Patents

Literature

111results about How to "Save on packaging costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

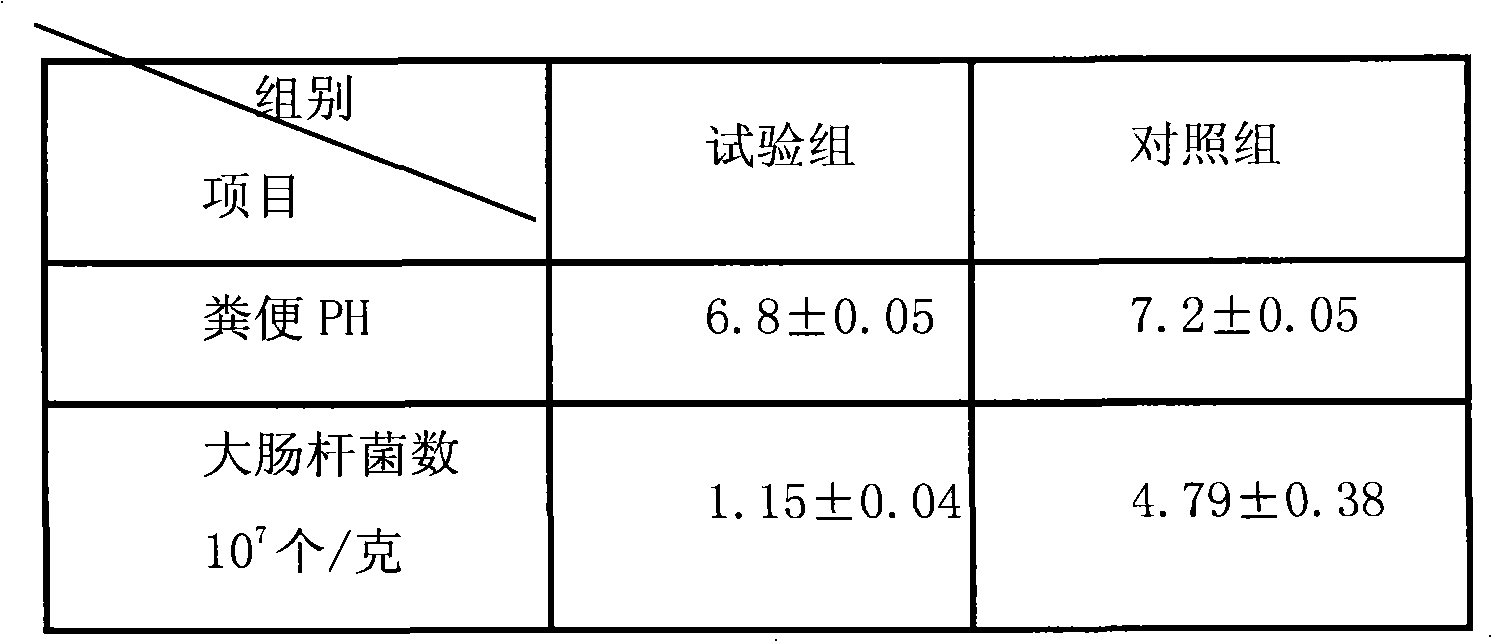

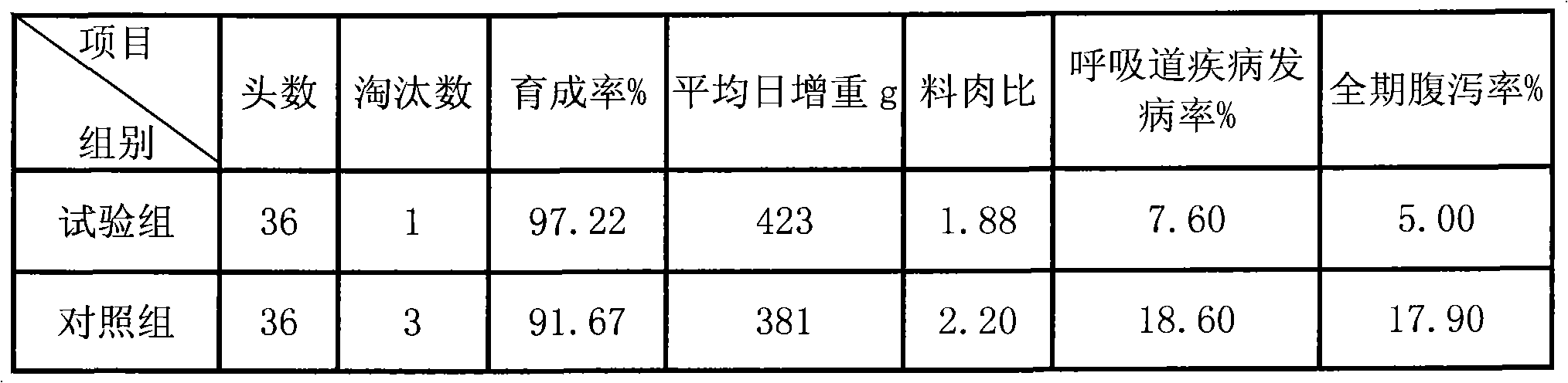

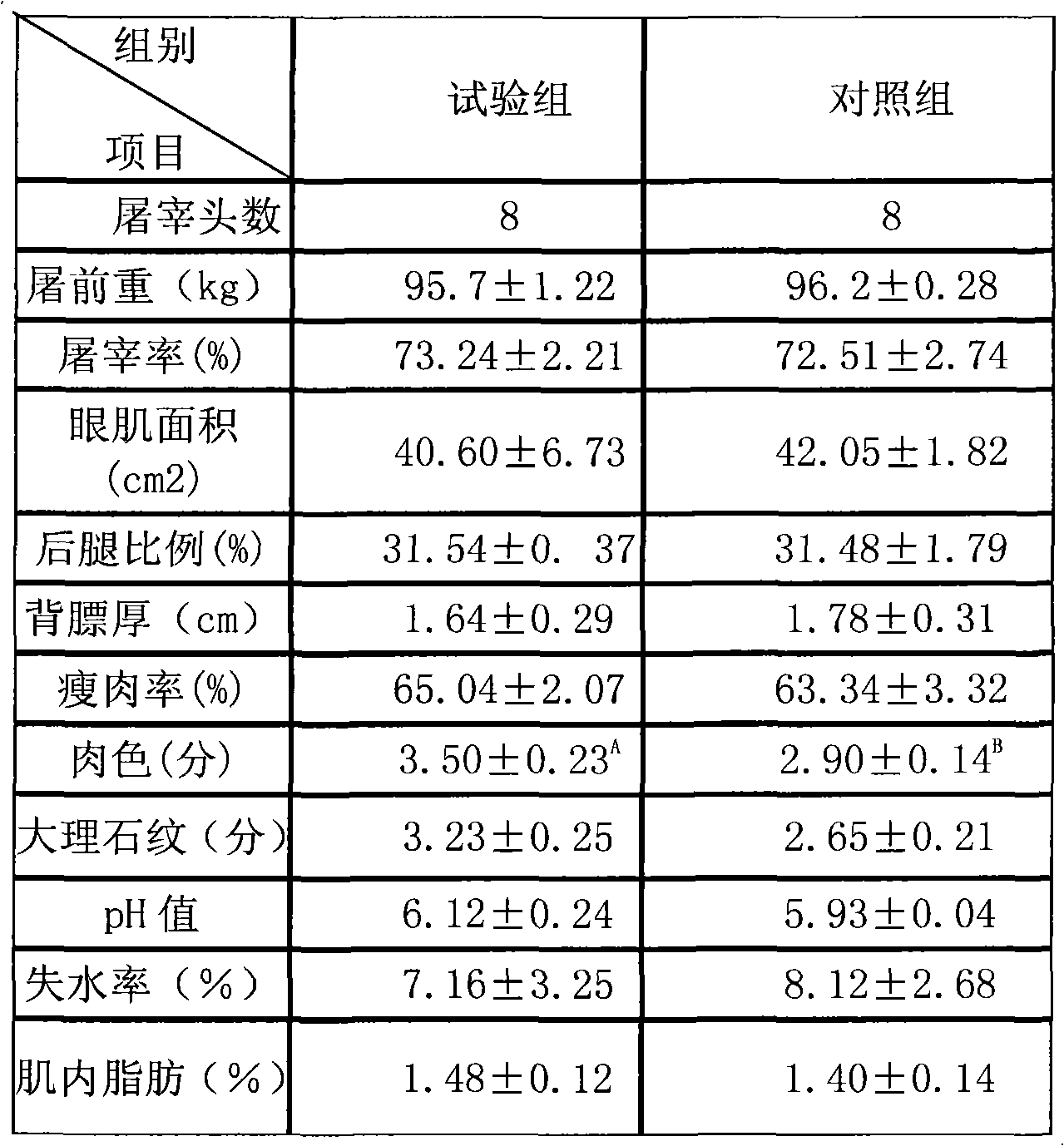

Microbial fermentation antibiotic-free feed and preparing method thereof

InactiveCN101828634AImprove immunityGood for healthFungiBacteriaLactobacillus acidophilusAspergillus niger

The invention discloses a microbial fermentation antibiotic-free feed, which comprises a batch and a composite fermentation material. The batch consists of the following raw materials in part by weight: 30 to 50 parts of corn, 20 to 40 parts of bean pulp, 5 to 20 parts of cotton seed meal, 2 to 5 parts of calcium hydrophosphate, 0.2 to 0.4 part of salt, 0.1 to 0.2 part of composite trace element, and 0.2 to 0.4 part of composite vitamin; and the composite fermentation material consists of the following fermentation materials in part by weight: 30 to 70 parts of lactobacillus acidophilus fermentation material, 10 to 20 parts of bacillus subtilis fermentation material, 20 to 35 parts of saccharomyces cerevisiae fermentation material, 1 to 3 parts of trichoderma longbrachiatum fermentation material, 1 to 3 parts of aspergillus niger fermentation material, and 1 to 3 parts of aspergillus oryzae fermentation material, wherein the weight ratio of the batch to the composite fermentation material is 96-92:4-8.

Owner:湖南创新生物科技有限公司

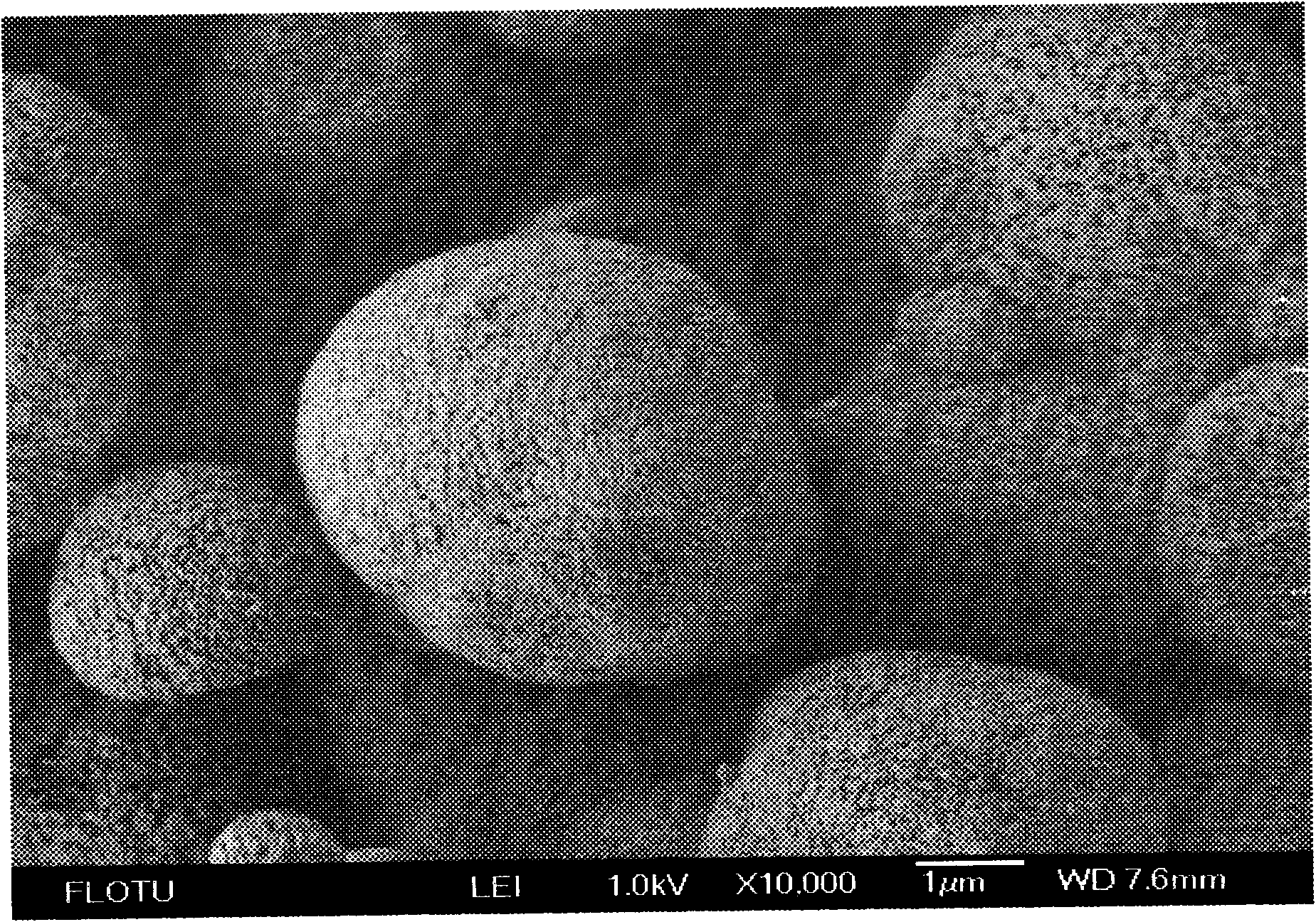

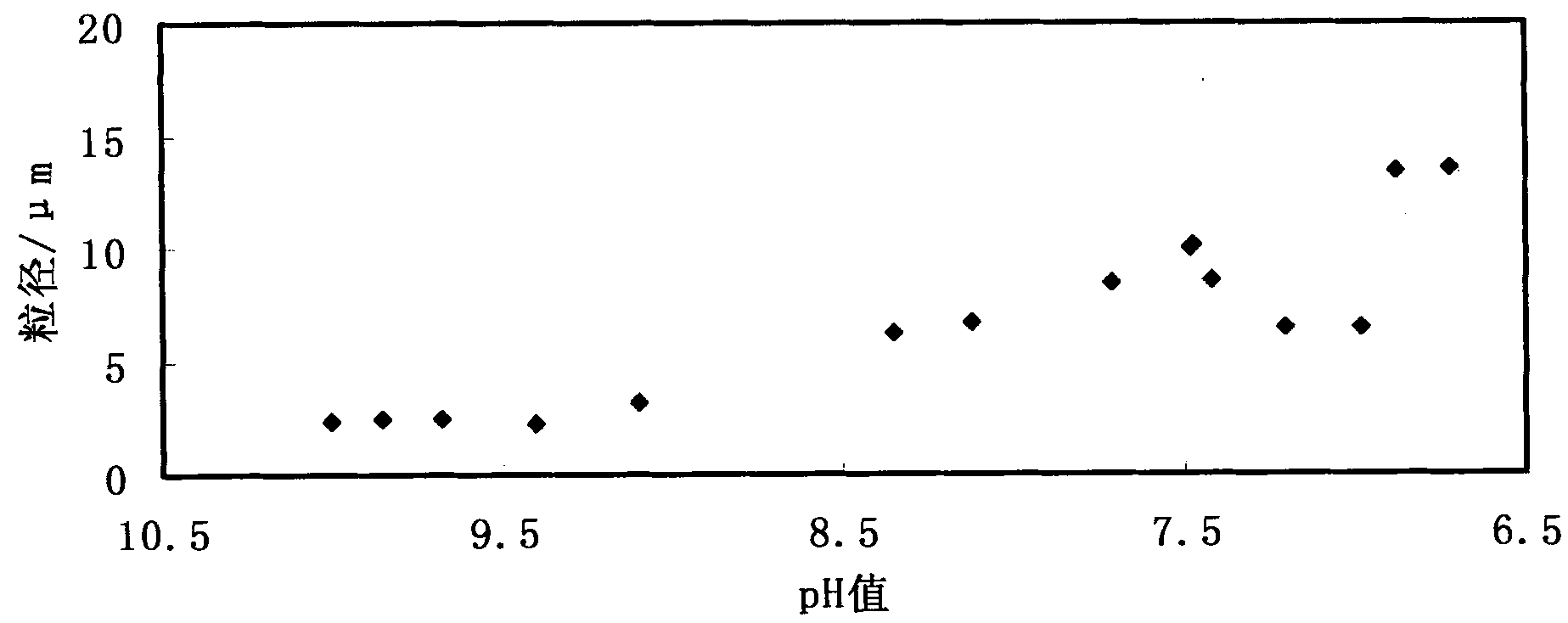

Novel method for producing superfine calcium carbonate by using carbide slag as raw material

InactiveCN101993104ASolve the possibility of industrializationRealize the possibility of industrializationCalcium/strontium/barium carbonatesCosmetic preparationsSlagCarbide

The invention relates to a method for preparing superfine calcium carbonate by adopting glycine as a dissolving agent, a modifying agent and an acid-binding agent, extracting effective calcium from calcium sources, such as carbide slag or lime, and the like and charging carbon dioxide into a reactor for calcifying, filtering and washing and application of the superfine calcium carbonate to paper making, paint production, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

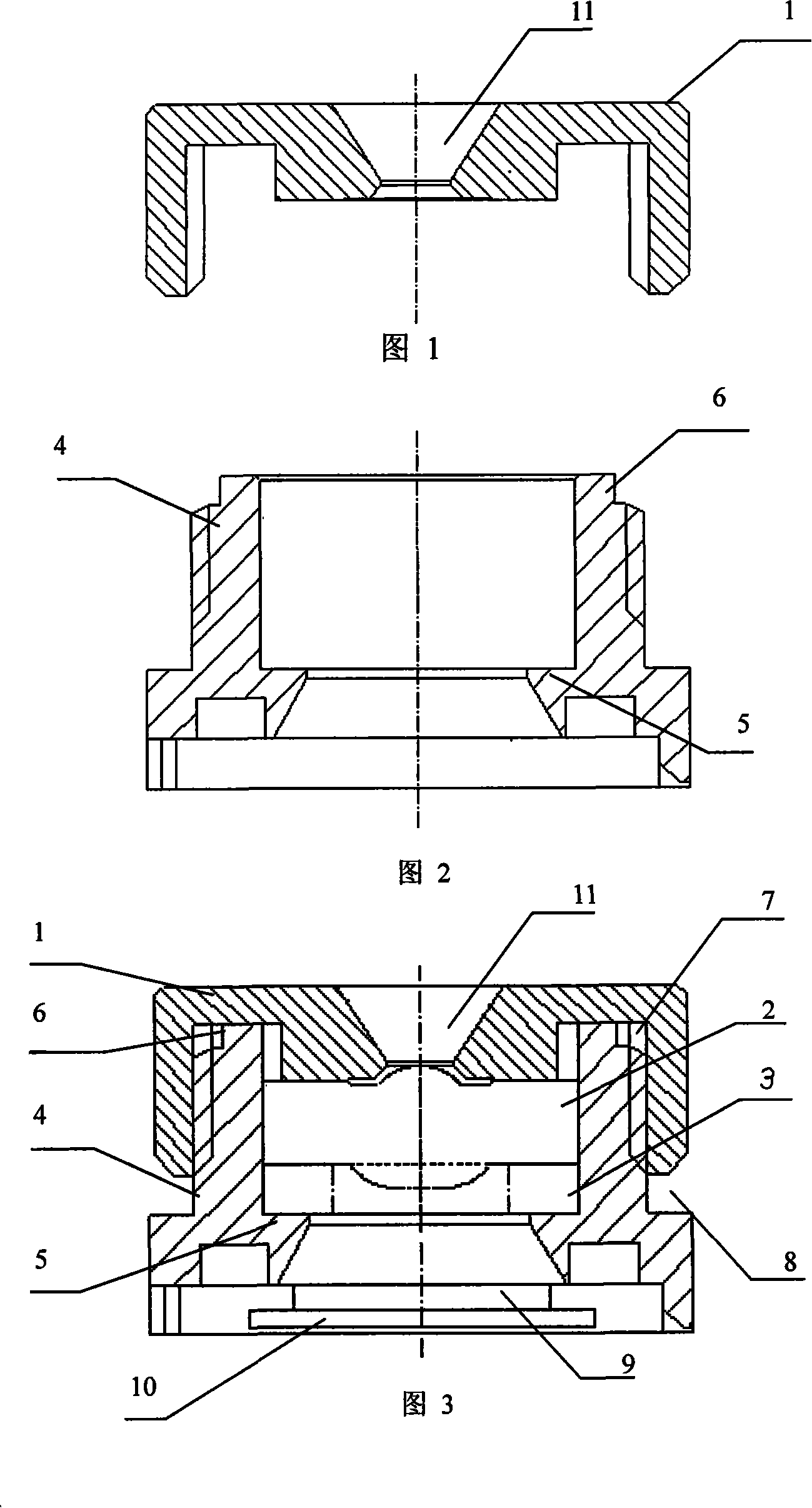

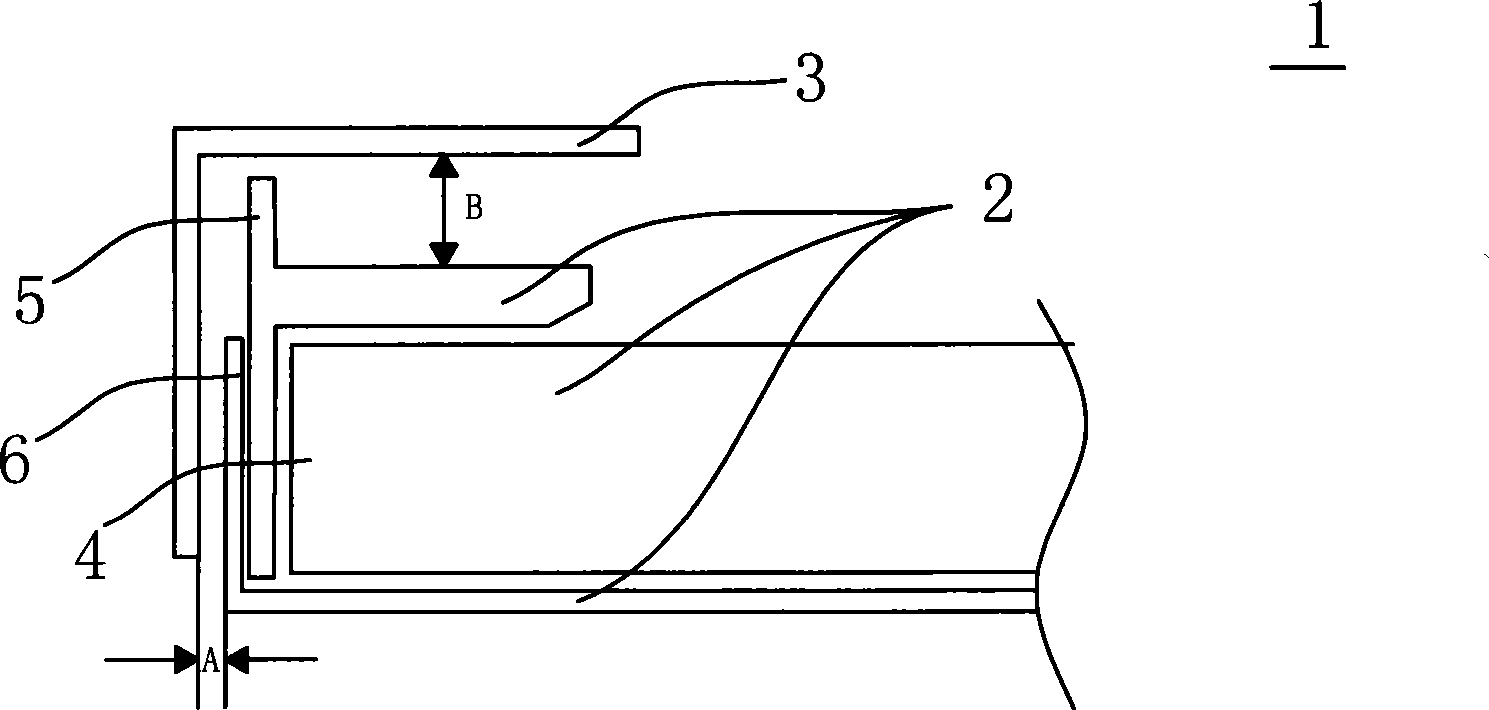

Glasses lens plated non-focusing mobile phone camera

InactiveCN101109840ASave on packaging costsOmit the manual focus procedureTelevision system detailsPrintersMobile cameraLens plate

The invention relates to a mobile camera without focusing and coated lens, which comprises a lens cone, a lens-cone cover with a light-passing hole, a lens in the lens cone, and a photosensitive chip and a printed circuit board at the bottom of the lens cone. The invention is characterized in that, a supporting table is provided around the lower part of the inner wall of the lens cone, on the supporting table, an elastic pressure ring is provided; the lens is on the elastic pressure ring; the surface of the optics of the lens is coated with an infrared ray filter film; around the top of the lens cone, a top table is provided; when the inner surface of the lens-cone cover is tightly pressed on the upper surface of the top table, the optics in the lens are pressed tight and fixed at a correct position due to the fitting between the lens-cone cover and the thread on the lens cone as well as the elastic force of the elastic pressure ring. The structural design allows the lens to be directly fixed on a correct position, so as to eliminate the manual focusing procedure as with the production process for prior mobile camera. The infrared ray filter film coated on the surface of the optics in the lens can eliminate infrared ray filter of special-material glass, and reduce the overall height of the mobile camera, simplify structure and reduce cost.

