Patents

Literature

184 results about "Growth control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

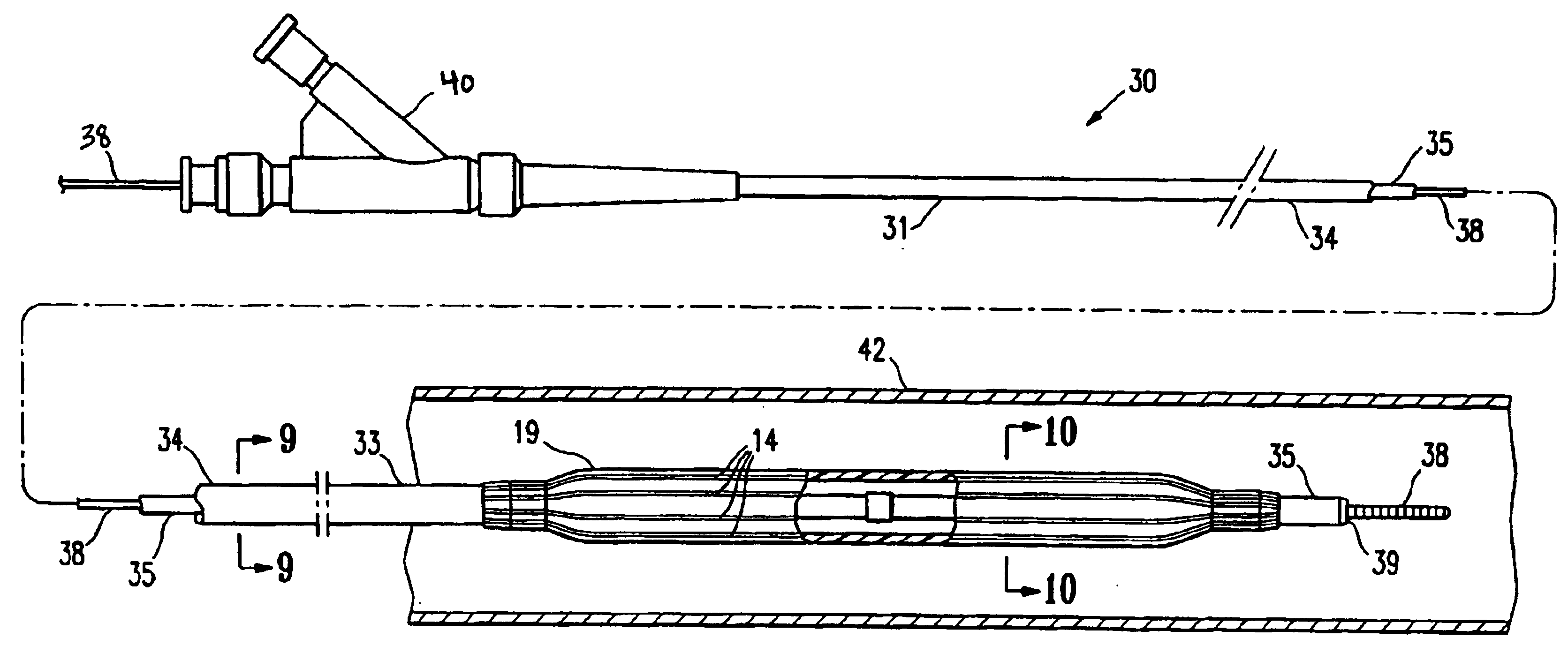

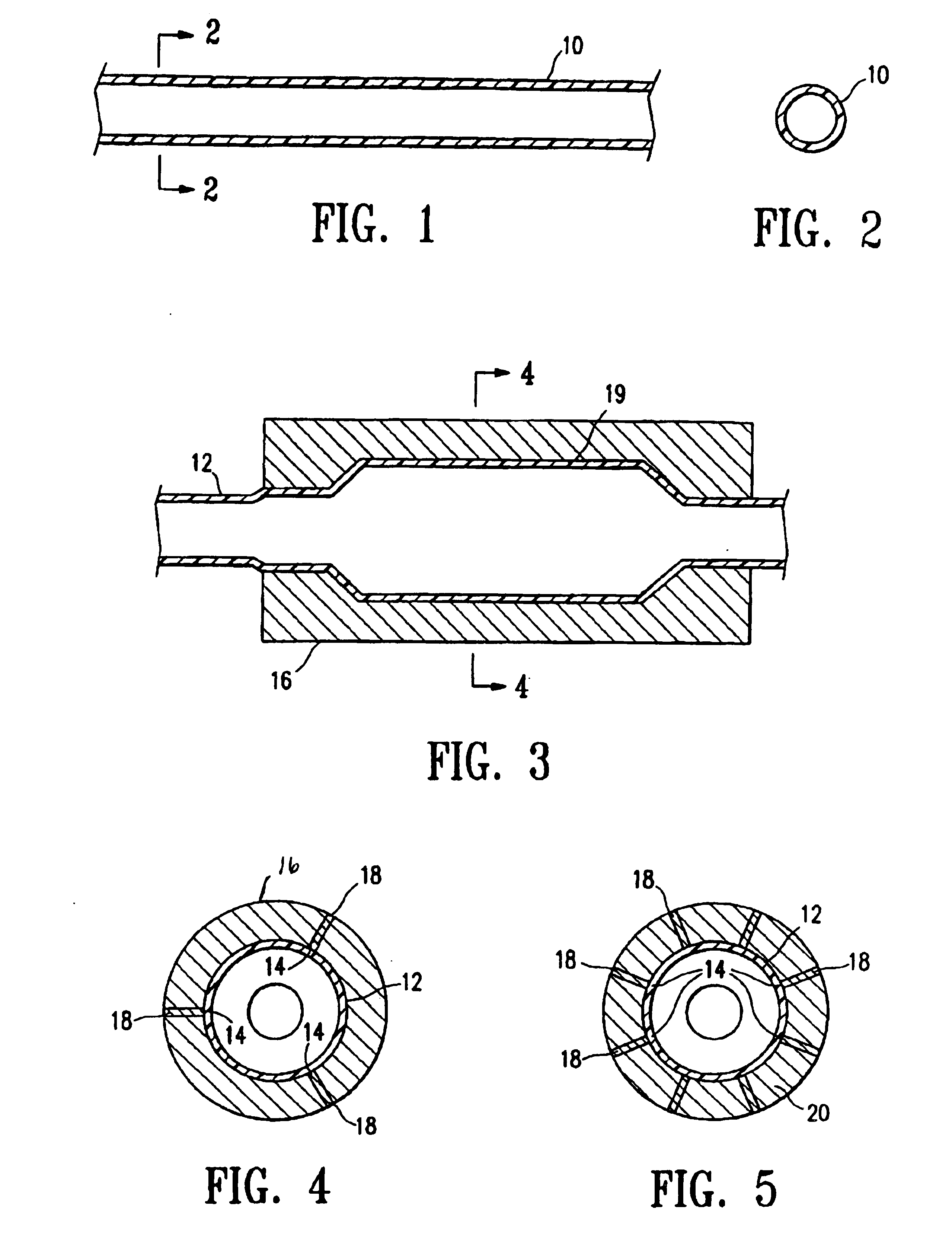

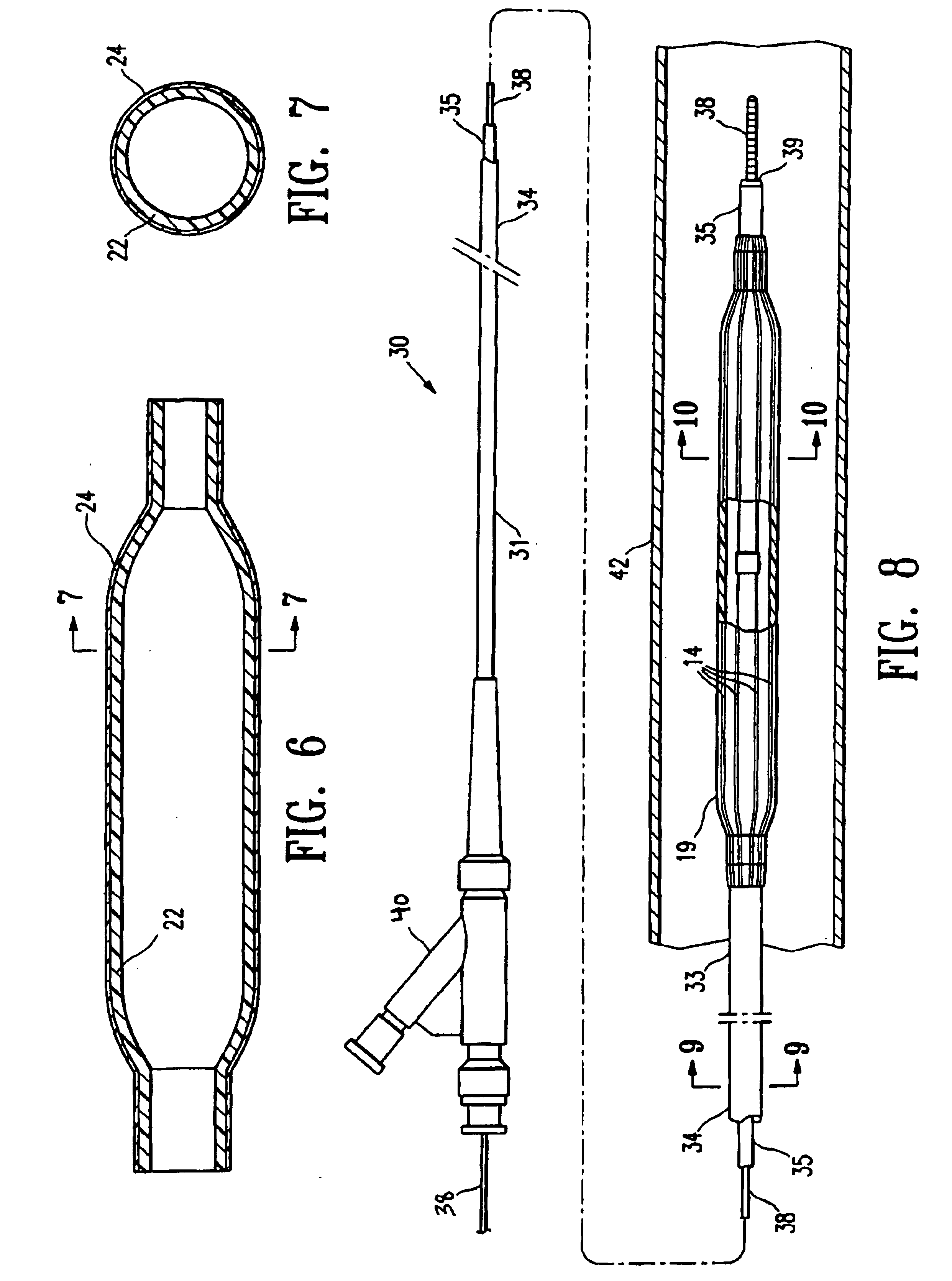

Dimensionally stable and growth controlled inflatable member for a catheter

A dimensionally stable and growth controlled inflatable member formed by adding a multifunctional agent to a soft polymer to form a compound, extruding an inflatable member from the compound, and crosslinking the compound. The inflatable member is configured to be formed-in-place with a body lumen. Preferably, the inflatable member is blown to a working diameter prior to use and then heated to the glass transition temperature of the polymer to shrink the diameter of the blown inflatable member back to about the nominal diameter of the tubing. In another embodiment, the invention is a dimensionally stable and growth controlled inflatable member comprising longitudinal zones of crosslinked material symmetrically spaced about the circumference of the inflatable member and a uniform working diameter. Preferably, there are three or more longitudinal zones that run the working length of the inflatable member. The selectively irradiated inflatable members are formed in a mold having symmetrically spaced longitudinal windows.

Owner:ABBOTT CARDIOVASCULAR

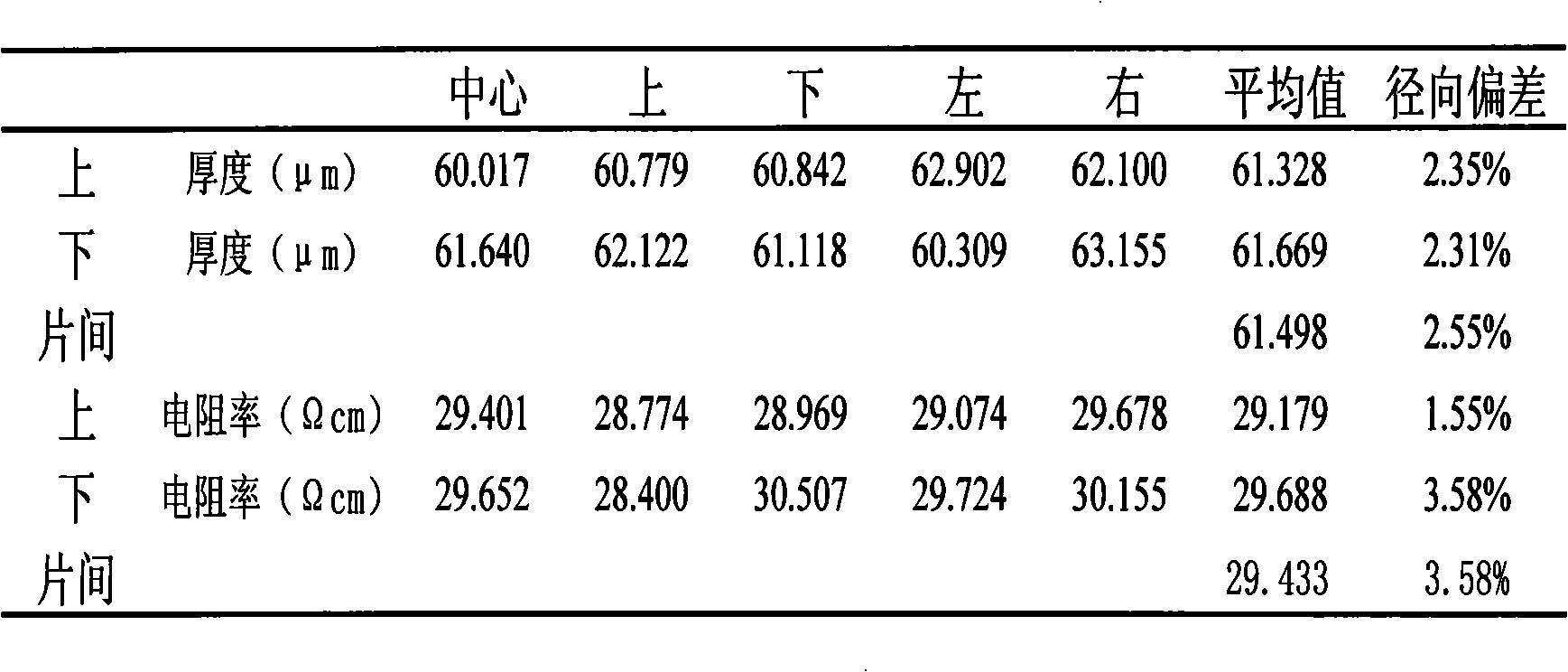

Method for manufacturing IGBT silicon epitaxial wafer

ActiveCN101256958AImprove uniformityGood repeatabilitySemiconductor/solid-state device manufacturingGrowth controlBoron

The present invention discloses a manufacturing method of IGBT silicon epitaxial wafer, the selecting P type of the heavily Boron-doped & 1t; 100 &g t; the polished piece, the electrical resistivity <= 0.02 Omega cm, the partial flatness <= 1.5 mm, the backing layer of oxide at side edge without the width <= 1mm; appropriate increasing polished time and improving the technique temperature, selecting appropriate HC1 flow quantity 8-10L at 1180 EDG C, polishing time 10 min, sweeping more than 10min by using high flow rate H2 after polishing; synthetic considering factors such as self-doping, crystal lattice quality, electric resistivity control and production efficiency, etc, selecting appropriate epitaxial process condition with double-layer, silicon source using ultra-pure trichlorosilane, first step developing temperature 1080-1100 EDG C, developing rate-controlling 0.8-1.0 Mu m, second step developing temperature 1120-1150 EDG C, developing rate-controlling 1.2-1.6 Mu m, the double-layer epitaxial growth controlled by different adulterate source accurately.

Owner:NANJING GUOSHENG ELECTRONICS

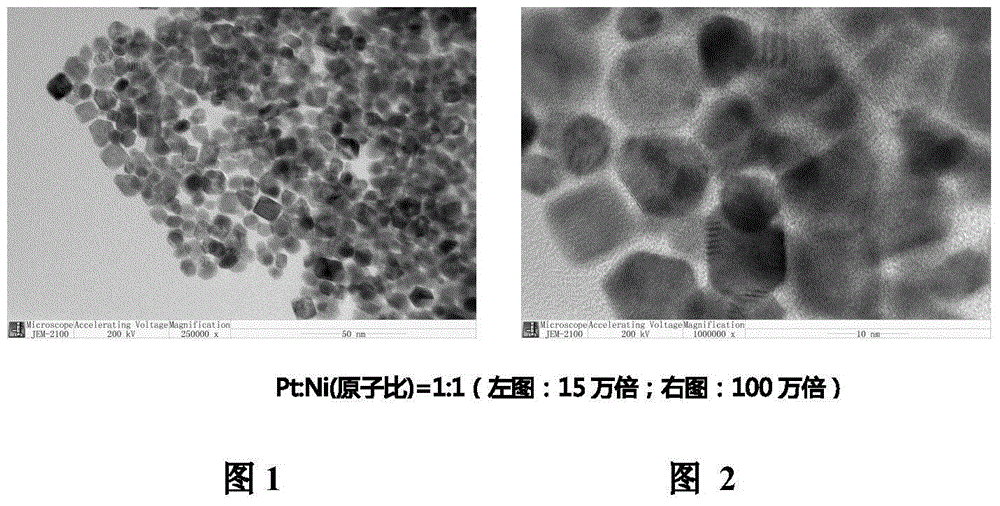

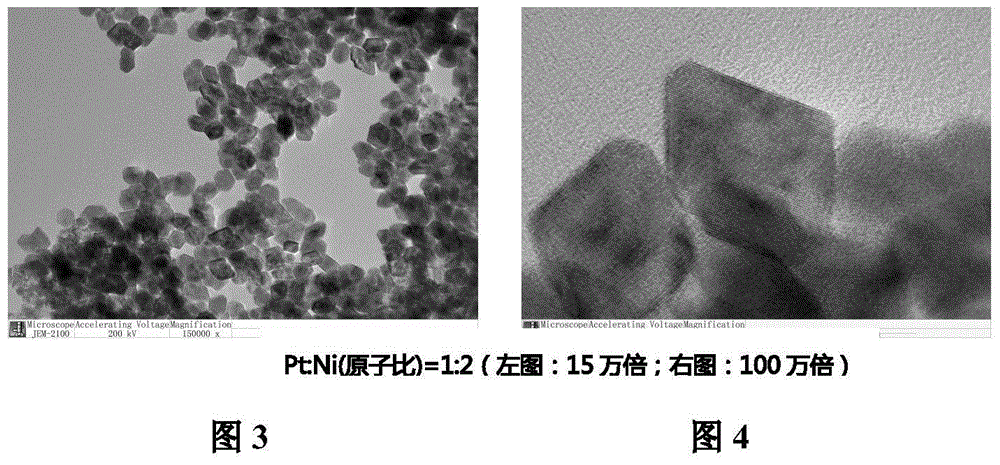

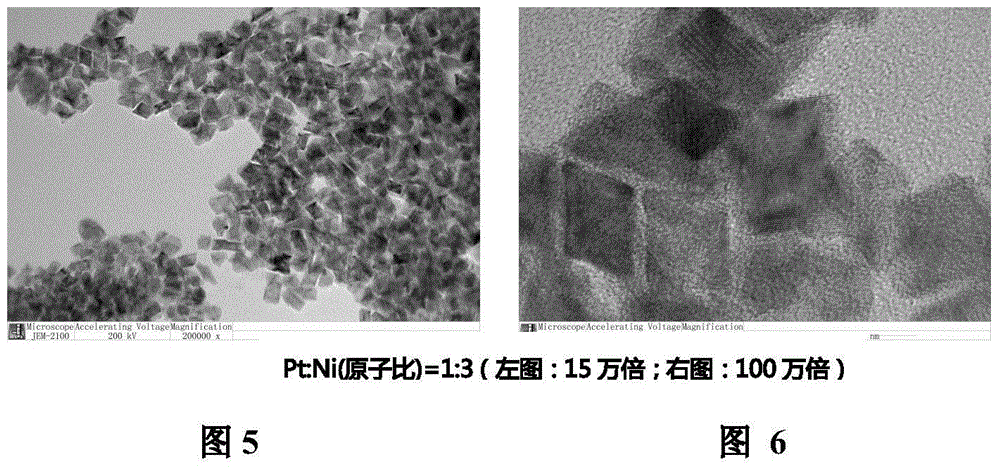

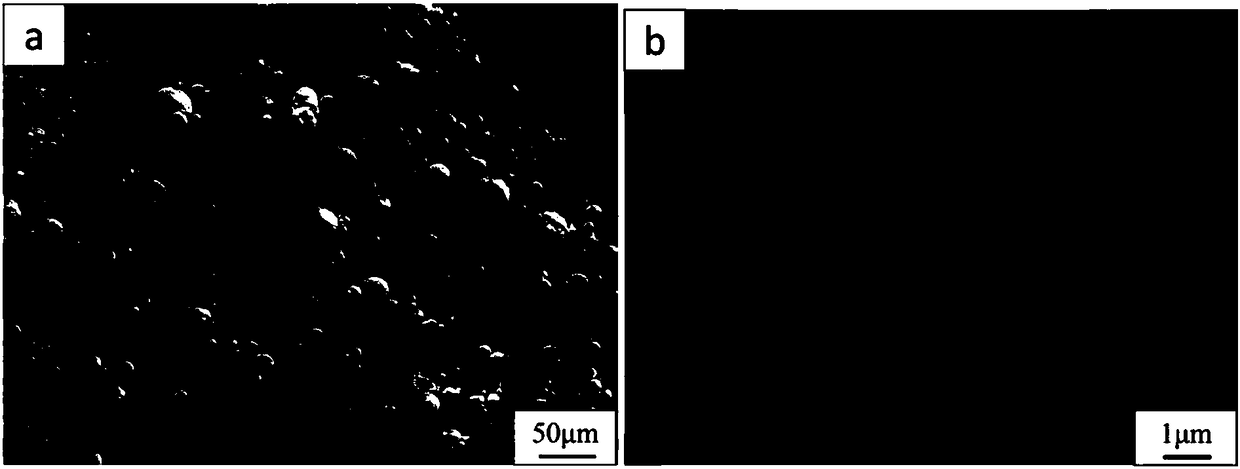

Method for preparing proton-exchange membrane fuel cell oxygen reduction catalyst based on PtNi (111) octahedral single crystal nanoparticles

InactiveCN104998658AHigh catalytic activity for oxygen reductionPt content decreasedCell electrodesMetal/metal-oxides/metal-hydroxide catalystsN dimethylformamideSingle crystal

Owner:昆明贵研催化剂有限责任公司

Pond-lake heavy-metal pesticide fertilizer pollutant solidifying removing agent and preparation method thereof

ActiveCN104478058APrevent infiltrationAbundant and cheap raw materialsWater/sewage treatment by ion-exchangeWater/sewage treatment using germicide/oligodynamic-processDisinfectantTotal nitrogen

A pond-lake heavy-metal pesticide fertilizer pollutant solidifying removing agent relates to the technical field of disinfectants, and is composed of the following raw materials: 450-600 parts of montmorillonite, 150-300 parts of silicate clinker, 80-150 parts of quicklime, 50-100 parts of modified starch, 10-30 parts of plaster, 3-6 parts of glucoside, 5-10 parts of alum, and 3-8 parts of calcium chloride. The beneficial effects comprise that the employed raw materials are abundant and cheap, the preparation technology is simple, the agent is applicable to pollution cleaning of large-scope water body of ponds, lakes and rivers, is capable of rapidly thoroughly eliminating organic harmful substances, chemical pesticides and harmful microbes and heavy metals in water body, has improving eliminating effect on total phosphorus and total nitrogen in eutrophic water, has growth-controlling effect on algae in water body, and has water-bottom anti-permeation effect and effect of preventing heavy metals from permeating and polluting water resource.

