Nanometer Al matrix composite powder and preparation method thereof

An aluminum-based composite material and composite material technology, applied in the field of nano-aluminum-based composite material powder and preparation, can solve the problem of material fatigue strength, plasticity and toughness reduction, which cannot fully meet the requirements of high-performance parts manufacturing, high residual stress cracks and holes To achieve the effects of inhibiting recrystallization growth, high strength and plasticity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a kind of nano-aluminum matrix composite material powder, and its preparation method comprises:

[0042] Pure aluminum, pure Ni or Al-Ni master alloy, Al-12Zr master alloy, Al-Cu master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 5wt.%TiB 2 Reinforced Al-10Ni-2.3Cu-3Zr composites. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 Mix evenly according to the mass ratio of 1:2, dry and add to the melt; after the reaction is finished, take out the reaction by-products, add Al-Ni master alloy, Al-12Zr master alloy, Al-Cu master alloy in turn, Add JZJ type harmless aluminum alloy refining agent to the body for degassing refining, let it stand at 750°C for 15 minutes, and then make powder through a gas atomization device.

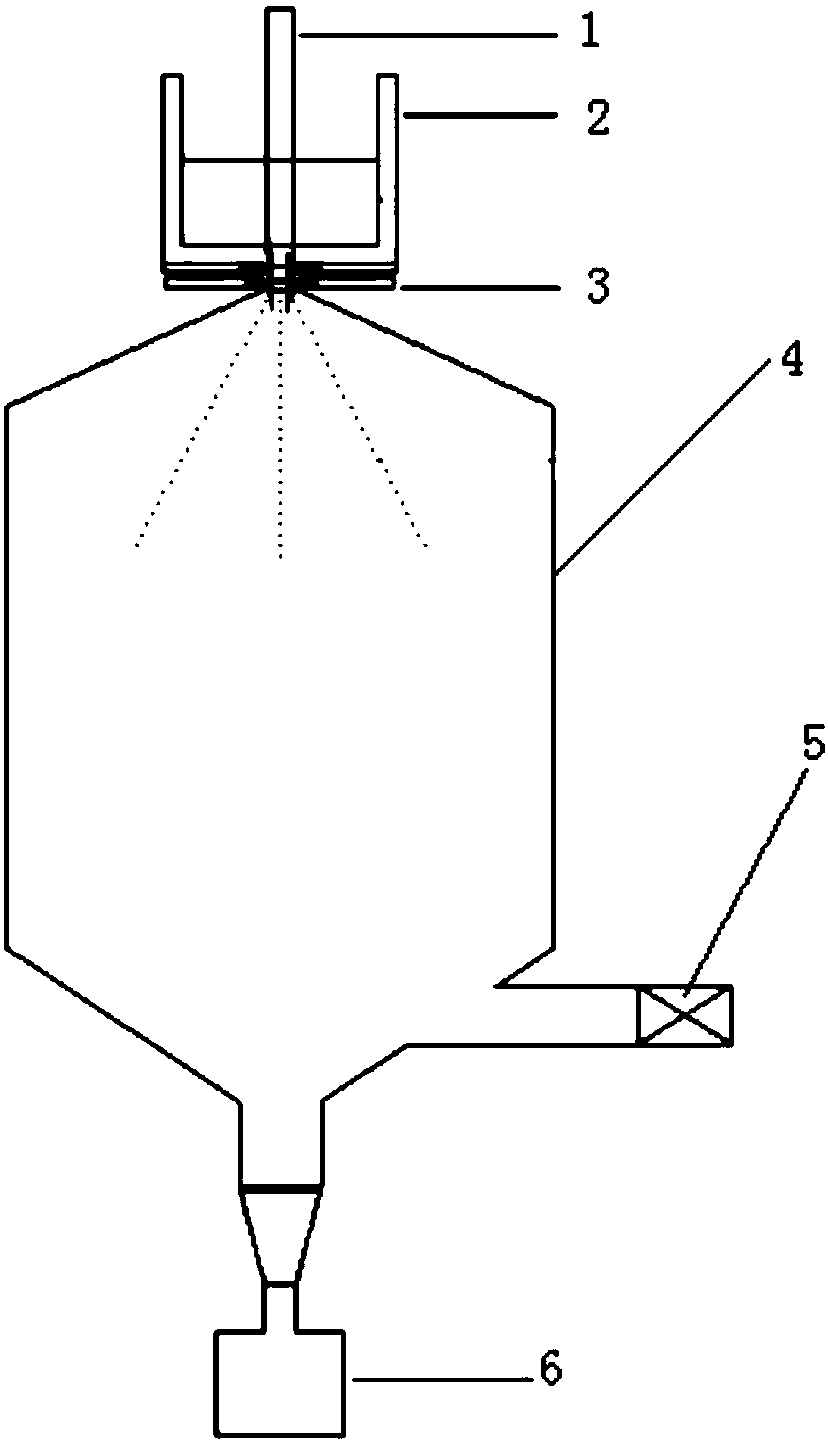

[0043] The gas atomization device includes a crucible 2, an atomizer 3, an atomization chamber 4, and a collection bucket ...

Embodiment 2

[0047] This embodiment provides a kind of nano-aluminum matrix composite material powder, and its preparation method comprises:

[0048] Pure aluminum, pure Ni or Al-Ni master alloy, Al-12Zr master alloy, Al-Cu master alloy, Al-Ti master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 5wt.%TiB was formulated for the raw material 2 Reinforced Al-10Ni-2.3Cu-3Zr-5Ti composites. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 After mixing evenly according to the mass ratio of 1:2, dry it and add it to the melt; For Ti master alloy, add JZJ type harmless aluminum alloy refining agent to the melt for degassing and refining, let it stand at 750°C for 15 minutes, and then make powder through a gas atomization device. The gas atomization device is the same as that in Example 1, and the gas atomization process is as follows: the melt temperature is 900° C., He is used for protectio...

Embodiment 3

[0051] This embodiment provides a kind of nano-aluminum matrix composite material powder, and its preparation method comprises:

[0052] Pure aluminum, pure Ni or Al-Ni master alloy, Al-Y master alloy, Al-Ce master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 10wt.%TiB was formulated for the raw material 2 Reinforced Al-15Ni-7Ce-6Y composites. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 Mix evenly according to the mass ratio of 1:2, dry and add to the melt; after the reaction is completed, take out the reaction by-products, and add pure Ni or Al-Ni master alloy, Al-Y master alloy, Al-Ce master alloy in turn , adding JZJ type harmless aluminum alloy refining agent to the melt for degassing refining, standing at 750°C for 15 minutes, and then making powder through a gas atomization device. The gas atomization device is the same as that in Example 1, and the gas atomi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com