Patents

Literature

602 results about "Rapid manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

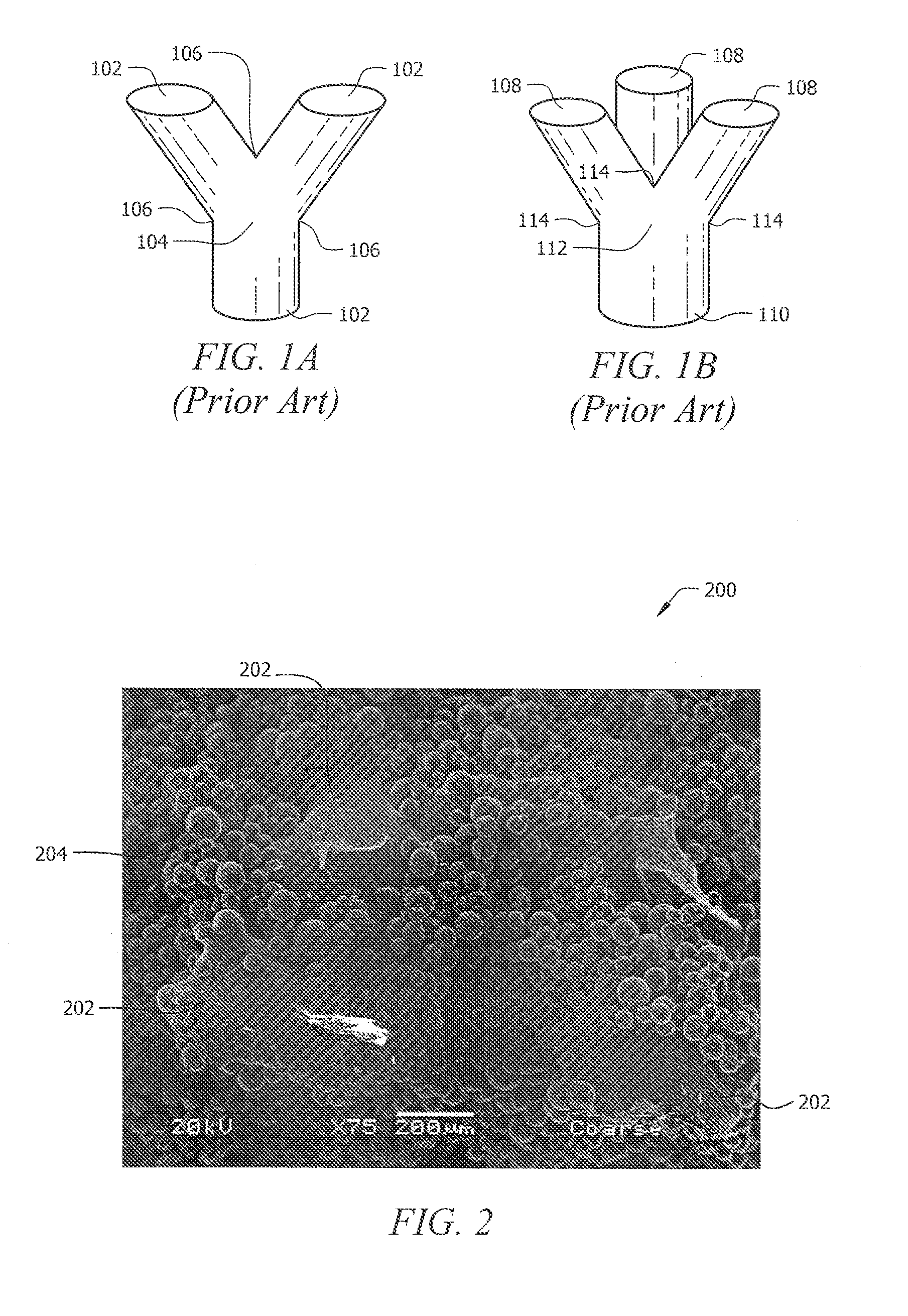

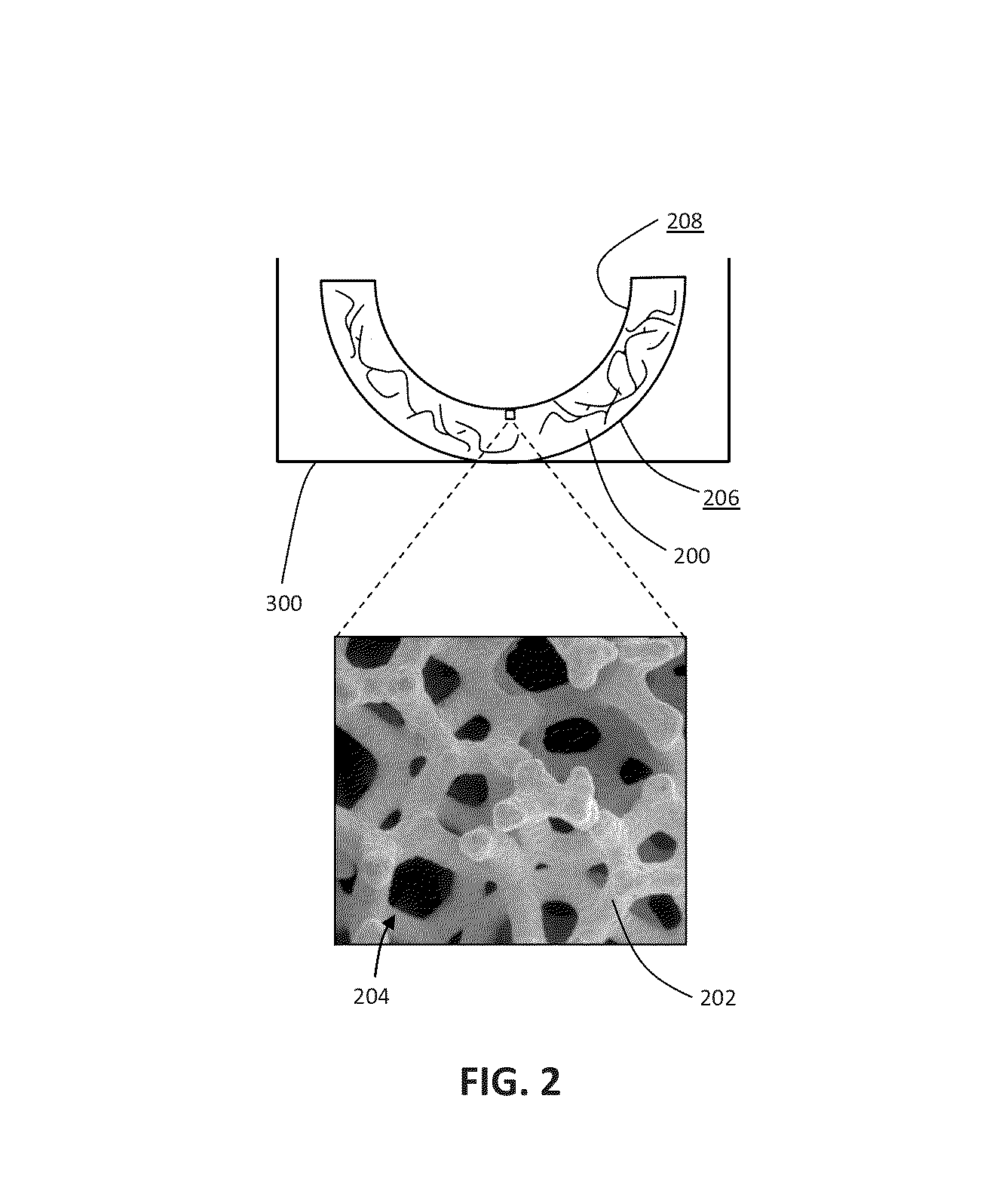

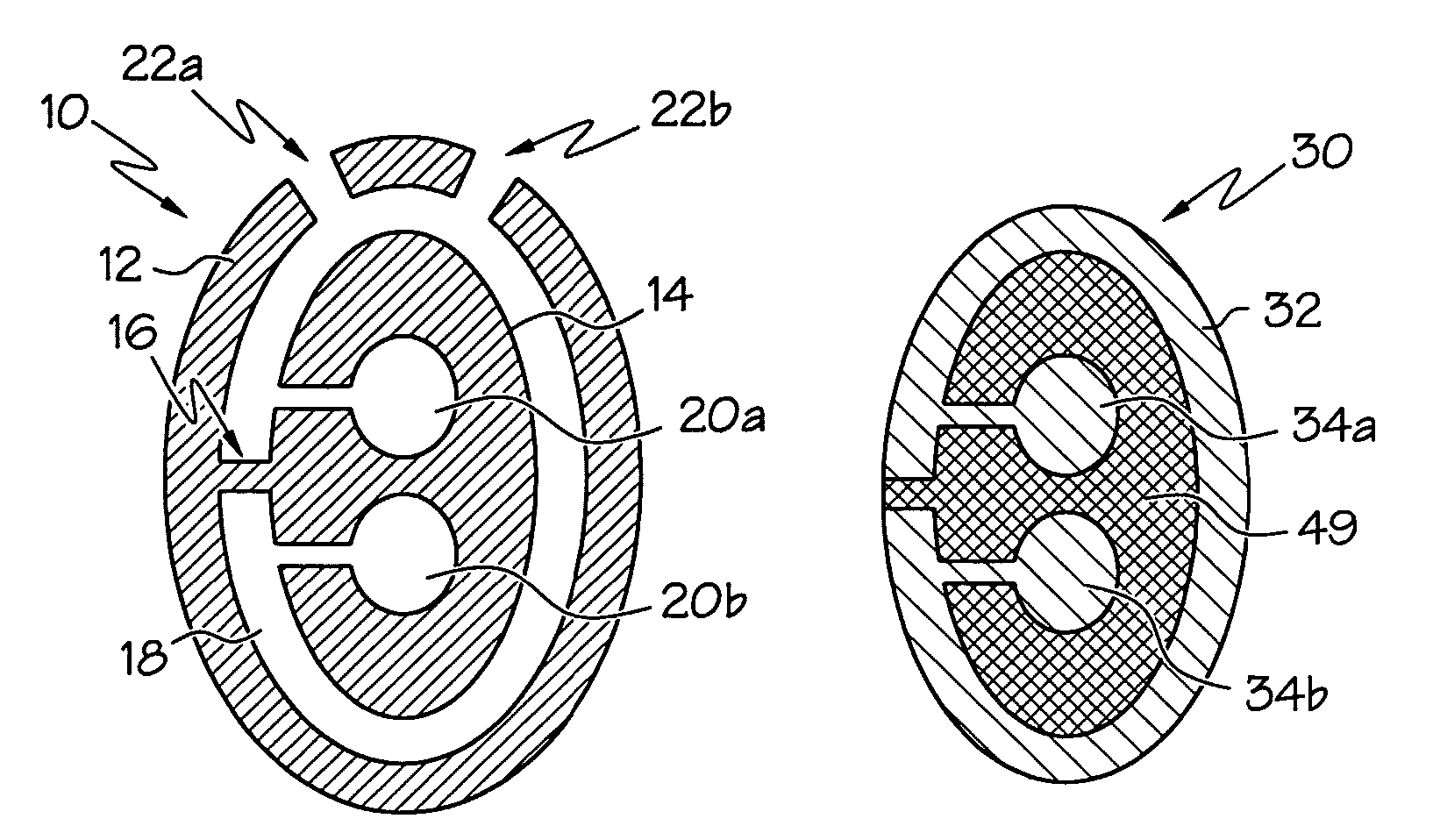

Porous implant structures

InactiveUS20120215310A1High porosityHigh strengthAdditive manufacturing apparatusSurgical adhesivesNODALManufacturing technology

Porous biocompatible structures suitable for use as medical implants and methods for fabricating such structures are disclosed. The disclosed structures may be fabricated using rapid manufacturing techniques. The disclosed porous structures has a plurality of struts and nodes where no more than two struts intersect one another to form a node. Further, the nodes can be straight, curved, portions that are curved and / or straight. The struts and nodes can form cells which can be fused or sintered to at least one other cell to form a continuous reticulated structure for improved strength while providing the porosity needed for tissue and cell in-growth.