Owner:保定赛德丽自动化环保设备有限公司

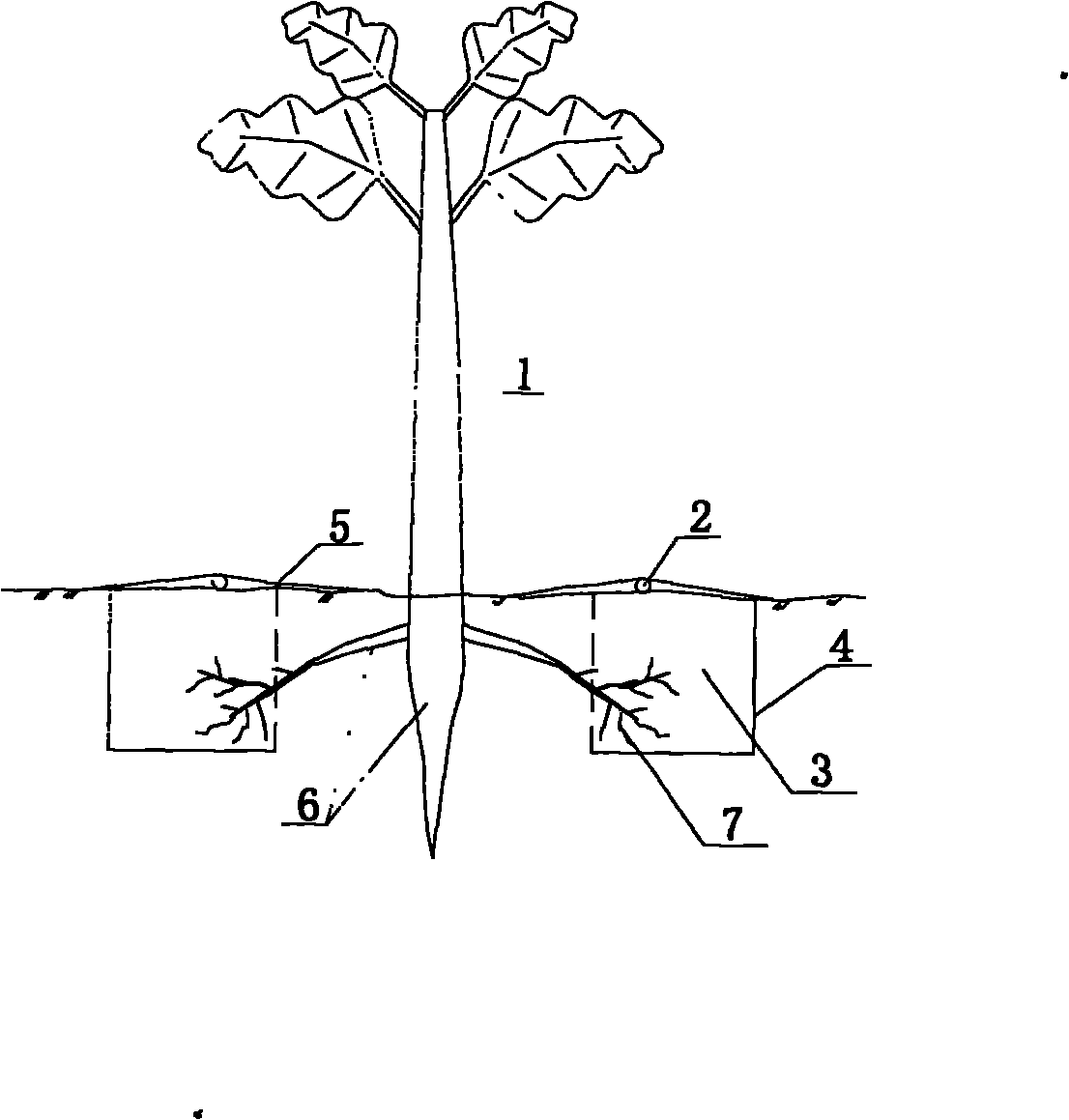

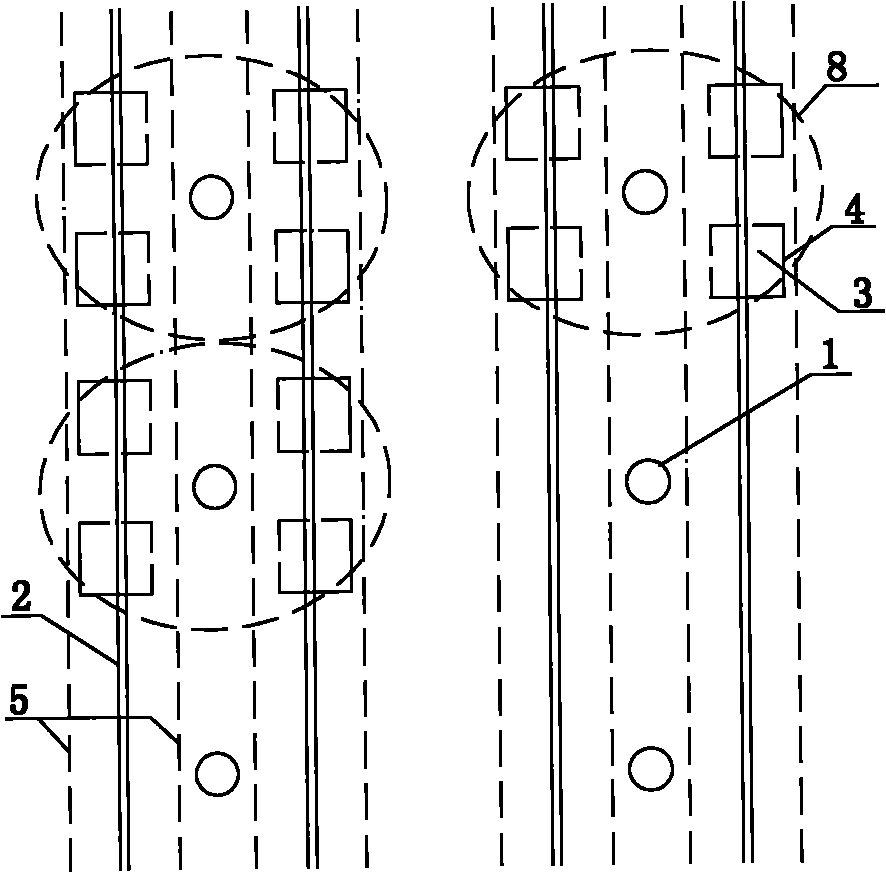

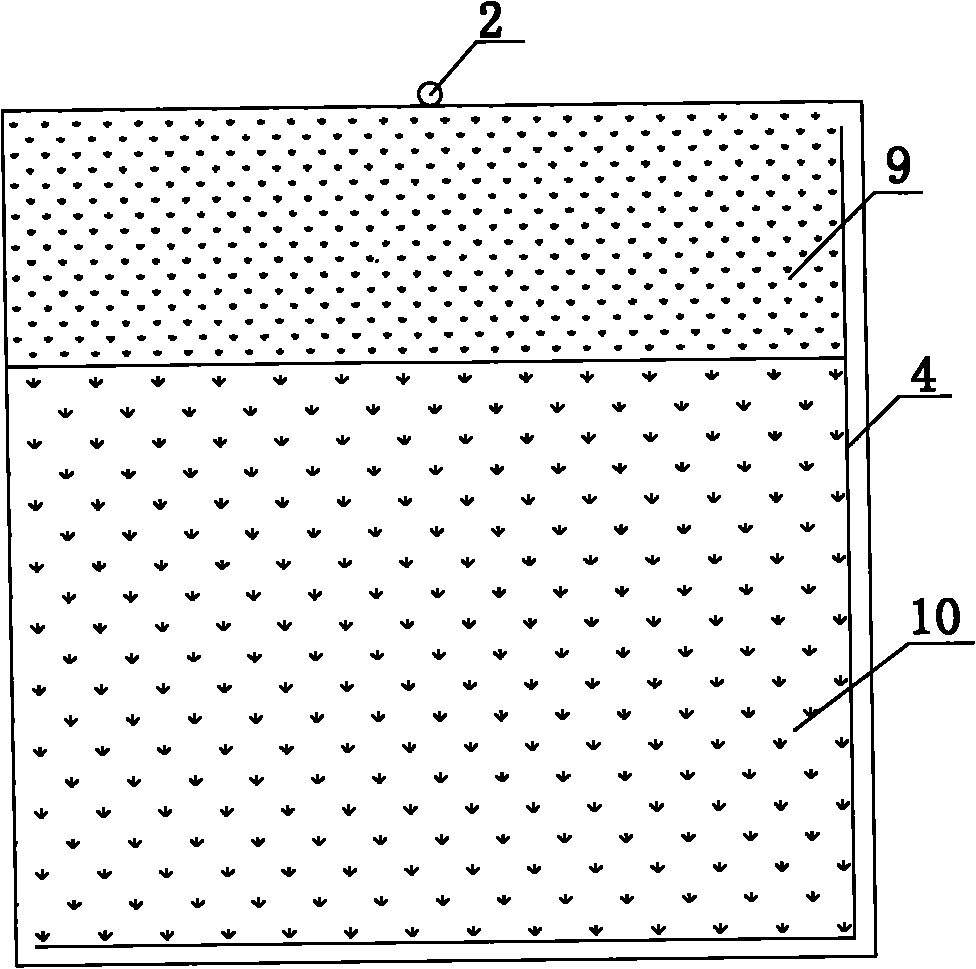

Drip irrigation under film of fruit tree and root field microenvironment regulation and controlling integrated method

InactiveCN102027874AAvoid getting lostImprove breathabilityClimate change adaptationWatering devicesGround temperatureEcological environment

The invention relates to a drip irrigation under a film of a fruit tree and root field microenvironment regulation and controlling integrated method. The method comrpsies: firstly opening a regulation and control delve on the anterior limb projected on the fruit tree canopy ground, laying a seeding raising film on the lateral surface and the bottom part of the regulation and controlling delve, and placing filling materials on the seeding raising film; then disposing a drip irrigation pipe along the fruit tree row according to duplex tubes or three tubes; and laying the ground film along both sides of the tree row, covering the drip irrigation pipe and the regulation and controlling delve, and compacting with soil. Through the invention, the water and fertilizer integration drip irrigated under the film, watering and manuring automation as well as the water and fertilizer slow release and growth control and flower promotion regulated and controlled at the root field microenvironment are combined together, the root system range of the fruit tree is controlled at a certain volume, the nutrient is released in the delve through regulating and controlling the soil moisture percentage, ground temperature, fertilizer and the like of the root field, the growing development of hair root is promoted, vegetative growth and reproductive growth process above the ground part is regulated, and the hair root is regulated and controlled within the range of the delve to reach the function of coronal controlling and flower promotion. The method is simple, practical, economic and reasonable, and is a fruit tree root field microenvironment regulation and controlling integrated method with ecological environment protection and water and fertilizer conservation.

Owner:XINJIANG AGRI UNIV

Layer processing

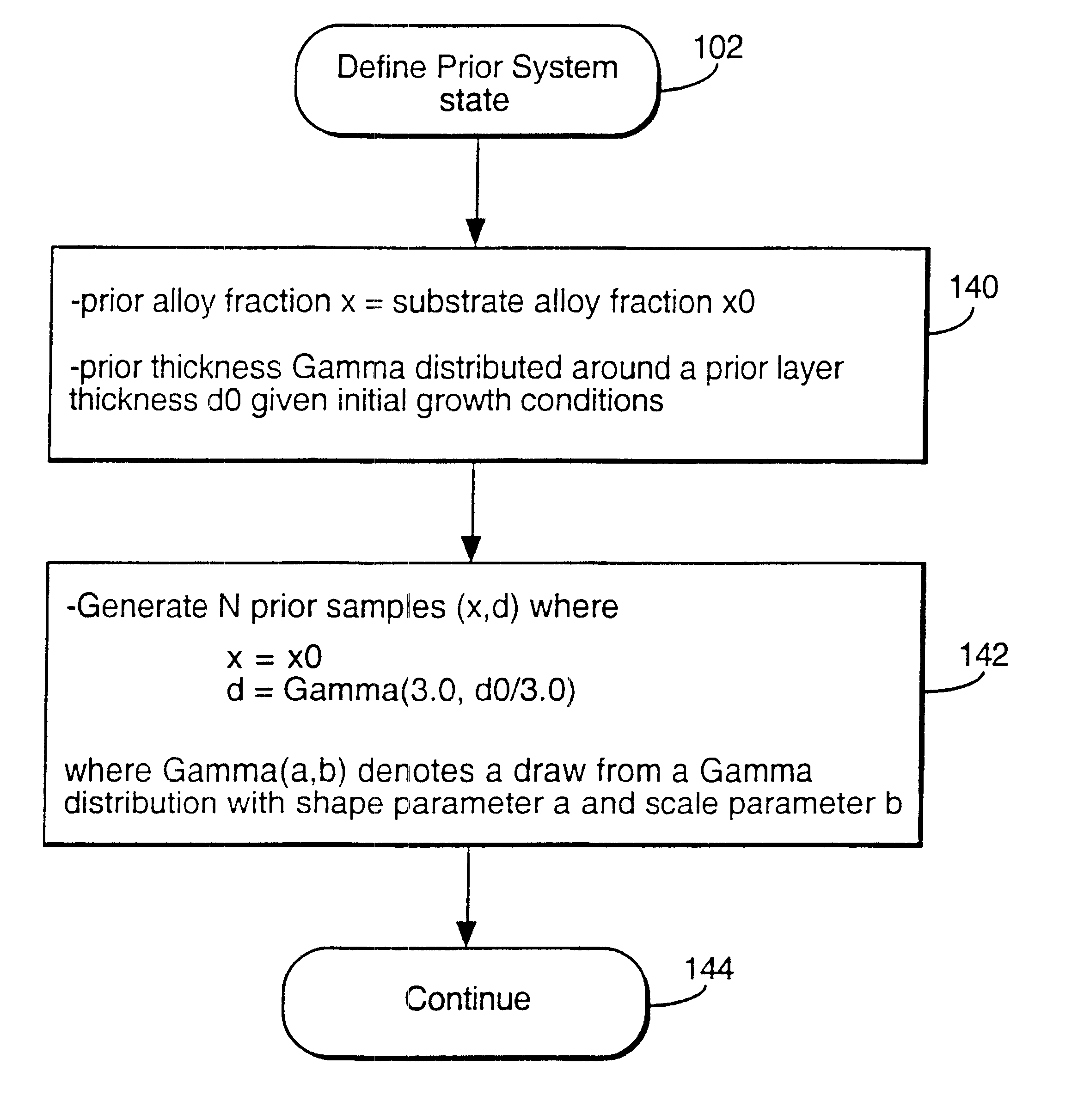

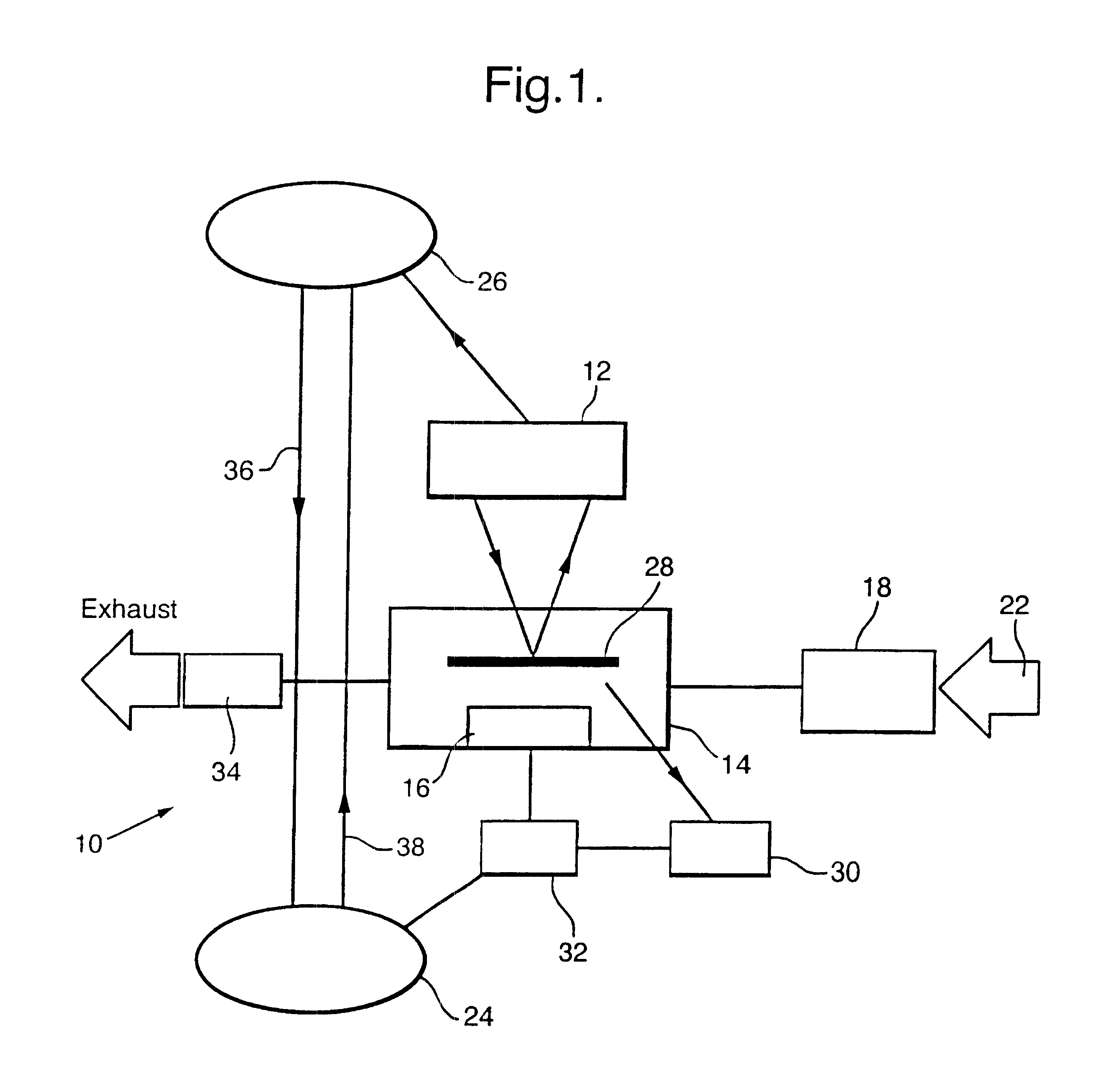

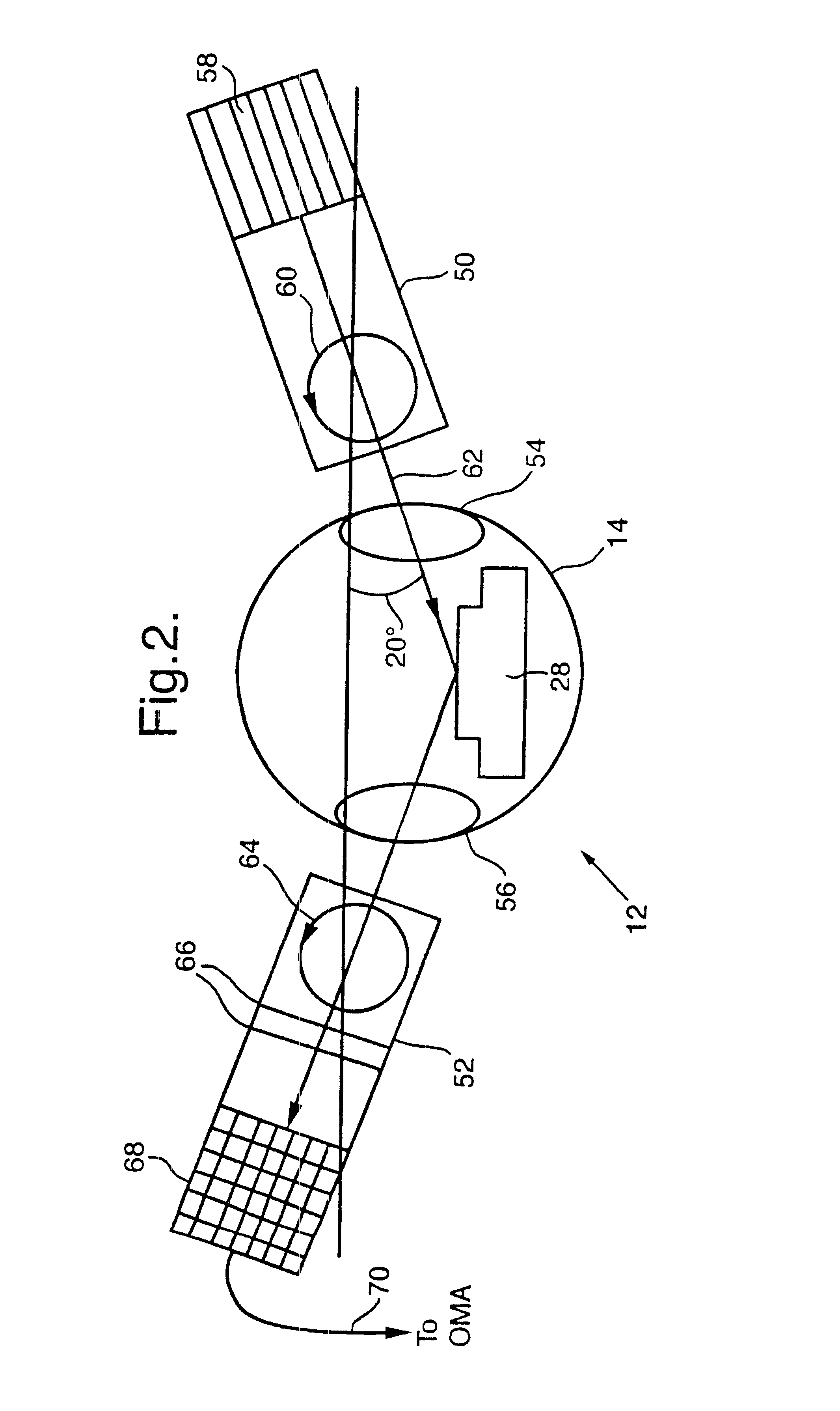

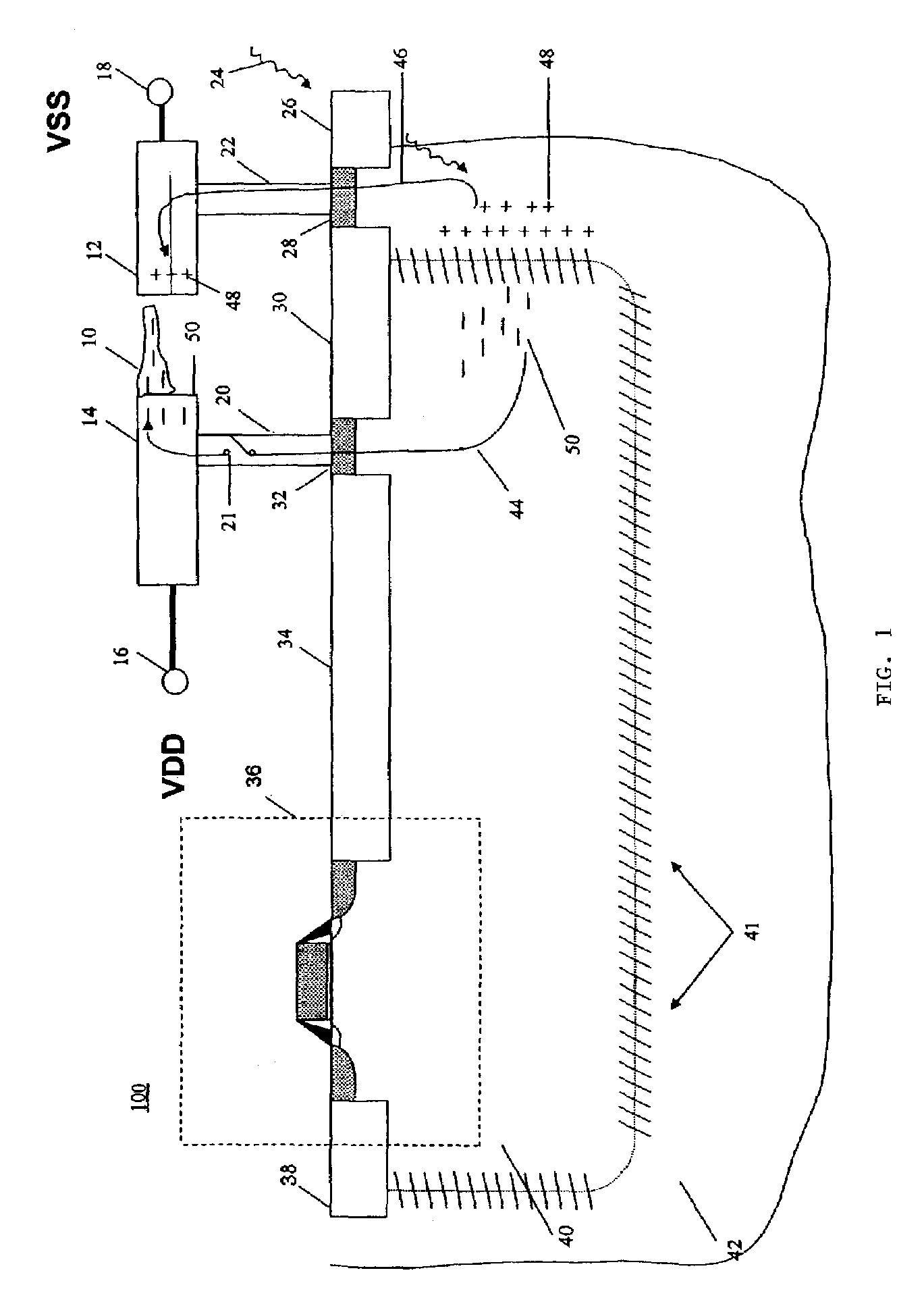

InactiveUS6726767B1Polycrystalline material growthSemiconductor/solid-state device testing/measurementNormal densityGrowth control

Layer processing to grow a layer structure upon a substrate surface comprises supplying a vapor mixture stream to the substrate (28) to deposit constituents, monitoring growth with an ellipsometer (12) and using its output in real-time growth control of successive pseudo-layers. A Bayesian algorithm is used to predict a probability density function for pseudo-layer growth parameters from initial surface composition, growth conditions and associated growth probabilities therewith, the function comprising discrete samples. Weights are assigned to the samples representing occurrence likelihoods based on most recent sensor output. A subset of the samples is chosen with selection likelihood weighted in favor of samples with greater weights. The subset provides a subsequent predicted probability density function and associated pseudo-layer growth parameters for growth control, and becomes a predicted probability density function for a further iteration of pseudo-layer growth.

