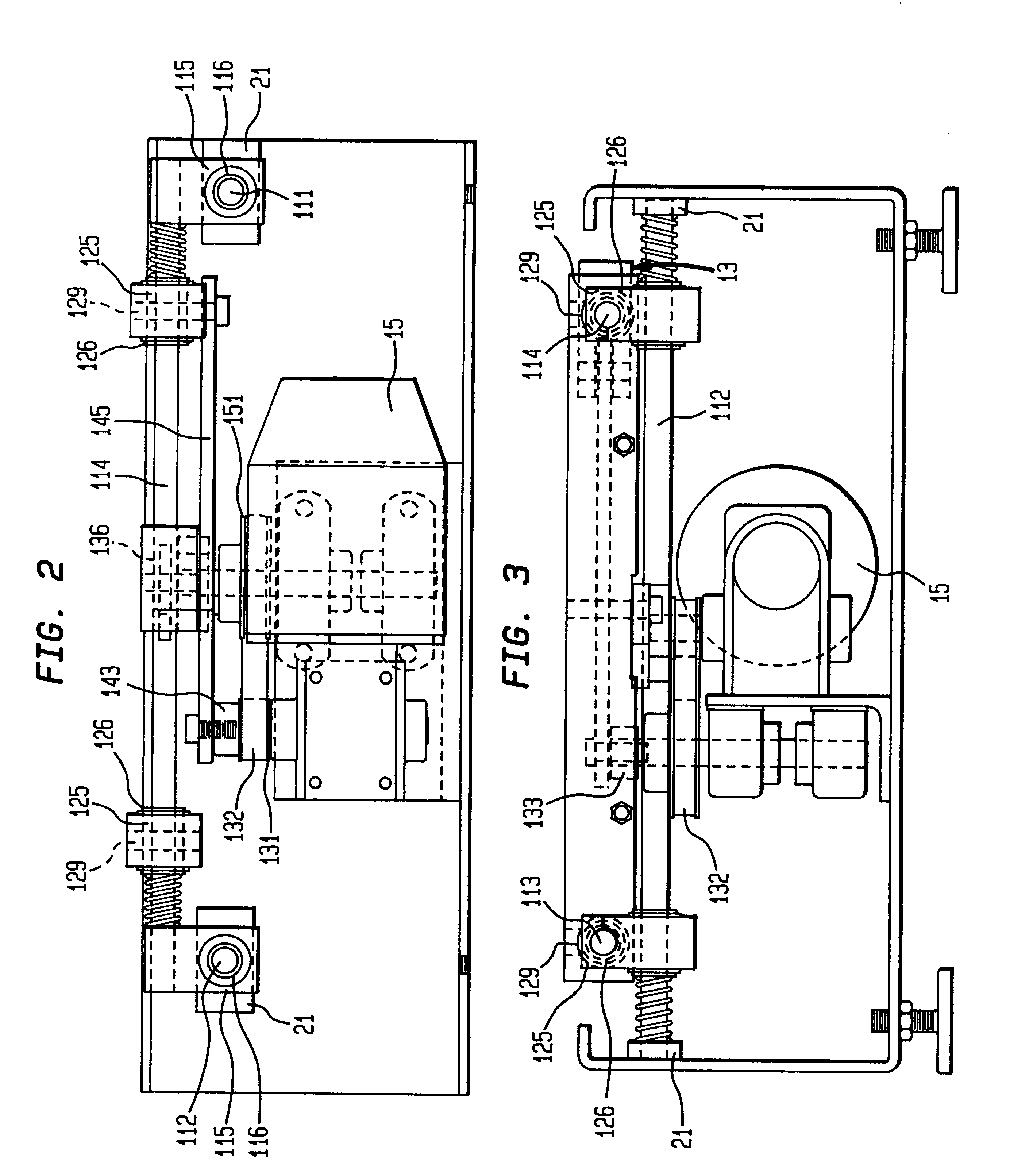

Reversing rotatory shaker movement

InactiveUS6322243B1Well mixedLower energy levelShaking/oscillating/vibrating mixersTransportation and packagingSynchronous motorHigh rate

A shaker movement permits an arbitrary path of motion in a shaker's shaking action. The shaker movement comprises independent control over the "X" and "Y" directions of the shaking actions by a pair of track assemblies, each track assembly comprising a pair of fixed rods and a pair of sliding rods that are interconnected with each other in a rectangular, grid-like pattern. Motion in both directions can be driven by a single motor utilizing independent pulley-and-belt systems or by two synchronized motors which are connected to a sliding rod of each track assembly. By altering the relative amplitude, phase angle, and frequency between the "X" and "Y" directions, the shaking action can follow a desired path. The shaker path can be varied from the traditional circular orbital motion or linear motion, to a new group of shaking patterns in which the direction of the shaking movement can reverse. The new patterns of shaker movement cause the liquid being shaken to be more thoroughly mixed, with less power input, and at a lower angular frequency than is practical with traditional paths of motion. This results in higher rates of gas transfer to and from the liquid, resulting in greater growth of a bacterial culture, and for higher rates of mass transfer at equivalent levels of energy input.

Owner:BULL DANIEL

Semiconductor devices and fabrication process thereof

InactiveUS20100052079A1Avoid damageImprove the immunityTransistorSemiconductor/solid-state device manufacturingManufacturing technologyDevice material

Owner:SONY CORP

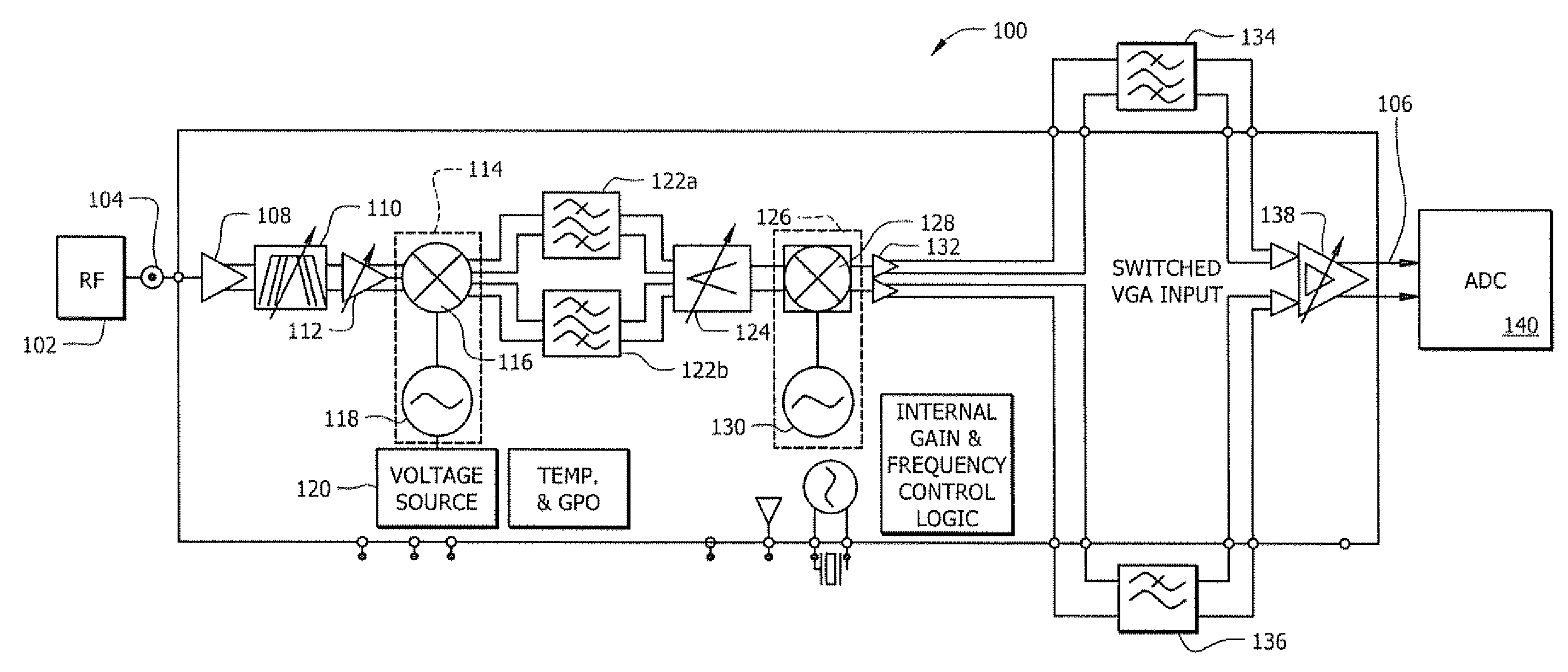

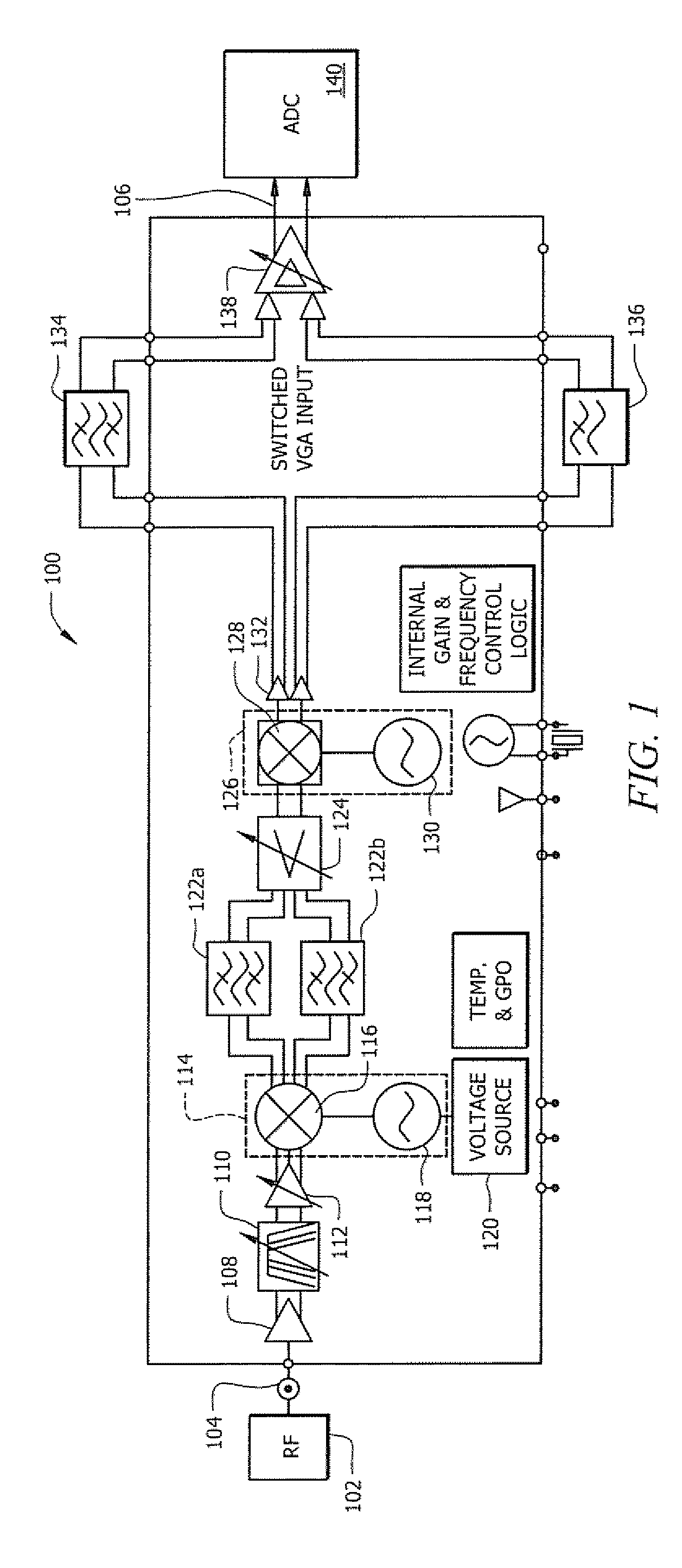

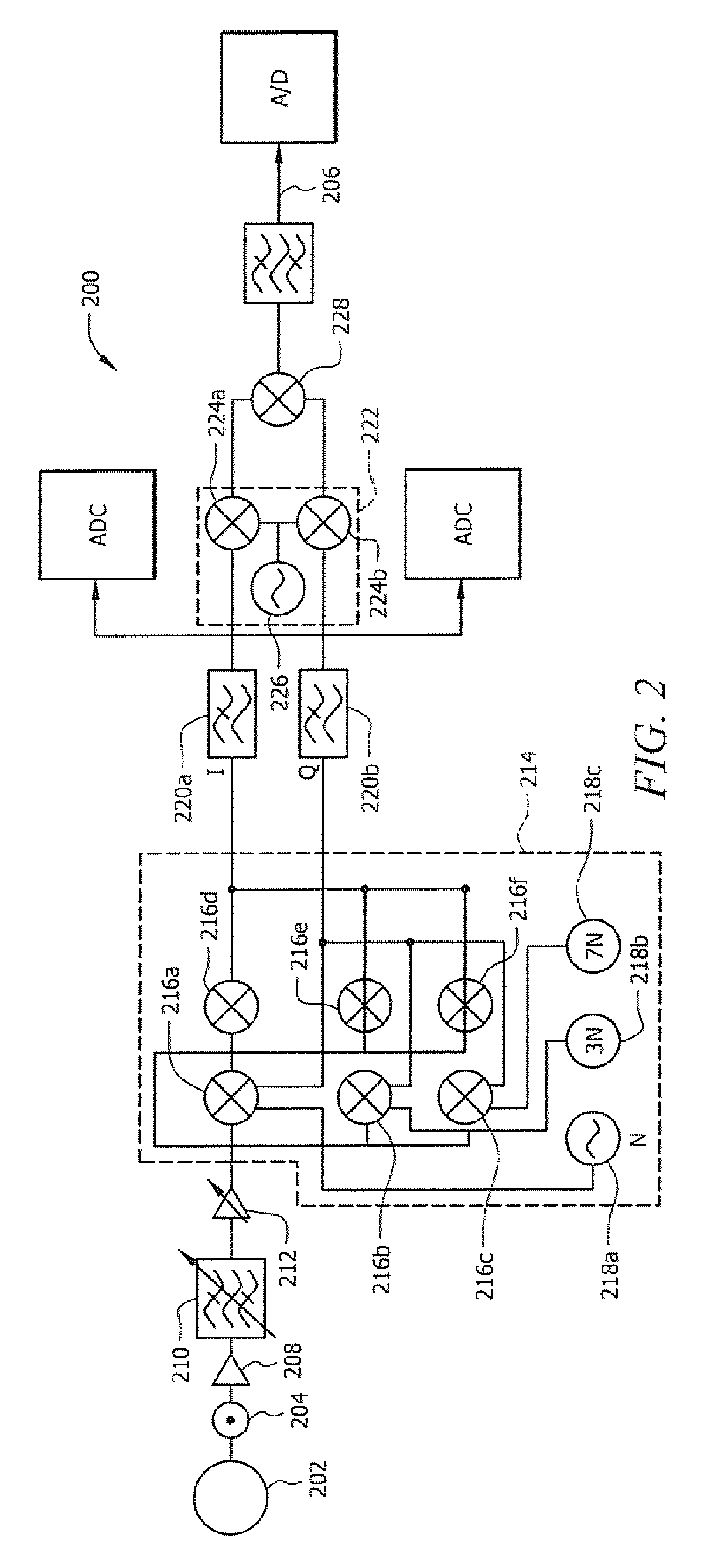

Broadband tuner for very wide signal conversion

InactiveUS20090258629A1Performance is not affectedDisadvantages and reduced eliminatedMultiple-port networksModulation transferenceHarmonicFrequency mixer

An agile RF tuner circuit capable of converting a wide portion of RF signal into an IF signal suitable for analog-to-digital conversion. The circuit up converts a received RF signal to a high IF signal and then down converts the high IF signal to a low IF signal. Embodiments of the RF circuit incorporate harmonic reject mixers to suppress harmonies and intermodulations typically associated with the frequency conversion process.