Owner:SAMSUNG HIGH TECH ELECTRO MECHANICS TIANJIN

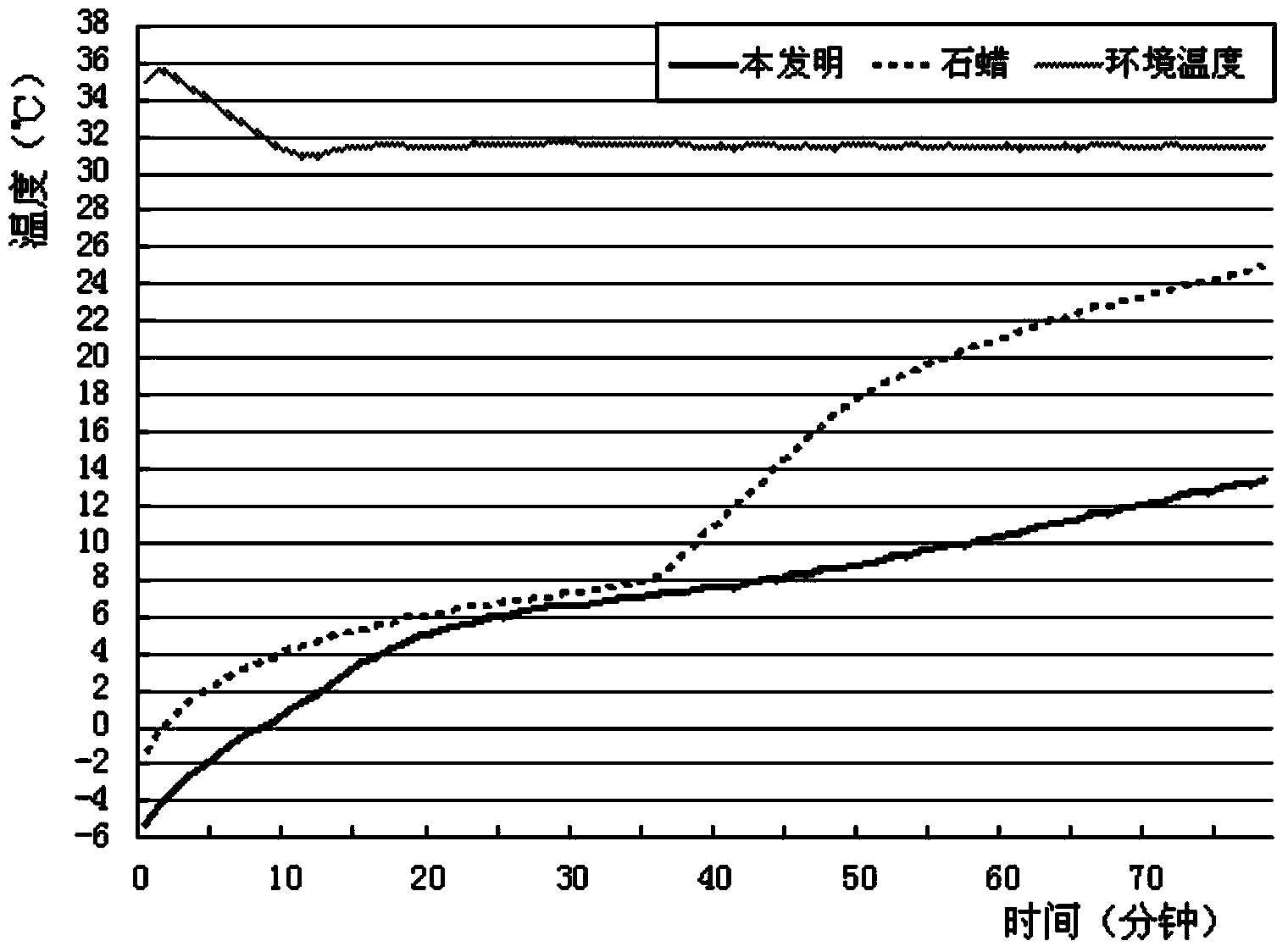

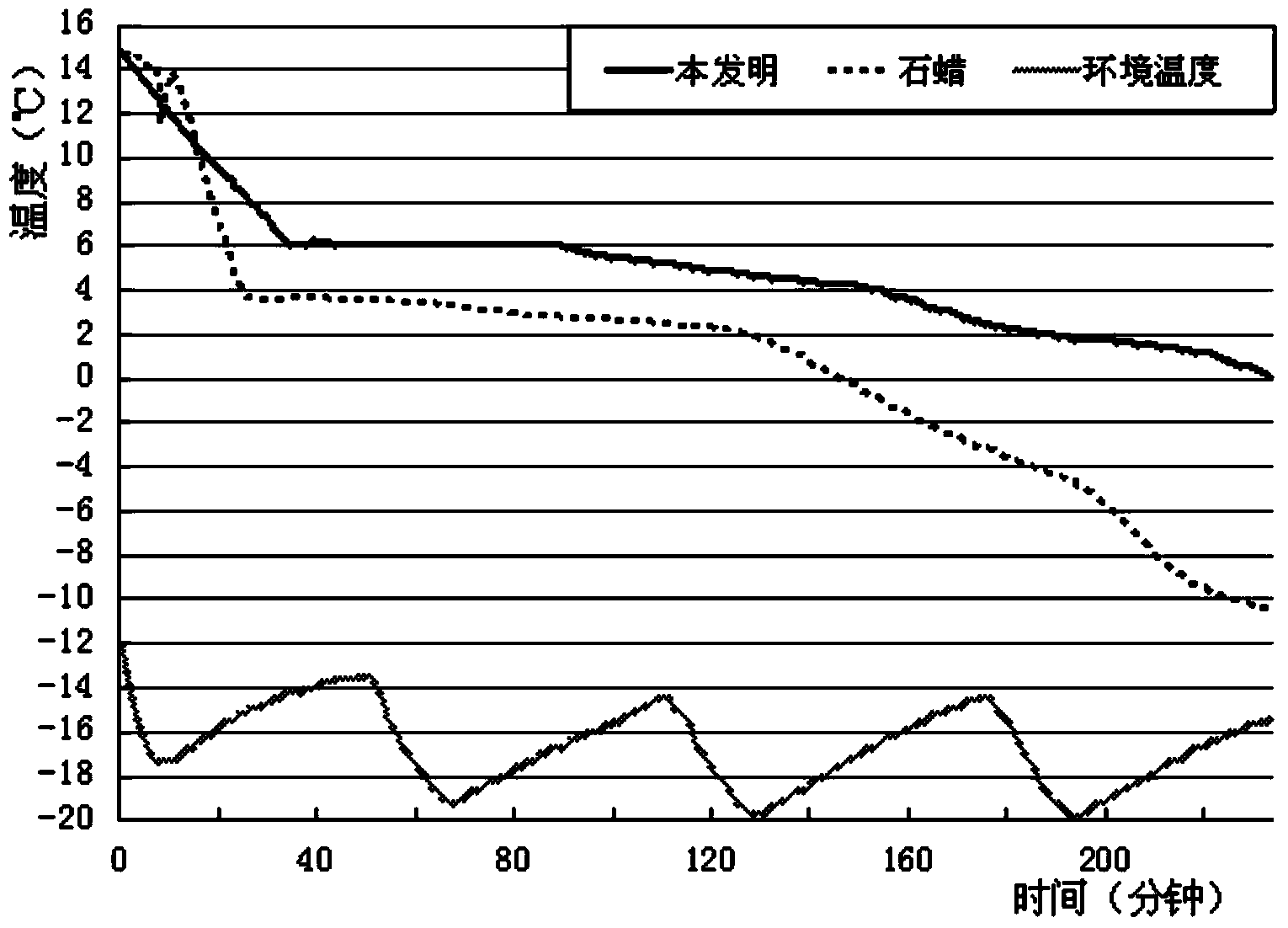

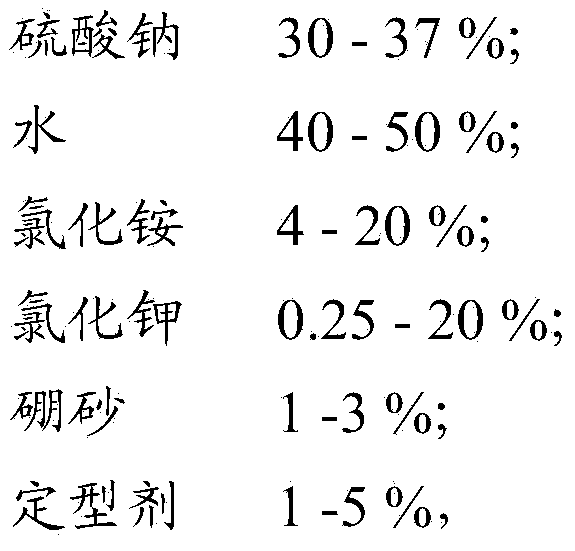

Cold-chain transportation phase change material and preparation method thereof

ActiveCN103756645AStir wellReduce the amount of investmentHeat-exchange elementsCold chainWhole blood product

The invention discloses a cold-chain transportation phase change material and a preparation method thereof. The phase change material is prepared from the following components by weight percent: 30-37% of sodium sulfate, 40-50% of water, 4-20% of ammonium chloride, 0.25-20% of potassium chloride, 1-3% of borax and 1-5% of sizing agent. The preparation method of the phase change material comprises the following steps: A, heating water in the components to 60-70 DEG C, and then adding sodium sulfate to evenly stir, so as to obtain a sodium sulfate solution; B, respectively adding the ammonium chloride, the potassium chloride and borax to the sodium sulfate solution in the step A, evenly stirring, and controlling the temperature of the solution at 60-70 DEG C; C, adding the sizing agent to the solution in the step B, evenly stirring, and filling into a plastic container to store when the temperature of the solution is controlled at 50-60 DEG C. The cold-chain transportation phase change material disclosed by the invention is used for maintaining long soaking time at 2-8 DEG C during cold chain transportation, and the quality of cold chain distribution of drugs, vaccines, blood products and medical devices is ensured.

Owner:益萃健(上海)生物科技有限公司

Wormkillers of methylamino avermectin benzoate for animals, method of preparing the same and application of the same

InactiveCN101129478AIncrease profitImprove usage activityPowder deliveryOrganic active ingredientsAquaculture industryHigh activity

The invention discloses a methylamine avermectin benzoate insecticide for animals and making method and application, which is characterized by the following: dissolving the insoluble methylamine avermectin benzoate in the water to form powder, particle and tablet; fitting for preventing multiple internal and external parasitism; reducing toxicity, high activity and securing the usage; avoiding the usage of toluene, xylene and carbinol; reducing the pollution; accelerating the health cultivation.

Owner:王安林

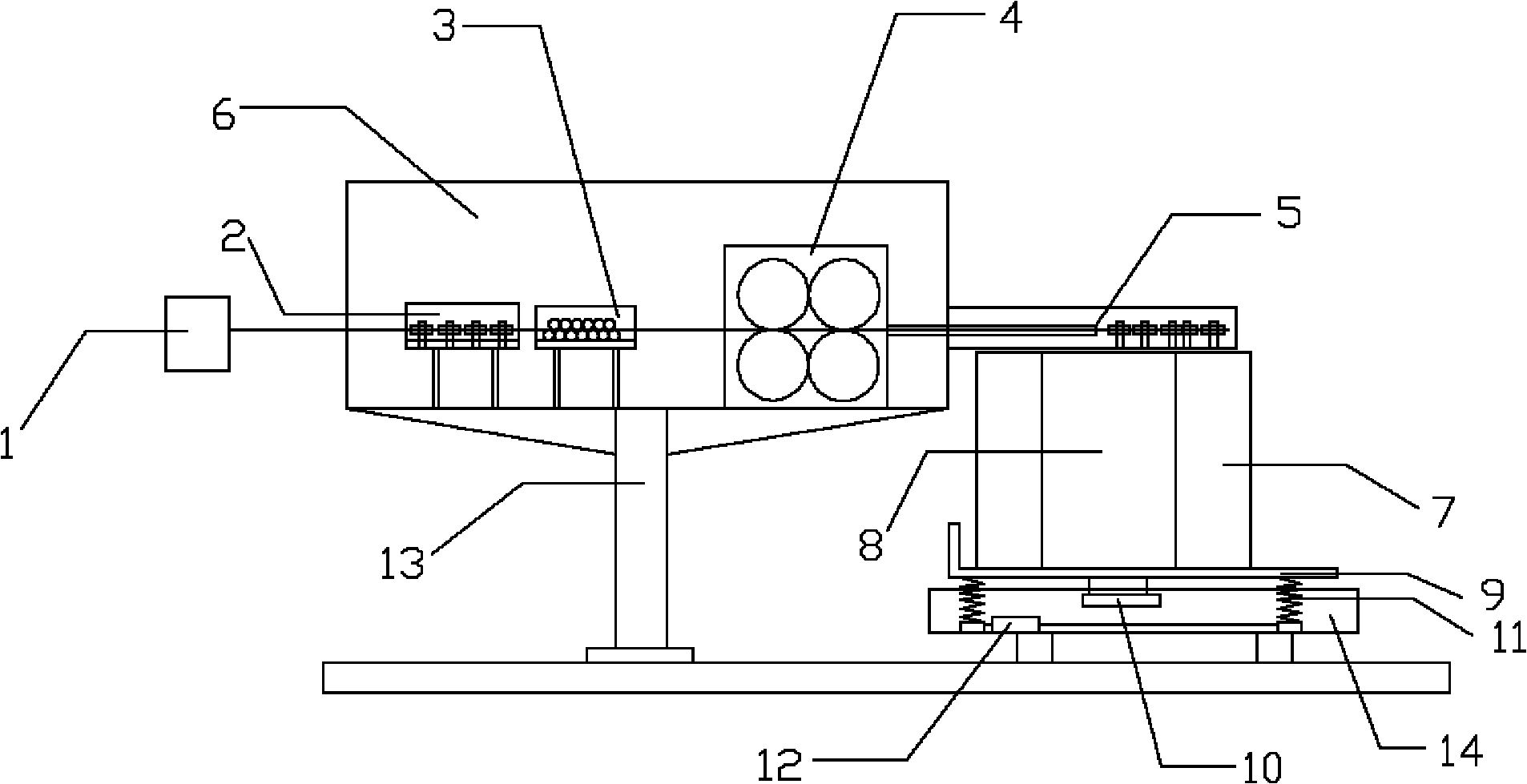

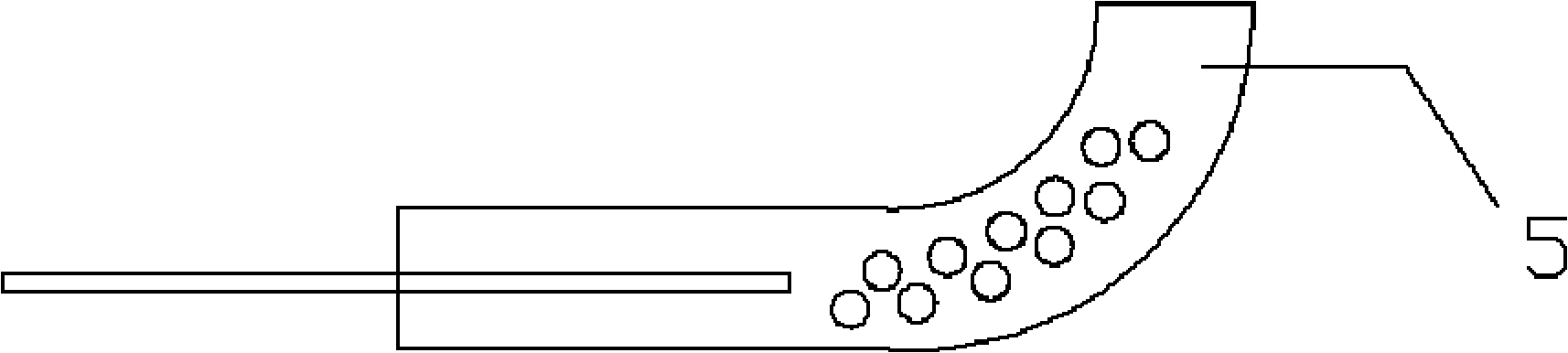

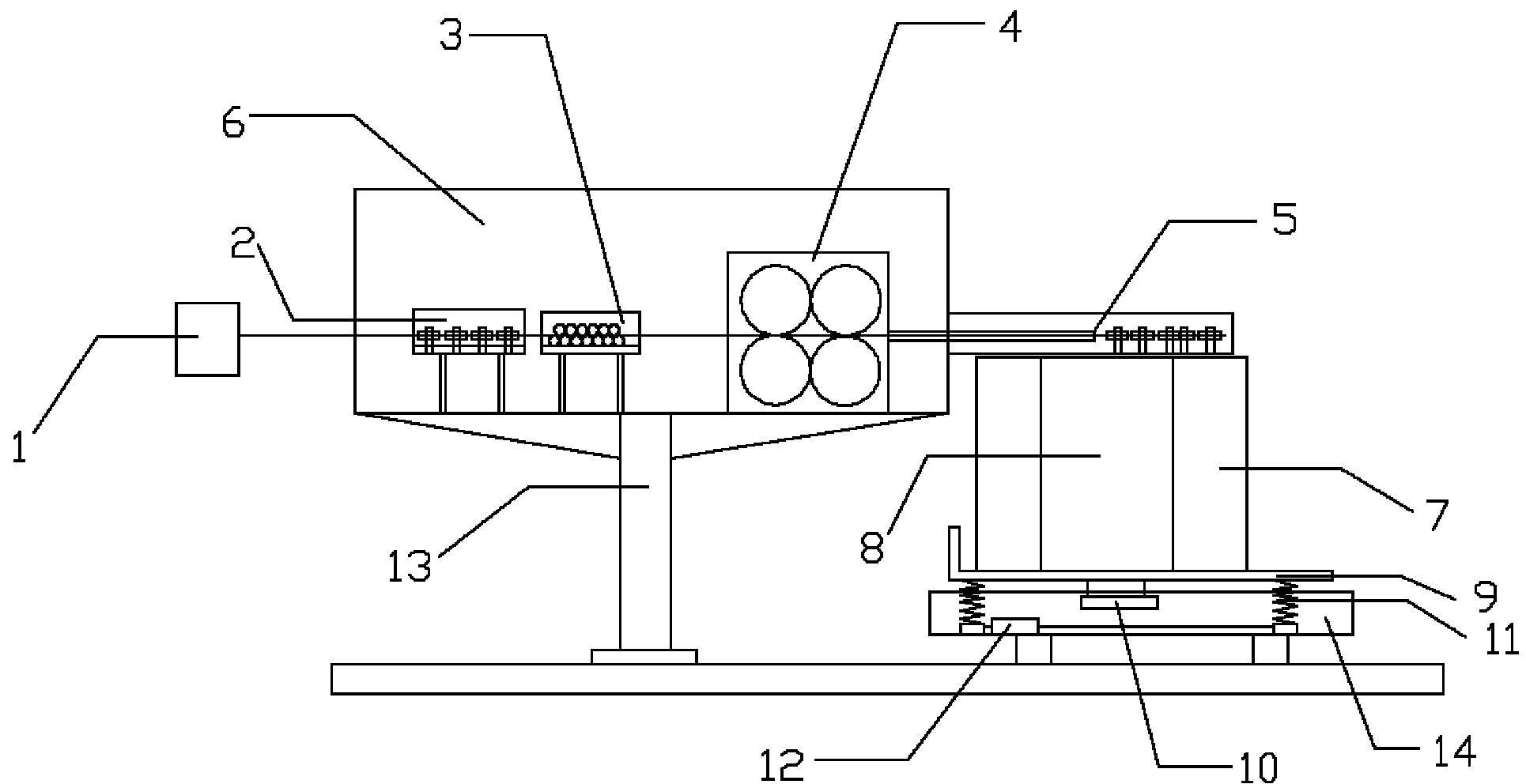

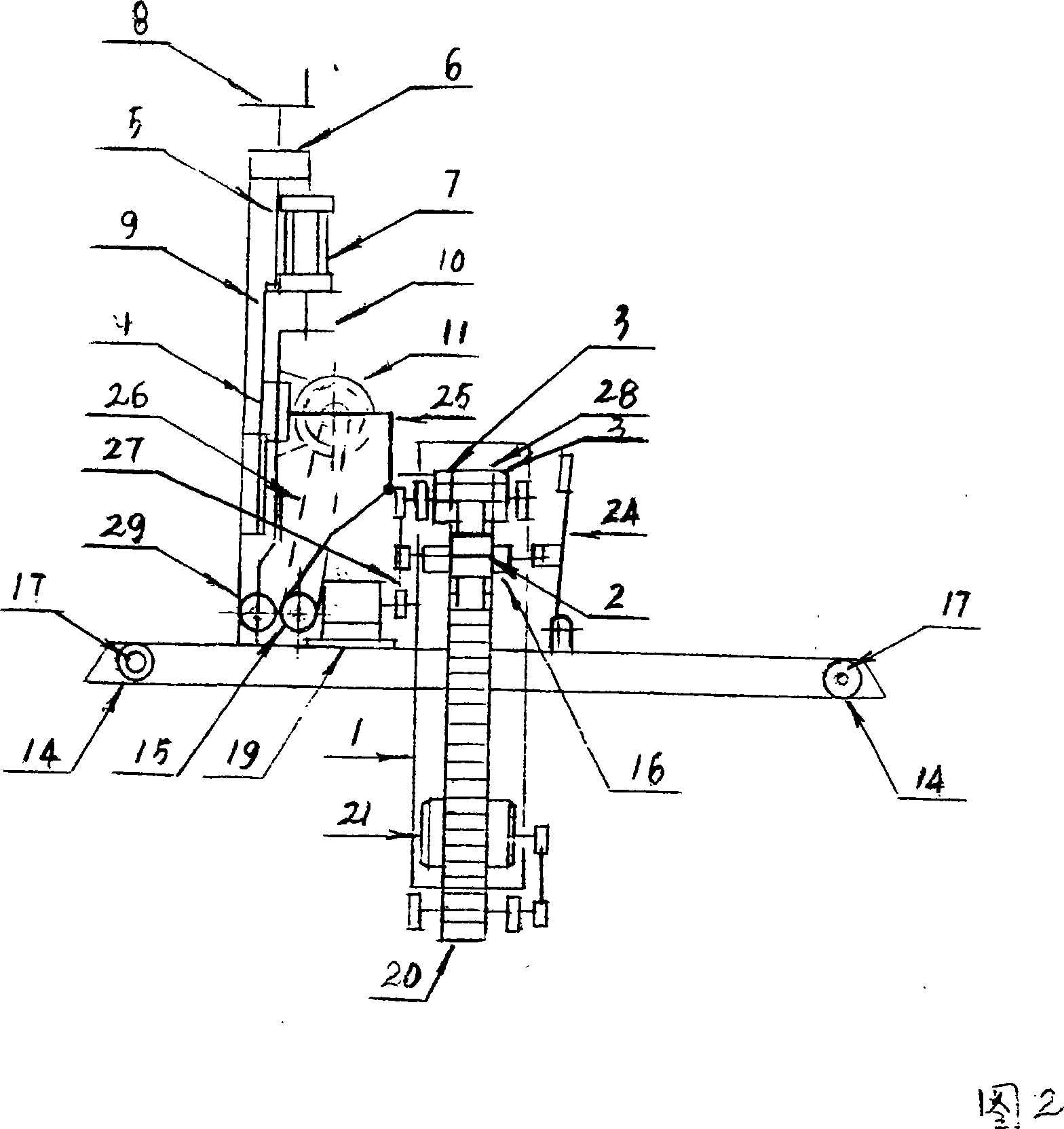

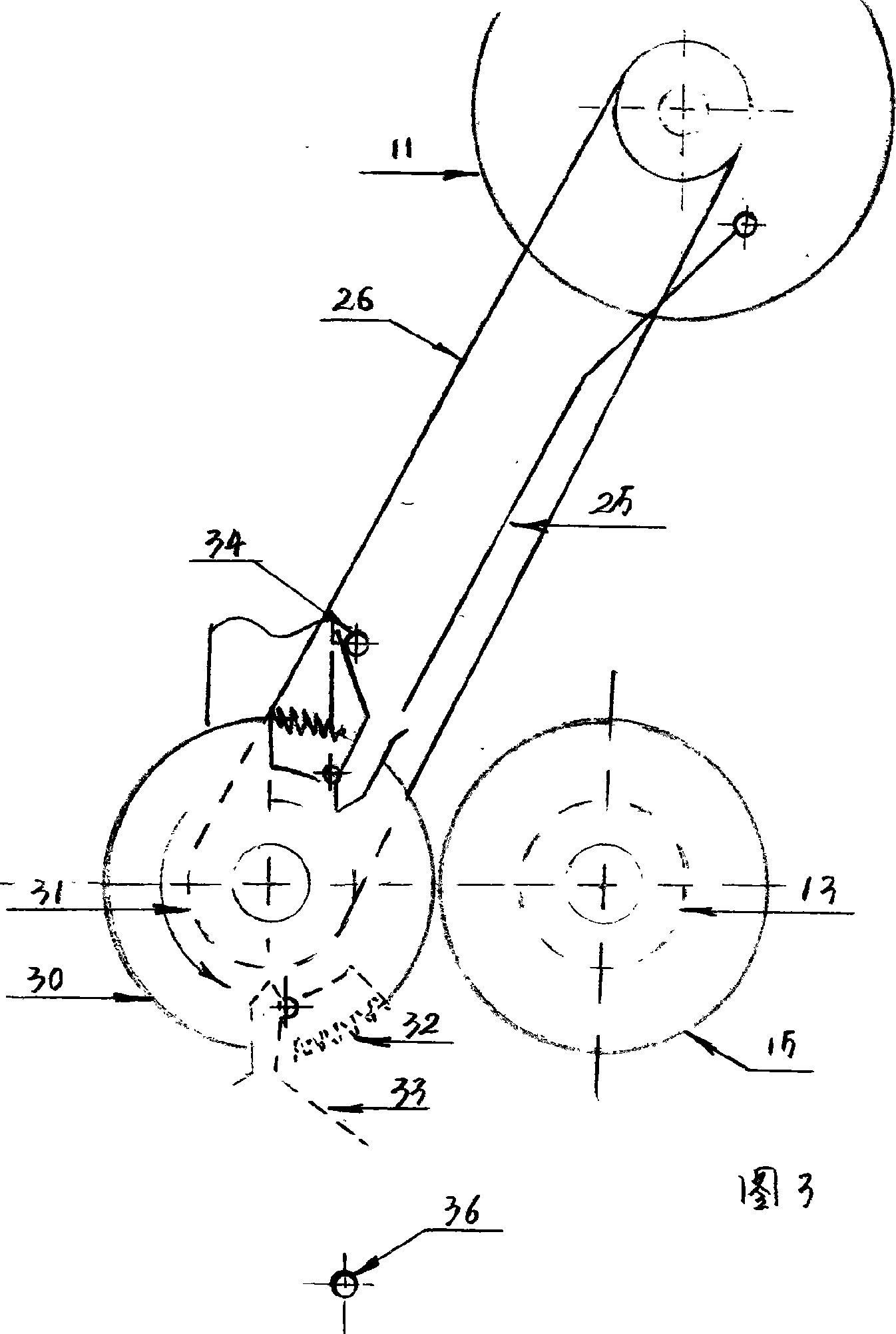

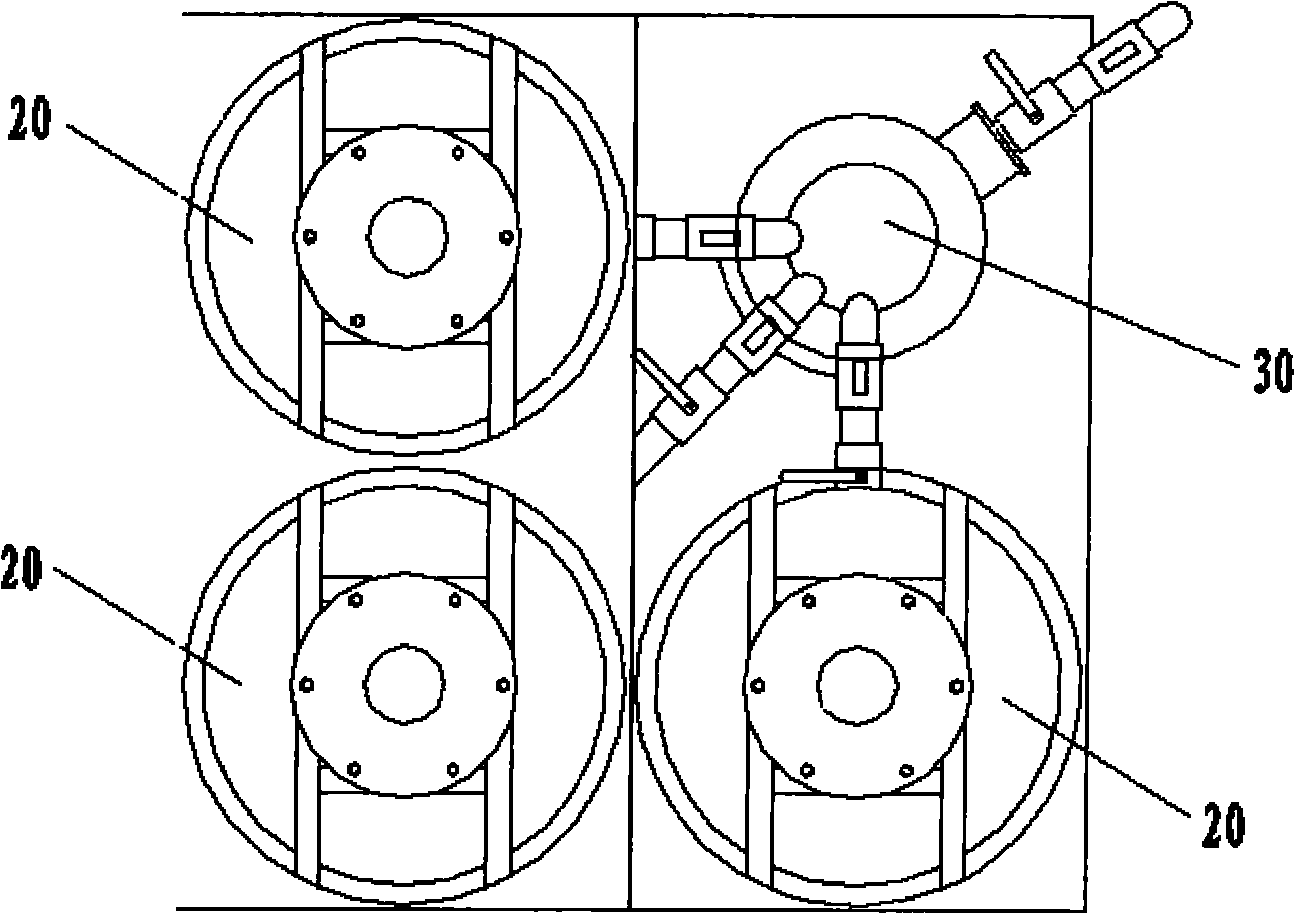

Novel barreled wire bonder

The invention provides a novel barreled wire bonder which comprises a payoff machine, an aligning mechanism, a winding-up barrel, a turntable and a rotary driving mechanism, wherein the aligning mechanism is positioned in a box body; the box body is arranged on a bracket; the pay-off machine is positioned on the front end of the box body; the outlet on the outer side of the box body is provided with a wire leading device; the rotary driving mechanism is positioned in the middle of a collet and is connected with the turntable by an eccentric shaft; the winding-up barrel and the turntable can be rotatably connected; the rear end of the aligning mechanism in the box body is provided with a conveyer device; a barrel core is built in the winding-up barrel; a vibrator is installed in the collet; a vibrator is connected with the turntable; and the welding wire is discharged from the pay-off machine to be on the same horizontal line according to the track of the horizontal device in the aligning mechanism, the conveyer device and the wire leading device. The novel barreled wire bonder has the advantages of high automatic degree, simple structure, low processing cost, high production efficiency and the like, performs the action on tightening the welding wires, is convenient to maintain, ensures that the welding wires are arranged in a plum blossom shape, ensures the quality of the barreled welding wires, ensures the total amount for the welding wire barrel to contain the welding wires to be increased, and is package-saving.