Owner:CUFER ASSET LTD LLC

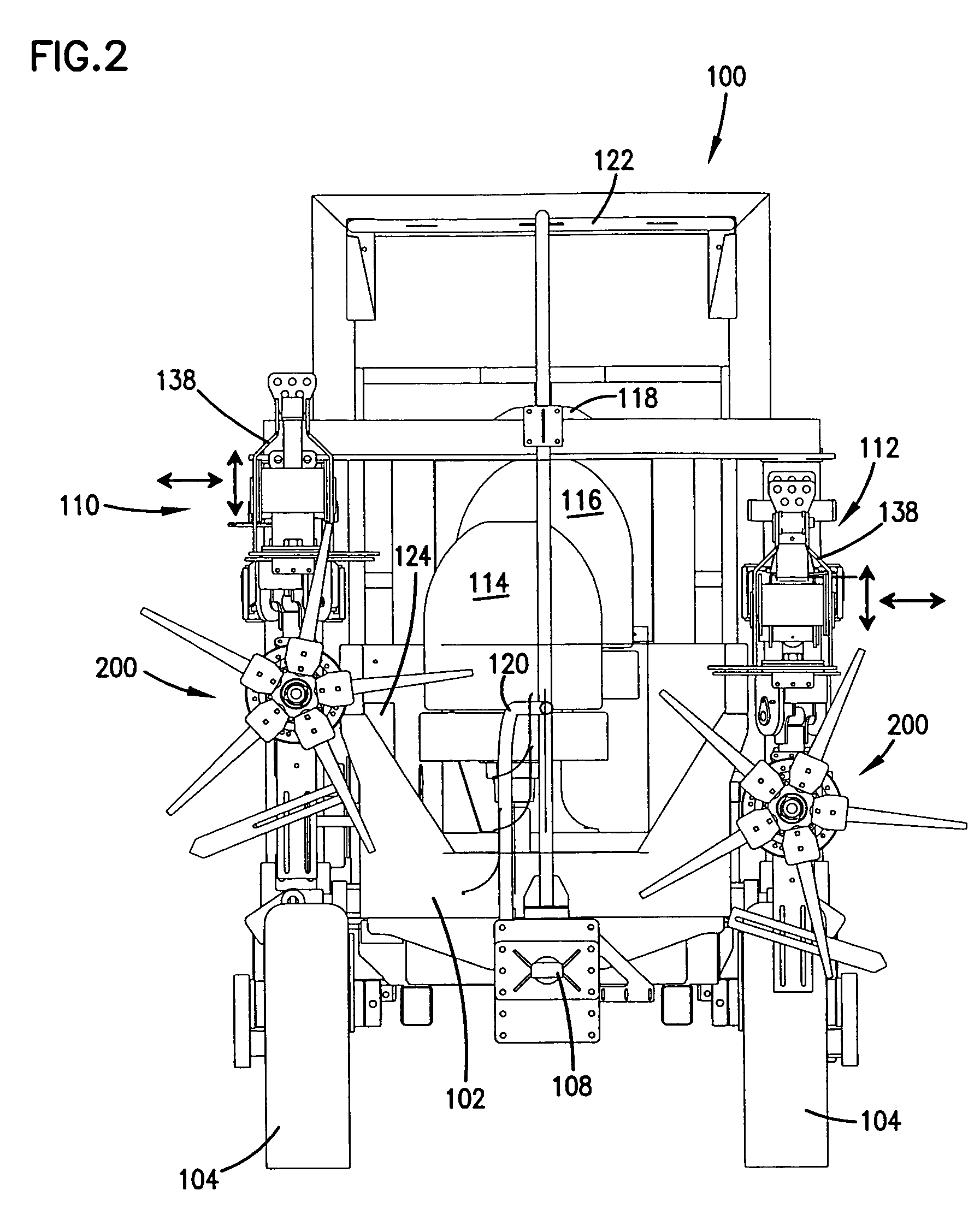

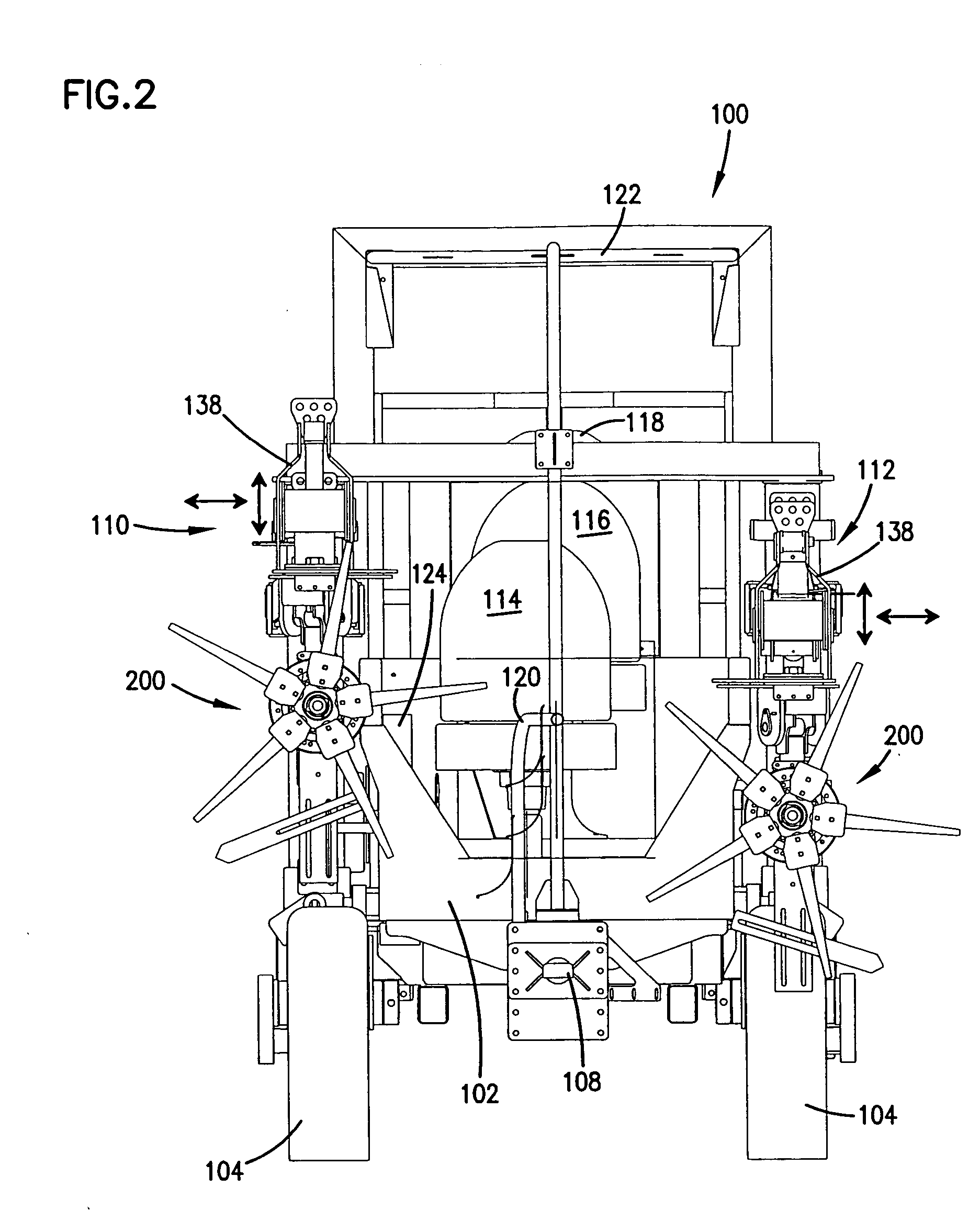

Control apparatus and method

InactiveUS7640091B2Accurate predictionShorten the timeHedge trimming apparatusAnalogue computers for trafficViticultureControl system

A programmable viticulture management system includes a mechanized device for removing excess undesired portions of plants advances through a vineyard to perform control operations on two rows or half-rows of grape vines simultaneously. Accessories mount to the mechanized device and include various engagement members for engaging the vines. A control system automatically varies the velocity of the engagement members in relation to the vehicle speed. The control system also receives various inputs and provides information on multiple growth control practices.

Owner:MIDWEST GROWER SUPPLY INC

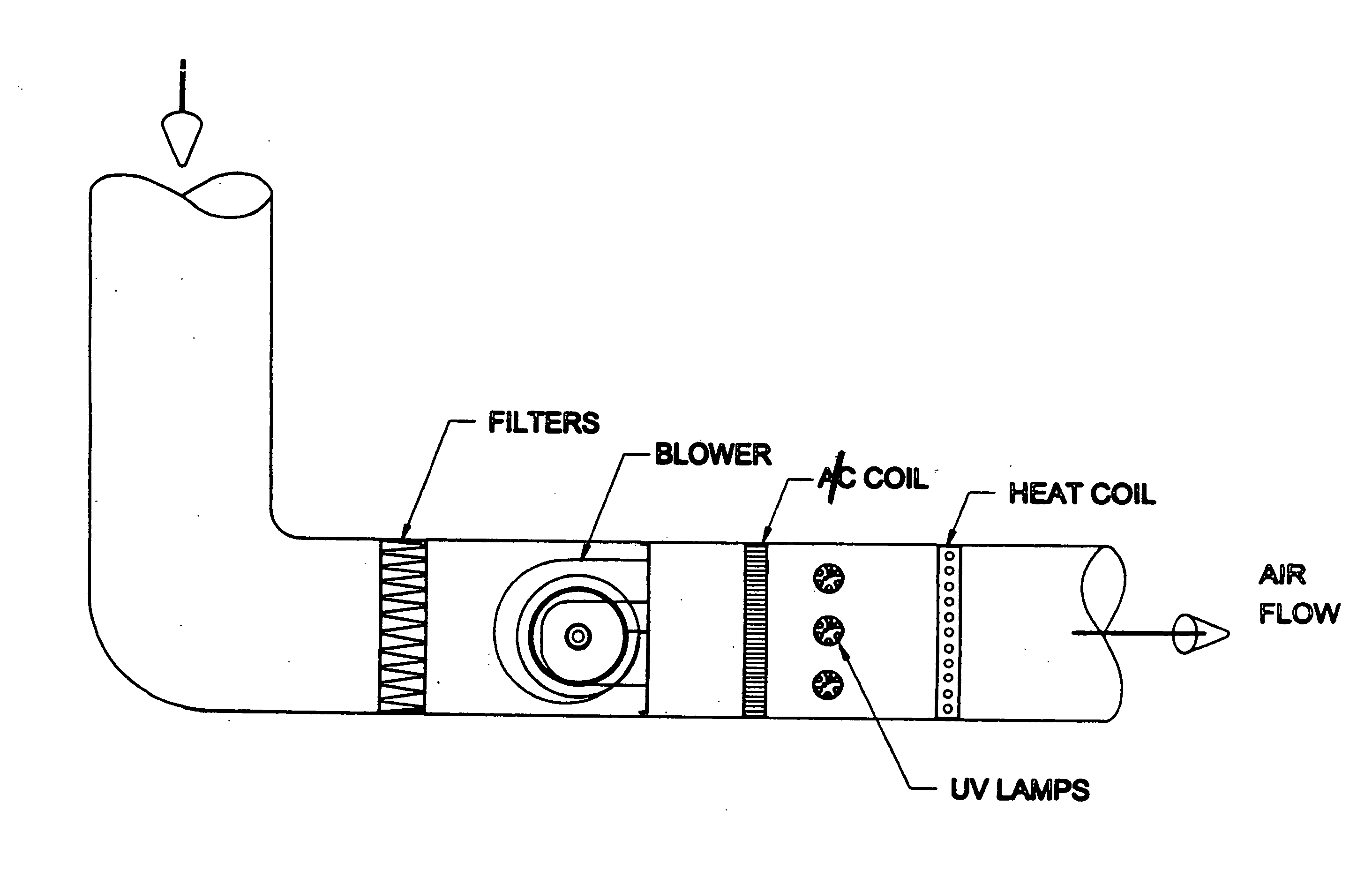

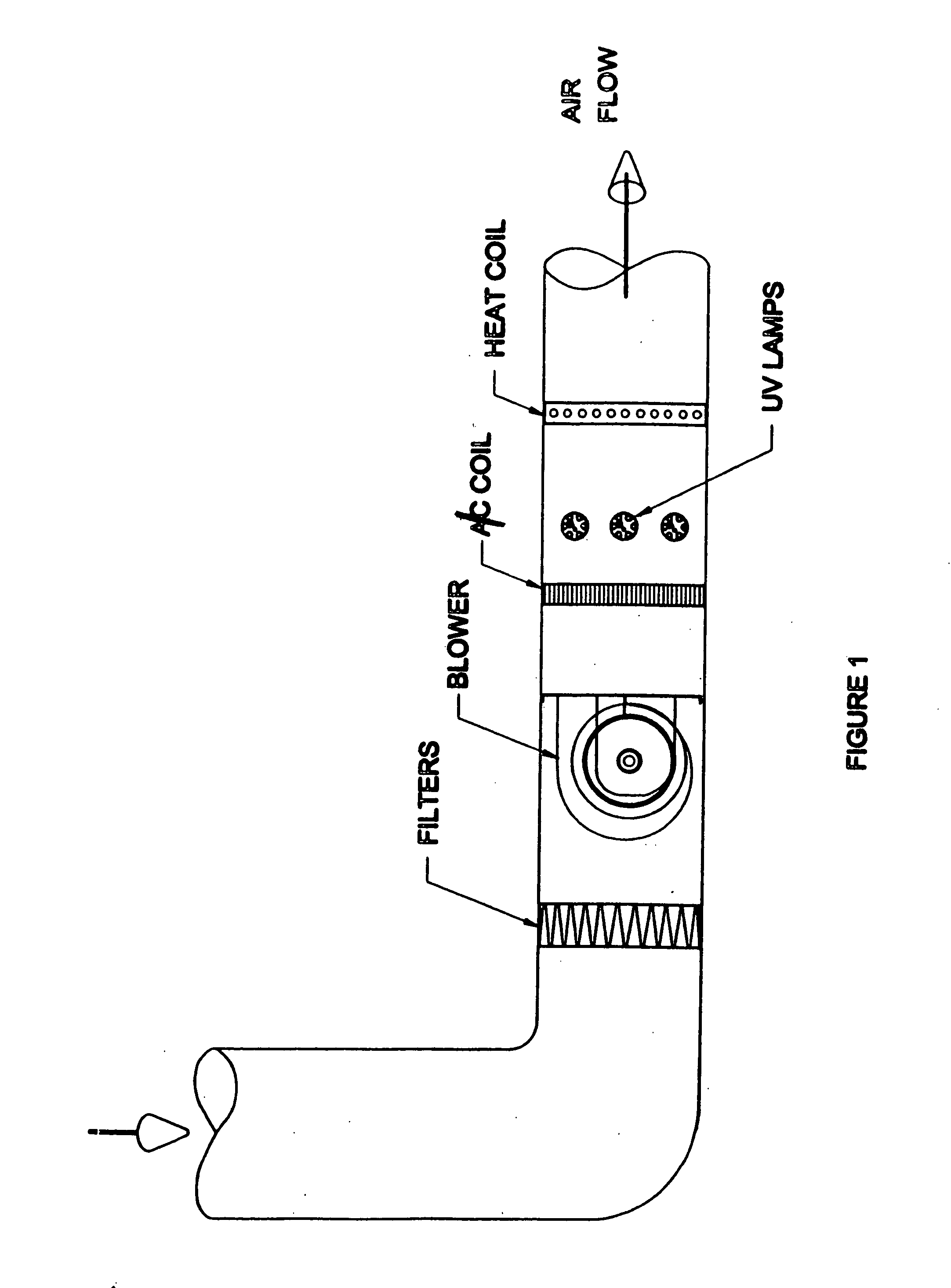

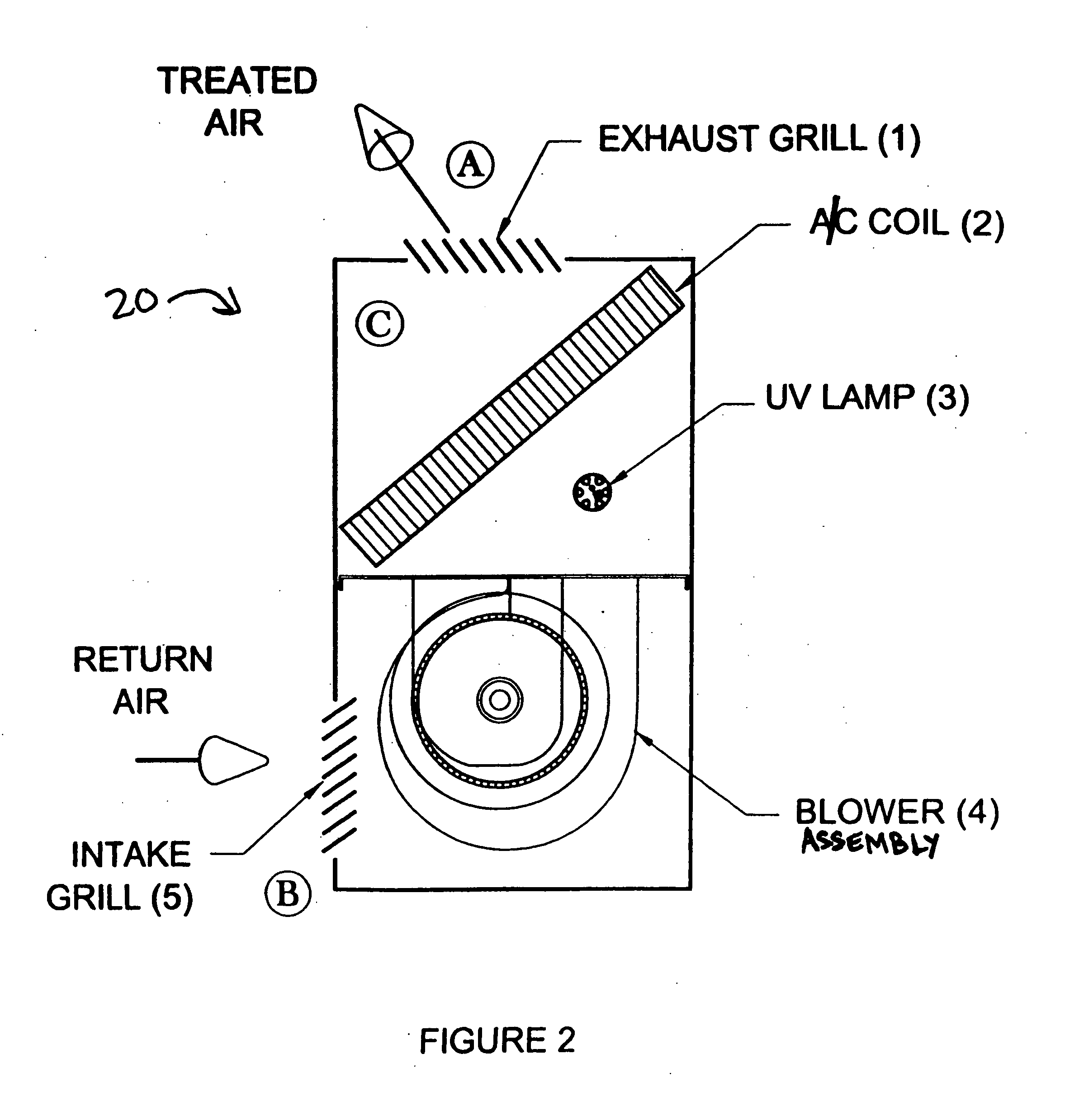

Low level ultraviolet disinfecting system

InactiveUS20050163652A1Safe exposure levelAdequate levelMechanical apparatusLighting and heating apparatusFluid intakeHuman exposure

A disinfecting system comprises a light source having output suitable for use as a germicidal agent, and a power supply for the light source that is adapted to limit the output of the light source to levels adequate for microbial growth control. The light source is operatively housed in fluid-conveying equipment for disinfecting fluids and surfaces therein. The limited output is attenuated by fluid-conveying equipment components disposed within the output range of the light source. The attenuated output provides safe human exposure levels in the vicinity of fluid intake and exhaust portions of the fluid-conveying equipment. The limited output inhibits the degradation of fluid-conveying equipment components disposed within the output range of the light source. The light source may be covered with a thin film or sleeve of material being semi-transparent to germicidal UV wavelengths to control the output of the light source.