Owner:SMITH & NEPHEW INC

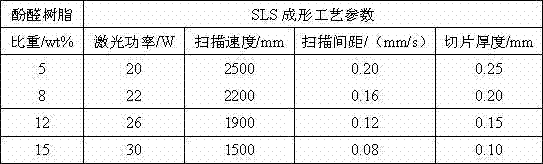

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

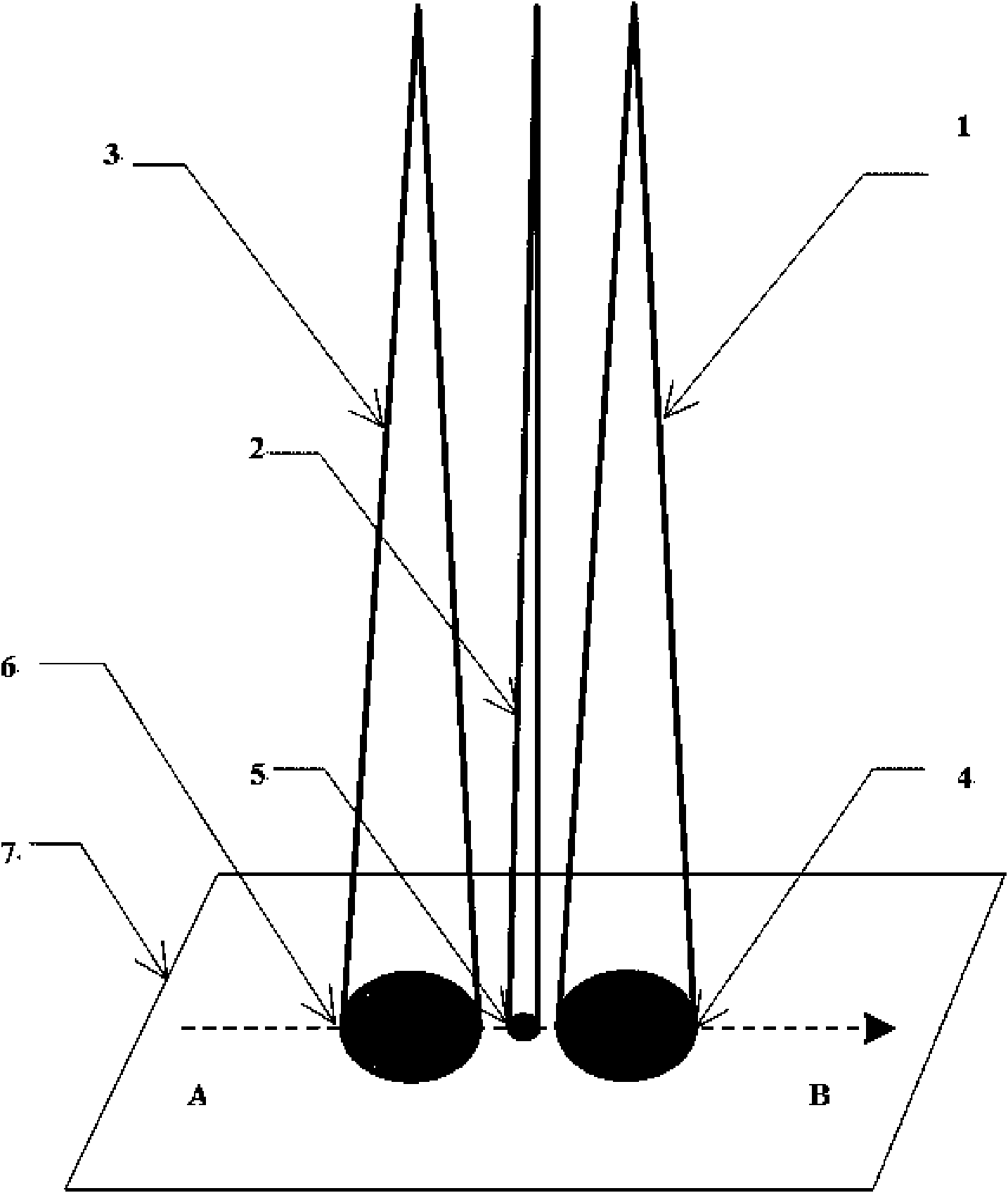

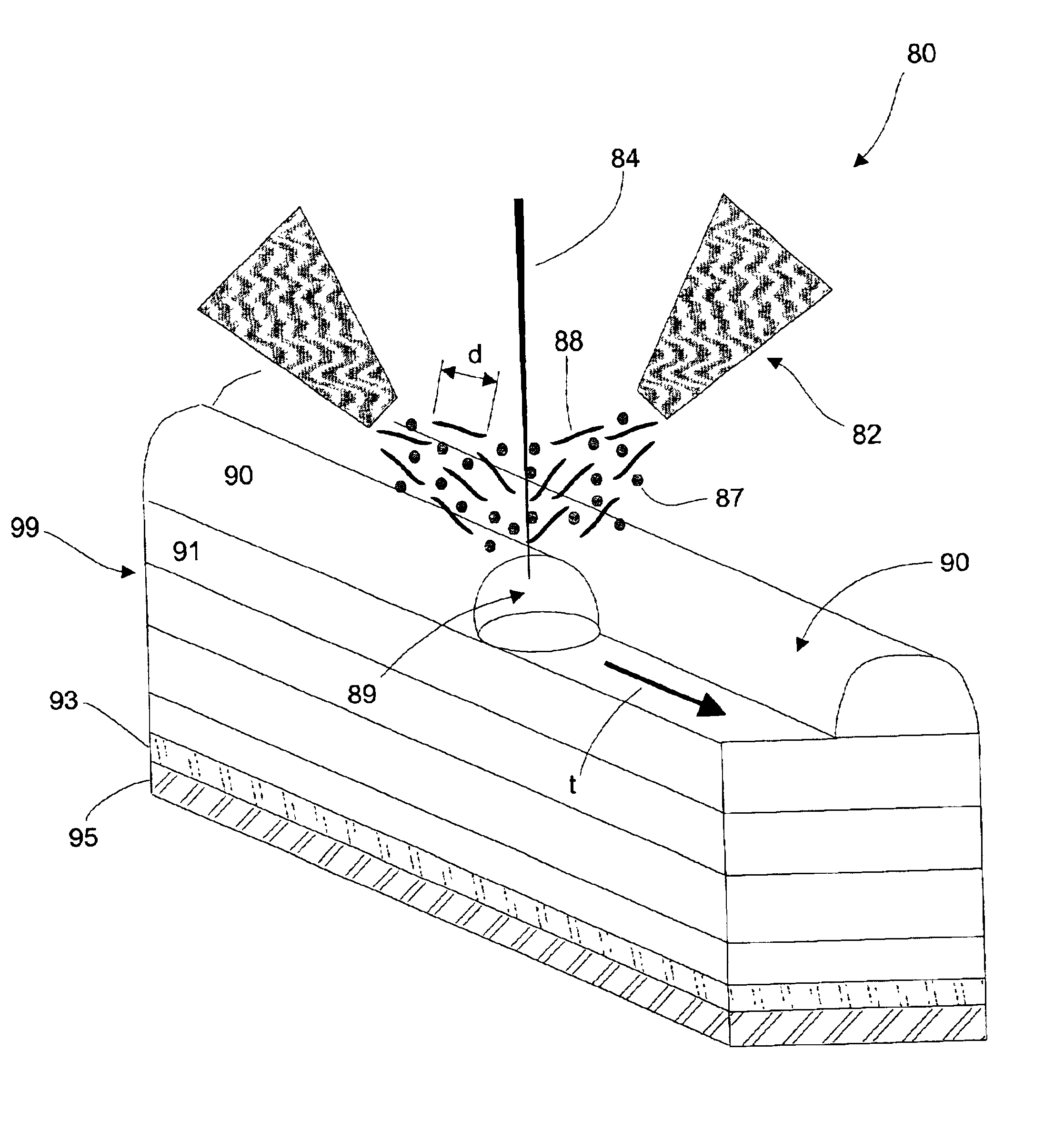

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

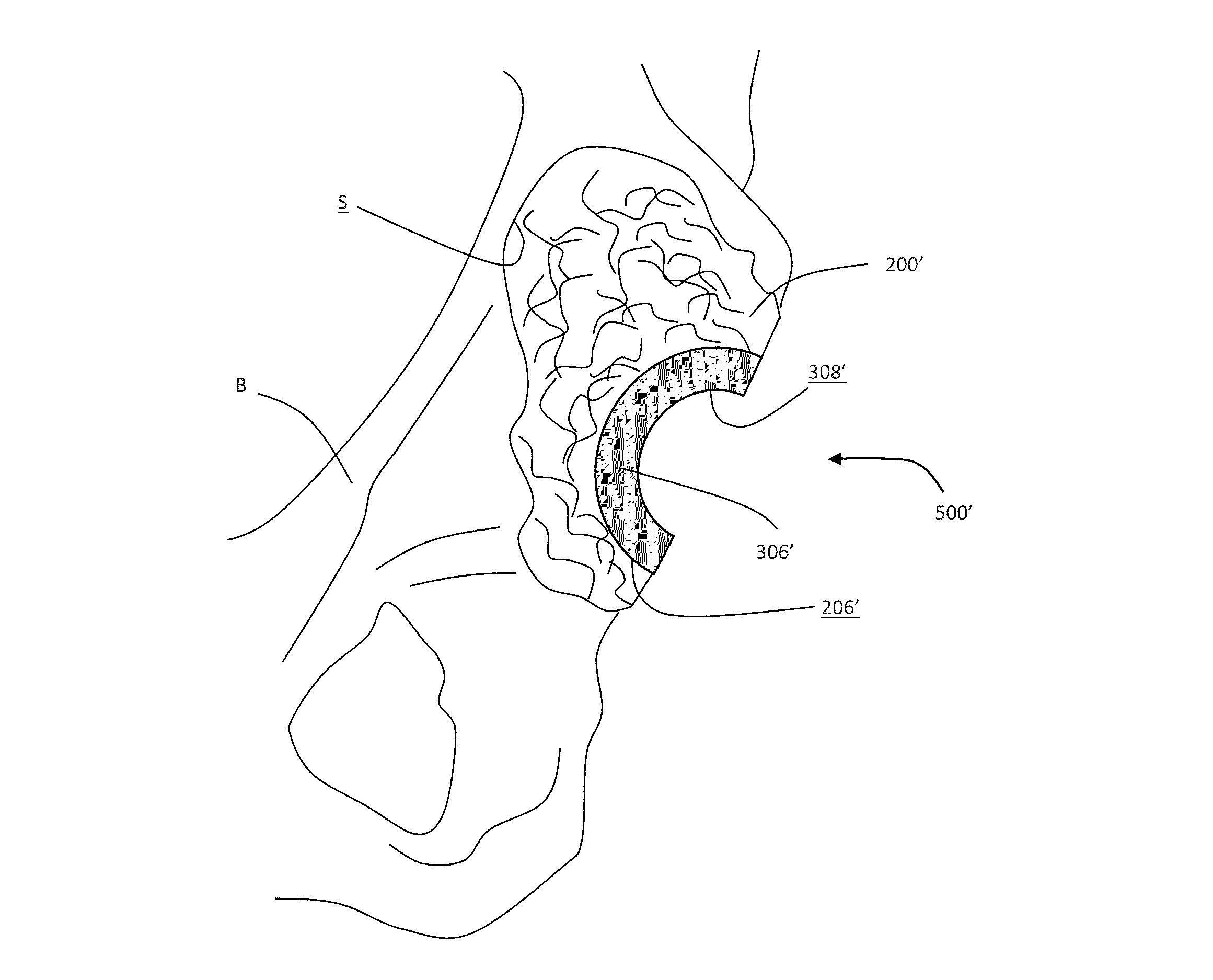

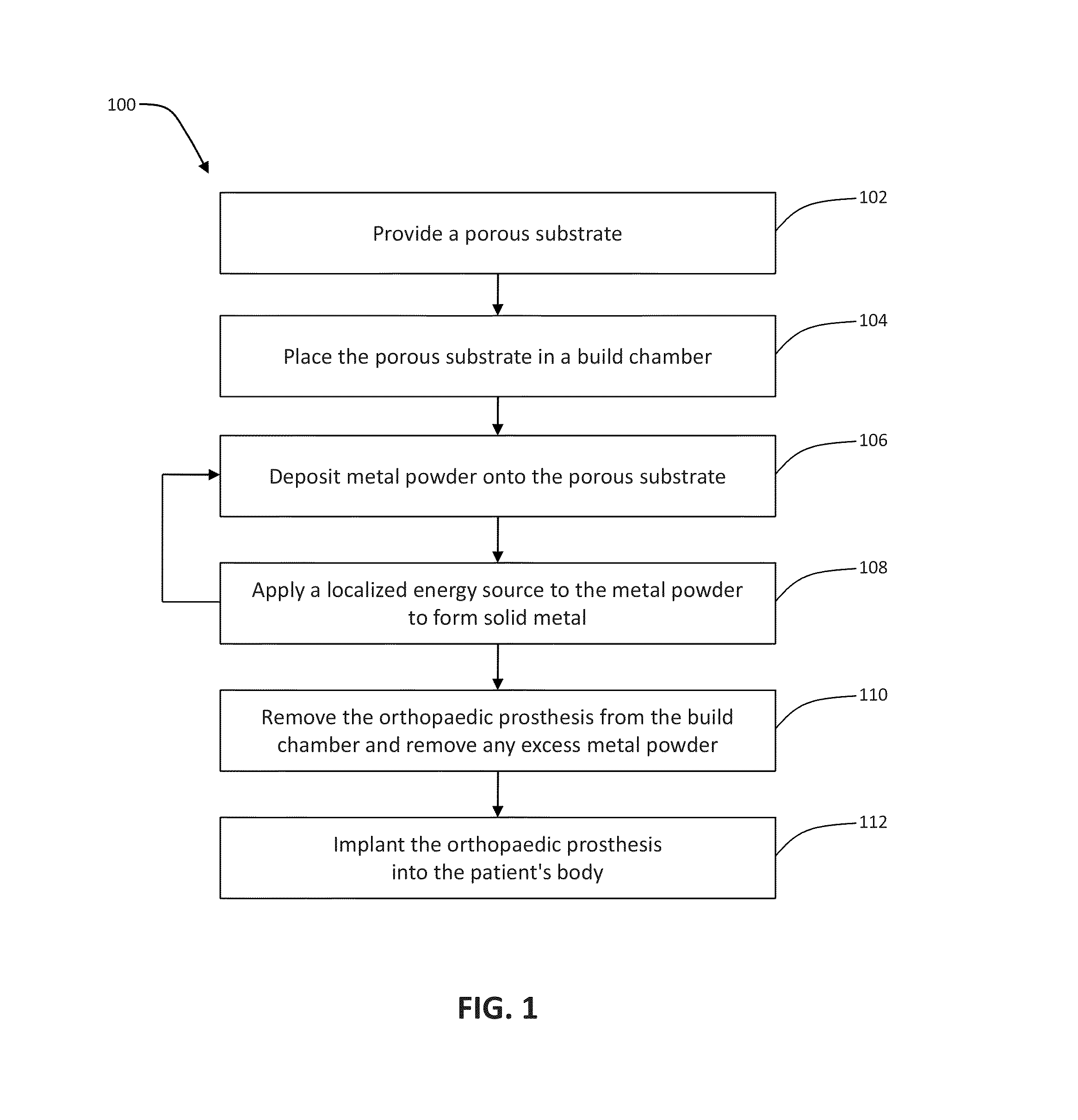

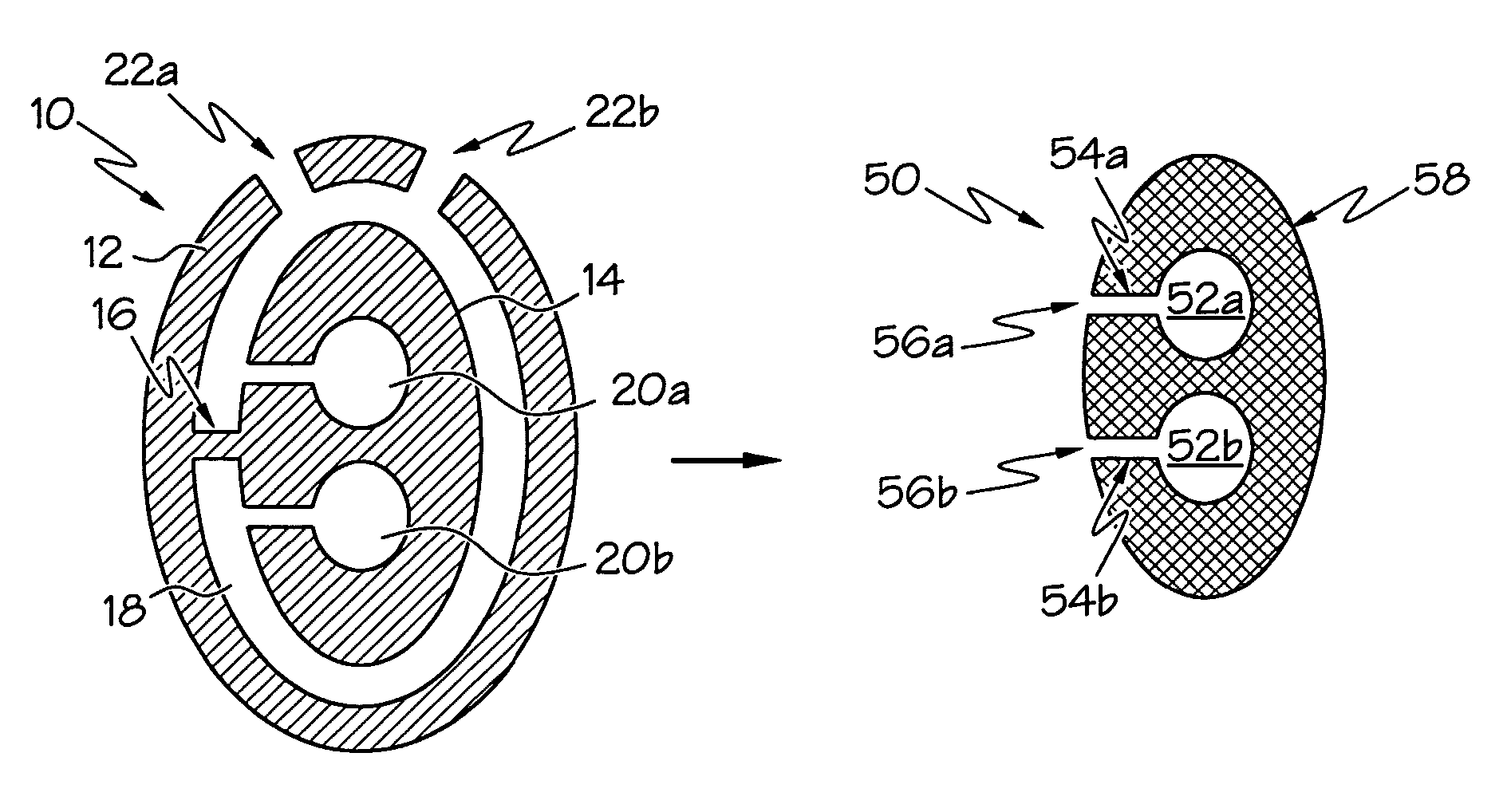

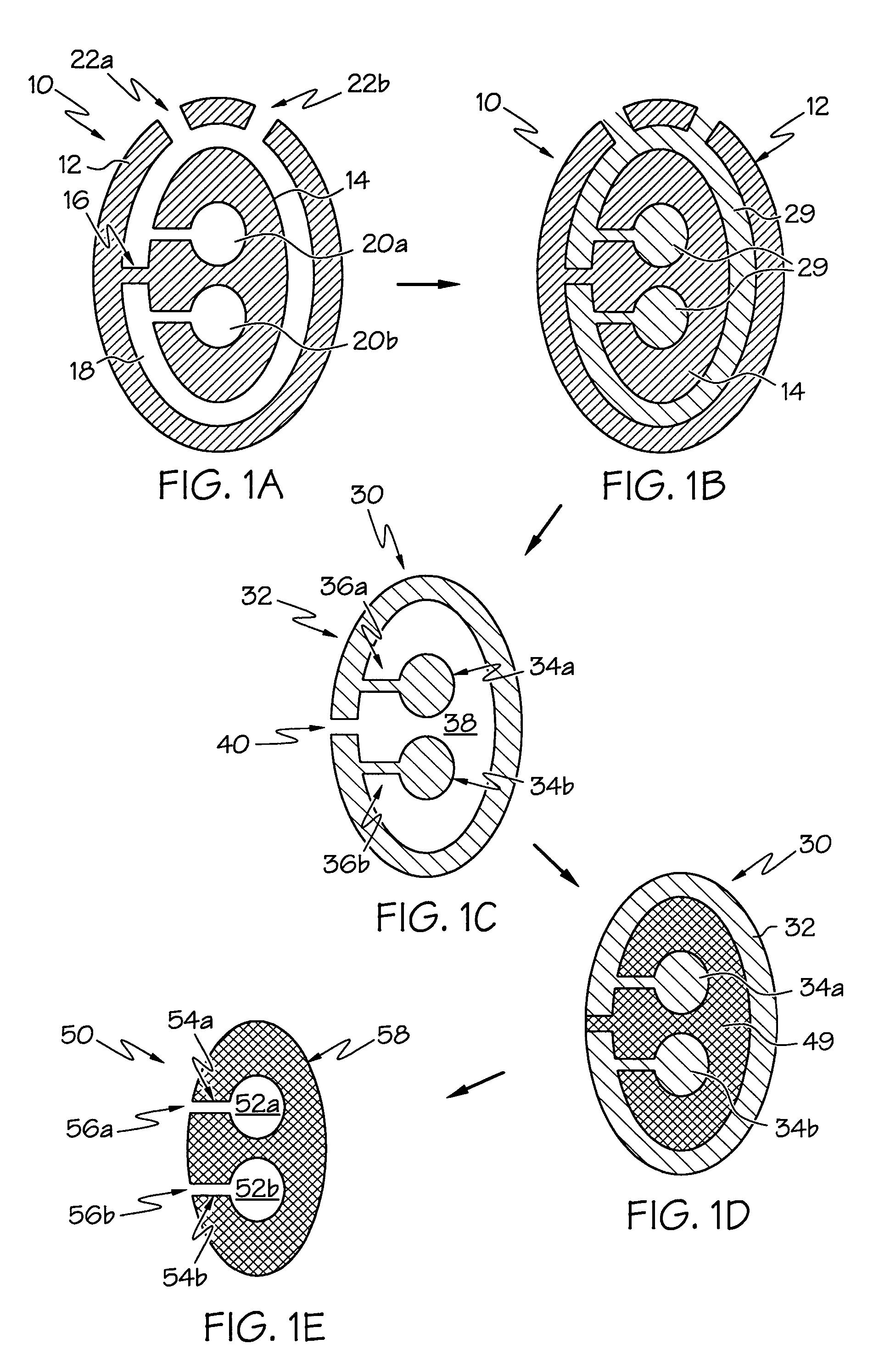

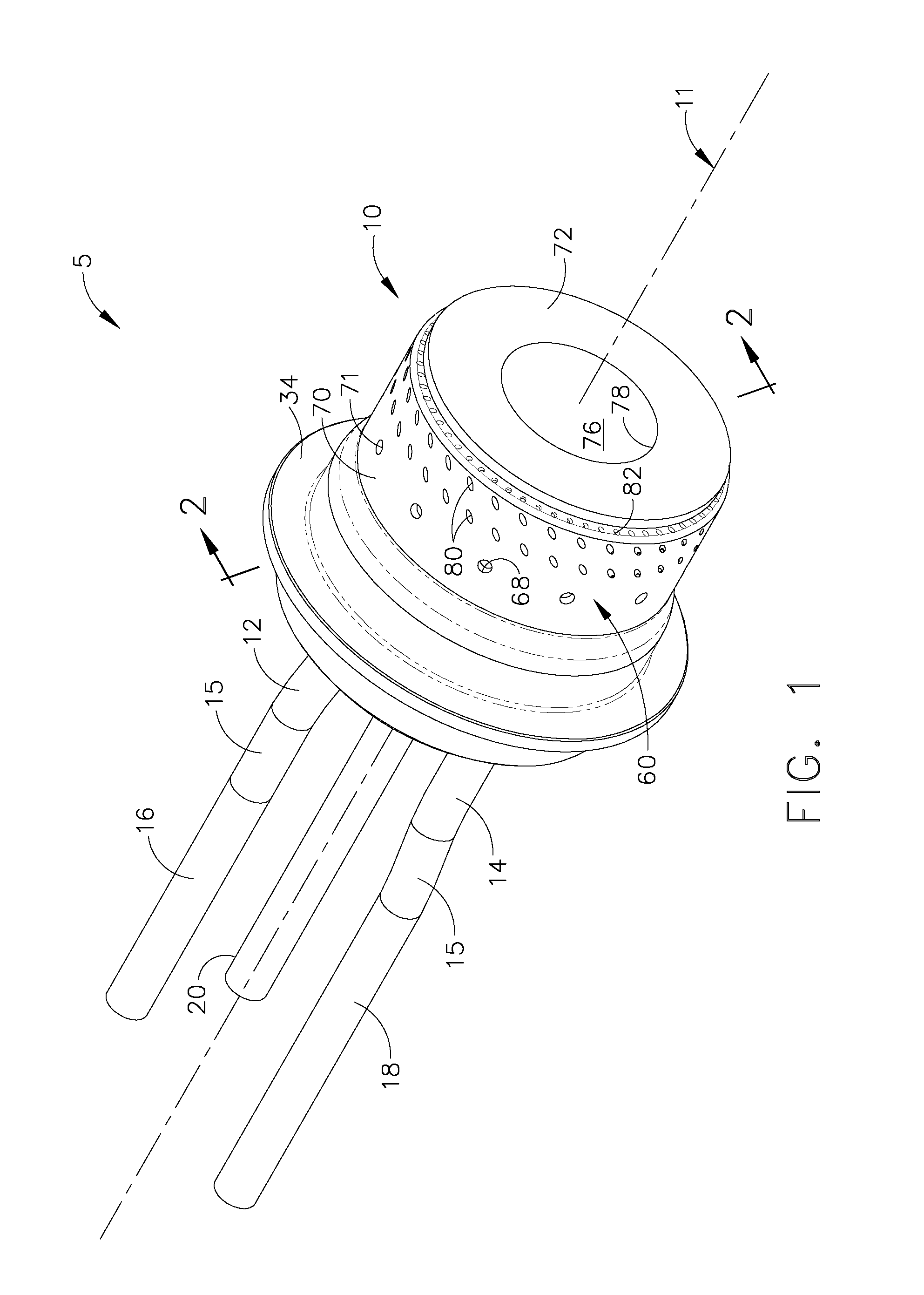

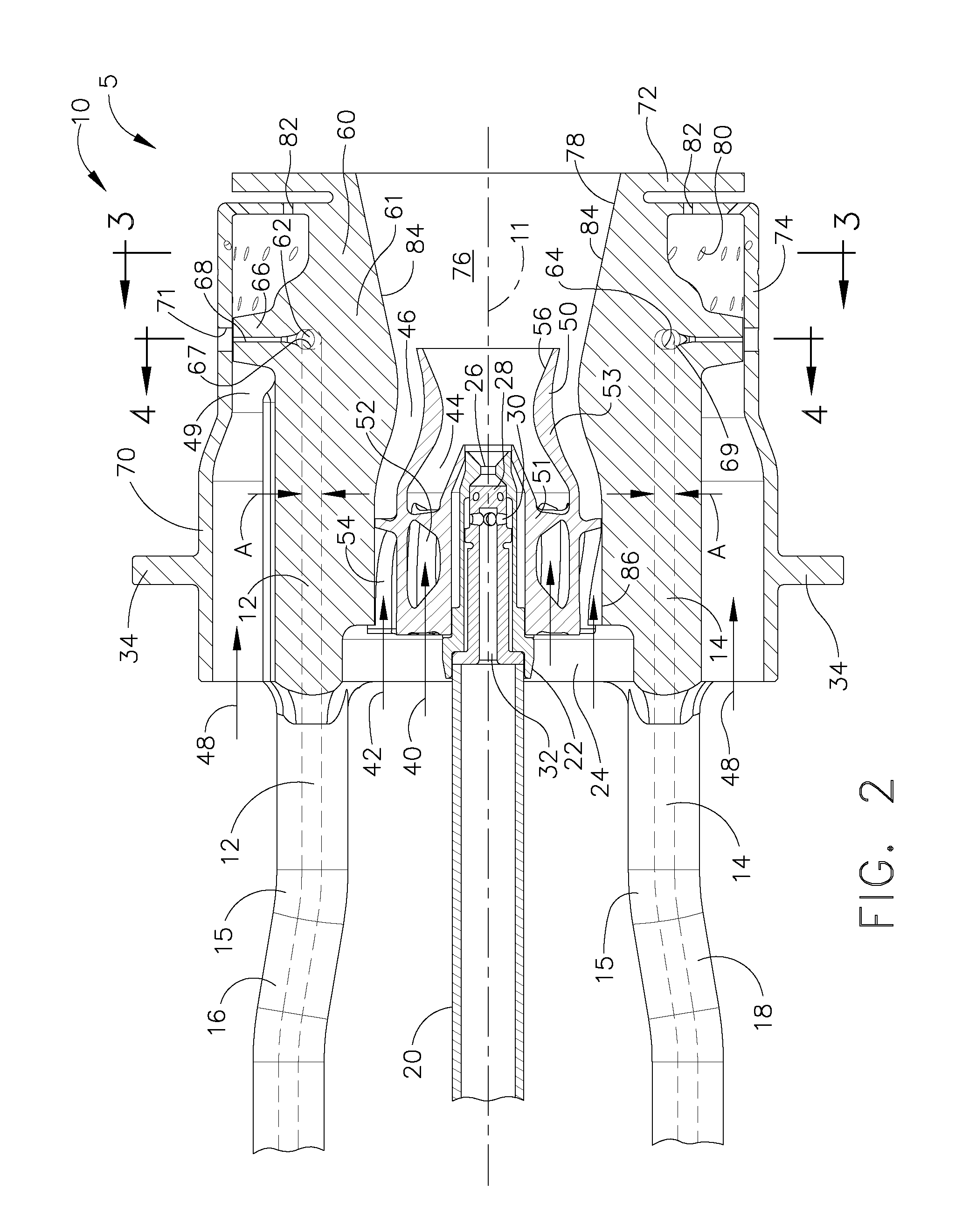

Rapid manufacturing of porous metal prostheses

ActiveUS20130018483A1Fast preparationAdditive manufacturing apparatusBone implantProsthesisPlastic surgery

An orthopaedic prosthesis and a method for rapidly manufacturing the same are provided. The orthopaedic prosthesis includes a solid bearing layer, a porous bone-ingrowth layer, and an interdigitating layer therebetween. A laser sintering technique is performed to manufacture the orthopaedic prosthesis.

Owner:ZIMMER INC

High-resolution rapid manufacturing

ActiveUS7236166B2Fast preparationGood physical propertiesAdditive manufacturing apparatusWood working apparatusStructural engineeringRapid manufacturing

The present invention is a method for forming an object, the method comprising jetting a first material to form a plurality of layers that define a support structure increment, and extruding a second material to form a layer of the object. The layer of the object substantially conforms to an interior surface of the support structure increment.

Owner:STRATSYS INC

High-resolution rapid manufacturing

ActiveUS20060158456A1Fast preparationGood physical propertiesAdditive manufacturing apparatusWood working apparatusStructural engineeringRapid manufacturing

The present invention is a method for forming an object, the method comprising jetting a first material to form a plurality of layers that define a support structure increment, and extruding a second material to form a layer of the object. The layer of the object substantially conforms to an interior surface of the support structure increment.

Owner:STRATSYS INC

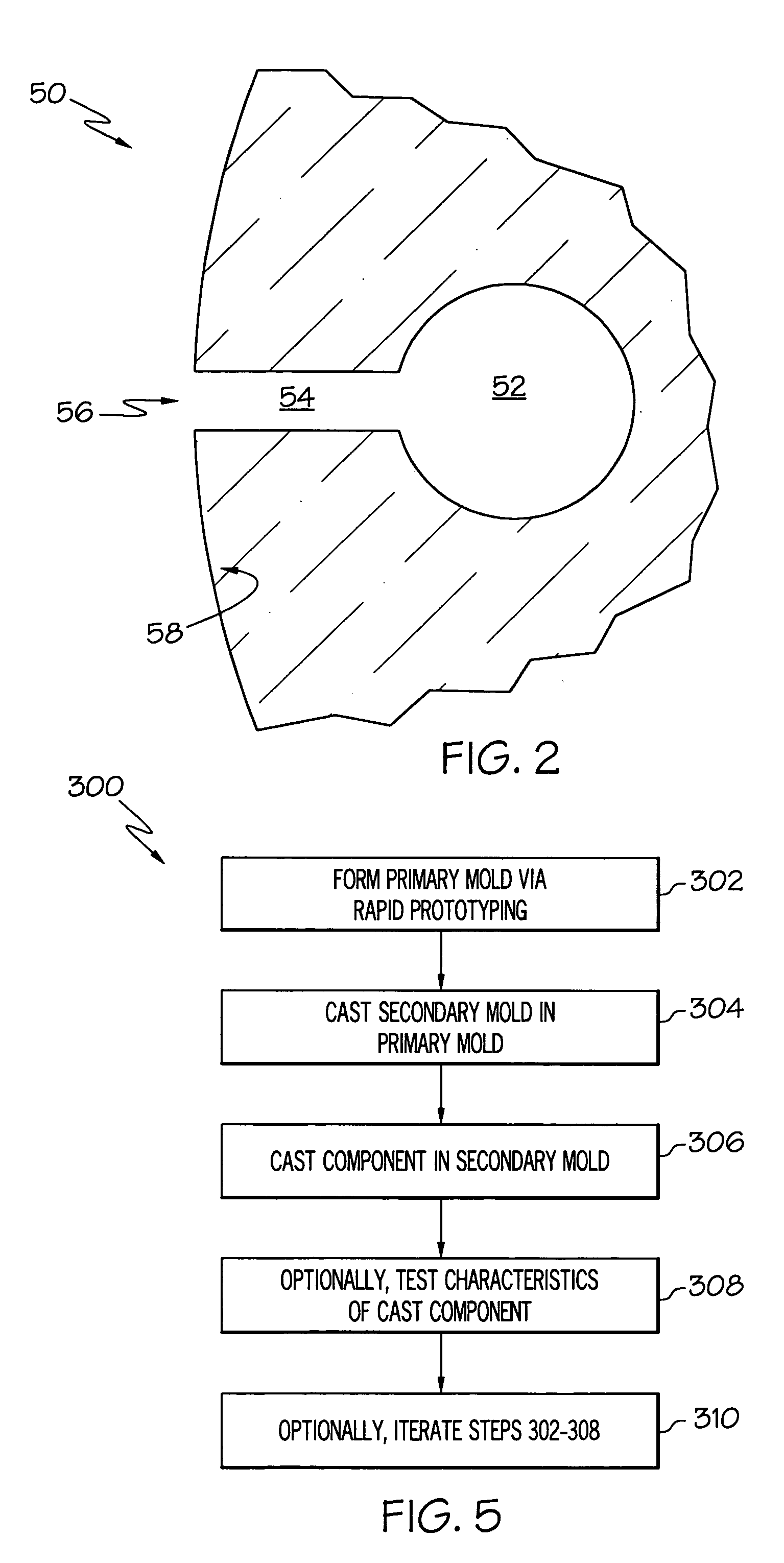

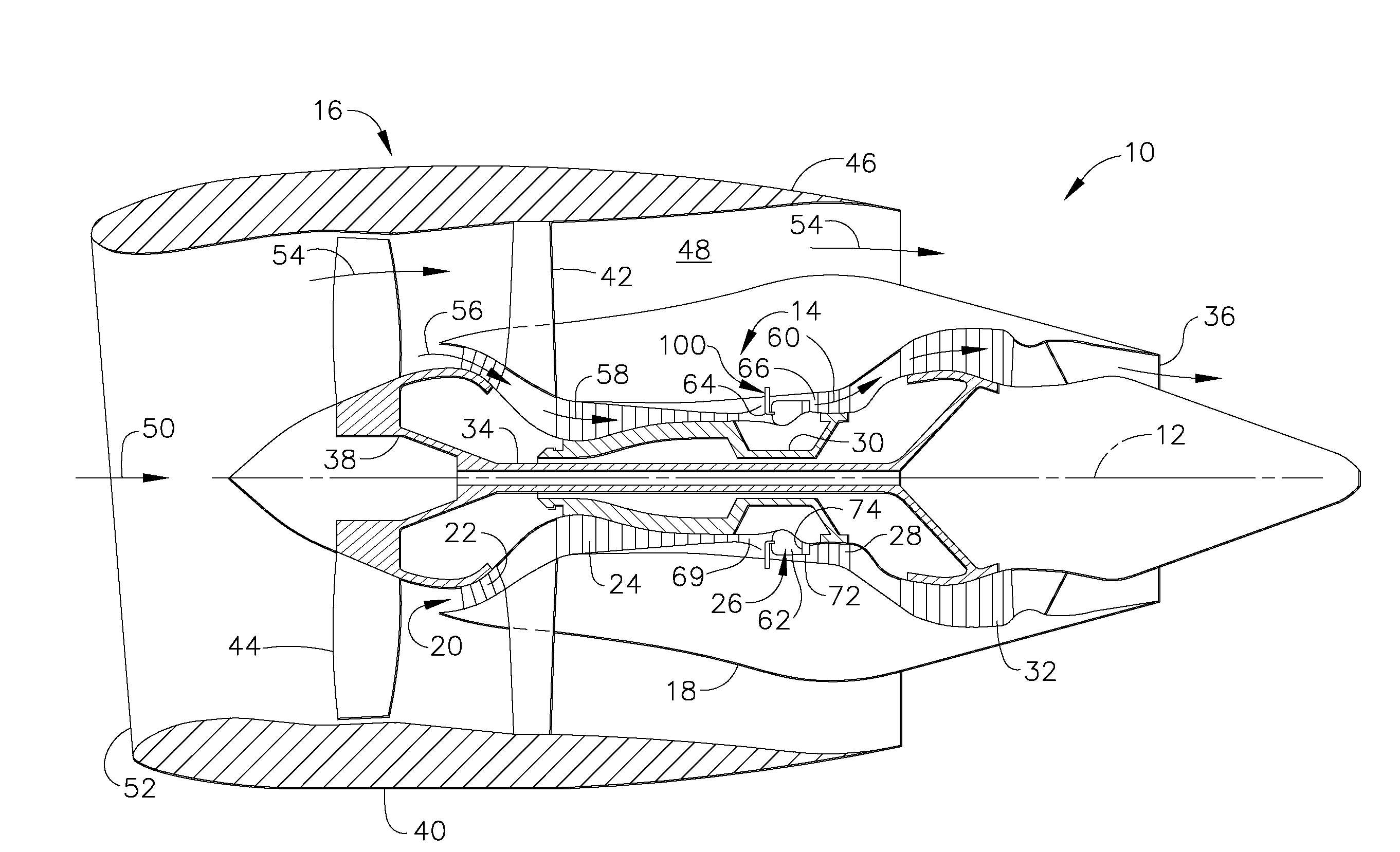

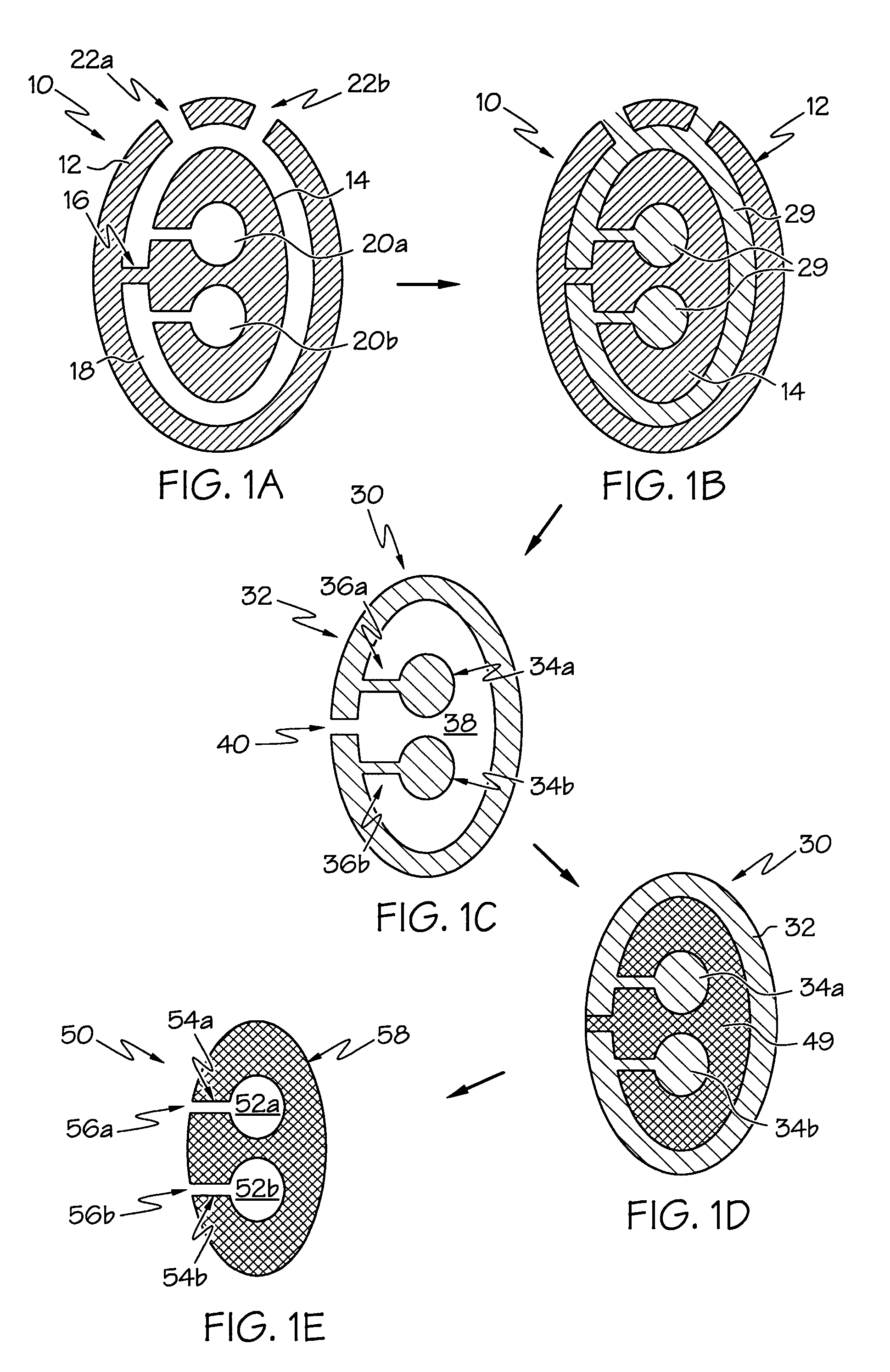

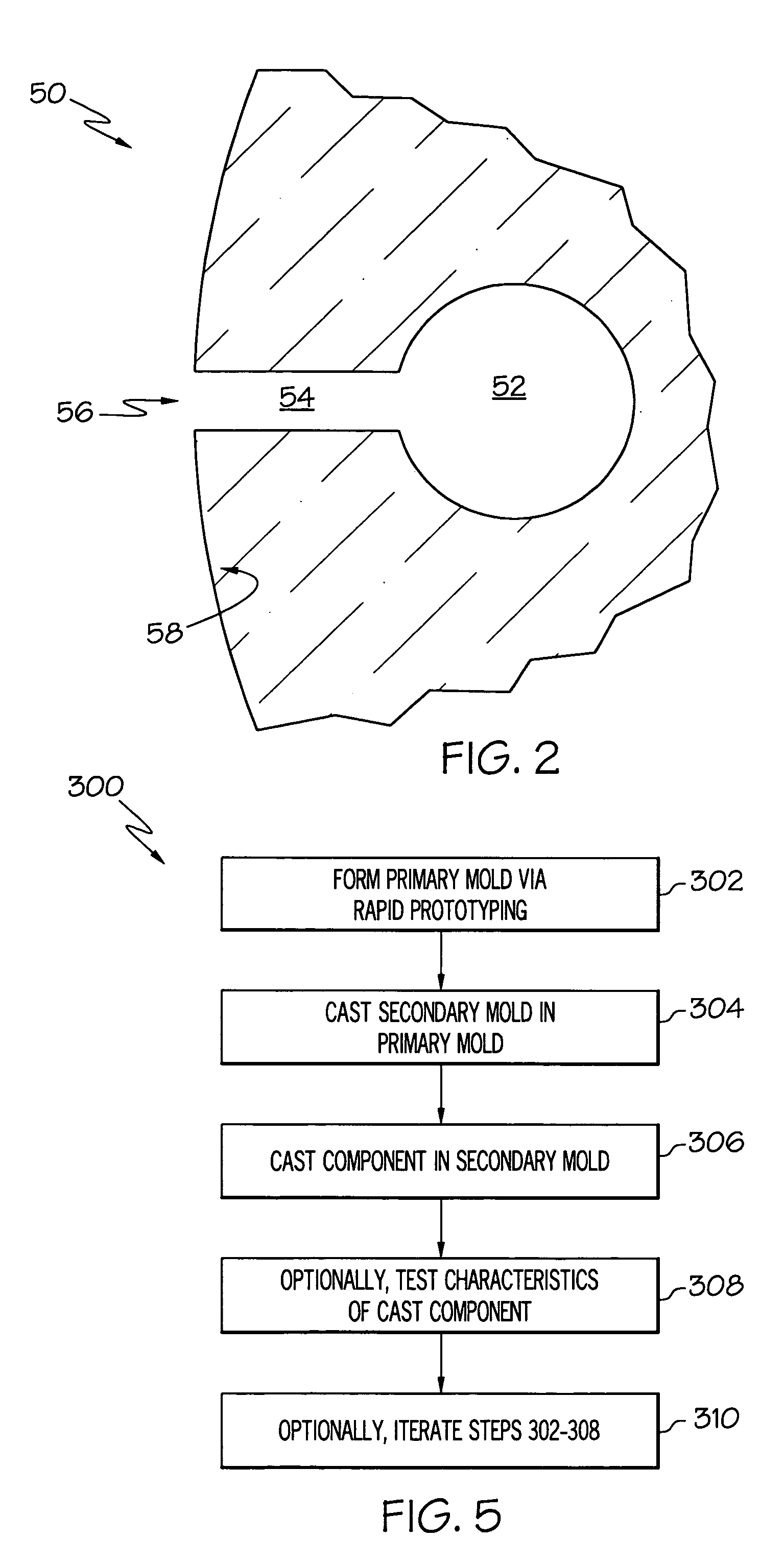

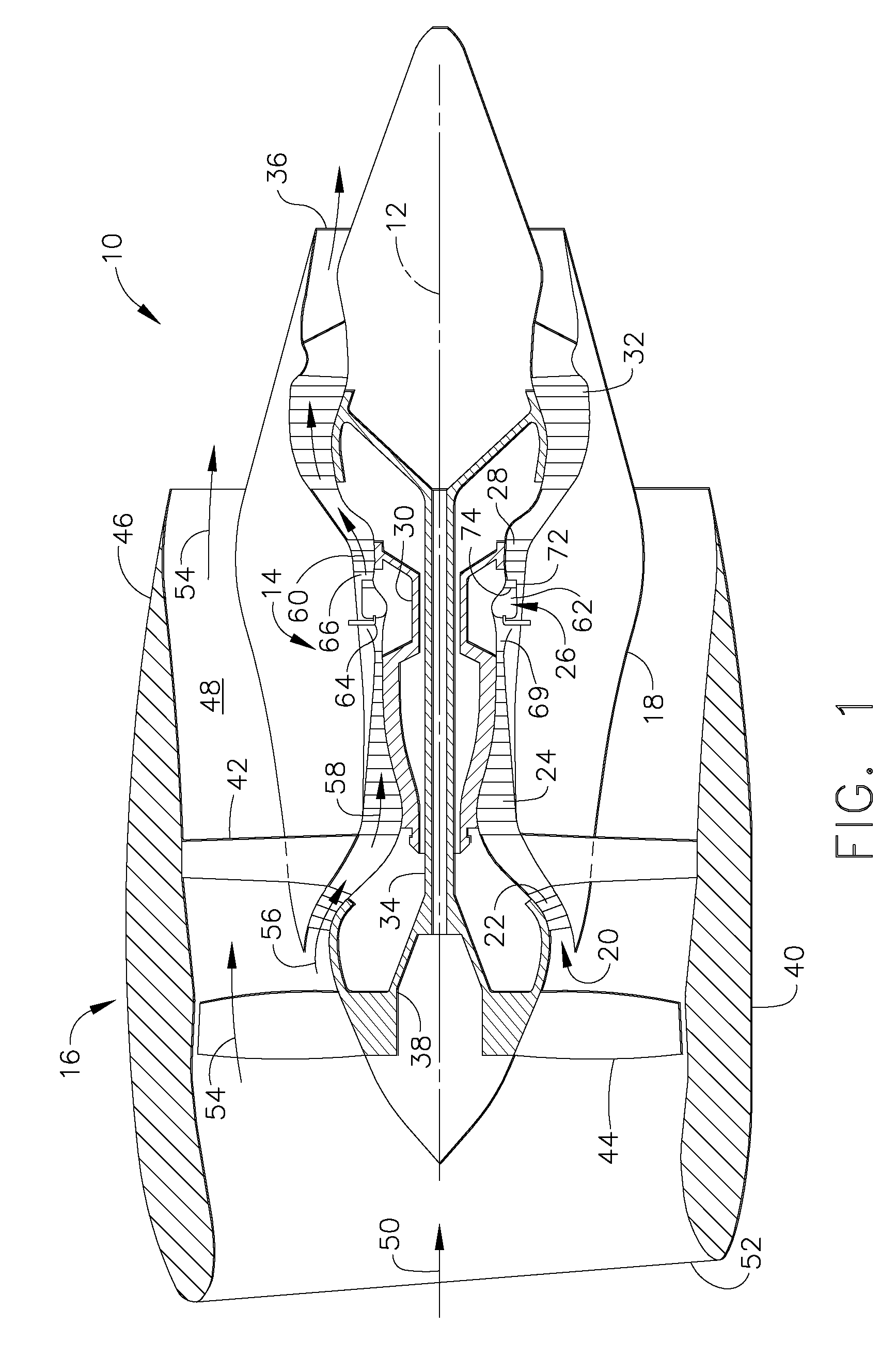

Rapid prototype casting

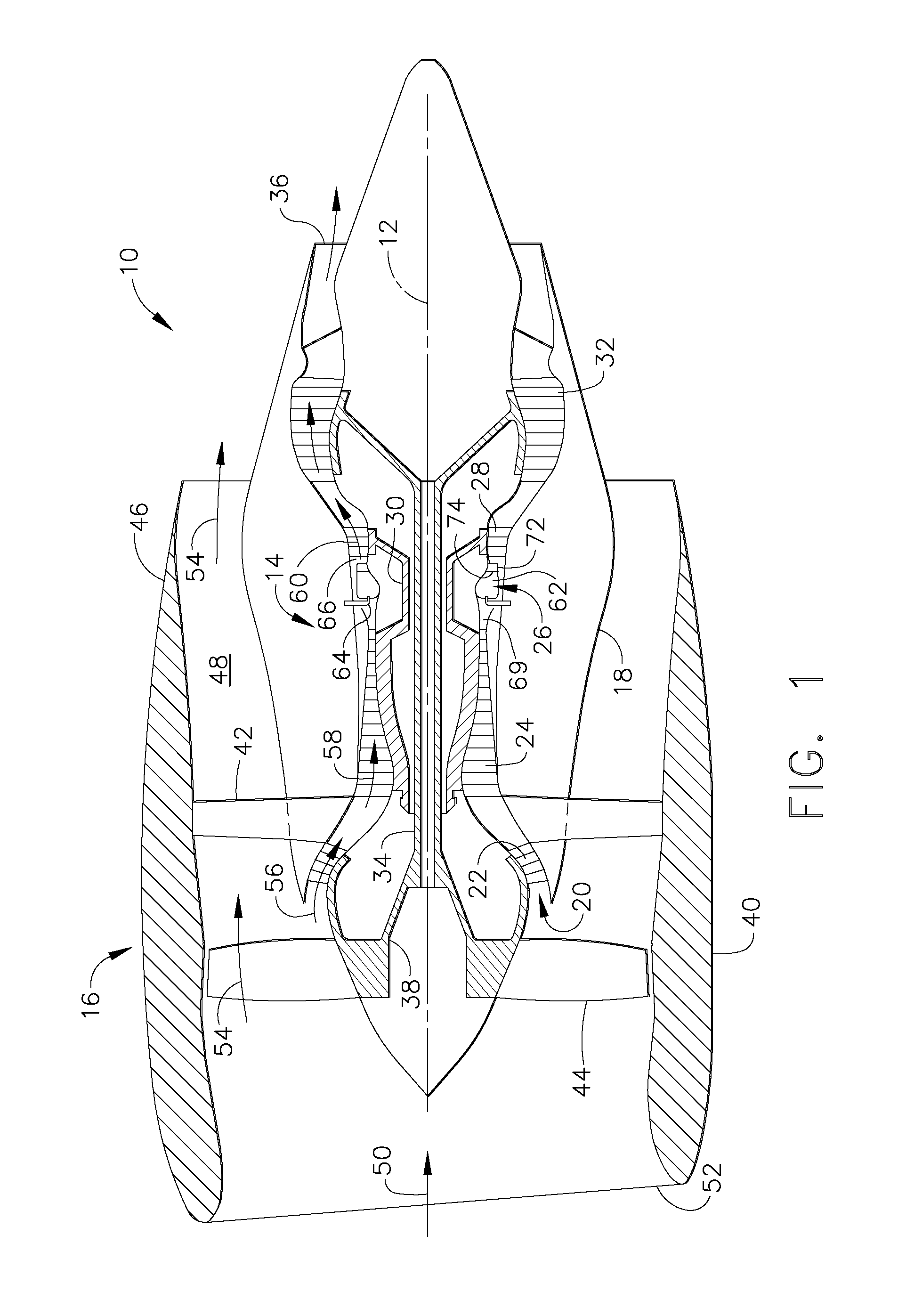

Methods for rapid prototype casting metal components, wherein the metal components are cast in a secondary ceramic mold, the secondary ceramic mold is cast in a primary mold, and the primary mold is formed by rapid prototyping or rapid manufacturing. The secondary ceramic mold may comprise a one-piece integral shell and core(s), and the metal components may have at least one hollow portion or void therein, such as a hollow airfoil for a gas turbine engine.