Owner:CSR TECH INC

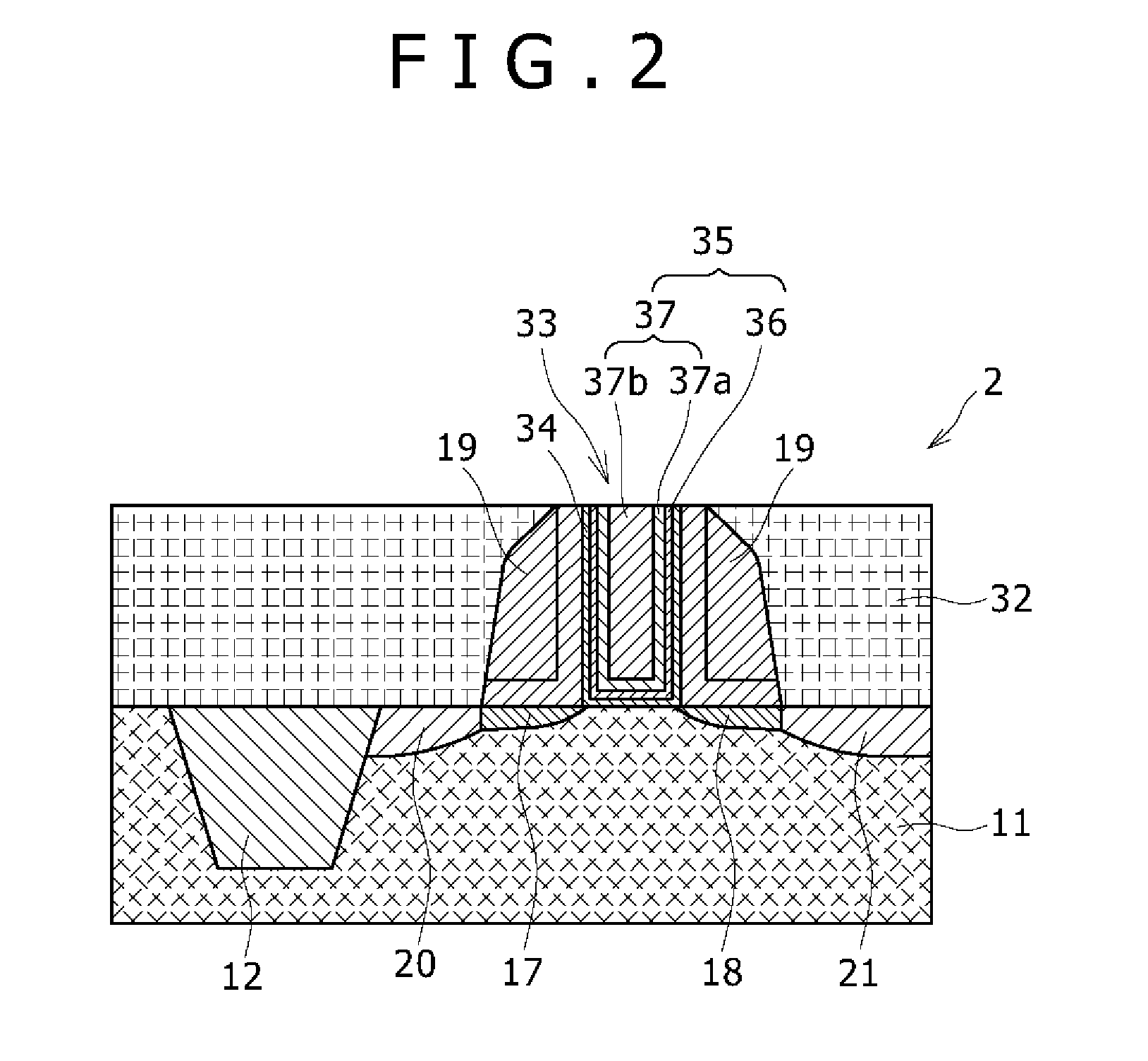

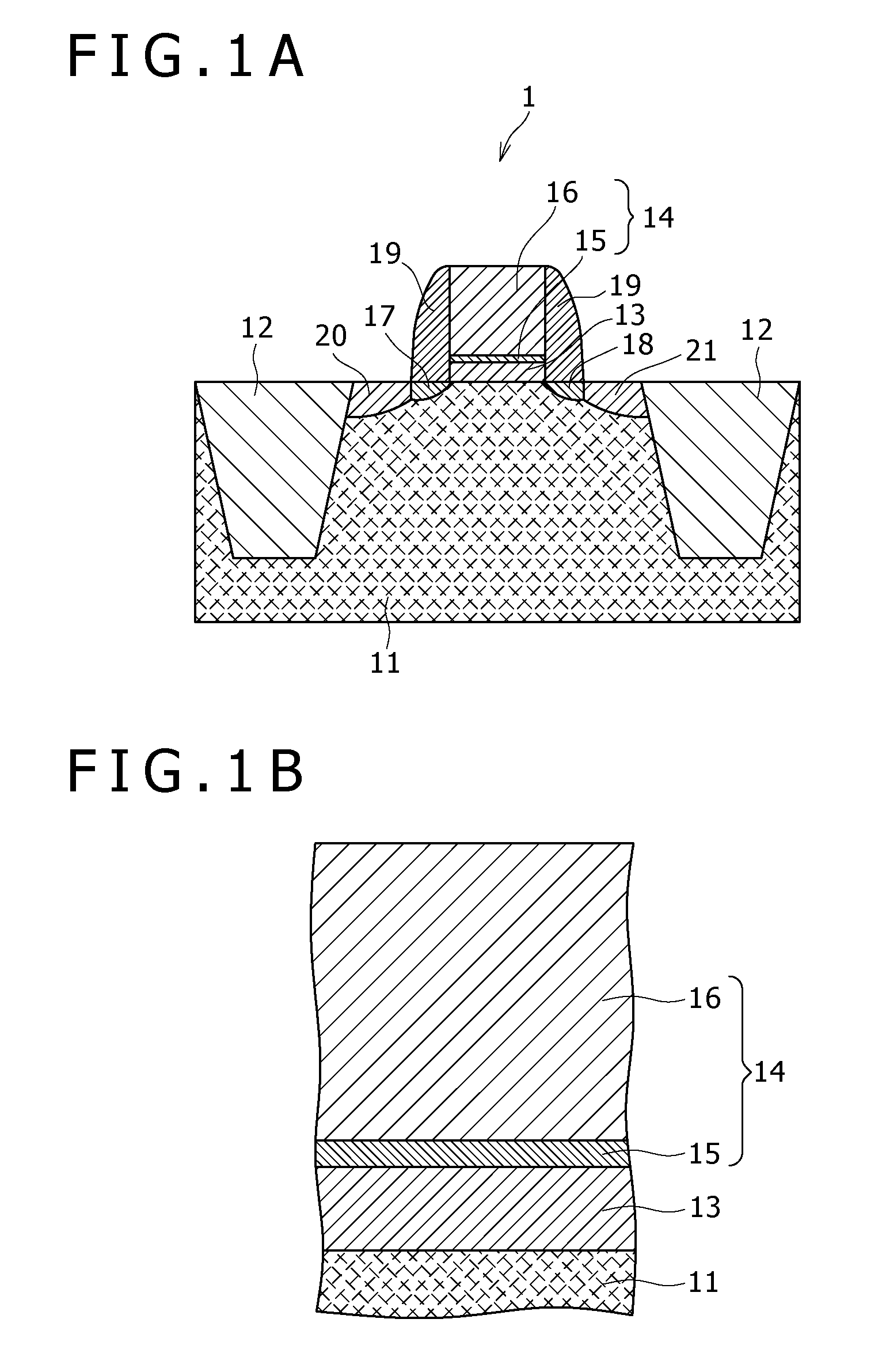

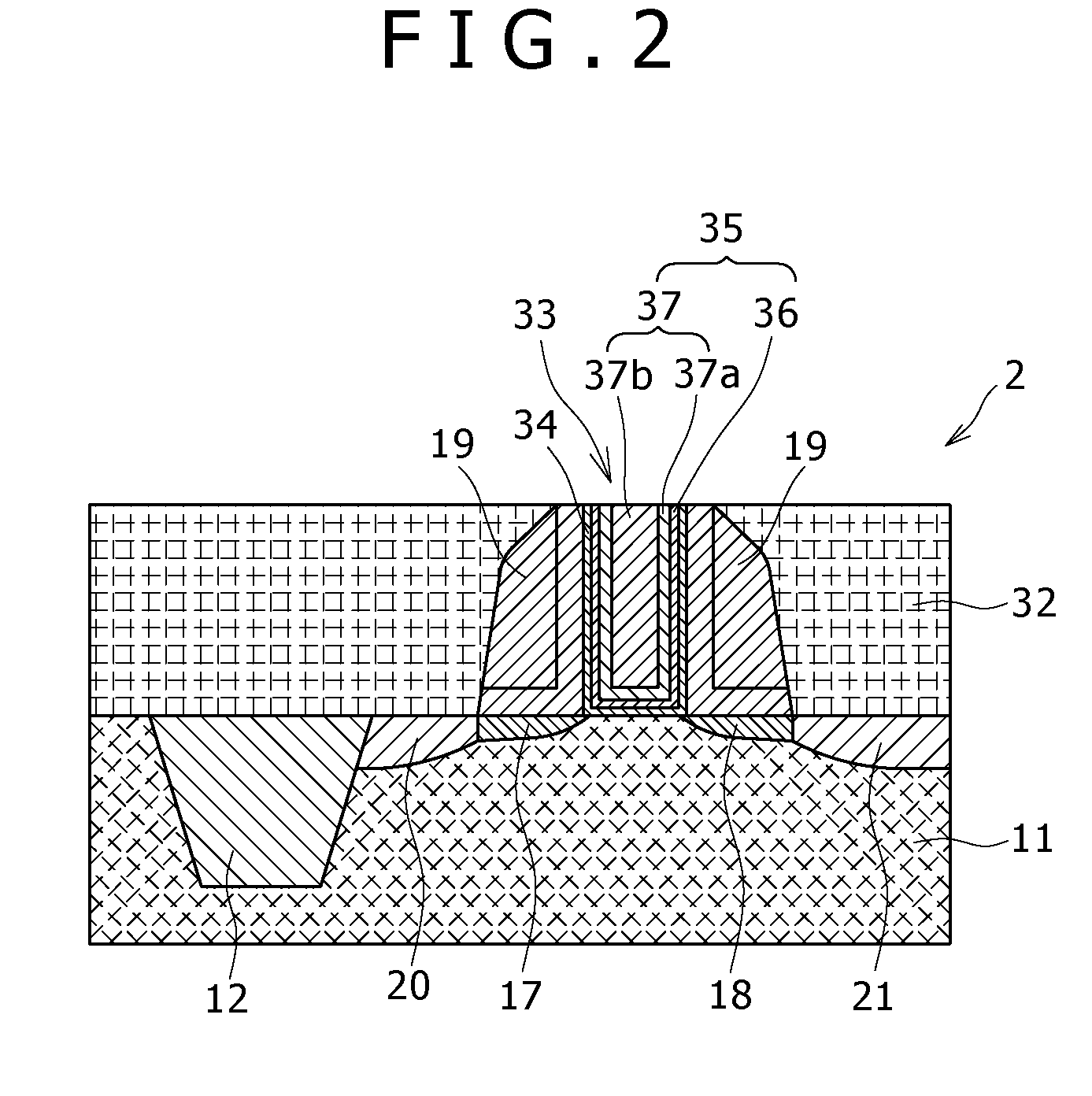

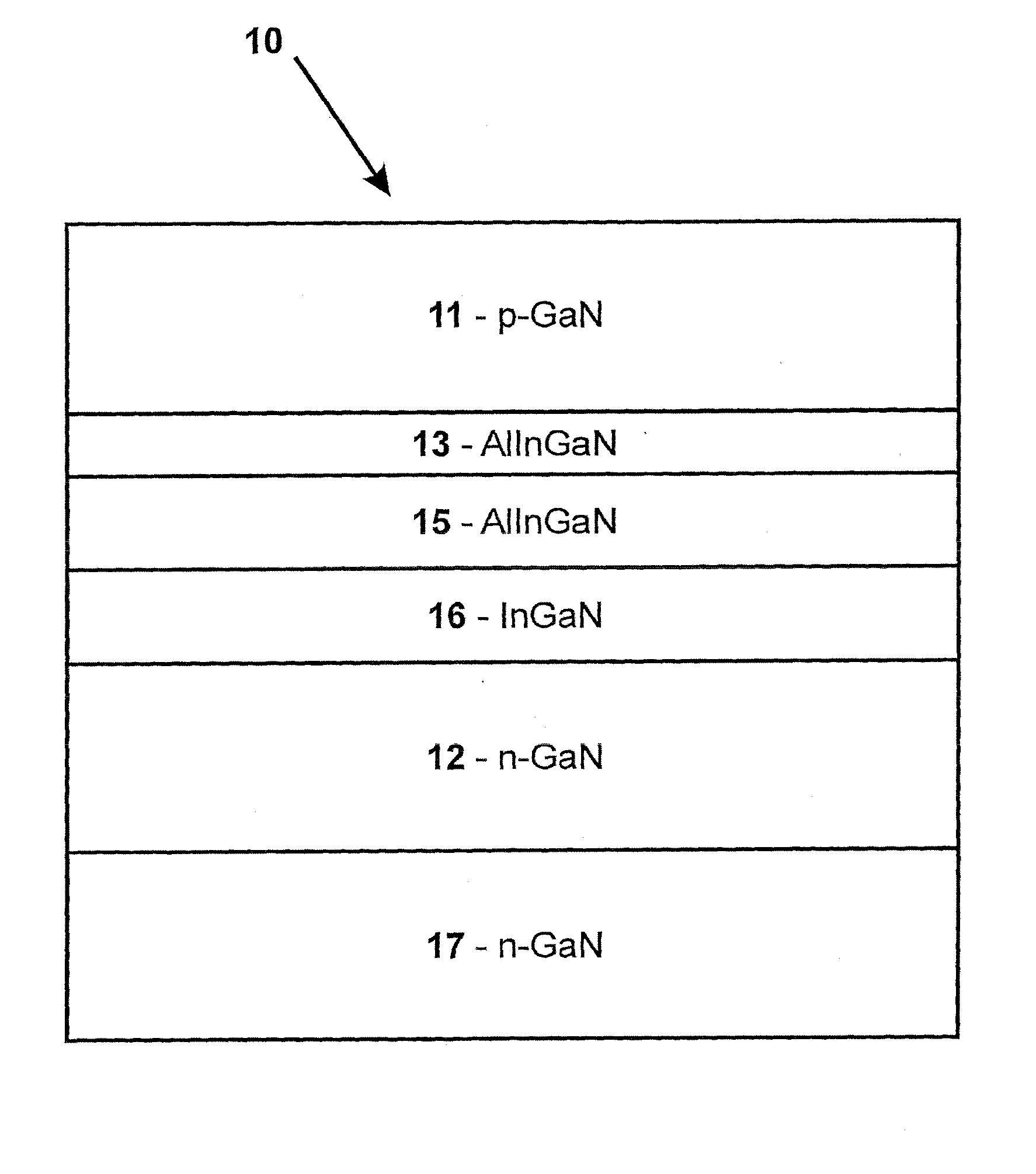

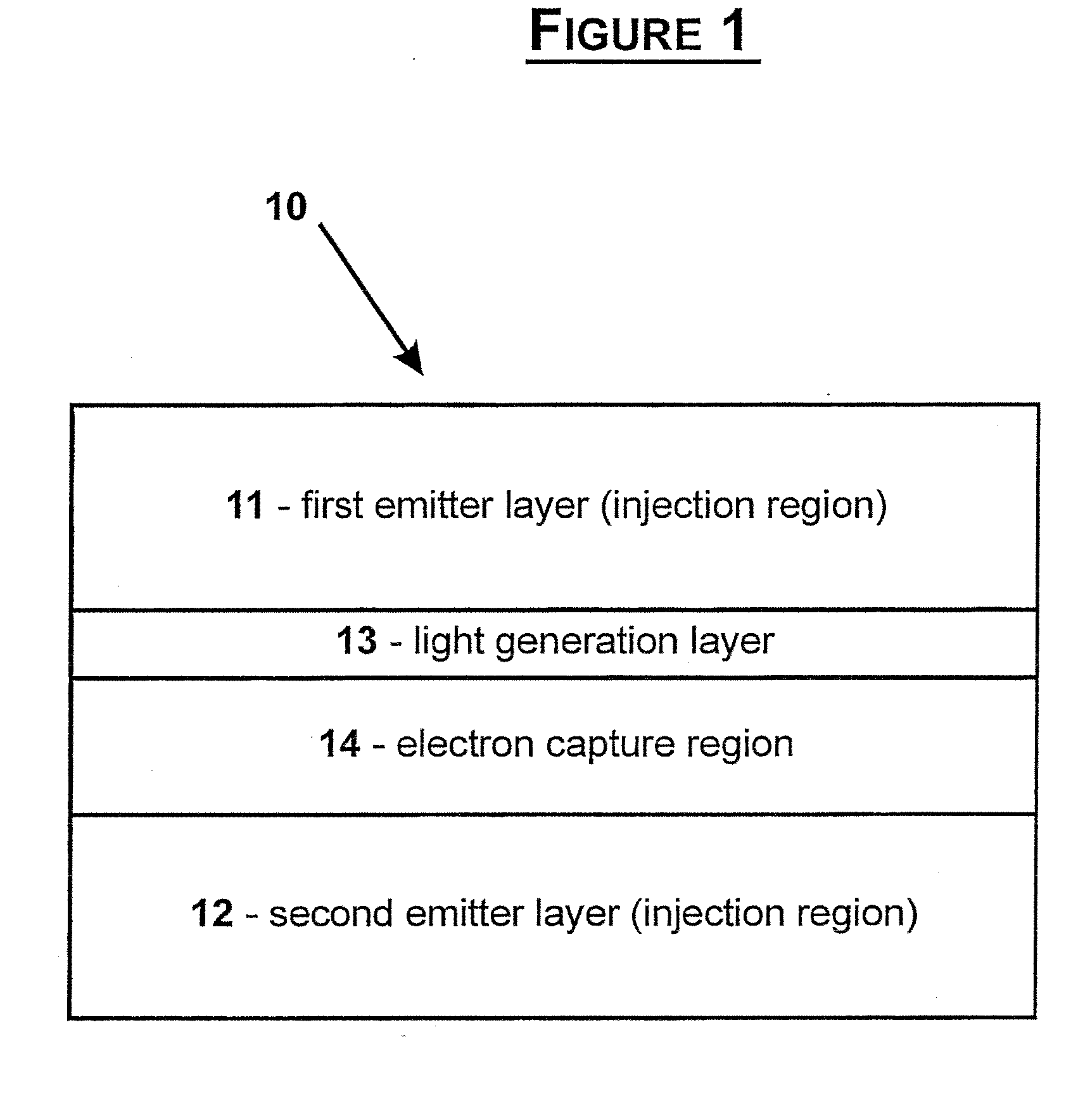

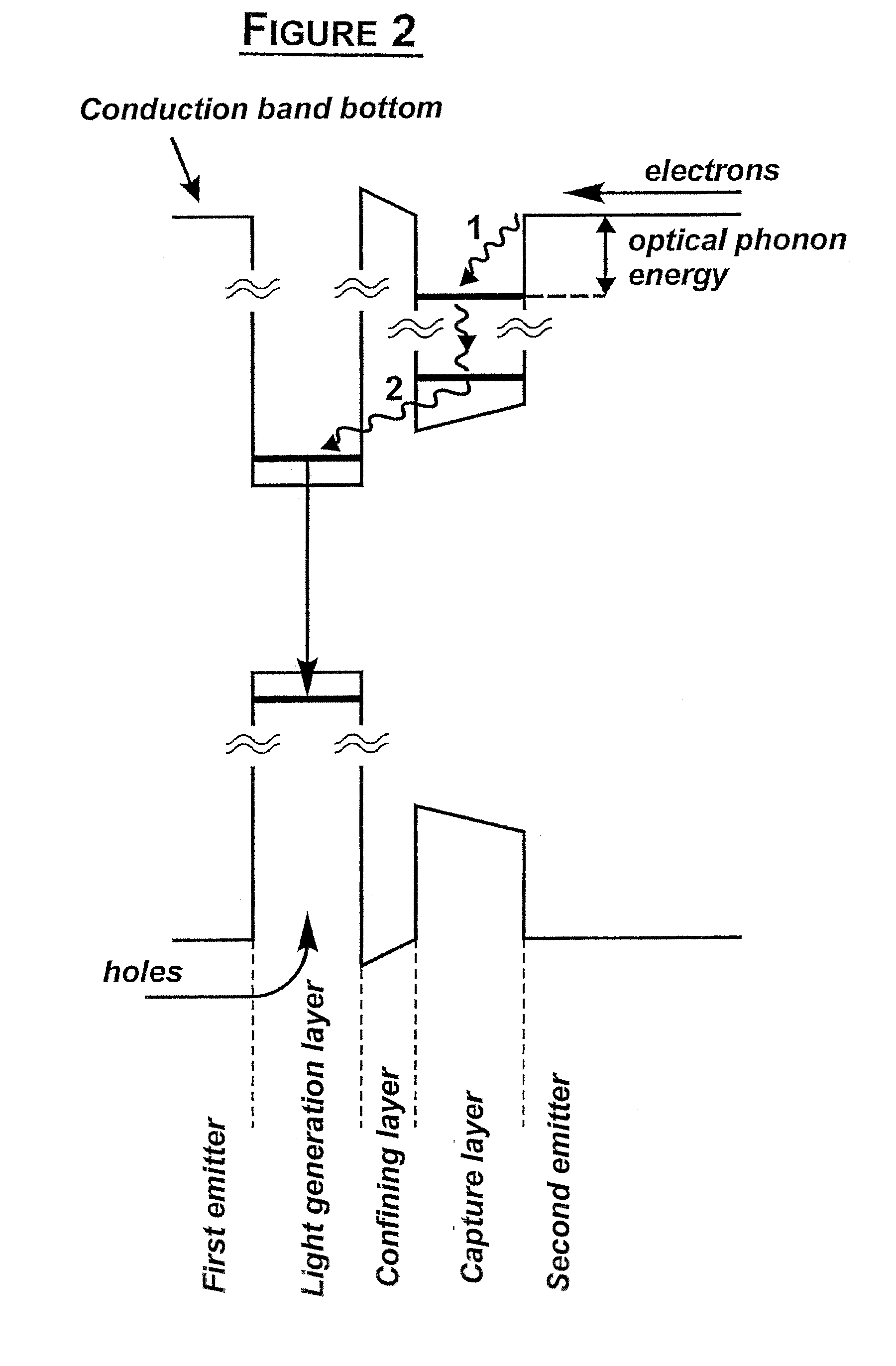

Semiconductor Heterostructure

InactiveUS20080283818A1Enhanced total light generating capabilityEmission rate can be suppressedNanoopticsSemiconductor devicesSemiconductor heterostructuresConduction band

A strained semiconductor heterostructure (10) comprises an injection region comprising a first emitter layer (11) having p-type conductivity and a second emitter layer (12) having n-type conductivity, and a light generation layer (13) positioned between the first emitter layer (11) and the second emitter layer (12). An electron capture region (14) is positioned between the light generation layer (13) and the second emitter layer (12), said electron capture region comprising a capture layer (16) adjacent to the second emitter layer, and a confining layer (15) adjacent to said electron capture layer. According to the present invention, the widths and materials of the confining and capture layers (15, 16) are selected to provide energy difference between one of localized energy levels for electrons in the capture layer (16) and the conduction band bottom of the second emitter layer (12) equal to the energy of the optical phonon.