Owner:ULTRAVIOLET DEVICES

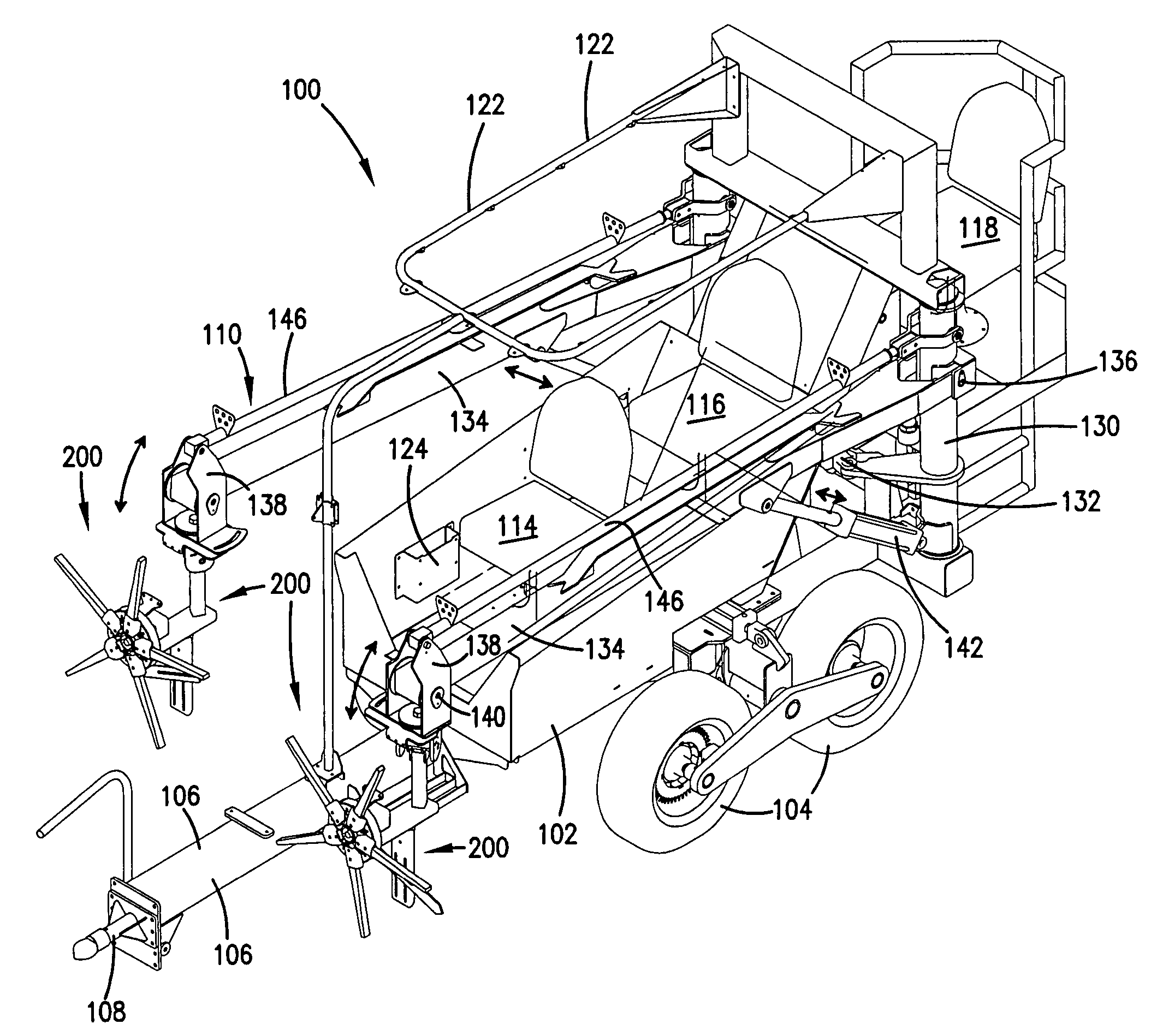

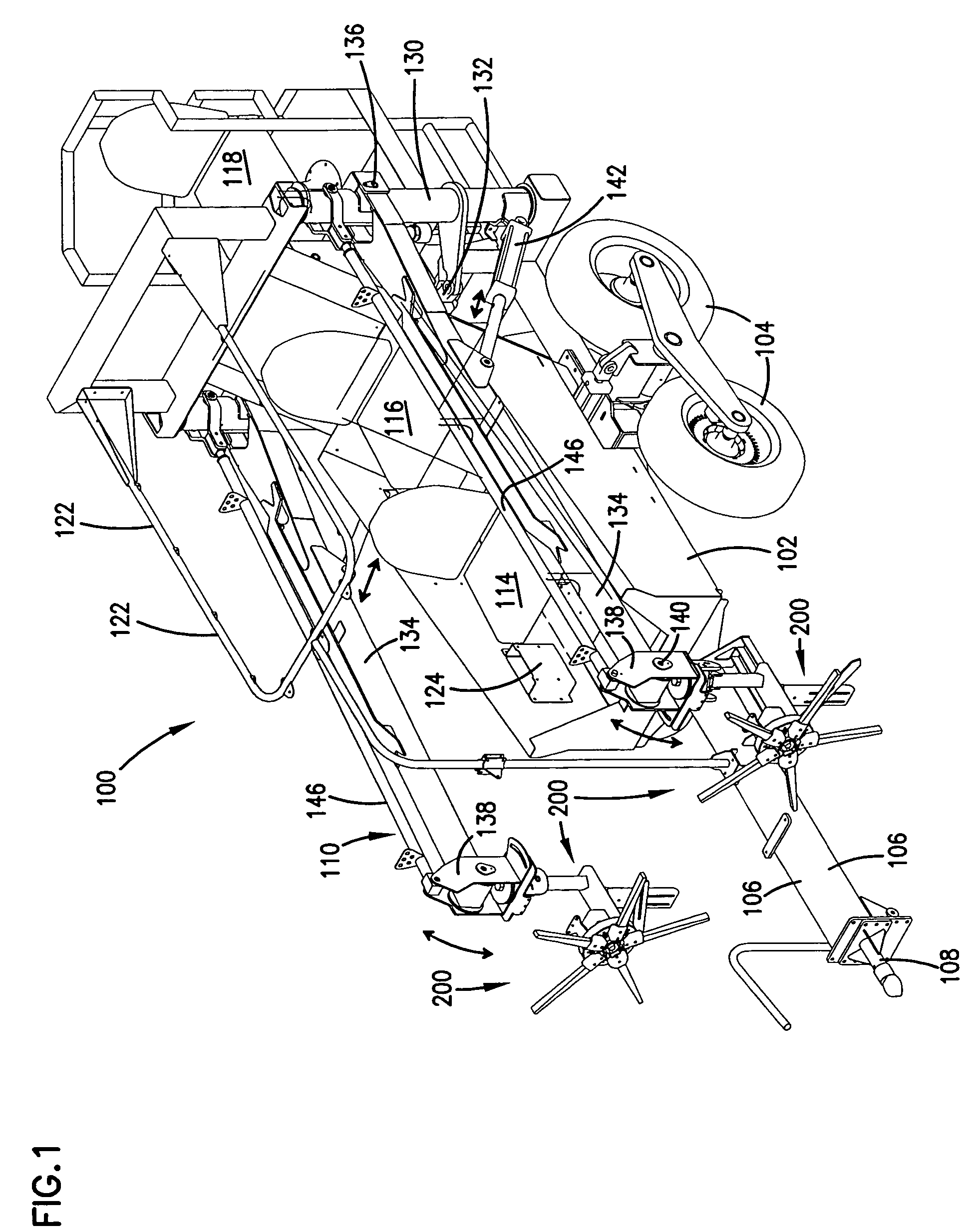

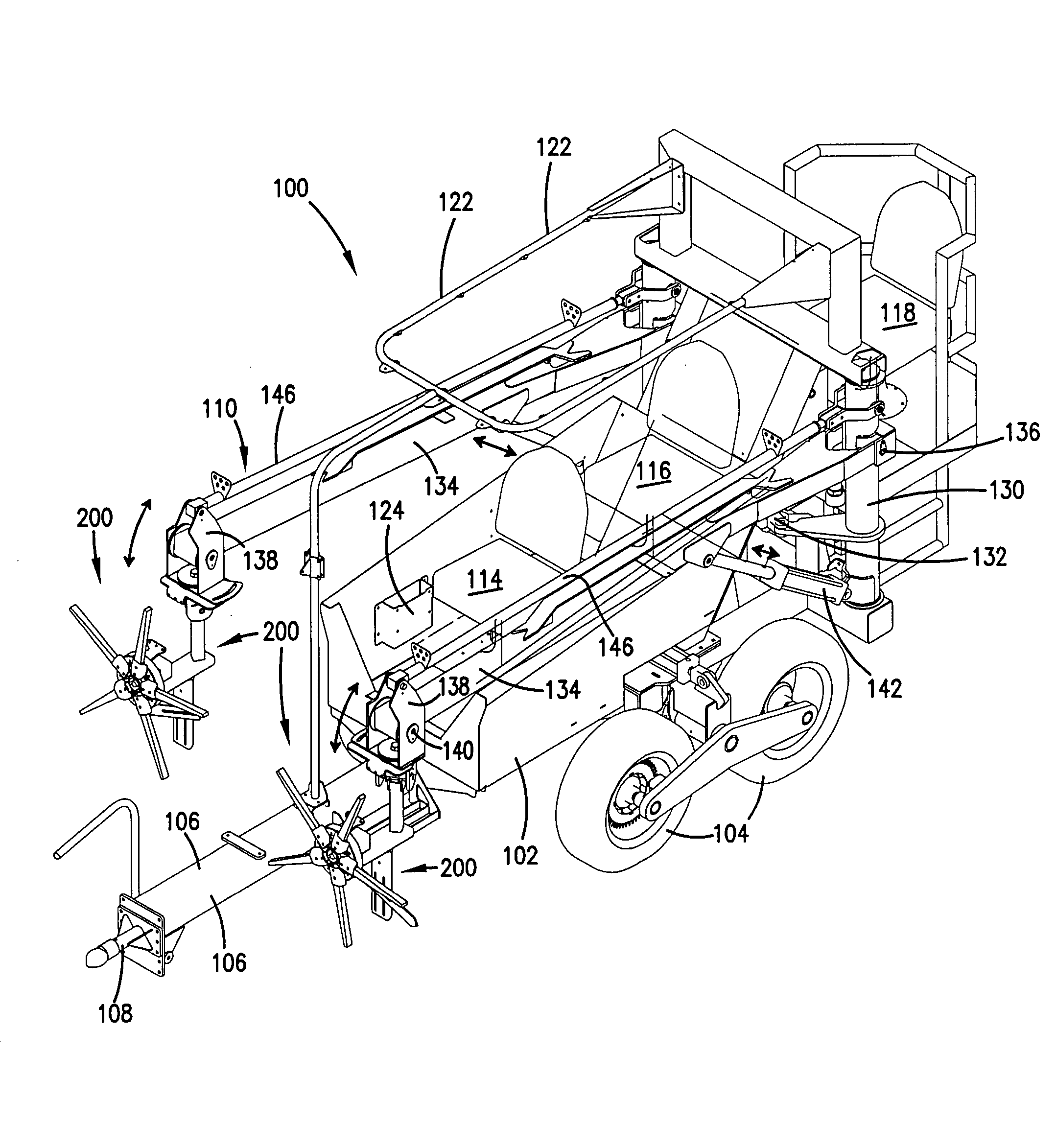

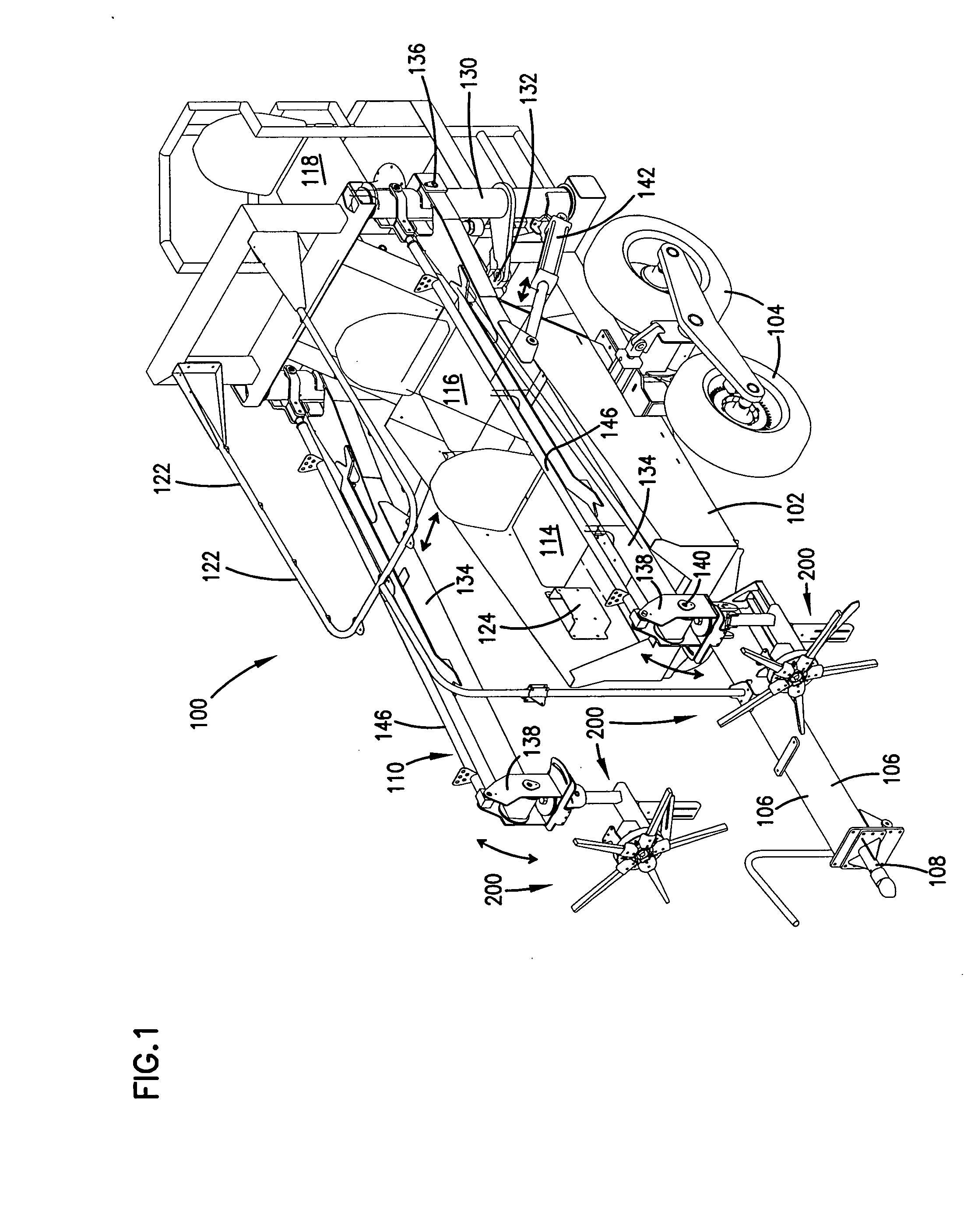

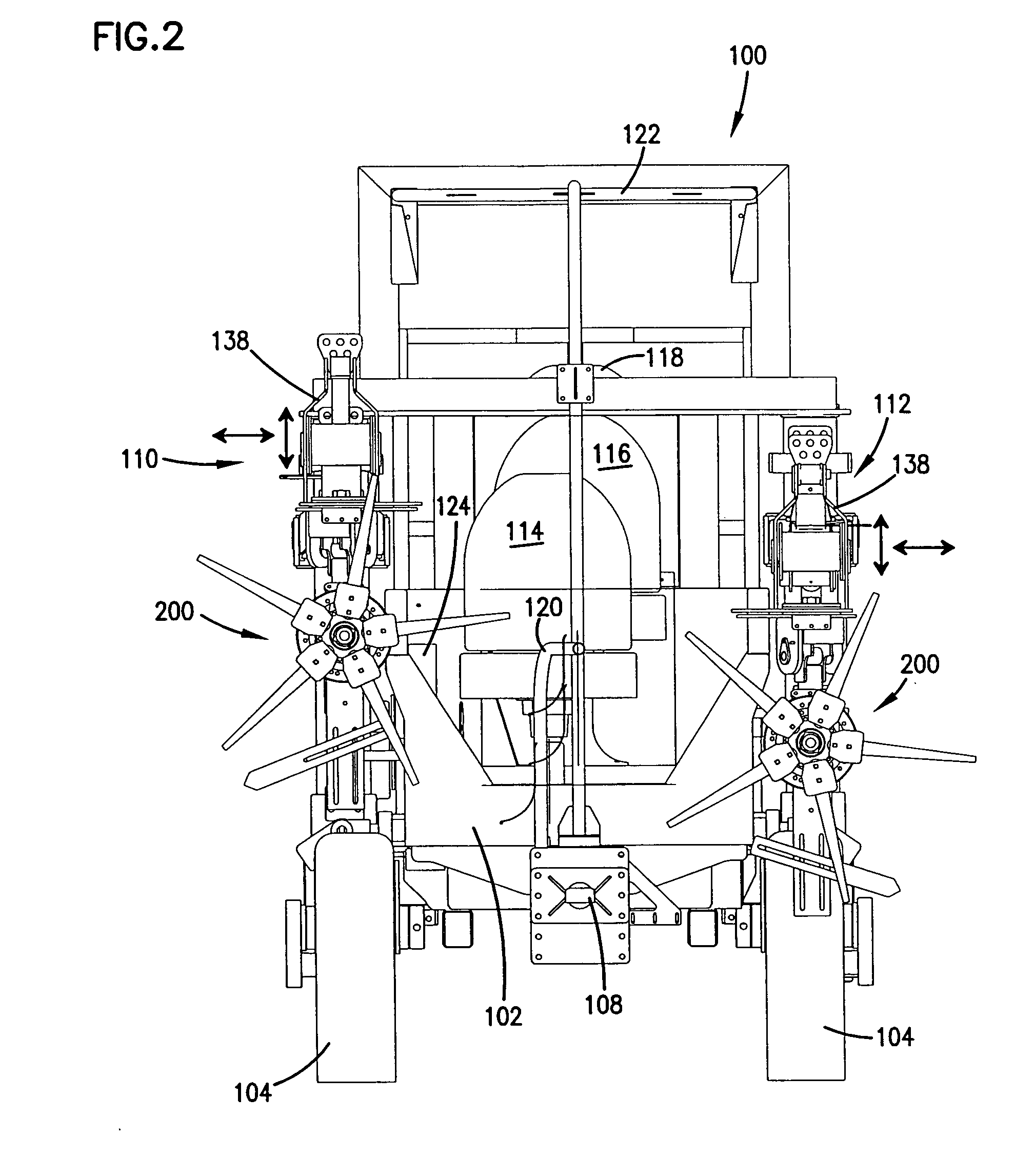

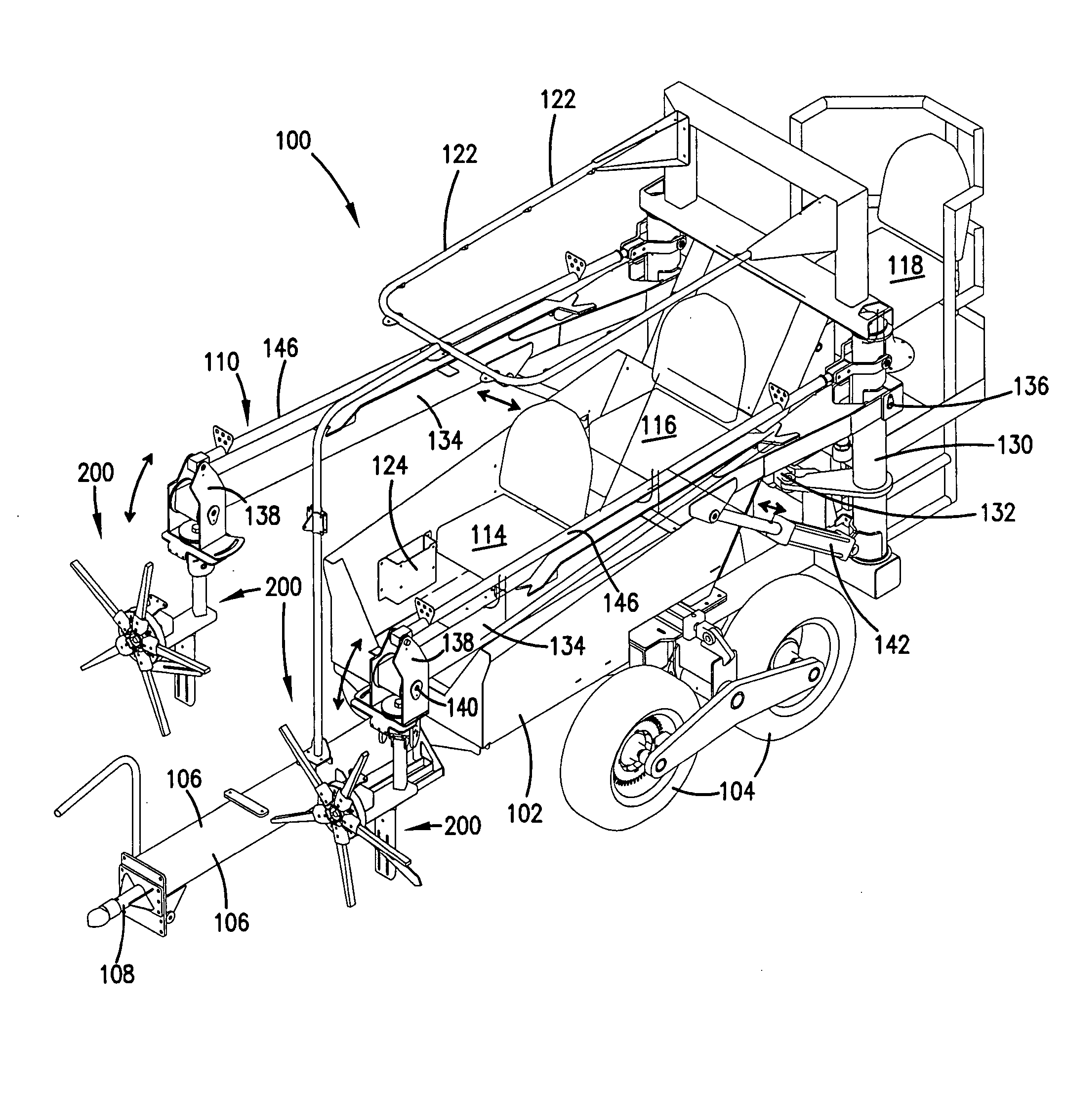

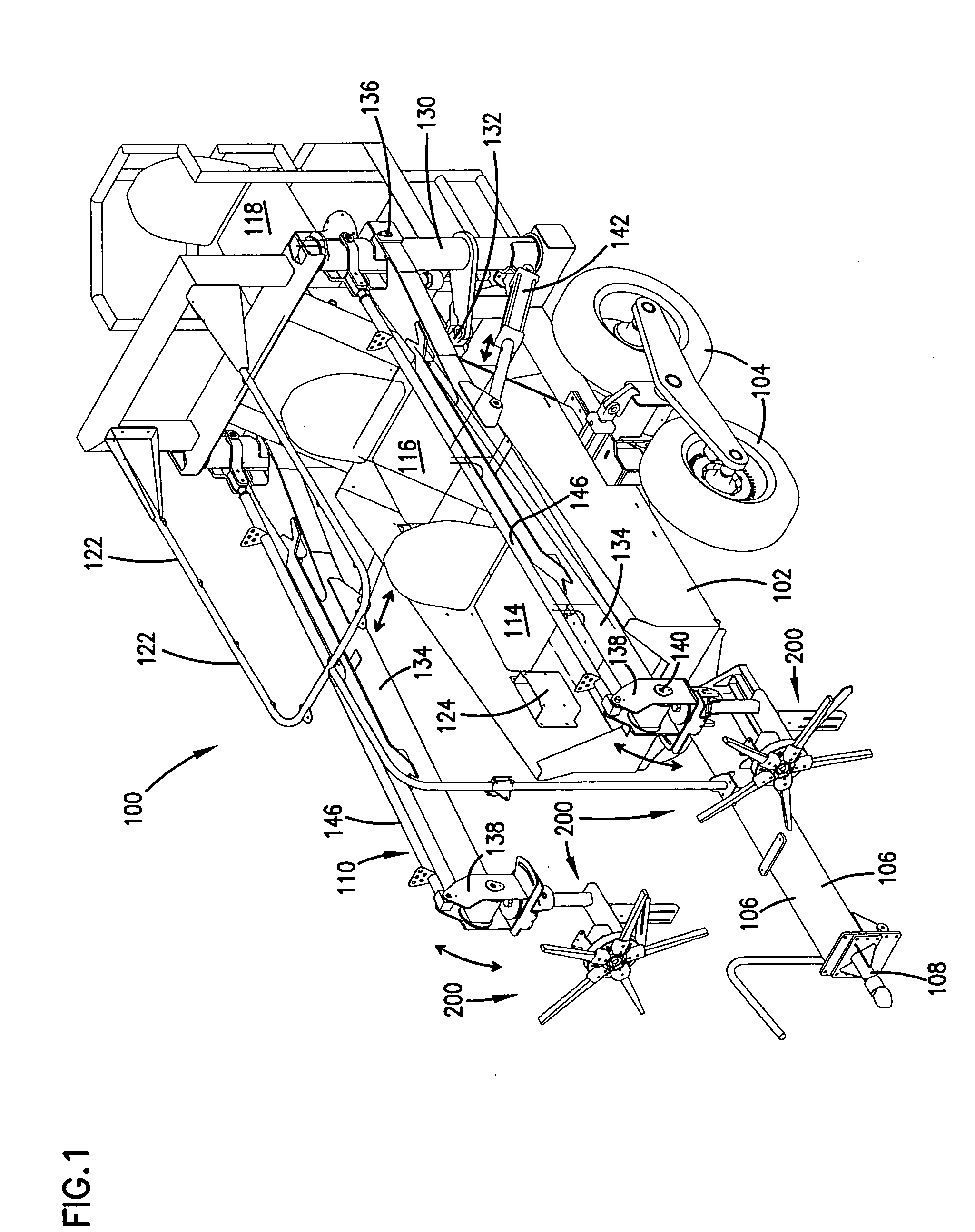

Viticulture apparatus and method

InactiveUS20050039431A1Continuous regulationShorten the timeHedge trimming apparatusCuttersViticultureShoot

A mechanized agriculture management apparatus includes a chassis supporting a first manually independently operable boom and a second manually independently operable boom. The booms extend from either side of the chassis and support interchangeable accessories. The accessories may be dedicated to perform various growth control operations such as shoot thinning, fruit thinning, vertical impacting, lateral impacting, hedging, trunk cleaning, shoot positioning, deleafing, pruning and / or wire lifting, as well as other operations and are interchangeable so that one mechanized apparatus may be utilized for the various operations.

Owner:OXBO INT CORP

Superabrasive particle synthesis with growth control

InactiveUS20080047484A1Narrow size distributionQuality improvementFrom gel stateDrill bitsOctahedronAdhesive

An improved method for synthesizing superabrasive particles provides high quality industrial superabrasive particles with high yield and a narrow size distribution. The synthesis method can include forming a growth precursor of a substantially homogeneous mixture of raw material and catalyst material or layers of raw material and metal catalyst. The growth precursor can have a layer of adhesive over at least a portion thereof. A plurality of crystalline seeds can be placed in a predetermined pattern on the layer of adhesive. The growth precursor can be maintained at a temperature and pressure at which the superabrasive crystal is thermodynamically stable for a time sufficient for a desired degree of growth. Advantageously, the patterned placement of crystalline seeds and disclosed processes allow for production of various morphologies of synthetic diamonds, including octahedral and cubic diamonds, and improved growth conditions generally. As a result, the grown superabrasive particles typically have a high yield of high quality particles and a narrow distribution of particle sizes.

Owner:SUNG CHIEN MIN

Rubber ferromagnetic oxide powder and preparation method thereof

InactiveCN101445363AImprove magnetismAppropriate granularityMagnetsStrontium carbonateGrowth control

The invention provides a rubber ferromagnetic oxide powder and a production process thereof. Iron red and strontium carbonate or barium carbonate are adopted as raw materials, an additive which is favorable to the low-temperature pre-sintering effect improvement and the growth control of crystal grains is preferably added, and a magnetic powder with higher magnetic property and processing property is obtained through the pre-sintering and pulverizing processes, and is suitable to be as a raw material of products such as seals of refrigerator doors, magnetic seals of doors and windows and advertising magnets. The invention has the advantages that the annealing process is not required in the process of preparing the ferromagnetic oxide powder, thereby reducing manufacture cost, lowering energy consumption, and reducing emission.