Owner:HONEYWELL INT INC

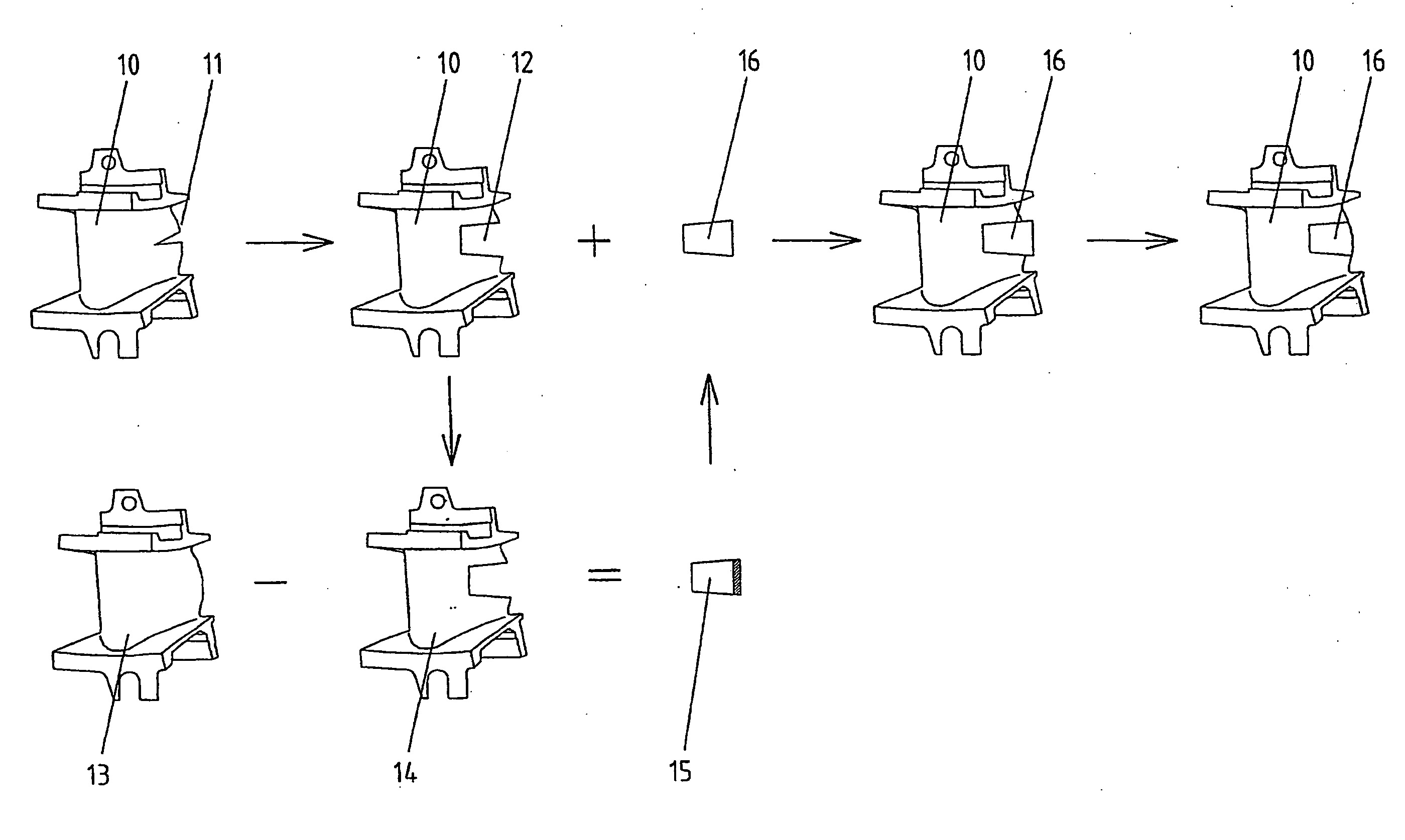

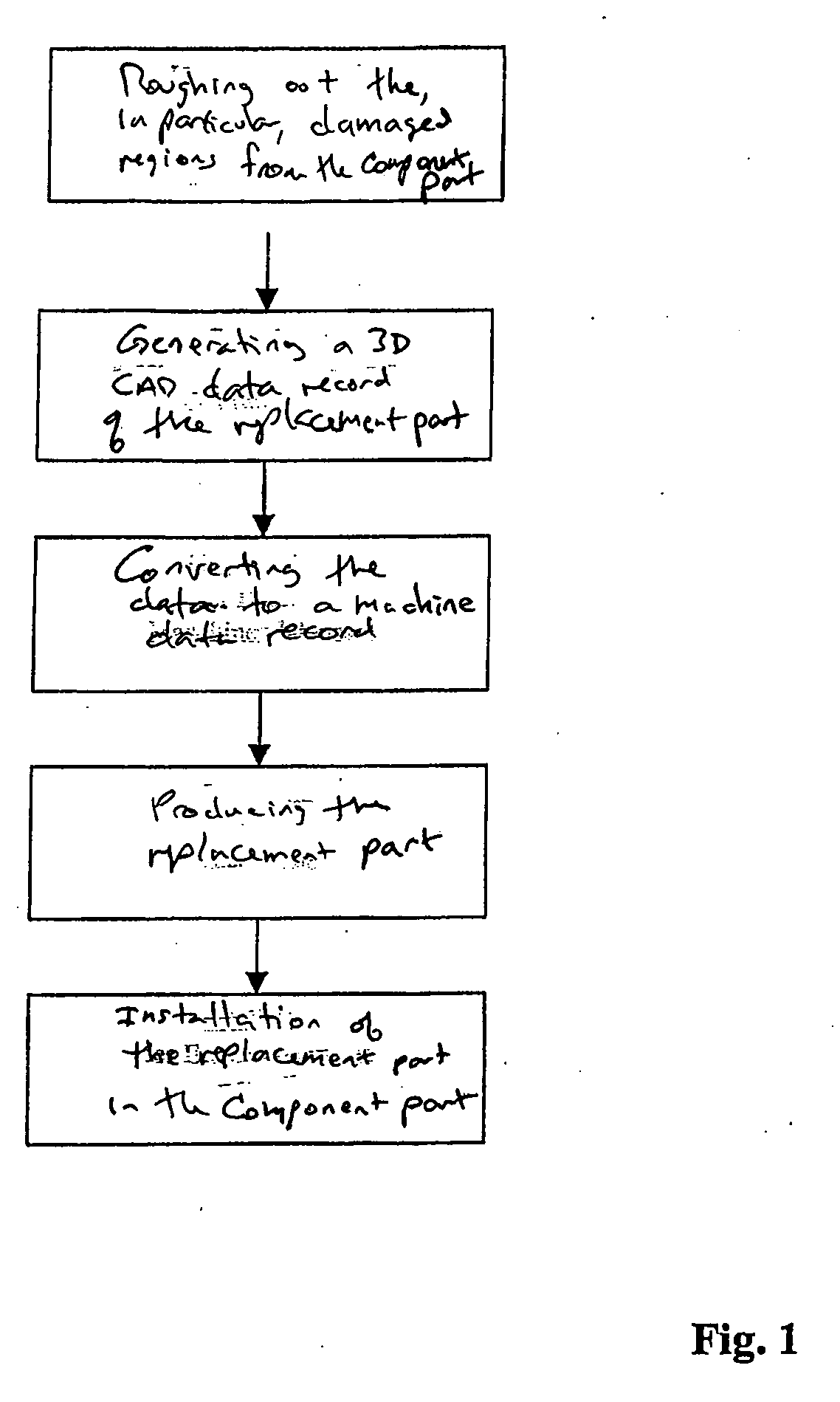

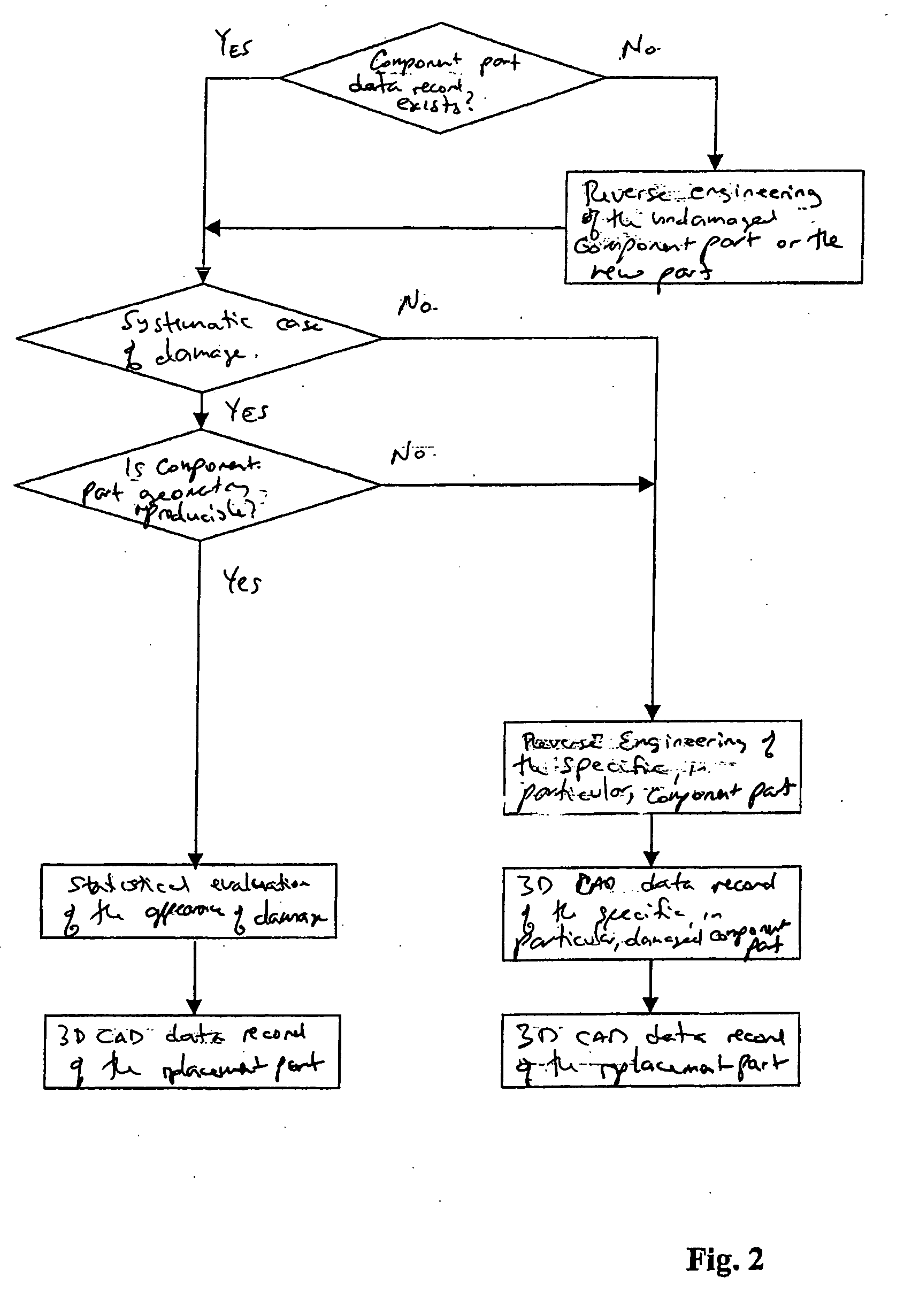

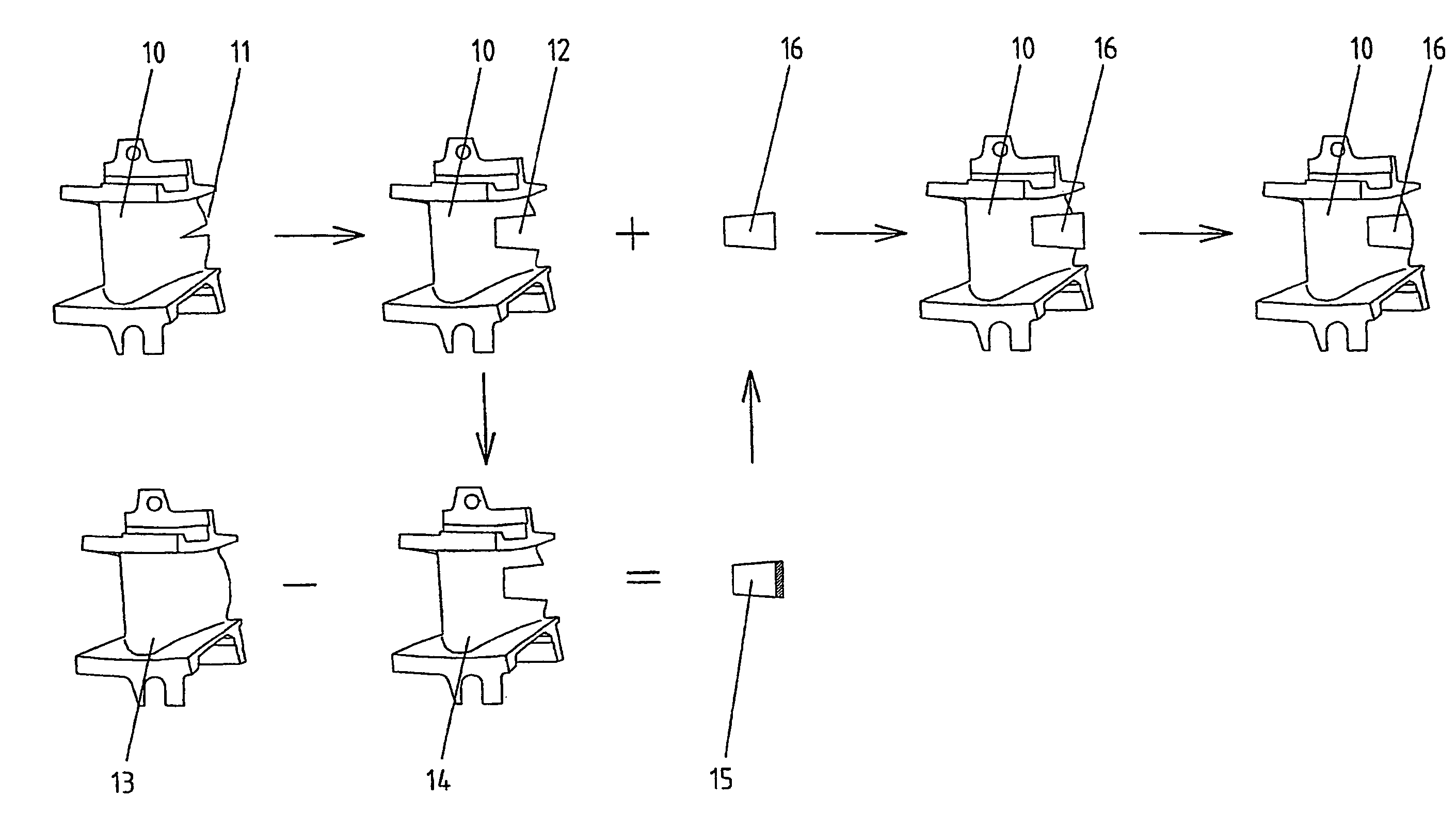

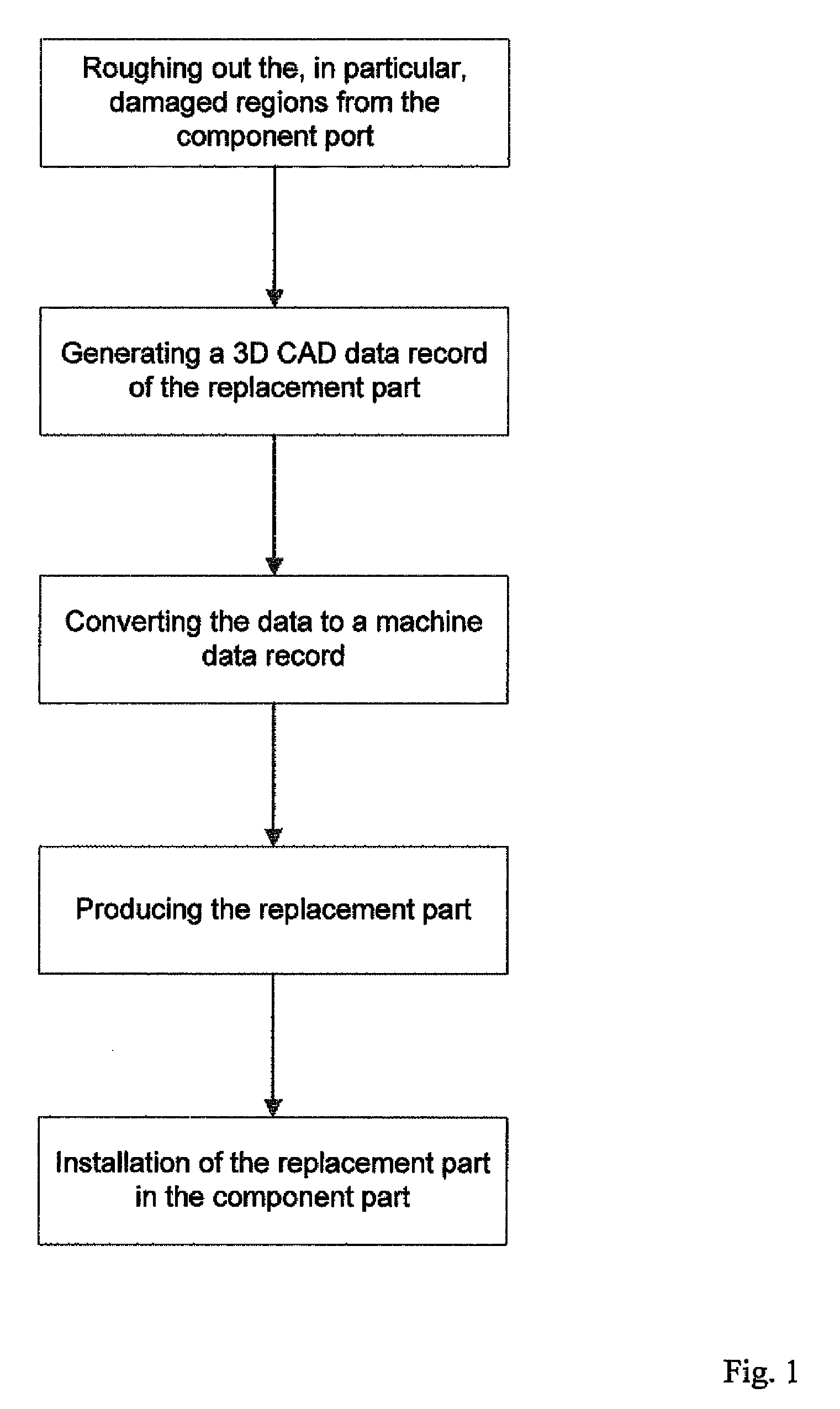

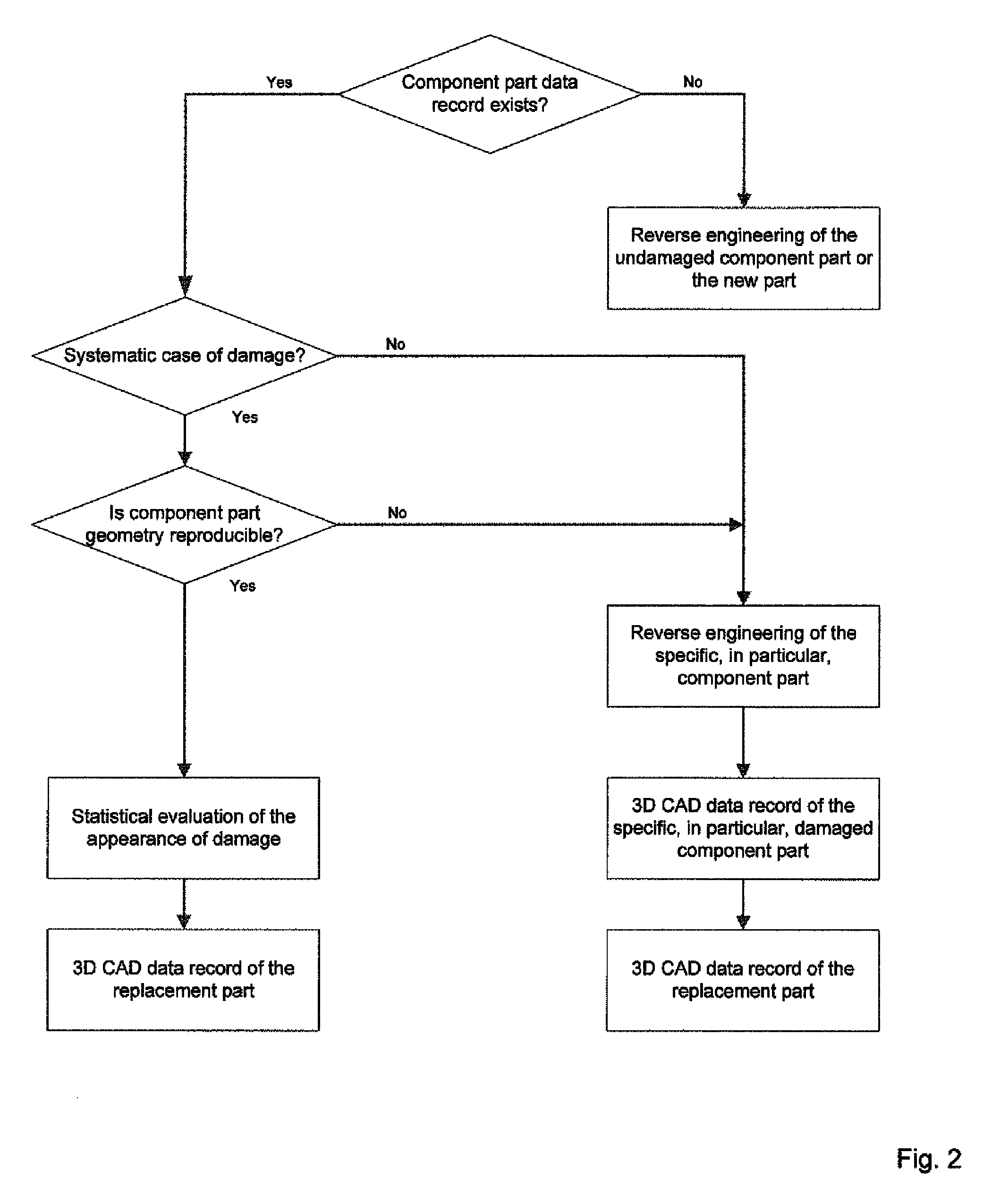

Method for repairing and/or modifying component parts of a gas turbine

InactiveUS20070084047A1Reduce sensitivityExtended operating timeAdditive manufacturing apparatusBlade accessoriesGas turbinesData records

A method is for repairing and / or modifying component parts of a gas turbine. First, at least one, particularly damaged section of the component part that is to be repaired is cut out of the component part. In addition, if it does not exist, a data record is generated for a replacement part that is to be produced. The replacement part is subsequently produced with the aid of a rapid manufacturing process. Subsequently, the replacement part produced is integrated into the component part that is to be repaired.

Owner:MTU AERO ENGINES GMBH

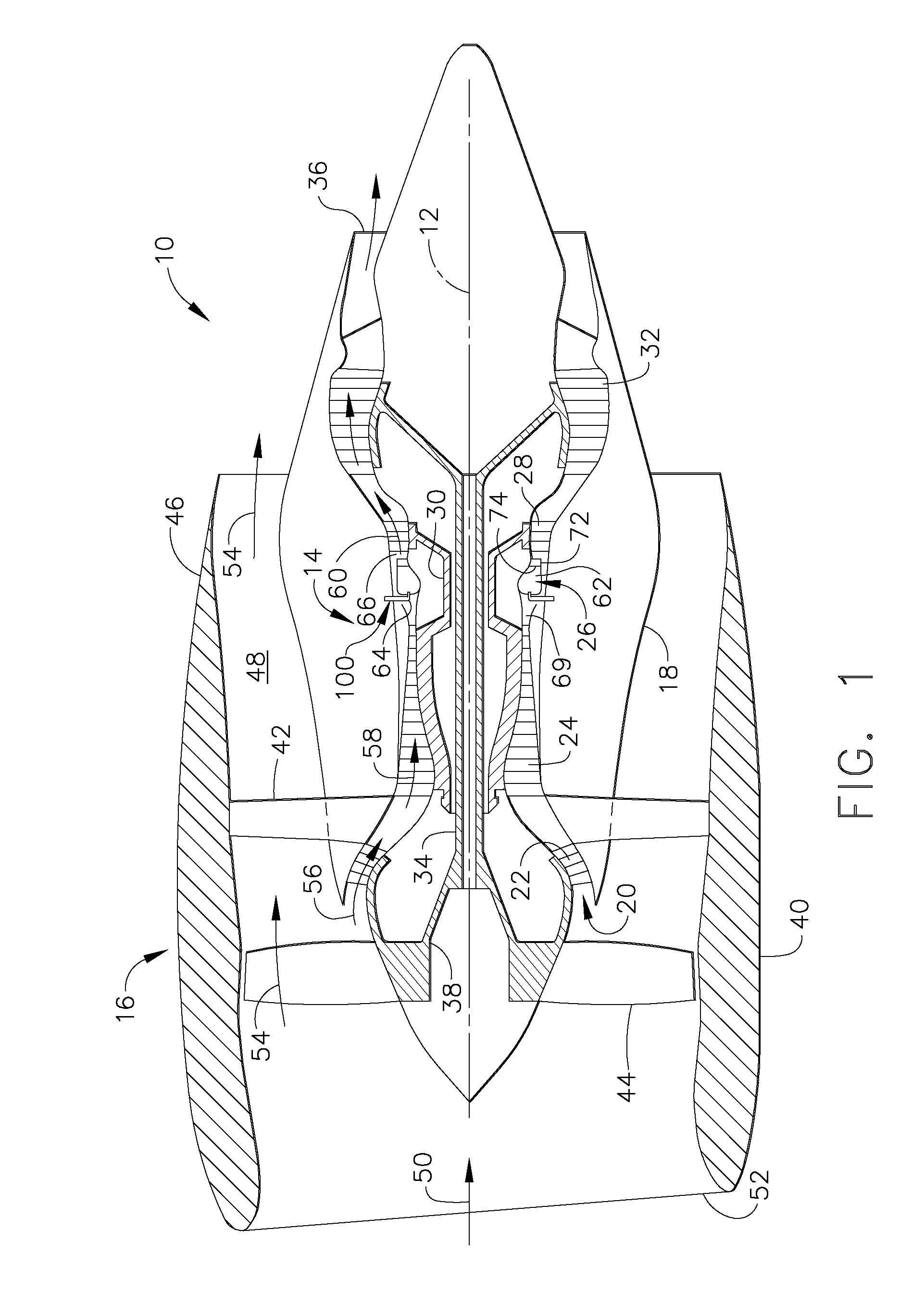

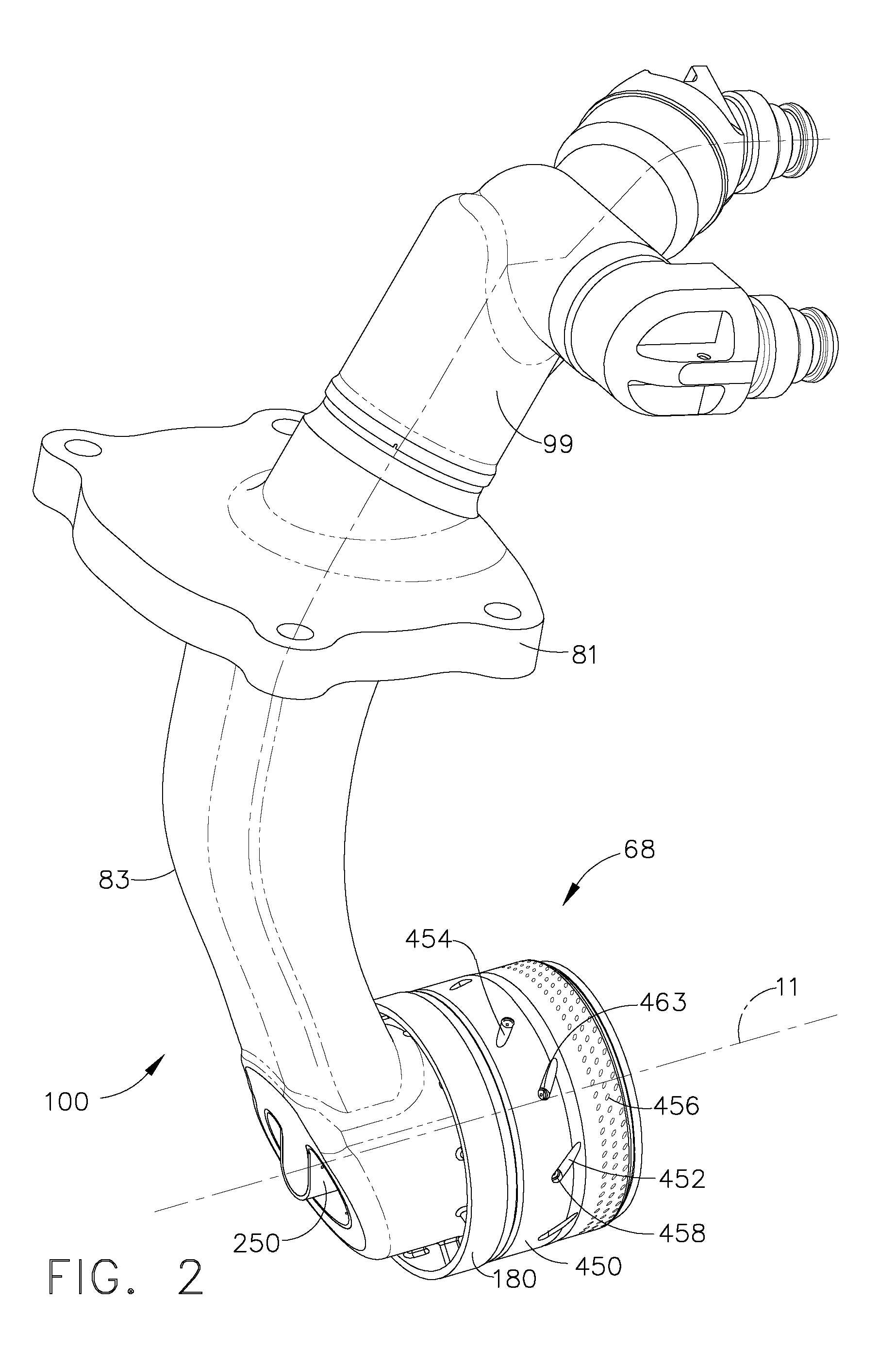

Fuel nozzle

ActiveUS20090255262A1Additive manufacturing apparatusContinuous combustion chamberDistributorGas turbines

A fuel nozzle for a gas turbine engine is disclosed, the fuel nozzle comprising at least one unitary component made using a rapid manufacturing process. In one aspect, the rapid manufacturing process is a laser sintering process. Unitary components disclosed include a conduit, swirler, distributor, venturi and a centerbody.

Owner:GENERAL ELECTRIC CO

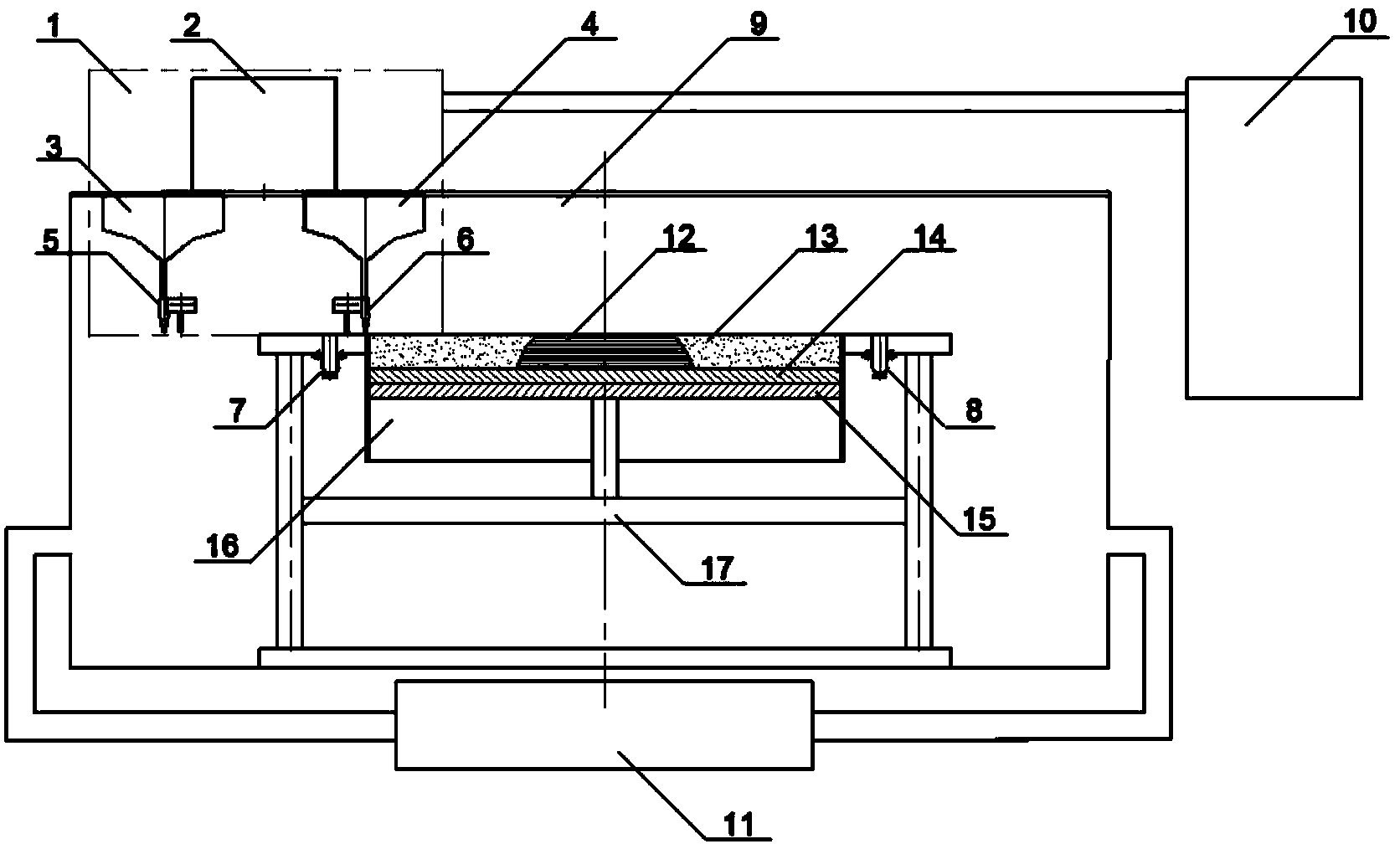

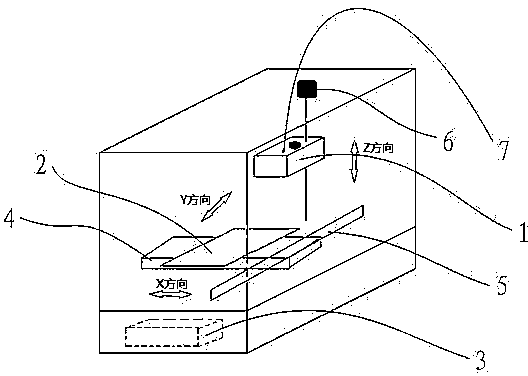

Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

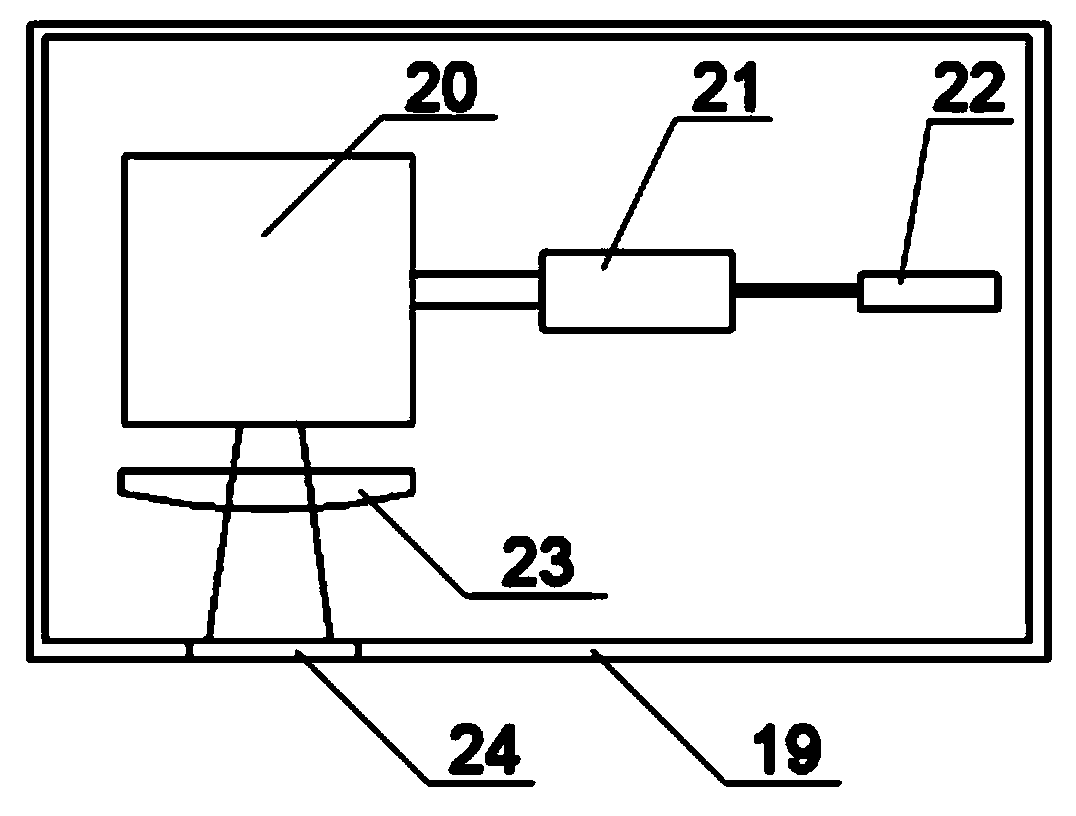

ActiveCN104001915AImprove forming efficiencyShorten the "waiting time"Increasing energy efficiencyControl systemEngineering

The invention discloses equipment for manufacturing a large-size metal part in a high energy beam additive manufacturing mode and a control method of the equipment. The equipment comprises a work cavity, a worktable, a control system, a high energy beam scanning generator, a powder storage hopper, a powder laying device and a gas purification module, wherein the worktable is composed of a forming cylinder and a powder recycling cylinder, and the upper surface of the forming cylinder and the upper surface of the powder recycling cylinder are coplanar and form a work plane. The control system controls the high energy beam scanning generator and the powder laying device to move opposite to the worktable in the powder laying direction. The equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment largely shorten the waiting time caused by pre-installation of a powder bed when a common laser / electron beam selective melting technology is used for processing a part, thereby obviously improving the forming efficiency of high energy beam additive manufacturing. Through the application of the equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment, a metal part with a meter-grade size, high performance, high accuracy and a complex structure can be manufactured efficiently and rapidly.