Owner:TIANJIN XUZHI MACHINERY & ELECTRICAL EQUIP

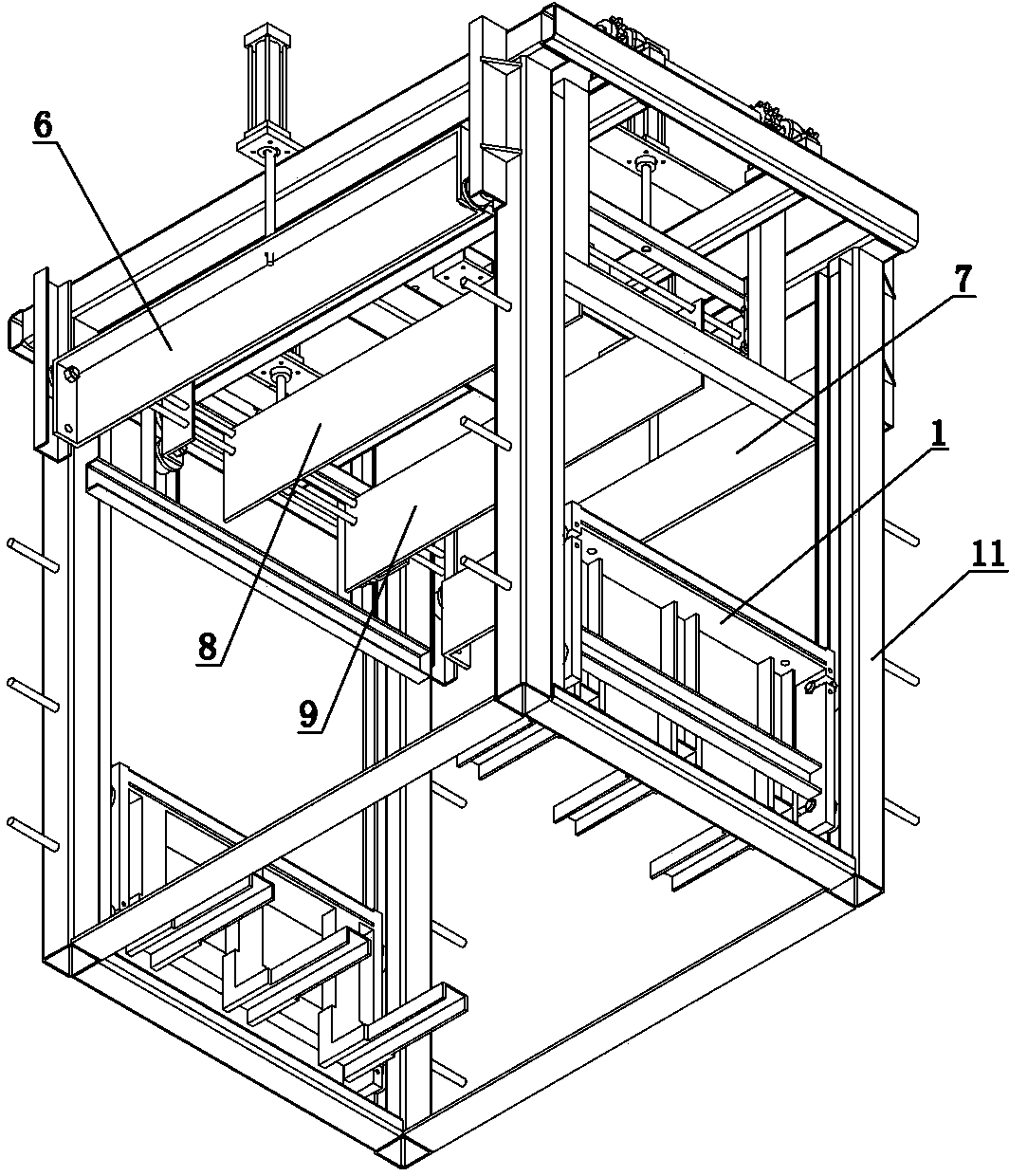

Tray-free stacking machine

ActiveCN103723523ALoading and unloading safetyReasonable designStacking articlesManufacturing FactoriesEngineering

A tray-free stacking machine comprises a carrier plate capable of moving left and right, a brick feeding device for feeding every layer of bricks to the carrier plate line by line and a brick collecting device which is arranged on one side of the carrier plate and capable of going up and down. A baffle capable of going up and down is arranged above one side of the carrier plate. The tray-free stacking machine further comprises two separating plates which are capable of going up and down and are arranged at intervals, the two separating plates are arranged above one side of the carrier plate, the arranging direction of the two separating plates is identical to that of the baffle, when the baffle and the two separating plates go down simultaneously, the multiple lines of bricks on the carrier plate can be divided into three separated parts, and two fork ports allowing two steel forks of a forklift are formed among the three parts of bricks. According to the tray-free stacking machine, after brick stacking is completed, the bricks are bound up and fastened tightly through packing belts, the two steel forks of the forklift are inserted into the two fork ports at the moment, and the forklift can carry the bricks away. Through the adoption of the tray-free stacking machine, stacked bricks can be in order and compact, the breakage rate is reduced, assembling and disassembling are convenient and safe, manufacturing factories do not need to purchase a large amount of trays, production cost and transportation cost are further reduced.

Owner:泉州盛科智能装备制造有限公司

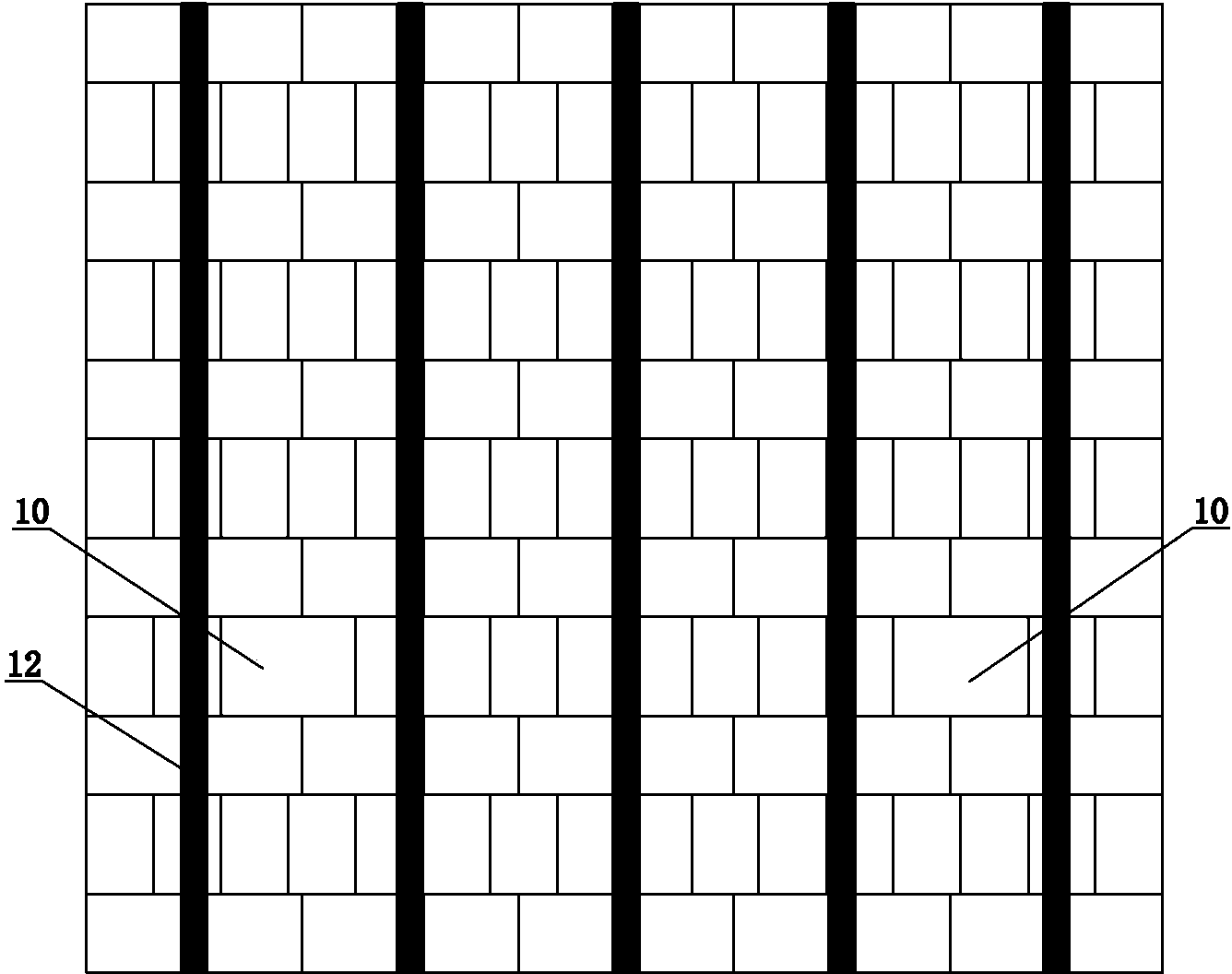

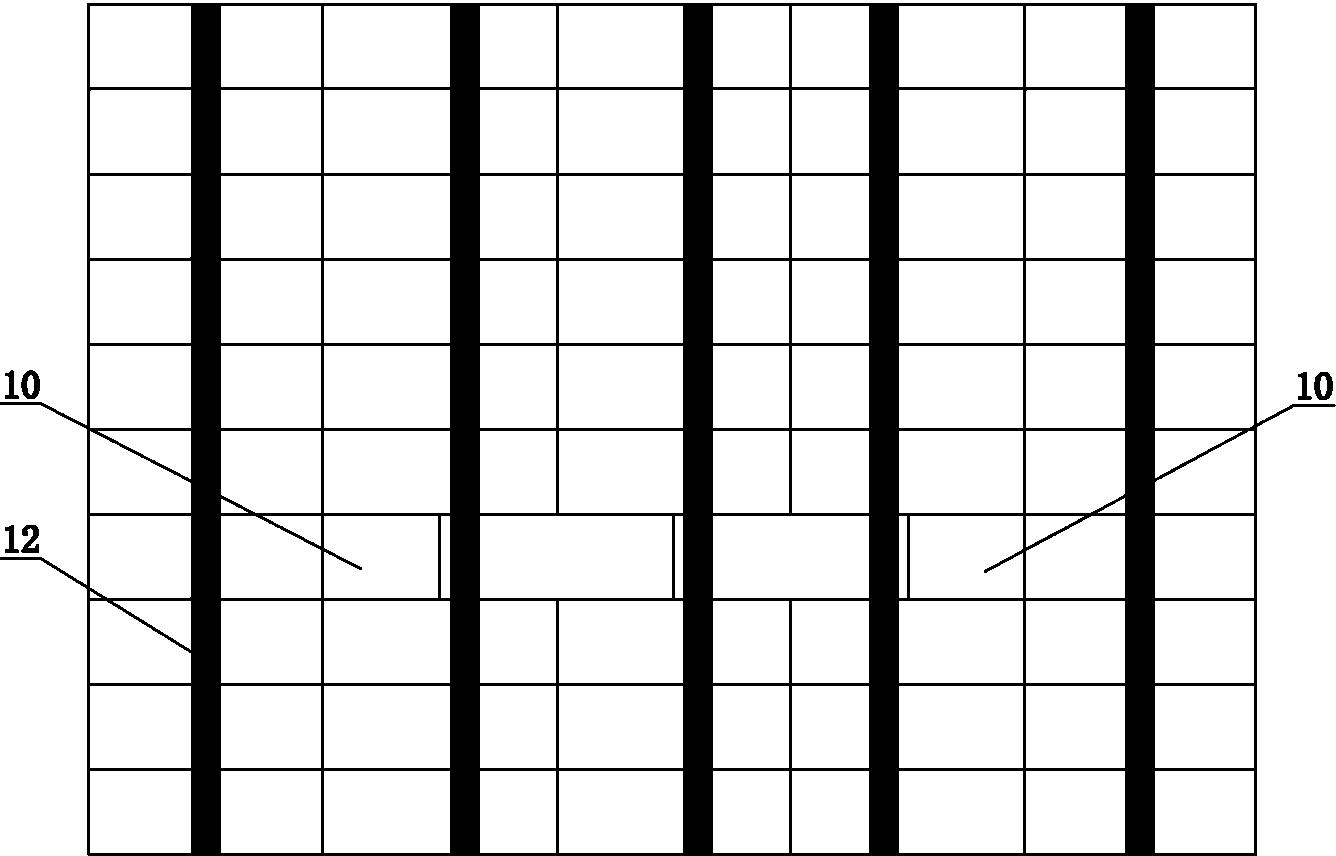

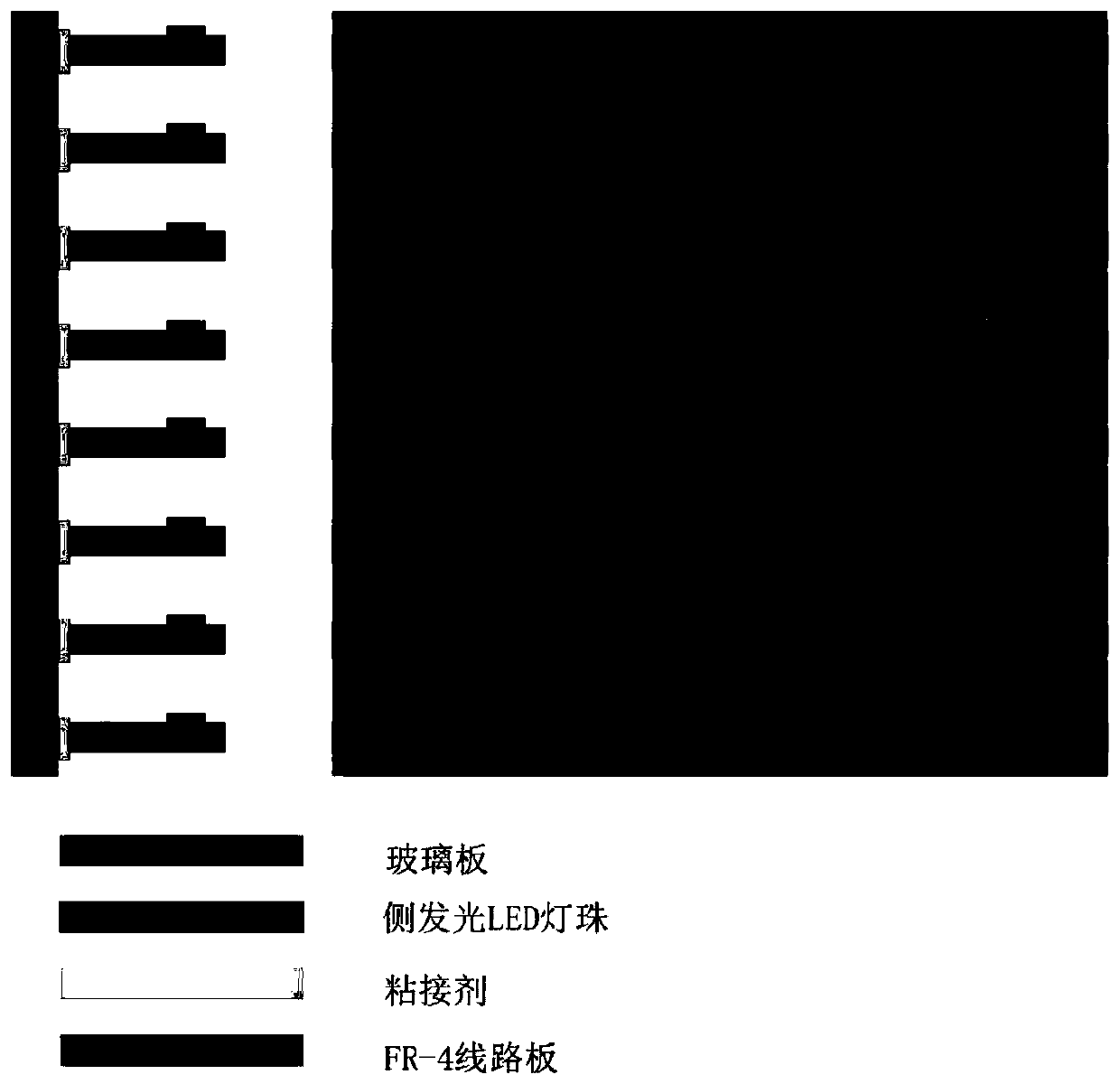

Glass-based heat conducting circuit board

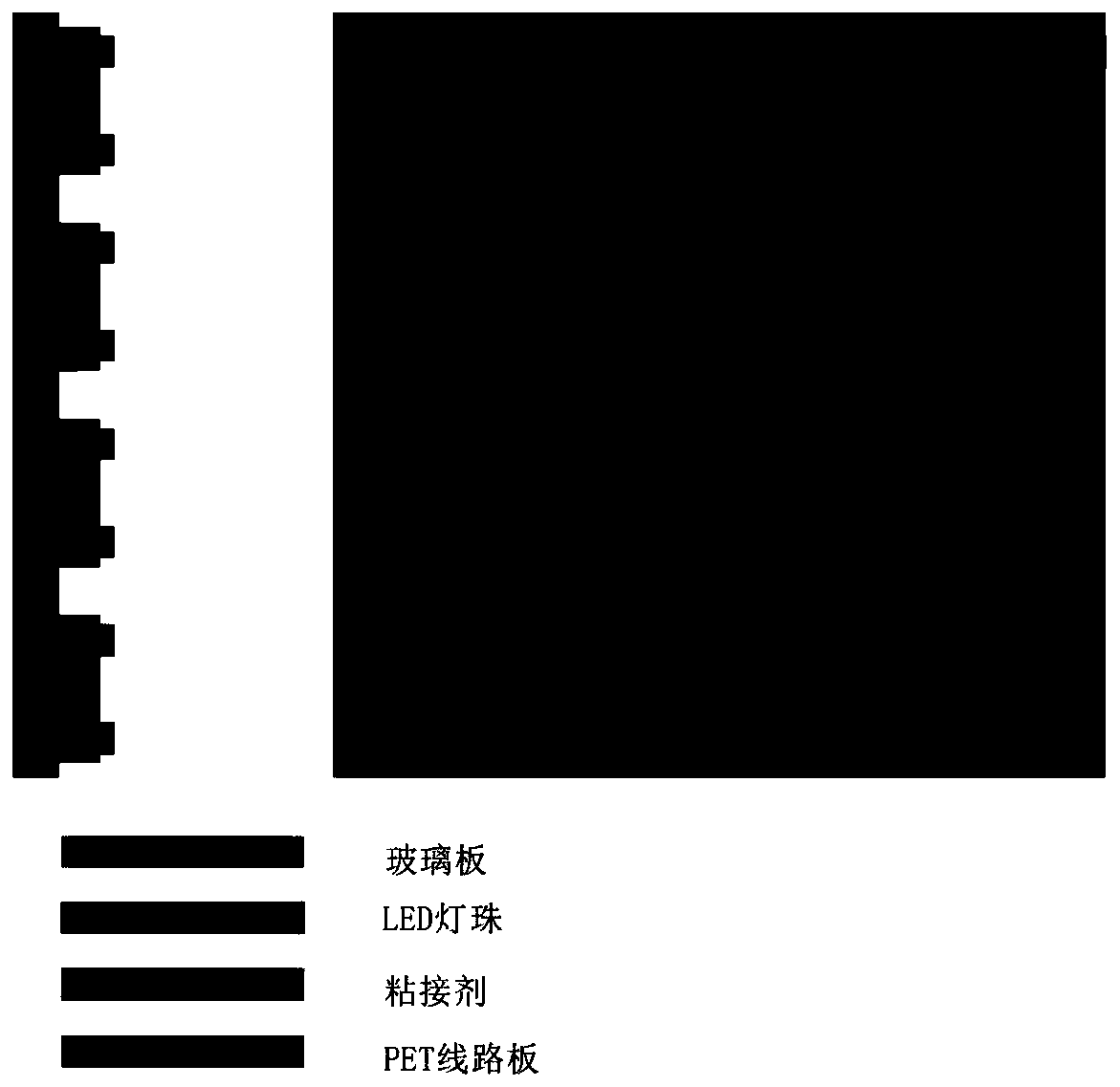

InactiveCN110225664AReduce thicknessReduce bondingPrinted circuit assemblingCircuit precursor manufactureEpoxyManufacturing technology

The invention belongs to the field of heat dissipation substrates for LED, and specifically relates to a glass-based heat conducting circuit board. The glass-based heat conducting circuit board is manufactured according to the following steps: S1, manufacturing of a glass-based copper clad laminate; a glass-based copper clad laminate is manufactured by vacuum hot pressing of glass and copper foilthrough epoxy resin as basic adhesive; S2, pressing of the glass-based copper clad laminate; the glass and the glued copper foil are stacked and put in a vacuum press for pressing; S3, manufacturing of a glass-based circuit board: a circuit part is manufactured by using a circuit board manufacturing technology; and S4, laser ablation of resin: laser of corresponding intensity is selected and usedto ablate the resin part outside the circuit to expose a transparent glass substrate. The structure does not have a circuit board and adhesive bonding part compared with the existing transparent screen, so that the thermal conductivity of the glass-based heat conducting circuit board is much better that of the existing product. Because the surface-mounted circuit board part is omitted, the thickness of the transparent screen can be reduced ultimately.

Owner:深圳市昱谷科技有限公司

Complex buffering pad for packaging TV set

ActiveCN101108680ALow vapor transmission rateLow water absorptionPackaging vehiclesContainers for machinesBursting strengthPolystyrene

The invention discloses a composite cushion pad for packing TV sets, which is a pad between an outer packing case and the TV sets. The invention comprises a corrugated paper buffer and a foam plastic buffer. Wherein, the corrugated paper buffer and the foam plastic buffer are fixed by bond or splicing; the corrugated paper buffer is provided with a shape coordinated with the inner wall of the outer packing case and is one or a plurality of monolithic structures; the connection parts among a plurality of monolithic structures are fixed by bond; the foam plastic buffer is provided with a slot coordinated with the connection part of the TV set and is one or a plurality of monolithic structures made of polyethylene foam EPE or polystyrene foam EPS and the connection parts among a plurality of monolithic structures are fixed are fixed by bond. After adopting the structure, the invention can improve the stacking strength, the burst strength and the integral packaging strength of the TV set package and greatly reduce the amount of the foam plastics easily polluting the environment, thus achieving the aims of lowering the cost and protecting the environment.

Owner:XIAMEN PRIMA TECH

Flower pot and its production process

InactiveCN1605240ASave on shipping costsSave on packaging costsCultivating equipmentsReceptacle cultivationPaper dustMethyl cellulose

The present invention relates to flower pot producing technology. The flower pot is produced through preparation of slurry with methyl cellulose, PVA, glue liquid or paste, waste paper, wood dust and water; combination of the slurry with gypsum powder and kraft paper; and other steps. The flower pot of the present invention has the features of being tough, watertight, and low in packing and transporting cost.