Owner:BGRIMM TECH CO LTD

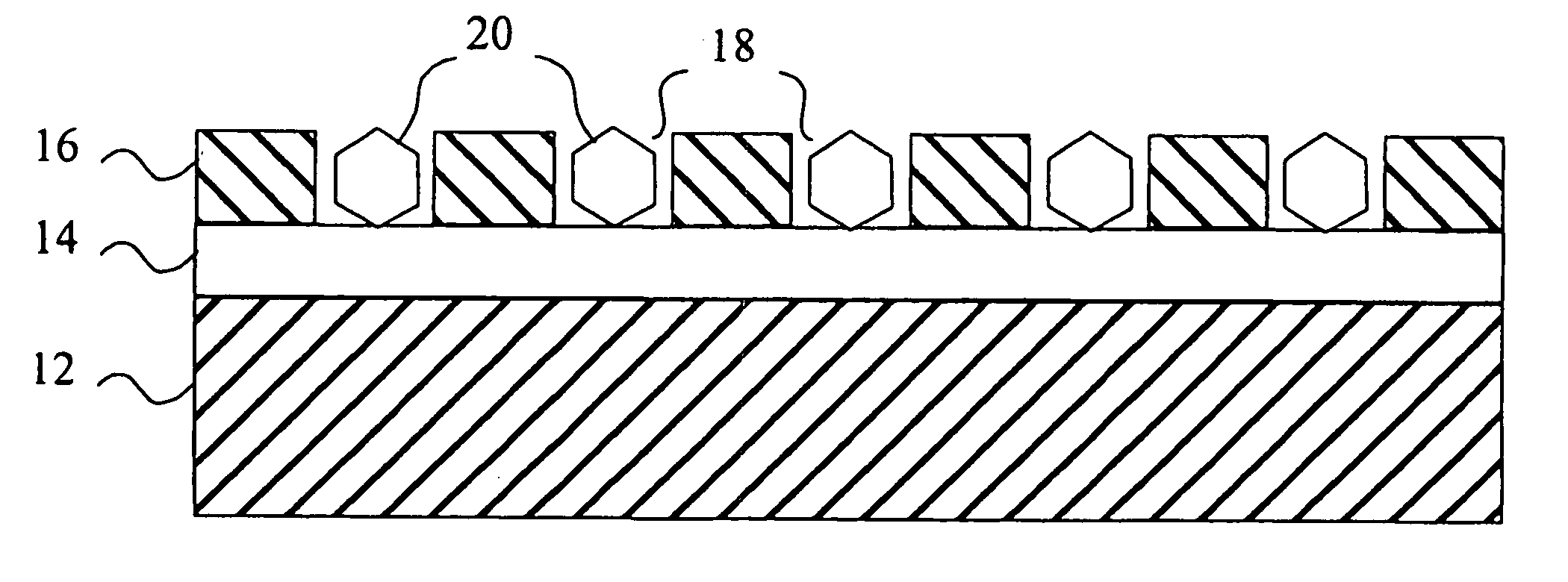

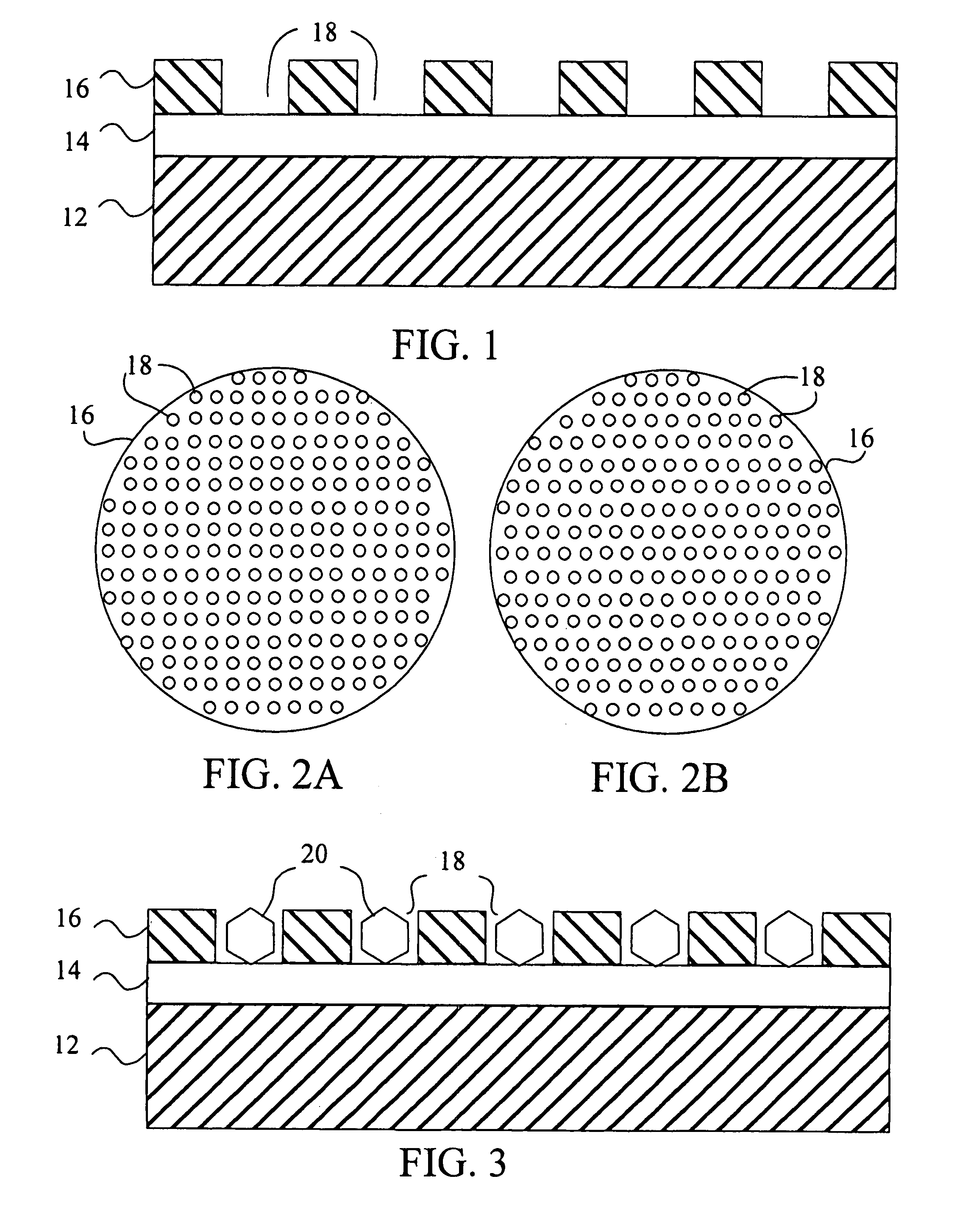

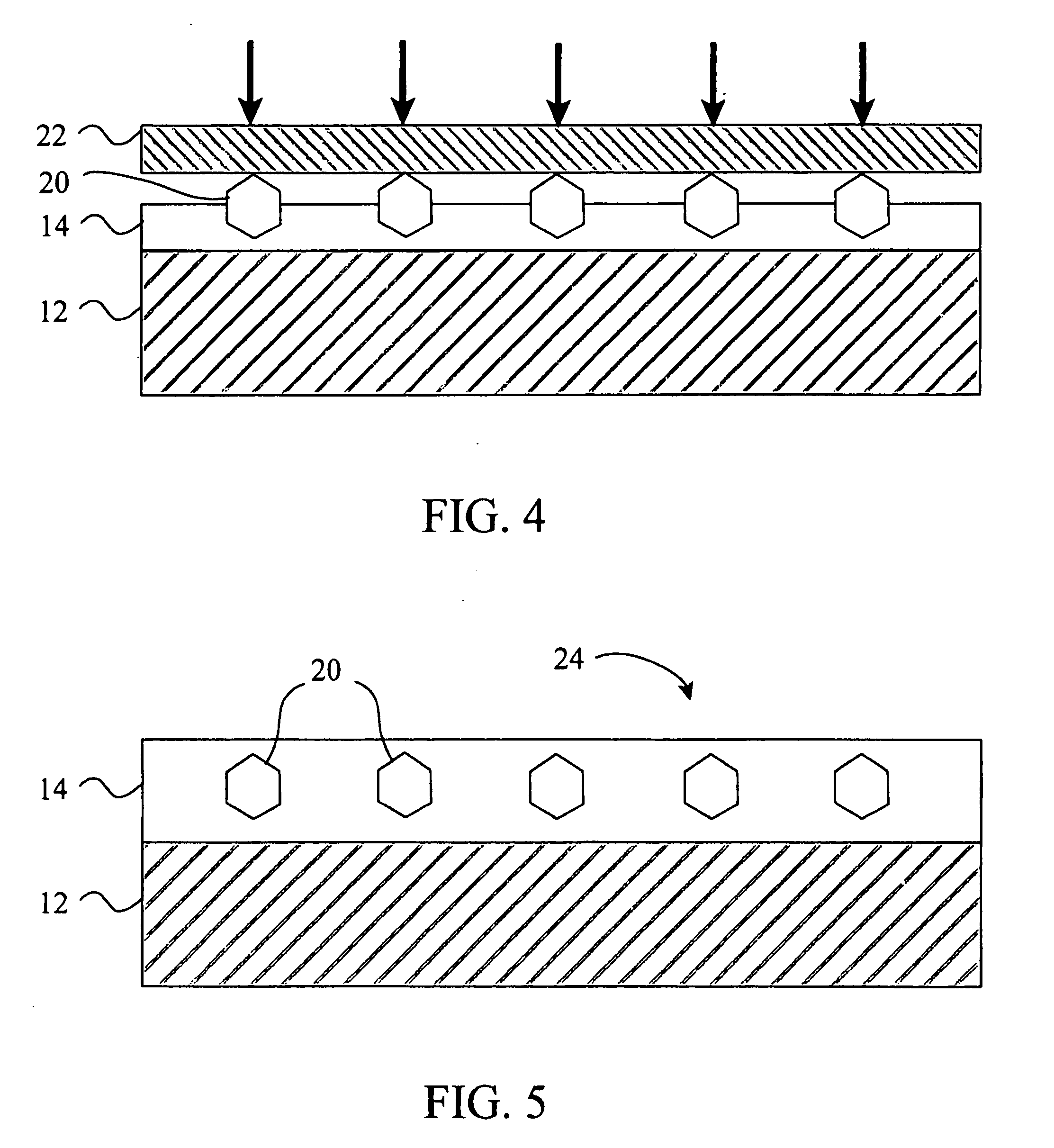

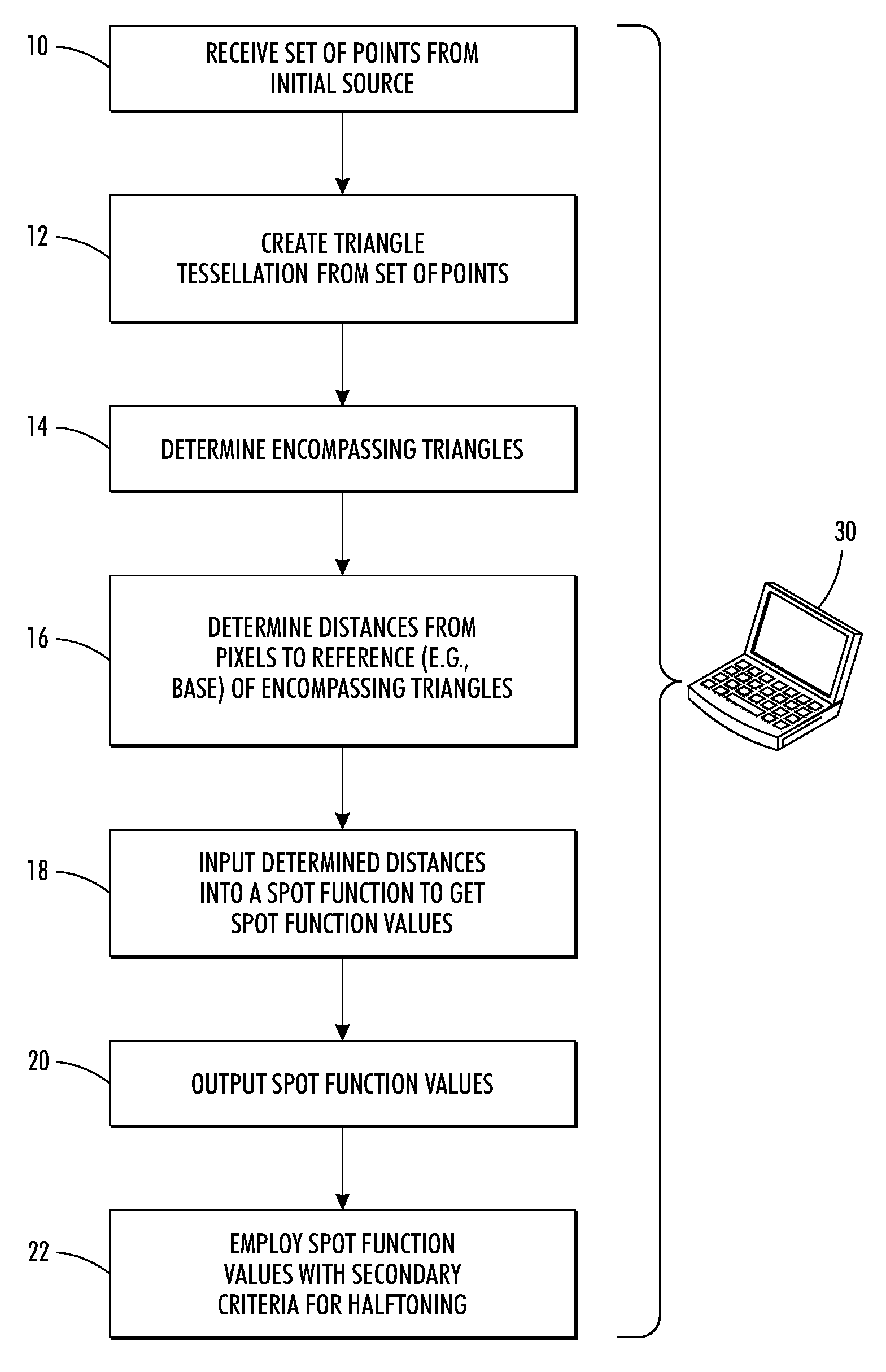

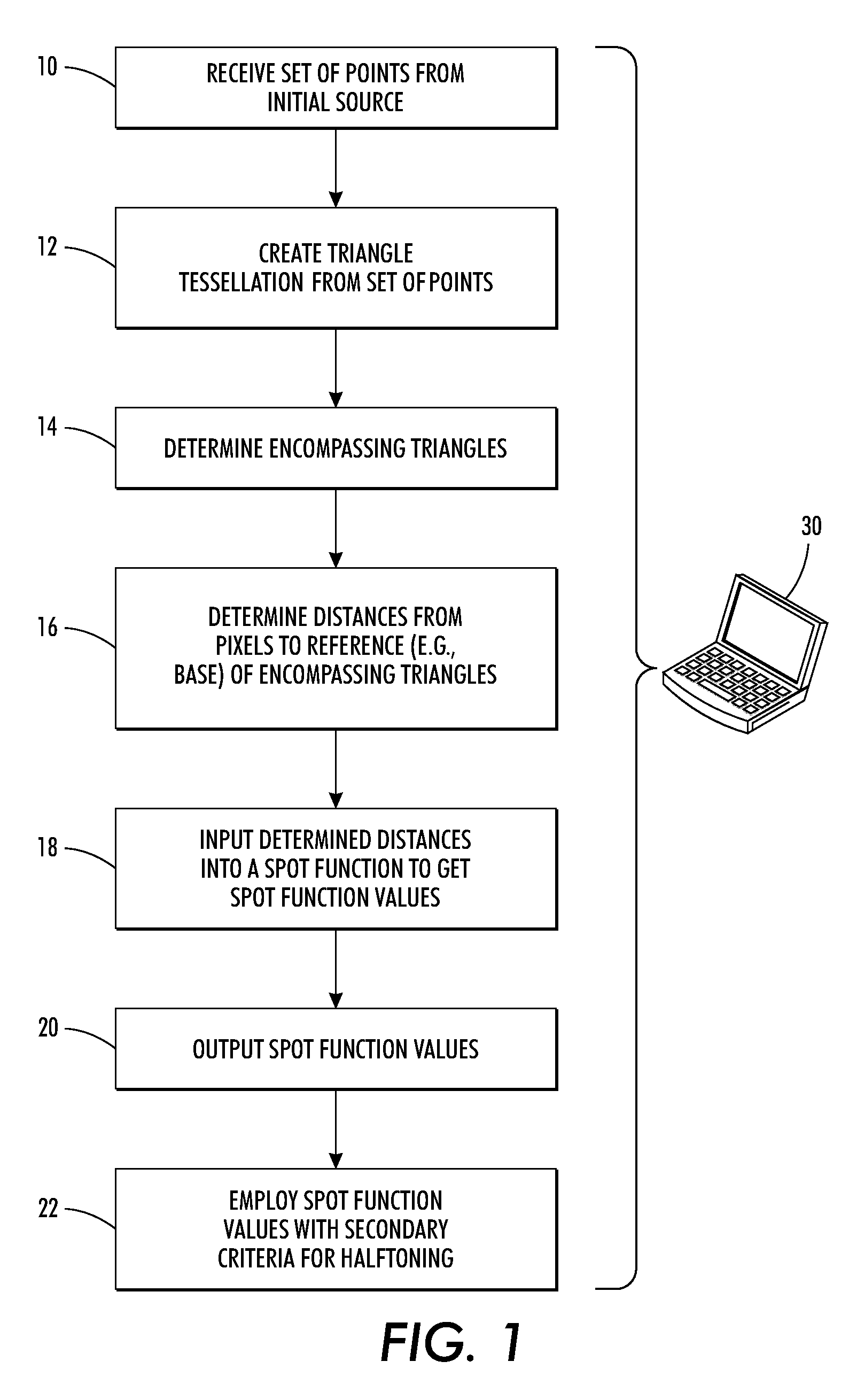

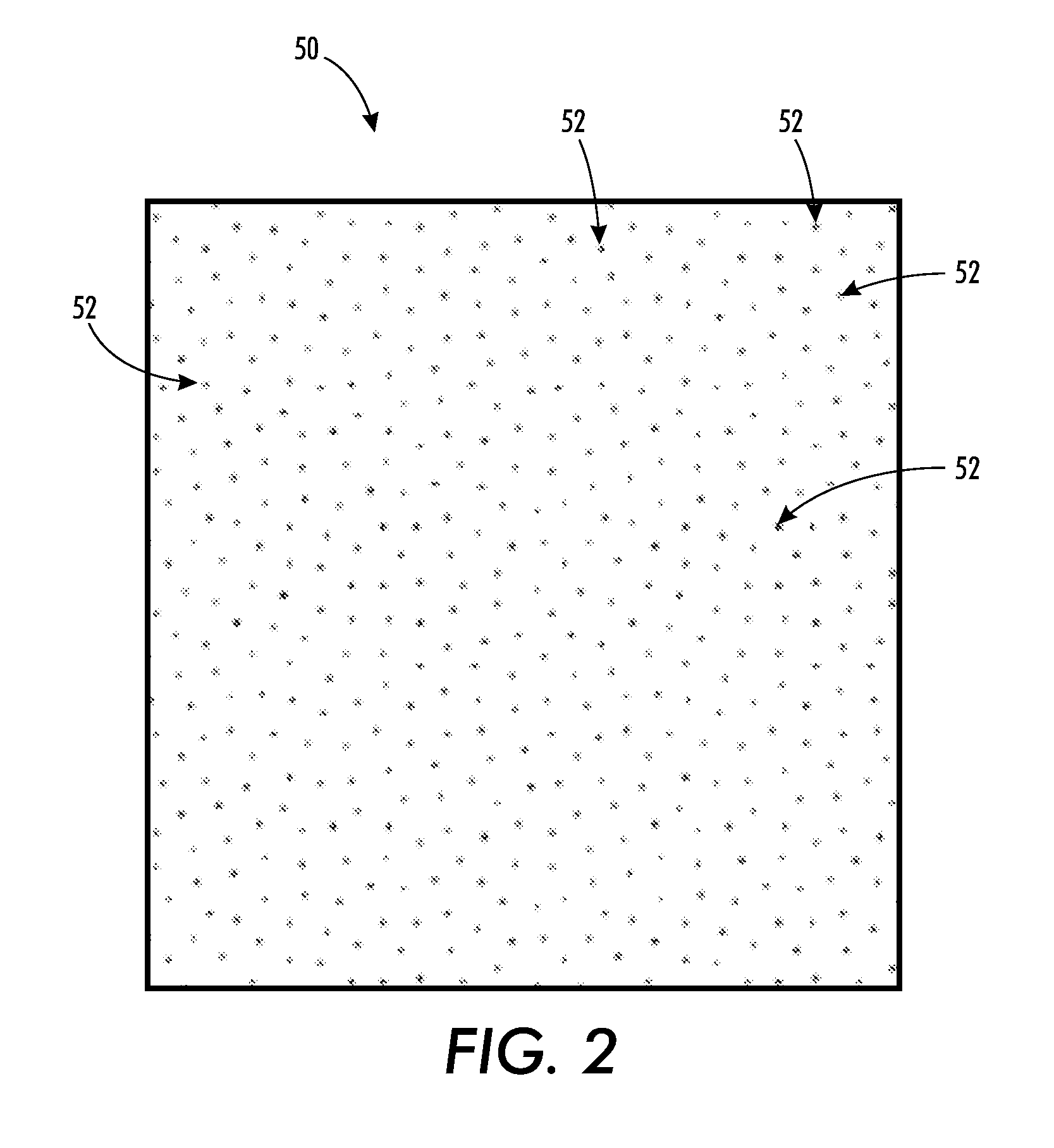

Parametrically controlled halftone spot function for an irregular halftone grid

InactiveUS20120274985A1Promote generationVisual presentationForme preparationRegular gridGrowth control

As set forth herein, computer-implemented methods and systems facilitate halftoning using a parametrically controlled spot function based on triangle tessellation, which in turn facilitates dot growth control of periodic halftone using an irregular seed structure. The spot function determines the shape of the halftone dot used to reproduce a given pixel. The spot function is well suited for growing halftone dots arrayed on a non-regular grid and can also be used for grids with regular order. The spot function includes adjustable parameters for controlling its sharpness and slope.

Owner:XEROX CORP

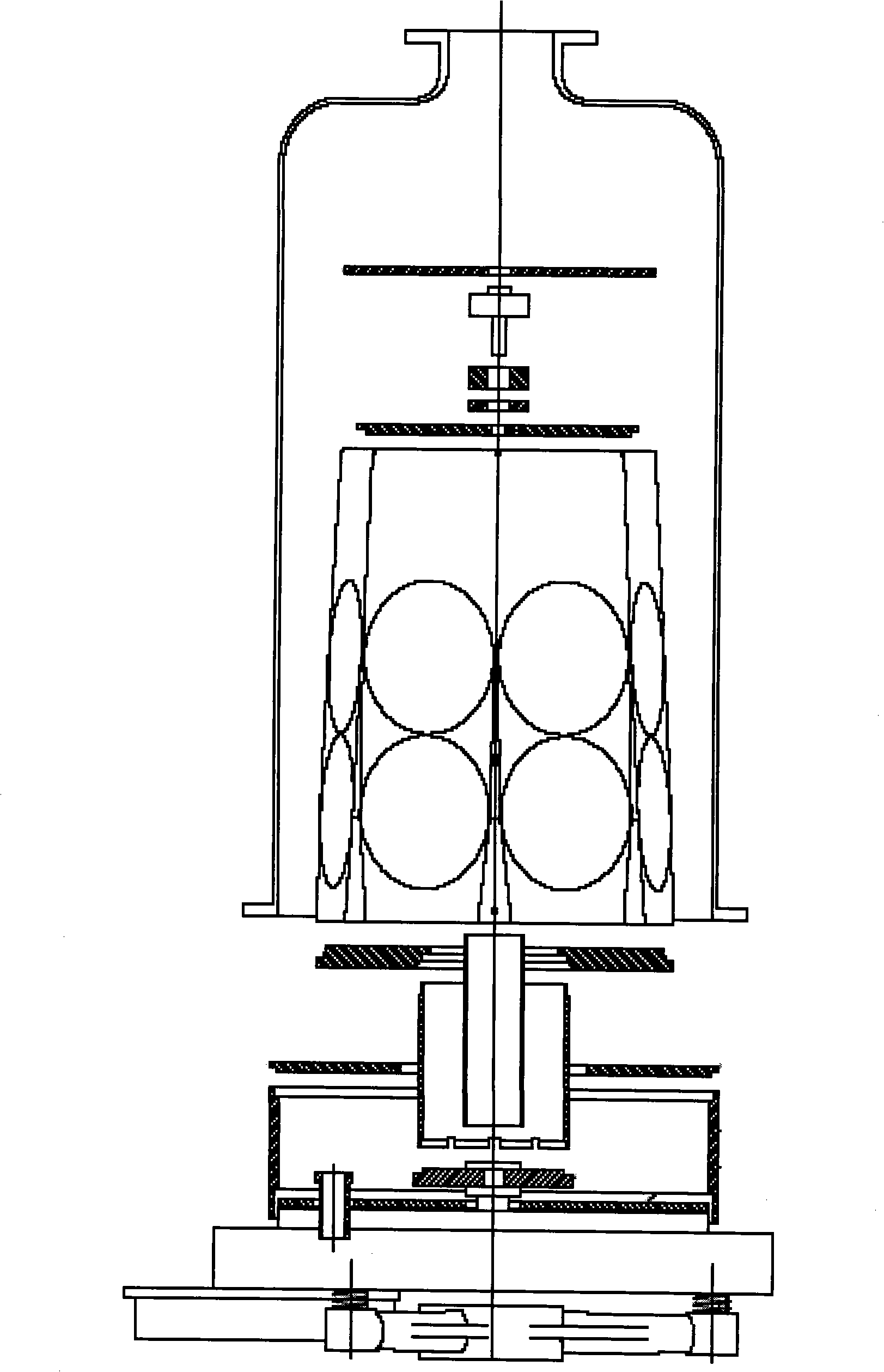

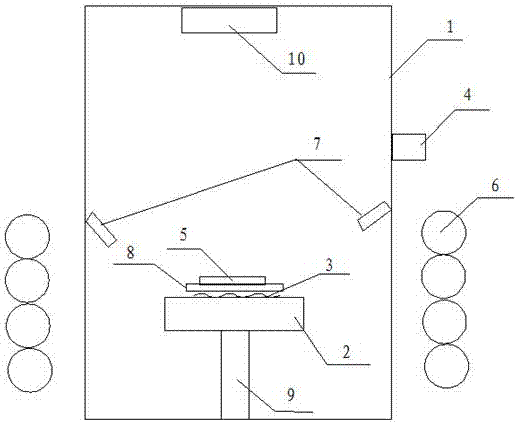

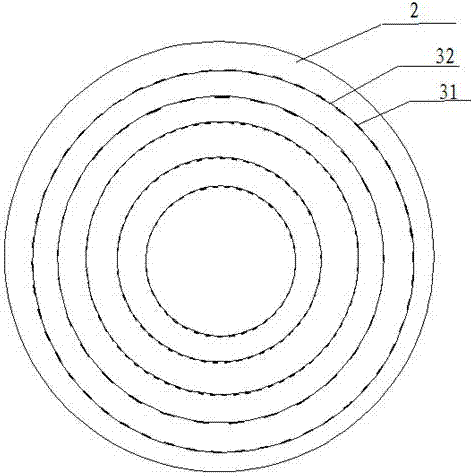

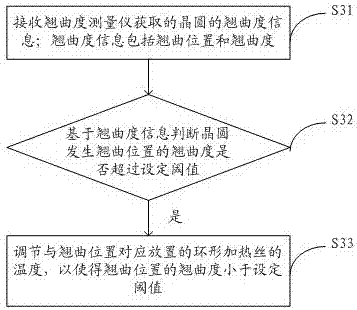

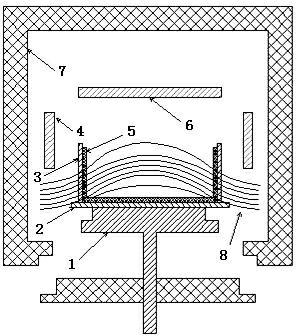

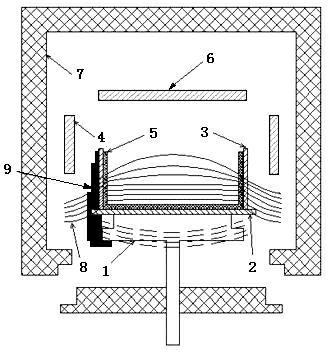

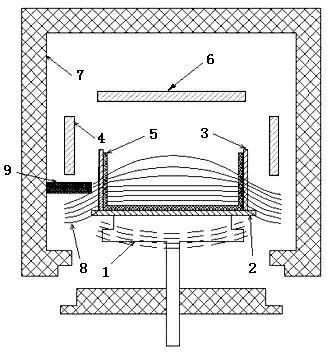

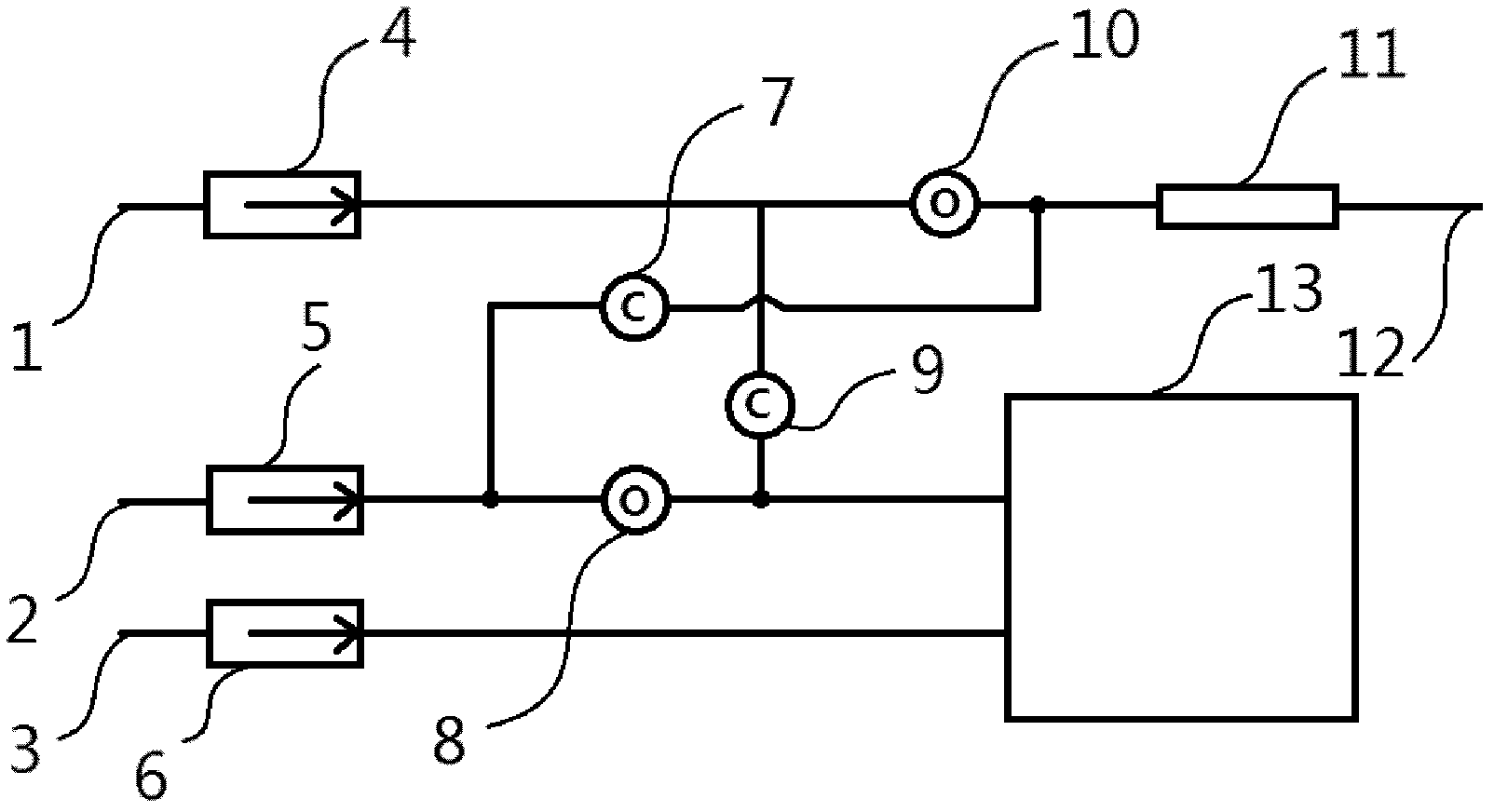

Wafer growth control apparatus and method

ActiveCN107170696AReduce warpageSolve the technical problem of warpingSemiconductor/solid-state device manufacturingGrowth controlEngineering

The invention discloses a wafer growth control apparatus and method. Multiple concentric annular heating wires are arranged on a substrate of a reaction chamber, and a wafer is placed on the substrate; in the epitaxial growth process of the wafer, a heating controller receives warping degree information obtained by a warping degree measurer arranged outside the reaction chamber; and when the controller judges that the wafer suffers from a warping condition exceeding a set threshold value based on the warping degree information, the controller adjusts the temperature of the annular heating wires arranged corresponding to the wafer warping position to be improved or declined, so as to achieve a technical effect of uniform heating of the wafer, adjust the warping degree in the wafer warping position to be less than the set threshold value, and solve the problem of low yield in the epitaxial growth process of the existing wafer caused by uneven heating.