Owner:TECH LASER TECH SHANGHAI CO LTD

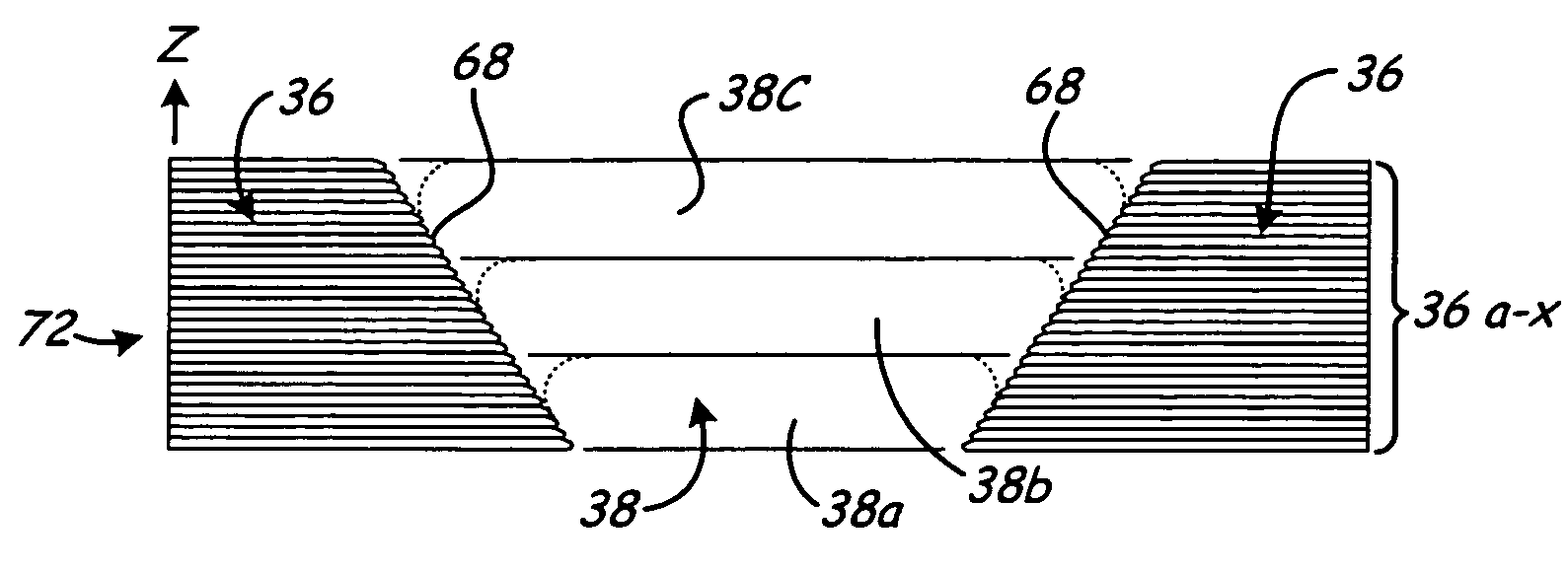

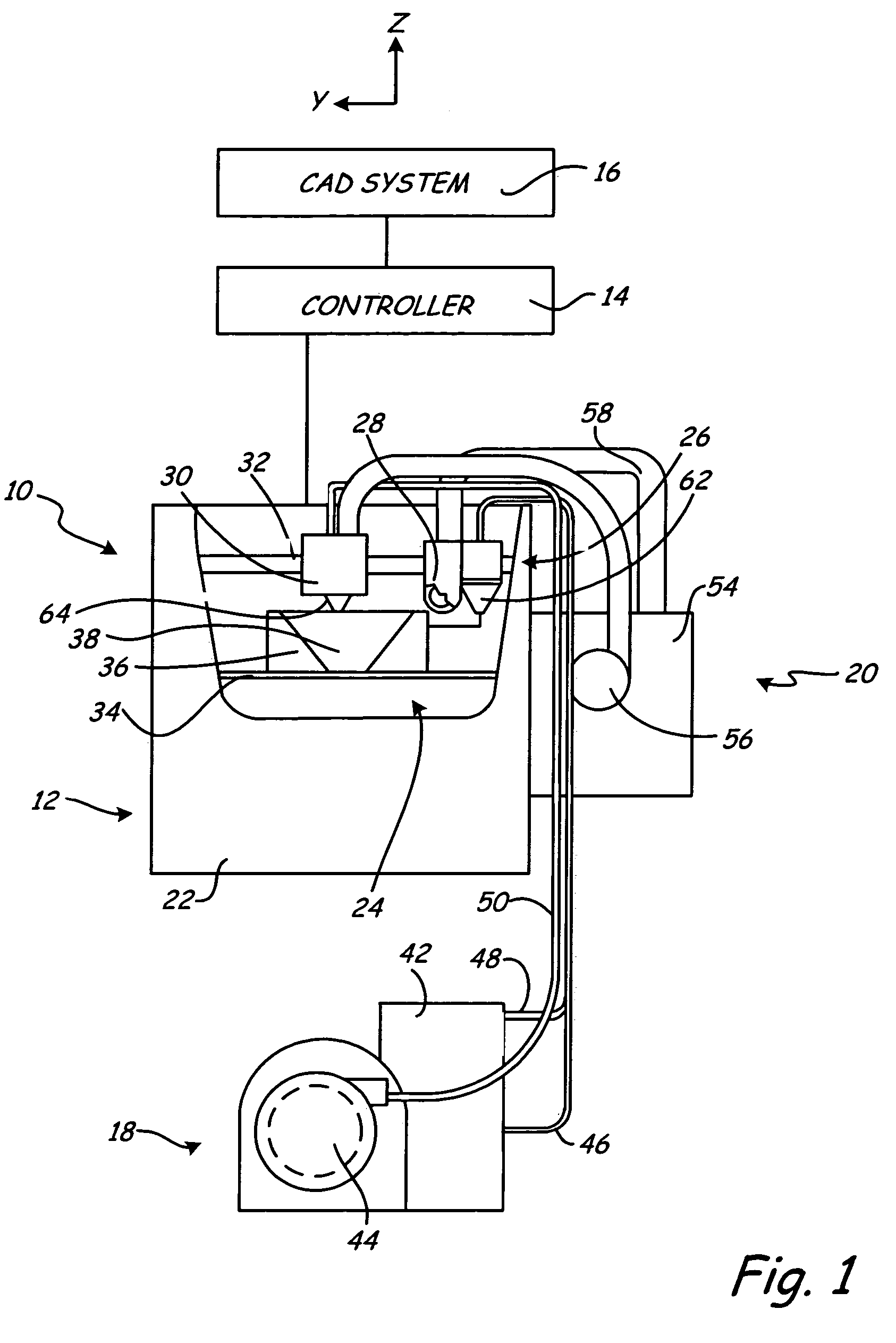

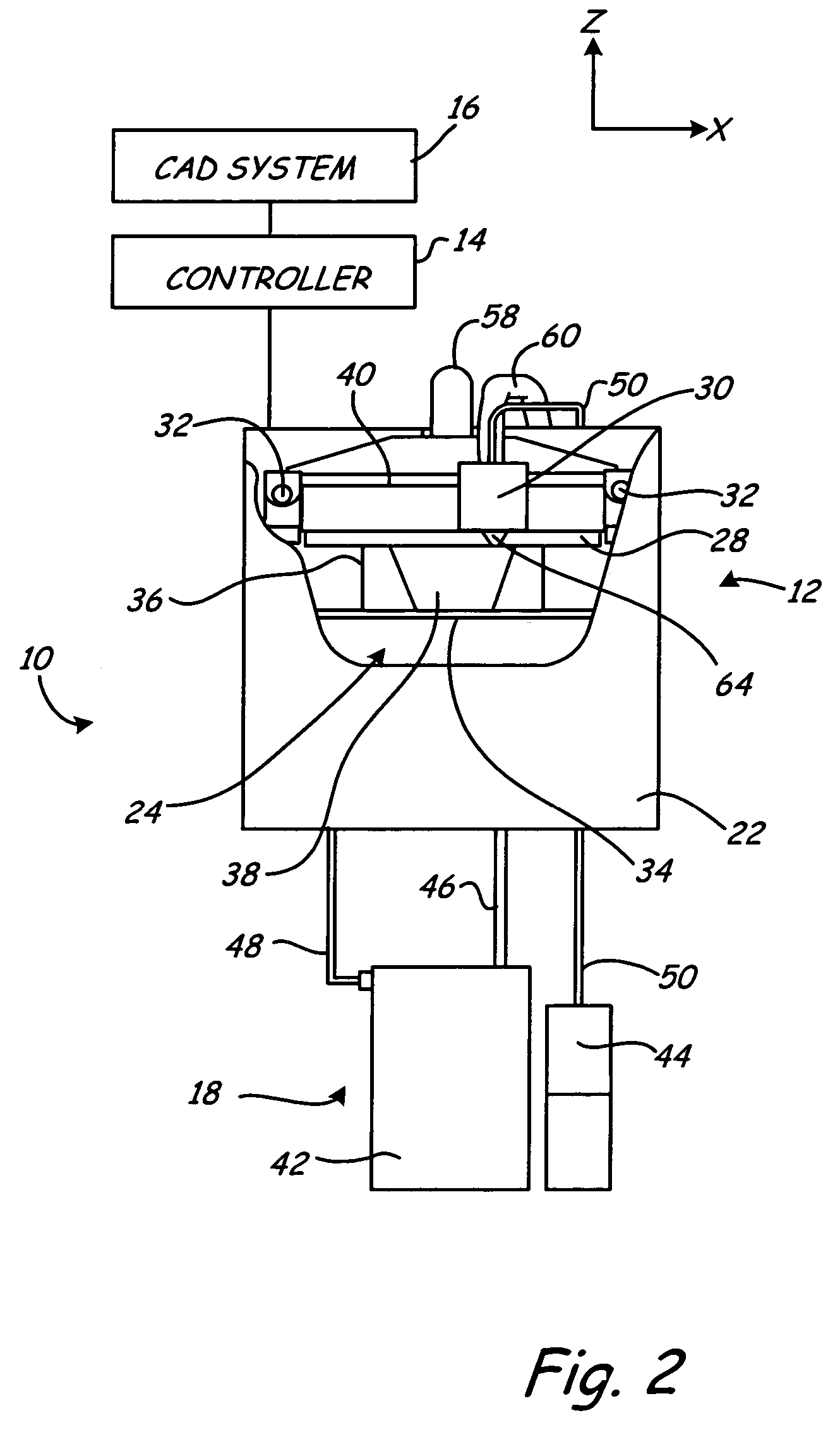

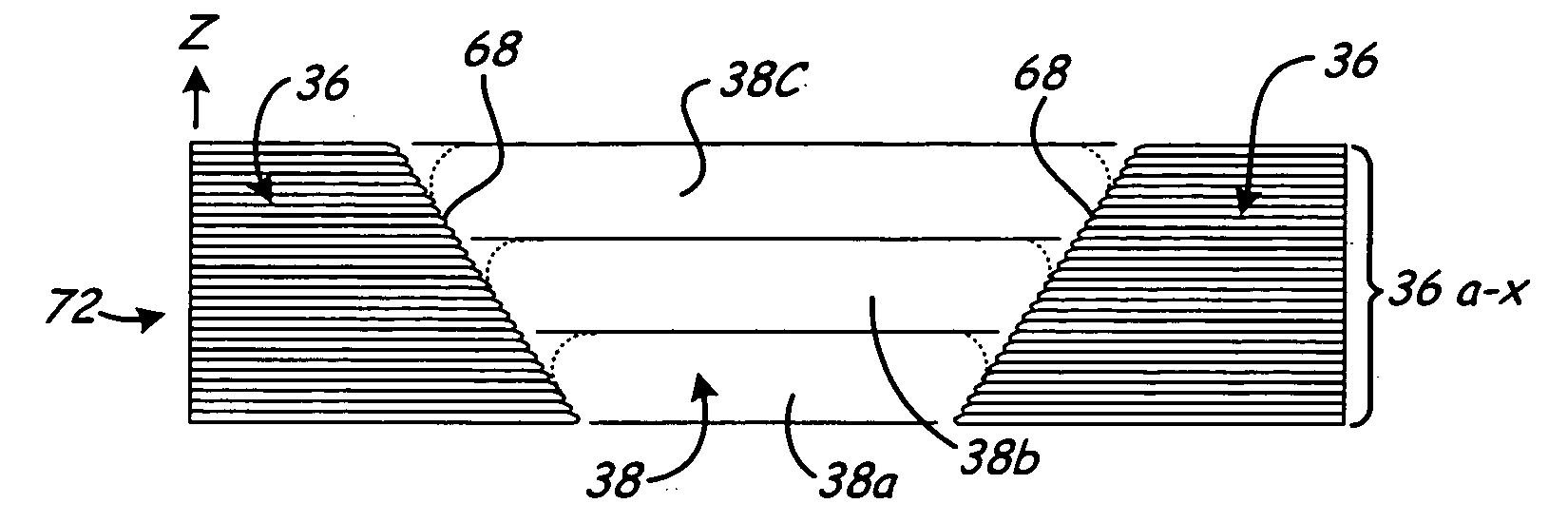

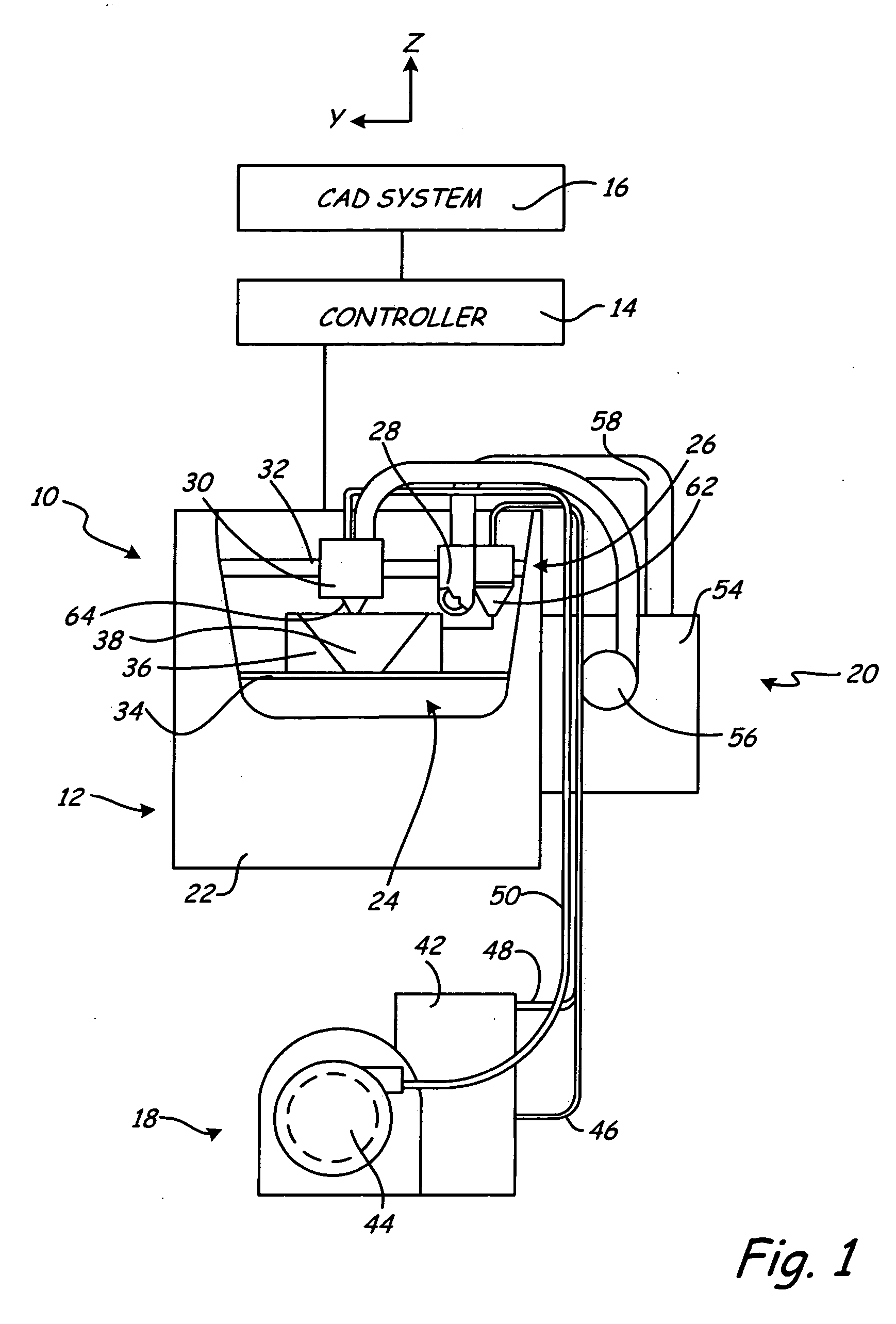

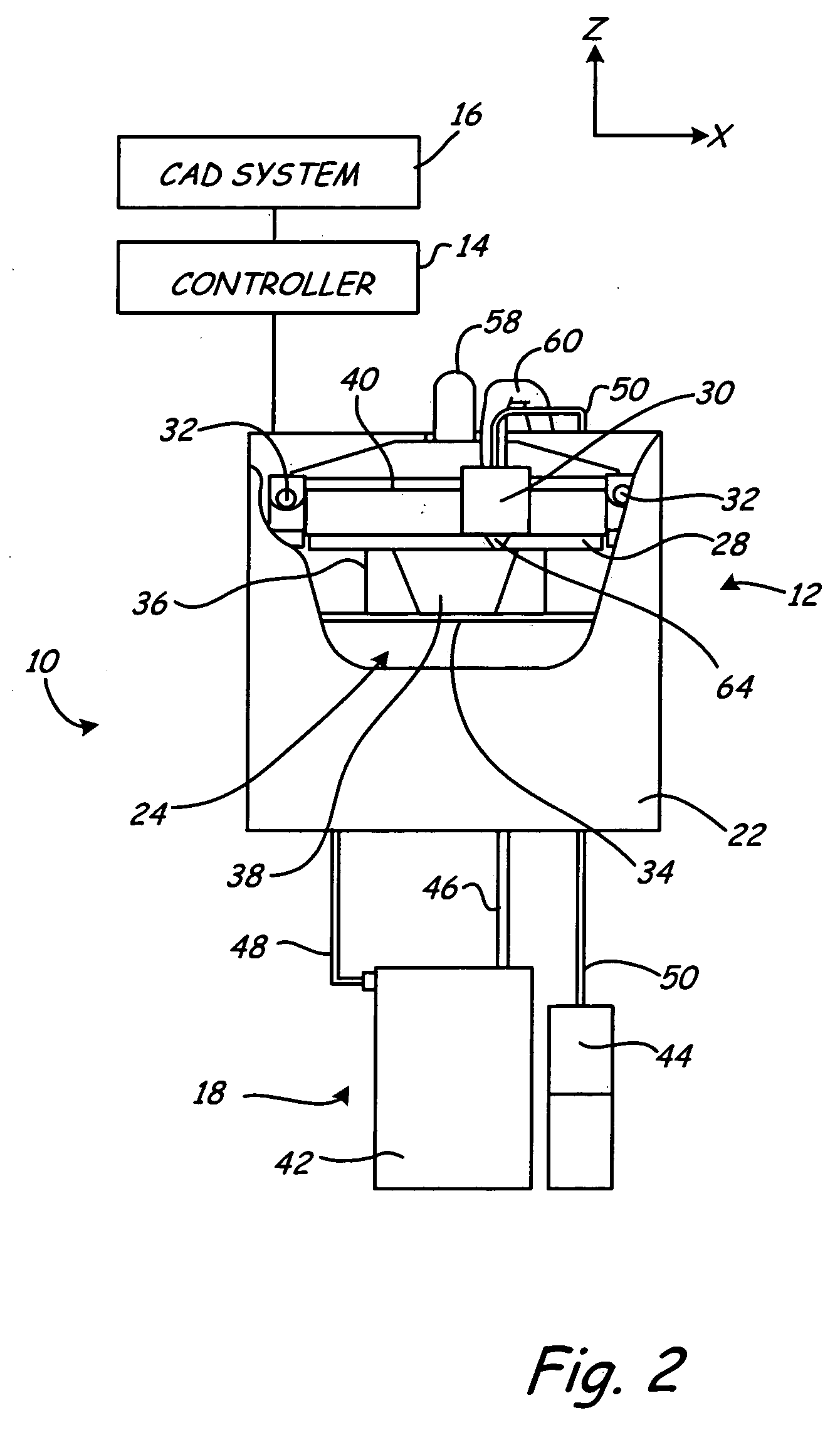

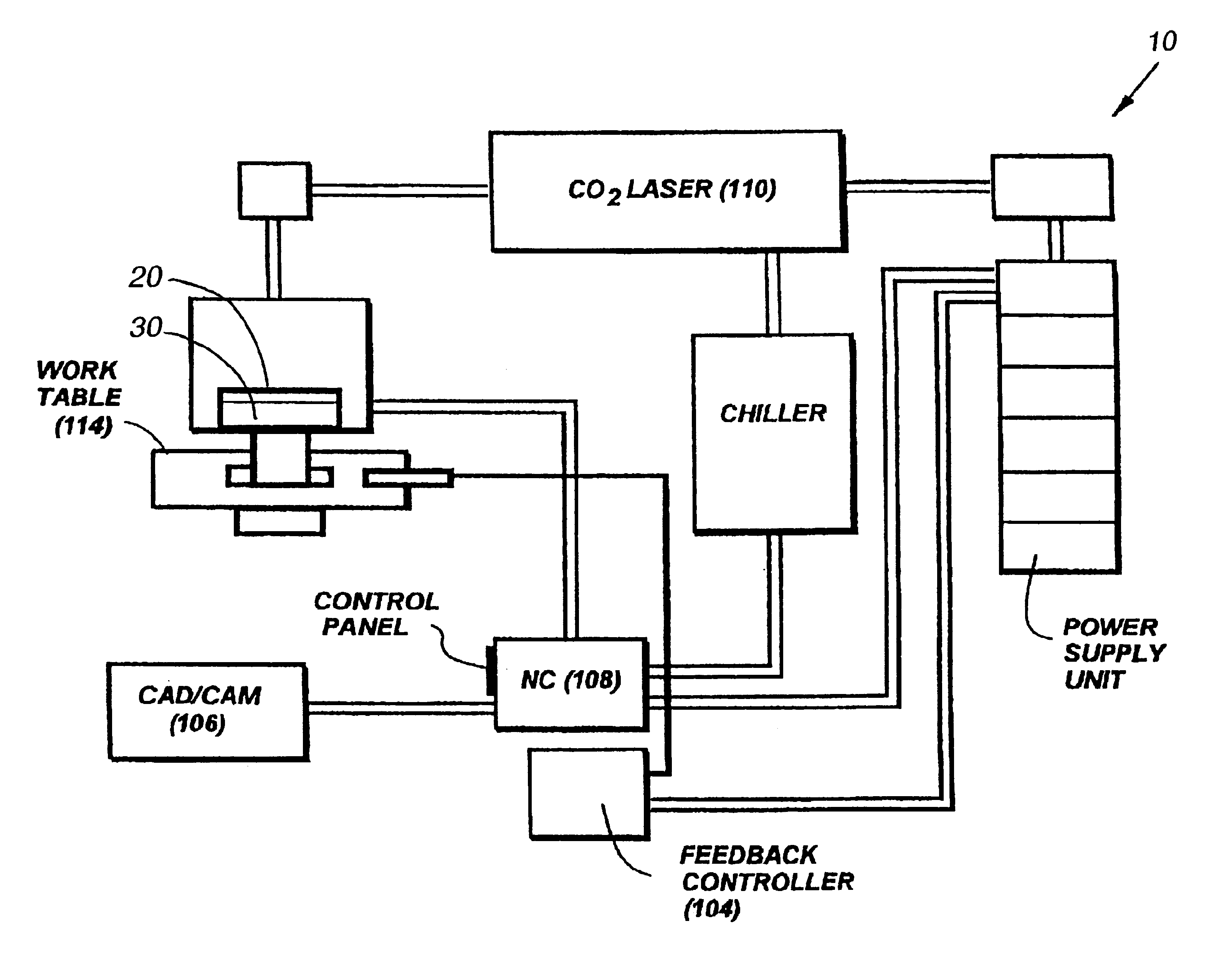

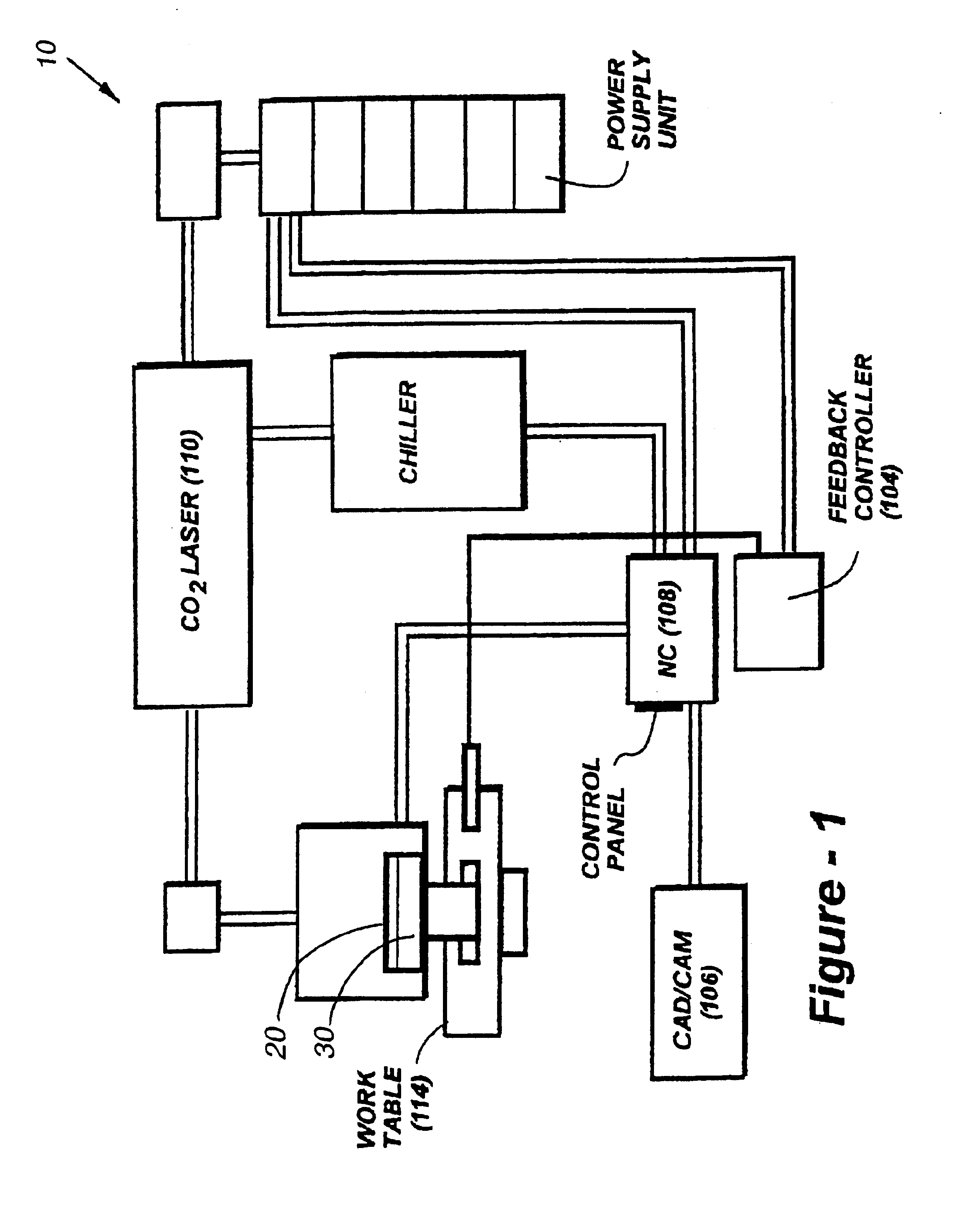

Closed-loop, rapid manufacturing of three-dimensional components using direct metal deposition

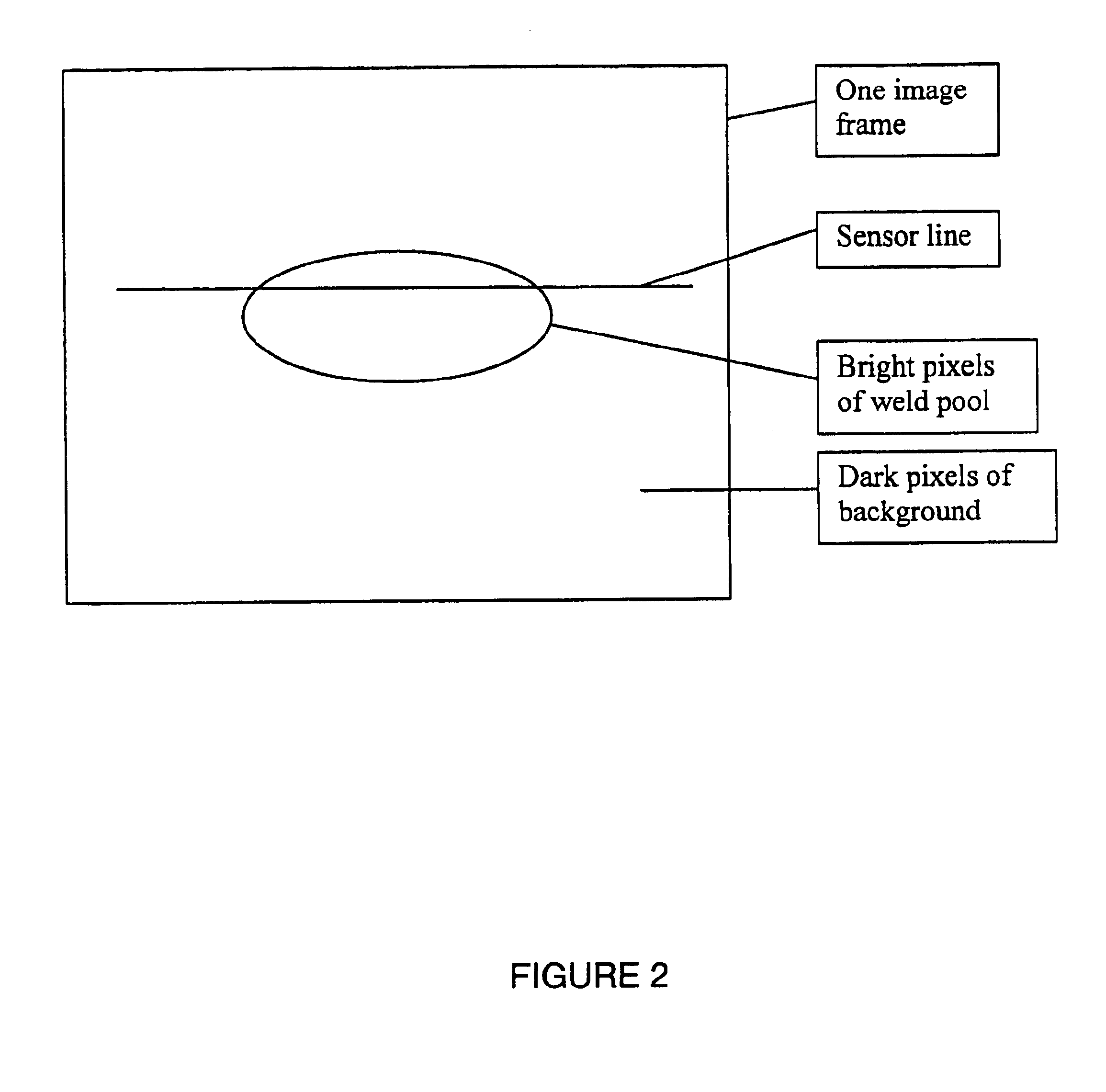

InactiveUS6925346B1Improve throughputImprove lead-timeAdditive manufacturing apparatusMolten spray coatingClosed loopHarmonic vibration

Multiple criteria are monitored and controlled to enhance the success of direct-metal deposition, including greater control over factors such as deposit layer height / thickness, sub-harmonic vibration, contour path shape, powder mass flow, and deposition speed, and stress accumulation. Sensors are used to monitor some or all of the following parameters during the deposition process: deposit height, width, temperature, and residual stress. A predetermined limit with respect to the yield strength of the material is preferably set. If the stress exceeds that limit sensors will automatically introduce one or more remedial measures, the priority of which is established using a look-up table generated in accordance with prior experimental knowledge. To control temperature induced distortion and stress, an infrared temperature detector may be used in conjunction with a controller to reduce temperature, increase speed and decreased power for purpose of stress management.