Owner:OPTOGAN OY

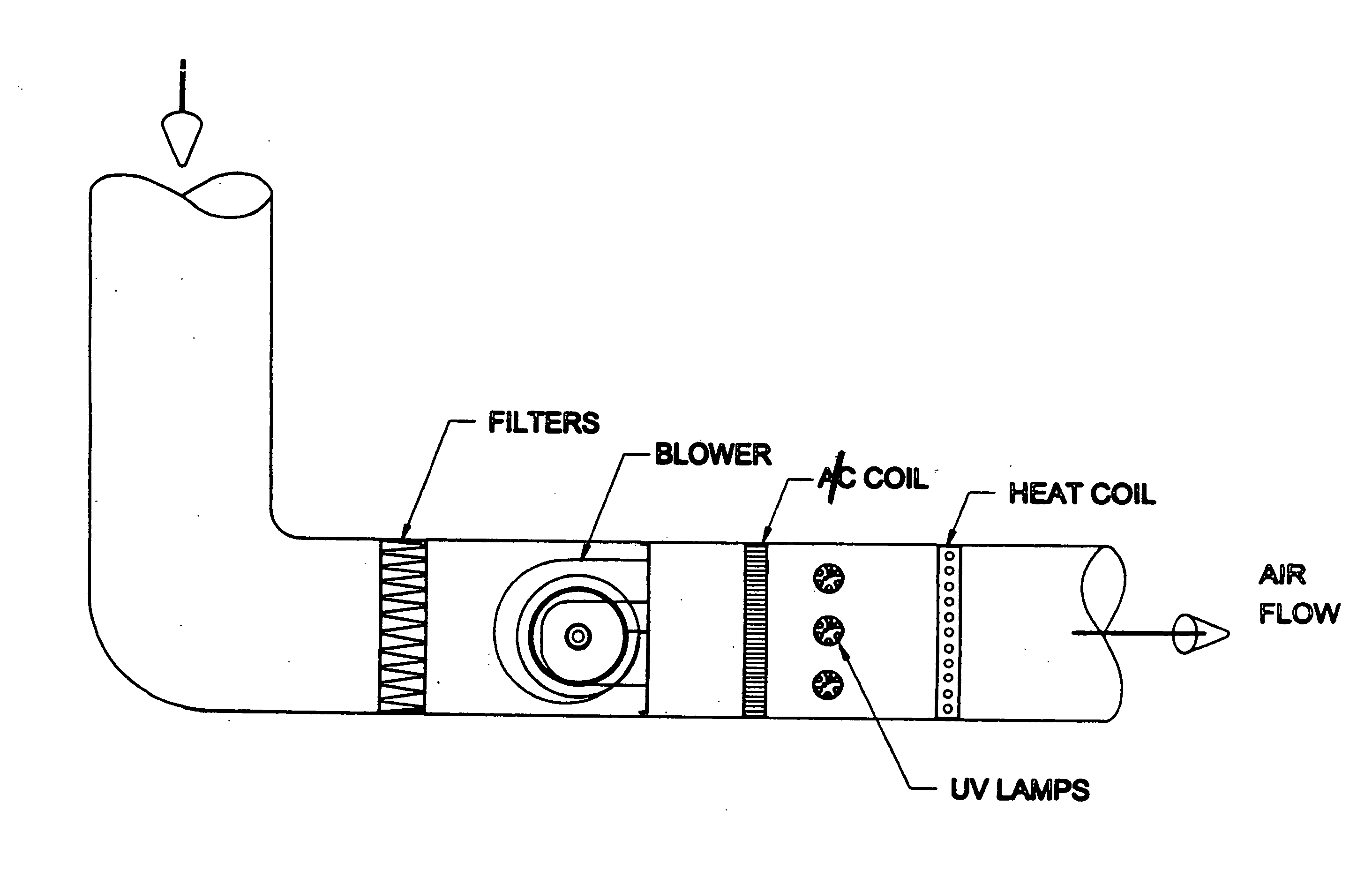

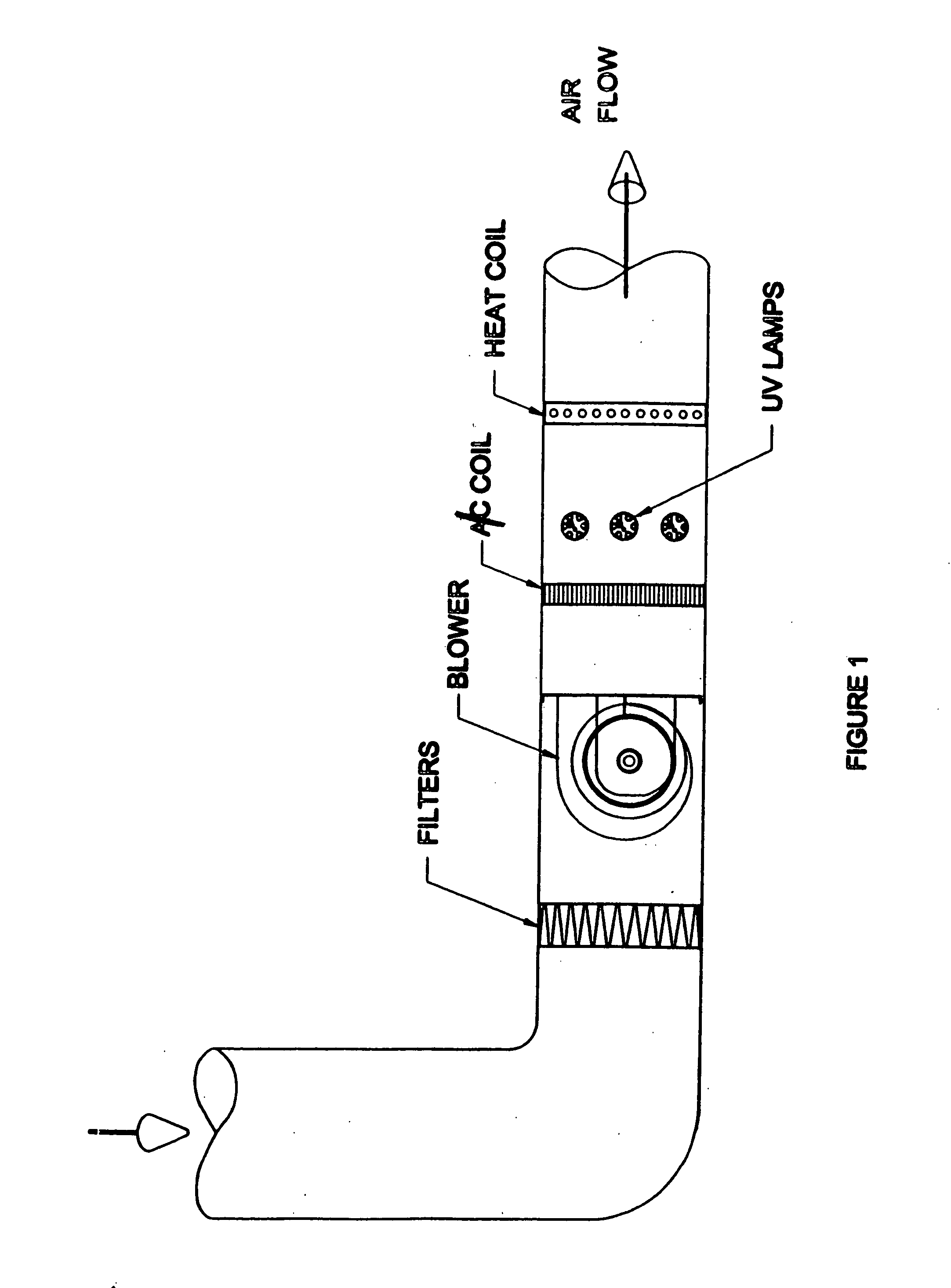

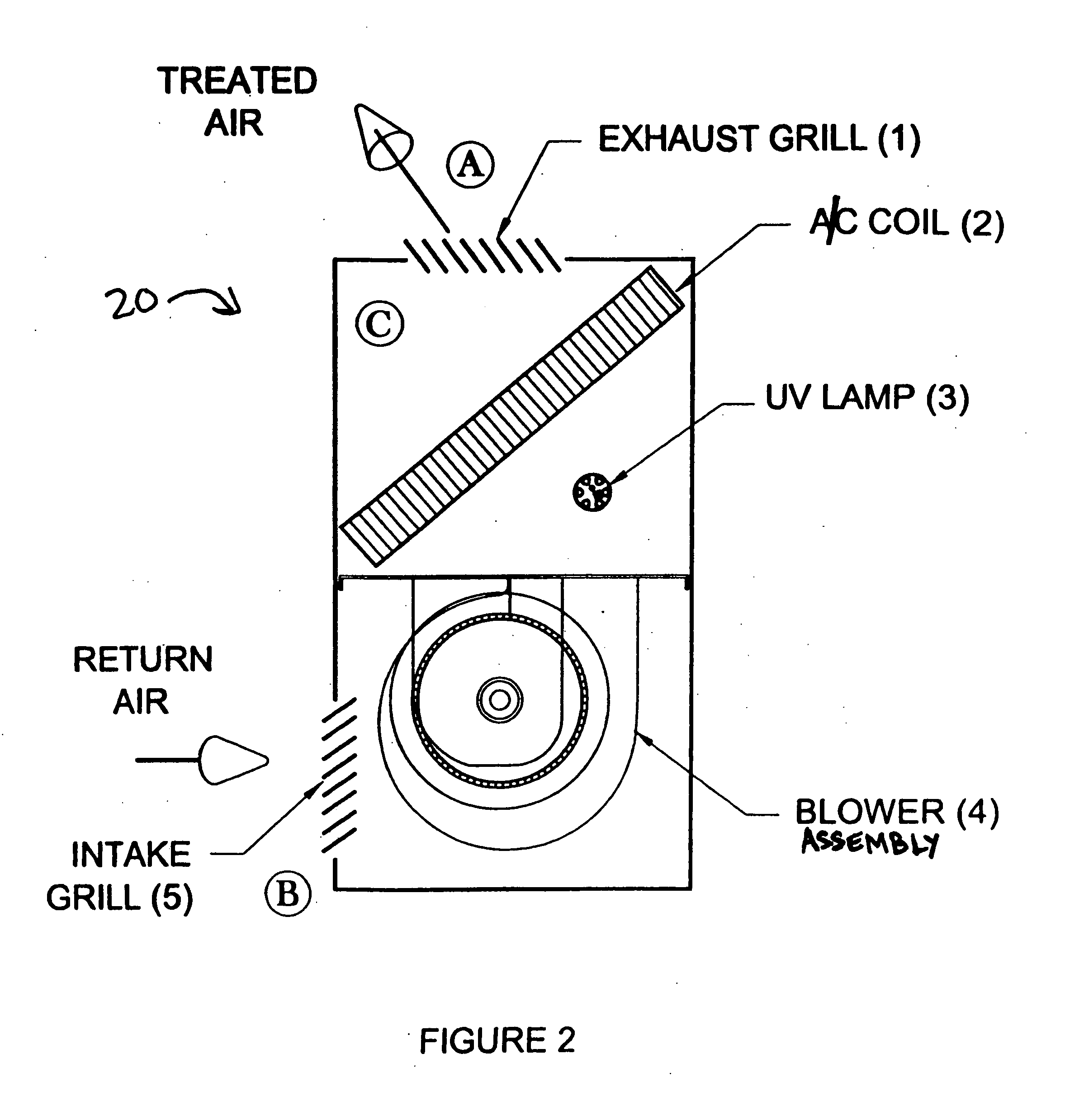

Low level ultraviolet disinfecting system

InactiveUS20050163652A1Safe exposure levelAdequate levelMechanical apparatusLighting and heating apparatusFluid intakeHuman exposure

A disinfecting system comprises a light source having output suitable for use as a germicidal agent, and a power supply for the light source that is adapted to limit the output of the light source to levels adequate for microbial growth control. The light source is operatively housed in fluid-conveying equipment for disinfecting fluids and surfaces therein. The limited output is attenuated by fluid-conveying equipment components disposed within the output range of the light source. The attenuated output provides safe human exposure levels in the vicinity of fluid intake and exhaust portions of the fluid-conveying equipment. The limited output inhibits the degradation of fluid-conveying equipment components disposed within the output range of the light source. The light source may be covered with a thin film or sleeve of material being semi-transparent to germicidal UV wavelengths to control the output of the light source.

