Entirety quick manufacture method of hot isostatic pressing metal wrapps

A metal sheath and manufacturing method technology, applied in the field of parts forming and manufacturing, can solve problems such as difficult operation and cumbersome process, and achieve the effects of avoiding pollution, high utilization rate, and shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

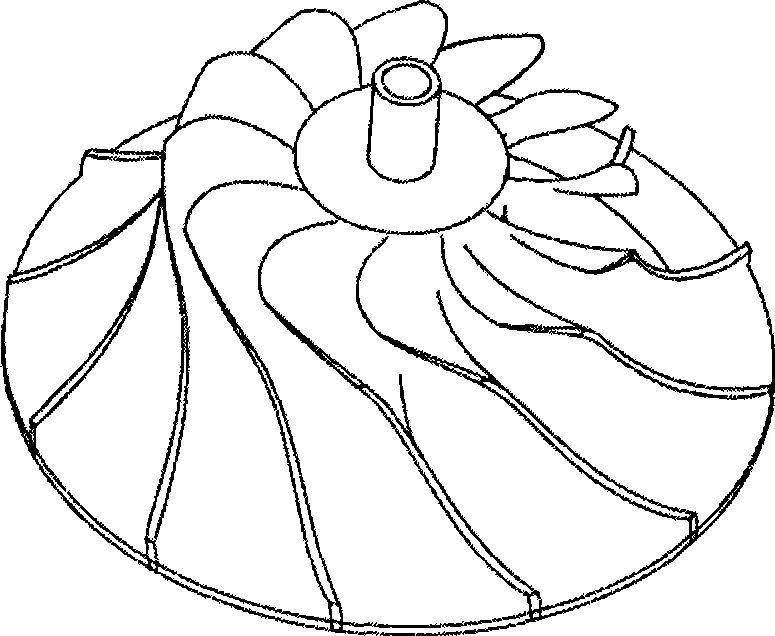

[0022] (1) Firstly, according to the possible deformation of SLM parts after hot isostatic pressing, three-dimensional modeling software (such as UG, Pro / E, etc.) is used to design the CAD three-dimensional model of the metal sheath before hot isostatic pressing. is a closed case, as attached figure 1 That is, the three-dimensional model of the impeller wrapping, and then processed by the slicing software and saved as an STL file, and the data information of the STL file is sent to the SLM rapid prototyping machine.

[0023] (2) Vacuum the forming chamber of the SLM rapid prototyping machine.

[0024] (3) The powder feeding mechanism spreads a layer of 304 stainless steel powder with a thickness of 60 μm and a particle size of 20 μm on the working platform.

[0025] (4) Use diode-pumped YAG lasers, fiber lasers or CO2 lasers with a laser power greater than or equal to 100W, with a laser spot of 30 μm, a scanning distance of 0.06 mm, and a scanning speed of 100 mm / s to scan th...

example 2

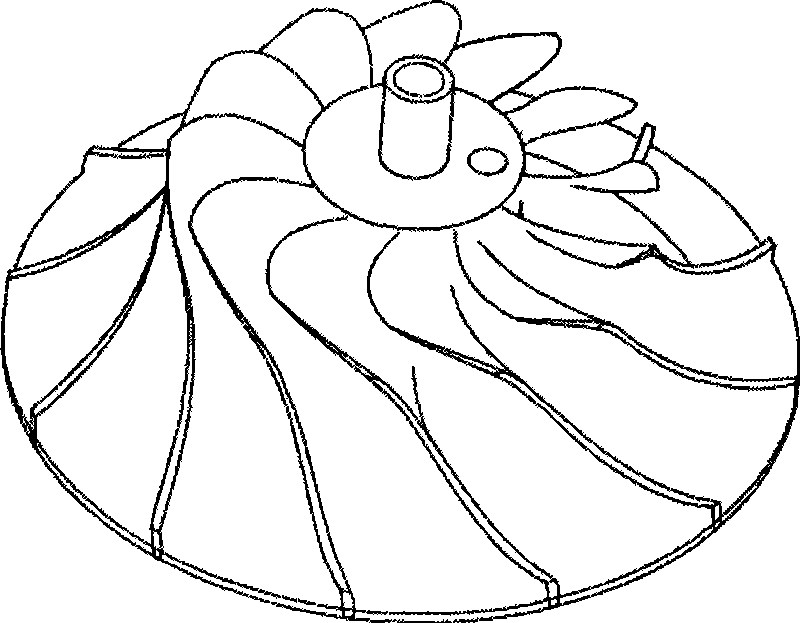

[0029] (1) Firstly, according to the possible deformation of SLM parts after hot isostatic pressing, three-dimensional modeling software (such as UG, Pro / E, etc.) is used to design the CAD three-dimensional model of the metal sheath before hot isostatic pressing. It is a shell with an opening, and a 1-2mm powder inlet hole is reserved on the cover. figure 2 It is the three-dimensional model of the impeller jacket with the powder inlet, and then processed by the slicing software and saved as an STL file, and the data information of the STL file is sent to the SLM rapid prototyping machine.

[0030] (2) Vacuum the forming chamber of the SLM rapid prototyping machine.

[0031] (3) The powder feeding mechanism spreads a layer of No. 45 steel powder with a thickness of 60 μm and a particle size of 20 μm on the working platform.

[0032] (4) Use diode-pumped YAG lasers, fiber lasers or CO2 lasers with a laser power greater than or equal to 100W, with a laser spot of 30 μm, a scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com