Owner:DM3D TECH

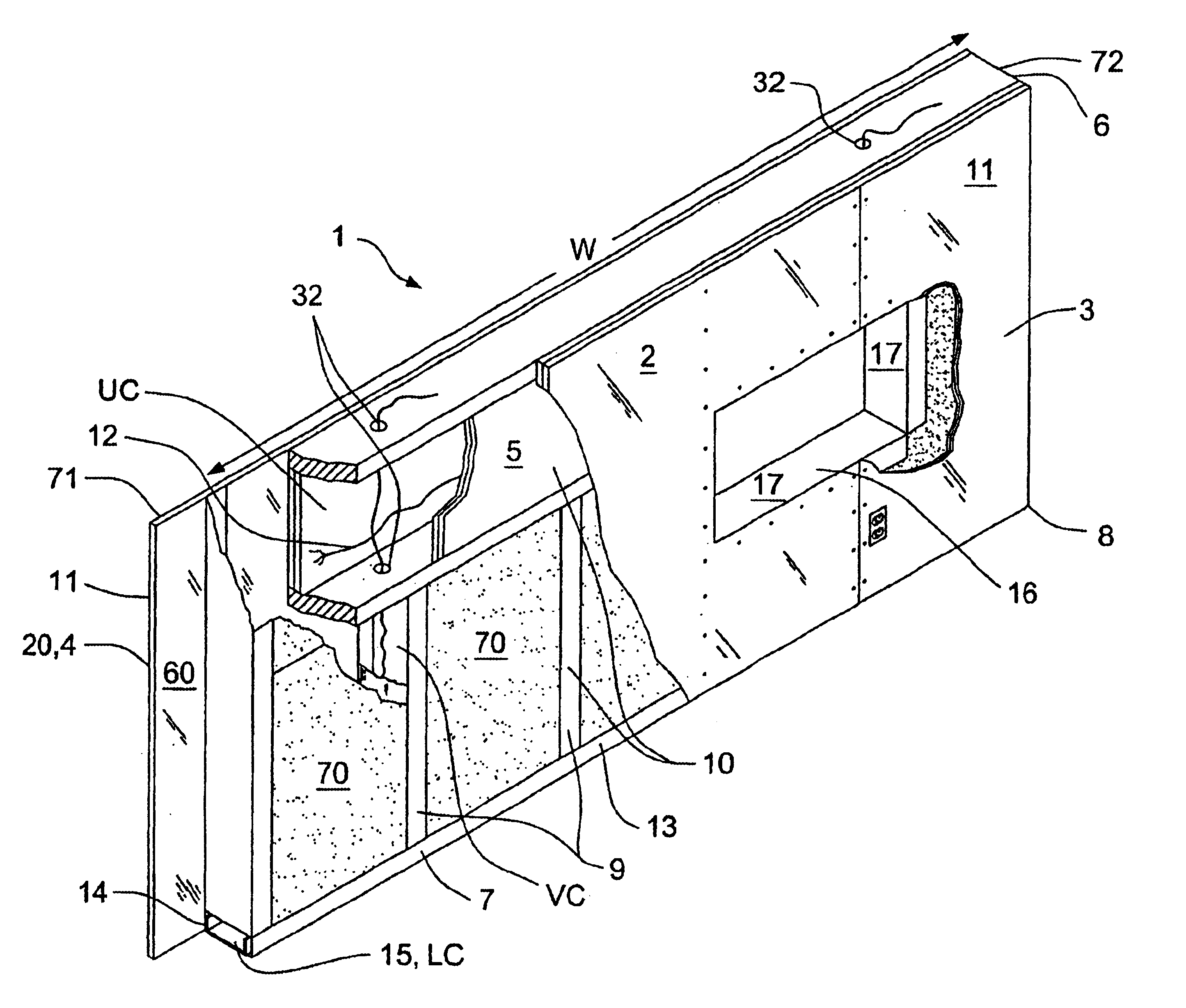

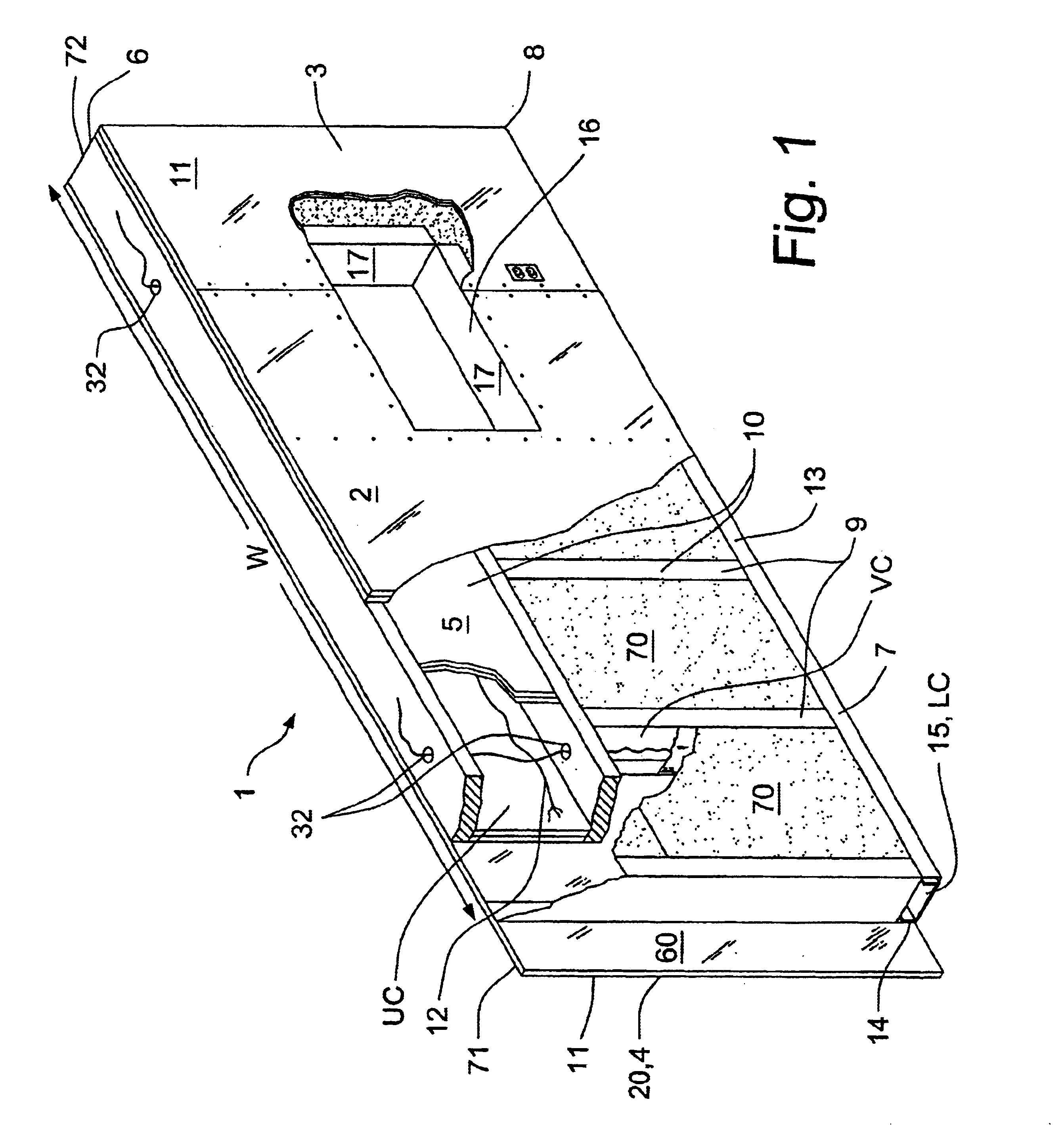

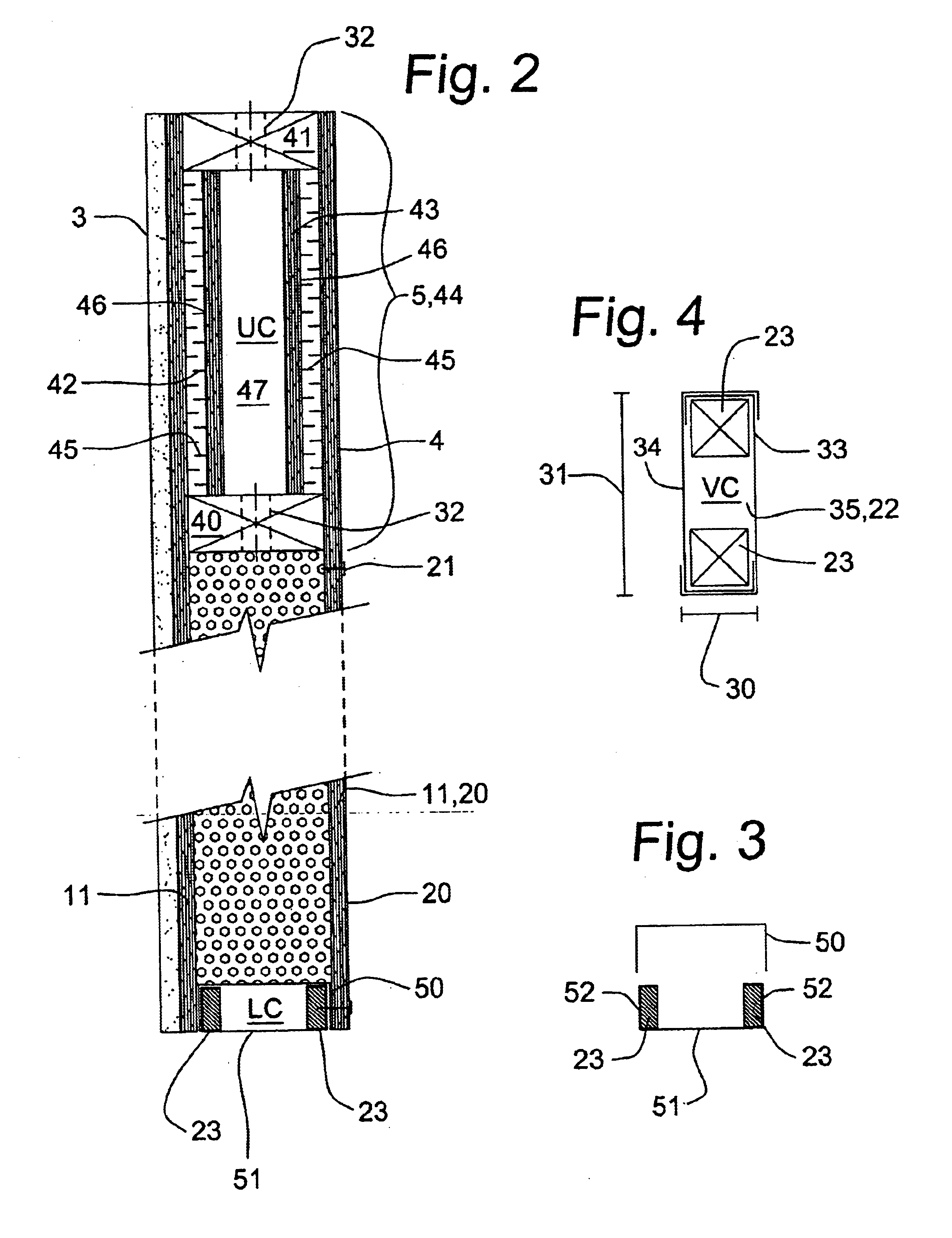

Continuous structural wall system

InactiveUS6854230B2Protection from damageProvide structural rigidityWallsPublic buildingsLoad-bearing wallWall plate

A composite wall panel having continuous upper and lower hollow horizontal chases and spaced hollow vertical chases formed throughout the panel to permit passage of electrical wiring and the like. The chases have protective barriers to protect the wiring from penetration and damage due to mechanical fasteners used to manufacture the panel and to construct load bearing walls using a plurality of manufactured panels. Further, the panel has a continuous header to provide structural rigidity and to permit rapid manufacturing of the panel without the need to frame openings, such as doors and windows, at the time of manufacture. Openings are cut in the panels and finished after the walls are constructed.

Owner:STARKE CHARLES

Method for repairing and/or modifying component parts of a gas turbine

InactiveUS7810237B2Reduce processing timeExtended operating timeAdditive manufacturing apparatusBlade accessoriesGas turbinesIndustrial engineering

A method is for repairing and / or modifying component parts of a gas turbine. First, at least one, particularly damaged section of the component part that is to be repaired is cut out of the component part. In addition, if it does not exist, a data record is generated for a replacement part that is to be produced. The replacement part is subsequently produced with the aid of a rapid manufacturing process. Subsequently, the replacement part produced is integrated into the component part that is to be repaired.

Owner:MTU AERO ENGINES GMBH

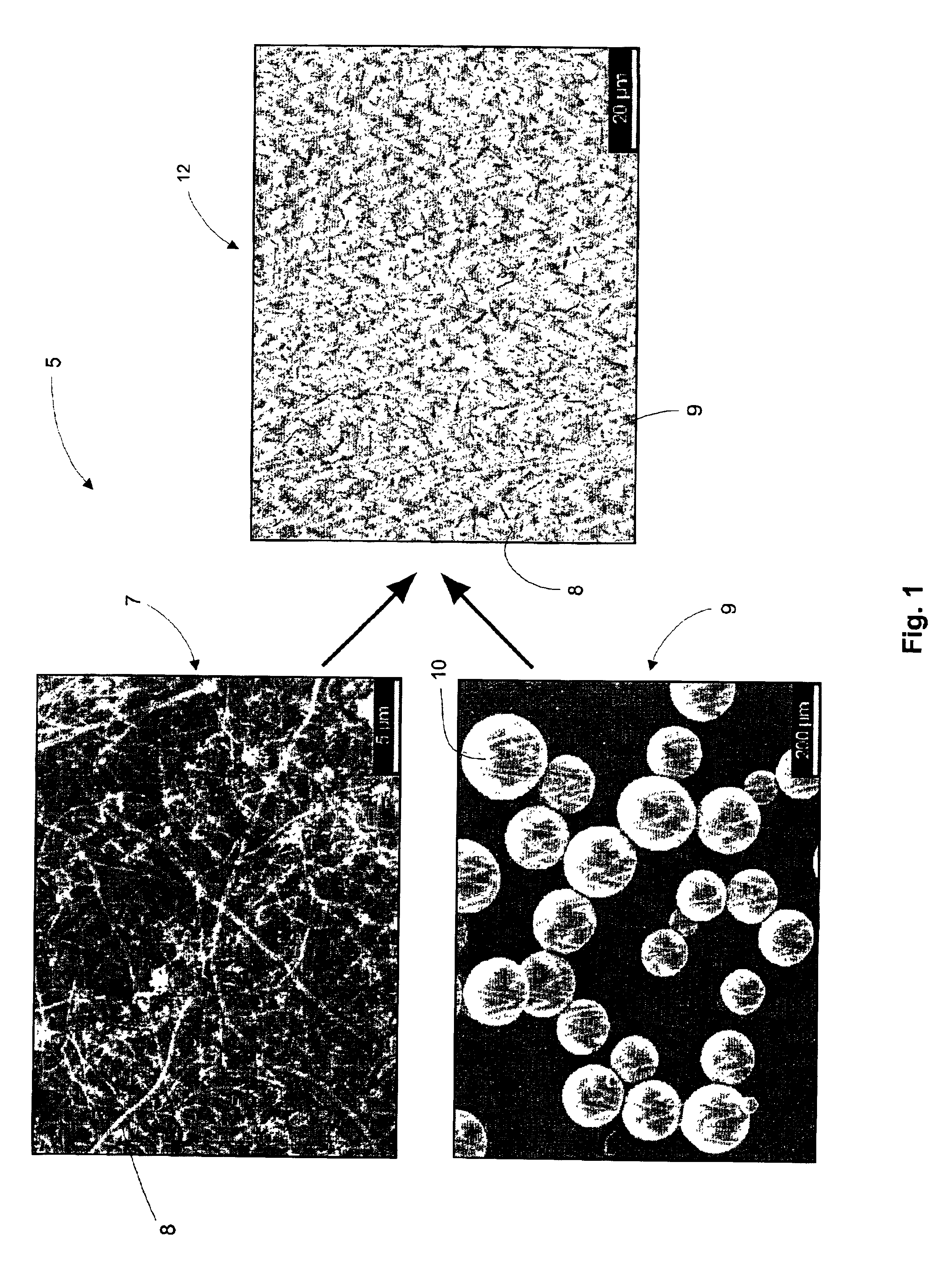

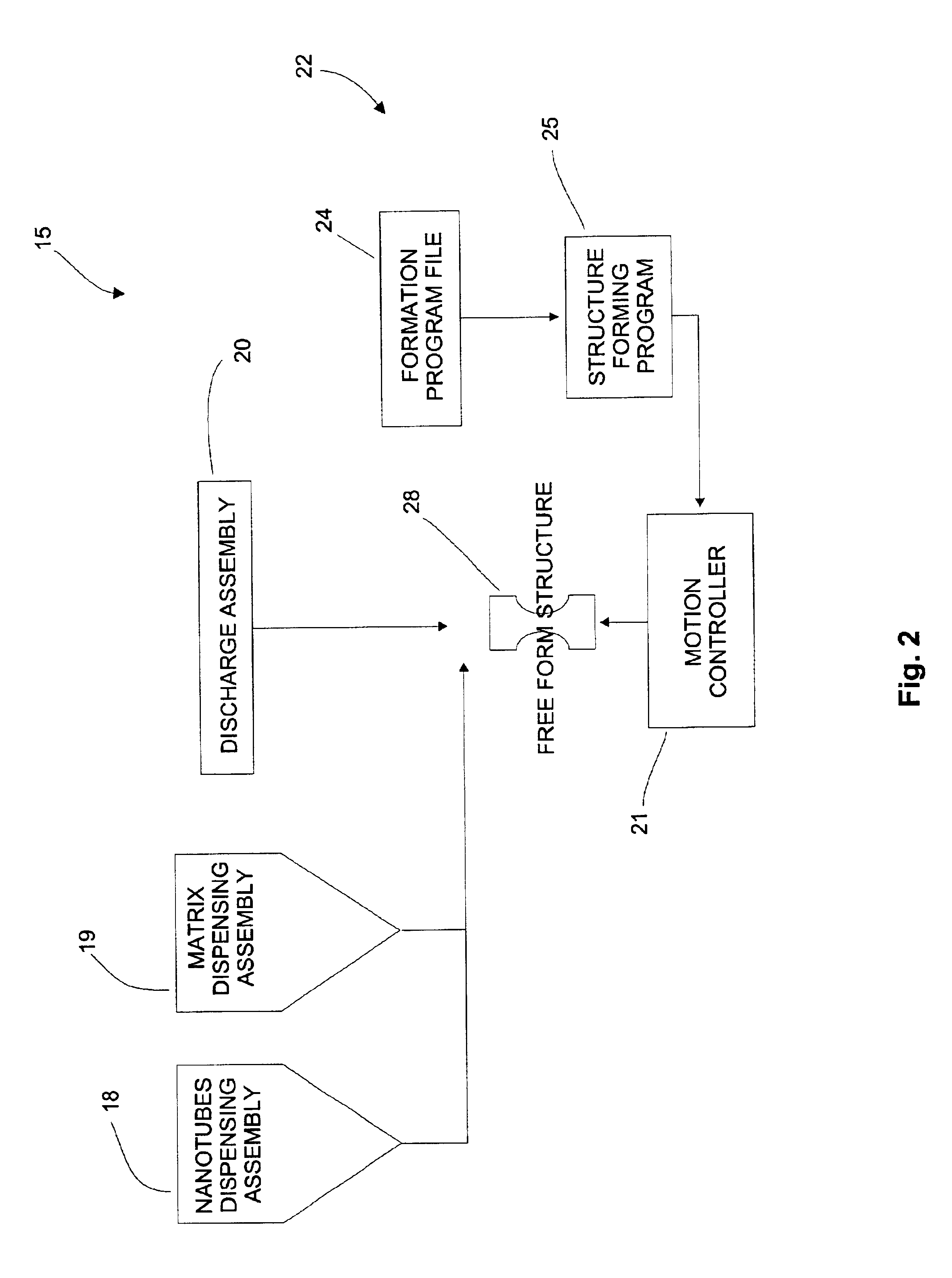

Rapid manufacturing of carbon nanotube composite structures

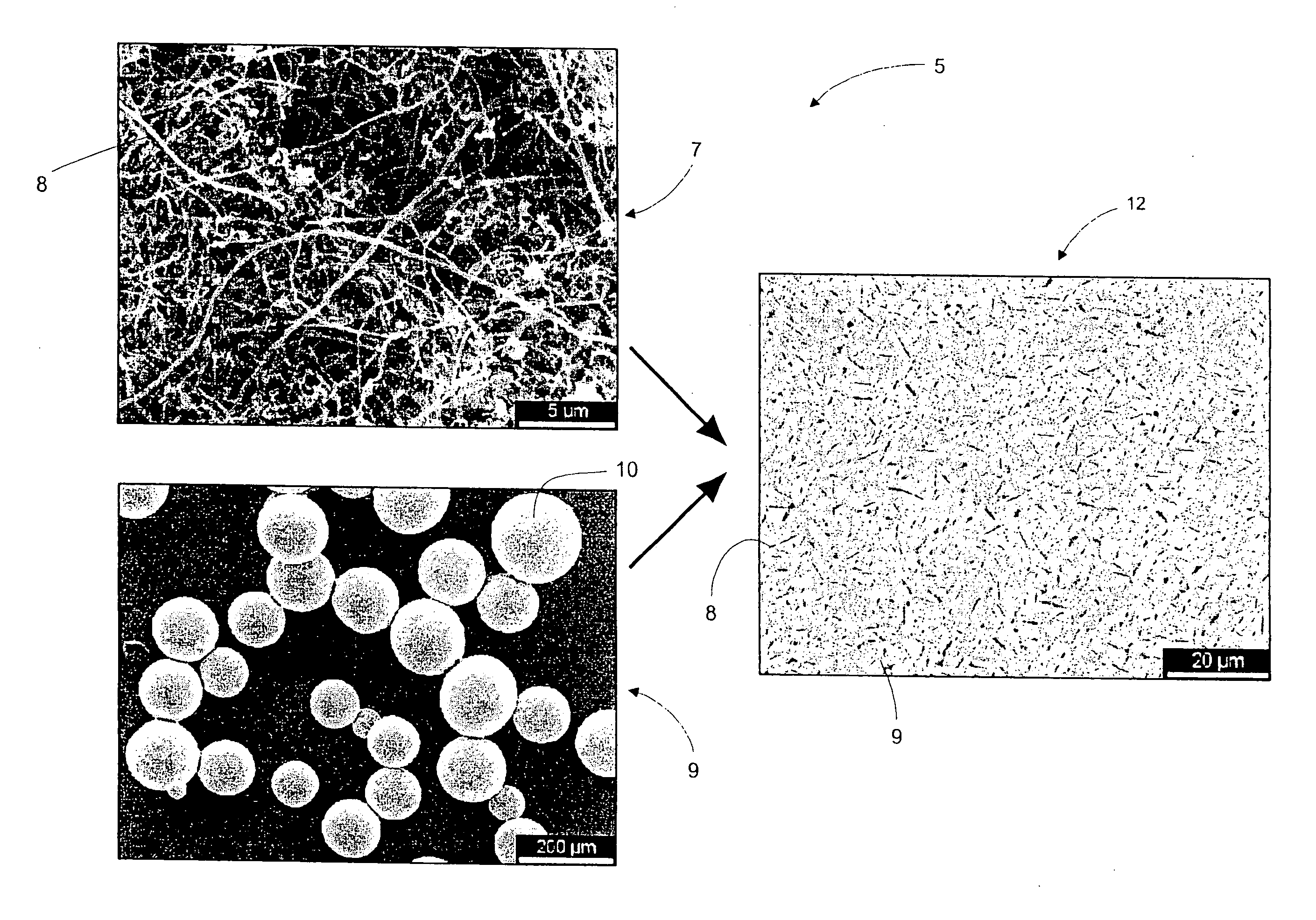

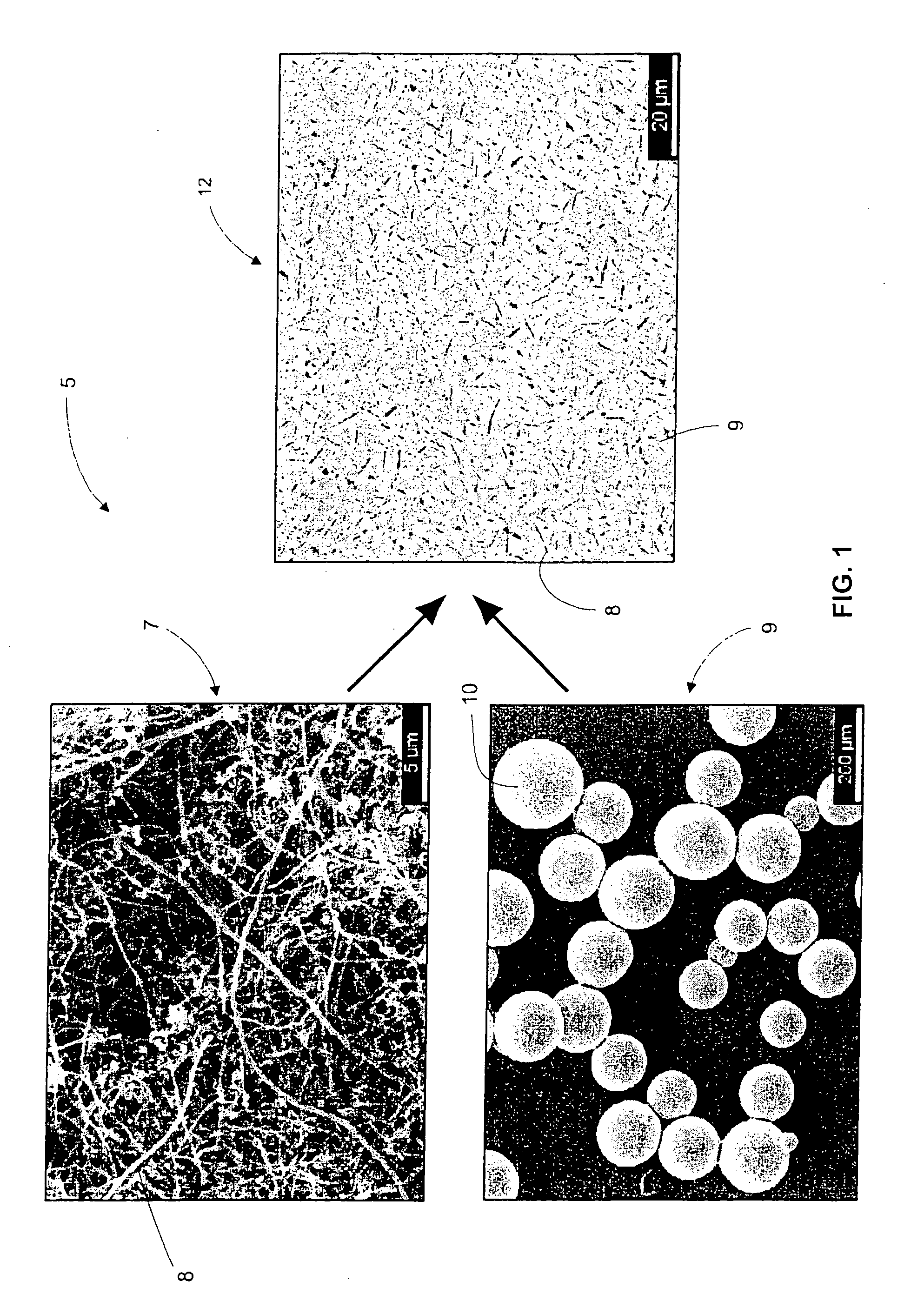

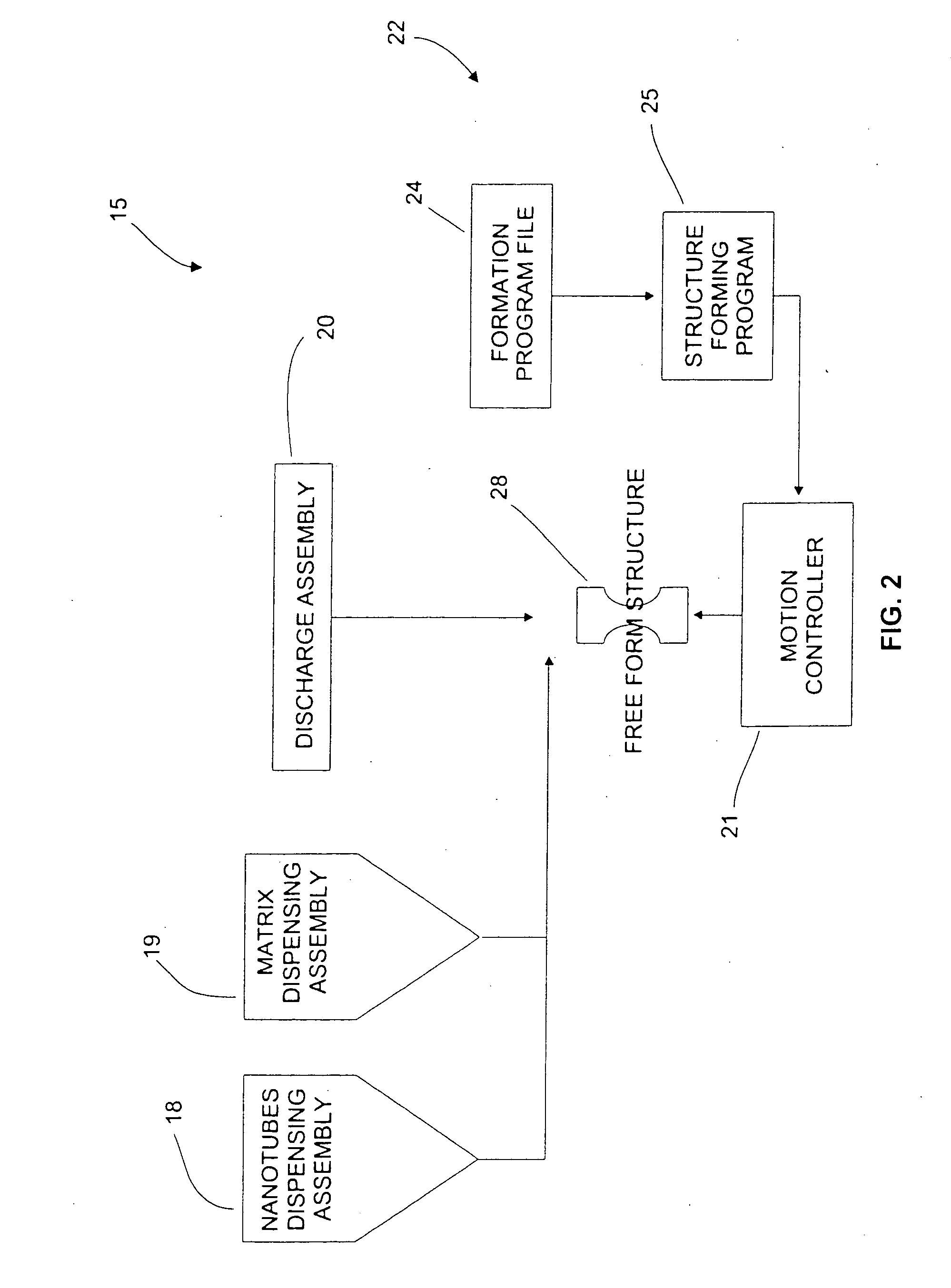

InactiveUS6949216B2Easy to identifyMaterial nanotechnologyNanostructure manufactureFiberParticle beam

A system for fabricating a free form structure of a composite material including carbon nanotubes. The system includes a discharge assembly and a composite formation device operatively linked with the discharge assembly. The discharge assembly dispenses a fusing agent such as for example a high energy density emission, a laser emission or a particle beam emission. The composite formation device includes a composite generator and an arranger in operative engagement with a composite generator. The composite generator engages with the fusing agent so as to create a composite nodal element. The composite nodal element includes a matrix and a multiplicity of fibers formed of carbon nanotubes dispersed throughout the matrix. The arranger positions one node relative to another to define the free form structure.

Owner:LOCKHEED MARTIN CORP

Entirety quick manufacture method of hot isostatic pressing metal wrapps

InactiveCN101391302ARelief of restrictions that make it difficult to make complex envelopesHot isostatic pressing process goes smoothlyAdditive manufacturing apparatusIncreasing energy efficiencyVacuum pumpingData information

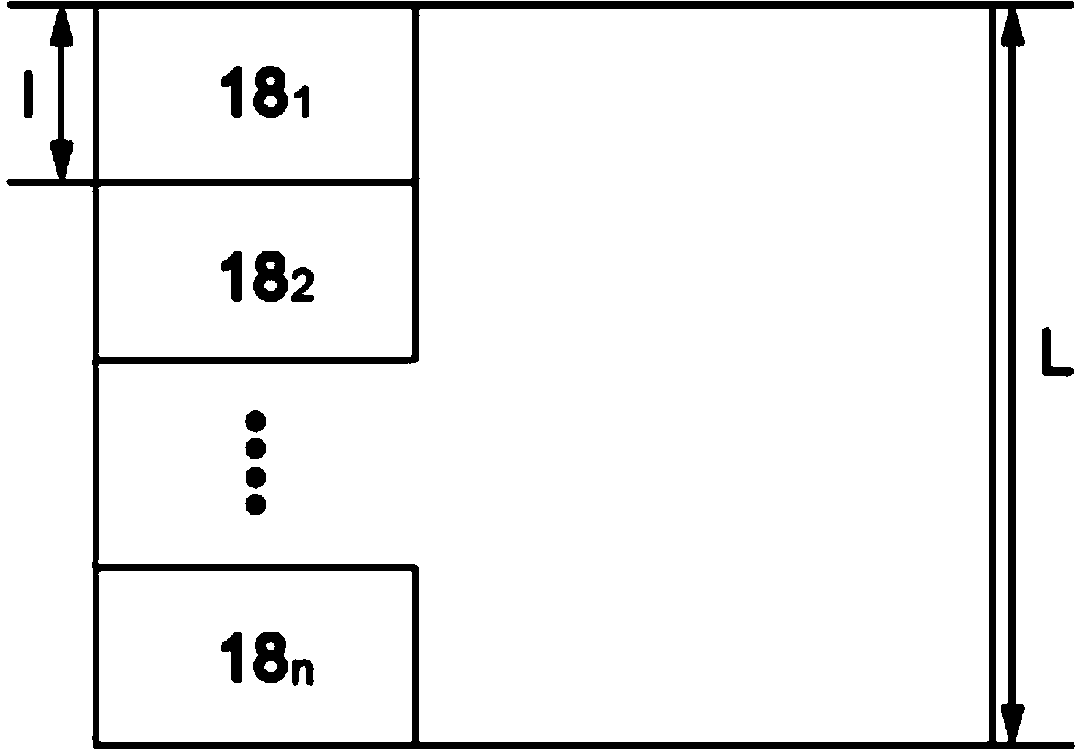

The invention discloses an integral rapid manufacturing method of a hot isostatic pressing metal sheath, comprising the steps: (1) a CAD three-dimensional model of the metal sheath is designed by adopting three-dimensional molding software, and is then processed by slicing software and saved as an STL file, and the data information of the STL file is transmitted to an SLM rapid forming machine; (2) a forming chamber is vacuumized; (3) a metal powder layer is spread on a work platform flatly; (4) a semiconductor pumping YAG laser or a fiber laser is adopted to scan the metal powder positioned at the boundary of the slice layer, and the powder material at the boundary is melted; and (5) the step (3) and the step (4) are repeated until the compact sheath is manufactured. Powder inlet holes can be reserved on the sheath when designing the three-dimensional model of the sheath, so as to facilitate the subsequent processes such as powder filling, compaction by vibration, vacuum pumping and encapsulation. The sheath is compact and has a controllable shape, and can form parts with any complex shapes and structures, and can realize the high utilization rate of material.

Owner:HUAZHONG UNIV OF SCI & TECH

Rapid manufacturing of carbon nanotube composite structures

InactiveUS20070290409A1Easy to identifyMaterial nanotechnologyNanostructure manufactureFiberHigh energy

A system for fabricating a free form structure of a composite material including carbon nanotubes. The system includes a discharge assembly and a composite formation device operatively linked with the discharge assembly. The discharge assembly dispenses a fusing agent such as for example a high energy density emission, a laser emission or a particle beam emission. The composite formation device includes a composite generator and an arranger in operative engagement with a composite generator. The composite generator engages with the fusing agent so as to create a composite nodal element. The composite nodal element includes a matrix and a multiplicity of fibers formed of carbon nanotubes dispersed throughout the matrix. The arranger positions one node relative to another to define the free form structure.