Owner:ULTRAVIOLET DEVICES

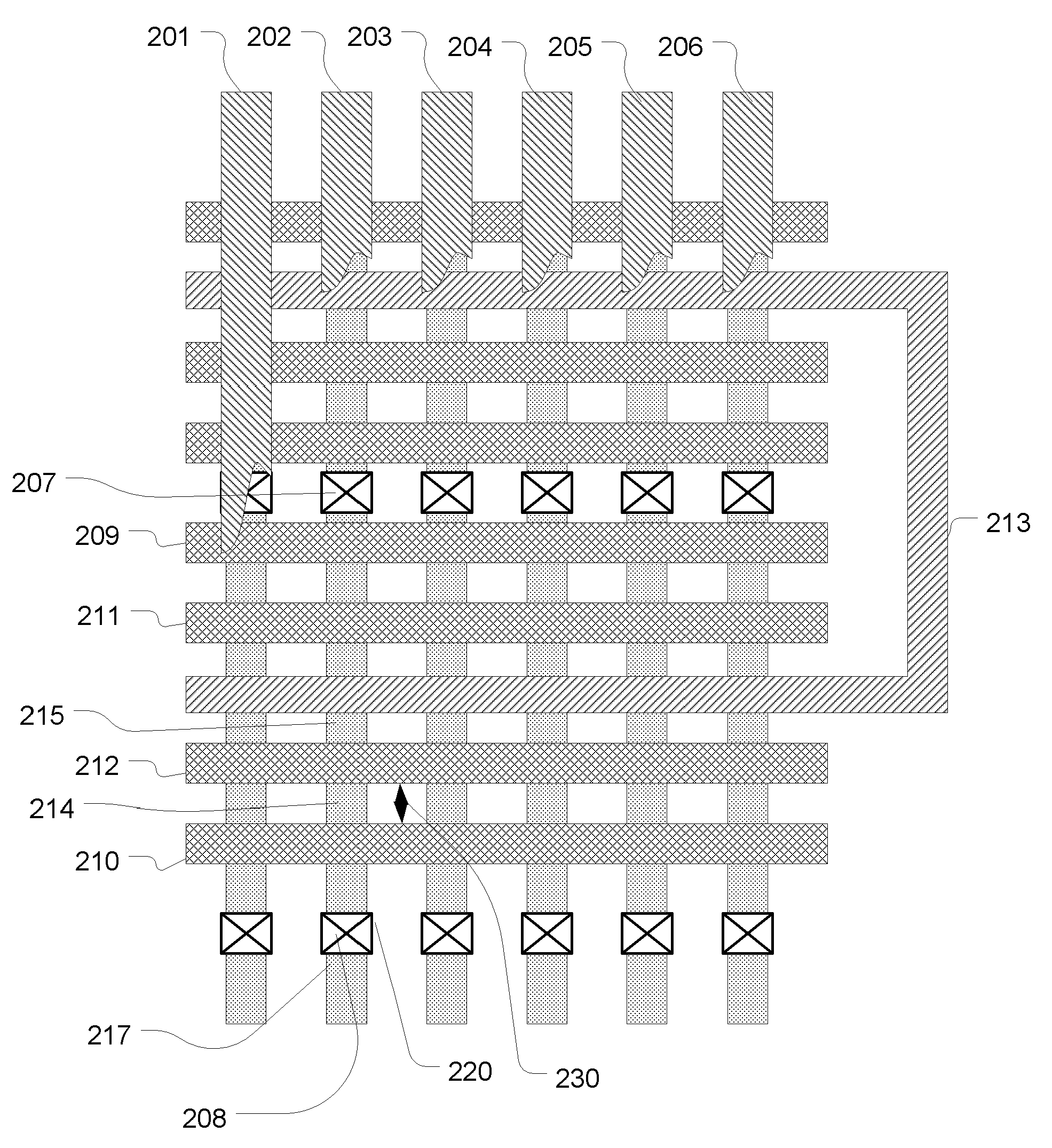

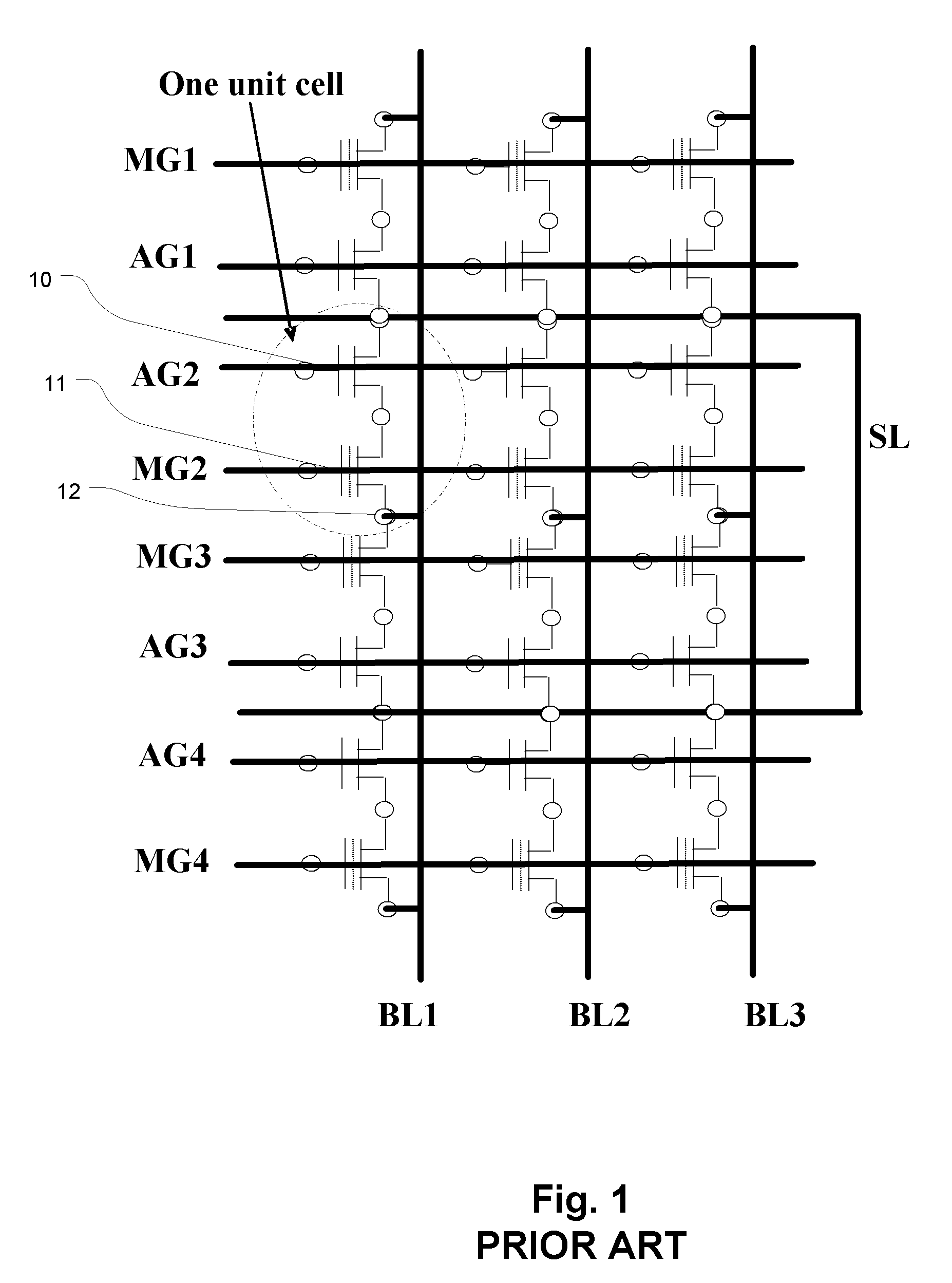

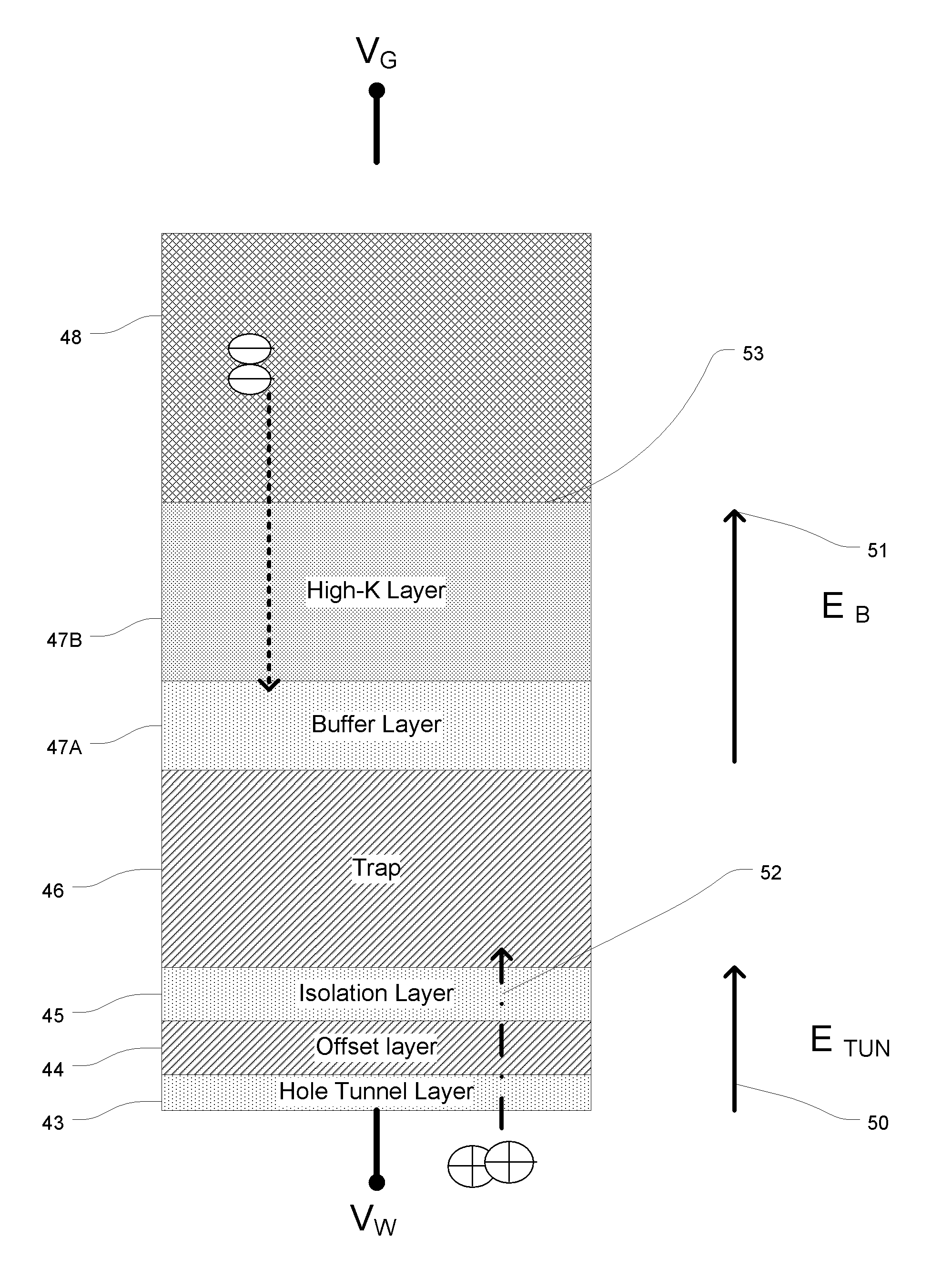

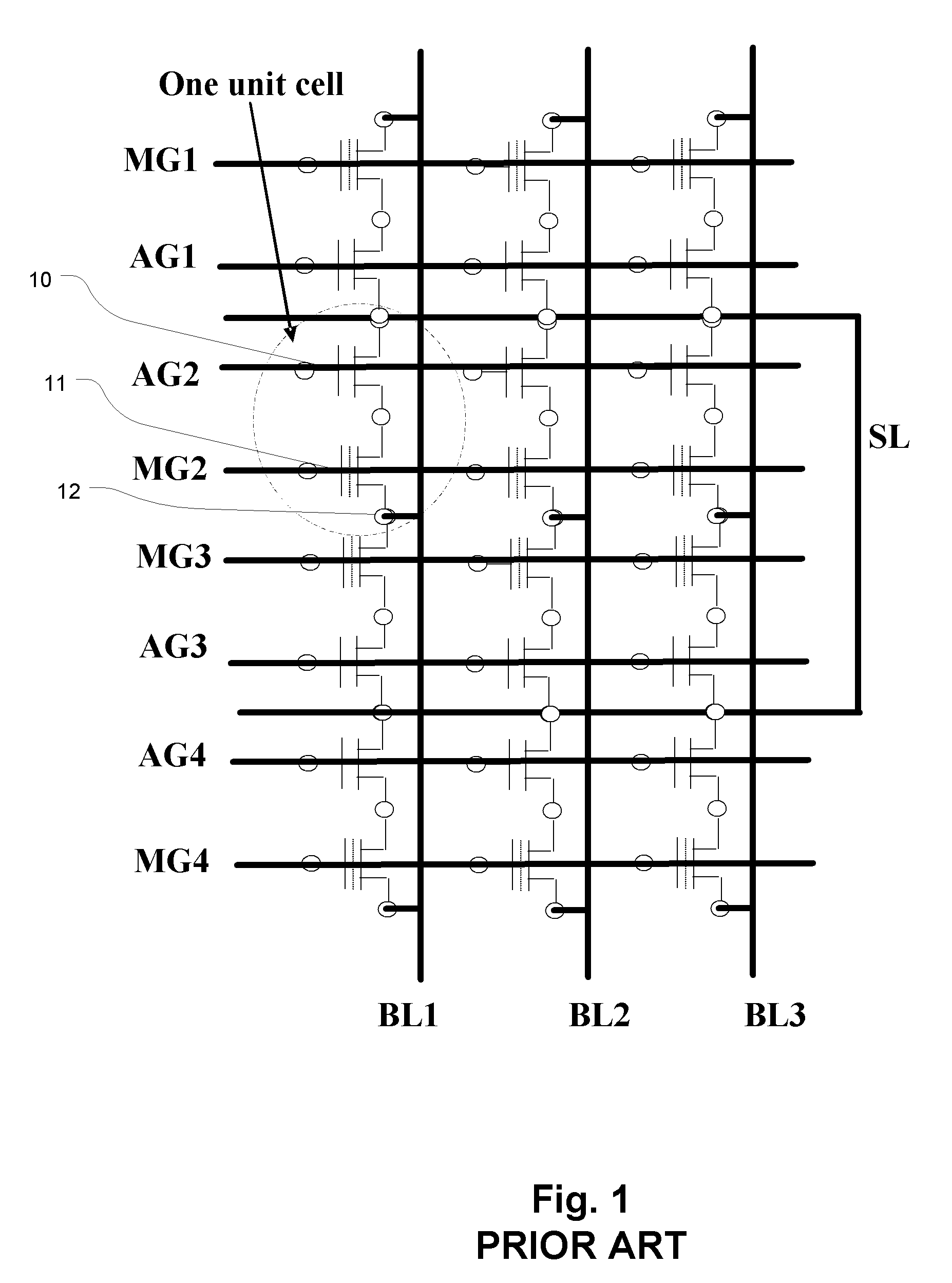

Bandgap engineered charge trapping memory in two-transistor nor architecture

ActiveUS20100265766A1Improve performanceReduce power consumptionSolid-state devicesRead-only memoriesBit lineTrapping

A 2T cell NOR architecture based on the use of BE-SONOS for embedded memory includes memory cells having respective access transistors having access gates and memory transistors having memory gates arranged in series between the corresponding bit lines and one of the plural reference lines. A memory transistor in a memory cell comprises a semiconductor body including a channel having a channel surface and a charge storing dielectric stack between the memory gate and the channel surface. The dielectric stack comprises a bandgap engineered, tunneling dielectric layer contacting one of the gate (for gate injection tunneling) and the channel surface (for channel injection tunneling). The dielectric stack of the memory cell also includes a charge trapping dielectric layer on the tunneling dielectric layer and a blocking dielectric layer.

Owner:MACRONIX INT CO LTD

Adaptive Cancellation System For Implantable Hearing Instruments

The invention is directed to an implanted microphone having reduced sensitivity to vibration. In this regard, the microphone differentiates between the desirable and undesirable vibration by utilizing at least one motion sensor to produce a motion signal when an implanted microphone is in motion. This motion signal is used to yield a microphone output signal that is less vibration sensitive. In a first arrangement, the motion signal may be processed with an output of the implantable microphone transducer to provide an audio signal that is less vibration-sensitive than the microphone output alone. Specifically, the motion signal may be scaled to match the motion component of the microphone output such that upon removal of the motion signal from the microphone output, the remaining signal is an acoustic signal.

Owner:COCHLEAR LIMITED

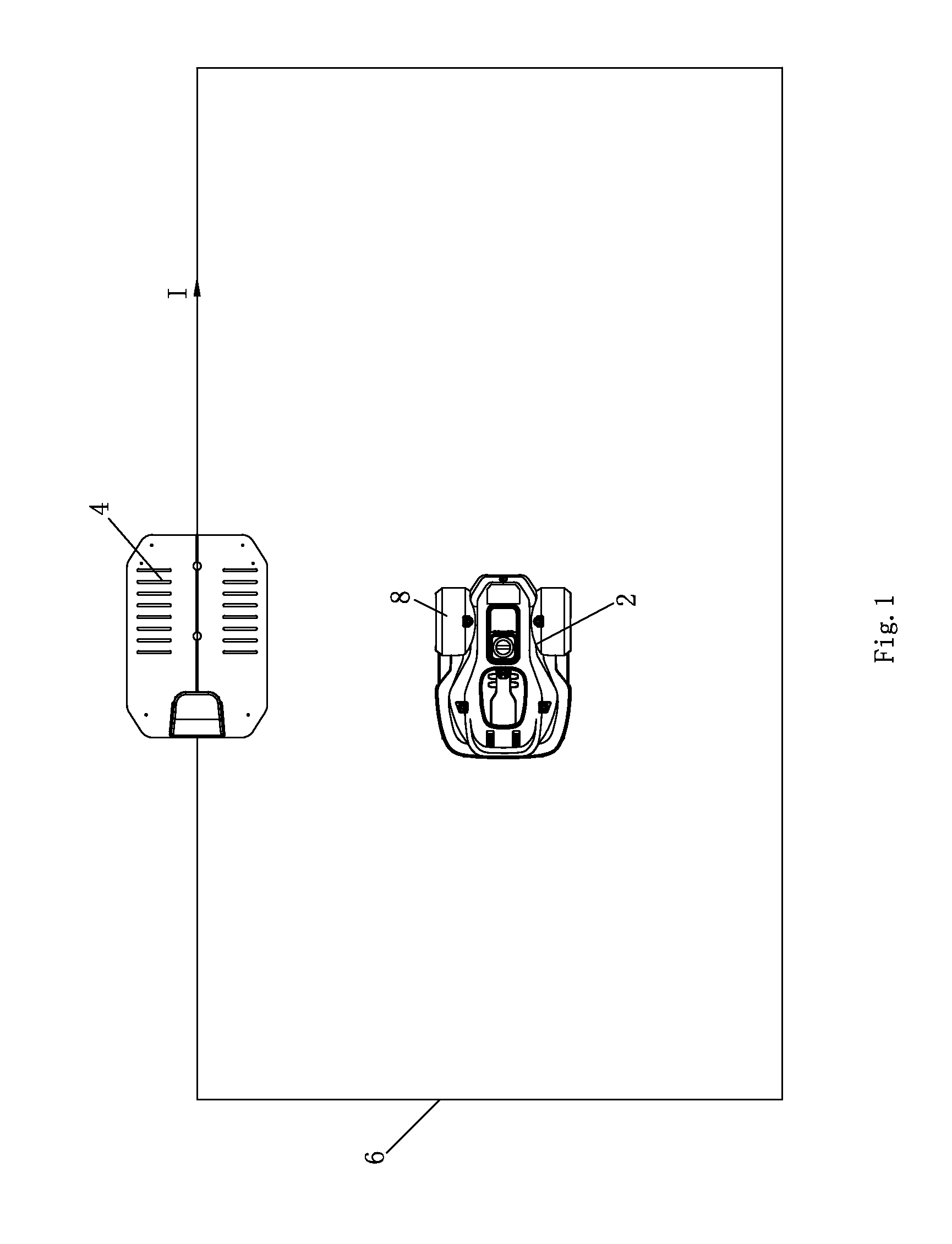

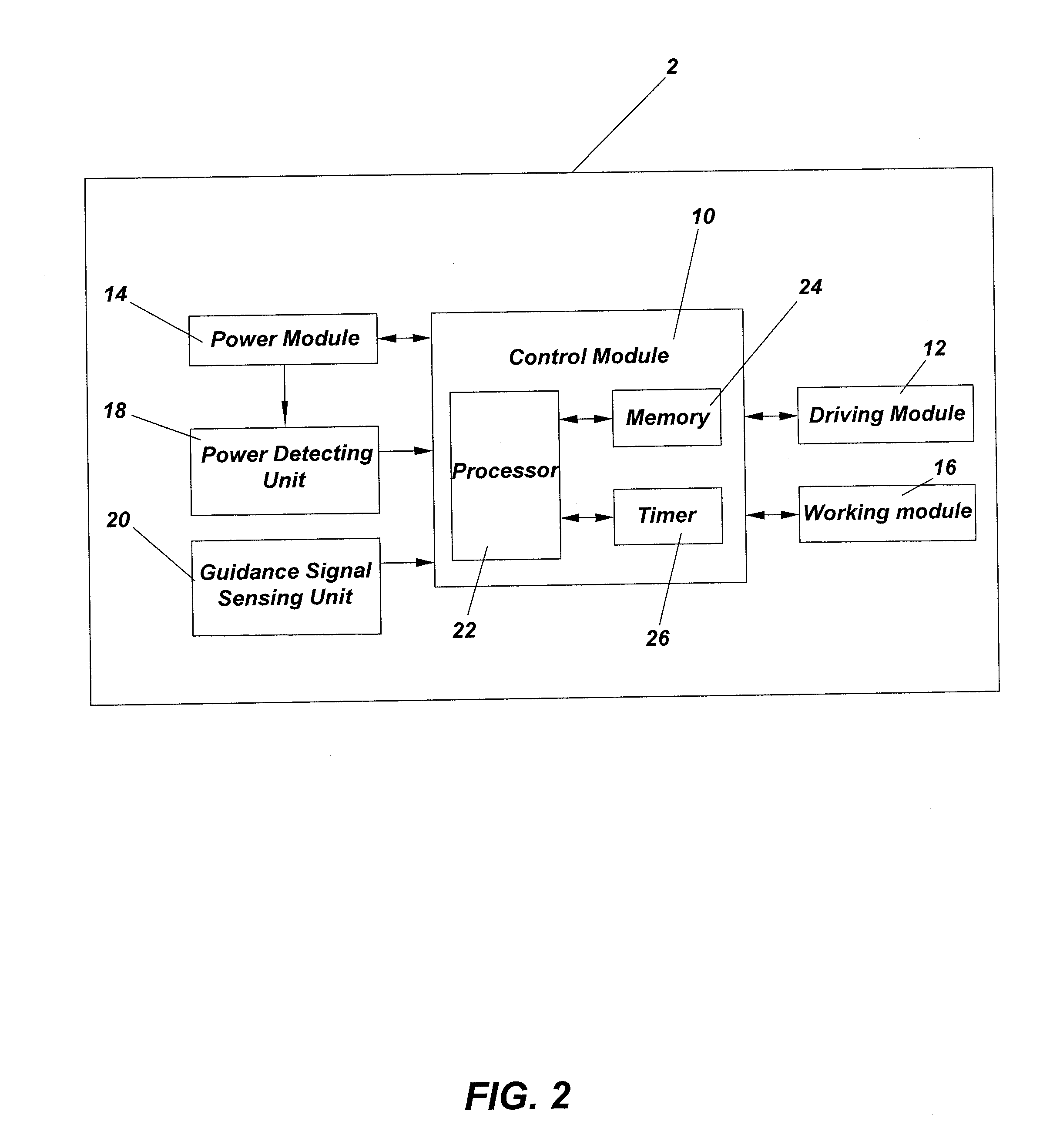

Automatically travelling device and control method therefor

ActiveUS20150105904A1Increase success rateAvoid damageProgramme-controlled manipulatorMowersCharging stationElectric power