Owner:沈添得

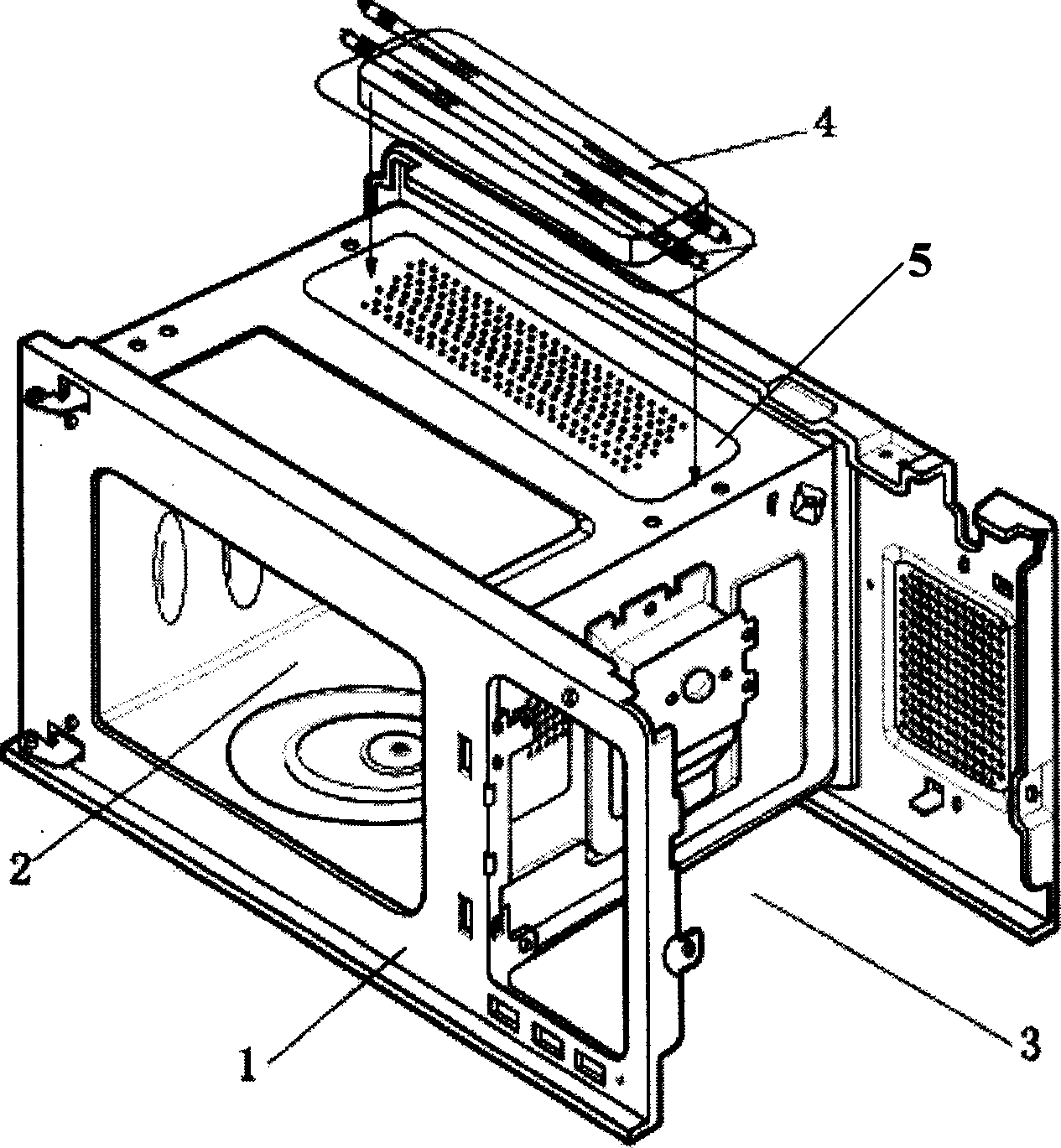

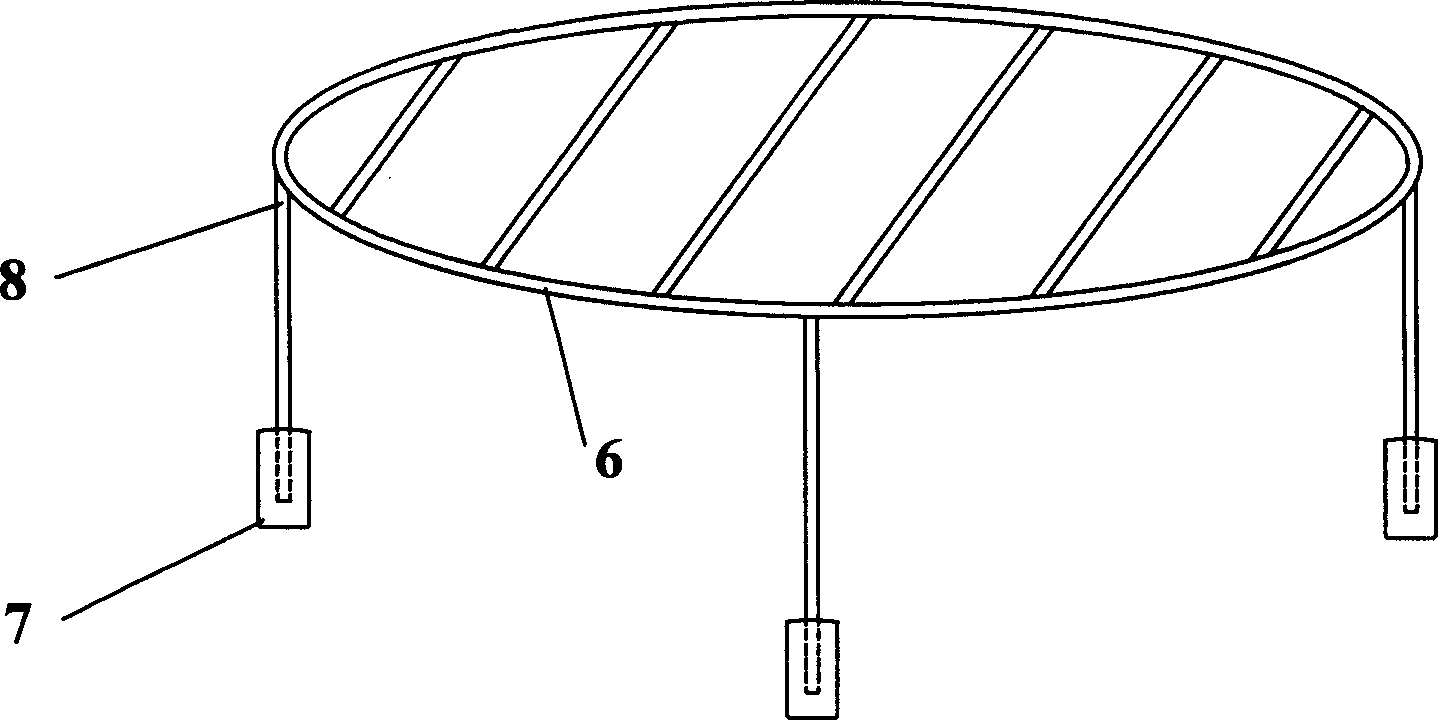

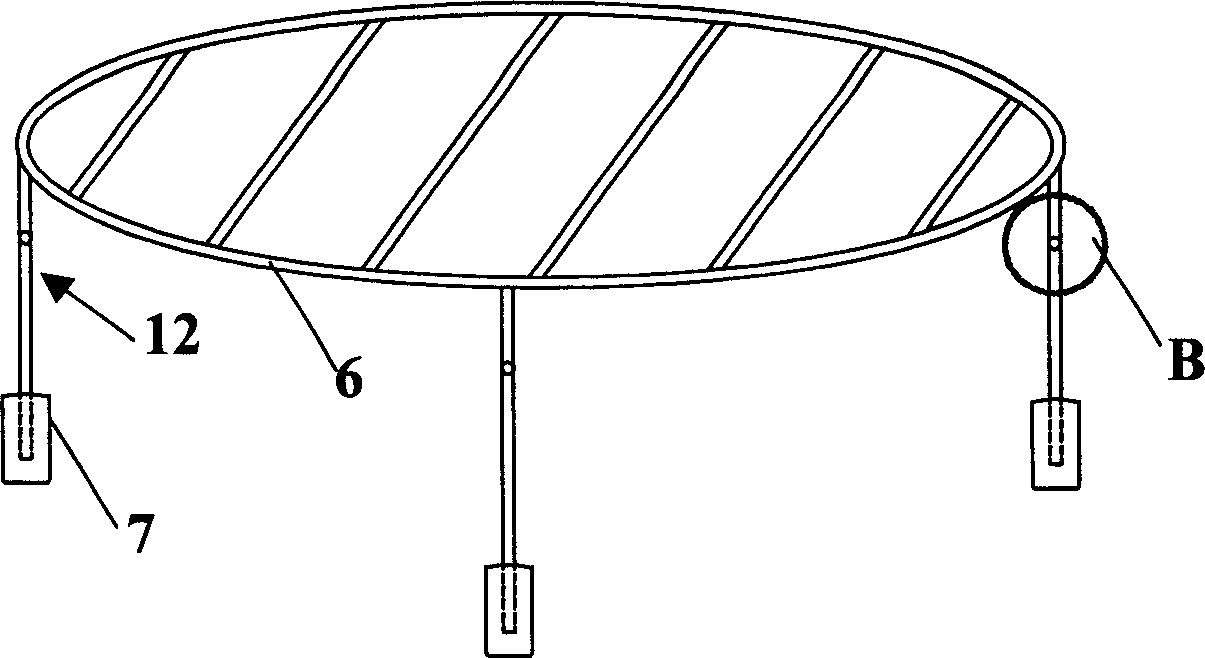

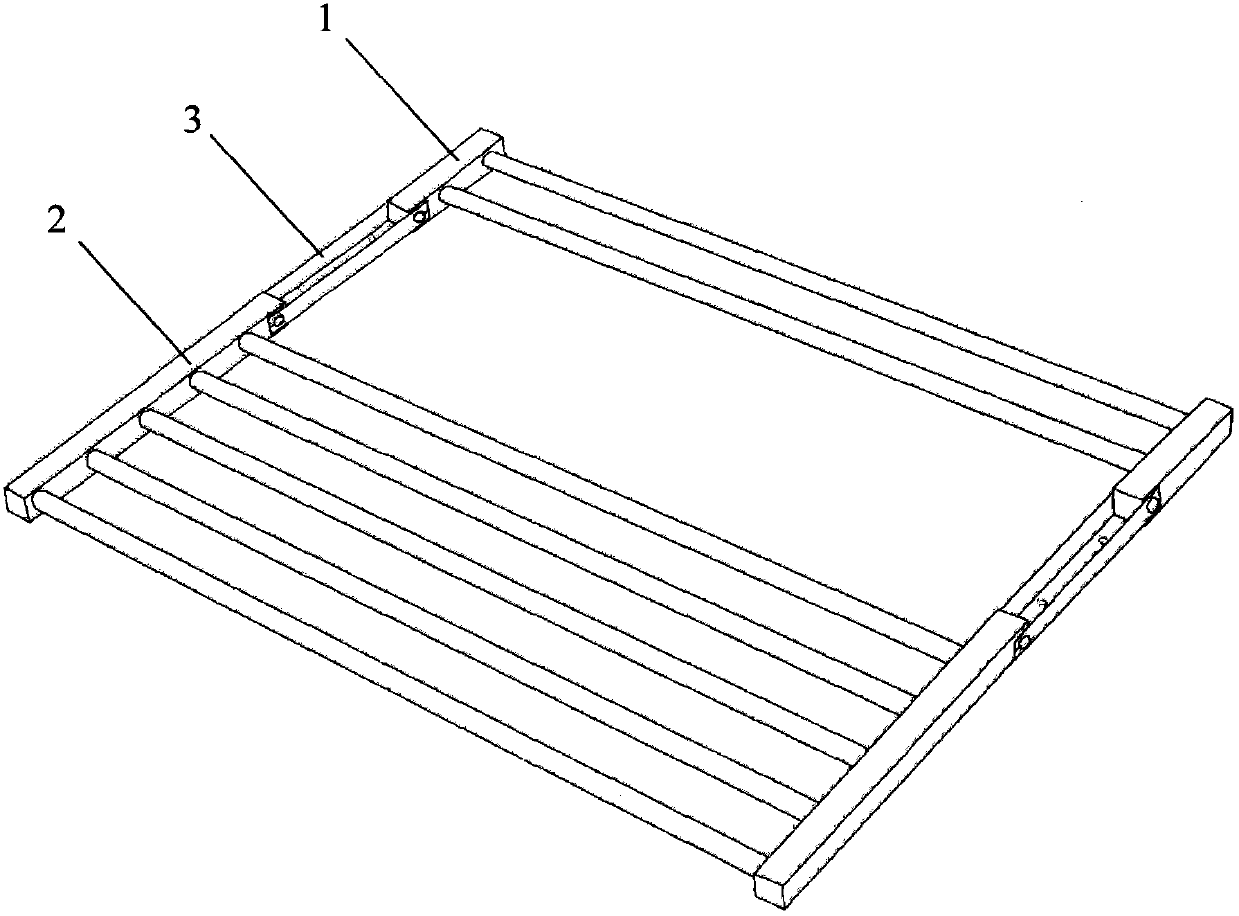

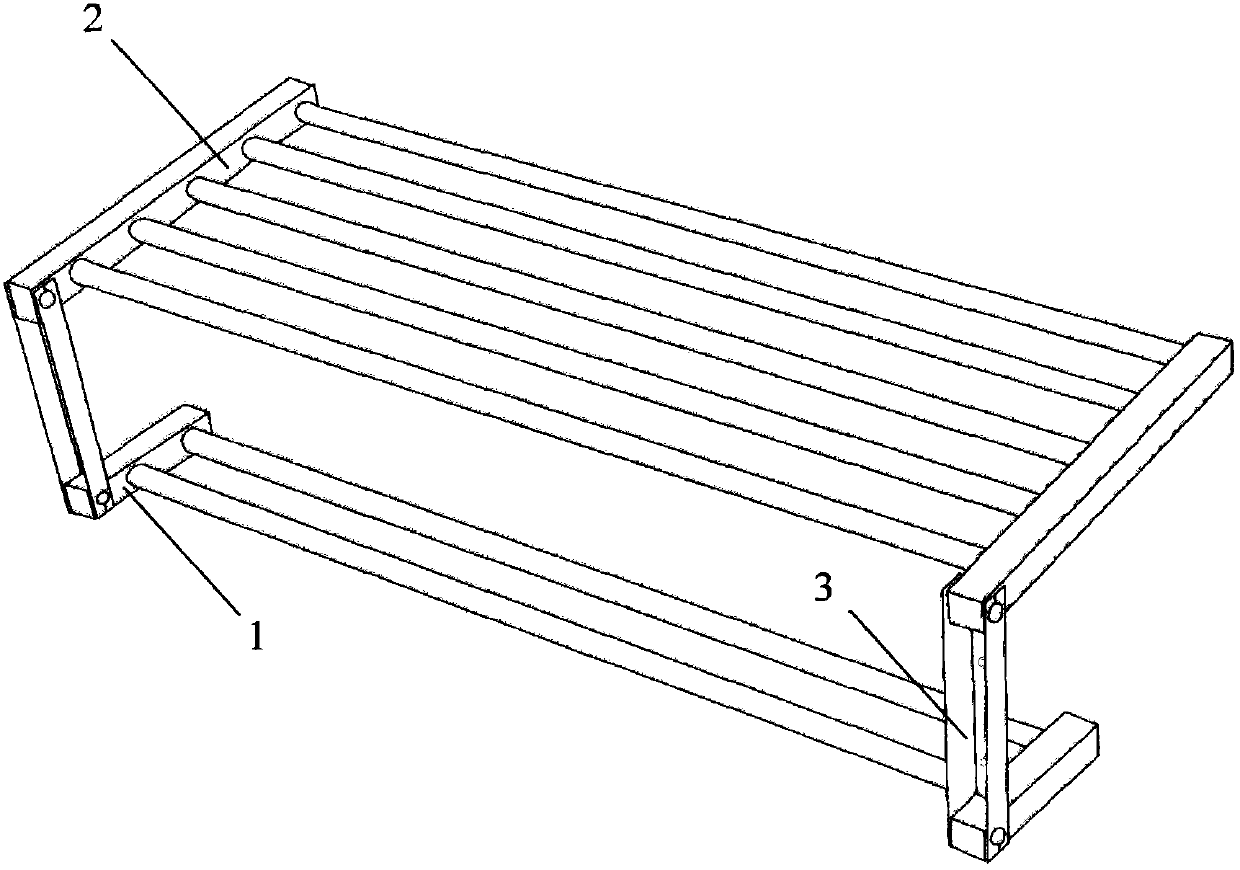

Foldable roasting supporter for microwave oven

InactiveCN1862108ACause damageSave space costDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

There is disclosed a folding grill for a microwave oven, which includes a grill main body, foldable legs disposed on the lower side of the grill main body edge and integrated with the grill main body for supporting the grill main body and shield sleeves of legs sleeved on the lower end part of the foldable legs.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

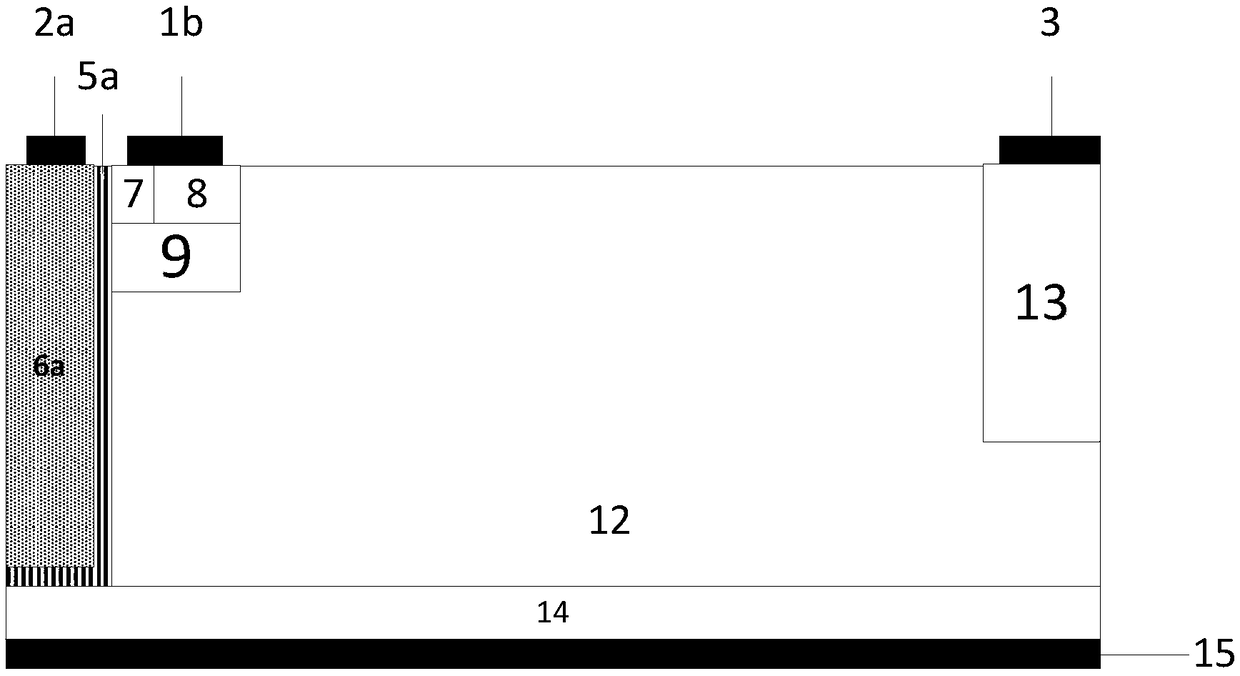

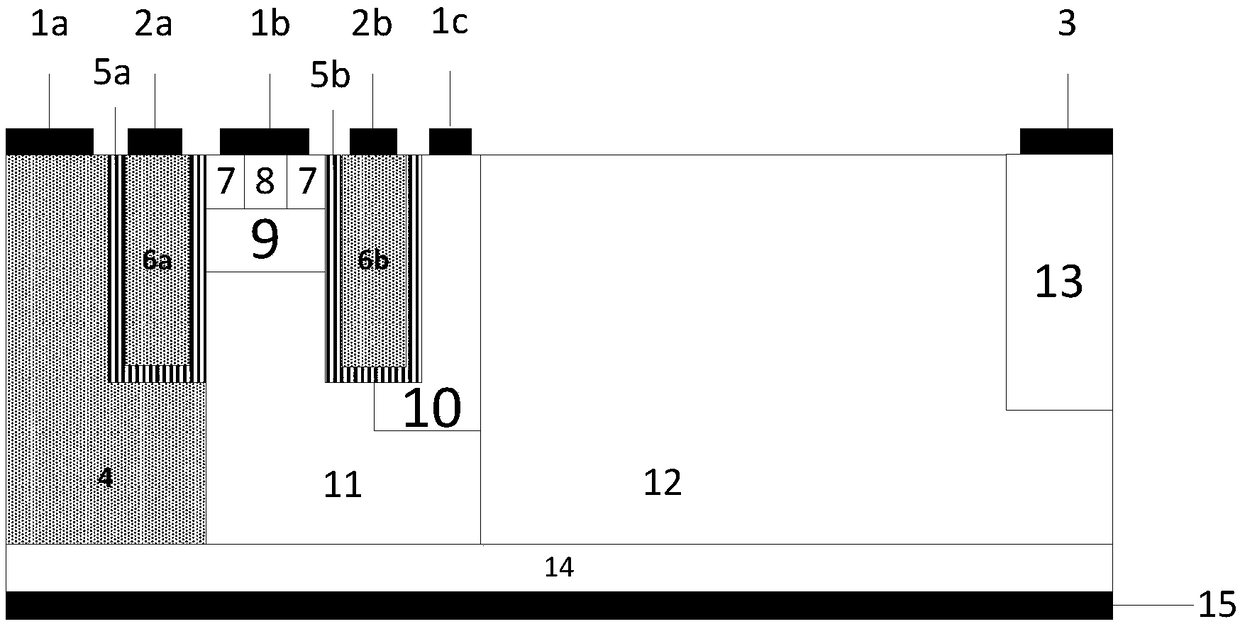

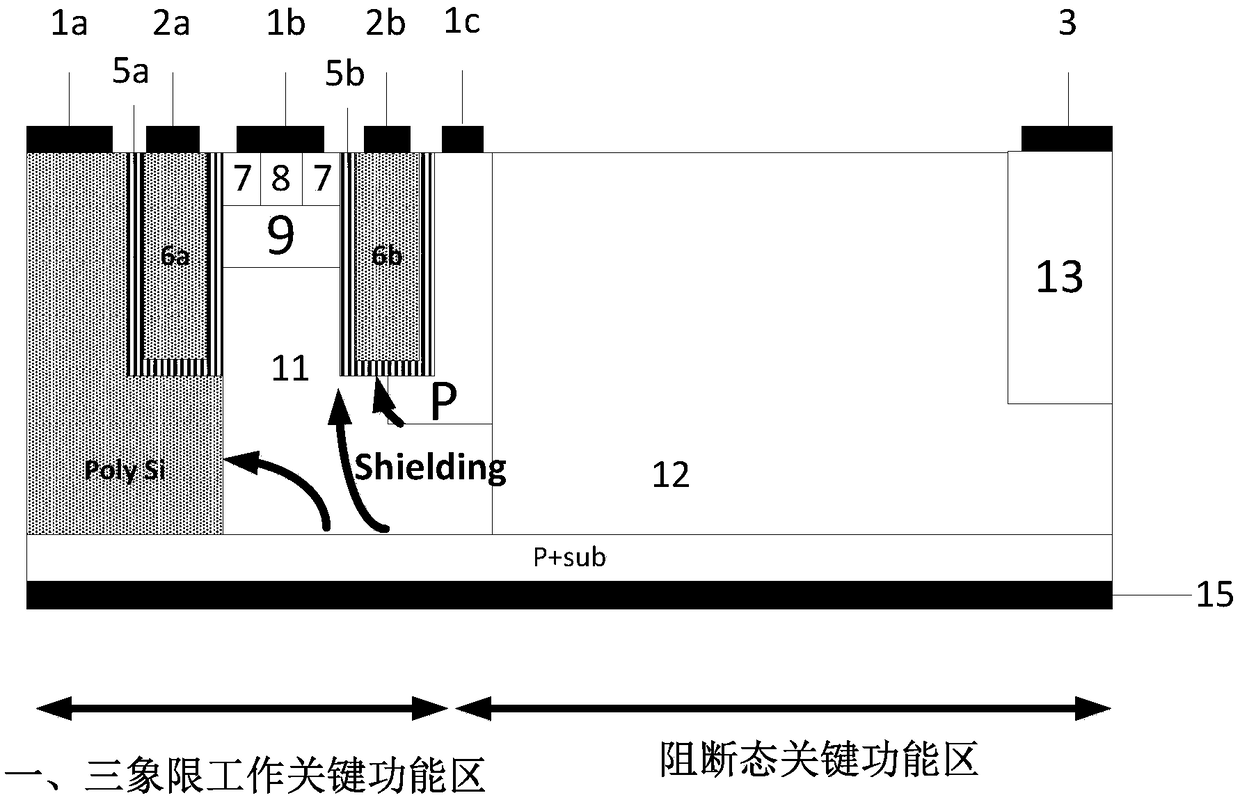

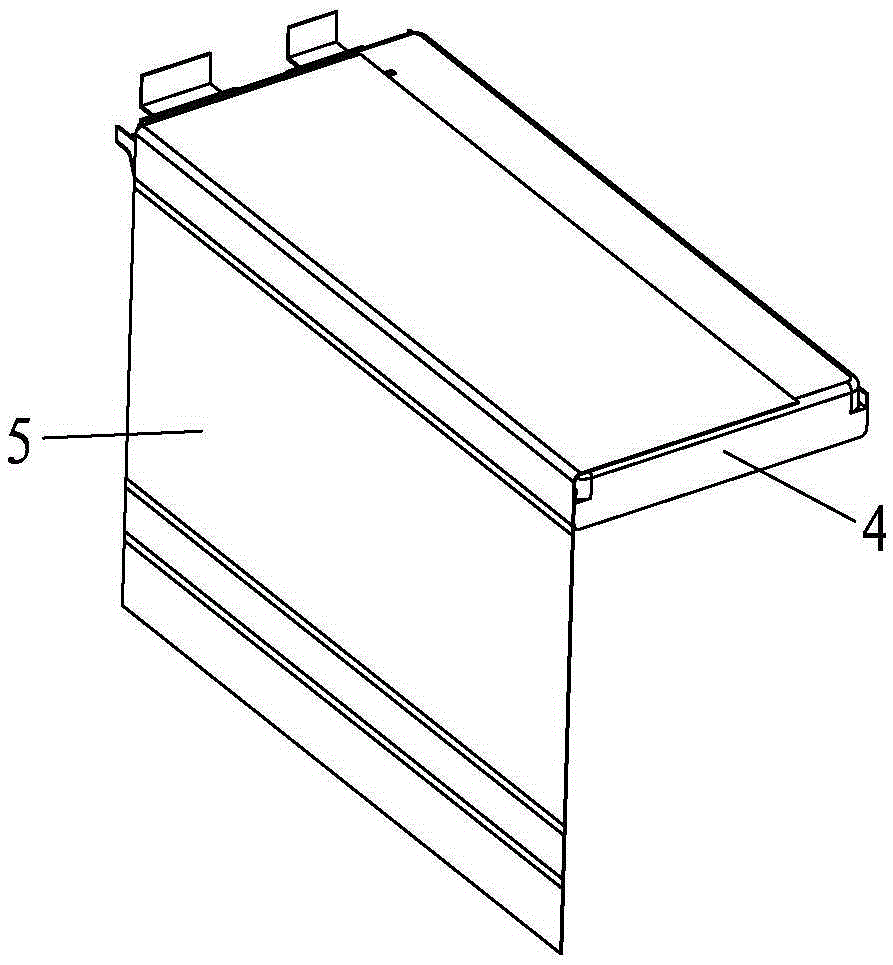

Transverse groove-type MOSFET device and preparation method thereof

ActiveCN109119463AAchieve integrationImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionMOSFET

The present invention provides a transverse groove-type MOSFET device, belonging to the technical field of semiconductor power devices. A polycrystalline silicon region or a Schottky contact metal region is formed at the circumference side of the gate structure to allow polycrystalline silicon region or the Schottky contact metal region and the drift region to form heterojunction or Schottky contact with rectification characteristics. Because the heterojunction or Schottky contact is multiple sub devices and is lower in conduction pressure drop compared to a traditional parasitic diode, the reverse recovery characteristic of the device can be optimized, and an excellent three-quadrant on-state performance is achieved; and compared to an external antiparallel diode mode, the size of the electrical power system can be significantly reduced, the package cost is reduced, interconnection lines are reduced, and the parasitic effect of the interconnection lines is reduced so as to improve thereliability of the system. Aiming at the problem that the device gate medium electric field is too high, the optimization is design to improve the long application reliability performance of the device. Besides, the preparation method of the device is simple and controllable and easy to achieve, and promotes the popularization of the semiconductor power device in the many actual applications.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

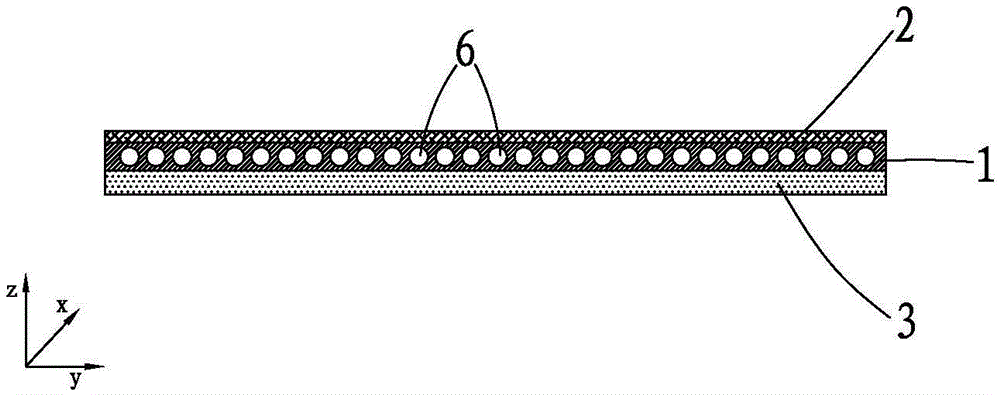

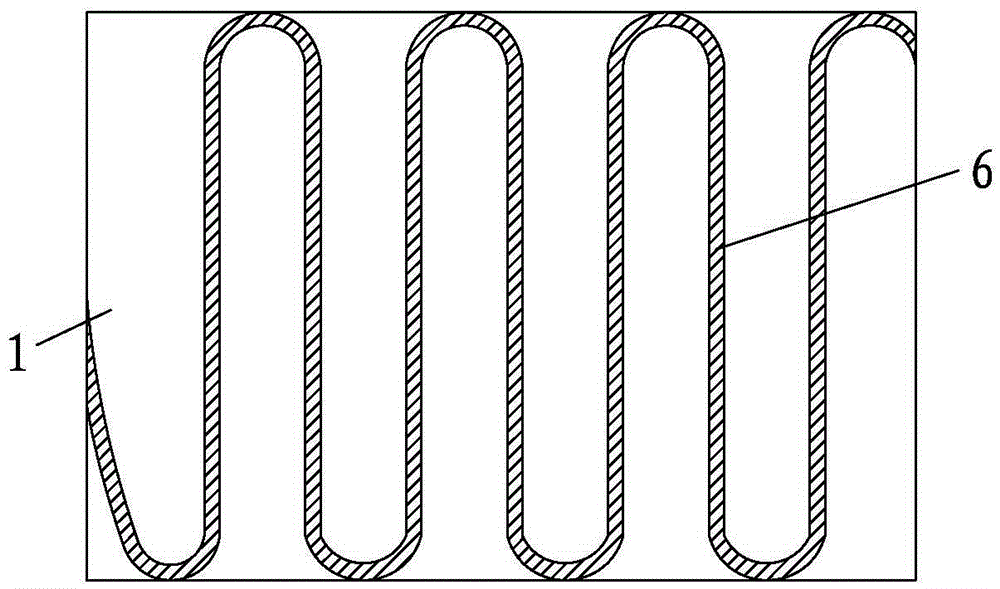

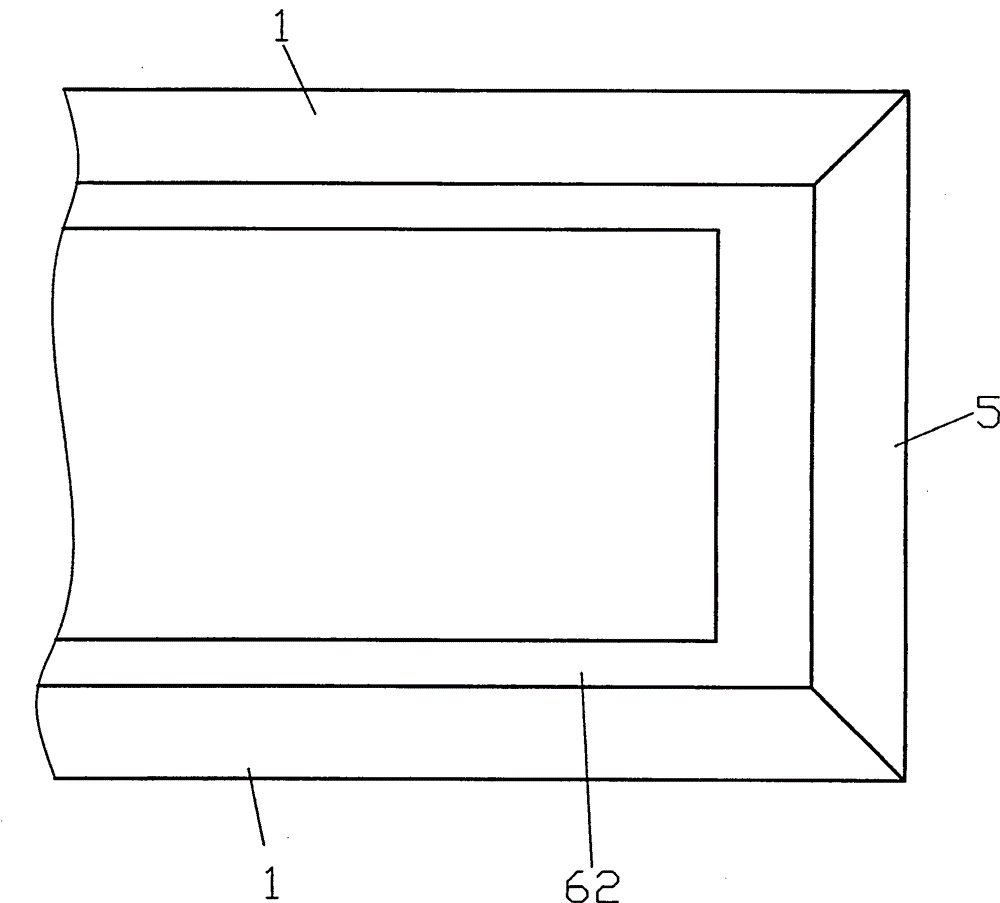

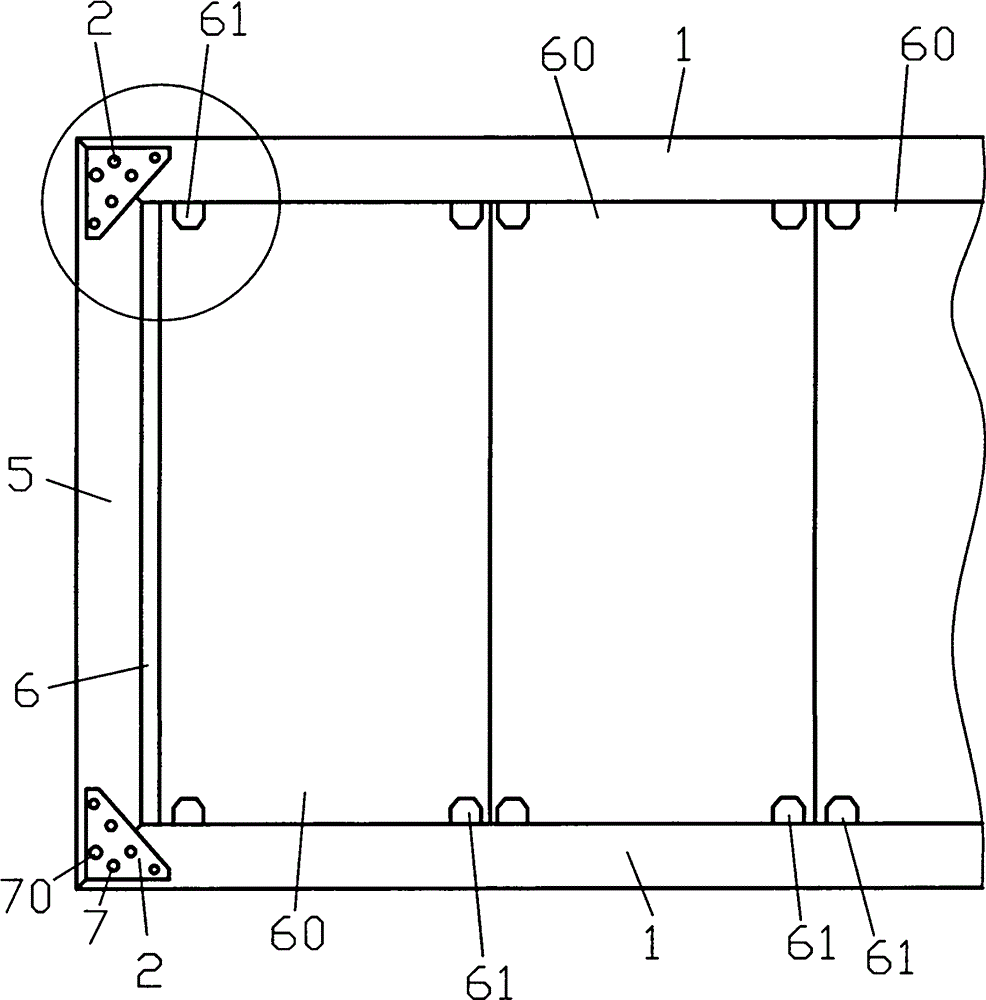

Battery and battery pack with radiating component

ActiveCN105406148AAvoid the problem of energy density dropEffective contactSecondary cellsHeat conductingEngineering

The invention belongs to the technical field of batteries, and in particular relates to a battery with a radiating component. The battery comprises a battery cell and the radiating component covered on the battery cell, the radiating component comprises a partition and a radiating medium, a channel for the flowing of the radiating medium is arranged in the partition, and a coating with wetting property is coated on the inner wall of the channel. When the battery produces a plenty of heat in the charged or discharging process, the partition material with good heat conducting performance and the coating with the wetting property are used for longitudinal heat conduction to longitudinally transfer the heat to the channel and the radiating medium, the radiating medium which is highly wetted and dispersed in the inner wall of the channel is used for quickly absorbing the heat so as to promote the convection motion of the radiating medium, thereby horizontally emitting the heat through the radiating medium with good heat conducting performance in time, and improving the stability of the battery working and prolonging the service life of the battery. Furthermore, the invention further disclosed a battery pack with the radiating component.