Owner:QINGDAO JASON ELECTRIC

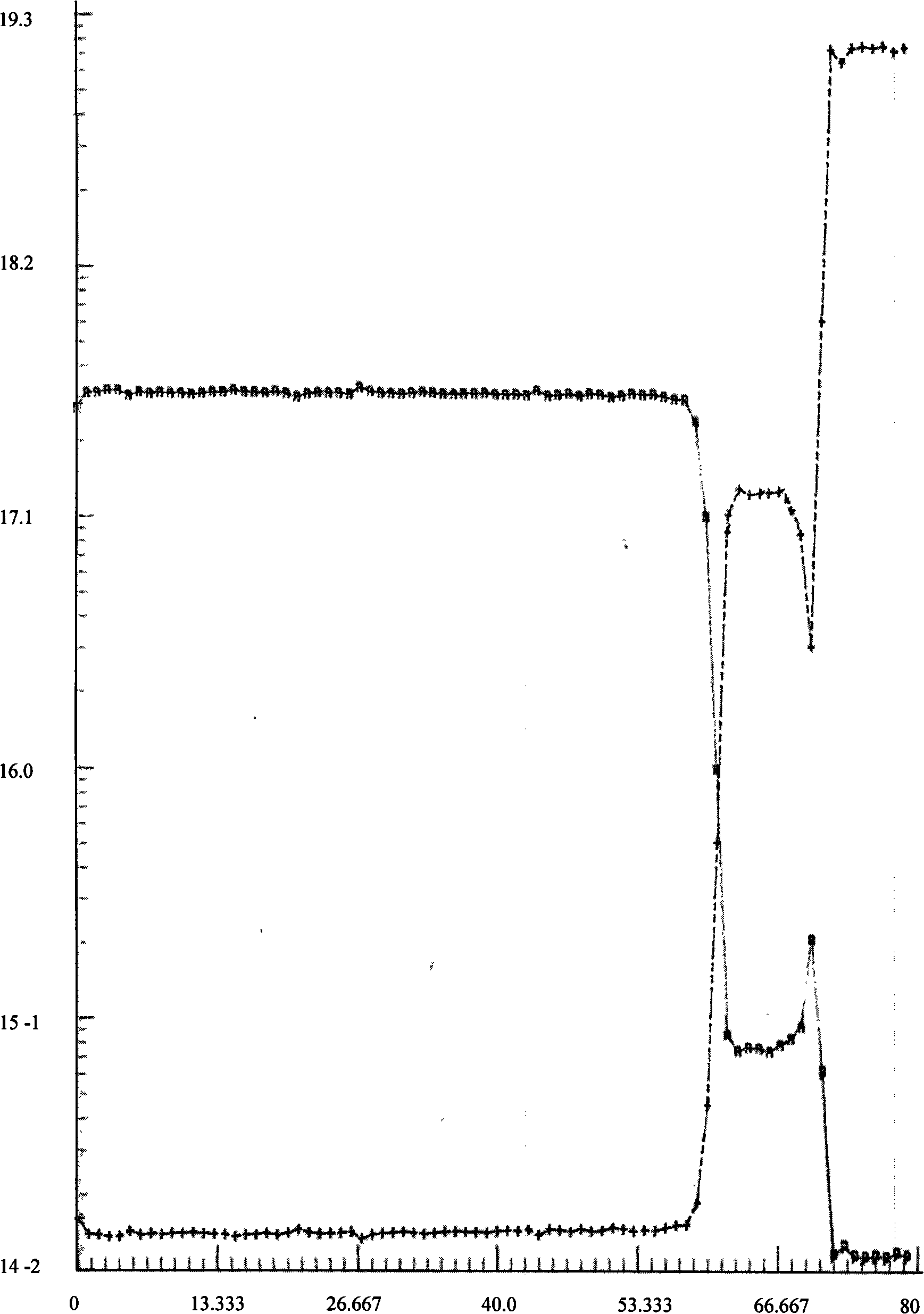

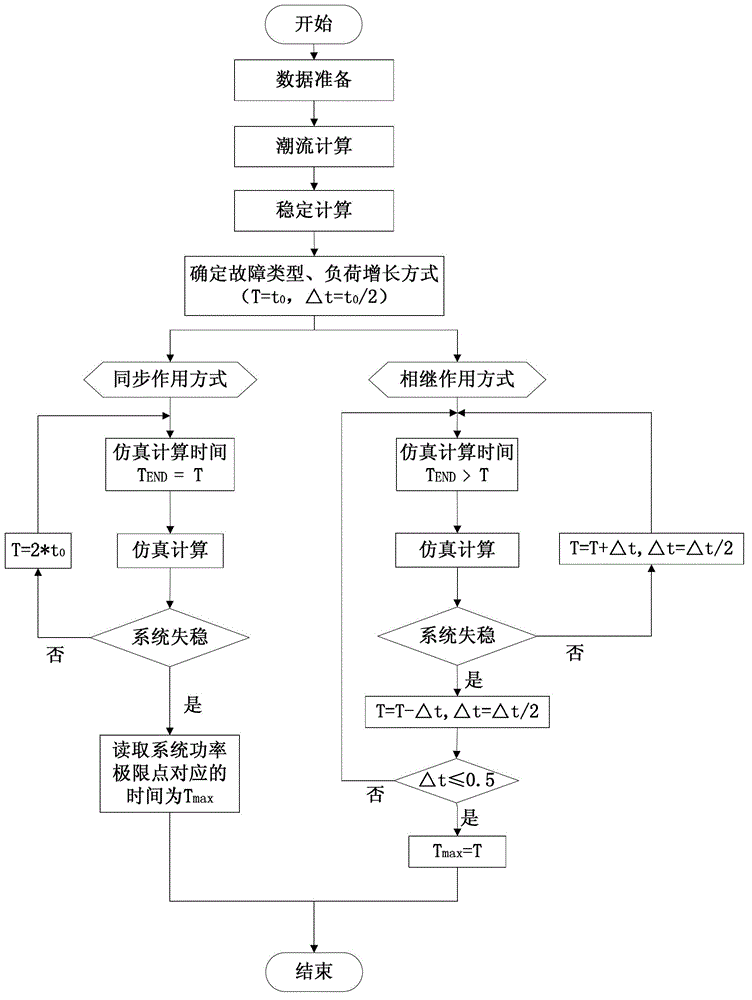

Evaluation method of overall process dynamic voltage stabilization margin based on time domain simulation

ActiveCN103336882AComplies with operating conditionsAccurate Guidance InformationSpecial data processing applicationsStreaming dataMode of action

The invention provides an evaluation method of an overall process dynamic voltage stabilization margin based on time domain simulation. The method comprises the steps that (1) a network topology and a system dynamic element model are constructed according to a computation requirement; a tidal stream file and a stable file required by system computation are established; element parameters are input according to actual conditions of a system; (2) tidal stream data is read in; a tidal stream solution is computed; a destination file is generated; (3) stable data is read in; a fault type and a load growth area or a bus name and a load growth rate are determined; action modes of dynamic elements such as a load, a ULTC (under load tap changer) and overexictation limitation are considered; a fault card and a load growth control statement are filled in; stability computation is performed; and (4) result analysis is performed according to the sustainable load growth time obtained according to simulation computation. According to the evaluation method, a result of successive action of load growth and the generator overexictation limitation or the ULTC can be computed, and a result of synchronous action of each element can be obtained, so that a simulation result can correspond with actual running conditions more.

Owner:STATE GRID CORP OF CHINA +1

Control apparatus and method

InactiveUS20050038587A1Continuous regulationAccurate predictionHedge trimming apparatusAnalogue computers for trafficViticultureControl system

A programmable viticulture management system includes a mechanized device for removing excess undesired portions of plants advances through a vineyard to perform control operations on two rows or half-rows of grape vines simultaneously. Accessories mount to the mechanized device and include various engagement members for engaging the vines. A control system automatically varies the velocity of the engagement members in relation to the vehicle speed. The control system also receives various inputs and provides information on multiple growth control practices.

Owner:MIDWEST GROWER SUPPLY INC

Method for culture of space-series soybean

InactiveCN1947487AIncrease productionReduce the amount of seed usedSeed coating/dressingHorticultureGrowth controlControl diseases

A method for culturing an outer space series soybean with high yield increased by more than two times includes such steps as carefully preparing field, choosing excellent seeds, treating seeds, culturing seedlings in nutritive soil, transplanting in the soil containing sufficient moisture, scientific application of fertilizer and irrigation, controlling diseases and pests, high-yield management, and spraying leaf fertilizer. It features the proper rotation of crops, proper density and growth control.

Owner:杨道敬

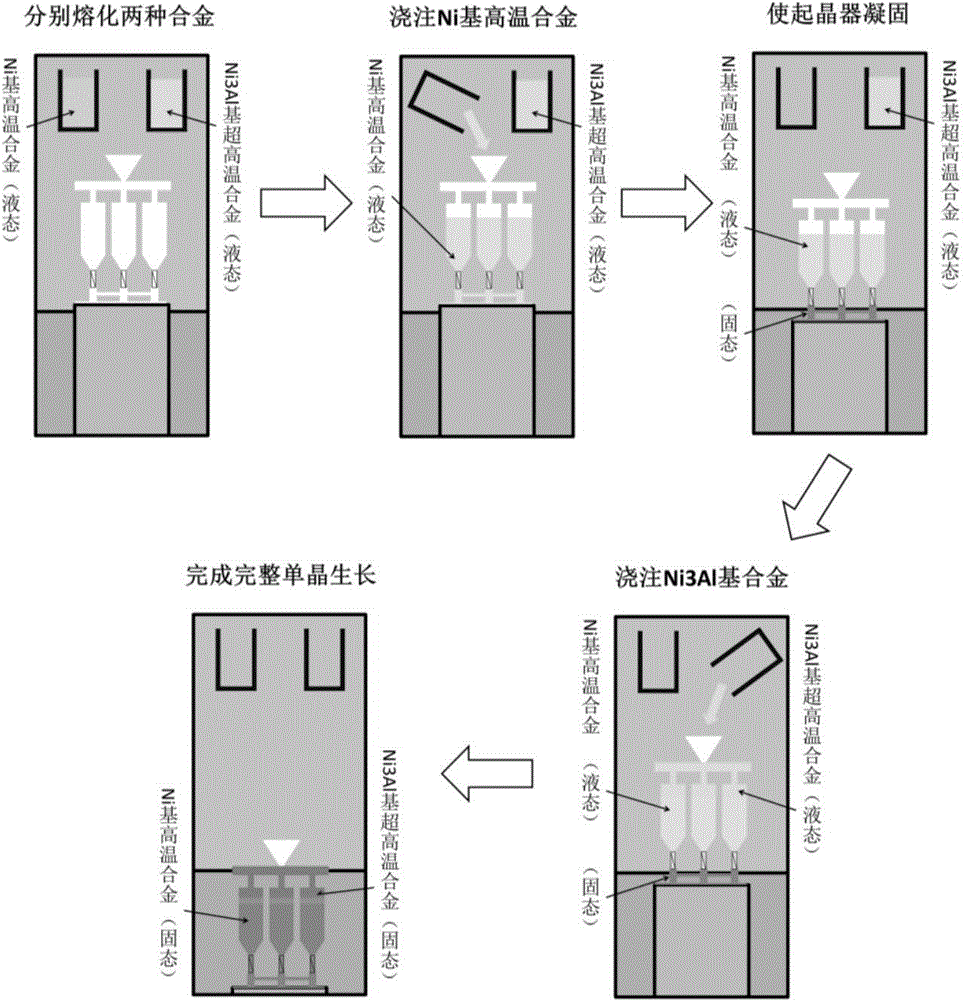

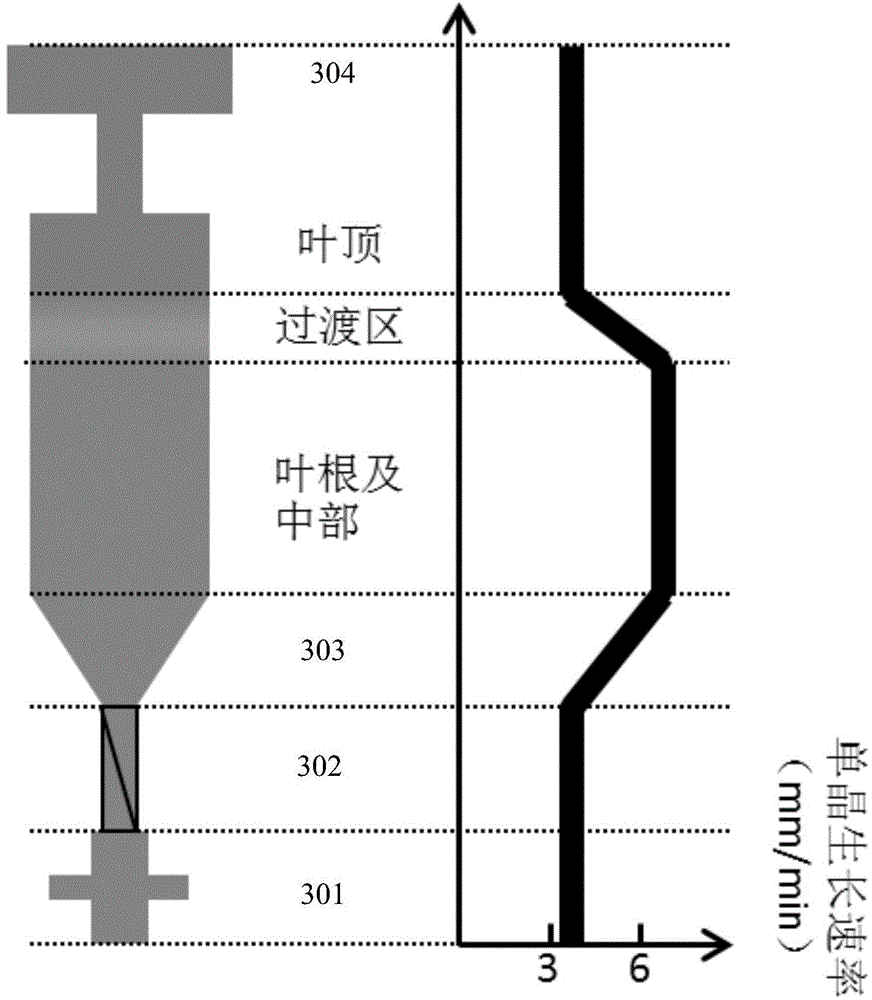

Two-alloy compounded functionally gradient monocrystal blade material and preparation method thereof

InactiveCN104858399ARealize design requirementsSpread evenlyPolycrystalline material growthBlade accessoriesGrowth controlSingle crystal

The invention discloses a two-alloy compounded functionally gradient monocrystal blade material and a preparation method thereof and belongs to the technical field of high-temperature alloy and preparation thereof. The blade root and middle part of a monocrystal blade are made of Ni-based high-temperature alloy, and the blade top of the monocrystal blade is made of monocrystal blade material of Ni3Al-based hyperthermia alloy; the blade root and middle part of the material are predicted to have a better medium and low temperature service performance, and the blade top of the material is predicted to have better hyperthermia service performance. The preparation method comprises the steps of design of form, pouring technology, monocrystal growth control and thermal treatment system. According to the invention, through the design of a narrow passage of a graining device, the longitudinal distribution of two alloys in the blade can be accurately controlled, so that the process stability and material designability are greatly improved; the obtained monocrystal blade material realizes functionally gradient service and meets the design demands of new-generation aero-engines.

Owner:BEIHANG UNIV

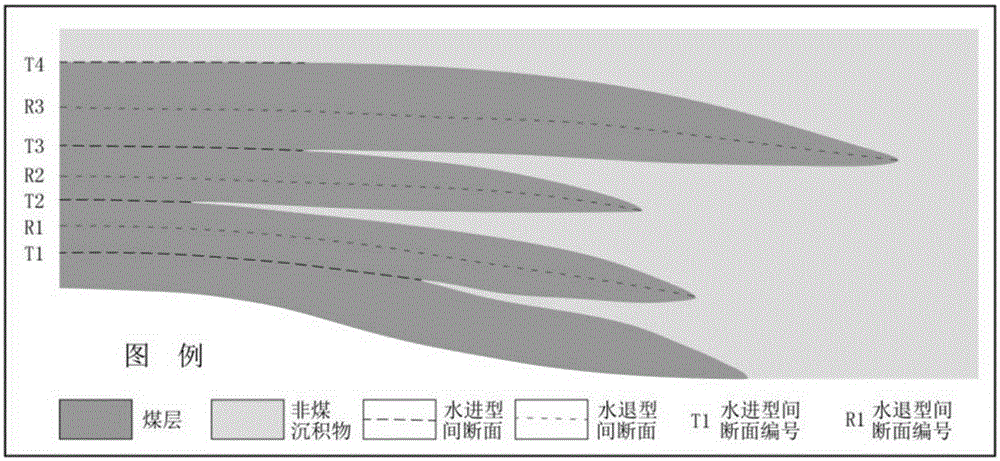

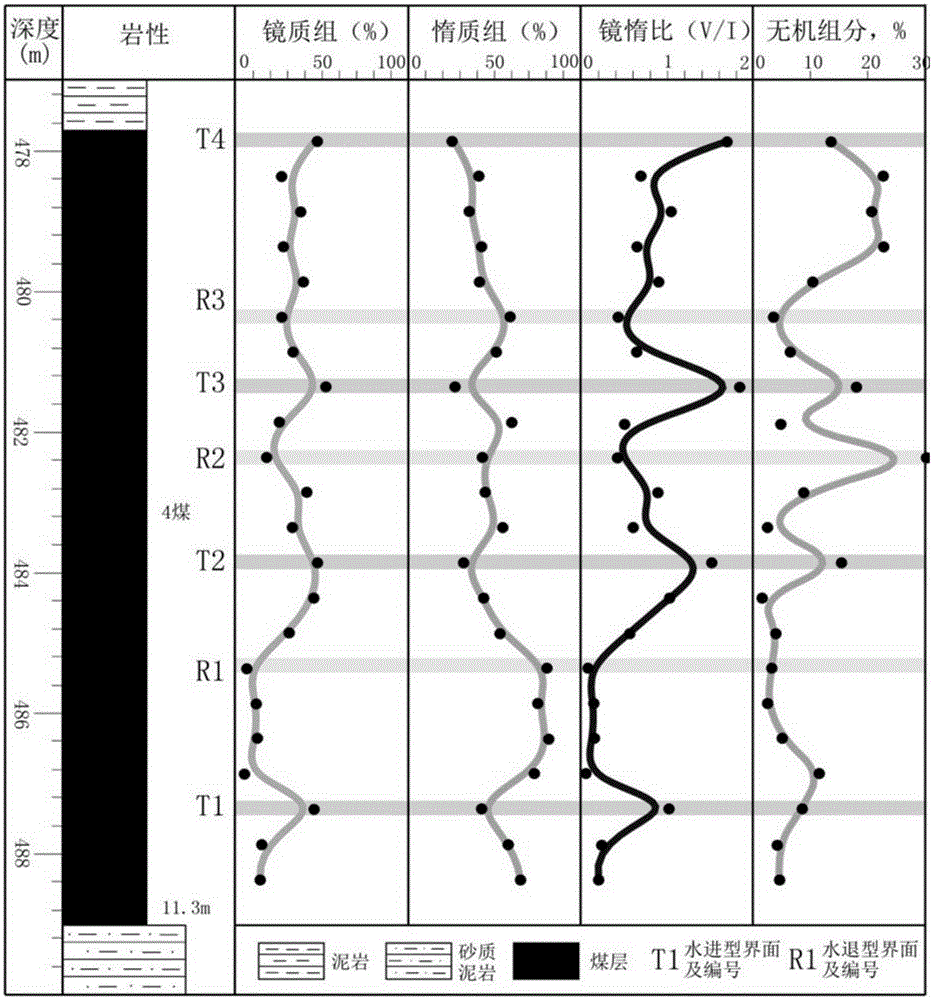

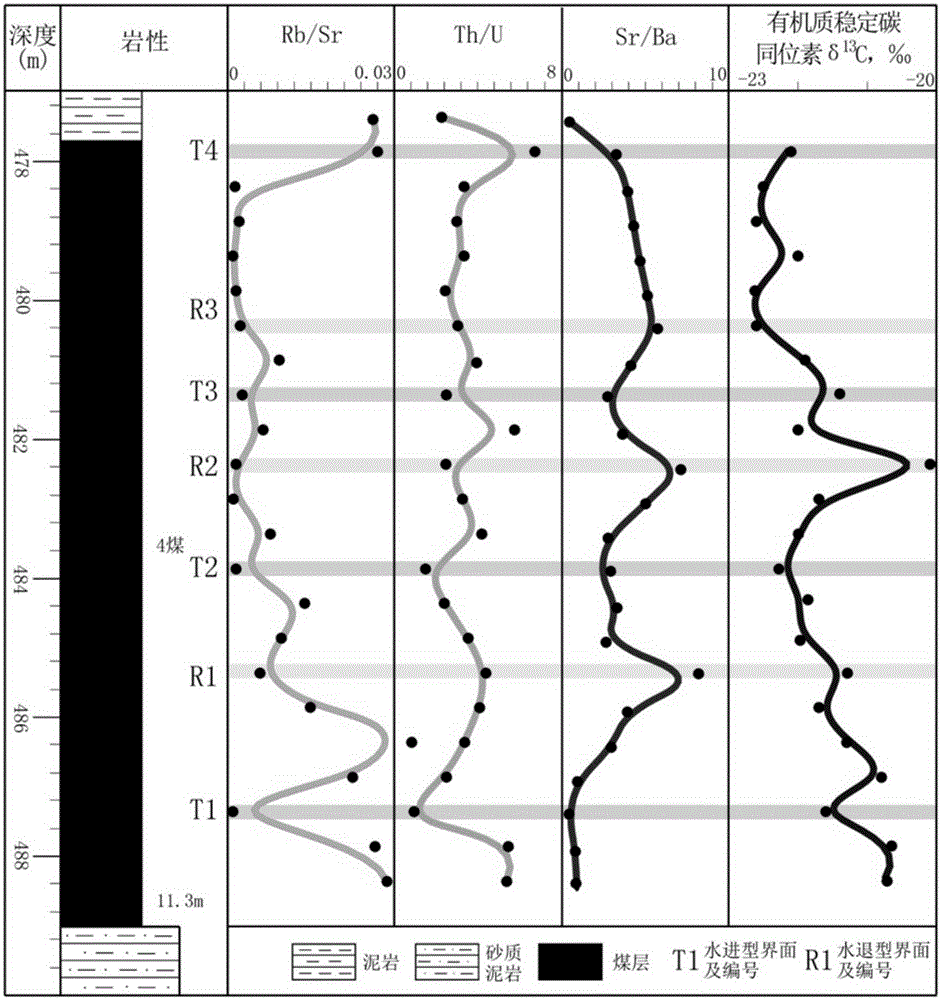

Method for comprehensively recognizing sedimentation hiatal surfaces in ultra-thick seam

InactiveCN105201492AHigh precisionStrong reliabilityBorehole/well accessoriesGrowth controlRoot cause

The invention discloses a method for comprehensively recognizing sedimentation hiatal surfaces in an ultra-thick seam. The sedimentation hiatal surfaces in the ultra-thick seam are comprehensively recognized according to five parameters acquired through coal petrography and coal quality analysis, microelement analysis, organic matter stable carbon isotope analysis, one-dimensional continuous wavelet transformation of log data and Milankovitch cycle analysis of the log data; growth control factors of the sedimentation hiatal surfaces are explained from the origin essentially through recognition of Milankovitch cycles in the ultra-thick seam, the root cause of growth of the sedimentation hiatal surfaces is found out, and the accuracy and the credibility of the sedimentation hiatal surfaces are greatly improved. Besides, weight scoring is performed according to sensitivity of different recognition methods, the recognized sedimentation hiatal surfaces are correspondingly assigned, the scores obtained with all the methods are added up, and the reliability of the sedimentation hiatal surfaces is described quantitatively. The recognition method is convenient and flexible and has better practicability.

Owner:SHANDONG UNIV OF SCI & TECH

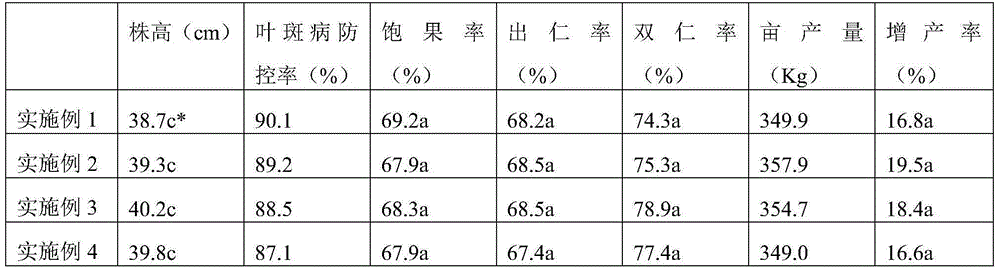

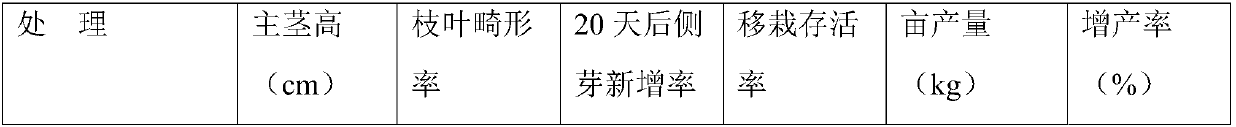

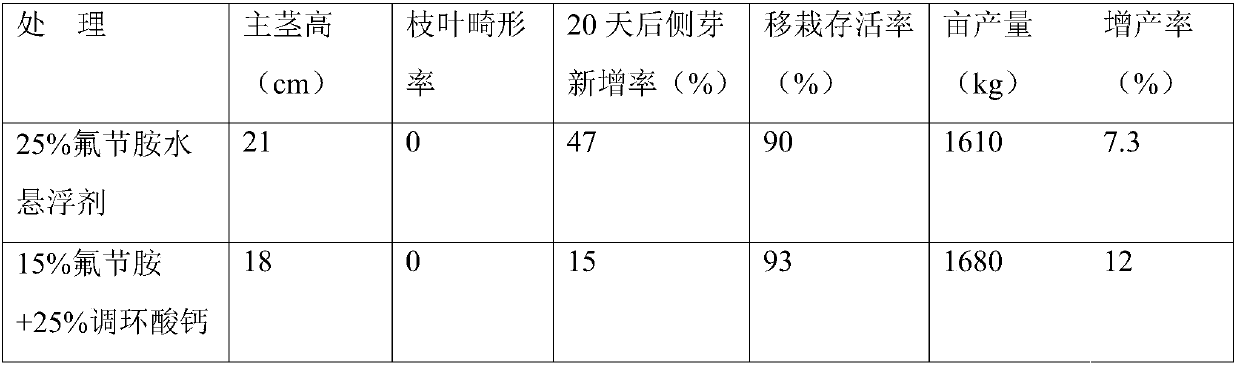

Peanut growing control medical fertilizer wettable powder and method for controlling growth and increasing yield of peanut plants

ActiveCN105237216AImprove biological activityNo residual toxicityPlant growth regulatorsBiocidePlant diseasePaclobutrazol

The invention relates to a peanut growing control medical fertilizer wettable powder and a method for controlling growth and increasing yield of peanut plants, wherein the peanut growing control medical fertilizer wettable powder comprises plant growth regulator adjustable ring acid calcium, brassinolide, bactericide azoxystrobin, macroelement water-soluble fertilizers, microelements and assistants. The peanut growing control medical fertilizer wettable powder and the method for controlling growth and increasing yield of the peanut plants solve a premature aging phenomenon of peanuts because a large amount of growth control agents such as paclobutrazol are used, effectively prevent and control fungal diseases such as leaf spot diseases and the like and supplies nutrient substances required by legumes, and achieves to solve many problems by spraying at one time. Stem leaves are sprayed with the peanut growing control medical fertilizer wettable powder in full-bloom stages and legumes stages, thereby increasing yield 15%-20%. The peanut growing control medical fertilizer wettable powder and the method for controlling growth and increasing yield of the peanut plants are simple to prepare, save labor in operation, are obvious to control growth and increase yield, and are suitable for industrial production and application.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

Nanometer Al matrix composite powder and preparation method thereof

InactiveCN108356259AImprove thermal stabilityImprove laser absorption rateGrowth controlNanoparticle

The invention provides nanometer Al matrix composite powder and a preparation method thereof. The preparation method comprises the following steps: pure Al, a pure Ni or Al-Ni intermediate alloy, an Al-Zr intermediate alloy, an Al-Sc intermediate alloy, an Al-Cu intermediate alloy, an Al-Ti intermediate alloy, an Al-Y intermediate alloy, an Al-Ce intermediate alloy, KBF4 and K2TiF6 are taken as raw materials; an in-situ TiB2 micro-nanometer-particle enhanced nanometer Al matrix composite is prepared by adopting an in-situ melt self-growth control method; and TiB2-particle Al matrix composite powder, namely the nanometer Al matrix composite powder, is prepared through a vacuum gas atomization method, wherein the spherical rate, the yield and the laser absorptivity of the prepared powder arecorrespondingly higher than 90%, higher than and equal to 60%, and higher than 55%. Compared with traditional Al alloy powder, the nanometer Al matrix composite powder provided by the invention has the following beneficial effects: (1) nanometer particles are dispersedly distributed in matrix grains, the thermal stability is higher, and the nanometer Al matrix composite powder is applicable to the powder metallurgy technology; and (2), the laser absorptivity is higher, and the nanometer Al matrix composite powder is more applicable to the laser additive manufacturing technology.