An automatic moving device and a control method therefor. The automatic moving device comprises a battery pack providing power. The automatic moving device can work within a working area and automatically return to a charging station for charging. The control method comprises the following steps: monitoring the power level of the battery pack; if the power level of the battery pack is less than or equal to a preset power level, initiating an action of returning the automatic moving device to the charging station; and after a preset time period, stopping the travel. By setting a preset time period simultaneously with initiating a return action, and executing a return action within the preset time period, the control method prevents damage to the battery pack from over-discharging caused by the automatic moving device continually returning, thus achieving the effects of protecting the battery pack and extending the life thereof.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Selective stimulation systems and signal parameters for medical conditions

ActiveUS9056197B2Lower energy levelFine granularitySpinal electrodesExternal electrodesSide effectNervous system

Owner:TC1 LLC

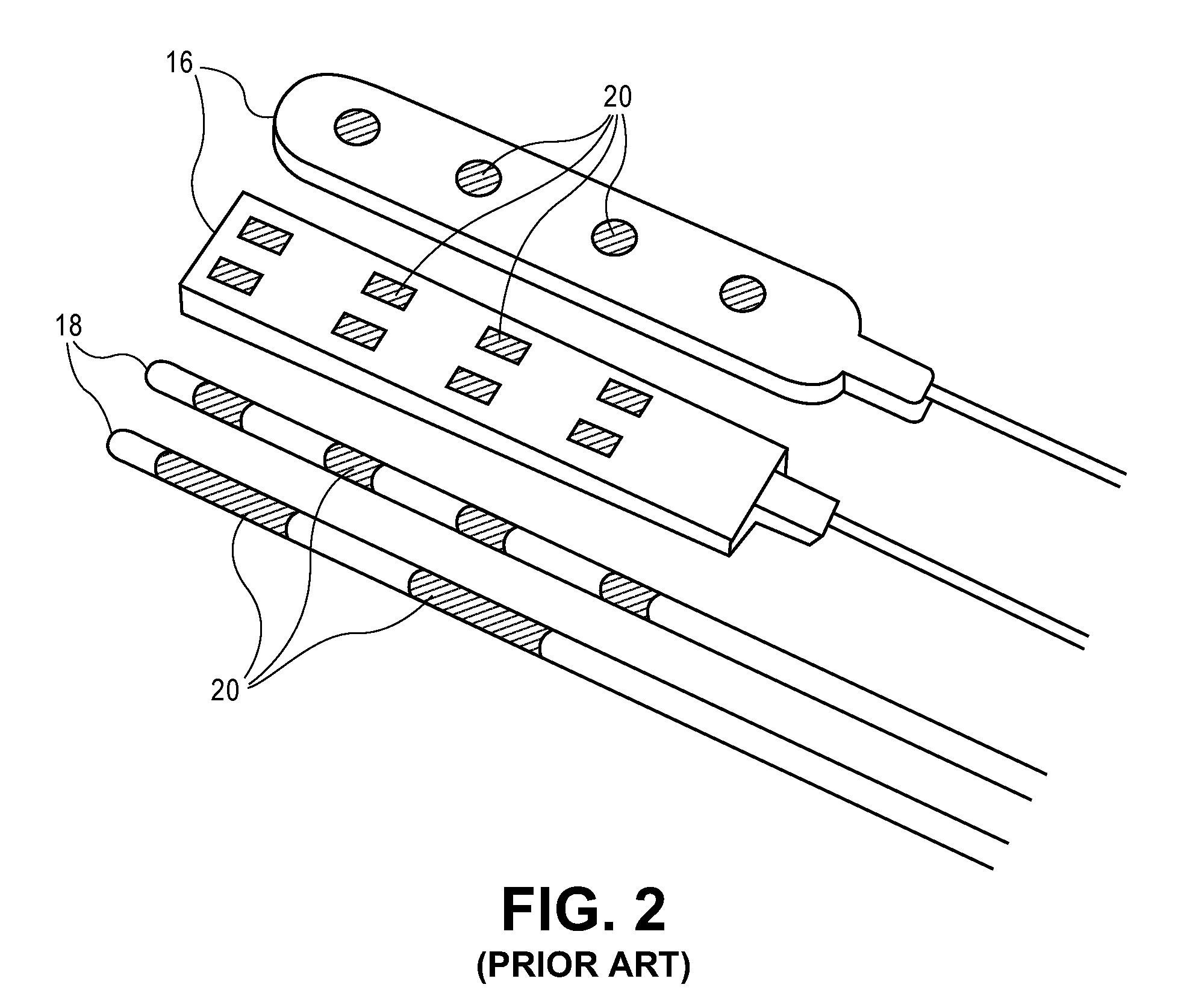

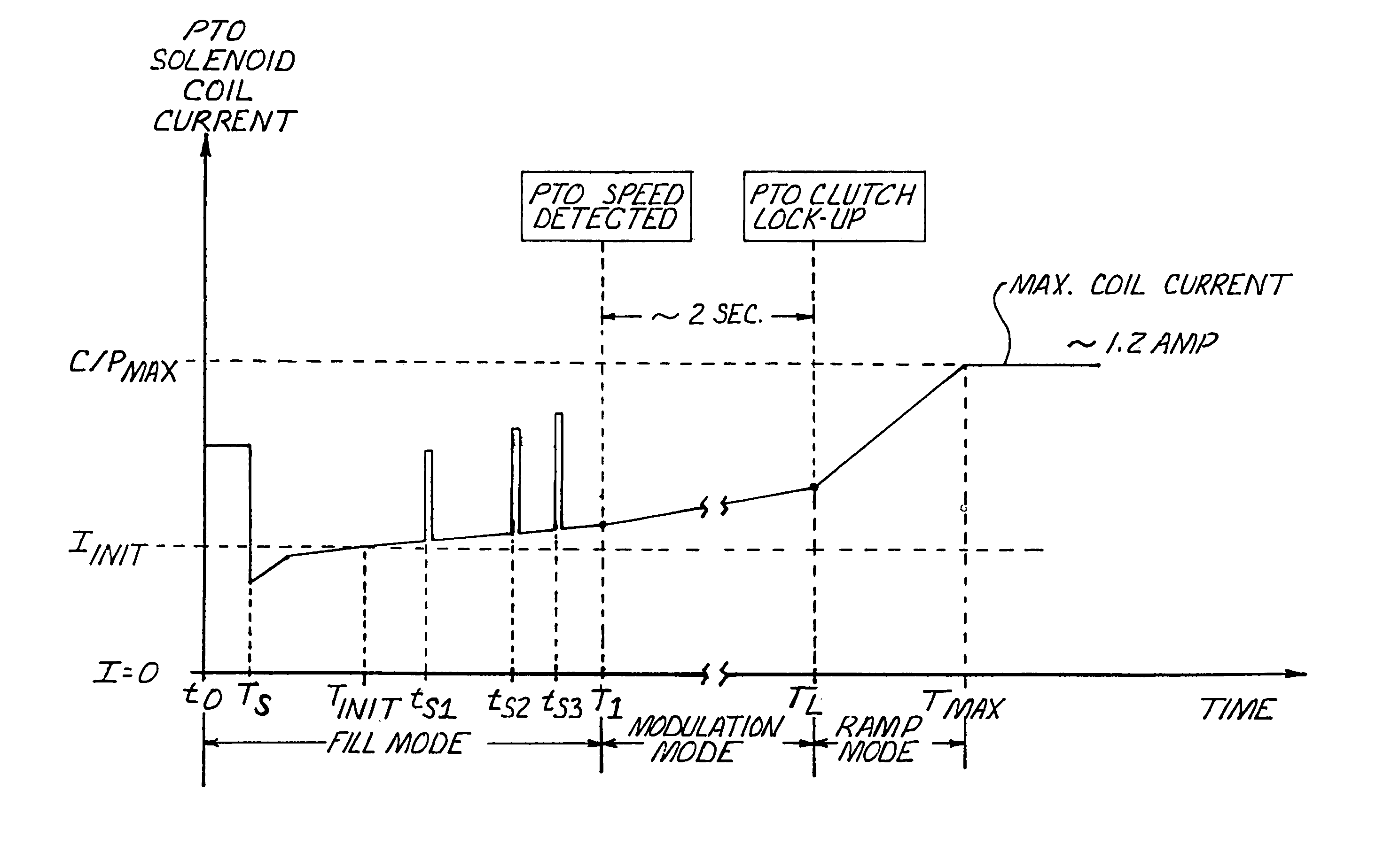

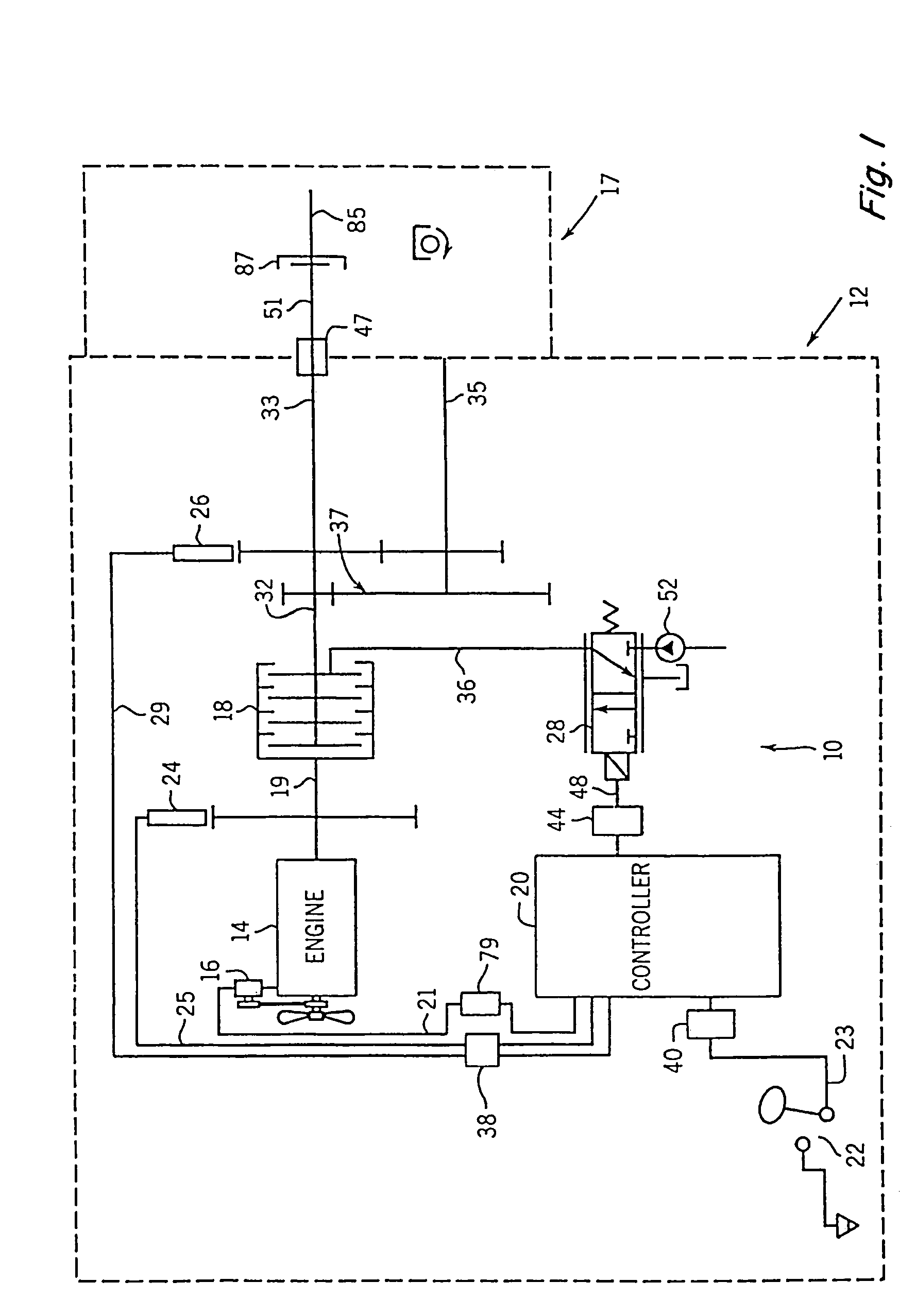

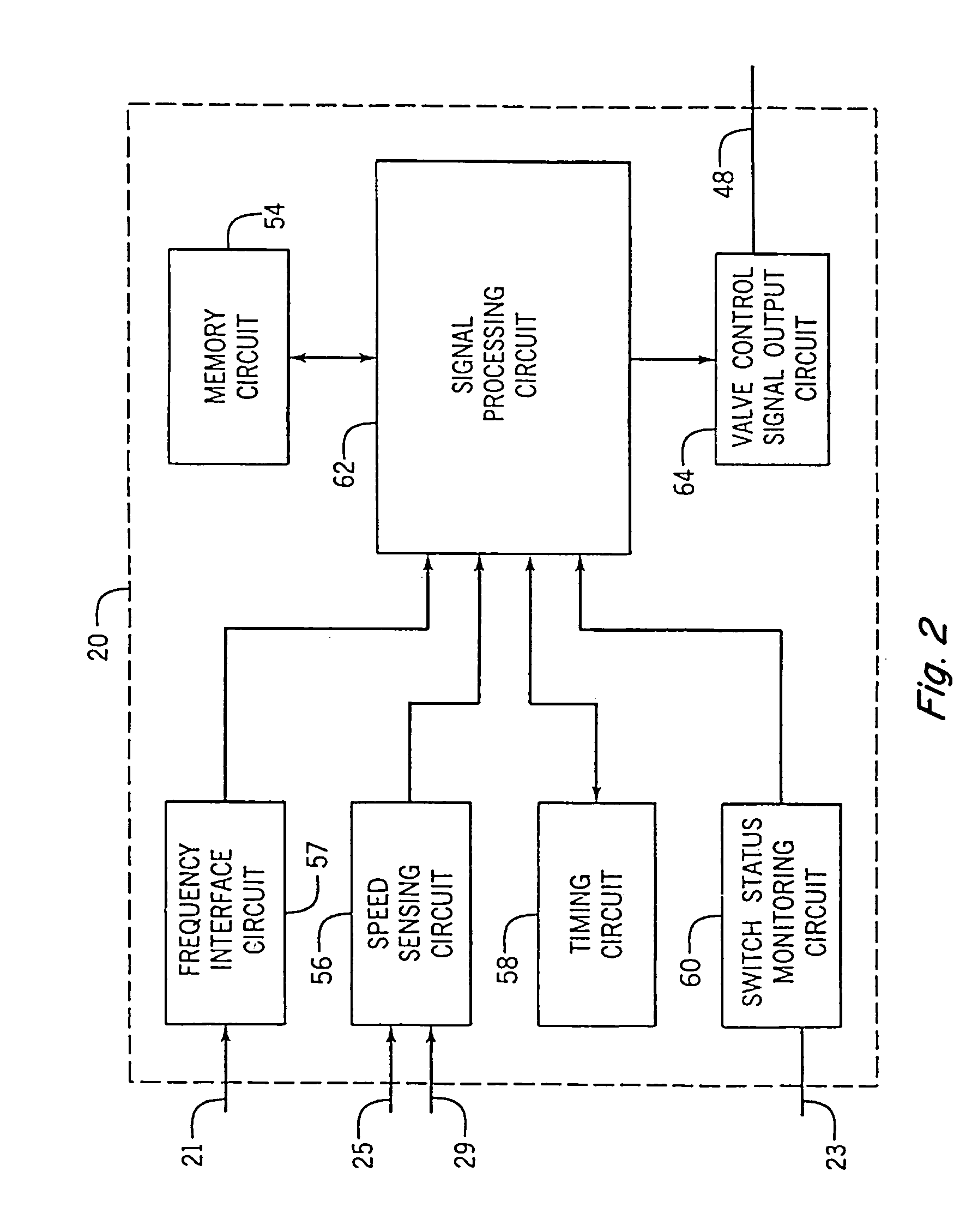

Power take-off control system

ActiveUS7234367B2Precious timeLong modulationDigital data processing detailsGearingControl systemControl signal

A control system and method for detecting variable load types and controlling the operation of a PTO clutch to effect engagement of the clutch with variable loads, and especially to more optimally effect the engagement of a clutch with a heavy load is disclosed. The control system includes a controller that receives input and output clutch shaft speed signals and generates control signals to control the pressure applied by the clutch. When heavier loads are applied to the PTO shaft, during the time when control signals are being generated before detection of initial movement of the output shaft, the controller generates one or more shock signals of short duration to cause momentary applications of significantly greater pressure to the clutch in order to break loose the applied load. Based upon the time of detection of initial movement by the output shaft, load categorization can be made, and control signals that are thereafter generated before lockup may be dependent, in part, upon the determined load categorization.