Owner:DONGGUAN POWERAMP TECH LTD

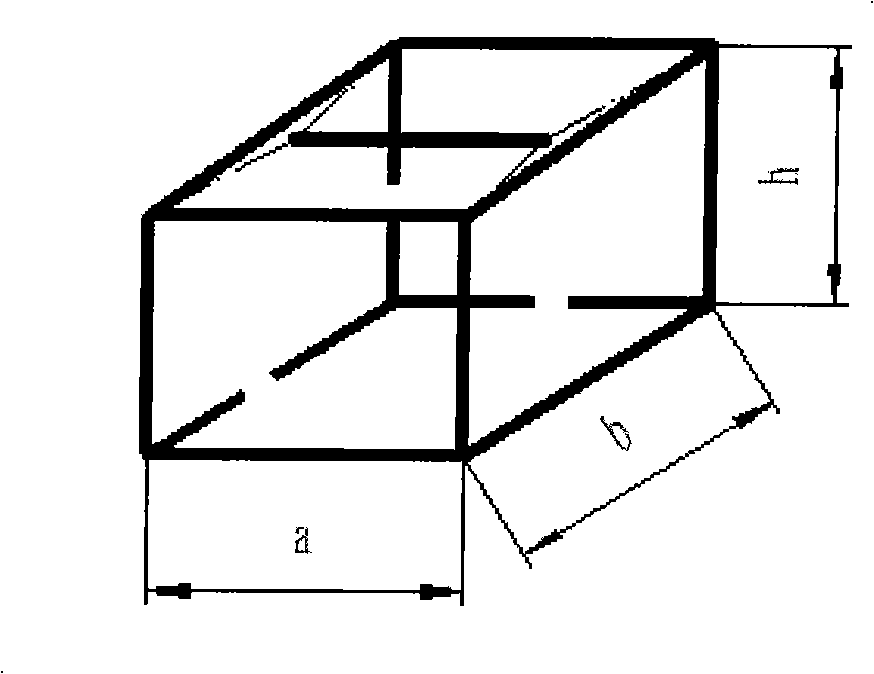

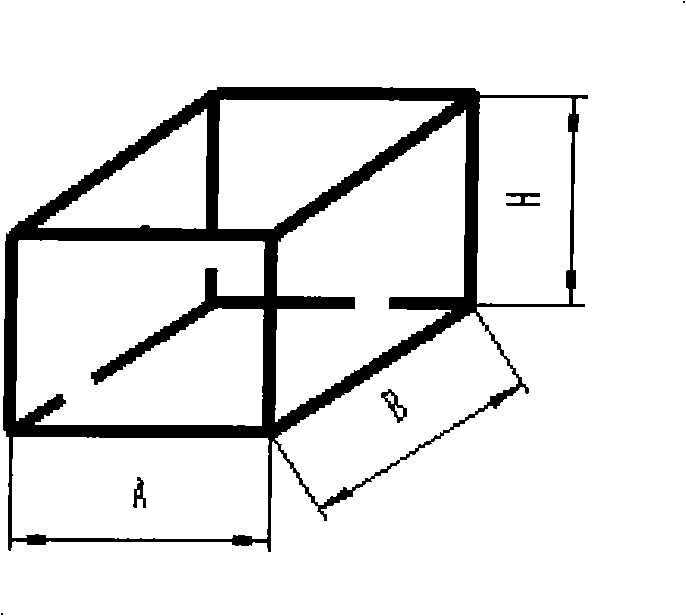

Prefabricated part assembling frame

InactiveCN104905611AEasy to carryEasy to hangPicture framesDomestic mirrorsButt jointAgricultural engineering

A prefabricated part assembling frame comprises prefabricated frame components, connecting parts and assembling components, wherein the prefabricated frame components are made by cutting magnetic frame strips and comprise two transverse magnet borders or butt-joint transverse magnet borders and two vertical magnet borders, and alternatively, the prefabricated frame components are made by cutting prefabricated frame strips and comprise two transverse borders or butt-joint transverse borders and two vertical borders; the connecting parts comprise bolts and bolt foundation pillars or comprise four lengthened wood screws and wood screw foundation pillars or comprise four lengthened wood screws or comprise four lengthened wood screws and screw base tubes; the assembling components comprise four steel connecting corners or four steel wrap corners, a plurality of wood screws, a frame picture, a plurality of backer boards and iron clamps, or a plurality of backer boards and a plurality of rotary blocking sheets in a matching and packaging mode. A screwdriver is used for assembling on a construction and installation site, and the prefabricated part assembling frame is assembled. Thus, the packaging size of the prefabricated part assembling frame can be remarkably reduced, packaging cost is reduced, the prefabricated part assembling frame is convenient to package, carry and hang, and the defects in the prior art are overcome.

Owner:DENGFENG HONGYI ART PROD

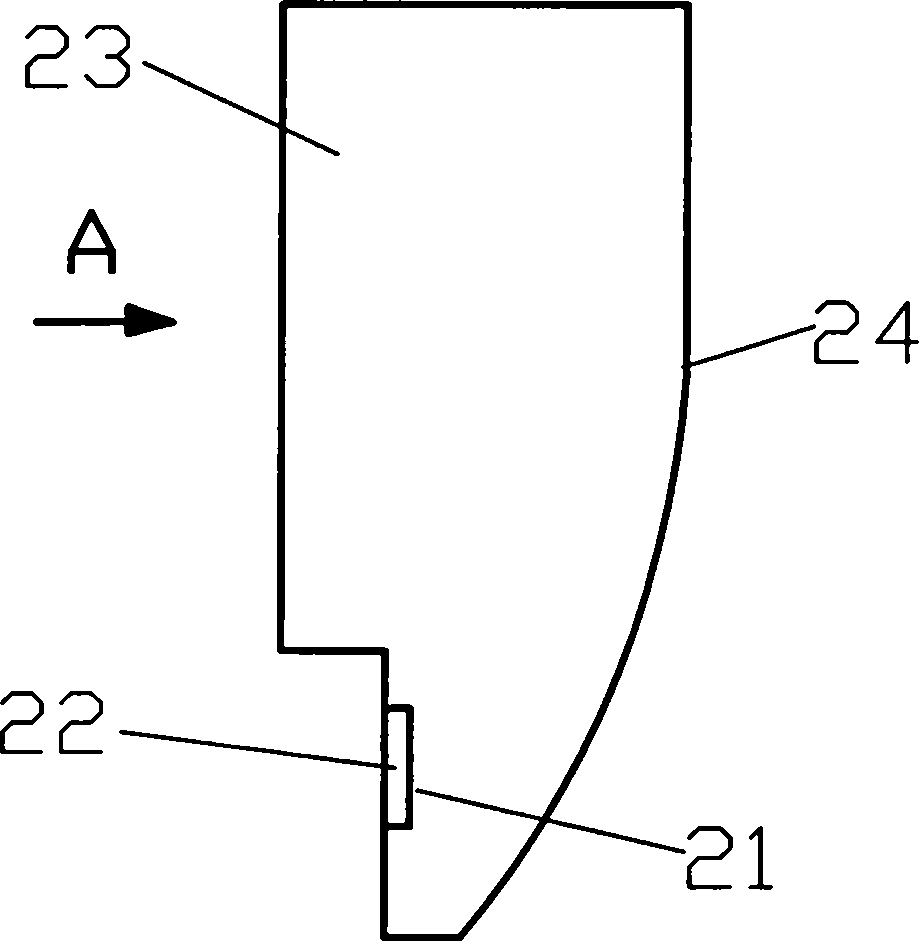

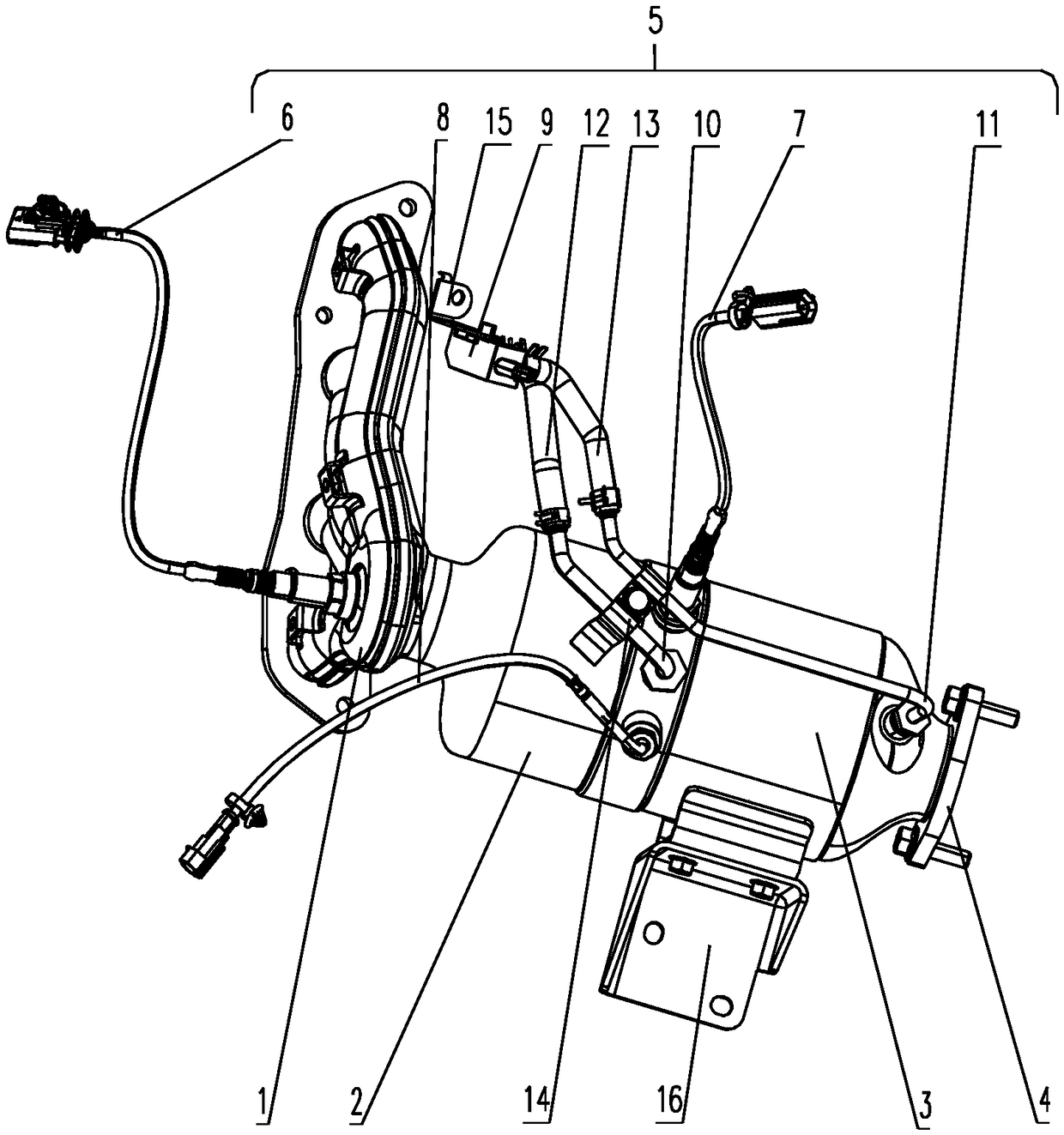

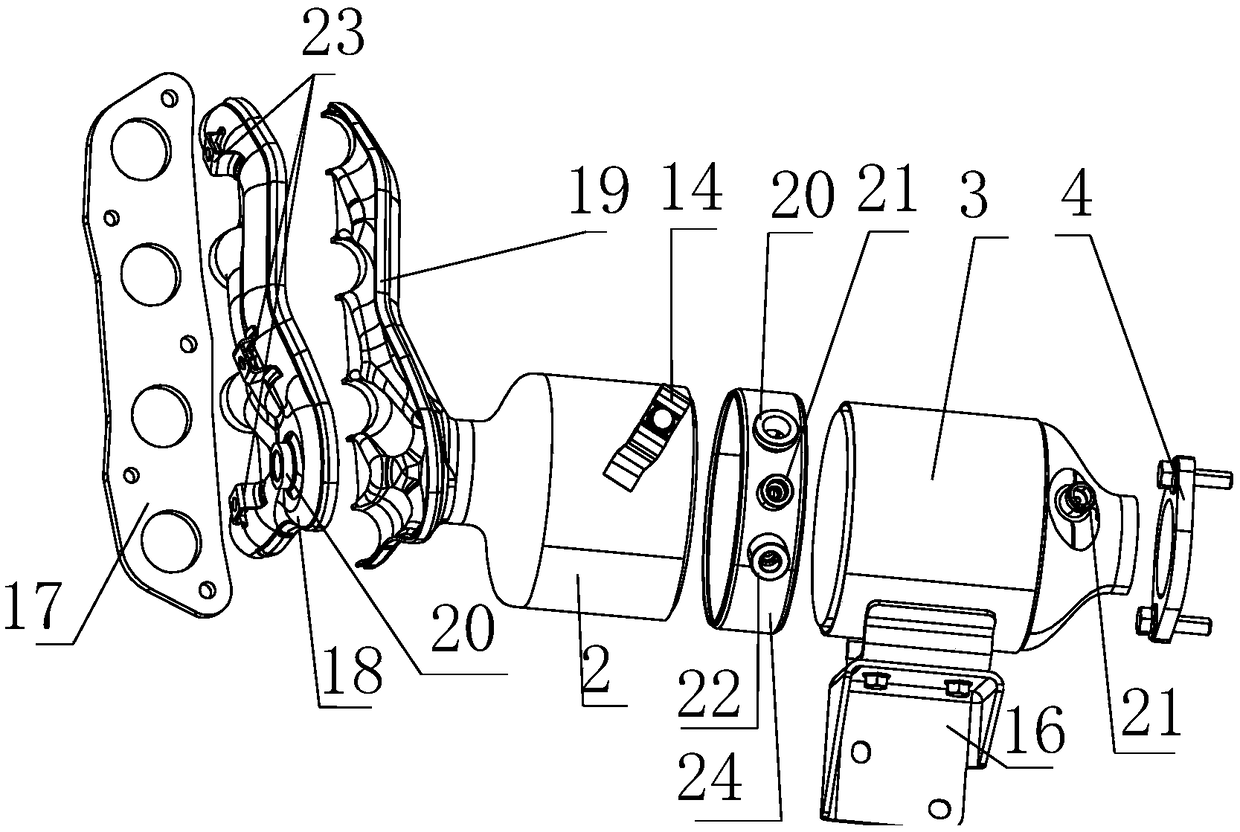

Tight coupling type gas exhaust system assembly

InactiveCN109322733AEmission controlSave on packaging costsExhaust apparatusSilencing apparatusChemical reactionCoupling

The invention relates to the field of gasoline engine gas exhaust systems, in particular to a tight coupling type gas exhaust system assembly. The tight coupling type gas exhaust system assembly comprises a gas exhaust manifold assembly, a three-way catalytic converter, a particle collector and a connecting barrel body, wherein one end of the three-way catalytic converter is connected with the gasexhaust manifold assembly, and the other end of the three-way catalytic converter is connected with the particle collector through the connecting barrel body; the gas exhaust manifold assembly, the three-way catalytic converter and the particle collector are arranged in an engine cabin. According to the tight coupling type gas exhaust system assembly disclosed by the invention, the tight couplingtype gas exhaust tube assembly, the three-way catalytic converter and the particle collector are connected oppositely to form barrel type catalytic purifying package, and therefore, fast light-off ofthe three-way catalytic converter is facilitated, the problems that a multi-stage catalyst pipeline is too long, is low in exhausted waste gas temperature, and is not beneficial for generating chemical reaction with a catalyst are solved, pollutant emission in tail gas can be effectively controlled, and encapsulating difficulty further can be reduced.

Owner:CHONGQING SOKON IND GRP CO LTD

Microemulsion agent as special-purpose preparation for controlling termite

InactiveCN1515154AHigh flash pointAbundant resourcesBiocideAnimal repellantsOrganic solventMicroemulsion

The present invention relates to a special-purpose preparation for controlling termite. It is made up by using flucyanobenzol whose chemical name is (RS)-5-amino-1-(2,6-dichloro-4- trifluoromethylphenyl)-4-trifluomethylsulfinyl pyrazole-3-nitrile and whose molecular formula is C12H14Cl2F6N4Os as effective component, emulsifying agent and water and mixing them. The invented flucyanobenzol microaemulsion is a thermomechanical stable system by using water as matrix, so that it can be stored for a long period of time, and not produce phase separation.

Owner:中国人民解放军南京军区联勤部军事医学研究所

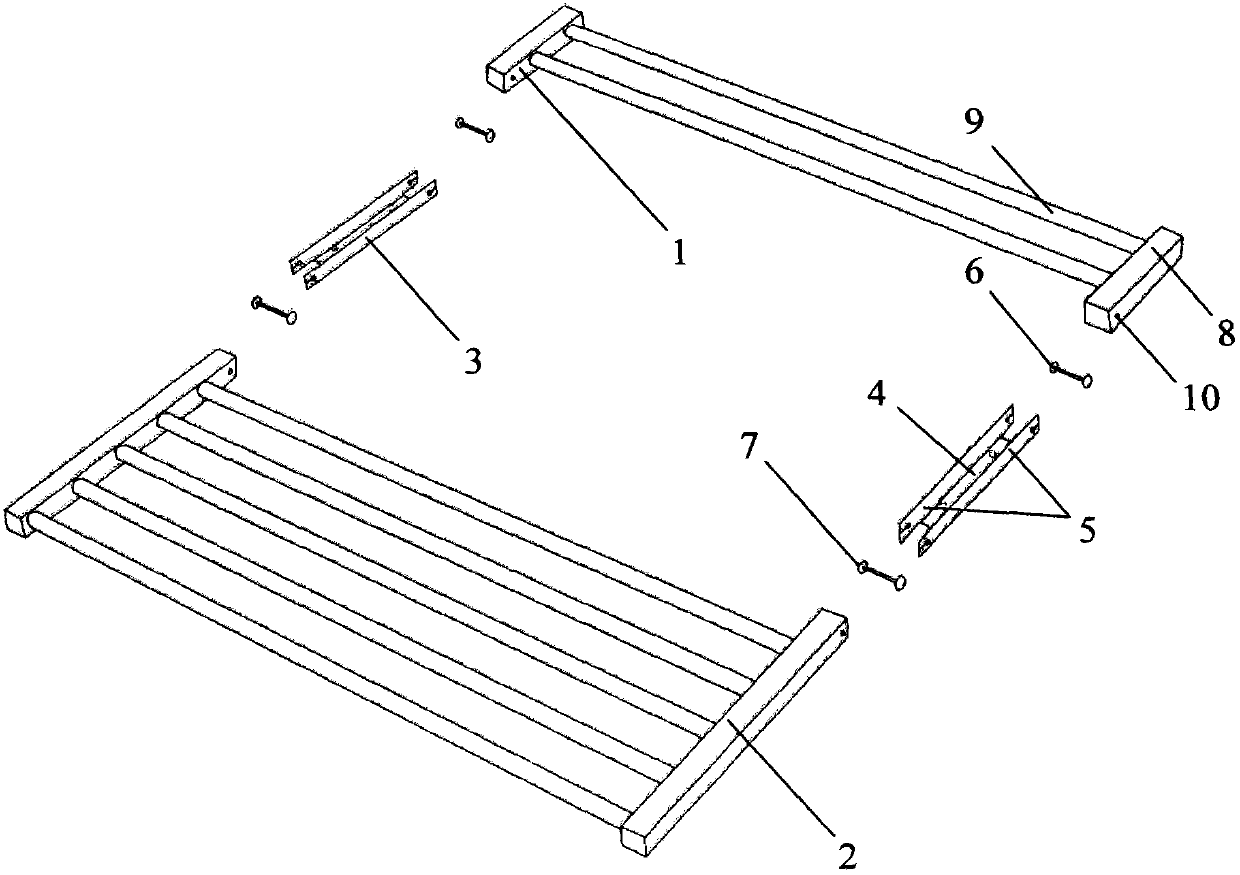

Folding towel rack

InactiveCN103126595ASave space and materialSave on packaging and shipping costsDomestic applicationsEngineeringMechanical engineering

The invention discloses a folding tower rack which comprises a first rotating component and a second rotating component which are used for hanging towels. A fixing piece is arranged between the first rotating component and the second rotating component and is respectively hinged with the first rotating component and the second rotating component. The fixing piece is provided with two parallel fixing sheets which are connected through a connecting sheet. Screw holes are formed in the connecting sheet. A first rotating shaft and a second rotating shaft are respectively arranged at two ends of the fixing sheets. The first rotating component is provided with a longitudinal support rod and a transverse hanging rod, and the second rotating component is provided with a longitudinal support rod and a transverse hanging rod. Shaft holes corresponding to the first rotating shaft and the second rotating shaft are formed in one ends, close to the fixing piece, of the support rods. The distance between the fixing sheets corresponds to the external contour of the support rods. The folding tower rack has the advantages that the first rotating component and the second rotating component are hinged with the fixing piece and can rotate around the fixing piece to meet different demands of people; and in the process that the towels are packed to end products and transported, a great amount of space and materials can be saved, and transportation expenses and packing expenses are saved.