Owner:SHANGHAI JIAO TONG UNIV

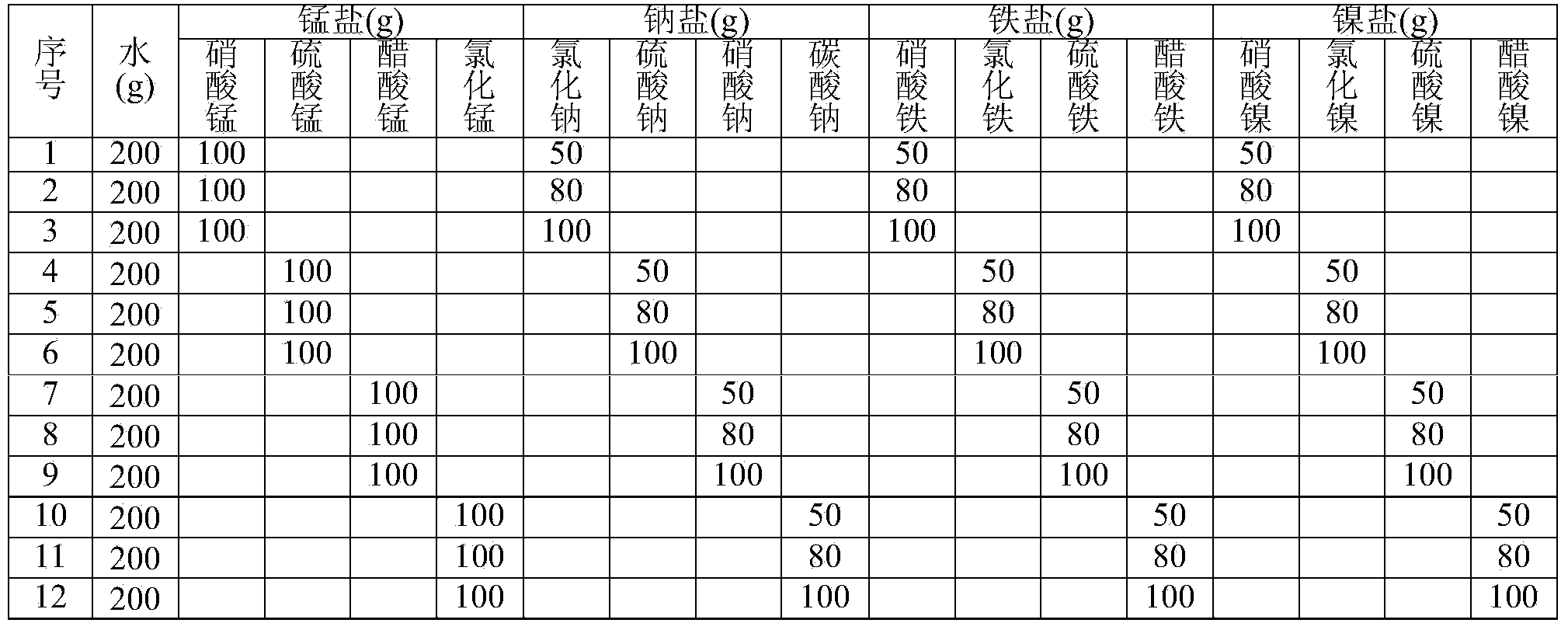

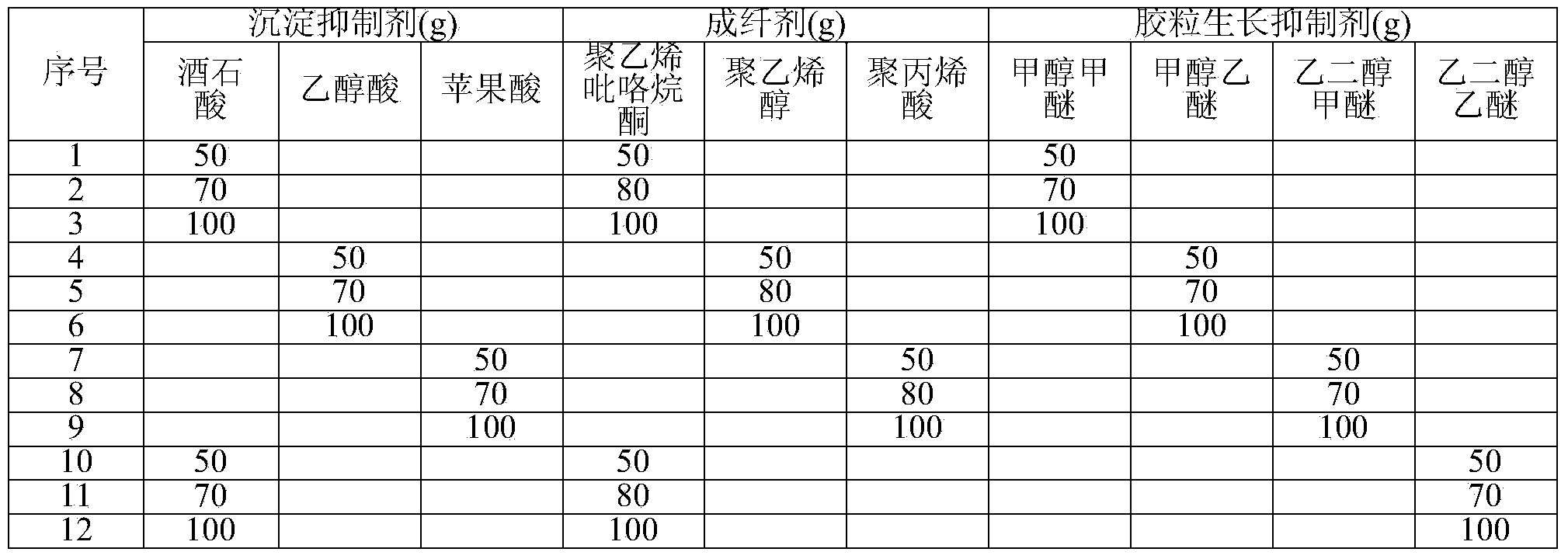

Preparation process of positive electrode material for sodium ion battery

InactiveCN104167541AImprove fiber performancePrevent precipitationCell electrodesSecondary cellsNickel saltGrowth control

The invention discloses a preparation process of a positive electrode material for a sodium ion battery. The preparation process is characterized by comprising the following steps: adding manganese salt, sodium salt, ferric salt and nickel salt into water, uniformly stirring, and then adding a precipitation inhibitor; after uniformly mixing, adding a fiber forming agent and a colloidal particle growth control agent, and uniformly stirring to obtain precursor sol; pouring a precursor solution into a centrifugal spinning machine, so as to obtain raw cotton of an electrode material; and drying and calcining the cotton wool, so as to obtain electrode material cotton at last. The sodium ion battery applying the cotton has the characteristics of high charge and discharge capacity and good cycle performance.

Owner:SHAANXI UNIV OF TECH

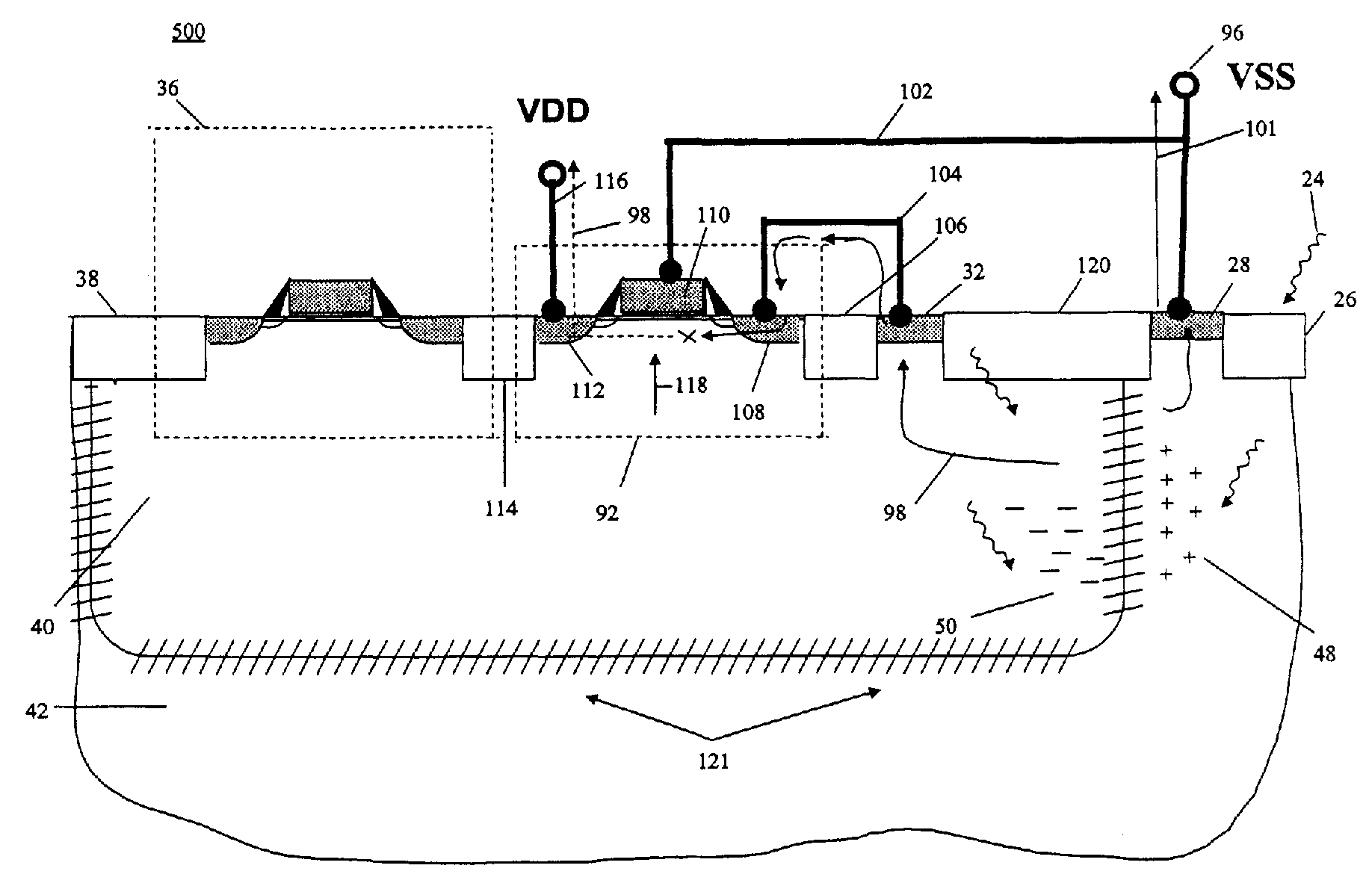

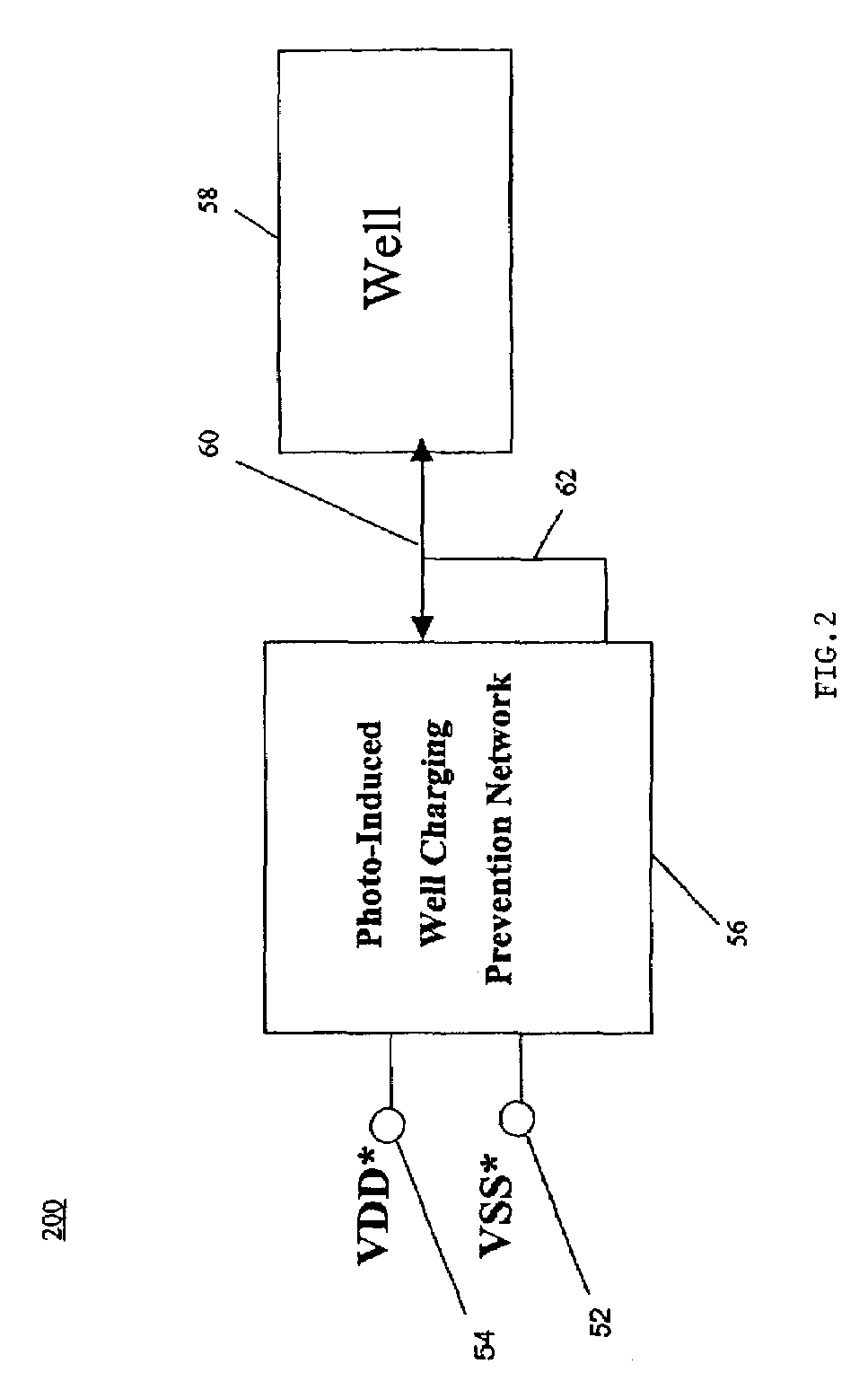

Dendrite growth control circuit

ActiveUS7109584B2Semiconductor/solid-state device detailsSolid-state devicesDevice materialGrowth control

A circuit is provided which prevents dendrite formation on interconnects during semiconductor device processing due to a dendrite-forming current. The circuit includes a switch located in at least one of the dendrite-forming current paths. The switch is configured to be open or in the “off” state during processing, and is configured to be closed or in the “on” state after processing to allow proper functioning of the semiconductor device. The switch may include an nFET or pFET, depending on the environment in which it is used to control or prevent dendrite formation. The switch may be configured to change to the “closed” state when an input signal is provided during operation of the fabricated semiconductor device.

Owner:GLOBALFOUNDRIES U S INC

Method for producing similar mono-crystalline silicon by using casting process

The invention discloses a method for producing similar mono-crystalline silicon by using a casting process. The method comprises the improvement on a GT (Gas Tight) furnace or ingot casting furnace equipment of heaters on the four surfaces and the top surface and the growth control of similar mono-crystal. The improvement of the ingot casting furnace equipment is that an improved similar mono-crystalline silicon ingot thermal field gradient device is provided. The growth control of the similar mono-crystal comprises one or a combination of a cast furnace silicon material and seed crystal placing method, a chemical material heating method and a method for stabilizing seed crystal at the bottom of a furnace after the seed crystal in the furnace is molten. The method disclosed by the invention has the benefits that: by changing a thermal field device and materials of the GT furnace or the heaters on the four surfaces and the top, completing the cast furnace silicon material and seed crystal placing method, the chemical material heating method and the method for stabilizing the seed crystal at the bottom of the furnace after the seed crystal in the furnace is molten, and the like, the internal temperature curve of the thermal field is changed, and a chemical material and growth isothermal curve can be obviously improved; furthermore, the seed crystal melting problem of the similar mono-crystal can be solved; and the problems of high cost, low reliability and low success rate of the similar mono-crystal production can be solved.

Owner:ANYANG PHOENIX PHOTOVOLTAIC TECH +1

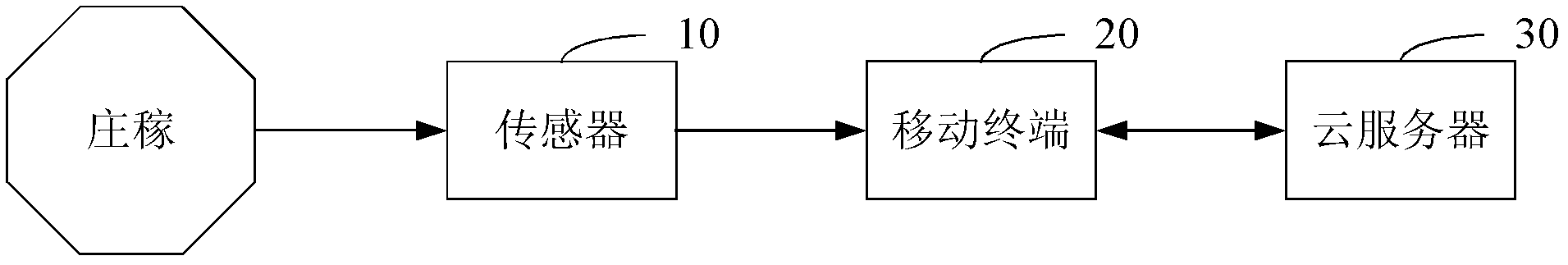

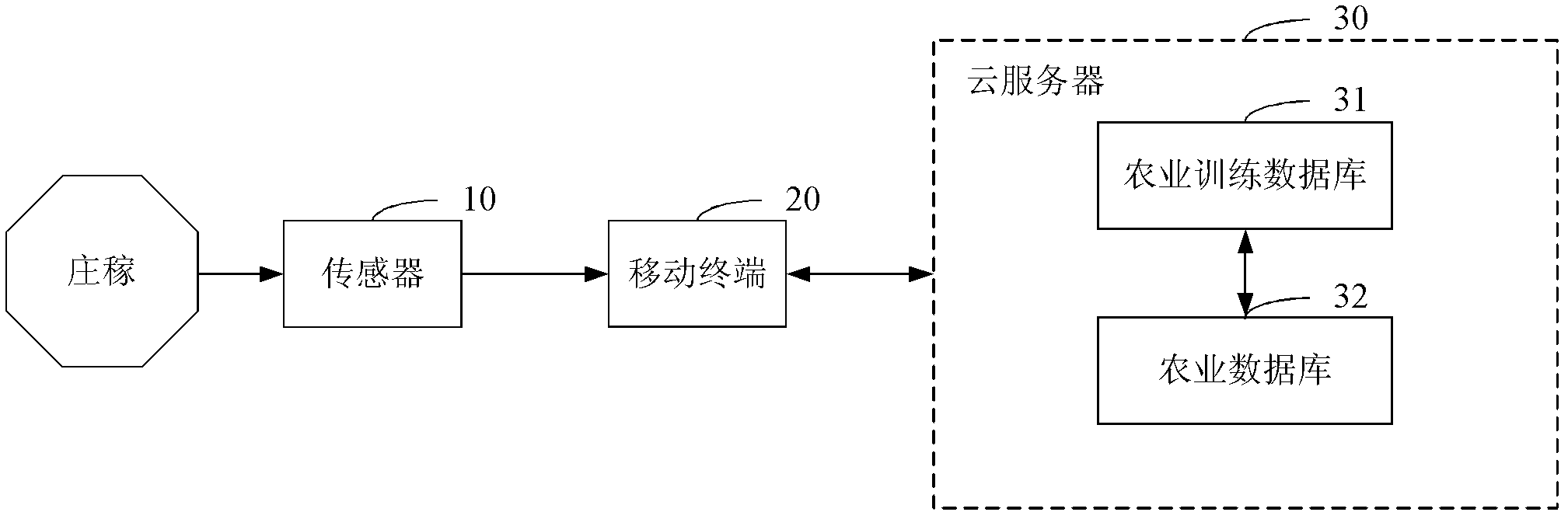

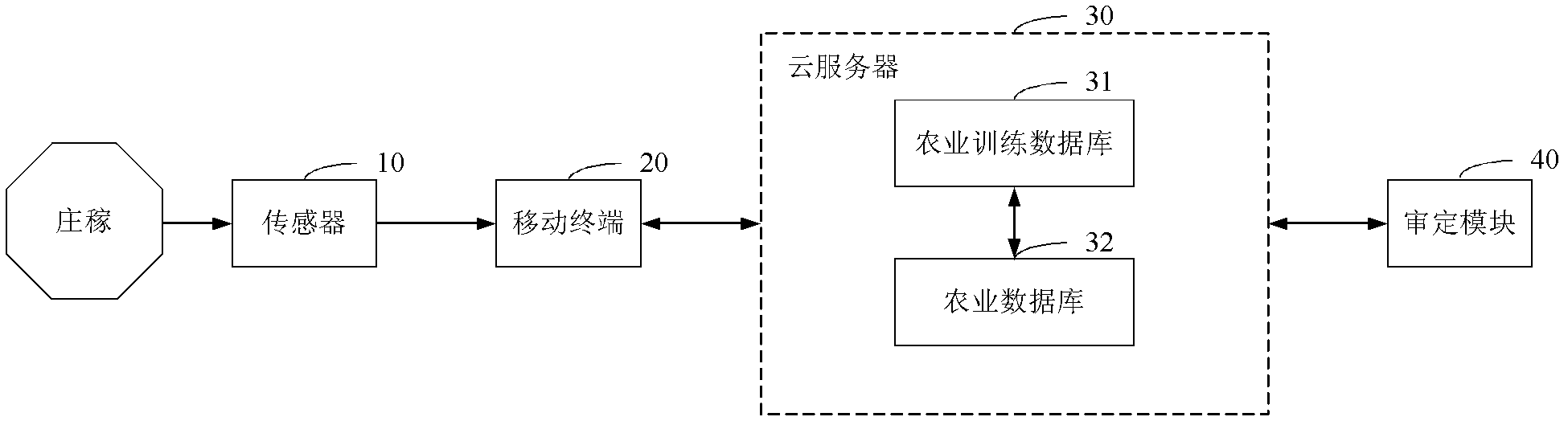

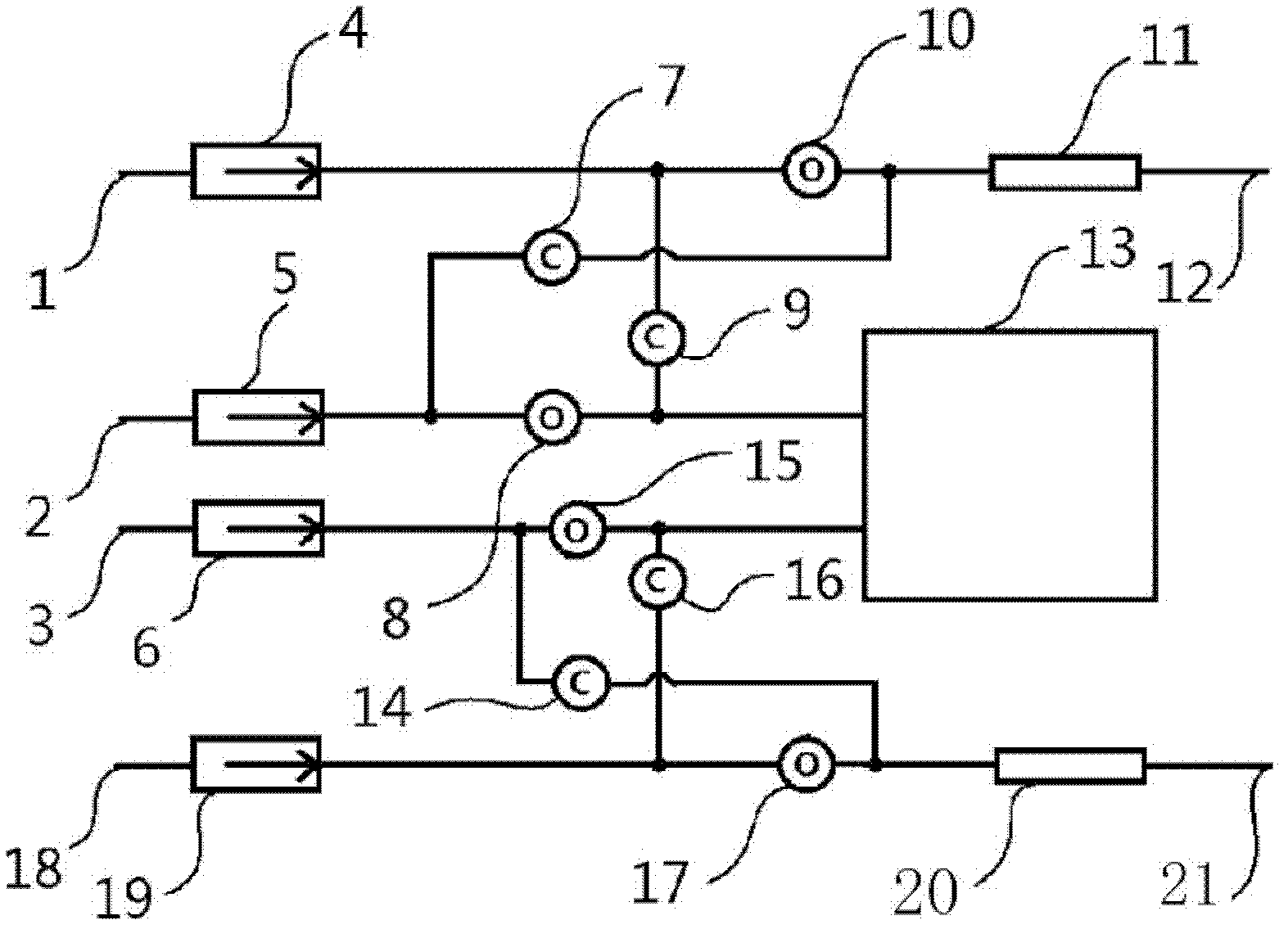

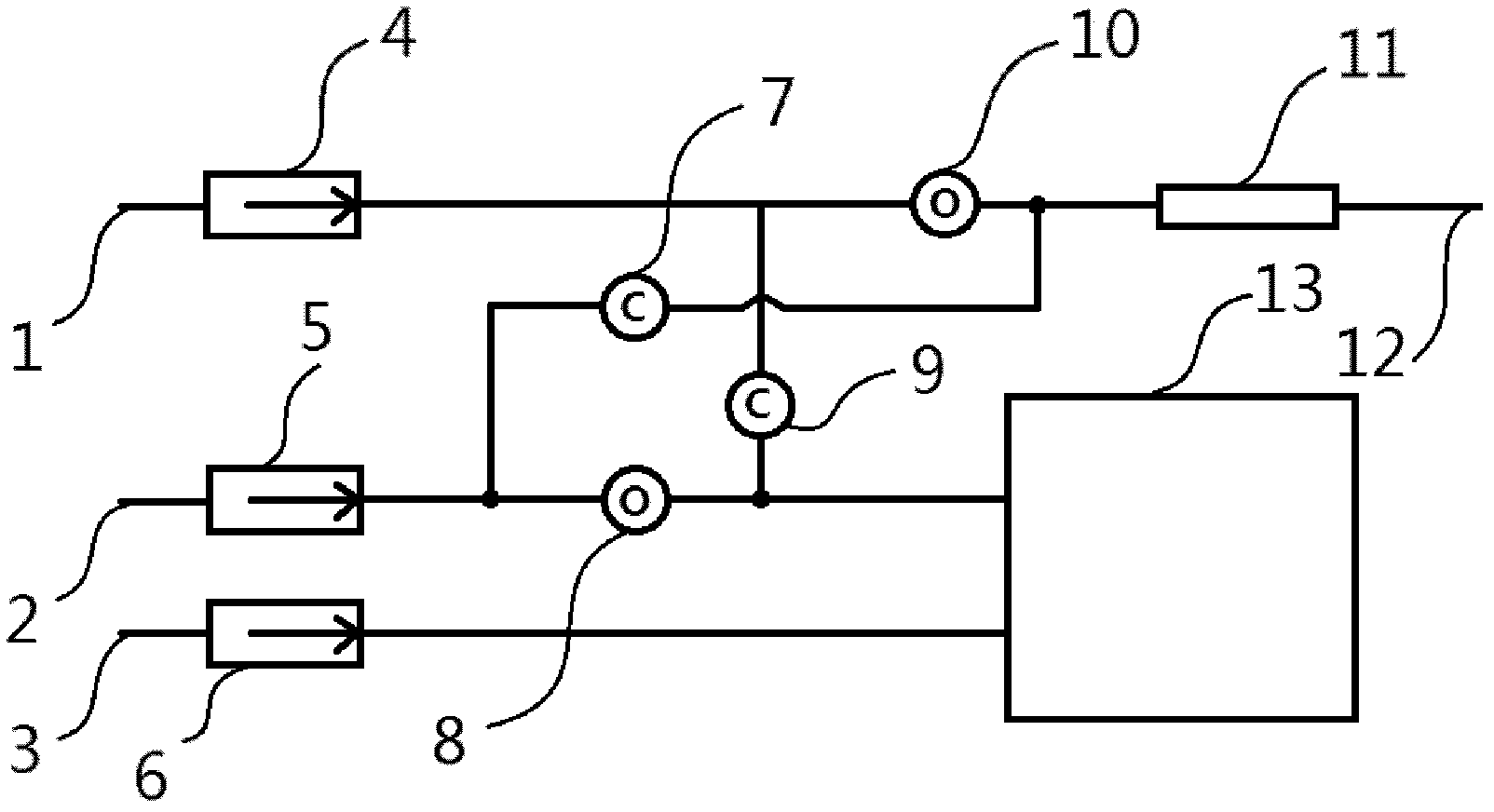

Agricultural growth control system and agricultural growth control method

InactiveCN102591279AGuaranteed harvestKnow in timeProgramme total factory controlControl systemGrowth control

Provided are an agricultural growth control system and an agricultural growth control method. The system comprises a sensor and a mobile terminal, wherein the sensor acquires agricultural growth information, the mobile terminal acquires the agricultural growth information acquired by the sensor and transmits the agricultural growth information into a cloud server, and the cloud server calculates the agricultural growth information to obtain agricultural farming information, feeds the agricultural farming information back to the mobile terminal and displays the agricultural farming information on the mobile terminal. By adopting the scheme, an agricultural production farmer having the mobile terminal can timely know the present agricultural growth information (crop growth data), can know framing measures should be adopted in the existing agriculture and timely acquires the agricultural growth information, and therefore the agricultural growth control system and the agricultural growth control method provide powerful guarantee for harvest of agricultural production.