Owner:BLUE LEAF I P INC

Magnetic reading head with first and second element units each including a ferromagnetic layer and each with a different spin-polarization

InactiveUS7969692B2Small sizeImprove the immunityNanomagnetismMagnetic measurementsSpin polarizationElectrical current

A magnetic head includes a pair of ferromagnetic electrodes, namely, a first ferromagnetic electrode layer which is in contact with a portion of a first electrode layer with a first insulating barrier layer interposed in between; and a second ferromagnetic electrode layer which is in contact with another portion of the first electrode layer with a second insulating barrier layer interposed in between. The first electrode layer and the first ferromagnetic layer collectively constitute part of a current-supplying circuit. Moreover, the first electrode layer and the second ferromagnetic layer which are in contact with the first electrode layer with the second insulating barrier layer interposed in between in a region where the two layers are not in contact with the first insulating barrier layer, collectively constitute part of a voltage-measurement circuit. Spin-polarization at the interface in an intersecting region of the second ferromagnetic layer and the second insulating barrier layer, is greater than spin-polarization at the interface in an intersecting region of the first ferromagnetic layer and the first insulating barrier layer.

Owner:HITACHI LTD

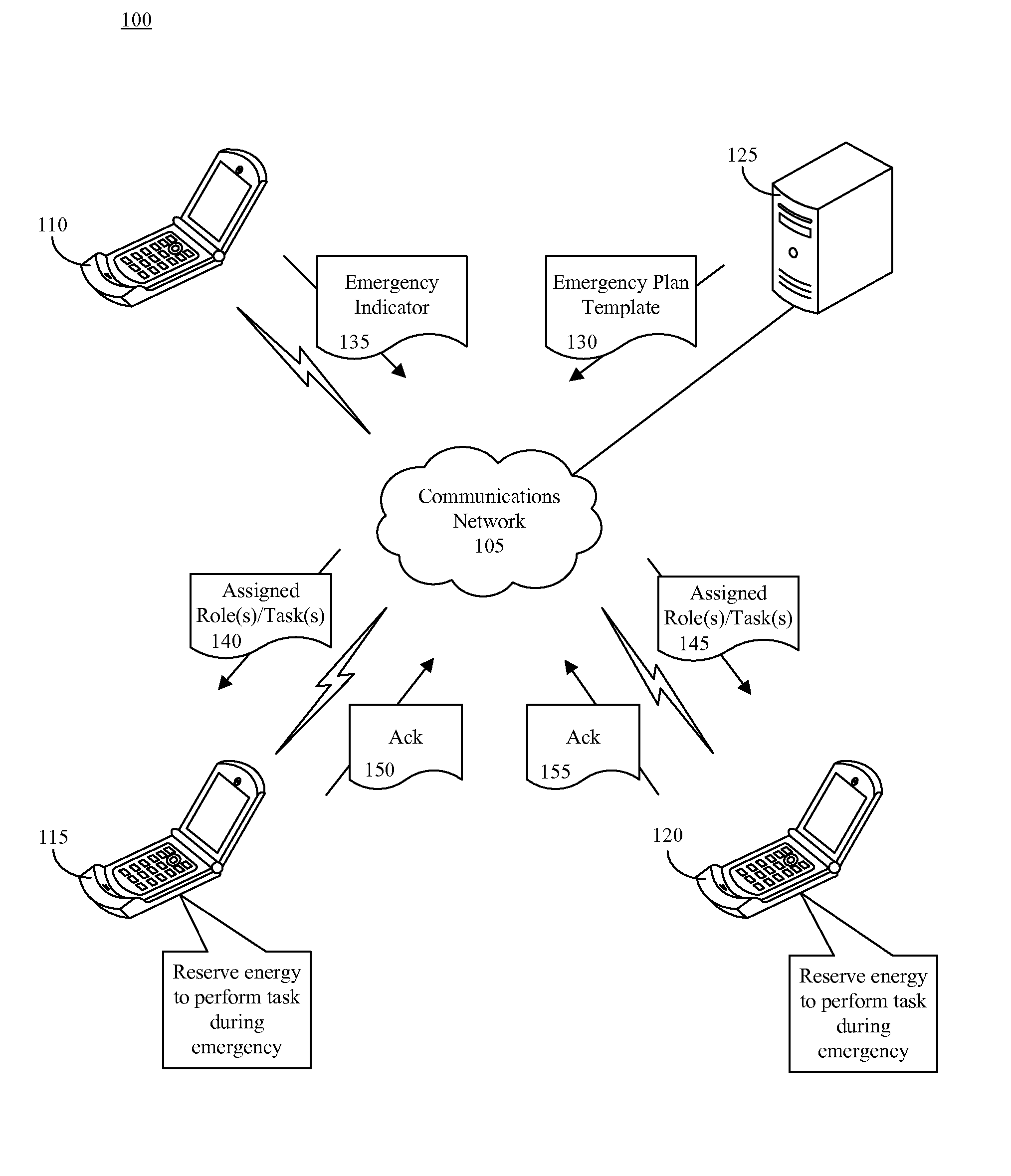

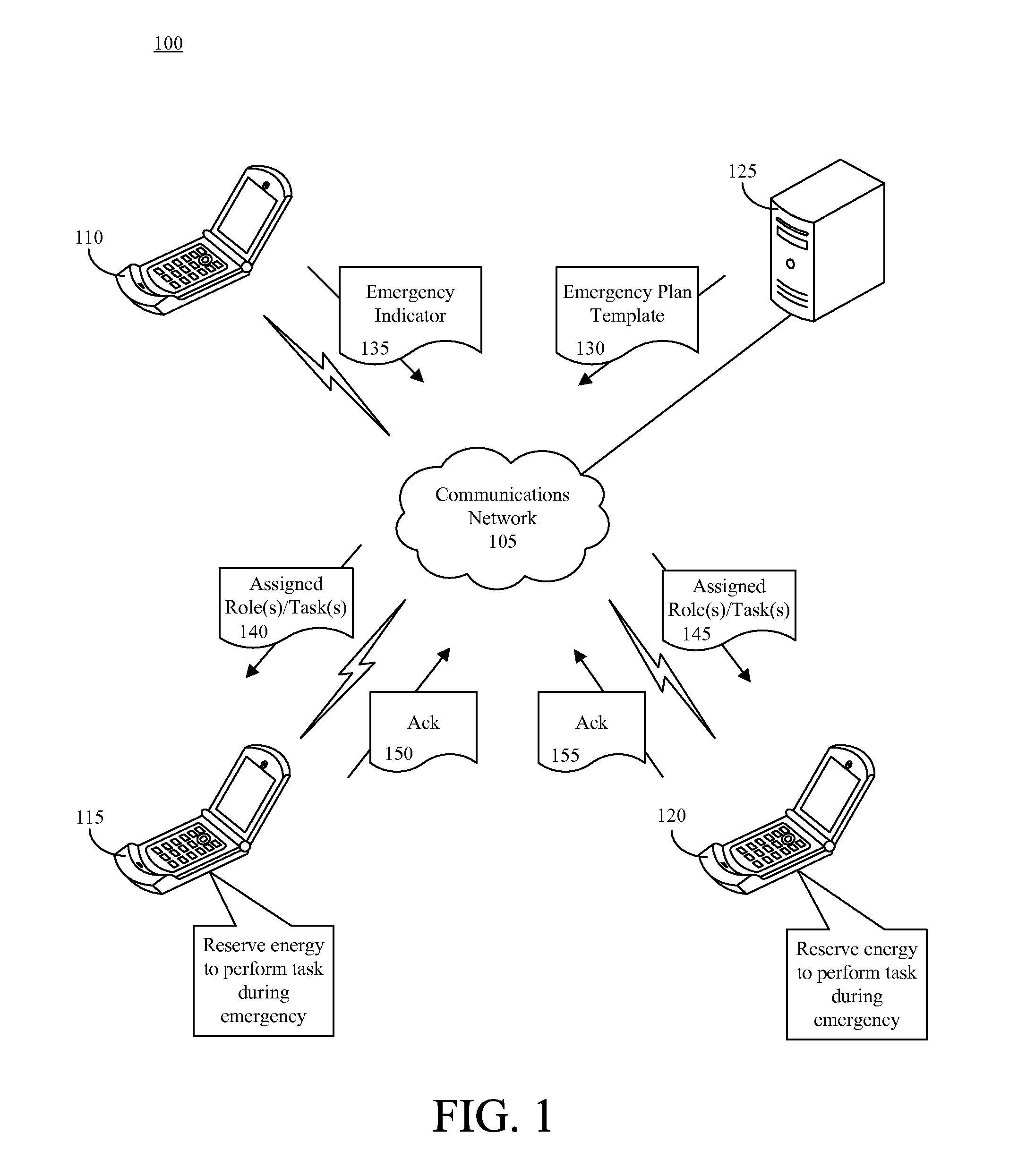

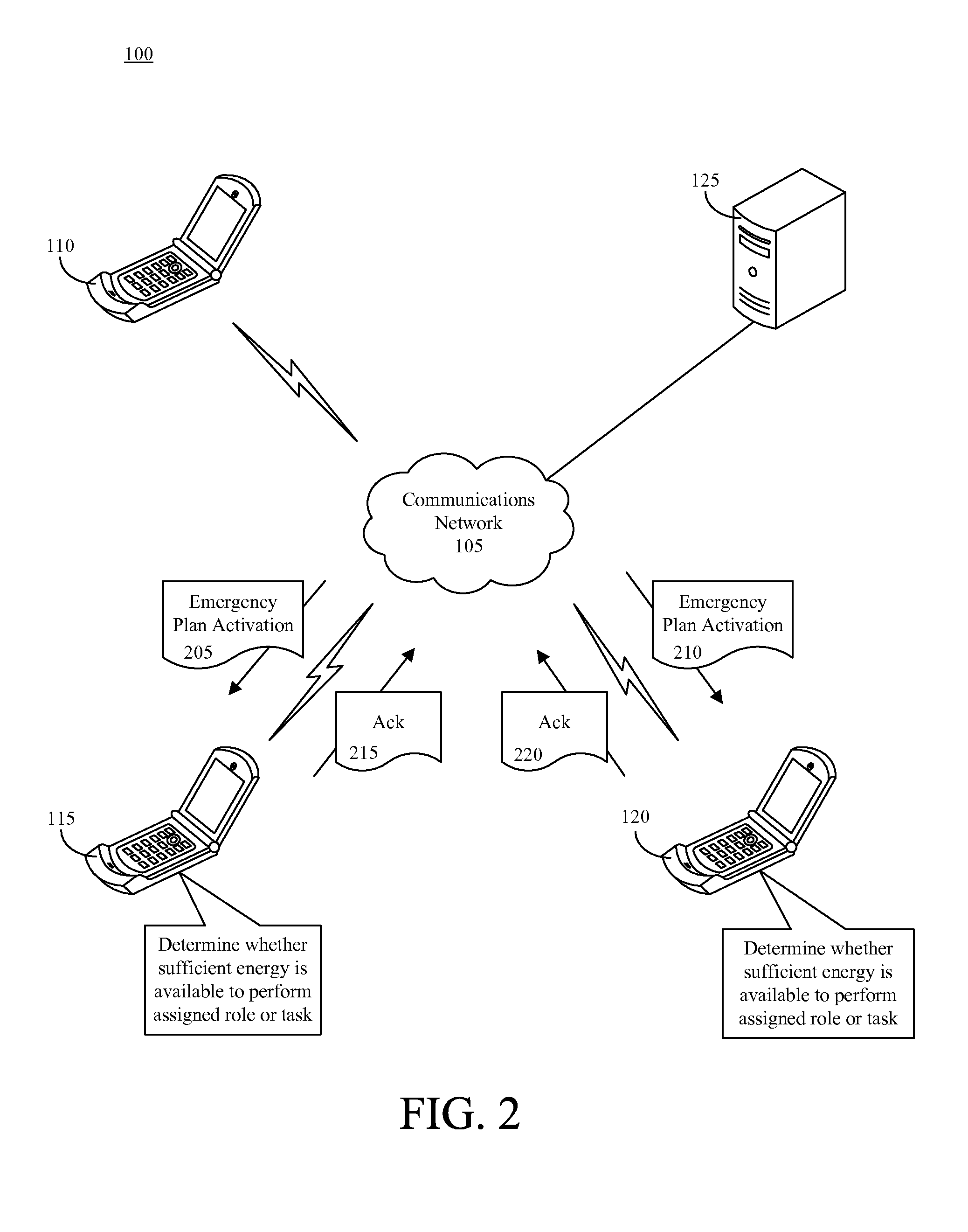

Emergency plan battery energy reservation

InactiveUS20080102903A1Lower energy levelPower managementEnergy efficient ICTEmergency planEngineering

A method (500) for reserving energy resources on a communication device (115, 120, 300). The method can include receiving an emergency indicator (135) associated with an emergency plan. Based on the emergency indicator, an amount of energy to reserve on a communication device can be selected. The selected amount of energy then can be reserved on the communication device. Receiving the emergency indicator can include receiving an indicator (140, 145) of an assigned role or task. Receiving the emergency indicator also can include receiving an indictor of the energy to be reserved. Selecting the amount of energy to reserve can include selecting an amount of energy associated with the role or task. In response to receiving the emergency indicator, an acknowledgement (150, 155) of whether an assignment of the role or task is accepted can be communicated.