Owner:沈壮煌

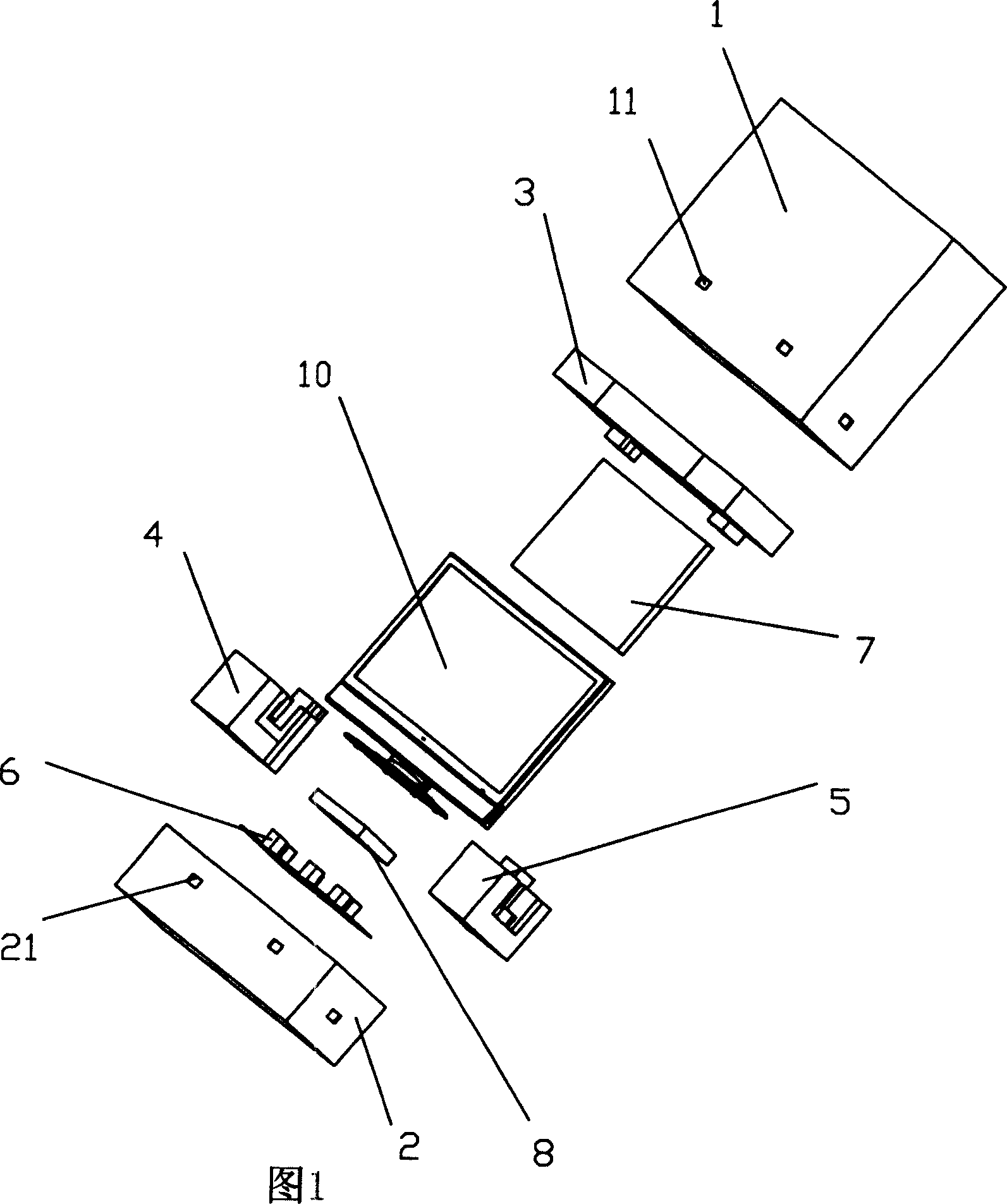

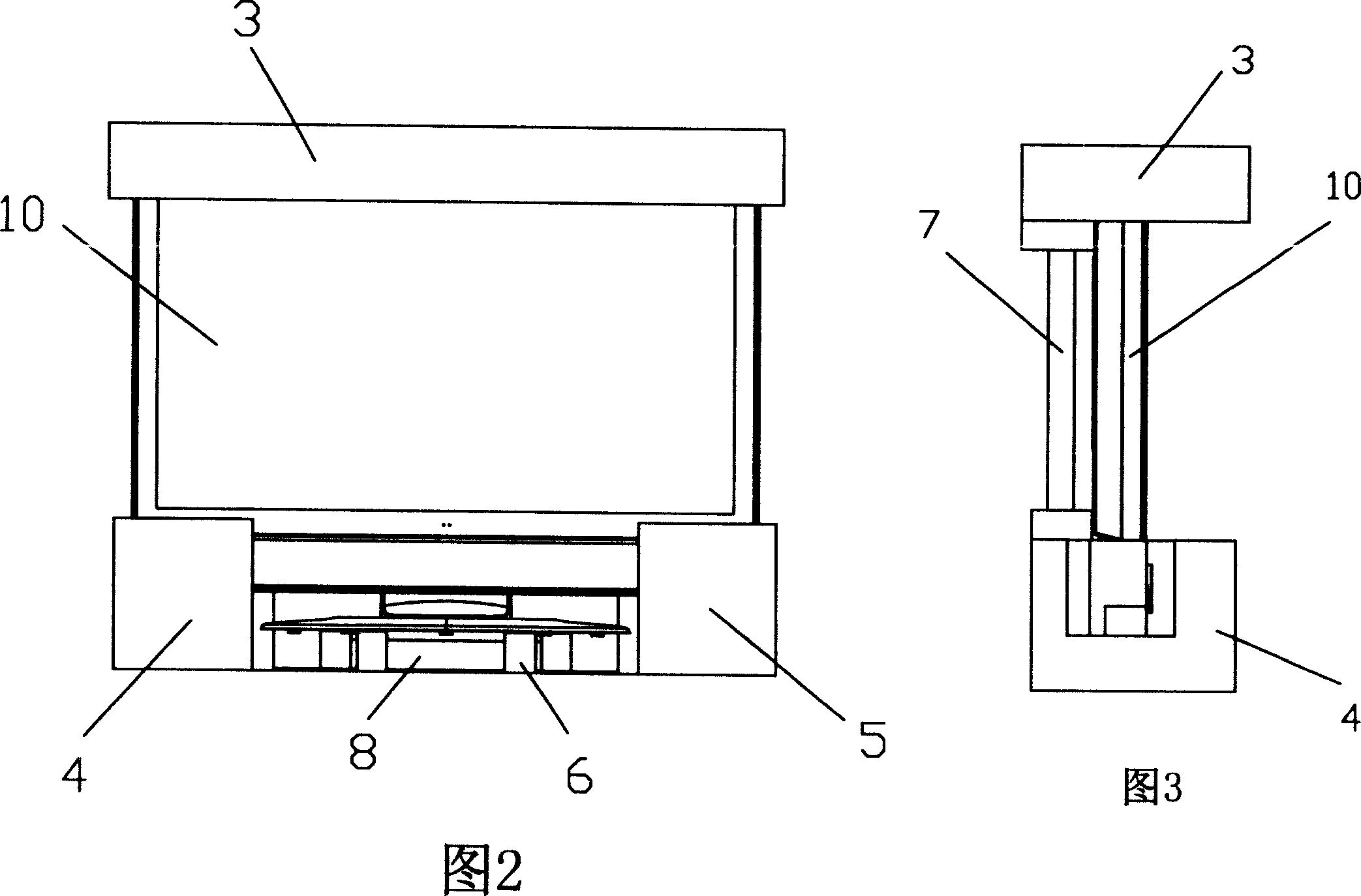

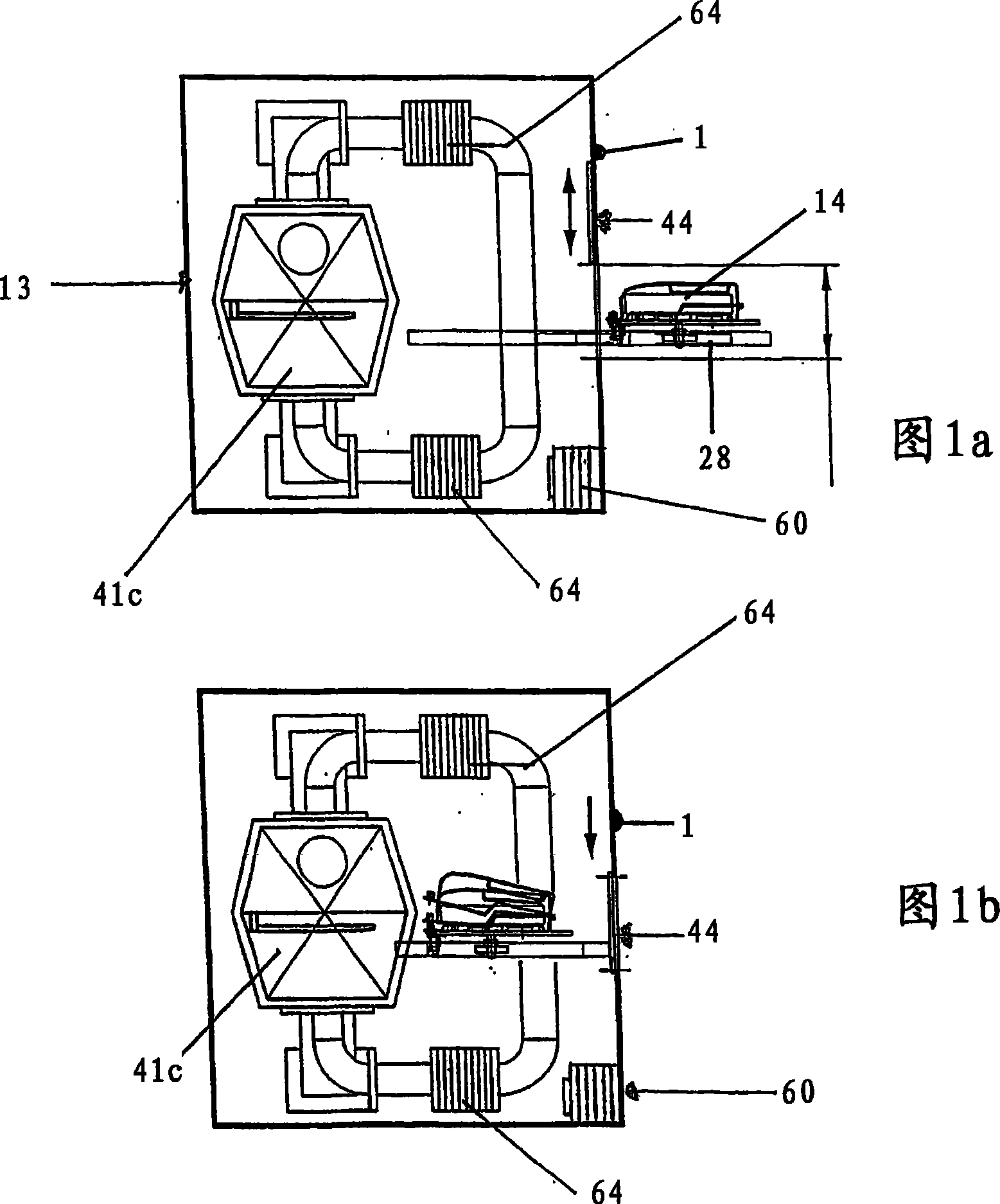

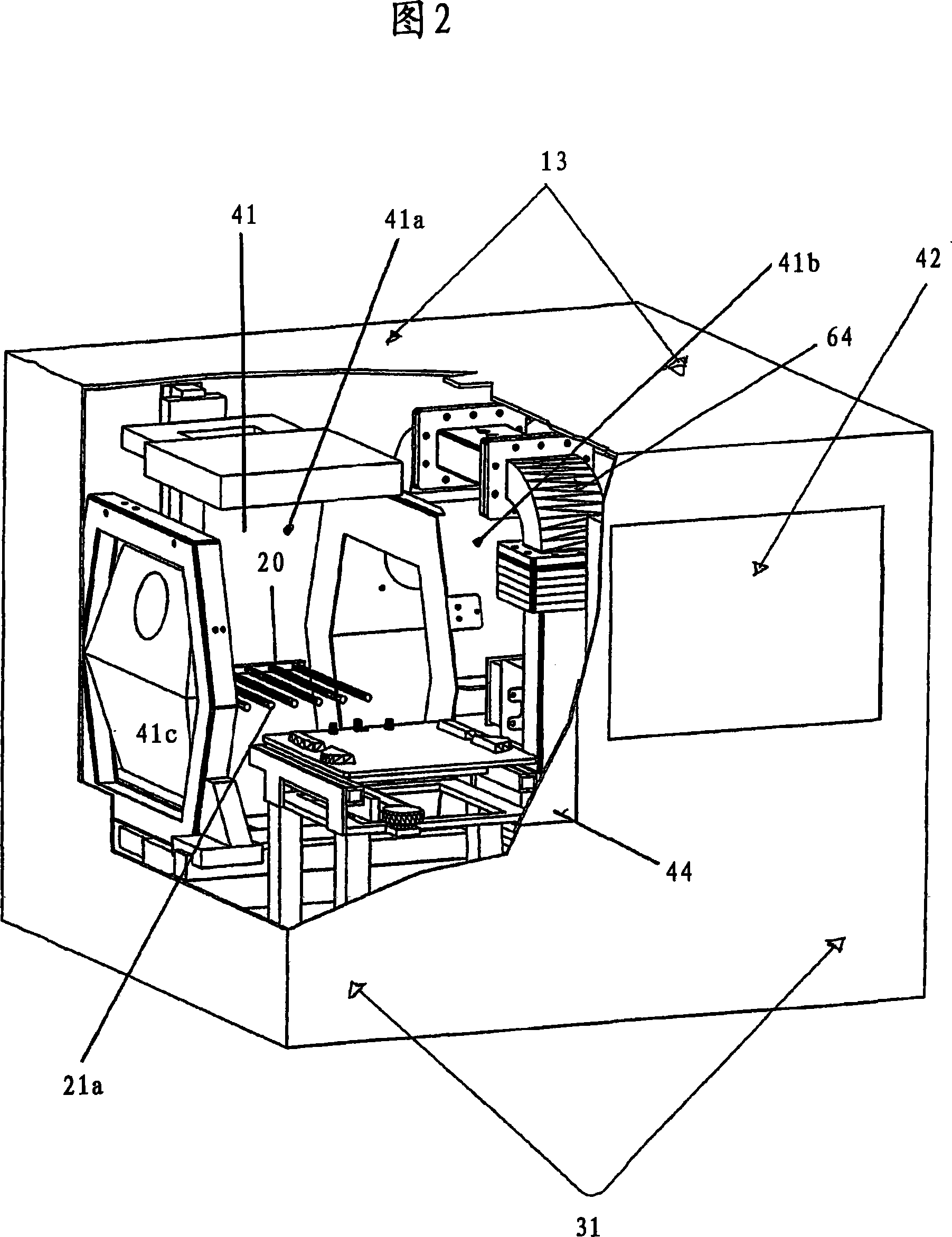

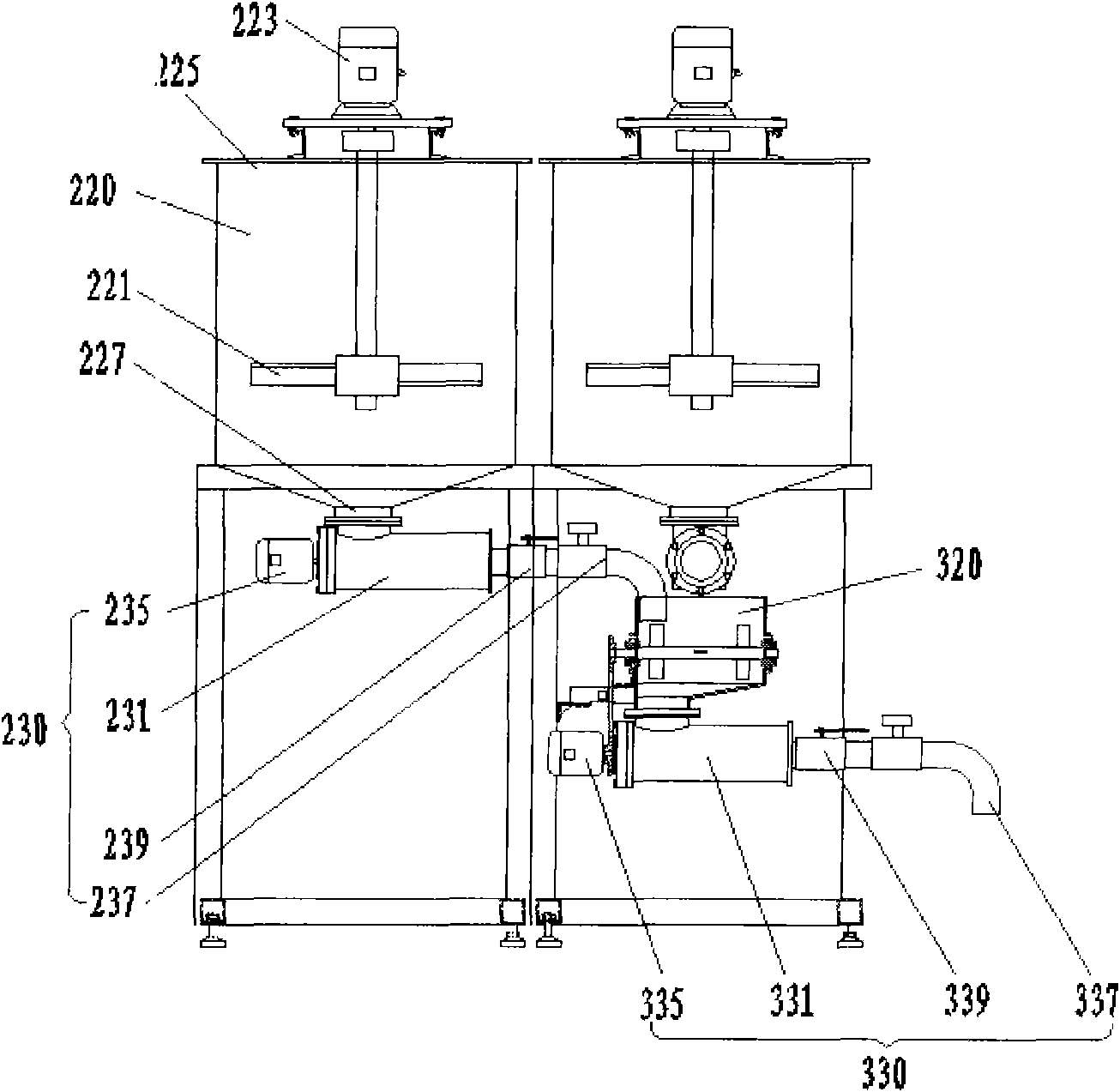

Installation for reheating portioned chilled or frozen snack food products

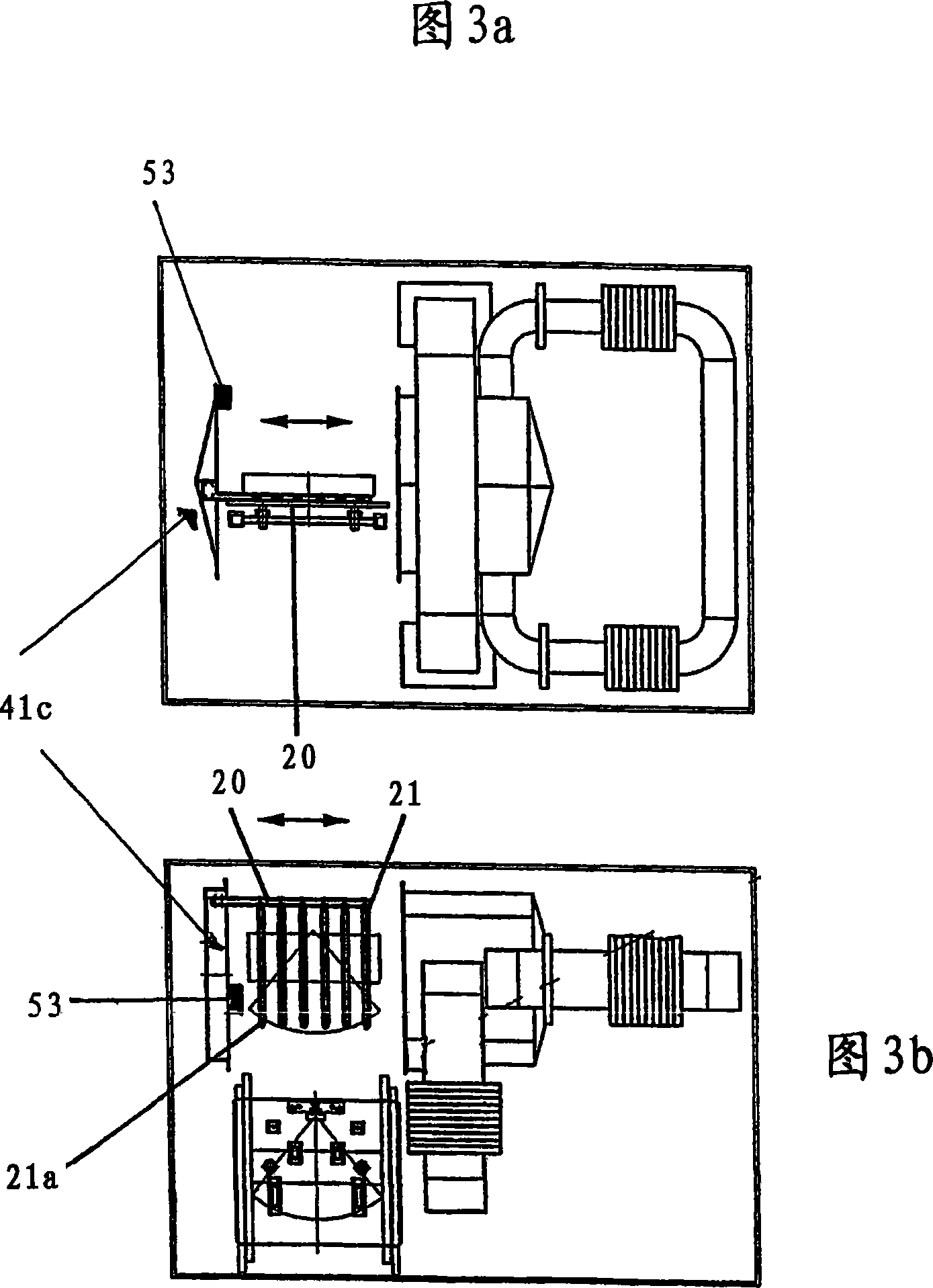

The invention relates to an installation for reheating portioned chilled or frozen snack food products packaged in a lower and upper hinged package parts closed by cooperation of snap means. It comprises a compact oven provided with a first cavity section (41a) infrared heating sand a second cavity section heated by microwave means (64) .The package with the food to reheat is taken into into the cavity (41), automatically opened and the food only is unload on a moving grill / fork device (20). The grill / fork (20) moves sidewards inside the microwave cavity section (41b) for microwave heating. A door (41c) moves with grill / fork (20) to isolate the microwave heated cavity. After the microwave heating the grill / fork moves inside the infrared cavity section (41a). At the end the food is automatically unloaded back to the package.

Owner:瓦尔特·尼梅茨

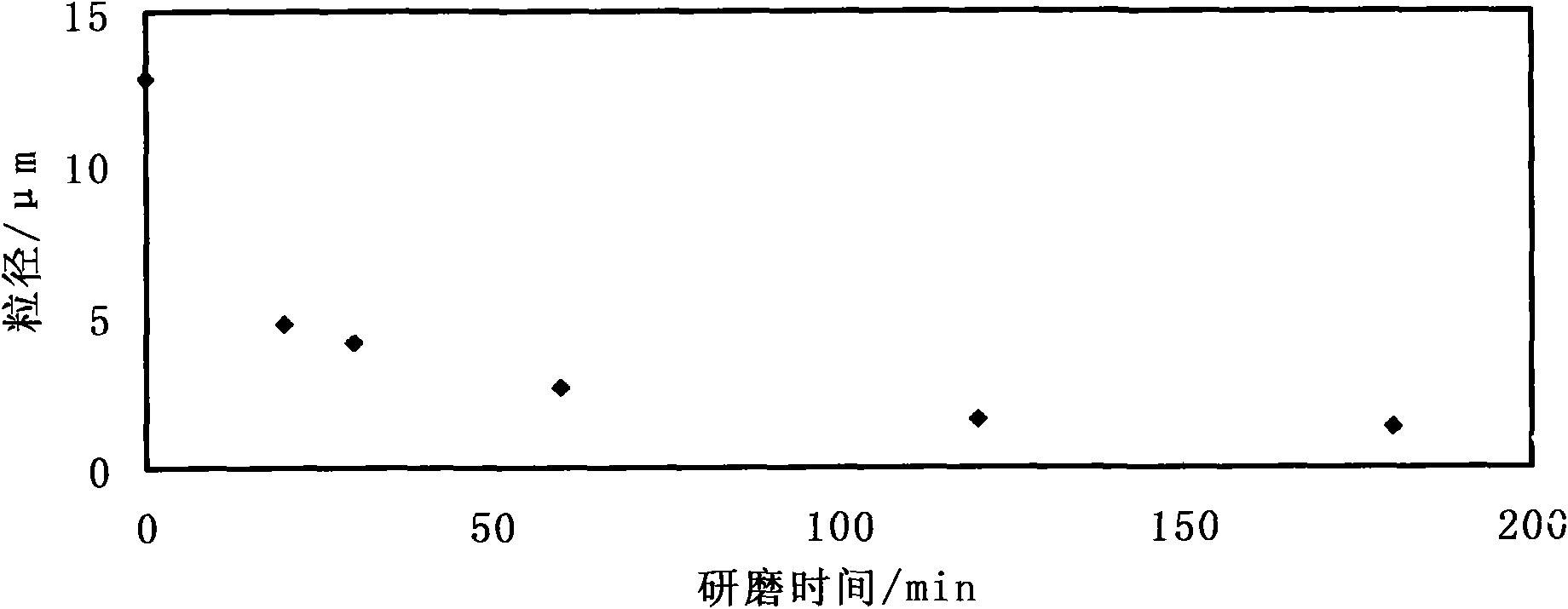

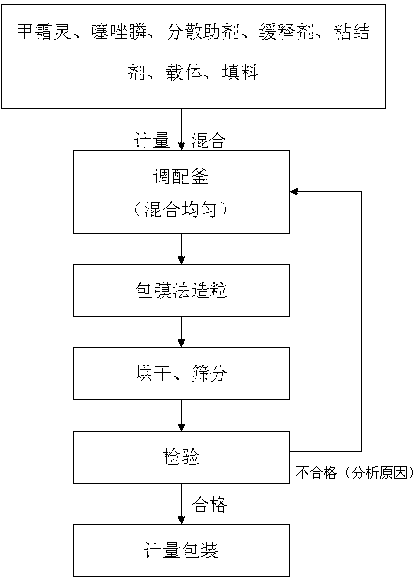

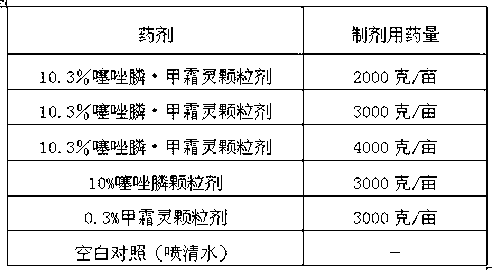

Thiazole phosphine and metalaxyl granule and preparation method thereof

The invention relates to a thiazole phosphine and metalaxyl granule and a preparation method thereof. The thiazole phosphine and metalaxyl granule includes the components by weight: 0.1%-20% of thiazole phosphine, 0.1%-5% of metalaxyl, 70%-80% of carrier attapulgite particles, 0.5%-3% of a dispersing agent, 0.1%-2% of a sustained-release agent, 0.1%-5% of a binder, and the balance a filler. The granule of the present invention is granulated by a film coating method. The invention effectively combines the control of plant nematodes and soil-borne diseases, uses resources efficiently, scientifically and rationally, has important significance on environment protection, and plays a positive role in reducing agricultural inputs and promoting agricultural output and income.