Owner:LOCKHEED MARTIN CORP

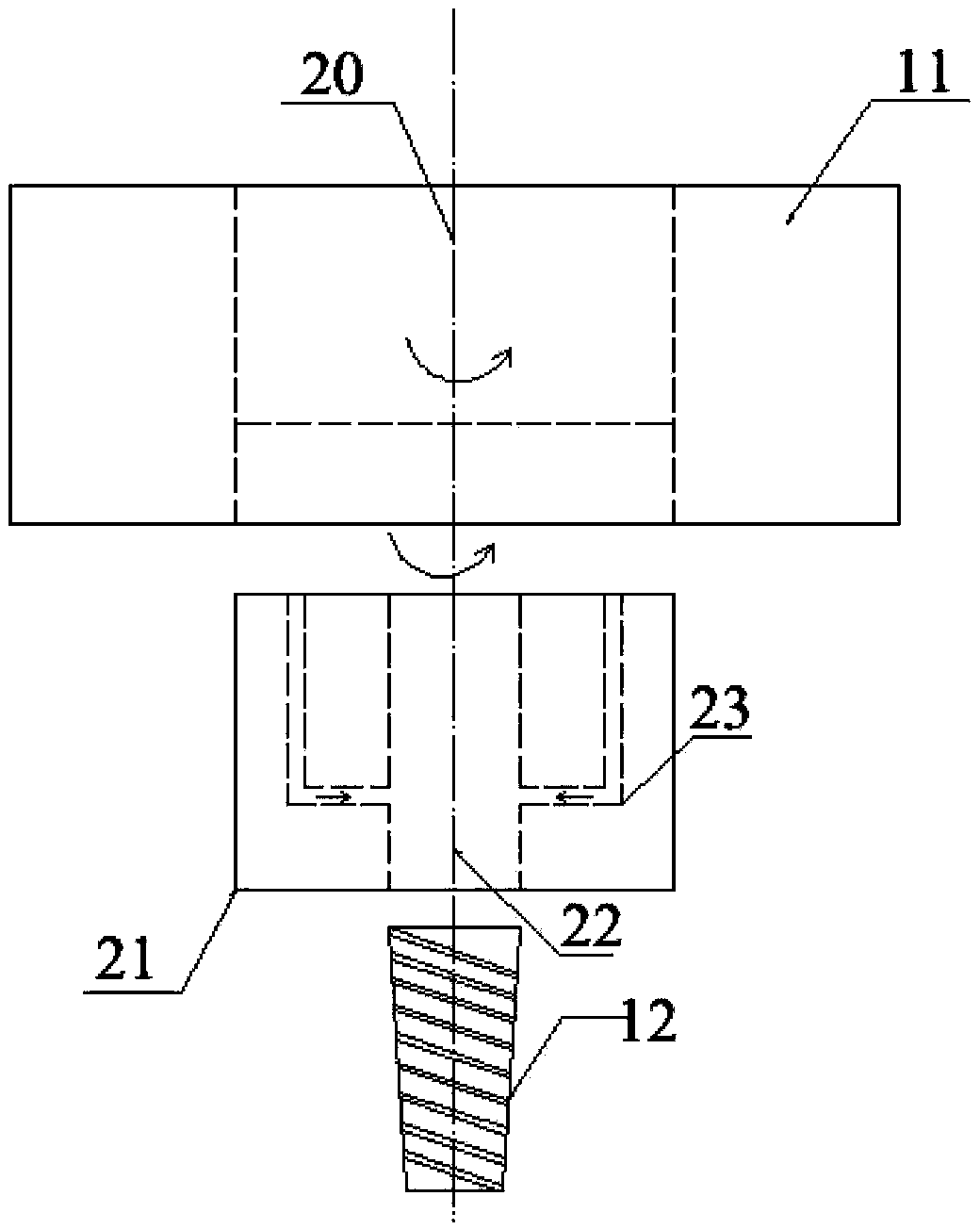

Three-dimensional (3D) rapid forming printing system and method

The invention relates to the field of rapid prototyping and discloses a three-dimensional (3D) rapid forming printing system. The system comprises a personal computer (PC) end with a control unit, an extruder, a printing base plate with a heating function, a servo motor which controls motion of the printing base plate, and a motion control unit, wherein the extruder is positioned above the printing base plate on the top of a body operating area; the servo motor and the printing base plate are positioned below the extruder at the bottom of the body operating area; the motion control unit is an embedded chip group; each chip comprises a task module for executing a control task; the motion control unit is positioned in a chip group slot below the body operating area; the extruder, the servo motor and the printing base plate are respectively and electrically connected with the motion control unit; the motion control unit is electrically connected with the PC end. By virtue of an incremental manufacturing method, namely models are established on the printing base plate layer by layer, rapid manufacturing is realized, processing of any model can be finished, and the system has certain application value and application prospects and can be applied to household and industrial production.

Owner:林岚 +1

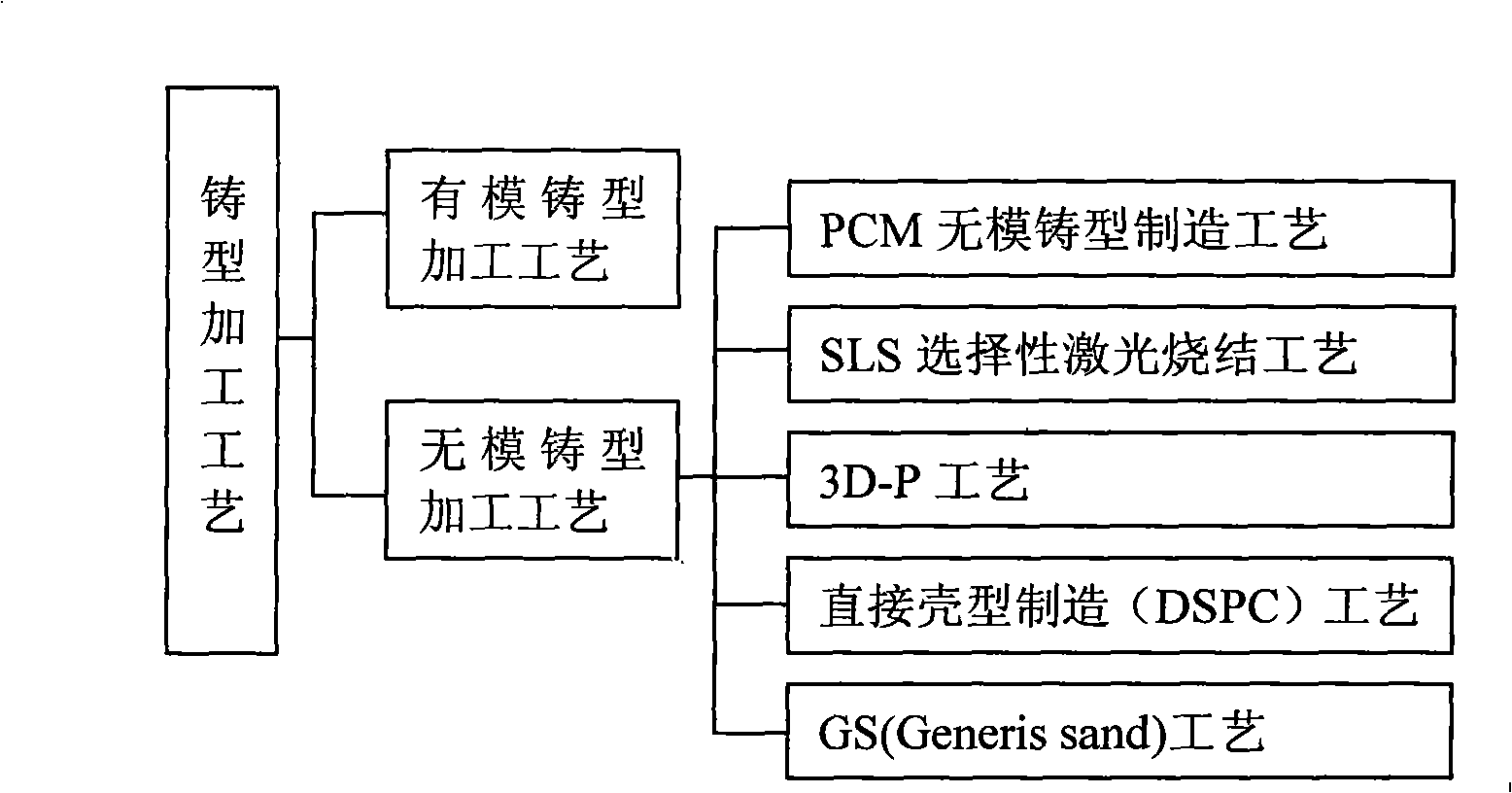

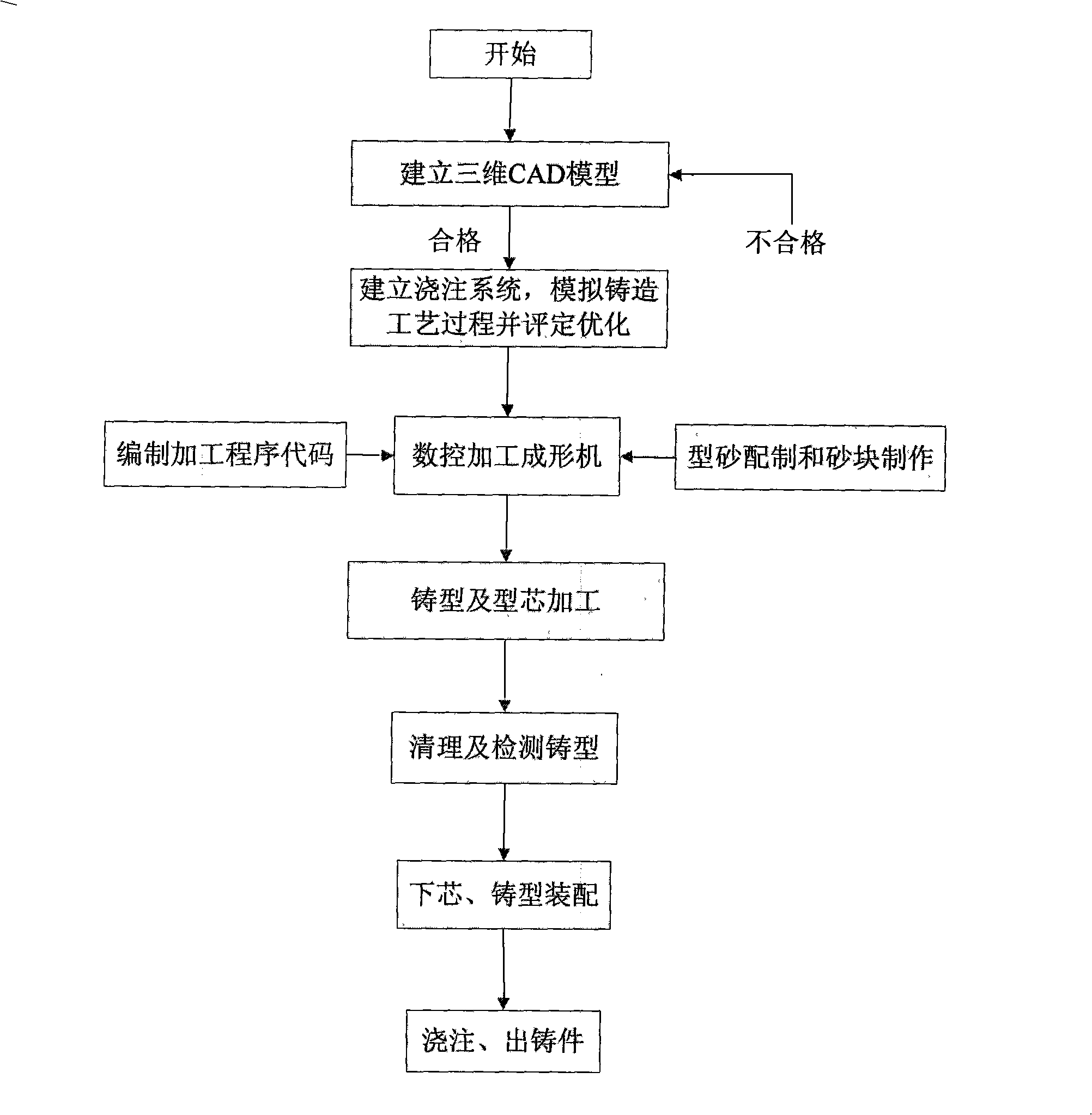

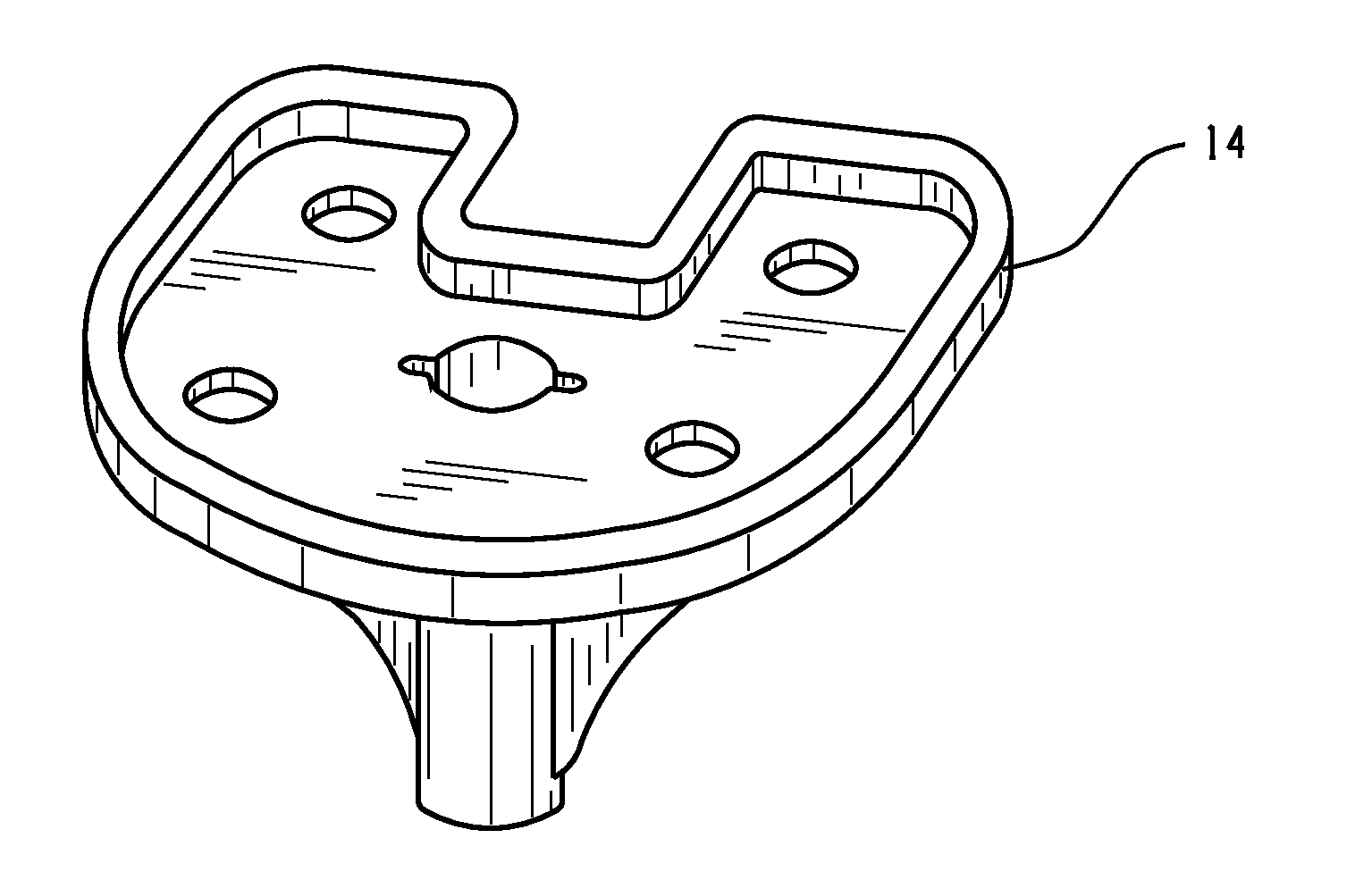

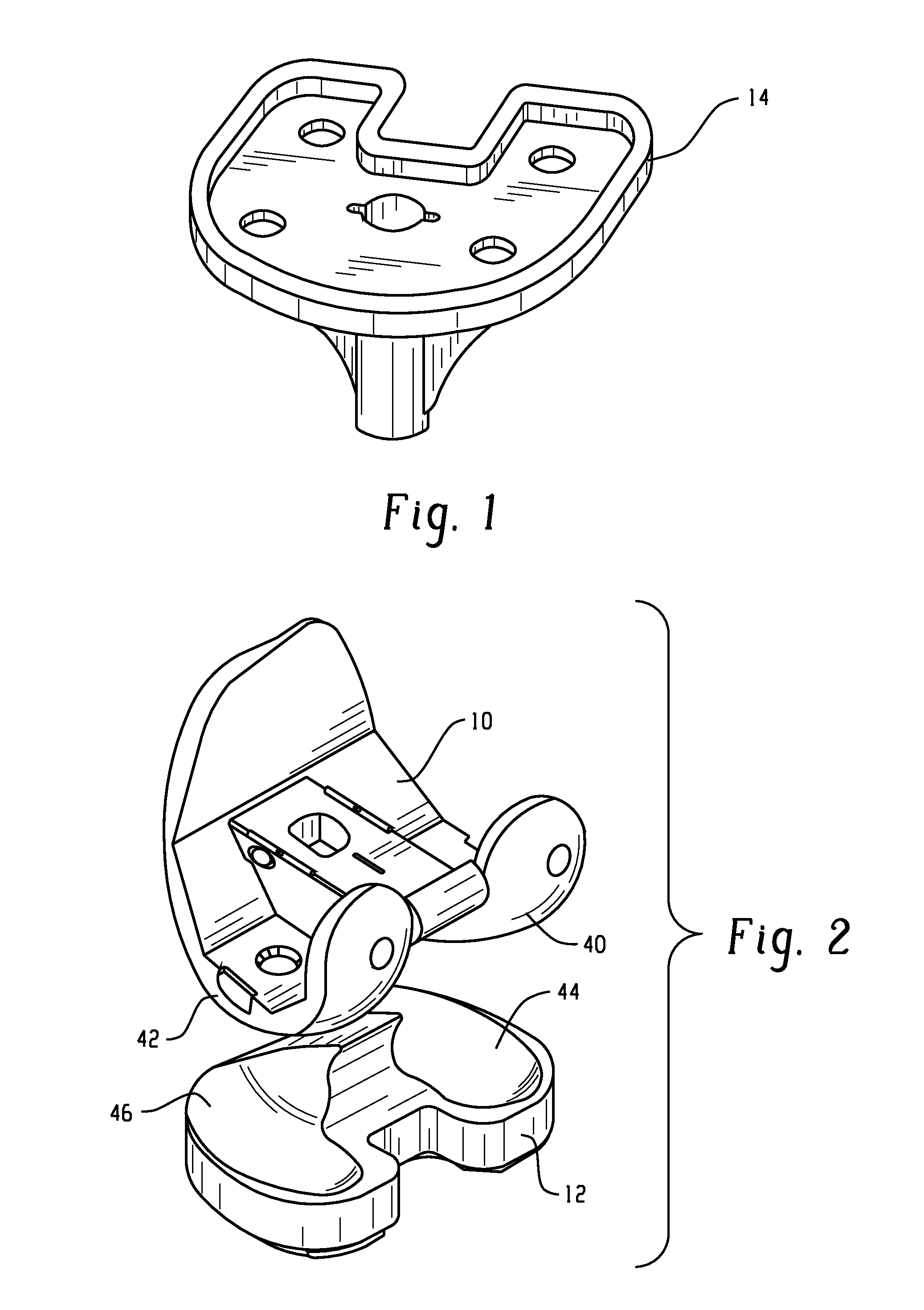

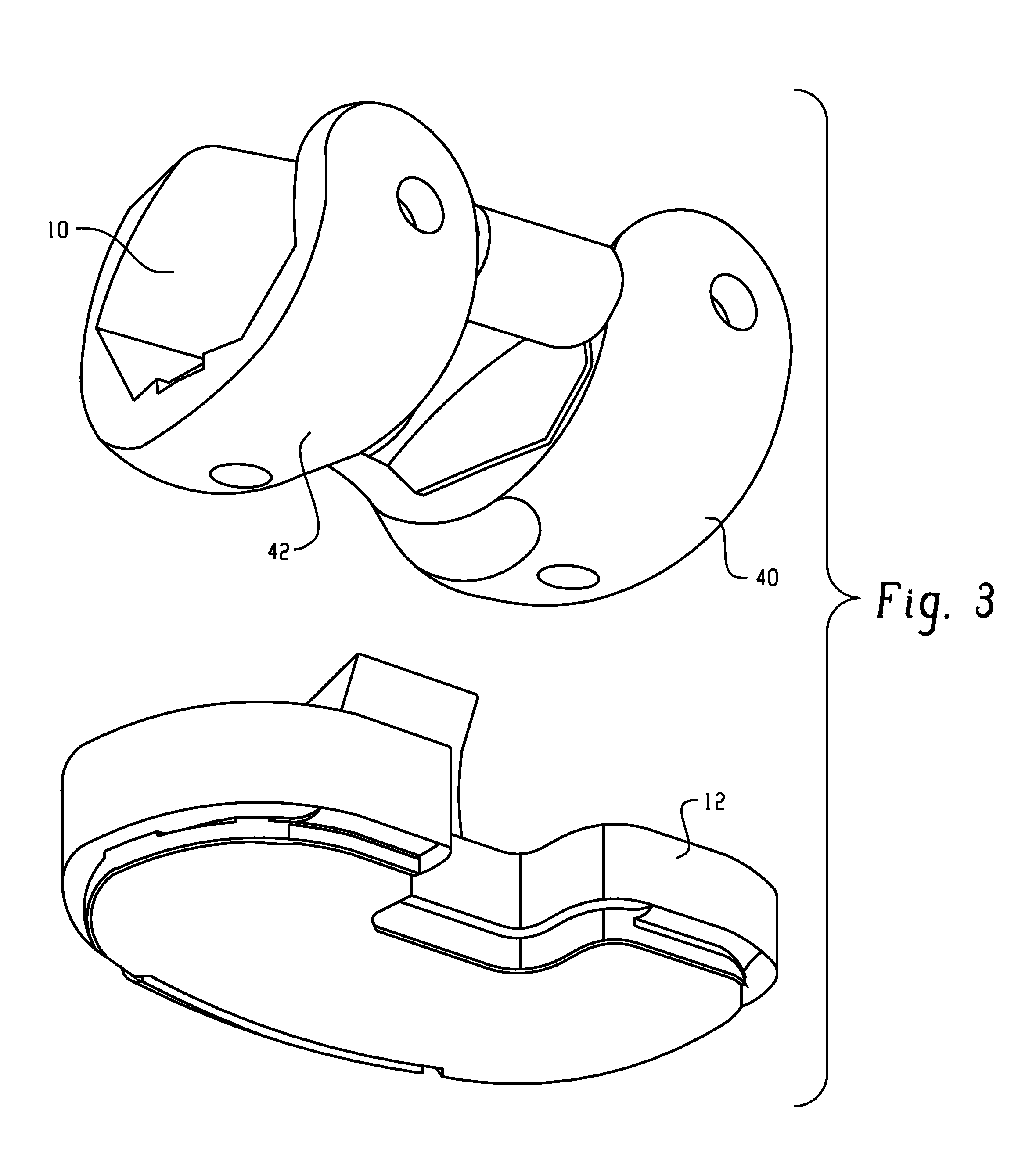

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method of Designing Orthopedic Implants Using In Vivo Data

The present disclosure is directed to orthopedic implants and methods of rapid manufacturing orthopedic implants using in vivo data specific to an orthopedic implant or orthopedic trial. Specifically, the instant disclosure utilizes permanent orthopedic implants and orthopedic trials (collectively, “implants”) outfitted with kinematic sensors to provide feedback regarding the kinematics of the trial or implant to discern which implant is preferable, and thereafter rapid manufacturing the implant.

Owner:WASIELEWSKI RAY C

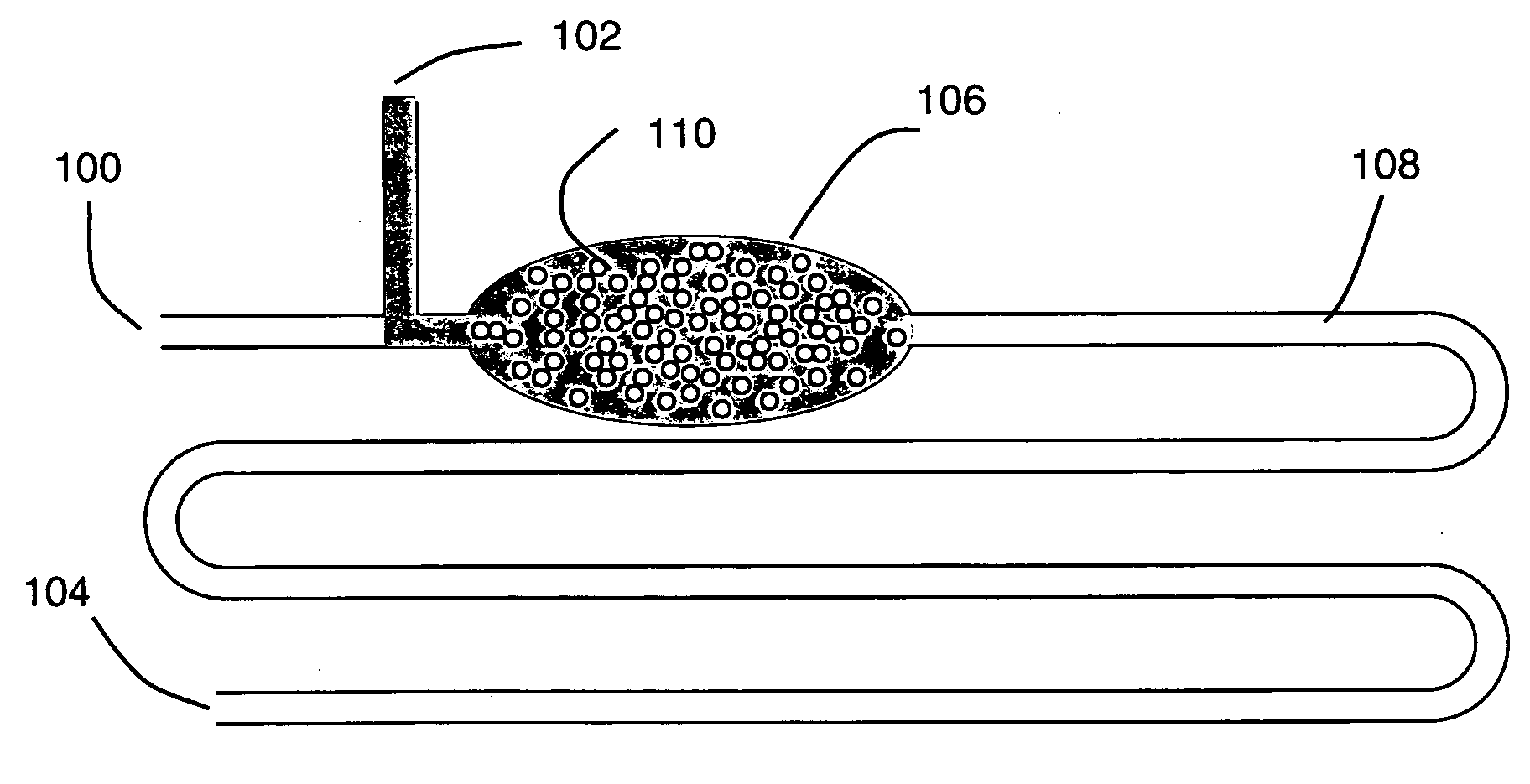

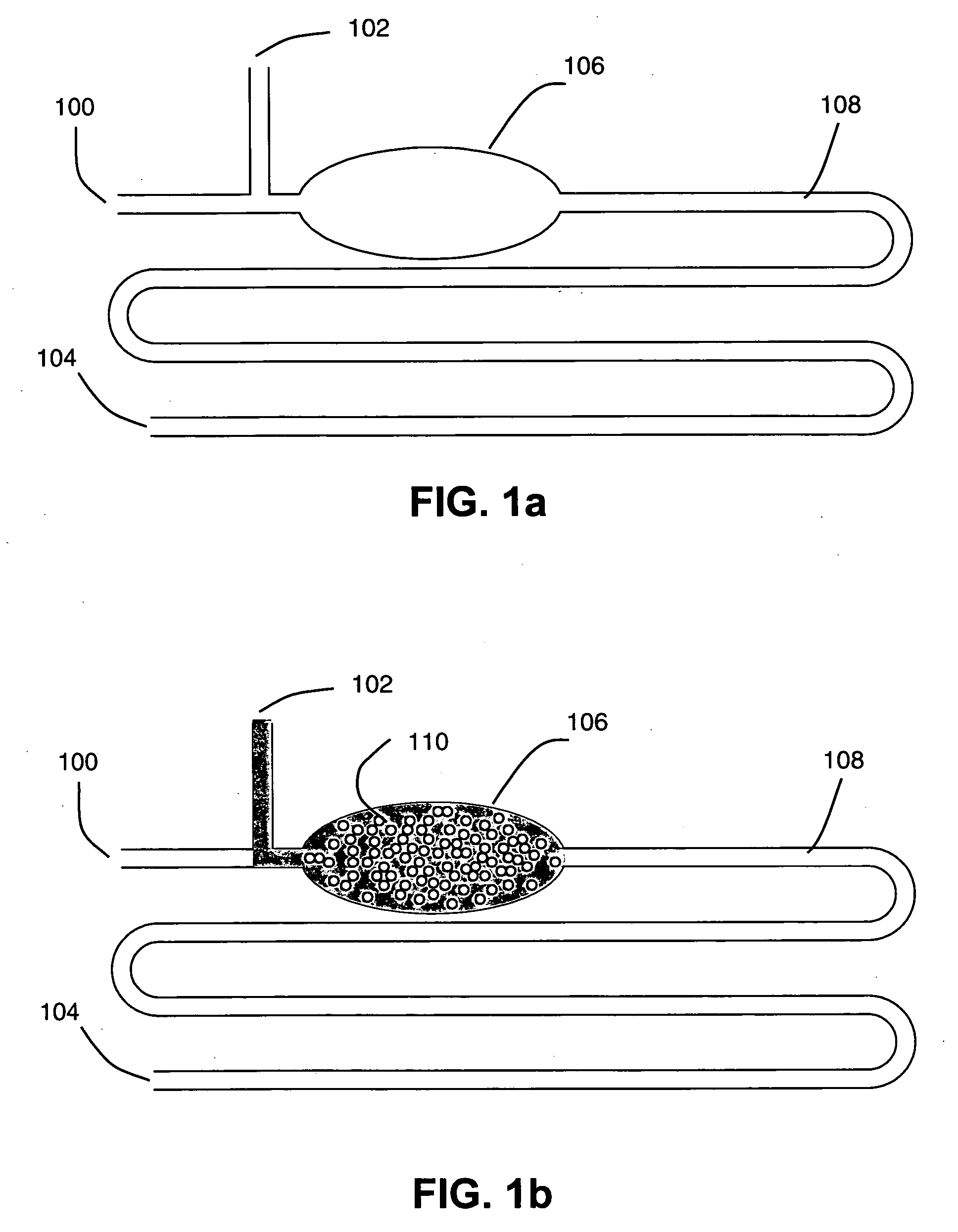

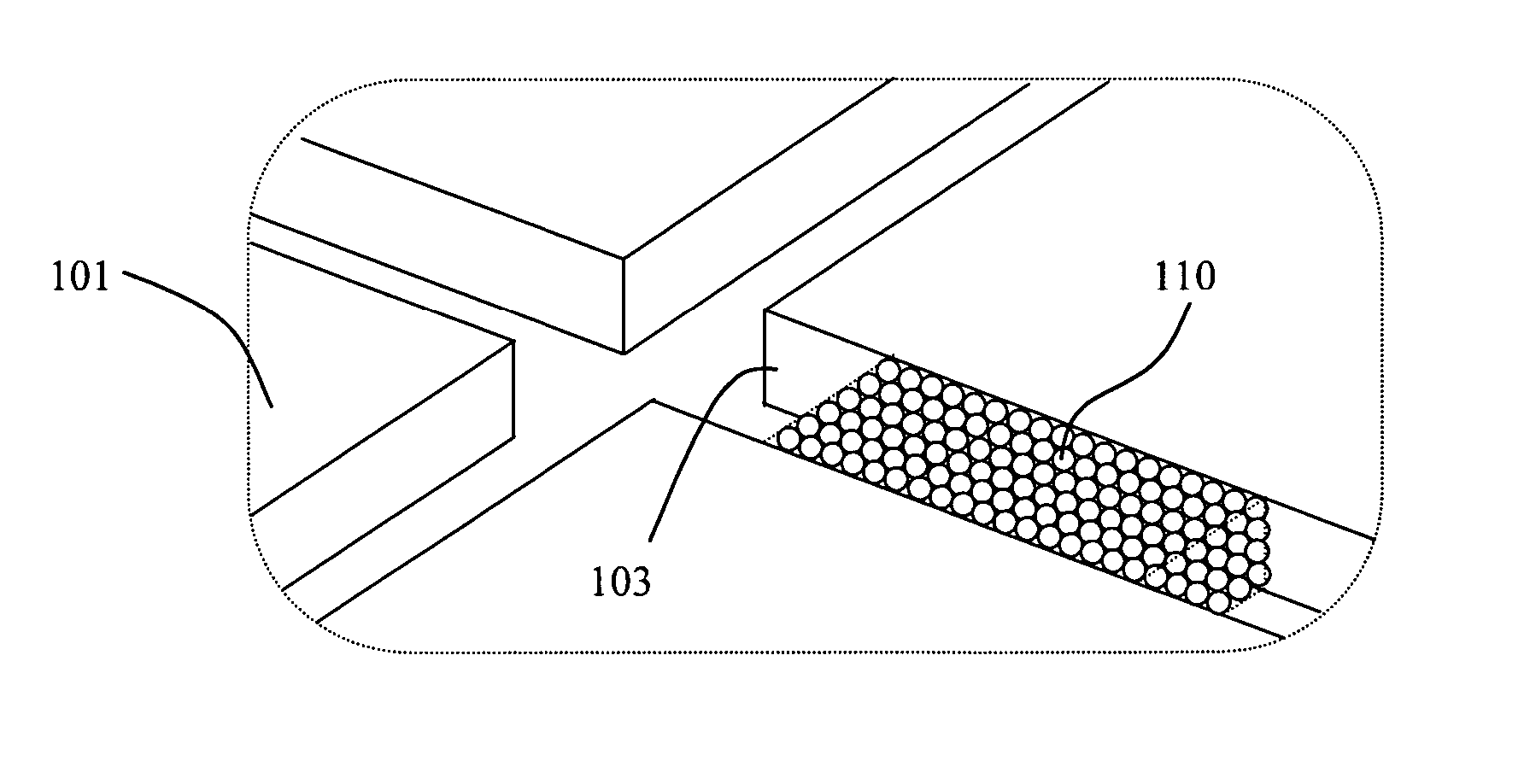

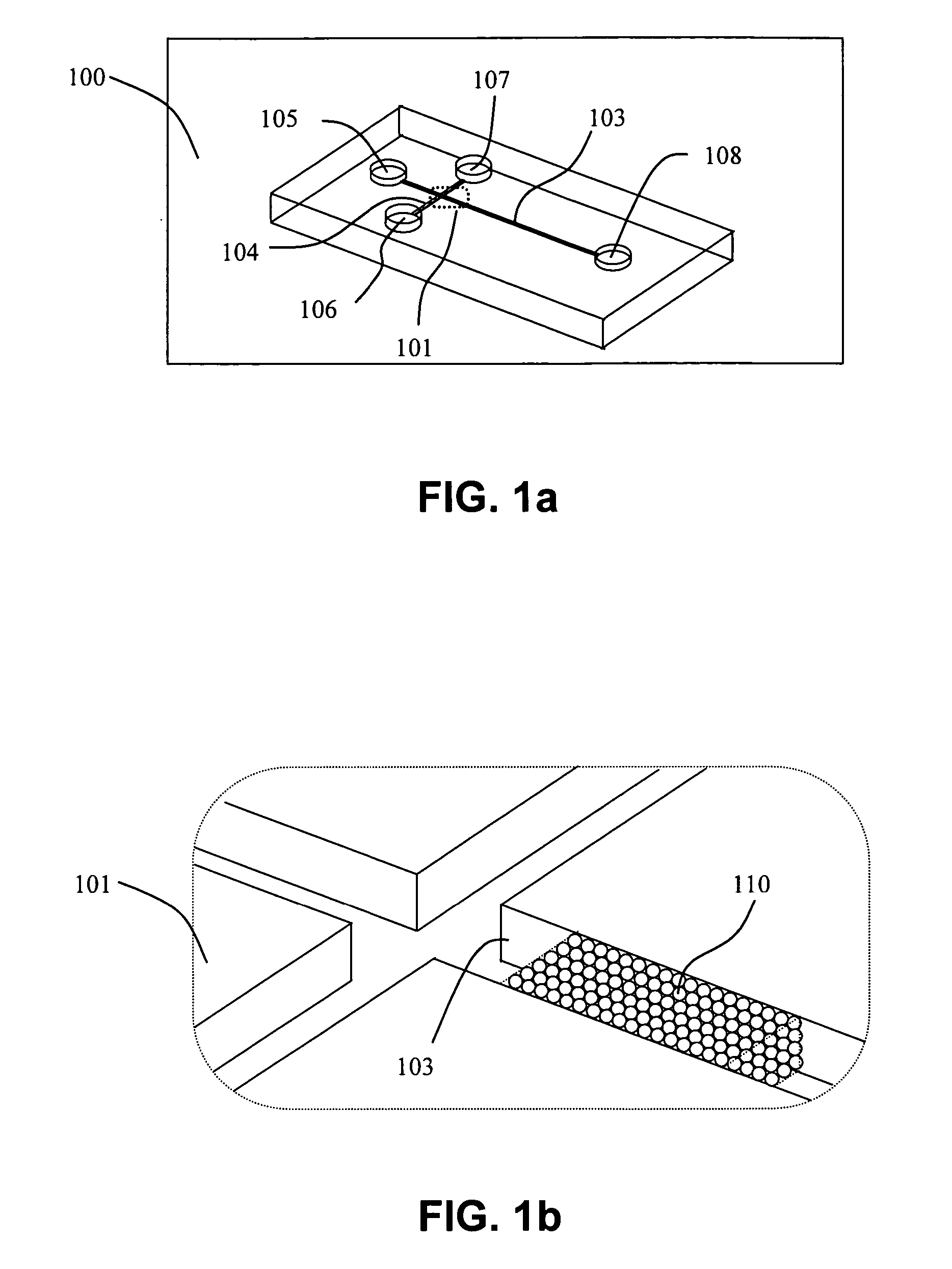

On-chip sample preparation for whole blood analysis

InactiveUS20050069459A1Easily fabricatedEasy to integrateCombination devicesLaboratory glasswaresSuspended particlesShort duration

A novel filter-less separation technique for separating suspended particles from a solution is disclosed. More specifically, an on-chip bioparticle separator is disclosed, which relies on the differential force exerted by application of a series of high magnitude, short duration pressure pulses on bioparticles in suspension within microchannels, resulting in separation of suspended bioparticles. The filter-less separation technique is inherently suited to μTAS (Micro Total Analysis System) since it exploits uniquely microscale phenomena to achieve separation. The on-chip bioparticle separator can be easily integrated with a disposable biochip, can be fabricated using low-cost, rapid manufacturing techniques, and can provide high performance for separation of bioparticles without the use of specialized or expensive equipment. Embodiments of the present invention address a significant challenge in the development of disposable microfluidic biochips, specifically, providing a reliable solution for separating bioparticles in a microfluidic system that may be immediately applied for a variety of microfluidic biochip applications.