Owner:MOTOROLA INC

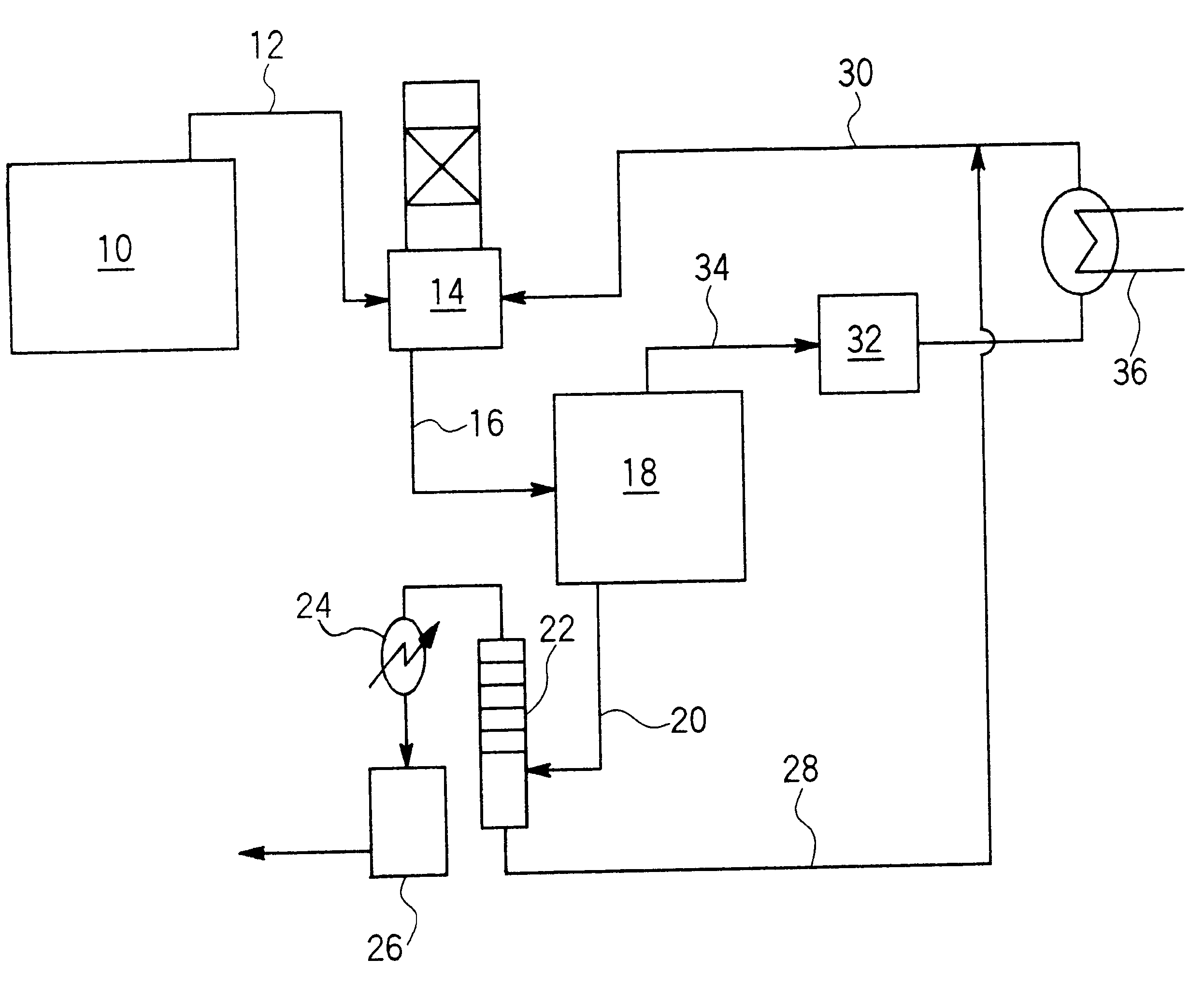

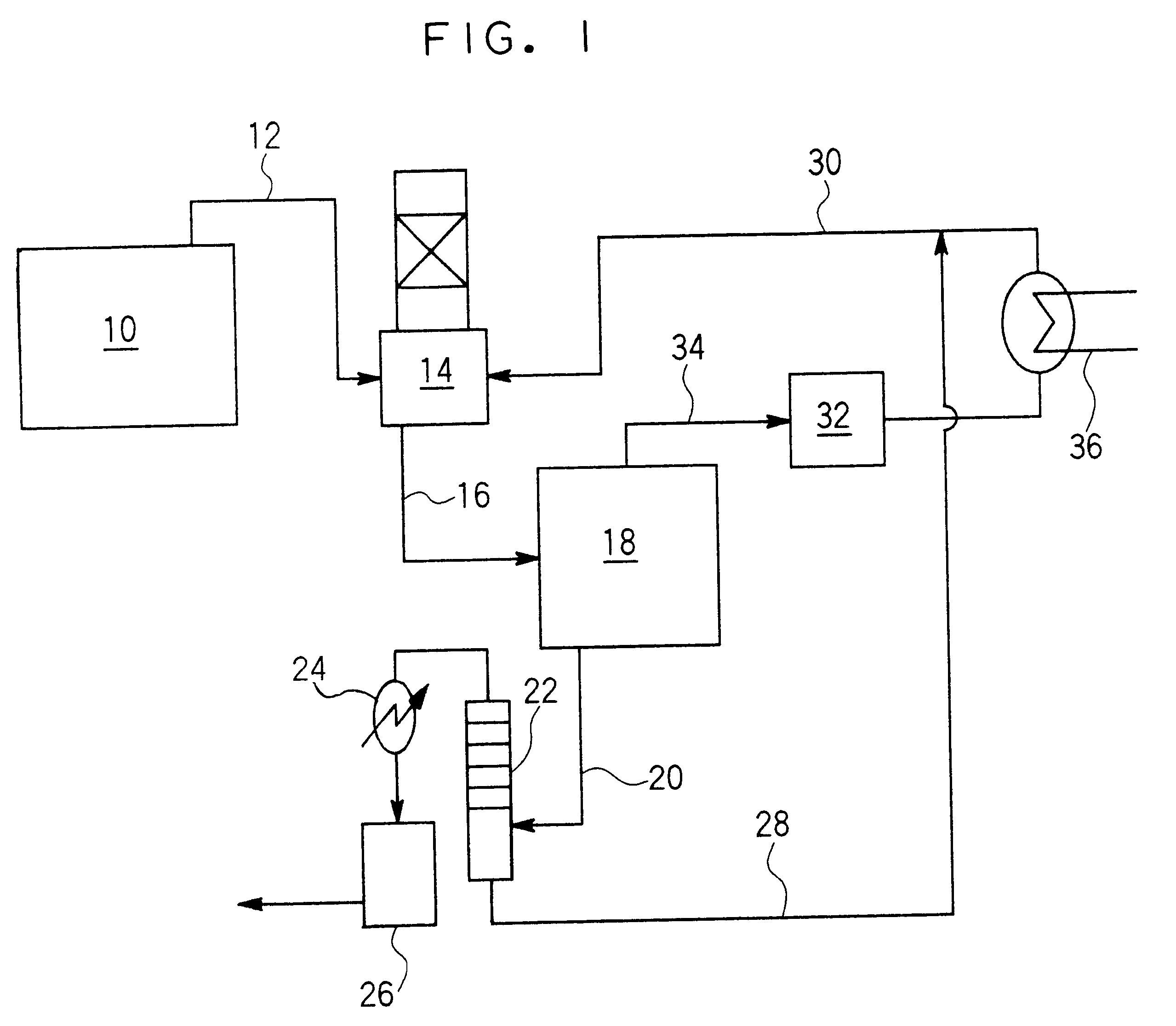

Exhaust gas recovery method and apparatus

InactiveUS6475266B2Lower energy levelIncrease concentrationSolidificationGas treatmentHigh concentrationRecovery method

An exhaust gas recovery method and apparatus including: a first process in which volatile organic compound gas in exhaust gas from a exhaust gas discharging source is absorbed into water by a scrubber; a second process in which water including the volatile organic compound, which is obtained in the first process, is frozen and the volatile organic compound herein concentrated such that the water including the volatile organic compound is separated into water including a high concentration of the volatile organic compound, level of concentration being higher than that of the water including the volatile organic compound which is obtained in the first process, and ice; a third process in which cold of the ice obtained in the second process is used; and a fourth process in which the water including a high concentration of the volatile organic compound, which is obtained in the second process, is reused, is provided.

Owner:FUJIFILM HLDG CORP +1

Acoustic add-on device for biofilm prevention in urinary catheter

ActiveUS7829029B2Disrupts biofilm formationInhibits biofilm formationUltrasonic/sonic/infrasonic diagnosticsSurgeryUrinary catheterMedicine

A urinary catheter clip-on device applies surface acoustic waves of Rayleigh-Lamb and / or Love type to a urinary catheter for preventing biofilms on the catheter surfaces. The bacteria is forced to move relative to the vibrating catheter surface. The amplitudes of bacteria vibrations are in nanometer range. The relative motion of bacteria results in bacteria quorum sensing, and disrupts the bacteria attachment process. The method is preventive as surface acoustic waves create low acoustic energy and bacteria is not killed.

Owner:NANOVIBRONIX INC CO P M G MEDICA LTD

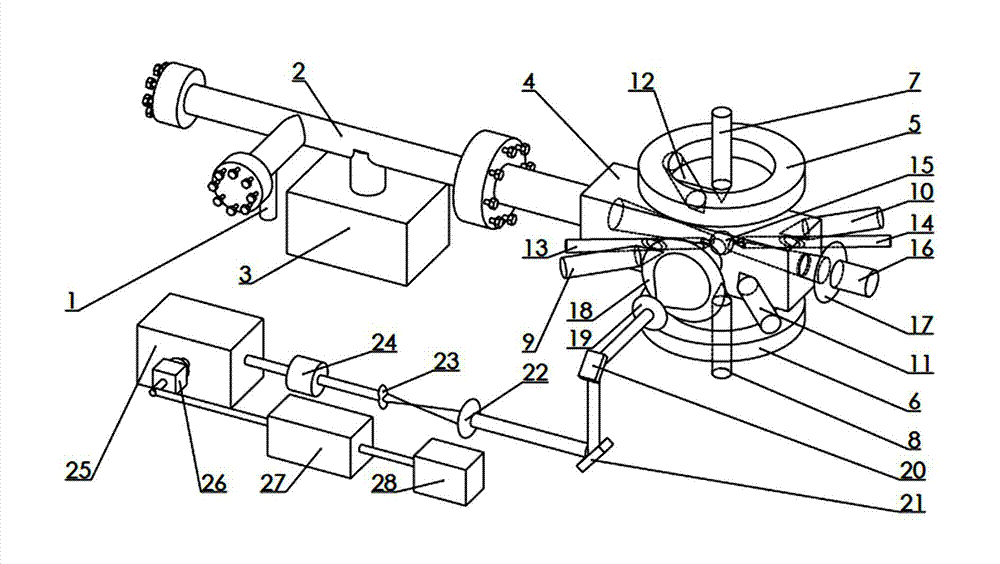

Method and device for directly producing and measuring ultra-cool ground state double-atom cesium molecule

InactiveCN102735672AHigh yieldLow temperature requirementFluorescence/phosphorescenceNon-linear opticsExcited stateFluorescence

The invention relates to an ultra-cool molecule preparation and measurement technique, and particularly relates to a method and a device for directly producing and measuring an ultra-cool ground state double-atom cesium molecule, solving the problems that the existing ultra-cool ground state double-atom cesium molecule preparation and measurement technique is high in the temperature requirement of the ultra-cool cesium molecule, the formed ultra-cool ground state double-atom cesium molecule is easily decomposed to two atoms, the yield of the ultra-cool ground state double-atom cesium molecule is low, the formed ultra-cool ground state double-atom cesium molecule is damaged during the measurement and the technological difficulty is large. The method for directly producing and measuring the ultra-cool ground state double-atom cesium molecule comprises the following steps: a. cooling cesium atoms to form ultra-cool cesium atoms; b. forming a long-range excited state double-atom cesium molecule from the ultra-cool cesium atoms under the action of photo-association lasers; c. tunneling the long-range excited state double-atom cesium molecule to form a short-range excited state double-atom cesium molecule; and d. collecting fluorescence with a lens. The method and the device provided by the invention are used for preparing and measuring the ultra-cool ground state molecules.

Owner:SHANXI UNIV

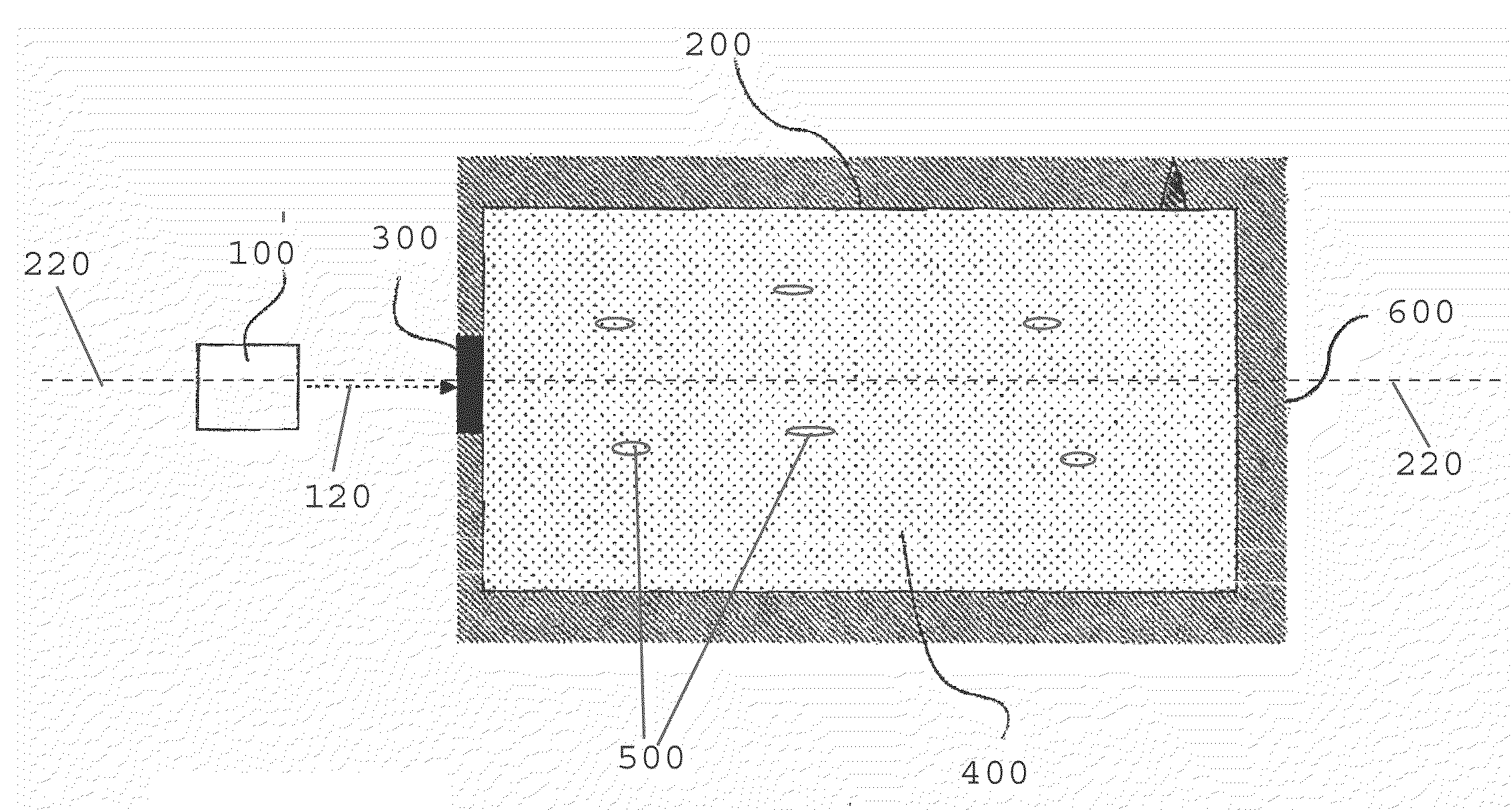

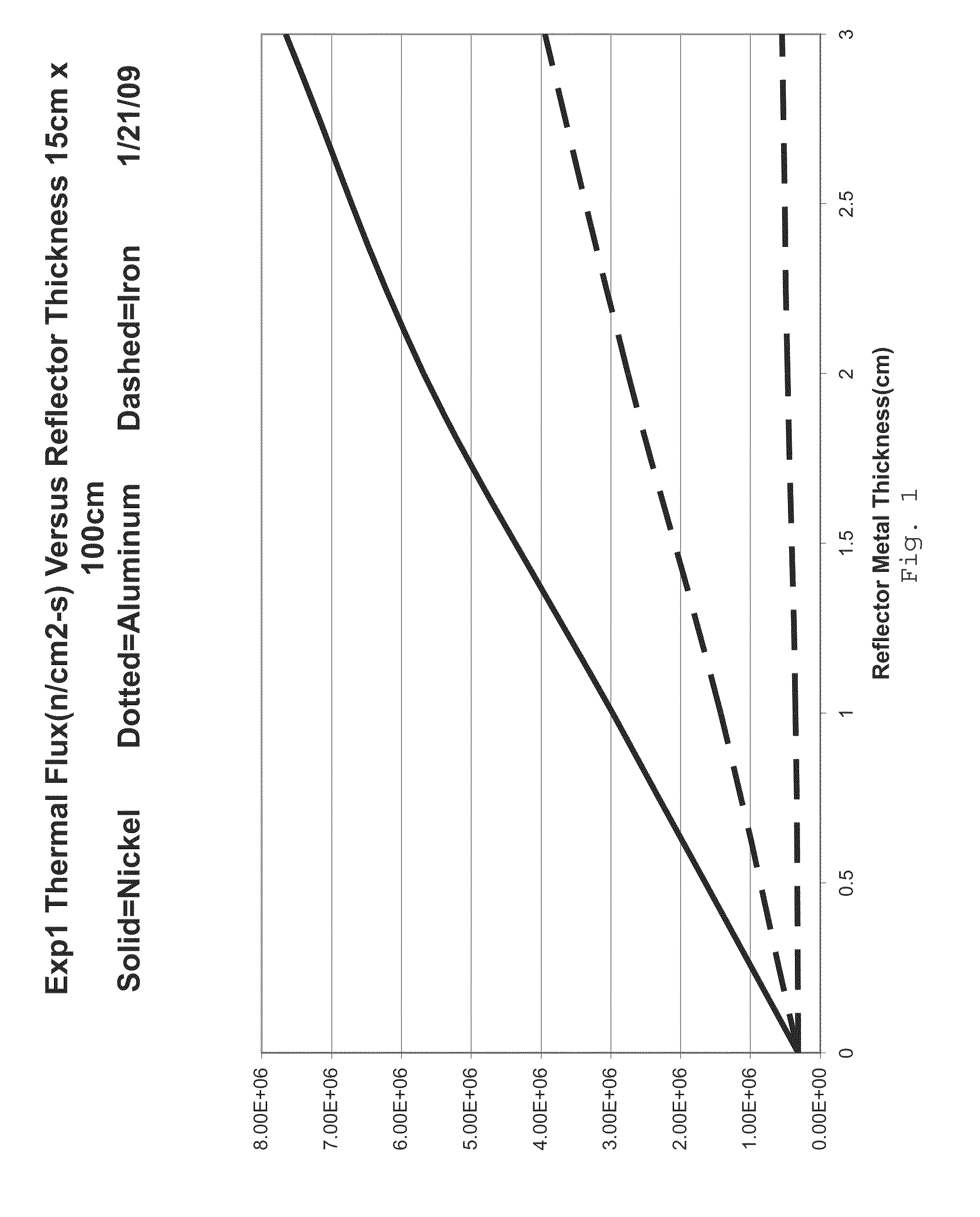

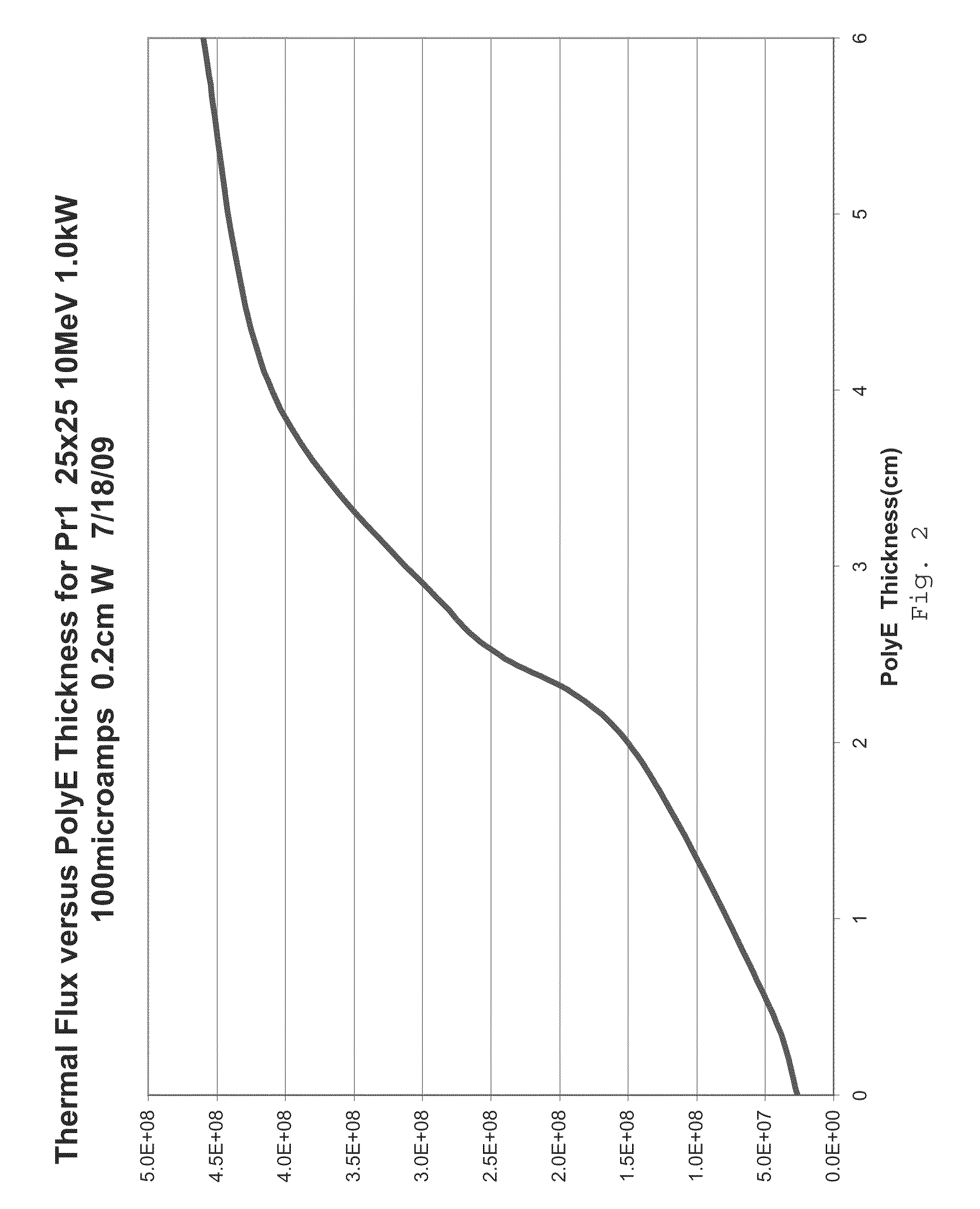

Very large enhancements of thermal neutron fluxes resulting in a very large enhancement of the production of molybdenum-99

InactiveUS20110129049A1Enhancement of the neutron fluxEnhanced neutron fluxConversion outside reactor/acceleratorsNeutron sourcesMetallic NickelThermal neutron flux

A large enhancement of neutron flux is realized when a primary target of D2O and H2O is contained in a vessel, is irradiated by an electron beam incident on a gamma converter and where the vessel is enclosed within a neutron reflector material including Nickel and Polyethylene. A very large enhancement of neutron flux is realized when a secondary target of LEU is mixed with the primary target resulting in a very large enhanced production of Molybdenum-99.