Owner:GUANGDONG ZHONGXUN AGRI TECH

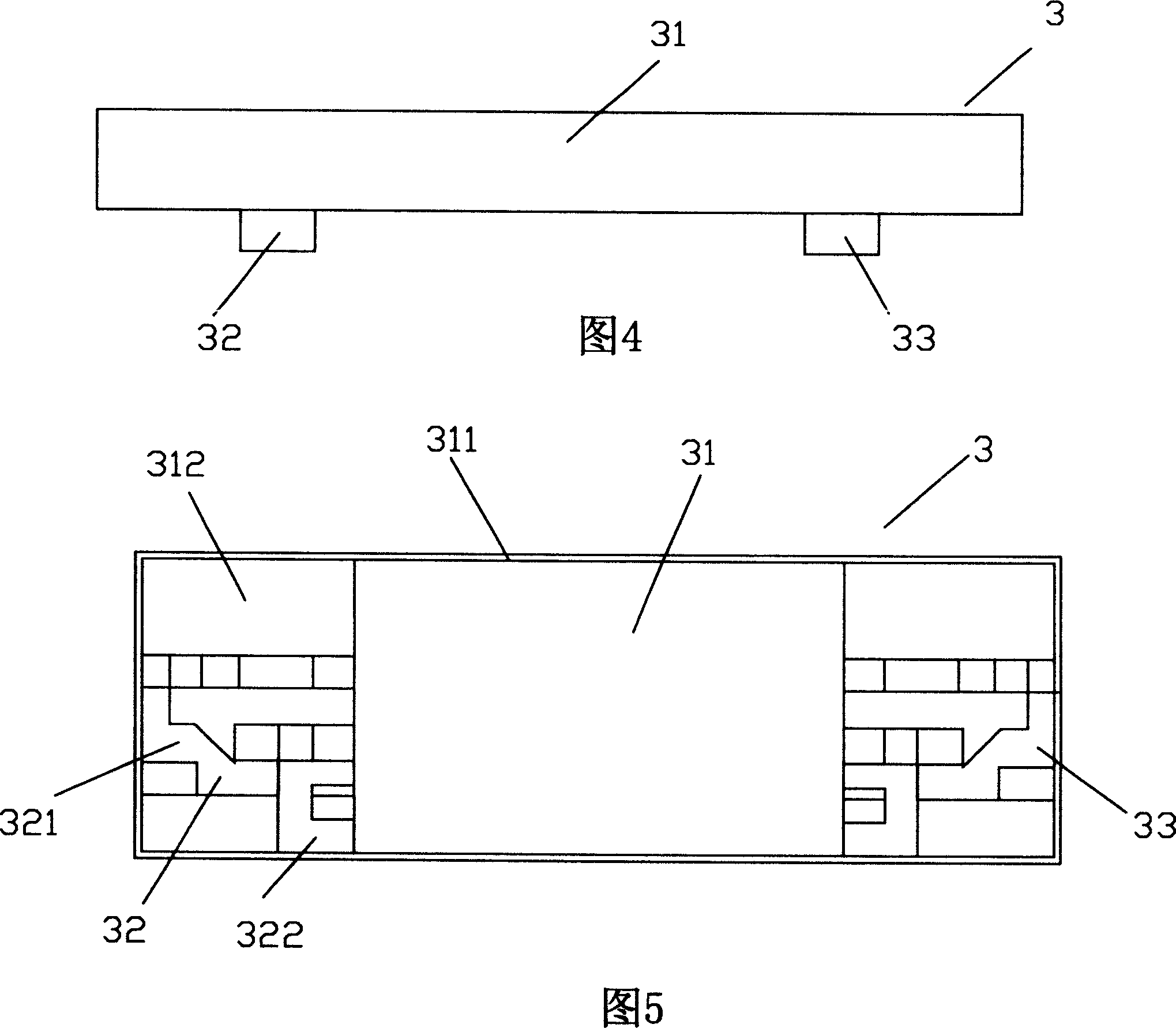

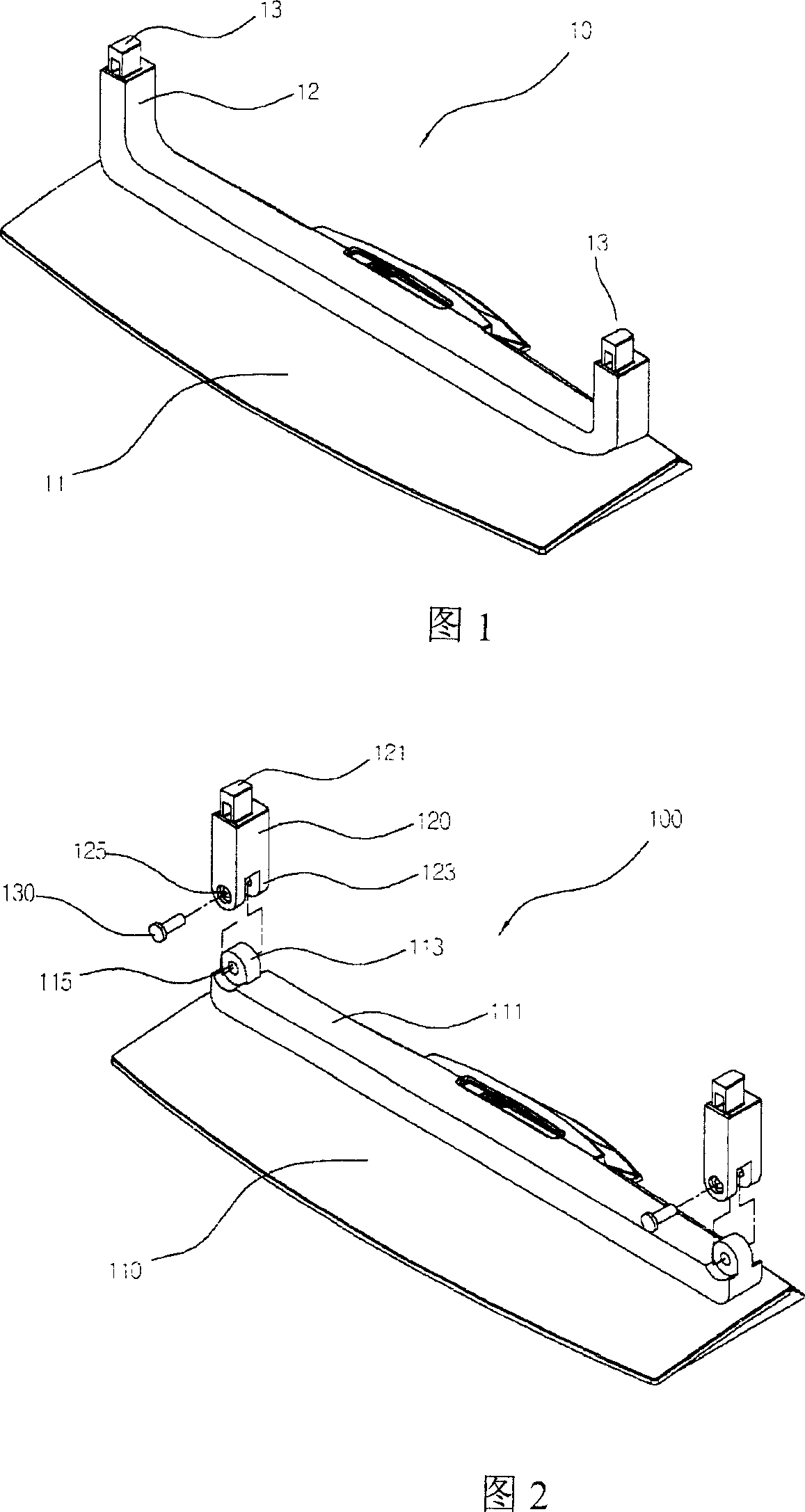

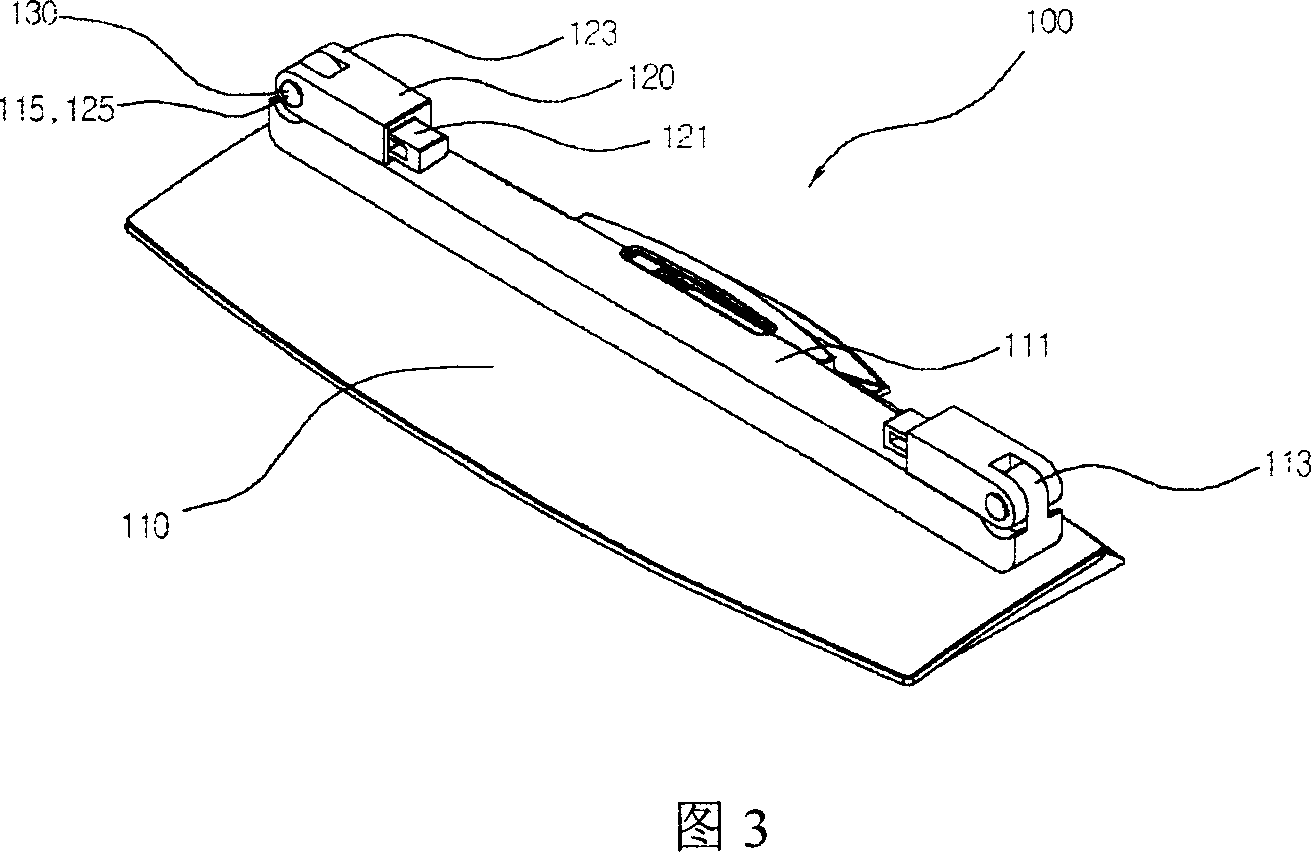

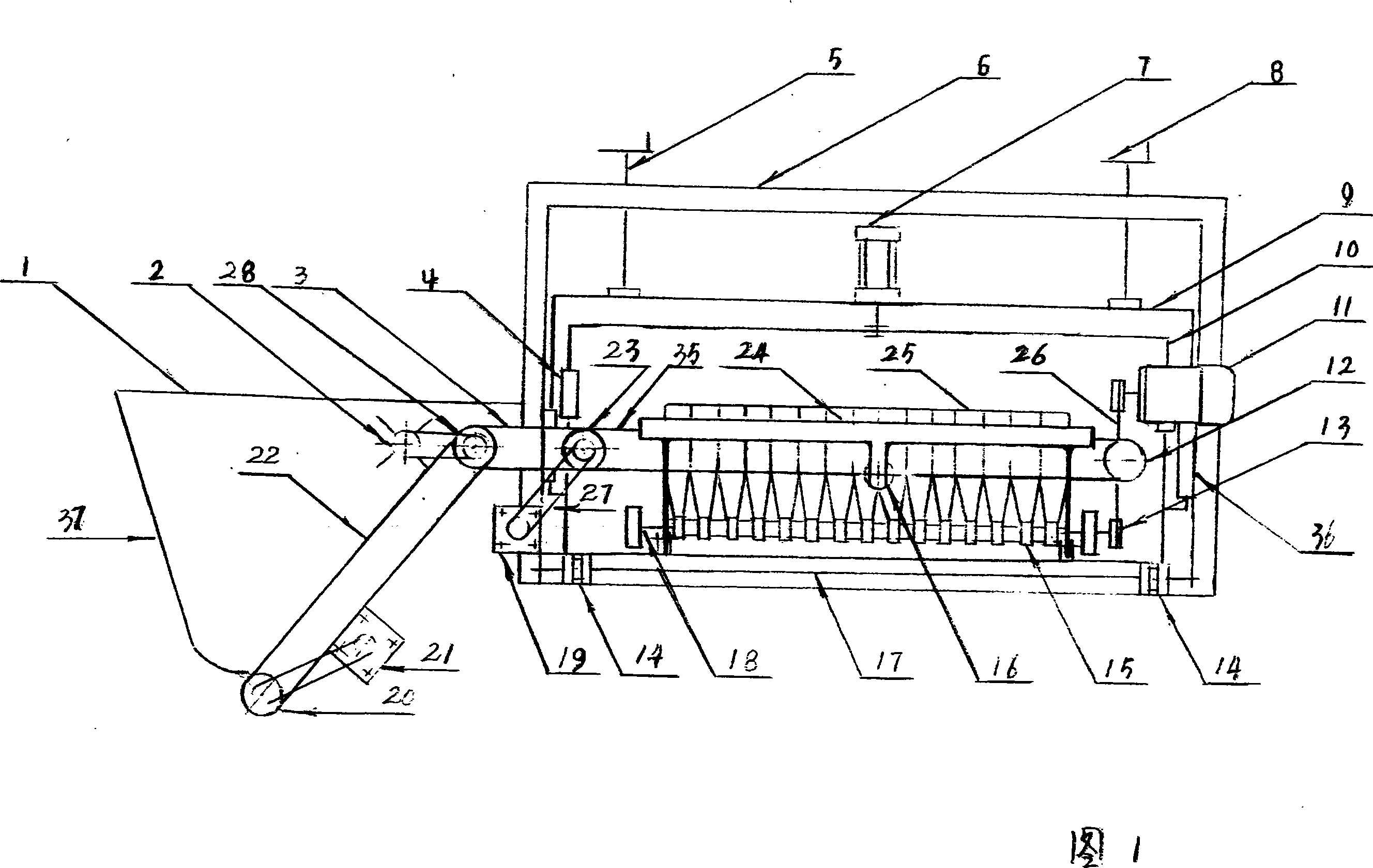

Support table structure of image display device

InactiveCN1988048ASave on packaging costsIncrease the number of cargo loadedInstrument housingStands/trestlesEngineeringDisplay device

This invention discloses a supporting stand structure of an image display device including the following two parts: a base plate along the long direction and a support stand frame bond on the ends of both sides of the base plate by gemels to fold or stretch the base plate so as to reduce volume of package.

Owner:LEIJIN ELECTRONIC SHENYANG CO LTD

Ice-cream rod dispersed-rod material-feeding rod-inserting machine

The popsicle bar loading and inserting machine in popsicle producing line includes a bar loading bin, a bottom plate, a bar lifting chain plate, a sweeper assembly, a synchronous bar distributing belt mechanism, a frame with a large slide plate and a small slide plate, a bar distributing bin, a bar rolling wheel assembly and a spare clamping wheel assembly. The present invention makes it possible to utilize bulk popsicle bar, and this can save timber and energy source and lower production cost. At the same time, the popsicle bar loading and inserting machine is suitable for popsicle bars of different sizes.

Owner:曹梦禹

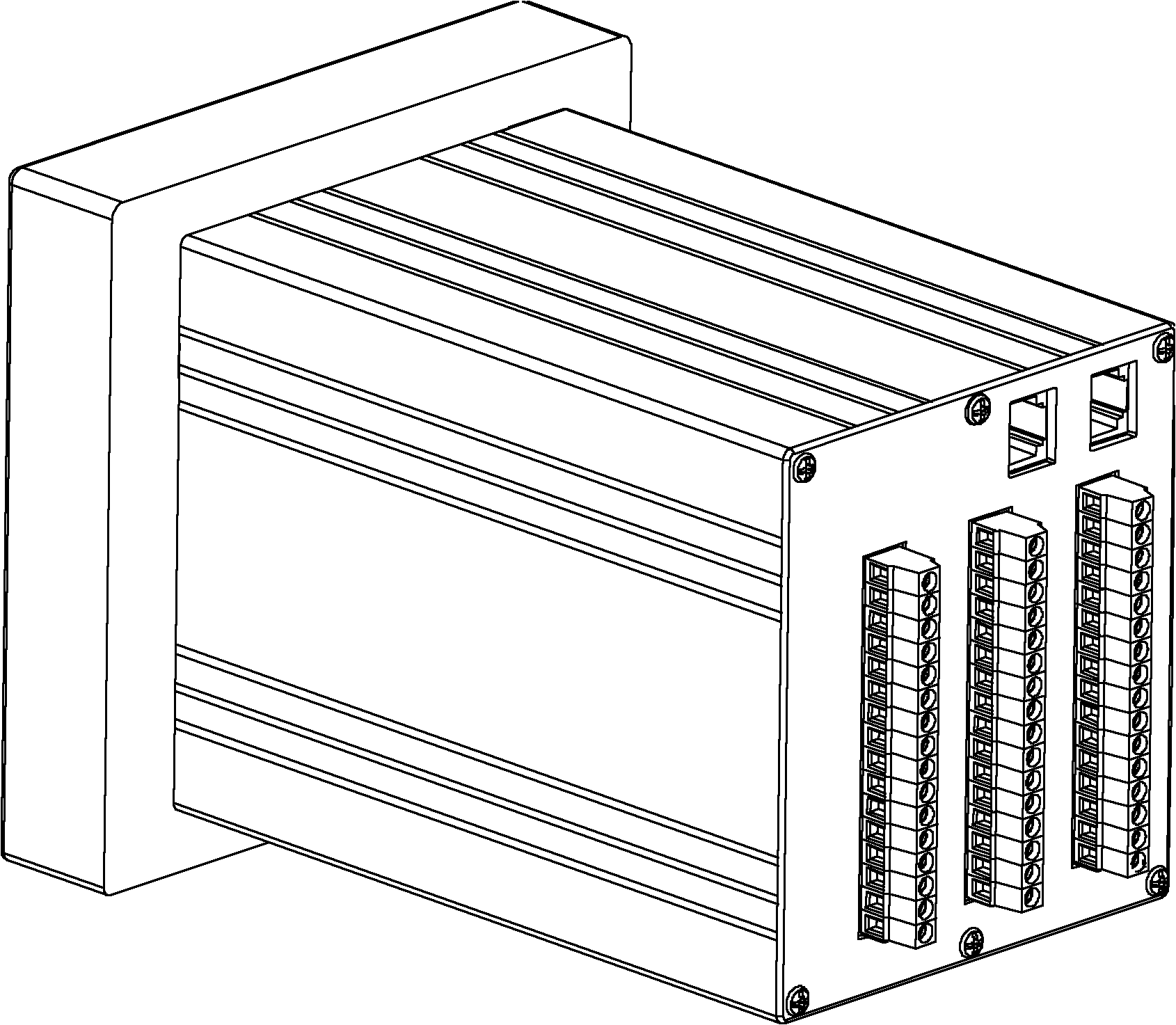

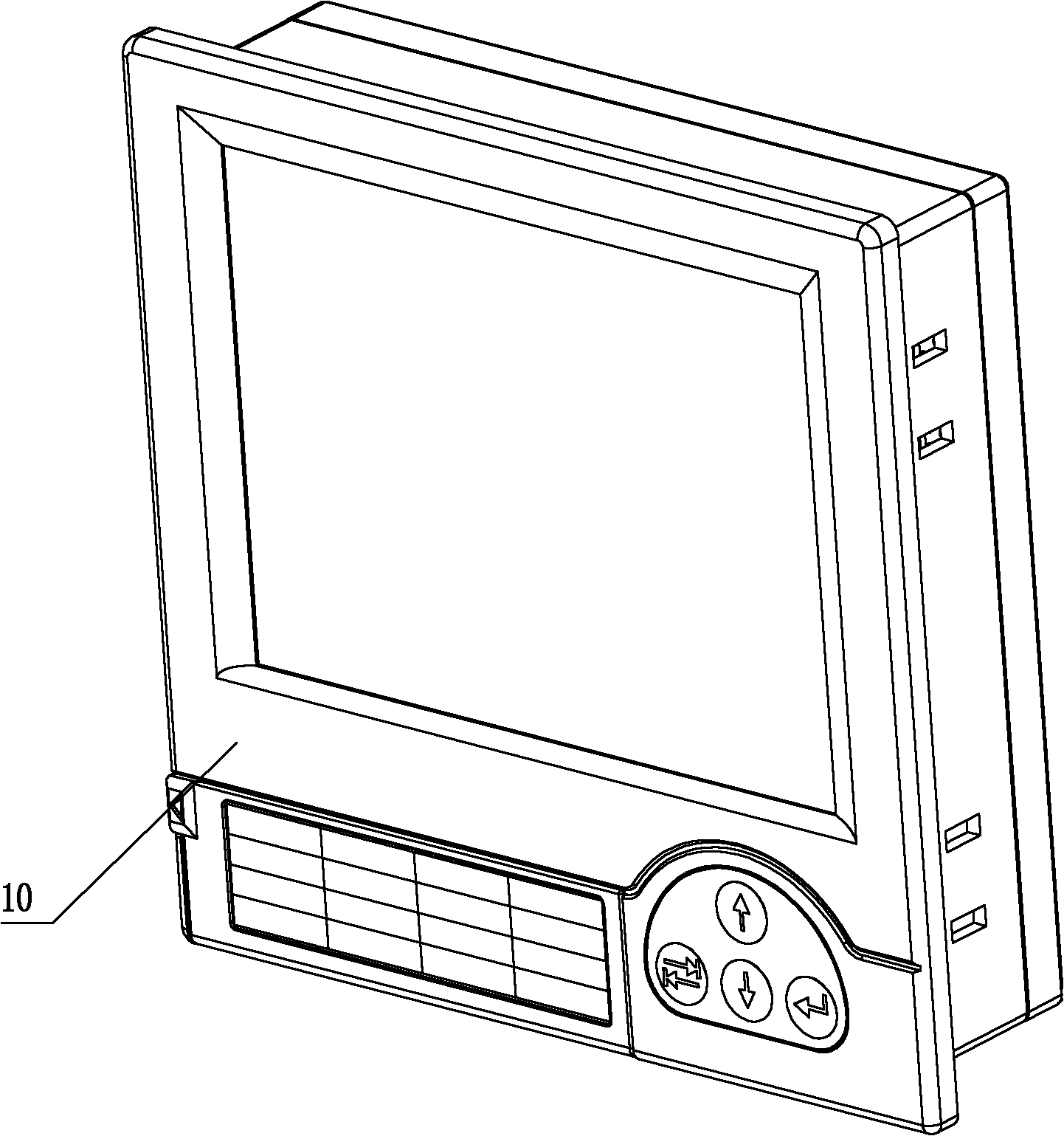

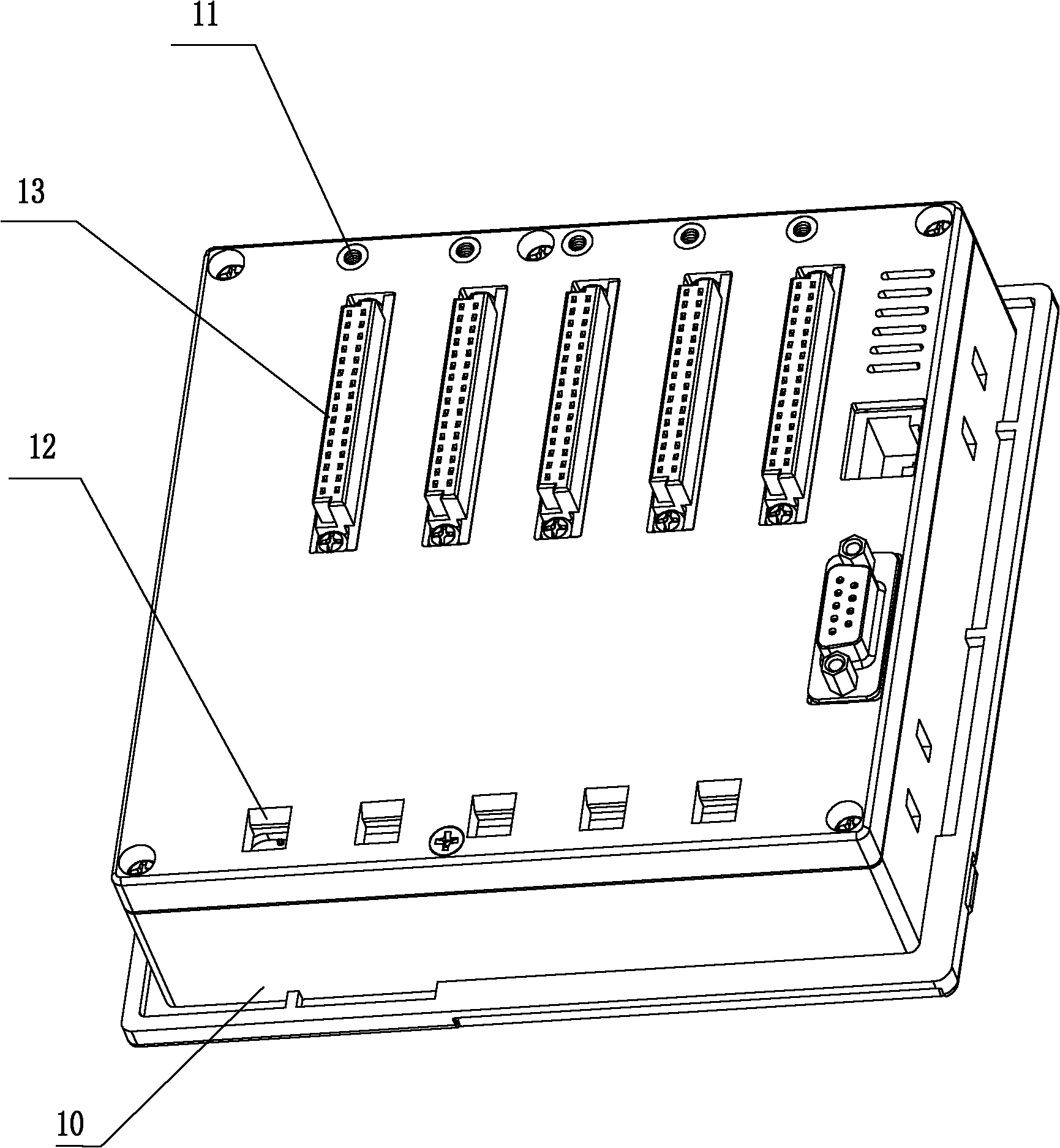

Function module-extendable intelligent meter

ActiveCN102074275ACompact structureIncrease productivityInstrument housingIndependent functionComputer module

The invention relates to a function module-extendable intelligent meter, which comprises a display panel and a function module, wherein a plurality of electrical connecting sockets are arranged on the back surface of the display panel in parallel, and electrical connecting plugs matched with the electrical connecting sockets are arranged on the function module; and the lower ends of the display panel and the function module are positioned by a clip and slots, and the upper ends of the display panel and the function module are locked and fixed by a screw. The invention provides the intelligent meter which can realize that extended signal channels and function components can be configured on site or by users through independent functions modules, and the intelligent meter has the characteristics of user-configuration, on-site adjustment, compact structure, flexible handling and high performance price ratio, and is convenient to maintain and the like.

Owner:杭州优稳自动化系统有限公司

Intumescent fireproof paint for tunnel

InactiveCN106833174AImprove sound absorptionGood hygroscopicityFireproof paintsCement coatingsFiberAluminium hydroxide

The invention relates to an intumescent fireproof paint for a tunnel. The intumescent fireproof paint is prepared from the following raw materials in percentage by weight: 10-30% of refractory cement, 10-30% of AEC expansive cement, 5-10% of a polyacrylate emulsifier solution, 8-15% of a polyvinyl acetate emulsion, 5-10% of a silicone acrylic emulsion, 5-10% of melamino-formaldehyde resin, 3-7% of disperse latex powder, 1-3% of aluminium hydroxide powder, 1-3% of perlite powder, 1-4% of flyash, 1-3% of melamine fiber, 1-3% of polyphenylene sulfide, 1-3% of polyether-ether-ketone, 1-3% of ammonium polyphosphate, 1-2% of fatty alcohol polyoxyethylene ether, 3-8% of kaolin, 3-10% of nano TiO2 and 3-8% of nano SiO2. According to the intumescent fireproof paint, a drying coating is relatively thin and excellent in bonding strength and fire resistance.

Owner:合肥英索莱特新材料科技有限公司

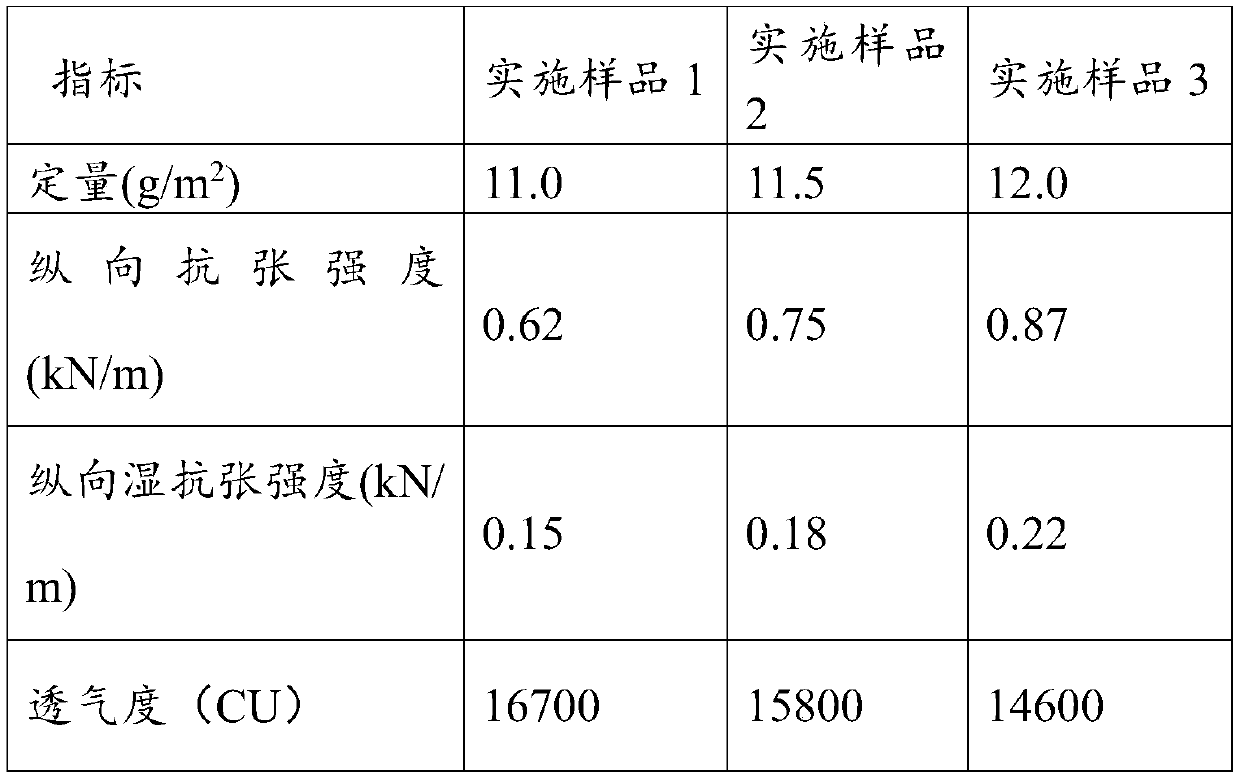

Light-weight green non-heat-seal type tea leaf filter paper and preparation method thereof

ActiveCN110924228AImprove toughnessSoft touchReinforcing agents additionPaper/cardboardFiberRolling paper

The invention relates to the field of papermaking, in particular to non-heat-seal type tea leaf filter paper. The filter paper is prepared by mixing paper mulberry bark pulp, bleached softwood pulp and viscose acetal fibers for papermaking, green natural polymer assistants are selected as chemical assistants added into the pulp, and the filter paper has the characteristics of complete natural circulation and biological decomposition. The invention also discloses a preparation method of the tea leaf filter paper. The preparation method comprises the following steps: (1) pulping; (2) preparing pulp; (3) forming on a net; (4) squeezing; (5) drying; and (6) slitting the roll paper. The tea leaf filter paper prepared by the preparation method has good dry and wet strength, uniformity and softness and high air permeability, is beneficial to permeation of tea fragrance, is light in weight, can save packaging cost for users, and has higher market competitiveness.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