Owner:CINCINNATI UNIVERISITY OF THE

Method of manufacturing combustor components

A method for fabricating a unitary component for a combustor is disclosed, said method comprising the steps of determining three-dimensional information of the unitary component, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary component, and successively forming each layer of the unitary component by fusing a metallic powder using laser energy. A fuel nozzle component is disclosed, comprising a body having a unitary construction wherein the body is made by using a rapid manufacturing process.

Owner:GENERAL ELECTRIC CO

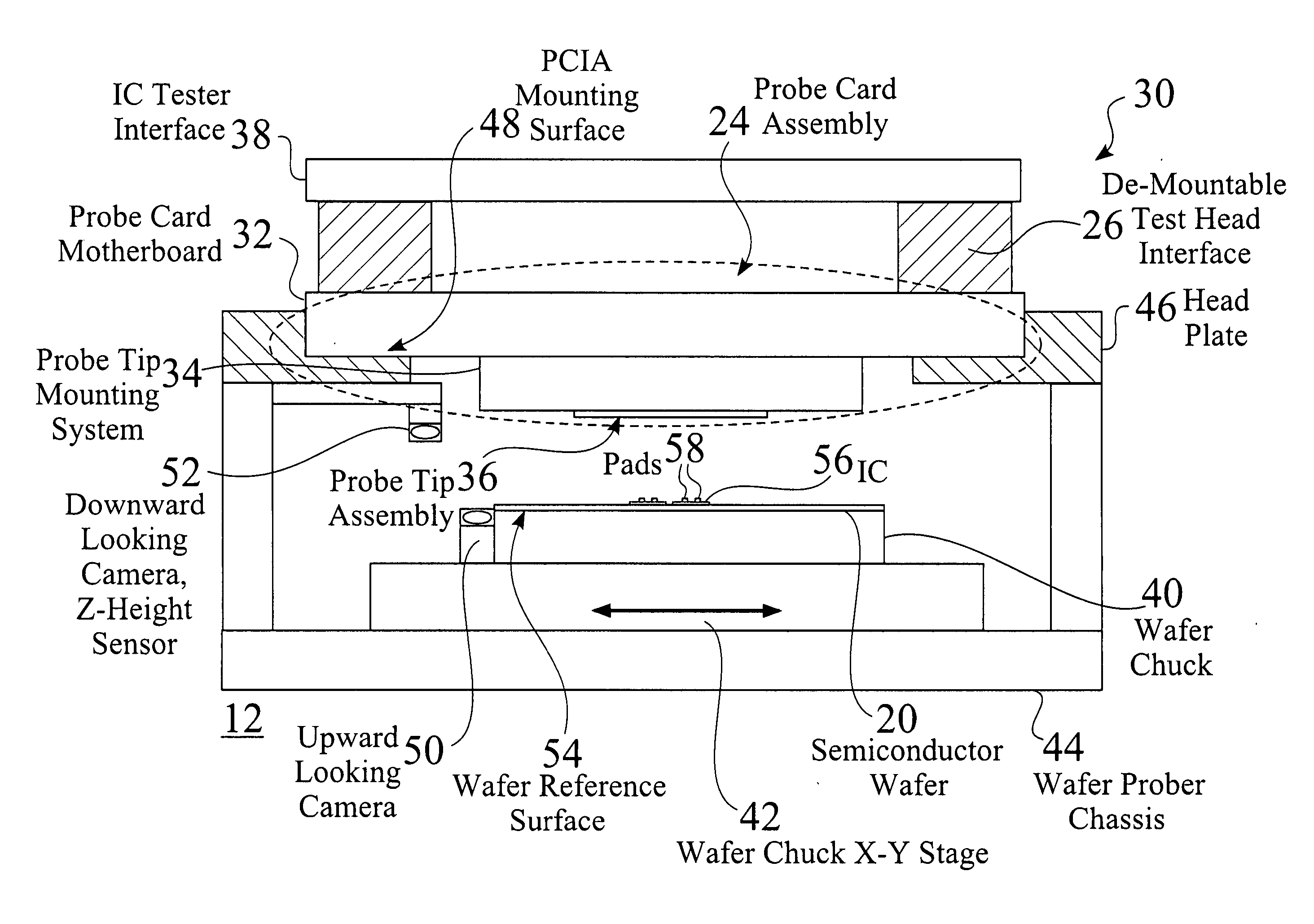

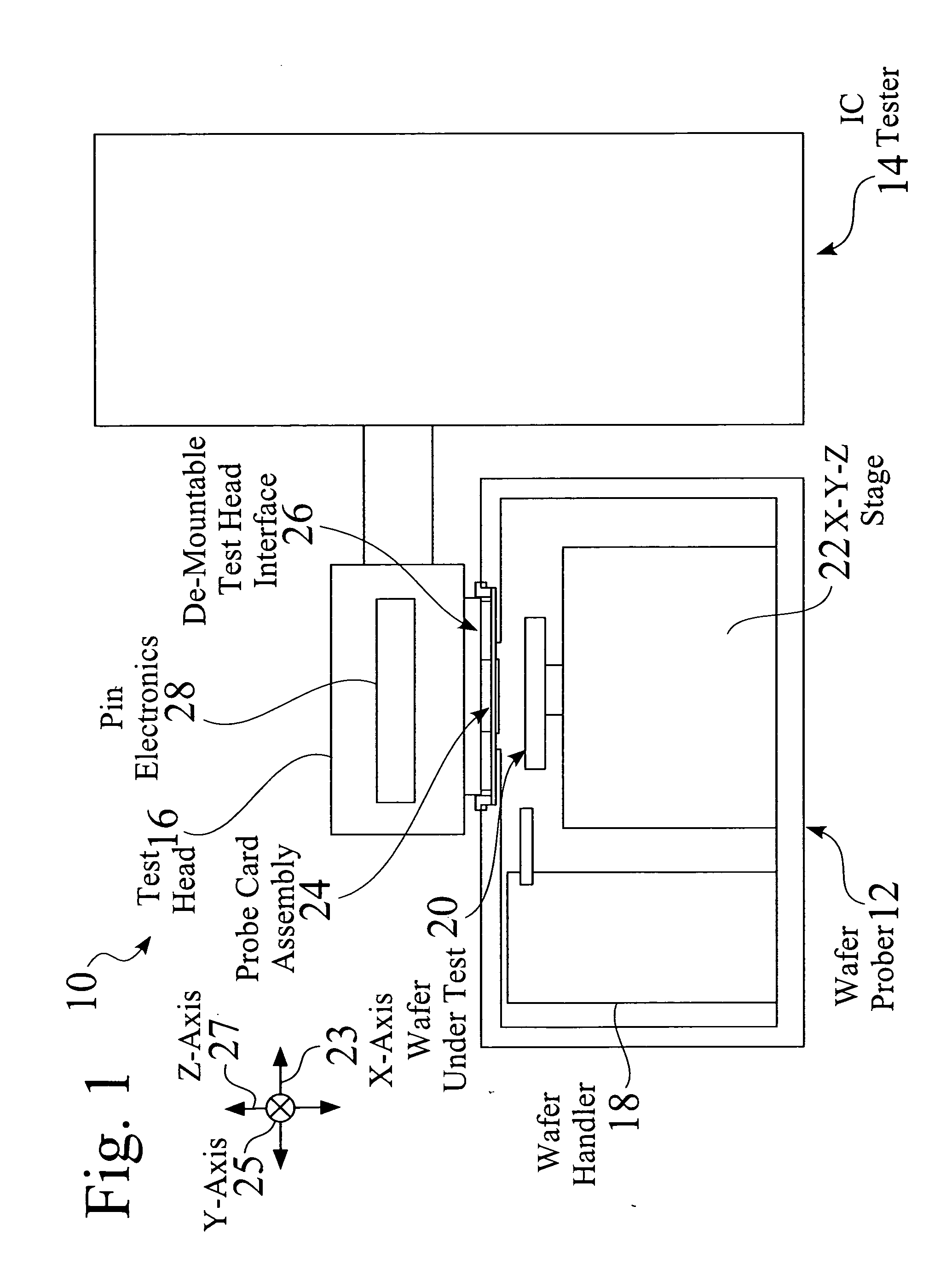

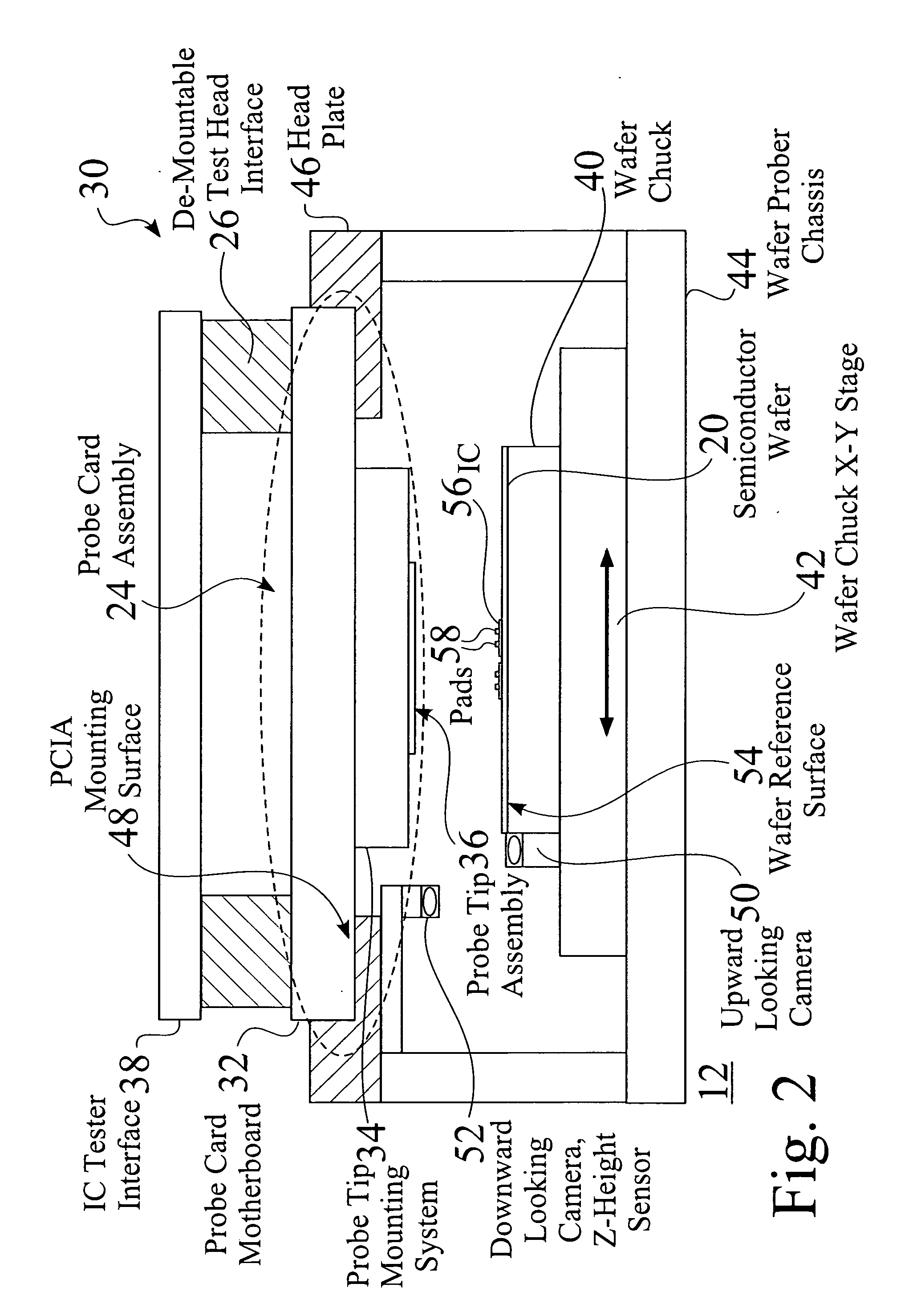

High density interconnect system having rapid fabrication cycle

InactiveUS20050275418A1Added fabricationSemiconductor/solid-state device testing/measurementElectronic circuit testingElectricityHigh density

An improved interconnection system and method is described, such as for connectors, socket assemblies and / or probe card systems. An exemplary system comprises a probe card interface assembly (PCIA) for establishing electrical connections to a semiconductor wafer mounted in a prober. The PCIA comprises a motherboard parallel to the semiconductor wafer having an upper surface and an opposing lower planar mounting surface, a reference plane defined by a least three points located between the lower surface of the motherboard and the wafer, at least one component located below the motherboard mounting surface, and a mechanism for adjusting the planarity of the reference plane with respect to the wafer. A probe chip having a plurality of spring probes extending there from is mountable and demountable from the PCIA, without the need for further planarity adjustment. The interconnection structures and methods preferably provide improved fabrication cycles.

Owner:ADVANTEST SINGAPORE PTE LTD

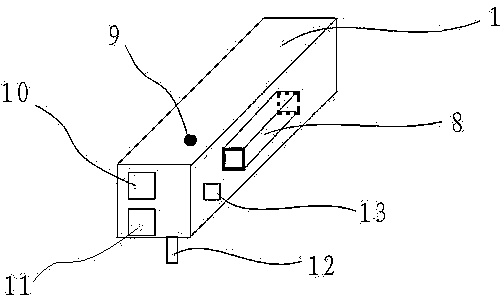

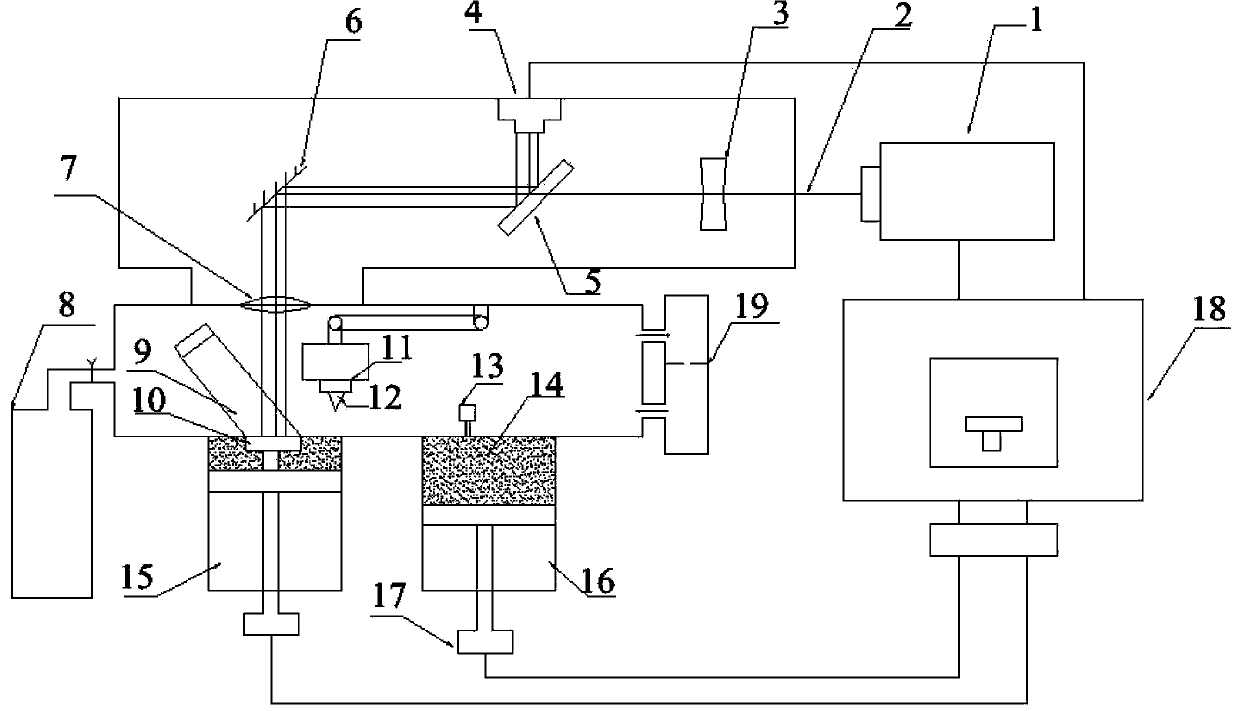

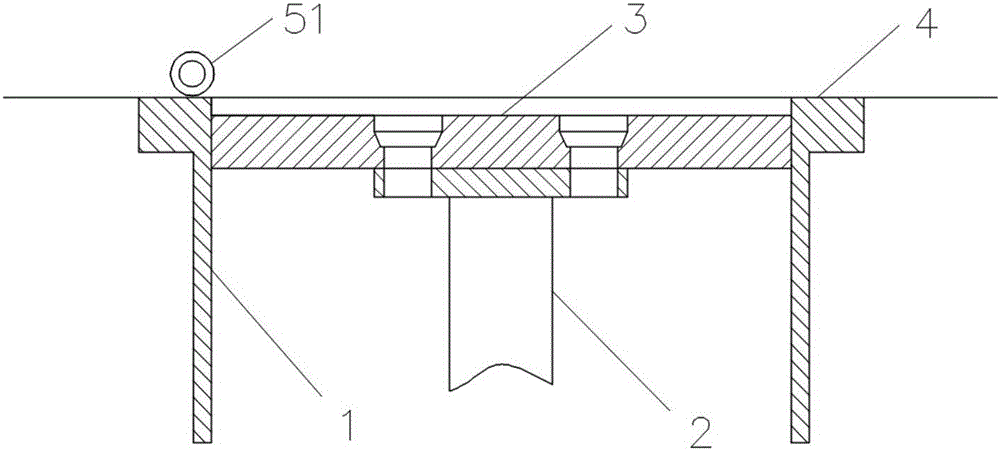

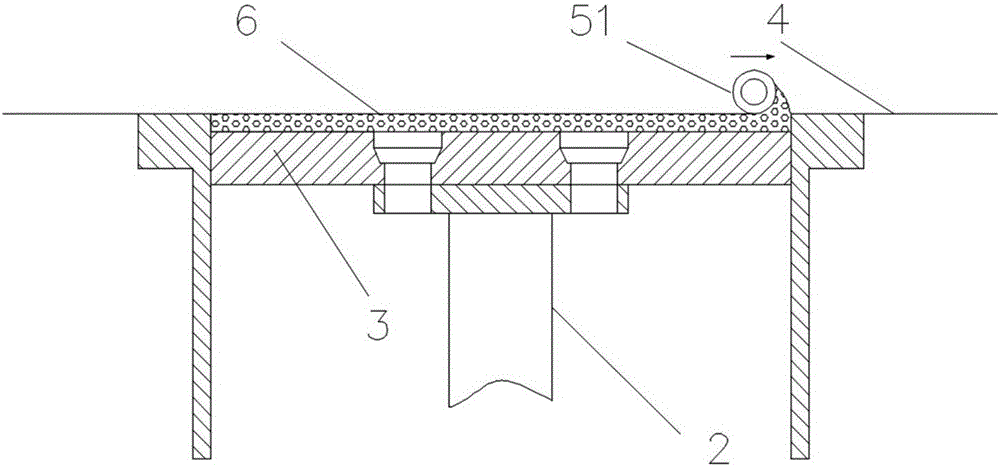

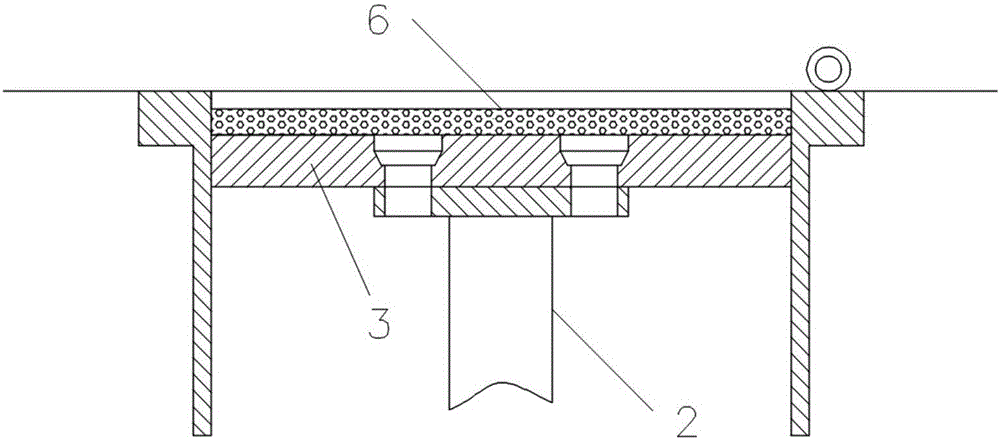

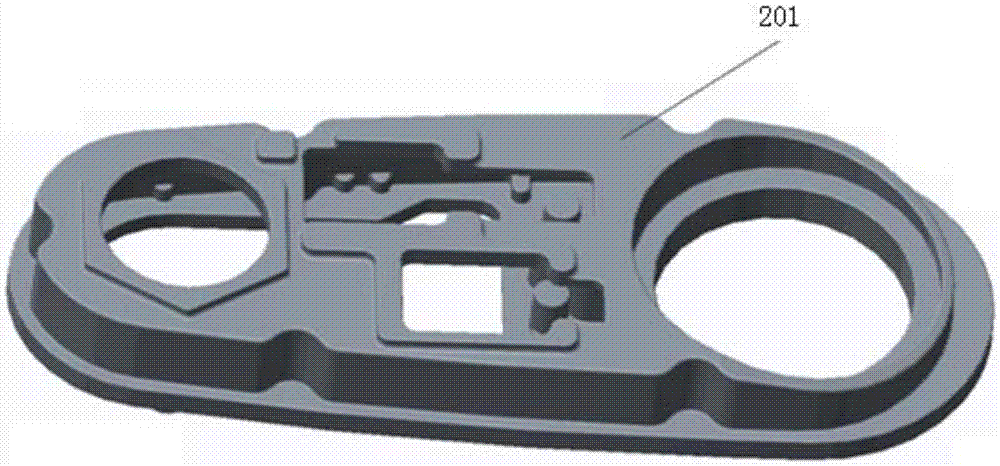

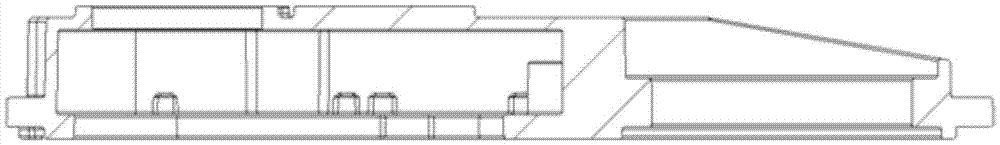

Combination manufacturing method and device for injection mold with conformal cooling water path

ActiveCN103418985AEasy to manufactureAvoid defectsIncreasing energy efficiencyManufacturing technologyLight beam

The invention discloses a combination manufacturing method and device for an injection mold with a conformal cooling water path. The device comprises a light beam focusing system, a close wave length coaxial vision positioning system, a powder pavement system and a gas protection system. The gas protection system comprises a sealed forming chamber, a shielding gas device and a powder purification device, wherein the shielding gas device is connected to one side of the sealed forming chamber, and the powder purification device is connected to the other side of the sealed forming chamber. The method is a combination processing method combined with the laser region selection fusion technology and the precision cutting processing technology, the advantages of the laser region selection fusion flexible processing are retained, and the feature that the precision of the high-speed cutting processing is good is given to play. In the process of region selection laser fusion processing, laser surface refusion processing is carried out on each layer, and the compactness and the surface quality of the mold are improved. The technique of density changing rapid manufacturing is adopted, and manufacturing efficiency is improved. Precision mold components with the interior special-shape cooling water path and the complex inner cavity structure can be integrally processed at a time.

Owner:SOUTH CHINA UNIV OF TECH

Rapid prototype casting

Methods for rapid prototype casting metal components, wherein the metal components are cast in a secondary ceramic mold, the secondary ceramic mold is cast in a primary mold, and the primary mold is formed by rapid prototyping or rapid manufacturing. The secondary ceramic mold may comprise a one-piece integral shell and core(s), and the metal components may have at least one hollow portion or void therein, such as a hollow airfoil for a gas turbine engine.

Owner:HONEYWELL INT INC

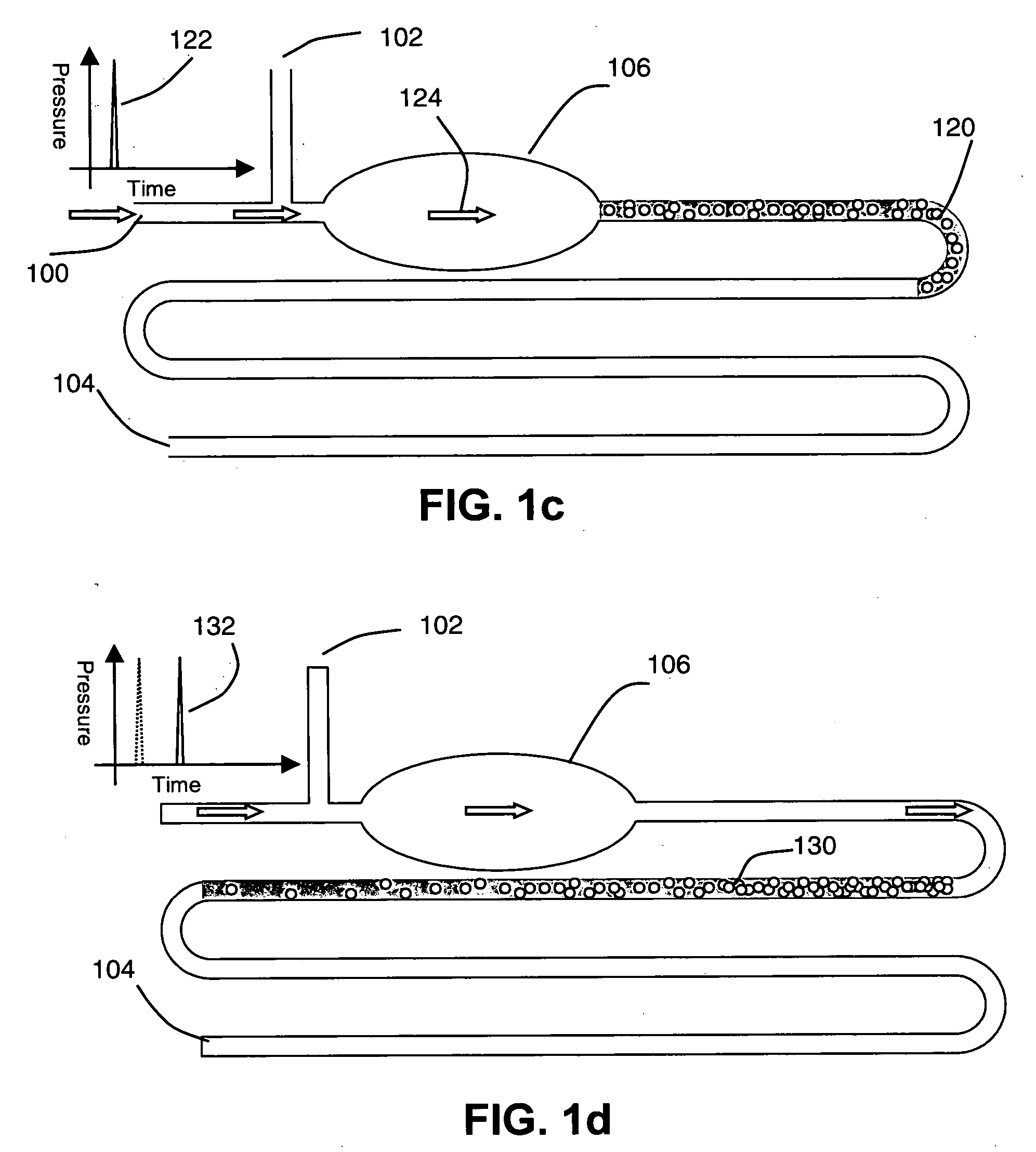

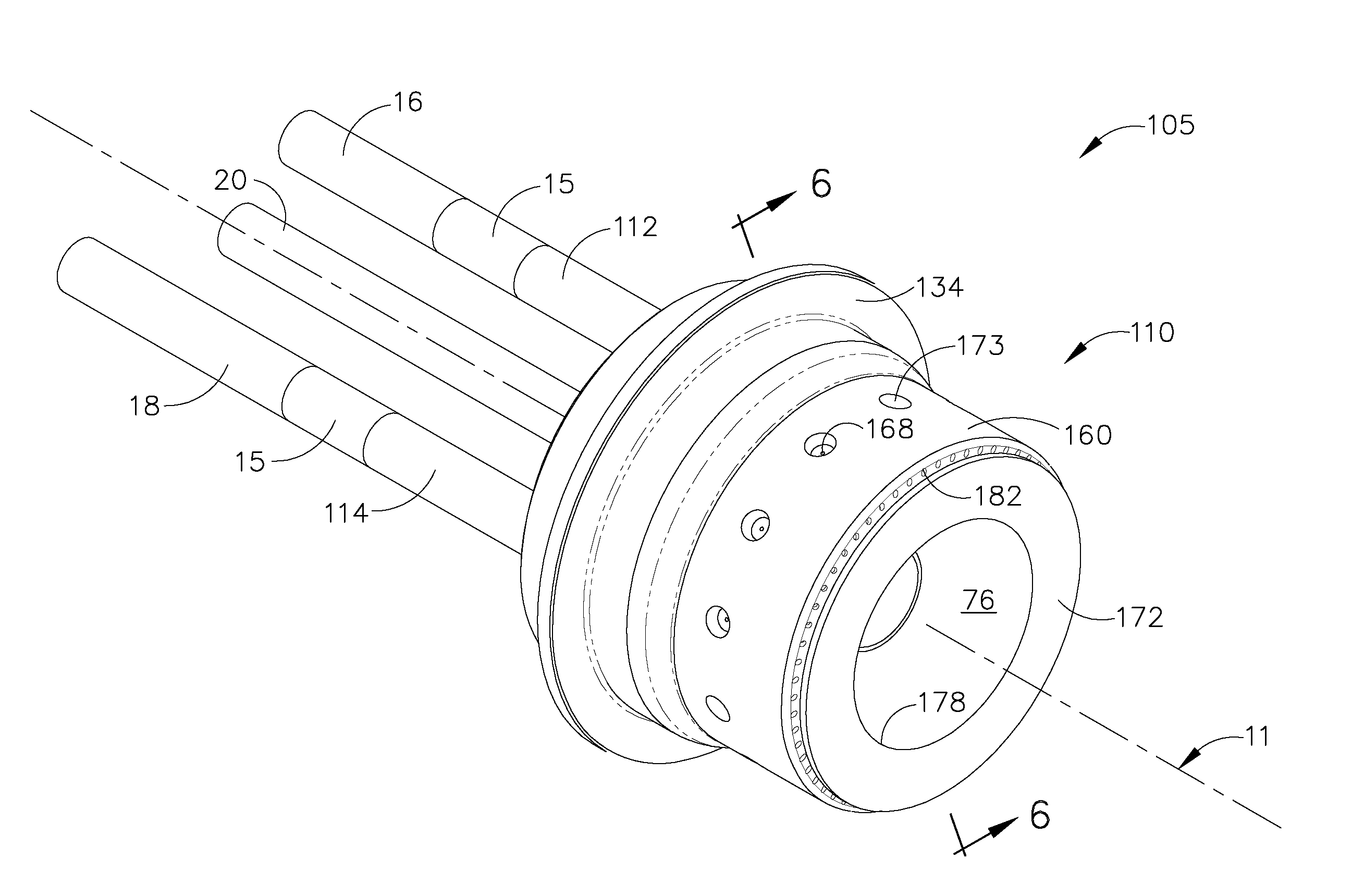

Fully packed capillary electrophoretic separation microchips with self-assembled silica colloidal particles in microchannels and their preparation methods

InactiveUS20060147344A1Rapid and improved separationEnhanced interactionComponent separationMaterial analysis by electric/magnetic meansCapillary electrophoresisElectrophoresis

A novel CEC column preparation method for various forms of CEC separation using selectively or fully packed microchannels with self-assembled silica colloidal particles is disclosed. The method relies on the three dimensional uniform silica colloidal packing through selective regions or whole channels resulting in uniform EOF and reproducibility. The fully packed capillary electrophoretic separation microchip is inherently suited for a handheld system since it exploits uniquely fully packed separation channels to achieve better separation efficiency and stability. The fully packed capillary electrophoretic separation microchip can be easily fabricated using low-cost, rapid manufacturing techniques, and can provide high performance for CEC separation with various chromatographic stationary support packing, functionalized surface of packed beads. The fully packed microchannels with self-assembled silica colloidal particles can be applied for preparation of a built-in submicron filter. Embodiments of the present invention address a significant challenge in the development of disposable CEC microchips, specifically, providing a reliable solution for preparation of the CEC separation column in a device that may be immediately applied for a variety of CEC applications.