Owner:李建成

Vigorous growth control medicament for strawberry plants

ActiveCN107624757AWon't cause shrinkage etc.Short residual periodBiocidePlant growth regulatorsGrowth retardantGrowth plant

The invention belongs to the technical field of agricultural production plant growth regulators, and discloses a vigorous growth control medicament for strawberry plants. The effective components of the vigorous growth control medicament for strawberry plants are flumetralin and prohexadione calcium, a weight ratio of the flumetralin to the prohexadione calcium is 30:1 to 1:30, and the total weight of the two components is 5-80% of the weight of the vigorous growth control medicament for strawberry plants. The vigorous growth control medicament for strawberry plants can effectively control thevigorous growth of the strawberry plants in the seedling stage in order to promote bud differentiation and improve the disease resistance and the output. The vigorous growth control medicament for strawberry plants, obtained through compounding low-toxicity plant growth inhibitors having two different acting modes, can improve the vigorous growth control effect, effectively reduce the use amount,reduces the use cost, and improves the eating safety of strawberries.

Owner:江西禾田科技有限公司

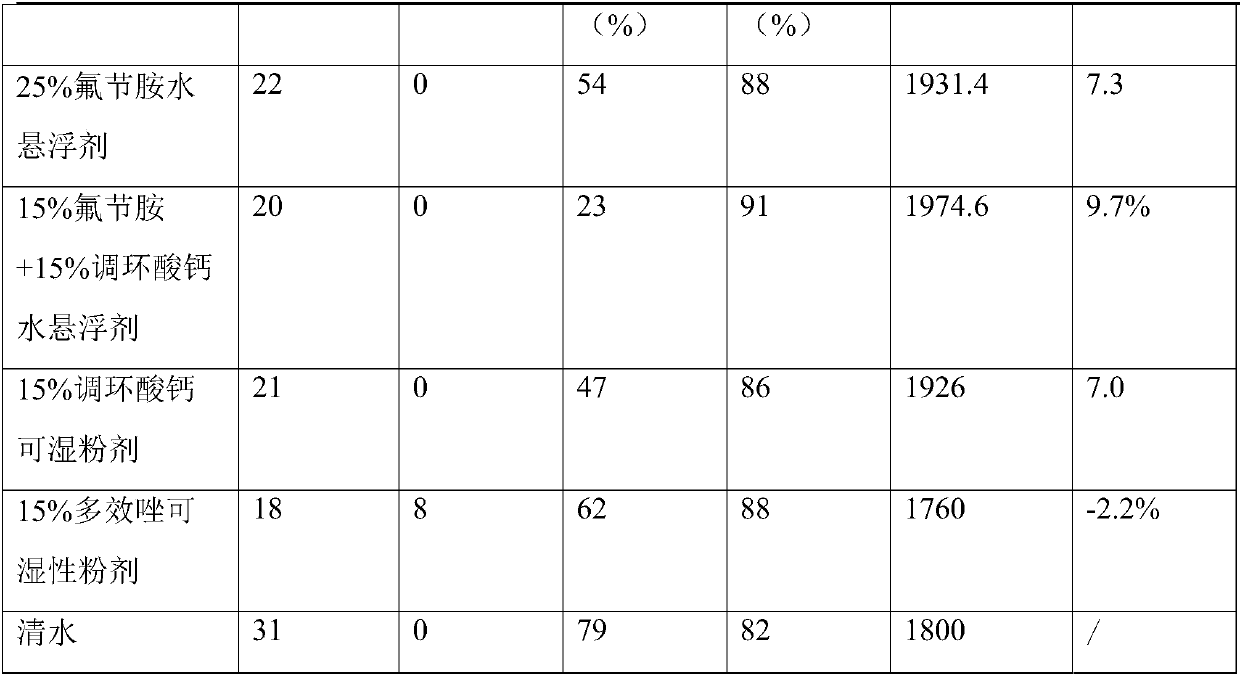

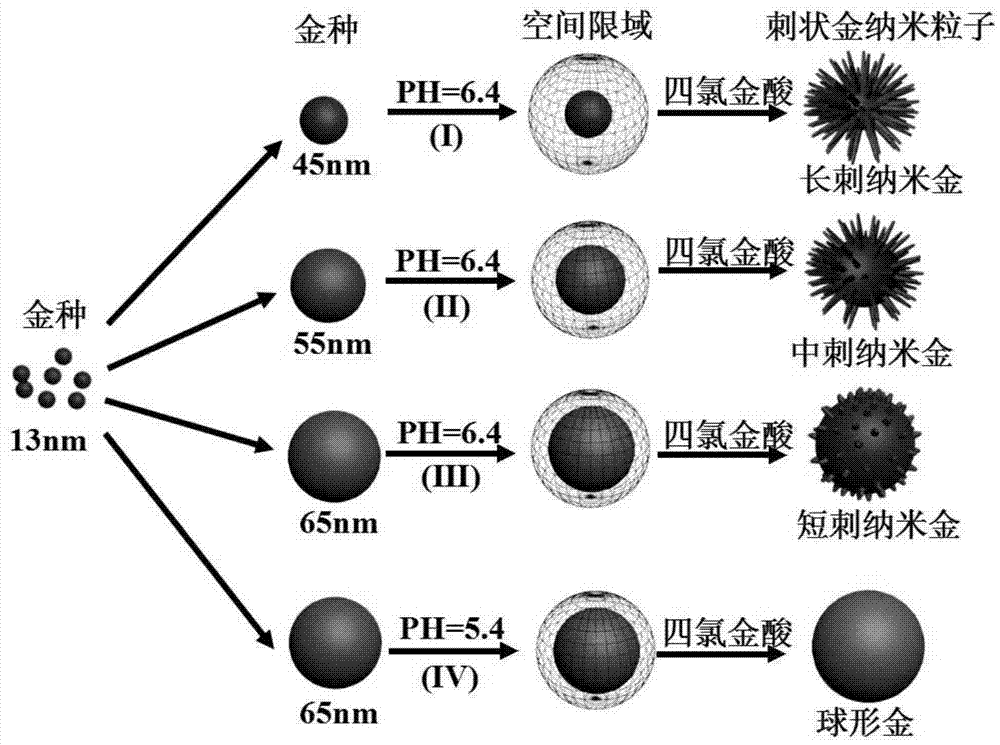

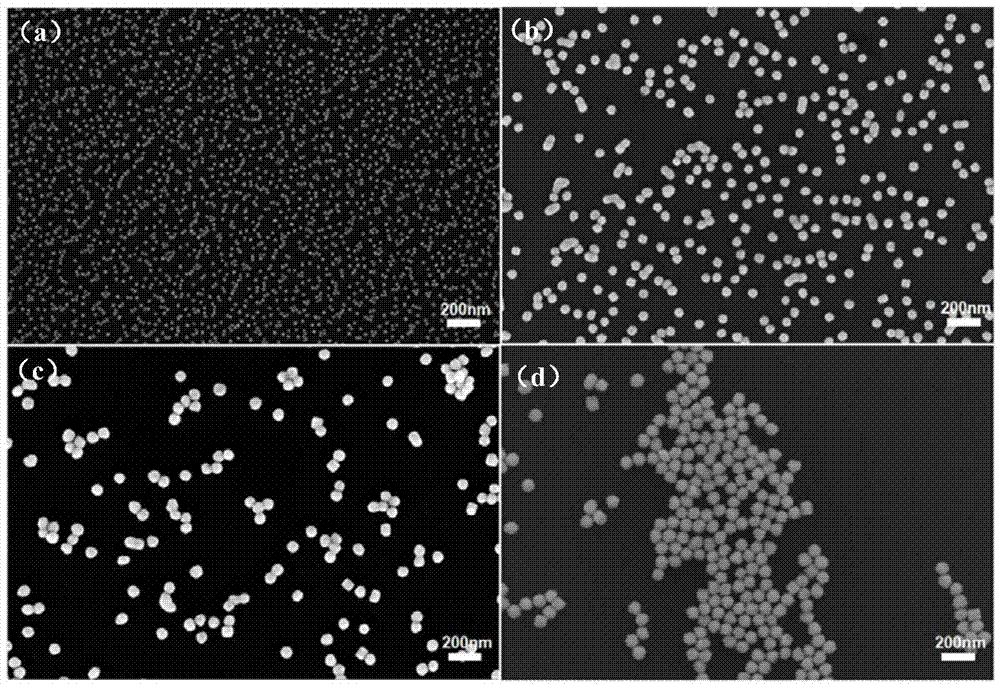

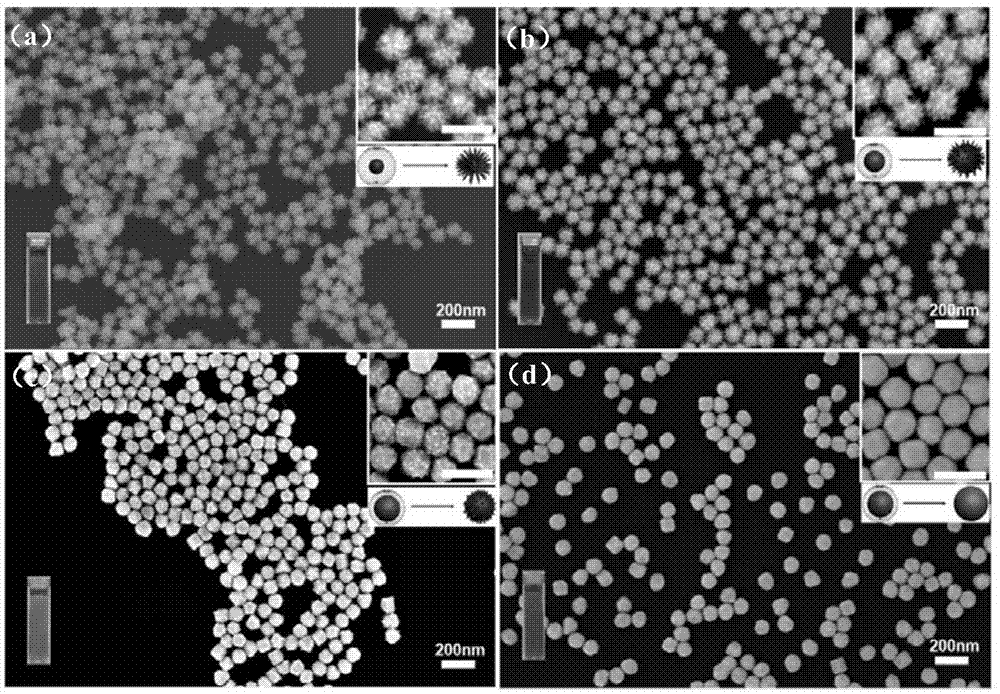

Preparation method of thorn-shaped gold nanoparticles and thrust-shaped gold nanoparticles prepared through method

ActiveCN104722773AGood for particle size controlGood for controlling uniformityGrowth controlNanoparticle

The invention relates to a preparation method of thorn-shaped gold nanoparticles and thrust-shaped gold nanoparticles prepared through the method. The method includes the following steps that step a, a first sodium citrate solution is added into a first boiled chloroauric acid solution, boiling is kept under the condition of constant stirring, and therefore a gold nanoparticle solution of which the particle size ranges from 10 nm to 30 nm is obtained; step b, a hydroxylamine hydrochloride solution and the gold nanoparticle solution are added into an acid gold chloride solution for performing growth control over the particle size, and large-particle-size gold nanoparticles are obtained in a centrifugal mode; step c, the large-particle-size gold nanoparticles are added into deionized water of which the pH is adjusted through a second sodium citrate solution, gold chloride is added under the condition of constant stirring for space limited-range core shell growth, and the gold nanoparticles can be obtained in a centrifugal mode. On one hand, the sodium citrate solutions are selected and used for adjusting the pH value of the solution, and on the other hand, the sodium citrate solutions have the unexpected advantages that the sodium citrate solutions are good stabilizers for the gold nanoparticles, and the particle size and the evenness of the gold nanoparticles are easily controlled.

Owner:SUZHOU UNIV

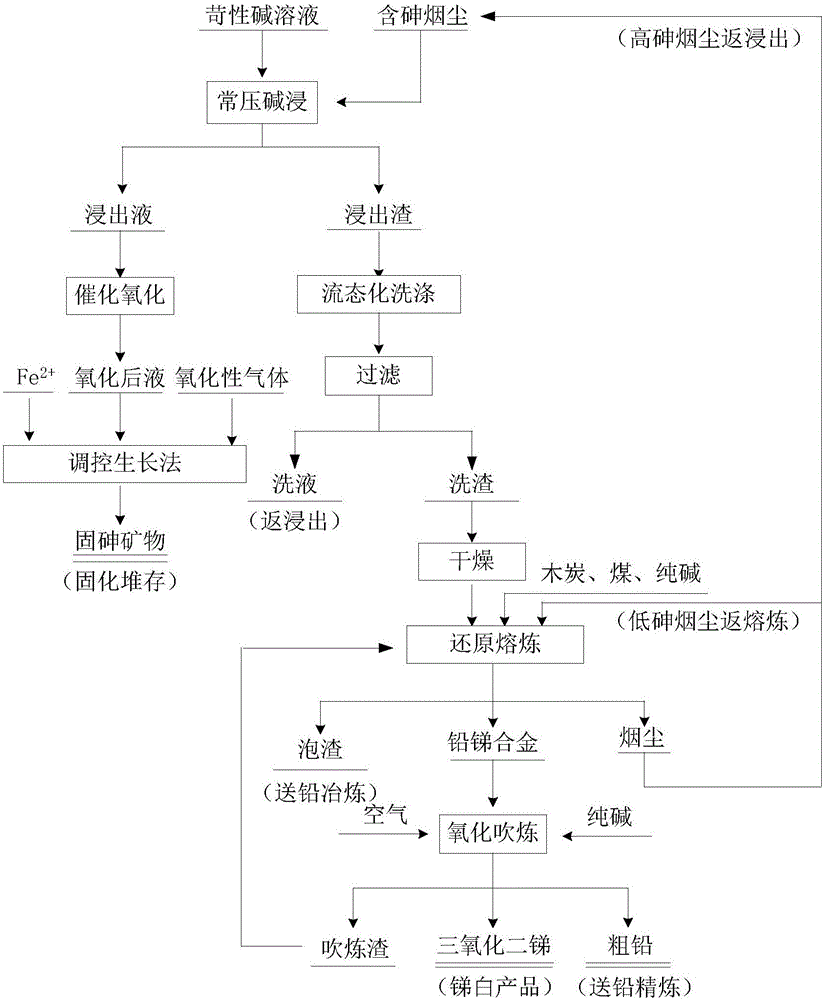

Method for removing arsenic from smoke containing arsenic and curing arsenic

ActiveCN106801145AAchieve separationImprove resource utilizationProcess efficiency improvementCatalytic oxidationPollution

The invention relates to a method for removing arsenic from smoke containing arsenic and curing arsenic. The method comprises production of comprehensively recycling valuable metals such as arsenic, antimony, lead and bismuth from the smelting smoke containing arsenic, antimony and lead, accumulation of arsenic in the system is reduced, and arsenic is made to be harmless. According to the method, through normal-pressure alkaline leaching, soluble arsenic is removed from the smoke, trivalent arsenic in a leaching agent is converted into pentavalent arsenic through catalytic oxidation, stable arsenic fixing minerals are synthesized through a growth control method, then the arsenic fixing minerals are cured through a stockpiling manner, the processes of washing, reduction smelting, oxidation blowing and the like are conducted on leaching residues, and valuable elements are recycled to the maximum extent. By the adoption of the method, arsenic is removed from the smoke, antimony, lead and bismuth are remained in the residues without arsenic as much as possible, and separation of arsenic and the valuable metals can be achieved and is harmless. By the adoption of the method, the comprehensive rate of resources is high, the raw material application range is wide, the pollution problem existing in a traditional process extraction process, especially the pollution caused by smoke generated in a lead-zinc smelting process is solved, and the advantages of the method are more remarkable.

Owner:CENT SOUTH UNIV

Litchi planting method

InactiveCN106900447AIncrease the absorption areaIncrease the areaBiocideCalcareous fertilisersGrowth controlObserved Survival

The invention belongs to the technical field of planting, and particularly relates to a litchi planting method. The litchi planting method comprises the following steps that 1, cultivated land is selected and a garden is built; 2, grafting is conducted; 3, soil preparation and field planting are conducted; 4, shoot growth controlling and clipping are conducted. According to the litchi planting method, the survival rate and the yield of planted litchis are increased obviously, the litchis are bright in color, the size is large and uniform, the skin is thin, the sarcocarp is thick, the litchis are tender, juicy and sweet, and the litchis are rich in fragrance.

Owner:陆川县钰荣种养专业合作社

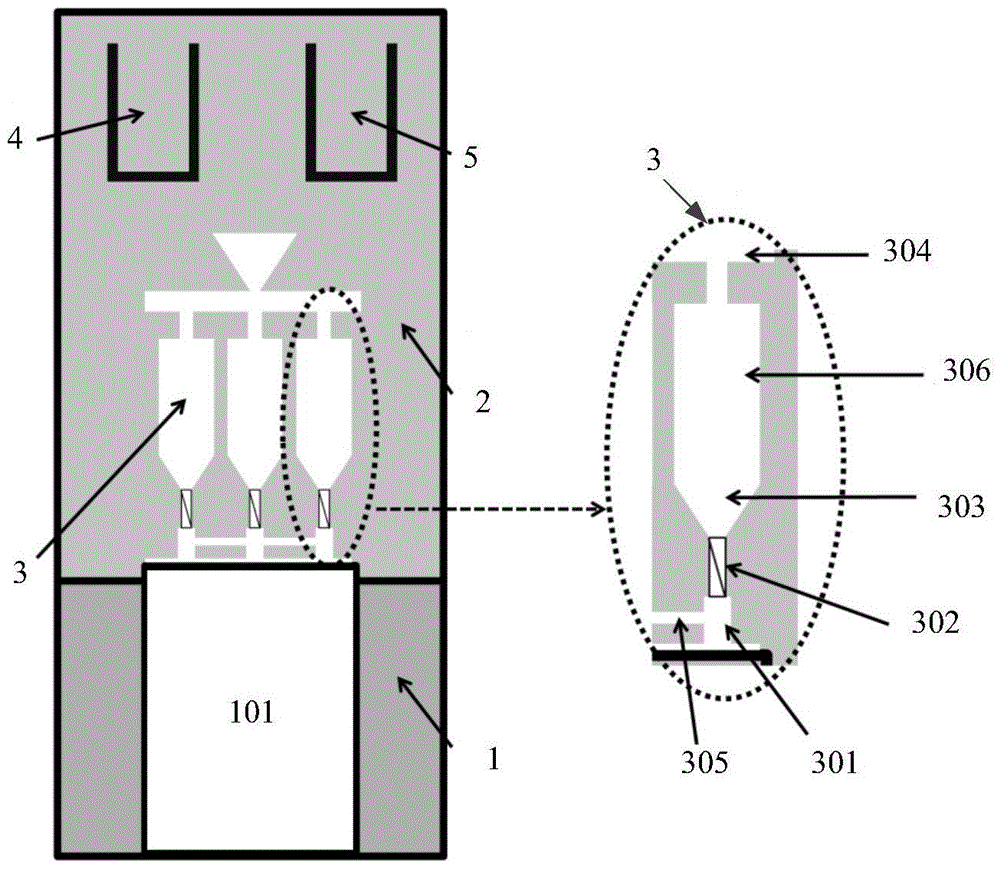

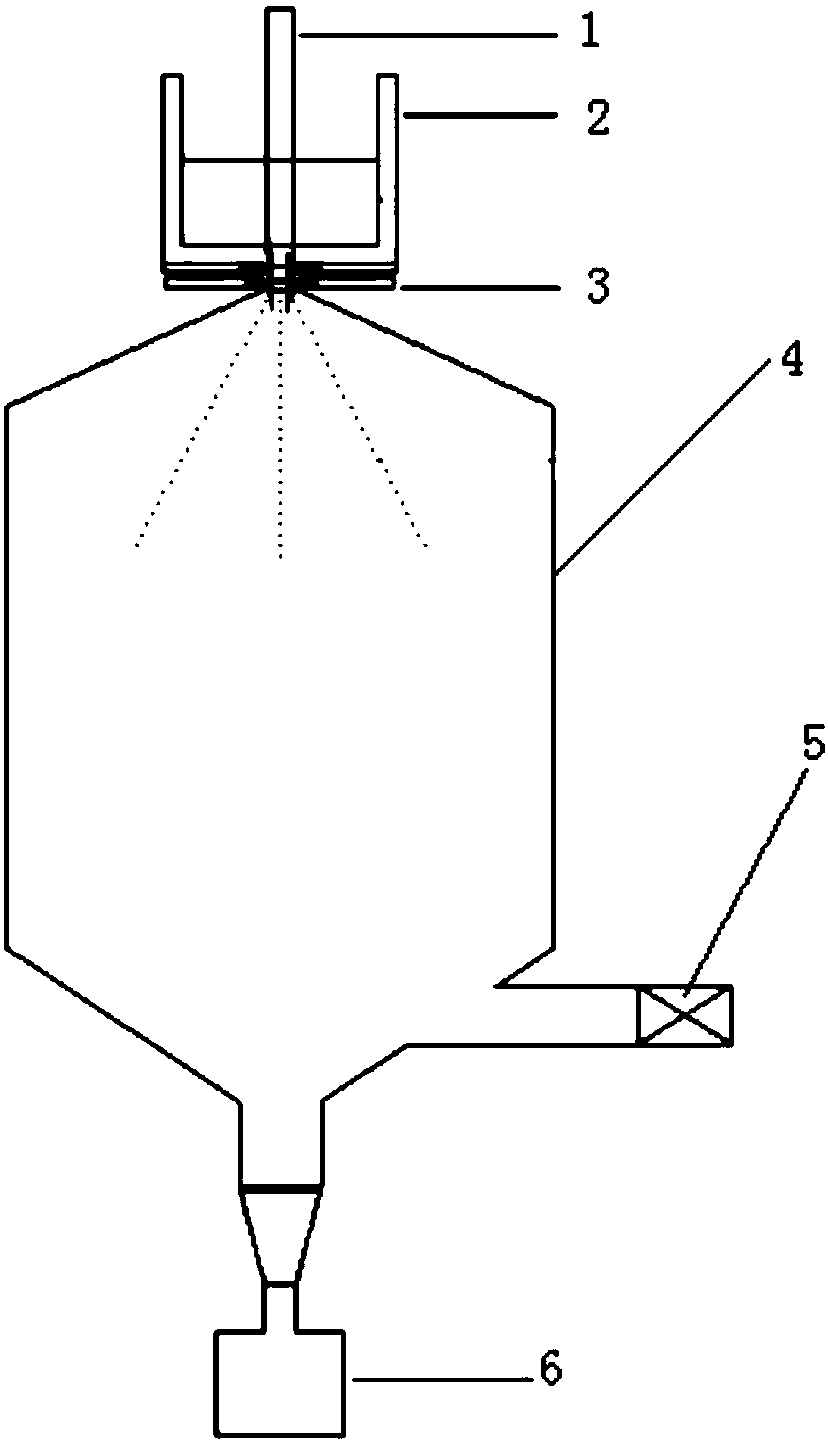

Semiconductor film growth control device and semiconductor film growth control method

InactiveCN102206814ASteep growth interfaceQuick switchChemical vapor deposition coatingFilm materialGrowth control

The invention particularly relates to a semiconductor film growth control device and a semiconductor film growth control method using the same. The semiconductor film growth control device provided by the invention comprises a response source pipeline and a semiconductor film growth response cavity, wherein the response source pipeline comprises a plurality of intake pipes; each intake pipe is provided with a valve and a flow controller; and the valve is arranged in a position adjacent to the semiconductor film growth response cavity. When the semiconductor film growth control device is used for preparing semiconductor film materials, since the valve is near enough to semiconductor film growth response cavity, the response source and carrier gas can be quickly switched to enter the response cavity, and the film growth can be quickly stopped or started, thereby implementing accurate control of film thickness. The invention can also implement quickly switching among different response gas atmospheres to reduce the growth of the transition layer, thereby implementing the steep growth interface between films of different components and greatly improving the properties of the film devices.

Owner:广东众元半导体科技有限公司

Breeding method for shortening productive phase of licorice root seeds

ActiveCN103988690AShorten the breeding periodMeet the growth conditionsHorticulture methodsGrowth controlShoot

The invention discloses a breeding method for shortening the productive phase of licorice root seeds. The breeding method includes the steps of land selection and preparation, breeding material selection and treatment, transplanting, fertilization and management, weeding and water and waterlogging prevention, artificial supplementary pollination, growth control and increase of the set of fruit, pest control, overwintering protection and timely seed collecting. According to the method, a licorice root old root which is more than five years old serves as a breeding female parent, a stolon is cut and transplanted, the productive phase of the licorice root seeds is shortened, and the yield and the quality of the licorice root seeds are improved through the methods that the growth environment of licorice roots is improved, young shoots are pinched off and the like.

Owner:LONGXI JIFENG SEED IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com