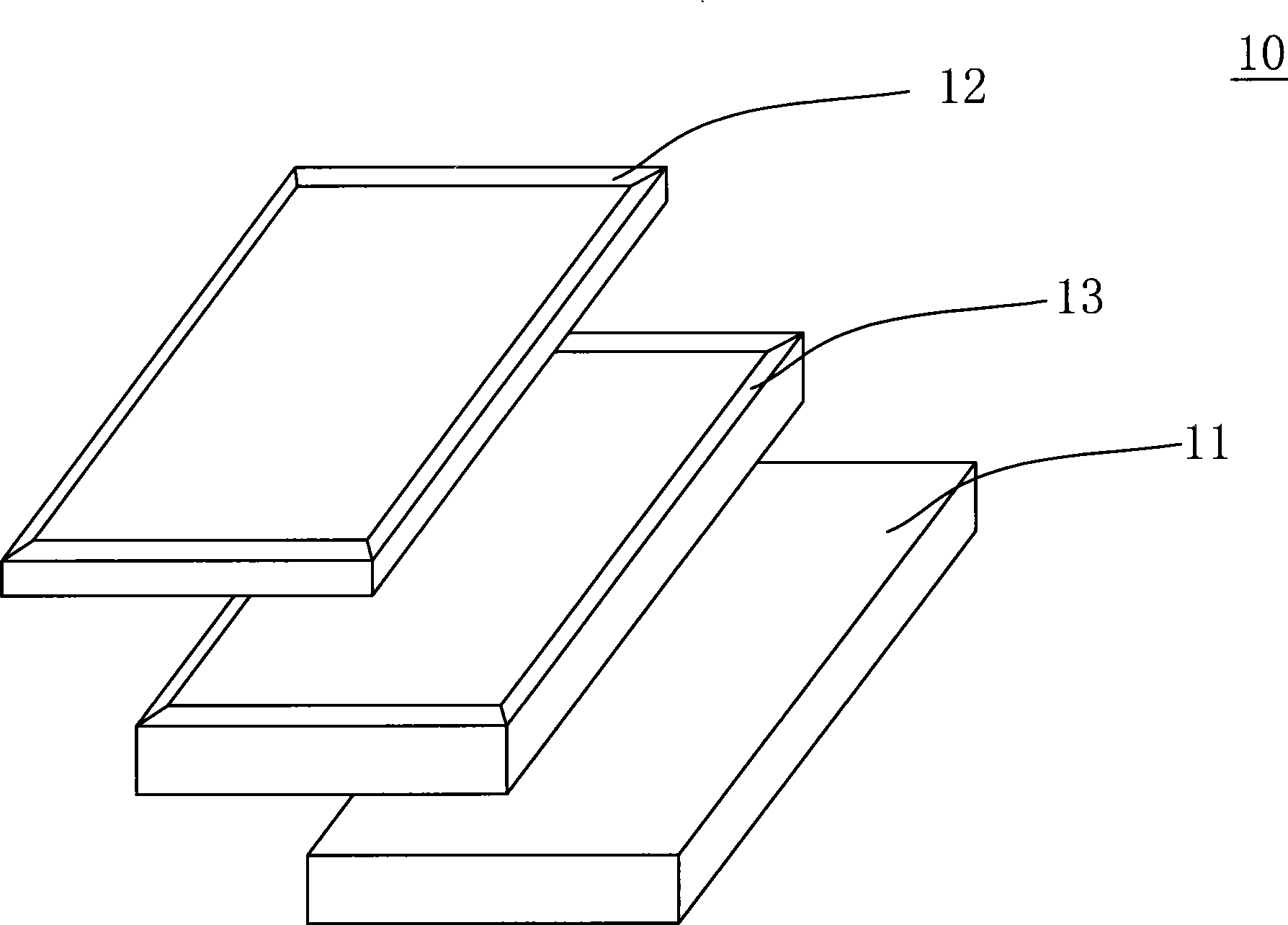

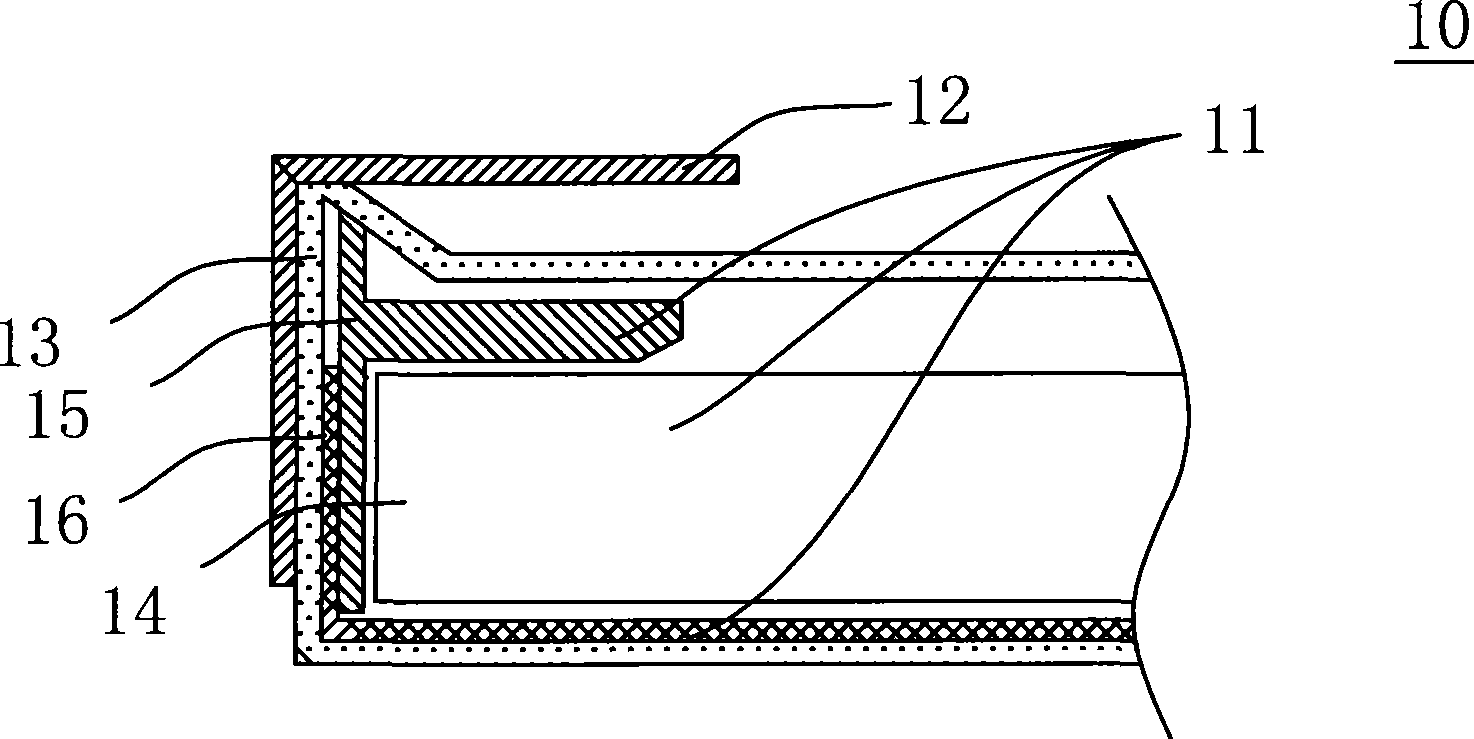

Semi-product display module and assembly method

InactiveCN101533165AEasy to shipAvoid vibration and frictionNon-linear opticsIdentification meansWork in processComputer science

The invention provides a semi-product display module and an assembly method. The display module includes a backlight module, a first frame body and a shock absorber. The backlight module is used for providing light source; the first frame body is coated on the backlight module; the shock absorber is set between the first frame body and the backlight module, and at least part is laid on an overlapping region of the first frame body and the backlight module. The shock absorber is set between the first frame body and the backlight module which can assemble the backlight module and the first frame body. The method can reduce defective rate of the semi-product display module and reduce follow-up transportation cost.

Owner:AU OPTRONICS CORP

Preparation method of anti-static carbon fibre functional composite paper

ActiveCN108035188AImprove surface activityImprove permeabilityCoatings with pigmentsPaper/cardboardCarbon fibersAdhesive

The invention discloses a preparation method of anti-static carbon fibre functional composite paper. The preparation method comprises the following steps: crushing wheat straw and waste paper, addingwater, standing, draining, soaking in a potassium hydroxide solution, steaming in a manner of insulating from water, drying, performing wet ball milling, concentrating, pulping, and performing papermaking to obtain blank paper; mixing waste paper and the potassium hydroxide solution, standing at a room temperature, then heating and stirring, performing suction filtration, washing a filter cake, drying to reach constant weight, adding a sepiolite powder, dodecyl ammonium chloride and silver nitrate solution, regulating the pH value of the system to be 6.4 to 6.8, stirring uniformly, adding a silane coupling agent KH-550, stirring uniformly, performing ultraviolet irradiation treatment, filtering, washing with deionized water, drying, and crushing to obtain a composite antibacterial agent; uniformly mixing graphite, carbon black, a coconut shell carbon powder and the composite antibacterial agent, adding an anti-static agent, a dispersing agent and an adhesive, mixing uniformly, concentrating, coating the surface of the blank paper with the mixture, drying, applying the adhesive to double surfaces, drying a finished product, and rolling paper.

Owner:安徽鑫光新材料科技股份有限公司 +1

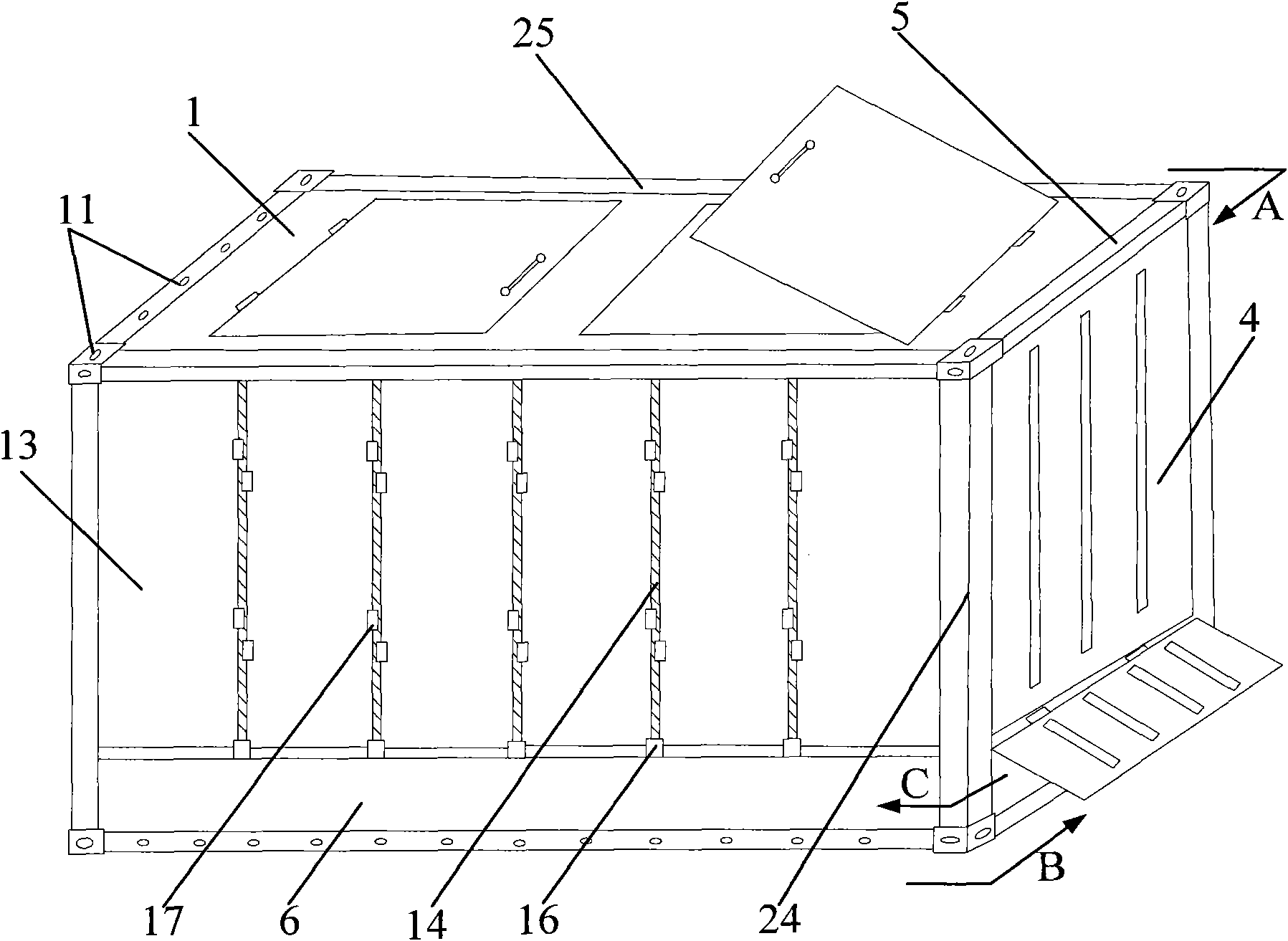

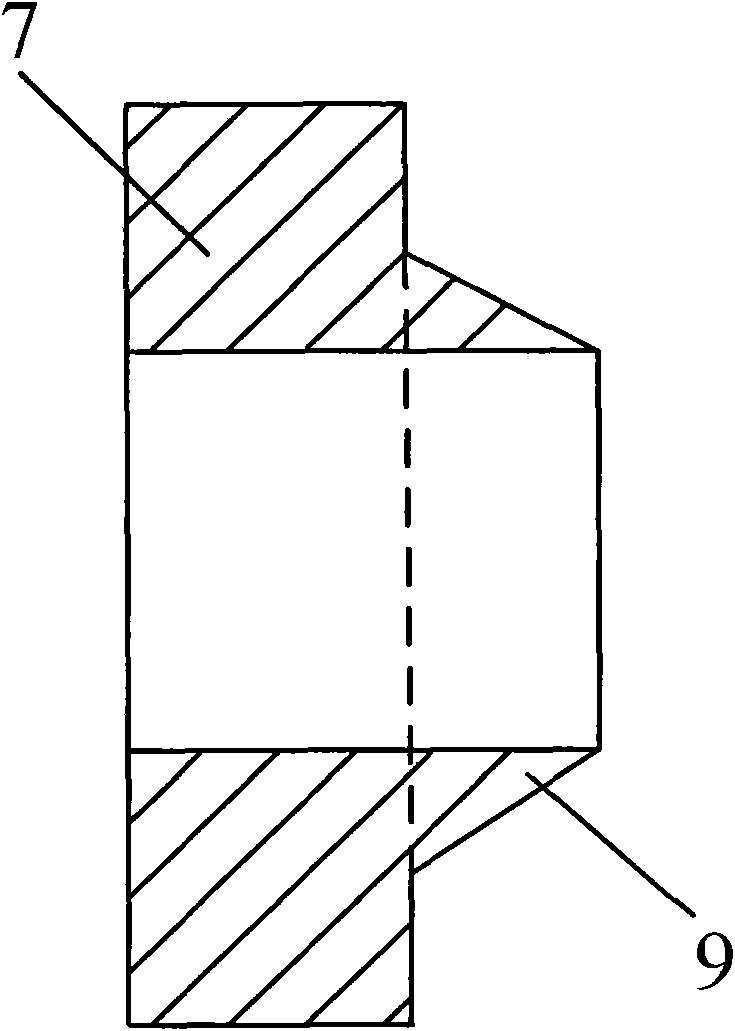

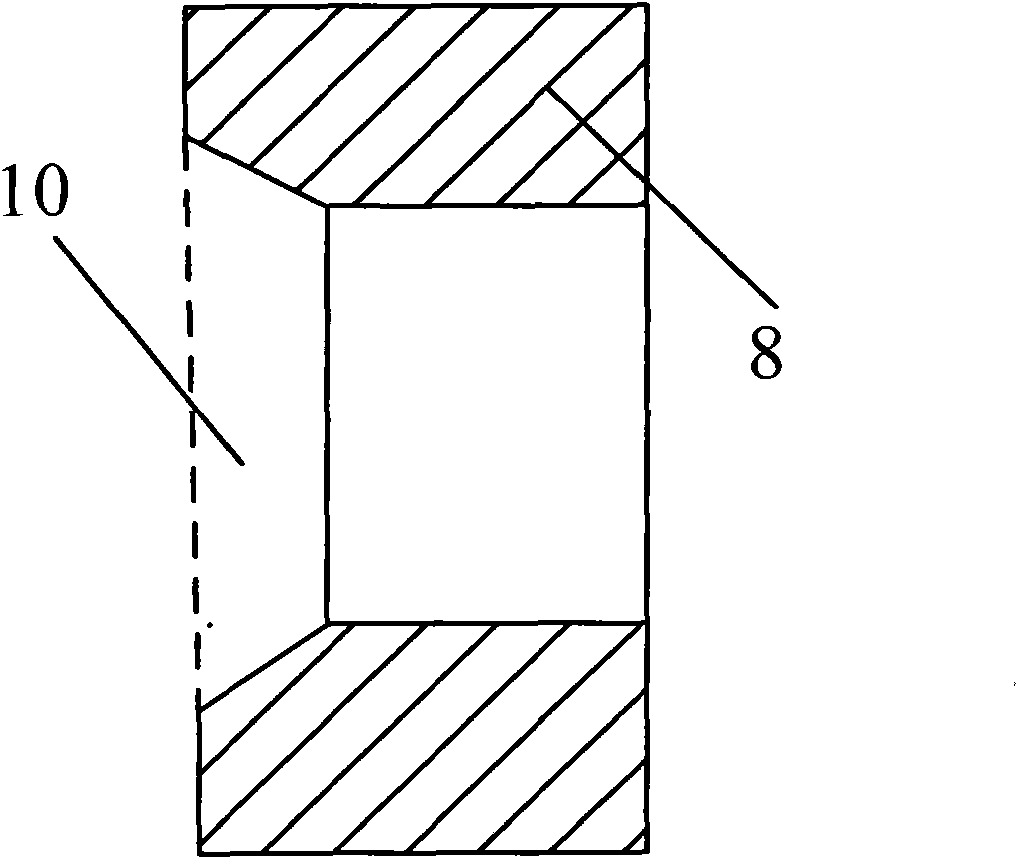

Removable special bulk grain container and dismounting system and dismounting method thereof

InactiveCN101966899ASolve the problem of high return costSmall footprintLarge containersConvex structureEngineering

The invention discloses a removable special bulk grain container belonging to the technical field of containers and mainly solving the problem that the empty return cost is overhigh because the container cannot be detached in the prior art. The removable special bulk grain container mainly comprises a closed box body formed by a top plate, a bottom plate, a side plate and an end plate, wherein the top plate is respectively connected with the side plate and the end plate through a crossbeam; the bottom plate is connected with the side plate through a side bottom beam and is connected with the end plate through the crossbeam; the crossbeam comprises a primary crossbeam and a secondary crossbeam which are jogged with each other, whereas the both mutually contacted surfaces of the primary crossbeam and the secondary crossbeam are respectively provided with a convex structure, a concave structure which is fit with a convex structure and a bolt which is used for bolting and passing through the convex structure and the concave structure. The invention also discloses a dismounting system and a dismounting method for the container. By combining with the dismounting system and the dismounting method, the invention not only ensures the sealing performance and the safety performance of the container but also realizes the dismountability, thereby achieving the goal of reducing the empty return cost through reducing the occupied space after the container is dismounted.

Owner:四川富臣集装箱有限公司

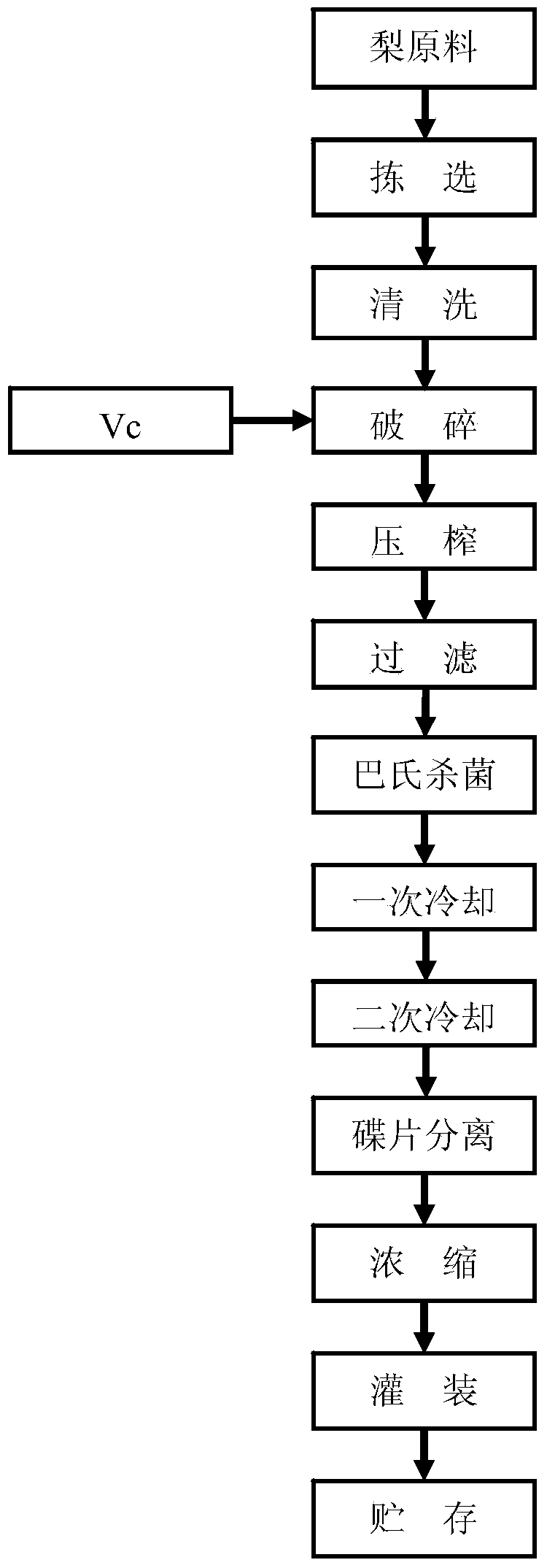

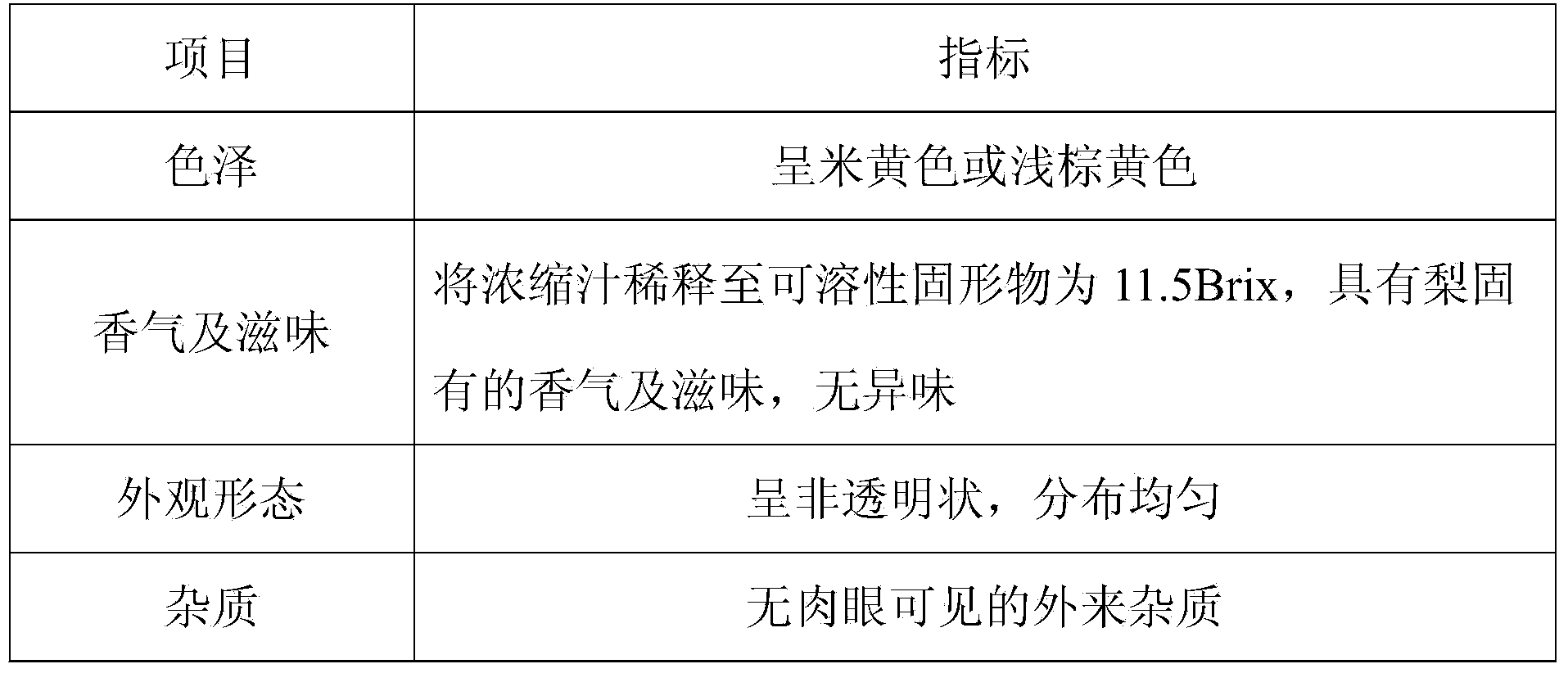

Method for preparing concentrated cloudy pear juice

The invention discloses a method for preparing concentrated cloudy pear juice. The method takes fresh and mature pears as a raw material and comprises the following steps of transporting the pears to a crusher, adding Vc (Vitamin C) for color protecting during crushing, and further squeezing to obtain raw cloudy pear juice; and then carrying out sieving with a vibrating screen, front pasteurization, disc separation and concentration to obtain the concentrated cloudy pear juice. The concentrated cloudy pear juice prepared by the method keeps the original nutrient content, color and flavor of pears furthest, is not transparent, is uniformly distributed, does not need additives such as essences, pigments and preservatives, has the inherent taste and fragrance of the mature pears, conforms to the real demands of publics on deliciousness, nutrition, nature and health, and has good market prospect.

Owner:QIXIA HAISHENG FRUIT IND

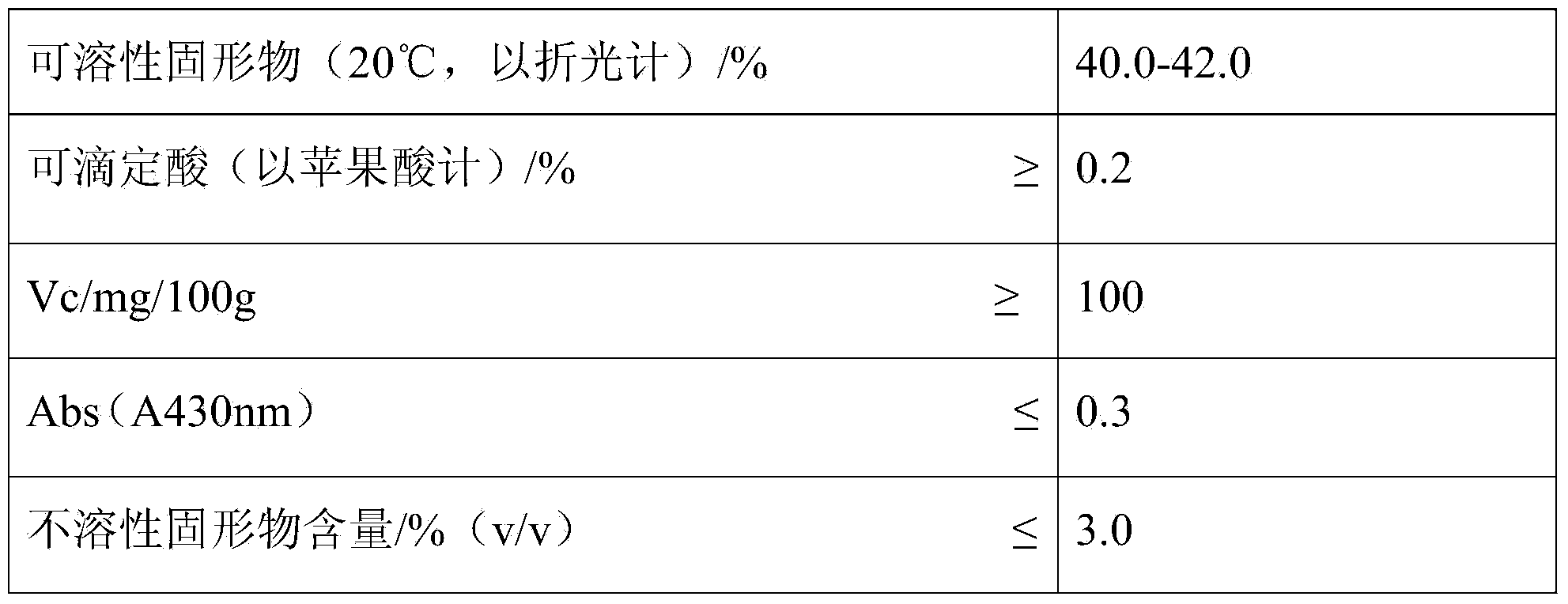

Production method and production equipment of fluid multi-element fertilizer

InactiveCN102211953AAvoid it happening againLow costFertilizer mixturesProcess engineeringMethods of production

The invention relates to a production method of a fluid multi-element fertilizer. The method comprises the steps of draining two or more fertilizer raw creams / liquids to a same outlet for mixing so as to obtain the fluid multi-element fertilizer. The production equipment of the fluid multi-element fertilizer comprises two or more material storage grooves, a mixing groove and a material amount control device, wherein the inlet of the mixing groove is connected with the two or more material storage grooves through a fluid pipe, and the outlet of the mixing groove faces the outside. The production equipment can be small or large, and the small-size equipment can be put in retail points to produce fertilizers with various nutrients, thereby meeting the demand of different users on the fertilizer.

Owner:和原生态控股股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com