Owner:UNIVERSITY OF CINCINNATI

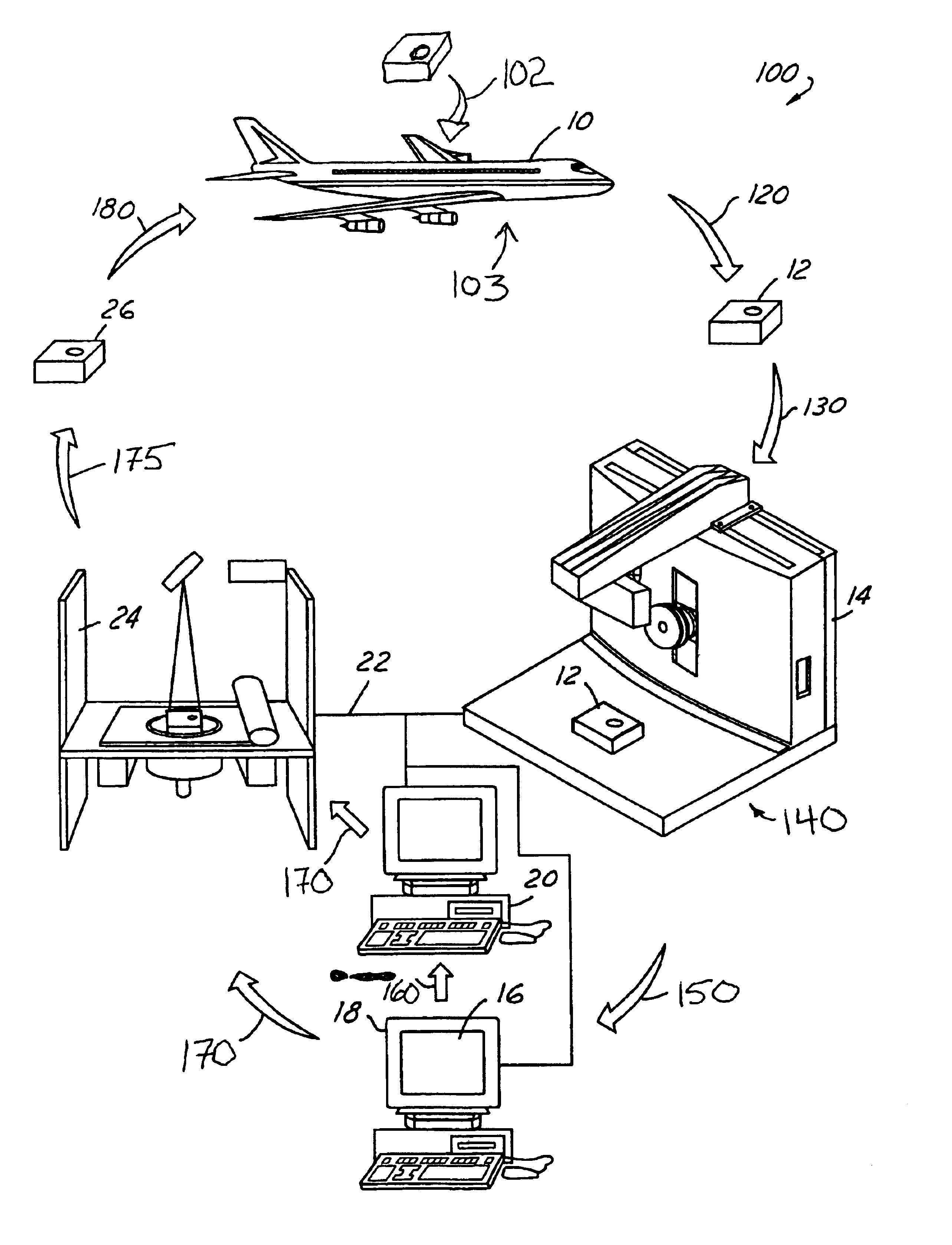

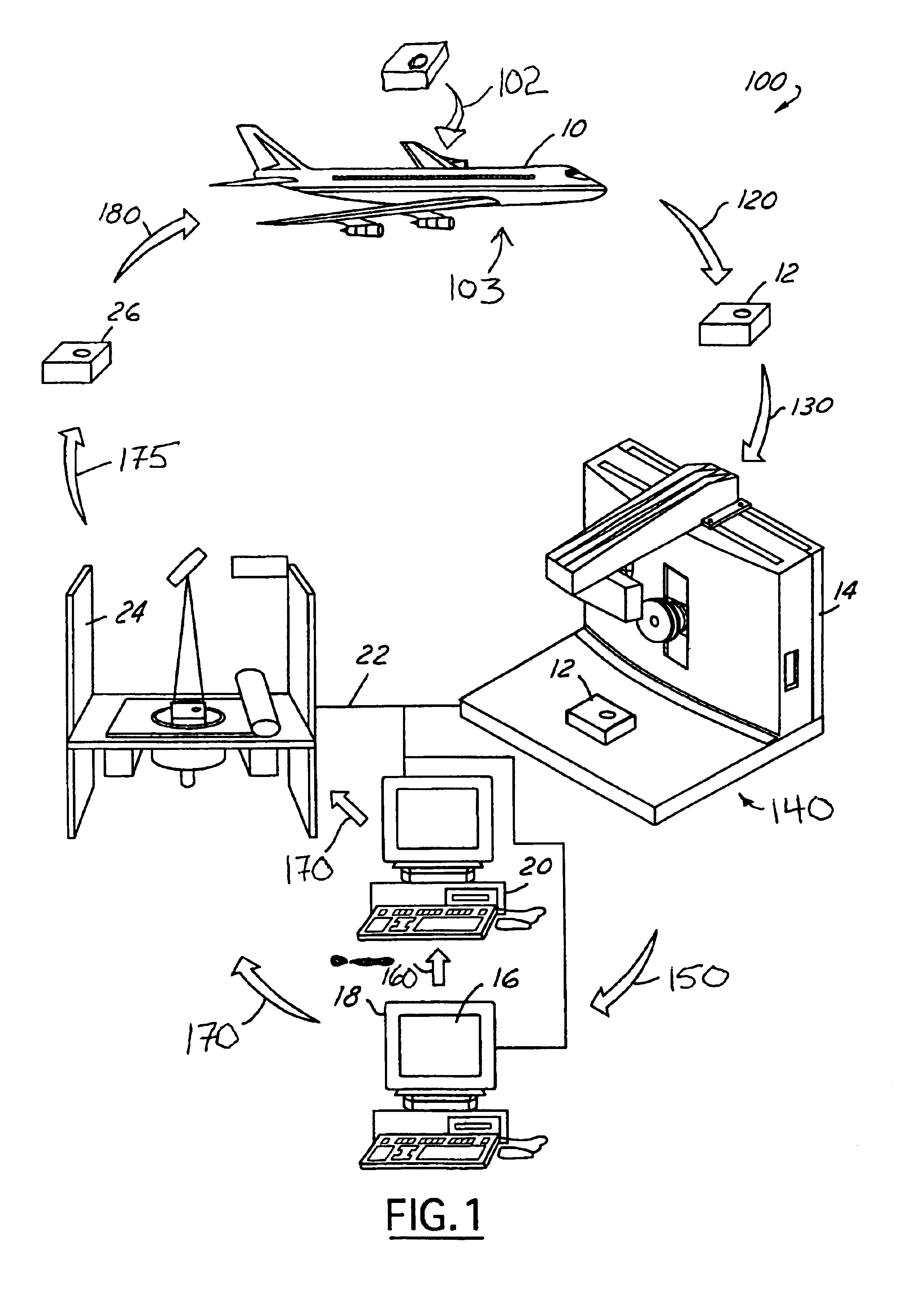

System for rapid manufacturing of replacement aerospace parts

InactiveUS6839607B2Fast preparationAdditive manufacturing apparatusComputer controlAviationComputer Aided Design

An method for the rapid manufacturing of aerospace replacement parts 100 is provided, including removing an in-service aerospace part from an aerospace system 120. The present invention further includes placing the in-service aerospace part into a three-dimensional scanning device 130. The invention then scans the in-service aerospace part utilizing the three-dimensional scanning device to develop a three-dimensional scan 140. A computer-aided-design model is then developed based on the three-dimensional scan 150. The invention then direct metal fabricates a replacement aerospace part from the computer-aided-design model utilizing layer-build technology device 170. Finally the replacement aerospace part is installed back into the aerospace system 180.

Owner:THE BOEING CO

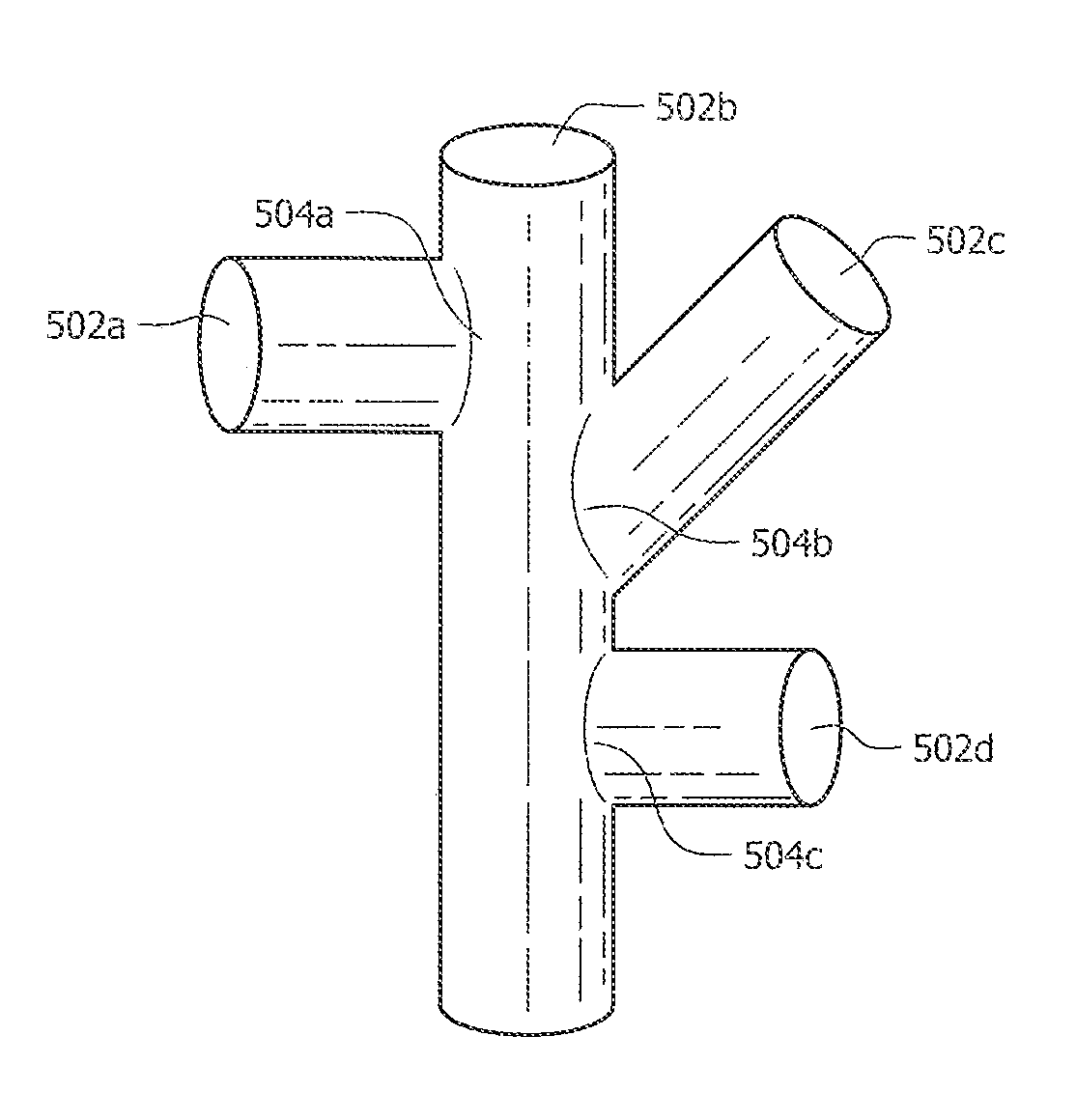

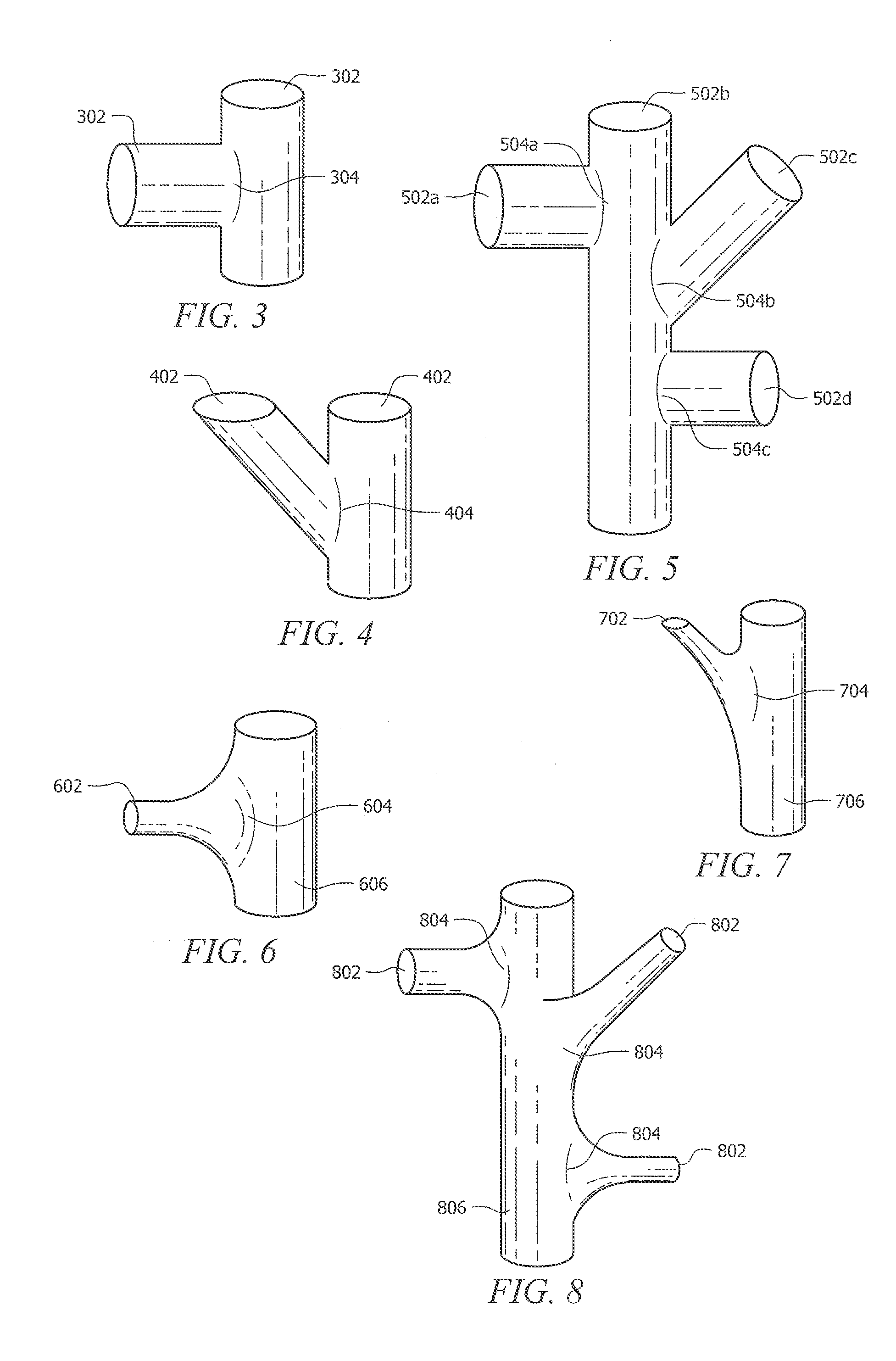

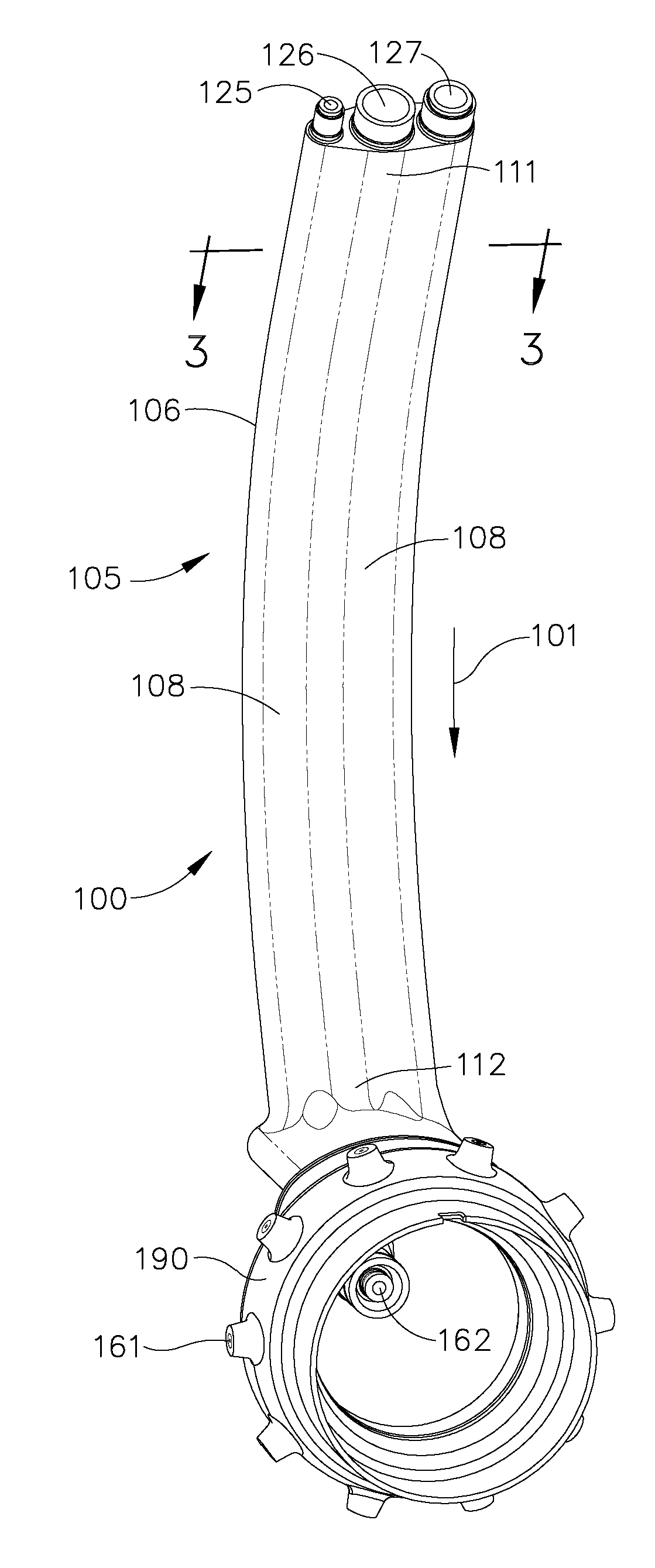

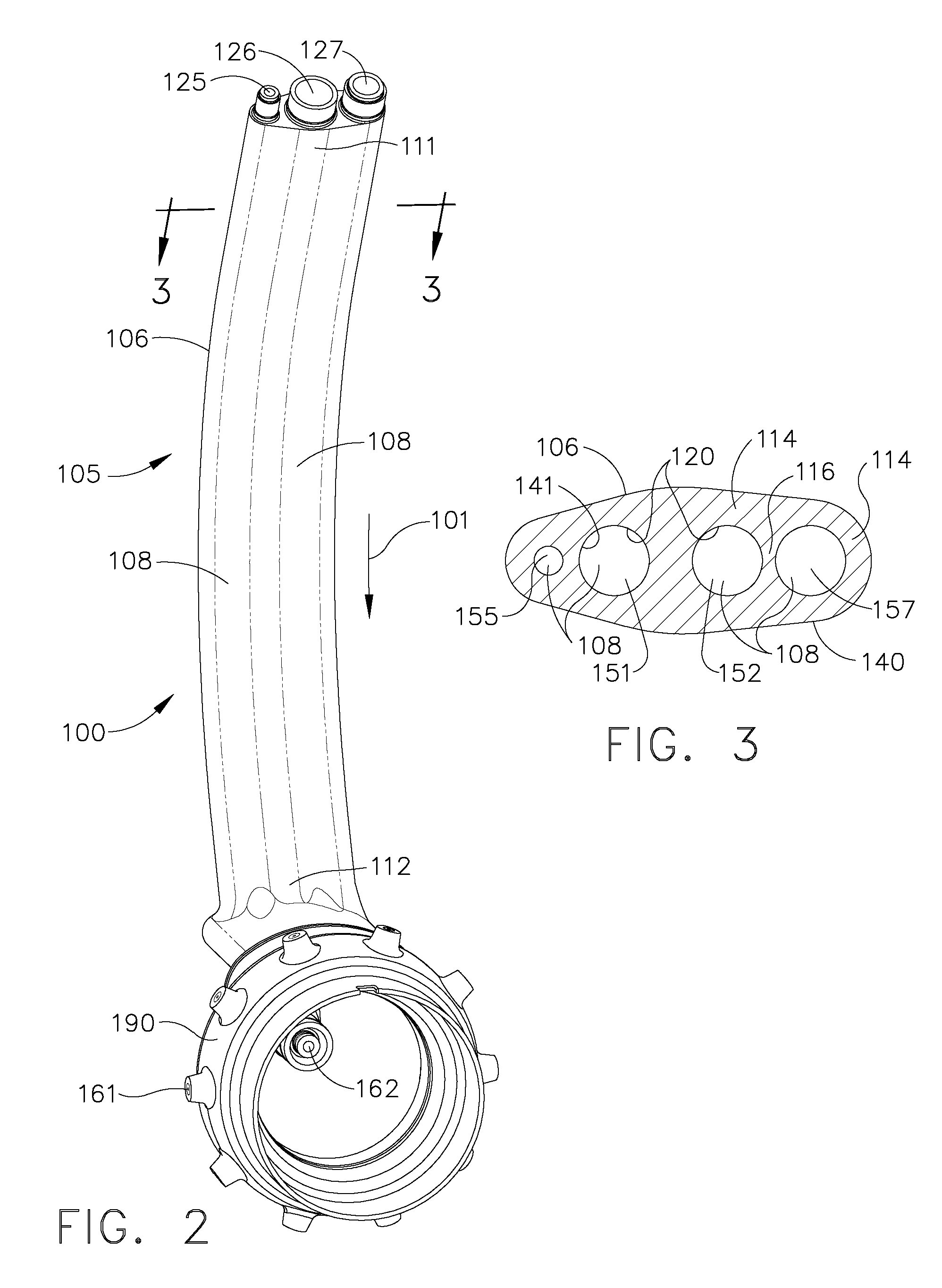

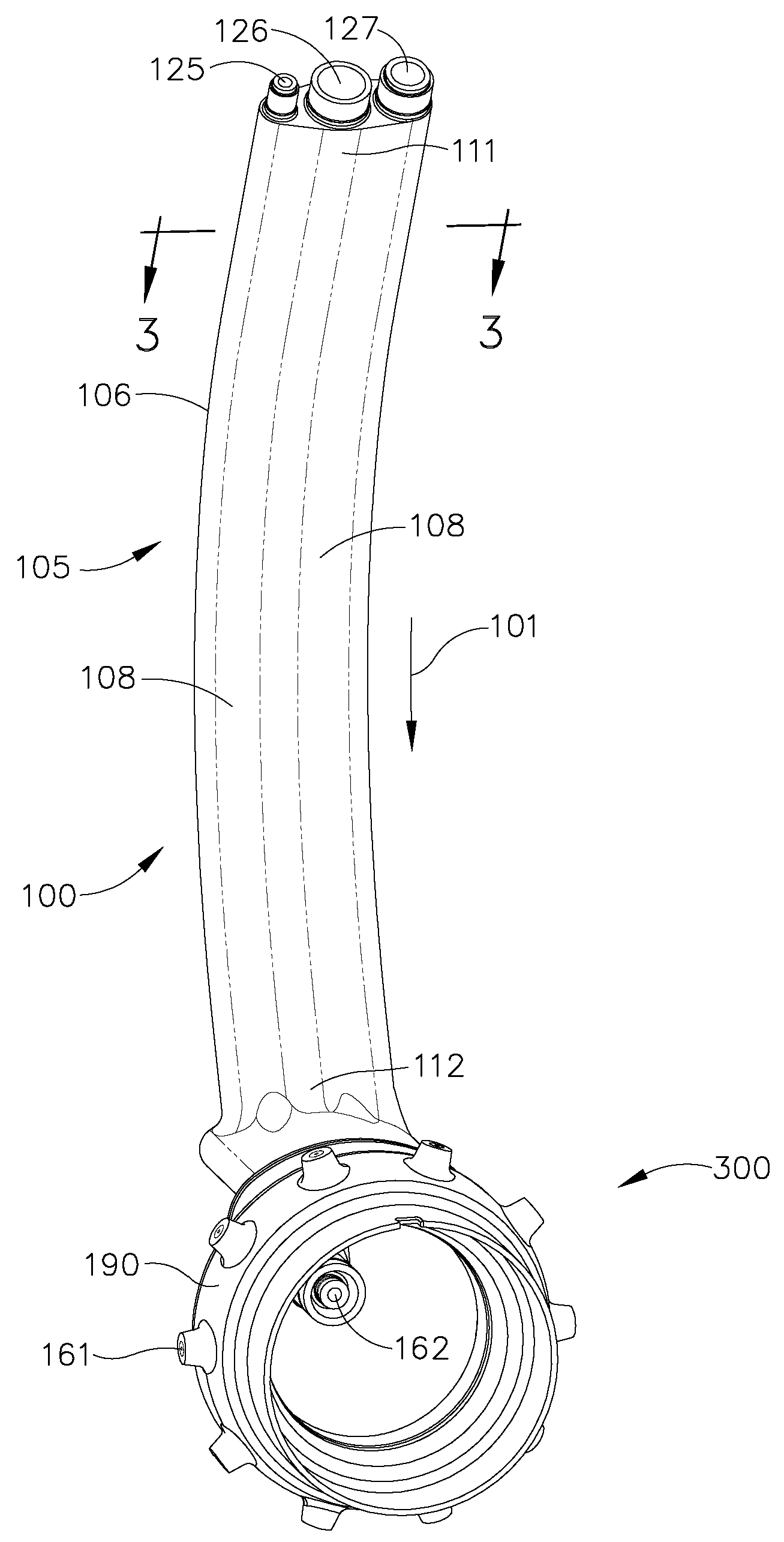

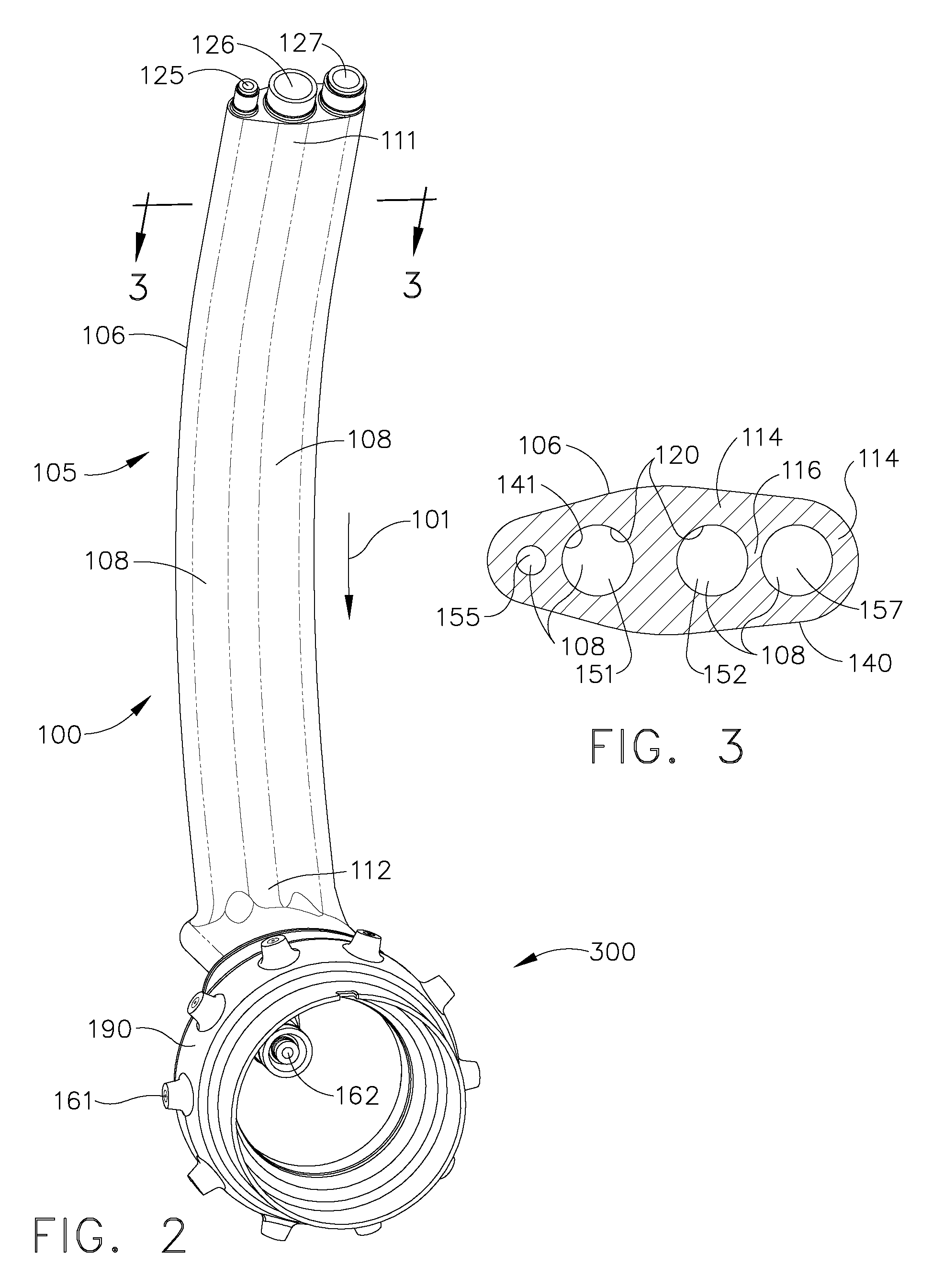

Method of manufacturing a unitary conduit for transporting fluids

A method for fabricating a unitary conduit is disclosed the method comprising the steps of determining three-dimensional information of the unitary conduit having at least one flow passage, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary conduit, and successively forming each layer of the unitary conduit by fusing a metallic powder using laser energy. A unitary conduit is disclosed, comprising a body and a flow passage, wherein the flow passage and the body have a unitary construction, and made by using a rapid manufacturing process.

Owner:GENERAL ELECTRIC CO

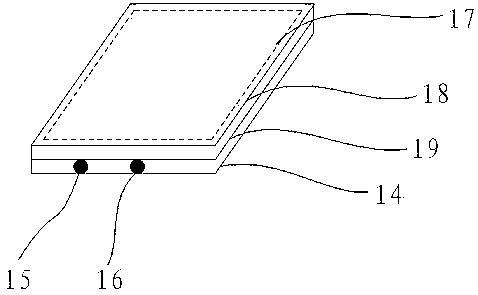

Rapid manufacturing method for sprayed and cured molding sand

InactiveCN104999031AReduce distortionImprove assembly qualityFoundry mouldsMould handling/dressing devicesCasting moldUltimate tensile strength

The invention discloses a rapid manufacturing method for sprayed and cured molding sand. The rapid manufacturing method is characterized by comprising the following steps: molding sand is mixed with a curing agent in advance, and diluted resin is sprayed onto the molding sand mixed with the curing agent through a spray; through powder layering and resin spraying, the molding sand with sprayed resin is cured, and then adhesive forming is realized; the formed layers are heated for drying; the entity of a casting mold is formed through layer-by-layer printing, stacking and curing, and then the strength of the casting mold is improved through further drying. Through adoption of the rapid manufacturing method, the problem that the amount of gas evolution of the casting mold is overlarge can be solved through reduction of the resin consumption, the spray is protected from blockage, the curing speed is increased, the assembly quality of the casting mold and a mold core is improved, and finally the casting mold with relatively high strength is obtained.

Owner:宁波高新区多维时空科技有限公司

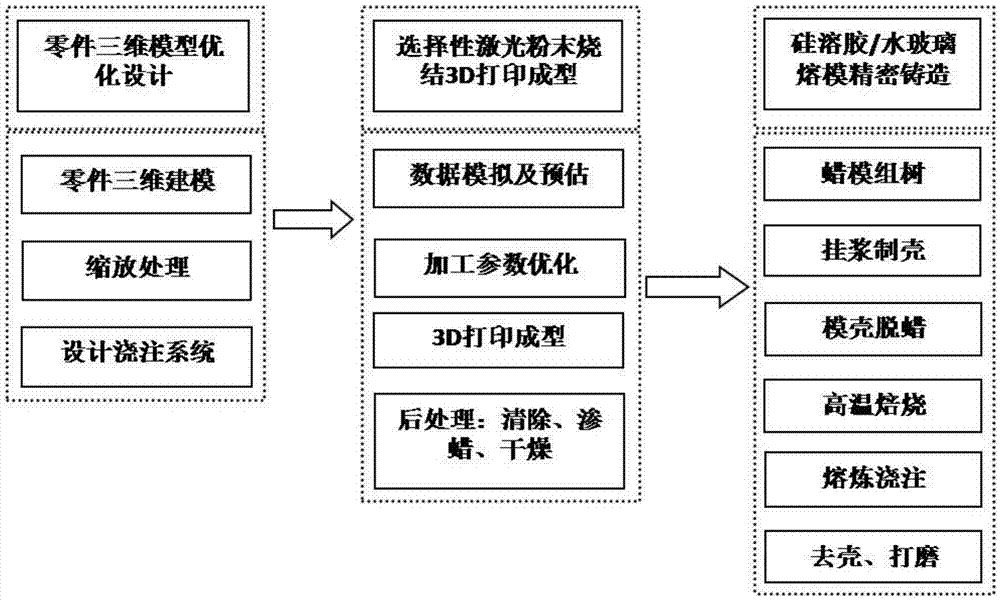

Precision lost wax casting technology based on selective laser powder sintering 3D printing

InactiveCN105436406AFast preparationCasting fastAdditive manufacturing apparatusFoundry mouldsInvestment castingOptimal design

The invention discloses a precision lost wax casting technology based on selective laser powder sintering 3D printing. The precision lost wax casting technology comprises the following steps that S101, a target part is subjected to optimal design of a CAD casting technology; S102, selective laser powder sintering 3D printing forming is carried out; and S103, silica sol / water glass precision investment casting is carried out. A wax mold of the part can be fast manufactured without molds, the metal part is fast manufactured, fast manufacturing of complex parts can be achieved, and integration, automation and fastness in the precision casting technology process can be achieved; and the development period of new products are greatly shortened, development cost is reduced, and the precision lost wax casting technology is especially suitable for production of single small-batch complex castings and trial-manufacturing of new products.

Owner:HUST WUXI RES INST +1

Method of manufacturing a fuel distributor

InactiveUS20090256003A1Liquid surface applicatorsTurbine/propulsion fuel flow conduitsDistributorLaser

A method for fabricating a unitary distributor is disclosed, the method comprising the steps of determining three-dimensional information of the unitary distributor having at least one flow passage having an arcuate portion located within a distributor ring body having an axis, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the unitary distributor and successively forming each layer of the unitary distributor by fusing a metallic powder using laser energy. A distributor is disclosed comprising a flow passage with an arcuate portion located in a distributor ring body wherein the distributor is made by using a rapid manufacturing process. A unitary fuel distributor comprising a fuel conduit and a distributor is disclosed wherein the unitary fuel distributor is made by using a rapid manufacturing process.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com