Owner:SCHENTER ROBERT E

Bandgap engineered charge trapping memory in two-transistor nor architecture

ActiveUS8861273B2Lower energy levelHigh energySolid-state devicesRead-only memoriesTrappingEngineering

A 2T cell NOR architecture based on the use of BE-SONOS for embedded memory includes memory cells having respective access transistors having access gates and memory transistors having memory gates arranged in series between the corresponding bit lines and one of the plural reference lines. A memory transistor in a memory cell comprises a semiconductor body including a channel having a channel surface and a charge storing dielectric stack between the memory gate and the channel surface. The dielectric stack comprises a bandgap engineered, tunneling dielectric layer contacting one of the gate (for gate injection tunneling) and the channel surface (for channel injection tunneling). The dielectric stack of the memory cell also includes a charge trapping dielectric layer on the tunneling dielectric layer and a blocking dielectric layer.

Owner:MACRONIX INT CO LTD

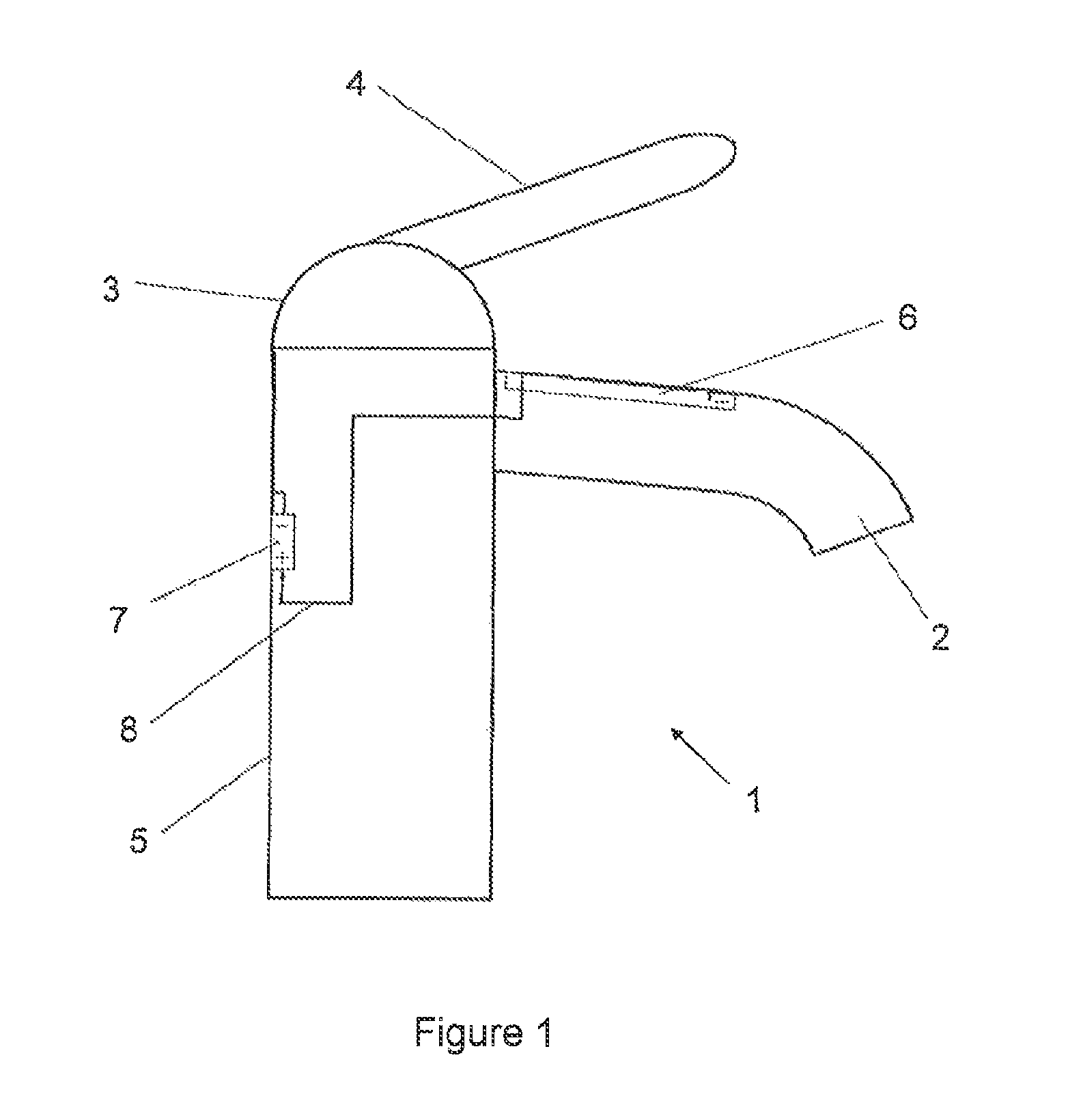

Disinfecting device having a power supply and a fluid outlet

ActiveUS8421032B2Reliable disinfectionSimple liquidGeneral water supply conservationScattering properties measurementsLiquid temperatureElectrical battery

A disinfecting device having an outlet (2, 42) for a flowing liquid, particularly water, and a UV irradiator (6), preferably a UV-C radiator (16) or one or more UV-C emitting light emitting diodes, and an electric power supply (7), such as a battery, turbine driven generator or a solar module, for supplying the UV irradiator with up to 25 V alternating voltage or up to 60 V direct voltage. The outlet may be constructed with a reflective interior, and a controller for regulating liquid temperature, liquid pressure and / or liquid flow rate and / or an aerator (14) for introducing air into the flowing liquid may be integrated into the device, which may be a plumbing fixture such as a water spigot.

Owner:KSB AG

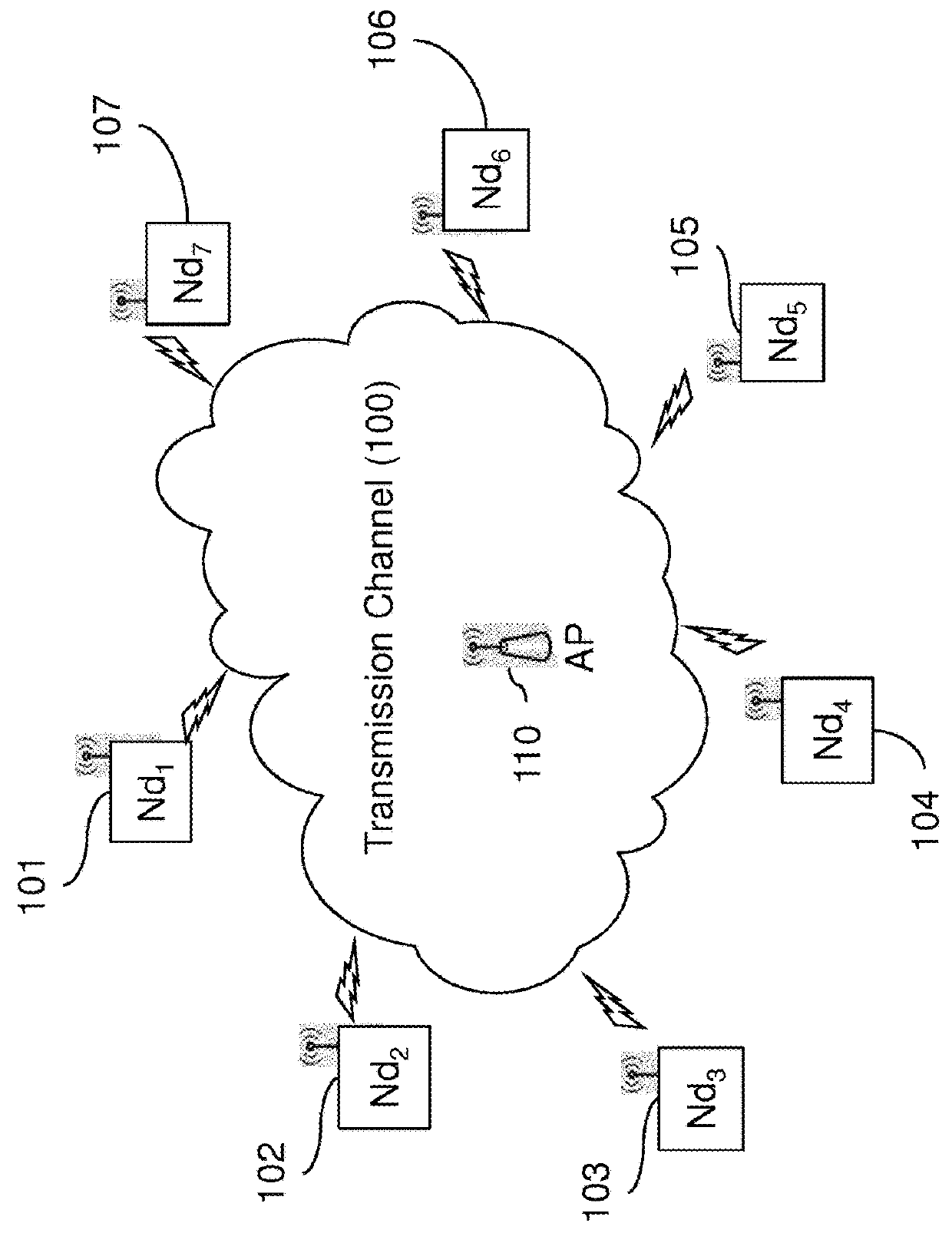

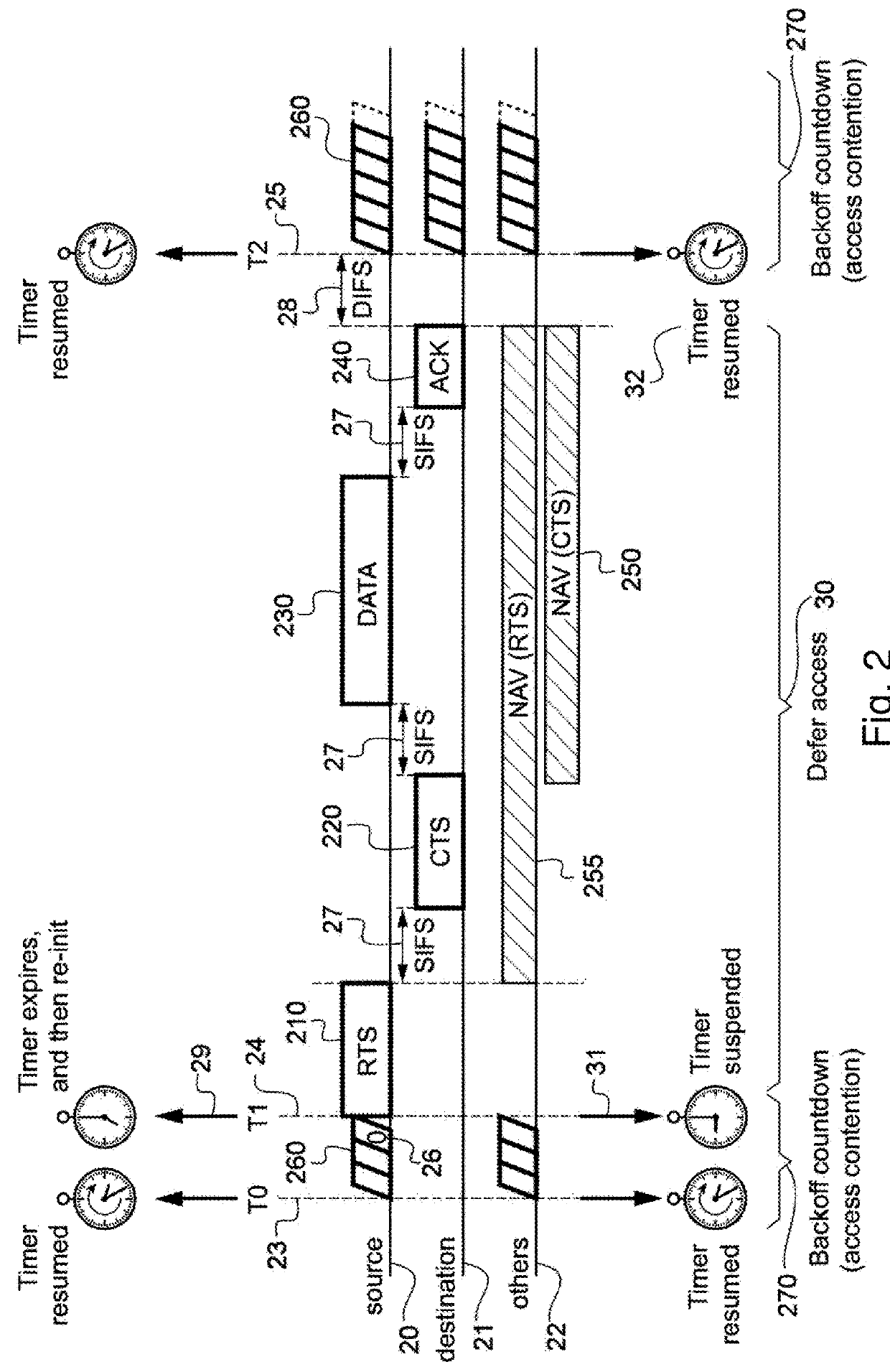

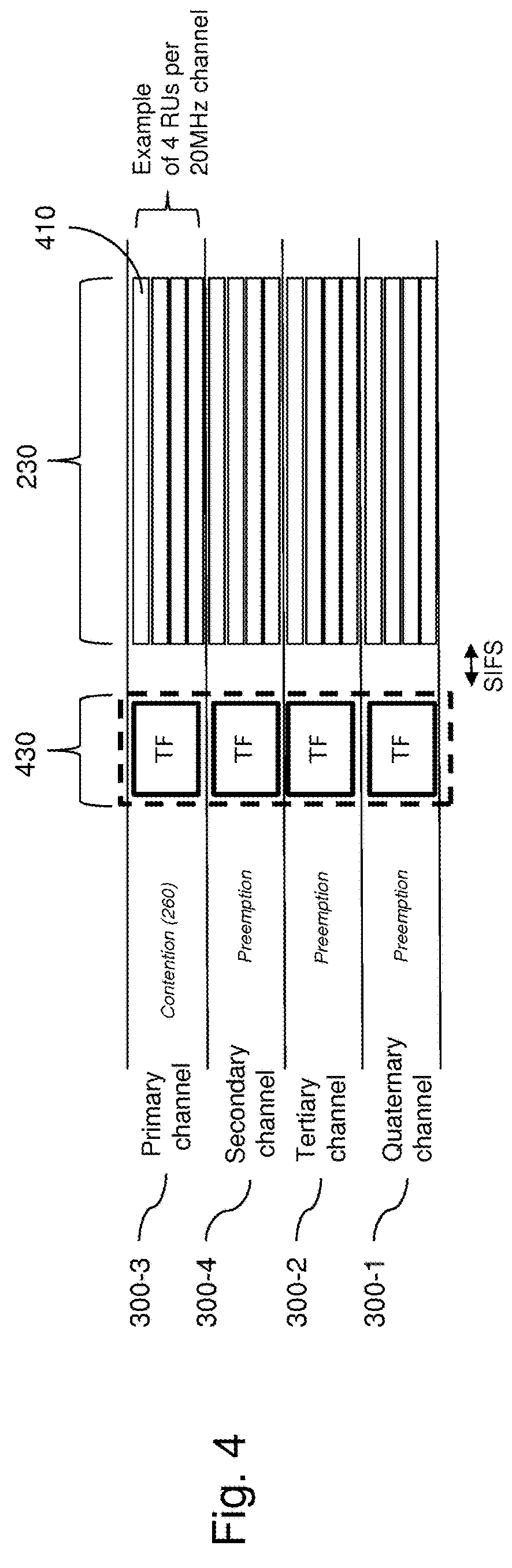

Emission of a signal in unused resource units to increase energy detection of an 802.11 channel

ActiveUS20180184454A1Optimization mechanismLower energy levelNetwork topologiesHigh level techniquesSignal onOverall Energy Level

In an 802.11ax network with an access point, a trigger frame offers scheduled and random resource units to nodes for data uplink communication to the access point. To avoid the overall energy level seen by legacy nodes for a communication channel to drop below a detection threshold, the invention provides two tools. First, the scheduled and random resource units may be interleaved over communication channels. Second, unused resource units may be detected, and a node or the access point may send a padding signal on them to increase the overall energy level. The latter may be evaluated during a monitoring period before deciding to emit the signal. As the overall energy level seen by legacy nodes is increased, the risk that such legacy nodes do not detect activity on a 20 MHz channel having only a subpart of its RUs used is reduced. And risks of collisions are consequently reduced.

Owner:CANON KK

Mixed pellet feed for over-sized fattening pigs and preparation method thereof

InactiveCN104489371AGuaranteed lean meatEmission reductionAnimal feeding stuffBiotechnologyAnimal science

The invention relates to mixed pellet feed for over-sized fattening pigs and a preparation method thereof, belonging to the technical field of pig feed. The mixed pellet feed is prepared from the following components in parts by weight: 500-600 parts of corn, 30-60 parts of bean pulp, 150-200 parts of corn DDGS (distillers dried grains with soluble), 150-200 parts of rice bran, 100-150 parts of middlings bran, 10-13 parts of mountain flour, 2.5-3.5 parts of salt, 0.5-1 part of choline, 3-4 parts of lysine hydrochloride, 1-1.5 parts of threonine, 0.2-0.3 part of an antioxidant, 0.4-1.5 parts of a mildew preventive, 10-20 parts of bentonite, 1-2 parts of calcium hydrogen phosphate, 8-10 parts of a vitamin premix and 8-10 parts of a trace element premix. On the premise of guaranteeing safety, the mixed pellet feed can be used for improving the production input and output efficiency, and achieving the purposes of improving feed conversion, pig meat quality and slaughter performance to meet the market needs.

Owner:TONGWEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com